Page 1

NEOLA ON-OFF SERIES

Service Manual 2012

11DSEU-B-1202

Page 2

CONTENTS

1. Precaution .................................................................................................................................................... 1

1.1 Safety Precaution .......................................................................................................................... 1

1.2 Warning ......................................................................................................................................... 1

2. Function ........................................................................................................................................................ 6

3. Dimension .................................................................................................................................................... 8

3.1 Indoor Units ................................................................................................................................... 8

3.2 Outdoor Units .............................................................................................................................. 10

4. Refrigerant Cycle Diagram ........................................................................................................................ 11

5. Wiring Diagram .......................................................................................................................................... 12

5.1 Indoor Units ................................................................................................................................. 12

5.2 Outdoor Units .............................................................................................................................. 14

6. Installation details ...................................................................................................................................... 16

6.1 Wrench torque sheet for installation ........................................................................................... 16

6.2 Connecting the cables ................................................................................................................ 16

6.3 Pipe length and the elevat ion ..................................................................................................... 17

6.4 Installation for the fir st time ......................................................................................................... 18

6.5 Adding the refrigerant after running t he s ystem for many years ................................................ 21

6.6 Re-installation w hi le t he indoor unit need to be repaired ........................................................... 22

6.7 Re-installation w hi le t he outdoor unit need to be repaired ......................................................... 24

7. Operation characteristics ......................................................................................................................... 27

8. Electronic function .................................................................................................................................... 28

8.1 Abbreviation ................................................................................................................................ 28

8.2 Display function ........................................................................................................................... 28

8.3 Main Protection ........................................................................................................................... 29

8.4 Operation Modes and Functions ................................................................................................. 29

9. Troubleshooting ......................................................................................................................................... 38

9.1 Indoor unit error displa y .............................................................................................................. 38

9.2 Diagnosis and Solution ............................................................................................................... 39

Page 3

1

1. Precaution

1.1 Safety Precaution

To prevent injury t o t he us er or other people and property damage, the following

instructions m us t be followed.

Incorrect operation due to ignoring inst ruction will cause harm or damage.

Before service unit, be sure to read this service manual at first.

1.2 Warning

Installation

Do not use a defective or und err at ed circuit breaker. Use this appliance on a dedicat ed

circuit.

There is risk of fire or electric shock.

For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized

service center.

Do not disassemble or repair the product, there is risk of fire or electr ic shock.

Always ground t he product.

There is risk of fire or electric shock.

Install the panel and the cover of control b ox securely.

There is risk of fire of electric shock.

Always instal l a dedicated circuit and breaker.

Improper wiring or installation may cause fore or electric shock.

Use the correctly rat ed breaker of f use.

There is risk of fire or electric shock.

Do not modify or extend the power cable.

There is risk of fire or electric shock.

Do not install, remove, or reinstall the unit by yourself(customer).

There is risk of fire, electric shock, explosion, or injury.

Be caution when unpacking and installing the product.

Sharp edges could cause injur y, be especially careful of the case edges and t he f ins on the

Page 4

2

condenser and evaporator.

For installation, always contact the dealer or an Authorized service center.

There is risk of fire, electric shock, explosion, or injury.

Do not inst all the product on a def ective installation stand.

It may cause injury, accident, or damage to the product.

Be sure the install ation area does not deteriorate with a ge.

If the base collapses, the air conditioner could fall with it, causing property damage, product failure,

and personal injury.

Do not let the air conditioner run for a l ong time when the humidity is very high and a

door or a windo w is le ft open.

Moisture may condense and wet or damage furniture.

T ake care to ensure that power cable could not be pulled out or damag ed during

operation.

There is risk of fire or electric shock.

Do not place any t hing on the power cable.

There is risk of fire or electric shock.

Do not plug or unplug the power supply plug during operation.

There is risk of fire or electric shock.

Do not touch (operation) the product with wet hands.

There is risk of fire or electric shock.

Do not place a heater or other appliance near the power cable.

There is risk of fire and electr ic shock.

Do not allow water to run into electric parts.

It may cause fire, failure of the product, or electric shock.

Do not store or use flammable g as or combustible near the product.

There is risk of fire or failure of product.

Do not use the pro duc t in a tightly closed space for a long time.

Oxygen deficiency could occur.

When flammabl e gas leaks, turn off the gas and open a window for ventilation before

turn the product on.

Do not use the telephone or t ur n sw it ches on or off.

Page 5

3

There is risk of explosion or fire.

If strange sounds, or small or smoke comes from product. Turn the breaker off or

disconnect the power supply cable.

There is risk of electric sh ock or fire.

Stop operation and close the window in storm or hurrica ne . If possible, remove the

product from the window before the hurricane arrives.

There is risk of property damage, failure of product, or electric shoc k.

Do not open the inl et gri ll of the pro duct dur ing o perati on. ( Do not to uch t he electr ostatic

filter, if the unit is so equipped.)

There is risk of physical injury, electric shock, or product failure.

When the product is soaked (flooded or submerged), contact an Authorized service

center.

There is risk of fire or electric shock.

Be caution that water could not enter the product.

There is risk of fire, electric shock, or product damage.

Ventilate the product from time to time when operating it together with a stove, etc.

There is risk of fire or electric shock.

Turn the main power off when cleaning or mai ntaining the pro duct.

There is risk of electric shock.

When the product is not be used for a long t ime, disconnect the power supply plug or

turn off the breaker.

There is risk of product dama ge or failure, or unintended operation.

T ake care to ensure that nobody could step on or fall onto the out door unit.

This could result in person al in jury and product damage.

CAUTION

Always check for gas (refri ger ant) leakage after inst allatio n or repair of product.

Low refrigerant levels may cause failure of product.

Install the drain h ose t o ensure that water is drained away pr op er l y.

A bad connection may cause water leakage.

Keep level even when installing the product.

Page 6

4

It can avoid vibration of water leakage.

Do not inst all the product wher e the noise or hot air from the outdoor unit could dama ge

the neighborho ods.

It may cause a problem for your neighbors.

Use two or more people to lift and t r ansport the product.

Avoid personal injury.

Do not install the product where it will be exposed to se a wind (salt spray) directly.

It may cause corrosion on the pr oduc t . Corr osion, particularly on the condenser and evaporator fins,

could cause product malfunction or inefficient operati on.

Operational

Do not expose th e sk i n directly to cool air f or long periods of time. (Do not sit in the

draft).

This could harm to your health.

Do not use the product for special purp oses, such as preser ving fo ods, works of art, etc.

It is a consumer air conditioner, not a precisi on refrigerant system.

There is risk of damage or loss of property.

Do not block the i nl e t or outlet of air flow.

It may cause product failur e.

Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

There is risk of fire, electric shock, or damage to the plasti c parts of the product.

Do not touch the metal parts of the product when removing the air filter. They are very

sharp.

There is risk of personal injury.

Do not step on or p ut anything on the product . (outdoor units)

There is risk of personal injury and f ailure of product.

Always insert the filt er securely. Clean the filter every two weeks or more often if

necessary.

A dirty filter r educes the efficiency of the air conditioner and could cause product malfun c t ion or

damage.

Do not insert hands or other object thro ugh air inlet or outlet whi l e t he product is

Page 7

5

operated.

There are sharp and moving p ar ts that could cause personal injur y.

Do not drink the water drained from the product.

It is not sanitary could ca use serious health issues.

Use a firm stool or l a dder when cleaning or m a i ntaining the product.

Be careful and avoid pers onal injury.

Replace the all batteries i n t he rem ote control with new ones of the same type. Do not

mix old and mew batteries or different types of batteries.

There is risk of fire or explosion.

Do not recharge or disassemble the batteries. Do not dispose of batt er i es in a fire.

They may burn of explode.

If the liquid from t he batteries gets onto your skin or clothes, wash it well with clean

water. Do not use the remote of the batteries have leaked.

The chemical in batteries could cause burns or other health hazards

The designs, and information in this book are subject to change witho ut not ice for product improvement.

Page 8

6

2. Function

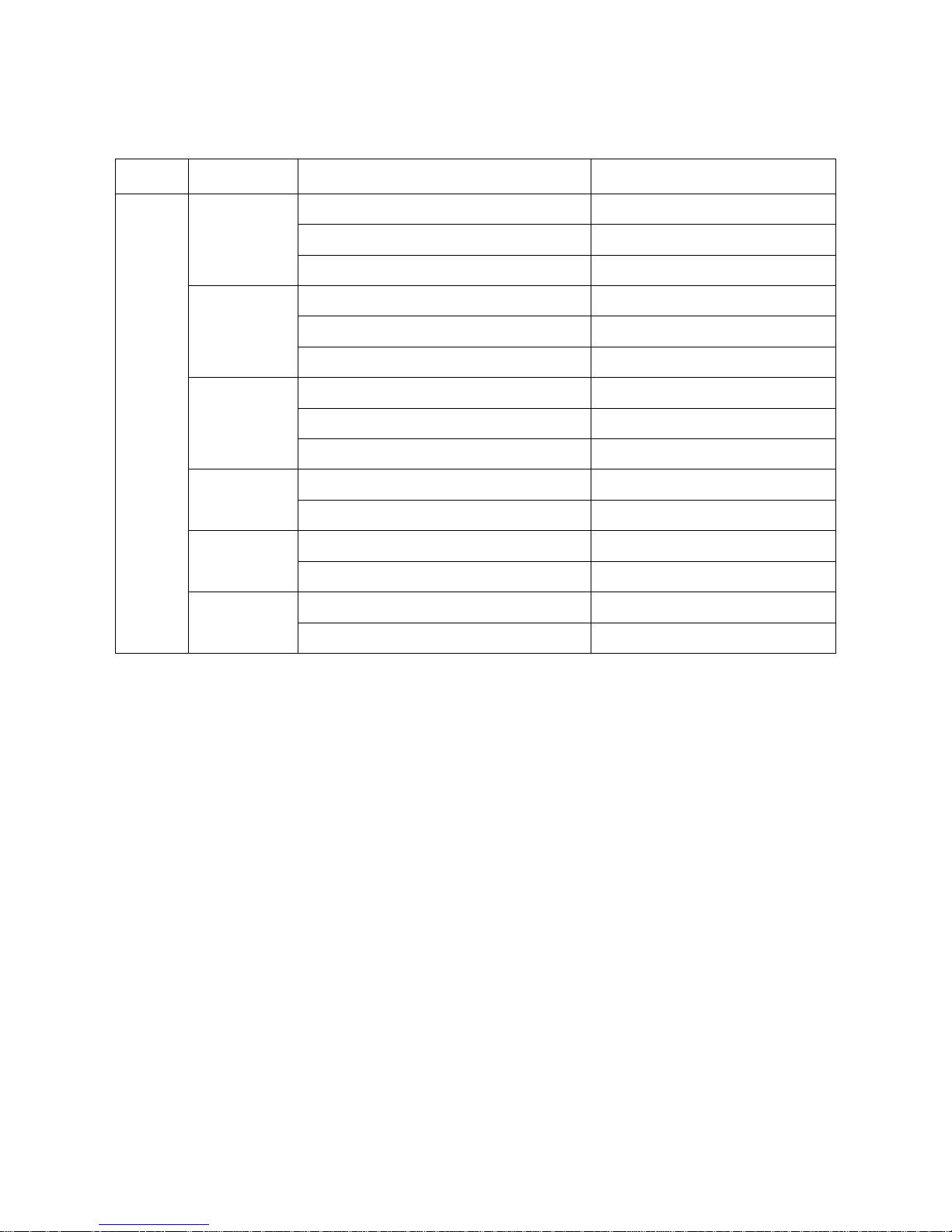

Model Names of Indoor/Outdoor Units

Series Capacity Indoor units Outdoor units

On-Off

7k

MS11D-07HRN1-QB6 MOK-07HN1-QB6

MS11D-07HRN1-QC2(2T0032100248) MOK3-07HN1-QC2

MS11D-07HRN1-QC2(2T0032100252) MOK3-07HN1-QC2

9k

MS11D-09HRN1-QB6 MOK-09HN1-QB6

MS11D-09HRN1-QC2(2T0032300727) MOA2-09HN1-QC2

MS11D-09HRN1-QC2(2T0032300764) MOA2-09HN1-QC2

12k

MS11D-12HRN1-QB6 MOA2-12HN1-QB6

MS11D-12HRN1-QC2(2T0032400199) MOB4-12HN1-QC2

MS11D-12HRN1-QC2(2T0032400212) MOB-11HN1-QC2

18k

MS11D-18HRN1-QB6 MOB-18HN1-QB6

MS11D-18HRN1-QB8 MOC-18HN1-QB8

21k

MS11D-21HRN1-QB6W MOC-21HN1-QB6W

MS11D-21HRN1-QB8W MOP-21HN1-QB8W

24k

MS11D-24HRN1-QB6W MOP-24HN1-QB6W

MS11D-24HRN1-QB8W MOF2-24HN1-QB8W

Page 9

7

Filter

Ionizer(O)

Plasma(O)

Silver Ico Filter(O)

Vitamin C Filter(O)

3M HAM Filter(O)

Bio Filter(O)

Killer Of Formaldehyde

Compressor Crankcase Heater(O)

Golden Fin(O)

Self Clean(O)

Louver Position Memory Function

Refrigerant Leakage Detect

Self-diag. Function

H

ydrophilic Aluminum Fin

Anti-rust Cabinet

Valve Protection Cover

PTC Heating Belt(O)

Follow Me(O)

0.5W Standby (O)

O: optional function

Page 10

8

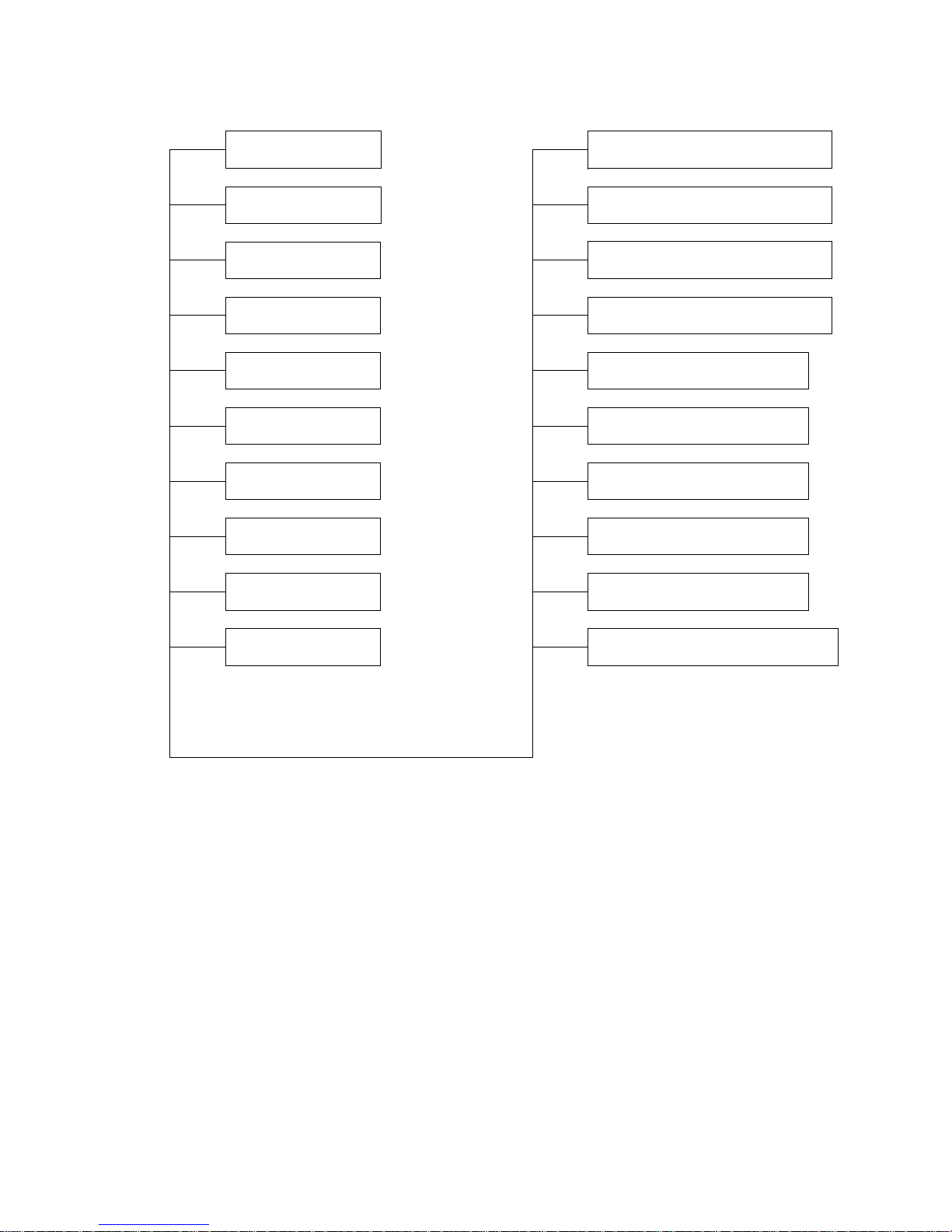

3. Dimension

3.1 Indoor Units

D

W

H

Model

W D H

MS11D-07HRN1-QB6

680 178 255

MS11D-07HRN1-QC2

MS11D-09HRN1-QB6

680 178 255

MS11D-09HRN1-QC2(2T0032300727)

MS11D-12HRN1-QB6

770 188 255

MS11D-12HRN1-QC2

MS11D-09HRN1-QC2(2T0032300764)

MS11D-18HRN1-QB6

905 198 275

MS11D-18HRN1-QB8

MS11D-21HRN1-QB6W

1030 218 315

MS11D-21HRN1-QB8W

MS11D-24HRN1-QB6W

1030 218 315

MS11D-24HRN1-QB8W

Page 11

9

L

R

H

Model R(mm) L(mm) H(mm)

Dimension of installation

hole(mm)

MS11D-07HRN1-QB6

92 170 45

¢65

MS11D-07HRN1-QC2

MS11D-09HRN1-QB6

MS11D-09HRN1-QC2(2T0032300727)

MS11D-12HRN1-QB6

95 170 45

MS11D-12HRN1-QC2

MS11D-09HRN1-QC2(2T0032300764)

MS11D-18HRN1-QB6

80 100 45

MS11D-18HRN1-QB8

Model R(mm) L(mm) H(mm) Dimension of installation hole(mm)

MS11D-21HRN1-QB6W

163 293 45

¢65

MS11D-21HRN1-QB8W

MS11D-24HRN1-QB6W

MS11D-24HRN1-QB8W

H

L

R

Page 12

10

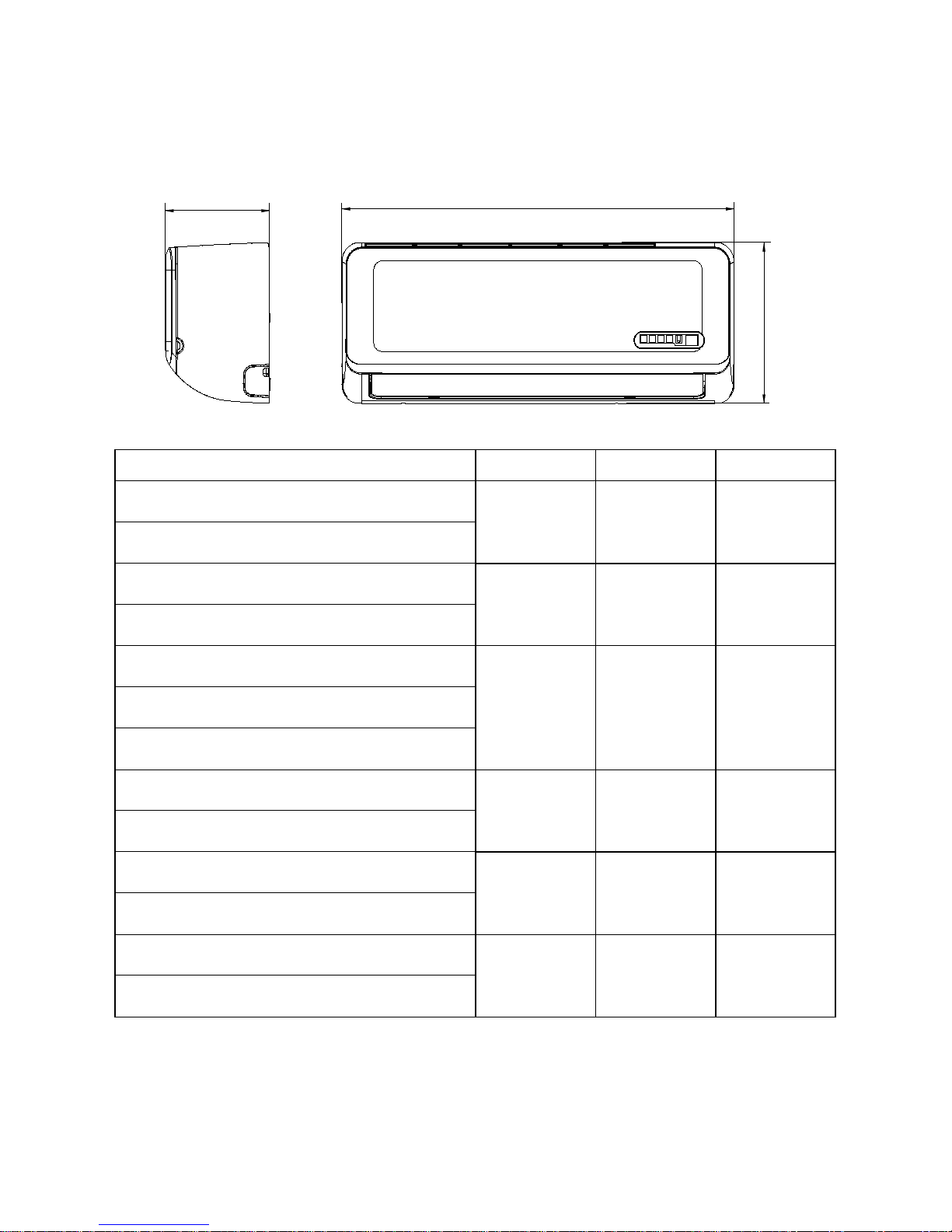

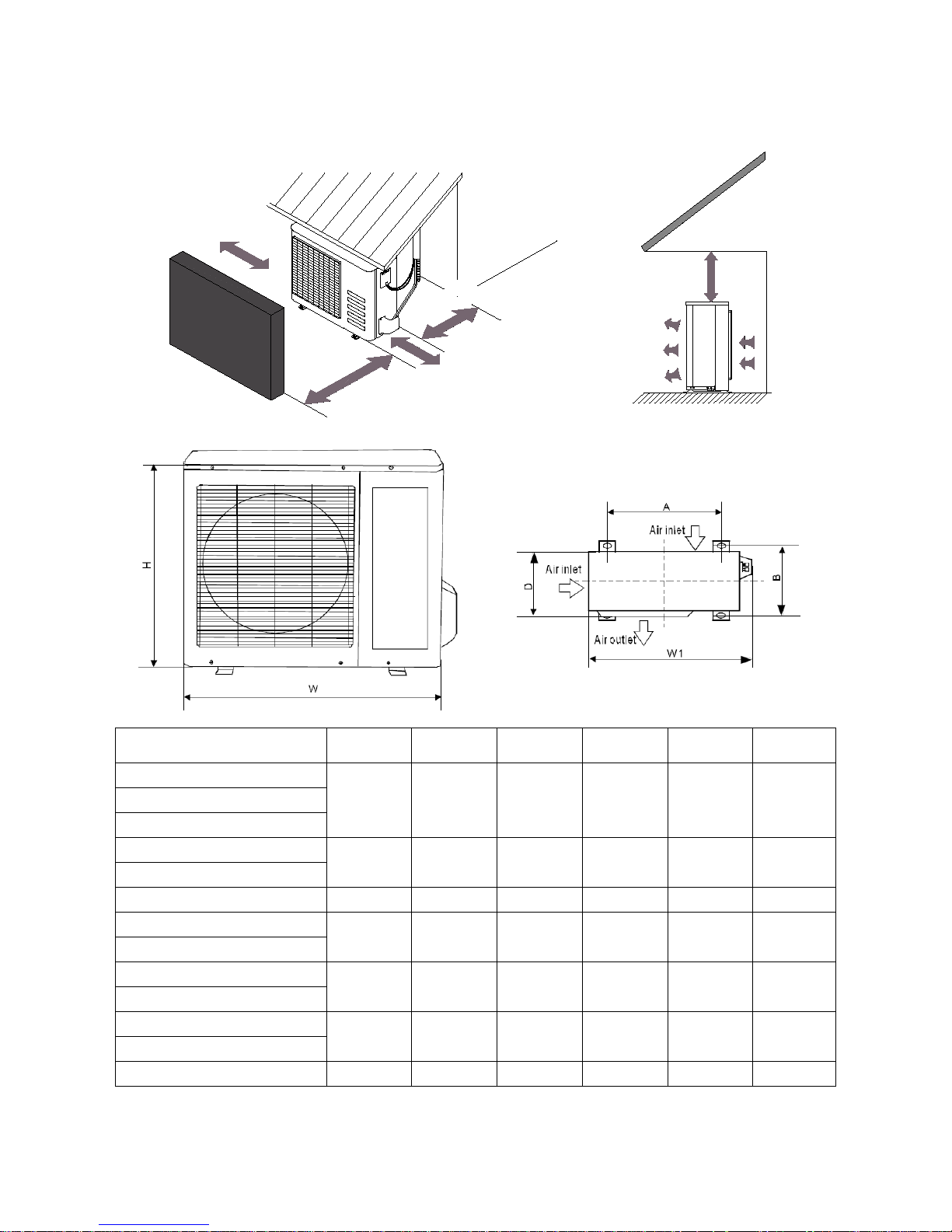

3.2 Outdoor Units

More than 30cm

More than 60cm

More than 70cm

More than 30cm

More than 60cm

(Service space)

Fence or

obstacles

Model W H D W1 A B

MOK-07HN1-QB6

685 260 430 742 460 276

MOK3-07HN1-QC2

MOK-09HN1-QB6

MOA2-09HN1-QC2

700 240 540 757 458 250

MOA2-12HN1-QB6

MOB-11HN1-QC2 780 250 540 843 549 276

MOB4-12HN1-QC2

780 250 540 843 549 276

MOB-18HN1-QB6

MOC-18HN1-QB8

760 285 590 823 530 290

MOC-21HN1-QB6W

MOP-21HN1-QB8W

820 330 595 870 523 340

MOP-24HN1-QB6W

MOF2-24HN1-QB8W 845 320 700 908 560 335

Page 13

11

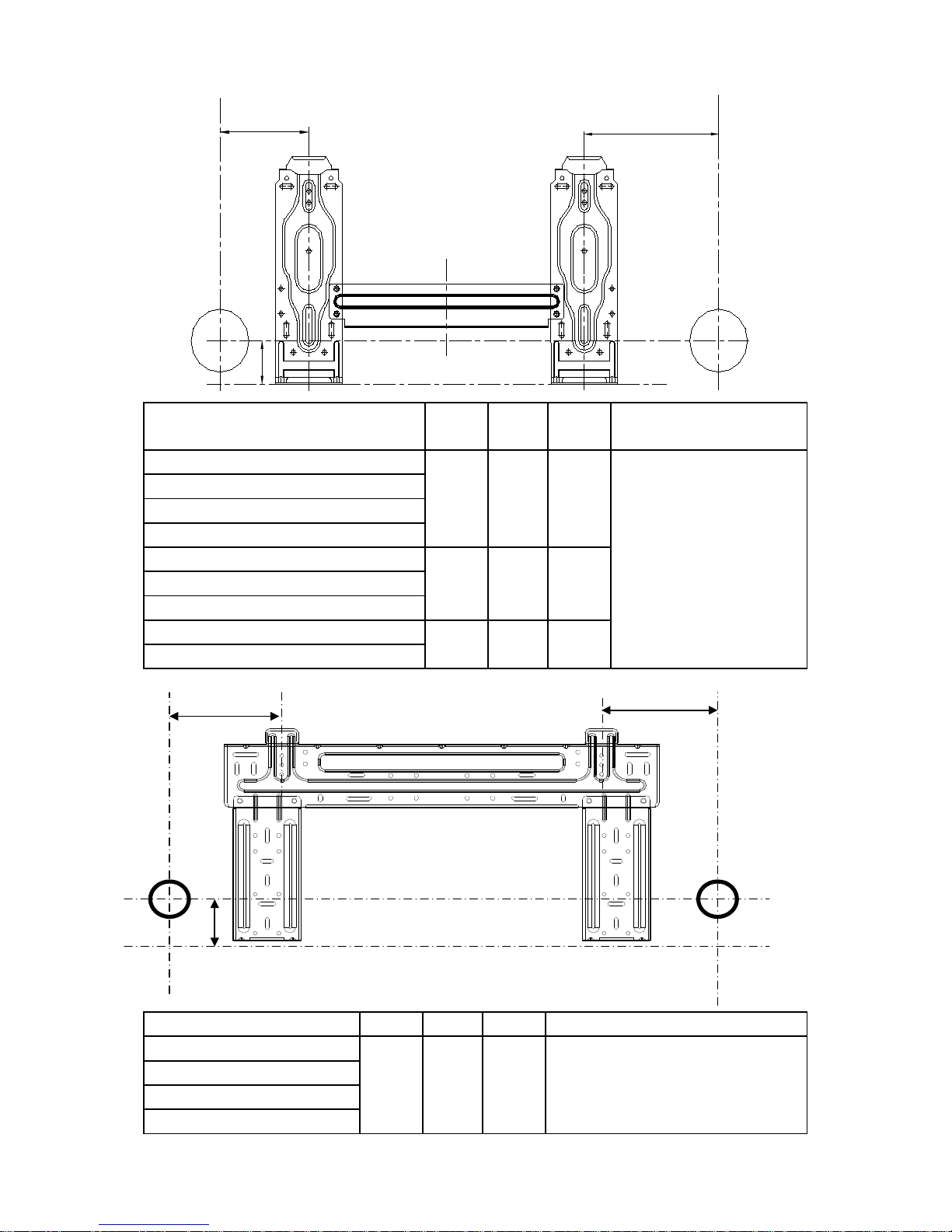

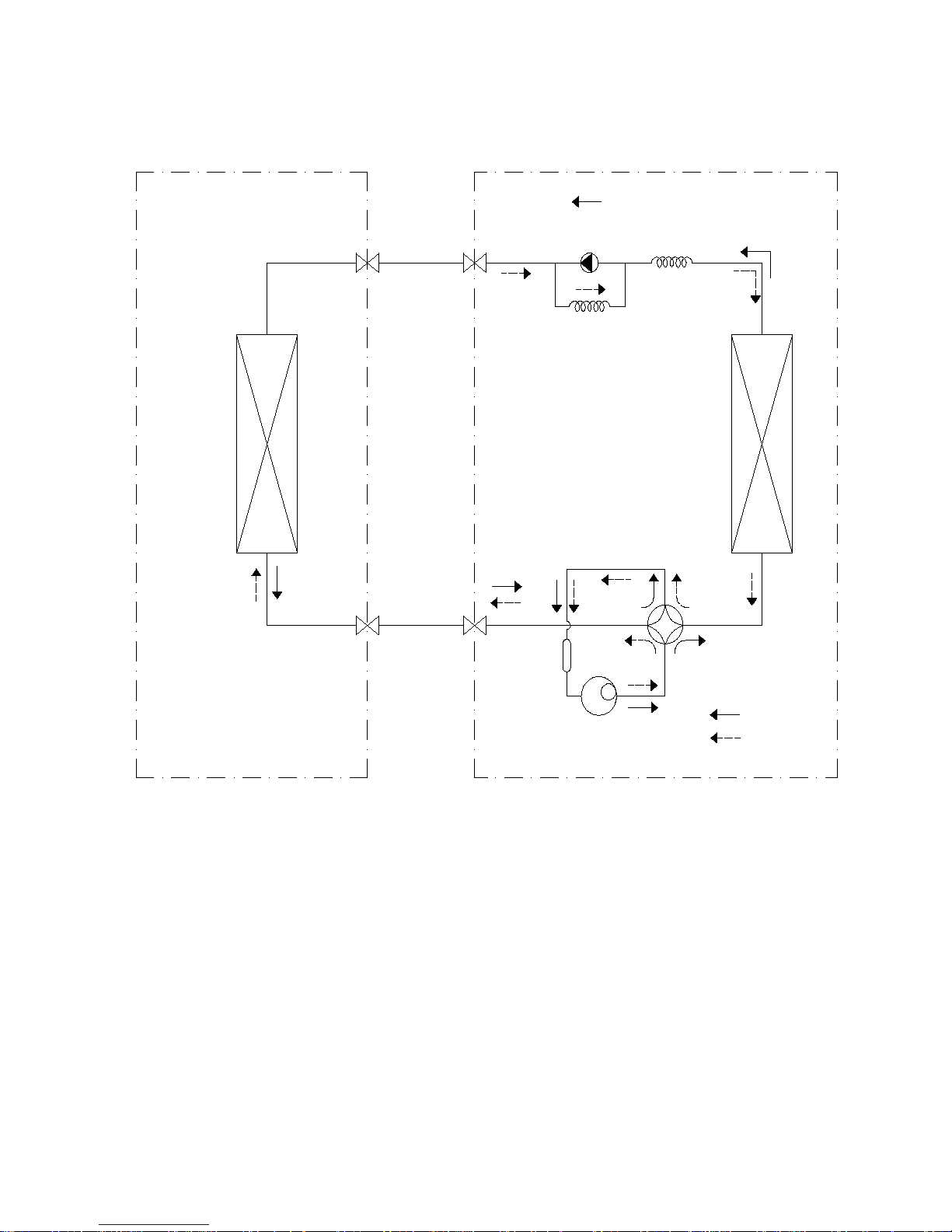

4. Refrigerant Cycle Diagram

INDOOR OUTDOOR

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COMPRESSOR

2-WAY VALVE

3-WAY VALVE

CHECK VALVE

(Heating Model only)

CAPILIARY TUBE

REVERSING VALVE

(Heating Model only)

COOLING

HEATING

ACCUMULATOR

Page 14

12

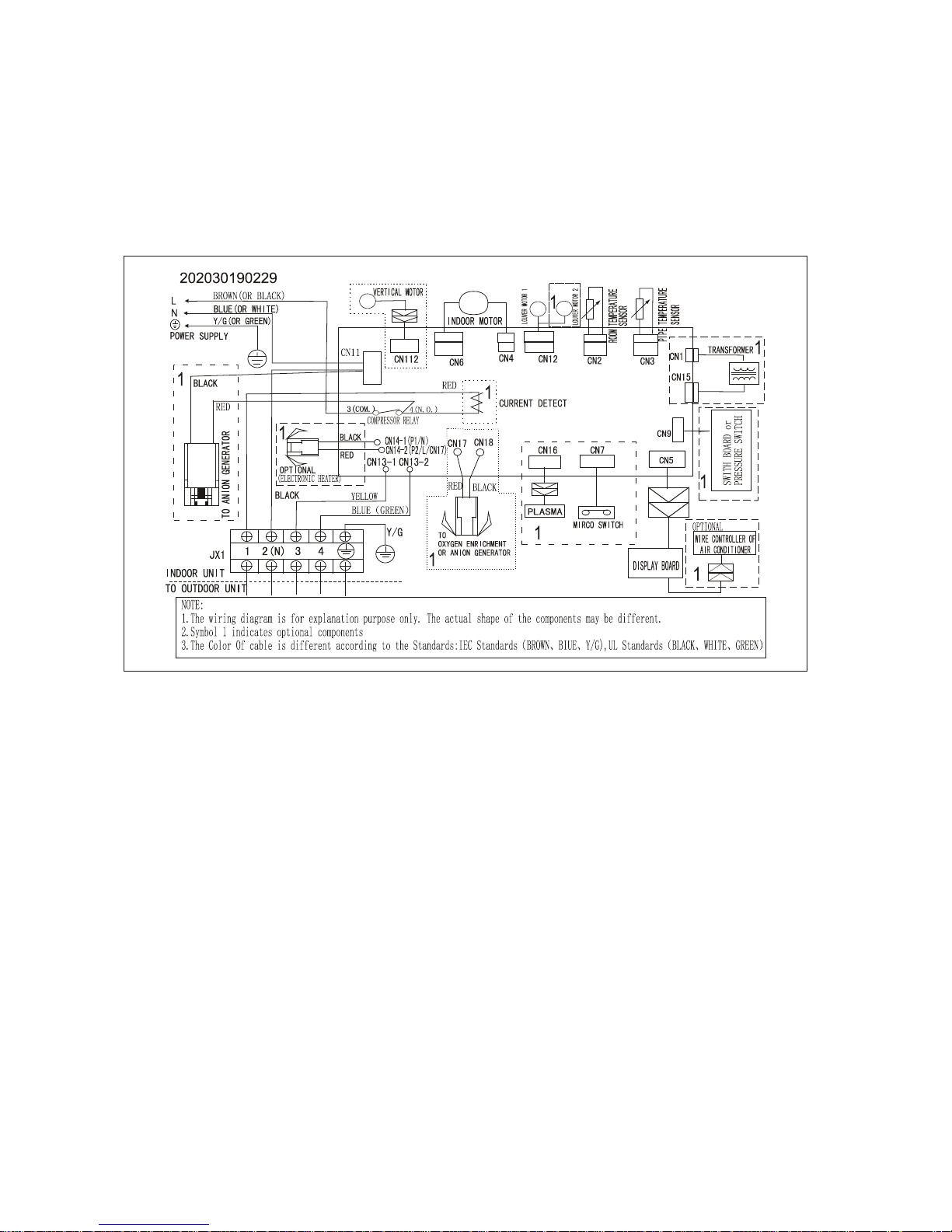

5. Wiring Diagram

5.1 Indoor Units

MS11D-07HRN1-QB6, MS11D-07HRN1-QC2, MS11D-09HRN1-QB6, MS11D-09HRN1-QC2,

MS11D-12HRN1-QB6, MS11D-12HRN1-QC2, MS11D-18HRN1-QB6, MS11D-18HRN1-QB8

Page 15

13

MS11D-21HRN1-QB6W, MS11D-21HRN1-QB8, MS11D-24HRN1-QB6W, MS11D-24HRN1-QB8W

Page 16

14

5.2 Outdoor Units

MOK-07HN1-QB6, MOK3-07HN1-QC2, MOK-09HN1-QB6, MOA2-09HN1-QC2, MOA2-12HN1-QB6,

MOB4-12HN1-QC2, MOB-18HN1-QB6, MOB-11HN1-QC2

MOC-18HN1-QB8

Page 17

15

MOC-21HN1-QB6W, MOP-21HN1-QB8W, MOP-24HN1-QB6W, MOF2-24HN1-QB8W

Page 18

16

6. Installatio n details

6.1 Wrench torque sheet for installation

Outside diameter Torque

Additional

tightening torque

mm inch N.cm N.cm

Ф6.35 1/4

1500

(153kgf.cm)

1600

(163kgf.cm)

Ф9.52 3/8

2500

(255kgf.cm)

2600

(265kgf.cm)

Ф12.7 1/2

3500

(357kgf.cm)

3600

(367kgf.cm)

6.2 Connecting the cables

The power cord of connect should be selected according to the follow ing specifications sheet.

Rated current of appliance Nominal cross-sectional area (mm²)

>3 and ≤6 0.75

>6 and ≤10 1.0

>10 and ≤16 1.5

>16 and ≤25 2.5

The cable size and the current of the fuse or switch are determin ed by the maximum current indicated

on the nameplate which located on the side panel of the unit. Please refer to the nameplate before

selecting the cable, fuse and switch.

Page 19

17

6.3 Pipe length and the elevation

The pipe length and refrig er ant amount:

Model

Pipe si ze

Standard

length

(m)

Max.

Elevation

B (m)

Max.

Length

A (m)

Additional

refrigerant

(g/m)

Gas Liquid

MS11D-07HRN1-QC2+ MOK3-07HN1-QC2

3/8’’

(Ф9.53)

1/4’’

(Ф6.35)

5 5 10 30

MS11D-07HRN1-QB6+ MOK-07HN1-QB6

MS11D-09HRN1-QB6+ MOK-09HN1-QB6

MS11D-09HRN1-QC2+ MOA2-09HN1-QC2

MS11D-12HRN1-QC2+ MOB4-12HN1-QC2

1/2’’

(Ф12.7)

1/4’’

(Ф6.35)

5 5 10 30

MS11D-12HRN1-QB6+ MOA2-12HN1-QB6

MS11D-12HRN1-QC2+MOB-11HN1-QC2

MS11D-18HRN1-QB8+ MOC-18HN1-QB8

5 8 15 30

MS11D-18HRN1-QB6+ MOB-18HN1-QB6

MS11D-21HRN1-QB6W+ MOC-21HN1-QB6W

5/8’’

(Ф16.0)

3/8’’

(Ф9.53)

5 10 20 60

MS11D-21HRN1-QB8+ MOP-21HN1-QB8W

MS11D-24HRN1-QB8W+ MOF2-24HN1-QB8W

MS11D-24HRN1-QB6W+ MOP-24HN1-QB6W

Caution:

The capacity test is based on the standard length an d the maximum permissive length is based on the

system reliability.

The oil trap should be inst all ed per 5-7 meters.

Page 20

18

6.4 Installation for the first time

Air and moisture in the refrigerant system have undesirable effects as below:

● Pressure in the system rises.

● Operating current rises.

● Cooling or heating efficiency drops.

● Moisture in the refrigerant circuit may freeze and block capillary tubing.

● Water may lead to corrosi on of parts in the refrigerant sys t em.

Therefore, the indoor units and the pipes between indoor and outdoor units must be leak tested

and evacuated to remove gas an d m oisture from the system.

Gas leak check (Soap water method):

Apply soap water or a liquid neutral detergent on the indoor unit connections or outdoor unit

connections by a soft brush to check for leakage of the connecting points of the piping. If bubbles

come out, the pipes have leakage.

1. Air purging with vacuum pump

1). Confirm that both the 2-way and 3-way valves are set to the opened position.

Remove the valve stem caps and confirm that the valve stems are i n t he opened position.

Be sure to use a hexagonal wrench to operate the valve stems.

2). Connect the charge hose with the push pin of handle lo to the 3-way v alv es gas service port.

(Indoor unit)

(Liquid side)

(Gas side)

Vacuum

pump

Vacuum

pump

Lo

Hi

Handle Hi

Two-way valve

Close

Manifold valve

Compound meter

Pressure

gauge

20Pa

Handle Lo

Charge hose

Charge hose

(Outdoor unit)

Close

Three

-way valve

Page 21

19

3). Air purging of the charge hose

Open the handle Lo valve of the ma ni fold valve slightly to purge air from the c harge hose for 5 seconds

and then close it quickly.

4). Set the 2-way valve to the close position

5). Operate the air conditi oner at t he cooling cycle and stop it when the gauge indi cat es 0.1MPa.

6). Set the 3-way valve to the closed position immediately.

Do this quickly so that the gauge ends up indicating 0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2-way and 3-way v alv e’s stem nuts.

Use a torque wrench to tight en t he 3-way valves service port cap to a torque o f 1. 8 kgf.m.

Be sure to check for gas lea kage.

2. Air pur gi ng by refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed positi on.

2). Connect the charge set and a char ging cylinder to the service port of the 3-way valve.

3). Air purging.

Open the valves on the chargin g cylinder and the charge set. Purge the air by loosening the flare nut on

the 2-way valve approximately 45’ for 3 seconds the n closing it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tight en the flare nut on the 2-way valve.

Page 22

20

4). Check the gas leakage.

Check the flare connections for gas leakage.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and discharge the refrigerant by loosening the flare nut on the

2-way valve approximatel y 45’ until the gauge indicates 0.3 to 0.5 Mpa.

6). Disconnect the charg e set and th e char gi ng cyli nder, and set the 2-way and 3-way valves to t he ope n

position.

Be sure to use a hexagonal wrench to operate the valve stems.

7). Mount the valve stems nuts and the service port cap.

Be sure to use a torque wrench to t ighten the service port cap to a torque 18N ·m.

Be sure to check the gas leakage.

3. Adding the refrigerant if the pipe length >5m

Procedure:

1). Connect the charge hose to t he c har ging cylinder , open t he 2-way valve and the 3-way valve.

Connect the charge hose w hich y ou disco nnecte d fr om the v acuu m pu mp to the v alve at the bot tom of

the cylinder. If the refrigerant is R410A, make the cylinder bottom up to ensure the liquid charge.

2). Purge the air from the charge h ose.

Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the

air (be careful of the liquid refrigerant).

Electronic scale

Page 23

21

3) Put the charging cylinder onto the electronic scale and record t he w eight.

4) Operate the air conditioner at the cooling mode.

5) Open the valves (Low side) on the charge set and charge the system with l i qui d r efrigerant.

6).When the electronic scale displays the proper weight (refer to the table), disconnect the charge hose

from the 3-way valve’ s ser vice port immediately and turn off the air conditioner before disconnecting the

hose.

7). Mount the valve stem caps and the service port

Use torque wrench to tighten the service port cap to a torque of 18N.m.

Be sure to check for gas lea kage.

6.5 Adding the refrigerant after running the system for many years

Procedure:

1). Connect the charge hose to t he 3-way service port, open the 2-way valv e and t he 3-way valve.

Connect the charge hose to the valve at the bottom of the cylinder. If the refrigerant is R410A, m ake

the cylinder bottom up to ensure liquid charge.

2). Purge the air from the charge h ose.

Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the

air (be careful of the liquid refrigerant).

Electronic scale

Page 24

22

3) Put the charging cylinder onto the electronic scale and recor d t he w eight.

4) Operate the air conditioner at t he c ool ing mode.

5) Open the valves (Low side) on the charge set and charge the system with l i qui d r efrigerant.

6).When the electronic scale displays the proper weight (refer to the gauge and t he pressure of the low

side), disconnect the charge hose from the 3-way valve’ s ser vice port immediately and turn off the air

conditioner before disconnecting the hose.

7). Mount the valve stem caps and the service port

Use torque wrench to tight en t he ser vice port cap to a torque of 18N.m.

Be sure to check for gas lea kage.

6.6 Re-installation while the indoor unit need to be repaired

1. Collecting the refrigerant into the outdoor unit

Procedure

1). Confirm that both the 2-way and 3-way valve s are set to the opened position

Remove the valve stem caps and confirm that the valve stems are i n t he opened position.

Be sure to use a hexagonal wrench to operate the valve stems.

2). Connect the charge hose with the push pin of handle lo to the 3-way valves gas service port.

3). Air purging of the charge hose.

Page 25

23

Open the handle Lo valve of the ma ni fold valve slightly to purge air from the c harge hose for 5 seconds

and then close it quickly.

4). Set the 2-way valve to the close position.

5). Operate the air conditi oner at t he cooling cycle and stop it when the gauge indi cat es 0.1MPa.

6). Set the 3-way valve to the closed position immediately

Do this quickly so that the gaug e ends up indicating 0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2-way and 3-way v alv e’s stem nuts.

Use a torque wrench to tight en t he 3-way valves service port cap to a torque o f 1. 8 kgf.m.

Be sure to check for gas lea kage.

2. Air purgi ng by the refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way valves are set to the closed positi on.

2). Connect the charge set and a char ging cylinder to the service port of the 3-way valve

Leave the valve on the chargin g cylinder closed.

3). Air purging.

Open the valves on the charging cylinder and the charge set. Purge t he air by loosening the flare nut on

the 2-way valve approximately 45’ for 3 seconds the n closing it for 1 minute; repeat 3 times.

After purging the air, use a torque wrench to tight en the flare nut on the 2-way valve.

Page 26

24

4). Check the gas leakage

Check the flare connections for gas leakage.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and discharge the refrigerant by loosening the flare nut on the

2-way valve approximatel y 45’ until the gauge indicates 0.3 to 0.5 Mpa.

6). Disconnect the charg e set and th e char gi ng cyli nder, and set the 2-way and 3-way valves to t he ope n

position

Be sure to use a hexagonal wrench to operate the valve stems.

7). Mount the valve stems nuts and the service port cap

Be sure to use a torque wrench to t ighten the service port cap to a torque 18N.m.

Be sure to check the gas leakage.

6.7 Re-installation while the outdoor unit need to be repaired

1. Evacuation for the whole sy stem

Procedure:

1). Confirm that both the 2-w ay and 3-way valve s are set to the opened positi on.

2). Connect the vacuum pump t o 3-way valve’s service port.

3). Evacuation for approxi mately one hour. Con firm that the compound meter indicates -0.1Mpa.

Page 27

25

4). Close the valve (Low side) on the charge set, turn off the vacuum pump, and confirm that the gauge

needle does not move (appr oximately 5 minutes after tur ning off the vacuum pump).

5). Disconnect the charge hose from the vacuum pump.

2. Refrigerant charging

Procedure:

1). Connect the charge hose to t he c har ging cylinder, open the 2-way valve and the 3-way valve

Connect the charge hose w hich y ou disco nnecte d fr om the v acuu m pu mp to the v alve at the bot tom of

the cylinder. If the refrigerant is R410A, make the cylinder bottom up to ensure liquid c har ge.

2). Purge the air from the charge hose

Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the

air (be careful of the liquid refrigerant).

3) Put the charging cylinder onto the electronic scale and record t he w eight.

4). Open the valves (Low side) o n the charge set and charge the syste m with liquid refrigerant

If the system cannot be char ge w ith the specified amount of refrigerant, or can be charged with a little at

a time (approximately 150g each t ime) , operating the air condition er in the cooling cycle; however, one

time is not sufficient, w ait approximately 1 minute and then repeat the procedure.

5).When the electronic scale displays the proper weight, disconnect t he charge hose from the 3-way

valve’s service port immediately

Electronic scale

Page 28

26

If the system has been charged with liqu id refriger ant while oper ating the air c onditioner, turn off the air

conditioner before disconnecting the hose.

6). Mounted the valve stem cap s and the service port

Use torque wrench to tight en t he ser vice port cap to a torque of 18N.m.

Be sure to check for gas lea kage

Page 29

27

7. Operation characteristics

Temperature

Mode

Cooling operation

Heating

operation

Drying operation

Room temperature 17℃~32℃ 0℃~30℃

10℃~32℃

(<21000Btu/h models)

17℃~32℃

(≥21000Btu/h models)

Outdoor

temperature

18℃~43℃

-7℃~24℃

11℃~43℃

(<21000Btu/h models)

-5℃~43℃

(For the models with

low temperature cooling system)

18℃~43℃

(≥21000Btu/h models)

21℃~52℃

(For special tropical models )

21℃~52℃

(For special tropical models )

CAUTION:

1. If air conditioner is used outside o f t he above conditions, certain safety protection feat ures may

come into operation and cause t he unit to function abnormally.

2. Room relative humid ity less tha n 80%. I f the air c onditioner operat es in exce ss of this figure, the

surface of the air conditioner may attract condensation. Please set the vertical air flow louver to its

maximum angle (vertically to the floor), and set HIGH fan mode.

3. Optimum performance w ill be achieved within this operating temper at ur e.

Page 30

28

8. Electronic function

8.1 Abbreviation

T1: Indoor ambient temperature

T2: Coil temperature of indoor heat exc hanger

8.2 Display function

8.2.1 Icon explanation on indoor disp lay boar d.

One of the following figures matches its display board.

Run indicator

Flash at 0.5Hz when the unit is st andby. I ll uminate when the unit is turned on.

Timer indicator

This indicator illuminates when TIMER is set ON/OFF.

Defrost Indicator

This indicator illuminates when the air conditioner star ts defrosting

automatically or when the warm air contr ol fe ature is activ ated in heatin g mode

Temperature indicator

Displays the temperature settings when the air conditioner is operational. Displays

the malfunction code.

Page 31

29

8.3 Main Protection

8.3.1 Time Delay at restart for compressor.

8.3.2 Sensor protection a t open ci r c ui t and breaking dis connection.

8.3.3 Zero crossi ng detection error protection

If AC can not det ect z ero cros sing signals for 4 minutes or the zero cr ossing sig nal time intervals is not

correct, the unit will stop and the LED will display the failure. The correct zero crossing signal time

interval should be betwee n 6-13ms.

8.3.4 Fan Spe ed is out of control

When Indoor Fan Speed is too low(lower than 300RPM) lasting 50 seconds, the unit stops and LED

displays failure information and can’t returns to normal operatio n aut omatically.

8.4 Operation Modes and Functions

8.4.1 Fan mode.

(1) Outdoor fan and co mp r essor st op.

(2) Temperature setting function is disabled, and no setting temperature is displayed.

(3) Indoor fan can be set to high/med/low / auto.

(4) The louver operates same as in cooling mode.

(5) Auto fa n:

8.4.2 Cooling Mode

8.4.2.1 Compressor running rules:

Once the compressor star ts up, it will follow the below rules:

When indoor room temp.T 1 is l ow er t han Tn, the compressor and o utdoor fan will shut off. When T1 is

higher than Tm, the compr essor and out door fa n will st art up. (If the unit has refrigerant leakage Detect

function, the compressor will run 5.5 minutes first.)

Page 32

30

Ts

Ts-2

On

Off

8.4.2.2 Outdoor fan running rules:

The On-off outdoor units have single fan speed. The outdoor fan will run following the compressor

except when AC is in evaporator high temp. protection in heating mode ,condenser high temp.

protection in cooling mode, defrosting mode and the current protection.

8.4.2.3 Indoor fan running rules

In cooling mode, indoor fan runs all the time and the speed can be selected as high, medium, low and

auto.

The auto fan:

5

T1-Ts

4

High

Low

1

Medium

8.4.2.4 Evaporator low t em perature T2 protection.

TE6

T2

On

Off

TE5

Page 33

31

When the evaporator coil temp.T2 keeps lower than TE5 for 5 minutes, the compressor and outdoor

fan will shut off.

When T2 is higher than TE6, the compressor and outdoor fan will restart up.

While TE5=4℃, TE 6=10℃ for 7k,9k,12k,18k models and TE5=3℃, TE 6=14℃ for 21,24 models.

8.4.3 Heating Mode (For Heating & Cooling mode l )

8.4.3.1 Compre ssor running rules:

When indoor room tem p.T1 is higher than Tj, th e compressor and outdoor fa n will shut off. When T1 is

lower than Tk, the compr essor and outdoor fan will start up.

TS+TB

T1

On

Off

TS+TB-2

While TB=2 for 7k,9k,12k,18k models and TB=0 for 21k,24k models

8.4.3.2 Out door fan running rules:

The outdoor units have single fan speed. The outdoor fan will run following the compressor except

when AC is in evaporator high temp. protection in heating mode , condenser high temp. protection in

cooling mode ,defrosting mode and the current protection.

8.4.3.3 Indoor fan running rules:

When the compressor is on, the indoor fan can be set to high/med/low/auto. And the anti-cold wind

function has the priority.

Anti-cold wind function:

Page 34

32

36

31

30

26

25

Setting

Low

Breeze

Off

20

Auto fan action :

2 0

T1-Ts

Medium

Low

0.0

When T1-Ts>2℃, the indoor fan will run at low spe ed.

When T1-Ts≤0℃, the indoor fan will run at medium speed.

8.4.3.4 Defrosting mode:

Conditi on of defrosting:

1、AC will enter defrostin g mo de i f all of the followi ng it ems is satisfied.

1.1 After the compressor keeps running 8 minutes, ΔT

max-ΔTmin≥4℃(ΔT=T2-T1)

1.2 AC meets A1 or A2.

A1: The cumulative compressor running time is between 45~120 minutes. Meanwhile the value of

T2-T1 meets the bel ow table.

℃

ΔT

High speed

<TH

DEFROST

Medium speed

<TM

DEFROST

Low speed

<TL

DEFROST

Breeze/off No need to compare the T2 and T1

Page 35

33

A2: The cumulative compressor running time is over 120 minutes. Meanwhile the value of ΔT meets

the below table.

℃

ΔT

High speed

<TH

DEFROST

+2

Medium speed

<TM

DEFROST

+2

Low speed

<TL

DEFROST

+2

While

Model

TH

DEFROST

(℃)

TM

DEFROST

(℃)

TL

DEFROST

(℃)

7k

14 15 16

MS11D-07HRN1-QC2

(2T0032100252)

12 13 14

9k

14

15

16

MS11D-09HRN1-QC2

(2T0032300764)

12 13 14

12k

12

13

14

18k

17

18

19

21k

16

17

18

24k

16 17 18

1.3

℃

T2

High speed

<43℃

Medium speed

<46℃

Low speed

<48℃

About the setting defrosting time:

runtime(minute)

Defrosting time(minute)

Case 1 Runtime=45 10

Case 2

45<runtime≤60

7.5

Case 3

60<runtime≤90

8.5

Case 4

90<runtime≤120

10

Case 5

120<runtime

12

2、The cumulative com pressor running time is over 45 minutes .Meanwhile the indoor fan off or run in

breeze mode automatically (for Anti-cold wind function), AC will enter defrosting mode and the

defrosting time is ten minutes.

3、If the AC haven't defrost before running and the indoor fan running in slow mode over 2 minutes,

meanwhile 1.2 and 1.3 is satisfied and the cu mulat iv e compres sor run ning time is over 45 minutes, AC

will enter defrosting mode and the defrosting time is ten minutes.

Conditi on of ending defrosting:

If any one of the following items is satisfied, the defrosting will terminate and the machine will turn to

Page 36

34

normal heating mode.

(1) The defrosting time is rea ched t o t he setting value.

(2) After defrosting for 3 m inu t es , T2≥2℃.

(3) If the defrosting time is betw een 2 and 4 minutes, T2

max-T2min≥2℃.

Defrosting action

:

Compressor

on

off

on

on

on

off

off

off

4-way valve

Outdoor fan

Indoor fan

Indoor fan breeze(10s)

DF-5

DF

Setting defrosting time

F8

DF-5

DF

DF=25SEC for 7k,9k,12k models and DF=45SEC for 21k,24k models.

8.4.3.5 High evaporator coi l t em p.T2 protection:

Model

TE7

TE8

TE9

7k

60

53

50

9k

60

53

50

12k

63

53

51

MS11D-12HRN1-QC2

(2T0032400212)

63 44 42

18k

60

53

50

Page 37

35

21k

60

53

50

24k

60

53

50

8.4.4 Auto-mode

The machine will choose cooling, heating or fan-only mode according to ΔT (ΔT =T1-Ts).

ΔT=T1-Ts Running mode

ΔT>2℃

Cooling

-3≤ΔT≤2℃

Fan-only

ΔT<-3℃

Heating(for cooling only models, they will run at fan-only mode)

AC will run in auto mode in the below cases:

(1) Press the forced auto button.

(2) If AC is off, it will run in auto mode when timer on function is active.

(3) After setting the mode, AC will run in auto mode if the compressor keeps not running for 15

minutes.

8.4.5 Drying mode

8.4.5.1 The compressor is cy cled running by 10 minutes on and then 5 minute s off. The indoor fan will

keep running at low speed.

8.4.5.2 In drying mode, if the room temperature is lower than 10 ℃, the indoor fan will run at breeze

while the compressor and outdoor fan will stop and not resu me until room temperature exceeds 13 ℃.

8.4.5.3 The system protection is active in this mode.

8.4.6 Forced operation funct i on

Press the touch button continually, the AC will run as below sequ ence:

Forced auto →Forced cooling →Off

Forced cooling mode:

The compressor and outdoor fan keep running and the indoor fan runs at low speed. After running for

30 minutes, AC will turn to auto mode with 24℃ setting temperature.

Forced auto mode:

The action of forced auto mode is the same as normal auto mode with 24℃ setting temperature.

When AC receives signals, such as switch on, switch off, timer on, timer off, mode setting, fan

speed setting, sleeping mode sett ing, follow me setting, it will quit t he forced operation.

The forced operation function can not be mem or ized if power off.

Page 38

36

8.4.7 Timer function

8.4.7.1 Timing range is 24 hours.

8.4.7.2 Timer on. The machine will tur n on aut omatically when reaching the set t ing time.

8.4.7.3 Timer off. The machine will turn off automatically w hen r eaching the setting time.

8.4.7.4 Timer on/off. The machine will turn on automatically when reaching the setting “on” time, and

then turn off automat ically when reaching the setting “off” time.

8.4.7.5 Timer off/on. The machine will turn off automatically when reaching the setting “off” time, and

then turn on automatically w hen r eaching the setting “on” time.

8.4.7.6 The timer function will not change the AC current operation mode. Suppose users set the

“timer off” function and AC is off now, the AC will keep the current running mode and t hen turn off when

reaching the setting time.

8.4.7.7 The setting time is r elat iv e t ime.

8.4.8 Sleep function mode

8.4.8.1 Operation time in sleep mode is 7 ho ur s. After 7 hours , the AC quits this mode and turns off.

8.4.8.2. Operation process in sleep mode is as follow:

After pressing ECONOM IC or SLEEP button on cont r oller, the machine will turn into sleep mode.

When cooli ng, t he setting temperature rises 1 ℃

(be lower th

setting temperature stops rising and indoor fan is fixed as low speed.

When heating, the setting temperature decreases 1 ℃

(be higher t

later the setting temperature stops rising and indoor fan is fixed as low speed.(Anti-cold wind function

has the priority)

8.4.8.3 Timer s et ting is available.

8.4.8.4 When user uses timer off function in sleep mode(or sleep function in timer off mode), if the

timing is less than 7 hours, sleep function w ill be cancel led when reac hing the setting tim e. If the timin g

is more than 7 hours, the mach ine w i ll n ot s t op unt i l reaches the setting time in sleep mode.

8.4.9 Auto-Restart function

The indoor unit is equipped with auto-restart function, which is carried out through an auto-restart

module. In case of a sudden power failure, the module memorizes the setting conditions before the

power failure. The unit will resume the previous operation setting (not including Swing function)

automatically after 3 m inutes when power returns.

If the memorization condition is forced cooling mode, the unit will run in cooling mode for 30 minutes

Page 39

37

and then turn to drying mode as 24 ℃ s e ttin g te m p.

8.4.10 Ionizer dust col l ector function (optional)

The indoor unit is equipped with Ionizer, which is controlled by the CLEAN AIR button on the remote

controller. When the unit is turned on, press the CLEAN AIR button to activate the function. Press it

again to stop the function. During the time when Ionizer being controlled by remote controller, Ionizer

will be turned of f a ut omatically, if indoor fan stops running due to malfunctions or ant i-cold-wind. When

indoor fan restarts after malfunctions being eliminated and anti-cold-wind being released, Ionizer will

be available again.

8.4.11 Louver Position M emory Function

When starting the unit again after shutting dow n, its louver will restore t o t he angle originally set by the

user, but the precondition is that the angle must be within the allowable range, if it exceeds, it will

memorize the maximum angle of the louver. During operation, if the power fails or the end user shuts

down the unit in the turbo mode, t he louver will restore to the default an gle.

8.4.12 Refrigerant Leakage Detection

With this new technology, the display area will show “EC” when the outdoor unit detects refrigerant

leakage.

Page 40

38

9. Troubleshooting

9.1 Indoor unit error display

For 7k, 9k, 12k, 18k

Display

Operation lamp flash times

Timer lamp

Failure

E1

1

X

EEPROM error

E2

2

X

Zero crossing detection err or

E3 3 X Indoor fan speed has been out of control

E4 4 X Default

E5 5 X

Indoor room temperature sensor T1 open circuit

or short circuit

E6 6 X

Evaporator coil temperature sensor T2 open

circuit or short circuit

EC

2

O

Refrigerant leak detection error

For 21k, 24k

Display

Operation lamp flash times

Timer lamp

Failure

E1

1

X

EEPROM error

E2

2

X

Zero crossing detection err or

E3 3 X

Indoor fan speed has been out of co nt r ol.

E4 4 X

Default

E5

5 X

Indoor room temperature sensor T1 open circuit

or short circuit

E6

6 X

Evaporator coil temperature sensor T2 open

circuit or short circuit

EC

2

O

Refrigerant leak detection error

E9 9 X

Indoor unit and outdoor unit communication error

O(light) X(off) ☆ (flash)

Page 41

39

9.2 Diagnosis and Solution

9.2.1 Indoor fan speed o ut of c ontrol diagnosis

Is the indoor fan motor connector and

connection good?

The unit does not work normally

Turn off the unit, rotate the cross

fan. Does it rotate freely?

No

Disassemble the connection between

fan and motor, check if the bearing is

normal. If not, change the bearing. If

yes, follow the below step.

Replace the fan motor

Yes

Replace the indoor PCB

No

Yes

Is the voltage bein g ap plie d to t he fa n

motor?

Yes

Shut off the power supp ly and turn on it 5s later

Page 42

40

9.2.2 Open or short circuit of temperature sensor diagnosis and solution.

9.2.3 EEPROM parameter error diagnosis and solution

9.2.4 Zero crossing detection error

When such failure occurs, t he ma in control board must have fault.

Shut off the power supply and turn on it 5s later

The problem comes out agai n

Is the EEPROM chip plugged i n indoor PCB well?

No

Correct the connection

Replace the main PCB of indoor unit

Yes

Replace outdoor PCB

Yes

Check the connections between

the sensors and the PCB. Are the

connections good?

Replace the sensor and check if

the errors happen again?

Page 43

41

9.2.5 Indoor / outdoor unit’s communicatio n error

No

Reconnect and retest

No

Yes

Yes

E1 after 8 munities

Check the wiring between indoor and outdoor

unit. Do the wires can work normal and connect

correctly?

No

Is all the wiring between terminal and

Indoor PCB connect ok?

Is all

the wiring to the Outdoor PCB

connecting correctly?

Reconnect and retest

Reconnect and retest

Yes

-24V<Vs<+24V? (Vs is th e

voltage between S and N).

Yes

No

Change the Indoor PCB. If the AC still

displays E1, Change the outdoor PC B.

Change the outdoor PCB. If the AC still

displays E1, Change the indoor PCB.

Turn of f the power supp ly, after 1 minute,

connect the power supply, turn on the

unit.

Page 44

42

9.2.6 Refrigerant Leakage Detecti on

Shut off the power supp ly and turn on it 5s later

The problem comes out agai n

Yes

Replace the T2 sensor

and check if the errors

happen again?

Is there any leakage? Especially the connection

parts, such as the gas valve and the liquid valve.

Is there cool air blowing out fro m the indoor air outlet?

No

No

Is there any block? (Such as the capillary or the

welded points of the pipes.)

Yes

Replace the indoor PCB

Loading...

Loading...