Midea MTA-48WN1, MTA-24WN1, MTA-36WN1, MTA-60WN1, MOVTB-18N1-13C Technical & Service Manual

...Page 1

Indoor unit

MTA-18WN1

MTA-24WN1

MTA-36WN1

MTA-36WN1

MTA-48WN1

MTA-60WN1

Power supply

220-240V~ 1Ph 50Hz

220-240V~ 1Ph 50Hz

220-240V~ 1Ph 50Hz

380-415V~ 3Ph 50Hz

380-415V~ 3Ph 50Hz

380-415V~ 3Ph 50Hz

Outdoor unit

MOVTB-18N1-13C

MOVTB-24N1-13C

MOVTB-36N1-13C

MOVTB-36N1-R13C

MOVTB-48N1-R13C

MOVTB-60N1-R13C

Model:

Technical Service Manual

Split AC

Page 2

Content

Part. 1 General information .............. 1

Part. 2 Indoor Unit ............................. 6

Part. 3 Outdoor Unit ........................ 48

Part. 4 Installation ........................... 67

Part. 5 Wired controller ................ 104

Page 3

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

1

Part. 1 General information

1. Model Names of Indoor/Outdoor Units .................................. 2

2. External Appearance ............................................................. 2

3. Nomenclature ....................................................................... 3

4. Product features .................................................................... 4

Page 4

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

2

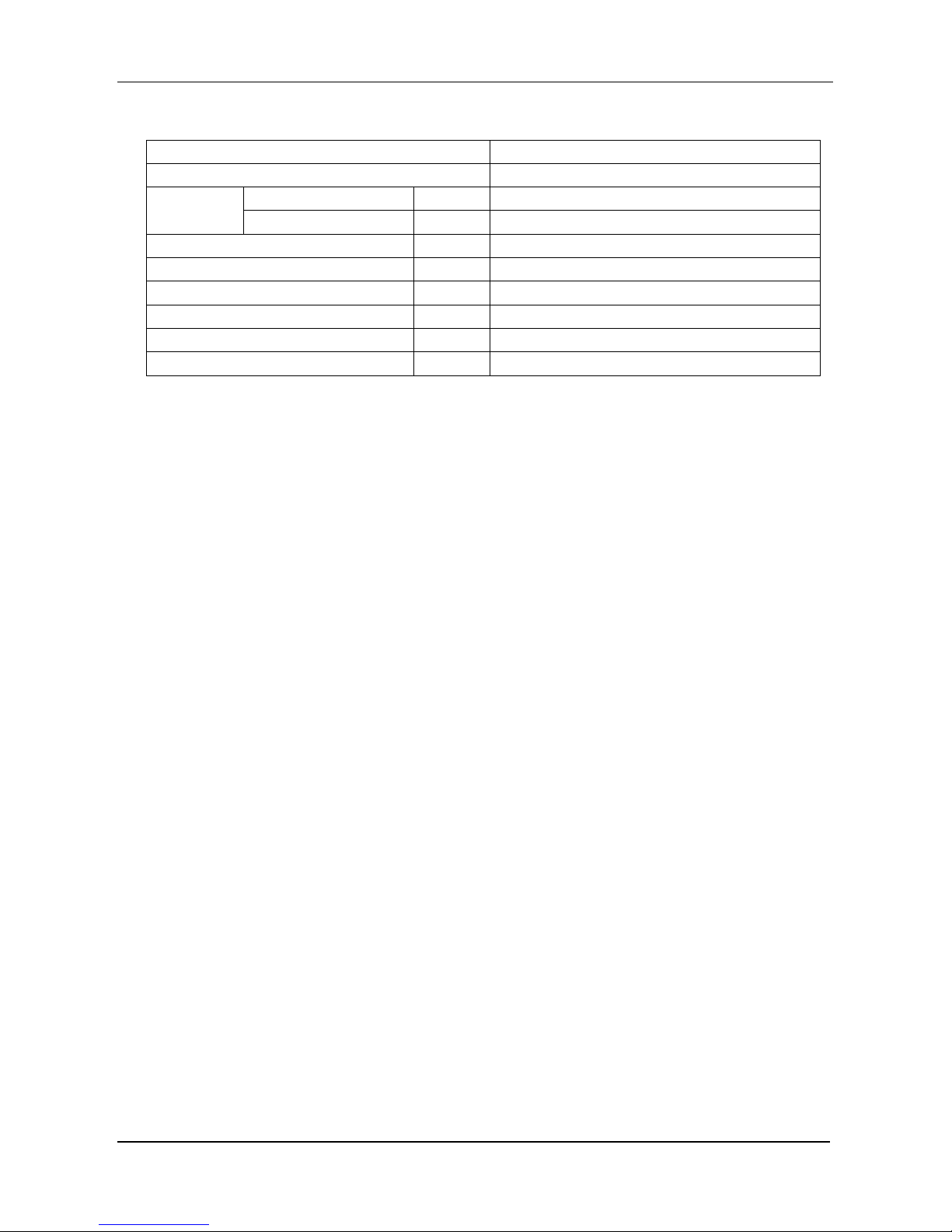

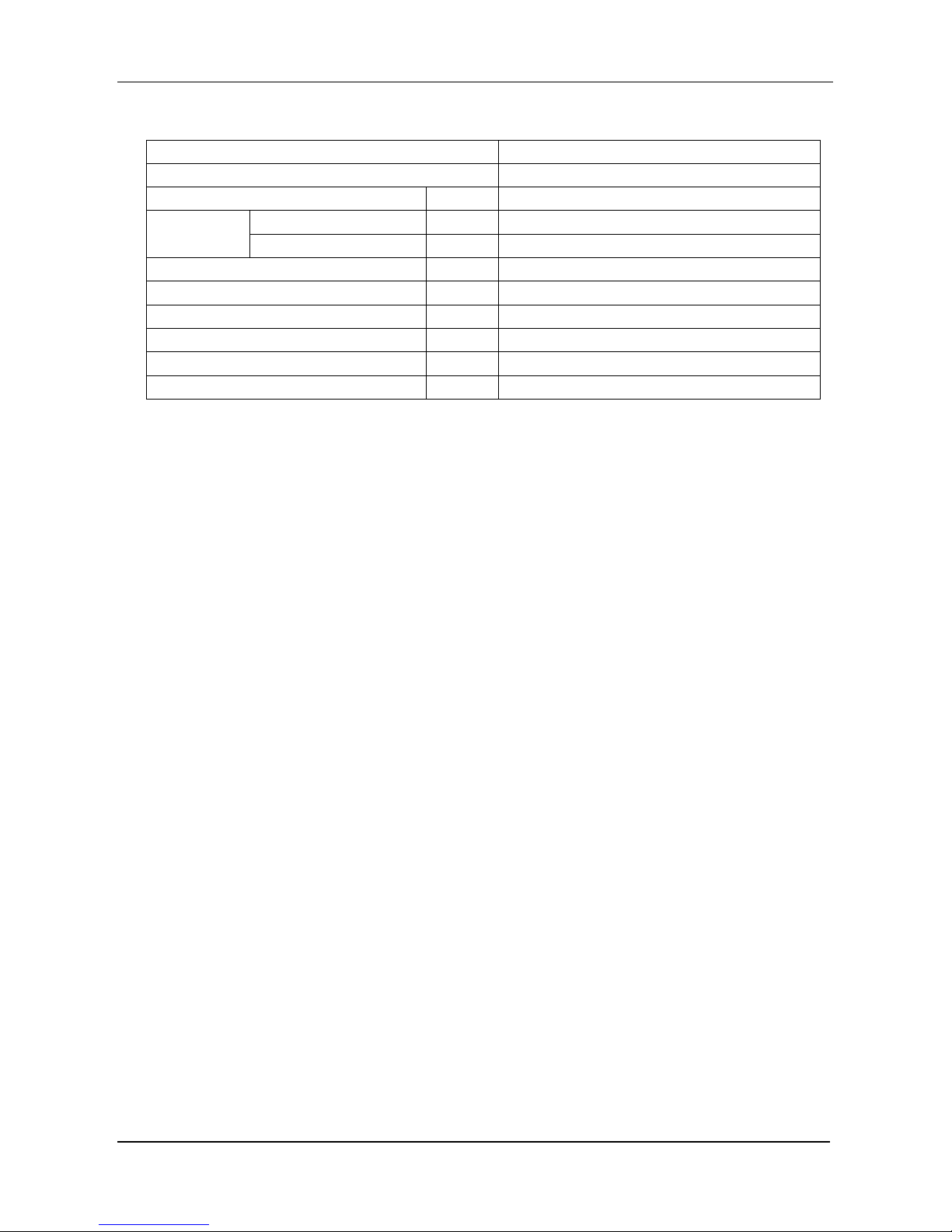

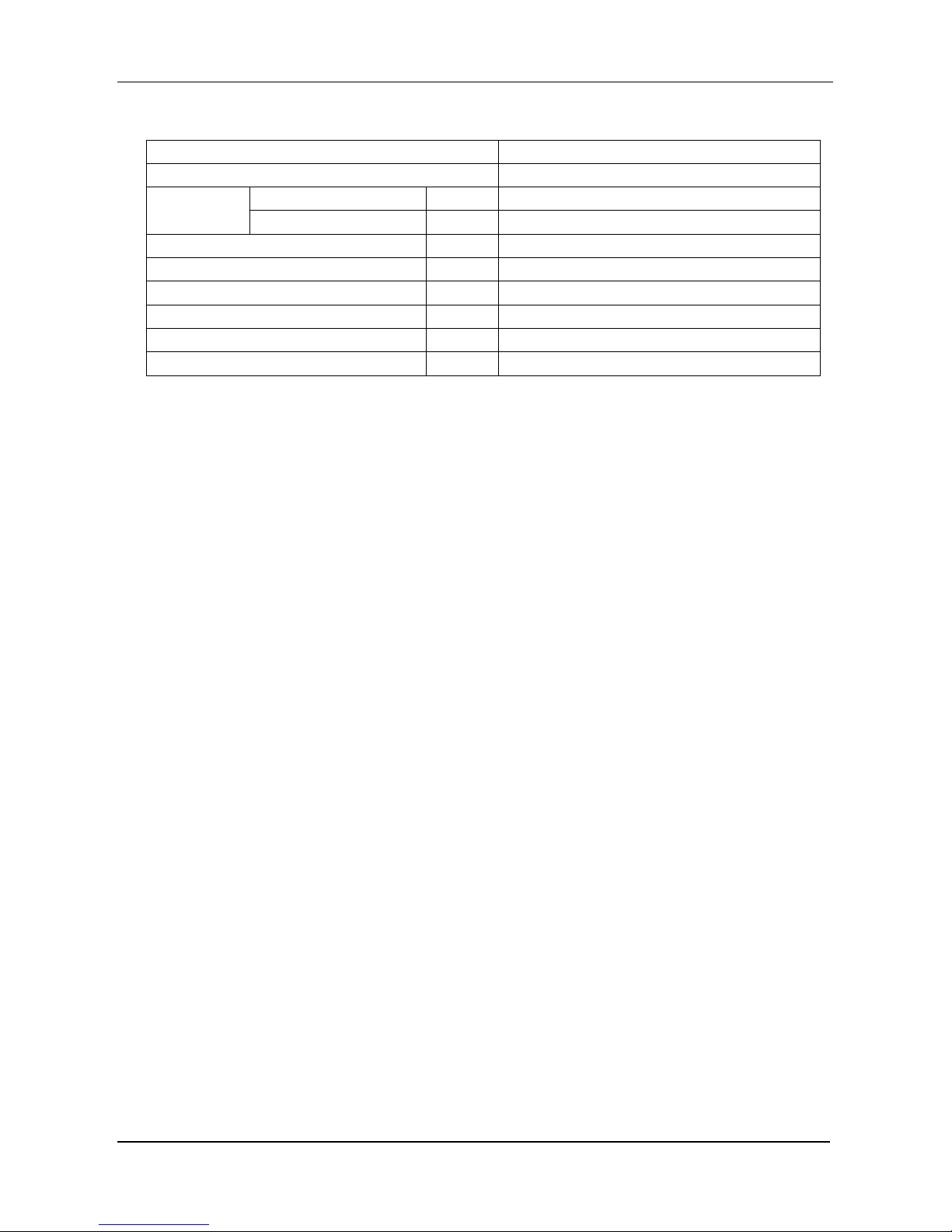

1. Model Names of Indoor/Outdoor Units

Nominal

Capacity

Indoor unit

Outdoor unit

Model

Power supply

Model

Power supply

1.5ton

MTA-18WN1

220-240V~, 50Hz, 1Ph

MOVTB-18CN1-13C

220-240V~, 50Hz, 1Ph

2ton

MTA-24WN1

220-240V~, 50Hz, 1Ph

MOVTB-24CN1-13C

220-240V~, 50Hz, 1Ph

3ton (1Ph)

MTA-36WN1

220-240V~, 50Hz, 1Ph

MOVTB-36CN1-13C

220-240V~, 50Hz, 1Ph

3ton (3Ph)

MTA-36WN1

220-240V~, 50Hz, 1Ph

MOVTB-36CN1-R13C

380-415V~, 50Hz, 3Ph

4ton (3Ph)

MTA-48WN1

220-240V~, 50Hz, 1Ph

MOVTB-48CN1-R13C

380-415V~, 50Hz, 3Ph

5ton (3Ph)

MTA-60WN1

220-240V~, 50Hz, 1Ph

MOVTB-60CN1-R13C

380-415V~, 50Hz, 3Ph

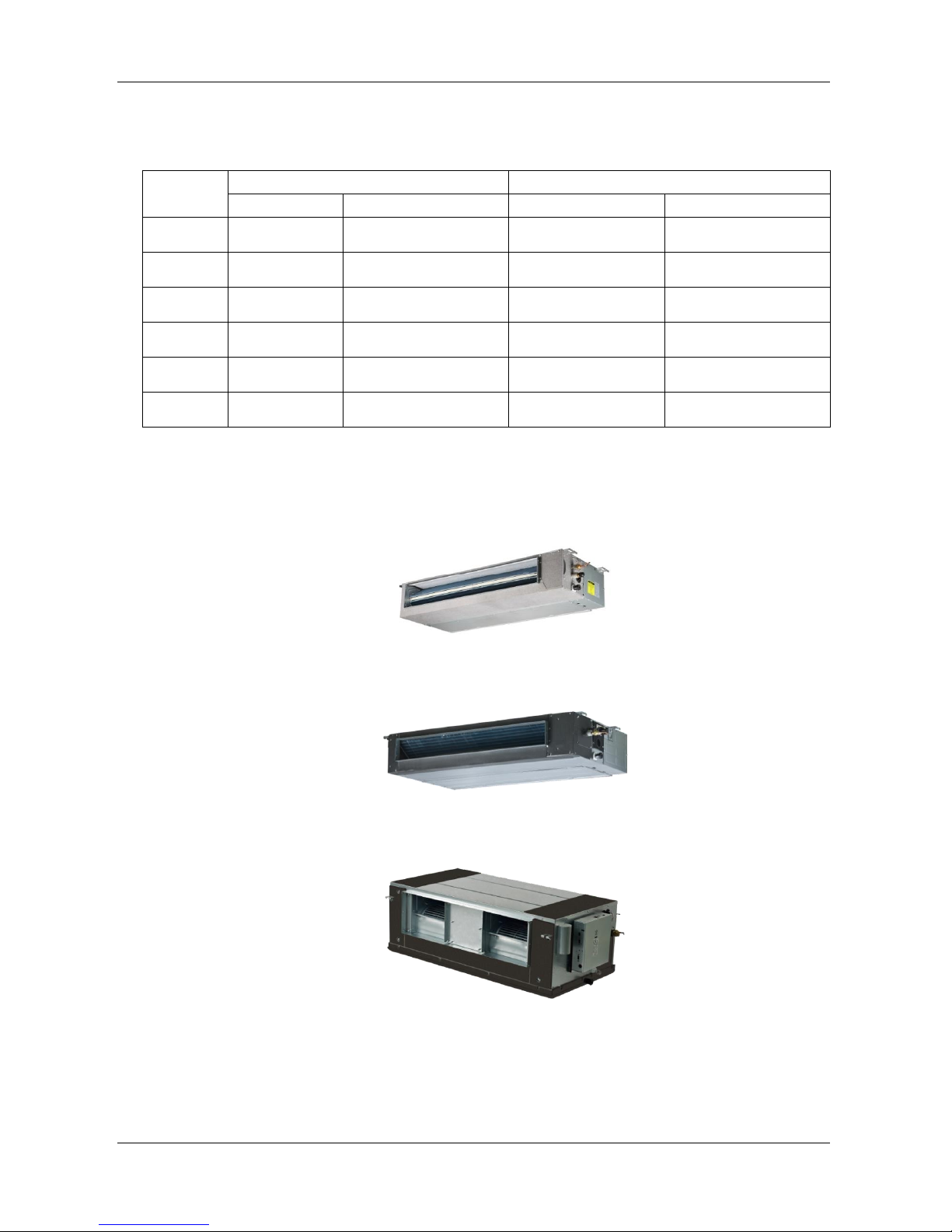

2. External Appearance

2.1 Indoor units

MTA-18WN1

MTA-24WN1, MTA-36WN1

MTA-48WN1, MTA-60WN1

Page 5

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

3

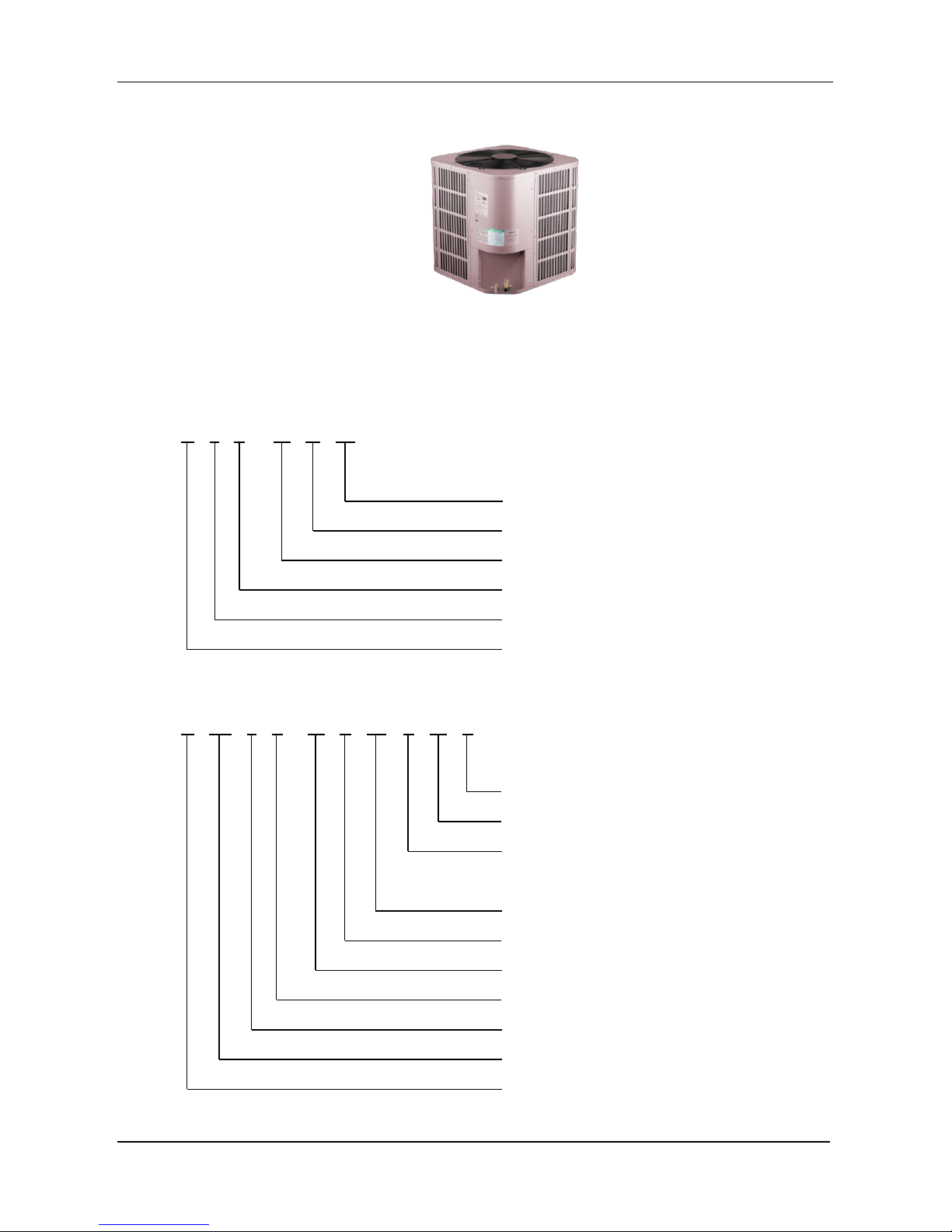

2.2 Outdoor unit

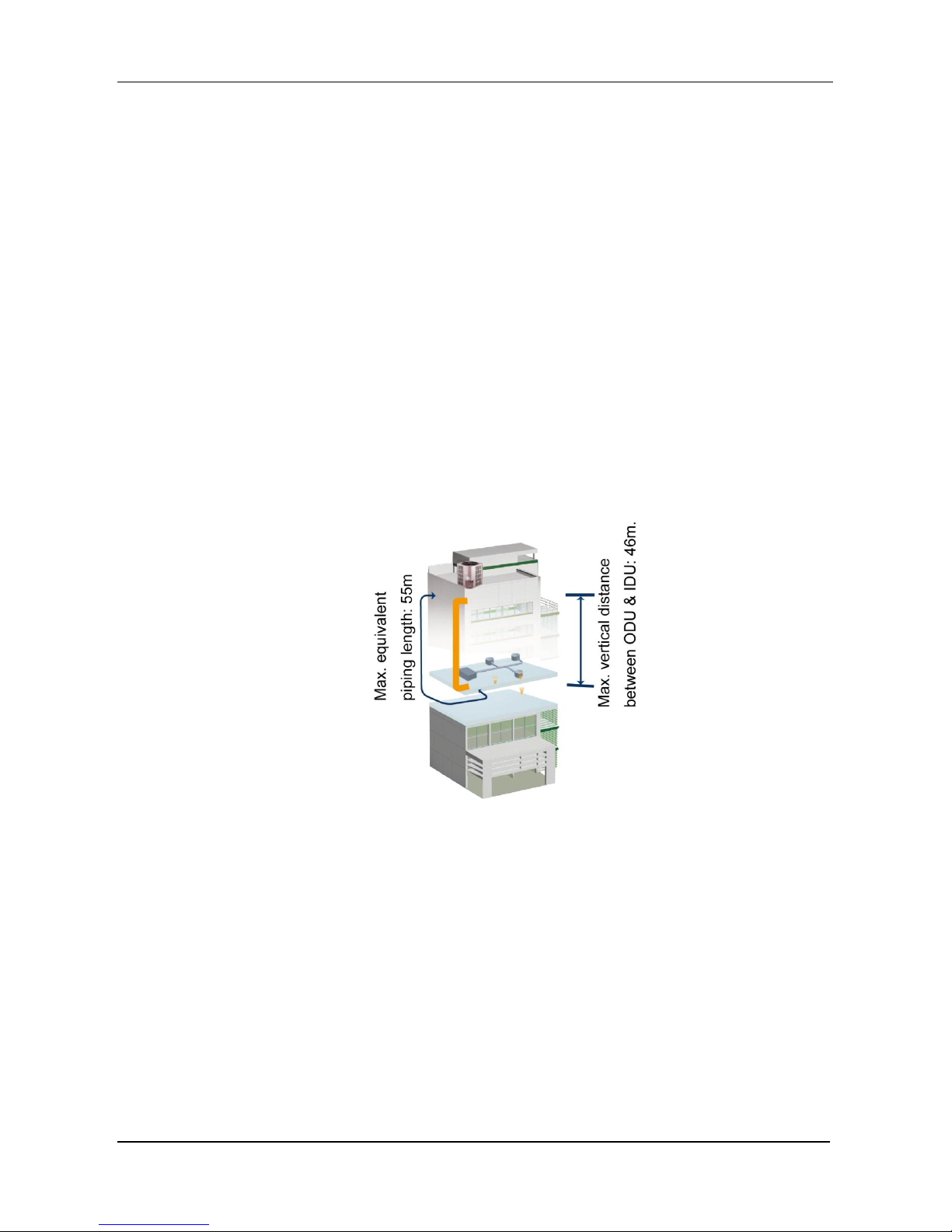

3. Nomenclature

3.1 Indoor unit:

M T A – 18 W N1

Refrigerant Type - N1: R410A

Control Type: Wired controller

Nominal Cooling Capacity (18×1,000Btu/h)

Series Number: A type

Medium Static Pressure Duct Type

Midea

3.2 Outdoor unit:

M OV T B - 36 C N1 – R 13 C

Compressor - C: Copeland

13SEER

Power Supply - R: 380-415V~, 3Ph, 50Hz

Omit: 220-240V~, 1Ph, 50Hz

Refrigerant Type - N1: R410A

Cooling only

Nominal Cooling Capacity (36×1,000Btu/h)

Series Number: B type

Tropical Appliance

Top-discharge Outdoor Unit

Midea

Page 6

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

4

4. Product features

Indoor Unit

General

These duct type indoor units which capacity range is from 1.5ton to 5ton, are suitable for

mounting above ceiling. The units are factory assembled, internally wired and tested before

leaving the manufacture. The indoor units are insulated by polyethylene foam.

Casing

The units are constructed form Heavy Gauge Zinc coated steel sheets. The sheet steel zinc

coated by hot dip process confirming to standard ASTMA 653.

Evaporator

Internally finned, copper tubes mechanically bonded to a configured hydrophilic aluminum fin

shall be standard. Coils are leak tested at the factory to ensure the pressure integrity. The

evaporator coil is already leak tested to 3,100kPa (450 psig). Anti-corrosion treatment for coils is

optional.

Drain pan

The condensate drain pan is fabricated of EPS. The inner of the drain pan adopts vacuum

forming technology.

Indoor fan

The indoor units have centrifugal fan. The fan is directly driven by indoor fan motor.

Filter

The filter is already fix in the frame of air return. It is Nylon washable type.

Outdoor unit

General

The outdoor units are top-discharge type. The units with weatherproof heavy gauge base are

factory assembled, internally wired, fully charged refrigerant and 100% run tested to check

cooling operation, fan rotation and control sequence before leaving the factory.

Page 7

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

5

Casing

Unit casing is constructed of zinc coated, heavy gauge, and galvanized steel. Exterior surfaces

shall be cleaned, G90 galvanized heavy gauge plate conforming to ASTMA 653, followed by

baked on electrostatic polyester dry powder coat paint on all external panels, completely

weatherized for outdoor installation and properly reinforced and brazed. Salt spray test for steel

sheet under 1,000 hours, specially treated can be up to 2,000 hours and even more (It should

be customized.). Cabinet construction allows for all maintenance on one side of the unit.

Service panels are removed easily and re-installed by removing screws.

Compressor

All the outdoor units have single totally enclosed hermetically scroll compressor - Copeland.

The compressors have internal overload relay. High pressure switch, low pressure switch and

discharge temperature sensor is standard.

Condenser

Internally finned, copper tubes mechanically bonded to a configured hydrophilic aluminum fin

shall be standard. Coils are leak tested at the factory to ensure the pressure integrity. The

evaporator coil is already leak tested to 3,100kPa (450 psig). Anti-corrosion treatment for coils is

optional.

Outdoor fan

The fan is direct driven by weather proof motor (IP44 and insulation class F) to ensure reliable

continuous operation. Statically and dynamically balanced drive motor design with maintenance

– free bearing for outdoor installation. The fan is multi-blade vane-axial type, made of metal

material for quiet operation and durability.

Electrical control box

In the electrical control box with the PCB board, wiring internal to the unit shall be colored and

numbered for simplified identification. The PCB parts can be coated with double-side moisture

proof paint, and the outer side of electric box metal cover is spray-painted (It should be

customized.).

Page 8

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

6

Part. 2 Indoor Unit

1. Features .............................................................................. 7

2. Specifications ...................................................................... 8

3. Dimensions ........................................................................ 19

4. Service Space ................................................................... 25

5. Refrigerant circuit .............................................................. 25

6. Wiring Diagrams ................................................................ 26

7. Capacity Table ................................................................... 35

8. Fan performance ............................................................... 41

9. Electric Characteristics ...................................................... 46

10. Sound Levels ..................................................................... 46

11. Accessories ....................................................................... 47

Page 9

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

7

1. Features

Full capacity range: 1.5ton, 2ton, 3ton, 4ton and 5ton.

Suitable for using refrigerant R410A.

Tropical design with Copeland compressor.

Blue hydrophilic fin and inner grooved copper pipe.

3-speed indoor fan for enhanced comfort.

Air intake filter as standard.

Highly efficient scroll compressor, with thermal protectors to prevent motor overheating.

Power supply of indoor and outdoor is separated, easy installation.

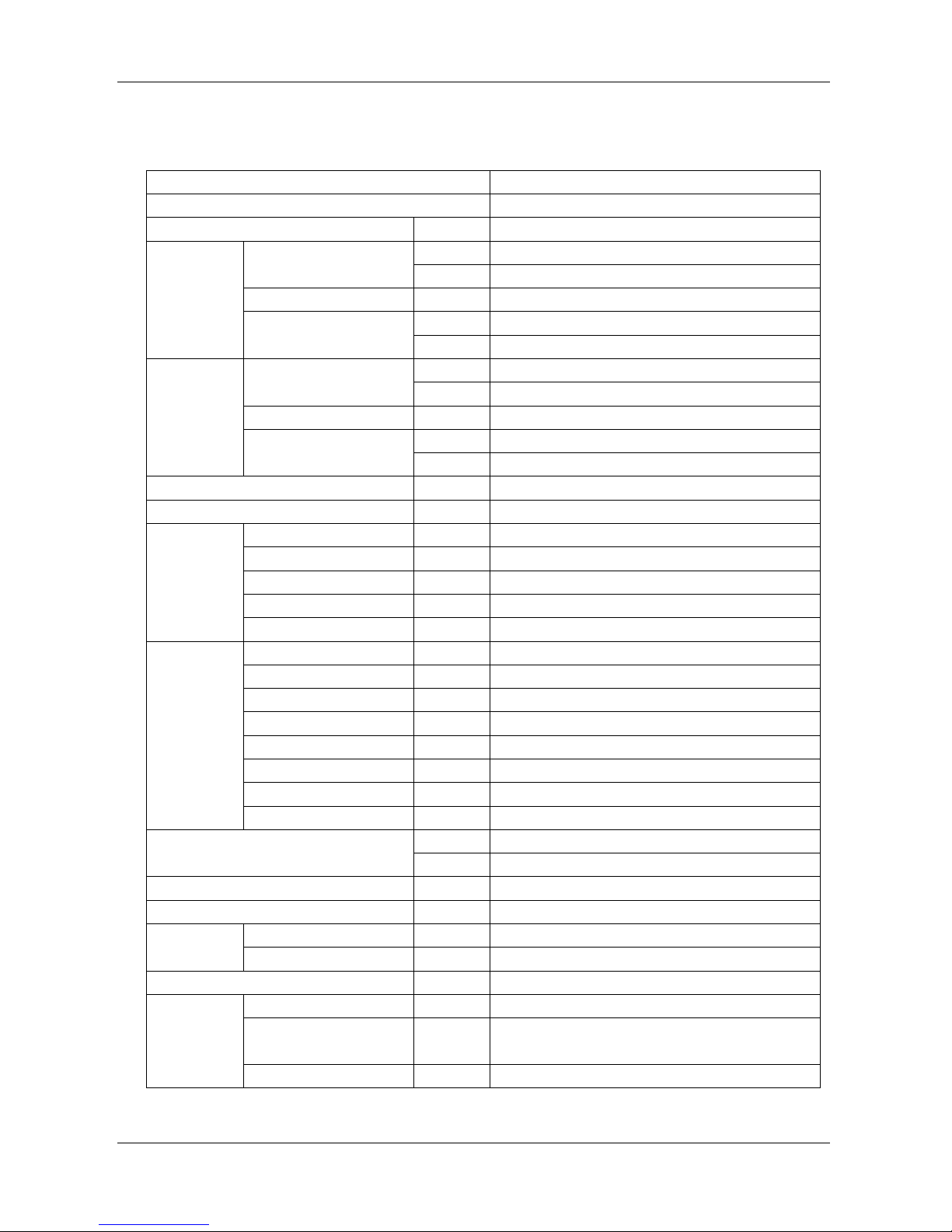

Long piping length. Max. equivalent piping length is 55m, and Max. vertical distance between

outdoor unit and indoor unit is 46m, when outdoor unit is up.

220V signal terminal of wired controller is reserved, and wired controller with 5V signal is

customized.

Page 10

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

8

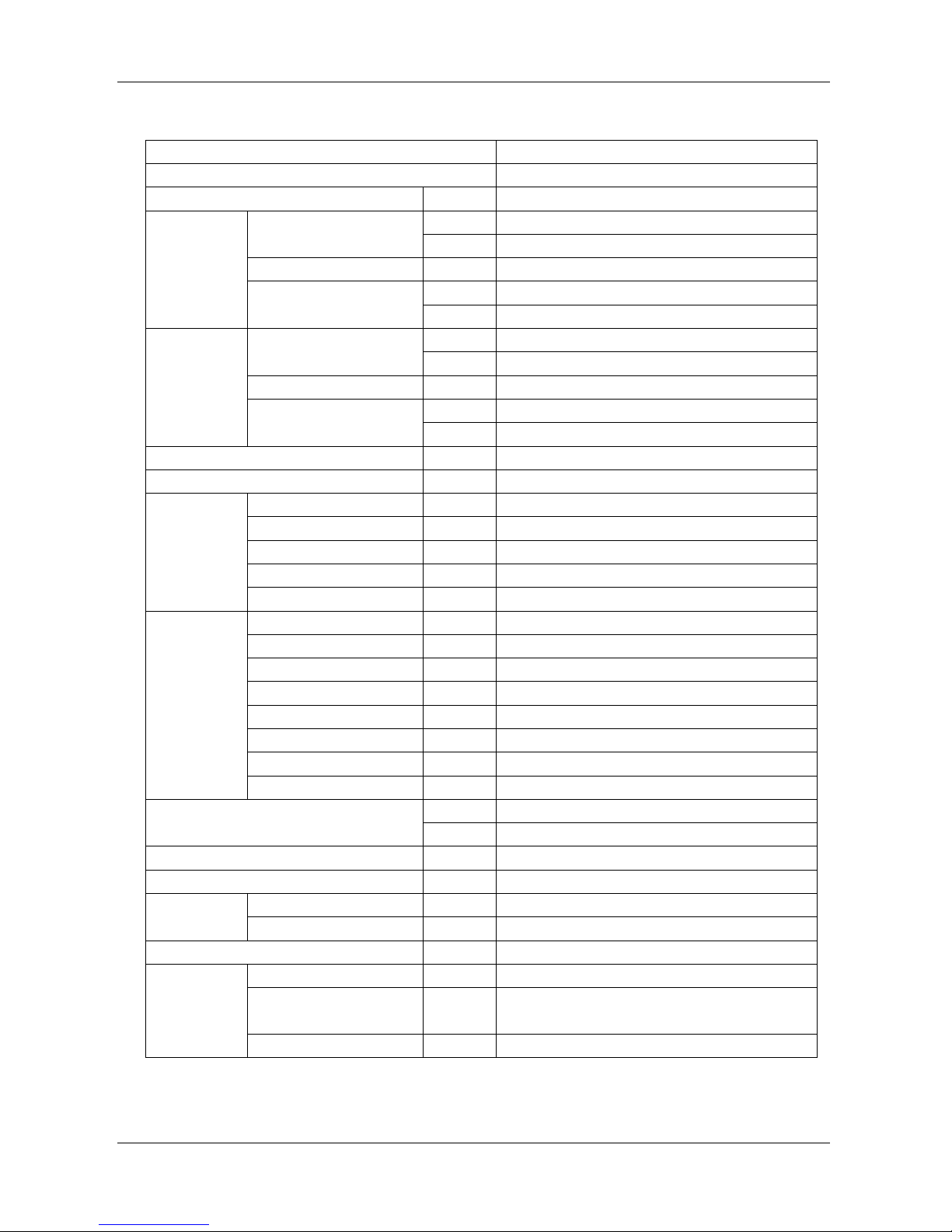

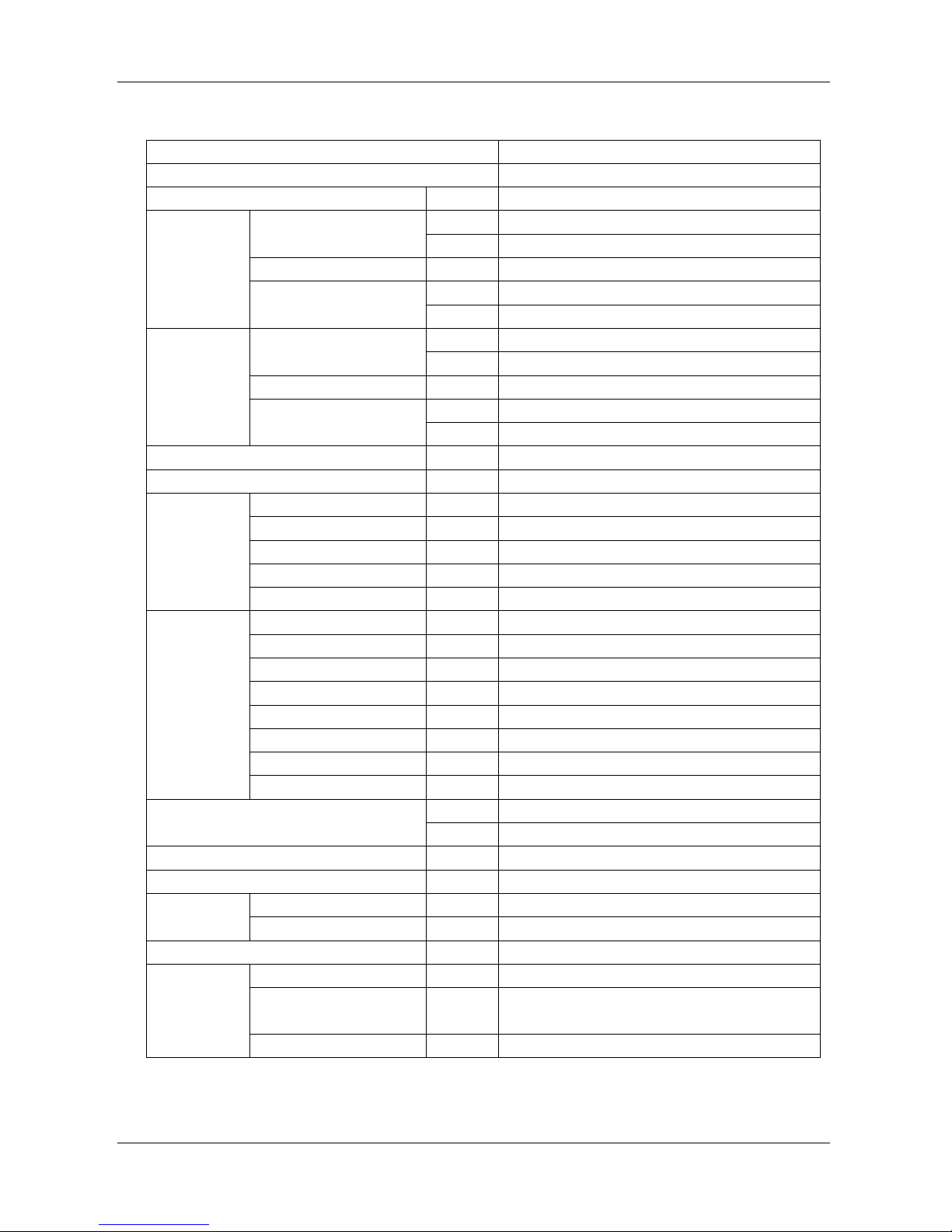

2. Specifications

Model

MTA-18WN1

Matched outdoor unit

MOVTB-18CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Cooling (T1)

Capacity

Btu/h

18,000

W

5,274

Input

W

1,552

EER

W/W

3.40

Btu/h.W

11.6

Cooling (T3)

Capacity

Btu/h

16,000

W

4,690

Input

W

1,975

EER

W/W

2.37

Btu/h.W

8.1

Rated input

W

120

Rated current

A

0.6

Indoor

fan motor

Model (× Quantity) \ YKSS-61-4-62 (×1)

Brand

\

Matchwell/Yongan/Tongde

Input (Hi/Med/Lo) W 152/125/117

Capacitor

\

3.5μF/450V

Speed (Hi/Med/Lo)

r/min

1,322/1,191/1,144

Indoor coil

Number of rows

\

2+2

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.3

Fin type

\

Hydrophilic aluminum fin

Tube size

mm

Ф7

Tube type \ Inner grooved copper pipe

Coil(W×H)

mm

(955×147) + (955×147)

Number of circuits

\

4

Indoor air flow

m3/h

1,125/901/831

CFM

662/530/489

External static pressure

Pa

25 (0 - 87)

Indoor noise level

dB(A)

42/38/37

Refrigerant

Type

\

R410A

Control

\

Throttle valve

Design pressure

MPa

4.4/2.6

Refrigerant

pipe

Liquid side/ Gas side

mm

Ф9.52/Ф19.1

Max. equivalent

refrigerant pipe length

m

55

Max. difference in level m 46

Page 11

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

9

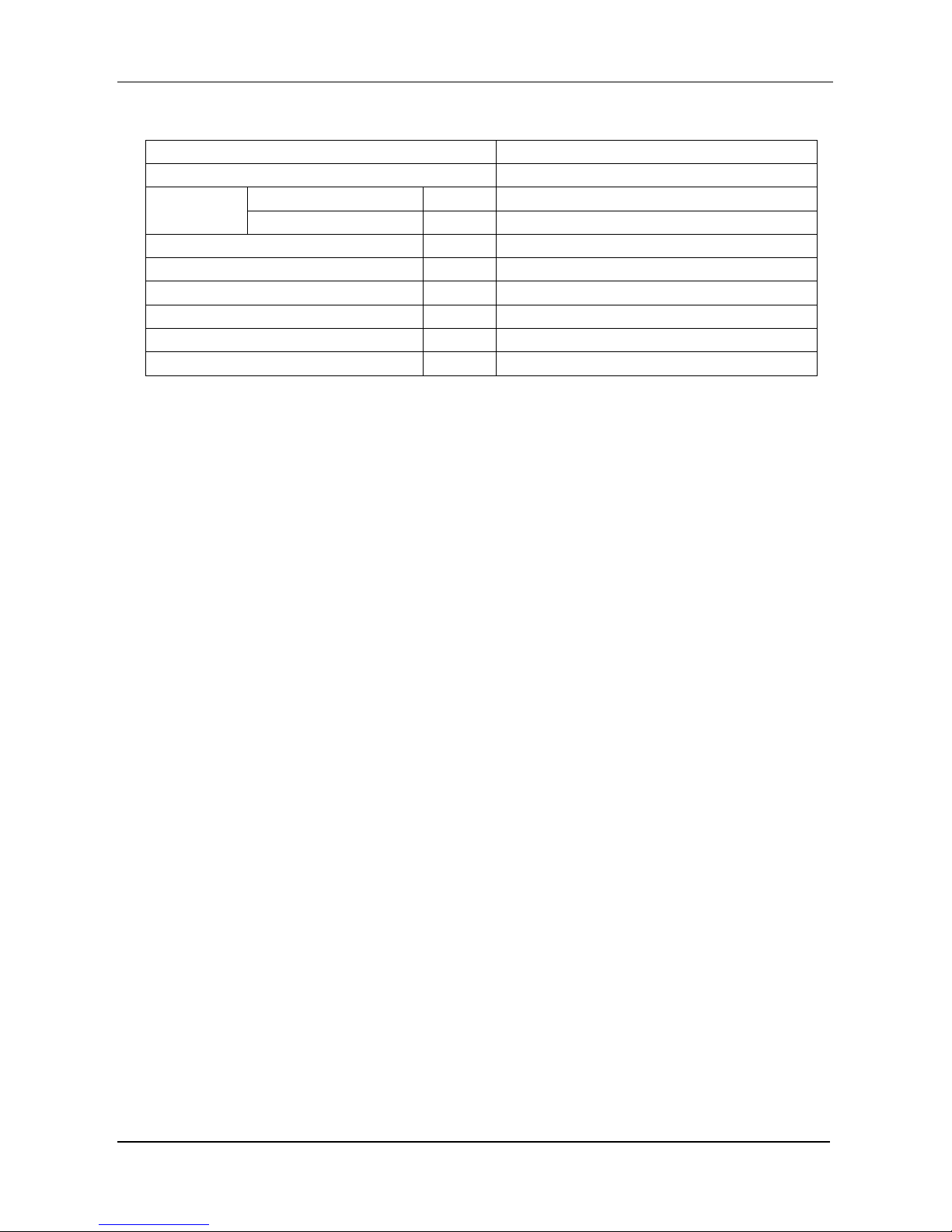

Model

MTA-18WN1

Matched outdoor unit

MOVTB-18CN1-13C

Connecting

wire

Power wire (Indoor unit) \ 3×2.5mm2

Signal wire

\

2×0.75mm2

Drain pipe size (OD)

mm

Ф25

Controller \ Optional (220V signal reserved)

Operation temperature

°C

18 - 30

Dimension (W×H×D)

mm

1,220×210×500

Packing (W×H×D)

mm

1,360×292×560

Net/Gross weight

kg

27/32

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi noise suppression lab. The sound level is measured 1m below the unit.

Page 12

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

10

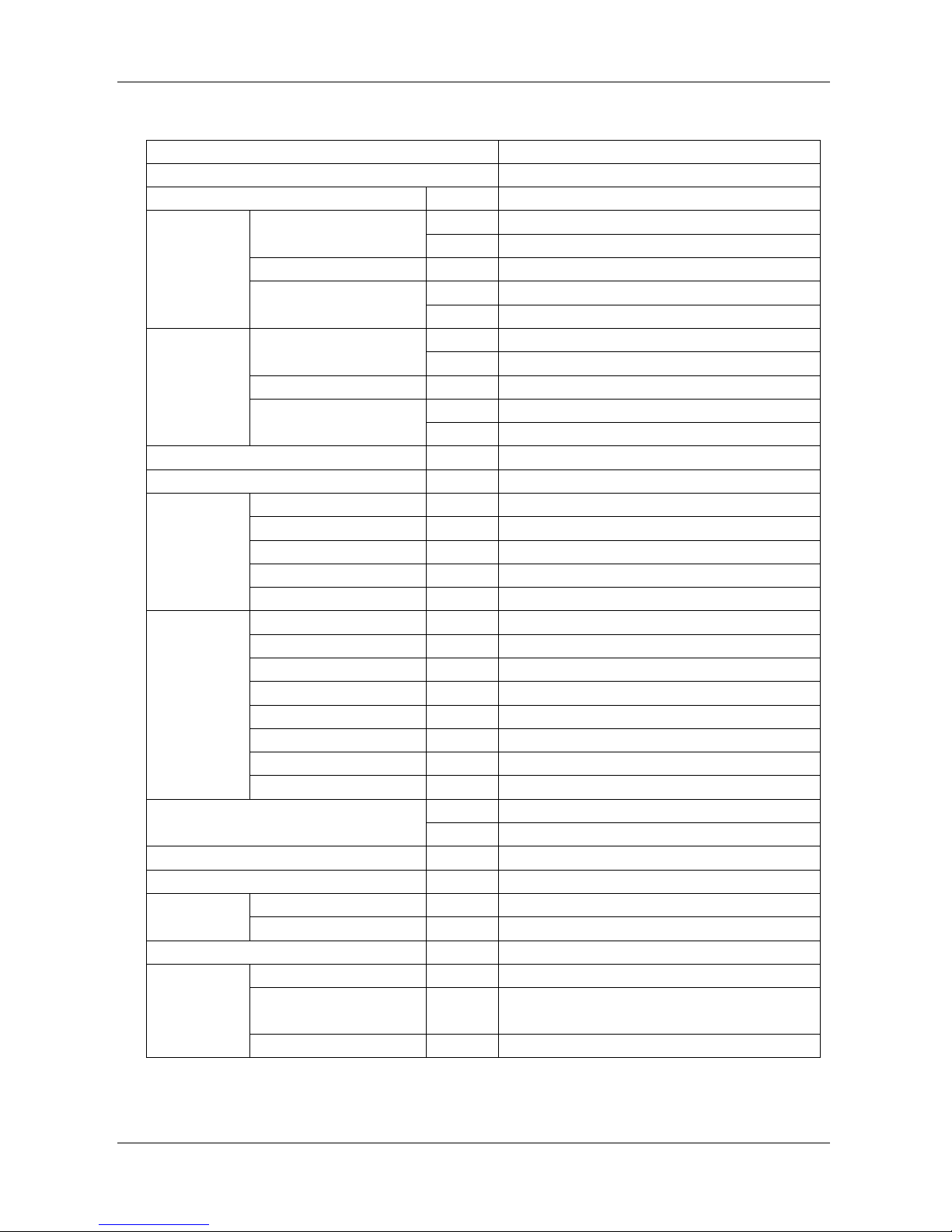

Model

MTA-24WN1

Matched outdoor unit

MOVTB-24CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Cooling (T1)

Capacity

Btu/h

23,800

W

6,975

Input

W

2,050

EER

W/W

3.40

Btu/h.W

11.6

Cooling (T3)

Capacity

Btu/h

20,600

W

6,038

Input

W

2,512

EER

W/W

2.40

Btu/h.W

8.2

Rated input

W

332

Rated current

A

1.53

Indoor

fan motor

Model (× quantity) \ YSK200-4P (×1)

Brand

\

Welling

Input (Hi/Med/Lo) W (393/)332/278/234

Capacitor

\

10μF/450V

Speed (Hi/Med/Lo)

r/min

(1,230/)1,120/990/880

Indoor coil

Number of rows

\

4

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.5

Fin type \ Hydrophilic aluminum fin

Tube size

mm

Ф7

Tube type \ Inner grooved copper pipe

Coil(W×H)

mm

955×336

Number of circuits

\

8

Indoor air flow

m3/h

1,743/1,530/1,338

CFM

1,025/900/787

External static pressure

Pa

25 (0 - 100)

Indoor noise level

dB(A)

49/46/44

Refrigerant

Type

\

R410A

Control

\

Throttle valve

Design pressure

MPa

4.4/2.6

Refrigerant

pipe

Liquid side/ Gas side

mm

Ф9.52/Ф19.1

Max. equivalent

refrigerant pipe length

m

55

Max. difference in level m 46

Page 13

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

11

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi noise suppression lab. The sound level is measured 1m below the unit.

Model

MTA-24WN1

Matched outdoor unit

MOVTB-24CN1-13C

Connecting

wire

Power wire (Indoor unit) \ 3×2.5mm2

Signal wire

\

2×0.75mm2

Drain pipe size (OD)

mm

Ф25

Controller \ Optional (220V signal reserved)

Operation temperature

°C

18 - 30

Dimension (W×H×D)

mm

1,230×270×775

Packing (W×H×D)

mm

1,355×350×795

Net/Gross weight

kg

38/44

Page 14

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

12

Model

MTA-36WN1

Matched outdoor unit

MOVTB-36CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Cooling (T1)

Capacity

Btu/h

35,000

W

10,258

Input

W

2,865

EER

W/W

3.58

Btu/h.W

12.2

Cooling (T3)

Capacity

Btu/h

30,200

W

8,851

Input

W

3,512

EER

W/W

2.52

Btu/h.W

8.6

Rated input

W

393

Rated current

A

1.8

Indoor

fan motor

Model (× quantity) \ YSK200-4P (×1)

Brand

\

Welling

Input (Hi/Med/Lo) W 393/332/278(/234)

Capacitor

\

10μF/450V

Speed (Hi/Med/Lo)

r/min

1,230/1,120/990(/880)

Indoor coil

Number of rows

\

4

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.5

Fin type \ Hydrophilic aluminum fin

Tube size

mm

Ф7

Tube type \ Inner grooved copper pipe

Coil(W×H)

mm

955×336

Number of circuits

\

8

Indoor air flow

m3/h

1,850/1,675/1,472

CFM

1,088/985/866

External static pressure

Pa

37 (0 - 75)

Indoor noise level

dB(A)

51/49/46

Refrigerant

Type

\

R410A

Control

\

Throttle valve

Design pressure

MPa

4.4/2.6

Refrigerant

pipe

Liquid side/ Gas side

mm

Ф9.52/Ф19.1

Max. equivalent

refrigerant pipe length

m

55

Max. difference in level m 46

Page 15

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

13

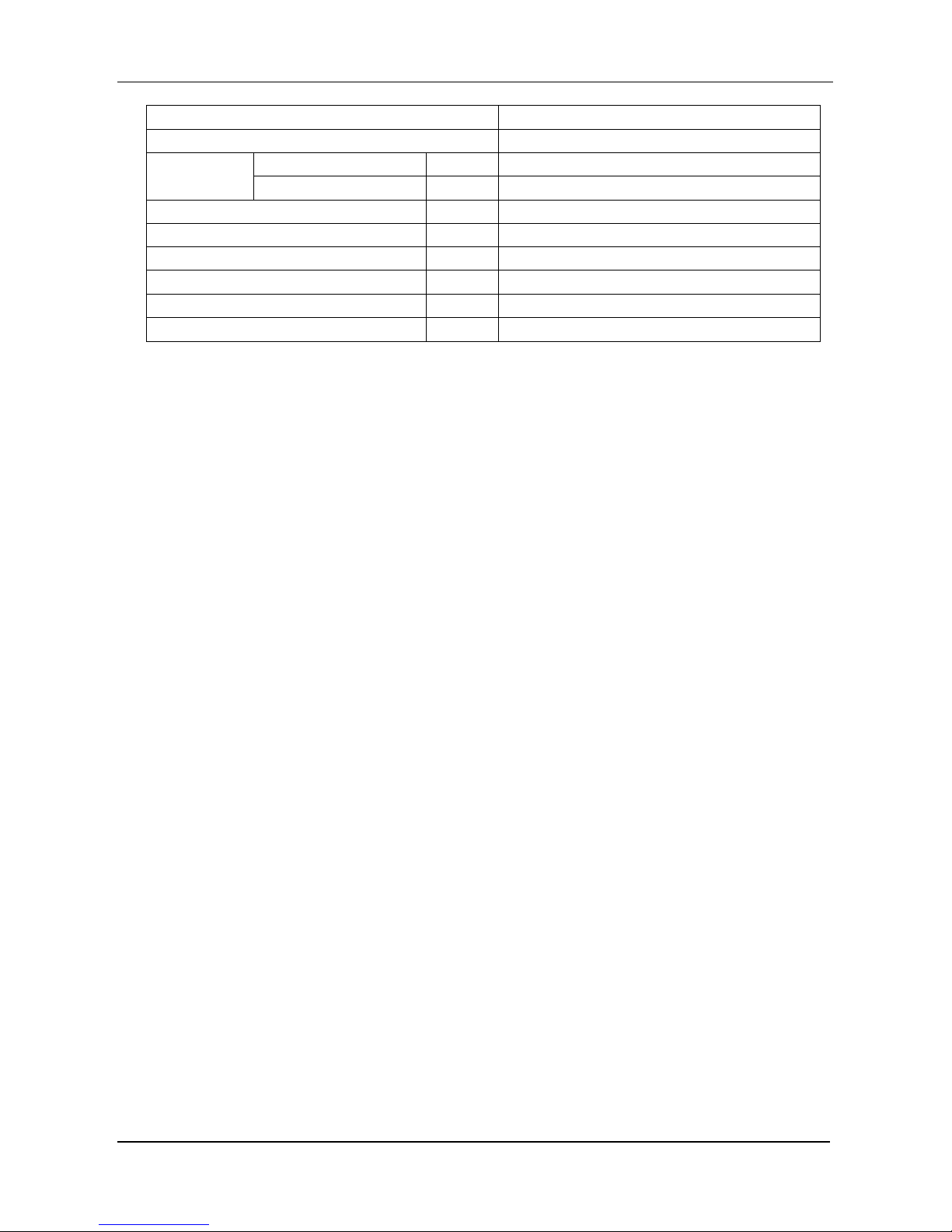

Model

MTA-36WN1

Matched outdoor unit

MOVTB-36CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Connecting

wire

Power wire (Indoor unit) \ 3×2.5mm2

Signal wire

\

2×0.75mm2

Drain pipe size (OD)

mm

Ф25

Controller \ Optional (220V signal reserved)

Operation temperature

°C

18 - 30

Dimension (W×H×D)

mm

1,230×270×775

Packing (W×H×D)

mm

1,355×350×795

Net/Gross weight

kg

38/44

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi noise suppression lab. The sound level is measured 1m below the unit.

Page 16

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

14

Model

MTA-36WN1

Matched outdoor unit

MOVTB-36CN1-R13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Cooling (T1)

Capacity

Btu/h

34,400

W

10,082

Input

W

2,970

EER

W/W

3.40

Btu/h.W

11.6

Cooling (T3)

Capacity

Btu/h

29,800

W

8,734

Input

W

3,634

EER

W/W

2.40

Btu/h.W

8.2

Rated input

W

393

Rated current

A

1.8

Indoor

fan motor

Model (× quantity) \ YSK200-4P (×1)

Brand

\

Welling

Input (Hi/Med/Lo) W 393/332/278(/234)

Capacitor \ 10μF/450V

Speed (Hi/Med/Lo)

r/min

1,230/1,120/990(/880)

Indoor coil

Number of rows

\

4

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.5

Fin type \ Hydrophilic aluminum fin

Tube size

mm

Ф7

Tube type \ Inner grooved copper pipe

Coil(W×H)

mm

955×336

Number of circuits

\

8

Indoor air flow

m3/h

1,850/1,675/1,472

CFM

1,088/985/866

External static pressure

Pa

37 (0 - 75)

Indoor noise level

dB(A)

51/49/46

Refrigerant

Type

\

R410A

Control

\

Throttle valve

Design pressure

MPa

4.4/2.6

Refrigerant

pipe

Liquid side/ Gas side

mm

Ф9.52/Ф19.1

Max. equivalent

refrigerant pipe length

m

55

Max. difference in level m 46

Page 17

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

15

Model

MTA-36WN1

Matched outdoor unit

MOVTB-36CN1-R13C

Connecting

wire

Power wire (Indoor unit) \ 3×2.5mm2

Signal wire

\

2×0.75mm2

Drain pipe size (OD)

mm

Ф25

Controller \ Optional (220V signal reserved)

Operation temperature

°C

18 - 30

Dimension (W×H×D)

mm

1,230×270×775

Packing (W×H×D)

mm

1,355×350×795

Net/Gross weight

kg

38/44

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi noise suppression lab. The sound level is measured 1m below the unit.

Page 18

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

16

Model

MTA-48WN1

Matched outdoor unit

MOVTB-48CN1-R13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Cooling (T1)

Capacity

Btu/h

48,000

W

14,068

Input

W

4,140

EER

W/W

3.40

Btu/h.W

11.6

Cooling (T3)

Capacity

Btu/h

41,500

W

12,163

Input

W

5,123

EER

W/W

2.37

Btu/h.W

8.1

Rated input

W

740

Rated current

A

3.27

Indoor

fan motor

Model (× quantity)

\

YSK400-4C-2 or YKSS-400-4-8 (×1)

Brand

\

Welling/Yongan

Input (Hi/Med/Lo)

W

(865/)701/621/545 or (930/)740/660/592

Capacitor

\

15μF/450V

Speed (Hi/Med/Lo)

r/min

(1,125/)995/915/850 or (1,080/)920/850/790

Indoor coil

Number of rows

\

4

Tube pitch(a)×row pitch(b)

mm

25.4×22

Fin space

mm

1.6

Fin type \ Hydrophilic aluminum fin

Tube size

mm

Ф9.52

Tube type \ Inner grooved copper pipe

Coil(W×H)

mm

996×355.6

Number of circuits

\

7

Indoor air flow

m3/h

2,759/2,536/2,332

CFM

1,623/1,492/1,372

External static pressure

Pa

50 (0 - 125)

Indoor noise level

dB(A)

52/51/50

Refrigerant

Type

\

R410A

Control

\

Throttle valve

Design pressure

MPa

4.4/2.6

Refrigerant

pipe

Liquid side/ Gas side

mm

Ф9.52/Ф22

Max. equivalent

refrigerant pipe length

m

55

Max. difference in level m 46

Page 19

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

17

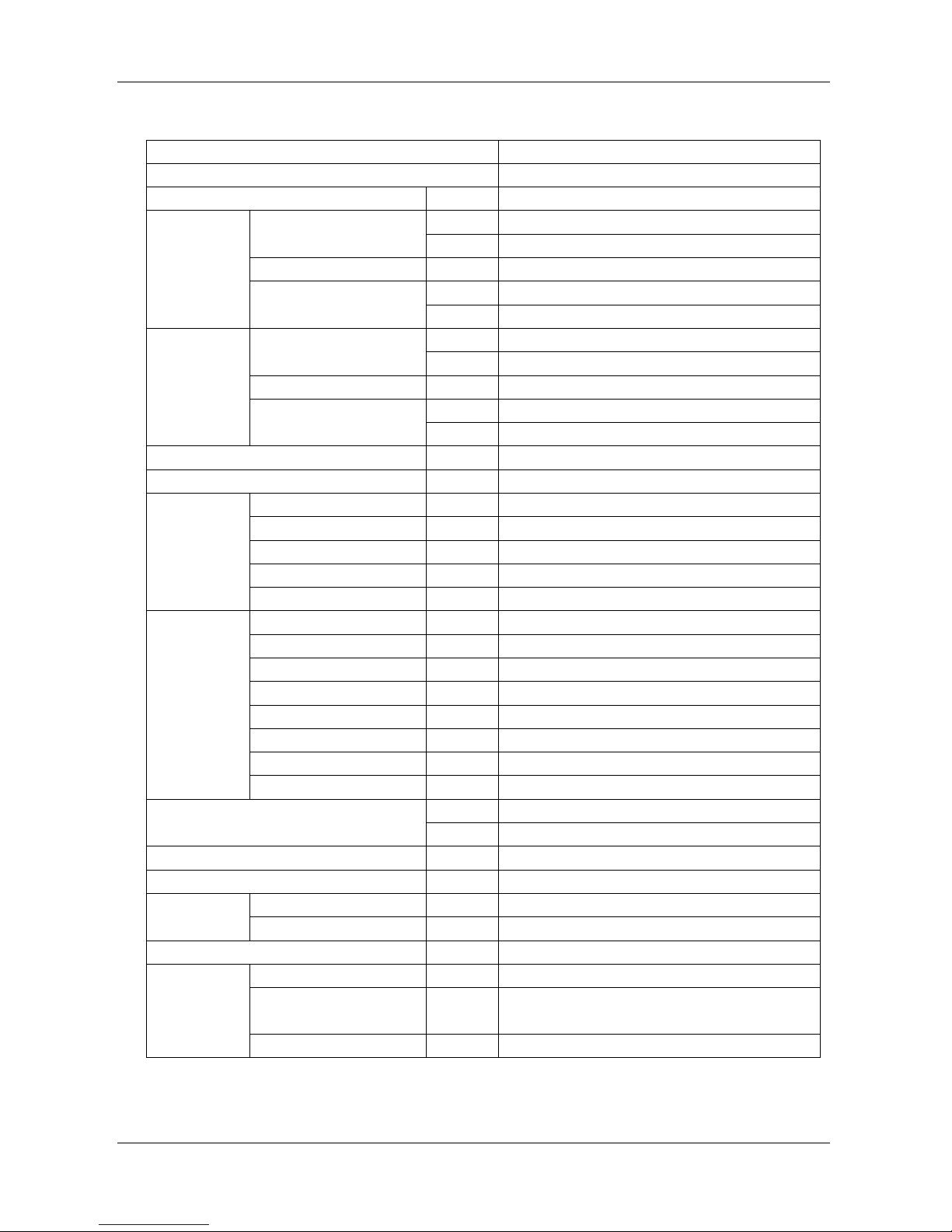

Model

MTA-48WN1

Matched outdoor unit

MOVTB-48CN1-R13C

Connecting

wire

Power wire (Indoor unit) \ 3×2.5mm2

Signal wire

\

2×0.75mm2

Drain pipe size (OD)

mm

Ф25

Controller \ Optional (220V signal reserved)

Operation temperature

°C

18 - 30

Dimension (W×H×D)

mm

1,300×420×691

Packing (W×H×D)

mm

1,436×450×768

Net/Gross weight

kg

65.5/73

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi noise suppression lab. The sound level is measured 1m below the unit.

Page 20

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

18

Model

MTA-60WN1

Matched outdoor unit

MOVTB-60CN1-R13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Cooling (T1)

Capacity

Btu/h

57,000

W

16,706

Input

W

4,870

EER

W/W

3.43

Btu/h.W

11.7

Cooling (T3)

Capacity

Btu/h

50,000

W

14,654

Input

W

6,173

EER

W/W

2.37

Btu/h.W

8.1

Rated input

W

930

Rated current

A

4.1

Indoor

fan motor

Model (× quantity)

\

YSK400-4C-2 or YKSS-400-4-8 (×1)

Brand

\

Welling/Yongan

Input (Hi/Med/Lo)

W

(865/)701/621/545 or (930/)740/660/592

Capacitor

\

15μF/450V

Speed (Hi/Med/Lo)

r/min

(1,125/)995/915/850 or (1,080/)920/850/790

Indoor coil

Number of rows

\

4

Tube pitch(a)×row pitch(b)

mm

25.4×22

Fin space

mm

1.6

Fin type \ Hydrophilic aluminum fin

Tube size

mm

Ф9.52

Tube type \ Inner grooved copper pipe

Coil(W×H)

mm

996×355.6

Number of circuits

\

7

Indoor air flow

m3/h

3,312/2,759/2,536

CFM

1,948/1,623/1,492

External static pressure

Pa

50 (0 - 125)

Indoor noise level

dB(A)

54/52/51

Refrigerant

Type

\

R410A

Control

\

Throttle valve

Design pressure

MPa

4.4/2.6

Refrigerant

pipe

Liquid side/ Gas side

mm

Ф9.52/Ф22

Max. equivalent

refrigerant pipe length

m

55

Max. difference in level m 46

Page 21

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

19

Model

MTA-60WN1

Matched outdoor unit

MOVTB-60CN1-R13C

Connecting

wire

Power wire (Indoor unit) \ 3×2.5mm2

Signal wire

\

2×0.75mm2

Drain pipe size (OD)

mm

Ф25

Controller \ Optional (220V signal reserved)

Operation temperature

°C

18 - 30

Dimension (W×H×D)

mm

1,300×420×691

Packing (W×H×D)

mm

1,436×450×768

Net/Gross weight

kg

65.5/73

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi noise suppression lab. The sound level is measured 1m below the unit.

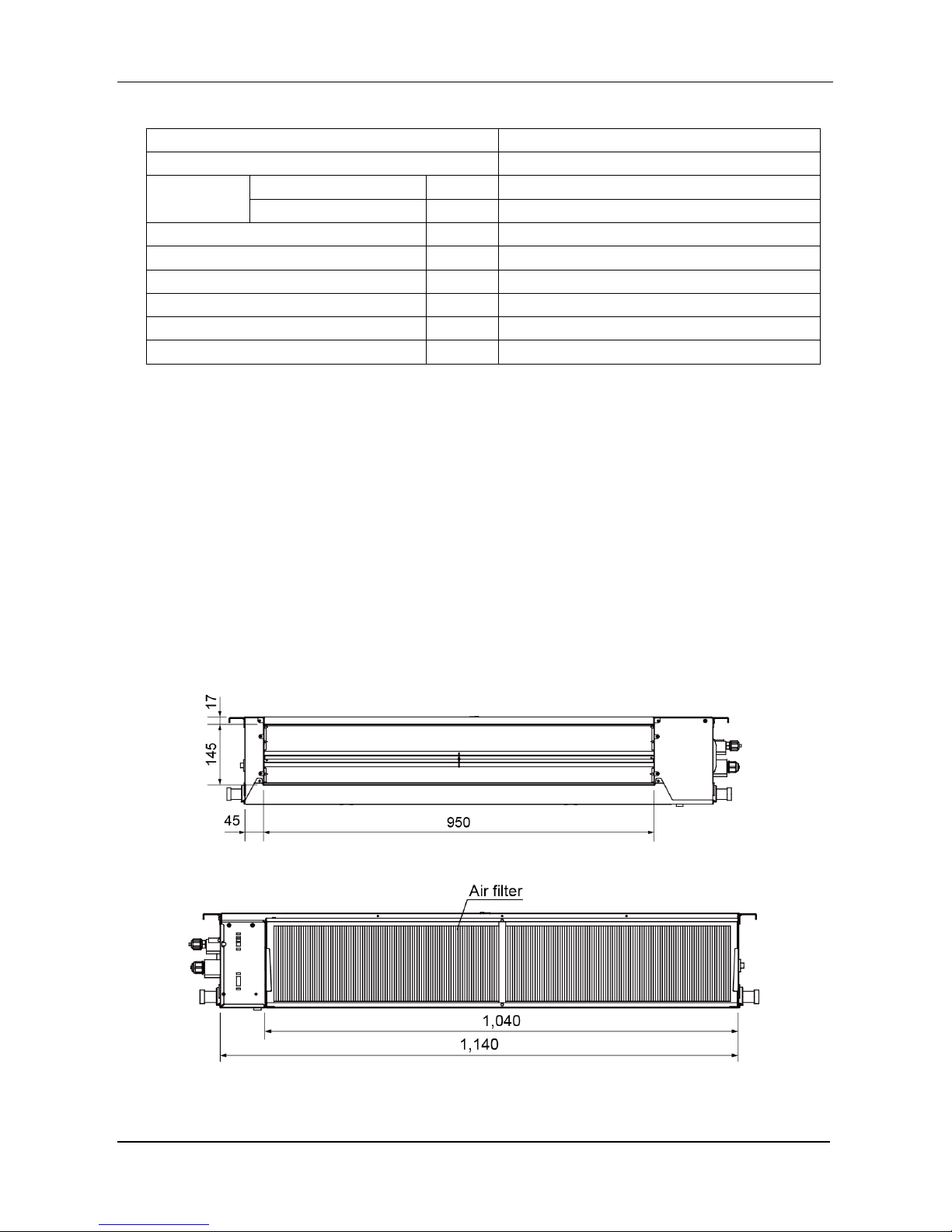

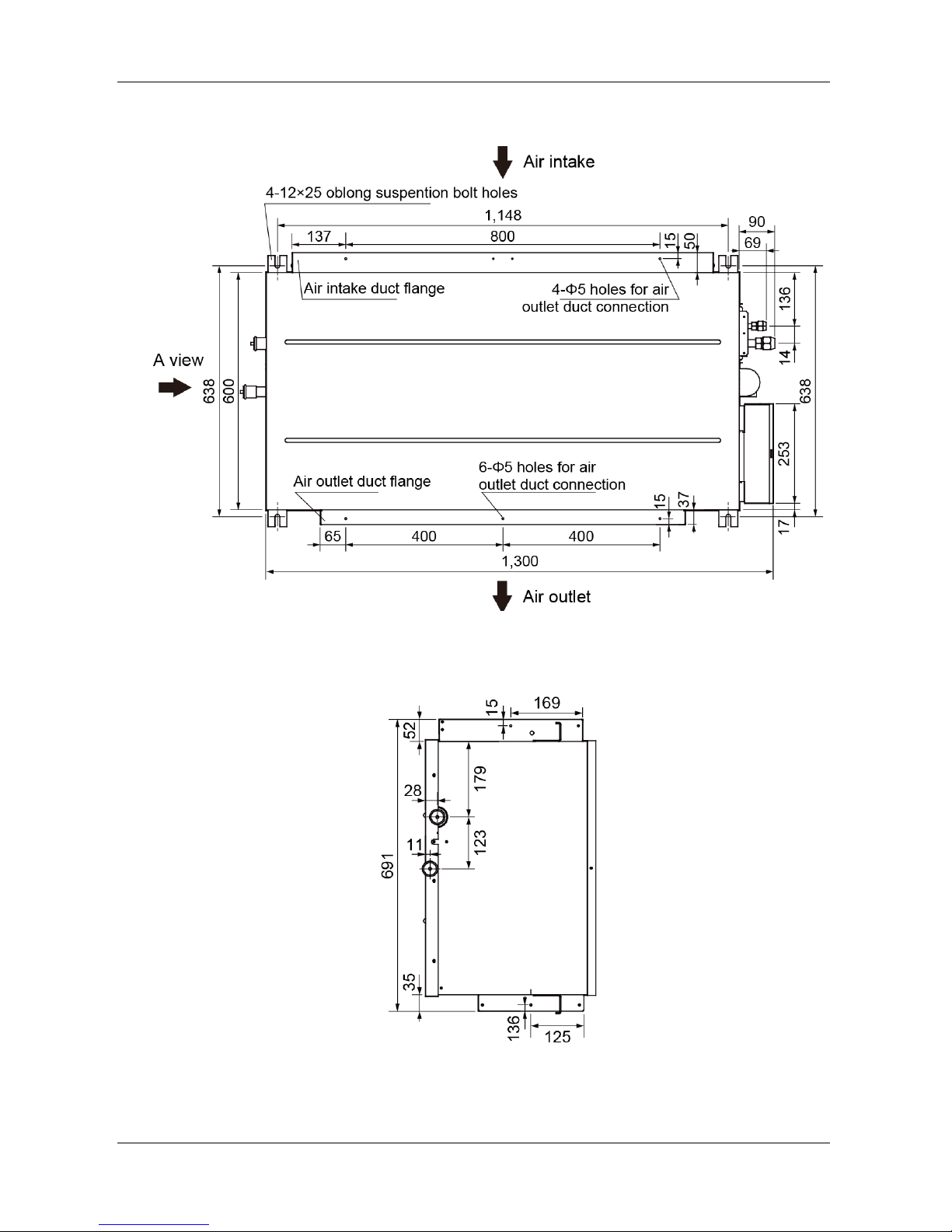

3. Dimensions

MTA-18WN1 (Unit: mm)

Air outlet side view

Air inlet side view

Page 22

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

20

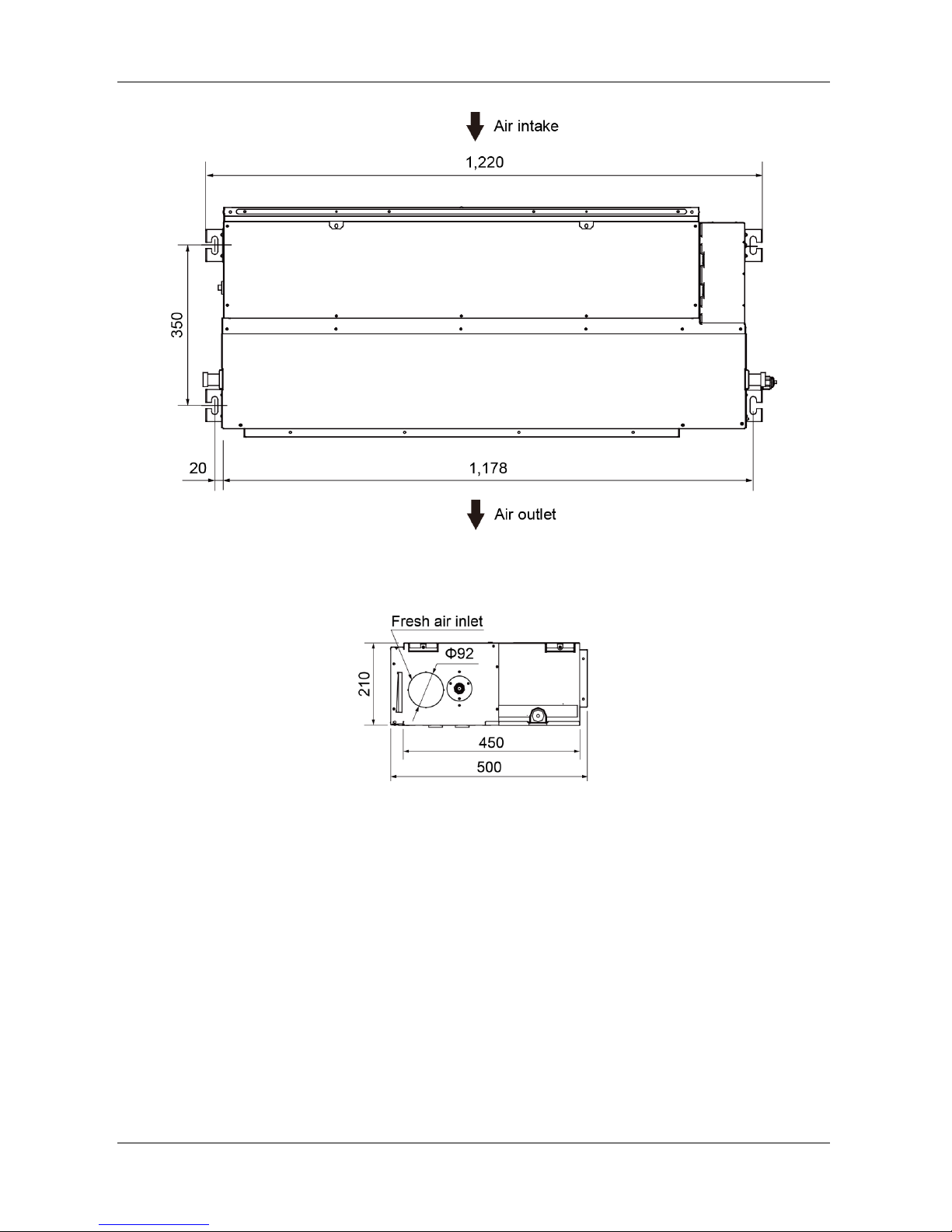

Top view

Left side view

Page 23

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

21

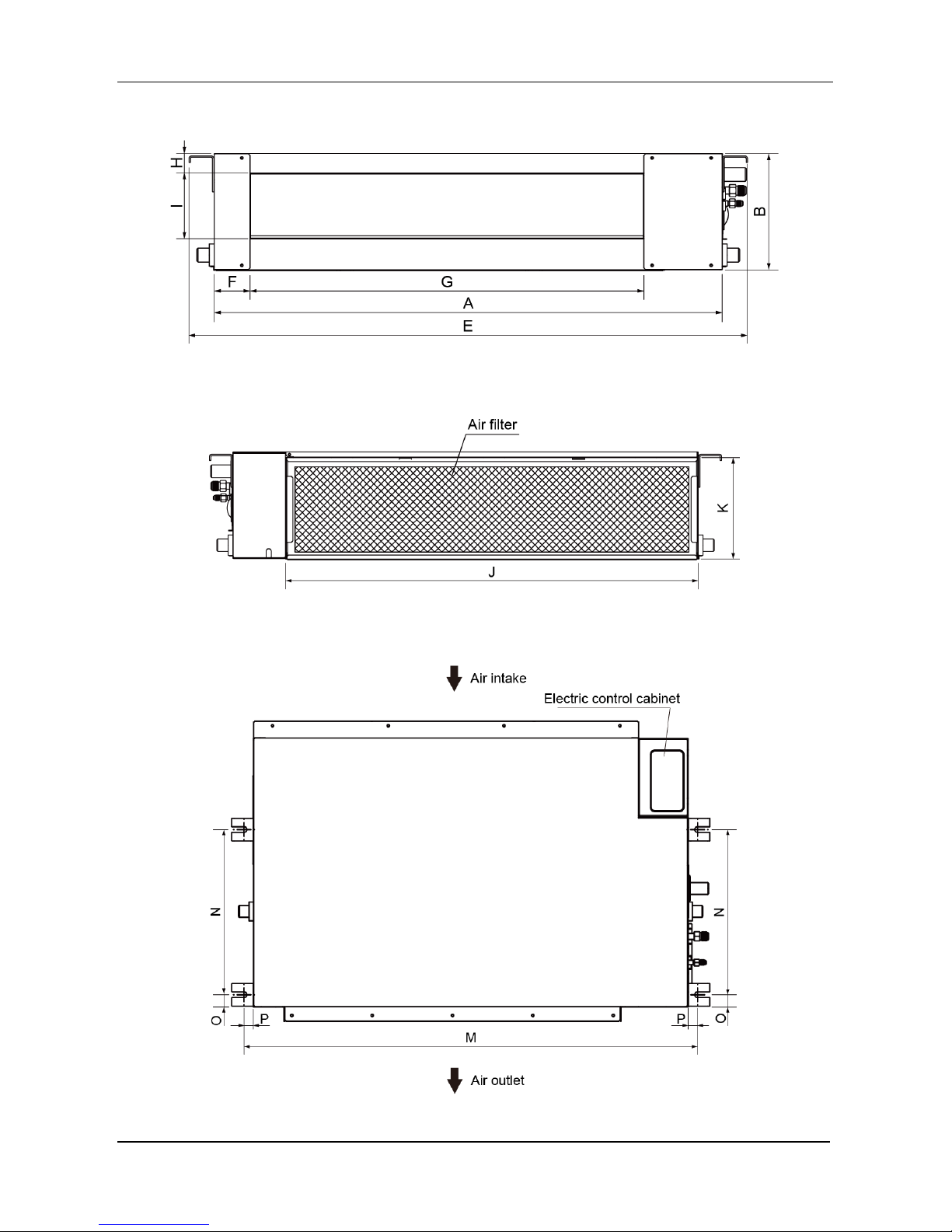

MTA-24WN1, MTA-36WN1 (Unit: mm)

Air outlet side view

Air inlet side view

Top view

Page 24

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

22

Left side view

(Unit: mm)

Model

Outline dimension

Air outlet opening size

A B C D E F G H I

MTA-24WN1

1,140

270

775

710

1,230

65

933

35

179

MTA-36WN1

1,140

270

775

710

1,230

65

933

35

179

(Unit: mm)

Model

Air return opening size

Size of mounted lug

Fresh air inlet

J K L M N O P T MTA-24WN1

1,035

260

20

1,180

490

26

20

Φ125

MTA-36WN1

1,035

260

20

1,180

490

26

20

Φ125

Page 25

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

23

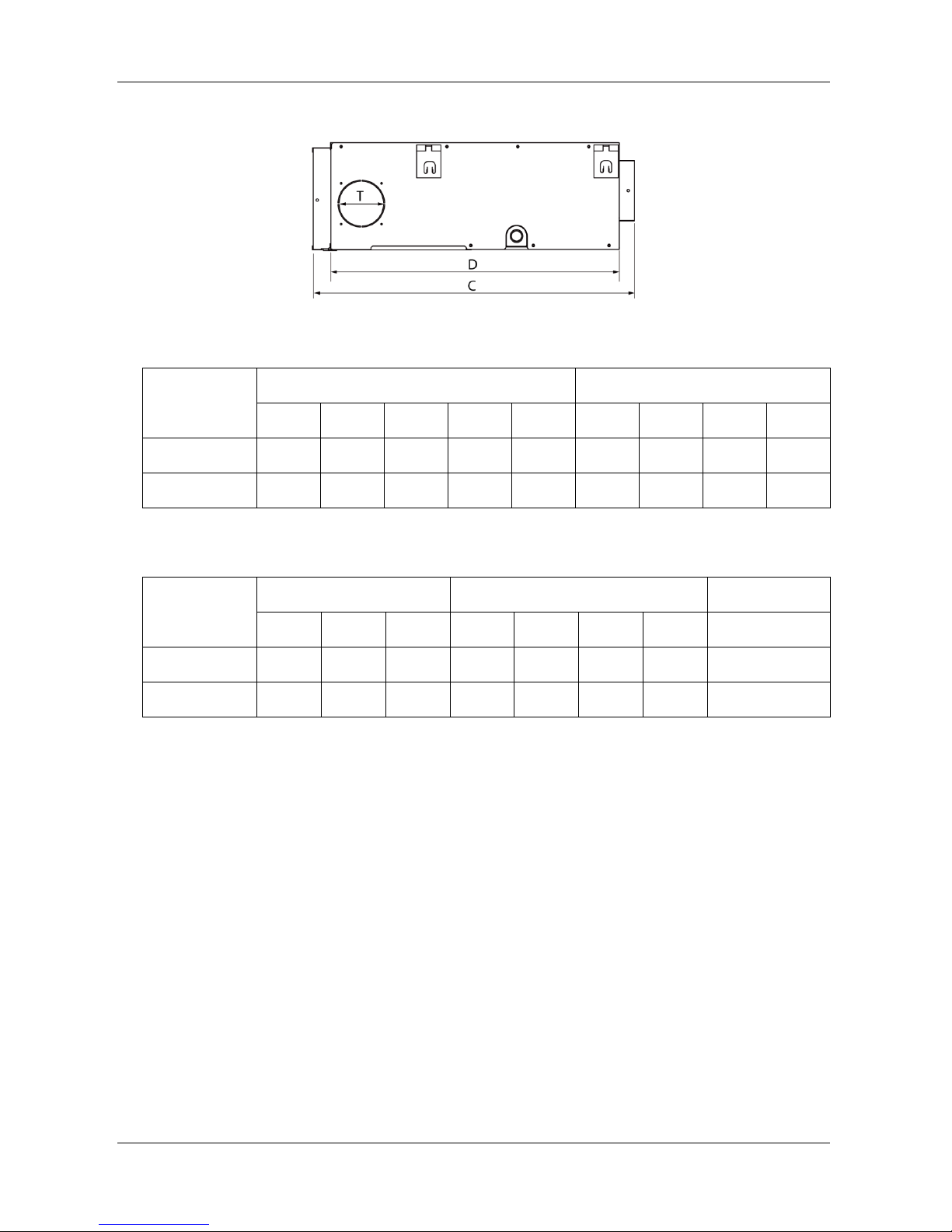

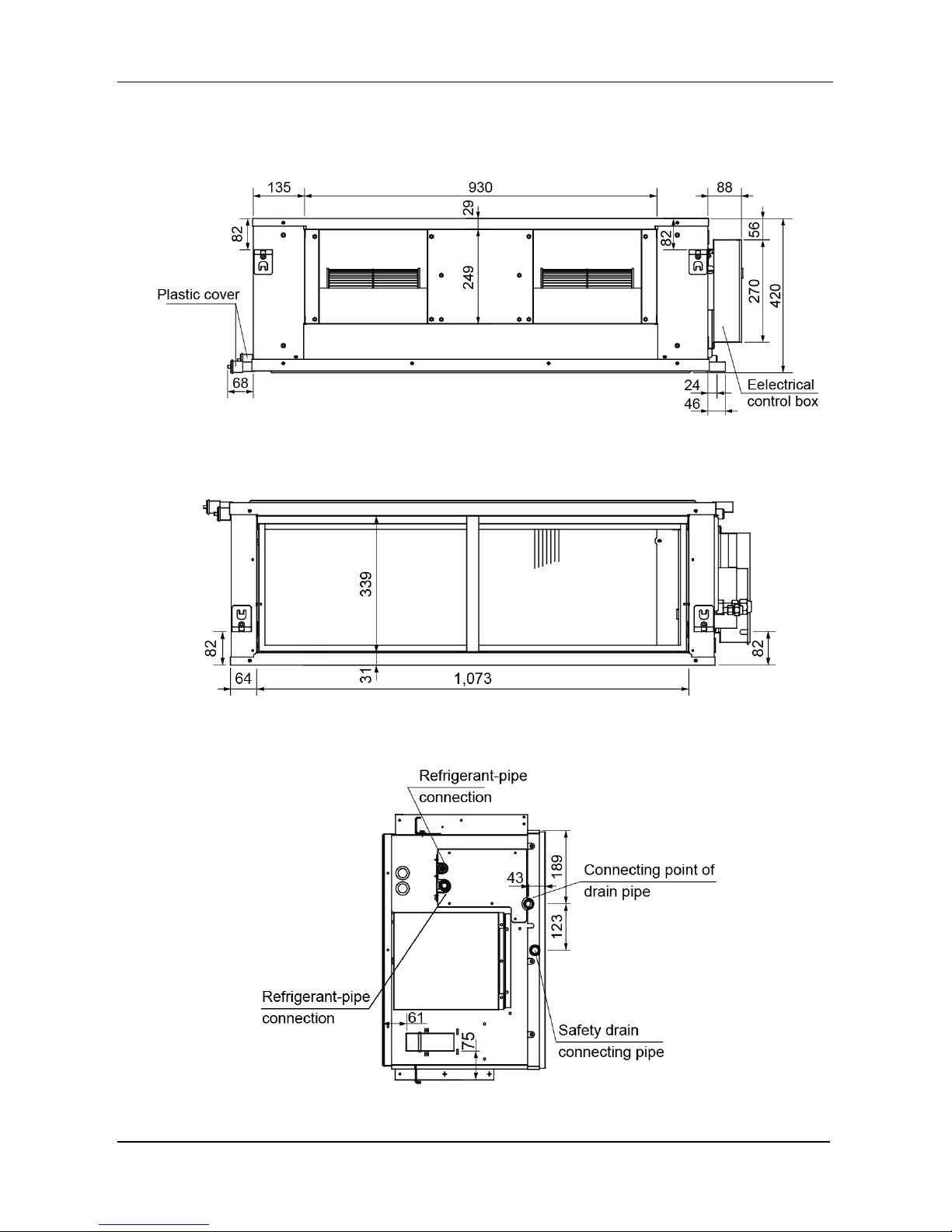

MTA-48WN1, MTA-60WN1 (Unit: mm)

Air outlet side view

Air inlet side view

Connecting pipe side view

Page 26

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

24

Top view

A view

Page 27

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

25

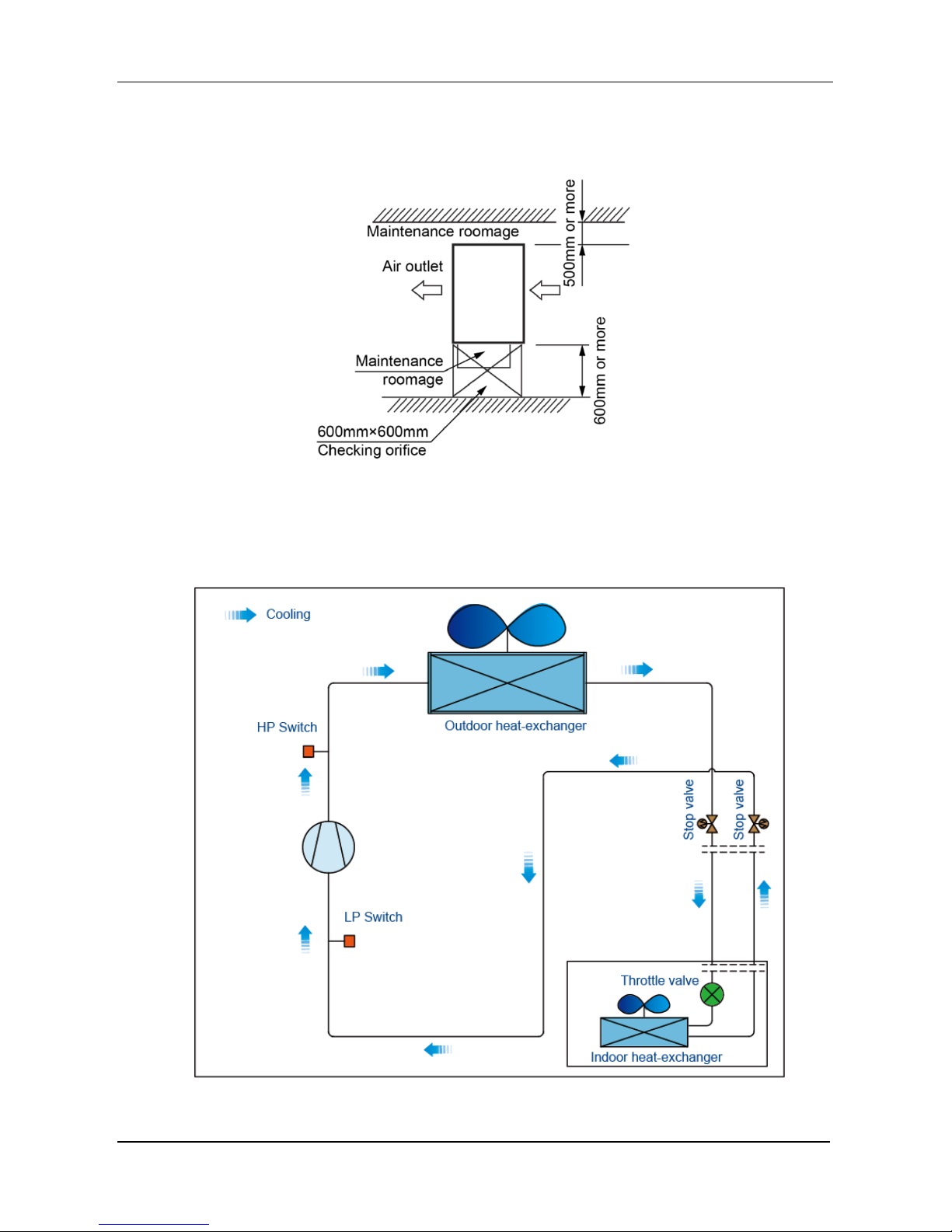

4. Service Space

Top view

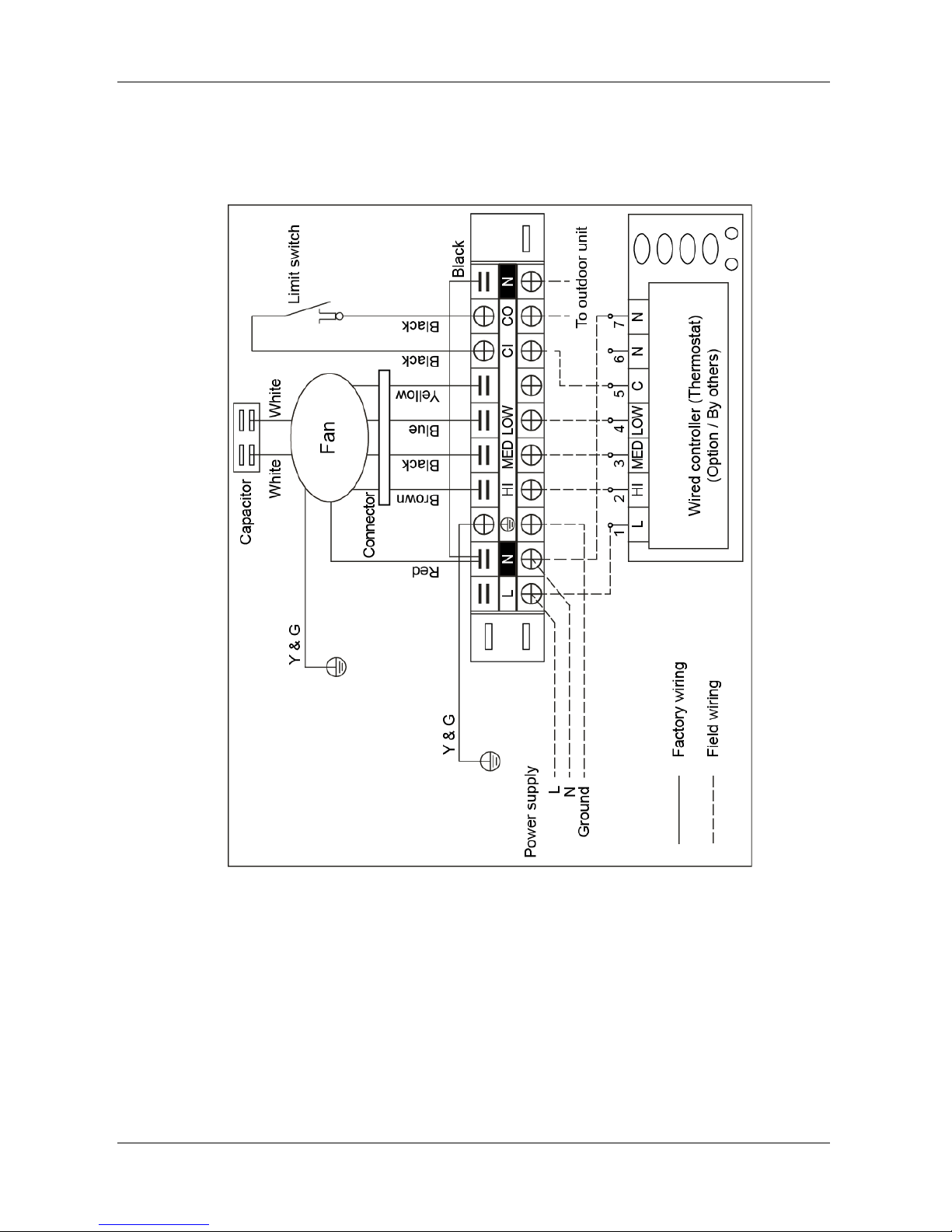

5. Refrigerant circuit

Page 28

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

26

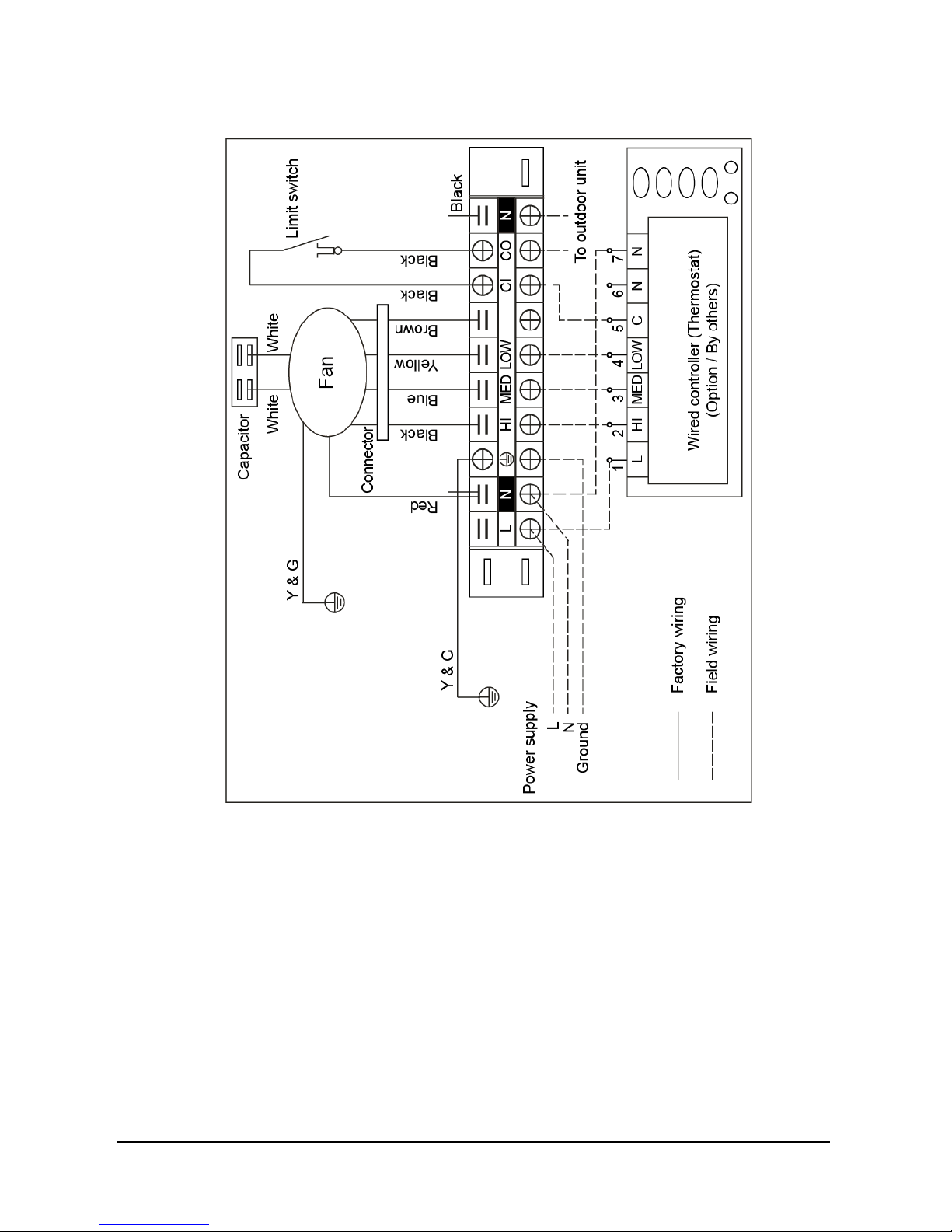

6. Wiring Diagrams

MTA-18WN1 (Other thermostat with 220V signal)

Page 29

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

27

MTA-24WN1 (Other thermostat with 220V signal)

Page 30

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

28

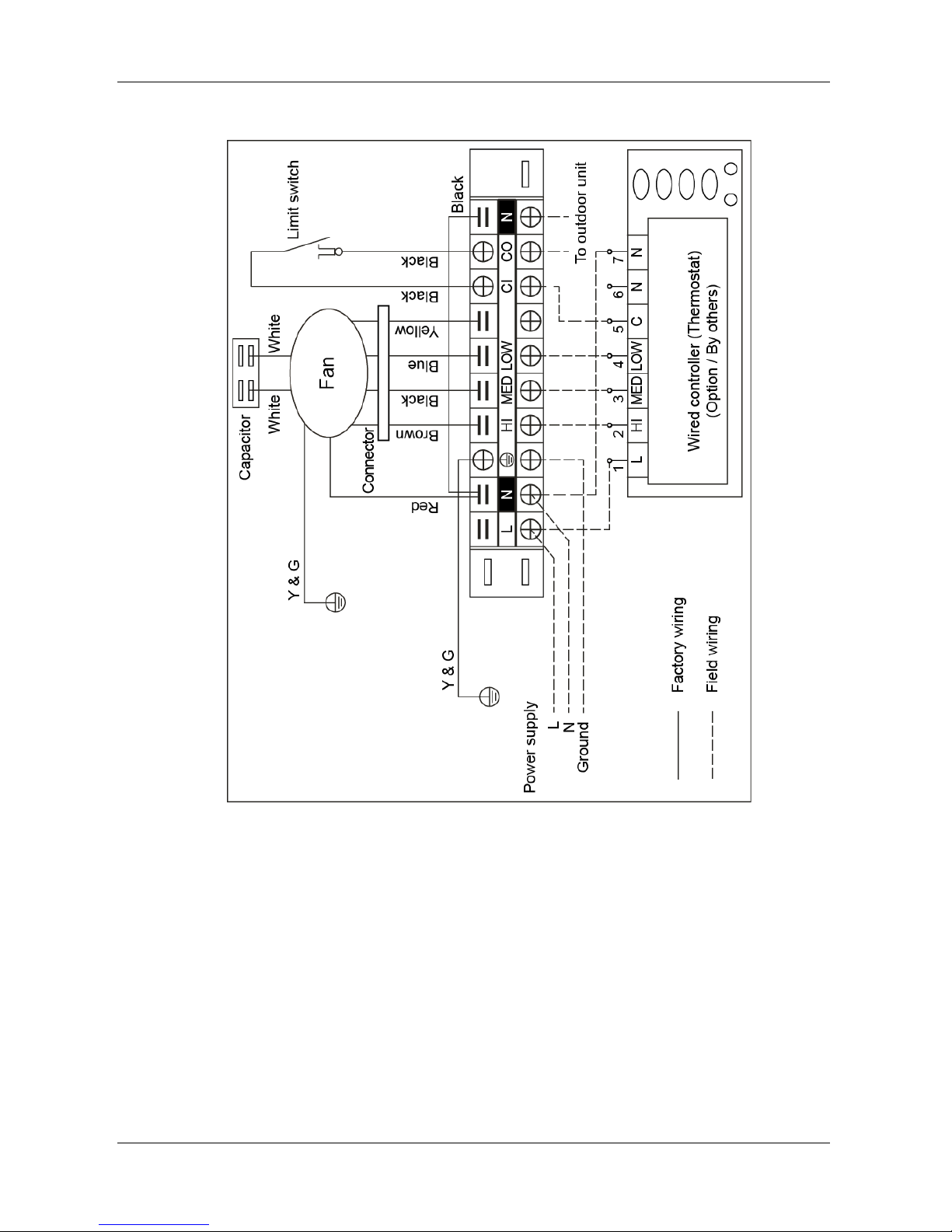

MTA-36WN1 (Other thermostat with 220V signal)

Page 31

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

29

MTA-48WN1 (Other thermostat with 220V signal)

Page 32

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

30

MTA-60WN1 (Other thermostat with 220V signal)

Page 33

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

31

MTA-24WN1 (Factory default thermostat with 5V signal) (Customized)

Page 34

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

32

MTA-36WN1 (Factory default thermostat with 5V signal) (Customized)

Page 35

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

33

MTA-48WN1 (Factory default thermostat with 5V signal) (Customized)

Page 36

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

34

MTA-60WN1 (Factory default thermostat with 5V signal) (Customized)

Page 37

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

35

7. Capacity Table

MTA-18WN1 + MOVTB-18CN1-13C

Indoor

air flow

Outdoor

Temp. (DB)

IWB (°C)

15.0

17.2

19.4

21.7

IDB (°C)

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

660CFM

1,120m3/h

29.4

TC

16.6

16.9

17.2

17.5

17.7

17.7

18.1

18.5

18.8

18.8

18.8

19.2 / 20.0

20.0

20.0

SC

13.6

16.9

17.2

17.5

10.6

14.2

18.1

18.5

7.5

11.1

14.9

18.6 / 8.0

11.6

15.4

kW

1.36

1.36

1.36

1.36

1.36

1.36

1.36

1.36

1.37

1.37

1.37

1.37 / 1.37

1.37

1.37

35.0

TC

15.9

16.2

16.5

16.8

16.9

16.9

17.2

17.5

18.0

18.0

18.0

18.4 / 19.1

19.1

19.1

SC

13.2

16.2

16.5

16.8

10.3

13.9

17.2

17.5

7.2

10.8

14.4

18.2 / 7.6

11.3

15.1

kW

1.54

1.54

1.54

1.54

1.54

1.54

1.54

1.54

1.55

1.55

1.55

1.55 / 1.55

1.55

1.55

40.6

TC

15.1

15.4

15.7

16.0

16.1

16.1

16.4

16.7

17.1

17.1

17.1

17.4 / 18.2

18.2

18.2

SC

12.8

15.4

15.7

16.0

9.8

13.5

16.4

16.7

6.8

10.4

14.0

17.4 / 7.5

11.1

14.7

kW

1.73

1.73

1.73

1.73

1.74

1.74

1.74

1.74

1.75

1.75

1.75

1.75 / 1.76

1.76

1.76

46.1

TC

14.2

14.5

14.8

15.1

15.1

15.1

15.4

15.7

16.1

16.1

16.1

16.4 / 17.1

17.1

17.1

SC

12.5

14.5

14.8

15.1

9.5

13.1

15.4

15.7

6.4

10.0

13.7

16.4 / 7.0

10.6

14.2

kW

1.95

1.95

1.95

1.95

1.96

1.96

1.96

1.96

1.97

1.97

1.97

1.97 / 1.98

1.98

1.98

47.8

TC

13.1

13.4

13.7

14.0

14.0

14.0

14.3

14.6

14.9

14.9

14.9

15.2 / 16.0

16.0

16.0

SC

11.9

13.4

13.7

14.0

9.0

12.6

14.3

14.6

6.0

9.5

13.3

15.2 / 6.6

10.2

13.9

kW

2.02

2.02

2.02

2.02

2.03

2.03

2.03

2.03

2.04

2.04

2.04

2.04 / 2.06

2.06

2.06

51.7

TC

12.1

12.3

12.5

12.8

13.0

13.0

13.3

13.6

13.9

13.9

13.9

14.2 / 14.8

14.8

14.8

SC

11.5

12.3

12.5

12.8

8.6

12.2

13.3

13.6

5.6

9.2

12.8

14.2 / 6.1

9.8

13.5

kW

2.21

2.21

2.21

2.21

2.22

2.22

2.22

2.22

2.23

2.23

2.23

2.23 / 2.24

2.24

2.24

Notes:

1. IDB = Indoor Dry Bulb Temp. (°C); IWB = Indoor Wet Bulb Temp. (°C); TC = Total Cap. (1,000Btu/h); SC = Sensible Cap. (1,000Btu/h); kW = Power Input (kW).

Airflow Correction Factors

Air flow

TC

SC

kW

580CFM (990m3/h)

×0.98

×0.96

×0.99

740CFM (1,260m3/h)

×1.02

×1.06

×1.01

Page 38

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

36

MTA-24WN1 + MOVTB-24CN1-13C

Indoor

air flow

Outdoor

Temp. (DB)

IWB (°C)

15.0

17.2

19.4

21.7

IDB (°C)

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

780CFM

1,326m3/h

29.4

TC

22.3

22.7

23.2

23.7

23.7

23.7

23.7

24.2

25.1

25.1

25.1

25.1 / 26.7

26.7

26.7

SC

17.2

21.6

23.2

23.7

13.5

17.8

22.0

24.2

9.8

14.1

18.3

22.6 / 10.1

14.4

19.0

kW

1.84

1.84

1.84

1.84

1.85

1.85

1.85

1.85

1.85

1.85

1.85

1.85 / 1.86

1.86

1.86

35.0

TC

21.0

21.4

21.8

22.2

22.4

22.4

22.8

23.3

23.8

23.8

23.8

23.8 / 25.3

25.3

25.3

SC

16.4

21.0

21.8

22.2

12.8

17.0

21.7

23.3

9.0

13.3

17.6

22.1 / 9.6

13.9

18.2

kW

2.03

2.03

2.03

2.03

2.04

2.04

2.04

2.04

2.05

2.05

2.05

2.05 / 2.05

2.05

2.05

40.6

TC

19.7

20.1

20.5

20.9

21.0

21.0

21.4

21.8

22.4

22.4

22.4

22.8 / 23.8

23.8

23.8

SC

15.8

20.1

20.5

20.9

12.2

16.6

21.0

21.8

8.5

12.8

17.2

21.7 / 9.0

13.3

17.6

kW

2.25

2.25

2.25

2.25

2.26

2.26

2.26

2.26

2.27

2.27

2.27

2.27 / 2.29

2.29

2.29

46.1

TC

18.3

18.7

19.1

19.5

19.5

19.5

19.9

20.3

20.8

20.8

20.8

21.2 / 22.2

22.2

22.2

SC

15.2

18.7

19.1

19.5

11.5

15.8

19.9

20.3

7.9

12.3

16.4

21.0 / 8.4

12.9

17.1

kW

2.50

2.50

2.50

2.50

2.51

2.51

2.51

2.51

2.53

2.53

2.53

2.53 / 2.54

2.54

2.54

47.8

TC

17.8

18.2

18.6

19.0

19.0

19.0

19.4

19.8

20.3

20.3

20.3

20.7 / 21.7

21.7

21.7

SC

15.0

18.2

18.6

19.0

11.4

15.6

19.4

19.8

7.7

12.0

16.2

20.7 / 8.2

12.6

16.9

kW

2.58

2.58

2.58

2.58

2.60

2.60

2.60

2.60

2.61

2.61

2.61

2.61 / 2.63

2.63

2.63

51.7

TC

16.7

17.0

17.3

17.6

17.8

17.8

18.2

18.6

19.1

19.1

19.1

19.5 / 20.4

20.4

20.4

SC

14.4

17.0

17.3

17.6

10.9

15.1

18.2

18.6

7.3

11.5

15.9

19.5 / 7.8

12.0

16.5

kW

2.80

2.80

2.80

2.80

2.81

2.81

2.81

2.81

2.82

2.82

2.82

2.82 / 2.84

2.84

2.84

Notes:

1. IDB = Indoor Dry Bulb Temp. (°C); IWB = Indoor Wet Bulb Temp. (°C); TC = Total Cap. (1,000Btu/h); SC = Sensible Cap. (1,000Btu/h); kW = Power Input (kW).

Airflow Correction Factors

Air flow

TC

SC

kW

680CFM (1,156m3/h)

×0.98

×0.96

×0.99

880CFM (1,496m3/h)

×1.02

×1.06

×1.01

Page 39

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

37

MTA-36WN1 + MOVTB-36CN1-13C

Indoor

air flow

Outdoor

Temp. (DB)

IWB (°C)

15.0

17.2

19.4

21.7

IDB (°C)

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

1,000CFM

1,700m3/h

29.4

TC

32.8

32.8

33.5

34.2

34.9

34.9

34.9

35.6

37.1

37.1

37.1

37.1 / 39.3

39.3

39.3

SC

24.3

29.8

33.5

34.2

19.5

25.1

30.7

35.6

14.8

20.4

26.0

31.5 / 15.7

21.2

26.7

kW

2.58

2.58

2.58

2.58

2.58

2.58

2.58

2.58

2.59

2.59

2.59

2.59 / 2.60

2.60

2.60

35.0

TC

30.9

30.9

31.5

32.1

32.9

32.9

32.9

33.6

35.0

35.0

35.0

35.0 / 37.2

37.2

37.2

SC

23.5

28.7

31.5

32.1

18.8

24.3

29.6

33.6

14.0

19.6

25.2

30.5 / 14.9

20.5

26.0

kW

2.84

2.84

2.84

2.84

2.85

2.85

2.85

2.85

2.86

2.86

2.86

2.86 / 2.86

2.86

2.86

40.6

TC

28.9

29.5

30.1

30.7

30.8

30.8

30.8

31.4

32.8

32.8

32.8

32.8 / 34.9

34.9

34.9

SC

22.3

28.3

30.1

30.7

17.9

23.4

29.0

31.4

13.1

18.7

24.3

29.8 / 14.0

19.5

25.1

kW

3.13

3.13

3.13

3.13

3.14

3.14

3.14

3.14

3.16

3.16

3.16

3.16 / 3.18

3.18

3.18

46.1

TC

26.7

27.2

27.7

28.3

28.5

28.5

29.1

29.7

30.4

30.4

30.4

30.4 / 32.4

32.4

32.4

SC

21.4

27.2

27.7

28.3

16.8

22.2

27.9

29.7

12.2

17.6

23.1

28.6 / 13.0

18.5

24.0

kW

3.47

3.47

3.47

3.47

3.49

3.49

3.49

3.49

3.51

3.51

3.51

3.51 / 3.53

3.53

3.53

47.8

TC

26.4

26.9

27.4

27.9

28.2

28.2

28.8

29.4

30.1

30.1

30.1

30.7 / 32.1

32.1

32.1

SC

21.1

26.9

27.4

27.9

16.6

22.3

27.9

29.4

12.0

17.5

23.2

28.9 / 12.8

18.3

24.1

kW

3.59

3.59

3.59

3.59

3.60

3.60

3.60

3.60

3.62

3.62

3.62

3.62 / 3.65

3.65

3.65

51.7

TC

24.8

25.3

25.8

26.3

26.5

26.5

27.0

27.5

28.3

28.3

28.3

28.9 / 30.2

30.2

30.2

SC

20.3

25.3

25.8

26.3

15.9

21.5

27.0

27.5

11.3

16.7

22.4

28.0 / 12.1

17.8

23.3

kW

3.88

3.88

3.88

3.88

3.89

3.89

3.89

3.89

3.91

3.91

3.91

3.91 / 3.94

3.94

3.94

Notes:

1. IDB = Indoor Dry Bulb Temp. (°C); IWB = Indoor Wet Bulb Temp. (°C); TC = Total Cap. (1,000Btu/h); SC = Sensible Cap. (1,000Btu/h); kW = Power Input (kW).

Airflow Correction Factors

Air flow

TC

SC

kW

880CFM (1,496m3/h)

×0.98

×0.96

×0.99

1,130CFM (1,921m3/h)

×1.02

×1.06

×1.01

Page 40

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

38

MTA-36WN1 + MOVTB-36CN1-R13C

Indoor

air flow

Outdoor

Temp. (DB)

IWB (°C)

15.0

17.2

19.4

21.7

IDB (°C)

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

1,000CFM

1,700m3/h

29.4

TC

32.2

32.2

32.8

33.5

34.2

34.2

34.2

34.9

36.3

36.3

36.3

36.3 / 38.6

38.6

38.6

SC

23.8

29.3

32.8

33.5

18.8

24.6

30.1

34.9

14.2

19.6

25.0

30.9 / 15.1

20.5

25.9

kW

2.67

2.67

2.67

2.67

2.67

2.67

2.67

2.67

2.68

2.68

2.68

2.68 / 2.69

2.69

2.69

35.0

TC

30.4

30.4

31.0

31.6

32.3

32.3

32.3

32.9

34.4

34.4

34.4

34.4 / 36.5

36.5

36.5

SC

22.8

28.3

31.0

31.6

18.1

23.6

29.1

32.9

13.4

18.9

24.4

29.9 / 13.9

19.7

25.2

kW

2.95

2.95

2.95

2.95

2.96

2.96

2.96

2.96

2.97

2.97

2.97

2.97 / 2.97

2.97

2.97

40.6

TC

28.5

29.1

29.7

30.3

30.4

30.4

30.4

31.0

32.3

32.3

32.3

32.3 / 34.4

34.4

34.4

SC

21.9

27.6

29.7

30.3

17.3

22.8

28.3

31.0

12.6

18.1

23.6

29.1 / 13.1

18.6

24.1

kW

3.26

3.26

3.26

3.26

3.27

3.27

3.27

3.27

3.29

3.29

3.29

3.29 / 3.31

3.31

3.31

46.1

TC

26.4

26.9

27.4

27.9

28.2

28.2

28.8

29.4

30.1

30.1

30.1

30.1 / 32.1

32.1

32.1

SC

20.9

26.6

27.4

27.9

16.1

21.7

27.4

29.4

11.4

17.2

22.6

28.0 / 12.2

17.7

23.4

kW

3.62

3.62

3.62

3.62

3.64

3.64

3.64

3.64

3.66

3.66

3.66

3.66 / 3.68

3.68

3.68

47.8

TC

25.7

26.2

26.7

27.2

27.5

27.5

28.1

28.7

29.4

29.4

29.4

30.0 / 31.3

31.3

31.3

SC

20.6

26.2

26.7

27.2

16.0

21.5

27.3

28.7

11.2

16.8

22.3

27.9 / 11.9

17.5

23.2

kW

3.75

3.75

3.75

3.75

3.76

3.76

3.76

3.76

3.78

3.78

3.78

3.78 / 3.81

3.81

3.81

51.7

TC

24.1

24.6

25.1

25.6

25.8

25.8

26.3

26.8

27.6

27.6

27.6

28.2 / 29.4

29.4

29.4

SC

19.8

24.6

25.1

25.6

15.2

20.6

26.3

26.8

10.5

16.0

21.5

27.4 / 11.2

16.8

22.3

kW

4.05

4.05

4.05

4.05

4.07

4.07

4.07

4.07

4.09

4.09

4.09

4.09 / 4.11

4.11

4.11

Notes:

1. IDB = Indoor Dry Bulb Temp. (°C); IWB = Indoor Wet Bulb Temp. (°C); TC = Total Cap. (1,000Btu/h); SC = Sensible Cap. (1,000Btu/h); kW = Power Input (kW).

Airflow Correction Factors

Air flow

TC

SC

kW

880CFM (1,496m3/h)

×0.98

×0.96

×0.99

1,130CFM (1,921m3/h)

×1.02

×1.06

×1.01

Page 41

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

39

MTA-48WN1 + MOVTB-48CN1-R13C

Indoor

air flow

Outdoor

Temp. (DB)

IWB (°C)

15.0

17.2

19.4

21.7

IDB (°C)

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

1,550CFM

2,635m3/h

29.4

TC

44.9

45.8

46.7

47.6

47.7

47.7

47.7

48.7

50.7

50.7

50.7

50.7 / 53.8

53.8

53.8

SC

34.1

43.1

46.7

47.6

26.7

35.3

43.9

48.7

19.8

27.9

36.5

45.1 / 20.4

29.1

37.7

kW

3.72

3.72

3.72

3.72

3.73

3.73

3.73

3.73

3.74

3.74

3.74

3.74 / 3.75

3.75

3.75

35.0

TC

42.4

43.2

44.1

45.0

45.1

45.1

46.0

46.9

48.0

48.0

48.0

48.0 / 51.0

51.0

51.0

SC

33.1

41.9

44.1

45.0

25.7

34.3

43.2

46.9

18.2

26.9

35.5

44.2 / 19.4

28.1

36.7

kW

4.11

4.11

4.11

4.11

4.12

4.12

4.12

4.12

4.14

4.14

4.14

4.14 / 4.14

4.14

4.14

40.6

TC

39.7

40.5

41.3

42.1

42.4

42.4

43.2

44.1

45.1

45.1

45.1

46.0 / 48.0

48.0

48.0

SC

31.8

40.5

41.3

42.1

24.6

33.1

41.9

44.1

17.1

25.7

34.3

43.2 / 18.2

26.9

35.5

kW

4.54

4.54

4.54

4.54

4.56

4.56

4.56

4.56

4.59

4.59

4.59

4.59 / 4.62

4.62

4.62

46.1

TC

36.9

37.6

38.4

39.2

39.4

39.4

40.2

41.0

42.0

42.0

42.0

42.8 / 44.7

44.7

44.7

SC

30.3

37.6

38.4

39.2

23.2

31.9

40.2

41.0

16.0

24.4

33.2

41.9 / 17.0

25.5

34.4

kW

5.05

5.05

5.05

5.05

5.07

5.07

5.07

5.07

5.10

5.10

5.10

5.10 / 5.13

5.13

5.13

47.8

TC

35.9

36.6

37.3

38.0

38.4

38.4

39.2

40.0

41.0

41.0

41.0

41.8 / 43.7

43.7

43.7

SC

29.8

36.6

37.3

38.0

22.7

31.5

39.2

40.0

15.6

24.2

32.8

41.4 / 16.6

25.3

33.6

kW

5.22

5.22

5.22

5.22

5.24

5.24

5.24

5.24

5.27

5.27

5.27

5.27 / 5.30

5.30

5.30

51.7

TC

33.6

34.3

35.0

35.7

36.0

36.0

36.7

37.4

38.4

38.4

38.4

39.2 / 41.0

41.0

41.0

SC

28.9

34.3

35.0

35.7

21.6

30.2

36.7

37.4

14.6

23.0

31.5

39.2 / 15.6

24.2

32.8

kW

5.65

5.65

5.65

5.65

5.67

5.67

5.67

5.67

5.70

5.70

5.70

5.70 / 5.74

5.74

5.74

Notes:

1. IDB = Indoor Dry Bulb Temp. (°C); IWB = Indoor Wet Bulb Temp. (°C); TC = Total Cap. (1,000Btu/h); SC = Sensible Cap. (1,000Btu/h); kW = Power Input (kW).

Airflow Correction Factors

Air flow

TC

SC

kW

1,360CFM (2,312m3/h)

×0.98

×0.96

×0.99

1,740CFM (2,958m3/h)

×1.02

×1.06

×1.01

Page 42

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

40

MTA-60WN1 + MOVTB-60CN1-R13C

Indoor

air flow

Outdoor

Temp. (DB)

IWB (°C)

15.0

17.2

19.4

21.7

IDB (°C)

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

21.1

23.9

26.7

29.4

1,700CFM

2,890m3/h

29.4

TC

53.0

53.0

54.1

55.2

56.4

56.4

56.4

57.5

60.0

60.0

60.0

60.0 / 63.6

63.6

63.6

SC

39.8

49.3

54.1

55.2

32.1

41.2

50.8

57.5

24.0

33.6

42.6

52.2 / 25.4

35.0

43.9

kW

4.29

4.29

4.29

4.29

4.30

4.30

4.30

4.30

4.31

4.31

4.31

4.31 / 4.33

4.33

4.33

35.0

TC

50.3

51.3

52.3

53.3

53.6

53.6

53.6

54.7

57.0

57.0

57.0

57.0 / 60.6

60.6

60.6

SC

38.7

48.2

52.3

53.3

30.6

40.2

49.3

54.7

22.8

32.5

41.6

50.7 / 24.2

33.3

43.0

kW

4.83

4.83

4.83

4.83

4.85

4.85

4.85

4.85

4.87

4.87

4.87

4.87 / 4.87

4.87

4.87

40.6

TC

47.4

48.3

49.3

50.3

50.6

50.6

51.6

52.6

53.8

53.8

53.8

53.8 / 57.3

57.3

57.3

SC

37.4

46.9

49.3

50.3

29.3

39.0

48.5

52.6

21.5

30.7

40.4

49.5 / 22.9

32.1

41.8

kW

5.43

5.43

5.43

5.43

5.45

5.45

5.45

5.45

5.48

5.48

5.48

5.48 / 5.51

5.51

5.51

46.1

TC

44.3

45.2

46.1

47.0

47.3

47.3

48.2

49.2

50.3

50.3

50.3

51.3 / 53.6

53.6

53.6

SC

35.9

45.2

46.1

47.0

27.9

37.4

47.2

49.2

20.1

29.7

38.7

48.7 / 21.4

31.1

40.2

kW

6.11

6.11

6.11

6.11

6.13

6.13

6.13

6.13

6.17

6.17

6.17

6.17 / 6.21

6.21

6.21

47.8

TC

42.1

42.9

43.8

44.7

45.0

45.0

45.9

46.8

48.1

48.1

48.1

49.1 / 51.3

51.3

51.3

SC

34.5

42.9

43.8

44.7

27.0

36.5

45.9

46.8

19.2

28.4

38.0

47.6 / 20.5

30.3

39.5

kW

6.33

6.33

6.33

6.33

6.36

6.36

6.36

6.36

6.39

6.39

6.39

6.39 / 6.43

6.43

6.43

51.7

TC

39.2

40.0

40.8

41.6

42.0

42.0

42.8

43.7

44.9

44.9

44.9

45.8 / 48.0

48.0

48.0

SC

33.3

40.0

40.8

41.6

25.6

34.9

42.8

43.7

18.0

27.4

36.8

45.8 / 19.2

28.8

38.4

kW

6.89

6.89

6.89

6.89

6.92

6.92

6.92

6.92

6.95

6.95

6.95

6.95 / 7.00

7.00

7.00

Notes:

1. IDB = Indoor Dry Bulb Temp. (°C); IWB = Indoor Wet Bulb Temp. (°C); TC = Total Cap. (1,000Btu/h); SC = Sensible Cap. (1,000Btu/h); kW = Power Input (kW).

Airflow Correction Factors

Air flow

TC

SC

kW

1,550CFM (2,635m3/h)

×0.98

×0.96

×0.99

2,000CFM (3,400m3/h)

×1.02

×1.06

×1.01

Page 43

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

41

8. Fan performance

MTA-18WN1

ESP

In.H2O

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

Pa

0

12.5

24.9

37.4

49.8

62.3

74.7

87.2

Air

volume

Low

CFM

540

519

489

455

404

345

284

210

m3/h

918

882

831

774

687

587

483

357

Medium

CFM

590

565

530

484

435

375

308

230

m3/h

1,003

961

901

823

740

638

524

391

High

CFM

768

717

662

605

534

460

382

290

m3/h

1,306

1,219

1,125

1,029

908

782

649

493

Notes:

ESP: External static pressure.

The values are based the unit with filter operating under cooling mode.

Shaded boxes: represent airflow outside the required.

Page 44

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

42

MTA-24WN1

ESP

In.H2O

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

Pa

0

12.5

24.9

37.4

49.8

62.3

74.7

87.2

99.6

Air

volume

Low

CFM

853

820

787

757

727

693

659

622

584

m3/h

1,450

1,394

1,338

1,287

1,236

1,178

1,120

1,057

993

Medium

CFM

983

942

900

866

832

795

757

713

669

m3/h

1,671

1,601

1,530

1,472

1,414

1,352

1,287

1,212

1,137

High

CFM

1,113

1,069

1,025

985

945

903

860

810

760

m3/h

1,892

1,817

1,743

1,675

1,607

1,535

1,462

1,377

1,292

Notes:

ESP: External static pressure.

The values are based the unit with filter operating under cooling mode.

Shaded boxes: represent airflow outside the required.

Page 45

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

43

MTA-36WN1

ESP

In.H2O

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

Pa

0

12.5

24.9

37.4

49.8

62.3

74.7

87.2

99.6

Air

volume

Low

CFM

983

942

900

866

832

795

757

713

669

m3/h

1,671

1,601

1,530

1,472

1,414

1,352

1,287

1,212

1,137

Medium

CFM

1,113

1,069

1,025

985

945

903

860

810

760

m3/h

1,892

1,817

1,743

1,675

1,607

1,535

1,462

1,377

1,292

High

CFM

1,248

1,192

1,136

1,088

1,040

990

940

886

831

m3/h

2,122

2,026

1,931

1,850

1,768

1,683

1,598

1,506

1,413

Notes:

ESP: External static pressure.

The values are based the unit with filter operating under cooling mode.

Shaded boxes: represent airflow outside the required.

Page 46

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

44

MTA-48WN1

ESP

In.H2O

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

Pa

0

12.5

24.9

37.4

49.8

62.3

74.7

87.2

Air

volume

Low

CFM

1,502

1,470

1,437

1,405

1,372

1,340

1,306

1,272

m3/h

2,553

2,499

2,443

2,389

2,332

2,278

2,220

2,162

Medium

CFM

1,629

1,597

1,566

1,529

1,492

1,459

1,421

1,386

m3/h

2,769

2,715

2,662

2,599

2,536

2,480

2,415

2,356

High

CFM

1,774

1,737

1,699

1,662

1,623

1,593

1,551

1,513

m3/h

3,016

2,953

2,888

2,825

2,759

2,708

2,637

2,572

ESP

In.H2O

0.40

0.45

0.5

Pa

99.6

112.1

124.5

Air

volume

Low

CFM

1,239

1,205

1,171

m3/h

2,106

2,049

1,991

Medium

CFM

1,349

1,318

1,287

m3/h

2,293

2,241

2,188

High

CFM

1,474

1,436

1,400

m3/h

2,506

2,441

2,380

Notes:

ESP: External static pressure.

The values are based the unit with filter operating under cooling mode.

Shaded boxes: represent airflow outside the required.

Page 47

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

45

MTA-60WN1

ESP

In.H2O

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

Pa

0

12.5

24.9

37.4

49.8

62.3

74.7

87.2

Air

volume

Low

CFM

1,629

1,597

1,566

1,529

1,492

1,459

1,421

1,386

m3/h

2,769

2,715

2,662

2,599

2,536

2,480

2,415

2,356

Medium

CFM

1,774

1,737

1,699

1,662

1,623

1,593

1,551

1,513

m3/h

3,016

2,953

2,888

2,825

2,759

2,708

2,637

2,572

High

CFM

2,138

2,090

2,043

1,995

1,948

1,900

1,855

1,811

m3/h

3,635

3,553

3,473

3,392

3,312

3,230

3,154

3,079

ESP

In.H2O

0.40

0.45

0.5

Pa

99.6

112.1

124.5

Air

volume

Low

CFM

1,349

1,318

1,287

m3/h

2,293

2,241

2,188

Medium

CFM

1,474

1,436

1,400

m3/h

2,506

2,441

2,380

High

CFM

1,766

1,722

1,677

m3/h

3,002

2,927

2,851

Notes:

ESP: External static pressure.

The values are based the unit with filter operating under cooling mode.

Shaded boxes: represent airflow outside the required.

Page 48

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

46

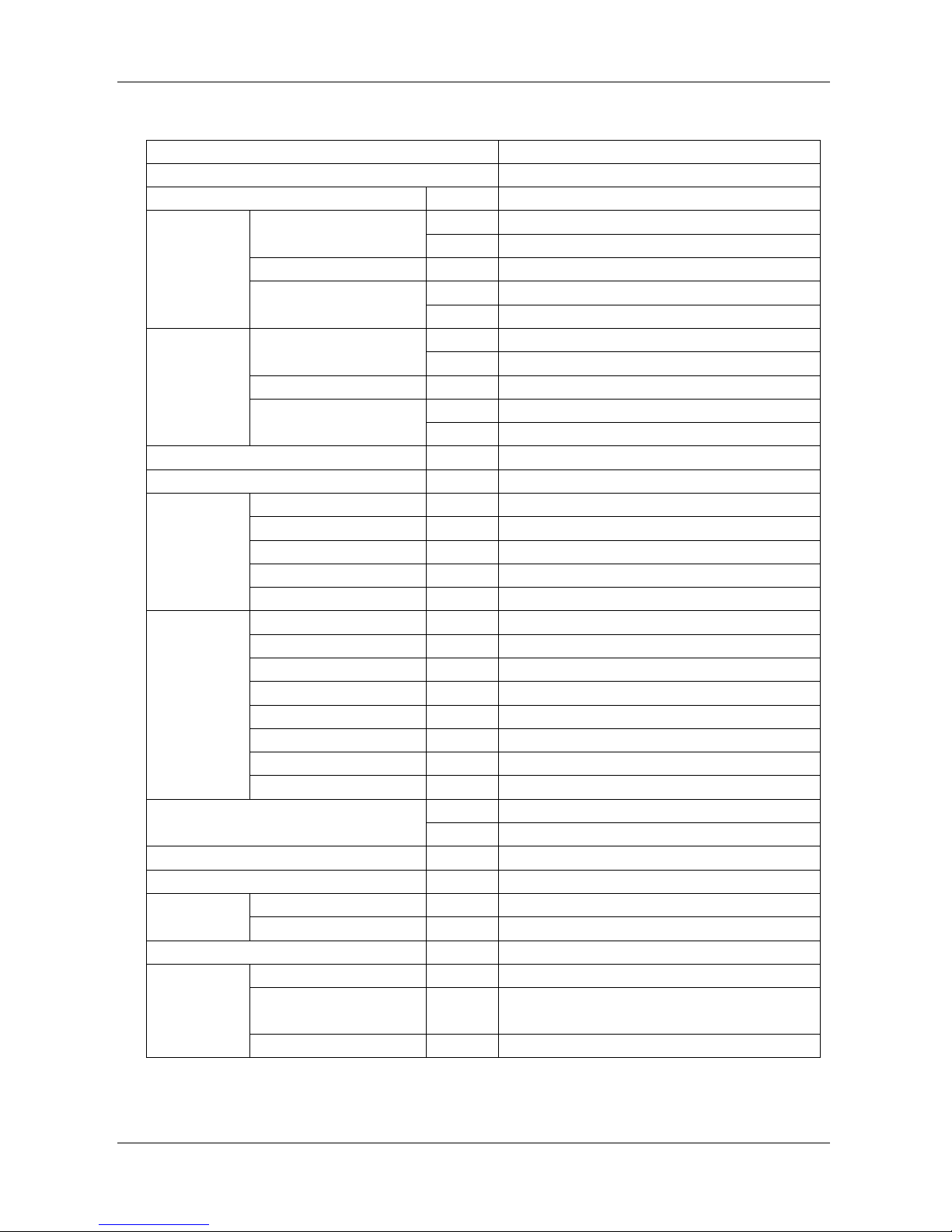

9. Electric Characteristics

Model

Indoor Unit

Power Supply

IFM

Hz

Voltage

Min.

Max.

MCA

MFA

kW

FLA

MTA-18WN1

50

220-240V

198V

254V

0.67

15

0.144

0.67

MTA-24WN1

50

220-240V

198V

254V

1.53

15

0.332

1.53

MTA-36WN1

50

220-240V

198V

254V

1.8

15

0.393

1.80

MTA-48WN1

50

220-240V

198V

254V

3.27

15

0.740

3.27

MTA-60WN1

50

220-240V

198V

254V

4.1

15

0.930

4.10

Note:

MCA: Min. Current Amps. (A)

MFA: Max. Fuse Amps. (A)

IFM: Indoor Fan Motor

kW: Fan Motor Rated Input (kW)

FLA: Full Load Amps. (A)

10. Sound Levels

Concealed Duct Type

Suction

Discharge

Microphone

1.4m

Duct

Model

Sound pressure level

High

Medium

Low

MTA-18WN1

42dB(A)

38dB(A)

37dB(A)

MTA-24WN1

49dB(A)

46dB(A)

44dB(A)

MTA-36WN1

51dB(A)

49dB(A)

46dB(A)

MTA-48WN1

52dB(A)

51dB(A)

50dB(A)

MTA-60WN1

54dB(A)

52dB(A)

51dB(A)

Page 49

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

47

11. Accessories

Name

Qty.

-

Purpose

Installation manual

1

-

-

Pipe insulation material

2

Heat insulation

Water outlet joint

1

For drainage

Clap

1

Chucking the joint which connect

the drain hose and the outlet of

the indoor unit

Real sponge

(Only available for MTA-18WN1)

1

Real the guiding frame

Copper nut

(Only available for MTA-18WN1)

1

Use for pipe connection of

installation

Connecting pipe

(Only available for MTA-18WN1)

3

Use for pipe connection of

installation

Page 50

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

48

Part. 3 Outdoor Unit

1. Specifications .................................................................... 49

2. Dimension ......................................................................... 61

3. Service Space ................................................................... 62

4. Wiring Diagrams ................................................................ 63

5. Electric Characteristics ...................................................... 66

6. Sound Levels ..................................................................... 66

Page 51

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

49

1. Specifications

Model

MOVTB-18CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Ambient temperature in cooling

°C

17 - 54

Rated input

W

2,400

Rated current

A

11.5

Compressor

Model

\

ZP20KSE-PFZ-522

Type

\

Scroll

Quantity

\

1

Brand

\

Copeland

Capacity

Btu/h

16,300

Input

W

1,750

Capacitor

\

40μF/450V

Rated current (RLA) A 10

Locked rotor Amp. (LRA) A 52

Thermal protector \ Internal

Refrigerant oil

ml

739

Fan

Type

\

Axial fan

Motor

\

YKS-85-6C

Motor quantity

\

1

Motor brand

\

Welling

Capacitor \ 6μF/450V

Motor input

W

150

Speed

r/min

970

Coil

No. of rows

\

1.8

Tube pitch(a)×row pitch(b)

mm

14.5×12.56

Fin space

mm

1.2

Fin type \ Hydrophilic aluminum fin

Tube outside Dia. and type

mm

Ф5

\

Inner grooved copper pipe

Coil (W×H)

mm

1,371×580

Number of circuits \ 12

Outdoor noise level

dB(A)

58

Indoor air flow

m3/h

1,400

CFM

824

Refrigerant

Type

\

R410A

Charge

g

1,920

Design pressure

MPa

4.4/2.6

Refrigerant pipe

Liquid side

mm

Ф9.52

Gas side

mm

Ф19.1

Page 52

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

50

Continued:

Model

MOVTB-18CN1-13C

Connection wire

Power wire (Outdoor unit)

\

3×2.5mm2

Signal wire

\

2×0.75mm2

Dimension (W×H×D)

mm

554×633×554

Packing (W×H×D)

mm

585×662×582

Net / Gross weight

kg

55/58

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi-anechoic room, at a position 1m in front of the unit and H meter above

the floor. (H=(1+Height of the unit)/2).

Page 53

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

51

Model

MOVTB-24CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Ambient temperature in cooling

°C

17 - 54

Rated input

W

3,000

Rated current

A

14.5

Compressor

Model

\

ZP25KSE-PFZ-522

Type

\

Scroll

Quantity

\

1

Brand

\

Copeland

Capacity

Btu/h

20,300

Input

W

2,110

Capacitor

\

40μF/450V

Rated current (RLA) A 12.5

Locked rotor Amp. (LRA) A 60

Thermal protector \ Internal

Refrigerant oil

ml

739

Fan

Type

\

Axial fan

Motor

\

YDK85-6G-2

Motor quantity

\

1

Motor brand

\

Welling

Capacitor \ 6μF/450V

Motor input

W

150

Speed

r/min

970

Coil

No. of rows

\

2

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.5

Fin type \ Hydrophilic aluminum fin

Tube outside Dia. and type

mm

Ф7

\

Inner grooved copper pipe

Coil (W×H)

mm

1,565×588

Number of circuits \ 6

Outdoor noise level

dB(A)

62

Indoor air flow

m3/h

3,000

CFM

1,765

Refrigerant

Type

\

R410A

Charge

g

2,420

Design pressure

MPa

4.4/2.6

Refrigerant pipe

Liquid side

mm

Ф9.52

Gas side

mm

Ф19.1

Page 54

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

52

Continued:

Model

MOVTB-24CN1-13C

Connection wire

Power wire (Outdoor unit)

\

3×2.5mm2

Signal wire

\

2×0.75mm2

Dimension (W×H×D)

mm

600×633×600

Packing (W×H×D)

mm

628×662×628

Net / Gross weight

kg

59/62

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi-anechoic room, at a position 1m in front of the unit and H meter above

the floor. (H=(1+Height of the unit)/2).

Page 55

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

53

Model

MOVTB-36CN1-13C

Power supply \ 220 - 240V~, 1Ph, 50Hz

Ambient temperature in cooling

°C

17 - 54

Rated input

W

4,000

Rated current

A

20

Compressor

Model

\

ZP36KSE-PFZ-522

Type

\

Scroll

Quantity

\

1

Brand

\

Copeland

Capacity

Btu/h

30,000

Input

W

2,940

Capacitor

\

80μF/450V

Rated current (RLA) A 17.7

Locked rotor Amp. (LRA) A 98

Thermal protector \ Internal

Refrigerant oil

ml

1,242 (POE)

Fan

Type

\

Axial fan

Motor

\

YDK160-6E-1

Motor quantity

\

1

Motor brand

\

Welling

Capacitor

\

6μF/450V

Motor input

W

230

Speed

r/min

900

Coil

No. of rows

\

2

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.3

Fin type \ Hydrophilic aluminum fin

Tube outside Dia. and type

mm

Ф7

\

Inner grooved copper pipe

Coil (W×H)

mm

2,005×714

Number of circuits \ 6

Outdoor noise level

dB(A)

64

Indoor air flow

m3/h

5,100

CFM

3,000

Refrigerant

Type

\

R410A

Charge

g

3,320

Design pressure

MPa

4.4/2.6

Refrigerant pipe

Liquid side

mm

Ф9.52

Gas side

mm

Ф19.1

Page 56

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

54

Continued:

Model

MOVTB-36CN1-13C

Connection wire

Power wire (Outdoor unit)

\

3×4.0mm2

Signal wire

\

2×0.75mm2

Dimension (W×H×D)

mm

710×759×710

Packing (W×H×D)

mm

738×779×738

Net / Gross weight

kg

86/90

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi-anechoic room, at a position 1m in front of the unit and H meter above

the floor. (H=(1+Height of the unit)/2).

Page 57

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

55

Model

MOVTB-36CN1-R13C

Power supply \ 380-415V~, 50Hz, 3Ph

Ambient temperature in cooling

°C

17 - 54

Rated input

W

4,000

Rated current

A

8

Compressor

Model

\

ZP36KSE-TFM-522

Type

\

Scroll

Quantity

\

1

Brand

\

Copeland

Capacity

Btu/h

29,300

Input

W

2,940

Capacitor

\

\

Rated current (RLA) A 6.6

Locked rotor Amp. (LRA) A 46

Thermal protector \ Internal

Refrigerant oil

ml

1,242

Fan

Type

\

Axial fan

Motor

\

YDK160-6E-1

Motor quantity

\

1

Motor brand

\

Welling

Capacitor

\

6μF/450V

Motor input

W

230

Speed

r/min

900

Coil

No. of rows

\

2

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.3

Fin type \ Hydrophilic aluminum fin

Tube outside Dia. and type

mm

Ф7

\

Inner grooved copper pipe

Coil (W×H)

mm

2,005×714

Number of circuits \ 6

Outdoor noise level

dB(A)

64

Indoor air flow

m3/h

5,100

CFM

3,000

Refrigerant

Type

\

R410A

Charge

g

3,420

Design pressure

MPa

4.4/2.6

Refrigerant pipe

Liquid side

mm

Ф9.52

Gas side

mm

Ф19.1

Page 58

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

56

Continued:

Model

MOVTB-36CN1-R13C

Connection wire

Power wire (Outdoor unit)

\

5×2.5mm2

Signal wire

\

2×0.75mm2

Dimension (W×H×D)

mm

710×759×710

Packing (W×H×D)

mm

738×779×738

Net / Gross weight

kg

81/85

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi-anechoic room, at a position 1m in front of the unit and H meter above

the floor. (H=(1+Height of the unit)/2).

Page 59

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

57

Model

MOVTB-48CN1-R13C

Power supply \ 380-415V~, 50Hz, 3Ph

Ambient temperature in cooling

°C

17 - 54

Rated input

W

6,000

Rated current

A

12

Compressor

Model

\

ZP51KSE-TFM-522

Type

\

Scroll

Quantity

\

1

Brand

\

Copeland

Capacity

Btu/h

41,500

Input

W

4,040

Capacitor

\

\

Rated current (RLA) A 8.6

Locked rotor Amp. (LRA) A 51.5

Thermal protector \ Internal

Refrigerant oil

ml

1,240

Fan

Type

\

Axial fan

Motor

\

YDK230-6H

Motor quantity

\

1

Motor brand

\

Welling

Capacitor

\

15μF/450V

Motor input

W

320

Speed

r/min

900

Coil

No. of rows

\

2

Tube pitch(a)×row pitch(b)

mm

21×13.37

Fin space

mm

1.3

Fin type \ Hydrophilic aluminum fin

Tube outside Dia. and type

mm

Ф7

\

Inner grooved copper pipe

Coil (W×H)

mm

2,005×798

Number of circuits \ 6

Outdoor noise level

dB(A)

68

Indoor air flow

m3/h

5,770

CFM

3,394

Refrigerant

Type

\

R410A

Charge

g

4,120

Design pressure

MPa

4.4/2.6

Refrigerant pipe

Liquid side

mm

Ф9.52

Gas side

mm

Ф22

Page 60

MCAC-UTSM-201707 Midea Tropical R410A High Efficient Duct Technical Manual 50Hz

58

Continued:

Model

MOVTB-48CN1-R13C

Connection wire

Power wire (Outdoor unit)

\

5×2.5mm2

Signal wire

\

2×0.75mm2

Dimension (W×H×D)

mm

710×843×710

Packing (W×H×D)

mm

738×862×738

Net / Gross weight

kg

89/93

Notes:

1. The nominal T1 cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB;

2. The nominal T3 cooling capacities are based on the following conditions:

Indoor temperature: 29°CDB, 19°CWB; Outdoor temperature: 46°CDB, 24°C WB;

3. The noise is measured in the semi-anechoic room, at a position 1m in front of the unit and H meter above

the floor. (H=(1+Height of the unit)/2).

Page 61

Midea Tropical R410A High Efficient Duct Technical Manual 50Hz MCAC-UTSM-201707

59

Model

MOVTB-60CN1-R13C

Power supply \ 380-415V~, 50Hz, 3Ph

Ambient temperature in cooling

°C

17 - 54

Rated input

W

7,450