Page 1

Cardell Touch Veterinary

Vital Signs Monitor

For Models:

8013-001

8013-002

8013-003

8013-004

User’s Guide

TP200 Rev. A

003-2840-00 Rev. AA2 (6/20/18)

Software Version V4.0.X

Page 2

Product Information

Dealer: Date of Purchase:

Model / Serial Number: Midmark Authorized Service

Company:

Product Registration

To register your product, go to www.midmark.com

TP200 Rev. A

i

© Midmark Corporation 2014-2018

Page 3

Table of Contents

SECTION 1 - PREFACE 1

1.1 General ................................................................... 1

1.2 Compliance ............................................................ 1

SECTION 2 - SAFETY 2

2.1 Safety Notice ......................................................... 2

2.1.1 Intended Use ..................................................... 2

2.1.2 Application Environment ...................................2

2.1.3 Operator Requirements .................................... 2

2.1.4 Terminology ....................................................... 2

2.1.5 Monitor Safety ................................................... 2

2.2 Safety Requirements ............................................ 3

2.2.1 WARNING: ........................................................ 3

2.2.2 CAUTION: ......................................................... 3

2.3 Safety Symbols .................................................... 4

SECTION 3 - CONTROLS & CONNECTORS 5

3.8.1 Color TFT Touch Screen ................................. 10

3.9 Display Screen .................................................... 12

3.9.1 Main Screen Display ....................................... 12

3.9.2 Status Bar ....................................................... 12

3.9.3 Waveform Area ............................................... 13

3.9.4 Parameter Box ................................................ 14

3.9.5 Touch Screen Menu ........................................ 14

SECTION 4 - ALARM SETUP 15

4.1 General Information ............................................ 15

4.2 Alarm Silence ....................................................... 15

4.3 Alarm Setup ......................................................... 16

4.3.1 Alarm Setup Menu .......................................... 16

4.3.2 Alarm Parameter Setup Menu ......................... 16

4.3.3 Current and Custom Alarm Settings ............... 17

4.3.4 Changes Made to Custom Alarm Settings ...... 18

4.3.5 Alarm Volume and Sound Setup ..................... 18

3.1 Installation and Connection ................................. 5

3.1.1 Environment Requirements .............................. 5

3.1.2 Power Supply Requirements ............................ 5

3.1.3 Shock Protection ............................................... 5

3.1.4 Patient Grounding ............................................. 5

3.1.5 Combination of Equipment ................................ 5

3.1.6 Unpacking ......................................................... 6

3.2 Before Monitoring ................................................. 6

3.3 Front Panel ............................................................ 7

3.4 Rear Panel .............................................................. 8

3.5 Side Panels ............................................................ 9

3.6 Power ................................................................... 10

3.6.1 AC Power ........................................................ 10

3.6.2 Battery Power ................................................. 10

3.7 Software Version ................................................. 10

3.8 Navigation Options ............................................. 10

4.3.6 Default Alarm Limit .......................................... 18

SECTION 5 - SETTING UP THE MONITOR 20

5.1 Display Setup ...................................................... 20

5.1.1 Parameter Display .......................................... 20

5.1.2 Display Mode Setup ........................................ 20

5.2 Historical Data Mode ........................................... 20

5.3 Large Font Mode ................................................. 20

5.4 AG Screen Mode .................................................. 20

5.5 Demo Mode .......................................................... 20

5.6 Trend Display ....................................................... 21

5.6.1 Displaying Trend Graph .................................. 21

5.6.2 Displaying Trend Table .................................... 21

5.6.3 Deleting Trend Information .............................. 22

5.7 Monitor Video Output .......................................... 22

5.8 Export Trend and ECG Data ............................... 22

5.9 Cardell® Touch Visualizer Tool ......................... 23

ii

Page 4

5.9.1 Importing ECG Data into the Visualizer .......... 23

6.6.1 Alarm Limit Setup ............................................ 34

5.9.2 Visualizer Data Tabs ....................................... 23

5.9.3 Reviewing Waveforms ....................................24

5.9.4 Printing Waveforms ........................................ 24

5.9.5 Cardell® Touch Visualizer Troubleshooting .... 25

5.10 Printing Setup (Optional) .................................. 26

5.10.1 Recorder ....................................................... 26

5.10.2 Manually Controlled Printing ......................... 26

5.10.3 Alarm Triggered Printing ............................... 26

5.10.4 Interval Printing ............................................. 27

5.10.5 Print Header .................................................. 27

5.10.6 Printing Paper ............................................... 27

5.10.7 Installing Paper ............................................. 27

5.11 Patient Setup .....................................................27

5.12 Date and Time Setup ......................................... 28

5.13 Sound and Volume Setup ................................. 29

5.14 Recall Functions ............................................... 29

5.14.1 NIBP Recall ................................................... 29

5.14.2 Alarm Recall .................................................. 29

5.14.3 Wave Recall .................................................. 30

5.15 Revert to Factory Default ................................. 30

SECTION 6 - ECG MONITORING 31

6.6.2 Parameter Adjustment Range ......................... 34

6.6.3 Abnormal Status Alarm ................................... 34

6.7 Precautions .......................................................... 34

6.8 Cleaning and Maintenance ................................. 35

6.8.1 ECG Cable Cleaning ....................................... 35

6.8.2 ECG Cable Disinfection .................................. 35

6.9 Troubleshooting .................................................. 35

6.9.1 Inaccurate Heart Rate ..................................... 35

6.9.2 No ECG Waveform ......................................... 35

6.9.3 ECG Baseline Shift ......................................... 35

SECTION 7 - NIBP MONITORING 36

7.1 General Information ............................................ 36

7.2 Cuff Placement .................................................... 36

7.2.1 Cuff Placement for Cat .................................... 36

7.2.2 Cuff Placement for Dog ................................... 37

7.2.3 Large Animals ................................................. 37

7.2.4 Cuff size selections ......................................... 37

7.3 NIBP Setup ........................................................... 38

7.3.1 NIBP Setup Menu ........................................... 38

7.3.2 Select Cuff Size............................................... 39

7.3.3 Select Measurement Mode ............................. 39

6.1 General Information ............................................ 31

6.2 Patient Cable ....................................................... 31

6.3 Animal Preparation and Lead Contact ..............31

6.4 Attaching ECG Electrodes ..................................31

6.4.1 Lead Wires and Color ..................................... 31

6.4.2 Lead Placement .............................................. 32

6.4.3 Positioning Anesthetized Patients ................... 32

6.4.4 Positioning Conscious Patients ....................... 32

6.5 ECG Setup ........................................................... 33

6.5.1 ECG Setup Menu ............................................ 33

6.5.2 Filter Menu ...................................................... 33

6.6 Alarm Setup .........................................................34

7.3.4 Alarm Limit Setup ............................................ 40

7.3.5 Alarm for Abnormal Status .............................. 40

7.4 Troubleshooting .................................................. 40

7.5 Precautions .......................................................... 40

7.6 Preparations ........................................................ 41

7.7 Maintenance ........................................................ 41

7.7.1 Cuffs ................................................................ 41

7.7.2 Reusable (Nylon) Large Cuffs ......................... 41

7.7.3 Disposable (Vivnyl) Small Cuffs ...................... 41

7.7.4 Calibrating NIBP.............................................. 41

SECTION 8 - SpO2 MONITORING 42

iii

Page 5

8.1 General Information ..................................... 42

10.2.9 Alarm Setup .................................................. 58

8.2 Sensor Placement ............................................... 42

8.3 SpO2 Setup Menu ............................................... 43

8.4 Alarm Setup .........................................................44

8.4.1 Alarm Range ...................................................44

8.5 Preparation for Monitoring ................................. 45

8.6 Precautions .......................................................... 45

8.7 Cleaning and Maintenance ................................. 46

8.7.1 Clean the Sensor and Clip .............................. 46

8.7.2 Clean the Cable .............................................. 46

8.8 Troubleshooting ..................................................46

8.8.1 No SpO2 Data ................................................. 46

8.8.2 Intermittent SpO2 Value .................................. 47

SECTION 9 - TEMPERATURE AND

RESPIRATION MONITORING 48

10.2.10 Cleaning and Maintenance ......................... 59

10.3 Respironics CO2 ............................................... 59

10.3.1 CO2 Setup Menu .......................................... 59

10.3.2 Connecting the CO2 Sensor to the Monitor .. 60

10.3.3 CAPNOSTAT 5 Sensor - Mainstream ........... 61

10.3.4 LoFlo CO2 Sensor - Sidestream ................... 62

10.3.5 Zeroing the CAPNOSTAT 5 and LoFlo CO2

Sensors ..................................................................... 63

10.3.6 LoFlo CO2 Sensor Holder (Optional) ............ 63

10.3.7 Removing Exhaust Gases from the System . 64

10.3.8 Alarm Setup .................................................. 64

10.3.9 Cleaning & Maintenance ............................... 64

SECTION 11 - IBP MONITORING (Optional) 65

11.1 General Information .......................................... 65

9.1 General Information ............................................ 48

9.1.1 Temperature ................................................... 48

9.2 Temperature Monitoring ..................................... 48

9.3 Temperature Setup Menu ................................... 49

9.4 Temperature Probe Cleaning ............................. 49

9.5 Respiration Monitoring ....................................... 49

9.6 Respiration Setup Menu ..................................... 50

9.7 Alarm Setup .........................................................51

SECTION 10 - CO2 MONITORING (Optional) 52

10.1 General Information .......................................... 52

10.2 Masimo CO2 ...................................................... 53

10.2.1 CO2 Setup Menu .......................................... 53

10.2.2 IRMA™ Probe ............................................... 54

10.2.3 ISA™ Analyzer .............................................. 55

10.2.4 Turn On or Off the CO2 Work Mode ............. 56

10.2.5 CO2 Exhaust ................................................. 56

10.2.6 Pre-Use Checks ............................................ 57

10.2.7 Using CO2 .................................................... 57

10.2.8 Zeroing .......................................................... 57

11.2 IBP Setup Menu ................................................. 65

11.3 Transducer ......................................................... 66

11.3.1 Transducer Connection ................................. 66

11.4 Preparation for Measurement .......................... 67

11.5 Zeroing the IBP Sensor ..................................... 67

11.6 IBP Labeling ....................................................... 67

11.7 Alarm Setup ....................................................... 67

11.8 Precautions ........................................................ 68

SECTION 12 - MULTI-GAS MONITORING

(Optional) 69

12.1 General Information ..................................... 69

12.2 Installation and Connection ........................ 69

12.2.1 Parts .............................................................. 69

12.2.2 IRMA™ Connection Procedures ................... 69

12.2.3 ISA™ Connection Procedures ...................... 71

12.2.4 Turn on the Multi-gas Module ....................... 72

12.2.5 Turn on the Multi-gas Screen Display ........... 72

12.2.6 Turn On or Off the Multi-gas Work Mode ...... 72

12.2.7 Multi-gas Exhaust ......................................... 72

iv

Page 6

12.3 Multi-gas Setup Menu ....................................... 73

13.4.8 Statute of Limitations .................................... 87

12.3.1 Multi-gas Measurement Menu: ..................... 73

12.3.2 CO2 Setup Menu Options ............................. 73

12.3.3 N2O Setup Menu Options ............................. 73

12.3.4 AA Setup Menu Options ............................... 74

12.4 Monitoring .................................................. 74

12.4.1 Pre-Use Checks ........................................... 74

12.4.2 Using Multi-gas ............................................ 74

12.4.3 Zeroing IRMA™ ............................................ 75

12.4.4 Zeroing ISA™ ............................................... 75

12.5 Alarm Setup .......................................................75

12.6 Cleaning and Maintenance ............................... 76

SECTION 13 - CLEANING,

TROUBLESHOOTING, WARRANTY 78

13.1 Cleaning ............................................................. 78

13.1.1 The Monitor ................................................... 78

13.1.2 The Display ................................................... 78

13.1.3 Patient Cable and Lead Wires ...................... 79

13.1.4 Cuffs .............................................................. 79

13.1.5 Reusable (Nylon) Cuffs ................................. 79

13.1.6 Disposable (Vinyl) Cuffs ................................ 79

13.5 After-sale Service and Support ........................ 87

APPENDIX 1 - SPECIFICATIONS 88

I. Safety ...................................................................... 88

II. Power Supply Requirements ............................... 88

III. Parameter Specications .................................... 88

A. ECG ..................................................................... 88

B. Pulse Oximetry (SpO2) - Nellcor ........................ 88

C. Non-invasive Blood Pressure (NIBP) – Cardell® 89

D. End-tidal CO2 ...................................................... 89

Masimo (Optional) ..................................................... 89

Respironics (Optional) .............................................. 89

E. Temperature (2-channel) ..................................... 90

F. Respiration ........................................................... 90

G. Multi-gas (Optional) ............................................. 90

H. IBP (Optional) ...................................................... 90

I. Display .................................................................. 90

J. Recorder (Optional) .............................................. 91

K. Physical Specications ........................................ 91

APPENDIX 2 - BP REFERENCE VALUES 92

13.1.7 Pneumatic Tubing .........................................79

13.1.8 Sensor and Clips ........................................... 79

13.1.9 Temperature Probes...................................... 80

13.2 Troubleshooting ................................................80

13.3 System Calibration and Maintenance ............. 85

13.4 Limited Warranty ............................................... 85

13.3.1 Registration ................................................... 85

13.4.2 Scope of Warranty ........................................86

13.4.3 Applicable Warranty Period ........................... 86

13.4.4 Exclusions ..................................................... 86

13.4.5 Exclusive Remedy; Consequential Damages

Disclaimer ................................................................. 87

13.4.6 No Authorization ............................................ 87

13.4.7 Warranty Disclaimer ...................................... 87

APPENDIX 3 - DEAD SPACE 94

APPENDIX 4 - DIRECT BP MONITORING 96

APPENDIX 5 - SPECTRAL BROADENING 99

I. Nitrous oxide, N2O .................................................. 99

II. Oxygen O

2 ................................................................................................................99

APPENDIX 6 - ACCESSORIES 100

v

Page 7

SECTION 1 - PREFACE

1.1 General

Welcome and thank you for choosing the Cardell® Touch portable multi-parameter veterinary monitor. The Cardell® Touch continuously

monitors and displays the following physiological parameters: ECG waveforms and heart rate, arterial blood oxygen saturation of

arterial hemoglobin (SpO2) and pulse rate, respiration rate, systolic (SYS), diastolic (DIA) and mean arterial pressure (MAP), and

temperature. Available options for this monitor include Invasive Blood Pressure, a built in printer, and export power cords.

This Cardell® Touch can be upgraded to offer CO2 or Multi-gas monitoring at any time. With the addition of a Masimo IRMA™

Mainstream CO2 probe or ISA™ Sidestream analyzer, one can also measure end-tidal CO2 as well as inspired CO2. With the addition

of the Masimo IRMA™ Mainstream multi-gas probe or ISA™ Sidestream multi-gas analyzer, one also has the ability to measure N2O

as well as ve anesthetic agents (HAL, ENF, ISO, SEV, DES) in addition to CO2.

This User’s Guide is an integral part of the product and contains detailed information about the performance specications, operation,

and maintenance of the Cardell® Touch and its intended use. Observance of this User’s Guide is a prerequisite for proper product

performance and correct operation and ensures patient and operator safety. It should always be kept close to the equipment.

1.2 Compliance

The manufacturer’s quality management system complies with the international standards ISO 9001:2008 and ISO 13485:2003 and

has the certicate issued by DNV.

TP200 Rev. A

1

© Midmark Corporation 2014-2018

Page 8

SECTION 2 - SAFETY

2.1 Safety Notice

2.1.1 Intended Use

The Cardell® Touch is a portable multi-parameter monitoring device for animals intended to give qualied veterinarians and technicians

an efcient and accurate patient vital sign monitoring solution during veterinarian procedures.

2.1.2 Application Environment

This device is for use by trained veterinary personnel in veterinary centers. The device is to be used on one patient at a time.

Transport and Storage Conditions

Temperature: 14°F (-10°C) to 104°F (40°C)

Humidity: ≤95% (non-condensing)

Atmospheric Pressure: 50kPa to 106kPa

Working Conditions

Temperature: 41°F (5°C) to 104°F (40°C)

Humidity: ≤80% (non-condensing)

Atmospheric Pressure: 86kPa to 106kPa

2.1.3 Operator Requirements

Only qualied veterinary personnel who have read the User’s Guide should use this monitor. The monitor is intended only as an adjunct

in patient assessment. It must be used in conjunction with clinical signs and symptoms. United States Federal Law restricts this device

to sale, distribution and use by or on the order of a veterinarian.

2.1.4 Terminology

The terms NOTE, CAUTION, and WARNING are used throughout this User’s Guide to point out hazards and to designate a degree or

level of seriousness. Familiarize yourself with their denitions and signicance.

NOTE

provides application tips or other useful information to assure that you get the most from your equipment.

CAUTION

indicates a potential hazard or unsafe practice which, if not avoided, could result in minor personal injury or product /property

damage.

WARNING

indicates a potential hazard or unsafe practice which, if not avoided, could result in death or serious injury.

2.1.5 Monitor Safety

The safety statements presented in this chapter refer to the equipment in general and in most cases, apply to all aspects of the monitor.

There are additional safety statements in the parameter chapters, which are specic to that monitored parameter.

The order in which safety statements are presented in no way implies order of importance.

TP200 Rev. A

2

© Midmark Corporation 2014-2018

Page 9

2.2 Safety Requirements

The following warnings and cautions must be read and understood before operating the veterinary monitor.

2.2.1 WARNING:

• The Cardell® Touch veterinary monitor is not intended to be used as an apnea monitor.

• The Cardell® Touch veterinary monitor is not intended to be used during MRI or CT scan.

• When a debrillator is used, make sure the patient does not make contact with the ground, metal objects, or other conductors or

devices. During debrillation, never touch the patient, table or the device.

• Please do not rely on the alarm functions of the veterinary monitor. The alarm limits may have been improperly set or the alarm

may have been disabled.

• Alarm functions of the veterinary monitor must be checked regularly.

• Before putting the system into operation, visually inspect all connecting cables for signs of damage. Damaged cables and

connectors must be replaced immediately.

• When several devices are used on the same patient, leakage current may increase and become a danger to the patient. Before

using, please consult a professional to do a leakage current test to make sure the leakage current is within safety limits.

• Before using on another patient, make sure the previous monitoring data is cleared.

• Use properly grounded power sockets and ensure adequate grounding. If there is any doubt about the grounding, please use

battery operation.

2.2.2 CAUTION:

• Check accessories on a regular basis and discard damaged accessories properly.

• To ensure patient’s safety and performance of the product, use only the manufacturer recommended accessories.

• Service parts must be in conformity with IEC 60601 standards. The system conguration of the monitor must be in conformity with

IEC 60601-1-1 medical electric standard; otherwise, it will reduce the safety of the monitor.

• Even while not being used, the battery may still discharge. Check battery level every month.

• The ECG cable socket is for connecting ECG lead wires only. Please do not connect it to any other signal source. Pay attention to

the color label and marks of ECG lead wires.

• Please clean the monitor and accessories according to instructions. Always unplug the power cord before cleaning.

• Electromagnetic Interference - This product is designed and built to minimize electromagnetic interference with other devices.

However, if interference is noticed between another device and this monitor:

◦ Remove interfering device from room

◦ Plug monitor into an isolated circuit

◦ Increase separation between Midmark product and interfering device

◦ Contact Midmark if interference persists

• For continual safe use of this equipment, it is necessary to follow the instructions. However, instructions listed in this User’s Guide

in no way supersede established medical practices concerning patient care.

• In the event of interrupted data or loss of data, please keep patient under close observation until the device returns to normal.

• Other devices connecting to the device should meet IEC standards (for example, data processing device should meet IEC 950,

and medical device should meet IEC60601-1) and the whole system should meet the latest version of IEC60601-1-1 standards.

• Plastic bags and other packaging materials should be disposed of in accordance with related regulations.

• At the end of product life, the monitor, accessories, battery, and other consumable goods may become contaminated from normal

use. Consult local codes and ordinances for proper disposal of equipment and other consumable goods.

TP200 Rev. A

3

© Midmark Corporation 2014-2018

Page 10

• Do not open the enclosure of the monitor to avoid the risk of electrical shock.

2.3 Safety Symbols

NOTE

Some symbols may not appear on all equipment.

Type BF Applied Part: F-type, debrillation proof applied part (oating/insulated) complying with the specied

requirements of IEC 60601-1 Medical Standards to provide a higher degree of protection against electric shock

than that provided by Type B applied parts. There are six BF type debrillation proof applied parts (NIBP, TEMP1,

TEMP2, Nellcor SpO2, Masimo AG, Masimo or Respironics CO2) and following exposure to a debrillation event, the

parameters will resume normal operation after 10 seconds.

Type CF Applied Part: F-type, debrillation proof applied part (oating/insulated) complying with the specied

requirements of IEC 60601-1 Medical Standards to provide a higher degree of protection against electric shock than

that provided by Type BF applied parts. There are three CF type debrillation proof applied parts (ECG, IBP1, IBP2)

and following exposure to a debrillation event, the ECG parameter will resume normal operation after 5 seconds,

while IBP will resume after 10 seconds.

Attention: Consult accompanying documents.

Fuse

Equipotentiality

Power ON/OFF

Alternating

Current Earth Connector

Caution: U.S. federal law restricts this device to sale by or on the order of a veterinarian.

TP200 Rev. A

4

© Midmark Corporation 2014-2018

Page 11

SECTION 3 - CONTROLS & CONNECTORS

3.1 Installation and Connection

3.1.1 Environment Requirements

To ensure electric installation safety, the environment should be reasonably dust free, without corrosive or combustible gas, or extreme

temperature or humidity.

Keep a space for the veterinary monitor at least 5cm from the wall to ensure good air ventilation.

Extreme temperature can affect the accuracy of the monitor and damage accessories or circuits.

Please ensure that water does not condense in the veterinary monitor when using the device. For instance, when the monitor

is transferred between buildings, there is a risk of condensation because of exposure to humidity combined with a difference in

temperature.

WARNING

Never use the veterinary monitor in an environment with combustible anesthetic gases.

3.1.2 Power Supply Requirements

Rated Input Voltage: AC115V/230V

Rated Frequency: 50Hz/60Hz

Rated Input Power: 70VA

Fuses: T1.6AL, 250V fuse, (2)

Battery: 14.8V 4400mAh Lithium polymer

3.1.3 Shock Protection

The Cardell® Touch multi-parameter veterinary monitor is a Class I device, in conformity with IEC60601/EN60601 requirements, with

protective grounding (through three pin power plug).

WARNING

To turn off the AC power, please unplug the power cord from power socket or unplug the power cord from the AC

power receptacle on the monitor.

The On/Off button will not turn off the AC power of the veterinary monitor.

3.1.4 Patient Grounding

The equipotential or grounding cable may be yellow or yellow and green.

During heart or head check, in order to eliminate the potential difference between different equipment, the monitor has a special cable

to connect to the grounding system. The grounding cable should be used when using high electrical output equipment such as a

debrillator or electric cautery, or any equipment that may cause interference with the monitor.

Connect the small end of the grounding cable to the grounding (Equipotentiality) connector on the monitor as shown in Fig. 3-2, Item 8.

The large end (which may be a clamp-like object) of the grounding cable should be connected to any metal surface or copper pipes.

3.1.5 Combination of Equipment

Both medical and non-medical equipment must comply with IEC60601-1-1 standard.

TP200 Rev. A

5

© Midmark Corporation 2014-2018

Page 12

CAUTION

The use of several machines together can increase the current leakage which risks injury to patient and medical personnel.

3.1.6 Unpacking

After conrming the outside packing is intact, please open the box and inspect the contents:

• Cardell® Touch Multiparameter Veterinary Monitor

• Battery

• Component Package

If any damage is found during shipping, please keep the package and contact Midmark immediately.

3.2 Before Monitoring

Before monitoring patient, please check the following:

• Check if there is any mechanical damage.

• Check the external connections.

• Check if the veterinary monitor is in good working condition.

WARNING

If any abnormalities are found or mechanical damage is suspected, please do not use the monitor and contact Midmark

as soon as possible.

Step 1: Turn the monitor on. The monitor will begin a sequence of self-diagnostic tests. If the tests are successful, you can start

monitoring the patient. If changes need to be made to the operation or settings of the monitor, see the User’s Guide.

Step 2: Make sure the monitor is connected to the patient with the appropriate accessories.

Step 3: After connections are in place, there should be waveforms or data on the screen, otherwise:

• Check the connections to the patient.

• Check the connections to the monitor.

TP200 Rev. A

6

© Midmark Corporation 2014-2018

Page 13

3.3 Front Panel

The front panel of the Cardell® Touch veterinary monitor is as shown in Fig.3-1:

The Cardell® Touch veterinary monitor front enclosure (Fig.3-1)

1. Power Switch: When the monitor is connected to the wall socket or there is enough battery power,

press this button and the veterinary monitor will turn on or off. After the veterinary monitor is turned

off, the battery continues to charge if the monitor is connected to AC power.

2. Power Indicator: AC indicator. When the monitor is connected to the wall socket, whether the

veterinary monitor is turned on or not, the indicator light will remain on.

3. Battery Charging Indicator: When the battery is charging, the indicator light is lit. When the battery

is fully charged, the indicator light will not be lit.

4. Silence: Press this button to enable /disable the alarm sound.

5. Freeze/Restore: When the waveform is sweeping across the screen, press this button to freeze the

waveform. Press the button again to unfreeze the waveform sweep.

6. Start/Stop Printing: Press this button to start printing. Press it again to stop printing. If this button is

not pressed to stop printing, the monitor will stop printing automatically after printing out 8 seconds

worth of data/waveform. The monitor may also be set to print at user selected intervals.

TP200 Rev. A

7. Start/Stop BP: Press this button to start blood pressure measurement; press it again to stop blood

pressure measurement. If this button is not pressed to stop blood pressure measurement, the

monitor will stop automatically when the measurement is completed.

7

© Midmark Corporation 2014-2018

Page 14

8. Return: Press the Return Key to return to the Main Screen from any menu or submenu. If no

menus are open, press the Return Key to access the Main Menu.

9. Knob: Rotate this knob to navigate the menus. Press the knob to conrm a selection or to enter into

an editable eld.

10. Alarm Indicator: Dual-color (red/yellow alarm indicator). This lights up whenever there is an alarm.

For physiological alarms, it is dependent on the alarm level for each parameter. Red LED ashes

if the parameter alarm level is set to High. Yellow LED ashes if the parameter alarm level is set to

Med. Yellow LED stays on without ashing if the parameter alarm level is set to Low.

For technical alarms, the user is not able to adjust alarm levels. Therefore, it will also be a Yellow

LED light, no ashing.

3.4 Rear Panel

The rear panel of the Cardell® Touch veterinary monitor is as shown in Fig.3-2:

TP200 Rev. A

The Cardell® Touch veterinary monitor rear panel (Fig.3-2)

1. Speaker 7. USB Port

2. AC Power Connector 8. Grounding (Equipotentiality) Port

3. Label 9. Stylus Holder

4. Pole Mount Attachment Point 10. Stylus

5. VGA Port 11. Handle

6. Ethernet Port

8

© Midmark Corporation 2014-2018

Page 15

WARNING

Other equipment connected to the device should be certified according to IEC standards (i.e. IEC 950 for dataprocessing equipment, IEC 60601-1 for medical equipment and IEC 60601-1-1 for whole system).

3.5 Side Panels

The side panel of the Cardell® Touch veterinary monitor is as shown in Fig.3-3:

The Cardell® Touch veterinary monitor side panel (Fig.3-3)

1. IBP 1/2: Receptacles for IBP cables. (Optional)

2. Temperature 1/2: Receptacles for temperature probes.

3. ECG: Receptacle for ECG cable.

4. CO2 /AG: Receptacle for Mainstream or Sidestream CO2 or AG module accessories.

5. NIBP: Receptacle for NIBP ination hose.

6. SpO2: Receptacle for SpO2 extension cable.

7. Fan (for heat dissipation)

8. Printer: Internal built in printer. (Optional)

8a. Printer: Error indicator light.

8b. Printer: Power indicator light.

8c. Printer: Paper compartment.

9. Battery compartment.

NOTE

The monitor you receive may differ from the image above depending on the parameters ordered.

TP200 Rev. A

9

© Midmark Corporation 2014-2018

Page 16

3.6 Power

3.6.1 AC Power

When AC power is used, the Cardell® Touch may be turned on at any time. Before plugging it into AC power, compare the resident

power output with the requirements of the device. On the rear panel, you can see the power supply requirements.

After conrming all cables are properly connected, press the power button on the front panel. The system will start a self-diagnostic test

which lasts about 15 seconds. If the tests are successful, the monitor will display the main screen. The device can then be used for vital

signs monitoring, communication, and battery charging.

When the device is plugged into AC power and turned off, the power indicator on the front panel continues to be lit, indicating the

monitor is in standby mode and the battery is being charged.

3.6.2 Battery Power

When AC power is shut off, the Cardell® Touch monitor can still work using the internal battery. Insert the battery into the monitor

label up with arrows pointing in. The battery will click and lock into place when inserted completely. Improper insertion of the battery

will damage the battery door. Make certain the battery is inserted completely before closing. Before use, the battery must be charged.

Whenever the device is plugged into AC power, the battery will automatically be charged. The battery needs to be charged for at least

8 hours before a full charge is achieved. To ensure the battery is fully charged, it is recommended that the device be plugged into AC

power even when the device is not in use.

A fully charged battery can support a working device continuously for approximately 2-4 hours, depending on the parameters in use.

The frequency of NIBP measurements and printing may accelerate the consumption of battery power. As the battery power depletes the

battery icon in the top right hand corner of the monitor changes from four to three green bars to two yellow bars and nally to one red

bar. When the battery power is almost depleted, the alarm indicator light in the upper left hand corner of the monitor will ash red and a

ashing red warning signal with 60 second countdown appears in the Status Bar . This alerts the user to plug the device into AC power

as soon as possible or the unit will shutdown in 60 seconds.

WARNING

• Even when the device is not working, the battery power will be discharged slowly.

• When the device is being stored for a long time, remove the battery prior to storage.

• Check the battery status and recharge at least once a month.

3.7 Software Version

Follow the steps below to determine the software version of your monitor:

Step 1: Press the “NEXT” Touch Screen Quick Access Button.

Step 2: Press the “MAIN MENU” Touch Screen Quick Access Button.

Step 3: Press “INFO”.

The software loaded on your monitor will be listed next to “SOFTWARE VERSION”. Please refer to the proper manual for operation

instructions of your Cardell® Touch monitor.

3.8 Navigation Options

3.8.1 Color TFT Touch Screen

The Cardell® Touch features a color touch screen for ease of navigation. Use your nger or the stylus and press on the screen to

access menus and input data. The stylus can be stored away by snapping it into the stylus holder at the back of the monitor.

Touch Screen Quick Access Buttons: These touch screen buttons allow quick access to frequently used menus and functions.

There are 2 rows of Touch Screen Quick Access Buttons. The image below shows the rst row, which is the row that appears by default

when the monitor is rst powered on.

TP200 Rev. A

10

© Midmark Corporation 2014-2018

Page 17

First row Touch Screen Quick Access Buttons (Fig.3-4)

SILENCE Press this button to silence the alarm. See Section 4.2 for Alarm Silence instructions and explanations.

FREEZE Press this button to freeze the waveform on the screen for closer observation. Press the BACK button

to unfreeze. Press FIRST PAGE to display the waveforms from 240 seconds prior to pressing the freeze

button. Press PRE PAGE or NEXT PAGE to move backward or forward in time by 8 second increments,

respectively. Press LAST PAGE to move to the 8 second period before freeze was pressed. A yellow

FREEZE RECALL depicting point in time will display at the top of the screen.

NOTE

When printing from within the Freeze screen, the waveforms will print as frozen on the screen.

However, the data values that print are real time.

DISPLAY MODES Press this button to access the Display Modes Menu. Choose from STANDARD, HISTORICAL DATA,

LARGE FONT, and DEMO mode.

NIBP START Press this button to start taking NIBP manually. Press again to stop.

DATA EXPORT/FTP Press this button to access the USB Data Export and FTP Remote Server functions.

PRINT Press this button to start printing manually. Printing will automatically stop after reaching the default time

set. Press again to stop printing before the default time limit is reached.

SCR LOCK Press this button to lock the screen. This will disable the Touch Screen function. To enable the Touch

Screen function again, press and hold the “SCR LOCK” button for 3 seconds. Alternatively, the user can

use the knob to navigate to the “SCR LOCK” button and then press the knob to unlock the screen.

NEXT Press this button to access the next row of Touch Screen Quick Access Buttons.

Press the “NEXT” button on the rst row to access the next row.

Second row Touch Screen Quick Access Buttons (Fig.3-5)

PATIENT SETUP Press this button to access the Patient Setup Menu.

ALARM PARA SETUP Press this button to access the Alarm Parameter Setup Menu. This menu will display all available Alarm

Setup submenus for all of the parameters enabled for the monitor.

PRINT SETUP Press this button to access the Printer Setup Menu.

SUSPEND Press this button to stop all alarms and recordings until it is pressed again. Intended to be used while

entering new patient information and attaching them to the monitor.

MAIN MENU Press this button to access the Main Menu. Main Menu includes some of the Touch Screen Quick

Access Button menus as well as other menus not found among the Touch Screen Quick Access Buttons.

TREND Press this button to access the Trend Graph and Trend Table functions.

PREV. Press this button to access the previous row of Touch Screen Quick Access Buttons.

Press “PREV.” on the second row to return to rst row.

TP200 Rev. A

11

© Midmark Corporation 2014-2018

Page 18

3.9 Display Screen

3.9.1 Main Screen Display

Main Screen Display (Fig.3-7)

Fig.3-7 above displays the Main Screen Display the user will see after turning on the monitor. The following standard parameters are

displayed on the Main Screen Display: ECG, SpO2, and RESP waveforms; ECG HR, Temperature, SpO2 %, SpO2 Pulse Rate, RESP,

and NIBP data. At the bottom of the Main Screen Display, the Mini Historical Data section displays the following data: Date, Time, SYS,

DIA, MAP, HR, PR, SpO2, RR, TEMP1, TEMP2, ETCO2, and INCO2 when NIBP is displayed. The Mini Historical Data section is only

visible when 3 or less waveforms are displayed.

NOTE

Main Screen Display may vary from monitor to monitor depending on the number of parameters available on the monitor.

Monitors with only standard parameters will not display optional parameter information.

3.9.2 Status Bar

Main Screen Status Bar (Fig.3-8)

The Status Bar is located at the very top of the Main Screen. The Status Bar provides the following information: Network Setting Status,

Patient Information, Date and Time, Alarm Messages, Battery Power Status, Battery Charging Status, and Sound Settings. Press on the

different icon/section within the Status Bar to access the menu related to that icon/section.

1. This icon displays the Network Setting Status for the monitor. Pressing the screen in this area will open up the menu for Network

Settings.

2. This area displays the patient name. Pressing the screen in this area will open up the Patient Setup menu.

3. This area displays the patient species in picture format. The only species available for display in picture format are cats, dogs, and

horses. If “Other” is chosen, no picture will be displayed. To change species, press the area associated with the patient name (No.

2 in Fig.3-8 above).

4. This area displays the date in YYYY-MM-DD format and time in HH:MM:SS format. Pressing the screen in this area will open the

Date/Time Setup menu.

TP200 Rev. A

12

© Midmark Corporation 2014-2018

Page 19

5. This area displays technical alarm messages. If multiple alarm events are occurring simultaneously, this area will rotate through all

alarm event messages.

6. This area displays physiological alarm messages. If multiple alarm events are occurring simultaneously, this area will rotate through

all alarm event messages.

7. This area displays the alarm volume in 10 increments. The monitor is loudest when all 10 bar increments are lit. The bell icon

above the alarm volume bar increments displays sound status. An “X” will appear over the bell icon whenever alarms are silenced.

Pressing the screen in this area will open up the Sound Setup menu.

8. This area displays the charge status of the battery as well as AC connection status. The more green segments present within

the battery icon, the more power is in the battery. A plug icon will be displayed within the battery icon whenever the monitor is

connected to AC power.

3.9.3 Waveform Area

Main Screen Waveform Area (Fig.3-9)

The Waveform Area displays real-time waveform data for ECG, SpO2, Respiration, CO2, IBP, and AG depending on monitor settings.

Press on a waveform to access the menu associated with that waveform parameter.

Waveforms include the following:

• ECG 3-Leads: I, II, III

• ECG 5-Leads: I, II, III, V, avL, avR, avF

• SpO2

• Respiration Leads: RA-LA (I), RA-LL (II)

• CO2

• IBP: ART1, ART2, PA, CVP, AO, RA, ICP, FA

• AG: CO2, N2O, ISO, DES, HAL, ENF, SEV

TP200 Rev. A

13

© Midmark Corporation 2014-2018

Page 20

3.9.4 Parameter Box

Main Screen Parameter Box (Fig.3-10)

The Parameter Box is located on the right side of the Main Screen and displays numerically the following parameter values in realtime: HR/PR, SpO2%, DIA/SYS/MAP NIBP, EtCO2, InCO2, RR, TEMP1, TEMP2, and Temperature Difference. Press on a displayed

parameter to access that parameter’s setup menu.

NOTE

Main Screen Display may vary from monitor to monitor depending on the number of parameters available on the monitor.

Monitors with only standard parameters will not display optional parameter information.

3.9.5 Touch Screen Menu

The Touch Screen offers easy access to parameter menus by attaching them to each displayed waveform within the Waveform Area

and each displayed parameter within the Parameter Box. To congure the displayed parameters, press on a parameter (waveform

or numeric) to access the setup menu associated with that parameter. The Knob can also be used to access all the available options

shown on the Main Screen Display. Rotate the Knob to navigate to the desired selection and press the Knob to conrm the selection

and access the selected setup menu.

TP200 Rev. A

14

© Midmark Corporation 2014-2018

Page 21

SECTION 4 - ALARM SETUP

4.1 General Information

Alarms are designed to give an alert when the monitoring results are abnormal. These alerts are given via audible sounds, visual LED

indicators, and ashing alarm messages. Alarms have three levels: Emergency (High) (2 sets of 5 beeps every 5-10 seconds with

continuous red ashing visual alarm), Medium: (3 beeps every 10 seconds with yellow ashing visual alarm) and Warning (Low) (1

beep every 10 seconds with yellow solid visual alarm).

• Emergency Alarms: Example: Asystole, Parameter values exceed set limits when Alarm Level is defaulted to “High”, SYS-DIA is

too low, Apnea Alarm Low Battery Alarm

• Medium alarms: Example: Parameter values exceed set limits when Alarm Level is defaulted to Medium.

• Warning Alarms: Example: Equipment Alarms or when parameter values exceed set limits when Alarm Level is defaulted to Low.

Typical warning alarms for equipment conditions are as follows:

• LEAD OFF

• PROBE OFF

• SENSOR OFF

• AIR LEAKAGE

• OVER PRESSURE

Other alarm messages will appear depending on the parameter in use.

When sensors are unplugged, the screen will display “NO SENSOR”. When probes are not connected to a patient, the screen will

display “PROBE OFF”.

NOTE

When “Asystole” is displayed on the screen, please check patient first, then the ECG gain of the relative channel to see if it is

too low to detect heart rate. If so, the user can adjust ECG gain, switch the ECG lead, or change the ECG filtering mode.

Different aspects of the alarm function, such as Alarm Sound ON/OFF and Alarm Level (which will change the tone alarm) may be

adjusted within the setup menu of each individual parameter.

4.2 Alarm Silence

To silence the alarm for a pre-determined amount of time, press the Silence Button on the front panel of the veterinary monitor or

press the Touch Screen Quick Access Button shown below.

Touch Screen Quick Access Silence Button (Fig.4-1)

To end the silence timer or ALM PAUSE TIME before the pre-determined time frame has elapsed, press the Silence Button or the Touch

Screen Quick Access Silence Button again. The alarm will also resume normal alarm functions when the pre-determined alarm silence

period expires.

The default ALM PAUSE TIME is 120 seconds.

TP200 Rev. A

15

© Midmark Corporation 2014-2018

Page 22

The ALM PAUSE TIME can be changed by accessing the Alarm Setup Menu as described in Section 4.3.1 below.

Step 1: In the Alarm Setup Menu, selected the ALM PAUSE TIME. This will allow you to choose between Forever, 1min, 2min, 3min,

5min, or 10min.

When the alarm is silenced using the Silence Button, the occurrence of a new technical alarm, such as probe off, will cancel the silence

feature. This will end the silence function before the silence timer runs out and sound the new alarm as well as the old alarms.

WARNING

New technical alarms, such as leads off, as well as new physiological alarms, such as exceeding upper limits, will

cancel the silence feature. The Asystole and Respiration Apnea alarms cannot be silenced in this manner.

WARNING

The Low Battery Power Alarm may be silenced by the Silence Button. Please plug the monitor into AC power as soon

as you see and hear the Low Battery Power Alarm

WARNING

When the alarm sound is silenced using the Silence Button, the user should pay close attention to the patient and the

monitor screen for visual cues to ensure the safety of the patient.

4.3 Alarm Setup

4.3.1 Alarm Setup Menu

Using the Touch Screen or the Knob, follow the steps below to access the Alarm Setup Menu:

Step 1: Select the “MAIN MENU” Touch Screen Quick Access Button.

Step 2: Select the “MONITOR SETUP” Touch Screen Button.

Step 3: Select the “ALARM SETUP” Touch Screen Button.

Alarm Setup Menu Options:

ALM REC TIME ALM REC TIME is used for Alarm Triggered Printing. Alarm Record Time can be set up to record 4s, 8s,

or 16s during an alarm event.

ALM PAUSE TIME Alarm pause time is the setting used for the Alarm Silence feature. The Alarm Silence Period can be set

to Forever, 1Min, 2Min, 3Min, 5Min, or 10Min.

ALM LIMIT DISPLAY Turning the ALM LIMIT DISPLAY on will display the upper and lower limits of each parameter next to

their parameter values within the Main Screen Parameter Box. User can set this to Off or On.

ALM LATER ALM LATER allows the user to delay alarms. The user can set this to Disabled, 5s, 10s, 15s, and 20s.

If turned on, an alarm event will not trigger an alarm until the set time has passed. If the alarm resolves

before the set time has passed, no audio or visual alarms will sound at all.

4.3.2 Alarm Parameter Setup Menu

Alarm limits include upper and lower limits that are user adjustable. All parameter limits are available within this menu on the Cardell®

Touch veterinary monitor.

Accessing the Alarm Parameter Setup Menu using the Touch Screen or the Knob:

Step 1: Select the “NEXT” Touch Screen Quick Access Button.

Step 2: Select the “ALARM PARA SETUP” Touch Screen Quick Access Button.

Step 3: Select the alarm limits to be adjusted. The following parameter alarm limits are available: ECG, SpO2, Temp1, Temp2,

Respiration, IBP1, IBP2, NIBP, Multi-gas, and CO2. Make sure to press the name of the parameter to access the parameter menu (ex.

TP200 Rev. A

16

© Midmark Corporation 2014-2018

Page 23

ECG, TEMP…etc.).

Changing Alarm Limits through the Alarm Parameter Setup Menu:

Step 1: Once inside the Alarm Parameter Setup Menu, press on the parameter you would like to set up. This will open the menu for that

specic parameter. Make sure to press the title of the parameter such as ECG, TEMP…etc.

Step 2: Press on the upper or lower limit buttons to display a number pad. The default limit number will be displayed initially.

Step 3: Use the “Clear” button to delete the current number and then enter the new number using the number pad.

Step 4: Press the “Enter” button on the number pad once the new number has been entered. This will return the user to the setup menu

for that specic parameter. Press the “X” button on the upper right corner to exit the menu. The changes will not be applied without

completing the steps below.

Step 5: Press the “Enter” button at the bottom of the Alarm Setup menu to apply the changes and exit.

NOTE

The user can make changes to all the parameters before pressing the “Enter” button located on the bottom right of the Alarm

Parameter Setup Menu to apply them.

NOTE

It is very important to press the “Enter” button on number pad menu and the Alarm Setup Menu in order to apply the changes.

Changing Alarm Limits through the Waveform Area:

Press on any waveform within the Waveform Area to access the menu for that particular parameter. Within this menu, the user may also

set the upper and lower limits associated to that particular parameter.

Changing Alarm Limits through the Parameter Box:

Press on any data within the Parameter Box to access the menu for that particular parameter. Within this menu, the user may also set

the upper and lower limits associated to that particular parameter.

4.3.3 Current and Custom Alarm Settings

There are four total alarm setting accounts available within the Alarm Parameter Setup Menu: Current, User 1, User 2, and User 3. The

monitor will come with factory default settings within the Alarm Parameter Setup Menu. When the user rst enters the Alarm Parameter

Setup Menu, the “Current/DEFAULT” account is open.

Users may change the limits as required and save up to 3 customer accounts using the steps below:

Step 1: Follow the instructions in Section 4.3.2 (Changing Alarm Limits through the Alarm Parameter Setup Menu) to setup all the

parameter settings. Make sure to press “Enter” on the Alarm Parameter Setup Menu when all the settings have been entered. This will

exit the user from the menu into the Main Screen.

Step 2: Go back into the Alarm Parameter Setup Menu. Check to make sure the parameter settings are as desired.

Step 3: Press the SAVE AS button on the bottom of the menu. This will open the Save As Menu.

Step 4: Choose which account you would like to save this setup in. For this example, we will choose User 1. Press User 1 to display

the onscreen key board.

Step 5: Type in the name you wish to use. For example: Cat, Dog, Dr. Smith, Small Surgery…etc. Press enter to apply the name.

This will take you back into the Save As Menu. Close the box to return to the Alarm Parameter Settings Menu. The new user name is

displayed on the top of the screen next to Alarm Setting Name.

Step 6: Enter the Alarm Parameter Setup menu. Press the “Alarm Setting Name” button. This will display the Alarm Setting Name

menu. Choose the user account you would like to use. A pop up window will display the following alert message:

Select YES to return to the USER 1 conguration. The current conguration will be lost!

Step 7: Select YES to load the conguration. The warning message will always display USER 1, USER 2, or USER 3. However, once

loaded, the Alarm Parameter Setup menu will show the name the user has entered for this account.

TP200 Rev. A

17

© Midmark Corporation 2014-2018

Page 24

Step 8: Press the ENTER button at the bottom of the menu to apply the changes and exit.

4.3.4 Changes Made to Custom Alarm Settings

CAUTION

It is recommended that before using the monitor on a patient, the desired Alarm Parameter Setting Account is re-loaded onto the

monitor using the steps described in Section 4.3.3.

The alarm parameter settings may be changed by different users throughout the day. To ensure that the proper setting is being used,

always reload the Alarm Parameter Setting Account associated with the current patient before using the monitor.

In order to save an alarm parameter setting change, the user must do a SAVE AS for the intended user and “Enter” on the User menu,

and “Enter” on the Save As menu. In order for those changes to also save to the “Current” user, the user must also press “Enter” on the

Alarm Setup menu. If a user makes a change to alarm settings outside of the Alarm Parameter Setup Menu, an asterisk (*) will appear

next to the Alarm Setting Name. In order for the revised data to be saved as part of that user’s alarm settings, the user must enter the

Alarm Parameter Setup Menu, and then enter the user Alarm Setting Name menu to select the Current * user, close out of that menu

with the X , select Save As the user if you want those user settings to save and then choose Enter from the Alarm Parameter Setup

Menu.

4.3.5 Alarm Volume and Sound Setup

Sound Setup Menu

Press the sound icon located on the Status Bar to access the Sound Setup Menu.

Select from Sound Setup Menu options below:

ALARM VOL Choose from Off, 1-10, 10 being the loudest. If ALARM VOL is set to Off, there will not be any audio

alarms for either the physiological or technical alarms. However, the visual alarms will still be active.

HR BEAT VOL Choose from Off, 1-10, 10 being the loudest.

PR BEAT VOL Choose from Off, 1-10, 10 being the loudest.

KNOB VOL Choose from Off, 1-10, 10 being the loudest.

TOUCH SOUND On or Off

Parameter Alarm Sound ON/OFF

The user may choose to turn the alarm sound On or Off for each particular parameter. For this example, we will use the ECG Alarm

Sound feature.

To turn the alarm sound off for the ECG function, follow the steps below:

Step 1: Select the ECG waveform or ECG data in the Parameter box to enter the ECG Setup Menu.

Step 2: Select “ALM SOUND”. Choose Off. The physiological out of range audio alarms for the ECG parameter will no longer sound.

Alarms relating to the detection of a heart beat (Asystole) will continue to sound, until the Silence Button is pressed .

Repeat Steps 1 – 2 above to set up the ALM SOUND option for each individual parameter.

4.3.6 Default Alarm Limit

The Cardell® Touch includes default alarm limits recommended by members of the American College of Veterinary Anesthesia for

general veterinary practice.

Using the Touch Screen or the Knob, follow the steps below to return to the factory alarm setting, i.e., default alarm limits:

Step 1: Select the “NEXT” Touch Screen Quick Access Button.

Step 2: Select the “ALARM PARA SETUP” Touch Screen Quick Access Button.

Step 3: Select the “Alarm Setting Name” Touch Screen Button.

Step 4: Select the “RESTORE DEFAULT” Touch Screen Button.

TP200 Rev. A

18

© Midmark Corporation 2014-2018

Page 25

Step 5: A pop up box will appearing warning the user that the current conguration will be lost if they continue.

Step 6: Select “Yes” to return to the default conguration! The current conguration will be lost!

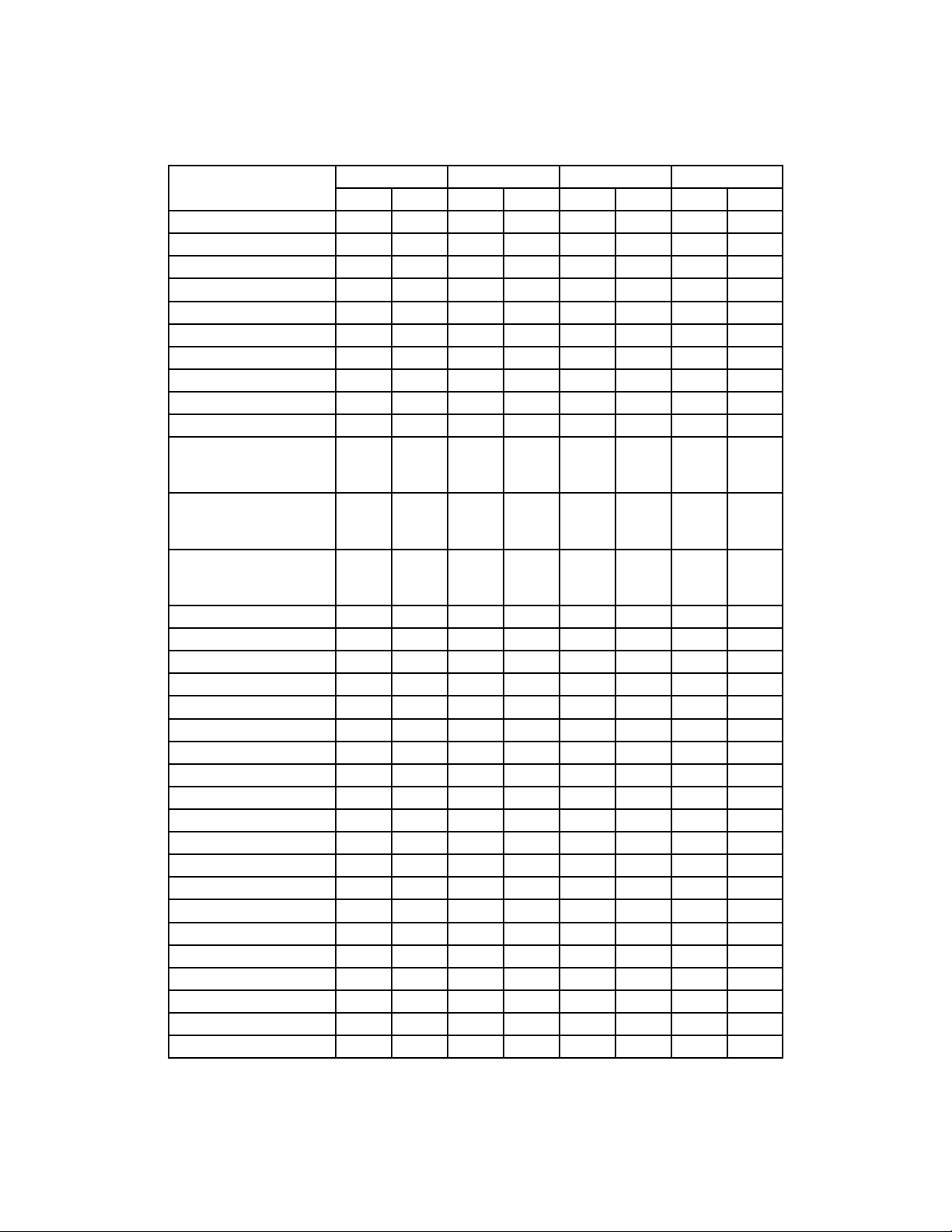

There are 4 default category of animal sizes to choose from: Cat, Dog, Horse, and Other. The following default alarm limits were set in

the factory before delivery for each category:

Parameter Cat Dog Horse Other

Low High Low High Low High Low High

HR/PR (bpm) 90 180 50 180 24 50 50 180

SpO2 (%) 95 100 95 100 95 100 95 100

NIBP SYS (mmHg) 70 160 70 160 70 160 70 160

NIBP DIA (mmHg) 40 100 40 100 40 100 40 100

NIBP MAP (mmHg) 70 140 70 140 70 140 70 140

Resp. (rpm) 5 55 5 55 5 55 5 55

Temp. (°F) 96.8 104 96.8 104 96.8 104 96.8 104

AwRR (rpm) 5 55 5 55 5 55 5 55

Et CO2 (mmHg) 20 60 20 60 20 60 20 60

In CO2 (mmHg) 0 10 0 10 0 10 0 10

IBP SYS (mmHg) –

100 160 100 160 100 130 100 160

ART1, ART2, AO, RA,

FA

IBP DIA (mmHg) –

50 90 50 90 50 80 50 90

ART1, ART2, AO, RA,

FA

IBP MAP (mmHg) –

60 120 70 130 60 100 70 130

ART1, ART2, AO, RA,

FA

IBP SYS (mmHg) – PA 5 38 5 38 5 38 5 38

IBP DIA (mmHg) – PA -4 4 -4 4 0 16 -4 4

IBP MAP (mmHg) – PA 12 16 12 16 8 25 12 16

IBP MAP (mmHg) – CVP 0 7 0 7 0 23 0 7

IBP MAP (mmHg) – ICP 0 4 0 4 0 10 0 4

AG: Et CO2 (mmHg) 20 60 20 60 20 60 20 60

AG: Fi CO2 (mmHg) 0 10 0 10 0 10 0 10

AG: AwRR (rpm) 5 55 5 55 5 55 5 55

AG: Et N2O (%) 40 70 40 70 40 70 40 70

AG: Fi N2O (%) 40 70 40 70 40 70 40 70

AG: Et HAL (%) 1.0 3.0 1.0 3.0 2.0 4.0 1.0 3.0

AG: Fi HAL (%) 1.0 3.0 1.0 3.0 2.0 4.0 1.0 3.0

AG: Et ENF (%) 2.0 5.0 2.0 5.0 2.0 5.0 2.0 5.0

AG: Fi ENF (%) 2.0 5.0 2.0 5.0 2.0 5.0 2.0 5.0

AG: Et ISO (%) 1.5 3.0 1.0 3.0 1.5 3.5 1.0 3.0

AG: Fi ISO (%) 1.5 3.0 1.0 3.0 1.5 3.5 1.0 3.0

AG: Et DES (%) 9.0 14 7.0 14 7.0 15 7.0 14

AG: Fi DES (%) 9.0 14 7.0 14 7.0 15 7.0 14

AG: Et SEV (%) 2.5 5.0 2.0 5.0 2.5 6.0 2.0 5.0

AG: Fi SEV (%) 2.5 5.0 2.0 5.0 2.5 6.0 2.0 5.0

TP200 Rev. A

19

© Midmark Corporation 2014-2018

Page 26

SECTION 5 - SETTING UP THE MONITOR

5.1 Display Setup

5.1.1 Parameter Display

The waveform display of each parameter can be changed by pressing on the waveform. This will open the selected waveform’s Setup

menu. Use the down arrows to scroll through the parameter setup menus. The user may change the Sweep speed, Wave Type, and

Wave Color of the waveform.

Sweep speed is the speed the waveform travels across the screen. This value is in mm/sec.

Wave Type is the option to show the waveform in Line or Fill. Fill will make the underside of the waveform solid. This option is not

available for ECG or Multi-gas waveforms.

Wave Color is the option to change the color of the waveform to Green, Cyan, Red, Yellow, White, Blue, or Purple. Display Color is also

an option for parameters without a waveform.

5.1.2 Display Mode Setup

By default, the Standard Display Mode is chosen. Another display mode may be selected by accessing the Display Modes Menu.

Press the Display Modes Touch Screen Quick Access Button. Select from Standard, Historical Data, Large Font, AG Screen (if AG

module is ON) or Demo modes. The Knob can also be used to navigate to the “DISPLAY MODES” Touch Screen Quick Access Button.

5.2 Historical Data Mode

Follow the steps below to enter Historical Data Mode using the Touch Screen Quick Access Buttons:

Step 1: Select the “DISPLAY MODES” Touch Screen Quick Access Button.

Step 2: Select “Historical Data”.

Historical Data Mode may be used to review numerical data for the patient. The information is displayed in table format, including the

following: Date, Time, SYS, DIA, MAP, HR, PR, SpO2, RR, Temp1, Temp2, Et CO2, In CO2, IBP1, and IBP2.

The system stores up to 2000 sets of history data. The Historical Data screen can display 20 sets of data per page. On the bottom of

the screen, there is a set of Touch Screen Buttons that will allow the user to navigate through the Historical Data screen. As always, the

Knob can also be used to navigate to these Touch Screen Buttons.

Historical Data will automatically clear itself when clearing patient data. The user may restart the monitor and still retain historical data.

5.3 Large Font Mode

Follow the steps below to enter Large Font Mode using the Touch Screen Quick Access Buttons:

Step 1: Select the “DISPLAY MODES” Touch Screen Quick Access Button.

Step 2: Select “Large Font”.

Large Font Mode may be used when observing the screen from a long distance. The Large Font Mode is only visible when 3 or less

waveforms are displayed. Large Font Mode will display IBP and AG data values but not IBP or AG waveforms.

5.4 AG Screen Mode

Follow the steps in 12.2.5 to turn on the Multi-gas Screen Display

5.5 Demo Mode

For the purpose of training, the Cardell® Touch provides a Demo Mode function.

TP200 Rev. A

20

© Midmark Corporation 2014-2018

Page 27

CAUTION

Never attempt to use the Demo Mode while monitoring patients.

Follow the steps below to enter the Demo Mode:

Step 1: Press the “DISPLAY MODES” Touch Screen Quick Access Button.

Step 2: Press “Demo” to bring up the password dialogue box for Demo Mode.

Step 3: Use the key pad to input “5188” and press “Enter”.

To conrm that the monitor is in Demo Mode, the word “DEMO” should be displayed at the top of the Waveform Area in yellow.

To exit Demo Mode, simply press the “DISPLAY MODES” Touch Screen Quick Access Button and then press “Exit Demo”.

5.6 Trend Display

5.6.1 Displaying Trend Graph

Follow the steps below to enter the Trend Graph Screen:

Step 1: Press the “NEXT” Touch Screen Quick Access Button.

Step 2: Press the “TREND” Touch Screen Quick Access Button.

Step 3: Press “Trend Graph”.

Trend Display Buttons:

PARAM: Use the Parameter button on the bottom left corner to choose the parameter to observe. The user may

choose from: HR, RR, SpO2, PR, Temp, NIBP, IBP1, IBP2, CO2, InCO2, or AwRR.

RES.: Use the resolution button to set the resolution for moving the cursor on the graph. Choose from 1s, 5s,

1Min, 5Min, or 10Min.

TIME AXIS Select the Time Axis to move the range. When Time Axis is selected, use the arrows located below this

button to move the X-axis forward in time or backwards in time.

CURSOR The cursor is a little arrow that is on the very top of the trend graph. When the Cursor is selected, use the

arrows located below this button to move the cursor along the X-axis. The date / time stamp on the top of

the graph will change depending on where the cursor is pointing to.

Left and Right Arrows These buttons are used in conjunction with the Time Axis button and the Cursor button to navigate across

the X-axis.

Up and Down Arrows These buttons are found to the right of the trend graph and is used to navigate across the Y-axis.

5.6.2 Displaying Trend Table

Follow the steps below to enter the Trend Table Screen:

Step 1: Press the “NEXT” Touch Screen Quick Access Button.

Step 2: Press the “TREND” Touch Screen Quick Access Button.

Step 3: Press “Trend Table”.

The Trend Table will display the following parameters: AG ETAA. AG FIAA, AG ETN2O, AG FIN2O, AG ETCO2, AG FICO2, AG AWRR,

ETCO2, INCO2, AWRR, IBP2, IBP1, NIBP, SpO2, PR, T1, T2, TD, and RR. NOTE: AG data will not display if AG module is OFF.

Trend Table Buttons:

RES.: Use the resolution button to set the resolution for the graph. Choose from 1Min, 5Min, 10Min, 30Min, or

60Min.

Left and Right Arrows These buttons are found on the top of the table and is used to navigate to different parameters.

TP200 Rev. A

21

© Midmark Corporation 2014-2018

Page 28

Up and Down Arrows These buttons are found on the bottom of the table and is used to navigate through the time range

displayed on the left side of the table for each parameter.

5.6.3 Deleting Trend Information

To delete the trend information, the user may press Clear Patient Data within the Patient Setup Menu, or restart the monitor.

CAUTION

All trend information and historical data is erased when clearing patient data. All trend information is also erased any time the

monitor is turned off. Historical data is retained when the monitor is turned off.

5.7 Monitor Video Output

The Cardell® Touch provides a VGA (15-pin) output for mirrored display on a computer monitor. For best results, please use a VGA-toVGA cable and follow the computer monitor’s instructions for selecting signal source.

NOTE

Some computer monitors will flash a warning box to ask the user to adjust the refresh rate on the Touch. This is not needed.

Ignore the warning and continue using the monitor.

5.8 Export Trend and ECG Data

To Export Trend and ECG Data, follow the steps below:

Step 1: Make sure your USB device is plugged in.

Step 2: Press the “DATA EXPORT/FTP” Touch Screen Quick Access Button.

Step 3: Press “USB DATA EXPORT”. The button will highlight and start export. An Exporting In Progress message will appear in the

Main Screen Status Bar. Once export has been successful, a message will be displayed: “File export success”.

Two excel les will be exported and placed onto the USB device under a folder named CARDELL_DATA_EXPORT. One le will contain

up to 24 hours of Trend information. The other le will contain the last 12 minutes of ECG waveform information. Only data from Lead II

will be exported. The le name format is as shown below:

Patient name-Trend-Year-MonthDay-HoursMinutesSeconds

Patient name-ECG-Year-MonthDay-HoursMinutesSeconds

For example:

Fluffy-Trend-2014-0318-171838

Fluffy-ECG-2014-0318-171838

NOTE

Please note that the hours are counted in the 24 hour format. For example, 17:00 hour is 5:00pm.

NOTE

Only data from Lead II will be exported regardless of Lead viewed on screen.

Saved les will not be deleted unless the user manually deletes it from the USB device. All new les will be saved onto the USB device

until the USB device is full.

TP200 Rev. A

22

© Midmark Corporation 2014-2018

Page 29

NOTE

If exporting of data is used frequently, please keep the USB storage device plugged into the monitor at all times. Since all

data stored on the monitor is purged when power is lost or the monitor is turned off, be sure to download the case data before

powering down or if running on battery power and a low-battery status message appears.

5.9 Cardell® Touch Visualizer Tool

The Cardell® Touch comes with a USB device preloaded with the Cardell® Touch Visualizer Tool. This tool will take the exported ECG

data and map it into a waveform for easy reference. This tool requires Microsoft Excel 2007, 2010, 2013, or 2016 to work.

NOTE

The Cardell® Touch Visualizer Tool is for use with the ECG data export only. It is not meant to be used with the Trend data

export. Please do not load the Trend data into the visualizer.

5.9.1 Importing ECG Data into the Visualizer

To import ECG data into the visualizer, follow the steps below:

Step 1: Connect the USB device to your computer.

Step 2: Copy the Cardell® Touch Visualizer Tool onto the computer. You only need to do this once.

Step 3: Copy the exported data onto the computer.

Step 4: Double click on the Cardell® Touch Visualizer Tool to open it. If a warning pops up for the macro embedded within the program,

please see the Section 5.9.5 on Cardell® Touch Visualizer Troubleshooting.

Step 5: Once opened, the Start Menu will appear as shown below:

Step 6: Click on the “Import New ECG Data” button. Navigate to the ECG excel le exported from the monitor (see 5.8) and click

“Open”.

Step 7: Once the data has been imported, the Start Menu will pop up again. Click on the Review Waveform button. This will close the

Start Menu and allow the user to look over the waveform.

5.9.2 Visualizer Data Tabs

The visualizer will look like an excel document. There are 4 worksheet tabs on the bottom.

ECGData This worksheet stores the ECG Data that was imported. The user does not need to use this worksheet.

NewECGData This worksheet interprets the ECG data that was imported. The user does not need to use this worksheet.

TP200 Rev. A

23

© Midmark Corporation 2014-2018

Page 30

ECGWave This worksheet is where the ECG data will be displayed as a waveform. Please see below for a more

detailed explanation.

ECGPrintCharts This worksheet stores the most recently printed waveforms with the exception of current view (print).

5.9.3 Reviewing Waveforms

1. Menu Button. Allows user to import new ECG data, review ECG data or print ECG data.

2. Waveform Information. Includes date of export, patient name, patient number, client name, species, ECG lead used, and ECG

gain used.

3. ECG mV

4. ECG waveform interpreted from the imported data.

5. Time of data point.

6. Time frame scroll bar. The ECG visualizer will interpret up to 12 minutes of ECG data. However, this is not enough space on the

screen to show all 12 minutes at the same time. Move the scroll bar left and right to show different ranges of time within the 12

minutes.

7. Sweep speed scroll bar. Click on the arrow keys on the top or bottom of the scroll bar to display the ECG waveform at 25mm/

sec, 30mm/sec, 50mm/sec or 100mm/sec, which will be displayed under the waveform. The user may also move the scroll bar

with the mouse to increase or decrease the sweep speed outside of the preset sweep speeds noted above. Using this method,

a “CUSTOM” message will be displayed under the waveform.

5.9.4 Printing Waveforms

To print the waveforms from the visualizer, follow the steps below:

Step 1: Click on the “Menu” button.

Step 2: Click on the “Print Waveform” button. The print menu will be displayed.

Step 3: Use the drop down buttons to select the range of ECG data you would like to print. Choose from “Current View”, “Entire 12

mins”, or “Specic Time Range”. If “Specic Time Range” is chosen, the Print Range section below will become editable. Choose the

desired time range and click on “Print”.

NOTE

The visualizer prints to your currently selected (default) printer. If another printer (such as PDF) is desired, select File > Print

from the Excel menu and select that specific printer before using the Midmark UI “Print Waveform” option.

NOTE

The ECG waveform chosen to be printed will also be displayed in the ECGPrintCharts tab. Only the most recently printed ECG

waveform will be displayed here. Note: Current View (Print) does not display in the ECGPrintCharts tab.

TP200 Rev. A

24

© Midmark Corporation 2014-2018

Page 31

5.9.5 Cardell® Touch Visualizer Troubleshooting

Error Message Resolution

Run Time Error (when

loading an ECG le)

Security Warning for

Macros and Active X

Make sure the patient’s name does not contain any symbols. Use of capital letters, small case letters, and

spaces are acceptable. The le name must not be longer than 31 characters; shorten if needed.

Macros from an unknown source may cause harm to the computer. However, the Cardell® Touch

Visualizer Tool utilizes macros and will not operate without having macros enabled. To do this safely,

please follow the steps below:

Step 1: Create a new folder on the computer and name it Cardell® Touch Visualizer Tool.

Step 2: Open Microsoft Excel. Click on “File” and then click on “Options”. Choose “Trust Center” and then

click on “Trust Center Settings” as shown below.

Step 3: Click on “Trusted Locations” and then click on “Add new location”.

Step 4: Use the “Browse” button to navigate to the folder you just made in Step 1 and click “OK”. Make

sure the check box for “Subfolders of this location are also trusted” is checked. Click “OK”.

TP200 Rev. A

25

© Midmark Corporation 2014-2018

Page 32

Step 5: This will add the location of that folder into the list of trusted locations displayed in the window

shown in Step 3. Click “OK” to save. If you do not click “OK” here, the added folder will not save.

Step 6: Go to the Midmark USB and save the Cardell® Touch Visualizer Tool into the folder you have just

created. You can drag the les from the USB window right into the folder.

Step 7: Go to the folder and double click the Cardell® Touch Visualizer Tool. It should now open without

any security warnings.