Page 1

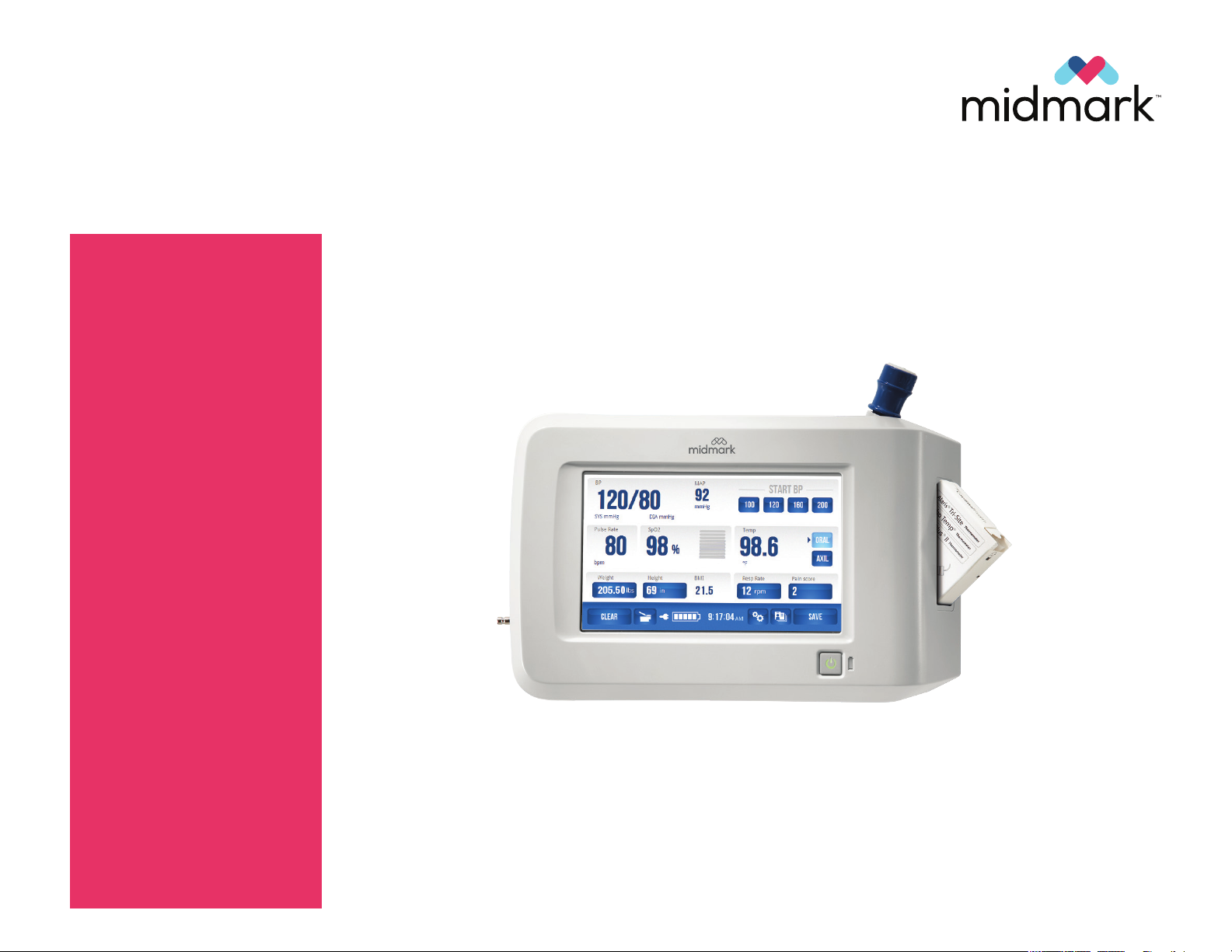

IQvitals +

Digital Vital Signs Device

MODEL NUMBERS

1-100-1630

1-100-1635

1-100-1620

Service and

Parts Manual

TP204 Rev. A

1-100-1625

1-100-1610

1-100-1615

FOR USE BY QUALIFIED PERSONNEL

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

Language of origin: English

3-100-1154 Rev. B

Page 2

Table of Contents

TP204 Rev. A

GENERAL INFORMATION

Symbols ................................................................................... iii

Scope ....................................................................................... iii

Related Documents ................................................................ iii

Device Warranty ...................................................................... iv

Device + Serial Number Location ..................................... iv

General Info

Device Specications.............................................................. v

Compliance Chart ................................................................... vi

Warnings ............................................................................. vii

Cautions .............................................................................. viii

Maintenance/Cleaning Chart ................................................ ix

Disposal ................................................................................... x

TROUBLESHOOTING

Device Description ................................................................. A-2

General Troubleshooting Notes ............................................ A-2

Error Codes ............................................................................. A-3

Power Issues ............................................................................ A-4

Section A

Communication Issues with IQmanager® ............................. A-6

Blood Pressure (BP) Measurement Issues ............................. A-7

Pulse Oximetry (SP02) Measurement Issues .......................... A-10

Temperature Measurement Issues ........................................ A-12

Weight Measurement Issues .................................................. A-15

Printing Issues ......................................................................... A-17

Touchscreen User Interface Issues ......................................... A-18

SERVICE TOOLS + CALIBRATION CHECKS

USB Service Tools Kit .............................................................. B-2

Overview .......................................................................... B-2

One-time Installations .................................................... B-2

Install USB Service Tools Kit ................................................... B-3

Install USB Installer ................................................................. B-4

Section B

Install Service Test Program ................................................... B-6

Service Test Program View ..................................................... B-9

USB Service Test Program .............................................. B-10

Touch Panel Calibration Program Conguration ......... B-10

Functional Verication Tests ............................................ B-11

Calibration Checks ........................................................... B-12

Blood Pressure ........................................................ B-12

SpO2 ......................................................................... B-17

Temperature ............................................................ B-19

Weight ...................................................................... B-21

Touchscreen ............................................................. B-23

PURCHASING GUIDE + PARTS LIST

Ordering Service Parts ..................................................... C-2

Purchasing Guide .............................................................. C-3

Parts List............................................................................. C-5

Section C

SERVICE PART REPLACEMENT

IQvitals and Digital Vital Signs Device ............................ D-2

Disassembly ............................................................... D-3

Removing the Main Board .......................................D-5

Section D

Reassembly ................................................................ D-6

Replacing the Main Board ........................................ D-7

Replacing the Back Panel ......................................... D-9

Replacing the Battery Door ....................................D-10

IQvitals PC with SpO2 ..................................................... D-11

Disassembly ............................................................. D-12

Removing the Main Board......................................D-13

Replacing the Main Board ...................................... D-15

Replacing the Back Panel ....................................... D-16

Replacing the Battery Door ....................................D-18

Specic Part Installation ................................................. D-19

© Midmark Corporation 2020

[Revised: 01/2020]

ii

Page 3

General Information

SYMBOLS

DANGER

Indicates an imminently

hazardous situation which will

result in serious or fatal injury

if not avoided. This symbol

is used only in the most

extreme conditions.

WARNING

Indicates a potentially hazardous

situation which could result in

serious injury if not avoided.

Note

Used for special instructions or

additional information.

RELATED DOCUMENTS

One or more of the following documents may need to be referenced in addition to the information

contained within this Service and Parts Manual

CAUTION

Indicates a potentially hazardous

situation which may result in minor

or moderate injury if not avoided.

It may also be used to alert

against unsafe practices

EQUIPMENT ALERT

Indicates a potentially hazardous

situation whichcould result in

equipment damage if not avoided.

SCOPE

The Digital Vital Signs Device and IQvitals® Service and Parts Manual is

intended for use only by experienced Biomed service personnel. This

manual provides information regarding troubleshooting, maintenance

and performance checks, calibration verication, as well as guides service

personnel through the identication and replacement of eld serviceable

components for these devices.

For detailed information regarding the operation and functions of the

Digital Vital Signs Device and IQvitals® devices, refer to the applicable

device Operation Manuals (see Related Documents).

Document Name Midmark Part #

Digital Vital Signs Device Operation Manual 21-78-0001

Barrier-Free® Exam Table with Digital Scale 003-10027-99

IQvitals, IQmanager, Barrier Free, and Digital Scale are trademarks of Midmark Corporation.

Windows is a registered trademark of Microsoft Corporation in the US and other countries.

Fairbanks and TeleWeigh are registered trademarks of Fairbanks Scales, Inc.

TP204 Rev. A

DuPont and Kapton iare are traedemarks or registered trademarks of E.I. du Pont de Nemours and Company.

© Midmark Corporation 2020

[Revised: 01/2020]

iii

Page 4

DEVICE WARRANTY

Any device covered under Midmark’s Limited Warranty term shall be serviced by Midmark only. Service by any person or entity other than midmark, on a Midmark

device, will void the Warranty and the device will not be eligible for coverage under an extended service agreement.

To conrm the Limited Warranty term for a specic device, contact midmark Support Services and provide the device serial number (see Device Model Number

and Serial Number Location).

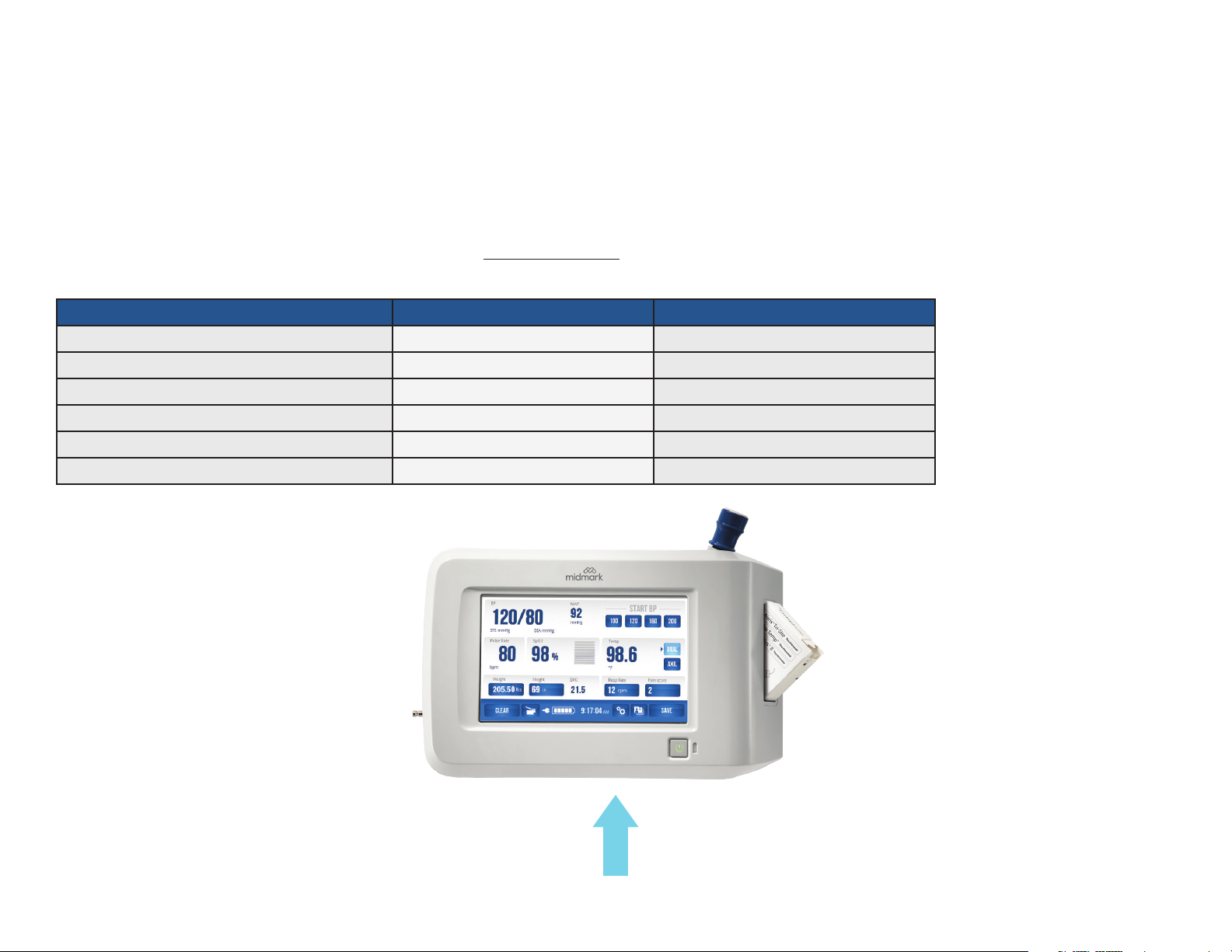

DEVICE MODEL NUMBER AND SERIAL NUMBER LOCATION

To identify and order service parts, it is important to have the correct device model number of the device to be serviced. Both the device model number and the

serial number are located on bottom of the device.

Device Number Kit Part Number Device Model Number

IQvitals PC 4-000-0400 1-100-1620

IQvitals PC with SpO

2

4-000-0410 1-100-1625

IQvitals (touchscreen) 4-000-0500 Rev C 1-100-1610

IQvitals (touchscreen) with SpO

Digital Vital Signs Device

Digital Vital Signs Device

2

4-000-0510 Rev C 1-100-1615

4-000-0500 Rev D 1-100-1630

4-000-0510 Rev D 1-100-1635

TP204 Rev. A

[Revised: 01/2020]

Device Model Number and Serial Number Label

iv© Midmark Corporation 2020

Page 5

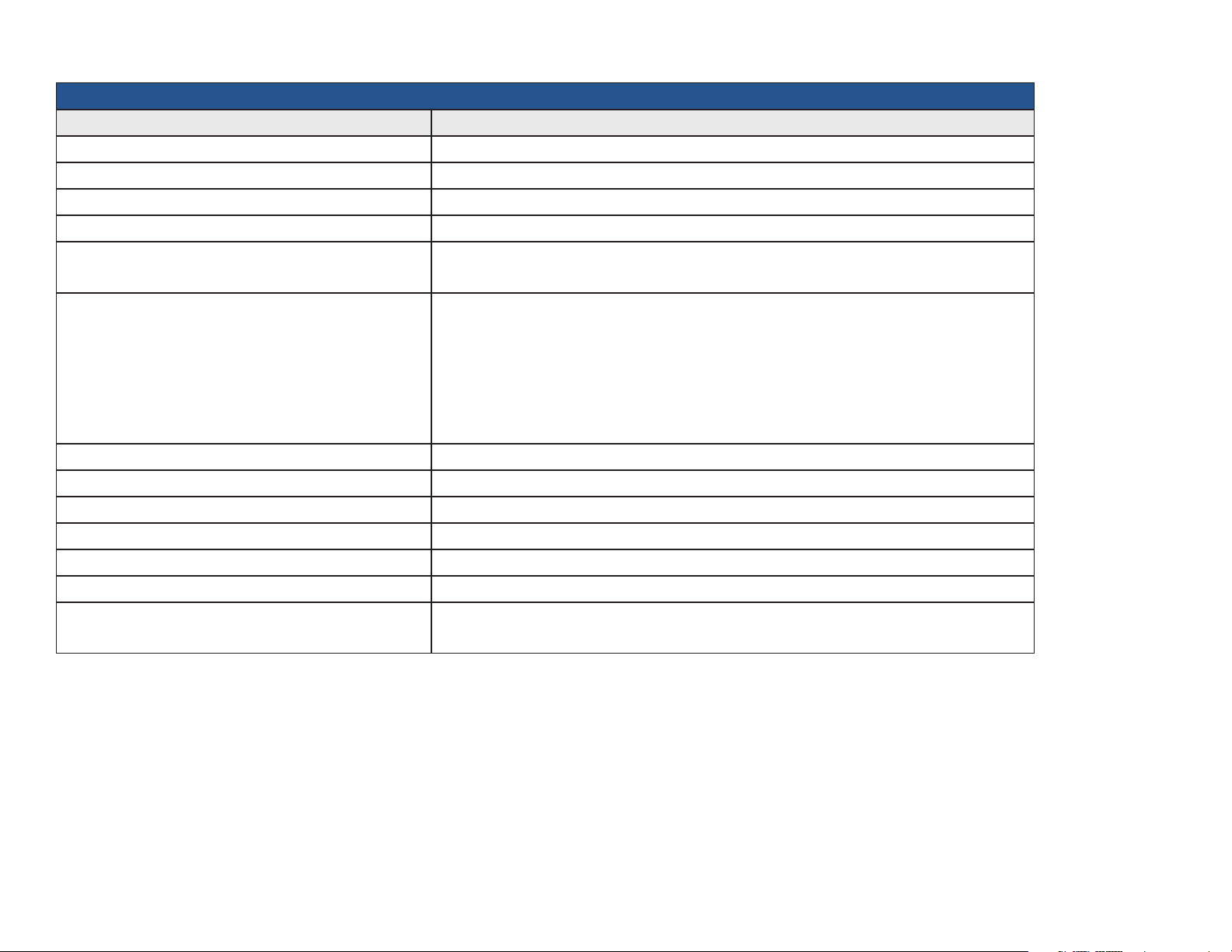

DEVICE SPECIFICATIONS

General Performance

Category Specication

Product Name IQvitals, IQvitals PC + Digital Vital Signs Device

Product Type Non-invasive, automated, multi-parameter vital signs device

Product Weight Digital Vital Signs Device = 3.9 lbs (1.77 kg) / IQvitalsPC = 3.2 lbs (1.45 kg)

Product Dimensions 10.5"L X 4"W X 7"H (0.27 x 0.10 x 0.18 m)

Power Requirements 100–240 VAC

1.2 A max

Battery Requirements • Battery Type: Rechargeable, 10.8 V lithium ion

• Low Power Indicator

• Automatic Shutdown on low power

• Operating Time: Approximately 8 hours

• Leakage Current: Meets AAMI/IEC/CSA 60601-1 requirements

• Battery Charge Time: 4 hours to fully charge, 3 hours for 95% charge

Type of Protection (Electrical) Class I

Degree of Protection (Water) IPX1. Protection against dripping water

Disinfecting Method Per the instructions in the Maintenance/Cleaning Chart section of this service manual

Degree of Safety (Flammable Anesthetic Mixture) Not suitable for use in the presence of a Flammable Anesthetic Mixture

EMC Standard Per IEC 60601-1-2 and FCC Part 15 (Emissions Class B)

Device Connectivity USB (Client) and serial (not supported in Digital Vital Signs Device)

Accessory Connectivity USB 1.1 (Master) — IQvitals

USB 2.0 (Master) — Digital Vital Signs Device

TP204 Rev. A

[Revised: 01/2020]

v© Midmark Corporation 2020

Page 6

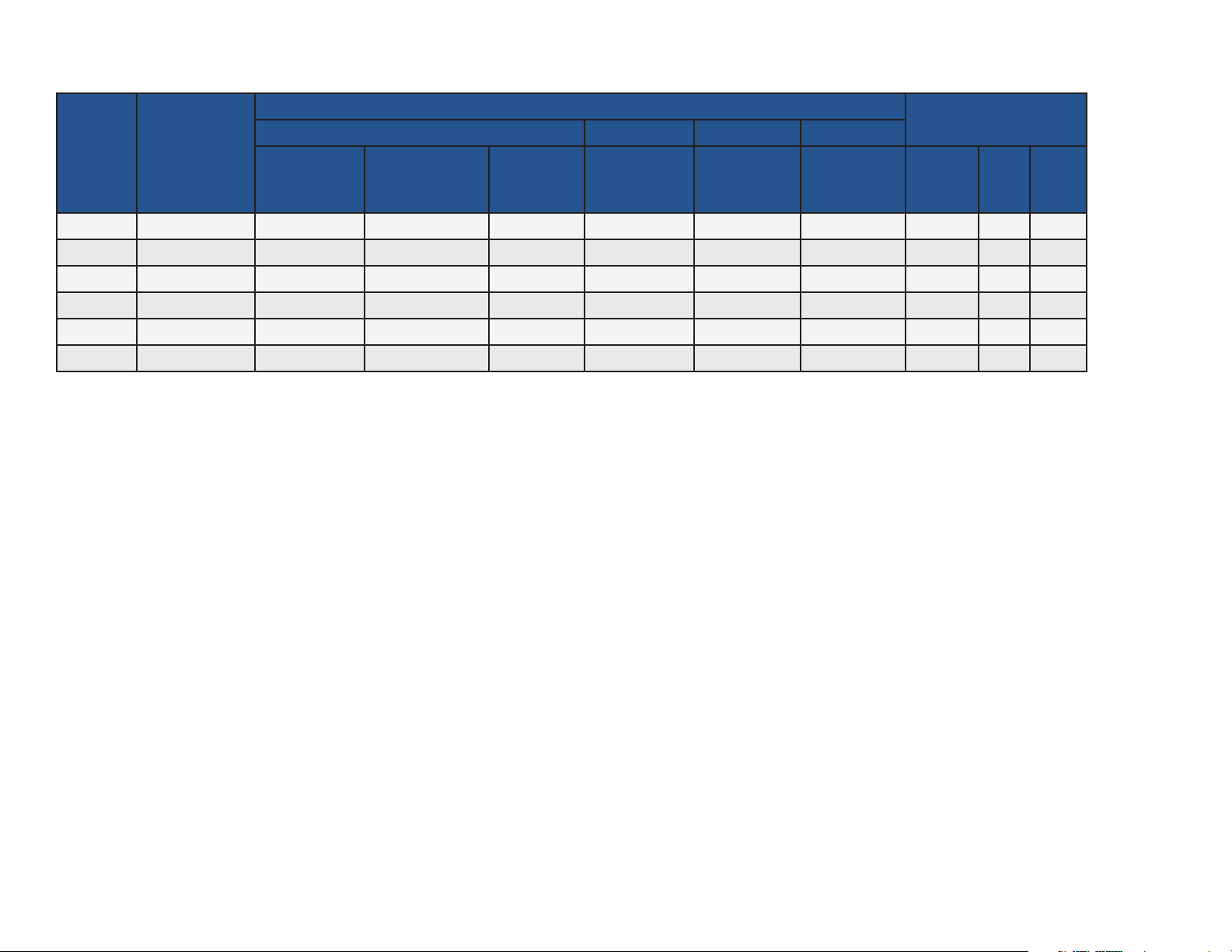

COMPLIANCE CHART

Complies To (All Models):

Electrical Ratings:

Safety EMC NIBP SpO2

CSA

C22.2.60601.1

(2008)

IEC 6060

1-1 (2005)

IEC 60601-1-2

(2007), Class B

IEC 8060

1-2-30 (2009)

1-2-61(2011)

ISO 80601

VAC

+/- 10%

Amps

Cycles

(Hz)

Model

Fire Code

Rating

AAMIES 6060

1-1(2005)

1-100-1620 UL 94 V-0 • • • • • 100 – 240 1.2 50/60

1-100-1625 UL 94 V-0 • • • • • • 100 – 240 1.2 50/60

1-100-1610 UL 94 V-0 • • • • • 100 – 240 1.2 50/60

1-100-1615 UL 94 V-0 • • • • • • 100 – 240 1.2 50/60

1-100-1630 UL 94 V-0 • • • • • 100 – 240 1.2 50/60

1-100-1635 UL 94 V-0 • • • • • • 100 – 240 1.2 50/60

TP204 Rev. A

[Revised: 01/2020]

vi© Midmark Corporation 2020

Page 7

Warnings

WARNING

Do not use this device for any purpose other than its specified

intended use.

WARNING

Digital Vital Signs Device is not intended for continuous monitoring.

Do not leave a patient unattended while taking measurements with

this device.

WARNING

Digital Vital Signs Device is not intended for use during

patient transport.

WARNING

To ensure patient safety, only use supplies and accessories that are

supplied with the Digital Vital Signs Device and recommended by

Midmark. Using unapproved acces stories can affect patient and/or

operator safety.

WARNING

Regularly inspect the blood pressure cuff, SpO2 cable, and other

accessories for damage. Replace accessories as needed.

WARNING

Digital Vital Signs Device is not intended for use in the following cases:

• Neonatal patients

• Apnea monitoring

• In a magnetic resonance imaging

• (MRI) environment

• In an electro-static unit (ESU) environment

• Applications requiring arrhythmia detection

WARNING

FLAMMABLE ANESTHETICS: An explosion hazard exists if the monitor is

used in the presence of flammable anesthetics.

WARNING

BLOOD PRESSURE MEASUREMENT: Avoid frequent and prolonged blood

pressure measurements, which can result in petechia, ischemia, purpura,

or neuropathy. In addition, be sure that the blood pressure hose does not

become kinked during a measurement. If left unattended, this could result in

sustained pressure in the blood pressure cuff.

TP204 Rev. A

WARNING

Digital Vital Signs Device is not intended to

be hand-held during operation.

WARNING

Do not connect more than one patient to the device at the

same time.

WARNING

Do not route the cables of the device in a way that they may present

a stumbling hazard.

[Revised: 01/2020]

WARNING

BATTERY HANDLING: Digital Vital Signs Device contains a lithium ion battery.

The following precautions should be taken regarding these batteries:

• Do not immerse in water.

• Do not heat or throw in fire.

• Do not leave in conditions over 60° C or in a heated car.

• Do not attempt to crush or drop.

• Only use the battery with the Digital Vital Signs Device

• Follow the instructions in the Disposal section of the devices’ Operation

Manual when any Digital Vital Signs Device device is taken out of service.

vii© Midmark Corporation 2020

Page 8

Cautions

Review the following information to avoid damage to the device and to ensure proper operation:

TP204 Rev. A

Caution

Familiarize yourself thoroughly with the operational procedures of the

device prior to use.

Caution

Substitution of components different from those supplied could result

in measurement error.

Caution

Do not operate the Digital Vital Signs Device device near

high-frequency emissions (e.g. microwaves).

Caution

Do not operate the Digital Vital Signs Device device near highfrequency emissions (e.g. microwaves).

Caution

The Digital Vital Signs Device is intended for indoor use only.

Caution

The device and its accessories are not intended to be sterilized by any

method. Attempting to do so may permanently damage

the equipment.

Caution

In case of malfunction, call the Midmark Support Services

depar™ent at 1-800-624-8950, option 2, and be prepared to

describe the problem.

Caution

To ensure proper operation, perform routine inspection and

maintenance on the device according to the instructions in this

Service Manual.

Caution

Do not make any modifications to the device. Any modifications made

will void the warranty.

Caution

Refer servicing to qualified personnel.

Caution

ARRHYTHMIA PATIENTS: The Digital Vital Signs Device is designed to operate

in the presence of cardiac arrhythmias. However, the pulse rate meter may be

adversely affected in some cases.

Caution

BLOOD PRESSURE MEASUREMENT

• Do not allow the blood pressure cuff or hose to come into contact with

fluids. If this occurs, See “Cleaning“ of the devices’ Operations Manual

for drying instructions.

• Check the hose and cuff frequently for signs of damage or debris. An

obstruction in the hose may interfere with inflation and deflation, resulting

in inaccurate readings.

• To obtain accurate blood pressure readings, keep the limb and cuff

motionless.

• The blood pressure cuff should be at the same level as the patient’s

heart. If you cannot place the NIBP cuff at this level, add 1.4 mmHg to the

measured pressure values for each 2 cm above the heart level, or subtract

1.4 mmHg for each 2 cm below heart level.

• Blood pressure measurements may not be accurate if the patient is

convulsive or experiencing tremors.

• Check for kinks in the blood pressure hose if the device reports a

measurement problem.

Caution

• Read instructions provided with the sensor to understand the best

application technique and all relevant safety information.

• Do not apply the sensor on the same limb as the NIBP cuff. During blood

pressure measurements, the perfusion is temporarily reduced, which can

result in inaccurate pulse oximetry readings.

• Elevated levels of carboxyhemoglobin or methemoglobin can result in

inaccurate pulse oximetry readings.

• Bright light can create problems with the pulse oximetry measurements,

resulting in inaccurate readings. If the sensor is in a place where it may be

exposed to bright light, cover it with opaque material.

• Pulse oximetry readings may be inaccurate in the presence of excessive

motion artifact or tremors.

[Revised: 01/2020]

viii© Midmark Corporation 2020

Page 9

MAINTENANCE/CLEANING CHART

The following table provides instructions for cleaning the IQvitals

cleaning, refer to the cautions listed in the following table or refer to the “Cleaning” section of the Operation Manual for each device.

Part Recommended Cleaning Method

IQvitals

®

+ Digital Vital Signs Device

®

+ the Digital Vital Signs Device. The devices should be cleaned monthly or as warranted. Before

Procedure

1. Disconnect the unit from the wall outlet.

2. Put on gloves and protective eyewear.

3. Prepare the enzymatic detergent, or disinfectant solution, according to the

manufacturer’s instructions and in separate containers.

4. Apply detergent to the product using a soft cloth. If the material is dried

on, allow it to sit for one minute.

5. Wipe smooth surfaces with the cloth.

6. Use a soft-bristle brush on visibly soiled areas and irregular surfaces.

7. Remove the detergent from the product using a cloth dampened in

distilled water.

8. Repeat as necessary.

9. Apply the disinfectant solution to the affected area using a soft cloth. Allow

the product to sit for ve minutes.

10. Wipe away excess solution, and clean the product again with a cloth

dampened in distilled water.

11. Allow two hours for drying.

SpO2 Sensor Procedure

1. Remove sensor from the patient, and disconnect the sensor cable from the

device prior to cleaning.

2. Refer to the cleaning instructions from the sensor manufacturer.

Temperature Probe Covers Temperature probe covers are for one-time use only.

TP204 Rev. A

NIBP Cuff Refer to the cleaning instructions from the cuff manufacturer.

[Revised: 01/2020]

ix© Midmark Corporation 2020

Page 10

DISPOSAL

The disposal of Midmark Diagnostic Devices and their accessories should be carried out according to local medical waste disposal policies and procedures. Do not discard these

items in unsorted municipal waste. Contact your local waste disposal agency for guidance on proper recycling or disposal.

Certain items contain electronic circuit boards or lithium ion batteries that should not be incinerated, crushed, disassembled or exposed to extreme heat. Do not put the lithium ion

battery in a refuse container. Lithium batteries and electronic components should be recycled appropriately.

TP204 Rev. A

[Revised: 01/2020]

x© Midmark Corporation 2020

Page 11

Troubleshooting

SECTION A

TP204 Rev. A

[Revised: 01/2020]

A-1© Midmark Corporation 2020

Page 12

DEVICE DESCRIPTION

IQvitals® + Digital Vital Signs Device

The IQvitals

®

and Digital Vital Signs Device contains a Main Board, an I-O Board, and a Processor Board. The Main Board contains signal acquisition and power management

circuitry. The I-O Board contains data port connectors. The Processor Board runs both signal analysis software to generate the patient’s physiological readings and user interface

software to display the patient’s readings and trend them over time. The IQvitals contains an SD card to store the patient’s readings and the device settings, while the Digital Vital

Signs Device uses on-board ash memory.

®

IQvitals

The IQvitals

PC

®

PC device contains a Main Board and an I-O Board, but no Processor Board. In this case, the signal analysis software runs as part of the IQmanager® software package

on the clinician’s workstation.

Both devices are powered from either an external, medical-grade mains supply or an internal, rechargeable lithium-ion battery.

Both devices can connect to select digital scales.

Both devices are available with or without the SpO2 function.

A thermal printer purchased from Midmark, can be connected to the Digital Vital Signs Device device, but does not connect to the IQvitalsPC device.

GENERAL TROUBLESHOOTING NOTES

As a general rule, it is good idea to power-cycle the device to see if a problem persists. The device has numerous self-checks that will continue to trigger if the issue persists.

It is often necessary to isolate a problem to a particular component – the device, the power supply, a patient sensor, etc. It is a good idea to swap in a “known-working” component

to see where a problem lies.

Conrm that Midmark-approved SpO2 sensors and temperature probe covers are being used.

TP204 Rev. A

[Revised: 01/2020]

A-2© Midmark Corporation 2020

Page 13

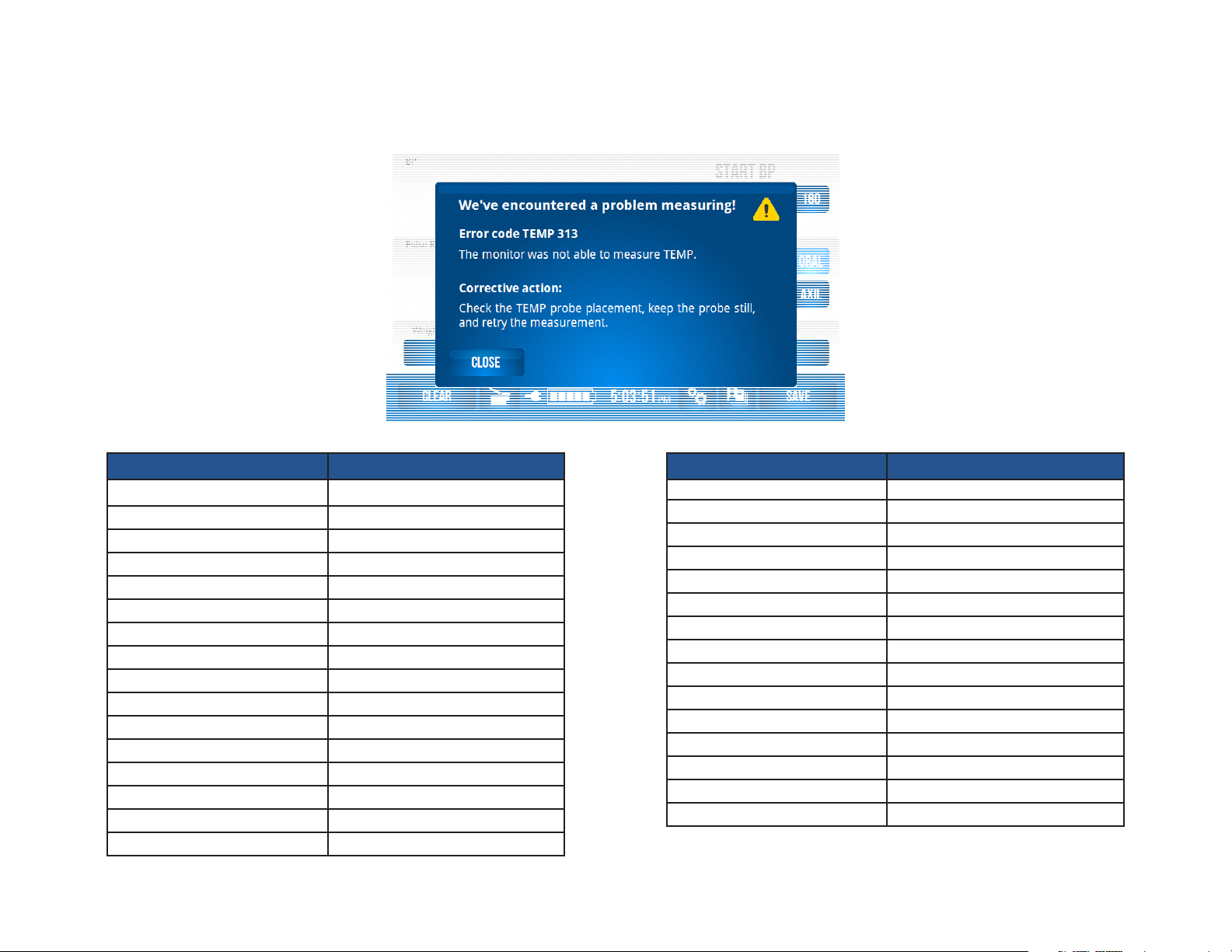

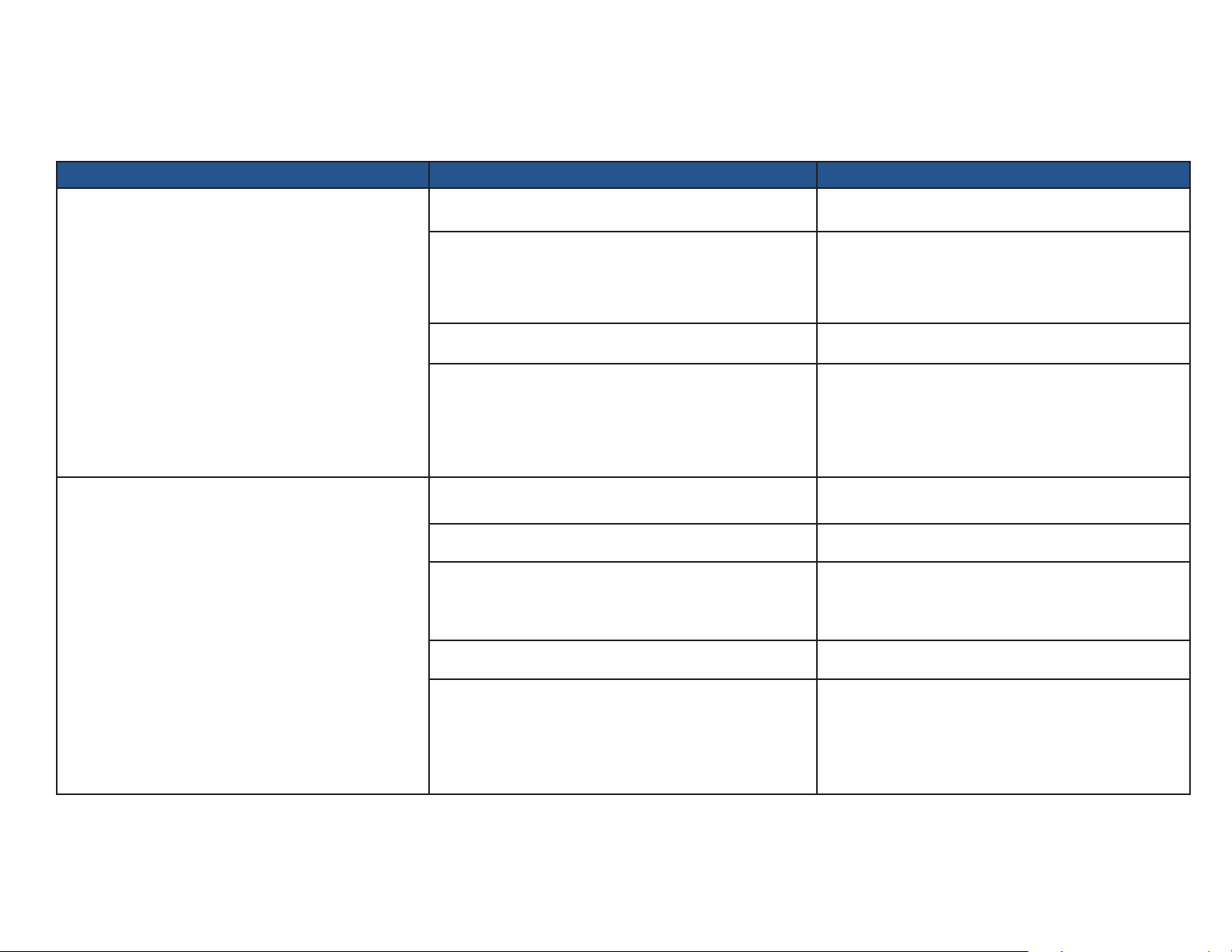

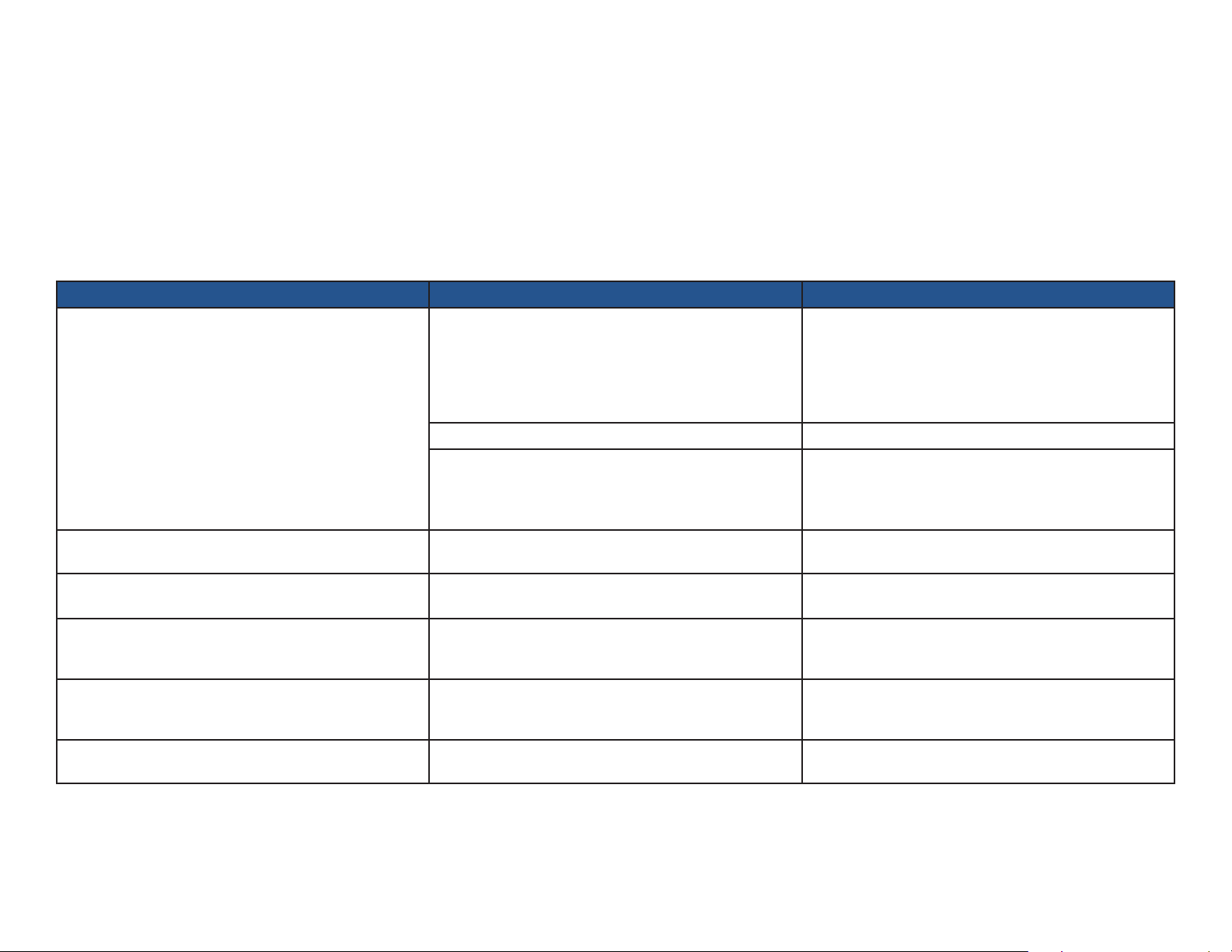

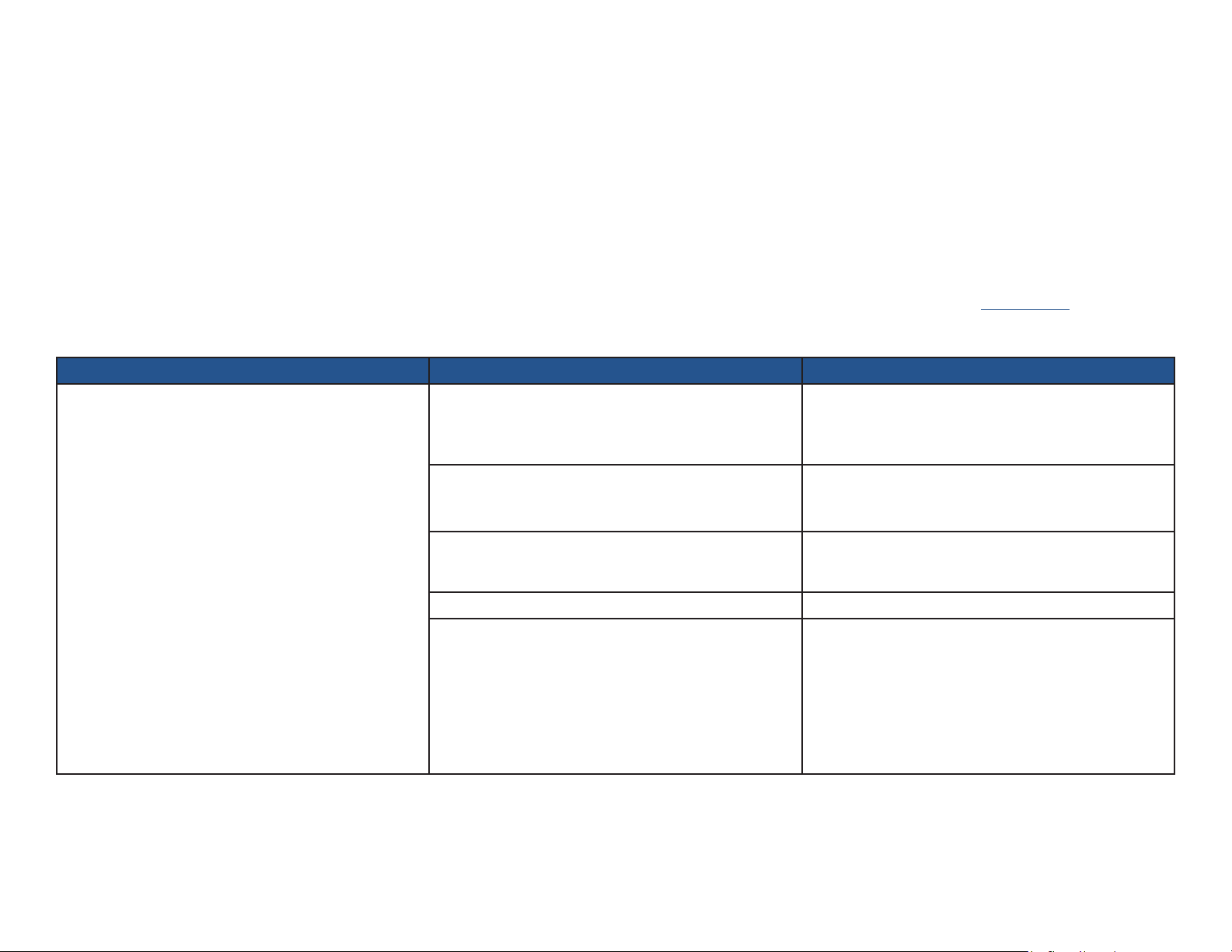

ERROR CODES

The following table contains the error codes that may be encountered while operating the Digital Vital Signs Device or IQvitals® devices. All error codes will appear in separate

boxes similar to the image below. See the Troubleshooting section of this Service Manual for each code’s appropriate corrective action.

TP204 Rev. A

Code Indication

NIBP 305 Artifact

NIBP 306 Hardware failure

NIBP 309 Overpressure

NIBP 310 Blocked line

NIBP 311 Open line

NIBP 312 Measurement time-out

NIBP 313 Cannot measure

NIBP 314 Weak signal

SpO2 302 Unplugged

SpO2 305 Artifact

SpO2 306 Hardware failure

SpO2 314 Weak signal

SpO2 315 Probe fault

SpO2 316 Check sensor

Code Indication

TEMP 302 Unplugged

TEMP 304 Temp too high

TEMP 306 Hardware failure

TEMP 313 Cannot measure

TEMP 315 Probe fault

TEMP 330 Temp too low

BAT 325 Battery low

REC 327 Recorder door open

REC 328 Recorder paper out

REC 329 Recorder fault

Monitor

MON 332 Monitor fault

[Revised: 01/2020]

A-3© Midmark Corporation 2020

Page 14

POWER ISSUES

The Digital Vital Signs Device use an external mains power supply. Each device contains a rechargeable lithium ion battery that is automatically recharged when the device is

connected to mains.

The device’s power switch is on the front of the device. When the device is on, the on/off switch is lit green.

The Battery Charging Light is also on the front of the device. It indicates the charging status:

solid green: device is on mains power and battery is charged

blinking green: device is on mains power and battery is charging

off: device is not on mains power and battery is not charging

The Digital Vital Signs Device will run on battery power for approximately 8 hours (longer for the IQvitals® PC device). The battery takes about 4 hours to recharge from a fully

depleted state.

A “Battery Low“ message will be reported when the battery is nearly depleted (approximately 40% remaining battery power). The device automatically shuts itself off when the

battery is too low to function.

The battery should last for 2-3 years under normal use and can be replaced via a dedicated access door on the back of the device.

Caution

The device should only be used with the power supply and

battery that are listed in the Operation Manual.

Issue/Error Code Probable Cause Check

Device won’t start.

Screen stays black, on/off switch does not illuminate.

TP204 Rev. A

[Revised: 01/2020]

No power to wall outlet.

Bad power supply.

Power supply not fully connected to device.

Device is not powered on.

Battery is dead.

A-4© Midmark Corporation 2020

Green LED on power supply is lit.

Check wall outlet with a known-working power supply.

Green LED on power supply is lit.

Check wall outlet with a known-working power supply.

Power supply cable is rmly inserted in the power

connector on the back of the device.

Battery Charging Light on the front of the device is

lit (green). See notes above or refer to the Operation

Manual.

On/off button on the front of the device is lit (green).

Reconnect device to mains power. Power cycle the device.

Page 15

Issue/Error Code Probable Cause Check

Device won’t start. (continued)

Device won’t start.

Screen is white, Midmark start-up banner

never displayed.

Device won’t start.

Screen is frozen at Midmark start-up banner

or home screen.

Device won’t start.

Midmark start-up banner is displayed and

then the screen becomes white.

Device immediately powers off when

disconnected from mains.

Internal problem.

Internal problem.

Internal problem.

Internal problem.

Battery is fully discharged.

• Replace I-O Board (likely), Power Switch which is

part of the Front Bezel (possible) or Main Board

(less likely).

• Power cycle the device.

• Reseat display cable in connector on Processor

Board.

• If problem persists, replace Processor Board.

• Power cycle the device.

• If problem persists, reseat or replace SD Card

(IQvitals only) (more likely) or Processor

Board (possible).

• Power cycle the device.

• If problem persists, reseat or replace SD Card

(IQvitals only).

• Charge battery by plugging device into mains power.

Conrm that the battery charging light on the front of

the device is blinking (charging).

• If problem persists, replace Main Board (likely) or

Battery (less likely).

TP204 Rev. A

Battery Gauge not full after sufcient

charging time.

Battery at end of life. • Replace Battery.

Battery Life shorter than usual. Battery at end of life. • Replace Battery.

[Revised: 01/2020]

A-5© Midmark Corporation 2020

Page 16

COMMUNICATION ISSUES WITH IQMANAGER

®

The Digital Vital Signs Device can connect to a personal computer (PC) or laptop via a USB or serial cable (IQvitals only). This allows for the

transfer of patient data between the device and IQmanager® software.

Issue/Error Code Probable Cause Check

USB disconnect or Error Code MON 0.

Computer won’t connect to the device.

USB cable became detached from device or IQmanager PC.

Device is no longer powered on.

Cable problem.

Internal problem.

USB or serial cable (IQvitals only) not attached to device or

IQmanager PC.

Device is not powered on.

Wrong communication set-up.

Cable problem.

• Check cable connection.

• Conrm that device is on mains.

• Follow the power checks from earlier in this

document.

• Test with a 2nd cable.

• Power cycle the device.

• If problem persists, check for damaged connector on

I-O Board. Replace I-O Board (most likely) or Main

Board (possible).

• Check cable connection.

• Follow the power supply checks.

• Conrm that the communication set-up is correct on

the IQmanager PC (USB or Serial Port (IQvitals only),

correct Serial Port number).

• Test with a known-working cable.

TP204 Rev. A

[Revised: 01/2020]

Internal problem.

• Power cycle the device.

• If problem persists, check for damaged connector on

I-O Board. Replace I-O Board (most likely) or Main

Board (possible).

A-6© Midmark Corporation 2020

Page 17

BLOOD PRESSURE (BP) MEASUREMENT ISSUES

It is always suggested that the cuff manufacturers’ instructions for use or product insert be consulted.

For best practice techniques when obtaining blood pressure measurement for a patient using the Digital Vital Signs Device refer to the “Device Operation“ section of the device

Operation Manual.

Periodic BP measurement accuracy check:

• The BP circuitry contains a calibration potentiometer that is set at the factory. This potentiometer will remain stable for the life of the product and is not eld serviceable.

• An accuracy check of the BP pressure transducer and a leak test should be conducted annually. See Section B of this Service Manual.

Issue/Error Code Probable Cause Check

• Refer to the Operation Manual for recommended

measurement technique.

Incorrect measurement technique.

• Retake measurement.

BP readings seem low or high.

Measurement taking too long.

NIBP 305

Artifact.

TP204 Rev. A

• Test with a known-working device.

• Test with a known-working device.

Internal problem.

• Check accuracy of BP circuit. See Section B of this

Service Manual.

• Select the “BP Start“ pressure button that is 30

Initial ination pressure too low.

mmHg above the patient’s systolic value (to avoid

“double pumping“).

• Ask patient to remain still.

Patient motion.

• Retake measurement.

Arrhythmia or valvular defect. • Measure on opposite arm.

• Ask patient to remain still.

Too much patient movement.

• Retake measurement.

• Apply the cuff to the opposite arm where variability

Patient’s pulse signal has persistent variability due to

may be reduced.

arrhythmia or valvular problem.

• Retake measurement.

[Revised: 01/2020]

A-7© Midmark Corporation 2020

Page 18

NIBP 306

Hardware failure.

Issue/Error Code Probable Cause Check

• Power cycle the device.

• If problem persists, connect device to Test Harness

and power up. See Section B of this Service Manual.

• If problem is persistent, it will occur when running the

Test Harness. When “Code 306“ is reported as the

NIBP parameters (either at start-up or after starting

a measurement), check the NIBP status eld for the

fault description.

• If NIBP status is “Pump / Transducer Failure“,

(1) the NIBP Manifold tubing may have become

Internal problem.

disconnected from the transducer or pump, (2) the

Pump may not be starting, or (3) the transducer may

be faulty. Inspect the NIBP Manifold and retest. If

problem persists, listen for the sound of the Pump

at measurement start (must power-cycle the device

rst). If Pump is not starting, replace Pump (most

likely) or Main Board (possible). If Pump is starting,

replace transducer which is part of the Main Board.

• If NIBP status is “Pressure Not Releasing“, check

NIBP Manifold tubing for debris or replace (possible)

or replace Valve Assembly (possible).

TP204 Rev. A

NIBP 309

Overpressure.

NIBP 310

Blocked line.

[Revised: 01/2020]

• For all other NIBP status, replace Main Board.

• Instruct patient to remain still.

Cuff pressure was too high.

• Retake measurement.

• Check the BP hose for damage or kinks.

BP hose is constricted.

• Retake measurement.

A-8© Midmark Corporation 2020

Page 19

Issue/Error Code Probable Cause Check

NIBP 311

Open line.

NIBP 312

Measurement time-out.

NIBP 313

Cannot measure.

• Attach BP hose.

BP hose is not attached to device or cuff.

• Retake measurement.

• Test with a known-working cuff.

Cuff may be worn or damaged.

• Retake measurement.

• Check cuff for proper t.

Cuff is too loose.

• Retake measurement.

• Perform Leak Test. See Section B of this Service

Manual.

• If device fails leak test with a small steady leak, check

Leak in device’s internal pneumatic system.

all connections on NIBP Manifold or replace. Retest.

• If device fails leak test with a signicant leak, check

or replace Valve Assembly (most likely), or step-valve

which is part of the Main Board (possible) or Pump

(unlikely).

• Instruct patient to remain still.

Measurement was taking too long to complete.

• Retake measurement.

Ination pressure was less than patient’s systolic pressure. • Retake measurement at higher ination pressure.

• Wait 10 seconds after powering on device or

Device is auto-zeroing after power-up.

connecting to device.

• Retake measurement.

• Check that cuff is not too large for patient.

TP204 Rev. A

NIBP 314

Weak signal.

[Revised: 01/2020]

Patient’s pulse signal is too small.

Patient’s pulse signal is too small.

A-9© Midmark Corporation 2020

• Check cuff for proper t and placement.

• Retake measurement.

• Check that cuff is not too large for patient.

• Check cuff for proper t and placement.

• Retake measurement.

Page 20

PULSE OXIMETRY (SPO2) MEASUREMENT ISSUES

It is always suggested that the SpO2 sensor manufacturers’ instructions for use or product insert be consulted.

For best practice techniques when obtaining an SpO2 measurement for a patient using the Digital Vital Signs Device refer to the “Device Operation” section of the device Operation

Manual

Periodic SpO2 measurement accuracy check:

• The SpO2 circuitry contains a calibration potentiometer that is set at the factory. This potentiometer will remain stable for the life of the product and is not eld serviceable.

• An accuracy check of the SpO2 circuitry should be conducted annually. See Section B of this Service Manual.

Issue/Error Code Probable Cause Check

• Refer to manufacturer’s instructions for use.

Readings seem low or high.

SpO2 302

Unplugged.

SpO2 305

Artifact.

SpO2 306

Hardware failure.

SpO2 312

Measurement time-out.

SpO2 314

Weak signal.

Incorrect measurement technique.

• Retake measurement. Wait for measurement value to

stabilize.

• Test with a known-working device.

Sensor problem. • Test with a known-working sensor.

• Test probe with a known-known device.

Internal problem.

• Perform a BP Calibration Check. See Section B of this

Service Manual.

The Spo2 cable is disconnected from the device. • Connect the SpO2 cable to the device.

Too much patient movement. • Ask patient to remain still.

• Power cycle the device.

Internal problem.

• If problem persists, replace Main Board.

Cannot measure.

• Refer to manufacturer’s instructions for use.

Incorrect sensor size or too much motion.

Weak patient pulsations. • Refer to manufacturer’s instructions for use.

TP204 Rev. A

[Revised: 01/2020]

A-10© Midmark Corporation 2020

Page 21

Issue/Error Code Probable Cause Check

• Detach and reattach sensor. Retest.

SpO2 315

Check sensor.

SpO2 316

Check sensor.

No response by device when SpO2 sensor is applied to

the patient.

Faulty sensor.

Cannot measure.

The SpO2 sensor is misaligned or came off the patient.

Internal problem or faulty sensor.

• Test with a known-working sensor. If problem goes

away, replace faulty sensor. If problem persists,

replace Main Board.

• Refer to manufacturer’s instructions for use.

• If no red light is coming from the sensor, detach and

reattach sensor. Retest.

• Test with a known-working sensor. If problem goes

away, replace faulty sensor. If problem persists,

replace Main Board.

TP204 Rev. A

[Revised: 01/2020]

A-11© Midmark Corporation 2020

Page 22

TEMPERATURE MEASUREMENT ISSUES

It is always suggested that the temperature probe manufacturers’ instructions for use be consulted.

For best practice techniques when obtaining a temperature measurement for a patient using the Digital Vital Signs Device, refer to the “Device Operation” section of the device

Operation Manual.

Proper probe installation:

• Make sure the probe cord is threaded through the cord guide on the back of the device.

o Heavy strain on the probe can cause the probe wire to break inside the connector.

Periodic temperature accuracy checks:

• The Temperature circuitry is self-calibrating.

• An accuracy check of the temperature circuitry should be conducted annually. See section B of this Service Manual.

TP204 Rev. A

[Revised: 01/2020]

A-12© Midmark Corporation 2020

Page 23

Issue/Error Code Probable Cause Check

• Refer to Operation Manual for proper probe

placement.

Readings seem low or high.

No measurement started when probe is removed from

the probe well.

Temperature measurement starts even though the

probe is in the probe well.

TEMP 302

Unplugged.

Incorrect measurement technique or probe placement.

Probe damaged.

Internal problem.

Probe unplugged.

Internal problem.

Internal problem.

Probe unplugged.

• Verify correct temperature measurement with a

calibrated water bath.

• Test with a known-working probe.

• Test with a known-working probe.

• Make sure the probe is threaded through the cord

guide on the back of the device.

• Check probe and cable for damage.

• Test with a known-working probe.

• Perform Temperature Calibration Check. See Section

B of this Service Manual.

• Check that probe is rmly connected to the device.

• Test with a known-working probe.

• Test with a known-working probe.

• If problem persists, check connectors between I-O

Board and Main Board for physical damage, and

replace board(s) if needed (possible). Or replace

probe well switch which is part of the Temp Assembly

(less likely).

• Reinsert probe into well, power cycle the device and

retest.

• If problem persists, replace probe well switch which is

part of the Temp Assembly (most likely) or I-O Board

(possible).

• Check that probe is rmly connected to the device.

• Test with a known-working probe.

TP204 Rev. A

[Revised: 01/2020]

A-13© Midmark Corporation 2020

Page 24

Issue/Error Code Probable Cause Check

TEMP 304

Temp too high.

TEMP 306

Hardware failure.

TEMP 313

Cannot measure.

TEMP 315

Probe fault.

TEMP 330

Temp too low.

Temperature reading > 106 ºF.

• Verify correct temperature measurement with a

calibrated water bath.

• Power cycle the device.

Internal problem.

• If problem persists, replace Main Board.

Probe is too warm at start of measurement process

• Wait 10 seconds between measurements so probe

can return to a valid starting temperature point.

(> 92 ºF).

• Check for proper “oral“ or “axillary“ temp setting.

• Hold probe steady and retake measurement.

It is taking too long to get a stable temperature.

• Refer to the Operation Manual for proper probe

placement.

• Test with a known-working probe.

Room is too cold (< 60 ºF). • Retake measurement in warmer environment.

Room is too warm (> 92 ºF). • Retake measurement in cooler environment.

• Retake measurement.

Probe heating element not working.

• Test with a known-working probe.

• If problem persists, replace Main Board.

• Power cycle the device and retake measurement.

Faulty probe.

• Test with a known-working probe.

• If problem persists, replace Main Board.

Temperature reading < 95 ºF.

• Verify correct temperature measurement with a

calibrated water bath.

Probe Problem.

TP204 Rev. A

[Revised: 01/2020]

A-14© Midmark Corporation 2020

Page 25

WEIGHT MEASUREMENT ISSUES

®

The Digital Vital Signs Device and IQvitals

with Digital Scale. The Fairbanks® scale can measure weight from 10 to 500 lb and receives its power from the Digital Vital Signs Device or IQvitals® PC device (no batteries required

for the scale). The Midmark 626 power exam chair with Digital Scale can measure weight from 30 to 600 lb.

Periodic weight measurement accuracy check:

• The Fairbanks® scale is calibrated at the factory and should not need further calibration.

• The Fairbanks® scale is self-zeroing.

• An accuracy check of the Fairbanks® scale should be conducted annually. See Section B of this Service Manual.

• For service instructions for the Midmark 626 Barrier Free® Power Examination Chair with Digital Scale, contact Midmark customer support or visit midmark.com.

Issue/Error Code Probable Cause Check

PC devices can connect to either a Fairbanks® TeleWeigh® digital oor scale or a Midmark 626 Barrier Free® Power Examination Chair

• Check scale cable connection.

No reported weight (Fairbanks® Scale).

TP204 Rev. A

Scale cable not attached to device.

• If connected, scale should power on and show weight

in its local display.

Fairbanks® scale feature not enabled (device is congured

to communicate with Midmark 626 with Digital

• Conrm that the “Chair“ feature is disabled via the

Service Settings menu.

Scale instead).

• Ask patient to stand in the middle of the scale.

Weight is above scale capacity.

• Is patient more than 500 lb?

Weight is below scale capacity. • Is patient less than 10 lb?

• Check scale cable connection.

• If connected, scale should power on and show weight

Internal problem.

in its local display.

• Test with a known-working scale and/or device to

isolate problem. If problem is device-related, replace

I-O Board (more likely) or Main Board (less likely).

[Revised: 01/2020]

A-15© Midmark Corporation 2020

Page 26

Issue/Error Code Probable Cause Check

No reported weight (Midmark 626 Exam Chair with

Digital Scale).

Scale cable not attached to device.

• Check scale cable connection.

• Conrm that the “Chair Scale“ feature is enabled via

Midmark 626 with Digital Scale feature not enabled

the Settings menu.

(device is congured to communicate with Fairbanks®

scale instead).

• Refer to the Operation Manual for Settings

information.

“Out of Range“ weight is reported. • Is patient less than 30 or greater than 600 lb?

• Check scale cable connection.

• Test with a known-working scale or different device to

Internal problem.

isolate problem.

• If problem is device-related, replace I-O Board (more

likely) or Main Board (less likely).

TP204 Rev. A

[Revised: 01/2020]

A-16© Midmark Corporation 2020

Page 27

PRINTING ISSUES

An optional external, thermal printer purchased from Midmark, can used with the Digital Vital Signs Device touchscreen device. The thermal printer technology heats the paper to

®

create the image, rather than employing an ink cartridge and receives its power directly from the Digital Vital Signs Device device. IQvitals

Periodic thermal printer accuracy check:

• The thermal printer does not need calibration.

• A periodic functional check is warranted. See section B of this Service Manual.

Problem Probable Cause Check

Printer not connected to device. • Check printer cable connection.

Printer out of paper. • Check printer paper.

Printer door open. • Check that printer door is fully closed.

Thermal Printer Not Printing.

• Test with a known-working printer or different

device to isolate problem. If problem is device-

Internal problem.

related, replace Processor Board (possible), SD Card

(possible) (IQvitals only), I-O Board (unlikely) or Main

Board (unlikely).

PC does not support a thermal printer.

TP204 Rev. A

[Revised: 01/2020]

A-17© Midmark Corporation 2020

Page 28

TOUCHSCREEN USER INTERFACE ISSUES

Issue/Error Code Probable Cause Check

No Touch Response. Touchscreen out of calibration or not working.

• Power cycle the device.

• If problem persists, re-calibrate touch panel. See

Section B of this Service Manual.

• If touch screen cannot be re-calibrated (e.g., no

response to touch), reseat touch panel cable in

connector on Main Board. Recalibrate.

• If problem persists, replace touch panel which is part

of the Display (likely), touch panel cable connector

which is part of the Main Board (possible) or

Processor Board (possible).

• Power cycle the device.

Display image is corrupted (not steady, missing colors,

vertical lines on image).

Internal problem.

Display is dark even though device is running (power

switch is illuminated, audio feedback is heard when

Internal problem.

temperature probe is removed from the well).

Can’t delete patient readings from memory or change

device settings. (Pop-up message appears.)

SD card problem (IQvitals only).

Poor sound quality. Internal problem.

Time-of-Day on device is incorrect after power cycle. Internal problem.

TP204 Rev. A

MON 332

Monitor fault.

Internal problem.

• If problem persists, reseat display cable in connector

on Processor Board.

• If problem persists, replace Processor Board

(possible) or Display (less likely).

• Power cycle the device.

• If problem persists, reseat backlight cable in

connector on Main Board.

• If problem persists, replace Display (more likely) or

Main Board (possible).

• Power cycle the device.

• If problem persists, reseat or replace SD Card (more

likely) or replace Processor Board (possible).

• Replace speaker which is part of the Rear Cover

(possible) or Processor Board (less likely).

• If problem persists, replace Processor Board (more

likely) or coin cell battery which is part of the Main

Board (possible).

• Power cycle the device.

• If problem persists, replace Main Board (possible) or

Processor Board (possible).

[Revised: 01/2020]

A-18© Midmark Corporation 2020

Page 29

Service Tools +

Calibration Checks

SECTION B

TP204 Rev. A

[Revised: 01/2020]

B-1© Midmark Corporation 2020

Page 30

USB SERVICE TOOLS KIT

OVERVIEW

The IQvitals/IQvitals PC USB Service Tools Kit (P/N 181-6763) Includes the following tools.

However it is congured to automatically run the IQvitals service program tool (below). Just connect it to the USB port of the IQvitals device, power-on the unit, and the program will

run, allowing you to check the accuracy of the unit:

• IQvitals Service Program (compatible with Digital Vital Signs Device)—runs on the touchscreen device from a USB drive, providing the ability to conduct accuracy and safety

service-level functions

• IQvitals®PC Service Program—runs on a personal computer and connects to an IQvitalsPC device, providing the ability to conduct accuracy and safety service-level functions

• IQvitals® Touch Panel Calibration Program (compatible with Digital Vital Signs Device)—runs on the touchscreen device from the USB drive, providing the ability to calibrate

the touchscreen

• IQvitals®USBInstaller—enables a USB connection for IQvitalsPC

Note: USB connection only operates on personal computers running Windows® XP or Windows® 10.

Note: Version 1.0 will not work with a unit built after 9/2018 (Serial #IFDD or Later) 2.0 will work with any unit.

ONE-TIME INSTALLATIONS

TP204 Rev. A

• IQvitalsUSBInstaller

• IQvitals PC Service Test Program

• Saving IQvitals® Test Harness Folders

[Revised: 01/2020]

B-2© Midmark Corporation 2020

Page 31

INSTALL USB SERVICE TOOLS KIT:

INSTALL: USB SERVICE KIT

Step 1: Connect USB Service

Tools Kit (part # 181-6763) to your Windows® XP or

Windows® 7 or 10 computer.

INSTALL: USB SERVICE KIT

Step 2: Using Windows Explorer, view the contents of the USB

stick (see picture displaying contents of USB).

TP204 Rev. A

[Revised: 01/2020]

B-3© Midmark Corporation 2020

Page 32

INSTALL IQVITALS USB INSTALLER:

INSTALL: IQVITALSUSBINSTALLER

Step 1: Open the IQvitalsUSBInstaller folder. Double click on

IQvitalsUSBInstaller.exe. This is a quiet installation procedure,

and no pop-up message will appear when installation is

complete.

Note

It is only necessary to install IQvitalsUSBInstaller if you are

using a USB connection to connect to the IQvitalsPC device.

IQvitalsUSBInstaller is not needed when using the serial

connection to connect to the IQvitalsPC device.

TP204 Rev. A

Open

[Revised: 01/2020]

B-4© Midmark Corporation 2020

Page 33

INSTALL IQVITALS USB INSTALLER:

(CONTINUED)

INSTALL USB SERVICE KIT

Step 1: To conrm that the driver is installed:

• Connect the device to a computer using a mini USB

connection and power the unit on.

• Two notices will appear (only the rst time) at the bottom

task bar“

1. “Found New Hardware“, then

TP204 Rev. A

2. “IQvitals Device“

[Revised: 01/2020]

Double-click

B-5© Midmark Corporation 2020

Page 34

INSTALL SERVICE TEST PROGRAM:

Install: IQvitalspcService Test Program

Step 1: Copy the IQvitalspcService Program Folder onto the

computer’s hard drive.

TP204 Rev. A

[Revised: 01/2020]

Copy to Hard Drive

B-6© Midmark Corporation 2020

Page 35

INSTALL SERVICE TEST PROGRAM:

(CONTINUED)

INSTALL: IQVITALSPCSERVICE PROGRAM

Step 2: After the folder is copied to the hard drive:

• Open the IQvitalspcService Program (the copy on the computer),.

• Select IQvitalspcService Program.exe, and

• Create a shortcut on the desktop.

Note

To start the IQvitalspcService Program, launch IQvitalspcService

Program.exe from the desktop. This will start the Test Proagram

(see Test Program View).

Create Desktop Shortcut

TP204 Rev. A

[Revised: 01/2020]

B-7© Midmark Corporation 2020

Page 36

INSTALL SERVICE TEST PROGRAM:

(CONTINUED)

INSTALL: SERVICE TEST PROGRAM

Step 3:

• Copy the IQvitalsService Program and Touch Panel

Calibration Program onto the computer’s hard drive.

• The USB drive will be re-used to run these test programs on

the device.

TP204 Rev. A

[Revised: 01/2020]

Copy Both Folders onto Hard Drive

B-8© Midmark Corporation 2020

Page 37

SERVICE TEST PROGRAM VIEW

IQvitals Service Program

Runs on touchscreen device

IQvitals Service Program

Runs on a personal computer for IQvitalsPC

Connection Status

Codes are described in

Error Codes Section

Comm. Port is not part

of the Digital Vital Signs

DeviceServiceProgram

Mini USB (“0”) or Serial

Connection (“1“); click Set

after making a change to

switch connection types.

SpO2 Reading

Pulse Rate Reading

Temp. Reading

Blood Pressure Reading

Cuff Pressure Reading

Weight Reading

Power Status

TP204 Rev. A

[Revised: 01/2020]

Temperature Accuracy

Check Controls

BP Measurement Controls

BP Accuracy Check Controls

B-9© Midmark Corporation 2020

Page 38

USB SERVICE TEST PROGRAM OR

TOUCH PANEL CALIBRATION PROGRAM CONFIGURATION

SERVICE TEST PROGRAM OR TOUCH PANEL

CALIBRATION PROGRAM CONFIGURATION

Step 1: To run the IQvitals programs on the touchscreen device:

• Copy the program’s folder contents from the PC hard drive

to the Startup folder in the USB drive’s root directory. This

process applies for both the IQvitals Service and IQvitals

Touch Panel Calibration programs.

Step 2: Once the desired program is loaded into the Startup

folder:

• Plug the USB drive into the touchscreen device, and

• Power the unit on.

• The device will boot up and display the congured test

program automatically.

Make copies of both folders

Note

The USB drive can only be congured to run one program at

a time. Be sure to delete the Startup folder contents using the

drive to run a new program.

Note

When the device touchscreen is connected to a USB drive with

a Startup folder, it will run the executable les within that folder

instead of the software in the device.

TP204 Rev. A

[Revised: 01/2020]

B-10© Midmark Corporation 2020

Page 39

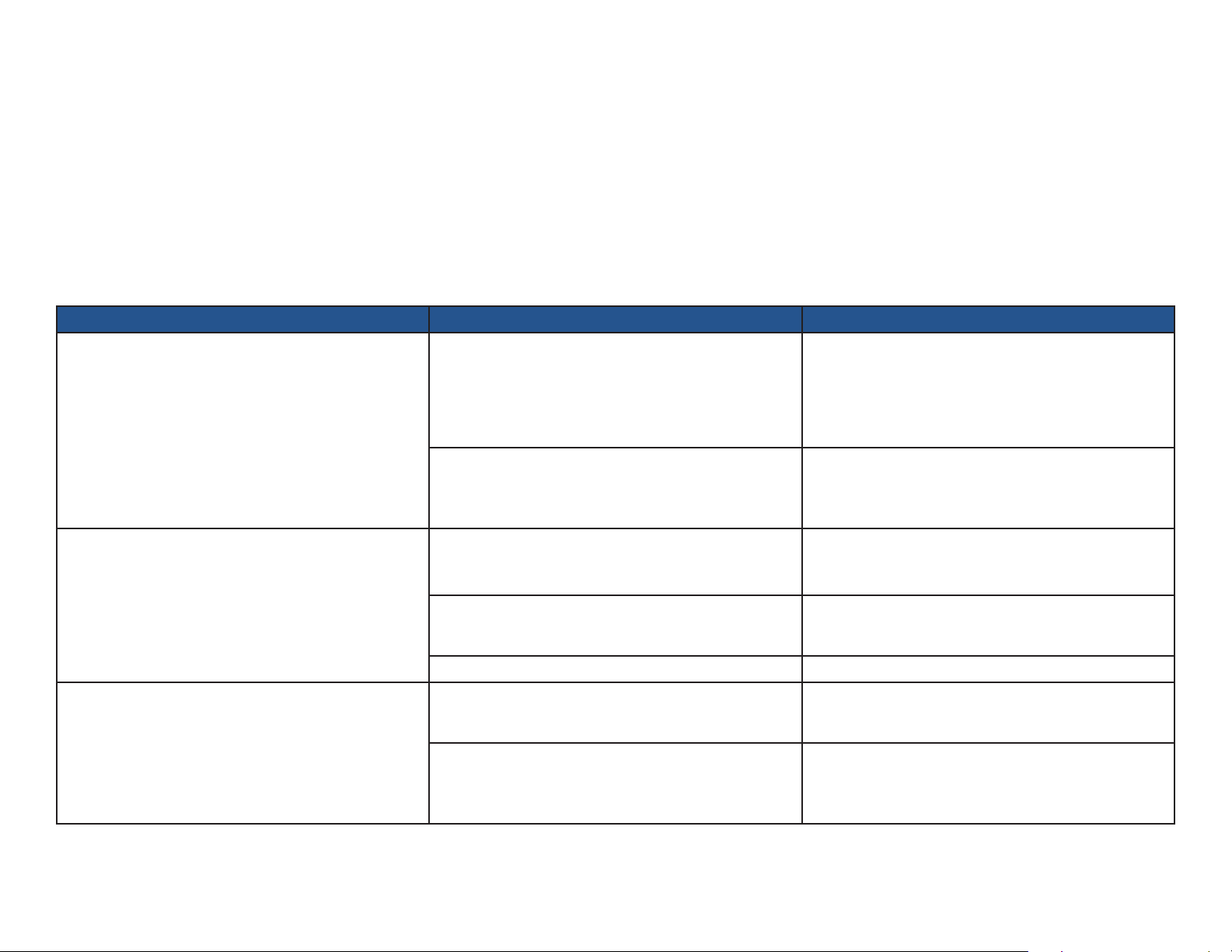

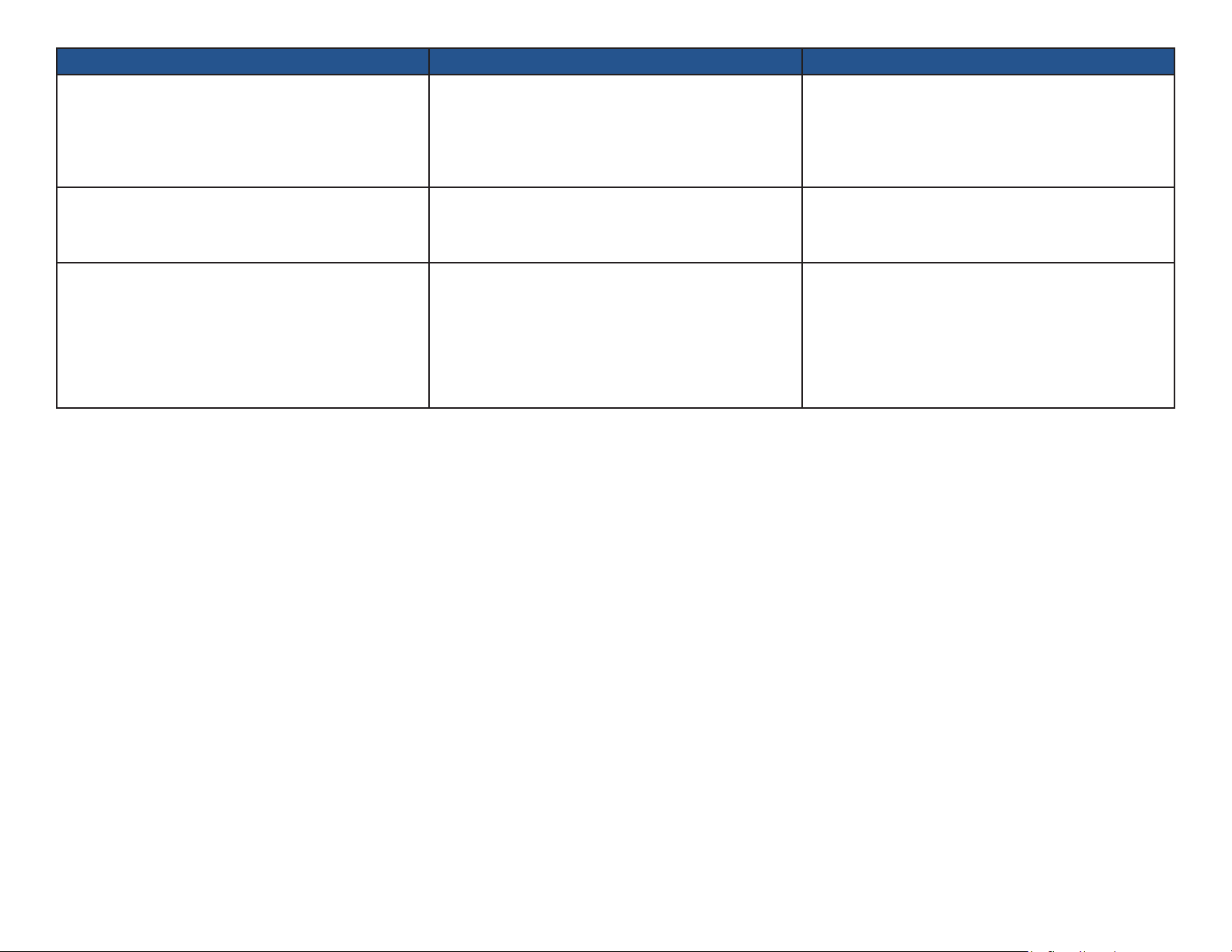

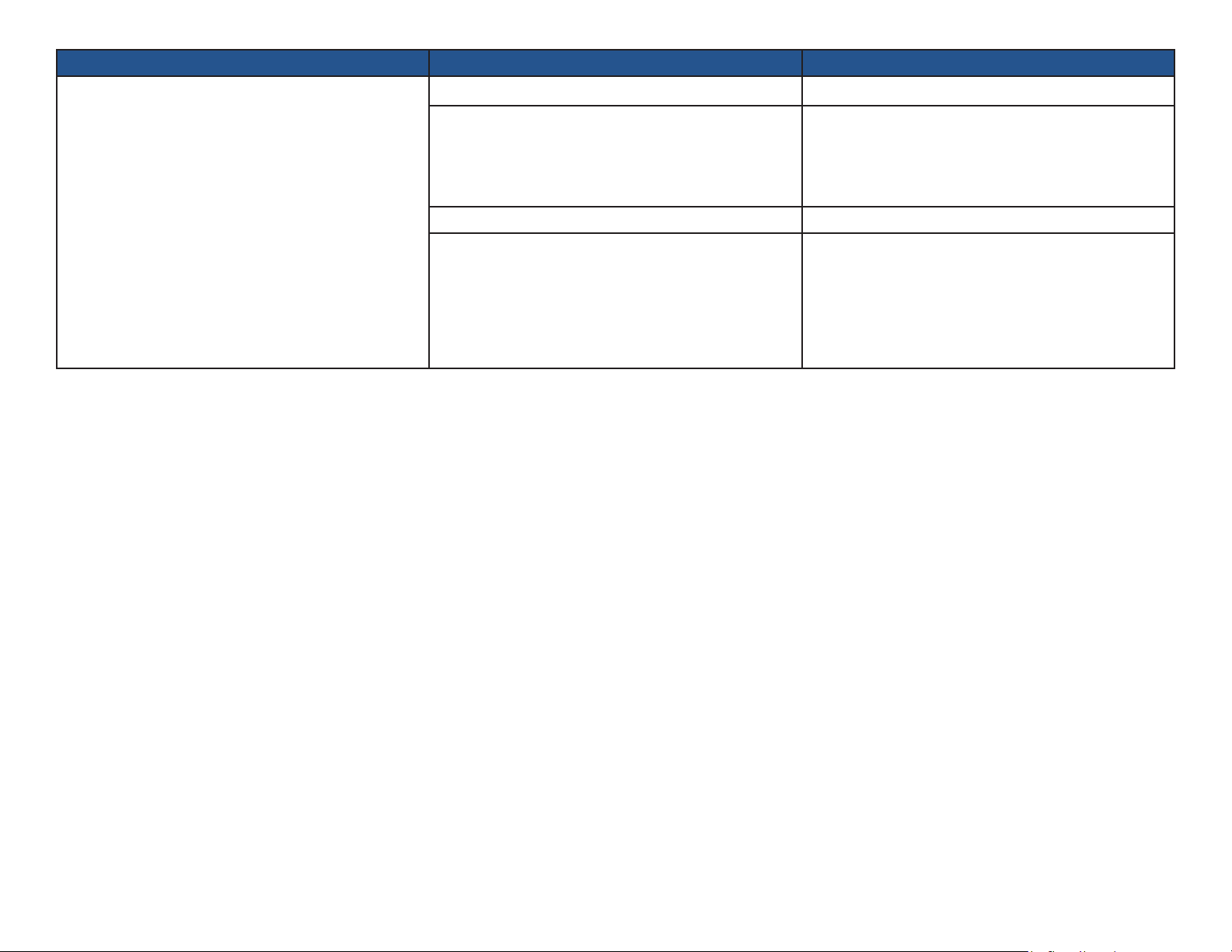

FUNCTIONAL VERIFICATION CHECKS + CALIBRATION CHECKS

Functional Verication Checks

Perform a functional verication check annually or after repairing a device.

Digital Vital Signs Device Function Procedure

Mechanical Integrity Check for cracks, abrasive edges, and other signs of damage.

Power Supply LED

Battery Charging LED

On/Off LED

Battery

Verify that the green “power“ LED is illuminated on the Digital Vital Signs Device Power Supply when the

power supply is plugged into AC power.

Verify that the green “battery charging“ LED is illuminated on the Digital Vital Signs Device power supply

when the power supply is plugged into AC power.

Verify that the green “On/Off“ LED is illuminated on the back of the Digital Vital Signs Device device when

the unit is on.

Verify that the device continues to run after it has been disconnected from mains and that the battery gas

gauge displays the correct charge level.

Touchscreen Verify that the screen is responsive to touch.

Speaker

SpO

2

Verify that the speaker sounds when the SpO2 nger clip is attached to your nger and is sensed by the

device.

Verify the accuracy of the SpO2 parameter with the SpO2 simulator at 96% SpO2.

NIBP Verify the BP accuracy against the simulator at a BP of 120/80.

Thermometer Verify the temperature accuracy with a calibrated water bath at or near 98.6°F.

Scale Verify the scale accuracy against calibrated weights.

TP204 Rev. A

[Revised: 01/2020]

B-11© Midmark Corporation 2020

Page 40

CALIBRATION CHECKS

Perform safety and calibration checks annually.

Blood Pressure (BP) Calibration Check

BP Checks Include:

• BP Accuracy

• Cuff Pressure Accuracy

• Leak Rate

• Overpressure Detection

Note: The BP circuitry contains a factory-set calibration potentiometer. This will remain stable for the life of the product and is not eld serviceable.

Tools Needed:

• BP Simulator (Fluke Biomedical “BP Pump 2“ or equivalent)

• IQvitalsService or IQvitalspcService Test Program (depending on the device model number)

• BP Hose

Test Set-up:

Note: Each procedure requires the correct Test Program to be installed. For installation instructions, see section USB ServiceTools Kit.

• Connect the device to simulator using a BP hose (see picture).

• For touchscreen device, run the IQvitalsService Test Program.

• For an IQvitals PC device, run the IQvitalspcService Test Program on a personal computer.

TP204 Rev. A

[Revised: 01/2020]

B-12© Midmark Corporation 2020

Page 41

Note: Touchscreen device

connects to the BP

Simulator in same way

BP CALIBRATION CHECK PROCEDURE:

• Set BP Simulator to 120/80 mmHg. Refer to the usage instructions provided with the BP simulator used for this procedure.

• Click Start BP Meas, and wait for measurement to complete. The Test Program should report a BP result within ±5 mmHg of the simulator setting (see picture).

• If it is determined the device is out of tolerance, replace Main Board.

Note: All testing assumes a properly functional and calibrated test equipment. The device has been tested with the Fluke Biomedical BP

Pump2 simulator. BP simulator behavior can vary from manufacturer to manufacturer.

TP204 Rev. A

[Revised: 01/2020]

Click Start BP Meas.

Ensure reading is within specications.

B-13© Midmark Corporation 2020

Page 42

CUFF PRESSURE CALIBRATION CHECK:

• Click Start BP Cal.

• Set the BP Simulator to Pressure Gauge mode, and inate it to 200 mmHg. If the simulator does not have a built-in pump, then use a hand-bulb and a calibrated

manometer to inate it to 200 mmHg.

• Wait for pressure to reach 200 mmHg, then observe the pressure values on the BP simulator and Test Program.

• Ensure that they differ by no more than ±5 mmHg.

• If it is determined the device is out of tolerance, replace Main Board.

• Click Stop BP Cal when nished.

Note: All testing assumes a properly functional and calibrated test equipment. The device has been tested with the Fluke Biomedical BP

Pump2 simulator. BP simulator behavior can vary from manufacturer to manufacturer.

Before starting the BP simulator,

click Start BP Cal.

TP204 Rev. A

[Revised: 01/2020]

Compare the Test Program reading to the BP

simulator once the simulator reaches 200 mmHg

B-14© Midmark Corporation 2020

Page 43

LEAK RATE CALIBRATION CHECK:

• Click Start BP Cal.

• Set the BP Simulator to Pressure Gauge mode, and inate it to 200 mmHg. If the simulator does not have a built-in pump, then use a hand-bulb and calibrated manometer

to inate it to 200 mmHg.

• Allow pressure to reach 200 mmHg, and wait 30 seconds for the pressure to stabilize.

• Watch the pressure value for a full minute, and ensure that the device pressure reading does not drop by more than 5 mmHg (see picture).

• If the leak rate is out of tolerance, conrm that the test xture is not the source of the leak. Check all connections on the NIBP Manifold and retest. If leak rate is still out of

tolerance, check or replace: Valve Assembly (most likely), NIBP Manifold (possible), step-valve which is part of the Main Board (possible) or Pump (unlikely).

• Click Stop BP Cal when nished.

Note: All testing assumes a properly functional and calibrated test equipment. The device has been tested with the Fluke Biomedical BP Pump2

simulator. BP simulator behavior can vary from manufacturer to manufacturer.

Before starting the BP simulator, click Start BP Cal.

TP204 Rev. A

[Revised: 01/2020]

Compare the Test Program reading to

the BP simulator for one minute once

the simulator reaches 200 mmHg.

B-15© Midmark Corporation 2020

Page 44

OVERPRESSURE DETECTION CALIBRATION CHECK:

• Click Start BP Cal.

• Set the BP Simulator to Pressure Gauge mode, and inate it to 200 mmHg.

• Wait 10 seconds for the pressure to stabilize. If the simulator does not have a built-in pump, then use a hand-bulb and calibrated manometer to inate it to 200 mmHg.

• Change the simulator setting, or use a hand-bulb to inate to 300 mmHg, and verify that the device releases pressure before reaching 300 mmHg.

• If pressure is not released before 300 mmHg, check the accuracy of the test xture. If this is OK, replace Main Board.

• Click Stop BP Cal when nished.

Note: All testing assumes properly functional and calibrated test equipment. The device has been tested with the Fluke Biomedical BP

Pump2 simulator. BP simulator behavior can vary from manufacturer to manufacturer.

Before starting the BP simulator, click Start BP Cal.

TP204 Rev. A

[Revised: 01/2020]

Make sure that the valve releases

(pressure drops to zero) before

pressure reaches 300 mmHg.

B-16© Midmark Corporation 2020

Page 45

SpO2 CALIBRATION CHECK

SpO2 Checks Include:

• SpO2 Accuracy

Note: The SpO2 circuitry contains a factory-set calibration potentiometer. This will remain stable for the life of the product and is not eld serviceable.

Tools Needed:

• SpO2 Simulator (Fluke Biomedical “Index 2” or similar)

• IQvitalsService or IQvitalspcService Test Program (depending on the device model number)

• SpO2 Finger sensor

Test Set-up:

Note: This procedure requires the Test Program to be installed. For installation instructions, see section USB Service Tools Kit.

• Connect the device to the simulator using an SpO2 nger sensor (see picture).

• Ensure that the SpO2 simulator is set to Nellcor mode.

• Set the SpO2 simulator to 96% SpO2 and 75 PR.

TP204 Rev. A

• For a touchscreen device, run the IQvitalsService Test Program.

• For an IQvitalsPC device, run the IQvitalspcService Test Program on a PC.

[Revised: 01/2020]

Note: The touchscreen device con-

nects to the SpO2 simulator in same

way.

B-17© Midmark Corporation 2020

Page 46

SPO2 CALIBRATION CHECK PROCEDURE:

• Make sure that the SpO2 and BP codes in the Test Program display change from Code 302 to a numeric reading when connected (see pictures).

• Compare the SpO2 and PR readings in the Test Program to the 96% SpO2 and 75 PR on the SpO2 simulator display. There should be a difference of no greater than ±2%

for the SpO2 parameter and ±5 bpm for PR parameter

• If the readings are out of tolerance there may be a difference between the SpO2 simulator and the processing of the SpO2 signal.

• Conrm that the SpO2 sensor is properly aligned on the SpO2 simulator’s “nger“.

• If it is determined the SpO2 measurements are out of tolerance, replace Main Board.

Note: All testing assumes properly functional and calibrated test equipment. The device has been tested with the Fluke Biomedical “Index

2“ simulator. SpO2 simulator behavior can vary from manufacturer to manufacturer.

Ensure that readings are within specications.

Display Changes to Numerical Value

TP204 Rev. A

[Revised: 01/2020]

B-18© Midmark Corporation 2020

Page 47

TEMPERATURE CALIBRATION CHECK

Temperature Checks Include:

• Temperature Accuracy

Note: The Temperature circuitry self-calibrates using internal, high-precision reference resistors. The device will report a “TEMP 306”

error code if the circuitry is out of tolerance.

Tools Needed:

• Calibrated Water Bath

• Digital Vital Signs Device Service or IQvitals PC Service Test Program (depending on the device model number)

• Temperature Probe

Test Set-up:

Note: This procedure requires the Test Program to be installed. For installation instructions, see section Digital Vital Signs Device/

IQvitals PC USB Service Tools Kit.

• Connect the temperature probe to the device.

• Prepare a Calibrated Water Bath at approximately 98.6°F.

TP204 Rev. A

• For a touchscreen device, run the IQvitalsService Test Program.

• For an IQvitalsPC device, run the IQvitalsPC Service Test Program on a PC.

[Revised: 01/2020]

B-19© Midmark Corporation 2020

Page 48

TEMPERATURE CALIBRATION CHECK PROCEDURE:

• Click Set Temp Monitor on the Test Program (see picture) to directly read the temperature of the probe tip.

• Place the temperature probe into water bath and check that the Test Program temperature is within ±0.3°F of the water bath.

• If temperature is out of tolerance check the accuracy of the test xture. If this is OK, replace the probe (most likely), I-O Board (possible), or Main Board (possible).

Before placing the Temperature

Probe into the Calibrated Water

Bath, click Set Temp Monitor.

TP204 Rev. A

[Revised: 01/2020]

Ensure that the temperature reading is

within specications.

B-20© Midmark Corporation 2020

Page 49

WEIGHT CALIBRATION CHECK

This procedure is for the Fairbanks® TeleWeigh® digital oor scale, which is calibrated at the factory and should not need further calibration.

For service instructions for the Midmark 626 Barrier Free® Power Examination Chair with Digital Scale contact Midmark customer support or visit

midmark.com.

Weigh Checks Include:

• Weight Accuracy

Tools Needed:

• 4 Calibrated 50 lb Weights

• Digital Vital Signs Device Service or IQvitals PC Service Test Program (depending on unit model)

Test Set-up:

Note: This procedure requires the Test Program to be installed. For installation instructions, see section Digital Vital Signs Device/

IQvitals PC USB ServiceTools Kit.

• Connect the scale to the device.

TP204 Rev. A

• For a touchscreen device, run the IQvitalsService Test Program.

• For an IQvitals PC device, run the IQvitals PC Service Test Program on a PC.

[Revised: 01/2020]

B-21© Midmark Corporation 2020

Page 50

WEIGHT CALIBRATION CHECK PROCEDURE:

• Place weights on the scale to check the calibrated weight against the reported weight in the program display.

• Check weight at 50, 100, and 200lb.

• Ensure that the reported weight is within ±1lb of the calibrated weight.

• If scale is out of range contact Midmark Support Services at 1-800-624-8950, option 2, for further information.

TP204 Rev. A

[Revised: 01/2020]

Ensure that the reported

weight is within specications.

B-22© Midmark Corporation 2020

Page 51

TOUCHSCREEN CALIBRATION

The Touch Panel Calibration Program runs on the touchscreen device from a USB drive. It allows you to calibrate the touch panel. In normal use, the touch panel does not need

recalibrating. However, touch panel calibration is required after the replacement of the display or processor board.

Tools Needed:

• Stylus

• Touch Panel Calibration Program

Touch Panel Calibration Procedure:

Note: This procedure requires the Touch Panel Calibration Program to be installed. For installation instructions, see section USB Service Test Program or Touch Panel Calibration

Program Conguration.

• Connect the USB drive (with the Touch Panel Calibration Program) to the device.

• Run Device; the Touch Panel Calibration Program will automatically start.

• Follow the Touch Panel Calibration screen instructions using a stylus.

• If the touch panel calibration is successful, a second window will open. This will allow you to save the touch panel calibration constants and complete the calibration.

Note: The touch panel calibration sequence will automatically restart if calibration is not successful.

TP204 Rev. A

[Revised: 01/2020]

B-23© Midmark Corporation 2020

Page 52

Purchasing Guide

+ Parts List

Section C

XXX-XXXX-XX

TP204 Rev. A

[Revised: 01/2020]

XXX-XXXX-XX

XXX-XXXX-XX

C-1© Midmark Corporation 2020

Page 53

ORDERING SERVICE PARTS

When placing a service parts order please have the following information available:

• Device model

number and serial number of the device to be serviced

• Part numbers and quantities of service parts to be ordered

• Payment information

For payment details and placing an order contact Midmark Support:

eMail: techsupport@midmark.com

Phone: 1.844.856.1230

Hours: 5:00 am to 5:00 pm PST

TP204 Rev. A

[Revised: 01/2020]

C-2© Midmark Corporation 2020

Page 54

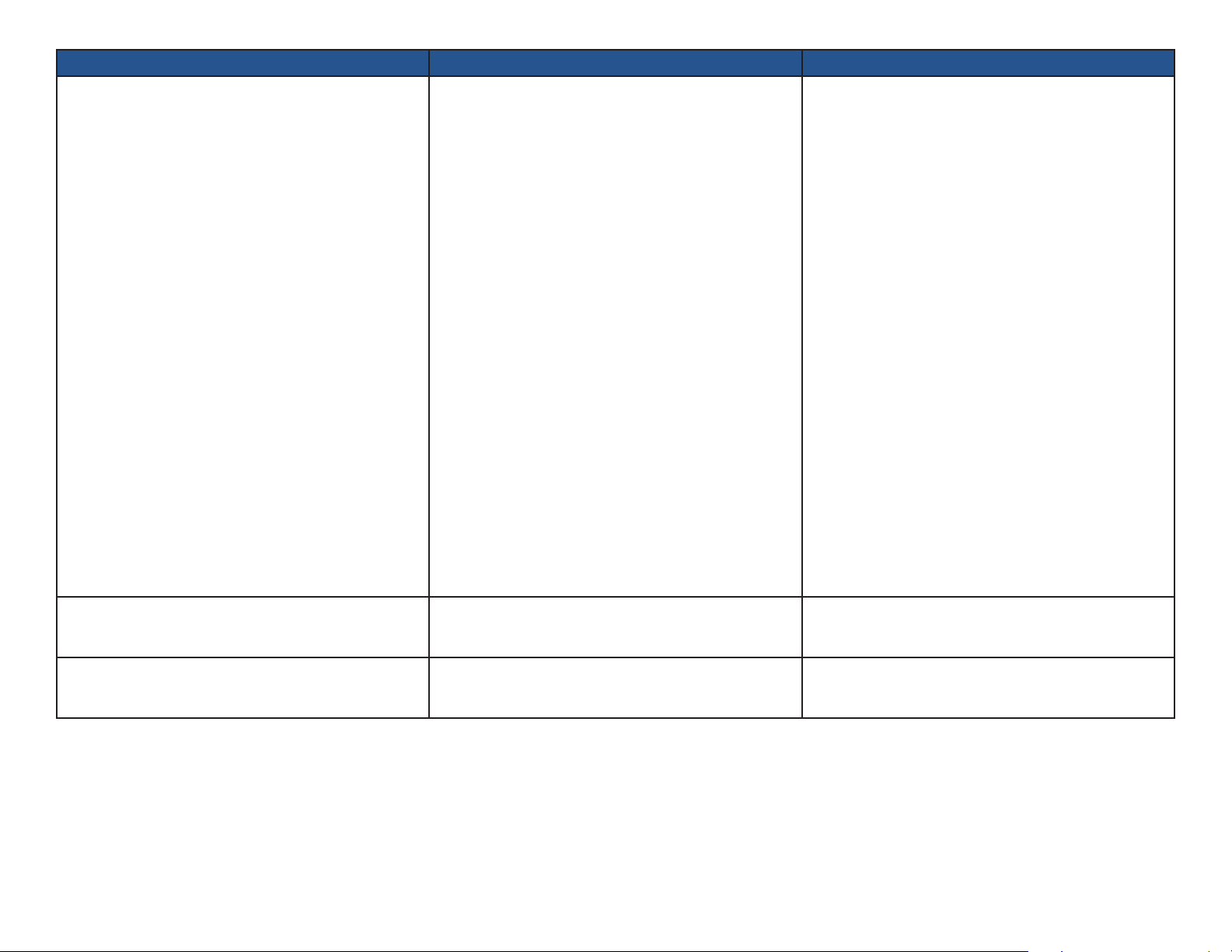

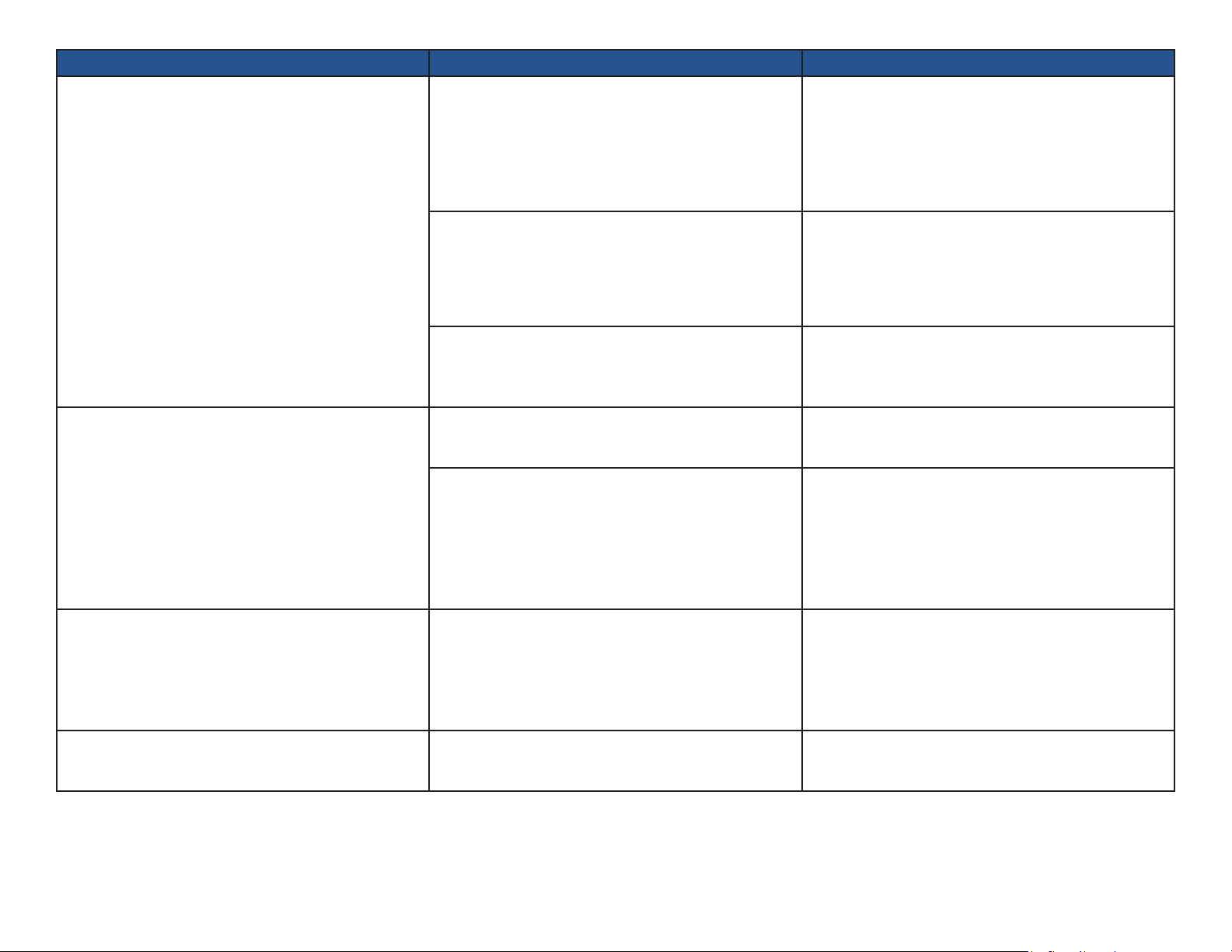

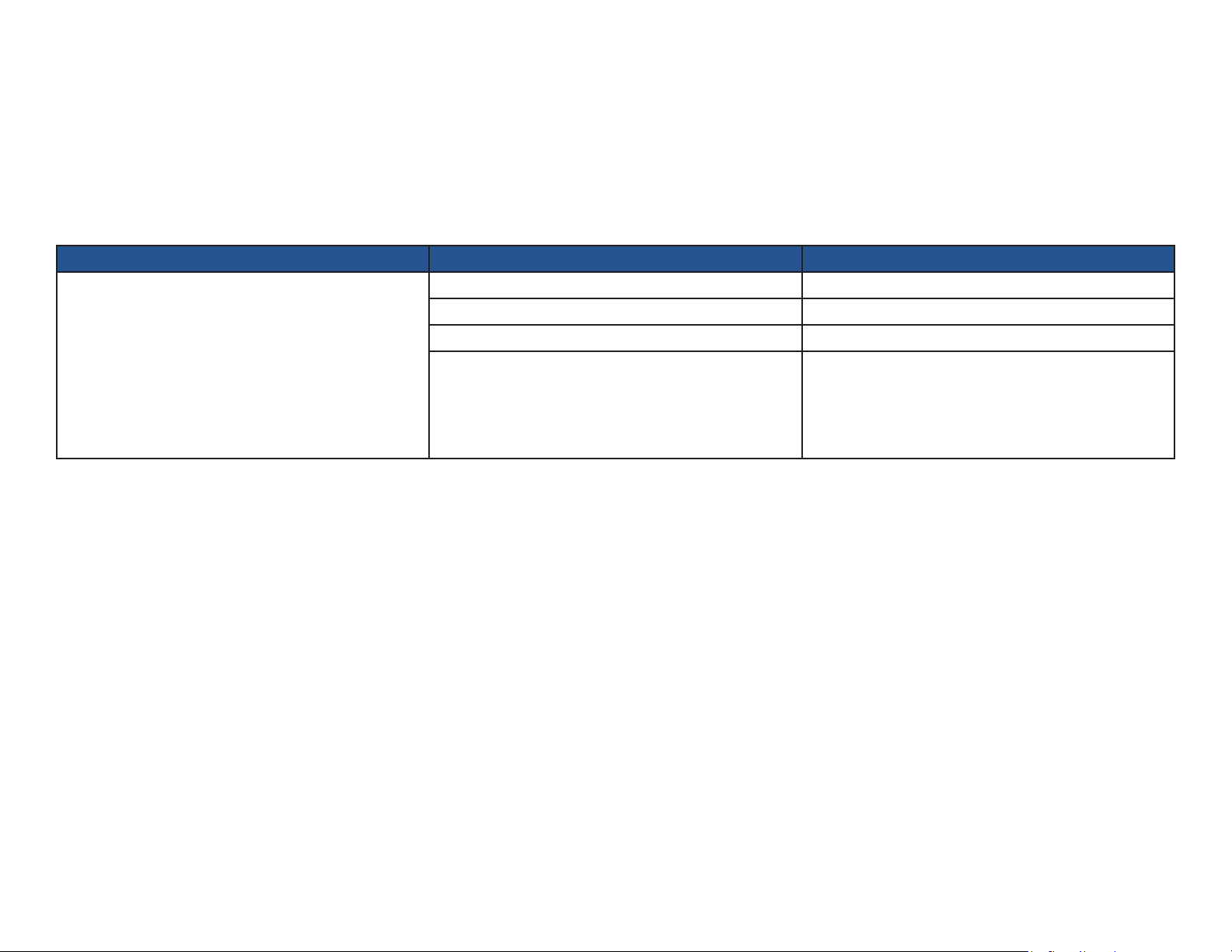

PURCHASING GUIDE

The following chart identies all available service kits for the Digital Vital Signs Device and IQvitals PC devices.

Device Model Number

Part # Service Kit Name

181-6110 IQvitals NIBP Pump

181-6111 DVSD NIBP Pump

181-6120 IQvitals Valve Assembly

181-6121 DVSD Valve Assembly

181-6130 IQvitals NIBP Manifold

183-6700 IQvitals Main Board w/ SpO

183-6701 IQvitals Main Board - no SpO

183-6702 IQvitalsPC Main Board w/ SpO

183-6703 IQvitalsPC Main Board - no SpO

183-6704 DVSD Main Board

183-6711 IQvitalsPC I-O Board

183-6712 IQvitals I-O Board

183-6713 DVSD I-O Board

183-6720 IQvitals Processor Board

183-6721 DVSD Processor Board

181-6740 IQvitals Temp Assembly

181-6770 DVSD Temp Assembly

181-6741 IQvitals Battery Door

181-6771 DVSD Battery Door

181-6742 IQvitals Rear Cover

181-6743 IQvitalsPC Rear Cover

181-6772 DVSD Rear Cover

TP204 Rev. A

1-100-1620

(Kit # 4-000-0400)

IQvitalsPC

1-100-1625

(Kit # 4-000-0410)

IQvitalsPC w/

SpO2

1-100-1610

(Kit # 4-000-0500 Rev C)

IQvitals Device

Touchscreen

1-100-1615

(Kit # 4-000-0510 Rev C)

IQvitals Device

Touchscreen

w/ SpO2

1-100-1630

(Kit #4-000-0500 Rev D)

Digital Vital

Signs Device

1-100-1635

(Kit #4-000-0510 Rev D)

Digital Vital

Signs Device

with SpO2

• • • •

• •

• • • •

• •

• • • • • •

2

2

2

2

•

•

•

•

• •

• •

• •

• •

• •

• •

• • • •

• •

• • • •

• •

• •

• •

• •

[Revised: 01/2020]

C-3© Midmark Corporation 2020

Page 55

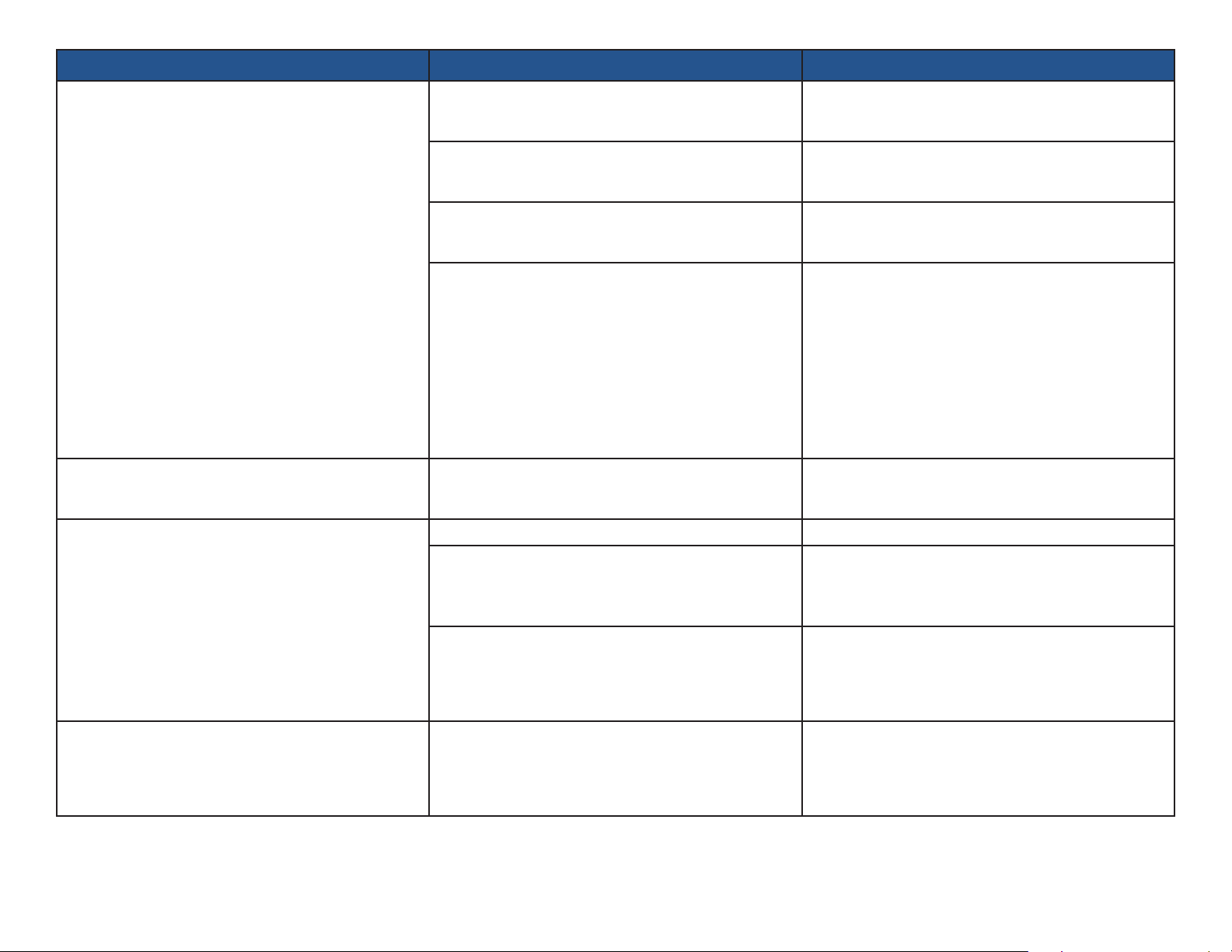

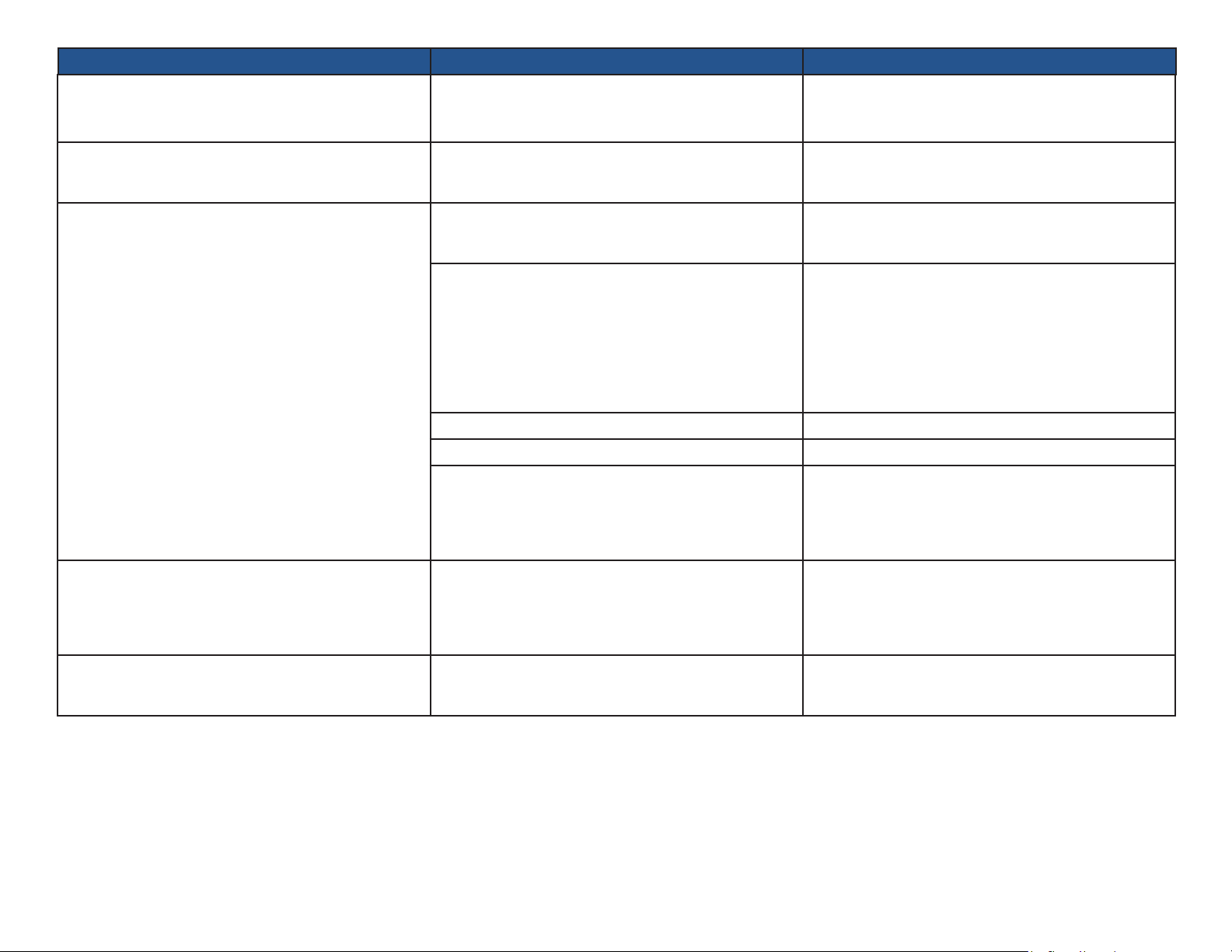

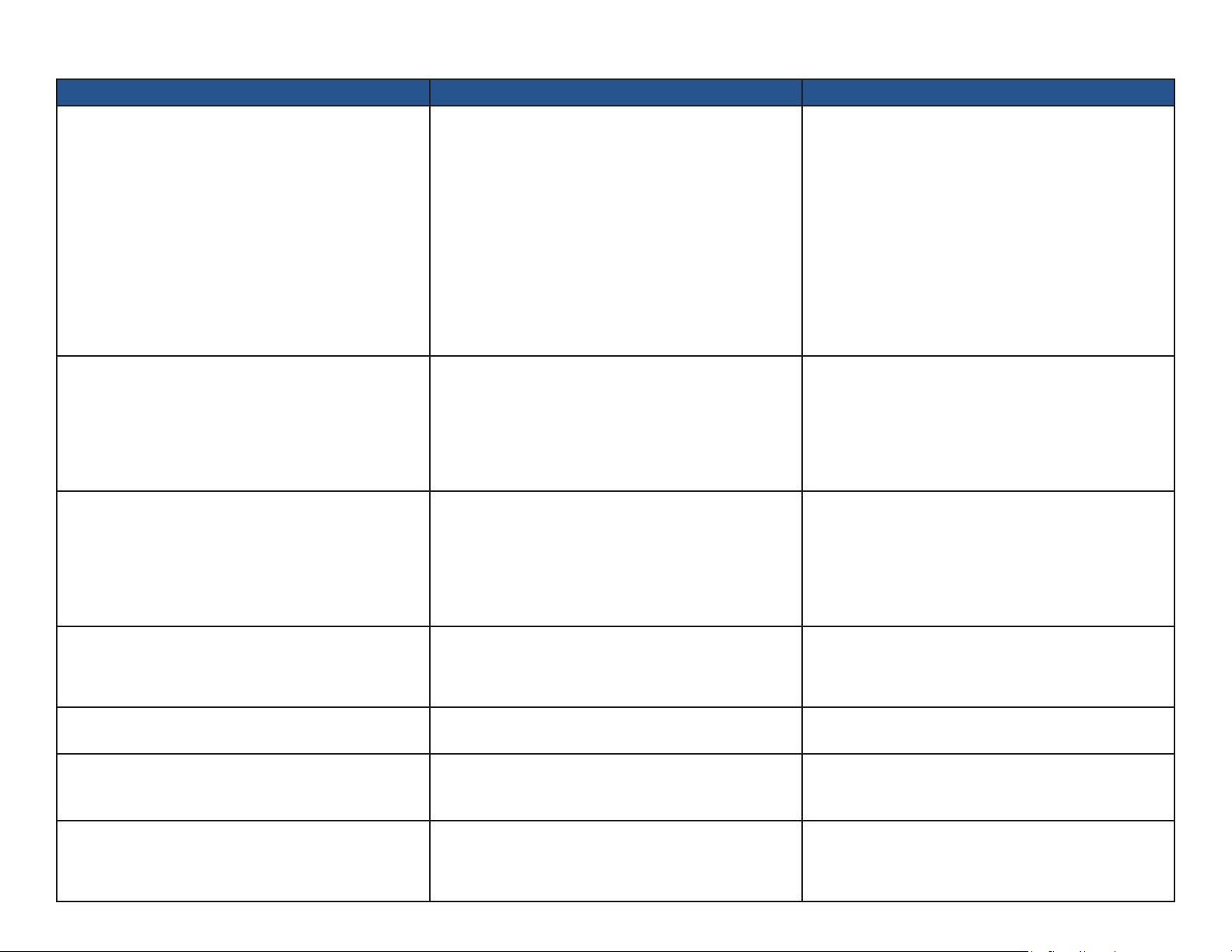

PURCHASING GUIDE

The following chart identies all available service kits for the Digital Vital Signs Device and IQvitals PC devices.

Device Model Number

Part # Service Kit Name

181-6744 IQvitals Front Bezel

181-6745 IQvitalsPC Front Bezel

181-6750 IQvitals

181-6751 IQvitals Display Brackets

181-6752 IQvitals Replacement Display

181-6775 DVSD Replacement Display

181-6761 IQvitals SD Card Assembly

181-6746 IQvitals Input Panel w/ SpO

181-6747 IQvitals Input Panel - no SpO

181-6773 DVSD Input Panel w/ SpO2

181-6774 DVSD Input Panel - no SpO2

181-6762

181-6763

Digital Vital Signs Device

Battery Board

Digital Vital Signs Device USB

Service Tools Kit

1-100-1620

(Kit # 4-000-0400)

IQvitalsPC

1-100-1625

(Kit # 4-000-0410)

IQvitalsPC w/

SpO2

1-100-1610

(Kit # 4-000-0500 Rev C)

IQvitals Device

Touchscreen

1-100-1615

(Kit # 4-000-0510 Rev C)

IQvitals Device

Touchscreen

w/ SpO2

1-100-1630

(Kit #4-000-0500 Rev D)

Digital Vital

Signs Device

1-100-1635

(Kit #4-000-0510 Rev D)

Digital Vital

Signs Device

with SpO2

• •

• •

• •

• •

• •

• •

• •

2

2

• •

• •

•

•

• • • • • •

• • • • • •

TP204 Rev. A

[Revised: 01/2020]

C-4© Midmark Corporation 2020

Page 56

PARTS LIST

Service Kit Name and Number Service Kit Components Information

181-6110

IQvitals NIBP Pump Service Kit

181-6111

Digital Vital Signs Device NIBP Pump

Service Kit

Note:

This service kit is compatible with

IQvitals units only

Note:

This service kit is compatible with

Digital Vital Signs Device units only

181-6120

IQviitals NIBP Manifold Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with

IQvitals units only

C-5© Midmark Corporation 2020

Page 57

Service Kit Name and Number Service Kit Components Information

181-6121

Digital Vital Signs Device Valve

Assembly Service Kit

181-6130

IQvitals NIBP Manifold Service Kit

Note:

This service kit is compatible with

Digital Vital Signs Device units only

Note:

This service kit is compatible with all

Digital Vital Signs Device and

IQvitals units.

183-6700

IQvitals Main Board w/ SpO2 Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with

IQvitals units only

C-6© Midmark Corporation 2020

Page 58

Service Kit Number and Name Service Kit Components Information

183-6701

IQvitals Main Board – no SpO2 Service Kit

183-6702

IQvitals PC Main Board w/ SpO2 Service Kit

Note:

This service kit is compatible with IQvitals

units only

Note:

This service kit is compatible with IQvitals

units only

183-6703

IQvitals PC Main Board - no SpO2 Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with IQvitals

units only

C-7© Midmark Corporation 2020

Page 59

Service Kit Number and Name Service Kit Components Information

183-6704

Digital Vital Signs Device Main Board

Service Kit

183-6711

IQvitalsPC I-O Board Service Kit

Note:

This service kit is compatible with Digital Vital Signs

Device units only

Note:

This service kit is compatible with IQvitals units only

183-6712

IQvitals I-O Board Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with IQvitals units only

C-8© Midmark Corporation 2020

Page 60

Service Kit Number and Name Service Kit Components Information

183-6713

Digital Vital Signs Device I-O Board Service Kit

181-6720

IQvitals Processor Board Service Kit

Note:

This service kit is compatible with Digital Vital

Signs Device units only

Note:

This service kit is no longer available.

If the unit contains this processor board, the

unit needs to be sent in to the factory for

an upgrade.

183-6721

Digital Vital Signs Device Processor Board Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with all Digital Vital

Signs Device and newer IQvitals units.

If the unit contains this processor board, use this

service kit for repair.

C-9© Midmark Corporation 2020

Page 61

Service Kit Number and Name Service Kit Components Information

181-6740

IQvitals Temp Assembly Service Kit

181-6770

Digital Vital Signs Device Temp

Assembly Service Kit

Note:

This service kit is compatible with

IQvitals units only

Note:

This service kit is compatible with Digital

Vital Signs Device units only

181-6741

IQvitals Battery Door Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with

IQvitals units only

C-10© Midmark Corporation 2020

Page 62

Service Kit Number and Name Service Kit Components Information

181-6771

Digital Vital Signs Device Battery

Door Service Kit

181-6742

IQvitals Rear Cover Service Kit

Note:

This service kit is compatible

with Digital Vital Signs

Device units only

Note:

This service kit is compatible

with IQvitals units only

181-6772

Digital Vital Signs Device Rear

Cover Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible

with Digital Vital Signs

Device units only

C-11© Midmark Corporation 2020

Page 63

Service Kit Number and Name Service Kit Components Information

181-6743

IQvitals PC Rear Cover Service Kit

181-6744

IQvitals Front Bezel Service Kit

Note:

This service kit is compatible with

IQvitals units only

Note:

This service kit is compatible with

IQvitals units only

This service kit is only compatible for

units with the display panel below.

181-6745

IQvitals PC Front Bezel Service Kit

TP204 Rev. A

[Revised: 01/2020]

Note:

This service kit is compatible with

IQvitals units only

C-12© Midmark Corporation 2020

Page 64

Service Kit Number and Name Service Kit Components Information

Note:

This service kit is compatible with

IQvitals units only

181-6750

IQvitals Display Service Kit

181-6751

IQvitals Display Brackets Service Kit

This service kit is only compatible for

units with the display panel below.

Note:

This service kit is no longer available.

Note:

This service kit is compatible with

IQvitals units only

181-6752

IQvitals Replacement Display

TP204 Rev. A

[Revised: 01/2020]