Page 1

TP202 Rev. A

M3 UltraFast

®

Automatic Sterilizer

For Models:

M3 (-001 thru -004)

User Guide

003-1658-00 Rev. S (11/9/15)

Page 2

2

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Serial Number VXXXXXX

VXXXXXX

VXXXXXX

Model / Serial Number:

Date of Purchase:

Midmark Authorized Service

Company:

Dealer:

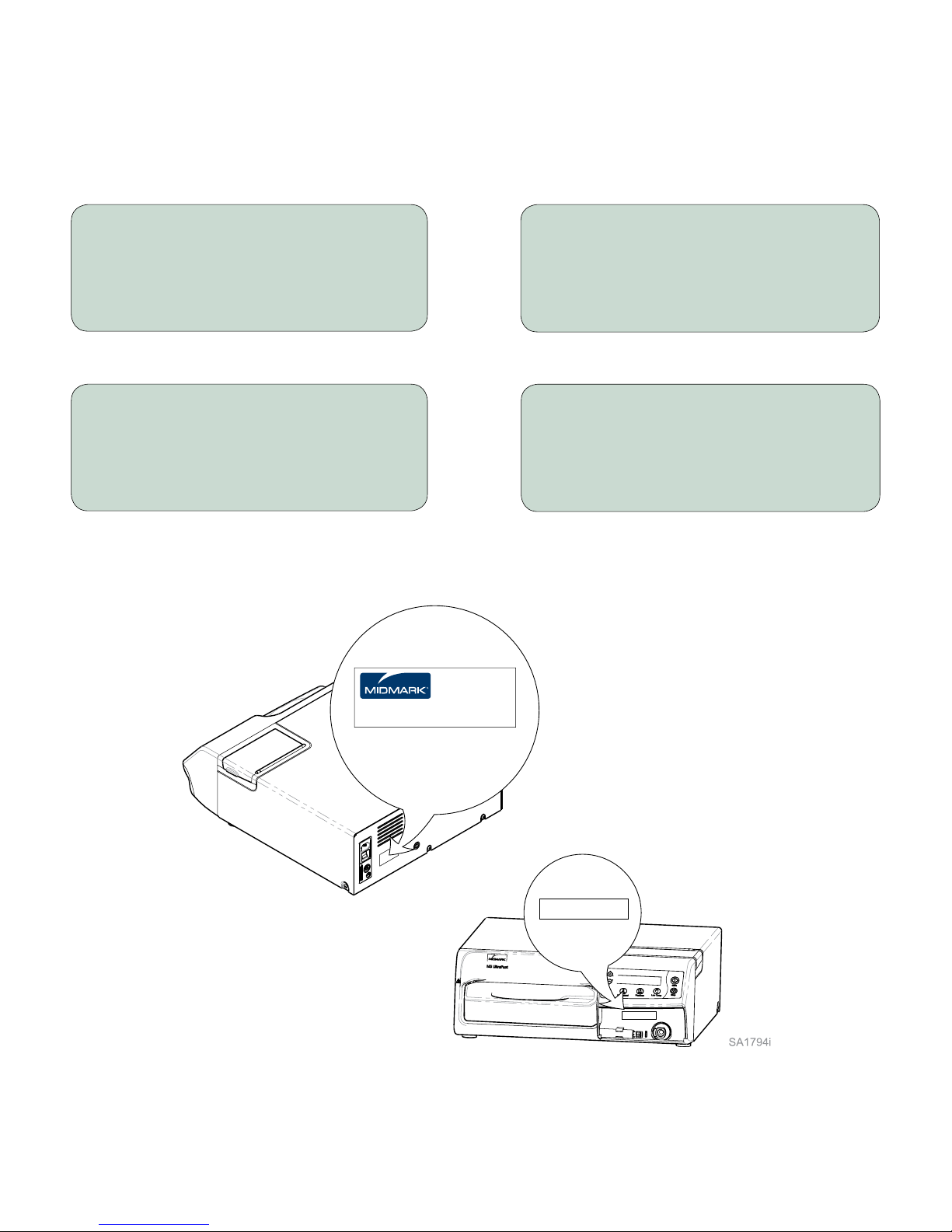

Product Information

Model / Serial

Number Location

Page 3

3

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Table of Contents

Important Information

Component Location ........................................4

Safety Instructions ...........................................5

Intended Use....................................................5

Electromagnetic Interference ...........................5

Safety Symbols ................................................6

Transportation / Storage Conditions ................6

Operating Environment ....................................7

Electrical Ratings / Requirements ....................7

Sterilization Monitoring Guidelines...................8

Installation

Location Requirements ....................................9

Power Cord Connection .................................10

External Condensing Tank

Connections ................................................... 11

External Condensing Tank

Draining Procedures ......................................13

Operation

Quick Reference ............................................14

Power Switch .................................................15

Filling the Reservoir .......................................15

Qualication Testing .......................................16

Loading the Tray ............................................16

Cycle Selection ..............................................20

Post Sterilization Processing .........................22

‘Additional Heat’ Cycle ..................................22

Adjusting the Dry Time ...................................23

Accessories

Accessory Chart.............................................23

Maintenance

Maintenance Messages .................................23

Daily Care ......................................................24

Periodic Maintenance ....................................25

Monthly Maintenance .....................................27

Extended Use Maintenance ...........................28

Printer (optional)

Printer Harness Connection ...........................29

Printer Readout ..............................................30

Paper Roll Installation ....................................31

Printer Ribbon Cartridge Replacement ..........32

Troubleshooting

Error Codes....................................................33

User Diagnostic Mode....................................34

Calling for Service ..........................................35

Specications

Specication Information................................36

Water Purity Specications ............................37

Warranty Information

Scope of Warranty .........................................38

Page 4

4

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Important Information

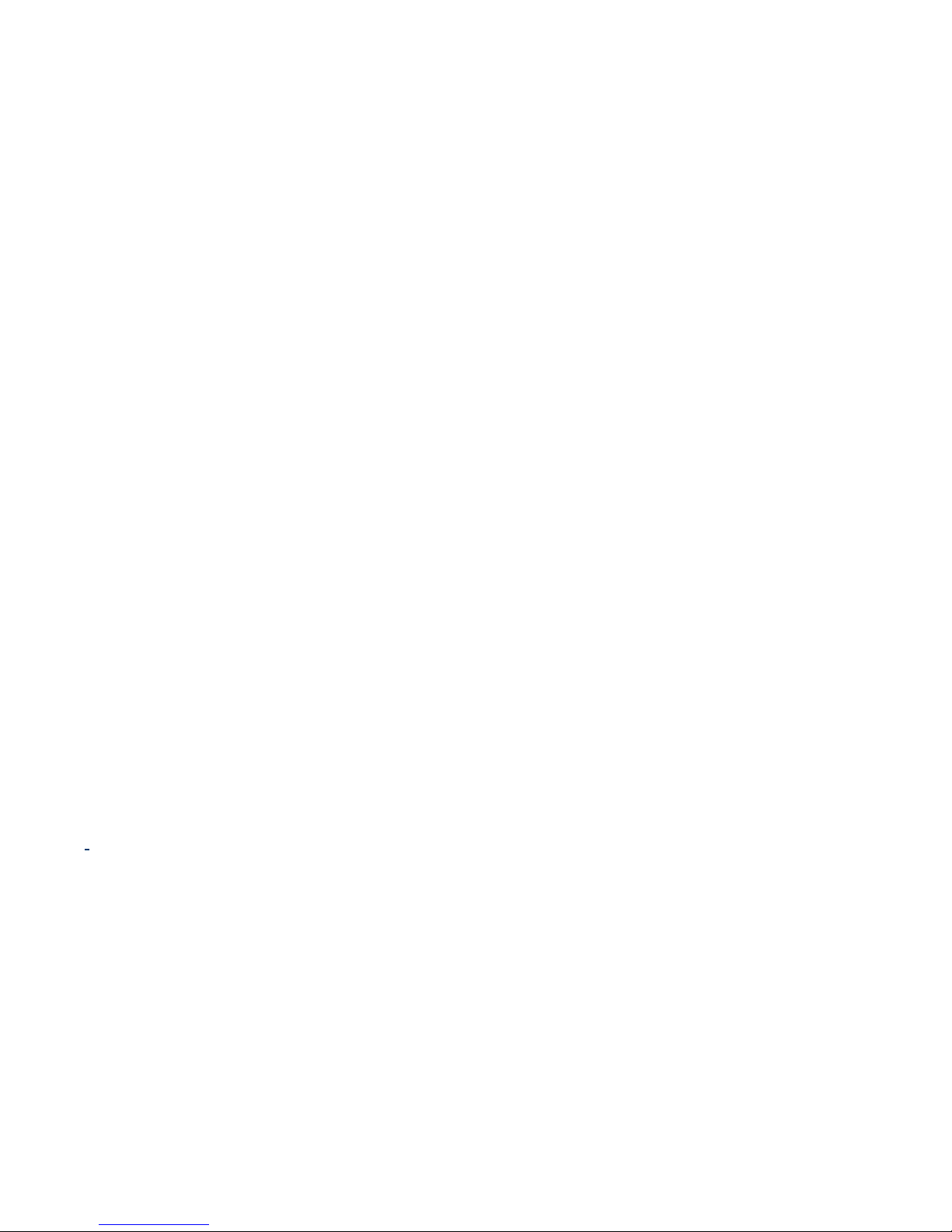

Component Location

Distilled

Water

0

Power Switch

(ON / OFF)

Reservoir

Fill Port

Display Panel

Drain

Coupling

Drain Hose

Drain Hose

(storage location)

Door / Tray

Door

Gasket

External

Condensing

Tank

Operation & Care Sheet

w/ User Training CD

Page 5

5

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Intended Use

The M3 UltraFast® Automatic Sterilizer can be used in medical, dental, and veterinary ofces, hospitals,

clinics, nursing homes, laboratories, and other facilities to sterilize heat and moisture stable reusable items

(including dental handpieces) that are compatible with steam sterilization.

Refer to ‘Loading the Tray’ & ‘Cycle Parameters’ in this manual for detailed information.

Electromagnetic Interference

The Midmark M3 is designed and built to minimize electromagnetic interference with other devices.

However, if interference is noticed between another device and this sterilizer:

• Remove interfering device from room

• Plug sterilizer into a dedicated circuit

• Increase separation between sterilizer and interfering device

• Contact Midmark if interference persists

Safety Instructions

The primary concern of Midmark is that this equipment is operated and maintained with the safety of

the patient and staff in mind. To assure safe and reliable operation:

• Read and understand this manual before attempting to install or operate the sterilizer.

• Assure that the appropriate personnel are informed on the contents of this manual.

(This is the responsibility of the purchaser).

• Assure that this manual is located near the sterilizer, or if possible, permanently afxed

to the sterilizer.

Page 6

6

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

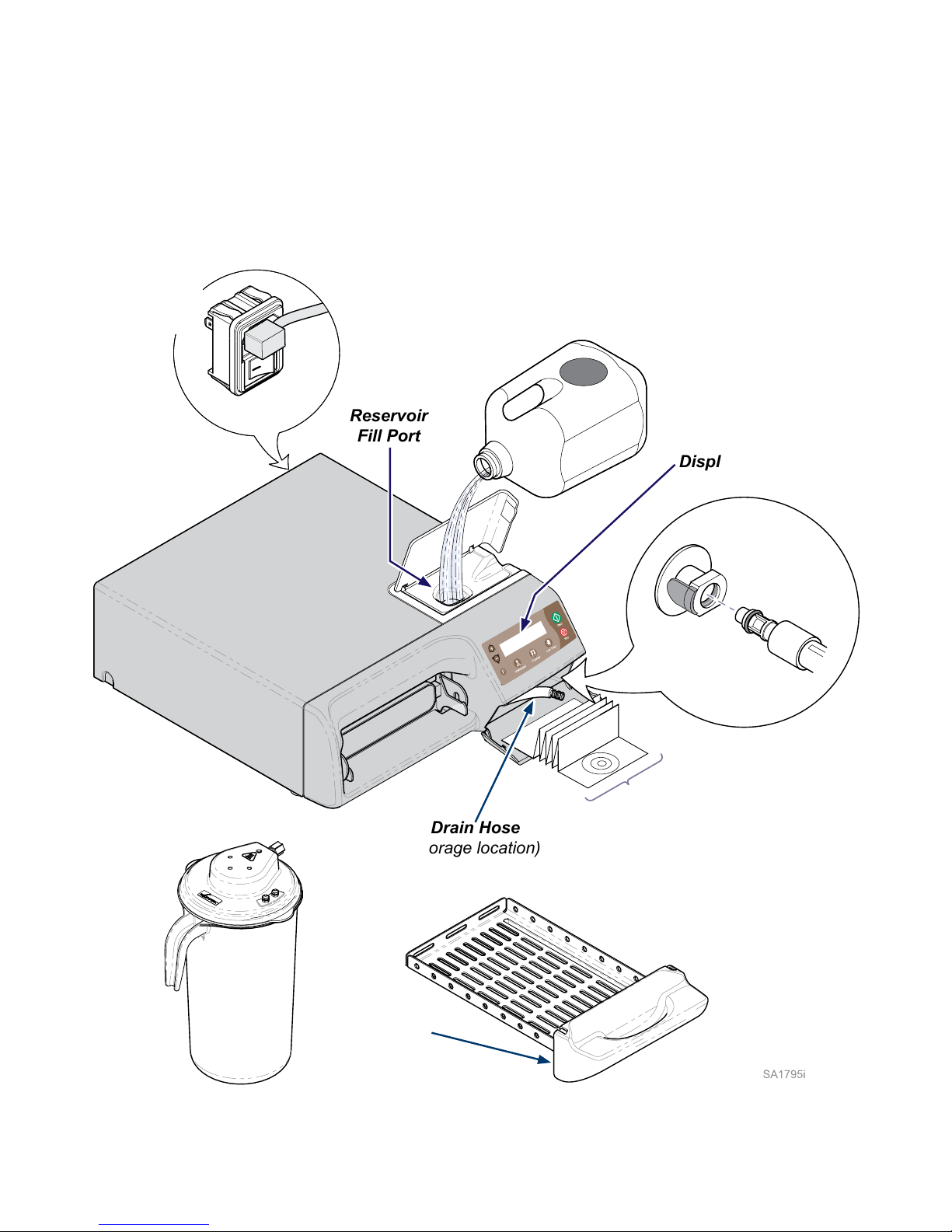

Safety Symbols

Equipment Alert

Indicates a potentially hazardous situation

which could result in equipment damage.

WARNING

Indicates a potentially hazardous situation which could result in serious injury.

DANGER

Indicates an imminently hazardous situation which will result in serious or fatal injury.

This symbol is used only in the most extreme conditions.

Caution

Indicates a potentially hazardous situation which may result in minor or moderate injury.

It may also be used to alert against unsafe practices

Note

Amplifies a procedure, practice, or condition.

Transportation / Storage Conditions

Ambient Temperature Range: .......... -22°F to +140°F (-30°C to +60°C)

Relative Humidity:............................ 10% to 90% (non-condensing)

Atmospheric Pressure: .................... 49.6 kPa to 106.4 kPa (7.2 psi to 15.4 psi)

Equipment Alert

All water must be removed from the reservoir before

transporting or storing at +32°F (0°C) or below.

Shipping Symbols

Proper shipping orientation

Fragile

Caution Shipping Damage

Keep dry

2 Person Lift

Page 7

7

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Operating Environment

Equipment Alert

Unit should be allowed to reach room temperature before operating.

Failure to do so could result in damage.

Ambient Temperature Range: .......... +68°F to 104°F (+20°C to 40°C)

Relative Humidity:............................ less than 80% (non-condensing)

(Pollution Degree 2, in accordance to IEC664)

Normal Operating Altitude: ..............less than 9842 ft. (3000 m) above sea level

• Approved for indoor use only

• Environment should be relatively dust-free

Electrical Ratings / Requirements

Note

To ensure unit is properly grounded, it must be connected to a

matching grounded, dedicated, correctly polarized receptacle.

WARNING

Use 104-127 VAC, 50/60 HZ alternating current only for 115 VAC rated models and

207-253, 50/60 HZ alternating current only for 230 VAC rated models. Failure to do

so could result in electrical shock to personnel and will result in damage to sterilizer.

M3 (115V model): ...........................115 VAC, 50/60 Hz, 12 amp

Max. Power Consumption: ............1400 Watts

Requires*: .......................................Dedicated supply circuit rated at 120 VAC, 50/60 Hz, 12 amp

M3 (230V model): ...........................230 VAC, 50/60 Hz, 6 amp

Max. Power Consumption: ............1400 Watts

Requires*: .......................................Dedicated supply circuit rated at 230 VAC, 50/60 Hz, 6 amp

*Power source must have over voltage limits less than 1500 watts from mains to ground.

(Installation Category II in accordance to IEC 664)

Page 8

8

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Sterilization Monitoring Guidelines

Note

The information below is provided for reference only. Contact appropriate state / local agencies for

specific sterilization guidelines for your office. Additional information on infection control is available

from the Centers for Disease Control and Prevention (CDC), Organization for Safety and Asepsis

Procedures (OSAP), and the American Dental Association (ADA).

Physical Monitors

Temperature and pressure measuring devices can help detect sterilizer malfunctions.

The sterilizer’s control system aborts the cycle and displays a message if physical conditions go

outside established limits. The optional printer can be used to create a record of each load’s actual

cycle time, temperature, and pressure.

Note

Use only FDA cleared chemical & biological indicators designed for steam sterilization that are

compatible with the particular sterilization cycle temperature and exposure time being monitored.

Use sterility monitors with each sterilization load. If a sterilization cycle is terminated prematurely,

reprocess instruments to ensure sterility of the load. Process the load according to your regular

practice, placing indicators near the handle side of tray. Follow manufacturer’s instructions for

proper disposal of used indicators.

Chemical Indicators

Chemical indicators are designed to verify that conditions in the sterilizer chamber were adequate to

achieve sterilization. They do not validate that a processed item is sterile. If a chemical indicator shows

a failure, items in that load are considered non-sterile. Potential causes for sterilization failures include:

improper cleaning, packing, loading, or a sterilizer malfunction. Determine the cause of any sterilization

failure, and remedy the situation before running the next cycle. Only FDA cleared chemical indicators

labeled for use with the nontraditional steam sterilization cycle parameters, e.g. temperature and exposure

time, of the M3 Sterilizer should be used for monitoring the three M3 UltraFast® cycles. Follow the chemical

indicator’s instructions for proper storage, use, interpretation, and disposal.

Biological Indicators

Biological indicators are microbiological devices designed to accompany items being sterilized to monitor

adequacy of the sterilization process. If a biological indicator shows a failure, items in that load are

considered non-sterile. Potential causes for sterilization failures include: improper cleaning, packing,

loading, or a sterilizer malfunction. Determine the cause of any sterilization failure, and remedy the

situation before running the next cycle. Only FDA cleared biological indicators labeled for use with the

nontraditional steam sterilization cycle parameters, e.g. temperature and exposure time, of the M3 Sterilizer

should be used for monitoring the three M3 UltraFast® cycles. Follow the biological indicator’s instructions

for proper storage, use, interpretation, and disposal.

Page 9

9

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Installation

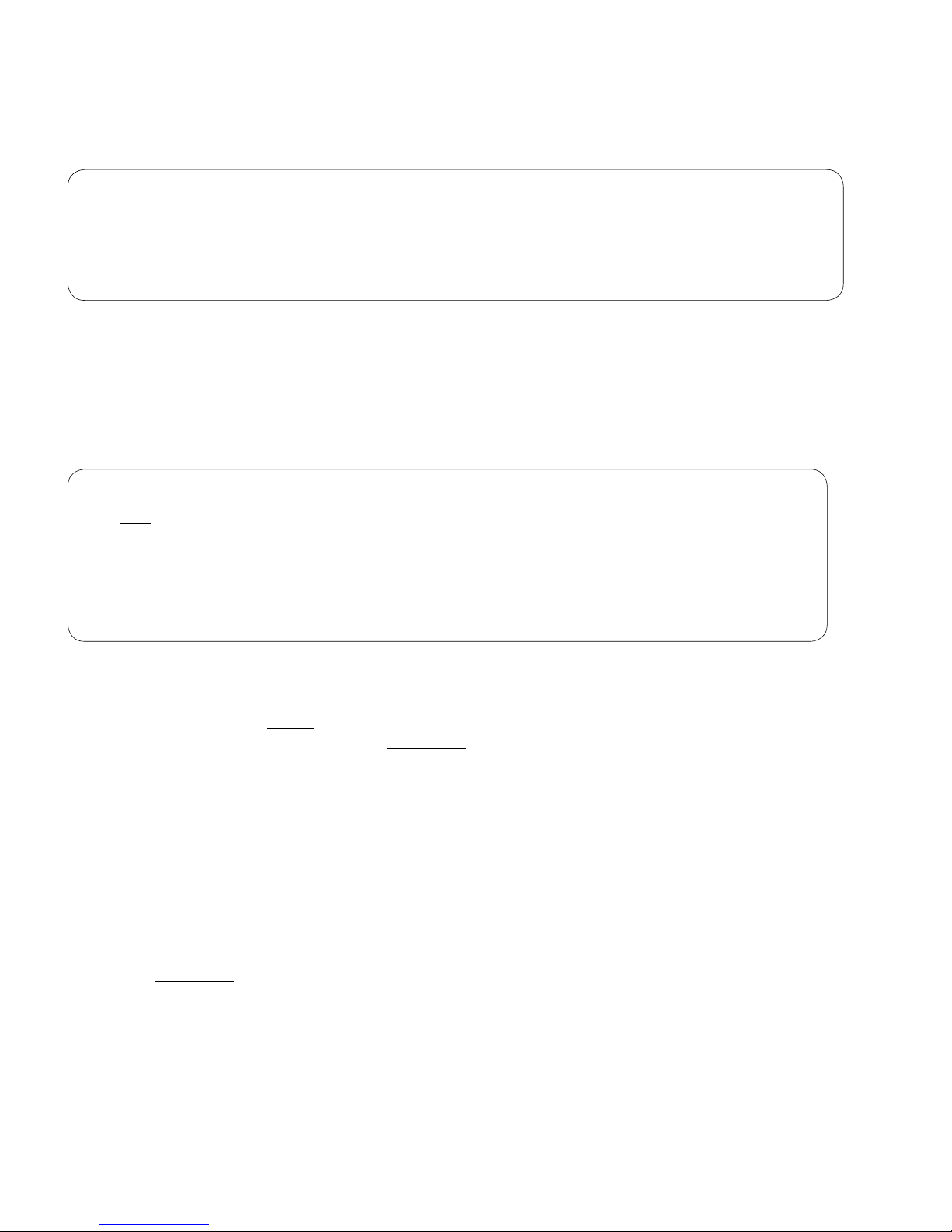

Location Requirements

(Allow clearance on both sides)

2"

(5 cm)

4"

(10 cm)

2"

(5 cm)

2"

(5 cm)

24"

(61 cm)

Support Surface

Clearance

Requirements

4"

(10 cm)

22"

(56 cm

)

Support Surface

• Material should be water-resistant material

(Ex. laminate, stainless steel, stone, etc.)

• Surface must be level to ensure proper operation.

• Surface should meet minimum dimensions listed below:

Dimensions

Depth (front to back) .................24 in. (61 cm)

Width (side to side) ...................22 in. (56 cm)

Clearance Requirements

To ensure proper air circulation, and to allow access to the reservoir ll port and drain coupling,

adhere to the minimum clearance requirements listed below.

Clearance Requirements

Back of Unit - Back Wall .................................................4 in. (10 cm)

Front Sterilizer Feet - Front of Support Surface .............4 in. (10 cm)

Side of Unit - Side Wall ...................................................2 in. (5 cm) each side

Distance Above Unit* ......................................................2 in (5 cm)*

* The minimum clearance for proper air circulation is listed.

However, be sure to allow access to the reservoir ll port located on top of the sterilizer.

Page 10

10

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

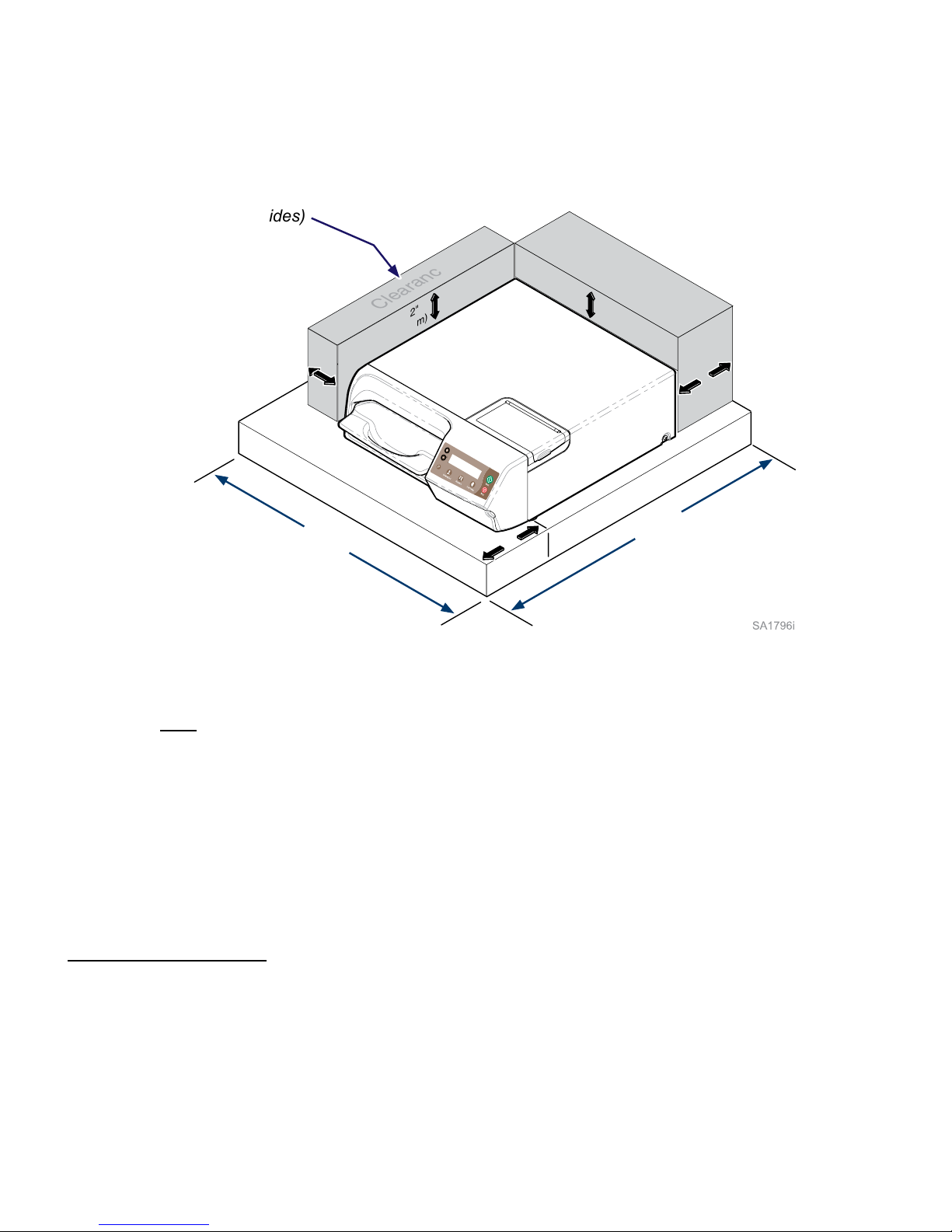

Power Cord Connection

0

0

WARNING

Check the serial number label on back panel of sterilizer to verify voltage rating for

the unit. Failure to connect sterilizer to an appropriate power supply could result in

damage to the unit, and electrical shock to personnel.

Voltage

Rating

WARNING

Equipment is not suitable for use in the presence of a flammable anesthetic mixture

with oxygen, air, or nitrous oxide.

Clarification: Equipment is suitable for use in the presence of oxygen, air, or nitrous oxide.

Equipment Alert

For optimal performance, allow sterilizer to reach

room temperature before operating.

To connect the power cord...

A) Plug power cord into receptacle on back of sterilizer.

B) Plug power cord into a properly polarized and grounded receptacle rated for a

minimum of 15 amps. A dedicated circuit only used for the sterilizer is recommended.

Page 11

11

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

0

0

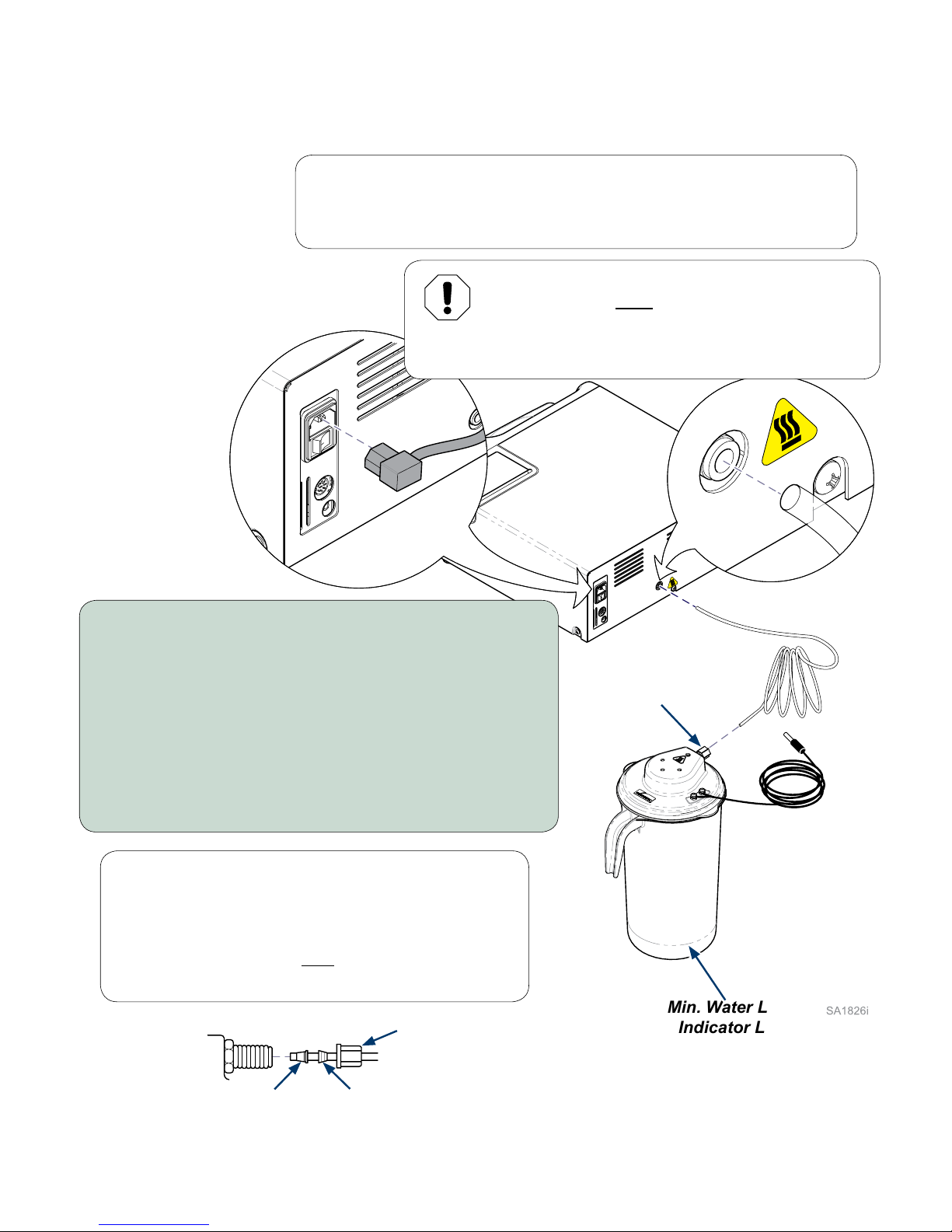

External Condensing Tank

Connections

Equipment Alert

The tank hose must be properly connected

(and not kinked). Improper connection will

cause water / steam leaks or a sterilizer

malfunction if water flow to the tank is restricted.

Note

External Condensing Tank is not needed if M3 UltraFast® is connected

to the VistaCool direct-to-drain thermal reduction system.

To connect the condensing tank...

A) If connected, disconnect sterilizer power cord.

B) Push tank hose into compression fitting on lid.

Tighten nut. (If step B is difficult - see NOTE)

C) Connect tank hose to back of sterilizer.

D) Fill condensing tank with tap water to minimum

water level indicator line.

E) Secure the lid on the condensing tank by aligning

the tabs and rotate lid clockwise to secure.

Note

If tubing is difficult to install...

A) Remove compression nut & two ferrules.

B) Install nut and ferrules onto tank hose as shown.

(Large & small ferrules must be positioned as shown)

C) Insert hose into tank fitting, then tighten nut.

Power Cord

Compression

Fitting

Tank Hose

Min. Water Level

Indicator Line

Ferrule

(small)

Ferrule

(large)

Nut

Page 12

12

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

0

0

External Condensing Tank

Connections - continued

Note

Clearance...

Maintain a minimum of 6 inch clearance above the condensing tank for

proper steam ventilation. If enclosed in a cabinet the support surface

and surrounding surfaces, should be protected with a water resistant

material (e.g. plastic, laminate, stainless steel, etc.). If enclosed in a

cabinet, it is recommended that the door be vented to avoid heat,

moisture build up and potential damage to the inside of cabinet.

To connect the condensing tank - continued...

F) Place tank on a level surface, preferably below

the sterilizer but in no case should it be higher

than the sterilizer support surface.

G) Connect sensor plug.

H) Connect sterilizer power cord.

Power Cord

Sensor Plug

Page 13

13

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Caution

Water that is discharged to external condensing tank can be VERY HOT;

person emptying pitcher should allow the temperature to cool.

Always use carrying handle and use caution when emptying.

External Condensing Tank

Draining Procedure

To replace lid...

Note: Lid can be reinstalled in one of four locations

to facilitate safe water disposal.

A) Insert lid assembly into pitcher.

B) Align the four tabs for correct positioning.

C) Rotate lid clockwise to secure.

To remove lid...

A) Rotate lid counterclockwise.

B) Lift lid assembly out of

condensing tank pitcher.

To drain pitcher...

A) Grasp pitcher by handle.

B) Pour cool water into an

approved drain.

Lid

Assembly

Tab

Page 14

14

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

0

Distilled

Water

Operation

Quick Reference

(Detailed instructions for each step are outlined in the following pages of the Operation section).

Basic Operation...

A) Turn power switch ON (I).

B) Fill reservoir.

C) Load tray.

D) Press desired cycle button.

E) Press <Start> button.

Note

There is a 10 minute (dry) heat cycle that can be used

to pre-heat the chamber, or for additional drying time.

Refer to: ‘Additional Heat’ Cycle in this section.

Cycle

Buttons

Page 15

15

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

0

0

0

Power Switch

To fill reservoir...

Pour one (1) gallon of distilled water into fill port.

Do not fill above lower lip of fill port.

The power cord must be connected

and the power switch must be ON (I)

for the sterilizer to operate.

Filling the Reservoir

Lower

Lip

Equipment Alert

Use distilled water or water that meets the

referenced water purity specifications.

Failure to comply may result in sterilizer

malfunction and/or premature failure due

to excessive corrosion.

OFF (O)

ON (I)

Page 16

16

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Loading the Tray

Types of Items

Before placing any instrument in the M3 UltraFast®,

check with the instrument manufacturer to be sure the

materials are compatible with steam sterilization, and

to verify the acceptability of sterilization parameters.

The M3 is designed to sterilize the following:

• High & low speed handpieces

• Metal instruments

• Rubber / plastic devices (ex. suction cannulas, impression trays, etc.)

• Wrapping / bundling materials (ex. CSR wrap, instrument pouches, etc.)

• Cassettes (Hu-Friedy Signa-Stat [6.5” x 10.5” x 1.25”] or smaller)

• Surgical instruments (ex. ophthalmologic instruments)

Equipment Alert

Do not sterilize items composed of any of the following materials in the M3:

• Corrosion sensitive metal (ex. carbon steel, iron, etc.)

• Fragile items susceptible to breaking under pressure / high temperature

• Liquids

• Biomedical waste

• Textiles (including towels, gauze, etc.)

• Plastics that may break down or produce residue when exposed to

steam / high temperatures.

Examples

Polyethylene Styrene Cellulosics ABS

PVC Textiles Acrylic (Plexiglass™)

PPO (Noryl™) Latex Neoprene

Qualication Testing

Your sterilizer should be tested after sterilizer installation, malfunctions, relocation, major repairs, and

after sterilization process failure. Qualication testing should be performed prior to placing the sterilizer in

service. If multiple cycles types are used, e.g. “Pouches” and “Low Temp” each cycle type should be

qualied. Qualication testing should include at least one Biological Indicator (BI) (sometimes referred to as

Spore Tests) and one Chemical Indicator (CI). The test pack should be performed with items routinely

processed and considered to be the most difcult to sterilize. Additional items should be placed in the

chamber along with the Biological Indicator and Chemical Indicator so that chamber is fully loaded (don’t

exceed the maximum capacities listed in the tables under “Guidelines for Loading” in this manual). Three

consecutive test runs, for each cycle type tested, with negative results from the BIs, and the appropriate

readings from all physical monitors and chemical indicators demonstrating complete sterilization, provide

verication that the sterilizer has been properly installed (or reinstalled after relocation) or repaired to the

manufacturer’s specications and that it will function effectively in the facility in which it is installed. All items

processed during qualication testing should be quarantined until the results of the biological testing for all

three test runs are available.

Page 17

17

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Pouching and Wrapping Items

The M3 is capable of sterilizing pouched or wrapped items.

• When pouching or wrapping items, use only sterilizer pouches and wraps that have

been cleared by the FDA and labeled for use with the nontraditional steam sterilization

cycle parameters, e.g. temperature and exposure time, of the M3 sterilizer. Follow the

manufacturer’s instructions for use.

• When using cassettes in the M3 follow the manufacturer’s instructions for use.

• Pouched items to be sterilized should be placed lengthwise with plastic side of

pouch facing up in the M3 UltraFast® tray.

The pouches may overlap slightly, but items must not be layered. Refer to diagram below.

Loading the Tray - continued

Caution

Failure to comply with these guideline may adversely affect sterilization and/or drying.

Immediate Use Sterilization

The M3 is capable of immediate use sterilization - sterilizing unwrapped instruments for immediate use.

Please consider the following when choosing whether or not to sterilize your instruments unwrapped:

• The sterility of unwrapped instruments is compromised upon exposure to a non-sterile

environment. Follow CDC guidelines for using unwrapped, sterilized instruments.

• Due to the sensitive nature of some types of surgery (including, but not limited to

ophthalmological), instruments used in such procedures must be wrapped or pouched

in order to reduce their exposure to sterilization process residues. The water reservoir

should also be drained and relled with fresh distilled water on a daily basis when

processing instruments for these procedures on a routine basis.

POUCH

POUCH

POUCH

POUCH

POUCH

POUCH

POUCH

POUCH

Page 18

18

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Loading the Tray - continued

Load Size

The M3 UltraFast® can accommodate loads weighing up to 2.4 lbs (1.1 kg).

[Note: This is the weight of the contents in the tray (ex. instruments, cassettes, pouches, etc.).

The weight of the tray itself has already been accounted for].

Item Description Weight*

lbs. kg

Scissors 0.066 0.030

Dental Scalers 0.044 0.020

Forceps 0.033 0.015

Dental Handpiece 0.121 0.055

Suction Cannula 0.022 0.010

Plastic Mouth Mirror 0.018 0.008

Impression Tray 0.033 0.015

Plastic X-Ray Positioning Ring 0.044 0.020

Hu-Friedy Signa-Stat Cassette 1.500 0.680

(*actual weights may vary)

Packing the Tray

Caution

Failure to comply with these guidelines may adversely affect sterilization and/or drying.

Caution

Clean and dry instruments thoroughly before placing them into tray. Improper cleaning may

result in non-sterile instruments or damage to the unit. Follow instrument manufacturer’s

guidelines and CDC recommendations for handling and cleaning instruments prior to

sterilization.

In addition to total load weight outlined above, all items must be processed in accordance with Centers

for Disease Control and Prevention (CDC), ‘Guidelines for Infection Control in Dental Healthcare

Settings’ - 2003, MMWR 2003; 52 (no. RR-17), which states:

“Items to be sterilized should be arranged to permit free circulation of the sterilizing agent (e.g., steam,

chemical vapor, or dry heat); manufacturer’s instructions for loading the sterilizer should be followed.”

• All items must t in M3 UltraFast® tray.

• Loaded tray must slide into chamber opening without scraping.

• Items must not touch one another.

• Pouched items should be loosely packed.

• Pouches may overlap slightly, but items must not be layered.

Equipment Alert

Do not use towels or packaging which contains chlorine bleach residue. Chamber and/or tray

rusting or discoloration may occur. The life of the sterilizer may be shortened significantly.

WARNING

Do not overload the sterilizer tray. Failure to allow adequate space

around items for circulation will compromise sterilization and drying.

Use the table below as a general guideline for weights of commonly used items.

Consult manufacturer’s specications for the exact weight of any particular instrument.

Page 19

19

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Yes

Yes

Yes

Yes

No

No

No

No

Loading the Tray - continued

Add new item to

M3 tray.

Begin loading

the M3

Yes

No

Is item

constructed of

materials compatible

with the M3?

Can item

fit within tray and

into chamber?

Can item

fit without touching

or laying on top of

other items?

Total

load < 2.4 lbs

(1.1 kg)?

Done loading tray?

End loading the

M3.

Remove item -

damage to item or

M3 could result.

Remove item -

it is too large for

use with M3.

Remove item-

tray is at max.

item capacity.

Remove item-

tray is at max.

weight capacity.

Page 20

20

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Cycle Selection

(The parameters for each cycle are outlined on the following page.)

Will you

be pouching your

instruments/handpieces

or wrapping a

cassette?

Select the proper

M3 sterilization

cycle.

Does

your load contain

plastic or rubber?

Is cycle

speed or gentleness

to your instruments/

handpieces more

important?

Proper Cycle

Selected.

Unwrapped

Pouches

Low Temp

Yes

Yes

GentlenessSpeed

No

No

Page 21

21

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Cycle Selection - continued

Cycle Parameters

(Before sterilizing any items in the M3, refer to Loading the Tray in this section.)

CYCLE

STERILIZATION

PARAMETERS

DRY TIME ITEMS TO BE STERILIZED

Temperature:

270°F (132°C)

Pressure:

27.1 psi (186 kPa)

Time:

3:30 Minutes

Time:

25 Minutes

• Dental instruments / handpieces loose on a tray.

• Items manufacturers recommend for exposure at

270°F (132°C), loose on tray.

Temperature:

270°F (132°C)

Pressure:

27.1 psi (186 kPa)

Time:

5:30 Minutes

Time:

30 Minutes • Dental instruments / handpieces in pouches,

wrapped, or in a wrapped cassette.

• Items manufacturers recommend for exposure

at 270°F (132°C), in pouches, wrapped, or in a

wrapped cassette.

Temperature:

250°F (121°C)

Pressure:

15.0 psi (104 kPa)

Time:

20:00 Minutes

Time:

50 Minutes

• Rubber or plastic dental devices, dental

instruments / handpieces loose on a tray,

in pouches, wrapped, or in a wrapped

or unwrapped cassette.

• Items manufacturers recommend for exposure at

250°F (121°C), loose on tray, in pouches,

wrapped, or in a wrapped or unwrapped cassette.

Unwrapped

Pouches

Low Temp

Page 22

22

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Post-Sterilization Processing

Qualied personnel responsible for infection control should prepare a protocol for handling sterilized items.

This protocol should be followed by all personnel responsible for handling sterilized items.

‘Additional Heat’ Cycle

The Additional Heat Cycle activates the

dry heaters for ten minutes.

This cycle can be used to pre-heat the

chamber at the beginning of the workday,

or for extended drying time at the

end of a cycle.

To pre-heat chamber prior to running a cycle...

A) Press <Start> button when ‘SELECT CYCLE’ appears on display.

B) During the ten minute pre-heat mode, ‘ADDITIONAL HEAT’ will flash on the display.

C) When ‘ADDITIONAL HEAT’ stops flashing, press desired cycle button, then press <Start>.

For extended drying time at the end of a cycle...

A) Press <Start> button when ‘SELECT CYCLE’ appears on display.

B) During the ten minute drying mode, ‘ADDITIONAL HEAT’ will flash on the display.

After sterilization is complete, all items must be handled in accordance with accepted and documented

standards, such as the Centers for Disease Control and Prevention (CDC) document, ‘Guidelines for

Infection Control in Dental Healthcare Settings’ - 2003, MMWR 2003; 52 (no. RR-17), as well as any local

requirements that may apply.

Page 23

23

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

The M3 allows the operator to adjust

the drying time from 20 - 60 minutes

using 1 minute increments for the three

pre-programmed cycles.

Adjusting the Drying Time

To adjust the drying time for a pre-programmed cycle...

A) After pressing desired cycle button, press <P> button.

[Display will show current setting. (ex. DRY TIME: 30 MINUTES)]

B) Press the <+> / <_> buttons to increase / decrease the drying time.

C) Press the <P> button to save your changes.

(Pressing the <Stop> button cancels the changes & returns to last saved setting.

Accessories

Accessory Chart

Description Part Number Intended Use

Printer 9A401001

Prints sterilizer cycle information

and data.

Door Tray 9A402001 Used to stage cycles.

Top Cover Protector 9A404001

Used to protect painted top

cover from damage.

Maintenance

Maintenance Messages

To assure correct operation and maximum sterilizer life, the M3 provides the operator with reminders

when it’s time to perform operator maintenance. After the M3 is powered ON for 7, 14, and 21 days,

a message “Perform Periodic Maintenance” will be displayed. After 28 days, a “Perform Monthly

Maintenance” message will be displayed. Refer to the appropriate maintenance instructions in this manual.

The maintenance reminders are removed from the display when a cycle is started.

If power is turned OFF, the timer will reset, initiating a new cycle of messages.

Page 24

24

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Daily Care

• Clean External Surfaces / Tray & Chamber

A. Wash unit according to your facility’s procedure for clinical contact surfaces noting the

following:

(Use only quaternary disinfectants to disinfect unit. Staining, pitting, discoloration, or

softening could occur if phenolic, iodophor, or glutaraldehyde-based disinfectant is used

on plastic surfaces of the unit. Also, use of alcohol or aerosol spray cleaner / disinfectant

containing substantial amounts of alcohol in the formula can damage the faceplate.)

B. Wring excess solution from cloth.

C. Using soft cloth, wipe all external surfaces.

D. Follow the instructions provided with the cleaner / disinfectant used regarding rinsing and drying

of external surfaces.

WARNING

Check to assure the

chamber filter is not blocked by

debris and that it is properly seated;

in the bottom hole in the back of the

chamber. Failure to make sure the

filter is in place and clear of debris

could result in serious personal

injury and or equipment damage.

• Clean Chamber Filter

Check that the chamber lter is free of debris and

properly positioned in the hole at the back of the

sterilizer chamber. If the lter is blocked by debris

follow the procedures under “Monthly Maintenance”

to remove and clean the lter.

• Clean Door Gasket / Mating Surface

A. Wash with a damp cloth.

B. Inspect gasket for damage.

C. Replace gasket if necessary.

Chamber Filter

Door Gasket

Chamber

Filter

Page 25

25

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

• Drain / Rell Reservoir (As Needed)

A. Remove drain hose from storage location.

B. Place open-end of drain hose into container or sink.

C. Connect adapter-end of drain hose to coupling as shown.

D. Once water has drained, press release lever and remove hose.

E. Return drain hose to storage location.

F. Rell reservoir with distilled water.

Distilled

Water

Note

If coupling leaks, reinsert hose

several times to clean seal.

Release Lever

Drain Hose (storage location)

Periodic Maintenance

Equipment Alert

Use distilled water or water that meets the

referenced water purity specifications.

Failure to comply may result in sterilizer

malfunction and/or premature failure due

to excessive corrosion.

Page 26

26

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

• Empty / Clean External Condensing Tank (As Needed)

A. Empty water from tank. (Do not reuse water!)

B. Clean tank with diluted bleach solution (1/4 cup bleach : 1 gallon water) and a brush.

C. Rinse tank thoroughly.

D. Rell tank to minimum water level indicator line.

Note

This process is not necessary if the sterilizer is connected to a direct-to-drain thermal reduction system.

Periodic Maintenance - continued

Caution

Water may be HOT!

Allow water to cool before emptying tank.

Minimum Water Level

Indicator Line

Page 27

27

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

• Clean Condensing Tank Level Sensors

Clean two sensors with mild soap solution, then wipe dry.

Note

This process is not necessary if the sterilizer is connected to a direct-to-drain thermal reduction system.

Monthly Maintenance

• Remove & Clean Filter

Wash with mild soap solution to remove debris. Rinse with distilled water.

(Use a stiff brush to scrub, or place in ultrasonic cleaner if necessary.)

Level Sensors

Refer to following page for

Filter Removal / Installation

Filter

Equipment Alert

Never use abrasive or bleaching

agents to clean level sensors or filter.

Page 28

28

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Monthly Maintenance - continued

Tapered End

To remove filter...

A) Slide notch in filter tool (provided) over filter.

B) Pull out to remove.

To install filter...

A) Position filter in notch of tool as shown.

B) Align filter with hole in back of chamber*, and press in gently.

C) Flip tool over, then gently press filter in to secure.

*Tip: Slide tool along bottom of chamber to align filter with hole.

Filter Tool

Filter

Extended Use Maintenance

The M3 is designed and tested to provide exceptional reliability throughout its service life. However, like

all electro-mechanical devices it is subject to wear and degradation with use.

To ensure the integrity, performance, and safety of all major components it is the responsibility of the user

to have the sterilizer performance / operation veried by a Midmark Authorized Service Provider after

8 years or 20,000 cycles of use, whichever comes rst. After 8 years or 20,000 cycles of use an annual

inspection by a Midmark Authorized Service Provider is recommended.

Page 29

29

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

0

Printer (optional)

Printer Harness Connection

To connect printer harness...

A) Turn sterilizer power switch OFF (O).

B) Connect printer harness as shown.

C) Turn sterilizer power switch ON (I).

Power

Switch

Page 30

30

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

If printer readout becomes light ...

A) Separate lid / printer from housing.

B) Press Paper Feed button for three seconds.

(This advances the ribbon inside the cartridge).

C) Repeat step B as necessary*.

*Note: If pressing the Paper Feed button fails to correct

the problem, replace the printer cartridge.

Paper

Feed Button

Set Temperature & Time

BEGIN

UNWRAPPED

270 deg F 3.5 MINUTES

MM - DD - YYYY

- -

TOTAL CYCLES 140

HEATING

MM:SS degF PSI

STERILIZING

MM:SS degF PSI

MIN TEMP 271.0 degF

MAX TEMP 275.7 degF

MIN PRESS 23.2 PSI

MAX PRESS 32.1 PSI

VENTING CHAMBER

DRYING

MM:SS

0:00

TOTAL PROCESS TIME

9:50

COMPLETE

0:00

0:30

1:00

1:30

2:00

2:30

151.5

193.1

218.1

243.2

244.6

268.5

0.1

0.2

3.8

11.9

13.5

27.8

0:00

0:30

1:00

1:30

2:00

2:30

3:00

3:30

271.0

274.8

272.9

275.1

273.7

273.8

273.5

275.2

28.8

31.6

29.2

25.8

30.8

30.0

29.3

25.8

Printer Readout

Selected Cycle

Total # of cycles

run on unit

During Sterilization phase,

the printer records chamber

temperature & pressure in

30-second increments.

Indicates Venting

phase initiated

Date

During Heat-Up phase, the printer

records chamber temperature &

pressure in 30-second increments.

Summary of Sterilization phase

Indicates Drying phase initiated

(Printer records drying time

in 5 minute increments).

HH : MM

:

Page 31

31

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Paper Roll Installation

To install paper roll...

A) Loosen thumbscrew, then

separate lid / printer from housing.

B) Slide paper into slot as shown*.

C) Press paper feed button until approx.

2 in. (5 cm) of paper is fed thru printer.

D) Pull paper thru slot in lid.

E) Position paper roll / spindle in slots.

F) Reassemble lid / printer / housing.

Paper Feed

Button

*Feed Paper

from top of roll

Thumbscrew

Page 32

32

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Printer Ribbon Cartridge Replacement

To remove old printer ribbon cartridge...

A) Turn sterilizer power switch OFF (O).

B) Separate lid from printer.

C) Press down on side of printer cartridge labeled “EJECT”.

To install new printer ribbon cartridge...

A) Install new cartridge as shown* (it will “snap” into place).

*Note: The printer paper must be between the cartridge ribbon & the metal plate.

B) Turn Adjustment Knob clockwise until ribbon is tight.

Metal Plate

(Printer Paper)

Ribbon

Adjustment

Knob

Printer Paper

Cartridge

Ribbon

Page 33

33

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Error Codes

If a malfunction is detected during a cycle, a numeric error code will appear on the display panel.

Use the chart below to diagnose and correct the most common, maintenance-related error codes.

If you encounter an error code not identied below, follow the instructions on the display panel.

If error code persists, contact your authorized service provider.

Troubleshooting

Example:

Error Code Probable Cause Corrective Action

C010

Sterilizer lost power

during cycle.

Press <STOP> button,

then restart cycle.

C100-series (all

(C101, C102, etc.)

<STOP> button was

pressed during the cycle.

Press <STOP> button,

then restart cycle.

C231, C232

Not enough water in

reservoir to complete

the cycle.

Fill reservoir with distilled water,

or water that meets the

referenced water purity specications.

C441, C442

External condensing

tank is full.

Empty external condensing tank.

C533, C633 Water pump needs primed.

Put the sterilizer in the User

Diagnostic Mode and prime

the pump. (see following page)

Page 34

34

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Troubleshooting - continued

User Diagnostic Mode

The User Diagnostic Mode is used:

• To set “English” or “Metric” units on the display panel,

• To retrieve the last ve (5) error codes stored in the unit memory.

• To prime the water pump if needed.

To activate User Diagnostic Mode...

A) Turn Power Switch OFF (O).

B) Press and hold the <START> button.

C) Turn Power Switch ON ( I ).

D) Press the <START> button when the display shows “USER DIAGNOSTIC”.

To change Display Units...

A) Put the unit in User Diagnostic Mode.

B) Press the <P> button to select units.

C) Press the <+> button to change the temperature and pressure display from

English-to-Metric or Metric-to-English units. (Factory default setting is English).

D) Press the <START> button to continue.

E) Turn the power switch OFF (O) to exit User Diagnostic Mode.

To retrieve the five (5) most recent error codes...

A) Put the unit in User Diagnostic Mode.

B) Press the <STOP> button to recall errors.

C) The last five (5) error codes will be displayed.

D) Press the <START> button to return to the User Diagnostic Mode display.

E) Turn the power switch OFF (O) to exit User Diagnostic Mode.

To prime the sterilizer pump...

A) Put the unit in User Diagnostic Mode.

B) Press the <START> button to start the pump priming progress.

The unit will automatically cycle through a pre programmed priming cycle...

• Closing the sterilizer door.

• Heating the boiler.

• Cycling the pump ON and OFF until the pump is primed.

When finished the 2nd line of the display will show “PRIMING COMPLETE”.

C) Press the <START> button to return to the User Diagnostic Menu.

D) Turn the power switch OFF (O) to exit User Diagnostic Mode.

Page 35

35

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Calling for Service

Note

Please mark down any displayed Code(s) and be sure to relay this information to the service technician.

Contact your Midmark Authorized Dealer, or log on to www.midmark.com/technical-library.

Model and serial number information will be required when calling for service.

To contact Midmark directly:

1-800-MIDMARK (1-800-643-6275) or 937-526-3662

8 am to 5 pm EST (Monday thru Friday)

[excluding standard U.S. holidays]

Page 36

36

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Fuse Ratings:

115 VAC Unit

F1 .........................................................................15 Amp, 250 V, Fast Acting, 1/4” x 1 1/4”

F2 .........................................................................0.25 Amp, 250 V, Slo-blo, 1/4” x 1 1/4”

230 VAC Unit

F1 .........................................................................8 Amp, 250 V, Fast Acting, 5 x 20 mm

F2 .........................................................................0.125 Amp, 250 V, Slo-blo, 5 x 20 mm

Specications

Certications:

ASME Boiler & Pressure Vessel Code, Section VIII, Division 1

Canadian Registration Number Available

UL 61010-1, 2nd Edition

IEC 61010-2-040

CAN/CSA-C22.2 No. 61010-1, 2nd Edition

FCC Part 15, Sub-part B

Physical Dimensions:

Overall Length: .....................................................21 in. (53.3 cm)

Overall Width: ....................................................... 17.8 in. (45.2 cm)

Overall Height: ...................................................... 7.1 in. (18 cm)

Shipping Carton Length: ....................................... 25 in. (63.5 cm)

Shipping Carton Width:.........................................22 in. (55.9 cm)

Shipping Carton Height: .......................................16.6 in. (42.2 cm)

Counter Area: .......................................................24 in. (61 cm) deep x 22 in. (55.9 cm) wide

Chamber Volume: .................................................0.49 gal (1.8 liter)

Weight:

Empty Reservoir: .................................................. 71 lbs. (32.2 kg)

Full Reservoir: ......................................................80 lbs. (36.3 kg)

With Shipping Carton:...........................................80 lbs. (36.3 kg)

Water Reservoir Capacity: ....................................1.20 gal (4.5 liter)

Pressure Relief Valve Setting: .............................40 PSI (275.8 kPa)

Chamber Pressure:

@ 270°F (132°C) .................................................... 27.1 psi. (186.2 kPa)

Page 37

37

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Water Purity Specications

Water Purity Specication Chart

AAMI ST-46 (ref.)

Evaporate Residue ≤ 15 mg/l

Silica ≤ 2 mg/l

Iron ≤ 0.2 mg/l

Cadmium ≤ 0.005 mg/l

Lead ≤ 0.05 mg/l

Rest of heavy metals, excluding

Iron, Cadmium, & Lead

1

≤ 0.1 mg/l

Chloride ≤ 3 mg/l

Phosphate ≤ 0.5 mg/l

Conductivity (at 20°C)

2

≤ 50 μs/cm

pH 6.5 to 8

Appearance Colorless, clean, w/o sediment

Hardness ≤ 0.1 mmol/l (.585 gr/gal)

Page 38

38

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Warranty Information

SCOPE OF WARRANTY

Midmark Corporation (“Midmark”) warrants to the original retail purchaser that it will repair or replace

components of the domestic and international medical products manufactured by Midmark (except

for components not warranted under “Exclusions”) that are defective in material or workmanship

under normal use and service. Midmark’s obligation under this warranty is limited to the repair or

replacement, at Midmark’s option, of the applicable components. This limited warranty shall only

apply to defects that are reported to Midmark within the applicable warranty period and which, upon

examination by Midmark, prove to be defective. This warranty extends only to the rst retail purchaser of a product and is not transferable or assignable.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the date of delivery to the original user, shall be one

(1) year for all warranted products and components.

OBTAINING WARRANTY SERVICE

Warranty service must be obtained through either Midmark or an authorized dealer in the Midmark

product line for which warranty service is requested. Midmark may be contacted for warranty service

inquiries or issues via email at www.midmark.com; by phone at 1-800-MIDMARK; by facsimile at

1-800-365-8631; or by mail to Midmark Corporation, 60 Vista Drive, Versailles, Ohio 45380.

It is the retail purchaser’s obligation to arrange for delivery of a product to Midmark or one of its authorized dealers for warranty service, which delivery shall be at retail purchaser’s expense. It is also

the retail purchaser’s obligation to comply with the warranty service instructions provided either by

Midmark or its authorized dealer. The retail purchaser must provide Midmark with completed

warranty registration information within thirty (30) days after purchase in order to obtain the bene ts

of this warranty.

EXCLUSIONS

This warranty does not cover, and Midmark shall not be liable, for the following:

(1) defects, damage or other conditions caused, in whole or in part, by misuse, abuse, negligence,

alteration, accident, freight damage, tampering or failure to seek and obtain repair or replacement in

a timely manner;

(2) products which are not installed, used, and properly cleaned and maintained as required in the

Midmark “Installation” and/or “Installation/Operation Manual” for the applicable product;

(3) products considered to be of a consumable nature;

(4) accessories or parts not manufactured by Midmark;

(5) charges by anyone for adjustments, repairs, replacement parts, installation or other work

performed upon or in connection with such products which are not expressly authorized in writing in

advance by Midmark;

(6) costs and expenses of routine maintenance and cleaning; and

(7) representations and warranties made by any person or entity other than Midmark.

Scope of Warranty

Page 39

39

TP202 Rev. A

003-1658-00 © Midmark Corporation 2015

Warranty Information (continued)

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER:

MIDMARK’S ONLY OBLIGATION UNDER THIS WARRANTY IS THE REPAIR OR REPLACEMENT

OF DEFECTIVE PARTS. MIDMARK SHALL NOT BE LIABLE FOR AND HEREBY DISCLAIMS ANY

DIRECT, SPECIAL, INDIRECT, INCIDENTAL, EXEMPLARY OR CONSEQUENTIAL DAMAGES OR

DELAYS, INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR LOSS OF PROFITS OR INCOME,

LOSS OF USE, DOWNTIME, COVER AND EMPLOYEE OR INDEPENDENT CONTRACTOR

WAGES, PAYMENTS AND BENEFITS.

NO AUTHORIZATION

No person or rm is authorized to create or approve for Midmark any other obligation or liability in

connection with the products.

WARRANTY DISCLAIMER

THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED WARRANTIES OF ANY

KIND INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT

OF DEFECTIVE PARTS.

STATUTE OF LIMITATIONS

No action may be brought against Midmark for breach of this limited warranty, an implied warranty, if

any, or for any other claim arising out of or relating to the products, more than ninety (90) days

following expiration of the limited warranty period.

Page 40

TP202 Rev. A

Midmark Corporation

60 Vista Drive

Versailles, OH 45380 USA

1-800-643-6275

1-937-526-3662

Loading...

Loading...