Midea MGBT-F60W/RN1, MGBT-F120W/RN1, MGBT-F180W/RN1, MGBT-F250W/RN1, MGBT-D25W/RN1 Series Manual

...

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Content

Part 1 System outline ........................................................................................................................ 1

1. General outline .......................................................................................................................... 3

2. Pipe connection drawing .......................................................................................................... 26

3. Refrigeration system drawing ................................................................................................... 32

4. Wiring diagram ........................................................................................................................ 36

5 Networking communication wiring diagram .............................................................................. 42

6.Exploded view .......................................................................................................................... 48

Part 2 Capacity tables and control system ........................................................................................ 74

1. Capacity tables ......................................................................................................................... 75

2 Control system .......................................................................................................................... 89

Part 3 Trouble shooting ................................................................................................................. 138

1. Malfunction & protection codes ............................................................................................. 139

2 Troubles and Solutions ............................................................................................................ 145

3 Typical malfunction solutions .................................................................................................. 147

Part 4 Installation ......................................................................................................................... 156

1. Transportation and foundation installation............................................................................. 157

2. Water system installation ...................................................................................................... 165

3. Installation of water system pipeline ...................................................................................... 168

4. Wiring installation ................................................................................................................. 178

5. Trial run ................................................................................................................................. 182

Part 5 Maintenance ...................................................................................................................... 185

1. About maintenance ............................................................................................................... 186

2. Periodical check ..................................................................................................................... 188

Part 6 Wired controller.................................................................................................................. 190

1.1 KJRM-120D/BMK-E(Standard) .............................................................................................. 191

1.2 KJR-120A/MBTE(Optional) ................................................................................................... 200

Appendix ...................................................................................................................................... 209

※ Manufacture reserves the right to discontinue, or change at any time, specifications or designs without notices and

without incurring obligations

Content 1

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Part 1 System outline

Part 1 System outline ........................................................................................................................ 1

1. General outline .......................................................................................................................... 3

1.1 Nomenclature ................................................................................................................................................................ 3

1.2 Products list .................................................................................................................................................................... 3

1.3 External appearance ...................................................................................................................................................... 4

1.4 Features ......................................................................................................................................................................... 5

1.5 Capacity lineup ............................................................................................................................................................... 8

1.6 Specification: MGBT-F25W/RN1, MGBT-D25W/RN1 ..................................................................................................... 9

1.7 Specification: MGBT-F30W/RN1, MGBT-D30W/RN1 ................................................................................................... 11

1.8 Specification: MGBT-F60W/RN1, MGBT-D60W/RN1, MGBT-F120W/RN1 ................................................................... 13

1.9 Specification: MGBT-F180W/RN1, MGBT-F250W/RN1 ................................................................................................ 15

1.10 Electric Characteristics ............................................................................................................................................... 17

1.11 Outlook drawing: MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-D30W/RN1, MGBT-F30W/RN1 .............................. 18

1.12 Outlook drawing: MGBT-F60W/RN1 .......................................................................................................................... 19

1.13 Outlook drawing: MGBT-D60W/RN1.......................................................................................................................... 20

1.14 Outlook drawing: MGBT-F120W/RN1 ........................................................................................................................ 21

1.15 Outlook drawing: MGBT-F180W/RN1 ........................................................................................................................ 22

1.16 Outlook drawing: MGBT-F250W/RN1 ........................................................................................................................ 24

2. Pipe connection drawing .......................................................................................................... 26

2.1MGBT-F25W/RN1,MGBT-D25W/RN1,MGBT-F30W/RN1,MGBT-D30W/RN1 ................................................................ 26

2.2 MGBT-F60W/RN1 ......................................................................................................................................................... 27

2.3 MGBT-D60W/RN1 ........................................................................................................................................................ 28

2.4 MGBT-F120W/RN1 ....................................................................................................................................................... 29

2.5 MGBT-F180W/RN1 ....................................................................................................................................................... 30

2.6 MGBT-F250W/RN1 ....................................................................................................................................................... 31

3. Refrigeration system drawing ................................................................................................... 32

3.1 MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-F30W/RN1 ,MGBT-D30W/RN1 ............................................................. 32

3.2 MGBT-F60W/RN1 ......................................................................................................................................................... 32

3.3 MGBT-D60W/RN1 ........................................................................................................................................................ 33

3.4 MGBT-F120W/RN1 ....................................................................................................................................................... 33

3.5 MGBT-F180W/RN1 ....................................................................................................................................................... 34

3.6 MGBT-F250W/RN1 ....................................................................................................................................................... 34

4. Wiring diagram ........................................................................................................................ 36

4.1 MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-F30W/RN1, MGBT-D30W/RN1 ............................................................. 36

4.2 MGBT-F60W/RN1 ......................................................................................................................................................... 37

1

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

4.3 MGBT-D60W/RN1 ........................................................................................................................................................ 38

4.4 MGBT-F120W/RN1 ....................................................................................................................................................... 39

4.5 MGBT-F180W/RN1 ....................................................................................................................................................... 40

4.6 MGBT-F250W/RN1 ....................................................................................................................................................... 41

5 Networking communication wiring diagram .............................................................................. 42

5.1 MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-F30W/RN1, MGBT-D30W/RN1 ............................................................. 42

5.2 MGBT-F60W/RN1 ......................................................................................................................................................... 43

5.3 MGBT-D60W/RN1 ........................................................................................................................................................ 44

5.4 MGBT-F120W/RN1 ....................................................................................................................................................... 45

5.5MGBT-F180W/RN1 ........................................................................................................................................................ 46

5.6MGBT-F250W/RN1 ........................................................................................................................................................ 47

6.Exploded view .......................................................................................................................... 48

6.1 MGBT-F25W/RN1 ......................................................................................................................................................... 48

6.2 MGBT-D25W/RN1 ........................................................................................................................................................ 50

6.3 MGBT-F30W/RN1 ......................................................................................................................................................... 53

6.4 MGBT-D30W/RN1 ........................................................................................................................................................ 55

6.5 MGBT-F60W/RN1 ......................................................................................................................................................... 58

6.6 MGBT-D60W/RN1 ........................................................................................................................................................ 61

6.7 MGBT-F120W/RN1 ....................................................................................................................................................... 65

6.8 MGBT-F180W/RN1 ....................................................................................................................................................... 68

6.9 MGBT-F250W/RN1 ....................................................................................................................................................... 70

2

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

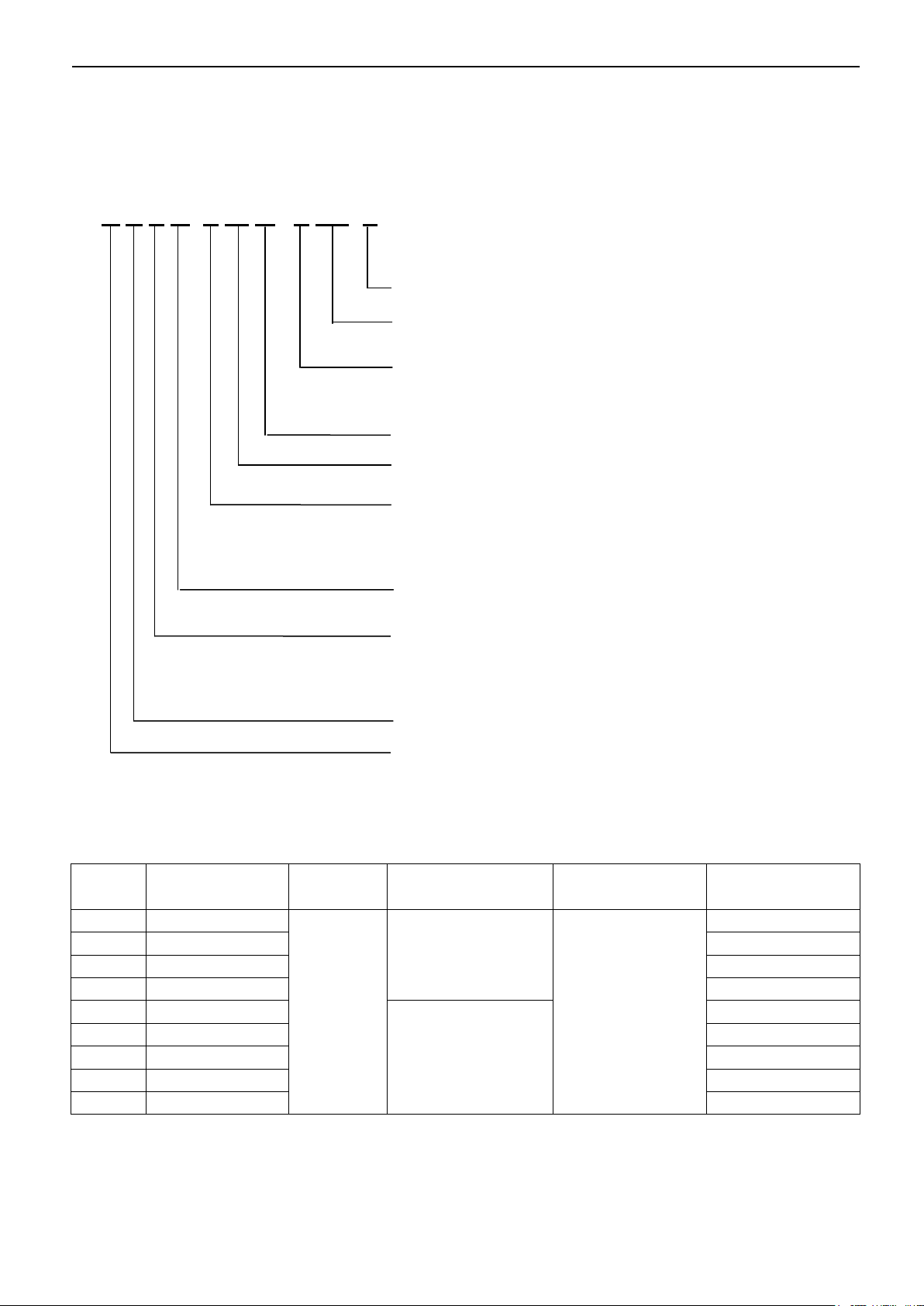

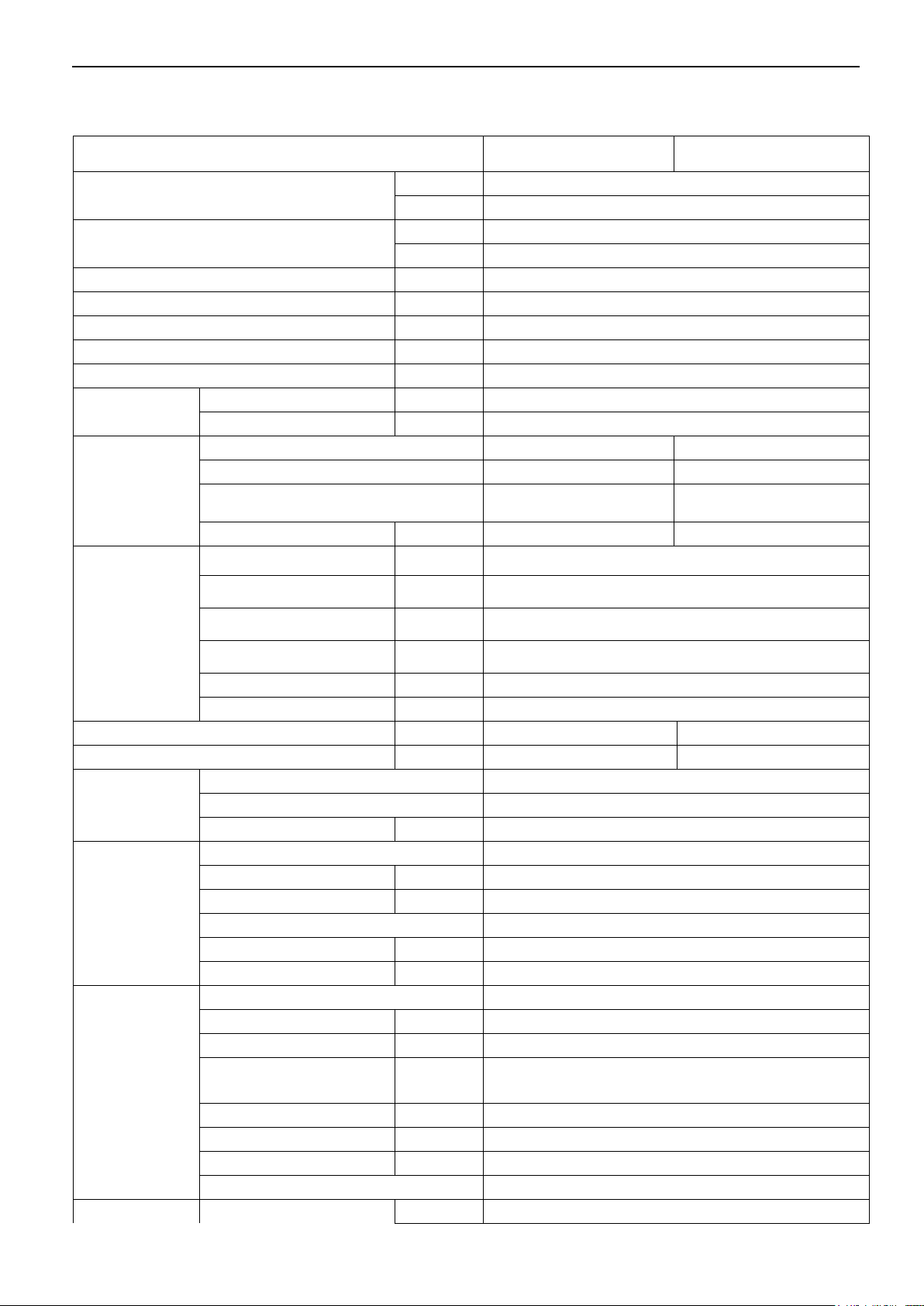

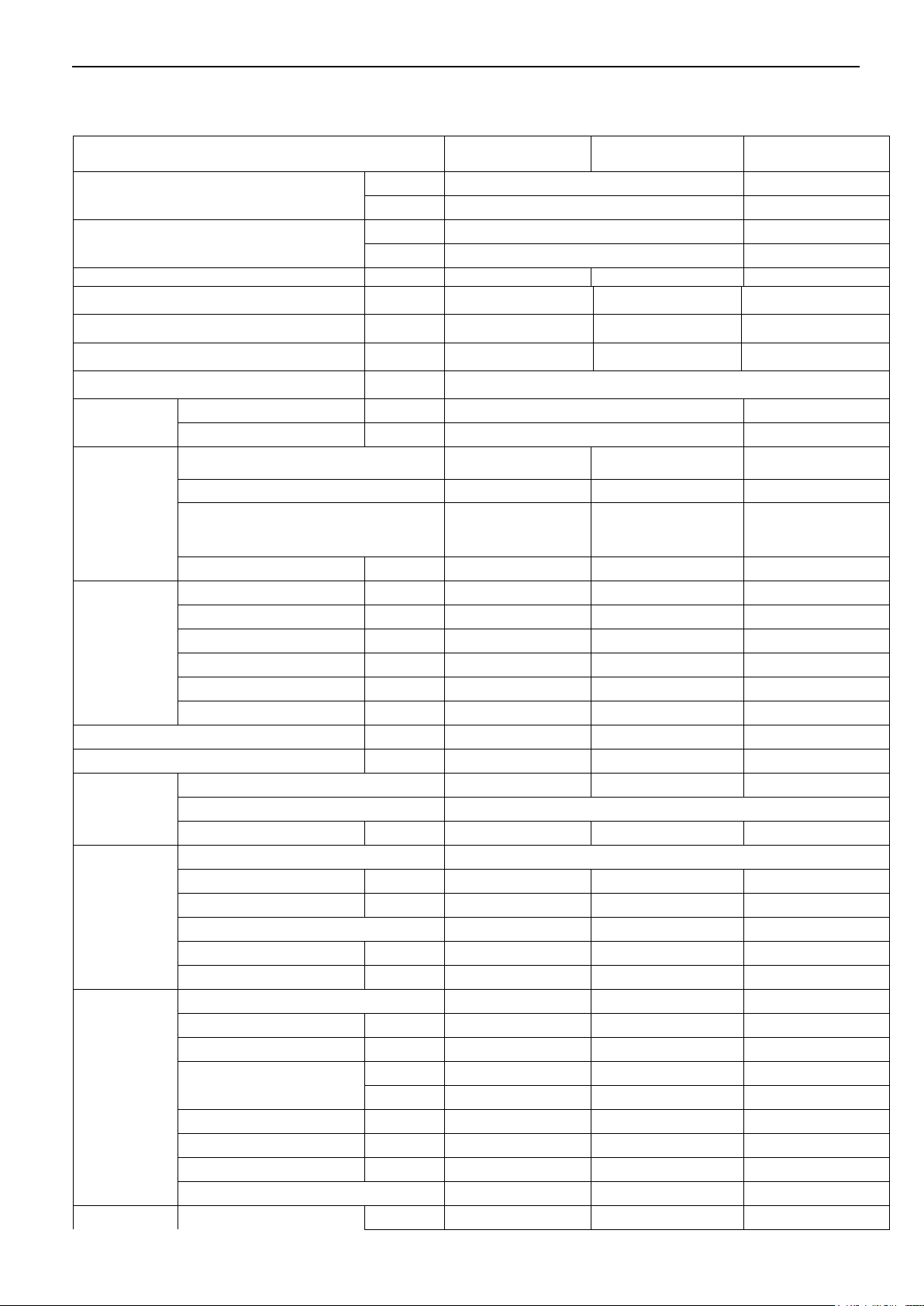

No

Model

Refrigerant

Heat exchanger type

Power supply

Wired controller

1

MGBT-F25W/RN1

R410A

Double pipe

380~415V/50Hz/3Ph

KJRM-120D/BMK-E

2

MGBT-D25W/RN1

KJRM-120D/BMK-E

3

MGBT-F30W/RN1

KJRM-120D/BMK-E

4

MGBT-D30W/RN1

KJRM-120D/BMK-E

5

MGBT-F60W/RN1

Shell and tube

KJRM-120D/BMK-E

6

MGBT-D60W/RN1

KJRM-120D/BMK-E

7

MGBT-F120W/RN1

KJRM-120D/BMK-E

8

MGBT-F180W/RN1

KJRM-120D/BMK-E

9

MGBT-F250W/RN1

KJRM-120D/BMK-E

Design Serial Number

Refrigerant type

N1:R410A Omit for R22

Power Supply

R: 380~415V, 50Hz, 3N

D: 220V, 60Hz,3N

Outdoor Unit

Rated cooling capacity (kW)

The special function code

D: Digital scroll

F: Constant feed

V: Inverter system

T: T3 condition

Omit for T1 condition

The heat exchanger type

A: Plate heat exchanger

B: Tube and shell or double pipe heat exchanger

Light chiller system

Midea

1. General outline

1.1 Nomenclature

M G B T - D 30 W / R N1 - A

1.2 Products list

3

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

MGBT-F120W/RN1

MGBT-F60W/RN1

MGBT-D60W/RN1

MGBT-F180W/RN1

MGBT-F250W/RN1

MGBT-F25W/RN1

MGBT-D25W/RN1

MGBT-F30W/RN1

MGBT-D30W/RN1

1.3 External appearance

4

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

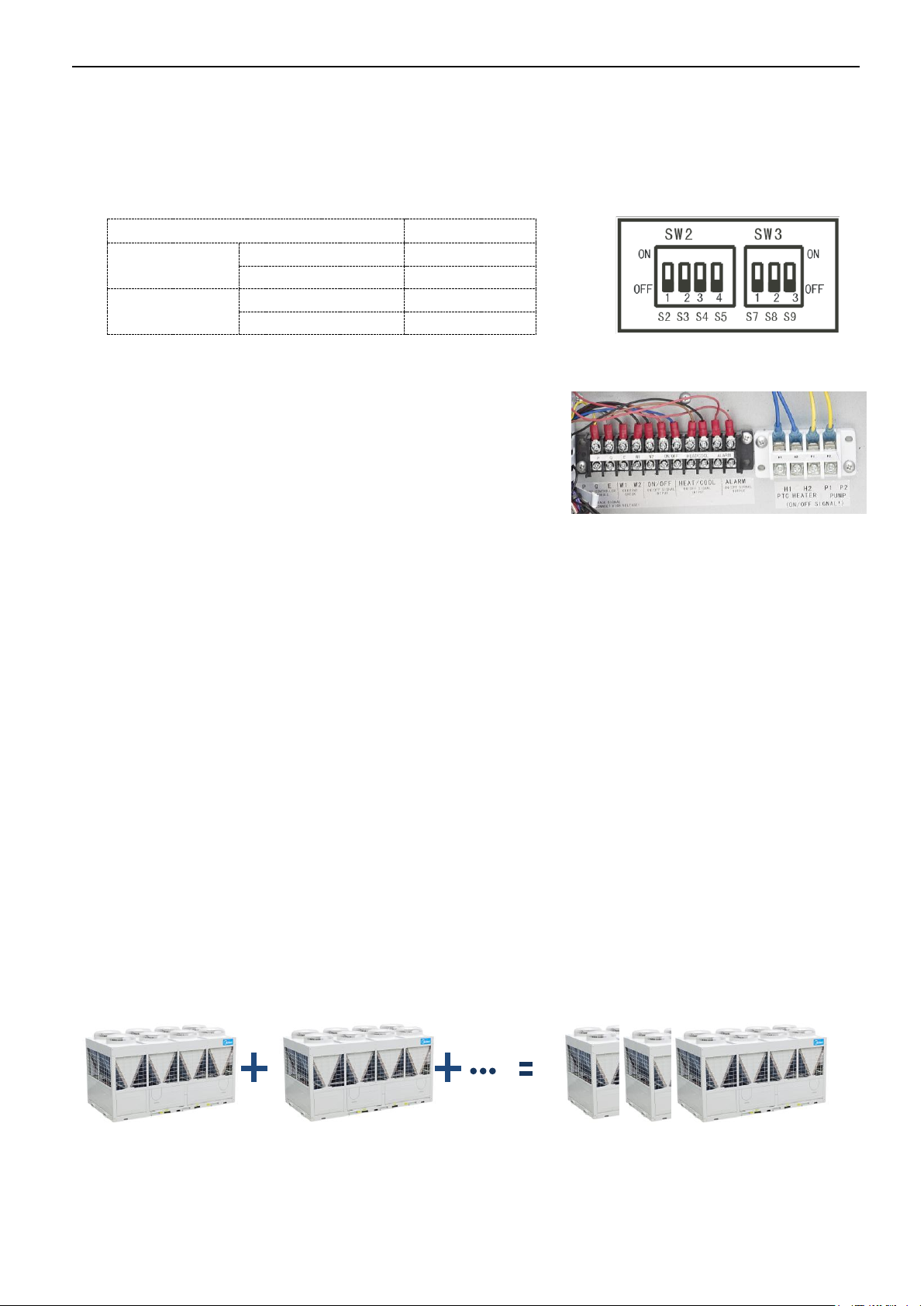

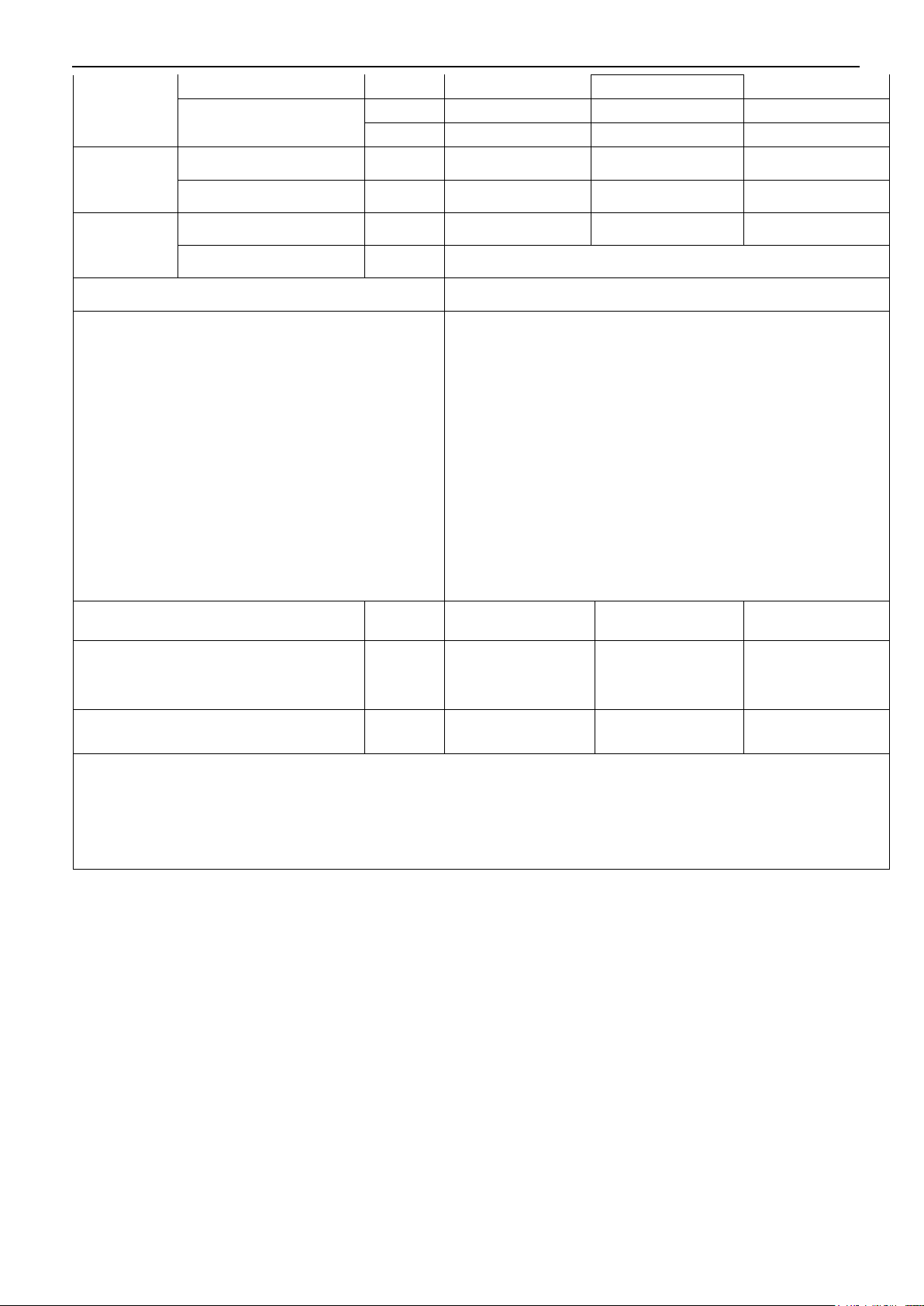

Mode

Outlet water temp.

Cooling(S5

address)

Normally(OFF)

5~17℃

Low water temp.(ON)

0~17℃

Heating(S4

address)

Normally(OFF)

40~50℃

Low water temp. (ON)

22~50℃

Max 8 units

Picture2

2000kW

250kW

250kW

1.4 Features

1). Wide range of outlet water temp. (For MGBT-D60W/RN1, MGBT-F250W/RN1)

Cooling: 5~17˚C (7˚C set in factory), 0~17˚C can be available by switch the S5 on PCB, the antifreeze must be

put into pipeline.

Heating: 40~50˚C (45˚C set in factory), 22~50˚C can be available by switch the address.

2).Humanization remote control (For MGBT-D60W/RN1, MGBT-F250W/RN1)

S7 address on PCB should be switched to ON to realize remote

control, which including: Remote ON/OFF, remote heating and

cooling mode selection, remote alarm. The customer can simply

and conveniently control the module and acquire the running

information on real time in door.

3).Digital scroll technique,new type air-cooled modular chiller system.

Capacity output is controlled depending on controlling compressor to on/off in traditional modular air-cooled

chiller system control. The precision of the control mode is not very good, and the compressor is frequently on

and off, which is very bad for the compressor’s life.

Digital scroll modular air-cooled chiller system breaks traditional design, which is inconceivably designed with

digital scroll compressor and constant scroll compressor parallel connection. The system can achieve linear

capacity output within 0.5%-100% after modules combined, the scope is widest in industry. When the system

operates at the part-load, the system can accurately adjust cooling and heating capacity output basing on

actual requirement of the indoor room.

4). Easy and fast installation

The unit adopts modular design, which can make more units connect together. The unit can combine 16

separate module(equal and less than 65kW) or 8 module(250kW).Cooling(heating) capacity can increase

step by step by 5KW per each time within 15kW-2000kW,meanwhile every separate module can operate as

main unit, also each module can be a slave unit with modules combination, more convenient for design and

installation.

The maximum combination of the system consists of 1 main unit and 15 slave units for 25kW&30kW&60kW

module,1 main unit and 7 slave units for 120kW module, 1 main unit and 4 slave units for 180kW module, 1

main unit and 7 slave units for 250kW module.

5

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

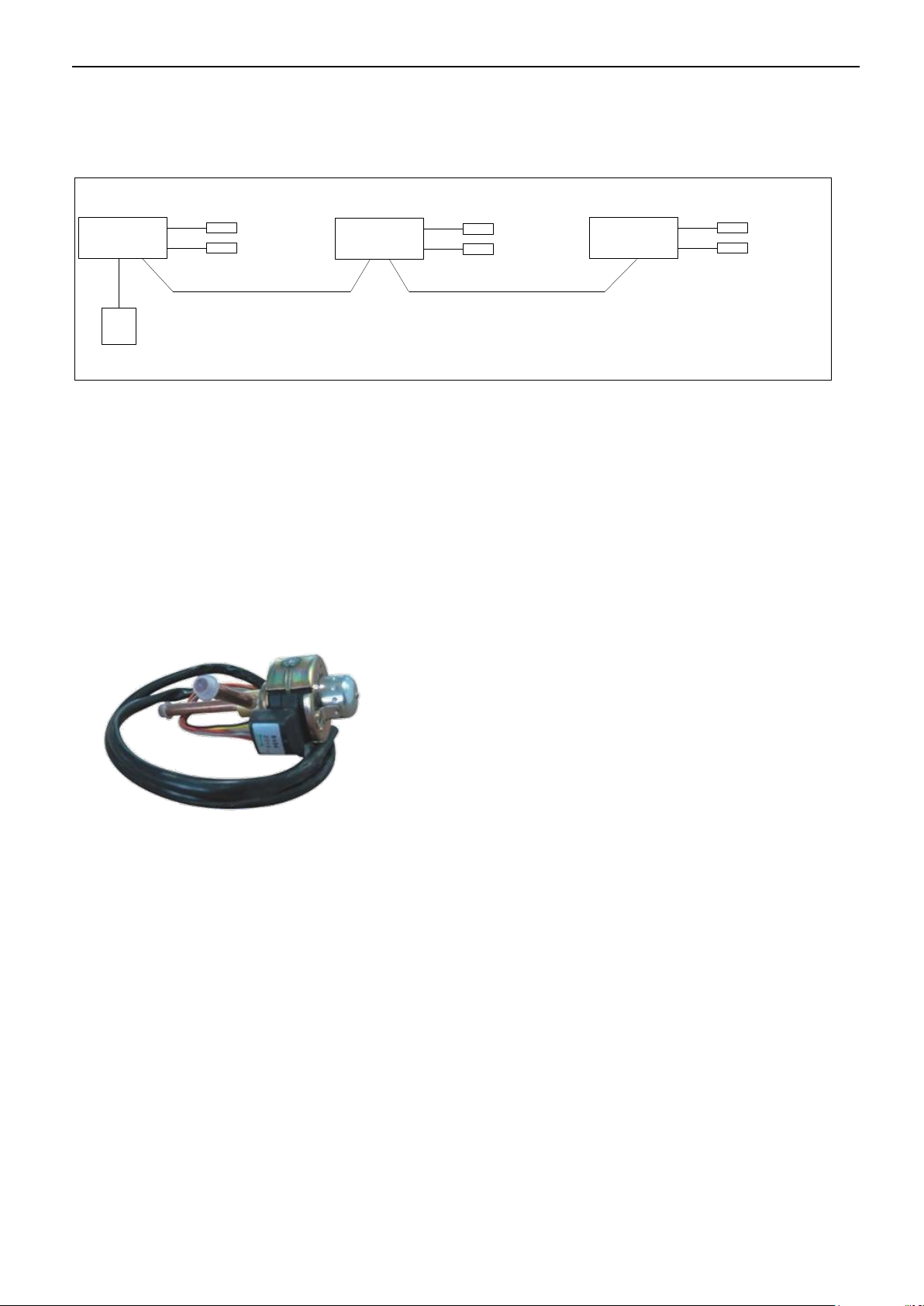

Wired controller

Three-core shielding

twisted pair

Three-core shielding

twisted pair

Water outlet temp.

Water outlet temp.

Water outlet temp.

Total water outlet temp.

(Just for master unit)

Total water outlet temp.

(Just for master unit)

Total water outlet temp.

(Just for master unit)

Easily connect between main unit and slave units.

All the units can be connected together with a wired controller in series type. Using three-core shielded

twisted wire as communication wire.

5).Environmental care

R410a— the environmental refrigerant.

Chlorine-free and environmental friendly refrigerant, zero ozone depletion potential.

High density refrigerant, therefore, less refrigerant required.

Leak-tight refrigerant circuit, Brazed refrigerant connections for increased leak-tightness.

6). Economical operation

New design adopts electronic expansion valve precise refrigerant control in wider range. Electronic

expansion valve allows operation at lower condensing pressure, the adjustment can be made fast linear

response, making the system more stable output, the indoor temp. more uniform, and enhanced human

comfortable.

7). Compact structure

The structure of air-cooled modular chiller is compact, light weight. The system adopts double-pipe or shell

and tube heat exchanger, which not only greatly enhanced the transfer performance, but also reduced the

unit weight, the lightest single module has only 380kg.

8). Back up function

6

When unit is failure

If master unit fails, all the units will stop.

If one slave unit fails, this unit will stop but the others will keep running.

When the master unit fails, any of the slave one can be set as the master unit by manual setting.

When unit is under protection

If master unit’s protection occurs, this unit will stop but the others will keep running.

If slave unit’s protection occurs, this unit will stop but the others will keep running.

( Except PE, P9 protection happen)

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Master Slave

Master Slave

Mode

Ambient temp. range

Water outlet temp. range

Cooling

10˚C ~52˚C

5˚C ~17˚C (7˚C is default)

10˚C ~46˚C

0~17˚C(0˚C must add antifreeze)

Heating

-10˚C ~21˚C

45˚C ~50˚C (45˚C is default)

22˚C ~50˚C

9).Strong micro-computer intelligent control and monitor function.

Optimizing the design of system and using varieties of protection devices, to make the system more safe and

reliable.

10). Superior reliability

System will be more reliable with new type efficient heat exchanger.

Evaporator of 25KW and 30KW module adopt double pipe heat exchanger,evaporator of 60kW ,120kW and

180kW modules adopt shell and tube heat exchanger.

Double pipe heat exchanger Shell and tube heat exchanger

11) Applicable temp. range

7

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

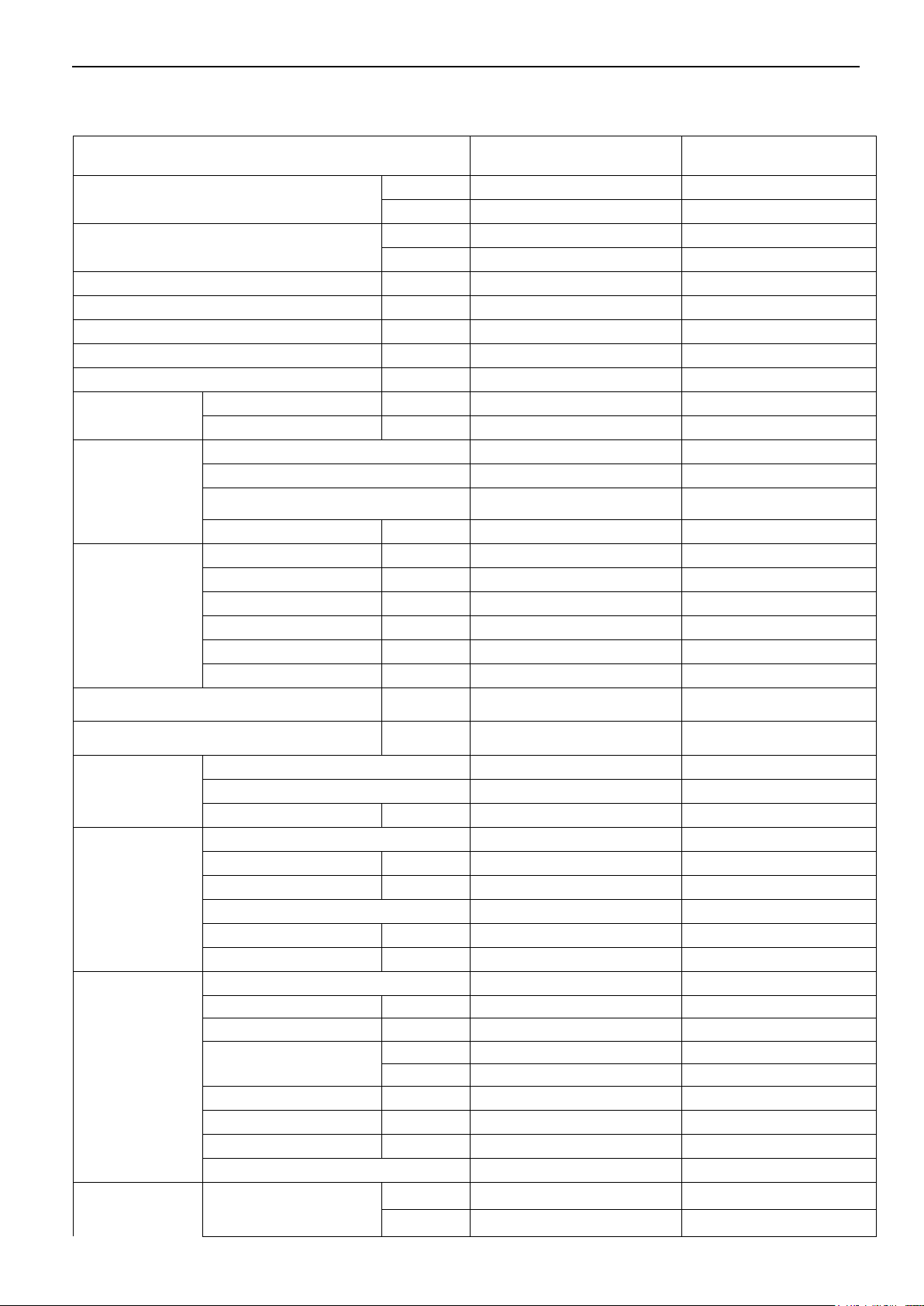

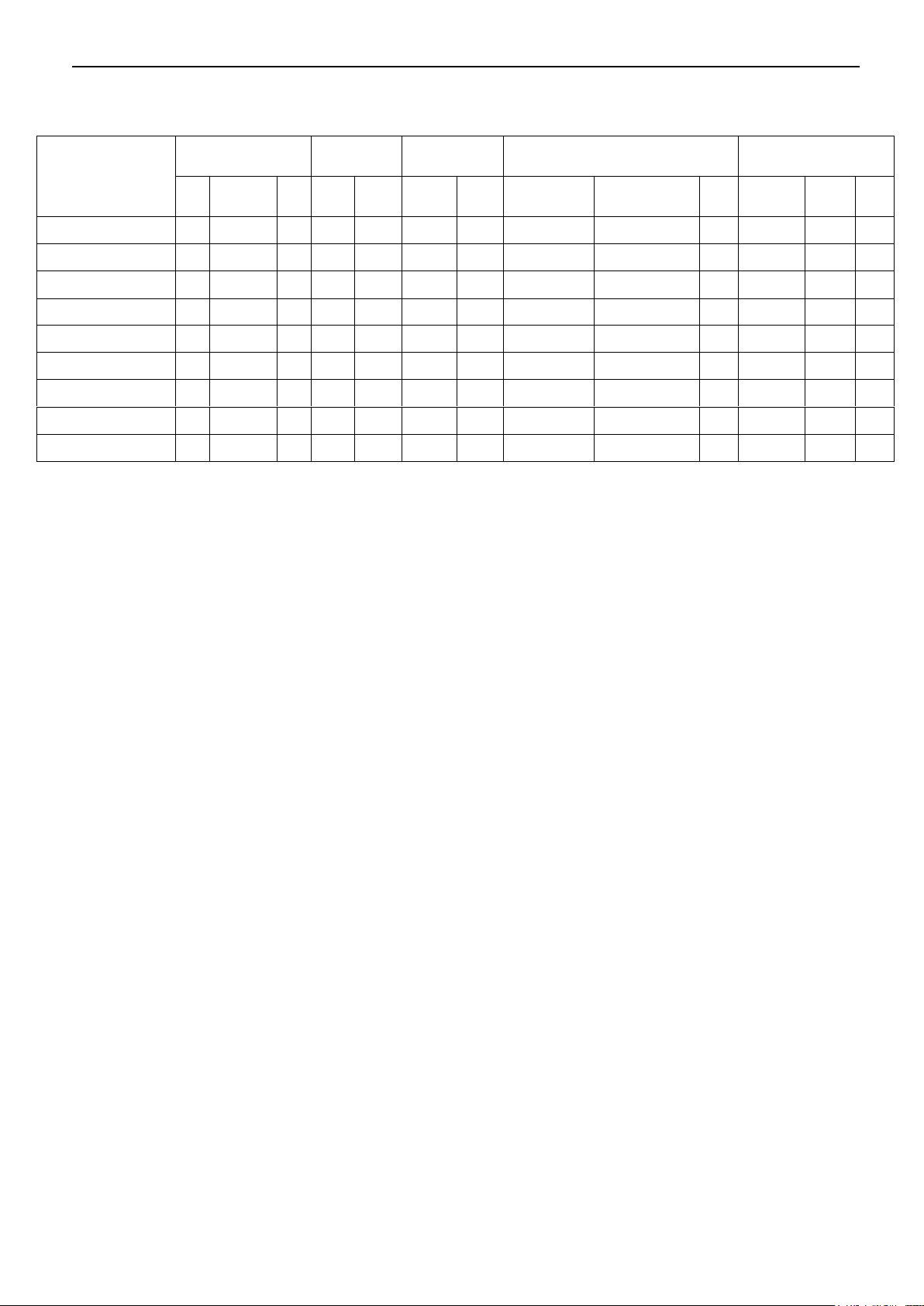

Model

Mode

Compressor

quantity

Refrigerant

Refrigeration

system

Electrical

controller no.

Maximum

combinations

Digital

Constant

MGBT-D25W/RN1

Cooling & Heating

1 1 R410A 2 1

16

MGBT-F25W/RN1

Cooling & Heating

0 2 R410A 2 1

16

MGBT-D30W/RN1

Cooling & Heating

1 1 R410A 2 1

16

MGBT-F30W/RN1

Cooling & Heating

0 2 R410A 2 1

16

MGBT-F60W/RN1

Cooling & Heating

0 2 R410A 2 1

16

MGBT-D60W/RN1

Cooling & Heating

1 2 R410A 3 1

16

MGBT-F120W/RN1

Cooling & Heating

0 4 R410A 4 2

8

MGBT-F180W/RN1

Cooling & Heating

0 6 R410A 6 3

5

MGBT-F250W/RN1

Cooling & Heating

0 8 R410A 4 2

8

-15˚C

Ambient temp. range

-10˚C

-5˚C

0˚C

5˚C

10˚C

15˚C

20˚C

25˚C

30˚C

35˚C

40˚C

45˚C

50˚C

Cooling range

10˚C

52˚C

Heating range

-10˚C

21˚C

Water outlet temp. range

5˚C

17˚C

50˚C

5˚C

17˚C

Heating range

Cooling range

45˚C

22˚C

0˚C

45˚C

50˚C

Cooling range

0˚C

17˚C

Heating range

22˚C

50˚C

Chilled outlet water temp. can be adjusted by wired controller according to customer’s requirement.

1.5 Capacity lineup

8

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

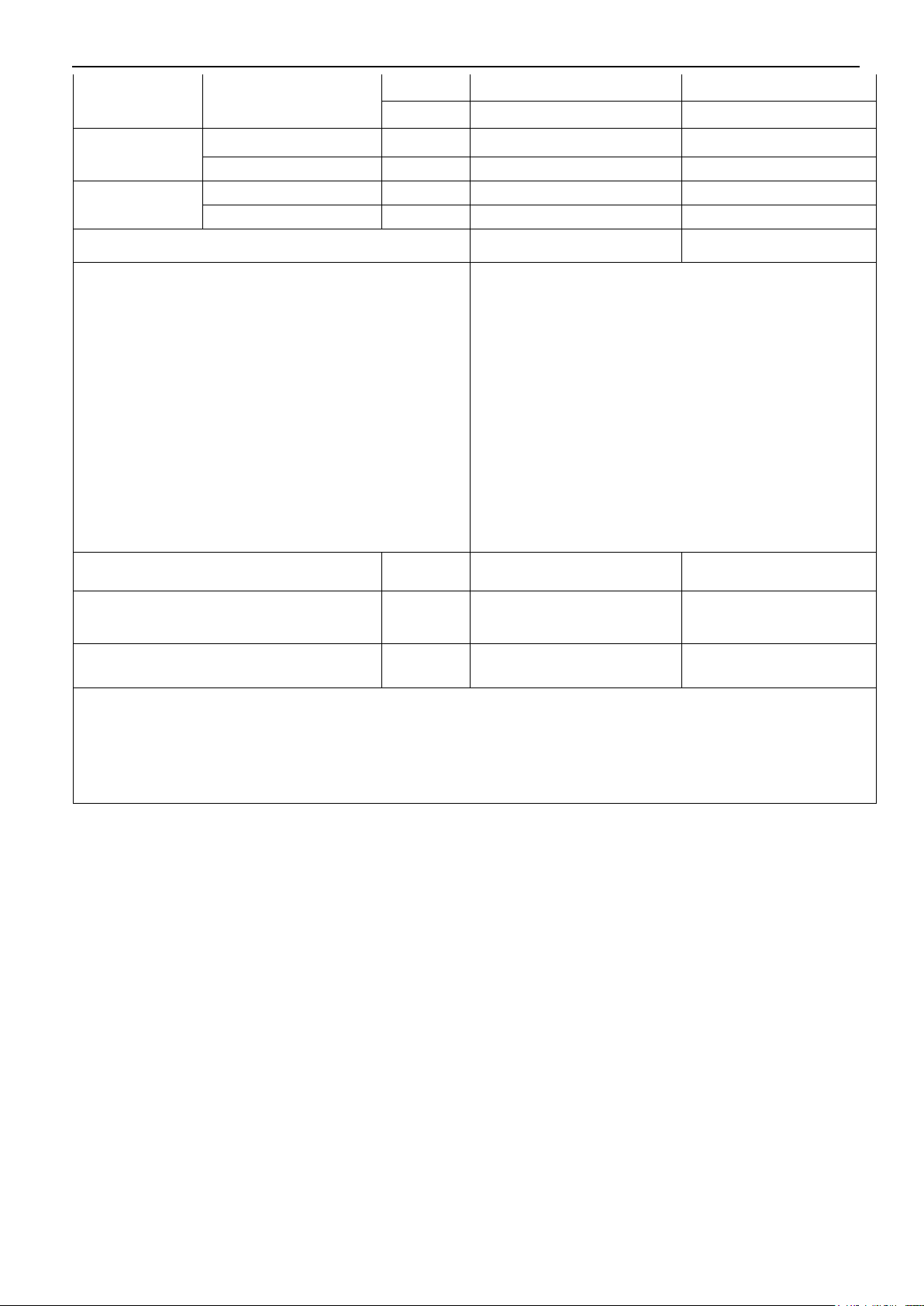

Model

MGBT-F25W/RN1

MGBT-D25W/RN1

Cooling Capacity (*1)

kW

28

Btu/h

95,500

Cooling Capacity (*2)

kW

24.9

Btu/h

85,000

Heating Capacity

kW

29.5

EER(*1)

kW/ kW

3.01

EER(*2)

kW/ kW

2.20

COP

kW/ kW

3.21

Power supply

V/Ph/Hz

380~415/3/50

Power supply

Manual switch

A

50

Fuse

A

36

Compressor

Type

Scroll (fixed speed)

Digital Scroll + Fixed speed

Brand

Copeland

Copeland

Model

ZP61KCE-TFD-522

ZPD61KCE-TFD-532/

ZP61KCE-TFD-522

Quantity

Pieces

2

1+1

Power input

Cooling (*1)

kW

9.3

Cooling rated current (*1) A 14.6

Cooling (*2)

kW

11.16

Cooling rated current (*2) A 17.52

Heating

kW

9.2

Heating rated current

A

14.3

Max. Input consumption

kW

12.6

12.5

Rated Current

A

19

19

Refrigerant

Type

R410A

Refrigerant control

EXV

Weight

kg

3.1×2

Condenser

(Air side)

Air side heat-exchanger type

Fin-coil

Quantity of fan motor

Pieces

1

Air flow volume

×103m3/h

12

Fan motor model

YDK400-8-YA

Fan motor rated current

A

2.95

Fan motor input

kW

0.65

Evaporator

(Water side)

Water side heat-exchanger type

Double-pipe

Water pressure drop

kPa

60

Volume

L

10

Water inlet/outlet pipeline

inside normal diameter

inch

1-1/2”

Water flow volume

m3/h

4.8

Max. Pressure

MPa

1

Evaporator volume

L

10

Water pipe connection type

Flexible joint

Dimension

Net(W×H×D)

mm

1514×1865×841

1.6 Specification: MGBT-F25W/RN1, MGBT-D25W/RN1

9

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

inch

59.6×73.4×33.1

Packing size(W×H×D)

mm

1590×2065×995

inch

62.6×81.3×39.2

Weight

Net weight

kg

380

Gross weight

kg

400

Connection wire

Power wire

mm2×No.

10×4+6×1

Signal wire

mm2×No.

0.75×3-core with shielding

Control type

Wired controller

Safety protection device

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-freezing protection in cooling mode.

5) Anti-freezing protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temp. difference protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

12) Low-temperature protection of shell and tube heat

exchanger.

Sound level(semi-anechoic )

dB(A)

65

Operation water temp.

℃

Cooling:5~17 Heating:45~50

Ambient temp.

℃

Cooling:10~52 Heating:-10~21

Note: Specifications are based on the following conditions:

Cooling : (*1) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 35°C (117℉) DB.

(*2) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 46˚C(140℉) DB.

Heating : warm water inlet/outlet: 40˚C / 45˚C, and outdoor ambient temp. 7˚C DB/6°CWB.

Water side fouling factor: 0.086m2˚C /kW.

10

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

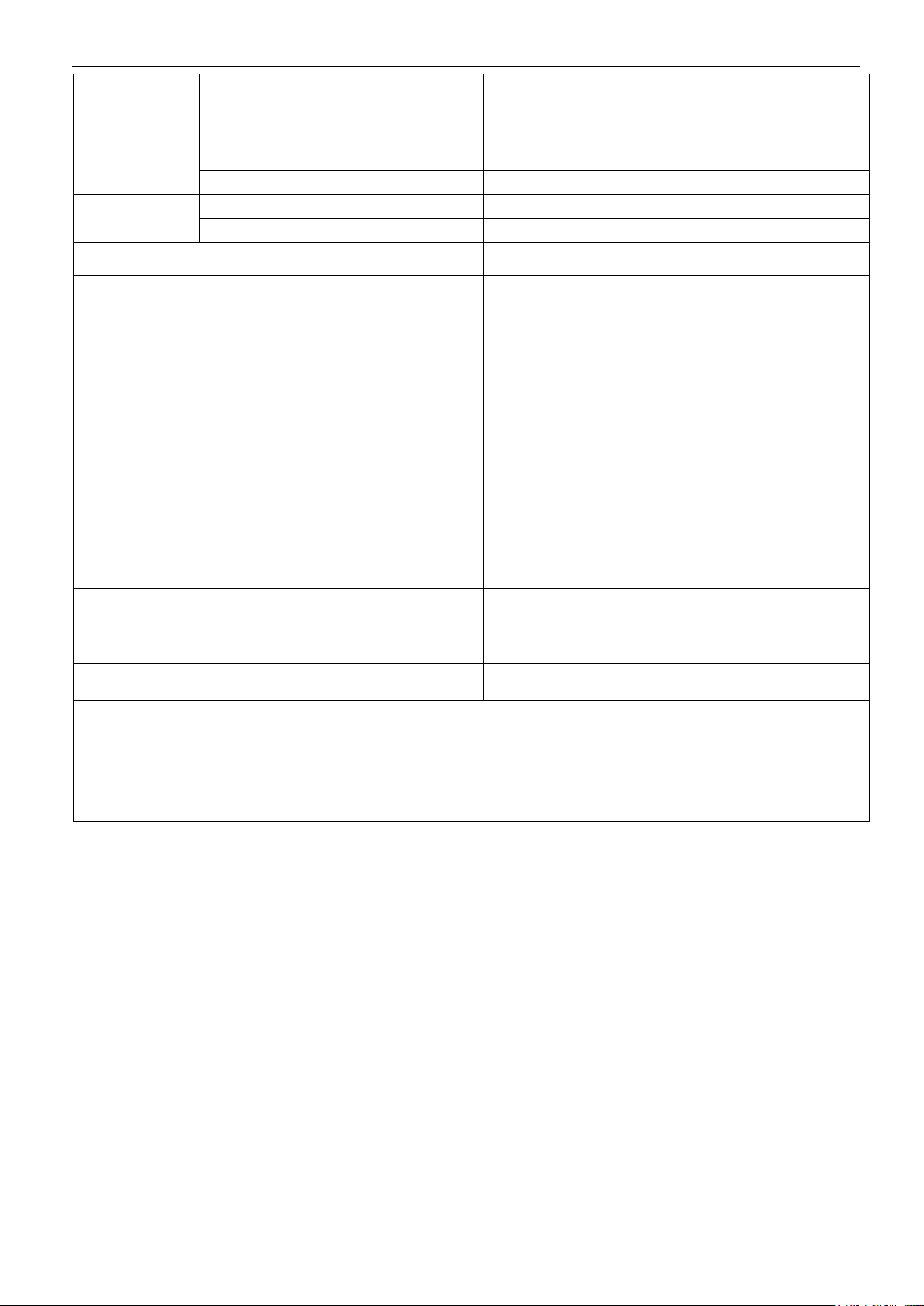

Model

MGBT-F30W/RN1

MGBT-D30W/RN1

Cooling Capacity (*1)

kW

30

Btu/h

102,300

Cooling Capacity (*2)

kW

25.8

Btu/h

88,030

Heating Capacity

kW

32

EER(*1)

kW/ kW

3.00

EER(*2)

kW/ kW

2.15

COP

kW/ kW

3.27

Power supply

V/Ph/Hz

380~415/3/50

Power supply

Manual switch

A

50

Fuse

A

36

Compressor

Type

Scroll (fixed speed)

Digital Scroll + Fixed speed

Brand

Copeland

Copeland

Model

ZP61KCE-TFD-522

ZPD61KCE-TFD-532/

ZP61KCE-TFD-522

Quantity

Pieces

1+1

1+1

Power input

Cooling (*1)

kW

10.0

Cooling rated current (*1)

A

16.3

Cooling (*2)

kW

12

Cooling rated current (*2) A 19.56

Heating

kW

9.8

Heating rated current

A

16.0

Max. Input consumption

kW

12.6

12.5

Rated Current

A

21.1

21.1

Refrigerant

Type

R410A

Refrigerant control

EXV

Weight

kg

3.1×2

Condenser

(Air side)

Air side heat-exchanger type

Fin-coil

Quantity of fan motor

Pieces

1

Air flow volume

×103m3/h

12

Fan motor model

YDK400-8-YA

Fan motor rated current

A

2.95

Fan motor input

kW

0.65

Evaporator

(Water side)

Water side heat-exchanger type

Double-pipe

Water pressure drop

kPa

60

Volume

L

10

Water inlet/outlet pipeline

inside normal diameter

mm

DN40

inch

1-1/2”

Water flow volume

m3/h

5.2

Max. Pressure

MPa

1

Evaporator volume

L

10

Water pipe connection type

Flexible joint

Dimension

Net(W×H×D)

mm

1514×1865×841

inch

59.6×73.4×33.1

1.7 Specification: MGBT-F30W/RN1, MGBT-D30W/RN1

11

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Packing (W×H×D)

mm

1590×2065×995

inch

62.6×81.3×39.2

Weight

Net weight

kg

380

Gross weight

kg

415

Connection wire

Power wire

mm2×No.

10×4+6×1

Signal wire

mm2×No.

0.75×3-core with shielding

Control type

Wired controller

Safety protection device

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temp. difference protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

12) Low-temperature protection of shell and tube heat

exchanger.

Sound level(semi-anechoic )

dB(A)

65

Operation water temp.

℃

Cooling:5~17 Heating:45~50

Ambient temp.

℃

Cooling:10~52 Heating:-10~21

Note: Specifications are based on the following conditions:

Cooling : (*1) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 35°C (117℉) DB.

(*2) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 46˚C (140℉)DB

Heating : warm water inlet/outlet: 40˚C / 45˚C, and outdoor ambient temp. 7˚C DB/6°CWB.

Water side fouling factor: 0.086m2˚C /kW.

12

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

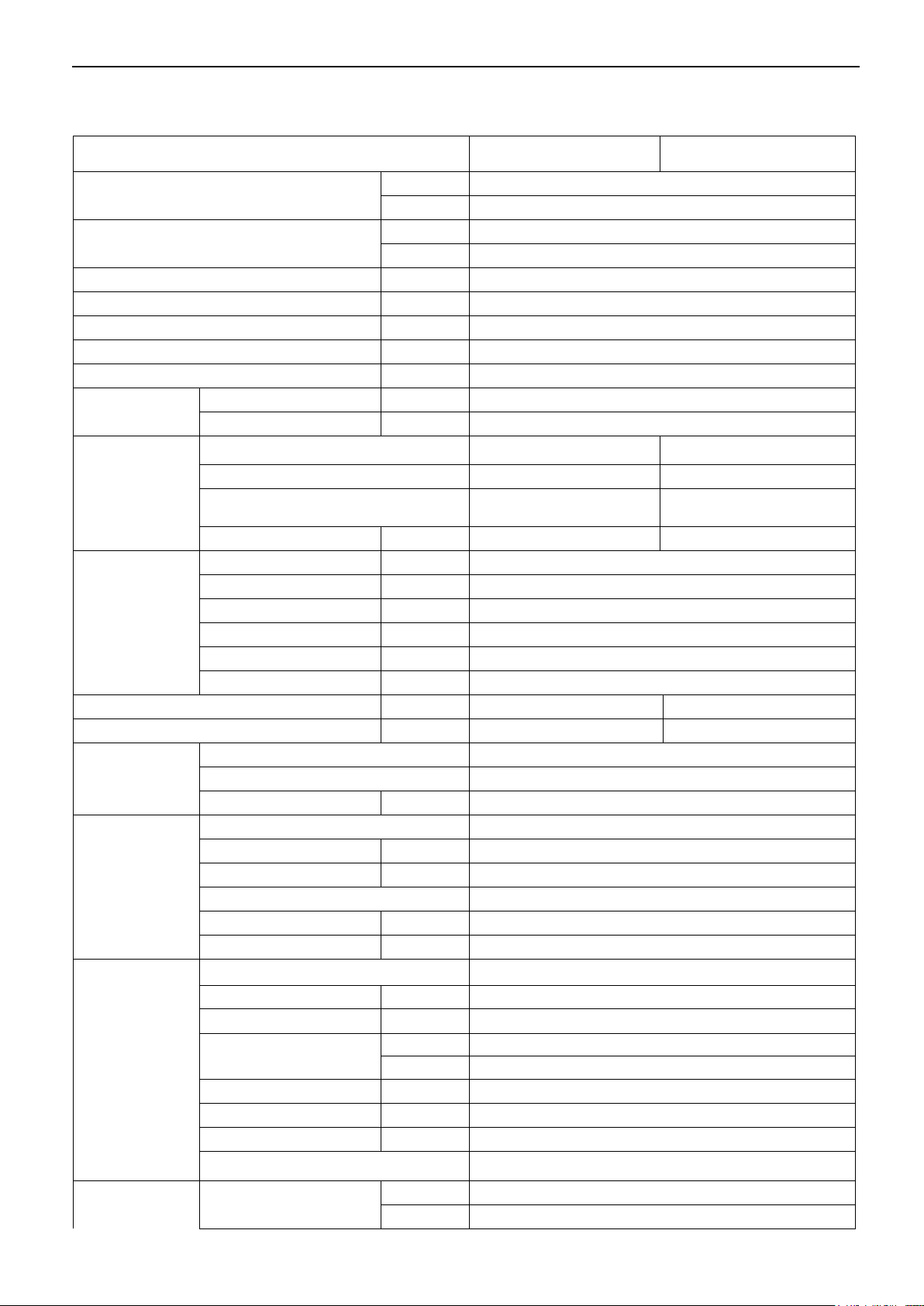

Model

MGBT-F60W/RN1

MGBT-D60W/RN1

MGBT-F120W/RN1

Cooling Capacity (*1)

kW

60

120

Btu/h

204,700

409,400

Cooling Capacity (*2)

kW

51.6

103.2

Btu/h

176,100

352,100

Heating Capacity

kW

64

65

128

EER(*1)

kW/ kW

3.11

3.09

3.12

EER(*2)

kW/ kW

2.20

2.22

2.23

COP

kW/ kW

3.23

3.19

3.08

Power supply

V/Ph/Hz

380~415/3/50

Power supply

Manual switch

A

100

200

Fuse

A

70

150

Compressor

Type

Scroll (fixed speed)

Digital Scroll + Fixed

speed

Scroll (fixed speed)

Brand

Copeland

Copeland

Copeland

Model

ZP137KCE-TFD-522

ZP137KCE-TFD-522

/ZPD72KCE-TFD-433

/ ZP67KCE-TFD-420

ZP137KCE-TFD-522

Quantity

Pieces 2 1+1+1

4

Power input

Cooling (*1)

kW

19.3

19.4

38.5

Cooling rated current (*1)

A

33.6

33.6

68.8

Cooling (*2)

kW

23.16

23.28

46.2

Cooling rated current (*2)

A

40.32

40.32

82.56

Heating

kW

19.8

20.4

41.5

Heating rated current

A

34.3

35.1

71.8

Max. Input consumption

kW

29.5

29

55.5

Rated Current

A

51.5

51.5

130

Refrigerant

Type

R410A

R410A

R410A

Refrigerant control

EXV+ capillary

Weight

kg

6.0×2

6.5×2

6.0×4

Condenser

(Air side)

Air side heat-exchanger type

Fin-coil

Quantity of fan motor

Pieces 2 2

4

Air flow volume

×103m3/h

24

24

48

Fan motor model

YS700-6F

YDK550-6E

YS700-6F

Fan motor rated current

A

1.8×2

4.0×2

1.8×4

Fan motor input

kW

0.9×2

0.865×2

0.9×4

Evaporator

(Water side)

Water side heat-exchanger type

Shell and tube

Shell and tube

Shell and tube

Water pressure drop

kPa

15

15

25

Volume L 42

42

64

Water inlet/outlet pipeline

inside normal diameter

mm

DN100

DN100

DN65

inch

4”

4”

2-1/2”

Water flow volume

m3/h

10.3

10.3

22.4

Max. Pressure

MPa 1 1

1

Evaporator volume

L

42

42

46

Water pipe connection type

Flexible joint

Flexible joint

Flexible joint

Dimension

Net(W×H×D)

mm

2000×1880×900

2000×1880×900

2000×1685×2090

1.8 Specification: MGBT-F60W/RN1, MGBT-D60W/RN1, MGBT-F120W/RN1

13

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

inch

78.7×74×35.4

78.7×74×35.4

78.7×66.3×82.3

Packing (W×H×D)

mm

2090×2095×985

2090×2095×985

2090×1755×2240

inch

82.3×82.5×38.8

82.3×82.5×38.8

82.3×69×88.2

Weight

Net weight

kg

580

600

1150

Gross weight

kg

650

640

1200

Connection

wire

Power wire

mm2×No.

25×4+16 ×1

16×4+10×1

35×3+16 ×2

Signal wire

mm2×No.

0.75×3-core with shielding

Control type

Wired controller

Safety protection device

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temp. difference protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

12) Low-temperature protection of shell and tube heat exchanger.

Sound level(semi-anechoic )

dB(A)

65

67

70

Operation water temp.

℃

Cooling:5~17

Heating:45~50

Cooling:0~17(5℃

must add antifreeze)

Heating:22~50

Cooling:5~17

Heating:45~50

Ambient temp.

℃

Cooling:10~52

Heating:-10~21

Cooling:10~52

Heating:-10~21

Cooling:10~52

Heating:-10~21

Note: Specifications are based on the following conditions:

Cooling : (*1) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 35°C (117℉) DB.

(*2) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 46˚C (140℉)DB

Heating : warm water inlet/outlet: 40˚C / 45˚C, and outdoor ambient temp. 7˚C DB/6°CWB.

Water side fouling factor: 0.086m2˚C /kW.

14

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

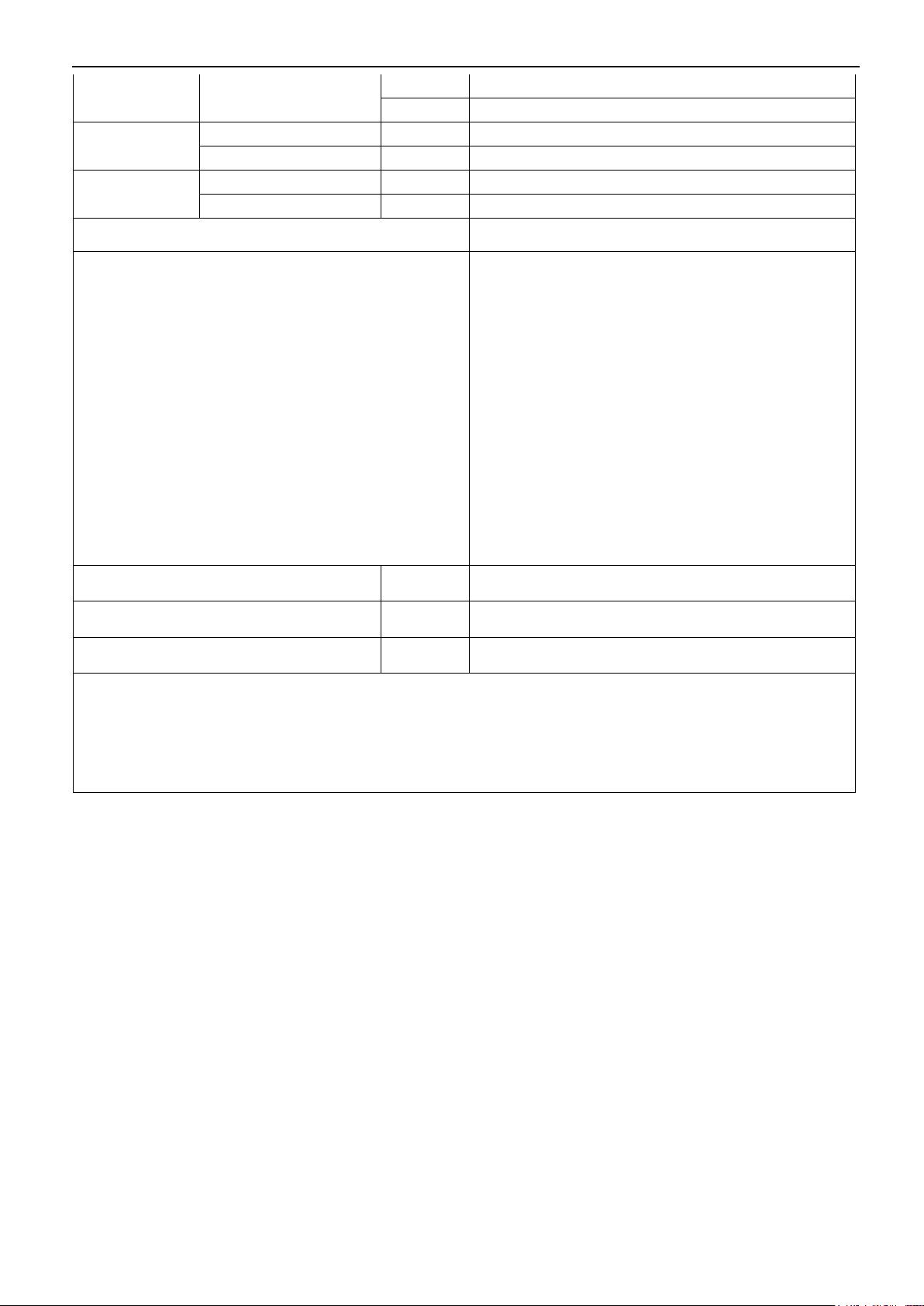

Model

MGBT-F180W/RN1

MGBT-F250W/RN1

Cooling Capacity (*1)

kW

180

250

Btu/h

614,100

830000

Cooling Capacity (*2)

kW

155.8

216

Btu/h

528,200

737000

Heating Capacity

kW

195

270

EER(*1)

kW/ kW

3.11

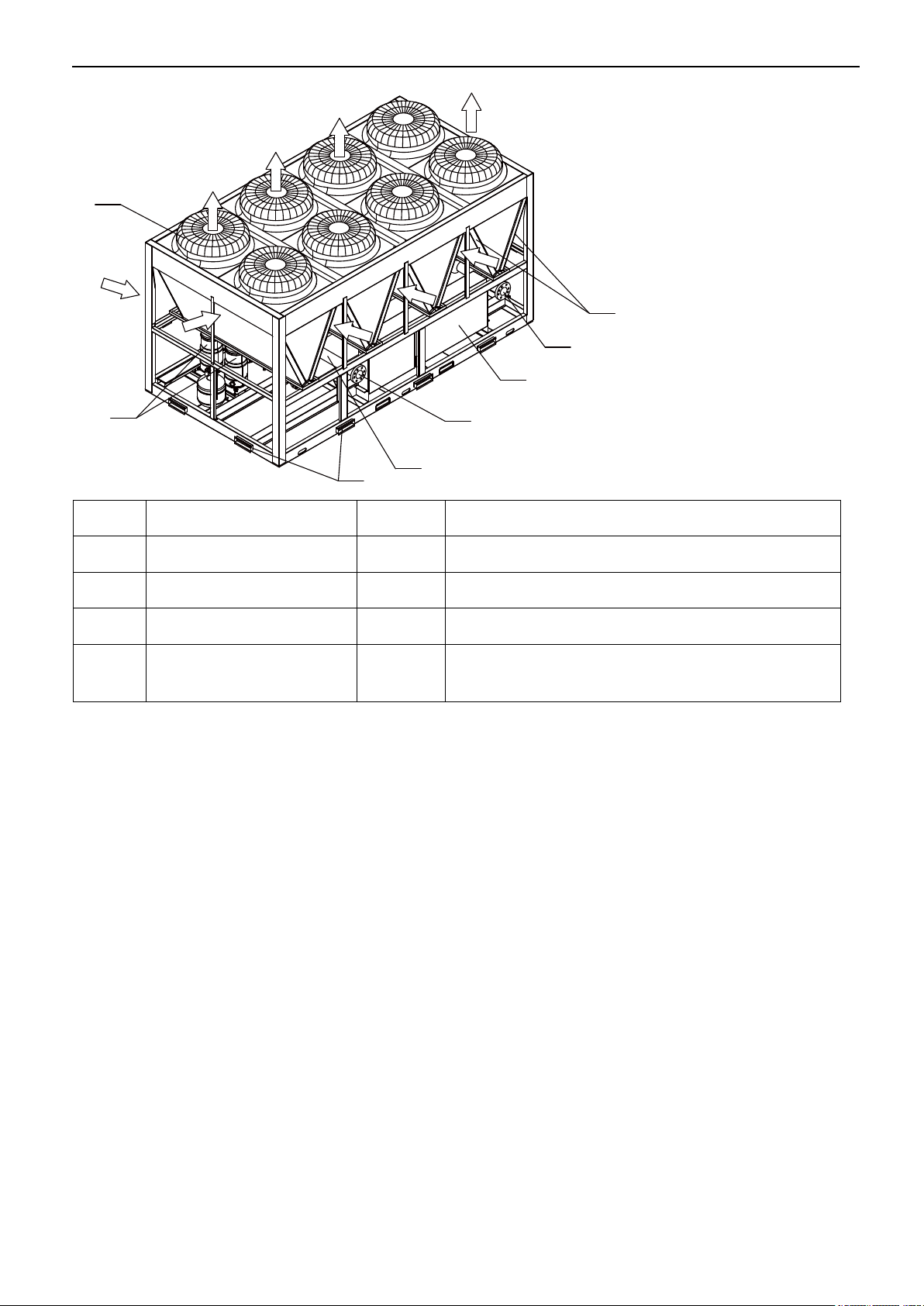

3.19

EER(*2)

kW/ kW

2.66

2.50

COP

kW/ kW

3.28

3.38

Power supply

V/Ph/Hz

380~415/3/50

380~415/3/50

Power supply

Manual switch A 300

450

Fuse

A

200

300

Compressor

Type

Scroll (fixed speed)

Scroll (fixed speed)

Brand

Copeland

Copeland

Model

ZP137KCE-TFD-522

SH120A4ALC

Quantity

Pieces 6 8

Power input

Cooling (*1)

kW

57.9

78.3

Cooling rated current (*1)

A

100.8

141.9

Cooling (*2)

kW

58.5

86.3

Cooling rated current (*2)

A

121

170.3

Heating

kW

59.4

80

Heating rated current

A

102.9

146

Max. Input consumption

kW

78.3

104.9

Rated Current A 155.1

200

Refrigerant

Type

R410A

R410A

Refrigerant control

EXV+ capillary

EXV+ capillary

Weight

kg

6.0×6

15×4

Condenser (Air

side)

Air side heat-exchanger type

Fin-coil

Fin-coil

Quantity of fan motor

Pieces 6 8

Air flow volume

×103m3/h

72

96

Fan motor model

YS700-6F/ YS700-6F-1

YS700-6F-1/YS700-6F-2

Fan motor rated current

A

1.8×6

1.8×8

Fan motor input

kW

0.9×6

0.9×8

Evaporator

(Water side)

Water side heat-exchanger type

Shell and tube

Shell and tube

Water pressure drop

kPa

30

40

Volume

L

90

131

Water inlet/outlet pipeline

inside normal diameter

mm

DN80

DN100

inch

3”

4”

Water flow volume

m3/h

31

43

Max. Pressure

MPa 1 1

Evaporator volume L 90

131

Water pipe connection type

Flexible joint

Flexible joint

Dimension

Net(W×H×D)

mm

2850×2000×2110

3800×2130×2000

inch

112.2×78.7×83.1

149.6×83.86×78.74

1.9 Specification: MGBT-F180W/RN1, MGBT-F250W/RN1

15

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Packing size(W×H×D)

mm

2980×2135×2260

3900×2200×2100

inch

117.3×84.1×89

153.54×86.61×82.68

Weight

Net weight

kg

1730

2450

Gross weight

kg

1780

2500

Connection wire

Power wire

mm2×No.

70×3+35×2

185×4+70×1

Signal wire

mm2×No.

0.75×3-core with shielding

0.75×3-core with shielding

Control type

Wired controller

Wired controller Wired controller

Safety protection device

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temp. difference protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

12)Low-temp. protection of shell-and-tube heat exchanger.

Sound level(semi-anechoic )

dB(A)

74

74

Operation water temp.

℃

Cooling:5~17

Heating:45~50

Cooling:0~17(5℃ must

add antifreeze)

Heating:22~50

Ambient temp.

℃

Cooling:10~52

Heating:-10~21

Cooling:10~52

Heating:-10~21

Note: Specifications are based on the following conditions:

Cooling : (*1) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 35°C (117℉) DB.

(*2) chilled water inlet/outlet: 12˚C / 7˚C, and outdoor ambient temp. of 46˚C (140℉)DB

Heating : warm water inlet/outlet: 40˚C / 45˚C, and outdoor ambient temp. 7˚C DB/6°CWB.

Water side fouling factor: 0.086m2˚C /kW.

16

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Model

Outdoor Unit

Application

Power

Supply

Compressor

OFM

Hz

VOL

Ph

Min.

Max.

TOCA

MFA

LRA

RLA

Qty

KW

FLA

Qty

MGBT-F25W/RN1

50

380-415

3

342

456

25

36

64

10.9

2

0.65

2.95

1

MGBT-D25W/RN1

50

380-415

3

342

456

25

36

64/64

10.9/10.9

2

0.65

2.95

1

MGBT-F30W/RN1

50

380-415

3

342

456

25

36

64

10.9

2

0.65

2.95

1

MGBT-D30W/RN1

50

380-415

3

342

456

25

36

64/64

10.9/10.9

2

0.65

2.95

1

MGBT-F60W/RN1

50

380-415

3

342

456

52

100

118

20.7

2

0.9x2

1.8x2

2

MGBT-D60W/RN1

50

380-415

3

342

456

52

100

118/82.4/74

20.7/12.7/11.8

3

0.865x2

4.0x2

2

MGBT-F120W/RN1

50

380-415

3

342

456

90

200

118

20.7

4

0.9x4

1.8x4

4

MGBT-F180W/RN1

50

380-415

3

342

456

135

300

118

20.7

6

0.9x6

1.8x6

6

MGBT-F250W/RN1

50

380-415

3

342

456

191

300

142

20.7

8

0.9x8

1.8x8

8

Voltage imbalance between phases to be <2%.

1.10 Electric Characteristics

Remark:

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

LRA: Locked Rotor Amps. (A)

RLA: Rated Load Amps. (A)

OFM: Outdoor Fan Motor.

FLA: Full Load Amps. (A)

KW: Rated Motor Input (KW)

17

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

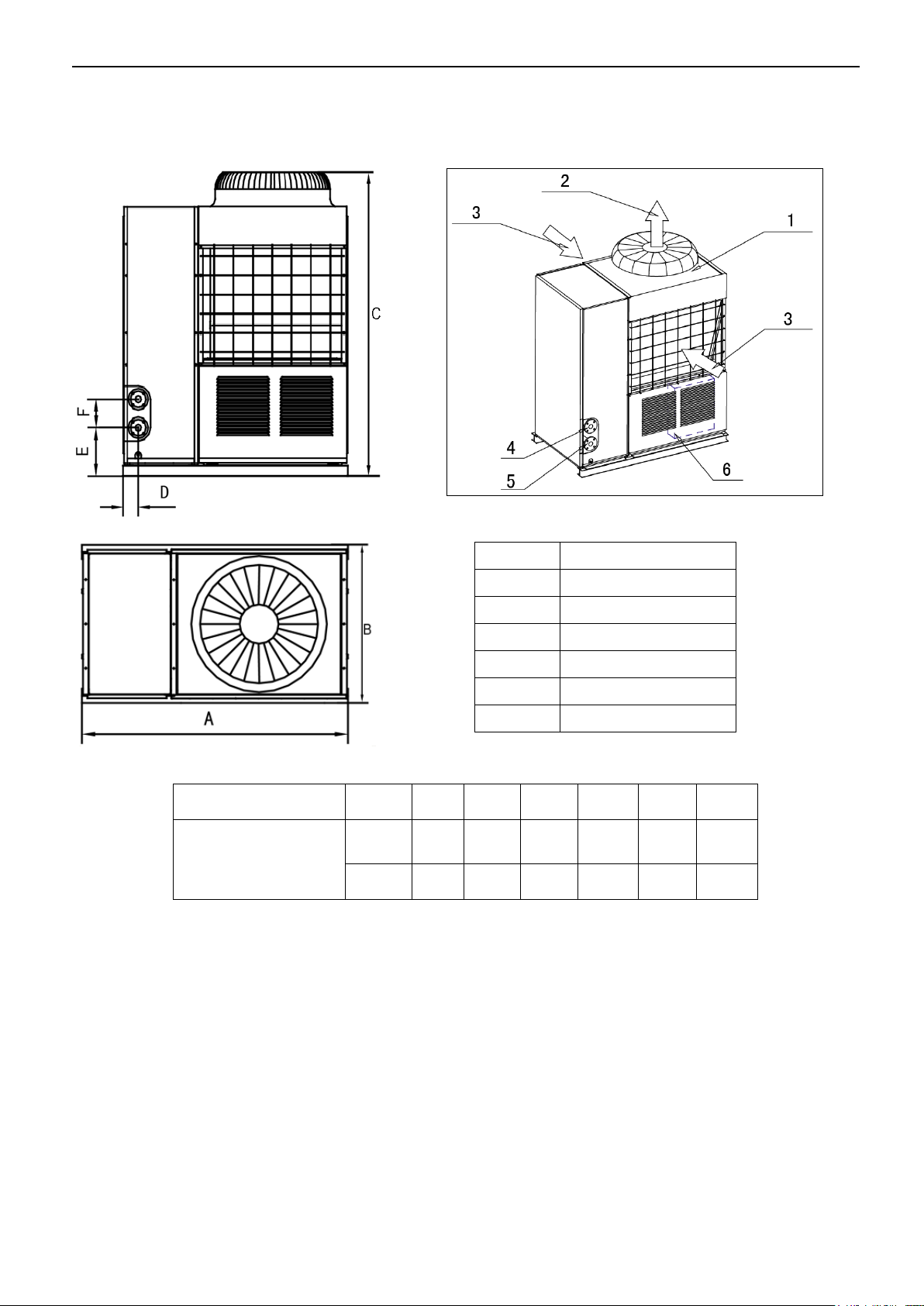

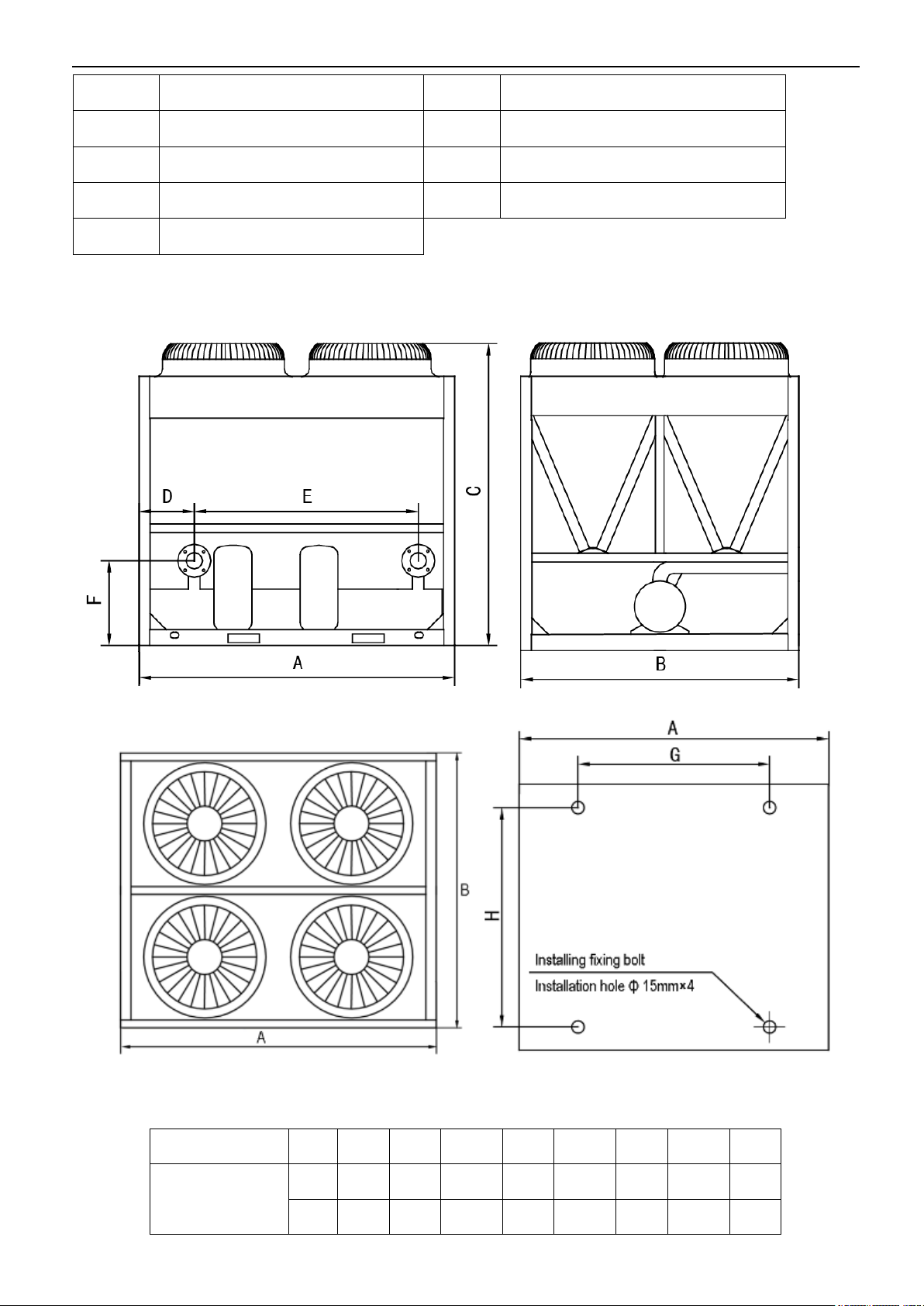

Model

Unit

A B C D E

F

MGBT-F(D)25W/RN1

MGBT-F(D)30W/RN1

mm

1514

841

1865

115

315

172

inch

59.6

33.11

73.43

4.53

12.4

6.77

No.

Name

1

Top cover

2

Air outlet

3

Air inlet

4

Water outlet

5

Water inlet

6

Electric control box

1.11 Outlook drawing: MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-D30W/RN1, MGBT-F30W/RN1

Front view

Top view

18

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

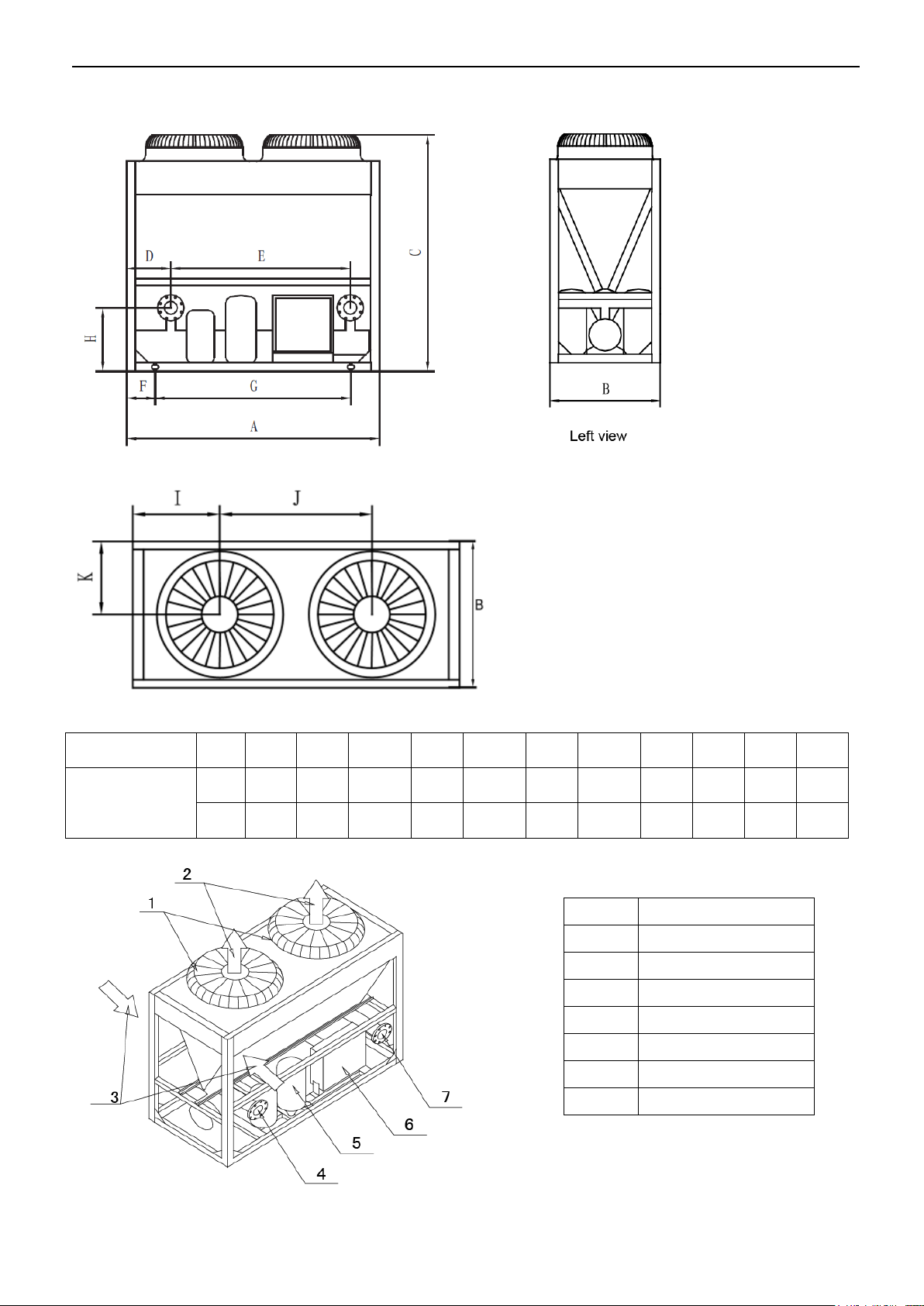

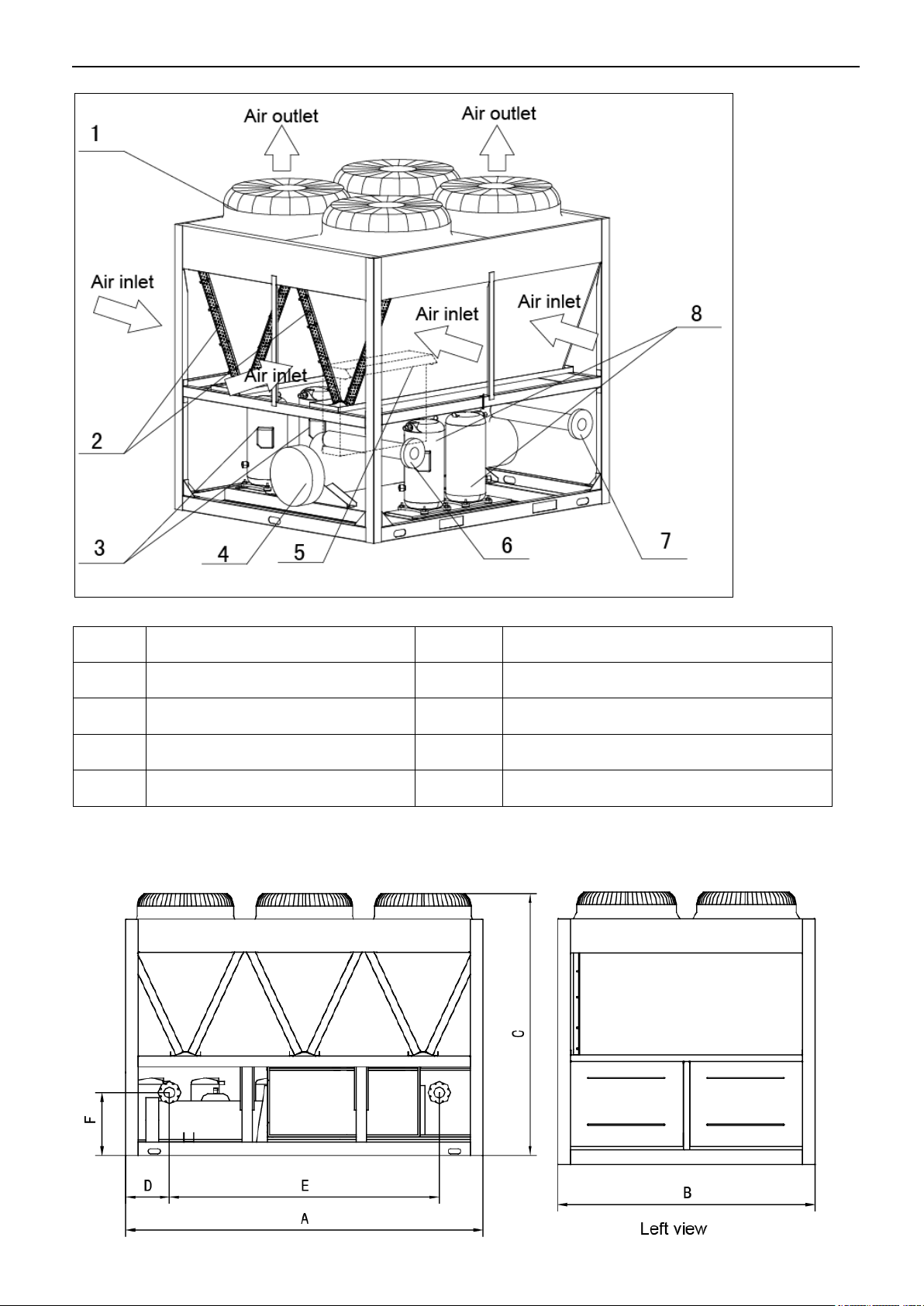

Model

Unit

A B C D E F G H I J K

MGBT-F60W/RN1

mm

2000

900

1880

350

1420

225

1500

506

530

930

450

inch

78.74

35.4

74

13.78

55.91

8.86

59.06

19.92

20.87

36.61

17.72

No.

Name

1

Top cover

2

Air outlet

3

Air inlet

4

Water outlet

5

Compressor

6

Electric control box

7

Water inlet

1.12 Outlook drawing: MGBT-F60W/RN1

Front view

Top view

19

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

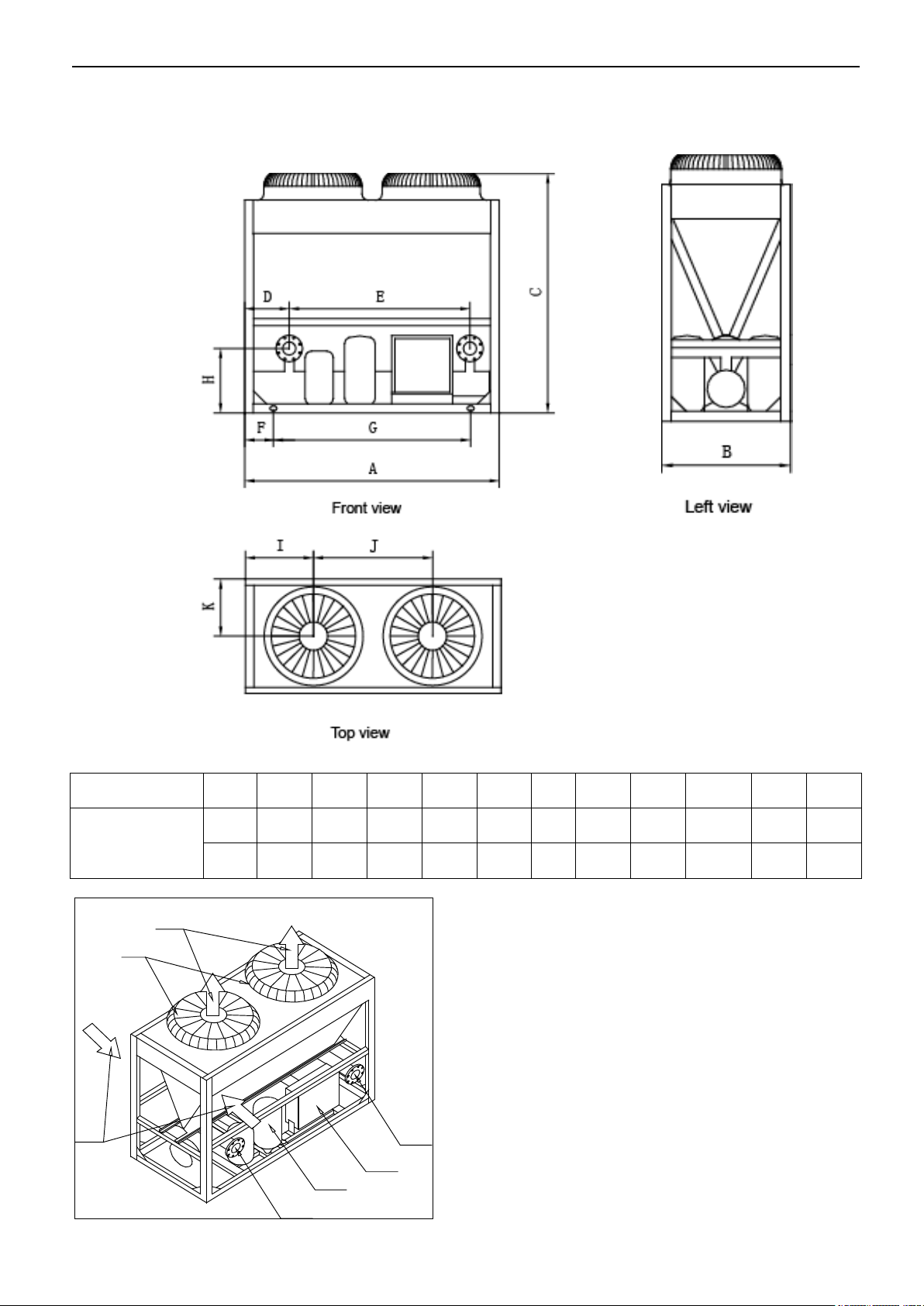

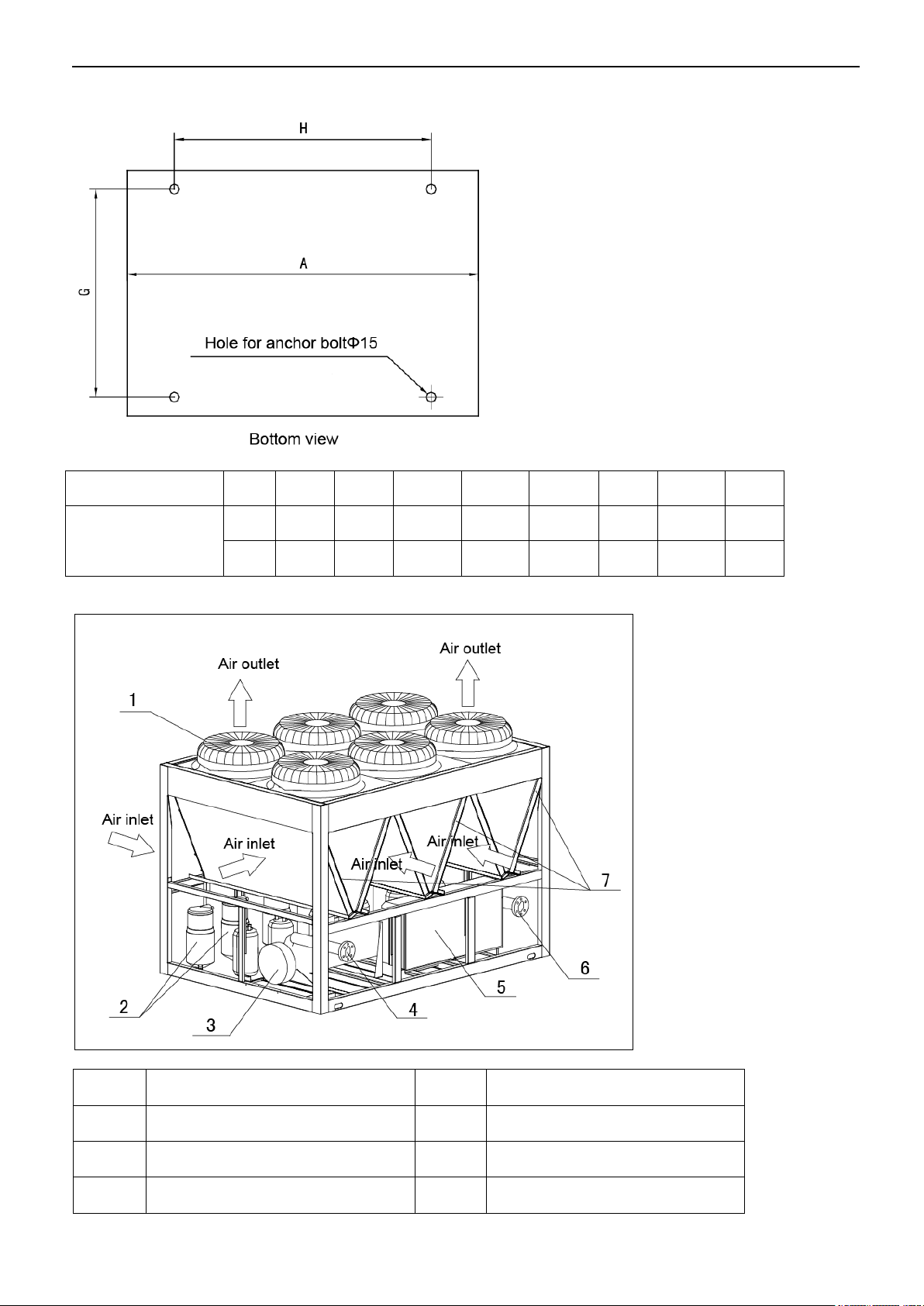

Model

unit A B C D E F G H I J

K

MGBT-D60W/RN1

mm

2000

900

1880

350

1420

225

1500

506

530

930

450

inch

78.74

35.43

74

13.78

55.9

8.86

59.05

19.92

28.87

36.61

17.72

3

1

2

4

5

6

7

1.13 Outlook drawing: MGBT-D60W/RN1

20

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

No.

Name

No.

Name

1

Top cover

5

Compressor

2

Air outlet

6

Electric control box

3

Air inlet

7

Water inlet

4

Water outlet

Model

Unit

A B C D E F G

H

MGBT-F120W/RN1

mm

2000

1685

2080

350

1420

506

1550

1586

inch

78.74

66.34

81.89

13.78

55.91

19.92

61.02

62.44

1.14 Outlook drawing: MGBT-F120W/RN1

Front view Side view

Top view Anchor hole

:

21

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

No.

Name

No.

Name

1

Top cover

5

Electric control box Air inlet

2

Condenser

6

Water outlet

3

Compressor

7

Water inlet

4

Evaporator

8

Compressor

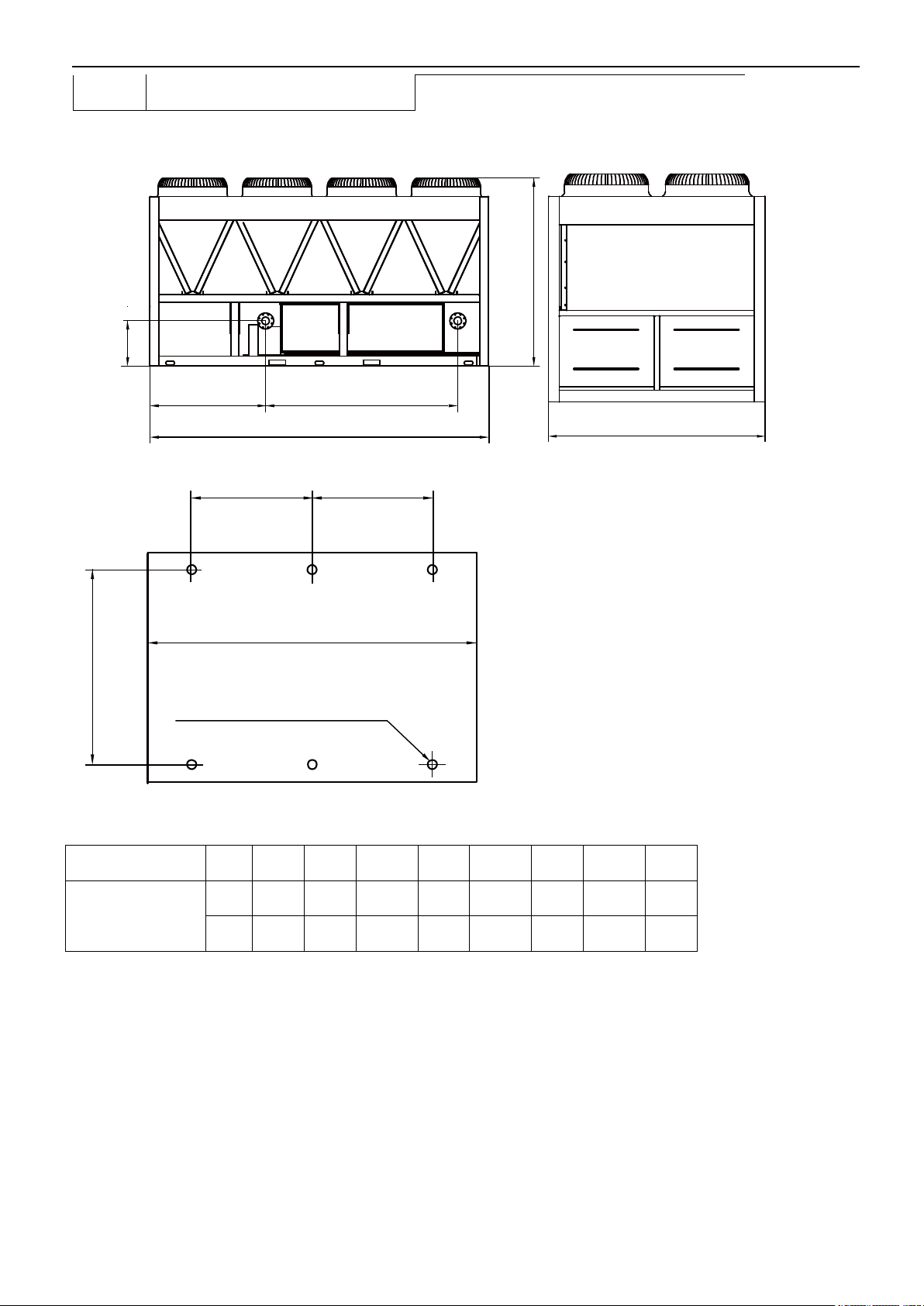

1.15 Outlook drawing: MGBT-F180W/RN1

22

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Model

unit A B C D E F G H

MGBT-F180W/RN1

Mm

2850

2000

2110

3470

2156

506

1888

2388

inch

112.2

78.74

83.07

136.61

84.88

19.92

74.33

94.02

No.

Name

No.

Name

1

Top cover

5

Electric control box

2

Compressor

6

Water inlet

3

Evaporator

7

Condenser

Front view

23

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

4

Water outlet

Front view

E

A

C

F

D

Left view

B

Bottom view

H H

G

A

Hole for anchor boltΦ15

Model

unit A B C D E F G H

MGBT-F250W/RN1

Mm

3800

2000

2130

1235

2156

573

1888

1551

inch

149.6

78.74

83.86

48.62

84.88

22.56

74.33

61.06

1.16 Outlook drawing: MGBT-F250W/RN1

24

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

1

Air outlet

Air outlet

Air outlet

Air outlet

Air inlet

2

8

4

5

6

7

3

A

i

r

i

n

l

e

t

A

i

r

i

n

l

e

t

A

i

r

i

n

l

e

t

A

i

r

i

n

l

e

t

No.

Name

No.

Name

1

Top cover

5

Electric control box

2

Compressor

6

Water inlet

3

Evaporator

7

Condenser

4

Water outlet

8

Transportation guard plate (Be removed off

after installation)

25

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

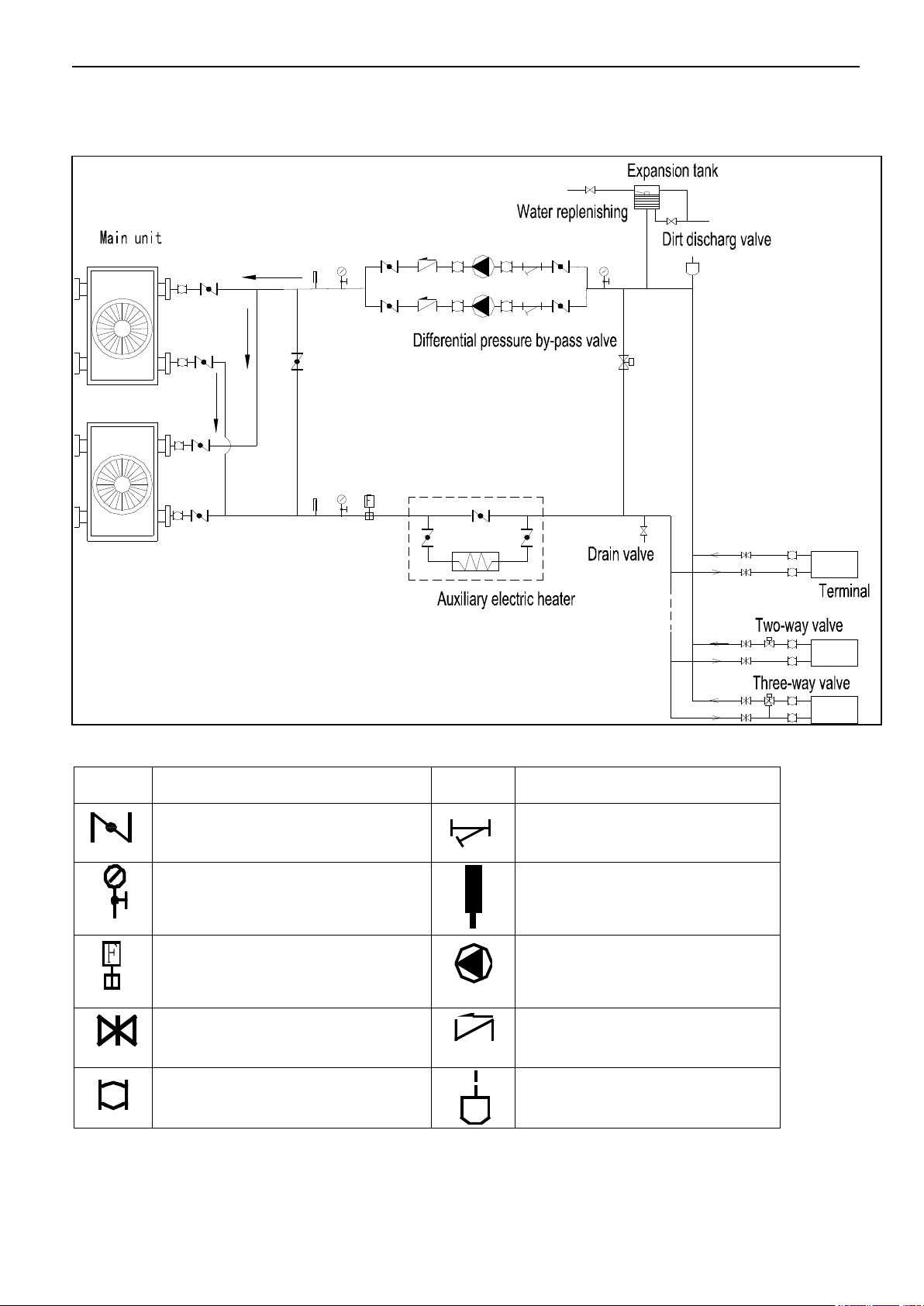

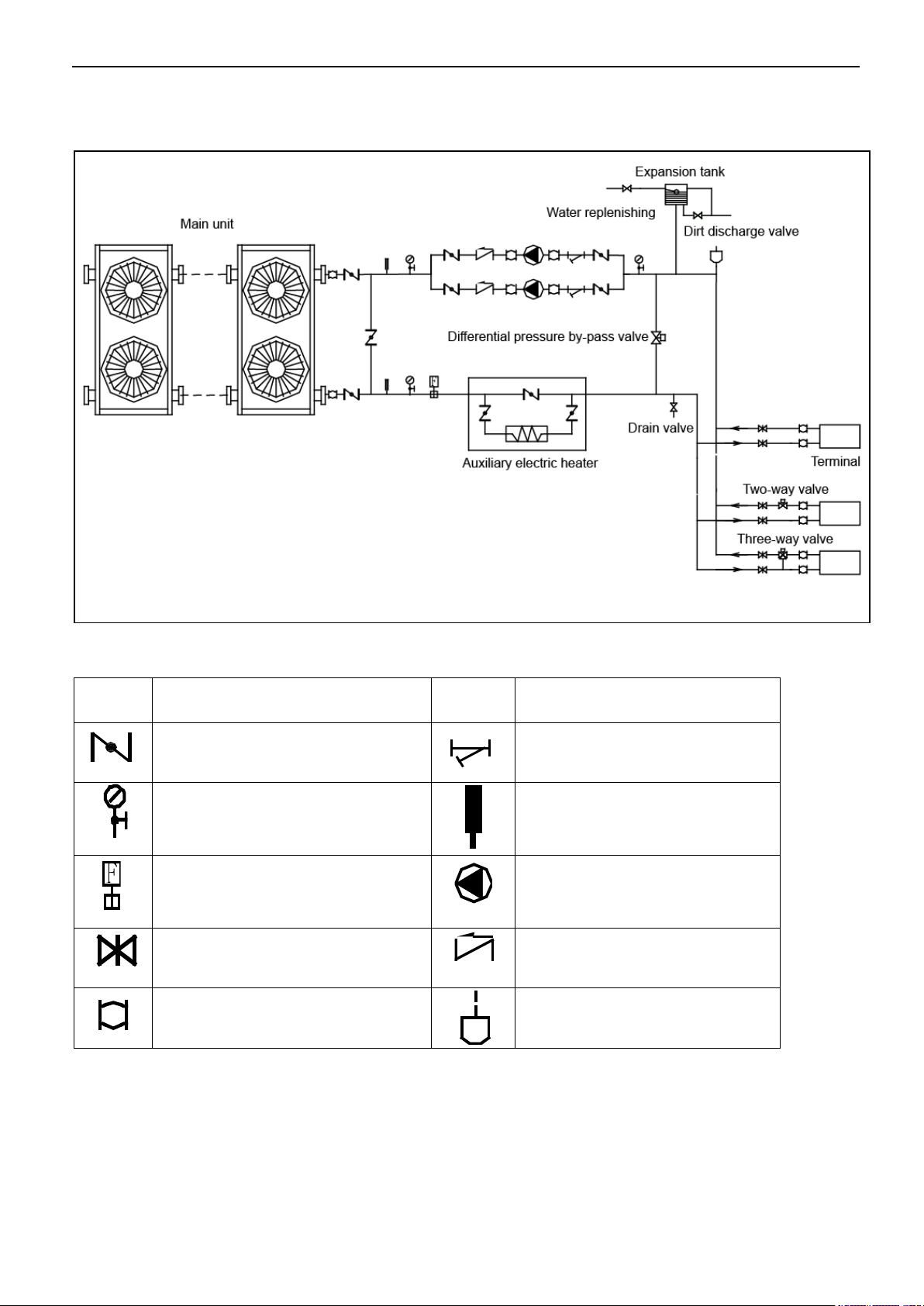

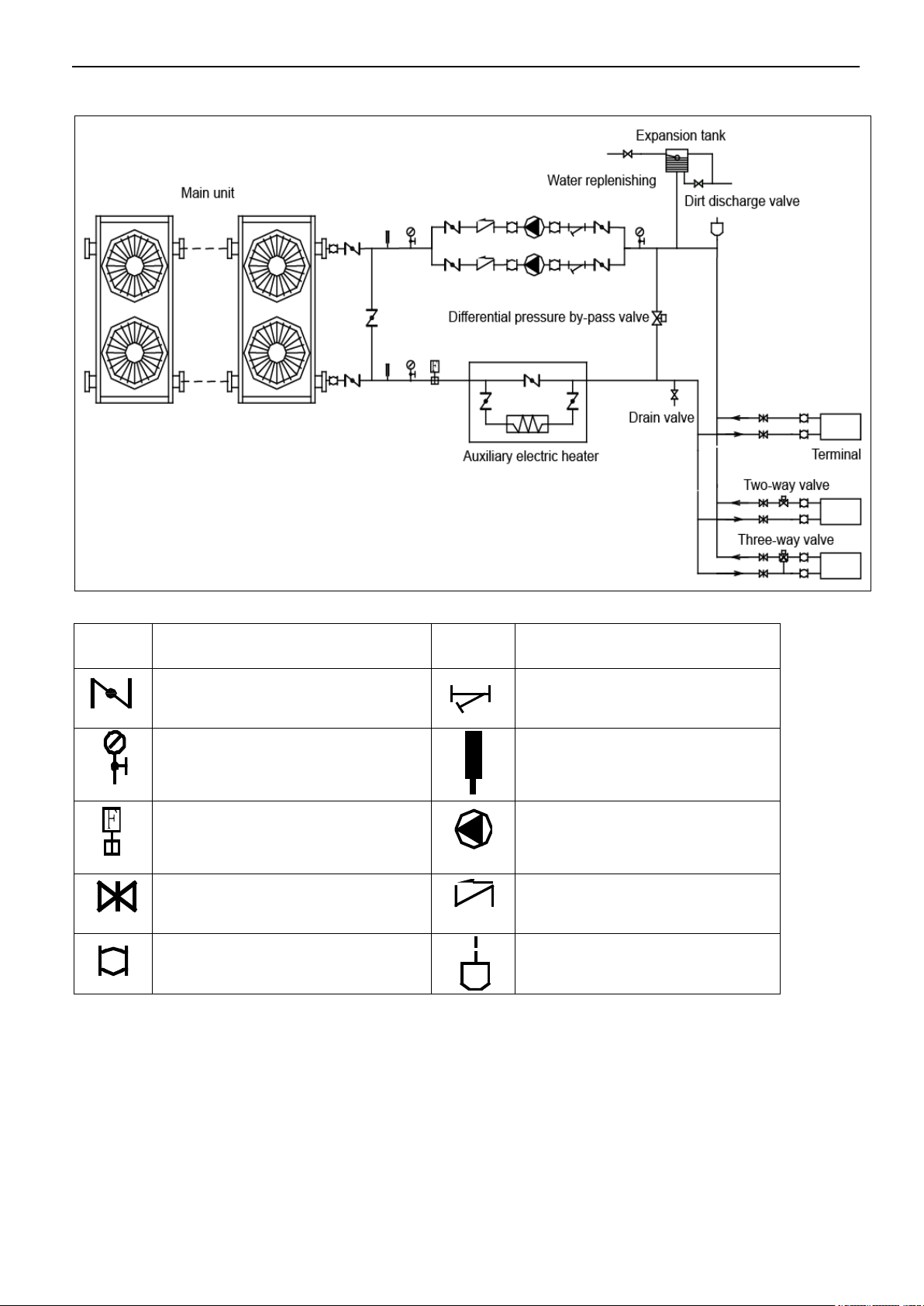

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

2. Pipe connection drawing

2.1MGBT-F25W/RN1,MGBT-D25W/RN1,MGBT-F30W/RN1,MGBT-D30W/RN1

The table below describes the symbols.

26

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

2.2 MGBT-F60W/RN1

The table below describes the symbols.

27

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

2.3 MGBT-D60W/RN1

The table below describes the symbols.

28

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

2.4 MGBT-F120W/RN1

The table below describes the symbols.

29

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

2.5 MGBT-F180W/RN1

The table below describes the symbols.

30

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Symbol

Symbol explanation

Symbol

Symbol explanation

Stop valve

Y-shaped filter

Pressure gauge

Thermometer

Water flow switch

Circulating pump

Gate valve

Check valve

Flexible joint

Automatic discharge valve

2.6 MGBT-F250W/RN1

The table below describes the symbols.

31

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Compressor A

Compressor B

Low pressure cylinder A

Low pressure cylinder B

4-way valve A

4-way valve B

Condenser

Evaporator

(Double-pipe heat exchanger)

Fan

Water outlet

Water inlet

EXV

EXV

Shell and tube

evaporator

Condenser

Water flow direction

Compressor B

low pressure cylinder B

4-Way valve A

Fan A

EEV

Capillary

EEV

Capillary

Fan B

4-Way valve B

Compressor A

low pressure cylinder A

3. Refrigeration system drawing

3.1 MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-F30W/RN1 ,MGBT-D30W/RN1

Each module has two compressors with one separate unit, one double-pipe evaporator for two refrigerant

systems.

3.2 MGBT-F60W/RN1

Each module has two compressors with one separate unit, one shell and tube evaporator for two refrigerant

systems.

32

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Shell and tube evaporator

Condenser

Water flow direction

Compressor

B

low pressure cylinder B

4-Way valve A

Fan A

EEV

Capillary

EEV

Capillary

Fan B

4-Way valve B

Compressor

A1 digital

low pressure cylinder A

Compressor

A2

3.3 MGBT-D60W/RN1

Each module has three compressors with one separate units, one shell and tube evaporator for two

refrigerant systems.

3.4 MGBT-F120W/RN1

Each module has four compressors with two separate unit, one shell and tube evaporator for four refrigerant

systems.

33

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Shell and tube

evaporator

Condenser

Water flow direction

Compressor B

low pressure cylinder B

4-Way valve A

Fan A

EEV

Capillary

EEV

Capillary

Fan B

4-Way valve B

Compressor A

low pressure cylinder A

Unit 2

Unit 1

Shell and tube evaporator

Condenser

Water flow direction

Compressor B

low pressure cylinder B

4-Way valve A

Fan A

EEV

Capillary

EEV

Unit 2

Unit 3

Capillary

Fan B

4-Way valve B

Compressor A

low pressure cylinder A

Unit 1

3.5 MGBT-F180W/RN1

Each module has six compressors with three separate unit, one shell and tube evaporator for six refrigerant

systems.

3.6 MGBT-F250W/RN1

Each module has eight compressors with two separate unit, one shell and tube evaporator for four refrigerant

systems

34

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Shell and tube

evaporator

Condenser

Water flow direction

Compressor B1

low pressure cylinder B

4-Way valve A

Fan A

EEV

Capillary

EEV

Capillary

Fan B

4-Way valve B

Compressor A1

low pressure cylinder A

Unit 2

Unit 1

Compressor A2

Compressor B2

35

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Attached Drawing (I) Electric Drawing of Main Unit and Auxiliary Unit

XP8

XP7

XS8

XS7

T

3

B

T

3

A

HEAT_A

L_PRO(2B)

H_PRO(B)

K1(B)

1 2

ON

PMV(B)

QUERY

L_PRO(2A)

H_PRO(A)

K1(A)

CN18(WHIT E)

POWER

CN20(RED)

TRANS I N

CN15(WHITE)

CN11(BLACK)

COMP(B) S.V(B )

COMP(A) S.V(A )

CN9

PUMP

CN7

HEAT

CN1(WHITE)

PMV(A)

CN2(RED)

PMV(B)

CN21

TBH2

CN3(RED)

WATER_PR O

CN5

H&L_PRO

COM(I)

COM(O)

CN6

CN8

CN10

CN12 CN13

CN14

CT1

CURRENT(A )

CT2

CURRENT(B )

PMV(A)

CN19(WHITE)

TRANS OUT

FAN _H

FAN _L

(YE LLOW)

(BLUE)

COMP B

2

1

5

21

3

6

22

4

T3

A1

A2

T2

T1

HEAT_B

RE D

H2 P 1 P 2H1

X T 3

S1

S2

T3A T3 B T 4

XT4

XT5

R

T

6

R

T

7

CN22

TBH1

T61

T62

L_PRO(1A)

L_PRO(1B)

COMP A

2

5

21

3

6

22

4

T3

A1

A2

T2

T1

FAN

( )

(U)

(V)

(W)

(U)

(V)

(W)

Y&G

POWER IN

Y & G

S1

16 -W AY DAI L SWI TCH FUNC TI O N

1

2

SW IT CH

FU NC TIO N

D I GITA L

M O DULE

N O RMAL

M O DULE

2- WA Y J UMP SWIT C H F UNC T ION

DA I L S WIT C H

AD DR ES S

R E D

W H I T E

B LU E

S2

Q

P

(E)

GRAY

7- WA Y

TE RM INA L

XT 2

4- WA Y

TE RM INA L

H E A T

P U M P

BL U EBL U EBL U E

BL U E

YE L L O W

YE L L O W

Y

E

L

L

O

W

B

L

A

C

K

(E F FEC T O N N O.0 M ODU L E)

(ON/OFF SIGNAL!)

L O W V O LT A GE S IG N AL

D O N ' T C O N N E CT H IG H V OL T AG E !

ORANGE

RED

ELE CTRI C EXPA N SIV E VALV E (B )

HIG H PRE SSUR E

PRO TEC TOR B

LOW P RESSU RE

PRO TEC TO R 2 B

PURPLE

LOW P RESSU RE

PRO TEC TO R 2A

YELLOW

HIG H P RESS URE

PRO TEC TO R A

TEM P P ROT ECTO R

SWI TCH A

IN-LET WATER TEMP. SENSOR

ANTI-FREEZIN G TEMP. SENSOR

TEM P P ROT ECTO R

SWI TCH B

LOW P RESSU RE

PRO TEC TO R 1B

LOW P RESSU RE

PRO TEC TO R 1A

RED BLACK

CONDENSER

TEMP B

CONDENSER

TEMP A

TOT AL OUT - LET

WAT ER TEM P .

UNI T O UT- LE T

WAT ER TEM P .

CR AN K

COMPRESSOR A

Y& G

BLUE

BL AC K

AC CO NTACTO R

BLACK

BLUE

RED

WH IT E

CR AN K

COMPRESSOR B

AC CO NTACTOR

BLACK

BLUE

RED

WH IT E

Y& G

Y& G

S.V(A)

4-VALVE A

S.V(B)

4-VALVE B

MIDDL E

WIRE JO IN T

MIDDL E

WIRE JO IN T

PURPLE

BLUE

B

LACK

BLACK

MIDDL E

WIRE JO IN T

XT6

WHITE

BLUE

RED

BLACK

BL U EBL U EBL U E

BL U E

YE L L O W

YE L L O W

OR A N G E

BLUE

PU R P LE

XP9

XS9

XP9

OUTDOOR TEMP SENSOR

T

4

XP10

XS10

WHITE

OUT DO OR WI RI NG DI AG RA M

GRAY

GRAY

4-WA Y TERMI NA L

XT1

W1 W2

Q

P

(E)

HIGH

N

LOW

BLACK

BALCK

BLACK

BLACK

RED

WHITE

FAN CAP

CN23(WHITE)

ON/OFF

MIDDL E

WIRE JO IN T

XT7

RED

PWM

CN17

PWM PRESSURE

RELIF VALVE

RED

RED RED

RED

BLACK

RED

BLUE

RY8RY7

10K

T-COMP SHORT

BE CO NNEC T ED TH E

COR RES PON D TE RMIN A L

4. Wiring diagram

4.1 MGBT-F25W/RN1, MGBT-D25W/RN1, MGBT-F30W/RN1, MGBT-D30W/RN1

36

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Attached picture (I) Electric Drawing of Main Unit and

Auxiliary Unit

XP8

XP7

XS8

XS7

T

3

B

T

3

A

FAN B

HEAT_A

L_PRO (2B)

H_PRO (B)

K1(B )

1 2

ON

KM1

PMV(B)

QUERY

L_PRO (2A)

H_PRO (A)

K1(A )

CN18(WHITE)

POWER

CN2 0(RED)

TRANS IN

PWM

CN1 7

CN1 5(WHITE)

CN1 1(BLACK)

COMP(B) S.V(B)

COMP(A) S.V(A)

CN9

PUM P

CN7

HEA T

CN1(WHITE)

PMV(A)

CN2(RED)

PMV(B)

CN2 1

TBH 2

CN3(RED)

WATER_PRO

CN5

H&L_PRO

COM(I)

COM(O)

CN6

CN8

CN1 0

CN1 2 CN 13

CN1 4

CT1

CURRENT(A)

CT2

CURRENT(B)

PMV(A)

CN1 9(WHITE)

TRANS OUT

FAN_H

RY7

FAN_L

RY8

(YELLOW)

(BLUE)

COMP B

2

1

5

21

3

6

22

4

T3

A1

A2

T2

T1

HEAT_B

RED

H2 P1 P2H1

XT 4

S1

S2

T3A T3B T4

XT5

XT6

R

T

6

R

T

7

CN2 2

TBH 1

T61

T62

L_PRO (1A)

L_PRO (1B)

COMP A

2

5

21

3

6

22

4

T3

A1

A2

T2

T1

FAN A

KM2

(U )

(V )

(W )

(U )

(V )

(W )

Y&G

4-WA Y TERMINAL

XT1

POWER I N

Y& G

S1

16-WAY DAIL SWITCH FUNCTION

1

2

SWITCH

FUNCTION

RE SE RVE

NO RM AL

2-WAY JUMP SWITCH FUNCTION

DAIL SWITCH

ADDRESS

BLUE

WHITE

RED

RE D

WH ITE

BL UE

BL ACK

S2

(FACTORY SET TING)

4-WAY

TERMINAL

HEAT

PUMP

BLU EBLU EBLU E

BLU E

YEL LO W

YEL LO W

(EFFECT ON NO.0 MODULE)

(O N/O F F SIGNAL! )

ORANGE

RED

ELECTRI C EXPANSIVE

VA LVE(B)

HI GH P RES SUR E

PR OTE CTO R B

LO W PR E SSU R E

PR OTE CTO R 2B

PURPLE

LO W PR E SSUR E

PR OTE CTO R 2 A

YELLOW

HI GH P RESS UR E

PR OTE CTO R A

TE MP PR OTEC TOR

SW ITC H A

IN-LE T WATE R TEMP. SENSO R

ANTI-FREEZING T EMP. SEN SOR

TE MP P ROTE C TO R

SW ITC H B

LO W PR ESSU RE

PR OTE CTO R 1B

LO W PR E SSUR E

PR OTE CTO R 1 A

RED

BLACK

CONDENSER

TEMP B

CONDENSER

TEMP A

TO TAL O UT-L ET

WAT E R T EMP .

UN IT O U T-L E T

WAT E R T EMP .

RELAY

RELAY

CRANK

COMPRESSOR A

Y&G

RED

RED

WHITE

RED

RED

Y&G

BLACK

RED

WHITE

AC C O N T A C T O R

BLACK

WHITE

BLUE

RED

RED

BLUE

RED

WHITE

CRANK

COMPRESSOR B

RED

AC CONTACT O R

BLACK

WHITE

BLUE

RED

BLUE

RED

WHITE

Y&G

Y&G

S.V (A)

4-V ALV E A

S.V (B)

4-V ALV E B

MIDDL E

WIR E JOIN T

MIDDL E

WIR E JOIN T

ORANGE

PURPL E

BLUE

BLACK

BLACK(N)

BLACK

BLACK

MIDDL E

WIR E JOIN T

XT 7

RED

RED

WHITE

BLUE

RED

BLACK

BLU EBLU EBLU E

BLU E

YEL LO W

YEL LO W

ORA NG E

BLUE

PUR PL E

RED

XP9

XS9

XP9

OUTDOOR T EM P SENSO R

T

4

XP10XS10

WHITE

BLACK

BLACK(N)

RED

WHITE

BLUE

BLACK

BLACK

RED

3

2

2

2

2

BROWN

BROWN

4

2

2

BROWN

BROWN

RED

RED

BLACK(N)

OUTDOOR WIRING DI AGRAM

Q

P

(E)

GRAY

7-WAY

TERMINAL

XT2

Y

E

L

L

O

W

B

L

A

C

K

LOW VO LTAGE SIGNAL

DON'T CONNECT HIGH VOLTAGE !

G

R

A

Y

GRAY

W1 W2

Q

P

(E)

CN2 3(WHITE)

ON/OFF

B

L

U

E

R

E

D

TO NEX T

MO DULE

TO TIM E R

ON/ O F F

PR OVI DE

BY USE R

BE CON N ECTE D TH E

CO RRE SPON D TE R MIN A L

4.2 MGBT-F60W/RN1

37

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Attached picture (I) Electric Drawing of Main Unit and Auxiliary Unit

XP8

XP7

XS8

XS7

T

3

B

T

3

A

HEAT_A1

PMV(B)

QUER Y

CN18 (WHIT E)

POWE R

CN20(RED)

TRAN S IN

PWM

CN17

CN15(WHITE)

CN9(WHITE)

COMP .B2 COMP. A2

COMP .A1 S.V(A )

CN24

PUMP

CN16

ALAR M

CN8(WHITE )

ANTI-F REEZI NG

CN3(YELLOW )

PH_PRO

CN2( RED)

PMV( B)

COM( I)

COM(O )

CN6

CN27 CN10 CN22 CN32

CN14

PMV(A)

CN11(RED)

POWE R OUT

FANA

CN30

FANB

CN31

(Y ELLO W)

(RED)

COMP B

2

1

5

21

3

6

22

4

T3

A1

A2

T2

T1

HEAT_B

ORA NGE

H2 P1 P 2H1

XT4

S1

SW3

ICOMP- B2

XT5

XT6

RT6

R

T

7

CN23 (WHIT E)

ON/O FF

RT 4

RT 5

COMP A1

2

5

21

3

6

22

4

T3

A1

A2

T2

T1

FAN B

(U)

(V)

(W)

(U)

(V)

(W)

Y&G

4-WAY TER MINAL

XT1

P O W E R I N

Y&G

S1

16- WAY DA IL SW ITCH F UNCTIO N

DAI L SWIT CH

ADD RES S

BLUE

WHITE

RED

RED

WHI TE

BLU E

BLA CK

4-W AY

TER MIN AL

HEAT

PUMP

BLU EBLU EBLU E

BLU E

YEL LOW

YEL LOW

(EFFEC T ON NO. 0 MOD ULE)

(ON/ OFF SIGN AL! )

ELE CTRIC E XPA NSIVE

VAL VE(B)

IN -LE T W ATE R TEM P. S EN SOR

AN TI- FRE EZ ING TE MP. S ENS OR

RED BLAC K

CO ND ENS ER

TE MP B

CO NDEN SER

TE MP A

TOTAL OU T-LE T WATER TEM P.

UNIT OU T-LE T WATER TEM P.

CRA NK

COMPRESSOR A1

Y&G

ORANGE

BLACK

WHITE

BLUE

RED

RED

BLUE

RED

WHI TE

CRA NK

COMPRESSOR B

RED

AC CO NTA CT OR

BLACK

WHITE

BLUE

RED

BLUE

RED

WHI TE

Y&G

Y&G

S.V(A)

4-VALVE A

S.V(B)

4-VALVE B

MID DLE

WIR E JO INT

MID DLE

WIR E JO INT

ORA NGE

PURPLE

BLUE

MID DLE

WIR E JO INT

XT7

RED

WHITE

BLUE

RED

BLACK

BLU EBLU EBLU E

BLUE

YELL OW

YEL LOW

BLUE

PUR PLE

RED

XP9XP9

T

4

WHITE

Q

P

(E)

GRAY

7-W AY

TER MIN AL

XT2

Y

E

L

L

O

W

B

L

A

C

K

LOW VO LTAGE SI GNA L

DON 'T CON NECT HIG H VOLT AGE!

G

R

A

Y

GRAY

W1 W 2

Q

P

(E)

B

L

A

C

K

R

E

D

PRO VID E

BY U SER

AC CO NTA CT OR

CN5

H&L_ PRO

CN1( WHIIT E)

PMV( A)

CN28 (RED)

HEAT /COO L

CN4(RED)

WATER_ PRO

CN21 CN26 CN33 CN35CN34

1 2 3

ON

3 4

SW2

1 2

OFF

T3A T3B T4 ICOMP- A2ICOMP- A1 ICOMP- B1

CN7

(BLU E)

HEAT

CN12(BLACK)

COMP .B1 S.V(B )

RED

CN19(WHITE)

TRAN S OUT

L_PRO(2B )

H_PRO(B)

K1(B)

L_PRO(2A )

H_PRO(A)

CURRENT( A2)

ORANGE

RED

HIG H PR ESSU RE

PRO TEC TOR B

LOW PRE SSUR E

PRO TEC TOR 2 B

PURPLE

LOW PRE SSUR E

PRO TEC TOR 2 A

YELLOW

HIG H PR ESSU RE

PRO TEC TOR A

TEM P PR OTEC TOR

SWI TCH A2

TEM P PR OTEC TOR

SWI TCH B1

K1(A1)

TEM P PR OTEC TOR

SWI TCH A1

K1(A2)

CURRENT( B1)

CURRENT( A1)

XS9

L_PRO(1B )

L_PRO(1 A)

RED

LOW PRE SSUR E

PRO TEC TOR 1 B

PURPLE

LOW PRE SSUR E

PRO TEC TOR 1 A

MAIN BOARD

CURRENT BOARD

L2L3L4 L1

CN6

CN7

CN8

CN5

CN4

HEAT_A2

COMP A2

2

5

21

3

6

22

4

T3

A1

A2

T2

T1

(U)

(V)

(W)

CRA NK

COMPRESSOR A2

RED

BLACK

WHITE

BLUE

RED

BROWN

BLUE

RED

WHI TE

Y&G

AC CO NTA CT OR

HIGH

BLUE

HIGH

FAN A

Y&G

L3

L1

L2

PWM PRESSURE

RELIF VALVE

BROW N

LOW

BROWN

BLACKBLACK

BLUE

RED

RED

BLACK

RED

BROWN BLUE

BROWN

BROWN

BLUE

WHITE

BLACK

WHITE RED

BLACK

BLUE

S2 ON:COOL ONLY OFF:R&C

S3 ON:DIGITAL OFF:FIXED

S4 ON:H-EEPROM OFF:NORMAL

S5 ON:C-EEPROM OFF:NORMAL

S7 ON:REMOTECONTROL OFF:WIRECONTROL

S8 ON:LOW TEMP.MODE OFF:NORMAL

S9 ON:30KW OFF:65/130/200/260KW

S2 S3S4 S5 S7 S8 S9

B

R

O

W

N

R

E

D

RED

ORANGE

ORANGE

O U T D O O R WI R I N G DI A G R A M

R

E

D

B

L

U

E

SW3

1 2 3

ON

3 4

SW2

1 2

ON

S2 S3S4 S5 S7 S8 S9

SW2/SW3 FUCTION DEFINATION

ON

OFF

PRO VID E

BY U SER

DEFAULT SETTING

REMOTETURN OFF

OFF

ON/O FF

S7

ON

REMOTE FUCTIONSETTING

REMOTECOOL

ON OFF

REMOTE HEAT

ON OFF

(O N/ O FF S IG N AL ! )

4.3 MGBT-D60W/RN1

38

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

4.4 MGBT-F120W/RN1

39

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Auxiliary Unit

KM1

A

B

C

A

N

B

C

XT1

KM2

A B

C

KM3

A B

C

KM4

A

B

C

Y/G

XT3

(T 1)

(T 3)

(T 2)

(T 1)

(T 3)

(T 2)

(T 1)

(T 3)

(T 2)

(T 1)

(T 3)

(T 2)

KM5

A

B

C

KM6

A

B

C

(T 1)

(T 3)

(T 2)

(T 1)

(T 3)

(T 2)

H1

H2

P1

P2

XT9

HEATER

PUMP

XP8

XP7

XS8

XS7

T

3

-

1

B

T

3

-1A

L_PR O(1B2)

H_PRO(1B)

K1(1B)

1 2

ON

XP9

XS9

L_PR O(1A2)

H_PRO(1A)

K1(1A)

POWER

TRANS IN

CN 11( BL ACK)

CO MP( B) S.V (B )

CO MP( A) S.V( A)

H&L_P RO

COM(O )

CN 6

CN 8

CN 10

CN 12

CN 14

CT 1

CU RRE NT (A)

CT 2

CU RRE NT (B)

TRANS OUT

BL AC K

BL UE

WH IT E

RE D

S1

S2

T

U

1

CN 5

CN 19

(W HI TE)

CN 20

(R ED )

CN 18

(W HI TE )

S. V( 1A)

S. V( 1B)

KM 2

1 (MAIN)

CN 7

CN 9

HEAT

PUMP

#

L_PR O(1A1)

L_PR O(1B1)

Q

P

(E)

XP18

XP17

XS18

XS17

T

3

-

3

B

T

3

-3A

L_PR O(3B2)

H_PRO(3B)

K1(3B)

1 2

ON

XP19

XS19

CH EC K

L_PR O(3A2)

H_PRO(3A)

K1(3A)

POWER

TRANS IN

CO MP( B) S.V (B ) C OM P(A )S .V(A )

H&L_P RO

COM(O )

CN 6

CN 8

CN 12

CN 14

CT 1

CU RRE NT (A)

CT 2

CU RRE NT (B)

TRANS OUT

S1

S2

T

U

3

CN 5

S. V( 3A)

S. V( 3B)

KM 6

KM 5

3 (SLAVE)

CN 7

CN 9

HEAT

PUMP

#

L_PR O(3A1)

L_PR O(3B1)

XP13

XP12

XS13

XS12

T

3

-

2

B

T

3

-

2

A

L_PR O(2B2)

H_PRO(2B)

K1(2B)

1 2

ON

XP14

XS14

L_PR O(2A2)

H_PRO(2A)

K1(2A)

POWER

TRANS IN

CO MP( B) S.V (B )

CO MP( A) S.V( A)

H&L_PR O

COM(O )

CN 6

CN 8

CN 12

CN 14

CT 1

CU RRE NT (A)

CT 2

CU RRE NT (B)

TRANS OUT

S1

S2

T

U

2

CN 5

KM 4

KM 3

2 (SLAVE)

CN 7

CN 9

HEAT

PUMP

#

L_PR O(2A1)

L_PRO( 2B1)

TB H2- 1

TB H1- 1

TB H2- 2

TB H1- 2

TB H2- 3

TB H1- 3

RE D

RE D

RE D

RE D

T

4

-

1

XP10XS10

T

4

-

2

XP15

XS15

T

4

-

3

XP20

XS20

S1

16-WA Y DAI L SWITC H F UNCTI ON

1

2

SWITC H

FUNCTIO N

RESERV E

NORMAL

2-WA Y JUMP SW ITCH FUNCTIO N

DAIL SWITC H

ADDRES S

S2

(F AC TORY S ET TING )

RED

BLACK

POWER IN

WHITE

BLUE

Hea t1A

COMP1A

BLUE

RED

WHITE

BROWN

BLUE

RED

RED

BLACK

BROWN

BROWN

BROWN

Hea t1B

Hea t2A

Heat 2B

Hea t3A

Heat 3B

BROWN

BLUE

RED

WHITE

RED

BLUE

RED

WHITE

RED

BLUE

RED

WHITE

RED

BLUE

RED

WHITE

RED

BLUE

RED

WHITE

BROWN

BLUE

RED

BROWN

BLUE

RED

BROWN

BLUE

RED

BROWN

BLUE

RED

BROWN

BLUE

RED

COMP1B COMP2A COMP 2B COMP3A COMP3B

Y/G Y/G

Y/G Y/G Y/G

MI DDL E

WI RE J OIN T

ORANGE

RED

PURPLE

YELLOW

HI GH P RESS UR E

PR OTE CT OR 1 B

LO W PR ESSU RE

PR OTE CT OR 1 B1

LO W PR ESSU RE

PR OTE CT OR 1 A1

HIGH PRESSURE

PROTECTOR 1A

TEMP PROTECTOR

SWITCH 1A

TE MP P ROTE CT OR

SW ITC H 1B

LO W PR ESSU RE

PR OTE CT OR 1 B2

LO W PR ESSU RE

PR OTE CT OR 1 A2

TO TAL OU T-L ET

WA TER TE MP.

AN TI- FR EEZ ING

TE MP. SE NSO R 1

IN -LE T W ATE R

TE MP. SE NSO R 1

UN IT O UT -LE T

WA TER TE MP. 1

RED

BLACK

WHITE

OUTDOOR

TEMP.1

CONDENSER

TEMP.1B

CONDENSER

TEMP.1A

CH EC K

TR AN S1

BL UE

BL UE

YE LL OW

YE LL OW

BLUE

(EFFEC T ON NO. 0 MODULE)

(ON /OF F SIG N AL)

LOW VOLTAGE SIGNAL

DON'T CONNECT HIGH VOLTAGE!

GRAY

BLUE

GRAY

BLACK

YELLO W

TR AN S2

CN 19

(W HI TE)

CN 20

(R ED )

CN 18

(W HI TE )

BL AC K

BL UE

WH IT E

RE D

RE D

RE D

UN IT O UT -LE T

WA TER TE MP. 2

WHITE

OUTDOOR

TEMP.2

CONDENSER

TEMP.2B

CONDENSER

TEMP.2A

RED

BLACK

CH EC K

ORANGE

RED

PURPLE

YELLOW

HI GH P RESS UR E

PR OTE CT OR 2 B

LO W PR ESSU RE

PR OTE CT OR 2 B1

LO W PR ESSU RE

PR OTE CT OR 2 A1

HI GH P RESS UR E

PR OTE CT OR 2 A

TEMP PR OTECTOR

SWIT CH 2A

TEMP PR OTECTOR

SWITC H 2B

LO W PR ESSU RE

PR OTE CT OR 2 B2

LO W PR ESSU RE

PR OTE CT OR 2 A2

AN TI- FR EEZ ING

TE MP. SE NSO R 2

IN -LE T W ATE R

TE MP. SE NSO R 2

CN 15( WH ITE)

CN 11( BL ACK)

BLUE

OR ANG E

TR AN S3

CN 19

(W HI TE)

CN 20

(R ED )

CN 18

(W HI TE )

BL AC K

BL UE

WH IT E

RE D

UN IT O UT -LE T

WA TER TE MP. 3

WHITE

OUTDOOR

TEMP.3

CONDENSER

TEMP.3B

CONDENSER

TEMP.3A

RED

BLACK

ORANGE

RED

PURPLE

YELLOW

HI GH P RESS UR E

PR OTE CT OR 3 B

LO W PR ESS URE

PR OTE CT OR 3 B1

LO W PR ESSU RE

PR OTE CT OR 3 A1

HI GH P RESS UR E

PR OTE CT OR 3 A

TEMP PR OTECTOR

SWIT CH 3A

TEMP PR OTECTOR

SWIT CH 3B

LO W PR ESSU RE

PR OTE CT OR 3 B2

LO W PR ESSU RE

PR OTE CT OR 3 A2

AN TI- FR EEZ ING

TE MP. SE NSO R 3

IN -LE T W ATE R

TE MP. SE NSO R 3

CN 15( WH ITE)

CN 11( BL ACK)

BLUE

OR ANG E

S. V( 2A)

S. V( 2B)

Y&G

WH ITE

BL ACK

KM 1

CN 15( WH ITE)

FA N_LFA N_H

OR AN GE

WH IT E

7- WAY

TE RMI NAL

XT 8

W1 W2

Q

P

(E)

XT4

MI DDL E

WI RE J OIN T

XT5

MI DDL E

WI RE J OIN T

XT6

MI DDL E

WI RE J OIN T

XT1 1

MI DDL E

WI RE J OIN T

XT2

MI DDL E

WI RE J OIN T

XT7

MI DDL E

WI RE J OIN T

BROWN

RED

FAN3A PRO

FAN1A PRO

FAN2A PRO

PURPL E

PU RPL E

PU RPL E

RED

RED

BLUE

MI DDL E

WI RE J OI NT

XT1 0

OUTDOOR WIRING DIAGRAM

FAN3B PRO

FAN2B PRO

FAN1B PRO

BROWN

BLUE

BLUE

PURPLE

BLUE

PURPLE

PURPLE

BLACK

BLACKBLACKBLA CKBLACKBLACK

FA N_LFA N_H FA N_LFA N_H

BLA CK

3# FAN_L

1# FAN_H

1# FAN_L

2# FAN_H

2# FAN_L

3# FAN_H

BROWN

BLA CK

BLA CK

BLACK

RED

GRAY

RED

W1

CONNE CT NEXT M ODULE

W2

RED

RED/BLUE

RED/BLUE

TO T IMER

4.5 MGBT-F180W/RN1

40

MCAC-ATSM-2014-09 Aqua tempo power series tropical air-cooled scroll chiller 50Hz

Attached Drawing (I) Electric Drawing of Main Unit and Auxiliary Unit

4.6 MGBT-F250W/RN1

41

Aqua tempo power series tropical air-cooled scroll chiller 50Hz MCAC-ATSM-2014-09

Attached Drawing (II) Networking Communication Schematic of Main Unit and

Auxiliary Unit

A B