Page 1

Attention!

For OSHPD Regulated Installations, please go to

www.midmark.com to download the appropriate

OSHPD Approval and Installation documents.

6275-001 Installation Instructions

INS-6275-001 (Rev. F)

Page 2

Installation Hardware

6275-001 Installation Instructions

INS-6275-001 (Rev. F)

Tools required:

Electric Drill with driver extension

Phillips head screwdriver/bit

1/2” Drill Bit

Punch

Parts Included:

(1) Monitor Track Assembly

(6) 1/4-20 Hilti Snaptoggle Heavy-Duty Toggle Bolts (2 extra)

(4) 1/4-20 x 2” Long Phillips Drive Pan Head Machine Screws

(4) M4-0.7 x 10mm Long Phillips Drive Flat Head Machine Screws

(4) M4-0.7 x 16mm Long Phillips Drive Flat Head Machine Screws

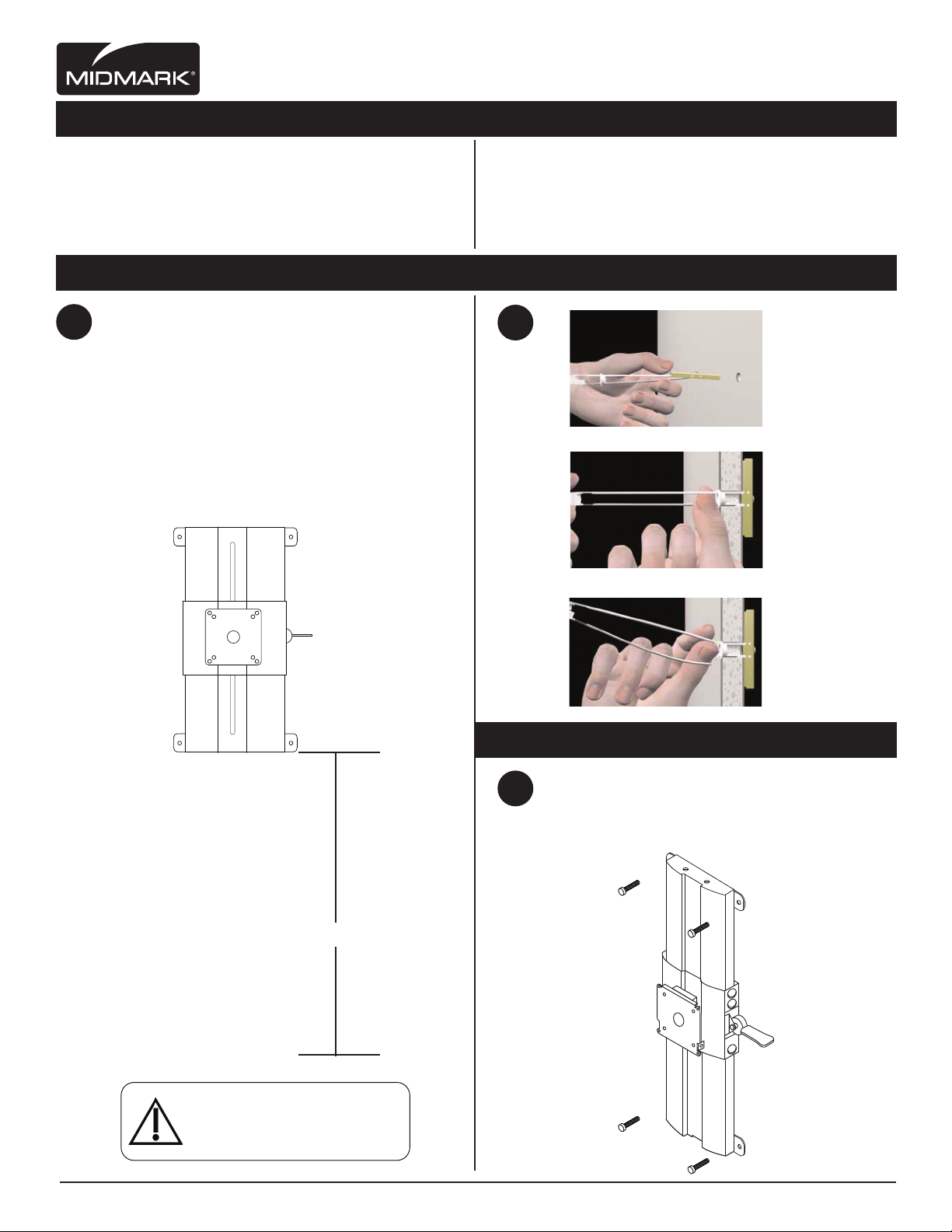

Drilling Hole Preparation: Toggler Bolt Installation:

a. Choose desired height position: sitting or

1

standing for Monitor Track Assembly.

2

a.

b. Compare level to top of monitor track to

ensure mounting template is perfectly plumb.

c. Using punch to locate holes in wall.

Install Toggler Bolts

b.

c.

(1/2” Hole)

Drill 1/2” size hole.

Hold metal channel

fl at alongside plastic

straps and slide

channel through

the hole. Minimum

clearance beind wall:

only 1 7/8”

Hold ends of straps

together between

thumb & forefi nger

and pull toward you

until channel rests

behind wall. Rachet

cap along straps

with other hand until

fl ange of cap is

fl ush with wall.

Place thumb between

straps at wall. Push

thumb side to side,

snapping off straps

level with fl ange

of cap.

X”

Floor

Caution

Properinstallationoftoggleboltsrequired

toprovidesecurewallmounting.Minimum

drywallthicknesstobe½”.

Mounting Wall-Mount to Wall:

Align the four monitor track mounting holes

3

with holes in wall. Secure with (4) 1/4-20 x 2”

Long Phillips Drive Pan Head Machine Screws.

Midmark Corporation | 60 Vista Drive | PO Box 286 | Versailles, Ohio 45380-0286 | USA | midmark.com

Page 3

6275-001 Installation Instructions

INS-6275-001 (Rev. F)

Attach Monitor to Bracket:

a. Align VESA mounting hole pattern on

4 5

monitor with mounting pattern on

Monitor Bracket (See FIG. A).

b. Attach Monitor Bracket to Monitor.

Secure with either (4) M4-0.7 x 10mm or

(4) M4-0.7 x 16mm Long Phillips Drive

Flat Head Machine Screws (See FIG.B)

c. Attach monitor with Monitor Bracket to

Monitor Security Bracket Assembly.

Note: Monitor Bracket has a top slot which

the Monitor Security Bracket Assembly fi ts

into (See FIG. C).

d. Secure brackets with two (2) #10-24 x 1/2”

Long Phillips Drive Pan Head Machine

Screws (See FIG D).

.

Upper Cable Management:

Upper Cable Management: For CPU’s, monitors:

For Monitor cables: Remove Cable Management

Cover (See FIG. A). Place in channel and zip-tie cables

at the top by monitor (See FIG. B).

Continue to run cables behind keyboard

pivot housing (See FIG. C).

Reinstall cable mangement cover when fi nished

(See FIG. A).

For Upper CPU’s: Cables can be run arround the

cable management insert (See FIG. D). Additional

cables running out of upper cpu holder, can be

run down behind Height Adjustable Monitor

Bracket (See FIG. E).

FIG. B

Monitor

Bracket

FIG. A

FIG. C

Monitor Security

Bracket Assembly

FIG. B

FIG. D

FIG. A

FIG. C

FIG. D

FIG. E

Midmark Corporation | 60 Vista Drive | PO Box 286 | Versailles, Ohio 45380-0286 | USA | midmark.com

Loading...

Loading...