Midmark 641-003, 641-002, 641-004, 641-005 Parts Manual

Power

Go To Table Of Contents

Next

Procedures Table

Model Numbers:

641

-002 thru -005

Service and

Parts Manual

SF-1891 Part No. 004-0521-00 Rev (9/20/17)

FOR USE BY MIDMARK TRAINED TECHNICIANS ONLY

GENERAL INFORMATION

Back

Next

Symbols ....................................iii

Ordering Parts ......................... iii

Serial Number Location .......... iii

Specifications ........................... iv

Model Identification /

Compliance Charts:............... v

Scheduled Maintenance .......... vi

Warranty Information............... vii

General Information

OPERATION &

TROUBLESHOOTING

Power to the Chair:

Standard Base .........................

Rotational Base .......................

Base Up / Down ....................... A-8

Section A

Back Up / Down ....................... A-16

Tilt Up / Down ........................... A-23

Foot Up / Down ........................ A-30

Crash Avoidance System ........ A-38

Position Programming ............ A-41

"Home" Function ..................... A-44

Quick Chair™ Function ........... A-49

Foot Extension ......................... A-52

Chair Receptacles .................... A-54

Rot. Base Brake System .......... A-56

A-2

A-4

TESTING & REPAIR -

Main System Transformer ....... B-29

Position Sensors...................... B-31

Main PC Board ......................... B-37

Rotational Base

Brake System ......................... B-41

continued

Section B

ACCESS PROCEDURES

PC Board Cover:

Standard Base .........................

Rotational Base .......................

Base Shrouds:

Raising w/bungee cord ............

Lowering / Removing ...............

Section C

Upholstery Installation ............ C-6

WIRING DIAGRAMS

641 (-002) .................................. D-2

641 (-003) .................................. D-3

641 (-004 & -005) ....................... D-4

Section D

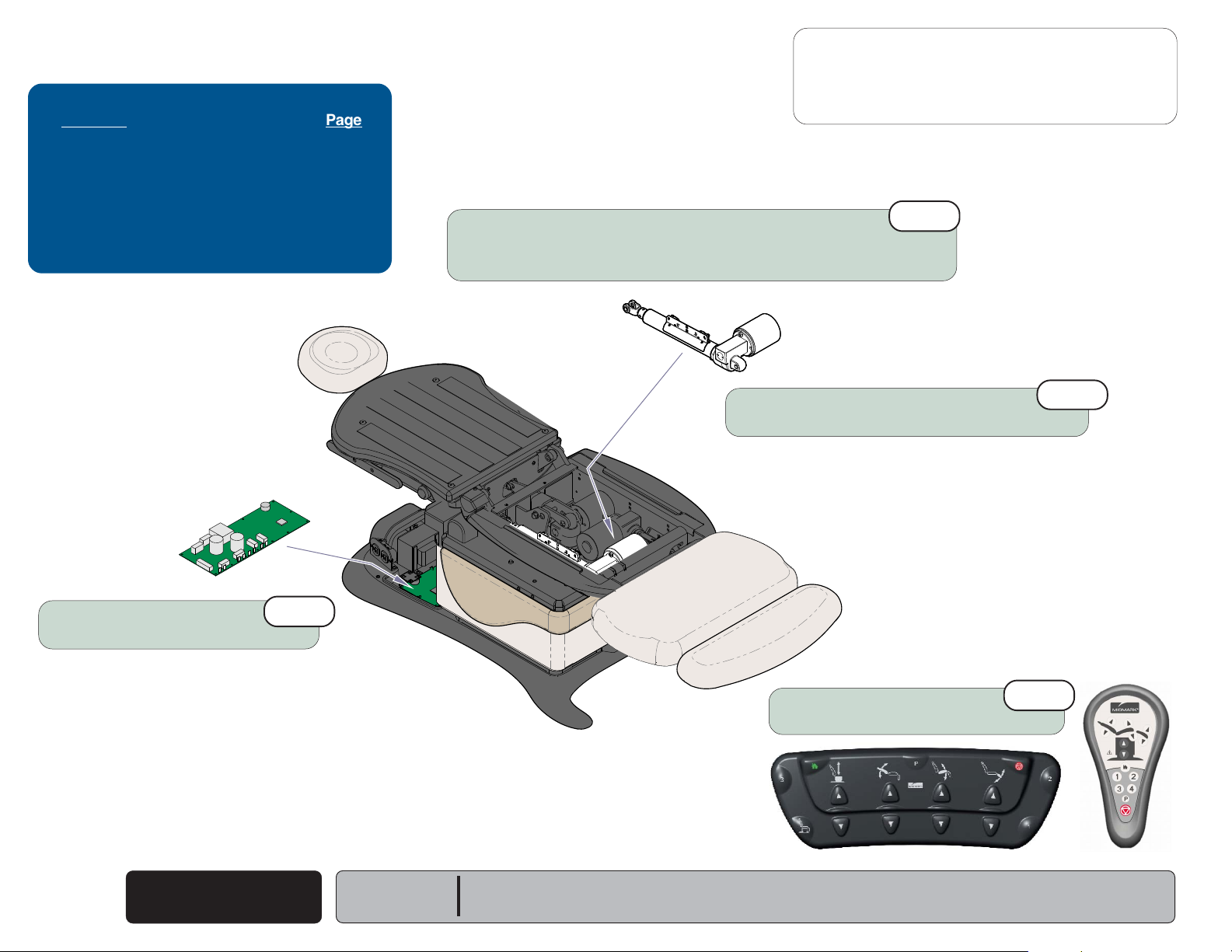

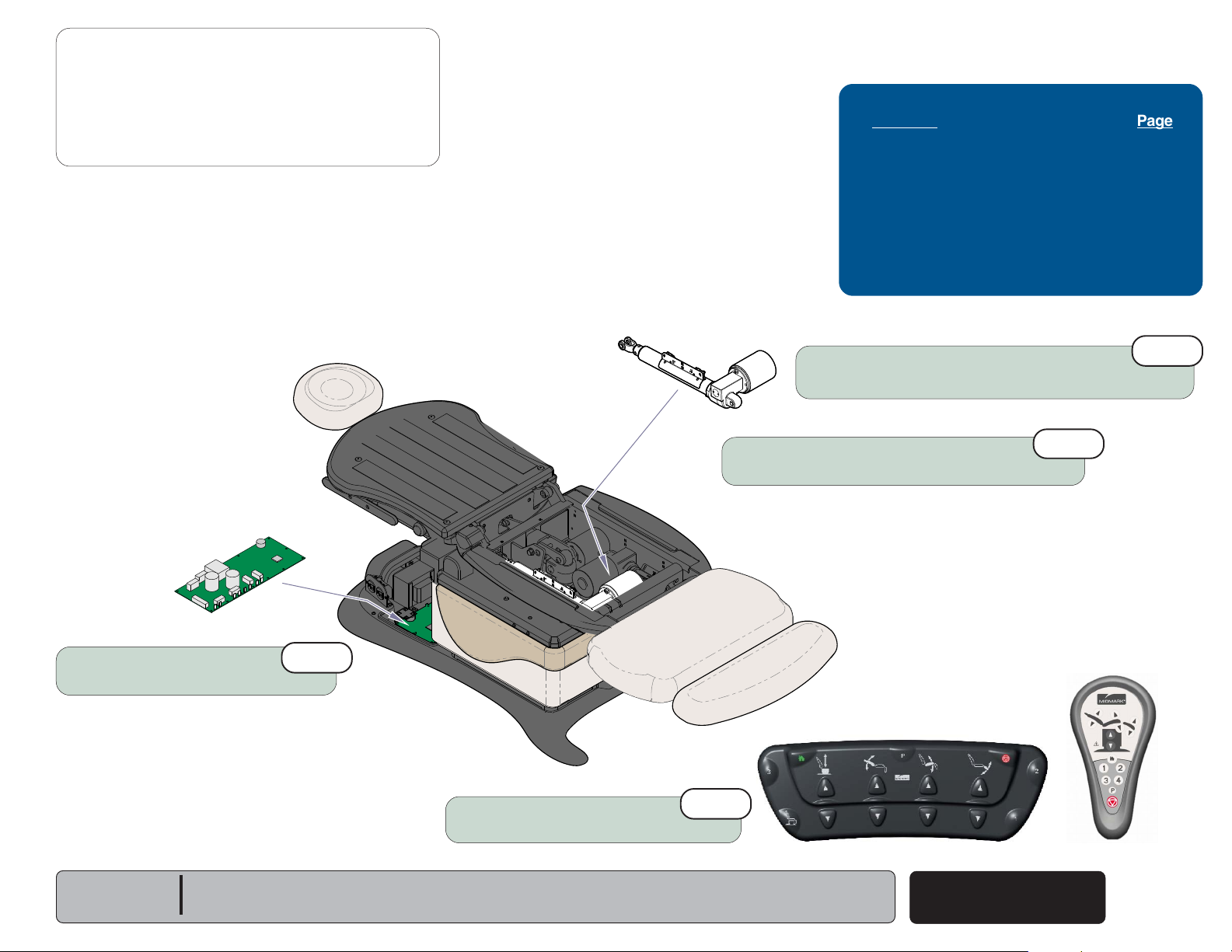

EXPLODED VIEWS / PARTS LISTS

641 (-002 & -003) ....................... E-2

641 (-004 & -005) ....................... E-3

C-2

C-3

C-4

C-5

TESTING & REPAIR

Primary Fuses .......................... B-2

Hand / Foot Control ................. B-3

Actuators / Limit Switches:

Base ........................................

Section B

Table Of Contents

Back ........................................

Tilt ............................................

Foot ..........................................

Foot Extension ......................... B-24

Gas Springs.............................. B-27

Isolation Transformer /

Chair Receptacles.................. B-28

B-6

B-10

B-14

B-19

Section E

* Indicates multiple pages due to model / serial number break(s)

General Information

Next

Go To Table Of Contents

Back

Symbols

DANGER

Indicates an imminently hazardous situation which

will result in serious or fatal injury if not avoided. This

symbol is used only in the most extreme conditions.

WARNING

Indicates a potentially hazardous situation which

could result in serious injury if not avoided.

CAUTION

Indicates a potentially hazardous situation which may

result in minor or moderate injury if not avoided. It may also be

used to alert against unsafe practices.

Equipment Alert

Indicates a potentially hazardous situation

which could result in equipment damage if not avoided.

In Section A, test the components in the order indicated.

1st

(ex.

Refer to Section B for component testing procedures.

then,

2nd

)

Ordering Parts

The following information is required when ordering parts:

• Serial number & model number

• Part number for desired part.

[Refer to Exploded Views / Parts Lists section]

Non-warranty parts orders may be faxed to Midmark using

the Fax Order Form in the back of this manual.

For warranty parts orders, call Midmark's Technical Service

Department with the required information.

Hours: 8:00 am until 5:00 pm EST [Monday - Friday]

Phone: 1-(800)-Midmark

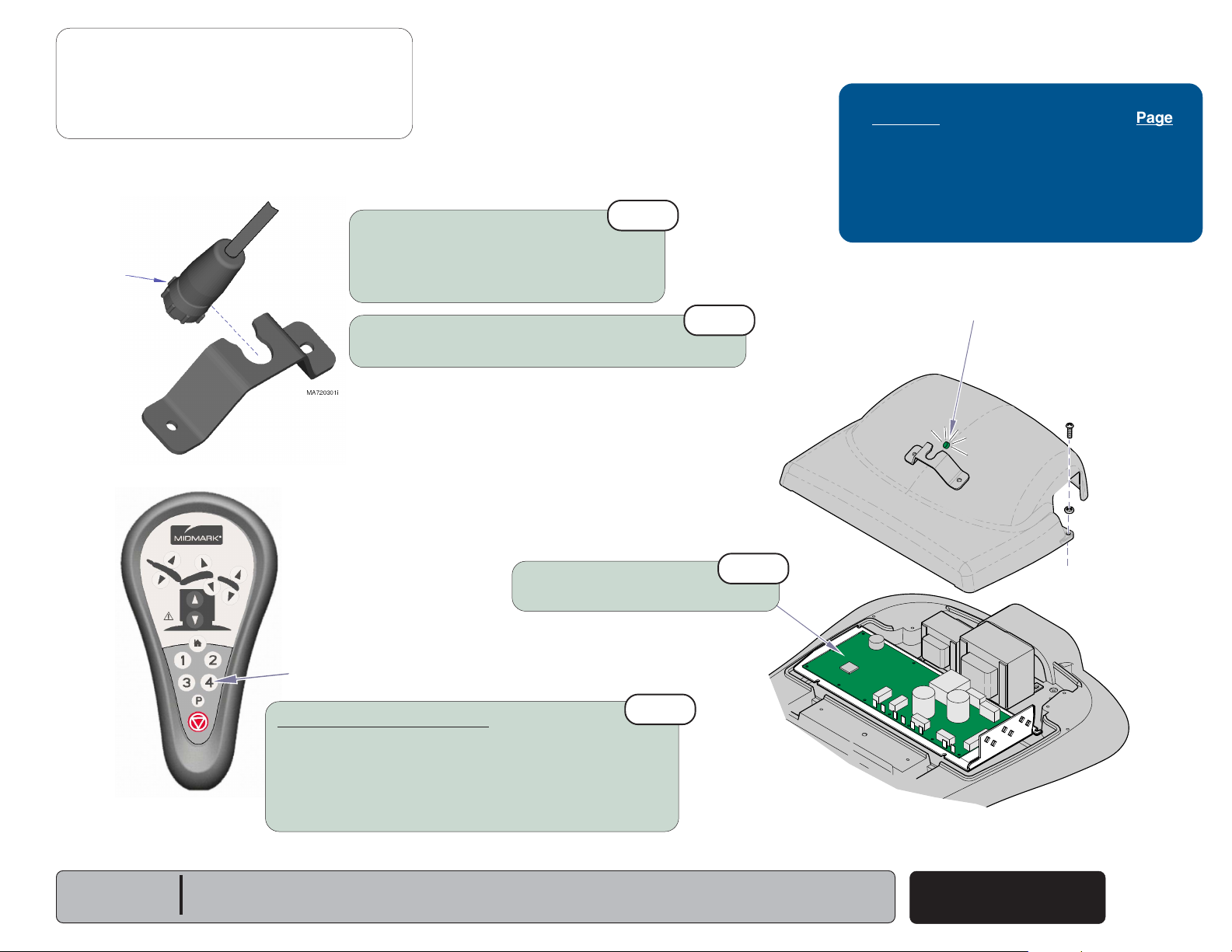

Model / Serial Number Location

Model / Serial

Number Label

The symbols below may be used in this manual to represent

the operational status of table functions and components.

Indicates the function / component is working properly.

No action required.

Indicates the function / component is working,

but a problem exists.

Indicates the function / component is not working at all.

General Information

© Midmark Corporation 2007 SF-1891

MA774500i

iii

Rev. 7/6/12

General Information

Next

Go To Table Of Contents

Back

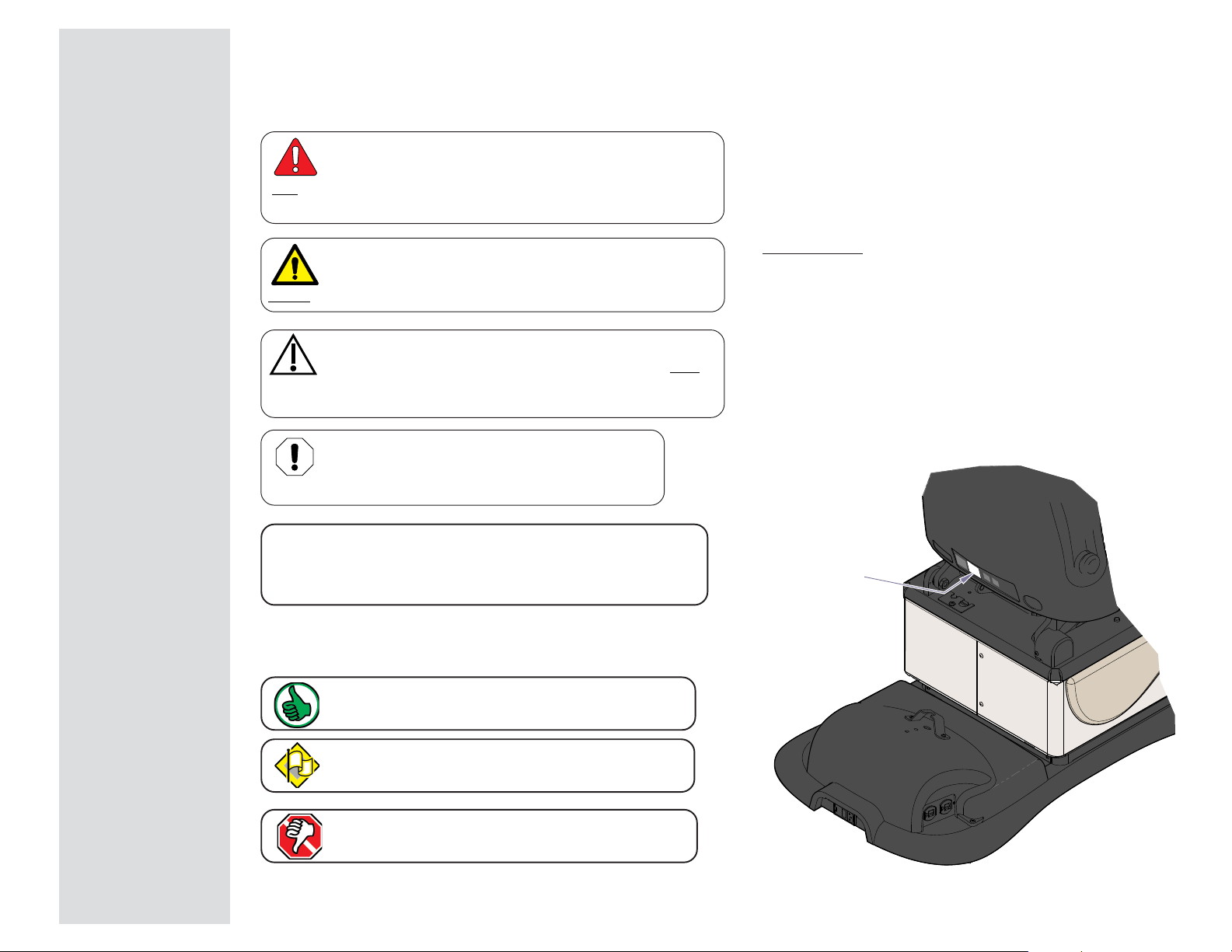

Specifications

Patient Weight (maximum)................................. 450 lbs (204 kgs)

Range of Motion ................................................. See illustration on this page

Dimensions .........................................................See illustration on next page

Weight of Table:

w/ Standard Base .............................................

w/ Rotational Base ...........................................

(Note: For packaged weight, contact Midmark Customer Service)

Power Cord: ........................................................8 ft. (243.8 cm) long

Electrical Requirements: ................................... See Compliance Charts

Foot / Hand Control Voltage:.............................10 VAC, SELV (Safety Extra Low Voltage)

Duplex Receptacle (optional)

maximum load: .................................................115 VAC, 5A, 50/60 Hz

Fuses:

Main Power

(located at power cord inlet)

:

F1 & F2 ................................................................. 6.3A, 250V, Type-T, 5 x 20 mm

High-Breaking Current

Duty Cycle:

Actuator motor run time: ...................................

(30 seconds ON / 5 minutes off)

440 lbs (200 kg)

525 lbs (238 kg)

Intermittent Operation

19 in.

(48.2 cm)

Min.

* see below

* Minimum Height

standard base:

rotational base:

Max.

0° +0.5°

Maximum Height

standard base:

rotational base:

19 in. (48.2 cm)

22.5 in. (57.1 cm)

MA767700i

40 in. (101.6 cm)

43.5 in. (110.5 cm)

MA767500i

Max.

30° +2°

Min.

0° +0.5°

Classifications: ...................................................Class 1, Type B Applied Part,

Protection against ingress of fluids: ............... Ordinary Equipment

Foot Control only: .............................................

IPX1

Regulatory Compliance: .................................... See Compliance Charts

Table Speeds (by function):

Back / Tilt:

w/Patient Load <200lbs (<90 kg) ...................

w/Patient Load >200lbs (>90 kg) ...................

Base ..................................................................

Foot ...................................................................

Equipment not suitable for use in the presence of a flammable anesthetic mixture with air, or with oxygen, or nitrous oxide.

iv

© Midmark Corporation 2007 SF-1891

less than 16 seconds

less than 20 seconds

less than 20 seconds

less than 14 seconds

MA767800i

Min.

89° +1°

Max.

85° +3°

Min.

0° +0.5°

MA767600i

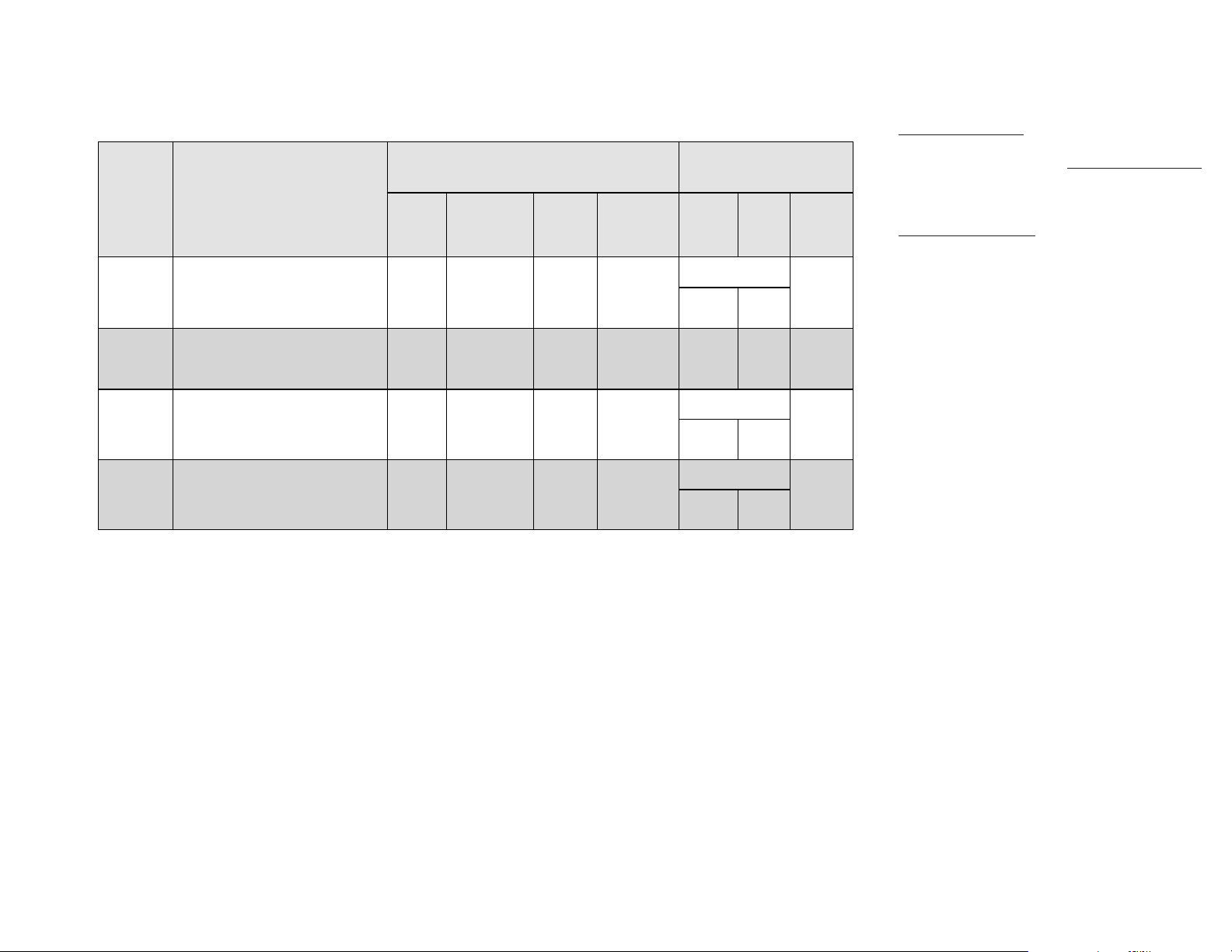

Model Identification / Compliance Chart

Next

Go To Table Of Contents

Back

Complies To: Electrical Ratings:

General Information

Fire Code Ratings:

All Standard upholstery complies with California

Bureau of Home Furnishing Technical Bulletin 117.

Model Description

641-002

641-003

641-004

641-005

Power Procedures Chair

(Non-Programmable)

Power Procedures Table

(Programmable)

w/ Receptacles

Power Procedures Chair

(Non-Programmable)

w/Rotational Base

Power Procedures Table

(Programmable)

w/ Rotational Base

UL

60601-1

CAN/CSA

22.2,

#601.1-M90

EN

60601-1

EN

60601-1-2

(EMC)

•• ••

• • • •

•• ••

• • • •

VAC

+/-10%

Configurable

115

230

Amps

8.5

4.5

Cycles

(Hz)

50 / 60

115 11.5 50 / 60

Configurable

115

230

Configurable

115

230

8.5

4.5

8.5

4.5

50 / 60

50 / 60

Optional upholstery is available that complies

with California Bureau of Home Furnishing

Technical Bulletin 133.

© Midmark Corporation 2007 SF-1891

v

Rev. (5/8/12)

General Information

Next

Go To Table Of Contents

Back

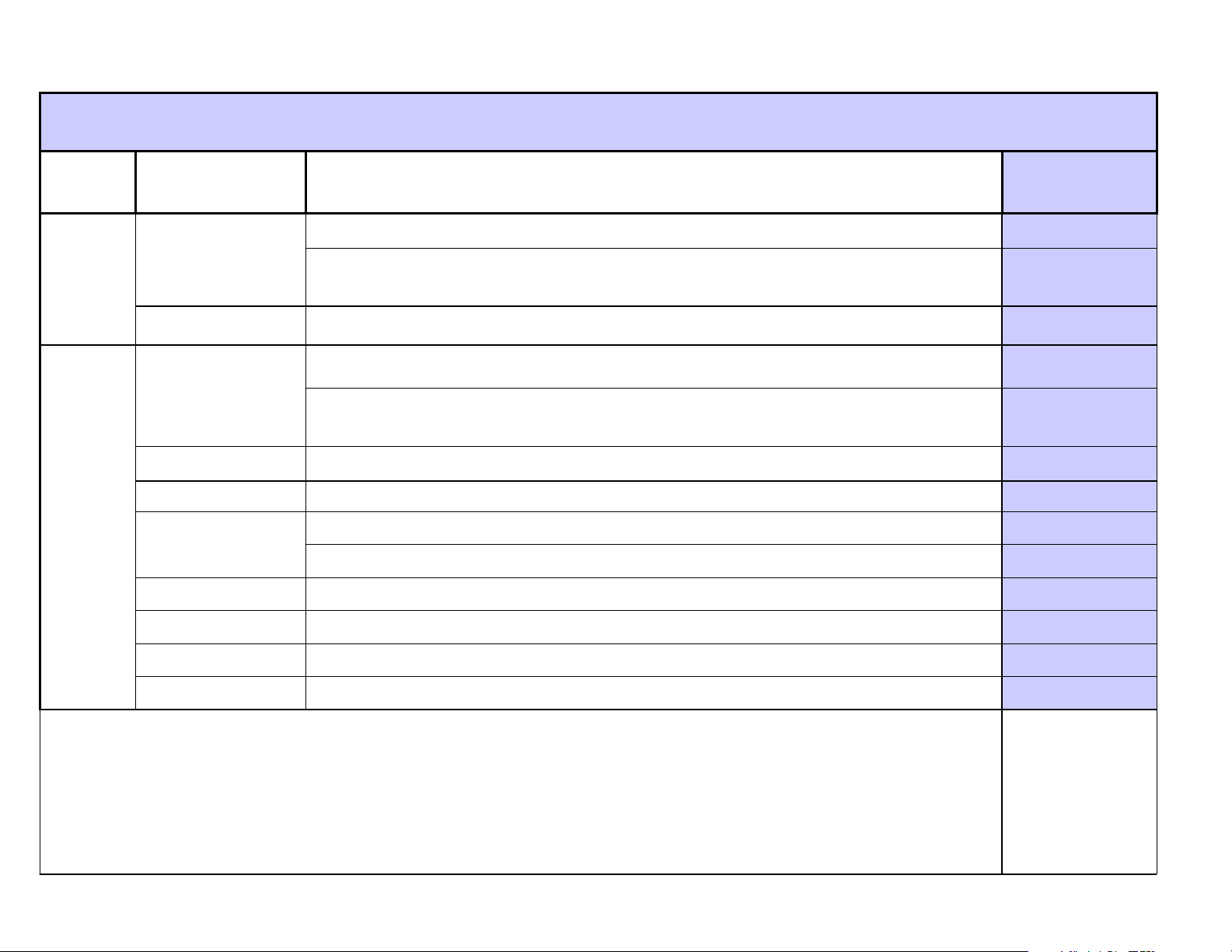

Interval Inspection or Service

Scheduled Maintenance

641 Power Procedures Chair

Service, Adjust, Repair,

and / or Replace as Required

(Refer to appropriate S&P or Quick Reference Guide)

641

Weekly

Semi-Annually

Clean upholstery with appropriate diluted bleach solution 10:1 (water:bleach)

Cleaning

Obvious Damage

Mechanical Operation

Labels / Decals

Hardware All fasteners must be present and fastened securely.

Electrical System

Wipe painted metal & plastic surfaces with a clean soft cloth and mild cleaner.

(NOTE: Periodic application of common furniture wax will ease cleaning, and maintain the luster of the surfaces).

Visually inspect components for damage that could cause problems during operation or unsafe operation.

Check all mechanical functions using the foot control.

Repeat using the hand control when present.

Table shrouds should move smoothly & quietly when base is raised & lowered.

(NOTE: There are plastic glides on the shroud tabs. Missing glides may result in noisy operation)

Replace any missing or illegible labels.

Inspect power cord and all wiring for damage.

Be sure all electrical connections are tight.

X

X

X

X

X

X

X

X

X

Date of Service: _____/______/______

Location:

Service Technician:

vi

© Midmark Corporation 2007 SF-1891

Model:

Serial Number:

Warranty Information

Next

Go To Table Of Contents

Back

SCOPE OF WARRANTY Midmark Corporation (“Midmark”) warrants to the original retail purchaser that it will, at Midmark’s option,

repair or replace components of the domestic and international medical products manufactured by Midmark (except for components not warranted under “Exclusions”) that are defective in material or workmanship under normal use and service. The sole

remedy under this limited warranty is the repair or replacement, at Midmark’s option, of the applicable components. This limited

warranty shall only apply to defects that are reported to Midmark within the applicable warranty period and which are determined

to exist upon examination by Midmark,. This warranty extends only to the original retail purchaser of a product and is not

transferable or assignable. Replacement components or products may be used and/or refurbished components or products,

provided they are of like quality and specifications as new components or products.

Midmark warrants to the original retail purchaser that during the applicable warranty period it will repair or replace software

contained within the products manufactured by Midmark (except for those not warranted under “Exclusions”) if: (1) the media on

which the software is furnished exhibits defects in material or workmanship under normal use; or (2) the software does not

substantially conform to its published specifications.

APPLICABLE WARRANTY PERIOD The applicable warranty period, measured from the date of invoice to the original retail

purchaser of the product and shall be one (1) year for all warranted products and components.

BTAINING WARRANTY SERVICE Warranty service must be obtained through either Midmark or an authorized dealer in the

O

Midmark product line for which warranty service is requested. Midmark may be contacted for warranty service inquiries or issues

via email at www.midmark.com; by phone at 1-800-MIDMARK or by mail to Midmark Corporation, 60 Vista Drive, Versailles, Ohio

45380. It is the retail purchaser’s obligation to arrange for delivery of a product to Midmark or one of its authorized dealers for

warranty service, which delivery shall be at retail purchaser’s expense. It is also the retail purchaser’s obligation to comply with

the warranty service instructions provided either by Midmark or its authorized dealer. The retail purchaser must provide Midmark

with completed warranty registration information within thirty (30) days after purchase in order to obtain the benefits of this limited

warranty.

EXCLUSIONS: This limited warranty does not cover and Midmark shall not be liable for the following:

(1) Defects, damage or other conditions caused, in whole or in part, by misuse, abuse, negligence, alteration, accident, freight

damage, negligent storage, tampering or failure to seek and obtain repair or replacement in a timely manner;

(2) Products which are not installed, used, and properly cleaned and maintained as required or recommended in the Midmark

“Installation” and/or “Installation/Operation Manual” for the applicable product, including the specified structural and operational

environmental conditions and electrical requirements;

(3) Products considered to be of a consumable or sterile nature;

(4) Accessories or parts not manufactured by Midmark;

(5) Charges by anyone for adjustments, repairs, replacement parts, installation or other work performed upon or in connection

with such products which are not expressly authorized in writing in advance by Midmark;

(6) Costs and expenses of routine maintenance and cleaning; and

(7) Representations and warranties made by any person or entity other than Midmark.

(8) Matching of color, grain or texture except to commercially acceptable standards;

(9) Changes in color caused by natural or artificial light;

(10) Custom manufactured products;

(11) Alterations or modifications to the product by any person or entity other than Midmark; and

(12) Products that would otherwise by covered under this limited warranty, but are acquired: (i) from a person or entity that is not

Midmark or one of its authorized dealers; or (ii) from a Midmark dealer that is not authorized to sell the product at issue in the

geographic territory where the purchaser is located, or is not authorized to sell the product at issue within the medical market.

SOFTWARE; WITH RESPECT TO SOFTWARE THAT IS A PRODUCT OR COMPONENT THEREOF, MIDMARK DOES NOT

WARRANT THAT THE SOFTWARE: (1) IS ERROR FREE; (2) CAN BE USED WITHOUT PROBLEMS OR INTERRUPTIONS; OR (3)

IS FREE FROM VULNERABILITY TO INTRUSION OR ATTACK BY VIRUSES OR OTHER METHODS.

EXCLUSIVE REMEDY; CONSEQUENTIAL DAMAGES DISCLAIMER MIDMARK’S ONLY OBLIGATION UNDER THIS LIMITED

WARRANTY IS THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS. MIDMARK SHALL NOT BE LIABLE FOR AND HEREBY

DISCLAIMS ANY DIRECT, SPECIAL, INDIRECT, INCIDENTAL, EXEMPLARY OR CONSEQUENTIAL DAMAGES OR DELAYS,

INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR LOSS OF PROFITS OR INCOME, LOSS OF USE, LOSS OF DATA, DOWNTIME, COVER AND EMPLOYEE OR INDEPENDENT CONTRACTOR WAGES, PAYMENTS AND BENEFITS. THIS DISCLAIMER

SHALL SURVIVE ANY FAILURE OR ASSERTED FAILURE OF THE ESSENTIAL PURPOSE OF THIS LIMITED WARRANTY OR ITS

REMEDIES SPECIFIED HEREIN. WARRANTY DISCLAIMER THIS WARRANTY IS MIDMARK’S ONLY WARRANTY AND IS IN LIEU

OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. MIDMARK MAKES NO IMPLIED WARRANTIES OF ANY KIND INCLUDING

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THIS WARRANTY IS LIMITED

TO THE REPAIR OR REPLACEMENT OF DEFECTIVE PARTS.

General Information

Warranty Information Continued

STATUTE OF LIMITATIONS No action may be brought against Midmark for breach of

this limited warranty, an implied warranty, if any, or for any other claim arising out of or

relating to the products, more than ninety (90) days following expiration of the limited

warranty period.

NO AUTHORIZATION No person or firm is authorized to create or approve for Midmark

any other obligation or liability in connection with the products.

Additional Information

Failure to follow the guidelines listed below will void the warranty and/or render the table unsafe for use.

• If a malfunction is detected, do not use the table until

necessary repairs are made.

• Do not attempt to disassemble table, replace

components, or perform adjustments unless you are

a Midmark authorized service technician.

• Do not use another manufacturer's parts to replace

malfunctioning components. Use only Midmark

replacement parts

vii

© Midmark Corporation 2007 SF-1891

General Information

Next

Go To Table Of Contents

Back

viii

© Midmark Corporation 2007 SF-1891

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Click on the Go To Page button and enter the desired

page number. (Note: Letters are case sensitve. ex. E-2)

Operation &

Troubleshooting

Function / System Page

Power To The Table:

models w/Standard Base ..................

models w/Rotational Base .................

Base Up / Down ................................... A-8

Back Up / Down .................................... A-18

Tilt Up/Down ......................................... A-23

Foot Up/Down ....................................... A-30

Crash Avoidance System ..................... A-38

Position Programming ........................... A-41

"Home" Function ................................... A-44

Quick Chair Function ............................ A-49

Foot Extension ...................................... A-52

Table Receptacles ................................ A-54

Rotational Base Brake System ............. A-56

A-2

A-4

Section A

Models:

Serial Numbers:

© Midmark Corporation 2007 SF-1891

A-1

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

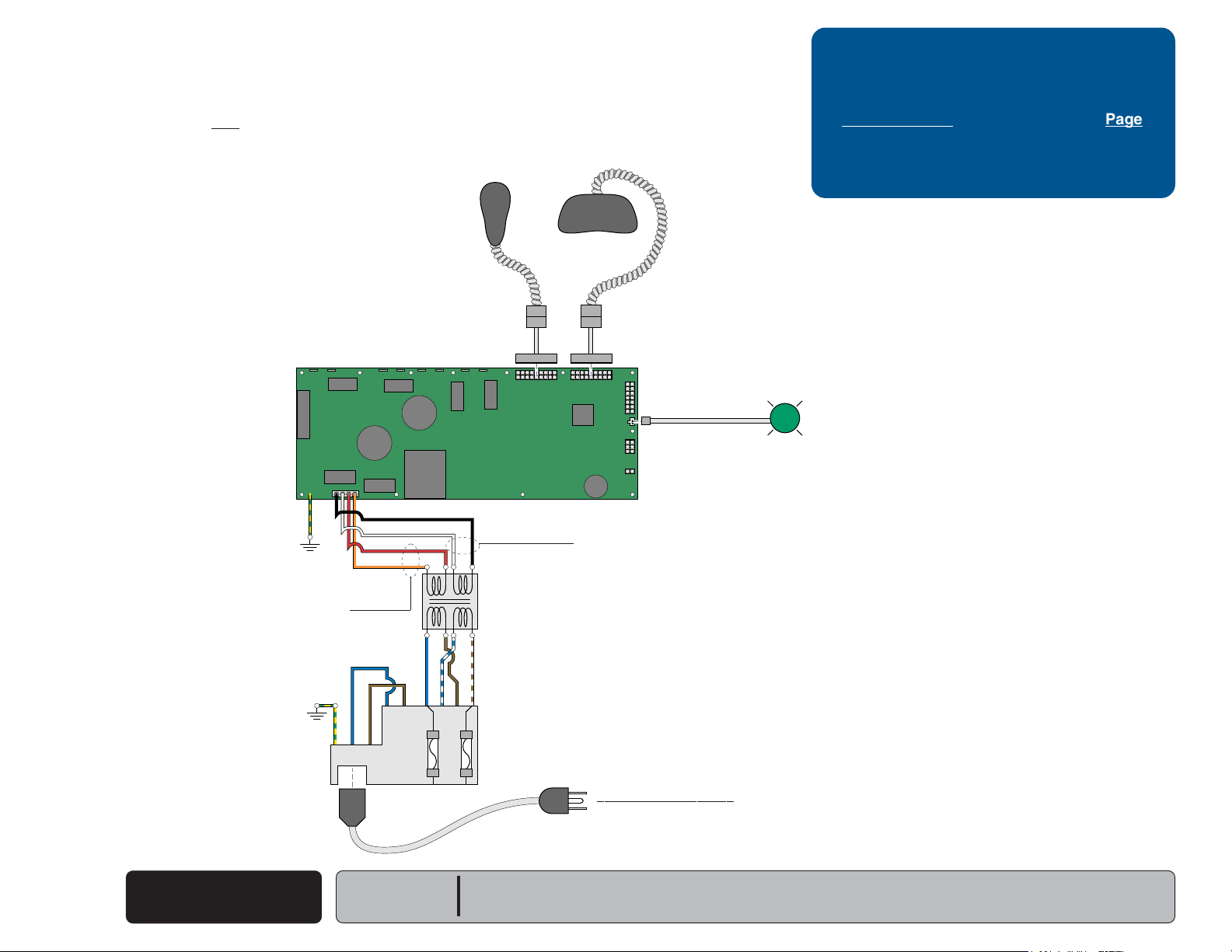

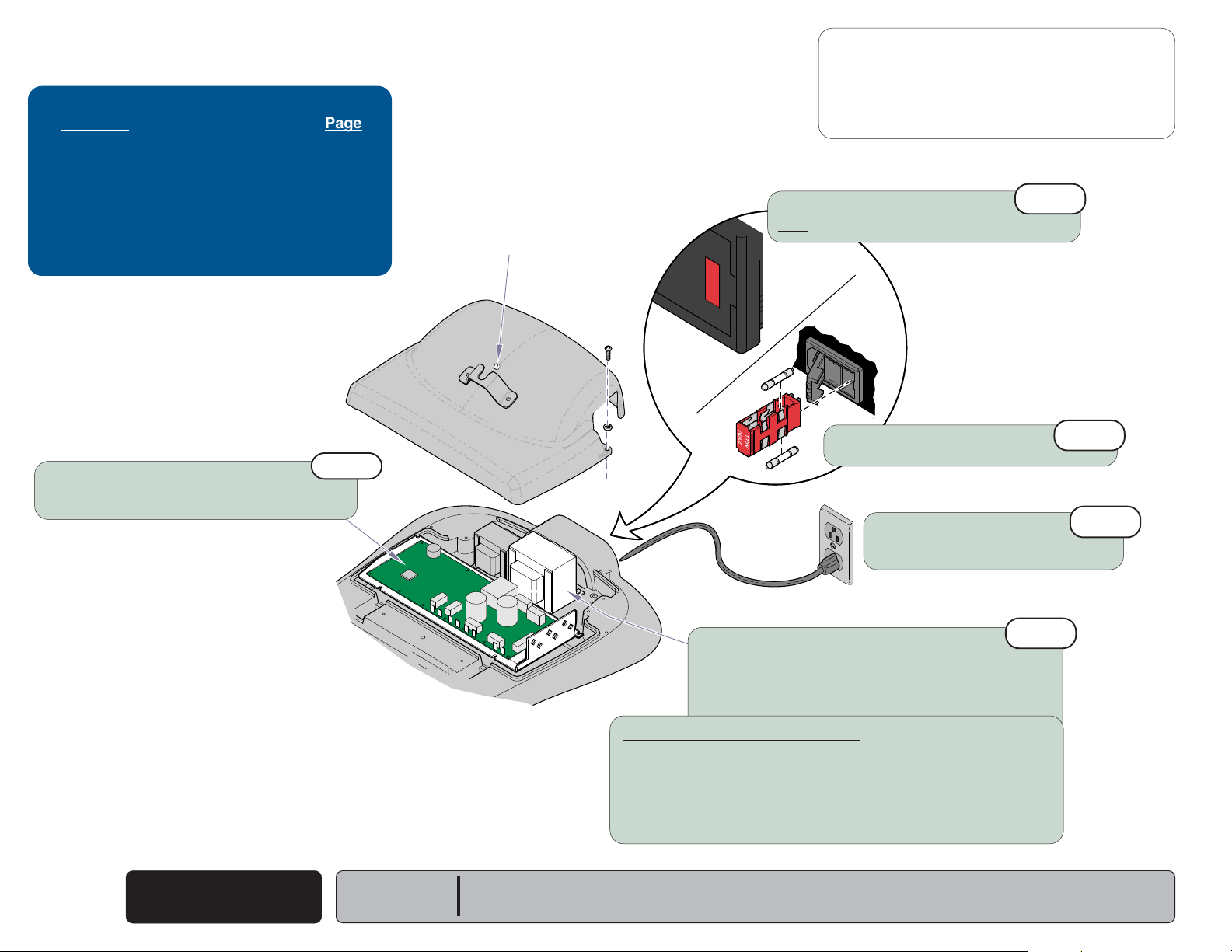

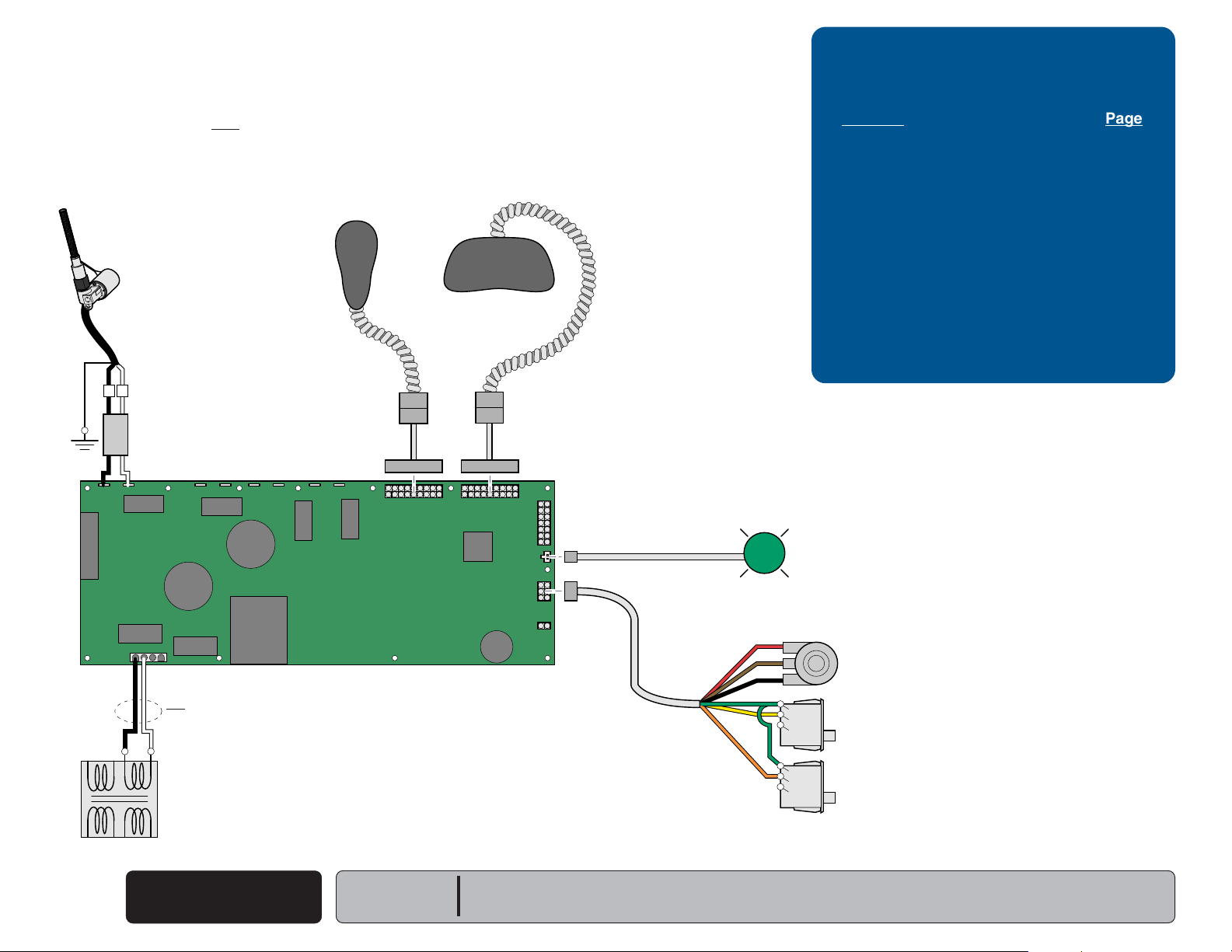

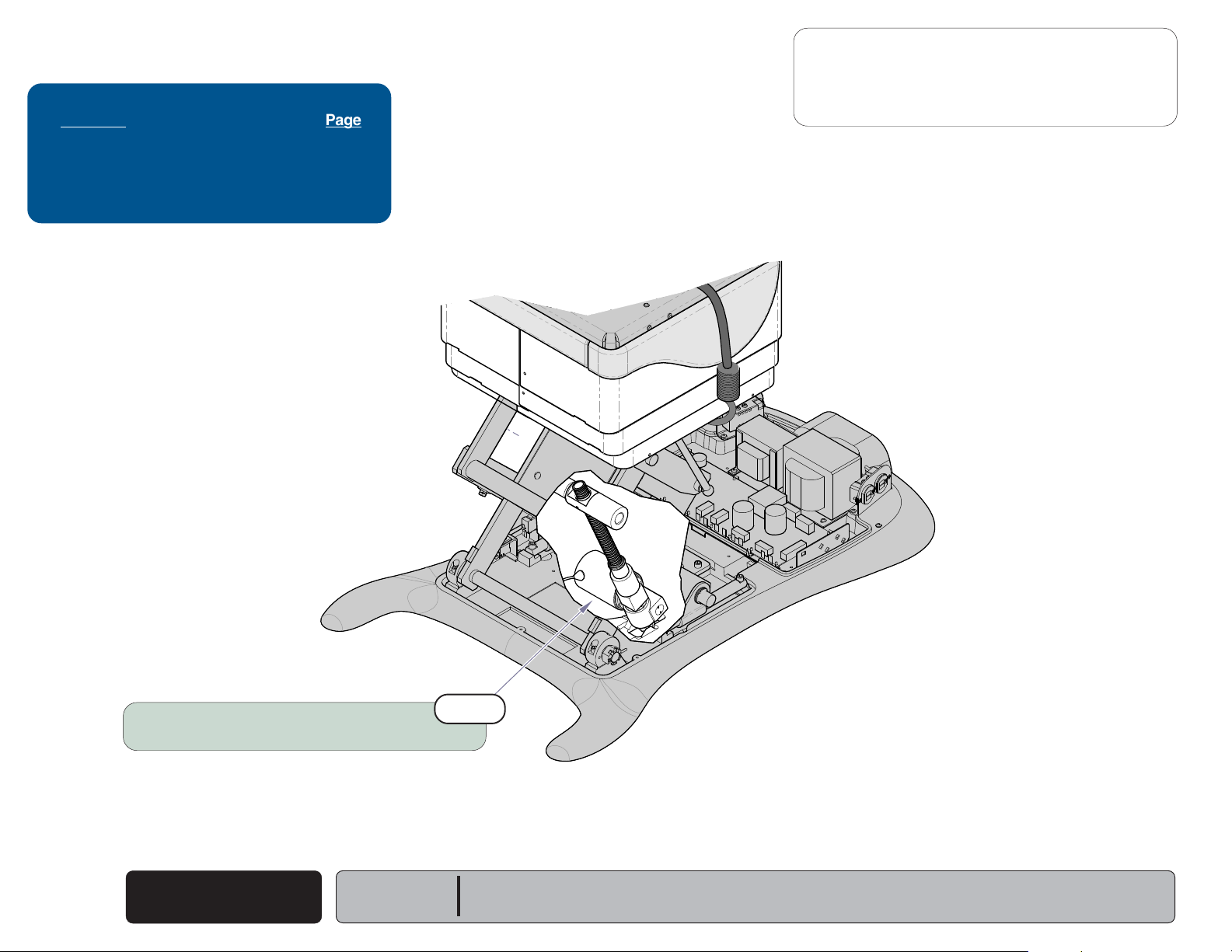

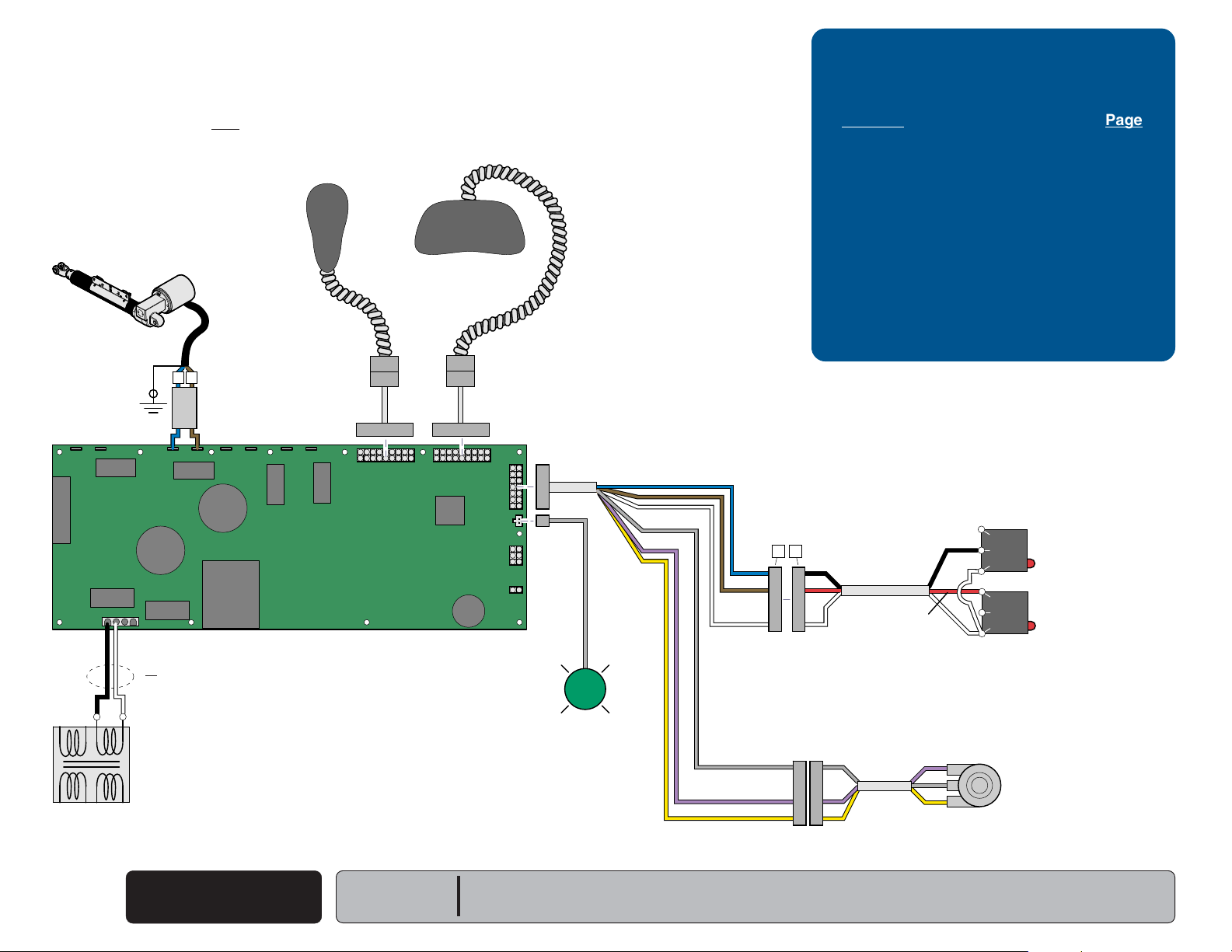

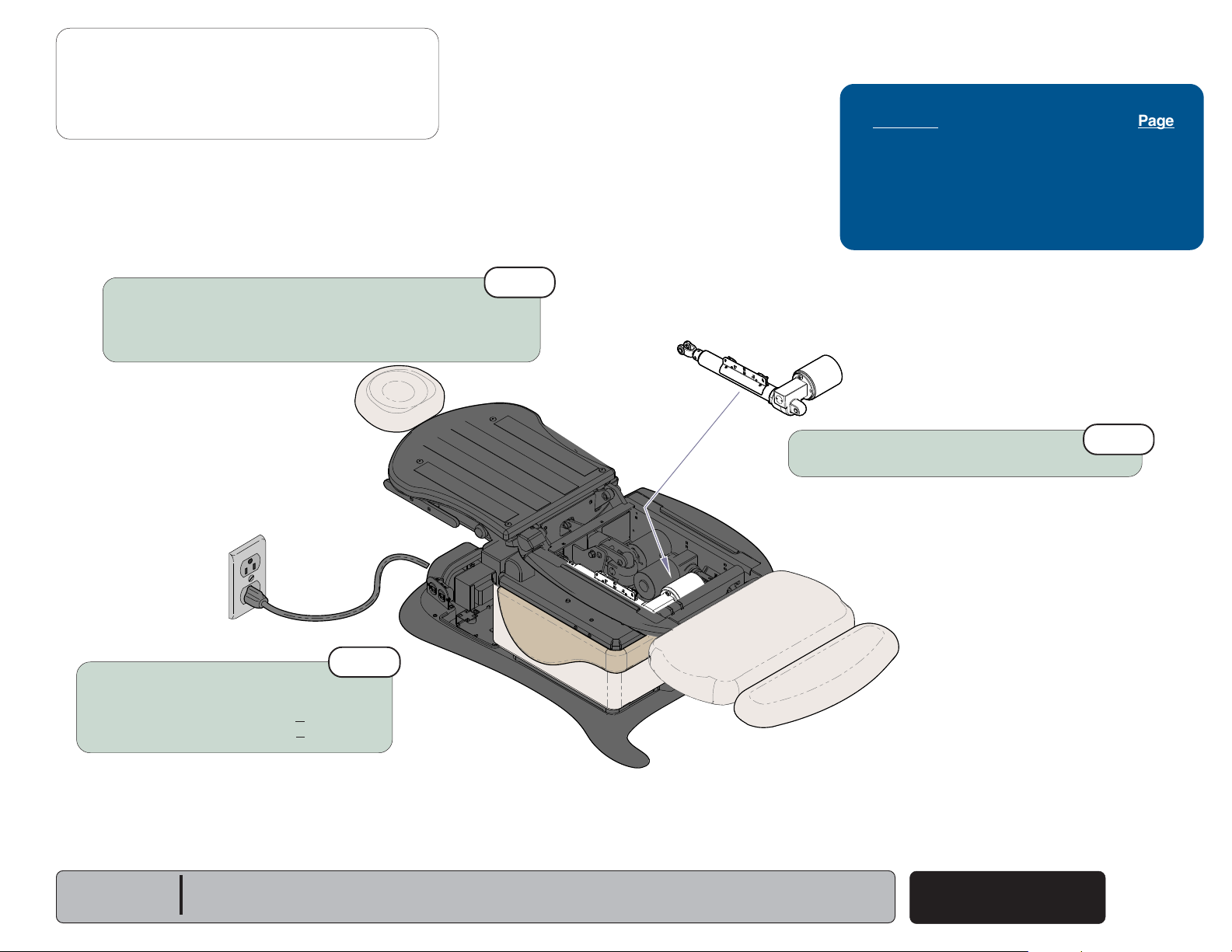

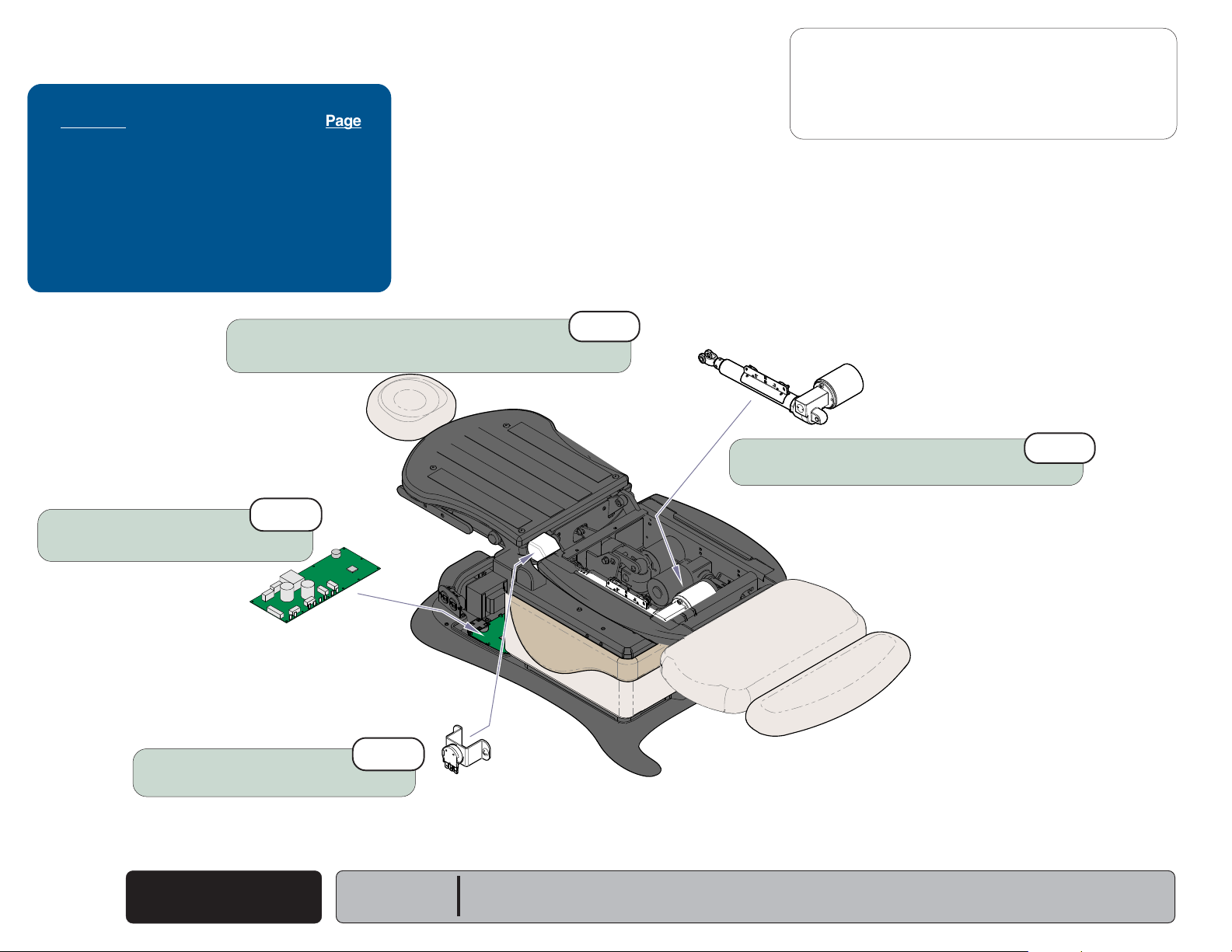

Power To The Table

This illustration shows only the components that affect ALL TABLE FUNCTIONS.

Refer to the following page for a detailed description of the power supply to the table.

(models w/ Standard Base)

Hand

Control

P9 P10

Foot

Control

Troubleshooting

[No Power / No Functions Will Operate]

Power Light is: Page

OFF

..................................................... A-6

ON .......................................................

8-10 VAC8-10 VAC

A-7

J2

J1

J15

GN / YL

[Red & orange wires supply 34-37 VAC to power

circuitry for the Tilt & Foot actuators, hand/foot controls,

power light, all limit switches, and position sensors]

GN / YL

J4J3

BK

WH

RD

OR

J8J7J6J5

Main PC

Board

J10J9

MA646300i

J11

J12

J13

J14

P11

P12

Power

Light

[Black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators]

If Power Light is OFF, there is no power to PC Board.

If Power Light is ON, proper voltage is present at PC Board.

Main System

Transformer

BL

BR

N

BL

BR

BR / WH

BL / WH

A

B

C

D

G

H

Power

F1

L

F2

Inlet

Facility Supply Voltage

Power To The Table

A-2

© Midmark Corporation 2007 SF-1891

(Standard Base)

Models:

Serial Numbers:

641

(-002 & -003)

all

Operation & Troubleshooting

115V

MA646200i

230V

115V

Next

Go To Table Of Contents

Back

Power To The Table

Facility Supply Voltage

With the table's power cord properly connected, facility supply

voltage

inlet.

Power Inlet

(115 or 230 VAC)

(models w/ Standard Base)

is supplied thru the cord to the power

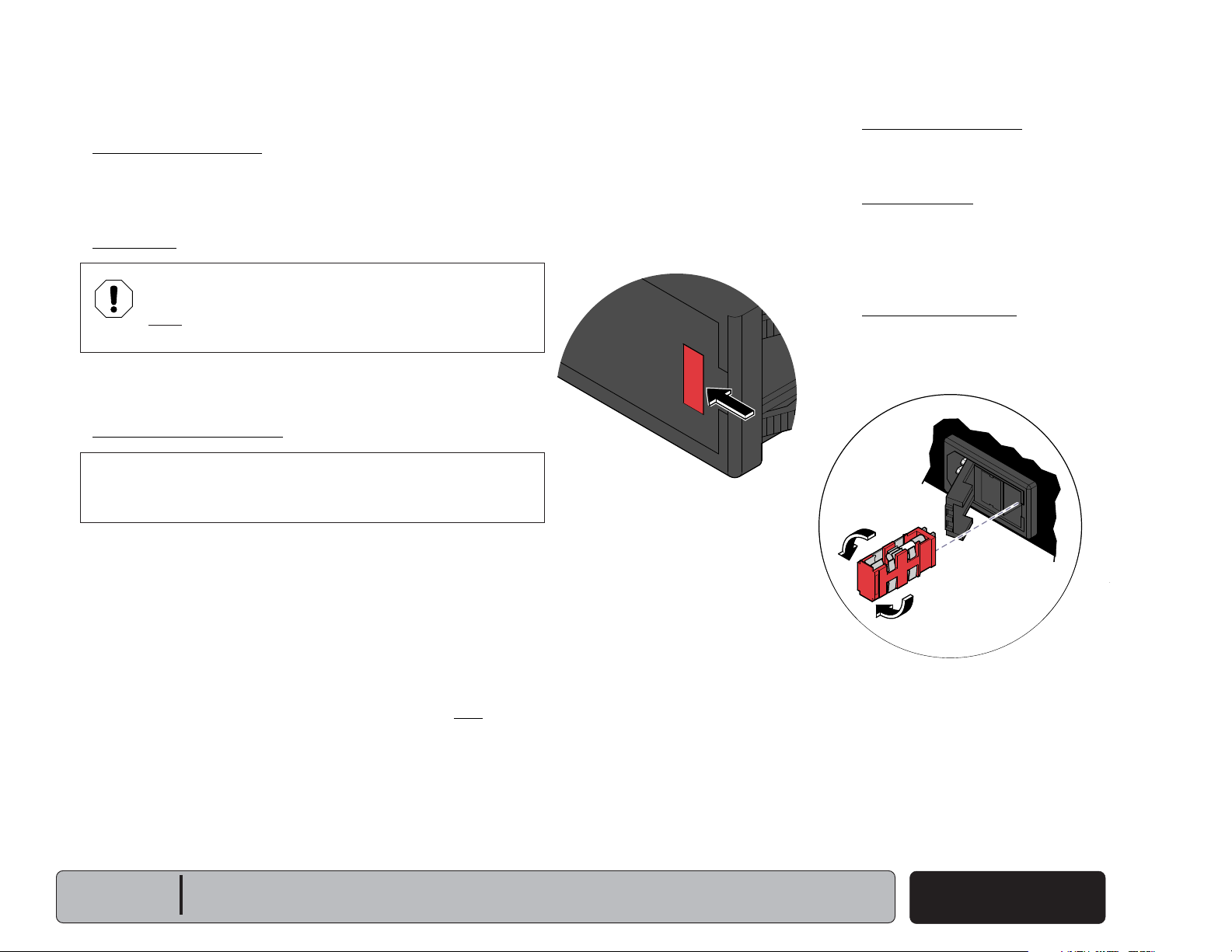

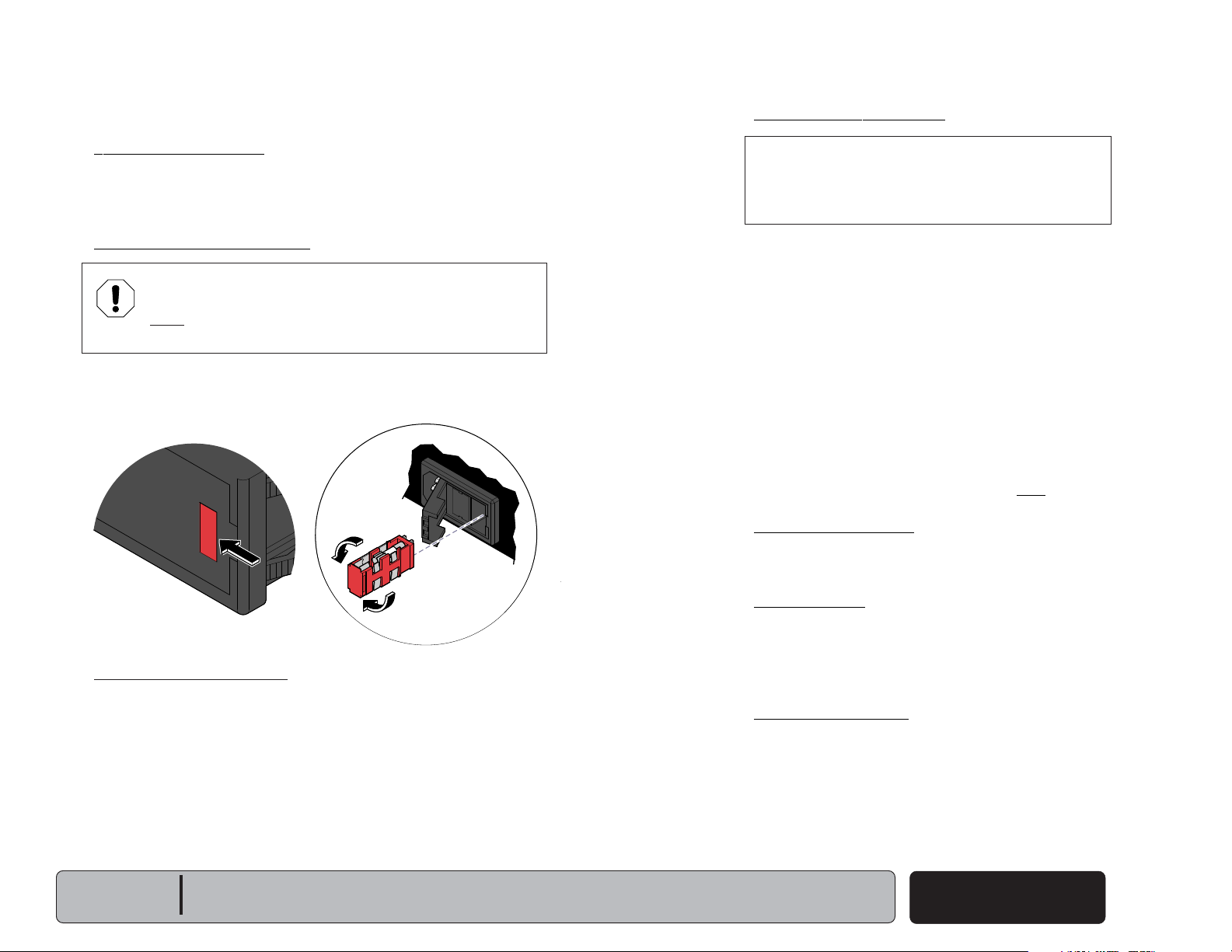

EQUIPMENT ALERT

The voltage setting displayed in the power inlet window

must match facility supply voltage

(115 or 230 VAC)

.

[Remove fuse holder and rotate 180° to change voltage setting].

Current flows thru two fuses in the power inlet, to the main system

transformer.

Main System Transformer

NOTE

This transformer is protected from overload by a thermal cutout

feature. This will automatically reset when the transformer cools.

Line voltage

transformer. The transformer reduces the voltage and current

flows to the main PC board thru two separate windings

(115 or 230 VAC)

is supplied to the main system

(four wires)

Power Indicator Light

When voltage is applied to the PC board, the

power light is illuminated.

Main PC Board

Circuitry on the PC board provides the required

voltage to power all of the table's components:

hand/foot controls, actuators, limit switches, and

position sensors.

Hand / Foot Controls

Circuitry on the main PC board supplies 8-10

VAC to the hand / foot control connection ports.

.

[The black & white wires supply 48-54 VAC to power circuitry for

the Base & Back actuators only].

[The red & orange wires supply 34-37 VAC to power circuitry for

the Tilt & Foot actuators, hand/foot controls, power light, all limit

switches, and position sensors (on Midmark models only)].

Models:

Serial Numbers:

641

(-002 & -003)

all

Power To The Table

(Standard Base)

© Midmark Corporation 2007 SF-1891

Rev. 7/6/12

A-3

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

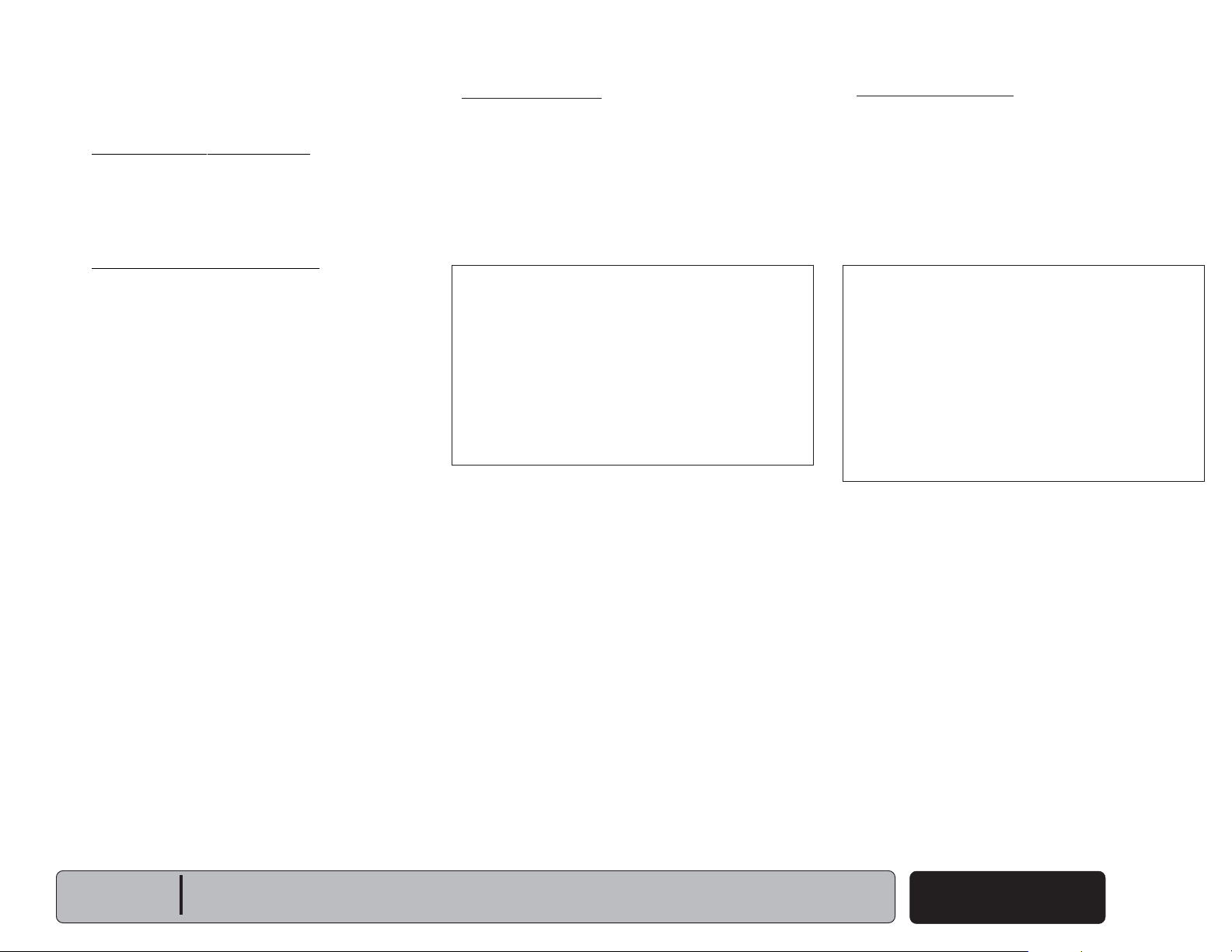

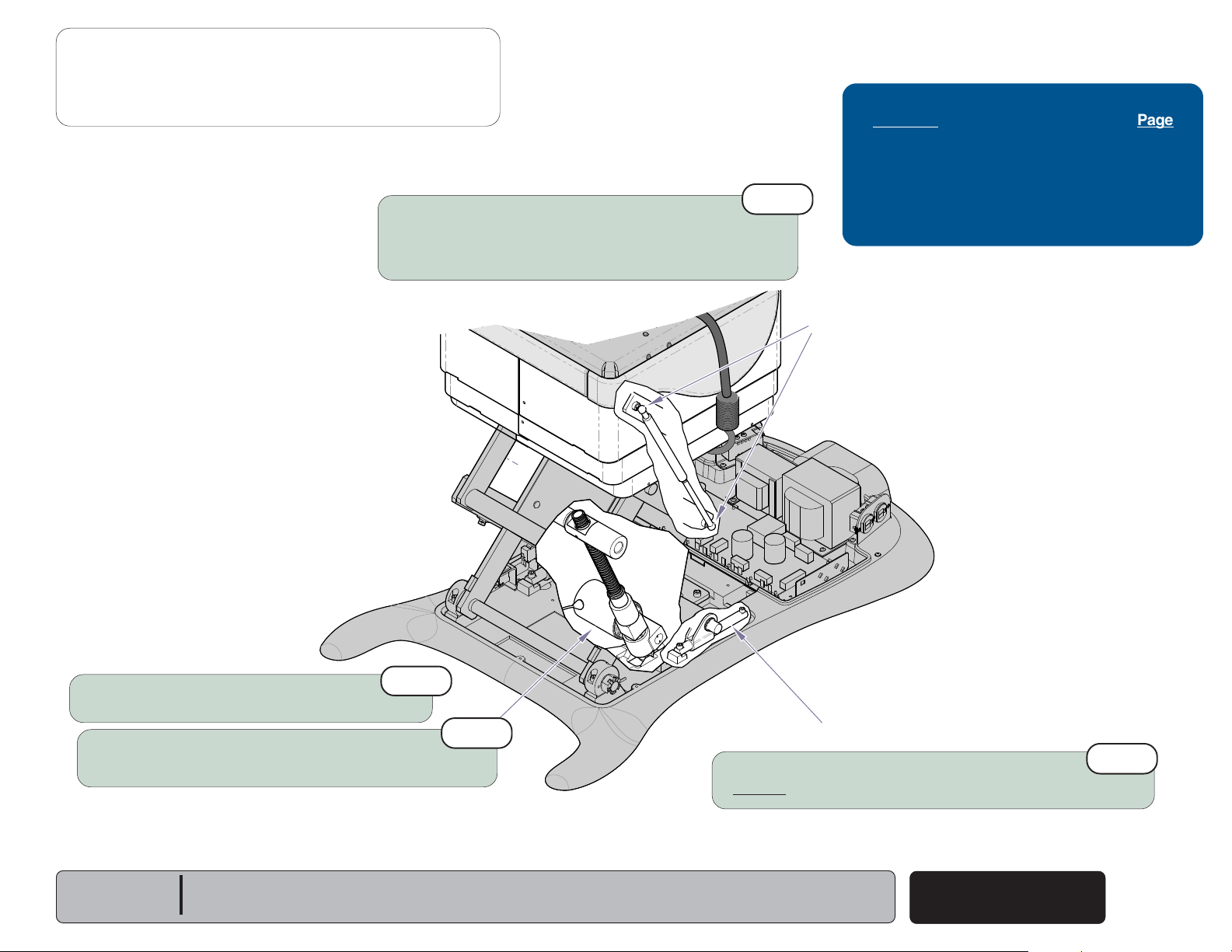

Power To The Table

This illustration shows only the components that affect ALL TABLE FUNCTIONS.

Refer to the following page for a detailed description of the power supply to the table.

(models w/ Rotational Base)

Hand

Control

Foot

Control

Troubleshooting

[No Power / No Functions Will Operate]

Power Light is: Page

OFF

..................................................... A-6

ON .......................................................

A-7

[Black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators]

[Red & orange wires supply 34-37 VAC

to power circuitry for the Tilt & Foot actuators,

hand/foot controls, power light, all limit switches,

and position sensors]

J1

J15

GN / YL

WH

BK

8-10 VAC

P9 P10

J2

J4J3

J8J7J6J5

J10J9

Main PC

Board

8-10 VAC

J11

J12

J13

J14

P12

If Power Light is OFF, there is no power to PC Board.

If Power Light is ON, proper voltage is present at PC Board.

Power

Light

OR

RD

Rotational

Base

PC Board

J10

J9

OR

RD

WH

BK

Main System

Transformer

J3

J7

BL

BR

BR/WH

J6

J5

BL/WH

J12

J2

GN / YL

J4

C

A

B

Power Inlet

GN / YL

BR

D

G

GN / YL

H

BR

L

N

BL

BL

J4

EMI Filter

J6

PC Board

J5

J1

J2

J3

Facility Supply Voltage

MA709900i

Power To The Table

A-4

© Midmark Corporation 2007 SF-1891

(Rotational Base)

Models:

Serial Numbers:

641

(-004 & -005)

all

Operation & Troubleshooting

115V

Next

Go To Table Of Contents

Back

Power To The Table

Facility Supply Voltage

With the table's power cord properly connected, facility supply

voltage

inlet.

Power Inlet / EMI Filter Board

(115 or 230 VAC)

(models w/ Rotational Base)

is supplied thru the cord to the power

EQUIPMENT ALERT

The voltage setting displayed in the power inlet window

must match facility supply voltage

(115 or 230 VAC)

.

[Remove fuse holder and rotate 180° to change voltage setting].

Current flows from the power inlet thru the EMI filter board,

then back thru the power inlet fuses to the rotational base

PC board.

115V

230V

MA646200i

Rotational Base PC Board

Current flows thru the rotational base PC board to the main system

transformer. The transformer reduces the voltage and current flows

back to the rotational base PC board.

Circuitry on the rotational base PC board provides the required

voltage to power the rotational base brake system.

The reduced voltage is supplied to the main PC board thru the

rotational base PC board.

Main System Transformer

NOTE

This transformer is protected from overload by a

thermal cutout feature. This will automatically reset

when the transformer cools.

Line voltage

main system transformer thru the rotational base

PC board. The transformer reduces the voltage

and current flows back to the rotational base

PC board, then to the main PC board thru two

separate windings

[The black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators only].

[The red & orange wires supply 34-37 VAC to

power circuitry for the Tilt & Foot actuators, hand/

foot controls, power light, all limit switches, and

position sensors (on Midmark models only)].

Power Indicator Light

When voltage is applied to the PC board, the power

light is illuminated.

Main PC Board

Circuitry on the PC board provides the required

voltage to power all of the table's components:

hand/foot controls, actuators, limit switches, and

position sensors.

Hand / Foot Controls

Circuitry on the main PC board supplies 8-10 VAC

to the hand / foot control connection ports.

(115 or 230 VAC)

(four wires)

is supplied to the

.

Models:

Serial Numbers:

641

(-004 & -005)

all

Power To The Table

(Rotational Base)

© Midmark Corporation 2007 SF-1891

Rev. 7/6/12

A-5

Operation & Troubleshooting

115V

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

Primary Fuses ...................................... B-2

Main System Transformer ..................... B-29

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

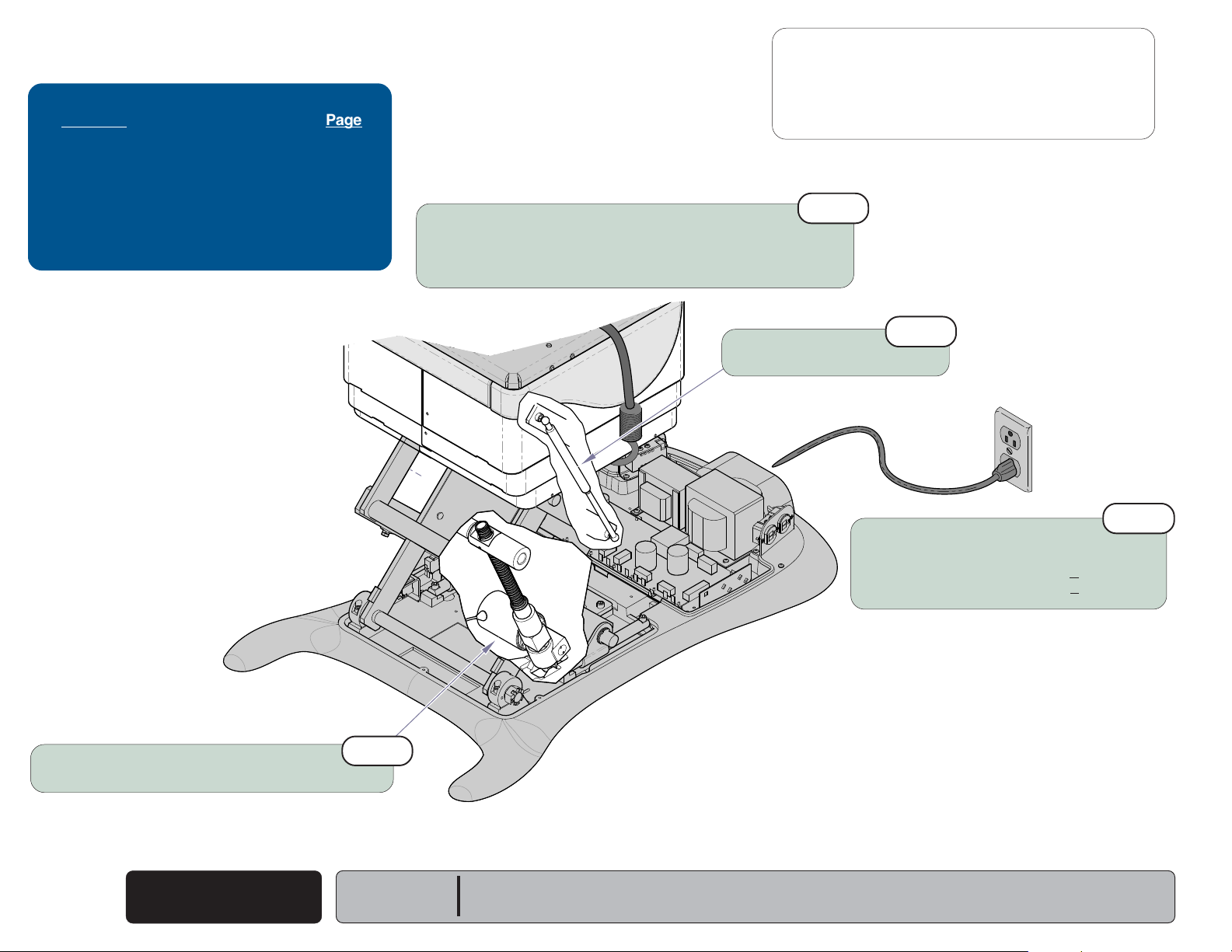

Power Light: OFF

Power to the Table

Problem: No functions will operate - and

Power light is OFF.

Voltage setting

Must match facility supply voltage (115 / 230 V).

- continued

2nd

Main PC Board

If the transformer is OK, replace main PC board.

Refer to: Section B - Main PC Board

5th

(Standard Base shown)

Primary Fuses

Refer to: Section B - Primary Fuses

Faclity Supply Voltage

Check power cord connections.

Check facility circuit breaker.

MA755900i

4th

Main System Transformer

Check all wire connections between power inlet

& main PC board. If connections are OK, test transformer.

Refer to: Section B - Main System Transformer

Models w/Rotational Base only:

If there is no power to the main system transformer...

Rotational Base PC Board / EMI Filter Board

Check all wire connections between rotational base PC board &

the transformer. If connections are OK, perform EMI Filter Board Test.

Refer to: Section B - Rotational Base Brake System

3rd

1st

Power To The Table

A-6

© Midmark Corporation 2007 SF-1891

Rev. 9/05

Models:

Serial Numbers:

ALL

Power to the Table

Next

Go To Table Of Contents

Back

Go To Page:

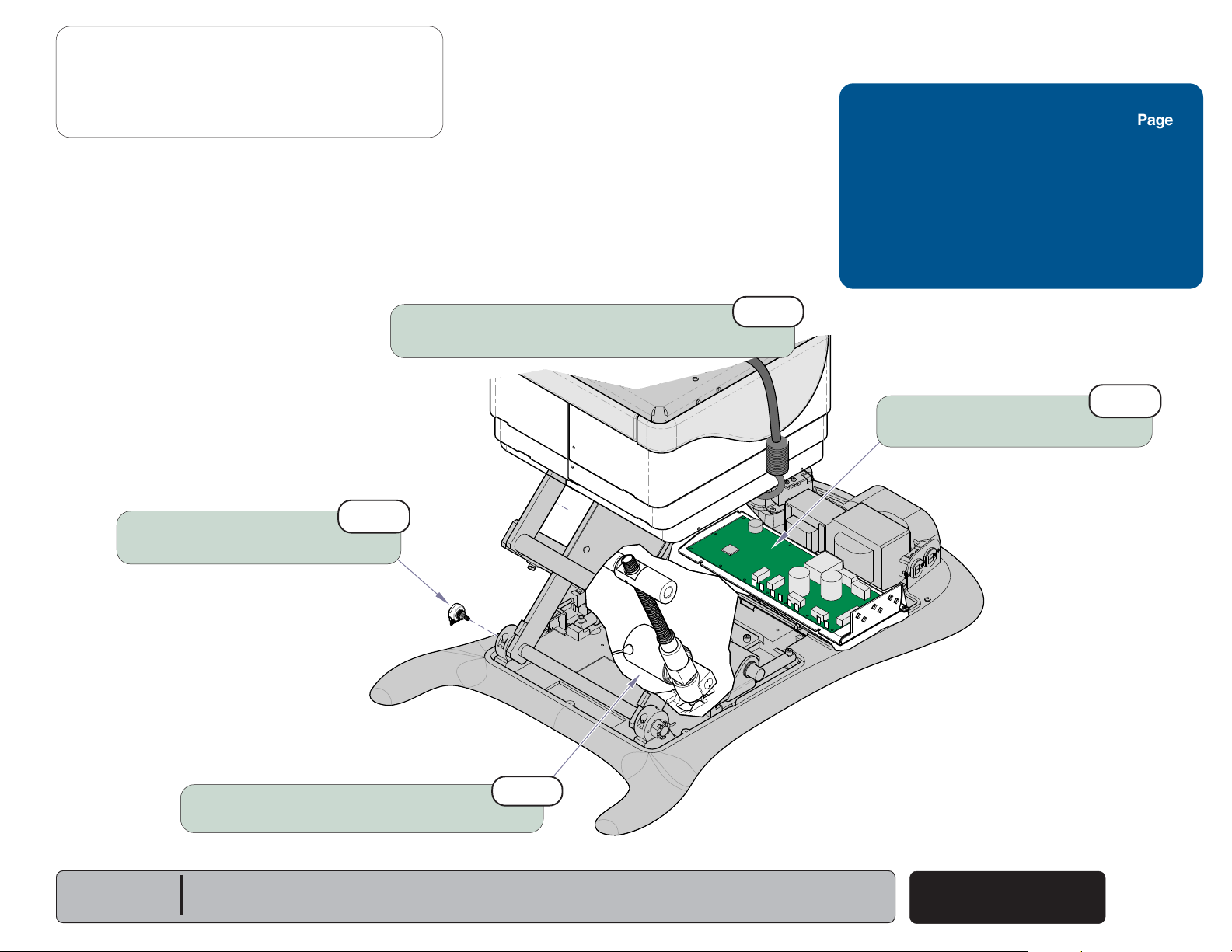

Problem: No functions will operate - and

Power light is ON.

Note: The cord connector is “keyed” and must be oriented properly to connect.

Tighten lockig ring to secure connector.

Locking

Ring

- continued

Hand / Foot Controls

Check cords for damage / proper connection.

Check both connection ports on table.

Refer to: Section B - Hand & Foot Controls

Loose / Damaged Wire Connections

(between connection ports & PC board)

1st

Operation & Troubleshooting

Refer To: Page

Hand & Foot Controls ............................ B-3

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Power Light: ON

3rd

Models:

Serial Numbers:

Check for error code(s)

Refer to: Section B - Main PC Board

Position "4" Button

Programmable Models only:

Press "4" button on hand control for

five seconds, then try functions again...

If table functions operate, go to Section B,

Main PC Board (Hand/Foot Control Lockout Feature)

If table functions still will not move, go to next check.

ALL

2nd

4th

(Standard Base shown)

Power To The Table

© Midmark Corporation 2007 SF-1891

MA756000i

A-7

Rev. 9/05

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

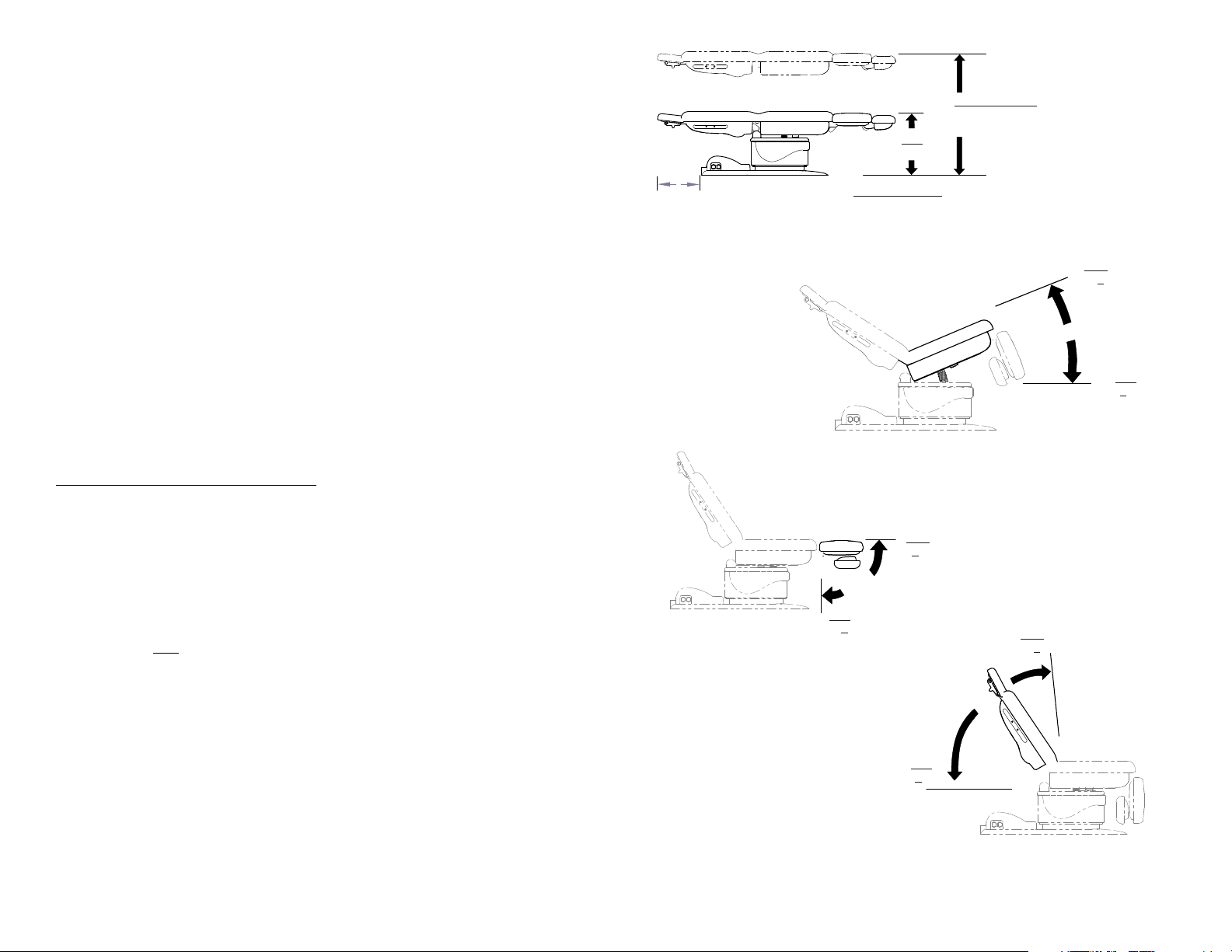

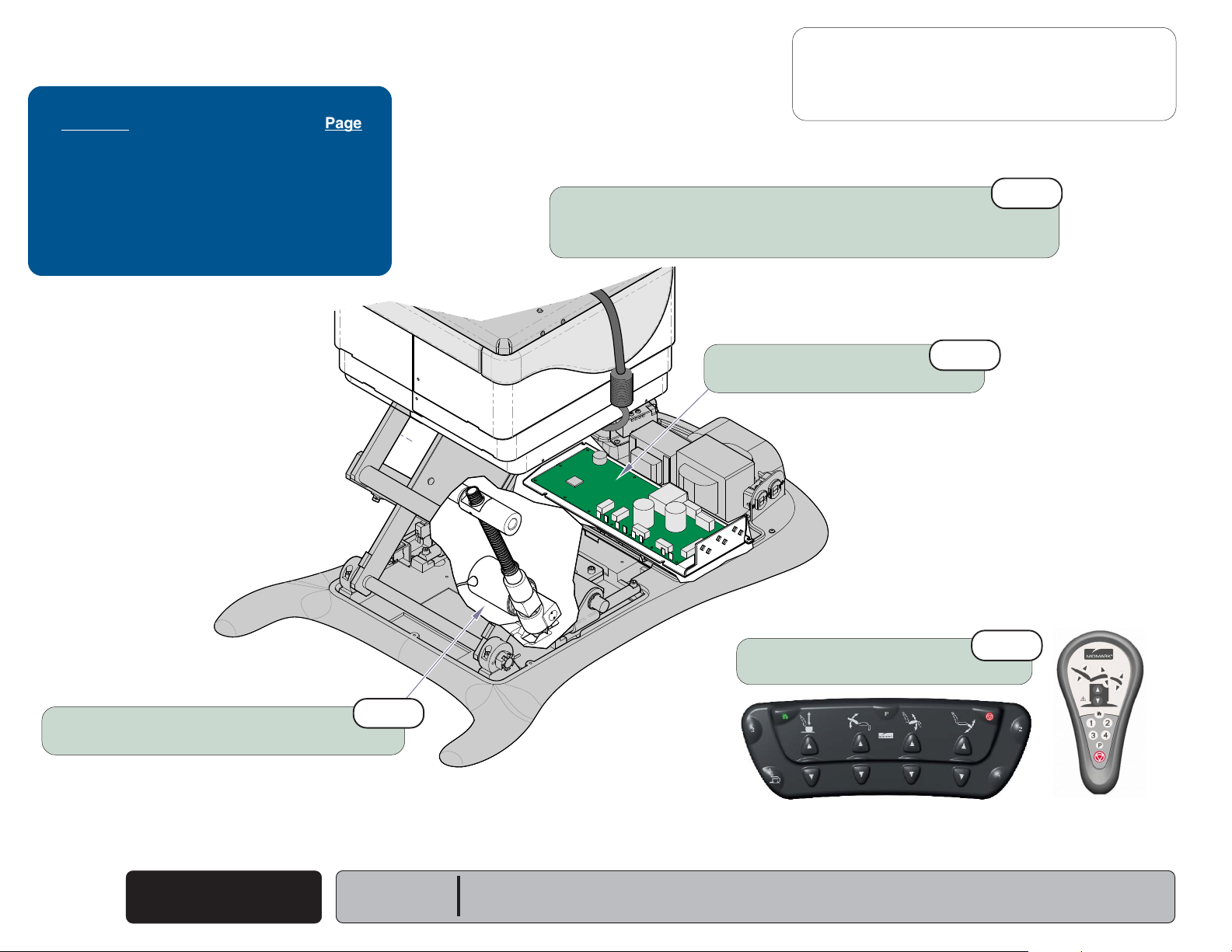

Base UP / DOWN Function

This illustration shows only the components that affect the Base UP / DOWN function.

Refer to the following page for a detailed description of Base UP / DOWN operation.

Hand

Base

BK

BK

Actuator

WH

WH

Control

Foot

Control

Troubleshooting

[Base Up / Down Function]

Problem Page

No Base UP or DOWN

No Base UP (DOWN - OK)

No Base DOWN (UP - OK) ...................

Base Drifts Down .................................

Noisy Operation ...................................

Moves Slowly / Will Not Lift Patient .....

Up and/or Down Function

Moves Briefly, Then Stops ...............

Headrest and/or Foot Extension

Collides w/Floor ................................

........................ A-10

.................. A-11

A-11

A-12

A-13

A-14

A-15

A-38

Choke

WH

BK

J2

J1

J15

BK

WH

A-8

© Midmark Corporation 2007 SF-1891

P9 P10

J4J3

J8J7J6J5

Main PC

Board

[Black & white wires supply 48-54 VAC to

power circuitry for the Base & Back actuators]

Main System

Transformer

Base Up / Down

Note: On models w/ rotational base, the Main System

Transformer connections are supplied thru the

Rotational Base PC Board (not shown).

Models:

Serial Numbers:

J10J9

J11

J12

J13

J14

MA646400i

ALL

P12

P13

Only the wires that affect the Base Function are shown.

If Power Light is ON, proper voltage is present at PC Board.

If Power Light is OFF, refer to Page A-2 for troubleshooting.

Power

Light

RD

OR

YL

BN

BK

GN

GN

1

2

3

COM

NC

NO

COM

NC

NO

Base

Sensor

Base Up

Limit Switch

Base Down

Limit Switch

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Base UP / DOWN Function

Is There Power To The Table?

When voltage is present at the PC board, the

power light is illuminated.

[Refer to 'Power To The Table' (page A-2), for

description of current flow to the PC board].

Power To Foot / Hand Controls

Circuitry on the PC board supplies 8-10 VAC

to the hand / foot control connection ports.

Base Up Operation

When the Base Up function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the base

actuator motor.

The actuator motor runs and raises the table.

NOTE

The PC board continuously monitors the Base

Up limit switch and the Base position sensor.

If the Base Up limit switch is tripped (open),

the Base Up function will not operate.

If the Base position sensor detects that the

table has reached its upper limit, the Base Up

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Base Up limit switch is tripped.

3. Emergency Stop button is pressed.

4. Position Sensor detects upper limit.

5. Overcurrent protection tripped.

6. Software time-out limit is reached

(approx. 25 seconds)

.

Base Down Operation

When the Base Down function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 40 VDC to the base

actuator motor.

The actuator motor runs and lowers the table.

NOTE

The PC board continuously monitors the Base

Down limit switch and the Base position sensor.

If the Base Down limit switch is tripped (open),

the Base Down function will not operate.

If the Base position sensor detects that the table

is in a potential "crash position", or that the base

has reached its lower limit, the Base Down

function will not operate*.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Base Down limit switch is tripped.

3. Emergency Stop button is pressed.

4. Crash Avoidance System activated*.

5. Position Sensor detects lower limit.

6. Overcurrent protection tripped.

7. Software time-out limit is reached

(approx. 25 seconds)

.

Models:

Serial Numbers:

ALL

*Note: Refer to

"crash position", and the table functions that are disabled.

Section A: Crash Avoidance System

for a detailed description of

Base Up / Down

Base Up / Down

© Midmark Corporation 2007 SF-1891

A-9

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

Hand & Foot Controls ............................ B-3

Base Actuator / Limit Switches ............. B-6

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Up / Down Function

Problem: No Base Up or Base Down

1st

Loose / Damaged Wire Connections

(Base Actuator, Base Up/Down Limit Switches, hand/foot control ports,

black & white wires between main system transformer & PC board)

- continued

Base Actuator

Refer to: Section B - Base Actuator / Limit Switches

3rd

Main PC Board

Refer to: Section B - Main PC Board

MA756400i

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

4th

2nd

A-10

© Midmark Corporation 2007 SF-1891

Base Up / Down

Models:

Serial Numbers:

ALL

Base Up / Down Function

Next

Go To Table Of Contents

Back

Go To Page:

Problem: No Base Up. [Base Down - OK]

-or

No Base Down. [Base Up - OK]

Attention: If Base Down is inoperable, move the other

chair functions to the positions listed below:

Back / Foot: full UP

Tilt: full DOWN

If Base Down function becomes operable,

refer to: Section A - Crash Avoidance System

Loose / Damaged Wire Connections

(Hand/Foot Control & Base Up / Down Limit Switches)

Base Up/Down Limit Switches

Refer to: Section B - Base Actuator / Limit Switches

- continued

1st

2nd

Operation & Troubleshooting

Refer To: Page

Crash Avoidance System ..................... A-38

Hand & Foot Controls ............................ B-3

Base Actuator / Limit Switches ............. B-6

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Main PC Board

Refer to: Section B - Main PC Board

5th

Models:

Serial Numbers:

Base Actuator

Refer to: Section B - Base Actuator / Limit Switches

ALL

4th

MA756100i

3rd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Base Up / Down

© Midmark Corporation 2007 SF-1891

A-11

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

Base Actuator / Limit Switches ............ B-6

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Up / Down Function

Problem: Base drifts down.

- continued

Base Actuator

Refer to: Section B - Base Actuator / Limit Switches

A-12

© Midmark Corporation 2007 SF-1891

Base Up / Down

Models:

Serial Numbers:

1st

MA756700i

ALL

Base Up / Down Function

Next

Go To Table Of Contents

Back

Go To Page:

Problem: Noisy operation. (Grinding, squeaking, etc)

- continued

Clean / lubricate gas spring pivot joints

Recommended lubricant: Lithium grease

Refer to: Section B - Gas Springs

Operation & Troubleshooting

Refer To: Page

Base Actuator / Limit Switches ............. B-6

Gas Springs .......................................... B-27

1st

Pivot Joints

Wiring Diagrams .................................... D-1

Exploded Views / Part Numbers ........... E-1

Base Actuator

Refer to: Section B - Base Actuator / Limit Switches

Clean / lubricate base actuator threads.

Recommended lubricant: Lithium grease

Models:

Serial Numbers:

ALL

4th

2nd

MA756800i

Guide Bars

Wipe guide bars with a clean, dry cloth.

NEVER lubricate base slides / scissor mechanism.

Base Up / Down

© Midmark Corporation 2007 SF-1891

3rd

A-13

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

General Information

Base Actuator ....................................... B-6

Gas Springs .......................................... B-27

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

(Specifications) .....

ii

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

Refer to: General Information section

Base Up / Down Function

Problem: Moves slowly - and/or

Will not lift patient.

1st

3rd

Gas Springs

Refer to: Section B - Gas Springs

- continued

Base Actuator

Refer to: Section B - Base Actuator / Limit Switches

Base Up / Down

A-14

© Midmark Corporation 2007 SF-1891

4th

Models:

Serial Numbers:

ALL

MA756900i

2nd

Low voltage to table

Required voltage:

115 VAC setting ............ 115 +10% VAC

230 VAC setting ............ 230 +10% VAC

Base Up / Down Function

Next

Go To Table Of Contents

Back

Go To Page:

Problem: Base Up and/or Base Down

moves briefly, then stops ("beeps").

Attention: Before performing any of the checks on this page,

move the chair functions to the positions listed below:

Back / Foot: full UP

Tilt: full DOWN

If Base function becomes operable,

refer to: Section A - Crash Avoidance System

- continued

Loose / Damaged Wire Connections

(Base Position Sensor, Hand/Foot Controls)

Operation & Troubleshooting

Refer To: Page

Crash Avoidance System ..................... A-38

Base Actuator / Limit Switches ............. B-6

Position Sensors ................................... B-31

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

2nd

1st

Calibrate PC Board

Refer to: Section B - Main PC Board

Base Position Sensor

Refer to: Section B - Position Sensors

Models:

Serial Numbers:

3rd

Base Actuator

Refer to: Section B - Base Actuator / Limit Switches

ALL

4th

MA757000i

Base Up / Down

© Midmark Corporation 2007 SF-1891

A-15

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

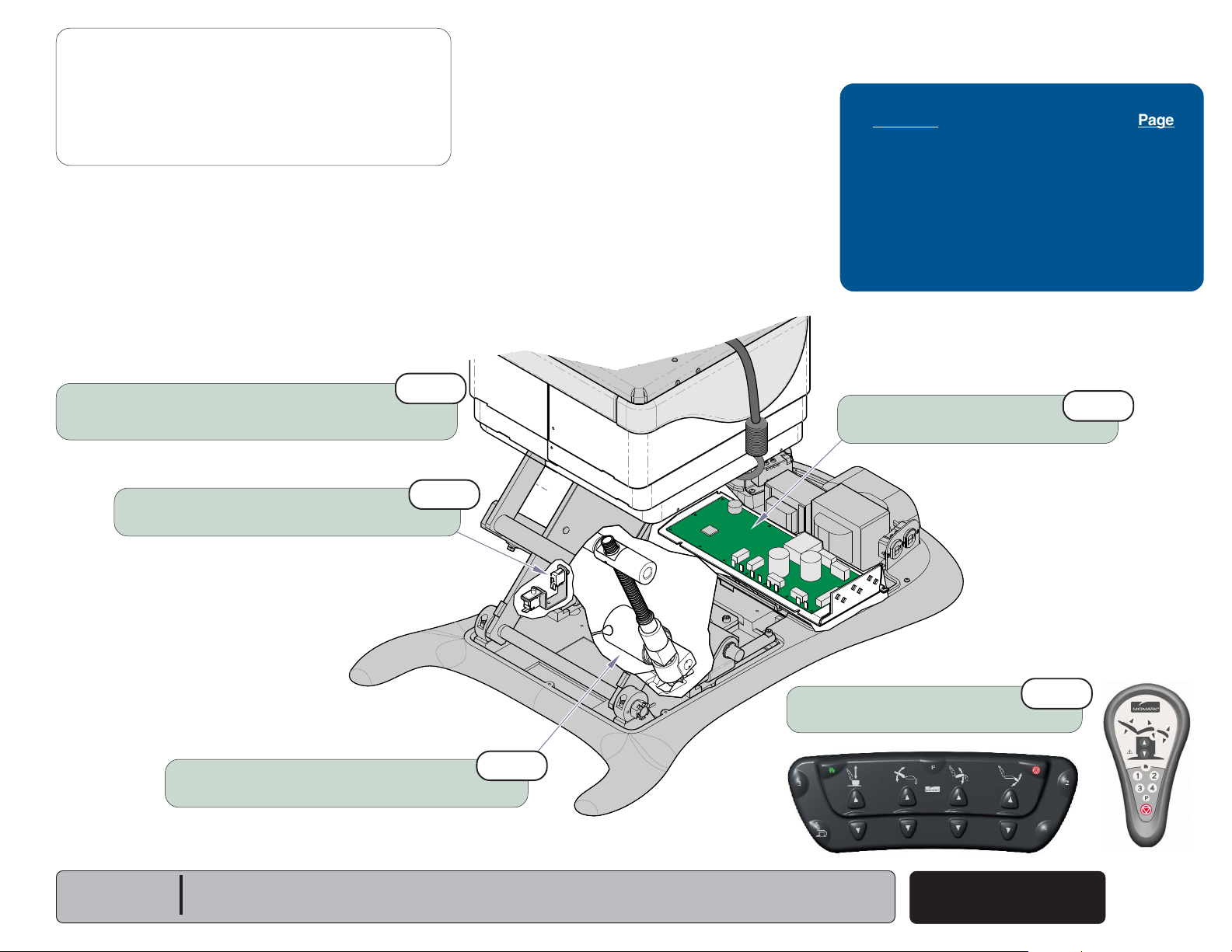

Back UP / DOWN Function

This illustration shows only the components that affect the Back UP / DOWN function.

Refer to the following page for a detailed description of Back UP / DOWN operation.

Hand

Control

Back

Actuator

Foot

Control

Troubleshooting

[Back Up / Down Function]

Problem Page

No Back UP or DOWN

No Back UP (DOWN - OK)

No Back DOWN (UP - OK) ...................

Back Drifts Down .................................

Noisy Operation ...................................

Moves Slowly / Will Not Lift Patient .....

Up / Down Function

Moves Briefly, then Stops ("beeps") ..

Headrest Collides w/Floor ....................

......................... A-18

................... A-19

A-19

A-20

A-20

A-21

A-22

A-38

Choke

J1

BL

J2

BR

J4J3

J8J7J6J5

Main PC

Board

J15

BK

WH

[Black & white wires supply 48-54 VAC

to power the Base & Back actuators]

Main System

Transformer

Note: On models w/ rotational base, the Main System

Transformer connections are supplied thru the

Rotational Base PC Board (not shown).

If Power Light is ON, proper voltage is present at PC Board.

If Power Light is OFF, refer to Page A-2 for troubleshooting.

P9 P10

J10J9

J11

J12

J13

J14

P12

P11

Power

Light

YL

Only the wires that affect the Back Function are shown.

BL

3 3

BK

4

4

3

BR

WH

GY

VI

3

RD

2

2

1

1

WH

GY

4

4

3

3

VI

2

2

YL

1

1

BK

RD

WH

VI

GY

YL

1

2

3

WH

NC

Back Up

NO

Limit Switch

COM

NC

Back Down

NO

Limit Switch

COM

Back

Position

Sensor

MA758500i

A-16

© Midmark Corporation 2007 SF-1891

Back Up / Down

Models:

Serial Numbers:

ALL

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Back UP / DOWN Function

Is There Power To The Table?

When voltage is present at the PC board, the

power light is illuminated.

[Refer to 'Power To The Table' (page A-2), for

description of current flow to the PC board].

Power To Foot / Hand Controls

Circuitry on the PC board supplies 8-10 VAC

to the hand / foot control connection ports.

Back Up Operation

When the Back Up function is activated,

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

supplies approximately 48 VDC to the back

actuator motor.

The actuator motor runs and raises the back

section.

NOTE

The PC board continuously monitors the Back

Up limit switch and the Back position sensor.

If the Back Up limit switch is tripped (closed),

the Back Up function will not operate.

If the Back position sensor detects that the back

section has reached its upper limit, the Back Up

function will not operate.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Back Up limit switch is tripped.

3. Emergency Stop button is pressed.

4. Position Sensor detects upper limit.

5. Overcurrent protection tripped.

6. Software time-out limit is reached

(approx. 30 seconds)

.

Back Down Operation

Troubleshooting

When the Back Down function is activated,

[Crash Protection System]

current flows thru the hand / foot control,

back to the PC board. Circuitry on the PC Board

Problem Page

supplies approximately 44 VDC to the back

Headrest Mechanism

actuator motor.

Collides w/Floor .................................

The actuator motor runs and lowers the back

section.

Chair NOT in "Crash Position:

Base Down, Back Down, & Tilt Up

NOTE

Functions Will Not Move ...................

The PC board continuously monitors the Back

Down limit switch and the Back position sensor.

If the Back Down limit switch is tripped (open),

the Back Down function will not operate.

If the Back position sensor detects that the table

is in a potential "crash position", or that the back

section has reached its lower limit, the Back Down

function will not operate*.

Actuator Motor runs until:

1. Hand / foot control button is released.

2. Back Down limit switch is tripped.

3. Emergency Stop button is pressed.

4. Crash Avoidance System activated*.

5. Position Sensor detects lower limit.

6. Overcurrent protection tripped.

7. Software time-out limit is reached

(approx. 30 seconds)

.

A-x

A-x

Models:

Serial Numbers:

ALL

*Note: Refer to

"crash position", and the table functions that are disabled.

Section A: Crash Avoidance System

for a detailed description of

Back Up / Down

© Midmark Corporation 2007 SF-1891

A-17

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

Hand & Foot Controls ............................ B-3

Back Actuator / Limit Switches ............ B-10

Main PC Board...................................... B-37

Wiring Diagrams .................................... D-1

Exploded Views / Part Numbers ........... E-1

Loose / Damaged Wire Connections

(Back Actuator, Back Up/Down Limit Switches, hand/foot control ports,

black & white wires between main system transformer & PC board)

Back Up / Down Function

Problem: No Back Up or Back Down.

1st

Back Actuator / Limit Switches

Refer to: Section B - Back Actuator / Limit Switches

3rd

- continued

Main PC Board

Refer to: Section B - Main PC Board

Back Up / Down

A-18

© Midmark Corporation 2007 SF-1891

4th

Models:

Serial Numbers:

ALL

MA765800i

2nd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Back Up / Down Function

Next

Go To Table Of Contents

Back

Go To Page:

Problem: No Back Up. [Back Down - OK]

-or

No Back Down. [Back Up - OK]

Attention: If Back Down is inoperable, move the other

chair functions to the positions listed below:

Base / Foot: full UP

Tilt: full DOWN

If Back Down function becomes operable,

refer to: Section A - Crash Avoidance System

- continued

Operation & Troubleshooting

Refer To: Page

Crash Avoidance System ..................... A-38

Hand & Foot Controls ............................ B-3

Back Actuator / Limit Switches ............. B-10

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

1st

Loose / Damaged Wire Connections

(Hand/Foot Control & Back Up / Down Limit Switches)

Back Actuator / Limit Switches

Refer to: Section B - Back Actuator / Limit Switches

3rd

Main PC Board

Refer to: Section B - Main PC Board

Models:

Serial Numbers:

ALL

4th

MA765800i

2nd

Hand / Foot Control

Refer to: Section B - Hand & Foot Controls

Back Up / Down

© Midmark Corporation 2007 SF-1891

A-19

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

Back Actuator / Limit Switches ............. B-10

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Back Actuator

Refer to: Section B - Back Actuator / Limit Switches

1st

Back Up / Down Function

Problem: Back drifts down.- and/or

Noisy operation. (Grinding / squeaking)

- continued

A-20

© Midmark Corporation 2007 SF-1891

Back Up / Down

Models:

Serial Numbers:

MA765900i

ALL

Back Up / Down Function

Next

Go To Table Of Contents

Back

Go To Page:

Problem: Moves slowly - and/or

Will not lift patient.

Did patient exceed 450 lb. weight limit?

Inform staff that max. patient weight is 450 lbs.

Refer to: General Information Section

- continued

1st

Operation & Troubleshooting

Refer To: Page

General Information

Back Actuator / Limit Switches ............. B-10

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

(Specifications) .....

ii

Low voltage to table

Required voltage:

115 VAC setting ............ 115 +10% VAC

230 VAC setting ............ 230 +10% VAC

Models:

Serial Numbers:

ALL

2nd

MA766000i

Back Actuator

Refer to: Section B - Back Actuator / Limit Switches

Back Up / Down

© Midmark Corporation 2007 SF-1891

3rd

A-21

Operation & Troubleshooting

Next

Go To Table Of Contents

Back

Go To Page:

Refer To: Page

Crash Avoidance System ..................... A-38

Back Actuator / Limit Switches ............ B-10

Position Sensors ................................... B-31

Main PC Board...................................... B-37

Wiring Diagrams ................................... D-1

Exploded Views / Part Numbers ........... E-1

Loose / Damaged Wire Connections

(Back Position Sensor, Hand/Foot Controls)

2nd

Back Up / Down Function

Problem: Back Up and/or Back Down

moves briefly, then stops ("beeps").

Attention: Before performing any of the checks on this page,

move the chair functions to the positions listed below:

Base / Foot: full UP

Tilt: full DOWN

If Tilt function becomes operable,

refer to: Section A - Crash Avoidance System

- continued

Calibrate PC Board

Refer to: Section B - Main PC Board

Back Position Sensor

Refer to: Section B - Position Sensors

A-22

© Midmark Corporation 2007 SF-1891

1st

Back Up / Down

3rd

Models:

Serial Numbers:

ALL

MA766100i

Back Actuator

Refer to: Section B - Back Actuator / Limit Switches

4th

Loading...

Loading...