Page 1

1

Technical Service Guide

Compact Dishwasher (6 settings)

MODEL SERIES: WQP6-3705-AU

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing adequate backgrounds of

electrical, electronic, and mechanical experience. Any attempt to repair a major appliance may result in personal

injury and property damage. The manufacturer or seller cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this product. If electrical power is required for diagnosis

or test purposes, disconnect the power immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path to ground are removed for

service, they must be returned to their original position and properly fastened.

MIDEA CONSUMER PRODUCTS

TECHNICAL SERVICE GUIDE

COPYRIGHT. 2014

ALL RIGHTS RESERVED. THIS SERVICE GUIDE MAY NOT BE REPRODUCED IN WHOLE OR IN PART, IN ANY FORM, WITHOUT

WRITTEN PERMISSION FROM THE MIDEA DISHWASHER MANUFACTURING COMPANY.

CONTENTS

Introduction ............................................................................................................................................................. 3

Specification ........................................................................................................................................................... 3

Control Panel Features ......................................................................................................................................... 3

Component Locator Views ................................................................................................................................... 4

Dishwasher Components ..................................................................................................................................... 5

Main control board ......................................................................................................................................... 6

Floater assembly ........................................................................................................................................... 7

Heating pump motor assembly .................................................................................................................... 7

Heating pump assembly ............................................................................................................................... 8

Motor assembly .............................................................................................................................................. 9

Drain pump assembly ................................................................................................................................. 10

Check plate ................................................................................................................................................... 11

Inlet valve ...................................................................................................................................................... 11

Control panel ................................................................................................................................................ 12

Page 2

2

Operating board ........................................................................................................................................... 13

Outer Door .................................................................................................................................................... 13

Dispenser ...................................................................................................................................................... 14

Inner Door ..................................................................................................................................................... 14

Shell ............................................................................................................................................................... 15

Door lock assembly ..................................................................................................................................... 16

Air breaker .................................................................................................................................................... 16

Hinge assembly and spring system .......................................................................................................... 17

Tank assembly ............................................................................................................................................. 18

..................................................................................................................................................... 19

Troubleshooting .....................................................................................................................................................21

Test program

Page 3

3

WQP6-3705-AU compact electrical dishwasher with 6 washing cycles offers good washing

performance to satisfy every washing requirement. Its electronic control is easy and convenient to

operate. The rack can hold up to 6 sets of dishes. The size (width * depth * height: 550mm *

500mm * 438mm) can easily fit in any corner of the kitchen, and it’s recommended to locate at

which the water hose connection is accessible.

Rated voltage: 220~240V / 50Hz

Rated power: 1170-1380W

Water pressure: 0.04~1.0MPa

Water temperature:

maximum 60℃

Capacity: 6 settings

Note:

all models have different control panel features and appearances. All detail can be

referred to user manuals of the model.

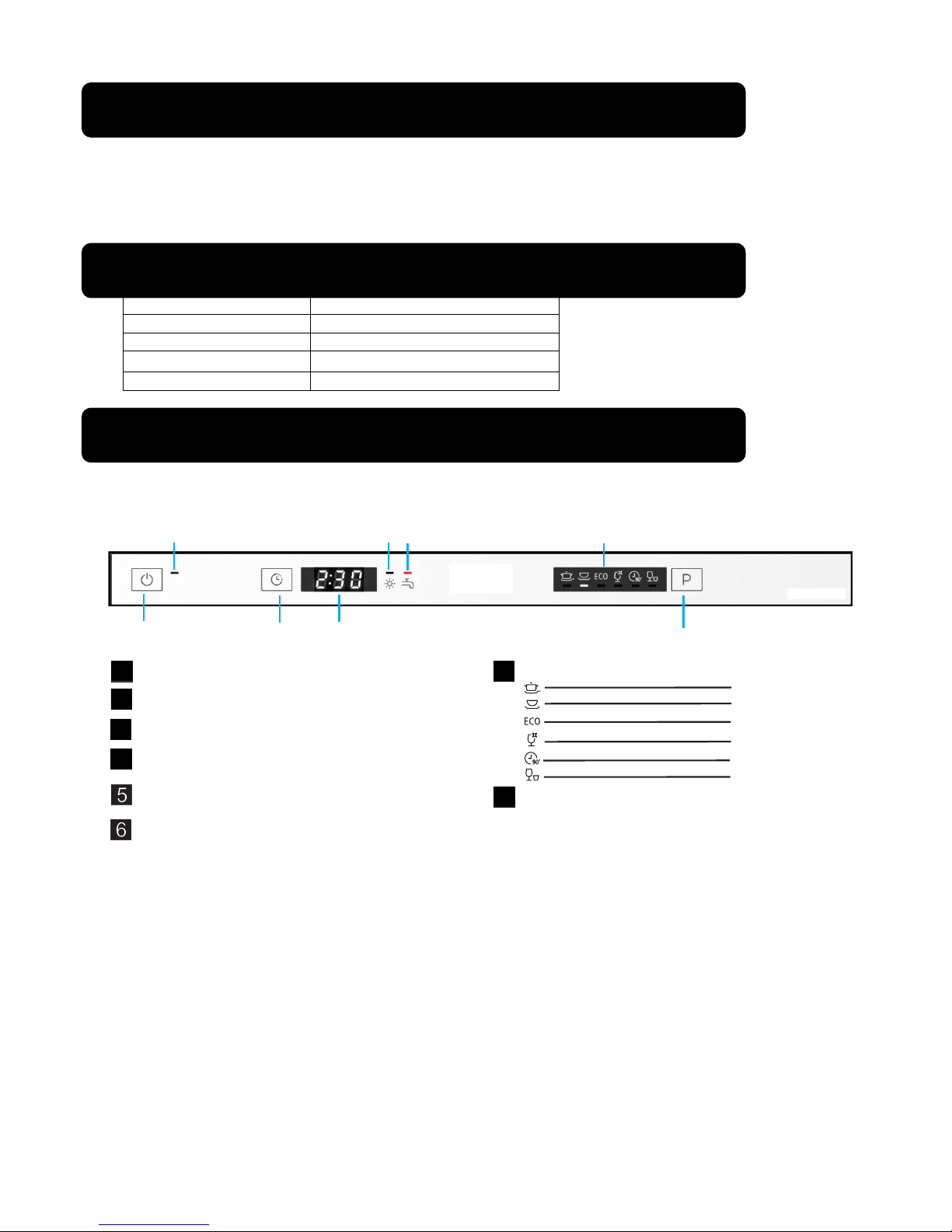

Control Panel Features

Specification

Introduction

1

2

3

4

7

Power Button: To turn on/off the power supply.

Delay Button : To press the button to delay.

Display screen: To show the reminding time

and the state(running state, delay time etc ) .

Rinse Aid Warning Light : To be on when the

rinse aid dispenser needs to be refilled.

.

8

Faucet Light : To be on when the faucet is opened.

1

3

2

4

5

6

8

7

Power indicator

Program Button : To press the button to choose

the pro gramme.

Program indicator expla ins as belo w:

Intensi ve

Heavy

ECO

Glass

90Min

Rapid

Page 4

4

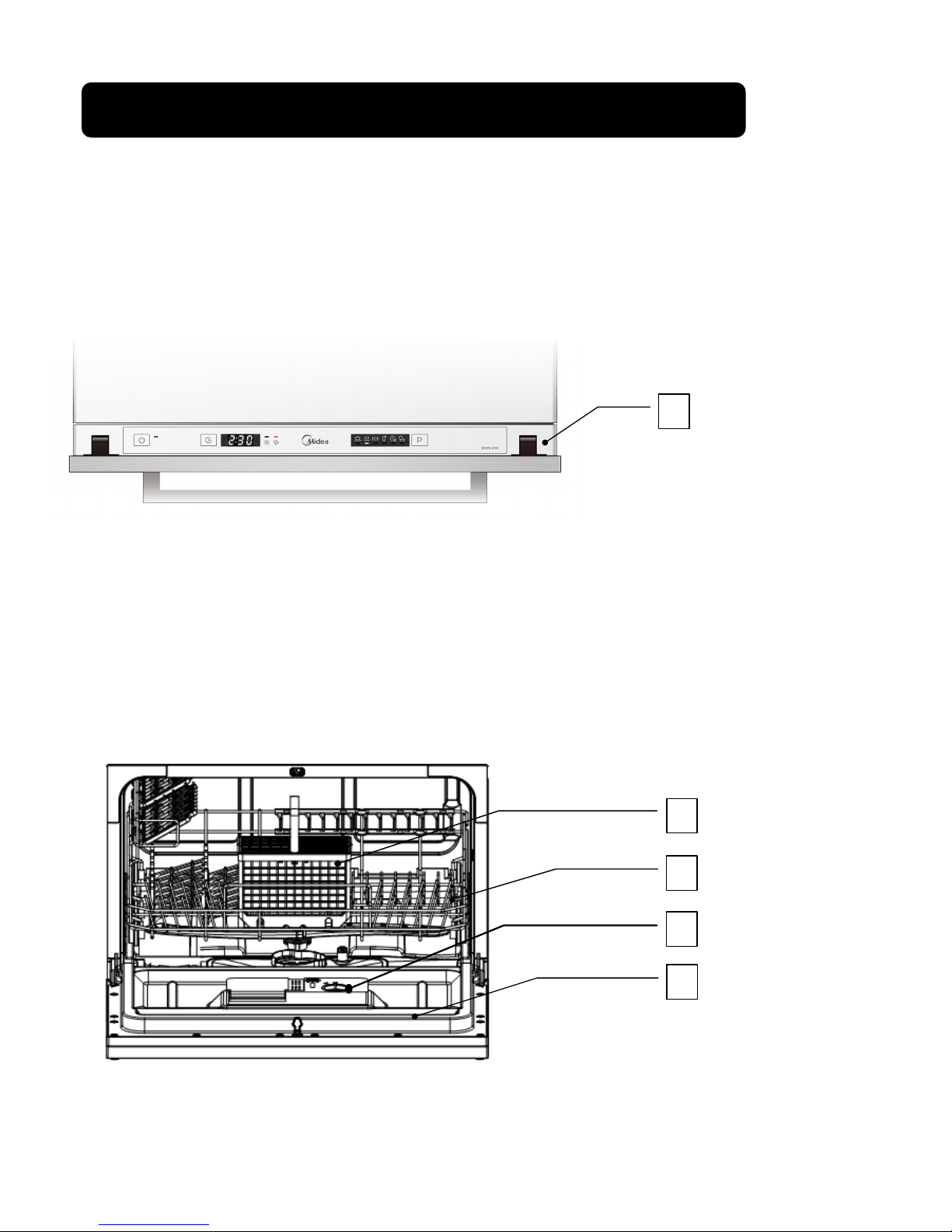

Front View

Part Name:1 – –

outer door

–

Interior View (with basket)

Part Name: 1

–

cutlery basket 2 – basket 3 – dispen

ser

4 – inner d

oor

Component Locator Views

1

2

3

4

1

Page 5

5

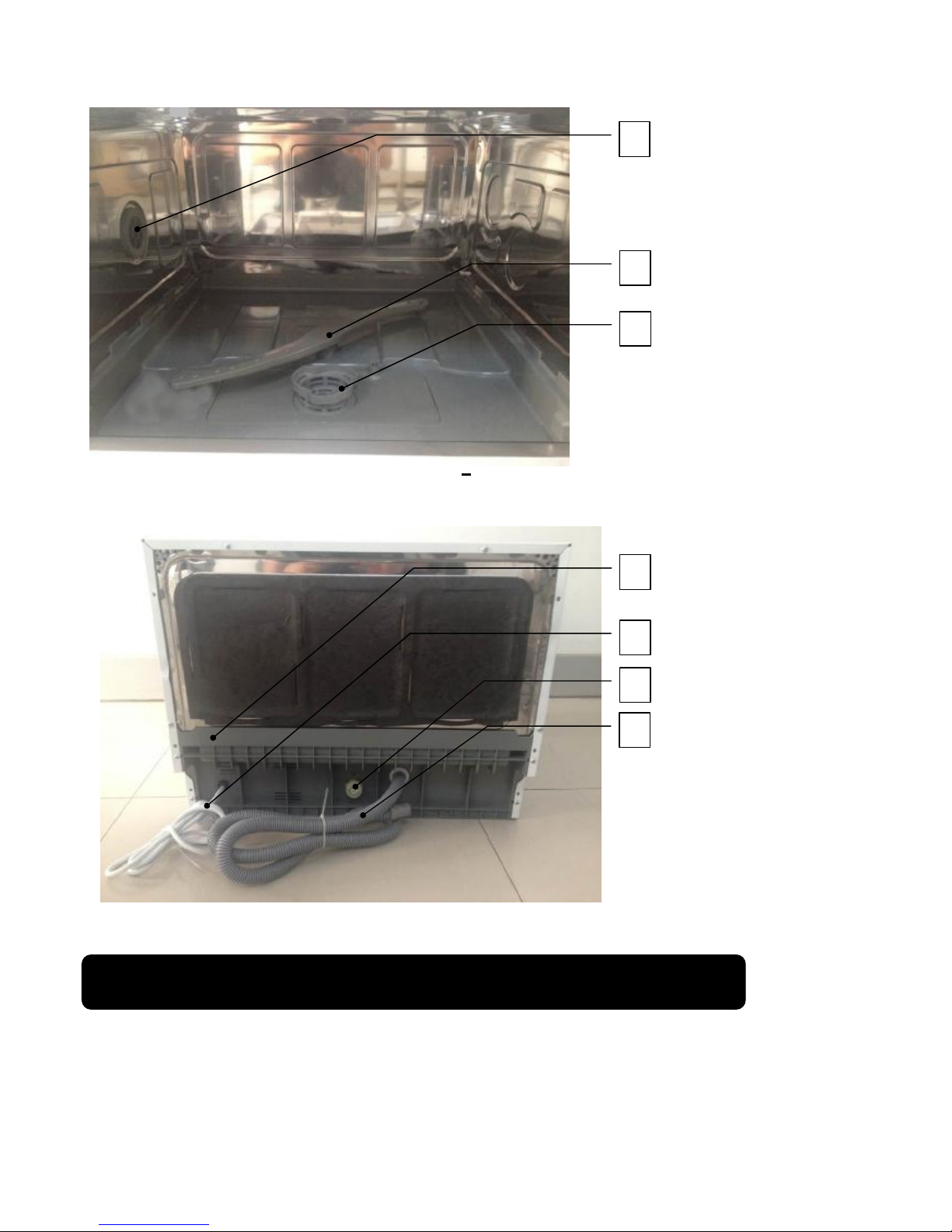

Interior View (With Basket Removed)

Part Name: 1

–

Nut of air breaker

–

2–Sprayer

3

–

Back View

Part Name: 1

–

Bottom board 2 –Power cord 3 –Inlet hose connecter

4 – Outer drain hose

Note: Throughout this manual, features and appearance may vary from your model.

WARNING: Always turn off the electric power supply before servicing any electrical component,

making ohmmeter checks, or replacing any parts.

Note: All voltage checks should be made with a voltmeter having a full scale range of 250 volts

Dishwasher Components

1

2

1

2

3

4

3

Filter System

Page 6

6

or higher. After service is completed, be sure all safety grounding circuits are complete,

all electrical connections are secure, and all access panels are in place.

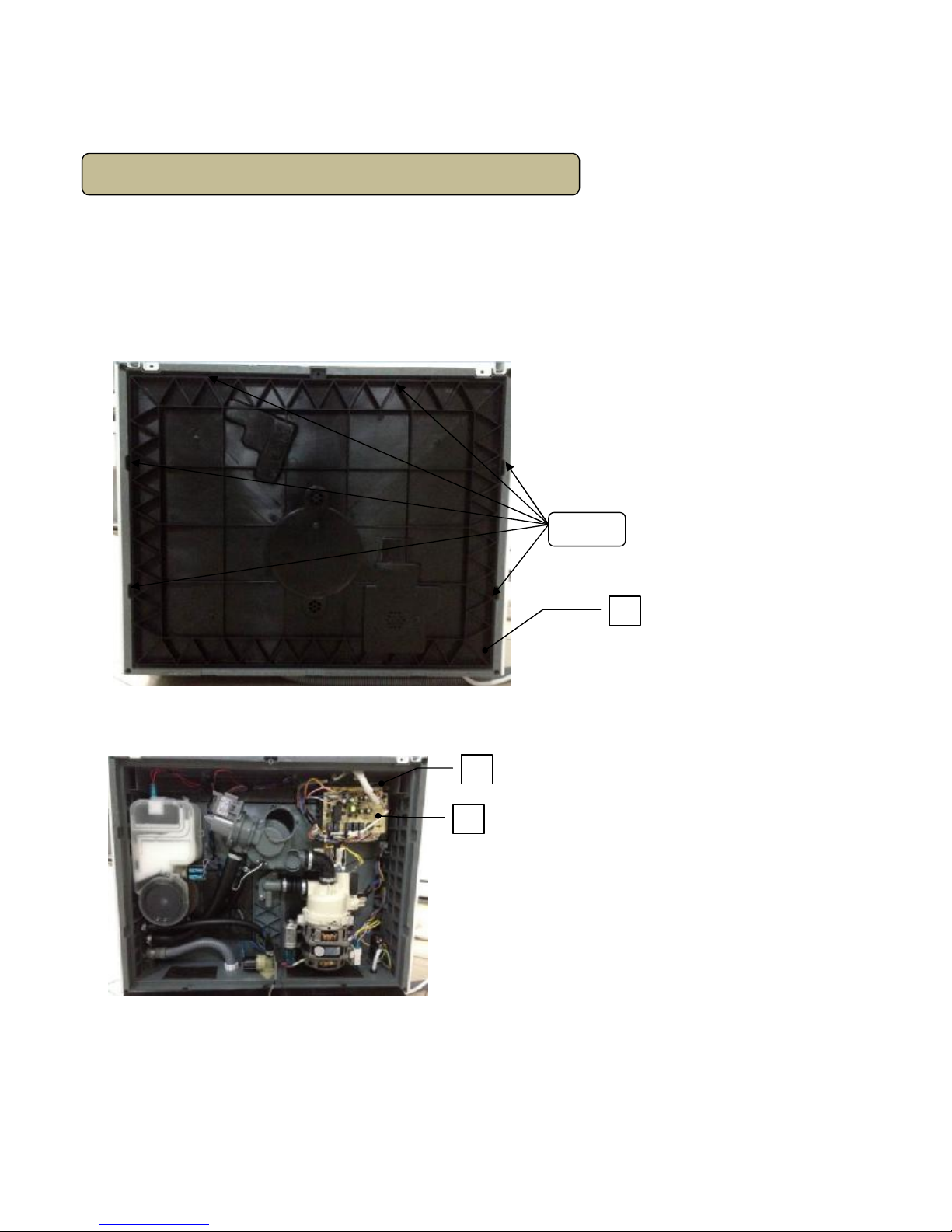

The main control board controls all electrical elements in the dishwasher machine. It located in

the protecting box in the bottom of dishwasher machine. And it easy is replaced when it cannot

work.

Removal and Replacement

1. Disconnect power supply.

2. Take off cutlery basket, basket and filter system.

3. Turn the dishwasher machine. And unfix all snaps for fixing cover of bottom board

.

Part Name: 1

–

cover of bottom board

4. Pull out all housings and terminals (including some locking terminals), then unfix all snaps

for fixing main control board.

Part name: 1 – protecting box 2 – main control board

Note: mark all housings and terminals’ positions and colors before pulling out them.

Note: some terminals are locking terminals.

5. Reverse the above procedure to install. And check out all connectors connects well.

Main control board

1

1

2

snap

s

Page 7

7

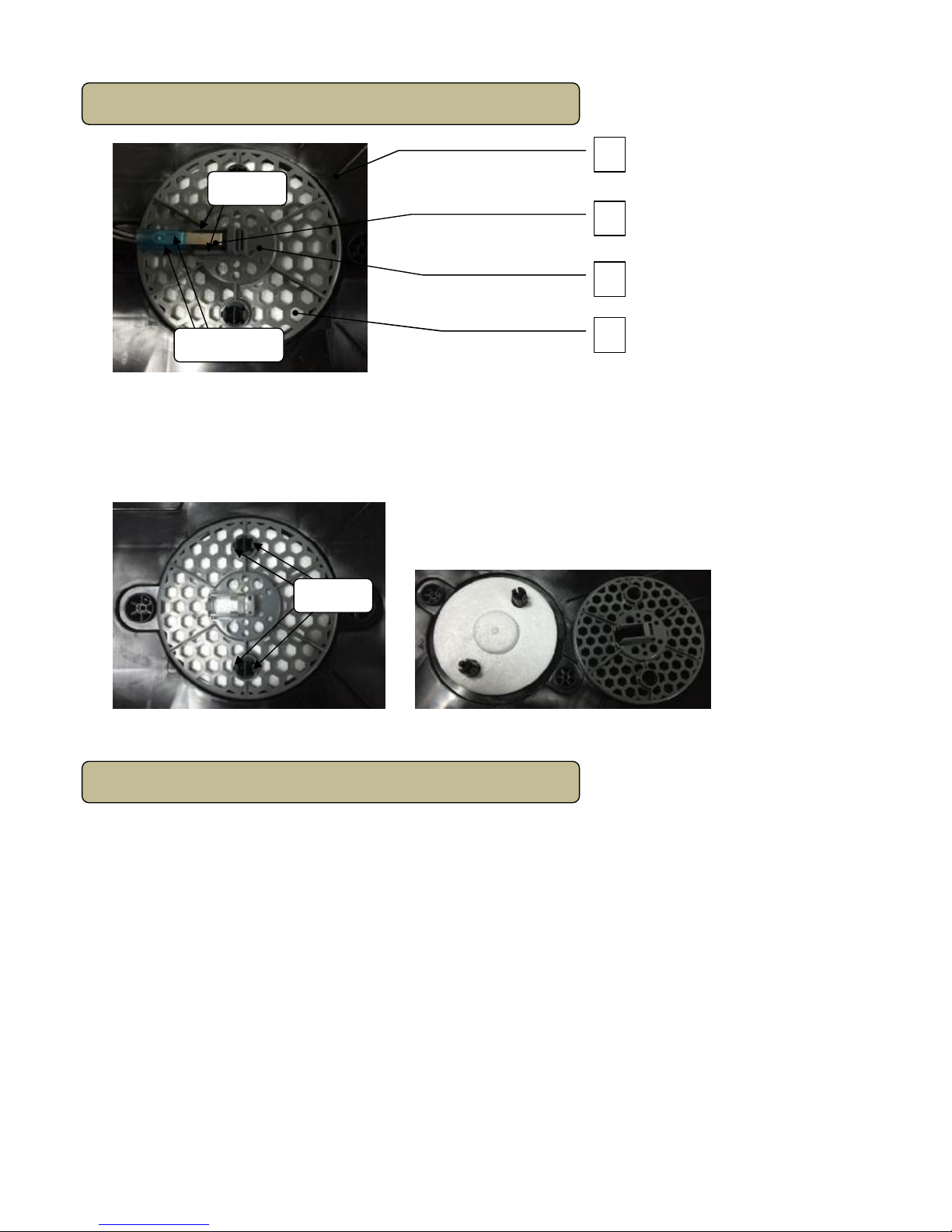

Part Name: 1

–

cover of bottom board 2 – microswitch

3 – floater holder 4 – floater

Removal and Replacement

1. Remove cover of bottom board. (see main control board removal and replacement)

2. Pull out all terminals of microswitch.

3. Unfit snaps fixing microswitch to floater holder.

4. Unfit snaps fixing floater holder to cover of bottom board.

5. Reverse the above procedure to install. And check out all connectors connected well.

Floater assembly

Heating pump motor assembly

2

1

3

4

Terminlals

Sn

aps

Sn

aps

Page 8

8

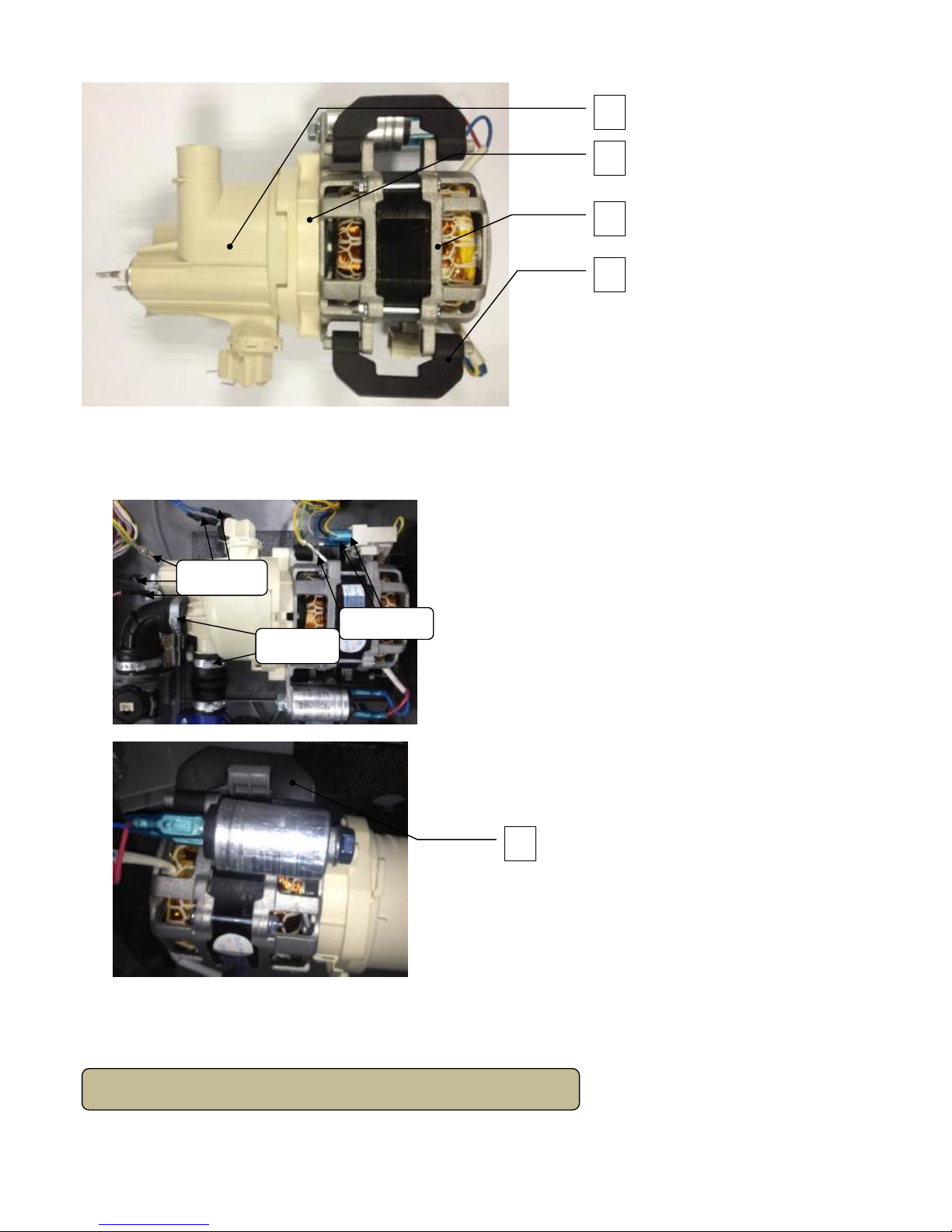

Part Name: 1

–

heating pump assembly 2 – lower pump cover

3 – motor assembly 4 – motor hunger

Removal and Replacement

1. Remove cover of bottom board. (see main control board removal and replacement)

2. Pull out all terminals of heating pump motor assembly.

Part Name: 1 – motor hunger

3. Remove clamps fixing heating pump motor assembly to sump of bottom board.

4. Unfit motor hungers fixing heating pump motor assembly to bottom board.

5. Reverse the above procedure to install. And check out all connectors connected well.

Heating pump assembly

2

1

3

4

Clamps

Terminals

Terminals

1

Page 9

9

Part Name: 1

–

upper pump cover 2 – heating element

3 – pressure switch assembly

Removal and Replacement

1. Take out heating pump motor assembly from the dishwasher machine. (see main heating

pump motor assembly removal and replacement)

2. Unfit snap of heating pump assembly, and contrarotate heating pump assembly.

3. Reverse the above procedure to install. And check out all connectors connected well.

Motor assembly

2

1

3

Snap

Page 10

10

Part Name: 1

–

motor hunger 2 – impeller assembly 3 – pump seal ring

4 – lower pump 5 – motor assembly

Removal and Replacement

1. Take out heating pump motor assembly from the dishwasher machine. (see main heating

pump motor assembly removal and replacement)

2. Disassemble heating pump motor assembly. (see heating pump assembly removal and

replacement)

3. Take out two motor hungers, and remove screws for fixing impeller assembly and lower

pump to motor assembly.

4. Reverse the above procedure to install. And check out all connectors connected well.

Removal and Replacement

1. Remove cover of bottom board. (see main control board removal and

replacement)

Drain pump assembly

2

1

3

5

Screws

4

Page 11

11

2. Pull out all terminals of drain pump assembly.

3. Unfit snap of drain pump assembly, and contrarotate drain pump assembly to take it out.

4. Reverse the above procedure to install. And check out all connectors connected well.

Removal and replacement

1. Remove cover of bottom board. (see main control board removal and

replacement)

2. Remove clamp fixing inner drain hose to bottom board, and pull it out .

Part Name: 1 – inner drain hose 2 –check plate assembly

3. Pull out check plate from check plate holder, and replace a new check plate.

4. Reverse the above procedure to install. And check out all connectors connects well.

Removal and Replacement

1. Remove cover of bottom board. (see main control board removal and replacement)

2. Pull out all terminals of inlet valve.

Check plate

Inlet valve

Terminals

Snap

1

2

Page 12

12

3. Remove clamp for fixing connecting hose to inlet valve, and contrarotate inlet valve to take it

out.

4. Reverse the above procedure to install. And check out all connectors connected well.

The outer door covers the door to the dishwasher and protects the detergent dispenser.

Removal and Installation

1. Open the door of dishwasher. And remove all screws for fixing control panel.

2. Remove screw, and unfix all snaps for fixing the pcb cover,then take out operating board.

Part Name: 1

–

Control panel 2

–

operating board

–

3. Reverse the above procedure to install. And check out all connectors connected well.

Control Panel

Clamps

Terminals

Screws

1

2

Page 13

13

Removal and Replacement

1. Disconnect power supply.

2. Remove all screws for fixing control panel. (see control panel removal and installation)

3. Put out all housings for connecting operating board.

4. Remove screw and unfix all snaps for fixing the operating board. (see control panel

removal and installation)

5. Reverse the above procedure to install. And check out all connectors connected well.

The outer door covers the door to the dishwasher and protects the detergent dispenser.

Removal and Installation

1. Open the door of dishwasher. And remove all screws for fixing outer door.

2. Reverse the above procedure to install. And check out all connectors connected well.

Front View (with outer door assembly removed)

Part Name: 1

–

stream resistant cotton 2 – dispen

ser

3 – sound absorbing

cotton 4 –door hinge (left) 5 –door hinge(right) 6 – rod for door

hinges 7 – kick board

Operating board

Outer Door

5

1

2

3

4

6

7

Screws

Page 14

14

The dispenser automatically dispenses both the detergent and the rinse agent at the appropriate

times. The dispenser is activated twice during a wash cycle.

The first time, the dispenser is activated, the lever slides up the right-hand path of the

connecting rod. This action moves the cover catch and releases the detergent cover. When

deactivated, the lever resets to rest under the notch in the center of the connecting rod. When

activated for the second time in a cycle, the lever lifts the connecting rod by the notch, lifting

the rinse dispenser plunger and releasing the rinse agent. When deactivated, the lever returns

to its original starting position. The magnetic sensor is connected to rinse aid warning light at

control panel by wires. When the indicator lights up, it should add more rinse aid.

Part Name: 1

–

cover catch 2 – detergent power compartment

3 – cover 4 –sight glass 5 – rinse agent cap

6 – detergent tablet compartment

Part Name: 1

–

electromagnetic valve 2 – lever

3 – plunger 4 – connecting rod

5 – magnetic sensor

Removal and Replacement

1. Remove outer door assembly. (see outer door removal and installation)

2. Pull out all terminals of dispenser. Then remove all screws for fixing dispenser.

Part Name: 1 – dispenser brackets 2 – dispenser

3. Reverse the above procedure to install. And check out all connectors connected well.

Caution: Inner door of edges are sharp.

Inner Door

Dispenser

5

1

2

3

4

6

4

1

2

3

5

terminals

2

1

Screws

Page 15

15

Removal and Replacement

1. Remove outer door assembly. (see outer door removal and installation)

2. Remove control panel .(see control panel removal and installation)

3. Remove dispenser. (see dispenser removal and replacement)

4. Remove all screws for fixing inner door to right hinge assembly and left hinge assembly.

5. Remove dispenser. (see dispenser removal and replacement)

6. Reverse the above procedure to install. And check out all connectors connected well.

Removal and Installation

1. Remove all screws for fixing shell with tank and bottom board assembly in the rear of

dishwasher machine.

2. Push the shell from front to back. And take it away from the machine.

3. Reverse the above procedure to install. And check out all connectors connects well.

Top View (with shell removed)

Shell

Screws

Screws

Page 16

16

Part Name: 1

–

door switch assembly 2 – absorber 3 – 4 –backboard

Removal and Replacement

1. Disconnect power supply.

2. Remove shell. (see shell removal and installation)

3. Unfit snap of door lock assembly, and push it out.

4. Pull out all terminals of microswitch fixed on the door lock assembly.

5. Reverse the above procedure to install. And check out all connectors connected well.

Removal and Replacement

1. Remove shell. (see shell removal and installation)

2. Take out absorbing cotton, upper basket and lower basket.

3. Contrarotate nut of air breaker and take out it.

4. Pull out terminal of air breaker, and unfit snaps of air breaker fixing on softener.

Door Lock Assembly

A

ir breaker

1

2

3

4

Snap

Locking terminals

clamps

Page 17

17

5. Turn the dishwasher machine, remove the cover of bottom board. (see main control board

removal and installation)

6. Remove all clamps for fixing connecting hoses to air breaker.

7. Reverse the above procedure to install. And check out all connectors connected well.

Part Name: 1 – spring holder 2 – spring 3 – friction strip 4 – absorbing cotton

5 – hinge assembly

Removal and Replacement

1. Remove shell. (see shell removal and installation)

2. Take out absorbing cotton.

3. Take off spring holder from the slot of bottom board.

Caution: This operation must be more carefully, it is easy to be injured by the friction strip.

Hinge assembly and Spring system

snap

1

2

3

4

5

Page 18

18

4. Remove all screws for fixing hinge assembly to bottom board.

5. Reverse the above procedure to install. And check out all connectors connected well.

Removal and Installation

1. Remove shell. (see shell removal and installation)

2. Take out absorbing cotton.

3. Remove air breaker. (see air breaker removal and replacement)

4. Remove all screws for fixing tank assembly to bottom board.

5. Reverse the above procedure to install. And check out all connectors connected well.

Tank assembly

Screws

Screws

Page 19

Test Program

During test program running you can press Program button to jump into

next step except inlet valve step

,

().

How to activate Test Program

In order to check the operation of components of appliance and find out the malfunction, we

designed this program for technician.

How to ac tivate

Test Program

With door opened,

Program+ Power

Start Test

Program

Close the door

Jump into next

step

Program

E1

E3

E4

E6

E7

Test Program Operation

19

To activate test program, with the door opened and within 60s after power on,

hold down the Program button and press the POWER button until the

machine enter into Test Program.

Then close the door to start the Test Program.

E1

E3

E4

E6

E7

Page 20

Test Program

No. Process

0 Intialization

1 Inlet Valve

2

Washing Pump

and Heating

Element

3 Washing Pump

and Dispenser

4

static

5DrainPump

6 finish

Procedure of Test Program

(for models controlling w ater filling by flowmeter)

Display on

the screen

05 or

Turbidity

value

03

Description

8:88 Power on, stand by

Open inlet valve and feeds with 1.9L wate

04/Temper-

ature value

Run washing pump and 10s later run heating

element until the water temperature reaches 57℃. Then the

machine will pause.

Press Program button to jump into the next step.

F* Buzz one sound, stop, and stand by.

washing pump for 10s, dispenser will

act for 45s in this step.

static 30s.02

01 Drain for 30s.

Running fan closed after 10 seconds

20

Page 21

21

Troubleshooting

E1 Water filling exceed pre-set time

If the inlet valve has been opened for 4 minutes but the water quantity hasn’t reached the

desired value(measure by pluses), E1 would occur.

When E1 occurs, the drain pump will run until flowmeter keep motionless for 2 minutes

and all the other components will be stopped immediately.At the same time, the buzzer

will alarm for 30 seconds and error 1 will be shown.

How does the appliance react when error code occurred

E3 Heating exceed pre-set time

If the heating element has been working for 60 minutes but the water temperature

detected by NTC hasn’t reached desired value. E3 would occur.

When E3 occurs, the drain pump will run until flowmeter keep motionless for 2 minutes.

and all the other components will be stopped immediately.At the same time, the buzzer

will alarm for 30 seconds and the error 3 will be shown.

E4 Overflow

In test program, once open-circuit failure of thermistor is detected by controller, the E6

would occur. When E6 occurs, the drain pump will run until flowmeter keep motionless for 2

minutes. and all the other components will be stopped immediately.

At the same time, the buzzer will alarm for 30 seconds and error 6 will be shown.

E6 Open-circuit failure of thermistor

At any time, if overflow micro-switch act and keep for longer than 2 seconds, the E4 would

occur. When E4 occurs, the drain pump will run until flowmeter keep motionless for 2

minutes . and all the other components will be stopped immediately.

At the same time, the buzzer will alarm for 30 seconds and error 4 will be shown.

Note: Priority level of E4 is the highest. E4 operation is valid after other error operations

have done. When E4 operation has done, all the others are invalid.

Page 22

22

’

In test program, once short-circuit failure of thermistor is detected by controller, the E7

would occur. When E7 occurs, the drain pump will run until flowmeter keep motionless for 2

minutes . and all the other components will be stopped immediately. At

the same time, the buzzer will alarm for 30 seconds and error 7 will be shown.

E7 Short-circuit failure of thermistor

Page 23

E1 Tree

If the problem has not been solved through all

the inspection mentioned above, maybe the

PCB has a malfunction. So, replace PCB and

test again.

E1 code

Longer inlet time

Make a check of Tap

No water

Not open

Open it to solve the

problem

Opened

Check whether the Inlet

Valve circuit is correct or

not. (mentioned in section

4)

solve the problem

Not

Correct

Make a check of the

Hydraulic pressure.

(0.04-1.0MPa is ok)

Little water

Give advice to

consumer

Lower

Make a check of

Drain Hose

OK

Is there any

water in the Tub?

Reconnect the wire of

Inlet Valve circuit and

check again

OK

Still wrong

Replace the Inlet

Valvetosolve

problem

Make a check of Inlet

Hose

solve the problem

Inlet Hose is blocked or

kinked

OK

Failure Failure

Make a check of inlet

hose of AQUASTOP,

(only for the dishwasher

with AQUASTOP device)

Replace it to solve

the problem

Failure

Hang correctly to

solve the problem

Wrong

Check whether the

Flowmeter circuit is correct

or not. (mentioned in

section 4)

Reconnect the wire of

Flowmeter circuit and

check again

Not

solve the problem

OK

Replace the

Flowmeter to solve

problem

Still wrong

Model with Flowmwter

23

Page 24

E3

Longer heating time

Check water

temperature in the tub

Low

Check whether the

NTC circuit is correct

or not.(mentioned in

section 4)

High

Not

Make a check of over heat

proof heating Micro-switch.

Replace Switch to

solve the problem

Failure

OK

Make a check of Heater.

(mentioned in section 4)

Failure

solve the problem

Reconnect the wire of

Heater circuit and check

again

OK

Still wrong

Replace the Inlet

Valvetosolve

problem

Check whether the

Washing Pump circuit is

correct or not. (mentioned

in section 4)

Reconnect the wire of

Washing Pump circuit

and check again

Not

solve the problem

OK

Replace the

WashingPumpto

solve problem

Still wrong

OK

Reconnect the wire of

NTC circuit and check

again

solve the problem

OK

Replace the NTC to

solve problem

Still wrong

Check whether the filter is

jammed severely or not

Clear or replace filter

to solve the problem

Jammed

OK

E3 Tree

24

Page 25

E4

Overflow

Is there any water on

the bottom board?

Makeacheckof

Flooding Switch

circuit(normally closed)

solve the problem

Reconnect the wire of

Flooding Switch circuit

and check again

OK

Still wrong

Repair or Replace it

to solve problem

No water

Check whether Flooding

Switch is blocked or not

Blocked

Failure

Makeacheckof

Drain Hose

Some

water

Drain Hose is kinked

or blocked

Solve the problem

Failure Failure

OK

Make sure consumer use

the proper detergent and

rinse

Give advice

OK

Improper

Do as follows

Remove the water from the bottom board and make sure there is no water at the bottom board.

Restart the dishwasher with a strong or standard wash program as a leakage could easily repeat at a higher temperature and after a long period

of running time.

Observe the bottom tray every twenty minutes.

If any water appears, you will found out which areas, such as motor, drain pump, sump, softener, and hoses between them, and also clips at the

end of each hose, besides the weld seam at the bottom of the tub.

If hours passed, but no water comes out, you should stop the dishwasher with sufficient water in the inner tub, and observe it again after leaving

it alone for one to two hours.

Check whether the

Flowmeter circuit is correct

or not. (mentioned in

section 4)

Reconnect the wire of

Flowmeter circuit and

check again

Not

solve the problem

OK

Replace the

Flowmeter to solve

problem

Still wrong

Correct

Model with

Flowmeter

E4 Tree

25

Remove the shell

Page 26

E6

Open-circuit failure of

thermistor

Check whether the NTC

circuit is correct or not.

(mentioned in section 4)

Reconnect the wire of

Flowmeter circuit and

check again

Not

solve the problem

OK

Replace the NTC to

solve problem

Still wrong

E7

Short-circuit failure of

thermistor

Check whether the NTC

circuit is correct or not.

(mentioned in section 4)

Reconnect the wire of

Flowmeter circuit and

check again

Not

solve the problem

OK

Replace the NTC to

solve problem

Still wrong

E6-E7 Tree

If the problem has not been solved through all the inspection mentioned above, maybe the

PCB has a malfunction. So, replace PCB and test again.

Caution:

Because the real situation is unpredictable, inspection trees mentioned in this manual are

for reference only.

26

Loading...

Loading...