Page 1

y

VISION DX

600 Series

Digital Sensor System

User Guide

0120

REF.KIT #30-A2160

REV. G

00-02-1594

Revision G01

Februar

2019

Page 2

Vision DX 600 Series

Digital Sensor System

User Guide

Midmark Corporation

1001 Asbury Drive

Buffalo Grove, IL 60089, U.S.A.

Phone +1 (847) 415-9800

Toll Free +1 (888) 924-3800

Fax: +1 (847) 415-9810

www.progenydental.com

Copyright © 2019 Progeny. All rights reserved.

Page 3

Vision DX 600 Series: User Guide

Table of Contents:

General Information ............................................................................................................................. 4

Indications for Use .................................................................................................................. 4

Contraindications ........................................................................................................................... 4

Warnings/Precautions .................................................................................................................... 4

Product Description ....................................................................................................................... 5

Explanation of Symbols on Technical Labels ............................................................................... 5

Installation Configurations ............................................................................................................. 6

Compliance with Applicable Standards ......................................................................................... 7

Obtaining Technical Support ......................................................................................................... 7

EC Declaration of Conformity ........................................................................................................ 8

Authorized Representatives .......................................................................................................... 9

Operating the VisionDX USB ............................................................................................................ 10

Acquiring Images ......................................................................................................................... 10

Using the Sensor Sheaths (PN 500-430/500-431) ..................................................................... 10

Using a Sensor Positioning System ............................................................................................ 1 1

Recommended Maintenance ...................................................................................................... 1 1

Cleaning and Disinfecting ............................................................................................................ 12

Specifications .................................................................................................................................... 13

X-Ray Sensor .............................................................................................................................. 13

Control Module ............................................................................................................................ 13

Environmental .............................................................................................................................. 13

Terms ................................................................................................................................................ 14

Accessories and Part Numbers ........................................................................................................ 15

Warranty and Service ........................................................................................................................ 18

3

Page 4

Vision DX 600 Series: User Guide

General Information

Indications for Use

Vision DX is intended to be used as an intraoral receiver of X-Rays for dental radiography.

Contraindications

None known.

Warnings/Precautions

Radiation

Safety

Electrical

Safety

Only qualified and authorized personnel may operate this equipment observing all laws

and regulations concerning radiation protection.

The operator at all times must remain at least 2 m (6 ft.) from the focal spot and the X-

Ray beam for operator protection.

Full use must be made of all radiation safety features on the X-Ray equipment.

Full use must be made of all radiation protection devices, accessories and procedures

available to protect the patient and operator from X-Ray radiation.

The Vision DX sensor cable should be handled with care. Do not kink or crimp the sensor

cable. Doing so could permanently damage the sensor.

Only qualified and authorized service personnel should remove covers on the equipment.

This equipment must only be used in rooms or areas that comply with all applicable laws

and recommendations concerning electrical safety in rooms used for medical purposes,

e.g., IEC, US National Electrical code, or VDE standards.

Before cleaning or disinfecting, this equipment must always be disconnected from the

main electrical supply.

The Vision DX Intraoral Dental X-Ray Sensor is ordinary type medical equipment without

protection against ingress of liquids. To protect against short-circuit and corrosion, no

water or any other liquid should be allowed to leak inside the equipment.

Patient

Safety

Prior to use always cover the sensor with a disposable hygienic protective cover. A new

cover must be used for each patient.

The Vision DX, USB Module, Computer, and provided cables comprise a Medical

Electrical System. The Computer and USB Module are not intended to be located in the

patient environment (within a 1.5 m radius of the patient).

System installation shall be in accordance with the requirements of IEC 60601-1, the

Standard for Safety Requirements of Medical Electrical Systems

Patients should only be connected to applied parts of equipment complying with

IEC 60601-1. The computer and USB Module used for connection to the VisionDX USB

shall comply with the standard for Information Technology Equipment, IEC 60950-1.

4

Page 5

Vision DX 600 Series: User Guide

Product Description

Progeny Vision DX Sensor is a state of the art intraoral system intended for digital imaging

of teeth and the oral cavity. The system provides:

Immediate production of an image

Digital image storage and management

Efficient archiving and recall of images

Reduction of the X-Ray dose to patient

Elimination of film processing

The components of the Vision DX Sensor system are the Digital Sensor, the USB Module,

the USB Cable, and the Sensor Calibration Files disk. An optional component is the USB

Dual-Host Switch.

Digital Sensor

USB Module

USB Cable

Sensor Calibration

Files Disk

Software

USB Dual-Host

Switch

The Digital Sensor is designed to transform a two dimensional X-Ray picture into an

electrical signal. The structure of the sensor is assembled with a first layer of phosphor

material (scintillator) which, when exposed by incident X-Rays, emits a luminous radiation.

This light is then transferred to the photo sensitive elements of the Sensor where it is

transformed to electrical potential. The electrical signal is sent to the USB Module for

processing.

The USB Module processes the image and sends it as a digital signal to the software.

Connects the USB Module (standalone configuration) or the Bus-powered USB Hub

(Preva Plus integrated configuration) and the computer’s USB 2.0 port. The total cable

length may not exceed 5 m (15 ft).

During installation of the Vision DX Sensor System, files specific to the sensor serial

number are stored on each computer where the sensor will be used. For more details,

refer to the Vision DX 600 Series Installation Guide.

Provides the user interface to acquire, store, retrieve, transmit, review and post process

images acquired by the Vision DX Sensor system. For more details refer to the Vision DX

600 Series Installation Guide or the specific software user guide.

The USB Dual-Host Switch is an option that allows two separate computers to connect to

one Vision DX Sensor when the sensor is installed in the Preva Plus integrated

configuration.

Explanation of Symbols on Technical Labels

Type BF: Protection against electric shock (IEC 60601-1)

Class II: Double Isolation to protect against electric shock (I

5

54H

EC 60601-1)

Page 6

Vision DX 600 Series: User Guide

Consult written instructions in User’s Manual.

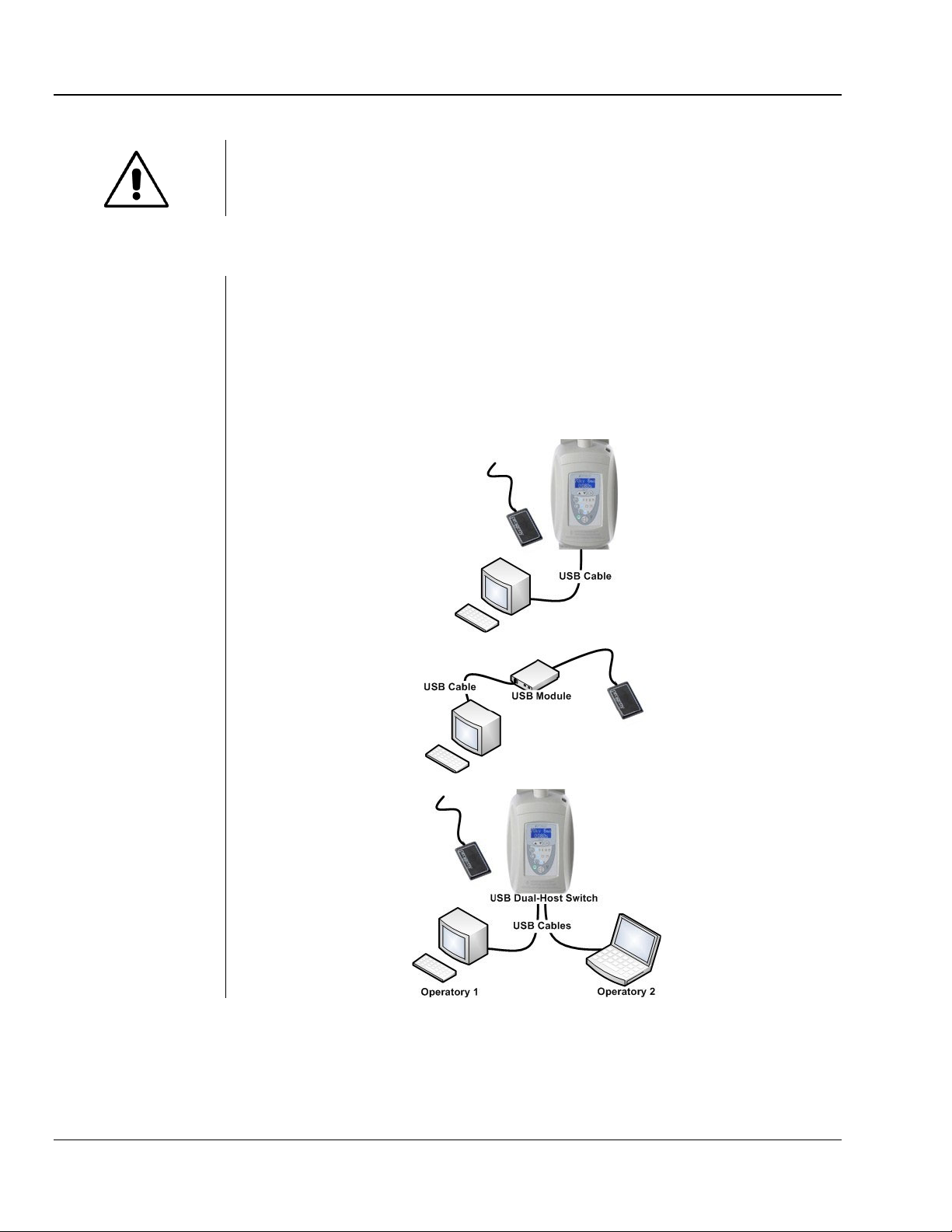

Installation Configurations

The Vision DX Sensor can be installed with the Preva Plus Dental Intraoral X-Ray

System or it can be used as a standalone sensor. These configurations are shown

in Figures 1 and 2. With the addition of the optional USB Dual-Host Switch, the

Vision DX Sensor integrated with the Preva Plus can be shared by two computers.

This setup, shown in Figure 3, might be desired when the Preva Plus is mounted

in a pass-through cabinet between two operatories.

Figure 1:

Vision DX Sensor

Integrated with

Preva Plus

Figure 2:

Vision DX Sensor

Standalone

Figure 3:

Vision DX Sensor

Integrated with

Preva Plus with

Optional Dual-Host

USB Switch

6

Page 7

Vision DX 600 Series: User Guide

Compliance with Applicable Standards

The following regulatory documents apply:

General

EMI/EMC

General Safety

IEC 60601-1

Classifications

EMC Statement

EEC 93/42 Medical Device Directive

ISO 13485: 2003

IEC 60601-1-2

EC 60601-1, 2

IEC 60601-1, 2

Protection Against Electrical Shock:

Degree of Protection Against Electrical Shock:

Degree of Protection Against Ingress of Water:

nd

nd

Ed.

Ed.

Class II

Type BF Applied Part

IPX0 (Ordinary)

Not suitable for use in the presence of flammable anesthetic mixture with air or

with oxygen or nitrous oxide.

Information Regarding Potential EMC Interference And Advice For Avoidance

Magnetic and Electrical fields are capable of interfering with the proper

performance of this device. For this reason, make sure that all external devices

operated in the vicinity comply with the relevant EMC requirements.

Main power quality should be that of a typical commercial or hospital

environment.

Power frequency magnetic fields should be at levels characteristic of a typical

location in a commercial or hospital environment.

If the above criteria cannot be verified, precautions shall be taken when using

this equipment as the device may inadvertently operate.

Obtaining Technical Support

Contact

7

Midmark Corporation

1001 Asbury Drive

Buffalo Grove, IL 60089

Phone: +1 (847) 415-9800 Toll free +1 (888) 924-3800

Fax: +1 (847) 415-9810

Page 8

Vision DX 600 Series: User Guide

EC Declaration of Conformity

Product Name and

Description

Catalog

Part Number

Progeny Vision DX 600 Series Intraoral Dental X-Ray Sensor

Sensors:

600-301

600-302

600-303

600-304

Size 1 sensor integrated cable

Size 2 sensor integrated cable

Size 1 sensor long cable

Size 2 sensor long cable

Sensor Systems:

600-105

600-106

600-107

600-401

600-402

600-403

600-404

Mobile Upgrade Kit with size 1 sensor

Mobile Upgrade Kit with size 2 sensor

Mobile Upgrade Kit with size 1 and size 2 sensors

Integrated system with size 1 sensor

Integrated system with size 2 sensor

Integrated system with size 1 and size 2 sensors

Integrated system without sensors.

600-405

600-406

600-407

600-408

600-501

600-502

600-503

P7017-MD1

P7017-MD2

P7017-MDV1

P7017-MDV2

PE7015-PD1

PE7015-PD2

PE7015-PD3

8

Standalone system without sensors

Standalone system with size 1 sensor

Standalone system with size 2 sensor

Standalone system with size 1 and size 2 sensors

Standalone Vet VisionDX system with size 1 sensor

Standalone Vet VisionDX system with size 2 sensor

Standalone Vet VisionDX system with size 1 and size 2 sensors

Integrated Preva Plus Mobile system with size 1 sensor

Integrated Preva Plus Mobile system with size 2 sensor

Integrated VetVision Complete Mobilewith size 1 sensor

Integrated VetVision Complete Mobilewith size 2 sensor

Integrated Preva Plus with Compact Arm and size 1 sensor

Integrated Preva Plus with Compact Arm and size 2 sensor

Integrated Preva Plus with Compact Arm and size 1 and size 2

Page 9

Vision DX 600 Series: User Guide

sensors

Class (93/42/EEC)

Reference

Documents

Declaration

PE7016-PD1

PE7016-PD2

PE7016-PD3

Integrated Preva Plus with Short Arm and size 1 sensor

Integrated Preva Plus with Short Arm and size 2 sensor

Integrated Preva Plus with Short Arm and size 1 and size 2

sensors

PE7017-PD1

PE7017-PD2

PE7017-PD3

Integrated Preva Plus with Long Arm and size 1 sensor

Integrated Preva Plus with Long Arm and size 2 sensor

Integrated Preva Plus with Long Arm and size 1 and size 2

sensors

1

nd

IEC60601-1 (1988) 2

edition with Amendments No.1 (1991) and No. 2 (1995)

IEC60601-1-1, Ed. 2 (2000)

EN60601-1-2 (CISPR 11) B level radiated emissions

EN60601-1-2 (CISPR 11) B level conducted emissions

Midmark Corporation declares that the products described herein meet all the

applicable Essential Requirements of the EC Medical Device Directive

93/42/EEC in Annex VII. For Class Ila products described herein, the product

is manufactured, inspected, tested and released in accordance with the

approved quality assurance system established in accordance with ISO 13485

and Annex II of the EC Medical Device Directive under the Supervision of the

SGS United Kingdom Ltd., a Notified Body.

Contact

Technical Support

+1 (888) 924-3800

Authorized Representatives

Europe

9

CE Partner 4U

Esdoornlaah 13

3951DB Maarn

The Netherlands

Phone: +31 (343) 442-524

Fax: +31 (343) 442-162

Page 10

A

Vision DX 600 Series: User Guide

Operating the VisionDX USB

Acquiring Images

Prerequisites

Connect the

Sensor

Taking images

Install the imaging software following the installation guide provided with

the product.

Connect and calibrate the Vision DX as described in the Vision DX 600

Series Installation Guide.

1.

Place the Vision DX in the operating environment.

55H

Connect the Vision DX

2.

X-Ray Sensor to the USB Module (standalone

configuration) or to the USB Interface Module on the Preva Articulated

(Integrated with Preva Plus configuration) by inserting the round connector

into the receptacle on the front of the USB Module or USB Interface

Module. The sensor connector will only fit one way.

If you are sharing the Vision DX Integrated Sensor between operatories

3.

using the optional USB Dual-Host Switch, be sure that the switch is set to

your operatory.

1. Refer to the specific imaging software manual for patient selection and

X-Ray image acquisition.

Verify that the X-Ray system exposure parameters are adequate to the

2.

desired imaging procedure.

Insert the

3.

56H

X-Ray Sensor into a sensor sheath and position the sensor inside

the patient’s mouth in the desired position.

4.

Position the tube head of the X-Ray system to the patient, using standard

accepted positioning procedures.

5.

Activate the Vision DX via the specific software (refer to imaging software

guide).

Repeat steps 1-5 for additional images

6.

rm

Using the Sensor Sheaths (PN 500-430/500-431)

Prior to using the Vision DX Sensor always cover the

S

58H

anitary Sensor Sheaths). Follow the procedure below. protective cover (

10

57H

X-Ray Sensor with a disposable hygienic

Page 11

Vision DX 600 Series: User Guide

Figure 4:

Using a

protective sensor

sheet

1. Hold sheath and insert sensor into opening between the white tab and the

paper.

2.

Gently slide the sensor into the sheath until it reaches the tip of the sheath.

Do not force it.

3.

Peel back the protective cover.

4.

Peel away the paper backing. The sensor is now protected and ready for

normal use.

Using a Sensor Positioning System

To facilitate positioning of the 60HX-Ray Sensor in the patient’s mouth it is recommended an

optional plastic holder to be used. Refer to the manufacture’s manual for instructions for optimal

usage.

Recommended Maintenance

In the interest of equipment safety, a regular maintenance program must be

established. This maintenance program should consist of cleaning and

disinfecting as well as annual system function checking. It is the owner’s

responsibility to arrange for this service and to assure that the personnel

performing these steps are fully qualified and authorized to service Progeny

X-Ray equipment.

11

Page 12

Vision DX 600 Series: User Guide

Cleaning and Disinfecting

Sensor must always be used with sanitary sheaths. The sheath must be

changed after use on every patient.

Any part of Vision DX system should be cleaned by the following procedure:

1. The Vision DX Sensor, USB Module, and cables may be disinfected by

wiping with an EPA approved hospital grade surface disinfectant as per

manufacturer's directions (USA and Canada).

2. To clean the

alcohol, then wipe with gauze or sleeve soaked with on of the following

solutions:

WARNING:

61H

X-Ray Sensor, first wipe off gross debris with water or ethyl

Ethyl alcohol (Ethanol)

2% aqueous glutaraldehyde

2% aqueous sodium hypochlorite solution.

Do not use disinfectants that contain phenol combinations.

WARNING:

Do not heat sterilize or autoclave the sensor, cable, or control unit, as this will

damage the electronics, carbon case and enclosure and void the warranty. Do

not submerge the sensor in any liquids. Do not spray any aerosol or nonaerosol sprays into the control module.

NOTICE:

PROPER DISINFECTION AND STERILIZATION IS THE SOLE

RESPONSIBILITY OF THE USER ACCORDING TO THEIR PRACTICE

PROTOCOL AND THE INSTRUCTIONS, REQUIREMENTS AND

LIMITATIONS OF THE STERILIZING/DISINFECTING AGENT/DEVICE

BEING USED, AS PER THE MANUFACTURER OF THE AGENT/DEVICE.

12

Page 13

Vision DX 600 Series: User Guide

Specifications

X-Ray Sensor

Film Size

equivalent

Active Area

Number of

Pixels

Pixel Size

Theoretical

Resolution

Dynamic Range

Sensor Cable

Connection type

Control Module

Size 1

Size 2

33 x 20 mm (Size 1)

36 x 27 mm (Size 2)

1.3 million Pixels (Size 1)

1.9 million Pixels (Size 2)

22 µm x 22 µm

22 lp/mm

>72 dB

2.5 m, Shielded

LEMO FGG 1B.314, 14 Pins

Power Supply

Signal-to-Noise

Ratio

Levels of gray

+5V/ 0.5 mA supplied by the USB port on the computer

70 dB

4096

Environmental

Operating

Temperature

Storage

Temperature

Relative

Humidity

13

+10 ºC/+35 ºC (+50 ºF/+95 ºF)

-25 ºC/+66 ºC (-13 ºF/+150 ºF)

10 – 80 %, non-condensing

Page 14

Vision DX 600 Series: User Guide

Terms

Film Size

Equivalent

Active Area

Number of

Pixels

Pixel Size

Theoretical

Resolution

Dynamic Range

The size of the X

63H

-Ray Sensor active area in relation to traditional film based

X-Ray systems available to the dentistry profession.

The equivalent sensor area used to produce an image, measured in square

millimeters (mm

2

). The larger the number the larger the active area.

The total number of pixels in the sensor active area. It has no unit value;

however, a larger number results in a finer image.

The size of the smallest discrete picture element used in the process of image

acquisition, measured in micrometers (µm). The smaller the pixel size the finer

the image.

Measures the maximum level of detail that the sensor system is capable of

acquiring, measured in line-pairs per millimeter (lp/mm). The larger the

number the finer the image.

Represents the largest output of the device as a ratio to the smallest output,

measured in decibels (dB). A larger number shows a greater X-Ray exposure

range in which the X-Ray sensor system can produce an image without

degradation.

Sensor Cable

Connection

Type

Power Supply

Signal to Noise

Ratio

Identifies the type and length of the sensor cable.

Specifies the connection type used to attach the sensor system to the

computer.

Specifies the power supply source used to power the sensor system.

A logarithmic ratio between output generated by the X-Ray exposure and the

output generated by the inherent system noise, expressed in decibels (db).

The larger the number, the better the image quality.

Levels of gray

Measures the maximum number of X-Ray intensity steps used to represent

the image in levels of gray. It has no unit value; however, a larger number

results in a finer image.

14

Page 15

Vision DX 600 Series: User Guide

Accessories and Part Numbers

A variety of accessories and replacement parts are available from Progeny – A Midmark Company

for the VisionDX USB System. Please contact us or your dealer for pricing and ordering details.

A summary of the available systems is shown on Table 1. A summary of the available parts and

accessories is shown on Table 2. A summary of the available software is shown on Table 3.

Table 1: Summary of the available VisionDX systems

Part Number

600-406

600-407

Sensor(s)

Size

1

3.0 m (118’) standalone

2

3.0 m (118’) standalone

600-408 1 & 2 3.0 m (118’) standalone

600-405

600-401

600-402

—

1

0.9 m (35”) integrated

2

0.9 m (35”) integrated

600-403 1 & 2 0.9 m (35”) integrated

600-404

600-105

600-106

—

1

0.9 m (35”) integrated

2

0.9 m (35”) integrated

600-107 1 & 2 0.9 m (35”) integrated

600-501

600-502

1

3.0 m (118’) standalone

2

3.0 m (118’) standalone

600-503 1 & 2 3.0 m (118’) standalone

P7015-D1

P7015-D2

1

0.9 m (35”) integrated 1.422 m (56”) one stud

2

0.9 m (35”) integrated 1.422 m (56”) one stud

Sensor

Cable

Length

—

standalone

—

integrated

Sensor

Control

Module

Preva Plus

Arm Length

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Preva Plus

Mounting

Option

—

—

—

—

—

—

—

—

—

—

—

—

—

—

P7015-D3 1 & 2 0.9 m (35”) integrated 1.422 m (56”) one stud

P7015-D4

P7015-DV1

P7015-DV2

—

1

0.9 m (35”) integrated 1.422 m (56”) one stud VetVision Complete

2

0.9 m (35”) integrated 1.422 m (56”) one stud VetVision Complete

—

integrated 1.422 m (56”) one stud

Notes

Upgrade Kit

Upgrade Kit

Upgrade Kit

Upgrade Kit

Mobile Upgrade Kit

Mobile Upgrade Kit

Mobile Upgrade Kit

Vet VisionDX

Vet VisionDX

Vet VisionDX

P7015-DV3 1 & 2 0.9 m (35”) integrated 1.422 m (56”) one stud VetVision Complete

P7015-PD1

P7015-PD2

1

0.9 m (35”) integrated 1.422 m (56”) two stud

2

0.9 m (35”) integrated 1.422 m (56”) two stud

P7015-PD3 1 & 2 0.9 m (35”) integrated 1.422 m (56”) two stud

P7015-PD4

P7015-PDV1

P7015-PDV2

—

1

0.9 m (35”) integrated 1.422 m (56”) two stud VetVision Complete

2

0.9 m (35”) integrated 1.422 m (56”) two stud VetVision Complete

—

integrated 1.422 m (56”) two stud

P7015-PDV3 1 & 2 0.9 m (35”) integrated 1.422 m (56”) two stud VetVision Complete

P7016-D1

P7016-D2

1

0.9 m (35”) integrated 1.676 m (66”) one stud

2

0.9 m (35”) integrated 1.676 m (66”) one stud

P7016-D3 1 & 2 0.9 m (35”) integrated 1.676 m (66”) one stud

P7016-D4

P7016-DV1

—

1

0.9 m (35”) integrated 1.676 m (66”) one stud VetVision Complete

—

integrated 1.676 m (66”) one stud

15

Page 16

Vision DX 600 Series: User Guide

Part Number

P7016-DV2

Sensor(s)

Size

2

0.9 m (35”) integrated 1.676 m (66”) one stud VetVision Complete

Sensor

Cable

Length

Sensor

Control

Module

Preva Plus

Arm Length

Preva Plus

Mounting

Option

Notes

P7016-DV3 1 & 2 0.9 m (35”) integrated 1.676 m (66”) one stud VetVision Complete

P7016-PD1

P7016-PD2

1

0.9 m (35”) integrated 1.676 m (66”) two stud

2

0.9 m (35”) integrated 1.676 m (66”) two stud

P7016-PD3 1 & 2 0.9 m (35”) integrated 1.676 m (66”) two stud

P7016-PD4

P7016-PDV1

P7016-PDV2

—

1

0.9 m (35”) integrated 1.676 m (66”) two stud VetVision Complete

2

0.9 m (35”) integrated 1.676 m (66”) two stud VetVision Complete

—

integrated 1.676 m (66”) two stud

P7016-PDV3 1 & 2 0.9 m (35”) integrated 1.676 m (66”) two stud VetVision Complete

P7017-D1

P7017-D2

1

0.9 m (35”) integrated 1.930 m (76”) one stud

2

0.9 m (35”) integrated 1.930 m (76”) one stud

P7017-D3 1 & 2 0.9 m (35”) integrated 1.930 m (76”) one stud

P7017-D4

P7017-DV1

P7017-DV2

—

1

0.9 m (35”) integrated 1.930 m (76”) one stud VetVision Complete

2

0.9 m (35”) integrated 1.930 m (76”) one stud VetVision Complete

—

integrated 1.930 m (76”) one stud

P7017-DV3 1 & 2 0.9 m (35”) integrated 1.930 m (76”) one stud VetVision Complete

P7017-MD1

P7017-MD2

P7017-MDV1

P7017-MDV2

P7017-PD1

P7017-PD2

1

0.9 m (35”) integrated

2

0.9 m (35”) integrated

1

0.9 m (35”) integrated

2

0.9 m (35”) integrated

1

0.9 m (35”) integrated 1.930 m (76”) two stud

2

0.9 m (35”) integrated 1.930 m (76”) two stud

—

mobile

—

mobile

—

mobile VetVision Complete

—

mobile VetVision Complete

P7017-PD3 1 & 2 0.9 m (35”) integrated 1.930 m (76”) two stud

P7017-PD4

P7017-PDV1

P7017-PDV2

—

1

0.9 m (35”) integrated 1.930 m (76”) two stud VetVision Complete

2

0.9 m (35”) integrated 1.930 m (76”) two stud VetVision Complete

—

integrated 1.930 m (76”) two stud

P7017-PDV3 1 & 2 0.9 m (35”) integrated 1.930 m (76”) two stud VetVision Complete

PE7015-PD1

PE7015-PD2

1

0.9 m (35”) integrated 1.422 m (56”) one stud Export

2

0.9 m (35”) integrated 1.422 m (56”) one stud Export

PE7015-PD3 1 & 2 0.9 m (35”) integrated 1.422 m (56”) one stud Export

PE7016-PD1

PE7016-PD2

1

0.9 m (35”) integrated 1.676 m (66”) one stud Export

2

0.9 m (35”) integrated 1.676 m (66”) one stud Export

PE7016-PD3 1 & 2 0.9 m (35”) integrated 1.676 m (66”) one stud Export

PE7017-PD1

PE7017-PD2

1

0.9 m (35”) integrated 1.930 m (76”) one stud Export

2

0.9 m (35”) integrated 1.930 m (76”) one stud Export

PE7017-PD3 1 & 2 0.9 m (35”) integrated 1.930 m (76”) one stud Export

Table 2: Summary of the VisionDX replacement parts and accessories

Part

Number

600-301 Sensor size 1, 0.9 m cable

600-302 Sensor size 2, 0.9 m cable

600-303 Sensor size 1, 3.0 m cable

600-304 Sensor size 2, 3.0 m cable

600-405 Sensor control module for standalone configuration

600-404 Sensor control module for Preva articulating arm integration

16

Description

Page 17

Vision DX 600 Series: User Guide

Part

Number

Description

500-432 Protective Sheets Size 1

500-433 Protective Sheets Size 2

45-A2004 Sensor Holder Assembly for standalone configuration

45-A2005 Sensor Holder Assembly for Preva articulating arm integration

600-100 USB Cable Extension Kit (integrated)

600-108 USB Cable Extension Kit (standalone)

30-A2153 USB A/B Switch

40-07001 4-port USB hub

Table 3: Summary of the VisionDX Software

Part

Number

500-405 Progeny Imaging, International

500-420 Progeny Imaging, International, Demo

500-427 Progeny Imaging, Domestic

500-428 Progeny Imaging, Domestic, Upgrade

500-429 Progeny Imaging, Domestic, Light

500-430 Progeny Imaging, Domestic, Light, Demo

500-431 Progeny Imaging, Domestic, Demo

Description

17

Page 18

Vision DX 600 Series: User Guide

Warranty and Service

Warranty:

A separate Limited Warranty card has been included with your system. Please complete and return the

warranty registration card immediately to validate your warranty and receive technical support. Progeny

cannot offer technical support or assistance unless your product has been registered.

Extended Warranty Options are available. For more details, contact Progeny Dental or your dealer.

Service:

In the event you should require factory service, please follow these instructions:

Call +1.888.924.3800 and request a Return Authorization Number. Be sure to have the model number,

serial number, nature of the problem, and a major credit card readily available for our customer service

representative. Please mark the RA number clearly on the OUTSIDE of the shipping box and packing slip.

If the RA# is not readily in sight, our receiving clerk is not authorized to accept the package. Progeny

Dental cannot accept responsibility for merchandise returned without a Return Authorization

Number.

Returns:

Please review your dealer’s return policy if you purchased this product from an authorized Progeny dealer.

Progeny Return Policy: Returns are not accepted without prior written approval of Progeny – A Midmark

Company Defective products will be repaired or replaced per Progeny warranty program. No returns are

accepted more than 30 days after the order date. Sterile sheaths are considered perishable items and are

not returnable under any circumstances unless defective. Progeny cannot be responsible for any missing

items unless contacted within 72 hours of shipment receipt by the customer. Any verbal representations

are superseded by this written document. Progeny representatives may not modify any of the above terms

and conditions without Progeny management’s written approval.

IMPORTANT:

SAVE ALL BOXES AND PACKING MATERIALS. ALWAYS SHIP THE SYSTEM

IN THE ORIGINAL BOXES TO PREVENT DAMAGE. FAILURE TO RETURN

THE SYSTEM IN ITS ORIGINAL PACKAGING MAY VOID YOUR WARRANTY.

18

Loading...

Loading...