Page 1

004-0390-00 Rev. H (8/8/13)

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Error Codes Chart

(Abbreviated List)

Caution

Service diagnostics requires power to be

connected to the unit with panels removed. Use

caution when performing this procedure.

NOTES

Always run Service Diagnostics (Switch 1 must be ON).

Check and record last five Error Codes when in Service

Diagnostics. If a C099 code is displayed in the Error Codes,

ignore it - was generated at the factory, so nothing is wrong.

The chart below cross-references the numeric

error code with the Component, Problem, & Mode.

First Digit

(Component)

where problem

occurred

Second Digit

(Problem)

what was detected

Third Digit

(Mode)

when detected

0 = General

System

0 (not used) 0 = Power-Up Mode

1 = Stop Button 1 = Power Loss 1 = Select Cycle

2 = Water Level

Sensor

2 = Closed 2 = Fill Mode

3 = Door Switch 3 = Low 3 = Heat-Up Mode

4 (not used) 4 = High 4 = Sterilizing Mode

5 = Temperature

Sensor

5 (not used) 5 = Vent

6 = Pressure

Sensor

6 = Hardware 6 = Door To Open

7 (not used) 7 = Over Limit 7 = Dry

8 (not used) 8 = Open 8 (not used)

9 = High Limit

Thermostat

9 (not used) 9 (not used)

General Codes (C010, C060)

• Supply power interrupted due to storm, etc.

• Check all connections between outlet to PC board.

• Unplug for 60 seconds to reset unit.

Stop Button Codes (C100 Series)

• Operator pressed Stop button.

M9, M9D, M11, M11D

Sterilizer Quick Reference Sheet

Serial Number Prexes

(RN, RP, RR, RS, RT, RV, RW, RX, RY, RZ,V)

Troubleshooting Chart

No Power

• Is unit plugged in to wall and back of unit?

• Is there supply voltage to unit (check outlet)?

• Check F1, F2 fuses (Main PCB).

Has Power, No Display or Touchpad

• Check harness (J13 Main PCB to J3 Display PCB).

• Display PCB is malfunctioning

• Check adjustment on display board.

Has Power, No Display

• Check J2 harness & plug (Display PCB).

• Check adjustment on display board.

Instruments Not Drying

• Sterilizer overloaded?

• Door fully open before completion of Dry Cycle?

• Pouches placed paper side up?

• Sterilizer not level?

• Filter screen(s) in chamber clogged?

Biological Strips Show Unsterile

• Sterilizer overloaded?

• Improper operation by end user?

• Instrument trays not made for sterilizer or operation?

• Wrong type of biological strips being used?

Must use strips for Gravity Displacement Steam Sterilizers?

• Chemical indicator has been in contact with water?

• Strips stored in damp / hot environment?

Printer Does Not Print

• Printer out of paper?

• Cartridge ribbon dry?

• Printer wire harness disconnected?

Water Fill Codes (C200 Series)

• Reservoir water low.

• Filter screen in chamber clogged.

• Water Fill Level Sensor dirty.

• Fill Valve restricted, open coil or harness.

• Check J8 (Water Level Sensor) harness and plug connection.

Door Latch Codes (C300 Series)

• Door remains closed after door opening motor has operated.

• Check door springs and possibly add another for more opening

force.

• Door interlock switch malfunctioning.

• Door open during specic mode of operation.

Steam Temperature Codes (C500 Series)

• Unit not level.

C533 - C534 – C544 Steam temperature low/high

• Check for internal and external steam and water leaks (see

leakage chart).

• Check resistance on heater (see schematics).

• Check for resistance on steam temp probe (see schematics).

• Check for 5.0VDC between TP2 & TP4 test points on the board.

• Remove J12 and check for voltage on the 1st & 2nd pin. Should

be 4.5 VDC.

C560 to C567 Steam temp hardware

• Check J12 plug & conditions of wires. Ensure solid connection.

• Check for resistance on steam temp probe (see schematics).

• Check for 5.0VDC between TP2 & TP4 test points on the board.

• Remove J12 and check for voltage on the 1st & 2nd pin. Should

be 4.5 VDC.

• Allow sterilizer to reach room temperature before operating.

C570 to C577 Steam temp over limit

• Check for internal and external steam and water leaks (see

leakage chart)

• Check for resistance on steam temp probe (see schematics).

• Check for 5.0VDC between TP2 & TP4 test points on the board.

• Remove J12 and check for voltage on the 1st & 2nd pin. Should

be 4.5 VDC.

• Check for restriction in tubing and chamber access hole for

pressure transducer.

Pressure Codes (C600 Series)

• Door not fully opening.

• Air or Vent Valve malfunctioning or lines restricted.

500 Series)

C633 Pressure low

• Check for internal and external steam and water leaks (see

leakage chart).

• Check for resistance on heating element (see schematics).

• Check for 5.0VDC between TP2 & TP4 test points on the board.

• Check water sensor to be clean and dry.

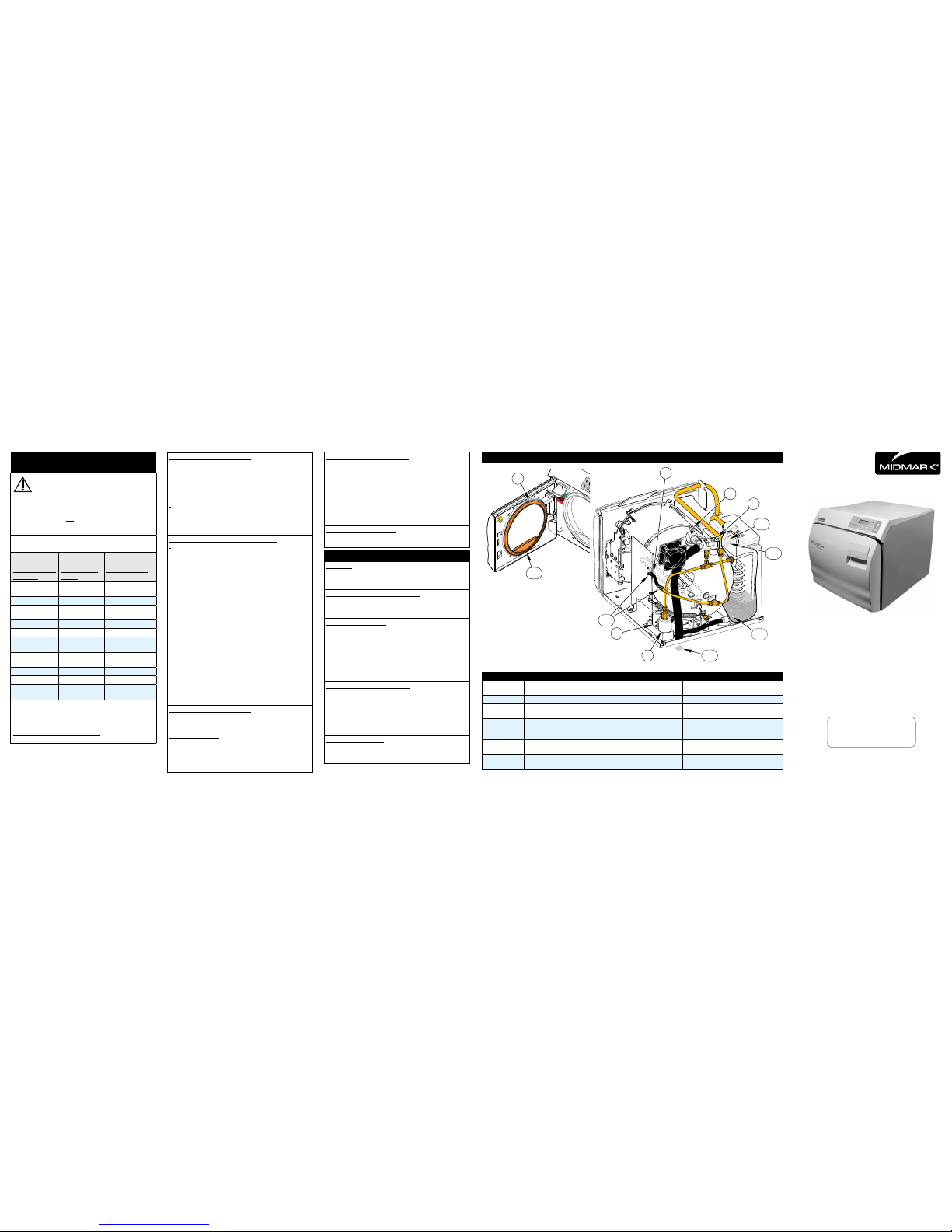

Component Check Correction

Door / Dam

Gaskets

Check for water leaking around door (1a). Inspect / clean gaskets.

Replace gasket(s) if necessary.

Vent Valve

Check for water leaking from condensing coil spout (2a). Clean / replace vent valve.

Fill Valve

Check for water leaking back into reservoir thru the ll line (3a).

Look for bubbles coming from bottom of reservoir.

Clean / replace ll valve.

Air Valve

Check for excessive steam coming thru condensing coil spout (4a).

NOTE: During the HEAT & VENT modes, it is normal for steam to be

exhausted thru the spout.

Clean / replace air valve.

Pressure

Relief Valve

Check for water / steam leakage from beneath the rear (5a) of the sterilizer.

Refer to: Pressure Relief Valve Test.

Replace valve if necessary.

Pressure

Sensor Hose

Check for steam leakage at pressure sensor hose connections (6a). Secure pressure sensor hose conection with

high temperature cable ties.

Leakage Check Chart

MA620200i

2

3

4

5

6

5a

6a

1a

1

4a

2a

3a

High Limit Codes (C900 Series)

• Skip ll cycle.

• Condensing coil outlet beneath reservoir water level.

• High Limit Switch(es) malfunctioning (normally closed).

• Wire connections broken or loose on High Limit(s).

• Temperature surpassing 450°F (232°C). Run Service

Diagnostics to determine probable cause.

• Water Level Sensor shorted because:

• • Tray rack in backwards

• • Dirty sensor

• • Wet sensor

C980 to C987 Hi limit open

• Make sure water level sensor is clean and dry

• Check for internal and external leaks. (See leakage chart)

Note

Refer to your Service manual for

complete instructions.

Page 2

004-0390-00 (8/8/13)

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Normal Sterlilizer Operation

Unit Plugged Into Outlet

Audible Display Action / Notes

Beeps INITIALIZING SYSTEM Note: The fan may run if the temperature inside cabinet is 130°F [54°C] (±8°F [4.4°C])

or greater.

Total number of cycles that have been run on Sterilizer.

Model Number* system is set up, Software version number.

(*System can be set for M9, M11 or M9D, M11D using SW1 [switch2]).

• Fill Valve - Closed / • Vent Valve - Open / • Heater - Off

• Air Valve - Energized [Open for 10 minutes or until Cycle started]

TOTAL CYCLES XXXX

M9*, vX.XX

SELECT CYCLE

Press Cycle Key (i.e. UNWRAPPED)

Audible Display Action / Notes

UNWRAPPED

270° F 3:00 MINUTES

FAST VENT 30 MINUTE DRY

Sterilization program, temperature, time per., venting type & dr cycle time is displayed.

• Fill Valve - Closed / • Vent Valve - Open / • Heater - Off

• Air Valve - Energized [Open for 10 minutes or until Cycle started]

Press Start Key

Audible Display Action / Notes

Beeps FILLING CHAMBER • Fill Valve - Energized [Open] / • Vent Valve - Energized [Closed]

• Air Valve - Energized [Open] / • Heater - Off

CHAMBER IS FULL Water reaches level of Water Level Sensor sending signal back to main P.C. Board.

• Fill Valve - De-energized [Closed] / • Vent Valve - Energized [Closed]

• Air Valve - Energized [Open] / • Heater - Off

HEATING - UNWRAPPED

XXX° F XX.X PSI

(temp) (pressure)*

• Fill Valve - De-energized [Closed] / • Vent Valve - Energized [Closed]

• Air Valve - Energized (*) [Open] / • Heater - On

(* The air valve will open 3 times at approximately one half of the operating (sterilization) pressure

and closes between 38 & 72 seconds {dependent on selected cycle and model of unit [M9 / M11]}.)

STERILIZING

03:00 270° F 27.1 PSI

READY TO VENT

00:10 270° F 27.1 PSI

Displayed sterilization time begins to count down.

• Fill Valve - De-energized [Closed] / • Vent Valve - Energized [Closed]

• Air Valve - De-energized [Closed] / • Heater - Cycles On & Off

In nal 10 seconds of Sterilization Mode “READY TO VENT” blinks on & off in display.

• Fill Valve - De-energized [Closed] / • Vent Valve - Energized [Closed]

• Air Valve - De-energized [Closed] / • Heater - Cycles On & Off

FAST VENT

XXX° F XX.X PSI

(temp) (pressure)

Chamber vents into reservoir.

• Fill Valve - De-energized [Closed] / • Vent Valve - De-energized [Open]

• Air Valve - De-energized [Closed] / • Heater - Off

Beeps

(Occurs 5

seconds

before Door

opens.)

DOOR TO OPEN

XXX° F XX.X PSI

(temp) (pressure)

Chamber pressure reaches 0.7 PSIg [5 kPa] “DOOR TO OPEN” blinks on & off in

display

• Fill Valve - De-energized [Closed] / • Vent Valve - De-energized [Open]

• Air Valve - Energized [Open] / • Heater - Off

• Door Opening Motor - Energizes, rotating the motor lever arm, unlatching the door.

Door opens to partial open position then motor automatically reverses back to original

position. Displayed drying time begins to count down.

DRYING

30:00 (time)

• Fill Valve - De-energized [Closed] / • Vent Valve - De-energized [Open]

• Air Valve - De-energized [Closed] / • Heater - Cycles On & Off

Beeps (10 s)

DRYING CYCLE COMPLETE • Fill Valve - De-energized [Closed] /• Vent Valve - De-energized [Open]

• Air Valve - De-energized [Closed] / • Heater - Off

SELECT CYCLE • Unit is ready for another operation.

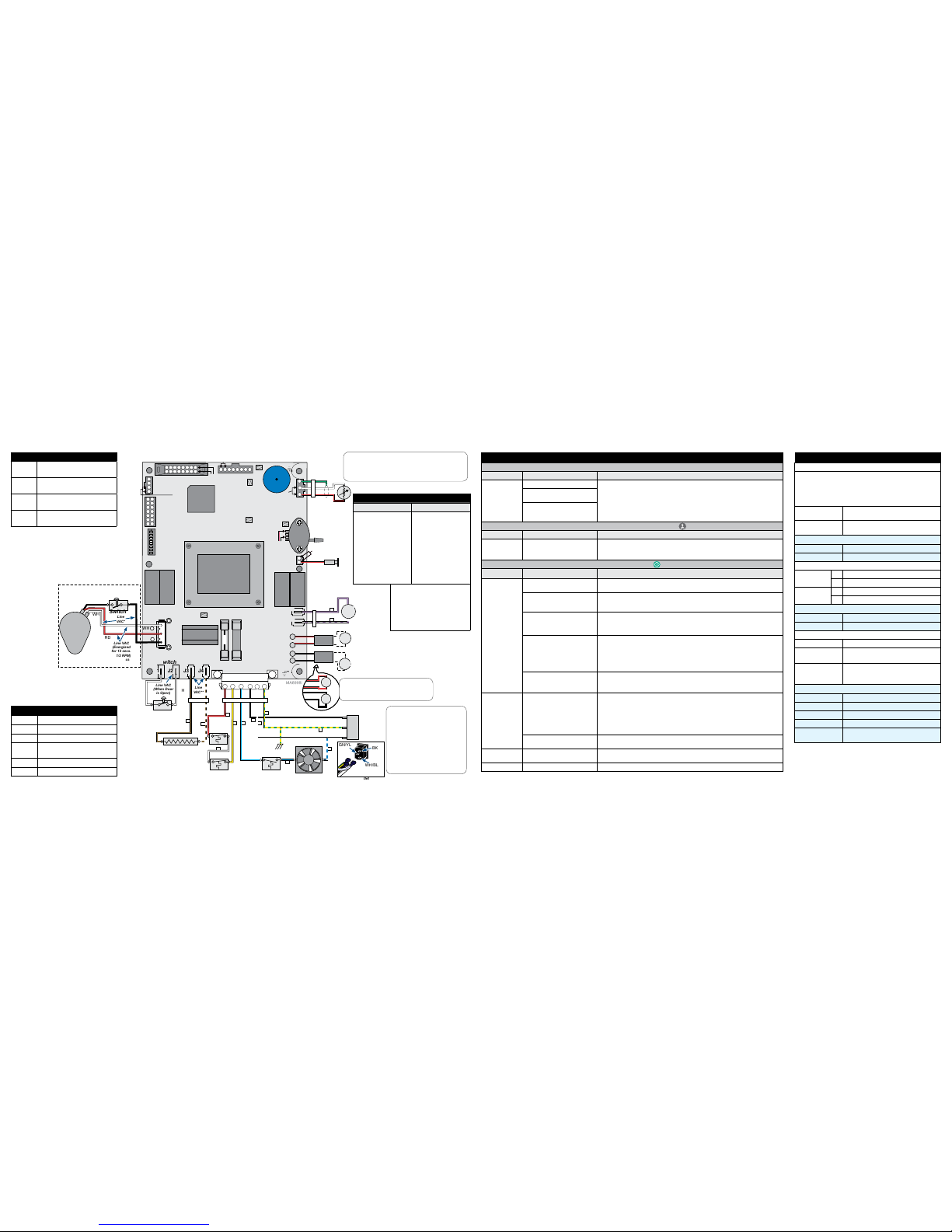

WH/BL

GN/YL

BK

12

10

9

14

1

8

13

1

2

3

4

T1

J1

J2

J3

J4

L1 N/L2

W1

J5

F1

F2

J7

J6

J8

U7

SW1

TP1

+12VDC*

TP3

+5VDC*

TP4

+5VDC*

+5

VDC*

J12

DS1

J14

J13

J10

RS232

PSD

JTAG

J9

14

12

10

8

6

4

2

13

11

9

7

5

3

1

L1

L1

N / L2

L1

L1

VI

RD

BK

WH

GN/YL

GN

GN/YL

3

Lt BL

Lt BL

BK

YL

WH/BL

6

WH

WH

RD

VI/WH

RD

4

BR

BR/WH

+5

VDC*

+5

VDC*

+4.5*

VDC

+4.5*

VDC

+5

VDC*

NO

C

K4

K1

K5

K2

5

6

11

1

4

3

2

1

135791113

15

246810121416

1234567

8

PS1

WH

1

2

1

WH

5

K3

3

2

WH

J15

3

C

NO

2

W2

1

WH

RD

BK

4

3

2

1

8

7

6

5

2

TP2

TP5

+5VDC*

Line**

VAC

W5

W6

W4

W3

RD

BK

RD

BK

VDC***

VDC***

VAC / VDC

VAC / VDC

BK or WH

BK or

WH

RD or WH

RD or WH

GND

ON

NO

C

NC

C

BK

WH

RD

RD

BK

RD

BK

Steam

Temp

Sensor

Printer

Display

Interface

(see

Settings)

Pressure

Transducer

Chamber

Sensor

Harness

Chamber

Level

Transformer

Vent

Valve

Air

Valve

Door

Fill

Valve

Door

Heater

Motor

(Line

Voltage)

Door Opening Motor Assy.

(M9 / M11 Only)

Switch

(Motor Lever Arm Depresses

Switch to open position)

Line

VAC*

Line VAC

(Energized

for 12 secs.

(1 1/2 RPM)

to 30 secs.

(1 RPM))

Air

Solenoid

Coil

Vent

Solenoid

Coil (NO)

Fill

Solenoid

Coil

Plug

Outlet

Door

Interlock

Switch

Line VAC

(When Door

is Open)

Door Interlock

Switch

Steam Heating

Element

Line

VAC**

SW1 Settings

1

On for Service Diagnostics

2

On for Model Designation

3, 4, 5

Not Used, leave Off

6

On for Communication Port

hook-up to computer.

7

Off-English, On-Metric

8

Not Used, Leave Off

Test Points (TP)

TP2 TP1

12 VDC supply to K1 - K5

relay coils.

TP2 TP3

5 VDC supply to low voltage

circuit components.

TP2 TP4

5 VDC supply to Temp. &

Pressure Sensors.

TP2 TP5

5 VDC supply to Printer.

Note

Disconnect plug connector

when checking voltage.

* Constant Voltage

** Voltage Present Only

During Component

Operation

*** Rectified DC Voltage Only

Present During Operation

Heater

Fan Thermostat (N/O)

Closes 130° F ± 8°

Opens 101° F ± 6°

Hi Limits (N/C)

Opens 450° F ± 25°

Closes 350° F ± 25°

Plug Outlet

(Rectified)

(Rectified)

Vent

Fill

Fan Motor

High

Limit

High

Limit In

VAC

Out

Fan

Port

(Line VAC)

Note

Steam Temperature Sensor/red and white wires,

75° F = 1090 Ω; 545° F degrees = 2066 Ω

Resistance (Ω )Cold (±10%)

115 VAC 230 VAC

• Door Opening

Motor (±7.5%)

6000 - 9300 Ω

• Fill Solenoid

See Note M Ω

• Air Solenoid

See Note M Ω

• Vent Solenoid

See Note - M Ω

• Heating Element

10 Ω

• Door Opening

Motor (+/- 7.5%)

13K - 16K Ω

• Fill Solenoid

See Note - M Ω

• Air Solenoid

See Note - M Ω

• Vent Solenoid

See Note - M Ω

• Heating Element

38 Ω

Note: Some Solenoid Coils may

be marked FWR (Full Wave

Rectified). Use the M Ω scale

to measure these coils. If read-

ing is 0.2 M Ω or above, coil is

GOOD. If OL is displayed, coil

is BAD.

Note

Previous coils had built-in rectifiers.

Specications

Electrical Rating:

NOTE

A separate (dedicated) circuit is required for this sterilizer.

Sterilizer should not be connected into an electrical circuit

with other appliances or equipment unless circuit is rated for

the additional load.

115 VAC Unit

104-127 VAC, 50/60 Hz, alternating current

50/60 Hz, single phase, Dedicated PS, 15 A

230 VAC Unit

207-250 VAC, 50/60 Hz, alternating current

50/60 Hz, single phase, Dedicated PS, 10 A

Power Consumption:

115 VAC Unit

Max. 1425 Watts, 12 Amp @ 120 VAC

230 VAC Unit

Max. 1500 Watts, 6.5 Amp @ 230 VAC

Fuse Ratings:

115 VAC F1

0.25 Amp, 250 V, Slo-blo, 1/4” x 1 1/4”

F2

15 Amp, 250 V, Fast Acting, 1/4” x 1 1/4”

230 VAC F1

0.125 Amp, 250 V, Slo-blo, 5 x 20 mm

F2

8 Amp, 250 V, Fast Acting, 5 x 20 mm

Important Cleaning Instructions:

Weekly

Drain water and rell with new distilled water.

Monthly

Run Speed-Clean solution through sterilizer.

Chamber Pressures:

Operating

27-31 PSI (186-215 kPag)

Max. Pressure @

Door Release

0.7 PSIg (5 kPag)

Max. Pressure

[Safety Valve

opens]

40 PSIg (276 kPag)

Specic Chamber Operating Temperature / Time:

Unwrapped

270-275°F (132-135°C) / 3 Min

Pouches

270-275°F (132-135°C) / 5 Min

Handpieces

270-275°F (132-135°C) / 6 Min

Packs

250-255°F (121-124°C) / 30 Min

O/L Temp.

settings

Opens 450°F, (232°C) ± 25°F Closes 350°F,

(177°C) ± 25°F

Loading...

Loading...