Midmark 630 Troubleshooting Manual

Troubleshooting Guide:

midmark.com

Style A

Midmark 630 Human Form™ Procedures Table

630 (-010 thru -013 and -020 thru -023)

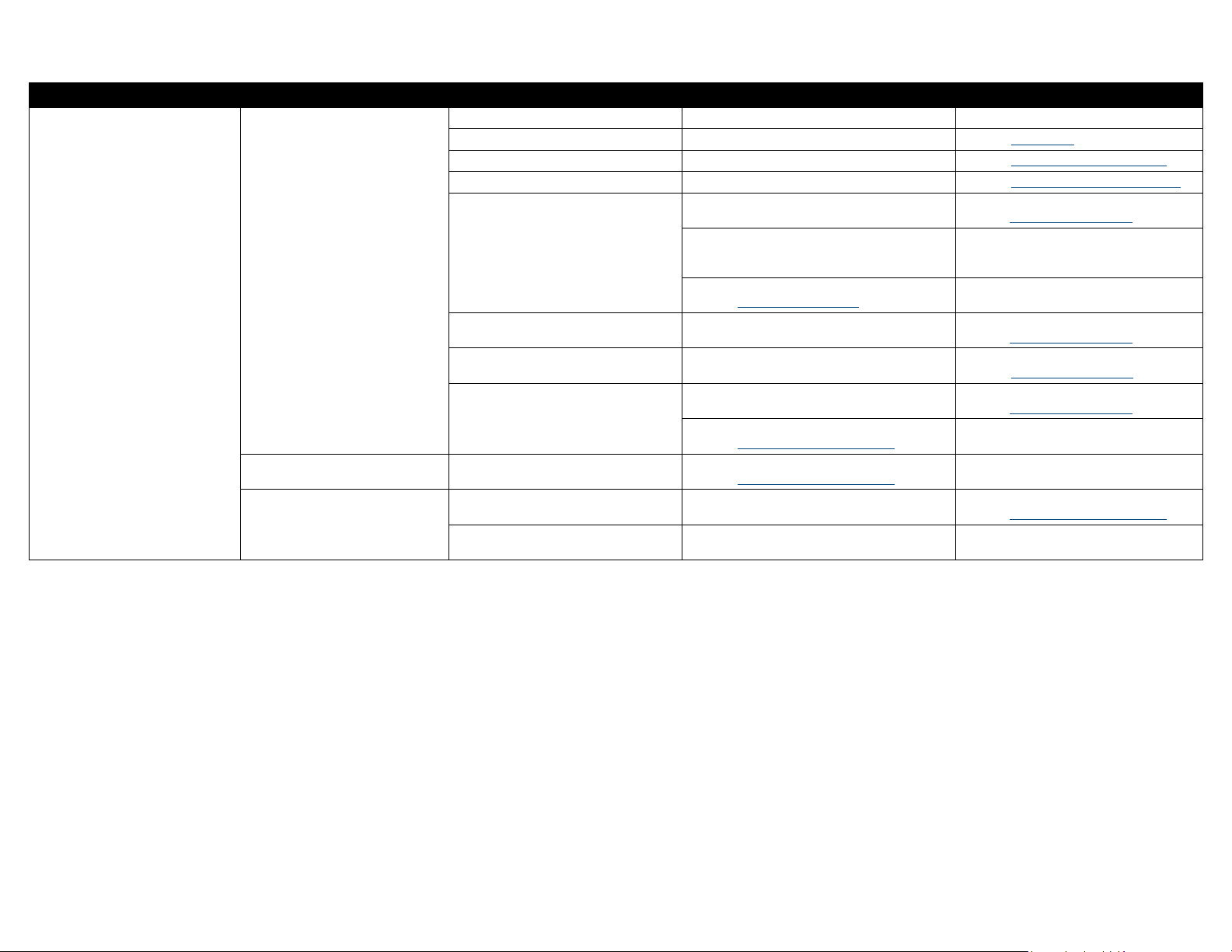

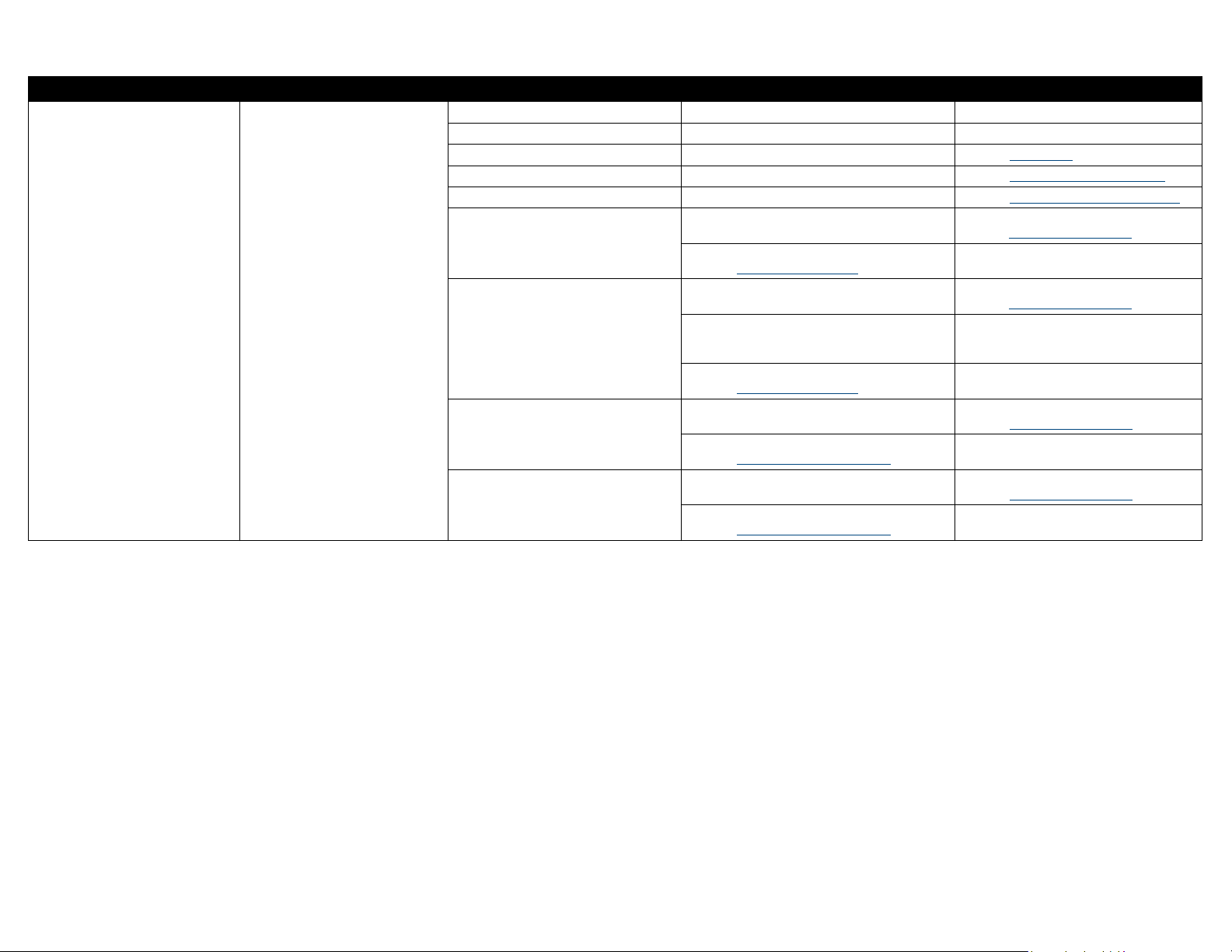

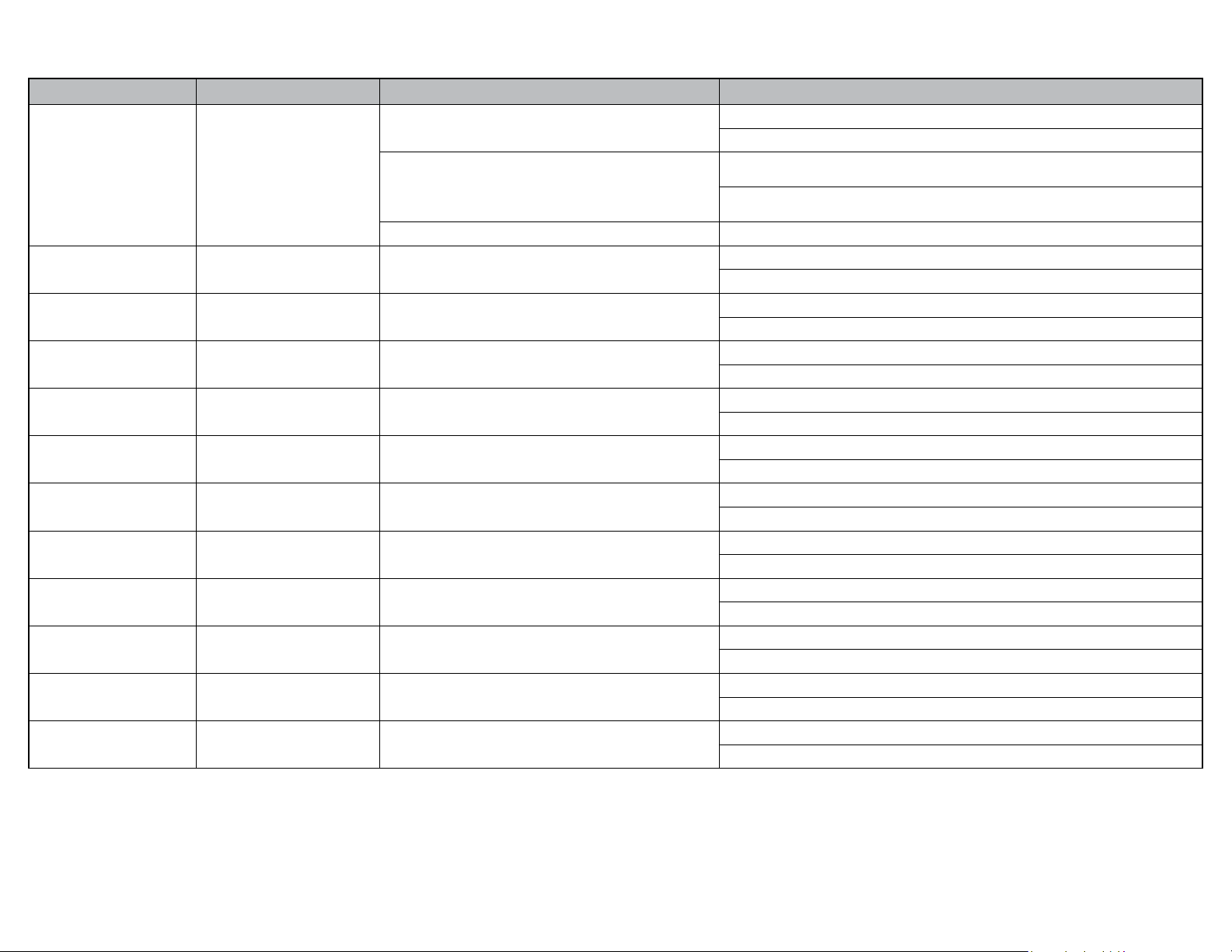

Contents Description Refer To:

Troubleshooting

Testing

Symptom Troubleshooting Chart

Error Codes Recalling Error Codes / Error Code Chart

Diagnostic LED’s Diagnostic LED’s

Wired Controls Wired Controls

Wireless Controls Wireless Controls

Smart Sensor Switches Smart Sensor Switches

Base Actuator / Limit Switches

Base Function

Base Function / Fuses and Connections

Back Actuator / Limit Switches

Back Function

Back Function / Fuses and Connections

Tilt Actuator / Limit Switches

Tilt Function

Tilt Function / Fuses and Connections

Foot Actuator / Limit Switches

Foot Function

Foot Function / Fuses and Connections

Calibration Procedure Calibration Procedure

TP210 Rev. A

Access Access Procedures Access Procedures

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Control Lockout Control Lockout

Active Sensing Technology

TM

Active Sensing Technology

Rotational Base Rotational Base Brake System

English-1

TM

004-1055-00

[Revised: 6/7/16]

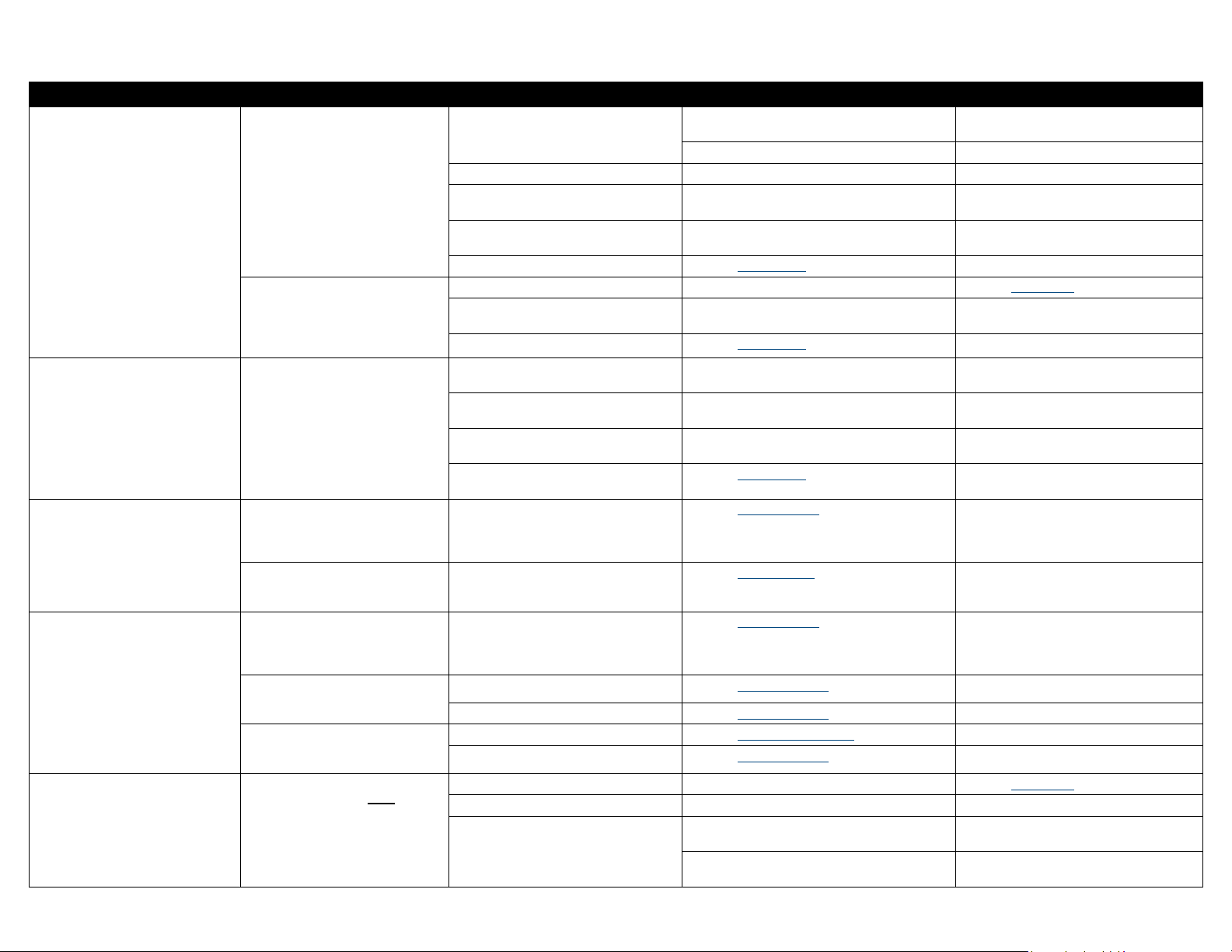

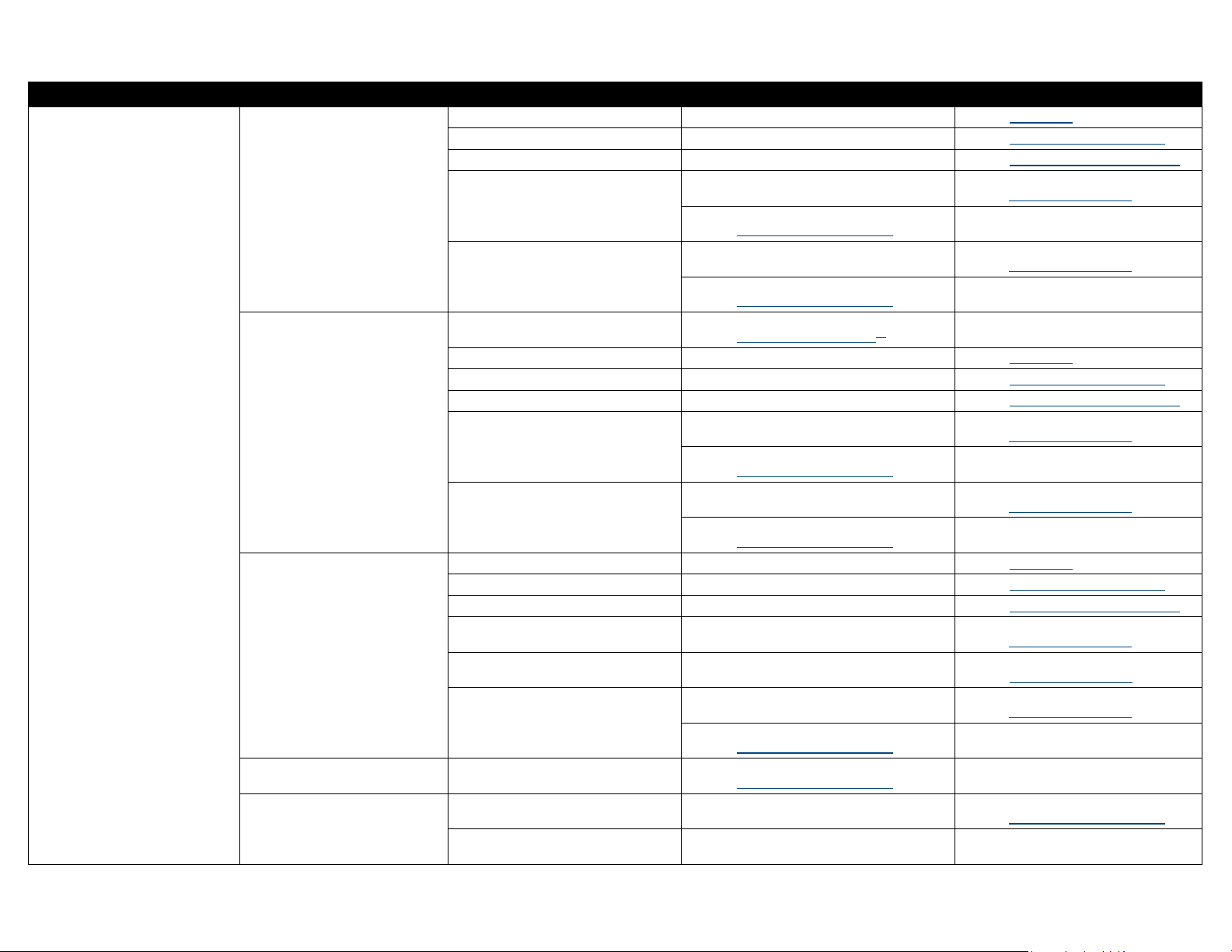

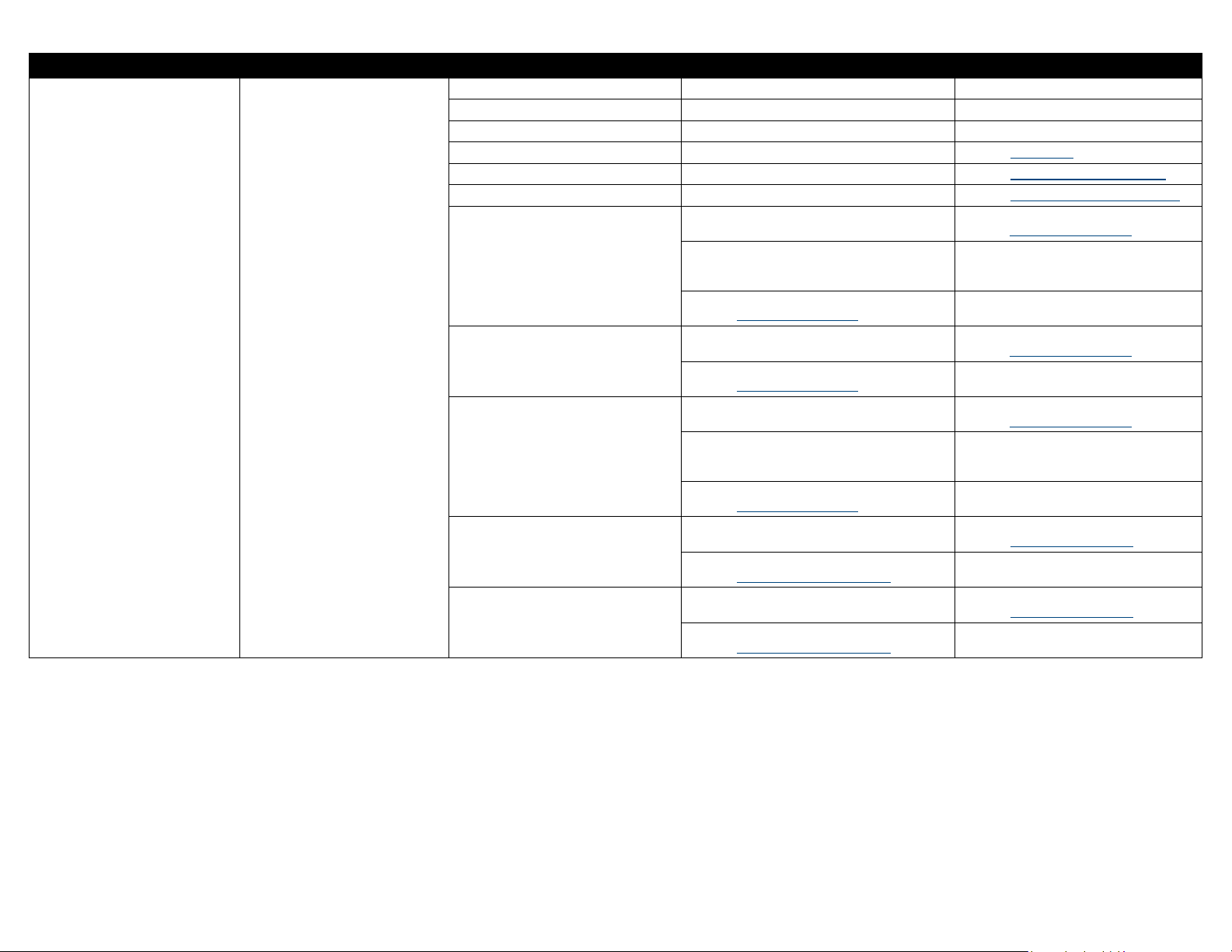

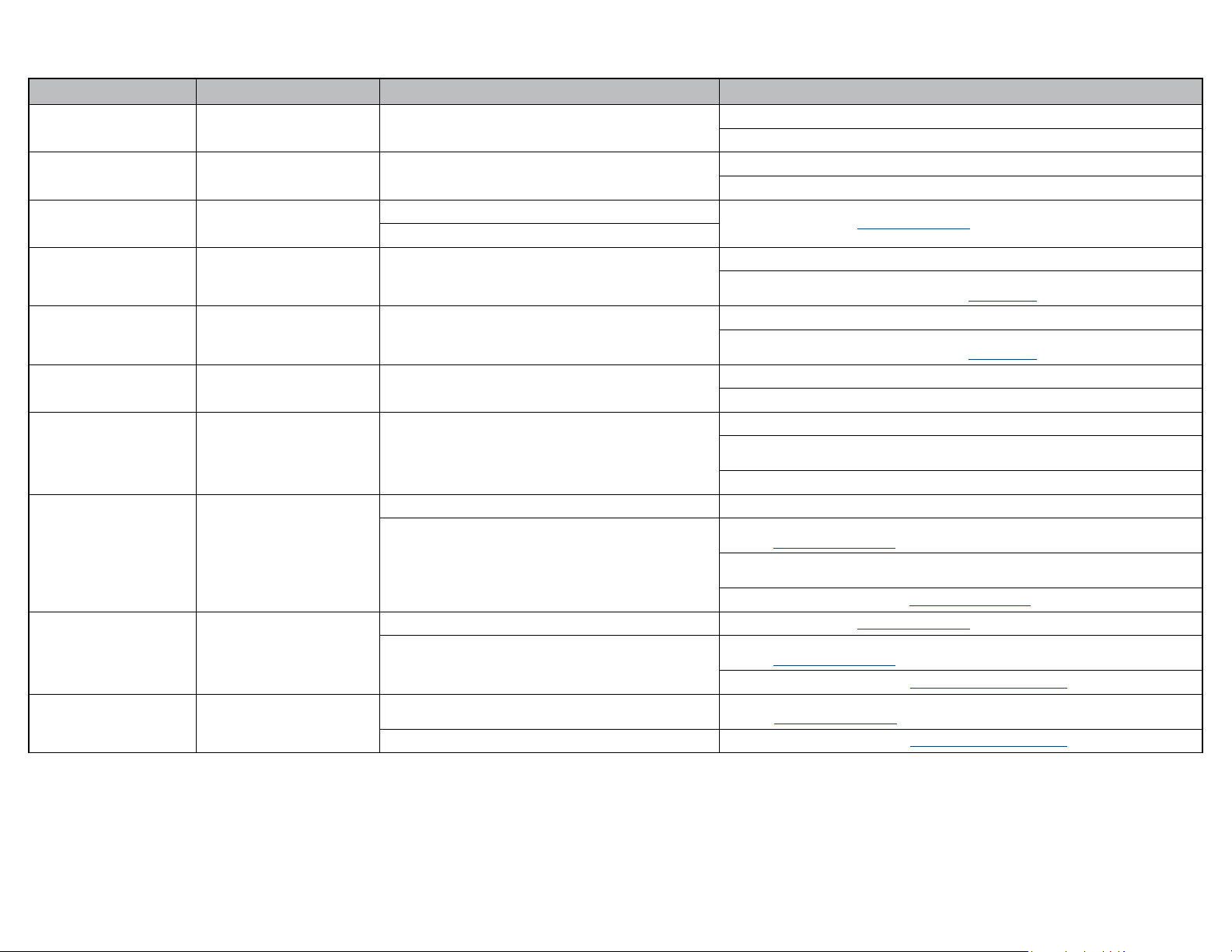

Troubleshooting Chart

midmark.com

Style A

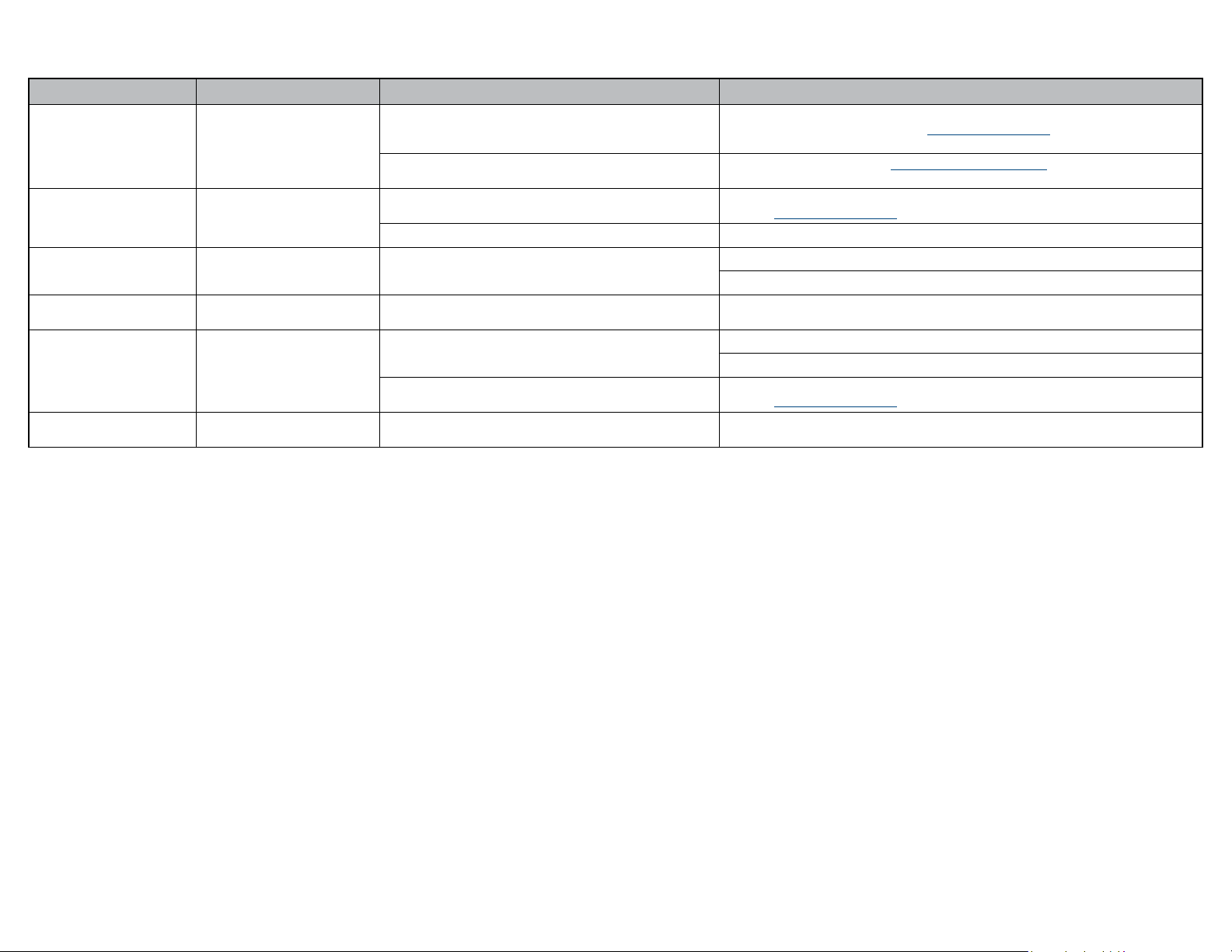

Problem Symptom Probable Cause Check Solution

Table has no power.

Table Receptacle(s)

malfunctioning.

No functions will operate.

(No power at table receptacles)

No functions will operate.

(Power at table receptacles)

No power at table receptacle(s).

(All other functions work)

Facility supply voltage. Power cord connections at wall outlet

and Power Entry Module at base of table.

Facility circuit breaker. Reset facility circuit breaker if necessary.

Power Supply PC Board fuse(s) blown. Test F1 & F2 fuses on Power Supply PC Board. Replace faulty fuse(s).

Loose wire connection. Wire connection between Power Entry Module

and Power Supply PC Board.

Loose Power Toroid wire connections. Wire connections at J9 and J10 on Power Supply

PC Board.

Power Toroid malfunctioning. Refer to: Power Toroid Replace Power Toroid.

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Foot / Hand control. Try activating functions from both foot and hand

controls.

Power Toroid malfunctioning. Refer to: Power Toroid Replace Power Toroid.

Table circuit breaker. If table circuit breaker is tripped. Reset table circuit breaker located at the

Loose wire connection. Wire connections at J11 on Power Supply

PC Board and table receptacle.

Table Receptacle. Voltage at receptacle. Replace faulty receptacle.

Power Toroid malfunctioning. Refer to: Power Toroid Replace Power Toroid.

Secure power cord connections.

Secure loose wire connections.

Secure loose wire connections.

Replace faulty hand / foot control.

base of table, press to reset.

Secure loose wire connections.

Wired Controls

malfunctioning.

Wireless Controls

malfunctioning.

Tilt, Back, and Foot

functions not operating.

When any control button is pressed,

the table sounds a series of three

beeps. (No functions operate)

When any control button is pressed,

nothing happens.

(No “beeps”, no movement, ect.)

When any control button is pressed,

the table sounds a series of three

beeps. (No functions operate)

When any control button is pressed,

that controller sounds a single “beep”.

(All functions operate)

When any control button is pressed,

nothing happens.

(No “beeps”, no movement, ect.)

Tilt, Back, and Foot functions will not

operate. Base function does operate.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

Control Lockout is enabled. Refer to: Control Lockout Press and hold the Stop and Back Down

Faulty controller. Refer to: Wired Controls Replace faulty controller.

Control Lockout is enabled. Refer to: Control Lockout Press and hold the Stop and Back Down

Low battery. Refer to: Wireless Controls Replace batteries. (size: AA)

Faulty controller. Refer to: Wireless Controls Replace faulty controller.

Controller not associated to table. Refer to: Association Procedure Perform Association Procedure.

Faulty controller. Refer to: Wireless Controls Replace faulty controller.

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Power Supply PC Board fuse(s) blown. Test F3 & F4 fuses on Power Supply PC Board. Replace faulty fuse(s).

Loose wire connection. Wire connections at J3 on Power Supply

PC Board and J13 on Motor Control Hub Board.

Wire connections at J16 on Machine Control PC

Board and J14 on Motor Control Hub PC Board.

English-2

buttons simultaneously for two seconds.

You will hear a single “Beep” to indicate

control lockout is enabled / disabled.

buttons simultaneously for two seconds.

You will hear a single “Beep” to indicate

control lockout is enabled / disabled.

Secure loose wire connections.

Secure loose wire connections.

004-1055-00

[Revised: mo/dd/yr]

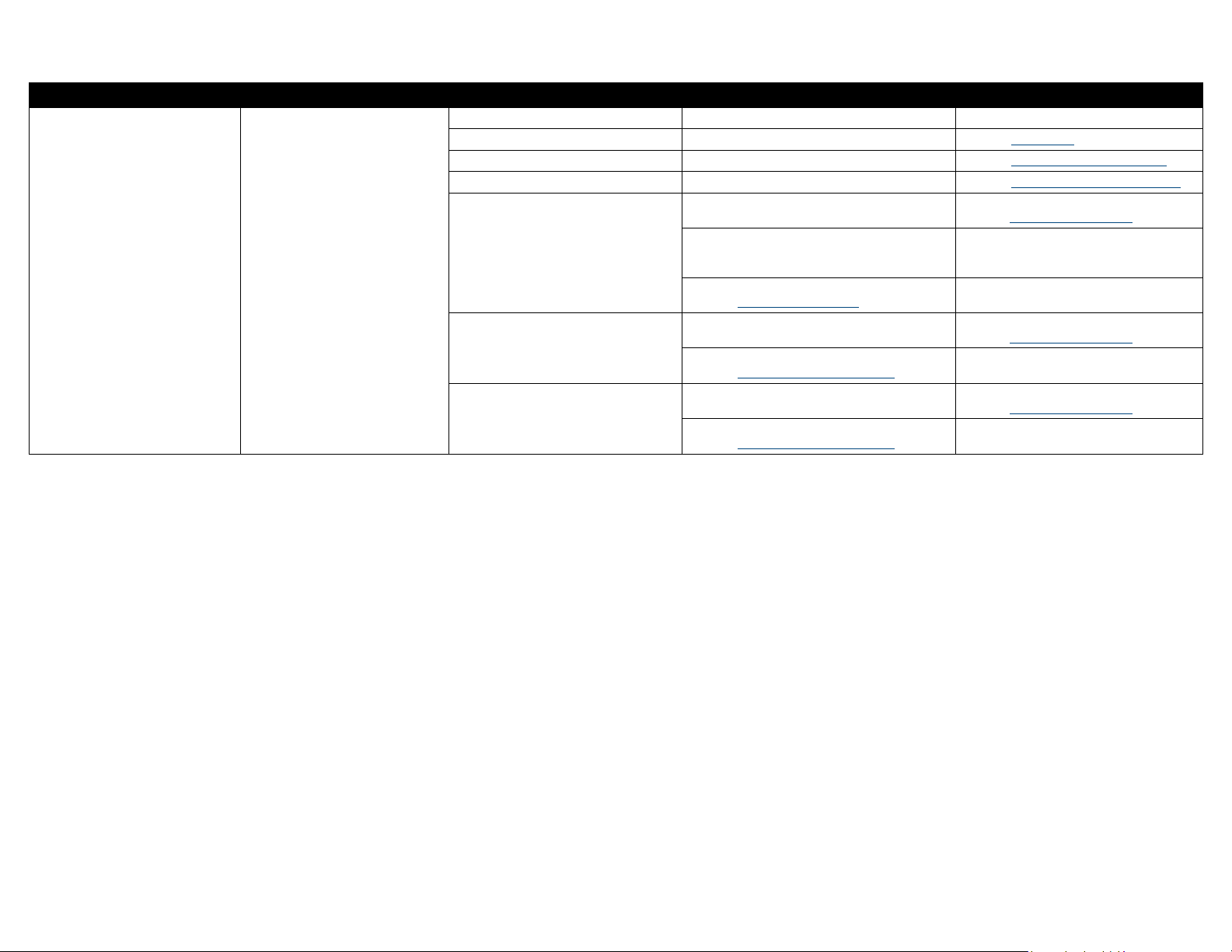

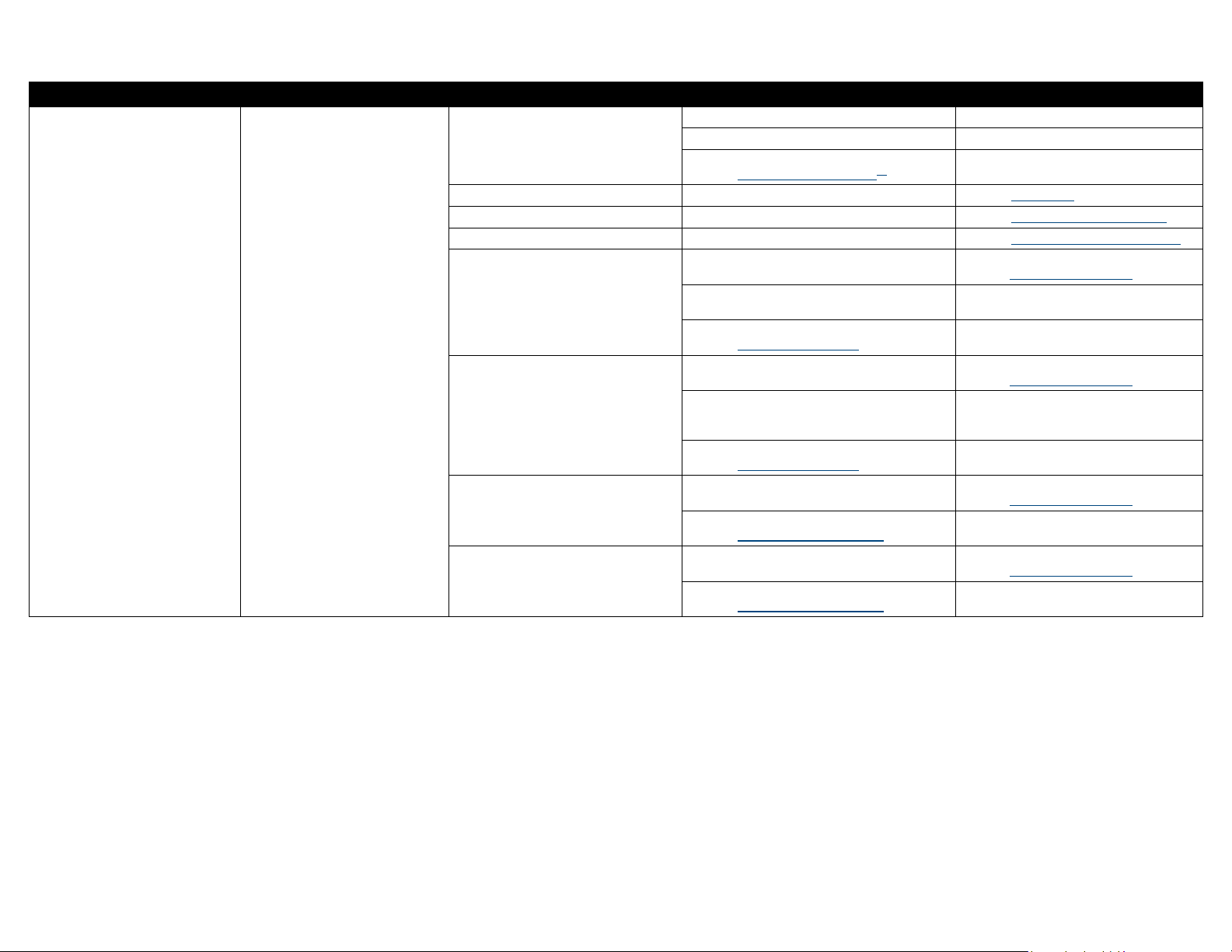

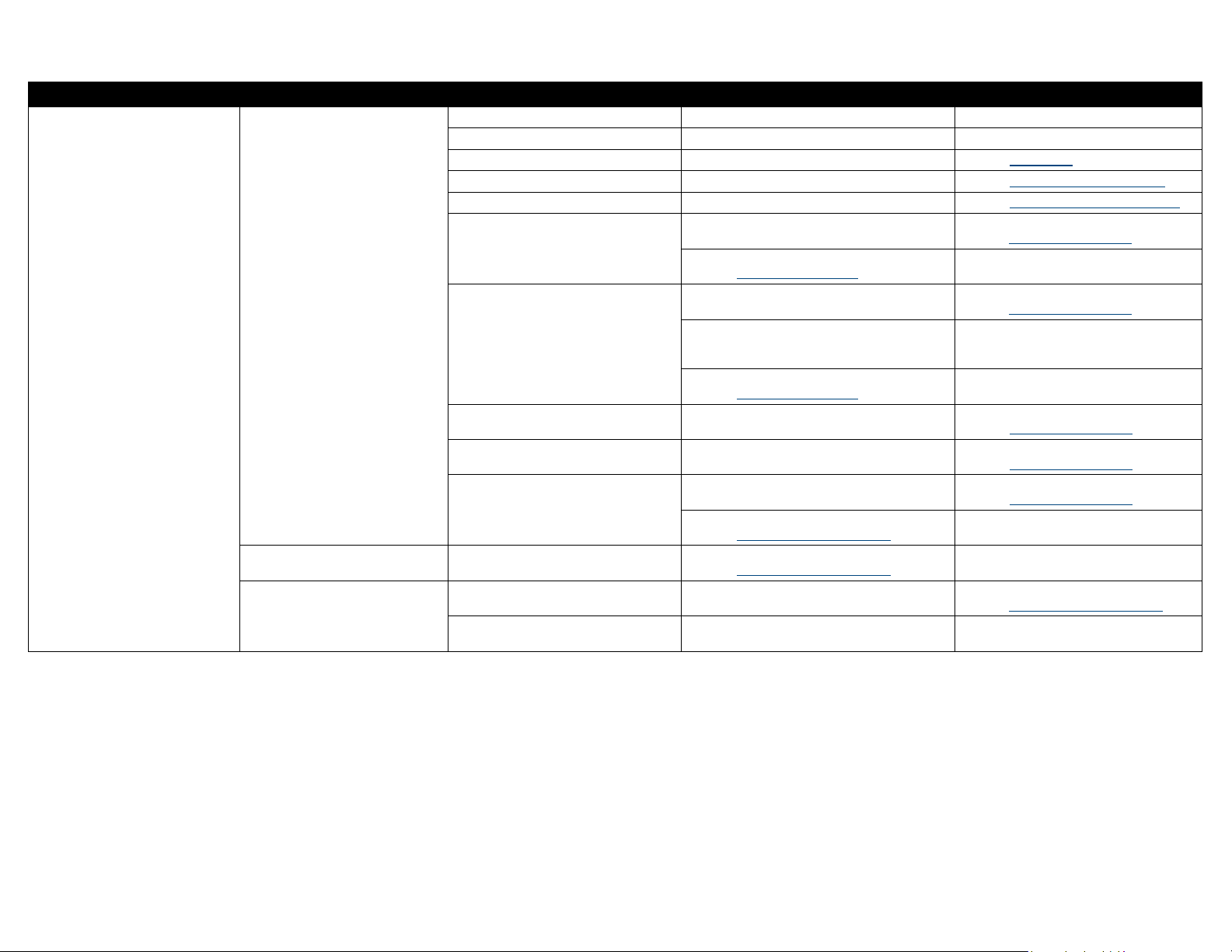

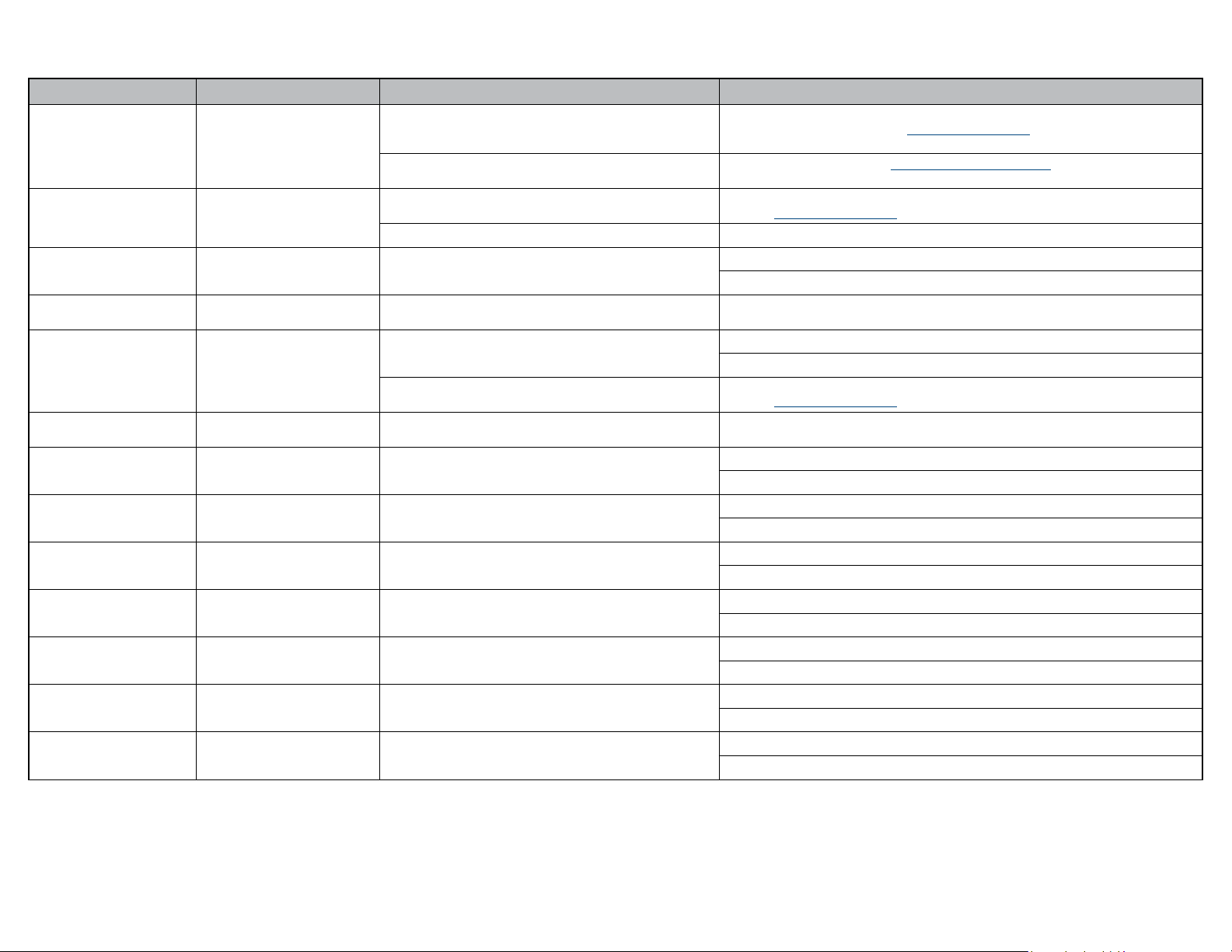

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

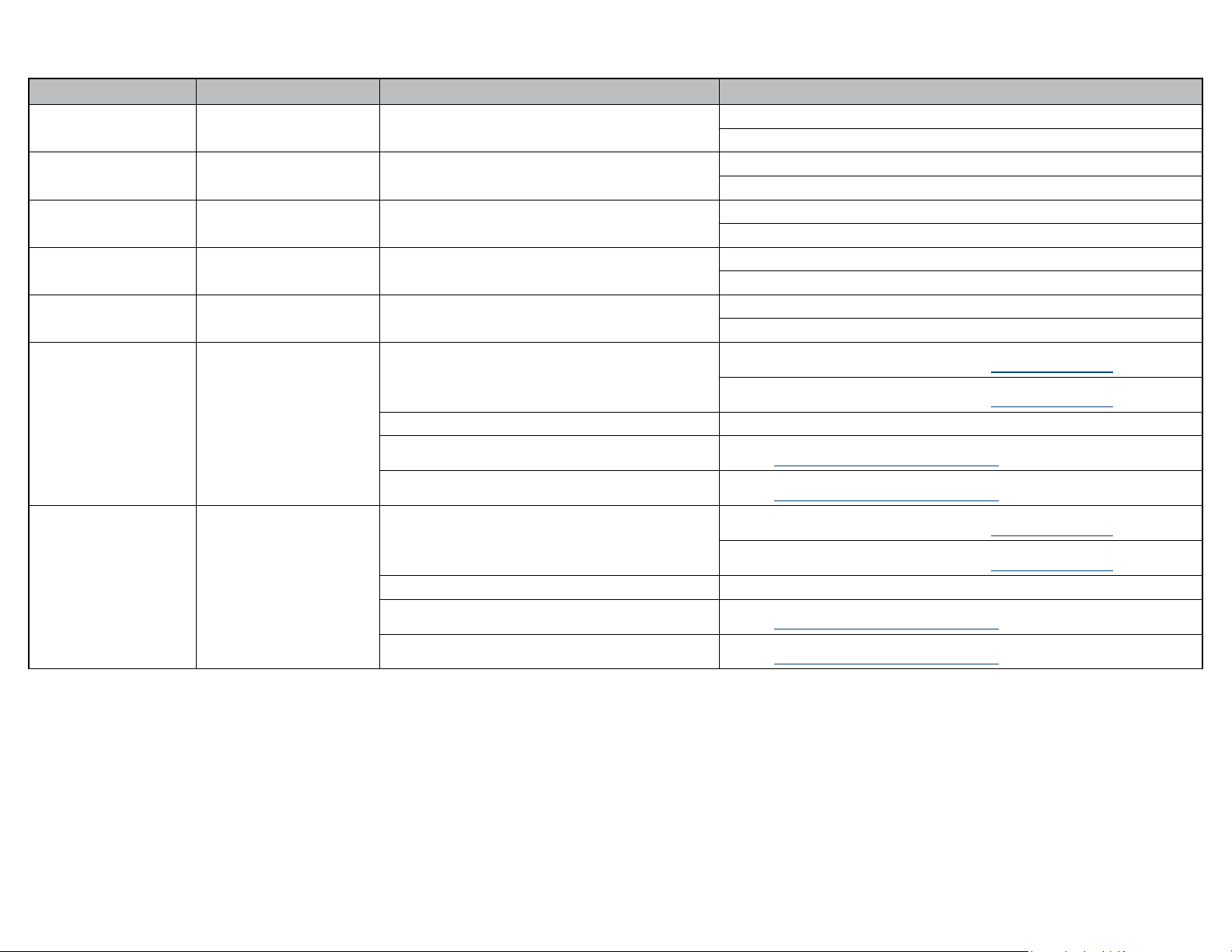

Base function not

operating properly.

No Base Up. Active Sensing Technology

TM

activated. For obstruction under foot section. Remove object from under foot section.

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Foot Smart Sensor switches. Check wire connections at J18 on Machine

Control PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Base Up limit switch. Wire connections at J5 on Power Supply

PC Board and at limit switch.

Test limit switch.

Refer to: Base Actuator / Limit Switches

Base Up Overtravel limit switch. Wire connections at J5 on Power Supply

PC Board and at limit switch.

Test limit switch.

Refer to: Base Actuator / Limit Switches

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace Switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-3

004-1055-00

[Revised: mo/dd/yr]

Problem Symptom Probable Cause Check Solution

midmark.com

Style A

Base function not

operating properly.

(continued)

No Base Down. Foot extension is extended. If foot extension is extended. Move foot extension in or raise foot section.

Active Sensing Technology

TM

activated. For obstruction under foot section. Remove object from under foot section.

Position of table.

Refer to: Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Foot Extension switch. Check wire connections at J6 on Machine Control

PC Board and at switch.

Check Black and Red wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switch.

Refer to: Smart Sensor Switches

Foot Smart Sensor switches. Check wire connections at J18 on Machine

Control PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Base Down limit switch. Wire connections at J5 on Power Supply

PC Board and at limit switch.

Test limit switch.

Refer to: Base Actuator / Limit Switches

TM

Activate Tilt Up / Down and Back Up,

then try Base Down again.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-4

004-1055-00

[Revised: mo/dd/yr]

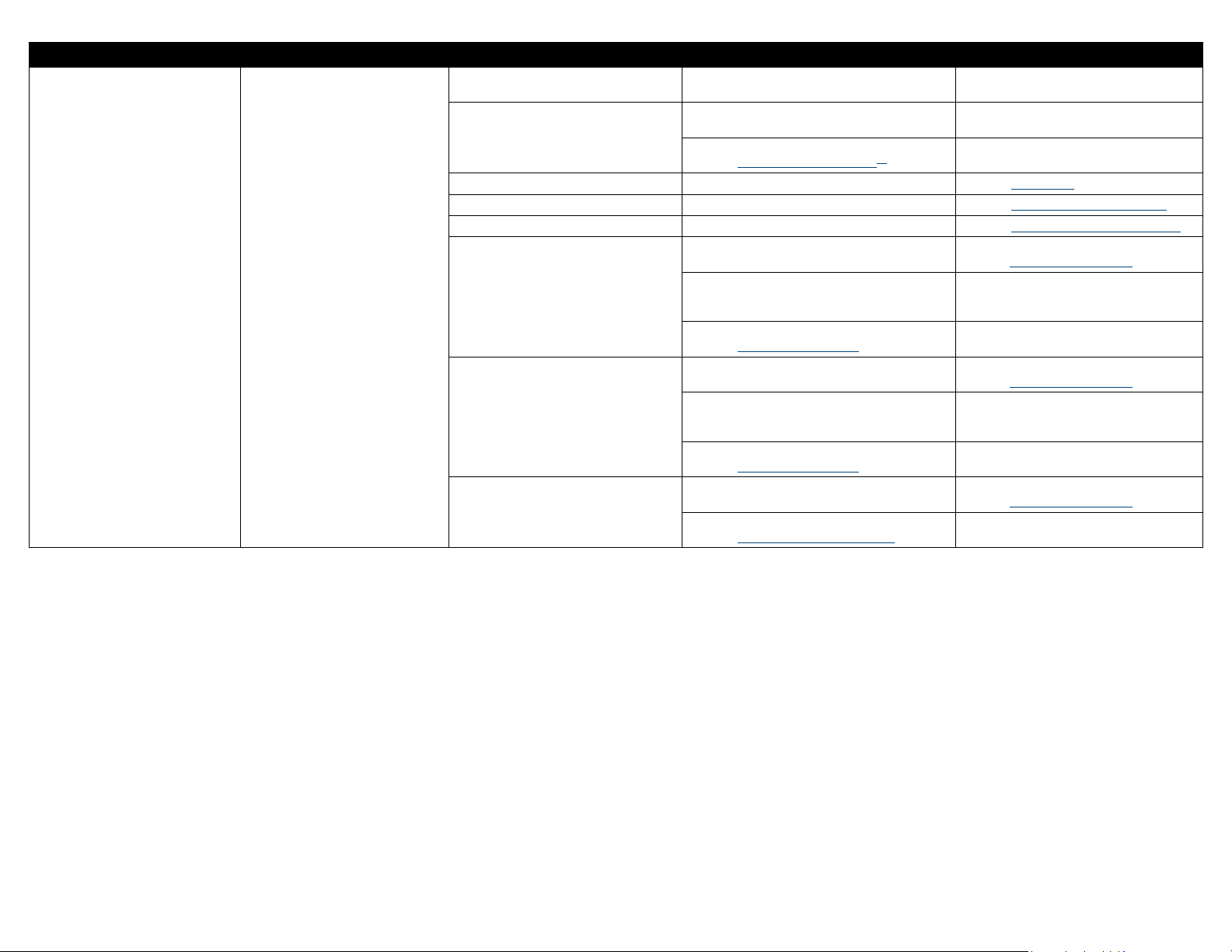

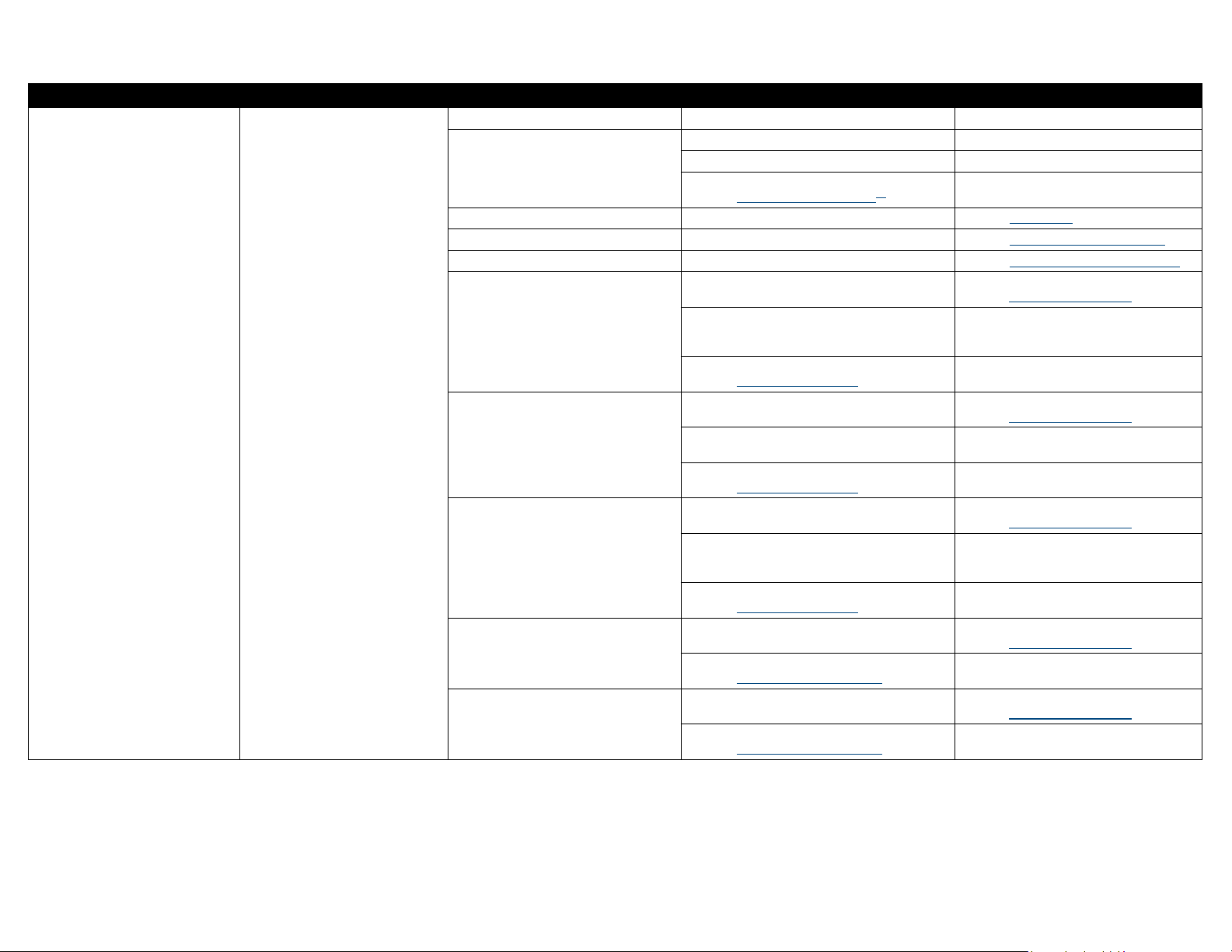

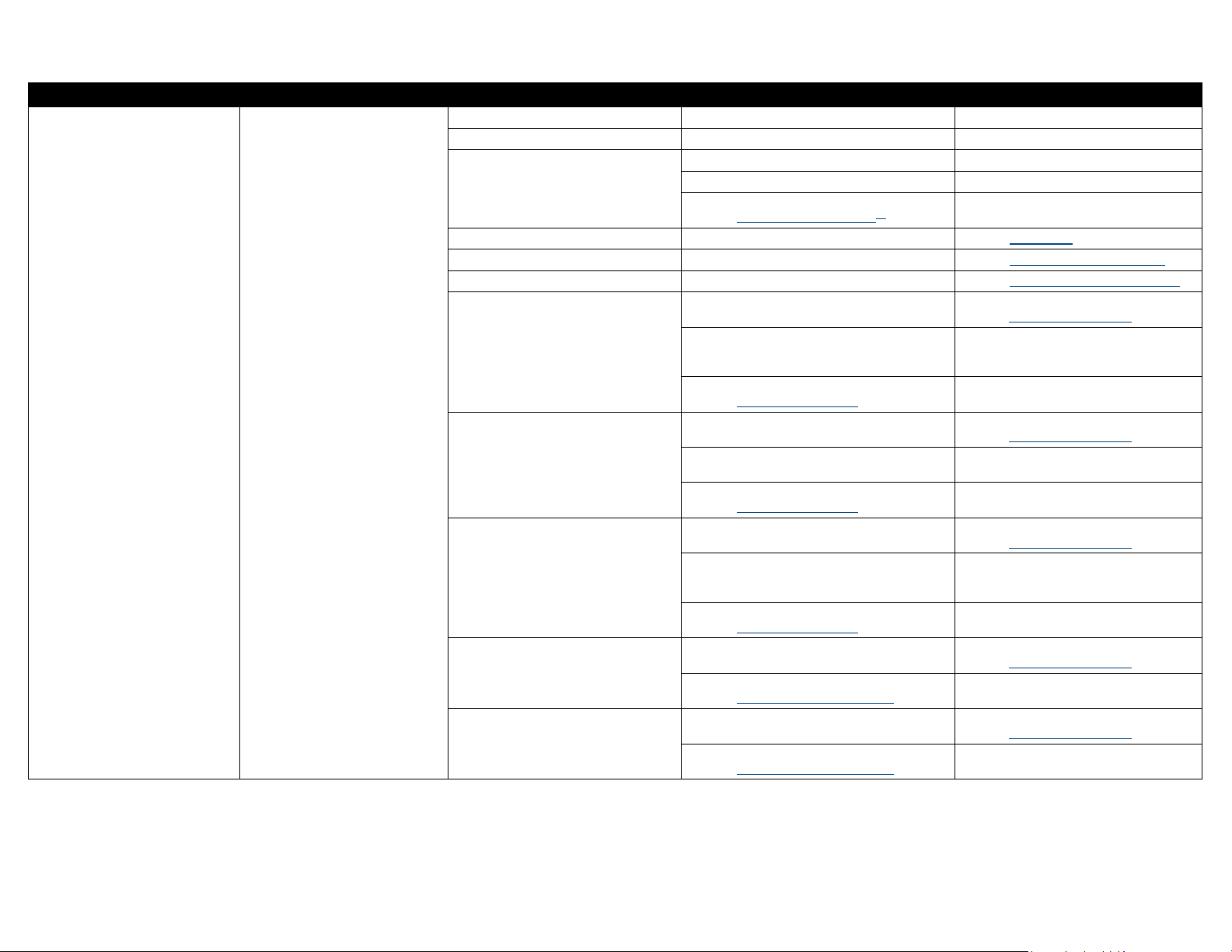

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Base function not

operating properly.

(continued)

No Base Up or Base Down. Active Sensing Technology

Motor runs, but table does not move. Motor coupler broken. Motor coupler.

Base Up / Down noisy, grinding or

squeaking.

TM

activated. For obstruction under foot section. Remove object from under foot section.

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Foot Smart Sensor switches. Check wire connections at J18 on Machine

Control PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Loose wire connections. Wire connections at J5, J6 and J7 on Power

Supply PC Board.

Power PC Board fuse blown. Test F5 fuse on Power Supply PC Board. Replace faulty fuse.

Base Up Overtravel limit switch. Wire connections at J5 on Power Supply

PC Board and at limit switch.

Test limit switch.

Refer to: Base Actuator / Limit Switches

Refer to: Base Actuator / Limit Switches

Actuator threads dry. Actuator threads. Clean and lubricate base actuator threads.

Base Actuator. Run table up and down, if squeaking or grinding

continue check base actuator.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace Switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Refer to: Fuses and Connections

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Replace motor coupler.

Refer to: Base Actuator / Limit Switches

Replace base actuator.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-5

004-1055-00

[Revised: mo/dd/yr]

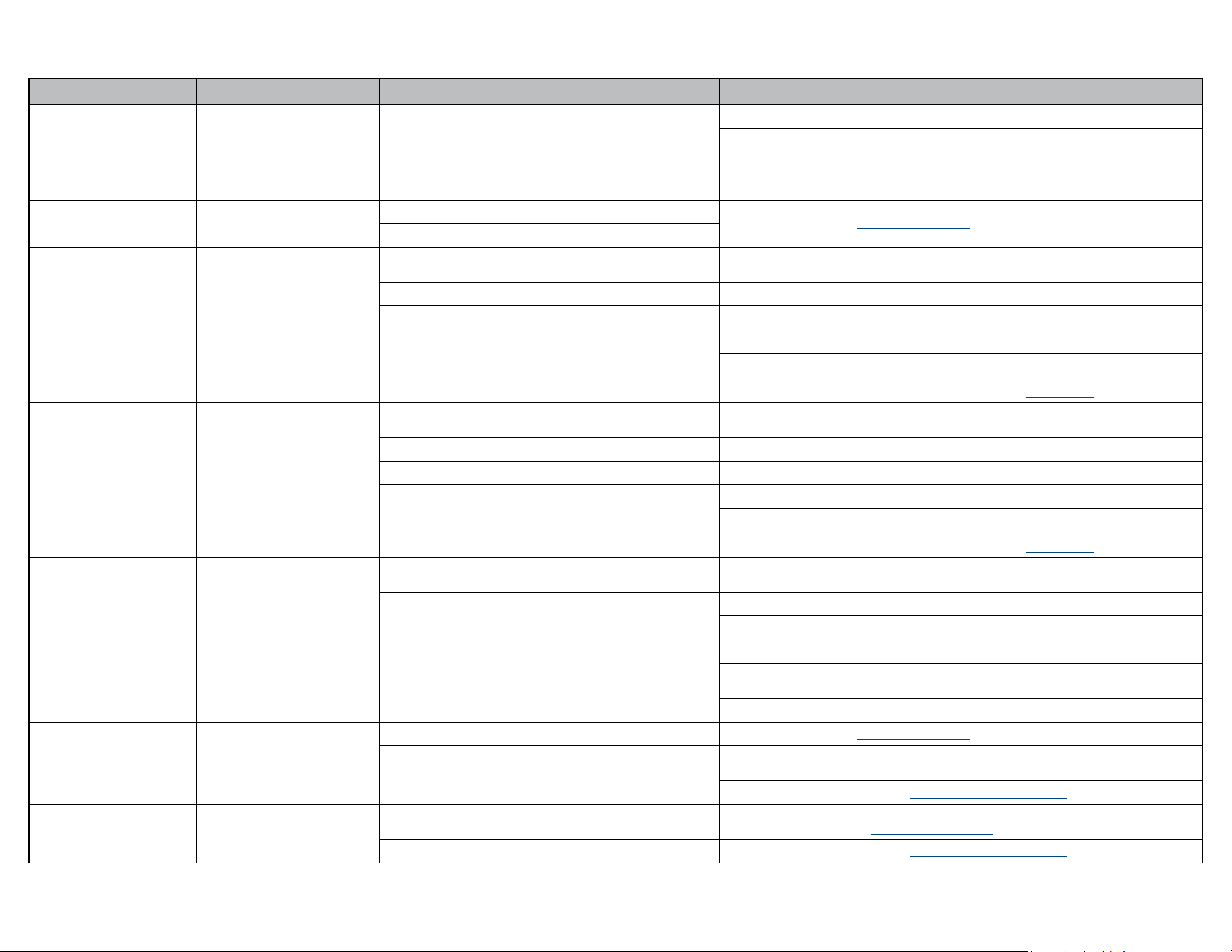

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Back function not

operating properly.

TP210 Rev. A

No Back Up. System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

No Back Down. Active Sensing Technology

No Back Up or Back Down. System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Motor runs, but table does not move. Motor coupler broken. Motor coupler.

Back Up / Down noisy, grinding or

squeaking.

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Back Up limit switch. Wire connections at J12 on Motor Control Hub

Back Up Overtravel limit switch. Wire connections at J12 on Motor Control Hub

TM

activated. Position of table.

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Back Down limit switch. Wire connections at J12 on Motor Control Hub

Back Down Overtravel limit switch. Wire connections at J12 on Motor Control Hub

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Loose wire connections. Wire connections at J10, J11 and J12 on

Motor Control Hub PC Board fuse blown. Test F3 fuse on Motor Control Hub PC Board. Replace faulty fuse.

Back Up and/or Down Overtravel limit

switch.

Actuator threads dry. Actuator threads. Clean and lubricate back actuator threads.

Back Actuator. Run back up and down, if squeaking or grinding

PC Board and at limit switch.

Test limit switch.

Refer to: Back Actuator / Limit Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Back Actuator / Limit Switches

Refer to: Active Sensing Technology

PC Board and at limit switch.

Test limit switch.

Refer to: Back Actuator / Limit Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Back Actuator / Limit Switches

Motor Control Hub PC Board.

Wire connections at J12 on Motor Control Hub

PC Board and at limit switch(es).

Test limit switch(es).

Refer to: Back Actuator / Limit Switches

Refer to: Back Actuator / Limit Switches

continue check back actuator.

TM

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Activate Base Up and Tilt down,

then try Back Down again.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Refer to: Fuses and Connections

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch(es).

Replace motor coupler.

Refer to: Back Actuator / Limit Switches

Replace back actuator.

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-6

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

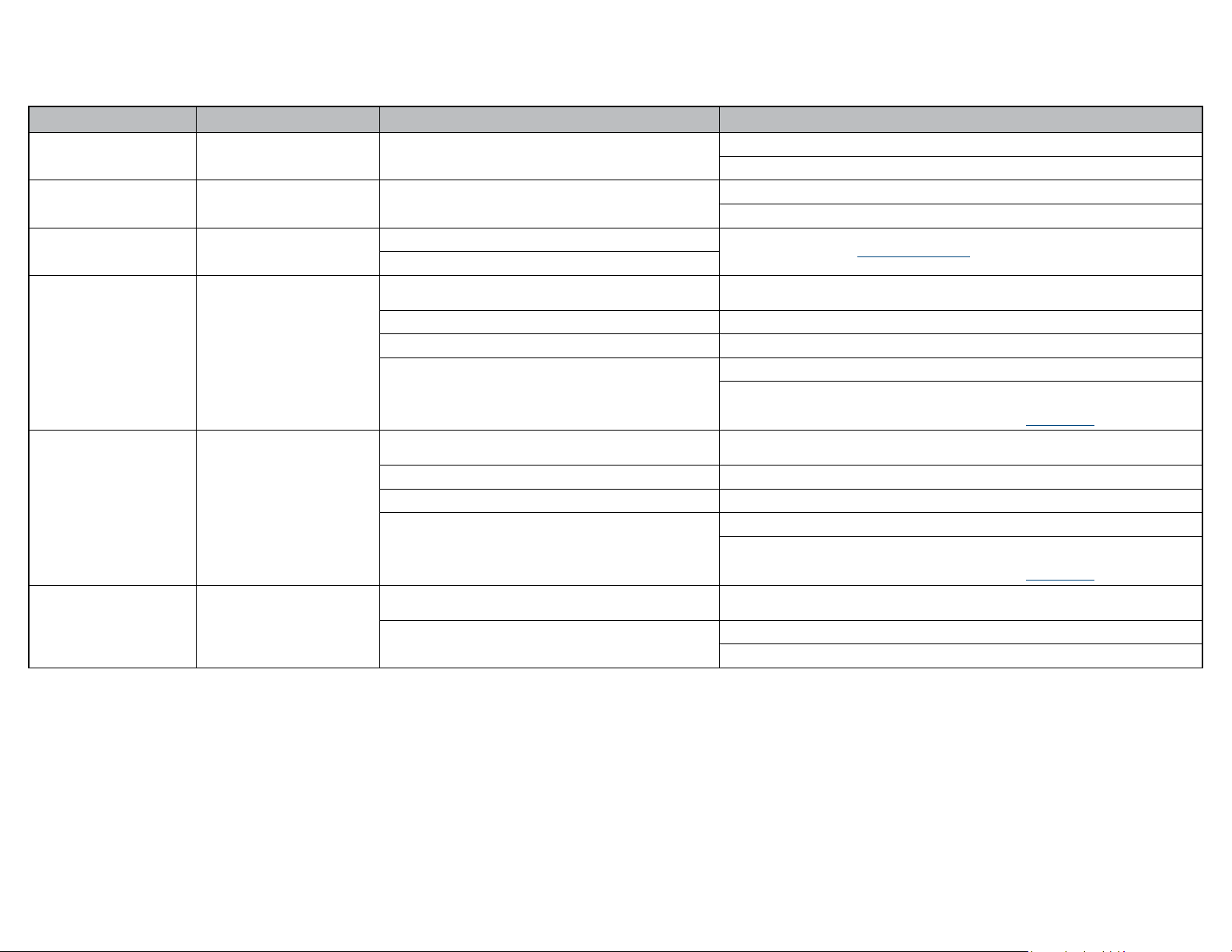

Tilt function not

operating properly.

No Tilt Up. Active Sensing Technology

TM

activated. For obstruction on the top of column. Remove object from the top of the column.

For obstruction under the foot section. Remove object from under the foot section.

Position of table.

Refer to: Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Seat Smart Sensor switches. Wire connections at J18 on Machine

Control PC Board and at switch.

Check two pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Foot Smart Sensor switches. Wire connections at J18 on Machine

Control PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Tilt Up limit switch. Wire connections at J8 on Motor Control Hub

PC Board and at limit switch.

Test limit switch.

Refer to: Tilt Actuator / Limit Switches

Tilt Up Overtravel limit switch. Wire connections at J8 on Motor Control Hub

PC Board and at limit switch.

Test limit switch.

Refer to: Tilt Actuator / Limit Switches

TM

Activate Base Up and Back Up,

then try Tilt Up again.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-7

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Tilt function not

operating properly.

(continued)

No Tilt Down. Foot extension extended. If foot extension is extended. Move foot extension in or raise foot section.

Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Foot Extension switch. Check wire connections at J6 on Machine Control

Seat Smart Sensor switches. Wire connections at J18 on Machine

Foot Smart Sensor switches. Wire connections at J18 on Machine

Tilt Down limit switch. Wire connections at J8 on Motor Control Hub

Tilt Down Overtravel limit switch. Wire connections at J8 on Motor Control Hub

TM

activated. For obstruction on the top of column. Remove object from the top of the column.

For obstruction under the foot section. Remove object from under the foot section.

Position of table.

Refer to: Active Sensing Technology

PC Board and at switch.

Check Black and Red wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Control PC Board and at switches.

Check two pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Control PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Tilt Actuator / Limit Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Tilt Actuator / Limit Switches

TM

Activate Base Up and Foot Up,

then try Tilt Down again.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-8

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Tilt function not

operating properly.

(continued)

No Tilt Up or Tilt Down. Active Sensing Technology

Motor runs, but table does not move. Motor coupler broken. Motor coupler.

Tilt Up / Down noisy, grinding or

squeaking.

TM

activated. For obstruction on the top of column. Remove object from the top of the column.

For obstruction under the foot section. Remove object from under the foot section.

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Seat Smart Sensor switches. Wire connections at J18 on Machine

Foot Smart Sensor switches. Wire connections at J18 on Machine

Loose wire connections. Wire connections at J6, J7 and J8 on

Motor Control Hub PC Board fuse blown. Test F2 fuse on Motor Control Hub PC Board. Replace faulty fuse.

Tilt Up and/or Down Overtravel limit

switch.

Actuator threads dry. Actuator threads. Clean and lubricate tilt actuator threads.

Tilt Actuator. Run tilt up and down, if squeaking or grinding

Control PC Board and at switches.

Check two pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Control PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Motor Control Hub PC Board.

Wire connections at J8 on Motor Control Hub

PC Board and at limit switch(es).

Test limit switch(es).

Refer to: Tilt Actuator / Limit Switches

Refer to: Tilt Actuator / Limit Switches

continue check tilt actuator.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch(es).

Secure loose wire connections.

Refer to: Fuses and Connections

Refer to: Fuses and Connections

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch(es).

Replace motor coupler.

Refer to: Tilt Actuator / Limit Switches

Replace tilt actuator.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-9

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Foot function not

operating properly.

No Foot Up. Treatment pan not in the stowed position. If treatment pan is not completely pushed in. Push treatment pan all the way in.

Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Treatment Pan switch. Wire connections at J6 on Machine Control

Foot Smart Sensor switches. Wire connections at J18 on Machine Control

Foot Up limit switch. Wire connections at J4 on Motor Control Hub

Foot Up Overtravel limit switch. Wire connections at J4 on Motor Control Hub

TM

activated. For obstruction under the foot section. Remove object from under the foot section.

PC Board and at switch.

Test switch.

Refer to: Smart Sensor Switches

PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Foot Actuator / Limit Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Foot Actuator / Limit Switches

Secure wire connections.

Refer to: Fuses and Connections

Replace Switch.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-10

004-1055-00

[Revised: mo/dd/yr]

Problem Symptom Probable Cause Check Solution

midmark.com

Style A

Foot function not

operating properly.

(continued)

No Foot Down. Foot extension extended. If foot extension is extended. Move foot extension in.

Treatment pan not in the stowed position. If treatment pan is not completely pushed in. Push treatment pan all the way in.

Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Foot Extension switch. Check wire connections at J6 on Machine Control

Treatment Pan switch. Wire connections at J6 on Machine Control

Foot Smart Sensor switches. Wire connections at J18 on Machine Control

Foot Down limit switch. Wire connections at J4 on Motor Control Hub

Foot Down Overtravel limit switch. Wire connections at J4 on Motor Control Hub

TM

activated. For obstruction under the foot section. Remove object from under the foot section.

PC Board and at switch.

Check Black and Red wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

PC Board and at switch.

Test switch.

Refer to: Smart Sensor Switches

PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Foot Actuator / Limit Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Foot Actuator / Limit Switches

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-11

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Foot function not

operating properly.

(continued)

No Foot Up or Foot Down. Treatment pan not in the stowed position. If treatment pan is not completely pushed in. Push treatment pan all the way in.

Motor runs, but table does not move. Motor coupler broken. Motor coupler.

Foot Up / Down noisy, grinding or

squeaking.

Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Treatment Pan switch. Wire connections at J6 on Machine Control

Foot Smart Sensor switches. Wire connections at J18 on Machine Control

Loose wire connections. Wire connections at J2, J3 and J4 on

Motor Control Hub PC Board fuse blown. Test F1 fuse on Motor Control Hub PC Board. Replace faulty fuse.

Foot Up and/or Down Overtravel limit

switch.

Actuator threads dry. Actuator threads. Clean and lubricate foot actuator threads.

Foot Actuator. Run foot up and down, if squeaking or grinding

TM

activated. For obstruction under the foot section. Remove object from under the foot section.

PC Board and at switch.

Test switch.

Refer to: Smart Sensor Switches

PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

Motor Control Hub PC Board.

Wire connections at J4 on Motor Control Hub

PC Board and at limit switch.

Test limit switch.

Refer to: Foot Actuator / Limit Switches

Refer to: Foot Actuator / Limit Switches

continue check foot actuator.

Secure wire connections.

Refer to: Fuses and Connections

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connection.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Refer to: Fuses and Connections

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Replace motor coupler.

Refer to: Foot Actuator / Limit Switches

Replace foot actuator.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-12

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

“Home” function not

operating properly.

“Home” function does not lower the

table to a height of 18 inches.

(Rotation Models 21.5 inches)

“Home” button pressed, then released. If operator pressed and released “Home” button. Press and hold “Home” button.

Foot extension extended. If foot extension is extended. Move foot extension in.

Active Sensing Technology

System malfunction. Error code on Machine Control PC Board. Refer to: Error Codes

Malfunctioning Wired Controls. Wired Controls. Refer to: Wired Controls Malfunctioning

Malfunctioning Wireless Controls. Wireless Controls. Refer to: Wireless Controls Malfunctioning

Foot Extension switch. Wire connections at J6 on Machine Control

Seat Smart Sensor switches. Wire connections at J18 on Machine

Foot Smart Sensor switches. Wire connections at J18 on Machine Control

Base Down limit switch. Wire connections at J5 on Power Supply

Base Up Overtravel limit switch. Wire connections at J5 on Power Supply

TM

activated. For obstruction on the top of column. Remove object from the top of the column.

For obstruction under foot section. Remove object from under foot section.

Position of table.

Refer to: Active Sensing Technology

PC Board and at switch.

Check Black and Red wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switch.

Refer to: Smart Sensor Switches

Control PC Board and at switches.

Check two pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

PC Board and at switches.

Check Green and White wire connections

at four pin inline connection next to

Motor Control Hub PC Board.

Test switches.

Refer to: Smart Sensor Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Base Actuator / Limit Switches

PC Board and at limit switch.

Test limit switch.

Refer to: Base Actuator / Limit Switches

TM

Activate Tilt Up / Down and Back Up,

then try Base Down again.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connections.

Replace switch.

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connection.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Secure wire connection.

Replace switch(es).

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

Secure wire connections.

Refer to: Fuses and Connections

Replace limit switch.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-13

004-1055-00

[Revised: mo/dd/yr]

Troubleshooting Chart - continued

midmark.com

Style A

Problem Symptom Probable Cause Check Solution

Rotational Base

Brake System not

operating properly.

Rotational brake will not lock. Brake pedal switch(s). Unplug table power cord.

Rotational brake will not unlock. Loose wire connections. Wire connections at J12 on Machine Control

Base wobbles when locked.

- and/or -

Grinding noise when base rotates.

If base rotation locks, check brake pedal switch(s).

Rotational brake mechanism Unplug table power cord.

Electro-magnet not energized. If neither brake pedal works:

Brake pedal switch(s) If one Brake Pedal Switch works: Test switch. Replace switch.

PC Board Test Power Supply PC Board.

Debris between upper & lower castings. Inspect between upper and lower castings

Loose hub screws Check the four screws securing the

Damaged rotation bearings and/or brake

disc.

If base rotation does not lock, check mechanical

brake components for any obstruction.

PC Board and at switch.

Check Red and Black wire connections at J4

on Power Supply PC Board.

Perform Screwdriver Test.

If neither pedal works. Refer to: Rotational Brake PCB Input Test.

Refer to: Rotational Brake PCB Input Test.

for debris.

upper & lower castings.

Inspect rotation bearings and brake disc.

Refer to: Brake, Electro-magnet Access.

Replace sticking brake pedal switch(s).

Refer to: Brake Pedal Switch Access.

Clean mechanical brake components and

remove any obstruction. Refer to: Brake,

Electro-magnet, Rotation Bearing Access.

Secure wire connections.

Secure wire connections.

Refer to: Screwdriver Test.

Refer to: Brake Pedal Switch Access.

If necessary, replace Power Supply

PC Board.

Remove debris.

Tighten Hub Screws.

Replace rotational base assembly.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-14

004-1055-00

[Revised: 6/7/16]

S2

S3

Error Codes

Troubleshooting Chart .................................... 2

I D Code 01 .................................................. 16

I D Code 02 .................................................. 19

I D Code 03 .................................................. 21

I D Code 04 .................................................. 24

I D Code 05 .................................................. 28

Troubleshooting Chart .................................... 2

I D Code 01 .................................................. 16

I D Code 02 .................................................. 19

I D Code 03 .................................................. 21

I D Code 04 .................................................. 24

I D Code 05 .................................................. 28

S2

J19

J18

J16

S3

midmark.com

Style A

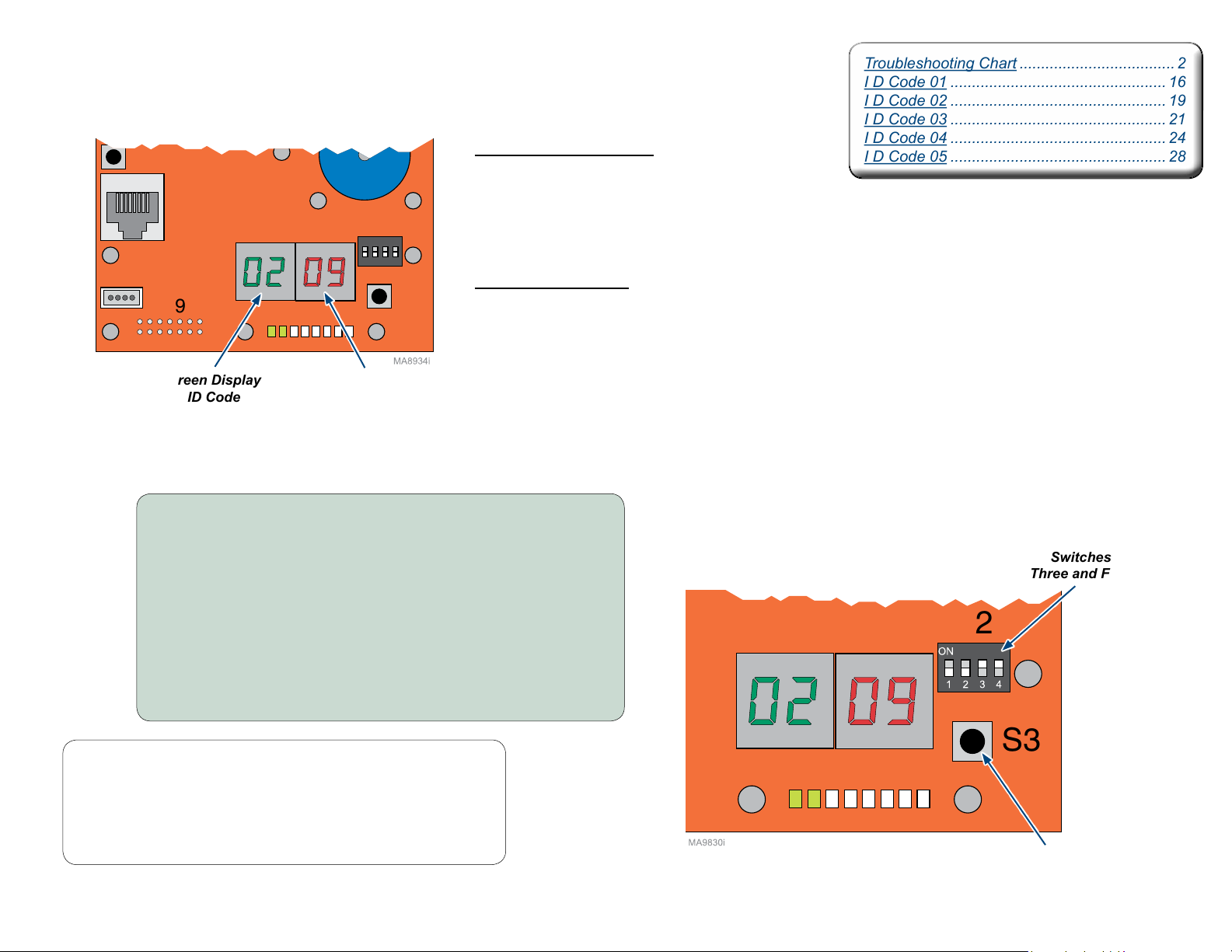

Example:

Machine

Control

PC Board

Green Display = Where?

The green display indicates the function

or system where the problem occurs.

(example: 02 = Base)

Red Display = What?

The red display indicates what

problem or symptom was detected.

(example: 09 = Switch Error)

Green Display

ID Code

Red Display

Error Code

To recall the last ten system errors...

A) Unplug table power cord.

B) When the digital display darkens,

move S2 switches three and four to ON (up).

C) Plug in table power cord.

D) When the digital display darkens, press and release S3 button.

E) When all errors have been displayed, pressing and releasing

S3 button again will repeat errors.

F) When recall is complete, unplug table power cord.

G) Move S2 switches three and four to OFF (down).

H) When the digital display darkens, plug in table power cord.

Note

When S3 button is pressed, then released, you will hear a “beep”

to indicate displaying of errors. (Most recent displaying first.)

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

When switching errors, the board will again emit a “beep”.

The displays will show “FFFF” if there are not ten errors to display.

After all ten errors have been displayed you will hear three”beeps”.

English-15

Switches

Three and Four

S3

(Enter)

Button

004-1055-00

[Revised: 7/16/15]

ID Code 01 (Machine Control Board)

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

00

01

02

03

04

05

06

07

08

09

0A

0b

0C

0d

0E

TP210 Rev. A

0F

Power-Up Image Fault Board Malfunction.

Power-Up Memory Fault Board Malfunction.

Power-Up Clock Fault Board Malfunction.

Power-Up Clock Fault Board Malfunction.

Loose connection.

Power-Up Voltage Fault

Board Malfunction.

Process Execution Fault Board Malfunction.

Power-Up Initialization Fault Board Malfunction.

Headrest Clearance

Back Cover Clearance

Foot Clearance

Programmability Time-out

Programmability Mistake

Programmability Error

however, at least one of the axis positions was out of range.

Calibration Failed Table not calibrated. Reference associated error code(s). Calibrate Table. Refer to: Calibration Procedure

Calibration Not Completed

Calibration Foot Extension Error Foot extension is extended. Move foot extension in.

Refer to: Active Sensing Technology

Refer to: Active Sensing Technology

Refer to: Active Sensing Technology

The Program button was pressed and no buttons

were pressed within the allotted time.

The Program button was pressed to initiate

programming a position and a non-programmable

button was attempting to be programed.

The program command was received, and during

the program time a proper command was received;

Movement button on Hand / Foot Control pressed.

Position of table.

Position of table.

Position of table.

Table not calibrated.

TM

TM

TM

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Check all connections between Machine Control Board and

Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Activate Back Up, Base Up, and/or Tilt Down.

Activate Back Up, Base Up, and/or Tilt Down.

Activate Base Up, Tilt Up, and/or Foot Up.

Error goes away by itself.

Error goes away by itself.

Error goes away by itself.

Run all functions to their maximum and minimum positions.

Calibrate Table. Refer to: Calibration Procedure

Calibrate Table. Refer to: Calibration Procedure

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-16

004-1055-00

[Revised: mo/dd/yr]

ID Code 01 (Machine Control Board) - continued

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

Check all connections between Machine Control Board and

Power Supply PC Board.

If LED (D-24) is illuminated, replace Machine Control PC Board.

If LED (D-24) is not illuminated, replace Power Supply PC Board.

Check all connections between Machine Control PC Board and

Power Supply PC Board.

If LED (D-25) is illuminated, replace Machine Control PC Board.

If LED (D-25) is not illuminated, replace Power Supply PC Board.

Check all connections between Machine Control PC Board and

Power Supply PC Board.

If LED’s (D-21 & D-22) are illuminated, replace Power Supply PC Board.

If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Disconnect power cord for at least ve seconds, then plug back in.

Remove power for ve minutes to allow Machine Control PC Board to cool,

then reapply power. Check if Power Supply PC Board is overheating.

Replace Power Supply PC Board if overheating continues.

Press and hold the Stop and Back Down buttons simultaneously for two seconds.

You will hear a single “Beep” to indicate control lockout is disabled.

Disconnect power cord for at least ve seconds, then plug back in.

Ensure brake pedal is not depressed during power up.

Check and secure wire connections at J12 on Machine Control PC Board

and rotation brake switch.

Check and secure wire connections at J6 on Machine Control PC Board

and treatment pan switch.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Check and secure wire connections at J3 on Power Supply PC Board

and J13 on Motor Control Hub PC Board.

Check and secure wire connections at J16 on Machine Control PC Board

and J14 on Motor Control Hub PC Board.

10

11

12

13

14

15

16

17

18

19

1A

Flashing

TP210 Rev. A

1A

Continuously Illuminated

Loose connection.

Low Voltage 5 VDC

Board Malfunction.

Loose connection.

Low Voltage 12 VDC

Board Malfunction.

Loose connection.

Low Voltage 48 VDC

Board Malfunction.

Temperature Out of Range Board Malfunction.

Control Lockout

Rotation brake switch detected pressed during power-up.

Rotation Locked Out

Treatment Pan Out

Communication Error to

Motor Control

Communication Error to

Motor Control

Communication Error to

Motor Control

None Normal Operation. No action required.

Communication Error to

Motor Control

Control Lockout is activated.

Refer to: Control Lockout

Loose wire connection.

Rotation brake switch(es). Test / replace switch(es).

Treatment pan not in the stowed position. Push treatment pan all the way in.

Loose wire connection.

Treatment Pan switch. Test / replace switch.

Message failure.

Communication failure.

Communication failure.

Loose wire connection.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-17

004-1055-00

[Revised: 2/17/16]

ID Code 01 (Machine Control Board) - continued

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Check and secure wire connections at J3 on Power Supply PC Board

and J13 on Motor Control Hub PC Board.

Check and secure wire connections at J16 on Machine Control PC Board

and J14 on Motor Control Hub PC Board.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Machine Control PC Board.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

1b

1C

1d

1E

1F

20

21

22

23

24

25

26

Message failure.

Communication Error to

Motor Control

Communication Error to

Motor Control

Communication Error to

Keypad

Communication Error to

Keypad

Communication Error to

Keypad

Communication Error to

Keypad

Serial Diagnostics Port Error Communication failure.

Corrupt Memory Last save to memory failed.

Memory Save Error Saving to memory failed.

Memory Recall Error Recalling information from memory failed.

Memory Erase Error Erasing information from memory failed.

Incorrect Movement

An axis was detected moving when the commanded

Loose wire connection.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Communication failure.

Message failure.

Communication failure.

Communication failure.

Message failure.

motion was to be stopped.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-18

004-1055-00

[Revised: mo/dd/yr]

ID Code 02 (Base / Power Supply Board)

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

00

01

02

03

04

05

06

07

08

09

Power-Up Fault Board malfunction.

Power-Up Initialization Fault Board malfunction.

Calibration Failed / Not Complete

Low Voltage 48 VDC Board Malfunction.

Low Voltage 48 VDC Board Malfunction.

Low Voltage 5 VDC Board Malfunction.

Temperature Out of Range Board Malfunction.

Active Sensing Technology

activated.

Position Out of Range

Limit Switch

TM

The maximum position was unable to be set.

A motor control error occurred.

Active Sensing Technology

Foot Smart Sensor Switches.

Not calibrated. Calibrate Table. Refer to: Calibration Procedure

Limit Switch.

Loose wire connection.

Base limit switch(es). Test / Replace switch(es). Refer to: Base Actuator / Limit Switches

TM

activated. Remove object from under the foot section.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Calibrate Table. Refer to: Calibration Procedure

Disconnect power cord for at least ve seconds, then plug back in.

If LED’s (D-21 & D-22) are illuminated, replace Power Supply PC Board.

If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Disconnect power cord for at least ve seconds, then plug back in.

If LED’s (D-21 & D-22) are illuminated, replace Power Supply PC Board.

If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Remove power for ve minutes to allow Power Supply PC Board to cool,

then reapply power.

Replace Power Supply PC Board.

Check and secure wire connections at J18 on Machine Control PC Board and at switches.

Refer to: Fuses and Connections

Check and secure Green and White wire connections at four pin inline connection next to

Motor Control Hub PC Board.

Test / Replace switch(es). Refer to: Smart Sensor Switches

Check and secure wire connections for Up limit switches.

Refer to: Fuses and Connections

Test / Replace switch(es). Refer to: Base Actuator / Limit Switches

Check and secure wire connections at J5 on Power Supply PC Board and at limit switch.

Refer to: Fuses and Connections

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-19

004-1055-00

[Revised: mo/dd/yr]

ID Code 02 (Base / Power Supply Board) - continued

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

Check and secure wire connections at J5 on Power Supply PC Board and

at Overtravel limit switch. Refer to: Fuses and Connections

Disconnect power cord for at least ve seconds, then plug back in.

Test / Replace switch. Refer to: Base Actuator / Limit Switches

Disconnect power cord for at least ve seconds, then plug back in.

Check and secure hall sensor wire connection at J7 on Power Supply PC Board.

Refer to: Fuses and Connections

Check / Reduce patient load. (650 lb. Maximum)

Check mechanical structure for binding.

Check actuator / motor and limit switches.

Check / Reduce patient load. (650 lb. Maximum)

Check mechanical structure for binding.

Check and secure wire connections at J6 on Power Supply PC Board.

Refer to: Fuses and Connections

Check actuator / motor.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Test / Replace F5 fuse on Power Supply PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Test / Replace F5 fuse on Power Supply PC Board.

0A

0b

0C

0d

0E

0F

10

11

12

13

14

15

16

Loose wire connection.

Overtravel Error

Overtravel limit switch.

Hall Sensors

Motor Current Excessive load on actuator.

Motor Run On Error

Motor Stall Error

Motor Direction Error

Communication Error to

Machine Control

Corrupt Memory Last save to memory failed.

Memory Save Error Saving to memory failed.

Memory Recall Error Recalling information from memory failed.

Memory Erase Error Erasing information from memory failed.

I2C Slave Not Present Power Supply PC Board fuse blown.

I2C Slave Not Initialized Power Supply PC Board fuse blown.

The motor has been detected moving for a longer period of

The motor is being commanded to move in one direction,

Loose wire connection.

Motor Failure. Replace Base actuator motor.

time than the run-on time allows.

Excessive load on actuator.

Loose wire connection.

but is actually moving in another.

Message / Communication failure.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-20

004-1055-00

[Revised: mo/dd/yr]

ID Code 03 (Back / Motor Control Hub Board)

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

00

01

02

03

04

05

06

08

TP210 Rev. A

09

Power-Up Fault Board malfunction.

Power-Up Initialization Fault Board malfunction.

Calibration Failed / Not Complete

Low Voltage 48 VDC

Low Voltage 48 VDC

Low Voltage 5 VDC

Temperature Out of Range Board Malfunction.

Position Out of Range

Limit Switch

The maximum position was unable to be set.

A motor control error occurred.

Loose connection.

Motor Control Hub PC Board fuse blown. Test / Replace F3 fuse on Motor Control Hub PC Board.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Board Malfunction.

Loose connection.

Motor Control Hub PC Board fuse blown. Test / Replace F3 fuse on Motor Control Hub PC Board.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Board Malfunction.

Loose connection.

Board Malfunction.

Not calibrated. Calibrate Table. Refer to: Calibration Procedure

Limit Switch.

Loose wire connection.

Back limit switch(es). Test / Replace switch(es). Refer to: Back Actuator / Limit Switches

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Calibrate Table. Refer to: Calibration Procedure

Check all connections between Power Supply PC Board and Motor Control Hub PC Board,

and all connections between Machine Control PC Board and Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

If LED’s (D-21 & D-22) are illuminated on Power Supply PC Board, check for 24 VDC at

J-13 on Motor Control Hub Board. If voltage is present, replace Motor Control Hub

PC Board. If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Check all connections between Power Supply PC Board and Motor Control Hub PC Board,

and all connections between Machine Control PC Board and Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

If LED’s (D-21 & D-22) are illuminated on Power Supply PC Board, check for 24 VDC at

J-13 on Motor Control Hub Board. If voltage is present, replace Motor Control Hub

PC Board. If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Check all connections between Power Supply PC Board and Motor Control Hub PC Board,

and all connections between Machine Control PC Board and Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Remove power for ve minutes to allow Motor Control Hub PC Board to cool,

then reapply power.

Replace Motor Control Hub PC Board.

Check and secure wire connections for Up limit switches.

Refer to: Fuses and Connections

Test / Replace switch(es). Refer to: Back Actuator / Limit Switches

Check and secure wire connections at J12 on Motor Control Hub PC Board and

at limit switch(es). Refer to: Fuses and Connections

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-21

004-1055-00

[Revised: mo/dd/yr]

ID Code 03 (Back / Motor Control Hub Board) - continued

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

Check and secure wire connections at J12 on Motor Control Hub PC Board and

at Overtravel limit switch(es). Refer to: Fuses and Connections

Disconnect power cord for at least ve seconds, then plug back in.

Test / Replace switch. Refer to: Back Actuator / Limit Switches

Disconnect power cord for at least ve seconds, then plug back in.

Check and secure hall sensor wire connection at J10 on Motor Control Hub PC Board.

Refer to: Fuses and Connections

Check / Reduce patient load. (650 lb. Maximum)

Check mechanical structure for binding.

Check actuator / motor and limit switches.

Check / Reduce patient load. (650 lb. Maximum)

Check mechanical structure for binding.

Check and secure wire connections at J11 on Motor Control Hub PC Board.

Refer to: Fuses and Connections

Check actuator / motor.

0A

0b

0C

0d

0E

0F

Loose wire connection.

Overtravel Error

Overtravel limit switch(es).

Hall Sensors

Motor Current Excessive load on actuator.

Motor Run On Error

Motor Stall Error

Motor Direction Error

The motor has been detected moving for a longer period of

The motor is being commanded to move in one direction,

Loose wire connection.

Motor Failure. Replace Back actuator motor.

time than the run-on time allows.

Excessive load on actuator.

Loose wire connection.

but is actually moving in another.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-22

004-1055-00

[Revised: 6/5/14]

ID Code 03 (Back / Motor Control Hub Board) - continued

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

10

11

12

13

14

15

16

Communication Error to

Machine Control

Corrupt Memory Last save to memory failed.

Memory Save Error Saving to memory failed.

Memory Recall Error Recalling information from memory failed.

Memory Erase Error Erasing information from memory failed.

I2C Slave Not Present

I2C Slave Not Initialized

Message / Communication failure.

Loose wire connection.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Motor Control Hub PC Board.

Power Supply PC Board.

Loose wire connection.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Motor Control Hub PC Board.

Power Supply PC Board.

Error goes away by itself.

Disconnect power cord for at least ve seconds, then plug back in.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Check and secure wire connections at J3 on Power Supply PC Board

and J13 on Motor Control Hub PC Board. Refer to: Fuses and Connections

Check and secure wire connections at J16 on Machine Control PC Board

and J14 on Motor Control Hub PC Board. Refer to: Fuses and Connections

Check supply power to Motor Control Hub PC Board.

Refer to: Motor Control Hub PC Board Supply Power

Check supply power to Motor Control Hub PC Board.

Refer to: Motor Control Hub PC Board Supply Power

Check and secure wire connections at J3 on Power Supply PC Board

and J13 on Motor Control Hub PC Board. Refer to: Fuses and Connections

Check and secure wire connections at J16 on Machine Control PC Board

and J14 on Motor Control Hub PC Board. Refer to: Fuses and Connections

Check supply power to Motor Control Hub PC Board.

Refer to: Motor Control Hub PC Board Supply Power

Check supply power to Motor Control Hub PC Board.

Refer to: Motor Control Hub PC Board Supply Power

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-23

004-1055-00

[Revised: mo/dd/yr]

ID Code 04 (Tilt / Motor Control Hub Board)

midmark.com

Style A

Error Code Error Denition Probable Cause Correction

00

01

02

03

04

05

Power-Up Fault Board malfunction.

Power-Up Initialization Fault Board malfunction.

Calibration Failed / Not Complete

Low Voltage 48 VDC

Low Voltage 48 VDC

Low Voltage 5 VDC

The maximum position was unable to be set.

A motor control error occurred.

Loose connection.

Motor Control Hub PC Board fuse blown. Test / Replace F2 fuse on Motor Control Hub PC Board.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Board Malfunction.

Loose connection.

Motor Control Hub PC Board fuse blown. Test / Replace F2 fuse on Motor Control Hub PC Board.

Power Supply PC Board fuse(s) blown. Test / Replace F3 & F4 fuses on Power Supply PC Board.

Board Malfunction.

Loose connection.

Board Malfunction.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

Calibrate Table. Refer to: Calibration Procedure

Check all connections between Power Supply PC Board and Motor Control Hub PC Board,

and all connections between Machine Control PC Board and Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

If LED’s (D-21 & D-22) are illuminated on Power Supply PC Board, check for 24 VDC at

J-13 on Motor Control Hub Board. If voltage is present, replace Motor Control Hub

PC Board. If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Check all connections between Power Supply PC Board and Motor Control Hub PC Board,

and all connections between Machine Control PC Board and Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

If LED’s (D-21 & D-22) are illuminated on Power Supply PC Board, check for 24 VDC at

J-13 on Motor Control Hub Board. If voltage is present, replace Motor Control Hub

PC Board. If LED’s (D-21 & D-22) are not illuminated, test Power Toroid

Check all connections between Power Supply PC Board and Motor Control Hub PC Board,

and all connections between Machine Control PC Board and Motor Control Hub PC Board.

Disconnect power cord for at least ve seconds, then plug back in.

Replace Motor Control Hub PC Board.

TP210 Rev. A

© 2013 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

English-24

004-1055-00

[Revised: mo/dd/yr]

Loading...

Loading...