Page 1

MSG-24CR; MSG-24HR

MSG-30CR; MSG-30HR

MSG-36CR; MSG-36HR

Page 2

Page 3

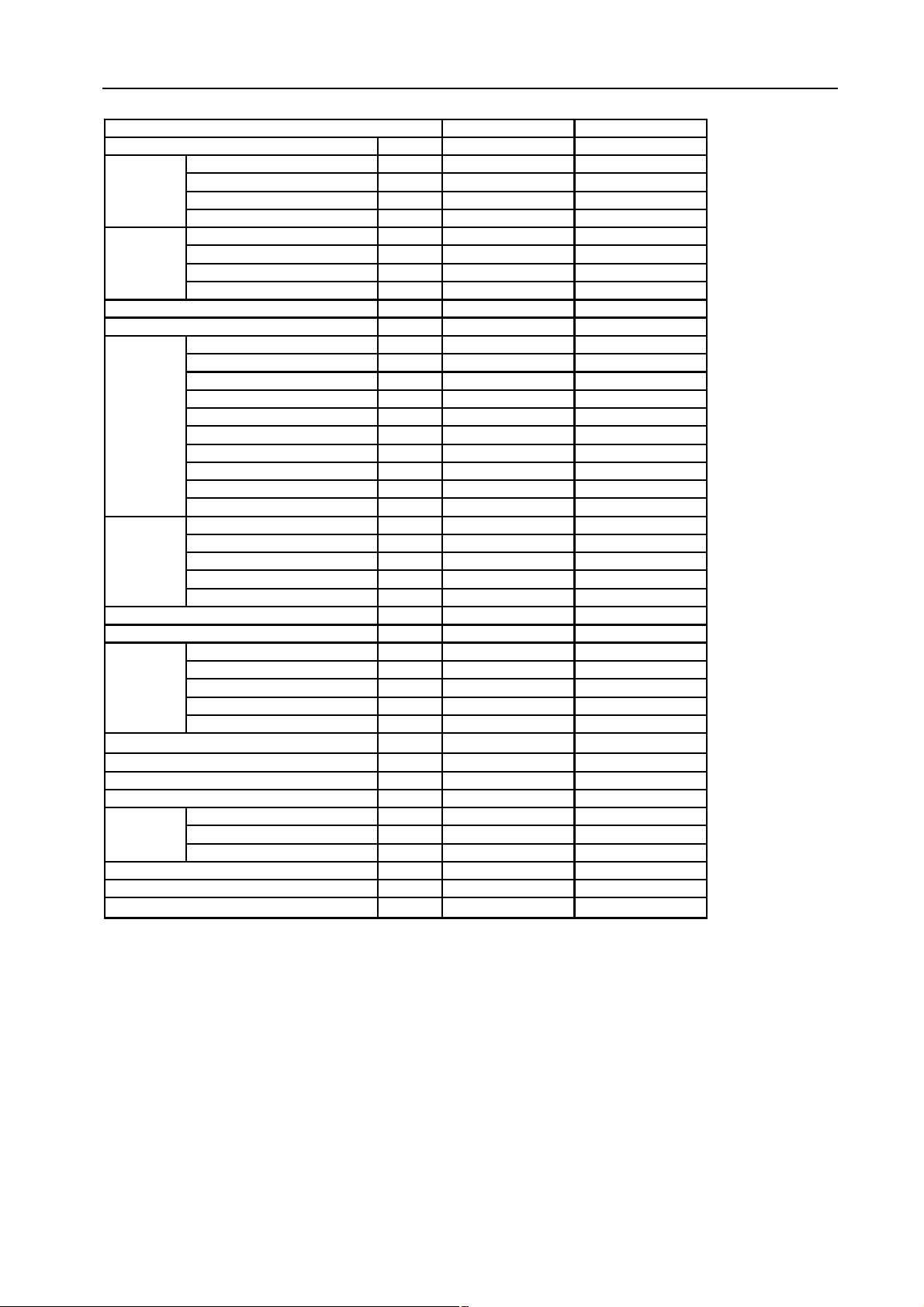

Content

Content

1. Precaution....................................................................................................................1

1.1 Safety Precaution.........................................................................................................................1

1.2 Warning.........................................................................................................................................1

2. Function........................................................................................................................3

3. Dimension.....................................................................................................................5

3.1 Indoor unit.....................................................................................................................................5

3.2 Outdoor unit..................................................................................................................................6

4. Specification.................................................................................................................7

5. Refrigerant cycle diagram.........................................................................................12

6. Operation limits..........................................................................................................13

6.1 Cooling operation........................................................................................................................13

6.2 Heating operation.......................................................................................................................13

7. Schematic diagram and Wiring diagram..................................................................15

7.1 Schematic diagram.....................................................................................................................15

7.2 Wiring diagram............................................................................................................................16

8. Installation details......................................................................................................24

8.1 Wrench torque sheet for installation...........................................................................................24

8.2 Connecting the cables................................................................................................................24

8.3 Pipe length and the elevation.....................................................................................................24

8.4 Air purging of the piping and indoor unit....................................................................................25

8.5 Pumping down (Re-installation)..................................................................................................26

8.6 Re-air purging (Re-installation)...................................................................................................27

8.7 Balance refrigerant of the 2-way, 3-way valves..........................................................................28

8.8 Evacuation..................................................................................................................................29

8.9 Gas charging..............................................................................................................................30

9. Capacity table.............................................................................................................31

9.1 MSG-24CR.................................................................................................................................31

9.2 MSG-24HR.................................................................................................................................31

9.3 MSG-30CR.................................................................................................................................32

9.4 MSG-30HR.................................................................................................................................32

9.5 MSG-36CR.................................................................................................................................33

9.6 MSG-36HR.................................................................................................................................33

10. Electronic function.....................................................................................................34

10.1 Electronic control working environment......................................................................................34

10.2 Proper symbols and their meaning.............................................................................................34

10.3 Function......................................................................................................................................34

10.4 Protection....................................................................................................................................36

10.5 Fan only mode............................................................................................................................36

10.6 Cooling mode..............................................................................................................................36

10.7 Dehumidifying mode...................................................................................................................37

- 1 -

Page 4

Content

10.8 Heating mode.............................................................................................................................37

10.9 Defrosting mode(available for heating mode)............................................................................38

10.10 Auto mode..................................................................................................................................39

10.11 Force cooling function................................................................................................................39

10.12 Sleep mode.................................................................................................................................40

10.13 Auto restart function....................................................................................................................41

11. Model and Parameters...............................................................................................42

12. Troubleshooting.........................................................................................................43

12.1 Display board..............................................................................................................................43

12.2 Troubleshooting..........................................................................................................................44

12.3 Diagnostic chart..........................................................................................................................45

12.4 Resetting phenomenon often occurs during operation..............................................................46

12.5 Operation lamp flashes and Timer lamp off...............................................................................46

12.6 Operation lamp flashes and Timer lamp on...............................................................................46

12.7 Operation lamp off and Timer lamp flashes................................................................................47

12.8 Operation lamp on and Timer lamp flashes...............................................................................47

12.9 Operation lamp flashes, Timer lamp flashes .............................................................................47

13. Characteristic of temperature sensor......................................................................48

- 2 -

Page 5

T

he function will be

Room temperature sensor.

Maintain the room temperature in accordance with the setting temperature.

Indoor fan is delayed for 5 sec at the starting.

Restarting is for approx.

3

minutes..

High

, med, low, breeze.

Light up in

the LED (LCD) for each operation mode.

The unit will decide the louver direction according to operation mode.

The fan is turn to low speed (cooling/heating).

The function is usually used in rainy days in

The louver can be set at the desired position or swing up and

The unit can be change by the room temperature.

P

revent the cold wind at

2. Function

Indoor unit

Operation ON/OFF by remote controller

Sensing by room temperature

Pipe temperature sensor.

Room temperature control

Starting temperature control

Service manual

Time Delay Safety control

Indoor fan speed control

Operation indication Lamps (LED)

Two-direction air vane

Sleep mode auto control

The unit will be turn off after seven hours.

Independent dehumidification

springtime or damp areas.

Self-diag. function

Anti-cold function

the beginning of unit start.

Temp. Compensation

Defrost mode

Auto-restart function

operate in any operation

Air flow Direction control

down automatically

Auto mode

- 3 -

Flexible wiring connection

Easy clean panel

Page 6

T

he unit can operate in cooling mode at low

ambient

temperature conditions.

The unit has

3 mins delay between

continuously

ON/OFF

operations

.

Outdoor unit

B

ird tail propeller fan makes the outdoor unit run more quietly.

T

he hydrophilic fin can improve the heating efficiency at operation mode.

I

t is only operated in the heating operation mode except defrosting

operation

.

Made from

electrolytic zinc steel sheet and anti

-

rust coated components.

I

t protects the valves and prevents water from dripping.

Power relay control

Low ambient kit

Low noise air flow system

Hydrophilic aluminum fin

4 way valve control

Service manual

Discharge pipe temperature protect

Anti-rust cabinet

Valve protection cover

- 4 -

Page 7

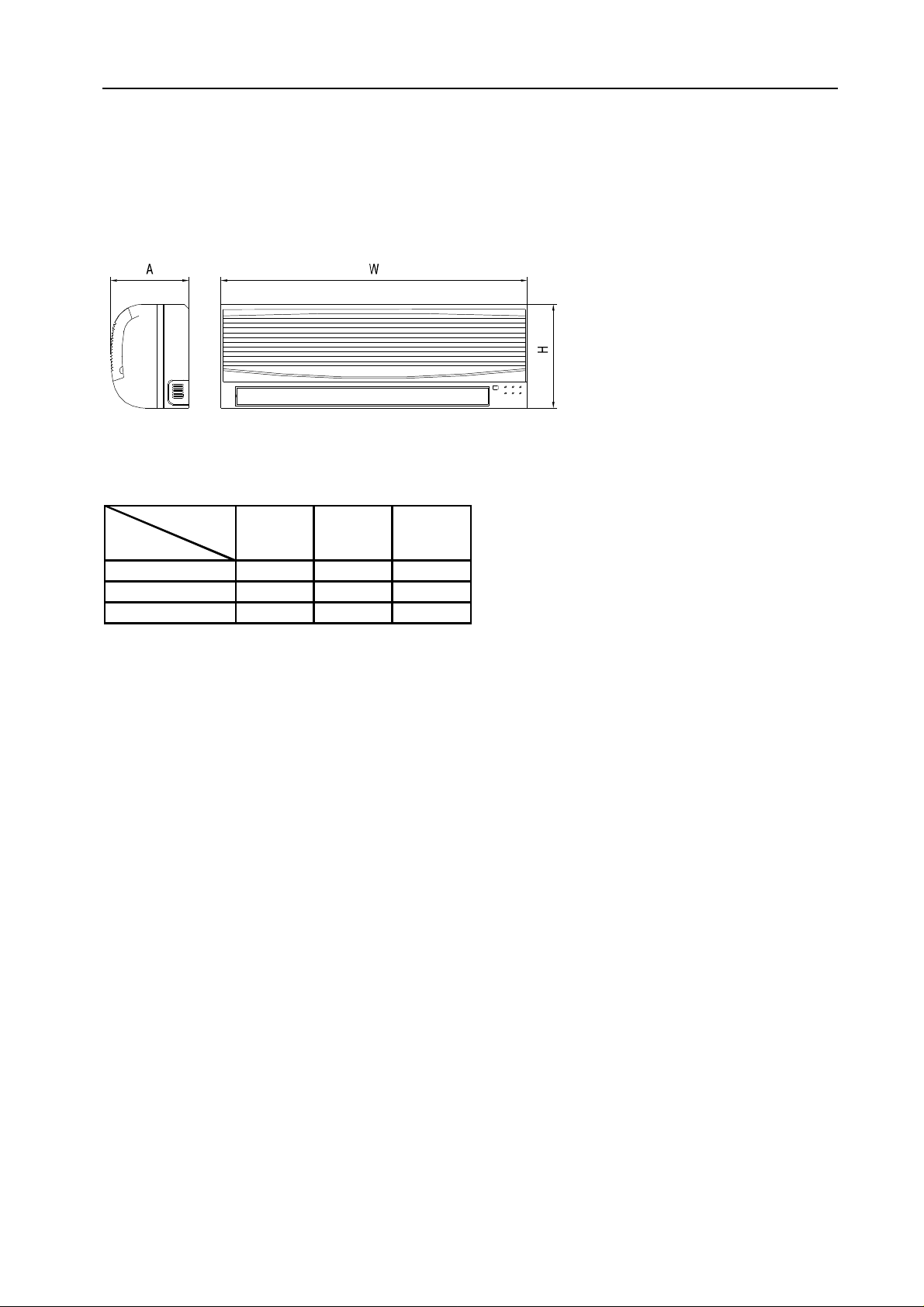

3. Dimension

3.1 Indoor unit

Service manual

Dimension

Mode

24K 1080 330 222

30K 1080 330 222

36K 1250 325 230

W H L

- 5 -

Page 8

560

360

735

560

360

735

560

360

735

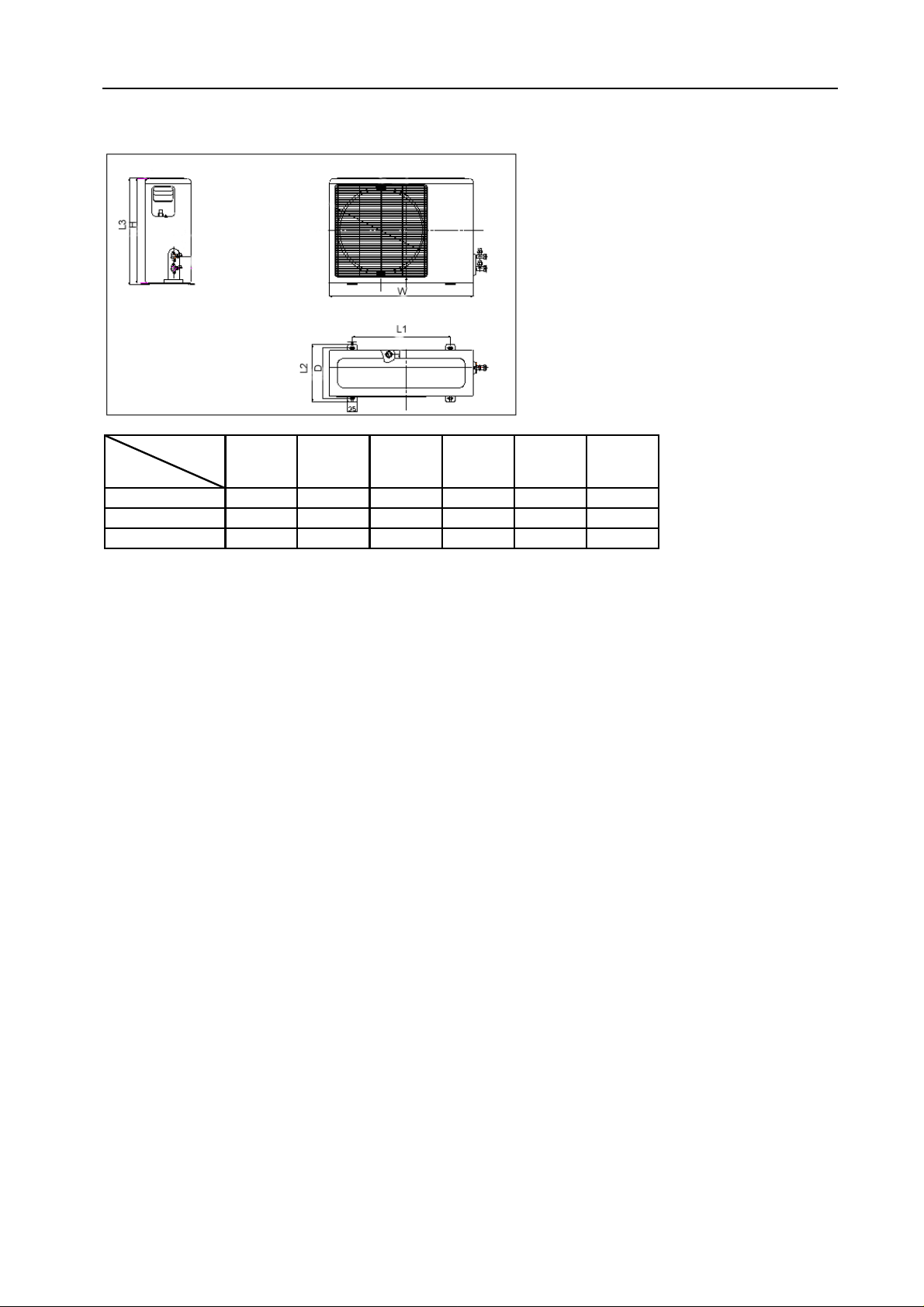

3.2 Outdoor unit

Service manual

Dimension

Mode

24K 845 695 335

30K 845 695 335

36K 895 860 302

W H D L1 L2 L3

- 6 -

Page 9

Ph-V-Hz

1, 220-240V~,50Hz

1, 220-240V~,50Hz

m3/h

≤56≤

Ф

Ф

m

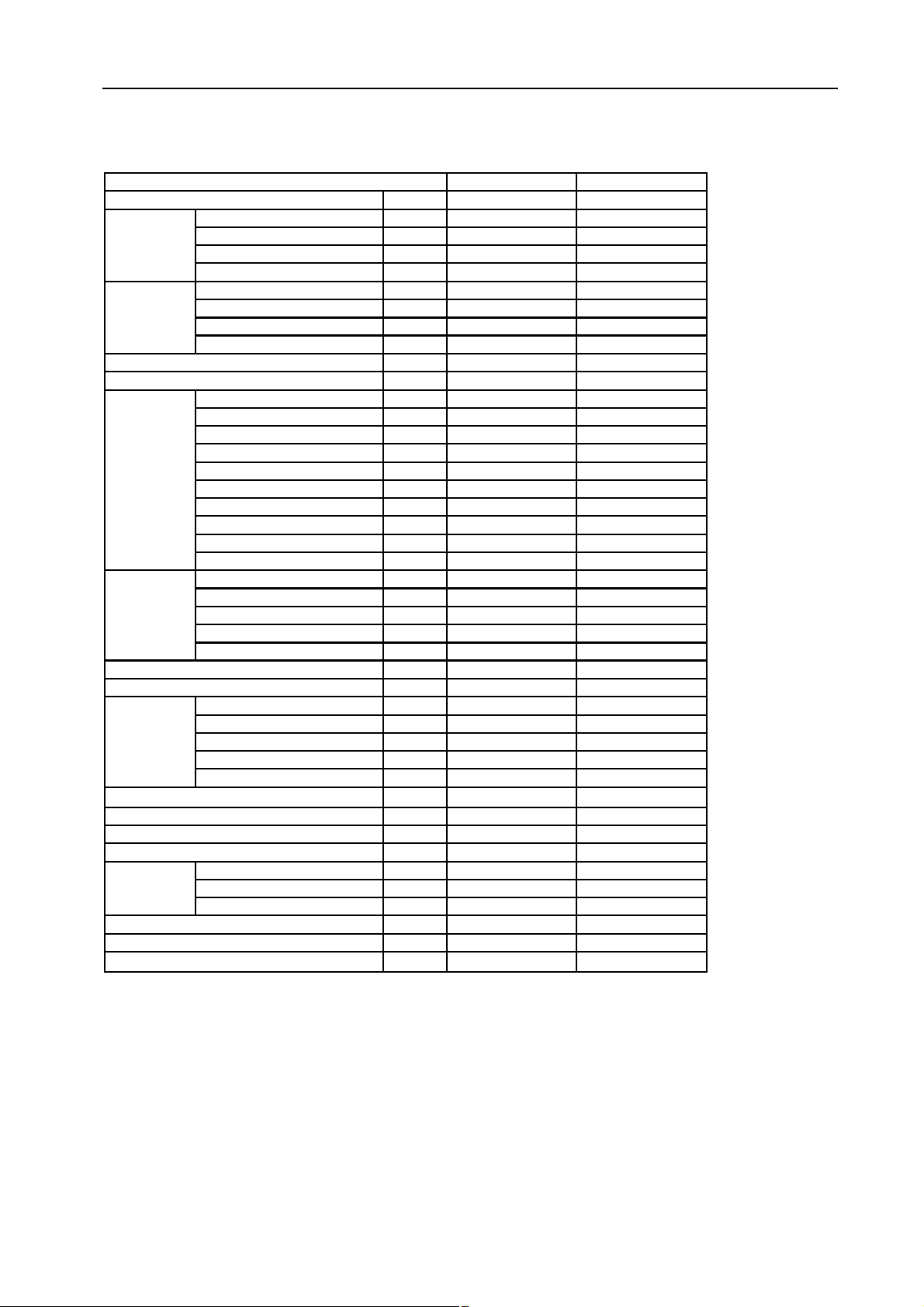

4. Specification

Service manual

Model

Power supply

Capacity Btu/h

Cooling

Input W

Rated current A

EER Btu/w.h

Capacity Btu/h

Heating

Input W

Rated current A

COP W/W

Max. current

Starting current

Model

Type

Brand

Capacity Btu/h

Compressor

Input W

Rated current(RLA) A

Locked rotor Amp(LRA) A

Thermal protector

Capacitor uF

Refrigerant oil ml

Model

Indoor

fan motor

Brand

Input W

Capacitor uF

Speed(hi/mi/lo) r/min

Indoor air flow (Hi/Mi/Lo)

Indoor noise level (Hi/Mi/Lo)

Model

Outdoor

fan motor

Brand

Input W

Capacitor uF

Speed r/min

Outdoor air flow

Outdoor noise level

Refrigerant type R410A

Design pressure

Refrigerant

piping

Liquid side/ Gas side mm

Max. refrigerant pipe length m

Max. difference in level m

Operation temp

Ambient temp

Application area

A

A

m3/h

dB(A)

dB(A)

g

MPa

℃

℃

2

MSG-24CR MSG-24HR

24000 24000

2750 2750

12.5 12.5

8.7, 2.6 8.7, 2.6

-----

----- 2750

-----

----- 2.9

16 16

50 50

QP407PT24C QP407PT24C

Rotary Rotary

LG LG

23400 23400

2317 2317

10.1 10.1

54 54

Internal Internal

45 45

650 650

YDK36-4G YDK36-4G

Welling Welling

65/63/60 65/63/60

2μF/450V 2μF/450V

1050/950/850 1050/950/850

1050/950/850 1050/950/850

43/40/37 43/40/37

YDK53-6K YDK53-6K

Welling Welling

130 130

3.5 3.5

800 800

2500 2500

R22/1850 R22/1900

2.6 2.6

9.53/Ф16.0

20 20

10 10

17-30 17-30

18-45 -7 - 45

40~56 40~56

27000

12.5

56

9.53/Ф16.0

Note:

- 7 -

The noise date is base on hemi-anechoic chamber, during actual operation; these values are normally somewhat

different as a result of ambient condition.

The above design and specifications are subject to change without prior notice for product improvement.

Page 10

Service manual

Ph-V-Hz

1, 220-240V~,50Hz

1, 220-240V~,50Hz

m3/h

≤58≤

Ф

Ф

m

Model

Power supply

Capacity Btu/h 28000 28000

Cooling

Input W 3200 3200

Rated current A 15 15

EER Btu/w.h 8.8 8.8

Capacity Btu/h

Heating

Input W ----- 3100

Rated current A

COP W/W ----- 9.7

Max. current

Starting current

Model ZR34KH-PFJ-522 ZR34KH-PFJ-522

Type Scroll Scroll

Brand Copeland Copeland

Capacity Btu/h 28800 28800

Compressor

Input W 2520 2520

Rated current(RLA) A 12.1 12.1

Locked rotor Amp(LRA) A 76 76

Thermal protector Internal Internal

Capacitor uF 50 50

Refrigerant oil ml 1242 1242

Model

Indoor

fan motor

Brand Welling Welling

Input W 68/65/62 68/65/62

Capacitor uF

Speed(hi/mi/lo) r/min 1150/1050/950 1150/1050/950

Indoor air flow (Hi/Mi/Lo)

Indoor noise level (Hi/Mi/Lo)

Model YDK53-6K YDK53-6K

Outdoor

fan motor

Brand Welling Welling

Input W 140 140

Capacitor uF 3.5 3.5

Speed r/min 800 800

Outdoor air flow

Outdoor noise level

Refrigerant type R410A

Design pressure

Refrigerant

piping

Liquid side/ Gas side mm

Max. refrigerant pipe length m 20 20

Max. difference in level m 10 10

Operation temp

Ambient temp

Application area

MSG-30CR MSG-30HR

-----

-----

30000

14.5

A 20 20

A 76 76

YDK36-4G YDK36-4G

3μF/450V 3μF/450V

m3/h 1150/1050/950 1150/1050/950

dB(A) 47/44/41 47/44/41

2500 2500

dB(A)

58

g R22/2250 R22/2450

MPa 2.6 2.6

℃

℃

9.53/Ф16.0

17-30 17-30

2

18-45 -7 - 45

50~68 50~68

9.53/Ф16.0

Note:

- 8 -

The noise date is base on hemi-anechoic chamber, during actual operation; these values are normally somewhat

different as a result of ambient condition.

The above design and specifications are subject to change without prior notice for product improvement.

Page 11

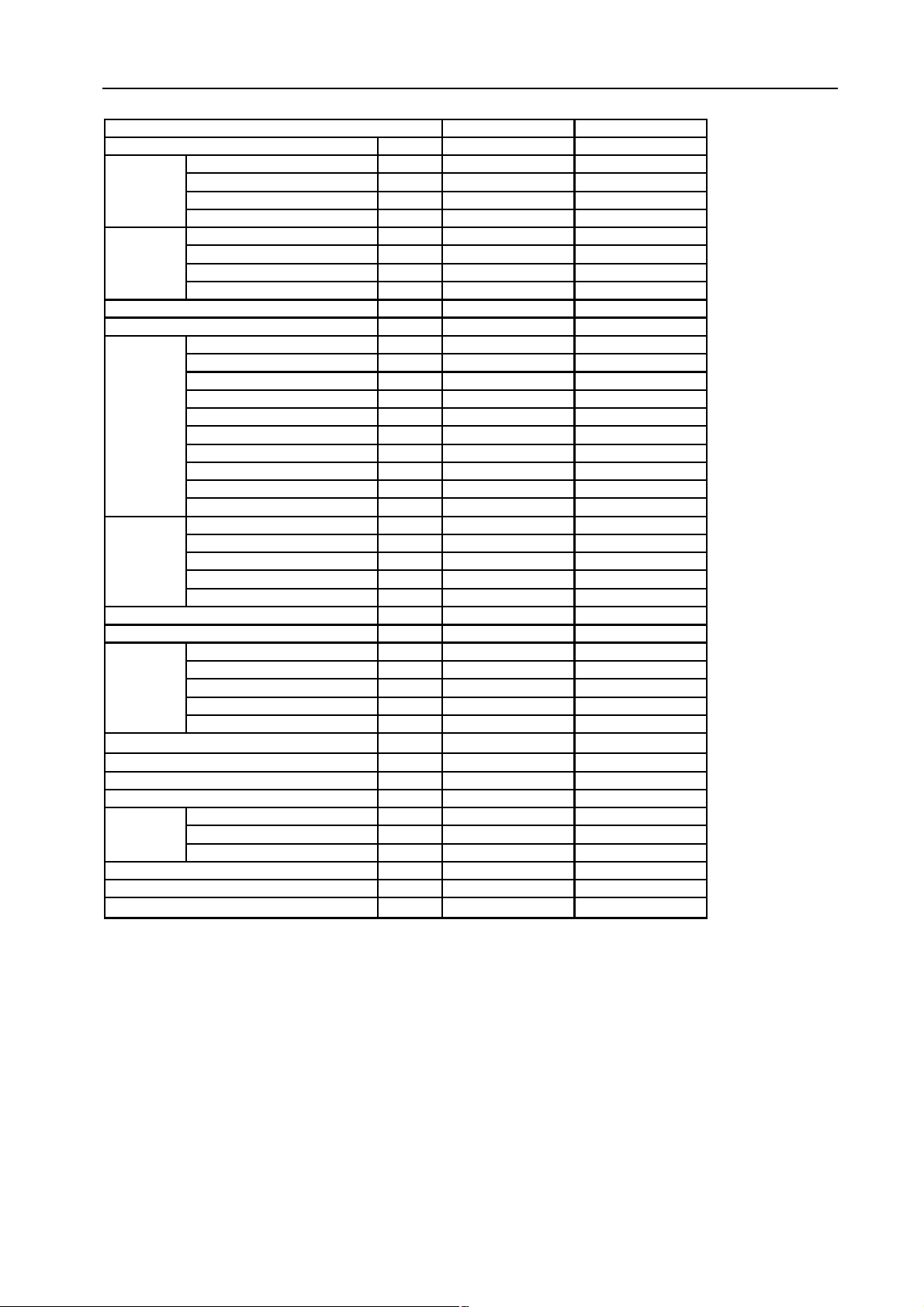

Service manual

Ph-V-Hz

≥

m3/h

Φ

Φ

m

Model

Power supply

Capacity Btu/h

Cooling

Input W

Rated current A

EER Btu/w.h

Capacity Btu/h

Heating

Input W -----

Rated current A

COP W/W ----- 9.3

Max. current

Starting current

Model

Type

Brand

Capacity Btu/h

Compressor

Input W

Rated current(RLA) A

Locked rotor Amp(LRA) A

Thermal protector 15HM1637 15HM1637

Capacitor uF 60uF/

Refrigerant oil ml 1240 1240

Model

Indoor

fan motor

Brand Welling Welling

Input W

Capacitor uF 3 3

Speed(hi/mi/lo) r/min 1260/1150/990 1260/1150/990

Indoor air flow (Hi/Mi/Lo)

Indoor noise level (Hi/Mi/Lo)

Model YDK100-6 YDK100-6

Outdoor

fan motor

Brand Welling Welling

Input W 169 169

Capacitor uF 5 5

Speed r/min 900 900

Outdoor air flow

Outdoor noise level

Refrigerant type R410A

Design pressure

Refrigerant

piping

Liquid side/ Gas side mm

Max. refrigerant pipe length m 25 25

Max. difference in level m 10 10

Operation temp

Ambient temp

Application area

MSG-36CR MSG-36HR

1, 220-240V~, 50Hz 1, 220-240V~, 50Hz

35000 35000

4120 4120

18.6 18.6

8.5 8.5

-----

-----

38000

4100

18.5

A 32 32

A 150 150

ZR47K3-PFJ-522 ZR47K3-PFJ-522

SCROLL SCROLL

COPELAND COPELAND

39000 39000

3510 3510

19.3 19.3

114 114

400VAC 60uF/≥400VAC

YDK50-4E YDK50-4E

85/80/77 85/80/77

m3/h 1350/1200/1050 1350/1200/1050

dB(A)

49/46/42 49/46/42

3000 3000

dB(A) 59 59

g 2400 2450

MPa 2.6 2.6

℃

℃

9.52/Φ16

17-30 17-30

2

18-45 -7 - 45

60~78 60~78

9.52/Φ16

Note:

The noise date is base on hemi-anechoic chamber, during actual operation; these values are normally somewhat

different as a result of ambient condition.

The above design and specifications are subject to change without prior notice for product improvement.

- 9 -

Page 12

Service manual

Ph-V-Hz

3Ph,380-420V,50Hz

3Ph,380-420V,50Hz

m3/h

≤58≤

Ф

Ф

m

Model

Power supply

Capacity Btu/h 28000 28000

Cooling

Input W 3000 3000

Rated current A 5.3 5.3

EER Btu/w.h 9.3 9.3

Capacity Btu/h

Heating

Input W ----- 3000

Rated current A

COP W/W ----- 10.7

Max. current

Starting current

Model ZR34KH-TFD-522 ZR34KH-TFD-522

Type Scroll Scroll

Brand Copeland Copeland

Capacity Btu/h 28000 28000

Compressor

Input W 2480 2480

Rated current(RLA) A 4.6 4.6

Locked rotor Amp(LRA) A 40 40

Thermal protector Internal Internal

Capacitor uF ----- -----

Refrigerant oil ml 1242 1242

Model

Indoor

fan motor

Brand Welling Welling

Input W 72/67/63 72/67/63

Capacitor uF

Speed(hi/mi/lo) r/min 1150/1060/960 1150/1060/960

Indoor air flow (Hi/Mi/Lo)

Indoor noise level (Hi/Mi/Lo)

Model YDK53-6K YDK53-6K

Outdoor

fan motor

Brand Welling Welling

Input W 140 140

Capacitor uF 3.5 3.5

Speed r/min 800 800

Outdoor air flow

Outdoor noise level

Refrigerant type R410A

Design pressure

Refrigerant

piping

Liquid side/ Gas side mm

Max. refrigerant pipe length m 20 20

Max. difference in level m 10 10

Operation temp

Ambient temp

Application area

MSG-30CR MSG-30HR

-----

-----

32000

5.3

A 7 7

A 40 40

YDK36-4G YDK36-4G

3μF/450V 3μF/450V

m3/h 1150/1050/950 1150/1050/950

dB(A) 47/44/41 47/44/41

2500 2500

dB(A)

58

g R22/2250 R22/2450

MPa 2.6 2.6

℃

℃

9.53/Ф16.0

17-30 17-30

2

18-45 -7 - 45

50~68 50~68

9.53/Ф16.0

Note:

- 10 -

The noise date is base on hemi-anechoic chamber, during actual operation; these values are normally somewhat

different as a result of ambient condition.

The above design and specifications are subject to change without prior notice for product improvement.

Page 13

Service manual

m3/h

Φ

Φ

m

Model

Power supply

Capacity Btu/h

Cooling

Input W

Rated current A

EER Btu/w.h

Capacity Btu/h

Heating

Input W

Rated current A

COP W/W

Max. current

Starting current

Model

Type

Brand

Capacity Btu/h

Compressor

Input W

Rated current(RLA) A

Locked rotor Amp(LRA) A

Thermal protector

Capacitor uF

Refrigerant oil ml

Model

Indoor

fan motor

Brand

Input W

Capacitor uF

Speed(hi/mi/lo) r/min

Indoor air flow (Hi/Mi/Lo)

Indoor noise level (Hi/Mi/Lo)

Model

Outdoor

fan motor

Brand

Input W

Capacitor uF

Speed r/min

Outdoor air flow

Outdoor noise level

Refrigerant type R410A

Design pressure

Refrigerant

piping

Liquid side/ Gas side mm

Max. refrigerant pipe length m

Max. difference in level m

Operation temp

Ambient temp

Application area

Ph-V-Hz

A

A

m3/h

dB(A)

dB(A)

g

MPa

℃

℃

2

MSG-36CR MSG-36HR

3, 380-420V~, 50Hz3, 380-420V~, 50Hz

35000 35000

4120 4120

6.5 6.5

8.5 8.5

-----

-----

-----

----- 9.3

11 11

48 48

ZR34KH-TFD-522 ZR34KH-TFD-522

Scroll Scroll

Copeland Copeland

39000 39000

3480 3480

6.3 6.3

43/48 43/48

34HM224 34HM224

----- -----

SONTEX 200LT 1242 SONTEX 200LT 1242

YDK50-4E YDK50-4E

Welling Welling

85/80/77 85/80/77

3 3

1260/1150/990 1260/1150/990

1350/1200/1050 1350/1200/1050

49/46/42 49/46/42

YDK100-6 YDK100-6

Welling Welling

169 169

5 5

900 900

3000 3000

59 59

2400 2450

2.6 2.6

9.52/Φ16

25 25

10 10

17-30 17-30

18-45 -7 - 45

60~78 60~78

38000

4100

6.4

9.52/Φ16

Note:

The noise date is base on hemi-anechoic chamber, during actual operation; these values are normally somewhat

different as a result of ambient condition.

The above design and specifications are subject to change without prior notice for product improvement.

- 11 -

Page 14

Service manual

5. Refrigerant cycle diagram

Ø Cooling only

Ø Heat pump mode

- 12 -

Page 15

Service manual

7. Schematic diagram and Wiring diagram

7.1 Schematic diagram

- 15 -

Page 16

7.2.2 Heating mode

MSG-24HR, MSG-30HR

Service manual

A2

A1

- 18 -

Page 17

MSG-36HR

Service manual

A1A2

- 19 -

Page 18

7.2.3 Cooling mode (3 Ph)

MSG-30CR (3ph)

Service manual

- 20 -

Page 19

7.2.4 Heating mode (3 Ph)

MSG-30HR (3ph)

Service manual

1

2

4

6

73

5

- 22 -

Page 20

MSG-36HR (3ph)

Service manual

- 23 -

Page 21

Service manual

length

Btu/h

GAS

LIQUID

B (m)A

(m)

(g/m)

3/8’’ (φ9.52)

1/4’’ (φ6.35)

5510301/2’’ (φ12.7)

1/4’’ (φ6.35)

5510301/2’’ (φ12.7)

1/4’’ (φ6.35)

5815305/8’’ (φ15.88)

1/4’’ (φ6.35)

51020305/8’’ (φ15.88)

3/8’’ (φ9.52)

51020655/8’’ (φ15.88)

3/8’’ (φ9.52)

51530653/4’’ (φ19.05)

3/8’’ (φ9.52)

51530

65

8. Installation details

8.1 Wrench torque sheet for installation

Outside diameter

mm inch Kg.m

φ6.35 1/4 1.8

φ9.52 3/8 4.2

φ12.7 1/2 5.5

φ15.88 5/8 6.6

φ19.05 3/4 6.6

Torque

8.2 Connecting the cables

The power cord of connect should be selected according to the following specifications sheet.

Grade

Unit 7K 9K 12K 18K 24K 28K

mm2 1.0 1.0 1.5 2.5 2.5 2.5

8.3 Pipe length and the elevation

Capacity

7k~12K

Standard

Pipe size

(m) Elevation Elevation refrigerant

Max. Max. Additional

16K~28K

30K~36K

In case that

more than

Caution:

Capacity is base on standard length and maximum allowance length is base of reliability.

Oil trap should be install per 5-7 meters.

- 24 -

Page 22

Service manual

8.4 Air purging of the piping and indoor unit

Required tools:

Hexagonal wrench; adjustable wrench; torque wrenches, wrench to hold the joints and gas leak

detector.

Note:

The air in the indoor unit and in the piping must be purged. If air remains in the refrigeration piping, it

will affect the compressor, reduce the cooling capacity, and could lead to a malfunction of unit.

Be sure, using a torque wrench to tighten the service port cap (after using the service port), so that it

prevents the gas leakage from the refrigeration cycle.

Procedure

1. Recheck the piping connections.

2. Open the valve stem of the 2-way valve

counterclockwise approximately 90’, wait

10 seconds, and then set it to closed

position.

§ Be sure to use a hexagonal wrench to operate

the valve stem

3. Check for gas leakage.

§ Check the flare connection for gas leakage

4. Purge the air from the system.

§ Set the 2-way valve to the open position and

remove the cap from the 3-way valve’s

service port.

§ Using the hexagonal wrench to press the

valve core pin, discharge for three seconds

and then wait for one minute.

5. Use torque wrench to tighten the service

port cap to a torque of 1.8 kg.m. (18n.m)

6. Set the 3-way valve to the opened

position.

- 25 -

7. Mounted the valve stem nuts to the 2-way

and 3-way valves.

8. Check for gas leakage.

§ At this time, especially check for gas leakage

from the 2-way and 3-way stem nuts, and

from the service port.

Caution:

If gas leakage is discovered in step (3) above,

take the following measures.

If the leaks stop when the piping connections

are tightened further, continue working from

step (4).

If the gas leaks do not stop when the

connections are retightened, repair the location

of the leak, discharge all of the gas through the

service port, and then recharge with the

specified amount of gas from a gas cylinder.

Page 23

8.5 Pumping down (Re-installation)

Service manual

Procedure

1. Confirm that both the 2-way and 3-way valves are set to the opened position.

§ Remove the valve stem caps and confirm that the valve stems are in the opened position.

§ Be sure to use a hexagonal wrench to operate the valve stems.

2. Operate the unit for 10 to 15 minutes.

3. Stop operation and wait for 3 minutes, then connect the charge set to the service port of the

3-way valve.

§ Connect the charge hose with the push pin to the gas service port.

4. Air purging of the charge hose.

§ Open the low-pressure valve on the charge set slightly to purge air from the charge hose.

5. Set the 2-way valve to the close position.

6. Operate the air conditioner at the cooling cycle and stop it when the gauge indicates 0.1MPa.

7. Immediately set the 3-way valve to the closed position.

§ Do this quickly so that the gauge ends up indicating 0.3 to 0.5Mpa.

8. Disconnect the charge set, and amount the 2-way and 3-way valve’s stem nuts and service

port caps.

§ Use a torque wrench to tighten the service port cap to a torque of 1.8 kg.m.

§ Be sure to check for gas leakage.

- 26 -

Page 24

8.6 Re-air purging (Re-installation)

Service manual

Procedure:

1. Confirm that both the 2-way and 3-way valves are set to the closed position.

2. Connect the charge set and a charging cylinder to the service port of the 3-way valve.

§ Leave the valve on the charging cylinder closed.

3. Air purging.

§ Open the valves on the charging cylinder and the charge set. Purge the air by loosening the flare nut

on the 2-way valve approximately 45’ for 3 seconds then closing it for 1 minutes; repeat 3 times.

§ After purging the air, use a torque wrench to tighten the flare nut to on the 2-way valve.

4. Check the gas leakage.

§ Check the flare connections for gas leakage.

5. Discharge the refrigerant.

§ Close the valve on the charging cylinder and discharge the refrigerant until the gauge indicate 0.3 to

0.5 Mpa.

6. Disconnect the charge set and the charging cylinder, and set the 2-way and 3-way valves to

the open position.

§ Be sure to use a hexagonal wrench to operate the valve stems.

7. Mount the valve stems nuts and the service port cap.

§ Be sure to use a torque wrench to tighten the service port cap to a torque 18N.m.

§ Be sure to check the gas leakage.

- 27 -

Page 25

Service manual

8.7 Balance refrigerant of the 2-way, 3-way valves

Procedure:

1. Confirm that both the 2-way and 3-way valves are set to the open position.

2. Connect the charge set to the 3-way valve’s service port.

§ Leave the valve on the charge set closed.

§ Connect the charge hose with the push pin to the service port.

3. Open the valves (Low side) on the charge set and discharge the refrigerant until the gauge

indicates 0.05 to 0.1 Mpa.

§ If there is no air in the refrigeration cycle [the pressure when the air conditioner is not running is

higher than 0.1Mpa, discharge the refrigerant until the gauge indicates 0.05 to 0.1 Mpa. If this is the

case, it will not be necessary to apply a evacuation.

§ Discharge the refrigeration gradually; if it is discharged too suddenly, the refrigeration oil sill be

discharged.

- 28 -

Page 26

8.8 Evacuation

Service manual

Procedure:

1. Connect the vacuum pump to the charge set’s centre hose.

2. Evacuation for approximately one hour.

§ Confirm that the gauge needle has moved toward -0.1 Mpa (-76 cmHg) [vacuum of 4 mmHg or less].

3. Close the valve (Low side) on the charge set, turn off the vacuum pump, and confirm that the

gauge needle does not move (approximately 5 minutes after turning off the vacuum pump).

4. Disconnect the charge hose from the vacuum pump.

§ Vacuum pump oil, if the vacuum pump oil becomes dirty or depleted, replenish as needle.

- 29 -

Page 27

8.9 Gas charging

Service manual

Procedure:

1. Connect the charge hose to the charging cylinder.

§ Connect the charge hose which you disconnected from the vacuum pump to the valve at the bottom

of the cylinder.

2. Purge the air from the charge hose.

§ Open the valve at the bottom of the cylinder and press the check valve on the charge set to purge the

air (be careful of the liquid refrigerant).

3. Open the valves (Low side) on the charge set and charge the system with liquid refrigerant.

§ If the system cannot be charge with the specified amount of refrigerant, if can be charged with a little

at a time (approximately 150g each time0 while operating the air conditioner in the cooling cycle;

however, one time is not sufficient, wait approximately 1 minute and then repeat the

procedure.(pumping down-pin).

4. Immediately disconnect the charge hose from the 3-way valve’s service port.

§ Stopping partway will allow the refrigerant to be discharged.

§ If the system has been charged with liquid refrigerant while operating the air conditioner, turn off the

air conditioner before disconnecting the hose.

5. Mounted the valve stem caps and the service port

§ Use torque wrench to tighten the service port cap to a torque of 18N.m.

§ Be sure to check for gas leakage.

- 30 -

Page 28

9. Capacity table

Cooling mode

Conditions

21ºC D

Total capacity kW

6.76

6.35

5.88

5.41

5.05

4.69

15ºC W

Sensitive capacity kW

4.93

4.74

4.44

4.11

3.86

3.61

24ºC D

Total capacity kW

7.31

6.99

6.53

6.17

5.75

5.30

17ºC W

Sensitive capacity kW

5.38

5.21

4.96

4.72

4.43

4.11

27ºC D

Total capacity kW

7.79

7.44

6.64

6.19

5.71

19ºC W

Sensitive capacity kW

5.92

5.73

5.22

4.88

4.51

2.97

3.30

3.41

32ºC D

Total capacity kW

8.68

8.32

8.05

7.49

6.84

6.45

23ºC W

Sensitive capacity kW

6.68

6.49

6.32

5.91

5.47

5.22

Cooling mode

Conditions

21ºC D

Total capacity kW

6.76

6.35

5.88

5.41

5.05

4.69

15ºC W

Sensitive capacity kW

4.93

4.74

4.44

4.11

3.86

3.61

24ºC D

Total capacity kW

7.31

6.99

6.53

6.17

5.75

5.30

17ºC W

Sensitive capacity kW

5.38

5.21

4.96

4.72

4.43

4.11

27ºC D

Total capacity kW

7.79

7.44

6.64

6.19

5.71

19ºC W

Sensitive capacity kW

5.92

5.73

5.22

4.88

4.51

2.97

3.30

3.41

32ºC D

Total capacity kW

8.68

8.32

8.05

7.49

6.84

6.45

23ºC W

Sensitive capacity kW

6.68

6.49

6.32

5.91

5.47

5.22

-7ºC D

-8ºC W

7.91

2.75

9.1 MSG-24CR

SUMMER

Indoor

Input kW. 2.35 2.48 2.59 2.79 3.10 3.21

Input kW. 2.43 2.56 2.67 2.88 3.20 3.31

Input kW. 2.50 2.64

Input kW. 2.60 2.75 2.86 3.09 3.43 3.55

9.2 MSG-24HR

SUMMER

Indoor

Service manual

OUTDOOR TEMPERATURE DRY

25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

7.03

5.48

2.75

OUTDOOR TEMPERATURE DRY

25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

WINTER

Indoor

Conditions

15ºC

18ºC

20ºC

22ºC

Input kW. 2.35 2.48 2.59 2.79 3.10 3.21

Input kW. 2.43 2.56 2.67 2.88 3.20 3.31

7.03

5.48

Input kW. 2.50 2.64

Input kW. 2.60 2.75 2.86 3.09 3.43 3.55

OUTDOOR CONDITIONS

Capacity kW

Input kW.

Capacity kW

Input kW.

Capacity kW

Input kW.

Capacity kW

Input kW.

12ºC D

11ºC W

9.33 8.19 7.50 6.58 5.67 4.98

2.95 2.68 2.50 2.31 2.01 1.83

9.16 8.04 7.31 6.35 5.38 4.66

3.03 2.73 2.53 2.37 2.07 1.85

9.08

3.11

9.00 7.82 7.12 6.10 5.01 4.15

3.22 2.78 2.65 2.51 2.27 2.03

7ºC D

6ºC W

2.75

4ºC D

3ºC W

7.23 6.19 5.09 4.22

2.61 2.42 2.13 1.95

0ºC D

-1ºC W

-4ºC D

-6ºC W

- 31 -

Page 29

Cooling mode

Conditions

21ºC D

Total capacity kW

7.88

7.40

6.86

6.31

5.90

5.47

15ºC W

Sensitive capacity kW

5.75

5.52

5.18

4.79

4.50

4.21

24ºC D

Total capacity kW

8.53

8.15

7.62

7.20

6.71

6.19

17ºC W

Sensitive capacity kW

6.27

6.07

5.79

5.51

5.17

4.79

27ºC D

Total capacity kW

9.09

8.68

7.75

7.22

6.66

19ºC W

Sensitive capacity kW

6.91

6.69

6.08

5.69

5.26

3.46

3.84

3.97

32ºC D

Total capacity kW

10.12

9.71

9.39

8.73

7.98

7.52

23ºC W

Sensitive capacity kW

7.79

7.57

7.37

6.90

6.38

6.09

Cooling mode

Conditions

21ºC D

Total capacity kW

7.88

7.40

6.86

6.31

5.90

5.47

15ºC W

Sensitive capacity kW

5.75

5.52

5.18

4.79

4.50

4.21

24ºC D

Total capacity kW

8.53

8.15

7.62

7.20

6.71

6.19

17ºC W

Sensitive capacity kW

6.27

6.07

5.79

5.51

5.17

4.79

27ºC D

Total capacity kW

9.09

8.68

7.75

7.22

6.66

19ºC W

Sensitive capacity kW

6.91

6.69

6.08

5.69

5.26

3.46

3.84

3.97

32ºC D

Total capacity kW

10.12

9.71

9.39

8.73

7.98

7.52

23ºC W

Sensitive capacity kW

7.79

7.57

7.37

6.90

6.38

6.09

-7ºC D

-8ºC W

8.79

3.10

9.3 MSG-30CR

SUMMER

Indoor

9.4 MSG-30HR

SUMMER

Indoor

Service manual

OUTDOOR TEMPERATURE DRY

25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Input kW. 2.74 2.89 3.01 3.25 3.61 3.73

Input kW. 2.82 2.98 3.10 3.35 3.72 3.85

8.20

6.40

Input kW. 2.91 3.07

Input kW. 3.03 3.19 3.33 3.59 3.99 4.13

OUTDOOR TEMPERATURE DRY

25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

3.20

WINTER

Indoor

Conditions

15ºC

18ºC

20ºC

22ºC

Input kW. 2.74 2.89 3.01 3.25 3.61 3.73

Input kW. 2.82 2.98 3.10 3.35 3.72 3.85

8.20

6.40

Input kW. 2.91 3.07

Input kW. 3.03 3.19 3.33 3.59 3.99 4.13

OUTDOOR CONDITIONS

Capacity kW

Input kW.

Capacity kW

Input kW.

Capacity kW

Input kW.

Capacity kW

Input kW.

12ºC D

11ºC W

10.37 9.10 8.33 7.31 6.30 5.53

3.33 3.03 2.81 2.60 2.27 2.06

10.18 8.93 8.13 7.06 5.98 5.18

3.41 3.07 2.86 2.67 2.33 2.09

10.09

3.51

10.00 8.69 7.91 6.78 5.56 4.61

3.63 3.13 2.99 2.83 2.55 2.29

7ºC D

6ºC W

3.20

4ºC D

3ºC W

8.03 6.88 5.66 4.69

2.95 2.73 2.41 2.20

0ºC D

-1ºC W

-4ºC D

-6ºC W

- 32 -

Page 30

Cooling mode

Conditions

21ºC D

Total capacity kW

9.87

9.27

8.59

7.90

7.38

6.85

15ºC W

Sensitive capacity kW

7.21

6.92

6.48

6.00

5.64

5.28

24ºC D

Total capacity kW

10.69

10.21

9.54

9.02

8.41

7.75

17ºC W

Sensitive capacity kW

7.85

7.61

7.25

6.90

6.47

6.00

27ºC D

Total capacity kW

11.38

10.88

9.71

9.05

8.34

19ºC W

Sensitive capacity kW

8.65

8.37

8.01

7.62

7.13

6.59

4.45

4.94

5.11

32ºC D

Total capacity kW

12.68

12.16

11.76

10.94

10.00

9.42

23ºC W

Sensitive capacity kW

9.76

9.48

9.23

8.64

8.00

7.63

Cooling mode

Conditions

21ºC D

Total capacity kW

9.87

9.27

8.59

7.90

7.38

6.85

15ºC W

Sensitive capacity kW

7.21

6.92

6.48

6.00

5.64

5.28

24ºC D

Total capacity kW

10.69

10.21

9.54

9.02

8.41

7.75

17ºC W

Sensitive capacity kW

7.85

7.61

7.25

6.90

6.47

6.00

27ºC D

Total capacity kW

11.38

10.88

9.71

9.05

8.34

19ºC W

Sensitive capacity kW

8.65

8.37

8.01

7.62

7.13

6.59

4.45

4.94

5.11

32ºC D

Total capacity kW

12.68

12.16

11.76

10.94

10.00

9.42

23ºC W

Sensitive capacity kW

9.76

9.48

9.23

8.64

8.00

7.63

-7ºC D

-8ºC W

11.14

4.12

9.5 MSG-36CR

SUMMER

Indoor

Service manual

OUTDOOR TEMPERATURE DRY

25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Input kW. 3.52 3.72 3.87 4.18 4.65 4.80

Input kW. 3.64 3.84 4.00 4.32 4.80 4.96

10.27

9.6 MSG-36HR

SUMMER

Indoor

WINTER

Indoor

Conditions

15ºC

18ºC

20ºC

22ºC

Input kW. 3.75 3.96

Input kW. 3.90 4.11 4.28 4.63 5.14 5.31

OUTDOOR TEMPERATURE DRY

25ºC 30ºC 35ºC 40ºC 45ºC 50ºC

Input kW. 3.52 3.72 3.87 4.18 4.65 4.80

Input kW. 3.64 3.84 4.00 4.32 4.80 4.96

Input kW. 3.75 3.96

Input kW. 3.90 4.11 4.28 4.63 5.14 5.31

OUTDOOR CONDITIONS

Capacity kW

Input kW.

Capacity kW

Input kW.

Capacity kW

Input kW.

Capacity kW

Input kW.

12ºC D

11ºC W

13.14 11.53 10.56 9.27 7.98 7.01

4.42 4.02 3.74 3.46 3.02 2.73

12.90 11.32 10.30 8.94 7.58 6.56

4.53 4.08 3.80 3.55 3.10 2.78

12.79

4.66

12.67 11.02 10.03 8.59 7.05 5.84

4.83 4.16 3.97 3.77 3.40 3.04

7ºC D

6ºC W

4.12

10.27

4.12

4ºC D

3ºC W

10.18 8.72 7.17 5.95

3.91 3.63 3.20 2.93

0ºC D

-1ºC W

-4ºC D

-6ºC W

- 33 -

Page 31

11. Model and Parameters

Service manual

Model

I3SEC [A]

I5MIN [A]

IFAN [A]

IDEFROST [A]

TE1 ['C]

TE2 ['C]

TE3 ['C]

TE4 ['C]

TE5 ['C]

TE6 ['C]

TE7 ['C]

TE8 ['C]

TE9 ['C]

TE10 ['C]

TE11 ['C]

TE14 ['C]

TE16 ['C]

3Ph 380~420V

Model

I3SEC [A]

I5MIN [A]

IFAN [A]

IDEFROST [A]

TE1 ['C]

TE2 ['C]

TE3 ['C]

TE4 ['C]

TE5 ['C]

TE6 ['C]

TE7 ['C]

TE8 ['C]

TE9 ['C]

TE10 ['C]

TE11 ['C]

TE14 ['C]

TE16 ['C]

MSG-24CR MSG-24HR MSG-30CR MSG-30HR MSG-36CR MSG-36HR

22 22 26 26 34 34

20 20 24 24 32 32

16 16 20 20 25 25

14 14 18 18 22 22

25 25 30

32 32 37

30 30 34

20 20 24

2 2 2 2 2 2

12 12 12 12 12 12

63 63 63

54 54 54

50 50 50

65 65 70

55 55 65

32 32 32

42 42 34

MSG-30CR MSG-30HR MSG-36CR MSG-36HR

26 26 34 34

24 24 32 32

20 20 25 25

18 18 22 22

25 30

32 37

30 34

20 24

2 2 2 2

12 12 12 12

63 63

54 54

50 50

65 70

55 65

32 32

42 34

- 42 -

Page 32

Service manual

12. Troubleshooting

12.1 Display board

§ Operation

The indicator flashes once every second after power is on and illuminates when the air conditioner is

in operation.

§ Timer indicator:

The indicator illuminates then TIMER is set ON.

§ PRE-DEF. indicator (For cooling & heating mode only)

The air conditioner starts defrosting automatically if outdoor unit frosts in heating operating.

At this time, PRE-DEF. indicator illuminates.

§ Auto indicator:

This indicator flashes when the air conditioner is in AUTO operation.

§ ECON indicator

This indicator illuminates while the air conditioner is in economic operation.

- 43 -

Page 33

lamp

lamp

Indoor fan speed has been out of control for over 1 minute

X

Indoor room temp. or evaporator sensor is open circuit or short circuit

On

Over current protection of the compressor occurs 4 times

X

EEROM error

On

No over-zero signal

Flash at 5Hz

lamp

lamp

lamp

Over current protection of the compressor occurs 4 times

X

Indoor fan speed has been out of control for over 1 minute

X

No over-zero signal

Temp. sensor on indoor evaporator is open circuit or short circuit

X

X

Indoor room temp. sensor is open circuit or short circuit

X

X

EEROM error

On

Xr Extinguish

Flash at 5Hz

12.2 Troubleshooting

For cooling mode:

Service manual

Failure phenomenon

r

Extinguish

For heat pump mode:

Failure phenomenon

Operation

Operation

Timer

Timer

Defrosting

- 44 -

Page 34

Service manual

12.3 Diagnostic chart

After energizing, no indicator is lighted and the air conditioner can’t be operated.

- 45 -

Page 35

Service manual

12.4 Resetting phenomenon often occurs during operation.

(That is automatically entering to the status when power is on.)

The reason is that the instantaneous voltage of main chip is less than 4.5V. Check according to the

following procedure:

Resetting phenomenon often occurs during operation.

Yes

After changing indoor PCB, check if the failure realease.

Yes

After changing indoor fan motor, check if the failure realease.

YES

Power supply circuit has problems.

Indoor PCB is defective.

12.5 Operation lamp flashes and Timer lamp off.

Yes

12.6 Operation lamp flashes and Timer lamp on.

- 46 -

Page 36

Service manual

12.7 Operation lamp off and Timer lamp flashes

12.8 Operation lamp on and Timer lamp flashes

EEROM error, indoor PCB is defective.

12.9 Operation lamp flashes, Timer lamp flashes .

This is alarm signal when the main chip can’t detect over-zero signal. When such failure occurs, the

main control board must have fault.

- 47 -

Loading...

Loading...