Page 1

MCAC-UTSM-2008-11 Contents

Part 1 General Information ..................................................................................................... 1

Part 2 Outdoor Unit ................................................................................................................. 4

Part 3 Installation .................................................................................................................. 45

※The specifications, designs, and information in this book are subject to change without notice for

product improvement.

Contents i

Page 2

MCAC-UTSM-2008-11 General Information

Part 1

General Information

1. Model Names of Outdoor Units.................................. 2

2. External Appearance .................................................. 2

3. Nomenclature ............................................................. 3

4. Features ...................................................................... 3

General Information 1

Page 3

Model Names of Outdoor Units MCAC-UTSM-2008-11

1. Model Names of Outdoor Units

Model Refrigerant Capacity (kW) Power Supply (V-ph-Hz)

MGA-D10/N1 R410A 10 220-240, 1, 50

MGA-D12/N1 R410A 12 220-240, 1, 50

MGA-D14/SN1 R410A 14 380-415, 3, 50

MGA-D16/SN1 R410A 16 380-415, 3, 50

2. External Appearance

2.1 Outdoor Unit

MGA-D10/N1

MGA-D12/N1 MGA-D14/SN1 MGA-D16/SN1

2.2 Water Pump Box

2 General Information

Page 4

MCAC-UTSM-2008-11 Nomenclature

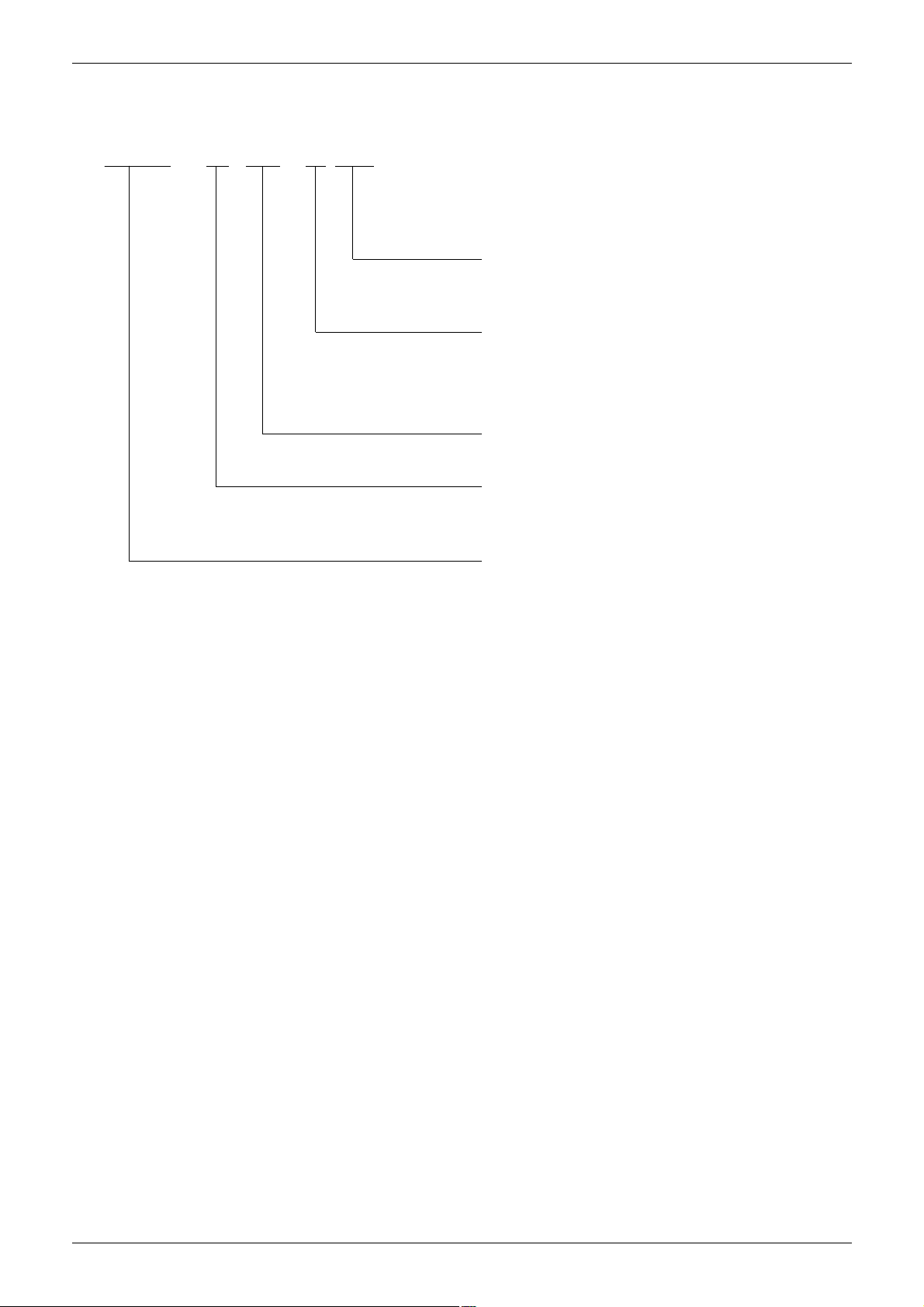

3. Nomenclature

Outdoor Unit:

- D 14 / S N1

Refrigerant

N1 R410A

Power Supply

S: 380-415V, 50Hz, 3ph

--: 220-240V, 50Hz, 1ph

Capacity(14kW)

D: Digital Scroll Type

Midea Chiller

4. Features

1. R410A environment friendly refrigerant.

2. Energy saving and reliable: Adopting Copeland digital scroll compressor, which can adjust the capacity

output and satisfy the capacity demands in different working conditions.

3. With remote on-off port and malfunction alarming output port on the main board.

4. Convenient and simple installation: With international popular split design, the pump box can be installed

inside the room and its outdoor unit is compact and light.

5. Flexible and convenient control: New wired controller with the Auto-restart functions of adjusting outlet

water temperature and power failure memory, etc..

6. The system doesn’t have EMC problem.

7. Built-in with emergency switch: Switch off the unit manually in any emergency case.

8. An AC contactor interface is added on the outdoor unit to connect with the auxiliary electric heater, which

can improve the capacity output in heating mode of low temperature.

9. One chiller can connect with more than 1 wired controller, it’s convenient to maintain and use.

General Information 3

Page 5

Outdoor Unit MCAC-UTSM-2008-11

Part 2

Outdoor Unit

1. Specifications ............................................................. 5

2. Dimensions ................................................................. 7

3. Service Space ............................................................. 8

4. Piping Diagram ........................................................... 9

5. Wiring Diagrams ....................................................... 10

6. Electric Characteristics ............................................ 12

7. Capacity Tables ........................................................ 12

8. Operation Limits ....................................................... 20

9. Hydraulic Performance ............................................ 21

10. Sound Levels .......................................................... 22

11. Exploded View ........................................................ 23

12. Troubleshooting ..................................................... 31

4 Outdoor Unit

Page 6

MCAC-UTSM-2008-11 Specifications

1. Specifications

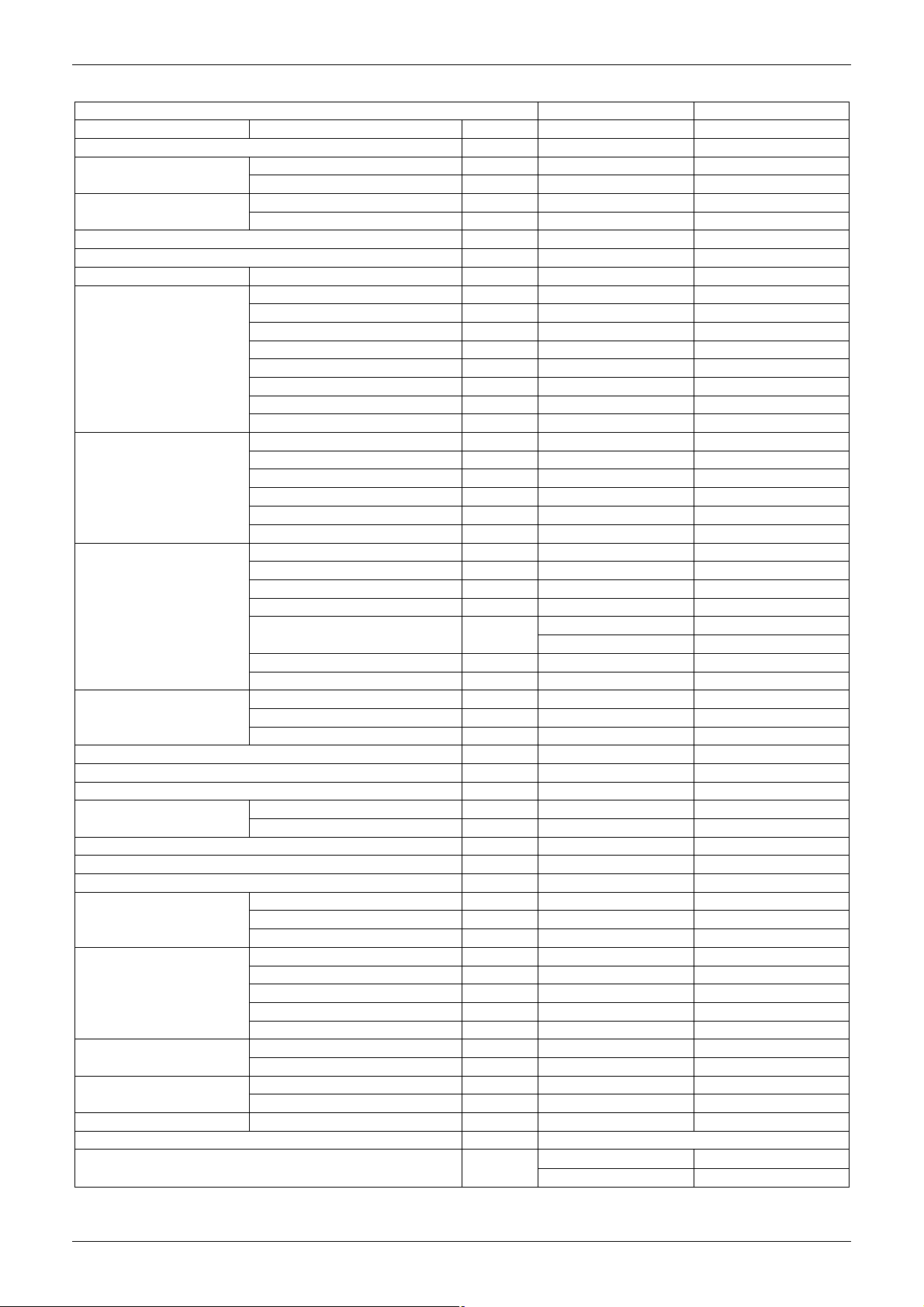

Model MGA-D10/N1 MGA-D12/N1

Code 220090400050 220090400030

Power supply V-Ph-Hz

Cooling

Heating

Max. input consumption W 5430 5615

Max. input current A 27.4 28.2

Starting current A 124 130

Compressor

Outdoor fan motor

Outdoor coil

Water pump

Rated water flow m3/h 1.80 2.06

Max. air flow m3/h 4500 5800

Throttle Capillary Capillary

Noise level (sound

pressure)

Minimum water flow m3/h 0.9 1.03

The max. and min. water inlet pressure bar 5.0/0.5 5.0/0.5

The volume of expansion tank L 3 3

Outdoor unit

Water pump box

Refrigerant

Refrigerant pipe diameter

Pipe diameter Water inlet/outlet mm DN32 DN32

Control Wired controller KJR-08B/BE

Ambient temperature

Capacity kW 10 12

Input W 3912 3978

Capacity kW 13.6 14.3

Input W 4216 4164

Model ZPD61KCE-PFZ-532 ZPD61KCE-PFZ-532

Type Digital Scroll Digital Scroll

Brand Copeland Copeland

Rated current (RLA) A 31.4 31.4

Locked rotor Amp (LRA) A 147 147

Thermal protector Inner Inner

Capacitor uF 80uF/440V 80uF/440V

Refrigerant oil ml POE OIL, 1892 POE OIL, 1892

Model YDK250-6E YDK100-6A(×2)

Type AC motor AC motor

Brand Welling Welling

Input (Hi/Lo) W 307/194 185/120(×2)

Capacitor uF 10uF±5% 450V 5uF/450V

Speed (Hi/Lo) r/min 740/530 860/610

Number of rows 2 2

Tube pitch(a)x row pitch(b) mm 25.4×22 25.4×22

Fin spacing mm 1.7 1.5

Fin type Hydrophilic aluminium Hydrophilic aluminium

Tube outside dia. and type mm

Coil length x height x width mm 863×915×44 888×1220×44

Number of circuits 4 7

Type LDPB2-30(S) LDPB2-30(S)

Input W 420 420

Pumping head m 22 20

Outdoor unit dB(A) 57 60

Water pump box dB(A) 38.4 38.9

Dimension (W×H×D) mm 990×966×340 940×1250×340

Packing (W×H×D) mm 1120×1100×440 1058×1380×435

Net/ Gross weight kg 109/115 122/128

Model CE-SBX/N1-01 CE-SBX/N1-01A

Code 220095700030 220095700010

Dimension (W×H×D) mm 905×370×366 905×370×366

Packing (W×H×D) mm 1057×439×436 1057×439×436

Net/ Gross weight kg 52/57 54/59

Type R410A R410A

Charged volume g 2700 3600

Liquid side mm Φ9.5 Φ9.5

Gas side mm Φ19 Φ19

℃

220-240, 1, 50 220-240, 1, 50

Φ9.53 Φ9.53

inner grooved tube inner grooved tube

Cooling: 10℃~43℃ Cooling: 10℃~43℃

Heating: -15℃~24℃ Heating: -15℃~24℃

Outdoor Unit 5

Page 7

Specifications MCAC-UTSM-2008-11

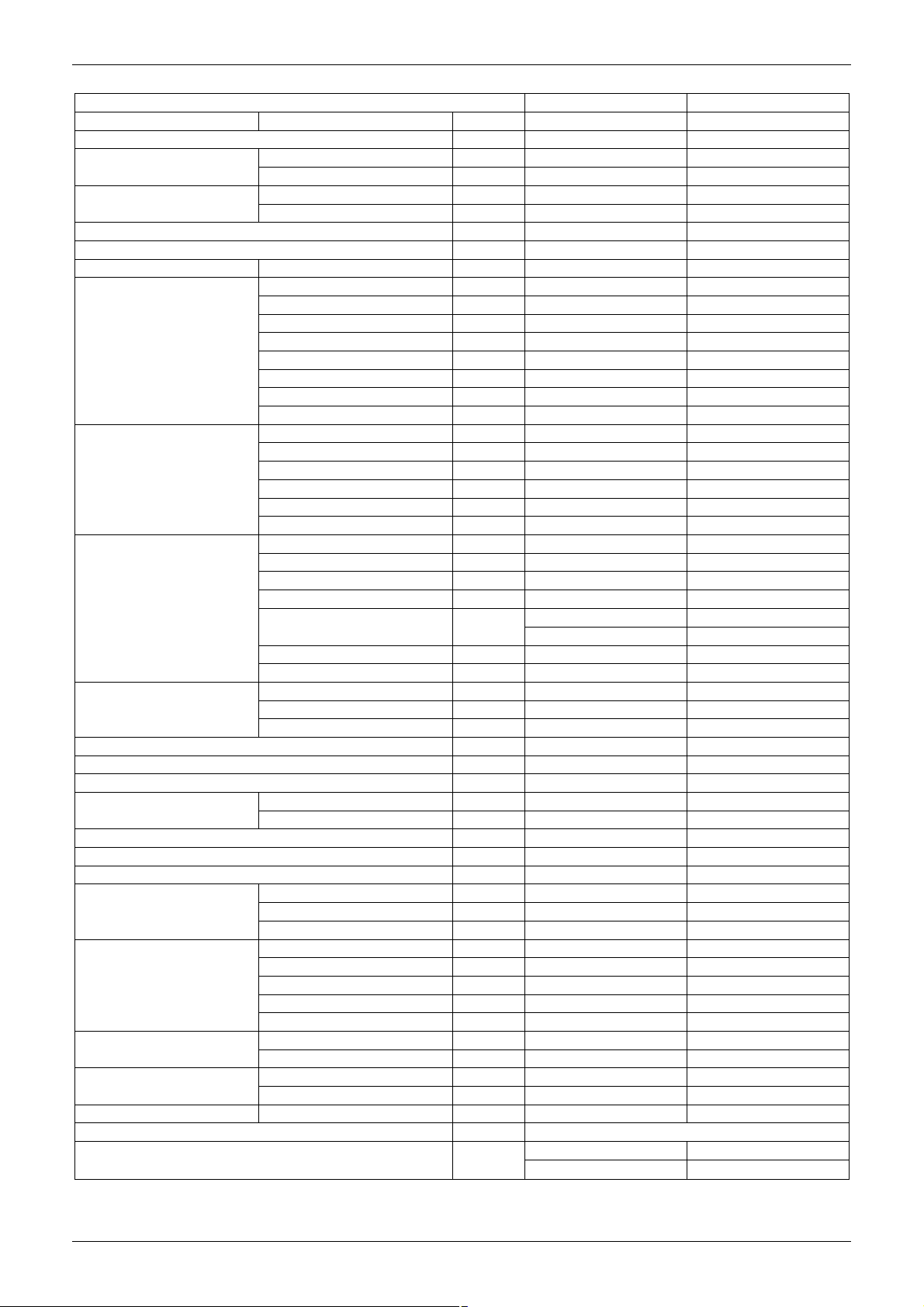

Model MGA-D14/SN1 MGA-D16/SN1

Code 220090400020 220090400040

Power supply V-Ph-Hz

Cooling

Heating

Max. input consumption W 6533 6573

Max. input current A 11.7 11.5

Starting current A 60 64

Compressor

Outdoor fan motor

Outdoor coil

Water pump

Rated water flow m3/h 2.4 2.58

Max. air flow m3/h 5600 5600

Throttle Capillary Capillary

Noise level (sound

pressure)

Minimum water flow m3/h 1.2 1.29

The max. and min. water inlet pressure bar 5.0/0.5 5.0/0.5

The volume of expansion tank L 3 3

Outdoor unit

Water pump box

Refrigerant

Refrigerant pipe diameter

Pipe diameter Water inlet/outlet mm DN32 DN32

Control Wired controller KJR-08B/BE

Ambient temperature ℃

Capacity kW 14 16

Input W 4453 4904

Capacity kW 16 17

Input W 4828 4943

Model ZPD72KCE-TFD-532 ZPD72KCE-TFD-532

Type Digital Scroll Digital Scroll

Brand Copeland Copeland

Rated current (RLA) A 9.8 9.8

Locked rotor Amp (LRA) A 82.4 82.4

Thermal protector Inner Inner

Capacitor uF / /

Refrigerant oil ml 3MAF POE, 1893 3MAF POE, 1893

Model YDK100-6A(×2) YDK100-6A(×2)

Type AC motor AC motor

Brand Welling Welling

Input (Hi/Lo) W 185/120(×2) 185/120(×2)

Capacitor uF 5uF/450V 5uF/450V

Speed (Hi/Lo) r/min 860/610 860/610

Number of rows 2.5 3

Tube pitch(a)x row pitch(b) mm 25.4×22 25.4×22

Fin spacing mm 1.5 1.5

Fin type Hydrophilic aluminium Hydrophilic aluminium

Tube outside dia. and type mm

Coil length x height x width mm 775×1220×66 875×1220×66

Number of circuits 12 8

Type LDPB2-30(S) LDPB2-30(S)

Input W 420 420

Pumping head m 18 17

Outdoor unit dB(A) 60 60

Water pump box dB(A) 41.2 37.8

Dimension (W×H×D) mm 940×1250×340 940×1250×340

Packing (W×H×D) mm 1058×1380×435 1058×1380×435

Net/ Gross weight kg 123/130 126/133

Model CE-SBX/SN1-01 CE-SBX/SN1-01A

Code 220095700000 220095700020

Dimension (W×H×D) mm 905×370×366 905×370×366

Packing (W×H×D) mm 1057×439×436 1057×439×436

Net/ Gross weight kg 54/59 55/60

Type R410A R410A

Charged volume g 4100 4400

Liquid side mm Φ9.5 Φ9.5

Gas side mm Φ19 Φ19

380-415, 3, 50 380-415, 3, 50

Φ9.53 Φ9.53

inner grooved tube inner grooved tube

Cooling: 10℃~43℃ Cooling: 10℃~43℃

Heating: -15℃~24℃ Heating: -15℃~24℃

6 Outdoor Unit

Page 8

MCAC-UTSM-2008-11 Dimensions

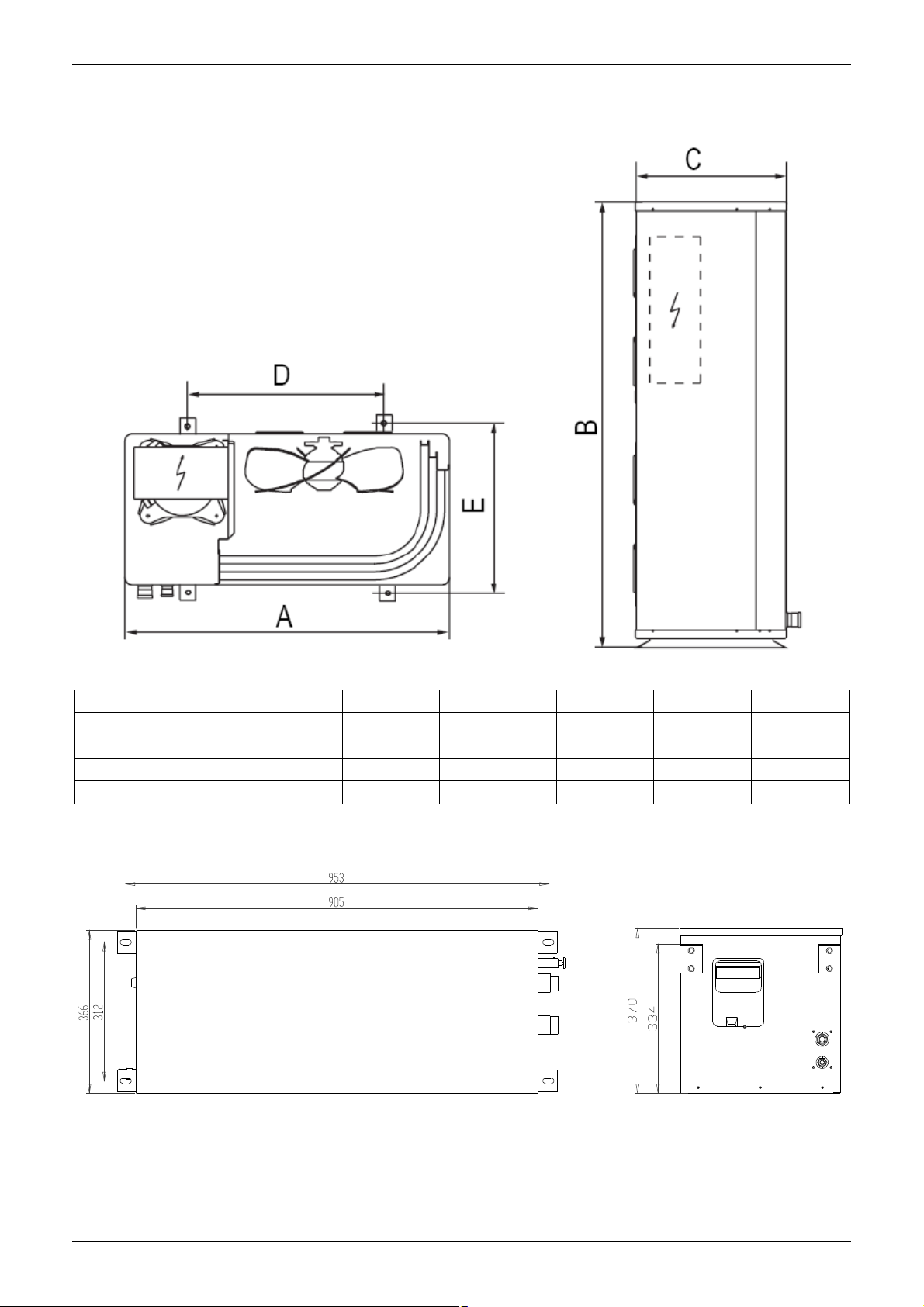

2. Dimensions

2.1 Outdoor Unit

Dimensions A B C D E

MGA-D10/N1 990 966 340 624 366

MGA-D12/N1 940 1250 340 600 376

MGA-D14/SN1 940 1250 340 600 376

MGA-D16/SN1 940 1250 340 600 376

2.2 Water Pump Box

Unit: mm

Outdoor Unit 7

Page 9

Service Space MCAC-UTSM-2008-11

3. Service Space

8 Outdoor Unit

Page 10

MCAC-UTSM-2008-11 Piping Diagram

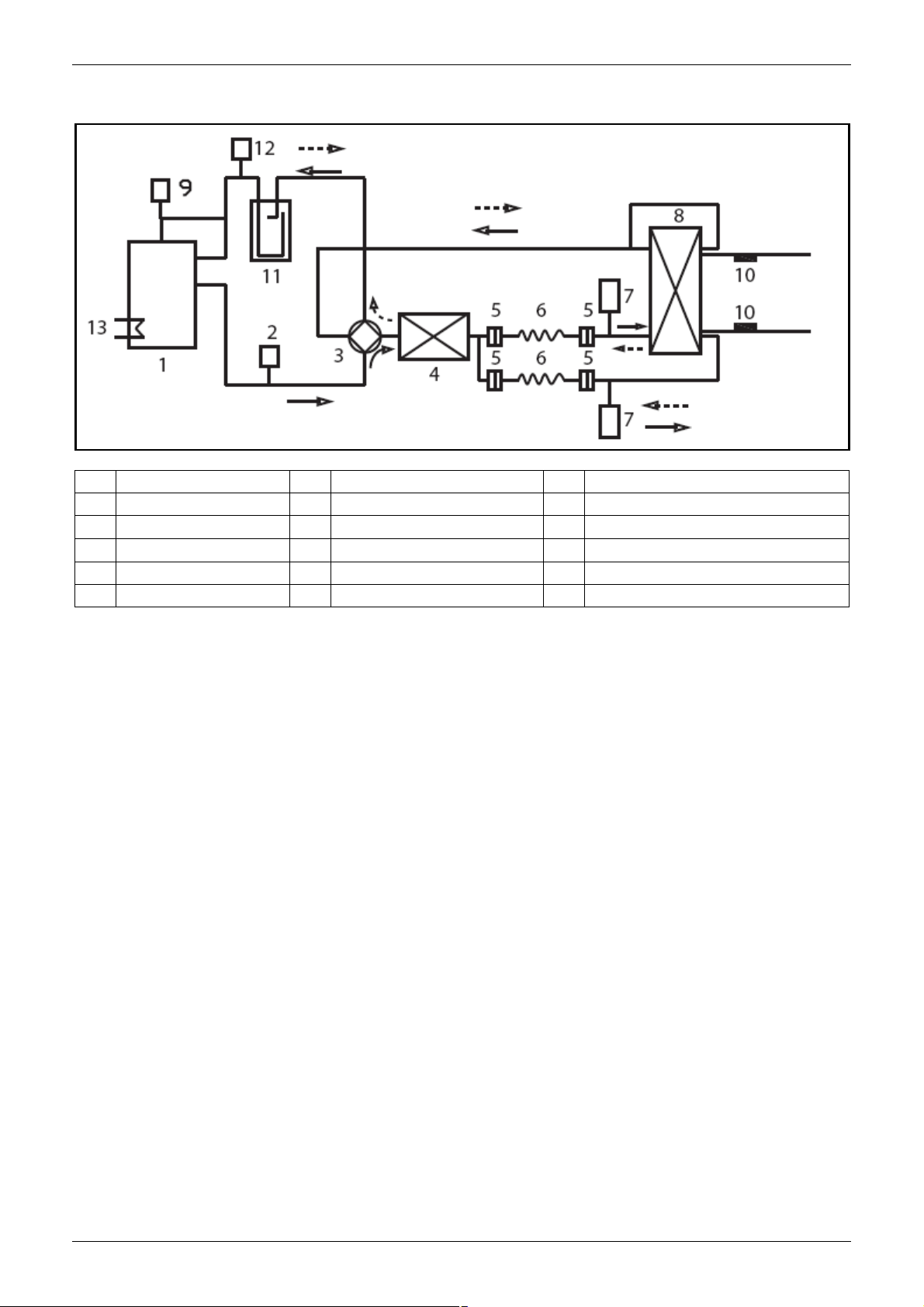

4. Piping Diagram

Remark:

No Name No Name No Name

1 Compressor 6 Capillary 11 Liquid receiver

2 High pressure switch 7 Liquid receiver 12 Low pressure switch

3 4 -way valve 8 Plate heat exchanger 13 Crank heater

4 Condenser 9 PWM valve

5 Filter 10 Water temperature sensor

Outdoor Unit 9

Page 11

Wiring Diagrams MCAC-UTSM-2008-11

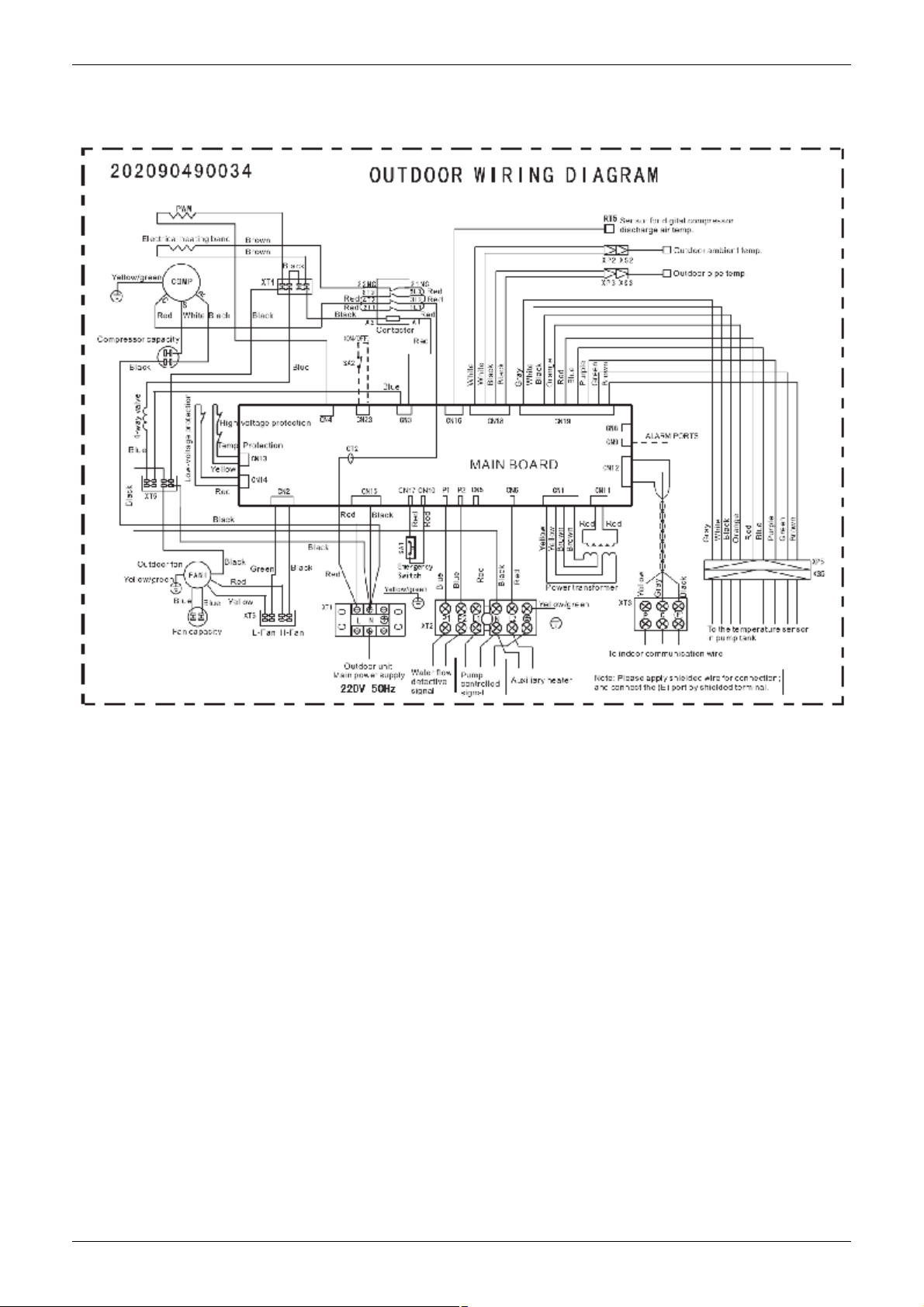

5. Wiring Diagrams

5.1 MGA-D10/N1

10 Outdoor Unit

Page 12

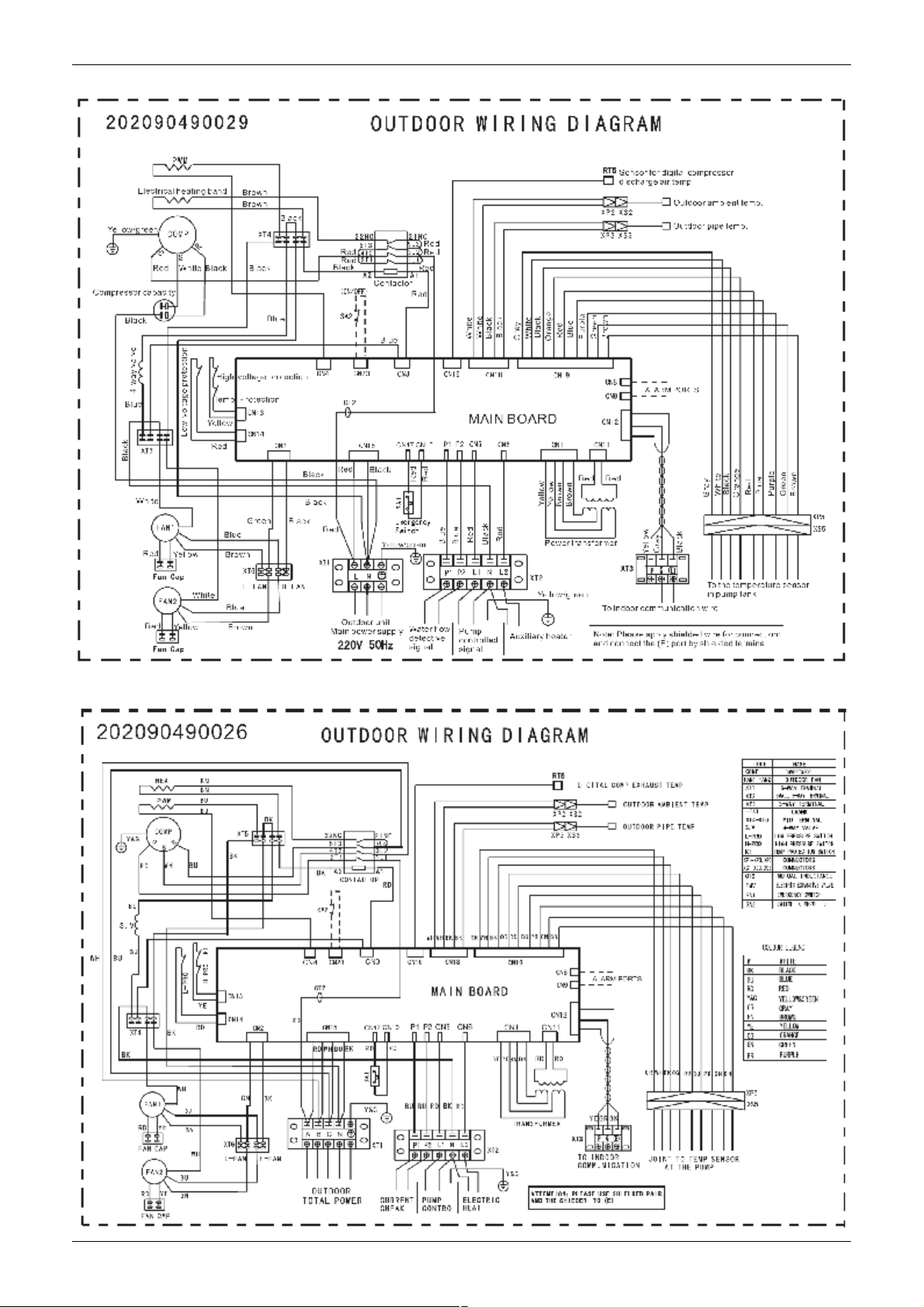

MCAC-UTSM-2008-11 Wiring Diagrams

5.2 MGA-D12/N1

5.3 MGA-D14/SN1 MGA-D16/SN1

Outdoor Unit 11

Page 13

Electric Characteristics MCAC-UTSM-2008-11

3

3

3

3

3

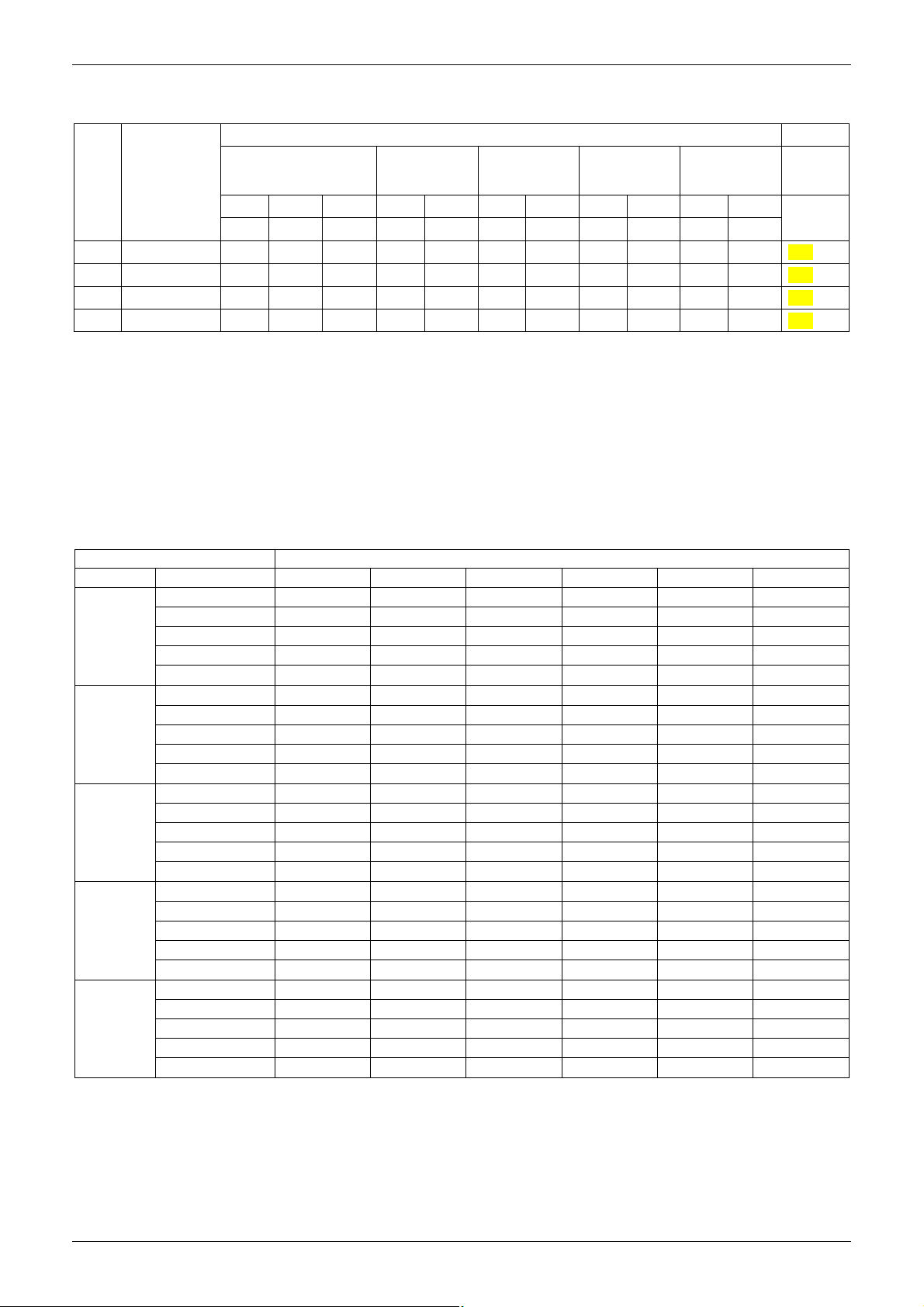

6. Electric Characteristics

Rated values Fuses

Mod.

kW

10 220-240-1-50 5.0 23.2 147 0.3 1.4 0.5 2.2 5.8 26.8 7.54 34.8 45A

12 220-240-1-50 5.0 23.2 147 0.37 1.6 0.5 2.2 5.8 27 7.63 35.1 45A

14 380-415-3-50 5.75 9.8 82.4 0.37 1.6 0.5 2.2 6.62 13.6 8.6 17.7 25A

16 380-415-3-50 5.75 9.8 82.4 0.37 1.6 0.5 2.2 6.62 13.6 8.6 17.7 25A

Remark:

F.L.I. Power input

F.L.A. Current input

L.R.A. Compressor start-up current

(1) Outside air temperature 35℃-Water temperature at evaporator 12/7℃

(2) Values refer to the lower rated voltage(50Hz). These values are used to judge the protection switch size and the thickness

Electrical

Power supply

(V-ph-Hz)

of the power supply cable.

Compressors Fan/fans Pump Total

F.L.I. F.L.A. L.R.A. F.L.I. F.L.A. F.L.I. F.L.A. F.L.I. F.L.A. F.L.I. F.L.A.

(kW) (A) (A) (kW) (A) (kW) (A) (kW) (A) (kW) (A)

Max.

values(2)

Glass

5×20mm

250V

Fuse 1

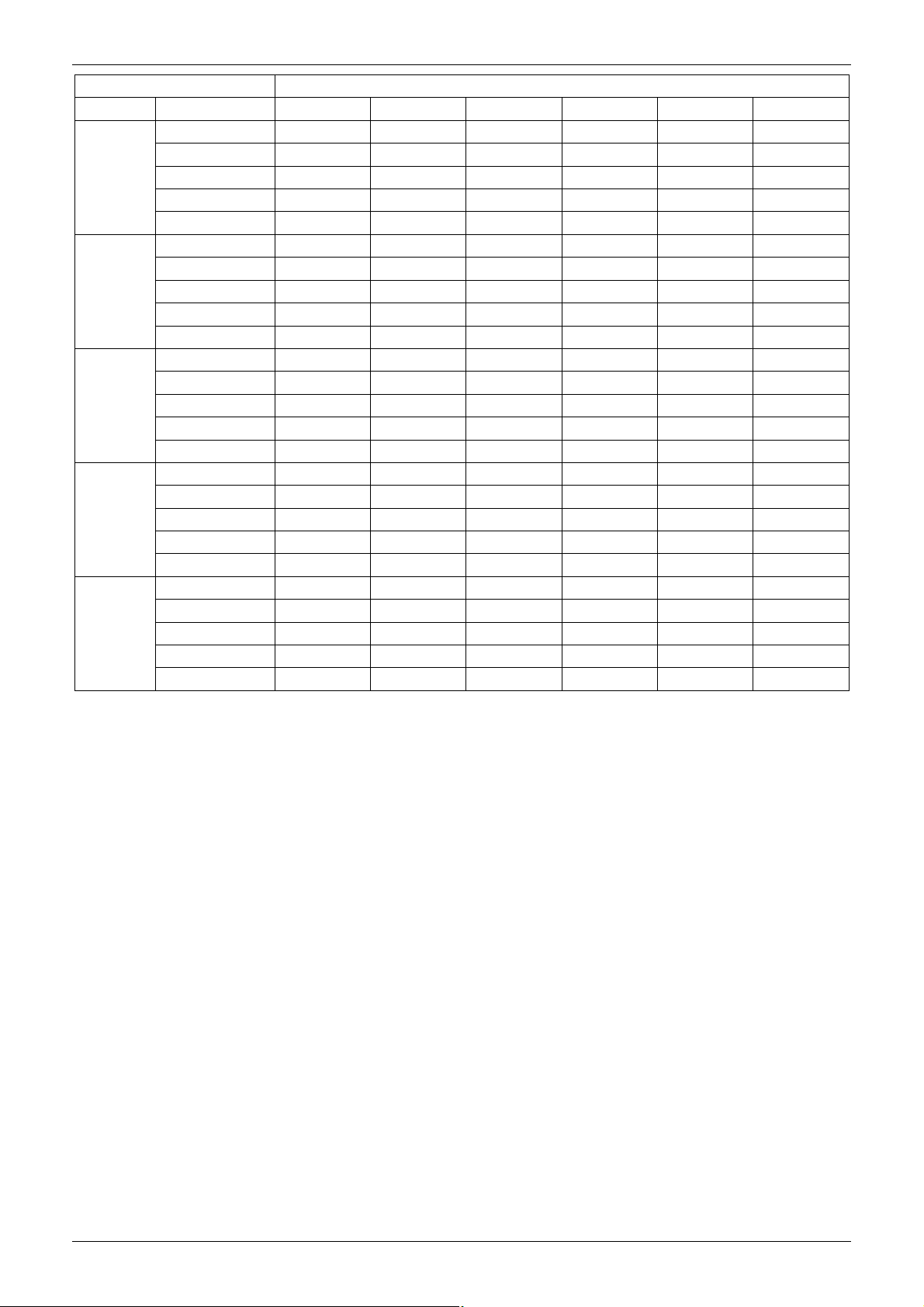

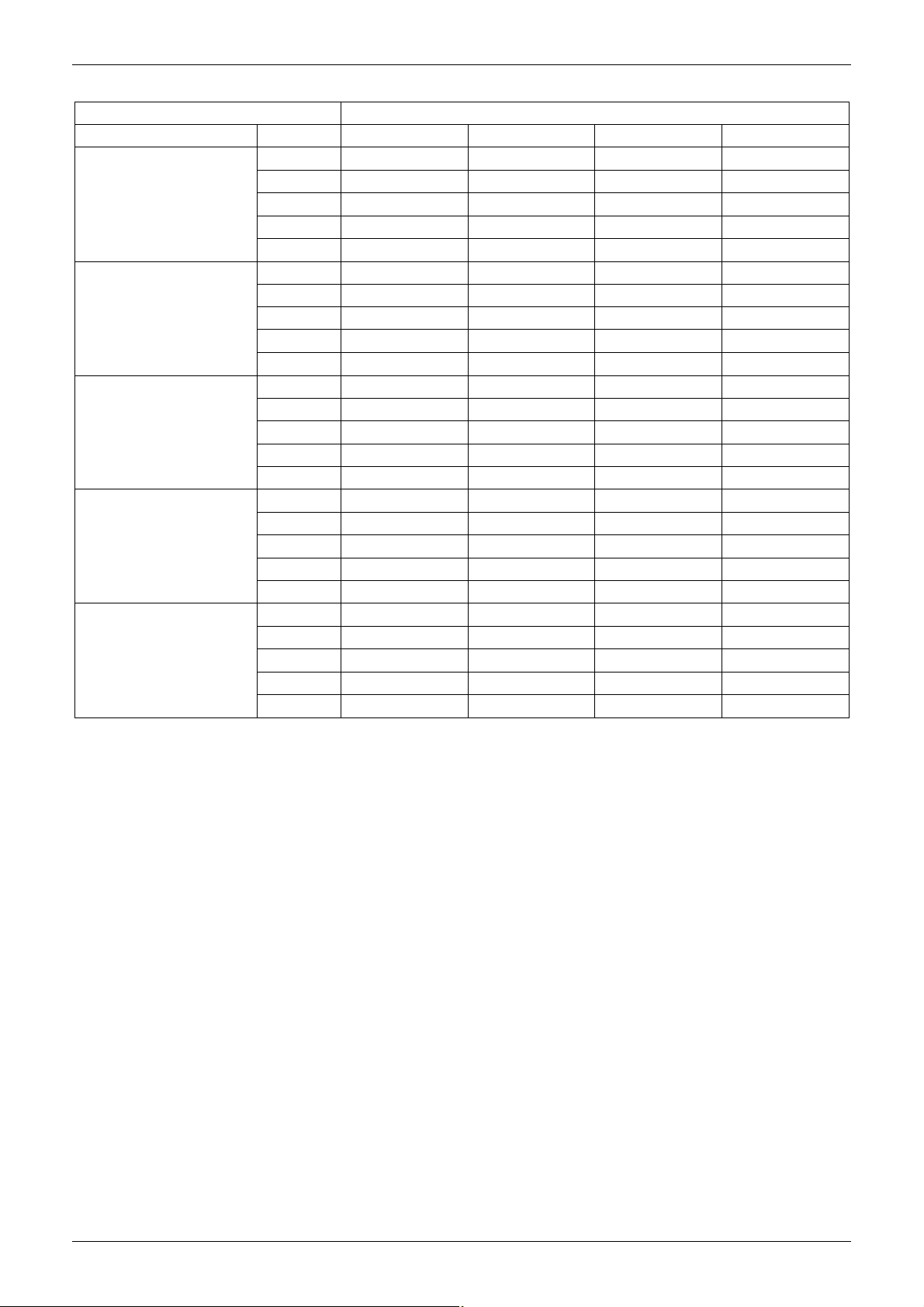

7. Capacity Tables

7.1 Cooling capacity

Model MGA-D10/N1

Ta. (°C) Tw (°C)

Pf (kW)

Pa (kW)

25

30

35

40

43

Remark:

Ta: outside air temperature (°C)

Tw : evaporator water outlet temperature (°C)

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

Pat (kW)

Qev (m

△Pev (kPa)

/h)

/h)

/h)

/h)

/h)

Pf: cooling capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qev: evaporator water flow (m3/h)

Pev: evaporator△ pressure drop (kPa)

5 6 7 8 9 10

10.9 11.2 11.5 11.8 12.1 12.4

3.3 3.3 3.4 3.4 3.4 3.5

4.1 4.1 4.2 4.2 4.2 4.3

1.9 1.9 2.0 2.0 2.1 2.2

47.3 47.6 50.0 50.3 54.0 57.0

10.4 10.8 11.1 11.5 11.8 12.1

2.9 2.9 3.0 3.1 3.1 3.1

3.4 3.4 3.5 3.6 3.6 3.6

1.8 1.8 1.9 2.0 2.0 2.0

44.7 45.6 47.7 49.8 50.4 50.9

9.9 10.2 10.5 10.7 11.0 11.3

3.3 3.3 3.4 3.4 3.5 3.5

3.8 3.8 3.9 3.9 4.0 4.0

1.7 1.7 1.8 1.9 1.9 2.0

40.5 41.3 45.0 48.0 48.6 51.0

9.4 9.7 10.0 10.3 10.6 11.0

3.6 3.6 3.7 3.7 3.8 3.8

4.1 4.1 4.2 4.2 4.3 4.3

1.6 1.6 1.7 1.7 1.8 1.8

36.0 36.6 40.8 41.4 45.5 45.8

9.0 9.3 9.5 9.8 10.0 10.3

3.8 3.8 3.9 3.9 4.0 4.0

4.3 4.3 4.4 4.4 4.5 4.5

1.5 1.6 1.6 1.7 1.7 1.8

31.5 35.7 36.6 40.5 41.3 46.5

12 Outdoor Unit

Page 14

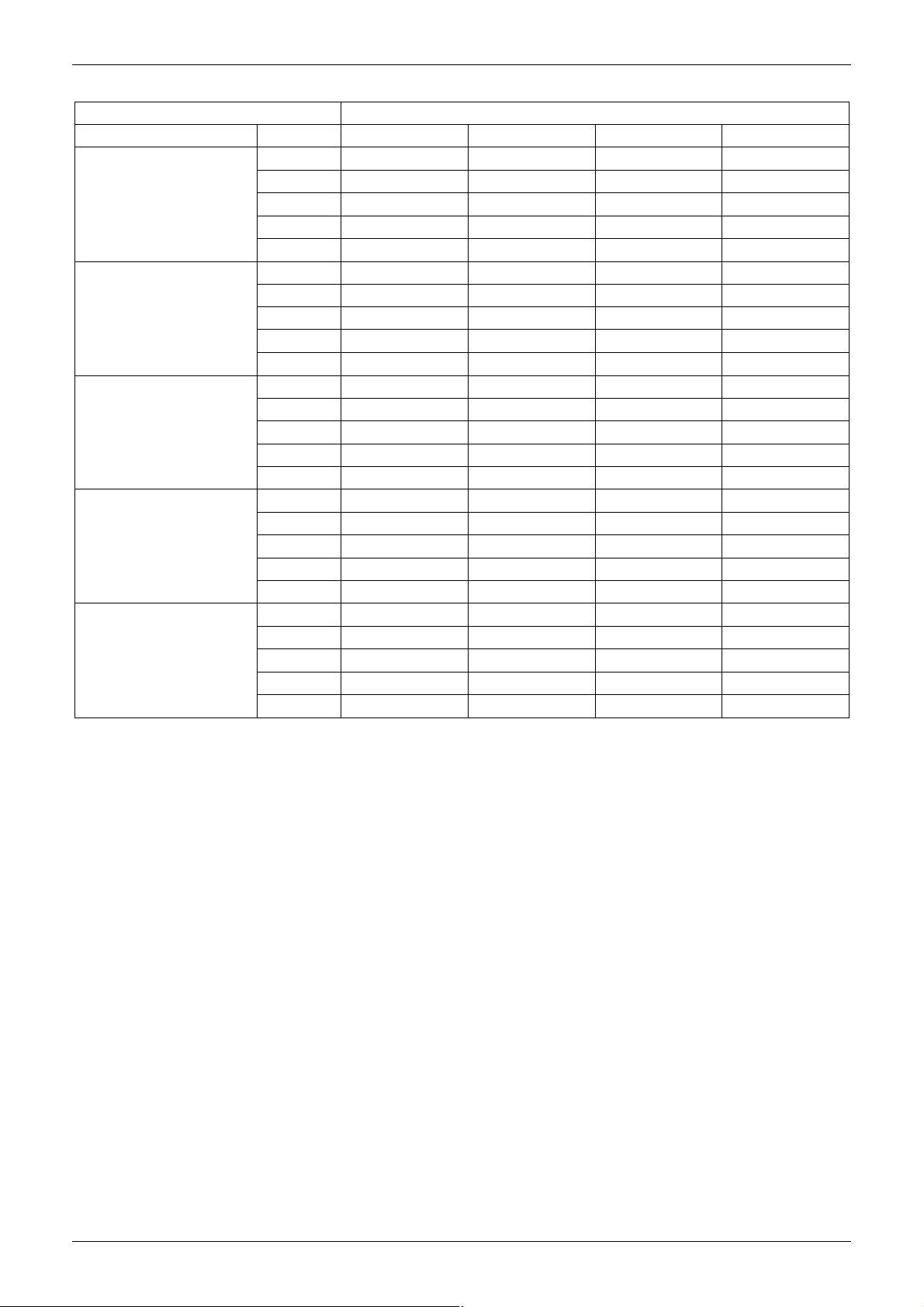

MCAC-UTSM-2008-11 Capacity Tables

3

3

3

3

3

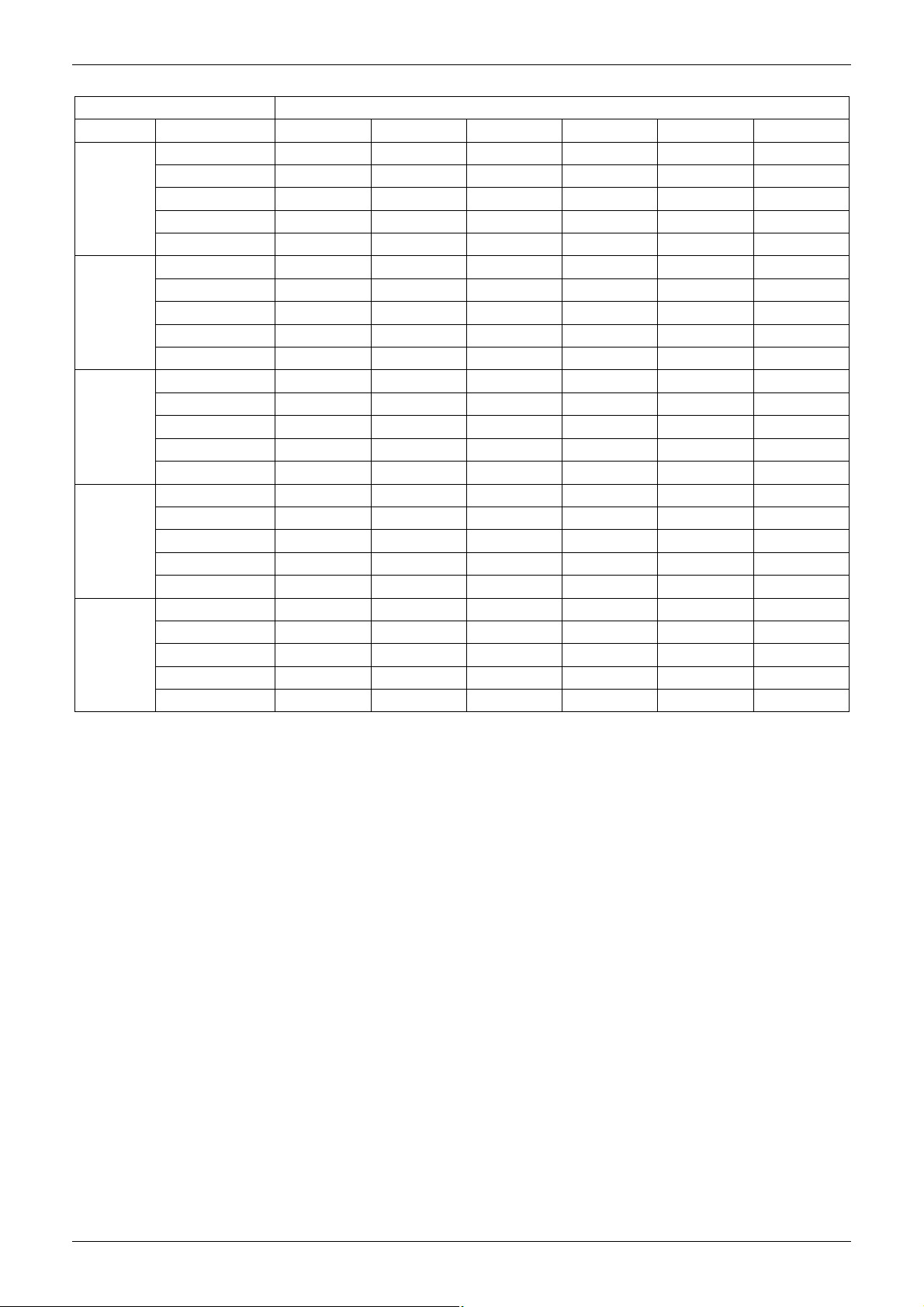

Model MGA-D12/N1

Ta. (°C) Tw (°C)

Pf (kW)

Pa (kW)

25

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

30

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

35

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

40

Pat (kW)

Qev (m

△Pev (kPa)

Pf (kW)

Pa (kW)

43

Pat (kW)

Qev (m

△Pev (kPa)

/h)

/h)

/h)

/h)

/h)

5 6 7 8 9 10

12.4 12.7 13.0 13.3 13.6 13.9

3.5 3.5 3.5 3.6 3.6 3.6

4.1 4.1 4.1 4.2 4.2 4.2

2.2 2.2 2.3 2.3 2.3 2.4

46.6 47.8 49.6 51.8 54.6 60.0

11.9 12.2 12.5 12.8 13.1 13.4

3.8 3.8 3.8 3.9 3.9 3.9

4.4 4.4 4.4 4.5 4.5 4.5

2.0 2.1 2.1 2.2 2.2 2.3

37.0 37.1 40.6 43.2 46.1 48.0

11.4 11.7 12.0 12.3 12.6 12.9

4.2 4.2 4.2 4.3 4.3 4.3

4.8 4.8 4.8 4.9 4.9 4.9

2.0 2.0 2.1 2.1 2.2 2.2

33.8 37.1 40.6 43.2 46.1 48.0

10.9 11.2 11.5 11.8 12.1 12.4

4.5 4.5 4.5 4.6 4.6 4.6

5.1 5.1 5.1 5.2 5.2 5.2

1.9 2.0 2.0 2.0 2.1 2.1

32.3 35.0 36.3 38.4 41.0 45.1

10.5 10.8 11.1 11.4 11.7 12.0

4.7 4.7 4.7 4.8 4.8 4.8

5.3 5.3 5.3 5.4 5.4 5.4

1.8 1.9 1.9 2.0 2.0 2.0

28.0 30.1 33.8 37.4 38.6 40.5

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pf: cooling capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qev: evaporator water flow (m3/h)

Pev: evaporator△ pressure drop (kPa)

Outdoor Unit 13

Page 15

Capacity Tables MCAC-UTSM-2008-11

Model MGA-D14/SN1

Ta. (°C) Tw (°C) 5 6 7 8 9 10

Pf (kW) 14.8 15.1 15.4 15.7 16.1 16.4

Pa (kW) 3.6 3.6 3.6 3.7 3.7 3.7

25

30

35

40

43

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pf: cooling capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qev: evaporator water flow (m3/h)

Pev: evaporator△ pressure drop (kPa)

Pat (kW) 4.1 4.1 4.1 4.2 4.2 4.2

Qev (m3/h) 2.6 2.6 2.7 2.7 2.8 2.8

△Pev (kPa) 49.3 50.0 51.7 53.0 56.1 57.8

Pf (kW) 14.1 14.4 14.7 15.0 15.3 15.6

Pa (kW) 4.1 4.1 4.1 4.2 4.2 4.2

Pat (kW) 4.6 4.6 4.7 4.7 4.7 4.7

Qev (m3/h) 2.4 2.5 2.5 2.6 2.6 2.7

△Pev (kPa)

Pf (kW) 13.4 13.7 14.0 14.3 14.6 14.9

Pa (kW) 4.6 4.6 4.6 4.7 4.7 4.7

Pat (kW) 5.1 5.1 5.1 5.2 5.2 5.2

Qev (m3/h) 2.3 2.4 2.4 2.5 2.5 2.5

△Pev (kPa) 40.8 43.5 44.2 46.9 47.8 48.3

Pf (kW) 12.5 12.8 13.1 13.4 13.7 14.0

Pa (kW) 5.1 5.1 5.1 5.2 5.2 5.2

Pat (kW) 5.6 5.6 5.6 5.7 5.7 5.7

Qev (m3/h) 2.2 2.2 2.3 2.3 2.4 2.4

△Pev (kPa) 33.3 34.5 36.7 39.8 43.7 44.9

Pf (kW) 12.0 12.3 12.6 12.9 13.2 13.5

Pa (kW) 5.5 5.5 5.5 5.6 5.6 5.6

Pat (kW) 6.0 6.0 6.0 6.1 6.1 6.1

Qev (m3/h) 2.1 2.1 2.2 2.2 2.3 2.3

△Pev (kPa) 30.6 32.5 35.2 36.2 39.1 40.5

43.9 47.9 48.3 49.1 50.2 52.7

14 Outdoor Unit

Page 16

MCAC-UTSM-2008-11 Capacity Tables

3

3

3

3

3

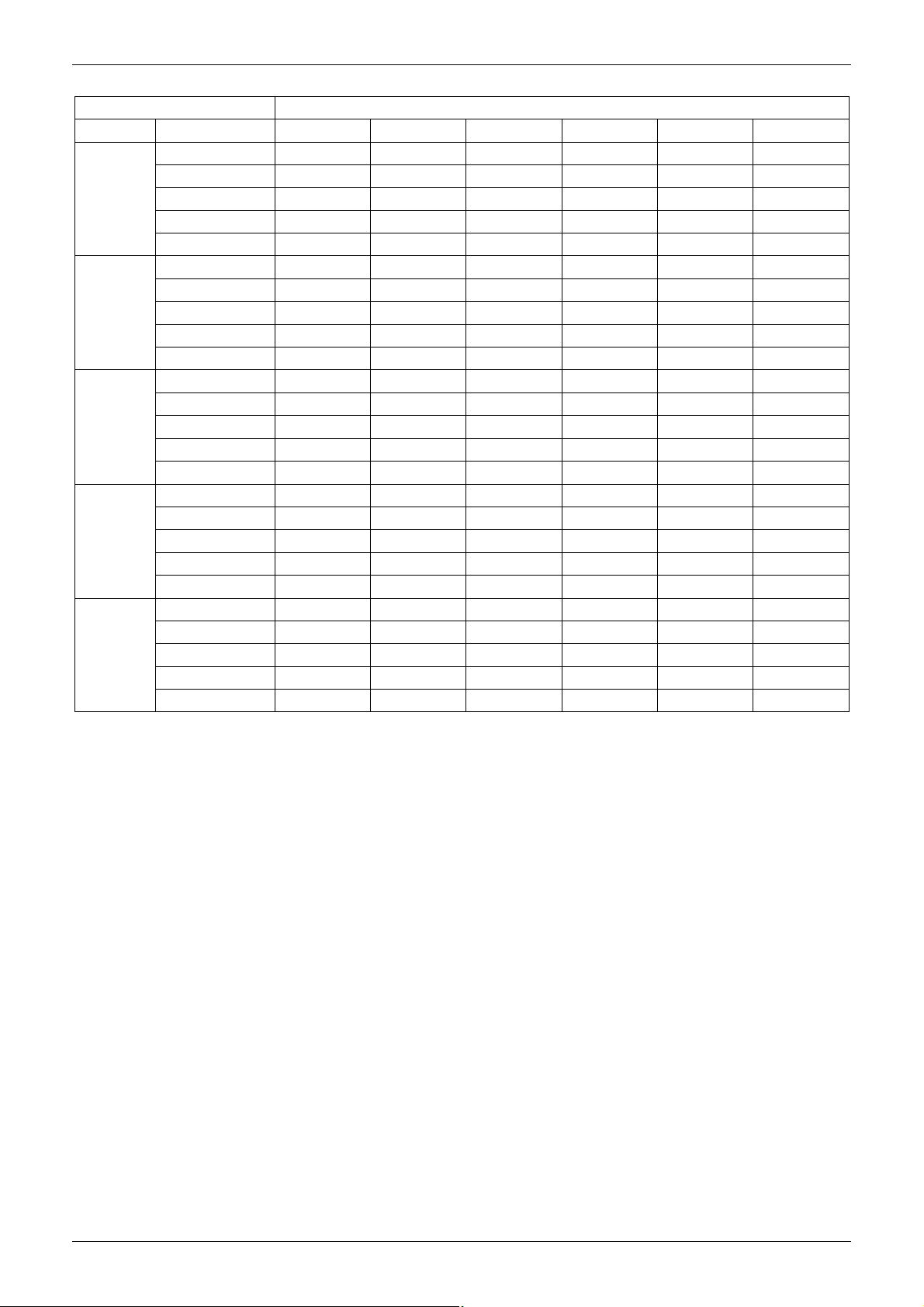

Model MGA-D16/SN1

Ta. (°C)

Tw (°C)

Pf (kW)

Pa (kW)

25

Pat (kW)

Qev (m

/h)

△Pev (kPa)

Pf (kW)

Pa (kW)

30

Pat (kW)

Qev (m

/h)

△Pev (kPa)

Pf (kW)

Pa (kW)

35

Pat (kW)

Qev (m

/h)

△Pev (kPa)

Pf (kW)

Pa (kW)

40

Pat (kW)

Qev (m

/h)

△Pev (kPa)

Pf (kW)

Pa (kW)

43

Pat (kW)

Qev (m

/h)

△Pev (kPa)

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pf: cooling capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qev: evaporator water flow (m3/h)

Pev: evaporator△ pressure drop (kPa)

5 6 7 8 9 10

15.5 15.7 16.0 16.3 16.5 16.8

3.9 3.9 3.9 4.0 4.0 4.0

4.7 4.7 4.7 4.8 4.8 4.8

2.7 2.7 2.8 2.8 2.9 2.9

54.9 57.6 59.4 62.1 65.2 67.7

14.9 15.2 15.5 15.8 16.1 16.4

4.4 4.4 4.4 4.5 4.5 4.5

5.2 5.2 5.2 5.4 5.4 5.4

2.6 2.6 2.7 2.7 2.8 2.8

51.0 52.9 50.9 54.7 59.9 63.0

14.4 14.7 15.0 15.3 15.6 15.9

4.9 4.9 4.9 5.0 5.0 5.0

5.7 5.7 5.7 5.8 5.8 5.8

2.6 2.6 2.7 2.7 2.8 2.8

50.8 53.1 55.8 58.1 61.2 63.2

13.9 14.2 14.5 14.8 15.1 15.2

5.3 5.3 5.3 5.4 5.4 5.4

6.1 6.1 6.1 6.2 6.2 6.2

2.5 2.5 2.6 2.6 2.7 2.7

46.8 49.1 51.5 53.1 55.8 59.4

13.5 13.8 14.1 14.4 14.7 14.8

5.7 5.7 5.7 5.8 5.8 5.8

6.5 6.5 6.5 6.6 6.6 6.6

2.4 2.4 2.5 2.5 2.6 2.6

41.4 44.3 47.0 49.1 51.5 59.4

Outdoor Unit 15

Page 17

Capacity Tables MCAC-UTSM-2008-11

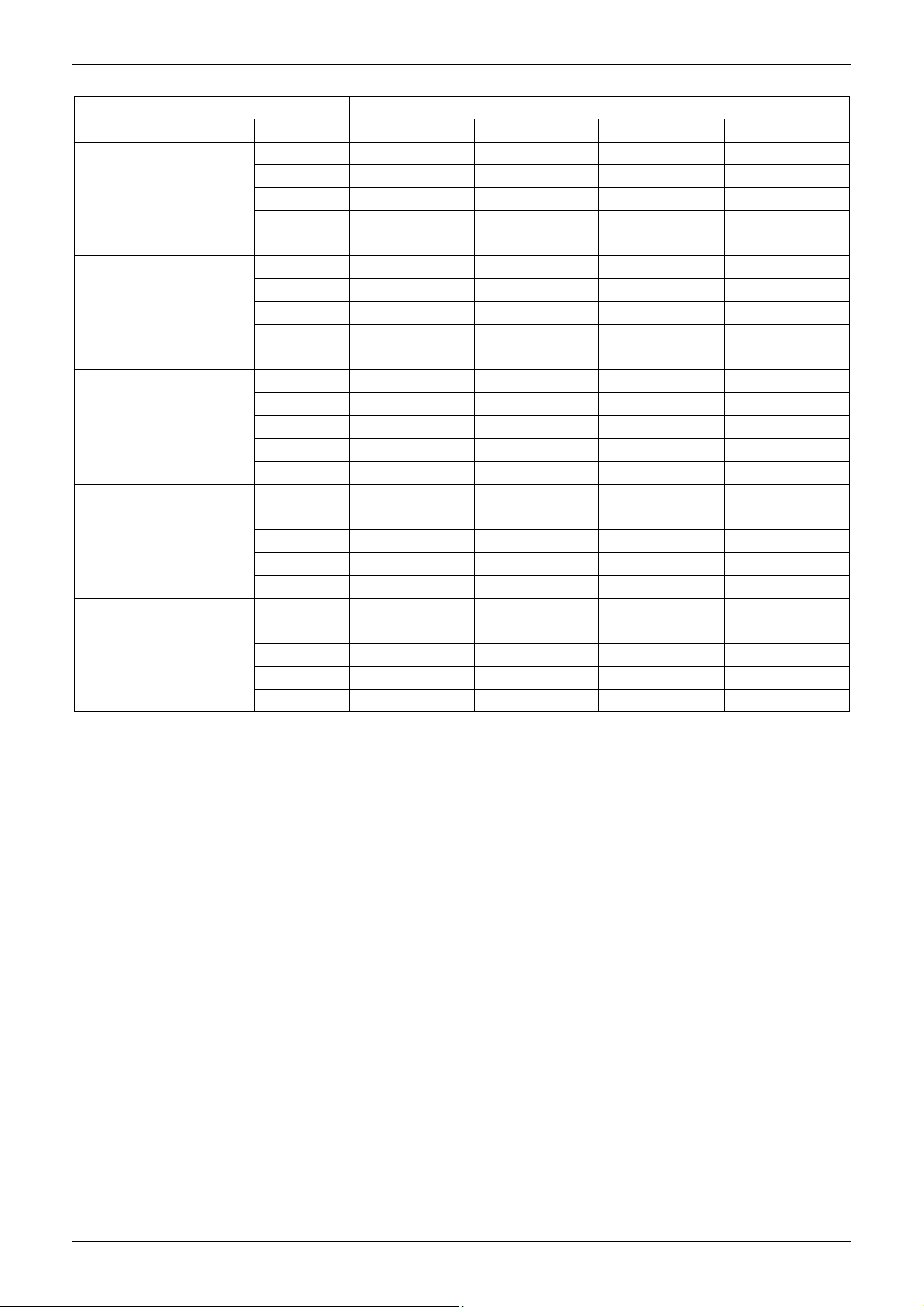

7.2 Heating capacity

Model MGA-D10/N1

Ta. U.R.87% (°C) Tw (°C) 35 40 45 50

Pt (kW) 8.3 8.3 8.3 —

Pa (kW) 3.6 3.9 4.2 —

-5

0

7

10

15

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pt: heating capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qc: condenser water flow (m3/h)

ΔPc: evaporator pressure drop (kPa)

— : conditions outside of operating limits

Pat (kW) 4.4 4.7 5.0 —

Qc (m3/h) 1.5 1.5 1.5 —

Pc (kPa)△ 29.4 28.4 27.0 —

Pt (kW) 9.4 9.4 9.4 9.2

Pa (kW) 3.7 4.0 4.3 4.5

Pat (kW) 4.5 4.8 5.1 5.3

Qc (m3/h) 1.8 1.8 1.8 1.8

Pc (kPa)△ 27.5 25.6 24.8 23.2

Pt (kW) 13.2 13.1 13.0 12.9

Pa (kW) 3.8 4.1 4.4 4.7

Pat (kW) 4.6 4.9 5.2 5.5

Qc (m3/h) 2.2 2.2 2.2 2.2

Pc (kPa)△ 37.2 35.8 34.5 33.1

Pt (kW) 12.3 12.2 12.1 12.0

Pa (kW) 3.9 4.2 4.5 4.8

Pat (kW) 4.7 5.0 5.3 5.1

Qc (m3/h) 2.3 2.3 2.3 2.3

Pc (kPa)△ 40.5 40.0 39.2 38.8

Pt (kW) 13.8 13.7 13.6 13.5

Pa (kW) 4.0 4.3 4.6 4.9

Pat (kW) 4.8 5.1 5.4 5.7

Qc (m3/h) 2.4 2.4 2.3 2.3

Pc (kPa)△ 45.8 45.1 43.6 42.9

16 Outdoor Unit

Page 18

MCAC-UTSM-2008-11 Capacity Tables

Model MGA-D12/N1

Ta. U.R.87% (°C) Tw (°C)

Pt (kW) 11.0 10.9 10.8 —

Pa (kW) 3.7 4.0 4.3 —

-5

0

7

10

15

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pt: heating capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qc: condenser water flow (m3/h)

ΔPc: evaporator pressure drop (kPa)

— : conditions outside of operating limits

Pat (kW) 4.5 4.8 5.1 —

Qc (m3/h) 1.7 1.7 1.7 —

Pc (kPa)△

Pt (kW) 12.2 12.1 12.0 11.9

Pa (kW) 3.8 4.1 4.4 4.6

Pat (kW) 4.6 4.9 5.2 5.4

Qc (m3/h) 2.0 2.0 2.0 2.0

Pc (kPa)△

Pt (kW) 14.2 14.1 14.0 13.9

Pa (kW) 3.9 4.2 4.5 4.8

Pat (kW) 4.7 5.0 5.3 5.6

Qc (m3/h) 2.4 2.4 2.4 2.4

Pc (kPa)△

Pt (kW) 15.2 15.1 15.0 14.9

Pa (kW) 4.0 4.3 4.6 4.9

Pat (kW) 4.8 5.1 5.4 5.7

Qc (m3/h) 2.5 2.5 2.5 2.5

Pc (kPa)△

Pt (kW) 16.7 16.6 16.5 16.4

Pa (kW) 4.1 4.4 4.7 5.0

Pat (kW) 4.9 5.2 5.5 5.8

Qc (m3/h) 2.8 2.8 2.8 2.8

Pc (kPa)△

35 40 45 50

41.6 41.0 40.3 —

33.0 32.6 32.1 31.8

44.0 43.6 43.1 42.8

38.0 37.6 37.2 37.0

45.0 44.8 44.6 44.2

Outdoor Unit 17

Page 19

Capacity Tables MCAC-UTSM-2008-11

Model MGA-D14/SN1

Ta. U.R.87% (°C) Tw (°C)

Pt (kW) 10.4 10.5 10.6 —

Pa (kW) 4.0 4.4 4.9 —

-5

0

7

10

15

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pt: heating capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qc: condenser water flow (m3/h)

ΔPc: evaporator pressure drop (kPa)

— : conditions outside of operating limits

Pat (kW) 4.8 5.2 5.7 —

Qc (m3/h) 1.9 1.9 1.9 —

Pc (kPa)△

Pt (kW) 13.1 13.0 13.0 12.9

Pa (kW) 4.0 4.4 4.9 5.4

Pat (kW) 4.8 5.2 5.7 6.1

Qc (m3/h) 2.3 2.3 2.3 2.3

Pc (kPa)△

Pt (kW) 16.2 16.1 16.0 15.9

Pa (kW) 4.1 4.5 5.0 5.5

Pat (kW) 4.9 5.3 5.8 6.3

Qc (m3/h) 2.8 2.8 2.8 2.8

Pc (kPa)△

Pt (kW) 17.6 17.5 17.4 17.4

Pa (kW) 4.2 4.6 5.1 5.6

Pat (kW) 5.0 5.4 5.9 6.4

Qc (m3/h) 3.1 3.1 3.1 3.1

Pc (kPa)△

Pt (kW) 19.8 19.7 19.6 19.4

Pa (kW) 4.3 4.7 5.2 5.7

Pat (kW) 5.1 5.5 6.0 6.5

Qc (m3/h) 3.5 3.5 3.5 3.5

Pc (kPa)△

35 40 45 50

25.8 27.2 27.0 —

21.1 21.1 21.0 21.0

31.2 31.1 31.0 31.0

36.4 36.2 36.0 35.9

45.4 45.2 45.0 44.9

18 Outdoor Unit

Page 20

MCAC-UTSM-2008-11 Capacity Tables

Model MGA-D16/SN1

Ta. U.R.87% (°C) Tw (°C)

Pt (kW) 11.5 11.4 11.3 —

Pa (kW) 4.1 4.5 5.0 —

-5

0

7

10

15

Remark:

Ta: outside air temperature (°C )

Tw : evaporator water outlet temperature (°C)

Pt: heating capacity (kW)

Pa: compressor power input (kW)

Pat: total power input (kW)

Qc: condenser water flow (m3/h)

ΔPc: evaporator pressure drop (kPa)

— : conditions outside of operating limits

Pat (kW) 4.9 5.3 5.8 —

Qc (m3/h) 2.0 2.0 2.0 —

Pc (kPa)△

Pt (kW) 14.2 14.1 14.0 13.9

Pa (kW) 4.2 4.6 5.1 5.6

Pat (kW) 5.0 5.4 5.1 5.6

Qc (m3/h) 5.0 5.4 5.9 6.4

Pc (kPa)△

Pt (kW) 17.2 17.1 17.0 16.9

Pa (kW) 4.3 4.7 5.2 5.7

Pat (kW) 5.1 5.5 6.0 6.5

Qc (m3/h) 2.9 2.9 2.9 2.9

Pc (kPa)△

Pt (kW) 18.7 18.6 18.5 18.4

Pa (kW) 4.4 4.8 5.3 5.8

Pat (kW) 5.2 5.6 6.1 6.6

Qc (m3/h) 3.2 3.2 3.2 3.2

Pc (kPa)△

Pt (kW) 21.0 20.9 20.8 20.7

Pa (kW) 4.5 4.9 5.4 5.9

Pat (kW) 5.3 5.7 6.2 6.7

Qc (m3/h) 3.6 3.6 3.6 3.6

Pc (kPa)△

35 40 45 50

25.0 25.0 24.8 —

20.2 20.1 20.0 19.9

30.2 30.1 30.0 30.0

35.4 35.2 35.0 34.8

46.2 45.6 45.0 44.4

Outdoor Unit 19

Page 21

Operation Limits MCAC-UTSM-2008-11

8. Operation Limits

Cooling operation

Heating operation

Outdoor temperature: 10℃~43℃

Water temperature: 4℃-20℃

Outdoor temperature: 4℃~24℃ (-15℃~24 , when charge enough antifreeze)℃

Water temperature: 30℃-50℃

8.1 Ethylene Glycol Solutions

Water and ethylene glycol solutions used as a thermal vector in the place of water reduce the performance

of the unit. Multiply the performance figures by the values given in the following table.

Freezing point (°C)

0 -5 -10 -15 -20 -25

Percentage of ethylene glycol in weight

0 12% 20% 28% 35% 40%

cPf 1 0.98 0.97 0.965 0.96 0.955

cQ 1 1.02 1.04 1.075 1.11 1.14

cdp 1 1.07 1.11 1.18 1.22 1.24

cPf: correction factor refrigerating capacity

cQ: correction factor flow rate

cdp: correction factor pressure drop

Note:

1. During winter leaving the unit unused, please drain water out completely from unit if no antifreeze were

charged into pipeline, or keep power on (at standby or off status) and ensure that water is contained

inside of unit.

2. When ambient temperature is lower than 5, running cooling mode must be charged antifreeze. Refer to ℃

upper parameters for the charged volume.

8.2 Fouling Factors

The performance data given refer to conditions with clean evaporator plates (fouling factor=1). For different

fouling factors, multiply the figures in the performance tables by the coefficient given in the following table.

Fouling factors Evaporator

(m2°C/W) f1 fk1 fx1

-5

4.4×10

0.86×10-4 0.96 0.99 0.99

1.72×10-4 0.93 0.98 0.98

f1 capacity correction factor

fk1 compressor power input correction factor

fx1 total power input correction factor

- - -

20 Outdoor Unit

Page 22

MCAC-UTSM-2008-11 Hydraulic Performance

8.3 Quantity of Water in Installation

Model MGA-D10/N1 MGA-D12/N1 MGA-D14/SN1 MGA-D16/SN1

Minimum water volume (L) 43 50 60 68

If the total water volume in the system is less than the value in the table above, the additional water tank is

necessary in order to avoid the compressor On/Off frequency.

The minimum size of the water tank is calculated as:

Size of additional water tank(L)=Minimum water volume (L) –Actual water volume(L)

9. Hydraulic Performance

9.1 Pump head curves(*)

Note:

(*) To obtain the useful head of the installation, subtract the pressure drop of the plate heat exchanger.

9.2 Heat exchanger pressure drop (water side)

Model

10kW

Water flow

Pressure drop kPa 26 29 33 37 42 46 50

m 3 / h 0.8 1.0 1.2 1.4 1.6 1.8 2.0

l/sec 0.222 0.278 0.333 0.389 0.444 0.500 0.556

Model Water flow

12 kW

14 kW kPa 28 31 36 40 43 46 50 54

16 kW kPa 26 29 32 37 41 45 49 52

Pressure drop

m 3 / h 1.2 1.4 1.6 1.8 2.0 2.2 2.4 2.6

l/sec 0.333 0.389 0.444 0.500 0.556 0.611 0.667 0.722

kPa 35 39 44 47 50 53 58

Outdoor Unit 21

Page 23

Sound Levels MCAC-UTSM-2008-11

10. Sound Levels

10kW 12/14/16kW

Microphone

H

1.0m

Note: H= 0.5 × height of outdoor unit Note: The point A is in the middle of the whole outdoor

panel.

Model Noise level dB(A)

MGA-D10/N1 57

MGA-D12/N1 60

MGA-D14/SN1 60

MGA-D16/SN1 60

22 Outdoor Unit

Page 24

MCAC-UTSM-2008-11 Exploded View

11. Exploded View

11.1 MGA-D10/N1

Matched water pump box- CE-SBX/N1-01

Outdoor Unit 23

Page 25

Exploded View MCAC-UTSM-2008-11

MGA

-

D10/N1

No.

Part Name

Quantity

No. Part Name

Quantity

CE-SBX/N1

-

01

No. Part Name

Quan

tity No. Part Name

Quantity

1 Top cover ass'y 1 7.25 Wire joint 1

2 Rear Supporter 1 7.26 Compressor capacitor 1

3 Condenser ass'y 1 7.27 Wire clamp 1

4 High pressure valve ass'y 1 8 Separator 1

4.1 Low pressure valve 1 9 Big handle 1

5 Partition board ass'y 1 10 Front right clapboard ass'y 1

6 Rear right clapboard ass'y 1 11 Valve plate 1

7 E-part box ass'y 1 12 Compressor 1

7.1 485 communication wire 1 13 Branch pipe ass'y 1

7.2 Transformer 1 14 Compressor electric heater 1

7.3 Cable 1 15 Base ass'y 1

7.4 Damp 1 16 Suction pipe ass'y 1

7.5 Electric installation board 1 16.1 Pressure controller 1

7.6 Capacitor 1 17 Solenoid valve ass'y 1

7.7 Capacitor installation board 1 17.1 Pressure-relief-valve 1

7.8 Capacitor clamp 1 18 4-way valve ass'y 1

7.9 Capacitor clamp 1 18.1 Solenoid 1

7.10 Wire clamp 1 18.2 4-way valve 1

7.11 Terminal board 1 18.3 Low pressure valve 1

7.12 Urgency switch 1 18.4 Pressure controller 1

7.13 AC contactor 1 19 Axial flow fan 1

7.14 Wire joint ass'y 1 20 Motor 1

7.15 Wire joint 1 21 Motor bracket ass'y 1

7.16 Wire joint 1 22 Grille 1

7.17 Wire joint 3 23 Front panel 1

7.18 Wire joint 1 24 Wire controller 1

7.19 Wire joint 1 25 Left holder 1

7.20 Surge suppresser 1 26 Temp sensor 1

7.21 Caution label 1 27 Pipe temp sensor ass'y 1

7.22 Power supply wire 1 28 Discharge temp sensor ass'y 1

7.23 Main control board ass'y 1 29 Discharge temp sensor 1

7.24 Outdoor communication cable 1

Water pump box

1 Up covering plate 1 18.2 Branch pipe 2

2 Water-inlet pipe ass'y 1 18.3 Screw 1

2.1 Pipe joint 1 18.4 Elbow pipe 1

2.2 Elbow pipe 1 18.5 Inner joint 1

3 Hook 4 19 Water charge valve 1

4 Pipe clamp I 1 20 Rear clapboard 2

5 Front clapboard 1 21 Input pipe ass'y 1

6 Pipe clamp II 1 21.1 Pipe joint 1

7 Right cover ass'y 1 21.2 Copper nut 1

8 Capacitor clamp 1 22 Water-outlet pipe ass'y 1

9 Water-inlet pipe supporter 2 22.1 Water-outlet pipe ass'y I 1

10 Input pipe ass'y 1 22.2 Drain pipe adapter 1

10.1 Accumulator tank 1 23 Water-outlet pipe ass'y II 1

11 Water-inlet pipe ass'y 1 23.1 Elbow pipe 1

11.1 outer joint 1 23.2 Water-outlet pipe II 1

11.2 Pipe joint 1 23.3 Pipe joint 1

11.3 Water-inlet pipe ass'y I 1 24 Pump 1

12 Base 1 25 Water-outlet pipe ass'y I 1

13 Expansion vessel 1 25.1 Pipe joint 3

14 Heat-exchanger plate ass'y 1 25.2 Elbow pipe 2

14.1 Plate Heat-exchanger 1 26 Installation bracket 1

14.2 Elbow pipe 1 27 Big handle 1

14.3 Pipe joint 1 28 Left clapboard ass'y 1

14.4 Pipe hoop 1 29 Safety valve 1

14.5 Pipe joint 1 30 Discharge valve 1

14.6 Copper nut 1 31 Water-outlet pipe III 1

15 Target flow-volume controller 1 32 Input pipe ass'y 1

16 Clamp 1 32.1 Accumulator tank 1

17 Water charge pipe 1 33 Temp. sensor ass'y 1

18 Water-inlet pipe ass'y II 1 34 Wire joint, 5p 1

18.1 Pipe joint 3

24 Outdoor Unit

Page 26

MCAC-UTSM-2008-11 Exploded View

11.2 MGA-D12/N1

Matched water pump box- CE-SBX/N1-01A

Outdoor Unit 25

Page 27

Exploded View MCAC-UTSM-2008-11

MGA

-

D12/N1

No. Part Name

Quantity

No. Part Name

Quantity

CE-SBX/N1

-

01A

No. Part Name

Quantity

No. Part Name

Quantity

1 Top cover ass'y 1 11 4-way valve ass'y 1

2 Accumulator cylinder 1 11.1 4-way valve 1

3 Condenser ass'y 1 11.2 4-Ways valve solenoid 1

4 Valve plate 1 11.3 Low pressure valve 1

5 Front clapboard ass'y 1 12 Compressor 1

6 E-part box ass'y 1 13 Base 1

6.1 AC contactor 1 14 Compressor electric heater 1

6.2 Surge suppresser 1 15 Discharge pipe ass'y 1

6.3 Capacitor clamp 1 15.1 Pressure controller 1

6.4 Compressor capacitor 1 16 Suction pipe ass'y 1

6.5 Main control board ass'y 1 16.1 Pressure controller 1

6.6 Transformer 1 16.2 Pressure-relief-valve 1

6.7 Wire joint 1 17 Partition board ass'y 1

6.8 Motor capacitor 2 18 Grille 2

6.9 Wire joint, 3p 1 19 Motor 2

6.10 Wire joint 1 20 Wire controller 1

6.11 Electric installation board ass'y 1 21 Axial flow fan 2

6.12 Cable 1 22 Motor bracket ass'y 1

6.13 Power supply wire 1 23 Rear support board I 1

6.14 Wire joint 3 24 Rear net clip 1

6.15 Wire joint 1 25 Front panel 1

6.16 Wire joint 1 26 Discharge temp sensor ass'y 1

7 Urgency switch 1 27 Temp sensor ass'y 1

8 Rear clapboard ass'y 1 28 Room temp sensor ass'y 1

9 Handle 2 29 Discharge temp sensor 1

10 High pressure valve ass'y 1 30 Fixing ring 1

10.1 Low pressure valve 1 31 Rear support board II 1

Water pump box

1 Up covering plate 1 18.2 Branch pipe 2

2 Water-inlet pipe ass'y 1 18.3 Screw 1

2.1 Pipe joint 1 18.4 Elbow pipe 1

2.2 Elbow pipe 1 18.5 Inner joint 1

3 Hook 4 19 Water charge valve 1

4 Pipe clamp I 1 20 Rear clapboard 2

5 Front clapboard 1 21 Input pipe ass'y 1

6 Pipe clamp II 1 21.1 Pipe joint 1

7 Right cover ass'y 1 21.2 Copper nut 1

8 Capacitor clamp 1 22 Water-outlet pipe ass'y 1

9 Water-inlet pipe supporter 2 22.1 Water-outlet pipe ass'y I 1

10 Input pipe ass'y 1 22.2 Drain pipe adapter 1

10.1 Accumulator tank 1 23 Water-outlet pipe ass'y II 1

11 Water-inlet pipe ass'y 1 23.1 Elbow pipe 1

11.1 outer joint 1 23.2 Water-outlet pipe II 1

11.2 Pipe joint 1 23.3 Pipe joint 1

11.3 Water-inlet pipe ass'y I 1 24 Pump 1

12 Base 1 25 Water-outlet pipe ass'y I 1

13 Expansion vessel 1 25.1 Pipe joint 3

14 Heat-exchanger plate ass'y 1 25.2 Elbow pipe 2

14.1 Plate Heat-exchanger 1 26 Installation bracket 1

14.2 Elbow pipe 1 27 Big handle 1

14.3 Pipe joint 1 28 Left clapboard ass'y 1

14.4 Pipe hoop 1 29 Safety valve 1

14.5 Pipe joint 1 30 Discharge valve 1

14.6 Copper nut 1 31 Water-outlet pipe III 1

15 Target flow-volume controller 1 32 Input pipe ass'y 1

16 Clamp 1 32.1 Accumulator tank 1

17 Water charge pipe 1 33 Temp. sensor ass'y 1

18 Water-inlet pipe ass'y II 1 34 Wire joint, 5p 1

18.1 Pipe joint 3

26 Outdoor Unit

Page 28

MCAC-UTSM-2008-11 Exploded View

11.3 MGA-D14/SN1

Matched water pump box- CE-SBX/SN1-01

Outdoor Unit 27

Page 29

Exploded View MCAC-UTSM-2008-11

MGA-D14/SN1

No. Part Name Quantity No. Part Name Quantity

1 Top cover ass'y 1 11.1 4-way valve 1

2 Accumulator cylinder 1 11.2 4-Ways valve solenoid 1

3 Condenser ass'y 1 11.3 Low pressure valve 1

4 Valve plate 1 12 Compressor 1

5 Front clapboard ass'y 1 13 Base 1

6 E-part box ass'y 1 14 Compressor electric heater 1

6.1 AC contactor 1 15 Discharge pipe ass'y 1

6.2 Surge suppresser 1 15.1 Pressure controller 1

6.3 Main control board ass'y 1 16 Suction pipe ass'y 1

6.4 Transformer 1 16.1 Pressure controller 1

6.5 Wire joint 1 16.2 Pressure-relief-valve 1

6.6 Motor capacitor 2 17 Motor bracket ass'y 1

6.7 Wire joint, 3p 1 18 Grille 2

6.8 Wire joint 1 19 Motor 2

6.9 Electric installation board ass'y 1 20 Wire controller 1

6.10 Cable 1 21 Axial flow fan 2

6.11 Outdoor communication cable 1 22 Motor bracket ass'y 1

6.12 Wire joint 3 23 Rear support board I 1

6.13 Wire joint 1 24 Rear net clip 1

6.14 Wire joint, 5p 1 25 Front panel 1

7 Urgency switch 1 26 Discharge temp sensor ass'y 1

8 Rear clapboard ass'y 1 27 Temp sensor ass'y 1

9 Handle 2 28 Discharge temp sensor 1

10 High pressure valve ass'y 1 29 Room temp sensor ass'y 1

10.1 Low pressure valve 1 30 Fixing ring 1

11 4-way valve ass'y 1 31 Rear support board II 1

Water pump box CE-SBX/SN1-01

No. Part Name Quantity No. Part Name Quantity

1 Up covering plate 1 18.2 Branch pipe 2

2 Water-inlet pipe ass'y 1 18.3 Screw 1

2.1 Pipe joint 1 18.4 Elbow pipe 1

2.2 Elbow pipe 1 18.5 Inner joint 1

3 Hook 4 19 Water charge valve 1

4 Pipe clamp I 1 20 Rear clapboard 2

5 Front clapboard 1 21 Input pipe ass'y 1

6 Pipe clamp II 1 21.1 Pipe joint 1

7 Right cover ass'y 1 21.2 Copper nut 1

8 Capacitor clamp 1 22 Water-outlet pipe ass'y 1

9 Water-inlet pipe supporter 2 22.1 Water-outlet pipe ass'y I 1

10 Input pipe ass'y 1 22.2 Drain pipe adapter 1

10.1 Accumulator tank 1 23 Water-outlet pipe ass'y II 1

11 Water-inlet pipe ass'y 1 23.1 Elbow pipe 1

11.1 outer joint 1 23.2 Water-outlet pipe II 1

11.2 Pipe joint 1 23.3 Pipe joint 1

11.3 Water-inlet pipe ass'y I 1 24 Pump 1

12 Base 1 25 Water-outlet pipe ass'y I 1

13 Expansion vessel 1 25.1 Pipe joint 3

14 Heat-exchanger plate ass'y 1 25.2 Elbow pipe 2

14.1 Plate Heat-exchanger 1 26 Installation bracket 1

14.2 Elbow pipe 1 27 Big handle 1

14.3 Pipe joint 1 28 Left clapboard ass'y 1

14.4 Pipe hoop 1 29 Safety valve 1

14.5 Pipe joint 1 30 Discharge valve 1

14.6 Copper nut 1 31 Water-outlet pipe III 1

15 Target flow-volume controller 1 32 Input pipe ass'y 1

16 Clamp 1 32.1 Accumulator tank 1

17 Water charge pipe 1 33 Temp. sensor ass'y 1

18 Water-inlet pipe ass'y II 1 34 Wire joint, 5p 1

18.1 Pipe joint 3

28 Outdoor Unit

Page 30

MCAC-UTSM-2008-11 Exploded View

11.4 MGA-D16/SN1

Matched water pump box- CE-SBX/SN1-01A

Outdoor Unit 29

Page 31

Exploded View MCAC-UTSM-2008-11

CE-SBX/SN1

-

01A

No. Part Name Quantity No. Part Name Quantity

1 Top cover ass'y 1 11.1 4-way valve 1

2 Accumulator cylinder 1 11.2 4-Ways valve solenoid 1

3 Condenser ass'y 1 11.3 Low pressure valve 1

4 Valve plate 1 12 Compressor 1

5 Front clapboard ass'y 1 13 Base 1

6 E-part box ass'y 1 14 Compressor electric heater 1

6.1 AC contactor 1 15 Discharge pipe ass'y 1

6.2 Surge suppresser 1 15.1 Pressure controller 1

6.3 Main control board ass'y 1 16 Suction pipe ass'y 1

6.4 Transformer 1 16.1 Pressure controller 1

6.5 Wire joint 1 16.2 Pressure-relief-valve 1

6.6 Motor capacitor 2 17 Motor bracket ass'y 1

6.7 Wire joint, 3p 1 18 Grille 2

6.8 Wire joint 1 19 Motor 2

6.9 Electric installation board ass'y 1 20 Wire controller 1

6.10 Cable 1 21 Axial flow fan 2

6.11 Outdoor communication cable 1 22 Motor bracket ass'y 1

6.12 Wire joint 3 23 Rear support board I 1

6.13 Wire joint 1 24 Rear net clip 1

6.14 Wire joint, 5p 1 25 Front panel 1

7 Urgency switch 1 26 Discharge temp sensor ass'y 1

8 Rear clapboard ass'y 1 27 Temp sensor ass'y 1

9 Handle 2 28 Discharge temp sensor 1

10 High pressure valve ass'y 1 29 Room temp sensor ass'y 1

10.1 Low pressure valve 1 30 Fixing ring 1

11 4-way valve ass'y 1 31 Rear support board II 1

Water pump box

No. Part Name Quantity No. Part Name Quantity

1 Up covering plate 1 18.2 Branch pipe 2

2 Water-inlet pipe ass'y 1 18.3 Screw 1

2.1 Pipe joint 1 18.4 Elbow pipe 1

2.2 Elbow pipe 1 18.5 Inner joint 1

3 Hook 4 19 Water charge valve 1

4 Pipe clamp I 1 20 Rear clapboard 2

5 Front clapboard 1 21 Input pipe ass'y 1

6 Pipe clamp II 1 21.1 Pipe joint 1

7 Right cover ass'y 1 21.2 Copper nut 1

8 Capacitor clamp 1 22 Water-outlet pipe ass'y 1

9 Water-inlet pipe supporter 2 22.1 Water-outlet pipe ass'y I 1

10 Input pipe ass'y 1 22.2 Drain pipe adapter 1

10.1 Accumulator tank 1 23 Water-outlet pipe ass'y II 1

11 Water-inlet pipe ass'y 1 23.1 Elbow pipe 1

11.1 outer joint 1 23.2 Water-outlet pipe II 1

11.2 Pipe joint 1 23.3 Pipe joint 1

11.3 Water-inlet pipe ass'y I 1 24 Pump 1

12 Base 1 25 Water-outlet pipe ass'y I 1

13 Expansion vessel 1 25.1 Pipe joint 3

14 Heat-exchanger plate ass'y 1 25.2 Elbow pipe 2

14.1 Plate Heat-exchanger 1 26 Installation bracket 1

14.2 Elbow pipe 1 27 Big handle 1

14.3 Pipe joint 1 28 Left clapboard ass'y 1

14.4 Pipe hoop 1 29 Safety valve 1

14.5 Pipe joint 1 30 Discharge valve 1

14.6 Copper nut 1 31 Water-outlet pipe III 1

15 Target flow-volume controller 1 32 Input pipe ass'y 1

16 Clamp 1 32.1 Accumulator tank 1

17 Water charge pipe 1 33 Temp. sensor ass'y 1

18 Water-inlet pipe ass'y II 1 34 Wire joint, 5p 1

18.1 Pipe joint 3

30 Outdoor Unit

Page 32

MCAC-UTSM-2008-11 Troubleshooting

12. Troubleshooting

12.1 Troubles Cause and Solution

Troubles Causes Solution

1. Voltage is out of operation

Water pump doesn’t work

Water pump works while

compressor not

Temp. of chilled or hot water

abnormal

Compressor can’t run

automatically after stop

range.

2. Water flow in the water pump

box is abnormal

1. Open-circuit of compressor

connector

2. Open-circuit of compressor

wiring

1. Improper adjustment to water

valve

2. Overload Change to a bigger capacity chiller.

1. Heating in summer Change the mode into cooling mode.

2. Cooling in winter Change the mode into heating mode.

12.2 Malfunction Code

Code Malfunction Code Malfunction

E0 Water flow test malfunction P0 Current protection

E1 Phase sequence malfunction P1 High pressure protection

E2

E3

E4

E5

E6

E7

E8

E9

In-outdoor unit communication checking

channel is abnormal

Backwater temperature sensor checking

channel is abnormal

Outdoor environment temperature sensor

checking channel is abnormal

Outlet water temperature sensor checking

channel is abnormal

Condenser temperature sensor checking

channel is abnormal

Plate heat exchanger temperature sensor

1 checking channel is abnormal

Plate heat exchanger temperature sensor

2 checking channel is abnormal

Digital scroll compressor discharge

temperature sensor is abnormal

(thermostat display E4)

P2 Low pressure protection

P3 Discharge air temperature protection

P4 Inlet–outlet water temperature difference protection

P5 Condenser high temperature protection

P6 Plate heat exchanger low temperature protection

Pb System anti-frozen protection

P8

Check wiring and circuit

Check whether the water system is blocked with

sundries. Clean the filter and refill water.

Check the cable connection.

Check the cable connection.

Adjust the water valve.

Inlet temperature protection (three times in one hour and

system should be powered on again) At this time, the

wired controller displays P4

Outdoor Unit 31

Page 33

Troubleshooting MCAC-UTSM-2008-11

insufficient

E0: Water flow test malfunction

LED indicates E0

Judge 1: The water pump gets faulty.

No

Judge 2: Water flow switch gets faulty.

No

Judge 3: Check whether the water system is blocked.

The ︳T

inlet water

– T

outlet water

︳>10℃

No

Yes

Check the water pump, and repair or replace it

if necessary.

Yes

Check the water flow switch, and repair or

replace it if necessary.

Yes

Check the water system and clean the filter.

Judge 4: There is air left in the water system.

Yes

Exhaust the air.

No

Judge 5: Check whether the circulation water is

Yes

Check the water system and make

adjustment.

32 Outdoor Unit

Page 34

MCAC-UTSM-2008-11 Troubleshooting

lack of phase

E1: Phase sequence malfunction

LED indicates E1

Judge 1: Check whether the phase order of 3-phase

power supply is incorrect

Yes

No

Yes

Judge 2: Check whether the 3-phase power supply is

E2: In-outdoor unit communication checking channel is abnormal

Judge 1: Check whether the signal wires of P, Q, (E)

Judge 2: Check whether the wired controller and

LED indicates E2

Yes

are wrong connected.

No

No

outdoor unit are all powered on

Yes

Replace the PCB

Swap the power lines of any two phases.

Check the power supply and power cable

Connect them well

Put on the power

Outdoor Unit 33

Page 35

Troubleshooting MCAC-UTSM-2008-11

E3: Backwater temperature sensor checking channel is abnormal

LED indicates E3

Judge 1: Check whether the wiring of backwater

temperature sensor is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the backwater temperature

sensor is broken: see whether the resistance of

backwater temperature sensor is wrong refer to the

Annex 1

Yes

Replace the backwater temperature sensor

No

Replace the PCB

E4: Outdoor environment temperature sensor checking channel is abnormal

LED indicates E4

Judge 1: Check whether the wiring of outdoor

environment temperature sensor is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the outdoor environment

temperature sensor is broken: see whether the

resistance of outdoor environment temperature

sensor is wrong refer to the Annex 1

Yes

Replace the outdoor environment temperature

sensor

No

Replace the PCB

34 Outdoor Unit

Page 36

MCAC-UTSM-2008-11 Troubleshooting

E5: Outlet water temperature sensor checking channel is abnormal

LED indicates E5

Judge 1: Check whether the wiring of outlet water

temperature sensor is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the outlet water temperature

sensor is broken: see whether the resistance of outlet

water temperature sensor is wrong refer to the

Annex 1

Yes

Replace the outlet water temperature sensor

No

Replace the PCB

E6: Condenser temperature sensor checking channel is abnormal

LED indicates E6

Judge 1: Check whether the wiring of condenser

temperature sensor is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the condenser temperature

sensor is broken: see whether the resistance of

condenser temperature sensor is wrong refer to the

Annex 1

Yes

Replace the condenser temperature sensor

No

Replace the PCB

Outdoor Unit 35

Page 37

Troubleshooting MCAC-UTSM-2008-11

E7: Plate heat exchanger temperature sensor 1 checking channel is abnormal

LED indicates E7

Judge 1: Check whether the wiring of plate heat

exchanger temperature sensor 1 is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the plate heat exchanger

temperature sensor 1 is broken: see whether the

resistance of plate heat exchanger temperature

sensor is wrong refer to the Annex 1

Yes

Replace the plate heat exchanger

temperature sensor 1

No

Replace the PCB

E8: Plate heat exchanger temperature sensor 2 checking channel is abnormal

LED indicates E8

Judge 1: Check whether the wiring of plate heat

exchanger temperature sensor 2 is break off

Yes

Connect the wiring well

No

Judge 2: Check whether the plate heat exchanger

temperature sensor 2 is broken: see whether the

resistance of plate heat exchanger temperature

sensor is wrong refer to the Annex 1

Yes

Replace the plate heat exchanger

temperature sensor 2

No

Replace the PCB

36 Outdoor Unit

Page 38

MCAC-UTSM-2008-11 Troubleshooting

too high.

too

little

E9: Digital scroll compressor discharge temperature sensor is abnormal (thermostat display E4)

LED indicates E9

Judge 1: Check whether air outlet is blocked by

sundries.

Yes

Clear the sundries to ensure smooth air

exhaust.

Judge 2: Check whether the condenser coil fin

gets dirty

No

Yes

Clean the condenser.

No

Judge 3: Check whether the ambient temperature is

Yes

Add sunshade facilities.

No

Judge 4: Check whether the condenser fan is

abnormal

Yes

Check the outdoor fan.

No

Judge 5: Check whether the refrigerant is charged

Yes

Recharge the refrigerant

Outdoor Unit 37

Page 39

Troubleshooting MCAC-UTSM-2008-11

too much (the high pressure> 3.8MPa)

exhaust

.

dirty

too high.

abnormal

P0: Current protection

LED indicates P0

Judge 1: Check whether the compressor motor gets

faulty.

Yes

Check the compressor, and repair or replace it

if necessary.

No

Judge 2: Check whether the refrigerant is charged

Yes

Reduce the refrigerant

No

Judge 3: Check whether air outlet is blocked by

sundries.

Yes

Clear the sundries to ensure smooth air

Judge 4: Check whether the condenser coil fin gets

No

Yes

Clean the condenser.

No

Judge 5: Check whether the ambient temperature is

Yes

Add sunshade facilities.

No

Judge 6: Check whether the condenser fan is

Yes

Check the outdoor fan.

No

Judge 7: Check whether the power voltage is too low,

For 1 phase unit: power voltage <198V; for 3 phase

unit: <342V

Yes

Check and repair the power supply.

38 Outdoor Unit

Page 40

MCAC-UTSM-2008-11 Troubleshooting

temperature is too high

ventilation

Yes

No

P1: High pressure protection

LED indicates P1

High pressure protection

Judge 1: Whether the wiring between the high

pressure switch and main control board is connected

well and correctly

No

Connect it well

Judge 2: Whether the high pressure switch is broken

Validate: Short connect the high pressure switch

socket, check whether the system can run normally

Yes

Replace high pressure switch

Judge 3: Whether the air exhaust temperature

controller gets faulty

No

Yes

Replace air exhaust temperature controller

Check whether the refrigerant system is ok

Judge 4: Check whether the outdoor ambient

Yes

Stop the unit

Judge 5: Check whether the outdoor unit is bad

No

Yes

Make the outdoor unit ventilate well

Judge 6: Check whether the heat exchanger is dirty

No

Yes

Clean the heat exchanger

Judge 6: Check whether the refrigerant pipe is

blocked

No

Yes

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe,

vacuumize and add the refrigerant again

Outdoor Unit 39

No

Replace outdoor main board

Page 41

Troubleshooting MCAC-UTSM-2008-11

P2: Low pressure protection

LED indicates P2

Low pressure protection

Judge 1: The wiring between the low pressure switch

and main control board is connected well or correctly

No

Connect it well

Yes

Judge 2: Whether the low pressure switch is broken

Validate: Short connect the low pressure switch

socket, check whether the system can run normally

Yes

Replace low pressure switch

No

Check whether the refrigerant system is ok

Judge 3: Check whether the outdoor ambient

temperature is too low

No

Judge 4: The refrigerant of the system is leakage

Validate: Connect the pressure gauge to the gauge

joint of the system, check whether the pressure is

lower than 0.15MPa

No

Judge 5: The refrigerant pipe is blocked

Yes

Yes

Leak hunting: charge nitrogen or refrigerant to

the system, if the leakage is serious, there will

be distinct gas leakage “cici” sound; if the

leakage is little, use the suds(mixture of water

and abluent is also ok, if it can make bubble)

or electronic leak detector.

Drop refrigerant, then use the high pressure

nitrogen or refrigerant to blow pipe,

vacuumize and add the refrigerant again

No

Replace outdoor main board

40 Outdoor Unit

Page 42

MCAC-UTSM-2008-11 Troubleshooting

is bad.

pipe gets dirty.

P3: Discharge air temperature protection

Refer to the E9 to solve the problem

P4: Inlet–outlet water temperature difference protection

LED indicates P4

Judge 1: Check whether inlet–outlet water

temperature-sensitive kits gets faulty.

Yes

Replace the temperature-sensitive kits

No

Judge 2: Check whether the sequence of the four

temperature-sensitive kits in the water pump is wrong

connected.

Yes

Fix it well

No

Judge 3: Check whether the water flow is too small

(Q<0.6×Q

rated

).

Yes

Adjust the water flow

P5: Condenser high temperature protection

Judge 1: Check whether outdoor ambient

temperature is too high. compressor motor gets

faulty.

Yes

Add sunshade facilities.

Judge 2: Check whether the outdoor unit’s ventilation

No

Yes

Check if there are sundries blocking the

ventilation and clear them to make good

ventilation

No

Judge 3: Check whether the outdoor condenser coil

Yes

Clean the condenser.

Outdoor Unit 41

Page 43

Troubleshooting MCAC-UTSM-2008-11

insufficient

insufficient

P6: Plate heat exchanger low temperature protection

LED indicates P6

Judge 1: Check whether the temperature-sensitive kit

at the plate heat exchanger side gets faulty

Yes

Replace the temperature-sensitive kit

No

Judge 2: The heat exchange of water side is

Yes

Clean the water side heat exchanger or pipe

Judge 3: Check whether the circulation water is

No

Yes

Refill water periodically

No

Judge 4: Check whether the FCU are not started.

Yes

Start the FCU

42 Outdoor Unit

Page 44

MCAC-UTSM-2008-11 Troubleshooting

(Q<0.6

Q

rated

).

Pb: System anti-frozen protection

P8: Inlet temperature protection (three times in one hour and system should be powered on again) At this

time, the wired controller displays P4

-----Refer to the P4 to solve the problem

Judge 1: Check whether the circulation water is

Judge 2: Check whether the plate heat exchanger

Judge 4: Check whether the ambient temperature is

LED indicates Pb

insufficient:

×

No

temperature sensor is abnormal

No

too low (in cooling mode).

Yes

Yes

Yes

Check the water system and make

adjustment.

Replace the temperature sensor.

Adjust outdoor fan and increase the outdoor

air flow.

Outdoor Unit 43

Page 45

Troubleshooting MCAC-UTSM-2008-11

Annex 1

Unit: ℃--K Room temperature sensor \Pipe temperature sensor Table

-20 115.266 20 12.6431 60 2.35774 100 0.62973

-19 108.146 21 12.0561 61 2.27249 101 0.61148

-18 101.517 22 11.5 62 2.19073 102 0.59386

-17 96.3423 23 10.9731 63 2.11241 103 0.57683

-16 89.5865 24 10.4736 64 2.03732 104 0.56038

-15 84.219 25 10 65 1.96532 105 0.54448

-14 79.311 26 9.55074 66 1.89627 106 0.52912

-13 74.536 27 9.12445 67 1.83003 107 0.51426

-12 70.1698 28 8.71983 68 1.76647 108 0.49989

-11 66.0898 29 8.33566 69 1.70547 109 0.486

-10 62.2756 30 7.97078 70 1.64691 110 0.47256

-9 58.7079 31 7.62411 71 1.59068 111 0.45957

-8 56.3694 32 7.29464 72 1.53668 112 0.44699

-7 52.2438 33 6.98142 73 1.48481 113 0.43482

-6 49.3161 34 6.68355 74 1.43498 114 0.42304

-5 46.5725 35 6.40021 75 1.38703 115 0.41164

-4 44 36 6.13059 76 1.34105 116 0.4006

-3 41.5878 37 5.87359 77 1.29078 117 0.38991

-2 39.8239 38 5.62961 78 1.25423 118 0.37956

-1 37.1988 39 5.39689 79 1.2133 119 0.36954

0 35.2024 40 5.17519 80 1.17393 120 0.35982

1 33.3269 41 4.96392 81 1.13604 121 0.35042

2 31.5635 42 4.76253 82 1.09958 122 0.3413

3 29.9058 43 4.5705 83 1.06448 123 0.33246

4 28.3459 44 4.38736 84 1.03069 124 0.3239

5 26.8778 45 4.21263 85 0.99815 125 0.31559

6 25.4954 46 4.04589 86 0.96681 126 0.30754

7 24.1932 47 3.88673 87 0.93662 127 0.29974

8 22.5662 48 3.73476 88 0.90753 128 0.29216

9 21.8094 49 3.58962 89 0.8795 129 0.28482

10 20.7184 50 3.45097 90 0.85248 130 0.2777

11 19.6891 51 3.31847 91 0.82643 131 0.27078

12 18.7177 52 3.19183 92 0.80132 132 0.26408

13 17.8005 53 3.07075 93 0.77709 133 0.25757

14 16.9341 54 2.95896 94 0.75373 134 0.25125

15 16.1156 55 2.84421 95 0.73119 135 0.24512

16 15.3418 56 2.73823 96 0.70944 136 0.23916

17 14.6181 57 2.63682 97 0.68844 137 0.23338

18 13.918 58 2.53973 98 0.66818 138 0.22776

19 13.2631 59 2.44677 99 0.64862 139 0.22231

44 Outdoor Unit

Page 46

MCAC-UTSM-2008-11 Installation

Part 3

Installation

1. General Information ................................................. 46

2. Description of Standard Unit ................................... 47

3. Installation ............................................................... 49

4. Hydraulic Connection .............................................. 54

5. Electrical Connection .............................................. 56

6. Auxiliary Electric Heater Installation ...................... 58

7. Maintenance............................................................. 59

Installation 45

Page 47

General Information MCAC-UTSM-2008-11

1. General Information

General warning

1. These units have been designed to chill and heat water and must be used in applications compatible with

their performance characteristics; these appliances are designed for residential or similar applications.

2. Incorrect installation, regulation and maintenance or improper use absolves the manufacturer from all

liability, whether contractual or otherwise, for damage to people, animals or things. Only those

applications specifically indicated in this list are permitted.

3. Read this manual carefully. All work must be carried out by qualified personnel in conformity with

legislation in force in the country concerned.

4. The guarantee is invalidated if the above instructions are not respected and if the unit is started up for the

first time without the presence of personnel authorized by the Company (where specified in the supply

contract) who should draw up a “start-up” report.

5. The documentation supplied with the unit must be consigned to the owner who should keep it carefully for

future consultation in the event of maintenance or service.

6. All repair or maintenance work must be carried out by the Company’s Technical Service or qualified

personnel following the instructions in this manual. The air-conditioner must under no circumstances be

modified or tampered with as this may create situations of risk. Failure to observe this condition absolves

the manufacturer of all liability for resulting damage.

Fundamental safety rules

Prohibition

This appliance is not intended for use by persons (including children) with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their safety.

Do not touch the unit with bare feet or with wet or damp parts of the body.

Do not carry out cleaning operations without first disconnecting the system from the electricity supply.

Do not modify safety or regulation devices without authorization and instructions from the manufacture.

Do not pull, detach or twist the electrical cables coming from the unit , even when disconnected from the

mains electricity supply.

Do not open doors or panels providing access to the internal parts of the unit without first ensuring that the

mains switch is in the off position.

Do not introduce pointed objects through the air intake and outlet grills.

Do not dispose of, abandon or leave within reach of children packaging materials (cardboard, staples, plastic

bags, etc.) as they may represent a hazard.

1. The chiller appliances are supplied without the main switch. The power supply to the unit must be

disconnected using a suitable main switch that must be supplied and installed by the installer.

2. Respect safety distances between the unit and other equipment or structures. Guarantee adequate

space for access to the unit for maintenance and/or service operations;

Power supply: the cross section of the electrical cables must be adequate for the power of the unit and the

power supply voltage must correspond with the value indicated on the respective units. All units must be

earthed in conformity with legislation in force in the country concerned.

3. Hydraulic connections should be carried out as indicated in the instructions to guarantee correct operation

of the unit. Empty the water circuit or add glycol if the unit is not used during the winter. Handle the unit

with the utmost care to avoid damage.

46 Installation

Page 48

MCAC-UTSM-2008-11 Description of Standard Unit

2. Description of Standard Unit

These air cooled reverse-cycle chillers with axial-flow fans operate with refrigerant fluid and are suitable for

outdoor installation. They are factory tested and on site installation is limited to water and electrical

connections.

Structure:

Panels and base are made from galvanized steel plate painted with epoxy powder to ensure total resistance

to atmospheric agents. Condensate collection pan as standard.

Compressors:

Digital scroll compressor with crankcase heater and thermal cut-out.

Evaporator:

AISI 316 stainless steel plate type evaporator complete with electric heater and differential pressure switch.

Casing lined with anti-condensate closed cell neoprene cladding.

Pump:

The units feature a pump with the moving parts in contact with the water made from corrosion resistant

materials, extra wear ring on the impeller, built-in capacitor for high starting torque and automatic venting of

impeller chamber.

Pump assembly:

Pump assembly with expansion tank, auto water replenishing assembly, pump.

Condensing coil:

Made from copper tubes and high surface area aluminum fins. Condensing coil protection grills as standard.

Fans:

Axial-flow fans. Six-pole electric motor with built-in thermal cut-out. Housed in aerodynamic tubes with

accident prevention grill. Device for operation with low outside air temperatures: continuous fan rotation

speed control via condensing temperatures transducer.

Power and control electrical panel:

Power and control electrical panel constructed in accordance with IEC 204-1/EN60335-2-40, complete with

compressor contactor. Control via “HSW7” control panel.

Emergency stop pushbuttons:

In case system crisis is occur (e.g: Compressor out of control ), press the emergency stop pushbuttons at

once, and turn it clockwise, until crisis is removed.

Optional accessories:

- Removable metal mesh filter.

- Remote keyboard kit.

The above accessories are optional. Consult the relative documentation for assembly instructions and

technical data.

Installation 47

Page 49

Description of Standard Unit MCAC-UTSM-2008-11

Outdoor Unit

10kW

12 14 16kW

Water pump box

48 Installation

Page 50

MCAC-UTSM-2008-11 Installation

3. Installation

3.1 Choice of installation site

Before installing the unit, agree with the customer the site where it will be installed, taking the following

points into consideration:

- check that the fixing points are adequate to support the weight of the unit;

- pay scrupulous respect to safety distances between the unit and other equipment or structures to ensure

that air entering the unit and discharged by the fans is free to circulate.

3.2 Positioning

Before handling the unit, check the capacity of the lifting equipment used, respecting the instructions on the

packaging. To move the unit in the horizontal, make appropriate use of a lift truck or similar, bearing in mind

the weight distribution of the unit. To lift the unit, insert tubes long enough to allow positioning of the lifting

slings and safety pins in the feet on the unit.

To avoid the slings damaging the unit, place protection between the slings and the unit. Position the unit in

the site indicated by the customer. Place either a layer of rubber (min. thickness 10 mm) or vibration damper

feet (optional) between the base and support surface. Fix the unit, making sure it is level and that there is

easy access to hydraulic and electrical components. If the site of installation is exposed to strong winds, fix

the unit adequately to the support surface using tie rods if necessary. If a heat pump unit is being installed,

make sure the condensate is drained using the drain hose supplied as standard. Prevent leaves, branches

or snow from accumulating around the unit. These could reduce the efficiency of the unit.

3.3 Installation of outdoor unit

3.3.1 Installation space

1) At least 600mm distance should be left between outdoor units:

2) Distance between foot screws is shown below:

Installation 49

Page 51

Installation MCAC-UTSM-2008-11

3.3.2 Refrigerant Piping

Note:

1. Refrigerant piping connection is on the right side of outdoor unit.

2. The piping connects to refrigerant piping connection.

3. Install the refrigerant piping towards left, right or back.

4. Refer to system identifiers in valve installation board for corresponding connections of indoor units.

a. Choose the sizes of refrigerant piping: φ9.5+φ19

b. Connection: refer to connection of refrigerant piping

c. Length and height drop permitted of refrigerant piping

Maximum length of piping (L) 10m

Maximum height drop

(Height drop between water pump box and outdoor unit H)

Outdoor unit (up) 5m

Outdoor unit (down) 5m

d. Remove dirt or water in the piping

● Make sure there is no any dirt or water in the piping before connecting it to the outdoor unit.

● Please clean the piping with high-pressure nitrogen rather than refrigerant of outdoor unit.

e. Vacuuming with vacuum pump

● Please vacuum with vacuum pump.

● Vacuuming should be done from the gas side.

f. Open all valves

g. Refrigerant volume to be added

Calculate the volume according to the diameter and the length of the liquid side piping between

outdoor unit and water pump box. The refrigerant volume to be added is based on the following table:

Piping on liquid side Method Refrigerant volume to be added

<5m Use refrigerant in outdoor unit —

≥5m Use vacuum pump or refrigerant box 60g/m× (length of piping -5m)

Expel the air

1. Flaring

Cut a pipe with a pipe cutter.

Insert a flare nut into a pipe and flare the pipe.

2. Fasten the nuts

Put the connecting tubing at the proper position, wrench the nuts with hands then fasten it with a wrench.

50 Installation

Page 52

MCAC-UTSM-2008-11 Installation

Caution

Too large torque will harm the bell-mouth and too small will cause leakage. Please determine the torque

according to the table below:

Pipe gauge Tightening torque

Φ6.4

Φ9.5

Φ12.7

Φ15.9

Φ19.1

15~16N.m

(153~163kgf.cm)

25~26N.m

(255~265kgf.cm)

35~36N.m

(357~367kgf.cm)

45~47N.m

(459~480kgf.cm)

65~67N.m

(663~684kgf.cm)

Flare dimension A

Min (mm) Max

8.3 8.7

12.0 12.4

15.4 15.8

18.6 19.0

22.9 23.3

Flare shape

3. How to expel the air

A. Expel the air with refrigerant in outdoor unit: connect the wiring between water pump box and outdoor unit,

refer to the example below:

1. Totally fasten the joint nut of stop valve B and nut C and D.

2. Loosen the joint nut of stop valve A a little.

3. For 3~5m s piping, turn the valve rod of B anticlockwise to 45°for about 6~7seconds. After the air is

expelled from A, fasten the joint nut of stop valve A. (Refer to former page for the torque)

4. Totally open the valve rods of stop valve A and B.

5. Totally fasten the valve bonnet.

B. Expel the air with vacuum pump (following procedures are for all the Lo-stop valve)

1. Connect the charging hose of the manifold valve with the charging inlet of the Lo-stop valve. (All the

Hi-stop valves should be closed)

2. Connect the connection of charge hose with vacuum pump.

3. Totally open the Lo-lever of the manifold valve.

4. Turn on the vacuum pump. First loosen the joint nut of Lo-stop valve a little to check whether the air

comes in (the noise of vacuum pump changes and the indicator of multi-meter turns to be above 0). Then

fasten the joint nut.

Installation 51

Page 53

Installation MCAC-UTSM-2008-11

5. After vacuuming, close the Lo-lever of manifold valve and turn off vacuum pump. When doing vacuuming

for more than 15 minutes, please confirm that the indicator of multi-meter points to-1.0X105Pa(-76cmHg)

6. Totally open the Hi-stop valve and Lo-stop valve.

7. Remove the charge hose from the charging inlet of Lo-stop valve.

8. Fasten the valve bonnets on Hi-stop valve, Lo-stop valve and on the charging inlet of Lo-stop valve.

C. Expel air with refrigerant container

1. Connect the charge hose of refrigerant container with charging inlet of Lo-stop valve.

2. Fasten the joint nuts C, D and the joint nut of stop valve A.

3. Loosen the joint nut of stop valve B a little.

4. Open the valve of refrigerant container, after the refrigerant air is expelled from joint nut on Hi-stop valve

side for 10~15 seconds, fasten the joint nut of stop valve B.

5. Remove the charge hose from the connection of Lo-stop valve and push the air valve core with a screw

driver to discharge the refrigerant from piping until there is no noise. Then put back the air valve core at

once in case the air goes into the system.

6. Remove the valve bonnet and totally open the stop valve B on high-pressure side and the valve rod on

low-pressure side of the outdoor unit, then fasten the valve bonnet.

7. Make sure to fasten the valve bonnets of both Hi-stop valve and Lo-stop valve.

3.4 Installation of water pump box

3.4.1 Installation location

Please keep away from the following places:

● Such places where the temperature is high, water pump box can be installed outdoors. In other places,

please install it indoors, such as washroom and the places that prevents it from water.

● There is combustible gas leakage.

● There is much salty ingredients.

● There is caustic gas such sulfide in the air. (The copper tubes and welding parts will be rusted and

damaged, causing refrigerant to leak.)

● There is mineral oil, cooking oil or gasoline. (This may cause damage to plastic parts, looseness of

components and leakage.

● A place that is too weak to bear the weight of water pump box.

● There is equipment that produces electromagnetic wave. (It will disturb the controlling system of air

conditioner.)

3.4.2 Install the refrigerant piping

Check whether the height drop between water pump container and outdoor unit, the length of refrigerant

piping, and the quantity of the bends meet the following requirements:

The Max. Height drop 5m (if longer than 5m, outdoor unit should be above the water pump container.); The

length of refrigerant piping shorter than 10m;

The quantity of bends fewer than 15.

● Do not let air, dust, moisture or other impurities fall in the piping system during installation.

● Fix the outdoor unit and water pump box before installing the refrigerant piping.

● The refrigerant piping should not be installed until you check that the H-stop valve and Lo-stop valve or

outdoor unit have been closed.

52 Installation

Page 54

MCAC-UTSM-2008-11 Installation

3.4.3 The procedures for connecting pipe

1) Connect the water inlets and water outlets of water pump box and indoor unit with soft connection and

charge water into the pipe to check whether there is leakage. Then connect the outdoor unit piping. Bend

the piping carefully and do not damage them.

2) The stop valve of the outdoor unit should be closed absolutely (as original state). Every time you connect

it, remove the nut of stop valve then connect the flaring pipe immediately (with 5 minutes). Before

connecting, use refrigerant to expel the air in the pipe.

3) Connect the Hi-stop valve and Lo-stop valve of A and B system in outdoor unit to water pump box with

piping. Make sure that the connection of both outdoor unit and water pump box should be corresponding.

4) The flexible pipe should be used on water pump side. (The bending angle should not exceed 90°. The

bending part is preferably in the middle of the pipe, the bigger the bending radius, the better it is. Do not

bend the pipe more than 3 times.)

5) Bending the connecting pipe of thin wall.

● Cut out a desired concave at the bending part of the insulating pipe.

● To avoid distortion or damage, please bend the pipe at its biggest radius.

● Use bender to get a pipe with small radius.

Note: Make sure to use insulation material for the copper tube which you purchase by yourself.

Installation 53

Page 55

Hydraulic Connection MCAC-UTSM-2008-11

4. Hydraulic Connection

The choice and installation of components is the responsibility of the installer who should follow good

working practice and current legislation. Before connecting the pipes, make sure they do not contain stones,

sand, rust, dross or other foreign bodies which might damage the unit. Construction of a bypass is

recommended to enable the pipes to be washed through without having to disconnect the unit (see drain

valves). The connection piping should be supported in such a way as to avoid it weighing on the unit. It is

recommended that the following devices are installed in the water circuit of the evaporator: A hydraulic

safety valve shall be mounted in water system, which should open constantly.

1. Two pressure gauges with a suitable scale (inlet and outlet).

2. Two vibration damper joints (inlet and outlet).

3. Two gate valves (normal inlet and calibrating in outlet)

4. A flow switch (inlet) or a differential pressure switch (inlet-outlet).

5. Two thermometers (inlet and outlet).

6. An inlet filter as close as possible to the evaporator and positioned to allow easy access for routine

maintenance.

7. An energy-saving water tank.

8. Additional pump.

1) The chillers must be provided with a filling/top-up system connected to the return line and a drain cock in

the lowest part of the installation. Installations containing anti-freeze or covered by specific legislation

must be fitted with hydraulic disconnections.

2) The manufacturer is not liable for obstruction, breakage or noise resulting from the failure to install filters

or vibration dampers. Particular types of water used for filling or topping up must be treated with

appropriate treatment systems. For reference values, see the table.

P H 6-8

Electrical conductivity less than 200 mV/cm (25°C )

Chlorine ions less than 50 ppm

Sulphuric acid ions less than 50 ppm

Total iron less than 0.3 ppm

Alkalinity M less than 50 ppm

Total hardness less than 50 ppm

Sulphur ions none

Ammonia ions none

Silicon ions less than 30ppm

54 Installation

Page 56

MCAC-UTSM-2008-11 Hydraulic Connection

Filling the installation

- Before filling, check that the installation drain cock is closed.

- Open all installation and terminal air vents.

- Open the gate valves.

- Begin filling, slowly opening the water filling cock outside the unit

- When water begins to leak out of the terminal air vent valves, close them and continue filling until the

pressure gauge indicates a pressure of 1.5 bars.

Emptying the installation

- Before emptying, place the mains switch in the “off” position

- Make sure the installation fill/top-up water cock is closed

- Open the drain cock outside the unit and all the installation and terminal air vent valves.

Size and position of connections

Model MGA-D10/N1 MGA-D12/N1 MGA-D14/SN1 MGA-D16/SN1

Water inlet/outlet (Ø) R5/4” R5/4” R5/4” R5/4”

Auto-water replenishing(Ø) R1/2” R1/2” R1/2” R1/2”

Security discharge(Ø) G1/2” G1/2” G1/2” G1/2”

Mesh filter (Ø ) R5/4” R5/4” R5/4” R5/4”

Air vent (Ø ) G3/8” G3/8” G3/8” G3/8”

a) The installation must be filled to a pressure of between 1 and 2 bars.

b) It is recommended that this operation be repeated after the unit has been operating for a number of hours.

The pressure of the installation should be checked regularly and if it drops below 1 bar, the water content