Page 1

3 phase, 380-415V, 50Hz

MDV-V120W/DRN1

MDV-V140W/DRN1

MDV-V160W/DRN1

MDV-V180W/DRN1

Model:

Technical Service Manual

Mini VRF

Page 2

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Contents

Part 1 General Information ................................................................................. 1

Part 2 Specifications & Performance ............................................................... 10

Part 3 Installation .............................................................................................. 54

Part 4 Troubleshooting ..................................................................................... 70

Page 3

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

Page 4

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

General Information 1

Part 1 General Information

1. Product Lineup ..................................................................................... 2

2. Nomenclature ........................................................................................ 3

3. Features................................................................................................. 4

4. Indoor Units Lineup .............................................................................. 8

Page 5

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

2 General Information

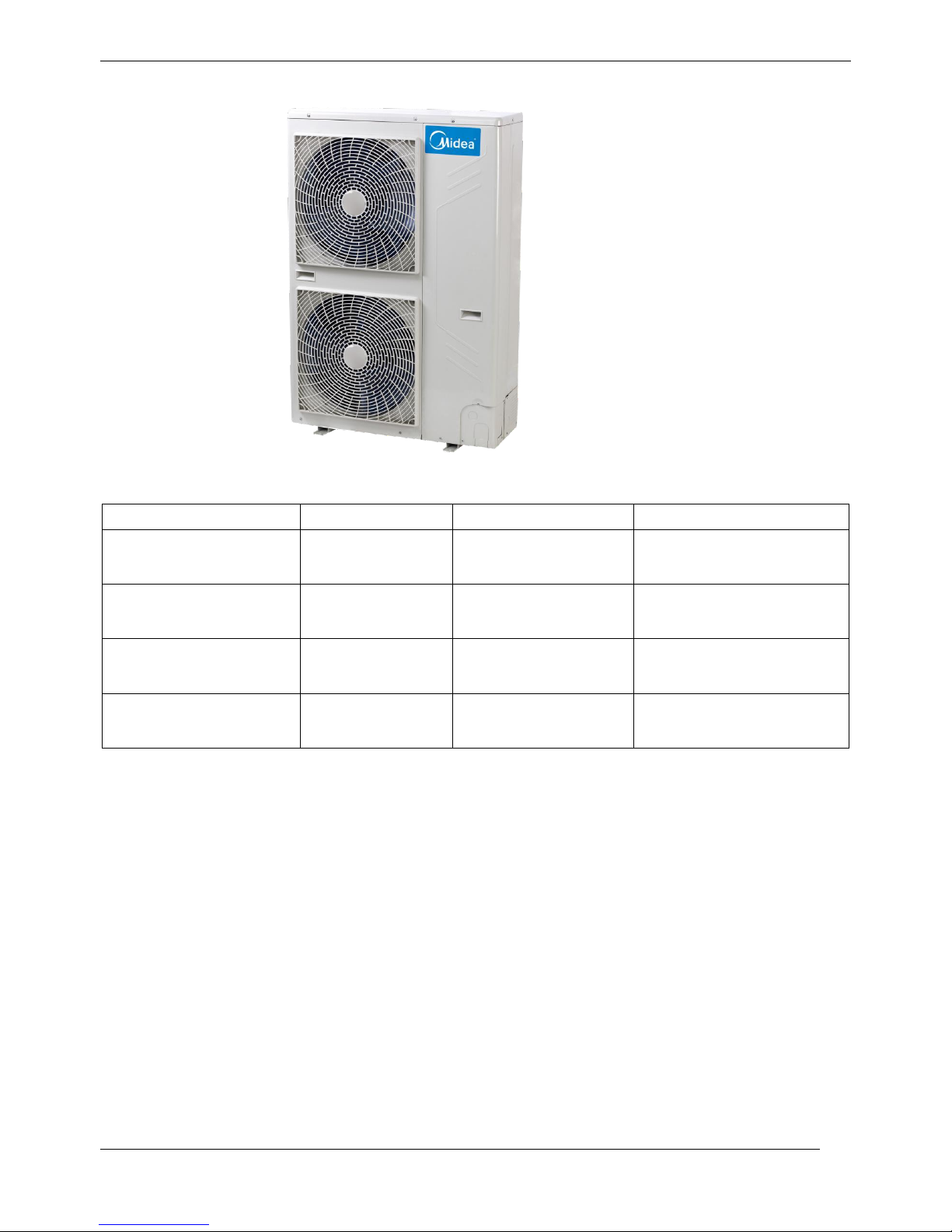

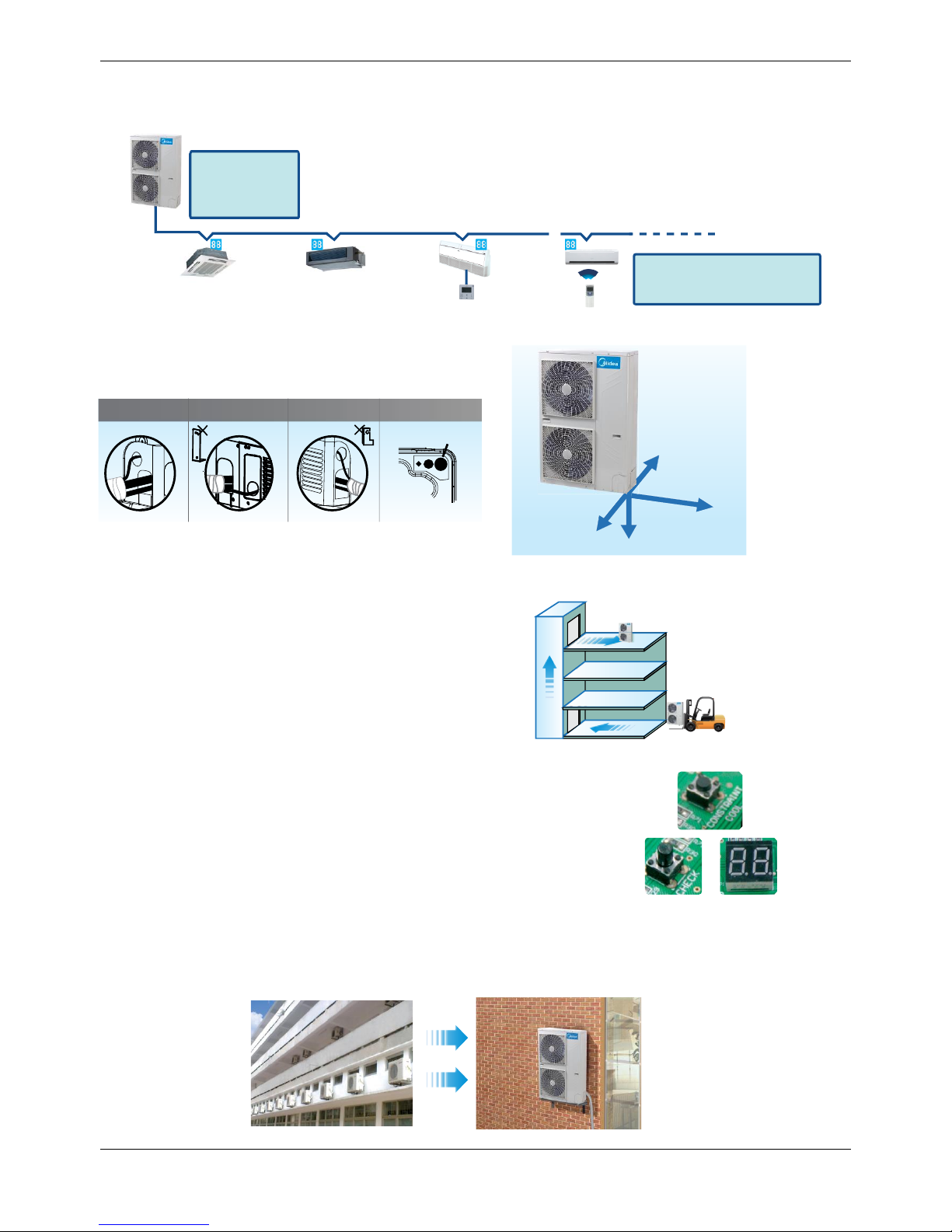

1. Product Lineup

Outdoor Units

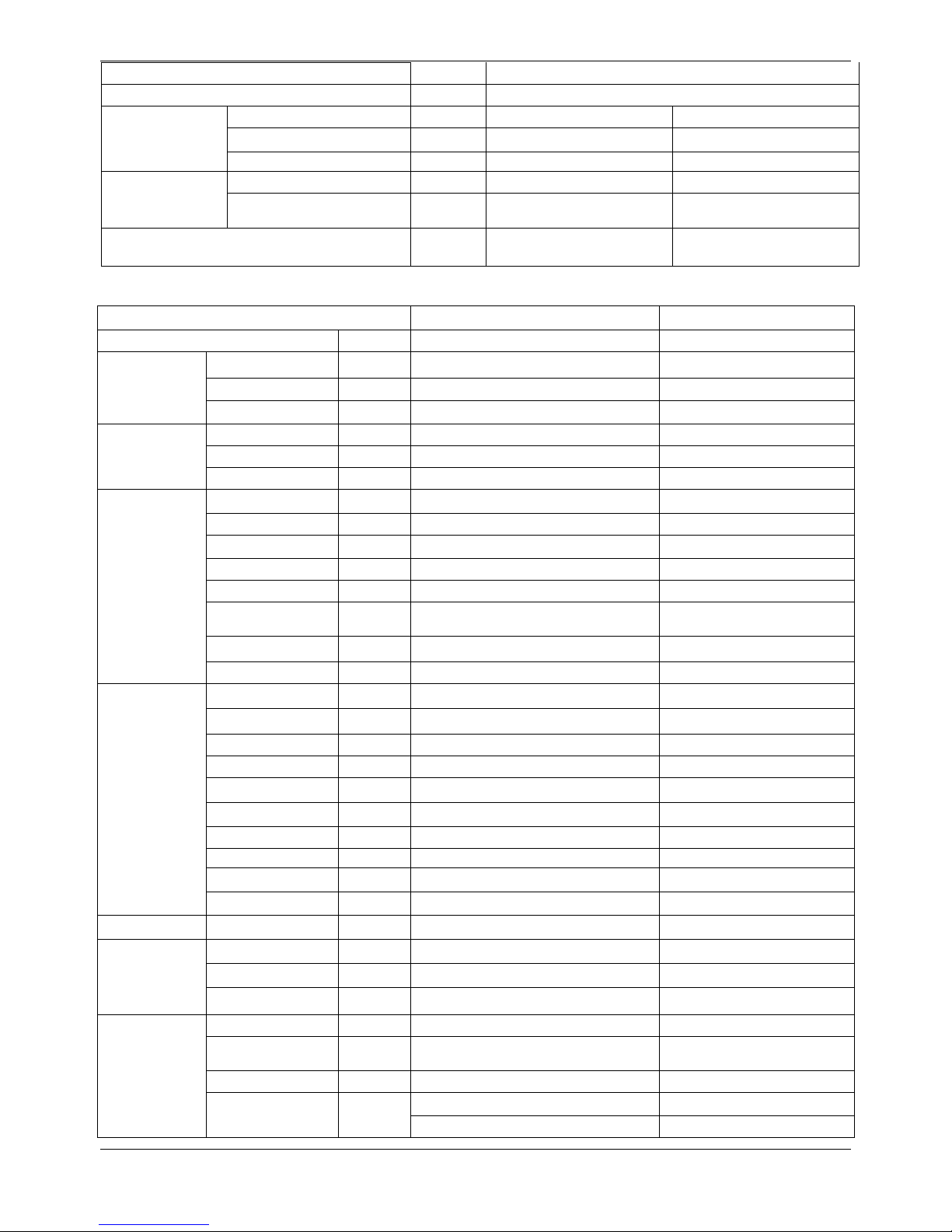

Model name

Dimension body(mm)

Net/Gross weight (kg)

Power supply

MDV-V120W/DRN1

Width: 900

Height: 1327

Depth:400

95/106

380-415V-3ph~ 50Hz

MDV-V140W/DRN1

Width: 900

Height: 1327

Depth:400

95/106

380-415V-3ph~ 50Hz

MDV-V160W/DRN1

Width: 900

Height: 1327

Depth:400

102/113

380-415V-3ph~ 50Hz

MDV-V180W/DRN1

Width: 900

Height: 1327

Depth:400

107/118

380-415V-3ph~ 50Hz

Page 6

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

General Information 3

2. Nomenclature

MDV-V120W/DRN1

Refrigerant

N1: R410A

Power Supply

-- 220~240V, 50Hz, 1ph

R 380~415V, 50Hz, 3ph

Outdoor unit

Cooling Capacity (×100W )

Midea VRF

Inverter

DC Inverter

Page 7

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

4 General Information

3. Features

3.1 Wide application

The All DC Inverter Mini VRF system is a highly efficient solution for small commercial buildings requiring

heating and cooling of up to 9 zones with one outdoor unit. Such as villa, restaurant, school etc.

Midea offers various indoor units, more than 100 models of 15 types. Capacity ranges are from 1.5kW to 16

kW. It is all compliance with residential and light commercial place. Our systems can be operated up to 130%

of capacity which allows any system to be designed to the customers’ and applications’ needs.

Page 8

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

General Information 5

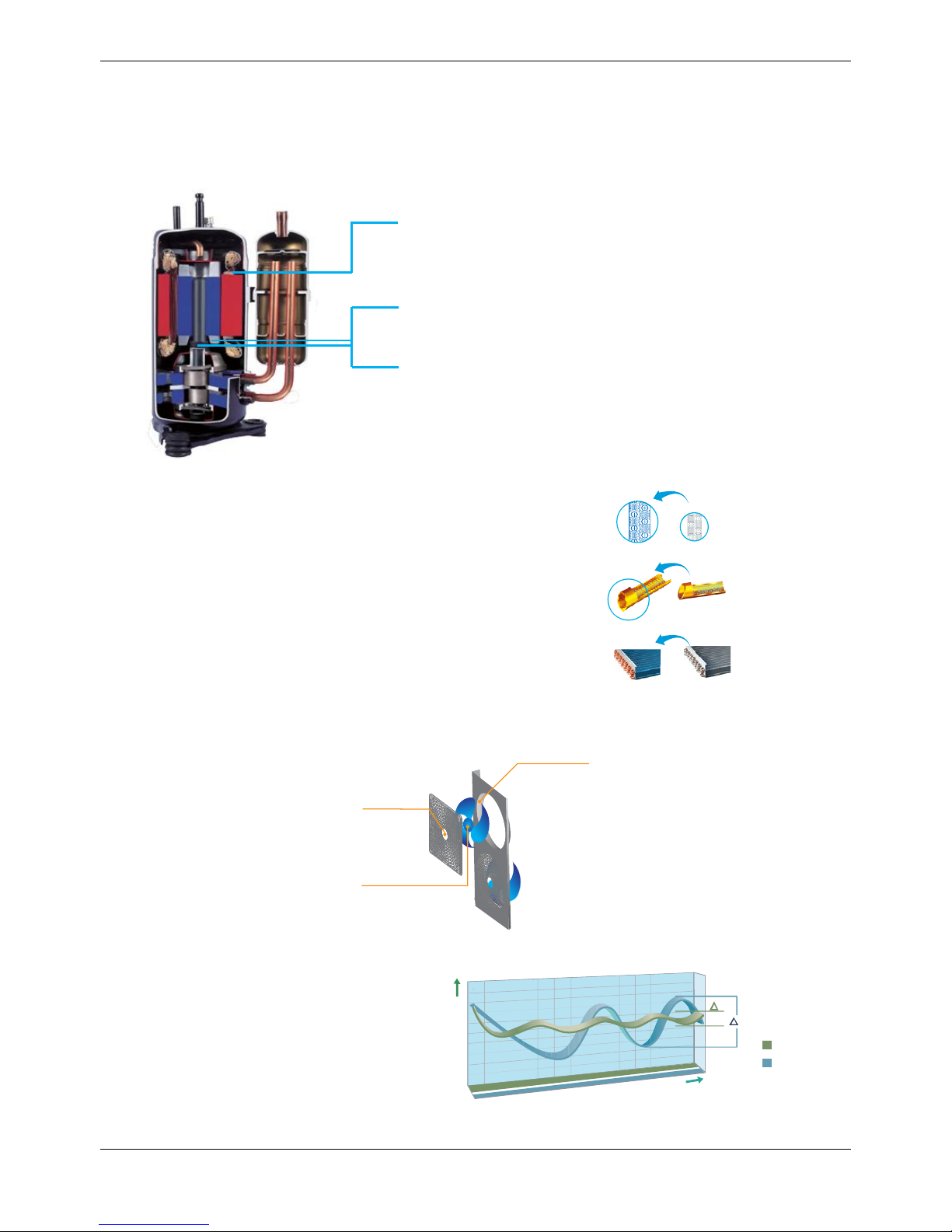

Compressor

(Twin Rotary) structure

3.2 High efficient DC inverter compressor

All DC inverter Mini VRF adopts highly intelligent inverter-driven compressor. This advanced technology

enables the output of the outdoor unit to be modulated by the real heat load demands..

This advanced system ensures precise temperature regulation and highly efficient energy usage, making a

significant contribution to the limiting the impact on the environment.

3.3 High performance heat exchanger

The new designed window fins enlarge the heat-exchanging area ,

which decrease the air resistance, save more power and enhance heat

exchange performance.

Hydrophilic film fins and inner-threaded copper pipes optimize heat

exchange efficiency.

3.4 Low-operating sound design

Optimally design fan shape and new designed discharge air grille and air deflector, making higher air volume

and lower operation sound.

3.5 Quick warm-up & cool-down design and less temperature fluctuation

Utilizing the inverter compressor benefits,

the system can reach All load quickly and

shorten warm-up or cool-down time for an

immediate comfortable air solution.

Less temperature fluctuation will create a

better living environment.

New fan

Air deflector

New grille

Highly Efficient DC Motor:

- Creative motor core design

- High density neodymium magnet

- Concentrated type stator

-Wider operating frequency range

Better balance and Extremely Low Vibration:

- Twin eccentric cams

- 2 balance weights

Highly Stable Moving Parts:

- Optimal material matching rollers and vanes

-Optimize compressor drive technology

- Highly robust bearings

-Compact structure

Fluctuation of room temperature

Cooling operation

2

1

Temp.

Time

Notn-inverter

Inverter

New design Original design

High efficiency inner-thread pipe,

enhance heat transfer.

Page 9

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

6 General Information

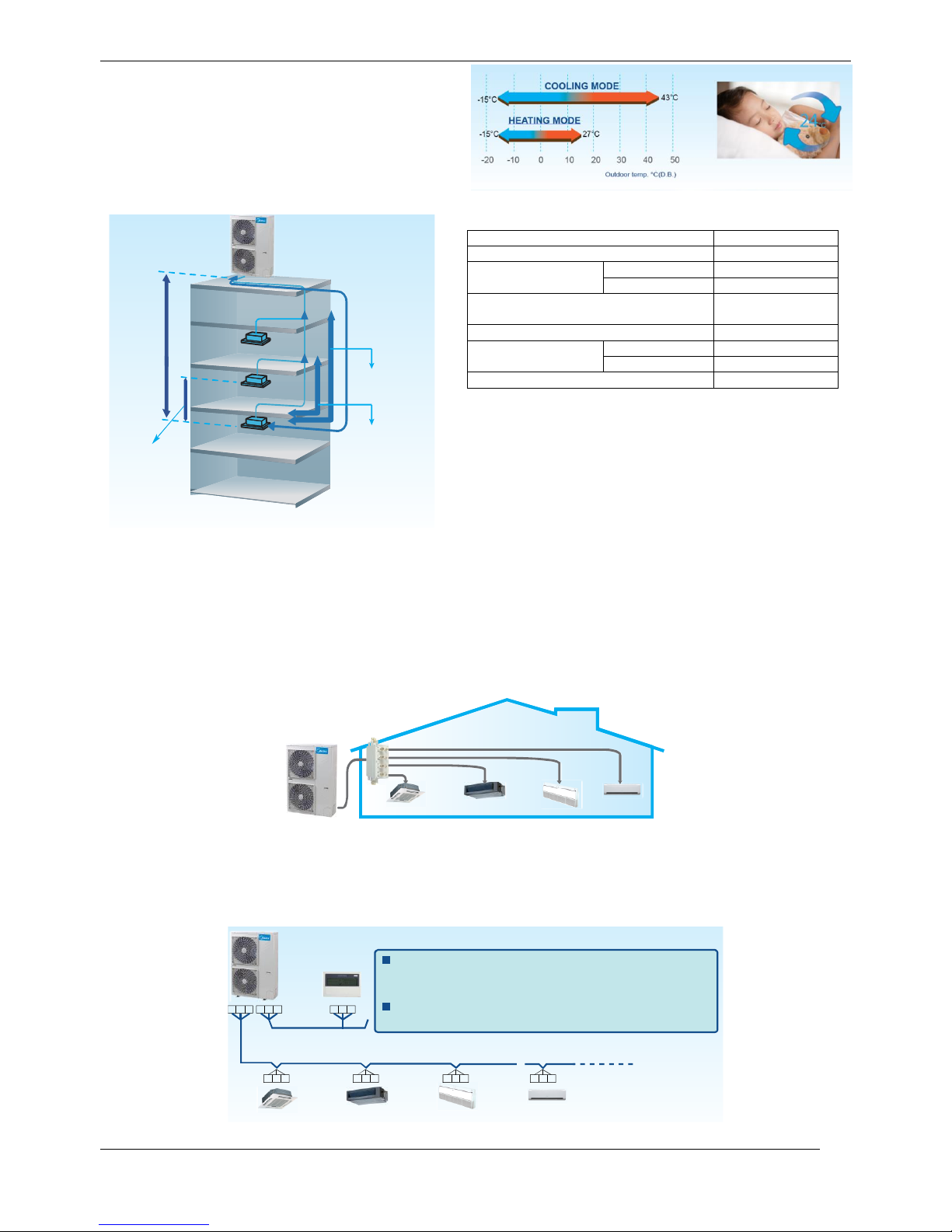

3.6 Wide operation temperature range

No matter in extremely cold winter when outdoor

temperature gets as low as -15°C or in hot summer

when temperature is up to 43°C, the Mini VRF

system will keep stable performance.

3.7 Flexible piping design

3.8 Flexible indoor unit’s connection

Mini VRF with intelligent control gives you independent zoning control with maximum flexibility.

A single outdoor unit supports up to nine indoor units, freeing up considerable space outside. Use your

backyard more wisely with much more space available created by less number of outdoor units.

Max. 6 indoor units for a 12kW outdoor unit installation

Max. 6 indoor units for a 14kW outdoor unit installation

Max. 7 indoor units for a 16kW outdoor unit installation

Max. 9 indoor units for a 18kW outdoor unit installation

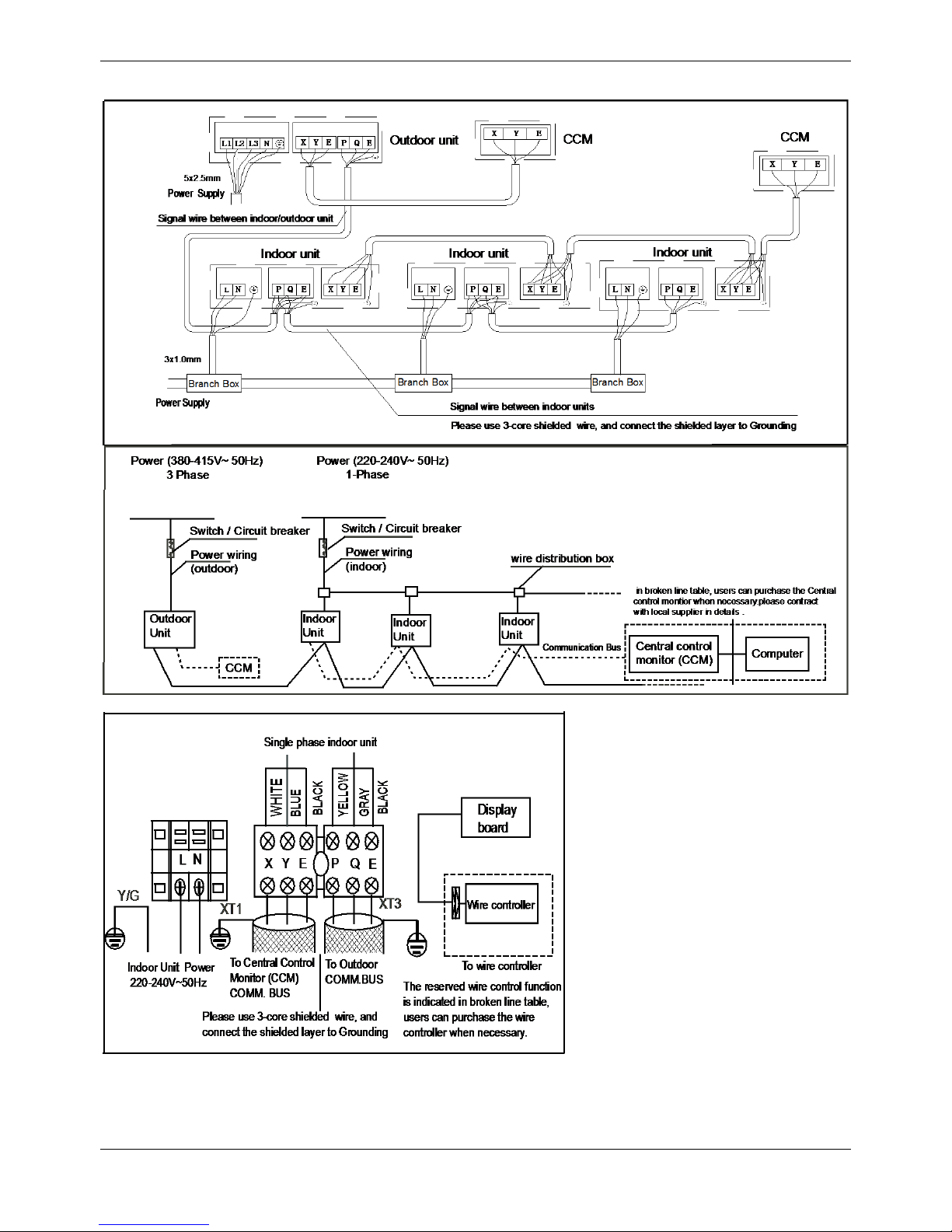

3.9 Simple signal line connection

Installation is much easier as the communication wiring between indoor & outdoor units can be shared.

It’s easy for the user to retrofit the existing system with a centralized control by simply connecting to outdoor

units.

PQE & XYE, just only one group of communication wire of PQE,

achieved both of communication for indoor & outdoor unit and

network.

Reversible communication, central controller can be connected

from indoor side or outdoor side as you wish.

P Q E

P Q E P Q E P Q E P Q E

X Y E X Y E

Piping Length

Permitted Value

Total piping length (Actual)

100m

Longest piping

length

Actual

60m

Equivalent

70m

The first branch joint to the

farthest IDU

20m

The IDU to the nearest branch pipe

15m

Level difference

between ODU~IDU

ODU up

30m

ODU down

20m

Level difference between IDU~IDU

8m

Longest

piping length

Level

difference

between

IDU~ODU

The IDU to the

nearest branch

pipe

The first branch

joint to the farthest

indoor unit

Level differece

between IDU~IDU

Page 10

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

General Information 7

3.10 Auto address setting function

The addresses of indoor units can be set automatically by outdoor unit.

Wired controller and wireless controller can enquire and modify the address of each indoor unit.

3.11 Easy piping connection

Offering four directions to connect pipes and wirings

to meet various installation requests.

3.12 Easy installation

The Mini VRF can be transported by elevator which makes

installation dramatically easy, and effectively reduces time

and labor thanks to the small size.

3.13 Easy maintenance

Forced cooling button makes outdoor unit run in cooling mode at

any condition, so it is very easy for you to charge refrigerant to the

system when it needs to be done. The self-diagnosis function

detects malfunctions in major locations in the system and displays

the type of malfunction and location. This allows service and maintenance

to be performed more efficiently.

3.14 Space saving

The Mini VRF units are more compact, resulting in significant savings in installation space. It is particularly

suitable for small offices, villas, shops, etc.

Outdoor unit can

distribute address

for indoor unit

automatically

Shield signal wire

Wired and wireless controller

can enquire and modify address

of each IDU.

Right side

Upper side

Back side

Front side

Bottom side

Front side

Back side

Right side Bottom side

Fat pipe

Easy to transport

Page 11

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

8 General Information

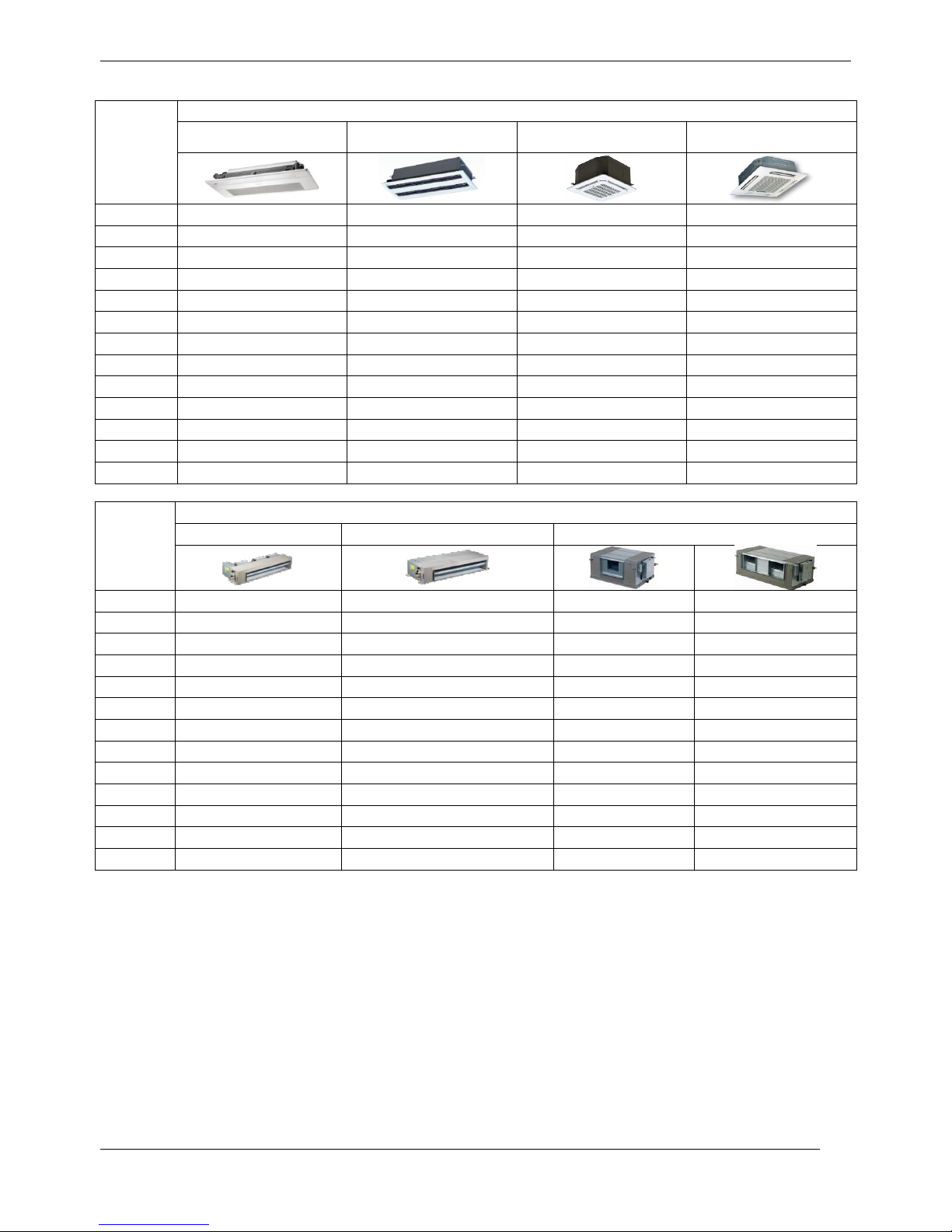

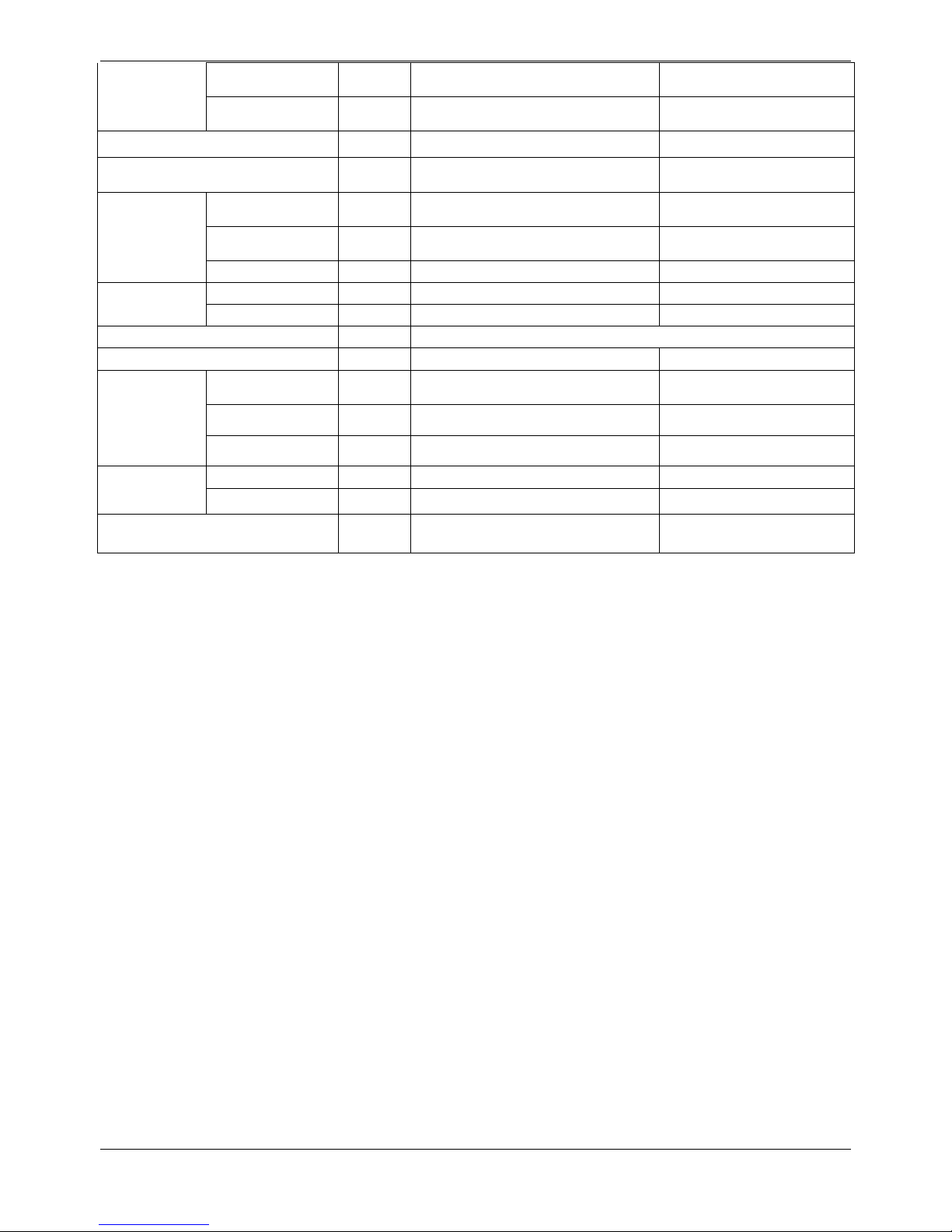

4. Indoor Units Lineup

Capacity

(×100W)

Cassette unit

One-way cassette

Two-way cassette

Compact four-way

cassette

Four-way cassette

15

●

18

●

22

● ● ●

28

● ● ●

●

36

● ● ●

●

45

● ● ●

●

56

●

● ●

71

●

● ●

80

●

90

●

100

●

112

●

140

●

Capacity

(×100W)

Duct unit

Low static pressure duct

Medium static pressure duct

High static pressure duct

15

●

18

●

22

●

●

28

●

●

36

●

●

45

●

●

56

●

●

71

● ● ●

80

●

●

90

●

●

112

●

●

140

●

●

160

●

Page 12

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

General Information 9

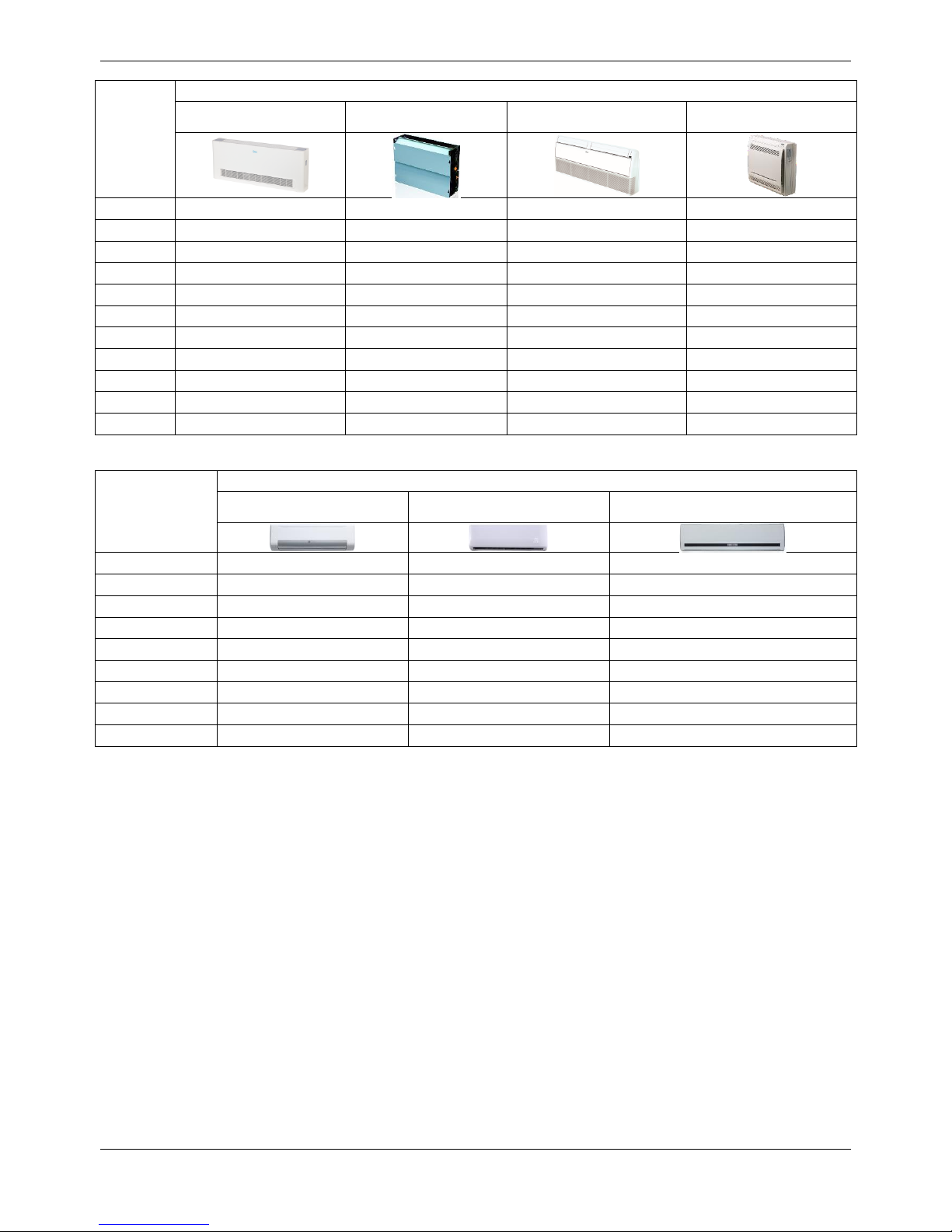

Indoor units lineup

Capacity

(×100W)

Floor-standing/Ceiling & Floor/Console

Floor standing (exposed)

Floor standing

(concealed)

Ceiling & floor

console

22

●

● ●

28

●

● ●

36

● ● ●

●

45

● ● ●

●

56

● ● ●

71

● ● ●

80

● ● ●

90

●

112

●

140

●

160

●

Capacity

(×100W)

Wall mounted

Wall mounted

(S panel)

Wall mounted

(M panel)

Wall mounted

(R panel)

15

●

22

●

●

28

●

●

36

●

●

45

●

●

56

●

●

71

●

●

80

●

●

90

●

●

Note: If ODU connect only one IDU, the capacity of IDU should be not more than ODU.

If ODU connect more than one IDU, the capacity of each IDU should be not more than 8kW for refrigerant uniform distribution.

Due to continuous improvement, specifications are subject to change without prior notice.

Page 13

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

10 Specifications&Performance

Part 2 Outdoor Units

1. Specifications ...................................................................................... 11

2. Dimensions ......................................................................................... 14

3. Service Space ..................................................................................... 15

4. Piping Diagrams ................................................................................. 16

5. Wiring Diagrams ................................................................................. 17

6. Field Wiring ......................................................................................... 19

7. Capacity Tables .................................................................................. 20

8. Electric Characteristics ...................................................................... 52

9. Sound Levels ...................................................................................... 53

10. Operation Limits ............................................................................... 53

Page 14

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 11

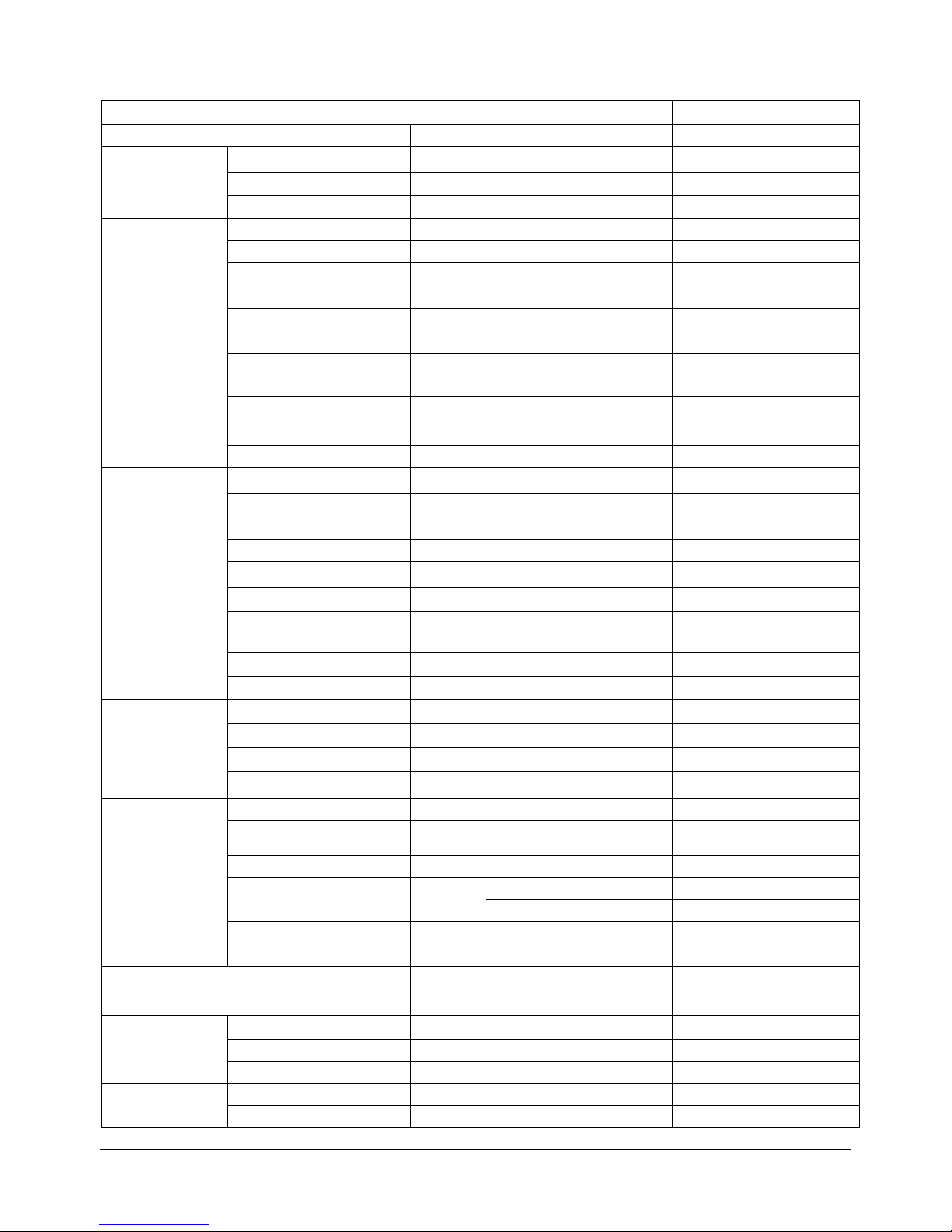

1. Specifications

Sale Model

MDV-V120W/DRN1

MDV-V140W/DRN1

Power supply

V-Ph-Hz

380-415V-3N~50Hz

380-415V-3N~50Hz

Cooling

Capacity

kW

12.3

14.0

Input

kW

3.25

3.95

EER

kW/ kW

3.78

3.54

Heating

Capacity

kW

13.2

15.4

Input

kW

3.47

4.16

COP

kW/ kW

3.80

3.7

Compressor

Model

TNB306FPNMC

TNB306FPNMC

Type

Rotary

Rotary

Brand

MITSUBISHI

MITSUBISHI

Capacity

Btu/h

33720

33720

Input

W

3010

3010

Rated current(RLA)

A

9.3

9.3

Crankcase W 27

27

Refrigerant oil

ml

FV50S 870+630ml

FV50S 870+630ml

Outdoor fan

motor

Model

WZDK100-38G

WZDK100-38G

Type

DC motor

DC motor

Brand

Panasonic

Panasonic

Insulation class

E E

Safe class

IP23

IP23

Input

W

2 x 100

2 x 100

Output W 2 x 85

2 x 85

Rated current A 2 x 0.9

2 x 0.9

Capacitor

uF / /

Speed

r/min

800

800

Outdoor fan

Material

ASG20

ASG20

Type

Axial fan

Axial fan

Diameter

mm

508

508

Height

mm

170

170

Outdoor coil

Number of rows

2 2

Tube pitch(a)x row

pitch(b)

mm

22 x 19.05

22 x 19.05

Fin spacing

mm

1.6

1.6

Tube outside dia.and type

mm

Ф7.94

Ф7.94

Inner groove tube

Inner groove tube

Coil length x height

mm

1276 x 870

1276 x 870

Number of circuits

7 7

Outdoor air flow

m3/h

6000

6000

Outdoor sound level(sound pressure level )

dB(A)

57

57

Outdoor Unit

Dimension(W x H x D)

mm

900 x 1327 x 400

900 x 1327 x 400

Packing (W x H x D)

mm

1030 x 1456 x 435

1030 x 1456 x 435

Net/Gross weight

kg

95/106

95/106

Refrigerant

Type

R410A

R410A

Charged volume

g

3300

3900

Page 15

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

12 Specifications&Performance

Throttle type

Electronic expansion valve

Design pressure

MPa

4.4/2.6

Refrigerant

piping

Liquid side/ Gas side

mm

Ф9.53/Ф15.9

Ф9.53/Ф15.9

Max. refrigerant pipe length

m

100

100

Max. difference in level

m 8 8

Connection

wiring

Power wiring

mm2

5 core x2.5

5 core x2.5

Signal wiring

mm2

3 core shielded wire x

0.75

3 core shielded wire x

0.75

Ambient temp

℃

(Cooling -15~43)

(Heating -15~27)

(Cooling -15~43)

(Heating -15~27)

Sale Model

MDV-V160W/DRN1

MDV-V180W/DRN1

Power supply

V-Ph-Hz

380-415V-3N~50Hz

380-415V-3N~50Hz

Cooling

Capacity

kW

15.5

17.5

Input

kW

4.52

5.3

EER

kW/ kW

3.43

3.3

Heating

Capacity

kW

17.0

19.0

Input

kW

4.77

5.0

COP

kW/ kW

3.56

3.8

Compressor

Model

LNB42FSAMC

LNB42FSAMC

Type

Rotary

Rotary

Brand

MITSUBISHI

MITSUBISHI

Capacity

Btu/h

47700

47700

Input

W

4240

4270

Rated

current(RLA)

A

12

12

Crankcase

W

25

25

Refrigerant oil

ml

FV50S 1400ml

FV50S 1400ml

Outdoor fan

motor

Model

WZDK100-38G

WZDK100-38G

Type

DC motor

DC motor

Brand

Panasonic

Panasonic

Insulation class

E

E

Safe class

IP23

IP23

Input

W

2 x 100

2 x 100

Output

W

2 x 85

2 x 85

Rated current

A

2 x 0.9

2 x 0.9

Capacitor

uF

/

/

Speed

r/min

800

800

Outdoor fan

Material

ASG20

ASG20

Outdoor fan

Type

Axial fan

Axial fan

Diameter

mm

508

508

Height

mm

170

170

Outdoor coil

Number of rows

2

2.5

Tube pitch(a)x

row pitch(b)

mm

22 x 19.05

22 x 19.05

Fin spacing

mm

1.6

1.6

Tube outside

dia.and type

mm

Ф7.94

Ф7.94

Inner groove tube

Inner groove tube

Page 16

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 13

Notes:

1. The cooling conditions: indoor temp.: 27℃DB (80.6℉), 19℃WB (66.2℉) outdoor temp.: 35℃DB (95℉), 24℃WB (75.2℉)

equivalent pipe length: 5m drop length: 0m.

2. The heating conditions: indoor temp.: 20℃DB (68℉), 15℃WB (59℉) outdoor temp.: 7℃DB (44.6℉), 6℃WB (42.8℉)

equivalent pipe length: 5m drop length: 0m.

3. Sound level: Anechoic chamber conversion value, measured at a point 1 m in front of the unit at a height of *m(1.2m for

120~180 model). During actual operation, these values are normally somewhat higher as a result of ambient conditions.

4. The aboved datas may be changed without notice for future improvement on quality and performance.

Coil length x

height

mm

1276 x 870

1276 x 870

Number of

circuits

7

12

Outdoor air flow

m3/h

6000

6800

Outndoor sound level(sound

pressure level )

dB(A)

57

59

Outdoor unit

Dimension

(W x H x D)

mm

900 x 1327 x 400

900 x 1327 x 400

Packing

(W x H x D)

mm

1030 x 1456 x 435

1030 x 1456 x 435

Net/Gross weight

kg

102/113

107/118

Refrigerant

Type

R410A

R410A

Charged volume

g

3900

4500

Throttle type

Electronic expansion valve

Design pressure

MPa

4.4/2.6

4.4/2.6

Refrigerant

piping

Liquid side/ Gas

side

mm

Ф9.53/Ф19.1

Ф9.53/Ф19.1

Max. refrigerant

pipe length

m

100

100

Max. difference in

level

m 8 8

Connection

wiring

Power wiring

mm2

5 core x2.5

5 core x2.5

Signal wiring

mm2

3 core shielded wire x 0.75

3 core shielded wire x 0.75

Ambient temp

℃

(Cooling -15~43)

(Heating -15~27)

(Cooling -15~43)

(Heating -15~27)

Page 17

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

14 Specifications&Performance

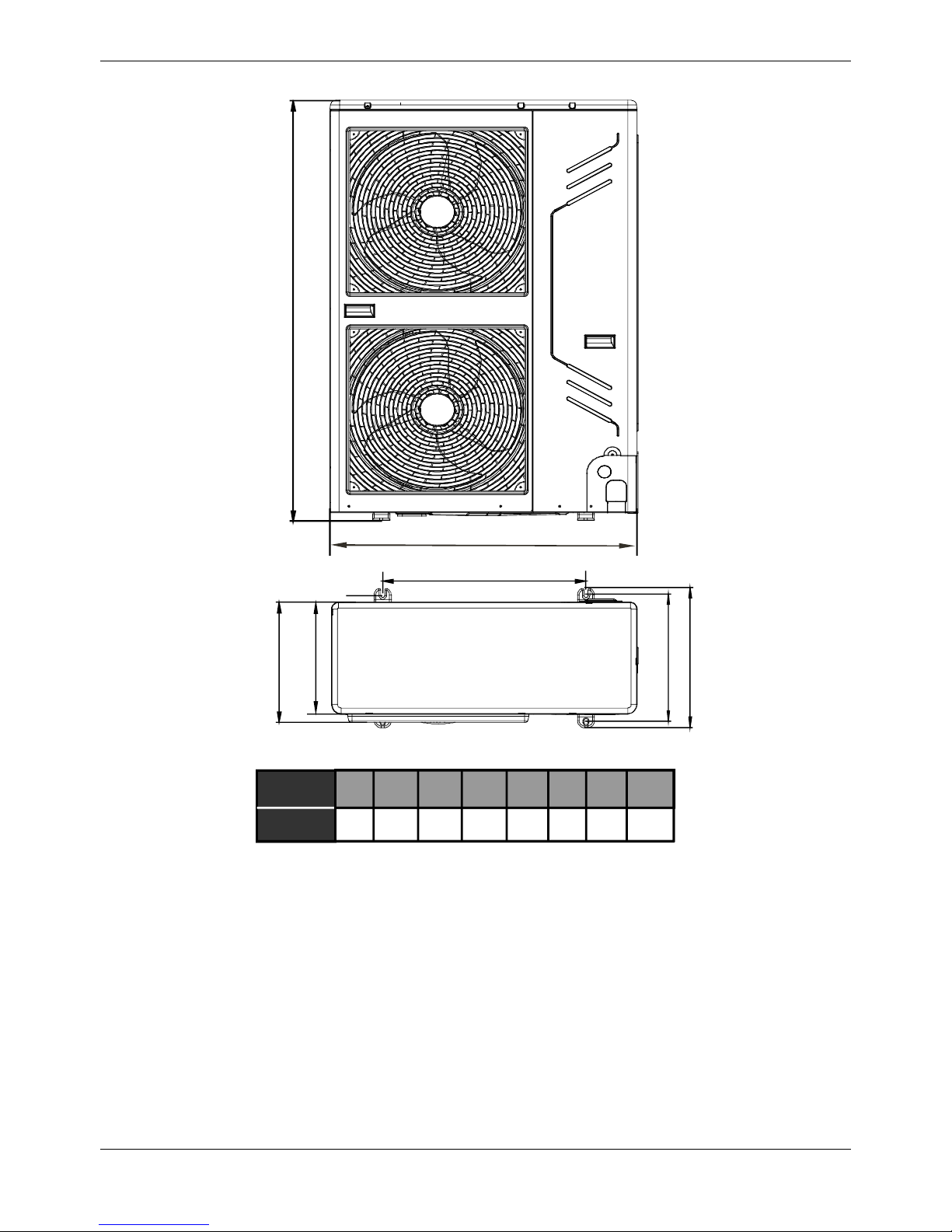

2. Dimensions

H

A

B

C

D

E

F

MODEL

(kW)

900 600 360400 1327

(unit:mm)

348

12/14/

16/18

A

B E

D GFC

320

H

——

Page 18

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 15

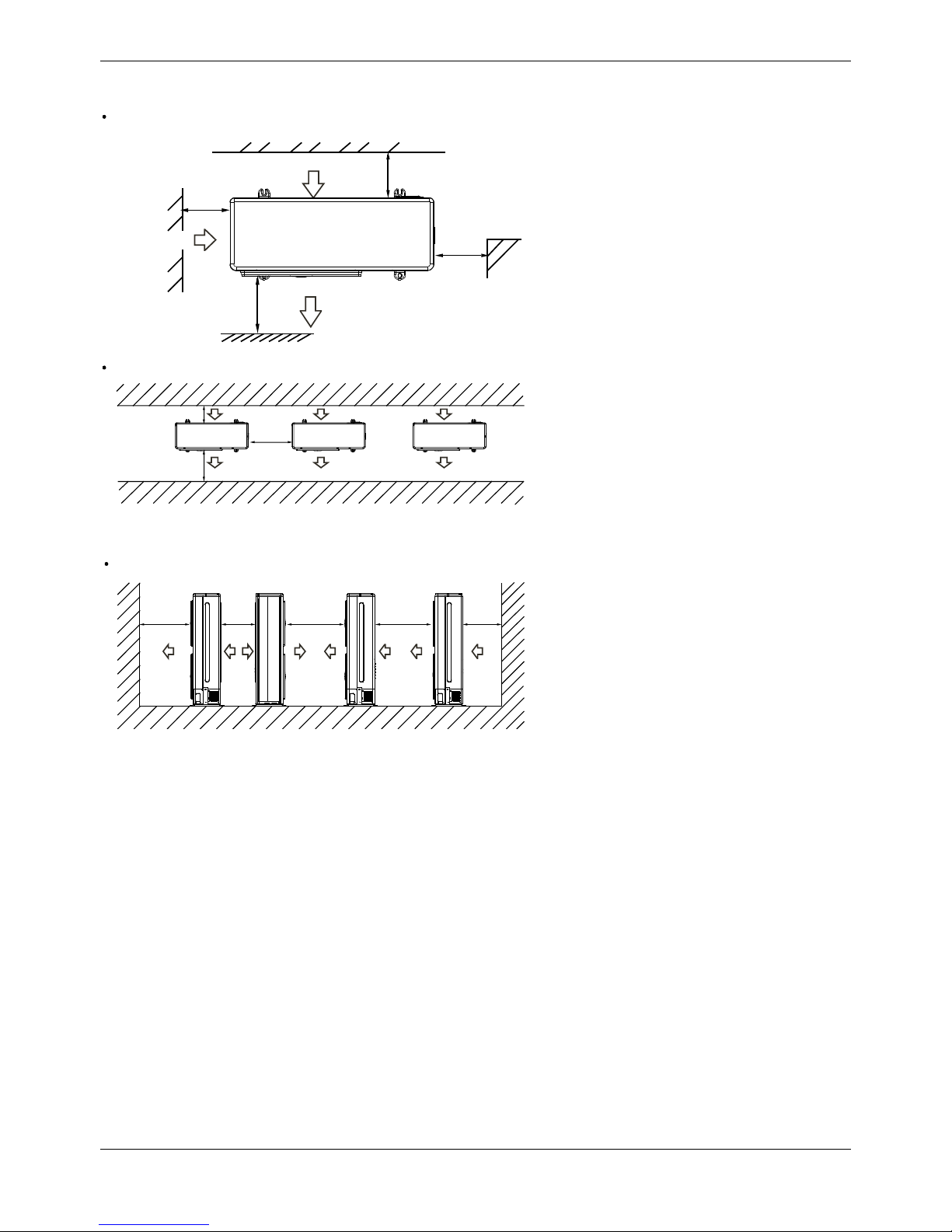

3. Service Space

>300

>600

>300

>

2000

(Wall or obstacle)

Maintain

channel

Air outlet

Air inlet

Air inlet

Single unit installation

>600

>2000

>300

Parallel connect the two units or above

>2000 >500 >3000 >3000 >300

Parallel connect the front with rear sides

Page 19

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

16 Specifications&Performance

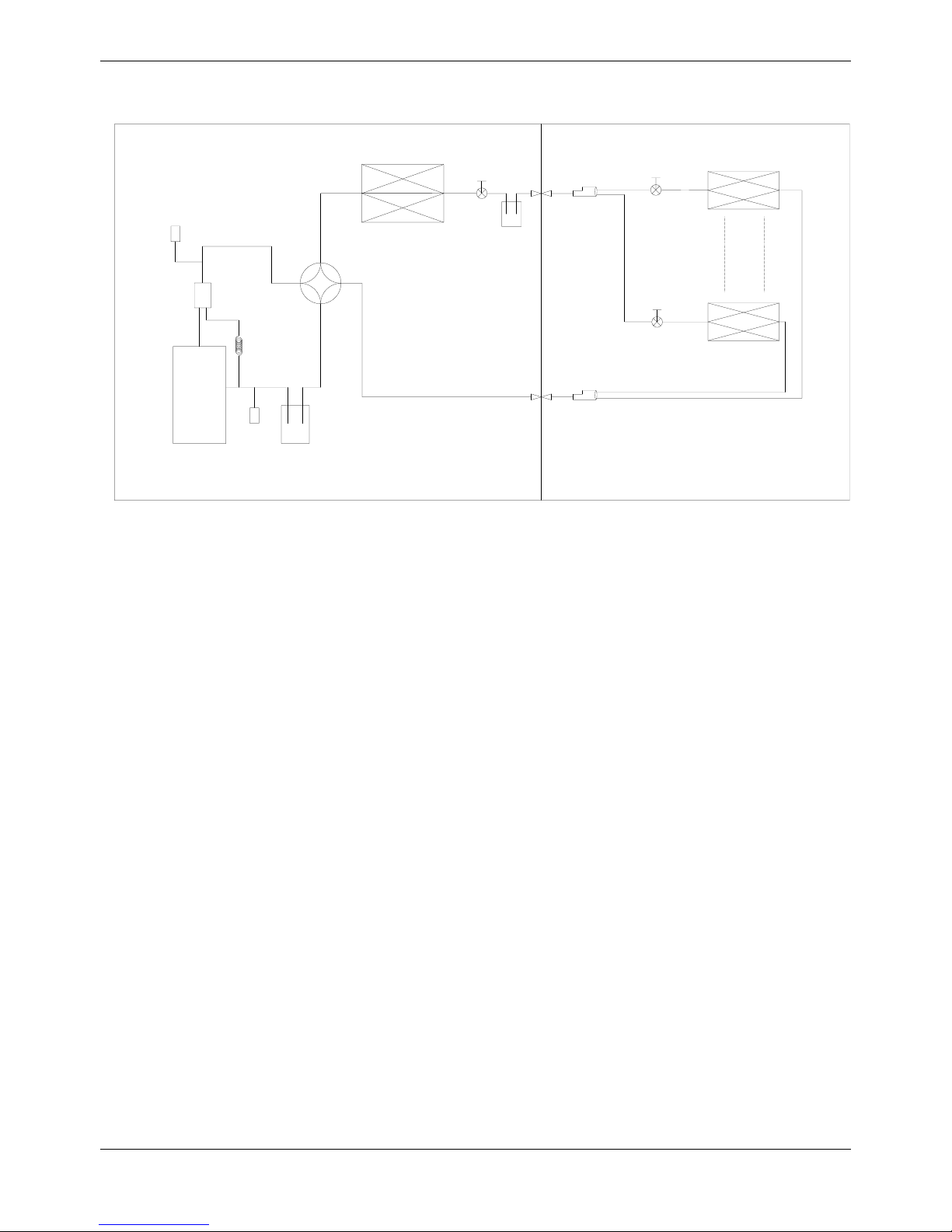

4. Piping Diagrams

High pressure

switch

Oil seperator

Oil return

capilary

Compressor

Low pressure

switch

Low pressure

liquid

accumulator can

Condensor

High pressure

liquid

accumulator

can

Electronic

expansion

valve

Electronic

expansion

valve

Evaporator

Oil separator: used to separate oil from high pressure & temperature gas refrigerant, which is pumped out

from compressor. It makes the oil return back to each compressor very soon.

Low pressure liquid receiver & High pressure liquid receiver: It is used to store the liquid refrigerant and

oil; it can protect the compressor from liquid hammer.

4-way valve: Closed in cooling mode and open in heating mode

Electronic expansion valve: The opening is of the valve is regulated according to the discharge air

temperature of compressor, used to regulating refrigerant flow.

High Pressure Switch: When the discharge pressure of compressor is 4.2Mpa or higher, the protection

switch will be triggered, and if the discharge pressure is down to 3.3MPa, the protection switch will be

recovered.

Low Pressure Switch: When thegas pressureback to compressor is 0.14Mpa or lower, the protection switch

will be triggered, and if the discharge pressure is down to 0.3MPa, the protection switch will be recovered.

Page 20

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 17

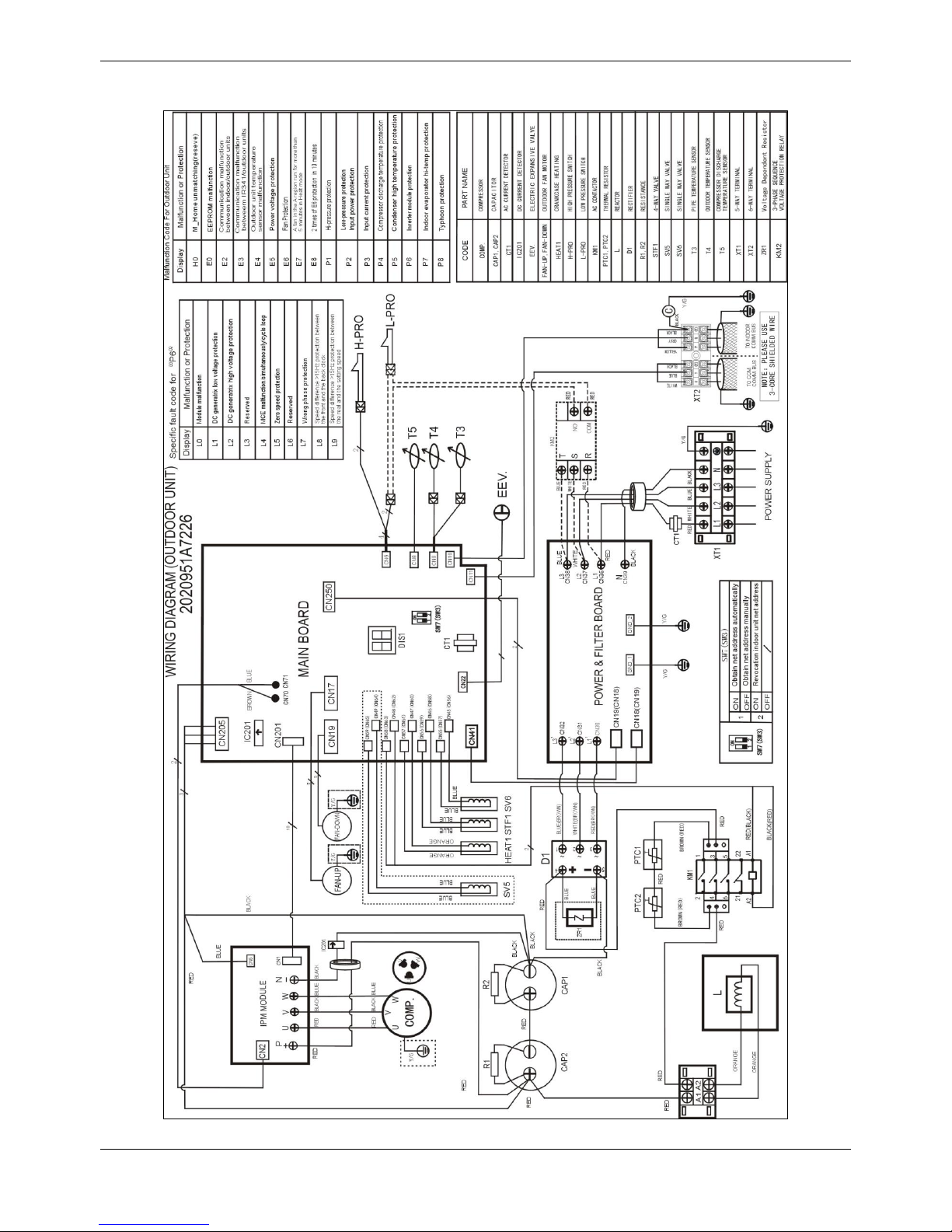

5. Wiring Diagrams(For 12-16kW)

Page 21

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

18 Specifications&Performance

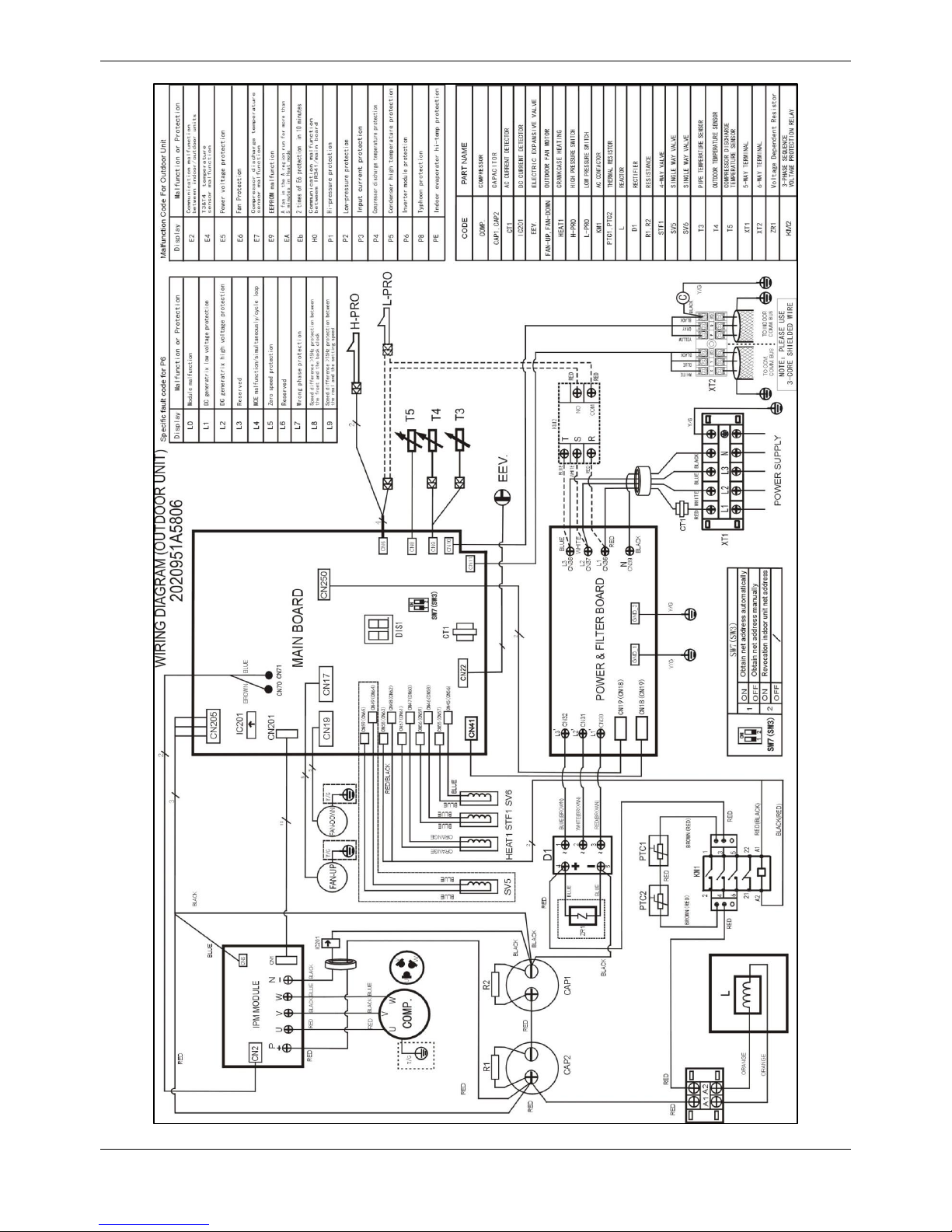

For 18kW

Page 22

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 19

6. Field Wiring

Page 23

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

20 Specifications&Performance

7. Capacity Tables

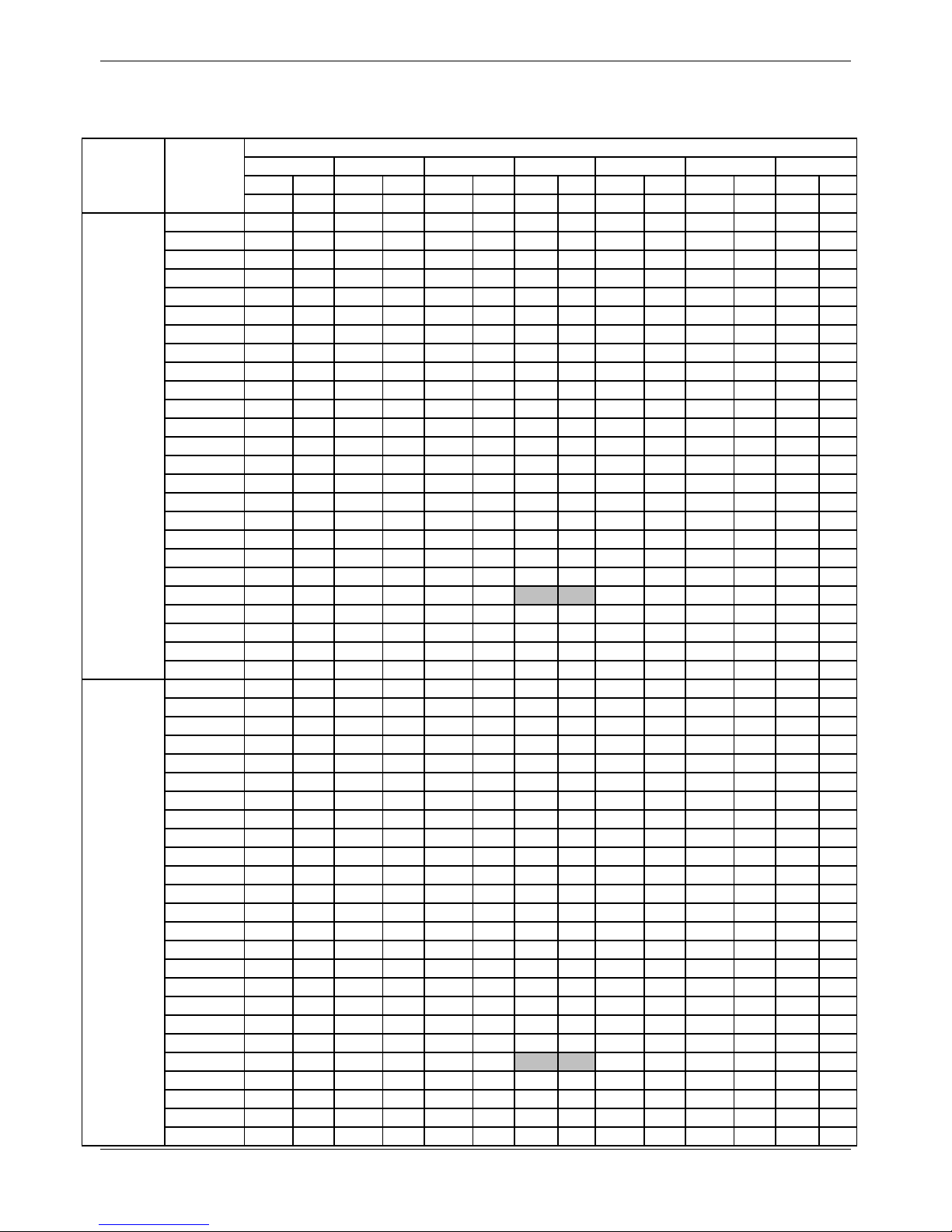

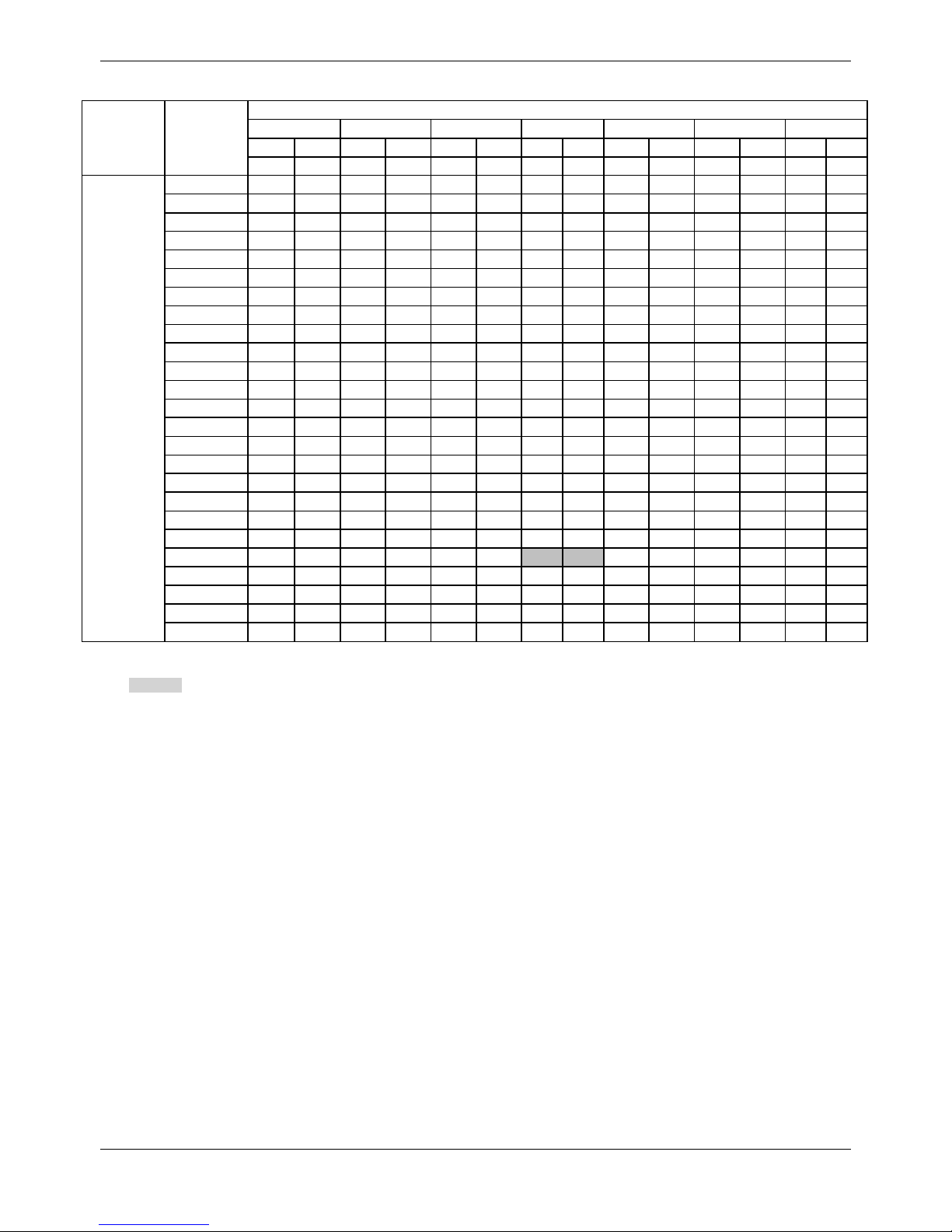

MDV-V120W/DRN1

Cooling TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination

(%)

(Capacity

index)

Outdoor

temperature

(°C DB)

Indoor temperature(°C DB/WB)

DB:20.8,WB:1

DB:23.3,WB:1

DB:25.8,WB:1

DB:27,WB:1

DB:28.2,WB:2

DB:30.7,WB:2

DB:32,WB:2

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

130%

-5

10.81

1.33

12.87

1.62

14.93

1.74

15.51

1.81

16.25

1.86

16.65

2.02

17.07

2.04

-2

10.81

1.33

12.87

1.65

14.93

1.74

15.51

1.82

16.25

1.86

16.65

2.05

17.07

2.06 0 10.81

1.35

12.87

1.68

14.93

1.8

15.51

1.92

16.25

1.97

16.65

2.07

17.07

2.08 2 10.81

1.38

12.87

1.69

14.93

1.86

15.51

2.03

16.25

1.99

16.65

2.09

17.07

2.11 4 10.81

1.41

12.87

1.72

14.93

1.93

15.51

2.04

16.25

2.02

16.65

2.09

17.07

2.15 6 10.81

1.43

12.87

1.75

14.93

2

15.51

2.05

16.07

2.08

16.44

2.09

16.88

2.17 8 10.81

1.47

12.87

1.79

14.93

2.1

15.51

2.15

15.87

2.15

16.27

3.9

16.66

2.19

10

10.81

1.5

12.87

1.83

14.93

2.18

15.51

2.23

15.68

4.04

16.08

4.06

16.47

2.25

12

10.81

1.52

12.87

1.87

14.93

2.22

15.29

4.03

15.51

4.06

15.86

4.07

16.25

2.27

14

10.81

1.56

12.87

1.9

14.89

4.05

15.11

4.06

15.29

4.08

15.68

4.09

16.08

2.32

16

10.81

1.58

12.87

1.94

14.72

4.06

14.89

4.08

15.07

4.1

15.46

4.12

15.86

2.36

18

10.81

1.61

12.87

1.98

14.5

2.32

14.67

2.33

14.89

2.35

15.29

2.37

15.68

2.39

20

10.81

1.65

12.87

2.11

14.28

2.44

14.5

2.45

14.67

2.46

15.07

2.48

15.46

2.51

21

10.81

1.69

12.87

2.18

14.19

2.49

14.41

2.51

14.58

2.52

14.98

2.55

15.37

2.57

23

10.81

1.81

12.87

2.34

14.01

2.61

14.19

2.62

14.36

2.63

14.76

2.66

15.15

2.69

25

10.81

1.94

12.87

2.51

13.79

2.72

13.97

2.73

14.19

2.75

14.58

2.78

14.98

2.8

27

10.81

2.07

12.87

2.68

13.62

2.83

13.79

2.85

13.97

2.86

14.36

2.9

14.76

2.93

29

10.81

2.21

12.87

2.86

13.4

2.95

13.57

2.97

13.79

2.98

14.19

3.01

14.58

3.04

31

10.81

2.36

12.83

3.03

13.18

3.07

13.4

3.08

13.57

3.1

13.97

3.13

14.36

3.17

33

10.81

2.51

12.61

3.15

13

3.18

13.18

3.2

13.4

3.22

13.79

3.25

14.14

3.29

35

10.81

2.68

12.39

3.26

12.78

3.3

13

3.32

13.18

3.33

13.57

3.37

13.97

3.41

37

10.81

2.85

12.21

3.38

12.61

3.42

12.78

3.43

13

3.46

13.35

3.5

13.75

3.54

39

10.81

3.03

11.99

3.41

12.39

3.53

12.61

3.55

12.78

3.57

13.18

3.61

13.57

3.66

41

10.81

3.19

11.87

3.45

12.26

3.56

12.48

3.59

12.65

3.61

13.05

3.62

13.05

3.69

43

10.81

3.27

11.78

3.46

12.19

3.57

12.41

3.6

12.52

3.61

12.81

3.63

12.9

3.7

120%

-5

9.97

1.28

11.86

1.55

13.79

1.84

14.76 2 15.46

2.09

15.81

2.16

16.17

2.21

-2

9.97

1.3

11.86

1.57

13.79

1.86

14.76

2.02

15.46

2.11

15.81

2.17

16.17

2.22 0 9.97

1.31

11.86

1.58

13.79

1.88

14.76

2.02

15.46

2.13

15.81

2.19

16.17

2.23 2 9.97

1.31

11.86

1.6

13.79

1.89

14.76

2.04

15.46

2.14

15.81

2.2

16.17

2.23 4 9.97

1.32

11.86

1.62

13.79

1.92

14.76

2.06

15.46

2.17

15.81

2.21

16.17

2.24 6 9.97

1.34

11.86

1.63

13.79

1.94

14.76

2.08

15.46

2.19

15.81

2.23

16.17

2.24 8 9.97

1.35

11.86

1.65

13.79

1.97

14.76

2.11

15.46

2.22

15.81

2.23

16.17

2.25

10

9.97

1.37

11.86

1.67

13.79

1.98

14.76

2.15

15.46

2.22

15.81

2.24

16.17

2.26

12

9.97

1.39

11.86

1.7

13.79

2.02

14.76

2.19

15.24

2.23

15.59

2.23

15.95

2.28

14

9.97

1.42

11.86

1.73

13.79

2.06

14.76

2.23

15.02

2.24

15.42

2.26

15.77

2.31

16

9.97

1.45

11.86

1.77

13.79

2.1

14.67

4.1

14.85

2.27

15.2

2.3

15.55

2.34

18

9.97

1.47

11.86

1.8

13.79

2.17

14.45

2.32

14.63

2.33

14.98

2.35

15.37

2.37

20

9.97

1.5

11.86

1.87

13.79

2.34

14.28

2.44

14.45

2.44

14.8

2.47

15.16

2.49

21

9.97

1.52

11.86

1.94

13.79

2.42

14.14

2.49

14.32

2.5

14.72

2.52

15.07

2.55

23

9.97

1.62

11.86

2.08

13.79

2.59

13.97

2.6

14.14

2.62

14.5

2.64

14.85

2.66

25

9.97

1.73

11.86

2.23

13.57

2.71

13.75

2.72

13.93

2.73

14.32

2.75

14.67

2.78

27

9.97

1.85

11.86

2.38

13.4

2.82

13.57

2.83

13.75

2.85

14.1

2.87

14.45

2.9

29

9.97

1.97

11.86

2.54

13.18

2.93

13.35

2.95

13.53

2.96

13.88

2.99

14.28

3.02

31

9.97

2.1

11.86

2.71

12.96

3.05

13.18

3.06

13.35

3.08

13.71

3.11

14.06

3.14

33

9.97

2.24

11.86

2.89

12.78

3.16

12.96

3.18

13.13

3.19

13.49

3.23

13.84

3.26

35

9.97

2.38

11.86

3.08

12.56

3.28

12.74

3.29

12.96

3.31

13.31

3.35

13.66

3.38

37

9.97

2.54

11.86

3.28

12.39

3.39

12.56

3.41

12.74

3.43

13.09

3.46

13.44

3.5

39

9.97

2.7

11.82

3.47

12.17

3.51

12.34

3.53

12.52

3.55

12.91

3.59

13.27

3.62

41

9.97

2.77

11.72

3.49

12.07

3.53

12.25

3.56

12.42

3.57

12.82

3.6

12.88

3.65

43

9.97

2.81

11.66

3.52

11.98

3.55

12.15

3.57

12.33

3.59

12.6

3.61

12.68

3.72

Page 24

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 21

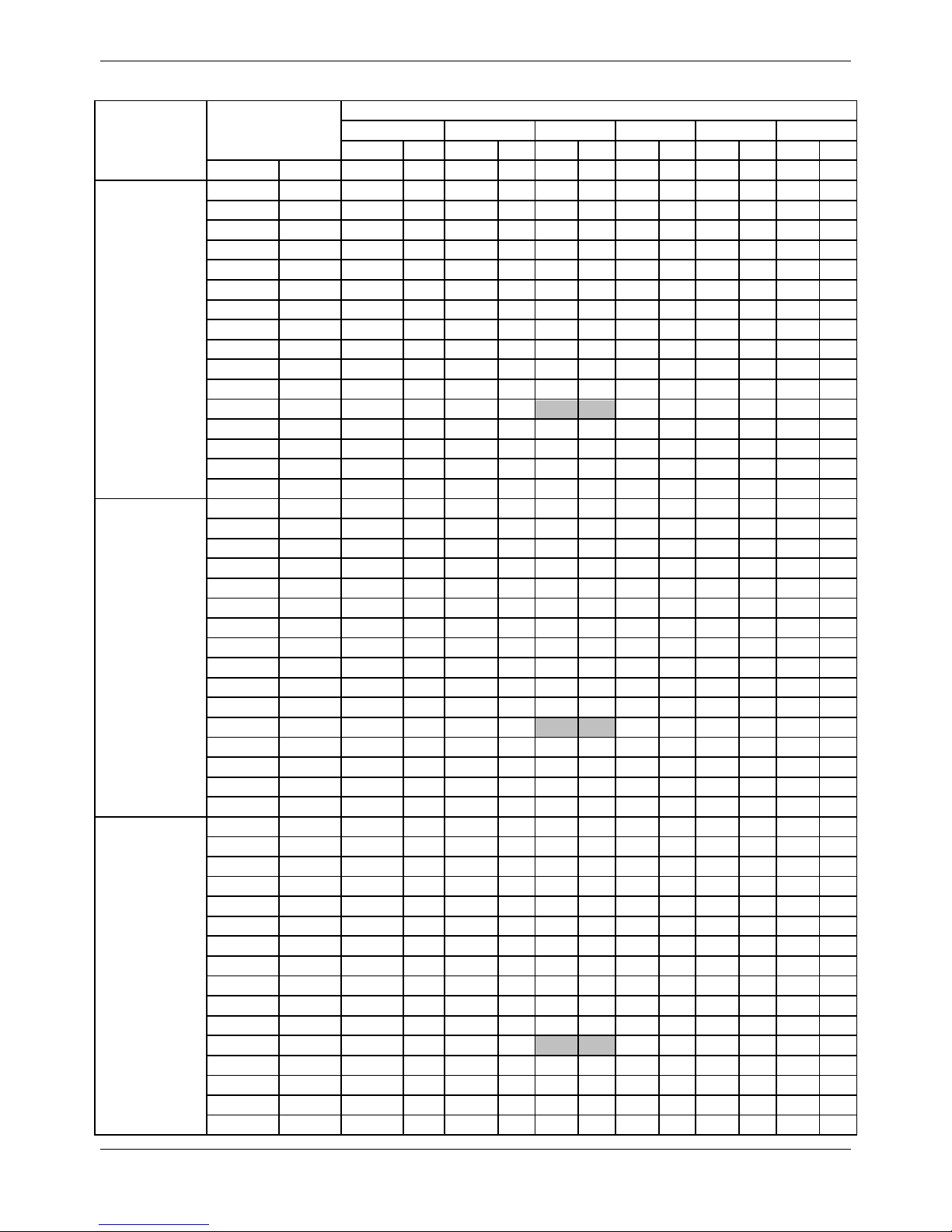

MDV-V120W/DRN1

Cooling TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination

(%)

(Capacity

index)

Outdoor

temperature

(°C DB)

Indoor temperature(°C DB/WB)

DB:20.8,WB:1

DB:23.3,WB:1

DB:25.8,WB:1

DB:27,WB:1

DB:28.2,WB:2

DB:30.7,WB:2

DB:32,WB:2

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

110%

-5

9.14

1.12

10.9

1.39

12.65

1.66

13.53

1.79

14.41

1.92

15.51

2

15.86

2.06

-2

9.14

1.14

10.9

1.41

12.65

1.68

13.53

1.8

14.41

1.94

15.51

2.02

15.86

2.07 0 9.14

1.15

10.9

1.42

12.65

1.69

13.53

1.82

14.41

1.96

15.51

2.04

15.86

2.09 2 9.14

1.18

10.9

1.43

12.65

1.72

13.53

1.84

14.41

1.98

15.51

2.07

15.86

2.12

4

9.14

1.2

10.9

1.45

12.65

1.73

13.53

1.86

14.41

2.01

15.51

2.09

15.86

2.14

6

9.14

1.21

10.9

1.47

12.65

1.75

13.53

1.89

14.41

2.03

15.51

2.12

15.86

2.17 8 9.14

1.23

10.9

1.49

12.65

1.77

13.53

1.91

14.41

2.06

15.51

2.13

15.86

2.2

10

9.14

1.24

10.9

1.51

12.65

1.8

13.53

1.94

14.41

2.09

15.51

2.15

15.86

2.21

12

9.14

1.27

10.9

1.54

12.65

1.83

13.53

1.98

14.41

2.13

15.33

2.18

15.64

2.24

14

9.14

1.29

10.9

1.57

12.65

1.87

13.53

2.01

14.41

2.17

15.11

2.19

15.46

2.26

16

9.14

1.31

10.9

1.6

12.65

1.9

13.53

2.05

14.41

2.21

14.94

2.22

15.24

2.28

18

9.14

1.34

10.9

1.63

12.65

1.94

13.53

2.11

14.41

2.32

14.72

2.33

15.07

2.36

20

9.14

1.36

10.9

1.66

12.65

2.05

13.53

2.27

14.19

2.43

14.54

2.45

14.85

2.47

21

9.14

1.38

10.9

1.71

12.65

2.13

13.53

2.35

14.1

2.49

14.41

2.51

14.76

2.53

23

9.14

1.44

10.9

1.84

12.65

2.28

13.53

2.52

13.88

2.6

14.23

2.62

14.54

2.65

25

9.14

1.54

10.9

1.96

12.65

2.44

13.53

2.7

13.71

2.71

14.01

2.74

14.36

2.76

27

9.14

1.64

10.9

2.1

12.65

2.61

13.31

2.82

13.49

2.83

13.84

2.85

14.15

2.88

29

9.14

1.75

10.9

2.24

12.65

2.79

13.13

2.93

13.31

2.94

13.62

2.97

13.97 3 31

9.14

1.86

10.9

2.39

12.65

2.98

12.92

3.04

13.09

3.06

13.44

3.08

13.75

3.11

33

9.14

1.98

10.9

2.55

12.56

3.14

12.74

3.16

12.92

3.17

13.22

3.2

13.57

3.23

35

9.14

2.11

10.9

2.71

12.34

3.25

12.52

3.27

12.7

3.29

13

3.32

13.36

3.35

37

9.14

2.24

10.9

2.89

12.17

3.37

12.34

3.39

12.48

3.4

12.83

3.44

13.13

3.47

39

9.14

2.38

10.9

3.08

11.95

3.49

12.12

3.5

12.3

3.52

12.61

3.56

12.96

3.59

41

9.14

2.41

10.9

3.1

11.86

3.51

12.03

3.53

12.21

3.55

12.45

3.58

12.57

3.62

43

9.14

2.43

10.9

3.14

11.76

3.54

11.94

3.55

12.11

3.57

12.34

3.59

12.38

3.69

100%

-5

8.3

1.02

9.88

1.23

11.51

1.46

12.3

1.57

13.09

1.7

14.72

1.94

15.55

2.02

-2

8.3

1.03

9.88

1.24

11.51

1.48

12.3

1.6

13.09

1.72

14.72

1.96

15.55

2.03 0 8.3

1.04

9.88

1.26

11.51

1.5

12.3

1.62

13.09

1.74

14.72

1.99

15.55

2.06

2

8.3

1.06

9.88

1.27

11.51

1.51

12.3

1.64

13.09

1.76

14.72

2.02

15.55

2.09

4

8.3

1.07

9.88

1.29

11.51

1.53

12.3

1.66

13.09

1.78

14.72

2.04

15.55

2.11 6 8.3

1.09

9.88

1.31

11.51

1.55

12.3

1.69

13.09

1.81

14.72

2.07

15.55

2.15 8 8.3

1.11

9.88

1.33

11.51

1.58

12.3

1.71

13.09

1.84

14.72

2.1

15.55

2.18

10

8.3

1.12

9.88

1.36

11.51

1.61

12.3

1.74

13.09

1.87

14.72

2.14

15.55

2.21

12

8.3

1.14

9.88

1.38

11.51

1.64

12.3

1.77

13.09

1.91

14.72

2.18

15.33

2.23

14

8.3

1.16

9.88

1.41

11.51

1.67

12.3

1.8

13.09

1.94

14.72

2.22

15.15

2.26

16

8.3

1.18

9.88

1.44

11.51

1.7

12.3

1.84

13.09

1.98

14.63

2.25

14.94

2.28

18

8.3

1.2

9.88

1.46

11.51

1.73

12.3

1.87

13.09

2.02

14.45

2.32

14.76

2.34

20

8.3

1.23

9.88

1.49

11.51

1.79

12.3

1.97

13.09

2.16

14.23

2.43

14.54

2.45

21

8.3

1.24

9.88

1.51

11.51

1.85

12.3

2.04

13.09

2.24

14.15

2.49

14.45

2.51

23

8.3

1.27

9.88

1.61

11.51

1.98

12.3

2.19

13.09

2.4

13.97

2.6

14.23

2.62

25

8.3

1.35

9.88

1.72

11.51

2.12

12.3

2.34

13.09

2.57

13.75

2.72

14.06

2.74

27

8.3

1.45

9.88

1.83

11.51

2.27

12.3

2.51

13.09

2.75

13.53

2.83

13.84

2.86

29

8.3

1.54

9.88

1.95

11.51

2.42

12.3

2.68

13.05

2.92

13.35

2.95

13.66

2.97

31

8.3

1.64

9.88

2.08

11.51

2.58

12.3

2.86

12.87

3.04

13.14

3.06

13.44

3.09

33

8.3

1.74

9.88

2.22

11.51

2.76

12.3

3.05

12.65

3.15

12.96

3.18

13.27

3.21

35

8.3

1.85

9.88

2.36

11.51

2.94

12.3

3.25

12.43

3.26

12.74

3.29

13.05

3.32

37

8.3

1.97

9.88

2.51

11.51

3.13

12.08

3.36

12.26

3.38

12.56

3.41

12.83

3.44

39

8.3

2.09

9.88

2.67

11.51

3.33

11.9

3.48

12.04

3.5

12.34

3.53

12.65

3.56

41

8.3

2.19

9.88

2.77

11.51

3.46

11.72

3.5

11.94

3.55

12.13

3.61

12.47

3.63

43

8.3

2.28

9.88

2.87

11.51

3.52

11.53

3.54

11.86

3.58

12.2

3.63

12.25

3.67

Page 25

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

22 Specifications&Performance

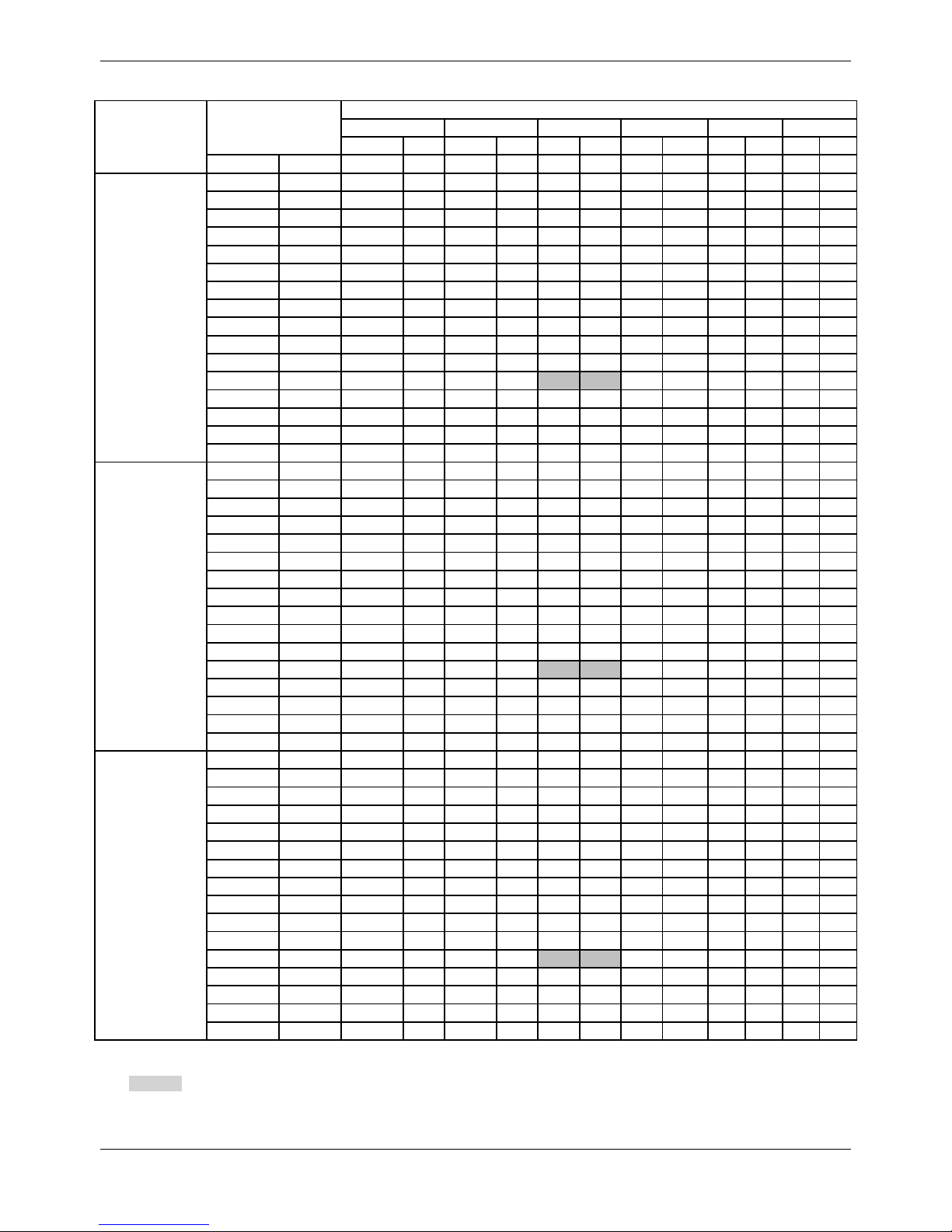

MDV-V120W/DRN1

Cooling TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination

(%)

(Capacity

index)

Outdoor

temperature

(°C DB)

Indoor temperature(°C DB/WB)

DB:20.8,WB:1

DB:23.3,WB:1

DB:25.8,WB:1

DB:27,WB:1

DB:28.2,WB:2

DB:30.7,WB:2

DB:32,WB:2

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

90%

-5

7.47

0.9

8.92

1.08

10.37

1.28

11.07

1.39

11.77

1.48

13.22

1.7

14.67

1.95

-2

7.47

0.91

8.92

1.09

10.37

1.29

11.07

1.41

11.77

1.5

13.22

1.72

14.67

1.97 0 7.47

0.92

8.92

1.11

10.37

1.31

11.07

1.43

11.77

1.52

13.22

1.74

14.67

1.99 2 7.47

0.94

8.92

1.12

10.37

1.33

11.07

1.45

11.77

1.54

13.22

1.78

14.67

2.02

4

7.47

0.95

8.92

1.14

10.37

1.35

11.07

1.47

11.77

1.56

13.22

1.8

14.67

2.05

6

7.47

0.97

8.92

1.16

10.37

1.37

11.07

1.5

11.77

1.59

13.22

1.83

14.67

2.08 8 7.47

0.98

8.92

1.18

10.37

1.4

11.07

1.52

11.77

1.62

13.22

1.87

14.67

2.1

10

7.47 1 8.92

1.21

10.37

1.43

11.07

1.54

11.77

1.66

13.22

1.89

14.67

2.13

12

7.47

1.02

8.92

1.23

10.37

1.45

11.07

1.57

11.77

1.69

13.22

1.93

14.67

2.17

14

7.47

1.04

8.92

1.25

10.37

1.48

11.07

1.6

11.77

1.72

13.22

1.96

14.67

2.21

16

7.47

1.06

8.92

1.27

10.37

1.51

11.07

1.63

11.77

1.75

13.22

2

14.63

2.25

18

7.47

1.07

8.92

1.3

10.37

1.54

11.07

1.66

11.77

1.79

13.22

2.04

14.45

2.32

20

7.47

1.09

8.92

1.33

10.37

1.57

11.07

1.69

11.77

1.85

13.22

2.19

14.23

2.43

21

7.47

1.1

8.92

1.34

10.37

1.59

11.07

1.75

11.77

1.92

13.22

2.27

14.15

2.49

23

7.47

1.13

8.92

1.39

10.37

1.71

11.07

1.88

11.77

2.06

13.22

2.44

13.92

2.6

25

7.47

1.19

8.92

1.49

10.37

1.83

11.07

2.01

11.77

2.2

13.22

2.61

13.75

2.72

27

7.47

1.26

8.92

1.59

10.37

1.95

11.07

2.15

11.77

2.35

13.22

2.79

13.53

2.83

29

7.47

1.34

8.92

1.69

10.37

2.08

11.07

2.29

11.77

2.51

13.09

2.92

13.35

2.94

31

7.47

1.43

8.92

1.8

10.37

2.22

11.07

2.44

11.77

2.68

12.87

3.04

13.13

3.06

33

7.47

1.52

8.92

1.91

10.37

2.37

11.07

2.61

11.77

2.86

12.7

3.15

12.96

3.18

35

7.47

1.61

8.92

2.04

10.37

2.52

11.07

2.78

11.77

3.05

12.48

3.27

12.74

3.29

37

7.47

1.71

8.92

2.16

10.37

2.68

11.07

2.96

11.77

3.25

12.26

3.38

12.56

3.41

39

7.47

1.81

8.92

2.3

10.37

2.85

11.07

3.15

11.77

3.46

12.08

3.5

12.34

3.53

41

7.47

1.88

8.92

2.41

10.37

2.96

11.07

3.23

11.77

3.48

12

3.59

12.26

3.61

43

7.47

1.97

8.92

2.51

10.37

3.06

11.07

3.32

11.77

3.56

11.93

3.64

12.16

3.66

80%

-5

6.63

0.8

7.91

0.94

9.18

1.11

9.84

1.18

10.5

1.27

11.77

1.47

13.05

1.68

-2

6.63

0.81

7.91

0.95

9.18

1.12

9.84

1.2

10.5

1.29

11.77

1.49

13.05

1.7 0 6.63

0.82

7.91

0.96

9.18

1.14

9.84

1.22

10.5

1.31

11.77

1.51

13.05

1.72

2

6.63

0.84

7.91

0.98

9.18

1.15

9.84

1.24

10.5

1.33

11.77

1.54

13.05

1.75

4

6.63

0.85

7.91

0.99

9.18

1.17

9.84

1.27

10.5

1.36

11.77

1.57

13.05

1.78 6 6.63

0.87

7.91

1.02

9.18

1.19

9.84

1.3

10.5

1.38

11.77

1.59

13.05

1.81 8 6.63

0.88

7.91

1.04

9.18

1.22

9.84

1.32

10.5

1.41

11.77

1.61

13.05

1.84

10

6.63

0.89

7.91

1.06

9.18

1.25

9.84

1.35

10.5

1.45

11.77

1.65

13.05

1.86

12

6.63

0.9

7.91

1.08

9.18

1.27

9.84

1.38

10.5

1.48

11.77

1.68

13.05

1.9

14

6.63

0.92

7.91

1.1

9.18

1.3

9.84

1.4

10.5

1.5

11.77

1.71

13.05

1.93

16

6.63

0.93

7.91

1.12

9.18

1.32

9.84

1.42

10.5

1.53

11.77

1.75

13.05

1.97

18

6.63

0.95

7.91

1.14

9.18

1.35

9.84

1.45

10.5

1.56

11.77

1.78

13.05

2.01

20

6.63

0.97

7.91

1.17

9.18

1.38

9.84

1.48

10.5

1.59

11.77

1.85

13.05

2.15

21

6.63

0.98

7.91

1.17

9.18

1.39

9.84

1.5

10.5

1.63

11.77

1.91

13.05

2.23

23

6.63

0.99

7.91

1.2

9.18

1.45

9.84

1.59

10.5

1.74

11.77

2.05

13.05

2.39

25

6.63

1.02

7.91

1.27

9.18

1.55

9.84

1.7

10.5

1.86

11.77

2.19

13.05

2.55

27

6.63

1.09

7.91

1.36

9.18

1.66

9.84

1.82

10.5

1.98

11.77

2.34

13.05

2.73

29

6.63

1.16

7.91

1.45

9.18

1.77

9.84

1.94

10.5

2.12

11.77

2.5

13.05

2.92

31

6.63

1.23

7.91

1.54

9.18

1.88

9.84

2.06

10.5

2.26

11.77

2.67

12.83

3.04

33

6.63

1.31

7.91

1.63

9.18 2 9.84

2.2

10.5

2.4

11.77

2.85

12.65

3.15

35

6.63

1.39

7.91

1.74

9.18

2.13

9.84

2.34

10.5

2.56

11.77

3.04

12.43

3.26

37

6.63

1.47

7.91

1.84

9.18

2.26

9.84

2.49

10.5

2.73

11.77

3.24

12.26

3.38

39

6.63

1.56

7.91

1.97

9.18

2.41

9.84

2.65

10.5

2.9

11.77

3.45

12.04

3.5

41

6.63

1.59

7.91

1.98

9.18

2.44

9.84

2.72

10.5

2.96

11.77

3.53

11.96

3.56

43

6.63

1.64

7.91 2 9.18

2.48

9.84

2.77

10.5 3 11.77

3.58

11.89

3.59

Page 26

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 23

MDV-V120W/DRN1

Cooling TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination

(%)

(Capacity

index)

Outdoor

temperature

(°C DB)

Indoor temperature(°C DB/WB)

DB:20.8,WB:1

DB:23.3,WB:1

DB:25.8,WB:1

DB:27,WB:1

DB:28.2,WB:2

DB:30.7,WB:2

DB:32,WB:2

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

70%

-5

5.8

0.71

6.94

0.83

8.04

0.94

8.61

1.01

9.18

1.08

10.28

1.23

11.42

1.42

-2

5.8

0.72

6.94

0.84

8.04

0.95

8.61

1.03

9.18

1.1

10.28

1.25

11.42

1.44 0 5.8

0.72

6.94

0.85

8.04

0.97

8.61

1.05

9.18

1.12

10.28

1.28

11.42

1.46 2 5.8

0.72

6.94

0.85

8.04

0.98

8.61

1.07

9.18

1.14

10.28

1.31

11.42

1.48

4

5.8

0.73

6.94

0.87

8.04

1.01

8.61

1.09

9.18

1.16

10.28

1.33

11.42

1.52

6

5.8

0.74

6.94

0.89

8.04

1.03

8.61

1.12

9.18

1.19

10.28

1.35

11.42

1.55 8 5.8

0.76

6.94

0.91

8.04

1.05

8.61

1.14

9.18

1.22

10.28

1.39

11.42

1.58

10

5.8

0.77

6.94

0.93

8.04

1.08

8.61

1.17

9.18

1.25

10.28

1.42

11.42

1.59

12

5.8

0.79

6.94

0.94

8.04

1.1

8.61

1.19

9.18

1.27

10.28

1.45

11.42

1.63

14

5.8

0.81

6.94

0.96

8.04

1.12

8.61

1.2

9.18

1.29

10.28

1.47

11.42

1.66

16

5.8

0.82

6.94

0.98

8.04

1.14

8.61

1.23

9.18

1.32

10.28

1.5

11.42

1.69

18

5.8

0.83

6.94

0.99

8.04

1.17

8.61

1.25

9.18

1.34

10.28

1.53

11.42

1.72

20

5.8

0.85

6.94

1.01

8.04

1.19

8.61

1.27

9.18

1.37

10.28

1.56

11.42

1.77

21

5.8

0.85

6.94

1.02

8.04

1.2

8.61

1.29

9.18

1.38

10.28

1.58

11.42

1.83

23

5.8

0.87

6.94

1.04

8.04

1.22

8.61

1.33

9.18

1.45

10.28

1.7

11.42

1.96

25

5.8

0.88

6.94

1.08

8.04

1.3

8.61

1.42

9.18

1.55

10.28

1.81

11.42

2.1

27

5.8

0.94

6.94

1.15

8.04

1.39

8.61

1.52

9.18

1.65

10.28

1.94

11.42

2.24

29

5.8

0.99

6.94

1.22

8.04

1.48

8.61

1.62

9.18

1.76

10.28

2.06

11.42

2.4

31

5.8

1.05

6.94

1.3

8.04

1.57

8.61

1.72

9.18

1.87

10.28

2.2

11.42

2.55

33

5.8

1.12

6.94

1.38

8.04

1.67

8.61

1.83

9.18

1.99

10.28

2.34

11.42

2.72

35

5.8

1.18

6.94

1.46

8.04

1.77

8.61

1.94

9.18

2.12

10.28

2.5

11.42

2.9

37

5.8

1.25

6.94

1.55

8.04

1.89

8.61

2.06

9.18

2.26

10.28

2.66

11.42

3.09

39

5.8

1.32

6.94

1.64

8.04 2 8.61

2.19

9.18

2.4

10.28

2.83

11.42

3.29

41

5.8

1.38

6.94

1.7

8.04

2.06

8.61

2.27

9.18

2.47

10.28

2.94

11.42

3.44

43

5.8

1.49

6.94

1.82

8.04

2.14

8.61

2.39

9.18

2.54

10.28

3.05

11.42

3.55

60%

-5

4.96

0.61

5.93

0.7

6.9

0.82

7.38

0.87

7.86

0.94

8.83

1.06

9.8

1.21

-2

4.96

0.61

5.93

0.71

6.9

0.83

7.38

0.88

7.86

0.95

8.83

1.07

9.8

1.22 0 4.96

0.62

5.93

0.72

6.9

0.84

7.38

0.9

7.86

0.97

8.83

1.09

9.8

1.24

2

4.96

0.63

5.93

0.74

6.9

0.86

7.38

0.91

7.86

0.98

8.83

1.11

9.8

1.25

4

4.96

0.65

5.93

0.75

6.9

0.88

7.38

0.92

7.86

0.99

8.83

1.13

9.8

1.27 6 4.96

0.65

5.93

0.77

6.9

0.89

7.38

0.94

7.86

1.01

8.83

1.15

9.8

1.3 8 4.96

0.67

5.93

0.78

6.9

0.91

7.38

0.96

7.86

1.04

8.83

1.17

9.8

1.32

10

4.96

0.68

5.93

0.8

6.9

0.92

7.38

0.99

7.86

1.06

8.83

1.2

9.8

1.34

12

4.96

0.69

5.93

0.81

6.9

0.94

7.38

1.01

7.86

1.07

8.83

1.22

9.8

1.36

14

4.96

0.7

5.93

0.82

6.9

0.95

7.38

1.02

7.86

1.09

8.83

1.24

9.8

1.39

16

4.96

0.71

5.93

0.84

6.9

0.97

7.38

1.04

7.86

1.11

8.83

1.26

9.8

1.41

18

4.96

0.72

5.93

0.85

6.9

0.99

7.38

1.06

7.86

1.13

8.83

1.28

9.8

1.44

20

4.96

0.73

5.93

0.87

6.9

1.01

7.38

1.08

7.86

1.16

8.83

1.31

9.8

1.47

21

4.96

0.74

5.93

0.87

6.9

1.02

7.38

1.09

7.86

1.16

8.83

1.32

9.8

1.48

23

4.96

0.75

5.93

0.89

6.9

1.03

7.38

1.11

7.86

1.19

8.83

1.38

9.8

1.58

25

4.96

0.76

5.93

0.9

6.9

1.07

7.38

1.16

7.86

1.26

8.83

1.47

9.8

1.69

27

4.96

0.79

5.93

0.96

6.9

1.14

7.38

1.24

7.86

1.34

8.83

1.56

9.8

1.8

29

4.96

0.84

5.93

1.02

6.9

1.22

7.38

1.32

7.86

1.43

8.83

1.67

9.8

1.92

31

4.96

0.89

5.93

1.08

6.9

1.29

7.38

1.41

7.86

1.52

8.83

1.77

9.8

2.05

33

4.96

0.94

5.93

1.14

6.9

1.37

7.38

1.49

7.86

1.62

8.83

1.89

9.8

2.18

35

4.96

0.99

5.93

1.21

6.9

1.45

7.38

1.59

7.86

1.72

8.83

2.01

9.8

2.32

37

4.96

1.05

5.93

1.28

6.9

1.54

7.38

1.68

7.86

1.83

8.83

2.14

9.8

2.47

39

4.96

1.11

5.93

1.36

6.9

1.63

7.38

1.78

7.86

1.94

8.83

2.27

9.8

2.63

41

4.96

1.14

5.93

1.42

6.9

1.69

7.38

1.85

7.86

2.01

8.83

2.38

9.8

2.75

43

4.96

1.18

5.93

1.48

6.9

1.75

7.38

1.91

7.86

2.08

8.83

2.48

9.8

2.87

Page 27

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

24 Specifications&Performance

MDV-V120W/DRN1

Cooling TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination

(%)

(Capacity

index)

Outdoor

temperature

(°C DB)

Indoor temperature(°C DB/WB)

DB:20.8,WB:14

DB:23.3,WB:1

DB:25.8,WB:1

DB:27,WB:1

DB:28.2,WB:2

DB:30.7,WB:2

DB:32,WB:2

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

50%

-5

4.15

0.53

4.96

0.61

5.75

0.7

6.15

0.73

6.55

0.77

7.34

0.88

8.17

0.95

-2

4.15

0.53

4.96

0.62

5.75

0.71

6.15

0.74

6.55

0.79

7.34

0.89

8.17

0.96 0 4.15

0.54

4.96

0.63

5.75

0.72

6.15

0.75

6.55

0.79

7.34

0.9

8.17

0.98 2 4.15

0.55

4.96

0.64

5.75

0.73

6.15

0.76

6.55

0.81

7.34

0.91

8.17

0.99

4

4.15

0.55

4.96

0.65

5.75

0.74

6.15

0.77

6.55

0.82

7.34

0.93

8.17

1.02

6

4.15

0.56

4.96

0.66

5.75

0.75

6.15

0.79

6.55

0.84

7.34

0.95

8.17

1.05 8 4.15

0.58

4.96

0.67

5.75

0.76

6.15

0.81

6.55

0.85

7.34

0.96

8.17

1.08

10

4.15

0.59

4.96

0.68

5.75

0.78

6.15

0.82

6.55

0.88

7.34

0.99

8.17

1.1

12

4.15

0.59

4.96

0.69

5.75

0.79

6.15

0.84

6.55

0.89

7.34 1 8.17

1.12

14

4.15

0.6

4.96

0.7

5.75

0.8

6.15

0.85

6.55

0.91

7.34

1.02

8.17

1.14

16

4.15

0.61

4.96

0.71

5.75

0.81

6.15

0.87

6.55

0.92

7.34

1.04

8.17

1.16

18

4.15

0.62

4.96

0.72

5.75

0.82

6.15

0.88

6.55

0.94

7.34

1.06

8.17

1.18

20

4.15

0.63

4.96

0.73

5.75

0.84

6.15

0.89

6.55

0.95

7.34

1.07

8.17

1.2

21

4.15

0.63

4.96

0.74

5.75

0.85

6.15

0.9

6.55

0.96

7.34

1.09

8.17

1.21

23

4.15

0.64

4.96

0.74

5.75

0.86

6.15

0.92

6.55

0.98

7.34

1.1

8.17

1.24

25

4.15

0.65

4.96

0.76

5.75

0.88

6.15

0.94

6.55

1.01

7.34

1.16

8.17

1.32

27

4.15

0.66

4.96

0.79

5.75

0.92

6.15 1 6.55

1.07

7.34

1.24

8.17

1.41

29

4.15

0.7

4.96

0.83

5.75

0.98

6.15

1.06

6.55

1.14

7.34

1.31

8.17

1.5

31

4.15

0.74

4.96

0.88

5.75

1.04

6.15

1.13

6.55

1.21

7.34

1.4

8.17

1.6

33

4.15

0.78

4.96

0.93

5.75

1.1

6.15

1.19

6.55

1.29

7.34

1.48

8.17

1.7

35

4.15

0.82

4.96

0.99

5.75

1.16

6.15

1.26

6.55

1.36

7.34

1.58

8.17

1.8

37

4.15

0.87

4.96

1.04

5.75

1.24

6.15

1.34

6.55

1.45

7.34

1.67

8.17

1.92

39

4.15

0.92

4.96

1.1

5.75

1.31

6.15

1.41

6.55

1.53

7.34

1.77

8.17

2.04

41

4.15

0.95

4.96

1.15

5.75

1.35

6.15

1.48

6.55

1.6

7.34

1.87

8.17

2.13

43

4.15

1.02

4.96

1.23

5.75

1.4

6.15

1.55

6.55

1.64

7.34

1.96

8.17

2.23

Note:

1. is tested under our standard condition.

2. In cooling mode, avoid running the unit when outdoor air temperature is above 43 degrees.

3. The above table shows the average value of conditions may operate.

4. It is recommended to connect less than 130%.

Page 28

MCAC-VTSM-2016-10 R410A All DC Inverter Mini VRF

Specifications&Performance 25

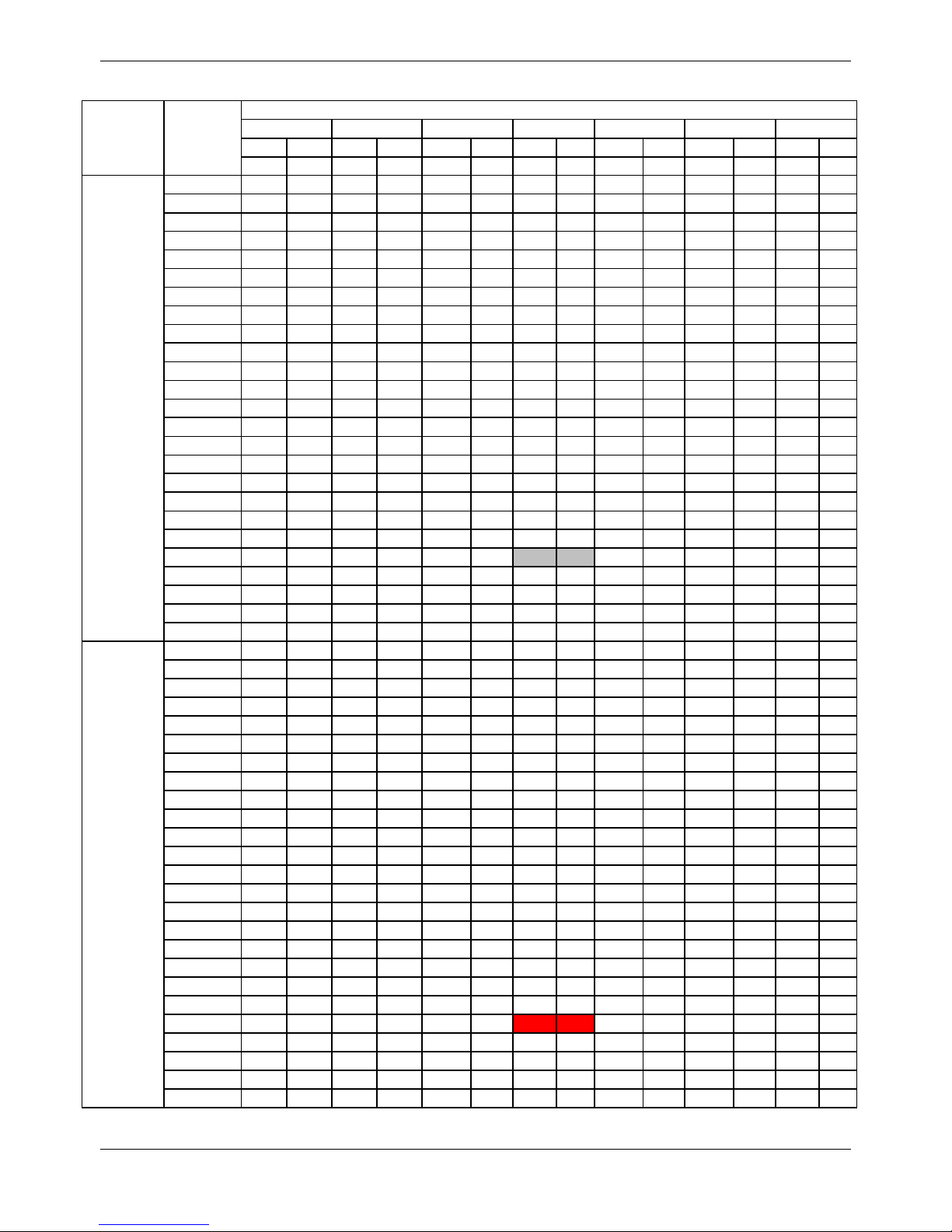

MDV-V120W/DRN1

Heating TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination (%)

(Capacity index)

Outdoor Air

temperature(°C DB)

Indoor temperature(°C WB)

16

18

20

21

22

24

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

°C DB

°C WB

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

130%

-13.7

-15

9.39

2.74

9.35

2.9

9.3

3.06

9.3

3.14

9.26

3.22

9.26

3.38

-11.8

-13

9.76

2.87

9.76

3.02

9.72

3.17

9.68

3.24

9.68

3.32

9.64

3.47

-9.8

-11

10.23

2.99

10.18

3.14

10.14

3.28

10.14

3.35

10.14

3.42

10.1

3.57

-9.5

-10

10.48

3.06

10.43

3.2

10.39

3.33

10.39

3.41

10.35

3.47

10.35

3.61

-8.5

-9.1

10.68

3.11

10.64

3.24

10.64

3.38

10.6

3.45

10.6

3.52

10.56

3.66

-7

-7.6

11.06

3.2

11.06

3.33

11.02

3.47

11.02

3.53

10.98

3.6

10.94

3.73

-5

-5.6

11.65

3.32

11.61

3.45

11.56

3.57

11.56

3.64

11.52

3.7

11.52

3.82

-3

-3.7

12.19

3.43

12.15

3.55

12.15

3.67

12.11

3.73

12.11

3.79

12.07

3.91

0

-0.7

13.16

3.6

13.16

3.71

13.12

3.82

13.12

3.86

13.07

3.93

13.07

4.04 3 2.2

14.2

3.74

14.16

3.85

14.12

3.95

14.12 4 14.12

4.06

14.08

4.16

5

4.1

14.92

3.84

14.88

3.94

14.88

4.03

14.83

4.08

14.83

4.13

14.79

4.23

7 6 15.67

3.93

15.63

4.02

15.63

4.11

15.59

4.16

15.59

4.2

14.96

4.04 9 7.9

16.47

4.01

16.43

4.1

16.43

4.19

16.39

4.23

16.05

4.14

14.96

3.79

11

9.8

17.31

4.09

17.27

4.17

17.18

4.23

16.59

4.06

16.05

3.89

14.96

3.57

13

11.8

18.23

4.17

18.19

4.25

17.18

3.96

16.59

3.8

16.05

3.65

14.96

3.35

15

13.7

19.11

4.24

18.27

4.02

17.18

3.73

16.59

3.59

16.05

3.44

14.96

3.16

120%

-13.7

-15

9.35

2.96

9.3

3.1

9.26

3.24

9.26

3.32

9.26

3.39

9.22

3.54

-11.8

-13

9.72

3.07

9.72

3.21

9.68

3.35

9.68

3.42

9.64

3.49

9.64

3.63

-9.8

-11

10.18

3.19

10.14

3.32

10.14

3.45

10.1

3.52

10.1

3.58

10.06

3.72

-9.5

-10

10.44

3.24

10.39

3.38

10.35

3.5

10.35

3.57

10.35

3.63

10.31

3.76

-8.5

-9.1

10.64

3.29

10.6

3.42

10.6

3.55

10.56

3.61

10.56

3.68

10.52

3.8

-7

-7.6

11.02

3.38

11.02

3.5

10.98

3.62

10.98

3.69

10.94

3.75

10.94

3.87

-5

-5.6

11.61

3.49

11.57

3.61

11.52

3.72

11.52

3.78

11.52

3.84

11.48

3.95

-3

-3.7

12.15

3.59

12.15

3.7

12.11

3.81

12.11

3.87

12.07

3.93

12.07

4.03 0 -0.7

13.12

3.75

13.12

3.85

13.07

3.95

13.07 4 13.03

4.05

13.03

4.16

3

2.2

14.16

3.88

14.12

3.98

14.12

4.07

14.08

4.12

14.08

4.17

13.79

4.15

5

4.1

14.88

3.97

14.83

4.06

14.83

4.15

14.79

4.2

14.79

4.24

13.79

3.89 7 6

15.63

4.05

15.63

4.14

15.59

4.22

15.34

4.16

14.83

3.99

13.79

3.66

9

7.9

16.43

4.13

16.39

4.21

15.84

4.07

15.34

3.91

14.83

3.75

13.79

3.45

11

9.8

17.27

4.2

16.85

4.13

15.84

3.83

15.34

3.68

14.83

3.53

13.79

3.25

13

11.8

17.89

4.16

16.85

3.88

15.84

3.59

15.34

3.46

14.83

3.32

13.79

3.06

15

13.7

17.89

3.92

16.85

3.65

15.84

3.39

15.34

3.26

14.83

3.13

13.79

2.88

110%

-13.7

-15

9.3

3.17

9.26

3.3

9.22

3.43

9.22

3.5

9.22

3.57

9.18

3.7

-11.8

-13

9.68

3.28

9.68

3.4

9.64

3.53

9.64

3.59

9.6

3.66

9.6

3.79

-9.8

-11

10.14

3.38

10.1

3.5

10.1

3.62

10.06

3.69

10.06

3.74

10.06

3.87

-9.5

-10

10.39

3.43

10.35

3.55

10.31

3.67

10.31

3.73

10.31

3.79

10.27

3.91

-8.5

-9.1

10.6

3.48

10.56

3.6

10.56

3.71

10.52

3.77

10.52

3.83

10.52

3.49

-7

-7.6

10.98

3.56

10.98

3.67

10.94

3.78

10.94

3.84

10.94

3.89

10.9

4.01

-5

-5.6

11.57

3.66

11.52

3.77

11.48

3.87

11.48

3.93

11.48

3.98

11.44

4.09

-3

-3.7

12.11

3.75

12.11

3.85

12.07

3.96

12.07

4.01

12.03

4.06

12.03

4.16

0

-0.7

13.07

3.89

13.07

3.99

13.03

4.08

13.03

4.13

13.03

4.18

12.66

4.1

3

2.2

14.12

4.02

14.08

4.11

14.08

4.2

14.04

4.24

13.58

4.07

12.66

3.73 5 4.1

14.83

4.1

14.83

4.19

14.54

4.15

14.04

3.98

13.58

3.82

12.66

3.51

7 6 15.59

4.18

15.46

4.2

14.54

3.89

14.04

3.74

13.58

3.59

12.66

3.3

9

7.9

16.38

4.25

15.46

3.95

14.54

3.66

14.04

3.52

13.58

3.38

12.66

3.11

11

9.8

16.38

3.99

15.46

3.72

14.54

3.45

14.04

3.32

13.58

3.19

12.66

2.93

13

11.8

16.38

3.74

15.46

3.49

14.54

3.24

14.04

3.12

13.58 3 12.66

2.76

15

13.7

16.38

3.33

15.46

3.29

14.54

3.06

14.04

2.94

13.58

2.83

12.66

2.61

Page 29

R410A All DC Inverter Mini VRF MCAC-VTSM-2016-10

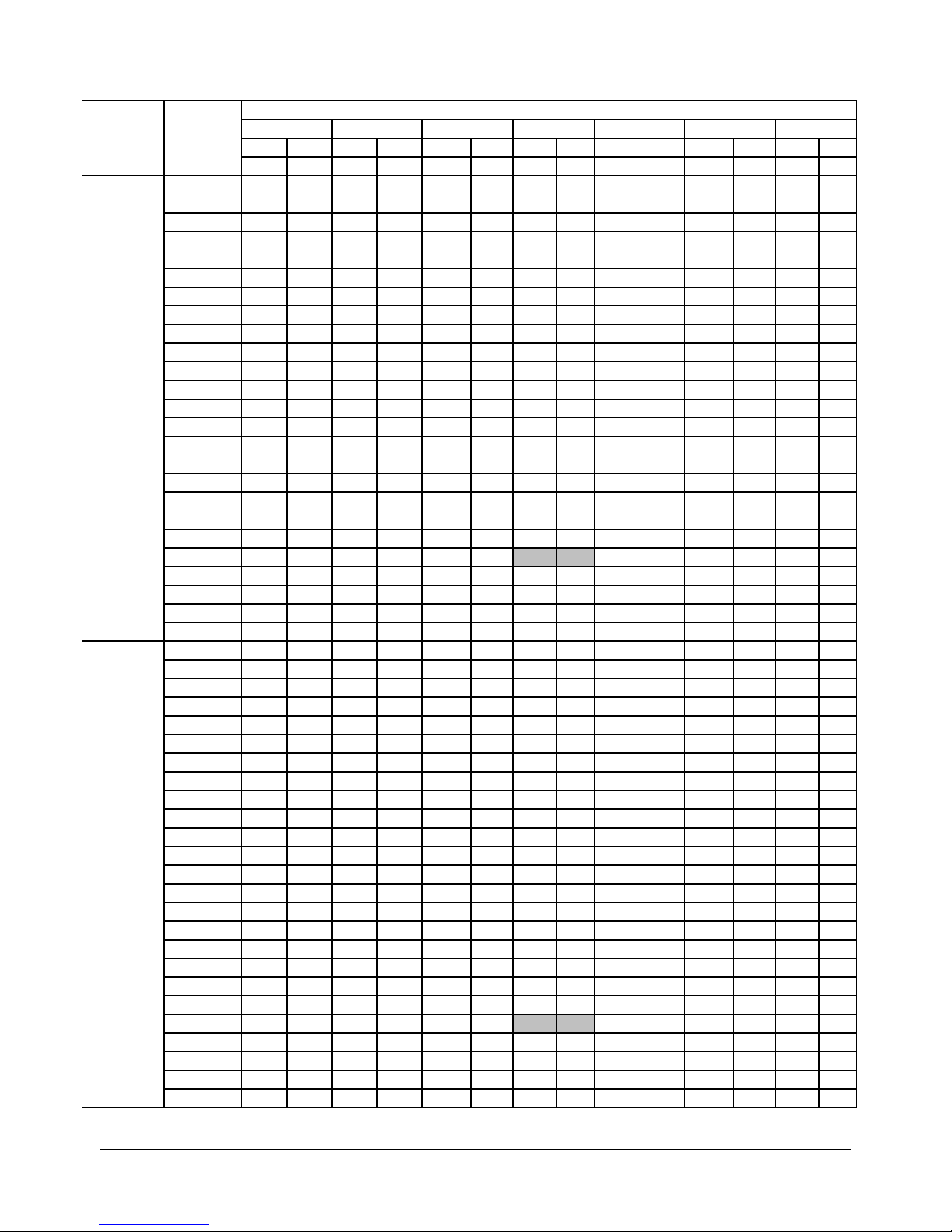

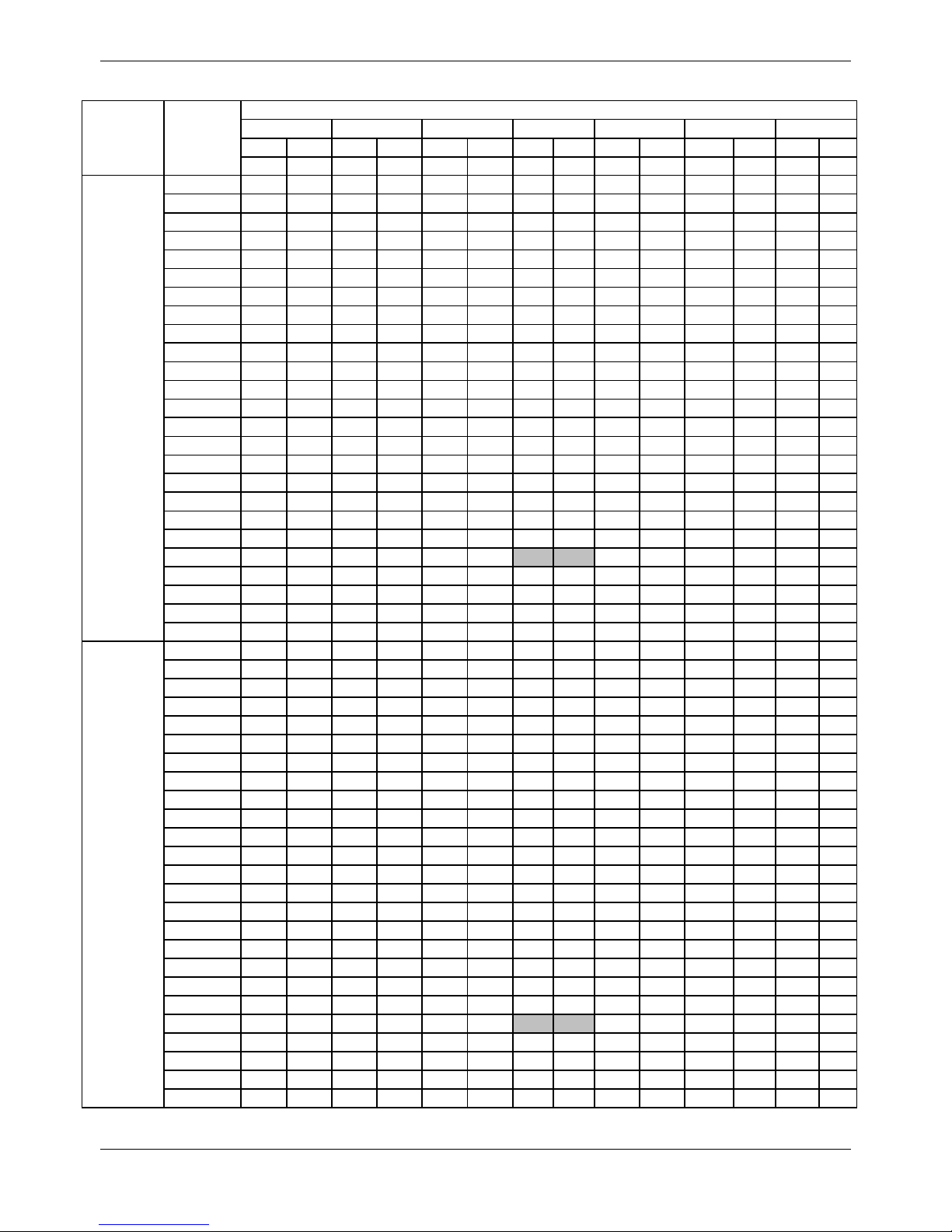

26 Specifications&Performance

MDV-V120W/DRN1

Heating TC: Total Capacity (kW); PI: Power Input (kW) (Compressor + Outdoor fan motor)

Combination (%)

(Capacity index)

Outdoor Air

temperature(°C DB)

Indoor temperature(°C WB)

16

18

20

21

22

24

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

TC

PI

°C DB

°C WB

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

kW

100%

-13.7

-15

9.26

3.38

9.22

3.5

9.18

3.62

9.18

3.69

9.18

3.74

9.14

3.87

-11.8

-13

9.64

3.48

9.64

3.59

9.6

3.71

9.6

3.77

9.6

3.83

9.55

3.94

-9.8

-11

10.1

3.57

10.06

3.69

10.06

3.79

10.06

3.85

10.01

3.91

10.01

4.02

-9.5

-10

10.35

3.62

10.31

3.73

10.31

3.84

10.27

3.89

10.27

3.95

10.22

4.06

-8.5

-9.1

10.56

3.66

10.52

3.77

10.52

3.88

10.52

3.93

10.48

3.98

10.48

4.09

-7

-7.6

10.94

3.74

10.94

3.84

10.9

3.94

10.9

3.99

10.9

4.04

10.85

4.15

-5

-5.6

11.52

3.83

11.48

3.93

11.48

4.02

11.44

4.07

11.44

4.12

11.4

4.22

-3

-3.7

12.07

3.92

12.07

3.56

12.03

4.1

12.03

4.15

12.03

4.19

11.52

4.02

0

-0.7

13.03

4.04

13.03

4.13

12.99

4.21

12.78

4.15

12.36

3.97

11.52

3.65

3

2.2

14.08

4.16

14.04

4.24

13.2

3.92

12.78

3.77

12.36

3.62

11.52

3.32 5 4.1

14.79

4.24

14.04

3.98

13.2

3.69

12.78

3.55

12.36

3.41

11.52

3.13

7 6 14.88

4.02

14.04

3.74

13.2

3.47

12.78

3.34

12.36

3.21

11.52

2.95

9

7.9

14.88

3.78

14.04

3.52

13.2

3.27

12.78

3.1

12.36

3.02

11.52

2.79

11

9.8

14.88

3.56

14.04

3.32

13.2

3.08

12.78

2.97

12.36

2.85

11.52

2.63

13

11.8

14.88

3.34

14.04

3.12

13.2

2.9

12.78

2.79

12.36

2.69

11.52

2.48

15

13.7

14.88

3.15

14.04

2.94

13.2

2.74

12.78

2.64

12.36

2.54

11.52

2.35

90%

-13.7

-15

9.2

3.6

9.16

3.7

9.16

3.81

9.12

3.87

9.12

3.92

9.12

4.03

-11.8

-13

9.58

3.68

9.58

3.79

9.54

3.89

9.54

3.94

9.54

3.99

9.5

4.1

-9.8

-11

10.04

3.77

10.04

3.87

10

3.97

10

4.02

10

4.07

9.96

4.17

-9.5

-10

10.29

3.81

10.25

3.91

10.25

4.01

10.21

4.06

10.21

4.11

10.21

4.2

-8.5

-9.1

10.5

3.85

10.5

3.95

10.46

4.04

10.46

4.09

10.46

4.14

10.33

4.18

-7

-7.6

10.88

3.92

10.88

4.01

10.83

4.1

10.83

4.15

10.83

4.19

10.33

3.99

-5

-5.6

11.46

4

11.42

4.09

11.42

4.17

11.38

4.22

11.09