Page 1

MCAC-UTSM-2008-05 Contents

Contents i

Part 1 General Information .................................................................................................... 1

Part 2 Ceiling and Floor Type................................................................................................ 6

Part 3 Outdoor Units............................................................................................................. 33

Part 4 Installation..................................................................................................................74

Part 5 Control........................................................................................................................ 99

Manufacture reserves the right to discontinue, or change at any time, specifications or designs without

notices and without incurring obligations.

Page 2

Page 3

MCAC-UTSM-2008-05 General Information

General Information 1

Part 1

General Information

1. Model Names of Indoor/Outdoor Units.......................2

2. External Appearance.....................................................3

3. Nomenclature ................................................................4

4. Features .........................................................................5

Page 4

Model Names of Indoor/Outdoor Units MCAC-UTSM-2008-05

2 General Information

1. Model Names of Indoor/Outdoor Units

1.1 Indoor Units

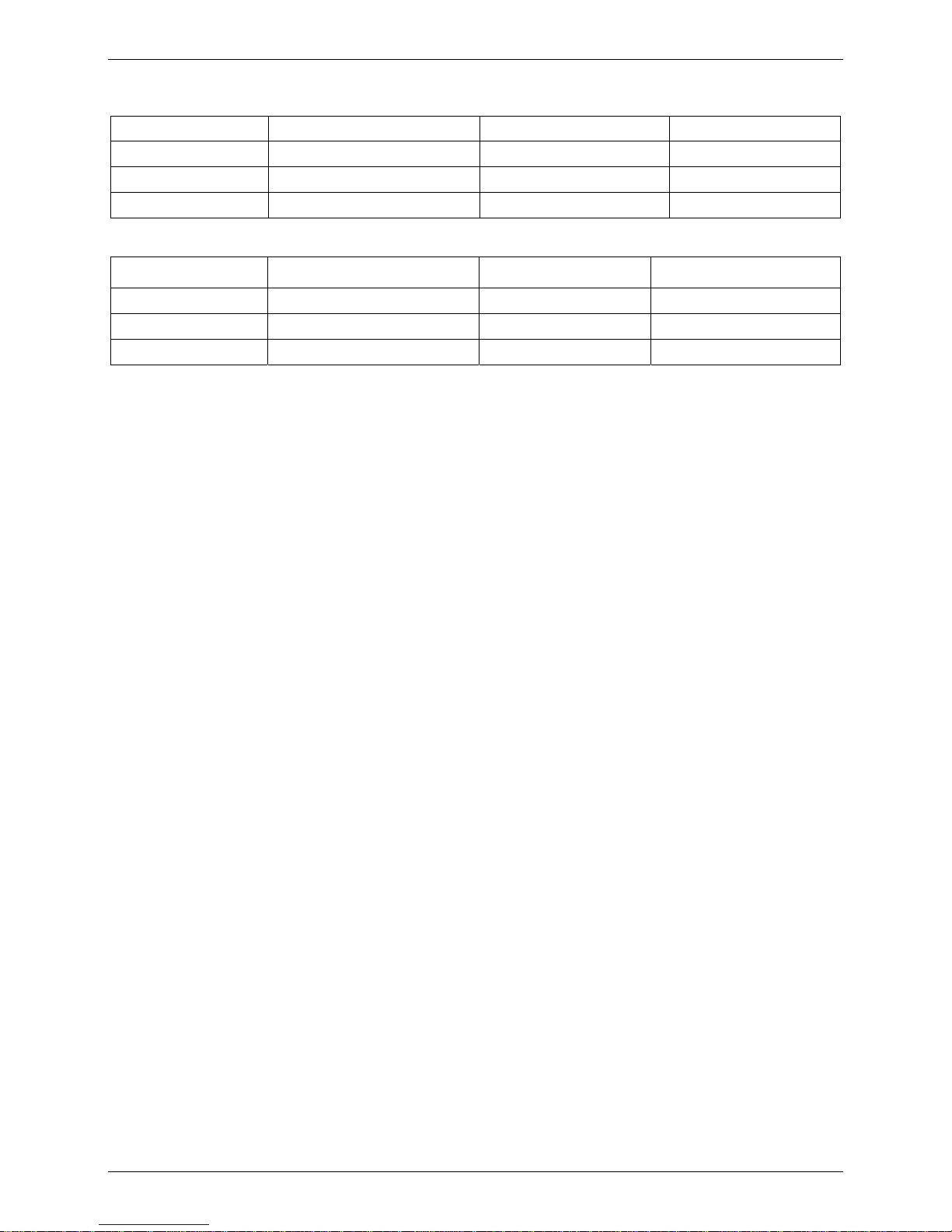

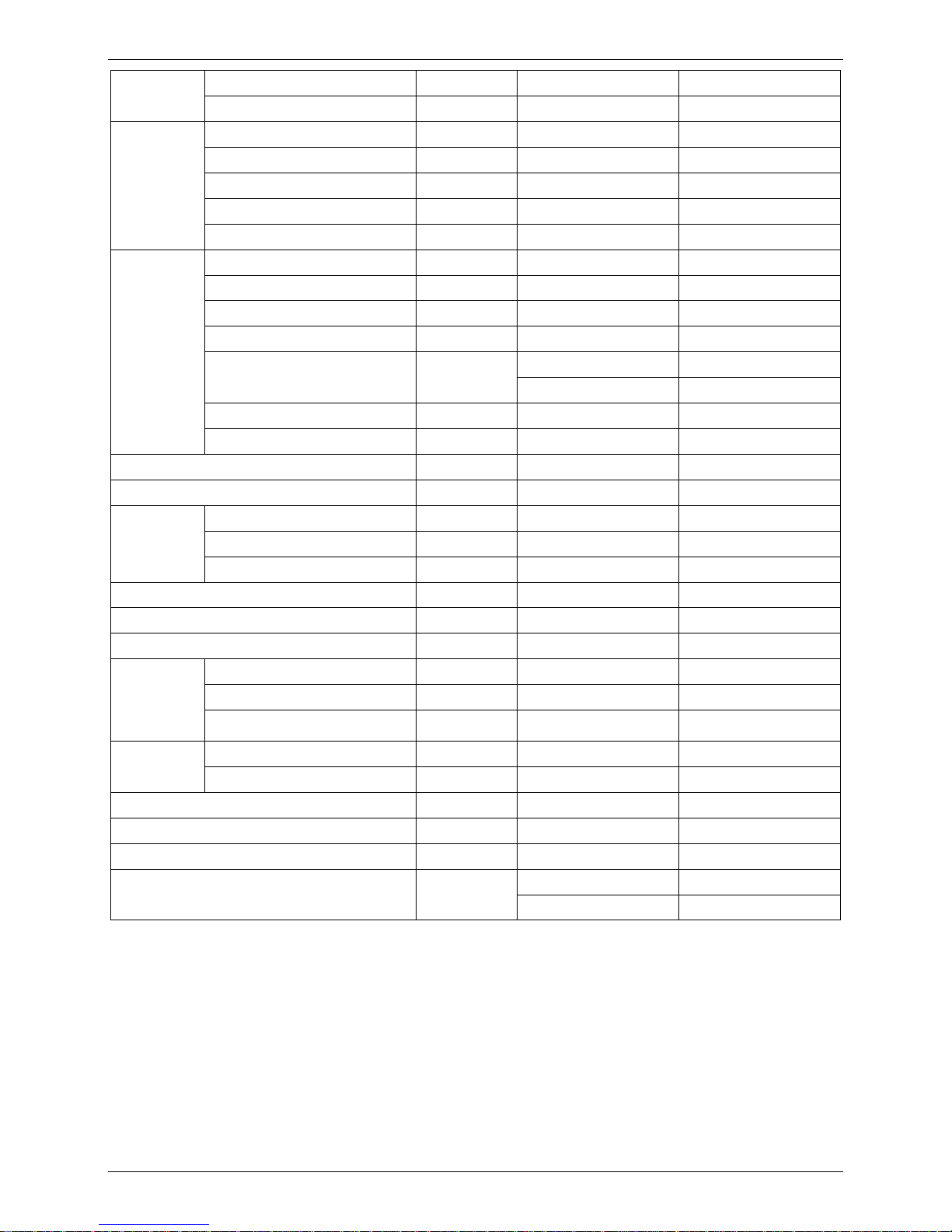

Model name Dimension W×H×D (mm) Net/Gross weight (kg) Power supply

MUB-12HRDN1

990×206×660

27/33 220~240V-1ph-50Hz

MUB-12HRDN1-Q

990×206×660

32/40 220~240V-1ph-50Hz

MUB-18HRDN1-Q

990×206×660

34.5/42.5 220~240V-1ph-50Hz

1.2 Outdoor Units

Model name Dimension W×H×D (mm)

Net/Gross weight

(kg)

Power supply

MOU-12HDN1

761×593×315

39.5/42.5 220~240V-1ph-50Hz

MOU-12HDN1-Q

761×593×315

42/45 220~240V-1ph-50Hz

MOU-18HDN1-Q

842×695×360

62/66 220~240V-1ph-50Hz

Page 5

MCAC-UTSM-2008-05 External Appearance

General Information 3

2. External Appearance

2.1 Indoor units

Ceiling and Floor Type:

12000Btu/h and 18000Btu/h

2.2 Outdoor unit

12000Btu/h 18000Btu/h

Page 6

Nomenclature MCAC-UTSM-2008-05

4 General Information

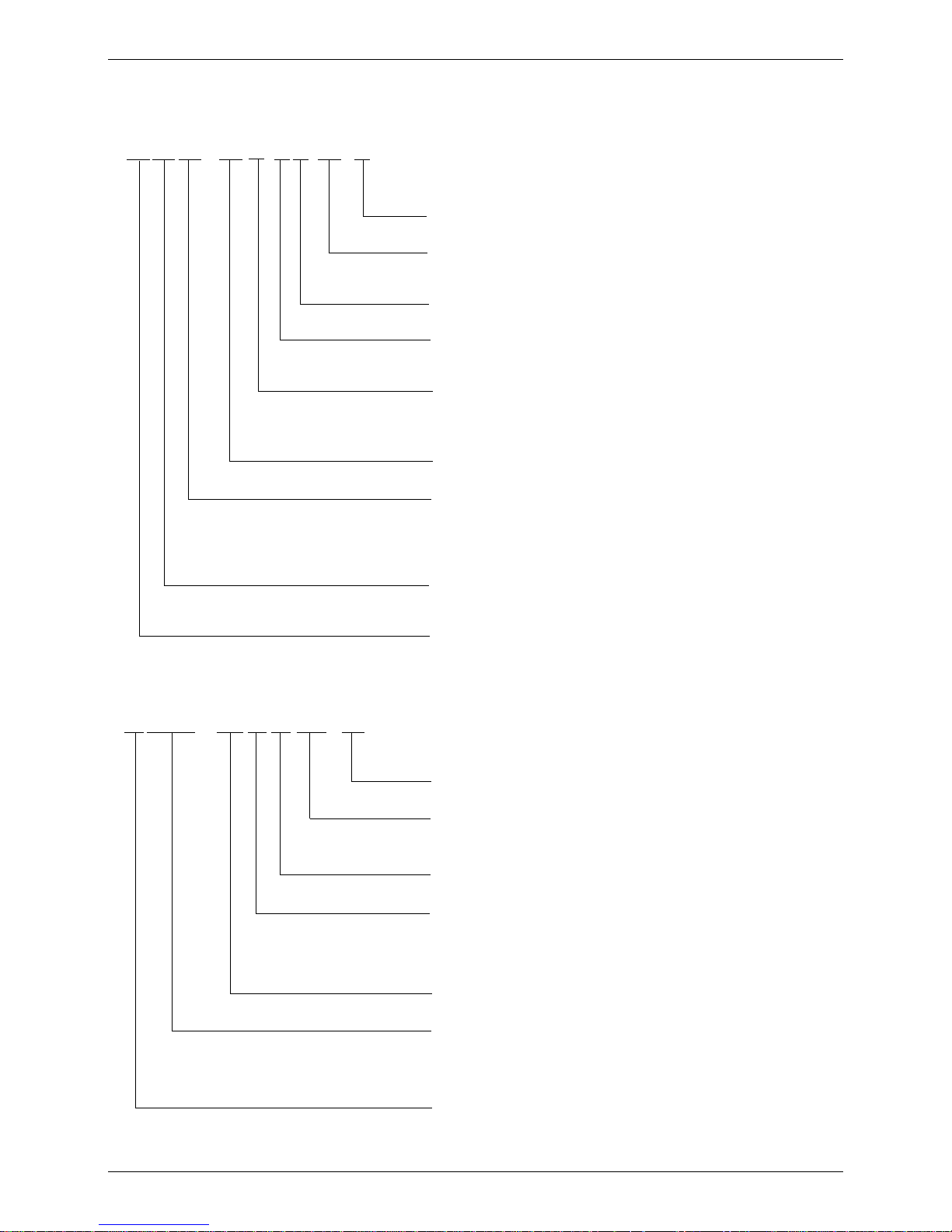

3. Nomenclature

3.1 Indoor Units:

M U B - 12 H R D N1-Q

Q: Quick Connector

Refrigerant Type

N1 : R410A

DC Inverter

Control Mode

R: Remote Control

Function Code

C: Cooling Only

H: Cooling & Heating

Capacity (×1000Btu/h)

Product Series

A: First Time Design

B: Second Time Design

C: Third Time Design

Product Category

U: Ceiling & Floor Type

Midea

3.2 Outdoor Units:

M O U - 12 H D N1- Q

Q: Quick Connector

Refrigerant

N1: R410A

DC Inverter

Function Code

C: Cooling Only

H: Cooling & Heating

Capacity (×1000Btu/h)

Universal Outdoor Unit

O: Outdoor unit

U: Universal

Midea

Page 7

MCAC-UTSM-2008-05 Features

General Information 5

4. Features

4.1 Universal outdoor unit design

Indoor unit with the same capacity can match with the same outdoor unit.

4.2 High efficiency and energy saving.

Thanks to the DC inverter technology and optimized piping system, the EER of whole series can

easily reach A-class.

4.3 Low noise and low starting current.

Thanks to the DC inverter technology, the system can work with low noise, and very small starting

current.

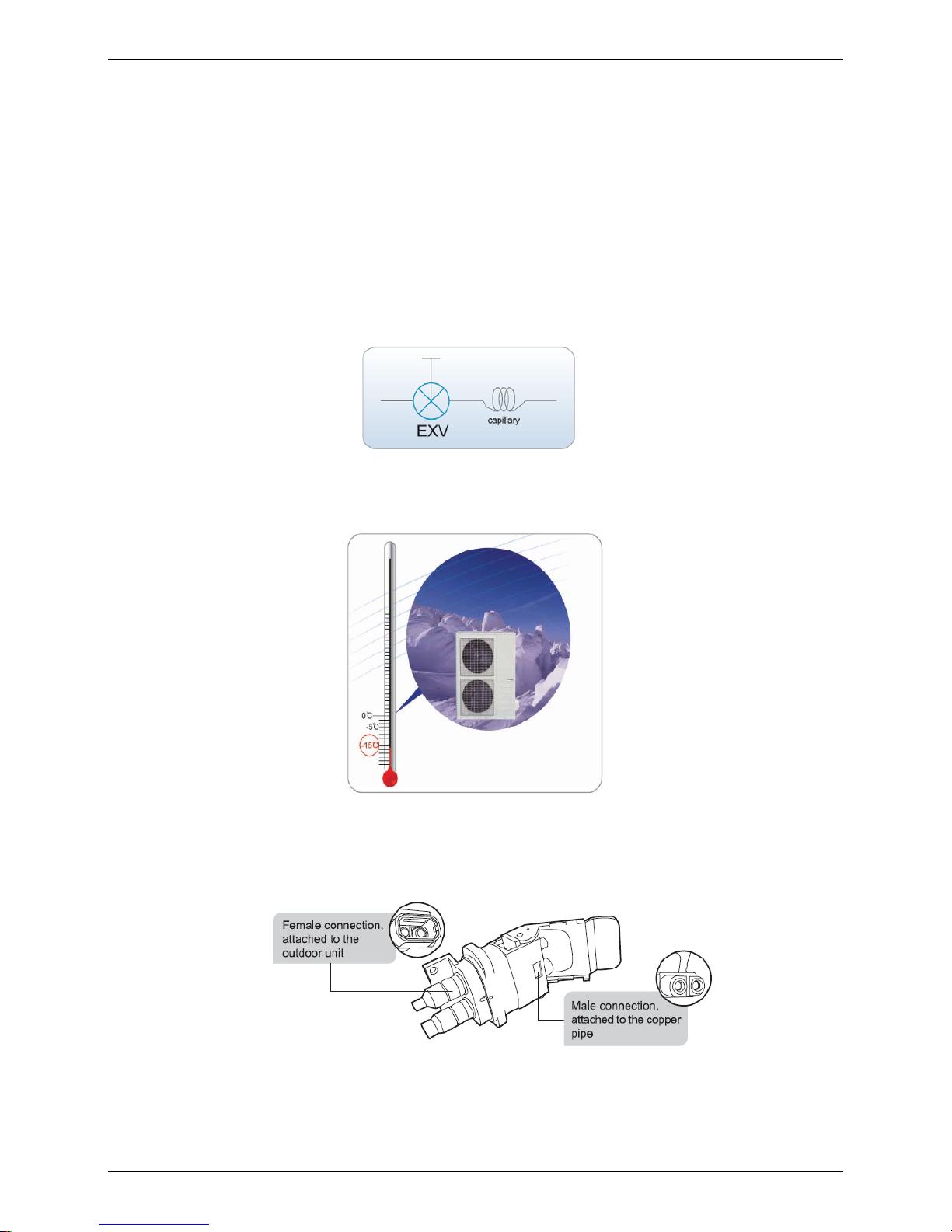

4.4 Intelligent refrigerant adjustment technology(except 12000Btu/h)

Throttle part is made up of capillary and electronic expansion valve (EXV). The outdoor unit can

output the most accurate capacity in any condition.

4.5 Working in cooling mode under -15℃(except 12000Btu/h)

Outdoor unit built-in with low ambient kit, it can control the outdoor unit’s fan and cooling can be

performed throughout the year for computer rooms, banquet halls, etc. Wide operation range

covers outdoor temperatures as low as -15℃ for cooling.

4.6 Convenient installation

--Adopt Quick Connector. The copper pipe connecting the indoor and the outdoor unit is delivered

already connected to the indoor unit. At the other end of the pipe is attached the male part of the

Quick Connector while the female part of the Quick Connector is fixed to the outdoor unit. So it’s easy

to installation.

4.7 Diversiform and universal controller for DC inverter air conditioners, including wireless remote

controller, wired controller (weekly timer, central controller, network controller for 18000Btu/h).

Page 8

Ceiling and Floor Type MCAC-UTSM-2008-05

6 Ceiling and Floor Type

Part 2

Ceiling and Floor Type

1. Features .........................................................................7

2. Specifications................................................................8

3. Dimensions..................................................................12

4. Service Space..............................................................13

5. Wiring Diagrams..........................................................16

6. Air Velocity and Temperature Distributions .............19

7. Capacity Tables...........................................................21

8. Electric Characteristics..............................................24

9. Sound Levels...............................................................25

10. Exploded View...........................................................26

1 1. Accessories ...............................................................32

Page 9

MCAC-UTSM-2008-05 Features

Ceiling and Floor Type 7

1. Features

1.1. New design, more modern and elegant appearance.

1.2. Convenient installation

--The ceiling type can be easily installed into a corner of the ceiling even if the ceiling is very narrow

--It is especially useful when installation of an air conditioner in the center of the ceiling is impossible

due to a structure such as one lighting

1.3. Two direction auto swing (vertical & horizontal) and wide angle air flow

--Air flow directional control minimizes the air resistance and produces wilder air flow to vertical

direction.

--The range of horizontal air discharge is widened which secures wider air flow distribution to provide

more comfortable air circulation no matter where the unit is set up

1.4. Three level fan speed, more humanism design, meets different air-supply requirement.

1.5. Water proof by utilizing the absorbing plastic film on water collector

1.6. Easy operation. Auto-restart function, remote control and optional wire control method.

1.7. Low noise level plus compact size

--Shape of the blades has been improved to prevent noise caused by turbulence.

Page 10

Specifications MCAC-UTSM-2008-05

8 Ceiling and Floor Type

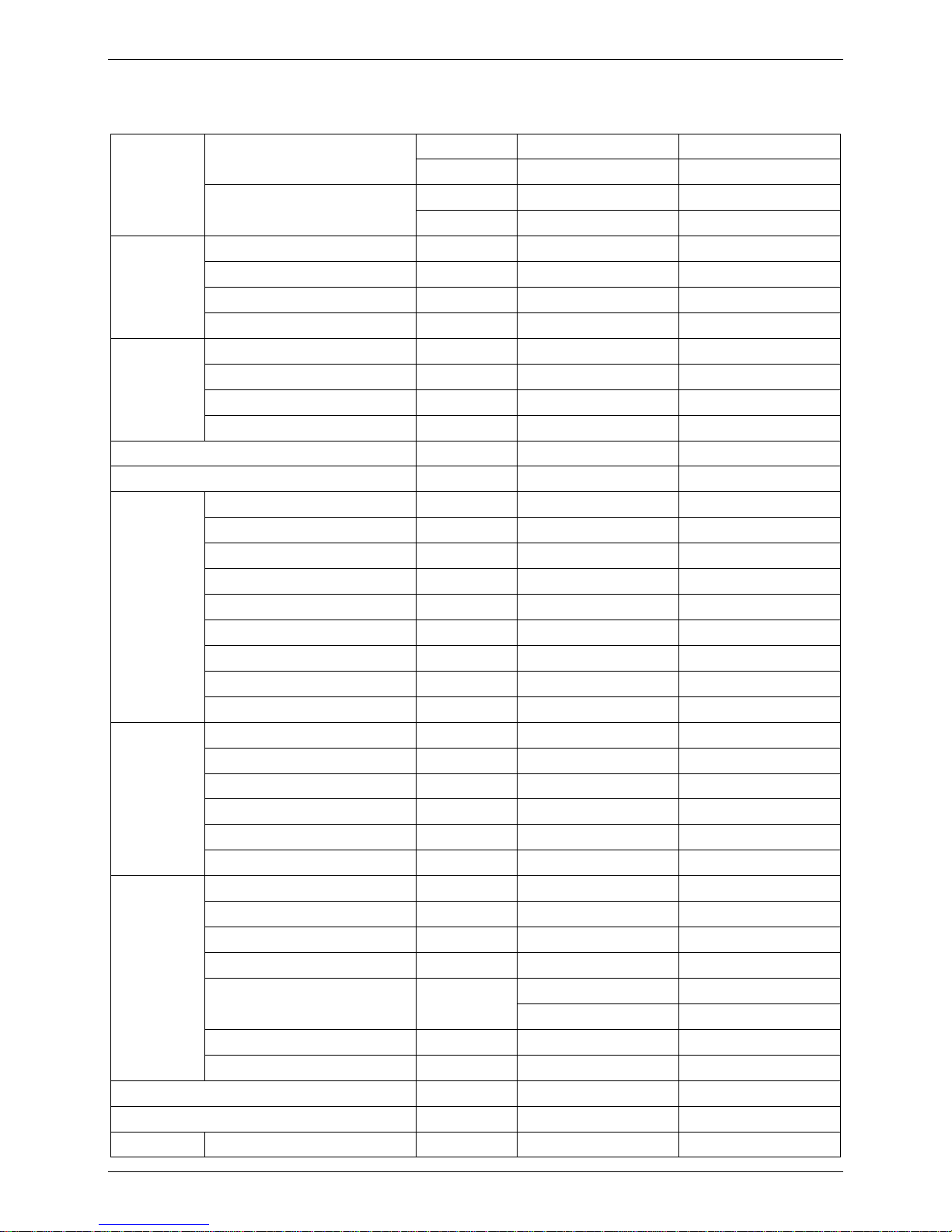

2. Specifications

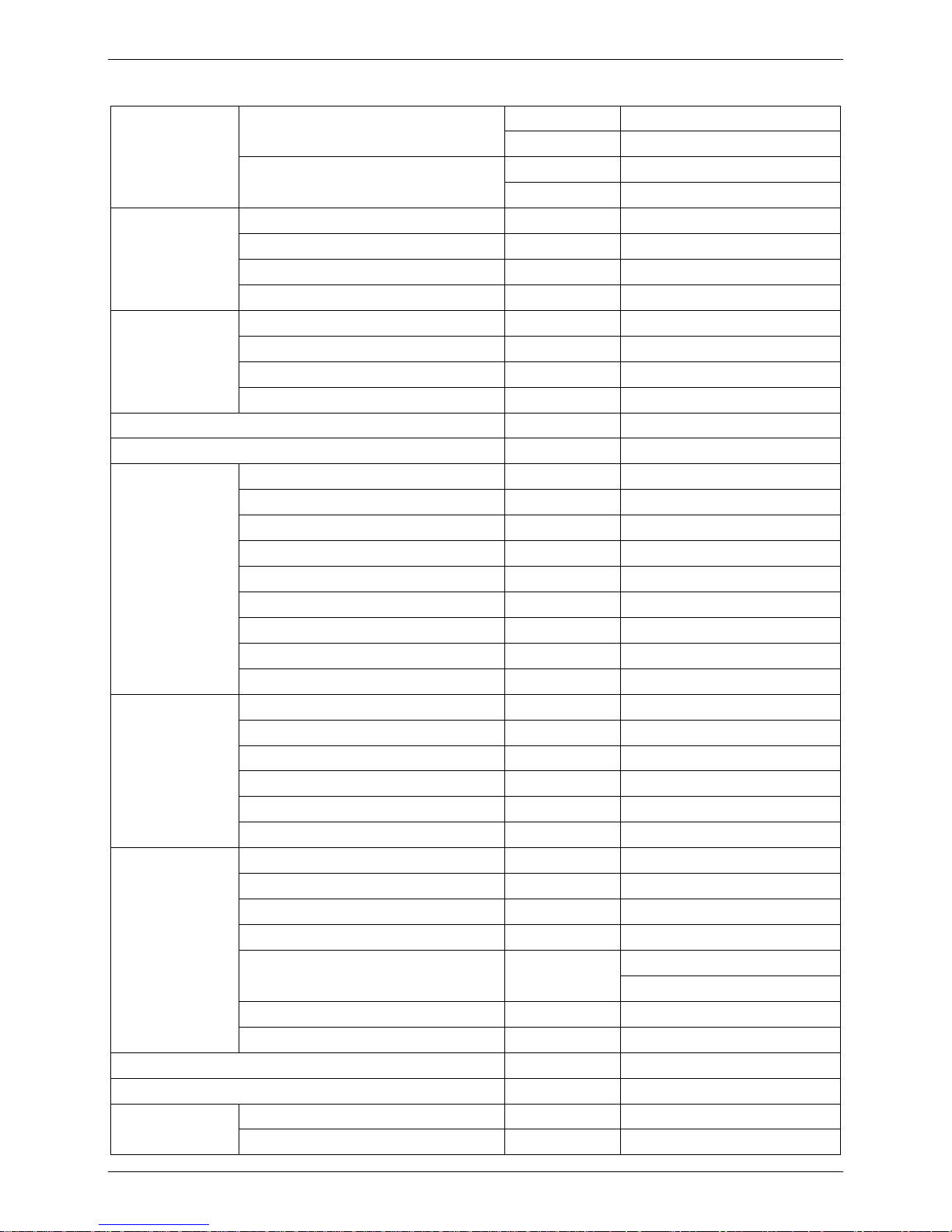

Table 1:

Model name

MUB-12HRDN1-Q MUB-18HRDN1-Q

Indoor Units

Power supply 220-240V-1Ph-50Hz 220-240V-1Ph-50Hz

Model name

MOU-12HRDN1-Q MOU-18HRDN1-Q

Model

Outdoor Units

Power supply 220~240V-1Ph-50Hz 220~240V-1Ph-50Hz

Capacity kW 4.0-3.5-1.4 5.65-5.27-1.7

Input kW 2.55-1.1-0.38 2.6-1.65-0.6

Rated current A 12-5.1-2.0 12.3-7.8-2.5

Cooling

EER 3.2 3.2

Capacity kW 4.75-4.0-1.4 6.2-5.86-1.45

Input kW 2.55-1.13-0.38 2.6-1.73-0.72

Rated current A 12-5.2-2.0 12.3-6.53-3.13

Heating

COP 3.54 3.4

Max. input consumption W 2550 2600

Max. current A 12 12.3

Model DA108X1C-20FZ3 JU1015D4

Type DC Inverter Rotary DC Inverter Rotary

Brand MIDEA TOSHIBA HITACHI

Capacity Btu/h 10921 15012

Input W 855 1585

Rated current(RLA) A 5.3 8.8

Locked rotor Amp(LRA) A 20 30

Thermal protector Internal Internal

Compressor

Refrigerant oil ml ESTER OIL VG74 480ml HAF68D1 580ml

Model YSK25-6L YSK55-4L

Type AC Motor AC Motor

Brand Welling Welling

Input W 33.4/31.1/29.5 125/105/88

Capacitor uF 1.2 2.5

Indoor fan

motor

Speed(hi/mi/lo) r/min 756/666/592 1310/1190/1040

a. Number of rows 3 3

b. Tube pitch(a)x row pitch(b) mm 25.4×22 25.4×22

c. Fin spacing mm 1.8 1.8

d. Fin type (code) Hydrophilic aluminium Hydrophilic aluminium

Ф9.53 Ф9.53

e. Tube outside dia. and type mm

innergroove tube innergroove tube

f. Coil length x height x width mm 804x254x66 804x254x66

Indoor coil

g. Number of circuits 3 3

Indoor air flow (Hi/Mi/Lo) m3/h 584/518/463 1003/907/761

Indoor noise level (Sound pressure)(Hi/Mi/Lo) dB(A) 39.6/36.7/33.1 44.6/41.8/37.3

Indoor unit

Dimension (W×H×D) mm 990x206x660 990x206x660

Page 11

MCAC-UTSM-2008-05 Specifications

Ceiling and Floor Type 9

Packing (W×H×D) mm 1105 x350 x805 1105 x350 x805

Net/Gross weight kg 32/40 34.5/42.5

Model YDK24-6G YDK53-6Y

Brand Welling Welling

Input W 59/43 129/86

Capacitor uF 2.5 3

Outdoor fan

motor

Speed r/min 800/550 770/560

Number of rows 2 2

Tube pitch(a)x row pitch(b) mm 25.4×22 25.4×22

Fin spacing mm 1.4 1.7

Fin type (code) Hydrophilic aluminium Hydrophilic aluminium

Φ9.5 Φ9.5

Tube outside dia. and type mm

Innergroove tube Innergroove tube

Coil length x height x width mm 637×558×44 748×660×44

Outdoor coil

Number of circuits 2 4

Outdoor air flow m3/h 2500/1600 2400/1680

Outdoor noise level(Sound pressure) dB(A) 48/44 52/47

Dimension(W×H×D) mm 761×593×315 842×695×360

Packing (W×H×D) mm 887×655×355 970×770×400

Outdoor unit

Net/Gross weight kg 42/45 62/66

Refrigerant type g R410A/1400 R410A/1700

Throttle type Capillary Capillary +EXV

Design pressure MPa 2.0/4.2 2.0/4.2

Liquid side/ Gas side mm Ф6.4/Ф12.7 Ф6.4/Ф12.7

Max. refrigerant pipe length m 5 5

Refrigerant

piping

Max. difference between outdoor

unit and indoor unit

m 5 5

Power wiring mm2 3×1.5 3×2.5

Connection

wiring

Signal wiring mm2 4×1.5 4×0.5

Drainage pipe diameter mm2 Ф16 Ф16

Controller R05/BGE (standard) R05/BGE (standard)

Operation temp

℃

17-30 17-30

Coolimg:21℃-43℃; Coolimg:-15℃-43℃;

Ambient temp ℃

Heating:-5℃-24℃ Heating:-5℃-24℃

Page 12

Specifications MCAC-UTSM-2008-05

10 Ceiling and Floor Type

Table 2:

Model name

MUB-12HRDN1

Indoor Units

Power supply 220-240V-1Ph-50Hz

Model name

MOU-12HRDN1

Model

Outdoor Units

Power supply 220~240V-1P-50Hz

Capacity kW 4.0-3.5-1.4

Input kW 2.55-1.08-0.38

Rated current A 12-5.1-2.0

Cooling

EER 3.24

Capacity kW 4.75-4.0-1.4

Input kW 2.55-1.12-0.38

Rated current A 12-5.2-2.0

Heating

COP 3.6

Max. input consumption W 2550

Max. current A 12

Model DA108X1C-20FZ3

Type DC Inverter Rotary

Brand MIDEA TOSHIBA

Capacity Btu/h 10921

Input W 855

Rated current(RLA) A 5.3

Locked rotor Amp(LRA) A 20

Thermal protector Internal

Compressor

Refrigerant oil ml ESTER OIL VG74 480ml

Model YSK25-6L

Type AC Motor

Brand Welling

Input W 33.4/31.1/29.5

Capacitor uF 1.2

Indoor fan motor

Speed(hi/mi/lo) r/min 756/666/592

a. Number of rows 3

b. Tube pitch(a)x row pitch(b) mm 25.4×22

c. Fin spacing mm 1.8

d. Fin type (code) Hydrophilic aluminium

Ф9.53

e. Tube outside dia. and type mm

innergroove tube

f. Coil length x height x width mm 804x254x66

Indoor coil

g. Number of circuits 3

Indoor air flow (Hi/Mi/Lo) m3/h 584/518/463

Indoor noise level (Sound pressure)(Hi/Mi/Lo) dB(A) 39.6/36.7/33.1

Dimension (W×H×D) mm 990x206x660

Indoor unit

Packing (W×H×D) mm 1089x296 x744

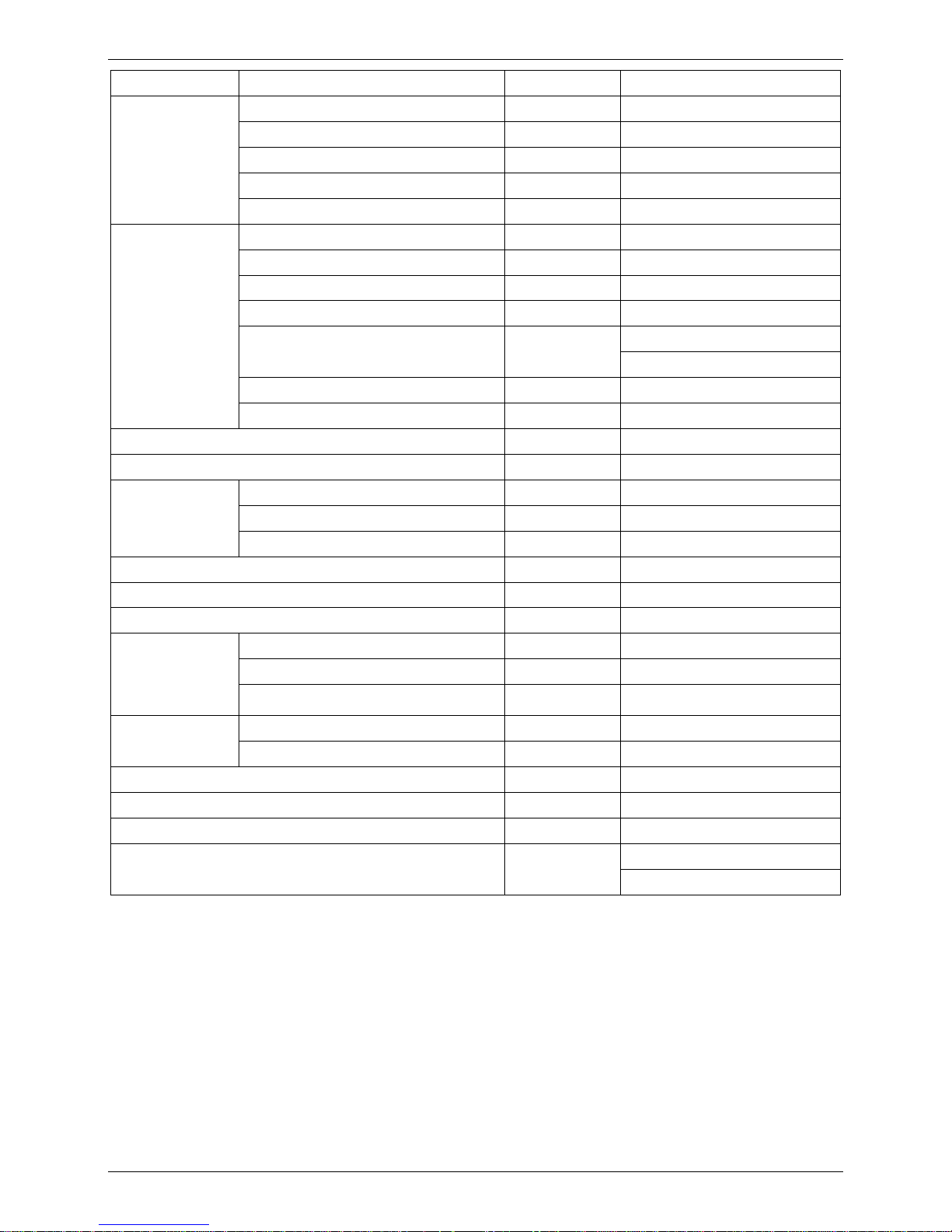

Page 13

MCAC-UTSM-2008-05 Specifications

Ceiling and Floor Type 11

Net/Gross weight kg 27/33

Model YDK24-6G

Brand Welling

Input W 59/43

Capacitor uF 2.5

Outdoor fan motor

Speed r/min 800/550

Number of rows 2

Tube pitch(a)x row pitch(b) mm 25.4×22

Fin spacing mm 1.4

Fin type (code) Hydrophilic aluminium

Φ9.5

Tube outside dia. and type mm

Innergroove tube

Coil length x height x width mm 637×558×44

Outdoor coil

Number of circuits 2

Outdoor air flow m3/h 2500/1600

Outdoor noise level(Sound pressure) dB(A) 48/44

Dimension(W×H×D) mm 761×593×315

Packing (W×H×D) mm 887×655×355

Outdoor unit

Net/Gross weight kg 39.5/42.5

Refrigerant type g R410A/1400

Throttle type Capillary

Design pressure MPa 2.0/4.2

Liquid side/ Gas side mm Ф6.4/Ф12.7

Max. refrigerant pipe length m 10

Refrigerant piping

Max. difference between outdoor unit and

indoor unit

m 5

Power wiring mm2 3×1.5

Connection wiring

Signal wiring mm2 4×1.5

Drainage pipe diameter mm2 Ф16

Controller R05/BGE (standard)

Operation temp

℃

17-30

Coolimg:21℃-43℃;

Ambient temp ℃

Heating:-5℃-24℃

Page 14

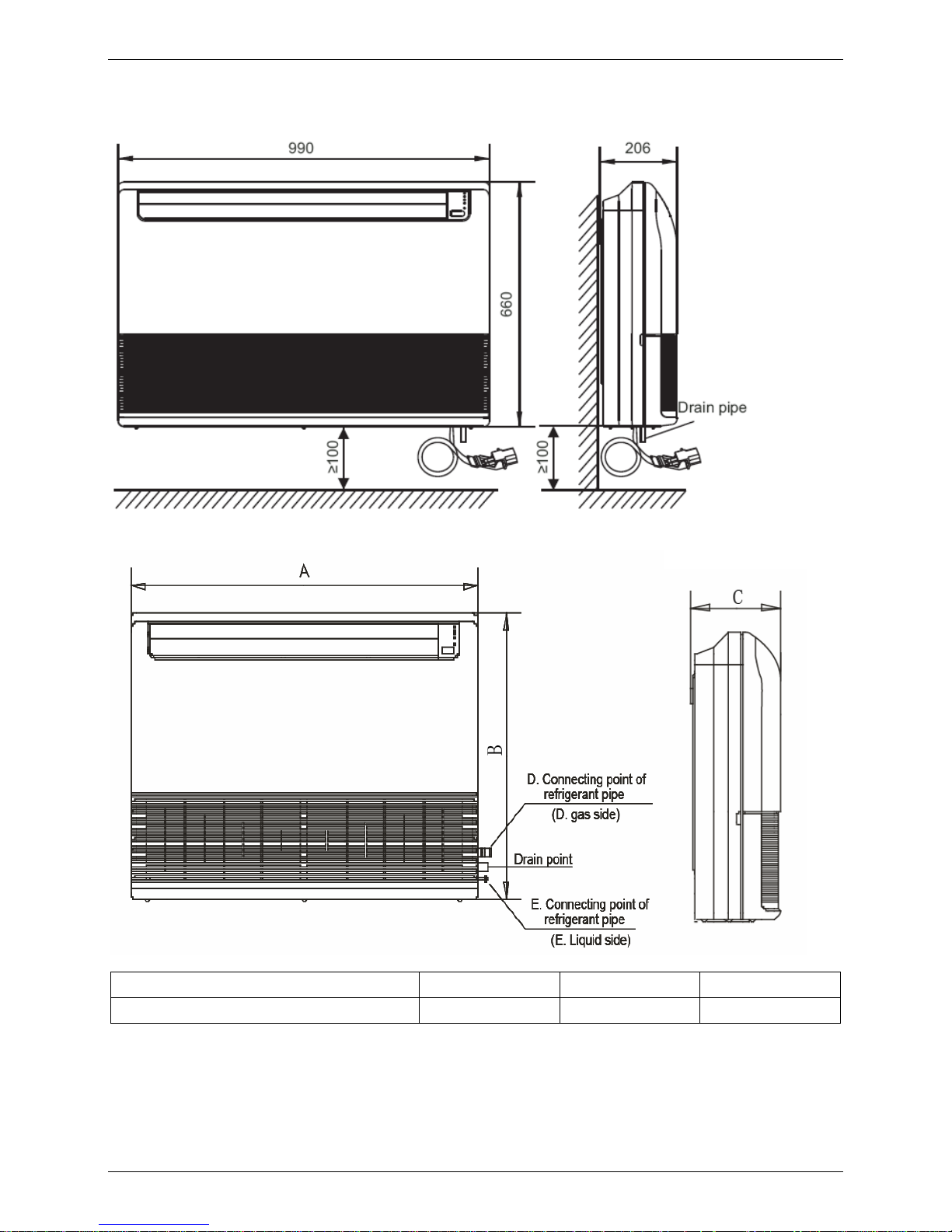

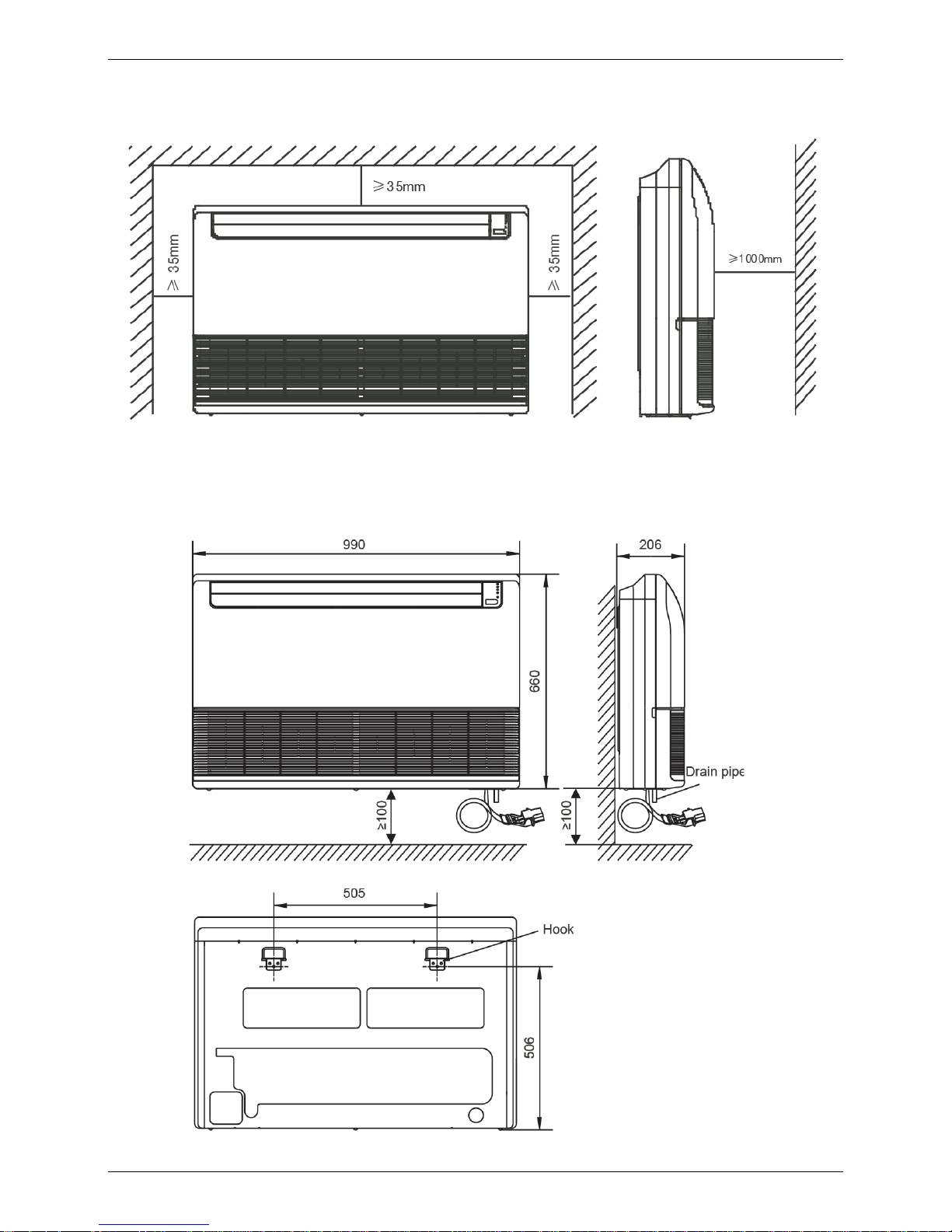

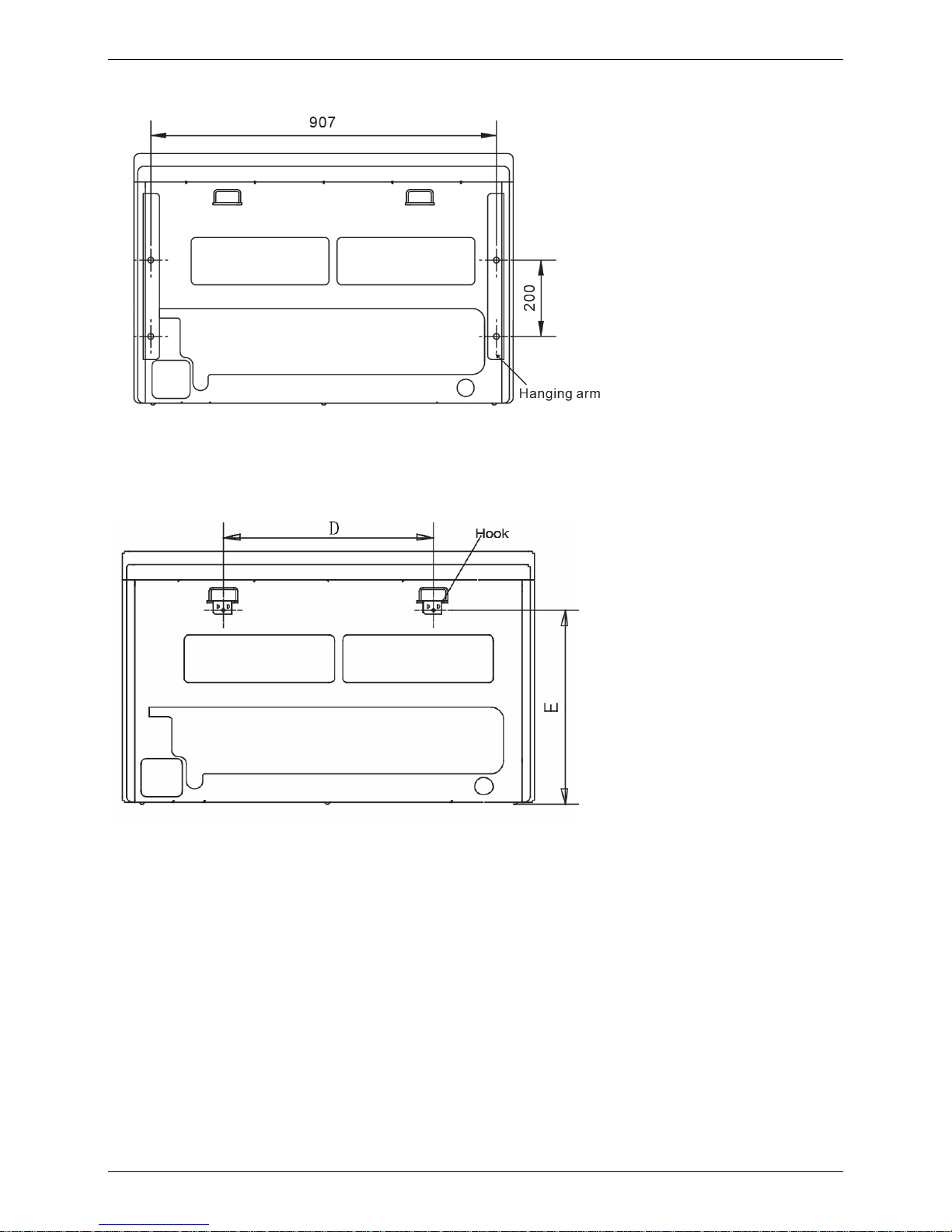

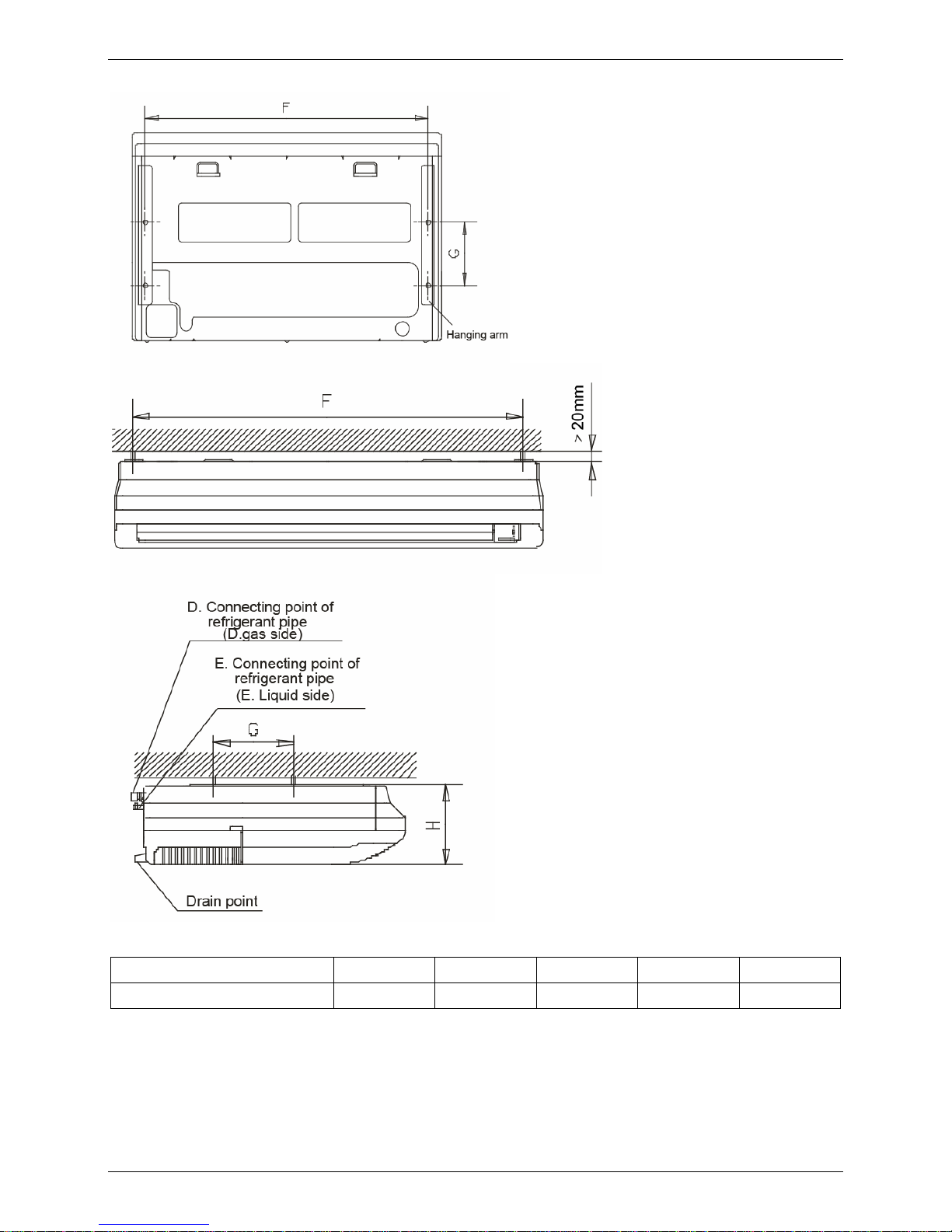

Dimensions MCAC-UTSM-2008-05

12 Ceiling and Floor Type

3. Dimensions

3.1 12HRDN1-Q MUB-18HRDN1-Q

3.2 MUB-12HRDN1-Q

Capacity A B C

12000Btu/h 990 606 206

Page 15

MCAC-UTSM-2008-05 Service Space

Ceiling and Floor Type 13

4. Service Space

4.1 MUB-12HRDN1-Q MUB-18HRDN1-Q

Wall Mounting Installation:

Page 16

Service Space MCAC-UTSM-2008-05

14 Ceiling and Floor Type

Ceiling Installation:

4.2 MUB-12HRDN1

Wall Mounting Installation:

Page 17

MCAC-UTSM-2008-05 Service Space

Ceiling and Floor Type 15

Ceiling Installation:

Capacity D E F G H

12000Btu/h 505 506 907 200 203

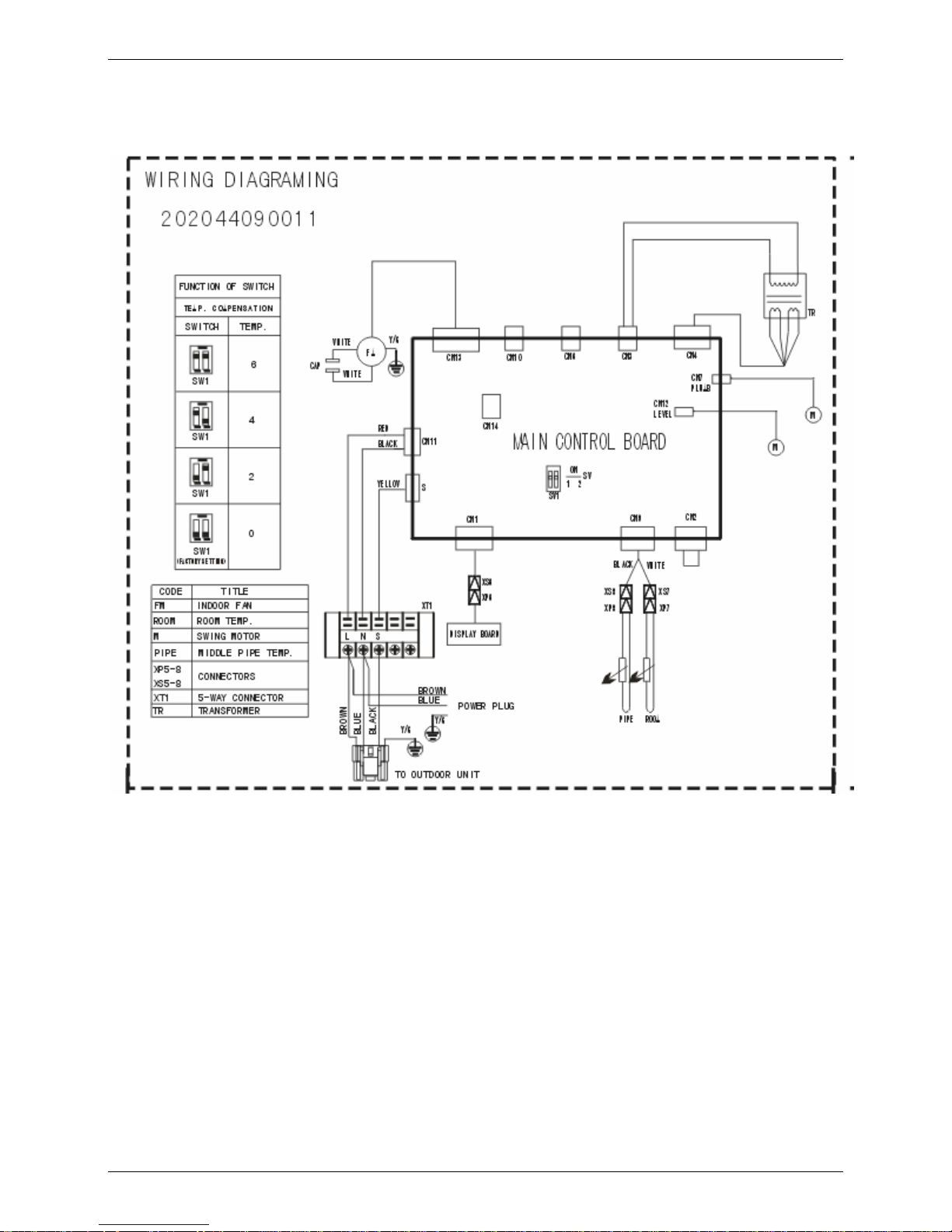

Page 18

Wiring Diagrams MCAC-UTSM-2008-05

16 Ceiling and Floor Type

5. Wiring Diagrams

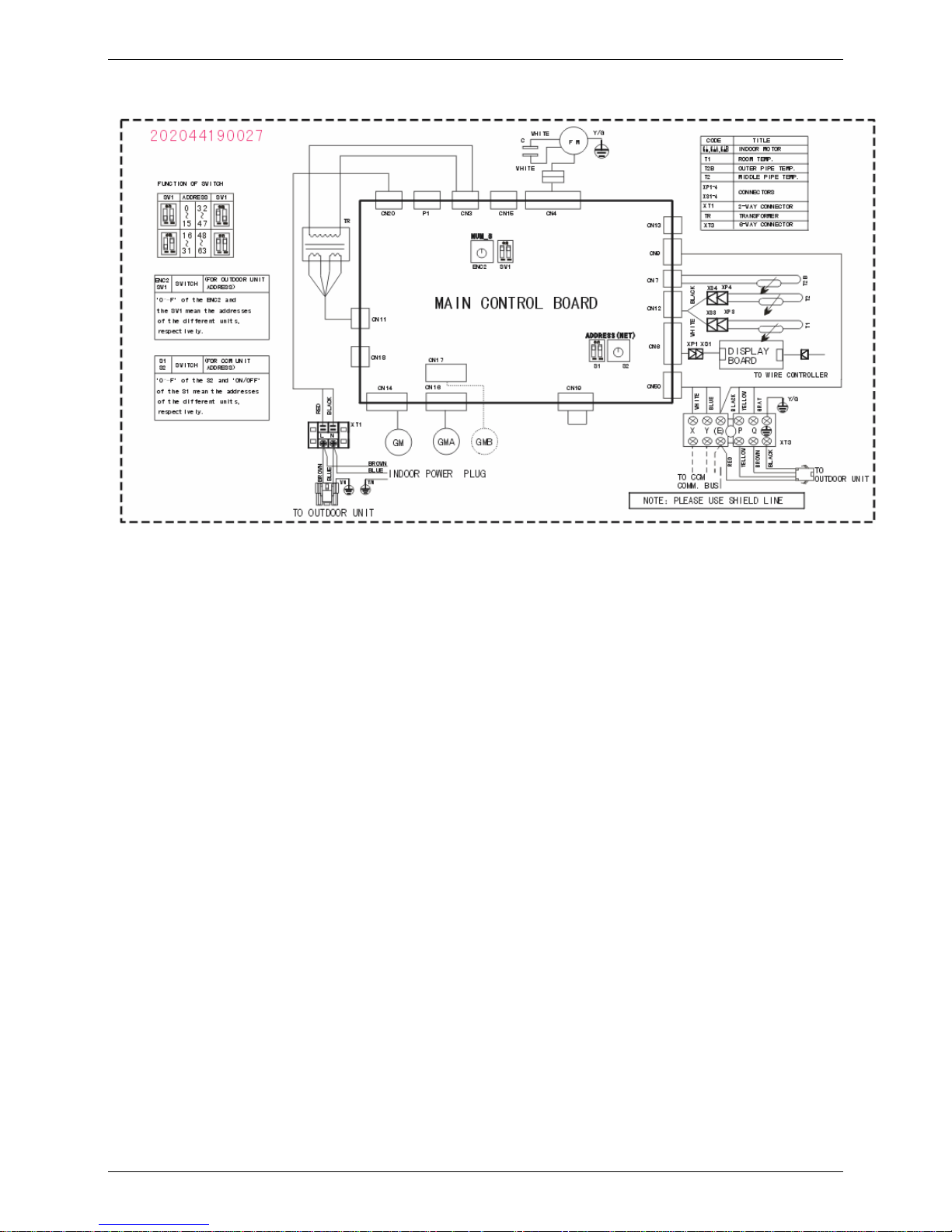

5.1 MUB-12HRDN1-Q

Page 19

MCAC-UTSM-2008-05 Wiring Diagrams

Ceiling and Floor Type 17

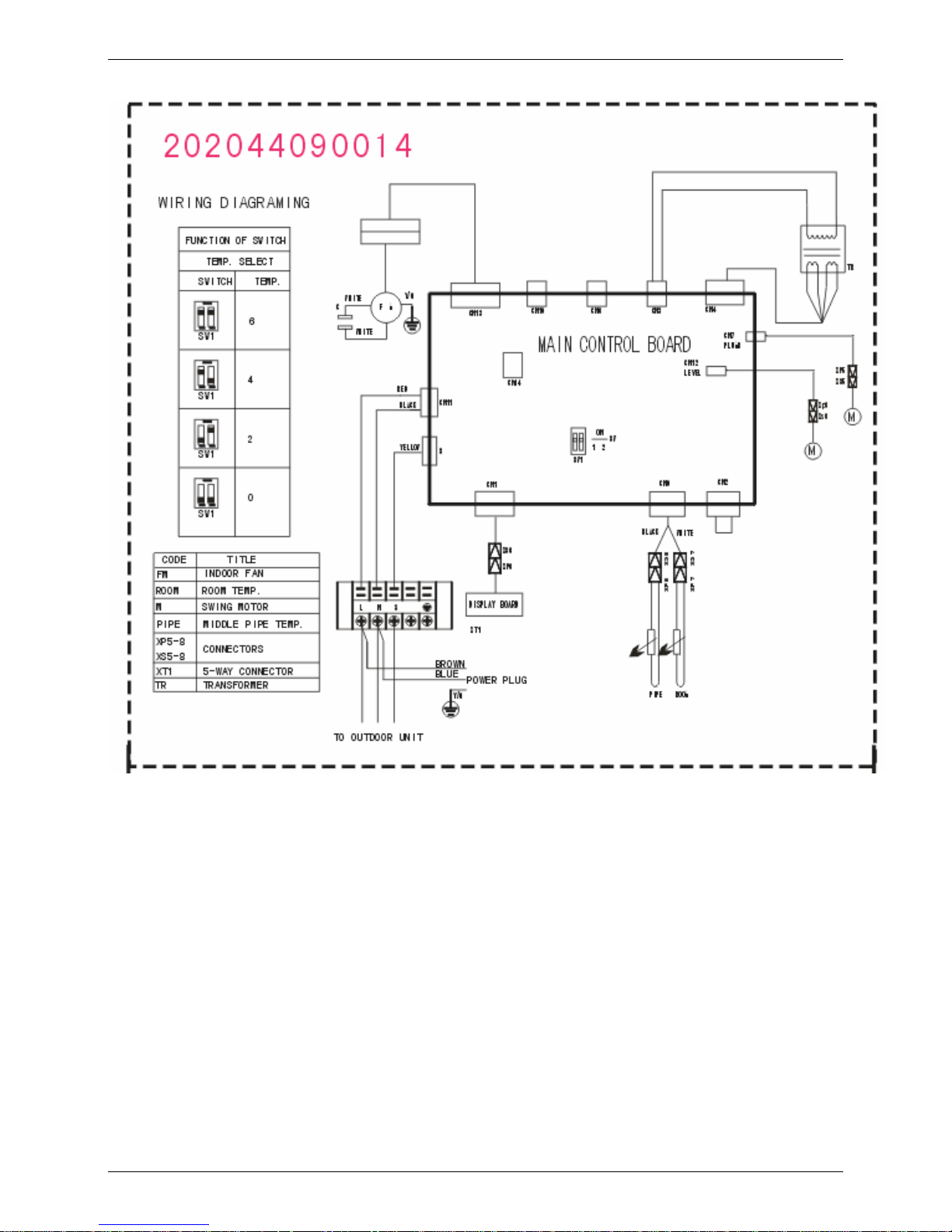

5.2 MUB-18HRDN1-Q

Page 20

Wiring Diagrams MCAC-UTSM-2008-05

18 Ceiling and Floor Type

5.3 MUB-12HRDN1

Page 21

MCAC-UTSM-2008-05 Air Velocity and Temperature Distributions

Ceiling and Floor Type 19

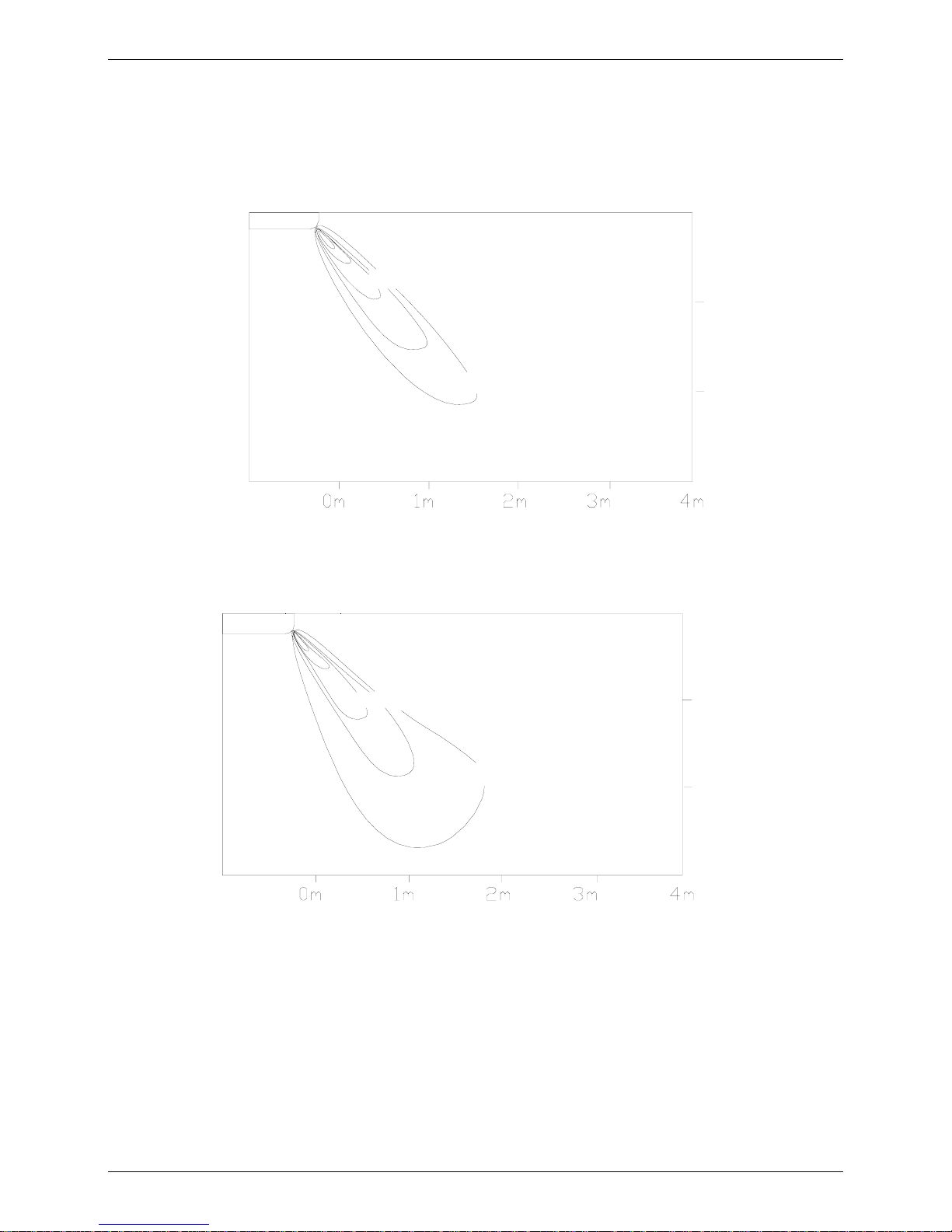

6. Air Velocity and Temperature Distributions

Discharge angle 60°(Ceiling)

Airflow velocity

1.5m/sec

0.5m/sec

3m

2m

1m

0m

Temperature

27° C

22° C

3m

2m

1m

0m

Page 22

Air Velocity and Temperature Distributions MCAC-UTSM-2008-05

20 Ceiling and Floor Type

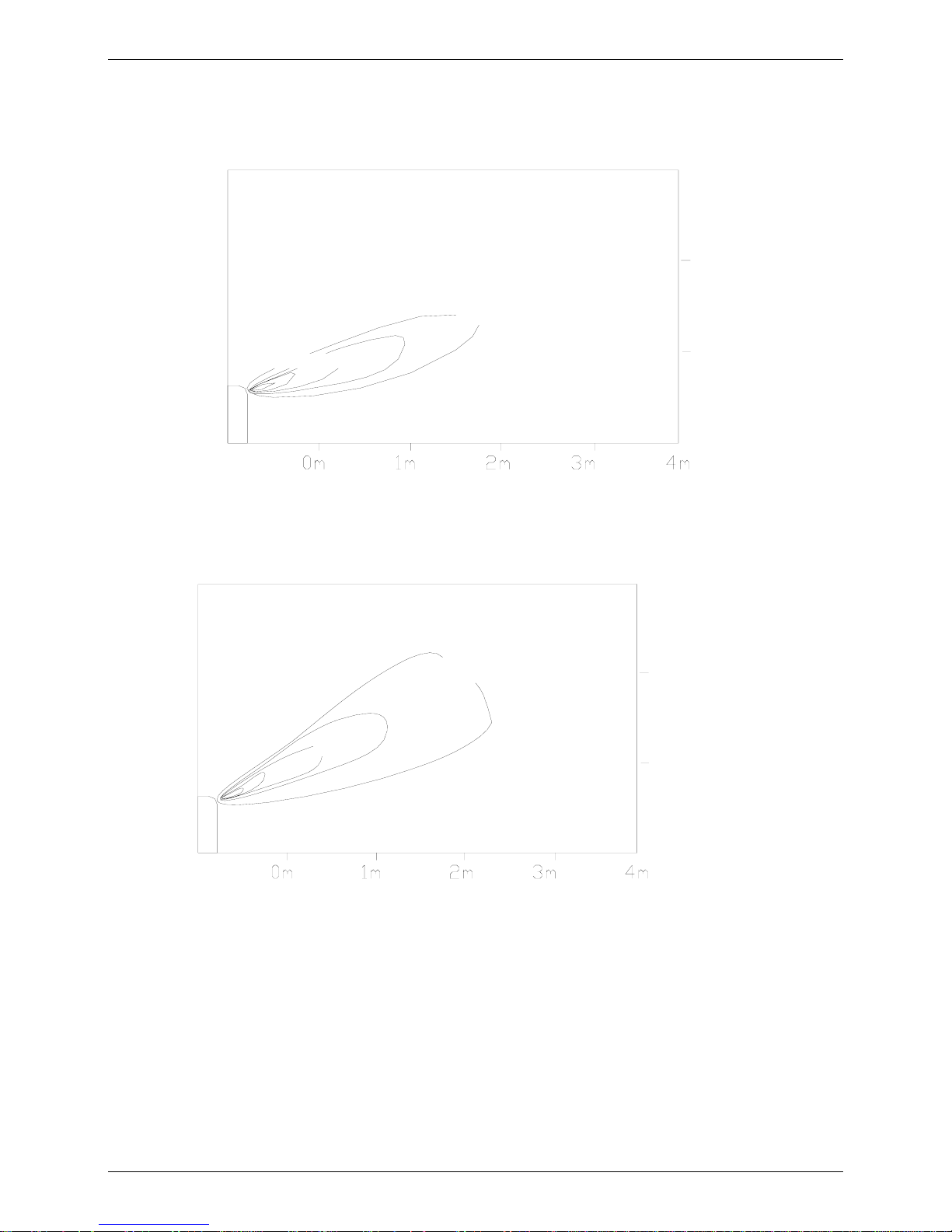

Discharge angle 60°(Floor)

Airflow velocity

0.5m/sec

1.5m/sec

3m

2m

1m

0m

Temperature

3m

2m

1m

0m

22° C

27° C

Page 23

MCAC-UTSM-2008-05 Capacity Tables

Ceiling and Floor Type 21

7. Capacity Tables

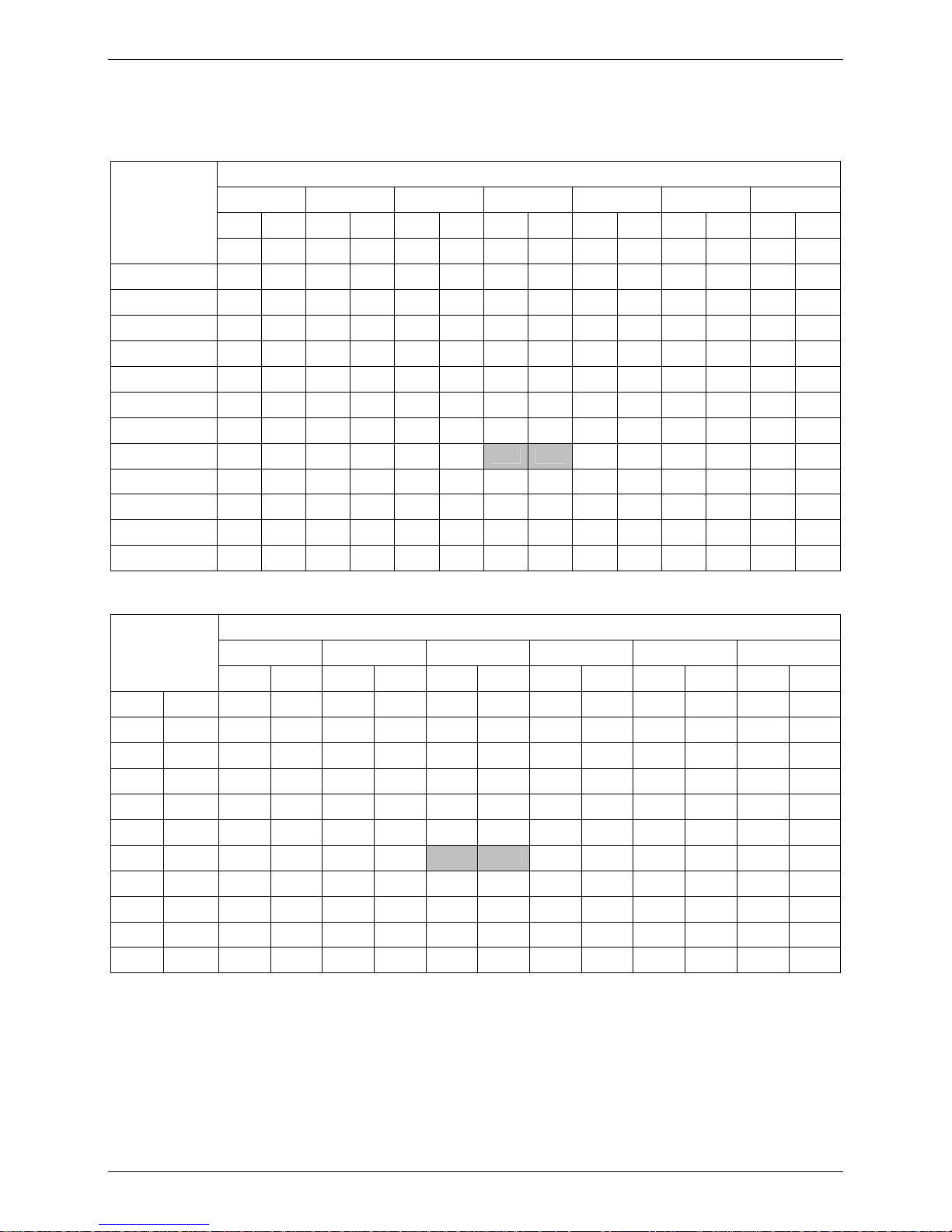

7.1 MUB-12HRDN1-Q:

Cooling:

Indoor temperature(°CWB)

14.00 16.00 18.00 19.00 20.00 22.00 24.00

TC PI TC PI TC PI TC PI TC PI TC PI TC PI

Outdoor

temperature(°C

DB)

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

21.00 2.42 0.43 2.86 0.54 3.30 0.64 3.50 0.70 3.70 0.75 3.78 0.75 3.86 0.76

23.00 2.42 0.46 2.86 0.57 3.30 0.69 3.50 0.75 3.70 0.80 3.78 0.81 3.86 0.81

25.00 2.42 0.49 2.86 0.61 3.30 0.74 3.50 0.80 3.70 0.86 3.78 0.86 3.86 0.87

27.00 2.42 0.53 2.86 0.66 3.30 0.79 3.50 0.85 3.70 0.92 3.78 0.92 3.86 0.93

29.00 2.42 0.56 2.86 0.70 3.30 0.84 3.50 0.91 3.70 0.98 3.78 0.98 3.86 0.99

31.00 2.42 0.60 2.86 0.75 3.30 0.90 3.50 0.97 3.70 1.05 3.78 1.05 3.86 1.06

33.00 2.42 0.64 2.86 0.80 3.30 0.95 3.50 1.03 3.70 1.11 3.78 1.12 3.86 1.13

35.00 2.42 0.68 2.86 0.85 3.30 1.01 3.50 1.10 3.70 1.19 3.78 1.19 3.86 1.20

37.00 2.42 0.72 2.86 0.90 3.30 1.08 3.50 1.17 3.70 1.26 3.78 1.27 3.86 1.28

39.00 2.42 0.73 2.86 0.90 3.30 1.08 3.50 1.18 3.70 1.27 3.78 1.27 3.86 1.28

41.00 2.42 0.73 2.86 0.91 3.30 1.09 3.50 1.18 3.70 1.27 3.78 1.28 3.86 1.29

43.00 2.42 0.73 2.86 0.91 3.30 1.09 3.50 1.19 3.70 1.28 3.78 1.28 3.86 1.29

Heating:

Indoor temperature(°C DB)

16 18 20 21 22 24

Outdoor air

temp.

TC PI TC PI TC PI TC PI TC PI TC PI

°C DB °C WB kW kW kW kW kW kW kW kW kW kW kW kW

-5 -5.6 3.19 1.00 3.19 1.02 3.19 1.04 3.07 0.99 2.94 0.95 2.69 0.86

-3 -3.7 3.33 1.01 3.33 1.03 3.33 1.05 3.20 1.01 3.06 0.96 2.80 0.87

0 -0.7 3.53 1.03 3.53 1.05 3.53 1.08 3.39 1.03 3.25 0.98 2.97 0.89

3 2.2 3.73 1.05 3.73 1.08 3.73 1.10 3.58 1.05 3.43 1.00 3.14 0.91

5 4.1 3.87 1.07 3.87 1.09 3.87 1.11 3.71 1.07 3.56 1.02 3.25 0.92

7 6 4.00 1.08 4.00 1.11 4.00 1.13 3.84 1.08 3.68 1.03 3.37 0.93

9 7.9 4.00 1.05 4.00 1.07 4.00 1.09 3.84 1.04 3.68 1.00 3.37 0.90

11 9.8 4.00 1.01 4.00 1.03 4.00 1.05 3.84 1.01 3.68 0.96 3.37 0.87

13 11.8 4.00 0.97 4.00 1.00 4.00 1.02 3.84 0.97 3.68 0.93 3.37 0.84

15 13.7 4.00 0.94 4.00 0.96 4.00 0.98 3.84 0.94 3.68 0.89 3.37 0.81

Page 24

Capacity Tables MCAC-UTSM-2008-05

22 Ceiling and Floor Type

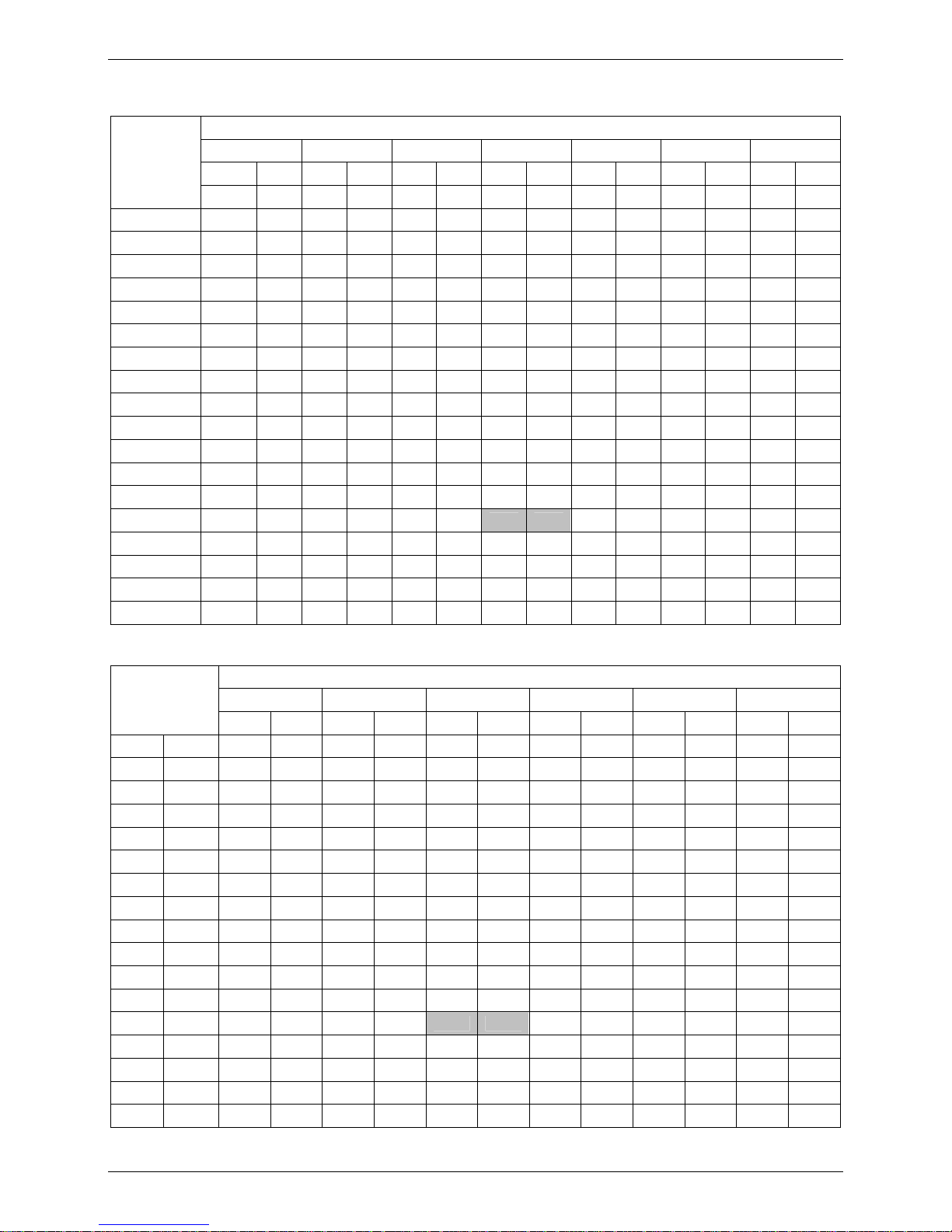

7.2 MUB-18HRDN1-Q:

Cooling:

Indoor temperature(°CWB)

14.00 16.00 18.00 19.00 20.00 22.00 24.00

TC PI TC PI TC PI TC PI TC PI TC PI TC PI

Outdoor

temperature

(°C DB)

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

10.00 3.65 0.55 4.31 0.69 4.97 0.82 5.27 0.89 5.57 0.96 5.69 0.96 5.82 0.97

12.00 3.65 0.56 4.31 0.70 4.97 0.84 5.27 0.91 5.57 0.98 5.69 0.98 5.82 0.99

14.00 3.65 0.57 4.31 0.71 4.97 0.85 5.27 0.92 5.57 1.00 5.69 1.00 5.82 1.01

16.00 3.65 0.58 4.31 0.72 4.97 0.87 5.27 0.94 5.57 1.01 5.69 1.02 5.82 1.03

18.00 3.65 0.59 4.31 0.74 4.97 0.88 5.27 0.96 5.57 1.03 5.69 1.03 5.82 1.04

19.00 3.65 0.60 4.31 0.75 4.97 0.90 5.27 0.97 5.57 1.05 5.69 1.05 5.82 1.06

21.00 3.65 0.64 4.31 0.80 4.97 0.96 5.27 1.04 5.57 1.13 5.69 1.13 5.82 1.14

23.00 3.65 0.69 4.31 0.86 4.97 1.03 5.27 1.12 5.57 1.21 5.69 1.21 5.82 1.22

25.00 3.65 0.74 4.31 0.92 4.97 1.10 5.27 1.20 5.57 1.29 5.69 1.29 5.82 1.31

27.00 3.65 0.79 4.31 0.98 4.97 1.18 5.27 1.28 5.57 1.38 5.69 1.38 5.82 1.40

29.00 3.65 0.84 4.31 1.05 4.97 1.26 5.27 1.37 5.57 1.47 5.69 1.48 5.82 1.49

31.00 3.65 0.90 4.31 1.12 4.97 1.34 5.27 1.46 5.57 1.57 5.69 1.57 5.82 1.59

33.00 3.65 0.96 4.31 1.19 4.97 1.43 5.27 1.55 5.57 1.67 5.69 1.68 5.82 1.69

35.00 3.65 1.02 4.31 1.27 4.97 1.52 5.27 1.65 5.57 1.78 5.69 1.78 5.82 1.80

37.00 3.65 1.08 4.31 1.35 4.97 1.62 5.27 1.75 5.57 1.89 5.69 1.90 5.82 1.92

39.00 3.65 1.09 4.31 1.36 4.97 1.63 5.27 1.76 5.57 1.90 5.69 1.91 5.82 1.92

41.00 3.65 1.09 4.31 1.36 4.97 1.63 5.27 1.77 5.57 1.91 5.69 1.91 5.82 1.93

43.00 3.65 1.10 4.31 1.37 4.97 1.64 5.27 1.78 5.57 1.92 5.69 1.92 5.82 1.94

Heating:

Indoor temperature(°C DB)

16 18 20 21 22 24

Outdoor air

temp.

TC PI TC PI TC PI TC PI TC PI TC PI

°C DB °C WB kW kW kW kW kW kW kW kW kW kW kW kW

-14.7 -15 3.72 1.42 3.72 1.45 3.72 1.48 3.57 1.41 3.43 1.35 3.13 1.22

-12.6 -13 3.93 1.44 3.93 1.47 3.93 1.50 3.77 1.44 3.62 1.37 3.30 1.24

-10.5 -11 4.13 1.46 4.13 1.50 4.13 1.53 3.97 1.46 3.81 1.39 3.48 1.26

-9.5 -10 4.23 1.48 4.23 1.51 4.23 1.54 4.07 1.47 3.90 1.40 3.56 1.27

-8.5 -9.1 4.33 1.49 4.33 1.52 4.33 1.55 4.16 1.48 3.99 1.41 3.64 1.28

-7 -7.6 4.48 1.50 4.48 1.54 4.48 1.57 4.30 1.50 4.12 1.43 3.77 1.29

-5 -5.6 4.68 1.53 4.68 1.56 4.68 1.59 4.49 1.52 4.31 1.45 3.93 1.31

-3 -3.7 4.87 1.55 4.87 1.58 4.87 1.61 4.68 1.54 4.49 1.47 4.10 1.33

0 -0.7 5.17 1.58 5.17 1.61 5.17 1.65 4.96 1.58 4.76 1.50 4.35 1.36

3 2.2 5.47 1.61 5.47 1.65 5.47 1.68 5.25 1.61 5.03 1.54 4.60 1.39

5 4.1 5.66 1.64 5.66 1.67 5.66 1.71 5.44 1.63 5.21 1.56 4.76 1.41

7 6 5.86 1.66 5.86 1.69 5.86 1.73 5.63 1.65 5.39 1.58 4.93 1.43

9 7.9 5.86 1.60 5.86 1.64 5.86 1.67 5.63 1.60 5.39 1.53 4.93 1.38

11 9.8 5.86 1.55 5.86 1.58 5.86 1.61 5.63 1.54 5.39 1.47 4.93 1.33

13 11.8 5.86 1.49 5.86 1.52 5.86 1.56 5.63 1.49 5.39 1.42 4.93 1.28

15 13.7 5.86 1.44 5.86 1.47 5.86 1.50 5.63 1.43 5.39 1.37 4.93 1.24

Page 25

MCAC-UTSM-2008-05 Capacity Tables

Ceiling and Floor Type 23

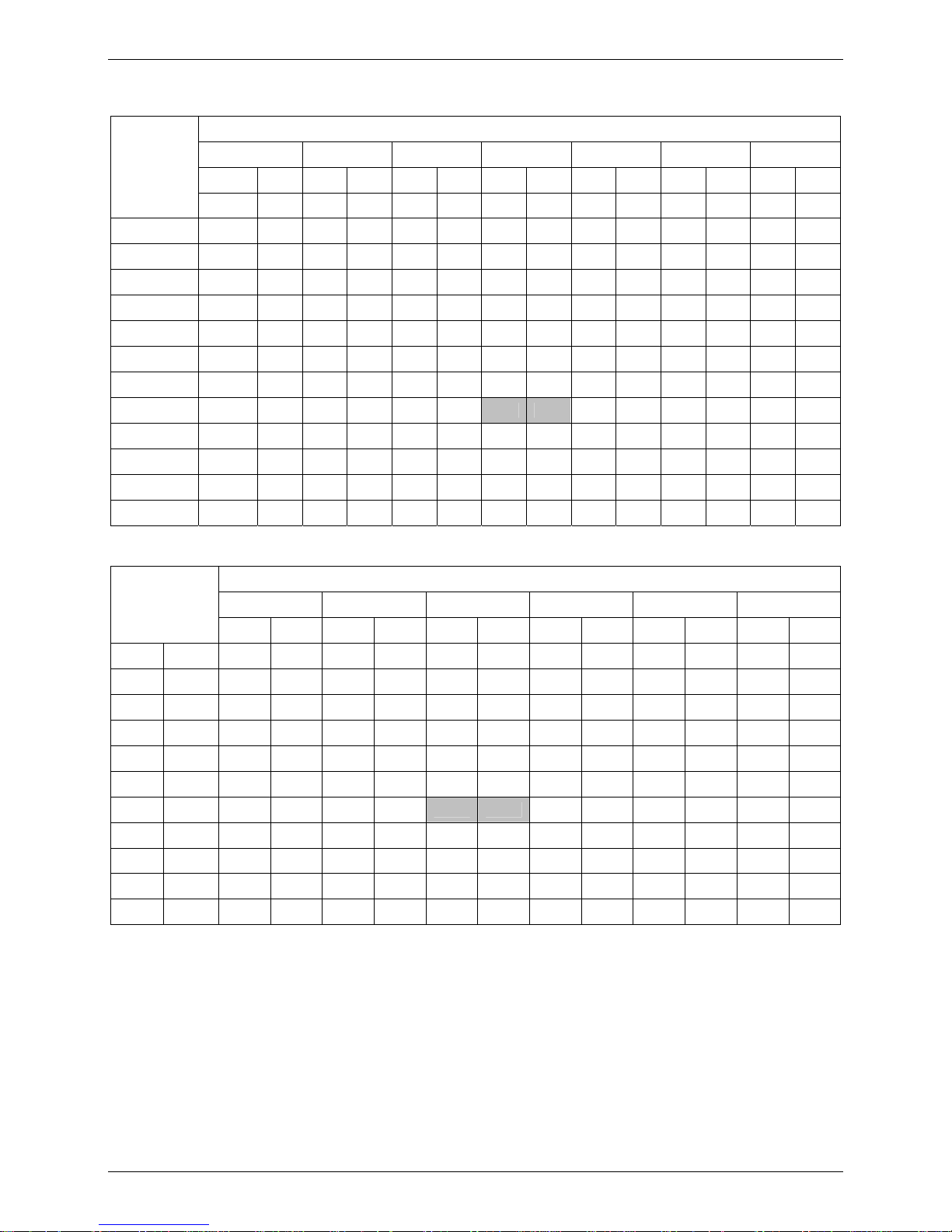

7.3 MUB-12HRDN1:

Cooling:

Indoor temperature(°CWB)

14.00 16.00 18.00 19.00 20.00 22.00 24.00

TC PI TC PI TC PI TC PI TC PI TC PI TC PI

Outdoor

temperature

(°C DB)

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

21.00 2.42 0.42 2.86 0.53 3.30 0.63 3.50 0.68 3.70 0.74 3.78 0.74 3.86 0.75

23.00 2.42 0.45 2.86 0.56 3.30 0.67 3.50 0.73 3.70 0.79 3.78 0.79 3.86 0.80

25.00 2.42 0.48 2.86 0.60 3.30 0.72 3.50 0.78 3.70 0.84 3.78 0.85 3.86 0.85

27.00 2.42 0.52 2.86 0.64 3.30 0.77 3.50 0.84 3.70 0.90 3.78 0.91 3.86 0.91

29.00 2.42 0.55 2.86 0.69 3.30 0.82 3.50 0.89 3.70 0.96 3.78 0.97 3.86 0.98

31.00 2.42 0.59 2.86 0.73 3.30 0.88 3.50 0.95 3.70 1.03 3.78 1.03 3.86 1.04

33.00 2.42 0.63 2.86 0.78 3.30 0.94 3.50 1.02 3.70 1.09 3.78 1.10 3.86 1.11

35.00 2.42 0.67 2.86 0.83 3.30 1.00 3.50 1.08 3.70 1.16 3.78 1.17 3.86 1.18

37.00 2.42 0.71 2.86 0.88 3.30 1.06 3.50 1.15 3.70 1.24 3.78 1.24 3.86 1.25

39.00 2.42 0.71 2.86 0.89 3.30 1.06 3.50 1.15 3.70 1.24 3.78 1.25 3.86 1.26

41.00 2.42 0.72 2.86 0.89 3.30 1.07 3.50 1.16 3.70 1.25 3.78 1.25 3.86 1.27

43.00 2.42 0.72 2.86 0.90 3.30 1.07 3.50 1.16 3.70 1.26 3.78 1.26 3.86 1.27

Heating:

Indoor temperature(°C DB)

16 18 20 21 22 24

Outdoor air

temp.

TC PI TC PI TC PI TC PI TC PI TC PI

°C DB °C WB kW kW kW kW kW kW kW kW kW kW kW kW

-5 -5.6 3.19 0.99 3.19 1.01 3.19 1.03 3.07 0.98 2.94 0.94 2.69 0.85

-3 -3.7 3.33 1.00 3.33 1.02 3.33 1.04 3.20 1.00 3.06 0.95 2.80 0.86

0 -0.7 3.53 1.02 3.53 1.05 3.53 1.07 3.39 1.02 3.25 0.97 2.97 0.88

3 2.2 3.73 1.05 3.73 1.07 3.73 1.09 3.58 1.04 3.43 0.99 3.14 0.90

5 4.1 3.87 1.06 3.87 1.08 3.87 1.10 3.71 1.06 3.56 1.01 3.25 0.91

7 6 4.00 1.07 4.00 1.10 4.00 1.12 3.84 1.07 3.68 1.02 3.37 0.92

9 7.9 4.00 1.04 4.00 1.06 4.00 1.08 3.84 1.03 3.68 0.99 3.37 0.89

11 9.8 4.00 1.00 4.00 1.02 4.00 1.04 3.84 1.00 3.68 0.95 3.37 0.86

13 11.8 4.00 0.97 4.00 0.99 4.00 1.01 3.84 0.96 3.68 0.92 3.37 0.83

15 13.7 4.00 0.93 4.00 0.95 4.00 0.97 3.84 0.93 3.68 0.88 3.37 0.80

Page 26

Electric Characteristics MCAC-UTSM-2008-05

24 Ceiling and Floor Type

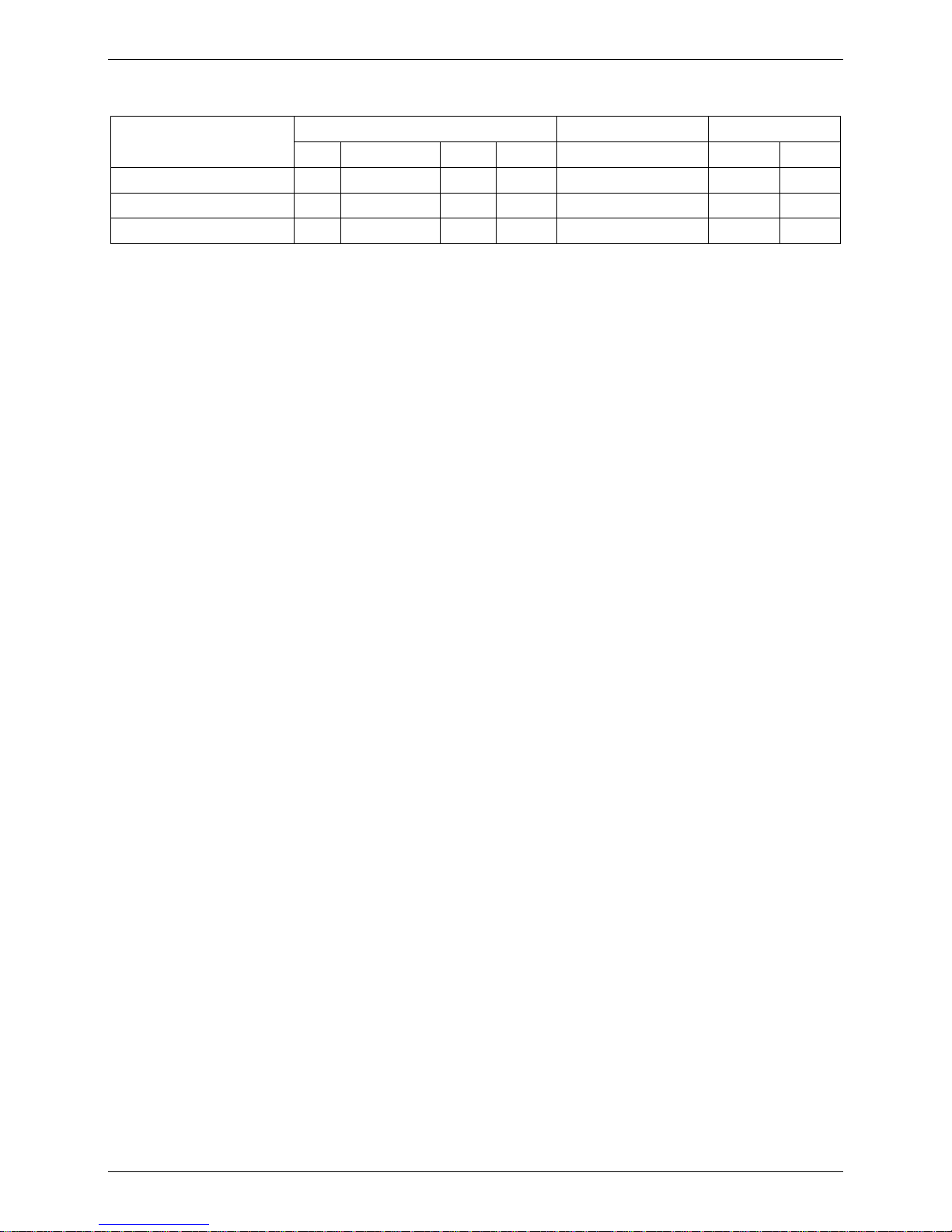

8. Electric Characteristics

Indoor Unit Power Supply IFM

Model

Hz Voltage Min Max MFA kW FLA

MUB-12HRDN1 50 220~240 198 254 15 0.025 0.15

MUB-12HRDN1-Q 50 220~240 198 254 15 0.025 0.15

MUB-18HRDN1-Q 50 220~240 198 254 18 0.55 0.52

Remark:

MFA: Max. Fuse Amps. (A)

KW: Fan Motor Rated Output (KW)

FLA: Full Load Amps. (A)

IFM: Indoor Fan Motor

Page 27

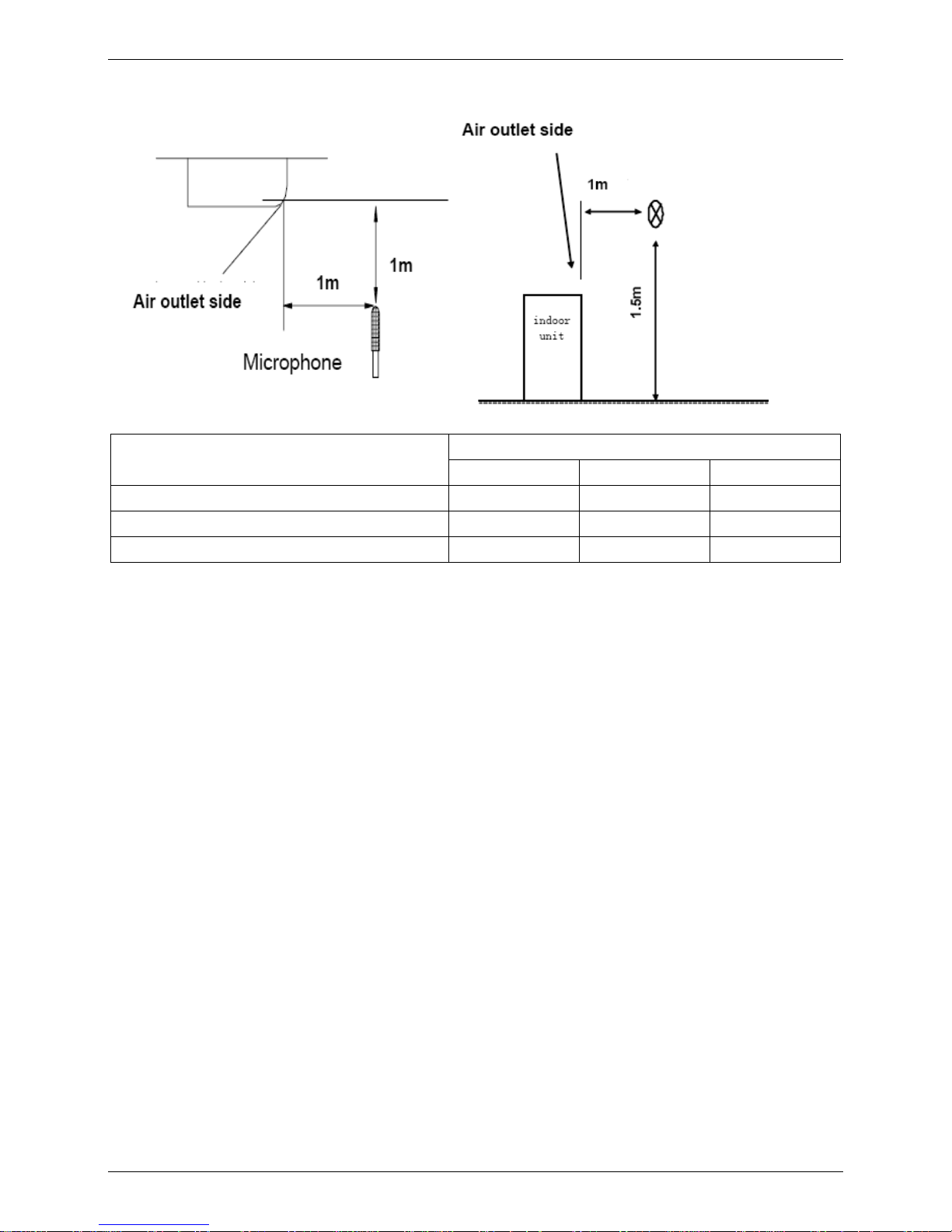

MCAC-UTSM-2008-05 Sound Levels

Ceiling and Floor Type 25

9. Sound Levels

Ceiling Floor

Noise level dB(A)

Model

H M L

MUB-12HRDN1 39.6 36.7 33.1

MUB-12HRDN1-Q 39.6 36.7 33.1

MUB-18HRDN1-Q 44.6 41.8 37.3

Page 28

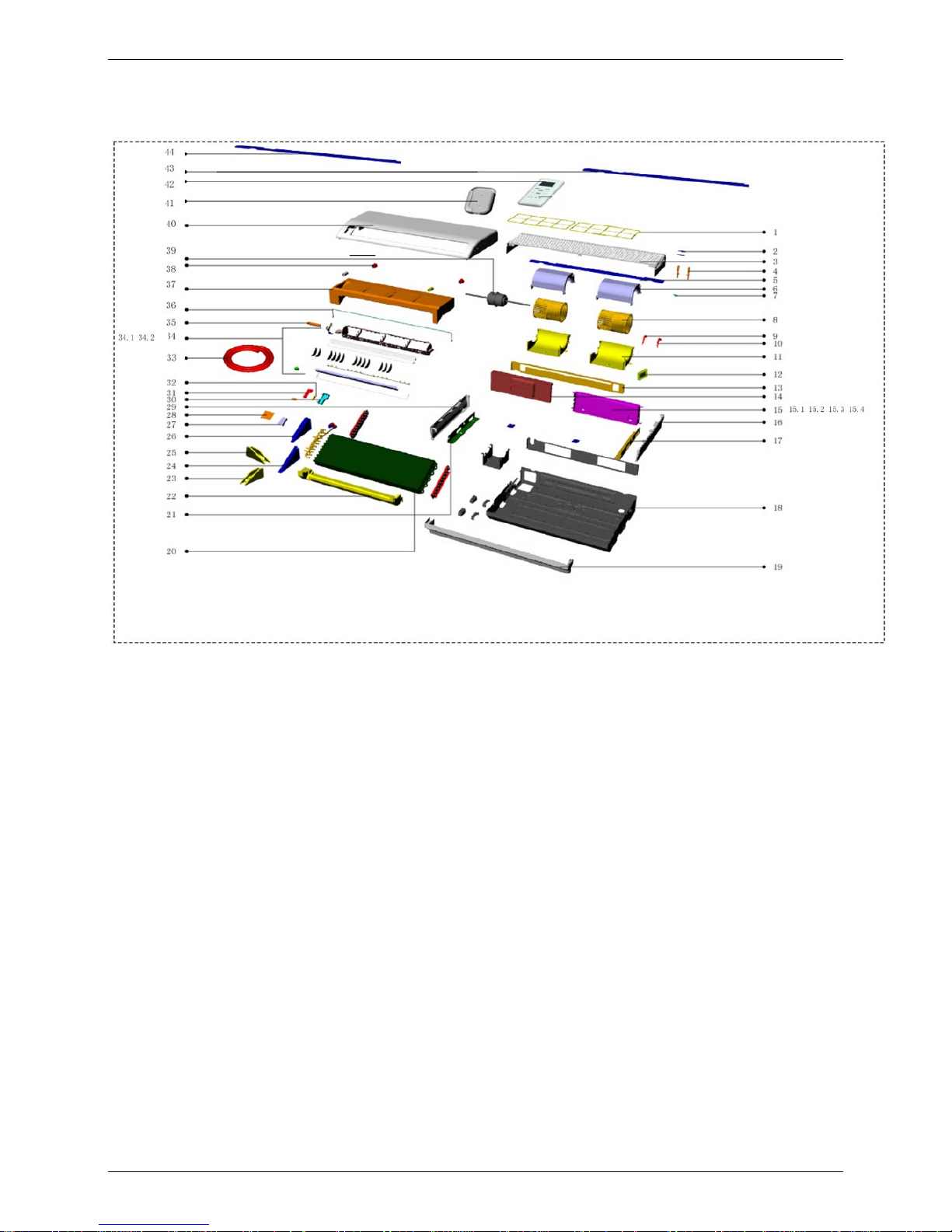

Exploded View MCAC-UTSM-2008-05

26 Ceiling and Floor Type

10. Exploded View

10.1 MUB-12HRDN1-Q

Page 29

MCAC-UTSM-2008-05 Exploded View

Ceiling and Floor Type 27

No. Part name Quantity No. Part name Quantity

1 Filter 2 22 Foam ass'y 1

2 Grille clamp 2 23 Foam ass'y 1

3 Grille 1 24 Evaporator Left support 1

4 Grille clamp 2 25 Foam ass'y 1

5 Grille strengthening rib 1 26 Support board 1

6 Volute shell 2 27 Evaporator right clapboard 1

7 Grille lock 1 28 Evaporator left clapboard 1

8 Plastic fan 2 29 Cover 1

9 Motor clamp 1 30 Display panel box 1

10 Motor clamp 1 31 Display board ass'y 1

11 Volute shell 2 32 Manual button 1

12 Board 1 33 Connecting hose ass'y 1

13 Middle beam 1 34 Air outlet ass'y 1

14 E-part box cover 1 34.1 Stepper motor(vertical) 1

15 E-part box ass'y 1 34.2 Stepper motor 1

15.1 Transformer 1 35 Foam 1

15.2 Main controller ass'y 1 36 Drainage pan holder 2

15.3 Wire joint 1 37 Drainage pan ass'y 1

15.4 Motor capacitor 1 38 Plastic cover 1

16 Left cover 1 39 Motor 1

17 Installation board 1 40 Panel ass'y 1

18 Base ass'y 1 41 Installation bracket 1

19 Rear cover 1 42 Remote controller 1

20 Evaporator ass'y 1 43 Temp. sensor ass'y 1

21 Installation board 1 44 Room temp sensor ass'y 1

Page 30

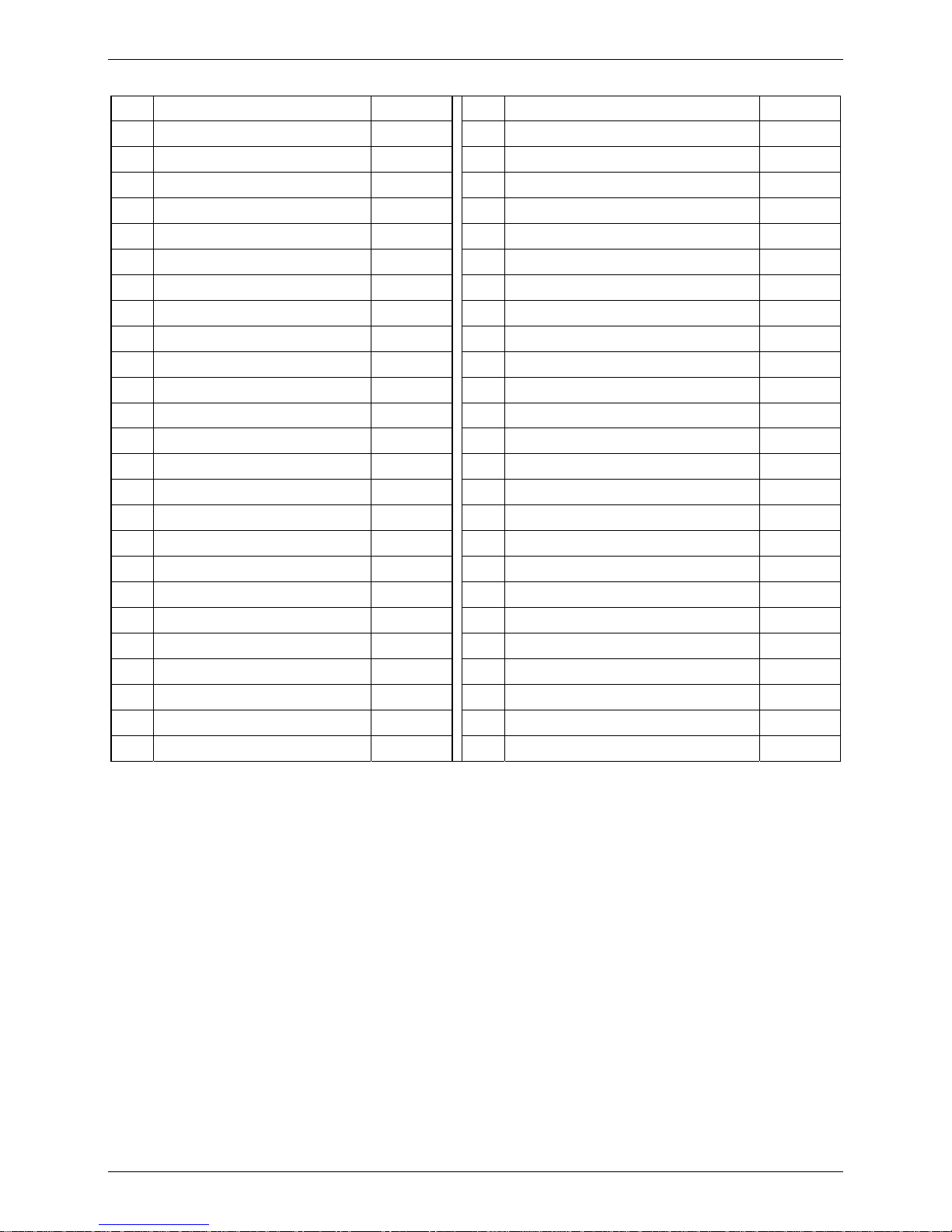

Exploded View MCAC-UTSM-2008-05

28 Ceiling and Floor Type

10.2 MUB-18HRDN1-Q

Page 31

MCAC-UTSM-2008-05 Exploded View

Ceiling and Floor Type 29

No. Part name Quantity No. Part name Quantity

1 Filter 2 22 Foam ass'y 1

2 Grille clamp 2 23 Foam ass'y 1

3 Grille 1 24 Evaporator Left support 1

4 Grille clamp 2 25 Foam ass'y 1

5 Grille strengthening rib 1 26 Support board 1

6 Volute shell 2 27 Evaporator right clapboard 1

7 Grille lock 1 28 Evaporator left clapboard 1

8 Plastic fan 2 29 Cover 1

9 Motor clamp 1 30 Display panel box 1

10 Motor clamp 1 31 Display board ass'y 1

11 Volute shell 2 32 Manual button 1

12 Board 1 33 Connecting hose ass'y 1

13 Middle beam 1 34 Air outlet ass'y 1

14 E-part box cover 1 34.1 Stepper motor(vertical) 1

15 E-part box ass'y 1 34.2 Stepper motor 1

15.1 Transformer 1 35 Foam 1

15.2 Main controller ass'y 1 36 Drainage pan holder 2

15.3 Wire joint, 2p 1 37 Drainage pan ass'y 1

15.4 Wire joint 1 38 Plastic cover 1

15.5 Motor capacitor 1 39 Motor 1

16 Left cover 1 40 Panel ass'y 1

17 Installation board 1 41 Installation bracket 1

18 Base ass'y 1 42 Remote controller 1

19 Rear cover 1 43 Temp. sensor ass'y 1

20 Evaporator ass'y 1 44 Temp. sensor ass'y 1

21 Installation board 1 45 Room temp sensor ass'y 1

Page 32

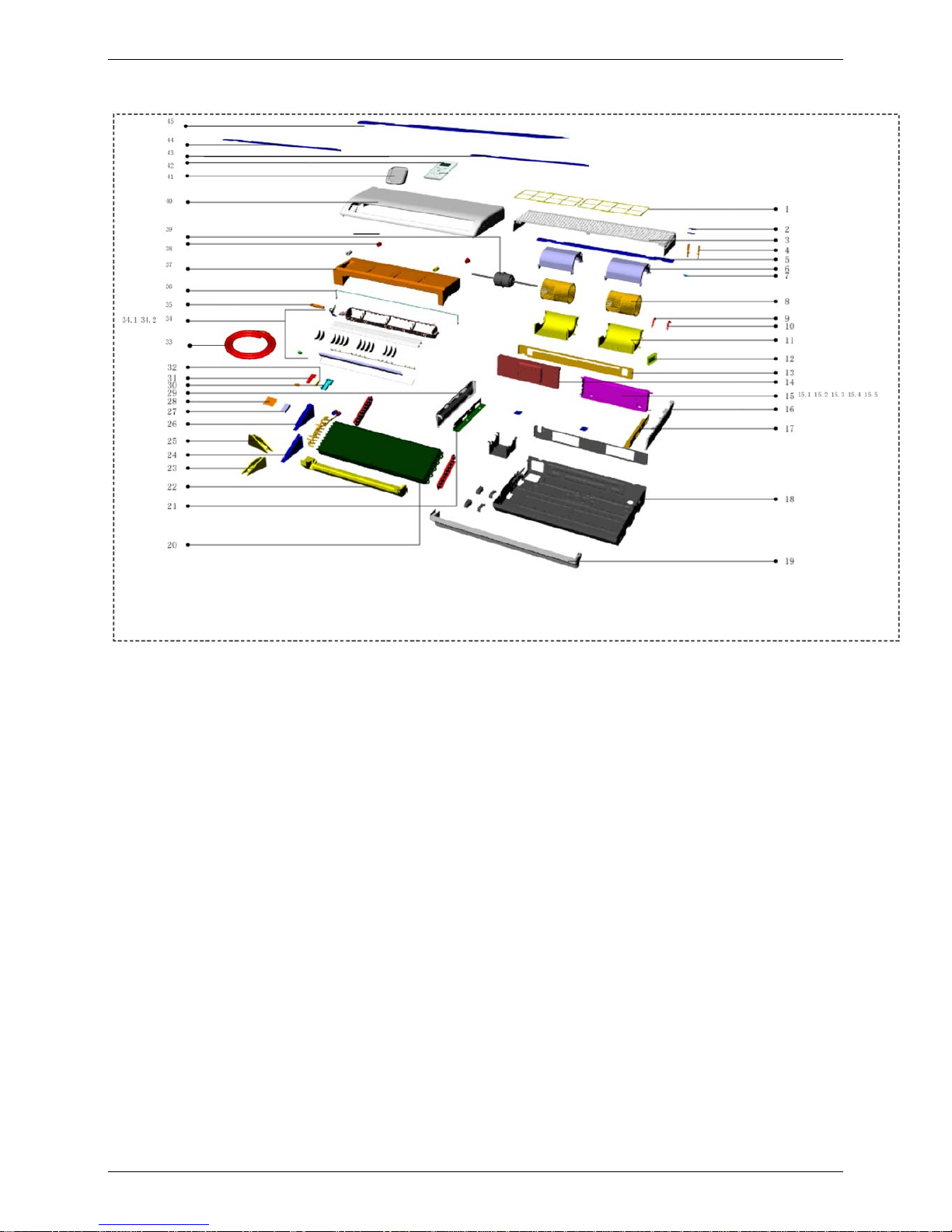

Exploded View MCAC-UTSM-2008-05

30 Ceiling and Floor Type

10.3 MUB-12HRDN1

Page 33

MCAC-UTSM-2008-05 Exploded View

Ceiling and Floor Type 31

No. Part name Quantity No. Part name Quantity

1 Filter 2 22 Foam ass'y 1

2 Grille clamp 2 23 Evaporator Left support 1

3 Grille 1 24 Foam ass'y 1

4 Grille clamp 2 25 Support board 1

5 Grille strengthening rib 1 26 Evaporator right clapboard 1

6 Volute shell 2 27 Evaporator left clapboard 1

7 Grille lock 1 28 Cover 1

8 Plastic fan 2 29 Display panel box 1

9 Motor clamp 1 30 Display board ass'y 1

10 Motor clamp 1 31 Manual button 1

11 Volute shell 2 32 Air outlet ass'y 1

12 Board 1 33 Stepper motor(vertical) 1

13 Middle beam 1 33.1 Stepper motor 1

14 E-part box cover 1 33.2 Foam 1

15 E-part box ass'y 1 34 Drainage pan holder 2

15.1 Transformer 1 35 Drainage pan ass'y 1

15.2 Main controller ass'y 1 36 Plastic cover 1

15.3 Wire joint 1 37 Motor 1

15.4 Motor capacitor 1 38 Panel ass'y 1

16 Left cover 1 39 Installation bracket 1

17 Installation board 1 40 Remote controller 1

18 Base ass'y 1 41 Temp. sensor ass'y 1

19 Rear cover 1 42 Temp. sensor ass'y 1

20 Evaporator ass'y 1 43 Room temp sensor ass'y 1

21 Installation board 1 44 Foam ass'y 1

Page 34

Accessories MCAC-UTSM-2008-05

32 Ceiling and Floor Type

11. Accessories

Name of accessories Quantity Outline Usage

Owner’s installation/remote controller

manual

1 /

Hook 2

For wall mounting installation

Hanging arm 2

For ceiling installation

Screw bolt with washer 4

For ceiling installation

Remote controller 1

_

Frame 1

_

Mounting screw(ST2.9×10-C-H)

2

_

Alkaline dry batteries (AM4) 2

_

Page 35

MCAC-UTSM-2008-05 Outdoor Units

Outdoor Units 33

Part 3

Outdoor Units

1. Dimensions......................................................................34

2. Service Space..................................................................35

3. Piping Diagrams..............................................................36

4. Wiring Diagrams .............................................................37

5. Electric Characteristics..................................................40

6. Sound Levels...................................................................41

7. Exploded View.................................................................42

8. Operation Limits .............................................................47

9. Troubleshooting..............................................................48

Page 36

Dimensions MCAC-UTSM-2008-05

34 Outdoor Units

1. Dimensions

Model A B C D E F H

MOU-12HDN1 761 530 290 315 270 279 593

MOU-12HDN1-Q 761 530 290 315 270 279 593

MOU-18HDN1-Q 842 560 335 360 312 324 695

Page 37

MCAC-UTSM-2008-05 Service Space

Outdoor Units 35

2. Service Space

Page 38

Piping Diagrams MCAC-UTSM-2008-05

36 Outdoor Units

3. Piping Diagrams

3.1 MOU-12HDN1-Q MOU-12HDN1

Compressor

Outdoor unit

4-way valve

Condenser

Indoor unit

Capillary ass'y

Evaporator

3.2 MOU-18HDN1-Q

Condenser

Compressor

Low pressure switch

Outdoor unit

High pressure

switch

4-way valve

Indoor unit

Capillary

Evaporator

Electronic expansion

valve ass'y

Page 39

MCAC-UTSM-2008-05 Wiring Diagrams

Outdoor Units 37

4. Wiring Diagrams

4.1 MOU-12HDN1-Q

Page 40

Wiring Diagrams MCAC-UTSM-2008-05

38 Outdoor Units

4.2 MOU-18HDN1-Q

Page 41

MCAC-UTSM-2008-05 Wiring Diagrams

Outdoor Units 39

4.3 MOU-12HDN1

Page 42

Electric Characteristics MCAC-UTSM-2008-05

40 Outdoor Units

5. Electric Characteristics

Outdoor Unit Power Supply Compressor OFM

Model

Hz Voltage Min. Max. TOCA MFA RLA kW FLA

MOU-12HDN1 50 220~240V 198 254 20 16 5.3 0.024 0.27

MOU-12HDN1-Q 50 220~240V 198 254 20 16 5.3 0.024 0.27

MOU-18HDN1-Q 50 220~240V 198 254 20 16 8.8 0.053 0.59

Remark:

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

RLA: Rated Locked Amps. (A)

OFM: Outdoor Fan Motor.

FLA: Full Load Amps. (A)

KW: Rated Motor Output (KW)

Page 43

MCAC-UTSM-2008-05 Sound Levels

Outdoor Units 41

6. Sound Levels

Noise level dB(A)

Model

Hi Lo

MOU-12HDN1 48 44

MOU-12HDN1-Q 48 44

MOU-18HDN1-Q 52 47

Page 44

Exploded View MCAC-UTSM-2008-05

42 Outdoor Units

7. Exploded View

7.1 MOU-12HDN1-Q

No. Part name Quantity No. Part name Quantity

1 Top cover 1 14 Drainage pan 1

2 E-part box ass'y 1 15 Big handle 1

2.1 Main controller ass'y 1 16 Discharge temp sensor ass'y 1

2.2 Compressor capacitor 1 17 Condenser ass'y 1

2.3 Radiator 1 17.1 Condenser inlet pipe ass'y 1

3 Grille 1 17.2 Condenser 1

4 Axial flow fan 1 17.3 Condenser outlet pipe 1

5 Left holder 1 18 Room temp sensor ass'y 1

6 Partition board ass'y 1 19 Connect couplings ass'y 1

7 Base ass'y 1 19.1 One way valve 1

8.1 Reactance 1 19.2 Connect couplings 1

8.2 Reactance 1 19.3 Strainer ass'y 1

9 Electric inductance cover ass'y 1 19.4 Four-way electro-magnetic reversing valve 1

10 Sponge 1 20 Temp. sensor ass'y 1

11 Compressor electric heater 1 21 Motor bracket 1

12 Compressor 1 22 Motor 1

13 Right cover 1 23 Front panel 1

Page 45

MCAC-UTSM-2008-05 Exploded View

Outdoor Units 43

7.2 MOU-18HDN1-Q

Page 46

Exploded View MCAC-UTSM-2008-05

44 Outdoor Units

No. Part name Quantity No. Part name Quantity

1 Top cover ass'y 1 13 Compressor 1

2 Rear net frame 1 14 Rear right clapboard ass'y 1

3 E-part box ass'y 1 15 Drainage cover 1

3.1 Inverter radiator 1 16 Big handle 1

3.2 Transformer 1 17 Discharge temp sensor ass'y 1

3.3 Transformer 1 18 Condenser ass'y 1

3.4 Main controller ass'y 1 18.1 Output pipe ass'y 1

3.5 Inverter control Module 1 18.2 Input pipe ass'y 1

3.6 Rectifier 2 18.3 Condenser 1

3.7 Compressor capacitor 1 19 Temp sensor 1

3.8 Power board ass'y 1 20 Connect coupling ass'y 1

3.9 Main controller ass'y 1 20.1 Solenoid 1

3.10 EMC filter 1 20.2 4-way valve 1

3.11 Motor capacitor 1 20.3 Connect coupling 1

3.12 Wire joint 1 20.4 Pressure controller 1

4 Grille 1 20.5 Pressure controller 1

5 Axial flow fan 1 20.6 Electronic expansion valve 1

6 Left holder 1 20.7 EEV solenoid 1

7 Partition board ass'y 1 21 Temp. sensor ass'y 1

8 Base ass'y 1 22 Motor bracket ass'y 1

9 Reactance 1 23 Motor 1

10 Electrical inductance box 1 24 Front panel 1

11 Sponge 1 25 Reactance 1

12 Compressor electric heater 1 26 Reactance 1

Page 47

MCAC-UTSM-2008-05 Exploded View

Outdoor Units 45

7.3 MOU-12HDN1

Page 48

Exploded View MCAC-UTSM-2008-05

46 Outdoor Units

No. Part name Quantity No. Part name Quantity

1 Top cover 1 14 Drainage pan 1

2 E-part box ass'y 1 15 Big handle 1

2.1 Main controller ass'y 1 16 Discharge temp sensor ass'y 1

2.2 Compressor capacitor 1 17 Condenser ass'y 1

2.3 Radiator 1 17.1 Condenser inlet pipe ass'y 1

2.4 Main controller ass'y 1 17.2 Condenser 1

2.4.1 Rectifier 1 17.3 Condenser outlet pipe 1

3 Grille 1 18 Room temp sensor ass'y 1

4 Axial flow fan 1 19 Low pressure valve ass'y 1

5 Left holder 1 19.1 Low pressure valve 1

6 Partition board ass'y 1 19.2 Four-way electro-magnetic reversing valve 1

7 Base ass'y 1 20 High pressure valve ass'y 1

8.1 Reactance 1 20.1 High pressure valve 1

8.2 Reactance 1 20.2 One way valve 1

9 Electric inductance cover ass'y 1 21 Temp. sensor ass'y 1

10 Sponge 1 22 Motor bracket 1

11 Compressor electric heater 1 23 Motor 1

12 Compressor 1 24 Front panel 1

13 Right clapboard 1

Page 49

MCAC-UTSM-2008-05 Operation Limits

Outdoor Units 47

8. Operation Limits

8.1 For 12000Btu/h:

Cooling mode Heating mode

Item

Model

Outdoor Indoor Outdoor Indoor

MOU-12HDN1 (-Q)

21℃~43℃ 17℃~30℃ -5℃~24℃ 17℃~30℃

50

Range for

intermittent operation

Range for intermittent operation

Range for continuous operation

Range for continuous

operation

5

Indoor temperature(℃ WB)

Outdoor temperature(℃ DB)

30

24

20

15

10

5

0

-5

-20

10 15 20 25 30

3025201510

15

20

25

30

35

40

43

Cooling

Heating

Outdoor temperature(℃ WB)

Indoor temperature(℃ DB)

8.2 For 1800Btu/h:

Cooling mode Heating mode

Item

Model

Outdoor Indoor Outdoor Indoor

MOU-18HDN1-Q

-15℃~43℃ 17℃~30℃ -15℃~21℃ 17℃~30℃

17 24 30

43

40

35

30

25

20

15

10

5

0

-5

-15

cooling

Indoor temp.( C)

0

Ambient

temp

.

( C)

0

17 24 30

21

6

-15

Heating

Indoor temp. (° C)

A

m

b

i

e

n

t

t

e

m

p

.

(

°

C

)

Page 50

Troubleshooting MCAC-UTSM-2008-05

48 Outdoor Units

9. Troubleshooting

9.1 Indoor unit malfunction

No Malfunction

Running

lamp

Timer

lamp

Defrosting

lamp

Alarm

lamp

1 Room temperature sensor checking channel is abnormal

☆ × × ×

2 Evaporator sensor checking channel is abnormal

× × ☆ ×

3

In-outdoor unit communication checking channel is

abnormal

× ☆ × ×

4 Water-level switch malfunction

× × × ☆

5 EEPROM malfunction

☆ ☆ × ×

6 IPM module protection

☆ × × ●

7 Condenser sensor checking channel is abnormal

☆ ● × ×

8 Outdoor unit voltage protection

☆ ● × ●

9 Compressor discharge over-temperature protection

☆ × ● ×

10 Outdoor unit over-current protection

☆ ☆ × ☆

(× Extinguish, ☆ Flash at 5Hz, ● On)

Page 51

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 49

1. Running lamp flash at 5Hz: Room temperature sensor is abnormal

2. Defrosting lamp flash at 5Hz: Evaporator temperature sensor is abnormal

Running lamp flash at 5Hz

Judge: Room temperature sensor is abnormal

Validate: Check whether the resistance of the

temperature sensor is correct according to

Replace room temperature sensor

No

Replace indoor PCB

Yes

Defrosting lamp flash at 5Hz

Judge: Evaporator temperature sensor is abnormal

Validate: Check whether the resistance of the

temperature sensor is correct according to Annex 1

Replace room temperature sensor

No

Replace indoor PCB

Yes

Page 52

Troubleshooting MCAC-UTSM-2008-05

50 Outdoor Units

3. Timer lamp flash at 5Hz: Communication malfunction between indoor/outdoor units

Timer lamp flash at 5Hz

Communication malfunction between indoor/outdoor units

Judge 3: Check whether the signal wiring between the

indoor and outdoor units is wrong polarity?

Connect the signal wiring correctly

Yes

No

Judge 4: Check whether the signal wiring between the

indoor and outdoor units is broken?

Yes

Replace the broken wiring

No

Judge 2: Check whether the signal wiring is shield cable or

whether the shield cable is earthing

Yes

Adopt the shield cable/ shield cable earthing

No

Indoor or outdoor main board is broken, replace the

main board until the malfunction is disappear

Judge 1: Check whether the indoor unit power is on

Turn on the indoor unit power

No

Yes

Page 53

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 51

4. Alarm lamp flash at 5Hz: Water-level switch malfunction

O

K

OK

Alarm lamp flashes at 5Hz

Exist

O

K

Water-level switch Connecting

wire between switch and main

board gets loose

Reconnect and ensure

that the connection is

reliable.

There is something wrong

with the water-level switch

Exist

Replace switch

Chip fault, or chip foot sheds off, or chip is

inverted (correct mode is semicircular bent

alignment)

Error

Reinstall chip, or install other chip

with same model on the faulty unit,

to check whether there is

something wrong with chip.

Main board error:

For example,

getting wet

Replace

main board

OK

Page 54

Troubleshooting MCAC-UTSM-2008-05

52 Outdoor Units

5. Running and Timer lamp flash at 5Hz: EEPROM malfunction

Running and Timer lamp flash at 5Hz

EEPROM malfunction

Judge 1: Check whether the EEPROM is inserted well

Yes

No

Insert the EEPROM well

Replace outdoor main board

Page 55

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 53

6. Running lamp flash at 5Hz and Alarm lamp on: IPM protection

Running lamp flash at 5Hz and Alarm lamp on

IPM protection

Check whether the voltage range of P-N on

IPM module is normal?

No

Check whether the input power supply

is correct? 220-240V, 1N, 50Hz

No

Regulate it to correct,

then check whether the

system can work

normally?

Yes

Check whether the power

supply line is connected

correctly and tightly

No

Connect it correctly and

tightly, check ok or not?

No

Yes

Check whether the lines in

E-part box are connected tightly

No

Connect it tightly,

check ok or not?

No

Yes

Check whether the single-phase bridge is

normal? Use the multimeter to measure the

resistance between each two terminals, check

whether there is the condition that value of

resistance is 0

Yes

Replace the

single-phase bridge

No

No

Check whether the connecting line

of every reactor is normal? If the

line is broken, the resistance of the

two ports is ∞

No

Replace the

connecting line

Yes

Check whether the connecting line

between main board and the IPM

module is connected tightly

Yes

Check whether the connecting

line of the compressor is

connected correctly or tightly

Yes

Replace the IPM module, check

whether the system can work

normally?

No

Replace the main board, check

whether the system can work

normally?

Yes

Trouble is solved

No

Replace the compressor, check

whether the system can work

normally?

Connect it tightly,

check ok or not?

No

Connect it well,

check ok or not?

No

Yes

Trouble is solved

No

No

Yes

Trouble is solved

Yes

Check whether the fuse on

the power board is normal?

No

Replace with

the same model

fuse

Yes

Replace the power board

Page 56

Troubleshooting MCAC-UTSM-2008-05

54 Outdoor Units

7. Running lamp flash at 5Hz and Timer lamp on: Condenser temperature sensor is malfunction

Running lamp flash at 5Hz and Timer lamp on

Check whether the wiring of the Condenser temperature sensor

is break off

Replace outdoor main board

Judge : Condenser temperature sensor is malfunction

Connect the wiring well

Yes

No

Check whether the resistance of Condenser temperature sensor

is wrong refer to the Annex 1

Yes

Replace Condenser

temperature sensor

No

Page 57

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 55

8. Running lamp flash at 5Hz, Timer and Alarm lamp on: Outdoor unit voltage protection

Running lamp flash at 5Hz, Timer and Alarm lamp on

Outdoor unit voltage protection

Check the voltage of outdoor unit power supply, whether the

voltage between L1 and N is about 198-254V

No

Replace the power board, then check whether the system can run normally

Check the power supply

Yes

Replace outdoor main board

Yes

Trouble is solved

No

Page 58

Troubleshooting MCAC-UTSM-2008-05

56 Outdoor Units

9. Running lamp flash at 5Hz and Defrosting lamp on: Compressor discharge temperature protection

Running lamp flash at 5Hz and Defrosting lamp on

Compressor discharge temperature protection

Check whether the compressor discharge temp. more than 115°C ?

No

Check whether the wiring connection is right

between compressor discharge temp.

sensor and PCB according to wiring

diagrams

Yes

Validate: Check whether the resistance of compressor

discharge temp. sensor is right refer to the Annex 2

No

Correct the wiring connection

Yes

Replace outdoor main board

Judge: The discharge temp. sensor is broken

No

Replace the compressor

discharge temp. sensor

Check whether the refrigerant is leakage

Stop leaking and add refrigerant

Yes

Yes

Page 59

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 57

10. Running lamp 、Timer lamp and Alarm lamp flash at 5Hz: Outdoor unit current protection

Running lamp 、Timer lamp and Alarm lamp flash at 5Hz

Outdoor unit current protection

Judge 1: Check whether the input current of the power supply wire

is more than 16A.

Check whether the refrigerant system is ok

Yes

Judge 2: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

Replace outdoor main board

No

No

Judge 3: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 4: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 5: The refrigerant pipe is blocked

Yes

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe,

vacuumize and add the refrigerant again

Page 60

Troubleshooting MCAC-UTSM-2008-05

58 Outdoor Units

9.2 Outdoor unit malfunctions:

12000Btu/h: Its malfunctions are displayed on the indoor units’ indicator.

18000Btu/h: Its malfunctions are displayed on the outdoor units’ digital tube.

Display Malfunction or Protection

E0 EEPROM malfunction

E2 Communication malfunction between indoor/outdoor units

E3 Communication malfunction in outdoor PCB

E4 Outdoor temperature sensors malfunction

E5 Compressor voltage protection

P1 High pressure protection

P2 Low pressure protection

P3 Compressor current protection

P4 Compressor discharge temperature protection

P5 Condenser high temperature protection

P6 IPM protection

1. E0 malfunction

LED indicates E0

EEPROM malfunction

Check whether the EEPROM is inserted well

Yes

No

Insert the EEPROM well

Replace outdoor main board

Page 61

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 59

2. E2 malfunction

LED indicates E2

Communication malfunction between indoor/outdoor units

Judge 3: Check whether the signal wiring between the

indoor and outdoor units is wrong polarity?

Connect the signal wiring correctly

Yes

No

Judge 4: Check whether the signal wiring between the

indoor and outdoor units is broken?

Yes

Replace the broken wiring

No

Judge 2: Check whether the signal wiring is shield cable or

whether the shield cable is earthing

Yes

Adopt the shield cable/ shield cable earthing

No

Indoor or outdoor main board is broken, replace the

main board until the malfunction is disappear

Judge 1: Check whether the indoor unit power is on

Turn on the indoor unit power

No

Yes

Page 62

Troubleshooting MCAC-UTSM-2008-05

60 Outdoor Units

3. E3 malfunction

LED indicates E3

Communication malfunction in outdoor PCB

Check whether the indicator lights LED1 on the main board are flashing Replace the outdoor main board

Yes

Check whether the connecting wiring between the IPM module and

the CN4 on the main board is break off

Insert the connecting wiring well

over again

Yes

No

Disconnect the connecting wiring between the IPM module and the

CN4 on the main board, use the multimeter to measure the voltage

between the IPM module CN1 port’s 3 and 4 pillar, check whether it is

5V, (the third pillar on the main board labels +5V)

No

Replace outdoor main board

Yes

No

Insert the connecting wiring well over again

Check whether the connecting wiring between the IPM module

positive pole and the CN12 on the power board is break off

Yes

No

No

Replace the IPM module

Use the multimeter to measure whether the voltage between the

CN12 and the CN13 on the power board is between

+(198V~254)V

Yes

Replace the power board

Check whether the connecting wiring between the IPM module

negative pole and the CN13 on the power board is break off

No

Insert the connecting wiring well over again

Yes

Page 63

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 61

4. E4 malfunction

LED indicates E4

Check whether the wiring of the outdoor ambient temperature

sensor (T4) is break off

Replace outdoor main board

Judge 1: Outdoor ambient temp. sensor (T4) is malfunction

Connect the wiring well

Yes

No

Check whether the resistance of outdoor ambient temperature

sensor (T4) is wrong refer to the Annex 1

Yes

Replace outdoor ambient

temperature sensor (T4)

No

Page 64

Troubleshooting MCAC-UTSM-2008-05

62 Outdoor Units

5. E5 malfunction

LED indicates E5

Outdoor unit voltage protection

Check the voltage of outdoor unit power supply, whether the

voltage between L1 and N is about 198-254V

No

Replace the power board, then check whether the system can run normally

Check the power supply

Yes

Replace outdoor main board

Yes

Trouble is solved

No

Page 65

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 63

6. P1 malfunction

LED indicates P1

High pressure protection

Judge 1: Whether the wiring between the high pressure switch

and main control board is connected well or correctly

Judge 2: Whether the high pressure switch is broken

Yes

No

Connect it well

Validate: Short connect the high pressure switch

socket, check whether the system can run normally

Yes

Replace high pressure switch

No

Check whether the refrigerant system is ok

Replace outdoor main board

No

Judge 3: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

No

Judge 4: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 5: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 6: Check whether the refrigerant pipe is blocked

Yes

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe,

vacuumize and add the refrigerant again

Page 66

Troubleshooting MCAC-UTSM-2008-05

64 Outdoor Units

7. P2 malfunction

LED indicates P2

Low pressure protection

Judge 1: The wiring between the low pressure switch and main

control board is connected well or correctly

Judge 2: Whether the low pressure switch is broken

Connect it well

Validate: Short connect the low pressure switch

socket, check whether the system can run normally

Check whether the refrigerant system is ok

Yes

No

Judge 3: Check whether the outdoor ambient temperature is too low

Yes

Stop the unit

No

Judge 4: The refrigerant of the system is leakage

Yes

Validate: Connect the pressure gauge to the gauge joint of the

system, check whether the pressure is lower than 0.15MPa

Leak hunting: charge nitrogen or

refrigerant to the system, if the leakage is

serious, there will be distinct gas leakage

“cici” sound; if the leakage is little, use

the suds(mixture of water and abluent is

also ok, if it can make bubble) or

electronic leak detector.

Judge 5: The refrigerant pipe is blocked

Yes

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe, vacuumize

and add the refrigerant again

No

Replace outdoor main board

No

No

Yes

Replace low pressure switch

Page 67

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 65

8. P3 malfunction

LED indicates P3

Outdoor unit current protection

Judge 1: Check whether the input current of the power supply wire

is more than 18A

Check whether the refrigerant system is ok

Yes

Judge 2: Check whether the outdoor ambient temperature is too high

Yes

Stop the unit

Replace outdoor main board

No

No

Judge 3: Check whether the outdoor unit is bad ventilation

Yes

Make the outdoor unit ventilate well

No

Judge 4: Check whether the heat exchanger is dirty

Yes

Clean the heat exchanger

No

Judge 5: The refrigerant pipe is blocked

Yes

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe,

vacuumize and add the refrigerant again

Page 68

Troubleshooting MCAC-UTSM-2008-05

66 Outdoor Units

9. P4 malfunction

LED indicates P4

Compressor discharge temperature protection

Check whether the compressor discharge temp. more than 115°C ?

No

Check whether the wiring connection is right

between compressor discharge temp.

sensor and PCB according to wiring

diagrams

Yes

Validate: Check whether the resistance of compressor

discharge temp. sensor is right refer to the Annex 2

No

Correct the wiring connection

Yes

Replace outdoor main board

Judge: The discharge temp. sensor is broken

No

Replace the compressor

discharge temp. sensor

Check whether the refrigerant is leakage

Stop leaking and add refrigerant

Yes

Yes

Page 69

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 67

10. P5 malfunction

.

LED indicates P5

Condenser high temperature protection

Check whether the condenser temperature is more than 65°C

No

Check whether the resistance of condenser

temp. sensor is correct refer to the Annex 1

Yes

Replace outdoor main board

No

Replace the temperature sensor

Yes

Judge1: The outdoor temp. is too high(more than 43 )℃

Replace outdoor main board

No

Judge 2: Check whether the heat exchanger is dirty

No

Judge 3: The refrigerant pipe is blocked

Clean the heat exchanger

Yes

Yes

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe,

vacuumize and add the refrigerant again

Yes

Stop the unit

No

Page 70

Troubleshooting MCAC-UTSM-2008-05

68 Outdoor Units

11. P6 malfunction

LED indicates P6

IPM protection

Check whether the voltage range of P-N on

IPM module is normal?

No

Check whether the input power supply

is correct? 220-240V, 1N, 50Hz

No

Regulate it to correct,

then check whether the

system can work

normally?

Yes

Check whether the power

supply line is connected

correctly and tightly

No

Connect it correctly and

tightly, check ok or not?

No

Yes

Check whether the lines in

E-part box are connected tightly

No

Connect it tightly,

check ok or not?

No

Yes

Check whether the single-phase bridge is

normal? Use the multimeter to measure the

resistance between each two terminals, check

whether there is the condition that value of

resistance is 0

Yes

Replace the

single-phase bridge

No

No

Check whether the connecting line

of every reactor is normal? If the

line is broken, the resistance of the

two ports is ∞

No

Replace the

connecting line

Yes

Check whether the connecting line

between main board and the IPM

module is connected tightly

Yes

Check whether the connecting

line of the compressor is

connected correctly or tightly

Yes

Replace the IPM module, check

whether the system can work

normally?

No

Replace the main board, check

whether the system can work

normally?

Yes

Trouble is solved

No

Replace the compressor, check

whether the system can work

normally?

Connect it tightly,

check ok or not?

No

Connect it well,

check ok or not?

No

Yes

Trouble is solved

No

No

Yes

Trouble is solved

Yes

Check whether the fuse on

the power board is normal?

No

Replace with

the same model

fuse

Yes

Replace the power board

Page 71

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 69

Annex 1

Temp

Resistance(KΩ)

Resist.tol %

Temp.tol℃

(℃)

Rmax

R(t)Normal

Rmin MAX(+) MIN(-) MAX(+) MIN(-)

-20 116.539 106.732 96.920 9.19 9.19 1.59 1.59

-19 110.231 100.552 91.451 9.63 9.05 1.57 1.57

-18 103.743 94.769 86.328 9.47 8.91 1.56 1.55

-17 97.673 89.353 81.525 9.31 8.76 1.54 1.54

-16 91.990 84.278 77.017 9.15 8.62 1.53 1.52

-15 86.669 79.521 72.788 8.99 8.47 1.51 1.50

-14 81.684 75.059 68.815 8.83 8.32 1.49 1.48

-13 77.013 70.873 65.083 8.66 8.17 1.47 1.47

-12 72.632 66.943 61.574 8.50 8.02 1.45 1.45

-11 68.523 63.252 58.274 8.33 7.87 1.44 1.43

-10 64.668 59.784 55.169 8.17 7.72 1.42 1.41

-9 61.048 56.524 52.246 8.00 7.57 1.40 1.39

-8 57.649 53.458 49.492 7.84 7.42 1.38 1.37

-7 54.456 50.575 46.899 7.67 7.27 1.35 1.35

-6 51.456 47.862 44.455 7.51 7.12 1.33 1.32

-5 48.636 45.308 42.150 7.35 6.97 1.31 1.30

-4 45.984 42.903 39.977 7.18 6.82 1.29 1.28

-3 43.490 40.638 37.927 7.02 6.67 1.27 1.26

-2 41.144 38.504 35.992 6.86 6.52 1.25 1.24

-1 38.935 36.492 34.165 6.70 6.38 1.23 1.21

0 36.857 34.596 32.440 6.53 6.23 1.21 1.19

1 34.898 32.807 30.810 6.38 6.09 1.18 1.17

2 33.055 31.120 29.271 6.22 5.94 1.16 1.15

3 31.317 29.528 27.815 6.06 5.80 1.14 1.12

4 29.681 28.026 26.440 5.90 5.66 1.12 1.10

5 28.138 26.608 25.140 5.75 5.52 1.10 1.08

6 26.682 25.268 23.909 5.60 5.38 1.07 1.06

7 25.310 24.003 22.745 5.45 5.24 1.05 1.03

8 24.016 22.808 21.644 5.30 5.10 1.03 1.01

9 22.794 21.678 20.601 5.15 4.97 1.01 0.99

10 21.641 20.610 19.614 5.00 4.83 0.99 0.97

11 20.553 19.601 18.680 4.86 4.70 0.96 0.94

12 19.525 18.646 17.794 4.71 4.57 0.94 0.92

13 18.554 17.743 16.955 4.57 4.44 0.92 0.90

14 17.636 16.888 16.160 4.43 4.31 0.90 0.88

15 16.769 16.079 15.406 4.29 4.19 0.88 0.85

16 15.949 15.313 14.691 4.15 4.06 0.86 0.83

17 15.174 14.588 14.014 4.02 3.94 0.84 0.81

Page 72

Troubleshooting MCAC-UTSM-2008-05

70 Outdoor Units

Temp

Resistance(KΩ)

Resist.tol %

Temp.tol℃

(℃)

Rmax

R(t)Normal

Rmin MAX(+) MIN(-) MAX(+) MIN(-)

18 14.442 13.902 13.372 3.89 3.81 0.81 0.79

19 13.748 13.251 12.762 3.75 3.69 0.79 0.76

20 13.093 12.635 12.183 3.62 3.57 0.77 0.74

21 12.471 12.050 11.634 3.50 3.46 0.75 0.72

22 11.883 11.496 11.112 3.37 3.34 0.73 0.70

23 11.327 10.971 10.617 3.25 3.23 0.71 0.68

24 10.800 10.473 10.147 3.12 3.11 0.69 0.66

25 10.300 10.000 9.700 3.00 3.00 0.67 0.63

26 9.848 9.551 9.255 3.11 3.10 0.69 0.66

27 9.418 9.125 8.834 3.21 3.19 0.72 0.69

28 9.010 8.721 8.434 3.31 3.29 0.75 0.71

29 8.621 8.337 8.055 3.41 3.38 0.77 0.74

30 8.252 7.972 7.695 3.51 3.47 0.80 0.77

31 7.900 7.625 7.353 3.61 3.57 0.83 0.79

32 7.566 7.296 7.029 3.70 3.66 0.85 0.82

33 7.247 6.982 6.721 3.80 3.74 0.88 0.84

34 6.944 6.684 6.428 3.89 3.83 0.91 0.87

35 6.656 6.401 6.150 3.98 3.92 0.93 0.90

36 6.381 6.131 5.886 4.08 4.00 0.96 0.93

37 6.119 5.874 5.634 4.17 4.09 0.98 0.95

38 5.870 5.630 5.395 4.26 4.17 1.01 0.98

39 5.631 5.397 5.167 4.34 4.26 1.03 1.01

40 5.404 5.175 4.951 4.43 4.34 1.06 1.03

41 5.188 4.964 4.745 4.52 4.42 1.09 1.06

42 4.982 4.763 4.549 4.60 4.50 1.12 1.09

43 4.785 4.571 4.362 4.69 4.58 1.14 1.12

44 4.596 4.387 4.183 4.77 4.66 1.17 1.14

45 4.417 4.213 4.014 4.85 4.74 1.19 1.17

46 4.246 4.046 3.851 4.93 4.81 1.22 1.20

47 4.082 3.887 3.697 5.02 4.89 1.25 1.23

48 3.925 3.735 3.550 5.10 4.97 1.28 1.25

49 3.776 3.590 3.409 5.18 5.04 1.30 1.28

50 3.632 3.451 3.274 5.25 5.12 1.33 1.30

51 3.495 3.318 3.146 5.33 5.19 1.35 1.33

52 3.363 3.191 3.023 5.41 5.26 1.41 1.36

53 3.237 3.069 2.905 5.49 5.34 1.43 1.38

54 3.116 2.952 2.793 5.56 5.41 1.46 1.41

55 3.001 2.841 2.685 5.64 5.48 1.48 1.44

56 2.890 2.734 2.582 5.71 5.55 1.51 1.46

57 2.784 2.632 2.484 5.79 5.62 1.54 1.49

Page 73

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 71

Temp

Resistance(KΩ)

Resist.tol %

Temp.tol℃

(℃)

Rmax

R(t)Normal

Rmin MAX(+) MIN(-) MAX(+) MIN(-)

58 2.682 2.534 2.390 5.86 5.69 1.56 1.52

59 2.585 2.440 2.299 5.93 5.76 1.59 1.54

60 2.491 2.350 2.213 6.01 5.83 1.62 1.57

61 2.401 2.264 2.130 6.08 5.90 1.64 1.60

62 2.315 2.181 2.051 6.15 5.96 1.67 1.62

63 2.233 2.102 1.975 6.22 6.03 1.70 1.65

64 2.154 2.026 1.903 6.29 6.10 1.72 1.68

65 2.077 1.953 1.833 6.36 6.16 1.75 1.70

66 2.004 1.883 1.766 6.42 6.23 1.77 1.73

67 1.934 1.816 1.702 6.49 6.29 1.80 1.76

68 1.867 1.752 1.641 6.56 6.35 1.83 1.78

69 1.802 1.690 1.582 6.62 6.41 1.85 1.81

70 1.740 1.631 1.525 6.69 6.48 1.88 1.84

71 1.680 1.574 1.471 6.75 6.54 1.91 1.86

72 1.622 1.519 1.419 6.82 6.60 1.93 1.89

73 1.567 1.466 1.369 6.88 6.66 1.96 1.92

74 1.514 1.416 1.321 6.94 6.71 1.98 1.94

75 1.463 1.367 1.275 7.00 6.77 2.01 1.97

76 1.414 1.321 1.230 7.06 6.83 2.04 2.00

77 1.367 1.276 1.188 7.12 6.88 2.06 2.02

78 1.321 1.233 1.147 7.17 6.94 2.09 2.05

79 1.277 1.191 1.108 7.23 6.99 2.12 2.08

80 1.235 1.151 1.070 7.28 7.04 2.14 2.11

81 1.195 1.113 1.034 7.33 7.09 2.17 2.13

82 1.156 1.076 0.999 7.39 7.14 2.20 2.16

83 1.118 1.041 0.966 7.44 7.18 2.22 2.19

84 1.082 1.007 0.934 7.48 7.23 2.25 2.21

85 1.047 0.974 0.903 7.53 7.27 2.27 2.24

86 1.014 0.942 0.874 7.57 7.31 2.30 2.27

87 0.982 0.912 0.845 7.62 7.35 2.33 2.29

88 0.951 0.883 0.818 7.66 7.39 2.35 2.32

89 0.921 0.855 0.791 7.69 7.43 2.38 2.35

90 0.892 0.828 0.766 7.73 7.46 2.41 2.37

91 0.864 0.802 0.742 7.76 7.49 2.43 2.40

92 0.838 0.777 0.719 7.80 7.52 2.46 2.43

93 0.812 0.753 0.696 7.82 7.54 2.48 2.45

94 0.787 0.730 0.675 7.85 7.57 2.51 2.48

95 0.763 0.708 0.654 7.87 7.59 2.54 2.51

96 0.740 0.686 0.634 7.89 7.61 2.56 2.53

97 0.718 0.666 0.615 7.91 7.62 2.59 2.56

Page 74

Troubleshooting MCAC-UTSM-2008-05

72 Outdoor Units

Temp

Resistance(KΩ)

Resist.tol %

Temp.tol℃

(℃)

Rmax

R(t)Normal

Rmin MAX(+) MIN(-) MAX(+) MIN(-)

98 0.697 0.646 0.597 7.93 7.63 2.62 2.59

99 0.677 0.627 0.579 7.94 7.64 2.64 2.61

100 0.657 0.609 0.562 7.94 7.65 2.67 2.64

101 0.638 0.591 0.546 7.95 7.65 2.70 2.67

102 0.620 0.574 0.530 7.95 7.65 2.72 2.69

103 0.602 0.558 0.515 7.94 7.64 2.75 2.72

104 0.585 0.542 0.501 7.94 7.63 2.77 2.75

105 0.569 0.527 0.485 7.92 7.92 2.80 2.77

Page 75

MCAC-UTSM-2008-05 Troubleshooting

Outdoor Units 73

Annex 2

Unit: ℃---K Discharge temp. sensor table

-20 542.7 20 68.66 60 13.59 100 3.702

-19 511.9 21 65.62 61 13.11 101 3.595

-18 483 22 62.73 62 12.65 102 3.492

-17 455.9 23 59.98 63 12.21 103 3.392

-16 430.5 24 57.37 64 11.79 104 3.296

-15 406.7 25 54.89 65 11.38 105 3.203

-14 384.3 26 52.53 66 10.99 106 3.113

-13 363.3 27 50.28 67 10.61 107 3.025

-12 343.6 28 48.14 68 10.25 108 2.941

-11 325.1 29 46.11 69 9.902 109 2.86

-10 307.7 30 44.17 70 9.569 110 2.781

-9 291.3 31 42.33 71 9.248 111 2.704

-8 275.9 32 40.57 72 8.94 112 2.63

-7 261.4 33 38.89 73 8.643 113 2.559

-6 247.8 34 37.3 74 8.358 114 2.489

-5 234.9 35 35.78 75 8.084 115 2.422

-4 222.8 36 34.32 76 7.82 116 2.357

-3 211.4 37 32.94 77 7.566 117 2.294

-2 200.7 38 31.62 78 7.321 118 2.233

-1 190.5 39 30.36 79 7.086 119 2.174

0 180.9 40 29.15 80 6.859 120 2.117

1 171.9 41 28 81 6.641 121 2.061

2 163.3 42 26.9 82 6.43 122 2.007

3 155.2 43 25.86 83 6.228 123 1.955

4 147.6 44 24.85 84 6.033 124 1.905

5 140.4 45 23.89 85 5.844 125 1.856

6 133.5 46 22.89 86 5.663 126 1.808

7 127.1 47 22.1 87 5.488 127 1.762

8 121 48 21.26 88 5.32 128 1.717

9 115.2 49 20.46 89 5.157 129 1.674

10 109.8 50 19.69 90 5 130 1.632

11 104.6 51 18.96 91 4.849

12 99.69 52 18.26 92 4.703

13 95.05 53 17.58 93 4.562

14 90.66 54 16.94 94 4.426

15 86.49 55 16.32 95 4.294 B(25/50)=3950K

16 82.54 56 15.73 96 4.167

17 78.79 57 15.16 97 4.045

R(90℃)=5KΩ±3%

18 75.24 58 14.62 98 3.927

19 71.86 59 14.09 99 3.812

Page 76

Installation Place MCAC-UTSM-2008-05

74 Installation

Part 4

Installation

1. Installation Place.........................................................75

2. Installation of Indoor Unit ..........................................76

3. Installation of Outdoor Unit .......................................83

4. Refrigerant Piping Connection..................................85

5. Connect the Drain Pipe ..............................................92

6. Wiring...........................................................................94

7. Test Operation.............................................................98

Page 77

MCAC-UTSM-2008-05 Installation Place

Installation 75

1. Installation Place

1.1 The indoor Unit

1) There is enough room for installation and maintenance.

2) The ceiling is horizontal, and its structure can endure the weight of the indoor unit.

3) The air outlet and the air inlet are not impeded, and the influence of external air is the least.

4) The air flow can reach throughout the room.

5) The connecting pipe and drainpipe could be extracted out easily.

6) There is no direct radiation from heaters Test operation.

1.2 The Outdoor Unit

1) There is enough room for installation and maintenance.

2) The air outlet and the air inlet are not impeded, and can not be reached by strong wind.

3) The place is dry and ventilative.

4) The support is flat and horizontal and can stand the weight of the outdoor unit. And no additional noise

or vibration.

5) Your neighborhood will not feel uncomfortable with the noise or expelled air.

6) There is no leakage of combustible gas.

7) It is easy to install the connecting pipe or cables.

Caution:

Location in the following places may cause malfunction of the machine. (If unavoidable, please consult your

local dealer.)

a. There exists petrolatum.

b. There is salty air surrounding (near the coast).

c. There is caustic gas (the sulfide, for example) existing in the air (near a hot spring).

d. The Volt vibrates violently (in the factories).

e. In buses or cabinets.

f. In kitchen where it is full of oil gas.

g. There is strong electromagnetic wave existing.

h. There are inflammable materials or gas.

i. There is acid or alkaline liquid evaporating.

j. Other special conditions

1.3 Notes before Installation

1) Select the correct carry-in path.

2) Move this unit as originally packaged as possible.

3) If the air conditioner is installed on a metal part of the building, it must be electrically insulated according

to the relevant standards to electrical appliances.

Page 78

Installation of Indoor Unit MCAC-UTSM-2008-05

76 Installation

2. Installation of Indoor Unit

2.1 Service Space

Installing Ø10 hanging screw bolts. (4 bolts)

1. Please refer to the following figures for the distance measurement between the screw bolts.

2. Please install with Ø10 hanging screw bolts.

3. The handling to the ceiling varies from the constructions, consult the construction personnels for the

specific procedures.

1) The size of the ceiling to be handled------ Do keep the ceiling flat. Consolidate the roof beam for

possible vibration.

2) Cut off the roof beam.

3) Strengthen the place that has been cut off, and consolidate the roof beam.

4. Carry out the pipe and line operation in the ceiling after finishing the installation of the main body. While

choosing where to start the operation, determine the direction of the pipes to be drawn out. Especially in

case there is a ceiling, position the refrigerant pipes, drain pipes, indoor & outdoor lines to the

connection places before hanging up the machine.

5. The installation of hanging screw bolts.

Wooden construction:

Put the square timber traversely over the roof beam, then install the hanging screw bolts.

Page 79

MCAC-UTSM-2008-05 Installation of Indoor Unit

Installation 77

New concrete bricks:

Inlaying or embedding the screw bolts.

For original concrete bricks:

Install the hanging hook with expansible bolt into the concrete deep to 45~50mm to prevent loose.

Steel for beam structure:

Install and use directly the supporting angle steel.

Page 80

Installation of Indoor Unit MCAC-UTSM-2008-05

78 Installation

2.2 Ceiling Installation:

1. Remove the side board and the grille.

Page 81

MCAC-UTSM-2008-05 Installation of Indoor Unit

Installation 79

2. Cut a gap on the grill.

3. Local the hanging arm on the hanging screw bolt.

Prepare the mounting bolts on the unit.

Page 82

Installation of Indoor Unit MCAC-UTSM-2008-05

80 Installation

4. Hang the unit on the hanging arm by sliding backward. Securely tighten the mounting bolts on both sides.

Note:

The pipe must cross the gap which is cut on the grill in step two.

Page 83

MCAC-UTSM-2008-05 Installation of Indoor Unit

Installation 81

2.3 Wall Mounting Installation:

Page 84

Installation of Indoor Unit MCAC-UTSM-2008-05

82 Installation

1. Fix the hook with tapping screw onto the wall.

2. Hang the indoor unit on the hook.

Page 85

MCAC-UTSM-2008-05 Installation of Outdoor Unit

Installation 83

3. Installation of Outdoor Unit

Caution:

1) Keep this unit away from direct radiation of the sun or other heaters. If unavoidable, please cover it with

a shelter.

2) In places near coast or with a high attitude where the wind is strong, please install the outdoor unit

against the wall to ensure normal performance.

3) Use a baffle when necessary.

4) In the case of extremely strong wind, please prevent the air from flowing backwards into the outdoor

unit.

5) Locate the outdoor unit as close to the indoor unit as possible.

6) The minimum distance between the outdoor unit and obstacles described in the installation chart does not

mean that the same is applicable to the situation of an airtight. Leave open two of three directions M, N, P.

3.1 Necessary Room for Installation and Maintenance.

If possible, please remove the obstacles nearby to prevent the performance from being impeded by too little

of air circulation. Leave open two of the three directions (M, N, P).

Page 86

Installation of Outdoor Unit MCAC-UTSM-2008-05

84 Installation

3.2 Moving and Installing

1) Since the gravity center of the unit is not at its physical center, so please be careful when lifting it with a

sling.

2) Never hold the inlet of the outdoor unit to prevent it from deforming.

3) Do not touch the fan with hands or other objects.

4) Do not lean it more than 45, and do not lay it sidelong.

5) Make concrete foundation according to the specifications of the outdoor units. (Refer to Fig.7-5)

6) Fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of earthquake or strong

wind. (Refer to Fig.7-5)

Page 87

MCAC-UTSM-2008-05 Refrigerant Piping Connection

Installation 85

4. Refrigerant Piping Connection

Caution:

For your safety, always wear safety eye wear and work gloves when connecting the pipes.

4.1 For MOU-12HDN1-Q and MOU-18HDN1-Q

Remove the water tray before performing the connection.

Page 88

Refrigerant Piping Connection MCAC-UTSM-2008-05

86 Installation

To connect the couplings:

Step 1: Ensure that the handle on the male coupling is in a reclined position away from the mating male

coupling.

Step 2: Retract the “Release Sleeve” on female coupling, insert the male coupling located on the indoor unit

into the female coupling.

Step 3:

Release the “Release Sleeve” to the lock the male coupling into places.

Step 4: Fold the male coupling handle towards the female coupling half and push until the handle seals

behind the “Release Sleeve” and flat against the entire coupling assembly.

Page 89

MCAC-UTSM-2008-05 Refrigerant Piping Connection

Installation 87

4.2 For MOU-12HDN1

Check whether the height drop between the indoor unit and outdoor unit, the length of refrigerant pipe, and

the number of the bends meet the following requirements:

Model MOU-12HDN1

When outdoor

unit is top

5

The max height

drop(m)

When outdoor unit is bottom 5

The length of refrigerant pipe(m) 10

The number of bends 5

4.2.1 The Procedure of Connecting Pipes

Caution:

z

All field piping must be provided by a licensed refrigeration technician and must comply with the

relevant local and national codes.

z Do not let air, dust, or other impurities fall in the pipe system during the time of installation.

z The connecting pipe should not be installed until the indoor and outdoor units have been fixed already.

z Keep the connecting pipe dry, and do not let moisture in during installation.

z Execute heat insulation work completely on both sides of the gas piping and the liquid piping. Otherwise,

this can sometimes result in water leakage.

1. Drill a hole in the wall (suitable just for the size of the wall conduit), then set on the fittings such as

the wall conduit and its cover.

2. Bind the connecting pipe and the cables together tightly with binding tapes.

3. Pass the bound connecting pipe through the wall conduct from outside. Be careful of the pipe

allocation to do on damage to the tubing.

4. Connect the pipes. Refer to "How to Connect the pipes" for details.

5. Expel the air with a vacuum pump. Refer to "How to expel the air with a vacuum pump" for details.

6. open the stop values of the outdoor unit to make the refrigerant pipe connecting the indoor unit with

the outdoor unit in fluent flow.

7. Check the leakage. Check all the joints with the leak detector or soap water.

8. Cover the joints of the connecting pipe with the soundproof / insulating sheath (fittings), and bind it

well with the tapes to prevent leakage.

Caution:

Be sure to with insulating materials cover all the exposed parts of the flare pipe joints and refrigerant

pipe on the liquid-side and the gas-side. Ensure that there is no gap between them.

Incomplete insulation may cause water condensation.

Page 90

Refrigerant Piping Connection MCAC-UTSM-2008-05

88 Installation

How to connect the pipes

1. Flaring:

Cut a pipe with a pipe cutter.

Insert a flare nut into a pipe and flare the pipe.

Refer to the following table for the dimension of flare nut spaces.

Flare dimension (A)

Pipe gauge Tightening torque

Min Max

Flare shape

Φ6.4

14.2~17.2 N.m

(144~176 kgf.cm)

8.3 8.7

Φ9.5

32.7~39.9 N.m

(333~407 kgf.cm)

12.0 12.4

Φ12.7

49.5~60.3 N.m

(504~616 kgf.cm)

15.4 15.8

Φ15.9

61.8~75.4 N.m

(630~770 kgf.cm)

18.6 19.0

Φ19.1

97.2~118.6 N.m

(990~1210 kgf.cm)

22.9 23.3

2. Connect the indoor unit at first, then the outdoor unit.

z Bend the tubing in proper way. Do not harm to them.

z The bending angle should not exceed 90.

z Bending position is preferably in the middle of the bendable pipe. The larger the bending radius the

better it is.

z Do not bend the pipe more than three times.

z When connecting the flare nut, coat the flare both inside and outside with either oil or ester oil and