Midea MGCT-F30W/PN1, MGBT-F60W/PN1, MGCT-D30W/PN1, MGBT-F120W/PN1, MGBT-F180W/PN1 User Manual

Page 1

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

2

Content

1 General information ....................................................................................... 3

2. Features ......................................................................................................... 4

3. Specification ................................................................................................. 8

4 Dimension .................................................................................................... 14

5 Refrigeration system drawing ..................................................................... 22

6. Piping diagram ............................................................................................ 24

7 Wiring diagram ............................................................................................. 28

8 Electric characteristics ................................................................................ 36

9 Capacity tables ............................................................................................ 38

10 Exploded view ............................................................................................ 46

11 Trouble shooting ........................................................................................ 61

12 Installation .................................................................................................. 76

13 Commissioning ........................................................................................ 101

14 Maintenance ............................................................................................. 102

15 Control system ......................................................................................... 106

Appendix ..................................................................................................... 167

Page 2

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

3

1 General information

1.1 Nomenclature

M G B T - F 60 W / P N1

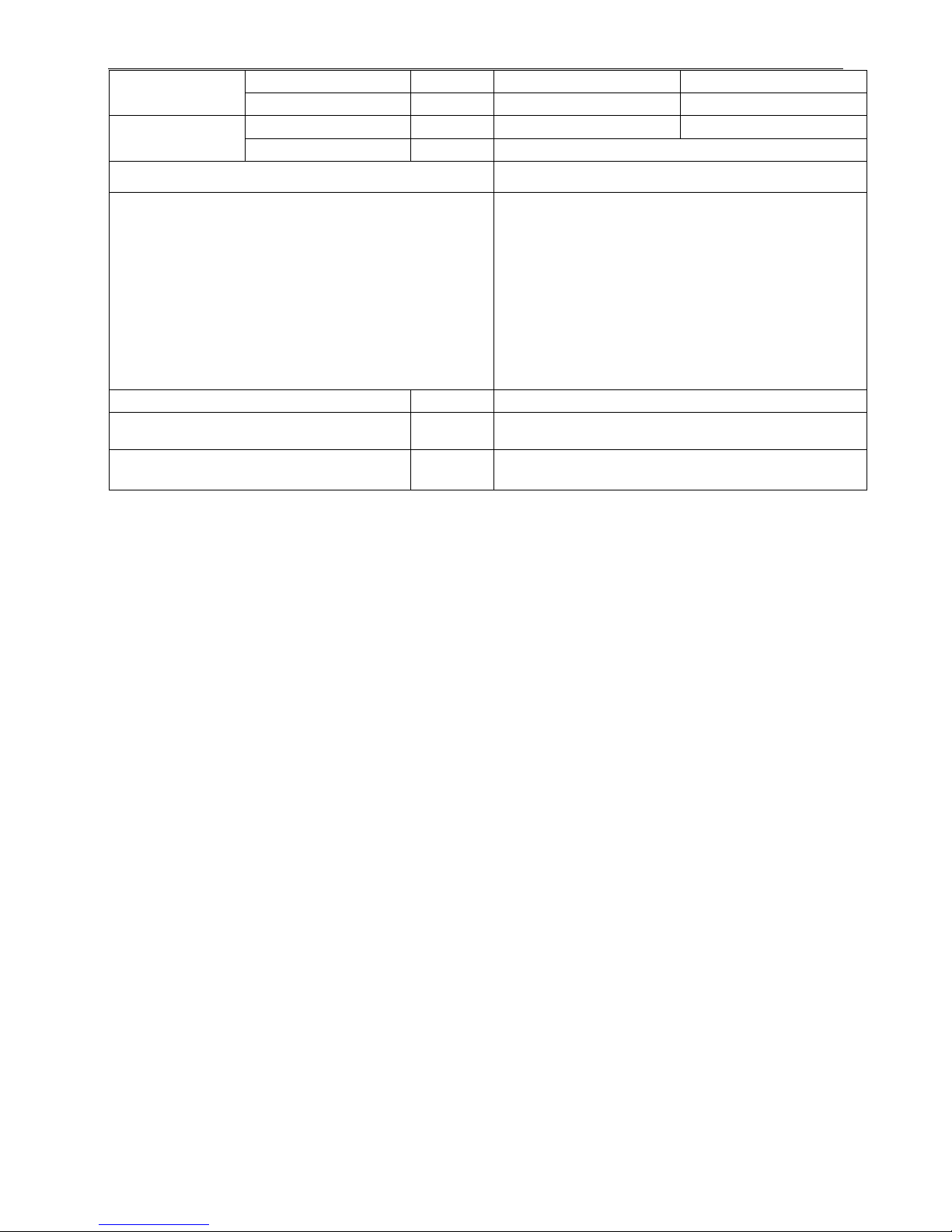

1.2 Product list

No

Model

Power supply

Heat exchanger

type

Maximum

combinations

Maximum

capacity(kW)

Wired controller

1

MGCT-F30W/PN1

380V/3Ph/60Hz

Double pipe

16

480

KJRM-120D/BMK-E

2

MGCT-D30W/PN1

380V/3Ph/60Hz

Double pipe

16

480

KJRM-120D/BMK-E

3

MGBT-F60W/PN1

380V/3Ph/60Hz

Shell and tube

16

960

KJRM-120D/BMK-E

4

MGBT-F120W/PN1

380V/3Ph/60Hz

Shell and tube

8

960

KJRM-120D/BMK-E

5

MGBT-F180W/PN1

380V/3Ph/60Hz

Shell and tube

5

900

KJRM-120D/BMK-E

Refrigerant type

N1:R410A Omit for R22

Power Supply

P: 380V, 60Hz, 3Ph

D: 220V, 60Hz, 3Ph

Outdoor Unit

Rated cooling capacity (kW)

The special function code

D: Digital scroll

F: Fixed scroll

V: Inverter system

T: T3 condition

Omit for T1 condition

The heat exchanger type

A: Plate

B: Shell and tube

C: Double pipe

Light chiller system

Midea

Page 3

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

4

1.3 External appearance

60kW

120kW

180kW

30kW

Page 4

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

5

2. Features

1). Wide range of outlet water temperature

Cooling: 5~17˚C (7˚C is default, set in factory), 0~17˚C can be available by switch the S5 on PCB, the

antifreeze must be put into pipeline.

Heating: 40~50˚C (45˚C is default, set in factory), 22~50˚C can be available by switch the address.

Mode

Outlet water temp.

Cooling(S5

address)

Normally(OFF)

5~17℃

Low water temp.(ON)

0~17℃

Heating(S4

address)

Normally(OFF)

40~50℃

Low water temp. (ON)

22~50℃

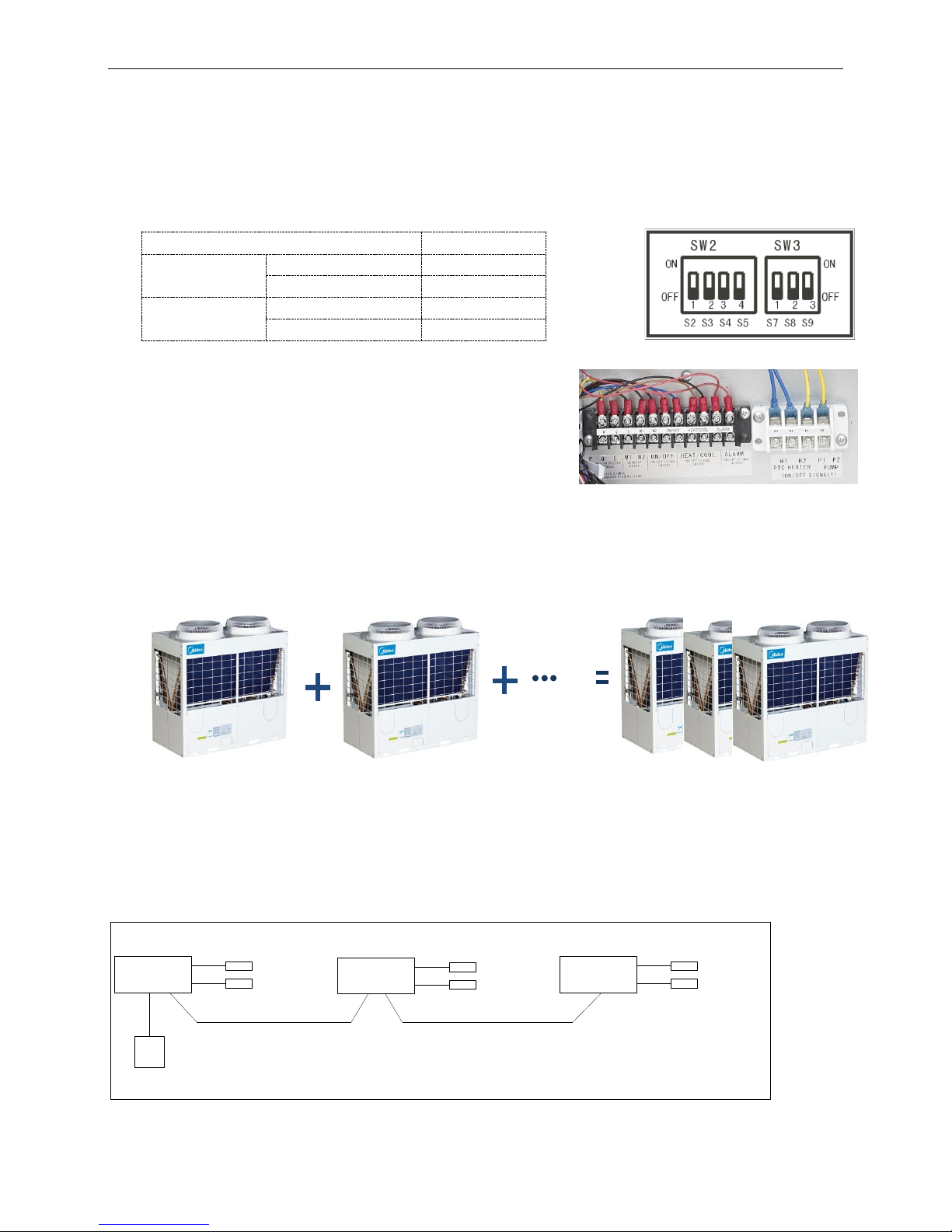

2).Humanized remote control

S7 address on PCB should be switched to ON to realize remote

control, which including remote ON/OFF, remote heating and

cooling mode selection, remote alarm. The customer can simply

and conveniently control the chiller and acquire the running

information on real time in door.

3).Modular design, flexible combination, more convenient for design and installation.

The unit adopts modular design, which can make more units to connect together. The units can be

combined freely, meanwhile every separate module can be operated as main unit, also each module can be

a slave unit with modules combination, more convenient for design and installation.

4).The maximum combination of the system consists of 1 main unit and 15 slave units for

30kW&60kW modules, 1 main unit and 7 slave units for 120kW module, 1 main unit and 4 slave units

for 180kW module.

Easy connection between main unit and slave units.

All the units can be connected together with a wired controller in series type. Using three-core shielded

twisted wire as communication wire.

Wired controller

Three-core shielding

twisted pair

Three-core shielding

twisted pair

Water outlet temp.

Water outlet temp.

Water outlet temp.

Total water outlet temp.

(Just for master unit)

Total water outlet temp.

(Just for master unit)

Total water outlet temp.

(Just for master unit)

5).Environmental care

Ecological R410A refrigerant.

60kW

60kW

960kW

Max 16 modules

Page 5

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

6

Chlorine-free and environmental friendly refrigerant, zero ozone depletion potential.

High-density refrigerant, therefore, less refrigerant required.

Leak-tight refrigerant circuit, Brazed refrigerant connections for increased leak-tightness.

6) Economical operation

New design adopts electronic expansion valve precise refrigerant control in wider range. Electronic

expansion valve allows operation at lower condensing pressure, adjustment can be made fast linear

response, making the system more stable output, the indoor temperature more uniform, and enhance

human comfortable.

7).Back up function

When unit is failure

If master unit fails, all the units will stop.

If one slave unit fails, this unit will stop but the others will

keep running.

When the master unit fails, any of the slave one can be set

as the master unit by manual setting.

When unit is under protection

If master unit’s protection occurs, this unit will stop but the

others will keep running.

If slave unit’s protection occurs, this unit will stop but the

others will keep running.

( Except PE, P9 protection happen)

8).Strong micro-computer intelligent control and monitor function.

Optimizing the design of system and using varieties of protection devices, to make the system more safe

and reliable.

9). Superior reliability

System will be more reliable with new type efficient heat exchanger. The 30kW module adopts double pipe

heat exchanger, the 60&120&180kW module adopt shell and tube heat exchanger for evaporator.

Shell and tube heat exchanger

Master Slave

Master Slave

Page 6

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

7

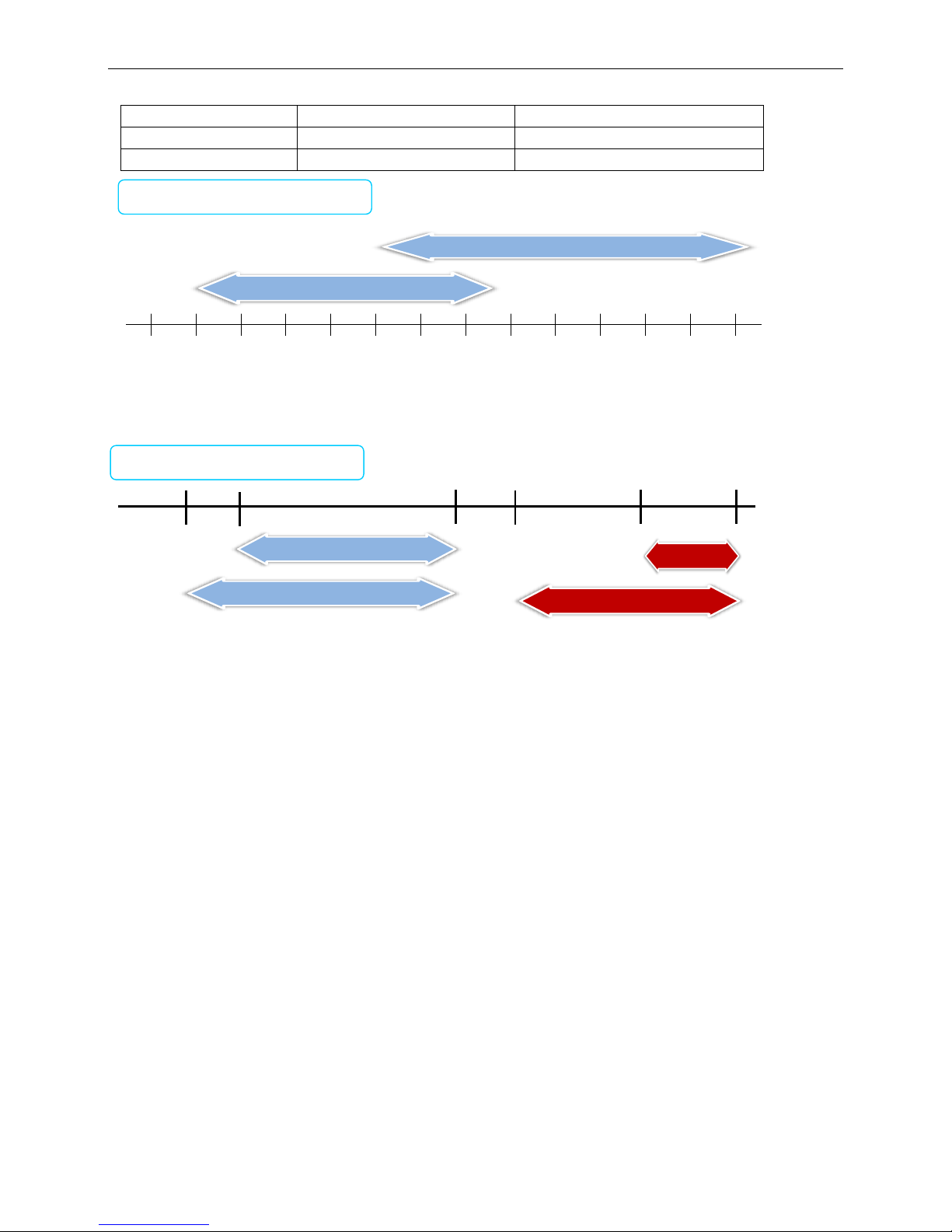

10). Applicable temperature range

Mode

Ambient temperature range

Water outlet temperature range

Cooling

10˚C ~52˚C

0~17˚C(The antifreeze must be added.)

Heating

-10˚C ~24˚C

22˚C ~50˚C

Chilled outlet water temperature can be adjusted by wired controller according to customer’s demand.

-15˚C

Ambient temperature range

-10˚C

-5˚C

0˚C

5˚C

10˚C

15˚C

20˚C

25˚C

30˚C

35˚C

40˚C

45˚C

50˚C

Cooling range

10˚C

52˚C

Heating range

-10˚C

24˚C

Water outlet temperature range

5˚C

17˚C

50˚C

5˚C

17˚C

Heating range

Cooling range

40˚C

22˚C

0˚C

40˚C

50˚C

Cooling range

0˚C

17˚C

Heating range

22˚C

50˚C

Page 7

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

8

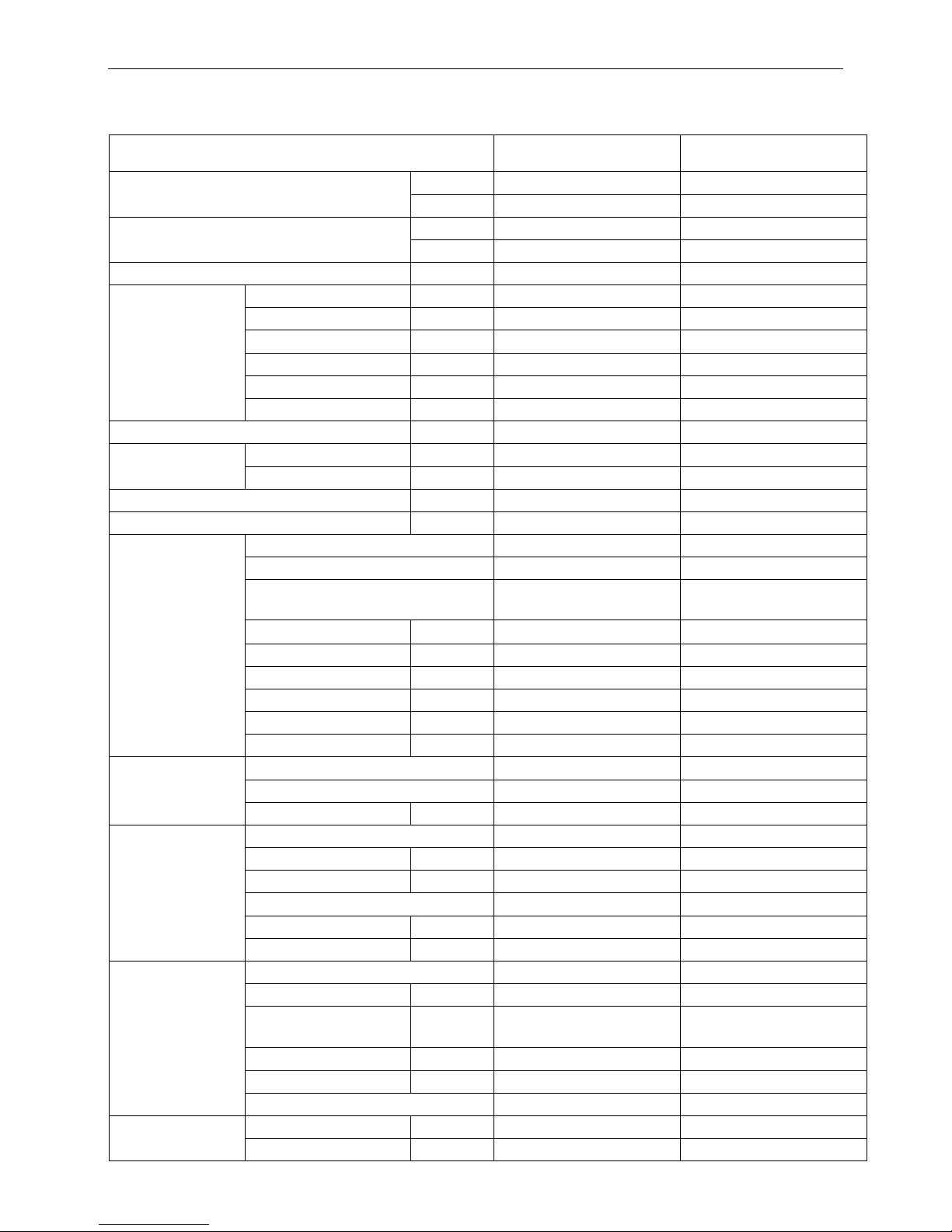

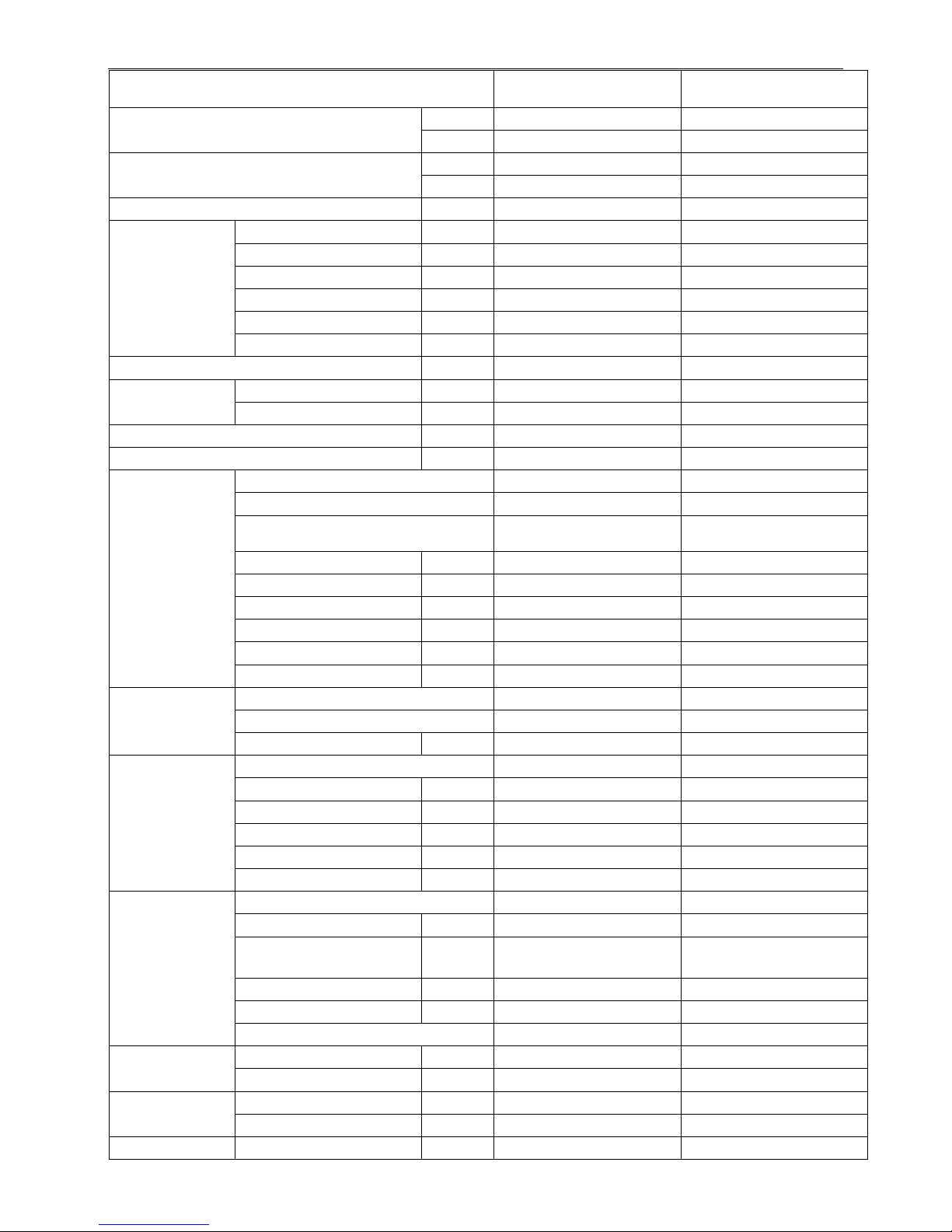

3. Specification

Model

MGCT-F30W/PN1

MGCT-D30W/PN1

Cooling Capacity (*1)

kW

30

30

Btu/h

102,300

102,300

Cooling Capacity (*2)

kW

25.8

25.8

Btu/h

88,030

88,030

Heating Capacity

kW

32

32

Power input

Cooling (*1)

kW

10.0

10.0

Cooling rated current (*1)

A

16.3

16.3

Cooling (*2)

kW

12

12

Cooling rated current (*2)

A

19.56

19.56

Heating

kW

9.8

9.8

Heating rated current

A

16.0

16.0

Power supply

V/Ph/Hz

380/3/60

380/3/60

Power supply

Manual switch A 50

50

Fuse

A

36

36

Max. Input consumption

kW

14.8

13.8

Max. Current

A

25.3

24.2

Compressor

Type

Scroll (fixed speed)

Scroll (Digital +fixed speed)

Brand

Copeland

Copeland

Model

ZP57K3E-TF7-522

ZPD51K5E-TF7-532/

ZP57K3E-TF7-522

Quantity

Pieces

2

1+1

Capacity

Btu/h

58000

50400/58000

Input

kW

5.48

4.71/5.48

Rate load current(RLA)

A

10.1

9.6/10.1

Locked rotor Amp(LRA)

A

94

65.6/94

Refrigerant oil

ml

1685

1242/1685

Refrigerant

Type

R410A

R410A

Refrigerant control

EXV

EXV

Weight

lb

6.834×2

6.834×2

Condenser (Air side)

Air side heat-exchanger type

Fin-coil

Fin-coil

Quantity of fan motor

Pieces

1

1

Air flow volume

×103m3/h

12

12

Fan motor model

YDK550-8B

YDK550-8B

Fan motor rated current

A

4

4

Fan motor input

kW

0.85

0.85

Evaporator (Water

side)

Water side heat-exchanger type

Double pipe

Double pipe

Water resistance loss

kPa

60

60

Water inlet/outlet pipeline

inside normal diameter

inch

1-1/2”

1-1/2”

Water flow volume

m3/h

5.2

5.2

Max. Pressure

MPa

1

1

Water pipe connection type

Flexible joint

Flexible joint

Dimension

Net(W×H×D)

inch

59.61×73.43×33.11

59.61×73.43×33.11

Packing size(W×H×D)

inch

62.6×81.3×39.17

62.6×81.3×39.17

Page 8

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

9

Weight

Net weight

lb

837.8

837.8

Gross weight

lb

881.8

881.8

Connection wiring

Power wire

mm2×No.

10×4+6 ×1

10×4+6 ×1

Signal wire

mm2×No.

0.75×3-core with shielding

Control type

Wired controller

Safety protection device

1) Protection for over-high discharge pressure

2) Protection for over-low suction pressure

3) Power supply phase sequence protection

4) Anti-freezing protection in cooling mode

5) Anti-freezing protection in winter

6) Protection for compressor over current

7) Protection for compressor overload

8) Outlet and inlet water temperature difference protection

9) Compressor discharge temperature protection

10) Water flow cut-off protection

11) Sensor malfunction protection

12) Low-temperature protection of shell and tube heat

exchanger.

Noise level

dB(A)

67

Operation water temperature

℃

Cooling:0~17(Less than 5℃ must add antifreeze.)

Heating:22~50

Ambient temperature

℃

Cooling:10~52 Heating:-10~21

Note:

Please refer to the water flow volume in the above table strictly to design and install.

Specifications are based on the following conditions:

Cooling : (*1)chilled water inlet/outlet: 12℃ / 7℃, and outdoor ambient temp. of 35°C DB.

(*2) chilled water inlet/outlet: 12℃ / 7℃, and outdoor ambient temp. of 46°C DB.

Heating : warm water inlet/outlet: 40℃ / 45℃, and outdoor ambient temp. 7°C DB/6°C WB.

Water side fouling factor: 0.086m2·℃/kW.

1m away in open field (sound pressure).

Page 9

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

10

Model

MGBT-F60W/PN1

MGBT-F120W/PN1

Cooling Capacity (*1)

kW

60

120

Btu/h

204,700

409,400

Cooling Capacity (*2)

kW

51.6

103.2

Btu/h

176,100

352,100

Heating Capacity

kW

65

130

Power input

Cooling (*1)

kW

19.7

39.4

Cooling rated current (*1)

A

63

126

Cooling (*2)

kW

23.64

47.28

Cooling rated current (*2)

A

75.6

151.2

Heating

kW

19.9

39.8

Heating rated current

A

65.5

130

Power supply

V/Ph/Hz

380/3/60

380/3/60

Power supply

Manual switch A 125

200

Fuse

A

100

150

Max. Input consumption

kW

26.9

51.44

Max. Current

A

48.7

95

Compressor

Type

Scroll (fixed speed)

Scroll (fixed speed)

Brand

Danfoss

Danfoss

Model

SH105A9ALC

SH105A9ALC

Quantity

Pieces

2

4

Capacity

Btu/h

97060

97060

Input

kW

9.9

9.9

Rate load current(RLA)

A

21.4

21.4

Locked rotor Amp(LRA)

A

124

124

Refrigerant oil

ml

3300

3300

Refrigerant

Type

R410A

R410A

Refrigerant control

EXV+ capillary

EXV+ capillary

Weight

lb

14.33×2

14.33×4

Condenser (Air

side)

Air side heat-exchanger type

Fin-coil

Fin-coil

Quantity of fan motor

Pieces

2

4

Air flow volume

×103m3/h

24

48

Fan motor model

YS650-8C

YS650-8C

Fan motor rated current

A

2.1×2

2.1×4

Fan motor input

kW

1.03×2

1.03×4

Evaporator (Water

side)

Water side heat-exchanger type

Shell and tube

Shell and tube

Water resistance loss

kPa

15

25

Water inlet/outlet pipeline

inside normal diameter

inch

4”

2-1/2”

Water flow volume

m3/h

10.3

20.6

Max. Pressure

MPa

1

1

Water pipe connection type

Flexible joint

Flexible joint

Dimension

Net(W×H×D)

inch

78.74×74.02×35.43

78.74×82.28×66.34

Packing size(W×H×D)

inch

82.28×82.48×38.78

81.89×88.19×69.09

Weight

Net weight

lb

1,300.727

2,601.455

Gross weight

lb

1,388.889

2,711.64

Connection wiring

Power wire

mm2×No

16×4+10 ×1

35×3+16 ×2

Page 10

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

11

Signal wire

mm2×No

0.75×3-core with shielding

0.75×3-core with shielding

Control type

Wired controller

Wired controller

Safety protection device

1) Protection for over-high discharge pressure

2) Protection for over-low suction pressure

3) Power supply phase sequence protection

4) Anti-freezing protection in cooling mode

5) Anti-freezing protection in winter

6) Protection for compressor over current

7) Protection for compressor overload

8) Outlet and inlet water temperature difference protection

9) Compressor discharge temperature protection

10) Water flow cut-off protection

11) Sensor malfunction protection

12) Low-temperature protection of shell and tube heat

exchanger.

Noise level

dB(A)

67

70

Operation water temperature

℃

Cooling:0~17(Less than 5℃ must add antifreeze.)

Heating:22~50

Ambient temperature

℃

Cooling:10~52 Heating:-10~21

Note:

Please refer to the water flow volume in the above table strictly to design and install.

Specifications are based on the following conditions:

Cooling : (*1)chilled water inlet/outlet: 12℃ / 7℃, and outdoor ambient temp. of 35°C DB.

(*2) chilled water inlet/outlet: 12℃ / 7℃, and outdoor ambient temp. of 46°C DB.

Heating : warm water inlet/outlet: 40℃ / 45℃, and outdoor ambient temp. 7°C DB/6°C WB.

Water side fouling factor: 0.086m2·℃/kW.

1m away in open field (sound pressure).

Page 11

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

12

Model

MGBT-F180W/PN1

Cooling Capacity (*1)

kW

180

Btu/h

614,100

Cooling Capacity (*2)

kW

154.8

Btu/h

528,200

Heating Capacity

kW

195

Power input

Cooling (*1)

kW

59.1

Cooling rated current (*1)

A

189

Cooling (*2)

kW

70.92

Cooling rated current (*2) A 226.8

Heating

kW

59.7

Heating rated current A 196.5

Power supply

V/Ph/Hz

380/3/60

Power supply

Manual switch

A

350

Fuse

A

300

Max. Input consumption

kW

76.5

Max. Current

A

140

Compressor

Type

Scroll (fixed speed)

Brand

Danfoss

Model

SH105A9ALC

Quantity

Pieces

6

Capacity

Btu/h

97060

Input

kW

9.9

Rate load current(RLA) A 21.4

Locked rotor Amp(LRA) A 124

Refrigerant oil

ml

3300

Refrigerant

Type

R410A

Refrigerant control

EXV+ capillary

Weight

lb

14.33×6

Condenser (Air side)

Air side heat-exchanger type

Fin-coil

Quantity of fan motor

Pieces

6

Air flow volume

×103m3/h

72

Fan motor model

YS650-8C

Fan motor rated current A 2.1×6

Fan motor input

kW

1.03×6

Evaporator

(Water side)

Water side heat-exchanger type

Shell and tube

Water resistance loss

kPa

30

Water inlet/outlet pipeline

inside normal diameter

inch

3”

Water flow volume

m3/h

31

Max. Pressure

MPa 1 Water pipe connection type

Flexible joint

Dimension

Net(W×H×D)

inch

112.21×83.07×78.74

Packing size(W×H×D)

inch

117.32×88.98×84.06

Weight

Net weight

lb

3,813.93

Gross weight

lb

3,924.16

Connection wiring

Power wire

mm2×No.

70×3+35 ×2

Page 12

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

13

Signal wire

mm2×No.

0.75×3-core with shielding

Control type

Wired controller

Safety protection device

12) Protection for over-high discharge pressure

13) Protection for over-low suction pressure

14) Power supply phase sequence protection

15) Anti-freezing protection in cooling mode

16) Anti-freezing protection in winter

17) Protection for compressor over current

18) Protection for compressor overload

19) Outlet and inlet water temperature difference

protection

20) Compressor discharge temperature protection

21) Water flow cut-off protection

22) Sensor malfunction protection

12) Low-temperature protection of shell and tube

heat exchanger.

Noise level

dB(A)

74

Operation water temperature

℃

Cooling:0~17(Less than 5℃ must add

antifreeze.)

Heating:22~50

Ambient temperature

℃

Cooling:10~52 Heating:-10~24

Note:

Please refer to the water flow volume in the above table strictly to design and install.

Specifications are based on the following conditions:

Cooling : (*1)chilled water inlet/outlet: 12℃ / 7℃, and outdoor ambient temp. of 35°C DB.

(*2) chilled water inlet/outlet: 12℃ / 7℃, and outdoor ambient temp. of 46°C DB.

Heating : warm water inlet/outlet: 40℃ / 45℃, and outdoor ambient temp. 7°C DB/6°C WB.

Water side fouling factor: 0.086m

2

·℃/kW.

Page 13

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

14

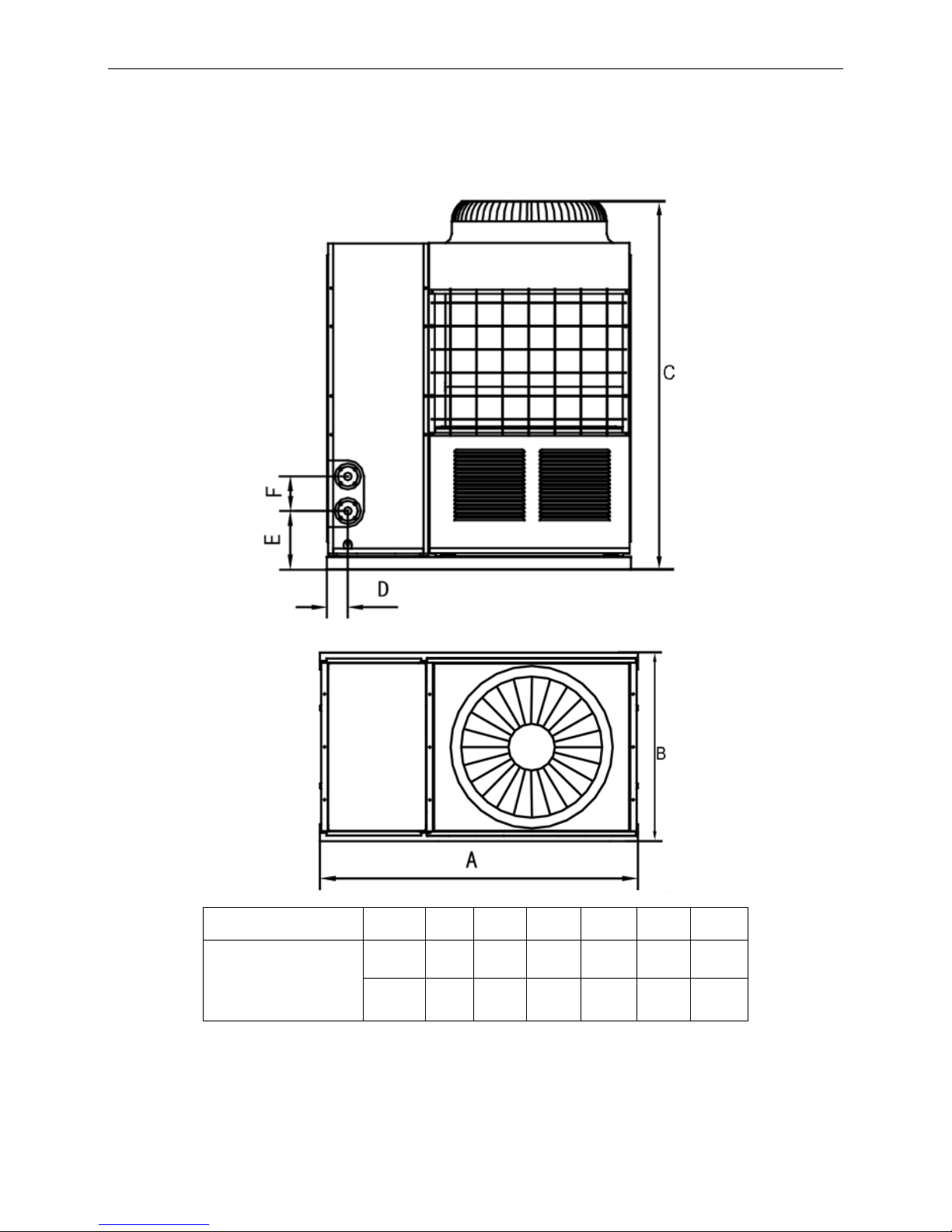

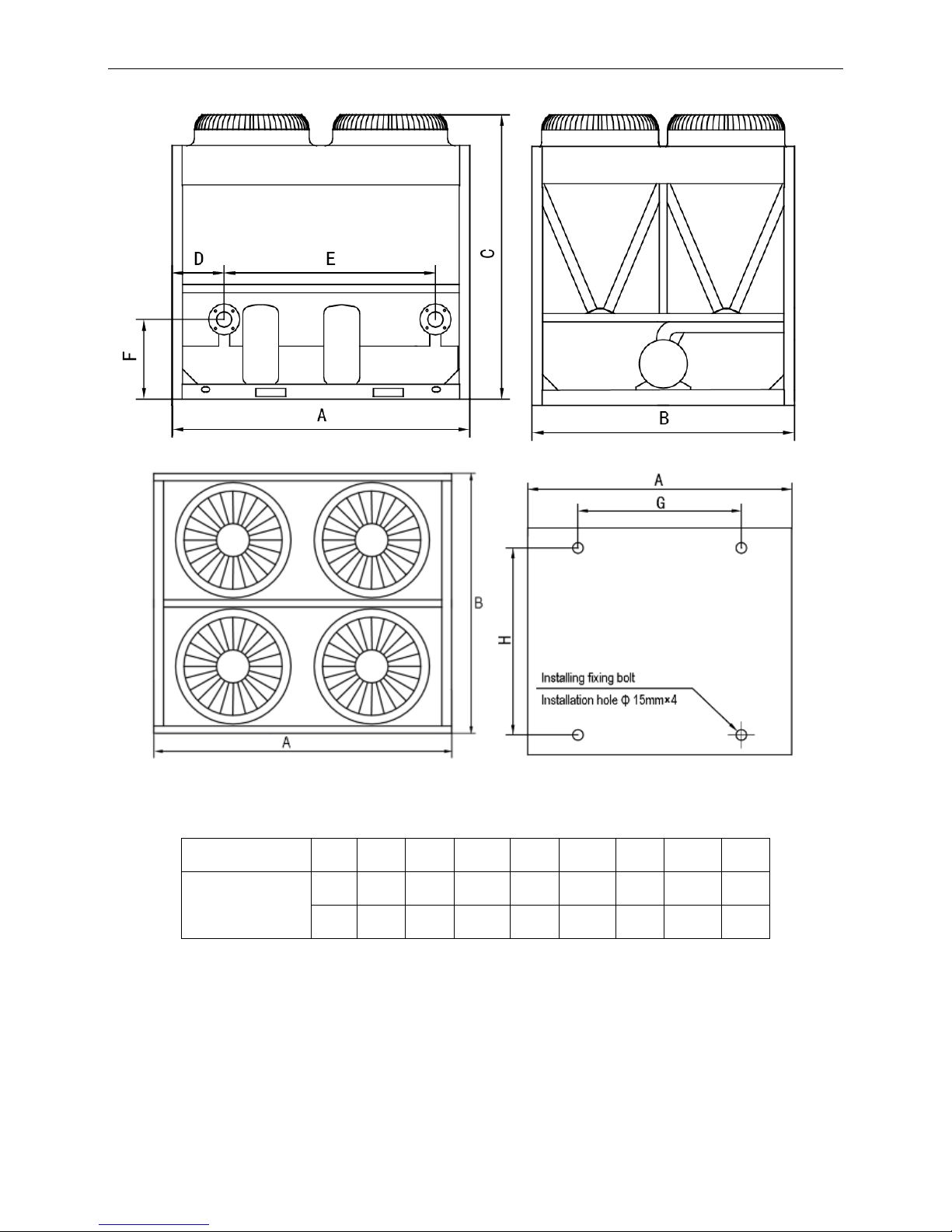

4 Dimension

30kW module

Model

Unit

A B C D E

F

MGCT-F30W/PN1

MGCT-D30W/PN1

mm

1514

841

1865

115

315

172

inch

59.6

33.11

73.43

4.53

12.4

6.77

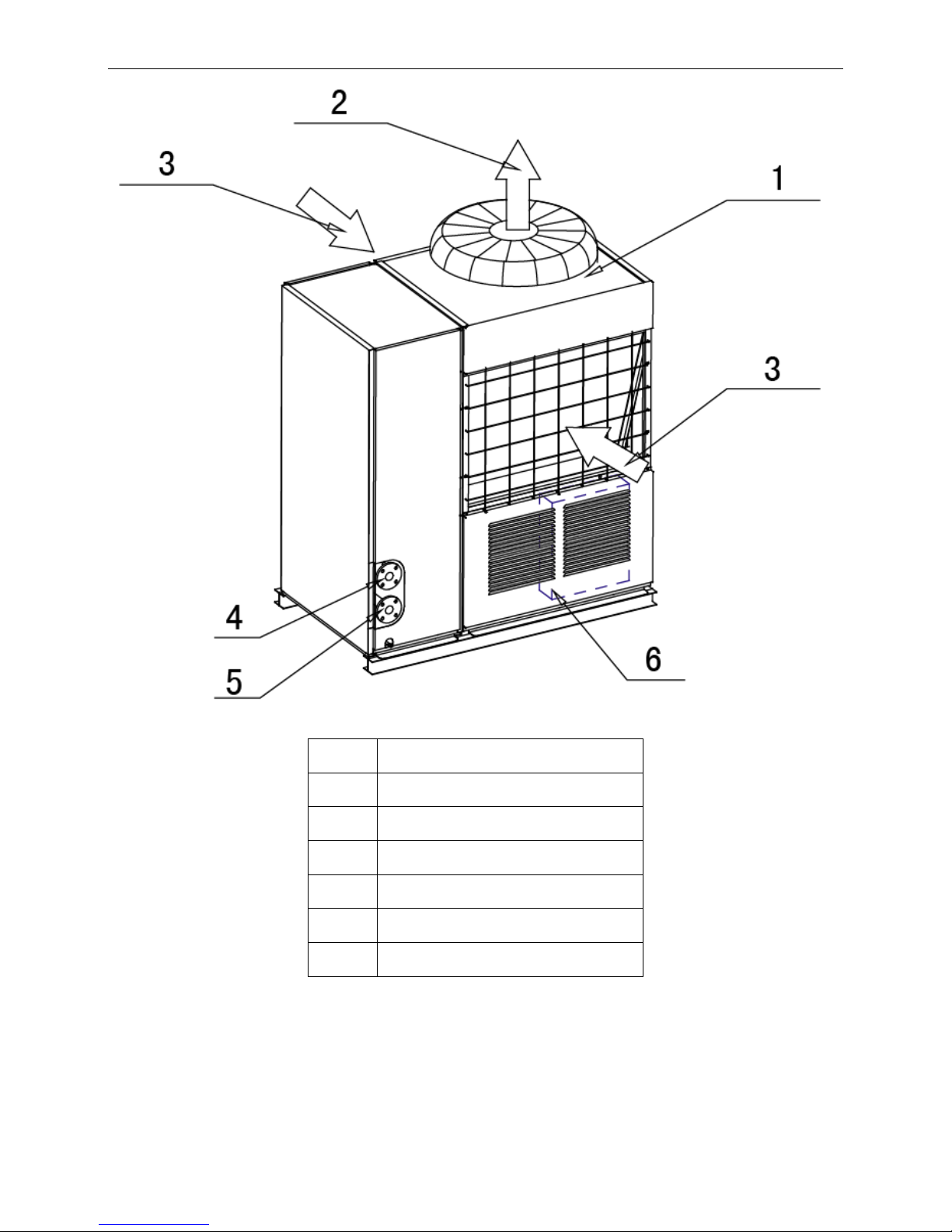

Page 14

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

15

No.

Name

1

Top cover

2

Air outlet

3

Air inlet

4

Water outlet

5

Water inlet

6

Electric control box

Page 15

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

16

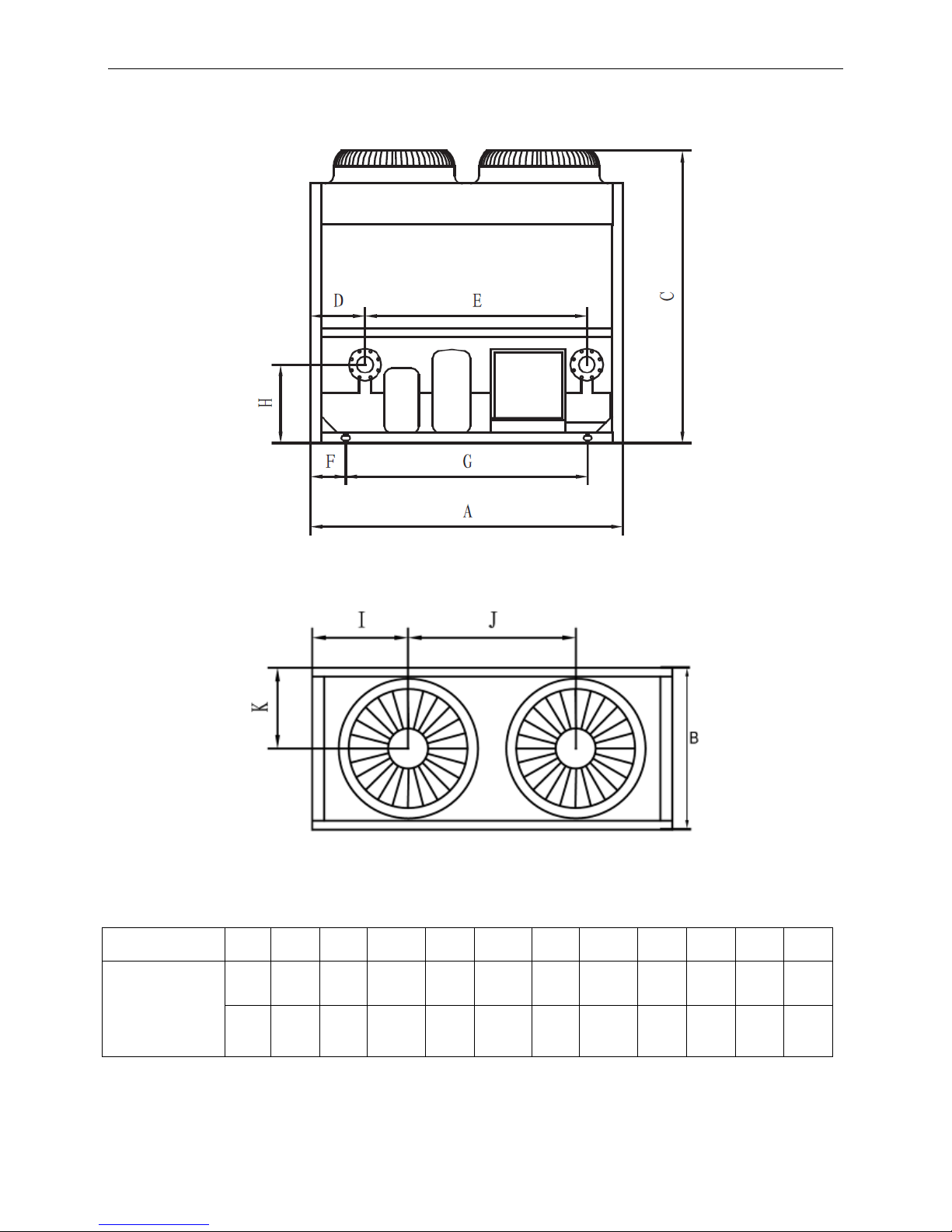

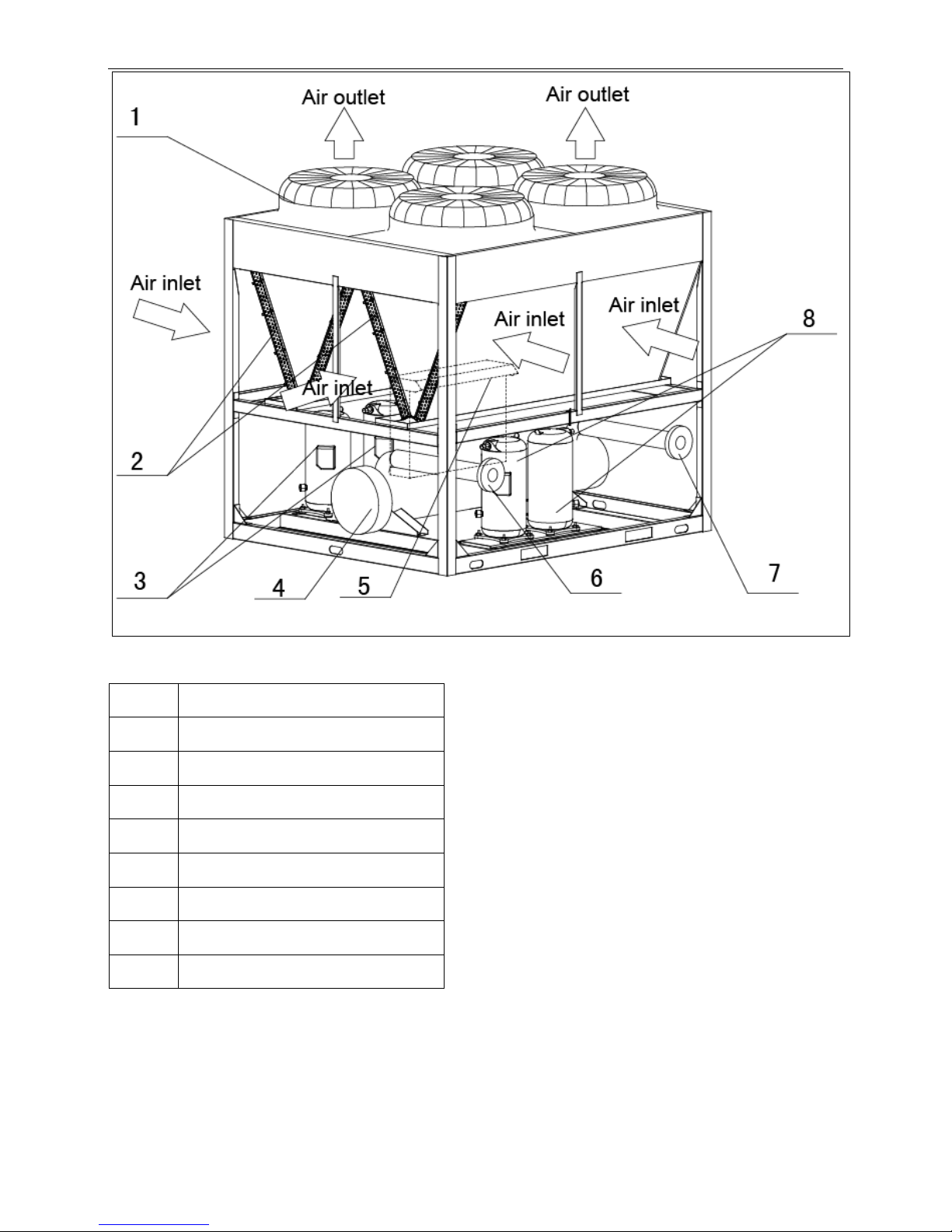

60kW module

Front view

Top view

Model

Unit

A B C D E F G H I J K

MGBT-F60W/PN1

mm

2000

900

1880

350

1420

225

1500

506

530

930

450

inch

78.74

35.4

74

13.78

55.91

8.86

59.06

19.92

20.87

36.61

17.72

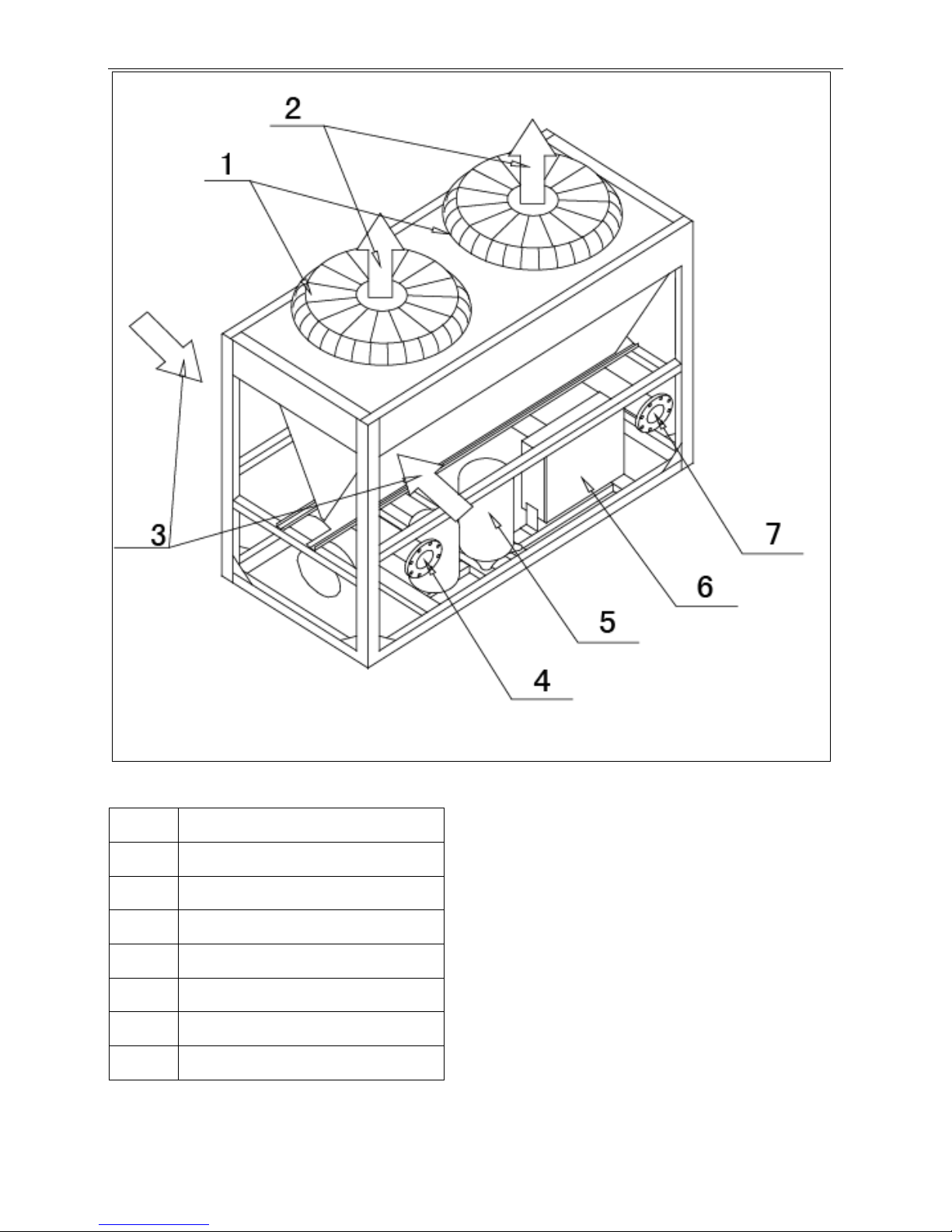

Page 16

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

17

No.

Name

1

Top cover

2

Air outlet

3

Air inlet

4

Water outlet

5

Compressor

6

Electric control box

7

Water inlet

Page 17

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

18

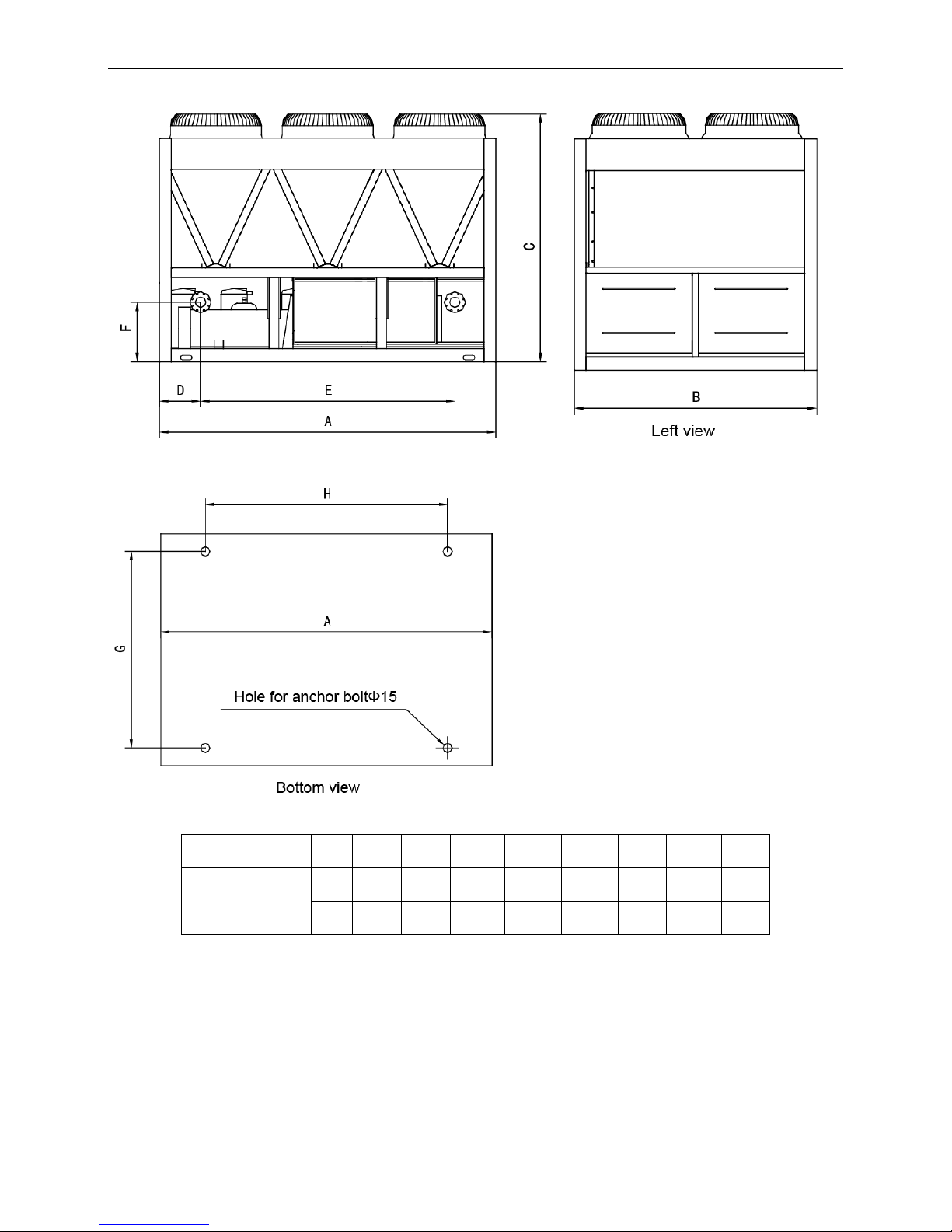

120kW module

Front view Side view

Top view Anchor hole

Model

Unit

A B C D E F G

H

MGBT-F120W/PN1

mm

2000

1685

2080

355

1420

506

1550

1586

inch

78.74

66.34

81.89

13.98

55.91

19.92

61.02

62.44

Page 18

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

19

No.

Name

1

Top cover

2

Condenser

3

Compressor

4

Evaporator

5

Electric control box air inlet

6

Water outlet

7

Water inlet

8

Compressor

Page 19

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

20

180kW module

Model

unit A B C D E F G H

MGBT-F180W/PN1

mm

2850

2000

2110

3470

2156

506

1888

2388

inch

112.2

78.74

83.07

136.61

84.88

19.92

74.33

94.02

Page 20

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

21

No.

Name

1

Top cover

2

Compressor

3

Evaporator

4

Water outlet

5

Electric control box

6

Water inlet

7

Condenser

Page 21

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

22

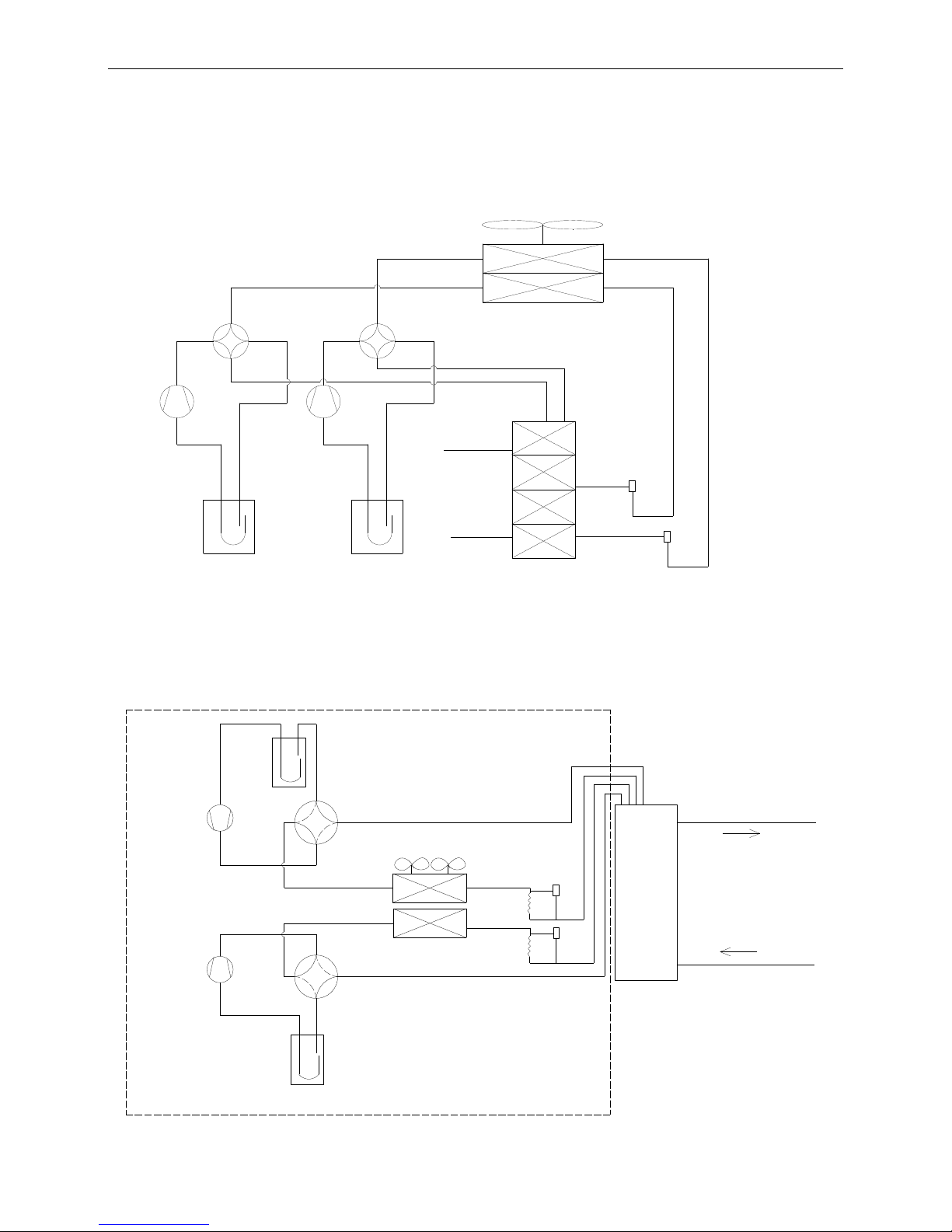

5 Refrigeration system drawing

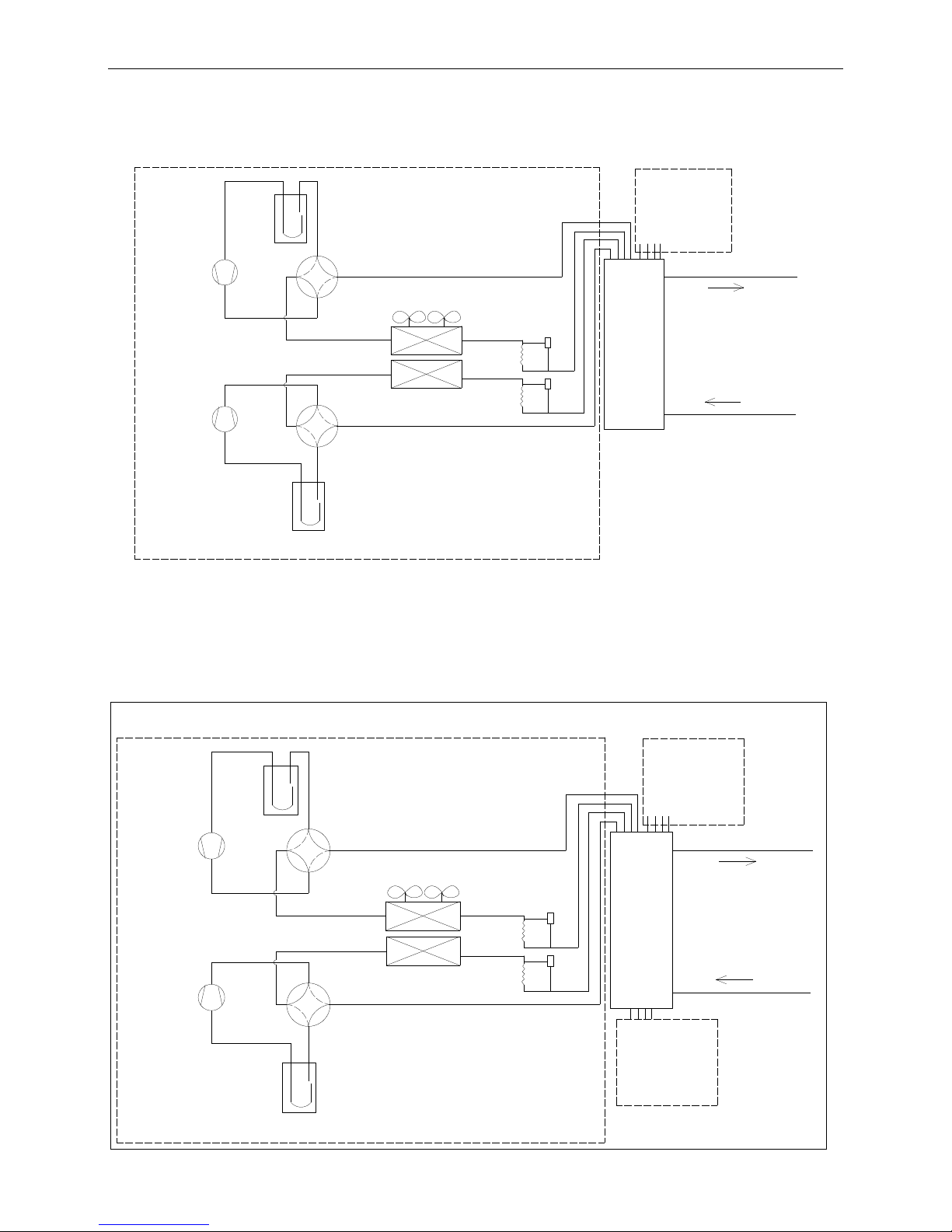

5.1 30kW module refrigeration system sketch drawing

Each module has two compressors with one separate unit, one double pipe evaporator for two refrigerant

systems.

Compressor A

Compressor B

Low pressure cylinder A

Low pressure cylinder B

4-way valve A

4-way valve B

Condenser

Evaporator

(Double-pipe heat exchanger)

Fan

Water outlet

Water inlet

EXV

EXV

5.2 60kW module refrigeration system sketch drawing

Each module has two compressors with one separate unit, one shell and tube evaporator for two refrigerant

systems.

Dry type evaporator

Condenser

Water flow direction

Compressor B

low pressure cylinder B

4-Way valve A

Fan A

EXV

Capillary

EXV

4"

Capillary

Fan B

4-Way valve B

Compressor A

low pressure cylinder A

Fan

Page 22

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

23

5.3 120kW module refrigeration system sketch drawing

Each module has four compressors with two separate units, one shell and tube evaporator for four

refrigerant systems.

Dry type evaporator

Condenser

Water flow direction

Compressor B

low pressure cylinder B

4-Way valve A

Fan A

EXV

Capillary

EXV

2-1/2"

Unit 2

Capillary

Fan B

4-Way valve B

Compressor A

low pressure cylinder A

Unit 1

5.4 180kW module refrigeration system sketch drawing

Each module has six compressors with three separate units, one shell and tube evaporator for six refrigerant

systems.

Dry type evaporator

Condenser

Water flow direction

Compressor B

low pressure cylinder B

4-Way valve A

Fan A

EXV

Capillary

EXV

3"

Unit 2

Unit 3

Capillary

Fan B

4-Way valve B

Compressor A

low pressure cylinder A

Unit 1

Page 23

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

24

6. Piping diagram

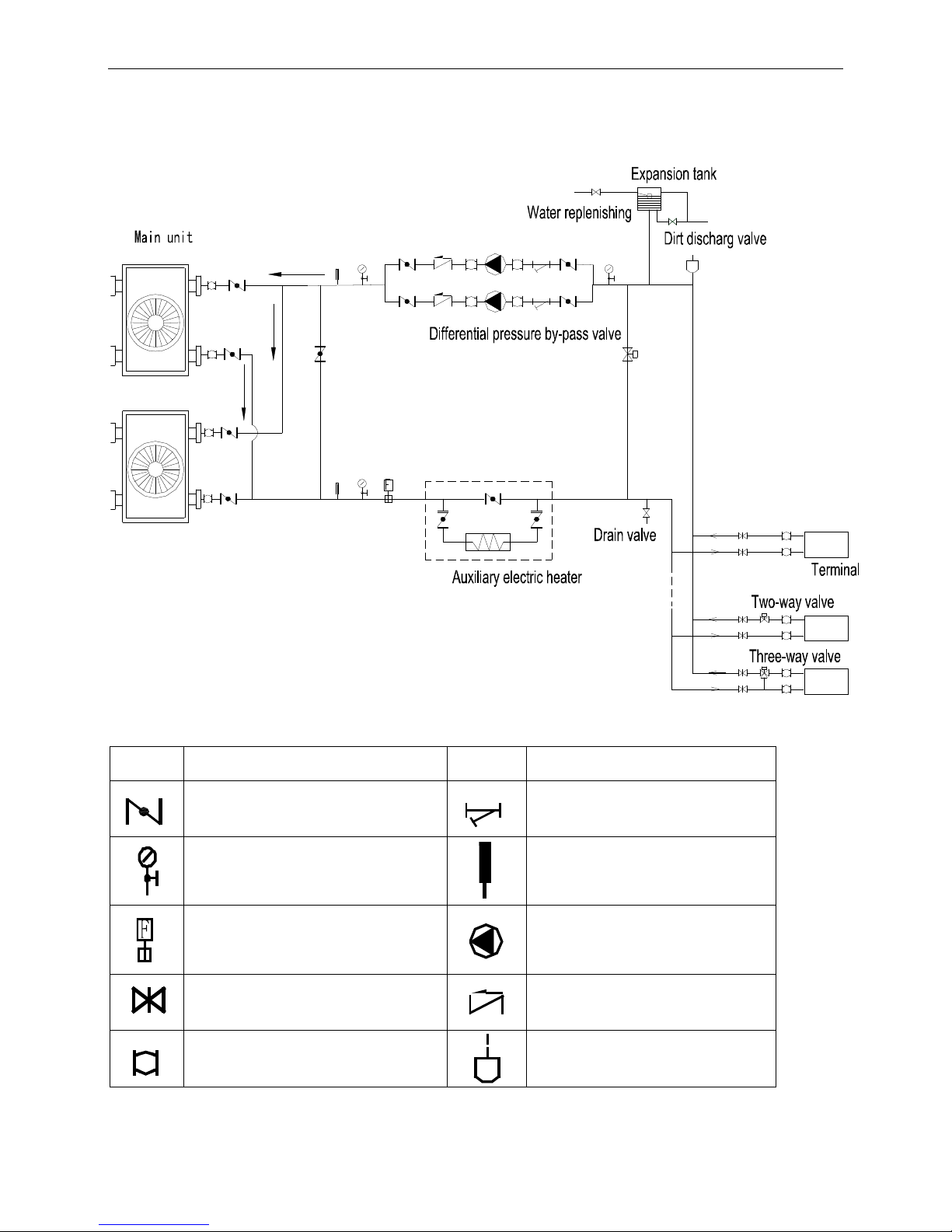

6.1 30kW module water pipeline sketch drawing

The table below describes the symbols.

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

Page 24

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

25

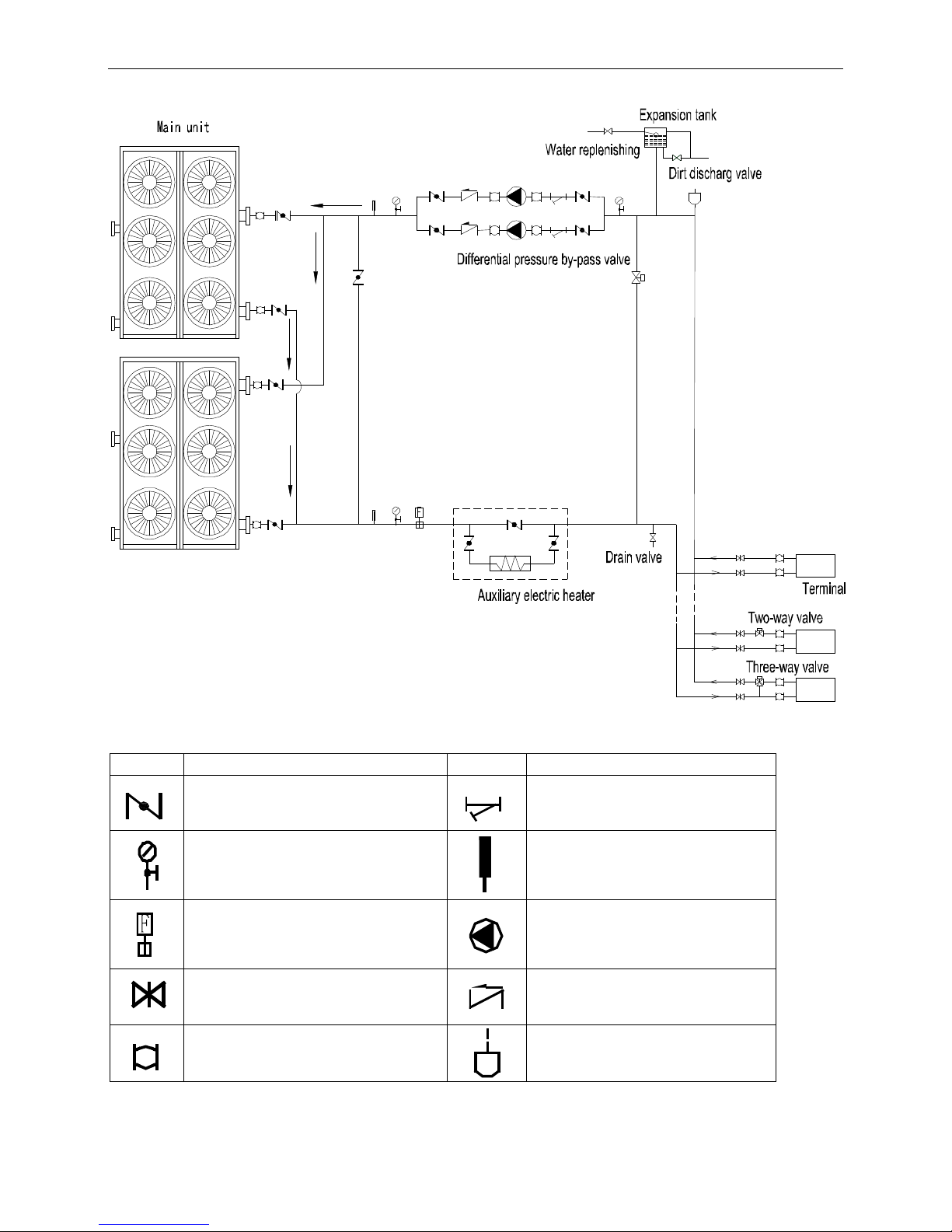

6.2 60kW module water pipeline sketch drawing

The table below describes the symbols.

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

Main unit

Expansion tank

Water replenishing

Dirt discharge valve

Differential pressure by-pass valve

Drain valve

Two-way valve

Three-way valve

Terminal

Auxiliary electric heater

Page 25

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

26

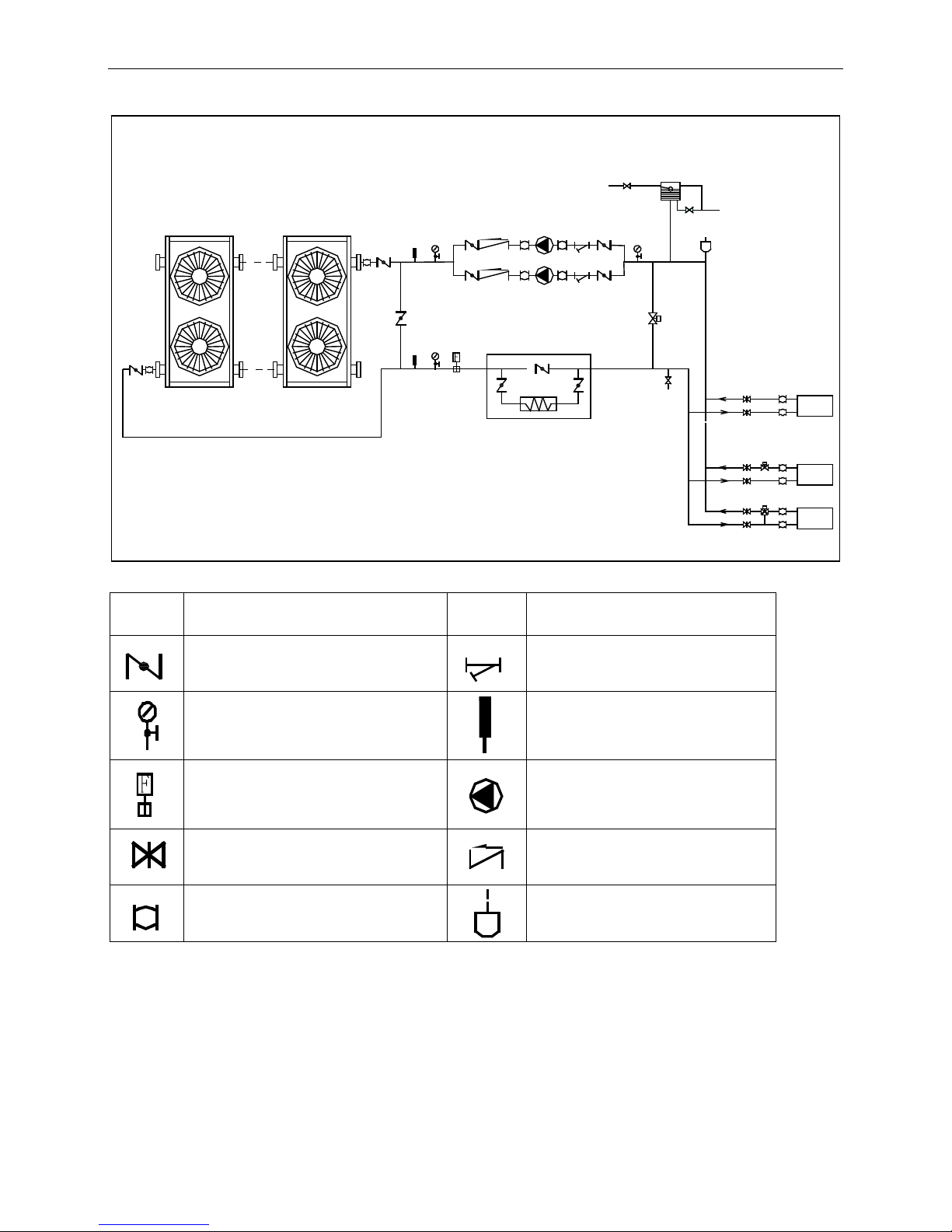

6.3 120kW module water pipeline sketch drawing

The table below describes the symbols.

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

Page 26

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

27

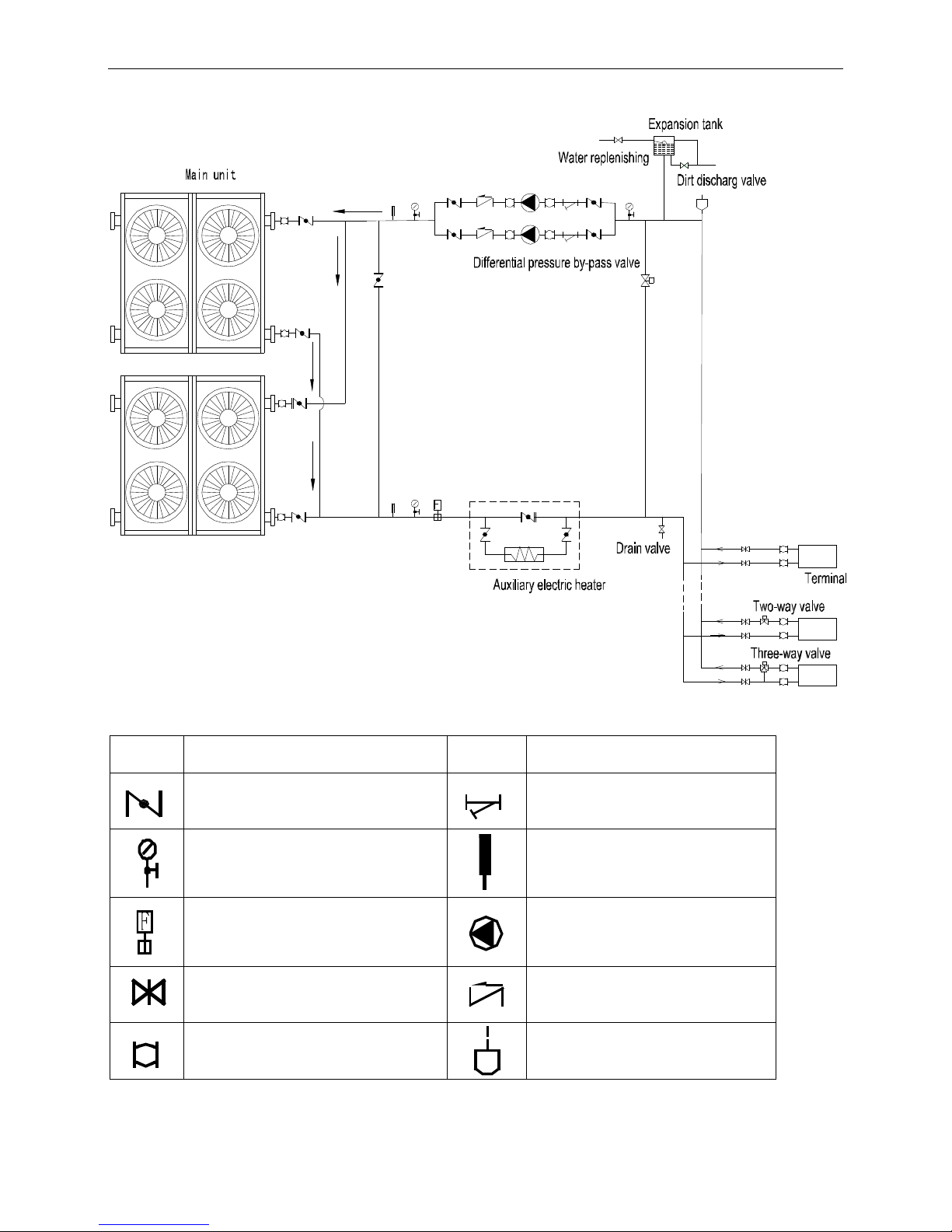

6.4 180kW module water pipeline sketch drawing

The table below describes the symbols.

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

Page 27

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

28

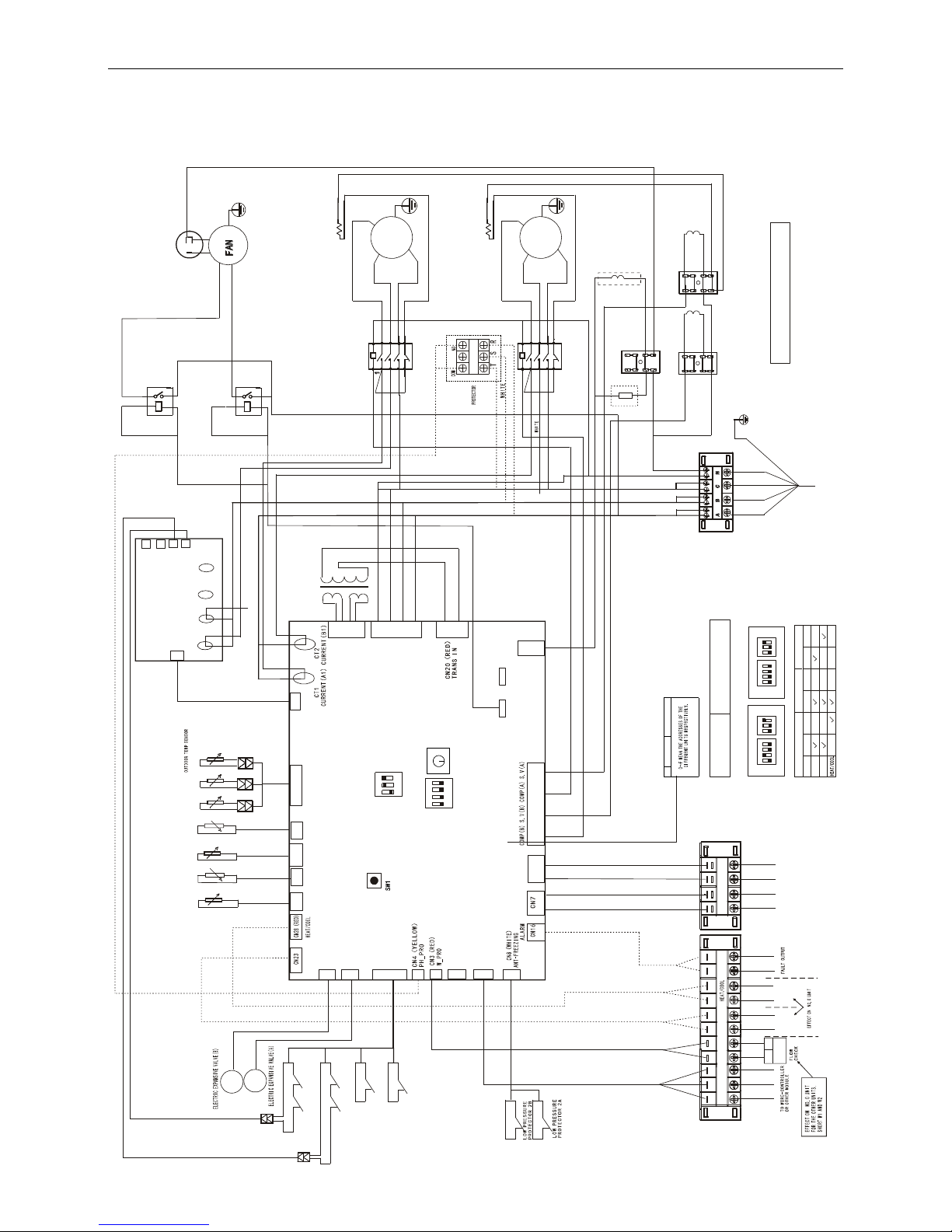

7 Wiring diagram

7.1 Wiring diagram

30kW module

XP8

XP7

XS8

XS7

T

3

B

T3A

COMP A

2

5

21

3

6

22

4

T3(W)

A1

A2

T2(V)

T1(U)

HEAT_A

QP

(E)

PMV(B)

RED BLACK

CH EC K

CN 18 ( WH I T E)

PO WE R

PW M

CN 17

CN 11 (BL AC K)

CN 24

PU MP

HE AT

CN 1(W HI TE )

PM V (A )

CN 2(R ED)

PM V( B )

CN 5

H& L_ P RO

CN 6

CO M (I )

CN 25

CO M( O )

CN 10

CN 21 CN 14

PMV(A)

CN 19(W H IT E)

TR AN S O UT

FA N_ A

CN 30

FA N_ B

CN 31

COMP B

2

1

5213

6

22

4

T3(W)

A1

A2

T2(V)

T1(U)

RED

PUR PL E

BLA CK

BLU E

RE D

WH IT E

S1

T3 A T3 B T 4

XT 7

XT 6

W1 W 2

HE A T_ B

TR AN S

ON /O F F

AL AR M

BL AC K

RED

RE D

BLUE

BLACK

XS9

XP9

T

4

WHITE

R

E

D

B

L

U

E

K1(A)

H_PRO(A)

K1(B)

H_PRO(B)

L_PRO(1A)

L_PRO(1B)

BLACK

L1 L2

CN 7

CN 8

BLA CK

S2 S3

ON

SW 2

S4 S5

OFF

S7 S8

ON

SW 3

S9

OFF

ORA NG E

L_PRO(2B)

L_PRO(2A)

CN 15

CN 5

CN 6

L3 L4

CN 4

CN 22

CN 26

ON /O FFP Q E

BLA CK

XT 5

BLACK

BLACK

BLACK

5V

Y&G

RED

WHITE

KM1

HIGH

BLA C K

BL UE

RE LA Y

FAN C A P

WHITE

BLUE

RED

RED

CON DENS ER

TEM P B

CON DENS ER

TE MP A

HIG H PR ES SU RE

PRO TE CT OR B

LOW P RE SSU RE

PRO TE CT OR 1B

LOW P RE SSU RE

PRO TE CTO R 1A

HIG H PR ES SU RE

PRO TE CT OR A

TEM P PR OTE CT OR

SWI TC H A

TEM P PR OTE CT OR

SWI TC H B

ORANGE

RED

PURPLE

YELLOW

CURRENT(B2)

CURRENT(A2)

RED

PURPLE

CO M

NC

FLO W

SWT IC H

PU MP

(EFF ECT ON NO.0 MODU LE)

(ON / OFF SI GN AL !)

LO W VO L T A G E S I G NAL

DO N' T C O N N E C T H IGH VO LT A G E !

PRO VI DE

BY US ER

PRO VI DE

BY US ER

(O N / O FF S I G N AL ! )

11- WA Y

TER MI NA L

XT2

BLU E

BLU E

GRA Y

Y

E

L

L

O

W

B

L

A

C

K

G

R

A

Y

B

L

A

C

K

R

E

D

B

R

O

W

N

R

E

D

R

E

D

G

R

A

Y

(YE LLOW)(R ED )

BL UE

BL UE

YEL L OW

(B LU E)

B

L

U

E

MAIN BOARD

CURRENT BOARD

ORA N GE

BLUE

PU RP LE

RE D

PWM PRESSURE

RELIF VALVE

BLUE

Y&G

MIDD LE

WIRE J OINT

MIDD LE

WIRE J OINT

MID DLE

WIR E JOINT

S.V(A)

4-VALVE A

4- WA Y TE RM IN AL

XT 1

POW E R I N

SW3

S1

16- WAY D AIL S WIT CH FU NCT IO N

DAI L SWI TCH A DDR ESS

1 2 3

ON

3 4

SW2

1 2

OFF

S2 ON:COOL ONLY OFF:R&C

S3 ON:DIGITAL OFF:FIXED

S4 ON:H-EEPROM OFF:NORMAL

S5 ON:C-EEPROM OFF:NORMAL

S7 ON:REMOTE CONTROL OFF:WIRE CONTROL

S8 ON:LOW TEMP.MODE OFF:NORMAL

S9 ON:30KW OFF:65/130/200/260K W

S2 S3 S4 S5 S7 S8 S9

SW2/SW3 FUCTION DEFINATION

ON

OFF

DEFAULT SETTING

REMOTE TURN OFF

OFF

ON/OFF

S7

ON

REMOTE FUCTION SETTING

REMOTE COOL

ON OFF

REMOTE HEAT

ON OFF

SW 3

1 2 3

ON

3 4

SW 2

1 2

OFF

S2 S3 S4 S5 S7 S8 S9

ON

OFF

DIGITAL

FIXED

BLACK

R

E

D

B

L

U

E

AC C ON T AC TO R

AC C O NT A CT OR COM PRES SOR A

COM PRES SOR B

BLUE

RED

WHI TE

Y&G

CR AN KC AS E HEAT ER

Y&G

BLACK

BLUE

RED

WHI TEBLACK

IN- LE T WAT ER T EM P SEN SO R

ANT I- FR EE ZIN G TE MP SE NS OR

TOT AL O UT- LE T WA TE R TEM P

UNI T OU T- LE T WAT ER T EMP

MA R K:NO RM A L MO D UL E S DO N 'T I NC L UD E

BR O KE N L IN E AN D T HE IR JO IN T W IR E S

OUT D O O R W I R ING DIAG R A M

BROWN

BROWN

BLACK BLACK

BLU E

BRO WN

BLACK

RE D

BLUE

WH IT E

S.V(B)

4-VALVE B

CR AN KC AS E HEAT ER

BRO WN

BRO WN

BRO WN

BRO WN

BRO WN

H2 P 1 P 2H1

4- WA Y T ER MI NA L

XT 3

YE LL OW

KM2

RE LA Y

LOW

BLU E

(WH IT E)

BLU E

YE LL OW

YE LL OW

202090191107

HEA T

RES

Page 28

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

29

60kW module

Page 29

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

30

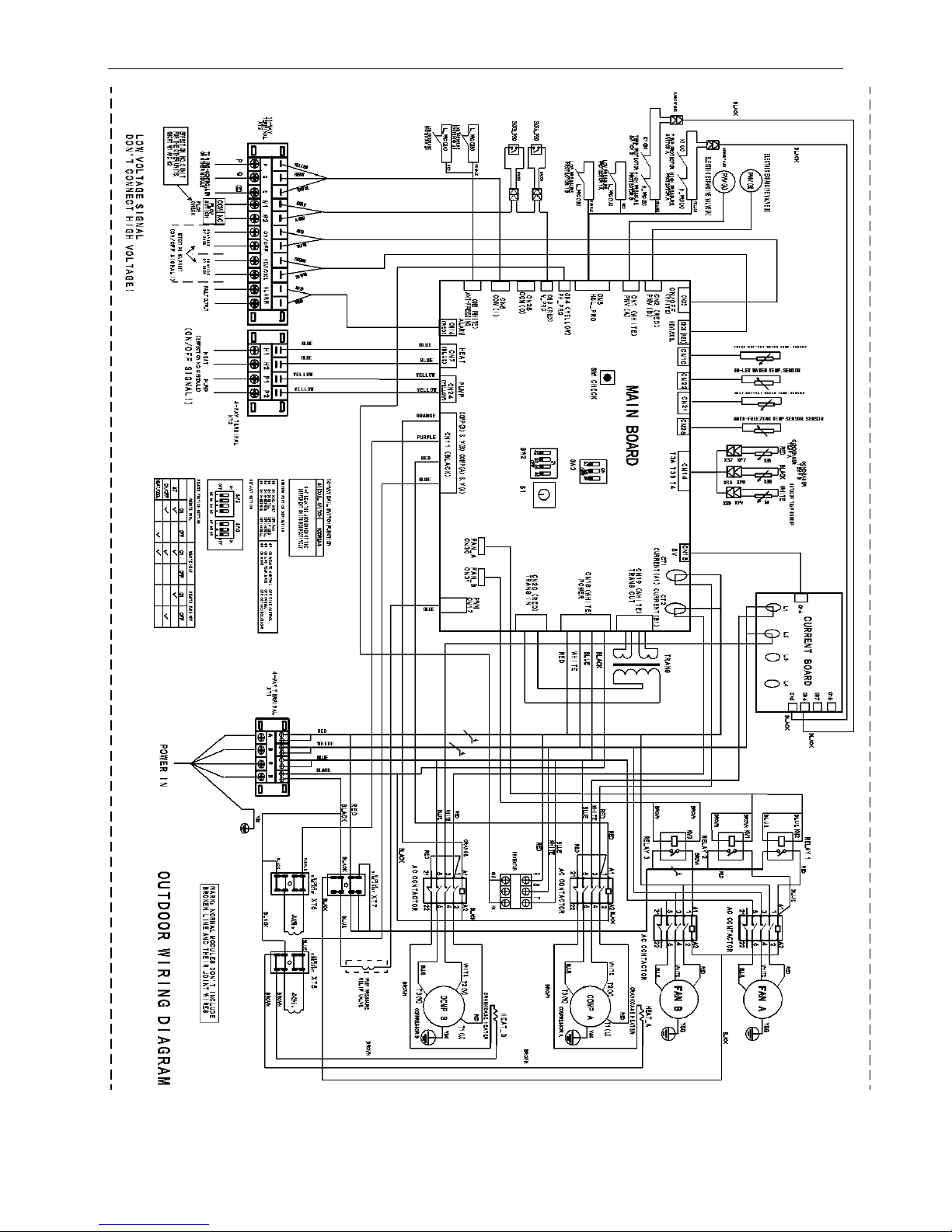

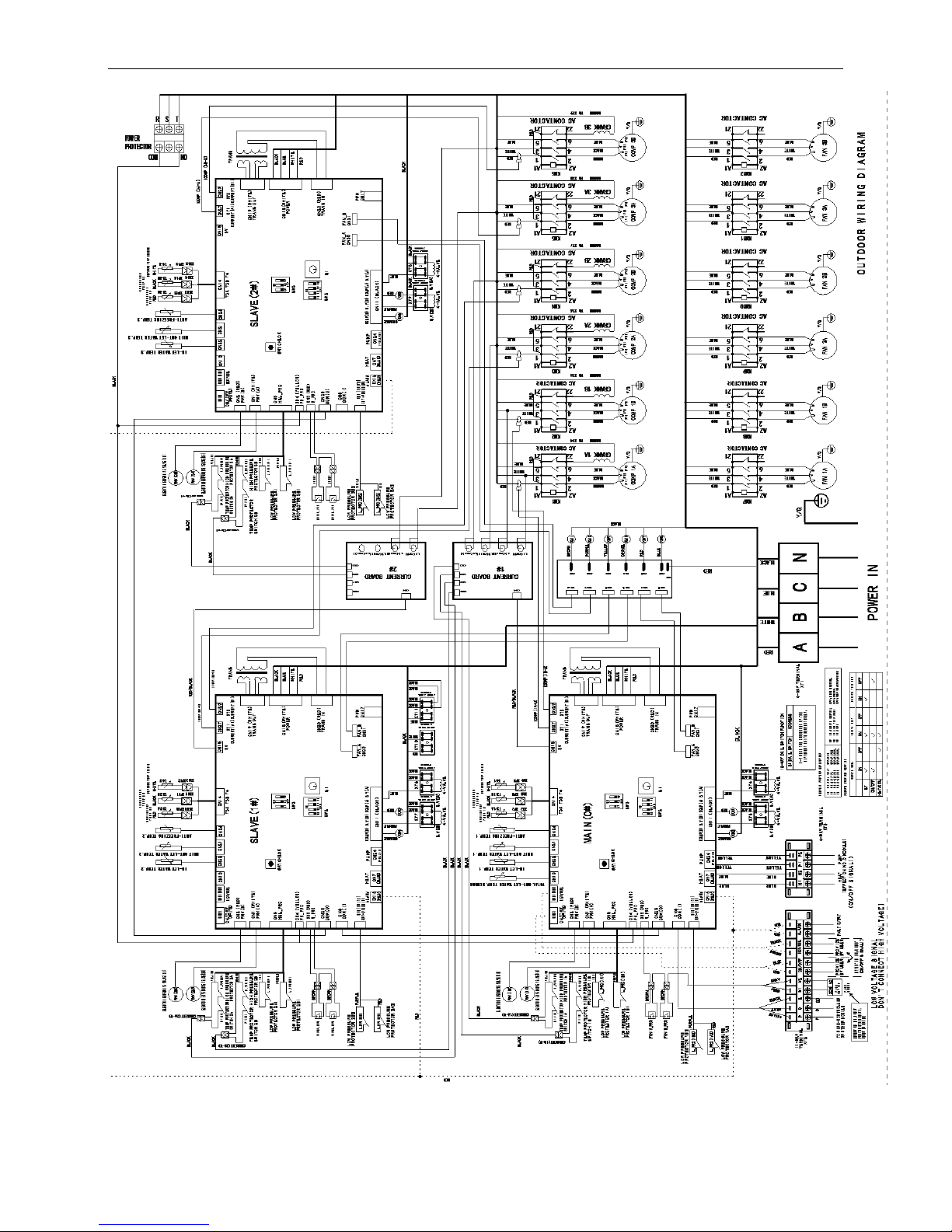

120kW module

Page 30

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

31

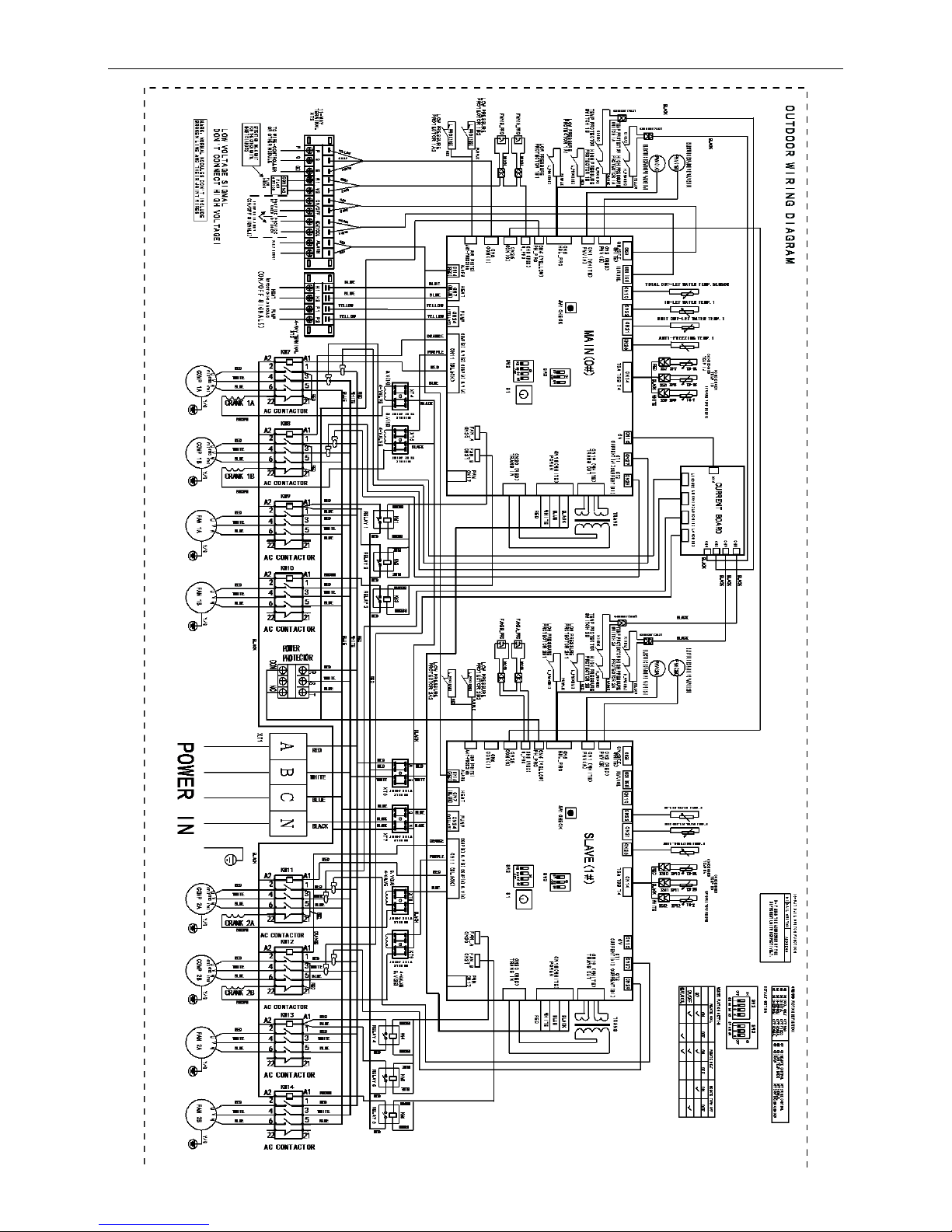

180kW module

Page 31

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

32

7.2 Networking communication schematic

30kW module

Page 32

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

33

60kW module

Page 33

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

34

120kW module

Page 34

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

35

180kW module

Page 35

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

36

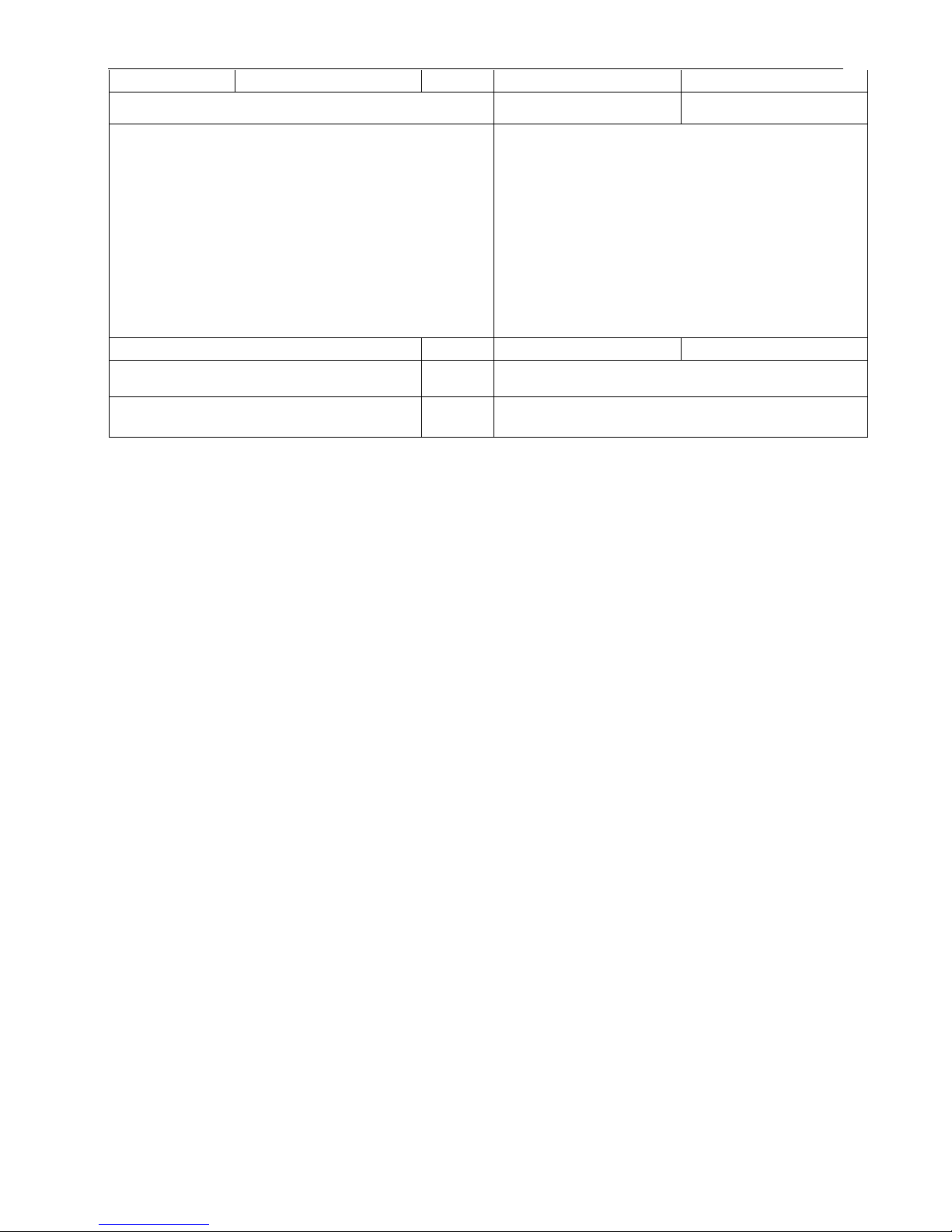

8 Electric characteristics

Model

Outdoor Unit

Power Supply

Compressor

OFM

Hz

Phase

Voltage

Min.

Max.

TOCA

MFA

LRA

RLA

KW

FLA

MGCT-F30W/PN1

60 3 380

342

418

28.5

36

94(×2)

10.1(×2)

0.85

4

MGCT-D30W/PN1

60 3 380

342

418

28.5

36

65.6/94

9.6/10.1

0.85

4

MGBT-F60W/PN1

60 3 380

342

418

55.6

70

124(×2)

21.4(×2)

1.03(×2)

2.1(×2)

MGBT-F120W/PN1

60 3 380

342

418

222.4

260

124(×4)

21.4 (×4)

1.03 (×4)

2.1(×4)

MGBT-F180W/PN1

60 3 380

342

418

180

300

124(×6)

21.4(×6)

1.03 (×6)

2.1(×6)

Remark:

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

LRA: Locked Rotor Amps. (A)

RLA: Rated Load Amps. (A)

OFM: Outdoor Fan Motor.

KW: Rated Motor Input (KW)

FLA: Full Load Amps.

Page 36

Page 37

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

38

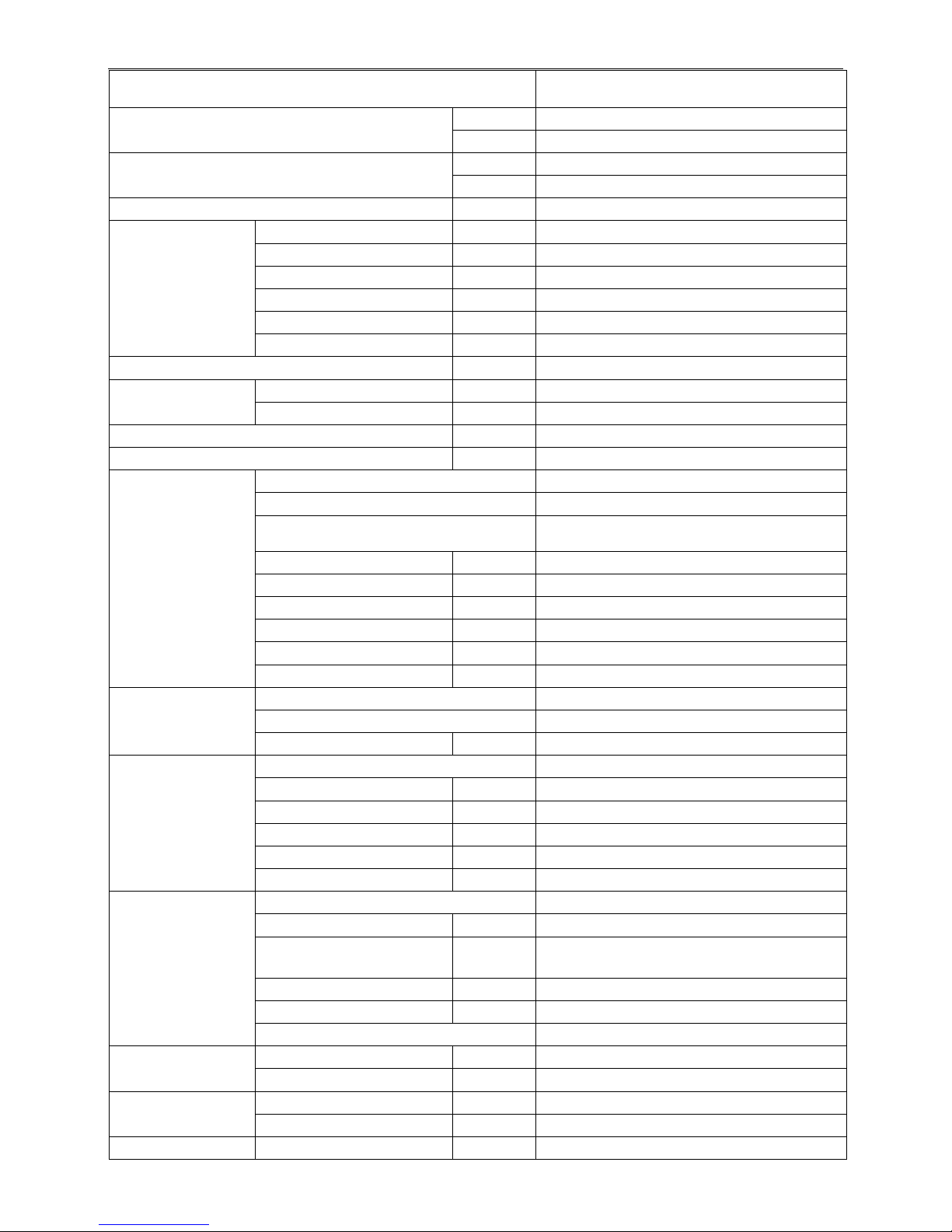

9 Capacity tables

9.1 MGCT-F30W/PN1, MGCT-D30W/PN1

Cooling:

Chilled water

outlet temp.

Ambient temp.(℃)

21.00

25.00

30.00

35.00

40.00

46.00

52.00

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

5.00

33.59

8.81

31.63

9.08

29.84

9.36

28.20

9.65

26.42

10.13

24.31

10.64

21.88

11.17

6.00

34.72

8.94

32.66

9.22

30.79

9.51

29.07

9.80

27.27

10.29

25.11

10.80

22.63

11.34

7.00

35.93

9.13

33.77

9.41

31.80

9.70

30.00

10.00

28.17

10.50

25.97

11.03

23.43

11.58

8.00

37.04

9.40

34.78

9.69

32.72

9.99

30.84

10.30

28.99

10.82

26.76

11.36

24.16

11.92

9.00

38.09

9.49

35.73

9.79

33.58

10.09

31.62

10.40

29.75

10.92

27.49

11.47

24.85

12.04

10.00

39.53

9.63

37.05

9.93

34.79

10.24

32.73

10.56

30.83

11.08

28.52

11.64

25.81

12.22

11.00

40.63

9.73

38.05

10.03

35.69

10.34

33.54

10.66

31.63

11.19

29.29

11.75

26.54

12.34

12.00

41.56

9.87

38.88

10.18

36.44

10.49

34.22

10.82

32.30

11.36

29.94

11.92

27.16

12.52

13.00

42.31

9.95

39.54

10.26

37.02

10.58

34.73

10.90

32.82

11.45

30.46

12.02

27.65

12.62

14.00

43.36

10.02

40.48

10.33

37.87

10.65

35.49

10.98

33.58

11.53

31.19

12.10

28.35

12.71

15.00

43.92

10.07

40.97

10.38

38.29

10.70

35.85

11.03

33.95

11.58

31.57

12.16

28.73

12.77

Page 38

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

39

Heating:

Hot water outlet

temp.

Ambient temp.(℃)

-10

-6

-2 2 7

10

13

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

40.00

19.89

6.13

24.86

6.97

29.25

7.74

32.50

8.42

35.33

8.86

39.57

9.39

45.50

10.14

41.00

19.22

6.26

24.06

7.11

28.34

7.90

31.52

8.59

34.30

9.04

38.34

9.58

44.02

10.35

42.00

18.67

6.38

23.39

7.26

27.58

8.06

30.72

8.76

33.46

9.22

37.34

9.78

42.79

10.56

43.00

18.22

6.52

22.86

7.40

26.98

8.23

30.08

8.94

32.80

9.41

36.54

9.98

41.81

10.77

44.00

17.86

6.65

22.44

7.55

26.53

8.39

29.61

9.12

32.32

9.60

35.94

10.18

41.04

10.99

45.00

17.60

6.78

22.14

7.71

26.21

8.57

29.28

9.31

32.00

9.80

35.52

10.39

40.49

11.22

46.00

17.26

6.85

21.74

7.79

25.76

8.65

28.81

9.40

31.52

9.90

34.92

10.49

39.74

11.33

47.00

16.75

6.99

21.12

7.94

25.06

8.82

28.06

9.59

30.73

10.10

33.99

10.70

38.61

11.56

48.00

16.09

7.20

20.31

8.18

24.13

9.09

27.05

9.88

29.66

10.40

32.74

11.02

37.13

11.90

49.00

15.21

7.49

19.23

8.51

22.87

9.45

25.67

10.27

28.17

10.81

31.05

11.46

35.15

12.38

50.00

14.23

7.86

18.02

8.93

21.45

9.92

24.10

10.79

26.48

11.36

29.13

12.04

32.92

13.00

Page 39

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

40

9.2 MGBT-F60W/PN1

Cooling

Chilled water

outlet temp.

Ambient temp.(℃)

21.00

25.00

30.00

35.00

40.00

46.00

52.00

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

5.00

67.17

17.35

63.25

17.89

59.67

18.44

56.40

19.01

52.85

19.96

48.62

20.96

43.76

22.01

6.00

69.44

17.62

65.33

18.17

61.57

18.73

58.14

19.31

54.54

20.27

50.23

21.28

45.25

22.35

7.00

71.87

17.98

67.54

18.54

63.60

19.11

60.00

19.70

56.34

20.69

51.95

21.72

46.85

22.81

8.00

74.09

18.52

69.57

19.09

65.44

19.68

61.68

20.29

57.98

21.31

53.51

22.37

48.32

23.49

9.00

76.18

18.70

71.46

19.28

67.16

19.87

63.24

20.49

59.51

21.51

54.99

22.59

49.71

23.72

10.00

79.06

18.98

74.10

19.57

69.58

20.17

65.45

20.80

61.66

21.84

57.03

22.93

51.61

24.07

11.00

81.27

19.17

76.09

19.76

71.38

20.37

67.09

21.00

63.27

22.05

58.58

23.15

53.08

24.31

12.00

83.13

19.45

77.76

20.05

72.88

20.67

68.43

21.31

64.60

22.37

59.88

23.49

54.31

24.67

13.00

84.61

19.60

79.08

20.21

74.04

20.83

69.46

21.48

65.64

22.55

60.91

23.68

55.31

24.86

14.00

86.72

19.74

80.97

20.35

75.74

20.98

70.99

21.63

67.15

22.71

62.38

23.84

56.71

25.04

15.00

87.83

19.84

81.93

20.45

76.57

21.08

71.70

21.73

67.90

22.82

63.14

23.96

57.46

25.16

Page 40

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

41

Heating

Hot water

outlet temp.

Ambient temp.(℃)

-10

-6

-2 2 7

10

13

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

40.00

40.40

12.45

50.50

14.15

59.41

15.72

66.02

17.09

71.76

17.99

80.37

19.07

92.42

20.59

41.00

39.04

12.71

48.87

14.44

57.56

16.04

64.02

17.44

69.67

18.36

77.89

19.46

89.41

21.01

42.00

37.92

12.96

47.51

14.73

56.03

16.37

62.39

17.79

67.97

18.73

75.85

19.85

86.93

21.44

43.00

37.00

13.23

46.42

15.03

54.81

16.70

61.10

18.16

66.63

19.11

74.23

20.26

84.92

21.88

44.00

36.28

13.50

45.58

15.34

53.88

17.04

60.14

18.53

65.65

19.50

73.00

20.67

83.37

22.33

45.00

35.76

13.77

44.98

15.65

53.23

17.39

59.48

18.91

65.00

19.90

72.15

21.09

82.25

22.78

46.00

35.06

13.91

44.15

15.81

52.32

17.57

58.52

19.09

64.03

20.10

70.94

21.30

80.73

23.01

47.00

34.02

14.19

42.90

16.13

50.90

17.92

56.99

19.48

62.42

20.50

69.04

21.73

78.43

23.47

48.00

32.68

14.62

41.26

16.61

49.01

18.46

54.94

20.06

60.24

21.12

66.50

22.38

75.42

24.17

49.00

30.90

15.20

39.07

17.27

46.45

19.19

52.13

20.86

57.23

21.96

63.06

23.28

71.39

25.14

50.00

28.91

15.96

36.60

18.14

43.57

20.15

48.95

21.91

53.79

23.06

59.17

24.44

66.87

26.40

Page 41

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

42

9.3 MGBT-F120W/PN1

Cooling:

Chilled water

outlet temp.

Ambient temp.(℃)

21.00

25.00

30.00

35.00

40.00

46.00

52.00

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

5.00

134.35

34.70

126.50

35.77

119.34

36.88

112.80

38.02

105.69

39.92

97.24

41.49

87.51

43.57

6.00

138.88

35.24

130.65

36.33

123.14

37.45

116.28

38.61

109.07

40.54

100.45

42.14

90.51

44.24

7.00

143.73

35.96

135.09

37.07

127.20

38.22

120.00

39.40

112.68

41.37

103.89

43.44

93.71

45.61

8.00

148.17

37.04

139.13

38.18

130.88

39.36

123.36

40.58

115.96

42.61

107.03

44.74

96.65

46.98

9.00

152.35

37.40

142.92

38.55

134.32

39.75

126.48

40.98

119.02

43.02

109.97

45.18

99.41

47.43

10.00

158.13

37.96

148.20

39.13

139.15

40.34

130.91

41.59

123.31

43.67

114.07

45.85

103.23

48.15

11.00

162.54

38.33

152.19

39.52

142.77

40.74

134.18

42.00

126.53

44.10

117.17

46.31

106.15

48.62

12.00

166.26

38.89

155.53

40.10

145.76

41.34

136.86

42.62

129.20

44.75

119.77

46.98

108.63

49.33

13.00

169.22

39.20

158.15

40.42

148.08

41.67

138.92

42.96

131.28

45.10

121.82

47.36

110.62

49.73

14.00

173.43

39.48

161.94

40.70

151.48

41.96

141.97

43.25

134.31

45.42

124.77

47.69

113.42

50.07

15.00

175.66

39.67

163.86

40.90

153.14

42.16

143.39

43.47

135.79

45.64

126.29

47.92

114.92

50.32

Page 42

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

43

Heating:

Hot water

outlet temp.

Ambient temp.(℃)

-10

-6

-2 2 7

10

13

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

40.00

80.80

24.90

101.00

28.30

118.83

31.44

132.03

34.18

143.51

35.98

160.73

38.13

184.85

41.19

41.00

78.09

25.41

97.73

28.88

115.11

32.08

128.05

34.87

139.33

36.71

155.77

38.91

178.83

42.03

42.00

75.83

25.93

95.03

29.47

112.06

32.74

124.79

35.59

135.93

37.46

151.70

39.71

173.85

42.88

43.00

74.00

26.46

92.85

30.07

109.62

33.41

122.21

36.31

133.27

38.22

148.46

40.52

169.84

43.76

44.00

72.57

27.00

91.17

30.68

107.76

34.09

120.27

37.05

131.30

39.00

146.01

41.34

166.74

44.65

45.00

71.52

27.55

89.96

31.31

106.46

34.79

118.95

37.81

130.00

39.80

144.30

42.19

164.50

45.56

46.00

70.12

27.83

88.31

31.62

104.63

35.13

117.04

38.19

128.05

40.20

141.88

42.61

161.46

46.02

47.00

68.05

28.38

85.81

32.25

101.79

35.84

113.99

38.95

124.85

41.00

138.08

43.46

156.86

46.94

48.00

65.36

29.23

82.52

33.22

98.01

36.91

109.88

40.12

120.48

42.23

133.01

44.77

150.83

48.35

49.00

61.80

30.40

78.13

34.55

92.90

38.39

104.27

41.73

114.46

43.92

126.13

46.56

142.78

50.28

50.00

57.82

31.92

73.19

36.28

87.14

40.31

97.90

43.81

107.59

46.12

118.35

48.88

133.73

52.80

Page 43

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

44

9.4 MGBT-F180W/PN1

Cooling:

Chilled water

outlet temp.

Ambient temp.(℃)

21.00

25.00

30.00

35.00

40.00

46.00

52.00

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

5.00

201.52

52.05

189.75

53.66

179.01

55.32

169.20

57.03

158.54

59.88

145.86

62.88

131.27

66.02

6.00

208.32

52.86

195.98

54.50

184.71

56.18

174.42

57.92

163.61

60.81

150.68

63.85

135.76

67.05

7.00

215.60

53.94

202.63

55.61

190.80

57.33

180.00

59.10

169.02

62.06

155.84

65.16

140.56

68.42

8.00

222.26

55.56

208.70

57.28

196.33

59.05

185.04

60.87

173.94

63.92

160.54

67.11

144.97

70.47

9.00

228.53

56.10

214.38

57.83

201.48

59.62

189.72

61.46

178.53

64.54

164.96

67.76

149.12

71.15

10.00

237.19

56.94

222.30

58.70

208.73

60.51

196.36

62.39

184.97

65.51

171.10

68.78

154.84

72.22

11.00

243.81

57.50

228.28

59.28

214.15

61.11

201.27

63.00

189.80

66.15

175.75

69.46

159.23

72.93

12.00

249.38

58.34

233.29

60.14

218.64

62.00

205.29

63.92

193.80

67.12

179.65

70.47

162.94

74.00

13.00

253.84

58.81

237.23

60.63

222.13

62.50

208.37

64.43

196.91

67.66

182.74

71.04

165.92

74.59

14.00

260.15

59.22

242.91

61.05

227.23

62.93

212.96

64.88

201.46

68.13

187.15

71.53

170.12

75.11

15.00

263.49

59.51

245.79

61.35

229.71

63.24

215.09

65.20

203.69

68.46

189.43

71.88

172.38

75.48

Page 44

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

45

Heating:

Hot water

outlet temp.

Ambient temp.(℃)

-10

-6

-2 2 7

10

13

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

Capacity

Power

(℃)

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

KW

40.00

121.21

37.35

151.51

42.45

178.24

47.16

198.05

51.27

215.27

53.96

241.10

57.20

277.27

61.78

41.00

117.13

38.12

146.60

43.31

172.67

48.13

192.07

52.31

209.00

55.07

233.66

58.37

268.24

63.04

42.00

113.75

38.89

142.54

44.20

168.09

49.11

187.18

53.38

203.90

56.19

227.56

59.56

260.78

64.33

43.00

111.00

39.69

139.27

45.10

164.43

50.11

183.31

54.47

199.90

57.34

222.69

60.78

254.76

65.64

44.00

108.85

40.50

136.75

46.02

161.64

51.13

180.41

55.58

196.95

58.51

219.01

62.02

250.11

66.98

45.00

107.28

41.32

134.94

46.96

159.69

52.18

178.43

56.72

195.00

59.70

216.45

63.28

246.75

68.34

46.00

105.18

41.74

132.46

47.43

156.95

52.70

175.56

57.28

192.08

60.30

212.82

63.91

242.19

69.03

47.00

102.07

42.57

128.71

48.38

152.69

53.75

170.98

58.43

187.27

61.50

207.12

65.19

235.29

70.41

48.00

98.04

43.85

123.79

49.83

147.02

55.37

164.82

60.18

180.72

63.35

199.51

67.15

226.25

72.52

49.00

92.70

45.60

117.20

51.82

139.35

57.58

156.40

62.59

171.68

65.88

189.19

69.83

214.17

75.42

50.00

86.73

47.88

109.79

54.41

130.70

60.46

146.86

65.72

161.38

69.18

177.52

73.33

200.60

79.19

Page 45

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

46

10 Exploded view

10.1 MGCT-F30W/PN1

Page 46

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

47

Page 47

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

48

No.

Part Name

Qty

No.

Part Name

Qty

1

Net

2

23.7

Wire joint,11p

1

2

Right seal plate condenser components D

1

23.8

Wire joint,4p

1

3

Tube heat exchanger

1

23.9

Wire joint

1

4

A seal plate condenser components of the

right

1

23.10

Terminal block

3

5

B-I input tube assemblies

1

23.11

Compressor capacitor

1

6

A machine control components II input

1

24

Base ass'y

1

7

A machine control component input I

1

25

Base

1

8

B components of the left seal plate

condenser

1

26

Fixed compressor(Copeland)

2

9

A machine component output tube casing

1

27

Drainage pan holder

2

10

A four-way valve assembly machine

1

29

The door of electrical box

1

11

Enter the pipe component II B

1

30

Welding parts water tray

1

12

B unit 4-way valve ass'y

1

31

A condenser components

1

13

Suction pipe ass'y A

1

32

Cover

1

14

Suction pipe ass'y B

1

33

C components of the left seal plate

condenser

1

15

Support board

2

34

Part B condenser

1

16

Cover

1

35

Motor holder

2

17

Cover board

1

36

Side sealed board

7

18

The welding part of small baseplate

1

37

Clapboard supporting board

3

19

Accumulator cylinder

2

38

Motor bracket bonding parts

2

20

Fixed compressor(Copeland)

2

39

Cover

2

21

Base ass'y

1

40

Asynchronous motor

1

22

Base

1

41

Axial flow fan

1

23

Outdoor electrical box ass'y

1

42

Top cover

1

23.1

Electrical box welding part

1

43

Middle partition plate

1

23.2

Outdoor current detection board ass'y

1

44

Top cover

1

23.3

Outdoor main board ass'y

1

45

Sealed board

1

23.4

Relay

2

46

Rear Cover

1

23.5

Contactor

2

47

Front cover

1

23.6

Transformer

1

48

About clapboard

2

Page 48

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

49

MGCT-D30W/PN1

Page 49

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

50

Page 50

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

51

No.

Part Name

Qty

No.

Part Name

Qty

1

Net

2

23.7

Wire joint,11p

1

2

Right seal plate condenser components D

1

23.8

Wire joint,4p

1

3

Tube heat exchanger

1

23.9

Wire joint

1

4

A seal plate condenser components of the right

1

23.10

Wire joint

3

5

B-I input tube assemblies

1

23.11

Compressor capacitor

1

6

A machine control components II input

1

24

Fixed compressor(Copeland)

1

7

A machine control component input I

1

25

Drainage pan holder

2

8

B components of the left seal plate condenser

1

26

The door of electrical box

1

9

A machine component output tube casing

1

27

Welding parts water tray

1

10

A four-way valve assembly machine

1

29

A condenser components

1

11

Enter the pipe component II B

1

30

Cover

1

12

B unit 4-way valve ass'y

1

31

C components of the left seal

plate condenser

1

13

Suction pipe ass'y A

1

32

Part B condenser

1

14

D machine back to the tube components

1

33

Motor holder

2

15

Support board

2

34

Compressor's cover

1

16

Cover

1

35

Side sealed board

7

17

Compressor's cover

1

36

Clapboard supporting board

3

18

The welding part of small baseplate

1

37

Motor bracket bonding parts

2

19

Accumulator cylinder

2

38

Cover

2

20

Digital compressor(Copeland)

1

39

Asynchronous motor

1

21

Base ass'y

1

40

Axial flow fan

1

22

Base

1

41

Top cover

1

23

Outdoor electrical box ass'y

1

42

Middle partition plate

1

23.1

Electrical box welding part

1

43

Top cover

1

23.2

Outdoor current detection board ass'y

1

44

Sealed board

1

23.3

Outdoor main board ass'y

1

45

Rear Cover

1

23.4

Relay

2

46

Front cover

1

23.5

Contactor

2

47

About clapboard

2

23.6

Transformer

1

Page 51

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

52

10.2 MGBT-F60W/PN1

Page 52

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

53

No.

Part Name

Qty

No.

Part Name

Qty

1

A combination of pieces of fixed plate

condenser

1

23

Vapor-liquid separator

2

2

Condenser side board

2

24

Shell and tube evaporator

1

3

Condenser ass'y A

1

25

Cover

1

4

Condenser ass'y B

1

26

Pole 4 5

Mid horizontal support

2

27

Electronic control box door

1 6 Fixed board

2

28

A unit suction pipe II

1 7 Mid upright support

2

29

B unit suction pipe ass'y

1

8

Pipe fixing clamp

2

30

A four-way valve assembly

machine

1

9

Evaporator input pipe ass'y

1

31

B unit four-way valve ass'y

1

10

Evaporator input pipe ass'y

1

32

Drainage pan ass'y

1

11

Cover

1

33

Middle partition plate

2

12

Cover

1

34

Net 2 13

Triangle reinforcement ass'y

8

35

Net 4 14

Reinforcement board

4

36

Top upright support

2

15

Base

1

37

Condenser seal connector

1

16

Compressor

2

38

Top cover

2

17

Cover

1

39

Axial flow fan

2

18

Wiring terminal fixing board

1

40

Motor

2

19

Cover

1

41

Mid horizontal support

2

20

Cover

1

42

Motor bracket ass'y

4

21

Outdoor unit electrical box ass'y

1

43

Motor mounting plate welded

2

21.1

Welding together pieces of electronic control

box

1

44

Condenser seal connector

1

21.2

Supporting board ass'y of wire joint

1

45

Temperature-kit card

1

21.5

21.4

21.6

21.7

21.8

21.9

21.10

21.11

21.12

21.13

Page 53

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

54

No.

Part Name

Qty

No.

Part Name

Qty

21.3

Electric installation board

1

46

Suction pipe ass'y A

1

21.4

Current detection board ass'y of outdoor unit

1

47

Electronic expansion valve coil

2

21.5

Outdoor main control board ass'y

1

48

Discharge temp sensor

2

21.6

Relay

3

49

Room temp sensor ass'y T41

1

21.7

AC contactor

2

50

Coil temp. sensor ass'y

2

21.8

AC contactor

2

51

Temp.sensor ass'y

1

21.9

Transformer

1

52

Coil temp sensor ass'y

3

21.10

Wire joint,11p

1

53

Electrical heating belt

compression

2

21.11

Wire joint,4p

1

54

4-Ways valve solenoid

2

21.12

Wire joint

1

55

R410A

13

21.13

Wire joint

3

56

Total water temperature mouth

components

1

22

Wiring trough

0.5

10.3 MGBT-F120W/PN1

Page 54

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

55

Page 55

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

56

Page 56

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

57

No.

Part Name

Qty

No.

Part Name

Qty

1

The top beam

2

29

I left panel

3

2

The condenser seal fittings. II

2

30

B2 machine evaporator inlet pipe assembly

1

3

Iron nets fixed plate. II

2

31

A2 machine evaporator inlet pipe assembly

1

4

Protect net around

4

32

B1 Evaporator inlet pipe assembly machine

1

5

pole

4

33

A1 machine evaporator inlet pipe assembly

1

6

Trough fixation plate

4

34

B1 machine four-way valve assembly

1

7

Left right panel by. II

1

35

A1 Machine four-way valve assembly

1

8

Iron nets fixed board I

2

36

Fixed plate

4

9

Protect network and

4

37

Pipe fixing clamp

6

10

In the frame beams

2

38

Welding parts water tray

2

11

Cover

1

39

Seal plate condenser

4

12

Outdoor electric box ass'y

1

40

A condenser components

2

12.1

Welding together pieces of electronic

control box

1

41

A combination of pieces of fixed plate

condenser

2

12.2

Outdoor current detection board

ass'y

1

42

Motor bracket bonding parts

8

12.3

Outdoor main board ass'y

2

43

Motor

4

12.4

Relay

6

44

Axial flow fan

4

12.5

AC contactor

4

45

Fixed plate with the condenser B

2

12.6

AC contactor

4

46

B condenser components

2

12.7

Transformer

1

47

A1 machine to take over the evaporator

component four-way valve

1

12.8

Transformer

1

48

4-way valve ass'y of B2 unit

1

12.9

A Terminal Block

1

49

B2 machines take over the four-way valve

assembly evaporator

1

12.10

A Terminal Block

3

50

A2 machine back to the tube components

1

12.11

Wire joint,11p

1

51

B1 machine back to the tube components

3

12.12

Wire joint,4p

1

52

A2 four-way valve assembly machine

1

12.13

Wire joint

6

53

I sealed connector condenser

2

13

Electronic control box cover plate

1

54

Roof rack beams II

1

14

Cover

1

55

Top cover

4

15

Cover

1

56

I beam roof rack

1

16

Cover

1

57

Vertical beam roof rack

2

17

Base weld parts

1

58

Total water temperature mouth components

1

18

Compressor

4

59

Accessory- wired controller(English)

1

19

Storage tank bottom II weld

installation

1

60

Coil temp sensor ass'y

2

20

Compressor installed base II weld

1

61

Pipe temperature sensor assemblies

1

21

Reinforcement board

4

62

Pipe temperature sensor assemblies

3

22

Triangle reinforcement ass'y

8

63

Coil temp sensor ass'y

4

23

Piping support-unit

2

64

Room temp sensor ass'y T41

2

24

Vapor-liquid separator

4

65

Pipe temperature sensor assemblies

1

25

Shell and tube evaporator

1

66

Discharge temperature controller

4

26

Storage tank bottom I weld parts

installation

1

67

Four-way valve coil

2

27

Compressor installed base I weld

1

68

Four-way valve coil

2

28

Vertical beams in the frame

2

69

Electronic expansion valve coil

4

Page 57

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

58

10.4 MGBT-F180W/PN1

Page 58

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

59

No.

Part Name

Qty

No.

Part Name

Qty

1

Column

4

35

Tube fixed plate II

2

2

About the protective screen

4

36

Welding parts water tray

3

3

Network Rail fixed plate II

2

37

In lane bridge II

2

4

Vertical beam in the frame

2

38

Tube fixed plate III

12

5

Roof rack crossbar

2

39

Evaporator tube assembly output

1

6

I sealed connector condenser

3

40

Evaporator tube assembly output

1

7

Vertical beam roof rack

2

41

Evaporator tube assembly output

1

8

Condenser sealed connector II

3

42

I four-way valve assembly

1

9

Roof rack beam welding parts

2

43

Four-way valve assembly III

1

10

Top cover

6

44

Evaporator tube assembly output

1

11

Rear Panel II

1

45

Evaporator tube assembly output

1

12

Condenser output tube II

3

46

Evaporator tube assembly output

1

13

In lane bridge I

2

47

Welding together pieces of the base

1

14

Block I installed electronic

control box

2

48

Left panel II

1

15

Block III electronic control box

installed

2

49

Strengthened beams II

2

16

Rear Panel I

1

50

I left panel

3

17

Block II Electronic Control Box

Installation

2

51

Panel fasteners II

8

18

Electronic control box cover

panel B

1

52

Triangular reinforcement

12

19

Air-cooled electronic control box

assembly module

1

53

Trunking II

1

19.1

Welding together pieces of

electronic control box

1

54

II trunking cover

1

19.2

Electrical component mounting

plate I

1

55

Four-way valve assembly Ⅳ

1

19.3

Electrical component mounting

plate II

1

56

Enter the evaporator tube assembly

1

19.4

Contactor

6

58

Enter the evaporator tube assembly

1

19.5

Wire joint

1

59

I output tube condenser

3

19.6

Wire joint

8

60

Output tube condenser (C drive)

transition tube assemblies

1

19.7

Three-phase power protection

devices

3

61

Condenser output tube (D drive)

transition tube assemblies

1

19.8

Transformer

2

62

Tube fixed plate Ⅳ

1

19.9

Outdoor control board assembly

3

63

Shell and tube evaporator

1

19.10

AC contactor

6

64

Duct I

1

19.11

A Terminal Block

1

65

I cover trunking

1

19.4

19.5

19.6

19.7

19.8

19.9

19.10

19.11

19.12

19.13 19.14

19.15

19.16

Page 59

R410A tropical air-cooled scroll chiller unit 60Hz MCAC-ATSM-2014-09

60

No.

Part Name

Qty

No.

Part Name

Qty

19.12

Seven Terminal Block

1

68

Four-way valve assembly II

3

19.13

Transformer

1

69

separator

6

19.14

A Terminal Block

3

70

The beams in the

2

20

A cover board electronic control

1

71

Front Panel

4

21

Components of the compressor

back to the trachea

5

72

Strengthen the beam I

4

22

I return to the trachea

compressor components

1

73

Network Rail fixed plate I

4

23

I return to the trachea

compressor components

1

74

Front grille

6

26

Part B condenser

3

75

Welding parts mounting base

compressors

6

27

B fixed plate with pieces of

condenser

3

76

Compressor

6

28

Axial flow fan

6

77

Enter the evaporator tube assembly

1

29

Motor

5

78

I fixed plate throttle parts

2

30

Three-phase asynchronous

motor

1

79

Enter the evaporator tube assembly

1

31

Motor bracket bonding parts

12

80.1

Electronic expansion valve

1

33

A fixed plate with pieces of

condenser

3

80.1

Enter the evaporator tube assembly

1

34

A machine Condenser Parts

3

Page 60

MCAC-ATSM-2014-09 R410A tropical air-cooled scroll chiller unit 60Hz

61

11 Trouble shooting

11.1 Failure & Protection Codes

30kW module

No

Code

Trouble

1

E0

Error of outdoor EEPROM

2

E1

Power phase sequence error

3

E2

Communication error

4

E3