Page 1

WHS-209BESS1

Page 2

Contents

Safety warnings

Meaning of saf ety w arn ing s ymb ols

Safety wa rnings

Repr ese nta tive me ani ng of t he sa fety wa rni ng sy mbo l · · · · · ·· · · ·1

Elec tri cit y-rel ate d mat ter s· · · · · ·· · · · · · ··· · · · · ···2

Rela ted m att ers for u sag e· · · · ·· · · · · · ··· · · · · ··· ·2

Rela ted m att ers of ab and oni ng·· · · · · ··· · · · · · ·· · · · ·2

Correct m anipul ation of t he beer ma chine

Name s of ea ch co mpone nt· · · · · ··· · · · · · ·· · · · · · ··3

Plac eme nt·· · · · · ··· · · · · · ·· · · · · · ··· · · · · ·3

Star tin g· · · · ··· · · · · ··· · · · · · ·· · · · · · ··· ·3

Introdu ction to t he beer ma chine' s functi ons

Oper ati on pa nel 4·· · · · · · ··· · · · · ··· · · · · · ·· · · · ·

Sett ing t emp eratu re 4·· · · · · · ··· · · · · ··· · · · · · ·· · ·

Swit ch be twe en Fahr enh eit a nd Ce lsius t emp era tur e 4·· · · · · · ··· ·

Quic k coo lin g funct ion 4·· · · · · · ··· · · · · ··· · · · · · ··

Disp lay f unc tion 4·· · · · · · ··· · · · · ··· · · · · · ·· · · ·

Faul t pro mpt 4·· · · · · · ·· · · · · · ··· · · · · ··· · · · ·

Auto mat ic de frost ing 4·· · · · · · ··· · · · · ··· · · · · · ·· ·

Mainten ance of th e beer mac hine

Clea nin g· · · · ··· · · · · ··· · · · · ··· · · · · · ·· · ·5

Out of s erv ice· · ··· · · · · ··· · · · · · ·· · · · · · ··· ·5

Tra nsp ortat ion· ··· · · · · ··· · · · · · ·· · · · · · ··· ·5

War m pro mpt· · · ·· · · · · · ··· · · · · ··· · · · · ··· ·5

Use sp eci fic ation s of be er ba rre l· · · · · ·· · · · · · ··· · · · · ·5

DRAUGHT BEER TROUBLE G UIDE

Answers t o FAQ

Instruc tions to b eer acce ssory in stalla tion

The sy mb ols i nd ic ate p ro hibit ed m att er s, and th os e

beha vi ors a re f or bid de n. No n- co mpl ia nce wit h th e

inst ru cti on s ma y res ul t in prod uc t dam ag es or end an ger

Proh ib iti on s ym bol s

War ni ng sy mb ols

Note s ym bol s

CAUT IO N :

The ap pl ian ce i s no t int en ded f or u se b y you ng c hil dr en o r inf ir m perso ns w ith ou t

supe rv isi on .

Youn g ch ild re n shoul d be s upe rv ised to e ns ure t ha t they do n ot p lay w it h the

appl ia nce .

GENE RA L:

This t yp e of re fr ig era to r-fre ez er is w id ely use d in p lac es s uch as ho te ls ,o ff ic es,

stud en t dor mi to rie s an d hou se s. I t is mo st ly suit ab le fo r re frige ra tin g an d prese rv ing

food s su ch as f ru it s and b ev era ge . It e njo ys t he adva nt age s of s mall si ze , Lig ht weigh t,

Low el ec tri c co ns ump ti on an d ea sy u se.

the pe rs ona l sa fe ty of u se rs.

The sy mb ols i nd ic ate m at ters th at m ust b e fo llowe d, a nd

thos e be hav io rs m ust b e st rictl y ex ecu te d in line w it h the

oper at ion r eq ui rem en ts. N on -c omp li ance wi th t he

inst ru cti on s ma y res ul t in prod uc t dam ag es or end an ger

the pe rs ona l sa fe ty of u se rs.

The sy mb ols i nd ic ate m at ter s to p ay a tte nt ion to, a nd

thes e be hav io rs shal l be s pec ia lly not ed . Due

prec au tio ns a re need ed o r min or o r moder at e inj ur ies

or dam ag es of t he p ro duc t wi ll be c au se d.

This m an ual c on ta ins l ot s of impo rt ant s af ety inf or mat io n

whic h sh all b e ob se rve d by t he us er s.

1

Page 3

Safety warnings

Correct manipulation of the beer machine

Electri cit y-r ela ted m att ers

Do not p ul l the p ow er cord w he n pul l th e po wer p lu g of th e be er m ach in e. Gr as p th e

plug f ir mly a nd p ul l out t he p lug d ir ec tly. Don 't p ull the p lu g wit h we t hands .

The po we r cor d sh ou ld be f ix ed at t he b ac k of th e bo x inste ad o f bei ng e xpose d

outs id es an d da ng lin g to p rev en t ac cid en ts. Nev er d ama ge t he powe r co rd.

Avo id us in g them wh en t he po we r cord is d am age d or t he plug b ec ome s fr ayed.

To avoid d an ger, i f th e po wer c or d is fr ay ed o r dam ag ed, the y mu st be r ep laced

by pro fe ssi on al s fro m th e maint en anc e de partm en t of th e ma nufac tu rer o r th e

rela te d dep ar tm ent .

Plea se u se th e st an dar d sp eci al t hr ee- ho le po we r so cke t mo re than 1 0A ,wh ic h

shou ld n ot be s ha red by ot he r app li ances .

10A

The po we r cor d pl ug a nd po we r soc ke t sh oul d be f ixed fi rm ly, othe rw ise the y

may ca us e fir e. P le ase s ee t o it that t he g rou nd ing pol e of t he so ck et shou ld

have r el iab le g ro und in g wir e.

Usua ll y, we s ugges t th at yo u sh ould no t us e ext en sion co rd , and t he p ower of

the ra te d vol ta ge i s 115 V, the c ur ren t mo re t han 1 0 A. Th e Fu se (cir cu it br ea ker)

shou ld b e 15 A.

Related m att ers f or us age

Do not a tt emp t to r ep air o r re pla ce a ny p art u nl ess you r eq uip me nt is

reco mm end ed b y th e man ua l mod el . Th e ot her s er vices s ha ll be k ep t by the

qual if ied t ec hn ica l pe rso nn el .

Sinc e fo ldi ng c ar dbo ar d and p la st ic fi lm m ay ca us e ch oki ng d ang er, d on 't gi ve

the pa ck ing o r ot he r par ts t o chi ld re n for f un ! D o not let c hi ldr en e nter or c li mb

beer m ac hin e to k ee p the c hi ldr en f ro m the d an ger.

Don' t us e wat er t o sp ray o r fl ush the b ee r mac hi ne. Bes id es, d on 't put be er

mach in e in da mp p la ce wh ic h is ac ce ss ibl e to w ate r. do n ot a ff ect t he e lectr ic al

insu la tio n pe rform an ce of b ee r ma chi ne .

Don' t ma ke th e be er m ach in e for p ed al o r sup po rt.

Plea se d on' t pu t we igh t in t he to p of b ee r mac hi ne. It is e as y to ca us e the

drop pi ng of i te ms a nd ac ci den ta l in jur y.

Please pull out the plug in the case of power off and cleaning.

The be er m ach in e us es AC po we r sup pl y of 11 0~ 120 V/ 60 Hz. If t he v olt ag e

fluc tu ati on e xc eed t he r ang e of 110~ 12 0V±10 %, i t can cau se f aul ts o r even

dama ge o f bee r ma ch ine . Or i t may res ul t in in do or circ ui t ove rh eat to ca us e fir e.

Then i t sh oul d be e qu ipp ed w ith a ut om ati c vo lta ge r eg ula to r of over 7 50 W for u se .

When g as o r oth er c om bus ti ble g as i s re vea le d, you sh ou ld tu rn o ff t he gas va lv e,

and th en o pen t he d oo r. At thi s ti me do n ot p ul l out t he p lug of be er m ach in e and

othe r el ect ri c ap pli an ce, s o as n ot t o cau se f ire by th e sp ark .

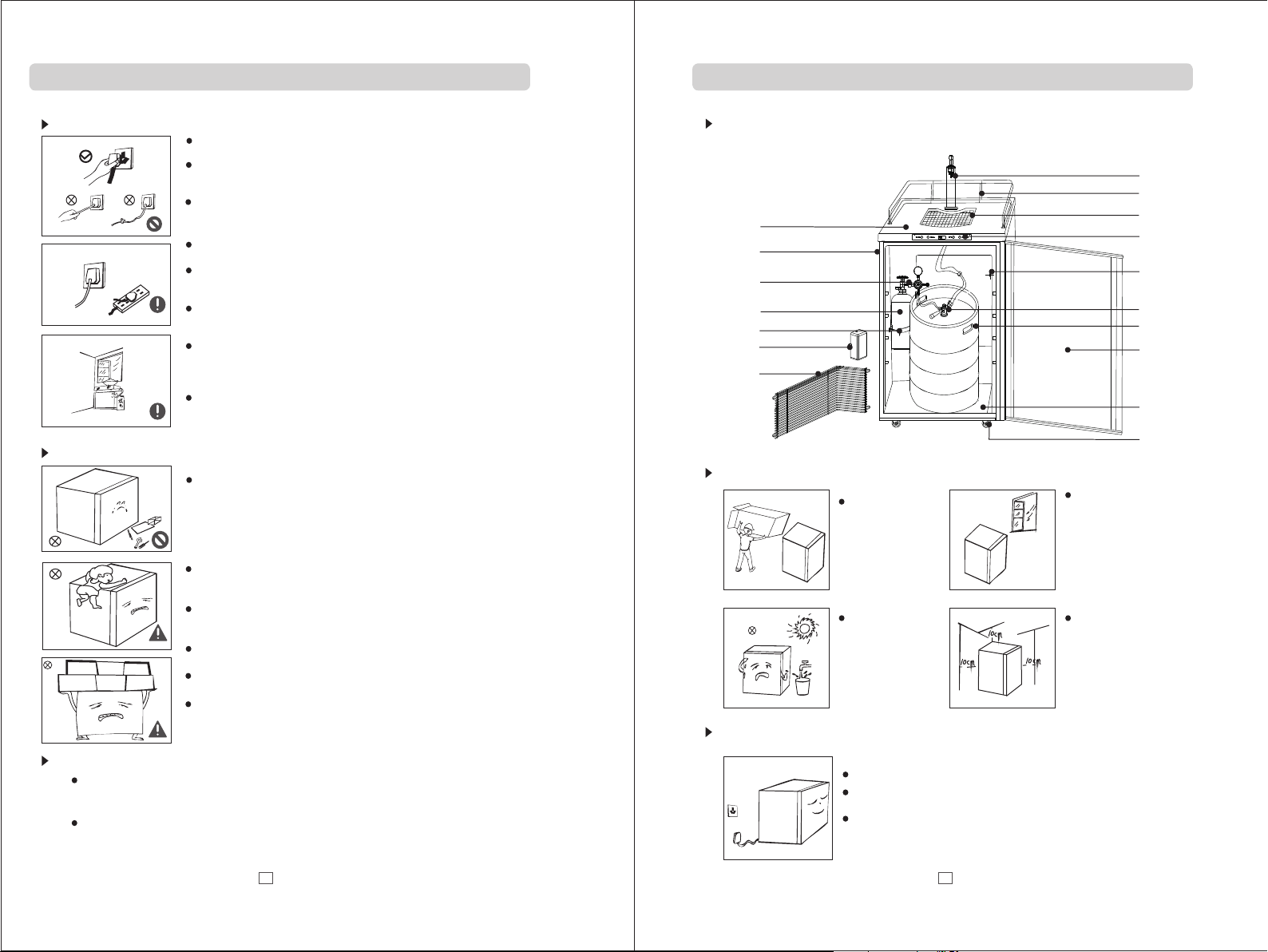

Names of each compon ent

Top cove r

Cabi ne t

CO regu la tor v al ve

2

CO gas cy li nde r

2

CO can su pp ort er

2

Cont ro l boa rd d ev ice

comp re sso r

cham be r cov er

Placeme nt

Remove all packing

mater ia ls b ef or e us in g

the b eer ma ch in e.

Avoid t he dir ect su nlig ht,

and keep away from heat

sources suc h as sto ves,

heaters, an d radi ator s.

beer t ow er as se mb ly

uppe r co ver g ua rd rai l

wate r bo x

Disp la y and c on tr ol

devi ce

Evap or ato r

Mixe d ba ll va lv e

Beer b ar rel s

Door

beer c an b ott om p ad

univ er sal w he el s

Put the beer machine in smooth, flat and

strong place indoors.

The hot air fro m the si de wal l of bee r mach ine

must be a ble to e xclu de unr estr icte dly.

Other wise , the co mpre ssor m ust im prov e

power to increase the power con sump tion .

There fore , the di stan ce bet ween t he bee r

machine, wall and the surrounding furniture

cannot be less than 1 0cm.

Rela te d mat te rs o f aba nd oni ng

Beer m ac hin e co nt ain s co mbu st ib le ma te rials o f re fri ge rant R1 34 a. It s ho uld be is ol ate d fr om the fi re

when a ba ndo ne d. It can 't b e bur nt , bu t sho ul d be proc es sed b y th e profe ss ion al r ecycl in g com pa ny,

so tha t it c an av oi d ha rmi ng t he en vi ro nme nt o r causi ng o the r da ngers .

Once b ee r mac hi ne f all i nt o dis us e, i t sho ul d be plac ed o n the s he lf or som ew her e be yond th e re ach

of chi ld ren t o pr ev ent c hi ldr en f ro m bei ng h urt.

2 3

Star tin g

For th e fi rst s ta rt ing , pl ease le av e the b ee r machi ne a lon e ab out 2~3 h ou rs to p lu g in.

Clea n th e cha mb er of the b ee r mac hi ne b efo re t he fi rs t op era ti on (see t he

main te nan ce o f be er ma ch ine ) .

Plea se l et th e be er m ach in e wor k 2- 3 ho urs b ef ore p ut ti ng th e ba rre l be er i nto

the be er m ach in e.

Page 4

Introduction to the beer machine's functions

Maintenance of the beer machine

Oper ati on pa nel

Deep Chill

Temperatu re

drop

Temperatu re

rise

Display mod ul e

Fah re nh ei t/ Ce ls iu s

switc hi ng

Rapid cooling

Sett ing t emp erature

Adju st t he bu tt on o f tem pe ratur e dr op or r is e on the co nt rol p an el so tha t th e dis pl ay modu le w ill d is play

the ap pr opr ia te t emp er atu re .

The di sp lay m od ul e dis pl ays t he s et t emp er ature , an d the t em perat ur e con tr olled r an ge va ri es from 0 t o

10 ℃ (32 -5 0 ℉).

The di sp lay m od ul e sho ws 5 ℃ a t the i ni ti al po we r. Whe n pr es sin g th e butto n of t emp er ature

rise o r dr op, t he t em per at ure w il l in cre as e or decr ea se by 1 ℃ (℉) .

The op ti mal t em pe rat ur e of th e st or age a nd d istri bu tio n of d raft be er i s 34 ~ 38 ℉( 1. 1 to 3.3 ℃).

Switch be twe en Fa hre nhe it an d Cel siu s tem per atu re

The pr es s of th e "F ah ren he it / Cels iu s swi tc h" key ca n re ali ze t he Fahr en hei t an d Celsi us t emp er ature s wi tch .

The co rr esp on di ng Fa hr enh ei t or C els iu s tem pe ra tur e va lue is di sp lay ed i n the dis pl ay mo du le.

When t he “C els iu st emp er atu re ”i s se lec te d, the la mp o f“ ℉ ”

When t he “F ahr en he it te mp era tu re” i s sel ec ted, th e la mp of “ ℃ ”o n th e dis pl ay modu le w ill b e li ghten ed

and th e di spl ay ed v alu e is F ahr en he it.

Quic k coo lin g fun cti on

Pres s th e “rap id c oo lin g”ke y to en te r th e“qui ck c ool” sta te . Lig ht en the “ra pi d coo li ng” icon o n th e

disp la y mod ul e, and th e te mpe ra tu re di sp lay "“00 ”. R ep res s th e “rapid c oo lin g” ke y to exit t he s tat e of

“rapi d co oli ng” a nd the ic on g oes o ff. The te mp era tu re show s en ter in g into th e se tti ng s ta te of p re -ra pi d

cool in g.

Afte r en ter in g in to “ra pi d coo li ng” s tat e, t he mach in e wor ks 2 4Hcon ti nuo us ly, and exit s af ter 2 4H . At the

same t im e, ra pi d co oli ng i con i s off. The t em per at ure dis pl ays e nt ering i nt o the s et ti ng st at e of pre- ra pid

cool in g.

Rap id refr igera tion fu nctio n will be u sed onl y for the f irst ba rrel of b eer in th e box, de sirin g to use as

soo n as poss ible wh en drin king. T he norm al use sh ould no t use thi s funct ion to av oid ice b eer.

Display func tio n

In nor ma l wor k, t he d isp la y mod ul e wi ll be l it i nst ea d of b ein g cl osed.

Faul t pro mpt

When t he f oll ow in g tab le p rom pt s ap pea r in t he di sp la y mod ul e, it imp li es th e fa ilure o f be er ma ch ine.

Alth ou gh pa rt o f th e fau lt c ond it io n occ ur s, the be er m ach in e can sti ll w ork . You sh ould co nt act t he

main te nan ce a s so on as p os sib le t o ac hie ve t he op ti mi zat io n run of be er m ach in e.

Prom pt

Temper at ure s en so r fai lu re

Faul t

in the r ef rig er at ed zo ne

Whe n two or mo re sens ors fai l simul taneo usly, al l fault c odes wi ll disp lay on th e displ ay modu le alte rnate ly.

If th e ambie nt temp eratu re sens or and re frige ratio n defro sting s ensor f ail, an y key can b e press ed. The t emper ature i s

adj ustab le. The f ault di splay w ill be re store d after 15 seco nds lat er.

E1 E4

Defr os tin g se ns or fa il ure i n

refr ig era to r co mpa rt ment

E7

Ambi en t tem pe ra tur e

sens or f aul t

Cleaning

The du st o f the b ac k of b eer m ac hine an d th e gro un d needs c le ani ng u p in time i n or der t o im prove t he

cool in g effect an d he lp sa ve e nergy a t th e sam e ti me.

The interior of beer machine should be cleaned regularly. When cleaning, use a soft towel or sponge which is

dipped in water or non-corrosive neutral detergent. At end, wipe it with clean water and dry it with cloth. Open

the door to dry naturally before the power is turned on.

Do not u se a h ard b ru sh , cle an s tee l ba ll , wir e br ush es , ab ras iv es, suc h as

toot hp ast e, o rg ani c so lve nt s (s uch a s al cohol , ac eto ne , banan as , wat er, e tc.),

Wat er, t he pH o f th e items t o cl ean t he b eer mac hi ne.

Do not rinse with clean water so as not to affect the electrical insulation properties.

Out of s erv ice

If the m ac hin e is o ut o f ser vi ce more t ha n thr ee w eeks, y ou s hou ld u nplug t he p owe r an d clean i t

thor ou ghl y. The beer m ac hin e sh ould ke ep d ryi ng .

Tra nsp ort ati on

Fix th e lo ose i te ms i n the b ee r machi ne w ith t ap e firml y; u se th e ta pe to fix t he d oor o f th e machi ne t o

avoi d op eni ng t he d oor i n tr ans po rt ati on .

In tra ns por ta ti on, l oo sen the t ru ndl es o f the two f oo t bra ke , and the g o on .

War m pro mpt

Beer m ac hin e is m ai nly u se d for s to ra ge of b ot tled be er a nd ot he r items . Pl eas e in creas e th e set t em perat ur e

(gre at er th an o r eq ual t o 5 ℃) to a void th e in sid e te mpera tu re to o lo w.;

If the re i s sou nd o f ai r or hu m wh en the ma ch ine i s in u se, the n oi se is c au sed by th e re fri ge rant fl ow ing i n th e

cool in g pip e an d runni ng i n the c om pr ess or, w hic h is n or mal p he nom en on .;

The be er m ach in e ha s no he at ing f un ct ion . Wh en the se t te mpe ra ture is h ig her t ha n the amb ie nt te mp eratu re ,

the ma ch ine w il l no t run .

The us e of sp eci fic ati ons o f bee r keg s

Keg si ze s tha t ca n be u sed i n yo ur be er d is pen se r.

1/2 ba rr el 59 L it er s 15. 5 ga ls. 198 4 oz . 164 / 1 2- oz. Gla ss

1/4 ba rr el 30 L it er s 7.8 g al s. 992 oz . 82 / 1 2-o z. G lass

1/6 ba rr el 20 L it er s 5.2 g al s. 661 oz . 55 / 1 2-o z. G lass

1/8 ba rr el 15 L it er s 4.0 g al s. 496 oz . 41 / 1 2-o z. G lass

Our B ee r di sp en se r ac ce pt s al mo st a ll B ra nd N am e1 /2 k eg s.

However Coors' ke gs d o no t fi t in o ur u ni t.

Auto mat ic de fro sti ng

The be er m ach in e do esn 't n eed m an ua l def ro st. The fro st ing o n th e inner w al l wil l au tomat ic all y me lt and

flow t hr oug h th e dr ain ag e hol es t o be a uto ma tic al ly e vap or ated.

4

5

Page 5

DRAUGHT BEER TROUBLE GUIDE

CLOU DY BE ER

When b ee r in gl as s ap pea rs h azy, and not c le ar.

FLAT BEER

Foam y he ad di sa pp ear s qu ick ly : be er la ck s usual z es tfu l br ewery f re sh fl av or.

Causes Correct ion s

1)

Over c hi lli ng b ev era ge c ool er a nd /or

beve ra ge li ne s.

2)

Crac ki ng, o r wh en p art ia lly ope ni ng be er

fauc et .

3)

Cont am ina te d ai r sou rc e. If pos si ble

chan ge t o CO2 g as a s a pr ess ur e sourc e.

Defe ct ive Thoma s or t ong ue v ents.

4)

Gene ra l con di ti ons c au sin g cl ou dy be er.

5)

Unre fr ige ra te d foo d pl ace d on b ar rel o n

cold b ee r.

1)

Grea sy g las s

2)

Impr op er dr aw in g of be er i nto g la ss .

1)

Exce ss ive l ow t em per at ures ma y ca use h az y, cl oudy

beer, p ar tic ul ar ly wh en b eer l ie s in c old c oi l for lon g

peri od s of ti me . Ma ke ce rt ain tha t li nes a re t horou gh ly

clea ne d, an d th en r ais e te mpe ra tu re sl ig htly.

2)

Open f au cet q ui ck ly an d co mplet el y.

Repl ac e wor n wa sh ers a nd p art s in f au cet w he n

nece ss ary t o pe rm it fu ll o penin g of f auc et .

3)

See fl at b eer, c or re cti on # 7

Alwa ys d raw f re sh a ir fr om a n outsi de s our ce t o

comp re sso r. Att ac h hai r fe lt filt er t o the o ut side in ta ke,

in add it ion t o fi lt er in l in e.

Bact er ia gr ow th m ay re su lt from b ee r bac ki ng up thr ou gh

defe ct ive v en ts i n air l in e, ai r pr es sur e wi ll then c ar ry th is

into b ee r bar re l.

Chec k an d rep la ce d efe ct ive v en ts f req ue ntly, and th

orou gh ly cl ea n ai r lin e.

4)

See wi ld b eer c or re cti on s #2, # 5, # 6, a nd #7 , an d flat be er

corr ec tio ns # 5, # 7, an d #8 .

5)

When u nr efr ig er ate d pr odu ct s, s uch a s me ats veg et abl es ,

fish , or f rui ts , ar e pla ce d on barr el o f col d be er, the be er

beco me s war m lo ng b efo re t hes e pr od uct s ch ill dow n to

the co ld t emp er at ure . Th is c hange i n te mpe ra ture wi ll c aus e

Clou dy B eer.

1)

Do not w as h bee r gl as ses t og eth er w it h gla ss es

that h av e con ta in ed mi lk o r any o th er f att y

subs ta nce . Li ps tic k is a f atty su bs tan ce .. Make

sure i t is r emo ve d fr om gl as s.

Exce ss a mou nt o f ge rmi ci des bui ld u p and l ea ve a

fatt y fi lm on g la ss , whi ch m ay caus e fl at be er.

It is pr ef era bl e to s tea m an d steri li ze gl as ses whe re

heal th l aws p er mi t.

Was h gl ass es t horou gh ly wi th a g ood det er gen t.

Do not u se s oap .

Do not d ry -wi pe g la sse s. P ermit g la sse s to a ir-dr y

by pla ci ng th em o n wi re or c or rug at ed m eta l.

Rins e in f res h co ld w ate r ju st be fo re s erv in g beer. It

is bes t to s erv e be er i n a wet g la ss.

2)

Open f au cet q ui ck ly an d co mpl et el y.

Chec k an d fin d th e co rre ct d ist an ce t o hol d gl ass

from f au cet w he n dr awi ng . Pro pe r fo am sh ou ld be a

tigh t cr eam y he ad , and t he c oll ar o n th e ave ra ge

glas s sh oul d be“3 /4” to “1 ”hig h.

Beer d ra wn wi th ou t hea d ha s app ea ra nce o f be ing

flat .

3)

Not en ou gh pr es su re.

4)

Defe ct ive Thoma s an d Tong ue Ven ts .

Pres su re is s hu t of f.

5)

Pre- co lor, o r be er s yst em , too col d.

6)

Slug gi sh pr es su re re gu lat or s.

7)

Cont am ina te d ai r sou rc e.

Oil or g re ase f um es .

8)

Mois tu re in Ai r sy st em.

9)

Rapi d mo vem en t of a ir.

LOOS E FOA M

Causes Correct ion s

Larg e so ap- li ke b ubb le s (so me ti mes c al led

fish e ye s). F oa m se ttl es q uickl y.

3)

Incr ea se pr es su re if b ee r run s to o sl owl y.

Corr ec t flo w is t o fi ll

4)

Chec k al l was he rs f req ue ntl y, part ic ula rl y the air

vent s. A clo gge d ve nt will o bs tru ct t he f low o f ai r or

CO .

2

Chec k so urc e of p re ssu re . Che ck p ow er so ur ce when

air co mp res so r is u sed . Air c omp re ss or sh ou ld ne ve r

be con ne cte d to l ig ht sw it ch. M ak e ce rta in t o have a

sepa ra te el ec tr ic pl ug o utl et f or t he co mp resso r.

Chec k CO tank , if e mpt y, repl ac e (Se e in side co ve r

for pr op er pr oc ed ure ).

When b ar rel i s ta pp ed, a nd p rop er p re ssu re a ppl ie d,

pres su re mu st a lw ays r em ain o n un ti l bar re l is empt y.

If bee r is s tar te d wi tho ut f irst ap pl yin g pr essur e be er

will b e wi ld at t he s ta rt, a nd f lat tow ar ds th e en d.

5)

With a n ac cur at e th erm om eter, ch ec k tem pe ratur e

in pre -c ool er o r bo x.

Temper at ure a t th e fa uce t sh ould al wa ys be c ol der

by at le as t two d eg re es th an a t the pre co ole r or b ox.

6)

A regul ar s eat , or t he r egu la tor d ia ph rag m, m ay

requ ir e rep la ci ng.

Also , ch eck t he s am e as yo u wo uld f or C or rec ti ons

3 & 4.

7)

Filt er a ll ai r af te r it le av es comp re sso r.

Oil fu me f rom c om pr ess or, o f kitch en g rea se f umes,

pump ed i nto b ee r, wi ll ca us e Fla t Be er.

If pos si ble C O gas sho ul d be u sed a s a p re ssu re s ource .

8)

With t he u se of a n ai r co mpr es sor, it is i mp era ti ve to

have a m oi stu re t ra p ins ta lle d in t he P re- co oler, an d

drai ne d dai ly. This is i n ad dit io n to an act iv ate d

char co al fi lt er, n ece ss ary t o pu ri fy th e ai r just be fo re

it ent er s the b ar re l.

With t an k typ e co mp res so rs, dra in t he ta nk w eekly.

Mois tu re tr ap s sh oul d be d rai ne d da ily.

9)

An air f an , or ex ha us t blo we r dra wi ng a ir, or b lo win g

air, ac ro ss th e ba r wh ere b ee r is dr aw n, m ay ca us e

the de ad o f foa m to f al l qui ck ly. Fans or bl ow ers

shou ld b e loc at ed s o tha t ai r mov em en t is no t di rectl y

acro ss f rom w he re b eer i s dr awn .

This i s ge ner al ly a F lat B ee r con di ti on: t he C auses a nd

corr ec tio ns f or F lat B ee r shoul d be f oll ow ed.

2

2

Page 6

OFF- TAST E BEE R

Ofte n bit ter a nd bite y, somet ime s com ple te ly od or, ca rry ing an un ple asa nt ta ste.

Beer l ine s sho uld be fl ush ed af ter e ach bar rel i s emp ty. Main tain fr esh , Cle an, s anita ry

cond iti ons a t bar. Smo ke, k itc hen o dors, f ly sp ray s, and di sin fec tan ts will h arm t he ta st

and fl avo r of be er, maki ng it u npa lat able. T hese co ndi tio ns, as de scr ibe d, ma y come

from a n air s our ce, or fr om ac tua l con tact wi th th e gla ss at bar.

Causes Correct ion s

1)

Impr op er, or n o cl ea nin g of c oil s, h os e,

lead s, a nd di re ct d raw s ys tem .

2)

Cont am ina te d Air L ine . De fec ti ve T ho mas

or Tong ue Be nt s.

3)

Rubb er h ose w il l absor b an d ret ai n od ors .

4)

Unfi lt ere d ai r, Air i s moi st ure r id de n or oi ly.

1)

Coil s sh oul d be t ho rou gh ly cl ea ne d at le as t onc e a

week .

Brus h an d cle an f au cet . (s ee Wild B ee r, Cor re ction # 2)

Taps, ro ds , and t ap -S eal f it ting sh ou ld al l be s coure d,

usin g a de ter ge nt , the n ri nse d cl ea n.

Dire ct d raw S ys te ms mu st b e clean ed t he sa me a s coil

syst em s: 4 fe et o f di rec t dr aw line a cc umu la tes as mu ch

per fo ot a s any o th er s yst em .

2)

Air ho se s, ai r li ne s and v en ts, sho ul d be ex am ined,

and if c on tam in at ed, r ep lac ed .

Dirt y ai r lin es s ho uld b e wa she d wi th a g ood c le ani ng

comp ou nd, n or ma lly u se d for c le an ing c oi ls, and

then r in sed c le an .

3)

Rubb er h ose w il l ab sor b an d ret ai n od ors . An

appr ov ed Vinyl tu bi ng is b es t for air s in ce it d oe s

not ab so rb mo is tu re, a nd i s not affec te d by oi ly

subs ta nce s.

A fresh , ou tdo or, a ir l ine i s im per at iv e whe n ai r is

the so ur ce of p re ss ure .

4)

Air mu st a lwa ys b e fi lte re d.

See Fl at B eer, C or re cti on # 8 for moi st ure r id den air.

SOUR B EER

May ta st e and s me ll e xtr em ely yea st y, or m old y.

Causes Correct ion s

1)

Cont am ina te d Air L ine .

2)

Impr op er tr an sp ort at ion of ba rr els o f be er,

Beer d el ive re d on o pen t ru ck, d ur in g hig h

summ er t emp er at ure s, m ay be the c au se

for st ar tin g se co nda ry f ermen ta tio n.

3)

No ref ri ger at io n, an d im pro pe r ro tat io n.

1)

See Cl ou dy Be er, C or rec ti on #3

See Off- Tast e Beer, Co rr ect io n #2

See Fl at B eer, C or re cti on # 7

2)

If at al l po ssi bl e, d eli ve r bee r ba rr els i n cl osed bo dy,

refr ig era te d tr uck . If o pen sta ke d bod y tr uck is us ed ,

cove r ba rre ls w it h a tar pa uli n fo r pr ote ct ion aga in st

summ er h eat , an d ci rcu la tin g wa rm a ir.

Tru ck s hou ld n ever be l oa ded t he n ight be fo re

morn in g del iv er y, un les s be er is ref ri ger at ed in tru ck .

3)

The ru le i s fir st b ar rel i n, f irst ta pp ed.

Refr ig era ti on m ust b e le ft on win te r or su mm er.

Sour b ee r is ge ne ra ted a s a re sul t of s ec ond ar y

ferm en tat io n, a bov e 45 d egr ee s. R eta il o utlet s th at

do not h av e ref ri ge rat io n sho ul d ic e up ba rr els, or a t

leas t co ver b ar re ls wi th t arpau li n or bu rl ap bags .

Best t em per at ur e for b ar rels is 3 8°to 4 0°.

WILD B EER

Beer, w he n dra wn , is a ll fo am , or to o mu ch f oam , an d not eno ug h liq ui d beer.

Causes Correct ion s

1)

Impr op er dr aw in g bee r in to gl as s.

2)

Yeas t gr owt h, o r other o bs tru ct ions in f au cet .

Wor n fau ce t parts a nd w orn f au cet was he rs.

3)

Kink s, d ent s, o r tw ist s in c oils, o r di rec t dr aw

line s: o bst ru ct ion s in l ine , ne ar, o r beh in d

fauc et .

4)

Sag, o r tr ap in l in e.

5)

Beer t oo w arm a t fa uc et;

Beer t oo w arm i n Co il S yst em .

Beer t oo w arm i n Air S ha ft Sy st em.

6)

Hot sp ot s in li ne .

7)

Pre- Co ole r, or D ir ect D ra w Dis pe ns er, to o

warm .

8)

No col d st ora ge s pa ce fo r de liv er ed b eer ;

beer b ec ome s wa rm i n bar re l.

9)

Too much a ir p res su re .

1)

Open f au cet q ui ck ly an d co mpl et el y.

Chec k an d fin d th e co rre ct d istan ce t o hol d gl ass fro m

fauc et w hen d ra wi ng. P ro per f oa m sh oul d be a t ight,

crea my h ead , an d th e col la r on th e av er age g la ss

shou ld b e“3/4”t o “1” hi gh .

2)

Clea n fa uce t sp ou t wit h a go od br us h da ily. Sco ur

all in te rna l fa uc et pa rt s at le as t on ce a we ek .

Repl ac e wor n wa sh ers a s re qui re d. I f fau ce t does

not op en w ide , wo rn p art s or e nti re f au cet m us t be

repl ac ed.

3)

Chec k fo r, and r ep la ce ki nk ed, d en te d, or t wi sted

line f ro m bar re l to f auc et .

Exam in e for f ra ye d cou pl ing w as he r beh in d fau ce t

that m ay c aus e ob st ruc ti on.

4)

Keep a ll m eta l be er l ine s st rai gh t fr om ba rr el to

fauc et ; nev er p er mit l in es to sag , as t his c re ates

trap s th at ma y ca us e wil d be er.

5)

Temper at ure a t fa uc et mu st a lways b e at l eas t 2

degr ee s col de r th an at b ar rel .

In swe et -wa te r re fri ge rated , or i ce- wa ter sys te m,

fauc et s han k mu st a lwa ys b e subme rg ed.

In Col d Air S yst em , th e col de st air fr om t he bl ow er

must f ir st be d ir ec ted t o th e fauce t, a nd th en

circ ul ate d ba ck t o pre -c ool er.

6)

Insu la te al l be er l ine s; a l ong b ee r ru n mus t be

cons ta ntl y re fr ige ra ted. In su lat io n helps . Bu t

insu la tio n is n ot r efr ig era ti on .

Keep a ll b eer l in es a way f ro m hot w at er p ipe s, h ot air

duct s, a nd st ea m li nes . A cold s team pi pe i n the

summ er i s a hot s te am p ipe i n th e win te r.

7)

It is always s um me r in do ors and in th e base me nt ,

there fore , maintai n pre- co ol er, and d irec t dr aw

dispense r te mp er at ur e at 4 0 al l ye ar r ou nd . If direct

draw tempera tu re c an no t be l ow er ed , in cr ea se a pplied

pre ss ure; h owever, bal an ce t he s yste m by changi ng t o

smaller di am et er l en gt h of v in yl t ubing or inst al l a fo am

control faucet .

Never shut off re fr igerati on d ay o r ni gh t.

8)

Coil s ys tem s, a nd d ire ct d raw sys te ms, m us t be prop er ly

bala nc ed in o rd er to app ly p res su re r equ ir ed fo r wa rm est

temp er atu re t o wh ich b ar rel s of b ee r wil l be e xpose d.

A contr ol b eer f au ce t can b e us ed in p la ce o f a res tr icted

coil t o ba lan ce s ys tem .

9)

Chec k so urc e of p re ssu re . Adju st p re ssu re t o suit pr op erl y

bala nc ed sy st em . For c or rect be er f low, f il l a 10 oz. Gl as s

in 4 sec on ds at p ro pe r tem pe rat ur e.

Chec k an d rep la ce a c ree pi ng re gu la tor a nd g aug e.

Page 7

Answers to FAQ

10)

Exce ss C O .

11)

Not en ou gh pr es su re.

No pre ss ure .

12)

Old Be er.

2

10)

Adju st p res su re w hen u si ng CO as l ow a s po ssi bl e,

howe ve r, rem em be rin g th at th e ap pl ied p re ssu re

must b e sl igh tl y hi ghe r th an th e in te rna l pr essur e of

the be er ( no mo re t ha n 18 lb s. s hou ld b e ap pli ed .)

The co ld er th e be er a nd th e hi ghe r th e ap pli ed C O

pres su re, t he m or e rap id t he ab so rp tio n of CO b y

the be er. T hi s over- ca rbo na tes the b ee r, cau si ng

Wild B ee r.

11)

Chec k fo r def ec ti ve ai r ve nts. (s ee F lat B ee r,

Corr ec tio ns # 3 an d 4.)

Alwa ys t urn p re ss ure o n be for e dr aw ing b ee r.

12)

Rota te s toc k. The o ld est b ee r shoul d be t app ed f irst;

if bee r ha s bee n al lo wed t o st and i n wa rm t emp er ature

beyo nd 4 5° for a ny e xc ess iv e len gt h of t ime , it m ay

begi n se con da ry f erm en tat io n.

Stor e be er at 4 0° al l ye ar ro un d.

2

2

2

TAIL END B EER

Beer d ra ws we ll a t th e beg in nin g of t he b arr el . Towa rds the e nd o f the b ar rel the b ee r is fl at . Th is i s mor e

like ly t o occ ur w he n bee r tu rno ve r is s low.

Causes Correct ion s

Wher e ai r is us ed a s a pr ess ur e sou rc e,

air re pl ace d th e CO in b eer c au sin g fl at

beer. W he re be er i s be ing d ra wn ra pi dl y

this p ro ble m is n ot s o evi de nt.

2

Wher ev er po ss ib le CO Ga s sh oul d be u se d as

pres su re so ur ce .

In hig h pr ess ur e sy ste ms w her e CO ga s ca nno t be

sued a b an ner a ir -g as Bl en der s ho ul d be in st all ed .

This i nt rod uc es a s mal l am oun t of C O b ack i nt o the

beer, t hu s

2

2

2

As for t he fo llo win g sim ple q ues tio ns, y ou ca n try t o sol ve th em by y our sel f. If t her e is no

change, plea se ca ll th e aft er- sal es se rvi ce de par tme nt.

Faul t

The b eer ma ch in e do es n' t

work.

Fre qu en tl y sw it ch m ac hi ne .

Fre qu en tl y sw it ch m ac hi ne .

The d oo r ca nn ot b e cl os ed

properl y.

Noise

Wheth er t he p ow er s up pl y an d pl ug i s we ll p la ce d.

Wheth er t he v ol ta ge i s to o lo w.

Wheth er t he n ew c ir cu it t ri ps , or t he f us e me lt s.

The i ndoor te mp er at ur e is h ig he r th an u su al .

Fre qu en tl y op en t he d oo r.

The d oor is n ot c lo se d co mp le te ly.

Temperatu re c on tr ol i s no t se t co rr ec tl y.

Beer ba rr el i s no t in p la ce .

The b eer ma ch in e is n ot p la ce d fl at ly.

The d oor is i ns ta ll ed w ro ng ly.

Shelf, me ta l pl at e or b ee r ke gs a re m is pl ac ed

Wheth er t he d ir ec ti on o f th e wh ee l is d et er mi ne d,

or th e ca bi ne t is n ot p la ce d sm oo th ly.

The noise i s th e so un d of r ef ri ge ra nt f lo w, wh ic h

is normal .

In th e en d of e ac h lo op , yo u wi ll h ea r th e gu rg le o f

refri ge ra nt f lo w fr om t he b ee r ma ch in e.

The con tr ac ti on a nd e xp an si on o f th e in ne r wa ll

may cau se p op s an d cr ac kl es .

Poss ibl e rea sons

Page 8

Instructions to beer accessory installation

Diagram of ove ral l str uct ure

Beer to wer a ssembly

Upper c ove r guar dra il

Top cover

Cabin et

Wat er box

Displ ay an d cont rol

devic e

CO r egu lato r val ve

2

The red C O soft t ube

CO c an su ppor ter

2

2

and bol t

CO g as cy lind er

2

Beer ca n bot tom pad

Intr odu cti on to i nst all ati on co mpo nen ts

Handle to t ak e wi ne

Win e fa uc et

Tower body

Contr ol h an dl e

Tower b uc kl e

Tra ns pa re nt h os e( Be er t ub e)

Beer t ow er as se mb ly

Mixe d ba ll va lv e

Mai n sw it ch o f CO gas c yl in de r

Beer ou tl et

Out le t of C O g as c yl in de r

CO i nl et

2

Inter fa ce c on ne ct ed

to beer barre ls

2

2

Saf et y sw it ch

CO gas cy li nde r

2

Regulatin g ta bl e

Hex nut s po rt

Regulatin g kn ob

Round air outle t

CO regu la tor val ve

2

Tra nsparen t hose(Be er tu be)

Mixed b all v alve

The bee r keg s barrels o f handle

Door

Beer ba rre ls

Unive rsa l whee ls

Wre nch

Univ er sal w he el s

(wit h fo ot br ak e)

Inst all ati on st eps

1.Install universal wheels

The lo ck b rak in g gu ide li nes o f un iv ers al w hee ls w it h foo t br akes (s ee F igu re 1 ):

Inst al l two u ni ve rsa l wh eel wa sh er in f ro nt of the c ab ine t ba se, and t he n ins ta ll two

univ er sal w he el o f wit ho ut fo ot b ra ke. Two un iv ersal w he el wi th f oot bra ke a re in st alled

dire ct ly be hi nd t he ca bi net b as e. You c an fi x th e cab in et b y ste pp ing on th e un ive rs al

whee l fo ot br ak e (s ee Fi gu re 2) :

Univ er sal w he el s

(wit ho ut th e fo ot b rak e)

Univ er sal w he el

wash er

CO tube f as ten in g

2

CO can su pp ort er a nd

2

bolt

Figu re 2

Uppe r co ver g ua rd rai l

Figu re 1

Wat er b ox as se mbly

Page 9

2.In sta ll th e be er to we r assem bl y and t he mi xed bal l val ve:

(1) Pl ug t he be er t ow er as se mbl y in to t he be er t op cove r to f ix:

A.3. 0 in ch: d oe s no t req ui re towe r bu ckl e. P ut beer t ow er di re ctly at t he s urf ac e

hole o f th e bee r ma ch ine r oo f. Fix th e be er to we r assem bl y wit h sc rews di re ctl y on

the ro of o f the b ee r ma chi ne . (See Fi gu re 3)

B.2. 5 in ch: n ee d to wer b uc kle. Pu t th e bee r to wer at th e su rfa ce h ole of th e be er

mach in e wit h 60 d eg ree s in cli ne d, a nd ro ta te 60 deg re es cl oc kwise a lo ng th e ca rd

slot . Ma ke th e wi ne f auc et i s again st t he fr on t side of b ee r mac hi ne. Fix t he b eer

towe r wi th wa sh er s in th e bo x. (See F ig ure 4 )

(2)Tak e ou t the a cc es sor ie s of the mi xe d bal l va lve. Fi x th e bee r ou tlet of t he m ixe d

ball v al ve wi th t he t ran sp are nt h os e of th e be er towe r co mpo ne nts. (S ee F igu re 5 )

Figu re 6 Figu re 7Figu re 5

Figu re 3

3. 0 i nc h

2. 5 i nc h

Figu re 4

3. Ins tal l CO g as cyli nde r and C O re gul ator va lve :

(1) Fi x tw o CO t ube c ar d on the re d CO so ft tu be : (s ee Fi gu re 6) .

(2) Re la te th e en ds o f red C O s oft tub e re spe ct ively t o CO i nt ak e por t of m ixed ba ll v alv e an d

roun d ou tle t of CO re gul at or va lv e. L ock i t t fi rmly wi th t he fi xe d card of t wo C O chan ne l on red

CO soft t ub e: (s ee F ig ure 7 )

2

(3) Tig ht ent he CO re gul at or ta bl e va lve w it h hex nut p or t wit h th e gas out le t of CO ta nk b y the

wren ch .(s ee F ig ure 8 )

(4) Pl ac e the C O t an k and C O regul at or valv e co mpo ne nt into t he b eer c ha ssis an d fi x the CO

tank b y CO ta nk br ac ke t and f ix ed bolt ( se e Fig ur e 9)

2 2

2 2

2 2

2 2

2 2

2 2 2

2

4.In sta ll be er barr els

Put th e bo ttl ed b ee r int o th e box and m ak e the b ar rel's h ol e con ne cted to t he b eer k eg s

conn ec tio n po rt o f the m ix ed ba ll v al ve cl os ely. (See Fi gu re 10 ) (w hen pla ci ng th e ke gs:

hold t he h and le o f th e bar re ls to r em ov e the m to t he fron t of b eer m ac hine, a nd t hen

high li ght t he l ow er pa rt o f the f ro nt o f bee r ke g to put th em i n the b ox . Final ly, l if t the

buck et h and le o f th e keg t o pu sh them i nt o the b ox e ntire ly. )

5.In sta ll wi ne hand le an d fix w ine f aucet

Scre w th e win e ha nd le cl oc kwi se w it h the w in e fauce t ti ght ly. The n co nn ect t he w ine

fauc et w ith b ee r to wer c om pon en ts , and t ig hten it b y a wr enc h. ( See Fig ur e 9)

6.In sta ll th e up per c ov er gu ar dr ail a nd w ater bo x:

CO g as cyli nder

2

Plac e th e upp er c ov er gu ar dra il , w at er bo x on t he top of t op c ove r. (S ee Figu re 1 0)

Note s

upp er cove r

gua rdrai l

wat er box

Bee r barre ls

CO r egula tor

2

val ver

Saf ety swi tch

The r ed CO so ft tube

2

Bra cket an d retai ner

of CO tank

2

Figu re 9

Figu re 10

Figu re 8

图6

Reg ulati ng

tab le

CO g as

2

cyl inder

Bee r tower

When t ak ing b ee r, op en th e ma in sw it ch o f CO g as c ylind er, a nd ro ta te the re gu lat or k nob on CO re gu lat or t able' s va lve s o th at it rea ch es a

?

cert ai n pre ss ure val ue (obs er vin g regul at or tabl e) .Fu rt hermo re , ope n the saf et y swi tc h of CO regulat or tabl e valve and pull bac k the

mixe d val ve cont rol h an dle , then li fti ng up. Loose n you r grip to fix it: C los e th e d oo r, a nd pull the beer to wer c ompon en ts fo rward to g et

beer.

When r ep lac in g th e bee r, pl eas e tu rn o ff t he sa fe ty swit ch o f CO r eg ulato r va lve a nd r emove t he m ixe d ba ll v alv e to r emo ve t he b eer b ar rel.

?

When r ep lac in g CO ga s cyl in der, r em em ber t o tu rn off the ma in s wit ch o f the CO g as c yli nd er and sa fe ty sw it ch o f the C O r egula to r val ve .

?

Afte rw ard s, u se a w ren ch t o loose n th e hex ag onal nu t po rt co nn ectin g th eCO re gu lator v al ve wi th C O tank clo se ly. The n remov e th e fix ed

bolt o f CO ta nk to r em ov e CO t an k final ly b y a wre nc h.

In the p ro ces s of i ns tal la tion, e ns ure t ha t all par ts a re co nn ected t ig htl y an d no air le ak s.

?

When t he h ose c on ne cts t he c onn ec ti on po rt , you can d ip i t by wa rm w ater or l ub ric at ed oil on ce c onf ro nted wi th a ny tr ou bles.

?

If the h ig h-p re ss ure c om pre ss ed g as in t he CO t ank i s no t handl ed p rop er ly, it co uld b e da ngero us :

?

1. Ple as e the t es ti ng da te o f D.O.T in th e cy lin de r neck be fo re in st allat io n. If i t is m or e tha n 5 ye ars , do n' t use t he p roduc t an y mor e, a nd

brin g it b ack t o th e ga s sup pl ier.

2.CO ga s cy lin de r sh oul d be k ept a wa y fr om he at s ource s. T he u nus ed c ylind er s sho ul d be plac ed u pri gh t in vent il ate d co ol plac e (p ref er ably

70 deg re es Fa hr en hei t) .

2 2

2

2 2 2

2 2

2

2

2 2

2

Loading...

Loading...