Midland SP-8, SPD-8, SP-10, SPD-10 Service Manual

Model SP-8 & 10

SP-8 &10 Operation, Parts & Service Manual

Midland Machinery Co., Inc.

101 Cranbrook Ext.

Tonawanda, NY 14150

Phone: 716-692-1200

Fax: 716-692-1206

www.midlandmachinery.com

Revision July 2012

www.roadwidener.com

Machine Serial Number : ______________

1

Model SP-8 & 10

Contents

1. IntroduCtIon And WArrAnty .................................................................... 2

1.1 Introduction ...................................................................................................... 2

1.2 Serial Number .................................................................................................. 2

1.3 Warranty ........................................................................................................... 3

1.4 Engine Warranty .............................................................................................. 3

2. Component IdentIfICAtIon .......................................................................... 4

2.1 Overall Machine ............................................................................................... 4

2.2 Operators Console .......................................................................................... 5

3. speCIfICAtIons ........................................................................................... 6

3.1 SP-8/SPD-8 Specifications .............................................................................. 6

3.2 SP-10/SPD-10 Specifications .......................................................................... 6

4. sAfety ...................................................................................................... 7

4.1 Safety Alert Symbol And Signal Words ......................................................... 7

4.2 Hazards ............................................................................................................. 7

4.2.1 mAIntenAnCe ..................................................................................................................... 7

4.2.2 Burn preventIon ............................................................................................................... 7

4.2.3 pressurIzed HydrAulIC fluId And GreAse ......................................................................... 8

4.2.4 HAzArdous CHemICAls ....................................................................................................... 8

4.2.5 fIre or explosIon preventIon ......................................................................................... 8

4.3 Operation And Maintenance ........................................................................... 8

4.3.1 CAlIfornIA proposItIon 65 WArnInG ................................................................................ 10

4.3.2 prepAre for emerGenCIes ............................................................................................... 10

4.3.3 do not AlloW rIders ..................................................................................................... 11

4.3.4 AvoId poWer lInes ......................................................................................................... 11

4.4 Hazards From Modifying Equipment ............................................................11

4.5 Safety Warning Labels .................................................................................. 12

5. operAtIon ............................................................................................... 18

5.1 Operational Safety ......................................................................................... 18

5.2 Startup Procedure ......................................................................................... 18

5.3 Strike-Off Blade Setup ................................................................................... 19

5.3.1 posItIon BlAde .............................................................................................. 19

5.3.2 CHAnGe BlAde lenGtH ..................................................................................................... 22

5.4 Push Roller Setup .......................................................................................... 24

5.4.1 pIvot pIn loCAtIon .......................................................................................................... 24

5.4.2 pusH roller dIstAnCe setup .......................................................................................... 25

5.4.3 HydrAulIC pusH roller dIstAnCe setup .......................................................................... 26

5.5 Set Hopper Gates ........................................................................................... 26

www.roadwidener.com

I

Model SP-8 &10

5.6 Operation ........................................................................................................ 27

5.7 Side Changeover For Material Discharge And Blade ................................. 28

5.7.1 sIde CHAnGeover for mAterIAl dIsCHArGe ...................................................................... 28

5.7.2 BlAde sIde CHAnGeover ................................................................................................... 29

5.7.3 HydrAulIC extensIon CHAnGeover .................................................................................... 31

5.8 Loading For Transport................................................................................... 34

6. servICe And mAIntenAnCe ...................................................................... 36

6.1 Service Intervals ............................................................................................ 36

6.2 Drive Axle And Transmission Lubrication ................................................... 38

6.3 Conveyor Belt ................................................................................................ 39

6.3.1 Adjust Conveyor Belt tensIon ....................................................................................... 39

6.3.2 replACe Conveyor Belt .................................................................................................. 40

6.3.3 Conveyor Belt mAIntenAnCe ........................................................................................... 45

6.4 Hydraulic System Flushing Procedure ........................................................ 46

6.4.1 flusH Conveyor system ................................................................................................. 47

6.4.2 flusH trACtIon drIve system ......................................................................................... 51

6.4.3 flusH Conveyor And trACtIon drIve system .................................................................. 52

7. revIsIon reCords ................................................................................... 53

7.1 Revision Record By Serial Number ............................................................. 53

8. fInAl AssemBly ....................................................................................... 54

8.1 Final Assembly (Dual Sided) ......................................................................... 54

8.1.1 spd-8-001 rev-d (spd-8, duAl sIded) ........................................................................ 55

8.1.2 spd-10-001 rev-f (spd-10, duAl sIded) .................................................................... 55

8.2 Final Assembly (Single Sided) ...................................................................... 56

8.2.1 sp-8-001 rev-H (sp-8, sInGle sIded) .......................................................................... 57

8.2.2 sp-10-001 rev-f (sp-10, sInGle sIded) ........................................................................ 57

9. CHAssIs AssemBly ................................................................................... 58

9.1 Chassis Assembly (SP-8 & SPD-8), SP-005 Rev-F ...................................... 59

9.2 Chassis Assembly (SP-10 & SPD-10), SP-395 Rev-F .................................. 61

9.3 Manual Shift Assembly SP-534 Rev-A ......................................................... 62

9.4 Trailer Axle And Brake Assembly SP-144 Rev-C ........................................ 64

9.4.1 InstruCtIons for BrAke yoke InstAllAtIon And Adjustment: .......................................... 65

10. Conveyor And Hopper AssemBly ......................................................... 66

10.1 Conveyor And Hopper Assembly, Dual Sided, SPD-808 .......................... 66

10.2 Conveyor And Hopper Assembly, Single Sided, SP-808 .......................... 68

10.3 Adjustable Discharge Gate Assembly, SP-276 Rev-A .............................. 70

10.4 Deflector Assembly, SP-717 Rev-A ............................................................ 71

10.5 Bib Assembly, SP-718 ................................................................................. 72

II

www.roadwidener.com

Model SP-8 & 10

10.6 Push Roller Assembly SP-151 Rev-A ......................................................... 73

11. BlAde And Column AssemBly ............................................................... 74

11.1 Blade And Column Assembly SP-8/SPD-8 .................................................. 74

11.1.1 BlAde And Column AssemBly, rIGHt sIde, sp-579 rev-A ............................................. 74

11.1.2 BlAde And Column AssemBly, left sIde, sp-593 rev-A ............................................... 76

11.2 Blade And Column Assembly SP-10/SPD-10 ............................................. 78

11.2.1 BlAde And Column AssemBly, rIGHt sIde, sp-420 rev-B ............................................. 78

11.2.2 BlAde And Column AssemBly, left sIde, sp-588 rev-A ............................................... 80

11.3 Hydraulic Blade Extension Installation For SP-8, SP-751 ........................ 82

11.4 Hydraulic Blade Extension Installation For SP-10, SP-752 ...................... 83

11.5 Hydraulic Blade Extension Assembly, SP-470 Rev-A ............................... 84

11.6 Adjustable Edger Plate Assembly , SP-744 Rev-A .................................... 85

12. enGIne And Controls AssemBly ............................................................ 86

12.1 Engine And Controls Assembly SP-8/SPD-8 ............................................. 86

12.2 Engine And Controls Assembly SP-10/SPD-10 ......................................... 88

13. eleCtrICAl InstAllAtIon ........................................................................ 90

13.1 Electrical Install’n, Standard Config’n, Single Sided, SP-772 Rev-A ...... 90

13.2 Electrical Installation, Optional Neutral Position Brake Switch Safety .. 93

13.3 Electrical Installation, Optional Dual Discharge System ........................ 94

13.4 Electrical Installation, Other Options ........................................................ 96

13.5 Electrical Installation, Optional Auto Grade And Slope (Single Sided) . 98

13.6 Electrical Installation, Optional Auto Grade And Slope (Dual Sided) .. 100

13.7 Electrical Installation, Diode Box Assembly (Single Sided) SP-2161 ... 102

13.8 Electrical Installation, Diode Box Assembly (Dual Sided) SP-2162 ...... 104

14. optIonAl lIGHt pACkAGe .................................................................... 106

14.1 Optional Light Package Schematic SP-2065 Rev-A ................................ 106

14.2 Optional Strobe Light Only Schematic SP-2065 Rev-A .......................... 109

15. operAtor Console AssemBly ............................................................. 110

15.1 Operator Console Assembly (Single Sided) SP-1355 Rev-B ..................111

15.2 Operator Console Assembly (Dual Sided) SPD-1355 Rev-B ...................111

16. HydrAulIC InstAllAtIon ....................................................................... 112

16.1 Hydraulic Installation SPD-8, SPD-10 (Dual Sided), SP-770 Rev-C .......112

16.2 Hydraulic Installation SP-8, SP-10 (Single Sided), SP-769 Rev-C ..........118

17. nAmeplAte And deCAl loCAtIons ........................................................ 124

www.roadwidener.com

III

Model SP-8 &10

18. optIons .............................................................................................. 130

18.1 Hydraulic Push Roller Assembly, SP-711 ................................................ 130

18.1.1 HydrAulIC InstAllAtIon, sp-707 rev-A ....................................................................... 131

18.1.2 HydrAulIC CylInder InstAllAtIon, sp-708 rev-A ........................................................ 131

18.1.3 eleCtrICAl InstAllAtIon, sp-866 rev-B ...................................................................... 132

18.2 Diesel Washdown System, SP-273 ........................................................... 134

18.3 Trench Box Assembly ............................................................................... 136

18.3.1 trenCH Box AssemBly sA/sp duAl sIded, sA-1513 rev-A ........................................ 136

18.3.2 trenCH Box AssemBly sA/sp sInGle sIded, sA-726 rev-B ........................................ 137

19. oem Component pArts And servICe InformAtIon ............................... 139

IV

www.roadwidener.com

Model SP-8 & 10

sp-8 &10 operAtIon, pArts & servICe mAnuAl

www.roadwidener.com

1

Model SP-8 &10

1. IntroduCtIon And WArrAnty

1.1 IntroduCtIon

Congratulations on your purchase of the Midland

Machinery SP machine. This SP machine has

been designed and manufactured to the strictest

specications. It is our utmost desire that you achieve

success and are rewarded years of service from your

equipment purchase.

Midland Machinery reserves the right to change,

improve, modify or expand features of this equipment

at any time. Specications, models, or equipment are

subject to change without notice, and without incurring

any obligations to change, improve or expand features

of previously delivered equipment. Because of

variations in optional equipment and continued design

improvement, certain information contained within this

manual may not apply.

Carefully examine your machine upon receipt. Report

any damage immediately to the freight carrier and

register any claim. Should any material or manufacturing

defects be discovered, report your ndings to our

service department along with the model, serial number

and date of purchase. We want to know that you are

satised with the machine. As always, we welcome

input on how our products can be improved to serve

you better.

Read and understand this manual before using your

machine and follow all of the safety instructions. Keep

this manual with your machine at all times.

Some components may have separate operation and

maintenance manuals. Where this manual indicates

that you should read another manual, and you do

not have that manual, contact Midland Machinery for

assistance.

This manual explains the operation and routine

maintenance of the SP machine. It does not instruct

you how to transport, travel and/or operate on specic

roadways or terrain.

This Operator’s Manual does not replace, nor does its

use release the operator from observing all safety or

operating limitations as well as any applicable federal,

state, provincial or local regulations.

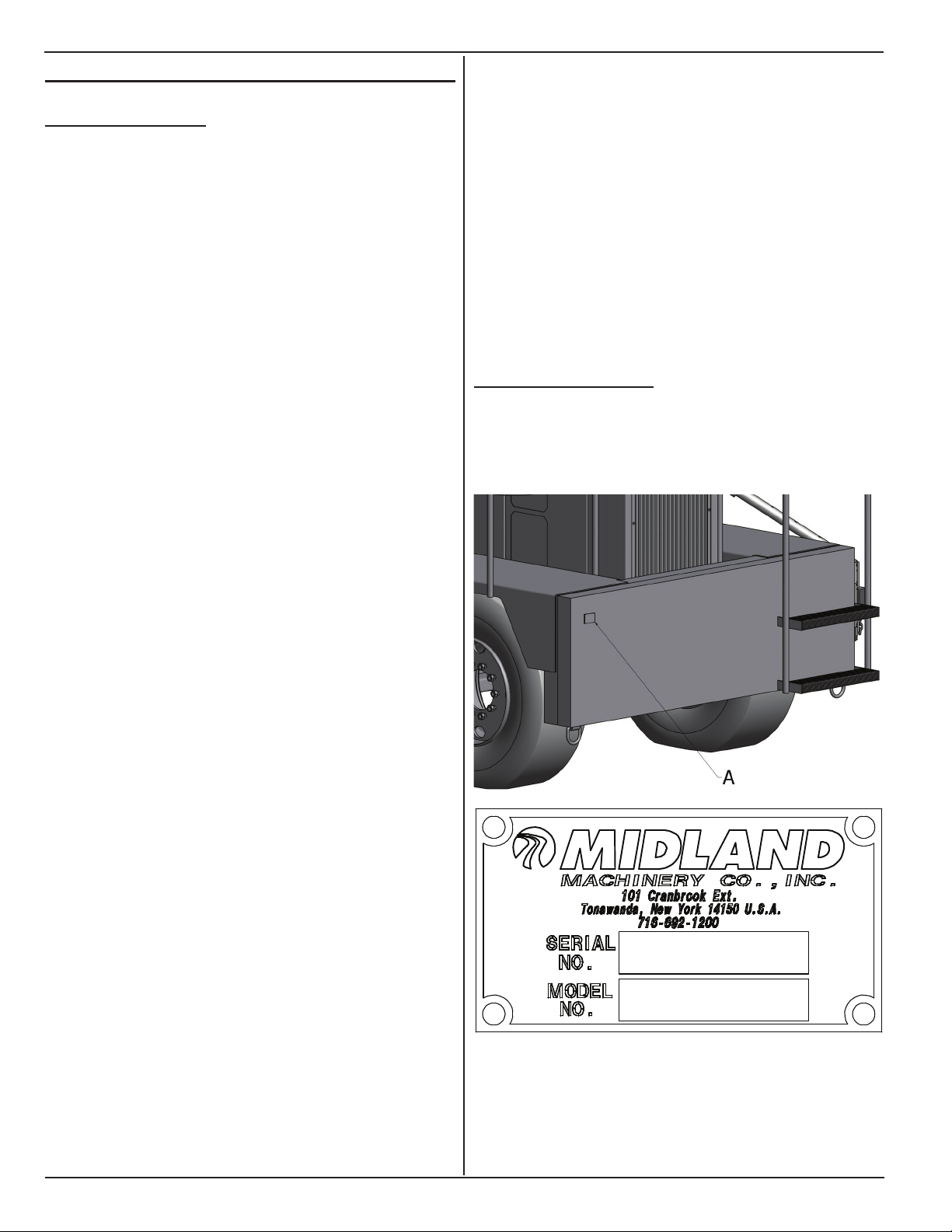

1.2 serIAl numBer

The serial number plate (A) is located on left rear

corner of the machine.

Information furnished in this manual does not include

all of the details of design, production, or variations

of the equipment. It does not cover all the possible

contingencies, which may arise during operation,

setup, or maintenance. Should special problems

arise, or further information be desired, please contact

Midland Machinery. This manual is provided to the SP

owner to assist in the safe operation and maintenance

of the equipment.

The text contained in this manual is for current

production models. Some instructions and maintenance

procedures may not apply to your specic unit.

Equipment modications from original design and

specications are strictly prohibited. Modications may

compromise safe operation of the machine, subjecting

users to serious injury or death and may void any

remaining warranty.

2

www.roadwidener.com

1.3 WArrAnty

Model SP-8 & 10

1.4 enGIne WArrAnty

Midland warrants to the original purchaser only,

that each part of the Road Building Machine, or

components, or the other manufactured items, sold

herein, under normal use and service, shall be free

from defects in workmanship and material for 180 days

or 500 working hours, from initial start-up, whichever

occurs rst, except that this warranty shall not apply

to tires, engines, batteries, manufactured hydraulic

components, which items shall be subject only to the

original manufacturer’s warranty. No adjustment shall

be made for defective items unless notice is given in

writing within ten days after the defect is noted and the

equipment is immediately taken out of service. Use of

equipment thereafter shall constitute acceptance and

waiver of the alleged defects.

This warranty shall be fullled by Midland repairing or

replacing at its factory, products or parts that have been

returned to it with transportation charges prepaid and

that appear to its satisfaction to have been defective in

workmanship or material.

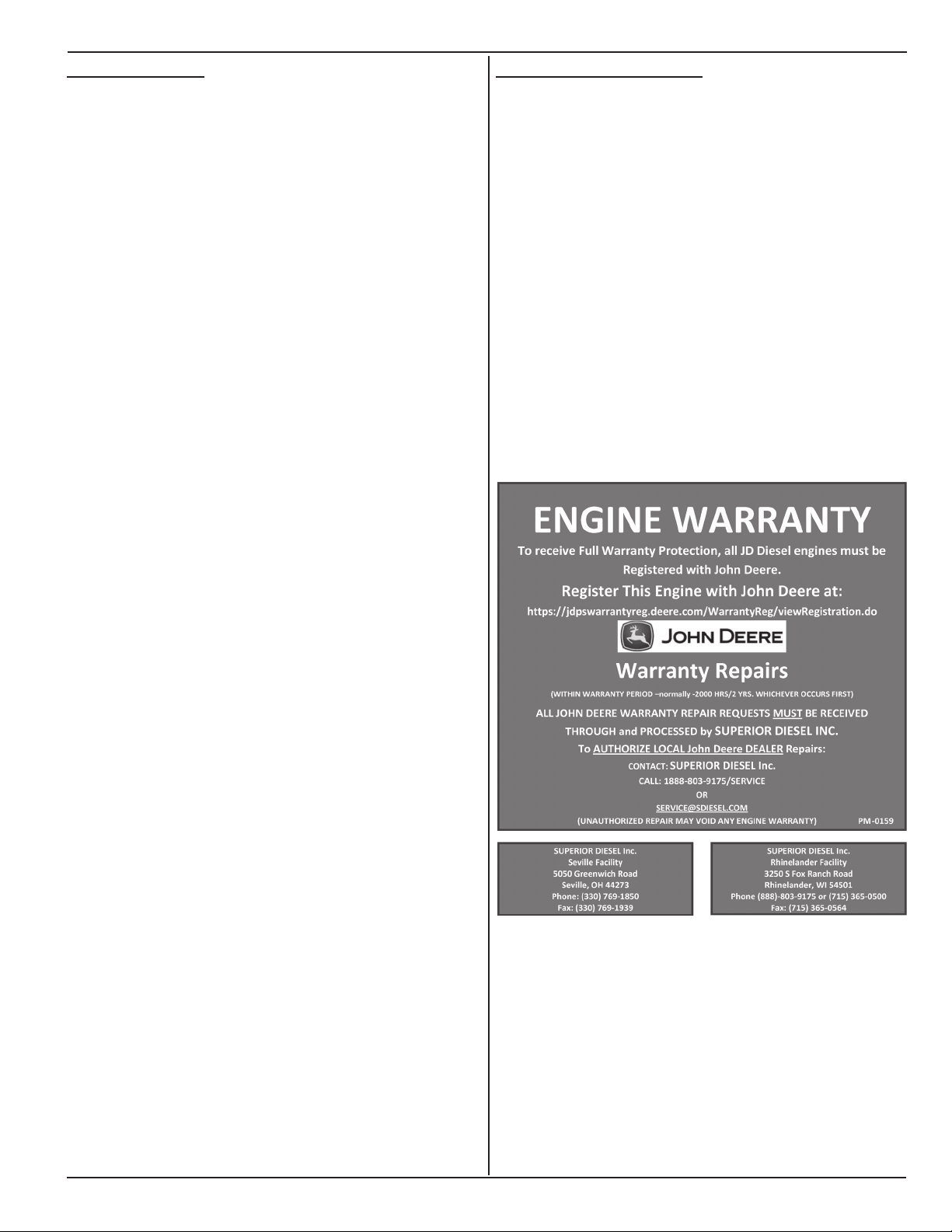

To receive full warranty protection, All John Deere

engines must be registered with John Deere company.

To register your engine with John Deere, please

visit the website: https://jdpswarrantyreg.deere.com/

WarrantyReg/viewRegistration.do.

Warranty Period is normally 2000 engine hours or 2

years from the date of purchase which ever occurs rst.

ALL WARRANTY REPAIR REQUESTS MUST BE

RECEIVED THROUGH AND PROCESSED BY

SUPERIOR DIESEL INC.

TO AUTHORIZE LOCAL JOHN DEERE DEALER

REPAIRS, CONTACT SUPERIOR DIESEL INC AT

PHONE NUMBER 1-888-803-9175/SERVICE OR

THROUGH E-MAIL AT SERVICE@SDIESEL.COM.

THE FOREGOING SPECIFIC WARRANTY IS IN

LIEU OF ANY OTHER EXPRESSED OR IMPLIED

WARRANTIES INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR USE, AND ANY OTHER OBLIGATION

ON PART OF MIDLAND. MIDLAND SHALL NOT BE

RESPONSIBLE UNDER THIS WARRANTY FOR

ANY LOSS OF USE OF THE VEHICLE, LOSS OF

TIME, INCONVENIENCE, COMMERCIAL LOSS OR

CONSEQUENTIAL DAMAGE.

NO AGENT, EMPLOYEE OR REPRESENTATIVE OF

MIDLAND HAS ANY AUTHORITY TO BIND MIDLAND

TO ANY AFFIRMATION, REPRESENTATION OR

WARRANTY CONCERNING THE MACHINE SOLD

UNDER THIS CONTRACT NOT STATED WITHIN, AND

UNLESS AN AFFIRMATION, REPRESENTATION OR

WARRANTY MADE BY AN AGENT, EMPLOYEE OR

REPRESENTATIVE IS SPECIFICALLY INCLUDED

WITHIN THIS WRITTEN AGREEMENT, IT SHALL

NOT BE ENFORCEABLE AGAINST MIDLAND.

UNAUTHORIZED REPAIR MAY VOID ANY ENGINE

WARRANTY.

www.roadwidener.com

3

Model SP-8 &10

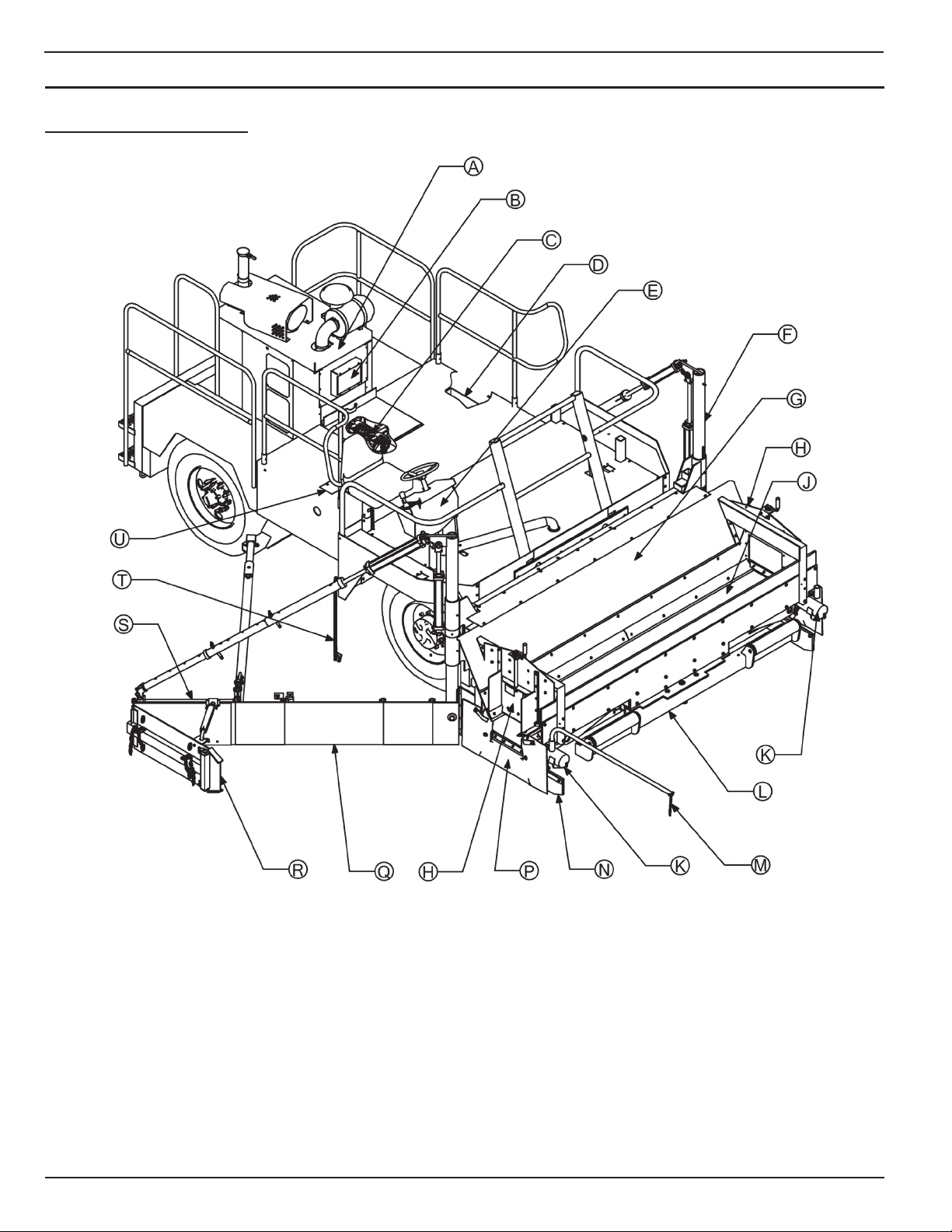

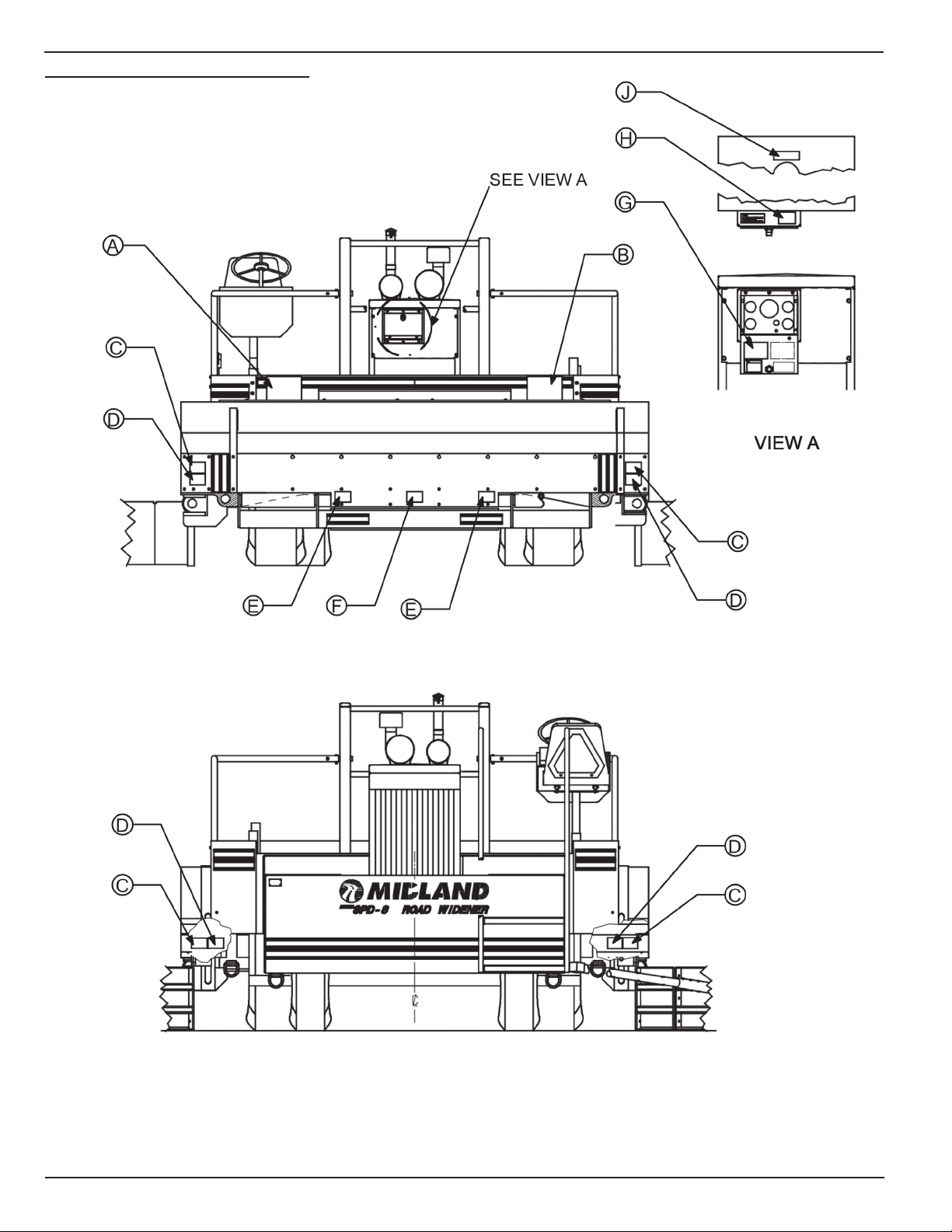

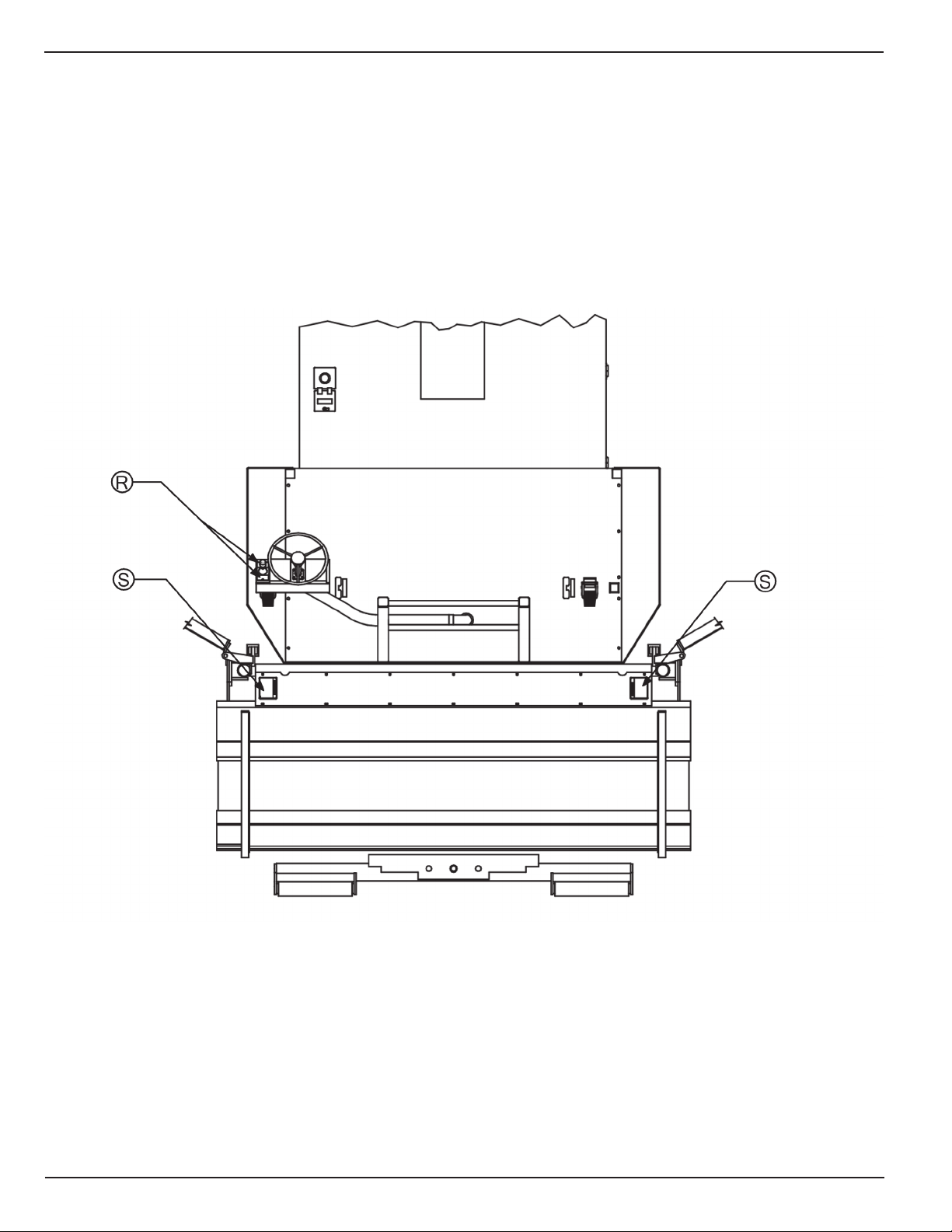

2. Component IdentIfICAtIon

2.1 overAll mACHIne

A - Engine

B - Engine controls

C - Hydraulic Pumps

D - Manual Pack

E - Operator Console

F - Blade And Column Assembly (L/S)*

G - Conveyor And Hopper Assembly

H - Discharge Gate Assembly**

J - Conveyor Belt

K - Conveyor Motor

* Available only in dual side configuration

** Available as option

4

L - Push Roller Assembly

M - Guide Rod Assembly

N - Deector Assembly

P - Bib Assembly

Q - Blade And Column Assembly (R/S)

R - Outer Edger Assembly

S - Hydraulic Blade Extension**

T - Blade Restraint Assembly

U - Hydraulic Tank

www.roadwidener.com

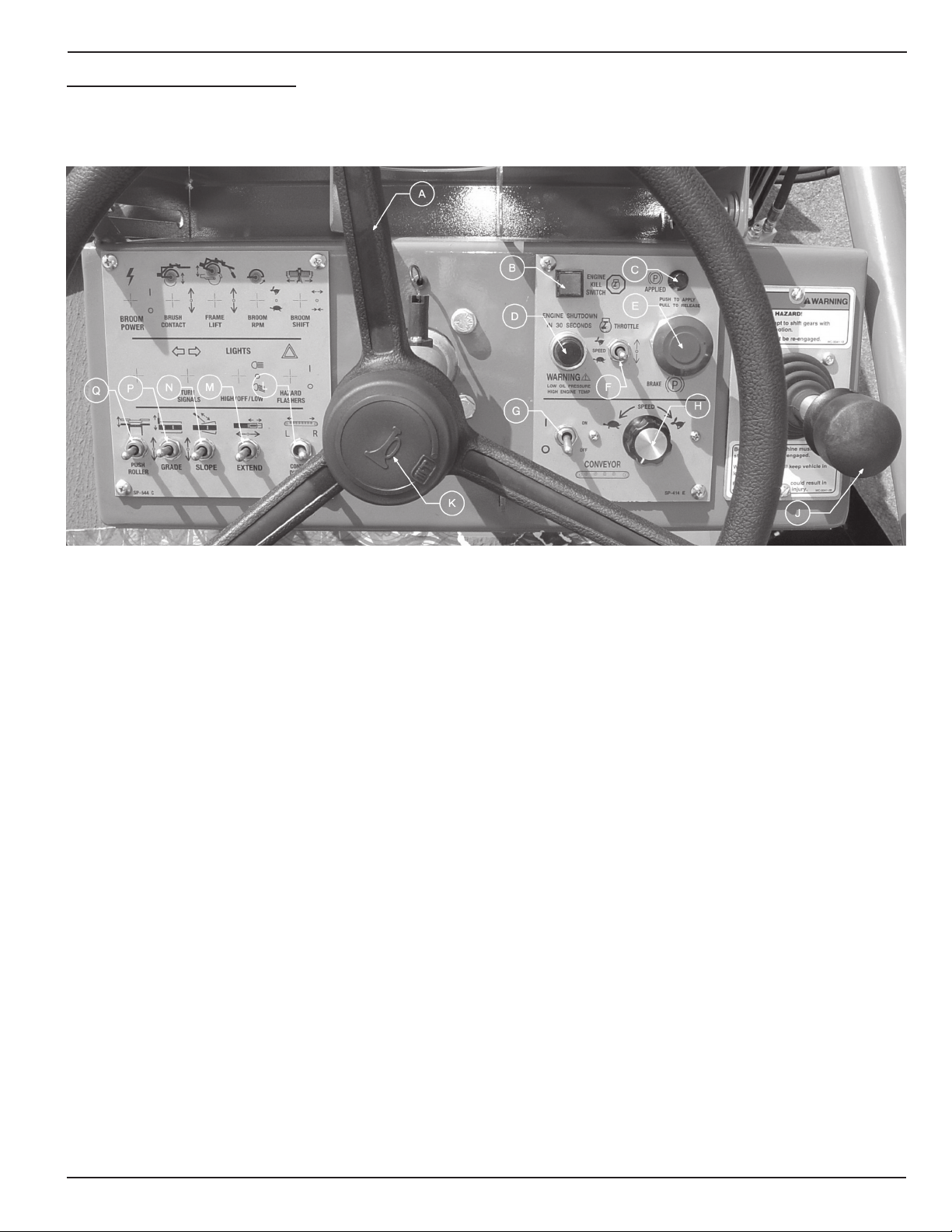

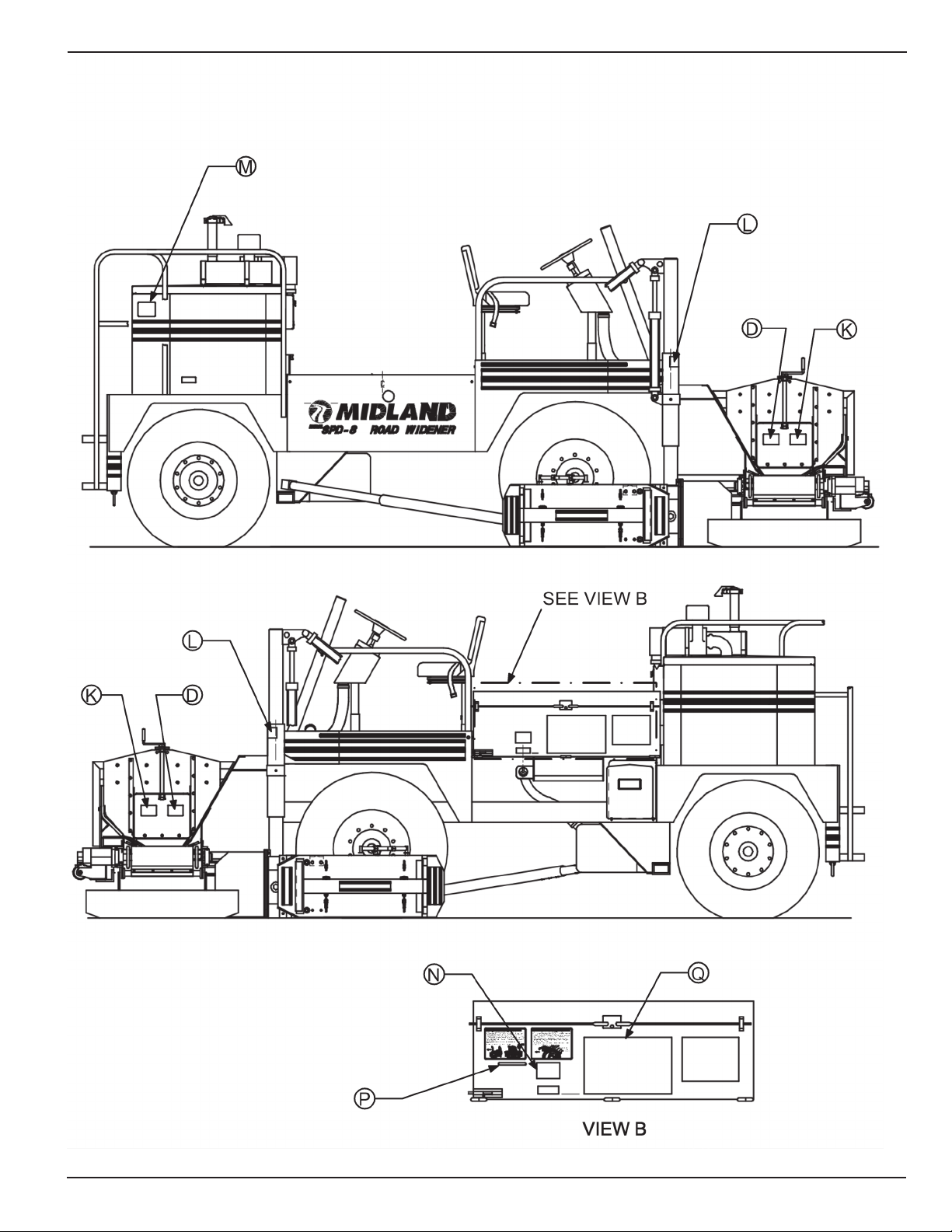

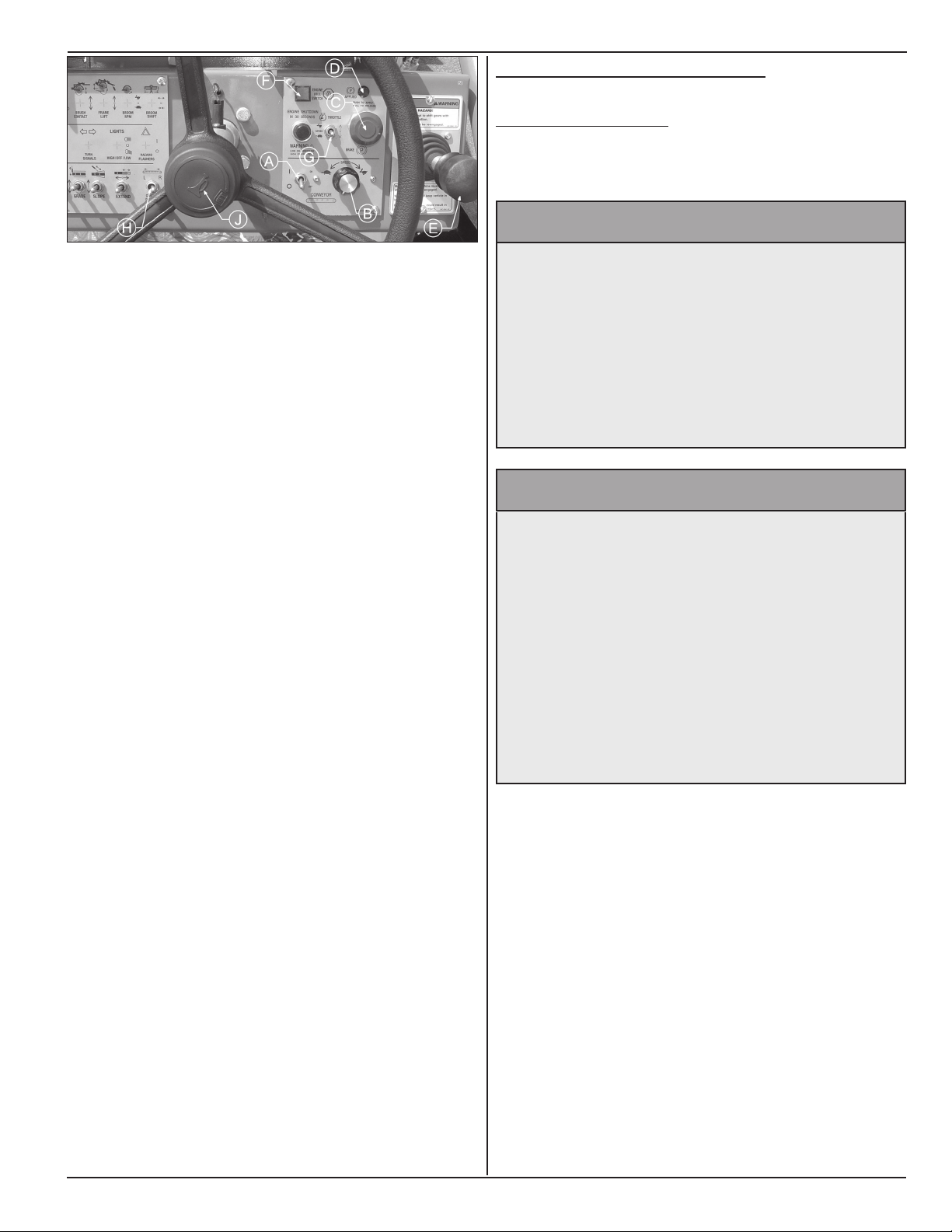

2.2 operAtors Console

Model SP-8 & 10

A - Steering Wheel

B - Engine Kill Switch

C - Parking Brake Applied Indicator

D - Dual Alarm

E - Parking Brake (E-Stop) Button

F - Engine Throttle Switch

G - Conveyor On/Off Switch

H - Conveyor Speed Controller

* Available only in dual side configuration

** Available as option

J - Travel Controller

K - Horn Button

L - Conveyor Direction Switch*

M - Blade Hydraulic Extension Switch**

N - Blade Slope Switch

P - Blade Grade Switch

Q - Hydraulic Push Roller Switch**

www.roadwidener.com

5

Model SP-8 &10

3. speCIfICAtIons

3.1 sp-8/spd-8 speCIfICAtIons

3.2 sp-10/spd-10 speCIfICAtIons

Dimensions-

Length: 19 ft.

Width: Travel - 11 ft. 2 in.

Track (Front) - 80 in.

Track (Rear) - 60 in.

Turn Radius : 15 ft.

Height: 7 ft. 10 in.

Weight: 19,000 lbs.

Wheelbase: 98 in.

Tires: Front : 2 x 425/65R/22.5 Pneumatic

Rear : 2 x 11 R22.5 Pneumatic

Engine/Drive -

John Deere Diesel Model 4045D Tier III 80 hp

Front Wheel Drive, Front Wheel Steering.

Two Speed Hydrostatic Transmission.

Hydraulic Service Brakes

SAHR Emergency/ Parking Brake.

Travel Speed: 0 - 11 mph.

Working Speed: 0 - 150 ft/min.

Strike-Off Blade -

4 - 8 ft. Maximum Spread Width.

18 in. Tall, 1 ft. & 2 ft. long, Modular Blade Sections.

Optional 2 - 4 ft. Hydraulic Extension Section.

Adjustable Height Outer Edger.

Hydraulic Grade Control - 12 in. Above / Below.

Hydraulic Slope Control +/- 16%.

Dimensions-

Length: 19 ft. 4 IN.

Width: Travel - 11 ft. 2 in.

Track (Front) - 80 in.

Track (Rear) - 60 in.

Turn Radius : 15 ft.

Height: 8 ft. 3 in.

Weight: 27,500 lbs.

Wheelbase: 98 in.

Tires: 4 x 425/65R/22.5 Pneumatic

Engine/Drive -

John Deere Diesel Model 4045T Tier III 100 hp Turbo

Charged

Front Wheel Drive, Front Wheel Steering.

Two Speed Hydrostatic Transmission.

Hydraulic Service Brakes

SAHR Emergency/Parking Brake.

Travel Speed: 0 - 11 mph.

Working Speed: 0 - 150 ft/min.

Strike-Off Blade -

1-10 ft. Maximum Spread Width.

18 in. Tall, 1 ft. & 2 ft. long, Modular Blade Sections.

Optional 2 - 4 ft. Hydraulic Extension Section.

Adjustable Height Outer Edger.

Hydraulic Grade Control - 12 in. Above / Below.

Hydraulic Slope Control +/- 16%.

Receiving Hopper -

11 ft. 2 in. Width, Adjustable Discharge Gates.

3 cubic yard Capacity

Conveyor -

Right or Left Hand Discharge.

Heat And Oil Resistant Conveyor Belt

Chain Driven 18 in. Conveyor Belt with

Variable Speed Hydraulic Drive to 450 TPH Output.

Push Rollers -

Extendable, Oscillating, Self Cleaning

Specications subject to change without notice.

6

Receiving Hopper -

11 ft. 2 in. Width, Adjustable Discharge Gates.

3 cubic yard Capacity

Conveyor -

Right or Left Hand Discharge.

Heat And Oil Resistant Conveyor Belt

Chain Driven 18 in. Conveyor Belt with

Variable Speed Hydraulic Drive to 450+ TPH Output.

Push Rollers -

Extendable, Oscillating, Self Cleaning

Specications subject to change without notice.

www.roadwidener.com

Model SP-8 & 10

4. sAfety

4.1 sAfety Alert symBol And sIGnAl Words

This manual covers the SP-8, SPD-8, SP-10 and

SPD-10 machines produced by Midland Machinery

(henceforth mentioned as “SP” or “SP machine”, unless

required otherwise). Before setting up, operating or

servicing SP machine, you must read, understand

and follow the instructions and safety warnings in this

manual. Your machine may not be equipped with some

of the optional equipment shown in the illustrations in

this manual.

All personnel that will be operating, maintaining

and working around the SP machine must read and

understand these documents before interacting with

the SP.

NEVER ALLOW ANYONE TO OPERATE THIS

EQUIPMENT WITHOUT PROPER TRAINING!

If you have any safety concerns or questions that are

not covered by this manual, please contact Midland

Machinery at 1-716-692-1200.

^

^ CAUTION

CAUTION - Indicates a hazardous situation,

which, if not avoided, could result in minor

or moderate injury.

NOTICE

NOTICE - Indicates a situation that could

result in damage to the equipment or other

property.

4.2 HAzArds

SP machine is a complex machines and its operation

requires a high level of machine knowledge and skill.

Safe use is dependant on correct operation and proper

maintenance.

4.2.1 mAIntenAnCe

Before servicing machine:

1. Park on a rm level surface.

2. Apply parking brakes.

3. Turn engine off, close and lock control panel

cover.

4. Chock tires.

5. Place a “Do Not Operate” tag on operators

console.

This symbol means ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The level of risk is indicated by the following signal

words:

^ DANGER

DANGER - Indicates a hazardous situation,

which, if not avoided, WILL result in death

or serious injury.

^ WARNING

WARNING - Indicates a hazardous

situation, which, if not avoided, could

result in death or serious injury.

Read and understand this manual. If you do not

understand any part of this manual, contact your

dealer.

Always wear face or eye protection, safety shoes, and

other protective items as required.

Do not make unauthorized modications to machine.

Contact your dealer before you weld, cut/drill holes, or

make any other modications to your machine. Always

use Midland Machinery replacement parts.

If you must service machine with engine running, have

someone in constant visual contact who can shut off

engine if necessary.

If you must service machine with an attachment raised,

block attachment up to prevent attachment falling in

case of pressure or power loss.

4.2.2 Burn preventIon

Battery acid causes severe burns. Batteries contain

sulfuric acid. Avoid contact with skin, eyes or clothing.

www.roadwidener.com

7

Model SP-8 &10

• If acid contacts skin: Flush with water. Apply baking

soda or lime to neutralize acid and get immediate

medical attention.

• If acid contacts eyes: Flush with water for 15

minutes and get immediate medical attention.

• If acid is swallowed: Drink large quantities of water

or milk, then drink milk of magnesia, beaten eggs, or

vegetable oil and get immediate medical attention.

Keep battery fully charged to avoid battery freezing. If

battery electrolyte freezes, battery can explode if you

try to charge or jump start the battery.

Explosive release of coolant can cause serious burns.

Turn off engine and let engine cool before removing

coolant cap. Loosen cap to rst stop to relieve pressure

before removing cap completely.

4.2.3 pressurIzed HydrAulIC fluId And GreAse

Hydraulic uid and grease injected into your skin

may cause serious injury or death. Keep your hands

and body away from any pressurized leak. Tighten

connections before applying pressure. Never use your

hand to check for leaks; use a piece of cardboard

or paper. If uid is injected into the skin, it must be

surgically removed within a few hours or gangrene

may result. Get immediate medical attention.

4.2.4 HAzArdous CHemICAls

• When connecting battery cables, connect negative

(-) cable last.

• Do not short circuit battery posts with metal items.

Remove all trash and debris from engine. Do not store

oily rags or ammable materials on or near engine.

Always have a re extinguisher available on machine.

Keep the extinguisher serviced according to

manufacturer’s instructions.

Check for fuel, oil and hydraulic uid leaks. Replace

worn or damaged hoses or lines. Clean up spilled

uids.

4.3 operAtIon And mAIntenAnCe

^ WARNING

Prevent serious injury or death.

Read and understand this manual before

operating machine.

Always stop engine and remove key before

leaving operators console.

Never allow anyone near machine during

operation.

Fluids, lubricants, coolants, can be hazardous. Before

servicing machine, check Material Safety Data Sheet

(MSDS) for each uid or lubricant to understand

the product, safe handling procedures, and rst aid

measures relating to the product. Follow this information

when servicing machine.

Do not drain or pour any uids or lubricants on

ground. Check with local environmental agencies,

recycling centers, or your dealer for correct disposal

information.

4.2.5 fIre or explosIon preventIon

Engine fuel can cause an explosion or re. Do not

service or refuel with engine running or near open

ame. Do not weld or smoke near fuel. Never allow

fuel to spill on hot machine components.

Keep sparks and ames away from batteries to prevent

explosion of hydrogen gas in and near a battery. Other

precautions include:

• When disconnecting battery cables, disconnect

negative (-) cable rst.

8

Travel at a safe speed.

^ WARNING

Crush hazard.

Chock wheels before mechanically

releasing brakes.

Do not operate machine with brakes

mechanically released.

^ WARNING

Carbon monoxide hazard.

Do not operate engine with machine in an

enclosed building or conned area.

Avoid actions or areas that expose you and

others to carbon monoxide.

www.roadwidener.com

Model SP-8 & 10

^ WARNING

Prevent serious injury or death from

moving parts.

Moving parts can crush and dismember.

Do not operate without guards and shields

in place.

Disconnect and lockout power source

before adjusting or servicing.

^ DANGER

Sulfuric acid can cause blindness or

severe burns. When servicing battery:

• Wear appropriate protective equipment.

• No smoking, sparks or ames near

battery.

If sulfuric acid gets on your skin or in your

eyes:

• Immediately ush the affected area with

clean water for 15 minutes.

• Seek immediate medical attention.

^ WARNING

Prevent serious injury or death.

Do not operate, work on or around

machine while under the inuence of

alcohol, drugs or if feeling ill.

^ WARNING

Flammable material. Diesel fuel.

No open ames and no smoking while

fueling.

^ WARNING

Entanglement hazard.

Loose tting clothing and long hair can

become entangled in moving or rotating

parts.

Do not wear loose tting clothing.

Long hair must be tied back or netted.

^ WARNING

Prevent serious injury or death.

Before performing inspections, service or

maintenance:

• Park machine on rm, level surface and

engage parking brake.

• Switch engine off.

• Close and lock control panel cover.

• Chock tires.

^ WARNING

Corrosive chemicals may be present.

Exposure may result in serious injury.

Wear appropriate protective equipment.

Read and follow handling instructions and

MSDS for the chemical.

Keep clear of moving components.

Never operate machine with open or

removed guards or shields.

Observe federal, state/provincial and local safety codes

and regulations that apply to the job site.

^ WARNING

Prevent serious injury or death.

Walk platforms and covers may be

slippery. Keep steps, handrails, and

platform clean.

Use handrails and face machine when

climbing up or down steps. Use three

points of support when climbing up or

down steps.

Use caution while walking on machine to

avoid falling. Do not jump off machine.

www.roadwidener.com

9

Model SP-8 &10

^ WARNING

Noise hazard.

Prolonged exposure to loud noise can

cause impairment or loss of hearing

Operator, workers and bystanders must

use ear protection while machine is in

operation.

^ WARNING

Prevent serious injury or death.

Do not operate with covers, guards or

doors open or removed.

Keep clear of moving components.

Follow lockout procedure before servicing.

^ WARNING

Pressurized uids can penetrate the skin.

Hydraulic hoses can fail from age, damage

and exposure.

Do not search for hydraulic leaks without

body and face protection. A tiny, almost

invisible leak can penetrate the skin,

thereby requiring immediate medical

attention.

Use wood or cardboard to detect hydraulic

leaks, never use your hands.

^ WARNING

Prevent serious injury or death.

Operator must wear seat belt while

operating machine.

^ WARNING

Prevent serious injury or death.

Do not mount or dismount moving

equipment.

Do not enter hopper while machine is

running.

^ WARNING

Prevent serious injury or death.

Hot and high pressure hydraulic oil.

Allow to cool before servicing.

^ WARNING

Pinch point.

Push rollers may move suddenly.

Keep clear during operation.

NOTICE

Dispose of waste properly.

Improper disposal of waste can harm the

environment.

Use leak proof container when draining

uids. Do not use food or beverage

containers.

Contact local environmental or recycling

center for proper way to recycle or dispose

of waste.

4.3.1 CAlIfornIA proposItIon 65 WArnInG

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects and other reproductive harm.

Battery posts, terminals and related accessories contain

lead and leads compounds, chemicals known to the

State of California to cause cancer, birth defects and

other reproductive harm. Wash hands after handling.

10

4.3.2 prepAre for emerGenCIes

Be prepared in case of emergencies.

www.roadwidener.com

Keep a re extinguisher and rst aid kit close to

machine.

Keep emergency phone numbers in a easy to access

location.

Know your location so emergency services can locate

you if an emergency arises.

4.3.3 do not AlloW rIders

Never allow riders on machine. Machine is equipped to

carry the operator only.

Model SP-8 & 10

4.3.4 AvoId poWer lInes

^ WARNING

Prevent electrocution.

Death or serious injury can result if

equipment comes near or contacts power

lines.

Electrocution can occur without direct

contact.

DO NOT leave operator’s seat if any part of equipment

contacts electric lines or cables.

4.4 HAzArds from modIfyInG equIpment

Do not modify or alter machine. Modifying or altering

may cause machine to be unsafe and will void the

manufacturers’ warranty.

www.roadwidener.com

11

Model SP-8 &10

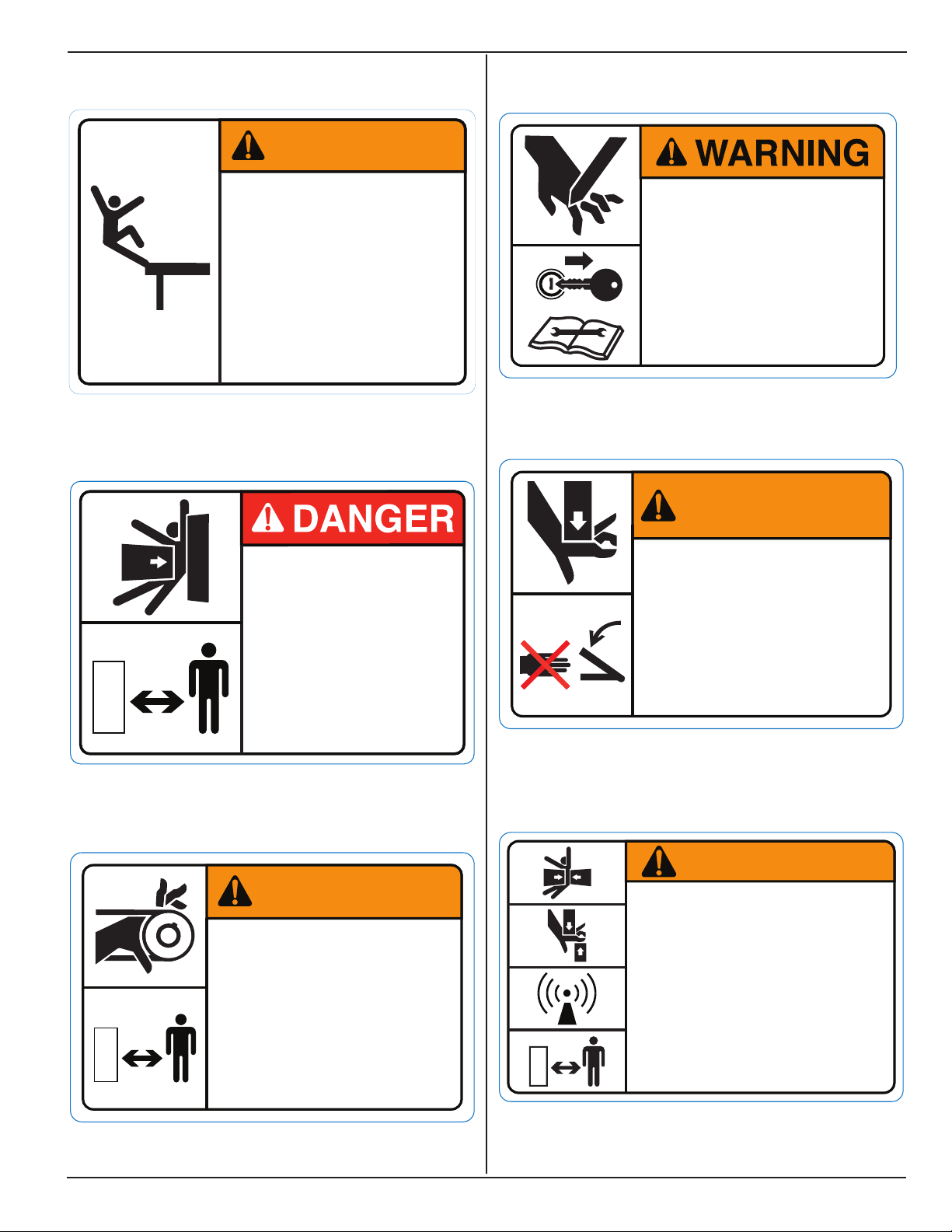

4.5 sAfety WArnInG lABels

12

www.roadwidener.com

Model SP-8 & 10

www.roadwidener.com

13

Model SP-8 &10

14

www.roadwidener.com

Model SP-8 & 10

Decal A - WC-0003

Decal B - WC-0004

WARNING

FALL H AZ ARD!

Do not stand in

hopper when engine

is running.

Failure to comply

could result in death

or serious injur y.

WC-0003A

Decal D - WC-0006

Decal E - WC-0007

SEV ER H AZ ARD!

Moving parts can sever.

Do not perform

maintenance on conveyor

with engine running.

Failure to comply could

result in death or serious

injury.

WC-0006A

WARNING

Decal C - WC0020

CRUSH H AZ ARD!

Do not stand in front

of machine when

engine is running.

Failure to comply will

result in death or

serious injury.

WC-0004A

WARNING

ENTANGLEM EN T

HAZ ARD!

Stay clear while conveyor

is in operation.

Failure to comply could

result in death or serious

injury.

WC-0020A

Decal F - WC-0047

CRU SH HAZ ARD!

STAND CLEAR!

Hydraulic cylinder is

operated by remote

control.

Failure to comply could

result in death or serious

injury.

CRU SH HAZARD!

Keep hands clear.

Failure to comply

could result in death

or serious injury.

WC-0007A

WARNING

WC-0047A

www.roadwidener.com

15

Model SP-8 &10

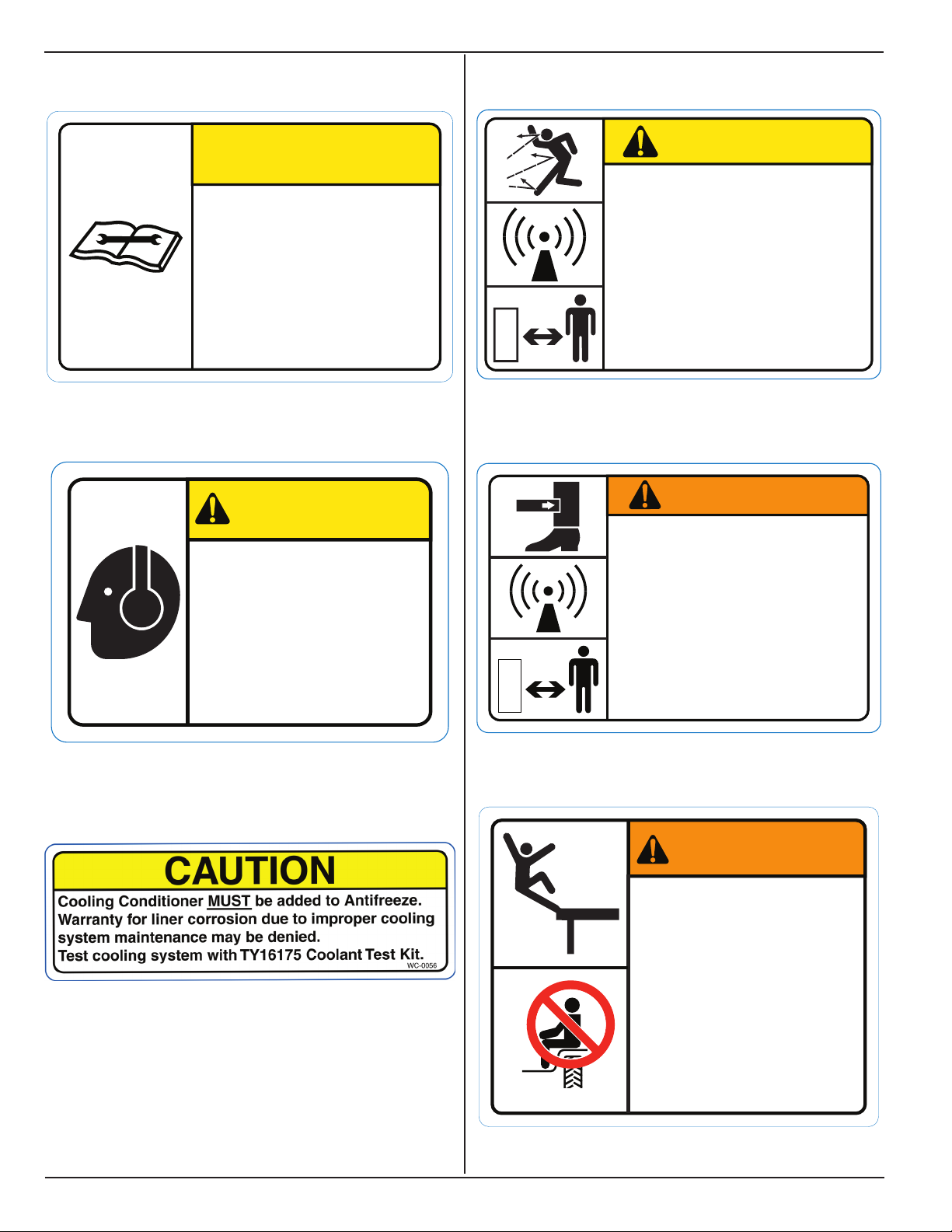

Decal G - WC-0001

Decal H - WC-0052

CAUTION

Before assembling,

operating, cleaning,

lubricating or adjusting

machinery, operator

should read and follow

manufacturer s

instructions.

CAUTION

,

WC-0001A

Decal K - WC-0022

STAND CLEAR!

Material discharge

hopper is operated by

remote control.

Failure to comply may

result in minor or

moderate injury.

Decal L - WC-0012

CAUTION

WC-0022A

WARNING

C RU SH H AZARD!

Decal J - WC-0056

NOI SE H AZARD!

Ear protection

must be worn

when operating

machine.

WC-0052A

Stand clear.

Material discharge area and

strike off blade operated by

remote control.

Failure to comply could

result in death or serious

injury.

Decal M - WC-0053

WC-0012A

WARNING

FALL H AZ ARD !

NO RI DERS!

Machine is to be

operated by one

16

person only.

Failure to comply

could result in death

or serious injury.

www.roadwidener.com

WC-0053

Model SP-8 & 10

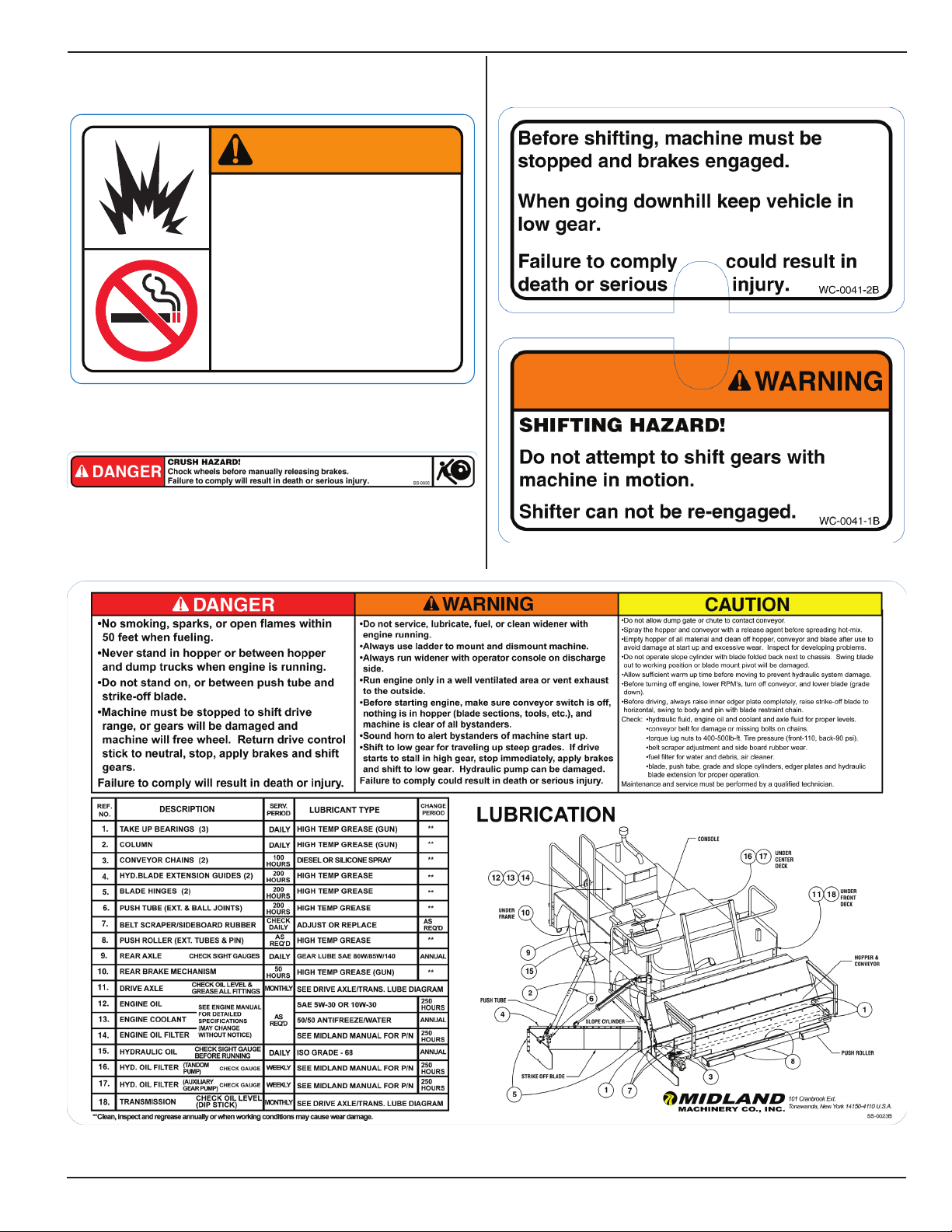

Decal N - WC-0014

Decal P - SS-0035

WARNING

EXPLOSI ON HAZ ARD!

No smoking or open

flame within 50 feet

during fueling or

washdown.

Failure to comply could

result in death or serious

injury.

WC-0014B

Decal R - WC-0041

Decal Q - SS-0035

www.roadwidener.com

17

Model SP-8 &10

5. operAtIon

5.1 operAtIonAl sAfety

^ Keep bystanders away from equipment while in

use.

^ Always wear face or eye protection, ear protection,

safety shoes, and other protective equipment

appropriate for the job.

^ Do not operate, work on or around this machine

while under the inuence of alcohol, drugs or if

feeling ill.

^ Keep clear of moving machinery at all times.

^ Turn off machine before exiting operator station.

^ WARNING

Carbon monoxide hazard.

Do not operate engine with machine in an

enclosed building or conned area.

Avoid actions or areas that expose you and

others to carbon monoxide

^ WARNING

Prevent serious injury or death.

Before performing inspections, service or

maintenance:

• Park machine on rm, level surface and

engage parking brake.

• Switch engine off.

• Close and lock control panel cover.

• Chock tires.

^ You must inspect, maintain and service equipment

regularly for safe and reliable operation.

^ Operate equipment safely. Read and understand

this manual before operating machine.

^ It is your responsibility to operate this machine

safely. You must be familiar with machine and all

safety practices before use.

^ Do not allow untrained or unqualied people to

operate machine.

^ Wear close tting clothing and safety equipment

that is appropriate to the job. Do not wear music

or radio headphones while operating equipment.

5.2 stArtup proCedure

Check the following items before operating machine:

• Check fuel, engine oil, coolant and hydraulic oil

levels. Add uids if low.

• Check conveyor belt for damage or missing parts.

• Check belt scraper adjustment. Adjust if needed.

• Check side board rubber wear. Replace if worn.

• Check engine fuel lter. Drain water or debris.

• Check air lter restriction gauge.

• Inate tires to 120 psi.

• On SP-10 and SPD-10, rear tires are lled with

calcium ballast. Use suitable equipment to inate

tires.

• Tighten wheel lugs to 400-500 lb/ft of torque.

• Inspect tires for signs of wear or damage.

• Check hydraulic components for proper operation.

• Visually inspect engine belts, fan, alternator and

battery.

• Inspect hydraulic hoses for signs of wear or

damage.

• Verify all guards, covers, shields and access doors

are installed and properly latched.

• Check for oil and coolant leaks.

NOTICE

Prevent equipment damage.

Do not drive machine or increase engine

rpm at low operating temperature.

18

Refer to engine manufacturers’ manual provided for

engine pre-start procedure, routine maintenance and

additional safety information.

While operating machine, operator must be seated

with seat belt properly fastened.

www.roadwidener.com

Model SP-8 & 10

5.3 strIke-off BlAde setup

5.3.1 posItIon BlAde

Procedure illustrates blade on right side. On dual side

machines, procedure is the same for left side blade.

^ WARNING

1. On engine, turn ignition key clockwise to “On”

position.

2. Check the operator console panel and make sure

the conveyor switch (A) is in the “Off” position and

the conveyor speed (B) is turned down to slow.

3. Check to make sure that the parking brake (E-stop)

button (C) is fully down and parking light (D) is “on”.

The brakes are automatically applied when the

engine is turned off.

4. Set the drive control stick (E) and gear shift lever

in neutral (center). Check if engine kill switch (F) is

reset.

5. For safe operation, engine will not start if the drive

control stick (E) is not in neutral, engine kill switch

(F) is not reset, or if the conveyor switch (A) is in

the “On” position.

6. Start engine and toggle throttle switch (G) to run at

a high idle or 1100 rpm for approximately 5 minutes

to warm up. Longer warm up may be needed in

colder temperatures.

Prevent serious injury or death.

Before performing inspections, service or

maintenance:

• Park machine on rm, level surface and

engage parking brake.

• Switch engine off.

• Close and lock control panel cover.

• Chock tires.

^ WARNING

Prevent serious injury or death.

Blade components are heavy.

Use an adequate lifting device to raise, lift

and move blade and blade components.

Blade Pivot - 31 lbs.

1-Ft blade section - 57 lbs.

2 Ft blade section - 98 lbs.

Outer Edger Assembly - 113 lbs.

Hydraulic Extension Assembly - 225 lbs.

7. After the warm-up period, increase engine speed

to 1/2 throttle.

8. Pull E-stop button (C) to middle position.

9. In this scenario, Rear brakes are still applied but

grade, slope and hydraulic extension cylinders can

be extended and retracted. At least 2000 rpm is

needed to move cylinders. Full throttle is needed

for full cylinder speed. Conveyor belt can also be

moved.

10. On dual side machine, toggle conveyor direction

switch (H) to select side for material discharge

and grade, slope and hydraulic extension cylinder

control.

11. Sound horn (J) to alert everyone near machine.

www.roadwidener.com

1. Start machine as in section 5.2. If machine is in

motion, park machine on a rm level surface,

engage parking brake by pushing E-stop button

fully down. Keep engine running at full rpm.

2. On dual side machine, toggle conveyor direction

switch to right side.

3. Toggle grade switch on operator console upward

to raise blade assembly slowly up. This will release

blade from blade restraint. Swing blade outward

from machine body.

4. Set blade angle to approximately 45°. Blade length

may have to be changed for required spreading

width. See section 5.3.2 for changing blade

length. See following blade illustrations for blade

congurations.

19

Model SP-8 &10

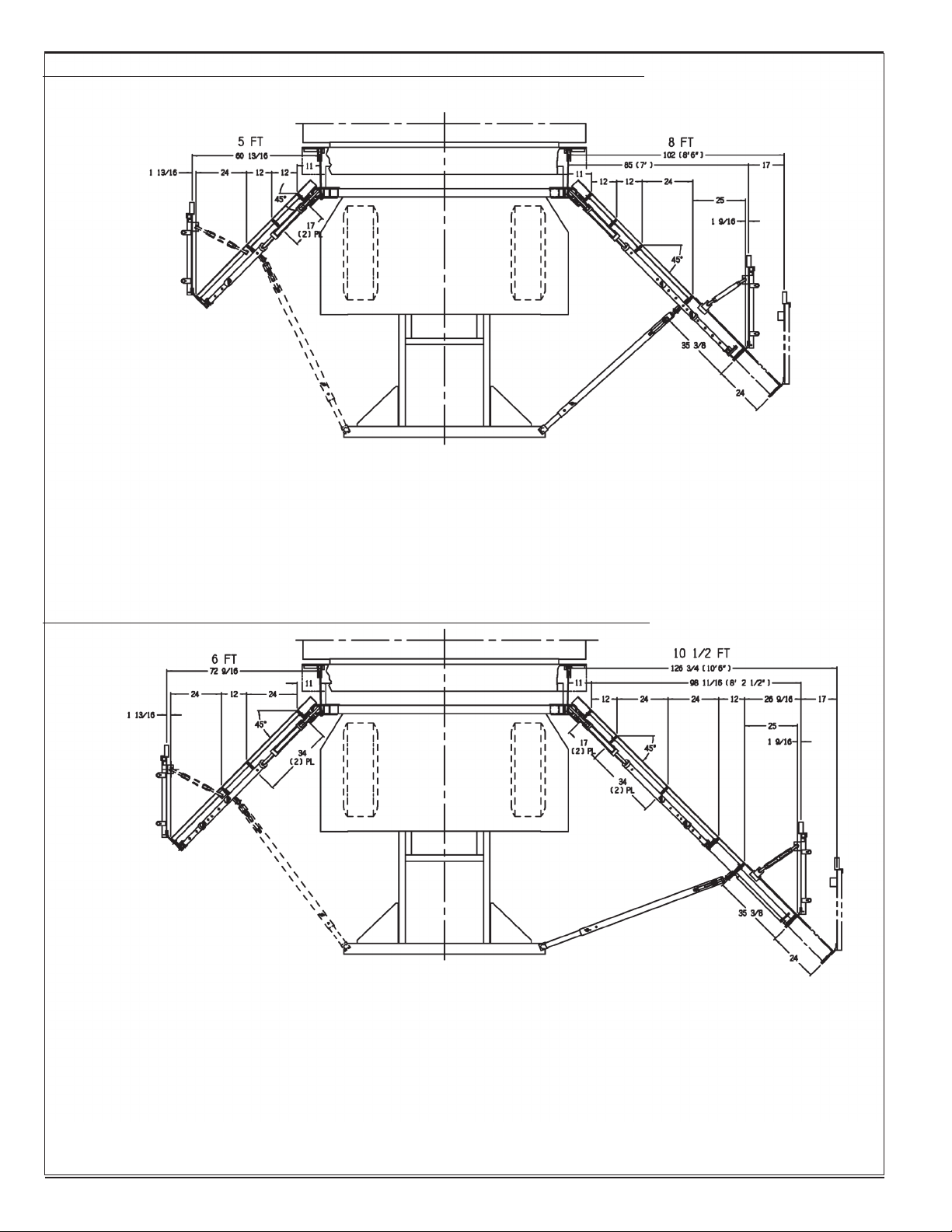

sp-8 BlAde ConfIGurAtIon WItH 2 ft HydrAulIC extensIon

SPD Left Side Discharge

SP-593 Rev-A blade & column assembly

(5 ft. fixed blade)

Consists of:

(1) SP-435 blade pivot

(2) SP-441 1 ft. blade section

(1) SP-444 2 ft. blade section

(1) SP-590 edger assembly

No push tube / turnbuckle

Paves 5 ft. at 45°

Right Side Discharge

SP-579 Rev-A, blade & column assembly

(5 ft. fixed blade)

Consists of:

(1) SP-435 blade pivot

(2) SP-441 1 ft. blade section

(1) SP-444 2 ft. blade section

(1) SP-590 edger assembly

With optional SP-751,

2 ft. hydraulic extension assembly

Paves 8’6” at 45°

sp-10 BlAde ConfIGurAtIon WItH 2 ft HydrAulIC extensIon

SPD Left Side Discharge

SP-588 Rev-A blade & column assembly

(6 ft. fixed blade)

Consists of:

(1) SP-435 blade pivot

(1) SP-441 1 ft. blade section

(2) SP-444 2 ft. blade section

(1) SP-590 edger assembly

No push tube / turnbuckle

Paves 6 ft. at 45°

Right Side Discharge

SP-420 Rev-B, blade & column assembly

(6 ft. fixed blade)

Consists of

(1) SP-435 blade pivot

(1) SP-441 1 ft. blade section

(2) SP-444 2 ft. blade section

(1) SP-590 edger assembly

With optional SP-752

(1) 2 ft. hydraulic extension assembly +

(1) SP-441 1 ft. blade section

Paves 10’6” at 45°

20

www.roadwidener.com

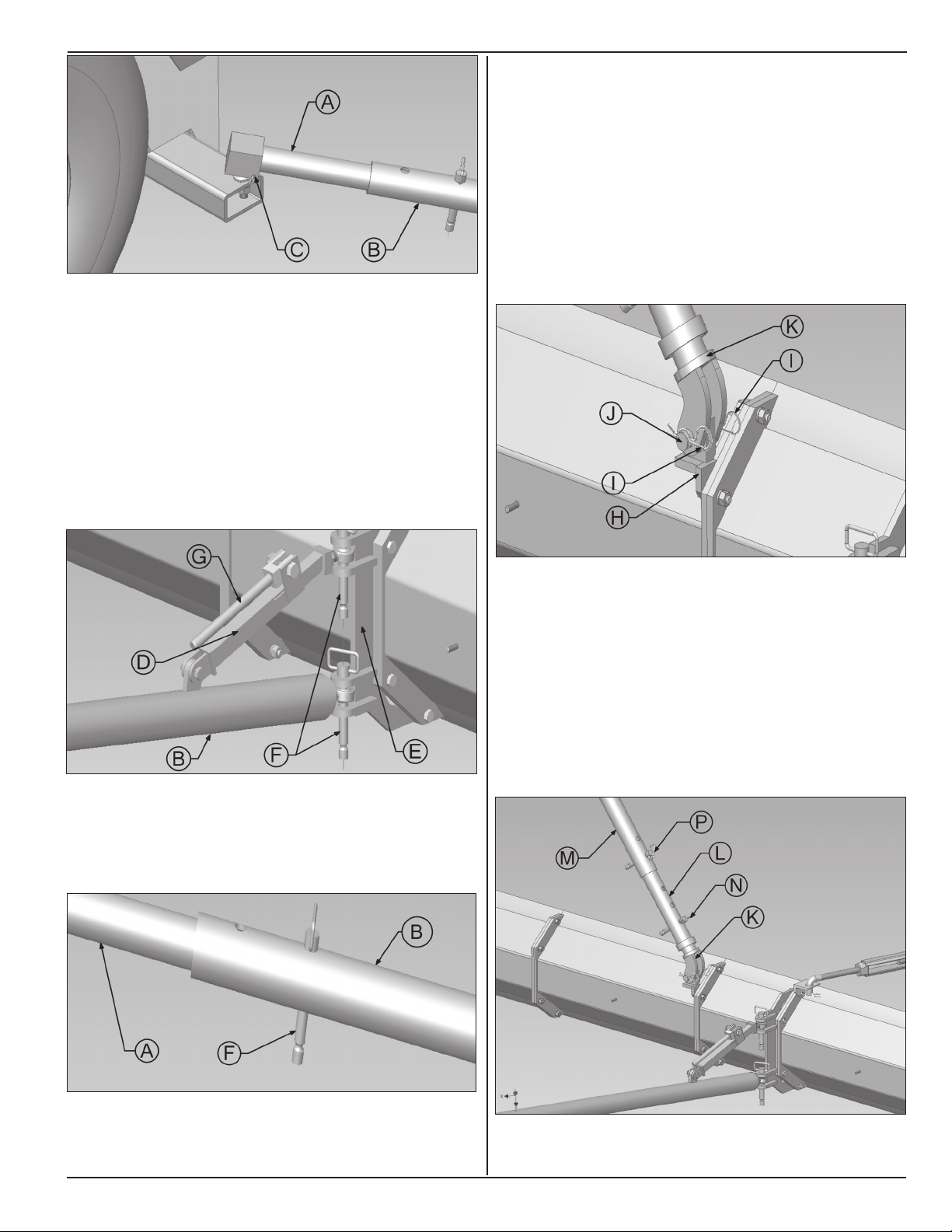

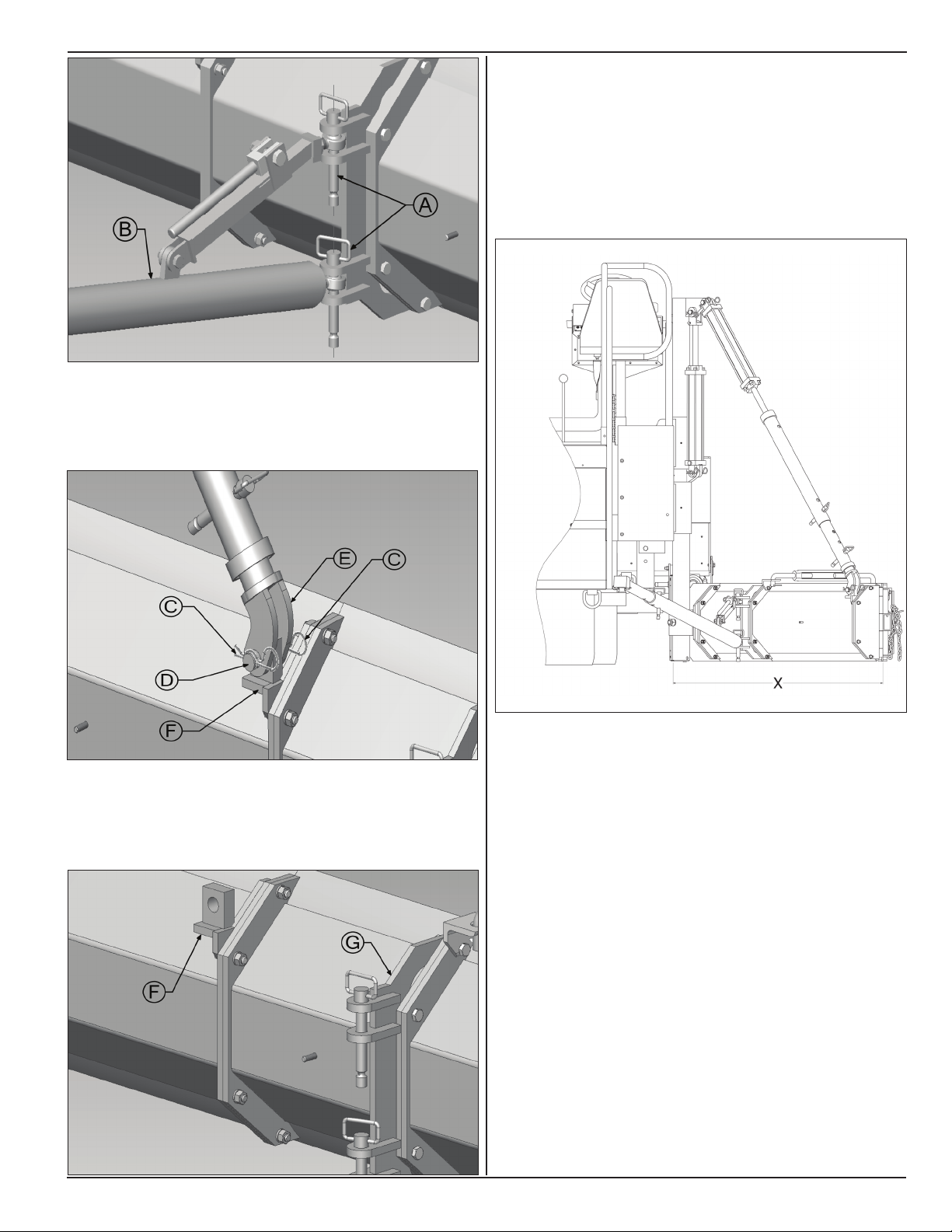

5. Insert inner push tube (A) into outer push tube (B).

6. Install push tube (A) over ball hitch on machine.

Install pins (C) to fasten push tube to ball hitch

7. On blade, align outer push tube (B) and stabilizer

(D) in mounting Bracket (E) holes and insert Hitch

pin (F).

Model SP-8 & 10

10. Slope mount (H) should be mounted at approximately

2/3rd of blade length. To change location of slope

mount (H), lower blade down to ground by toggling

grade & slope switches on operator console.

11. Pull out cotter pins (I) and remove hinge pin (J) to

remove end of the lower slope tube (K) from slope

mount (H).

12. Select blade section to install slope mount (H). Use

correct hardware.

8. Press reworked cam (G) to lock stabilizer.

9. Keeping blade angle as close as possible to 45

degrees, nd a conguration where one hole each

on inner push tube (A) and outer push tube (B) are

in-line and insert hitch pin (F) through them.

13. Remove pin (N) to release lower slope tube (K).

Bring lower end of slope tube (K) on to slope mount

(H). Reinsert hinge pin (J) through mounting holes

in lower slope tube (K) and slope mount (H). Install

cotter pins (I).

14. Adjust distance between in-line holes of lower (K),

middle (L) and top (M) slope tubes. Insert pins (N)

and (P) in in-line holes.

Note: Depending on material, a greater blade angle

may be needed to ll entire spread width. Narrow

spread widths do not require as much blade angle.

www.roadwidener.com

21

Model SP-8 &10

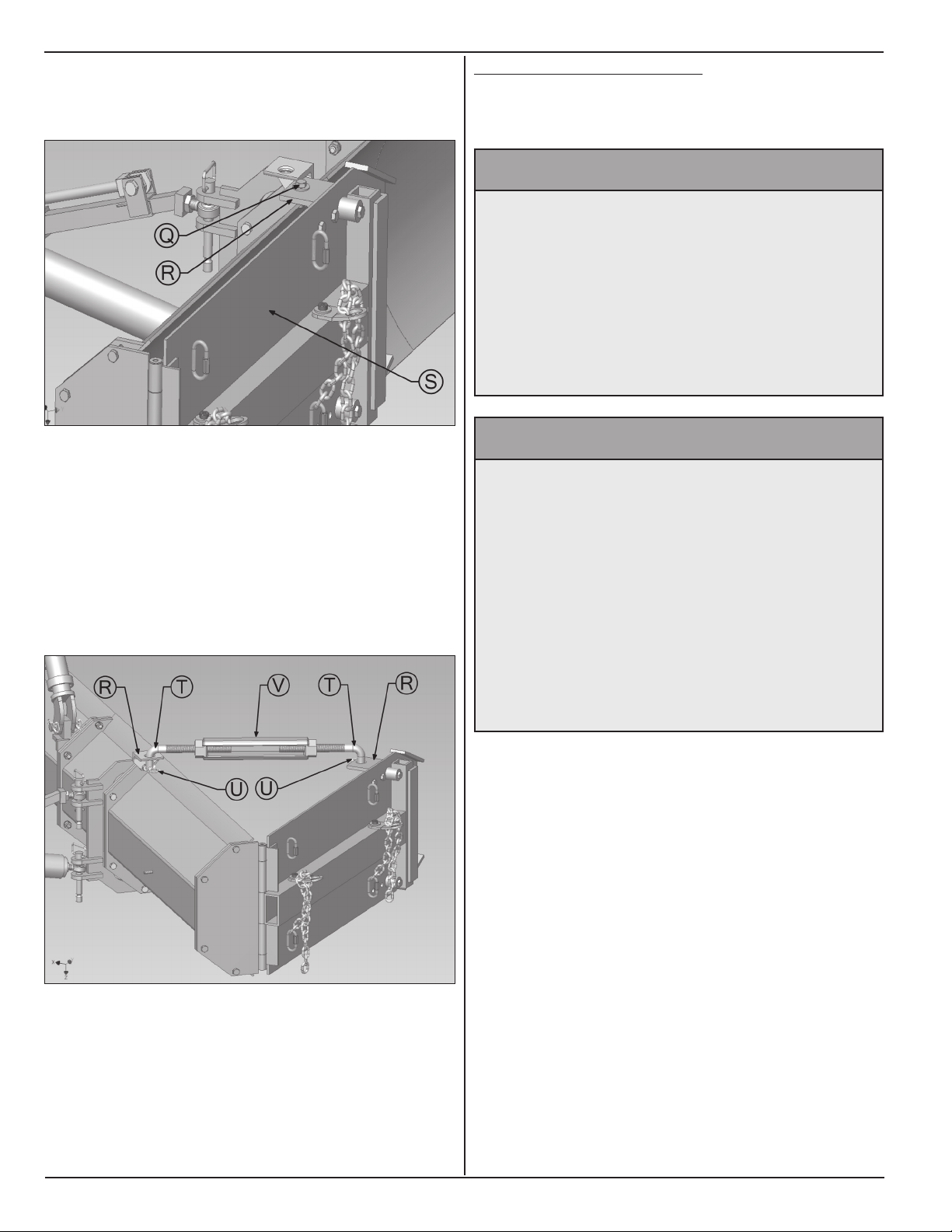

15. Remove locking hardware (Q) from turnbuckle

mount (R) on outer edger assembly (S). Swing

outer edger assembly (S) out.

5.3.2 CHAnGe BlAde lenGtH

Procedure illustrates blade on right side. On dual side

machines, procedure is the same for left side blade.

^ WARNING

Prevent serious injury or death.

Before performing inspections, service or

maintenance:

• Park machine on rm, level surface and

engage parking brake.

• Switch engine off.

• Close and lock control panel cover.

• Chock tires.

16. Retrieve outer edger brace from storage area.

Insert ends (T) of brace into turnbuckle mounts (R)

on outer edger and blade section.

17. Insert cotter pins (U) to secure outer edger brace.

18. Rotate turnbuckle (V) to adjust outer edger angle.

Outer edger should be parallel to blade assembly

inner edger.

^ WARNING

Prevent serious injury or death.

Blade components are heavy.

Use an adequate lifting device to raise, lift

and move blade and blade components.

Blade Pivot - 31 lbs.

1-Ft Blade Section - 57 lbs.

2 Ft Blade Section - 98 lbs.

Outer Edger Assembly - 113 lbs.

Hydraulic Extension Assembly - 225 lbs.

1. Start machine as in section 5.2. If machine is in

motion, park machine on a rm level surface,

engage parking brake by pushing E-stop button

fully down. Keep engine running at full rpm.

2. On dual side machine, toggle conveyor direction

switch to right side.

19. Toggle slope and grade switches on operator

console to adjust slope angle and grade of blade

for desired shoulder prole.

22

3. Lower blade to ground.

4. Switch engine off.

5. Close and lock control panel cover.

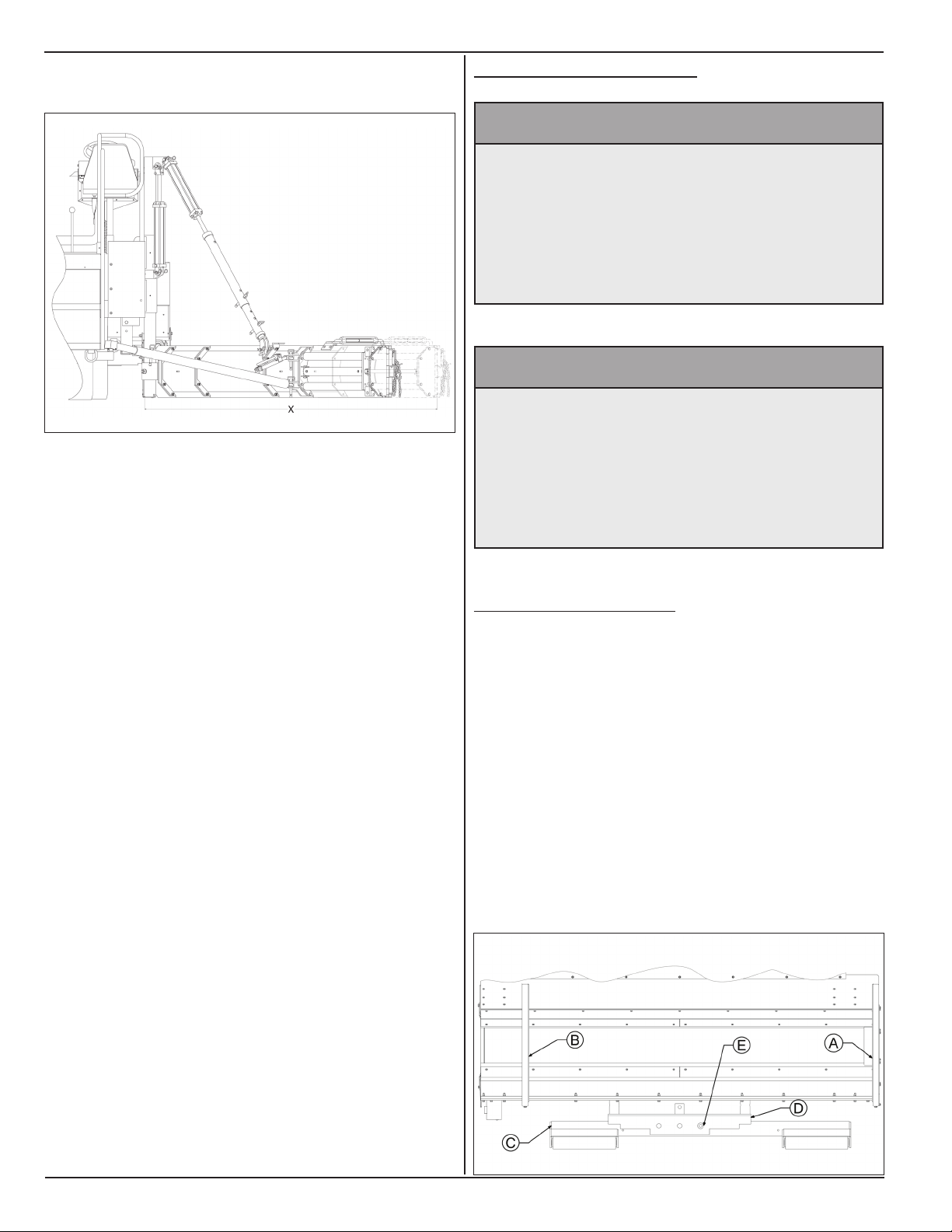

6. Remove pins (A) and remove push tube (B) from

blade.

www.roadwidener.com

7. Pull out cotter pins (C) and remove hinge pin (D) to

disengage end of lower slope tube (E) from slope

mount (F).

Model SP-8 & 10

9. Set blade length to desired paving width by adding

or removing 1 foot and 2 foot sections. Blade

length should be such that desired paving width is

achieved when blade is set at approximately at 45°

angle to direction of travel.

Following illustration shows different combinations of

blade sections.

8. Unbolt Blade slope mount (F) and push tube

mounting bracket (G).

www.roadwidener.com

Dimension X: 4 Ft Blade

• (1) - Pivot Section

• (1) - 1 Ft Section

• (1) - 2 Ft Section

Dimension X: 7 Ft Blade

• (1) - Pivot Section

• (2) - 1 Ft Section

• (2) - 2 Ft Section

Hydraulic extension (option) can be used to hydraulically

increase overall blade length by up to 2 feet.

Note: Hydraulic extension must be mounted at farthest

end of blade. Moveable section of hydraulic extension

must always extend toward outer edger assembly.

Only outer edger assembly can be bolted to moveable

section of hydraulic extension.

23

Model SP-8 &10

Following illustration shows different combinations of

blade sections with hydraulic extension.

Dimension X: 7 - 8.5 Ft Blade

• (1) - Pivot Section

• (2) - 1 Ft Section

• (1) - 2 Ft Section

• (1) - 2 - 3.5 Ft* Hydraulic Extension

* Projected stroke length at 45° Paving Angle.

Dimension X: 4 - 5.5 Ft Blade

• (1) - Pivot Section

• (1) - 1 Ft Section

• (1) - 2 - 3.5 Ft* Hydraulic Extension

* Projected stroke length at 45° Paving Angle.

5.4 pusH roller setup

^ WARNING

Prevent serious injury or death.

Do not pull out push roller beyond 6th

hole.

Push roller assembly may fall out of tubes

and cause serious injury.

^ WARNING

Prevent serious injury or death.

Use caution while taking pivot pin out of

the push roller mount.

Push roller beam may fall out of push roller

mount and cause serious injury.

5.4.1 pIvot pIn loCAtIon

Pivot pin position for the push roller must be such that

push roller beam is symmetrically in middle between

end gates.

10. Reinstall blade push tube anchor (G) at

approximately ½ to ⅔ of blade length. Reinstall

blade slope mount (F) at approximately ⅔ of blade

length. Use suitable hardware.

11. Reinstall slope tubes, push tubes and set up paving

and slope angles as in section 5.3.1.

12. Start engine, check operation and check for leaks.

Paving width can also be varied by adjusting the push

tubes and changing the blade paving angle. While

changing the blade paving angle material ow must be

taken into consideration. Depending on material ow, a

greater blade angle may be needed to ll entire spread

width. Narrow spread widths do not require as much

blade angle.

1. On a single sided machine, for right side paving,

location of left (A) and right (B) end gates are as

shown.

2. For this conguration, slide push roller beam (C)

towards left so pivot hole on push roller beam (C) is

in line with left hole on push roller mount (D).

3. Insert pivot pin (E) through in-line holes.

24

www.roadwidener.com

Loading...

Loading...