Page 1

User GuideUser Guide

Introduction ........................................... 2

Symbols ................................................ 2

Intended Use ........................................ 3

Electromagnetic Interference................ 3

Calling for Service ................................ 3

Specications / Compliance Chart ....... 3

Disposal of Equipment.......................... 3

Transportation / Storage /

Operating Conditions .......................... 3

Manual Shuto Valves /

Pressure Regulator Valves ................ 4

Controls ................................................ 5

Operation ............................................. 7

Cleaning & Maintenance ......................

Chair Mounted Units ......................... 16

Cabinet Mounted Units .................... 17

Doctor’s / Hygienist’s Carts .............. 17

Assistant’s Cart ................................ 18

Left / Right Duo Cart ........................ 18

EMC - Manufacturer’s Declaration and

Guidance ............................................ 19

Warranty Information .......................... 22

Introduction ........................................... 2

Symbols ................................................ 2

Intended Use ........................................ 3

Electromagnetic Interference................ 3

Calling for Service ................................ 3

Specications / Compliance Chart ....... 3

Disposal of Equipment.......................... 3

Transportation / Storage /

Operating Conditions .......................... 3

Manual Shuto Valves /

Pressure Regulator Valves ................ 4

Controls ................................................ 5

Operation ............................................. 7

Cleaning & Maintenance ......................

Chair Mounted Units ......................... 16

Cabinet Mounted Units .................... 17

Doctor’s / Hygienist’s Carts .............. 17

Assistant’s Cart ................................ 18

Left / Right Duo Cart ........................ 18

EMC - Manufacturer’s Declaration and

Guidance ............................................ 19

Warranty Information .......................... 22

midmark.com

© 2016 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Asepsis 21®

Delivery Systems

English

Español

Français

Style P

TP202 20-42-FO-00014 Rev A1 C2169

003-2237-99 Rev CA6 (7/19/19)

Page 2

Introduction

Your Asepsis 21 Delivery system has been designed and manufactured with care and you in mind. It is constructed of the highest quality material to provide years

of trouble-free service.

The instrument head provides for the control of up to ve air operated handpieces and a 3-way syringe. The handpieces are stored in their respective holders

which may be rotated to your preferred position. When the handpiece is removed from the holder, it is automatically selected to operate when the foot control is

depressed.

Your new Asepsis 21 also features a handpiece lubricant collection system. The handpiece exhaust tubes from the four port handpiece tubes are connected to a

collector jar which is located on the bottom center of the instrument head. The collection jar can be removed to be emptied and cleaned simply by unscrewing it

from the unit. The collector jar should be inspected daily and emptied when approximately 1/2 inch of oil has accumulated.

The aerodynamic shape of the instrument head lends itself to easy cleaning or wrapping for infection control.

Symbols

These symbols may appear on your equipment and/or in the manuals Warning and cautions are provided in the manuals where applicable.

WARNING

Indicates a potentially hazardous situation which

could result in serious injury if not avoided.

Caution

Indicates a potentially hazardous situation which may

result in minor or moderate injury if not avoided. It may

also be used to alert against unsafe practices

Equipment Alert

Indicates a potentially hazardous situation which

could result in equipment damage if not avoided.

NOTE

Amplifies a procedure, practice, or condition.

Type B,

Applied Part

Type BF,

Applied Part

Protective Earth

Ground

Proper Shipping Orientation

Fragile

Catalogue Number

Serial Number

Manufacturer

Refer to instruction

manual/booklet

Pressure

Limit

100 F

Temperature

38 C

23 F

-5 C

Limit

Humidity

Limit

Maximum stacking

height (Refer to “n”

number on package.)

Keep Dry

003-2237-99

English - 2

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 3

Intended Use

Midmark delivery systems are intended to provide dental

professionals with air, water and suction to operate dental

handpieces, syringes, and Midmark authorized accessories

during dental examinations and procedures.

Electromagnetic Interference

Midmark dental operatory components are designed and

built to minimize electromagnetic interference with other

devices. However, if interference is noticed between another

device and this operatory, remove the interfering

device from room and / or plug product into an isolated circuit.

Calling For Service

Direct all service inquiries to your authorized Midmark dealer.

When calling for service, you must provide the following information:

Specications

Air / Water Pressure

Operating Ranges:

Classications Class I, Type B, Applied Part,

Optional Accessories:

Handpiece tubing and connectors intended

to be used with ISO 7785-1 or ISO 7785-2

compliant air-driven handpieces

WARNING

Equipment is not suitable for use in the presence

of a flammable anesthetic mixture with oxygen, air,

or nitrous oxide.

Clarification: Equipment is suitable for use in the presence

of oxygen, air, or nitrous oxide.

Air: 80/100 PSI

Water: 30/50 PSI

Ordinary Equipment. [IPXO]

Type B Applied Part

Model / serial number

Date of purchase

Symptom(s) of malfunction

Description

Asepsis 21 Delivery Systems Ultra Chair

Asepsis 21 Delivery Systems

Mounted on

(Type)

Knight Chair

or Carts

UL

60601-1

(2nd

Edition)

• •

CAN / CSA

22.2,

#601.1 - M90

Disposal of Equipment

At the end of this product’s life, the unit, accessories and

other consumable goods may be contaminated from normal

use. Consult local codes and ordinances for proper disposal

of this equipment and other consumable goods.

Transportation / Storage / Operating Conditions

Transportation / Storage Temperature: ........23°F to 100°F (-5°C to +38°C)

Relative Humidity:........................................ 10% to 90% (non-condensing)

Atmospheric Pressure: ................. 7.2 PSI to 15.3 PSI (50 kPa to 106 kPa)

Operating Temperature Range: ...................... 59°F to 95°F (15°C to 35°C)

Complies To: Electrical Ratings:

ES/IEC/

EN

60601-1

• • •

EN

60601-1-2

(EMC Standards)

CAN / CSA

22.2,

#60601.1

Volt

+/- 10%

120 15 A 50/60

240 7.5 A 50/60

Maximimum

Connected

Load

N/A

Cycles

(Hz)

Power Supply Model No.:

153808-001, -002

003-2237-99

English - 3

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 4

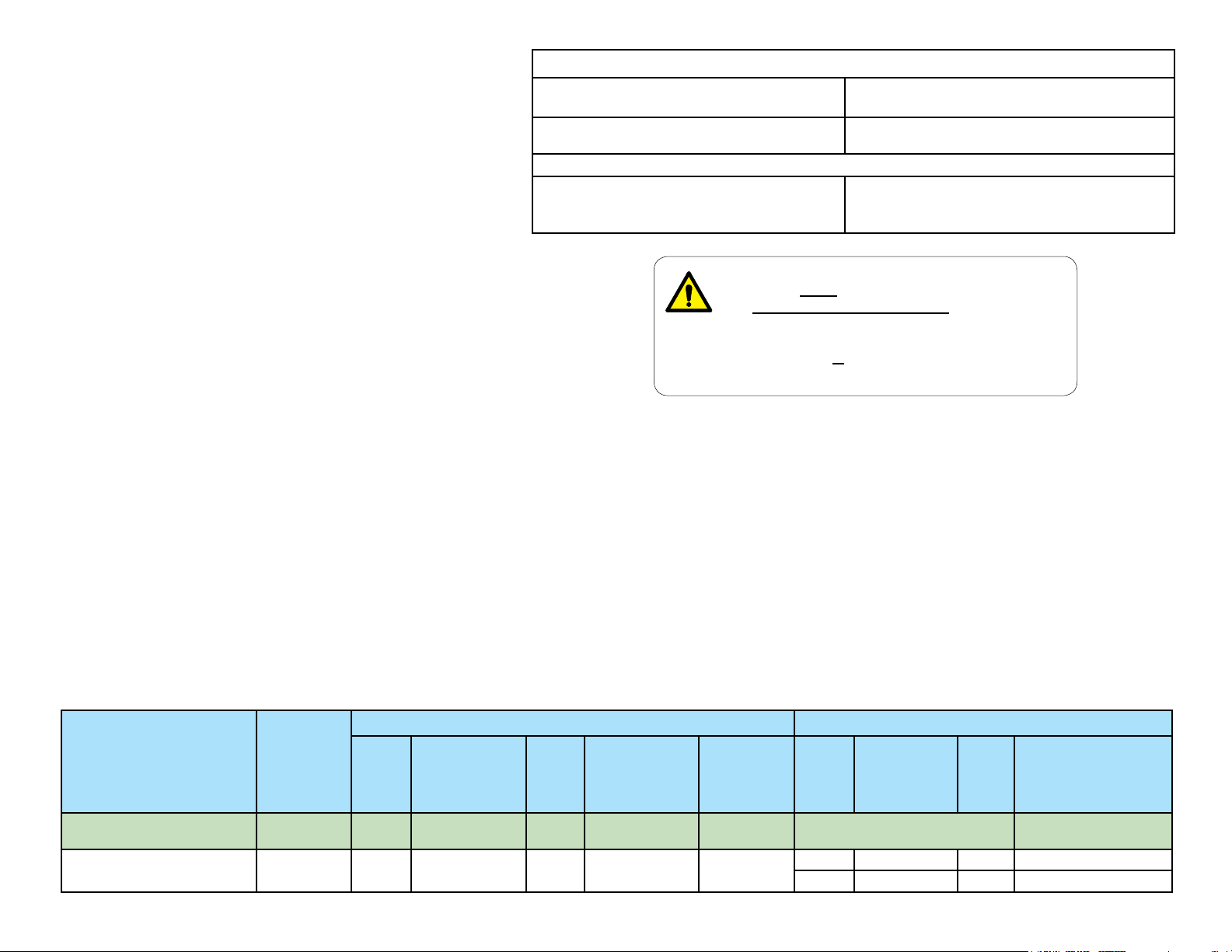

Manual Shut-O Valves / Pressure Regulator Valves

Manual shut-o valves allow you to stop the air and/or water supply at the point of input to the operatory. This is recommended during

extended periods of non-use (ex. vacation, holidays, etc.), or in the event of an equipment malfunction.

Pressure regulator valves allow you to control the air and water pressure supplied to the instruments of the delivery system.

Water Bottle

Regulator

DO NOT ADJUST

Air Regulator

Gauge

Air

Regulator

Adjustment

Knob

40

60

3

2

4

20

1

5

80

0

0

6

7

100

City Water

Gauge

City Water

Regulator

Adjustment

Knob

Water Manual

Shut-o Valve

Air Manual

Shut-o Valve

Shut-o Valves

Rotate clockwise 1/4

turn to Shut o.

To Adjust the Pressure Regulators...

A) Pull up knob and turn to adjust.

B) Watch regulator gauge as you turn knob to achieve desired setting.

Turn Clockwise

for more pressure

Turn Counter-Clockwise

for less pressure

Recommended Settings:

City Water

RegulatorGauge Setting

Air Pressure

RegulatorGauge Setting

Water Bottle Regulator

Setting

003-2237-99

30 psi

80 psi

Factory set to 30 psi

DO NOT adjust

Equipment Alert

Delivery components were designed

to operate at the recommended

settings. Poor performance or damage to the

equipment may result if recommended settings

are not maintained.

English - 4

4

80

5

6

7

0

100

KA947002

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 5

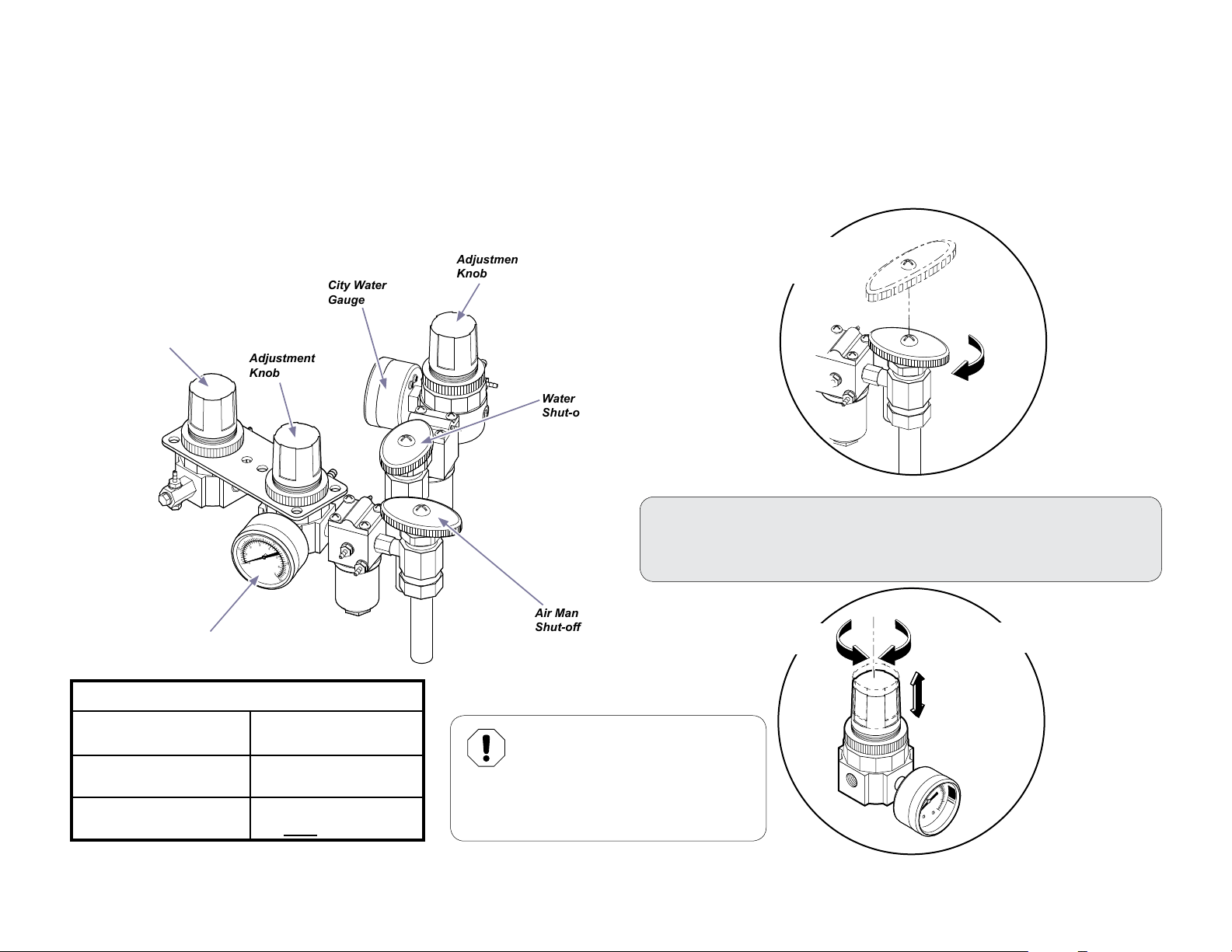

Controls

Asepsis 21 Instrument Head: A complete set of handpiece and syringe adjustments are located directly under the magnetically held cover for protection against

contamination. Lift up either back corner of the cover for easy removal. All controls are labeled with symbols identifying their function.

1 2 3

Handpiece Coolant Water Volume

Adjusts the amount of coolant water to each

respective handpiece.

4 5 6

Drive Air Pressure Setting

Individual adjustments are provided - one for

each respective handpiece. Set the maximum

handpiece pressure indicated on the gauge.

Refer to the handpiece manufacturer’s

specications for proper setting.

7

Syringe Air Volume Adjustment

Controls the volume of air to the syringe and

eects water spray pattern.

9

Coolant Air Volume Adjustment

This adjustment controls the volume of coolant

delivered to each handpiece. It aects the

spray pattern of air and water at the handpiece.

If the handpiece has a coolant air connection in

the handpiece itself, this adjustment will have

no eect and can be completely shut o.

10

Handpiece Pressure Gauge

Indicates individual handpiece pressure when

the handpiece is operating.

11 12 13

Magnetic Latches

These hold the cover in place.

8

Syringe Water Volume Adjustment

Controls the volume of water to the syringe and

eects water spray pattern.

003-2237-99

English - 5

14

Handpiece Coolant Water Flush Button

Controls the coolant water ush valve and is located

on the underside of the delivery head.

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 6

Controls - continued

External Controls

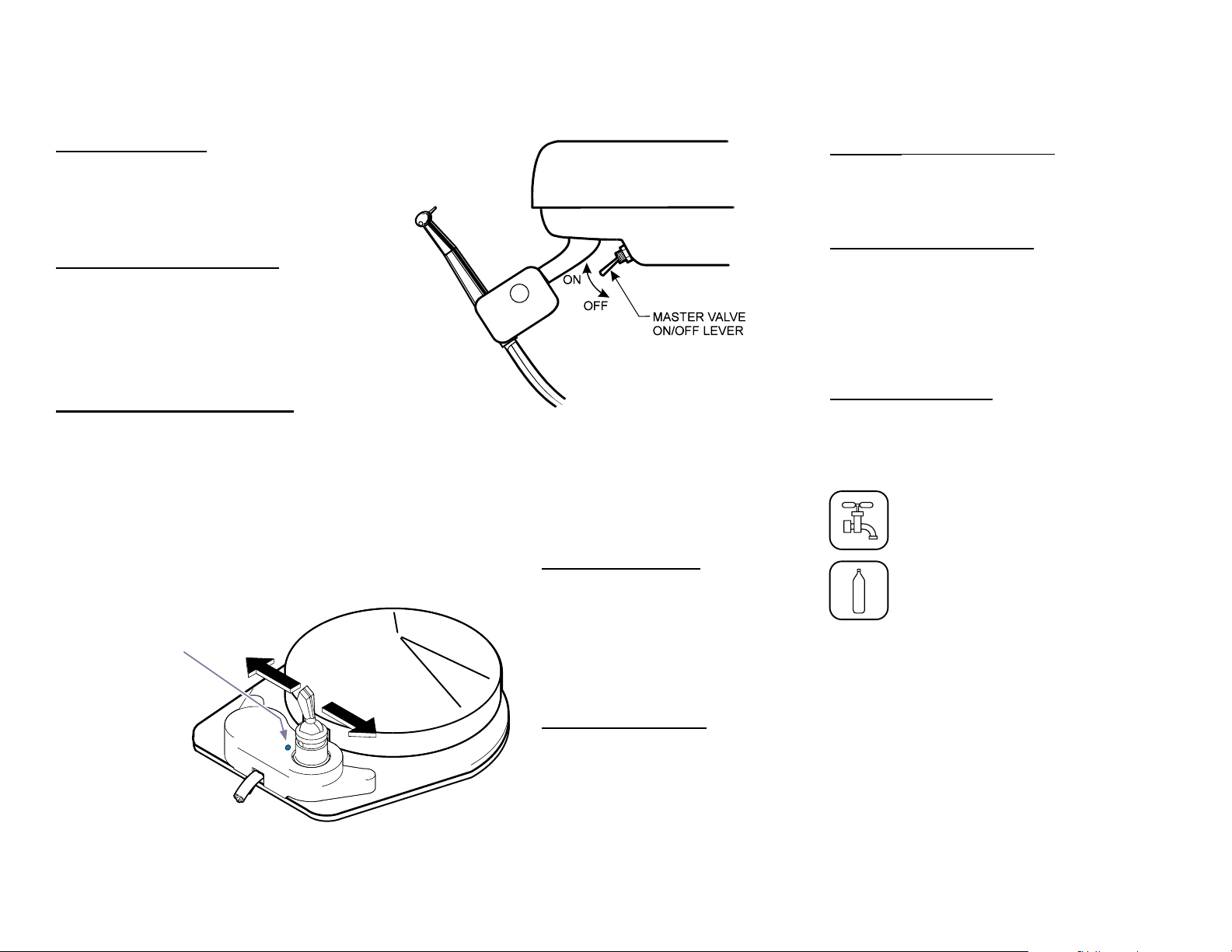

Main ON / OFF Valve

Located on the bottom center of the instrument

head directly behind the handpiece holder bar

support, this two position toggle control turns

the main air and water ON / OFF.

(See illustration below)

Water Outlet and Flow Control

Located on the front panel of the console, the

water outlet provides water for hydrocolloid

tubing or other accessories. The water is

controlled by a ow control knkob located next

to the water outlet. Turning the knob clockwise

decreases water ow, and counterclockwise

increases the ow.

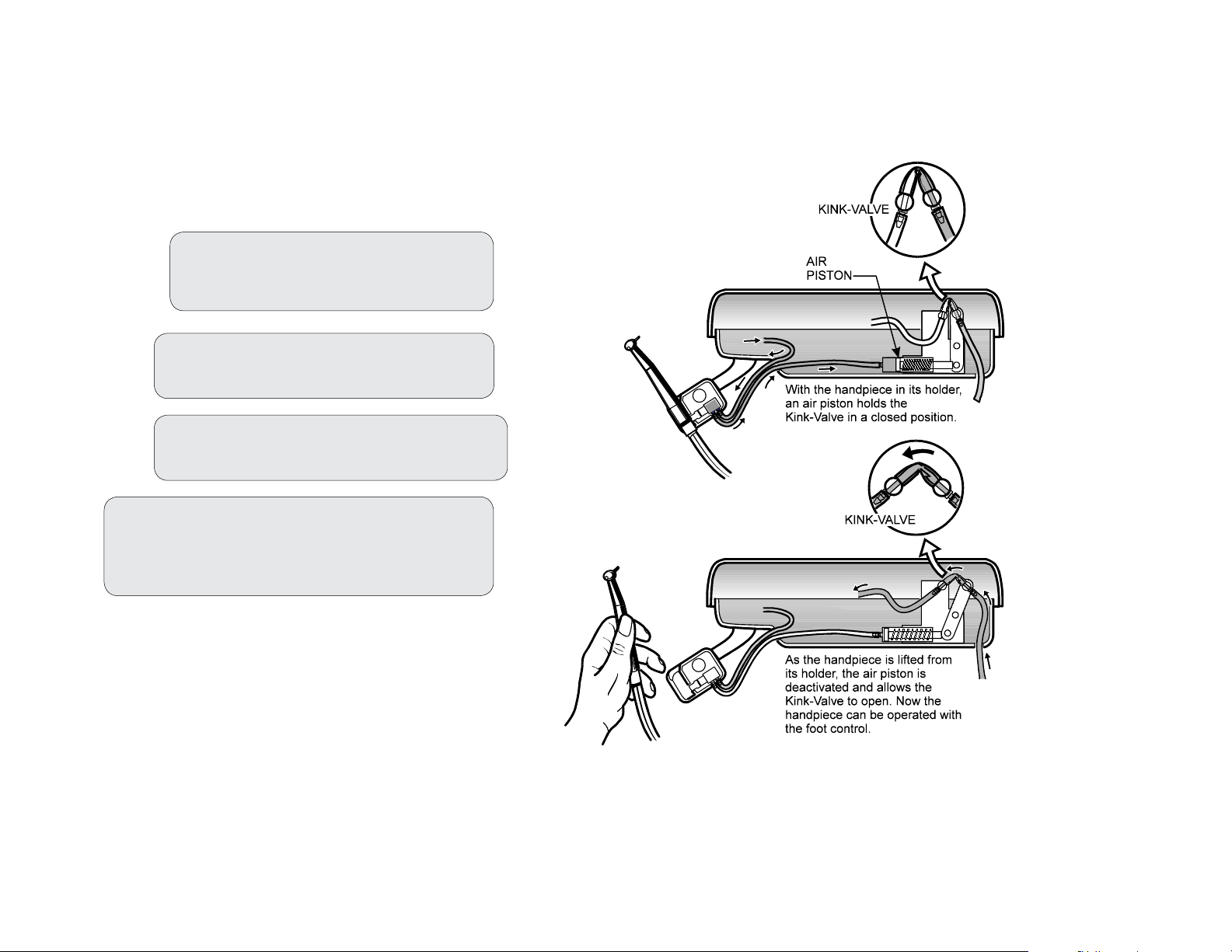

Automatic Handpiece Activation

The automatic kink valves are designed to

permit activation of the selected handpiece

when it is removed from its holder. Drive air will

be delivered to the withdrawn handpiece when

the foot control is depressed.

Blue dot indicates

“wet” operation

Water ON / OFF Valve

Located on the foot control, this switch

provides water for coolant spray to the

handpiece when the switch is moved forward

to the ON position (toward the blue dot) and

the foot control is depressed (wet cutting).

When the valve is in the OFF position, water

will not be delivered to any handpiece.

(See illustration below).

Arm Lock (chair mtd. units only)

Located on the bottom of the instrument head

adjacent to the handle, this two position toggle

controls the arm lock mechanism.

Assistant’s Instrumentation

A saliva ejector, HVE and syringe are

standard instrumentation on the unit. They are

positioned on a movable holder located on

the console. Syringe tip, saliva ejector valve

assembly and HVE valve assembly are easily

removed for sterilization.

Water Selector Switch

This switch, located on the front of the console

or the LR arm, allows you to choose the water

source for the delivery system. You may select

either “City” water (tap water), or water from

the Self-Contained Water System bottle.

“City” water

Self-Contained

Water System

003-2237-99

Wet / Dry Foot Control

The disc-type foot control operates the

selected handpiece at varying speeds

depending upon the foot pressure applied to

the disc. Positioning the coolant water selector

toggle allows coolant water for wet cutting to

be selected by the motion of the foot. Applying

foot pressure to the disc will operate the

selected handpiece and, if turned ON, water

spray. (See illustration below).

English - 6

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 7

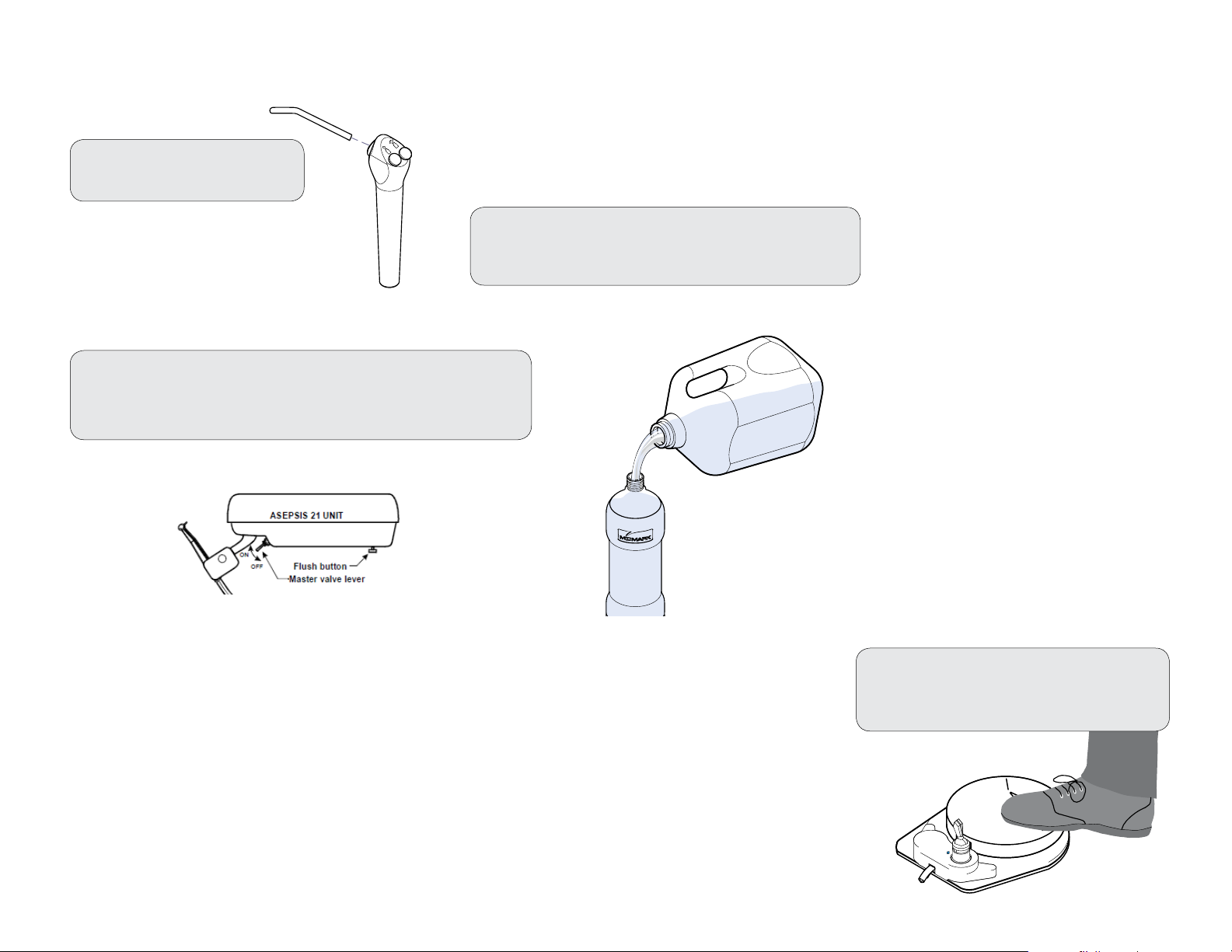

Operation

The automatic kink valves are designed to permit activation of the selected handpiece

when it is removed from its holder. Drive air will be delivered to the withdrawn handpiece

when the foot control is depressed. (See the illustration)

Basic Operation:

Step 1: Turn ON the master valve lever

located on the underside of the

Asepsis 21 instrument head.

Step 2: Flip the wet/dry toggle on the

foot control to the desired position.

Step 3: Lift the handpiece from its holder

and depress the foot control.

003-2237-99

Step 4: If necessary, make adjustments by lifting

the cover off the Asepsis 21 head and

adjusting the control knobs as desired.

(See Controls section)

English - 7

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 8

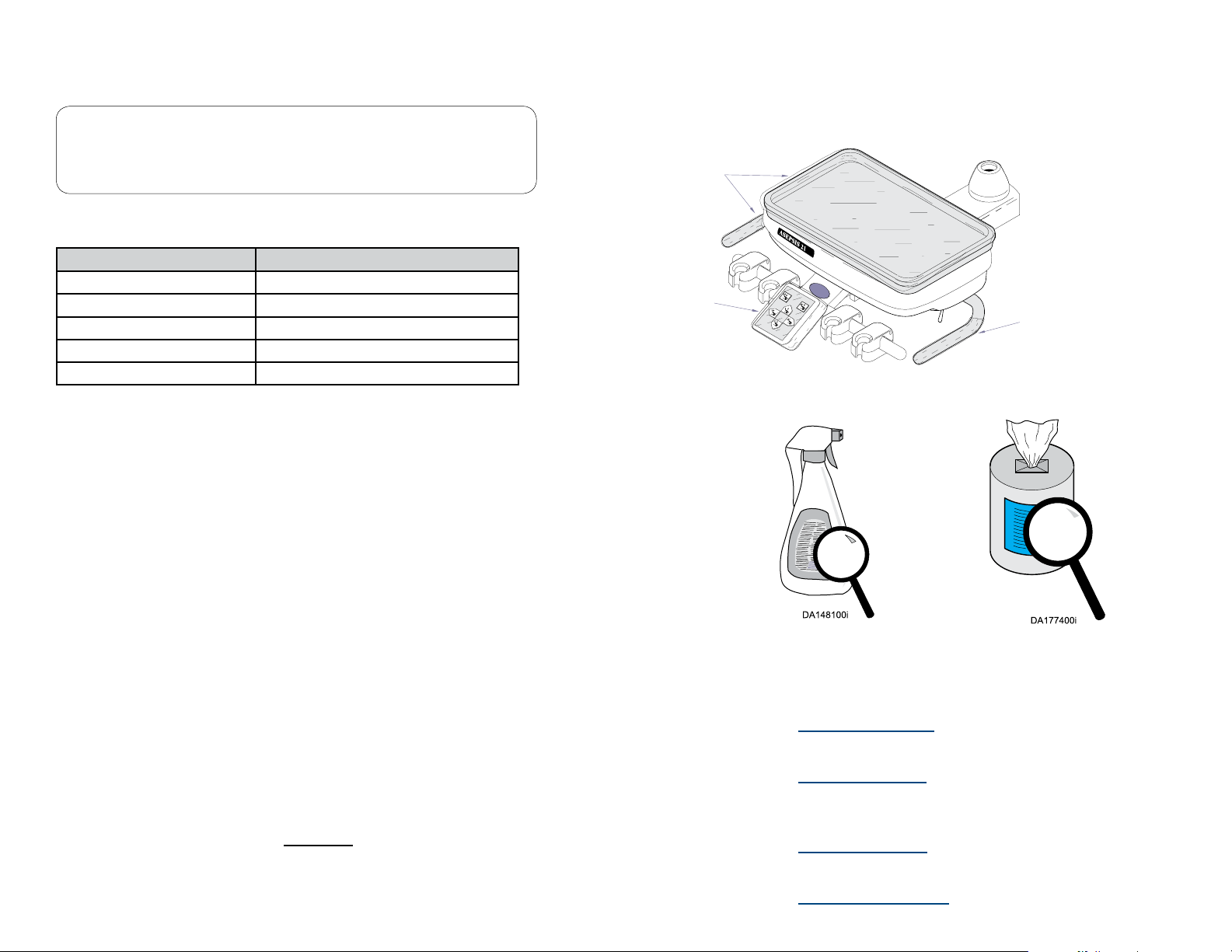

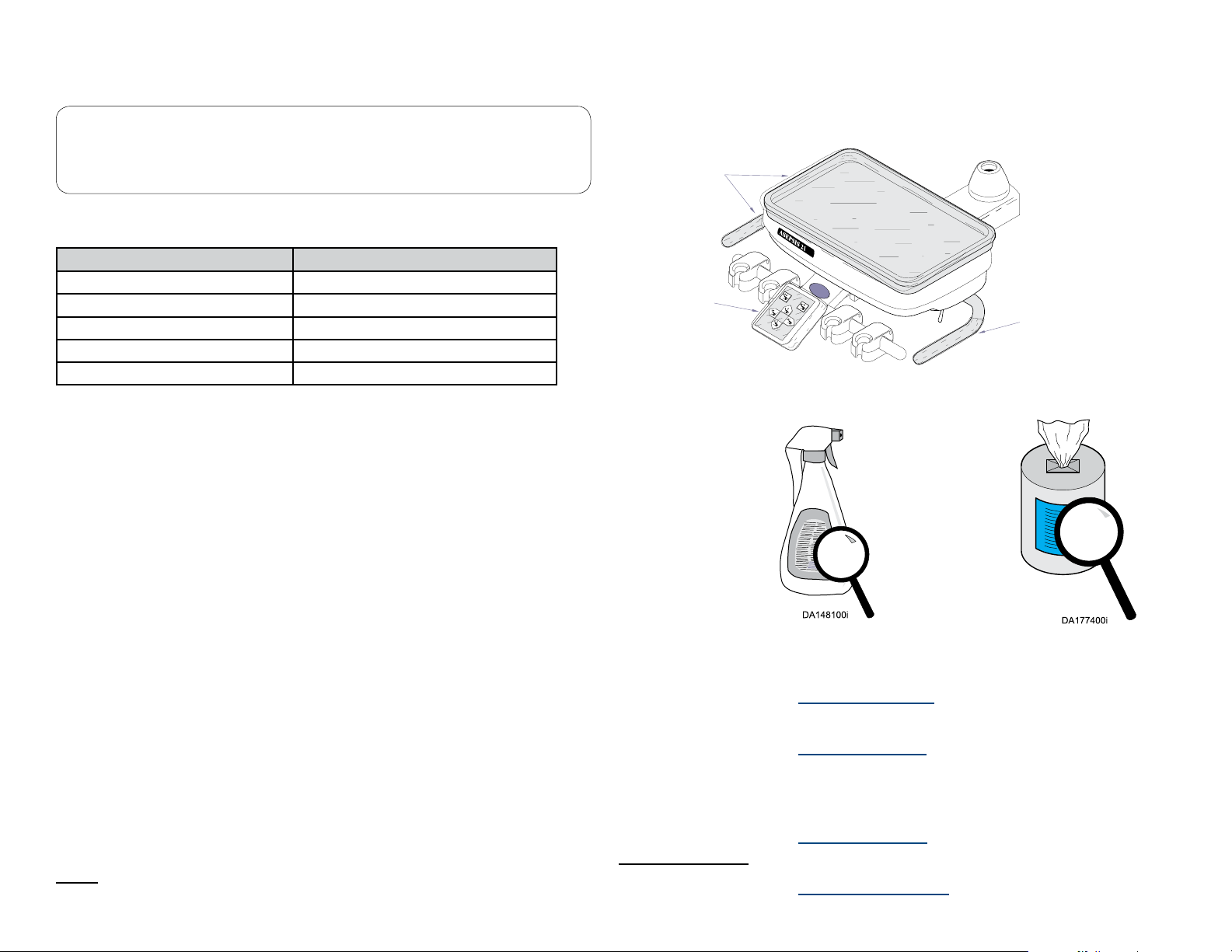

Cleaning, Disinfecting & Maintenance

Read all labels

ATTENTION

Midmark assumes no responsibility or liability for any result, expressed or

implied. These are suggested practices, based on the best information

available at this time this is written..

Scheduled Maintenance Chart

Area Frequency

Unit surfaces as necessary

Hoses as necessary

Vacuum system as necessary

Solids collector daily

Regulator lters (air / water) every 3 months

Barriers

Single-use barriers and disposable items signicantly reduce the need for chemical disinfectants,

thus prolonging the life of the equipment. Barrier material must be impervious to moisture / uids.

Examples of protective barriers:

Barrier

Barrier

Barrier

DA178400i

Cleaning and Disinfectant Procedures

Use cleaners and disinfectants that are appropriate for the situation, such as warm water and mild

detergents, or a 10% solution of bleach with water.

NOTE

Every dental practice is dierent, and no single disinfectant is the best choice for every facility. Listed

below are some organizations to assist you in choosing the best disinfectants available for your

practice.

003-2237-99

• Plastic covers (available from your dealer or equipment manufacturer)

• Clear plastic wrap

• Plastic bags

• Plastic sheets

• Plastic tubing

• Plastic-backed paper

• Materials similar to those listed here

English - 8

carefully!

• Organization for Safety & Asepsis Procedures:

http://www.osap.org

• American Dental Association:

http://www.ada.org

• Dept. of Health & Human Resources

Centers for Disease Control & Prevention (CDC):

http://www.cdc.gov

• European Dental Association:

http://www.eda-eu.org

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 9

Cleaning, Disinfecting & Maintenance (continued)

Barriers

Midmark recommends the use of disposable barriers on all clinician controls

that may be in contact with clinician hands and ngers during dental

procedures. The use of barriers signicantly reduces the need for chemical

cleaners, thus prolonging the life of the equipment.

General Purpose Cleaning

Use cleaners and disinfectants that are appropriate for the situation,

such as warm water and mild detergents, or a 10% solution of bleach

with water.

Visual Inspection

Only use barrier material that is intended for use with dental equipment.

Midmark recommends the use of an FDA market-cleared barrier such as

Pinnacle Cover-all™. Follow barrier manufacturer instructions for proper use

of these products.

Cleaning and Disinfecting

In addition to the use of barriers Midmark recommends the use of an EPA

registered and FDA market-cleared cleaner/disinfectant such as Cavicide™

to be used on all clinician controls or surfaces that may come in contact with

dental instruments during dental procedures.

Follow cleaner/disinfectant manufacturer instructions for proper use of the

product. Care should be taken to avoid excessive application and pooling of

liquids.

Handpiece Accessories

Only use dental handpiece accessories with the delivery system that are FDA

market-cleared and refer to manufacturer’s instructions for proper cleaning

and disinfecting. Either an autoclavable syringe tip or a single use disposable

syringe tip may be used.

Equipment Alert

AUTOCLAVABLE SYRINGE TIP STERILIZATION

The autoclavable syringe tips supplied with the delivery system must be

sterilized prior to use with each patient, including initial use. Be sure to thoroughly

rinse and clean syringe tips prior to sterilization, any debris may reduce the

effectiveness of the sterilization. Recommended sterilization process is steam

autoclave. Recommended parameters are 125°C (250°F) and 106 kPa (15 PSI) for 40

minutes at temperature and pressure.

After cleaning, visually inspect the product for deterioration of

covers and touch pads. Do not use the delivery system if excessive

discoloration, cracking, or other signs of wear are noticeable (see

Calling for Service instructions).

Waterline Maintenance

Waterline maintenance is necessary to keep the count of

heterotrophic bacteria from rising higher than desired levels. The

desired level for a specic location should be determined by any local

or regional guidelines. For example, The United States Centers for

Disease Control and Prevention (CDC) guideline for heterotrophic

bacteria is less than or equal to 500 CFU/mL (colony forming units

per milliliter). Midmark recommends keeping this level under 200

CFU/mL.

Treatment can come in many forms. The most popular methods on

the market currently are tablets and straw/cartridge based systems.

Midmark recommends the use of a straw/cartridge based system that

keeps the bacteria levels in check.

Regular monitoring should also take place to ensure that

heterotrophic bacteria is not exceeding the desired limit. If the level

is higher than desired, a shock treatment of the waterlines should

be performed. When performing a shock treatment, be sure to

check with the manufacturer of the regular treatment regimen being

used to ensure chemical compatibility. Monitoring frequency should

be established by your practice. As a suggestion, Midmark would

recommend that you begin by monitoring on a monthly basis, and

make adjustments to the frequency based on test results.

Per the CDC, routine ushing of the waterlines should be performed

between every patient. Extra ushing maybe needed within Midmark

equipment when tablets are used. Undissolved tablet particles can

gather over time in places within the waterlines, obstructing the line

and causing water ow to slow. By ushing the waterlines, water ow

is maximized and should push any undissolved particles through.

003-2237-99

English - 9

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 10

DA101201i

Cleaning and Disinfecting Assistance

For assistance with cleaning and disinfecting instructions contact the Midmark Technical Service Department at 1-800-Midmark; it is helpful to provide the

delivery system model number and serial number when asking for assistance.

Additional information is available from the organizations listed below:

Organization for Safety & Asepsis Procedures:

http://www.osap.org

American Dental Association:

http://www.ada.org

Cleaning the Delivery System

Dept. of Health & Human Resources, Centers for Disease Control & Prevention (CDC):

http://www.cdc.gov

European Dental Association:

http://www.eda-eu.org

At the beginning of each day...

Fill the Self contained water bottle with fresh water and

perform a Purging Procedure.

Note: See Purging Procedure described in this manual.

Note:

Water must be safe for drinking.

Distilled water is not required.

For each new patient...

Replace disposable tips, instruments, etc. and

perform a Purging Procedure.

Note: See Purging Procedure described in this manual.

003-2237-99

DA2536i

English - 10

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 11

Cleaning the Delivery System - At the end of each day...

A) Remove disposable tips,

instruments, etc.

B) Clean and disinfect the delivery system (see

Cleaning and Disinfecting instructions).

DA2536i

C) Fill the water bottle with fresh water and perform a perform

a purging procedure.

Note: See Purging Procedure described in this manual.

003-2237-99

English - 11

D) Turn Master Switch OFF.

Press and hold the foot control

pedal until all pressure is released.

DA2538i

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 12

DA255901i

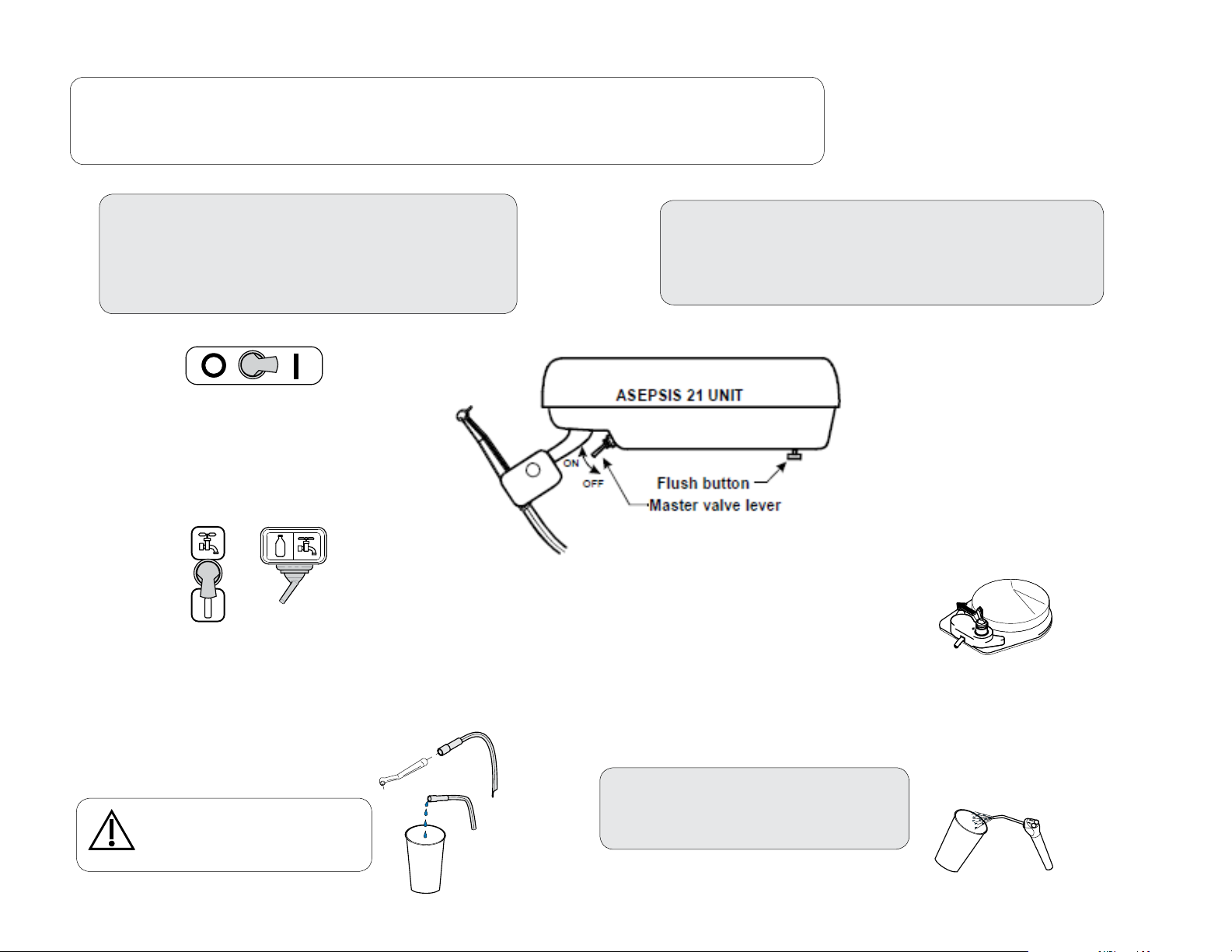

Purging Procedure for the Delivery

NOTE:

The purging procedure removes debris from the tubing to the handpieces and syringe.

Performing this procedure frequently may help reduce the accumulation of biofilm on your instruments.

To begin the purging procedure...

A) Turn Master Switch ON.

B) Turn Water Selector Switch to bottle setting

C) Move the foot control switch to the water setting.

D) Disconnect handpiece from tubing.

Master

Switch

SLIDE

ON

Position

Water

Selector

Switch

Flush the tubing to the handpieces ...

A) Press and hold the foot control pedal for 30 seconds.

B) Press and hold the flush button for 30 seconds.

C) Repeat for all tubing to the handpieces.

Water

Caution

Hold the tubing and syringe over a

container or drain while flushing.

003-2237-99

Flush the Syringe Tubing...

A) Press and hold both syringe buttons

(air and water) for 30 seconds.

English - 12

Foot Control Switch

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 13

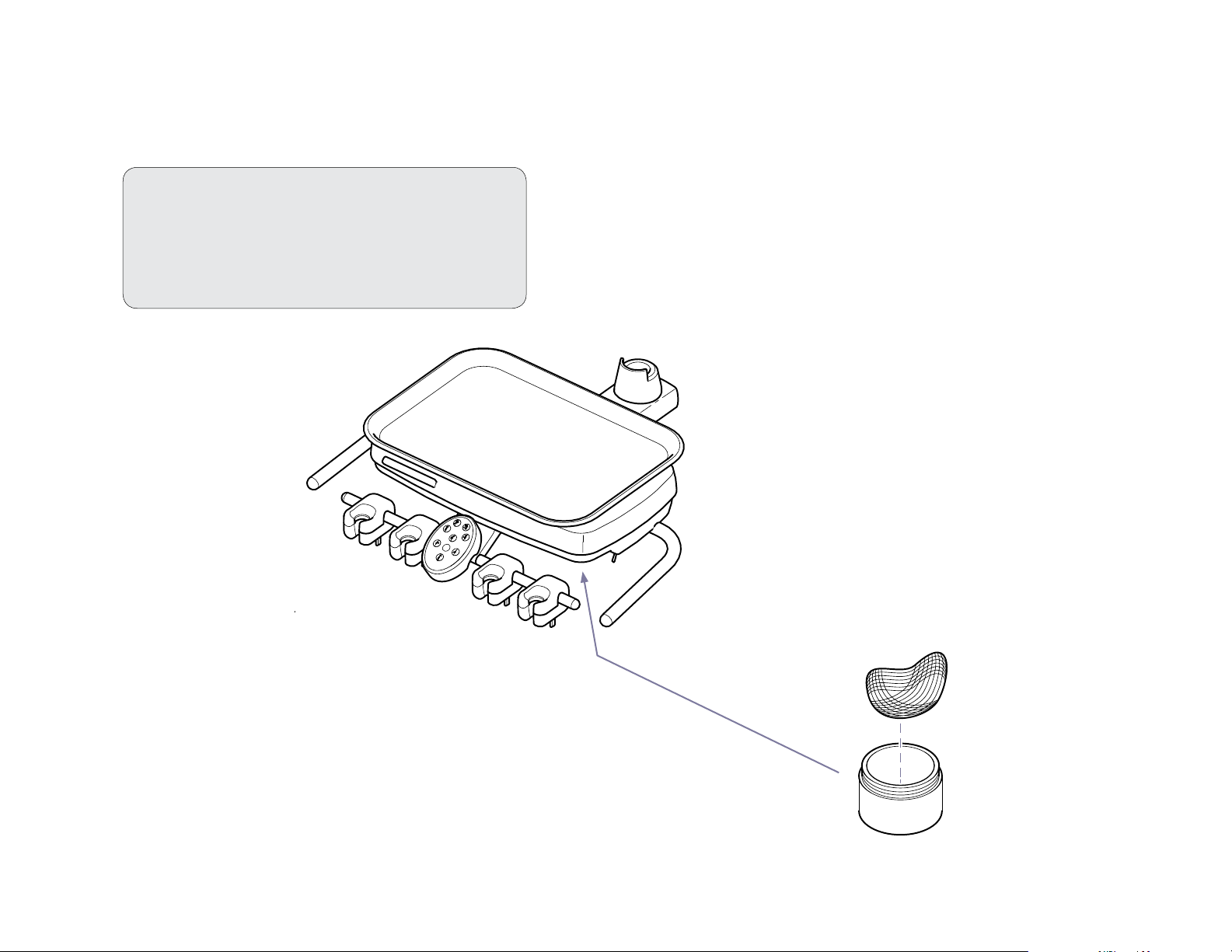

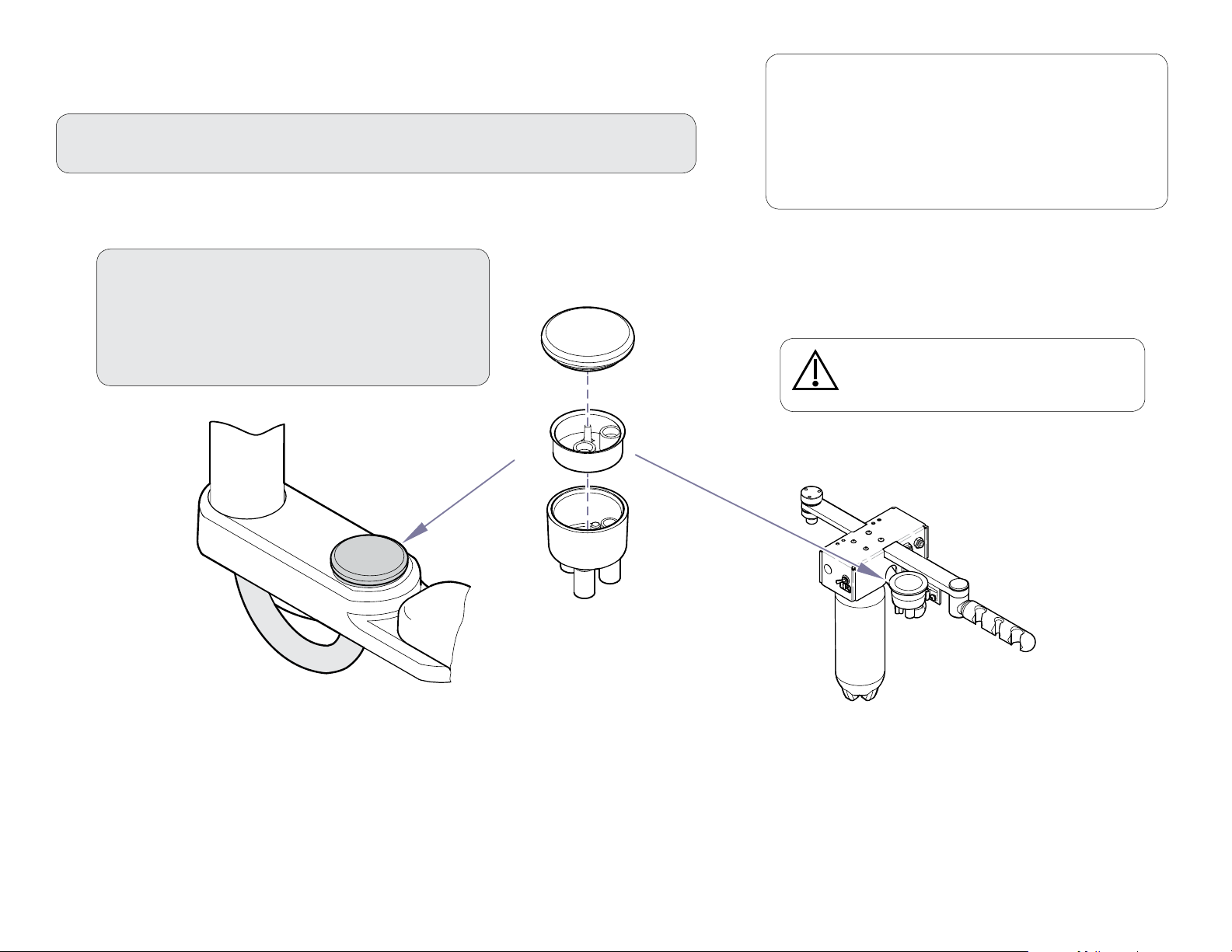

Air/Oil Separator - Cleaning and Maintaining

Periodically check the uid level in the air / oil separator container.

When the container is approximately 2/3 full, clean the air/oil

separator as shown below.

To clean the air/oil separator...

A) Turn master ON/Off switch Off.

B) Remove (unscrew) air/oil separator container.

C) Dispose of the fluid and saturated gauze.

D) Disinfect container and mounting cap.

E) Install clean gauze and reinstall the container.

003-2237-99

English - 13

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 14

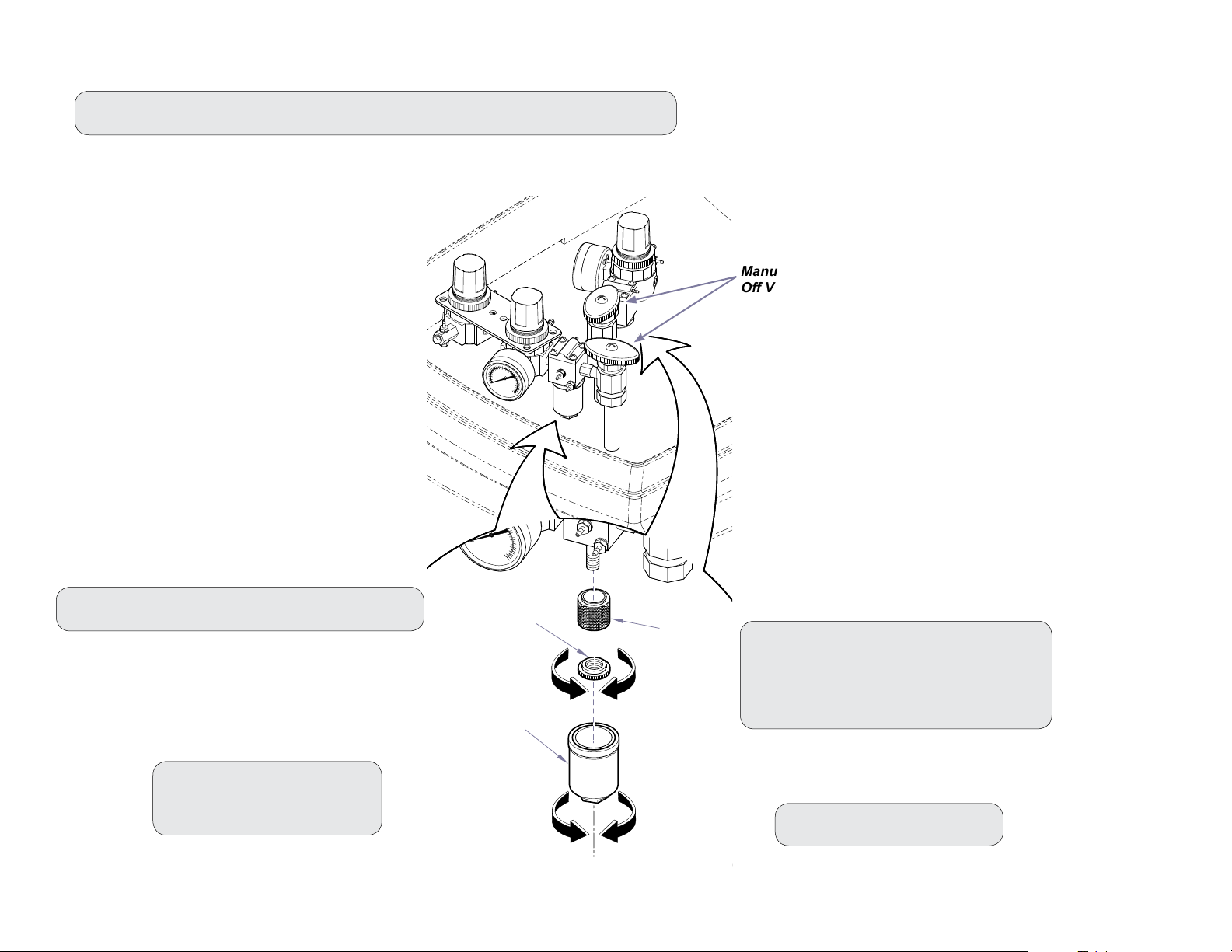

Maintaining and Replacing the Regulator Filters

40

60

80

100

20

0

1

2

3

5

6

7

4

0

Step 1: Shut off manual valves to turn off water and air supplies to the operatory.

40

60

3

2

4

20

1

5

80

0

0

6

7

100

Manual Shut

O Valves

Step 3: Unscrew retainer nut and remove filter.

Step 2: Unscrew filter cap.

Note: Use 9/16” wrench.

003-2237-99

Retainer Nut

Filter Cap

English - 14

Filter

KA947500

Step 4: Install new filter.

Secure with retainer nut.

Note: Install the filter & retainer nut with the ridged

side up (as shown).

Step 5: Reinstall filter cap.

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 15

Assistant’s Units - Cleaning

To clean the facility vacuum system...

Refer to the instructions provided by the vacuum system’s manufacturer.

To clean the solids collector...

A) Turn facility vacuum OFF.

B) Remove lid and basket.

C) Clean basket and housing.

D) Reinstall basket and lid.

Note:

Every dental practice is different, and no single

disinfectant is the best choice for every facility.

See the list of organizations that may assist you in

choosing the best disinfectants available for your

practice, in the front of this manual.

Caution

Always dispose of biohazardous

debris according to local regulations.

003-2237-99

English - 15

DA178800i

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 16

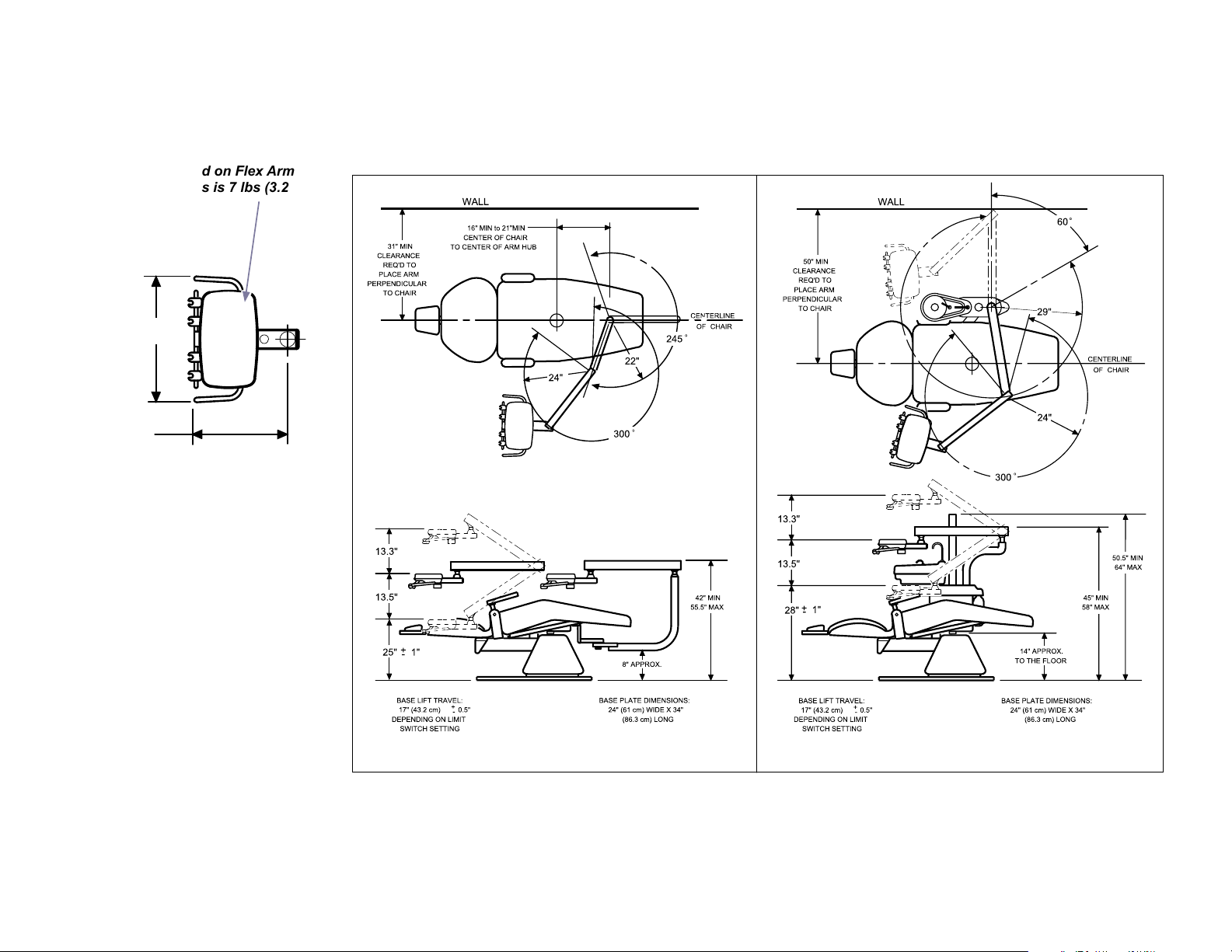

Dimensions / Range of Motion

Chair Mounted Units

Maximum load on Flex Arm

mounted units is 7 lbs (3.2 KG)

18.12"

14.3"

Asepsis 21

Delivery Head

003-2237-99

CONCEPT LR UNIT CHAIR MOUNTED CONSOLE UNIT

English - 16

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

KA940200

Page 17

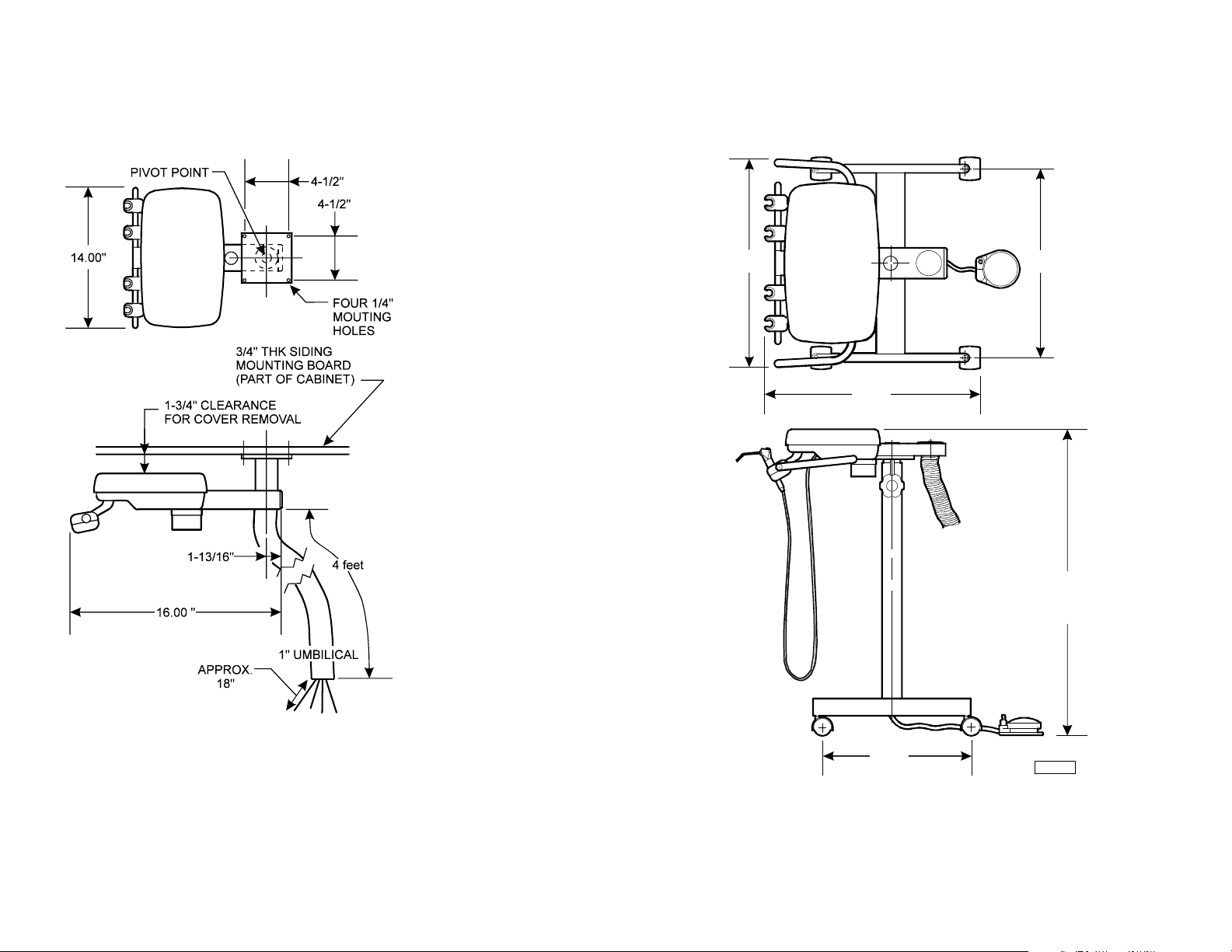

Dimensions / Range of Motion - continued

18.15"

18.86"

13.00"

28.25"

TO

36.75"

16.50"

AF 1119

Cabinet Mounted Units Doctor’s / Hygienist’s Carts

003-2237-99

English - 17

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 18

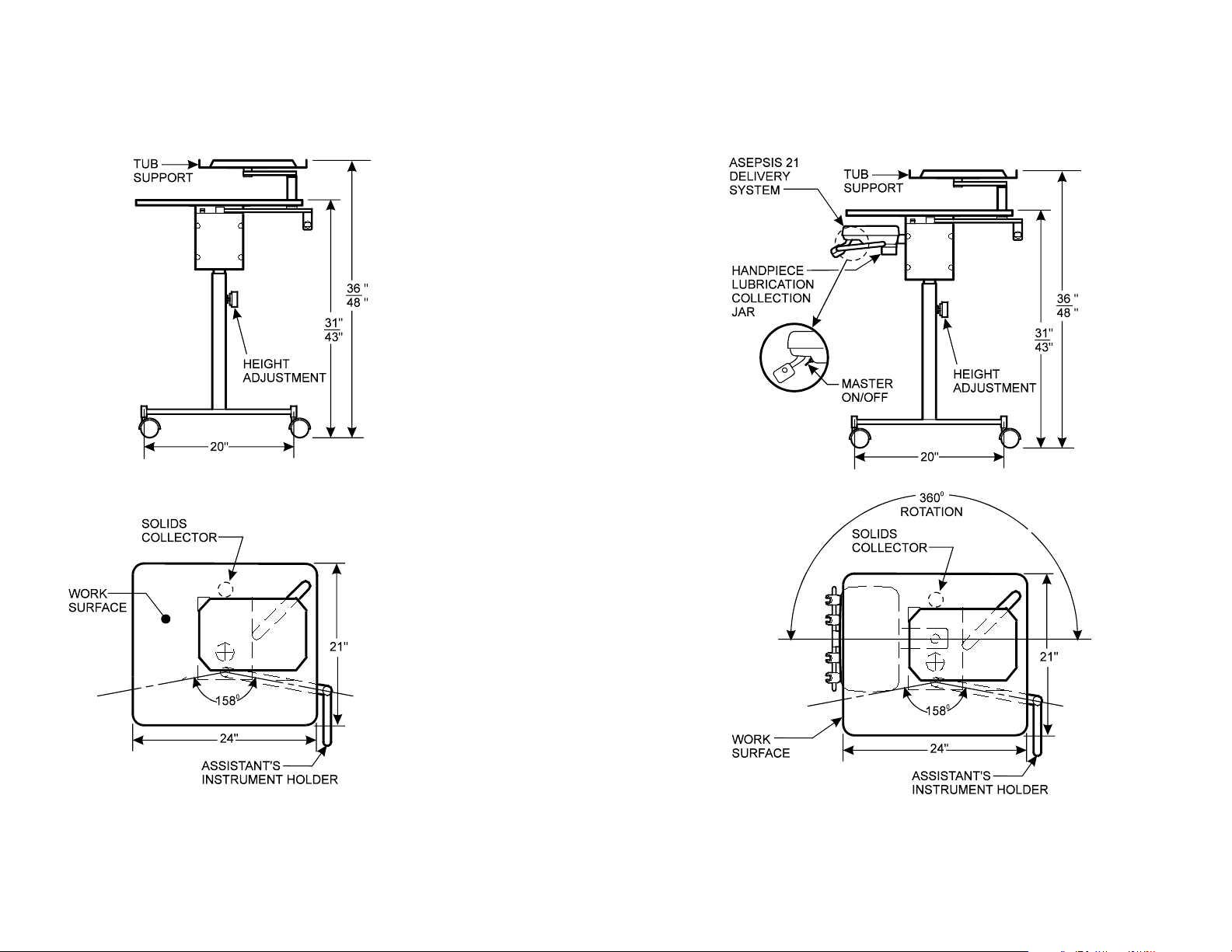

Dimensions / Range of Motion - continued

Assistant’s Cart Left / Right Duo Cart

003-2237-99

English - 18

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 19

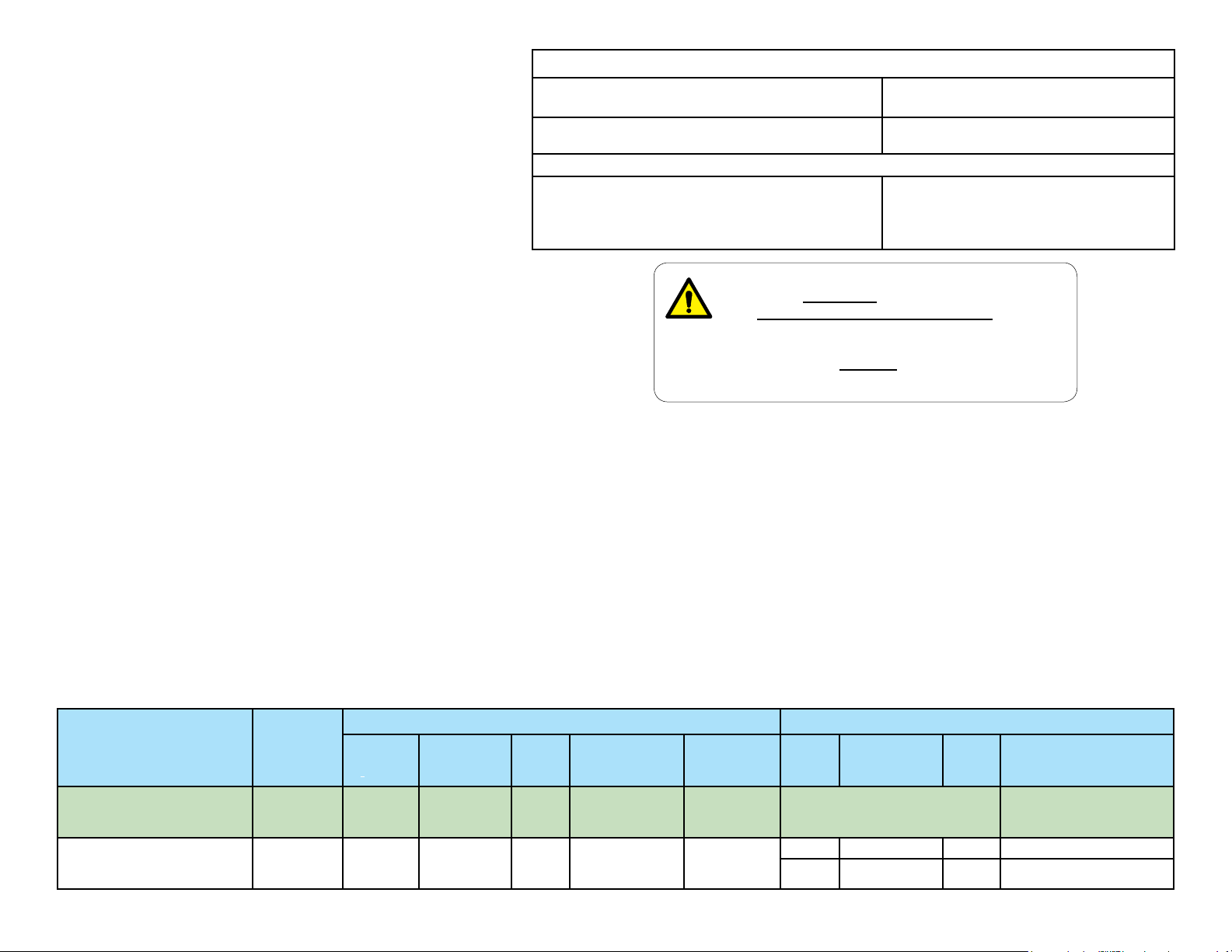

EMC - Manufacturer’s Declaration and Guidance

Guidance and manufacturer’s declaration – electromagnetic emissions

The Midmark Procenter Unit dental device is intended for use in the electromagnetic environment speci ed below. The customer or the user of the Midmark

Procenter Unit dental device should assure that it is used in such an environment.

Emissions Test Compliance Electromagnetic environment – guidance

RF Emissions CISPR 11 Group 1 The Midmark Procenter Unit dental device uses RF energy only for its internal functions.

Therefore, its RF emissions are very low and are not likely to cause any interference in nearby

electronic equipment.

RF Emissions CISPR 11 Class A The Midmark Procenter Unit dental device is suitable for use in all establishments, including

Harmonic emissions IEC 61000-3-2 Class A

domestic establishment and those directly connected to the public low-voltage power supply

network that supplies buildings used for domestic purposes.

Voltage uctuations/ icker emissions

IEC 61000-3-3

Complies

Recommended separation distances between portable and mobile RF communications equipment and the

Midmark Procenter Unit dental device

The Midmark Procenter Unit dental device is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer

or the user of the Midmark Procenter Unit dental device can help prevent electromagnetic interference by maintaining a minimum distance between portable and

mobile RF communication equipment (transmitters) and the Midmark Procenter Unit dental device as recommended below, according to the maximum output

power of the communications equipment.

Radiated maximum output

power of transmitter W

0.01 0.12 0.12 0.23

0.1 0.37 0.37 0.74

1 1.17 1.17 2.34

10 3.69 3.69 7.38

100 11.67 11.67 23.34

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be estimated using the

equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter

manufacturer.

150 kHz to 80 MHz

d = 1.2 x √P

Separation distance according to frequency of transmitter m

80 MHz to 800 MHz

d = 1.2 x √P

800 MHz to 2.5 GHz

d = 2.3 x √P

NOTE 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is a ected by absorption and re ection from structures, objects and

people.

003-2237-99

English - 19

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 20

Guidance and manufacturer’s declaration – electromagnetic immunity

The Midmark Procenter Unit dental device is intended for use in the electromagnetic environment speci ed below. The customer or the user of the Midmark

Procenter Unit dental device should assure that it is used in such an environment.

Immunity Test

Electrostatic discharge (ESD)

IEC 61000-4-2

Electrical fast Transient / burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips, short interruptions

and voltage variations on power

supply input lines

IEC 61000-4-11

IEC 60601

Test Level

± 6 kV contact

± 8 kV air

± 2 kV for power

supply lines

± 1 kV for input/output

lines

±1kV line(s) to line(s)

±2kV lines(s) to earth

<5% U

(>95% dip in U

T

T

for 0.5 cycle)

40% U

T

(60% dip in UT

for 5 cycles)

70% UT

(30% dip in UT

for 25 cycles)

Compliance Level Electromagnetic environmental - guidance

± 6 kV contact

Floors should be wood, concrete or ceramic tile. If oors are covered with

synthetic material, the relative humidity should be at least 30%.

± 8 kV air

± 2 kV for AC and DC

power lines

Mains power quality should be that of a typical commercial or hospital

environment.

I/O lines not tested, all

less than 3 meters

±1kV line(s) to line(s)

Mains power quality should be that of a typical commercial or hospital

environment.

±2kV lines(s) to earth

V Dip >30% of UT

for 500ms

Mains power quality should be that of a typical commercial or hospital

environment. If the user of the Midmark Procenter Unit dental device

requires continued operation during power mains interruptions, it is

V Dip < 60% of UT

for 100ms

recommended that the Midmark Procenter Unit dental device be powered

from an uninterruptible power supply or a battery.

V Dip > 95% of UT

for 5000ms and 10ms

Power frequency (50/60 Hz)

magnetic eld

IEC 61000-4-8

NOTE: U

003-2237-99

is the a.c. mains voltage prior to application of the test level.

T

<5% UT

(>95% dip in UT

for 5 s)

3 A/m 3 A/m Power frequency magnetic elds should be at levels characteristic of a

typical location in a typical commercial or hospital environment.

English - 20

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 21

Guidance and manufacturer’s declaration – electromagnetic immunity

The Midmark Procenter Unit dental device is intended for use in the electromagnetic environment speci ed below. The customer or the user of the Midmark

Procenter Unit dental device should assure that it is used in such an environment.

Immunity Test

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

IEC 60601

Test Level

3V rms

150kHz to 80MHz

3V/m

80MHz to 2.5GHz

Compliance Level Electromagnetic environmental - guidance

Portable and mobile RF communications equipment should be used no

closer to any part of the Midmark Procenter Unit dental device including

cables, than the recommended separation distance calculated from the

equation applicable to the frequency of the transmitter.

Recommended separation distance:

3V d=1.2 x √P

3V/m d= 1.2 x √P 80 MHz to 800 MHz

d= 2.3 x √P 800 MHz to 2.5 GHz

Where P is the maximum output power rating of the transmitter in watts

(W) according to the transmitter manufacturer and d is the recommended

separation in meters (m).

Field strength from xed RF transmitters, as determined by the

a

electromagnetic site survey,

Should be less than the compliance level

in each frequency range. b Interference may occur in the vicinity of

equipment marked with the following symbol:

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is a ected by absorption and re ection from structures, objects and

people.

a

Field strengths from xed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur radio, AM and FM

radio broadcast and TV broadcast cannot be predicted theoretically with accuracy. To assess the electromagnetic environment due to xed RF transmitters,

an electromagnetic site survey should be considered. If the measured eld strength in the location is which the Midmark Procenter Unit dental device is used

exceeds the applicable RF compliance level above, the Midmark Procenter Unit dental device should be observed to verify normal operation. If abnormal

performance is observed, additional measures may be necessary, such as re-orienting or relocating the Midmark Procenter Unit dental device.

b

Over the frequency range 150kHz to 80MHz, eld strengths should be less than 3 V/m.

003-2237-99

English - 21

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 22

Warranty Information

Midmark Limited Warranty - Dental Products

SCOPE OF WARRANTY

Midmark Corporation (“ Midmark”) warrants to the original retailpurchaser that it will atMidmark's

option repair or replace components ofthe dentalproducts manufactured byMidmark (exceptfor

componentsnot warranted under "Exclusions") that are defective in material or workmanship under

normal use and service. Midmark'sobligation under this limite d warranty is limited to the repair or

replacement of the applicable components.This limited warranty shall only apply to defectsthat are

reported to Midmark within the applicable warranty period and which, upon examination by Midmark,

prove to bedefective. This warranty extends onlyto the fir st retail purchaser of a product and is not

transferable or assignable. Replacement components or products may be used and/or refurbished

componentsor products,provided they are of like quality and specificationsas new componentsor

products.

APPLICABLE WARRANTY PERIOD

The applicable warranty period, measured from the dateof delivery to the originaluser, shall be as

follo ws: EffectiveMarch 1, 2018these applicable warranty periods are measured from the date of

invoice to the original user, shall be as follows:

1. OPERATORY PRODUCTS

a. Five (5) years for all products (except for the items in (b) through (e)).

b. Two(2) years for upholstery (chairs and stools) .

c. “KINK-VALVE” module carriesa ten(10) year warranty.

d. The original light bulb on a new light carries a one (1) year warranty.

e. Accessorie s notmanufactured byMidmark are excluded including but not limited to Bien Air

handpiecesystems, DentsplyCavitron scaler, Satelec scaler and curing light, and Sopro

cameras.

2. ORAL SURGERY PRODUCTSare warranted for a periodof one(1) year.

3. STERILIZER PRODUCTS are warranted for a period of one (1) year.

4. ULTRASONIC CLEANER PRODUCTS are warranted for a period of two (2) years.

5. AIR AND VACUUM PRODUCTS

a. PowerAir® oil- less compressors– Five (5) years or 3,500 hours of use, whichever occurs first.

b. PowerVac® andPowerVac® G dry vacuums – Five (5) years or 10,000 hours of use,

whichever occurs fir st (except that the vacuum pump warranty term is ten (10) yearsor 20,000

hours of use, whichever occur s first).

c. Classic Series®wet-ring vacuums – F ive (5) years or 10,000 hours of use,whichever occurs

first.

d. PowerMax surgicalsuction – Two (2) years.

e. Hg5 Series Amalgam Separator - One (1) year.

(1) year.

6. SYNTHESIS™ DENTAL CASEWORK AND ARTIZAN® EXPRESSIONS PRODUCT

a. Five (5) years for all products and components including door and drawer fronts, caster s and

slides, except for the items in (b), (c) and (d).

b. Three ( 3) years for electricalcomponentssuch as task lights/LED lights, cords, controlsand

accessories.

c. Two (2) years for sliding track monitor mount and components and upholstery. (d) One (1)

year for countertopsand resin, including accessories.

(f) Midmark manufactured accessor ies - One

7. IMAGING PRODUCTS are warranted for a period of two (2) years except for the ClearVision CR

reader which is warranted for a period of one ( 1) year.

8. MIDMARK Replacement Parts andAccessories carry a ninety (90) day warranty

EXCLUSIONS

Th is warranty does not cove r and Midmark shall not be liab le for the following;

1.

defects,damage or other conditions caused, in whole or in part, by misuse, abuse,

negligence, alteration,accident, freight damage, negligent storage, tampering or failur e to

seekand obtain repair or replacementin a timely manner;

2.

products which are not installed, used, and properly cleaned and maintained as required or

recommended in the Midmark "Installation" and/or "Installation/OperationManual" for the

applicable product, including the specified structural and operationalenvironment conditions

and electrical power requirements;

3.

products considered to be of a consumable or sterile nature;

4.

accessories or parts not manufactured by Midmar k;

5.

charges by anyone for adjustments,repairs, replacement parts, installa tion or other work

performed upon or in connection with such products which are not expre ssly authorized in

wr itin g in advance byMidmark

6.

costs and expenses of routine maintenance and cleaning;

7.

representations and warranties made by any per son or entity other than Midmark;

8.

matchingof color, grain or texture except to commer cially acceptable standards;

9.

changesin color caused by natural or artificial light ;

10.

custom manufactured products;

11.

alterationsor modifications to the product by anyperson or entity other than Midmark; and

12.

Products that wouldotherwise by covered under Sections1 and2 ofthis limited warranty, but

are acquired: (i) from a person or entity that is notMidmark or one ofits authorizeddealers;

or (ii) from a Midmark dealer that is not authorized to sell the product at issue in the

geographic territorywhere the purchaser is located, or is not authorized to sell the product at

issue with in the medical, animal

purchaser intendsto use the product.

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER

MIDM ARK'S ONLY OBLIGAT ION UNDER THIS LIMITED WARRANTY IS THE REPAIR OR

REPLACEMENT OF D EFECTIVE PARTS. MIDMARK SHALL NOT BE LIABLE F OR AND HEREBY

DISC LAIMS ANY DIRECT, SPECIAL, INDIRECT, INCIDENTAL, EXEMPLARY OR

CONSEQUEN TIAL DAMAGES OR DELAYS, INCLUDING, BUT NOT LIMITED TO, D AMAGES

FOR L OSS OF PROFITS OR INCOME, LOSS OF USE, DOWNTIME, COVER AND EMPLOYEE

OR INDEPENDENT CONTRACTOR WAGES, PAYMENT S AND BENEFIT S.

WARRANTY DISCLAIMER

THIS LIMIT ED WARRANTY IS MIDMARK'S ON LY WARRANTY AND IS IN LIEU OF ALL OT HER

WARRAN TIES, EXPRESS OR IMPLIED.MIDMARK MAKES NO IMPLIED WARRAN TIES OF ANY

KIND INCLUDING ANY IMPLIED WARRAN TIES OF MERC HANTABIL ITY OR FIT NESS FOR A

PARTICULAR PURPOSE. THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT

OF DEFECTIVE PARTS.

STATUTE OF LIMITATIONS

No action my be brought against Midmark for breach of this limited warranty, or implied warranty, if

any, or for any other claim ar ising out of or relating to the products, more than ninety (90) days

follo wing expiration of the limited w arranty period.

health or dental market, asthe case may be, in which

003-2237-99

English - 22

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 23

003-2237-99

English - 23

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 24

Midmark Corporation

60 Vista Drive

Versailles, OH 45380 USA

1-800-643-6275

1-937-526-3662

www.midmark.com

TP200 20-42-FO-00012 Rev A1 C2169

Page 25

Guía del usuarioGuía del usuario

Introducción ......................................... 2

Símbolos............................................... 2

Uso previsto ......................................... 3

Interferencia electromagnética ............. 3

Solicitud de servicio técnico ................. 3

Especicaciones/Tabla de

cumplimiento de las normativas ........ 3

Eliminación de equipos ........................ 3

Condiciones de transporte,

almacenamiento y funcionamiento ... 3

Válvulas de cierre manual/

Válvulas de regulación de presión ... 4

Controles .............................................. 5

Funcionamiento ................................... 7

Limpieza y mantenimiento .................... 8

Unidades instaladas en el sillón ...... 16

Unidades montadas en el armario... 17

Carros de doctor/higienista.............. 17

Carro de auxiliar ............................. 18

Carro dúo izquierdo/derecho ........... 18

CEM: directrices y declaración del

fabricante ............................................ 19

Información sobre la garantía ............. 22

Introducción ......................................... 2

Símbolos............................................... 2

Uso previsto ......................................... 3

Interferencia electromagnética ............. 3

Solicitud de servicio técnico ................. 3

Especicaciones/Tabla de

cumplimiento de las normativas ........ 3

Eliminación de equipos ........................ 3

Condiciones de transporte,

almacenamiento y funcionamiento ... 3

Válvulas de cierre manual/

Válvulas de regulación de presión ... 4

Controles .............................................. 5

Funcionamiento ................................... 7

Limpieza y mantenimiento .................... 8

Unidades instaladas en el sillón ...... 16

Unidades montadas en el armario... 17

Carros de doctor/higienista.............. 17

Carro de auxiliar ............................. 18

Carro dúo izquierdo/derecho ........... 18

CEM: directrices y declaración del

fabricante ............................................ 19

Información sobre la garantía ............. 22

Asepsis 21®

midmark.com

Sistemas de suministro

English

Español

Français

© 2016 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

TP202 20-42-FO-00014 Rev A1 C2169

003-2237-99

Page 26

Introducción

El sistema Asepsis 21 Delivery se ha diseñado y fabricado teniendo en cuenta tanto las necesidades del profesional como el cuidado del paciente. Está construido con

materiales de la máxima calidad para garantizar años de vida útil sin incidencias.

El cabezal del instrumento permite controlar un máximo de cinco piezas de mano con motor de aire y una jeringa de tres vías. Las piezas de mano se sujetan en

sus respectivos soportes, que pueden rotarse para colocarlos en la posición que usted preera. Cuando retire una pieza de mano de su soporte, se seleccionará

automáticamente para que pueda manejarla con el pedal de control.

Su nuevo Asepsis 21 también cuenta con un sistema de recogida de lubricante de las piezas de mano. Los escapes de las piezas de mano están conectados a un

recipiente colector situado en la parte inferior central del cabezal del instrumento. Este recipiente colector puede retirarse para su vaciado y limpieza simplemente

desatornillándolo de la unidad. El recipiente colector debe inspeccionarse a diario y vaciarse cuando haya acumulado aproximadamente 0,5 pulgadas o 1,27 cm de

aceite.

La forma aerodinámica del cabezal del instrumento facilita su limpieza y su recubrimiento para el control de infecciones.

Símbolos

Estos símbolos pueden aparecer en su equipo o en los manuales. Los avisos de advertencia y precaución se indicarán donde correspondan en el manual.

ADVERTENCIA

Indica una situación potencialmente peligrosa que,

de no evitarse, podría ocasionar lesiones graves.

Precaución

Indica una situación potencialmente peligrosa que, de

no evitarse, podría tener como resultado lesiones leves

o moderadas. También puede usarse para alertar contra

prácticas peligrosas.

Advertencia sobre el equipo

Indica una situación potencialmente peligrosa que, de

no evitarse, podría provocar daños al equipo.

NOTA

Desarrolla un procedimiento, una práctica o

una condición.

Pieza aplicada

Tipo B

Pieza aplicada

Tipo BF

Toma de tierra de

protección

Orientación correcta para el

transporte

Frágil

Número de serie

Número del catálogo

Fabricante

Consulte el manual de

instrucciones o folleto

Límite de presión

100 F

Límite de tempera-

38 C

23 F

-5 C

tura

Límite

de humedad

Altura máxima de

apilamiento (se reere a

«n°» número de bultos)

Mantener seco

003-2237-99

Español - 2

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 27

Uso previsto

Los sistemas dentales de Midmark suministran aire, agua y succión

a los estomatólogos para que puedan utilizar las piezas de mano,

las jeringas y los accesorios autorizados por Midmark durante las

exploraciones e intervenciones dentales.

Interferencia electromagnética

Los componentes del equipo dental de Midmark están

diseñados y construidos para reducir al mínimo las interferencias

electromagnéticas con otros dispositivos. Sin embargo, si se

observan interferencias entre este equipo y otros dispositivos, saque

de la habitación el dispositivo que produce la interferencia o conecte

el producto a un circuito aislado.

Solicitud de servicio técnico

Todas las solicitudes de servicio técnico deben dirigirse a un

distribuidor autorizado de Midmark. Al solicitar servicio técnico, debe

proporcionar la información siguiente:

Modelo, número de serie

Fecha de compra

Descripción del fallo

Especicaciones

Límites de presión de aire/agua: Aire: 80/100 PSI

Agua: 30/50 PSI

Clasicaciones Clase 1, parte aplicada tipo B,

Accesorios opcionales:

Tubos y conectores de la pieza de mano indicados

para uso con piezas de mano accionadas por aire que

cumplen las normas ISO 7785-1 o ISO 7785-2

equipo ordinario. [IPXO]

Pieza aplicada Tipo B

ADVERTENCIA

El equipo no debe utilizarse en presencia de

mezclas anestésicas inflamables con oxígeno, aire

u óxido nitroso.

Aclaración: el equipo puede utilizarse en presencia de

oxígeno, aire u óxido nitroso.

Eliminación de equipos

Al nal del ciclo de vida del producto, tanto la unidad como sus accesorios y otros

materiales fungibles podrían estar contaminados por efecto de su uso habitual.

Consulte la normativa local para saber cómo deshacerse adecuadamente del equipo

y otros materiales fungibles.

Descripción

Sistemas Asepsis 21 Delivery Sillón Ultra

Sistemas Asepsis 21 Delivery

003-2237-99

Montaje

(tipo)

Carros o

sillón Knight

UL

60601-1

(2.ª edición)

• •

CAN/CSA

22.2,

#601.1 - M90

Condiciones de transporte, almacenamiento y

funcionamiento

Temperatura de transporte/almacenamiento: De -5 °C a +38 °C (de 23 °F a 100 °F)

Humedad relativa: .............................. De 10 % a 90 % (sin condensación)

Presión atmosférica: ............. de 50 kPa a 106 kPa (de 7,2 PSI a 15,3 PSI)

Límites de temperatura ambiente: ..... De 15 °C a 35 °C (de 59 °F a 95 °F)

Conformidad con: Clasicaciones eléctricas:

ES/IEC/

EN

60601-1

(regulaciones EMC)

• • •

EN

60601-1-2

CAN/CSA

22.2,

#60601.1

Voltaje

+/- 10 %

120 15 A 50/60

240 7,5 A 50/60

Potencia

conectada

máxima

N/D

TP202 20-42-FO-00014 Rev A1 C2169

Ciclos

(Hz)

Modelo de alimentación

N.º: 153808-001, -002

Español - 3

© Midmark Corporation 2016

Page 28

Válvulas de cierre manual/Válvulas de regulación de presión

Las válvulas de cierre manual permiten detener el suministro de aire y agua en la entrada al equipo. Se recomienda hacerlo durante los

periodos prolongados de inactividad (por ejemplo, en vacaciones) o en caso de error de funcionamiento del equipo.

Las válvulas de regulación de presión permiten controlar la presión de aire y agua suministrada a los instrumentos del sistema de suministro.

Regulador de la

botella de agua

NO AJUSTAR

Indicador del

regulador de aire

Perilla de

ajuste del

regulador

de aire

40

60

3

2

4

20

1

5

0

0

7

Manómetro

de agua

Válvula

reguladora

de agua

corriente

Las válvulas de cierre

se giran 1/4 de vuelta

en sentido horario

para cerrarlas.

corriente

Válvula manual de

cierre del agua

Para ajustar los reguladores de presión...

A) Tire hacia arriba de la perilla y gírela para ajustar.

B) Observe el indicador del regulador mientras gira la perilla hasta

80

6

100

Válvula manual

de cierre del aire

alcanzar la configuración deseada.

Gírelas en sentido horario

para aumentar la presión

Gire en sentido antihorario

para reducir la presión

Conguraciones recomendadas:

Ajuste del regulador de

agua corriente

Ajuste del regulador de

presión del aire

Conguración del

regulador de la botella

de agua

003-2237-99

30 PSI

80 PSI

Conguración de

fábrica: 30 PSI

NO debe cambiarse

Advertencia sobre el equipo

Los componentes dentales han sido

diseñados para funcionar en las

configuraciones recomendadas. El rendimiento

deficiente del equipo o los daños en el mismo

pueden provocar que no se mantenga la

configuración recomendada.

Español - 4

4

80

5

6

7

0

100

KA947002

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 29

Controles

Cabezal del instrumento Asepsis 21: Debajo de la cubierta de cierre magnético, que garantiza la protección contra contaminación, se encuentra un juego

completo de ajustes para las piezas de mano y jeringas. Levante cualquiera de las esquinas posteriores de la cubierta para retirarla fácilmente. Todos los

controles están etiquetados con símbolos para identicar su función.

1 2 3

Volumen de agua de refrigeración de la

pieza de mano

Ajusta la cantidad de agua de refrigeración de cada

pieza de mano.

4 5 6

Ajustes de la presión de aire

Permiten ajustar individualmente cada una

de las piezas de mano. Ajuste la presión

máxima de cada pieza de mano indicada en

el manómetro. Consulte la información del

fabricante para realizar un ajuste adecuado.

7

Ajustes del aire de la jeringa

Controla el volumen de aire de la jeringa y el

efecto de los patrones del spray de agua.

CABEZAL DEL INSTRUMENTO ASEPSIS

21 SIN LA CUBIERTA SUPERIOR

DE SERIE

UBICACIÓN

NÚMERO

9

Ajustes del aire frío

Controla el volumen de refrigeración que se

da paso a cada pieza de mano. Afecta a los

patrones del spray de agua y de aire de la

pieza de mano. Si la pieza de mano cuenta

con una conexión de aire frío propia, este

ajuste no tendrá efecto y puede cerrarse por

completo.

10

Manómetro de las piezas de mano

Indica la presión de cada pieza de mano

cuando se están utilizando.

11 12 13

Cierres magnéticos

Mantienen la cubierta en su sitio.

8

Ajustes del volumen de agua de la jeringa

Controla el volumen de agua de la jeringa y el efecto de

los patrones del spray de agua.

003-2237-99

Español - 5

14

Botones de enjuague del agua de

refrigeración de la pieza de mano

Controlan la válvula de enjuague del agua de

refrigeración. Se encuentran en la parte inferior del

cabezal de suministro.

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 30

Controles (continuación)

Controles externos

Válvula principal de encendido/apagado

Se encuentra en la parte inferior central del cabezal

del instrumento, justo detrás de la barra de soporte de

las piezas de mano. Este interruptor de dos posiciones

controla la entrada y salida principal de aire y agua.

(Consulte la siguiente imagen).

Control de salida y ujo del agua

Se encuentra en el panel frontal de la consola. Esta

salida suministra agua a los tubos hidrocoloide u otros

accesorios. El agua se maneja con una perilla de

control de ujo situada junto a la salida de agua. Si gira

la perilla en el sentido horario, reducirá el ujo de agua.

Si lo hace en sentido antihorario, el ujo aumentará.

Activación automática de la pieza de mano

Las válvulas de estrangulamiento automáticas («kink valve»)

están diseñadas para permitir la activación de la pieza de

mano seleccionada cuando se retira de jación. Se dará

paso al aire a la pieza de mano retirada cuando se pulse el

pedal de control.

El punto azul indica

operación en húmedo

PALANCA DE

ACTIVACIÓN DE LA

VÁLVULA PRINCIPAL

Válvula de apertura/cierre del agua

Se encuentra en el pedal de control. Este

interruptor da paso al agua del spray

refrigerante de la pieza de mano cuando

se acciona hacia la posición «encendido»

(punto azul) y se pulsa el pedal (tallado en

húmedo). Cuando la válvula está en posición

«apagado», no se suministrará agua a ninguna

pieza de mano. (Consulte la siguiente imagen).

Bloqueo del brazo

(solo en unidades instaladas en el sillón)

Se encuentra en la parte inferior del cabezal del

instrumento junto al asa. Este interruptor de dos

posiciones controla el mecanismo de bloqueo del brazo.

Instrumental del auxiliar

El eyector de saliva, el evacuador de alto volumen y la

jeringa conforman el instrumental estándar de la unidad.

Se encuentran en una jación móvil de la consola. La

punta de la jeringa, el montaje de la válvula del eyector

de saliva y el montaje del evacuador de alto volumen se

pueden retirar fácilmente para su esterilización

Interruptor de selección de agua

Se encuentra en la parte delantera de la consola

o en el brazo LR permiten seleccionar la fuente de

agua del sistema de suministro. Puede seleccionar

agua corriente (del grifo) o agua procedente de la

botella del sistema hídrico autónomo.

Agua corriente

Sistema hídrico

autónomo

003-2237-99

Pedal de control húmedo/seco

El pedal de control de disco hace funcionar

la pieza de mano seleccionada a diferentes

velocidades en función de la presión ejercida

en el disco con el pie. Con el selector de agua

de refrigeración se puede tallar en húmedo con

tan solo mover un pie. Si se presiona el pedal

con el pie, se pondrá en funcionamiento la

pieza de mano seleccionada. Si el interruptor

está en posición «encendido», se accionará

además el spray de agua. (Consulte la

siguiente imagen).

Español - 6

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 31

Funcionamiento

Las válvulas de estrangulamiento automáticas («kink valve») están diseñadas para

permitir la activación de la pieza de mano seleccionada cuando se retira de jación.

Se dará paso al aire a la pieza de mano retirada cuando se pulse el pedal de control.

(Consulte la siguiente imagen).

Funcionamiento básico:

VÁLVULA DE ESTRANGULAMIENTO

Paso 1: Active la palanca de la

válvula principal situada en la

parte inferior del cabezal del

instrumento Asepsis 21.

Paso 2: Coloque el interruptor húmedo/

seco del pedal de control en la

posición que desee.

Paso 3: Saque la pieza de mano de su

soporte y pulsa el pedal de control.

Paso 4: Si necesita realizar cambios, levante la

cubierta del cabezal del Asepsis 21 y

ajuste las perillas como desee. (Consulte

el apartado Controles).

PISTÓN

DE AIRE

Cuando la pieza de mano está en su

jación, el pistón de aire mantiene

la válvula de estrangulamiento en la

posición «cerrado».

VÁLVULA DE ESTRANGULAMIENTO

Cuando se saca la pieza de mano

de su soporte, el pistón de aire se

desactiva y permite la apertura de la

válvula de estrangulamiento. En este

momento, podrá manejar la pieza de

mano con el pedal de control.

003-2237-99

Español - 7

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 32

Limpieza, desinfección y mantenimiento

ATENCIÓN

Midmark no aceptará responsabilidad u obligación algunas por ningún resultado,

expreso o implícito. Estas prácticas son sugerencias basadas en la mejor

información disponible en el momento de redactar esta advertencia.

Cuadro de programación del mantenimiento

Zona Frecuencia

Supercies de la unidad Cuando sea necesario

Tubos Cuando sea necesario

Sistemas de vacío Cuando sea necesario

Colector de sólidos Diariamente

Filtros del regulador (aire/agua) Cada 3 meses

Barreras

Las barreras de un solo uso y los artículos desechables reducen de forma notable la necesidad de

emplear desinfectantes químicos y prolongan, por consiguiente, la vida del equipo. El material de la

barrera debe ser impermeable a los líquidos y a la humedad.

Ejemplos de barreras protectoras:

• Cubiertas de plástico (disponibles en el distribuidor o fabricante del equipo)

• Envoltura de plástico transparente

• Bolsas de plástico

• Sábanas de plástico

• Tubos de plástico

• Papel plasticado

• Materiales similares a los enumerados

Procedimientos de limpieza y desinfección

Utilice limpiadores y desinfectantes adecuados para la situación, como agua templada y detergentes

suaves o una solución de agua y lejía al 10 %.

NOTA

Cada consulta dental es diferente y no hay un único desinfectante que sea la mejor opción para

todas las instalaciones. A continuación se enumeran algunas organizaciones que pueden servirle de

ayuda para elegir los mejores desinfectantes disponibles para su consulta.

003-2237-99

Español - 8

Barrera

Barrera

Barrera

DA178400i

¡Lea

cuidadosamente

todas las

etiquetas!

• Organización de Seguridad y

Procedimientos de Asepsia

http://www.osap.org

• Asociación Dental Americana:

http://www.ada.org

• Departamento de Salud y Recursos Humanos

de Centros para el Control y la Prevención de

Enfermedades (CDC):

http://www.cdc.gov

• Asociación Dental Europea:

http://www.eda-eu.org

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 33

Limpieza, desinfección y mantenimiento (continuación)

Barreras

Midmark recomienda el uso de barreras desechables en todos los controles

clínicos que puedan estar en contacto con las manos y los dedos del

doctor durante los procedimientos dentales. El uso de barreras reduce

signicativamente la necesidad de usar limpiadores químicos y, por tanto,

prolongan la vida del equipo.

Use solamente el material de la barrera indicado para ser usado con equipos

dentales. Midmark recomienda el uso de una barrera autorizada por la

FDA, como por ejemplo Cover-all™ de Pinnacle. Siga las instrucciones del

fabricante de las barreras para un uso correcto de estos productos.

Limpieza general

Utilice limpiadores y desinfectantes adecuados para la situación, como agua

templada y detergentes suaves o una solución de agua y lejía al 10 %.

Inspección visual

Después de la limpieza, inspeccione visualmente el producto en busca de

deterioro de cubiertas y paneles de control. No use el sistema dental si nota

una decoloración excesiva, grietas u otros signos de desgaste (consulte las

instrucciones en Contactar con el servicio técnico).

Mantenimiento de las tuberías de agua

Limpieza y desinfección

Además del uso de barreras, Midmark recomienda el uso de un desinfectante/

limpiador registrado por la EPA y aprobado por la FDA, como Cavicide™ para

todos los controles clínicos y supercies que puedan entrar en contacto con

instrumentos dentales durante los procedimientos relacionados.

Siga las instrucciones del fabricante del limpiador/desinfectante para un uso

correcto del producto. Hay que tener cuidado de evitar la aplicación excesiva

y la formación de charcas.

Accesorios de la pieza de mano

Use únicamente los accesorios de la pieza de mano aprobados por la FDA

y consulte las instrucciones del fabricante para su adecuada limpieza y

desinfección. Puede usar una punta de jeringa esterilizable en autoclave o

una única punta de jeringa desechable.

Advertencia sobre el equipo

ESTERILIZACIÓN DE LA PUNTA DE LA JERINGA ESTERILIZABLE EN

AUTOCLAVE

Las puntas de la jeringa esterilizable en autoclave que se adjuntan con

el sistema dental deben esterilizarse antes de su uso con cada paciente, incluido

su primer uso. Asegúrese de enjuagar y limpiar cuidadosamente las puntas de la

jeringa antes de esterilizarlas ya que cualquier suciedad puede reducir la eficacia

de la esterilización. El proceso de esterilización recomendado es el de autoclave de

vapor. Los parámetros de temperatura y presión recomendados son 125 °C (250 °F)

y 106 kPa (15 PSI) durante 40 minutos.

003-2237-99

Español - 9

El mantenimiento de las tuberías de agua es necesario para evitar que el

número de bacterias heterotrócas aumente por encima del nivel deseado.

El nivel deseado para una determinada ubicación debe determinarse en

base a las directrices locales o regionales. Por ejemplo, el Centro de Control

y Prevención de Enfermedades (CDC) de EE.UU. establece que el nivel de

bacterias heterotrócas debe ser igual o inferior a 500 UFC/ml (unidades

formadoras de colonias por mililitro). Midmark recomienda mantener dicho

nivel por debajo de 200 UFC/ml.

El tratamiento puede realizarse de múltiples maneras. En la actualidad,

los métodos más comúnmente utilizados consisten en el uso de tabletas y

sistemas basados en pajitas/cartuchos. Midmark recomienda el uso de un

sistema basado en pajitas/cartuchos que mantenga bajo control el nivel de

bacterias.

También debería llevarse a cabo una revisión regular para garantizar que el

nivel de bacterias heterotrócas no supere el límite deseado. Si el nivel es

superior al deseado, deberá llevarse a cabo un tratamiento de choque de las

tuberías de agua. Cuando lleve a cabo el tratamiento de choque, asegúrese

de revisar con el fabricante que el tratamiento regular que está utilizando

es el adecuado para garantizar la compatibilidad química. La frecuencia

de revisión deberá establecerla en base a su práctica. Como sugerencia,

Midmark recomendaría que comience realizando una revisión mensual, y

realice ajustes en la frecuencia en función de los resultados.

Según el CDC norteamericano, deberá realizar un lavado de rutina de

las tuberías de agua tras cada paciente. Si se usan tabletas en el equipo

Midmark, puede ser necesario realizar un lavado adicional. Las partículas de

las tabletas no disueltas pueden acumularse con el tiempo en determinados

lugares de las tuberías de agua, obstruyendo la tubería y reduciendo el

caudal de agua. Al lavar las tuberías de agua, el caudal de agua es máximo

y debería arrastrar cualquier partícula no disuelta.

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 34

DA101201i

Ayuda sobre limpieza y desinfección

Para obtener ayuda con las instrucciones de limpieza y desinfección, póngase en contacto con el Departamento de servicio técnico de Midmark llamando al

1-937-526-3662. Es útil proporcionar el número de modelo y el número de serie del sistema dental al pedir ayuda.

Puede encontrar información adicional en las siguientes organizaciones:

Organización de Seguridad y Procedimientos de

Asepsia: http://www.osap.org

Asociación Dental Estadounidense:

http://www.ada.org

Limpieza del sistema dental

Departamento de Salud y Recursos Humanos de los Centros para el Control y la

Prevención de Enfermedades (CDC): http://www.cdc.gov

Asociación Dental Europea:

http://www.eda-eu.org

Al comenzar cada jornada...

Llene la botella de agua del sistema autónomo con agua

limpia y realice un procedimiento de purga.

Nota: Consulte el procedimiento de purga descrito en este manual.

Botón de enjuague

Palanca de la válvula principal

Nota:

El agua debe ser potable. No es

necesario utilizar agua destilada.

Para cada paciente nuevo...

Sustituya las puntas, instrumentos y otros utensilios

desechables y realice un procedimiento de purga.

Nota: Consulte el procedimiento de purga descrito en este manual.

003-2237-99

DA2536i

Español - 10

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 35

Limpieza del sistema dental - Al nal de cada jornada...

A) Retire las puntas desechables,

los instrumentos, etc.

B) Limpie y desinfecte el sistema dental (consulte

las instrucciones de Limpieza y desinfección).

DA2536i

C) Llene la botella de agua con agua limpia y realice un

procedimiento de purga.

Nota: Consulte el procedimiento de purga descrito en este manual.

003-2237-99

Botón de enjuague

Palanca de la válvula principal

Español - 11

D) APAGUE el interruptor general.

Mantenga presionado el pedal de

control hasta que se hay liberado

toda la presión.

DA2538i

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 36

DA255901i

Procedimiento de purga para la unidad dental

NOTA:

El procedimiento de purga elimina los restos que hayan quedado desde la manguera a las piezas de

mano y la jeringa.

Este procedimiento a menudo ayuda a reducir la acumulación de una biopelícula en sus instrumentos.

Para comenzar el procedimiento de purga...

A) Encienda el interruptor general.

B) Gire el selector de agua hasta la posición de la botella.

C) Mueva el interruptor del pedal a la posición de agua.

D) Desconecte la pieza de mano de la manguera.

Interruptor

principal

SLIDE

ON

Position

Interruptor de

selección de

agua

Enjuague la manguera de las piezas de mano...

A) Mantenga presionado el pedal de control durante 30 segundos.

B) Mantenga presionado el botón de enjuague durante 30 segundos.

C) Repita para todos las mangueras de las piezas de mano.

Botón de enjuague

Palanca de la válvula principal

Agua

Pedal de control

Precaución

Al enjuagar, mantenga la manguera

y la jeringa encima de un recipiente.

003-2237-99

Enjuague de la manguera de la jeringa...

A) Mantenga presionados ambos botones de la

jeringa (aire y agua) durante 30 segundos.

Español - 12

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 37

Separador de aire y aceite: limpieza y mantenimiento

Compruebe periódicamente el nivel de líquido en el depósito del

separador de aire y aceite. Cuando el recipiente esté lleno hasta

aproximadamente 2/3 partes, limpie el separador de aire y aceite

como se indica a continuación.

Para limpiar el separador de aire y aceite...

A) Apague el interruptor general.

B) Retire (desatornille) el depósito del separador de aire y aceite.

C) Elimine el líquido y la malla saturada.

D) Desinfecte el recipiente y el tapón de montaje.

E) Instale una malla limpia y vuelva a colocar el recipiente.

003-2237-99

Español - 13

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 38

Mantenimiento y sustitución de los ltros reguladores

40

60

80

100

20

0

1

2

3

5

6

7

4

0

Paso 1: Cierre las válvulas manuales para desconectar los suministros de aire y agua al equipo.

40

60

3

2

4

20

1

5

80

0

0

6

7

100

Válvulas

manuales de

cierre

Paso 3: Desenrosque la tuerca de retención y

quite el filtro.

Paso 2: Desenrosque la tapa del filtro

Nota: Utilice una llave de 14 mm (9/16”).

003-2237-99

Tuerca de

retención

Tapa del ltro

Español - 14

Filtro

KA947500

Paso 4: Instale el nuevo filtro.

Fíjelo con la tuerca de retención.

Nota: Instale el filtro y la tuerca de retención con el lado

surcado hacia arriba (como se indica en la imagen).

Paso 5: Vuelva a instalar la tapa del filtro.

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 39

Limpieza de las unidades del auxiliar

Para limpiar el sistema de vacío de la instalación...

consulte las instrucciones facilitadas por el fabricante del sistema de vacío.

Para limpiar el colector de sólidos...

A) Apague el sistema de vacío.

B) Retire la tapa y el cesto.

C) Limpie el cesto y la caja.

D) Vuelva a colocar el cesto y cierre de

nuevo la tapa.

Nota:

Cada consulta dental es diferente y no hay un

único desinfectante que sea la mejor opción

para todas las instalaciones. Consulte la lista de

organizaciones que pueden ayudarle a elegir

los mejores desinfectantes disponibles para su

consulta al principio de este manual.

Precaución

Elimine siempre los restos con peligro

biológico respetando las normativas locales.

003-2237-99

Español - 15

DA178800i

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 40

Dimensiones/Rango de movimiento

Unidades instaladas en el sillón

La carga máxima de las

unidades instaladas en el

brazo exible es de 3,2 kg

(7 libras).

ESPACIO MÍNIMO

DE 78,74 CM (31’’)

PARA COLOCAR

EL BRAZO

EN POSICIÓN

PERPENDICULAR

RESPECTO DEL

SILLÓN

45,72 CM

18.12"

(18,12”)

36,32 CM

14.3"

(14,3”)

ASEPSIS 21

Asepsis 21

CABEZAL DE

Delivery Head

SUMINISTRO

33,78 cm

(13,3”)

34,29 cm

(13,5”)

PARES

ESPACIO MÍNIMO DE

40,64 CM A 53,34 CM

(16'' A 21'') DEL CENTRO

DEL SILLÓN AL CENTRO

DEL BRAZO

LÍNEA CENTRAL

DEL SILLÓN

106,68 cm

(42’’) MÍN.

139,7 cm

(55’’) MÁX.

ESPACIO MÍNIMO

DE 127 CM (50’’)

PARA COLOCAR

EL BRAZO

EN POSICIÓN

PERPENDICULAR

RESPECTO DEL

SILLÓN

33,78 cm

(13,3”)

34,29 cm

(13,5”)

71,12 cm (28”)

± 2,54 cm (1”)

PARES

LÍNEA CENTRAL

DEL SILLÓN

128,27 cm

(50,5”) MÍN.

162,56 cm

(64”) MÁX.

106,68 cm

(42’’) MÍN.

147,32 cm

(58’’) MÁX.

003-2237-99

63,5 cm (25”)

± 2,54 cm (1”)

DESPLAZAMIENTO DE

ELEVACIÓN DE LA BASE

43,2 cm (17'') ± 1,27 cm (0,5'') EN

FUNCIÓN DEL AJUSTE DEL LÍMITE

20,32 cm (14'')

APPR OX. 20,32 CM (8'')

DIMENSIONES DE LA BASE:

61 cm (24'') DE ANCHO X

86,3 cm (34'') DE LARGO

CONCEPT LR UNIT CHAIR MOUNTED CONSOLE UNIT

DESPLAZAMIENTO DE

ELEVACIÓN DE LA BASE

43,2 cm (17'') ± 1,27 cm (0,5'') EN

FUNCIÓN DEL AJUSTE DEL LÍMITE

UNIDAD DE CONSOLA MONTADA EN EL SILLÓNUNIDAD CONCEPT LR

TP202 20-42-FO-00014 Rev A1 C2169

AL SUELO

DIMENSIONES DE LA BASE:

61 cm (24'') DE ANCHO X

86,3 cm (34'') DE LARGO

© Midmark Corporation 2016

Español - 16

KA940200

Page 41

Dimensiones/Rango de movimiento (continuación)

18.15"

18.86"

13.00"

28.25"

TO

36.75"

16.50"

AF 1119

Unidades montadas en el armario

PUNTO DE REFERENCIA

35,56 CM (14”)

SUPERFICIE LATERAL DE

MONTAJE DE 1,905 CM DE

GROSOR (0,75’’) (PARTE

DEL ARMARIO)

ESPACIO LIBRE DE 2,54 CM

A 1,905 CM (1-3/4’’) PARA

RETIRAR LA CUBIERTA

4,60 (1-13/16”)

40,64 CM (16.00”)

Carros de doctor/higienista

11,43 CM (4-1/2”)

11,43 CM (4-1/2”)

46,10 CM (18,15”) 41,91 CM (16,50”)

CUATRO ORIFICIOS

DE MONTAJE DE

0,046 CM (0,25’’)

47,90 CM (18,86”)

121,92 CM (4 PIES)

71,755 CM

A 93,345 CM

(28,25”- 36,75”)

003-2237-99

APROX.

45,72 CM (18’’)

UMBILICAL DE 2,54 CM (1’’)

Español - 17

33,02 CM (13,00”)

TP202 20-42-FO-00014 Rev A1 C2169

© Midmark Corporation 2016

Page 42

Dimensiones/Rango de movimiento (continuación)

Carro de auxiliar

Carro dúo izquierdo/derecho

SOPORTE

DE LA CUBA

SUPERFICIE

DE TRABAJO

50,8 CM (20”)

COLECTOR

DE SÓLIDOS

78,74 CM/

109,22 CM

(31”/43”)

AJUSTE DE

ALTURA

91,44 CM/

121,92 CM

(36”/48”)

SISTEMA

ASEPSIS 21

DELIVERY