SM_AG(GA)_R32_INV_MY_NA_1912

XTREME INVERTER SERIES

SERVICE MANUAL

Table of Contents

§. Safety Precautions

1. Precautions

2. Information servicing(For flammable materials)

§. Specifications

1. Model Reference

2. Pipe length and the Drop Height

3. Electrical Wiring Diagrams

§. Product Features

1. Display Function

2. Safety Features

3. Basic Features

4. Optional Features

§. Maintenance

1. First Time Installation Check

2. Refrigerant Recharge

3. Re-Installation

§. Indoor Unit Disassembly

1. Dimension

2. Indoor Unit Disassembly

§. Outdoor Unit Disassembly

1. Outdoor Unit Table

2. Dimension

3. Outdoor Unit Disassembly

Table of Contents

§. Troubleshooting

1. Safety Caution

2. General Troubleshooting

3. Complain Record Form

4. Information Inquiry

5. Error Diagnosis and Troubleshooting Without Error Code

6. Quick Maintenance by Error Code

7. Troubleshooting by Error Code

8. Check Procedures

Appendix

i) Temperature Sensor Resistance Value Table for T1,T2,T3 and T4 (°C – K)

ii) Temperature Sensor Resistance Value Table for TP(for some units) (°C – K)

iii) Pressure On Service Port

Safety Precautions

Contents

1. Precautions .............................................................................................................2

2. Information servicing(For flammable materials) .................................................3

1. Precautions

To prevent personal injury, or property or unit damage,

adhere to all precautionary measures and instructions

outlined in this manual. Before servicing a unit, refer to this

service manual and its relevant sections.

Failure to adhere to all precautionary measures listed in this

section may result in personal injury, damage to the unit or

to property, or in extreme cases, death.

WARNING indicates a potentially hazardous

situation which if not avoided could result in serious

personal injury, or death.

CAUTION indicates a potentially hazardous situation

which if not avoided could result in minor or

moderate personal injury, or unit damage.

1.1 In case of Accidents or Emergency

WARNING

•• If a gas leak is suspected, immediately turn off the

gas and ventilate the area if a gas leak is suspected

before turning the unit on.

•• If strange sounds or smoke is detected from the unit,

turn the breaker off and disconnect the power supply

cable.

•• If the unit comes into contact with liquid, contact an

authorized service center.

•• If liquid from the batteries makes contact with skin or

clothing, immediately rinse or wash the area well with

clean water.

•• Do not insert hands or other objects into the air inlet

or outlet while the unit is plugged in.

•• Do not operate the unit with wet hands.

•• Do not use a remote controller that has previously

been exposed to battery damage or battery leakage.

CAUTION

•• Clean and ventilate the unit at regular intervals when

operating it near a stove or near similar devices.

•• Do not use the unit during severe weather conditions.

If possible, remove the product from the window

before such occurrences.

1.2 Pre-Installation and Installation

WARNING

•• Use this unit only on a dedicated circuit.

•• Damage to the installation area could cause the unit

to fall, potentially resulting in personal injury, property damage, or product failure.

•• Only qualified personnel should disassemble, install,

remove, or repair the unit.

•• Only a qualified electrician should perform electri-

cal work. For more information, contact your dealer,

seller, or an authorized service center.

CAUTION

•• While unpacking be careful of sharp edges around

the unit as well as the edges of the fins on the condenser and evaporator.

1.3 Operation and Maintenance

WARNING

•• Do not use defective or under-rated circuit breakers.

•• Ensure the unit is properly grounded and that a

dedicated circuit and breaker are installed.

•• Do not modify or extend the power cable. Ensure

the power cable is secure and not damaged during

operation.

•• Do not unplug the power supply plug during

operation.

•• Do not store or use flammable materials near the

unit.

•• Do not open the inlet grill of the unit during

operation.

•• Do not touch the electrostatic filter if the unit is

equipped with one.

•• Do not block the inlet or outlet of air flow to the unit.

•• Do not use harsh detergents, solvents, or similar items

to clean the unit. Use a soft cloth for cleaning.

•• Do not touch the metal parts of the unit when

removing the air filter as they are very sharp.

•• Do not step on or place anything on the unit or

outdoor units.

•• Do not drink water drained from the unit

•• Avoid direct skin contact with water drained from the

unit.

•• Use a firm stool or step ladder according to

manufacturer procedures when cleaning or

maintaining the unit.

CAUTION

•• Do not install or operate the unit for an extended

period of time in areas of high humidity or in an

environment directly exposing it to sea wind or salt

spray.

•• Do not install the unit on a defective or damaged

installation stand, or in an unsecure location.

•• Ensure the unit is installed at a level position

•• Do not install the unit where noise or air discharge

created by the outdoor unit will negatively impact the

environment or nearby residences.

•• Do not expose skin directly to the air discharged by

the unit for prolonged periods of time.

•• Ensure the unit operates in areas water or other

liquids.

•• Ensure the drain hose is installed correctly to ensure

proper water drainage.

•• When lifting or transporting the unit, it is

recommended that two or more people are used for

this task.

•• When the unit is not to be used for an extended time,

disconnect the power supply or turn off the breaker.

Safety Precautions 2

2. Information servicing(For

flammable materials)

2.1 Checks to the area

• Prior to beginning work on systems containing flammable

refrigerants, safety checks are necessary to ensure that the

risk of ignition is minimized.

• For repair to the refrigerating system, the following

precautions shall be complied with prior to conducting work

on the system.

2.2 Work procedure

• Work shall be undertaken under a controlled procedure so

as to minimise the risk of a flammable gas or vapour being

present while the work is being performed.

2.3 Work procedure

• All maintenance staff and others working in the local area

shall be instructed on the nature of work being carried out.

• Work in confined spaces shall be avoided.

• The area around the work space shall be sectioned off.

Ensure that the conditions within the area have been made

safe by control of flammable material.

2.4 Checking for presence of refrigerant

• The area shall be checked with an appropriate refrigerant

detector prior to and during work, to ensure the technician

is aware of potentially flammable atmospheres.

• Ensure that the leak detection equipment being used is

suitable for use with flammable refrigerants, i.e. no sparking,

adequately sealed or intrinsically safe.

2.5 Presence of fire extinguisher

• If any hot work is to be conducted on the refrigeration

equipment or any associated parts, appropriate fire

extinguishing equipment shall be available to hand.

• Have a dry powder or CO2 fire extinguisher adjacent to the

charging area.

• Prior to work taking place, the area around the equipment

is to be surveyed to make sure that there are no flammable

hazards or ignition risks.

• NO SMOKING signs shall be displayed.

2.7 Ventilated area

• Ensure that the area is in the open or that it is adequately

ventilated before breaking into the system or conducting any

hot work. A degree of ventilation shall continue during the

period that the work is carried out. The ventilation should

safely disperse any released refrigerant and preferably expel

it externally into the atmosphere.

2.8 Checks to the refrigeration equipment

• Where electrical components are being changed,

they shall be fit for the purpose and to the correct

specification. At all times the manufacturer’s

maintenance and service guidelines shall be followed.

If in doubt consult the manufacturer’s technical

department for assistance. The following checks

shall be applied to installations using flammable

refrigerants:

• the charge size is in accordance with the room size

within which the refrigerant containing parts are

installed;

• the ventilation machinery and outlets are operating

adequately and are not obstructed;

• if an indirect refrigerating circuit is being used, the

secondary circuit shall be checked for the presence

of refrigerant; marking to the equipment continues

to be visible and legible.

• markings and signs that are illegible shall be

corrected;

• refrigeration pipe or components are installed in

a position where they are unlikely to be exposed

to any substance which may corrode refrigerant

containing components, unless the components

are constructed of materials which are inherently

resistant to being corroded or are suitably protected

against being so corroded.

2.6 No ignition sources

• No person carrying out work in relation to a refrigeration

system which involves exposing any pipe work that contains

or has contained flammable refrigerant shall use any sources

of ignition in such a manner that it may lead to the risk of

fire or explosion.

• All possible ignition sources, including cigarette smoking,

should be kept sufficiently far away from the site of

installation, repairing, removing and disposal, during which

flammable refrigerant can possibly be released to the

surrounding space.

Safety Precautions 3

2.9 Checks to electrical devices

• Repair and maintenance to electrical components shall

include initial safety checks and component inspection

procedures. If a fault exists that could compromise

safety, then no electrical supply shall be connected to

the circuit until it is satisfactorily dealt with. If the fault

cannot be corrected immediately but it is necessary to

continue operation, an adequate temporary solution

shall be used. This shall be reported to the owner of

the equipment so all parties are advised. Initial safety

checks shall include:

• that capacitors are discharged: this shall be done in

a safe manner to avoid possibility of sparking;

• that there no live electrical components and wiring

are exposed while charging, recovering or purging

the system;

• that there is continuity of earth bonding.

2.10 Repairs to sealed components

• During repairs to sealed components, all electrical

supplies shall be disconnected from the equipment

being worked upon prior to any removal of sealed

covers, etc. If it is absolutely necessary to have an

electrical supply to equipment during servicing, then

a permanently operating form of leak detection shall

be located at the most critical point to warn of a

potentially hazardous situation.

• Particular attention shall be paid to the following to

ensure that by working on electrical components, the

casing is not altered in such a way that the level of

protection is affected. This shall include damage to

cables, excessive number of connections, terminals

not made to original specification, damage to seals,

incorrect fitting of glands, etc.

• Ensure that apparatus is mounted securely.

• Ensure that seals or sealing materials have not

degraded such that they no longer serve the

purpose of preventing the ingress of flammable

atmospheres. Replacement parts shall be in

accordance with the manufacturer’s specifications.

NOTE: The use of silicon sealant may inhibit the

effectiveness of some types of leak detection equipment.

Intrinsically safe components do not have to be isolated

prior to working on them.

2.11 Repair to intrinsically safe components

• Do not apply any permanent inductive or capacitance

loads to the circuit without ensuring that this will not

exceed the permissible voltage and current permitted

for the equipment in use. Intrinsically safe components

are the only types that can be worked on while live

in the presence of a flammable atmosphere. The test

apparatus shall be at the correct rating.

• Replace components only with parts specified by the

manufacturer. Other parts may result in the ignition of

refrigerant in the atmosphere from a leak.

2.12 Cabling

• Check that cabling will not be subject to wear,

corrosion, excessive pressure, vibration, sharp edges

or any other adverse environmental effects. The check

shall also take into account the effects of aging or

continual vibration from sources such as compressors

or fans.

2.13 Detection of flammable refrigerants

• Under no circumstances shall potential sources of

ignition be used in the searching for or detection of

refrigerant leaks. A halide torch (or any other detector

using a naked flame) shall not be used.

2.14 Leak detection methods

• The following leak detection methods are deemed

acceptable for systems containing flammable

refrigerants. Electronic leak detectors shall be used

to detect flammable refrigerants, but the sensitivity

may not be adequate, or may need re-calibration.

(Detection equipment shall be calibrated in a

refrigerant-free area.) Ensure that the detector is not

a potential source of ignition and is suitable for the

refrigerant used. Leak detection equipment shall be

set at a percentage of the LFL of the refrigerant and

shall be calibrated to the refrigerant employed and

the appropriate percentage of gas (25 % maximum)

is confirmed. Leak detection fluids are suitable for

use with most refrigerants but the use of detergents

containing chlorine shall be avoided as the chlorine

may react with the refrigerant and corrode the copper

pipe-work.

• If a leak is suspected, all naked flames shall be

removed or extinguished.

• If a leakage of refrigerant is found which requires

brazing, all of the refrigerant shall be recovered

from the system, or isolated (by means of shut off

valves) in a part of the systemremote from the leak.

Oxygen free nitrogen (OFN) shall then be purged

through the system both before and during the

brazing process.

2.15 Removal and evacuation

• When breaking into the refrigerant circuit to make

repairs or for any other purpose, conventional

procedures shall be used. However, it is important

that best practice is followed since flammability is a

consideration.

• The following procedure shall be adhered to:

• remove refrigerant;

• purge the circuit with inert gas;

• evacuate;

• purge again with inert gas;

• open the circuit by cutting or brazing.

Safety Precautions 4

• The refrigerant charge shall be recovered into the

correct recovery cylinders. The system shall be flushed

with OFN to render the unit safe. This process may

need to be repeated several times. Compressed air or

oxygen shall not be used for this task. Flushing shall

be achieved by breaking the vacuum in the system

with OFN and continuing to fill until the working

pressure is achieved, then venting to atmosphere, and

finally pulling down to a vacuum. This process shall

be repeated until no refrigerant is within the system.

When the final OFN charge is used, the system shall

be vented down to atmospheric pressure to enable

work to take place. This operation is absolutely vital if

brazing operations on the pipe-work are to take place.

• Ensure that the outlet for the vacuum pump is not

close to any ignition sources and there is ventilation

available.

2.16 Charging procedures

• In addition to conventional charging procedures, the

following requirements shall be followed:

• Ensure that contamination of different refrigerants

does not occur when using charging equipment.

Hoses or lines shall be as short as possible to

minimize the amount of refrigerant contained in

them.

• Cylinders shall be kept upright.

• Ensure that the refrigeration system is earthed prior

to charging the system with refrigerant.

• Label the system when charging is complete (if not

already).

• Extreme care shall be taken not to overfill the

refrigeration system.

• Prior to recharging the system it shall be pressure

tested with OFN. The system shall be leak tested on

completion of charging but prior to commissioning.

A follow up leak test shall be carried out prior to

leaving the site.

2.17 Decommissioning

Before carrying out this procedure, it is essential that the

technician is completely familiar with the equipment and

all its detail. It is recommended good practice that all

refrigerants are recovered safely. Prior to the task being

carried out, an oil and refrigerant sample shall be taken.

In case analysis is required prior to re-use of reclaimed

refrigerant. It is essential that electrical power is available

before the task is commenced.

• Become familiar with the equipment and its operation.

• Isolate system electrically.

• Before attempting the procedure ensure that:

• mechanical handling equipment is available, if

required, for handling refrigerant cylinders;

• all personal protective equipment is available and

being used correctly;

• the recovery process is supervised at all times by a

competent person;

• recovery equipment and cylinders conform to the

appropriate standards.

• Pump down refrigerant system, if possible.

• If a vacuum is not possible, make a manifold so that

refrigerant can be removed from various parts of the

system.

• Make sure that cylinder is situated on the scales before

recovery takes place.

• Start the recovery machine and operate in accordance

with manufacturer’s instructions.

• Do not overfill cylinders. (No more than 80 % volume

liquid charge).

• Do not exceed the maximum working pressure of the

cylinder, even temporarily.

• When the cylinders have been filled correctly and the

process completed, make sure that the cylinders and

the equipment are removed from site promptly and all

isolation valves on the equipment are closed off.

• Recovered refrigerant shall not be charged into

another refrigeration system unless it has been cleaned

and checked.

2.18 Labelling

• Equipment shall be labelled stating that it has been decommissioned and emptied of

• refrigerant. The label shall be dated and signed. Ensure

that there are labels on the equipment stating the

equipment contains flammable refrigerant.

2.19 Recovery

• When removing refrigerant from a system, either for

servicing or decommissioning, it is recommended good

practice that all refrigerants are removed safely.

• When transferring refrigerant into cylinders, ensure

that only appropriate refrigerant recovery cylinders

are employed. Ensure that the correct numbers of

cylinders for holding the total system charge are

available. All cylinders to be used are designated

for the recovered refrigerant and labelled for that

refrigerant (i.e. special cylinders for the recovery of

refrigerant). Cylinders shall be complete with pressure

relief valve and associated shut-off valves in good

working order.

Safety Precautions 5

• Empty recovery cylinders are evacuated and, if

possible, cooled before recovery occurs.

• The recovery equipment shall be in good working

order with a set of instructions concerning the

equipment that is at hand and shall be suitable for the

recovery of flammable refrigerants. In addition, a set

of calibrated weighing scales shall be available and in

good working order.

• Hoses shall be complete with leak-free disconnect

couplings and in good condition. Before using the

recovery machine, check that it is in satisfactory

working order, has been properly maintained and that

any associated electrical components are sealed to

prevent ignition in the event of a refrigerant release.

Consult manufacturer if in doubt.

• The recovered refrigerant shall be returned to the

refrigerant supplier in the correct recovery cylinder,

and the relevant Waste Transfer Note arranged. Do not

mix refrigerants in recovery units and especially not in

cylinders.

• If compressors or compressor oils are to be removed,

ensure that they have been evacuated to an

acceptable level to make certain that flammable

refrigerant does not remain within the lubricant.

The evacuation process shall be carried out prior to

returning the compressor to the suppliers. Only electric

heating to the compressor body shall be employed

to accelerate this process. When oil is drained from a

system, it shall be carried out safely.

Safety Precautions 6

Specifications

Contents

1. Model Reference ....................................................................................................2

2. Pipe Length and Drop Height ...............................................................................3

3. Electrical Wiring Diagrams ....................................................................................4

1. Model Reference

Refer to the following table to determine the specific indoor and outdoor unit model.

Indoor Unit Model Outdoor Unit Model Capacity (Btu/h) Power Supply

MSAGB-09CRDN8-QD6GA MOX130-09CDN8-QD6GA 9k

MSAGB-12CRDN8-QD6GA MOX130-12CDN8-QD6GA 12k

MSAGC-18CRDN8-QD0GA MOX230-18CDN8-QD0GA 18k

220~240V~, 50Hz,

1Phase

Specifications 2

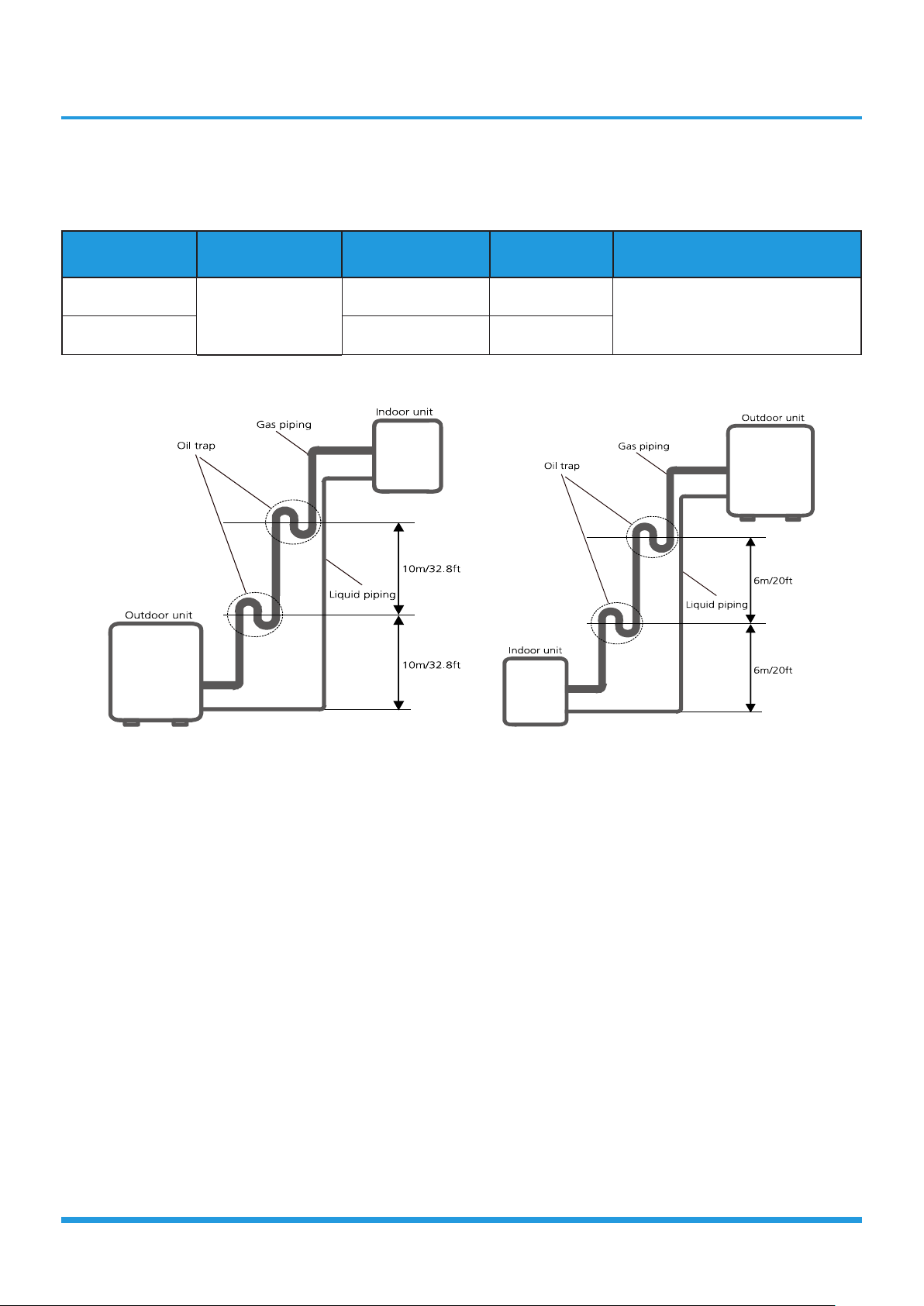

2. Pipe Length and Drop Height

The length and elevation of connection pipe are shown in the table below. if the pipe length exceeds max pipe length,

additional refrigerant should be charged to ensure nominal cooling/heating capacity.

Capacity(Btu/h) Standard Length Max Pipe Length Max Elevation Additional Refrigerant

9k/12k

5m (16.4ft)

18k 30m(98.4ft) 20m(65.6ft)

If oil flows back into the outdoor unit’s compressor, this might cause liquid compression or deterioration of oil return. Oil

traps in the rising gas pipe can prevent this.

25m (82.0ft) 10m (32.8ft)

12g/m (0.13oz/ft)

1. Indoor unit is installed higher than outdoor unit 2. Outdoor unit is installed higher than indoor unit

If indoor unit is installed higher than outdoor unit, oil trap should be set every 10m(32.8ft) of vertical distance.

If the outdoor unit is installed higher than the indoor unit, proper oil should return to the compressor along with the

suction of refrigerant to keep lubrication of compressor. If the suction flow velocity drops below 7.62m/s(1500fpm (feet

per minute)), oil won’t return to the compressor. An oil trap should be installed every 6m(20ft) of vertical distance.

Specifications 3

3. Electrical Wiring Diagrams

Indoor and outdoor unit wiring diagram

Indoor Unit Outdoor Unit

IDU Model IDU Wiring Diagram ODU Model ODU Wiring Diagram

MSAGB-09CRDN8-QD6GA

MSAGB-12CRDN8-QD6GA MOX130-12CDN8-QD6GA

MSAGC-18CRDN8-QD0GA MOX230-18CDN8-QD0GA

Outdoor unit printed circuit board diagram

MOX130-09CDN8-QD6GA

MOX130-12CDN8-QD6GA

MOX230-18CDN8-QD0GA

16022000024294

Outdoor Unit

ODU Model ODU Printed Circuit Board

MOX130-09CDN8-QD6GA

17122000048121

17122000048064

16022000019573

16022000019583

Specifications 4

Indoor unit abbreviations

Abbreviation Paraphrase

Outdoor unit abbreviations

Abbreviation Paraphrase

Y/G Yellow-Green Conductor

ION Positive and Negative Ion Generator

CAP Capacitor

PLASMA Electronic Dust Collector

L LIVE

N NEUTRAL

4-WAY Gas Valve Assembly/4-WAY VALVE

AC-FAN Alternating Current FAN

DC-FAN Direct Current FAN

COMP Compressor

L-PRO Low Pressure Switch

H-PRO High Pressure Switch

Specifications 5

Indoor unit wiring diagram: 16022000024294

INDOOR WIRING DIAGRAM

HEATER

L

N

1(L)

2(N)

S

- - - - This symbol indicates the

element is optional,the actual

shape shall prevail.

OPTIONAL

Y/G

ION

P1

P2

X Y E 12V/5V

To CCM Comm.Bus or

485 Wire-controller

OPTIONAL

Applicable to

AC motor only

HA HB

To Randomly

Connected

Wire-controller

3

To Remote Alarm

M

5(3or2)

CAP

4

To Remote Switch

M

M

2

SWITCH BOARD

2

CN701

OPTIONAL

3

OPTIONAL

OPTIONAL

OPTIONAL

16022000024294

Outdoor unit printed circuit board diagram: 17122000044714, 17122000048121

PMV

AC-FAN

4-WAY

HEAT1

H

N

L

DC-FAN

RED

BLUE

W

BLACK

V

U

Earth

HEAT2

KFR-35W/BP2N-(R X24T+TNY288+41560 B2+4134).D.13.WP2-1

L-IN

N-IN

[1.7] 2018-10-26

17122000044714

TP

T4

T3

Test

S

N-IN

L-IN

Earth

S

R606

R316

R611

R610

R607

E2

E1

R1

CN3_1

CN3

CN3_2

CN16

Q101

+

D2

C6

C7

CN60

IC1

IC2

R2

R21

R23

R128

R129

R132

R133

RY2

R195

CN25

RY3

RY4

RY5

RC1

R131

~ ~

IN

OUT

AC

-

+

C25

R18

CN17

R130

D1

+

L4

E409

R53

CN6

+

DZ601

R12

D3

CN11

CN10

IC101

+

DZ204

E283

C24

R14

IC5

R96

R71

R32

R31

R29

R28

R27

R19

IC8

IC6

IC4

E19

E8

E6

D10

D6

D5

D4

CY6

C31

C29

C28

C27

C26

IC103

C115

C103

1

3

X1

IC602

IC601

R619

L1

R514

R513

R512

R505

R502

R501

R17

R13

R10

IPM501

E282

E281

E280

CN31

CN7

C518

C516

C507

C276

C275

C274

C273

C271

C117

C23

C22

C21

C20

C19

C15

C13

C12

IPM301

C18

C8

C9

R11

D601

DZ301

R191

C105

R621

R617

R616

R196

R187

R186

R185

R182

R181

R180

R175

R155

R154

R152

R150

R149

R148

R147

R125

R121

R120

R115

R114

R110

R105

R104

R103

R102

C612

C133

C129

C128

C124

C123

C121

C120

C118

C116

C111

C101

IC105

Q601

C303

R695

C309

R603

CN50

C5

CN1A

R26

R24

R22

CN15

C134

R15

R16

R630

R627

R200

D605

C617

R9

R8

R7

R5

R3

CN21/CN22

ZR4

R626

R612

R608

R605

R604

R602

R601

R323

R315

R301

R190

R189

R188

R179

R178

R176

R172

R171

R170

R169

R168

R165

R156

R143

R142

R140

R138

R137

R136

R127

R112

R111

R108

R107

R106

PTC1

LED101

L3

L2

DAS1

D610

D602

D406

D103

D101

CN29

CN28

CN2

C695

C624

C618

C613

C606

C605

C322

C318

C316

C314

C312

C311

C310

C308

C307

C306

C305

C135

C132

C131

C130

C127

C126

C125

C119

C114

C113

C112

C107

C106

C104

C102

C11

C3

C2

L601

RY1

E102

C601

R623

C17

ZR2

CN1

R135

R20

CN30

R4

R6

R25

R118

E4

C4

FUSE1

T20A/250VAC

BR1

C1

ZR1

E332

E331

E330

R173

C10

R622

C16

C700

R330

R333

R335 R336

R117

R116

C272

R30

R33

C405

T1

R36

IC104

D401

C30

Rdi

R34

R618

R615

IC3

C32

C330

C331

C332

C319

R322

R321

R320

R319

R318

R317

C321

C320

IC603

C614

C611

C35

C36

R37

R38

R39

R40

R41

R42

R43

R44

R45

R46

R47

R48

R49 R50

R51

R52

CN4

CN5

E5

D104

C14

1

2

3

8

9

15

6

1414

13

4

5

10

7

11

12

No. Name CN# Meaning

CN3 Earth: connect to Ground

CN1 N_in: connect to N-line (208-230V AC input)

1 CN1A

CN2 L_in: connect to L-line (208-230V AC input)

CN16 S: connect to indoor unit communication

2 HEAT1 CN17 connect to compressor heater, 208-230V AC when is ON

3 4-WAY CN60 connect to 4 way valve, 208-230V AC when is ON.

4 HEAT2 CN15 connect to chassis heater, 208-230V AC when is ON

5 AC-FAN CN25 connect to AC fan

6 PMV CN31 connect to Electric Expansion Valve

7 TESTPORT CN6 used for testing

8 TP T4 T3 CN21/CN22

9 DC-FAN CN7 connect to DC fan

10 FAN_IPM IPM 501 IPM for DC fan

W CN28 connect to compressor

11

12 COMP_IPM IPM 301 IPM for compressor

Note: This section is for reference only. Please take practicality as standard.

V CN29 0V AC (standby)

U CN30 10-200V AC (running)

connect to pipe temp. sensor T3, ambient temp. sensor T4, exhaust

temp. sensor TP

Outdoor unit printed circuit board diagram: 17122000048064

No. Name CN# Meaning

CN6 Earth: connect to Ground

1 Power Supply

2 S CN2 S: connect to indoor unit communication

3 4-WAY CN60 connect to 4 way valve, 208-230V AC when is ON.

4 AC-FAN CN5 connect to AC fan

5 HEAT2 CN19 connect to chassis heater, 208-230V AC when is ON

6 TP T4 T3 CN17

7 PMV CN18 connect to Electric Expansion Valve

8 HEAT1 CN16 connect to compressor heater, 208-230V AC when is ON

9 DC-FAN CN414 connect to DC fan

10 TESTPORT CN23 used for testing

11 FAN_IPM IPM501 IPM for DC fan

CN7 N_in: connect to N-line (208-230V AC input)

CN8 L_in: connect to L-line (208-230V AC input)

connect to pipe temp. sensor T3, ambient temp. sensor T4, exhaust

temp. sensor TP

12 COMP_IPM IPM1 IPM for compressor

U CN27 connect to compressor

13

14 EE_PORT CN505 EEPROM programer port

Note: This section is for reference only. Please take practicality as standard.

V CN28 0V AC (standby)

W CN29 200-300V AC (running)

Product Features

Contents

1. Display Function ....................................................................................................2

2 Safety Features ......................................................................................................3

3. Basic Functions .......................................................................................................4

3.1 Abbreviation ..................................................................................................4

3.2 Fan Mode ......................................................................................................4

3.3 Cooling Mode ...............................................................................................4

3.4 Heating Mode(Heat Pump Units) ...................................................................5

3.5 Auto-mode ....................................................................................................6

3.6 Drying Mode .................................................................................................7

3.7 Forced Operation Function ............................................................................7

3.8 Timer Function ..............................................................................................7

3.9 Sleep Function ...............................................................................................7

3.10 Auto-Restart Function ....................................................................................8

3.11 Active Clean function ....................................................................................8

3.12 Follow me(Optional) ......................................................................................8

3.13 8°C Heating(Optional) ...................................................................................8

3.14 Silence (Optional) ..........................................................................................8

3.15 ECO function(Optional) .................................................................................8

3.16 Electrical energy consumption control function(Optional) ...............................8

3.17 Breeze away function(Optional) .....................................................................8

3.18 Wireless control(optional) ..............................................................................9

1. Display Function

Unit display functions

fresh defrost run timer

Display A Display B

Display Function

fresh Fresh(available on select units only)

defrost Defrost

run When the unit is on

timer When TIMER is on

Product Features

Temperature value Temperature

(3s)

(3s)

Note: Please select the display function according to your purchase product.

WiFi control (available on select units only)

Activation of Timer ON, Fresh, Swing, Turbo, or Silent

Cancellation of Timer OFF, Fresh, Swing, Turbo, or Silent

Defrost

Active Clean(For Inverter split type) or self-cleaning(For

Fixed-speed type)

Heating in room temperature under 8°C

Product Features 2

2. Safety Features

Compressor three-minute delay at restart

Compressor functions are delayed for up to ten seconds upon the fi rst startup of the unit, and are delayed for up

to three minutes upon subsequent unit restarts.

Automatic shutoff based on discharge temperature

If the compressor discharge temperature exceeds a certain level for a period of time, the compressor ceases operation.

Automatic shutoff based on fan speed

If the indoor fan speed registers below 200RPM or over 2100RPM for an extended period of time, the unit ceases

operation and the corresponding error code is displayed on the indoor unit.

Inverter module protection

The inverter module has an automatic shutoff mechanism based on the unit’s current, voltage, and temperature. If

automatic shutoff is initiated, the corresponding error code is displayed on the indoor unit and the unit ceases operation.

Indoor fan delayed operation

• When the unit starts, the louver is automatically activated and the indoor fan will operate after a period of setting

time or the louver is in place.

• If the unit is in heating mode, the indoor fan is regulated by the anti-cold wind function.

Compressor preheating

Preheating is automatically activated when T4 sensor is lower than setting temperature.

Sensor redundancy and automatic shutoff

• If one temperature sensor malfunctions, the air conditioner continues operation and displays the corresponding error

code, allowing for emergency use.

• When more than one temperature sensor is malfunctioning, the air conditioner ceases operation.

Product Features 3

3. Basic Functions

3.1 Abbreviation

Unit element abbreviations

Abbreviation Element

T1 Indoor room temperature

T2 Coil temperature of evaporator

T3 Coil temperature of condenser

T4 Outdoor ambient temperature

Tsc Adjusted setting temperature

TP Compressor discharge temperature

3.2 Fan Mode

When fan mode is activated:

• The outdoor fan and compressor cease operation.

• Temperature control is disabled and indoor room

temperature is displayed.

• The indoor fan speed can be set to 1%~100%, or

auto.

• The louver operations are identical to those in cooling

mode.

• Auto fan: In fan-only mode, AC operates the same as

auto fan in cooling mode with the temperature set at

24°C.(Tsc =24°C)

3.3 Cooling Mode

3.3.1 Compressor Control

Reach the configured temperature:

1) When the compressor runs continuously for within 120

minutes.

• If the following conditions are satisfied, the

compressor ceases operation.

• Calculated frequency(fb) is less than minimum limit

frequency(FminC).

• Compressor runs at FminC more than 10 minutes

• T1 is lower than or equal to (Tsc-CDIFTEMP-0.5°C)

Note: CDIFTEMP is EEPROM setting parameter. It is 2°C

usually.

2) When the compressor runs continuously for more than

120 minutes.

frequency(FminC).

• Compressor runs at FminC more than 10 minutes.

• T1 is lower than or equal to (Tsc-CDIFTEMP).

Note: CDIFTEMP is EEPROM setting parameter. It is 2°C

usually.

3) If one of the following conditions is satisfied, not judge

protective time.

• Compressor running frequency(fr) is more than test

frequency(TestFre).

• Compressor running frequency is equal to test

frequency, T4 is more than 15°C or T4 fault.

• Change setting temperature.

• Turbo or sleep function on/off

• Various frequency limit shutdown occurs.

3.3.2 Indoor Fan Control

1) In cooling mode, the indoor fan operates continuously.

The fan speed can be set to 1%-100%, or auto.

2) Auto fan

For DC fan motor units:

• Descent curve

• When T1-Tsc is lower than or equal to 3.5°C, fan

speed reduces to 80%;

• When T1-Tsc is lower than or equal to 1°C, fan

speed reduces to 60%;

• When T1-Tsc is lower than or equal to 0.5°C, fan

speed reduces to 40%;

• When T1-Tsc is lower than or equal to 0°C, fan

speed reduces to 20%;

• When T1-Tsc is lower than or equal to -0.5°C, fan

speed reduces to 1%.

• Rise curve

• When T1-Tsc is higher than 0°C, fan speed

increases to 20%;

• When T1-Tsc is higher than 0.5°C, fan speed

increases to 40%;

• When T1-Tsc is higher than 1°C, fan speed

increases to 60%;

• When T1-Tsc is higher than 1.5°C, fan speed

increases to 80%;

• When T1-Tsc is higher than 4°C, fan speed

increases to 100%.

• If the following conditions are satisfied, the

compressor ceases operation.

• Calculated frequency(fb) is less than minimum limit

Product Features 4

For AC fan motor units:

3.3.3 Outdoor Fan Control

• The outdoor unit will be run at different fan speed

according to T4 and compressor running frequency..

• For different outdoor units, the fan speeds are

different.

3.3.4 Condenser Temperature Protection

level per 1 minute.

• Hold: Keep the current frequency.

• Resume: No limitation for frequency.

3.4 Heating Mode(Heat Pump Units)

3.4.1 Compressor Control

1) Reach the configured temperature

• If the following conditions are satisfied, the

compressor ceases operation.

• Calculated frequency(fb) is less than minimum limit

frequency(FminH).

• Compressor runs at FminH more than 10 minutes.

• T1 is higher than or equal to Tsc+ HDIFTEMP2.

Note: HDIFTEMP2 is EEPROM setting parameter. It is 2°C

usually.

• If one of the following conditions is satisfied, not

judge protective time.

• Compressor running frequency(fr) is more than test

frequency(TestFre).

• When compressor running frequency is equal to

test frequency, T4 is more than 15°C or T4 fault.

• Change setting temperature.

• Turbo or sleep function on/off.

2) When the current is higher than the predefined safe

value, surge protection is activated, causing the

compressor to cease operations.

When the condenser temperature exceeds a configured

value, the compressor ceases operation.

3.3.5 Evaporator Temperature Protection

• Off: Compressor stops.

• Decrease: Decrease the running frequency to the lower

3.4.2 Indoor Fan Control:

1) In heating mode, the indoor fan operates continuously.

The fan speed can be set to 1%-100%, or mute.And

the anti-cold wind function has the priority.

• Anti-cold air function

• The indoor fan is controlled by the indoor

temperature T1 and indoor unit coil temperature

T2.

T1 ≥ 19°C(66.2°F) ΔTE1=0

15°C(59°F) ≤ T1 < 19°C(66.2°F)

T1<15°C(59°F) ΔTE1=4°C(7.2°F)

ΔTE1=19°C-T1

(34.2°F-T1)

Product Features 5

2) Auto fan

For DC fan motor units:

• Rise curve

• When T1-Tsc is higher than -1.5°C, fan speed

reduces to 80%;

• When T1-Tsc is higher than 0°C, fan speed reduces

to 60%;

• When T1-Tsc is higher than 0.5°C, fan speed

reduces to 40%;

• When T1-Tsc is higher than 1°C, fan speed reduces

to 20%.

• Descent curve

• When T1-Tsc is lower than or equal to 0.5°C, fan

speed increases to 40%;

• When T1-Tsc is lower than or equal to 0°C, fan

speed increases to 60%;

• When T1-Tsc is lower than or equal to -1.5°C, fan

speed increases to 80%;

• When T1-Tsc is lower than or equal to -3°C, fan

speed increases to 100%.

For AC fan motor units:

heating mode:

• T3 rises above TCDE1°C.

• T3 maintained above TCDE2°C for 80 seconds.

• Unit runs for 15 minutes consecutively in defrosting

mode.

• If T4 is lower than or equal to -22°C and compressor

running time is more than TIMING_DEFROST_TIME,

if any one of the following conditions is satisfied,

defrosting ends and the machine switches to normal

heating mode:

• Unit runs for 10 minutes consecutively in defrosting

mode.

• T3 rises above 10°C.

For some models:

• If T3 is lower than 3°C and compressor running time

is more than 120 minutes, at this time, if T3 is lower

than TCDI1+4°C(39.2°F) for 3 minutes, the unit

enters defrosting mode. If any one of the following

conditions is satisfied, defrosting ends and the

machine switches to normal heating mode:

• T3 rises above TCDE1+4°C.

• T3 maintained above TCDE2+4°C for 80 seconds.

• Unit runs for 15 minutes consecutively in defrosting

mode.

3.4.3 Outdoor Fan Control:

• The outdoor unit will be run at different fan speed

according to T4 and compressor running frequency.

• For different outdoor units, the fan speeds are

different.

3.4.4 Defrosting mode

• The unit enters defrosting mode according to changes

in the temperature value of T3, T4 as well as the

compressor running time.

• In defrosting mode, the compressor continues to run,

the indoor and outdoor motor will cease operation,

the defrost light of the indoor unit will turn on, and

the “ ” symbol is displayed.

• If any one of the following conditions is satisfied,

defrosting ends and the machine switches to normal

3.4.5 Evaporator Temperature Protection

• Off: Compressor stops.

• Decrease: Decrease the running frequency to the lower

level per 20 seconds.

• Hold: Keep the current frequency.

• Resume: No limitation for frequency.

3.5 Auto-mode

• This mode can be selected with the remote controller

and the setting temperature can be changed between

16°C~30°C.

• In auto mode, the machine selects cooling, heating,

Product Features 6

auto-drying or fan-only mode on the basis of T1,Ts, T4

and relative humidity.

• mode

• fan speed

• setting temperature

• Forced defrosting mode:

• Press AUTO/COOL button continuously for 5s

under forced cooling mode to enter this mode.

• Indoor fan will stop, defrosting lamp will light on.

• Quit this mode and turn off the unit when:

• quit normal defrosting

• turn off by RC

• Press AUTO/COOL button continuously for 5s

again

• If the setting temperature is modified, the machine

selects a new running function.

3.6 Drying mode

• In drying mode, AC operates the same as auto fan in

cooling mode.

• All protections are activated and operate the same as

they do that in cooling mode.

• Low Room Temperature Protection

If the room temperature is lower than 10°C, the

compressor ceases operations and does not resume until

room temperature exceeds 12°C.

3.7 Forced operation function

• Forced cooling mode:

The compressor and outdoor fan continue to run(fixed at

rated frequency), and the indoor fan runs at rated speed.

After running for 30 minutes, the AC will switch to auto

mode with a preset temperature of 24°C.

• Forced auto mode:

Forced auto mode operates the same as normal auto mode

with a preset temperature of 24°C.

• The unit exits forced operation when it receives the

following signals:

• Switch on

• Switch off

• Timer on

• Timer off

• Sleep mode

• Follow me

• Changes in:

3.8 Timer function

• Timing range is 24 hours.

• Timer on. The machine will turn on automatically

when reaching the setting time.

• Timer off. The machine will turn off automatically

when reaching the setting time.

• Timer on/off. The machine will turn on automatically

when reaching the setting “on” time, and then turn

off automatically when reaching the setting “off”

time.

• Timer off/on. The machine will turn off automatically

when reaching the setting “off” time, and then turn

on automatically when reaching the setting “on” time.

• The timer function will not change the AC current

operation mode. Suppose AC is off now, it will not

start up firstly after setting the “timer off” function.

And when reaching the setting time, the timer LED

will be off and the AC running mode has not been

changed.

• The setting time is relative time.

• The AC will quit the timer function when it has

malfunction

3.9 Sleep function

• The sleep function is available in cooling, heating, or

auto mode.

• The operational process for sleep mode is as follows:

• When cooling, the temperature rises 1°C (to not

higher than 30°C) every hour. After 2 hours, the

temperature stops rising and the indoor fan is fixed

at low speed.

• When heating, the temperature decreases 1°C(to

not lower than 16°C) every hour. After 2 hours, the

temperature stops decreasing and the indoor fan is

fixed at low speed. Anti-cold wind function takes

Product Features 7

priority.

• The operating time for sleep mode is 8 hours, after

which, the unit exits this mode.

• The timer setting is available in this mode.

3.10 Auto-Restart function

3.14 Silence (Optional)

Press “Silence” on the remote control to enable the

SILENCE function. While this function is active, the indoor

unit will run at faint breeze(1% fan speed), which reduces

noise to the lowest possible level.

• The indoor unit has an auto-restart module that

allows the unit to restart automatically. The module

automatically stores the current settings and, in the

case of a sudden power failure, will restore those

setting automatically within 3 minutes after power

returns.

• If there is a power failure while the unit is running, the

compressor starts 3 minutes after the unit restarts. If

the unit was already off before the power failure, the

unit stands by.

3.11 Active Clean function

• The Active Clean Technology washes away dust,

mold, and grease that may cause odors when it

adheres to the heat exchanger by automatically

freezing and then rapidly thawing the frost. The

internal wind wheel then keeps operating to blow-dry

the evaporator, thus preventing the growth of mold

and keeping the inside clean.

• When this function is turned on, the indoor unit

display window appears “CL”, after 20 to 45 minutes,

the unit will turn off automatically and cancel Active

Clean function.

3.15 ECO function (Optional)

• Used to enter the energy efficient mode.

• Under cooling mode, press ECO button, the remote

controller will adjust the temperature automatically

to 24°C, fan speed of Auto to save energy (but only

if the set temperature is less than 24°C). If the set

temperature is more than 24°C and 30°C, press the

ECO button, the fan speed will change to Auto, the

set temperature will remain unchanged.

• When AC receives signals, such as switch off, Turbo

operation , Silence operation , Self clean operation

, Forced cooling operation, mode setting, Sleeping

mode, or adjusting the set temperature to less than

24°C,it will quit the ECO operation.

• Operation time in ECO mode is 8 hours. After 8 hours

the AC quits this mode.

• When there’s any one temperature sensor in

malfunction, the AC will quit ECO mode .

• Indoor fan will run at auto fan when enter into the

ECO mode .The setting temperature and setting fan

speed can be changed through remote controller

signal.

3.12 Follow me(Optional)

• If you press “Follow Me” on the remote, the indoor

unit will beep. This indicates the follow me function is

active.

• Once active, the remote control will send a signal

every 3 minutes, with no beeps. The unit automatically

sets the temperature according to the measurements

from the remote control.

• The unit will only change modes if the information

from the remote control makes it necessary, not from

the unit’s temperature setting.

• If the unit does not receive a signal for 7 minutes or

you press “Follow Me,” the function turns off. The

unit regulates temperature based on its own sensor

and settings.

3.13 8°C Heating(Optional)

In heating mode, the temperature can be set to as low

as 8°C, preventing the indoor area from freezing if

unoccupied during severe cold weather.

3.16 Electrical energy consumption control

function (Optional)

Press the “Gear” button on remote controller to enter the

energy efficient mode in a sequence of following:

Turn off the unit or activate ECO, sleep, Super cool,

8°C Heating, Silence or self clean function will quit this

function.

3.17 Breeze Away function (Optional)

• This feature avoids direct airflow blowing on the body

and makes you feel indulging in silky coolness.

• NOTE: This feature is available under cooling mode,

fan-only mode and drying mode.

Product Features 8

3.18 Wireless Control (Optional)

• Wireless control allows you to control your air

conditioner using your mobile phone and a Wireless

connection.

• For the USB device access, replacement, maintenance

operations must be carried out by professional staff.

Product Features 9

Maintenance

Contents

1. First Time Installation Check .................................................................................2

2 Refrigerant Recharge ............................................................................................4

3 Re-Installation .......................................................................................................5

3.1 Indoor Unit ....................................................................................................5

3.2 Outdoor Unit .................................................................................................7

1. First Time Installation Check

/TJUUX[TOZ

2OW[OJYOJK

-GYYOJK

:]U]G_\GR\K

:NXKK]G_\GR\K

5[ZJUUX[TOZ

)RUYK

)RUYK

3GTOLURJ\GR\K

36G

6XKYY[XK

MG[MK

.GTJRK2U

.GTJRK.O

)NGXMKNUYK

)NGXMKNUYK

<GI[[S

V[SV

<GI[[S

V[SV

)USVU[TJSKZKX

2U

.O

Air and moisture trapped in the refrigerant system affects

the performance of the air conditioner by:

• Increasing pressure in the system.

• Increasing the operating current.

• Decreasing the cooling or heating efficiency.

• Congesting the capillary tubing due to ice build-up in

the refrigerant circuit.

• Corroding the refrigerant system.

Air purging with vacuum pump

To prevent air and moisture from affecting the air

conditioner’s performance, the indoor unit, as well as the

pipes between the indoor and outdoor unit, must be be

leak tested and evacuated.

Leak test (soap water method)

Use a soft brush to apply soapy water or a neutral liquid

detergent onto the indoor unit connections and outdoor

unit connections. If there is gas leakage, bubbles will form

on the connection.

Maintenance 2

Procedure:

1. Tighten the flare nuts of the indoor and outdoor

units, and confirm that both the 2- and 3-way valves

are closed.

2. Connect the charge hose with the push pin of Handle

Lo to the gas service port of the 3-way valve.

3. Connect another charge hose to the vacuum pump.

4. Fully open the Handle Lo manifold valve.

5. Using the vacuum pump, evacuate the system for

30 minutes.

a. Check whether the compound meter indicates

-0.1 MPa (14.5 Psi).

• If the meter does not indicate -0.1 MPa

(14.5 Psi) after 30 minutes, continue

evacuating for an additional 20 minutes.

• If the pressure does not achieve -0.1 MPa

(14.5 Psi) after 50 minutes, check for leakage.

• If the pressure successfully reaches -0.1 MPa

(14.5 Psi), fully close the Handle Lo valve, then

cease vacuum pump operations.

b. Wait for 5 minutes then check whether the gauge

needle moves after turning off the vacuum pump.

If the gauge needle moves backward, check

wether there is gas leakage.

6. Loosen the flare nut of the 3-way valve for 6 or

7 seconds and then tighten the flare nut again.

a. Confirm the pressure display in the pressure

indicator is slightly higher than the atmospheric

pressure.

b. Remove the charge hose from the 3-way valve.

7. Fully open the 2- and 3-way valves and tighten the

cap of the 2- and 3-way valves.

Maintenance 3

2. Refrigerant Recharge

)NGXMOTM

I_ROTJKX

+RKIZXUTOIYIGRK

/TJUUX[TOZ

)NKIQ\GR\K

56+4

2OW[OJYOJK

-GYYOJK

2U

.O

)259+

5[ZJUUX[TOZ

:]U]G_\GR\K

5VKT

:NXKK]G_\GR\K

5VKT

mV

V

A

V

mA

OFF

A

V

A

COM

AmA

:KSVKXGZ[XK9KTYUX

Procedure:

1. Close both 2- and 3-way valves.

2. Slightly connect the Handle Lo charge hose to the

3-way service port.

3. Connect the charge hose to the valve at the bottom

of the cylinder.

4. If the refrigerant is R410A/R32, invert the cylinder to

ensure a complete liquid charge.

5. Open the valve at the bottom of the cylinder for 5

seconds to purge the air in the charge hose, then fully

tighten the charge hose with push pin Handle Lo to

the service port of 3-way valve..

6. Place the charging cylinder onto an electronic scale

and record the starting weight.

7. Fully open the Handle Lo manifold valve, 2- and

3-way valves.

8. Operate the air conditioner in cooling mode to charge

the system with liquid refrigerant.

9. When the electronic scale displays the correct

weight (refer to the gauge and the pressure of the

low side to confirm, the value of pressure refers to

chapter Appendix), turn off the air conditioner, then

disconnect the charge hose from the 3-way service

port immediately..

10. Mount the caps of service port and 2- and 3-way

valves.

11. Use a torque wrench to tighten the caps to a torque

of 18 N.m.

12. Check for gas leakage.

Maintenance 4

3. Re-Installation

/TJUUX[TOZ

2OW[OJYOJK

-GYYOJK

)RUYK

)RUYK

:]U]G_\GR\K

:NXKK]G_\GR\K

5[ZJUUX[TOZ

5VKT

)RUYK

2U

.O

3.1 Indoor Unit

Collecting the refrigerant into the outdoor unit

Procedure:

1. Confirm that the 2- and 3-way valves are opened.

2. Connect the charge hose with the push pin of Handle

Lo to the 3-way valve’s gas service port.

3. Open the Handle Lo manifold valve to purge air

from the charge hose for 5 seconds and then close it

quickly.

4. Close the 2-way valve.

5. Operate the air conditioner in cooling mode. Cease

operations when the gauge reaches 0.1 MPa (14.5

Psi).

6. Close the 3-way valve so that the gauge rests

between 0.3 MPa (43.5 Psi) and 0.5 MPa (72.5 Psi).

7. Disconnect the charge set and mount the caps of

service port and 2- and 3-way valves.

8. Use a torque wrench to tighten the caps to a torque

of 18 N.m.

9. Check for gas leakage.

Maintenance 5

Air purging with vacuum pump

<GI[[S

V[SV

/TJUUX[TOZ

)USVU[TJSKZKX

36G

.GTJRK2U

)NGXMKNUYK

2OW[OJYOJK

-GYYOJK

3GTOLURJ\GR\K

2U

.O

)NGXMKNUYK

6XKYY[XK

MG[MK

.GTJRK.O

5[ZJUUX[TOZ

:]U]G_\GR\K

)RUYK

:NXKK]G_\GR\K

)RUYK

<GI[[S

V[SV

Procedure:

1. Tighten the flare nuts of the indoor and outdoor

units, and confirm that both the 2- and 3-way valves

are closed.

2. Connect the charge hose with the push pin of Handle

Lo to the gas service port of the 3-way valve.

3. Connect another charge hose to the vacuum pump.

4. Fully open the Handle Lo manifold valve.

5. Using the vacuum pump, evacuate the system for 30

minutes.

a. Check whether the compound meter indicates

-0.1 MPa (14.5 Psi).

• If the meter does not indicate -0.1 MPa (14.5

Psi) after 30 minutes, continue evacuating for

an additional 20 minutes.

• If the pressure does not achieve -0.1 MPa (14.5

Psi) after 50 minutes, check for leakage.

• If the pressure successfully reaches -0.1 MPa

(14.5 Psi), fully close the Handle Lo valve, then

cease vacuum pump operations.

b. Wait for 5 minutes then check whether the gauge

needle moves after turning off the vacuum pump.

If the gauge needle moves backward, check

wether there is gas leakage.

6. Loosen the flare nut of the 3-way valve for 6 or 7

seconds and then tighten the flare nut again.

a. Confirm the pressure display in the pressure

indicator is slightly higher than the atmospheric

pressure.

b. Remove the charge hose from the 3-way valve.

7. Fully open the 2- and 3-way valves and tighten the

cap of the 2- and 3-way valves.

Maintenance 6

3.2 Outdoor Unit

/TJUUX[TOZ

2OW[OJYOJK

-GYYOJK

56+4

)259+

:]U]G_\GR\K

:NXKK]G_\GR\K

5[ZJUUX[TOZ

5VKT

5VKT

2U

.O

<GI[[SV[SV

Evacuation for the whole system

Procedure:

1. Confirm that the 2- and 3-way valves are opened.

2. Connect the vacuum pump to the 3-way valve’s

service port.

3. Evacuate the system for approximately one hour.

Confirm that the compound meter indicates

-0.1 MPa (14.5Psi).

4. Close the valve (Low side) on the charge set and turn

off the vacuum pump.

5. Wait for 5 minutes then check whether the gauge

needle moves after turning off the vacuum pump. If

the gauge needle moves backward, check whether

there is gas leakage.

6. Disconnect the charge hose from the vacuum pump.

7. Mount the caps of service port and 2- and 3-way

valves.

8. Use a torque wrench to tighten the caps to a torque

of 18 N.m.

Maintenance 7

Refrigerant charging

/TJUUX[TOZ

2OW[OJYOJK

-GYYOJK

)NKIQ\GR\K

)NGXMOTM

I_ROTJKX

56+4

2U

.O

)259+

+RKIZXUTOIYIGRK

Procedure:

1. Close both 2- and 3-way valves.

2. Slightly connect the Handle Lo charge hose to the

3-way service port.

3. Connect the charge hose to the valve at the bottom

of the cylinder.

4. If the refrigerant is R410A/R32, invert the cylinder to

ensure a complete liquid charge.

5. Open the valve at the bottom of the cylinder for 5

seconds to purge the air in the charge hose, then fully

tighten the charge hose with push pin Handle Lo to

the service port of 3-way valve..

6. Place the charging cylinder onto an electronic scale

and record the starting weight.

5[ZJUUX[TOZ

:]U]G_\GR\K

5VKT

:NXKK]G_\GR\K

5VKT

mV

V

A

V

mA

OFF

A

V

A

COM

AmA

:KSVKXGZ[XK9KTYUX

7. Fully open the Handle Lo manifold valve, 2- and

3-way valves.

8. Operate the air conditioner in cooling mode to charge

the system with liquid refrigerant.

9. When the electronic scale displays the correct

weight (refer to the gauge and the pressure of the

low side to confirm, the value of pressure refers to

chapter Appendix), turn off the air conditioner, then

disconnect the charge hose from the 3-way service

port immediately..

10. Mount the caps of service port and 2- and 3-way

valves.

11. Use a torque wrench to tighten the caps to a torque

of 18 N.m.

12. Check for gas leakage.

Note: 1. Mechanical connectors used indoors shall comply with local regulations.

2. When mechanical connectors are reused indoors, sealing parts shall be renewed. When flared joints

are reused indoors, the flare part shall be re-fabricated.

Maintenance 8

Indoor Unit Disassembly

Contents

1. Dimension ..............................................................................................................2

2. Indoor Unit Disassembly .......................................................................................3

2.1 Front Panel ....................................................................................................3

2.2 Electrical parts ...............................................................................................9

2.3 Evaporator ...................................................................................................11

2.4 Fan motor and fan .......................................................................................13

2.5 Step motor ..................................................................................................15

2.6 Drain Hose ..................................................................................................16

1. Dimension

Capacity Body Code W(mm) D(mm) H(mm)

7K~9K A 726 210 291

9K~12K B 835 208 295

12K~18K C 969 241 320

18K~24K D 1083 244 336

Indoor Unit Disassembly 2

2. Indoor Unit Disassembly

2.1 Front Panel

Procedure Illustration

1) Hold the front panel by the tabs on

the both sides and lift it (see CJ_AG_

INV_001).

Front Panel

Tab

CJ_AG_INV_001

2) Push up the bottom of an air

filter (step 1), and then pull it out

downwards (step 2) (see CJ_AG_

INV_002).

CJ_AG_INV_002

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 3

Procedure Illustration

3) Open the horizontal louver and push

the hook towards left to open it (see

CJ_AG_INV_003).

Hook

Horizontal Louver

CJ_AG_INV_003

4) Bend the horizontal louver lightly by

both hands to loosen the hooks, then

remove the horizontal louver (see

CJ_AG_INV_003).

Hook

CJ_AG_INV_004

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 4

Procedure Illustration

5) Pry the electrical cover by a screw

driver, and rotate it towars left, then

remove it. (see CJ_AG_INV_005).

CJ_AG_INV_005

6) Disconnect the connector for display

board. (see CJ_AG_INV_006) .

7) Slid the front panel side to side to

release each axis (see CJ_AG_INV_006)

CJ_AG_INV_006

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 5

Procedure Illustration

8) Open the screw cap and then remove

the 3 screws (see CJ_AG_INV_008).

CJ_AG_INV_007

9) Release the hooks with hands. (see

CJ_AG_INV_008)

CJ_AG_INV_008

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 6

Procedure Illustration

10) Release the 5 hooks in the back (see

CJ_AG_INV_009).

CJ_AG_INV_009

11) Pull out the panel frame while

pushing the hook through a clearance

between the panel frame and the heat

exchanger. (see CJ_AG_INV_010)

CJ_AG_INV_010

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 7

Procedure Illustration

12) Release the 5 hooks of the vertical

blades, then pull the vertical blades

rightward and remove it (see CJ_AG_

INV_011).

CJ_AG_INV_011

13) Remove 1 screw of the display board.

(see CJ_AG_INV_012).

14) Rotate the display board in the

direction shown in the right picture.

(see CJ_AG_INV_012).

CJ_AG_INV_012

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 8

2.2 Electrical parts (Antistatic gloves must be worn.)

Note: Remove the front panel (refer to 1. Front panel) before disassembling electrical parts.

Procedure Illustration

1) Remove one fixing screw of electrical

control box subassembly. (see CJ_AG_

INV_013).

(If you want to repair the electrical control

box components, perform the first step;If

you want to repair the main control board

assembly, perform steps 2 to 5 below.)

CJ_AG_INV_013

2) Cut the ribbon by a shear, then pull

out the coil temperature sensor (T2)

(see CJ_AG_INV_014).

3) Remove one fixing screw of the

electronic control box and two screws

used for the ground connection (see

CJ_AG_INV_014).

Ground Screws

T2 Sensor

CJ_AG_INV_014

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 9

Procedure Illustration

4) Pull out the electrical main board

along the direction indicated in right

image. (see CJ_AG_INV_015).

CJ_AG_INV_015

5) Disconnect the connectors and remove

main control board. (see CJ_AG_

INV_016).

Fan motor

ION(some models)

CJ_AG_INV_016

swing motor

T1

T2

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 10

2.3 Evaporator

Note: Remove the front panel and electrical parts (refer to 1. Front panel and 2. Electrical parts) before

disassembling evaporator.

Procedure Illustration

1) Disassemble the pipe holder located at the

rear of the unit (see CJ_AG_INV_017).

CJ_AG_INV_017

2) Remove the 1 screws on the evaporator

located at the fixed plate (see CJ_AG_

INV_018).

CJ_AG_INV_018

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 11

Procedure Illustration

3) Remove 1 screw and release the hook on

the evaporator (see CJ_AG_INV_019).

4) Remote the 2 screws on the evaporator

located at the fixed plate (see CJ_AG_

INV_020).

CJ_AG_INV_019

CJ_AG_INV_020

5) Pull out the evaporator (see CJ_AG_

INV_021).

CJ_AG_INV_021

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 12

2.4 Fan motor and fan

Note: Remove the front panel, electrical parts and evaporator (refer to 1. Front panel, 2. Electrical parts, and

3. Evaporator). before disassembling fan motor and fan.

Procedure Illustration

1) Remove the two screws and remove the

fixing board of the fan motor (see CJ_AG_

INV_022).

Screws

2) Remove the bearing sleeve (see CJ_AG_

INV_023).

CJ_AG_INV_022

CJ_AG_INV_023

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 13

Procedure Illustration

3) Remove the fixing screw (see CJ_AG_

INV_024).

4) Pull out the fan motor and fan assembly

from the side.

CJ_AG_INV_024

Fixing Screw

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 14

2.5 Step motor

Note: Remove the front panel and electrical parts (refer to 1. Front panel, 2. Electrical parts) before

disassembling step motor.

Procedure Illustration

1) Remove the two screws, then remove

the horizontal swing motor(see CJ_AG_

INV_025).

Stepping Motor

CJ_AG_INV_025

2) Remove 1 screw, then remove the vertical

swing motor (see CJ_AG_INV_026).(for

some units)

3) Remove 1 screw, then remove the ionizer

generator (see CJ_AG_INV_026).(for some

units)

Ionizer generator

Stepping Motor

CJ_AG_INV_026

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 15

2.6 Drain Hose

Procedure Illustration

1) Rotate the fixed wire clockwise indicated

in right image (see CJ_AG_INV_027).

CJ_AG_INV_027

2) Pull up the drain hose to remove it (see

CJ_AG_INV_028).

CJ_AG_INV_028

Note: This section is for reference only. Actual unit appearance may vary.

Indoor Unit Disassembly 16

Outdoor Unit Disassembly

Contents

1. Outdoor Unit Table ................................................................................................2

2. Dimension ..............................................................................................................3

3. Outdoor Unit Disassembly ..................................................................................18

3.1 Panel Plate ...................................................................................................18

3.2 Electrical Parts .............................................................................................43

3.3 Fan Assembly ..............................................................................................60

3.4 Fan Motor ...................................................................................................61

3.5 Sound blanket .............................................................................................62

3.6 Four-way valve .............................................................................................63

3.7 Compressor .................................................................................................64

1. Outdoor Unit Disassembly

1.1 Outdoor Unit Table

Outdoor Unit Model Panel Plate PCB Board

MOX130-09CDN8-QD6GA X130 PCB Board 9

MOX130-12CDN8-QD6GA X130 PCB Board 9

MOX230-18CDN8-QD0GA X230 PCB Board 6

Outdoor Unit Disassembly 2

2. Dimension

1. Panel Plate AA30

Outdoor Unit Disassembly 3

2. Panel Plate AB30

Outdoor Unit Disassembly 4

3. Panel Plate BA30

Outdoor Unit Disassembly 5

For US models:

Outdoor Unit Disassembly 6

4. Panel Plate B30

Outdoor Unit Disassembly 7

For US models:

Outdoor Unit Disassembly 8

5. Panel Plate CA30

Outdoor Unit Disassembly 9

For US models:

Outdoor Unit Disassembly 10

6. Panel Plate D30

Outdoor Unit Disassembly 11

For US models:

Outdoor Unit Disassembly 12

7. Panel Plate X130

Outdoor Unit Disassembly 13

For US models:

Outdoor Unit Disassembly 14

8. Panel Plate X230

Outdoor Unit Disassembly 15

For US models:

Outdoor Unit Disassembly 16

9. Panel Plate X330

Outdoor Unit Disassembly 17

For US models:

Outdoor Unit Disassembly 18

10. Panel Plate X430

Outdoor Unit Disassembly 19

For US models:

Outdoor Unit Disassembly 20

3. Outdoor Unit Disassembly

3.1 Panel Plate

1. AA30 / AB30

Procedure Illustration

1) Turn off the air conditioner and the

power breaker.

2) Remove the screws of the big handle

and then remove the big handle

(1 screws) (see CJ_AA30_001).

Big Handle

Top Cover

3) Remove the screws of the top cover

and then remove the top cover (3

screws). One of the screws is located

underneath the big handle (see CJ_

AA30_002).

CJ_AA30_001

CJ_AA30_002

Note: This section is for reference only. Actual unit appearance may vary.

Outdoor Unit Disassembly 21

Procedure Illustration

4) Remove the screws of the front panel

and then remove the front panel (6

screws) (see CJ_AA30_003).

5) Remove the screws of water collecting

cover (2 screws) (see CJ_AA30_004).

Front Panel

CJ_AA30_003

Water Collecting Cover

CJ_AA30_004

Note: This section is for reference only. Actual unit appearance may vary.

Outdoor Unit Disassembly 22

Procedure Illustration

6) Remove the screws of the rear net and

then remove the rear net (2 screws)

(see CJ_AA30_005). (for some

models)

CJ_AA30_005

7) Remove the screws of the right panel

and then remove the right panel

(6 screws) (see CJ_AA30_006).

Right Panel

CJ_AA30_006

Note: This section is for reference only. Actual unit appearance may vary.

Outdoor Unit Disassembly 23

2. BA30

Procedure Illustration

1) Turn off the air conditioner and the

power breaker.

2) Remove the screws of the big handle

and then remove the big handle

(1 screws) (see CJ_BA30_001).

Big Handle

CJ_BA30_001

Top Cover