Page 1

M4.9

0th-0

Go To Table Of Contents

Place Order

To purchase a printed copy of this manual,

click on the "Place Order" button below.

-001 thru -002

Service and

Parts Manual

Self-Contained Steam Sterilizer

Serial Number Prefixes:

(LT, LV)

M4.9

NO LONGER IN PRODUCTION

-

Some service parts may not

be available for this product-

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

SF-1597 Part No. 004-0114-00 Rev. H (1/01/07)

Page 2

Go To Table Of Contents

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Section/Paragraph................................................Page Section/Paragraph ............................................... Page

IMPORTANT INSTRUCTIONS

General Safety Instructions .......................................... iii

Safety Alert Symbols ....................................................iii

Warranty Instructions ................................................. iii

SECTION I GENERAL INFORMATION

1.1 Description Of M4•9 Easyclave™ Sterilizer . 1-1

General Descriptions................................. 1-1

Component Descriptions........................... 1-1

1.2 Specifications ............................................... 1-3

1.3 Parts Replacement Ordering........................ 1-4

1.4 Special Tools ................................................ 1-4

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test ........................................... 2-1

Normal Operation (Table 2-1).................... 2-2

2.2 Service Diagnostics...................................... 2-4

2.3 Steam and Pressure Calibration .................. 2-7

2.4 Troubleshooting Procedures....................... 2-10

Sterilizer has no power............................ 2-11

Touch Pad / Display problems................. 2-11

Unit will not Fill ........................................ 2-12

Codes C010 - C060 ................................ 2-12

Codes C102 - C106 ................................ 2-12

Codes C232 ............................................ 2-13

Codes C326 ............................................ 2-13

Codes C382 ............................................ 2-13

Codes C383, C384, C385 ....................... 2-14

Codes C431 ............................................ 2-14

Codes C437 ............................................ 2-15

Codes C461, C467.................................. 2-16

Codes C470 - C477 ................................ 2-17

Codes C533 - C554 ................................ 2-21

Codes C560 - C567 ................................ 2-23

Codes C570 - C577 ................................ 2-23

Codes C633 ............................................ 2-29

Codes C642 - C647 ................................ 2-30

Codes C660 - C667 ................................ 2-31

Codes C670 - C677 ................................ 2-32

Codes C980 - C987 ................................ 2-37

Instruments not drying ............................ 2-39

Biological indicator strip problems........... 2-40

Maintenance Message ............................ 2-40

Printer problems...................................... 2-40

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance ............................. 3-1

SECTION IV MAINTENANCE / SERVICE

INSTRUCTIONS

4.1 Introductions ................................................ 4-1

4.2 Side and Back Panels

Removal ................................................... 4-1

Installation................................................. 4-1

4.3 Top Cover

Removal.................................................... 4-2

Installation................................................. 4-2

4.4 Display P.C. Board

Removal.................................................... 4-4

Installation................................................. 4-4

4.5 Decal Switch

Removal.................................................... 4-4

Installation................................................. 4-5

4.6 Tray Rack and Trays

Removal.................................................... 4-5

Installation................................................. 4-5

4.7 Draining / Filling Reservoir

Draining .................................................... 4-6

Filling ........................................................ 4-6

4.8 Internal Filter Screen

Removal.................................................... 4-6

Installation................................................. 4-6

4.9 Chamber Mesh Filter

Removal.................................................... 4-7

Installation................................................. 4-7

4.10 Door Gasket

Removal.................................................... 4-7

Installation................................................. 4-8

4.11 Door Interlock Plunger

Removal.................................................... 4-8

Installation................................................. 4-8

4.12 Fuse Replacement ..................................... 4-10

4.13 Fuse Body

Removal.................................................. 4-10

Installation............................................... 4-10

4.14 Axial Flow Fan

Removal.................................................. 4-11

Installation............................................... 4-11

4.15 Solid State Relay

Removal.................................................. 4-12

Installation............................................... 4-12

4.16 Main Relay

Removal.................................................. 4-12

Installation............................................... 4-13

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Midmark Corporation 1999 SF-1597 Page i Printed in U.S.A.

Rev. 10/02

Page 4

TABLE OF CONTENTS

Return To Table Of Contents

Section/Paragraph................................................Page Section/Paragraph ............................................... Page

4.17 Transformer

Removal .................................................. 4-13

Installation ............................................... 4-14

4.18 Pressure Transducer

Removal .................................................. 4-14

Installation ............................................... 4-14

4.19 Steam (Side)

Temperature Probe

Removal .................................................. 4-15

Installation ............................................... 4-15

4.20 Door Latch Interlock Switch

Removal .................................................. 4-16

Installation / Adjustment .......................... 4-16

4.21 Door Pulse Solenoid

Removal .................................................. 4-18

Installation ............................................... 4-18

4.22 Main Control P.C. Board

Removal .................................................. 4-19

Installation ............................................... 4-19

4.23 Fan Thermostat

Removal .................................................. 4-20

Installation ............................................... 4-20

4.24 Air Solenoid Valve

Removal .................................................. 4-20

Installation ............................................... 4-20

4.25 Pressure Relief Valve Test.......................... 4-21

4.26 Pressure Relief Valve

Removal .................................................. 4-22

Installation ............................................... 4-22

4.27 Vent or Fill Solenoid Valve

Removal .................................................. 4-23

Installation ............................................... 4-24

4.28 Auxiliary (Upper)

Hi-Limit Switch

Removal .................................................. 4-25

Installation ............................................... 4-25

4.29 Lower

Hi-Limit Switch

Removal .................................................. 4-25

Installation ............................................... 4-26

4.30 Auxiliary (Lower, Trough)

Temperature Probe

Removal .................................................. 4-27

Installation ............................................... 4-27

4.31 Lower

Steam Heating Element

Removal .................................................. 4-28

Installation ............................................... 4-28

4.32 Upper

Heating Element

Removal .................................................. 4-29

Installation ............................................... 4-29

4.33 Water Level Sensor

Removal .................................................. 4-30

Installation ............................................... 4-31

4.34 Vent Muffler

Removal.................................................. 4-31

Installation............................................... 4-32

4.35 Reservoir

Removal.................................................. 4-32

Disassembly ........................................... 4-32

Assembly ................................................ 4-33

Installation............................................... 4-33

4.36 Printer

Removal.................................................. 4-34

Installation............................................... 4-34

SECTION V SCHEMATICS AND DIAGRAMS

5.1 SW2 Dip Switch Settings ............................ 5-1

5.2 Main Control P.C. Board (115 VAC) ............. 5-3

5.3 Electrical Schematic (115 VAC) ................... 5-4

5.4 Wiring Diagram (115 VAC)........................... 5-5

5.5 Main Control P.C. Board (230 VAC) ............. 5-6

5.6 Electrical Schematic (230 VAC) ................... 5-7

5.7 Wiring Diagram (230 VAC)........................... 5-8

5.8 Fill Mode Flow Diagram .............................. 5-9

5.9 Heating Mode Flow Diagram ..................... 5-10

5.10 Sterilize Mode Flow Diagram .................... 5-11

5.11 Vent & Dry Modes Flow Diagram ............... 5-12

SECTION VI PARTS LIST

6.1 Introduction ................................................ 6-1

6.2 Description Of Columns ............................... 6-1

6.3 Torque Specifications And Important

Assembly Notes........................................ 6-1

Pictorial Index .............................................. 6-2

Labels and Decals ....................................... 6-3

Main Enclosure Components ....................... 6-4

Plumbing and Sensor Components ............. 6-5

Chamber Assembly Components ................ 6-6

Electrical Components ................................. 6-7

Printer Components ..................................... 6-8

Racks, Trays, and Cleaner ........................... 6-9

Packaging .................................................. 6-10

External Condensing Tank ........................ 6-11

Pouch Rack ............................................... 6-12

COMMENTS ............................................................. 7-1

FAX ORDER FORM.................................................. 7-2

© Midmark Corporation 1999 SF-1597 Page ii Printed in U.S.A.

Rev 5/02

Page 5

TABLE OF CONTENTS

Return To Table Of Contents

General Safety Instructions

Safety First: The primary concern of Midmark Corporation is that this sterilizer is maintained with the

safety of the patient and staff in mind. To assure that

services and repairs are completed safely and correctly,

proceed as follows:

(1) Read this entire manual before performing any

services or repairs on this sterilizer.

(2) Be sure you understand the instructions con-

tained in this manual before attempting to service or repair this sterilizer.

Safety Alert Symbols

Throughout this manual are safety alert symbols that

call attention to particular procedures. These items are

used as follows:

DANGER

A DANGER is used for an imminently

hazardous operating procedure, practice, or condition which, if not correctly followed,

will result in loss of life or serious personal

injury.

NOTE

A NOTE is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the Midmark “Limited Warranty” printed in the

Installation and Operation Manual for warranty information. Failure to follow the guidelines listed below will

void the warranty and/or render the M4•9 Easyclave™

Sterilizer unsafe for operation.

• In the event of a malfunction, do not attempt to use

the sterilizer until necessary repairs have been

made.

• Do not attempt to disassemble sterilizer, replace

malfunctioning or damaged components, or perform adjustments unless you are one of Midmark’s

authorized service technicians.

• Do not substitute parts of another manufacturer

when replacing inoperative or damaged components. Use only Midmark replacement parts.

WARNING

A WARNING is used for a potentially

hazardous operating procedure, practice, or condition which, if not correctly followed,

could result in loss of life or serious personal

injury.

CAUTION

A CAUTION is used for a potentially haz-

ardous operating procedure, practice, or

condition which, if not correctly followed, could result

in minor or moderate injury. It may also be used to

alert against unsafe practices.

EQUIPMENT ALERT

An EQUIPMENT ALERT is used for an

imminently or potentially hazardous operating procedure, practice, or condition which, if not

correctly followed, will or could result in serious, moderate, or minor damage to unit.

© Midmark Corporation 1999 SF-1597 Page iii Printed in U.S.A.

Page 6

TABLE OF CONTENTS

Return To Table Of Contents

© Midmark Corporation 1999 SF-1597 Page iv Printed in U.S.A.

Page 7

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Description Of M 4•9 Easyclave™

Sterilizer

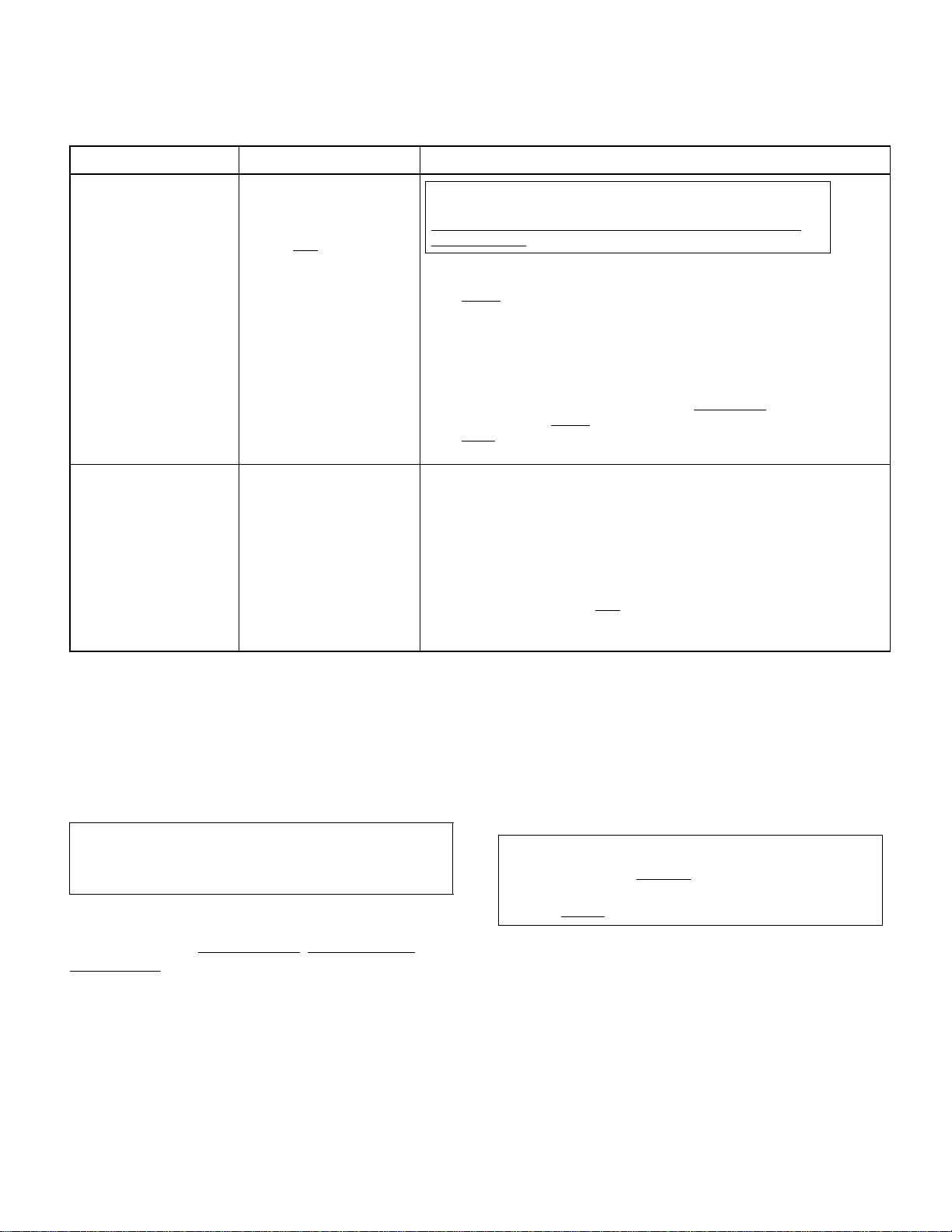

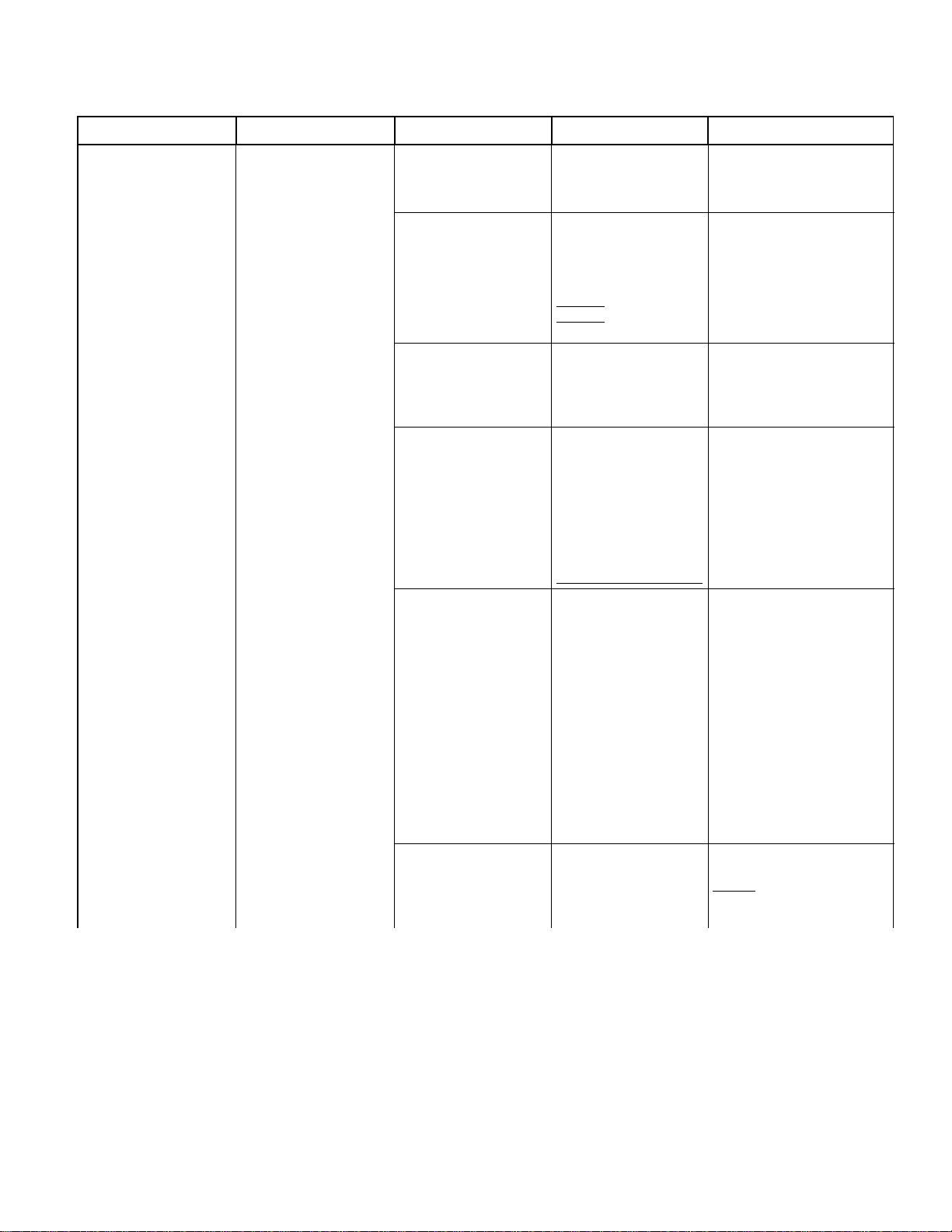

A. General Description (See Figure 1-1).

The M 4•9 EasyClave™ Sterilizer is to be used in medical and dental offices, hospitals, clinics, nursing homes,

laboratories, and other facilities to sterilize heat and

moisture stable reusable items (including dental handpieces) that are compatible with steam sterilization at

270°F (132°C). Follow state and federal guidelines for

sterilization of single use devices.

The major serviceable components of the sterilizer

are (refer to Figure 1-1, Major Components ).

Door Pulse Solenoid (1)

Door Pulse Solenoid is held in closed (latched) position

during sterilizer operation and automatically unlatches

after vent mode. Controlled by main control p.c. board.

Door Latch Interlock Switch (2)

Monitors position of door assembly. A normally open

switch that closes when door is closed. Prevents Initiating a Cycle unless door is closed.

Axial Flow Fan (3)

Thermostatically controlled fan for circulating air, in area

between chamber and inside of panels, to decrease

heat and condensation.

Fan Thermostat (4)

Controls Off / On of Axial Flow Fan. Normally open,

bimetal, auto-reset, thermostat that automatically

closes contacts at 122°F (50°C) to 138°F (59°C) to

power Fan. Thermostat opens at 95°F (35°C) to 106°F

(41°C), removing power, stopping Fan.

Air Solenoid Valve (5)

Removes air from chamber during operation. Controlled by main control p.c. board.

Steam (Side) Temperature Probe (6)

Temperature probe inside chamber monitors internal

chamber temperature during operation and transmits it

back to main p.c. board. Steam Probe is located in

lower front right side of chamber.

Auxiliary (Lower, Trough) Temperature Probe (7)

Located inside chamber in water trough. Senses temperature near lower heating element and transmits it

back to main control p.c. board.

© Midmark Corporation 1999 SF-1597 Printed in U.S.A.

Rev. 5/02

Page 1 - 1

Main Control P.C. Board (8)

Contains the program logic, EPROM, and various connections to send and receive data to operate the various

programs. SW2 dip switch assembly is located on top,

right corner of board. Service Diagnostics, calibrations,

and various display options can be accessed by changing switch positions.

Fuses F1 and F2 protect the main control p.c. board

should a problem exist in the transformer or related

components.

Fuse size is 1.6 Amp, 250 VAC, Slowblo, 3/16" D. x

13/16" L.

Auxiliary (Upper) Hi-Limit Switch (9)

Controls power to heating elements should overheat

conditions exist.

Normally closed, bimetal, thermostat that automatically

opens contacts at 450°F (232°C) to 500°F (260°C)

removing power to heating elements.

Automatically resets to close position at 370°F (188°C)

to 420°F (216°C).

Located on upper

Lower Hi-Limit Switch (10)

Controls power to heating elements should overheat

conditions exist.

Normally closed, bimetal, thermostat that automatically

opens contacts at 450°F (232°C) to 500°F (260°C)

removing power to heating elements.

Automatically resets to close position at 370°F (188°C)

to 420°F (216°C).

Located on lower

Transform e r (11)

Steps line voltage down to 18.5 VAC to power the main

control p.c. board.

Can be used with 115 VAC or 230 VAC supply voltage.

Main Fuse (12)

Protects sterilizer electrical circuit. 115 VAC Sterilizer

fuse is a 15 Amp, 600 VAC, 3AB Fast Acting, 13/32” D.

x 1 1/2" L.

The 230 VAC Sterilizer fuse is the same style but rated

at 8 amp.

Solid State Relay (13)

Solid state switch that closes when 12 VDC is supplied

from the main control P.C. Board to relay terminals 3

and 4.

With the relay operating, line current can pass thru (terminals 1 and 2) to common terminal of Main Relay.

Depending if Main Relay is operated, current will be

supplied to both heaters (auxiliary heat) or just the lower

(steam) heater.

Solid State Relay opens and closes, turning on and off

the heater(s), to control temperature in chamber.

front, outside surface of chamber.

front, outside surface of chamber.

Page 8

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

Main Relay (14)

Main Relay contains a set of Normally Open (NO) and

Normally Closed (NC) contacts that allow one (Steam,

lower) or both (Auxiliary, upper and lower) heaters to

operate depending if its coil is being supplied with 12

VDC from main control P.C. Board.

When coil is energized

(12 VDC) the contacts change

position, supplying line voltage thru the SSR and the

NO contacts to the Steam (lower) heater.

closed

If the coil is not energized

, the contacts remain in their

normally closed positions. Line voltage is now supplied

thru the SSR and the NC contacts to both the Upper

and Lower heaters.

Water Level Sensor (15)

Located in back of chamber, it monitors the water level

during the FILL cycle. When the water level reaches the

sensor, a circuit is completed which signals the main

control P.C. board to remove power from the Fill Valve

solenoid, closing the valve.

Pressure Transducer (16)

Monitors pressure inside chamber and transmits signal

back to main control p.c. board so conditions can be

controlled inside chamber. If conditions are not within

tolerances, specific Codes will be displayed to inform

Operator.

Fill Valve (17)

Fill Valve is a normally closed valve. When START key

is depressed K3 contacts on main control P.C. board

close supplying line voltage to the Fill Valve solenoid.

Normally closed valve opens, allowing water to enter

chamber. When water level reaches sensor a circuit is

complete. P.C. Board opens K3 contacts, removing

power from Fill Valve solenoid coil, closing the valve.

Vent Valve (18)

Vent Valve is a Normally Open

valve.Controlled by main

control P.C. board. When K2 contacts close Vent Valve

solenoid energizes, closing

the valve. Valve vents back

thru condensing coil in reservoir.

Lower (Steam) Heating Element (19)

Submersible, tubular, 1550 watt, heating element used

to generate steam for unit.

During the Heatup and Sterilization cycles, the Steam

temperature probe, monitors internal chamber conditions, sending signals back to main control P.C. board

which controls On / Off cycling of heater thru the Solid

State Relay (SSR).

Upper Heating Element (20)

Upper element is wired in series with lower element to

maintain conditions inside chamber during DRY

and

Preheat cycles.

10

27

29

4

2

1

28

5

26

6

8

16

25

11

Figure 1-1. Major Components

9

3

14

21

13

23

24

12

20

22

15

19

7

18

17

© Midmark Corporation 1999 SF-1597 Page 1- 2 Printed in U.S.A.

Rev. 4/02

Page 9

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

With the Main Relay not

plied thru the SSR and NC contacts of the Main Relay

to both

Lower and Upper temperature probes monitor internal

chamber conditions sending signal back to main P.C.

board which controls On / Off cycling of both heaters by

opening and closing the SSR.

Pressure Relief Valve (21)

Safety valve vents chamber should pressure inside

chamber reach 40 PSIG (275.8 kPa). Steam is vented

out below base of sterilizer.

Reservoir Tank w/ Condensing Coil (22)

Retains supply of distilled water for operation. During

Vent cycle steam is discharged from chamber back thru

condensing coil into reservoir.

Vent Muffler (23)

Located inside reservoir at end of Air Valve line. Used to

supress exhaust noise during operation. Periodically

inspect muffler for restriction to assure proper operation.

Filter Screen (24)

Fine stainless steel mesh, screen for filtering particals

from system preventing migration to Vent Valve. Filter

should be cleaned monthly.

Internal Filter Screen (25)

Fine stainless steel, mesh, tubular screen for filtering

particals from system preventing migration to Air Valve

and Pressure Transducer. Filter should be cleaned

monthly.

Pressure Vessel (26)

Includes chamber and door assembly which are ASME

certified.

Door Interlock Plunger (27)

Plunger device, installed in center of door assembly that

prevents unlatching and opening door. Operated by

internal chamber pressure. Locks at 2 PSIG (13.8 kPa).

Door Gasket (28)

Seals door when in latched position to prevent pressure

from escaping around door during operation.

Display / P.C. Board (29)

Operation and Service Diagnostic messages are

viewed though use of a liquid crystal display (LCD) on

front of top cover.

heaters.

energized, line voltage is sup-

1.2 Specifications

Factual data for the M 4•9 EasyClave™ Steam Sterilizer

is provided in Table 1-2.

Table 1-2. Specifications

Description Data

Dimensions (overall):

Width.................................................15.3 in. (38.9 cm)

Depth ................................................21.2 in. (53.8 cm)

Height (w/o printer) ...........................15.9 in. (40.4 cm)

Height (w/ printer ..............................16.3 in. (41.4 cm)

Chamber Size: ..........4.5 in. “H” x 9 in. “W” x 12 in. “D”

(11.4 cm x 22.9 cm x 30.5 cm)

Shipping Carton: 24.25 in. "L" x 20.5 in. "W" x 21 in. "H"

(61.6 cm x 52.1 cm x 53.3 cm)

Weight:

With Reservoir Empty .......................82.0 lbs (37.2 kg)

Shipping weight w/ skid ..................115.0 lbs (52.2 kg)

Water Reservoir Capacity ....................Apprx. 1.0 gallon

(3.8 Liters) to full mark

Electrical Requirements:

115 VAC Unit ................................. 115 VAC, 50/60 HZ

12 amp, single phase

230 VAC Unit.................................230 VAC, 50/60 HZ

6.5 amp, single phase

Power Consumption:

115 VAC Unit .......... 1550 Watts, 12 amps @ 120 VAC

230 VAC Unit ......... 1550 Watts, 6.5 amps @ 240 VAC

Recommended Circuit:

A separate (dedicated) circuit is recommended for this

sterilizer. Sterilizer should not

trical circuit with other appliances or equipment unless

circuit is rated for the additional load.

Certifications: ............................................... AAMI ST55

ASME Boiler & Pressure Vessel Code

Chamber Pressure:

Operating ............................... 27-31 psi (186-215 kPa)

Maximum Before Safety Valve Opens ............... 40 psi

be connected to an elec-

UL3101-1

(275.8 kPa)

© Midmark Corporation 1999 SF-1597 Printed in U.S.A.

Rev. 4/02

Chamber Temperature:

Operating .......................... 270 - 275° F (132 - 135° C)

Page 1 - 3

Page 10

SECTION I

Return To Table Of Contents

GENERAL INFORMATION

1.3 Parts Replacement Ordering

If a part replacement is required, order the part directly

from the factory as follows:

(1) Refer to Figure 1-2 to determine the location of

the model number and serial number of the unit

and record this data.

NOTE

To assure expedient service and correct parts you

must have the correct Model and Serial Number

the Sterilizer.

of

MA578400i

(2) • Refer to the Parts List to determine the item

Figure 1-2. Model / Serial Number Location

numbers of the parts, part numbers, descriptions, and quantities of parts needed and record

this data.

• Determine installation date of sterilizer and

record this data.

• Call Midmark (1-800 643-6275) and ask for

1.4 Special Tools

Table 1-3 lists all special tools needed to repair the sterilizer, how to obtain the tools, and purpose of each.

Technical Service Department. Please have

the Model and Serial Number

of the sterilizer.

• See back cover of this manual for the phone

number or use the Fax Order Form (See page

7-2 for Fax Order Form).

Table 1-3. Special Tool List

Description of Special Tool Manufacturer

Digital Multimeter w/ Amp

Clamp

(capable of displaying 3 digits)

Punch ( 3/32" diameter) Commercially Available Any Type For removal of roll pin that secures latch lever to

Digital Thermometer Commercially Available Any Type Used to check temperatures in order to diagnose

Pressure Gauge Test Harness Midmark Corporation

Combination Square (12" Rule) Commercially Available Any Type For Adjustment of Door Latch Interlock Switch

Commercially Available Any Type For performing continuity, voltage, and current

1-800 643-6275

Technical Service Dept.

Manufacturer’s Part

Number

checks.

pulse solenoid.

malfunctions.

002-0372-00 Used to check pressure in chamber during a cycle

in order to diagnose malfunctions.

Purpose of Special Tool

Thermal Joint Compound Commercially Available Obtain at Radio Shack Heat dissipation on Solid State Relay (SSR).

© Midmark Corporation 1999 SF-1597 Page 1- 4 Printed in U.S.A.

Rev. 4/02

Page 11

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

SECTION II

TESTING AND TROUBLESHOOTING

SECTION II

2.1 Operational Test (See Figure 2-1)

In order to effectively diagnose a malfunction of sterilizer, it may be necessary to perform an operational test

as follows:

WARNING

Refer to Operator Manual for complete

instructions on operating sterilizer.

Failure to do so could result in personal injury.

NOTE

Operational Test, for most part, only describes what

should happen when sterilizer is operated. If sterilizer does something other than described, a problem

has been discovered. Refer to Troubleshooting

Guide to determine cause of problem and its correction.

WARNING

Use 220 - 240 VAC, 50 / 60 HZ alternat-

ing current only for 230 VAC models

and 110 - 120 VAC, 50 / 60 HZ alternating current

only for 115 VAC models. Failure to do so could

result in electrical shock to personnel and will result in damage to sterilizer.

Do not use this sterilizer in an explosive or oxygen-enriched atmosphere. Failure to do so could

result in serious personal injury or death.

(1) Plug sterilizer power cord into a grounded, non-

isolated, correctly polarized outlet, that has

proper voltage for sterilizer.

NOTE

Grounding reliability can only be achieved if unit is

connected to a matching three-pronged, grounded,

non-isolated, correctly polarized receptacle.

(2) Electrical rating for 115 VAC Sterilizer:

115 VAC, 50 / 60 Hz, 12 amps

Connect to a dedicated branch circuit rated for

115 VAC, 50 / 60 Hz, 15 amps minimum.

Electrical rating for 230 VAC Sterilizer:

230 VAC, 50 / 60 Hz, 6.5 amps

Connect to a dedicated branch circuit rated for

220 VAC, 50 / 60 Hz, 10 amps.

Check label on back panel to verify electrical

specifications required for unit.

SELECT

CYCLE

U

nw

rapped

W

rapped

Figure 2-1. Display and Operator Control Pad

(3) Table 2-1, Operational Chart, describes a com-

plete cycle during Normal

operation, identifying

audible signals, various display prompts and

component operation.

S

tart

S

t

op

MA461200

© Midmark Corporation 1999 SF-1597 Page 2-1 Printed in U.S.A.

Page 12

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

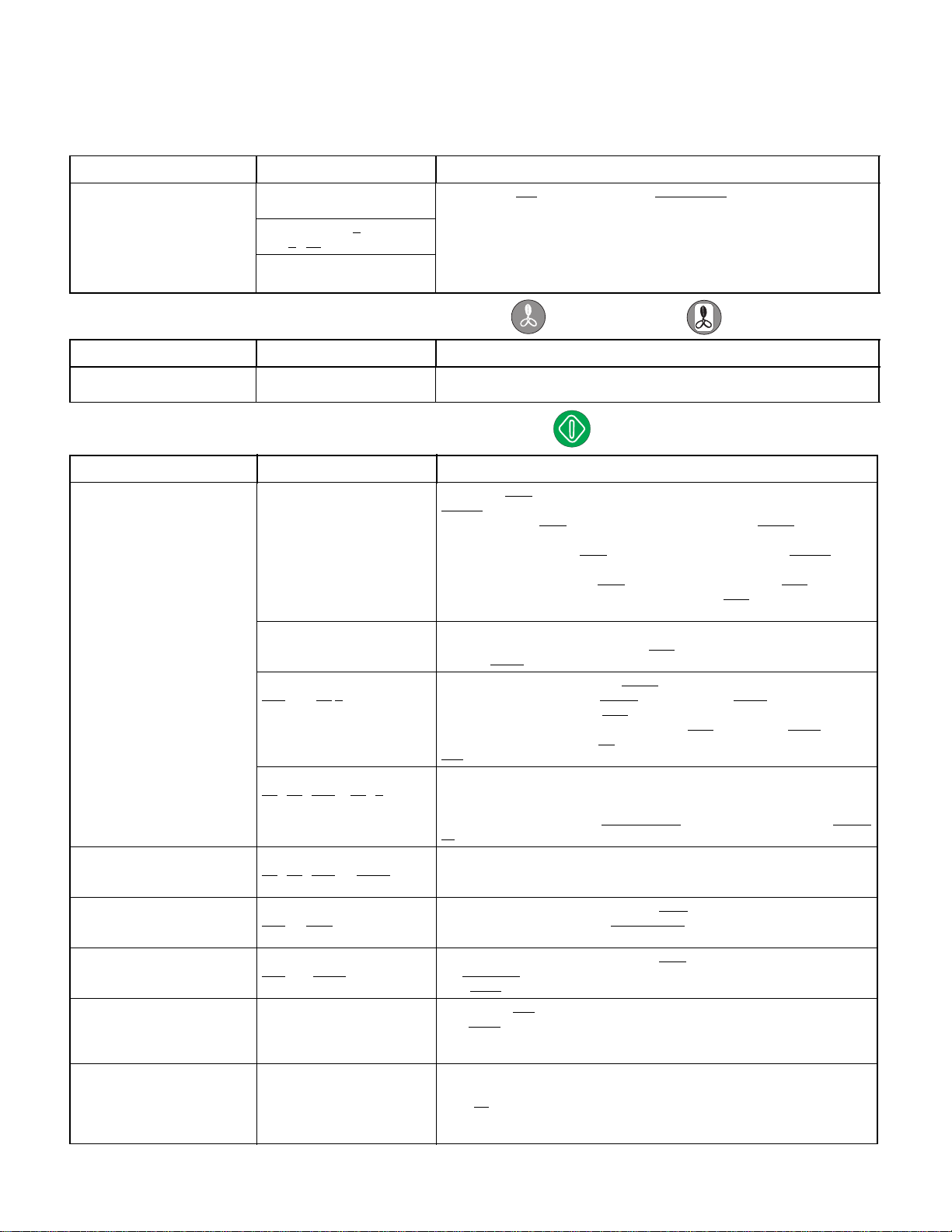

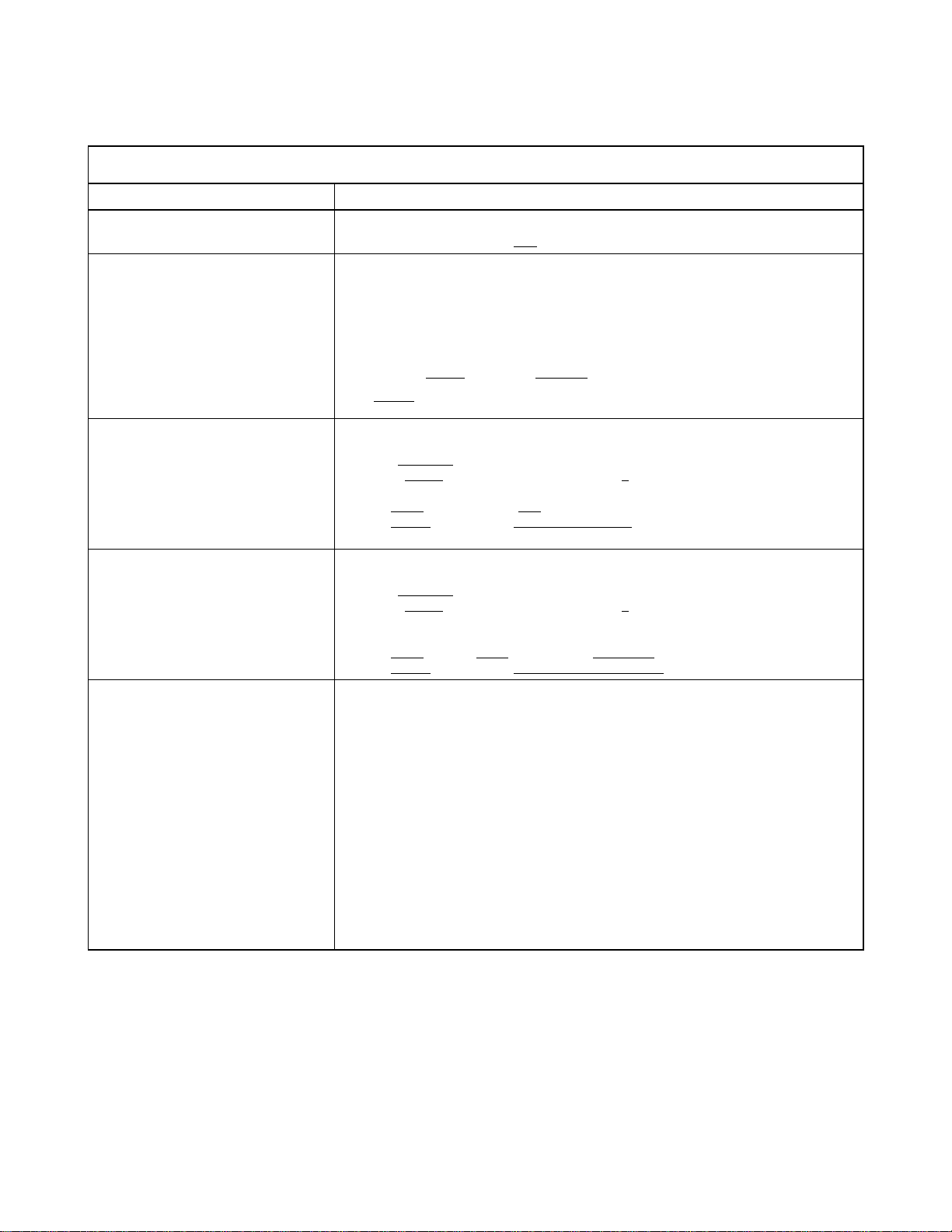

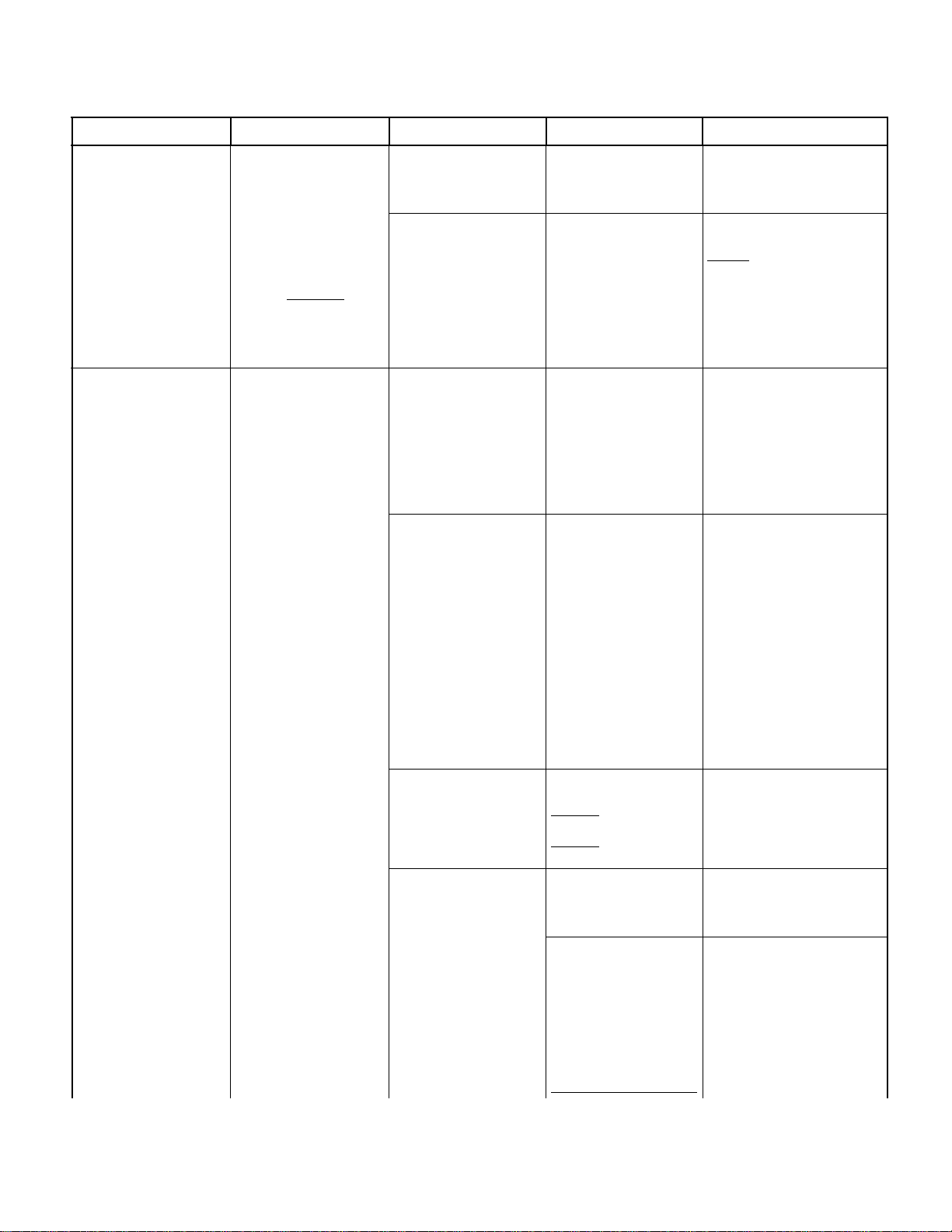

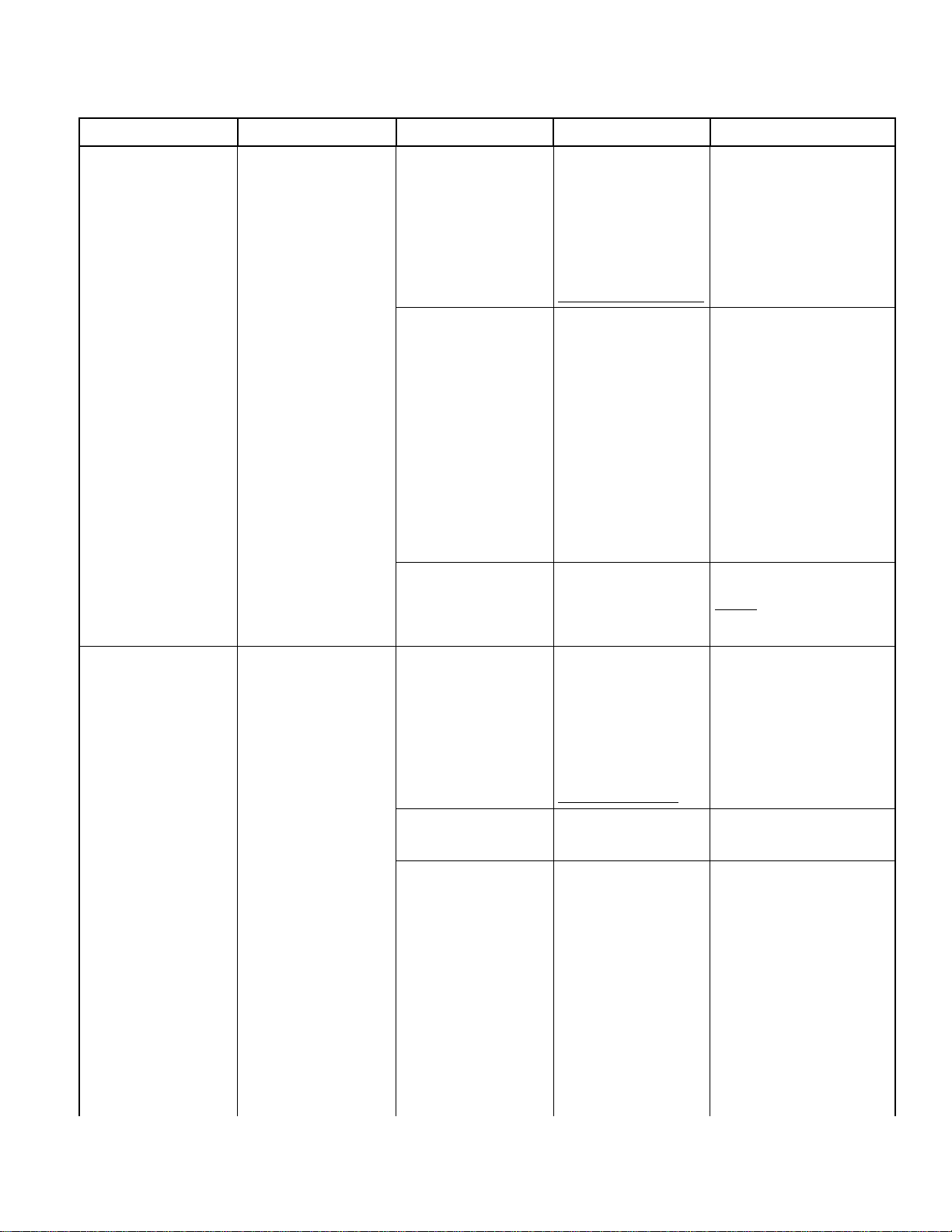

Normal Operation. Table 2-1.

Unit Plugged Into Outlet

Audible Display Action / Notes

Audible beeps INITIALIZING CYCLE Note: The fan may

TOTAL CYCLES X

VER X . XX

SELECT CYCLE

CHAMBER PREHEATED *

Press Cycle Key (i.e.: UNWRAPPED) or (WRAPPED)

Audible Display Action / Notes

UNWRAPPED

270° F 3:30 MINUTES

Audible Display Action / Notes

FILLING CHAMBER K3 contacts close

CHAMBER

IS FULL

HEATING - UNWRAPPED

°F XX.X PSI

XXX

(temp.) (pressure)

Note:

At Apprx. 271°F (133°C) and

28 Psi (193 kPa) countdown

begins.

Audible beeps (Occurs 5 seconds

before Door opens.)

Audible beeps DRY CYCLE COMPLETE

STERILIZING

: XX XXX°F XX . X PSI

XX

(time) (temp.) (pressure)

READY TO VENT

. XX XXX °F XX . X PSI

XX

(time) (temp.) (pressure)

VENTING CHAMBER

°F XX.X PSI

XXX

(temp.) (pressure)

DOOR TO OPEN

°F XX . X PSI

XXX

(temp.) (pressure)

ITEMS STERILIZED

DRY CYCLE XX:XX

(time counts down from 20 to 40

min.)

SELECT CYCLE

CHAMBER PREHEATED

or greater.

Display shows total amount of cycles that have been run.

(VER is the software version number).

*If a cycle has previously been run display will also indicate CHAMBER PREHEATED.

NOTE: Pressing WRAPPED button, display time for sterilization cycle will be 9 MINUTES.

Press START Key

valve. Water from reservoir enters chamber.

opening

K2 (Vent) contacts close

open valve.

At same time, K4 contacts close

mally closed valve. Main Relay coil energizes, changing the positions of the contacts. Normally open contacts close

Solid State Relay (SSR) is not energized, contacts are open

operate.

Water reaches level of Water Level Sensor sending signal back to main P.C. board.

K3 contacts on Main Control P.C. Board open

Fill Valve closes

Solid State Relay (SSR) energizes closing

With Main Relay, N/C contacts opened

Steam Heater. Air Valve, being open

temperature reaches 210°F (99°C) K4 contacts open

pressure to build up. Air Valve will

may

also open at 10, 14, & 18 Psi ( 69, 97, and 124 kPa).

Sterilization Time (3 1/2 min. Unwrapped or 9 min. Wrapped) counts down.

RTD Temperature probes and Pressure Transducer monitor temperature and pressure.

K4 contacts and Air Valve may open and close

off by Solid State Relay (SSR) to maintain temp. / pressure.

10 seconds before end of STERILIZING cycle “READY TO VENT” is displayed.

Main Control P.C. board K2 relay contacts Open

solenoid, returning Vent Valve to normally open

Chamber vents.

Main Control P.C. board K5 relay contacts close

just 1/2 second

Door opens

Main Relay is OFF

SSR cycles

and Off to maintain temp. in chamber during dr ying cycle.

Drying Cycle time is varible between 20 and 40 Minutes.

Open door completely and remove contents. Unit is ready for next sterilization cycle.

For 90 minutes, if no other cycle is initiated, SSR will open and close. With Main

Relay Off

and Steam (Lower) heaters to maintain preheat temperature at 212°F (100°C). After

90 minutes, if no cycle has been initiated, power is removed.

to partially open position.

open & closed turning Auxiliary (Upper) and Steam (Lower) heaters On

, current flows thru Main Relay N/C contacts energizing Auxiliary (Upper)

run if the temperature inside cabinet is 130°F (+/- 8°F) (54°C).

on Main Control P.C. Board, Fill Valve solenoid coil energizes,

, energizing Vent Valve solenoid coil, closing the normally

, energizing Air Valve solenoid coil, opening nor-

and normally closed contacts open.

and heaters do not

,

stopping water flow into chamber.

its normally open contacts.

and N/O contacts closed, power is applied to

, allows air to be expelled from chamber. When

and Air Valve closes allowing

open at 6 Psi (41 kPa) and 22 Psi (152 kPa) and

while steam heater is cycled on and

, removing power from Vent Valve

position.

. Door Pulse solenoid energizes for

, releasing door latch.

, contacts are in their normally open and normally closed position.

© Midmark Corporation 1999 SF-1597 Page 2-2 Printed in U.S.A.

Page 13

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

© Midmark Corporation 1999 SF-1597 Page 2-3 Printed in U.S.A.

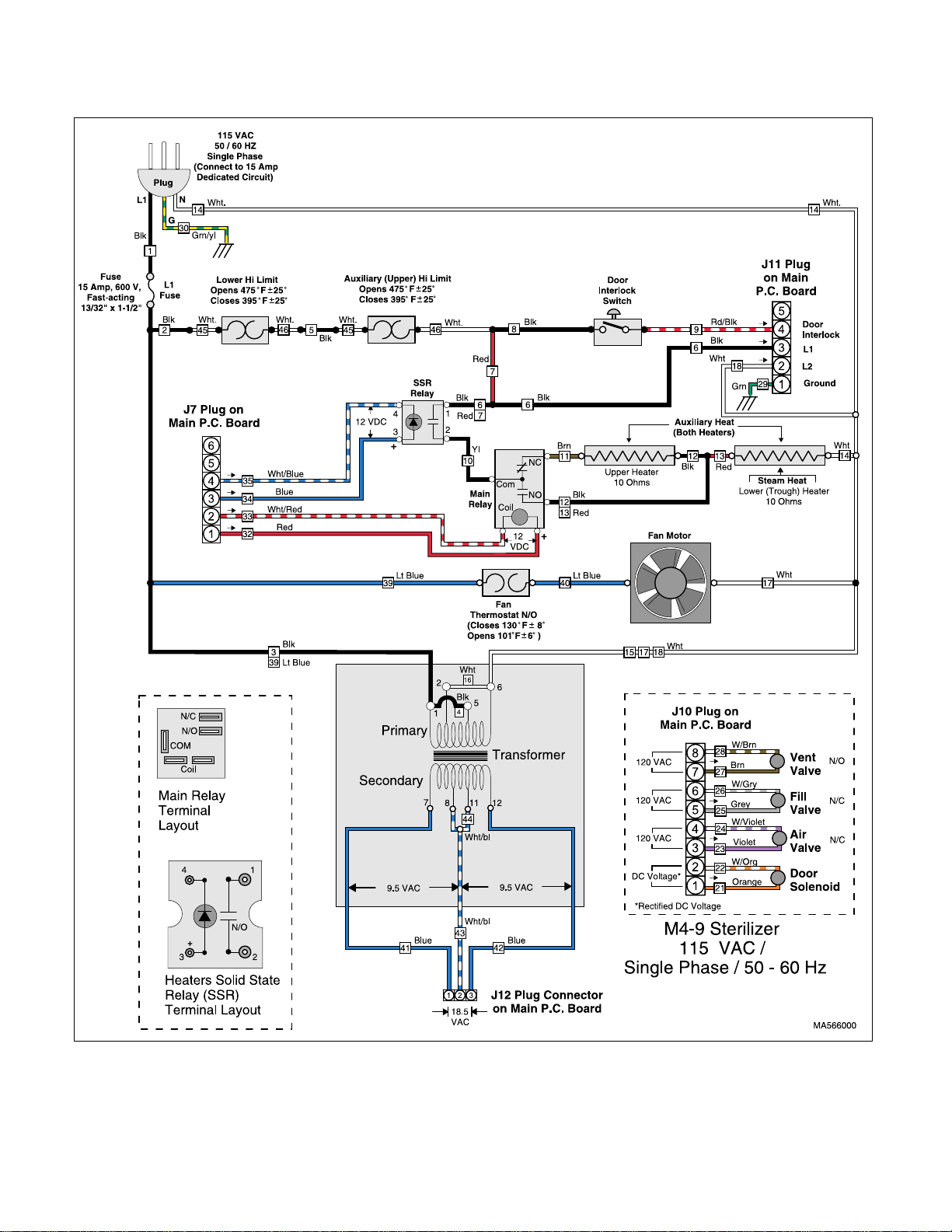

Figure 2-2. Schematic

Page 14

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

2.2 Service Diagnostics

EQUIPMENT ALERT

Always complete Service Diagnostics

(Section 2.2) before replacing any major

components especially the Main P.C. Board.

Service Diagnostics allows testing various components

of sterilizers through use of operator buttons, display

unit and LED’s on Main P.C. board. It will be necessary

to remove the panels of the sterilizer in order to view the

various LED’s.

WARNING

Unplug unit from electrical outlet to prevent possibility of personal injury or

death from electrical shock.

(1) Unplug unit from electrical outlet.

(2) Remove panels (Refer to para 4-2).

(3) Place SW2 Switch 1 (Figure 2-3) in ON

position.

(left)

WARNING

Use extreme caution when unit is

plugged into outlet to prevent possibil-

ity of personal injury from electrical shock.

(4) Plug unit into outlet.

(5) Use Table 2-2 to perform the Service Diagnos-

tics.

NOTE

Refer to Section 5 for Electrical Schematics / Wiring

Diagrams.

(6) Unplug unit from electrical outlet.

(7) Place dip switch 1 ( Figure 2-3) located on SW2

on Main P.C. board in OFF

normal operation.

(right) position for

NOTE

SW2, Dip Switch Assembly is located on upper, right

corner of Main P.C. Board.

(8) Install panels.

© Midmark Corporation 1999 SF-1597 Page 2-4 Printed in U.S.A.

Figure 2-3. Dip Switch Assembly (SW2)

Page 15

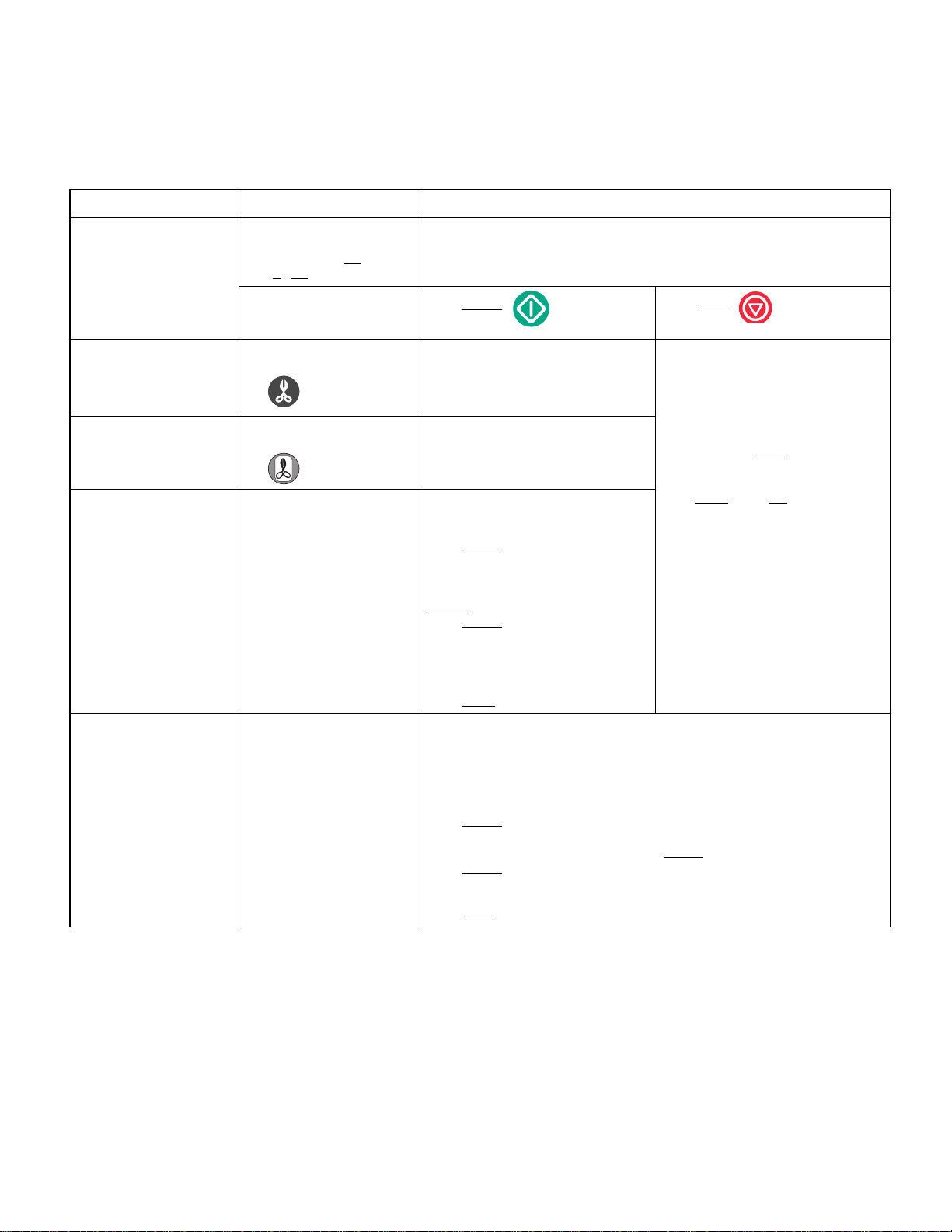

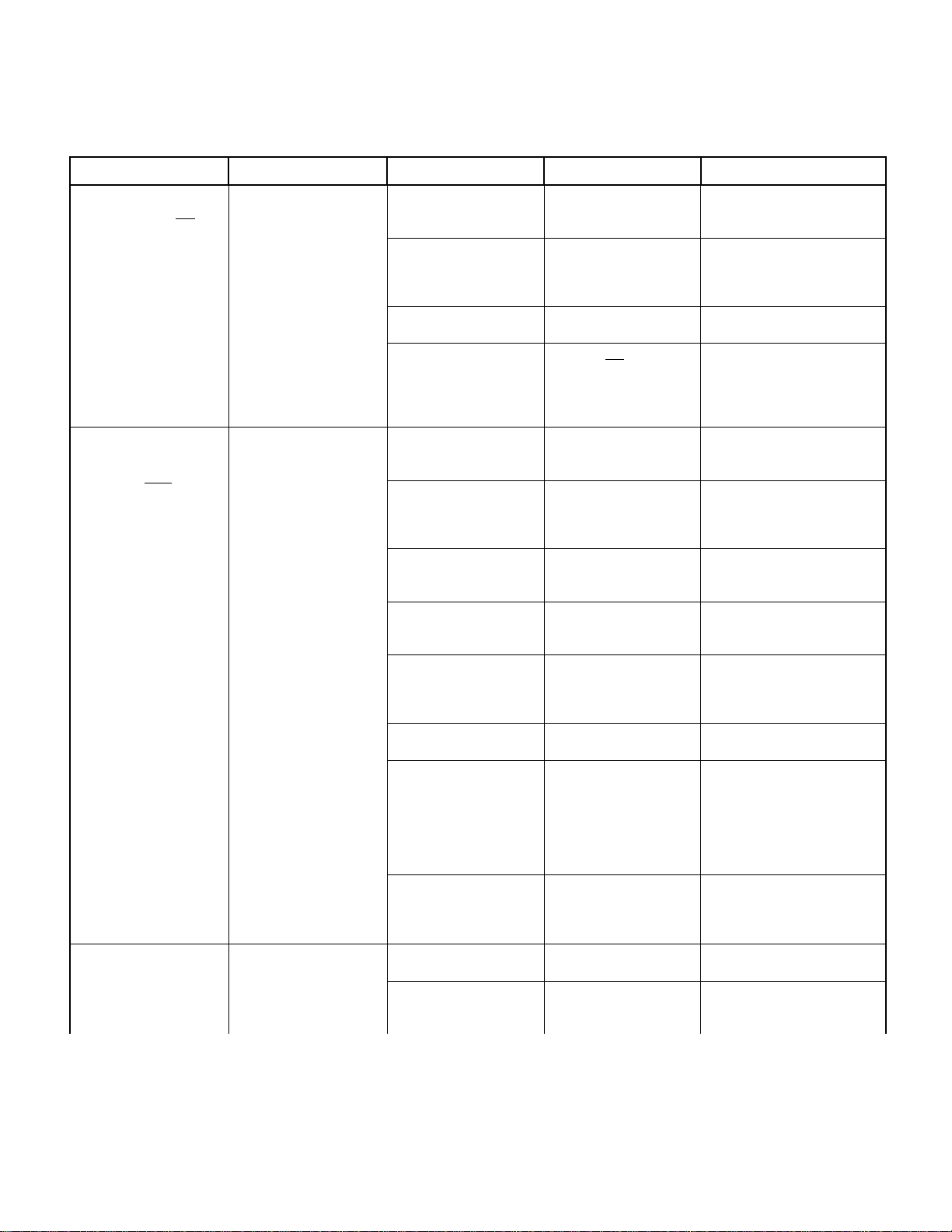

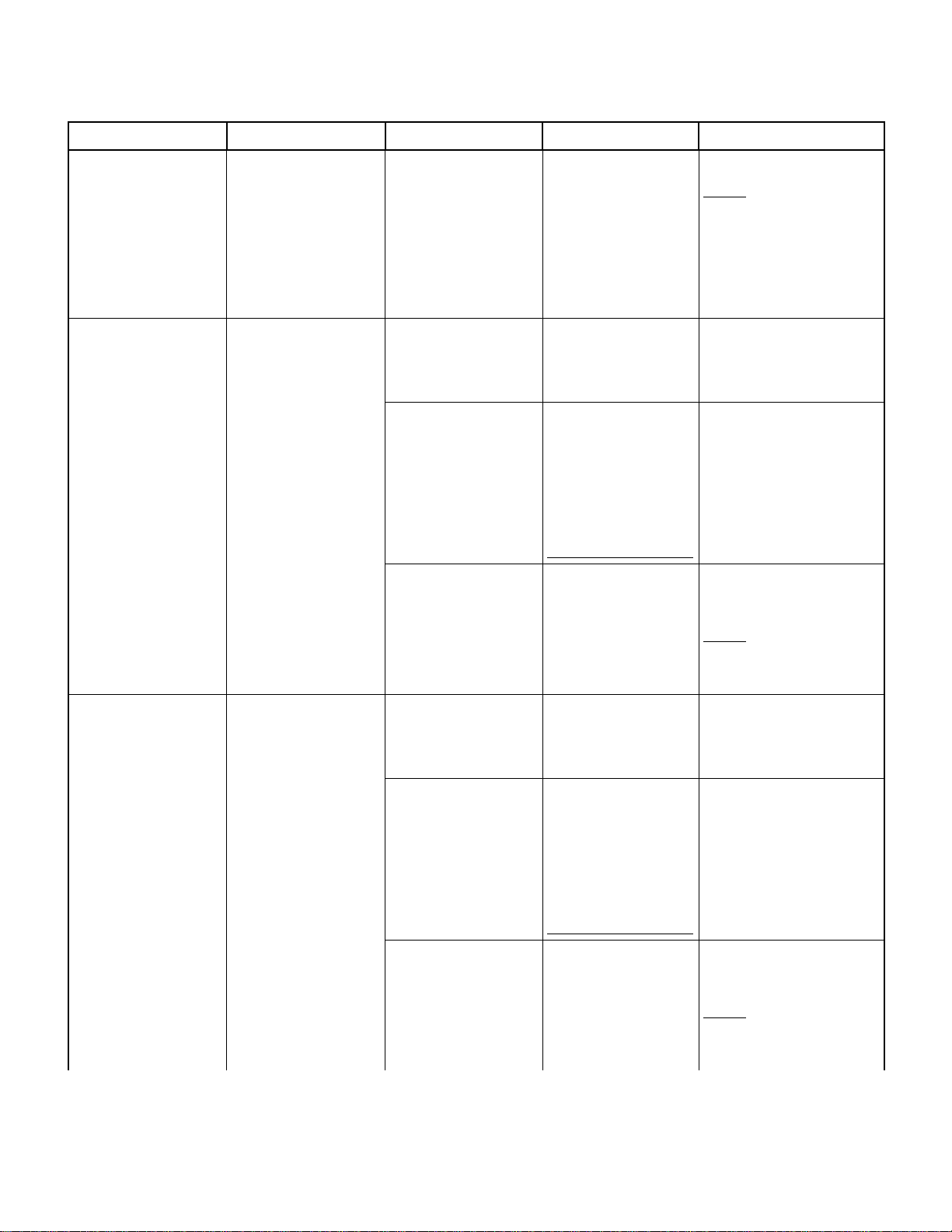

Service Diagnostics. Table 2-2.

Return To Table Of Contents

Table 2-2. Service Diagnostics (Refer to Schematic Fig. 2-2).

Audible Display Action / Notes

Audible beeps INITIALIZING CYCLE

SECTION II

TESTING AND TROUBLESHOOTING

Plug unit into outlet.

Audible beep when button is

depressed.

Audible beep when button is

depressed.

Audible beeps whenever

START or STOP buttons are

depressed.

Valve will emit a “clicking”

sound when operated.

Audible beeps whenever

START or STOP buttons are

depressed.

Valve will emit a “clicking”

sound when operated.

TOTAL CYCLES XX

VER X . XX

SERVICE DIAGNOSTIC

<START> I/O TEST

<STOP> RECALL ERRORS

PRESS

(UNWRAPPED) BUTTON

PRESS

(WRAPPED) BUTTON

AIR VALVE TEST

(START) TO TOGGLE

(STOP) FOR NEXT TEST

VENT VALVE TEST

(START) TO TOGGLE

(STOP) FOR NEXT TEST

Display shows total amount of cycles that have been run.

(VER is the software version number).

Press START

For testing button, when depressed an

audible beep should occur if button is

functioning correctly.

For testing button, when depressed an

audible beep should occur if button is

functioning correctly.

This function checks operation of Air

Valve and related L1 Fuse, and K4 relay

contacts on P.C. board.

Press START

K4 relay contacts close and the K4 LED

illuminates.

Power is applied to solenoid of AIR valve

opening

Press START

K4 relay opens and K4 LED goes out.

Solenoid of AIR valve deenergizes

returning valve to Normally Closed position.

Press STOP

NOTE: VENT VALVE is a Normally Open valve. Power must be applied to valve

solenoid to Close valve.

This function checks operation of Vent Valve and related L1 Fuse, and K3 relay contacts on P.C. board

Press START

K2 relay contacts close and K2 LED illuminates.

Power is applied to solenoid of VENT valve closing

Press START

K2 relay opens and K2 LED goes out.

Solenoid of VENT valve deenergizes returning valve to Normally Open position.

Press STOP

once.

valve.

again.

to go to VENT VALVE test.

once.

again.

to go to FILL VALVE test.

Press STOP

ERROR 1: CXXX 2: CXXX

3: CXXX 4: CXXX 5: CXXX

NOTE: Last 5 Error Codes are displayed

with the number 1 being the most recent

code.

<START> TO ZERO

Pressing START clears

<STOP> FOR NEXT TEST

Press STOP

END DIAGNOSTIC TEST

UNPLUG/RE-PLUG UNIT

STEAM AUX PRESS

XX.X F XX.X F XX.X P

NOTE: Pressure displayed is determined

by SW2 switch setting #7 and #8 for

PSIG, PSIA, or kPa.

Temperature displayed is °F or °C

depending on switch setting #7.

all Codes.

(Does Not clear codes)

valve.

© Midmark Corporation 1999 SF-1597 Page 2-5 Printed in U.S.A.

Rev. 4/02

Page 16

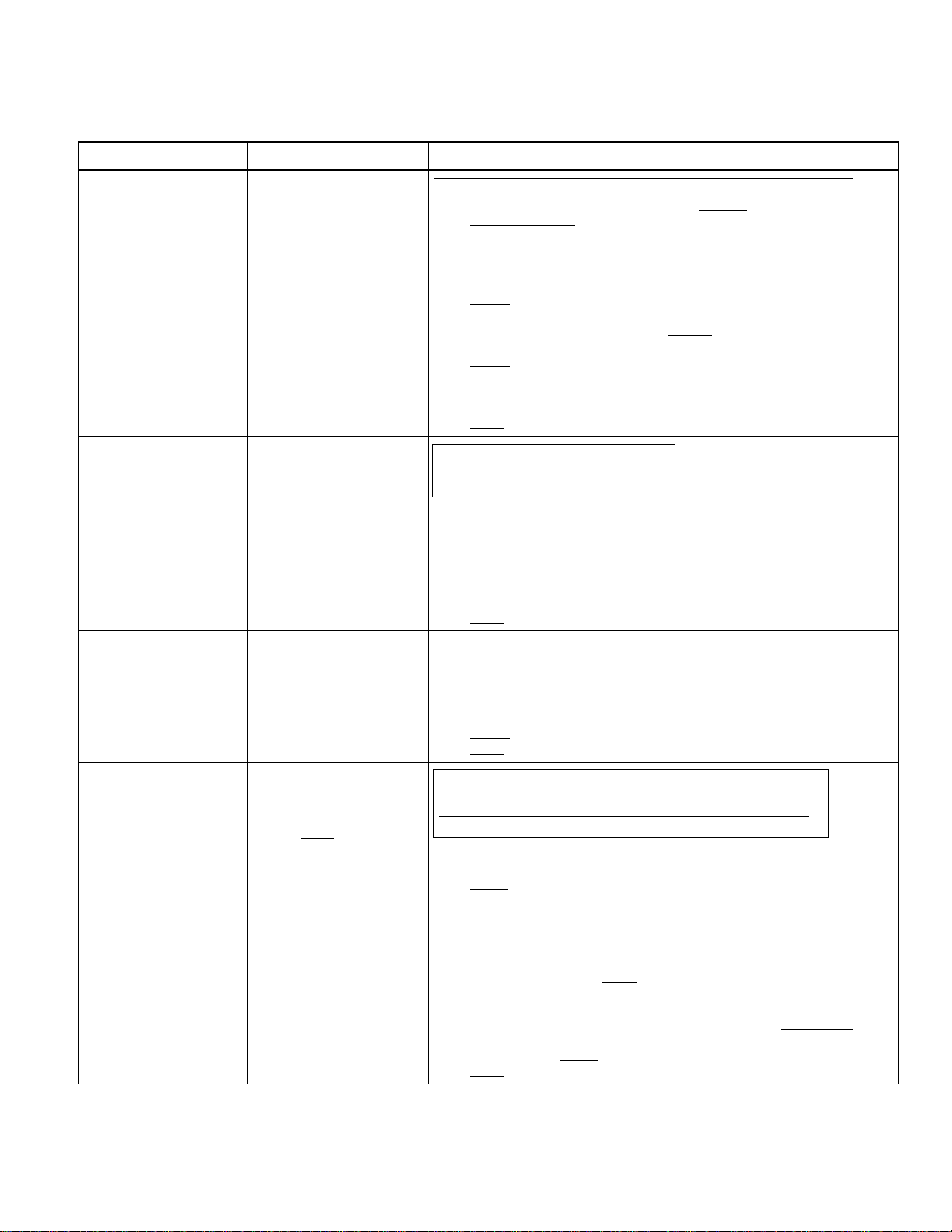

Audible Display Action / Notes

Return To Table Of Contents

Audible beeps whenever

START or STOP buttons are

depressed.

Valve will emit a “clicking”

sound when operated.

Audible beeps whenever

START or STOP buttons are

depressed.

Audible beeps whenever

START or STOP buttons are

depressed.

Audible beeps whenever

START or STOP buttons are

depressed.

TESTING AND TROUBLESHOOTING

Table 2-2. Service Diagnostics (Refer to Schematic Fig. 2-2).

FILL VALVE TEST

(START) TO TOGGLE

(STOP) FOR NEXT TEST

DOOR OPEN TEST

(START) TO OPERATE

(STOP) FOR NEXT TEST

MAIN RELAY TEST

(START) TO TOGGLE

(STOP) FOR NEXT TEST

STEAM HEATER TEST

(START) TO TOGGLE

(STOP) FOR NEXT TEST

(Checks Lower

Note: Amperage draw when

Steam heater is powered is

approximately 12 Amps.

Heater)

WARNING: Pressing START button energizes (Opens) FILL valve allowing

water to flow into chamber. Water Level Probe does not

test. Water can overflow

again or STOP button is pressed terminating test.

This function checks operation of Fill Valve and related L1 Fuse, and K3 relay contacts on P.C. board.

Press START

K3 relay contacts close and K3 LED illuminates.

Power is applied to solenoid of FILL valve, opening

ber.

Press START

K3 relay opens and K3 LED goes out.

Power is removed from Fill Valve solenoid returning valve to Normally Closed position.

Press STOP

WAR NING: Door will immediately go to

partially open position from closed position

when START button is depressed.

Checks operation of Door Pulse Solenoid and related L1 Fuse, and K5 relay contacts on P.C. board.

Press START

K5 relay contacts close and K5 LED illuminates .

Power is briefly ( 1/2 second ) applied to Door Pulse Solenoid, door springs to partially open position.

K5 relay opens, removing power from K5 LED and Door Pulse Solenoid.

Press STOP

Checks operation of Main Relay coil, N/O, N/C contacts and L1 Fuse.

Press START

Power is supplied thru P.C. board thru Plug J7 to coil of Main Relay energizing it.

Normally Open and Normally Closed contacts change condition, Open contacts

close and Close contacts open.

MAIN LED on P.C. board at Plug J7 illuminates.

Press START

Press STOP

WARNING: There is a 15 second maximum timing period that the

heater will be energized before it shuts off. To restart press START.

Do not restart cycle more than twice before allowing unit to cool for

apprx. 5 minutes.

Checks operation of Steam (Lower) Heater and related L1 Fuse, Upper and Lower

Thermostat O/L’s, Solid State Relay (SSR), and Main Relay.

Press START

12 VDC Power is supplied thru P.C. board thru Plug J7 to coil of Main Relay, energizing it, N/O contacts close.

12 VDC is also supplied thru Plug J7 to Solid State Relay (SSR) (3 & 4) closing it.

Line power is supplied thru the L1 fuse, N/C upper and lower thermostat O/L’s thru

the SSR closed contacts (1 & 2) to the Common terminal of Main Relay.

With Main Relay N/O contacts closed

Main Relay and SSR Steam Relay LED’s on P.C. board at Plug J7 illuminate.

SSR Steam LED on P.C. board at Plug J7 illuminates.

Heater remains energized for a 15 second time period before it automatically

off.

To restart test depress START

Press STOP

once.

again.

to go to DOOR OPEN test.

.

to go to MAIN RELAY test.

.

again to change back to normal unenergized condition

to go to STEAM HEATER test.

.

to go to AUXILIARY HEATER test.

from chamber unless START button is pressed

current flows to Steam (Lower) Heater.

.

SECTION II

function during

valve, water begins to fill cham-

turns

© Midmark Corporation 1999 SF-1597 Page 2-6 Printed in U.S.A.

Page 17

Audible Display Action / Notes

Note: Amperage draw when

Both heaters are powered is

approximately 6.5 Amps.

Return To Table Of Contents

Audible beeps whenever

START or STOP buttons are

depressed.

TESTING AND TROUBLESHOOTING

Table 2-2. Service Diagnostics (Refer to Schematic Fig. 2-2).

AUXILIARY HEATER TEST

(START) TO TOGGLE

(STOP) FOR NEXT TEST

(Checks Both

STEAM AUX PRESS

XX.X F XX.X F XX.X P

END DIAGNOSTIC TEST

UNPLUG/RE-PLUG UNIT

Heaters)

WAR NING: There is a 15 second maximum timing period that the

heater will be energized before it shuts off. To restart press START.

Do not restart cycle more than twice before allowing unit to cool for

apprx. 5 minutes.

Checks operation of both Auxiliary and Steam Heaters, L1 Fuse, Upper and Lower

Thermostat O/L’s, Solid State Relay (SSR), and Main Relay.

Press START

12 VDC is supplied thru Plug J7 to Solid State Relay (SSR) (3 & 4) closing it.

Line power is supplied thru L1 fuse and N/C Upper and Lower Thermostat O/L’s thru

the SSR closed contacts to the Common terminal of Main Relay.

With Main Relay N/C contacts closed current flows thru the Relay contacts to the

Auxiliary (Upper) Heater and then to the Steam (Lower) Heater.

SSR Surface LED on P.C. board at Plug J7 illuminates.

Heaters remain energized for 15 seconds before automatically

To restart test depress START

Press STOP

DIAGNOSTIC TEST.

Checks Steam (Side) and Auxiliary (Trough) Temperature Sensors and Pressure.

Displays temperature in °F or °C depending on setting of SW2, switch #7.

Should the particular sensor be open, shorted, or have a disconnected lead, display

will indicate a 32°F or 0.0°C reading.

Sensor plugs are located on P.C. Board at J3 for Auxiliary (Trough) Sensor and J5 for

Steam (Side) Sensor.

NOTE: When Service Diagnostics has been completed:

Unplug unit

Position SW2, Switch #1 to OFF

Install covers

Plug in unit.

.

.

to go to TEMPERATURE / PRESSURE DISPLAY & END

position

SECTION II

turning off.

2.3 Steam and Pressure Calibration.

When replacing a Steam temperature sensor (RTD),

pressure transducer or main P.C. board it will be necessary to assure the components and system are calibrated. Use the following steps and tables to calibrate

the system. Table 2-3 is for Temperature Calibration and

Table 2-4 is for Pressure Calibration.

NOTE

When a Lower Temperature Probe is replaced, calibration is not required.

When changing a P.C. Board:

You must have the Pressure Span

Steam Offset

replaced. This information can be obtained two ways:

(1) Documentation is supplied with sterilizer

(2) Use SW2 dipswitches #2 and #3 to recover

a.) Dipswitch #2: Pressure Span and Offset.

b.) Dipswitch #3: Steam Offset.

(3) After P.C. Board has been replaced re-enter old

© Midmark Corporation 1999 SF-1597 Page 2-7 Printed in U.S.A.

calibration data from P.C. Board being

data before replacing P.C. Board:

calibration data:

, Pressure Offset, and

(4) Use SW2 dipswitch #2 to enter Pressure Span

and Pressure Offset data. (Refer to Table 2-4).

(5) Use SW2 dipswitch #3 to enter Steam Offset

data. (Refer to Table 2-3).

If a Pressure Transducer or Steam Temperature

Probe is being replaced:

NOTE

Calibration data is shipped with the new component

but it is a good idea to record the old data from the

system before

(1) Recover the old data from the unit using SW2

dipswitch #2 (Pressure) and #3 (Temperature)

and record for reference.

(2) Replace the component (Transducer or Temp.

Probe).

(3) Enter the new calibration data that came with

the component using the appropriate SW2

dipswitch, #2 for Pressures, #3 for Temperature.

replacing the component.

Page 18

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

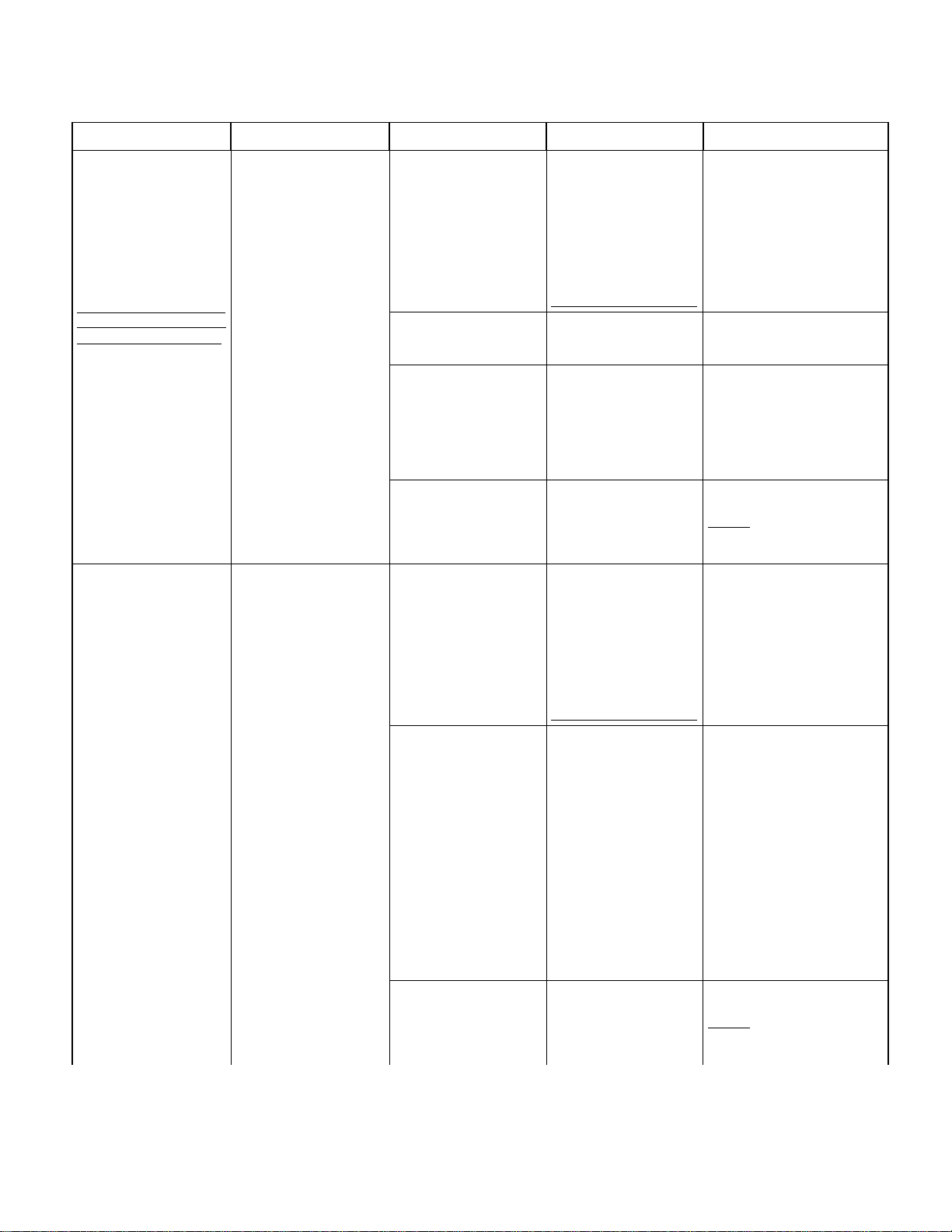

Table 2- 3

Steam (Side) Temperature Calibration (SW2 #3 Switch)

Display Action

WARNING: Unplug Unit.

Place SW2 dip switch #3 ON

INITIALIZING

SYSTEM

OFFSET: +0.000 °C

CURRENT STEAM TEMP

CALIBRATION DATA

PLEASE RECORD *

<START> TO CONTINUE

Plug Unit in.

(IMPORTANT*: Always

Press START

Button

record the displayed Offset Temperature [ +0.000 °C ])

SECTION II

. (All other dip switches should be OFF).

STEAM TEMP OFFSET

+0.00X °C

<UNWRAP> -0.1 C

<WRAPPED> +0.1 C

<STOP> TO CANCEL

<START> TO SAVE

STEAM TEMP

CALIBRATION MODE

SUCCESSFUL

UNPLUG / RE-PLUG UNIT

<UNWRAP> -0.1 C

<WRAPPED> +0.1 C

STEAM TEMP

CALIBRATION MODE

CANCELLED

UNPLUG / RE-PLUG UNIT

To change the Steam (Side) Offset Temperature depress the UNWRAP or WRAP button:

Each time UNWRAP

Depressing WRAP

Pressing STOP

Pressing START

Display after START was depressed

Display after STOP was depressed

IMPORTANT: Place SW2 dip switch #3 back to OFF position.

is depressed, increases reading 1 digit.

advances cursor to next digit (0.000).

here will cancel saving STEAM TEMP OFFSET data.

here will save STEAM TEMP OFFSET data.

© Midmark Corporation 1999 SF-1597 Page 2-8 Printed in U.S.A.

Page 19

TESTING AND TROUBLESHOOTING

Return To Table Of Contents

Table 2- 4

Pressure Calibration (SW2 #2 Switch)

Display Action

WAR NING: Unplug Unit.

. (All other dip switches should be OFF).

INITIALIZING

SYSTEM

SPAN: +1.000

OFFSET: +0.000 KPA

CURRENT PRESSURE

CALIBRATION DATA

PLEASE RECORD*

<START> TO CONTINUE

Place SW2 dip switch #2 ON

Plug Unit in.

(IMPORTANT: Always

Press START

Button

Record the displayed SPAN [ +1.000 ] and OFFSET [ +0.000 KPA ].)

SECTION II

PRESSURE SPAN

+ 1.000

<UNWRAP> INCR. DIGIT

<WRAP> NEXT DIGIT

<STOP> TO CANCEL

<START> TO SAVE

PRESSURE OFFSET

+0.000 KPA

<UNWRAP> INCR. DIGIT

<WRAP> NEXT DIGIT

<STOP> TO CANCEL

<START> TO SAVE

PRESSURE

CALIBRATION MODE

SUCCESSFUL

UNPLUG / RE-PLUG UNIT

SPAN +1.000

OFFSET +0.000 KPA

PRESSURE

CALIBRATION MODE

CANCELLED

UNPLUG / RE-PLUG UNIT

To change the Pressure Span depress the UNWRAP or WRAP button :

Each time UNWRAP

Depressing WRAP

Pressing STOP

Pressing START

To change the Pressure Offset depress the UNWRAP or WRAP button :

Each time UNWRAP

Depressing WRAP

Pressing STOP

Pressing START

Display after START was depressed

Display after STOP was depressed

is depressed, increases reading 1 digit.

advances cursor to next digit (0.000).

here will cancel ALL saving data.

here will save ONLY Pressure Span data.

is depressed, increases reading 1 digit.

advances cursor to next digit (0.000).

here will ONLY cancel saving Offset data.

here will save ONLY Pressure Offset data.

© Midmark Corporation 1999 SF-1597 Page 2-9 Printed in U.S.A.

IMPORTANT: Place SW2 dip switch #2 back to OFF position.

Page 20

SECTION II

Return To Table Of Contents

TESTING AND TROUBLESHOOTING

2.5 Troubleshooting Procedures

Table 2-5 is a Troubleshooting Guide which is used to

help to determine the cause of a malfunction.

Refer to Section V Schematics and Diagrams for tracing

circuits and referencing points in Troubleshooting

Guide.

Error Categories (Severity)

There are 4 categories of errors in the M4•9 software:

Automatic Errors:

Minor problem causing Operator to do something such

as close the door, etc. Once cleared the software continues on where it left off.

Fast Restart Errors:

• Possible problems with M4•9 control system or with

producing an effective sterilization cycle.

•May be due to something the Operator did such as

pressing the STOP button during a sterilization mode.

•Could also be due to temperature values being outside

the normal range required as sensed by the Lower

Temperature probe.

• Operator is prompted by display to press STOP

button to Restart

Software will abandon the sterilization cycle and return

to SELECT CYCLE / PREHEAT MODE.

.

Fatal Errors

• This would indicate possible serious problems

M4•9 control system.

• Pressing the STOP button before 60 seconds

(when it turns off automatically) will silence the audible

signal but the Power must be disconnected

error code display.

Unit should not be ran until a trained Service Technician

has repaired the malfunction.

with the

to clear the

NOTE

In the Troubleshooting Guide, Table 2-5, the Type of

Error Category of the specific Code will be included

on the chart.

EQUIPMENT ALERT

Always complete Service Diagnostics

(Section 2.2) before replacing any major

components, especially the Main P.C. Control Board.

WARNING

Use extreme caution when testing com-

ponents with Sterilizer plugged into

outlet. Line voltage is present. Failure to comply

could result in personal injury.

Restart Errors:

• Like Fast Restart, indicates possible problems with

M4•9 control system or with producing an effective sterilization cycle.

• Operator is prompted to press the STOP button,

abandoning the sterilization cycle.

Pressing the STOP button will stop the audible signal

but 60+ seconds must

indicated and the pressure inside the chamber must

equal to or below 5 Psig (34.5 Kpa) before it returns to

SELECT CYCLE / PREHEAT MODE to allow starting

another cycle.

© Midmark Corporation 1999 SF-1597 Page 2-10 Printed in U.S.A.

pass since the condition was

Rev. 4/02

be

Page 21

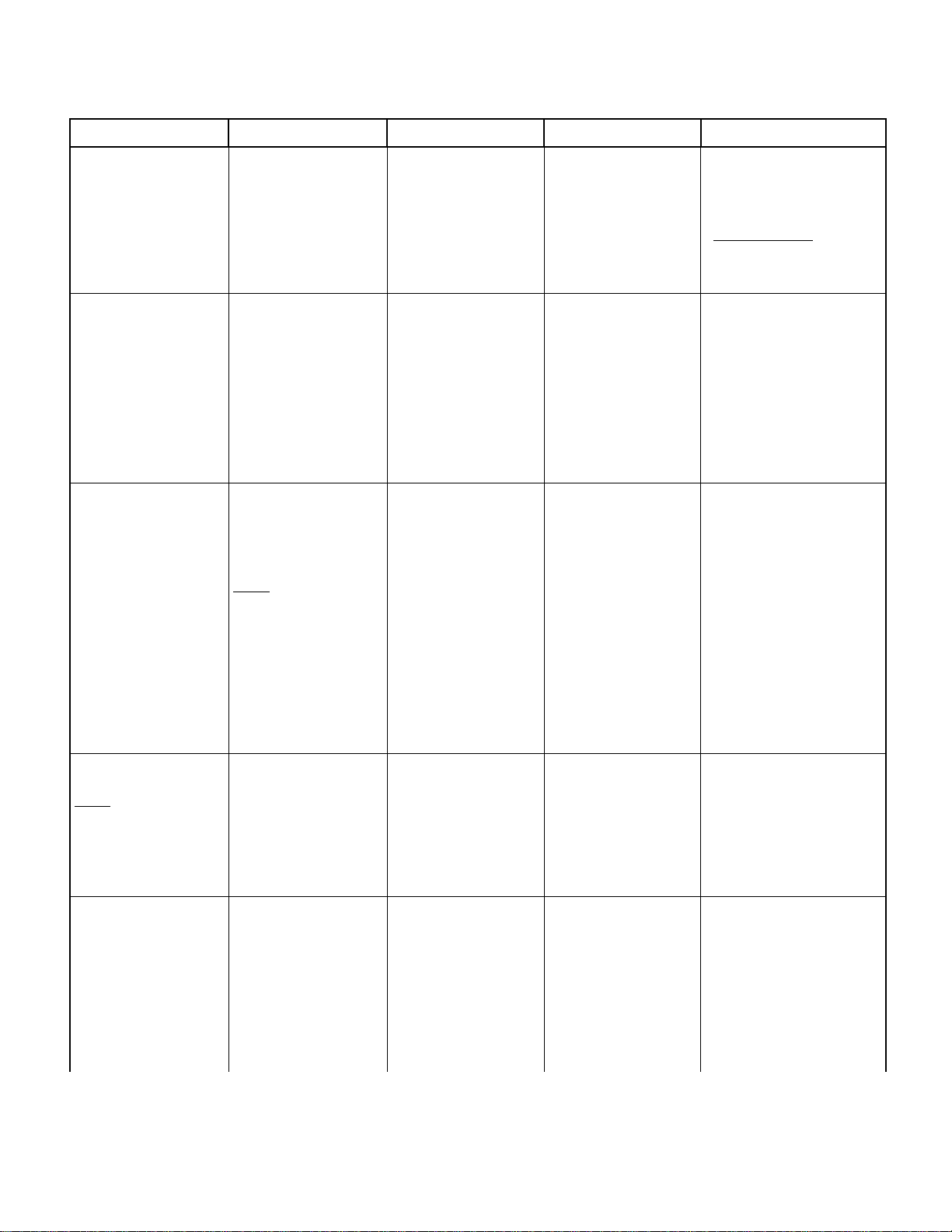

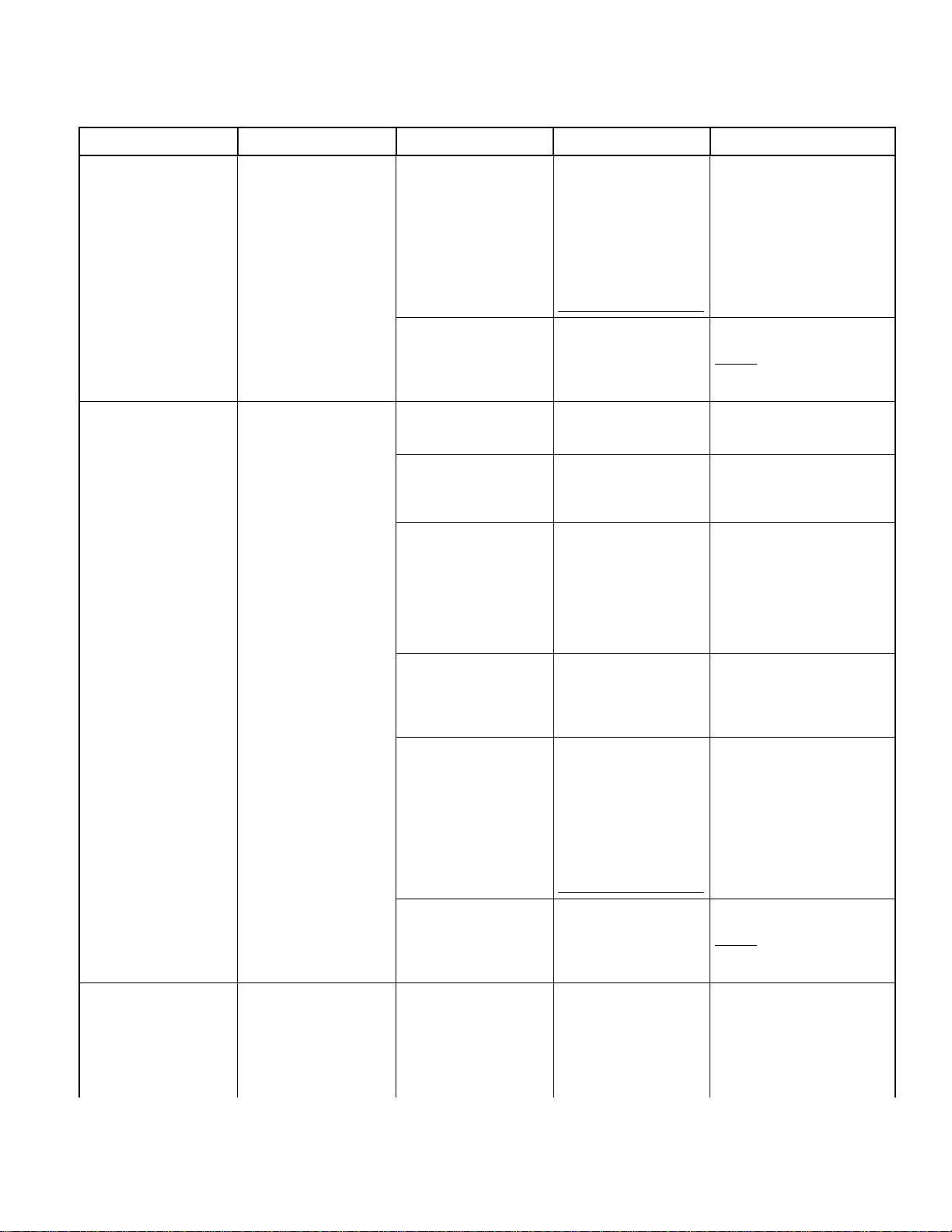

Problem Display / Symptom Probable Cause Check Correction

Return To Table Of Contents

(Non-Coded Errors)

Sterilizer has no

power.

Touch pad and display do not work.

Sterilizer has

power.

No Display.

Touch pads work.

Sterilizer has

power.

Table 2-5. Troubleshooting Guide

When depressed Touchpad or Display do not work.

There is no display and

touch pad does not work.

Displayed data is a line of

undefined characters and

intermitent beep continues.

SECTION II

TESTING AND TROUBLESHOOTING

Sterilizer is not plugged in. Check that power cord is

No power at outlet Check for voltage at outlet. Reset circuit breaker.

Main (L1) Fuse blown on

back of unit.

Transformer has Open

windings.

Plug on pin connection

J12 on Main P.C. board

has come loose.

Wire harness from Transformer and J12 pin connection has broken

wire(s).

Transformer has open or

shorted winding.

Fuses F1 and F2 on Main

P.C. board are blown or

open.

Ribbon cable from J1 on

Main P.C. board to J3 on

Display P.C. board is disconnected.

J1/ J3 ribbon cable has

open lead(s).

Main P.C. Board is malfunctioning.

Display P.C. Board is malfunctioning.

Ribbon cable from J2 to

touch pad is disconnected

J2 ribbon cable to touch

pad has open lead(s).

plugged into sterilizer and/

or outlet.

Check continuity of fuse. Replace fuse with same style

Check for line

pins 1 & 6 on primary side

of transformer.

Check condition of connector on J12 of Main P.C.

board.

Check continuity of wire

harness from transformer

to J12 pin connection.

Check for 18.5 VAC output

on terminals 7 & 12 at

transformer.

Check continuity of fuses

F1 and F2 with Ohm

meter.

Check plug connectors of

J1 on Main P.C. board and

J2 on Display P.C. board.

Check continuity of J1/J2

ribbon cable.

Check for 18.5 VAC on

outlet side of F1/F2 fuses

and 5 VDC on pin connector J1 across pins 1 & 2,

then across pins 15 & 16

(see Main P.C. Board diagram).

Check for 5 VDC

betweeen R1and Ground

on Display P.C. Board (see

Main P.C. Board diagram).

Check J2 Plug connection. Assure J2 Plug pins are aligned

Check continuity of J2 ribbon cable and touch pad.

voltage at

Plug power cord into sterilizer

and/or outlet.

Assure outlet is on dedicated

circuit capable of handling sterilizer power requirements.

and rating.

If 18.5 VAC is not present on

secondary side when line voltage is present on primary side,

replace Transformer (Refer to

para 4.17).

Plug connector into J12 on Main

P.C. board.

Repair or replace wire harness.

Replace transformer

(Refer to para 4.17).

Replace fuses with same style

and rating.

Assure printer ribbon cable connectors are plugged in securely

Replace ribbon cable.

If voltage is present at F1/F2 but

no voltage is present at J1 and

leads between transformer secondary and J12 have no broken

connections replace Main P.C

Board (Refer to para 4.22).

If no 5 VDC is present replace

Display P.C. Board (Refer to

para 4.4).

and connected securely.

Replace touch pad and ribbon

cable assembly (Refer to

para 4.5).

© Midmark Corporation 1999 SF-1597 Page 2-11 Printed in U.S.A.

Rev. 10/02

Page 22

Problem Display / Symptom Probable Cause Check Correction

Return To Table Of Contents

Unit will not fill.

(Coded Errors)

Code C010.

(Type: FAST RESTART)

Code

C060.

(Type: FATAL)

Code

C102.

(Type: FAST RESTART

unless

during Fill Mode,

prompted by TEMP REG

WARNING then it would be

RESTART.)

C103 HEATUP

Code

Code

C104 STERILIZE

Code

C105 VENT

C106 DOOR

Code

(Type: RESTART)

Table 2-5. Troubleshooting Guide

Display:

CHAMBER VENTING

BEFORE FILL

C010: POWER UP MODE

SYSTEM PWR LOSS

ITEMS NOT STERILE

PUSH STOP TO RESTART

Unit lost power for a few

seconds during Fill, Heat

Up, or Sterilization Mode.

Also, if power was lost during the Vent Mode for a

Temperature Regulation

Warning.

C060: POWER UP MODE

SYSTEM HARDWARE

ITEMS NOT STERILE *

UNPLUG/RE-PLUG UNIT

*No message on this line

power loss occurs

unless

during Fill, Heatup, Sterilization or Vent (only in

case of a Temp Reg Warning).

Also, if an error that

occurred in one of these

modes was not properly

cleared before unit was

Unplugged and Replugged

into power source.

C102: FILL MODE

STOP PRESSED

ITEMS NOT STERILE *

PUSH STOP TO RESTART

*No message on this line

unless it occurs during

Venting because of a Temp

Reg Warning.

(Refer to column on left for

codes and description)

C10X: XXXXXX MODE

STOP PRESSED

ITEMS NOT STERILE*

PUSH STOP TO RESTART

*No message on this line

unless it occurs during

Venting because of a Temp

Reg Warning.

TESTING AND TROUBLESHOOTING

Atmospheric pressure setting out of calibration.

Power interruption. Check voltage supply to

May be an internal glitch

due to a brief interruption

of power with components

on P.C. Board (RAM,

EEPROM, A/DC.

Operator pressed STOP

button, terminating FILL

Mode.

Operator pressed STOP

button, terminating

HEATUP Mode.

Calibrate Atmospheric

Pressure setting.

assure outlet is on a dedicated circuit with correct

circuit breaker or fuse.

Check voltage supply to

assure outlet is on a dedicated circuit with correct

circuit breaker or fuse.

Check with person operating unit.

Check with person operating unit.

SECTION II

• Unplug Unit & Open Door.

• Place SW2 dip switch #4 ON

• Plug in Unit.

• Displays: START TO ZERO.

• Press START

• Wait 1 - 2 minutes

• Unplug unit.

• Place SW2 dip switch #4 OFF

• Plug in unit.

Plug unit into a dedicated circuit

with correct circuit breaker or

fuse. Refer to Specifications

para 1.5).

Power interruption could be due

to an electrical storm, brown

out, etc.

Plug unit into a dedicated circuit

with correct circuit breaker or

fuse. Refer to Specifications

para 1.5).

Power interruption could be due

to an electrical storm, etc.

Explain proper operation.

Explain proper operation.

© Midmark Corporation 1999 SF-1597 Page 2-12 Printed in U.S.A.

Rev. 10/02

Page 23

Problem Display / Symptom Probable Cause Check Correction

Return To Table Of Contents

Code C232

(Type: RESTART)

Code

C326

(Type: AUTOMATIC)

C382

Code

(Type: AUTOMATIC)

Table 2-5. Troubleshooting Guide

C232: FILL MODE

WATER LOW

ITEMS NOT STERILE

PUSH STOP TO RESTART

After door is closed or

chamber vented, water fill

(level) sensor did not

detect water level within

the 2 minutes

period.

C326: DOOR MODE

Door remains closed one

second after door pulse

solenoid energized.

Door is Open

C326 is displayed.

ITEMS NOT STERILE

required time

DOOR CLOSED

OPEN DOOR

but Code

C382: FILL MODE

DOOR OPEN

CLOSE DOOR

TESTING AND TROUBLESHOOTING

Reservoir water level low. Check water level in Res-

Mesh filter restricted. Check if mesh filter is

Water Fill Level Sensor

dirty.

Fill Valve or related plumbing clogged.

Fill Valve coil malfunctioning.

J6 Plug connection loose

or disconnected or broken

wires.

P.C. board malfunctioning. • Check for 4.5 to 5.0 VDC

Door may be hanging up

on door pulse solenoid

latch.

Instrument(s) inside chamber depressing door interlock plunger.

Door Switch malfunctioning.

P.C. Board malfunctioning. Check for 115 VAC at J11,

Door Switch contacts

opened during Fill Mode.

ervoir.

clogged.

Check Water Fill (level)

Sensor for dirt or corrosion.

Check Water Fill Valve and

related tubing for restricted

or clogged.

Check continuity of Water

Fill Valve solenoid coil for

open winding.

Check Water Fill Valve

sensor plug connection at

J6 on P.C. Board and

related leads.

at J6 pins 1 & 2 on P.C.

Board.

• Run a Service Diagnostics to check functions of

Fill Valve and related components

• Check position of door

(open or closed).

• Run Service Diagnostics

and check operation of

door pulse solenoid.

Try opening door by lifting

door handle. If handle

does not move to open

position door interlock

plunger is stuck in locked

position.

Check Door Switch contacts to assure they close

when door is closed and

open when door is

opened.

3 (L2) & 4 (Door Interlock)

terminals.

Check with person operating unit to see if door was

opened as unit was filling.

Check Door Switch.

Contact should be closed

when door is in closed

position.

SECTION II

Add water to reservoir so that it

is in the correct range on the

water level label.

Push STOP to restart back to

SELECT CYCLE Mode.

Clean or replace mesh filter.

Clean or replace Water Fill

(level) Sensor (Refer to

para 4.33).

Clean or replace Water Fill

Valve (Refer to para 4.27).

Replace Water Fill Valve (Refer

to para 4.27).

Assure J6 plug connector is

securely connected and related

leads are not broken.

If no voltage replace P.C. Board

(Refer to para 4.22).

Always

run Service Diagnostics

(Para 2.2) before replacing P.C.

Board.

• Open door.

• Run another cycle. If condition

persist where door must be

manually opened check door

pulse solenoid for adjustment

(Refer to para 4-21).

Remove panels and if necessary, drain water from reservoir

then tilt unit back until instrument(s) slide away from plunger

and door can be opened.

Adjust Door Switch (Refer to

para 4-20).

If voltage is present and problem persist replace P.C. Board

(Refer to para 4-22).

run Service Diagnostics

Always

(Para 2.2) before replacing P.C.

Board.

Explain proper operation.

Close door, cycle will continue

where left off.

If contact of Door Switch shows

open when door is closed adjust

or replace switch (Refer to para

4.20).

© Midmark Corporation 1999 SF-1597 Page 2-13 Printed in U.S.A.

Rev. (10/02)

Page 24

Problem Display / Symptom Probable Cause Check Correction

Return To Table Of Contents

Code C383

(Type: RESTART)

C384

Code

(Type: FA TAL)

C385

Code

(Type: RESTART)

C431

Code

(Type: FAST RESTART)

Table 2-5. Troubleshooting Guide

C383: HEATUP MODE

DOOR OPEN

ITEMS NOT STERILE

PUSH STOP TO RESTART

C384: STERILIZE MODE

DOOR OPEN

ITEMS NOT STERILE

UNPLUG / RE-PLUG UNIT

C385: VENT MODE

DOOR OPEN

ITEMS NOT STERILE

PUSH STOP TO RESTART

C431: SELECT MODE

AUX TEMP LOW

PUSH STOP TO RESTART

Auxiliary temperature

(trough) has not risen to at

least 212°F (100°C) in 10

minutes while unit is in

SELECT/PREHEAT

Note: An initial cycle must

be ran and unit must be

warm for this code to display.

mode.

TESTING AND TROUBLESHOOTING

Door Switch contacts

opened during Heatup

Mode.

Door Switch contacts

opened during Sterilize

Mode.

Door Switch contacts

opened during Vent Mode.

Door left wide open and

tray rack not in position.

Water level of reservoir is

covering outlet of condensing coil. Water

siphons back into chamber

trough resulting in low

Auxiliary (trough) temperature.

Solid State Relay (SSR)

malfunctioning.

Auxiliary (upper) or Steam

(lower) heater has open

winding.

Check with person operating unit to see if door was

opened as unit was heating up.

Check Door Switch. Contact should be closed

when door is in closed

position.

Check Door Switch. Contact should be closed

when door is in closed

position.

Check with person operating unit to see if door was

opened during Vent.

Check Door Switch. Contact should be closed

when door is in closed

position.

Door is left wide open for

an extended length of

time* and tray rack is not in

place in chamber.

*Heaters will cycle on/off

for 90 minutes to maintain

preheat temp. 212°F

(100°C).

Check if condensing coil

outlet is beneath water

level in reservoir.

• Disconnect power from

unit.

• Remove line voltage

leads from terminals 1 & 2

of SSR, place terminals

out of way to prevent electrical shock.

• Place meter probes on

terminals 1 & 2 and check

ohms.

• Run Service Diagnostics,

go to Steam and Auxiliary

Heater Test. When Heaters are on (switch is

closed) apprx. 700 ohms

should register on meter.

Check continuity of both

heaters.

115 VAC

ohms, cold reading.

230 VAC

ohms, cold reading.

heaters are 10

heaters are 39

SECTION II

Explain proper operation.

Push STOP to restar t back to

SELECT CYCLE Mode.

If contact of Door Switch shows

open when door is closed adjust

or replace switch (Refer to para

4.20).

If contact of Door Switch shows

open when door is closed adjust

or replace switch (Refer to para

4.20).

Explain proper operation.

Push STOP to restar t back to

SELECT CYCLE Mode.

If contact of Door Switch shows

open when door is closed adjust

or replace switch (Refer to para

4.20).

Inform Operator that door

should be placed in the partially

open or closed position after

each cycle.

• Inform operator not to over fill

reservoir.

• If reservoir is not over filled but

coil outlet is submerged, bend

coil so outlet is a maximum of 1

7/8” below top of lid opening.

Do not allow coil to touch top or

sides of reservoir.

If ohms value did not register on

meter when heaters were energized replace Solid State Relay

(SSR) (Refer to para 4.15).

If a heater shows no or very different continuity, replace the

heater (Refer to para(s) 4.31 or

4.32).

© Midmark Corporation 1999 SF-1597 Page 2-14 Printed in U.S.A.

Rev. (10/02)

Page 25

Problem Display / Symptom Probable Cause Check Correction

Return To Table Of Contents

Code C431 (Continued)

(Type: FAST RESTART)

C437

Code

(Type: FAST RESTART)

Table 2-5. Troubleshooting Guide

(Continued)

C431: SELECT MODE

AUX TEMP LOW

PUSH STOP TO RESTART

Auxiliary temperature

(trough) has not risen to at

least 212°F (100°C) in 10

minutes while unit is in

SELECT/PREHEAT

Note: An initial cycle must

be ran and unit must be

warm for this code to dis-

C437: DRY MODE

AUX TEMP LOW

PUSH STOP TO RESTART

Chamber Temperature

sensed by Auxiliary

(trough) Temp. Sensor

(RTD) is lower than 158° F

(70°C) after 5 minutes into

DRY mode.

mode.

play.

TESTING AND TROUBLESHOOTING

Auxiliary Temperature

Sensor malfunctioning.

Main P.C. Board malfunctioning.

Door left wide open and

tray rack not in position.

Solid State Relay (SSR)

malfunctioning.

Auxiliary (upper) or Steam

(lower) heater has open

winding.

Auxiliary Temperature

Sensor malfunctioning.

Run Service Diagnostics

and check STEAM and

AUX temp readings.

Run Service Diagnostics

and check each function.

Also, make the various

voltage checks as indicated on the P.C. Board

Schematic in Section 5.

Door is left wide open for

an extended length of

time* and tray rack is not in

place in chamber.

*Heaters will cycle on/off

for 90 minutes to maintain

preheat temp. 212°F

(100°C).

• Disconnect power from

unit.

• Remove line voltage

leads from terminals 1 & 2

of SSR, place terminals

out of way to prevent electrical shock.

• Place meter probes on

terminals 1 & 2 and check

ohms.

• Run Service Diagnostics,

go to Steam and Auxiliary

Heater Test. When Heaters are on (switch is

closed) apprx. 700 ohms

should register on meter.

Check continuity of both

heaters.

115 VAC

ohms, cold reading.

230 VAC

ohms, cold reading.

Run Service Diagnostics

and check STEAM and

AUX temp readings.

Remove plug connector at

J3 on P.C. Board and

check resistance value

(ohms) of RTD.

Resistance values should

be between the following:

75°F (23°C) = 1090 ohms.

545°F (285°C) = 2066

ohms.

Above values +/- 10 Ohms

heaters are 10

heaters are 39

SECTION II

If AUX temperature reading is

not in line with STEAM replace

Auxiliary Temperature Sensor

(Refer to para 4.30).

Replace the P.C. Board (Refer

to para 4.22).

run Service Diagnostics

Always

(Para 2.2) before replacing P.C.

Board.

Inform Operator that door

should be placed in the partially

open or closed position after

each cycle.

If ohms value did not register on

meter when heaters were energized replace Solid State Relay

(SSR) (Refer to para 4.15).

If a heater shows no or very different continuity, replace the

heater (Refer to para(s) 4.31 or

4.32).

If AUX temperature reading is

not in line with STEAM replace

Auxiliary Temperature Sensor

(Refer to para 4.30).

If Auxiliary Temperature probe

shows open or values outside

resistance ranges replace

probe (Refer to para 4.30).

© Midmark Corporation 1999 SF-1597 Page 2-15 Printed in U.S.A.

Rev.(10/02)

Page 26

Problem Display / Symptom Probable Cause Check Correction

Return To Table Of Contents

Code C437 (Continued)

(Type: FAST RESTART)

C461

Code

(Type: FAST RESTART)

Code

C467

(Type: FAST RESTART)

Table 2-5. Troubleshooting Guide

(Continued)

C437: DRY MODE

AUX TEMP LOW

PUSH STOP TO RESTART

Chamber Temperature

sensed by Auxiliary

(trough) Temp. Sensor

(RTD) is lower than 158° F

(70°C) after 5 minutes into

DRY mode.

C461: SELECT MODE

AUX TEMP HARDWARE

PUSH STOP TO RESTART

Auxiliary A / D converter

reports an average value

outside the limits for normal operation during the

SELECT mode.

Note: This will only occur

during a warm start (back

to back cycles).

C467: DRY MODE

AUX TEMP HARDWARE

PUSH STOP TO RESTART

Auxiliary A / D converter

reports an average value

outside the limits for normal operation during the

DRY mode.

TESTING AND TROUBLESHOOTING

Main P.C. Board malfunctioning.

Auxiliary Temperature

Sensor (RTD) unplugged

from P.C. Board.

Auxiliary Temperature

Sensor (RTD) malfunctioning.

Main P.C. Board Malfunctioning.

Auxiliary Temperature

Sensor (RTD) unplugged

from P.C. Board.

Auxiliary Temperature

Sensor (RTD) malfunctioning.

Main P.C. Board Malfunctioning.

Run Service Diagnostics

and check each function.

Also, make the various

voltage checks as indicated on the P.C. Board

Schematic in Section 5.

Check condition of Auxiliiary RTD plug on P.C.

Board. (Refer to P.C.

Board Schematic in Section 5).

Remove plug connector at

J3 on P.C. Board and

check resistance value

(ohms) of RTD.

Resistance values should

be between the following:

75°F (23°C) = 1090 ohms.

545°F (285°C) = 2066

ohms.

Above values +/- 10 Ohms

Remove plug connector at

J3 on P.C. Board and

check voltage. Voltage

should be apprx. 4.5 VDC

at all times with unit

plugged in.

Also run Service Diagnostics.

Check condition of Auxiliiary RTD plug on P.C.

Board. (Refer to P.C.

Board Schematic in Section 5).

Remove plug connector at

J3 on P.C. Board and

check resistance value

(ohms) of RTD.

Resistance values should

be between the following:

75°F (23°C) = 1090 ohms.

545°F (285°C) = 2066

ohms.

Above values +/- 10 Ohms

Remove plug connector at

J3 on P.C. Board and

check voltage. Voltage

should be apprx. 4.5 VDC

at all times with unit

plugged in.

Also run Service Diagnostics.

SECTION II

Replace the P.C. Board (Refer

to para 4.22).

Always

run Service Diagnostics

(Para 2.2) before replacing P.C.

Board.

Assure Auxiliary RTD plug connector is secure.

If Auxiliary Temperature probe

shows open or values outside

resistance ranges replace

probe (Refer to para 4.30.

If voltage is not present or Service Diagnostics reveals a problem replace P.C. Board (Refer to

para 4.22).

Always

run Service Diagnostics

(Para 2.2) before replacing P.C.

Board.

Assure Auxiliary RTD plug connector is secure.

If Auxiliary Temperature probe

shows open or values outside