Page 1

Operation

Maintenance Manual

MKA/MKB/MKC/MKT/MKT2

200CFM~1500CFM

(50Hz/60Hz)

Fan Coil Unit

Cassette and Ceiling Concealed Series

Page 2

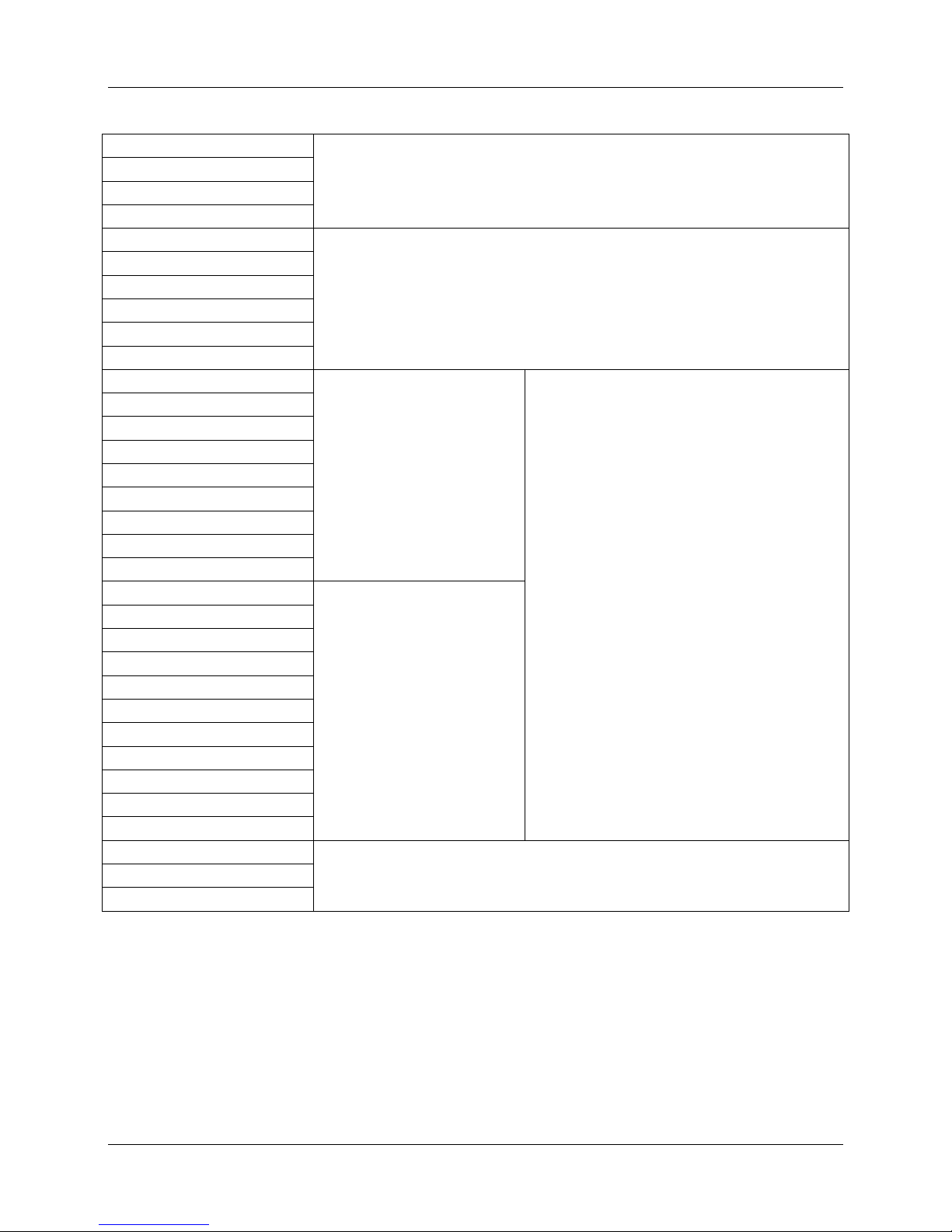

Content MCAC-KTSM-2007-2

i Content

Introduction…………………………………………………………………………………………..1

Part 1 General Information………………………………………………………………………...2

Part 2 Indoor Unit……………………………………………………………………......................7

Part 3 Installation………………………………….……………………………........................127

Page 3

MCAC-KTSM-2007-2 Introduction

Introduction 1

Introduction

Fan coil unit is a kind of compound device which assemble fan and surface-type coil heating-exchanger

together. Fan coil with fresh air supply system is a main type of center air-conditioner system, so it is an

important component of AC devices. Fan coil has horizontal type, vertical type, etc. A cooling (heating)

supply system usually consists of fan coil terminals and chilled water system (heated water system).

Midea

®

commercial AC fan coil is designed and manufactured on the base of advanced technology, and

utilize qualified galvanized iron as material. Due to its supper-thin design, it has such advantages: beautiful

outlook, space saving, easy installation, etc. And the most obvious advantage is that it can decrease the

outlet air Temp-difference as low as possible to make room more comfortable, as well as don’t decrease

cooling capacity output. For the large air flow volume design, it can increase room ventilation frequency,

supply more flesh air, and balance room temperature distribution. Benefiting from adoption of advanced

material and technology, it can effectively decrease the running noise and keep running smoothly. With the

advantages above, it can be widely applied in market, hospital, office building, hotel airport, etc.

Page 4

General information MCAC-KTSM-2007-2

2 General Information

Part 1

General Information

1. Model Names of Fan Coil…………......................................3

2. External Appearance……………………………………........4

3. Nomenclature…………………………………………………..5

4. Features…………………………………………….….………..6

Page 5

MCAC-KTSM-2007-2 Model Names of Fan Coil

General Information 3

1. Model Names of Fan Coil

MKB-300

Compact cassette type fan coil

MKB-400

MKB-450

MKB-500

MKA-600

Cassette type fan coil

MKA-750

MKA-850

MKA-950

MKA-1200

MKA-1500

MKT2(H)-200

2 Rows

Duct type fan coil

MKT2(H)-300

MKT2(H)-400

MKT2(H)-500

MKT2(H)-600

MKT2(H)-800

MKT2(H)-1000

MKT2(H)-1200

MKT2(H)-1400

MKT-300

3 and 4 Rows

MKT-400

MKT-450

MKT-500

MKT-600

MKT-750

MKT-850

MKT-950

MKT-1200

MKT-1500

MKT-2000

MKC-300

One way cassette type fan coil

MKC-400

MKC-600

Page 6

External Appearance MCAC-KTSM-2007-2

4 General Information

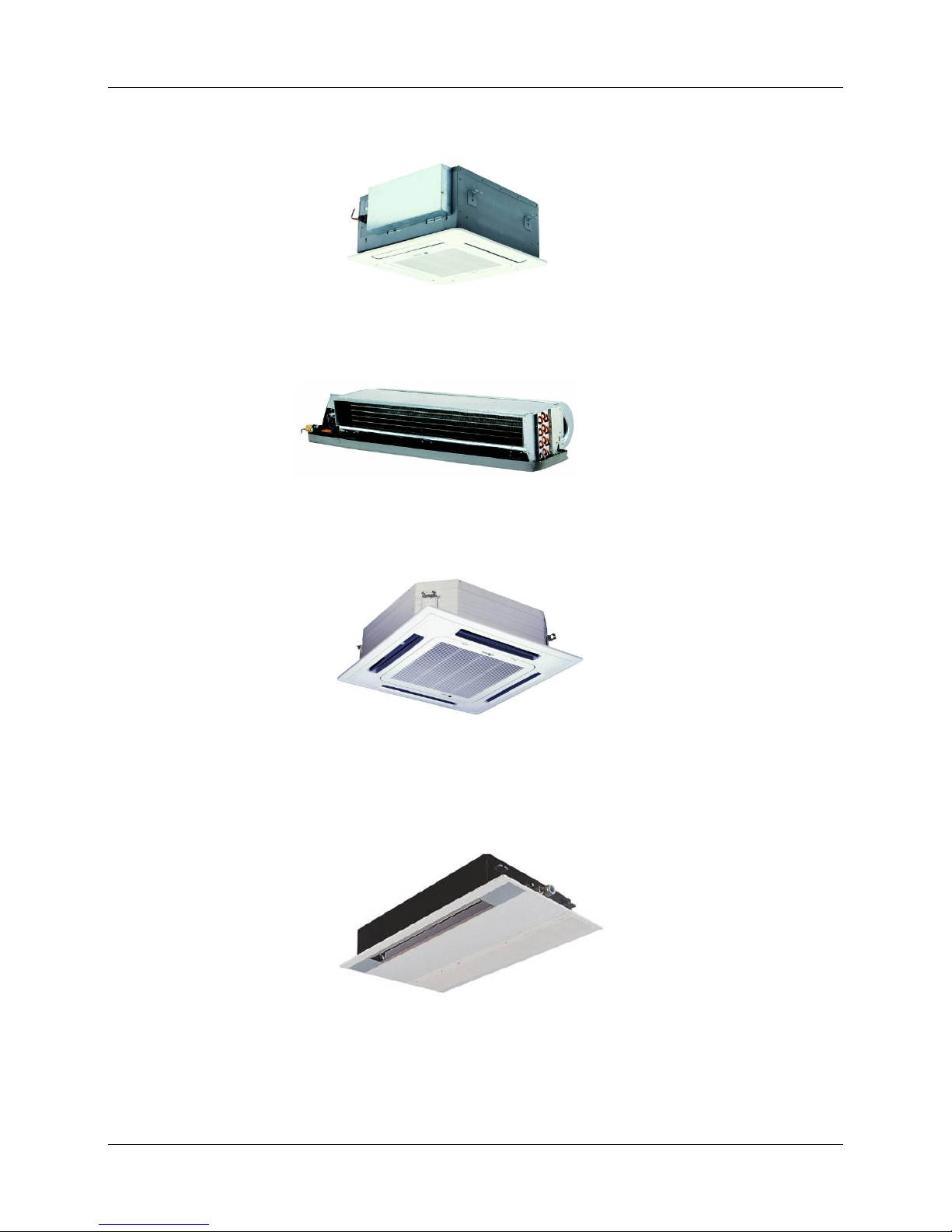

2. External Appearance

Compact four way cassette type

Duct type

Four way cassette type

One way cassette type

Page 7

MCAC-KTSM-2007-2 Nomenclature

General Information 5

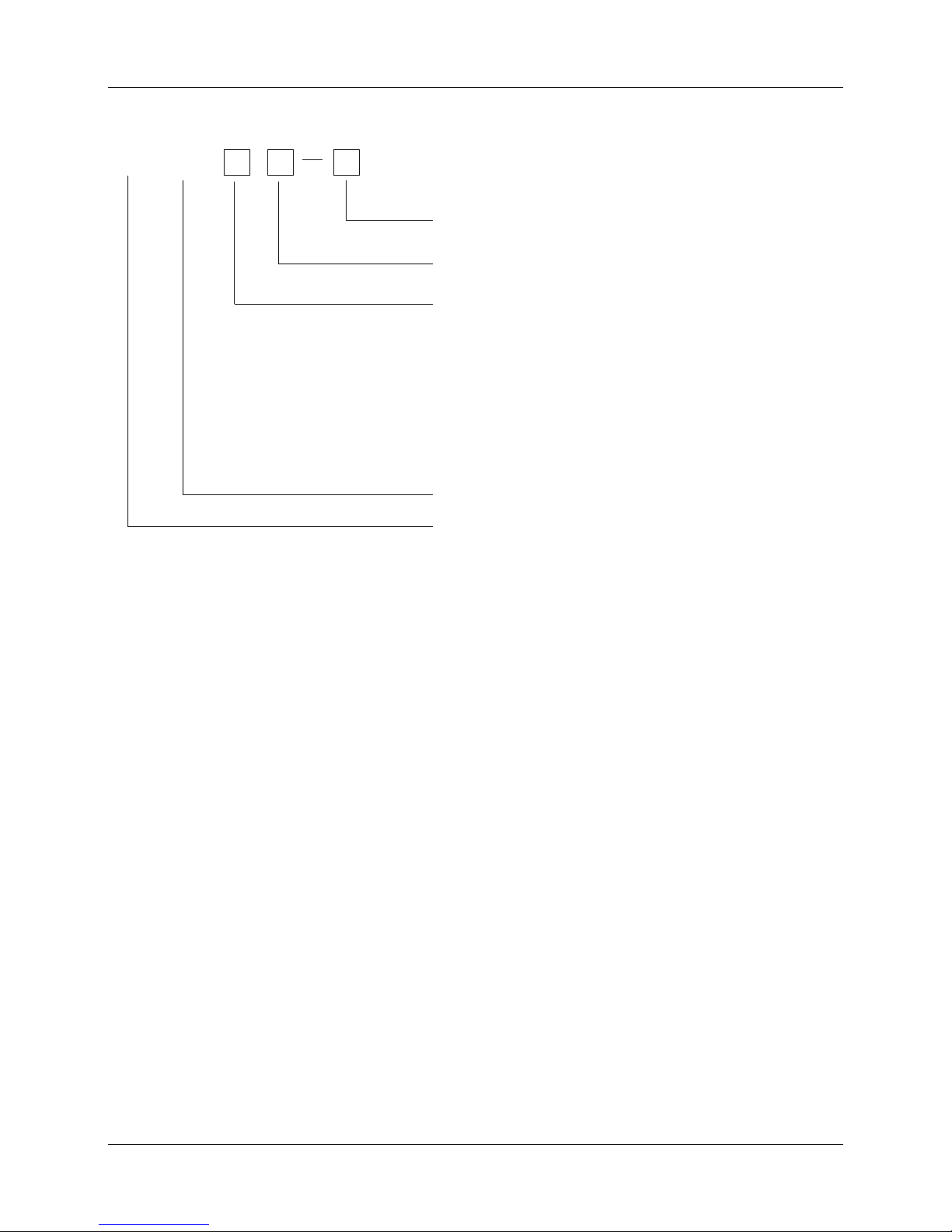

3. Nomenclature

KM

Nominal Air Volume(CFM)

Midea

Chilled Water Fan coil unit

-- 12Pa Static Pressure H 30Pa Static Pressure

F3 Concealed Flood-stand Type

F2 Exposed Flood-stand Type (below air intake)

Type Code

T2 2nd Generation Duct Type

A 4 Way Cassette B 4 Way Cassette (Compact)

C One Way Cassette T Duct

F1 Exposed Floor-stand Type (side air intake)

T1 127v 60 Hz Duct Type

Page 8

Features MCAC-KTSM-2007-2

6 Indoor Units

4. Features

Chilled water/Hot water (2 pipes)

Low height for easy installation

Low noise fan direct driven by single phase, 3 speed permanent split capacitor motor.

Copper tube/aluminum fin coils

Hydrophilic aluminum fin coils coated (optional)

Unit constructed by electrostatic galvanized sheet, providing maximum protection against corrosion

Heavy gauge zinc coated steel drainage pan with good insulation processing, avoiding sweating and

corrosion

Unit tested performance comply with GB4706.32-2004、JB9063-1999 and JB/T4283-1991.

Page 9

MCAC-KTSM-2007-2 Indoor Units

Indoor Units 7

Part 2

Indoor Units

Four Way Cassette Type …….................................................6

Compact Four Way Cassette Type.......................................25

Duct Type...............................................................................38

One Way Cassette Type ……..............................................106

Page 10

Four Way Cassette Type MCAC-KTSM-2007-2

8 Indoor Units

Four Way Cassette Type

1. Features…………………………………….......……………………….............. 9

2. Specification……………………………………………………………............ 10

3. Dimensions………………………………………………………………...........12

4. Service Space……………………………………………………………...........13

5. Wiring Diagrams…………………………………………………………..........14

6. Capacity Tables……………………………………………………………........15

7. Sound Levels……………………………………………………………...........22

8. Explored View……………………………………………………………..........23

Page 11

MCAC-KTSM-2007-2 Features

Four Way Cassette Type 9

1. Features

(1) Low operation noise

---Streamline plate ensures quietness

---Creates natural and comfortable environment

(2) Efficient cooling

---Equal, fast and wide—range cooling

(3) The adoption of the most advanced 3- Dimensional Screw fan

---Reduces the air resistance passing through

---Smoothes the air flow

---Makes air speed distribution to the heat exchange uniform

(4) Fresh air makes life healthier and more comfortable.

Page 12

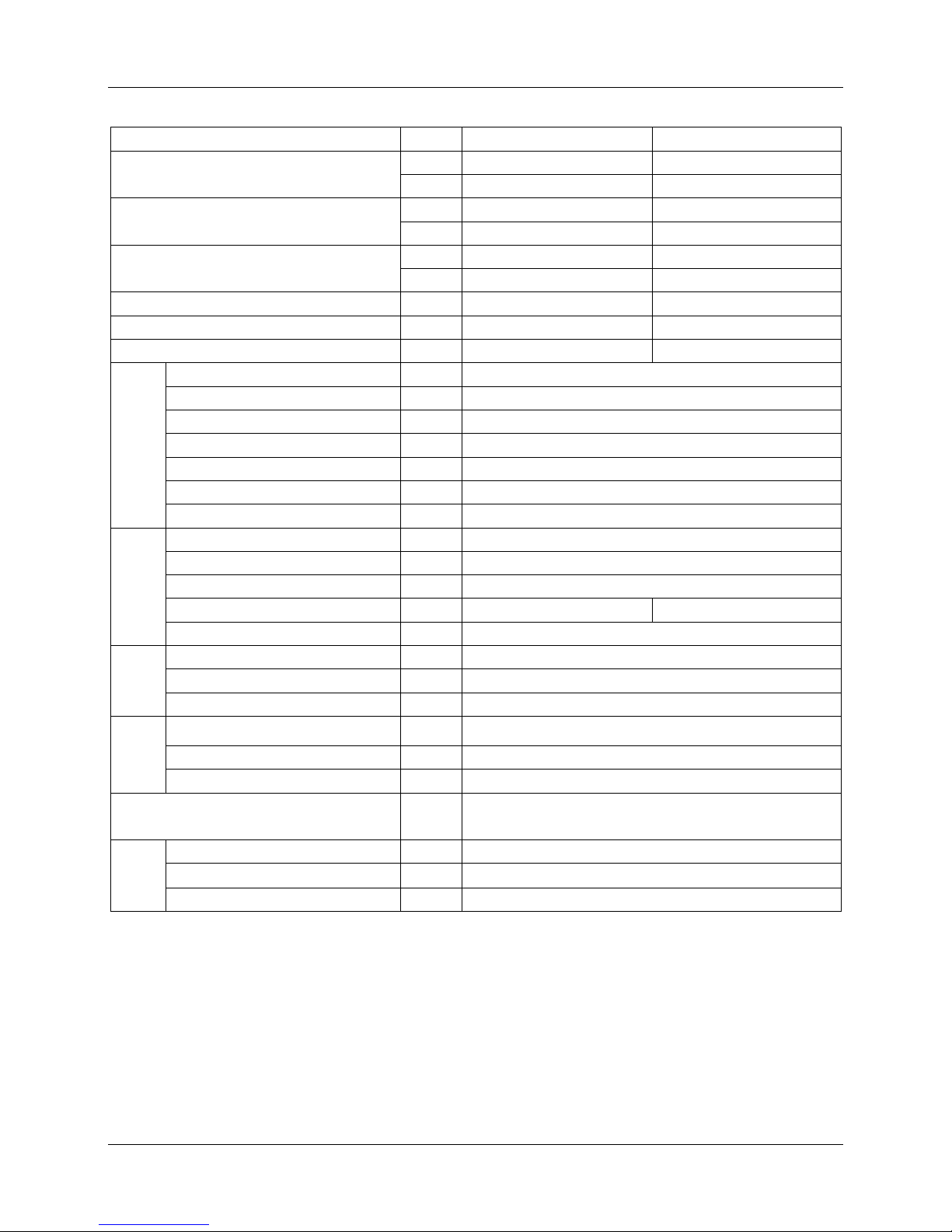

Specification MCAC-KTSM-2007-2

10 Four Way Cassette Type

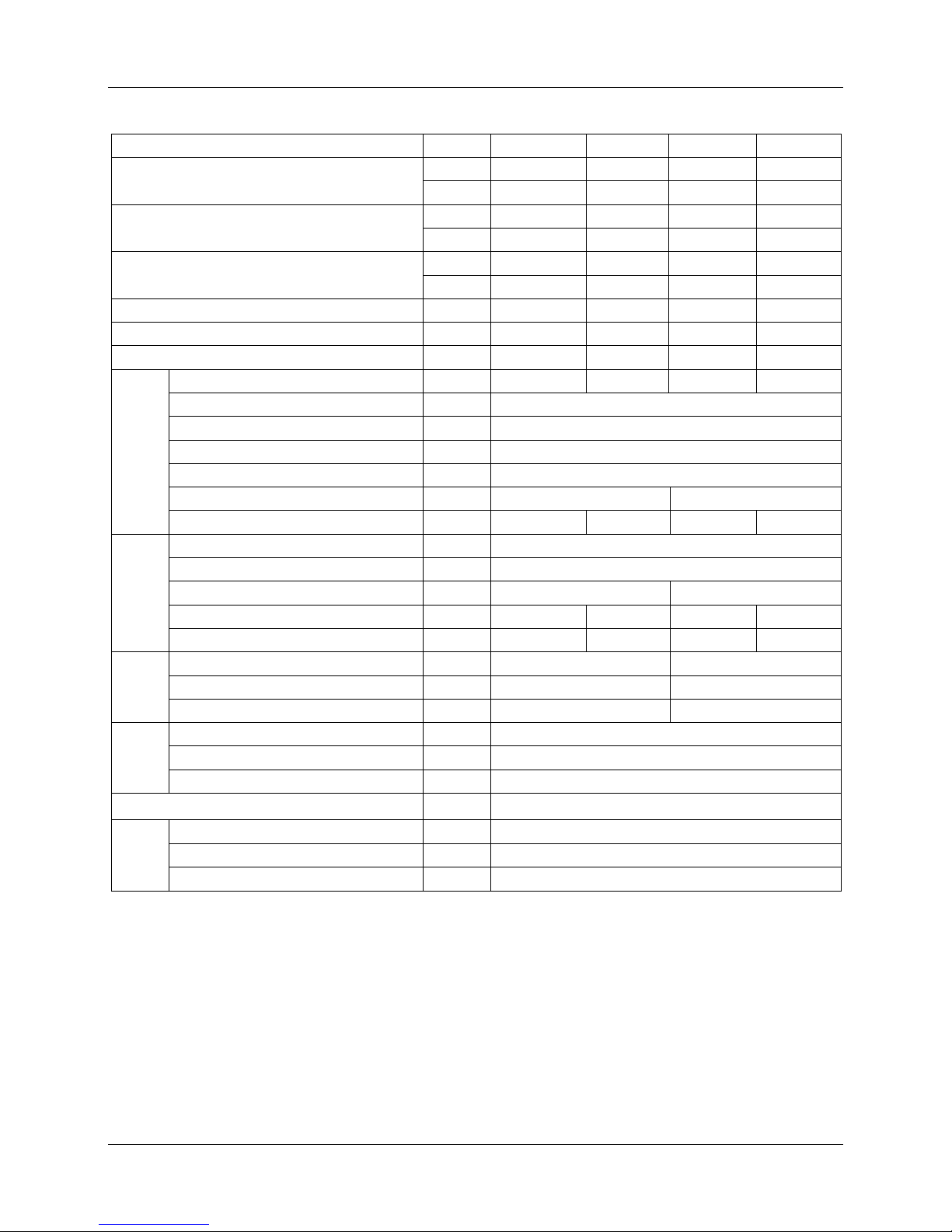

2. Specification

TYPE

MKA-950

MKA-850

MKA-750

MKA-600

Airflow

CFM

950

850

750

600

m3/h

1600

1400

1250

1000

Cooling Capacity

W

8110

7260

6385

5109

Btu/h

27635

24910

21835 17400

Heating Capacity

W

11311

10240

8850

7160

Btu/h

38690

34870

30570

24360

Noise

dB(A)

44

44

41

41

Water flow

LPH

1541

1382

1204

1005

Water resistance

kPa

30

27

25.2

23.8

Indoor

Coil

Number of rows

2 2 2 2

Tube pitch(a)x row pitch(b)

mm

25.4×22

Fin spacing

mm

1.3

Fin type

Hydrophilic aluminum

Tube outside dia.and type

mm

φ7,inner groove tube

Coil length x height x width

mm

2000×250×27

2000×170×27

Number of circuits

6 6 4 4

Fan

motor

Type

Low noise 3 speed fan motor

Number

1 Model YDK56-6

YDK55-6

Input W 144

144

128

120

Capacitor

uF

3.5

3.5

3.5

3.5

Indoor

unit

Dimension (W*H*D)

mm

840×310×840

840×240×840

Packing (W*H*D)

mm

1020×410×930

1020×330×930

Net/Gross weight

kg

40/50

36/46

Panel

Dimension (W*H*D)

mm

950×40×950

Packing (W*H*D)

mm

1030×145×1030

Net/Gross weight

kg

6/11

Control mode

wired controller(optional), remote controller (standard)

Pipe

Water-inlet pipe

RC3/4” internal thread

Water-return pipe RC3/4” internal thread

Condensation water-outlet pipe

EVA+LDPE 3/4” external thread

Remark: 1. All performance data above is based upon 0Pa ambient static pressure.

2. Cooling capacity test condition: air inlet Temp. : 27DB℃/19.5WB℃, water inlet Temp. 7℃,

water Temp. difference 5℃.

3. Heating capacity test condition:

Air inlet Temp. 21DB℃, water inlet Temp. 60 DB℃

The volume of air and water is same as cooling.

4. Noise level is tested in full-anechoic room.

Page 13

MCAC-KTSM-2007-2 Specifications

Four Way Cassette Type 11

Remark: 1. All performance data above is based upon 0Pa ambient static pressure.

2. Cooling capacity test condition: air inlet Temp. : 27DB℃/19.5WB℃, water inlet Temp. 7℃,

water Temp. difference 5℃.

3. Heating capacity test condition:

Air inlet Temp. 21DB℃, water inlet Temp. 60 DB℃

The volume of air and water is same as cooling.

4. Noise level is tested in full-anechoic room.

TYPE

MKA-1500

MKA-1200

Airflow

CFM

1500

1200

m3/h

2500

2000

Cooling Capacity

W

11556

9849

Btu/h

39240

33440

Heating Capacity

W

14920

13745

Btu/h

51000

46810

Noise

dB(A)

45

45

Water flow

LPH

2388

1928

Water resistance

kPa

46

44

Indoor

Coil

Number of rows

2 Tube pitch(a)x row pitch(b)

mm

25.4×22

Fin spacing

mm

1.3

Fin type

Hydrophilic aluminum

Tube outside dia.and type

mm

φ7,innergroove tube

Coil length x height x width

mm

2000×250×27

Number of circuits

6

Fan

motor

Type

Low noise 3 speed fan motor

Number

1 Model

YDK110-6

Input

W

190

180

Capacitor

uF

5

Indoor

unit

Dimension (W*H*D)

mm

840×310×840

Packing (W*H*D)

mm

1020×410×930

Net/Gross weight

kg

40/50

Panel

Dimension (W*H*D)

mm

950×40×950

Packing (W*H*D)

mm

1030×145×1030

Net/Gross weight

kg

6/11

Control mode

wired controller(optional) ,

remote controller (standard)

Pipe

Water-inlet pipe RC3/4” internal thread

Water-return pipe

RC3/4” internal thread

Condensation water-outlet pipe

EVA+LDPE 3/4” external thread

Page 14

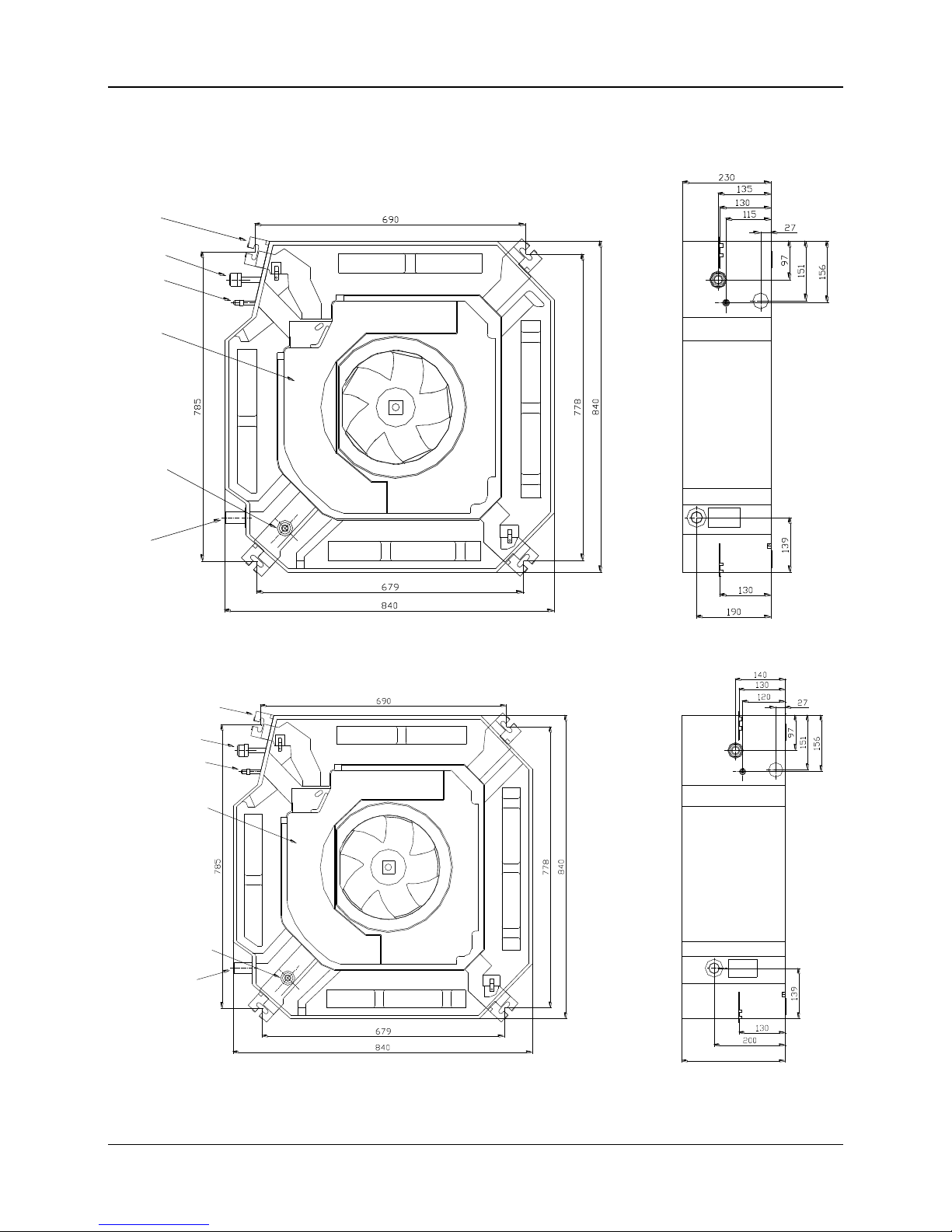

Dimensions MCAC-KTSM-2007-2

12 Four Way Cassette Type

3. Dimensions

MKA-600、MKA-750

Gas side

E-parts box

Liquid side

4-install hanger

Drain hole

Pump

inspect hole

MKA-850、MKA-950、MKA-1200、MKA-1500

310

4-install

hanger

Gas side

liquid side

E-parts box

Pump

inspect hole

Drain hole

Page 15

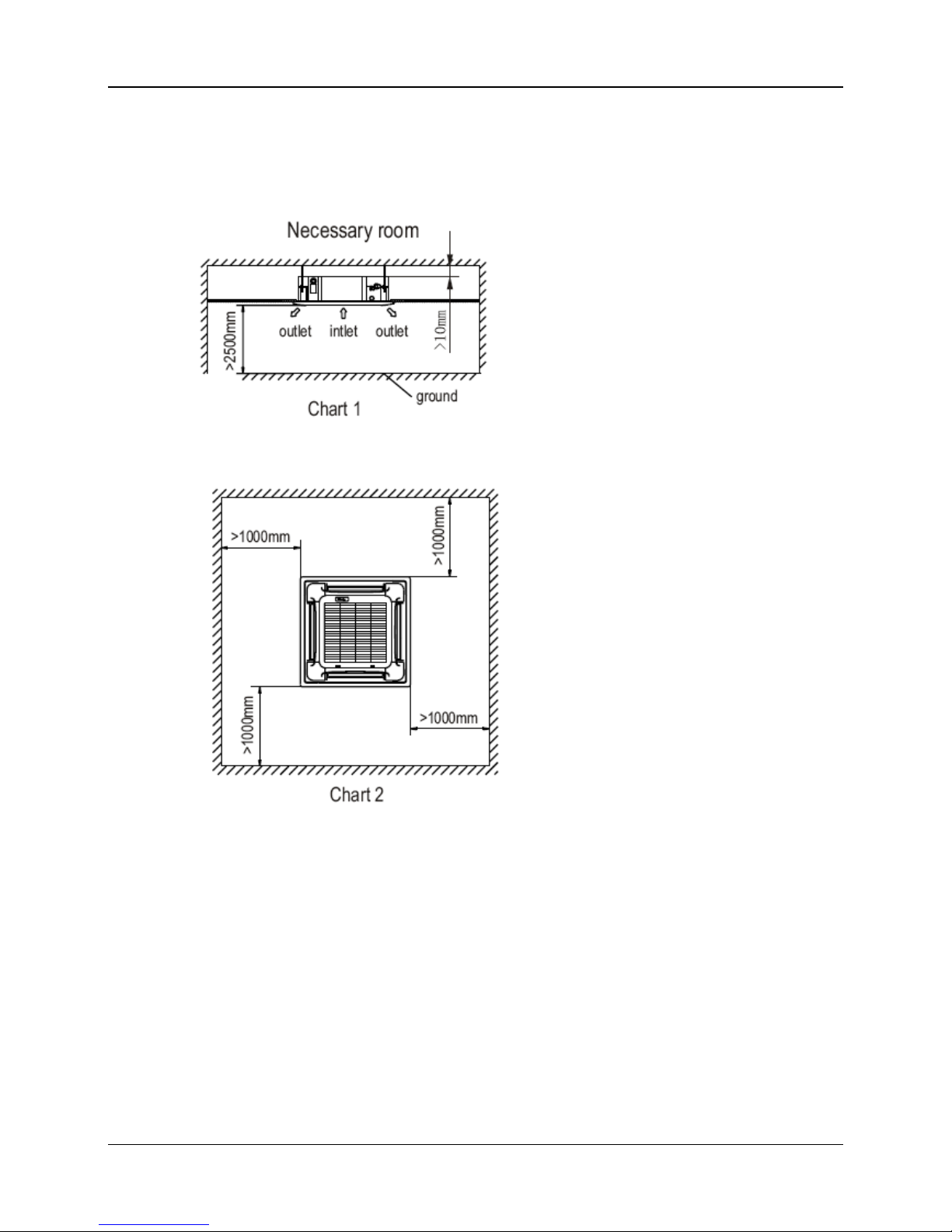

MCAC-KTSM-2007-2 Service Space

Four Way Cassette Type 13

4. Service Spaces

MKA-600、MKA-750、MKA-850、MKA-950、MKA-1200、MKA-1500

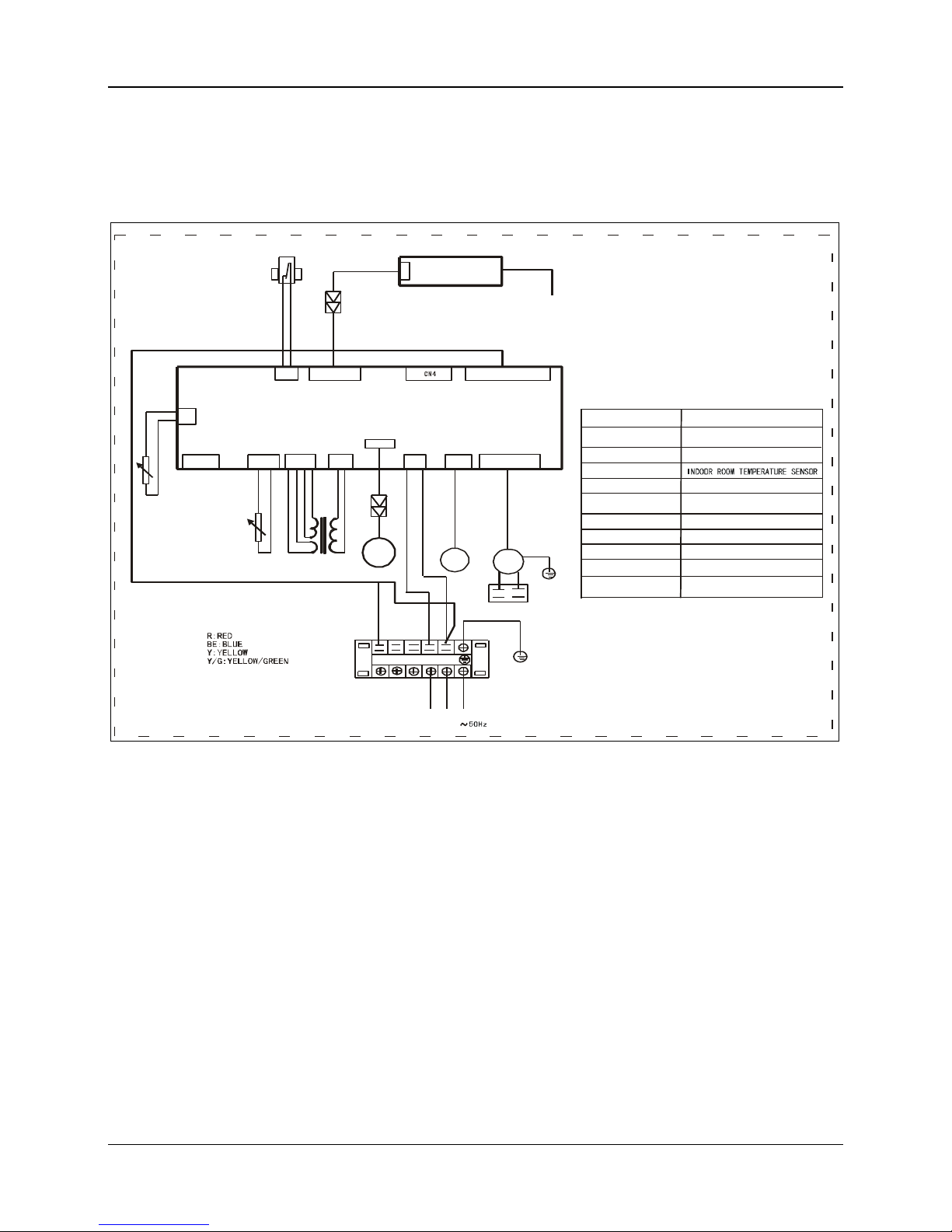

Page 16

Wring Diagram MCAC-KTSM-2007-2

14 Four Way Cassette Type

5. Wiring Diagram

MKA-600、MKA-750、MKA-850、MKA-950、MKA-1200、MKA-1500

XS1

XP1

R

POWER:220V-240V

MAINBOARD

XT1

L

T4

K3

INDOOR DRAWING

POWER:220V-240V~

50Hz

FAN1

BE

N

N1L1

PUMP

Y/G

CAP1

Y/G

XS1-XS2

Rt3

XT1

XP1-XP2

T4

K3

Rt2

FAN1

2CON10

DISPLAY

CAP1

CONNECTORS

6-WAY

TERMINAL

TRANSFORMER

PIPE TEMPERATURE SENSOR

PUMP WATER PUMP

CODE

WATER

LEVLE

INDOOR FAN

INDOOR FAN

PART

CAPACITOR

SWITCH

CN8

CN11 CN10

CN5

CN7

CN3

CN2

CN12

CN1 CN14 CN16

CN15

RT2

RT3

M

R Y

XS2

XP2

CONNECTORS

TO WIRE CONTROLER

(CHOICE)

REMARK:

Page 17

MCAC-KTSM-2007-2 Capacity Tables

Four Way Cassette Type 15

6. Capacity Tables

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKA-600

5

10

13.5

3439

4047

3537

4449

3636

4860

3823

5074

3823

5717

15

30.4

3716

4735

3850

5217

3975

5708

4172

5958

4207

6736

20

54

3913

5181

4056

5708

4199

6262

4404

6539

4467

7406

25

84.4

4029

5458

4181

6012

4333

6593

4547

6896

4627

7817 6 10

13.5

3296

3734

3404

4127

3502

4538

3689

4744

3689

5387

15

30.4

3555

4368

3689

4842

3815

5333

4011

5583

4047

6352

20

54

3734

4788

3877

6218

4020

5851

4225

6137

4297

6995

25

84.4

3841

5038

3993

5601

4154

6173

4359

6477

4449

7388 7 10

13.5

3162

3413

3270

3806

3368

4208

3555

4413

3564

5047

15

30.4

3395

4002

3529

4467

3654

4958

3850

5100

3895

5967

20

54

3555

4386

3707

4904

3850

5449

4056

5726

4118

6575

25

84.4

3654

4618

3815

5172

3966

5753

4181

6039

4261

6959 8 10

13.5

3028

3082

3136

3475

3234

3877

3421

4083

3430

4717

15

30.4

3243

3627

3368

4091

3502

4574

3698

4815

3743

5574

20

54

3386

3975

3529

4493

3672

5029

3877

5306

3949

6155

25

84.4

3466

4199

3627

4744

3788

5315

3993

5610

4083

6512 9 10

13.5

2894

2894

3002

3145

3109

3547

3296

3743

3305

4368

15

30.4

3082

3243

3216

3707

3341

4181

3538

4431

3591

5181

20

54

3207

3564

3359

4083

3502

4610

3707

4878

3779

5726

25

84.4

3287

3761

3448

4306

3600

4878

3815

5163

3904

6066

10

10

13.5

2760

2760

2877

2877

2975

3207

3162

3404

3180

4029

15

30.4

2930

2930

3064

3314

3189

3788

3386

4029

3439

4779

20

54

3037

3145

3189

3654

3332

4181

3538

4449

3618

5288

25

84.4

3109

3323

3270

3859

3421

4422

3636

4708

3725

5601

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 18

Capacity Tables MCAC -KTSM-2007-2

16 Four Way Cassette Type

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKA-750

5

15

11.9

4001

4838

4121

5316

4241

5811

4455

6058

4472

6839

20

21.2

4217

5372

4368

5907

4504

6465

4727

6752

4774

7636

25

33.1

4392

5779

4551

6369

4711

6975

4942

7285

5006

8250

30

47.7

4504

6034

4679

6656

4847

7294

5078

7772

5166

8640 6 15

11.9

3834

4455

3962

4934

4081

5421

4296

5676

4313

6448

20

21.2

4041

4950

4185

5492

4328

6042

4551

6448

4592

7206

25

33.1

4193

5333

4360

5922

4519

6520

4742

6831

4815

7787

30

47.7

4296

5580

4472

6193

4639

6831

4879

7158

4958

8162 7 15

11.9

3675

4073

3802

4551

3921

5038

4137

5284

4153

6050

20

21.2

3858

4536

4001

5309

4145

5779

4368

6385

4416

6767

25

33.1

4001

4886

4161

5548

4320

6146

4551

6433

4624

7326

30

47.7

4097

5110

4264

5723

4440

6353

4671

6679

4759

7684 8 15

11.9

3507

3690

3643

4161

3762

4639

3977

4886

4001

5644

20

21.2

3675

4105

3826

4639

3970

5181

4193

5539

4241

6321

25

33.1

3810

4432

3970

5006

4129

5603

4360

5907

4432

6847

30

47.7

3890

4639

4065

5245

4232

5875

4472

6193

4560

7189 9 15

11.9

3356

3356

3484

3762

3611

4241

3826

4487

3842

5237

20

21.2

3499

3675

3651

4200

3794

4742

4017

5022

4073

5875

25

33.1

3611

3970

3778

4543

3938

5134

4169

5436

4249

6369

30

47.7

3690

4161

3866

4759

4033

5380

4273

5699

4360

6688

10

15

11.9

3197

3197

3324

3364

3452

3842

3666

4081

3690

4830

20

21.2

3324

3324

3475

3762

3619

4296

3842

4568

3898

5421

25

33.1

3428

3499

3587

4065

3754

4655

3985

4950

4065

5882

30

47.7

3491

3666

3666

4264

3834

4886

4073

5197

4169

6177

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 19

Capacity Tables MCAC -KTSM-2007-2

Four Way Cassette Type 17

Cooling Capacity Table

unit:W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKA-850

5

15

11.9

4637

5607

4775

6161

4914

6734

5163

7020

5182

7925

20

21.2

4886

6225

5062

6844

5219

7491

5477

7823

5533

8849

25

33.1

5089

6697

5274

7380

5459

8082

5727

8442

5801

9560

30

47.7

5219

6992

5422

7713

5616

8452

5884

9006

5985

10013 6 15

11.9

4443

5163

4591

5717

4729

6281

4979

6576

4997

7472

20

21.2

4683

5736

4849

6364

5015

7001

5274

7472

5320

8350

25

33.1

4858

6179

5052

6863

5237

7556

5496

7916

5579

9024

30

47.7

4979

6466

5182

7177

5376

7916

5653

8295

5745

9458 7 15

11.9

4258

4720

4406

5274

4544

5838

4794

6124

4812

7011

20

21.2

4471

5256

4637

6152

4803

6697

5062

7260

5117

7842

25

33.1

4637

5662

4822

6429

5006

7121

5274

7454

5357

8488

30

47.7

4748

5921

4942

6632

5145

7362

5413

7740

5514

8904 8 15

11.9

4064

4277

4221

4822

4360

5376

4609

5662

4637

6540

20

21.2

4258

4757

4434

5376

4600

6004

4858

6419

4914

7325

25

33.1

4415

5136

4600

5801

4785

6493

5052

6844

5136

7934

30

47.7

4507

5376

4711

6078

4905

6807

5182

7177

5283

8331 9 15

11.9

3889

3889

4036

4360

4184

4914

4434

5200

4452

6068

20

21.2

4055

4258

4230

4868

4397

5496

4655

5819

4720

6807

25

33.1

4184

4600

4378

5265

4563

5948

4831

6299

4923

7380

30

47.7

4277

4822

4480

5514

4674

6235

4951

6604

5052

7750

10

15

11.9

3704

3704

3852

3898

3999

4452

4249

4729

4277

5597

20

21.2

3852

3852

4027

4360

4193

4979

4452

5293

4517

6281

25

33.1

3972

4055

4156

4711

4350

5394

4618

5736

4711

6817

30

47.7

4046

4249

4249

4942

4443

5662

4720

6022

4831

7158

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 20

Capacity Tables MCAC -KTSM-2007-2

18 Four Way Cassette Type

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKA-950

5

15

11.9

5180

6263

5334

6882

5490

7522

5768

7842

5789

8853

20

21.2

5459

6955

5654

7646

5830

8368

6118

8740

6180

9885

25

33.1

5686

7481

5891

8245

6098

9029

6397

9431

6480

10679

30

47.7

5830

7811

6057

8616

6274

9441

6573

10060

6686

11185 6 15

11.9

4963

5768

5128

6387

5283

7017

5561

7346

5582

8347

20

21.2

5232

6407

5417

7109

5603

7821

5891

8347

5944

9328

25

33.1

5428

6903

5644

7666

5850

8440

6139

8843

6232

10081

30

47.7

5561

7223

5789

8017

6005

8843

6315

9266

6418

10566 7 15

11.9

4757

5273

4922

5891

5076

6521

5355

6841

5376

7832

20

21.2

4994

5871

5180

6872

5365

7481

5654

8110

5717

8760

25

33.1

5180

6325

5386

7181

5592

7956

5891

8327

5985

9483

30

47.7

5304

6614

5520

7408

5747

8224

6047

8646

6160

9946 8 15

11.9

4540

4777

4716

5386

4870

6005

5148

6325

5180

7305

20

21.2

4757

5314

4953

6005

5138

6707

5428

7171

5490

8182

25

33.1

4933

5737

5138

6480

5345

7254

5644

7646

5737

8863

30

47.7

5035

6005

5262

6789

5479

7604

5789

8017

5902

9307 9 15

11.9

4344

4344

4509

4870

4675

5490

4953

5809

4974

6779

20

21.2

4530

4757

4726

5438

4911

6139

5201

6501

5273

7604

25

33.1

4675

5138

4890

5881

5097

6645

5396

7037

5500

8245

30

47.7

4777

5386

5004

6160

5221

6965

5531

7377

5644

8657

10

15

11.9

4137

4137

4303

4354

4468

4974

4747

5283

4777

6253

20

21.2

4303

4303

4499

4870

4685

5561

4974

5912

5046

7017

25

33.1

4437

4530

4643

5262

4860

6026

5159

6407

5262

7615

30

47.7

4519

4747

4747

5520

4963

6325

5273

6728

5396

7997

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 21

MCAC-KTSM-2007-2 Capacity Tables

Four Way Cassette Type 19

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKA-1200

5

25

18.2

6858

8651

7094

9517

7322

10418

7680

10873

7750

12282

32

29.8

7059

9141

7313

10060

7558

11022

7925

11503

8022

13017

35

35.6

7226

9526

7488

10497

7750

11494

8127

12011

8249

13603

40

46.5

7392

9832

7637

10838

7908

11879

8293

12413

8424

14066

6

25

18.2

6569

7978

6797

8844

7033

9736

7392

10191

7462

11591

32

29.8

6753

8433

7007

9360

7252

10305

7619

10786

7715

12290

35

35.6

6902

8800

7164

9762

7427

10751

7803

11267

7925

12842

40

46.5

7024

9089

7304

10086

7575

11118

7960

11652

8100

13734

7

25

18.2

6272

7304

6508

8162

6736

9045

7103

9054

7173

10882

32

29.8

6438

7724

6701

8634

6946

9579

7313

9849

7418

11547

35

35.6

6578

8057

6849

9010

7112

9999

7488

10506

7610

12081

40

46.5

6683

8328

6972

9316

7243

10348

7628

10873

7768

12509

8

25

18.2

5983

6613

6220

7471

6456

8345

6814

8791

6893

10174

32

29.8

6132

7007

6395

7908

6639

8844

7016

9316

7121

10795

35

35.6

6255

7304

6526

8258

6788

9238

7173

9745

7296

11293

40

46.5

6360

7558

6639

8538

6919

9561

7304

10086

7444

11704

9

25

18.2

5695

5922

5940

6762

6167

7637

6535

8074

6613

9447

32

29.8

5835

6272

6088

7173

6342

8100

6718

8573

6823

10034

35

35.6

5940

6543

6211

7488

6482

8468

6858

8966

6989

10506

40

46.5

6027

6771

6316

7750

6587

8765

6981

9281

7121

10891

10

25

18.2

5415

5415

5660

6053

5887

6919

6255

7357

6342

8713

32

29.8

5529

5529

5791

6421

6045

7339

6421

7812

6526

9264

35

35.6

5625

5773

5896

6709

6167

7672

6552

8170

6683

9701

40

46.5

5703

5975

5992

6946

6272

7952

6657

8468

6806

10060

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 22

Capacity Tables MCAC-KTSM-2007-2

20 Four Way Cassette Type

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKA-1500

5

25

18.2

8047

10151

8324

11167

8591

12224

9012

12758

9094

14410

32

29.8

8283

10726

8581

11803

8868

12932

9299

13497

9412

15273

35

35.6

8478

11177

8786

12317

9094

13487

9535

14092

9679

15960

40

46.5

8673

11536

8960

12717

9278

13938

9730

14564

9884

16504 6 25

18.2

7708

9361

7975

10377

8252

11424

8673

11957

8755

13600

32

29.8

7924

9894

8221

10982

8509

12091

8940

12655

9053

14421

35

35.6

8098

10325

8406

11454

8714

12614

9155

13220

9299

15067

40

46.5

8242

10664

8570

11834

8888

13045

9340

13671

9504

16114 7 25

18.2

7359

8570

7636

9576

7903

10613

8334

10623

8416

12768

32

29.8

7554

9063

7862

10130

8149

11239

8581

11556

8704

13548

35

35.6

7718

9453

8037

10572

8344

11732

8786

12327

8929

14174

40

46.5

7842

9771

8180

10931

8498

12142

8950

12758

9114

14677 8 25

18.2

7020

7759

7298

8765

7575

9792

7995

10315

8088

11937

32

29.8

7195

8221

7503

9278

7790

10377

8232

10931

8355

12666

35

35.6

7339

8570

7657

9689

7965

10839

8416

11434

8560

13251

40

46.5

7462

8868

7790

10017

8119

11218

8570

11834

8734

13733 9 25

18.2

6682

6949

6969

7934

7236

8960

7667

9473

7759

11085

32

29.8

6846

7359

7144

8416

7441

9504

7883

10059

8006

11773

35

35.6

6969

7677

7287

8786

7605

9935

8047

10520

8201

12327

40

46.5

7072

7944

7410

9094

7729

10284

8191

10890

8355

12778

10

25

18.2

6353

6353

6641

7103

6908

8119

7339

8632

7441

10223

32

29.8

6487

6487

6795

7534

7092

8611

7534

9166

7657

10869

35

35.6

6600

6774

6918

7872

7236

9001

7688

9586

7842

11383

40

46.5

6692

7010

7031

8149

7359

9330

7811

9935

7985

11803

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 23

MCAC-KTSM-2007-2 Capacity Tables

Four Way Cassette Type 21

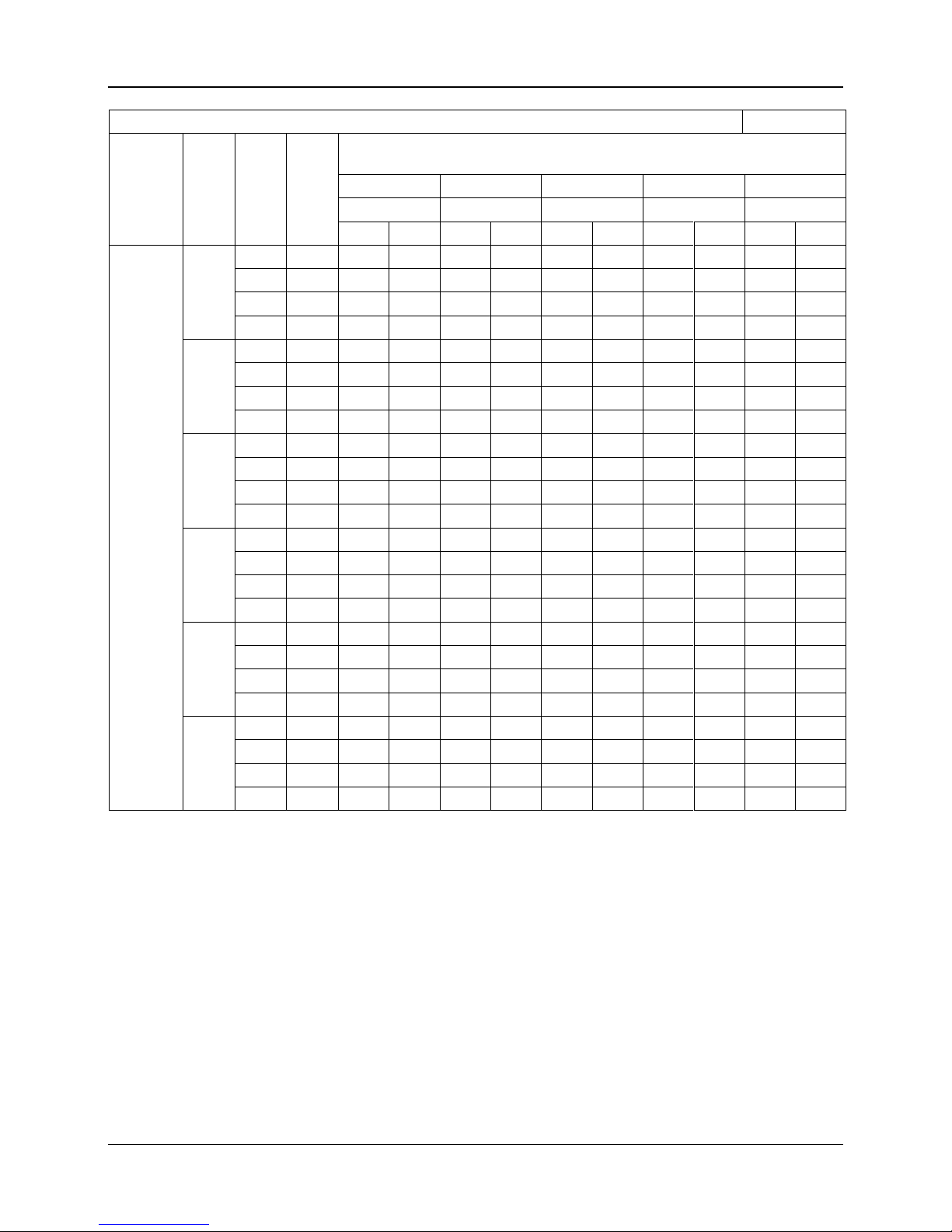

Heating Capacity Table:

Model

Water Flow

volume(LPM)

Hydraulic

Pressure

Drop (kPa)

Air inlet condition DB18℃

Water inlet temp.

40

45

50

55

60

70

80

MKA-600

10

13.5

3791

4650

5509

6375

7234

8959

10684

15

30.4

4087

5013

5946

6871

7804

9663

11521

20

54

4257

5227

6190

7160

8130

10063

12002

25

84.4

4369

5361

6353

7345

8337

10329

12313

MKA-750

15

11.9

4589

5641

6839

7659

8850

10926

13042

20

21.2

4777

5870

6960

8044

9114

11280

13454

25

33.1

4978

6114

7247

8384

9486

11748

14008

30

47.7

5109

6270

7438

8601

9738

12051

14372

MKA-850

15

11.9

5097

6261

7418

8582

9738

12058

14379

20

21.2

5363

6581

7806

9023

10240

12682

15117

25

33.1

5538

6794

8057

9312

10575

13093

15611

30

47.7

5660

6946

8239

9525

10811

13382

15961

MKA-950

15

11.9

5869

7199

8537

9868

11180

13830

16498

20

21.2

6174

7574

8971

10383

11754

14553

17351

25

33.1

6366

7820

9270

10716

12139

15025

17920

30

47.7

6518

7997

9473

10954

12403

15358

18315

MKA-1200

25

18.2

7315

8976

10637

12305

12694

17295

20617

32

29.8

7527

9238

10955

12666

14376

17804

21225

35

35.6

7690

9443

11189

12941

14687

18186

21684

40

46.5

7817

9598

11372

13153

14935

18490

22045

MKA-1500

25

18.2

7761

9529

11293

13063

14794

18305

21838

32

29.8

8063

9893

11729

13561

15353

19008

22666

35

35.6

8271

10155

12035

13912

15758

19502

23268

40

46.5

8437

10347

12263

14186

16066

19882

23710

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp.

TH: Total heat SH: Sensible heat

2. Table above is based on normal type fan coil high speed air-flow volume; heating capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 24

Sound Levels MCAC-KTSM-2007-2

22 Four Way Cassette Type

7. Sound Levels

TYPE

MKA-600

MKA-750

MKA-850

MKA-950

MKA-1200

MKA-1500

Noise

dB(A)

41

41

44

44

45

45

FOUR-WAY CASSETTE TYPE

Microphone

1.0m

Page 25

MCAC-KTSM-2007-2 Explored View

Four Way Cassette Type 23

8. Exploded View

MKA-600、MKA-750、MKA-850、MKA-950、MKA-1200、MKA-1500

No.

Part Name

Quantity

No.

Part Name

Quantity

1

Water Receiver, Assembly

1

26

Rubber washer, pump

1

2

Pipe Temperature Sensor Assembly

1

27

holder, pump

1

3

E-Parts Box Cover1

1

28

Water trying board

1

4

Capacity

1

29

Panel Assembly

4

5

E-Parts Box Assembly

1

30

Cover, installing

1

6

E-Parts Box Cover2

1

31

Swing motor

4

7

Transformer

1

32

Fan guide

1

8

PCB Assembly

1

33

Filter

2

9

Evaporator assembly

1

34

Switch, air inlet grille

1

1

2

3 4 5

6

7

8

10

9

11

12

13

14

15

16

17

18

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

394041

42

43

44

45

46

47

48

49

50

19

56

Page 26

Explored View MCAC-KTSM-2007-2

24 Four Way Cassette Type

10

Fixing board, Evaporator

1

35

Switch cover, air inlet grille

1

11

Clamp, fan

1

36

Air inlet grille

4

12

Fan assembly

1

37

Hanger for panel, assembly

1

13

Fan Motor

1

38

Control box

1

14

Gasket, motor

4

39

LED holder

1

Gasket, motor

4

40

Control board

1

15

Evaporator Base assembly

1

41

Cover, control box

1

16

Base Pan assembly

1

42

Panel

1

Wire clamp board

1

43

Back board, Air out 1

1

17

Sealing board, pipe out

1

44

Back board, Air out 2

1

18

Remoter

1

45

Back board, Air out 3

1

19

Eva out pipe, assembly

1

46

Back board, Air out 4

4

20

Drain Pump assembly

1

47

Foam, air out 1

4

21

Water switch

1

Foam, air out 2

1

22

Clamp, water pipe

1

48

Fixing hanger, Evaporator

2

23

Water pipe

1

49

Fixing hanger, Evaporator

1

24

Extend water pipe

1

50

Eva in pipe, assembly

25

Separate board, pump

1

Page 27

MCAC-KTSM-2007-2 Compact Four Way Cassette Type

Compact Four Way Cassette Type 25

Compact Four Way Cassette Type

1. Features..........……………………………………………………………............26

2. Specification……………………………………………………………............27

3. Dimensions………………………………………………………………...........28

4. Service Space……………………………………………………………............29

5. Wiring Diagrams…………………………………………………………..........30

6. Capacity Tables……………………………………………………………........31

7. Sound Levels……………………………………………………………..........35

8. Explored View……………………………………………………………..........36

Page 28

Features MCAC-KTSM-2007-2

26 Compact Four Way Cassette Type

1. Features

(1) Low operation noise

---Streamline plate ensures quietness

---Creates natural and comfortable environment

(2) Efficient cooling

---Equal, fast and wide—range cooling

(3) The adoption of the most advanced 3- Dimensional Screw fan

---Reduces the air resistance passing through

---Smoothes the air flow

---Makes air speed distribution to the heat exchange uniform

(4) Fresh air makes life healthier and more comfortable.

(4) Improvement for easy installation and maintenance (only available for small four-way cassette)

---Little space is required for installation into a shallow ceiling

---Because of the compactness and weight reduction of the main unit and panel, all models can be

installed without a hoist

The sketch map of installation (compact type)

Page 29

MCAC-KTSM-2007-2 Specification

Compact Four Way Cassette Type 27

2. Specification

TYPE

MKB-300

MKB-400

MKB-450

MKB-500

Airflow

CFM

300

400

450

500

m3/h

500

630

710

800

Cooling Capacity

W

2635

3190

3750

3935

Btu/h

8870

10920

12625

13310

Heating Capacity

W

3630

4425

5240

5510

Btu/h

12420

15285

17675

18630

Noise

dB(A)

38

39

40

41

Water flow

LPH

530

653

740

850

Water resistance

kPa

10.1

14.5

18.3

27.1

Indoor Coil

Number of rows

2 2 2 2

Tube pitch(a)x row pitch(b)

mm

21×13.37

Fin spacing

mm

1.3

Fin type Hydrophilic aluminium

Tube outside dia.and type

mm

φ7.94,innergroove tube

Coil length×height×width

mm

1185×210×26.74

Number of circuits

10

10

10

10

Fan

motor

Type Low noise 3 speed fan motor

Number

1 Model

YDK45-4F

Input W 30

45

55

70

Capacitor

uF 1 1.5 2 3

Indoor

unit

Dimension (W*H*D)

mm

580×254×580

Packing (W*H*D)

mm

750×340×750

Net/Gross weight

kg

21/30

Panel

Dimension (W*H*D)

mm

650×30×650

Packing (W*H*D)

mm

715×115×715

Net/Gross weight

kg

3/5

Control mode

wired controller(optional) , remote controller

(standard)

Pipe

Water-inlet pipe

RC3/4” internal thread

Water-return pipe

RC3/4” internal thread

Condensation water-outlet pipe

EVA+LDPE 3/4” external thread

Remark: 1. All performance data above is based upon 0Pa ambient static pressure.

2. Cooling capacity test condition: air inlet Temp. : 27DB℃/19.5WB℃, water inlet Temp. 7℃,

water Temp. difference 5℃.

3. Heating capacity test condition:

air inlet Temp. 21DB℃, water inlet Temp. 60 DB℃

the volume of air and water is same as cooling.

4. Noise level is tested in full-anechoic room.

Page 30

Dimensions MCAC-KTSM-2007-2

28 Compact Four Way Cassette Type

3. Dimensions

MKB-300、MKB-400、MKB-450、MKB-500

580(Body)

67

600(Ceiling hole)

650(Panel)

401(Hook-location)

611(Hook-location)

580(Body)

422 28.5

600(Ceiling hole)

650(Panel)

Drain side and

Tubing side

A

600

Hook

265

Panel

Chart 4

Body

Nut

Ceiling

Page 31

MCAC-KTSM-2007-2 Service Space

Compact Four Way Cassette Type 29

4. Service Space

Page 32

Wring Diagram MCAC-KTSM-2007-2

30 Compact Four Way Cassette

5. Wiring Diagram

CN7

CN 11 C N1 0

CN2

CN 19

CN1

CN5

CN 12

CN4 CN8 CN9

CN 17

T O CON T R OL E R

5

CN3

2

Y

BL

Page 33

MCAC-KTSM-2007-2 Capacity Tables

Compact Four Way Cassette Type 31

6. Capacity Tables

Cooling Capacity Table

unit:W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKB-300

5

6

4.6

1531

1809

1578

1989

1620

2170

1709

2273

1703

2553 8 8.1

1627

2038

1683

2239

1731

2448

1822

2559

1836

2886

10

12.7

1692

2193

1755

2414

1815

2643

1899

2761

1927

3122

12

18.2

1753

2322

1815

2559

1878

2810

1968

2935

2003

3324 6 6

4.6

1474

1669

1516

1843

1565

2024

1648

2121

1648

2406 8 8.1

1558

1878

1613

2079

1662

2288

1753

2392

1767

2726

10

12.7

1523

1620

1676

2246

1739

2476

1829

2587

1850

2948

12

18.2

1669

2149

1739

2385

1802

2629

1892

2754

1927

3144 7 6

4.6

1412

1523

1460

1696

1502

1878

1584

1974

1585

2253 8 8.1

1488

1717

1544

1920

1601

2130

1717

2267

1696

2559

10

12.7

1544

1850

1606

2072

1662

2295

1753

2635

1781

2775

12

18.2

1592

1968

1655

2336

1724

2608

1815

2816

1843

2955 8 6

4.6

1349

1377

1398

1551

1446

1731

1530

1822

1530

2107 8 8.1

1419

1558

1474

1753

1530

1961

1609

2061

1634

2392

10

12.7

1467

1676

1530

1899

1592

2121

1683

2239

1703

2594

12

18.2

1509

1788

1578

2017

1641

2260

1739

2378

1767

2761 9 6

4.6

1294

1294

1342

1405

1384

1585

1467

1676

1474

1954 8 8.1

1356

1391

1412

1592

1467

1795

1551

1899

1565

2218

10

12.7

1398

1502

1537

1717

1516

1940

1606

2059

1634

2406

12

18.2

1433

1599

1502

1829

1565

2072

1662

2190

1690

2573

10

6

4.6

1182

1231

1280

1280

1328

1433

1412

1523

1419

1802 8 8.1

1287

1287

1342

1419

1398

1627

1488

1724

1502

2045

10

12.7

1321

1321

1384

1537

1446

1760

1537

1871

1565

2225

12

18.2

1356

1412

1426

1641

1488

1878

1585

1996

1620

2371

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 34

Capacity Tables MCAC-KTSM-2007-2

32 Compact Four Way Cassette Type

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKB-400

5

6

4.6

1852

2188

1911

2407

1961

2626

2062

2744

2062

3089 8 8.1

1970

2466

2037

2710

2096

2963

2205

3097

2222

3493

10

12.7

2045

2651

2121

2921

2197

3198

2298

3342

2331

3779

12

18.2

2121

2811

2197

3097

2273

3400

2382

3552

2424

4023 6 6

4.6

1784

2020

1835

2230

1894

2449

1995

2567

1995

2912 8 8.1

1885

2273

1953

2517

2012

2769

2121

2895

2138

3299

10

12.7

1843

1961

2028

2719

2104

2996

2214

3131

2239

3569

12

18.2

2020

2601

2104

2887

2180

3182

2289

3333

2331

3804 7 6

4.6

1709

1843

1768

2054

1818

2273

1919

2390

1919

2727 8 8.1

1801

2079

1869

2323

1936

2576

2037

2702

2054

3097

10

12.7

1869

2239

1944

2508

2012

2778

2121

3190

2155

3358

12

18.2

1927

2382

2003

2828

2087

3156

2197

3409

2230

3577 8 6

4.6

1633

1667

1692

1877

1751

2096

1852

2205

1852

2550 8 8.1

1717

1885

1784

2121

1852

2374

1953

2500

1978

2895

10

12.7

1776

2028

1852

2298

1927

2567

2037

2710

2062

3139

12

18.2

1826

2163

1911

2441

1986

2735

2104

2879

2138

3342 9 6

4.6

1566

1566

1624

1700

1675

1919

1776

2028

1784

2365 8 8.1

1641

1683

1709

1927

1776

2172

1877

2298

1894

2685

10

12.7

1692

1818

1860

2079

1835

2348

1944

2491

1978

2912

12

18.2

1734

1936

1818

2214

1894

2508

2012

2651

2045

3114

10

6

4.6

1431

1490

1549

1549

1608

1734

1709

1843

1717

2180 8 8.1

1557

1557

1624

1717

1692

1970

1801

2087

1818

2475

10

12.7

1599

1599

1675

1860

1751

2129

1860

2264

1894

2693

12

18.2

1641

1709

1725

1986

1801

2273

1919

2416

1961

2870

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 35

MCAC-KTSM-2007-2 Capacity Tables

Compact Four Way Cassette Type 33

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKB-450

5

6

4.6

2305

2693

2366

2955

2435

3227

2559

3366

2552

3793 8 8.1

2505

3180

2591

3498

2676

3832

2808

4002

2831

4522

10

12.7

2629

3475

2722

3832

2823

4196

2955

4382

3002

4964

12

18.2

2722

3692

2831

4072

2932

4467

3079

4669

3134

5290 6 6

4.6

2210

2482

2280

2746

2342

3009

2466

3149

2466

3576 8 8.1

2397

2932

2482

3250

2567

3584

2699

3747

2722

4266

10

12.7

2513

3211

2606

3560

2707

3924

2839

4110

2885

4684

12

18.2

2598

3413

2707

3793

2808

4180

2947

4382

3009

5003 7 6

4.6

2117

2265

2187

2528

2257

2792

2381

2932

2381

3351 8 8.1

2288

2684

2373

3002

2459

2994

2590

3280

2622

3863

10

12.7

2389

2940

2490

3134

2583

3266

2722

3506

2769

4095

12

18.2

2473

3125

2575

3273

2683

3474

2823

3750

2885

4312 8 6

4.6

2032

2047

2102

2311

2172

2575

2303

2707

2296

3126 8 8.1

2179

2435

2272

2746

2358

3072

2490

3234

2513

3747

10

12.7

2272

2668

2373

3009

2474

3374

2606

3553

2653

4126

12

18.2

2342

2839

2451

3211

2559

3599

2699

3553

2761

4095 9 6

4.6

1939

1939

2016

2086

2078

2350

2203

2490

2210

2901 8 8.1

2078

2179

2164

2490

2249

2808

2381

2971

2412

3475

10

12.7

2156

2389

2257

2730

2358

3087

2497

3273

2544

3832

12

18.2

2218

2544

2327

2916

2435

3219

2583

3351

2645

3871

10

6

4.6

1853

1853

1923

1923

1993

2125

2117

2257

2125

2668 8 8.1

1970

1970

2063

2226

2148

2544

2280

2707

2311

3211

10

12.7

2047

2102

2141

2451

2241

2800

2381

2978

2428

3545

12

18.2

2102

2249

2210

2614

2319

2994

2459

3188

2521

3638

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 36

Capacity Tables MCAC-KTSM-2007-2

34 Compact Four Way Cassette Type

Cooling Capacity Table

Unit: W

Model

Water

inlet

temp.

(℃)

Water

FV

(LPM)

Water

PD

(kPa)

Air inlet condition

DB24℃

DB25℃

DB26℃

DB27℃

DB28℃

WB17℃

WB18℃

WB19℃

WB19.5℃

WB21℃

SH

TH

SH

TH

SH

TH

SH

TH

SH

TH

MKB-500

5

10

13.5

2759

3646

2857

4020

2962

4403

3101

4598

3150

5209

15

30.4

2857

3874

2971

4273

3076

4688

3231

4899

3288

5551

20

54

2319

2604

2393

2881

2458

3158

2588

3304

2588

3752

25

84.4

2515

3076

2604

3410

2694

3760

2832

3931

2857

4476 6 10

13.5

2637

3369

2735

3736

2840

4118

2979

4313

3028

4916

15

30.4

2726

3581

2840

3980

2946

4387

3093

4598

3158

5249

20

54

2222

2376

2295

2653

2368

2930

2499

3076

2499

3516

25

84.4

2401

2816

2490

3150

2580

3141

2718

3443

2751

4053 7 10

13.5

2507

3085

2612

3288

2710

3426

2857

3679

2905

4297

15

30.4

2596

3280

2702

3434

2816

3646

2962

3935

3028

4525

20

54

2132

2149

2206

2425

2279

2702

2417

2840

2409

3280

25

84.4

2287

2556

2385

2881

2474

3223

2612

3394

2637

3931 8 10

13.5

2385

2800

2490

3158

2596

3540

2735

3727

2783

4330

15

30.4

2458

2979

2572

3369

2686

3776

2832

3727

2897

4297

20

54

2035

2035

2116

2189

2181

2466

2311

2612

2319

3044

25

84.4

2181

2287

2271

2612

2360

2946

2499

3117

2531

3646 9 10

13.5

2263

2507

2368

2865

2474

3239

2621

3434

2669

4020

15

30.4

2328

2669

2442

3060

2556

3378

2710

3516

2775

4061

20

54

1945

1945

2018

2018

2092

2230

2222

2368

2230

2800

25

84.4

2067

2067

2165

2336

2254

2669

2393

2840

2425

3369

10

10

13.5

2149

2206

2246

2572

2352

2938

2499

3125

2547

3719

15

30.4

2206

2360

2319

2743

2433

3141

2580

3345

2645

3817

20

54

2343

2426

2460

2819

2571

3226

2730

3433

2792

4081

25

84.4

2398

2564

2523

2978

2640

3412

2805

3632

2875

4322

Remark:

1. DB: Dry Bulb Temp. WB: Wet Bulb Temp. FV: Flow Volume

TH: Total heat SH: Sensible heat PD: Pressure Drop

2. Table above is based on normal type fan coil high speed air-flow volume; cooling capacity on other speed

air flow volume should multiply with corresponding capacity modification coefficient (refer to capacity

modification coefficient diagram.)

Page 37

MCAC-KTSM-2007-2 Sound Levels

Compact Four Way Cassette Type 35

7. Sound Levels

TYPE

MKB-300

MKB-400

MKB-450

MKB-600

Noise

dB(A)

38

39

40

41

FOUR-WAY CASSETTE TYPE

Microphone

1.0m

Page 38

Explored View MCAC-KTSM-2007-2

36 Compact Four Way Cassette Type

8. Explored View

MKB-300、MKB-400、MKB-450、MKB-500

No.

Part Name

Quantity

No.

Part Name

Quantity

1

Collect Water Pan ,Assembly

1

26.1

Air inlet grille

1

1.1

Foam, Collect Water Pan

1

26.2

Switch cover, air inlet grille

1

2

Wire fixing board

1

26.3

Switch, air inlet grille

2

3

Stopper, Water Drain

1

26.4

Filter 1 5

Evaporator Fixture Board Assembly

1

26.5

Control box

1

6

Drain Pump

1

26.6

LED holder

1

7

Liquid Position Sensor Assembly

1

26.7

Control board

1

8

Desperation board, right

1

26.8

Cover, control box

1

9

Drain pipe

1

26.9

Fan guide

4

1

2

1.1

5

3

6 7 8 910

11

13

14

15 17

18

19

20

21

22

23

25

24

26

26.1

26.2

26.3

26.4

26.5

26.6

26.7

26.8

26.9

26.10

26.11

26.12

26.13

26.14

26.15

29.1

27

29

30

29.2

29.3

29.4

29.7

29.8

29.6

Page 39

MCAC-KTSM-2007-2 Explored View

Compact Four Way Cassette Type 37

10

Extend water pipe

1

26.10

Swing motor

1

11

Drain Pump Holder

1

26.11

Panel

1

13

Evaporator Assembly

1

26.12

Install cover, swing motor

1

14

Fixing clamp, evaporator

1

26.13

Install cover I

1

15

Desperation board, left

1

26.14

Install cover II

1

16

Inlet pipe, evaporator

1

26.15

Install cover I

1

17

Outlet pipe, evaporator

1

27

Remoter

1

18

Wire crossing board

1

29

E-control Assembly

1

19

Fan 1 29.1

Control Box

1

20

Fan Motor

1

29.2

Rubber, wire crossing

1

21

Fan Motor Underlay

1

29.3

PCB Assembly

1

22

Base Pan Assembly

1

29.4

Transformer

1

23

Fixing board, water pan

4

29.6

Capacitor

1

24

Sealing board, pipe out I

1

29.7

Base, wire fixing

1

24.1

Sealing board, pipe outⅡ

1

29.8

Cover, wire fixing

1

25

Rubber, wire c

2

30

Control Box Cover

1

26

Panel Assembly

1

Page 40

The Installation of MKA MCAC-KTSM-2007-2

142 The Installation of MKA

The Installation of MKA

1. Before Installation …………………………………………………................143

2. Install the Main Body...…………………………………………………...........144

3. Install the Panel...…………………………………………………..............146

4. Install the Drain Pipe...…………………………………………………...........148

5. Wiring...…………………………………………………...................................150

Page 41

MCAC-KTSM-2007-2 Before Installation

The Installation of MKA 143

1. Before Installation

Please check whether the accessories are of full scope. If there are some fittings free from use, please

restore them carefully.

Page 42

Install The Main Body MCAC-KTSM-2007-2

144 The Installation of MKA

2. Install the Main Body

A. The existing ceiling (to be horizontal)

a. Please cut a quadrangular hole of 880 880mm in the ceiling according to the shape of the installation

paper board. (Refer to Chart3, 4)

The center of the hole should be at the same position of that of the air conditioner body.

Determine the lengths and outlets of the connecting pipe, drain pipe and cables.

To balance the ceiling and to avoid vibration, please enforce the ceiling when necessary.

b. Please select the position of installation hooks according to the hook holes on the installation board.

Drill four holes of Ø12mm, 50~55mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

Face the concave side of the installation hooks toward the expansible hooks. Determine the length of the

installation hooks from the height of ceiling, and then cut off the unnecessary part.

If the ceiling is extremely high, please determine the length of the installation hook according to facts.

Cut the installation hook open in the middle position, and then use appropriate length of reinforcing rod (Ø12)

to weld together.

The length could be calculated from Chart5:

Length=H-181+L (in general, L=100mm and is half of the whole length of the installation hook).

c. Please adjust the hexangular nuts on the four installation hooks evenly, to ensure the balance of the body.

1. The transparent hose filled with water to check the lever of the main body from the four sides or diagonal

line direction, the lever indicator also can check the lever from four sides of the main body Refer to chart 6)

2. The drainpipe is awry, leakage will be caused by the malfunction of the water-level switch.

Adjust the position to ensure the gaps between the body and the four sides of ceiling are even.

3. The body's lower part should sink into the ceiling for 10~12mm (Refer to chart5).

Locate the air conditioner firmly by wrenching the nuts after having adjusted the body's position well.

Page 43

MCAC-KTSM-2007-2 Install The Main Body

The Installation of MKA 145

B. New built houses and ceilings

a. In the case of new built house, the hook can be embedded in advance (refer to the A.b mentioned above).

But it should be strong enough to bear the indoor unit and will not become loose because of concrete

shrinking.

b. After installing the body, please fasten the installation paper board onto the air conditioner with bolts (M6

16) to determine in advance the sizes and positions of the hole opening on ceiling.

Please first guarantee the flatness and horizontal of ceiling when installing it.

Refer to the A.a mentioned above for others.

c. Refer to the A.c mentioned above for installation.

d. Remove the installation paper board.

Page 44

Install The Panel MCAC-KTSM-2007-2

146 The Installation of MKA

3. Install the Panel

(1) Remove the inlet grid.

Cat ion

Never put the panel face down on floor or against the wall, or on bulgy objects.

Never crash or strike it.

a. Slide two grid switches toward the middle at the same time, and then pull them up. (Refer to chart 9)

b. Draw the grid up to an angle of about 45o, and remove it. (Refer to chart 10)

(2)Remove the installation covers at the four corners.

Wrench off the bolts, loose the rope of the installation covers, and remove them. (Refer to chart 11)

(3) Install the panel

a. Align the swing motor on the panel to the tubing joints of the body properly. (Refer to chart 12)

b. Fix hooks of the panel at swing motor and its opposite sides to the hooks of corresponding water receiver.

(Refer to chart 12) Then hang the other two panel hooks onto corresponding hangers of the body. (Refer to

chart 12)

Cautions

Do not coil the wiring of the swing motor into the seal sponge.

c. Adjust the four panel hook screws to keep the panel horizontal, and screw them up to the ceiling evenly.

(Refer to chart 12)

d. Regulate the panel in the direction of the arrow in Chart12 slightly to fit the panel's center to the center of

the ceiling's opening. Guarantee that hooks of four corners are fixed well.

e. Keep fastening the screws under the panel hooks, until the thickness of the sponge between the body and

the panel's outlet has been reduced to about 4~6mm. The edge of the panel should contact with the ceiling

well. (Refer to chart 13)

Malfunction described in Chart14 can be caused by inappropriate tightness the screw.

If the gap between the panel and ceiling still exists after fastening the screws, the height of the indoor unit

should be modified again. (Refer to chart 15-left)

You can modify the height of the indoor unit through the openings on the panel's four corners; if the lift of the

indoor unit and the drainpipe is not influenced (refer to chart 15-right).

(4) Hang the air-in grid to the panel, and then connect the lead terminator of the swing motor and that of the

control box with corresponding terminators on the body respectively.

(5) Relocate the air-in grid in the procedure of reversed order.

(6) Relocate the installation cover.

a. Fasten the rope of installation cover on the bolt of the installation cover. (Refer to chart 16-left)

b. Press the installation cover into the panel slightly. (Refer to chart 16-right)

Page 45

MCAC-KTSM-2007-2 Install The Panel

The Installation of MKA 147

Page 46

Connect Drain Pipe MCAC-KTSM-2007-2

148 The Installation of MKA

4. Connect the Drain Pipe

Install the drainpipe of the indoor unit

You can use a polyethylene tube as the drainpipe (out-dia. 37~39mm, in-dia. 32mm). It could be bought at

local market or from your dealer.

Set the mouth of the drainpipe onto the root of the body's pump-pipe, and clip the drainpipe and the out-let

pipe sheath (fittings) together firmly with the out-let pipe clasp (fitting).

Cautions: Use your strength carefully to prevent the pump-pipe from breaking. The body's pump pipe and

the drainpipe (especially the indoor part) should be covered evenly with the out-let pipe sheath (fittings) and

be bound tightly with the constrictor to prevent condensation caused by entered air.

To prevent water from flowing backwards into the air conditioner while the air conditioner stops, please lean

the drainpipe down toward outdoor (outlet-side) at a degree of over 1/50. And please avoid any bulge or

water deposit. (Refer to Chart 17.a)

Do not drag the drainpipe violently when connecting to prevent the body from being pulled. Meanwhile, one

support-point should be set every 1~1.5m to prevent the drainpipe from yielding (Refer to Chart 17.b). Or

you can tie the drainpipe with the connecting pipe to fix it. (Refer to Chart 17.c) In the case of prolonged

drainpipe, you had better tighten its indoor part with a protection tube to prevent it from loosing.

If the outlet of the drainpipe is higher than the body's pump joint, the pipe should be arranged as vertically as

possible. And the lift distance must be less than 200mm, otherwise the water will overflow when the air

conditioner stops. (Refer to Chart 18) The end of the drainpipe should be over 50mm higher than the ground

or the bottom of the drainage chute, and do not immerse it in water. If you discharge the water directly into

sewage is sure to make a U-form aqua seal by bending the pipe up to prevent the smelly gas entering the

house through the drain pipe.

Cautions: All the joints of the drain system must be sealed to prevent water leakage.

2. Drainage test

Check whether the drainpipe is unhindered

New built house should have this test done before paving the ceiling.

Remove the test cover, and stow water of about 2000ml to the water receiver through the stow tube. (Refer

to Chart 19)

Page 47

MCAC-KTSM-2007-2 Connect Drain Pipe

The Installation of MKA 149

Turn on the power, and operate the air conditioner under the "COOLING" mode. Listen to the sound of

the drain pump. Check whether the water is discharged well (a lag of 1min is allowed before

discharging, according to the length of the drain pipe), and check whether water leaks from the joints.

Cautions: