Midea MOBA02-09HFN1-QRD0GW, MOB03-12HFN1-QRD0GW, MOCA01-24HFN1-QRD0GW, MOB02-18HFN1-QRD0GW, MSMBBU-09HRDN8-QRD06W Installation Manual

...Page 1

Installation Manual

Mission Series

R410a Models

R32 Models

Page 2

a. Indoor Unit Parts .............................................. 07

b. Indoor Unit Installation Instructions .................. 08

a. Outdoor Unit Installation Instructions ................. 11

b. Outdoor Unit Types and Specifications ............... 12

c. Notes on Drilling Hole in Wall ............................. 13

Table of Contents

Installation Manual

1

2

5

3

4

6

Drainpipe Installation ............................... 14

Outdoor Unit Installation ......................... 11

Indoor Unit Installation

........................... 07

Accessories ............................................. 04

Safety Precautions ............................. 05

Installation Overview ....................... 06

Installation Manual

Page 3

Page 3

MC MC

7

8

9

10

11

LN

12

Refrigerant Piping Connection ............... 17

Wiring ................................................. 20

Pressure test and evacuation...............................24

Test Run .................................................27

13

A. Notes on Pipe Length and Elevation .................17

........

a. Outdoor Unit Wiring ..........................20

b. Indoor Unit Wiring .............................

21

c. Power Specificatio

ns ...........................22

d. Wiring Diagram....................................23

Ca ut io n: R is k of f ire

(for R32

B. Refrigerant Piping Connection Instructions........18

Service Info..............................28

14

Installation Manual

Installation Manual

Page 4

Page 4

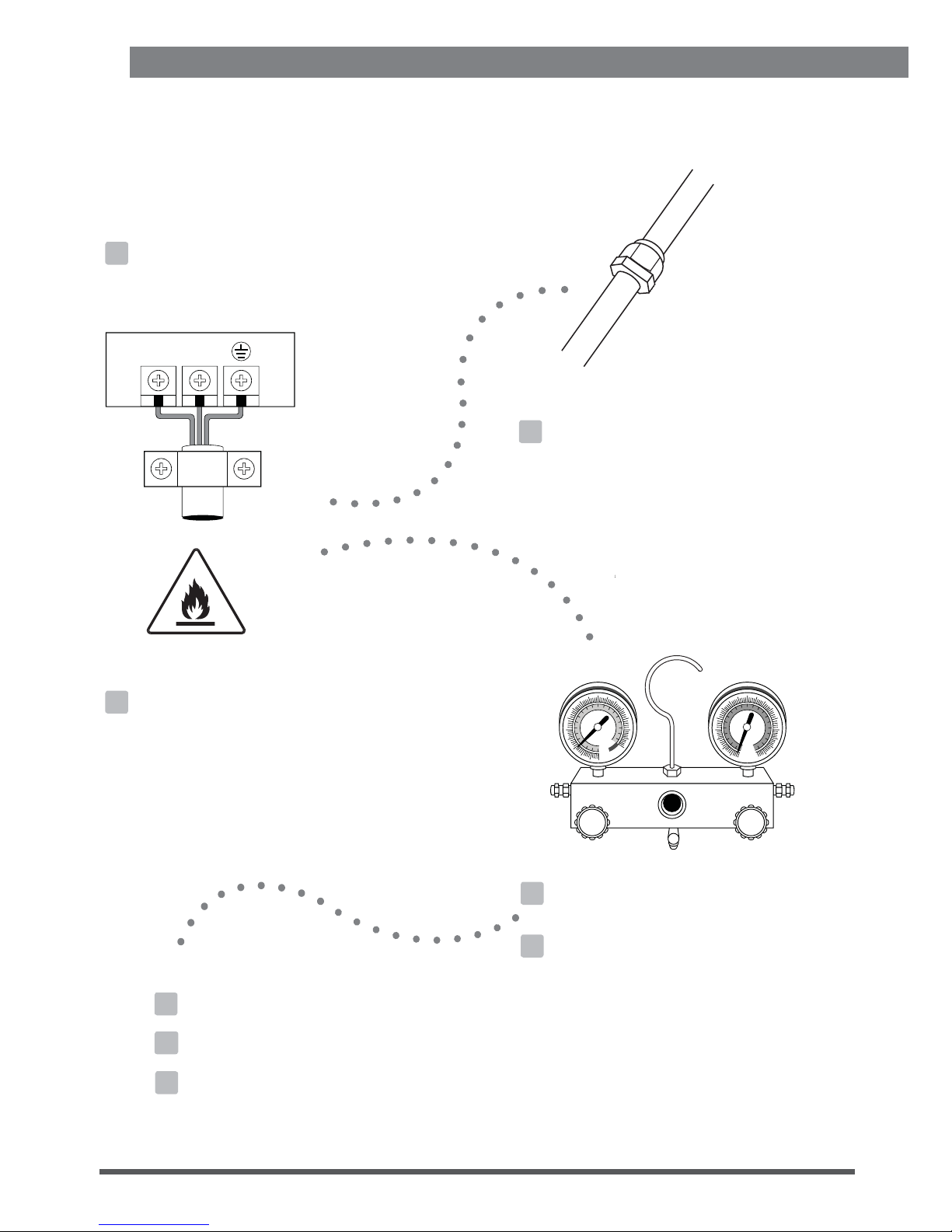

Accessories

1

The air conditioning system comes with the following accessories. Use all of the installation parts and accessories to

install the air conditioner. Improper installation may result in water leakage, electrical shock and fire, or cause the

equipment to fail.

Page 5

Page 5

Safety Precautions

2

Read Safety Precautions Before Installation

potential damage or injuries is classified as either a WARNING or CAUTION.

WARNING

• Carefully read the Safety Precautions before installation.

•

• Only trained and certified technicians should install, repair and service this air conditioning unit.

Improper installation may result in electrical shock, short circuit, leaks, fire or other damage to the equipment and

personal property.

• Strictly follow the installation instructions set forth in this manual.

Improper installation may result in electrical shock, short circuit, leaks, fire or other damage to the equipment.

toxic and flammable and poses a serious health and safety risk.

Note about Fluorinated Gasses

1. This air-conditioning unit contains fluorinated gasses. For specific information on the type of gas and the amount,

please refer to the relevant label on the unit itself.

2. Installation, service, maintenance and repair of this unit must be performed by a certified technician.

3. Product uninstallation and recycling must be performed by a certified technician.

4. If the system has a leak-detection system installed, it must be checked for leaks at least every 12 months.

5. When the unit is checked for leaks, proper record-keeping of all checks is strongly recommended.

national regulations.

Failure to observe a caution may result in injury or equipment damage.

WARNING

CAUTION

locate it accordingly. Failure to do so could cause the equipment to fail.

• After installation, ensure there are no refrigerant leaks and that the unit is operating properly. Refrigerant is

both

Incorrect installation due to ignoring instructions can cause serious damage or injury. The seriousness of

Failure to observe a warning may result in death. The appliance must be installed in accordance with

conditioning units is highly recommended.

In certain functional environments, such as server rooms, etc., the use of specially designed air-

NOTE: Requirements for units using R32 Refrigerant.

Do not accelerate the defrosting process or to clean, other than those

recommended by the manufacturer.

The system should not be installed in areas with ignition sources

(for example: open flames,an operating gas appliance or an operating

electric heater)

Do not pierce or burn.

The system should be installed where the room size corresponds to specific

operation.

Be aware that refrigerants may not contain an odour.

Page 6

Page 6

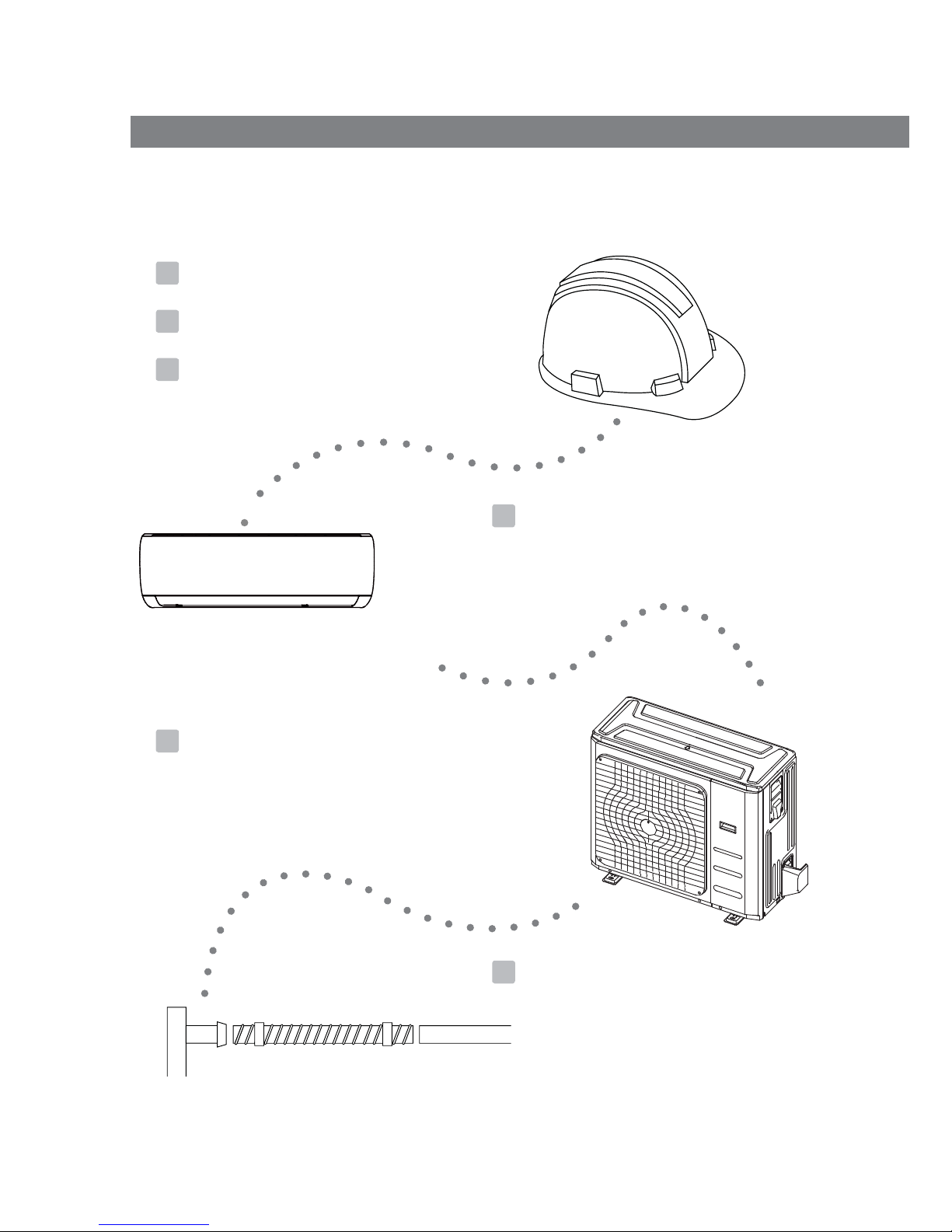

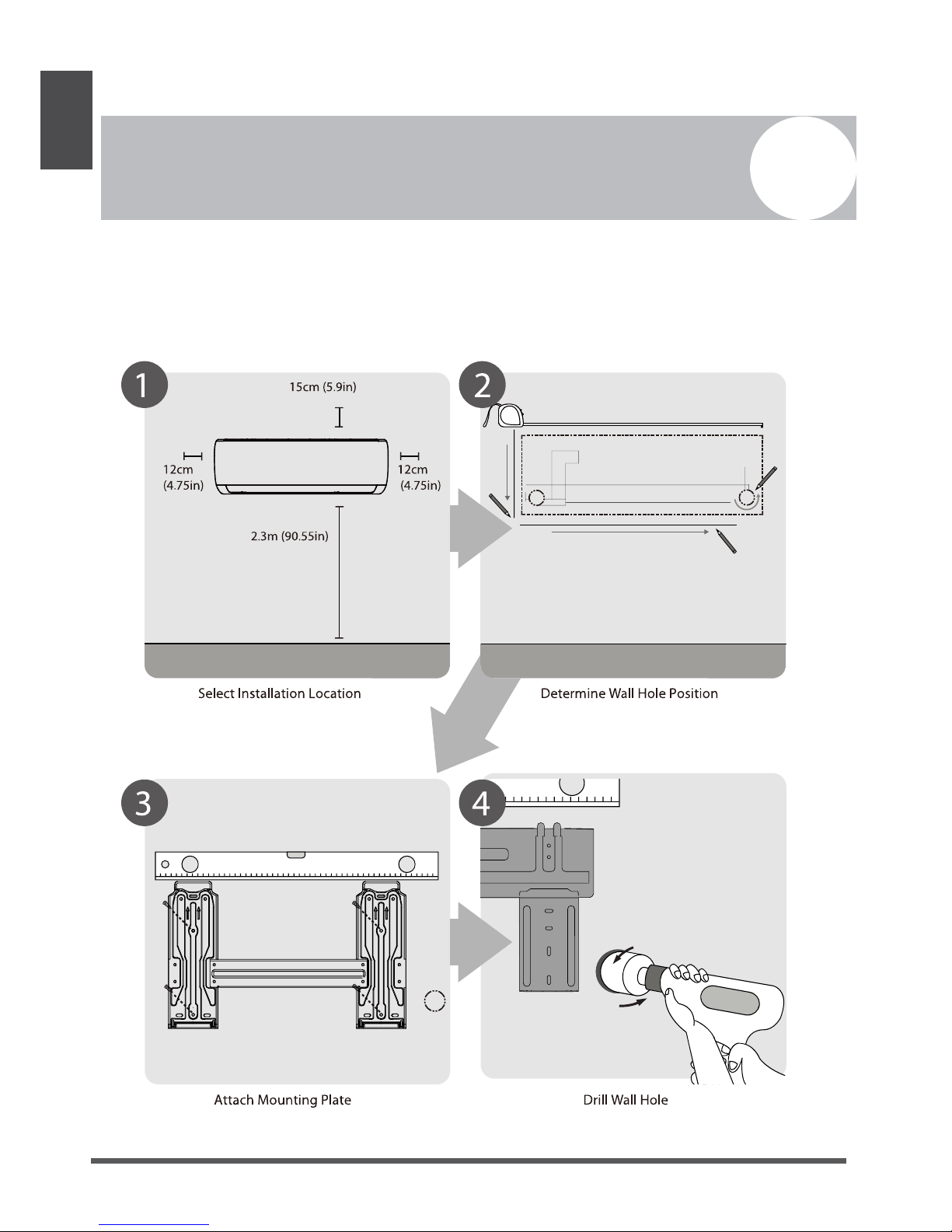

Installation Overview

3

Unit Installation

Overview

INSTALLATION ORDER

Page 7

Page 7

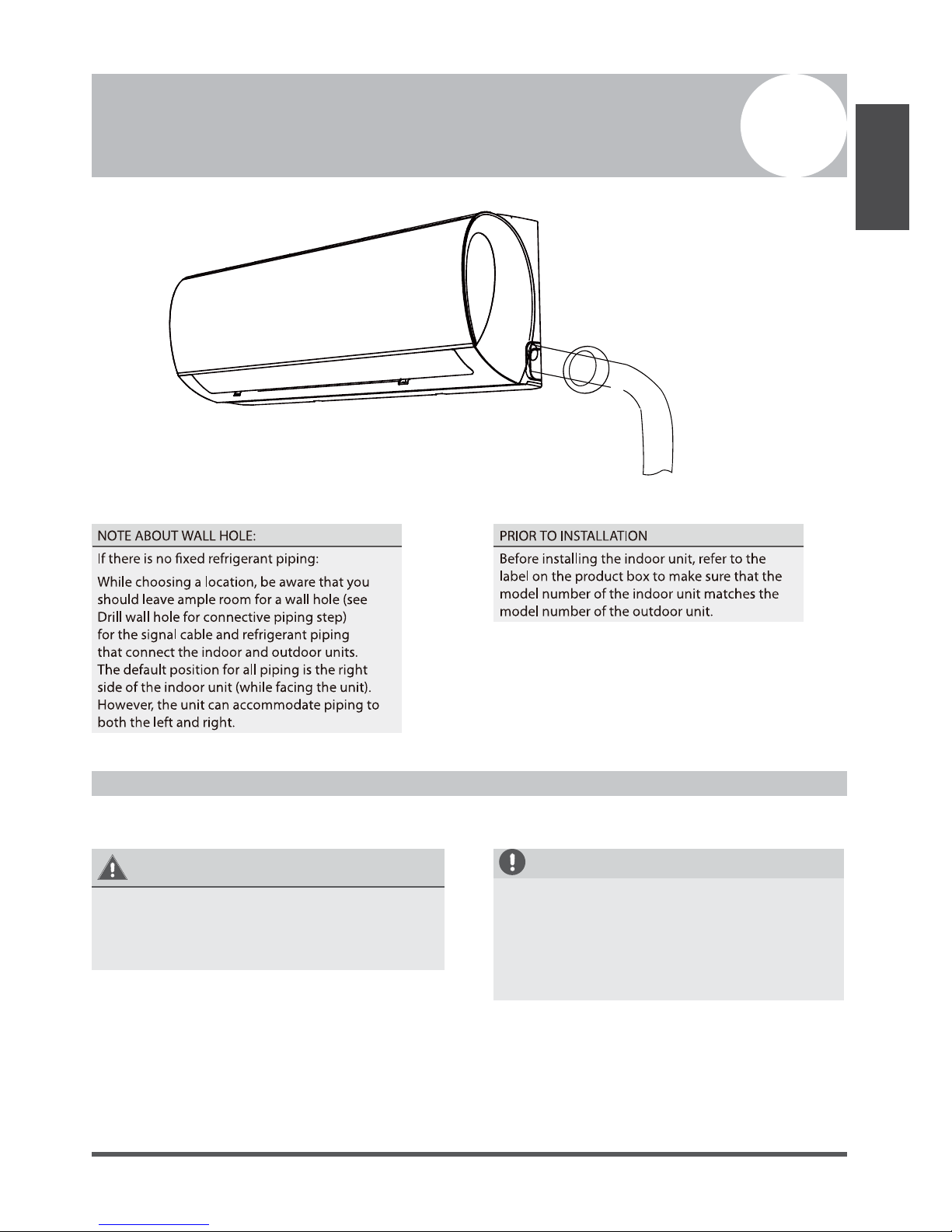

Indoor Unit Installation

4

Safety Precautions

WARNING

• Securely install the indoor unit on a structure that

can sustain its weight. If the structure is too weak

the unit may fall causing personal injury, unit and

property damage or death.

CAUTION

Indoor Unit

Installation

• Install the indoor and outdoor units, cables and

to prevent static or image distortion. Depending

• If the indoor unit is installed on a metal part of the

building, it must be electrically grounded.

on the appliances, a 1m distance may not be

wires at least 1m from televisions or radios

Page 8

Page 8

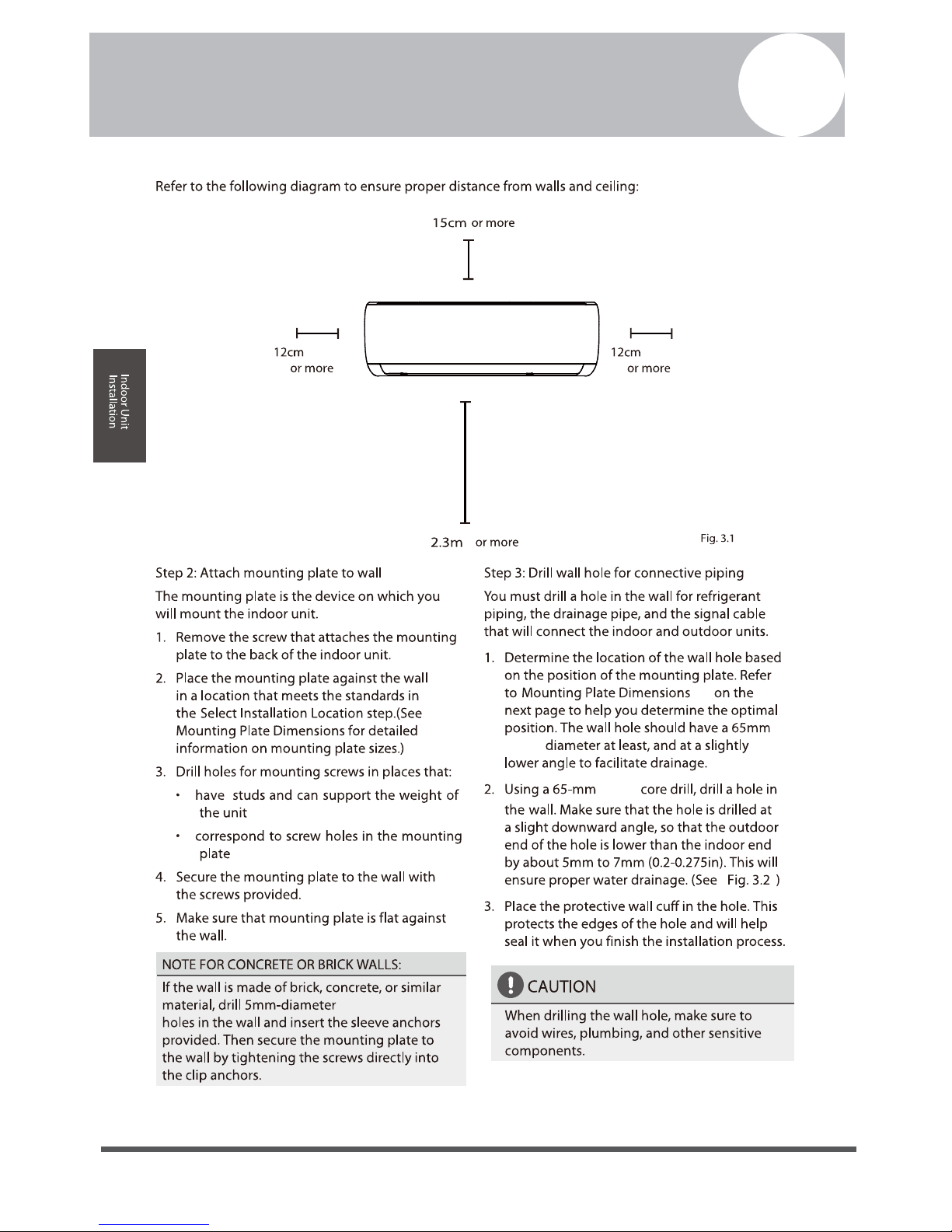

Indoor Unit Installation

4

Page 9

Page 9

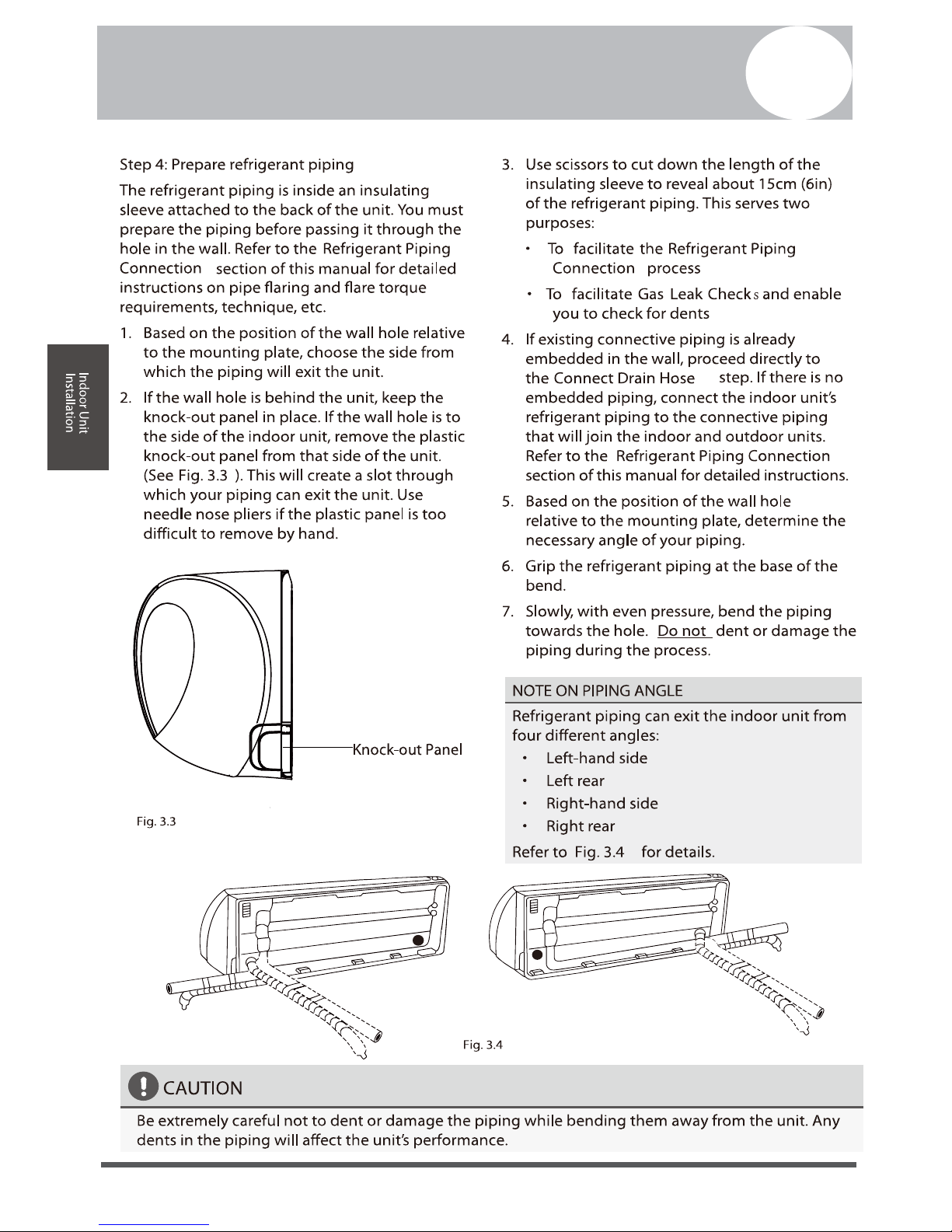

Indoor Unit Installation

4

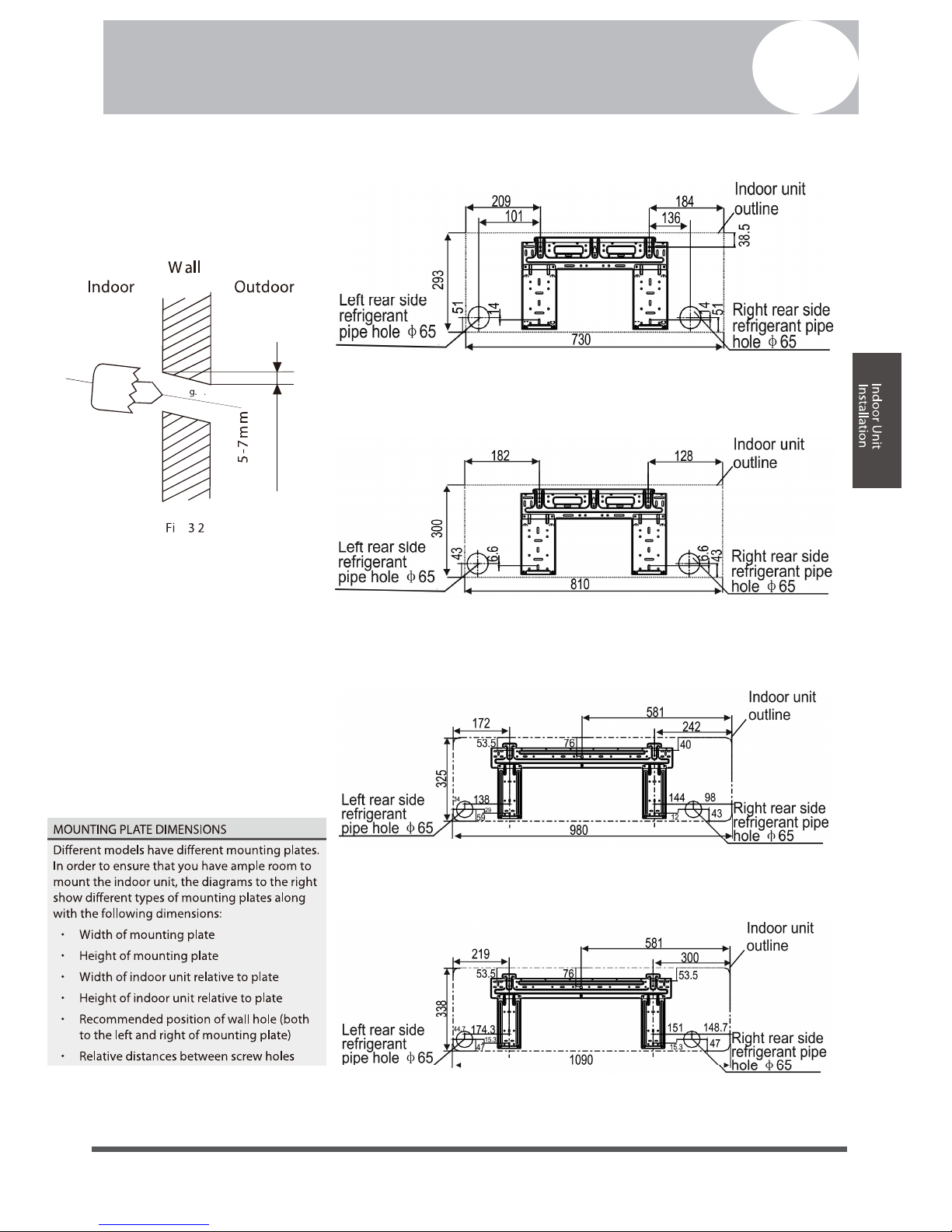

For MSMBAU-09HRFN1-QRD0GW:

For MSMBBU-12HRFN1-QRD0GW:

For MSMBCU-18HRFN1-QRD0GW:

For MSMBDU-24HRFN1-QRD0GW:

Page 10

Page 10

Indoor Unit Installation

4

Page 11

Page 11

Outdoor Unit Installation

5

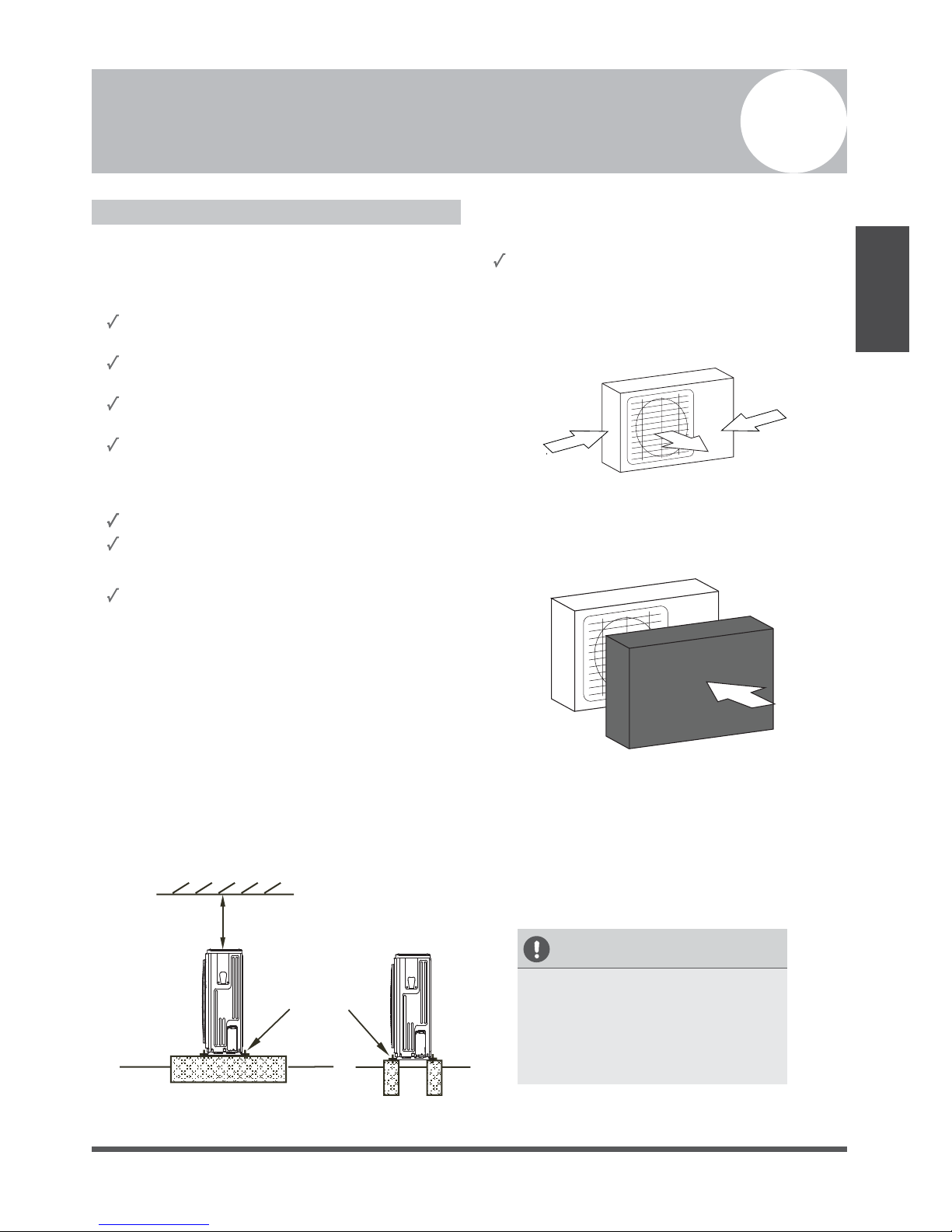

Outdoor Unit Installation Instructions

Step 1: Select installation location.

The outdoor unit should be installed in the location that

meets the following requirements:

Place the outdoor unit as close to the indoor unit as

possible.

Ensure that there is enough room for installation and

maintenance.

The air inlet and outlet must not be obstructed or

exposed to strong wind.

Ensure the location of the unit will not be subject to

snowdrifts, accumulation of leaves or other seasonal

debris. If possible, provide an awning for the unit.

Ensure the awning does not obstruct airflow.

The installation area must be dry and well ventilated.

There must be enough room to install the connecting

pipes and cables and to access them for maintenance.

The pipe length between the outdoor and indoor unit

may not exceed the maximum allowable pipe length.

Strong wind

Strong wind

Strong wind

Fig. 5.1

Step 2: Install outdoor unit.

Fix the outdoor unit with anchor bolts (M10)

Fix with bolts

CAUTION

• Be sure to remove any obstacles that

may block air circulation.

• Make sure you refer to Length

Specifications to ensure there is

enough room for installation and

maintenance.

Fig. 5.3

Outdoor Unit

Installation

>60cm

Fig. 5.2

If the location is exposed to strong winds the unit

must be placed against the wall to shelter it from

the wind.

Page 12

Page 12

Outdoor Unit

Installation

Since the gravity center of the unit is not at its physical center, so please be careful when lifting it with a sling.

Never hold the inlet of the outdoor unit to prevent it from deforming.

Do not touch the fan with hands or other objects.

Do not lean it more than 45, and do not lay it sidelong.

Make concrete foundation according to the specifications of the outdoor units.

Fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of earthquake or strong wind.

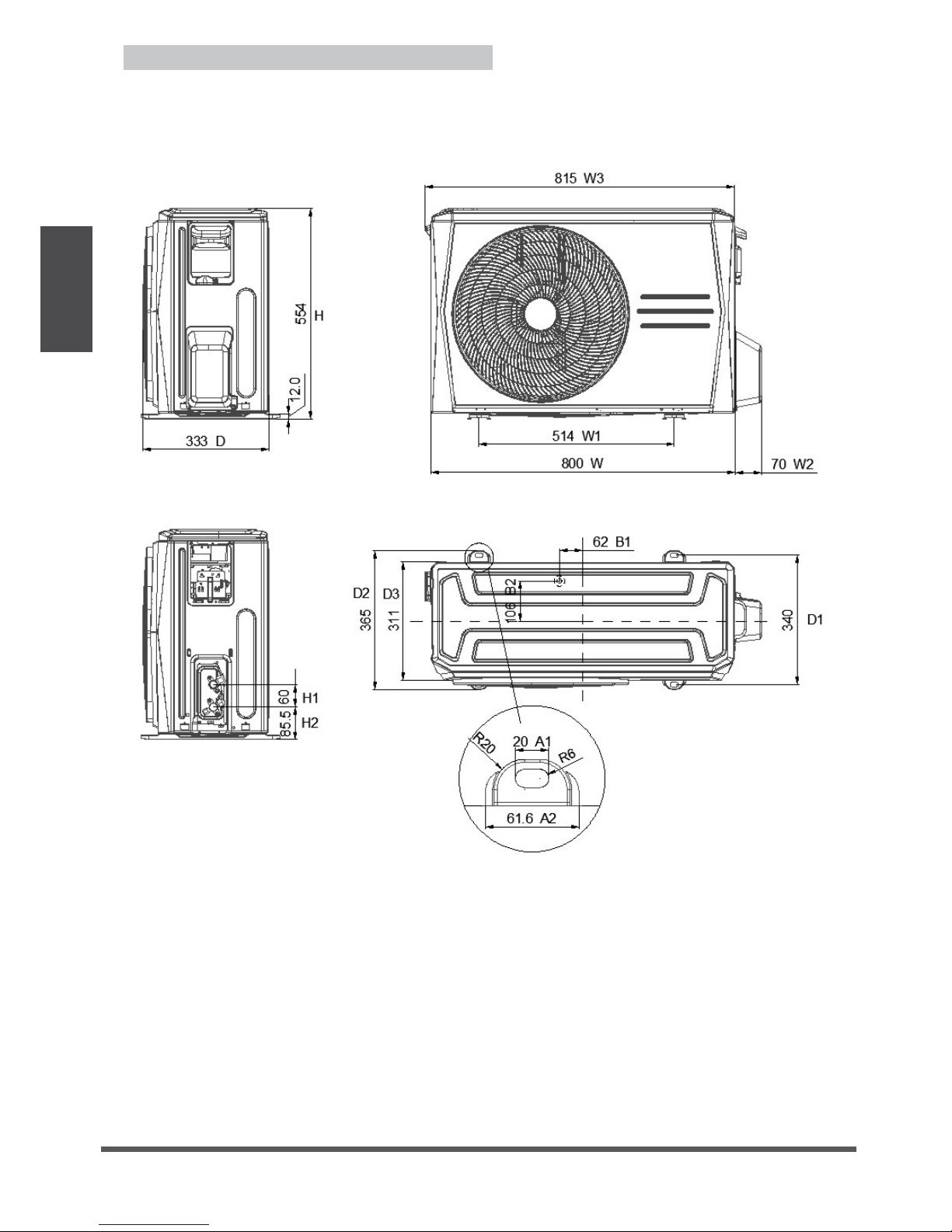

Outdoor Unit Installation Instructions

For MOB01-09HFN1-QRD0GW, MOB01-12HFN1-QRD0GW, MOB01-18HFN1-QRD0GW,

Page 13

8 0 0 W

5 1 4 W 1

815 W3

333 D

70 W2

H

H1

H2

D1

D2

D3

62 B1

20 A1

61.6 A2

For MOB02-18HFN1-QRD0GW

Page 13

Outdoor Unit Installation Instructions

Page 14

For MOCA02-24HFN1-QRD0GW,

Page 14

Outdoor Unit Installation Instructions

Page 15

NOTE: The minimum distance between the outdoor

unit and walls described in the installation guide does

not apply to airtight rooms. Be sure to keep the unit

unobstructed in at least two of the three directions (M,

N, P) (See Fig. 5.10)

Fig. 5.10

Drain Joint Installation

Before bolting the outdoor unit in place, you must install

the drain joint at the bottom of the unit. (See Fig. 5.11)

1. Fit the rubber seal on the end of the drain joint that

will connect to the outdoor unit.

2. Insert the drain joint into the hole in the base pan of

the unit.

3. Rotate the drain joint 90° until it clicks in place

facing the front of the unit.

4. Connect a drain hose extension (not included) to

the drain joint to redirect water from the unit during

heating mode.

NOTE: Make sure the water drains to a safe location

where it will not cause water damage or a slipping

hazard.

Seal

Drain joint

(A) (B)

Base pan hole of

outdoor unit

Seal

Fig. 5.11

Notes On Drilling Hole In Wall

You must drill a hole in the wall for the refrigerant piping,

and the signal cable that will connect the indoor and

outdoor units.

1. Determine the location of the wall hole based on the

location of the outdoor unit.

2.

NOTE: When drilling the wall hole, make sure

to avoid wires, plumbing, and other sensitive

components.

3. Place the protective wall cuff in the hole. This

protects the edges of the hole and will help seal it

when you finish the installation process.

Outdoor Unit

Installation

Using a 65-mm core drill, drill a hole in the wall.

Page 15

evoba

mc06

60cm

on right

30cm

on left

200cm

in front

30cm

Page 16

Drainpipe Installation

6

Page 16

Page 17

Refrigerant Piping Connection

7

WARNING

• All field piping must be completed by a licensed

technician and must comply with the local and

national regulations.

• When the air conditioner is installed in a small

room, measures must be taken to prevent the

refrigerant concentration in the room from

exceeding the safety limit in the event of

refrigerant leakage. If the refrigerant leaks and

its concentration exceeds its proper limit, hazards

due to lack of oxygen may result.

• When installing the refrigeration system, ensure

that air, dust, moisture or foreign substances do

not enter the refrigerant circuit. Contamination

in the system may cause poor operating capacity,

high pressure in the refrigeration cycle, explosion

or injury.

• Ventilate the area immediately if there is

refrigerant leakage during the installation. Leaked

refrigerant gas is both toxic and flammable.

Ensure there is no refrigerant leakage after

completing the installation work.

Notes On Pipe Length and Elevation

Ensure that the length of the refrigerant pipe, the number

of bends, and the drop height between the indoor and

outdoor units meets the requirements shown in Table 7.1:

Table 7.1: The Maximum Length And Drop Height

Maximum drop

height

Refrigerant Piping

Connection

Based on Models. (Unit: meters)

09 25

CAUTION

An angle of more than 10° may cause malfunction.

• DO NOT install the connecting pipe until both

indoor and outdoor units have been installed.

• Insulate both the gas and liquid piping to prevent

water leakage.

Refrigerant Piping Connection Instructions

Step1: Cut pipes

When preparing refrigerant pipes, take extra care

to cut and flare them properly. This will ensure

efficient operation and minimize the need for future

maintenance.

1. Measure the distance between the indoor and

outdoor units.

2. Using a pipe cutter, cut the pipe a little longer than

the measured distance.

Model Length of

piping

Page 17

12 25 10

18 30 20

24 25

Page 18

CAUTION

DO NOT deform pipe while cutting. Be extra careful not

to damage, dent, or deform the pipe while cutting. This

will drastically reduce the heating efficiency of the unit.

1. Make sure that the pipe is cut at a perfect 90°

angle. Refer to Fig. 7.2 for examples of bad cuts

Oblique

Rough

Warped

90°

Fig. 7.2

Step 2: Remove burrs.

1. Hold the pipe at a downward angle to prevent

burrs from falling into the pipe.

2. Using a reamer or deburring tool, remove all burrs

from the cut section of the pipe.

Pipe

Reamer

1. After removing burrs from cut pipe, seal the ends

with PVC tape to prevent foreign materials from

entering the pipe.

2. Sheath the pipe with insulating material.

3. Place flare nuts on both ends of pipe. Make sure

they are facing in the right direction, because you

can’t put them on or change their direction after

flaring. See Fig. 7.4

Flare nut

Copper pipe

Fig. 7.4

4. Remove PVC tape from ends of pipe when ready to

perform flaring work.

5. Clamp flare form on the end of the pipe. The end

of the pipe must extend beyond the flare form.

Flare form

Pipe

Fig. 7.5

Refrigerant Piping

Connection

piping connection. They must be completely

removed.

Point down

Burrs can affect the gas-tight seal of refrigerant

Refrigerant Piping Connection

7

Page 18

Step 3: Flare pipe ends

Proper flaring is essential to achieve an

Fig. 7.3

Page 19

6. Place flaring tool onto the form.

7. Turn the handle of the flaring tool clockwise until

the pipe is fully flared. Flare the pipe in accordance

with the dimensions shown in table 7-3.

Table 7.3: PIPING EXTENSION BEYOND FLARE FORM

Pipe

gauge

Tightening

torque

Flare dimension (A) Flare shape

Min. Max .

14.2-17.2 N.m

(144-176 kgf.cm)

R0.4~0.8

45

°

±

2

90

°

±

4

A

Fig. 7.6

32.7-39.9 N.m

(333-407 kgf.cm)

49.5-60.3 N.m

(504-616 kgf.cm)

61.8-75.4 N.m

(630-770 kgf.cm)

97.2-118.6 N.m

(990-1210 kgf.

cm)

8. Remove the flaring tool and flare form, then inspect

the end of the pipe for cracks and even flaring.

Step 4: Connect pipes

Connect the copper pipes to the indoor unit first, then

connect it to the outdoor unit. You should first connect the

low-pressure pipe, then the high-pressure pipe.

1. When connecting the flare nuts, apply a thin coat

of refrigeration oil to the flared ends of the pipes.

2. Align the center of the two pipes that you will

connect.

Indoor unit tubing

Flare nut

Pipe

Fig. 7.7

3. Tighten the flare nut as tightly as possible by hand.

4. Using a spanner, grip the nut on the unit tubing.

5. While firmly gripping the nut, use a torque wrench

to tighten the flare nut according to the torque

values in table 7-.3.

NOTE: Use both a spanner and a torque wrench when

connecting or disconnecting pipes to/from the unit.

Fig. 7.8

CAUTION

Check to make sure there is no refrigerant leak after

completing the installation work. If there is a refrigerant

leak, ventilate the area immediately and evacuate

the system (refer to the Air Evacuation section of this

manual).

Refrigerant Piping

Connection

109.5-133.7 N.m

(1117-1364 kgf.

cm)

(Unit: mm)

Page 19

8.3 8.3

12.4 12.4

15.4 15.8

18.6 19

22.9 23.3

27 27.3

Page 20

8

Safety Precautions

WARNING

• Be sure to disconnect the power supply before

working on the unit.

• All electrical wiring must be done according to

local and national regulations.

• Electrical wiring must be done by a qualified

technician. Improper connections may cause

electrical malfunction, injury and fire.

• An independent circuit and single outlet must

• Connect the power cable to the terminals and

fasten it with a clamp. An insecure connection

may cause fire.

• Make sure that all wiring is done correctly and the

control board cover is properly installed. Failure

to do so can cause overheating at the connection

points, fire, and electrical shock.

• Ensure that main supply connection is made

through a switch that disconnects all poles, with

CAUTION

• Connect the outdoor wires before connecting the

indoor wires.

• Make sure you ground the unit. The grounding

wire should be away from gas pipes, water pipes,

lightning rods, telephone or other grounding

wires. Improper grounding may cause electrical

shock.

• DO NOT connect the unit with the power source

until all wiring and piping is completed.

• Make sure that you do not cross your electrical

wiring with your signal wiring, as this can cause

distortion and interference.

Follow these instructions to prevent distortion when the

compressor starts:

• The unit must be connected to the main outlet.

Normally, the power supply must have a low output

impedance of 32 ohms.

• No other equipment should be connected to the

same power circuit.

• The unit’s power information can be found on the

Outdoor Unit Wiring

WARNING

Before performing any electrical or wiring work, turn off

the main power to the system.

1. Prepare the cable for connection

Rated Current of

Appliance (A)

Nominal Cross-Sectional

Area (mm²)

6 0.75

6 - 10 1

10 - 16 1.5

16 - 25 2.5

25- 32 4

32 - 45 6

Wiring

contact gap of a least 3mm.

Wiring

be used for this unit. If the

electrical circuit capacity is not enough or there

is a defect in the electrical work, it can lead to

shock, fire, unit and property damage.

Page 20

NOTE: The fuse is made of ceramic.

rating sticker on the product.

Page 21

b. Using wire strippers, strip the rubber jacket from

both ends of signal cable to reveal about 15cm

c. Strip the insulation from the ends of the wires.

d. Using a wire crimper, crimp u-lugs on the ends of

the wires.

NOTE: While connecting the wires, please strictly follow

the wiring diagram (found inside the electrical box cover).

2. Remove the electric cover of the outdoor unit.

If there is no cover on the outdoor unit, disassemble

the bolts from the maintenance board and remove the

protection board. (See Fig. 8.1, 8.2)

Cover

Screw

Fig. 8.1

3. Connect the u-lugs to the terminals

4. Clamp down the cable with designated cable clamp.

5. Insulate unused wires with electrical tape. Keep them

away from any electrical or metal parts.

6. Reinstall the cover of the electric control box.

Indoor Unit Wiring

1. Prepare the cable for connection

a. Using wire strippers, strip the rubber jacket from

both ends of signal cable to reveal about 15cm

b. Strip the insulation from the ends of the wires.

c. Using wire crimper, crimp the u-lugs to the ends of

the wires.

2. Open the front panel of the indoor unit. Using a

screwdriver, remove the cover of the electric control box

on your indoor unit.

3. Thread the power cable and the signal cable through

the wire outlet.

4. Connect the u-lugs to the terminals.

Connective wiring diagram

Wiring diagram

CAUTION

• While connecting the wires, please strictly follow

the wiring diagram.

• The refrigerant circuit can become very hot. Keep

the interconnection cable away from the copper

tube.

5. Clamp down cable with the designated cable clamp to

secure it in place. The cable should not be loose, and

6. Reinstall the electric box cover and the front panel of

the indoor unit.

Wiring

Fig. 8.4

of the wires inside.

of the wires inside.

should not pull on the u-lugs.

Terminal block

Wire cover

Screw

Cable clamp

Match the wire colours/labels with the labels on the

terminal block, and firmly screw the u-lug of each

wire to its corresponding terminal. Refer to the Serial

Number and Wiring Diagram located on the cover of

the electric control box.

Match the wire colours/labels with the labels on the

terminal block, and firmly screw the u-lug of each wire

to its corresponding terminal.

Page 21

Page 22

Power Specifications

POWER

PHASE 1 Phase 1 Phase 1 Phase 1 Phase

FREQUENCY

AND VOLT

CIRCUIT BREAKER/

FUSE(A)

Wiring

FREQUENCY

AND VOLT

CIRCUIT BREAKER/

FUSE(A)

POWER

Indoor Power Supply Specifications

Outdoor Inverter Power Supply Specifications

MODEL 09 12 18 24

MODEL 09 12 18 24

220-240V 220-240V 220-240V 220-240V

16A 16A 16A 20A

POWER FROM OUTDOOR UNIT

PHASE 1 Phase 1 Phase 1 Phase 1 Phase

Wiring Diagrams

220-240V 220-240V 220-240V 220-240V

Page 22

Page 23

Wiring Diagrams

Page 23

S

ROOM TEMPERATURE SENSOR

PIPE TEMPERATURE SENSOR

SWING MOTOR1

5

M

CN5

INDOOR UNIT

OUTDOOR UNIT

YELLOW

JX1

Y/G

WHI ET

RED

CN6_1

CN12_1

CN6_2

CN12_2

M

CN14

5(10)

SWING MOTOR2

OPTIONAL

MICRO SWITCH

PLASMA

2

CN43

CN44

OPTIONAL

IN FAN

M

5

CN4

N

CN11(CN1)

CN16

CN8

CN9

2

2

RY1

L-OUT

L-IN

P_1

W

2(N)

S

BLUE(BLACK)

ION

OPTIONAL

Y/G

HEATER

OPTIONAL

NOTE: If used as MONO unit, for the standby control needs, the cross section area of cable connected to W, 1(L)

must be sufficient for the maximum system current. The maximum system current is equal to the sum of indoor unit

and outdoor unit rated current. If used as MULTI unit, W on the terminal block does not need to be connected.

OPTIONAL

DISPLAY BOARD

CN10A

8(7)

(CN10)

Wire Controller

2

OPTIONAL

MULTI-FUCTION CONTROL BOX

OPTIONAL

1(L)

OPTIONAL

CN2(CN101)

CN3(CN301)

2

CN9

CN602

DISPLAY BOARD

CN1(OR CN201)

CN3(OR CN301)

CN2(OR CN101)

8

Wire Controller

WiFi Controller

4

4

4

8

5

5

5

OPTIONAL

WiFi Controller

Page 24

9

Pressure Test Instructions

Systems are pressure tested to ensure they are:

Pressure testing is hazardous and should be carried out carefully:

Nitrogen and regulation

Dry (oxygen free) nitrogen (OFN) is used to achieve the pressures required for the

pressure tests because it is inert. You must never use oxygen for pressure testing pure oxygen at high pressure reacts violently with oil and will explode.

Using the nitrogen regulator

to the pressure required.

Do not use a regulator with an

output pressure much higher

The pressure tests

Increase the pressure to approximately 5 bar g and check for leaks using leak

detection spray at this pressure initially – many leaks will be identified at this

pressure so you will not waste nitrogen and time. It is also safer to find leaks at a

lower pressure than the final test pressures.

Increase the pressure slowly to the strength test pressure and hold it for 15

minutes. Under the Pressure Equipment Regulation this strength test might need

to be witnessed by a notified body.

Safe – for this test a pressure above the system’s maximum allowable

pressure (PSi) is used

Leak tight – this test is at PSi.

The nitrogen used for pressure testing is an asphyxiant, so the area around

the system should be well-ventilated

High pressures are used, so all non-essential personal should be evacuated

from the area

Anyone carrying out the pressure testing should wear safety goggles.

2. Open the cylinder valve

3. Slowly open the regulator

Page 24

1. Ensure the regulator is

closed (wound fully anti

clockwise)

Page 25

Air Evacuation

9

Safety Precautions

CAUTION

than -0.1MPa and an air discharge capacity above

40L/min.

• The outdoor unit does not need vacuuming. DO

NOT open the outdoor unit’s gas and liquid stop

valves.

or below after 2 hours. If after three hours of

operation and the gauge reading is still above

-0.1MPa, check if there is a gas leak or water inside

the pipe. If there is no leakage, perform another

evacuation for 1 or 2 hours.

• DO NOT use refrigerant gas to evacuate the

system.

Evacuation Instructions

Before using manifold gauge and vacuum pump, read their

operation manuals to familiarize yourself with how to use

them properly.

Manifold Gauge

Compound gauge

-76cmHg

Low pressure valve

High pressure valve

Charge hose

Charge hose

Vacuum pump

Pressure gauge

Low pressure valve

Fig. 9.1

1. Connect the charge hose of the manifold gauge to

service port on the outdoor unit’s low pressure valve.

2. Connect another charge hose from the manifold gauge

to the vacuum pump.

3. Open the Low Pressure side of the manifold gauge.

Keep the High Pressure side closed.

4. Turn on the vacuum pump to evacuate the system.

5. Run the vacuum for at least 15 minutes, or until the

NOTE: If there is no change in system pressure, unscrew

the cap from the packed valve (high pressure valve). If

there is a change in system pressure, there may be a gas

leak.

8. Insert hexagonal wrench into the packed valve (high

pressure valve) and open the valve by turning the

wrench in a 1/4 counterclockwise turn. Listen for gas to

exit the system, then close the valve after 5 seconds.

Flare nut

Cap

Valve body

Valve stem

Fig. 9.2

9. Watch the Pressure Gauge for one minute to make sure

that there is no change in pressure. The Pressure Gauge

should read slightly higher than atmospheric pressure.

10. Remove the charge hose from the service port.

11. Using hexagonal wrench, fully open both the high

pressure and low pressure valves.

OPEN VALVE STEMS GENTLY

When opening valve stems, turn the hexagonal wrench

until it hits against the stopper. DO NOT try to force the

valve to open further.

12. Tighten valve caps by hand, then tighten it using the

proper tool.

Air Evacuation

turn off the vacuum pump.

change in system pressure.

7. Wait for 5 minutes, then check that there has been no

Gauge reads -76cmHG (-1x105Pa).

6. Close the Low Pressure side of the manifold gauge, and

• Use a vacuum pump with a gauge reading lower

• Ensure that the Compound Meter reads -0.1MPa

Page 25

Page 26

CAUTION

• Refrigerant charging must be performed after wiring, vacuuming and the leak test.

• DO NOT exceed the maximum allowable quantity of refrigerant or overcharge the system. Doing so can damage

or impact the unit’s function.

• Charging with unsuitable substances may cause explosions or accidents. Ensure that the appropriate refrigerant is

used.

• Refrigerant containers must be opened slowly. Always use protective gear when charging the system.

Air Evacuation

• DO NOT mix refrigerant types.

Refrigerant may only be charged after performed the vacuum drying process.

Always use gloves and glasses to protect your hands and eyes during the charge work.

Use electronic scale or fluid infusion apparatus to weight refrigerant to be recharged. Be sure to avoid

extra refrigerant charged, it may cause liquid hammer of the compressor or protections.

Use supplementing flexible pipe to connect refrigerant cylinder, pressure gauge and outdoor unit. And

The refrigerant should be charged in liquid state. Before recharging, The air in the flexible pipe and

manifold gauge should be exhausted.

After finished refrigerant recharge process, check whether there is refrigerant leakage at the connection

joint part.(Using gas leakage detector or soap water to detect).

Moooo

Min. Max .

Note :

Some systems require additional charging depending on pipe lengths

The additional refrigerant to be charged can be calculated using the following Table below.

9

Refrigerant Additional Charge

Page 26

5 Meter

5 Meter

R32 Additional Refrigerant Charge

R410a Additional Refrigerant Charge

Model Shipment Charge Charged To Additional Charge

18 2 Kg

30 g/m

24 2.4 Kg

30 g/m

09 1.35 Kg 5 Meter 15 g/m

12 1.5 Kg 5 Meter 30 g/m

Page 27

Test Run

Before Test Run

A test run must be performed after the entire system has

been completely installed. Confirm the following points

before performing the test:

a) The indoor and outdoor units are properly installed.

b) Piping and wiring are properly connected.

c) Ensure that there are no obstacles near the inlet

and outlet of the unit that might cause poor

performance or product malfunction.

d) The refrigeration system does not leak.

e) The drainage system is unimpeded and draining to

a safe location.

f) The heating insulation is properly installed.

g) The grounding wires are properly connected.

h) The length of the piping and the added refrigerant

stow capacity have been recorded.

i) The power voltage is the correct voltage for the air

conditioner.

CAUTION

Failure to perform the test run may result in unit

damage, property damage or personal injury.

Test Run Instructions

1. Open both the liquid and gas stop valves.

2. Turn on the main power switch and allow the unit to

warm up.

3. Set the air conditioner to COOL mode.

4. For the Indoor Unit

a. Ensure the remote control and its buttons work

properly.

b. Ensure the louvers move properly and can be

changed using the remote control.

c. Double check to see if the room temperature is

being registered correctly.

d. Ensure the indicators on the remote control and the

display panel on the indoor unit work properly.

e. Ensure the manual buttons on the indoor unit

works properly.

f. Check to see that the drainage system is

unimpeded and draining smoothly.

g. Ensure there is no vibration or abnormal noise

during operation.

5. For the Outdoor Unit

a. Check to see if the refrigeration system is leaking.

b. Make sure there is no vibration or abnormal noise

during operation.

c. Ensure the wind, noise, and water generated by the

unit do not disturb your neighbors or pose a safety

hazard.

6. Drainage Test

a. Ensure the drainpipe flows smoothly. New buildings

should perform this test before finishing the ceiling.

b. Remove the test cover. Add 2,000ml of water to the

tank through the attached tube.

c. Turn on the main power switch and run the air

conditioner in COOL mode.

d. Listen to the sound of the drain pump to see if it

makes any unusual noises.

e. Check to see that the water is discharged. It may

take up to one minute before the unit begins to

drain depending on the drainpipe.

f. Make sure that there are no leaks in any of the

piping.

g. Stop the air conditioner. Turn off the main power

switch and reinstall the test cover.

NOTE: If the unit malfunctions or does not operate

according to your expectations, please refer to the

Troubleshooting section of the Owner’s Manual before

calling customer service.

Test Run

10

Page 27

Page 28

Information

Servicing

1. Checks to the area

3. General work area

4. Checking for presence of refrigerant

5. Presence of fire extinguisher

If any hot work is to be conducted on the refrigeration equipment or any associated parts, appropriate

fire extinguishing equipment shall be available to hand. Have a dry power or CO2 fire extinguisher

adjacent to the charging area.

7. Ventilated area

Ensure that the area is in the open or that it it adequately ventilated before breaking into the system

or conducting any hot work. A degree of ventilation shall continue during the period that the work is

carried out. The ventilation should safely disperse any released refrigerant and preferably expel it

externally into the atmosphere.

2. Work procedure

All mintenance staff and others working in the local area shall be instructed on the nature of work

being carried out. work in confined sapces shall be avoided. The area around the work space shall

be sectioned off. Ensure that the conditions within the area have been made safe by control of

flammable material.

Prior to beginning work on systems containing flammable refrigerants, safety checks are necessary

to ensure that the risk of ignition is minimised. For repair to the refrigerating system, the following

precautions shall be complied with prior to conducting work on the system.

Works shall be undertaken under a controlled procedure so as to minimise the risk of a

flammable gas or vapour being present while the work is being performed.

The area shall be checked with an appropriate refrigerant detector prior to and during work,

to ensure the technician is aware of potentially flammable atmospheres. Ensure that the leak

detection equipment being used is suitable for use with flammable refrigerants, i.e. no sparking,

adequately sealed or intrinsically safe.

,

,

8. Checks to the refrigeration equipment

Where electrical components are being changed, they shall be fit for the purpose and to the correct

specification. At all times the manufacturers maintenance and service guidelines shall be followed.

If in doubt consult the manufacturers technical department for assistance. The following checks shall

be applied to installations using flammable refrigerants:

6. No ignition sources

No person carrying out work in relation to a refrigeration system which involves exposing any pipe

work that contains or has contained flammable refrigerant shall use any sources of ignition in such a

manner that it may lead to the risk of fire or explosion. All possible ignition sources, including cigarette

smoking, should be kept sufficiently far away from the site of installation, repairing, removing and

disposal, during which flammable refrigerant can possibly be accidentally released to the surrounding

space. Prior to work taking place, the area around the equipment is to be surveyed to make sure that

there are

no flammable hazards or ignition risks. NO SMOKING signs shall be displayed.

Servicing Info

Page 28

(Required for the units adopt R32 Refrigerant only)

11

Page 29

,

9. Checks to electrical devices

10. Repairs to sealed components

the charge size is in accordance with the room size within which the refrigerant containing

parts are installed;

the ventilation machinery and outlets are operating adequately and are not obstructed;

if an indirect refrigerating circuit is being used, the secondary circuits shall be checked

for the presence of refrigerant; marking to the equipment continues to be visible and

legible.

marking and signs that are illegible shall be corrected;

refrigeration pipe or components are installed in a position where they are unlikely to be

exposed to any substance which may corrode refrigerant containing components, unless

the components are constructed of materials which are inherently resistant to being

corroded or are suitably protected against being so corroded.

10.1 During repairs to sealed components, all electrical supplies shall be disconnected from the

equipment being worked upon prior to any removal of sealed covers, etc. If it is absolutely

necessary to have an electrical supply to equipment during servicing, then a permanently

operating form of leak detection shall be located at the most critical point to warn of a

potentially hazardous situation.

10.2 Particular attention shall be paid to the following to ensure that by working on electrical

components, the casing is not altered in such a way that the level of protection is affected.

This shall include damage to cables, excessive number of connections, terminals not made

to original specification, damage to seals, incorrect fitting of glands, etc.

Ensure that apparatus is mounted securely.

Ensure that seals or sealing materials have not degraded such that they no longer serve

the purpose of preventing the ingress of flammable atmospheres. Replacement parts shall

be in accordance with the manufacturer s specifications.

NOTE: The use of silicon sealant may inhibit the effectiveness of some types of leak detection

equipment. Instrinsically safe components do not have to be isolated prior to working on them.

Information

Servicing

Repair and maintenance to electrical components shall include initial safety checks and

component inspection procedures. If a fault exists that could compromise safety, then no

electrical supply shall be connected to the circuit until it is satisfactorily dealt with. If the fault

cannot be corrected immediately but it is necessary to continue operation, and adequate

temporary solution shall be used. This shall be reported to the owner of the equipment so all

parties are advised.

Initial safety checks shall include:

that capacitors are discharged: this shall be done in a safe manner to avoid possibility of

sparking

that there no live electrical components and wiring are exposed while charging, recovering

or purging the system;

that there is continuity of earth bonding.

Page 29

Page 30

11. Repair to intrinsically safe components

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring

that this will not exceed the permissible voltage and current permitted for the equipment in

use. Intrinscially safe components are the only types that can be worked on while live in the

presence of a flammable atmosphere. The test apparatus shall be at the correct rating.

Replace components only with parts specified by the manufacturer. Other parts may result

in the ignition of refrigerant in the atmosphere from a leak.

12. Cabling

Check that cabling will not be subject to wear, corrosion, excessive pressure, vibration, sharp

edges or any other adverse environmental effects. The check shall also take into account the

effects of aging or continual vibration from sources such as compressors or fans.

13. Detection of flammable refrigerants

Under no circumstances shall potential sources of ignition be used in the searching for or

detection of refrigerant leaks. A halide torch(or any other detector using a naked flame)

shall not be used.

Information

Servicing

14. Leak detection methods

The following leak detection methods are deemed acceptable for systems containing flammable

refrigerants. Electronic leak detectors shall be used to detect flammable refrigerants, but the

sensitivity may not be adequate, or may need re-calibration.(Detection equipment shall be

calibrated in a refrigerant-free area.) Ensure that the detector is not a potential source of ignition

and is suitable for the refrigerant. Leak detection equipment shall be set at a percentage of the

LFL of the refrigerant and shall be calibrated to the refrigerant employed and the appropriate

percentage of gas (25% maximum) is confirmed. Leak detection fluids are suitable for use with

most refrigerants but the use of detergents containing chlorine shall be avoided as the chlorine

may react with the refrigerant and corrode the copper pipe-work.

If a leak is suspected ,all naked flames shall be removed or extinguished. If a leakage of refrigernat

is found which requires brazing, all of the refrigerant shall be recovered from the system, or

isolated(by means of shut off valves) in a part of the system remote from the leak . Oxygen free

nitrogen(OFN) shall then be purged through the system both before and during the brazing process.

15. Removal and evacuation

When breaking into the refrigerant circuit to make repairs for any other purpose conventional

procedures shall be used, However, it is important that best practice is followed since

flammability is a consideration. The following procedure shall be adhered to:

remove refrigerant;

purge the circuit with inert gas;

evacuate;

purge again with inert gas;

open the circuit by cutting or brazing.

The refrigerant charge shall be recovered into the correct recovery cylinders. The system shall be

flushed with OFN to render the unit safe. This process may need to be repeated several times.

Compressed air or oxygen shall not be used for this task.

Flushing shall be achieved by breaking the vacuum in the system with OFN and continuing to

fill until the working pressure is achieved, then venting to atmosphere, and finally pulling down

to a vacuum. This process shall be repeated until no refrigerant is within the system.

Page 30

Page 31

17. Decommissioning

Before carrying out this procedure, it is essential that the technician is completely familiar

with the equipment and all its detail. It is recommended good practice that all refrigerants

are recovered safely. Prior to the task being carried out, an oil and refrigerant sample shall

be taken.

In case analysis is required prior to re-use of reclaimed refrigerant. It is essential that

electrical power is available before the task is commenced.

a) Become familiar with the equipment and its operation.

b) Isolate system electrically

c) Before attempting the procedure ensure that:

mechanical handling equipment is available, if required, for handling refrigerant cylinders;

all personal protetive equipment is available and being used correctly;

the recovery process is supervised at all times by a competent person;

recovery equipment and cylinders conform to the appropriate standards.

d) Pump down refrigerant system, if possible.

e) If a vacuum is not possible, make a manifold so that refrigerant can be removed from

various parts of the system.

f) Make sure that cylinder is situated on the scales before recovery takes place.

g) Start the recovery machine and operate in accordance with manufacturer s instructions.

h) Do not overfill cylinders. (No more than 80% volume liquid charge).

i) Do not exceed the maximum working pressure of the cylinder, even temporarily.

j) When the cylinders have been filled correctly and the process completed, make sure that

the cylinders and the equipment are removed from site promptly and all isolation valves

on the equipment are closed off.

k) Recovered refrigerant shall not be charged into another refrigeration system unless it has

been cleaned and checked.

16. Charging procedures

In addition to conventional charging procedures, the following requirements shall be followed:

Ensure that contamination of different refrigerants does not occur when using charging

equipment. Hoses or lines shall be as short as possible to minimize the amount of

refrigerant contained in them.

Cylinders shall be kept upright.

Ensure that the refrigeration system is earthed prior to charging the system with refrigerant.

Label the system when charging is complete(if not already).

Extreme care shall be taken not to overfill the refrigeration system.

Prior to recharging the system it shall be pressure tested with OFN. The system shall be

leak tested on completion of charging but prior to commissioning. A follow up leak test

shall be carried out prior to leaving the site.

,

When the final OFN charge is used, the system shall be vented down to atmospheric pressure

to enable work to take place. This operation is absolutely vital if brazing operations on the

pipe-work are to take place.

Ensure that the outlet for the vacuum pump is not closed to any ignition sources and there

is ventilation available.

Information

Servicing

Page 31

Page 32

1. Transport of equipment containing flammable refrigerants

Compliance with the transport regulations

2. Marking of equipment using signs

Compliance with local regulations

3. Disposal of equipment using flammable refrigerants

Compliance with national regulations

4. Storage of equipment/appliances

The storage of equipment should be in accordance with the manufacturer’s instructions.

5. Storage of packed (unsold) equipment

Storage package protection should be constructed such that mechanical damage to the

equipment inside the package will not cause a leak of the refrigerant charge.

The maximum number of pieces of equipment permitted to be stored together will be

determined by local regulations.

20. Transportation, marking and storage for units

18. Labelling

Equipment shall be labelled stating that it has been de-commissioned and emptied of

refrigerant. The label shall be dated and signed. Ensure that there are labels on the

equipment stating the equipment contains flammable refrigerant.

Information

Servicing

19. Recovery

When removing refrigerant from a system, either for service or decommissioning, it is

recommended good practice that all refrigerants are removed safely.

When tranferring refrigerant into cylinders, ensure that only appropriate refrigerant

recovery cylinders are employed. Ensure that the correct numbers of cylinders for holding

the total system charge are available. All cylinders to be used are designated for the

recovered refrigerant and labelled for that refrigerant(i.e special cylinders for the

recovery of refrigerant). Cylinders shall be complete with pressure relief valve and

associated shut-off valves in good working order.

Empty recovery cylinders are evacuated and, if possible, cooled before recovery occurs.

The recovery equipment shall be in good working order with a set of instructions

concerning the equipment that is at hand and shall be suitable for the recovery of

flammable refrigerants. In addition, a set of calibrated weighing scales shall be available

and in good working order.

Hoses shall be complete with leak-free disconnect couplings and in good condition. Before

using the recovery machine, check that it is in satisfactory working order, has been

properly maintained and that any associated electrical components are sealed to prevent

ignition in the event of a refrigerant release. Consult manufacturer if in doubt.

The recovered refrigerant shall be returned to the refrigerant supplier in the correct

recovery cylinder, and the relevant Waste Transfer Note arranged. Do not mix refrigerants

in recovery units and especially not in cylinders.

If compressors or compressor oils are to be removed, ensure that they have been

evacuated to an acceptable level to make certain that flammable refrigerant does not

remain within the lubricant. The evacuation process shall be carried out prior to retruning

the compressor to the suppliers. Only electric heating to the compressor body shall be

employed to accelerate this process. When oil is drained from a system, it shall be carried

out safely.

Page 32

Page 33

Quick Step Installation Guide

Mission High Wall Quick Step Installation Guide

Step 1: Prior to unpacking equipment please inspect boxes for any transport damage to ensure products are in perfect condition.

Step 2: Ensure the equipment model numbers on the boxes correspond with your companies purchase order.

Step 3: Unpack the equipment and ensure all parts are accounted for i.e Indoor / Outdoor & Infra-red Controller.

Step 4: Store the Infra-red service controller safely as this can be used to speed up commissioning and servicing process.

Step 5: Review the installation and maintenance manuals which are provided.

Step 6: Carry out the positioning and installation of indoor and outdoor units as per guidelines within the installation manual.

Step 7: Install refrigerant pipework (Purge with OFN while brazing), electrical wiring & drainage pipe work.

Step 8: Power & Interconnecting control wiring between indoor and outdoor units is made by linking into terminals W-1(L)-2(N)-S-E.

Step 9: Pressure test pipework (Note do not carry out pressure test while connected to outdoor unit to prevent contamination of factory charge)

(1) Strength test in 5 Bar increments up to full test pressure. (2) Then leak test at lower pressure. Evacuate system to 2 torr or lower for appropriate time.

Step 10: If required please add additional refrigerant charge (see table on reverse).

Step 11: Carry out all the commissioning checks required to activate the warranty of the newly installed system.

Step 12: Perform the test operation in accordance with the installation manual to ensure all functions and parts are working correctly.

Step 13: Complete your warranty card document and e-mail this with dated photo of outdoor serial number to: warranty@fgeuropeuk.co.uk

Note: Installation videos can also be found on the Midea UK YouTube channel.

Please contact your Midea support team if you have any issues during the installation and commissioning process.

Tel: 02074 092009 E-Mail: technical@fgeuropeuk.co.uk

Indoor

Model

Outdoor

Model

Cooling Duty

(Kw)

Heating Duty

(Kw)

Outdoor Dimensions

Outdoor Weight

(Kg)

Indoor Dimensions

Indoor

Weight(Kg)

W(mm)

D(mm)

H(mm)

W(mm)

D(mm)

H(mm)

MSMBAU-09

MOBA02-09

3.3

3.75

770

300

555

27.1

730

198

293

7.4

MSMBAU-12

MOBA02-12

4.5

4.9

800

333

554

29.7

810

200

300

8.2

MSMBAU-18

MOBA02-18

6.2

6.8

800

333

554

37.2

980

225

335

10.5

MSMBAU-24

MOBA02-24

8.1

9.3

845

363

702

48.5

1090

235

338

12.9

Piping Information

Model:

091218

24

Liquid Line

Inch

1/4

1/4

1/4

3/8

Gas Line

Inch

3/8

3/8

1/2

5/8

Drain Line

Φ mm

161616

16

Max Length

M25253050

Max Height

M10102025

Electrical Wiring Information

Model:

091218

24

Mains Outdoor

3x1.5mm²

3x2.5mm²

Interconnecting/Indoor Power

5x1.5mm²

5x2.5mm²

Power Supply Information

Model:

091218

24

Outdoor

Ph/A

1/16

1/16

1/16

1/20

Indoor

Powered from Outdoor Unit

Refrigerant Charging Information

Model:

091218

24

Pre – Charge

Kg

0.8

0.95

1.48

2.0

Charged to

M5555

Additional

g/m15151530

Refrigerant

Type

R410A

Wi Fi Control Available as Standard

Page 33

12

Page 34

Display Board & Fault Codes

8.1 Indoor Unit Error Display

Operation

lamp

Timer lamp Display LED STATUS

1 time

X E0 Indoor unit EEPROM parameter error

2 times

X E1 Indoor / outdoor units communication error

4 times

X E3 Indoor fan speed has been out of control

5 times

X E4

Indoor room temperature sensor T1 open circuit

or short

circuit

6 times

X E5

Evaporator coil temperature sensor T2 open circuit or

short circuit

7 times

X EC Refrigerant leakage detection

1 times

O F0

Overload current protection

2 times

O F1

Outdoor ambient temperature sensor T4 open circuit or

short circuit

3 times

O F2

Condenser coil temperature sensor T3 open circuit or

short circuit

4 times

O F3

Compressor discharge temperature sensor T5 open

circuit or short circuit

5 times

O F4 Outdoor unit EEPROM parameter error

6 times

O F5 Outdoor fan speed has been out of control

1 times

P0 IPM malfunction or IGBT over-strong current protection

2 times

P1 Over voltage or over low voltage protection

3 times

P2

High temperature protection of compressor top

diagnosis and solution

5 times

P4 Inverter compressor drive error

O

light

X

off

flash

Page 34

13

Page 35

Service Documents

Page 35

14

Customer Contact Information

Company Name: Contact Name:

Contact Number: E-Mail Address:

Site Reference Date of Visit:

Indoor Details

Model No. Serial No.

Location Served

Maintenance Interval (Months)

3 ☐ 6 ☐ 9 ☐ 12 ☐

Maintenance Activity

Task Frequency Complete/Reading

Check operation of the system in both heating and cooling mode Every Visit

☐

Check operation of all functions on the remote controller Every Visit

☐

Inspect & Clean Unit Air Filter(s) Every Visit

☐

Check unit for noise and vibration Every Visit

☐

Check Evaporator Coil for Dirt and Clean as required Every Visit

☐

Test & Clean drain pump (if fitted) and drip tray Every Visit

☐

Check Fan Motor and Fan Blade Movement Every Visit

☐

Check Air On Coil Temperature in Heating Every Visit ˚C

Check Air Off Coil Temperature in Heating Every Visit ˚C

Check indoor covers are secure & Clean Indoor Casing Every Visit ☐

Additional Notes (remedial/additional work completed, faults, follow-up required etc)

Mi Indoor Maintenance Checklist

17 Old Park Lane, London, W1K 1QT Tel: + 44 (0) 2074 092009

Page 36

Page 36

Customer Contact Information

Company Name: Contact Name:

Contact Number: E-Mail Address:

Site Reference Date of Visit:

Outdoor Details

Model No. Serial No.

Location Served

Maintenance Interval (Months)

3 ☐ 6 ☐ 9 ☐ 12 ☐

Maintenance Activity

Task Frequency Complete/Reading

Check and clean Heat Exchanger Every Visit

☐

Check for Visible Signs of Refrigerant Leaks Every Visit

☐

Check outdoor pipework and insulation Every Visit

☐

Check all Electrical Connections (including Mains Isolator) Every Visit

☐

Check Unit Operation Voltage and record Every Visit V

Check Unit Operation Current and record Every Visit A

Check Compressor Run Hours & Record Every Visit Hours

Check Discharge Temperature & Record Every Visit

˚C

Check Suction Temperature & Record Every Visit ˚C

Check Discharge Pressure & Record Every Visit

Bar

Check Suction Pressure & Record Every Visit

Bar

Check Operation of Crankcase Heater Every Visit

☐

Check outdoor covers are secure Every Visit

☐

Additional Notes (remedial/additional work completed, faults, follow-up required etc)

17 Old Park Lane, London, W1K 1QT Tel: + 44 (0) 2074 092009

Mi Outdoor Maintenance Checklist

Page 37

Page 37

Customer Contact Information

Company Name: Contact Name:

Contact Number: E-Mail Address:

Site Reference Date of Visit:

Site Address

County/Region:

Postcode:

System Details

Indoor Model No. Indoor Serial No. Location Served

Outdoor Model No. Outdoor Serial No. Location

Drain: Pumped or Gravity Refrigerant Type Refrigerant Charge

17 Old Park Lane, London, W1K 1QT Tel: + 44 (0) 2074 092009

Mi Commissioning & Installation Checklist

Checklist Complete

1) Indoor unit correctly located

☐

2) Outdoor unit correctly located

☐

3) Wall/Roof Penetration sealed

☐

4) Waffle pad under condensing unit feet

☐

5) Install outdoor unit drain or tray (if required)

☐

6) Purge nitrogen while brazing

☐

7) Pipe work pressure tested (Refer COP)

☐

8) Pipe work insulated, secured & covered

☐

9) Evacuation to less than 2 Torr (Refer COP)

☐

10) Open both L/Line & Suction valves

☐

11) Pour 2- 4 litres of water into the evaporator drain tray

☐

12) Configure wall controller to manufacturer’s manual

☐

13) Open remote control: insert batteries & set the clock

☐

14) Operate unit in all modes (cool, heat, dry, fan, auto)

☐

15) Check the operation of the ‘Auto’ function (if fitted)

☐

16) Measure Suction Pressure

Bar

☐

17) Measure Heard Pressure

Bar

☐

18) Compressor run current amps Amps

☐

19) Measure Indoor ambient temp

˚C

☐

20) Measure Indoor supply air temp ˚C

Δk

☐

21) Measure outdoor ambient temp ˚C

☐

22) Measure condensing unit ‘air off’ coil temp ˚C Δk

☐

23) Superheat: suction line temp ˚C - SST ˚C =

Δk

☐

24) Add or remove refrigerant according to pipe run (refer to manufacture manuals)

☐

25) Carry out site clean (walls, replace furniture, pick up all off cuts)

☐

Page 38

Page 38

!

!

!

Once this from is completed please return to: warranty@fgeuropeuk.co.uk

!

Customer Contact Information

Company Name:

Contact Name:

Contact Number:

E-Mail Address:

Site Reference:

Date:

!

Parts to Be Claimed

Model No.

Serial No.

Components (Including part numbers)

Suspected cause of failure

!

Defective Product Collection Address

Address:

County/Region:

Postcode:

Site Contact:

!

Warranty Claim Number (Internal Use Only):

!

Notes:

!

WARRANTY CLAIM REQUEST FORM

17 Old Park Lane, London, W1K 1QT Tel: + 44 (0) 2074 092009

Page 39

17 Old Park Lane, London, W1K 1QT

Tel: + 44 (0) 2074 092009

Loading...

Loading...