Midea MGB-F25W/RN1, MGB-F30W/RN1, MGCSL-D30W/RN1, MGB-F60W/RN1, MGB-F55W/RN1 User Manual

...Page 1

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

2

Content

1 General information ................................................................................ 3

2. Features ................................................................................................... 5

3. Specification ........................................................................................... 9

4 Dimension .............................................................................................. 21

5 Refrigeration system drawing .............................................................. 33

6. Piping diagram ...................................................................................... 36

7 Wiring diagrams..................................................................................... 42

8 Electric characteristics ......................................................................... 56

9 Capacity tables ...................................................................................... 58

10 Exploded view ...................................................................................... 74

11 Troubleshooting ................................................................................... 96

12 Installation .......................................................................................... 108

13 Commissioning .................................................................................. 132

14 Maintenance ....................................................................................... 135

15 Control system .................................................................................. 137

Appendix ................................................................................................. 174

Page 2

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

1 General information

1.1Nomenclature

M G C T S L - D 60 W / R N1 - A

Design Serial Number

Refrigerant type

N1:R410A Omit for R22

Power Supply

R: 380~415V, 50Hz, 3N

D: 220V, 60Hz, 3N

Outdoor Unit

Rated cooling capacity (kw)

The special function code

D: Digital scroll

F: Constant feed

V: Inverter system

The special function code

S: Hydraulic mole

L: Low temperature cooling

H: Heat recovery

Omit for 10 - 46C

T: 10 - 52C

The heat exchanger type

A: Plate heat exchanger

B: Tube and shell

C: Tube in tube heat exchanger

Light chiller system

MDV

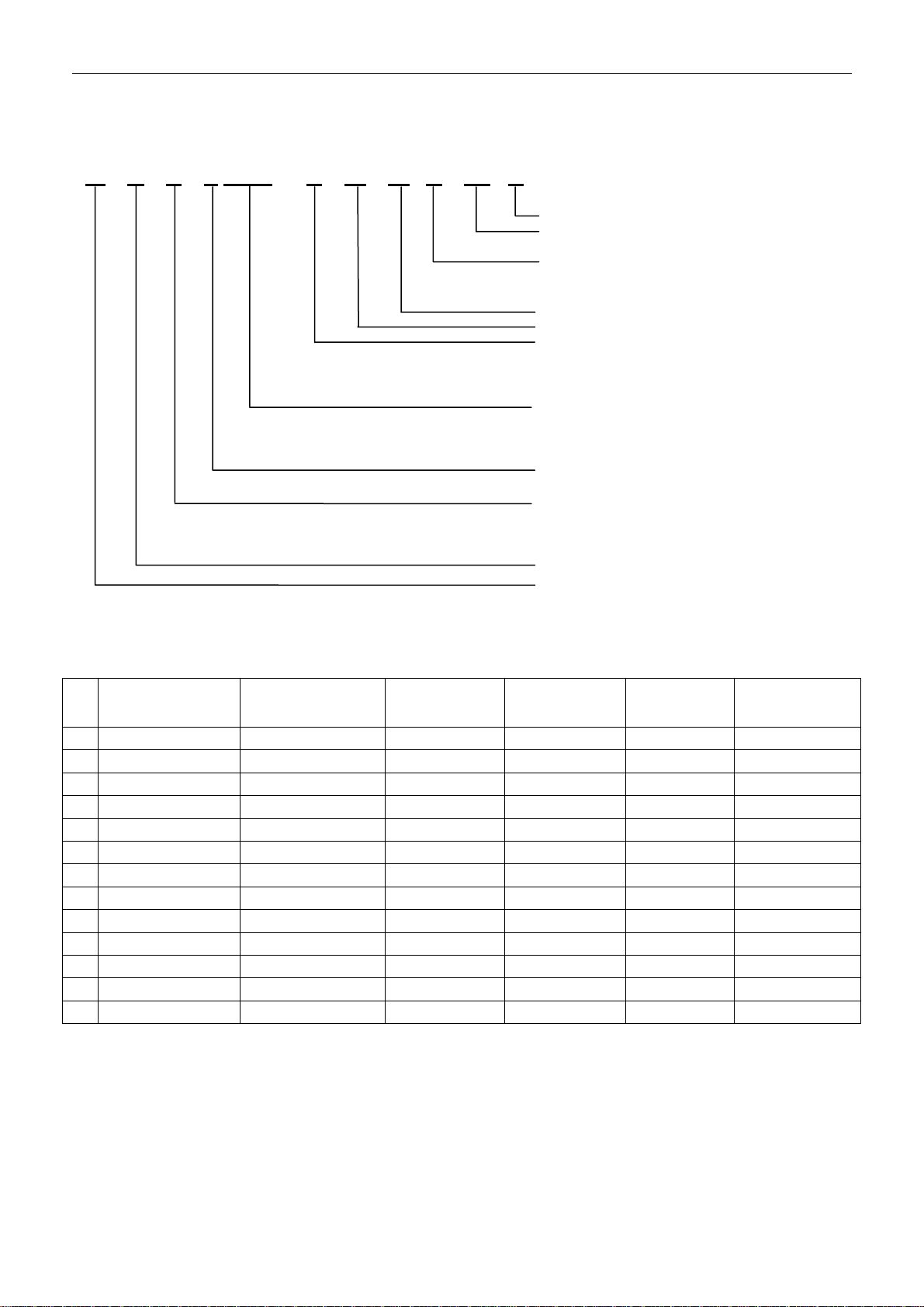

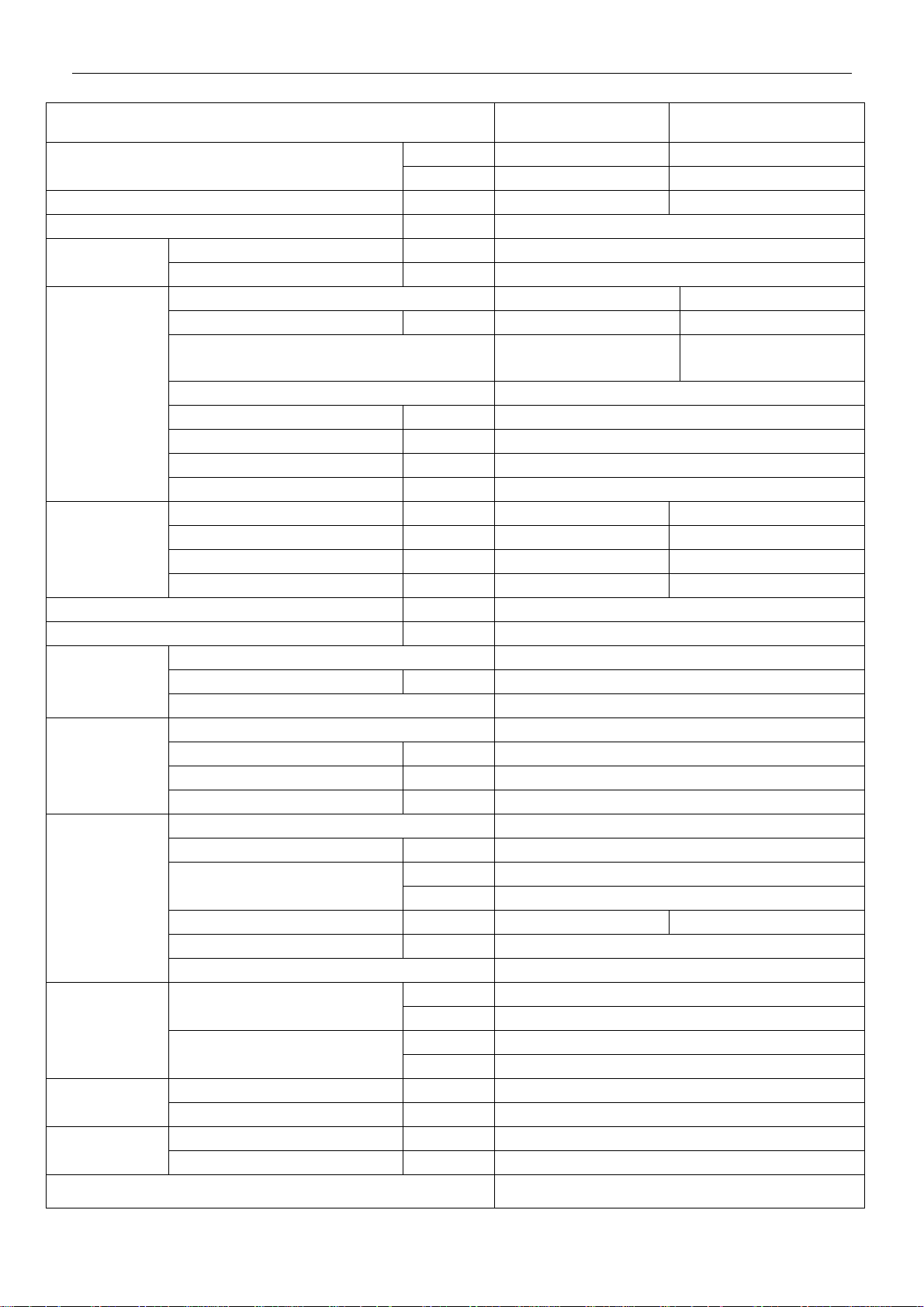

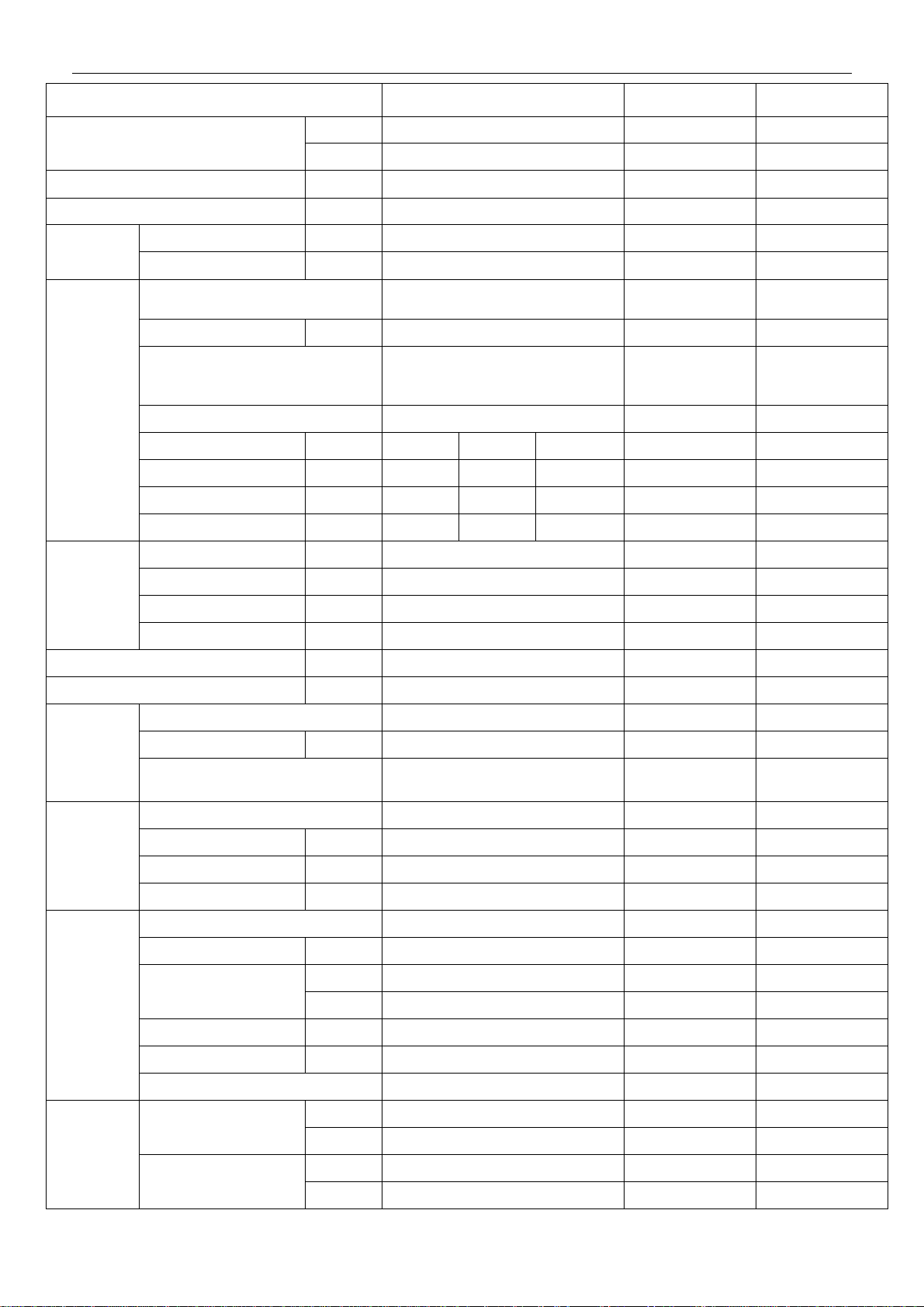

1.2 Product schedule

No Model Power supply

1 MGB-F25W/RN1 380~415V/3ph/50Hz Tube in tube 16 400 KJR-08B/BE

2 MGB-D25W/RN1 380~415V/3ph/50Hz Tube in tube 16 400 KJR-08B/BE

3 MGB-F30W/RN1 380~415V/3ph/50Hz Tube in tube 16 480 KJR-08B/BE

4 MGB-D30W/RN1 380~415V/3ph/50Hz Tube in tube 16 480 KJR-08B/BE

5 MGCSL-F30W/RN1

6 MGCSL-D30W/RN1

7 MGB-F55W/RN1 380~400V/3ph/50Hz Tube and shell 16 880 KJR-08B/BE

8 MGB-F60W/RN1 380~400V/3ph/50Hz Tube and shell 16 960 KJR-08B/BE

9 MGB-F65W/RN1 380~400V/3ph/50Hz Tube and shell 16 1040 KJR-08B/BE

10 MGB-D65W/RN1 380~415V/3ph/50Hz Tube and shell 16 1040 KJR-120A/MBE

11 MGB-F130W/RN1 380~400V/3ph/50Hz Tube and shell 8 1040 KJR-08B/BE

12 MGB-F185W/RN1 380~400V/3ph/50Hz Tube and shell 5 1000 KJR-08B/BE

13 MGBT-F250W/RN1 380~400V/3ph/50Hz Tube and shell 8 2000 KJR-120A/MBE

380~415V/3ph/50Hz

380~415V/3ph/50Hz

Heat

exchanger type

Tube in tube 1 30 KJR-120A/MBE

Tube in tube 1 30 KJR-120A/MBE

Maximum

combinations

Maximum

capacity(kw)

Wired controller

3

Page 3

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

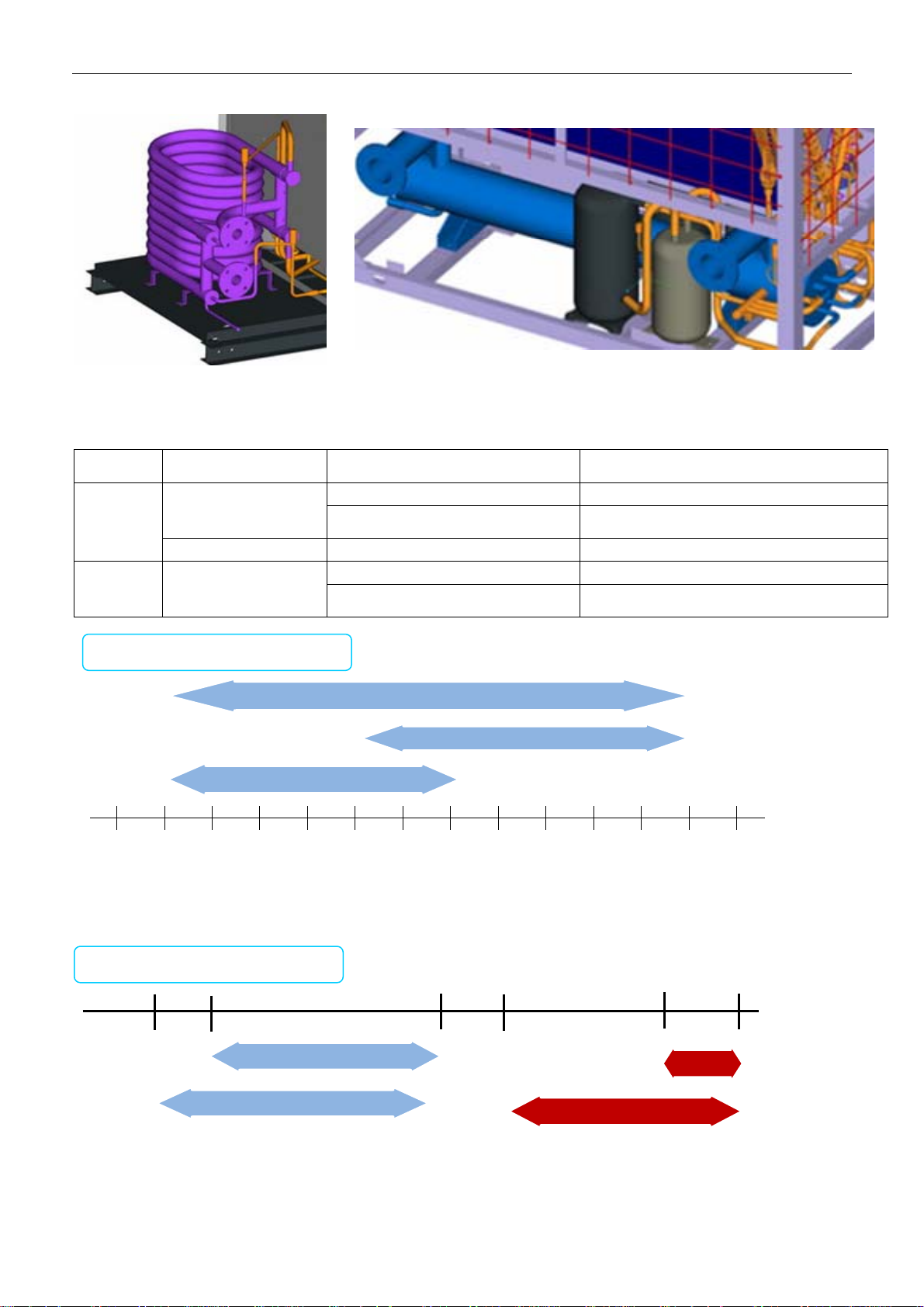

1.3 External appearance:

New 30KW module

25/30KW module

55/60/65KW module 130KW module

185KW module

250KW module

4

Page 4

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

2. Features

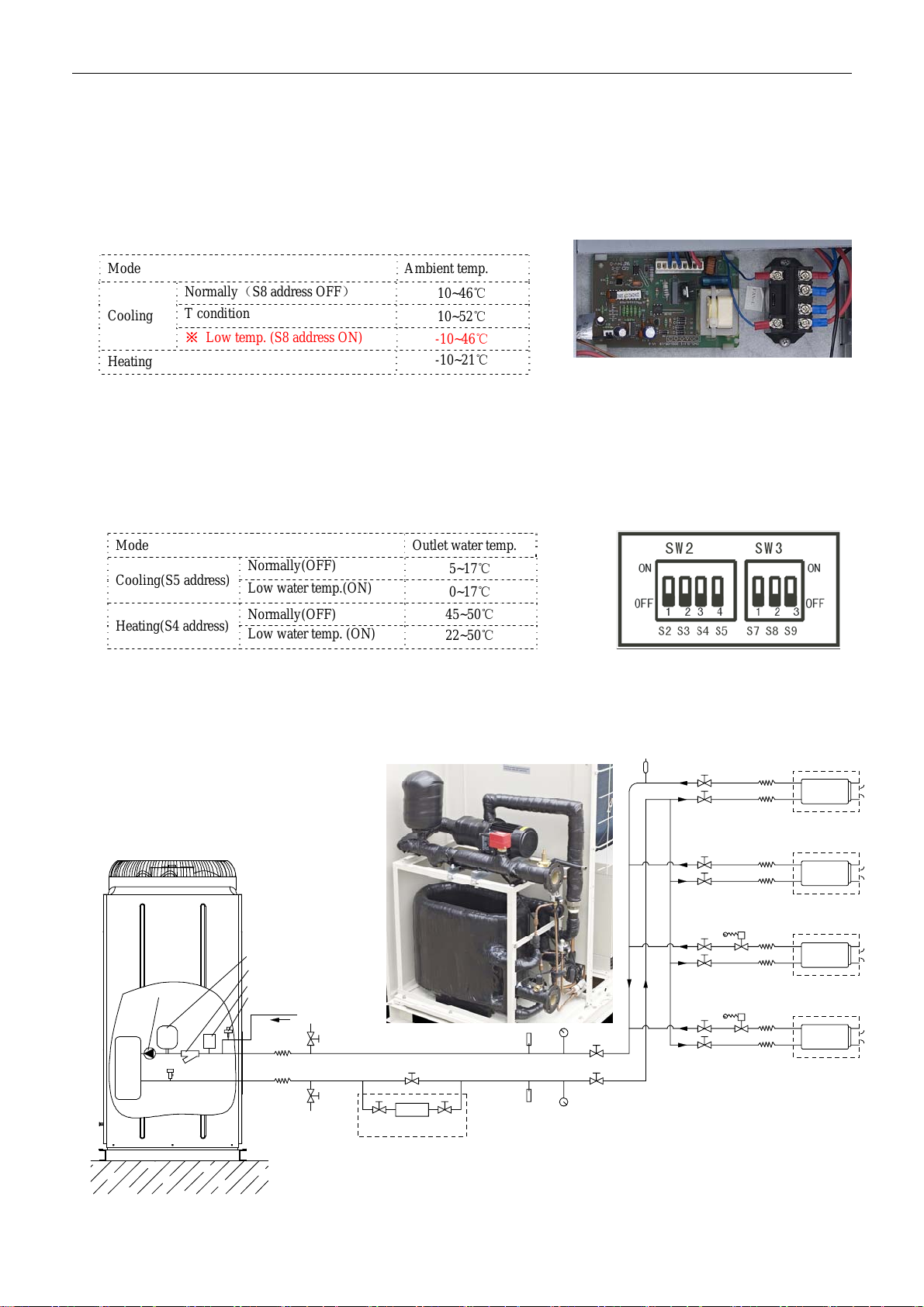

1). Low ambient temperature cooling function (Only for MGCSL-F30W/RN1 and MGCSL-D30W/RN1)

The ambient temperature is down to -10℃ in cooling mode, the cooling operating temperature up to 52˚C in

tropical model and heating down to -10˚C ambient by added one board (see picture1). Wide ambient

temperature range is selectable by adjustable address between different conditions to meet different

requirements.

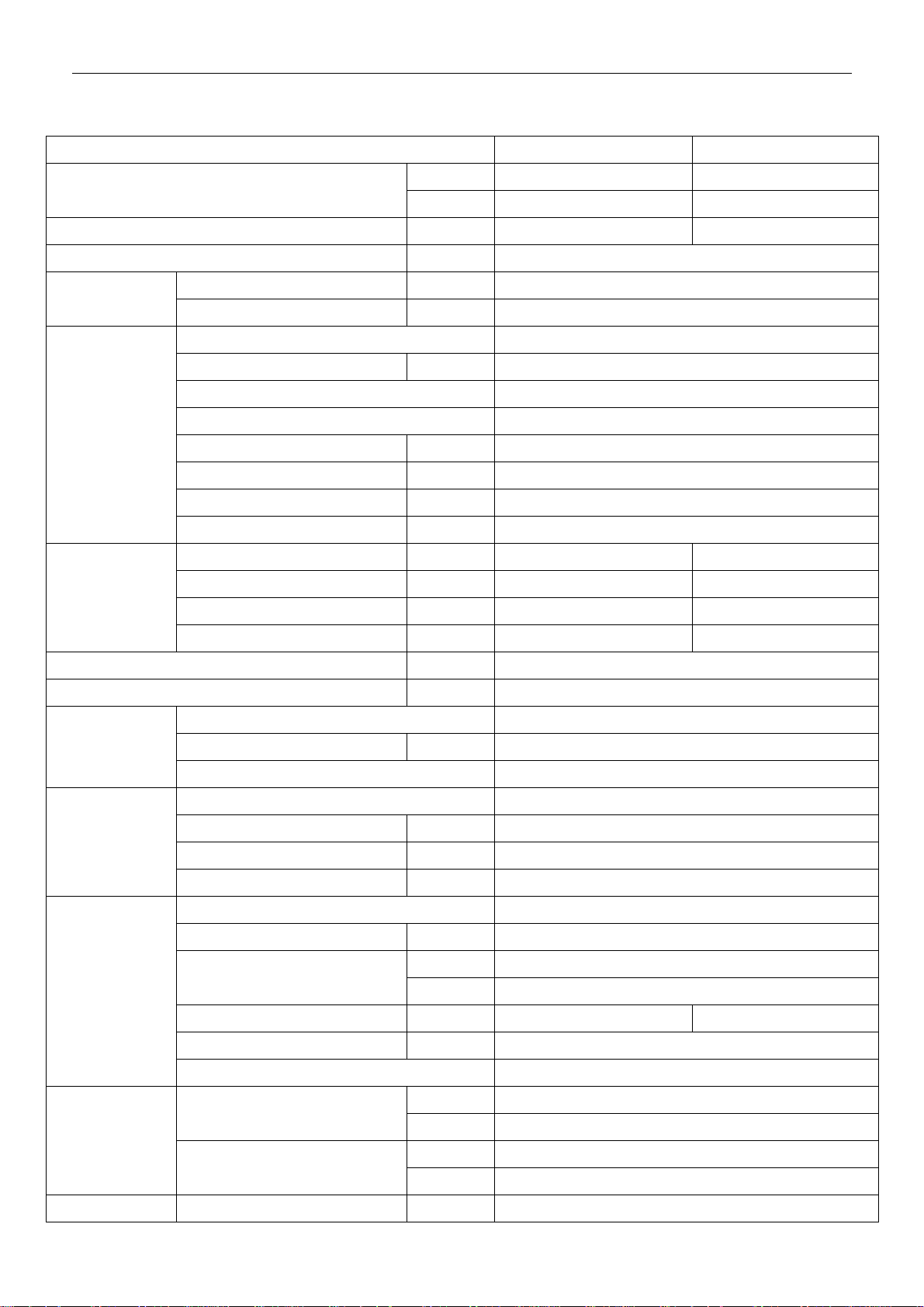

Mode Ambient temp.

Normally(S8 address OFF)

Cooling

T condition

※ Low temp. (S8 address ON)

Heating

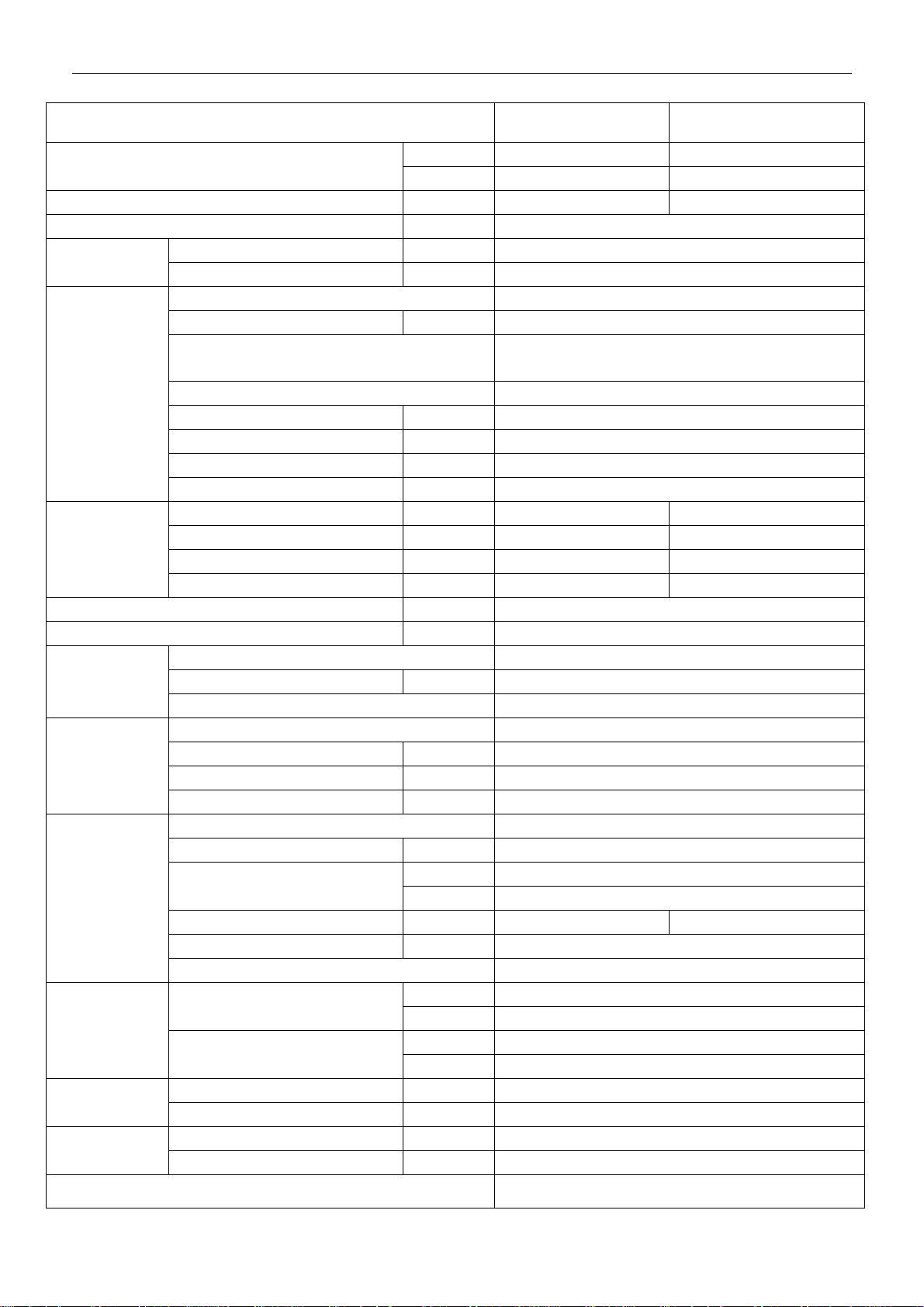

2). Wide range of outlet water temperature (For MGCSL-F(D)30W/RN1 ,MGB-D65W/RN1,

MGB-F250W/RN1)

Cooling: 5~17˚C (Set in factory), 0~17˚C can be available by switch the S5 on PCB, the antifreeze must be

put into pipeline.

10~46℃

10~52℃

-10~46℃

-10~21℃

Picture1

Heating: 40~50˚C (Set in factory), 22~50˚C can be available by switch the address.

Mode Outlet water temp.

Cooling(S5 address)

Heating(S4 address)

Normally(OFF)

Low water temp.(ON)

Normally(OFF)

Low water temp. (ON)

5~17℃

0~17℃

45~50℃

22~50℃

Picture2

3).Built-in hydraulic module (Only for MGCSL-F30W/RN1 and MGCSL-D30W/RN1)

The unit built-in hydraulic module to simplified installation, save space and beautification appearance,

simultaneous effectively reduce installation costs and covering area.

auto-air exchanse valve

2-way valve

Expansion tank

Double

-pipe

heat

exchanger

Water pump

Safety valve

Y-shaped filiter

Water-flow valve

Water replenishing valve

1.5kg<Water replenishing pres<6kg

Flexible joint

Flexible joint

Aux. heater

Thermometer

Cutoff valve

Manometer

Flexible joint

2-way valve

Flexible joint

Fan coil unit

Fan coil unit

Fan coil unit

Fan coil unit

This figure for reference purpose only, please in terms of the design rule for field installation.

5

Page 5

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

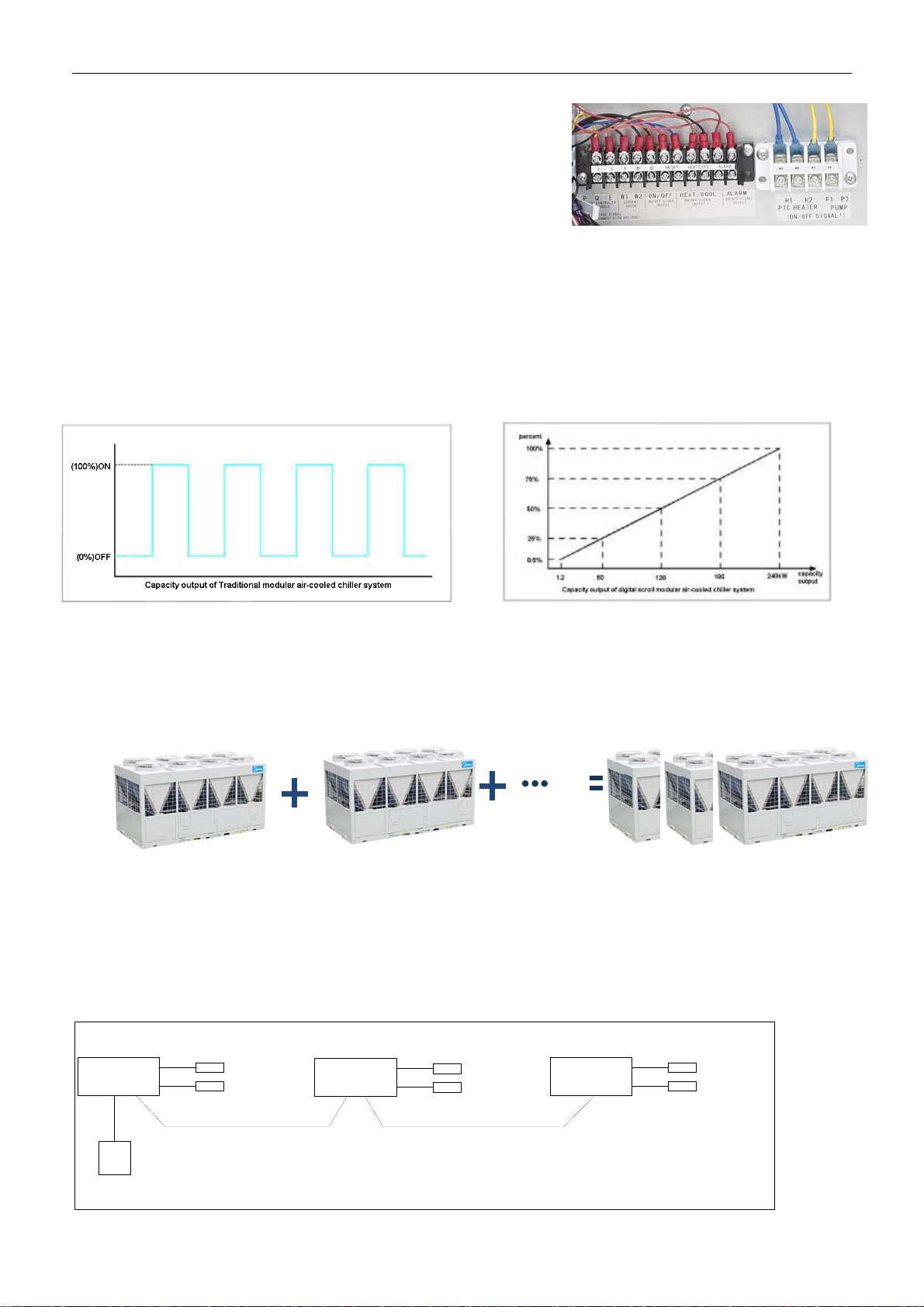

4).Humanization remote control (For MGCSL-F(D)30W/RN1 ,MGB-D65W/RN1, MGB-F250W/RN1)

S7 address on PCB should be switched to ON to realize remote

control, here are reliable: Remote ON/OFF, remote heating and

cooling mode selection, remote alarm. The customer can simply

and conveniently control the module and acquire the running

information on real time in door.

5)Digital scroll technique,new type modular air-cooled chiller

system.

Capacity output is controlled depending on controlling compressor to on/off in traditional modular air-cooled

chiller system control. The precision of the control mode is not very good, and the compressor is frequently

on and off, which is very bad for the compressor’s life.

Digital scroll modular air-cooled chiller system breaks traditional design, which is inconceivably designed

with digital scroll compressor and constant scroll compressor parallel connection. the system can achieve

linear capacity adjustment within 0.5%-100%,the scope is widest in industry. When the system operates at

the part-load, the system can accurately adjust cooling and heating capacity output basing on actual

requirement of the indoor room.

6).Modular design, flexible combination, more convenient for design and installation.

The unit adopt modular design, which can makes more unit connect together. The unit can combine 16

separate module(25,30.55.60.65KW module) or 8 module(250KW module).Cooling(heating) capacity can

increase step by step by 5KW per each time within 25kW-2000kW,meanwhile every separate module can

operate as main unit, also each module can be a slave unit with modules combination, more convenient for

design and installation.

Max 8 modules

250KW

250KW

2000KW

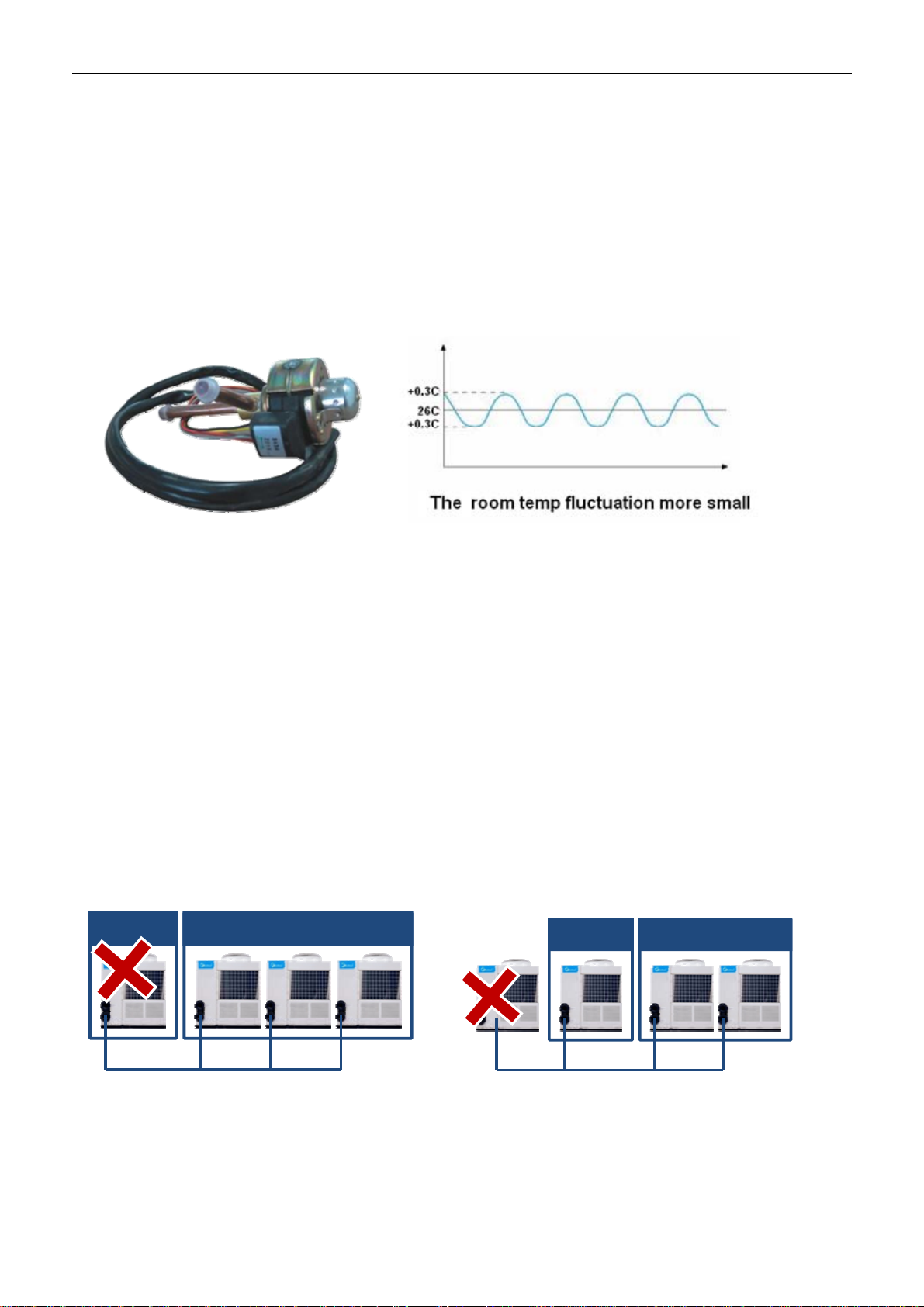

7).The maximum combination of the system consists of 1 main unit and 15 slave units for

25,30.55.60 and 65KW module, 1 main unit and 7 slave units for 130KW module, 1 main unit and 4

slave units for 200KW module,1 main unit and 7 slave units for 250KW module.

Easy connection between main unit and slave units.

All the units can be connected together with a wired controller in series type. Using three-core shielded

twisted wire as communication wire.

Wa te r outlet temp.

Wa te r outlet temp.

Wa te r outlet temp.

Wired c on troller

6

Total w a te r o u tlet te mp.

(Just fo r m a s te r u n it)

Thre e - c o re s hielding

twisted pair

Total w a te r o u tlet te mp.

(Just for m a s te r u n it)

Three-core shielding

twisted pair

Total w a te r o u tlet te mp.

(Just fo r maste r unit)

Page 6

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

8).Environmental care

Ecological R410A refrigerant.

Chlorine-free and environmental friendly refrigerant, zero ozone depletion potential.

High density refrigerant, therefore, less refrigerant required.

Leak-tight refrigerant circuit, Brazed refrigerant connections for increased leak-tightness.

9) Economical operation

New design adopts electronic expansion valve precise refrigerant control in wider range. Electronic

expansion valve allows operation at lower condensing pressure, adjustment can be made fast linear

response, making the system more stable output, the indoor temperature more uniform, and enhance

human comfortable.

10).Compact structure

Air cooled modular chiller structure are compact, light weight. The system adopts tube in tube, shell and tube

heat exchanger, not only greatly enhanced the transfer performance, but also reduce the unit weight, the

lightest single module only has 380kg.

The characteristic of unit decided cooling tower is not needed, not only reduced installation costs, but also

resolved the cooling tower generated noise when running.

11).Back up function

When unit is failure

If master unit fails, all the units will stop.

If one slave unit fails, this unit will stop but the others will keep running.

When the master unit fails, any of the slave one can be set as the master unit by manual setting.

When unit is under protection

If master unit’s protection occurs, this unit will stop but the others will keep running.

If slave unit’s protection occurs, this unit will stop but the others will keep running.

( Except PE, P9

Master Slave

protection happen

)

Master Slave

12).Strong micro-computer intelligent control and monitor function.

Optimizing the design of system and using varieties of protection devices, to make the system more safe

and reliable.

13). Superior reliability

System will be more reliable with new type efficient heat exchanger.

7

Page 7

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

Coo

ge

C

Evaporator of 25KW and 30KW module adopts tube in tube heat exchanger,evaporator of 60kw ,120kw and

180kw modules adopt Shell and tube heat exchanger.

Tube in tube heat exchanger Shell and tube heat exchanger

14). Applicable temperature range

Mode

Cooling

Heating -10˚C ~21˚C

Ambient temperature

range

10˚C ~46˚C

-10˚C ~46˚C 5˚C ~17˚C Only for MGCSL-F(D)30W/RN1

Water outlet temperature range Application module

5˚C ~17˚C (7˚C is default) The module with KJR-08B/BE

0~17˚C(0˚C must add antifreeze)

45˚C ~50˚C (45˚C is default) The module with KJR-08B/BE

22˚C ~50˚C

For MGCSL-F(D)30W/RN1,MGBT-D65W/RN1,

MGBT-F250W/RN1

For MGCSL-F(D)30W/RN1,MGBT-D65W/RN1,

MGBT-F250W/RN1

Ambient temperature range

Cooling range-10˚C

46˚C

-10˚C 21˚C

Heating range

10˚

ling ran

46˚C

-15˚C

-10˚C -5˚C 0˚C 5˚C 10˚C 15˚C

20˚C

30˚C 35˚C 40˚C

25˚C

45˚C

Chilled outlet water temperature can be adjusted by wire controller according to customer’s demand.

Water outlet temperature range

0˚C

8

5˚C

0˚C

5˚C

Cooling range

Cooling range

17˚C

17˚C

17˚C

22˚C

22˚C

Heating range

45˚C

45˚C

Heating range

50˚C

50˚C

50˚C

Page 8

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

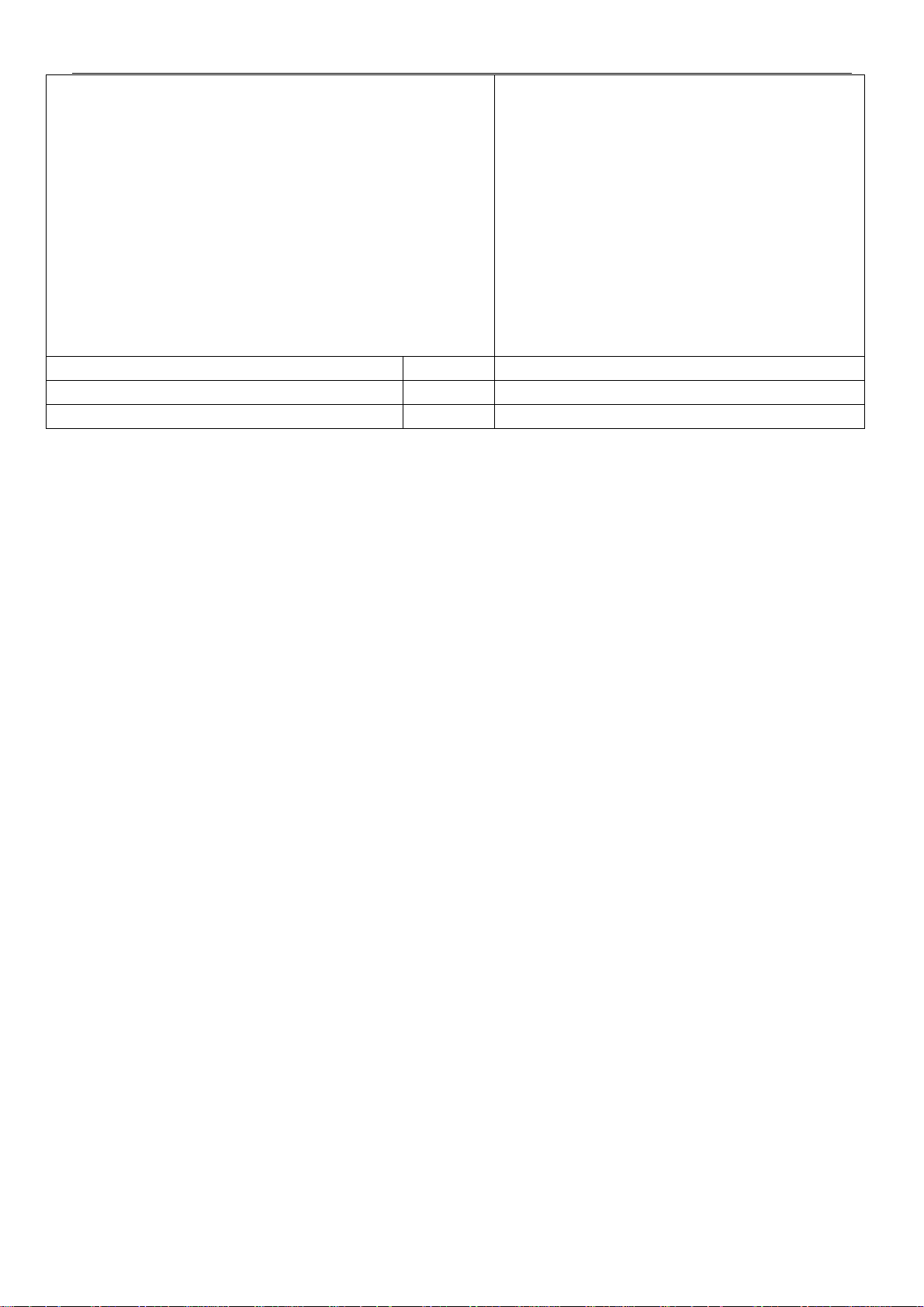

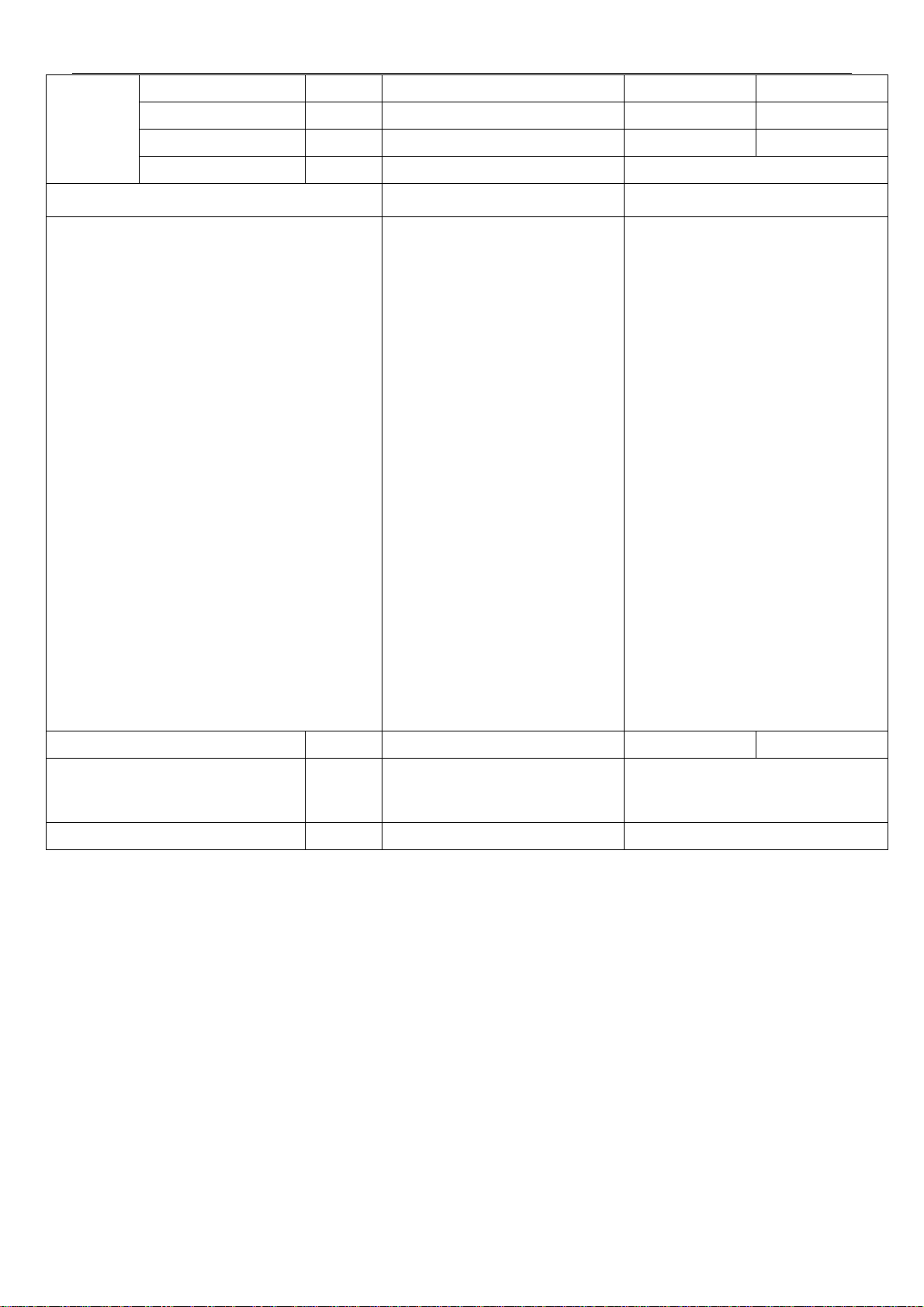

3. Specification

Model MGB-F25W/RN1 MGB-F30W/RN1

Cooling Capacity

Heating Capacity kW 29.5 32

Power supply V/Ph/Hz 380-415/3/50

Manual switch A 50

Power supply

Fuse A 36

Type Scroll (constant speed)

Quantity Pieces 2

Model ZP67KCE-TFD-522

Brand Copeland

Compressor

Capacity W 16200×2

Input W 5200×2

Rate current(RLA) A 9.1×2

Locked rotor Amp(LRA) A 74×2

Cooling kW 9.3 10.0

Cooling rated current A 14.6 16.3

Power input

Heating kW 9.2 9.8

kW 28 30

Btu/h 95,500 102,300

Heating rated current A 14.3 16

Max. Input consumption A 12.6

Max. Current A 21.8

Type R410a

Refrigerant

Condenser

(Air side)

Evaporator

(Water side)

Weight kg 3.5×2

Refrigerant control EXV+ capillary throttle

Air side heat-exchanger type Copper-fin-coil

Quantity of fan motor Pieces 1

Air flow volume ×103m3/h 12

Fan motor input kW 0.3

Water side heat-exchanger type Tube in tube

Water resistance loss kPa 60

Water inlet/outlet pipeline inside

normal diameter

Water flow volume m3/h 4.4 5.2

Max. Pressure MPa 1

Water pipe connection type Flexible joint

mm DN40

inch 1-1/2”

Net(W×H×D)

mm

inch

Dimension

mm

Packing(W×H×D)

inch

Weight Net weight kg 380

1514×1865×841

59.6×73.4×33.1

1590×2065×995

62.6×81.3×39.2

9

Page 9

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

Operation weight kg 400

Power wire mm

2

×No. 10×4+10×1

Connection wire

Signal wire mm2×No. 0.75×3-core

Control type Wired controller

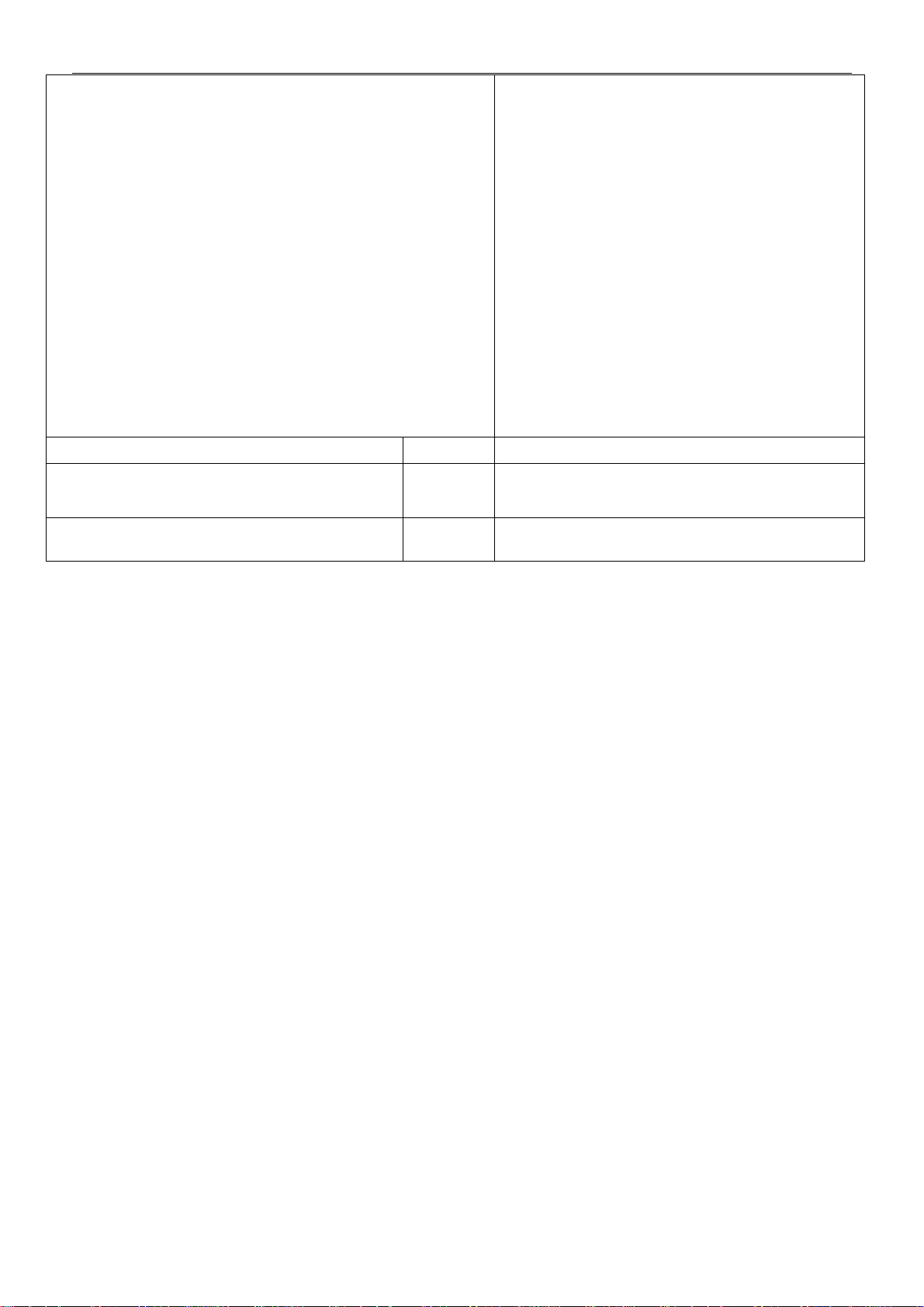

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

Safety protection device

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temperature difference protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

Noise level(semi-anechoic ) dB(A) 65

Operation water temp ℃ Cooling:5~17 Heating:45~50

Ambient temp ℃

Cooling:10~46

Heating:-10~21

Note: Please refer to the water flow volume in the above table strictly to design and install.

All the above data is measured base on the following working condition:

1. cooling mode under normal working condition: water flow 0.172 m

3

/(h•kW), outlet water temperature of chilled water is

7℃,air inlet temperature of condenser is 35℃;

2. heating mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

45℃,air inlet temperature of condenser is DB/WB 7/6℃.

10

Page 10

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Model MGB-D25W/RN1 MGB-D30W/RN1

Cooling Capacity

Heating Capacity kW 29.5 32

Power supply V/Ph/Hz 380-415/3/50

Power supply

Compressor

Power input

Max. Input consumption A 12.5

Max. Current A 21.5

Refrigerant

Condenser

(Air side)

Evaporator

(Water side)

Dimension

Weight

Connection wire

Manual switch A 50

Fuse A 36

Type Constant Speed Scroll + Digital Scroll

Quantity Pieces 1+1

Model

Brand Copeland

Capacity W 16200+16200

Input W 5200+5260

Rate current(RLA) A 9.1+9.3

Locked rotor Amp(LRA) A 74+74

Cooling kW 9.3 10.0

Cooling rated current A 14.6 16.3

Heating kW 9.2 9.8

Heating rated current A 14.3 16

Type R410a

Weight kg 3.5×2

Refrigerant control EXV+ capillary throttle

Air side heat-exchanger type Copper-fin-coil

Quantity of fan motor Pieces 1

Air flow volume ×103m3/h 12

Fan motor input kW 0.3

Water side heat-exchanger type Double-pipe heat exchanger

Water resistance loss kPa 60

Water inlet/outlet pipeline inside

normal diameter

Water flow volume m3/h 4.4 5.2

Max. Pressure MPa 1

Water pipe connection type Flexible joint

Net(W×H×D)

Packing(W×H×D)

Net weight kg 380

Operation weight kg 400

Power wire mm2×No. 10×4+10×1

Signal wire mm2×No. 0.75×3-core

kW 28 30

Btu/h 95,500 102,300

ZP67KCE-TFD-522+

ZPD67KCE-TFD-532

mm DN40

inch 1-1/2”

mm

inch

mm

inch

1514×1865×841

59.6×73.4×33.1

1590×2065×995

62.6×81.3×39.2

Control type Wired controller

11

Page 11

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

Safety protection device

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temperature difference

protection

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

Noise level(semi-anechoic ) dB(A) 65

Operation water temp ℃ Cooling:5~17 Heating:45~50

Ambient temp ℃ Cooling:10~46 Heating:-10~21

Note: Please refer to the water flow volume in the above table strictly to design and install.

All the above data is measured base on the following working condition:

1. cooling mode under normal working condition: water flow 0.172 m

3

/(h•kW), outlet water temperature of chilled water is

7℃,air inlet temperature of condenser is 35℃;

2. heating mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

45℃,air inlet temperature of condenser is DB/WB 7/6℃.

12

Page 12

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

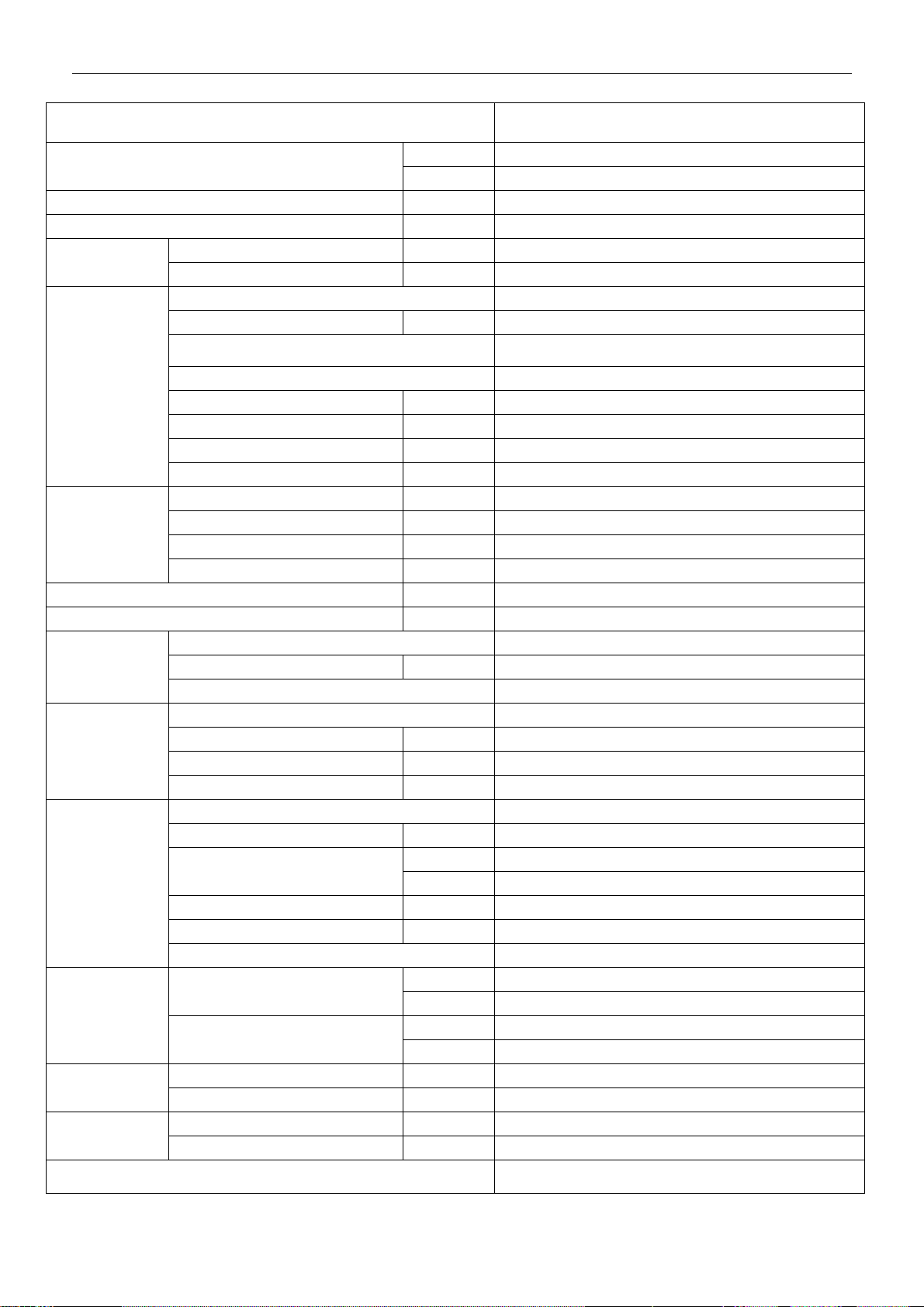

Model MGCSL-F30W/RN1 MGCSL-D30W/RN1

Cooling Capacity

Heating Capacity kW 32 32

Power supply V/Ph/Hz 380-415/3/50

Power supply

Compressor

Power input

Max. Input consumption A 13.4

Max. Current A 22.5

Refrigerant

Condenser

(Air side)

Evaporator

(Water side)

Dimension

Weight

Connection wire

Manual switch A 50

Fuse A 36

Type Fixed speed Digital Scroll + Fixed speed

Quantity Pieces 1+1 1+1

Model ZP67KCE-TFD-522

Brand Copeland

Capacity W 16200×2

Input W 5200×2

Rate current(RLA) A 9.1×2

Locked rotor Amp(LRA) A 74×2

Cooling kW 10 10

Cooling rated current A 16.3 16.3

Heating kW 9.8 9.8

Heating rated current A 16 16

Type R410A

Weight kg 3.5×2

Refrigerant control EXV

Air side heat-exchanger type Fin-coil

Quantity of fan motor Pieces 1

Air flow volume ×103m3/h 12

Fan motor input kW 0.55

Water side heat-exchanger type Double-pipe

Water resistance loss kPa /

Water inlet/outlet pipeline inside

normal diameter

Water flow volume m3/h 5.2 5.2

Max. Pressure MPa 1

Water pipe connection type Flexible joint

Net(W×H×D)

Packing(W×H×D)

Net weight kg 430

Operation weight kg 450

Power wire mm2×No. 10×4+6×1

Signal wire mm2×No. 0.75×3-core with shielding

kW 30 30

Btu/h 102,300 102,300

ZPD67KCE-TFD-532/

ZP67KCE-TFD-522

mm DN40

inch 1-1/2”

mm

inch

mm

inch

1514×1865×841

59.6×73.4×33.1

1590×2065×995

62.6×81.3×39.2

Control type Wired controller

13

Page 13

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

Safety protection device

8) Outlet and inlet water temperature difference

protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

12) Low ambient temperature drive-up protection

13) Low-temperature protection of shell-and-tube heat

exchanger.

Noise level(semi-anechoic ) dB(A) 67

Operation water temp

℃

Ambient temp ℃

Cooling:0~17(0℃ must add antifreeze)

Heating:22~50

Cooling:-10~46

Heating:-10~21

Note: Please refer to the water flow volume in the above table strictly to design and install.

All the above data is measured base on the following working condition:

1. cooling mode under normal working condition: water flow 0.172 m

3

/(h•kW), outlet water temperature of chilled water is

7℃,air inlet temperature of condenser is 35℃;

2. heating mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

45℃,air inlet temperature of condenser is DB/WB 7/6℃.

14

Page 14

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Model MGB-F55W/RN1 MGB-F60W/RN1 MGB-F65W/RN1

Cooling Capacity

Heating Capacity kW 59 64 69

Power supply V/Ph/Hz 380-400/3/50

Power

supply

Compressor

Power input

Manual switch A 125

Fuse A 100

Type Fixed speed Scroll

Quantity Pieces 2

Model SH140A4ALC

Brand Danfoss

Capacity W 34700×2

Input W 10860×2

Rate current(RLA) A 21.4×2

Locked rotor Amp(LRA) A 147×2

Cooling kW 17.5 19.3 20.4

Cooling rated current A 30.5 33.6 36.5

Heating kW 18.3 19.8 21.5

kW 55 60 65

Btu/h 187,660 204,700 221,780

Heating rated current A 31.5 34.3 37.2

Max. Input consumption A 28.2

Max. Current A 47.6

Type R410a

Refrigerant

Condenser

(Air side)

Evaporator

(Water side)

Weight kg 7×2

Refrigerant control EXV+ capillary throttle

Air side heat-exchanger type Copper-fin-coil

Quantity of fan motor Pieces 2

Air flow volume ×103m3/h 24

Fan motor input kW 0.65

Water side heat-exchanger type Shell and tube

Water resistance loss kPa 15

Water inlet/outlet pipeline

inside normal diameter

Water flow volume m3/h 9.4 10.3 11.2

Max. Pressure MPa 1

Water pipe connection type Flexible joint

mm DN100

inch 4”

Dimension

Weight

Net(W×H×D)

mm

inch

mm

Packing(W×H×D)

inch

Net weight kg 580

Operation weight kg 650

2000×1880×900

78.7×74×35.4

2090×2055×985

82.3×80.9×38.8

15

Page 15

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

2

Connection

wire

Control type Wired controller

Safety protection device

Noise level(semi-anechoic ) dB(A) 67

Power wire mm

Signal wire mm2×No. 0.75×3-core

×No. 16×4+10 ×1

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

8) Outlet and inlet water temperature difference protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

Operation water temp

Ambient temp ℃ Cooling:10~46 Heating:-10~21

℃ Cooling:5~17 Heating:45~50

Note: Please refer to the water flow volume in the above table strictly to design and install.

All the above data is measured base on the following working condition:

1. cooling mode under normal working condition: water flow 0.172 m

7℃,air inlet temperature of condenser is 35℃;

2. heating mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

45℃,air inlet temperature of condenser is DB/WB 7/6℃.

3

/(h•kW), outlet water temperature of chilled water is

16

Page 16

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

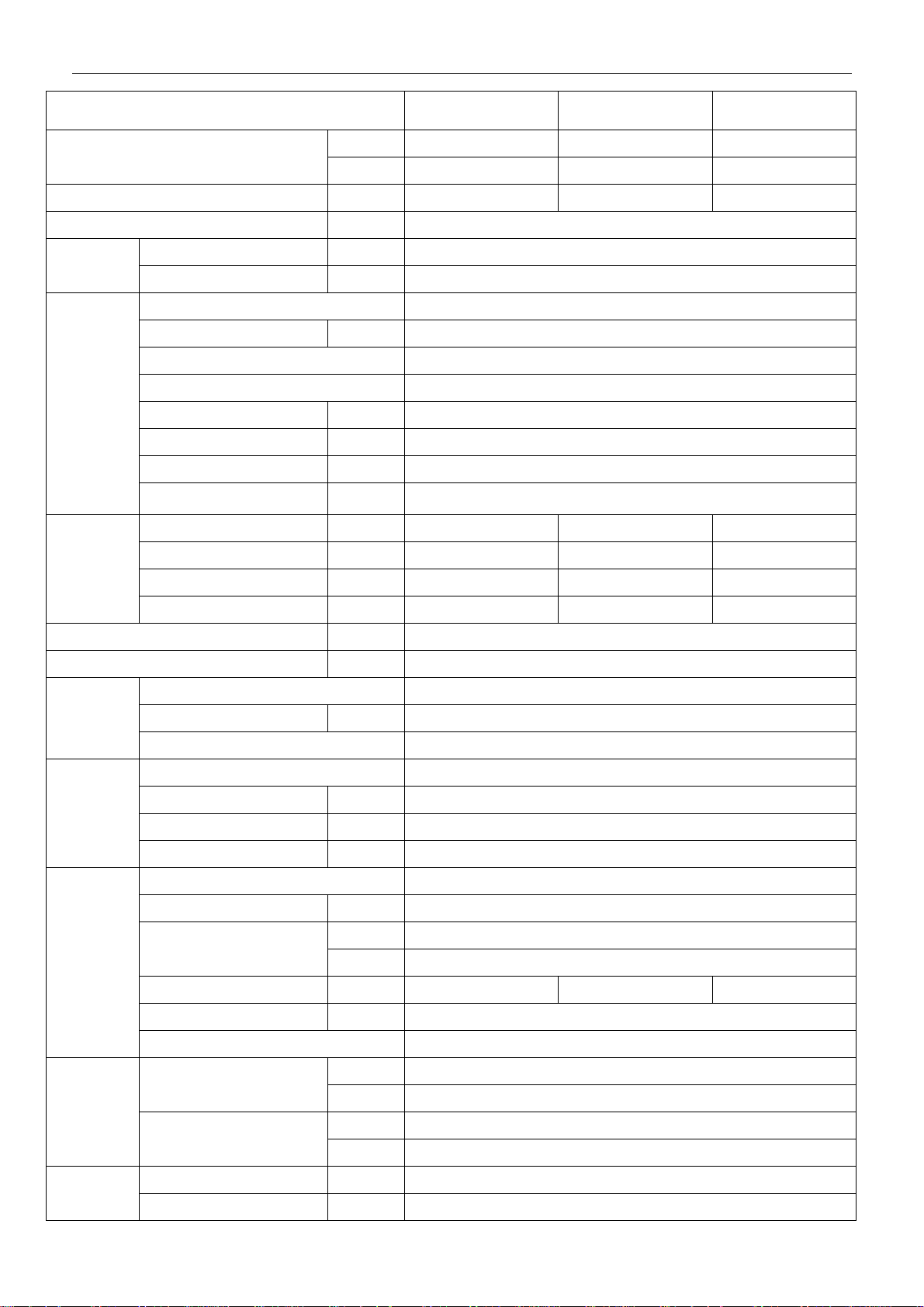

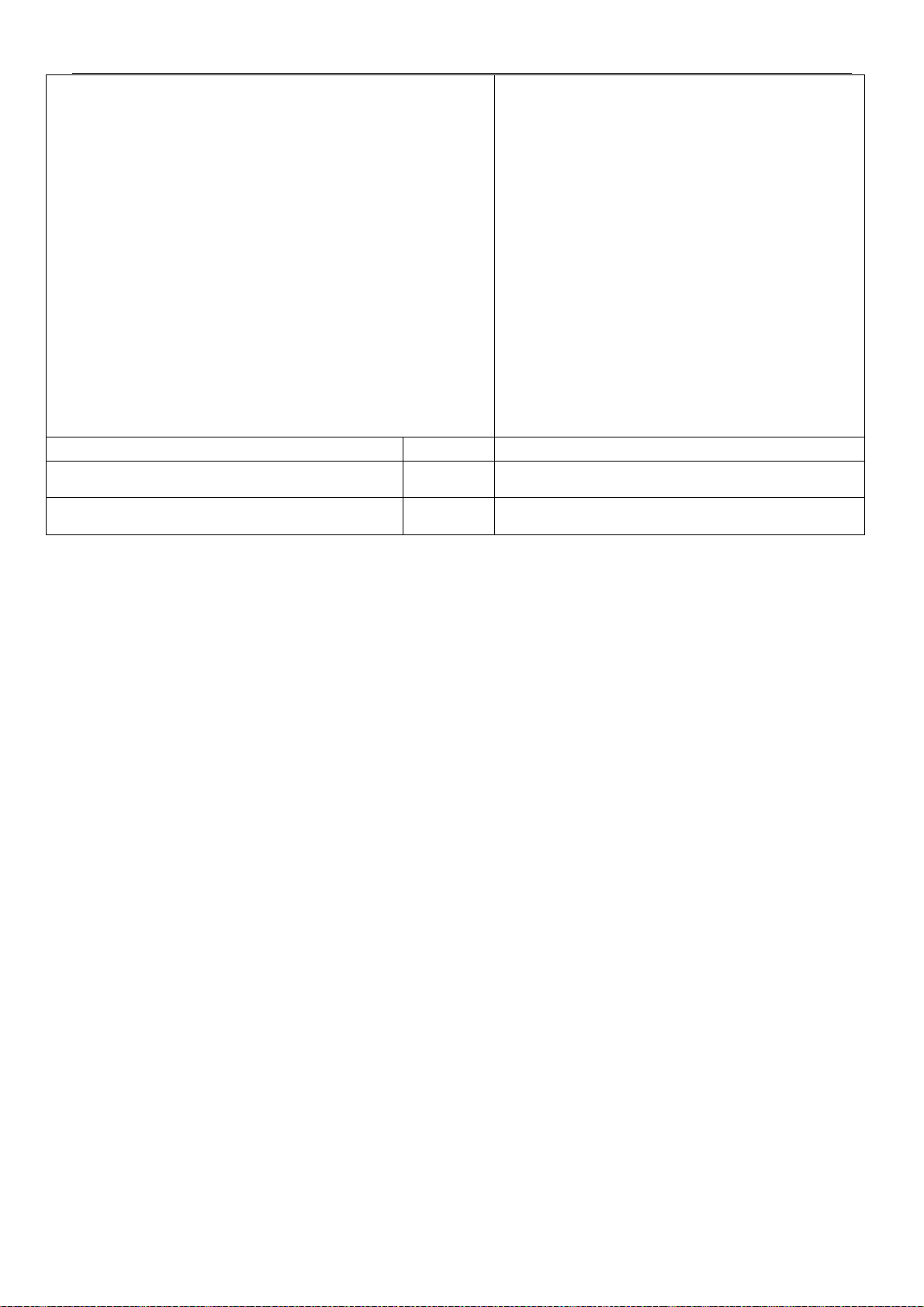

Model

MGB-D65W/RN1

MBG-F130W/R(S)N1

MGB-F185W/R(S)N1

Cooling Capacity

kW 65 130 185

Btu/h 221,780 443,560 631,220

Heating Capacity kW 69 138 200

Power supply V/Ph/Hz 380-415/ 3/50 380-400/3/50 380-400/3/50

Power

supply

Manual switch A 150 250 400

Fuse A 100 200 300

Type Scroll (fixed speed+digital scroll) Fixed speed Scroll Fixed speed Scroll

Quantity Pieces 3 4 6

ZP144KCE-TFD-522 /

Model

ZPD72KCE-TFD-433 /

SH140A4ALC SH140A4ALC

ZP67KCE-TFD-420

Compressor

Brand Copeland Danfoss Danfoss

Capacity kW 36 17 16.3 34.7×4 34.7×6

Input kW 10.8 5.75 5.2 10860×4 10860×6

Rate current(RLA) A 18.7 9.8 9.1 21.4×4 21.4×6

Locked rotor Amp(LRA) A 144 82.4 74 147× 4 147×6

Cooling kW

Cooling rated current A

Power input

Heating kW

Heating rated current A

Max. Input consumption A

Max. Current A

20.4

36.5

21.5

37.2

28.2 55.5 78.3

47.6 93.8 133.4

40.8 63

73 110

43.0 61

74.4 107

Type R410a R410a R410a

Refrigerant

Condenser

(Air side)

Evaporator

(Water side)

Dimension

Weight kg 7×2 7×4 7×6

Refrigerant control EXV+ capillary throttle

EXV+ capillary

throttle

EXV+ capillary

throttle

Air side heat-exchanger type Copper-fin-coil Copper-fin-coil Copper-fin-coil

Quantity of fan motor Pieces 2 4 6

Air flow volume ×103m3/h 24 48 72

Fan motor input kW 0.55×2 1.3 1.3

Water side heat-exchanger type Shell and tube Shell and tube Shell and tube

Water resistance loss kPa 15 25 30

Water inlet/outlet

mm DN100 DN65 DN80

pipeline inside normal

diameter

inch 4’’ 2-1/2” 3”

Water flow volume m3/h 11.2 22.4 31.8

Max. Pressure MPa 1 1 1

Water pipe connection type Flexible joint Flexible joint Flexible joint

Net(W×H×D)

mm 2000×1880×900

inch 78.7×74×35.4

mm 2090×2020×985

Packing(W×H×D)

inch 82.3×80.9×38.8

2000×2090×1685 2850×2110×2000

78.7×82.3×66.3 112.2×83.1×78.7

2090×2240×1755 2980×2260×2135

82.3×88.2×69 117.3×89×84.1

17

Page 17

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

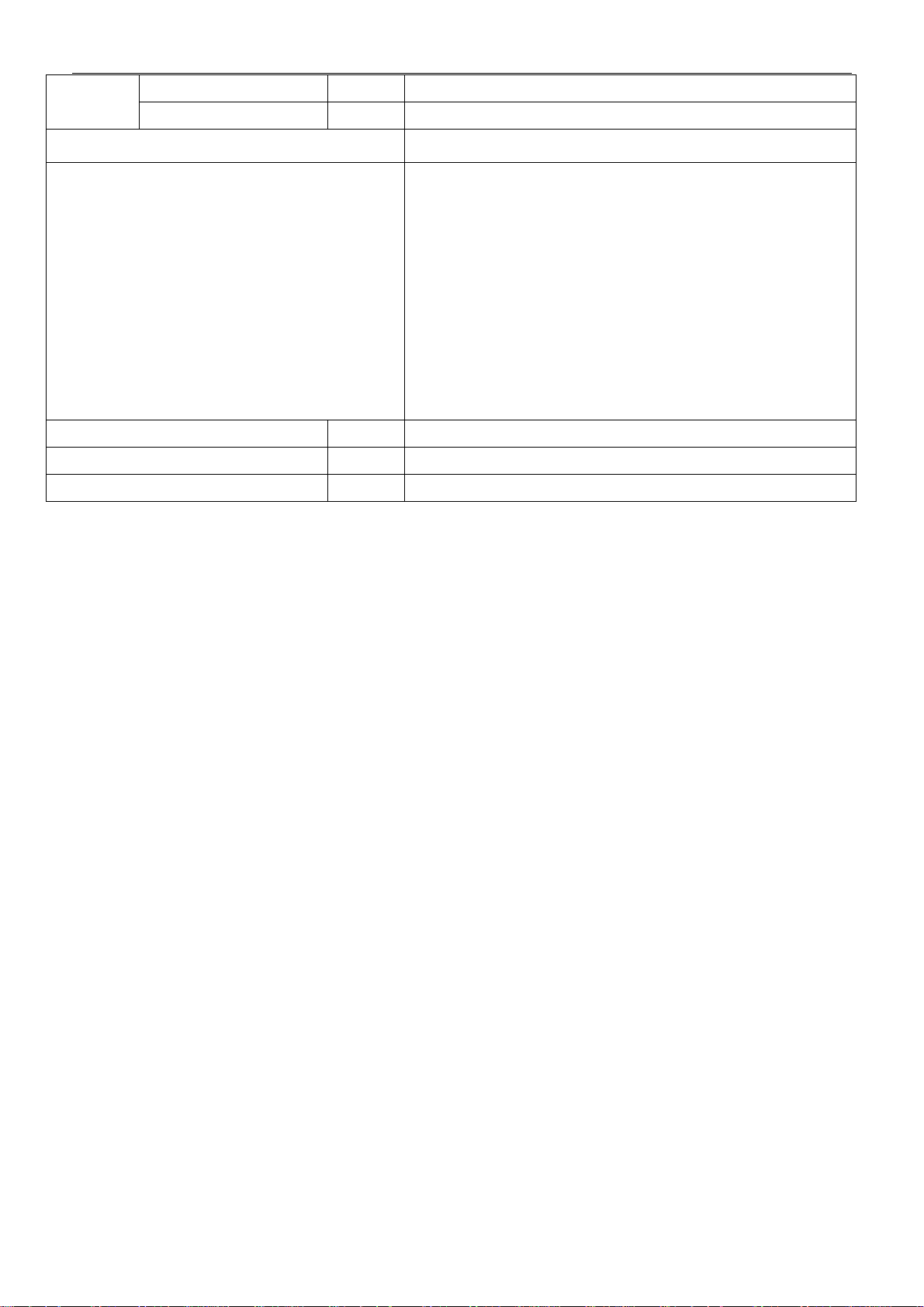

Weight

Control type Wired controller Wired controller

Safety protection device

Noise level(semi-anechoic ) dB(A) 67 70 74

Net weight kg 600 1150

Operation weight kg 670 1270

Power wi re mm2×No. 25×4+16×1 35×3+16×2 75×3+35 ×2

Signal wire mm2×No. 0.75×3-core 0.75×3-core

1) Protection for over-high discharge

pressure.

2) Protection for over-low suction

pressure.

3) Power supply phase sequence

protection.

4) Anti-frozen protection in cooling

mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over

current.

7) Protection for compressor

overload.

8) Outlet and inlet water

temperature difference protection.

9) Compressor discharge temp.

protection.

10) Water flow cut-off protection.

11)Sensor malfunction protection.

12)Low ambient temperature

drive-up protection

13)Low-temperature protection of

shell-and-tube heat exchanger.

1) Protection for over-high discharge

pressure.

2) Protection for over-low suction

pressure.

3) Power supply phase sequence

protection.

4) Anti-frozen protection in cooling

mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over

current.

7) Protection for compressor overload.

8) Outlet and inlet water temperature

difference protection.

9) Compressor discharge temp.

protection.

10) Water flow cut-off protection.

11) Sensor malfunction protection.

1730

2000

Cooling:0~17(0℃ must add

Operation water temp ℃

Ambient temp ℃ Cooling:10~46 Heating:-10~21 Cooling:10~46 Heating:-10~21

Note: Please refer to the water flow volume in the above table strictly to design and install.

All the above data is measured base on the following working condition:

1. cooling mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

7℃,air inlet temperature of condenser is 35℃;

2. heating mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

45℃,air inlet temperature of condenser is DB/WB 7/6℃.

antifreeze)

Heating:22~50

Cooling:5~17 Heating:45~50

18

Page 18

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Model MGBT-F250W/RN1

Cooling Capacity

Heating Capacity kW 270

Power supply V/Ph/Hz 380-400/3/50

Power supply

Compressor

Power input

Max. Input consumption A

Max. Current A

Refrigerant

Condenser

(Air side)

Evaporator

(Water side)

Dimension

Weight

Connection wire

Manual switch A 450

Fuse A 350

Type Scroll (fixed speed)

Quantity Copeland 8

Model SH120A4ALC

Brand

Capacity W

Input W

Rate current(RLA) A

Locked rotor Amp(LRA) A

Cooling kW

Cooling rated current A

Heating kW

Heating rated current A

Type R410A

Weight kg 15×4

Refrigerant control EXV+ capillary throttle

Air side heat-exchanger type Fin-coil

Quantity of fan motor Pieces 8

Air flow volume ×103m3/h 96

Fan motor input kW 5.6

Water side heat-exchanger type Shell-tube

Water resistance loss kPa 40

Water inlet/outlet pipeline inside

normal diameter

Water flow volume m3/h 43

Max. Pressure MPa 1

Water pipe connection type Flexible joint

Net(W×H×D)

Packing(W×H×D)

Net weight kg 2450

Operation weight kg 2600

Power wire mm2×No. 185×4+70×1

Signal wire mm2×No. 0.75×3-core with shielding

kW

Btu/h

mm DN100

inch 4”

mm

inch

mm

inch

149.6×83.86×78.74

153.54×86.61×82.68

250

830,000

Copeland

111231

10275

20.88

177

78.3

141.9

80

146

104.9

194.6

3800×2130×2000

3900×2200×2100

Control type Wired controller

19

Page 19

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

1) Protection for over-high discharge pressure.

2) Protection for over-low suction pressure.

3) Power supply phase sequence protection.

4) Anti-frozen protection in cooling mode.

5) Anti-frozen protection in Winter.

6) Protection for compressor over current.

7) Protection for compressor overload.

Safety protection device

8) Outlet and inlet water temperature difference

protection.

9) Compressor discharge temp. protection.

10) Water flow cut-off protection.

11)Sensor malfunction protection.

12)Low ambient temperature drive-up protection

13)Low-temperature protection of shell-and-tube heat

exchanger.

Noise level(semi-anechoic ) dB(A) 74

Operation water temp ℃

Ambient temp ℃

Cooling:0~17(0℃ must add antifreeze)

Heating:22~50

Cooling:10~52

Heating:-10~21

Note: Please refer to the water flow volume in the above table strictly to design and install.

All the above data is measured base on the following working condition:

1. cooling mode under normal working condition: water flow 0.172 m

3

/(h•kW), outlet water temperature of chilled water is

7℃,air inlet temperature of condenser is 35℃;

2. heating mode under normal working condition: water flow 0.172 m3/(h•kW), outlet water temperature of chilled water is

45℃,air inlet temperature of condenser is DB/WB 7/6℃.

20

Page 20

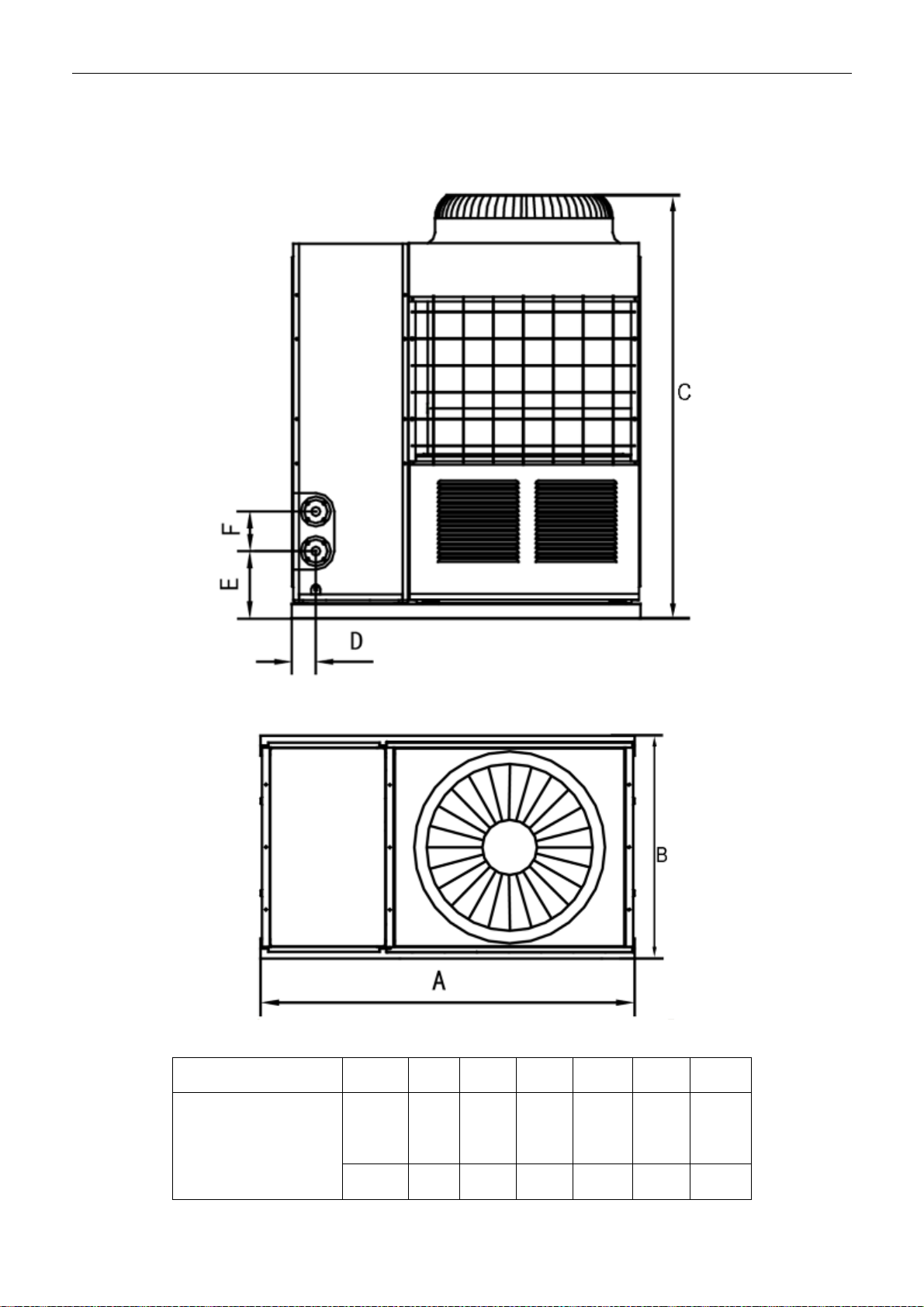

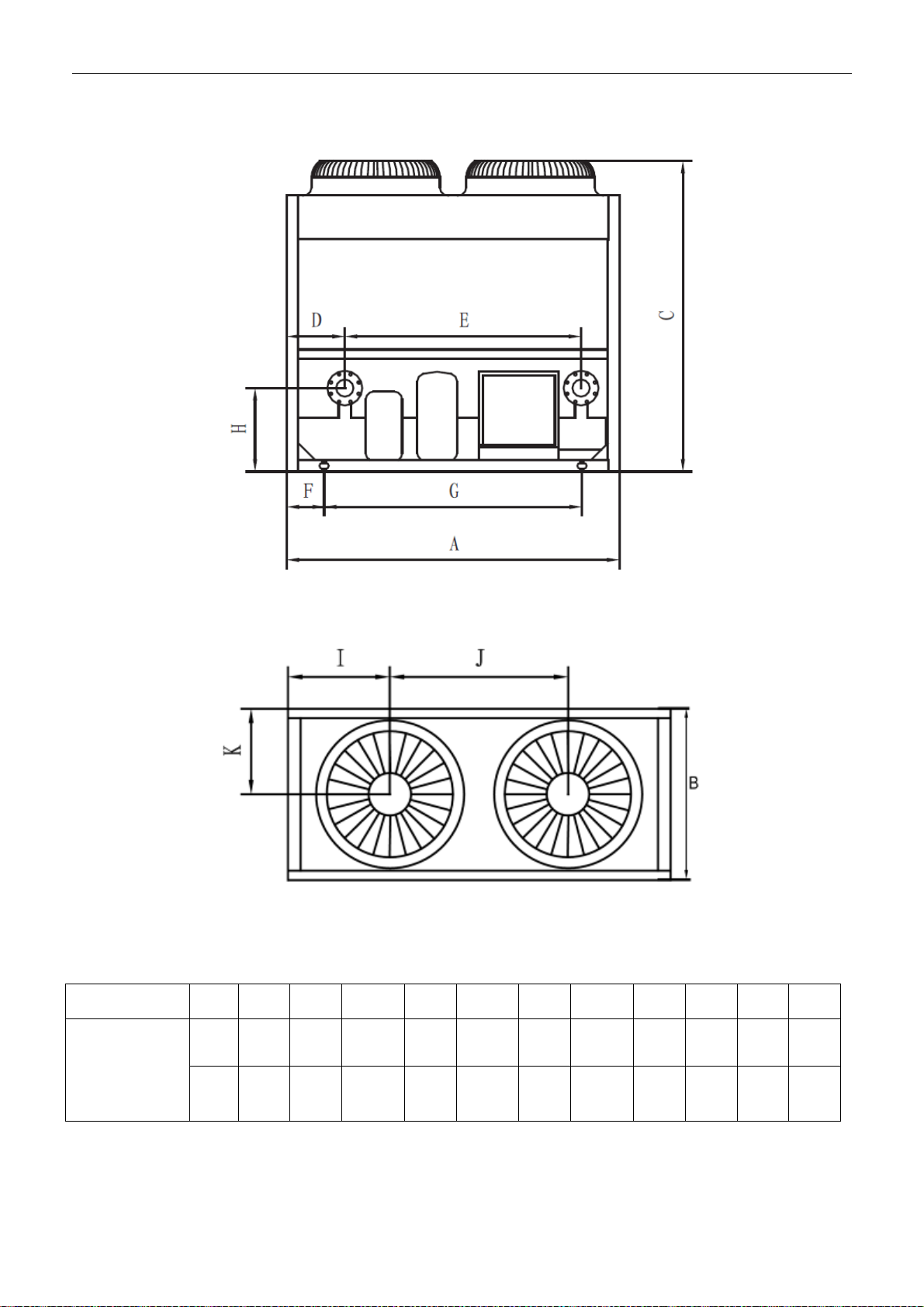

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

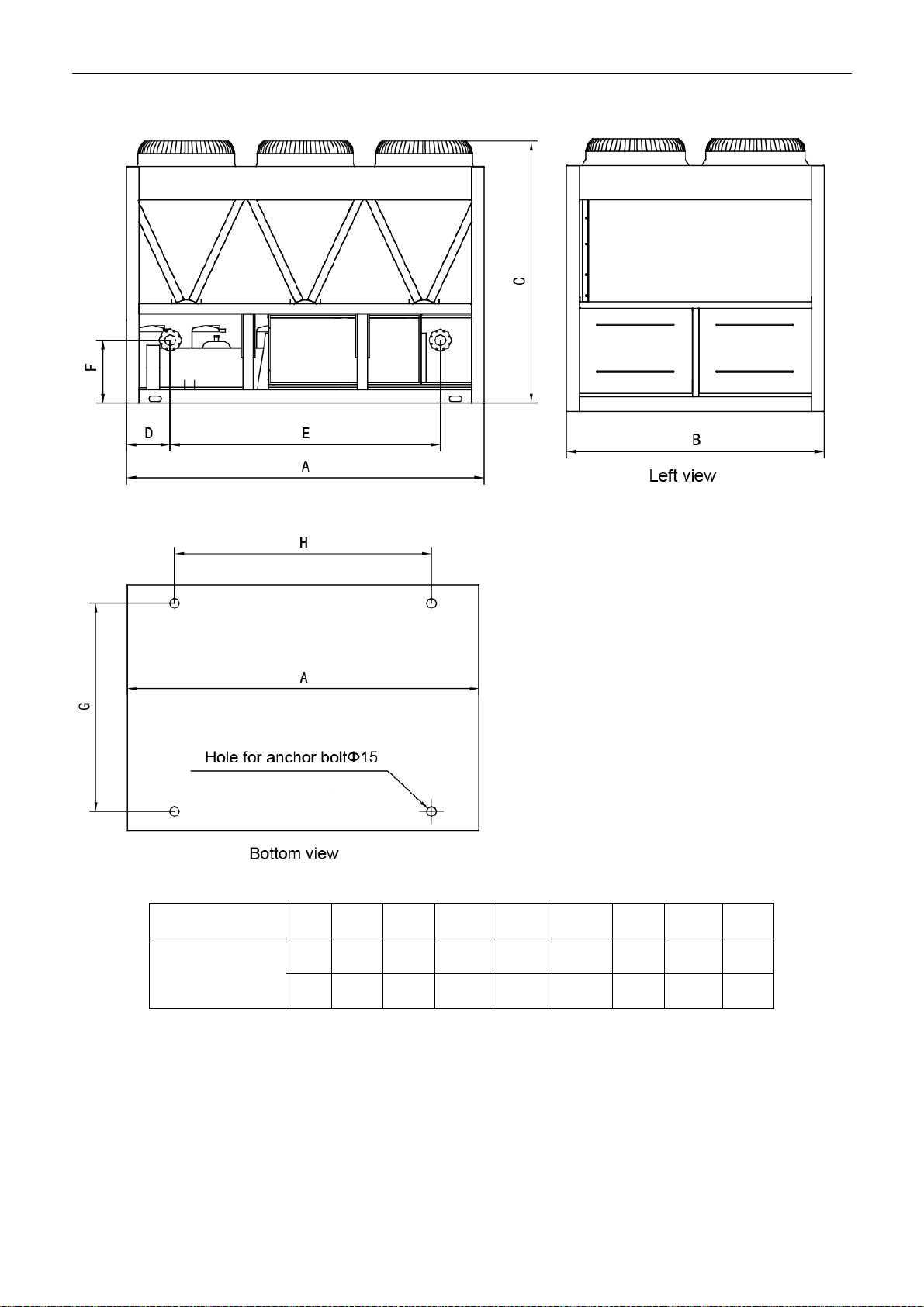

4 Dimension

25/30kw module

Front view

Top view

Model

MGB-F(D)25W/RN1

MGB-F(D)30W/RN1

Unit

mm

A B C D E F

1514 841 1865 115 315 172

inch 59.6 33.11 73.43 4.53 12.4 6.77

21

Page 21

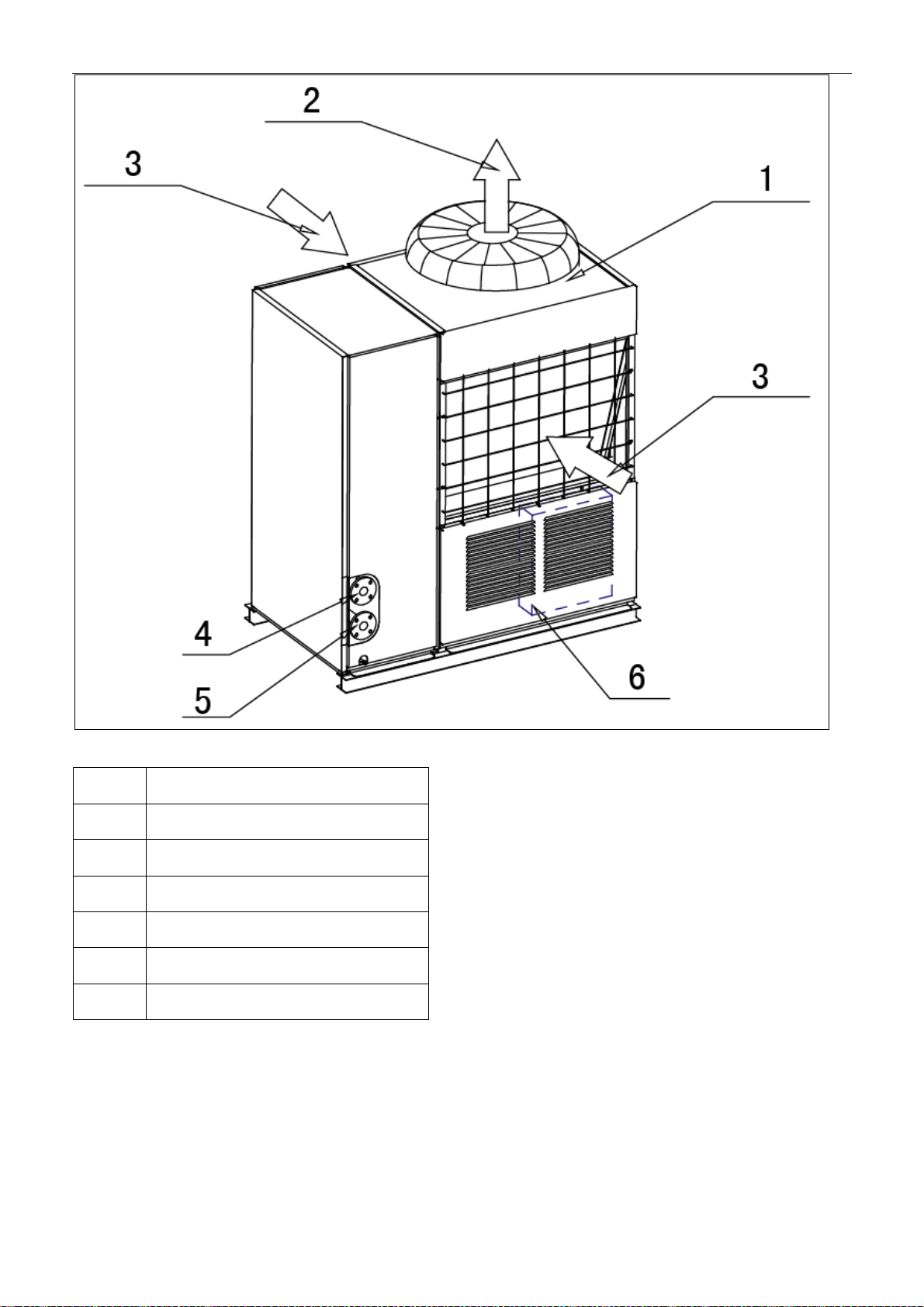

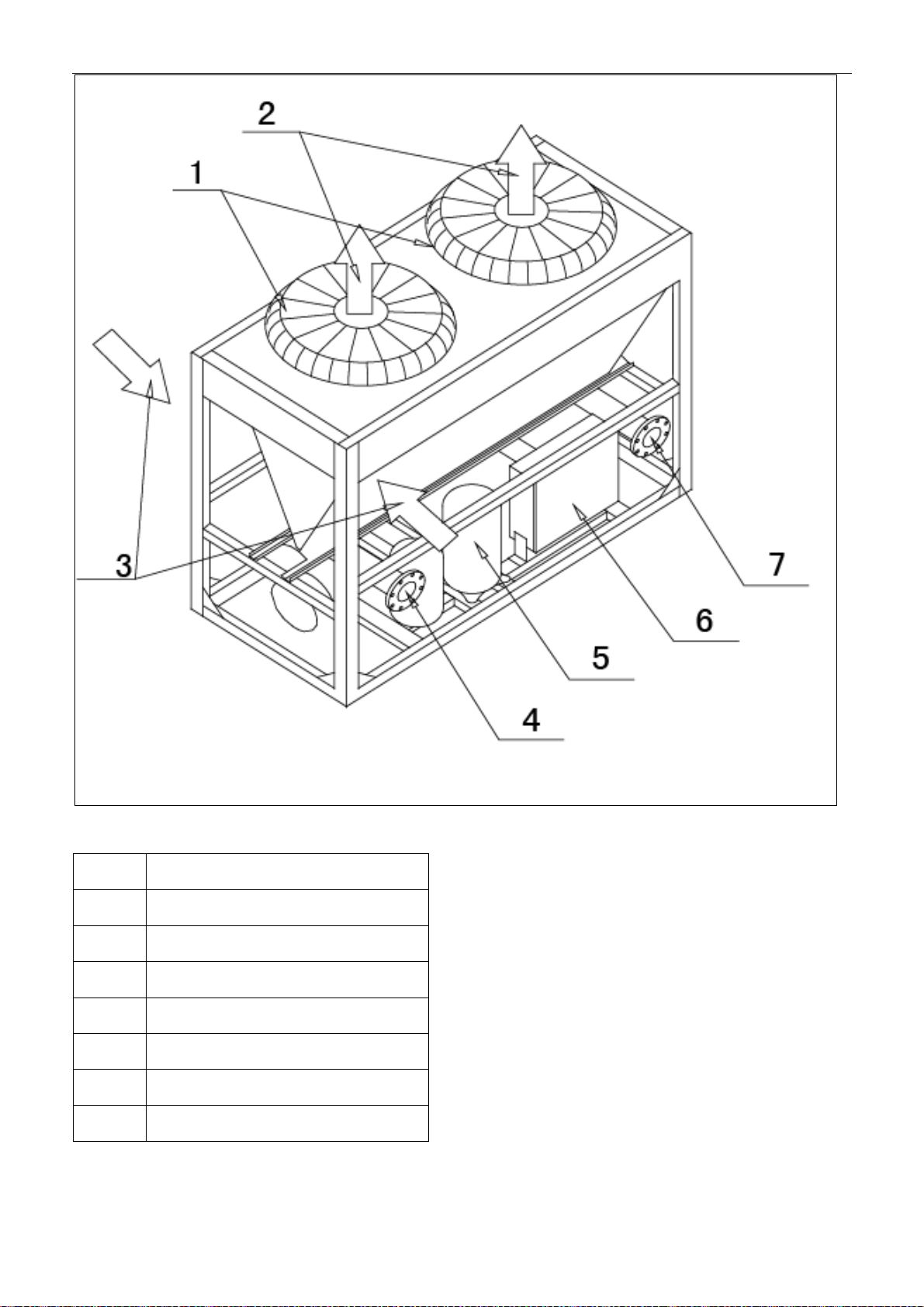

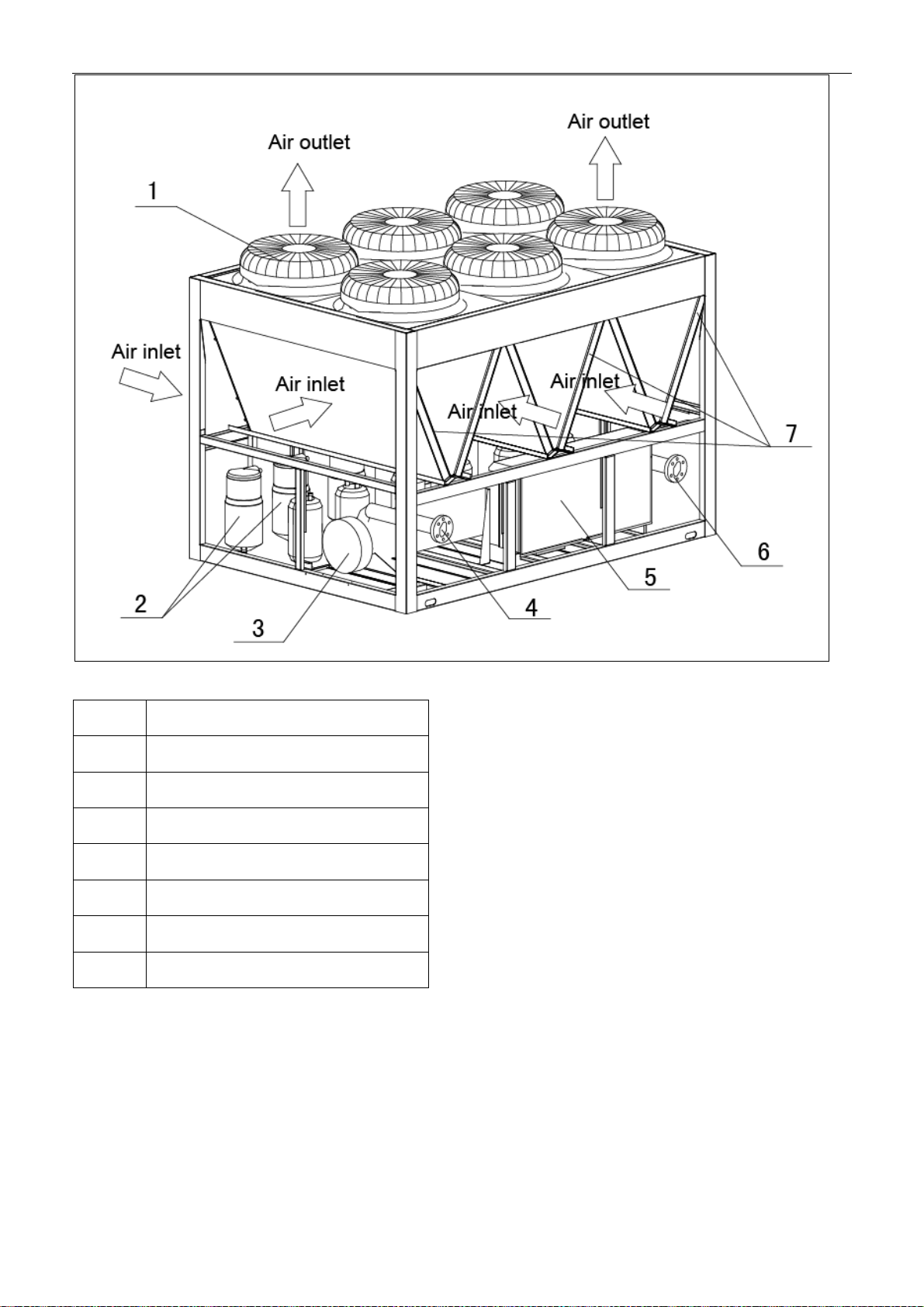

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

No. Name

1 Top cover

2 Air outlet

3 Air inlet

4 Water outlet

5 Water inlet

6 Electric control box

22

Page 22

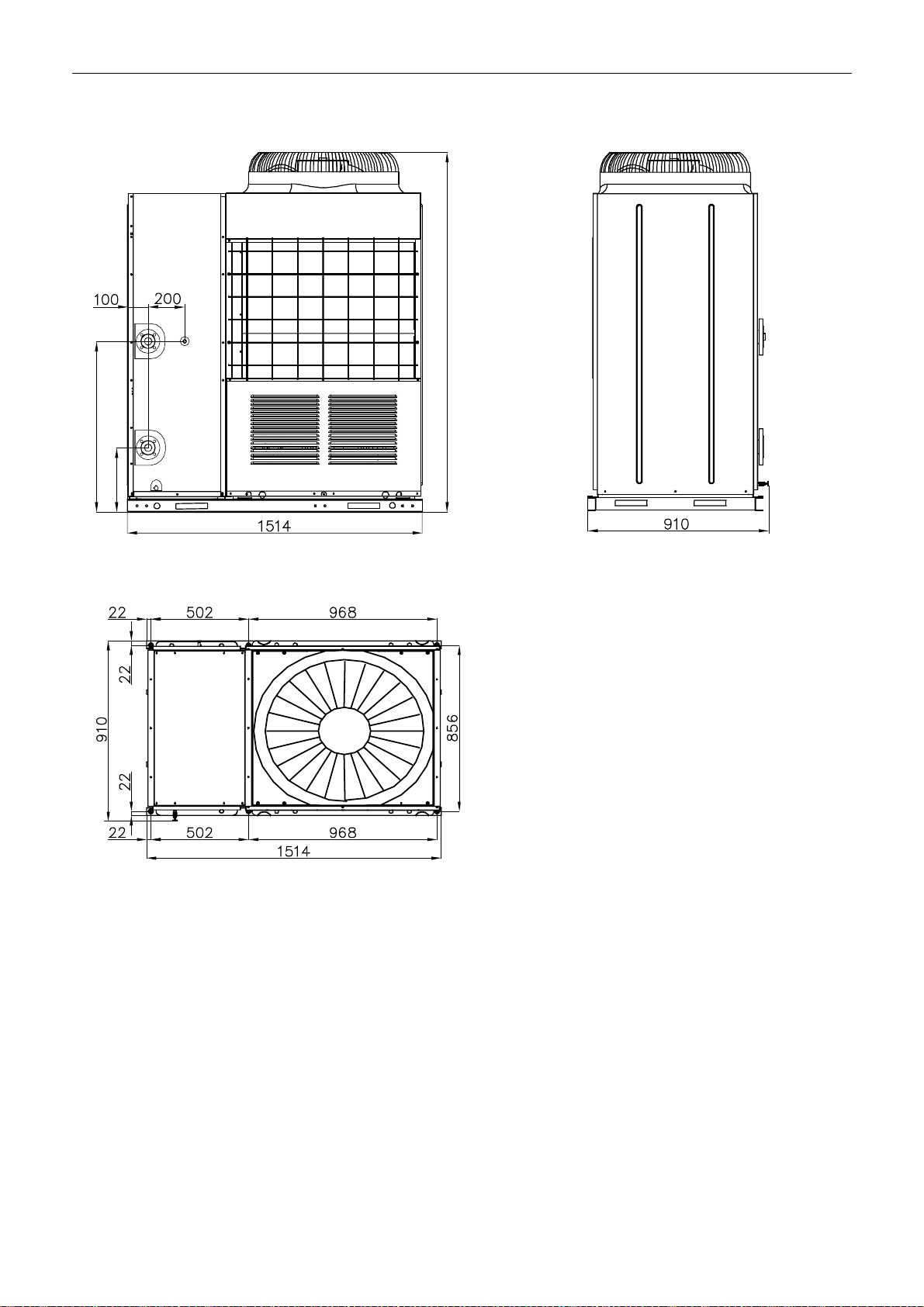

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

30KW new module

(Only for MGCSL-F30W/RN1 and MGCSL-D30W/RN1)

1865

874

317

Front view

Left view

Top view

23

Page 23

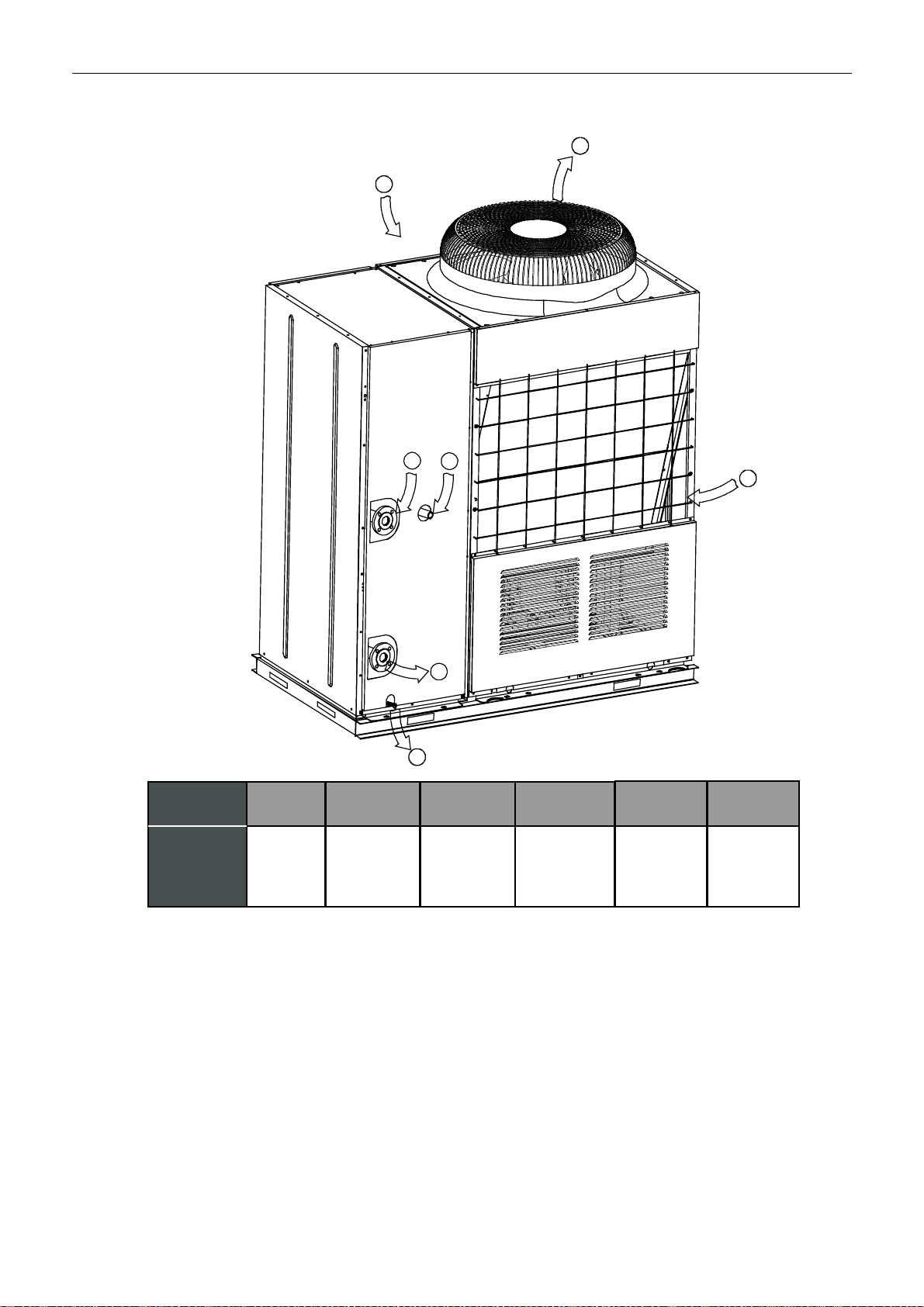

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

1

3

4

2

1

NO.

NAME

5

6

12 3 4

Air outletAir inlet Water outlet DrainWater inlet

Make-up

water inlet

5

6

24

Page 24

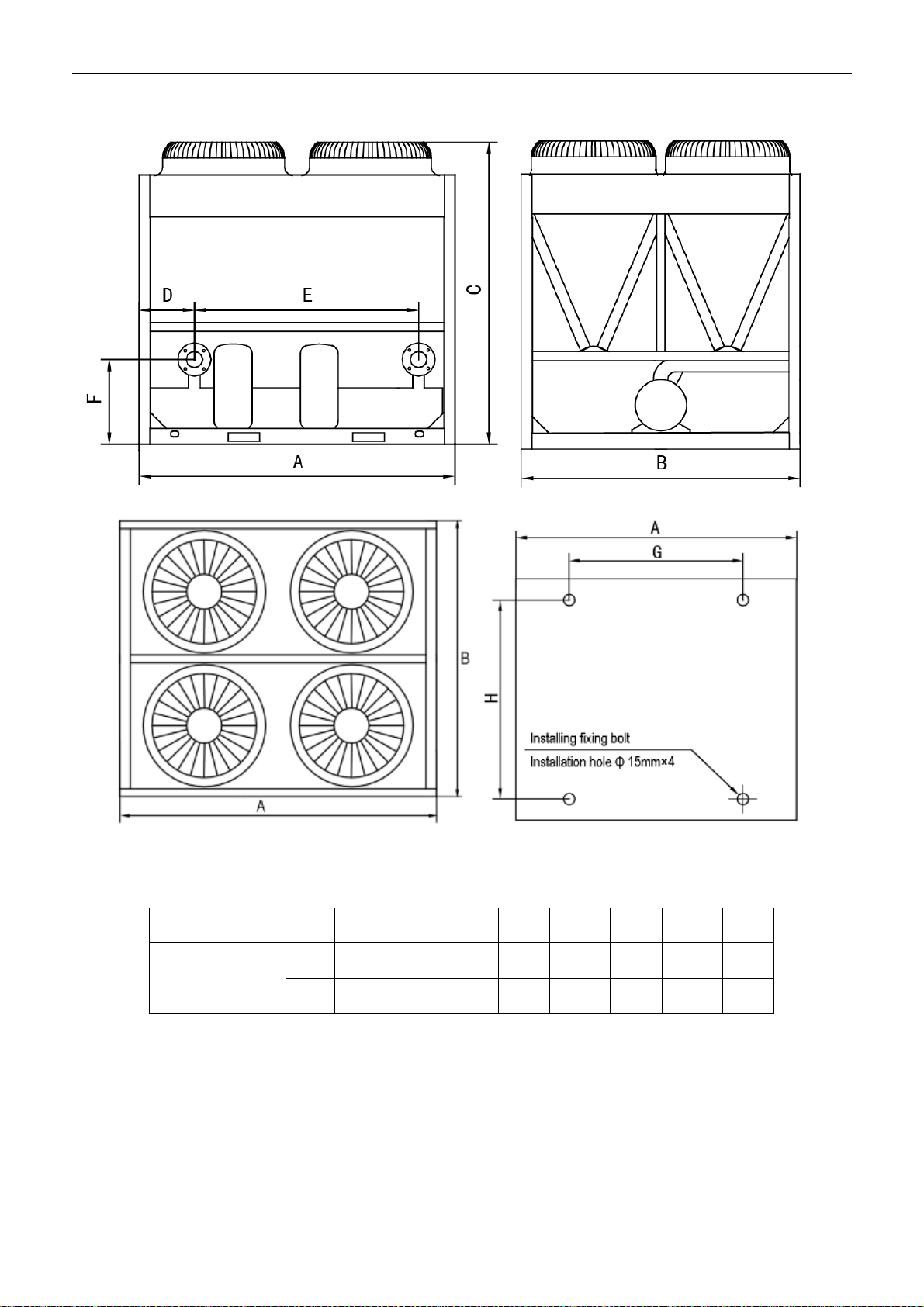

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

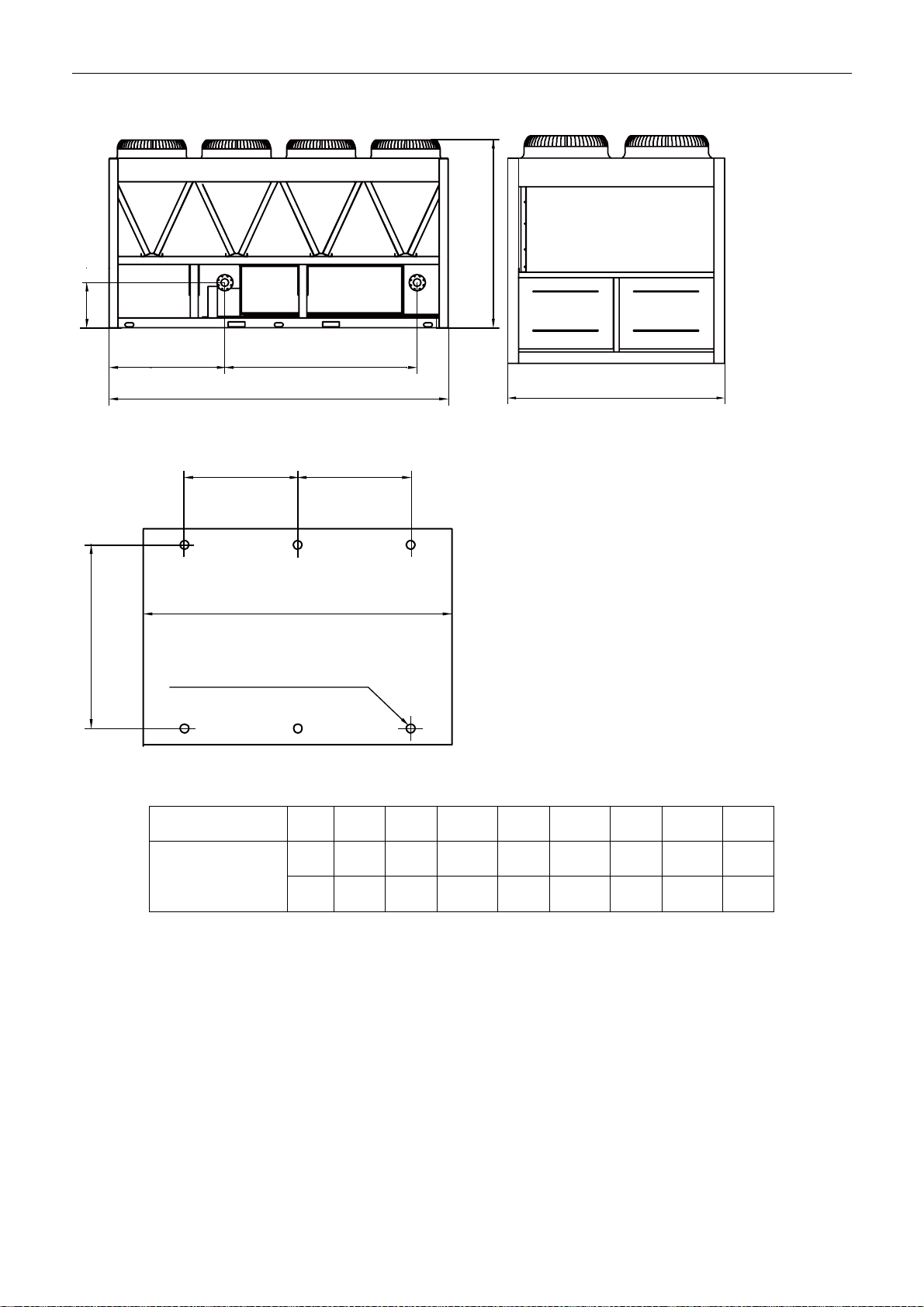

55/60/65KW module

Model

Unit

Front view

Top view

A B C D E F G H I J K

MGB-F55W/RN1

MGB-F60W/RN1

MGB-F65W/RN1

MGB-D65W/RN1

mm

inch 78.74 35.4 74 13.78 55.91 8.86 59.06 19.92 20.87 36.61 17.72

2000 900 1880 350 1420 225 1500 506 530 930 450

25

Page 25

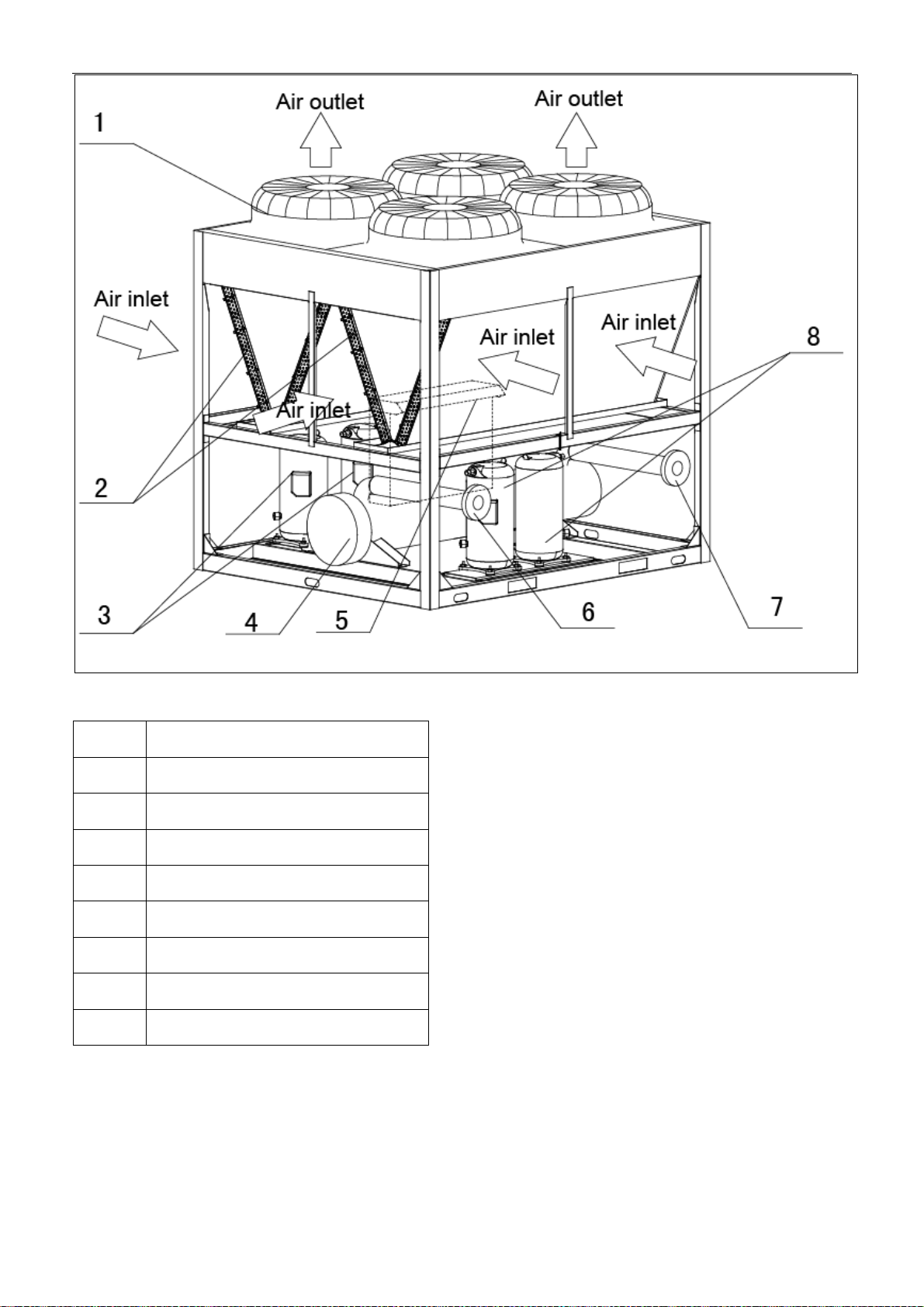

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

No. Name

1 Top cover

2 Air outlet

3 Air inlet

4 Water outlet

5 Compressor

6 Electric control box

7 Water inlet

26

Page 26

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

130KW module

Front view Side view

MGB-F130W/RN1

Model

Top view Anchor hole

A B C D E F G H

Unit

2000 1685 2080 350 1420 506 1550 1586

mm

inch 78.74 66.34 81.89 13.78 55.91 19.92 61.02 62.44

27

Page 27

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

No. Name

1 Top cover

2 Condenser

3 Compressor

4 Evaporator

5 Electric control box Air inlet

6 Water outlet

7 Water inlet

8 Compressor

28

Page 28

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

185KW module

Model unit A B C D E F G H

Mm 2850 2000 2110 3470 2156 506 1888 2388

MGB-F185W/RN1

inch 112.2 78.74 83.07 136.61 84.88 19.92 74.33 94.02

29

Page 29

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

No. Name

1 Top cover

2 Compressor

3 Evaporator

4 Water outlet

5 Electric control box

6 Water inlet

7 Condenser

30

Page 30

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

H

H

G

250KW module

C

F

D

A

Front view

E

B

Left view

A

Hole for anchor boltΦ15

Bottom view

Model unit A B C D E F G H

Mm 3800 2000 2130 1235 2156 573 1888 1551

MGB-F250W/RN1

inch 149.6 78.74 83.86 48.62 84.88 22.56 74.33 61.06

31

Page 31

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

A

Air outlet

Air outlet

Air outlet

Air outlet

1

A

i

r

i

n

l

e

ir inlet

A

i

r

i

n

l

e

t

t

e

l

n

i

r

i

A

A

i

r

i

n

l

e

t

t

7

6

5

2

No. Name

1 Top cover

2 Compressor

3 Evaporator

4 Water outlet

5 Electric control box

6 Water inlet

7 Condenser

8

Transportation guard plate (Be removed off

after installation)

8

4

3

32

Page 32

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

5 Refrigeration system drawing

5.1 25/30KW module refrigeration system sketch drawing

Each module has two compressors with two separate units, one double-pipe evaporator for two systems.

Fan

4-way valve A

Discharge pipe

Compressor A

Suction pipe

Low pressure cylinder A

4-way valve B

Compressor B

Water outlet

Low pressure cylinder B

Water inlet

Evaporator

(Double-pipe heat exchanger)

Condenser

Filter A

throttle parts A

throttle parts B

Filter B

5.2 55/60/65KW module refrigeration system sketch drawing(Fixed speed)

Each module has two compressors with two separate units, one shell and tube evaporator for two systems.

Compressor B

Compressor A

low pressure cylinder B

4-Way valve B

Fan A

Condenser

4-Way valve A

low pressure cylinder A

Fan B

Capillary

Capillary

4"

Water flow direction

EXV

Dry type evaporator

EXV

33

Page 33

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

65KW digital module refrigeration system sketch drawing (MGB-D65W/RN1)

Each module has three compressors with two separate units, one shell and tube evaporator for two systems.

Pressure switch

low pressure cylinder B

Compressor B

Discharge switch

Com. A1

digital

Pressure switch

Pressure switch

Com. A2

4-Way valve B

Pressure switch

Fan A

Fan B

Condenser

Pressure switch

T3B

Capillary

T3A

Capillary

Water flow direction

EXV

Dry type evaporator

EXV

Discharge switch

Pressure switch

4-Way valve A

low pressure cylinder A

5.3 130KW module refrigeration system sketch drawing

Each module has four compressors with two separate units, one shell and tube evaporator for four systems

low pressure cylinder B

Unit 2

Compressor B

4-Way valve B

Fan A

Condenser

Fan B

Capillary

Capillary

Water flow direction

EXV

Dry type evaporator

EXV

2-1/2"

Compressor A

34

4-Way valve A

Unit 1

low pressure cylinder A

Page 34

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

5.4 185KW module refrigeration system sketch drawing

Each module has six compressors with three separate units, one shell and tube evaporator for six systems.

low pressure cylinder B

Unit 2

Compressor B

Compressor A

4-Way valve B

Fan A

Condenser

4-Way valve A

Fan B

Capillary

Capillary

Water flow direction

EXV

Dry type evaporator

EXV

3"

Unit 3

Unit 1

low pressure cylinder A

5.5 250KW module refrigeration system sketch drawing

Each module has eight compressors with two separate units, one shell and tube evaporator for four systems

low pressure cylinder B

Unit 2

Compressor B2

Compressor B1

Compressor A2

4-Way valve B

Fan A

Condenser

Fan B

Capillary

Capillary

4"

Water flow direction

EXV

Dry type evaporator

EXV

Compressor A1

4-Way valve A

Unit 1

low pressure cylinder A

35

Page 35

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

6. Piping diagram

6.1 25/30KW module water pipeline sketch drawing

The table below describes the symbols.

Symbol Symbol explanation Symbol Symbol explanation

Stop valve

Pressure gauge

Water flow switch

Gate valve

Flexible joint

Y-shaped filter

Thermometer

Circulating pump

Check valve

Automatic discharge valve

36

Page 36

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

30KW module water pipeline sketch drawing

auto-air exchanse valve

Water pump

Expansion tank

Y-shaped filiter

Water-flow valve

Water replenishing valve

1.5kg<Water replenishing pres<6kg

Double

-pipe

heat

exchanger

Safety valve

Flexible joint

Flexible joint

This figure for reference purpose only, please in terms of the design rule for field installation.

The table below describes the symbols.

Aux. heater

Thermometer

2-way valve

Flexible joint

2-way valve

Flexible joint

Cutoff valve

Manometer

Fan coil unit

Fan coil unit

Fan coil unit

Fan coil unit

Symbol Symbol explanation Symbol Symbol explanation

Safety valve

Y-shaped filter

Pressure gauge

Water flow switch

Cut off valve

Manometer

Thermometer

Water pump

Expansion tank

Water replenishing valve

37

Page 37

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

6.2 55/60/65kw&(65kw digital) module water pipeline sketch drawing

DN100

The table below describes the symbols.

Symbol Symbol explanation Symbol Symbol explanation

Stop valve

Pressure gauge

Water flow switch

Gate valve

Flexible joint

Y-shaped filter

Thermometer

Circulating pump

Check valve

Automatic discharge valve

38

Page 38

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

6.3 130KW module water pipeline sketch drawing

The table below describes the symbols.

Symbol Symbol explanation Symbol Symbol explanation

Stop valve

Pressure gauge

Water flow switch

Gate valve

Flexible joint

Y-shaped filter

Thermometer

Circulating pump

Check valve

Automatic discharge valve

39

Page 39

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

6.4 185KW module water pipeline sketch drawing

The table below describes the symbols.

Symbol Symbol explanation Symbol Symbol explanation

Stop valve

Pressure gauge

Water flow switch

Gate valve

Flexible joint

Y-shaped filter

Thermometer

Circulating pump

Check valve

Automatic discharge valve

40

Page 40

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

6.5 250KW module water pipeline sketch drawing

Expansion tank

Main unit

The table below describes the symbols.

Water replenishing

Differential pressure by-pass valve

Drain valve

Auxiliary electric heater

Dirt discharge valve

Te rm i na l

Two-way valve

Three-way valve

Symbol Symbol explanation Symbol Symbol explanation

Stop valve

Pressure gauge

Water flow switch

Gate valve

Flexible joint

Y-shaped filter

Thermometer

Circulating pump

Check valve

Automatic discharge valve

41

Page 41

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

7 Wire Diagrams

7.1 Chiller wiring diagram

25/30KW module

Attached Drawing (I) Electric Drawing of Main Unit and Auxiliary Unit

42

Page 42

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

30KW new module (Only for MGCSL-F30W/RN1 and MGCSL-D30W/RN1)

XT4

MIDDLE

WIRE JOINT

BLAC K

Y&G

FAN CAP

T3A2

WHITE

RED

CN2

COLD MOD ULE

BLUE

8

LOW

BLUE

BLUE

BLACK

BLUE

BLUE

CN1

RED

RED

RED

2

6

4

RELAY

KM1

HIGH

BROWN

BLUE

Y&G

U

HEAT_A

PUMP

RED

PUMP

W

V

WHITE

BLUE

BLACK

2

6

4

A2

22

3

5

21

A1

RELAY

YEL LOW

BROWN

AC CONTACTOR

RED

BLU E

WHIT E

Y&G

T1(U)

RED

CRANK

WHITE

BLACK

A2

A1

COMPRESSOR A

COMP A

T3(W)

T2(V)

BLUE

2

6

4

22

3

5

21

AC CONTACTOR

RED

RED

RED

BLUE

WHITE

HEAT_B

)

C

N

(

)

M

O

C

(

)

O

N

(

POWER PROTECTOR

Y&G

T1(U)

RED

CRANK

E

U

D

L

E

B

R

COMPR ESSO RB

COMP B

T3(W)

T2(V)

BLUE

WHITE

BLACK

2

6

4

A2

22

3

1

5

A1

21

RED

E

D

U

E

L

R

B

ORANGE

PWM PRESSURE

RELIF VALVE

RED

RED

XT7

MIDDLE

WIRE JOINT

AC CONTACTOR

RED

BLACK

RED

S.V(A)

4-VALVE A

XT5

MIDDLE

WIRE JOINT

BLUE

BLUE

BLUE

BLACK

BLACK

BLACK

BLACK

S.V(A)

4-VALVE B

BLACK

XT6

MIDDLE

WIRE JOINT

PURPLE

BLACK

MARK:NORMA L MO DU LE S DO N 'T INC LU DE

Y&G

202090191055

BROKEN LINE AND THEIR J OINT WIRES

OUTDOO R W IRIN G DIAGRAM

BLACK

BLACK

BLACK

CN8

CN7

CN6

CN5

L3 L4

CURRENT BOARD

L1 L2

CN4

XS9

XP9

T

4

WHITE

TEMP B

CONDENSER

RED BLACK

TE MP A

CONDENSER

BLACK

BLACK

XS8

XP8

3

B

T

A

3

T

XS7

XP7

ANTI-FREEZING TEMP SENSOR

UNIT OUT-LET WATER TEMP

IN-LET WATER TEMPSENSOR

TOTAL OUT-LET WATER TEMP

PWM(B)

PWM(A)

CURRENT(A2)

TRANS

CN19(WHIT E)

TRANS OUT

5V

CN15

CN14

T3A T3B T4

CN26

CN21

CN22

MAIN BOARD

CN10

CN1(WHIT E)

PMV(A)

CN2(RED)

PMV(B)

ON/OFF

RED

ORANGE

YELLOW

H_PRO(A)

H_PRO(B)

HIGH PRESSURE

PROTECTOR A

K1(A)

TEMP PROTECTOR

SWITCH A

CURRENT( B2)

L_PRO(1A)

HIGH PRESSURE

PROTECTOR B

K1(B)

TEMP PROTECTOR

SWITCH B

RED

BLUE

BLACK

WHITE

PWM

POWER

CN18(WHITE)

S9

ON

OFF

S7 S8

SW3

S1

S4 S5

ON

OFF

S2 S3

SW2

CHECK

CN6

CN25

CN5

H&L_PRO

PURPLE

L_PRO(1B)

LOW PRESSURE

PROTECTOR 1B

LOW PRESSURE

PROTECTOR 1A

COM(I)

COM(O)

PURPLE

BLUE

CN17

FAN_B

CN31

FAN_A

CN30

BLUE

RED

PURPLE

CN11(BLACK )

ORANGE

YELLOW

P2

CN24

PUMP

(YELLOW)(RED)

RED

P1

BLUE

BLUE

HEAT

(BLUE)

RED

L_PRO(2B)

L_PRO(2A)

BLACK

BLUE

WHITE

RED

XT1

4-WAY TERMINA L

ON

OFF

1 2 3

SW3

FIXED

3 4

1 2

SW2

ON

OFF

S7 ON:REMOT E CONTROL OFF:WIR E CONTROL

S8 ON:LOW T EMP.MODE OFF:NOR M AL

S9 ON:30KW OFF:65/ 1 30/200/2 60KW

ON

ADDRE SS

DAIL SWITCH

S1

S2 ON:COOL ONLY OFF :R&C

S3 ON:DIGIT AL OFF : FIXED

SW2/S W3 FUCT ION DEFIN ATION

16-WA Y DAI L SWITC H FUNCTI ON

2-WAY

BLUE

BLUE

R

E

D

D

E

R

K

C

A

L

B

N

W

O

R

B

E

U

L

B

D

E

R

Y

A

R

G

Y

A

R

G

K

C

A

L

B

GRAY

W

O

L

L

E

Y

11-WAY

OFF

1 2 3

SW3

DIGIT AL

3 4

1 2

SW2

ON

OFF

S4 ON:H-EEP ROM OFF : NORMAL

S5 ON:C-EEP ROM OFF : NORMAL

DEFA ULT SETT I NG

XT3

TERMINAL

H2

H1

ALA R M

ON/ OF F

NC

W1 W2

PQ E

TERMINAL

FLOW

CO M

(E)

Q

P

XT2

POWER I N

OFF

ON

REMOT E TURN OFF

S2 S3 S4 S5 S7 S8 S9

REMOT E HEAT

ON OFF

ON OFF

REMOT E COOL

S2 S3 S4 S5 S7 S8 S9

S7

ON/OFF

REMOT E FUCTI ON SETTING

HEAT

EFFEC T ON NO. 0 MODUL E)

(

(ON/OFF SIGNAL!)

PROVI DE

BY USER

PROVI DE

BY USER

(ON/OFF SIGNAL!)

FLOW

SWTICH

LOW VOLTAGE SIGNAL

DON'T CONNECT HIGH VOLTAGE!

Attached picture (I) Electric Drawing of Main Unit and Auxiliary Unit

43

Page 43

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

55/60/65KW module

Attached picture (I) Electric Drawing of Main Unit and Auxiliary Unit

44

Page 44

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

65KW digital module(Only for MGB-D65W/RN1)

BLACK

Y&G

T1

(U)

HEAT_A1

RED

COMP A1

(W)

(V)

COMPRESSOR A1

T2

CRANK

T3

BLUE

WHITE

4

6

2

A2

22

BLACK

A1

5

21

3

AC CONTACTOR

RED

RED

RED

BLUE

WHITE

Y&G

T1

(U)

HEAT_A2

RED

COMP A2

(W)

(V)

COMPRESSOR A2

T2

T3

CRANK

ORANGE

BLUE

WHITE

4

6

2

A2

22

BLACK

A1

5

21

3

RED

RED

BROWN

BLUE

WHITE

Y&G

T1

(U)

HEAT_B

RED

COMP B

(W)

(V)

T2

CRANK

WHITE

ORANGE

4

6

2

A2

BLACK

A1

1

5

3

AC CONTACTOR

RED

BLUE

ORANGE

WHITE

Y&G

FAN A

COMPRESSOR B

T3

BLUE

ORANGE

22

21

RED

AC CONTACTOR

WHITE RED

BLACKBLACK

BLUE

LOW

BLUE

HIGH

BROWN

Y&G

RED

FAN B

WHITE

BLUE

BLACK

HIGH

BROWN B LUE

BROWN

BLUE

RED

RED

RED

XT7

MIDDLE

WIRE JOINT

RED

S.V(B)

4-VALVE B

S.V(A)

4-VALVE A

MIDDLE

WIRE JOINT

XT6

BLUE

BLACK

BROWN

XT5

MIDDLE

WIRE JOINT

PURPLE

OUTDOOR WIRING DIAGRAM

L1

L2

L3

L2L3L4 L1

CN4

CURRENT BOARD

CN6

CN7

CN8

CN5

RED

BLUE

BLACK

WHITE

ICOMP-B2

ICOMP-A2ICOMP-A1 ICOMP-B1

CN11(RED)

POWER OUT

CN19(WHITE)

T

4

XP9XP9

XS9

WHITE

T

3

B

XP8

XS8

TEMP B

CONDENSER

T

A

3

XP7

XS7

RED BLACK

TEMP A

CONDENSER

CN14

T3A T3B T4

ANTI-FREEZING TEMP. SENSOR

RT4

IN-LET WATER TEMP. SENSOR

RT5

CN21 CN26 CN33 CN35CN34

UNIT OUT-LETWATER TEMP.

R

T

6

TOTAL OUT-LETWATER TEMP.

7

T

R

TRANS OUT

MAIN BOARD

POWER

CN18(WHITE)

ON

123

SW3

34

ON

12

SW2

S2 S3 S4 S5 S7 S8 S9

QUERY

S1

CN27 CN10 CN22 CN32

COM(O)

CN2(RED)

CN23(WHITE)

PMV(B)

CN28(RED)

HEAT/COOL

ON/OFF

YELLOW

PMV(A)

CURRENT(A1)

CURRENT(A2)

CN6

COM(I)

PMV(B)

VALVE(B)

ELECTRIC EXPANSIVE

CN5

H&L_PRO

CN1(WHIITE)

PMV(A)

RED

ORANGE

H_PRO(A)

H_PRO(B)

HIGH PRESSURE

PROTECTOR B

HIGH PRESSURE

PROTECTOR A

L_PRO(1A)

LOW PRESSURE

K1(A1)

TEMP PROTECTOR

K1(A2)

TEMP PROTECTOR

PROTECTOR1A

K1(B)

TEMP PROTECTOR

SWITCH B1

SWITCHA1

SWITCH A2

CURRENT(B1)

PWM

CN17

CN20(RED)

TRANS IN

COMP.A1 S.V(A)

CN15(WHITE)

BLUE

RED

FANB

CN31

FANA

CN30

PURPLE

CN12(BLACK)

ORANGE

COMP.B1 S.V(B)

BROWN

CN9(WHIT E)

COMP.B2 COMP.A2

YELLOW

CN24

PUMP

YELLOW

(YELLOW)

BLUE

CN7

HEAT

BLUEBLUEBLUE

(BLUE)

CN16

ALARM

(RED)

CN8(WHITE)

ANTI-FREEZING

CN3(YELLOW)

PH_PRO

CN4(RED)

WATER_PRO

RED

PURPLE

L_PRO(1B)

PURPLE

LOW PRESSURE

PROTECTOR 1B

LOW PRESSURE

PROTECTOR 2B

L_PRO(2A)

L_PRO(2B)

LOW PRESSURE

PROTECTOR2A

S7 ON:REMOTE CONTROL OFF:WIRE CONTROL

S8 ON:LOW TEMP.MODE OFF:NORMAL

S9 ON:30KW OFF:65/130/200/260KW

ADDRESS

DAIL SWITCH

S1

16-WAY DAIL SWITCH FUNCTION

S2 ON:COOL ONLY OFF:R&C

S3 ON:DIGITAL OFF:FIXED

S4 ON:H-EEPROM OFF:NORMAL

S5 ON:C-EEPROM OFF:NORMAL

SW2/SW3 FUCTION DEFINATION

PWM PRESSURE

RELIF VALVE

XT1

Y&G

4-WAY TERMINAL

Y&G

BLUE

WHITE

RED

BLUE

BLUEBLUEBL UE

R

E

D

D

E

R

K

C

A

L

B

N

W

O

R

B

E

U

L

B

D

E

R

GRAY

Y

A

R

G

K

C

A

L

B

W

O

L

L

GRAY

OFF

ON

REMOTE TURN OFF

REMOTE HEAT

OFF

123

34

12

OFF

ON OFF

ON OFF

REMOTE COOL

S2 S3 S4 S5 S7 S8 S9

S7

ON/OFF

REMOTE FUCTION SETTING

ON

SW3

SW2

ON

DEFAULT SETTING

BLACK

BLUE

WHITE

POWER IN

RED

XT4

4-WAY

TERMINAL

YELLOW

YELLOW

E

Y

PUMP

H2 P1 P2H1

HEAT

EFFECT ON NO.0 MODULE)

(

(ON/OFF SIGNAL!)

PROVIDE

BY USER

PROVIDE

BY USER

(ON/OFF SIGNAL!)

W1 W2

(E)

(E)

Q

Q

P

P

XT2

7-WAY

TERMINAL

LOW VOLTAGE SIGNAL

DON'T CONNECT HIGH VOLTAGE!

Attached picture (I) Electric Drawing of Main Unit and Auxiliary Unit

45

Page 45

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

130KW module

Attached picture (I) Electric Drawing of Main Unit and Auxiliary Unit

46

Page 46

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

185KW module

2SNART

T

4

-

T

-

4

2

1SNART

4

T

-

1

1PAC

2PAC

)E(

Q

P

3TX

3

3SNART

C

B

A

C

AB

C

B

A

C

AB

C

AB

C

AB

KM6

KM5

KM4

KM3

KM2

KM1

G/YG/YG/YG/YG/Y

B3PMOCA3PMOCB2PMOCA2PMOCB1PMOC

W

V

U

W

V

U

W

V

U

W

V

U

W

V

U

G/Y

A1PMOC

W

V

U

B3taeH

A3taeH

B2taeH

A2taeH

B1taeH

A1taeH

Attached Drawing (I) Electric Drawing of Main Unit and Auxiliary Unit

2TX

A

50Hz

~

3N

C

B

N

380-400V

47

Page 47

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

250KW module

48

Attached Drawing (I) Electric Drawing of Main Unit and Auxiliary Unit

Page 48

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

7.2 Networking communication schematic of main unit and auxiliary unit

25/30KW module

49

Page 49

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

m

m

30KW new module(Only for MGCSL-F30W/RN1 and MGCSL-D30W/RN1)

RVV-300/500 4*10+1*6

H2 P1 P2H1

H2 P 1 P2H1

120Ω

RVV-300/500 4*10+1*6m

Please choose such accessory as power

Thewiringdiagramof auxiliaryheaterand

Notes

pump is justfor reference ,please follow the

instructions ofcorresponding auxiliary

heater products.

wire , switch of auxiliaryheateraccording to

the actual parameter of productsand national

N

C

AB

Black

100Ω

RVV-300/500 4*10+1*6mm

H2 P1 P2H1

The length of wire

shouldbeshorter

than 500m

Gray

Yel lo w

Query

Fault

Attached picture (II) Networking Communication Schematic of Main Unit and Auxiliary Unit

50

Page 50

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

55/60/65KW module

51

Page 51

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

m

m

m

65KW digital Mmodule(Only for MGB-D65W/RN1)

H2 P1 P2H1

atic of Main Unit and Auxiliary Unit

H2 P1 P2H1

120Ω

Please choose such acces sory aspower

The wiring diagramof auxiliaryheater and

Notes

pump is just for reference,please follow the

instructions of corresponding auxiliary

heater products.

wire,switchofauxiliaryheateraccordingto

the actual paramet er ofproducts and national

N

C

AB

unication Sche

Attached picture (II) Networking Co

52

100Ω

Black

Gray

Yellow

H2 P1 P2H1

The length of wire

should be shorter

than 500m

Query

Fault

Page 52

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

130KW module

53

Page 53

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

185KW module

Attached Drawing (II) Networking Communication Schematic of Main Unit and Auxiliary Unit

54

kcalB

yarG

w

o

lleY

yreuQ

tluaF

ylppuSrewoP

rotcennoC

Page 54

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

m

m

m

250KW module

H2 P1 P2H1

atic of Main Unit and Auxiliary Unit

H2 P1 P2H1

120Ω

Please ch oose such accessory as power

The wiringdiagram of auxiliary heaterand

Notes

pump is justfor reference,please follow the

instructions of corresponding auxiliary

heater products.

wire , swit ch of auxiliary heater according to

the actual parameter ofproducts and national

N

C

AB

unication Sche

Attached Drawing (II) Networking Co

Black

Gray

Yell ow

H2 P1 P2H1

The length of wire

should be shorter

than 500m

55

Page 55

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

8 Electric Characteristics

Model

MGB-F25W/RN1 50 380-415 342 456 21.3 36 74(×2) 9.1(×2) 0.67 3.1

MGB-D25W/RN1 50 380-415 342 456 21.3 36 74(×2) 9.1(×2) 0.67 3.1

MGB-F30W/RN1 50 380-415 342 456 22.6 36 74(×2) 9.1(×2) 0.67 3.1

MGB-D30W/RN1 50 380-415 342 456 22.6 36 74(×2) 9.1(×2) 0.67 3.1

MGCSL-F30W/RN1 50 380-415 342 456 25.3 25 74(×2) 11.8(×2) 0.55 4

MGCSL-D30W/RN1 50 380-415 342 456 25.3 25 74(×2) 11.8(×2) 0.55 4

MGB-F55W/RN1 50 380-400 342 440 49.8 100 110(×2) 17.6 (×2) 0.65(×2) 3.0(×2)

MGB-F60W/RN1 50 380-400 342 440 51.7 100 110(×2) 17.6(×2) 0.65(×2) 3.0(×2)

MGB-F65W/RN1 50 380-400 342 440 54.5 100 110(×2) 17.6 (×2) 0.65(×2) 3.0(×2)

MGB-D65W/RN1 50 380-415 342 456

MGB-F130W/RN1 50 380-400 342 440

MGB-F185W/RN1 50 380-400 342 440 160 180 110(×6) 17.6 (×6) 0.88(×6) 4.0(×6)

MGBT-F250W/RN1 50 380-400 342 440 191 280 177(×8) 20.8(×8) 5.6(×8) 14.4(×8)

Remark:

TOCA: Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A)

LRA: Locked Rotor Amps. (A)

RLA: Rated Locked Amps. (A)

OFM: Outdoor Fan Motor.

KW: Rated Motor Input (KW)

FLA: Full Load Amps.

Hz Voltage Min. Max. TOCA MFA LRA RLA KW FLA

Outdoor Unit Power Supply Compressor OFM

52 70 118/74/82.4 17.8/9.1/9.8 0.55(×2) 4.5(×2)

130 200 110(×4) 17.6 (×4) 0.88(×4) 4.0(×4)

56

Page 56

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

9 Capacity Tables

9.1 MGB-F(D)25W/RN1

Cooling:

Ambient temp.(℃)

Chilled water outlet

temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) KW KW KW KW KW KW KW KW KW KW KW KW

5.00 31.35 8.19 29.52 8.44 27.85 8.71 26.32 8.97 24.66 9.42 22.69 9.89

6.00 32.41 8.32 30.49 8.58 28.73 8.84 27.13 9.11 25.45 9.57 23.44 10.05

7.00 33.54 8.49 31.52 8.75 29.68 9.02 28.00 9.30 26.29 9.77 24.24 10.25

8.00 34.57 8.74 32.46 9.01 30.54 9.29 28.78 9.58 27.06 10.06 24.97 10.56

9.00 35.55 8.83 33.35 9.10 31.34 9.38 29.51 9.67 27.77 10.16 25.66 10.66

21.00 25.00 30.00 35.00 40.00 46.00

58

10.00 36.90 8.96 34.58 9.24 32.47 9.52 30.54 9.82 28.77 10.31 26.62 10.82

11.00 37.93 9.05 35.51 9.33 33.31 9.62 31.31 9.91 29.52 10.41 27.34 10.93

12.00 38.79 9.18 36.29 9.46 34.01 9.76 31.93 10.06 30.15 10.56 27.95 11.09

13.00 39.49 9.25 36.90 9.54 34.55 9.84 32.41 10.14 30.63 10.65 28.43 11.18

14.00 40.47 9.32 37.79 9.61 35.35 9.90 33.13 10.21 31.34 10.72 29.11 11.26

15.00 40.99 9.36 38.23 9.65 35.73 9.95 33.46 10.26 31.68 10.77 29.47 11.31

Page 57

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Heating:

Ambient temp.(℃)

Hot water outlet

temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) KW KW KW KW KW KW KW KW KW KW KW KW KW KW

39.00 18.34 5.76 22.92 6.54 26.97 7.27 29.96 7.90 32.57 8.32 36.47 8.82 41.95 9.52

41.00 17.72 5.87 22.18 6.67 26.12 7.42 29.06 8.06 31.62 8.49 35.35 8.99 40.58 9.71

42.00 17.21 5.99 21.56 6.81 25.43 7.57 28.32 8.23 30.85 8.66 34.42 9.18 39.45 9.91

43.00 16.79 6.12 21.07 6.95 24.88 7.72 27.73 8.39 30.24 8.84 33.69 9.37 38.54 10.12

44.00 16.47 6.24 20.69 7.09 24.45 7.88 27.29 8.57 29.80 9.02 33.13 9.56 37.84 10.32

45.00 16.23 6.37 20.41 7.24 24.16 8.04 26.99 8.74 29.50 9.20 32.75 9.75 37.33 10.53

46.00 15.91 6.43 20.04 7.31 23.74 8.12 26.56 8.83 29.06 9.29 32.20 9.85 36.64 10.64

-10 -6 -2 2 7 10 13

47.00 15.44 6.56 19.47 7.46 23.10 8.28 25.87 9.00 28.33 9.48 31.33 10.05 35.60 10.85

48.00 14.83 6.76 18.73 7.68 22.24 8.53 24.93 9.27 27.34 9.76 30.18 10.35 34.23 11.18

49.00 14.02 7.03 17.73 7.99 21.08 8.87 23.66 9.65 25.97 10.15 28.62 10.76 32.40 11.62

50.00 13.12 7.38 16.61 8.39 19.77 9.32 22.22 10.13 24.41 10.66 26.86 11.30 30.35 12.20

59

Page 58

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

9.2 MGB-F(D)30W/RN1

Cooling:

Chilled water

outlet temp.

Ambient temp.(℃)

21.00 25.00 30.00 35.00 40.00 46.00

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃)

5.00 33.59 8.81 31.63 9.08 29.84 9.36 28.20 9.65 26.42 10.13 24.31 10.64

6.00 34.72 8.94 32.66 9.22 30.79 9.51 29.07 9.80 27.27 10.29 25.11 10.80

7.00 35.93 9.13 33.77 9.41 31.80 9.70 30.00 10.00 28.17 10.50 25.97 11.03

8.00 37.04 9.40 34.78 9.69 32.72 9.99 30.84 10.30 28.99 10.82 26.76 11.36

9.00 38.09 9.49 35.73 9.79 33.58 10.09 31.62 10.40 29.75 10.92 27.49 11.47

10.00 39.53 9.63 37.05 9.93 34.79 10.24 32.73 10.56 30.83 11.08 28.52 11.64

11.00 40.63 9.73 38.05 10.03 35.69 10.34 33.54 10.66 31.63 11.19 29.29 11.75

12.00 41.56 9.87 38.88 10.18 36.44 10.49 34.22 10.82 32.30 11.36 29.94 11.92

KW KW KW KW KW KW KW KW KW KW KW KW

13.00 42.31 9.95 39.54 10.26 37.02 10.58 34.73 10.90 32.82 11.45 30.46 12.02

14.00 43.36 10.02 40.48 10.33 37.87 10.65 35.49 10.98 33.58 11.53 31.19 12.10

15.00 43.92 10.07 40.97 10.38 38.29 10.70 35.85 11.03 33.95 11.58 31.57 12.16

60

Page 59

Heating:

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Hot water outlet

temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) KW KW KW KW KW KW KW KW KW KW KW KW KW KW

39.00 19.89 6.13 24.86 6.97 29.25 7.74 32.50 8.42 35.33 8.86 39.57 9.39 45.50 10.14

41.00 19.22 6.26 24.06 7.11 28.34 7.90 31.52 8.59 34.30 9.04 38.34 9.58 44.02 10.35

42.00 18.67 6.38 23.39 7.26 27.58 8.06 30.72 8.76 33.46 9.22 37.34 9.78 42.79 10.56

43.00 18.22 6.52 22.86 7.40 26.98 8.23 30.08 8.94 32.80 9.41 36.54 9.98 41.81 10.77

44.00 17.86 6.65 22.44 7.55 26.53 8.39 29.61 9.12 32.32 9.60 35.94 10.18 41.04 10.99

45.00 17.60 6.78 22.14 7.71 26.21 8.57 29.28 9.31 32.00 9.80 35.52 10.39 40.49 11.22

46.00 17.26 6.85 21.74 7.79 25.76 8.65 28.81 9.40 31.52 9.90 34.92 10.49 39.74 11.33

47.00 16.75 6.99 21.12 7.94 25.06 8.82 28.06 9.59 30.73 10.10 33.99 10.70 38.61 11.56

48.00 16.09 7.20 20.31 8.18 24.13 9.09 27.05 9.88 29.66 10.40 32.74 11.02 37.13 11.90

-10 -6 -2 2 7 10 13

Ambient temp.(℃)

49.00 15.21 7.49 19.23 8.51 22.87 9.45 25.67 10.27 28.17 10.81 31.05 11.46 35.15 12.38

50.00 14.23 7.86 18.02 8.93 21.45 9.92 24.10 10.79 26.48 11.36 29.13 12.04 32.92 13.00

61

Page 60

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

9.3 MGB-F55W/RN1

Cooling:

Chilled water

outlet temp.

Ambient temp.(℃)

21.00 25.00 30.00 35.00 40.00 46.00

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW

5.00 61.58 15.41 57.98 15.89 54.70 16.38 51.70 16.89 48.44 17.73 44.57 18.62

6.00 63.65 15.65 59.88 16.14 56.44 16.64 53.30 17.15 49.99 18.01 46.04 18.91

7.00 65.88 15.97 61.91 16.47 58.30 16.98 55.00 17.50 51.65 18.38 47.62 19.29

8.00 67.91 16.45 63.77 16.96 59.99 17.48 56.54 18.03 53.15 18.93 49.06 19.87

9.00 69.83 16.61 65.50 17.12 61.56 17.65 57.97 18.20 54.55 19.11 50.40 20.07

10.00 72.48 16.86 67.92 17.38 63.78 17.92 60.00 18.47 56.52 19.40 52.28 20.37

11.00 74.50 17.03 69.75 17.55 65.43 18.10 61.50 18.66 57.99 19.59 53.70 20.57

12.00 76.20 17.28 71.28 17.81 66.81 18.36 62.73 18.93 59.22 19.87 54.89 20.87

13.00 77.56 17.41 72.49 17.95 67.87 18.51 63.67 19.08 60.17 20.03 55.84 21.04

14.00 79.49 17.53 74.22 18.08 69.43 18.64 65.07 19.21 61.56 20.17 57.19 21.18

15.00 80.51 17.62 75.10 18.17 70.19 18.73 65.72 19.31 62.24 20.27 57.88 21.29

62

Page 61

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Heating:

Ambient temp.(℃)

Hot water

outlet temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW

39.00 40.40 11.45 45.84 13.01 53.93 14.46 59.92 15.71 65.13 16.54 72.95 17.53 83.89 18.94

41.00 35.44 11.68 44.36 13.28 52.24 14.75 58.11 16.04 63.24 16.88 70.70 17.89 81.16 19.32

42.00 34.42 11.92 43.13 13.55 50.86 15.05 56.63 16.36 61.69 17.22 68.85 18.26 78.90 19.72

43.00 33.58 12.17 42.14 13.82 49.75 15.36 55.46 16.70 60.48 17.58 67.38 18.63 77.08 20.12

44.00 32.94 12.41 41.38 14.11 48.91 15.67 54.58 17.04 59.59 17.93 66.26 19.01 75.67 20.53

45.00 32.46 12.67 40.83 14.39 48.32 15.99 53.99 17.39 59.00 18.30 65.49 19.40 74.66 20.95

46.00 31.82 12.79 40.08 14.54 47.49 16.15 53.12 17.56 58.12 18.48 64.39 19.59 73.28 21.16

47.00 30.88 13.05 38.94 14.83 46.20 16.48 51.73 17.91 56.66 18.85 62.67 19.98 71.19 21.58

48.00 29.66 13.44 37.45 15.27 44.48 16.97 49.87 18.45 54.68 19.42 60.37 20.58 68.45 22.23

-10 -6 -2 2 7 10 13

49.00 28.05 13.98 35.46 15.89 42.16 17.65 47.32 19.19 51.95 20.19 57.24 21.41 64.80 23.12

50.00 26.24 14.68 33.22 16.68 39.55 18.53 44.43 20.14 48.83 21.20 53.71 22.48 60.69 24.28

63

Page 62

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

9.4 MGB-F60W/RN1

Cooling:

Ambient temp.(℃)

Chilled water

outlet temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW

5.00 67.17 17.00 63.25 17.52 59.67 18.07 56.40 18.62 52.85 19.56 48.62 20.53

6.00 69.44 17.26 65.33 17.80 61.57 18.35 58.14 18.91 54.54 19.86 50.23 20.85

7.00 71.87 17.61 67.54 18.16 63.60 18.72 60.00 19.30 56.34 20.27 51.95 21.28

8.00 74.09 18.14 69.57 18.70 65.44 19.28 61.68 19.88 57.98 20.87 53.51 21.92

9.00 76.18 18.32 71.46 18.89 67.16 19.47 63.24 20.07 59.51 21.08 54.99 22.13

10.00 79.06 18.59 74.10 19.17 69.58 19.76 65.45 20.37 61.66 21.39 57.03 22.46

11.00 81.27 18.78 76.09 19.36 71.38 19.96 67.09 20.57 63.27 21.60 58.58 22.68

12.00 83.13 19.05 77.76 19.64 72.88 20.25 68.43 20.87 64.60 21.92 59.88 23.01

21.00 25.00 30.00 35.00 40.00 46.00

13.00 84.61 19.20 79.08 19.80 74.04 20.41 69.46 21.04 65.64 22.09 60.91 23.20

14.00 86.72 19.34 80.97 19.94 75.74 20.55 70.99 21.19 67.15 22.25 62.38 23.36

15.00 87.83 19.43 81.93 20.03 76.57 20.65 71.70 21.29 67.90 22.36 63.14 23.47

64

Page 63

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Heating

Ambient temp.(℃)

Hot water

outlet temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW

39.00 39.78 12.39 49.73 14.08 58.50 15.64 65.00 17.00 70.65 17.90 79.13 18.97 91.00 20.49

41.00 38.44 12.64 48.11 14.37 56.67 15.96 63.04 17.35 68.59 18.26 76.69 19.36 88.04 20.91

42.00 37.33 12.90 46.78 14.66 55.17 16.29 61.43 17.70 66.92 18.64 74.68 19.75 85.59 21.33

43.00 36.43 13.16 45.71 14.96 53.97 16.62 60.16 18.07 65.61 19.02 73.09 20.16 83.61 21.77

44.00 35.73 13.43 44.88 15.26 53.05 16.96 59.21 18.43 64.64 19.40 71.88 20.57 82.09 22.21

45.00 35.21 13.71 44.29 15.57 52.41 17.31 58.56 18.81 64.00 19.80 71.04 20.99 80.99 22.67

46.00 34.52 13.84 43.48 15.73 51.51 17.48 57.62 19.00 63.04 20.00 69.85 21.20 79.49 22.89

47.00 33.50 14.12 42.24 16.05 50.11 17.83 56.12 19.38 61.46 20.40 67.98 21.62 77.22 23.35

48.00 32.18 14.54 40.63 16.53 48.25 18.36 54.09 19.96 59.31 21.01 65.48 22.27 74.26 24.05

-10 -6 -2 2 7 10 13

49.00 30.43 15.12 38.46 17.19 45.74 19.10 51.33 20.76 56.35 21.85 62.09 23.16 70.29 25.01

50.00 28.47 15.88 36.03 18.05 42.90 20.05 48.20 21.80 52.97 22.94 58.26 24.32 65.84 26.26

65

Page 64

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

9.5 MGB-F65W/RN1, MGB-D65W/RN1

Cooling

Ambient temp.(℃)

Chilled water

outlet temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW

5.00 72.77 17.97 68.52 18.52 64.64 19.10 61.10 19.69 57.25 20.67 52.67 21.70

6.00 75.23 18.25 70.77 18.81 66.70 19.39 62.99 19.99 59.08 20.99 54.41 22.04

7.00 77.85 18.62 73.17 19.19 68.90 19.79 65.00 20.40 61.04 21.42 56.27 22.49

8.00 80.26 19.18 75.36 19.77 70.90 20.38 66.82 21.01 62.81 22.06 57.97 23.17

9.00 82.52 19.36 77.41 19.96 72.76 20.58 68.51 21.22 64.47 22.28 59.57 23.39

10.00 85.65 19.65 80.27 20.26 75.38 20.89 70.91 21.53 66.80 22.61 61.79 23.74

11.00 88.04 19.85 82.44 20.46 77.33 21.09 72.68 21.75 68.54 22.83 63.47 23.98

21.00 25.00 30.00 35.00 40.00 46.00

12.00 90.06 20.14 84.24 20.76 78.95 21.40 74.13 22.06 69.98 23.17 64.87 24.33

13.00 91.66 20.30 85.67 20.93 80.21 21.57 75.25 22.24 71.11 23.35 65.99 24.52

14.00 93.94 20.44 87.72 21.07 82.05 21.72 76.90 22.40 72.75 23.52 67.58 24.69

15.00 95.15 20.54 88.76 21.18 82.95 21.83 77.67 22.51 73.55 23.63 68.41 24.81

66

Page 65

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Heating:

Ambient temp.(℃)

Hot water

outlet temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW Kw kW

39.00 42.89 13.45 53.61 15.29 63.07 16.99 70.08 18.46 76.17 19.43 85.31 20.60 98.11 22.25

41.00 41.45 13.73 51.87 15.60 61.10 17.33 67.96 18.84 73.95 19.83 82.68 21.02 94.92 22.70

42.00 40.25 14.01 50.44 15.92 59.48 17.69 66.23 19.22 72.15 20.24 80.52 21.45 92.28 23.17

43.00 39.28 14.29 49.28 16.24 58.18 18.05 64.86 19.62 70.74 20.65 78.80 21.89 90.15 23.64

44.00 38.52 14.58 48.39 16.57 57.20 18.42 63.84 20.02 69.69 21.07 77.50 22.33 88.50 24.12

45.00 37.96 14.88 47.75 16.91 56.51 18.79 63.14 20.43 69.00 21.50 76.59 22.79 87.31 24.61

46.00 37.22 15.03 46.87 17.08 55.54 18.98 62.12 20.63 67.97 21.72 75.31 23.02 85.70 24.86

47.00 36.12 15.33 45.54 17.42 54.03 19.36 60.50 21.04 66.27 22.15 73.29 23.48 83.26 25.36

48.00 34.69 15.79 43.80 17.95 52.02 19.94 58.32 21.67 63.95 22.81 70.60 24.18 80.06 26.12

-10 -6 -2 2 7 10 13

49.00 32.80 16.42 41.47 18.66 49.31 20.74 55.34 22.54 60.75 23.73 66.95 25.15 75.78 27.16

50.00 30.69 17.24 38.85 19.60 46.25 21.77 51.96 23.67 57.10 24.91 62.81 26.41 70.98 28.52

67

Page 66

Air-cooled modular chiller unit 50Hz MCAC-ATSM-2011-12

9.6 MGB-F130W/RN1

Cooling:

Ambient temp.(℃)

Chilled water

outlet temp.

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

21.00 25.00 30.00 35.00 40.00 46.00

(℃) kW kW kW

5.00 145.54 35.93 137.04 37.05 129.29 38.19 122.20 39.37 114.50 41.34 105.34 43.41

6.00 150.46 36.49 141.54 37.62 133.40 38.78 125.97 39.98 118.16 41.98 108.83 44.08

7.00 155.71 37.24 146.34 38.39 137.80 39.58 130.00 40.80 122.07 42.84 112.55 44.98

8.00 160.52 38.35 150.72 39.54 141.79 40.76 133.64 42.02 125.62 44.13 115.95 46.33

9.00 165.05 38.73 154.83 39.92 145.52 41.16 137.02 42.43 128.94 44.55 119.14 46.78

10.00 171.31 39.31 160.55 40.52 150.75 41.78 141.82 43.07 133.59 45.22 123.57 47.48

11.00 176.08 39.69 164.87 40.92 154.66 42.19 145.36 43.49 137.08 45.67 126.93 47.95

12.00 180.11 40.28 168.49 41.52 157.91 42.81 148.27 44.13 139.97 46.34 129.75 48.65

13.00 183.33 40.60 171.33 41.85 160.42 43.15 150.49 44.48 142.22 46.71 131.98 49.04

14.00 187.89 40.88 175.43 42.14 164.11 43.45 153.80 44.79 145.50 47.03 135.17 49.38

15.00 190.30 41.08 177.52 42.35 165.90 43.66 155.34 45.01 147.11 47.26 136.81 49.63

kW

kW

kW

kW

kW

kW

kW

kW

kW

68

Page 67

Heating:

Hot water

outlet temp.

MCAC-ATSM-2011-12 Air-cooled modular chiller unit 50Hz

Ambient temp.(℃)

-10 -6 -2 2 7 10 13

Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power Capacity Power

(℃) kW kW kW

39.00 85.78 26.91 107.22 30.57 126.14 33.97 140.16 36.93 152.34 38.87 170.63 38.33 196.22 41.39

41.00 82.89 27.45 103.75 31.20 122.20 34.66 135.93 37.68 147.91 39.66 165.36 39.11 189.83 42.24

42.00 80.50 28.01 100.87 31.83 118.96 35.37 132.47 38.45 144.30 40.47 161.04 39.91 184.55 43.10

43.00 78.55 28.59 98.56 32.48 116.37 36.09 129.73 39.23 141.47 41.30 157.60 40.72 180.29 43.98