Page 1

MCAC-UTSM-12

1

Content

Part 1 General Information ........................................... 1

Part 2 Indoor Units ........................................................ 4

Part 3 Outdoor Units ................................................... 50

Part 4 Installation ........................................................ 65

Part 1 General Information

1. Model Names of Indoor/Outdoor Units ............................. 1

2. External Appearance .......................................................... 2

3. Nomenclature ................................................................ ..... 3

1. Model Names of Indoor/Outdoor Units

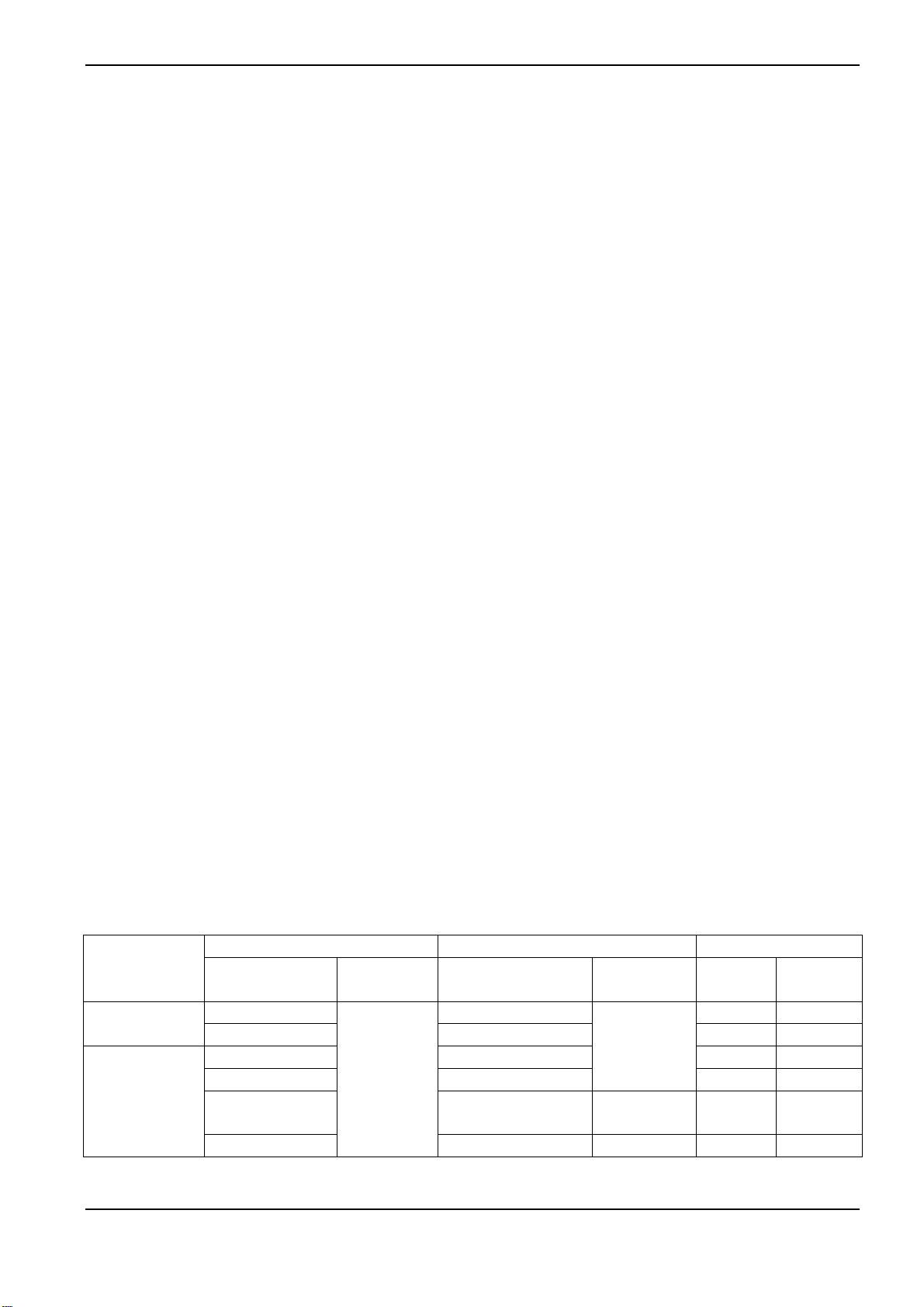

1.1 Model Names of Units with Cooling only:

Type

Indoor unit

Outdoor unit

Capacity

Model

Power

supply

Model

Power

supply

kW

kBtu/h

Floor-standing

type

MDFA-76CRN2

220~240V-

1N-50Hz

MOV-76C-CN2

380~415V-

3N-50Hz

22

76

MDFA-96CRN2

MOV-96C-CN2

28

96

Mid-static

pressure duct

type

MDTA-76CRN2

MOV-76C-CN2

22

76

MDTA-96CRN2

MOV-96C-CN2

28

96

MDTA-120CRN2

MOV-120C-CN2

380~400V-

3N-50Hz

35

120

Page 2

MCAC-UTSM-12

Type

Indoor unit

Capacity

Model

Power

supply

Model

Power

supply

kW

kBtu/h

Floor-standing

type

MDFA-76HRN2

220~240V-

1N-50Hz

MOV-76H-CN2

380~415V-

3N-50Hz

22

76

MDFA-96HRN2

MOV-96H-CN2

28

96

Mid-static

pressure duct

type

MDTA-76HRN2

MOV-76H-CN2

22

76

MDTA-96HRN2

MOV-96H-CN2

28

96

MDTA-120HRN2

MOV-120H-CN2

380~400V-

3N-50Hz

35

120

MDTA-76C(H)RN2

MDTA-96C(H)RN2

MDTA-120C(H)RN2

1.2 Model Names of Units with Cooling and heating:

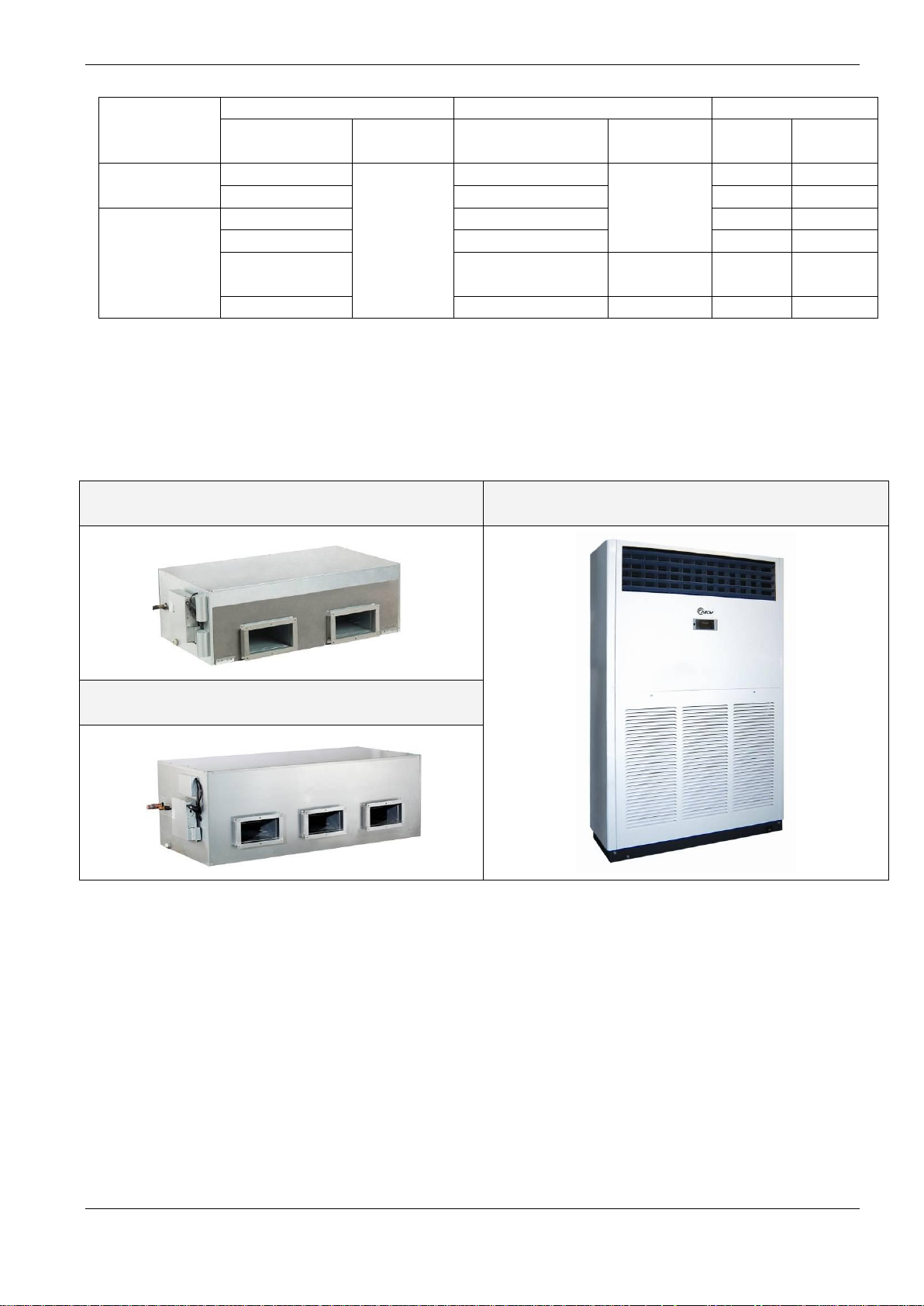

2. External Appearance

2.1 Indoor Units

Outdoor unit

MDFA-76C(H)RN2

MDFA-96C(H)RN2

2

Page 3

MCAC-UTSM-12

MDOV-76C(H)-CN2

MDOV-96C(H)-CN2

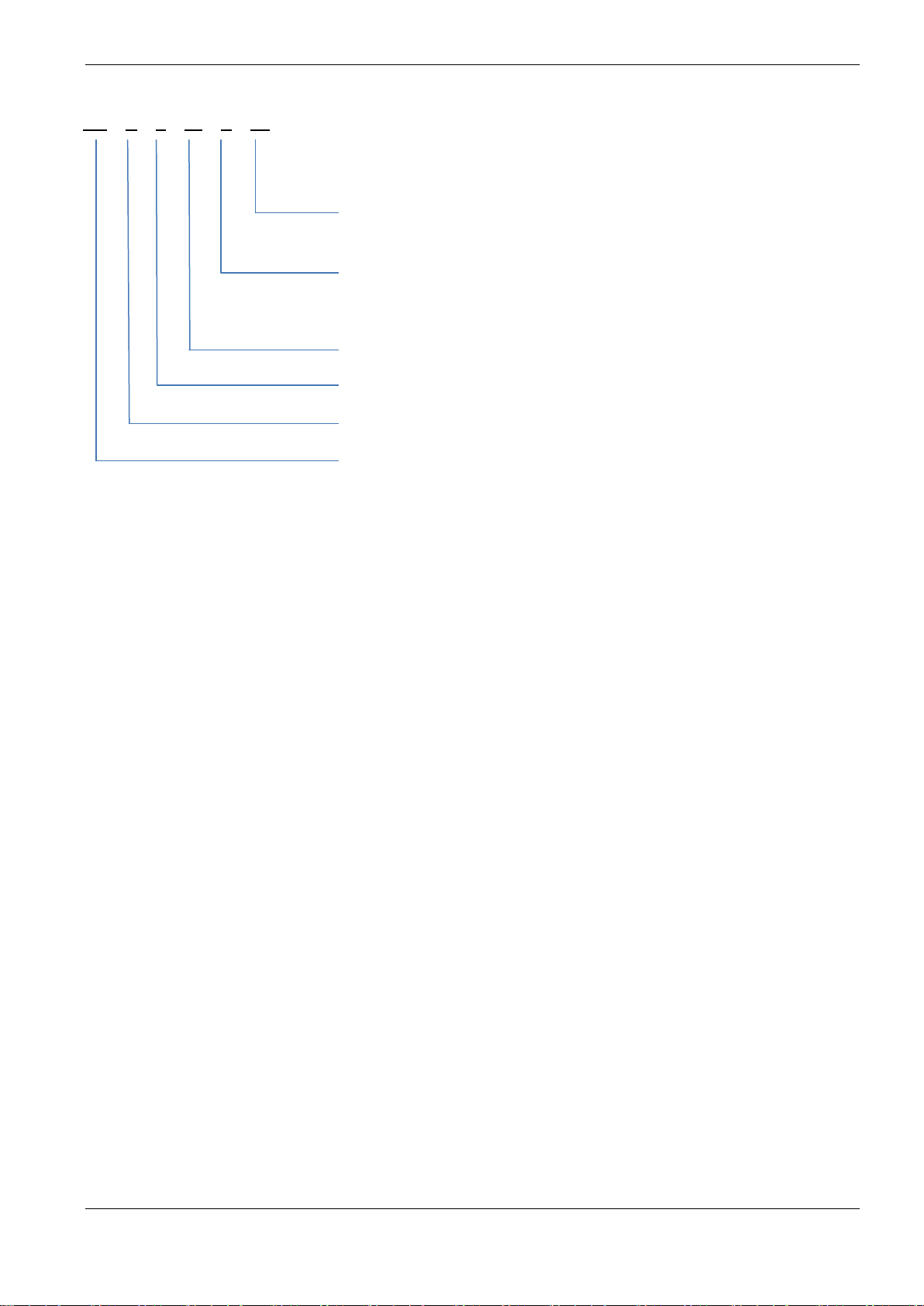

MD T A – 76 C R N2

N2:R407C;N1:R410a

R:Remote Controller

Function Code: C: Cooling

H: Cooling and Heating

Cooling Capacity (76 kBtu/h)

Product Series

A: 1st

time design

B: 2nd

time design

Indoor Units

T: Medium static pressure duct type

F: Floor-standing type

H: High static pressure duct type

MDV

2.2 Outdoor Unit

MDOV-120C(H)-CN2

3. Nomenclature

3.1 Indoor unit:

3

Page 4

MD O V

76 C N2

3.2 Outdoor unit:

MCAC-UTSM-12

N2:R407C;

N1:R410a

Function Code:

C: Cooling Only

H: Heat pump

Cooling Capacity (76 kBtu/h)

Universal Outdoor Unit

Outdoor Unit

MDV

Part 2 Indoor Units

Duct Type ................................................................................ 4

Floor-standing Type ............................................................. 31

Duct Type

1. Features .............................................................................. 5

2. Specifications ..................................................................... 5

3. Dimensions ......................................................................... 8

4. Service Space ..................................................................... 9

5. Refrigerant cycle Diagrams ............................................. 11

6. Wiring Diagrams ............................................................... 11

7.Capacity Table ................................................................... 15

8. Static Pressure ................................................................. 21

9. Electric Characteristics ................................................... 22

10. Sound Levels .................................................................. 23

12. Troubleshooting.............................................................24

4

Page 5

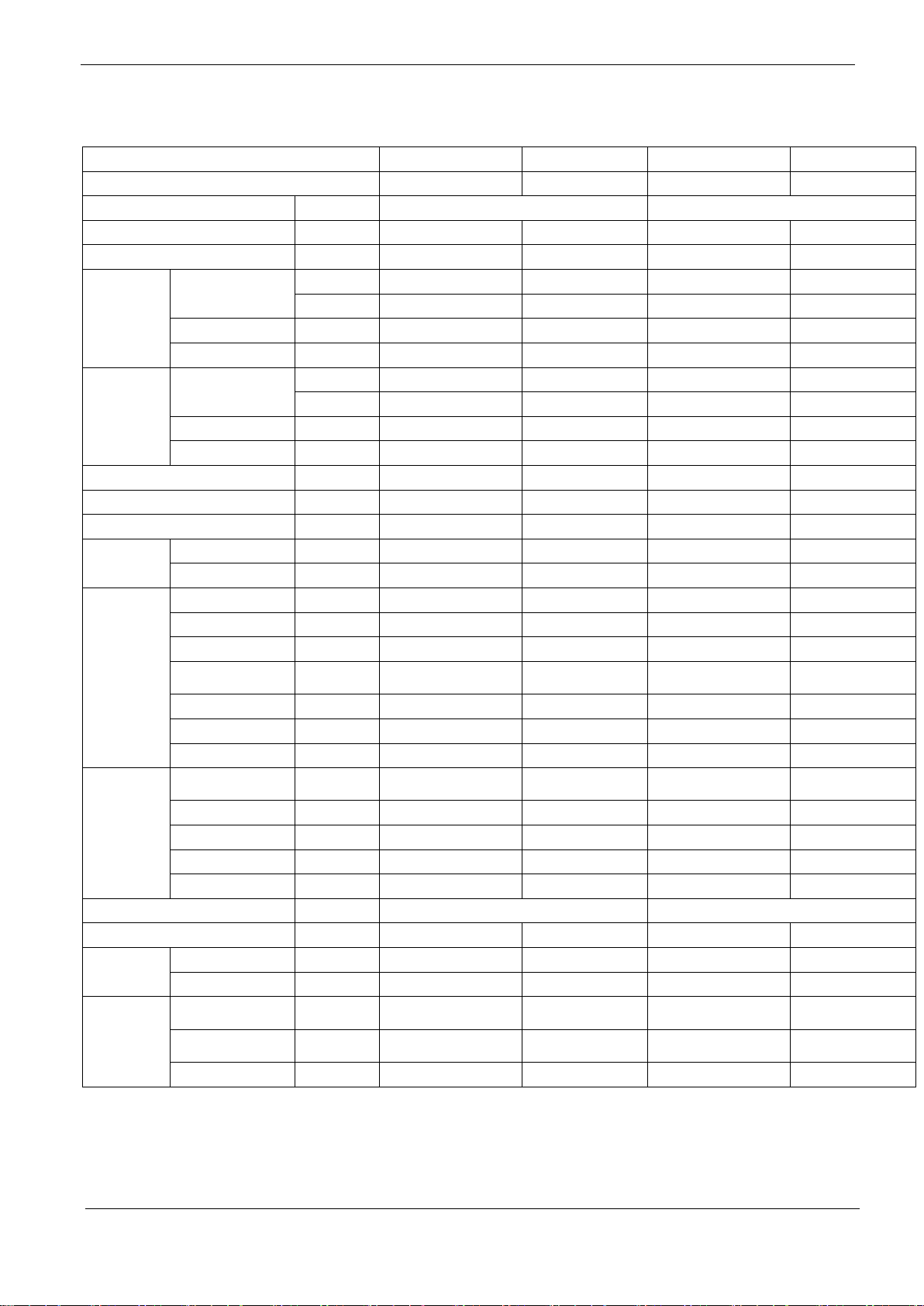

Model

MDTA-76HRN2

MDTA-96CRN2

MDTA-96HRN2

Code

220070900191

220070900181

220070900171

Power supply

- 220~240V-1N-50Hz

220~240V-1N-50Hz

Rated input power

W 11500

11500 14500

14700

Rated current

A 20 20 28 28.1

Cooling

Capacity

Btu/h 75,100

75,100

92,800

91,400

W 22000

22000 27200

26800

Input

W 7500

7500 9200

9200

EER W/W

2.93

2.93 2.96

2.91

Heating

Capacity

Btu/h

——

83600

——

109500

W

——

24500

——

32100

Input

W

——

7320

——

9800

COP W/W

——

3.35

——

3.28

Indoor air flow

m3/h(CFM)

4650(2700)

4650(2700)

5600(3300)

5600(3300)

Indoor external static pressure

Pa

100 100 100

Indoor noise level

dB(A)

54 55 55

Refrigerant

Type -

Control -

Capillary

Capillary

Capillary

Fan

Type -

Centrifugal fan

Centrifugal fan

Centrifugal fan

Fan model

-

SYZ9-9MD

SYZ9-9MD

SYZ9-9MD

Dimension

mm

Φ307 Φ307

Φ307

Drive type/ Motor

step

-

Direct/ Single

Direct/ Single

Direct/ Single

Motor model

-

YDK300-4X

YDK550-4X

YDK550-4X

Motor Input * No.

W

720*2

1015*2

1015*2

Motor speed

rpm 1040

1040 1300

1300

Coil

Type -

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Tube size

mm

Ф9.52

Ф9.52 Ф9.52

Ф9.52

No. of rows

- 4 4 4 4

Fin per inch

FPI 17 17 17 17

Length* height

mm 1200*406

1200*406

1200*406

1200*406

Controller -

Remote controller

Remote controller

Drain pipe size

mm

Ф41

Ф41 Ф41

Ф41

Connection

wiring

Power wiring

mm2

3*2.5

3*2.5 3*2.5

3*2.5

Signal wiring

mm2

2*1.0

4*1.0 2*1.0

4*1.0

Indoor unit

Dimension

(W*H*D)

mm 1350*450*760

1350*450*760

1350*450*760

1350*450*760

Packing

(W*H*D)

mm 1549*476*917

1549*476*917

1549*476*917

1549*476*917

Net/Gross weight

kg 105/120

105/120

105/120

105/120

2. Specifications

MCAC-UTSM-12

MDTA-76CRN2

220070900201

100

54

R407C

Capillary

Centrifugal fan

SYZ9-9MD

Φ307

R407C R407C R407C

Notes:

1. ESP: external static pressure

2. Nominal cooling capacities are based on the following conditions:

Indoor temp: 27°CDB, 19°CWB; Outdoor temp: 35°CDB, 24°CWB; Equivalent refrigerant piping: 7.5m (horizontal).

3. Nominal heating capacities are based on the following conditions:

Indoor temp: 20°CDB, 15°CWB; Outdoor temp: 7°CDB, 6°CWB; Equivalent refrigerant piping: 7.5m (horizontal).

6

Direct/ Single

YDK300-4X

720*2

Page 6

MCAC-UTSM-12

Model

MDTA-120HRN2

Code

220070900151

Power supply - 220~240V-1N-50Hz

Rated input power

W

18000

18000

Rated current A 28.7

28.7

Cooling

Capacity

Btu/h

116,000

116,000

W

34000

34000

Input

W

11900

11900

EER

W/W

2.86

2.86

Heating

Capacity

Btu/h

——

139900

W

——

41000

Input

W

——

12600

COP

W/W

——

3.25

Indoor air flow

m3/h

6800

6800

Indoor external static pressure

150

Indoor noise level

56

Refrigerant

Type

Control

Capillary

Fan

Type

Centrifugal fan

Fan model

SYZ9-9MD

Dimension

Φ307

Drive type/ Motor

step

Direct/ Single

Motor model

YDK300-4X

Motor Input * No.

720*3

Motor speed

rpm

1040/930/825

1040/930/825

Coil

Type

-

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Tube size

mm

Ф7

Ф7

No. of rows - 4

4

Fin per inch

FPI

17

17

Length* height

mm

1602*588

1602*588

Controller

-

Remote controller

Drain pipe size

mm

Ф41

Ф41

Connection

wiring

Power wiring

mm2

3*2.5

3*2.5

Signal wiring

mm2

2*1.0

4*1.0

Indoor unit

Dimension

(W*H*D)

mm

1828*638*858

1828*638*858

Packing

(W*H*D)

mm

2095*689*929

2095*689*929

Net/Gross weight

kg

188/220

188/220

MDTA-120CRN2

220070900161

Pa 150

dB(A) 56

-

- Capillary

- Centrifugal fan

- SYZ9-9MD

mm Φ307

R407C R407C

- Direct/ Single

- YDK300-4X

W 720*3

Notes:

1. ESP: external static pressure

2. Nominal cooling capacities are based on the following conditions:

Indoor temp: 27°CDB, 19°CWB; Outdoor temp: 35°CDB, 24°CWB; Equivalent refrigerant piping: 7.5m (horizontal).

3. Nominal heating capacities are based on the following conditions:

Indoor temp: 20°CDB, 15°CWB; Outdoor temp: 7°CDB, 6°CWB; Equivalent refrigerant piping: 7.5m (horizontal).

7

Page 7

MCAC-UTSM-12

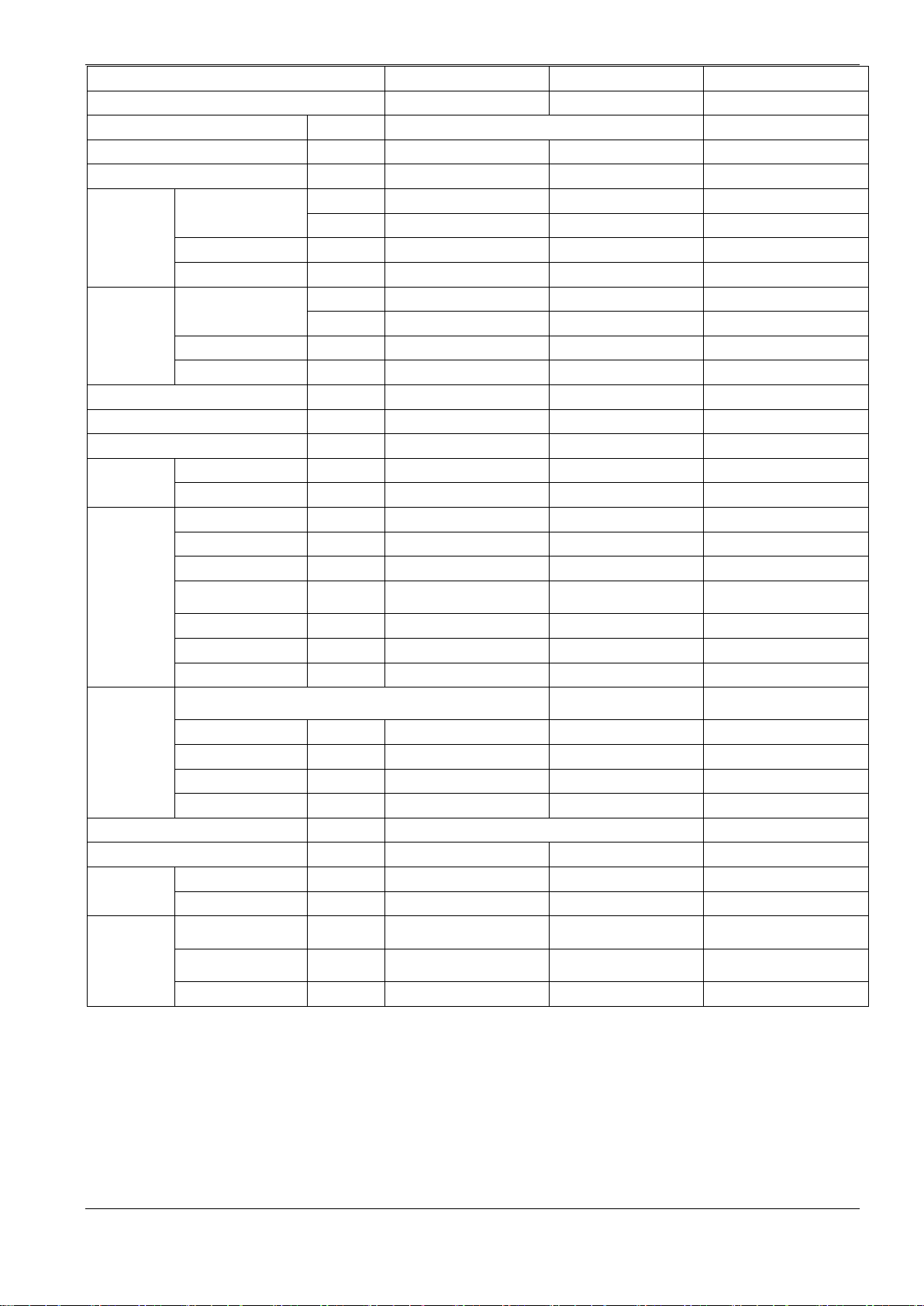

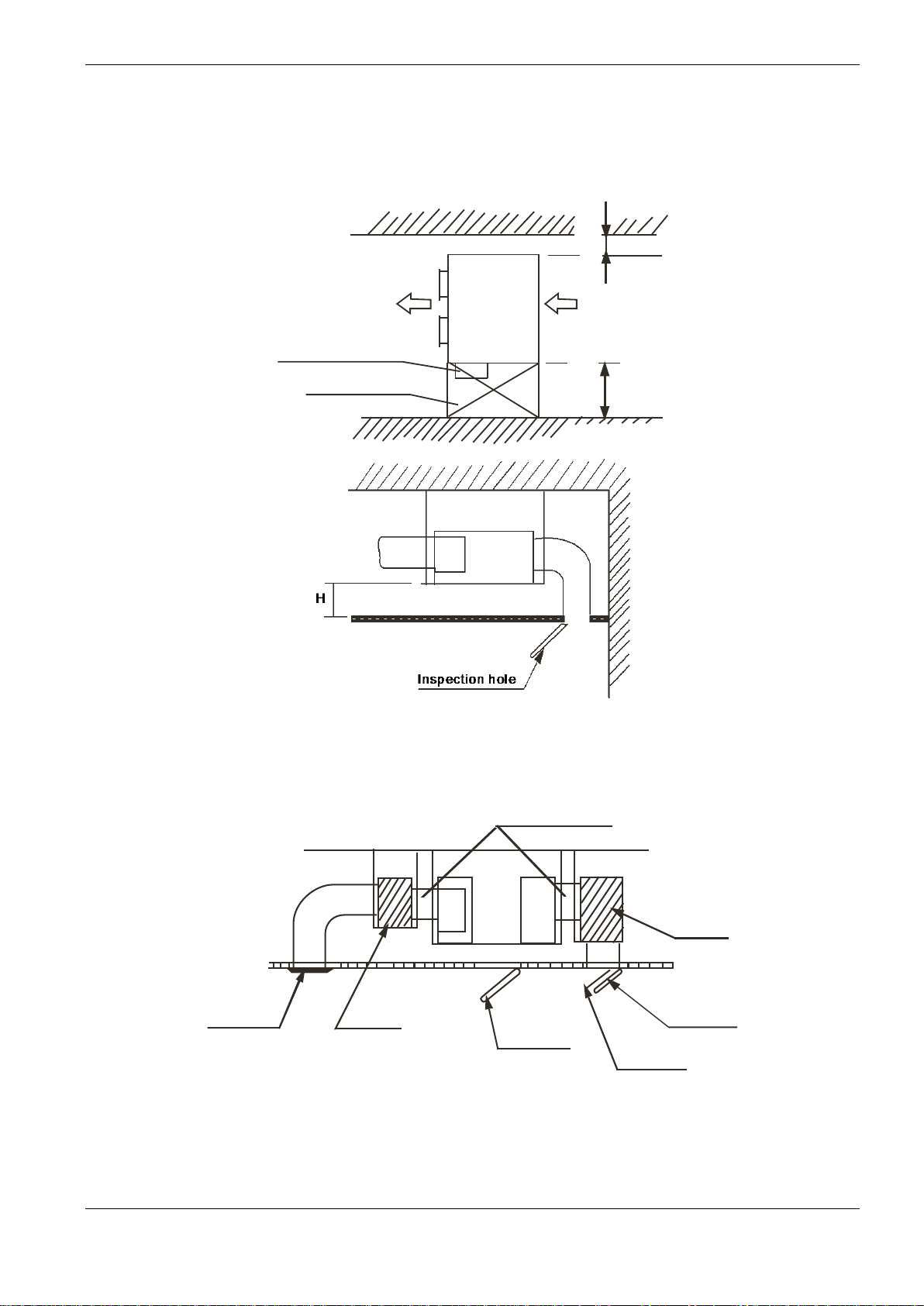

3. Dimensions

3.1 MDTA-76C(H)RN2, MDTA-96C(H)RN2

8

Page 8

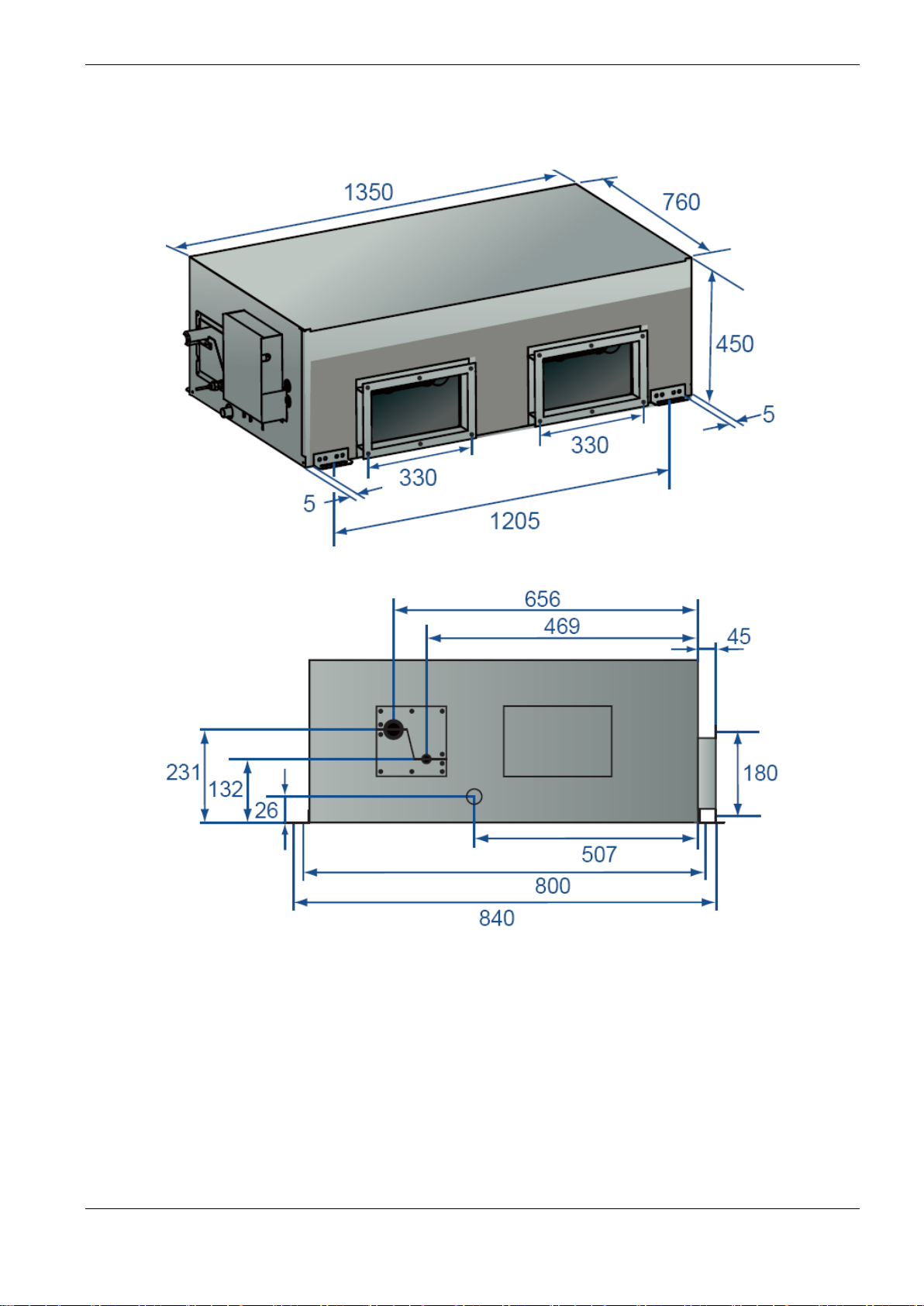

MCAC-UTSM-12

3.2 MDTA-120C(H)RN2

9

Page 9

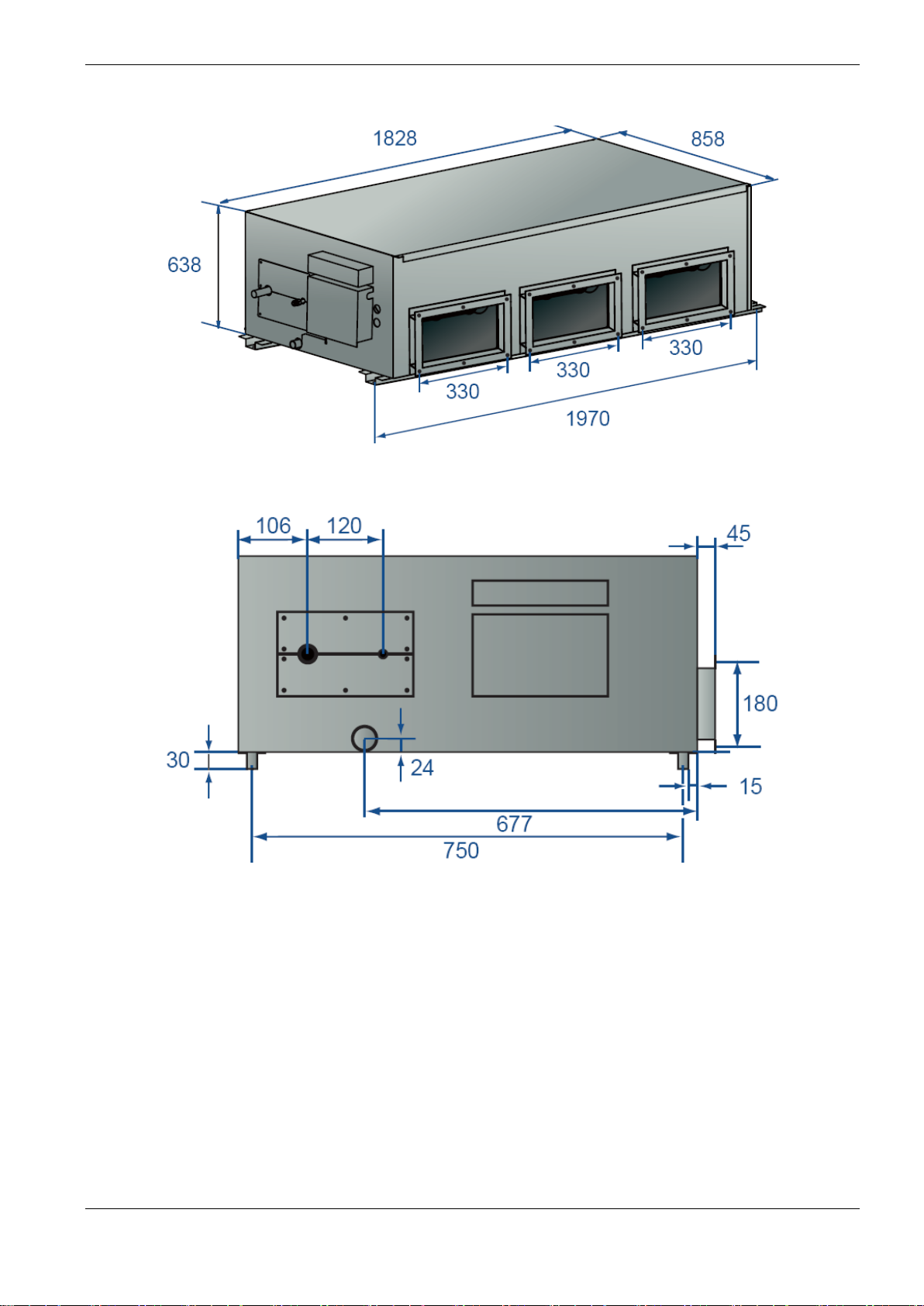

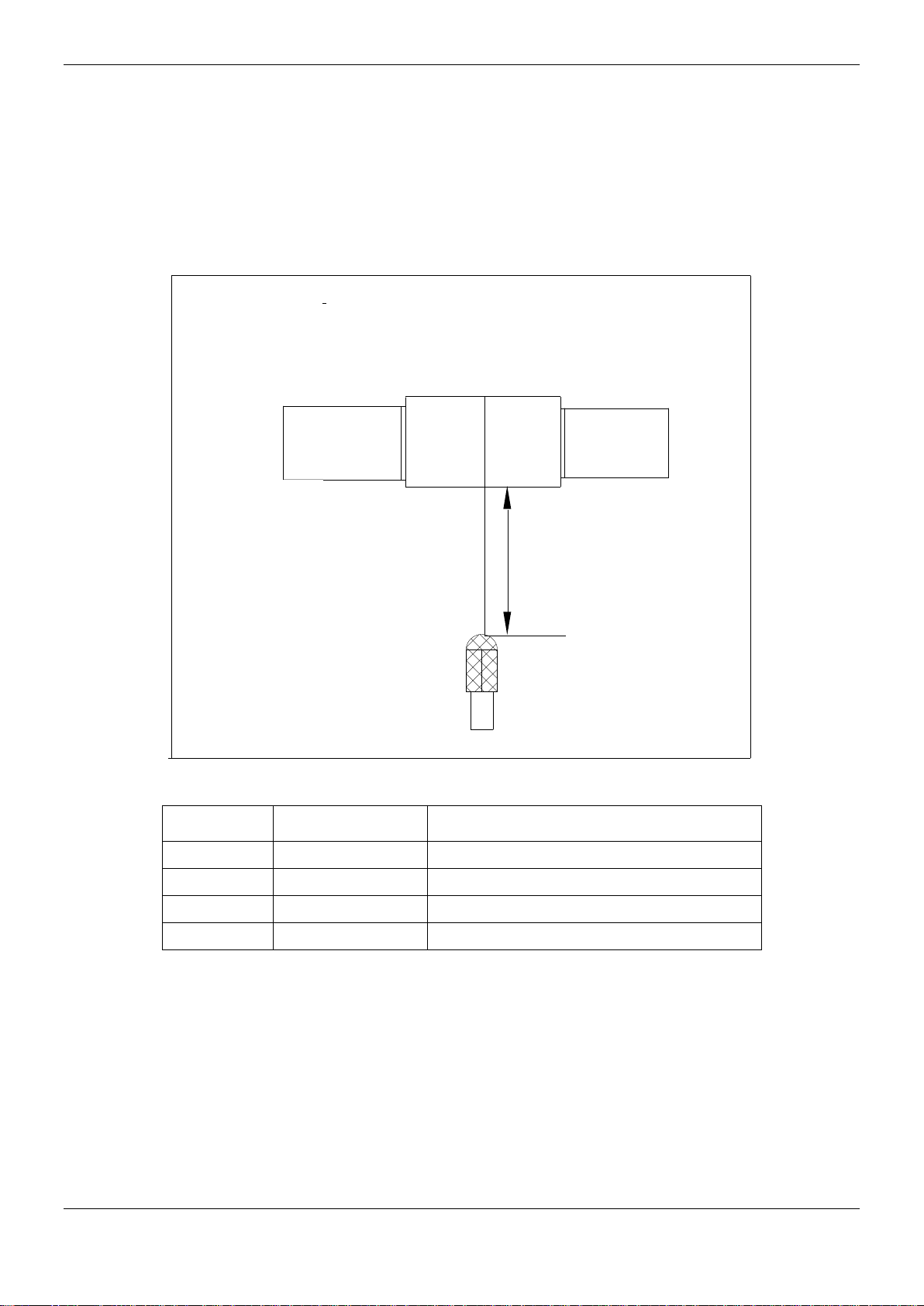

4. Service Space

MCAC-UTSM-12

m

m

0

0

5

≥

Electric control box

Inspection hole

m

m

0

0

6

≥

Top view Side view

10

ir outlet

Muffle

Canvas adapter

Inspection

Air duct system

hole

Air inlet

Air filter

Muffle

Page 10

MCAC-UTSM-12

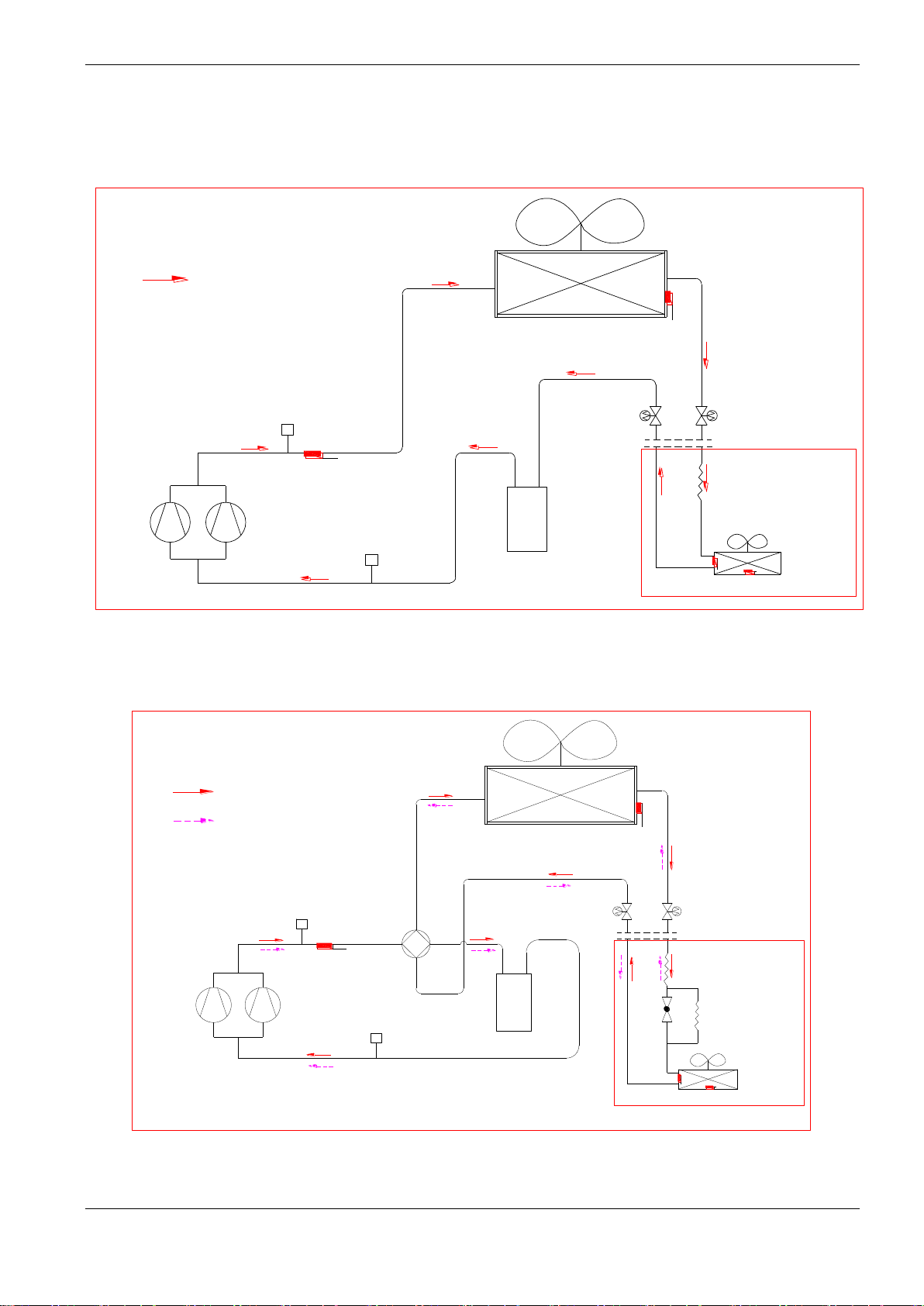

5. Refrigerant cycle diagrams

5.1 Cooling only: MDTA-76CRN2, MDTA-96CRN2, MDTA-120CRN2

Cooling

Outdoor heat-exchanger

HP Switch

Discharge temp. sensor

Compressors

LP Switch

Liquid-gas seperator

T3

Stop valve

5.3 Cooling and heating: MDTA-76HRN2, MDTA-96HRN2, MDTA-120HRN2

Stop valve

Indoor unit

Capillary

Indoor

heat-exchanger

T2

T4

Cooling

Heating

Outdoor heat-exchanger

HP Switch

4-way valve

Discharge temp. sensor

Compressors

LP Switch

Liquid-gas seperator

T3

Check valve

Stop valve

Capillary

Indoor unit

Indoor

heat-exchanger

Stop valve

T2

T4

11

Page 11

MCAC-UTSM-12

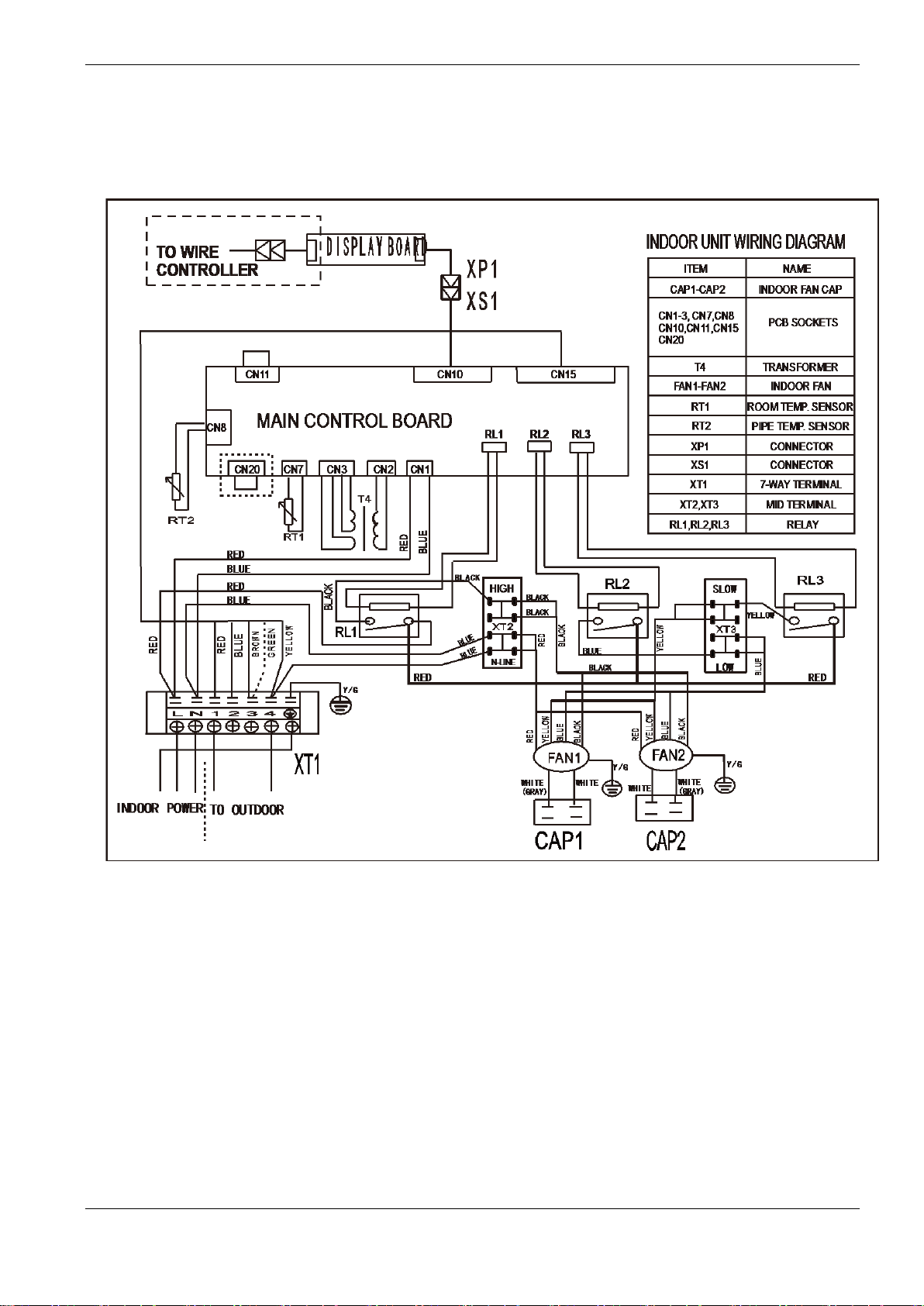

6. Wiring Diagrams

6.1 MDTA-76CRN2, MDTA-96CRN2

12

Page 12

MCAC-UTSM-12

6.2 MDTA-76HRN2, MDTA-96HN2

6.3 MDTA-120CRN2

13

Page 13

6.4 MDTA-120HRN2

MCAC-UTSM-12

14

Page 14

MCAC-UTSM-12

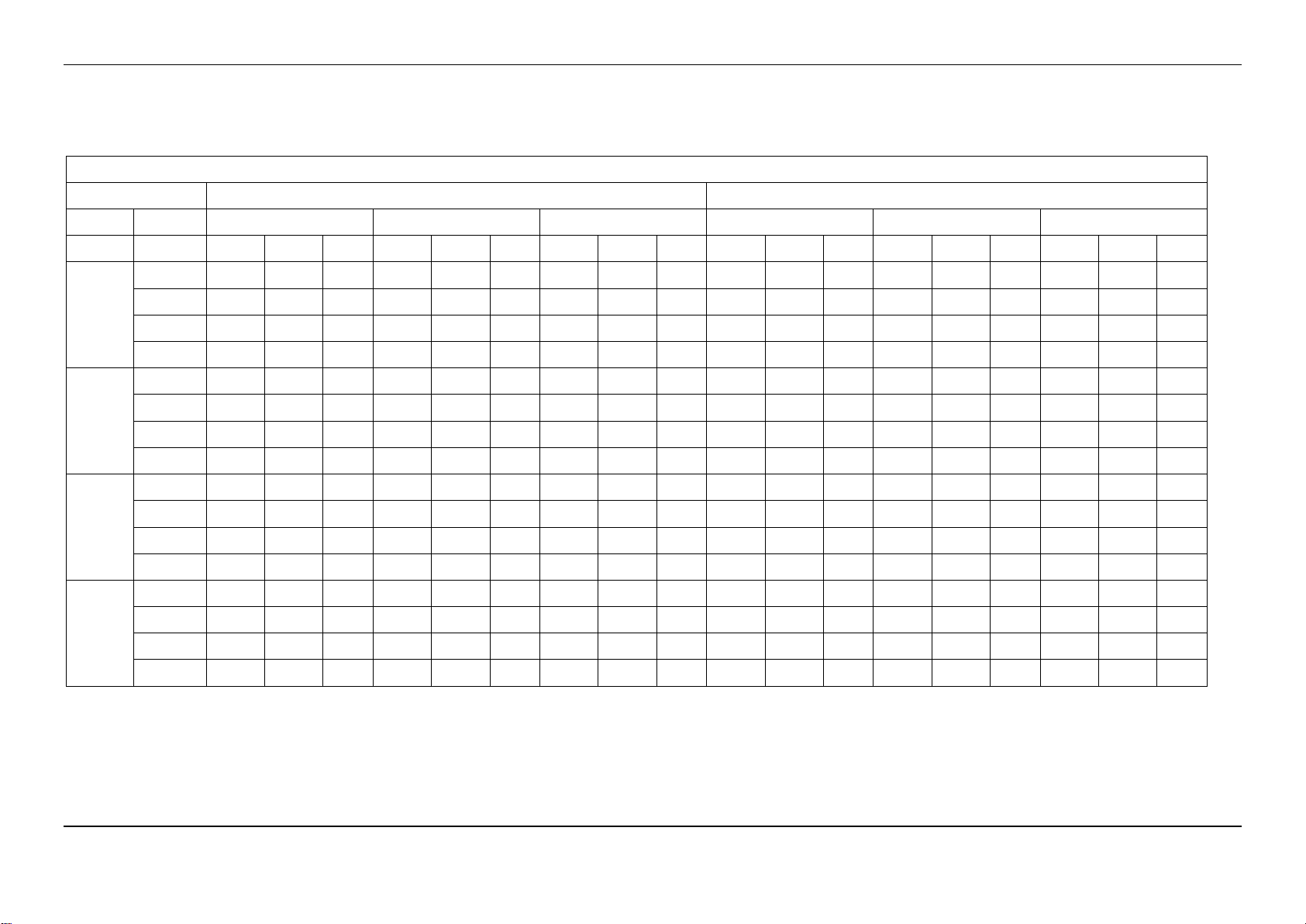

Gross Cooling Capacity (kW)

Outdoor DB(°C)

29.40

35.00

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2200

23.90

19.2

15.0

7.13

21.7

12.2

7.33

23.0

5.3

7.46

18.4

15.1

7.56

20.5

11.6

7.79

21.8

5.0

7.93

26.70

19.9

17.2

7.15

7.48

18.8

17.1

7.58

20.9

13.5

7.81

22.2

9.6

29.40

20.6

18.7

7.17

7.5

19.2

18.4

7.6

21.3

17.5

7.83

22.6

13.5

32.20

21.3

20.9

7.19

7.52

19.6

19.2

7.62

21.7

19.8

7.85

23.1

17.0

2500

23.90

20.3

16.2

7.33

7.66

19.4

16.3

7.76

21.1

12.2

7.99

22.4

5.3

26.70

21.0

18.3

7.35

7.68

19.8

18.3

7.78

21.5

15.3

8.01

22.8

10.0

29.40

21.7

20.1

7.37

7.7

20.2

19.8

7.8

21.9

18.4

8.03

23.3

14.2

32.20

22.5

21.4

7.39

23.6

21.9

7.59

25.1

18.7

7.72

20.6

20.6

7.82

22.4

20.7

8.05

23.7

17.7

8.19

2700

23.90

20.8

18.1

7.57

22.8

14.2

7.9

24.1

6.3

7.9

19.9

18.3

8

21.6

13.5

8.23

22.8

5.9

8.37

26.70

21.5

20.5

7.59

23.2

17.9

7.79

24.6

11.8

7.92

20.3

20.3

8.02

22.0

16.9

8.25

23.3

11.2

8.39

29.40

22.3

21.6

7.61

23.7

21.7

7.81

25.1

16.6

7.94

20.7

20.7

8.04

22.4

20.6

8.27

23.8

15.7

8.41

32.20

23.0

22.6

7.63

24.1

21.9

7.83

25.6

20.8

7.96

21.1

21.1

8.06

22.9

20.8

8.29

24.2

19.7

8.43

3000

23.90

21.3

18.8

7.88

23.2

13.9

8.08

24.6

6.0

8.21

20.7

18.3

8.31

22.1

13.2

8.54

23.3

5.7

8.68

26.70

22.0

21.2

7.9

23.7

17.4

8.1

25.1

11.4

8.23

21.1

20.3

8.33

22.5

16.5

8.56

23.8

10.8

8.7

29.40

22.8

22.1

7.92

24.2

21.0

8.12

25.6

16.2

8.25

21.5

21.5

8.35

23.0

20.0

8.58

24.3

15.4

8.72

32.20

23.6

23.1

7.94

24.7

23.7

8.14

26.1

20.2

8.27

22.0

22.0

8.37

23.4

22.5

8.6

24.8

19.2

8.74

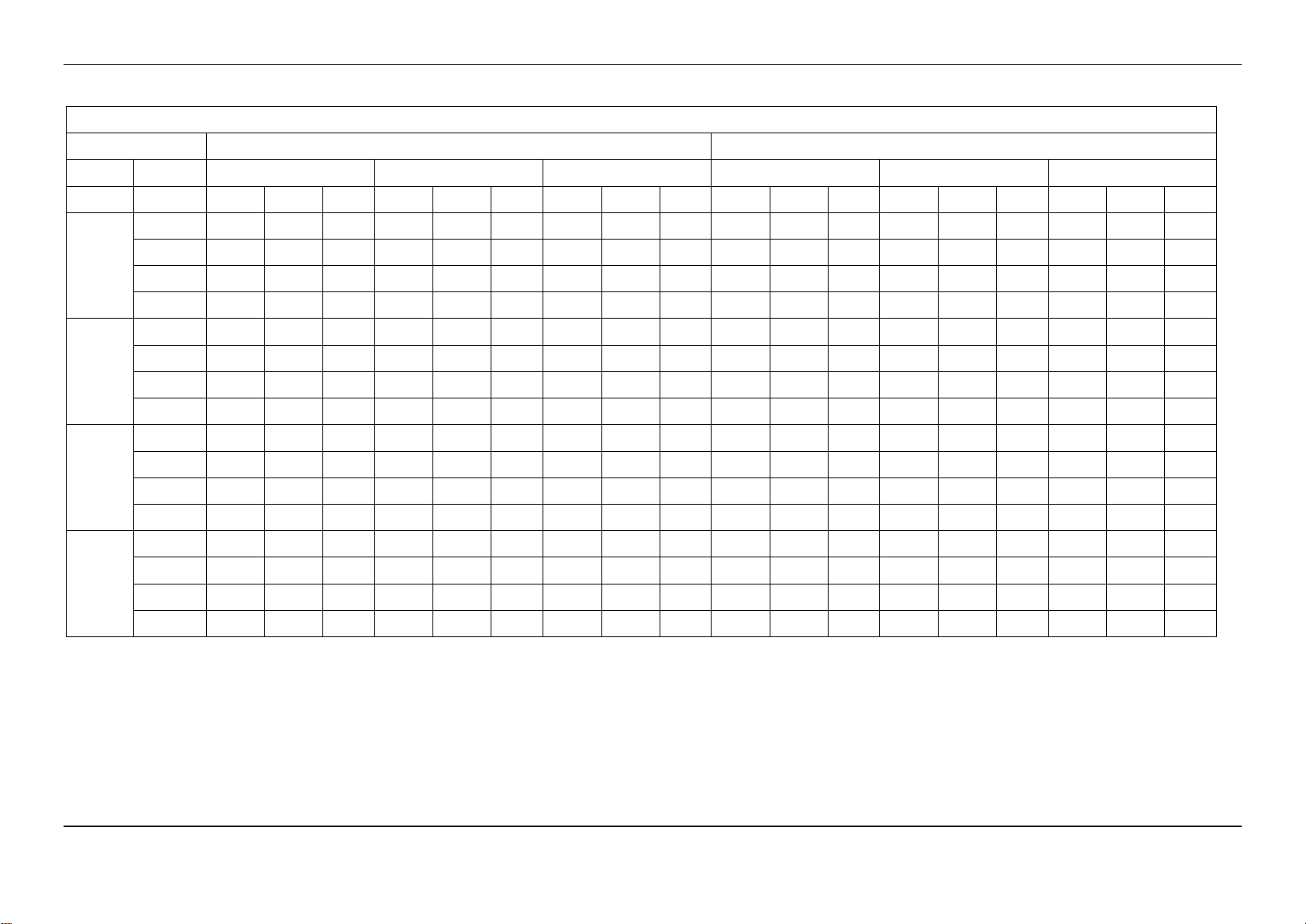

7. Capacity Table

7.1 76 kBtu/h

22.1 14.3 7.35 23.5 10.1

22.5 18.5 7.37 24.0 14.3

23.0 20.9 7.39 24.4 18.0

22.3 12.9 7.53 23.6 5.6

22.7 16.1 7.55 24.1 10.6

23.2 19.5 7.57 24.6 15.0

7.95

7.97

7.99

8.13

8.15

8.17

15

Page 15

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

40.60

46.10

51.70

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2200

23.9

18.41

15.09

8.49

19.98

11.29

8.73

21.25

4.91

8.88

16.9

13.9

8.68

18.4

10.4

8.94

19.6

4.5

9.19

16.1

13.2

10.67

17.3

9.8

11.03

18.4

4.3

11.28

26.7

18.78

17.07

8.51

20.38

13.2

8.75

21.68

9.34

8.9

17.3

15.7

8.7

18.8

12.2

8.96

20.0

8.6

9.21

16.4

14.9

10.7

17.7

11.5

11.06

18.8

8.1

11.31

29.4

19.16

18.42

8.53

20.79

17.04

8.77

22.11

13.16

8.92

17.6

17.0

8.72

19.2

15.7

8.98

20.4

12.1

9.23

16.7

16.1

10.73

18.0

14.8

11.09

19.2

11.4

11.34

32.2

19.54

19.16

8.55

21.2

19.28

8.79

17.8

9

20.8

15.3

9.26

17.0

16.7

10.75

18.4

16.7

11.12

19.5

2500

23.9

19.02

15.98

8.69

20.59

11.9

8.93

11.0

9.14

20.2

4.8

9.39

16.7

14.0

10.87

17.9

10.4

11.23

19.0

26.7

19.4

17.96

8.71

21

14.89

8.95

13.8

9.16

20.6

9.0

9.41

17.0

15.7

10.9

18.3

13.0

11.26

19.4

29.4

19.79

19.4

8.73

21.42

18

8.97

16.6

9.18

21.0

12.8

9.43

17.3

17.0

10.93

18.7

15.7

11.29

19.8

32.2

20.18

20.18

8.75

21.85

20.23

8.99

18.7

9.21

21.4

16.0

9.46

17.7

17.7

10.95

19.0

17.6

11.32

20.2

2700

23.9

19.51

17.9

8.39

21.08

13.17

8.78

12.2

9.38

20.7

5.4

9.63

17.2

15.7

11.11

18.4

11.5

11.47

19.5

26.7

19.9

19.9

8.41

21.5

16.54

8.65

15.3

9.4

21.1

10.1

9.65

17.5

17.5

11.14

18.8

14.5

11.5

19.9

29.4

20.3

20.3

8.43

21.93

20.12

8.67

23.26

15.4

8.82

18.8

18.8

9.16

20.3

18.6

9.42

21.5

14.3

9.67

17.9

17.9

11.17

19.2

17.6

11.53

20.3

13.4

11.78

32.2

20.7

20.7

8.45

22.37

20.34

8.69

23.72

19.29

8.84

19.1

19.1

9.19

20.7

18.8

9.45

22.0

17.9

9.7

18.2

18.2

11.2

19.6

17.8

11.56

20.7

16.8

11.81

3000

23.9

20

17.7

9.24

21.57

12.92

9.48

22.84

5.6

9.63

18.5

16.4

9.43

20.0

12.0

9.69

21.2

5.2

9.94

17.7

15.6

11.42

18.9

11.3

11.78

20.0

4.9

12.03

26.7

20.4

19.62

9.26

22

16.18

9.5

23.3

10.59

9.65

18.9

18.2

9.45

20.4

15.0

9.71

21.6

9.8

9.96

18.0

17.3

11.45

19.3

14.2

11.81

20.4

9.3

12.06

29.4

20.81

20.81

9.28

22.44

19.51

9.52

23.77

15.04

9.67

19.3

19.3

9.47

20.8

18.1

9.73

22.0

13.9

9.98

18.4

18.4

11.48

19.7

17.1

11.84

20.8

13.2

12.09

32.2

21.22

21.22

9.31

22.89

22.01

9.55

24.24

18.79

9.7

19.7

19.7

9.5

21.2

20.4

9.76

22.5

17.4

10.01

18.7

18.7

11.51

20.1

19.3

11.87

21.2

16.5

12.12

22.56 16.59 8.94 18.0 17.6 8.74 19.5

21.86 5.16 9.08 17.6 14.8 8.88 19.0

22.3 9.78 9.1 17.9 16.6 8.9 19.4

22.75 13.87 9.12 18.3 17.9 8.92 19.8

23.2 17.31 9.15 18.6 18.6 8.94 20.2

22.35 5.79 8.78 18.0 16.6 9.12 19.5

22.8 10.91 8.8 18.4 18.4 9.14 19.9

Notes:

1. DB = Dry Bulb Temperature (°C), WB = Wet Bulb Temperature (°C)

4. TGC = Total Cooling Capacity (kW)

5. SHC = Sensible Heating Capacity (kW)

6. PI = Power Input (kW)

14.4 11.37

4.5 11.48

8.5 11.51

12.1 11.54

15.1 11.57

5.1 11.72

9.5 11.75

16

Page 16

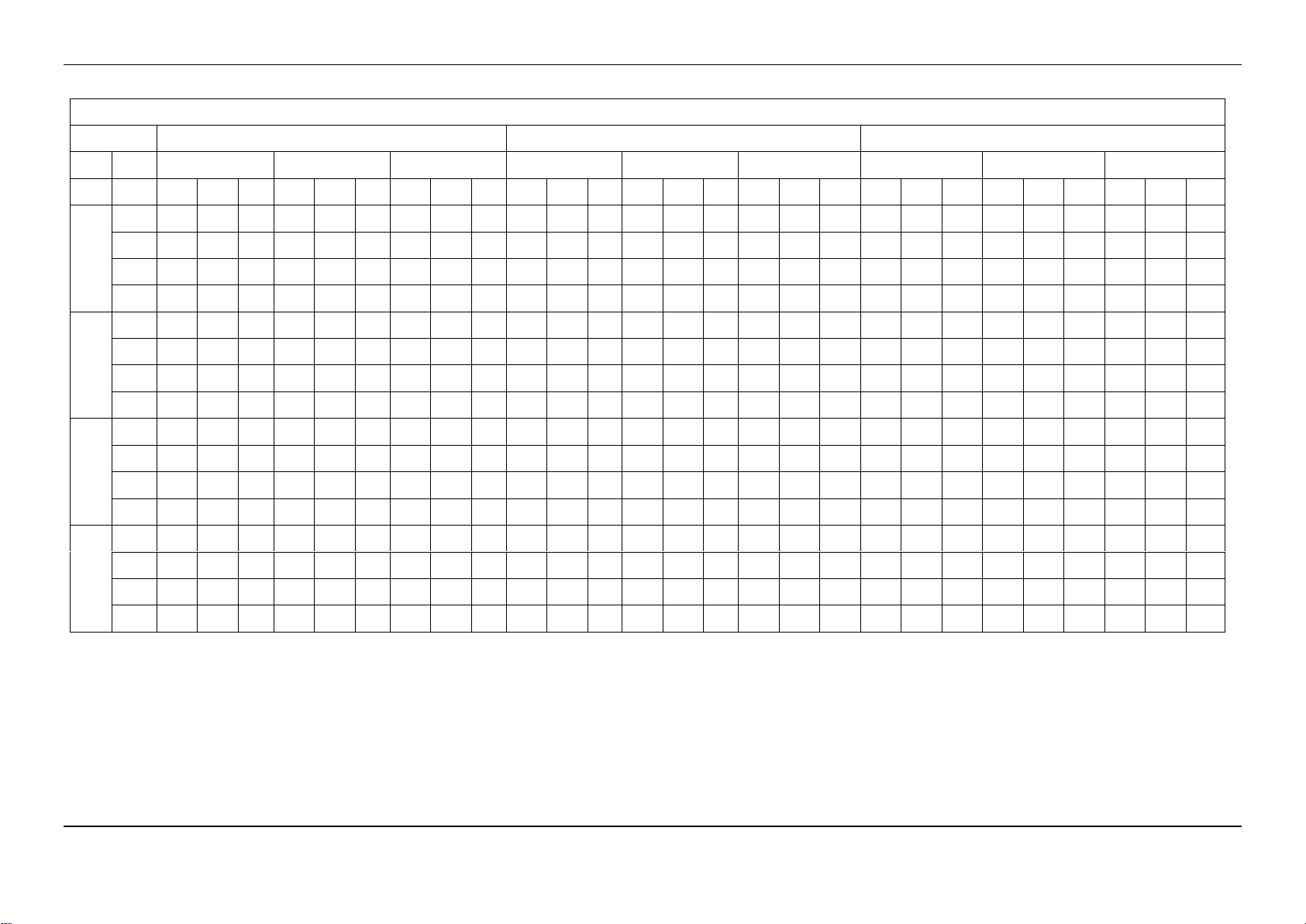

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

29.40

35.00

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2700

23.9

24.3

19.0

9.38

26.8

15.1

9.58

28.1

6.5

9.71

23.5

19.3

9.81

25.6

14.5

10.03

26.8

6.2

10.17

26.7

25.1

21.6

9.4

27.3

17.7

9.6

28.7

12.4

9.73

24.0

21.8

9.83

26.1

16.9

10.06

27.4

11.8

10.2

29.4

26.0

23.6

9.42

27.8

22.8

9.62

29.3

17.4

9.75

24.5

23.5

9.85

26.6

21.8

10.09

27.9

16.6

10.23

32.2

26.9

26.4

9.45

9.78

25.0

24.5

9.88

27.1

24.7

10.11

28.5

21.0

3000

23.9

25.3

20.3

9.58

9.91

24.5

20.6

10

26.2

15.1

10.23

27.5

6.5

26.7

26.2

22.8

9.6

9.93

25.0

23.2

10.03

26.7

18.9

10.26

28.0

12.3

29.4

27.1

25.1

9.62

9.95

25.5

25.0

10.06

27.2

22.9

10.29

28.6

17.4

32.2

28.1

26.7

9.65

9.98

26.0

26.0

10.08

27.8

25.7

10.31

29.1

21.7

3260

23.9

25.8

22.4

9.82

10.14

25.0

22.9

10.24

26.7

16.7

10.47

27.9

7.2

26.7

26.7

25.4

9.84

28.4

21.9

10.04

29.8

14.3

10.17

25.5

25.5

10.27

27.2

20.9

10.5

28.5

13.6

10.64

29.4

27.6

26.8

9.86

29.0

26.6

10.07

30.4

20.1

10.2

26.0

26.0

10.3

27.7

25.5

10.53

29.1

19.3

10.67

32.2

28.6

28.0

9.89

29.6

26.9

10.09

31.0

25.2

10.22

26.5

26.5

10.32

28.3

25.7

10.55

29.7

24.1

10.69

3500

23.9

26.3

23.3

10.12

28.3

17.0

10.32

29.7

7.3

10.45

25.8

22.8

10.55

27.2

16.3

10.78

28.4

7.0

10.92

26.7

27.2

26.2

10.15

28.9

21.3

10.35

30.3

13.8

10.48

26.3

25.3

10.58

27.7

20.4

10.81

29.0

13.2

10.95

29.4

28.2

27.3

10.18

29.5

25.6

10.38

30.9

19.6

10.51

26.8

26.8

10.61

28.3

24.6

10.84

29.6

18.7

10.98

32.2

29.1

28.6

10.2

30.1

28.9

10.4

31.5

24.4

10.53

27.4

27.4

10.63

28.8

27.7

10.86

30.2

23.4

11

7.1 96 kBtu/h

28.4 25.8 9.65 29.8 21.9

27.4 15.8 9.78 28.7 6.8

27.9 19.8 9.8 29.3 12.9

28.5 23.9 9.82 29.9 18.2

29.0 26.9 9.85 30.5 22.8

27.8 17.4 10.14 29.2 7.6

10.25

10.37

10.4

10.43

10.45

10.61

17

Page 17

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

40.60

46.10

51.70

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2700

23.9

23.8

19.5

10.85

25.4

14.3

11.09

26.7

6.2

11.24

22.3

18.3

11.04

23.8

13.5

11.3

25.0

5.8

11.55

19.6

16.1

12.37

20.9

11.8

12.73

21.9

5.1

12.98

26.7

24.3

22.1

10.88

25.9

16.8

11.12

27.2

11.7

11.27

22.8

20.7

11.07

24.3

15.7

11.33

25.5

11.0

11.58

20.0

18.2

12.4

21.3

13.8

12.76

22.4

9.7

13.01

29.4

24.8

23.8

10.91

26.4

21.6

11.15

27.7

16.5

11.3

23.2

22.3

11.1

24.8

20.3

11.36

26.0

15.5

11.61

20.4

19.6

12.43

21.7

17.8

12.79

22.8

13.6

13.04

32.2

25.3

24.8

10.93

26.9

24.5

11.18

28.3

20.8

11.33

23.7

23.2

11.13

25.3

23.0

11.39

26.5

19.5

11.64

20.8

20.4

12.46

22.1

20.1

12.82

23.3

17.1

13.08

3000

23.9

24.4

20.5

11.05

26.0

15.0

11.29

14.1

11.5

25.6

6.0

11.75

20.2

17.0

12.57

21.5

12.4

12.93

22.6

26.7

24.9

23.1

11.08

26.5

18.8

11.32

17.7

11.53

26.1

11.5

11.78

20.6

19.1

12.6

21.9

15.5

12.96

23.0

29.4

25.4

24.9

11.11

27.0

22.7

11.35

21.3

11.56

26.6

16.2

11.81

21.0

20.6

12.63

22.3

18.8

12.99

23.5

32.2

25.9

25.9

11.14

27.6

25.5

11.38

24.0

11.59

27.2

20.3

11.84

21.4

21.4

12.66

22.8

21.1

13.02

23.9

3260

23.9

24.9

22.9

11.29

26.5

16.5

11.68

15.6

11.74

26.1

6.8

11.99

20.7

19.0

12.81

22.0

13.7

13.17

23.0

26.7

25.4

25.4

11.32

27.0

20.8

11.56

19.5

11.77

26.6

12.7

12.02

21.1

21.1

12.84

22.4

17.2

13.2

23.5

29.4

25.9

25.9

11.35

27.5

25.3

11.59

28.9

19.1

11.74

24.4

24.4

11.54

25.9

23.8

11.8

27.1

18.0

12.05

21.5

21.5

12.87

22.9

21.0

13.23

24.0

15.9

13.48

32.2

26.4

26.4

11.38

28.1

25.5

11.62

29.4

23.9

11.77

24.9

24.9

11.57

26.4

24.0

11.83

27.7

22.5

12.08

22.0

22.0

12.9

23.3

21.2

13.27

24.5

19.9

13.52

3500

23.9

25.4

22.5

11.6

27.0

16.1

11.84

28.2

6.9

11.99

23.9

21.2

11.79

25.4

15.2

12.05

26.6

6.5

12.3

21.2

18.7

13.12

22.5

13.4

13.48

23.5

5.8

13.73

26.7

25.9

24.9

11.63

27.5

20.2

11.87

28.8

13.1

12.02

24.4

23.5

11.82

25.9

19.0

12.08

27.1

12.3

12.33

21.6

20.8

13.15

22.9

16.8

13.51

24.0

10.9

13.76

29.4

26.4

26.4

11.66

28.1

24.4

11.9

29.4

18.6

12.05

24.9

24.9

11.85

26.4

23.0

12.11

27.6

17.5

12.36

22.0

22.0

13.18

23.4

20.3

13.54

24.5

15.5

13.79

32.2

27.0

27.0

11.69

28.6

27.5

11.93

30.0

23.2

12.08

25.4

25.4

11.88

27.0

25.9

12.14

28.2

21.9

12.39

22.5

22.5

13.22

23.8

22.9

13.58

25.0

19.4

13.83

27.3 6.4 11.44 22.9 19.3 11.24 24.4

27.8 12.2 11.47 23.4 21.7 11.27 24.9

28.4 17.3 11.5 23.9 23.4 11.3 25.4

28.9 21.6 11.53 24.4 24.4 11.33 25.9

27.8 7.2 11.68 23.4 21.5 11.48 24.9

28.3 13.5 11.71 23.9 23.9 11.51 25.4

Notes:

1. DB = Dry Bulb Temperature (°C), WB = Wet Bulb Temperature (°C)

4. TGC = Total Cooling Capacity (kW)

5. SHC = Sensible Heating Capacity (kW)

6. PI = Power Input (kW)

18

5.3 13.18

10.1 13.21

14.3 13.24

17.9 13.28

6.0 13.42

11.2 13.45

Page 18

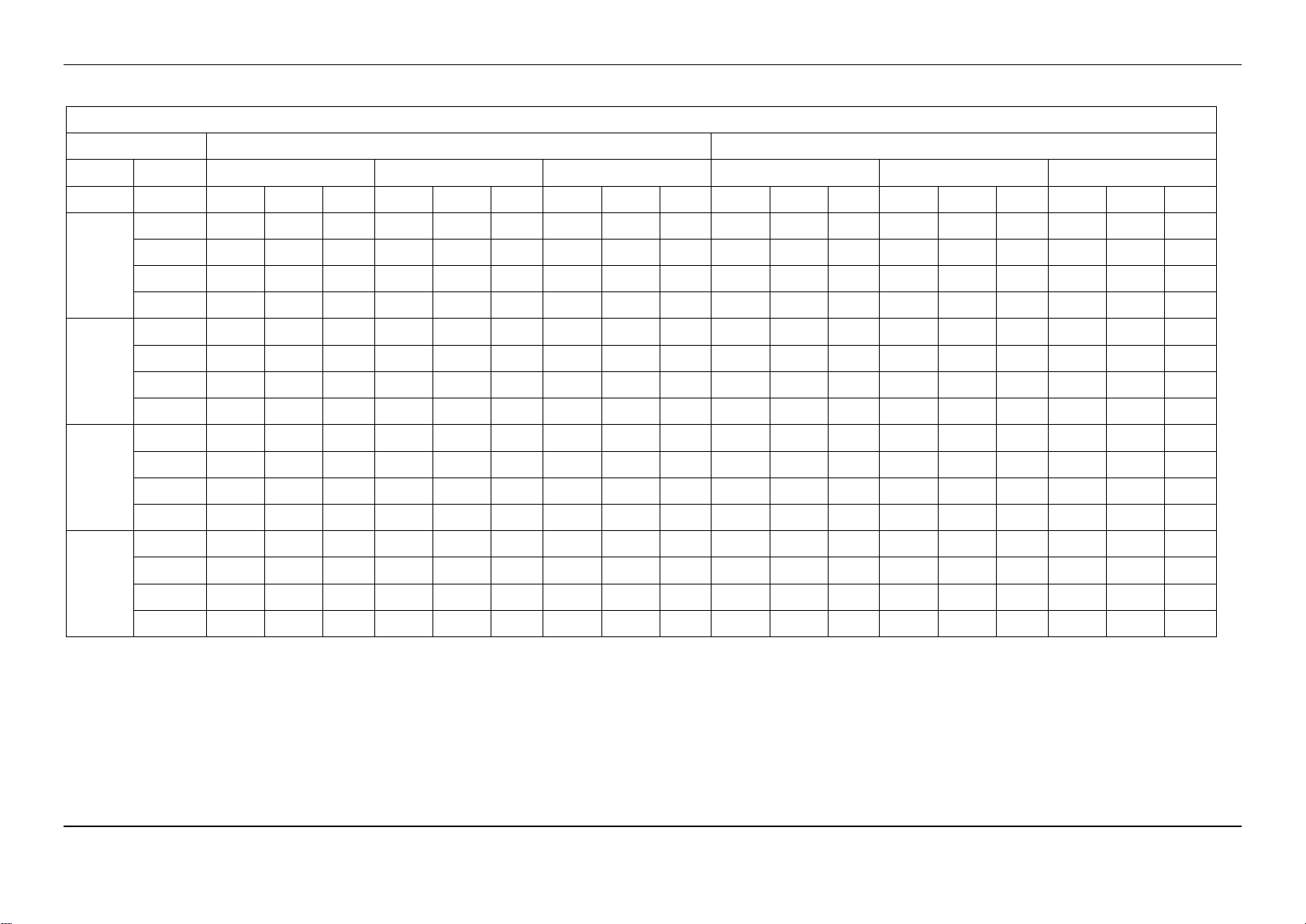

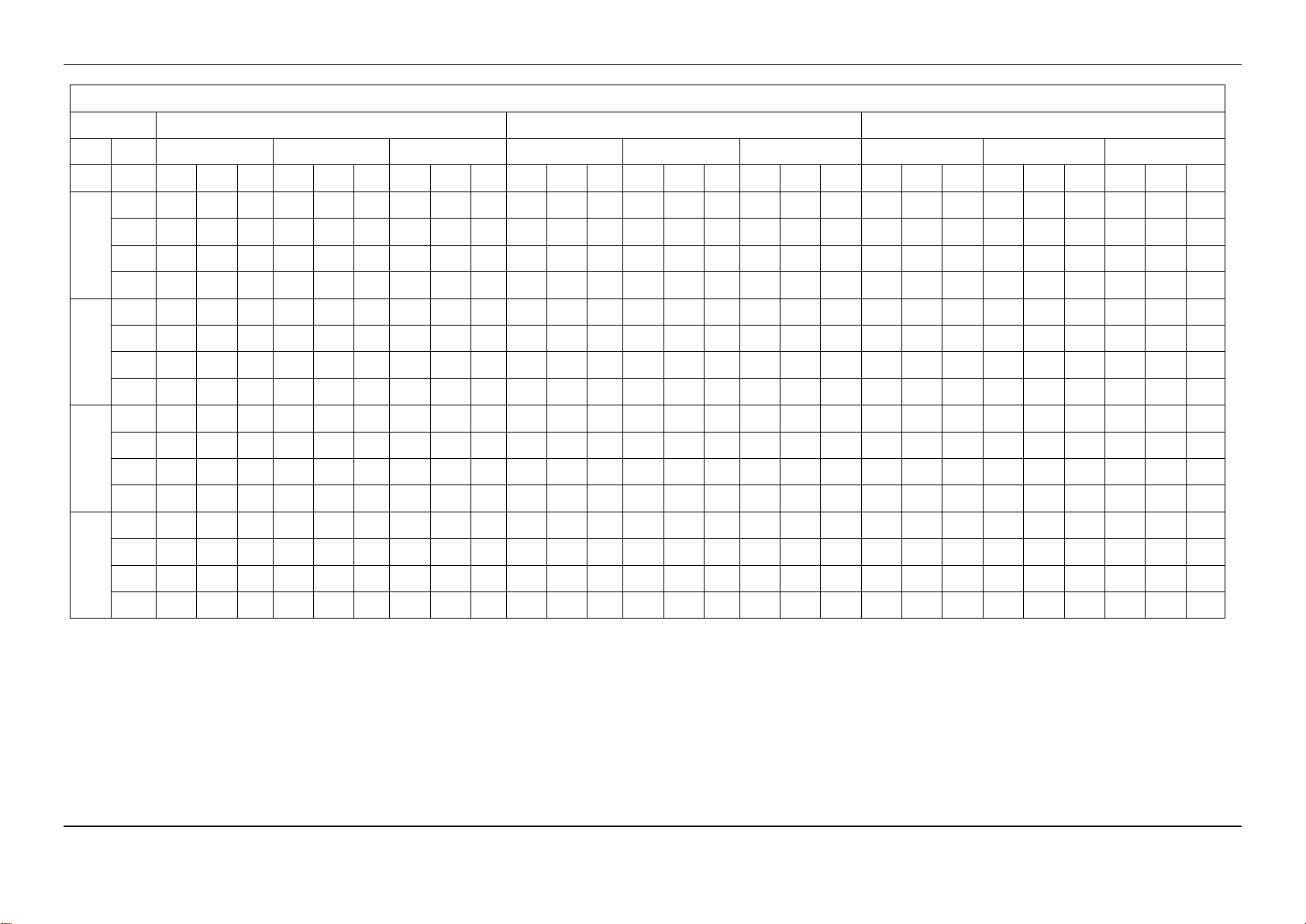

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

29.40

35.00

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

3300

23.9

30.8

24.1

11.97

33.4

18.9

12.17

34.8

8.0

12.3

30.2

24.8

12.4

32.2

18.2

12.63

33.5

7.7

12.77

26.7

31.9

27.5

12

34.1

22.1

12.2

35.5

15.3

12.33

30.8

28.0

12.43

32.9

21.3

12.66

34.2

14.7

12.8

29.4

33.0

30.0

12.03

34.8

28.5

12.23

36.2

21.5

12.36

31.4

30.2

12.46

33.5

27.5

12.69

34.9

20.8

12.83

32.2

34.2

33.5

12.06

12.39

32.0

31.4

12.49

34.2

31.1

12.72

35.6

26.2

3700

23.9

31.9

25.5

12.17

12.5

31.2

26.2

12.6

32.8

19.0

12.83

34.1

8.1

26.7

33.0

28.7

12.2

12.53

31.8

29.4

12.63

33.5

23.8

12.86

34.8

15.3

29.4

34.2

31.6

12.23

12.56

32.4

31.8

12.66

34.2

28.7

12.89

35.5

21.6

32.2

35.4

33.7

12.26

12.59

33.1

33.1

12.69

34.9

32.3

12.92

36.2

27.0

4000

23.9

32.4

28.2

12.41

12.74

31.7

29.1

12.84

33.3

20.8

13.07

34.6

9.0

26.7

33.5

31.9

12.44

35.2

27.1

12.64

36.6

17.5

12.77

32.3

32.3

12.87

34.0

26.2

13.1

35.3

16.9

13.24

29.4

34.7

33.7

12.47

35.9

32.9

12.67

37.3

24.7

12.8

33.0

33.0

12.9

34.7

31.8

13.13

36.0

23.9

13.27

32.2

35.9

35.2

12.5

36.6

33.3

12.7

38.1

31.0

12.83

33.6

33.6

12.93

35.4

32.2

13.17

36.7

29.9

13.31

4500

23.9

32.9

29.1

12.72

35.0

21.0

12.92

36.4

8.9

13.05

32.5

28.7

13.15

33.8

20.3

13.38

35.1

8.6

13.52

26.7

34.0

32.7

12.75

35.7

26.3

12.95

37.1

16.9

13.08

33.1

31.8

13.18

34.5

25.4

13.41

35.8

16.3

13.55

29.4

35.2

34.2

12.78

36.4

31.7

12.98

37.8

24.0

13.11

33.8

33.8

13.21

35.2

30.6

13.44

36.5

23.1

13.58

32.2

36.4

35.7

12.81

37.1

35.7

13.01

38.6

29.9

13.15

34.4

34.4

13.25

35.9

34.5

13.48

37.3

28.9

13.62

7.3 120 kBtu/h

35.5 32.2 12.26 36.9 27.1

34.0 19.7 12.37 35.4 8.4

34.7 24.6 12.4 36.1 15.8

35.4 29.7 12.43 36.8 22.5

36.1 33.4 12.46 37.6 28.0

34.5 21.6 12.74 35.9 9.3

12.86

12.97

13

13.03

13.07

13.21

19

Page 19

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

40.60

46.10

51.70

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

3300

23.9

29.8

24.4

14.37

31.4

17.7

14.61

32.6

7.5

14.76

28.3

23.2

14.56

29.8

16.8

14.82

31.0

7.2

15.07

29.5

24.2

16.36

30.8

17.4

16.72

31.8

7.4

16.97

26.7

30.4

27.6

14.41

32.0

20.7

14.65

33.3

14.3

14.8

28.9

26.3

14.6

30.4

19.7

14.86

31.6

13.6

15.11

30.1

27.4

16.4

31.4

20.3

16.76

32.5

14.0

17.01

29.4

31.0

29.8

14.45

32.6

26.7

14.69

34.0

20.2

14.84

29.5

28.3

14.64

31.0

25.4

14.9

32.2

19.2

15.15

30.7

29.5

16.44

32.0

26.2

16.8

33.1

19.7

17.05

32.2

31.6

31.0

14.48

33.3

30.3

14.72

34.6

25.5

14.87

30.1

29.5

14.67

31.6

28.7

14.93

32.9

24.2

15.19

31.3

30.7

16.48

32.7

29.7

16.84

33.8

24.9

17.1

3700

23.9

30.4

25.5

14.57

32.0

18.5

14.81

30.4

17.6

15.02

31.6

7.5

15.27

30.1

25.3

16.56

31.4

18.1

16.92

32.5

26.7

31.0

28.7

14.61

32.6

23.1

14.85

31.0

22.0

15.06

32.2

14.1

15.31

30.7

28.4

16.6

32.0

22.7

16.96

33.1

29.4

31.6

31.0

14.65

33.3

27.9

14.89

31.6

26.6

15.1

32.8

20.0

15.35

31.3

30.7

16.64

32.6

27.4

17

33.8

32.2

32.3

32.3

14.68

33.9

31.4

14.92

32.3

29.9

15.14

33.5

25.0

15.39

31.9

31.9

16.68

33.3

30.8

17.04

34.4

4000

23.9

30.9

28.3

14.27

32.5

20.3

14.66

30.9

19.3

15.26

32.1

8.3

15.51

30.6

28.1

16.8

31.9

19.9

17.16

32.9

26.7

31.5

31.5

14.31

33.1

25.5

14.55

31.5

24.2

15.3

32.7

15.7

15.55

31.2

31.2

16.84

32.5

25.0

17.2

33.6

29.4

32.1

32.1

14.35

33.8

31.0

14.59

35.1

23.2

14.74

30.6

30.6

15.08

32.1

29.5

15.34

33.4

22.1

15.59

31.8

31.8

16.88

33.2

30.4

17.24

34.3

22.7

17.49

32.2

32.8

32.8

14.38

34.4

31.3

14.62

35.8

29.1

14.77

31.2

31.2

15.12

32.8

29.8

15.38

34.0

27.7

15.63

32.5

32.5

16.92

33.8

30.7

17.29

35.0

28.4

17.54

4500

23.9

31.4

27.8

15.12

32.9

19.7

15.36

34.2

8.4

15.51

29.9

26.5

15.31

31.4

18.8

15.57

32.6

8.0

15.82

31.1

27.5

17.11

32.4

19.4

17.47

33.4

8.2

17.72

26.7

32.0

30.8

15.16

33.6

24.7

15.4

34.9

15.9

15.55

30.5

29.3

15.35

32.0

23.5

15.61

33.2

15.1

15.86

31.7

30.5

17.15

33.0

24.3

17.51

34.1

15.5

17.76

29.4

32.6

32.6

15.2

34.3

29.8

15.44

35.6

22.5

15.59

31.1

31.1

15.39

32.6

28.4

15.65

33.9

21.4

15.9

32.3

32.3

17.19

33.7

29.3

17.55

34.8

22.0

17.8

32.2

33.3

33.3

15.24

35.0

33.6

15.48

36.3

28.2

15.63

31.7

31.7

15.43

33.3

32.0

15.69

34.5

26.8

15.94

33.0

33.0

17.24

34.3

33.0

17.6

35.5

27.5

17.85

33.2 7.8 14.96 28.9 24.3 14.76

33.9 14.9 15 29.5 27.3 14.8

34.6 21.1 15.04 30.1 29.5 14.84

35.3 26.3 15.08 30.7 30.7 14.87

33.7 8.7 14.66 29.4 27.0 15

34.4 16.5 14.7 30.0 30.0 15.04

Notes:

1. DB = Dry Bulb Temperature (°C), WB = Wet Bulb Temperature (°C)

4. TGC = Total Cooling Capacity (kW)

5. SHC = Sensible Heating Capacity (kW)

6. PI = Power Input (kW)

20

7.7 17.17

14.5 17.21

20.6 17.25

25.7 17.3

8.5 17.41

16.1 17.45

Page 20

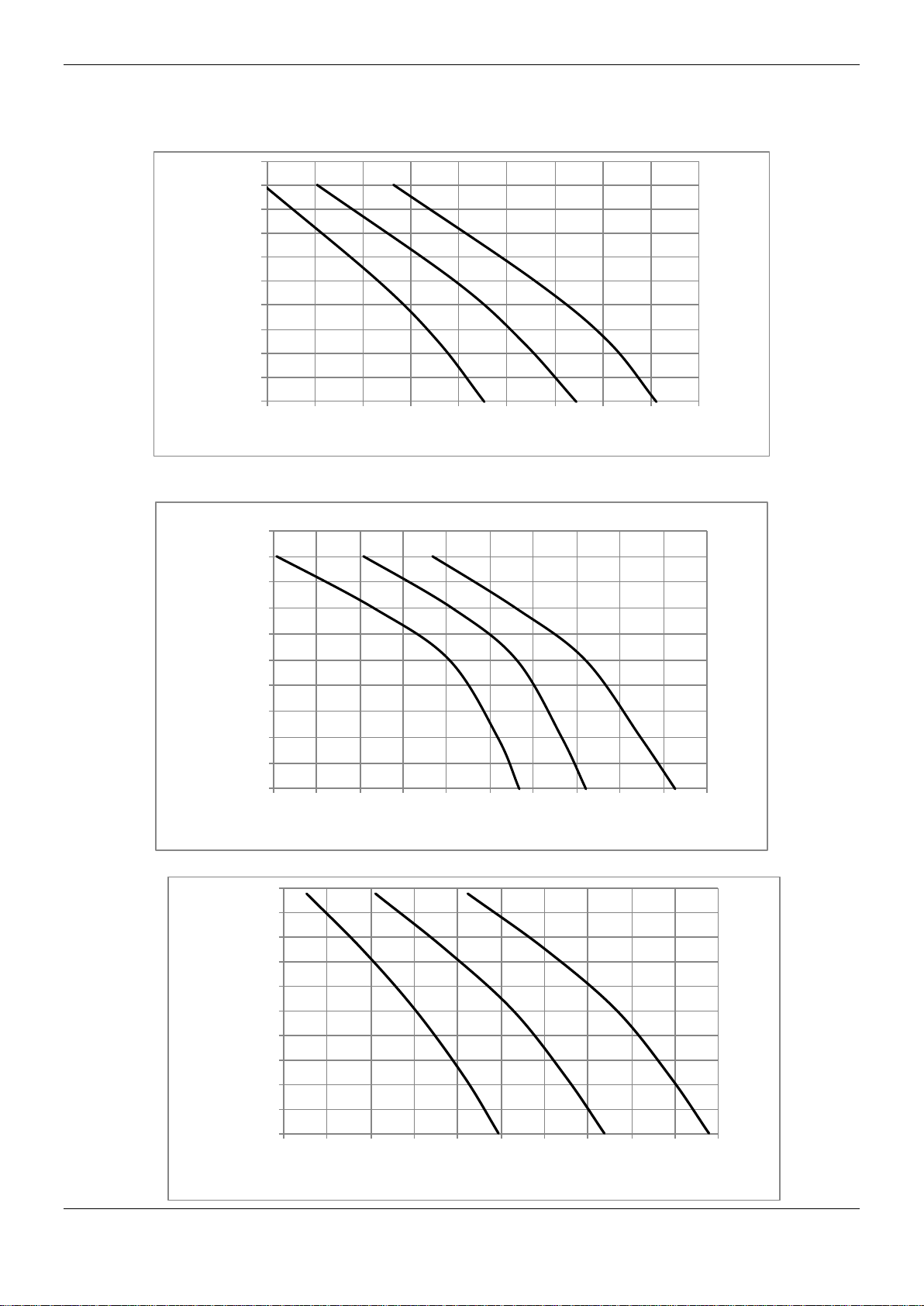

MCAC-UTSM-12

8. Air flow rate- Static pressure curve

8.1 76kBtu/h

8.2 96kBtu/h

200

180

160

140

120

100

Static Pressure (Pa)

Low

80

60

40

20

0

3250 3500 3750 4000 4250 4500 4750 5000

Medium

High

AirFlow (m3/h)

5250 5500

8.3 120kBtu/h

200

180

160

140

120

100

Static Pressure (Pa)

Low

80

60

40

20

0

3800 4050 4300 4550 4800 5050 5300 5550 5800 6050 6300

Medium

High

AirFlow (m3/h)

200

180

160

140

120

100

80

60

40

Static Pressure (Pa)

20

0

5000 5300 5600 5900 6200 6500 6800 7100 7400 7700 8000

Low

Medium

High

Air Flow (m3/h)

21

Page 21

MCAC-UTSM-12

Model

Indoor Unit

Power Supply

IFM

Hz Voltage

MCA

MFA kW FLA

MDTA-76CRN2

50 220-240

10

8

1.42

6.66

MDTA-76HRN2

50 220-240

10

8

1.42

6.66

MDTA-96CRN2

50 220-240

10

12

1.8 8.6

MDTA-96HRN2

50 220-240

10

12

1.8 8.6

MDTA-120CRN2

50 220-240

11.25

20

2.1 10

MDTA-120HRN2

50 220-240

198 254 11.25

20

2.1 10

Model

Outdoor Unit

Power Supply

Compressor

OFM

Hz Voltage

Min.

Max. MCA

TOCA MFA

MSC RLA KW FLA MDOV-76C-CN2

50 380-415

342 438 15.75

18.5 21.85

48*2 6.3*2

0.573

2.613

MDOV-76H-CN2

50 380-415

342 438 15.75

18.5 21.85

48*2 6.3*2

0.573

2.613

MDOV-96C-CN2

50 380-415

342 438 20 28 30 53*2 8.0*2 0.573

2.613

MDOV-96H-CN2

50 380-415

342 438 20 28 30 53*2 8.0*2 0.573

2.613

MDOV-120C-CN2

50 380-415

342 438 22.75

28.7 32.55

57*2 9.1*2 1.2

5.857

MDOV-120H-CN2

50 380-415

342 438 22.75

28.7 32.55

57*2 9.1*2 1.2

5.857

9. Electric Characteristics

Note:

MCA: Min. Current Amps. (A)

MFA: Max. Fuse Amps. (A)

IFM: Indoor Fan Motor

kW: Fan Motor Rated Output (kW)

FLA: Full Load Amps. (A)

Min.

198

198

198

198

198

Max.

254

254

254

254

254

Note:

MCA: Min. Current Amps. (A) TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A) MSC: Max. Starting Amps. (A)

RLA: Rated Locked Amps. (A) OFM: Outdoor Fan Motor

KW: Rated Motor Output (KW) FLA: Full Load Amps. (A)

22

Page 22

MCAC-UTSM-12

Unit Number

Model

Noise level under three speeds of fan (dB(A))

1

MDTA-76C(H)RN2

54

2

MDTA-96C(H)RN2

55

3

MDTA-120C(H)RN2

56

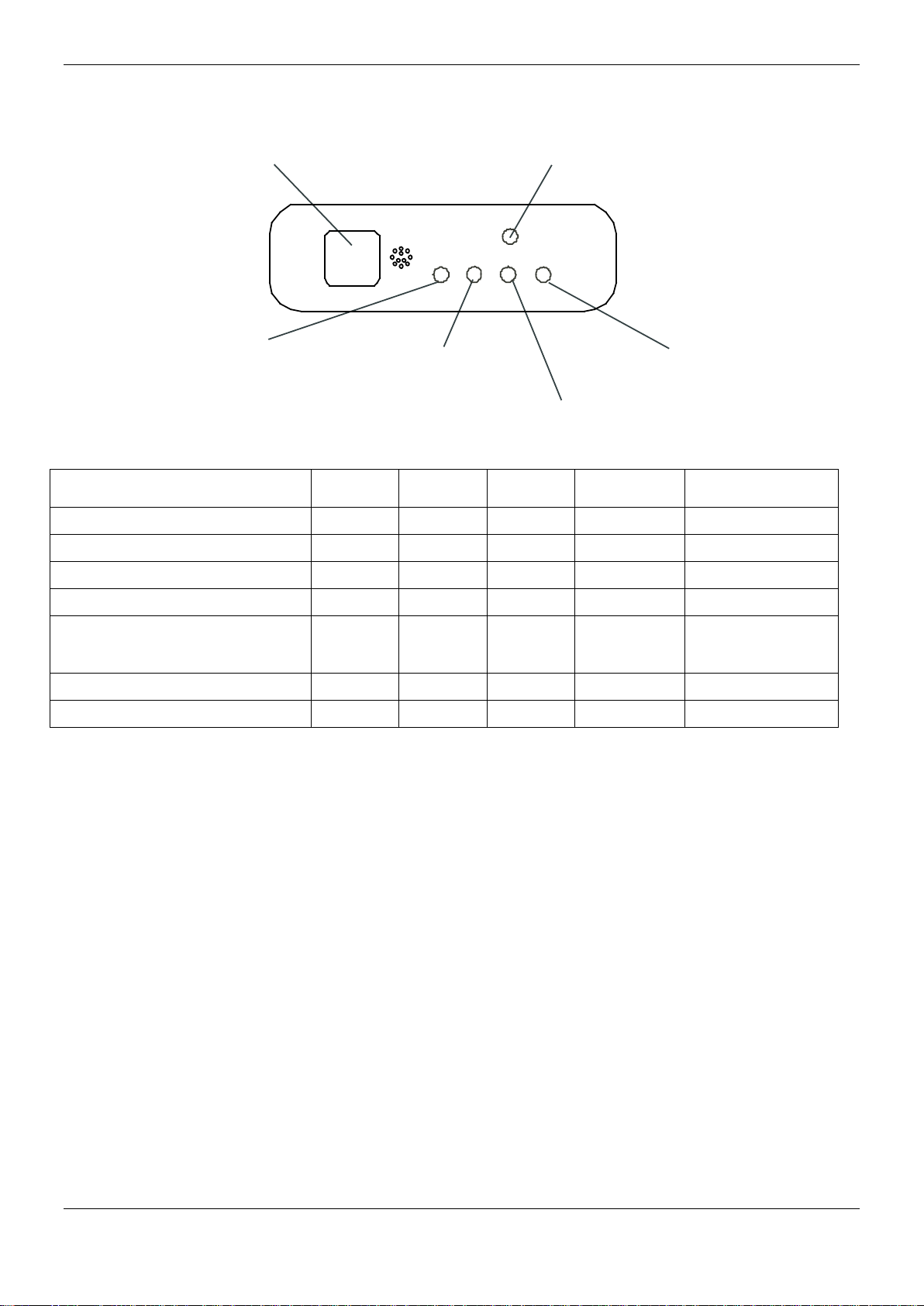

10. Sound Levels

Concealed Duct Type

Discharge

Duct

Suction

1.4m

Microphone

23

Page 23

MCAC-UTSM-12

f

Type

ALARM

Light

Remarks

Room temp. sensor error

- Manual reset

Evaporator temp. sensor error

☆

- - - Manual reset

Condenser temp. sensor error

- -

☆

- Manual reset

Water pump temp. sensor error

☆

- -

☆

Manual reset

The PRO terminal on PCB of

indoor unit without connected to

grounding wire

☆ ☆ ☆ ☆

Manual reset

EEPROM error

☆ ☆

- - Manual reset

Condensing water level full error

- - -

☆

Manual reset

12. Troubleshooting

rared signal receiver

In

Manual Switch

Operation lamp

Timer lamp

PRE-DEF lamp(cooling and heating type)

or fan only lamp(cooling only type)

OPT.

Light

-

TME.

Light

☆

Note:

OPT. Light: operation light; TME. Light: timer light;

DEF. Light: defrosting light; ☆: the light flashing.

Alarm lamp

DEF.

Light

-

13.1 Malfunctions of air conditioner

If any of the following malfunctions occur, stop operation of the air conditioner immediately. Turn off the power

switch, and contact the local after sales service center of manufacturer:

The RUN lamp flashes quickly (2 flash per second).

After turning off the power switch and then turning it on again, the RUN lamp still flashes quickly.

The receiving function of the remote controller fails, or the start/ shutdown operation is abnormal.

The fuse blows out frequently, or the circuit breaker protection occurs frequently.

Obstacles or water enter the air conditioner.

Condensing water leaks from indoor unit.

Other malfunctions occur.

24

Page 24

MCAC-UTSM-12

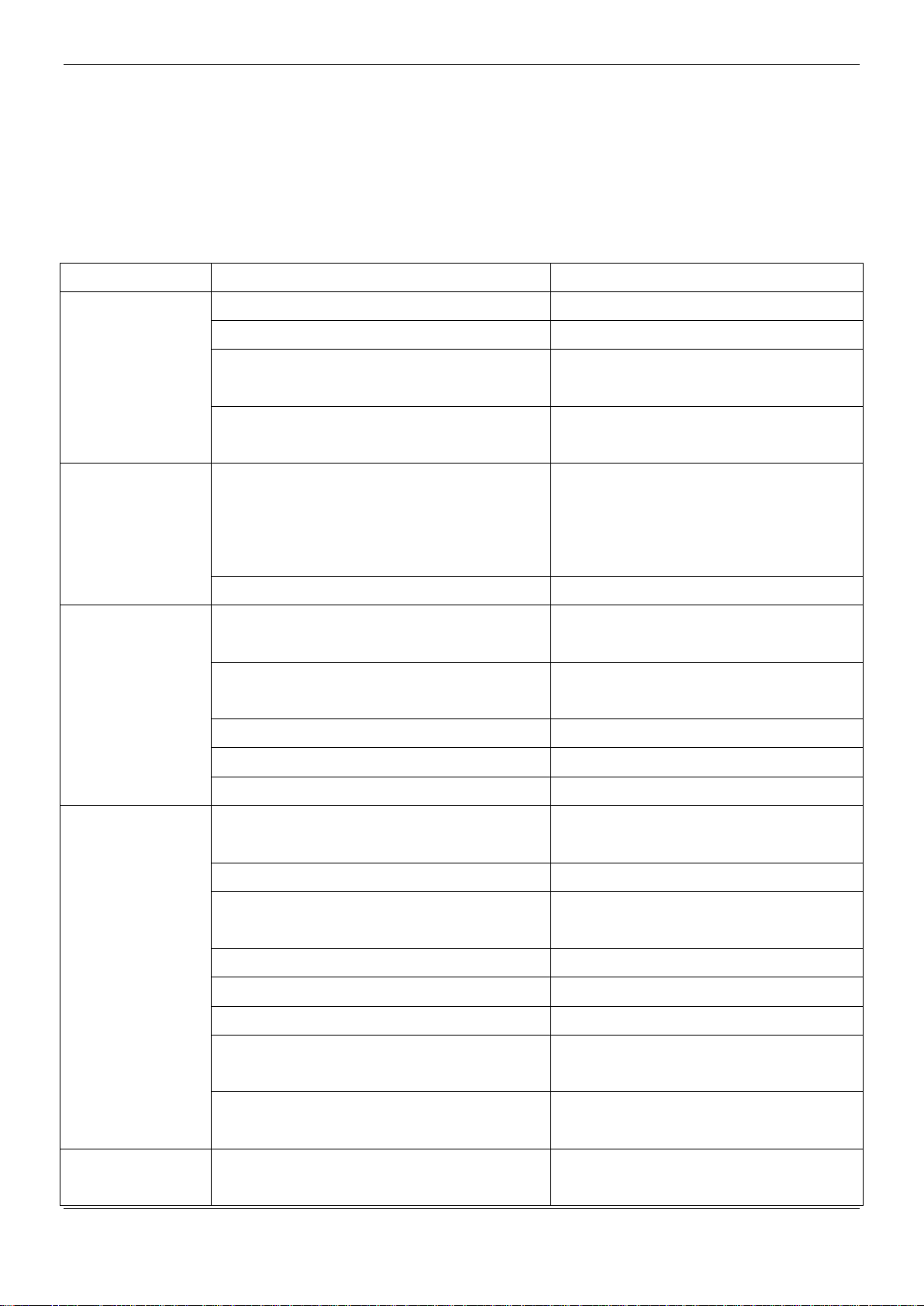

Symptoms

Causes

Handling methods

The unit does not

work

Power supply fails.

Operate after power resumes.

Power switch is not connected.

Connect the power supply properly.

Fuse blows out or circuit breaker snaps off.

Replace the fuse or check whether

electric leakage occurs.

The remote controller or the wire controller

fails.

Check the remote controller or wire

controller.

Air flowing

normally but

completely can’t

cooling

Temperature setting is improper.

Temperature setting is higher than the

room temperature in cooling mode. Or

temperature setting is lower than the

room temperature in heating mode.

3-minute protection of compressor.

Waiting for 3 minutes.

The unit starts or

stops frequently

The system is lack of refrigerant. Or there is

too much refrigerant in the system.

Fix the leakage places, and charge the

proper quantity of refrigerant.

Air or non-condensable gas exists in the

refrigerant system.

Vacuum the system and charge

refrigerant again.

Compressor fails.

Repair or replace the compressor.

The voltage is too high or too low.

Install a voltage regulator.

The refrigerant pipe is obstructed.

Locate and replace that part.

Poor cooling effect

The heat exchanger of outdoor unit or indoor

unit is too dirty.

Clean the heat exchanger.

The filter is too dirty.

Clean the filter.

Air inlet or air outlet of the indoor/ outdoor

unit is blocked.

Remove obstacles to keep well

ventilating.

Doors or windows of the room are open.

Close all the windows and doors.

Directly exposed to sunlight.

Use curtain to obstruct sunlight.

Too many heat sources in the room.

Reduce the heat sources.

The outdoor ambient temperature is too

high.

The cooling effect is poor but normal.

The system is lack of refrigerant.

Fix the leakage places, and charge the

proper quantity of refrigerant.

Poor heating

effect

The outdoor ambient temperature is lower

than -7℃.

Use an assistance heating device.

If the air conditioner fails and does not meet the above phenomena, check the system as the following table:

25

Page 25

Doors or windows of the room are not closed

tightly.

Close the doors and windows properly.

The system is lack of refrigerant.

Fix the leakage places, and charge the

proper quantity of refrigerant.

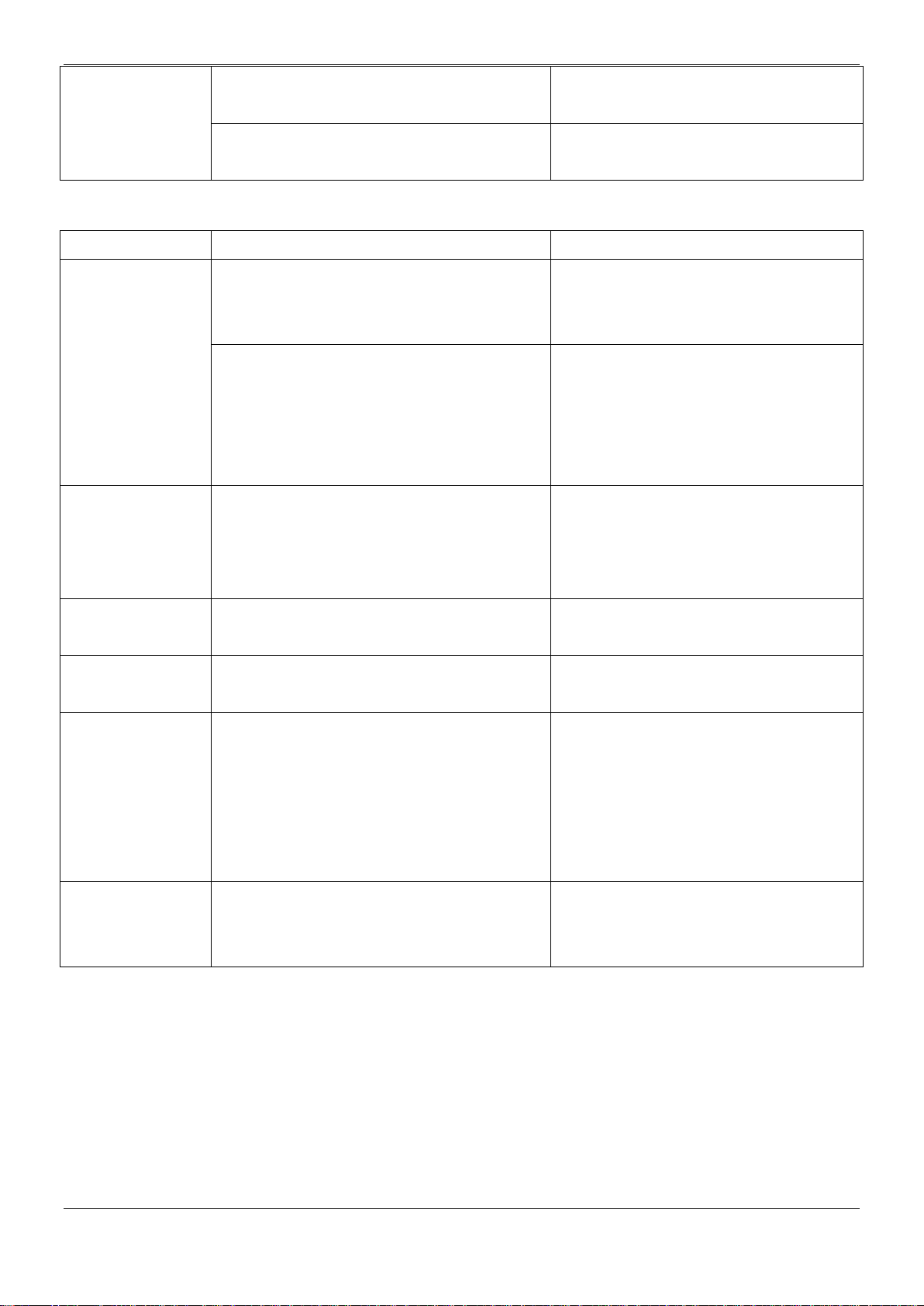

Symptoms

Causes

Handling methods

The fan speed

cannot be

changed

Check whether the mode marked on the

screen is “AUTO”.

When the “AUTO” mode is selected, the

unit will change the fan speed

automatically.

Check whether the mode marked on the

screen is “DEWET”.

When the “DEWET” mode is selected,

the unit will change the fan speed

automatically. The fan speed can be

selected in “COOLING”,”HEATING”

and ”SUPPLY AIR” mode.

The “ON/OFF”

button of remote

controller do not

work

Check whether the batteries of remote

controller are exhausted.

Replace the batteries.

The “ON/OFF”

lamp extinguishes

Check whether the time set on the timer has

expired.

Restart the unit.

The “TIMER ON”

lamp extinguishes

Check whether the time set on the timer has

expired.

It comes to the setting time and the unit

stat running automatically.

No receiving

sounds from the

indoor unit even

when the

“ON/OFF” button

is pressed

Check whether the signal transmitter of the

remote controller is properly directed to the

infrared signal receiver of the indoor unit

when the “ON/OFF” button is pressed.

Directly transmit the signal transmitter of

the remote controller to the infrared

signal receiver of the indoor unit, and

then push the “ON/OFF” button twice.

The buttons of the

remote controller

do not work

Check whether the settings are locked.

Push the “LOCK” button again.

MCAC-UTSM-12

26

Page 26

MCAC-UTSM-12

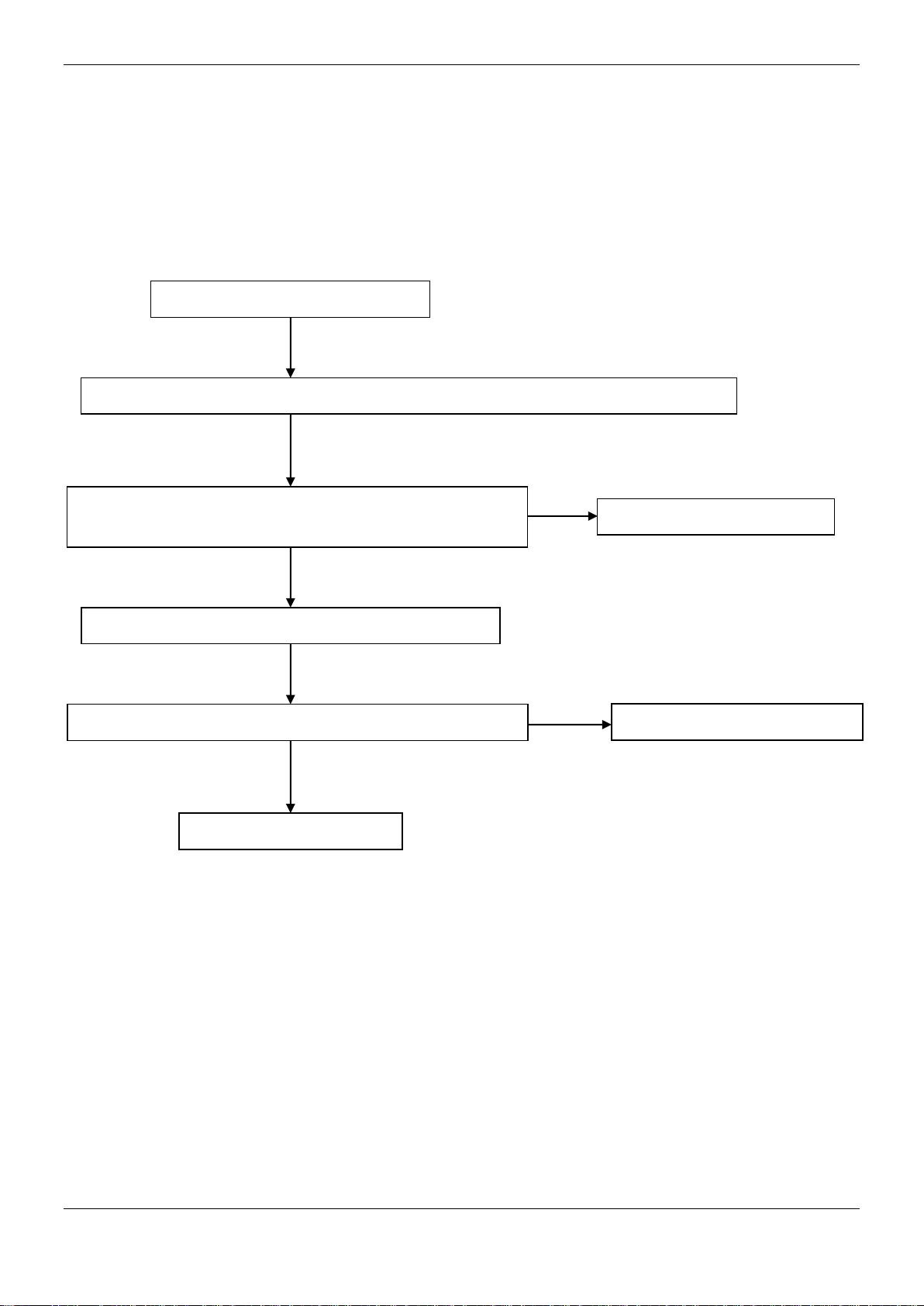

No

No

Yes

All lamps flashing at 5Hz

Judge 1: The PRO terminal on PCB of indoor unit without connecting to grounding wire

Validate: Check whether the PRO terminal on PCB of indoor

unit without connected to grounding wire.

Connect it to grounding wire.

Judge 2: Optical coupler on PCB malfunction

Validate: Check whether the Optical coupler is normal.

Replace optical coupler

Replace indoor PCB.

Operation lamp flashes:

Yes

27

Page 27

MCAC-UTSM-12

Timer lamp flashing at 5Hz

Room temperature sensor malfunction

Judge 1: Check the room temperature sensor

Is break off.

Connects it well.

Judge 2: Check the room temperature sensor

is abnormal.

Validate: Check whether the resistance of the

temperature sensor is correct according to Annex 1.

Replace temperature sensor

Replace indoor PCB.

No

Yes

No

Operation lamp flashes:

Yes

28

Page 28

MCAC-UTSM-12

Yes

No

Yes

Replace temperature sensor

Operation lamp flashing at 5Hz

Evaporate temperature sensor is abnormal.

Judge 1: Check evaporate temperature sensor is break off.

Judge 2: Evaporate temperature sensor is abnormal.

Validate: Check whether the resistance of the room

temperature sensor is correct according to Annex 1.

Replace temperature sensor

Replace indoor PCB.

Operation lamp flashes:

No

29

Page 29

Defrosting lamp flashing at 5Hz

Condenser temperature sensor malfunction

Judge 1: Check condenser temperature sensor is break off.

Replace temperature sensor

Yes

Judge 2: Condenser temperature sensor is abnormal.

Validate: Check whether the resistance of the condenser

temperature sensor is correct according to Annex 1.

Replace temperature sensor

No

Yes

Replace indoor PCB.

Operation lamp flashes:

MCAC-UTSM-12

No

30

Page 30

MCAC-UTSM-12

Floor-standing Type

1. Features ............................................................................ 32

2. Specifications .................................................................. 33

3. Dimensions ...................................................................... 34

4. Service Space .................................................................. 35

5. Refrigerant cycle diagrams ............................................. 36

6. Wiring Diagrams .............................................................. 37

7. Capacity Tables ................................................................ 39

8. Electric Characteristics ................................................... 43

9. Sound Levels ................................................................... 44

10. Exploded View .......... Ошибка! Закладка не определена.

11. Troubleshooting ............................................................. 45

12. Accessories ............... Ошибка! Закладка не определена.

31

Page 31

1. Features

MCAC-UTSM-12

1. The appearance is novel, luxurious, refined.

2. High capacity of cooling/heating, efficient, and energy-saving.

3. Adopt advanced and high efficient scroll compressor, wide angle and long distance air supply.

4. Remote control standard, screen control optional.

5. Easy installation and maintenance.

6. Suit for hotel, meeting room, airport lounge, etc. public occasion use.

32

Page 32

MCAC-UTSM-12

Model

MDFA-76CRN2

MDFA-76HRN2

MDFA-96CRN2

MDFA-96HRN2

Code

220043900081

220043900071

220043900061

220043900051

Power supply

-

220~240V-1Ph-50Hz

220~240V-1Ph-50Hz

Rated input power

W

11500

11500

14500

14700

Rated current

A

28

28.1

Cooling

Capacity

Btu/h

94,500

92,100

W

27700

27000

Input

W

9280

9450

EER

W/W

2.98

2.86

Heating

Capacity

Btu/h

——

103700

W

——

30400

Input

W

——

9130

COP

W/W

——

3.33

Indoor air flow

m3/h

4500

4500

Indoor noise level

dB(A)

54

54

Refrigerant

Type

-

Control - Capillary

Capillary

Capillary

Capillary

Fan

Type - Centrifugal fan

Centrifugal fan

Centrifugal fan

Centrifugal fan

Fan model

YSK300-6

YSK300-6

YSK300-6

YSK300-6

Dimension

mm

Φ250

Φ250

Φ250

Φ250

Drive type/ Motor

step

-

Direct/ Single

Direct/ Single

Direct/ Single

Direct/ Single

Motor model

-

YSK300-6

YSK300-6

YSK300-6

YSK300-6

Motor input* No.

W

590

590

590

590

Motor speed(Hi)

rpm

870

870

870

870

Coil

Type

-

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Copper tube and

aluminum fin

Tube size

mm

Ф9.52

Ф9.52

Ф9.52

Ф9.52

No. of rows - 3 3 3

3

Fin per inch

FPI

16

16

16

16

Length* height

mm

982*711

982*711

982*711

982*711

Controller - Remote controller

Remote controller

Drainage water pipe dia.

mm

Ф41

Ф41

Ф41

Ф41

Connection

wiring

Power wiring

mm2

3×2.5

3×2.5

3×2.5

3×2.5

Signal wiring

mm2

2×1.0

4×1.0

2×1.0

4×1.0

Indoor unit

Dimension

(WxHxD)

mm

1200*1860*420

1200*1860*420

1200*1860*420

1200*1860*420

Packing

(W*H*D)

mm

1362*2023*582

1362*2023*582

1362*2023*582

1362*2023*582

Net/Gross weight

kg

158/174

158/174

158/174

158/174

2. Specifications

18.5 18.5

75,100 75,100

22000 22000

7450 7450

2.95 2.95

—— 83600

—— 24500

—— 6500

—— 3.77

4500 4500

53 53

R407C R407C R407C R407C

33

Page 33

MCAC-UTSM-12

Notes:

1. Nominal cooling capacities are based on the following conditions:

Indoor temp: 27°CDB, 19°CWB; Outdoor temp: 35°CDB; Equivalent ref. piping: 7.5m (horizontal)

2. Nominal heating capacities are based on the following conditions:

Indoor temp: 20°CDB; Outdoor temp: 7°CDB, 6°CWB; Equivalent ref. piping: 7.5m (horizontal)

3. Dimensions

34

Page 34

MCAC-UTSM-12

4. Service Space

Front view

m

c

0

1

m

c

0

1

30 cm

No obstacle in front of it

Rear

35

Page 35

MCAC-UTSM-12

5. Refrigerant cycle diagrams

5.1 Cooling only: MDFA-76CRN2, MDFA-96CRN2

Cooling

Outdoor heat-exchanger

HP Switch

Discharge temp. sensor

Compressors

LP Switch

Liquid-gas seperator

5.2 Cooling and heating: MDFA-76HRN2, MDFA-96HRN2

Cooling

Stop valve

T3

Stop valve

Indoor unit

Capillary

Indoor

heat-exchanger

T2

T4

36

Heating

HP Switch

Discharge temp. sensor

Compressors

LP Switch

4-way valve

Outdoor heat-exchanger

Liquid-gas seperator

T3

Check valve

Stop valve

Capillary

Indoor unit

Indoor

heat-exchanger

Stop valve

T2

T4

Page 36

MCAC-UTSM-12

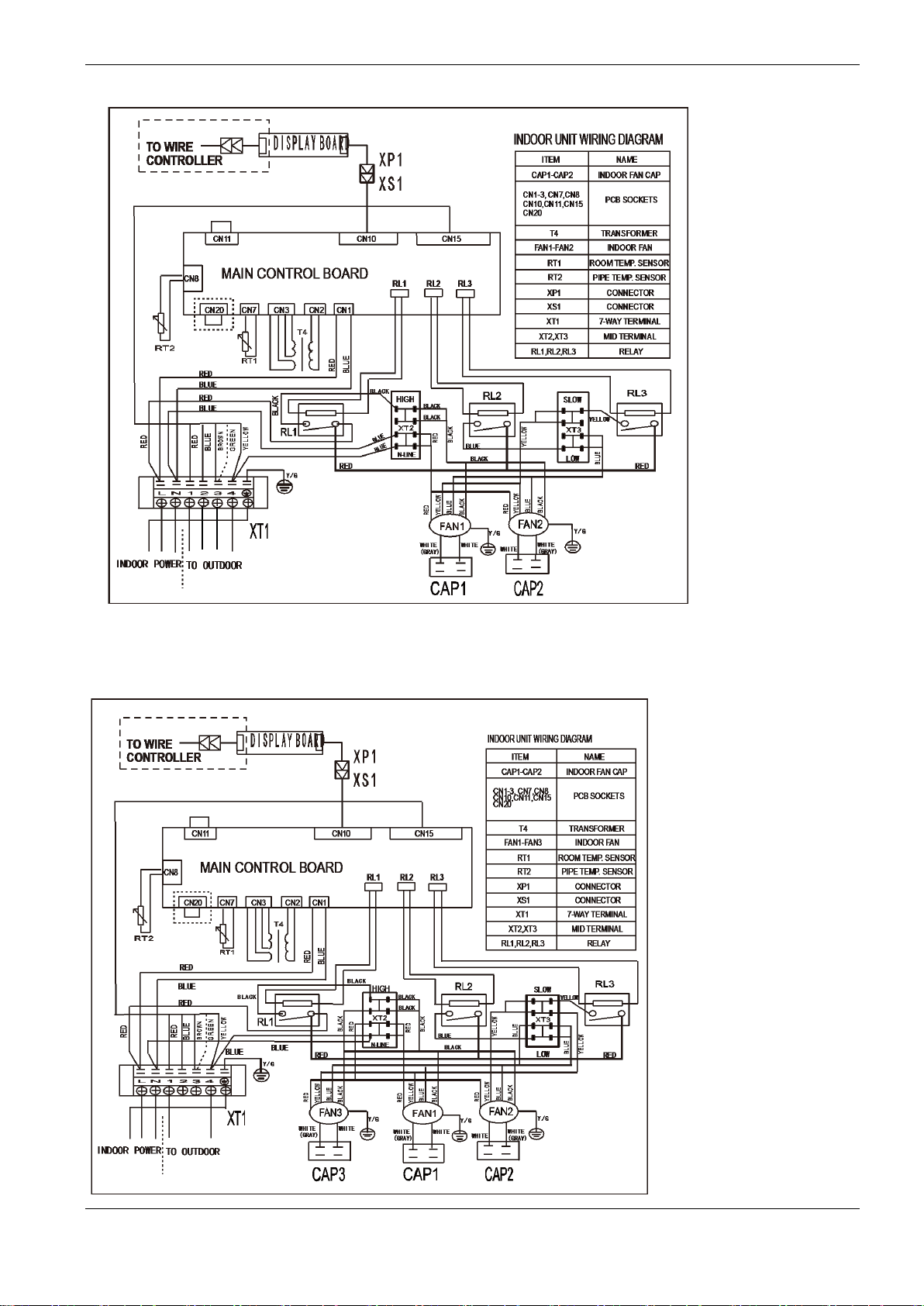

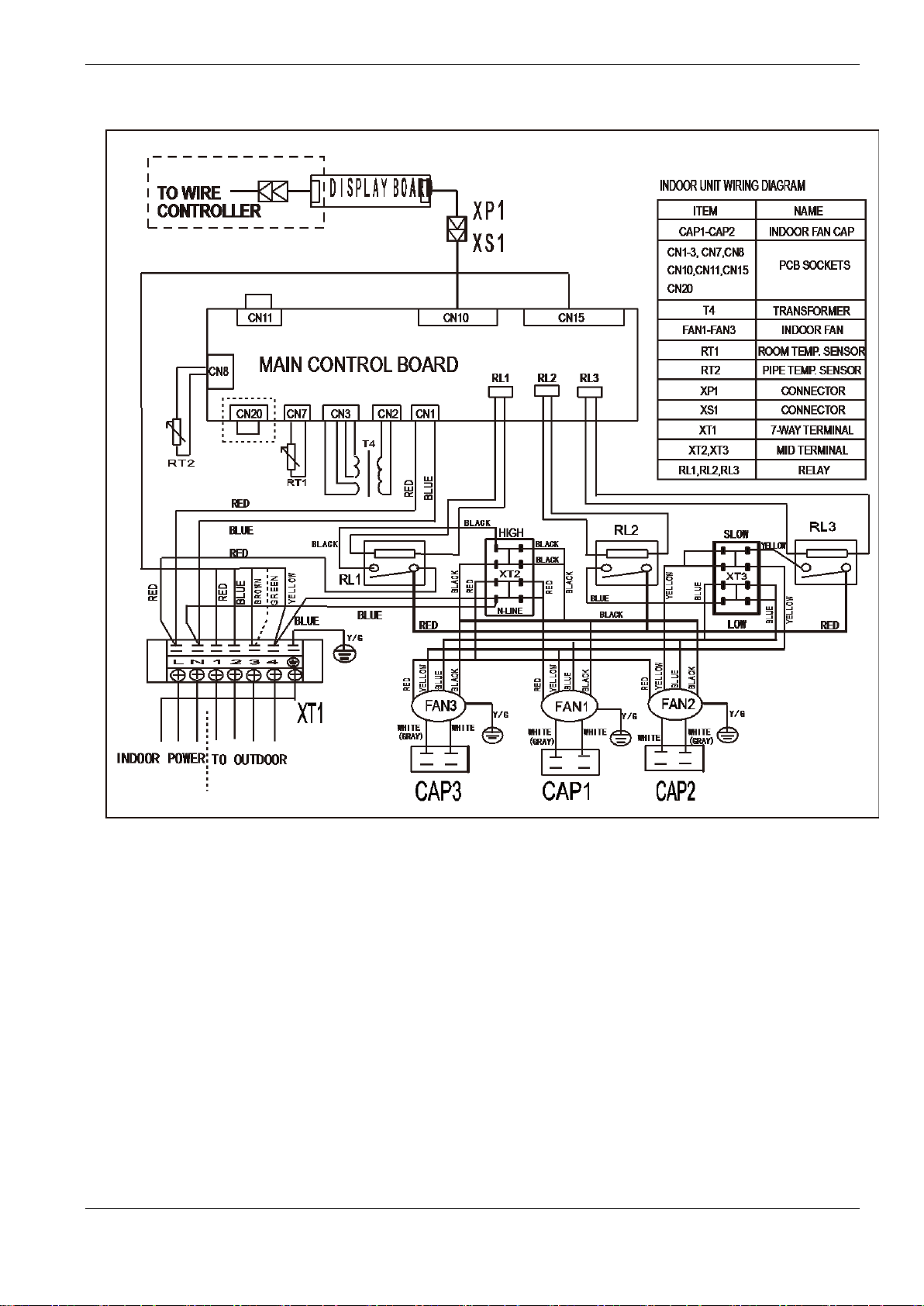

6. Wiring Diagrams

6.1 MDFA-76CRN2, MDFA-96CRN2

CN20CN20CN20

37

Page 37

MCAC-UTSM-12

6.2 MDFA-76HRN2, MDFA-96HRN2

CN20CN20CN20

38

Page 38

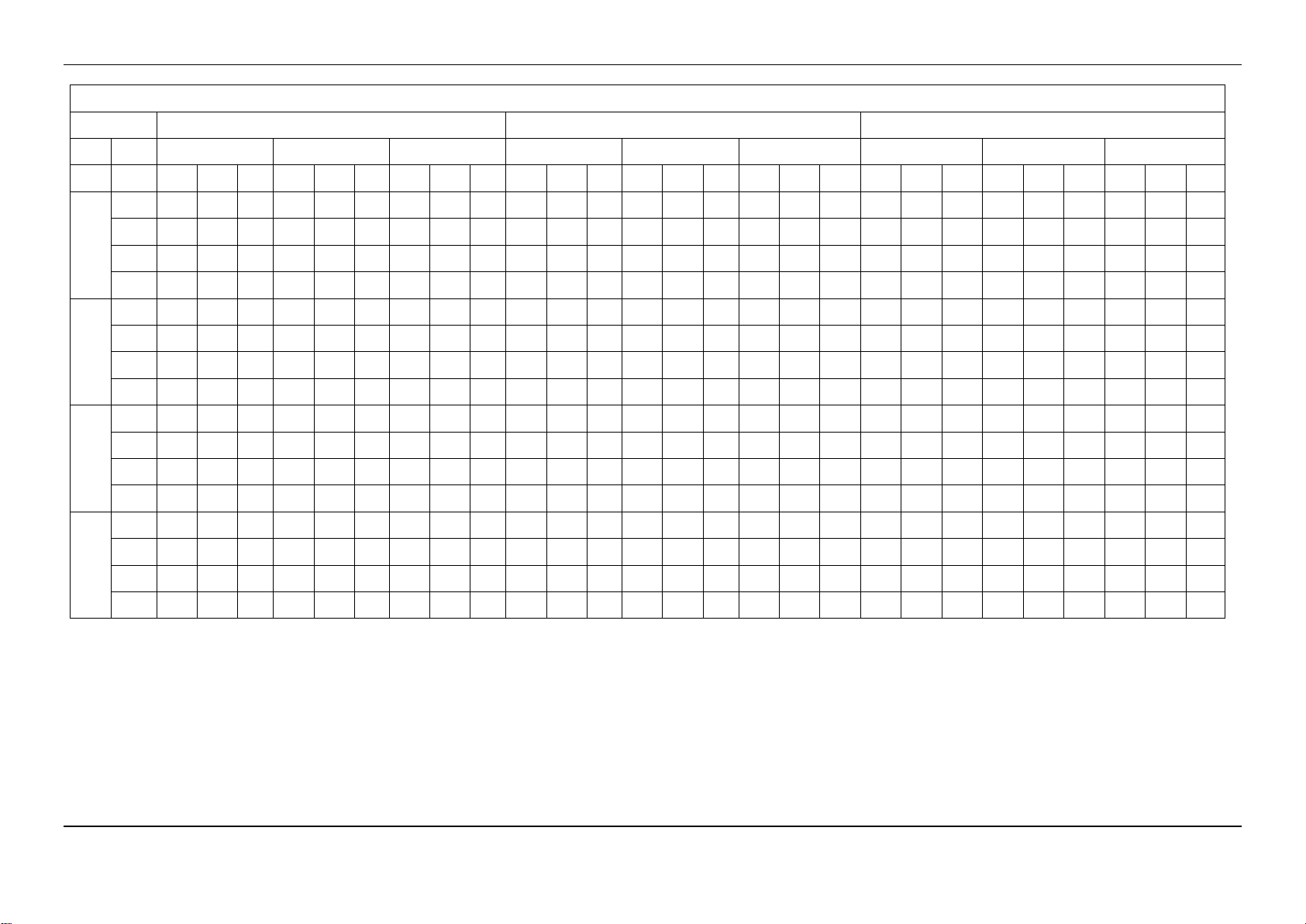

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

29.40

35.00

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2125

23.9

19.6

16.1

6.33

21.7

12.2

6.53

23.0

5.3

6.66

18.8

15.4

6.76

20.5

11.6

6.99

21.8

5.0

7.13

26.7

20.3

18.4

6.35

22.1

14.3

6.55

23.5

10.1

6.68

19.2

17.4

6.78

20.9

13.5

7.01

22.2

9.6

7.15

29.4

21.0

20.2

6.37

6.7

19.6

18.8

6.8

21.3

17.5

7.03

22.6

13.5

32.2

21.7

21.3

6.38

6.71

20.0

19.6

6.81

21.7

19.8

7.05

23.1

17.0

2310

23.9

20.2

17.0

6.53

6.86

19.4

16.3

6.96

21.1

12.2

7.19

22.4

5.3

26.7

20.9

19.4

6.55

6.88

19.8

18.3

6.98

21.5

15.3

7.21

22.8

10.0

29.4

21.6

21.2

6.57

6.9

20.2

19.8

7

21.9

18.4

7.23

23.3

14.2

32.2

22.4

22.4

6.58

6.91

20.6

20.6

7.01

22.4

20.7

7.25

23.7

17.7

2650

23.9

20.7

19.0

6.77

22.8

14.2

7.1

24.1

6.3

7.1

19.9

18.3

7.2

21.6

13.5

7.43

22.8

5.9

7.57

26.7

21.4

21.4

6.79

23.2

17.9

6.99

24.6

11.8

7.12

20.3

20.3

7.22

22.0

16.9

7.45

23.3

11.2

7.59

29.4

22.2

22.2

6.81

23.7

21.7

7.01

25.1

16.6

7.14

20.7

20.7

7.24

22.4

20.6

7.47

23.8

15.7

7.61

32.2

22.9

22.9

6.82

24.1

21.9

7.02

25.6

20.8

7.16

21.1

21.1

7.26

22.9

20.8

7.49

24.2

19.7

7.63

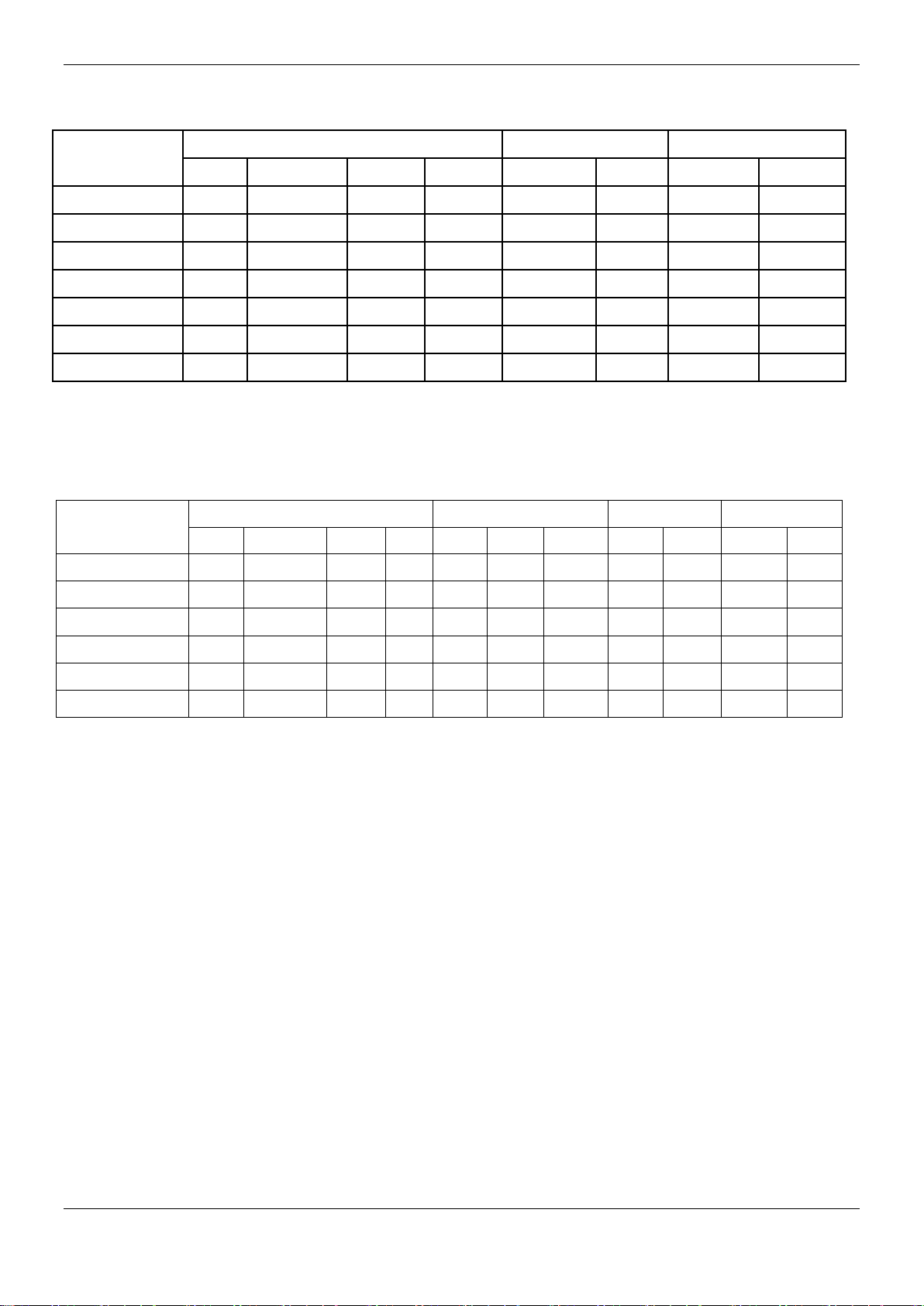

7. Capacity Tables

7.1 76kBtu/h

22.5 18.5 6.57 24.0 14.3

23.0 20.9 6.58 24.4 18.0

22.3 12.9 6.73 23.6 5.6

22.7 16.1 6.75 24.1 10.6

23.2 19.5 6.77 24.6 15.0

23.6 21.9 6.78 25.1 18.7

7.17

7.19

7.33

7.35

7.37

7.39

39

Page 39

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

40.60

46.10

51.70

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2125

23.9

18.3

15.0

7.59

19.9

11.2

7.83

21.2

4.9

7.98

16.8

13.8

7.78

18.3

10.4

8.04

19.5

4.5

8.29

16.1

13.2

9.68

17.3

9.8

10.03

18.4

4.3

10.28

26.7

18.7

17.0

7.61

20.3

13.1

7.85

21.6

9.3 8 17.2

15.6

7.8

18.7

12.1

8.06

19.9

8.6

8.31

16.4

14.9

9.7

17.7

11.5

10.06

18.8

8.1

10.31

29.4

19.1

18.3

7.63

20.7

17.0

7.87

22.0

13.1

8.02

17.5

16.9

7.82

19.1

15.6

8.08

20.3

12.1

8.33

16.7

16.1

9.72

18.0

14.8

10.09

19.2

11.4

10.34

32.2

19.4

19.1

7.65

21.1

19.2

19.4

17.7

8.1

20.7

15.2

8.35

17.0

16.7

9.75

18.4

16.7

10.11

19.5

2310

23.9

18.9

15.9

7.79

20.5

11.8

18.9

10.9

8.24

20.1

4.7

8.49

16.7

14.0

9.88

17.9

10.4

10.23

19.0

26.7

19.3

17.9

7.81

20.9

14.8

19.3

13.7

8.26

20.5

9.0

8.51

17.0

15.7

9.9

18.3

13.0

10.26

19.4

29.4

19.7

19.3

7.83

21.3

17.9

19.7

16.5

8.28

20.9

12.8

8.53

17.3

17.0

9.92

18.7

15.7

10.29

19.8

32.2

20.1

20.1

7.85

21.7

20.1

20.1

18.6

8.3

21.3

15.9

8.55

17.7

17.7

9.95

19.0

17.6

10.31

20.2

2650

23.9

19.4

17.8

7.49

21.0

13.1

19.4

12.1

8.48

20.6

5.3

8.73

17.2

15.7

10.11

18.4

11.5

10.47

19.5

26.7

19.8

19.8

7.51

21.4

16.5

19.8

15.2

8.5

21.0

10.1

8.75

17.5

17.5

10.14

18.8

14.5

10.5

19.9

29.4

20.2

20.2

7.53

21.8

20.0

7.77

23.2

15.3

7.92

18.7

18.7

8.26

20.2

18.5

8.52

21.4

14.2

8.77

17.9

17.9

10.17

19.2

17.6

10.53

20.3

13.4

10.78

32.2

20.6

20.6

7.55

22.3

20.2

7.79

23.6

19.2

7.94

19.0

19.0

8.28

20.6

18.7

8.54

21.9

17.8

8.79

18.2

18.2

10.19

19.6

17.8

10.55

20.7

16.8

10.8

7.89 22.5 16.5 8.04 17.9 17.5 7.84

8.03 21.8 5.1 8.18 17.5 14.7 7.98

8.05 22.2 9.7 8.2 17.8 16.5 8

8.07 22.6 13.8 8.22 18.2 17.8 8.02

8.09 23.1 17.2 8.24 18.5 18.5 8.04

7.88 22.3 5.8 7.88 17.9 16.5 8.22

7.75 22.7 10.9 7.9 18.3 18.3 8.24

Notes:

1. DB = Dry Bulb Temperature (°C), WB = Wet Bulb Temperature (°C)

4. TGC = Total Cooling Capacity (kW)

5. SHC = Sensible Heating Capacity (kW)

6. PI = Power Input (kW)

14.4 10.36

4.5 10.48

8.5 10.51

12.1 10.54

15.1 10.56

5.1 10.72

9.5 10.75

40

Page 40

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

29.40

35.00

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2125

23.9

25.1

20.6

8.23

27.2

15.4

8.43

28.6

6.6

8.56

24.4

20.0

8.66

26.1

14.7

8.89

27.3

6.3

9.03

26.7

26.0

23.6

8.25

8.58

24.9

22.6

8.68

26.6

17.2

8.91

27.9

12.0

29.4

26.9

25.9

8.27

8.6

25.4

24.4

8.7

27.1

22.2

8.93

28.4

16.9

32.2

27.8

27.3

8.29

8.62

25.9

25.4

8.72

27.7

25.1

8.95

29.0

21.3

2310

23.9

25.7

21.6

8.43

8.76

25.0

21.0

8.86

26.7

15.4

9.09

27.9

6.6

26.7

26.6

24.6

8.45

8.78

25.5

23.6

8.88

27.2

19.3

9.11

28.5

12.5

29.4

27.5

27.0

8.47

8.8

26.0

25.5

8.9

27.7

23.3

9.13

29.1

17.7

32.2

28.5

28.5

8.49

8.82

26.5

26.5

8.92

28.3

26.2

9.16

29.7

22.1

2650

23.9

26.2

24.0

8.67

28.3

17.7

9

29.7

7.7 9 25.5

23.4

9.1

27.2

17.0

9.33

28.4

7.4

9.47

26.7

27.1

27.1

8.69

28.9

22.2

8.89

30.3

14.5

9.02

26.0

26.0

9.12

27.7

21.3

9.35

29.0

13.9

9.49

29.4

28.1

28.1

8.71

29.5

27.0

8.91

30.9

20.5

9.04

26.5

26.5

9.14

28.3

25.9

9.37

29.6

19.6

9.51

32.2

29.0

29.0

8.73

30.1

27.3

8.93

31.5

25.6

9.07

27.1

27.1

9.17

28.8

26.2

9.4

30.2

24.5

9.54

7.2 96kBtu/h

27.8 18.0 8.45 29.2 12.6

28.3 23.2 8.47 29.8 17.7

28.9 26.3 8.49 30.4 22.3

27.8 16.1 8.63 29.2 6.9

28.4 20.1 8.65 29.8 13.1

29.0 24.3 8.67 30.4 18.5

29.6 27.4 8.69 31.0 23.1

9.05

9.07

9.1

9.23

9.25

9.27

9.3

41

Page 41

MCAC-UTSM-12

Gross Cooling Capacity (kW)

Outdoor DB(°C)

40.60

46.10

51.70

Indoor

WB(°C)

16.10

19.40

22.80

16.10

19.40

22.80

16.10

19.40

22.80

CFM

DB(°C)

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

TGC

SHC

PI

2125

23.9

24.0

19.7

9.49

25.6

14.5

9.73

26.8

6.2

9.88

22.5

18.5

9.68

24.0

13.6

9.94

25.2

5.8

10.18

20.2

16.5

11.67

21.5

12.1

12.03

22.5

5.2

12.28

26.7

24.5

22.3

9.51

26.1

16.9

9.75

27.4

11.8

9.9

23.0

20.9

9.7

24.5

15.9

9.96

25.7

11.1

10.21

20.6

18.7

11.7

21.9

14.2

12.06

23.0

9.9

12.31

29.4

25.0

24.0

9.53

26.6

21.8

9.77

27.9

16.6

9.92

23.4

22.5

9.72

25.0

20.5

9.98

26.2

15.6

10.24

21.0

20.2

11.73

22.3

18.3

12.09

23.4

14.0

12.34

32.2

25.5

25.0

9.56

27.1

24.7

9.8

28.5

21.0

9.95

23.9

23.4

9.75

25.5

23.2

10.01

26.7

19.7

10.26

21.4

21.0

11.76

22.8

20.7

12.12

23.9

17.6

12.37

2310

23.9

24.6

20.7

9.69

26.2

15.1

9.93

24.6

14.2

10.13

25.8

6.1

10.38

20.8

17.5

11.87

22.1

12.8

12.23

23.1

26.7

25.1

23.2

9.71

26.7

18.9

9.95

25.1

17.8

10.16

26.3

11.5

10.41

21.2

19.6

11.9

22.5

16.0

12.26

23.6

29.4

25.6

25.1

9.73

27.2

22.9

9.97

25.6

21.5

10.19

26.8

16.4

10.44

21.6

21.2

11.93

23.0

19.3

12.29

24.1

32.2

26.1

26.1

9.76

27.8

25.7

10

26.1

24.2

10.21

27.4

20.4

10.46

22.1

22.1

11.96

23.4

21.7

12.32

24.6

2650

23.9

25.1

23.0

9.93

26.7

16.7

10.31

25.1

15.7

10.37

26.3

6.8

10.62

21.3

19.5

12.11

22.6

14.1

12.47

23.6

26.7

25.6

25.6

9.95

27.2

20.9

10.19

25.6

19.7

10.4

26.8

12.8

10.65

21.7

21.7

12.14

23.0

17.7

12.5

24.1

29.4

26.1

26.1

9.97

27.7

25.5

10.22

29.1

19.3

10.37

24.6

24.6

10.17

26.1

24.0

10.43

27.3

18.1

10.68

22.1

22.1

12.17

23.5

21.5

12.53

24.6

16.3

12.78

32.2

26.6

26.6

10

28.3

25.7

10.24

29.7

24.1

10.39

25.1

25.1

10.19

26.6

24.2

10.45

27.9

22.7

10.7

22.6

22.6

12.2

23.9

21.8

12.56

25.1

20.4

12.81

27.5 6.5 10.07 23.1 19.4 9.88

28.0 12.3 10.1 23.6 21.9 9.9

28.6 17.4 10.13 24.1 23.6 9.92

29.1 21.7 10.15 24.6 24.6 9.95

27.9 7.2 10.31 23.6 21.7 10.11

28.5 13.6 10.34 24.1 24.1 10.14

Notes:

1. DB = Dry Bulb Temperature (°C), WB = Wet Bulb Temperature (°C)

4. TGC = Total Cooling Capacity (kW)

5. SHC = Sensible Heating Capacity (kW)

6. PI = Power Input (kW)

5.5 12.48

10.4 12.51

14.7 12.54

18.3 12.57

6.1 12.72

11.5 12.75

42

Page 42

MCAC-UTSM-12

Model

Indoor Unit

Power Supply

IFM

Hz

Voltage

Min.

Max.

MCA

MFA

KW

FLA

MDFA-76CRN2

50

220-240

198

254

3.25

8

0.59

2.773

MDFA-76HRN2

50

220-240

198

254

3.25

8

0.59

2.773

MDFA-96CRN2

50

220-240

198

254

3.25

12

0.59

2.773

MDFA-96HRN2

50

220-240

198

254

3.25

12

0.59

2.773

Model

Outdoor Unit

Compressor

OFM

Hz

Voltage

TOCA

MFA

MSC

RLA

KW

FLA

MDOV-76C-CN2

50

380-415

18.5

21.85

48*2

6.3*2

0.573

2.613

MDOV-76H-CN2

50

380-415

18.5

21.85

48*2

6.3*2

0.573

2.613

MDOV-96C-CN2

50

380-415

28

30

53*2

8.0*2

0.573

2.613

MDOV-96H-CN2

50

380-415

28

30

53*2

8.0*2

0.573

2.613

8. Electric Characteristics

Note :

MCA: Min. Current Amps. (A)

MFA: Max. Fuse Amps. (A)

KW: Fan Motor Rated Output (KW)

FLA: Full Load Amps. (A)

IFM: Indoor Fan Motor

Power Supply

Min. Max. MCA

342 438 15.75

342 438 15.75

342 438 20

342 438 20

Note:

MCA: Min. Current Amps. (A) TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A) MSC: Max. Starting Amps. (A)

RLA: Rated Locked Amps. (A) OFM: Outdoor Fan Motor

KW: Rated Motor Output (KW) FLA: Full Load Amps. (A)

43

Page 43

9. Sound Levels

1m

Microphone

1m

Unit Number

Model

Noise level under three speeds of fan (dB(A))

1 MFA-76C(H)R

53

2 MFA-96(H)R

54

Type

Code

Remarks

EEPROM error

E0

Manual reset

Room temp. sensor error

E1

Manual reset

Evaporator temp. sensor error

E2

Manual reset

Evaporator temp. too low protection in cooling mode

P1

Auto reset

Evaporator temp. too high protection in heating mode

P2

Auto reset

MCAC-UTSM-12

11. Troubleshooting

44

Page 44

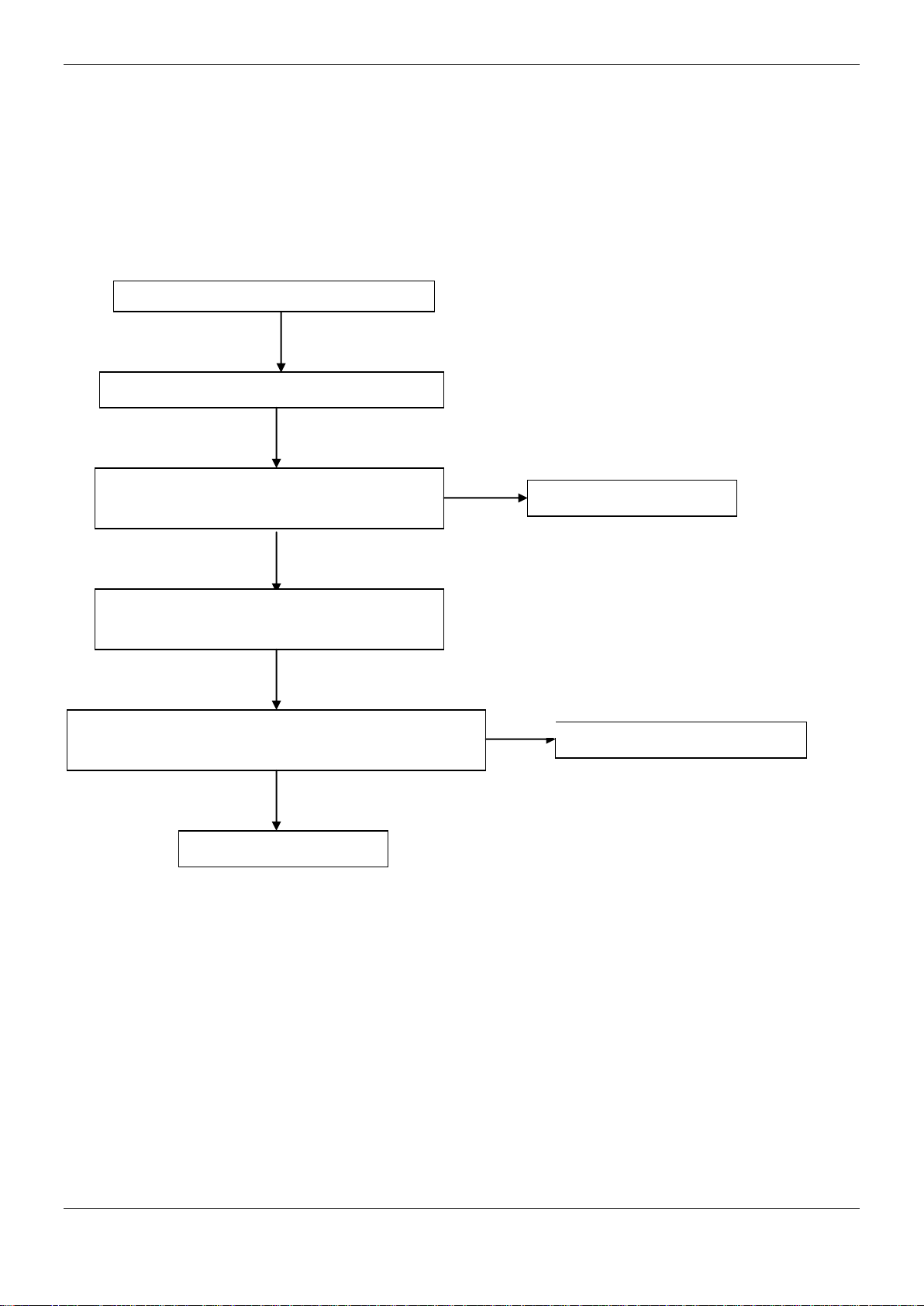

MCAC-UTSM-12

LED indicate E1

Fault of indoor temperature sensor T1

Judge 1: Whether the indoor temperature

sensor T1 is break off.

Connects it well.

No

Judge 2: Whether the indoor temperature

sensor T1 is malfunction.

Validate: Check whether the resistance of

the temperature sensor is correct

according to Annex 1.

Replace it.

No

Yes

Judge 3: PCB is malfunction

Replace indoor PCB

11.1 E1 malfunction

Yes

46

Page 45

MCAC-UTSM-12

Replace it.

LED indicate E2

Fault of indoor temperature sensor T2

Judge 1: Whether the indoor temperature

sensor T2 is break off.

Connects it well.

No

Judge 2: Whether the indoor temperature

sensor T2 is malfunction.

Validate: Check whether the resistance of

the temperature sensor is correct

according to Annex 1.

No

Yes

Judge 3: PCB is malfunction

Replace indoor PCB

11.2 E2 malfunction

Yes

47

Page 46

LED indicate P1

Under heating mode, T2 is on high

temperature protection

Judge 1: Check whether the evaporator temperature

sensor T2 is break off.

Connect it well.

Yes

Judge 2: Whether the evaporator temperature sensor

is malfunction.

Validate: Check whether the resistance of the

temperature sensor is correct according to Annex 1.

Replace the temperature sensor

No

Yes

Judge 3: Check whether the outdoor ambient

temperature is too high (more than 24℃)

Stop the unit.

Yes

No

Replace indoor PCB

11.3 P1 malfunction

MCAC-UTSM-12

No

48

Page 47

MCAC-UTSM-12

LED indicate P2

Under cooling mode, T2 is on low

temperature protection

Judge 1: Check whether the evaporator temperature

sensor T2 is break off.

Connects it well.

Yes