Page 1

Service Manual

Mobile type

GD Midea Refrigeration Equipment Co.,Ltd.

Model applied:

MPA-08CE

MPA-08CR

MPA-08EE

MPA-08ER

Page 2

CONTENTS

1. PREFACE

1.1 SAFETY PRECAUTIONS..................................................................................1

1.2 INSULATION RESISTANCE TEST......................................................................1

1.3 SPECIFICATIONS............................................................................................2

1.4 FEATURES......................................................................................................4

1.5 DISPLAY PANEL AND REMOTE CONTROL........................................................4

2. INSTALLATION

2.1 NAMES OF PARTS...........................................................................................5

2.2 WINDOW INSTALLATION.................................................................................6

3. TROUBLESHOOTING GUIDE

3.1 PIPING SYSTEM..............................................................................................7

3.2 ELECTRIC FUNCTION......................................................................................7

3.3 TROUBLESHOOTING GUIDE............................................................................8

4. SCHEMATIC DIAGRAM

4.1 CIRCUIT DIAGRAM.........................................................................................13

5. EXPLODED VIEW AND REPLACEMENT

PARTS LIST.................................................. ....................................................14

1.PREFACE

This SERVICE MANUAL provides various service information, including the mechanical and electrical

parts etc. This room air conditioner was manufactured and assembled under a strict quality control system.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the POWER SWITCH to OFF and unplug the power cord.

2. Observe the original lead dress.

If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

3. After servicing the unit, make an insulation resistance test to protect the customer from being exposed to

shock hazards.

1.2 INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper between 2 pins (black and white).

2. The grounding conductor (yellow/green) is to be open.

3. Measure the resistance value with an ohm metre between the jumped lead and each exposed metallic part

on the equipment at all the positions.

4. The value should be over 1M .

1

Page 3

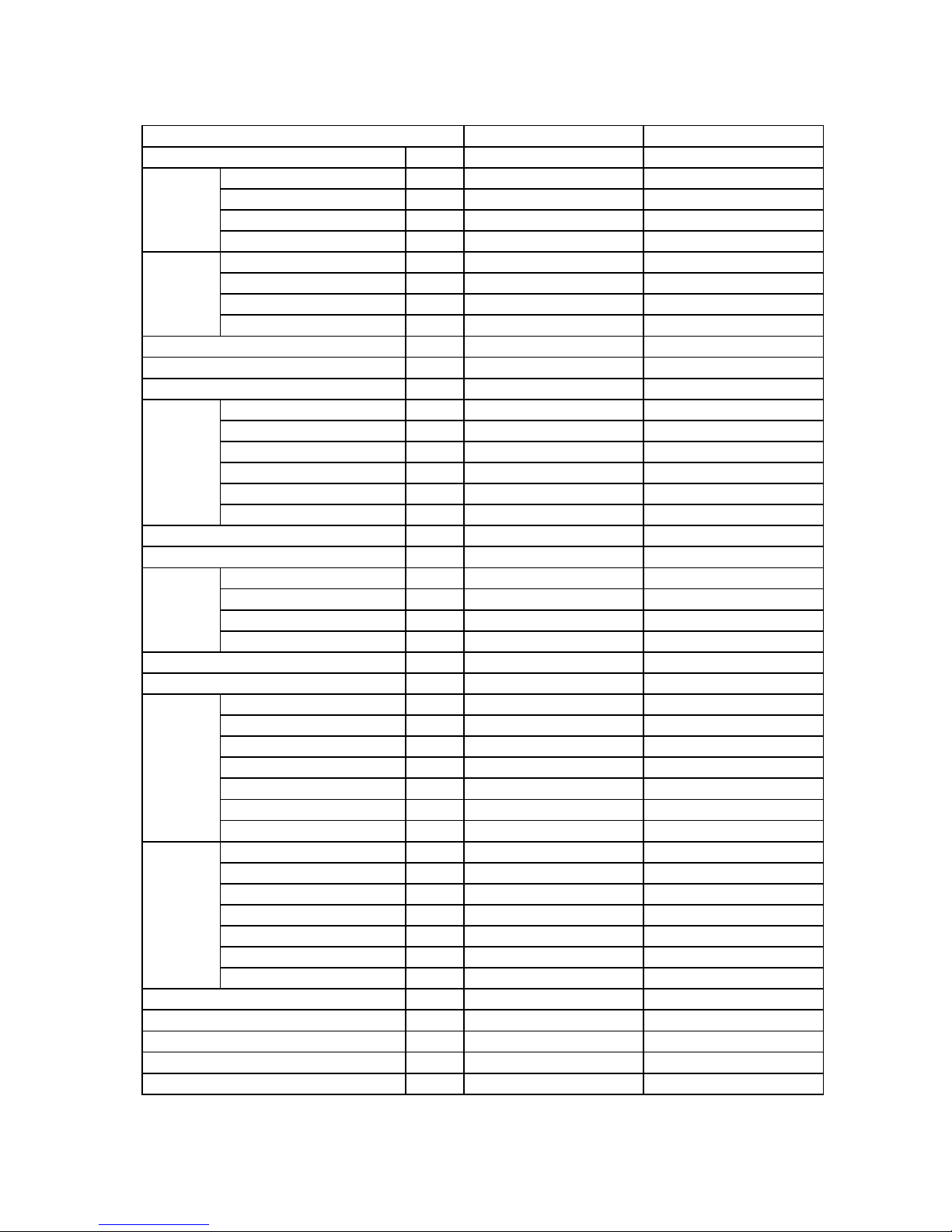

MPA-08CE MPA-08CR

Ph-V-Hz

115V,60Hz 115V,60Hz

Capacity Btu/h

8000 8000

Input W

850 850

Rated current A

7.4 7.4

EER Btu/w.h

9.4 9.4

Capacity Btu/h

----------------- -----------------

Input W

----------------- -----------------

Rated current A

----------------- -----------------

COP Btu/w.h

----------------- -----------------

L/h

1.1 1.1

L 5.5 5.5

A

39.7 39.7

Model EH120X1C-1BRU2 EH120X1C-1BRU2

Capacity Btu/h

8735 8735

Input W

840 840

Rated current(RLA) A

7.4 7.4

Thermal protector

UP3QE0591-T36 UP3QE0591-T36

Capacitor uF

45uF/ 250V 45uF/ 250V

g

550 550

MPa

2.1/0.9 2.1/0.9

Model

YSK40-6A-1 YSK40-6A-1

Input W 97/81/76/67 97/81/76/67

Capacitor uF

8uF/ 250V 8uF/ 250V

Speed(hi/mi/lo) r/min 1120/1060/1000/700 1120/1060/1000/700

m3/h

320 320

dB(A)

52 52

a.Number of rows

2 2

b.Tube pitch(a)x row pitch(b) mm

22X19.05 22X19.05

c.Fin spacing mm

1.4 1.4

d.Fin type (code) Hydrophilic aluminium Hydrophilic aluminium

e.Tube outside dia.and type mm

?7.94x0.35, innergroove tube ?7.94x0.35, innergroove tube

f.Coil length x height x width mm

274x264x38.1 274x264x38.1

g.Number of circuits

1 1

a.Number of rows

2 2

b.Tube pitch(a)x row pitch(b) mm

25.4x22 25.4x22

c.Fin spacing mm

1.5 1.5

d.Fin type (code) Unhydrophilic aluminium Unhydrophilic aluminium

e.Tube outside dia.and type mm

?9.52x0.27, innergroove tube ?9.52x0.27, innergroove tube

f.Coil length x height x width mm

497x304.8x22 515x304.8x22 497x304.8x22 515x304.8x22

g.Number of circuits

1 1

mm

387×830×456 387×830×456

Kg 37 37

℃

17-30 17-30

℃

10-35 10-35

m

2

12-18 12-18

Model

Power supply

Cooling

Heating

Moisture Removal

Water tank volume

Starting current

Compressor

Refrigerant type

Design pressure

Fan motor

Indoor air flow (Hi/Mi/Lo)

1.3 SPECIFICATION

2

Net weight

Operation temp

Ambient temp

Application area

Noise level (Hi/Mi/Lo)

Evaporator

Condenser

Dimension (W*H*D)

Page 4

MPA-08EE MPA-08ER

Ph-V-Hz

115V,60Hz 115V,60Hz

Capacity Btu/h

8000 8000

Input W

850 850

Rated current A

7.4 7.4

EER Btu/w.h

9.4 9.4

Capacity Btu/h

5000 5000

Input W

1500 1500

Rated current A

13.0 13.0

COP Btu/w.h

----------------- -----------------

L/h

1.1 1.1

L 5.5 5.5

A

39.7 39.7

Model EH120X1C-1BRU2 EH120X1C-1BRU2

Capacity Btu/h

8735 8735

Input W

840 840

Rated current(RLA) A

7.4 7.4

Thermal protector

UP3QE0591-T36 UP3QE0591-T36

Capacitor uF

45uF/ 250V 45uF/ 250V

g

550 550

MPa

2.1/0.9 2.1/0.9

Model

YSK40-6A-1 YSK40-6A-1

Input W 97/81/76/67 97/81/76/67

Capacitor uF

8uF/ 250V 8uF/ 250V

Speed(hi/mi/lo) r/min 1120/1060/1000/700 1120/1060/1000/700

m3/h

320 320

dB(A)

52 52

a.Number of rows

2 2

b.Tube pitch(a)x row pitch(b) mm

22X19.05 22X19.05

c.Fin spacing mm

1.4 1.4

d.Fin type (code) Hydrophilic aluminium Hydrophilic aluminium

e.Tube outside dia.and type mm

?7.94x0.35, innergroove tube ?7.94x0.35, innergroove tube

f.Coil length x height x width mm

274x264x38.1 274x264x38.1

g.Number of circuits

1 1

a.Number of rows

2 2

b.Tube pitch(a)x row pitch(b) mm

25.4x22 25.4x22

c.Fin spacing mm

1.5 1.5

d.Fin type (code) Unhydrophilic aluminium Unhydrophilic aluminium

e.Tube outside dia.and type mm

?9.52x0.27, innergroove tube ?9.52x0.27, innergroove tube

f.Coil length x height x width mm

497x304.8x22 515x304.8x22 497x304.8x22 515x304.8x22

g.Number of circuits

1 1

mm

387×830×456 387×830×456

Kg 37 37

℃

17-30 17-30

℃

≤35 ≤35

m

2

12-18 12-18

Model

Power supply

Cooling

Heating

Moisture Removal

Water tank volume

Starting current

Compressor

Refrigerant type

Design pressure

Fan motor

Indoor air flow (Hi/Mi/Lo)

3

Net weight

Operation temp

Ambient temp

Application area

Noise level (Hi/Mi/Lo)

Evaporator

Condenser

Dimension (W*H*D)

Page 5

1.4 FEATURES

All the models have two types of the cover and panel

structure.

No need for special installation. Four casters on the

bottom for easy movement and simple and convenient

use.

Only one exhaust pipe, and easier to use.

Remote-controlled or gentle-touch keys for easy and

comfortable use.

Compressors of famous brands are adopted for reliability

and low noise.

Multiple uses: dehumidifying and cloth drying.

The heating system uses PTC electrical heater and will not

be affected by ambient temperature, which saves energy.

Suitable for local cooling and heating.

Large volume tank, and convenient to use.

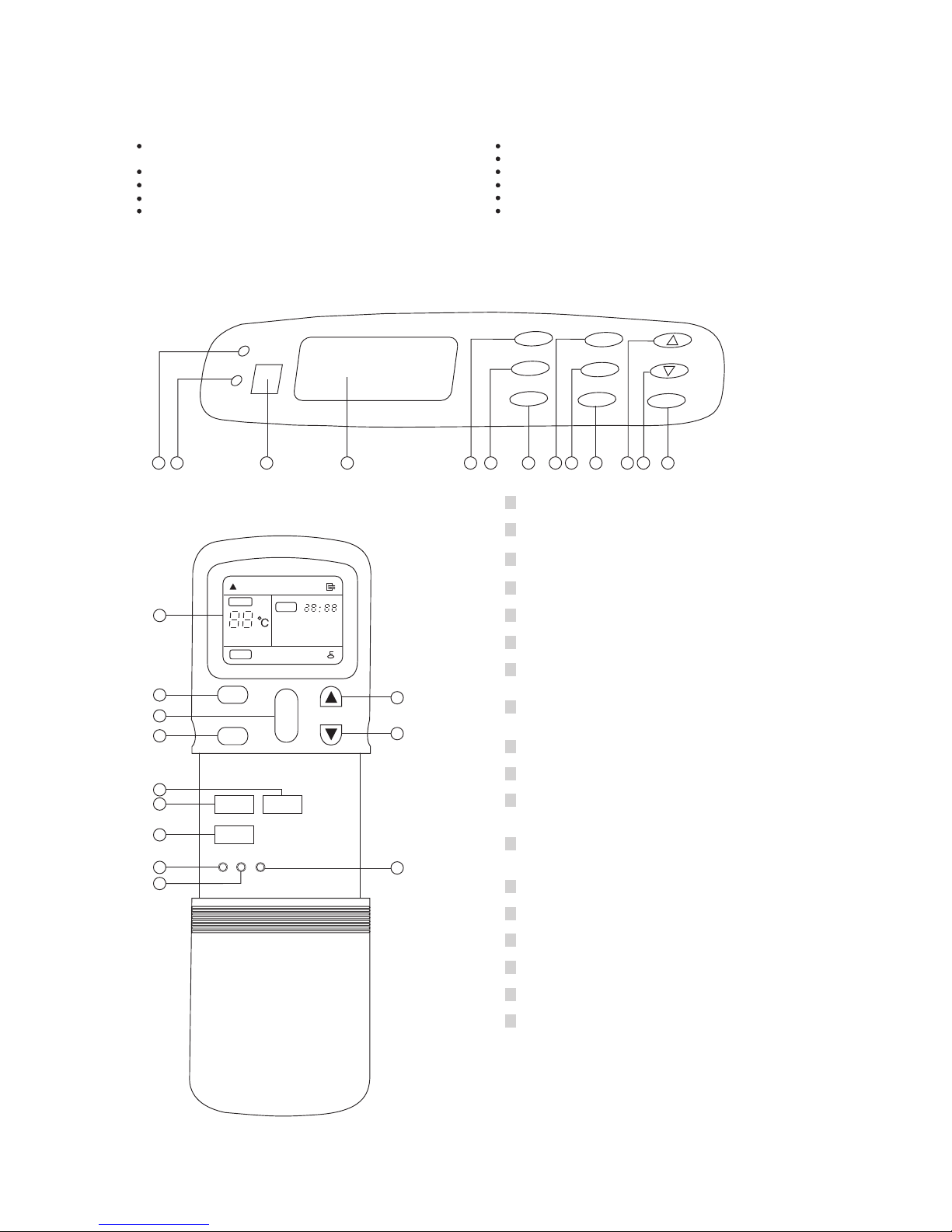

1.5 DISPLAY PANEL AND REMOTE CONTROL

DISPLAY PANEL

1

5432

1

Signal receiver

2

Heat/cool/dry lamp

3

Water full lamp

4

Operation display

5

1/0 button

AUTO COOL DRY HEAT FAN

TEMP

CLOCK

SPEED

AUTO LOW MED HIGH

MODE

1/0

TEMP/TIMER

FAN

SWING

CLOCK

SET

REMOTE CONTROL

6

8

5

6

7

D

E

F

G

H

A

9

I

6

Remote display

7

Mode button

8

9

Fan button

A

B

C

Swing button

D

Up button

E

Clock button

F

Reset button

G

Lock button

H

I

Timer on button

Timer off button

Display the situation of operation setting.

Select the operation mode, AUTO, COOL, DRY, HEAT

and FAN.

Press this button to operation the unit, again to stop.

Select the Fan speed, AUTO, LOW, MED, HIGH.

Press this button to activate the auto swing, again to

stop.

Press this button to increase the setting temperature

or Timer time.

Press this button to activate the time setting.

Press this button to reset all settings to original.

Press this button to lock all button except this button.

Press this button to activating TIMER ON time setting.

Press this button to activating TIMER OFF time setting.

WATER FULL

HEAT

COOL

DRY

1/0

FAN

SWING

MODE

ON

TIMER

OFF

CLOCK

TEMP./CLOCK

AD .

J

L R

Oo

C/ F

7 8

9

A B C D

Down button

Press this button to decrease the setting temperature

or Timer time.

Set button

Press this button to activate the Time ON/OFF setting.

Oo

C/ F button

Press this button to select temperature settings in

either Celsius or Farenheight .

`` `` `` ``

4

Page 6

Note: The Rear View and Side View as well as the performance of above styles are same as that of base style.

2.1 NAMES OF PARTS

The following models all are based on the model MPA-08CE and model MPA-O8EE Only change the external style.

FRONT VIEW

FRONT VIEW

FRONT VIEW

B Style

TOP

COVER

DRAIN TANK

FRONT VIEW

REAR VIEW

Base Style

ILLUMINATED

CONTROL PANEL

OSCILLATING

AIR VENTS

HANDLE

RECESS

DRAIN

TANK

CASTERS

AC POWER

CORD

EXHAUST AIR

OUTLET

SIDE VIEW

FILTER

COVER

A Style

TOP

COVER

OPERATION

COVER

DRAIN TANK

CASTERS

C Style

TOP

COVER

DRAIN

TANK

2. INSTALLATION

Installation Accessories

Description Quantity

Flexible exhaust hose with adapters..............3/set

13

stretches from 19 / " (50cm) up to 78 / " (200cm)

24

Window exhaust adapter(flat mouth)...............1Pc

Adjustable window/patio door slider kit.........2/set

53

from26 / " (67.5cm) up to 48 / "(203cm)

88

Drain hose connector.......................................1 Pc

continuous drain option (hose not included)

SPECIAL NOTE: Exterior drain hose extension

(direct drain) is not included with this unit and can

be purchased through any local Hardware Store.

Installation Accessories

Drain Hose Connector

Window Exhaust

Adapter

Adapter

Adapter

Adjustable Window/Patio Door Slider Kit

53

26/" - 48/

88

”

Flexible Exhaust Hose

13

19 / - 78 /

24

"

Adjustable Window/Patio Door Slider Kit

53

26 / - 48 /

88

”

"

"

"

5

Page 7

Window Kit Installation

Your window kit has been designed to fit most standard

"vertical"and "horizontal" window applications. However,

it may be necessary for you to improvise/modify some

aspects of the installation procedures for certain types

of windows. Please refer to Fig. 2 & Fig. 2a for minimum

and maximum window openings.

Before Starting This Unit

1) Select a suitable location, making sure you have easy

access to an electrical outlet.

2) Install the Flexible Exhaust Hose and the Adjustable

Window Slider Kit as depicted.

NOTE: Step 2 is required only while using the AIR

CONDITIONER MODE

3) Plug the unit into a 115V/60Hz grounded electrical

outlet.

DO NOT USE AN EXTENSION CORD.

4) Make sure the Water Tank is correctly positioned inside

the cabinet otherwise the unit will not operate.

5) To turn the unit on, press the I/O key (On/ Off Switch).

Water Tank Safety Feature

This unit is equipped with a fail-safe switch mechanism

which prevents the unit from condensing water in the

event the water tank is accidentally displaced, and/or

FULL with water. If this situation occurs, the unit will

signal 8 BEEPS and the WATER FULL indicator light

will flash red continuously until the water tank is correctly

positioned and/or emptied.

NOTE: The fan motor will continue to operate under this

condition. This is normal, but no cooling or

dehumidifying will occur until the tank is emptied and/or

correctly installed (It may take several minutes before the

compressor resumes normal operation).

2.2 Window Installation

Window Slider Kit

5

Minimum: 26 / "(67.5 cm )

8

3

Maximum: 48 / "(123cm)

8

Window Slider Kit

5

Minimum: 26 / "(67.5 cm )

8

3

Maximum: 48 / "(123cm)

8

Horizontal Window

Vertical

Window

6

Page 8

3. TROUBLE SHOOTING GUIDE

3.1 PIPING SYSTEM

The figure below is a brief description of the important components and their function in what is called the refrigeration system.

This will help to understand the refrigeration cycle and the flow of the refrigerant in the cooling cycle.

ROOM AIR CONDITIONER

CYCLE OF REFRIGERATION

EVAPORATOR

COMPLETE LIQUID BOIL

OFF POINT

COOLED

AIR

ROOM AIR HEAT LOAD

LIQUID

PRESSURE

DROP

(LIQUID REFRIGERANT)

CAPILLARY

OIL

COMPRESSOR

MOTOR

SUCTION LINE

COOL LOW

PRESSURE VAPOR

OUTSIDE COOLING

AIR FOR REFRIGERANT

PASS THROUGH

LIQUID OUTLET

HIGH PRESSURE VAPOR

LIQUID REFRIGERANT

LOW PRESSURE VAPOR

HOT DISCHARGE

AIR

VAPOR INLET

CONDENSER

3.2 ELECTRIC FUNCTION

3.2.1 Operational modes

3.2.1.1 Cooling mode

The air flow speed can be set at high, medium and

low; the fan can run continually in accordance with

the air flow speed.

oo

The temperature can be set from 16 C ~ -32 C.

The compressor starts operation when the ambient

temperature is higher than setpoint + 1 . When the

ambient temperature is lower than the setpoint, the

compressor stops.

3.2.1.2 Heating mode

The air flow speed can be set at high or low; the fan

actually operates at low and super low speed. When

the ambient temperature is higher than the setpoint,

the fan stops.

oo

The temperature can be set from 16 C ~ 32 C.

When the ambient temperature is lower than set point -1 , the PTC heater begins to work; when the

ambient temperature is higher than the setpoint,

the PTC heater stops.

3.2.1.3 Dehumidifying mode

oo

The temperature can be set from 10 C ~32 C.

The fan works at medium speed; the working

conditions of the compressor are the same as those

in cooling mode.

3.2.1.4 Fan only mode

The fan can run at high, medium or low speed.

`` ``

``

``

3.2.1

THE SETTING OF TIMER AND CLOCK

3.2.2.1

THE SETTING OF AUTO SWING

When the air conditioner is operating, press the

SWING key at any mode to start the auto swing

3.2.2

OFF TIMER

Set the OFF TIMER at any mode when the air condition is operating.

Press TIMER OFF or SET, the LED will display

TIMER OFF and flash with the close-down time.

Press TIMER up or TIMER down continually, you

can adjust the close-down time.

Press CLOCK key, you can verify the close-down

time.

3.2.2.2 ON TIMER

Set the starting up time before closing down the air

conditioner. And its starting up status will be the

working status of last time.

Press TIMER ON or SET, the LED will display

TIMER ON and flash with the operation time.

Press TIMER up or TIMER down continually, you

can adjust the close-down time.

Press CLOCK key, you can verify the operation time.

3.2.2.3 CLOCK

The clock displays time in the 24-hour system with

flashing at 1 Hz.

Setting:

At any mode, press and hold the CLOCK key for

more than 3 seconds, the clock display will flash at

1 Hz. Then press TIMER up or TIMER down, you

can adjust time.

Verifying:

Press CLOCK to verify.

3.2.3 TEMPERATURE SETTING

At cooling, dehumidifying or heating mode, you can

set the temperature. Press TEMP up key once, the

o

set-point increases for 1 C; press TEMP down key

o

once, the set-point decreases for 1 C.

3.2.4 FORCED OPERATION

3.2.4.1 When the power is turned on for the first time and no

other keys are pressed, press both CLOCK and

TEMP up. The machine instantly enters forced

heating mode.

3.2.4.2 When the power is turned on for the first time and

no other keys are pressed, press both CLOCK and

TEMP down. The machine instantly enters forced

cooling mode.

3.2.4.3 During the forced operation, you can set air flow,

auto swing, etc.

3.2.4.4 During the forced operation, press TEMP up or TEMP

down. You can see the pipe temperature Pxx and

room temperature Rxx at clock position.

3.2.4.5 Press I/O key or when the forced operation has

lasted for 30 minutes, the machine enters into

standby.

7

Page 9

3.2.5 PROTECTIVE FUNCTIONS

3.2.5.1 ALARM ON WATER TANK LEVER

At any mode, when the water tank level is up to the

limit, the buzzer alarms 8 times before it stops, the

alarm lamp flashes and the machine enters into air

blowing. (At heating mode, the machine keeps

original status.) The machine restores to former

operating status after the alarms go off. After 3

minutes, if the alarms can not go off, the machine

will enter into standby automatically.

3.2.5.2 LOW TEMPERATURE PROTECTION FOR THE

EVAPORATOR

At cooling and dehumidifying modes, if the pipe

o

temperature is lower than -3 C after compressor

runs for 10 minutes, the compressor will be shut

down instantly, the fan will start at high speed and

the green LED will flash at 1 Hz. When the pipe

o

temperature goes up to 10 C, the alarm goes off

and the machine operates at set conditions.

3.2.5.3 HIGH TEMPERATURE PROTECTION

At heating mode, when the temperature at air outlet

is too high, the PTC will be turned off (without

turning off the fan); when the temperature lowers

to normal, the PTC returns to work.

At heating mode, when the temperature above the

PTC is too high, the thermal fuse will be burnt out

and the power supply to PTC will be cut off.

At heating mode, when the temperature above PTC

increases abnormally, the PTC and the fan will be

turned off; red LED1 lamp flashes rapidly. When the

temperature lowers to normal, the machine returns

to work.

THE DELAYED PROTECTION FOR COMPRESSOR

When the power is on for the first time, the

compressor starts without waiting for 3 minutes;

re-starting the machine after the compressor is

stopped needs to wait for 3 minutes.

3.2.5.5 CURRENT PROTECTION FOR COMPRESSOR

During operation, if over-current lasts for 3 seconds,

the compressor will be shut down instantly and the

green LED1 flashes. After 3 minutes, the compressor

will re-start.

3.2.6 OTHER FUNCTIONS

3.2.6.1 FAN STARTING

When the fan works at medium, low, or super low

speed, there must be 3-second high speed starting.

3.2.6.2 THE INITIAL VALUES WHEN THE POWER IS ON

When the power is on, the starting status are:

MODE: FAN

FAN: HIGH

CLOCK: 12:00

There are no other displays

3.2.6.3 BUZZER

When the machine starts up, the buzzer sounds

twice. Press any key, the buzzer sounds once. When

there is water level alarm, the buzzer sounds 8 times.

3.2.5.4

3.3 TROUBLE SHOOTING GUIDE

ROOM AIR CONDITIONER VOLTAGE LIMITS

NAME PLATE RATING

MINIMUM MAXIMUM

115V 60Hz

98V 132V

8

Abnormal noise

Does this happen in

FAN ONLY mode?

Does this happen

without Auto Swing?

Yes

Check vertical

louver

Yes

No

Check swing

motor

Replace main

board

Check whether the

unit is on a flat, level

ground.

Remove the outdoor

discharging pipe.

Does it still happen?

Check the pipe, the

tie-in, the discharger.

Yes

Check motor

capacitor

Check fan

wheel

Check fan

motor

Replace main

board

Check air in-let and

out-let both inside

and outside

Check whether some

foam or other thing

is broken into fan in

the unit.

Check loosen part

No

Check loosen part

Check whether

there is collision

happened on pipes.

Check compressor

capacitor.

Check water depth

controller switch.

Is the noise coming

from inner pipe?

Check whether pipes

are collided flat.

Yes

Replace main

board

Replace

compressor

No

It is not faulty as the

refrigerant is flowing

in the pipe.

Page 10

9

No cooling

No operation

Is there indicator on

LCD?

Check power supply

and power cord

No

Check

transformer

Replace

display board

Replace main

board

Check wiring

Check room

temperature setting

Is the Water Full

lamp flashing?

Yes

Can the fan motor

operate?

Check wiring.

Yes

Check water

tank

Check water

depth controller

switch

Replace

display board

Replace main

board

No

No

Check fan motor

capacitor.

Is the voltage of

CN11 on main board

correct?

Replace main

board.

Yes

No

Replace fan

motor.

Yes

Check Whether the

evaporator or

condenser is

blocked.

Check compressor

capacitor.

Check temperature

sensor.

Is the voltage of

RL4 on main board

correct?

Replace compressor

Yes

No

Replace main board

No heating

Is there indicator on

LCD?

No

Can the fan motor

operate?

Check wiring.

Yes

No

Check over temp

protector on heater.

Is the voltage of

RL2 and RL3 on

main board correct?

Replace main

board.

Yes

No

Replace heater

Yes

Check compressor

over-current

protector

Page 11

10

Inefficient

cooling

Check wiring

Check room heat

load and windows

Check Whether the

evaporator or

condenser is

blocked.

Check compressor

and motor capacitor.

Check temperature

sensor.

Is the voltage of

RL4 and CN11 on

main board correct?

Check fan speed

Yes

No

Replace main board

Check air filter

Is temperature of

suction pipe on

compressor higher

o

than 19 C?

No

Replace compressor

Check leakage,

repair and recharge

refrigerant

Yes

Check room heat

load

Check the pipe, the

tie-in, the discharger.

Water seep from

unit

Check water tank

Check water stopper

Check heatinsulation foam inner

the unit.

Check water depth

controller switch

Replace main board

Check water pipe

in the unit.

Page 12

PROBLEM POSSIBLE CAUSE REMEDY

No power Check voltage at electrical outlet. Correct if none.

Transformer (Discharge

transformer before testing)

Check resistance between the two input/output lines on transformer.

Replace the transformer if either of the input/output is open or the

transformer is damaged.

Battery failure

Check the voltage of battery. Replace batteries if the voltage is lower

than 2.3V.

No power Check voltage at electrical outlet. Correct if none.

Power supply cord

Check voltage at the power cord termianl on Main board. Replace the

power cord if none.

Transformer (Discharge

transformer before testing)

Check resistance between the two input/output lines on transformer.

Replace the transformer if either of the input/output is open or the

transformer is damaged.

Wire disconnected or connection

loose

Connect wire. Refer to wiring diagram for termianl identification. Repair

or replace losse terminal.

Main board failure

Select fan speed and Check the voltage of CN11 on main board. Replace

the main board if no voltage.

Capacitor (Discharge capacitor

before testing)

Test capacitor.

Replace if not within +/-10% of manufacture's rating. Replace if shorted,

open or damaged.

Will not rotate

Fan blower hitting scroll. Realign assembly. Check

fan motor bearings. Replace the motor if motor shaft don't rotate.

Check voltage. Call an electrician if not within limits.

Test capacitor.

Replace if not within +/-10% of manufacture's rating.

Check bearings. Replace the motor if the fan blade cannot rotate freely.

Pay attention to any change from high speed to low speed. Replace the

motor if the speed does not change.

Fans Replace the fans if cracked, out of balance, or partially missing.

Loose screws Tighten them.

Worn bearings

Replace the motor if knocking sounds continue when running or loose,

or the motor hums or noise appears to be internal while running.

Copper tubing

Remove the cabinet and carefully rearrange tubing not to contact

cabinet, compressor, etc.

Discharging pipe

Check outdoor wind discharging pipe, the tie-in, the air discharger.

Correct if any problem. Replace if damaged.

Parts loosen Tighten them.

Compressor Replace after checked failure.

The ground is not level or not flat

enough

Place the unit on a flat, level ground.

Voltage Check voltage. Call an electrician if not within limits.

Wiring

Check the wire connections, if loose, repair or replace the terminal. If

wires are off, refer to wiring diagram for identification, and replace.

Check wire locations. If not per wiring diagram, correct.

Main board failure Check voltage RL4 of main board. Replace the main board if open.

Capacitor (Discharge capacitor

before testing)

Check the capacitor.

Replace if not within +/-10% of manufacturers rating. Replace if shorted,

open, or damaged.

Room temp sensor

Check the temperature setting if not at the coolest (in cooling mode) or

the heatest (in heating mode). Set it if not.

Pipe temp sensor

Check whether the evaporator is blocked. Check the pipe temp sensor

and replace if open circuit.

Water depth controller switch

Check whether the water tank is in correct postiong. Replace the water

depth controller switch if checked failure.

Over-current protector Replace after checked failure.

Compressor

Check the compressor for open circuit or ground. If open or grounded,

replace the compressor.

PROBLEM SOLVING

Check the voltage of CN7 on main board. Replace the display board after

checked faulty else replace the main board.

Fan motor will not run.

Remote control failure.

Display board or main PCB failure

No display on panel or

any one of the button

failure.

11

Revolves on overload.

Fan motor runs

intermittently

Fan motor noise.

Compressor will not run

while fan motor runs.

Excessive noise.

Page 13

PROBLEM POSSIBLE CAUSE REMEDY

Air filter Clean or replace if restricted.

Discharging pipe

Check outdoor wind discharging pipe, the tie-in, the air discharger.

Correct if any problem. Replace if damaged.

Unit undersized

Determine if the unit is properly sized for the area to be cooled or

heated.

Condenser and Evaporator Clean or replace if restricted.

Fan motor

Check the fan capacitor and replace if not within +/-10% of

manufactures rating.

Room structure and window kits

installation

Take proper measures or re-installate the windows kits to make the door

and windows sealed well if gap is found.

Air flow

Clean or remove if any barrier is found to block the inlet/outlet wind flow

of the unit.

Less refrigerant

Check the tubes for reasons of leakage. Recycle the refrigerant, correct

the leakage points and recharge.

Capillary tube

Regulate the flow if capillary tube and make the evaporating temerature

appropriate if the evaporator is frosted.

Compressor

The inlet and outlet valve of the compressor is damaged, making the low

pressure connected with the high pressure. The refrigerating system is

difficult to produce high pressure and low pressure. Replace the

compressor after checking for the reason.

Heat sources Reduce if too many.

Electric heater

Check the two over temp protectors. Replace if damaged. Replace after

the heater is checked faulty.

Refrigerant

The amount of the refrigerant is too much, making the compressor load

too big. Recycle and recharge the refrigerant after checking for the

reason.

Over-current protector Replace after checked failure.

Compressor The compressor is seized. Replace after checking for the reason.

Room temprature sensor Check and replace if the temprature is open or damaged.

Water depth controller switch

Check whether the water tank is in correct postiong. Replace the water

depth controller switch if checked failure.

Main board Check and replace the main board after checked failure.

Power supply

The input power supply voltage is too low. Call an electrician if not within

limits.

Main board

Check and replace the main board if the RL4 relay on main board is

shorted or damaged.

No power Check the voltage. Call an electrician if no within the limit.

Wiring Check the termianls. Repair and correct if loose.

Temperature setting Check and adjust the temperature setting.

Mode setting Check and adjust the mode setting.

Over-current protector Replace after checked failure.

Capacitor (Discharge capacitor

before testing)

Check the capacitor.

Replace if shorted, open, or damaged.

Compressor The compressor is damaged. Replace after checking for the reason.

Water depth controller switch

Check whether the water tank is in correct postiong. Replace the water

depth controller switch if checked failure.

Main board

Check the voltage of RL2 and RL3 on main board. Replace the main

board when the unit failure in heating mode.

Electric heater

Check the two over temp protectors. Replace if damaged. Replace after

the heater is checked faulty.

LCD is not clear LCD malfunction Replace LCD.

Transformer failure Check output voltage of transformer and replace after check faiulure.

Swing motor Replace after checked failure.

Wiring Correct according to wiring diagram.

Main board

Check the voltage of P1 on main board. Replace the main board after

checked failure.

Vertical louver is blocked Clean and repair after checked faulty.

PROBLEM SOLVING

12

No cooling or heating.

Insufficient cooling or

heating.

Stop instantly after

startup.

The compressor not to

stop even the room

temperature has got to

the setting temperature

or the water tank is full.

The unit starts and stops

frequently.

No auto swing

Page 14

13

4. SCHEMATIC DIAGRAM

4.1 CIRCUIT DIAGRAM

For Model MPA-08CE and MPA-08CR

For Model MPA-08EE and MPA-08ER

Loading...

Loading...