Page 1

Service Manual

TWIN TUB WASHING MACHINE

Model:MTE150-P2004S

Note:

Before serving the unit, please read this at first,

Always contact with your service center if meet problem.

Page 2

1. PRECAUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Servicing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CAUTION FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Description of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. . Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.DISASSEMBLY AND TEASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. CHECK POINT AFTER REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-1

1-1

2-1

3-1

3-2

3-3

3-4

4-1

5-1

6-1

7-1

CONTENTS

Page 3

1. PRECAUTION

When performing troubleshooting and part replacement during servicing, note the

following safety precautions:

1-1. Safety Precautions

1-1-1. Use Genuine Parts

The components of the washing machine have safety features such as non-combustibility

and voltage withstanding. Therefore, always use the same part as suggested by the maker.

In particular, be sure to use only designated parts in case of major safety parts identified

by the marker.

1-1-2. Grounding

Connect the grounding wire to the shell plate, and bury it under at least 25cm of earth :

alternatively, connect the ground wire to the appropriate pin on a properly grounded

power receptacle. Never connect the wire to a telephone line, lightning rod, or gas pipe.

1-2. Servicing Precautions

1-2-1. Observe Warnings

Be sure to follow special warning and precautions that are described on part labels and in

the owner's manual.

1-2-2. Parts Assembly and Wiring

Be sure to use insulation material (such as tube and tape). And be sure to restore all parts

and wires to their original position. Take special care to avoid contact with sharp edges.

1-2-3. Perform Safety Checks after Servicing

After servicing, check to see that the screws, parts, and wiring are restored to their

original positions, and check the insulation between the external metals and the socket

plug. In addition, place the washing machine in a level position (less than 1(one) degree)

to prevent vibration and noise during operations.

1-2-4. Insulation Checks

Pull out the plug from the power receptacle, pour water into the spin tub, and then set

the timer. Check to see that the resistance insulation between the terminals of the plug

and the externally exposed metal is greater than 1M• .

Note :When it is impossible to perform insulation check with a 500V insulation

resistance tester, use other testers for inspection.

1-1

Page 4

2-1

2. CAUTIONS FOR SAFETY

• Please observe the following notes for safety.

• The symbols indicate as follows.

Symbol Meaning

WARNING

Indicates possibility of death or serious injury of a repair technician and a

person nearby through the misconducted work, or of a user by a defect of the

product after the work performed by the technician.

CAUTION

Indicates possibility of injury or physical damages* of a repair technician and a

person nearby through the misconducted work, or of a user by a defect of the

product after the work performed by the technician.

*Means secondary damages of property, furniture, domestic animal and pet.

Symbol Meaning

ELECTRICSHOCK

• indicates a caution (including a warning).

Specific instruction is followed by a graphic or characters in or near • .

Symbol left warns an electric shock.

DONOT

DISASSEMBLE

indicates prohibition (act must not be conducted).

Specific instruction is followed by a graphic or characters in or near

Symbol left warns not to disassemble.

UNPLUG

• indicates forcing (act must be conducted).

Specific instruction is followed by a graphic or characters in or near • .

Symbol left warns to unplug the power cord.

WARNING

OUT OF CHILD

• Advise the customer to keep children out of the work place.

Children may be injured with a tool or a disassembled part.

UNPLUG POWER

• Unplug power cord for the work such as disassembling which is not

unnecessary to power on . Do not hold the plug by a wet hand.

Failing to unplug may cause an electric shock.

USE

REPAIR PARTS

• Use the specified repair parts when repairing the product.

Otherwise, a malfunction or a defect may occur.

Also, a short circuit, ignition or other danger to the customer may occur.

Page 5

2. CAUTIONS FOR SAFETY

WARNING

CHECK INSULATION

RESISTANCE

• After repair, measure insulation resistance between the charging part

(power cord plug) and the non-charging metallic part (ground) with an

insulation resistance meter (500V). The resistance shall be 10M• or more.

Failing to check the insulation resistance may cause a short circuit, electric

shock or other diseases to the customer.

DO NOT MODIFY

• Do not modify the product.

An electric shock or ignition may occur.

DO NOT

DISASSEMBLE AND

REPAIR

• Only a repair technician can disassemble and repair.

An electric shock, ignition or malfunction may cause injury.

USE EXCLUSIVE

SOCKET

• Use an exclusive 110 VAC/15 A socket for the washing machine.

(AW-B651B/B657B/B761S/B757S)

• Use an exclusive 220 VAC/17 A socket for the washing machine.(Except

above models)

Otherwise, an electric shock or ignition may cause. Sharing the same socket

with other instrument causes heating of a branch socket and result in a fire.

CONNECT

GROUNDING WIRE

• Connect the grounding wire.

Failing to do so may cause an electric shock when a short circuit occurs.

Consult an electric work shop or a sales shop.

DO NOT USE WET

PLACE

• Do not install in a bath room or a place exposed to wind or rain.

An electric shock or a short circuit may cause a fire.

DO NOT SPLASH

WATER

• Do not pour or immerse electrical parts into water or liquid solution.

An electric shock or ignition may occur.

REMOVE DUST

• Wipe off dust adhered to the plug of power cord.

Dust may cause a fire.

2-2

Page 6

2. CAUTIONS FOR SAFETY

WARNING

AVOID

INFLAMMABLE

• Do not put inflammable into the washing tub.

Do not put cloths stained with kerosene, gasoline, benzene, thinner, alcohol,

etc. lt may cause a fire or explosion.

DO NOT TOUCH

• Do not touch the laundry before the spin basket stops completely.

The laundry entangles your hand causing an injury even if the basket rotates

slowly. Pay special attention to children.

INSTALL

CAREFULLY

• Ask an electric work shop to install the product.

Install the product securely and safely according to the electrical equipment

technical standard and the wiring standard.

Incorrect work causes an electric shock and a fire.

DO NOT PULL

• Do not pull the power cord when unplugging.

Hold the power plug to unplug.

An electric shock or short circuit may cause a fire.

DANGER HAND

• Do not insert your hand under the washing machine during operation.

There is a rotary part under the machine which may cause an injury.

WATER LEAKAGE

• Before starting washing, open the faucet and check water supply hose joint

which shall not be loosened for no water leaks.

The loose screw or hose joint may cause water leakage resulting in an

unexpected damage.

2-3

Page 7

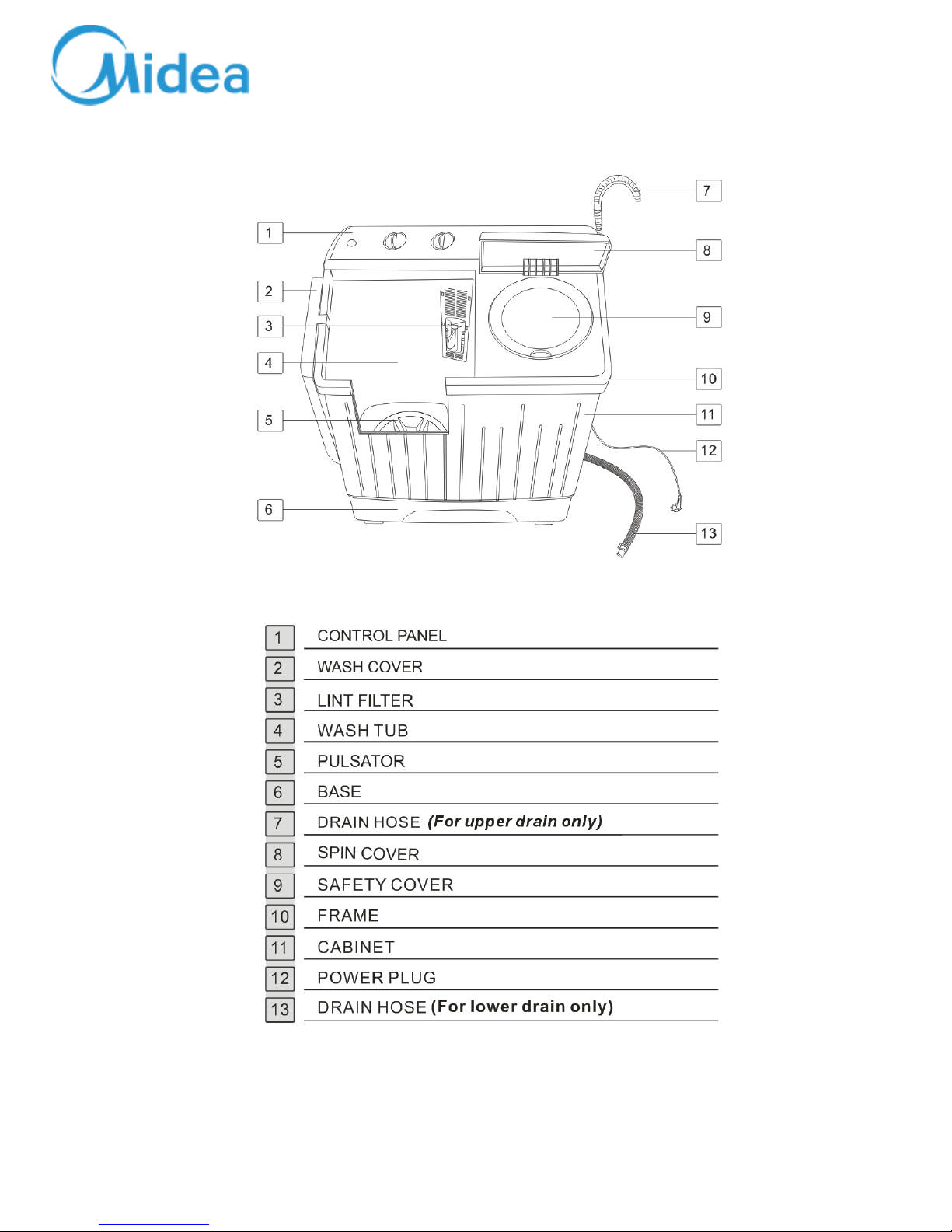

3. DESCRIPTION OF PARTS

3-1

Page 8

3. DESCRIPTION OF PARTS

3-1. Control Panel

3-2

● Water inlet: be used to inject water.

● Wash timer: be used to select required washing time.

● Spin timer: be used to select required spinning time.

● Wash selector: Choose “ Normal”or“ Heavy” according to laundry fabric.

● Drain selector: For upper drain,Choose “Wash”for washing,choose “Rinse”for

rinsing;choose “ Drain” for

draining.For lower drain,Choose “Wash/Rinse”for washing or

rinsing;choose “ Drain” for

draining.

Page 9

3. DESCRIPTION OF PARTS

3-2. Installation

3-2-1. Level Specifications and Wall - Clearance Distances

1) Install the washing machine on a solid and level floor.

2) Place the machine at least 15cm away from the wall.

3) Placement on an inclined, weak or rough floor may

cause abnormal noise or trembling.

3-2-2. Positioning the Drain Hose

1)When there is no threshold, the length of the

drain hose should not exceed 3m.

2)When it is necessary to connect the drain hose

with the drain outlet far away, connect the

extension hose and

applicable parts

available from

dealers or service

centers.

3) Do not install the drain hose where it must exceed

over a threshold of 3cm or more ; do not install

where there is a

threshold

and the hose

must exceed for

more than 2m.

3-3

Page 10

3. DESCRIPTION OF PARTS

3-2-3. Grounding

1) Upon installing grounding,make sure if power socket is out

of power outlet.

2) Grounding should be connected to eithermetal water

supply

pipe or copper grounding pole deeper than 25cm in the damp

ground. (Fig 1)

3) If water pipe is a plastic, no protection is obtained from

a possible electric shock.

4) If the power outlet is available with grounding connection,

grounding in the washingmachine should be firmly connected

to

the connection of the outlet. (Fig 2)

5) You should not connect, the grounding to the gas-pipe

because

it will cause an explosion. (Fig 3)

6) If the grounding is connected to either telecommunication

line

or lightning-arrest line, an extreme hazard is caused therefore,

no connection should bemade to such lines. (Fig 4)

3-4

Page 11

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE PICTURE

TIMERWASHING AND

TIMERSPINNING

1. Unscrew the screw of the plusator. (Fig

1)

2. Pull off the knobs by the screwdriver

which with"-"Sharp.

(Fig 2)

3. Pull off the control panel.(Fig 3)

4. Unscrew the screws of the washing

timer & Spin timer(Red circle part)

by the screwdriver which with "+"sharp.

(Fig 4)

(Fig 1)

(Fig 2)

(Fig 3)

(Fig 3)

Page 12

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

BASKETSPINNI

NG

1. Unscrew the screws (Red circle part)

from the back of model by

screwdriver. (Fig 1)

2. Unscrew the screws of the handle by

screwdriver. (Fig2)

3. Unscrew the screw caps by the blade.

(Fig 3)

4. Unscrew the screws of the washing

timer&Spin timer(Red circle part)

by the screwdriver which with "+"sharp.

(Fig 4)

5. Unscrew the screws of backs (Red

circle part) by screwdriver

which with "+"sharp. (Fig 5)

(Fig 1)

(Fig 2)

(Fig 3)

(Fig 4)

Page 13

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

BASKETSPINNI

NG

6. Pull off the breaking belt and drain

belt(Red circle part). (Fig 6)

7. Unscrew the screw at the joint of spin

tub & breaking plate.

(Fig 7)

(Used tool: M8 Box Driver)

8. Open the tub frame. (Fig 8)

9. Pull off the spin tub. (Fig 9)

(Fig 6)

(Fig 7)

(Fig 8)

(Fig 9)

M8 Box driver

Page 14

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

ASSY GEAR

BOX

1. Unscrew the screw of the plusator.

(Fig 1)

2. Take out the plusator's plate, (Fig 2)

3. Pull off the axle of spin tub & screw of

breaking plate, (Fig 3)

Further step check (Fig 6)

4. Unscrew the screws of base. (Fig4)

Take off the base.

5. Unscrew the 4 screws of gear box,

(Fig 5)

Take off the Gear box.

(Fig 1)

(Fig 2)

(Fig 3)

(Fig 4)

(Fig 5)

Page 15

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

MOTORSPINNING

&

MOTORWASHING

1. Unscrew the screw of the plusator.

(Fig 1)

2. Take out the plusator's plate, (Fig 2)

3. Pull off the axle of spin tub & screw of

breaking plate, (Fig 3)

Further step check (Fig 6)

4. Unscrew the screws of base. (Fig4)

Take off the base.

(Fig 1)

(Fig 2)

(Fig 3)

(Fig 4)

Page 16

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

MOTORSPINNING

&

MOTORWASHING

5. Remove the plastic bag on the

connection part,

&detach end connector of motor

wires(Fig 1)

6. Unscrew the 3 screws of Spin

motor(Red circle part). (Fig 2)

7. Unscrew the screws of breaking plate

by M8 tool. (Fig 3)

8. Pulll of the breaking plate by

screwdriver which with "-"

sharp. (Fig 4)

9. Take off the spring of the breaking

plate,and unscrew the

screws of motor(①②③). (Fig 5)

(Fig 1)

(Fig 2)

(Fig 3)

(Fig 4)

(Fig 5)

Page 17

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

MOTORSPINNING

&

MOTORWASHING

FILTER O.F G)

&

MAGIC

FILTER

1. Follow same as disassembling

sequence of the

Motor-Spinning, (1) through (2)

2. Unscrew pulley-Motor nut to

disassembled the pulley(Fig 1)

(Used M8 Spinner / open spinner)

3. Unscrew the 3 screws(①②③) of

washing motor,and take

off the motor. (Fig 2)

G) Disassembly of the FILTER O.F

1. Push the filter front and downward,

and remove it.

( 1 → 2 ) (fig 1)

2. Turn the net direction upside down

and put the dirt in water

and clean it (Fig 2)

3. Install the filter after cleanning. (Fig 3)

(Fig 1)

(Fig 2)

(Fig 1)

(Fig 2)

(Fig 3)

Page 18

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

MOTORSPINNING

&

MOTORWASHING

FILTER O.F G)

&

MAGIC

FILTER

1. Follow same as disassembling

sequence of the

Motor-Spinning, (1) through (2)

2. Unscrew pulley-Motor nut to

disassembled the pulley(Fig 1)

(Used M8 Spinner / open spinner)

3. Unscrew the 3 screws(①②③) of

washing motor,and take

off the motor. (Fig 2)

G) Disassembly of the FILTER O.F

1. Push the filter front and downward,

and remove it.

( 1 → 2 ) (fig 1)

2. Turn the net direction upside down

and put the dirt in water

and clean it (Fig 2)

3. Install the filter after cleanning. (Fig 3)

(Fig 1)

(Fig 2)

(Fig 1)

(Fig 2)

(Fig 3)

Page 19

4. DISASSEMBLY AND REASSEMBLY

4-1

ITEM

HOW TO DISASSEMBLE AND ASSEMBLE

PICTURE

COVER-TOP

FILTER O.F G)

&

MAGIC

FILTER

1. Open the spin lid,install

the tub frame.

(Fig 1)

2. Install the frame and control panel

rightly . (Fig 2)

3. Install the knobs rightly . (Fig 3)

(Fig 1)

(Fig 2)

(Fig 3)

(Fig 4)

(Fig 5)

Page 20

5. SCHEMATIC DIAGRAM

5-1 SINGLE VOLTAGE

5-1

Page 21

6. TROUBLE SHOOTING

6-1

TYPICAL FAILURE POSSIBLE CAUSE REPAIR

Spinning

basket does

not stop

Brake shoe is worn off or broken

Replace brake

shoe

Brake arm does not move

Replace

brake

frame

Brake spring is broken away or

elasticity is insufficient

Replace

brake

spring

Excessive

noise during

spin

Machine

is not level.

Weak floor.

Level the machine.

Install on a

horizontal and

stable floor.

Screw

for fixing motor come

loose.

Fix screw

Clothes break into

the gap

between Tub and basket

Remove clothes

Page 22

7. CHECK POINT AFTER REPAIR

After repairing, be sure to make the following trial operation to see if the washer operates normally.

Check Point Inspection & Judgement

1) Insulation resistance Unplug the cord from the power outlet and turn on all the timers. Then

measure the insulation resistance between the plug (both of 2 pins) and

grounding wire of the machine.

The measured value should be more than1MΩ

In the following case, check sufficiently.

1)Replace the electrical parts with new ones.

2) Used in a moist place.

3)Used more than 5 years.

2) Safety device Check the full stop time of the spin basket.

Braking time should be as follows.

3) Safety designated

parts

Replace with the designated parts in the case the used parts are not proper.

(Refer to '*" marked parts in the parts list)

4) Wiring Check to see if the lead wire is properly connected without looseness or

overtension and taping and setting are firmly performed.

5) Screws and Nuts Check to see if the screws, nuts, etc. are firmly tightened and the screw locks

are

applied.

6) Removal of useless

matter

Check to see if useless matters (Screws, bits of wire, etc.) are left inside the

machine.

7) Leakage of oil and

water

Check to see if oil or water leaks out around bellow-spinning, gear box, motors

and connection of d.v-case.

8) Power-cord Check to see if the cord, the plug, the outlet etc, are not damaged. Do not use

table

Tape with multi-wiring.

9) Level Installation Check to see if the machine installed horizontally.

Load Normal stop time

No load

Rated load

Within 7 sec.

Within 10 sec.

7-1

Loading...

Loading...