Midea MV6-i252WV2GN1-E, MV6-i450WV2GN1-E, MV6-i280WV2GN1-E, MV6-i335WV2GN1-E, MV6-i400WV2GN1-E Service Manual

...Page 1

Commercial Air Conditioners

R410A

Series

MV6-i252WV2GN1-E

MV6-i280WV2GN1-E

MV6-i335WV2GN1-E

MV6-i400WV2GN1-E

MV6-i450WV2GN1-E

MV6-i500WV2GN1-E

MV6-i560WV2GN1-E

MV6-i615WV2GN1-E

MV6-i670WV2GN1-E

MV6-i730WV2GN1-E

MV6-i785WV2GN1-E

MV6-i850WV2GN1-E

MV6-i900WV2GN1-E

Service

Manual

Page 2

V6-i VRF 50/60Hz

CONTENTS

CONTENTS

Part 1 General Information ............................................................................ 3

Part 2 Component Layout and Refrigerant Circuits ................................... 11

Part 3 Control ............................................................................................... 33

Part 4 Field Settings ..................................................................................... 49

Part 5 Electrical Components and Wiring Diagrams .................................. 55

Part 6 Diagnosis and Troubleshooting ......................................................... 69

1

Page 3

V5 X VRF 50/60Hz

Midea V6-i Series Service Manual

2

Page 4

V6-i VRF 50/60Hz

Part 1

- General Information

Part 1

General Information

1 Indoor and Outdoor Unit Capacities .................................................. 4

2 External Appearance ............................................................................ 6

3 Combination Ratio ................................................................................ 8

3

Page 5

V6-i VRF 50/60Hz

Midea V6-i Series Engineering Data Book

Abbreviation

code

Type

Abbreviation

code

Type

Q1

One-way Cassette

T1

High Static Pressure Duct

Q2

Two-way Cassette

G

Wall-mounted

Q4C

Compact Four-way Cassette

DL

Ceiling & Floor

Q4

Four-way Cassette

F

Floor Standing

T2

Medium Static Pressure Duct

Z

Console

Capacity

Capacity

index

Q1

Q2

Q4C

Q4

T2

T1 G DL F Z

kW

HP

1.8

0.6

18

18

— — — — — — —

18 — 2.2

0.8

22

22

22

22 — 22 — 22 — 22

22

2.8 1 28

28

28

28

28

28 — 28 — 28

28

3.6

1.25

36

36

36

36

36

36 — 36

36

36

36

4.5

1.6

45

45

45

45

45

45 — 45

45

45

45

5.6 2 56

56

56 — 56

56 — 56

56

56 — 7.1

2.5

71

71

71 — 71

71

71

71

71

71 — 8.0 3 80

— — —

80

80

80

80

80

80 — 9.0

3.2

90

— — —

90

90

90

90

90

90 — 10.0

3.6

100

— — —

100

— — — — —

—

11.2 4 112

— — —

112

112

112 — 112

—

—

14.0 5 140

— — —

140

140

140 — 140

—

—

16.0 6 160

— — — — —

160 — 160

—

—

20.0 7 200

— — — — —

200

— — —

—

25.0 9 250

— — — — —

250

— — —

—

28.0

10

280

— — — — —

280

— — —

—

40.0

14

400

— — — — —

400

— — —

—

45.0

16

450

— — — — —

450

— — —

—

56.0

20

560

— — — — —

560

— — —

—

Capacity

12.5kW

14kW

20kW

25kW

28kW

Capacity index

125

140

200

250

280

Capacity

200m3/h

300m3/h

400m3/h

500m3/h

800m3/h

1000m3/h

1500m3/h

2000m3/h

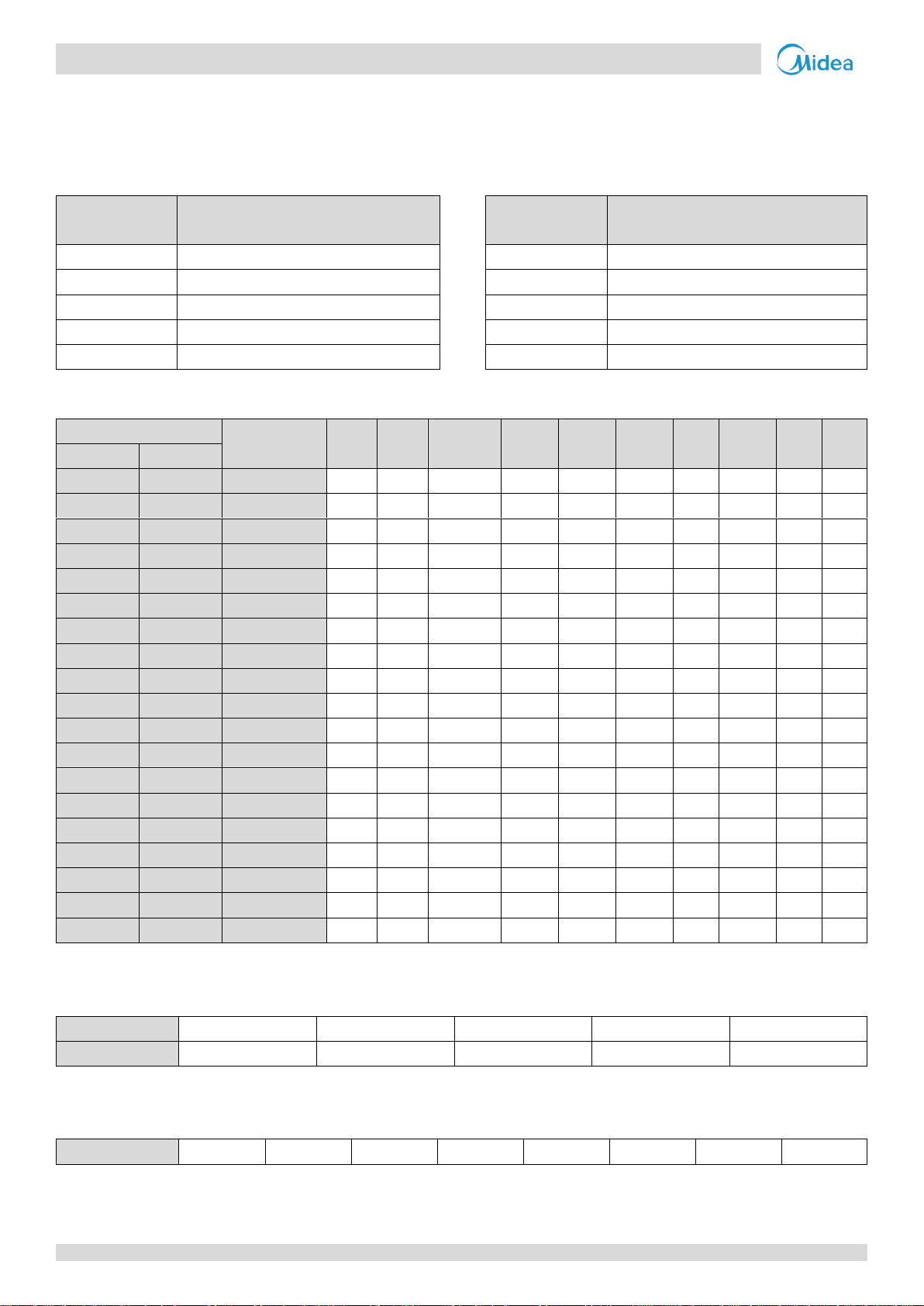

1 Indoor and Outdoor Unit Capacities

1.1 Indoor Units

1.1.1 Standard indoor units

Table 1-1.1: Standard indoor unit abbreviation codes

Table 1-1.2: Standard indoor unit capacity range

1.1.2 Fresh air processing unit

Table 1-1.3: Fresh air processing unit capacity range

1.2 Heat recovery ventilator

Table 1-1.4: Heat recovery ventilator capacity range

4

Page 6

V6-i VRF 50/60Hz

Part 1 - General Information

Capacity

Model Name

8HP

MV6-i252WV2GN1-E

10HP

MV6-i280WV2GN1-E

12HP

MV6-i335WV2GN1-E

14HP

MV6-i400WV2GN1-E

16HP

MV6-i450WV2GN1-E

18HP

MV6-i500WV2GN1-E

20HP

MV6-i560WV2GN1-E

22HP

MV6-i615WV2GN1-E

24HP

MV6-i670WV2GN1-E

26HP

MV6-i730WV2GN1-E

28HP

MV6-i785WV2GN1-E

30HP

MV6-i850WV2GN1-E

32HP

MV6-i900WV2GN1-E

1.3 Outdoor Units

Table 1-1.5: Outdoor unit capacity range

5

Page 7

V6-i VRF 50/60Hz

Midea V6-i Series Engineering Data Book

One-way Cassette

Two-way Cassette

Q1 Q2

Compact Four-way Cassette

Four-way Cassette

Q4C

Q4

Medium Static Pressure Duct

High Static Pressure Duct

T2 T1

Wall-mounted

Ceiling & Floor

G DL

Floor Standing

Console

F Z

Fresh Air Processing Unit

FA

Heat Recovery Ventilator

2 External Appearance

2.1 Indoor Units

2.1.1 Standard indoor units

Table 1-2.1: Standard indoor unit appearance

2.1.2 Fresh air processing unit

Table 1-2.2: Fresh air processing unit appearance

2.2 Heat Recovery Ventilator

Table 1-2.3: Heat recovery ventilator appearance

6

Page 8

V6-i VRF 50/60Hz

Part 1

- General Information

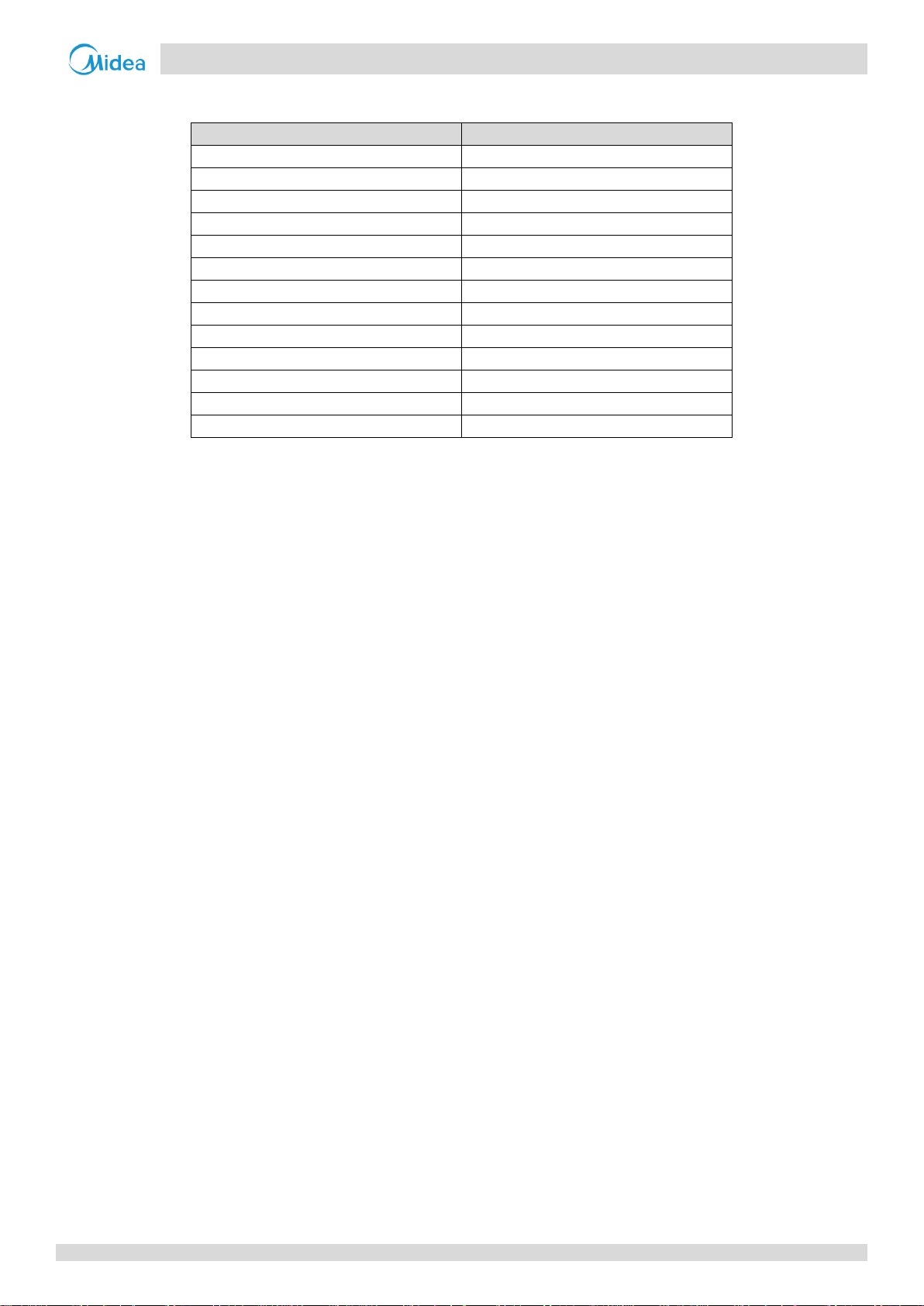

8/10/12HP

(with single fan)

14/16/18HP

(with single fan)

20/22HP

(with dual fans)

24/26/28/30/32HP

(with dual fans)

2.3 Outdoor Units

Table 1-2.4: Outdoor unit appearance

7

Page 9

V6-i VRF 50/60Hz

Midea V6-i Series Engineering Data Book

Type

Minimum

combination ratio

Maximum combination ratio

Standard indoor

units only

Fresh air processing

units only

Fresh air processing units and

standard indoor units together

V6-i Series outdoor units

50%

130%

100%

100%1

Outdoor unit capacity

Sum of capacity indexes of

connected indoor units (standard

indoor units only)

Sum of capacity indexes of connected indoor

units (fresh air processing units and standard

indoor units together)

Maximum number of

connected indoor

units

kW

HP

Capacity

index

25.2 8 252

126 to 327.6

126 to 252

13

28.0

10

280

140 to 364

140 to 280

16

33.5

12

335

167.5 to 435.5

167.5 to 335

20

40.0

14

400

200 to 520

200 to 400

23

45.0

16

450

225 to 585

225 to 450

26

50.0

18

500

250 to 650

250 to 500

29

56.0

20

560

280 to 728

280 to 560

33

61.5

22

615

307.5 to 799.5

307.5 to 615

36

67.0

24

670

335 to 871

335 to 670

39

73.0

26

730

365 to 949

365 to 730

43

78.5

28

785

392.5 to 1020.5

392.5 to 785

46

85.0

30

850

425 to 1105

425 to 850

50

90.0

32

900

450 to 1170

450 to 900

53

Combination ratio =

Sum of capacity indexes of the indoor units

Capacity index of the outdoor unit

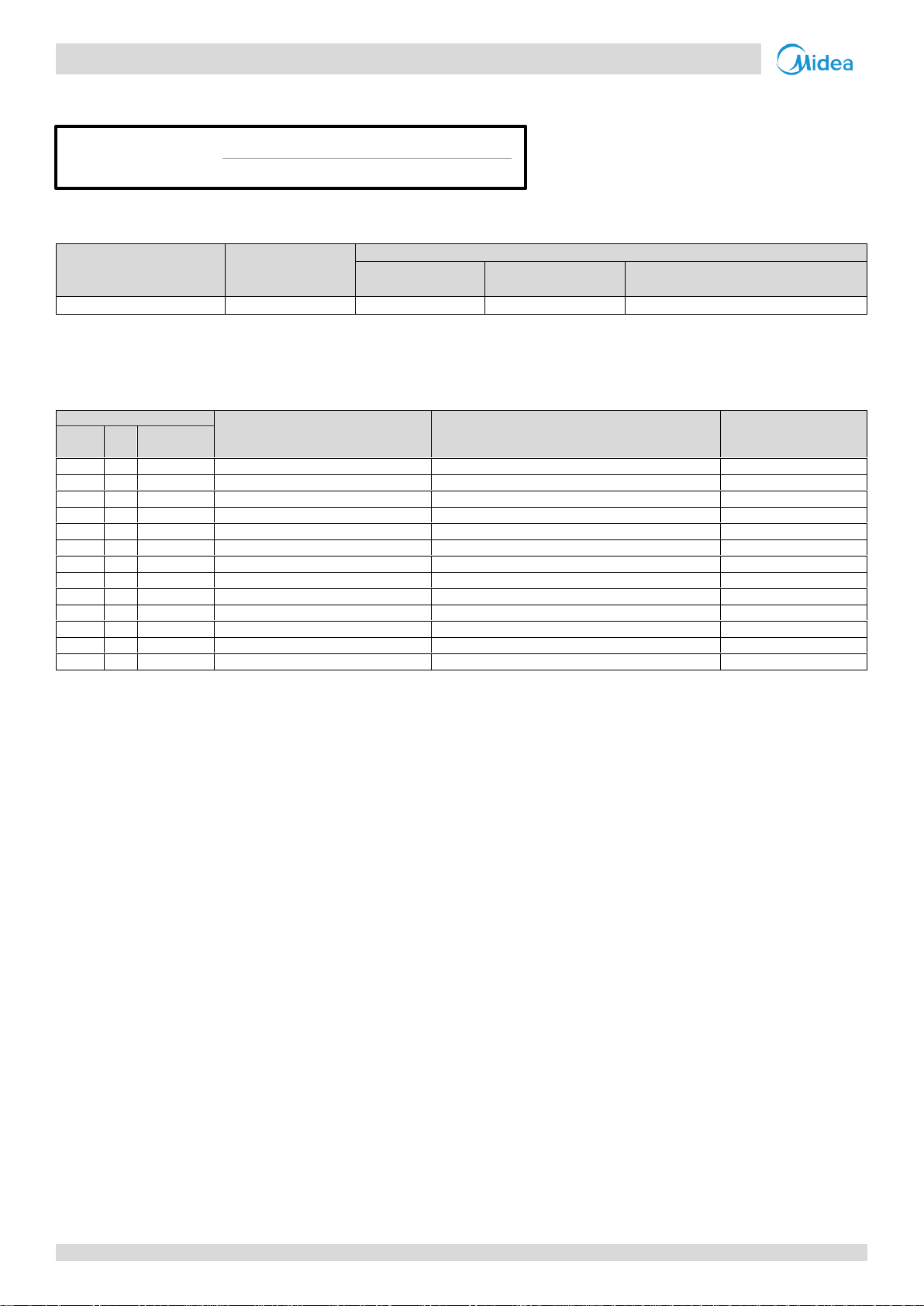

3 Combination Ratio

Table 1-5.1: Indoor and outdoor unit combination ratio limitations

Notes:

1. When fresh air processing units are installed together with standard indoor units, the total capacity of the fresh air processing units must not exceed 30%

of the capacity of the outdoor unit and the combination ratio must not exceed 100%.

Table 1-5.2: Combinations of Indoor and outdoor units

8

Page 10

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Part 2

Component Layout and

Refrigerant Circuits

1 Layout of Functional Components ....................................................... 10

2 Piping Diagrams .................................................................................. 16

3 Refrigerant Flow Diagrams .................................................................. 22

9

Page 11

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

No.

Parts name

1

Compressor

2

Discharge temperature switch

3

High pressure switch

4

High pressure sensor

5

Oil separator

6

Four-way valve

7

Heat exchanger

8

Electronic expansion valve (EXV)

9

Low pressure switch

10

Fan motor

11

Fan

12

Stop valve (liquid side)

13

Stop valve (gas side)

14

Plate heat exchanger

15

56

7

8

12

13

14

11

9

10

3

4 2

1

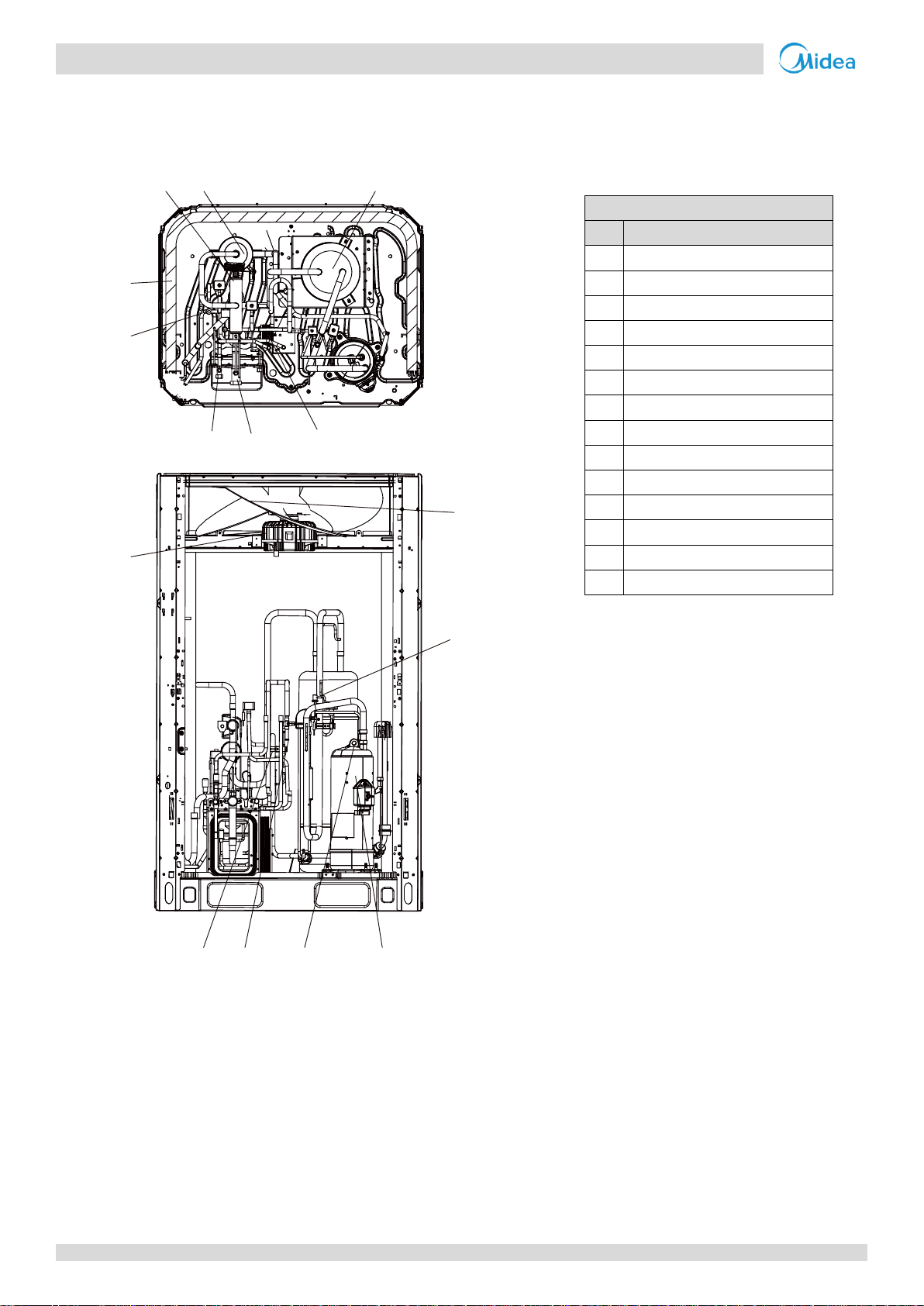

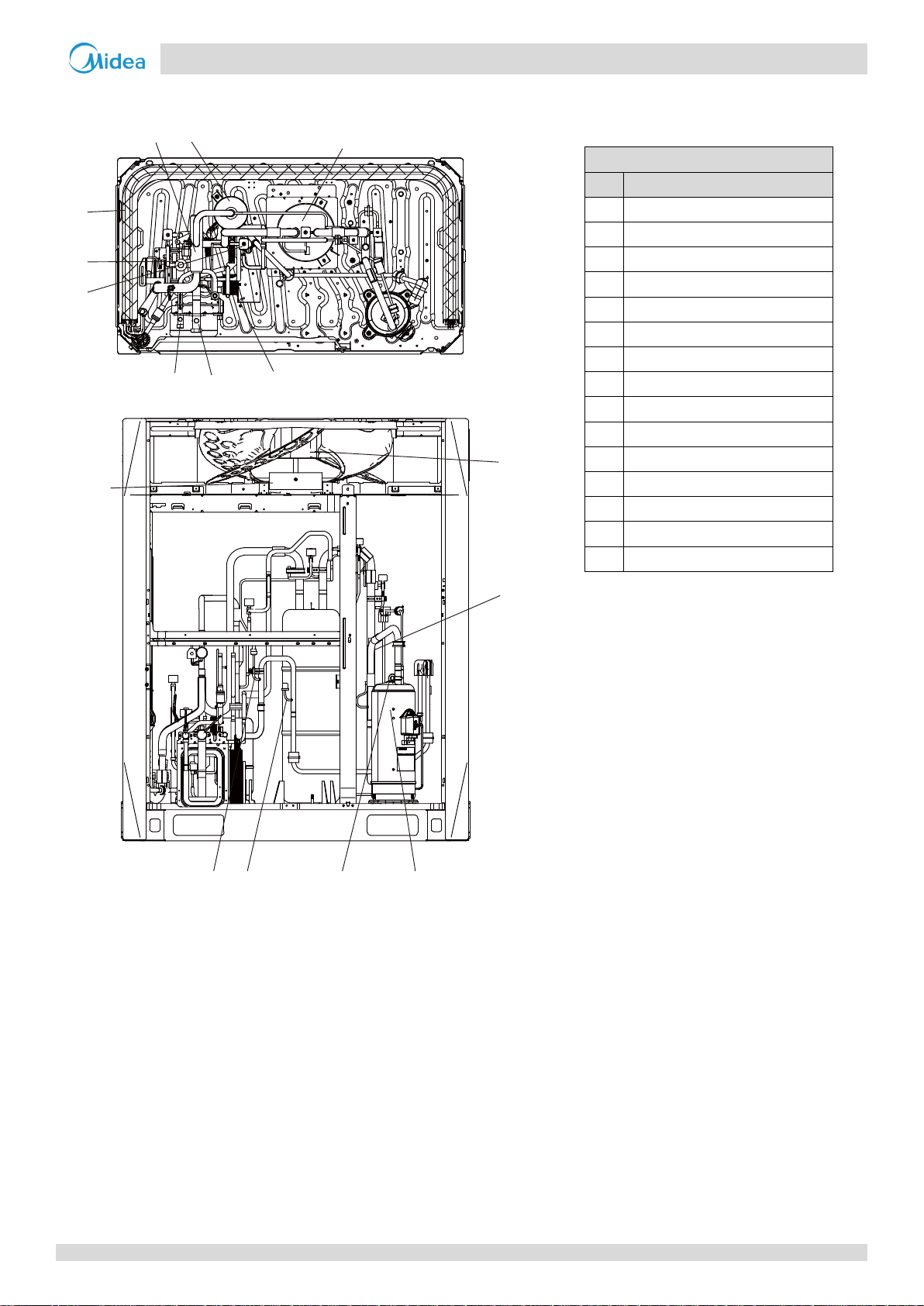

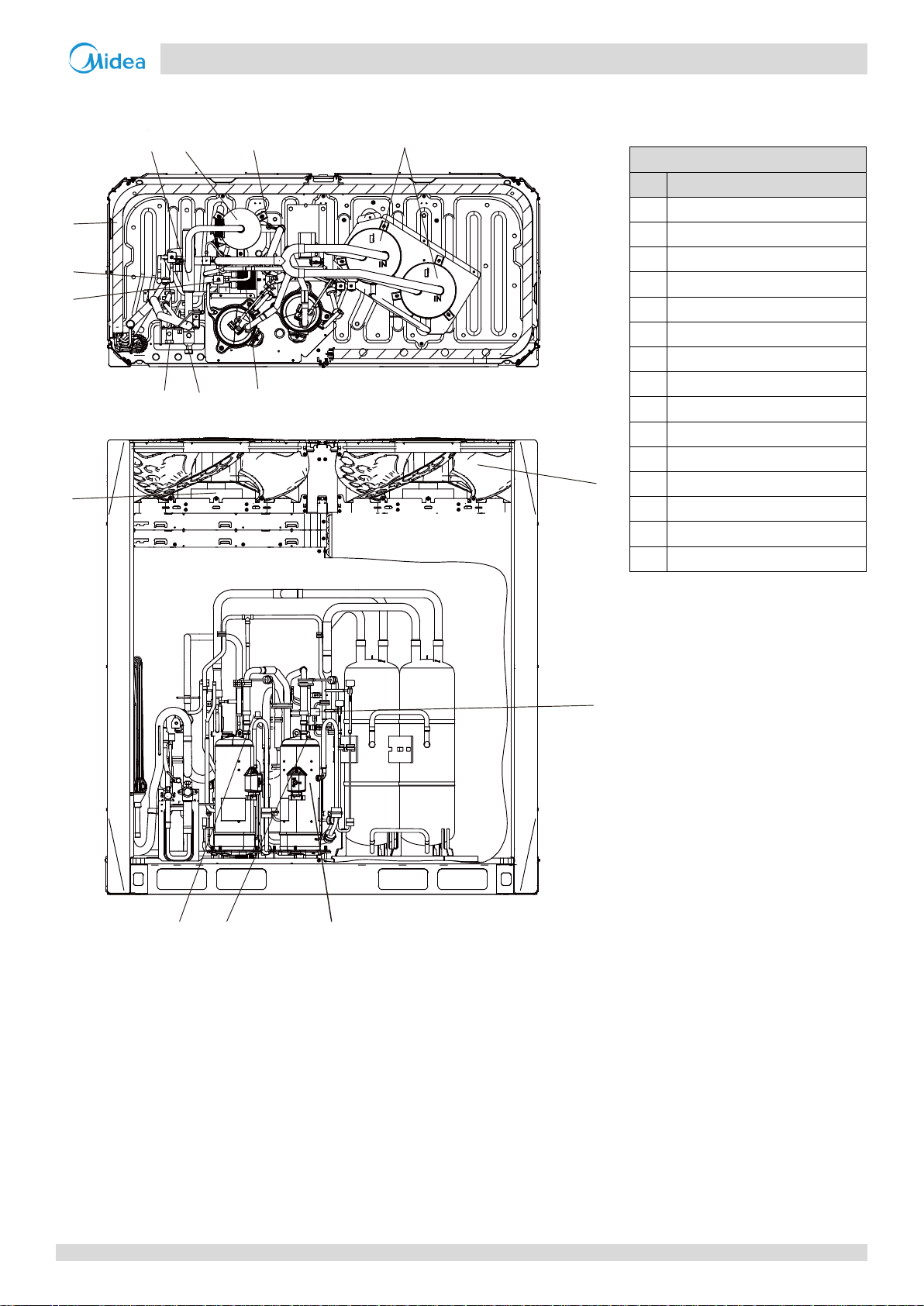

1 Layout of Functional Components

8/10/12HP

Figure 2-1.1: 8/10/12 layout of functional components

10

Page 12

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Legend

No.

Parts name

1

Compressor

2

Discharge temperature switch

3

High pressure switch

4

High pressure sensor

5

Oil separator

6

Four-way valve

7

Heat exchanger

8

Electronic expansion valve (EXV)

9

Low pressure switch

10

Fan motor

11

Fan

12

Stop valve (liquid side)

13

Stop valve (gas side)

14

Plate heat exchanger

15

Accumulator

15

5

6

7

8

9

12

13

14

11

9

10

3

4

2

1

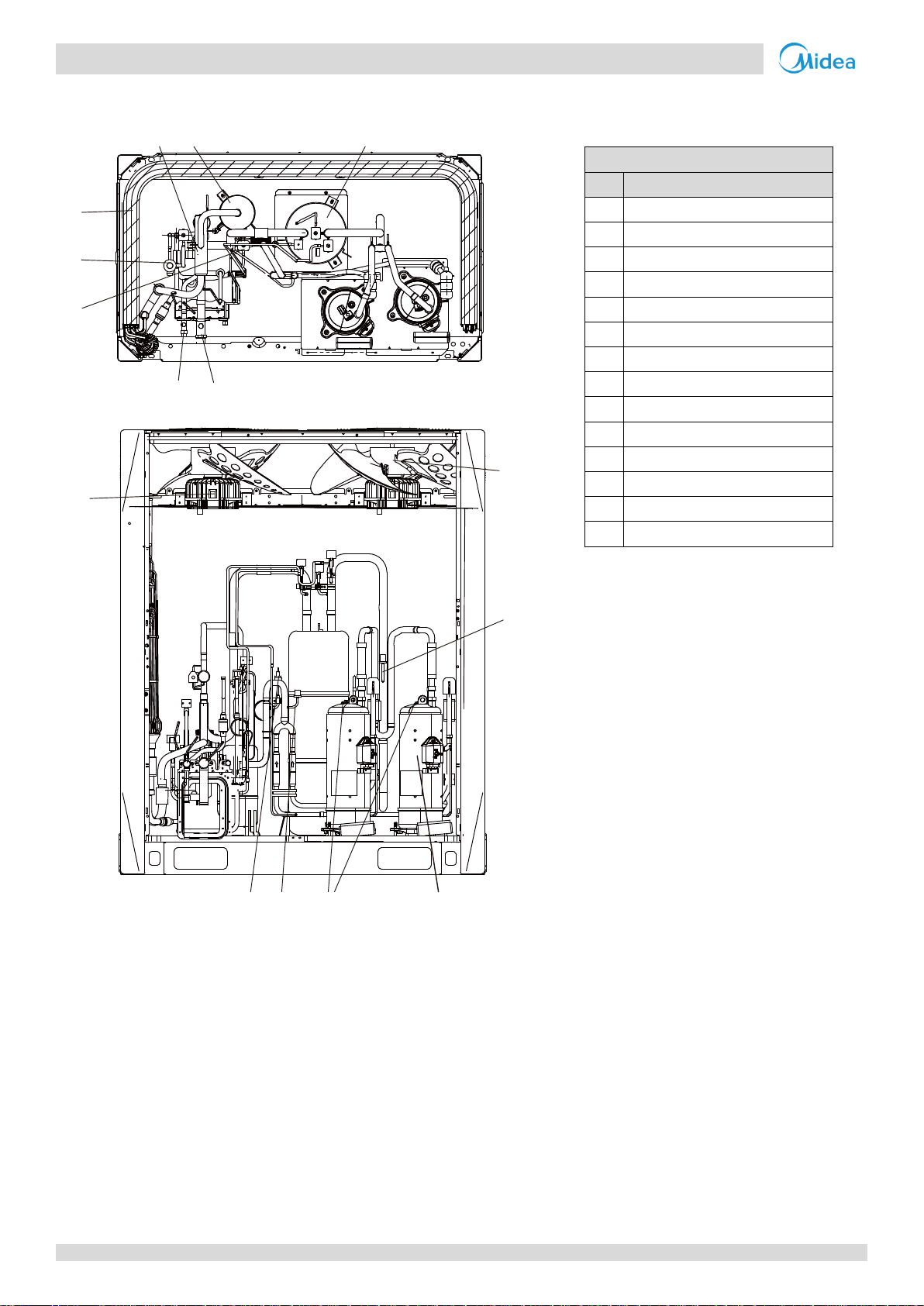

14/16/18HP

Figure 2-1.2: 14/16/18 layout of functional components

11

Page 13

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

No.

Parts name

1

Compressor

2

Discharge temperature switch

3

High pressure switch

4

High pressure sensor

5

Oil separator

6

Four-way valve

7

Heat exchanger

8

Electronic expansion valve (EXV)

9

Low pressure switch

10

Fan motor

11

Fan

12

Stop valve (liquid side)

13

Stop valve (gas side)

15

Accumulator

1556

7

8

9

12

13

11

9

10

3

4

2

1

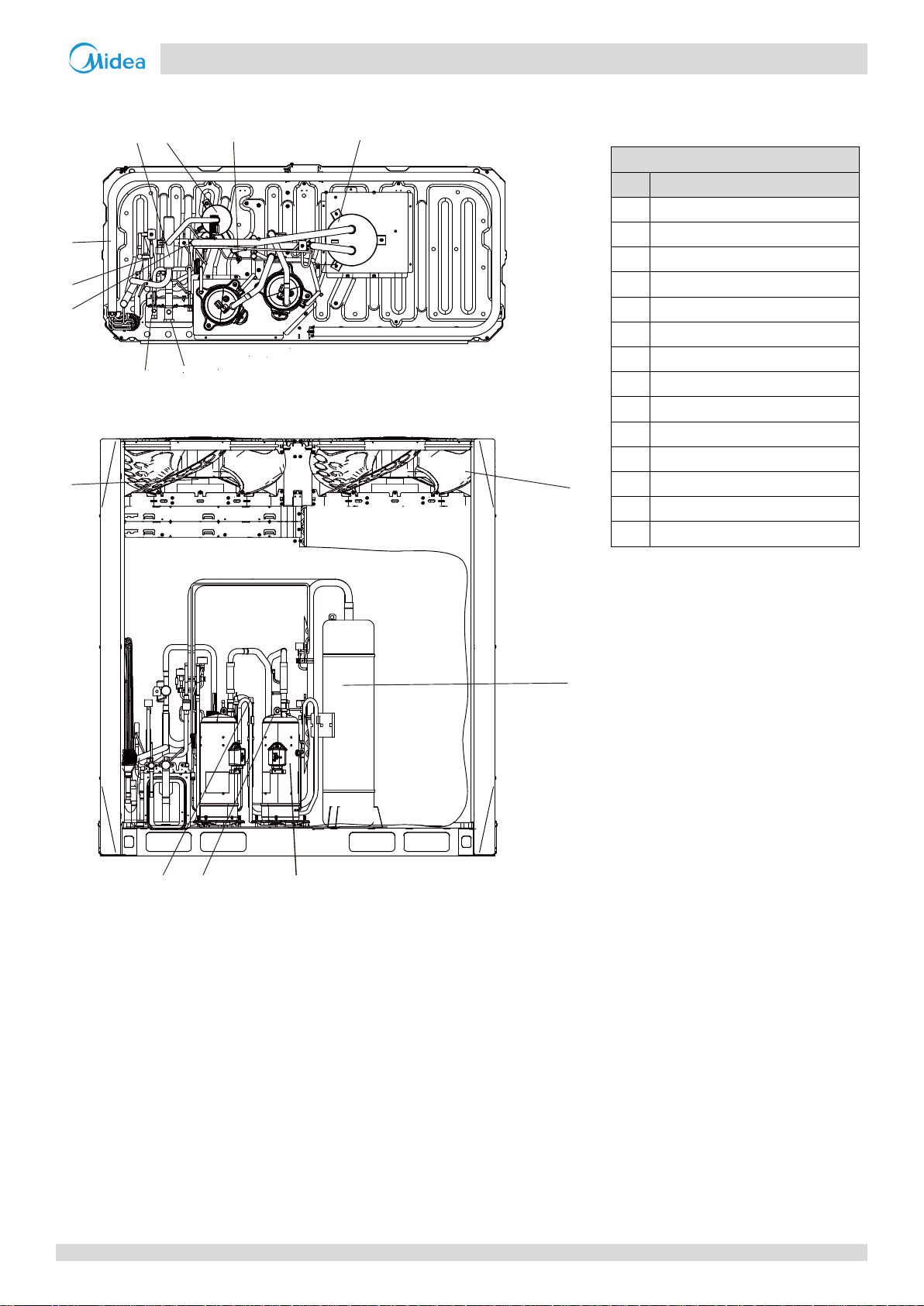

20/22HP

Figure 2-1.3: 20/22 layout of functional components

12

Page 14

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Legend

No.

Parts name

1

Compressor

2

Discharge temperature switch

3

High pressure switch

4

High pressure sensor

5

Oil separator

6

Four-way valve

7

Heat exchanger

8

Electronic expansion valve (EXV)

9

Low pressure switch

10

Fan motor

11

Fan

12

Stop valve (liquid side)

13

Stop valve (gas side)

15

Accumulator

15

5

4

6

7

8

9

12

13

11

9

10

3

2

1

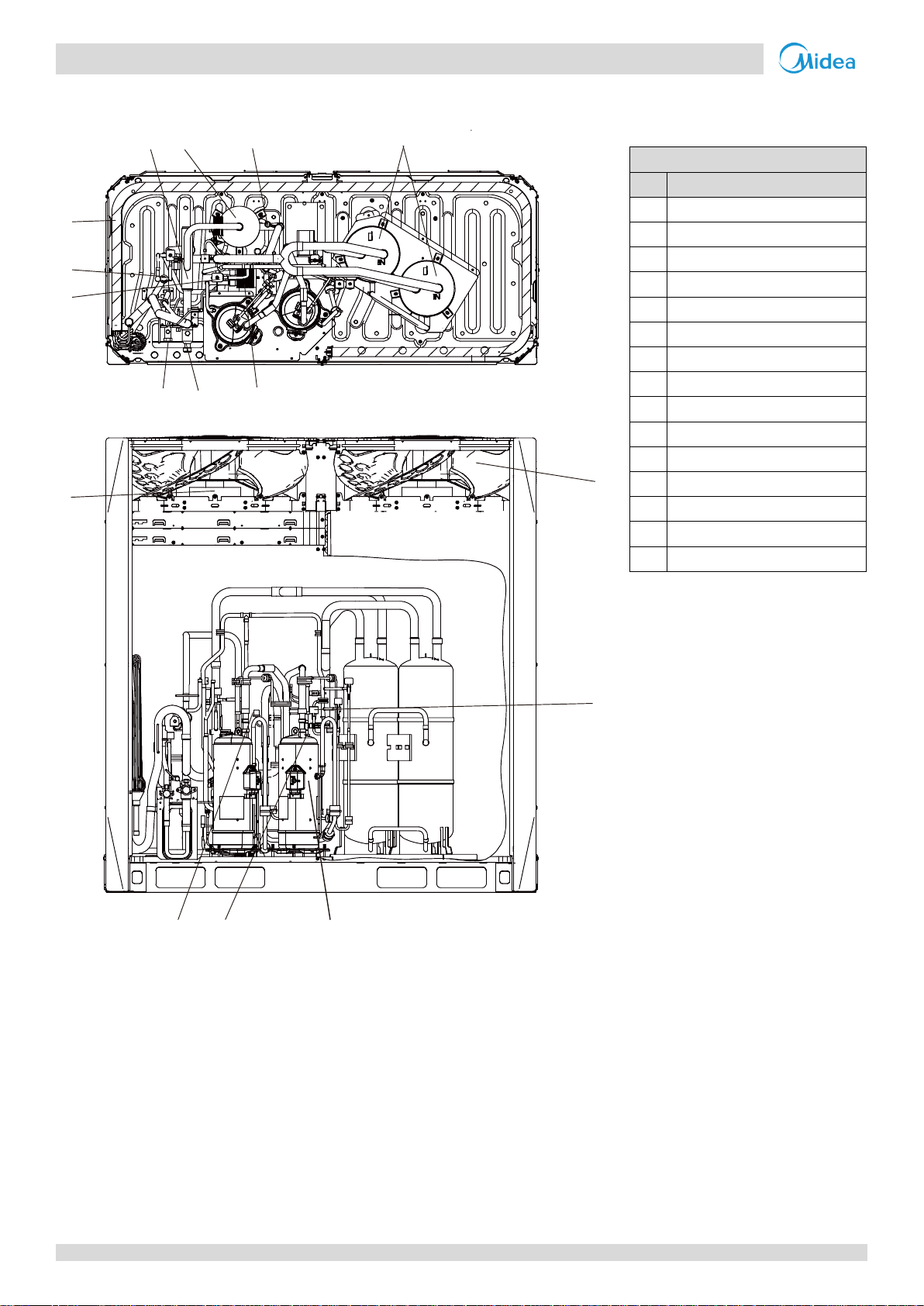

24HP

Figure 2-1.4: 24 layout of functional components

13

Page 15

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

No.

Parts name

1

Compressor

2

Discharge temperature switch

3

High pressure switch

4

High pressure sensor

5

Oil separator

6

Four-way valve

7

Heat exchanger

8

Electronic expansion valve (EXV)

9

Low pressure switch

10

Fan motor

11

Fan

12

Stop valve (liquid side)

13

Stop valve (gas side)

14

Plate heat exchanger

15

Accumulator

15

5

4

6

7

8

9

12

13

14

11

9

10

3

2

1

26/28HP

Figure 2-1.5: 26/28 layout of functional components

14

Page 16

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Legend

No.

Parts name

1

Compressor

2

Discharge temperature switch

3

High pressure switch

4

High pressure sensor

5

Oil separator

6

Four-way valve

7

Heat exchanger

8

Electronic expansion valve (EXV)

9

Low pressure switch

10

Fan motor

11

Fan

12

Stop valve (liquid side)

13

Stop valve (gas side)

14

Plate heat exchanger

15

Accumulator

15

5

4

6

7

8

9

12

13

14

11

9

10

3

2

1

30/32HP

Figure 2-1.6: 30/32 layout of functional components

15

Page 17

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

No.

Parts name

No.

Parts name

1

Compressor

14

Plate heat exchanger

2

Discharge temperature switch

15

Accumulator

3

High pressure switch

T3

Heat exchanger temperature sensor

4

High pressure sensor

T4

Outdoor ambient temperature sensor

5

Oil separator

T6A

Plate heat exchanger inlet temperature sensor

6

Four-way valve

T6B

Plate heat exchanger outlet temperature sensor

7

Heat exchanger

T7C1

Compressor A discharge temperature sensor

8

Electronic expansion valve (EXV)

T7C2

Compressor B discharge temperature sensor

9

Low pressure switch

SV4

Oil return valve

10

Fan motor

SV5

Fast defrosting (in heating) and unloading (in cooling) valve

11

Fan

SV6

Refrigerant bypass EXV valve

12

Stop valve (liquid side)

SV8A

Compressor A vapor injection valve

13

Stop valve (gas side)

7

1

15 12

9

3

2

4

5

6

11

10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

SV6

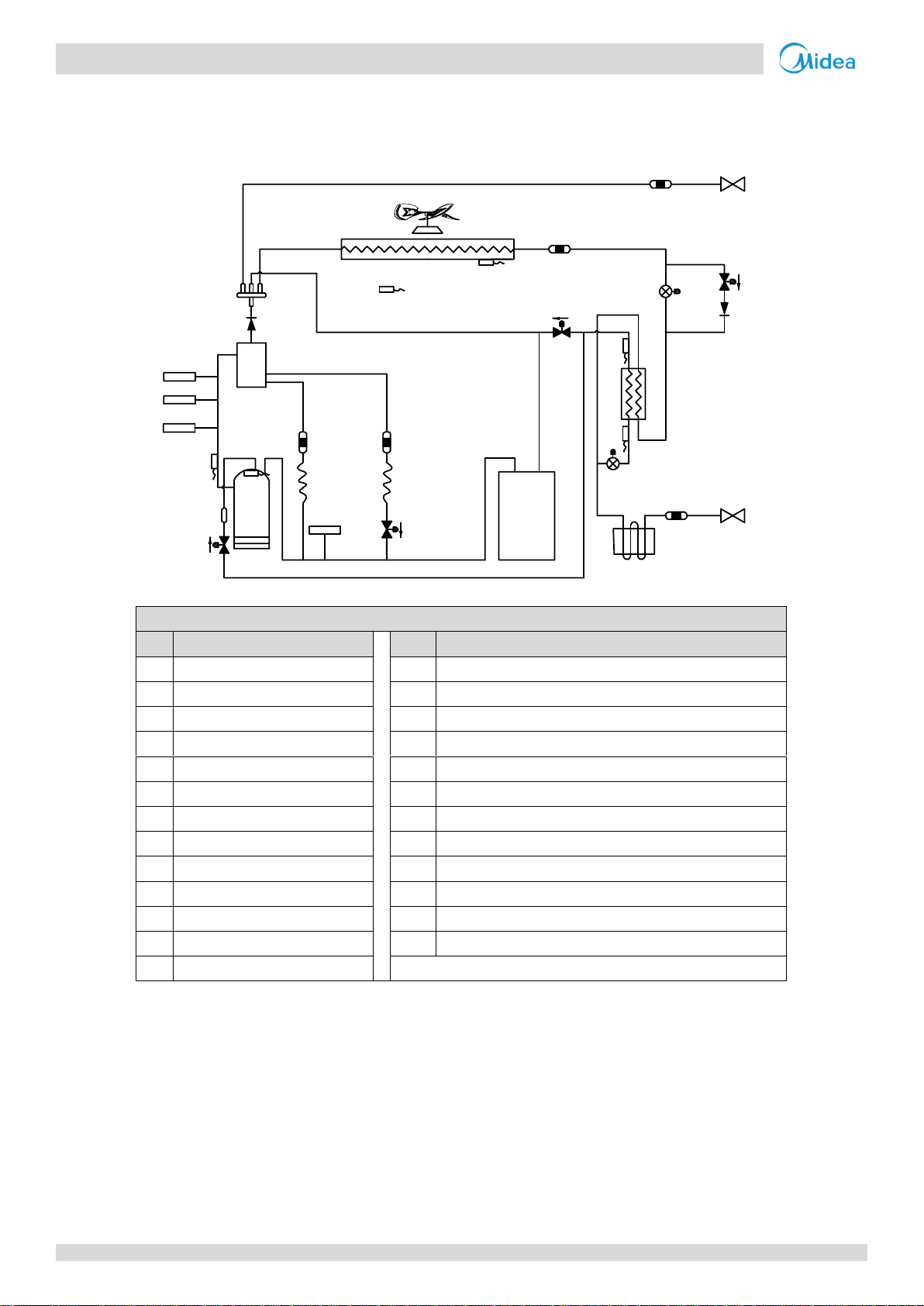

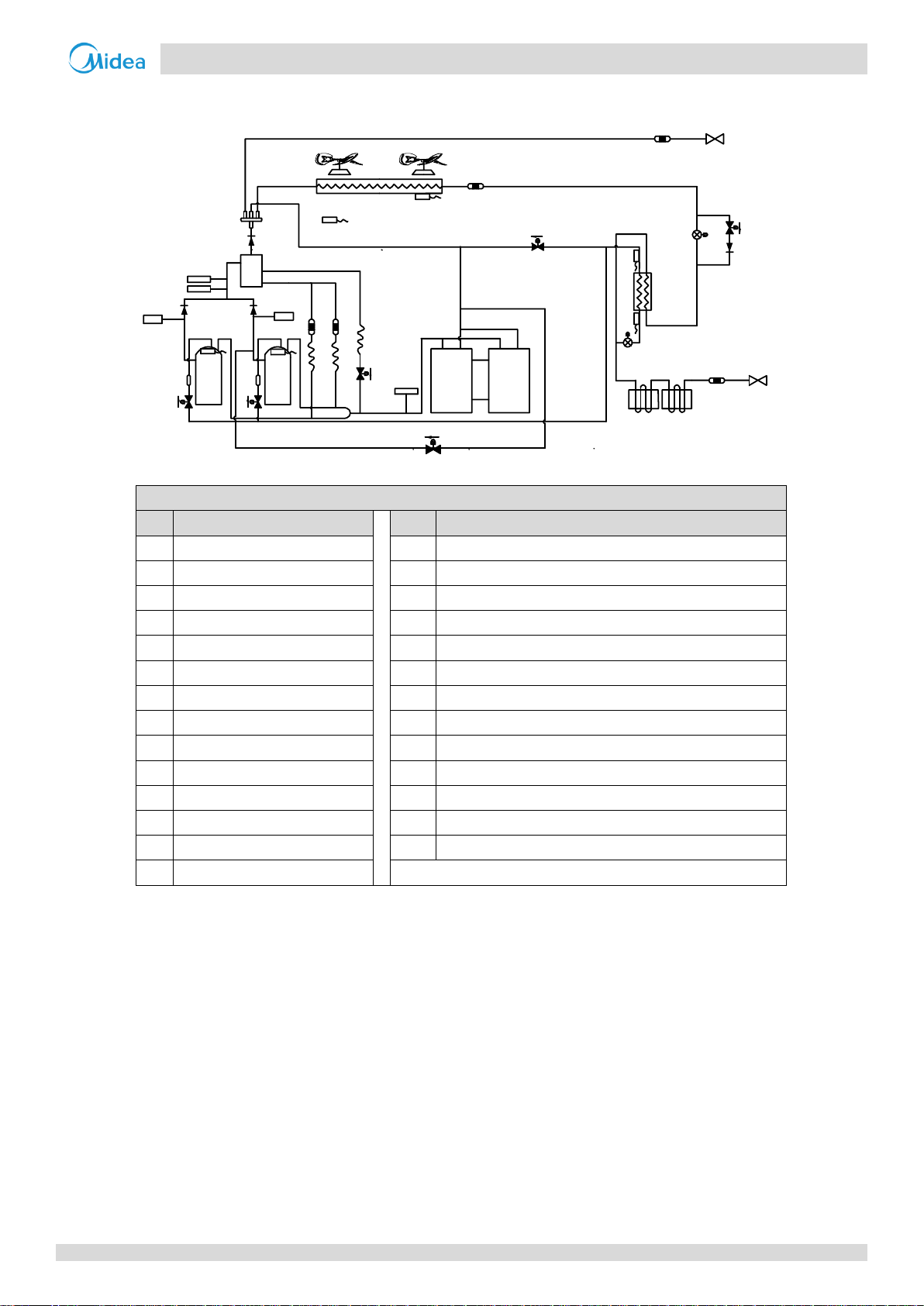

2 Piping Diagrams

8/10/12HP

Figure 2-2.1: 8/10/12HP piping diagram

16

Page 18

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Legend

No.

Parts name

No.

Parts name

1

Compressor

14

Plate heat exchanger

2

Discharge temperature switch

15

Accumulator

3

High pressure switch

T3

Heat exchanger temperature sensor

4

High pressure sensor

T4

Outdoor ambient temperature sensor

5

Oil separator

T6A

Plate heat exchanger inlet temperature sensor

6

Four-way valve

T6B

Plate heat exchanger outlet temperature sensor

7

Heat exchanger

T7C1

Compressor A discharge temperature sensor

8

Electronic expansion valve (EXV)

T7C2

Compressor B discharge temperature sensor

9

Low pressure switch

SV4

Oil return valve

10

Fan motor

SV5

Fast defrosting (in heating) and unloading (in cooling) valve

11

Fan

SV6

Refrigerant bypass EXV valve

12

Stop valve (liquid side)

SV7

Refrigerant bypass indoor units valve

13

Stop valve (gas side)

SV8A

Compressor A vapor injection valve

1

15

12

9

3

4

5

6

11

10

7

14

8

8

13

EXVA

EXVC

E

S

C

SV8A

SV4

SV7

SV5

SV6

T3

T4

T6B

T6A

2

T7C1

T7C2

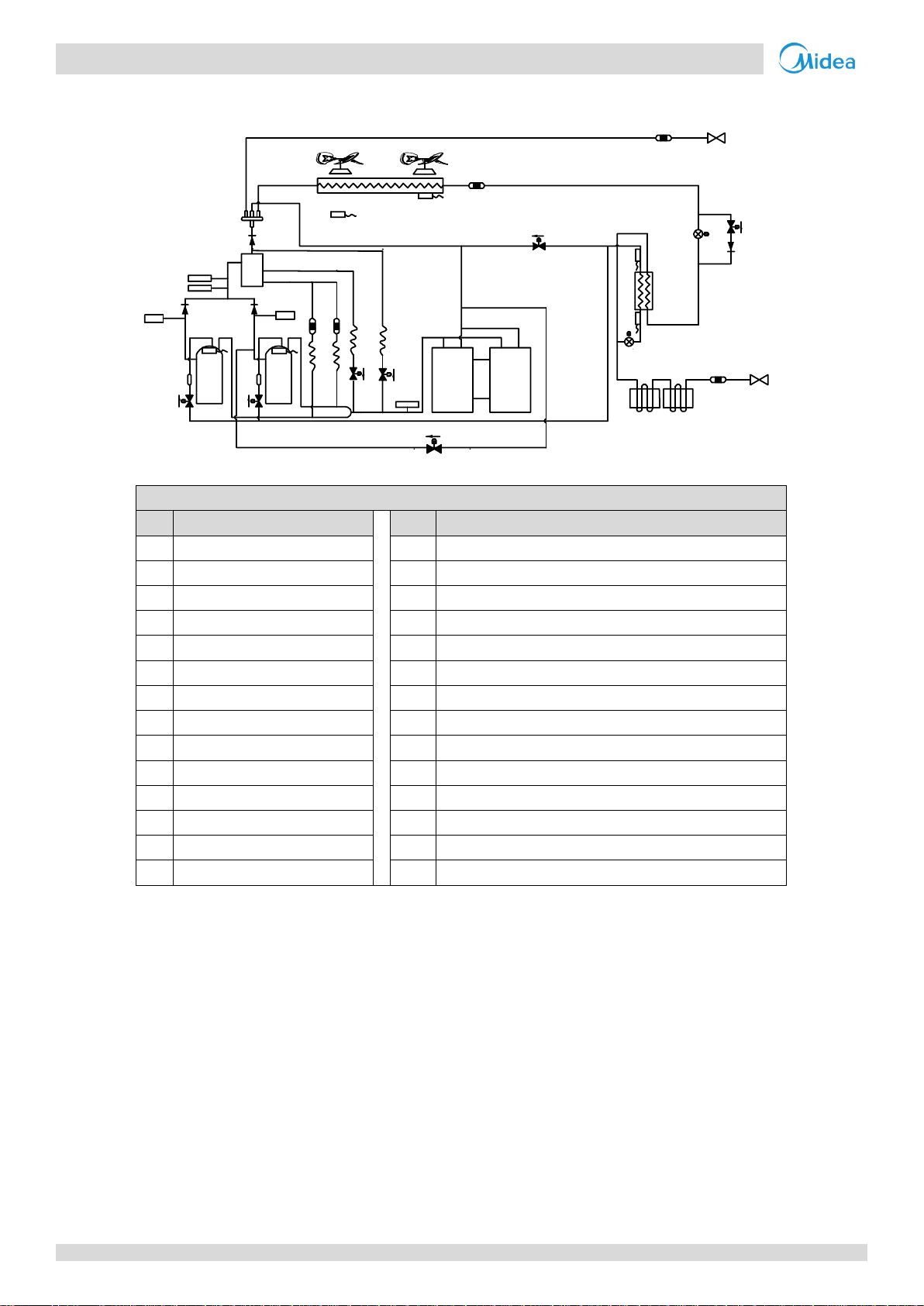

14/16/18HP

Figure 2-2.2: 14/16/18HP piping diagram

17

Page 19

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

No.

Parts name

No.

Parts name

1

Compressor

15

Accumulator

2

Discharge temperature switch

T3

Heat exchanger temperature sensor

3

High pressure switch

T4

Outdoor ambient temperature sensor

4

High pressure sensor

T6A

Plate heat exchanger inlet temperature sensor

5

Oil separator

T6B

Plate heat exchanger outlet temperature sensor

6

Four-way valve

T7C1

Compressor A discharge temperature sensor

7

Heat exchanger

T7C2

Compressor B discharge temperature sensor

8

Electronic expansion valve (EXV)

SV4

Oil return valve

9

Low pressure switch

SV5

Fast defrosting (in heating) and unloading (in cooling) valve

10

Fan motor

SV6

Refrigerant bypass EXV valve

11

Fan

SV8A

Compressor A vapor injection valve

12

Stop valve (liquid side)

SV8B

Compressor B vapor injection valve

13

Stop valve (gas side)

SV9

Compressor B pressure balance valve

14

Plate heat exchanger

7

1

1

15

12

9

3

4

5

6

11

11

10 10

8

13

EXVA

E

S

C

SV9

SV4

SV5

SV6

SV2

T3

T4

2

T7C1

T7C2

2

20/22/24HP

Figure 2-2.3: 20/22/24HP piping diagram

18

Page 20

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Legend

No.

Parts name

No.

Parts name

1

Compressor

15

Accumulator

2

Discharge temperature switch

T3

Heat exchanger temperature sensor

3

High pressure switch

T4

Outdoor ambient temperature sensor

4

High pressure sensor

T6A

Plate heat exchanger inlet temperature sensor

5

Oil separator

T6B

Plate heat exchanger outlet temperature sensor

6

Four-way valve

T7C1

Compressor A discharge temperature sensor

7

Heat exchanger

T7C2

Compressor B discharge temperature sensor

8

Electronic expansion valve (EXV)

SV4

Oil return valve

9

Low pressure switch

SV5

Fast defrosting (in heating) and unloading (in cooling) valve

10

Fan motor

SV6

Refrigerant bypass EXV valve

11

Fan

SV8A

Compressor A vapor injection valve

12

Stop valve (liquid side)

SV8B

Compressor B vapor injection valve

13

Stop valve (gas side)

SV9

Compressor B pressure balance valve

14

Plate heat exchanger

7

1

1

15

15

12

9

3

4

5

6

11

10

11

10

14

8

8

SV6

13

EXVA

EXVC

S

E

C

SV8A

SV8B

SV4

SV9

SV5

T3

T4

T6B

T6A

T7C1

T7C2

2

2

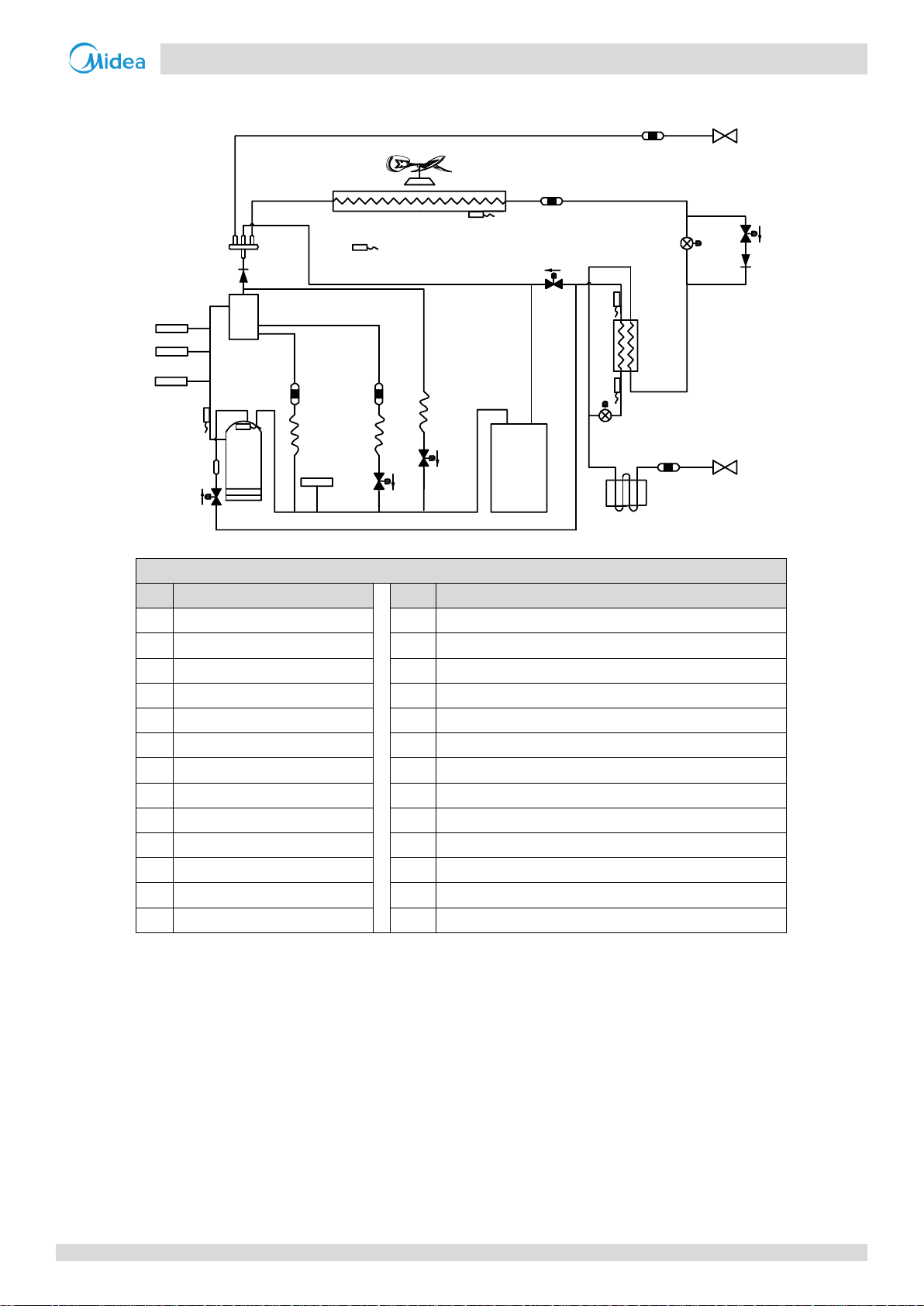

26/28HP

Figure 2-2.4: 26/28HP piping diagram

19

Page 21

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

No.

Parts name

No.

Parts name

1

Compressor

15

Accumulator

2

Discharge temperature switch

T3

Heat exchanger temperature sensor

3

High pressure switch

T4

Outdoor ambient temperature sensor

4

High pressure sensor

T6A

Plate heat exchanger inlet temperature sensor

5

Oil separator

T6B

Plate heat exchanger outlet temperature sensor

6

Four-way valve

T7C1

Compressor A discharge temperature sensor

7

Heat exchanger

T7C2

Compressor B discharge temperature sensor

8

Electronic expansion valve (EXV)

SV4

Oil return valve

9

Low pressure switch

SV5

Fast defrosting (in heating) and unloading (in cooling) valve

10

Fan motor

SV6

Refrigerant bypass EXV valve

11

Fan

SV7

Refrigerant bypass indoor units valve

12

Stop valve (liquid side)

SV8A

Compressor A vapor injection valve

13

Stop valve (gas side)

SV8B

Compressor B vapor injection valve

14

Plate heat exchanger

SV9

Compressor B pressure balance valve

7

1

1

15

15

12

9

3

4

5

6

11

10

11

10

14

8

8

13

EXVA

EXVC

E

S

C

SV6

SV5

SV9

S

V7

S

V4

SV8A

SV8B

T3

T4

T6B

T6A

T7C1

T7C2

2

2

30/32HP

Figure 2-2.5: 30/32HP piping diagram

20

Page 22

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

Key components:

1. Oil separator:

Separates oil from gas refrigerant pumped out of the compressor and quickly returns it to the compressor. Separation

efficiency is up to 99%.

2. Accumulator:

Stores liquid refrigerant and oil to protect compressor from liquid hammering.

3. Electronic expansion valve (EXV):

Controls refrigerant flow and reduces refrigerant pressure.

4. Four-way valve:

Controls refrigerant flow direction. Closed in cooling mode and open in heating mode. When closed, the heat

exchanger functions as a condenser; when open, the heat exchanger functions as an evaporator.

5. Solenoid valve SV4:

Returns oil to the compressor. Opens once the compressor has run for 200 seconds and closes 600 seconds later and

then opens for 3 minutes every 20 minutes.

6. Solenoid valve SV5:

Enables fast defrosting in heating mode and unloading in cooling mode. During defrosting operation, opens to

shorten the refrigerant flow cycle and quicken the defrosting process. In cooling mode, SV5 opens when outdoor

ambient temperature is above 40oC or compressor frequency is below 41Hz.

7. Solenoid valve SV6:

Allows refrigerant to bypass the expansion valves. Opens in cooling mode when discharge temperature exceeds the

limit. Closed in heating mode and standby.

8. Solenoid valve SV7:

Allows refrigerant to return directly to the compressor. Opens when indoor air temperature is close to the set

temperature to avoid frequent compressor on/off.

9. Solenoid valve SV8A / SV8B:

Allows refrigerant from plate heat exchanger inject directly to the compressor. SV8A opens when compressor A

startup and closes when compressor A stop. SV8B delays opening when compressor B startup and closes when

compressor B stop.

10. Solenoid valve SV9:

Balances compressor B pressure. Opens before compressor B startup and closed after compressor B running for 15

seconds. Opens after compressor B stops 10s and keep opening 60s.

11. High and low pressure switches:

Regulate system pressure. When system pressure rises above the upper limit or falls below the lower limit, the high or

low pressure switches turn off, stopping the compressor. After 10 minutes, the compressor restarts.

21

Page 23

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

7

1

15

12

9

3

2

4

5

6

11

10

14

8

13

EXVA

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

SV6

Closed

Filter

Filter

Closed

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

Fan

on

Fan

off

Fan

on

Fan

on

7

1

15

12

9

3

2

4

5

6

11

10

14

8

13

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

EXVA

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

SV6

300 steps

Filter

Filter

300 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

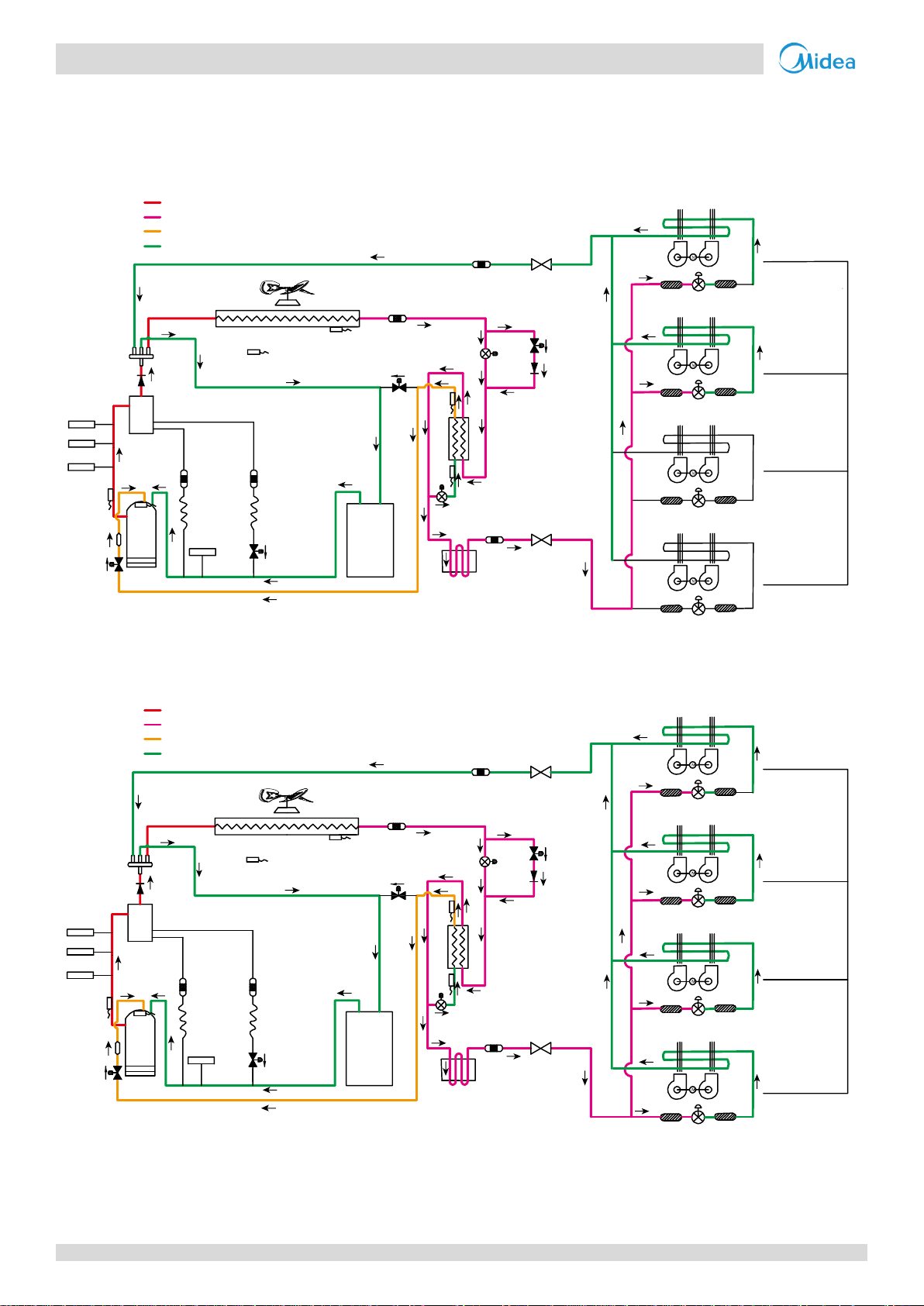

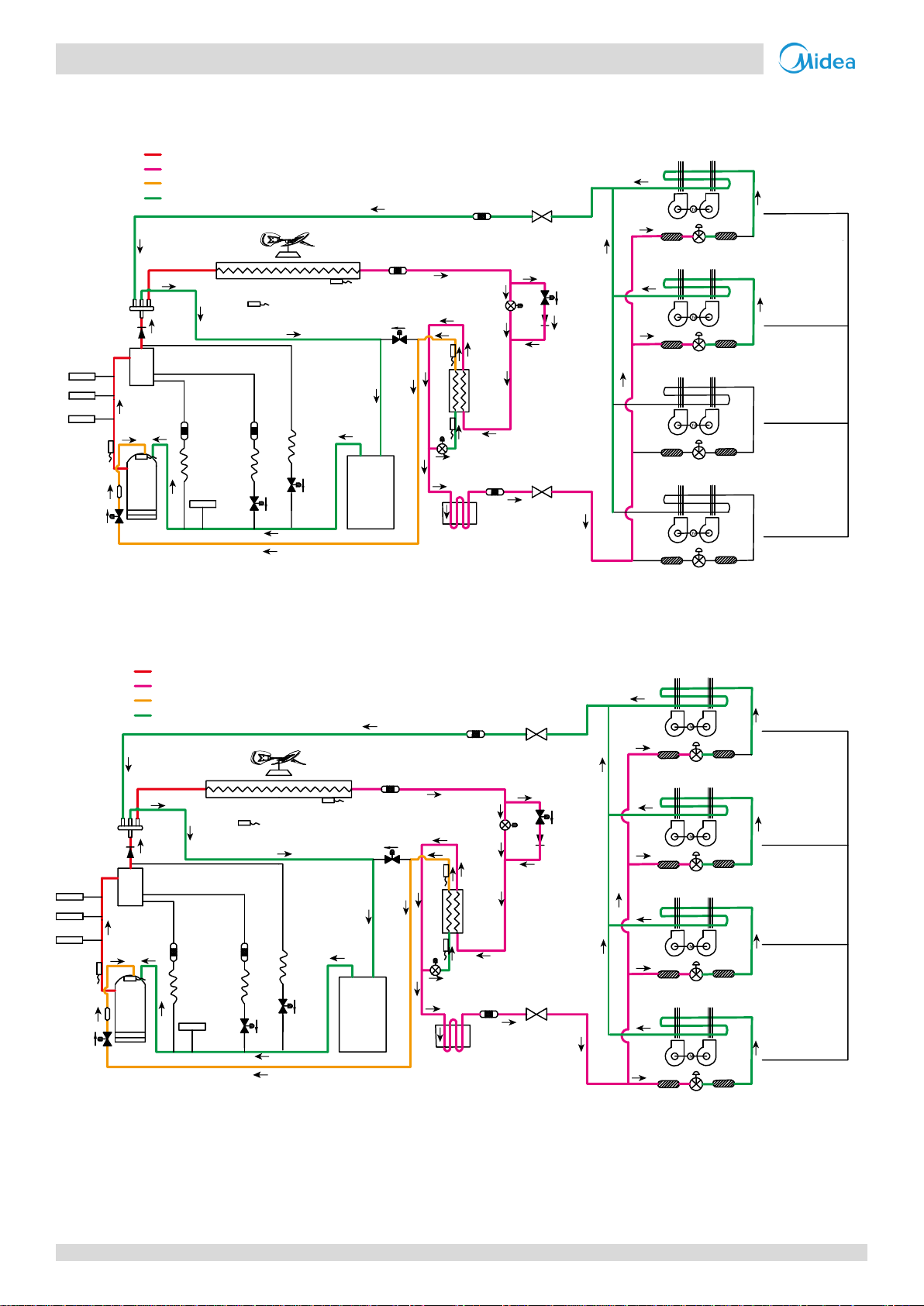

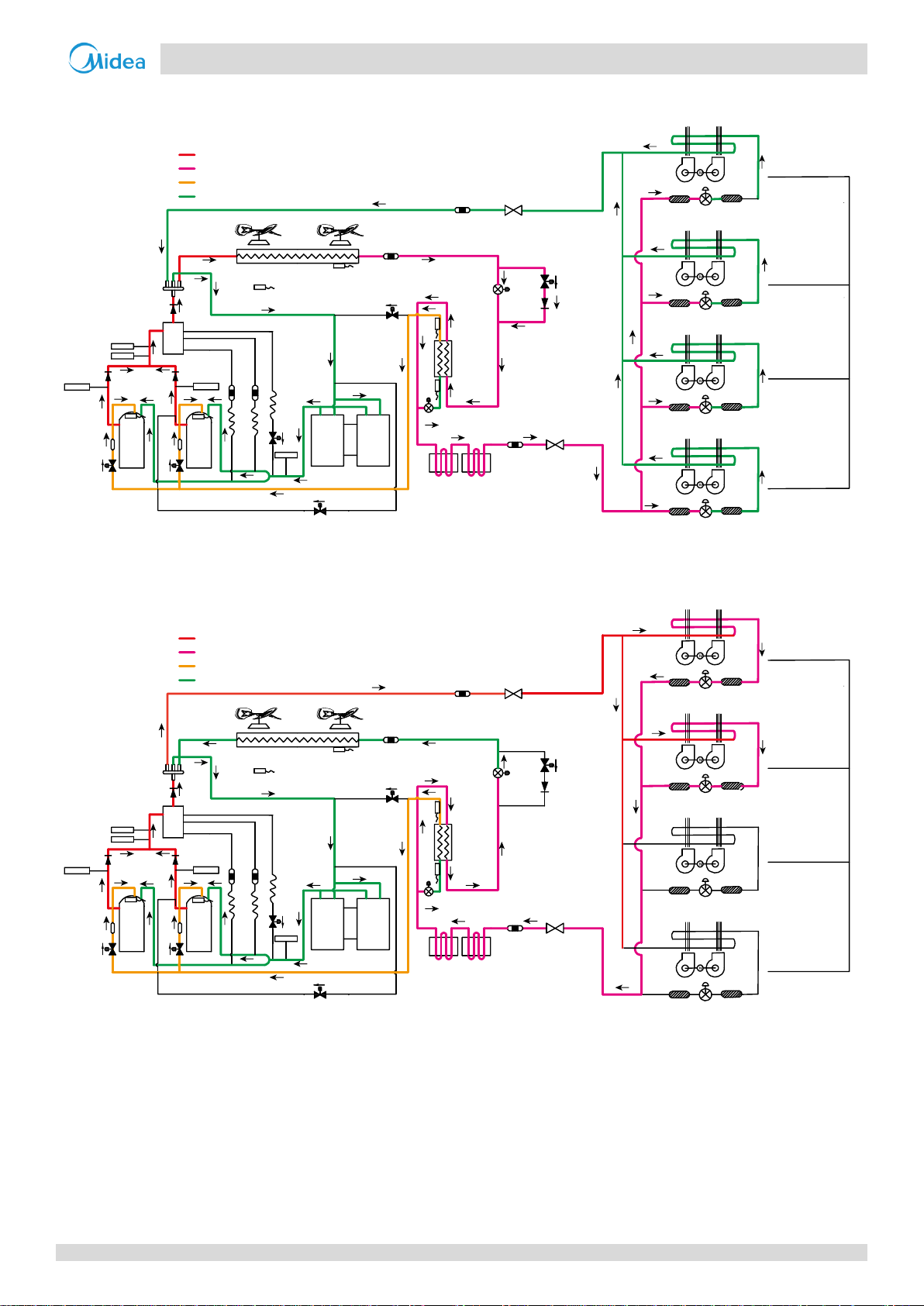

3 Refrigerant Flow Diagrams

8/10/12HP

Cooling operation

Figure 2-3.1: 8/10/12HP refrigerant flow during cooling operation

Oil return operation in cooling mode

Figure 2-3.2: 8/10/12HP refrigerant flow during oil return operation in cooling mode

22

Page 24

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

7

1

15

12

9

3

2

4

5

6

11

10

14

8

13

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

EXVA

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

SV6

480 steps

Filter

Filter

480 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

480 steps

Filter

Filter

480 steps

Filter

Filter

Fan

off

Fan

off

Fan

off

Fan

off

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

7

1

15

12

9

3

2

4

5

6

11

10

14

8

13

EXVA

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

SV6

Closed

Closed

Filter

Filter

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Normal control

Filter

Filter

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

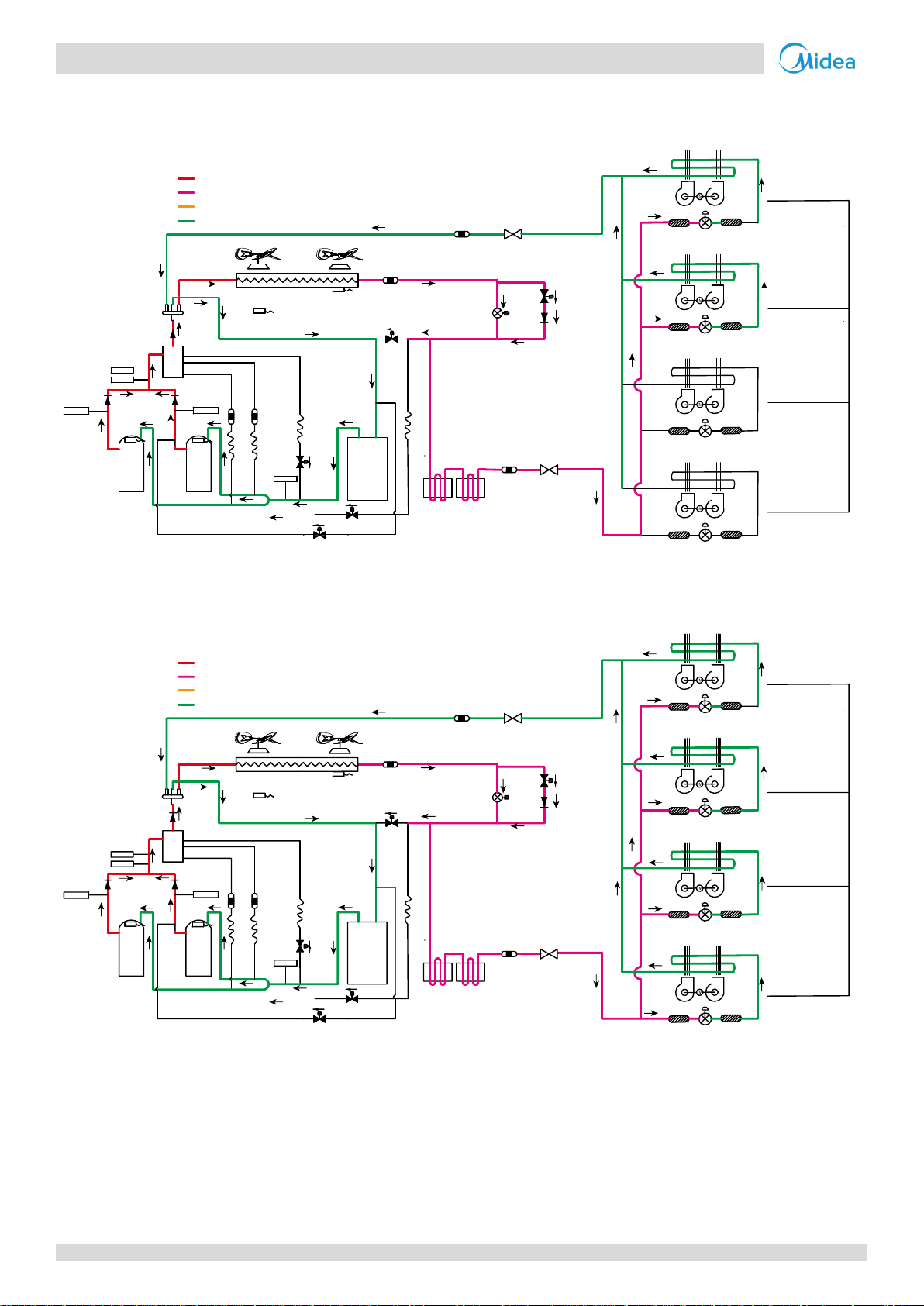

Oil return operation in heating mode and defrosting operation

Figure 2-3.3: 8/10/12HP refrigerant flow during oil return operation in heating mode and during defrosting operation

Heating operation

Figure 2-3.4: 8/10/12HP refrigerant flow during heating operation

23

Page 25

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

SV7

7

1

15

12

9

3

2

4

5

6

11

10

14

13

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

EXVA

8

SV6

Closed

Filter

Filter

Closed

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

SV7

EXVA

8

SV6

7

1

15

12

9

5

6

11

10

14

13

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

300 steps

Filter

Filter

300 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

14/16/18HP

Cooling operation

Figure 2-3.5: 14/16/18 refrigerant flow during cooling operation

Oil return operation in cooling mode

Figure 2-3.6: 14/16/18HP refrigerant flow during oil return operation in cooling mode

24

Page 26

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

SV7

EXVA

8

SV6

7

1

15

12

9

3

2

4

5

6

11

10

14

13

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

480 steps

Filter

Filter

480 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

480 steps

Filter

Filter

480 steps

Filter

Filter

Fan

off

Fan

off

Fan

off

Fan

off

SV7

EXVA

8

SV6

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

7

1

15

12

9

3

2

4

5

6

11

10

14

13

EXVC

E

S

C

T3

T4

T6B

T7C1

T7C2

T6A

SV8A

SV4

SV5

Closed

Closed

Filter

Filter

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Normal control

Filter

Filter

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

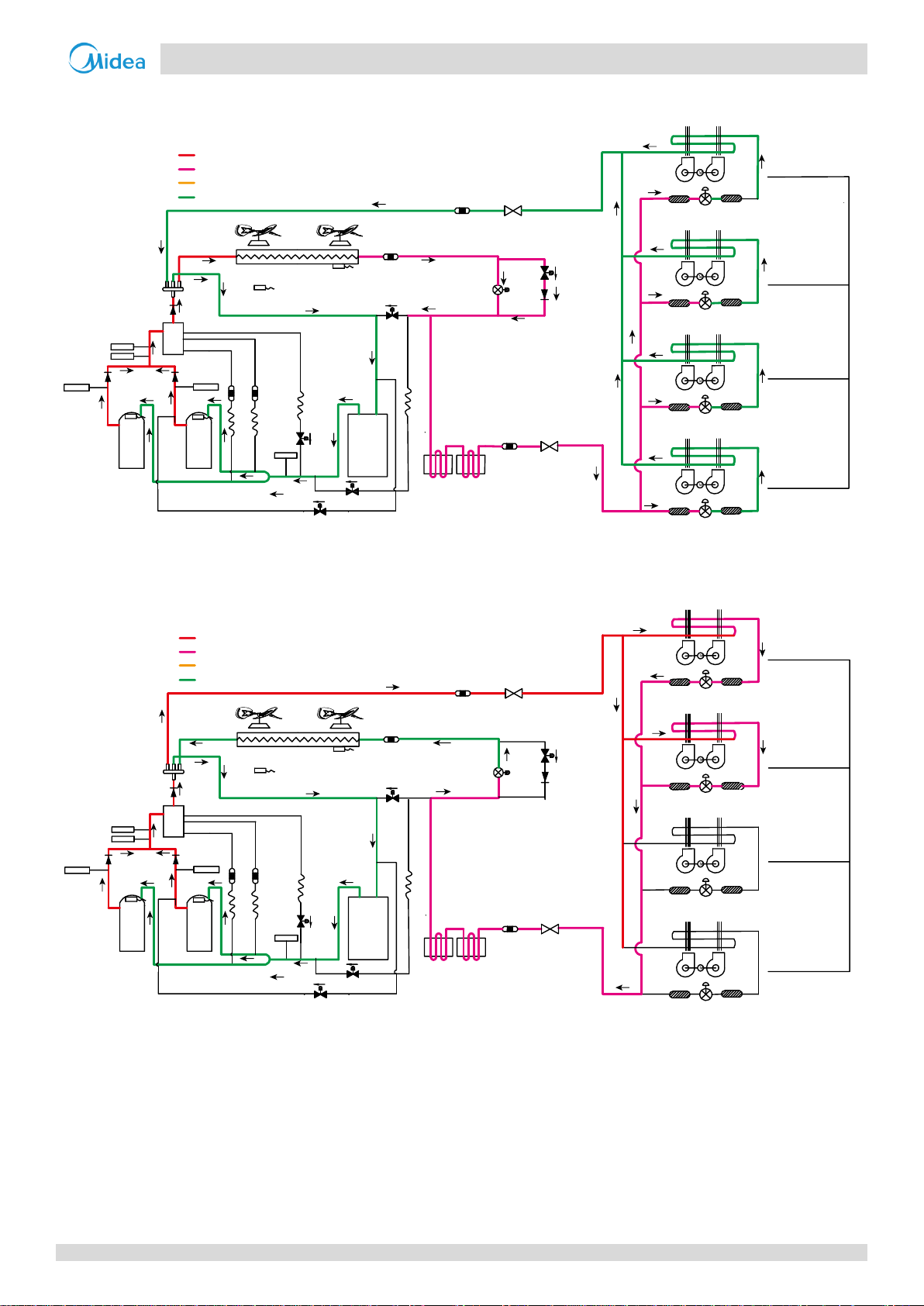

Oil return operation in heating mode and defrosting operation

Figure 2-3.7: 14/16/18HP refrigerant flow during oil return operation in heating mode and during defrosting operation

Heating operation

Figure 2-3.8: 14/16/18HP refrigerant flow during heating operation

25

Page 27

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

7

1

1

159

3

4

5

6

11

11

10 10

8

13

EXVA

E

S

C

T3

T4

2

T7C1

T7C2

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

Closed

Filter

Filter

Closed

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

12

SV2

300 steps

Filter

Filter

300 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

7

1

1

159

3

4

5

6

11

11

10 10

8

13

EXVA

E

S

C

T3

T4

2

T7C1

T7C2

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

12

SV2

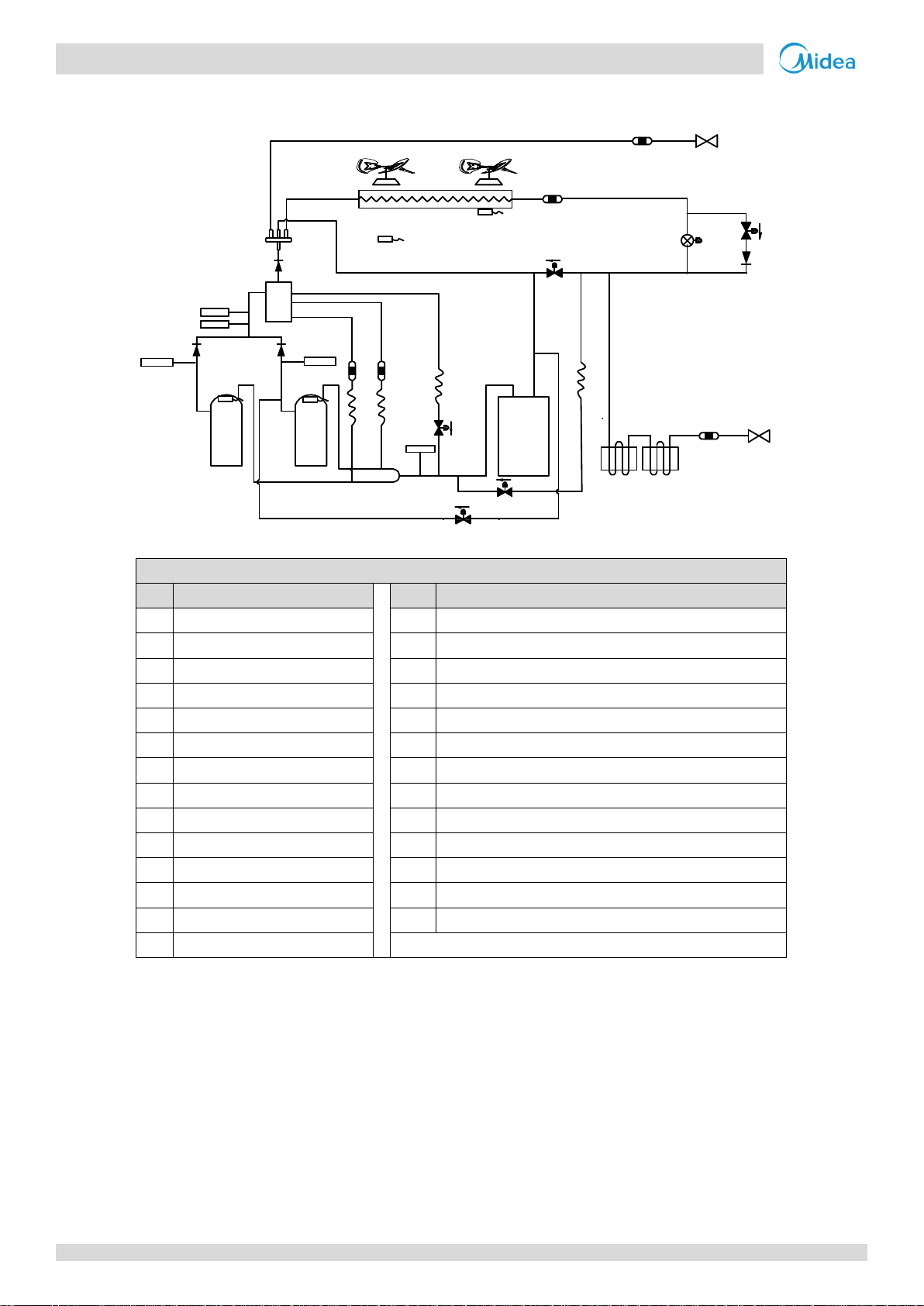

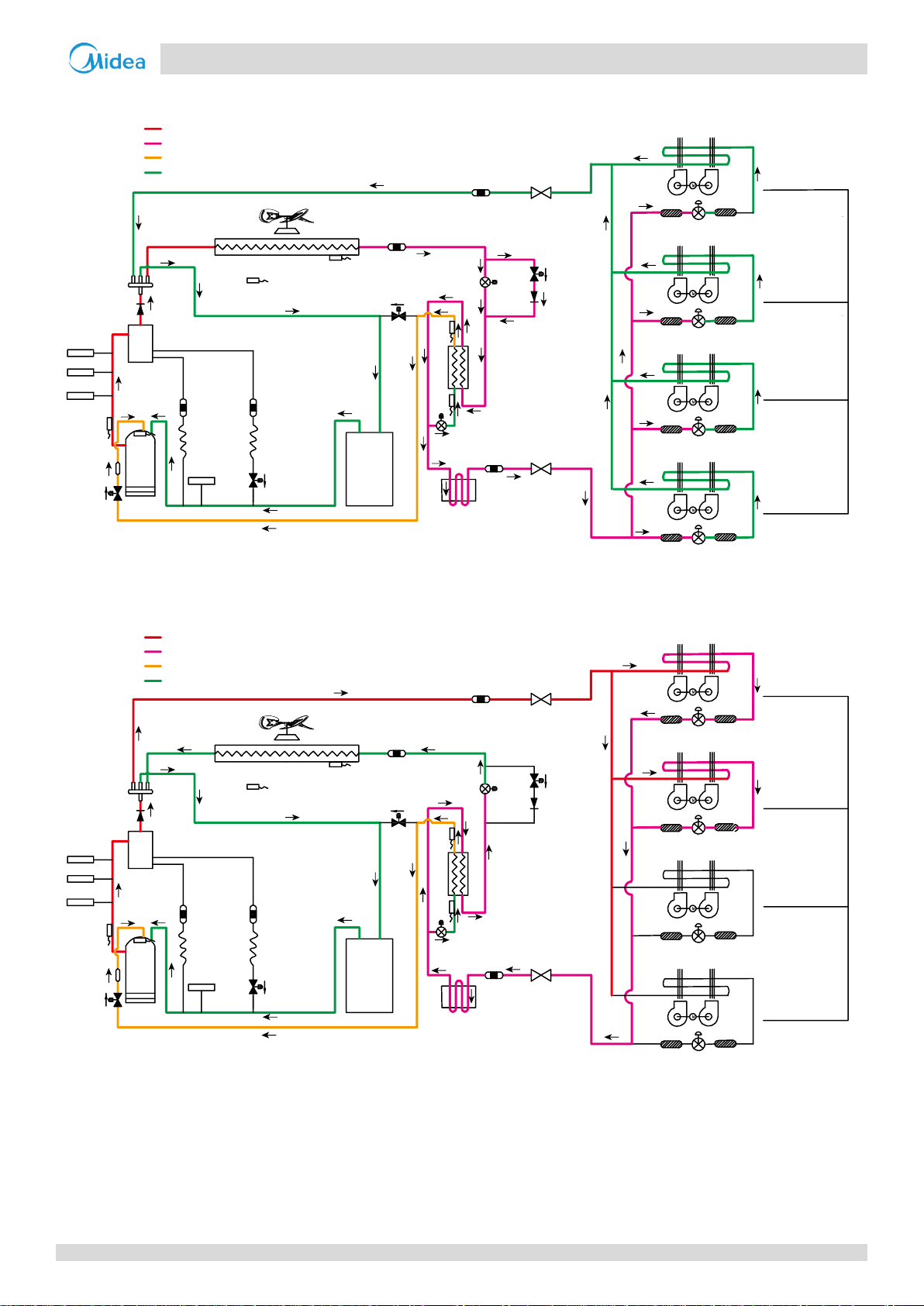

20/22/24HP

Cooling operation

Figure 2-3.9: 20/22/24 refrigerant flow during cooling operation

Oil return operation in cooling mode

Figure 2-3.10: 20/22/24HP refrigerant flow during oil return operation in cooling mode

26

Page 28

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

480 steps

Filter

Filter

480 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

480 steps

Filter

Filter

480 steps

Filter

Filter

Fan

off

Fan

off

Fan

off

Fan

off

7

1

1

159

3

4

5

6

11

11

10 10

8

13

EXVA

E

S

C

T3

T4

2

T7C1

T7C2

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

12

SV2

Closed

Closed

Filter

Filter

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Normal control

Filter

Filter

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

7

1

1

159

3

4

5

6

11

11

10 10

8

13

EXVA

E

S

C

T3

T4

2

T7C1

T7C2

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

12

SV2

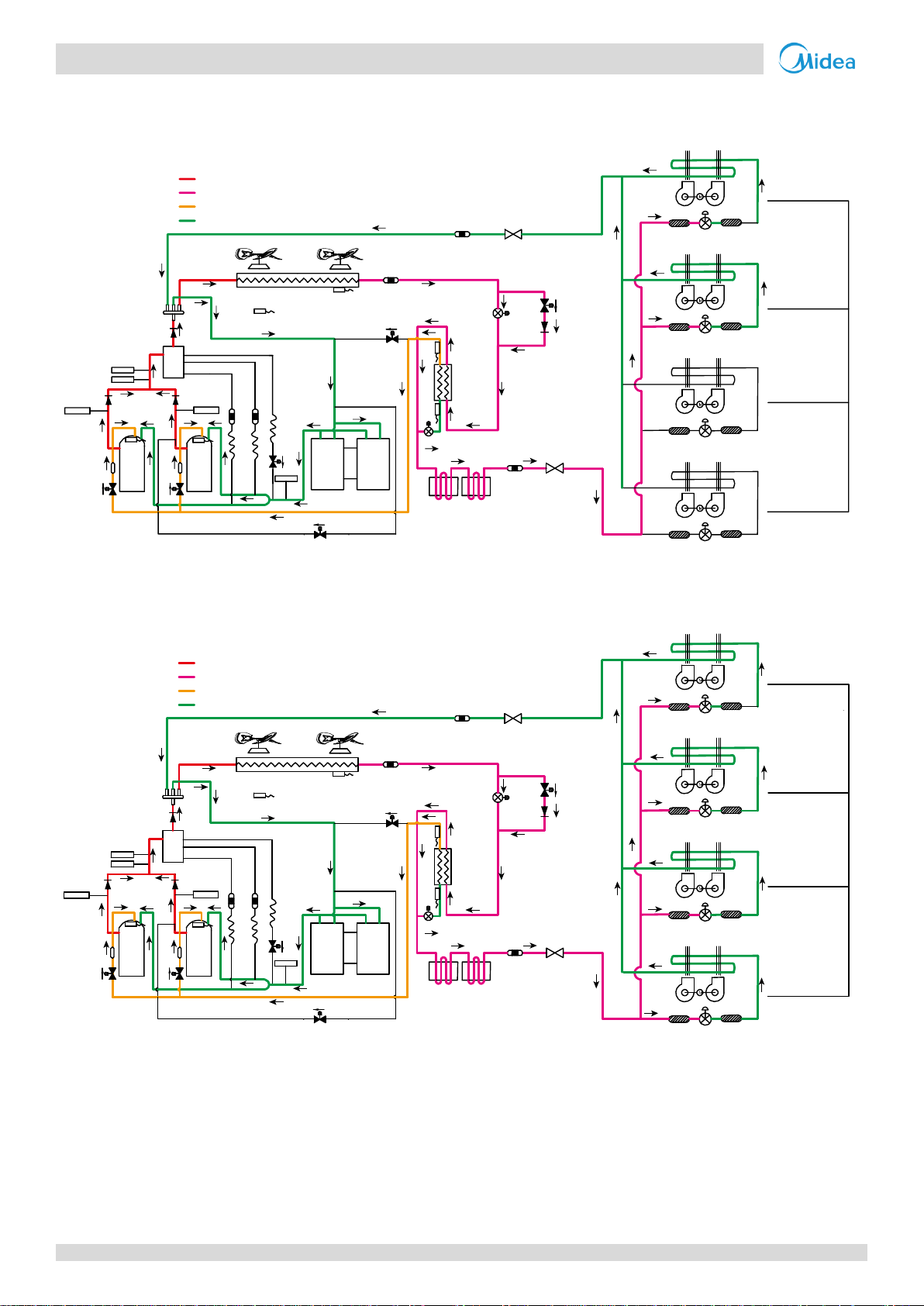

Oil return operation in heating mode and defrosting operation

Figure 2-3.11: 20/22/24HP refrigerant flow during oil return operation in heating mode and during defrosting operation

Heating operation

Figure 2-3.12: 20/22/24HP refrigerant flow during heating operation

27

Page 29

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

15

15

7

1

1

12

9

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

Closed

Filter

Filter

Closed

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

300 steps

Filter

Filter

300 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

15

15

7

1

1

12

9

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

26/28HP

Cooling operation

Figure 2-3.13: 26/28 refrigerant flow during cooling operation

Oil return operation in cooling mode

Figure 2-3.14: 26/28HP refrigerant flow during oil return operation in cooling mode

28

Page 30

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

480 steps

Filter

Filter

480 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

480 steps

Filter

Filter

480 steps

Filter

Filter

Fan

off

Fan

off

Fan

off

Fan

off

15

15

7

1

1

12

9

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

Closed

Closed

Filter

Filter

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Normal control

Filter

Filter

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

15

15

7

1

1

12

9

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

Oil return operation in heating mode and defrosting operation

Figure 2-3.15: 26/28HP refrigerant flow during oil return operation in heating mode and during defrosting operation

Heating operation

Figure 2-3.16: 26/28HP refrigerant flow during heating operation

29

Page 31

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

15

15

7

1

1

12

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

Closed

Filter

Filter

Closed

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

9

S

V7

300 steps

Filter

Filter

300 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Filter

Filter

Normal control

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

15

15

7

1

1

12

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

9

S

V7

30/32HP

Cooling operation

Figure 2-3.17: 30/32 refrigerant flow during cooling operation

Oil return operation in cooling mode

Figure 2-3.18: 30/32HP refrigerant flow during oil return operation in cooling mode

30

Page 32

-i V6-i VRF 50/60Hz

Part 2

- Component Layout

and

Refrigerant Circuits

480 steps

Filter

Filter

480 steps

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

480 steps

Filter

Filter

480 steps

Filter

Filter

Fan

off

Fan

off

Fan

off

Fan

off

15

15

7

1

1

12

3

4

5

6

11

11

10 10

14

8

8

13

EXVA

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

9

S

V7

Closed

Closed

Filter

Filter

Unit on

Thermostat off

Unit on

Thermostat on

Unit on

Thermostat on

Unit off

Filter

Indoor unit operation

Filter

Normal control

Normal control

Filter

Filter

Filter

Filter

Fan

on

Fan

off

Fan

on

Fan

on

15

15

7

1

1

12

3

4

5

6

11

11

10 10

14

8

8

13

EXVB

EXVC

E

S

C

T3

T4

2

T7C1

T7C2

T6B

T6A

SV8A

SV8B

SV9

SV4

SV5

SV6

2

High temperature, high pressure gas

High temperature, high pressure liquid

Medium temperature, medium pressure gas

Low temperature, low pressure

9

S

V7

Oil return operation in heating mode and defrosting operation

Figure 2-3.19: 30/32HP refrigerant flow during oil return operation in heating mode and during defrosting operation

Heating operation

Figure 2-3.20: 30/32HP refrigerant flow during heating operation

31

Page 33

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

32

Page 34

V6-i VRF 50/60Hz

Part 3

- Control

Part 3

Control

1 General Control Scheme Flowchart ...................................................... 34

2 Stop Operation .................................................................................... 35

3 Standby Control ................................................................................... 35

4 Startup Control .................................................................................... 36

5 Normal Operation Control ................................................................... 38

6 Protection Control ............................................................................... 43

7 Special Control ..................................................................................... 45

33

Page 35

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Legend

Numbers in the top right-hand

corners of boxes indicate the

relevant section of text on the

following pages.

Conditions met

for oil return

Conditions met

for defrosting

Thermo on

Special control

Outdoor unit duty cycling

Oil return operation

Defrosting operation

7

Stop operation

A unit stops when the load demanded decreases

2

Standby control

Crankcase heater control

3

Startup control

Startup control for heating operation

4

Thermo on

Normal operation control

Outdoor fan control

5

Protection control

Compressor and inverter module protection

Disable heating control

6

1 General Control Scheme Flowchart

Sections 3-2 to 3-7 on the following pages detail when each of the controls in the flowchart below is activated.

Abnormal shutdown

System stops

Compressor startup delay control

Startup control for cooling operation

Component control during normal operation

Compressor output control

Compressor step control

Operation priority and rotation of compressors

Electronic expansion valve control

High pressure protection control

Low pressure protection control

Discharge temperature protection control

control

34

Page 36

V6-i VRF 50/60Hz

Part 3

- Control

Figure 3-3.1: Crankcase heater controlled according to outdoor ambient temperature

Figure 3-3.2: Crankcase heater controlled according to discharge temperature

Ambient temperature < 35 oC

Ambient temperature > 40 oC

Crankcase heater off

Crankcase heater is controlled according to discharge temperature

Discharge temperature < 40 oC

Discharge temperature > 50 oC

Crankcase heater off

Crankcase heater on

2 Stop Operation

The stop operation occurs for one of the three following reasons:

1. Abnormal shutdown: in order to protect the compressors, if an abnormal state occurs the system makes a 'stop with

thermo off' operation and an error code is displayed on the outdoor unit digital displays.

2. The system stops when the set temperature has been reached.

3 Standby Control

3.1 Crankcase Heater Control

The crankcase heater is used to prevent refrigerant from mixing with compressor oil when the compressors are stopped.

The crankcase heater is controlled according to outdoor ambient temperature and discharge temperature. When the

outdoor ambient temperature is above 40°C, the crankcase heater is off; when the outdoor ambient temperature is below

35°C, the crankcase heater is controlled according to discharge temperature. Refer to Figures 3-3.1 and 3-3.2.

35

Page 37

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Component

Wiring

diagram

label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Controlled according to load requirement,

operating frequency increased by 1 step / sec

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Fan speed1 controlled according to discharge

pressure (Pc):

At initial speed for 90 seconds.

Subsequently, P

c

checked every 10

seconds:

P

c

≥ 2.7MPa => 1 step increase.

P

c

≤ 2.1MPa => 1 step decrease.

DC fan motor B

FANB

● ● ●

Electronic expansion

valve A

EXVA

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480 or

3000 (fully open), controlled according to

discharge temperature

Electronic expansion

valve C

EXVC

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

(fully open), controlled according to

temperature different between plate heat

exchanger inlet and outlet

Four-way valve

ST1

● ● ● ● ●

Off

Solenoid valve (oil

balance)

SV4

● ● ● ● ●

Closed for 200 secs, open for 600 secs, then

closed

Solenoid valve (fast

defrosting (in cooling)

and unloading (in

heating))

SV5

● ● ● ● ●

Open for 4 mins, then closed

Solenoid valve (EXV

bypass)

SV6

● ● ● ● ●

Open for 10 mins, then controlled according

to pressure

Solenoid valve (indoor

units bypass)

SV7

●

●

Controlled according to load requirement

Solenoid valve

(inverter compressor A

vapor injection)

SV8A

● ● ● ●

Controlled according to inverter compressor

A

Solenoid valve

(inverter compressor B

vapor injection)

SV8B

● ●

Controlled according to inverter compressor

B

Solenoid valve

(inverter compressor B

pressure balance)

SV9

● ● ●

Open before compressor B startup

Notes:

1. Refer to Table 3-5.3 in Part 3, 5.6 “Outdoor Fan Control” for more information on fan speed steps.

4 Startup Control

4.1 Compressor Startup Delay Control

In initial startup control, compressor startup is delayed for 12 minutes in order to let the outdoor unit search for the indoor

units’ addresses. In restart control (except in oil return operation and defrosting operation), compressor startup is delayed

such that a minimum of 7 minutes has elapsed since the compressor stopped, in order to prevent frequent compressor

on/off and to equalize the pressure within the refrigerant system.

4.2 Startup Control for Cooling Operation

Table 3-4.1: Component control during startup in cooling mode

36

Page 38

V6-i VRF 50/60Hz

Part 3

- Control

Component

Wiring

diagram

label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Controlled according to load requirement,

operating frequency increased by 1 step /

sec

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Open once the four-way valve has opened,

controlled according to outdoor ambient

temperature and load requirement

DC fan motor B

FANB

● ● ●

Electronic expansion

valve A

EXVA

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

or 3000 (fully open), controlled according

to discharge superheat

Electronic expansion

valve C

EXVC

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

(fully open), controlled according to

temperature different between plate heat

exchanger inlet and outlet

Four-way valve

ST1

● ● ● ● ●

On

Solenoid valve (oil

balance)

SV4

● ● ● ● ●

Closed for 200 secs, open for 600 secs, then

closed

Solenoid valve (fast

defrosting (in cooling)

and unloading (in

heating))

SV5

● ● ● ● ●

Open for 4 mins, then closed

Solenoid valve (EXV

bypass)

SV6

● ● ● ● ●

Off

Solenoid valve (indoor

units bypass)

SV7

●

●

Controlled according to load requirement

Solenoid valve (inverter

compressor A vapor

injection)

SV8A

● ● ● ●

Controlled according to inverter

compressor A

Solenoid valve (inverter

compressor B vapor

injection)

SV8B

● ●

Controlled according to inverter

compressor B

Solenoid valve (inverter

compressor B pressure

balance)

SV9

● ● ●

Open before compressor B startup

4.3 Startup Control for Heating Operation

Table 3-4.2: Component control during startup in heating mode

37

Page 39

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Component

Wiring

diagram

label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Controlled according to load requirement

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Controlled according to discharge pressure

DC fan motor B

FANB

● ● ●

Electronic expansion

valve A

EXVA

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

or 3000 (fully open), controlled according to

discharge temperature

Electronic expansion

valve C

EXVC

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

(fully open), controlled according to

temperature different between plate heat

exchanger inlet and outlet

Four-way valve

ST1

● ● ● ● ●

On

Solenoid valve (oil

balance)

SV4

● ● ● ● ●

Open regularly

Solenoid valve (fast

defrosting (in cooling)

and unloading (in

heating))

SV5

● ● ● ● ●

Controlled according to ambient

temperature, discharge pressure, discharge

temperature, compressor running

frequency and discharge superheat

Solenoid valve (EXV

bypass)

SV6

● ● ● ● ●

Controlled according to discharge pressure

and discharge temperature

Solenoid valve (indoor

units bypass)

SV7

●

●

Controlled according to load requirement

Solenoid valve (inverter

compressor A vapor

injection)

SV8A

● ● ● ● ●

Controlled according to inverter compressor

A on/off

Solenoid valve (inverter

compressor B vapor

injection)

SV8B

● ●

Controlled according to inverter compressor

B on/off

Solenoid valve (inverter

compressor B pressure

balance)

SV9

● ● ●

Open before compressor B startup and close

after compressor B running for 15 seconds.

Open after compressor B stop 10 seconds

and keep open 60 seconds.

5 Normal Operation Control

5.1 Component Control during Normal Operation

Table 3-5.1: Component control during normal cooling operation

38

Page 40

V6-i VRF 50/60Hz

Part 3

- Control

Component

Wiring

diagram

label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Controlled according to load requirement

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Controlled according to outdoor ambient

temperature, outdoor heat exchanger pipe

temperature, discharge pressure and load

requirement

DC fan motor B

FANB

● ● ●

Electronic expansion

valve A

EXVA

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

or 3000 (fully open), controlled according to

discharge superheat

Electronic expansion

valve C

EXVC

● ● ● ● ●

Position (steps) from 0 (fully closed) to 480

(fully open), controlled according to

temperature different between plate heat

exchanger inlet and outlet

Four-way valve

ST1

● ● ● ● ●

On

Solenoid valve (oil

balance)

SV4

● ● ● ● ●

Open regularly

Solenoid valve (fast

defrosting (in cooling)

and unloading (in

heating))

SV5

● ● ● ● ●

Controlled according to ambient

temperature, discharge pressure, discharge

temperature, compressor running

frequency and discharge superheat

Solenoid valve (EXV

bypass)

SV6

● ● ● ● ●

Off

Solenoid valve (indoor

units bypass)

SV7

●

●

Controlled according to load requirement

Solenoid valve (inverter

compressor A vapor

injection)

SV8A

● ● ● ●

Controlled according to inverter compressor

A on/off

Solenoid valve (inverter

compressor B vapor

injection)

SV8B

● ●

Controlled according to inverter compressor

B on/off

Solenoid valve (inverter

compressor B pressure

balance)

SV9

● ● ●

Open before compressor B startup and close

after compressor B running for 15 seconds.

Open after compressor B stop 10 seconds

and keep open 60 seconds.

Table 3-5.2: Component control during heating operation

39

Page 41

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Figure 3-5.1: Compressor priority and rotation – one outdoor unit

BP

No. 1

BP1

No. 1 No. 2

BP2

5.2 Compressor Output Control

The compressor rotation speed is controlled according to the load requirement. Before compressor startup, the outdoor

unit first estimates the indoor unit load requirement according to the nominal capacity of indoor units currently running,

and then correct for ambient temperature. The compressors then start up according to the corrected load requirement.

During operation the compressors are controlled according to the nominal capacity of indoor units currently running and

the indoor unit heat exchanger temperatures.

5.3 Compressor Step Control

The running speed of the compressors in rotations per second (rps) is one third of the frequency (in Hz) of the electrical

input to the compressor motors. The compressor speed can be altered in increments of 1 rps.

5.4 Operating Priority and Rotation of Compressors

Figures 3-5.1 shows the compressor operating priority and rotation in the outdoor unit. In units with two compressors,

inverter compressor A (BP1) operates in priority to inverter compressor B (BP2).

40

Page 42

V6-i VRF 50/60Hz

Part 3

- Control

Fan speed index

Fan speed (rpm)

8-18HP

20-22HP

24-32HP

FANA / FANB

FANA / FANB

0 0 0 / 0

0 / 0

1

120

150 / 0

120 / 0

2

150

190 / 0

150 / 0

3

170

230 / 0

170 / 0

4

190

270 / 0

190 / 0

5

210

310 / 0 (150 / 150)

210 / 0

6

230

350 / 0 (180 / 180)

230 / 0

7

250

380 / 0 (210 / 210)

250 / 0 (120 / 120)

8

270

410 / 0 (240 / 240)

270 / 0 ( 150 / 150)

9

290

280 / 280

330 / 0 (170 / 170)

10

310

320 / 320

370 / 0 (190 / 190)

11

330

360 / 360

210 / 210

12

350

400 / 400

230 / 230

13

370

440 / 440

250 / 250

14

390

480 / 480

270 / 270

15

410

520 / 520

290 / 290

16

430

560 / 560

310 / 310

17

450

600 / 600

330 / 330

18

470

640 / 640

350 / 350

19

490

680 / 680

370 / 370

20

510

720 / 720

400 / 400

21

530

760 / 760

430 / 430

22

560

800 / 800

470 / 470

5.5 Electronic Expansion Valve Control

EXVA control

The position of electronic expansion valves EXVA is controlled in steps from 0 (fully closed) to 480 (fully open) or 3000

(fully open).

In cooling mode:

When the outdoor unit is in standby:

EXVA is at position 352 (steps) or 2112 (steps).

When the outdoor unit is running:

EXVA is controlled according to discharge temperature.

In heating mode:

When the outdoor unit is in standby:

EXVA is at position 352 (steps) or 2112 (steps).

When the outdoor unit is running:

EXVA is controlled according to discharge superheat.

EXVC control

The positions of electronic expansion valves EXVC are controlled in steps from 0 (fully closed) to 480 (fully open).

In cooling / heating mode:

When the outdoor unit is in standby:

EXVC is fully closed.

When the outdoor unit is running:

EXVC is controlled according to temperature different between plate heat exchanger inlet and outlet.

5.6 Outdoor Fan Control

The speed of the outdoor unit fans is adjusted in steps, as shown in Table 3-5.3.

Table 3-5.3: Outdoor fan speed steps

41

Page 43

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

23

580

840 / 840

510 / 510

24

600

880 / 880

550 / 550

25

630

910 / 910

600 / 600

26

650

940 / 940

650 / 650

27

700

980 / 980

700 / 700

28

750

1010 / 1010

750 / 750

29

800

1020 / 1020

800 / 800

30

850

1050 / 1050

830 / 830

31

880

1080 / 1080

850 / 850

32

920

1120 / 1120

870 / 870

33

920

1140 / 1140

890 / 890

34

920

1140 / 1140

920 / 920

35

920

1140 / 1140

920 / 920

36 (ESP 40Pa mode)

950

1200 / 1200

950 / 950

37 (ESP 60Pa mode)

980

1200 / 1200

980 / 980

Note:

1. For 20-22HP unit fan speed 5 to 8 and 24-32HP unit fan speed 7 to 10, when fan speed decreases, the fan speed is shown in the bracket; when fan speed

increases, the fan speed is shown without bracket.

42

Page 44

V6-i VRF 50/60Hz

Part 3

- Control

Figure 3-6.1: High pressure protection control

Notes:

1. P

c

: Discharge pressure

Figure 3-6.2: Low pressure protection control

Notes:

1. P

e

: Suction pressure

Figure 3-6.3: Discharge temperature protection control

When P2 protection occurs 3 times

in 60 minutes, the H5 error is

displayed. When an H5 error occurs,

a manual system restart is required

before the system can resume

operation.

Pc > 4.4MPa

Pc < 3.2MPa

Normal operation

High pressure protection, error code P1 is displayed

Pe < 0.05MPa

Pe > 0.15MPa

Normal operation

Low pressure protection, error code P2 is displayed

120oC

100oC

90oC

Discharge temperature

Compressor off

90oC

6 Protection Control

6.1 High Pressure Protection Control

This control protects the system from abnormally high pressure and protects the compressors from transient spikes in

pressure.

6.2 Low Pressure Protection Control

This control protects the system from abnormally low pressure and protects the compressors from transient drops in

pressure.

6.3 Discharge Temperature Protection Control

This control protects the compressors from abnormally high temperatures and transient spikes in temperature. It is

performed for each compressor.

When the discharge temperature rises above 120°C the system displays P4 protection and all units stop running. When P4

protection occurs 3 times in 100 minutes, the H6 error is displayed. When an H6 error occurs, a manual system restart is

required before the system can resume operation.

43

Page 45

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Figure 3-6.4: Compressor current protection control

Compressor model

AA55PHDG –D1YG

DC80PHDG –D1YG

Current

max

24.6

33

Figure 3-6.5: Inverter module temperature protection control

Notes:

1. T

f

: Heat sink temperature

Figure 3-6.6: Disable heating control

When PL protection occurs 3 times

in 100 minutes, the C7 error is

displayed. When a C7 error occurs, a

manual system restart is required

before the system can resume

operation.

Current ≥ Current

max

Current < Current

max

Normal operation

Compressor current protection, error code xP3 is displayed

Tf > 75oC

Tf < 73oC

Normal operation

Compressor output reduced

Tf > 80oC

Tf < 65oC

Inverter module temperature protection,

error code PL is displayed

Outdoor ambient temperature > 25oC

Outdoor ambient temperature < 23oC

Heating operation

Units stop

6.4 Compressor and Inverter Module Protection Control

This control protects the compressors from abnormally high currents and protects the inverter modules from abnormally

high temperatures. It is performed for each compressor and inverter module.

6.5 Disable Heating Control

When the outdoor ambient temperature rises above 25°C heating mode is disabled to prevent the mechanical load on

compressors becoming too high and to prevent low compression ratios which can result in insufficient compressor internal

oil lubrication.

44

Page 46

V6-i VRF 50/60Hz

Part 3

- Control

Table 3-7.1: Outdoor unit component control during oil return operation in cooling mode

Component

Wiring

diagram label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Fixed frequency

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Fan speed controlled according

to discharge pressure

DC fan motor B

FANB

● ● ●

Electronic expansion valve A

EXVA

● ● ● ● ●

Position 480 (steps) or 3000

(steps)

Electronic expansion valve C

EXVC

● ● ● ● ●

Position 96 (steps)

Four-way valve

ST1

● ● ● ● ●

Off

Solenoid valve (oil balance)

SV4

● ● ● ● ●

Normal control

Solenoid valve (fast defrosting)

SV5

● ● ● ● ●

On

Solenoid valve (EXV bypass)

SV6

● ● ● ● ●

On

Solenoid valve (indoor units

bypass)

SV7

●

●

Normal control

Solenoid valve (inverter

compressor A vapor injection)

SV8A

● ● ● ●

Controlled according to inverter

compressor A

Solenoid valve (inverter

compressor B vapor injection)

SV8B

● ●

Controlled according to inverter

compressor B

Solenoid valve (inverter

compressor B pressure balance)

SV9

● ● ●

Open before compressor B

startup

Table 3-7.2: Indoor unit component control during oil return operation in cooling mode

Component

Unit state

Control functions and states

Fan

Thermo on

Remote controller setting

Standby

Off

Thermo off

Off

Electronic expansion valve

Thermo on

Normal control

Standby

300 (steps)

Thermo off

300 (steps)

7 Special Control

7.1 Oil Return Operation

In order to prevent compressors from running out of oil, the oil return operation is conducted to recover oil that has

flowed out of the compressor(s) and into the piping system. This operation is performed for all units including units that

are in standby. When the outdoor unit is running in oil return, the digital display on outdoor main PCB will display “d0”.

Timing of oil return operation:

When the initial cumulative operating time reaches 140 minutes and then every 8 hours.

Tables 3-7.1 and 3-7.2 show component control during oil return operation in cooling mode.

45

Page 47

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Table 3-7.3: Outdoor unit component control during oil return operation in heating mode

Component

Wiring

diagram label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Fixed frequency

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Fan speed controlled according

to discharge pressure

DC fan motor B

FANB

● ● ●

Electronic expansion valve A

EXVA

● ● ● ● ●

Position 480 (steps) or 3000

(steps)

Electronic expansion valve C

EXVC

● ● ● ● ●

Position 96 (steps)

Four-way valve

ST1

● ● ● ● ●

Off

Solenoid valve (oil balance)

SV4

● ● ● ● ●

Normal control

Solenoid valve (fast defrosting)

SV5

● ● ● ● ●

On

Solenoid valve (EXV bypass)

SV6

● ● ● ● ●

On

Solenoid valve (indoor units

bypass)

SV7

●

●

Normal control

Solenoid valve (inverter

compressor A vapor injection)

SV8A

● ● ● ●

Off

Solenoid valve (inverter

compressor B vapor injection)

SV8B

● ●

Off

Solenoid valve (inverter

compressor B pressure balance)

SV9

● ● ●

Open before compressor B

startup

Table 3-7.4: Indoor unit component control during oil return operation in heating mode

Component

Unit state

Control functions and states

Fan

Thermo on

Off

Standby

Off

Thermo off

Off

Electronic expansion valve

Thermo on

480 (steps)

Standby

480 (steps)

Thermo off

480 (steps)

Tables 3-7.3 and 3-7.4 show component control during oil return operation in heating mode.

46

Page 48

V6-i VRF 50/60Hz

Part 3

- Control

Table 3-7.5: Outdoor unit component control during defrosting operation

Component

Wiring

diagram label

8-12HP

14-18HP

20-24HP

26-28HP

30-32HP

Control functions and states

Inverter compressor A

COMP(A)

● ● ● ● ●

Fixed frequency

Inverter compressor B

COMP(B)

● ● ●

DC fan motor A

FANA

● ● ● ● ●

Off

DC fan motor B

FANB

● ● ●

Electronic expansion valve A

EXVA

● ● ● ● ●

Position 480 (steps) or 3000

(steps)

Electronic expansion valve C

EXVC

● ● ● ● ●

Position 480 (steps)

Four-way valve

ST1

● ● ● ● ●

Off

Solenoid valve (oil balance)

SV4

● ● ● ● ●

Normal control

Solenoid valve (fast defrosting)

SV5

● ● ● ● ●

On

Solenoid valve (EXV bypass)

SV6

● ● ● ● ●

On

Solenoid valve (indoor units

bypass)

SV7

●

●

Normal control

Solenoid valve (inverter

compressor A vapor injection)

SV8A

● ● ● ●

Off

Solenoid valve (inverter

compressor B vapor injection)

SV8B

● ●

Off

Solenoid valve (inverter

compressor B pressure balance)

SV9

● ● ●

Open before compressor B

startup

Table 3-7.6: Indoor unit component control during defrosting operation

Component

Unit state

Control functions and states

Fan

Thermo on

Off

Standby

Off

Thermo off

Off

Electronic expansion valve

Thermo on

480 (steps)

Standby

480 (steps)

Thermo off

480 (steps)

7.2 Defrosting Operation

In order to recover heating capacity, the defrosting operation is conducted when the outdoor unit heat exchanger is

performing as an evaporator. The defrosting operation is controlled according to outdoor ambient temperature, outdoor

heat exchanger temperature, indoor heat exchanger temperature and outdoor unit running time. When the outdoor unit is

running in defrosting, the digital display on outdoor main PCB will display “df”.

47

Page 49

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

48

Page 50

V6-i VRF 50/60Hz

Part 4

- Field Settings

Part 4

Field Settings

1 Outdoor Unit Field Settings ................................................................. 50

49

Page 51

V6-i VRF 50/60Hz

Midea V6-i Series Service Manual

Switch

Setting

Switch positions1

Description

S4

Static pressure

Standard static pressure (default)

Low static pressure mode (reserved)

Medium static pressure mode (reserved)

High static pressure mode (reserved)

Super high static pressure mode (reserved)

S5

Priority mode2

Auto priority (default)

Cooling priority

VIP priority or voting priority

Heating only

Cooling only

Set priority mode via centralized controller (reserved)

S6-1

Reserved

Reserved

S6-2

Clear indoor

unit addresses

No action (default)

Clear indoor unit addresses

Table continued on next page …

1 Outdoor Unit Field Settings

1.1 PCB Switches and Switch Settings

Figure 4-1.1: Outdoor unit main PCB switches

Table 4-1.1: Outdoor unit main PCB switch settings

50

Page 52

V6-i VRF 50/60Hz

Part 4

- Field Settings

Switch

Setting

Switch positions1

Description

S6-3

Addressing

mode

Auto addressing (default)

Manual addressing

S8-1

Reserved

Reserved

S8-2

Start-up time

Start-up time is 12 minutes (default)

Start-up time is 7 minutes

S8-3

Reserved