Midea MDV-D280W/SN2, MDV-D280W/S, MDV-D560W/SN2, MDV-D560W/S, MDV-D840W/SN2 Installation Manual

...Page 1

Liquid Side Piping

Diameter

Refrigerant to be Added

per meter piping

H 15m

L

1

L

2

L

3

L

4

L

5

L

6

A

B

C

D

E

F

G

H

I

Outdoor Unit (one or more outdoor units)

The first Line Branch Pipe

Indoor Unit

Indoor Unit

Indoor Unit to Indoor Unit

Drop Height

Maximum Piping Equivalent Length L 125m

(From the first Line branch pipe) Maximum piping

Equivalent Length L 40m

Header Branch Pipe

Drop Height between Indoor

unit and outdoor Unit H 50m

Branch Piping between indoor units

(Indoor piping)

Refer to table 3 for indoor unit connection

pipes.

Branch Connection Selection

Select according to the indoor units general

design capacity which it connects to.But if

the indoor units design capacity is more than

the outdoor unit design capacity, then select

branch connection according to the outdoor

unit.

Header Branch Selection.

The selection should according to the

number of branches it connects to.

3

Branch Piping between branches

Select pipe diameters according to the

table 2.

2

MDV-D280W/S

MDV-D560W/S

MDV-D840W/S

Digital Scroll Central Air Conditioner

(Outdoor Unit)

Installation Manual

PRECAUTION

Precautions before reading the installation

manual.

1. This installation manual is for the outdoor

unit.

2. Refer to the indoor unit installation manual

for indoor parts installation.

3.Please read the power source unit installation

manual to install the power source unit .

4. Please refer to the refrigerant distributor

installation manual to install the refrigerant

distributor.

IMPORTANT CHECKING POINTS DURING INSTALLATION

INSTALLATION

Confirm the model and name of your air

conditioner to avoid installation mistakes.

REFRIGERANT PIPING

Separately purchased refrigerant distributor (branch connection, header branch

pipe) should be used in the process or

refrigerant piping.

Refrigerant piping should meet the specified diameters.

Charge nitrogen under certain pressure in

the refrigerant piping before welding.

Refrigerant piping should undergo the heat

insulation process.

After the installing refrigerant piping, do not

electrify the indoor unit before the airtight

test and vacuum.

AIRTIGHT TEST

Refrigerant piping must be tested for gas

2

proof [2.94Mpa(30kg/cm ) nitrogen]

VACUUM

Vacuum pump must be used, and vacuuming should be done from the gas side and

liquid side simultaneously.

ADD REFRIGERANT

When the actual pipe length is longer than

the base length,the every outdoor unit added

refrigerant volume is decided on the

calculating according to the actual length

of pipes.

Fill the form on the outdoor unit electric

control box with the added volume, length

of pipes (actual length) and the relative

height drop between outdoor unit and indoor

unit.

WIRING

Choose power capacity and wire diameter

according to the design manual.The power

cord of the air conditioner should be wider

than the power cord of ordinary motor.

Never enwind or cross the power cord

(380V~) with signal wire (low voltage)

between indoor and outdoor unit, or malfunction is unavoidable.

Connect the indoor unit to the power after airtight test and vacuuming.

INSTALLATION LOCATION

CAUTION:

There is combustible gas leakage existing.

There is much oil (including engine oil)

ingredient.

1. Please keep away from the following

place, or malfunction of the machine

may be caused:

There is salty air surrounding(near the

coast)

There is caustic gas (the sulfide, for example) existing in the air (near a hotspring).

A place the heat air expelled out from the

outdoor unit can reach your neighbor's

window.

A place that the noise interferes your

neighbors every day life.

A place that is too weak to bear the

weight of the unit.

Uneven place.

Insufficient ventilation place.

Near a private power station or high

frequency equipment.

2. The insulation of the metal parts of the

building and the air conditioner should

comply with the regulation of National

Electric Standard.

1. Enough repairing space showing below

should be left during installation. When

install the outdoor unit, set the power

equipment at the side of the outdoor

unit, please refer to the power equipm ent installation manual.

2. Be sure to left enough room for installat ion and maintenance. (See Fig. Below)

INSTALLATION SPACE

Air-out

Air-in

Air-in

Install & Repair Surface.

10mm

10mm

1000mm

Or more

Or more

10mm

(Facade)

10mm or more

1000mm or more

Outdoor unit platform

NOTE: 1. Let the obstacle above the outdoor

unit at least 2000mm away.

2. The top of any pile around the outdoor

unit should at least 400mm below the unit top.

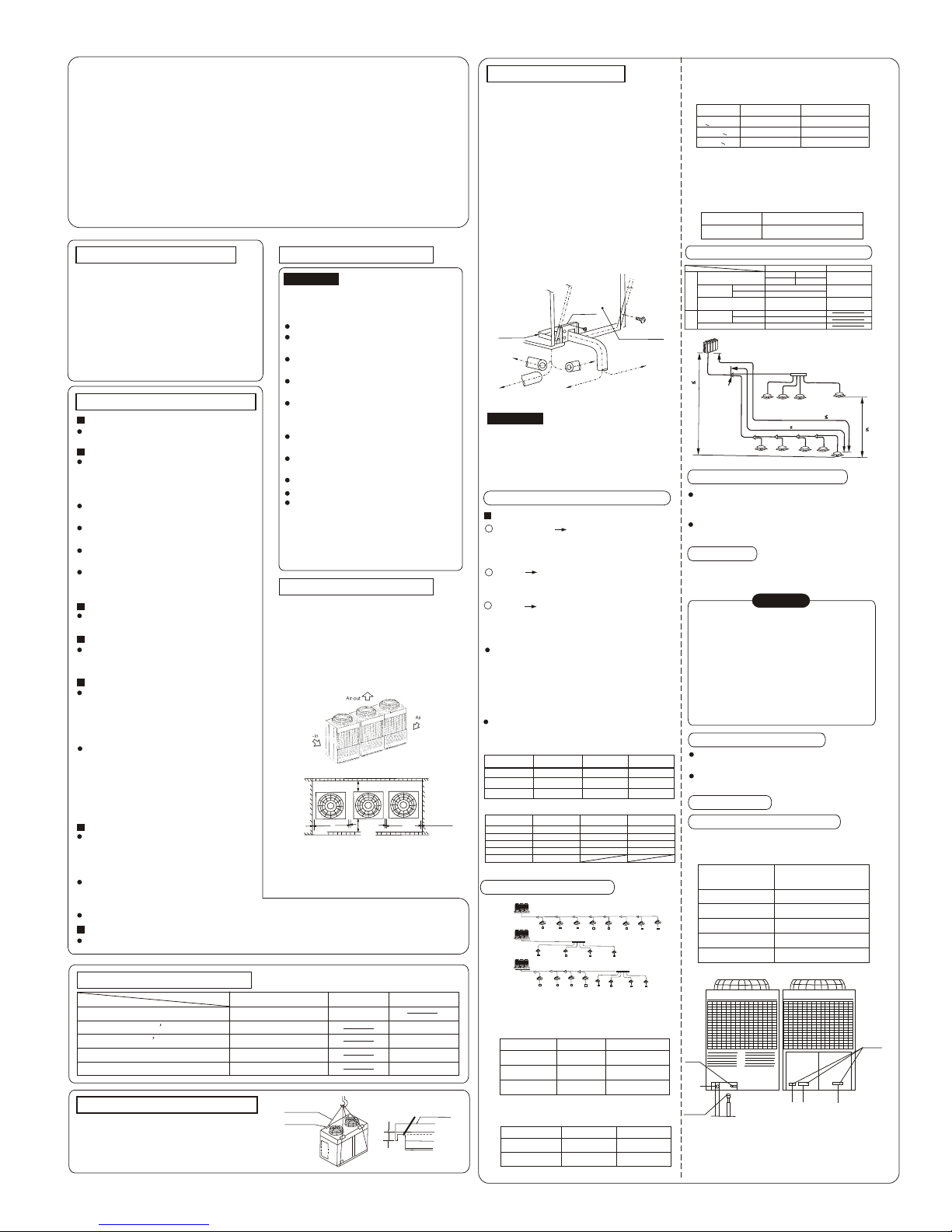

REFRIGERANT PIPING

1. Please remove the left-hand board first for

the connection of the refrigerant piping is ins ide the outdoor unit.(M6: 4; M4:1)

2. The pipe can be lead out through the down left corner of the front of the outdoor unit or

the soleplate gap.

3. When through out of the front, lead the pipe

out by wiring from the panel,and install the

refrigerant distributor at left or at right.

4. After through out of the soleplate, install

the refrigerant distributor at left,right or

rear direction.

5. When through out from the front, seal the so leplate gap with the rubber board to keep the

dust and rubbish out of the unit.

(M6)

(M4)

Soleplate for

piping and

wiring

Soleplate

Rear-Leading

piping

Left-Leading

piping

Left-Leading

piping

Right-Leading

piping

Panel for serving

Right-Leadin

g

piping

Select Sizes of Refrigerant Pipes and Materials

Select Sizes of Refrigerant Pipes

Outdoor Unit the Piping at the first

branch (Main piping)

Refer to table 1 for outdoor unit pipe

sizes.

1

1

1.25

1.7

2

2.5

3

3.2

4

5

Outdoor Unit

Capacity Rating

28 type

80type

36 type

90 type

45 type

56 type

112 type

140 type

71 type

Capacity Rating

Capacity

(horsepower)

Capacity

(horsepower)

Capacity of outdoor

unit(horsepower)

Sum Capacity of indoor

unit(horsepower)

Maximum Quantity

of Indoor unit

Size and Connecting Method

f28.6(Welding)

f38.0(Welding)

f45.0(Welding)

f12.7(Flaring nut)

f19.0(Flaring nut)

f22.0(Welding)

1. Table 1

Piping sizes and connecting method of the

outdoor unit.

MDV-D280W/SN2

MDV-D280W/S

MDV-D560W/SN2

MDV-D560W/S

MDV-D840W/SN2

MDV-D840W/S

Models

Gas Side

Liquid Side

2. Table 2

Piping sizes at the branch pipe

A: the total HP of indoor units

Header branch pipe

Branch joint

Note: The indoor unit must be connected with

MDV-HY1041 directly ,the further branch

connection is not allowed.

Length and Drop Height Permitted of the Refrigerant piping

100m

125m

40m

50m

30m

15m

250m

300m

L1+L2+L3+L4+L5+L6+L7

L1+L3+L4+L5+L6+j

L3+L4+L5+L6+j

+A+b+c+d+e+f+g+h+i+j

Permitted value

Total Pipe Length (Actual)

Maximum Piping (L)

Indoor Unit to Indoor Unit Drop Height

Indoor Unit-Outdoor

Unit Drop Height

Piping (farthest from the first line

pipe branch) Equivalent Length

Actual Length

Equivalent Length

Outdoor Unit Up

Outdoor Unit Down

Pipe Length

Drop

Height

Piping

Make sure there is no any dirt or water

before connecting the piping to the outdoor

Units.

Wash the piping with high pressure nitrogen,

never use refrigerant of the outdoor unit.

Remove Dirt or Water in the Piping

Airtight Test

Charge pressured nitrogen after connecting

indoor unit/outdoor unit piping to do airtight

test.

2

1. Pressured nitrogen [2.94MPa (30kg/cm )]

should be used in the airtight test.

2. Tighten high pressure/low pressure

valves before applying pressured nitrogen.

3. Apply pressure from air vent mouth on the

high pressure/low pressure valves.

4. The high pressure/low pressure valves

are closed when applying pressured nitrogen.

5. The airtight test should never use any

oxygen, flammable gas or poisonous gas.

Air Purge with Vacuum Pump

Open All Valves

Refrigerant Amount to be Added

Using vacuum pump to do the vacuum,never

using refrigerant to expel the air .

Vacuuming should be done from both liquid

side and gas side simultaneously.

Calculate the added refrigerant according to the

diameter and the length of the liquid side

pipe of the outdoor unit/indoor unit connection.

TEST RUNNING

The test running can not begin until the outdoor unit has been connected to the power for 12hr.

1. Sling the outdoor unit and carry it in with

4 steel wire (f6mm or more)

2. Use soft board to protect the unit surface

from scratch and distortion at where contact

the steel wire.

CARRY IN THE OUTDOOR UNIT

20

Steel wire

Mopboard

Soleplate

Give owner

Give owner

For maintenance

For the toggle switch

MDV-D280W/S(N2)

MDV-D560W/S(N2)

MDV-D840W/S(N2)

1

1

2

1

1

ACCESSORIES(outdoor unit)

Model

Name

Outline

Usage

Outdoor unit installation manual

Screws bag

Screw driver

This manual

Outdoor unit owner s manual

Indoor unit owner s manual

Model: MDV-D280W/SN2

MDV-D560W/SN2

MDV-D840W/SN2

MDV-D280W/S(N2)

MDV-D560W/S(N2)

MDV-D840W/S(N2)

10

20

30

16

20

30

5~13.5

10~27

15~40.5

2. Table 1

Select branch pipe

NAME

PIPE LOCATION

NUMBER IN THE TABLE

Directly connect to the

indoor unit

No directly connect to

the indoor unit

3

1, 2

A(HP)

Header branch pipe

(Gas side/ liquid side)

Branch joint

A< 10

10< A < 20

20<A < 30

f 28.6/ f 12.7

f 38.0 / f 19.0

f 45.0 / f 22.0

4. Table 4

Piping sizes and connecting method of the

Indoor Unit.

f19.0(Flaring nut) f9.5(Flaring nut)

Gas Side

Liquid Side

10 HP

20 HP & 30 HP

f 9.5

f 12.7

f 15.9

f 19.0

f 22.0

0.065kg

0.115kg

0.190kg

0.290kg

0.380kg

Low

Pressured

Valve

High

Pressured

Valve

Joint

Indoor Unit

& Branch pipe

Terminal

Connecting

Block

Connecting

signal wire

Connecting

power wire

Connecting

power wire

MDV03I-017bW

MDV-BY101 MDV-HY1041

MDV-BY102

MDV-BY103

11

223322 22 22 22 22

33 33 33 33 33 33 33

11

33

33

33

33

11

22

22

22 22

33 33 33 33

33

33 33

33

Outdoor Unit

Outdoor Unit

Outdoor Unit

CAUTION

To prevent the refrigerant piping from oxidizing inside when welding, it is necessary to

charge nitrogen, or oxide will choke the

circulation system.

CAUTION:

Page 2

Name Quantity

2-core

Size

Indoor/Outdoor Unit Signal Wire

22

1.0mm 500m RVVP-1.0mm X2

Model of indoor unit

Room Name

For example: Indoor unit (A)

of the first system on second

floor is record as: 2F 1A.

Outdoor Unit

Ground

(Open)

(Series Control)

(Open)

Indoor/Outdoor

Unit Signal

Wire

Close end of the connection shield wire

ITEM

MODEL

Non Electric

Heating

Electric

Heating

Indoor Unit

Power

source

2

Minimum wire diameter(mm )

Dimension(m)

(continuous length)

2.0

(30m)

3.5

(50m)

f1.6mm

30

15

Single

Phase

220V~

50Hz

3-Phase

380V~

50Hz

Leakage

protector

Grounding Capacity

Fuse

Manual switch(A)

20A 30mA

0.1sec or

less

£¬

Distance between foot screws is shown as follow.

(15x20 Long hole)

A

B

C

Air inlet snow proof shed Air outlet snow proof shed

Air inlet snow proof shed

2. In snowy places, equipment should be installed to prevent

snow.(As the figure below)(defective snow proof equipment

is easy to cause malfunction).To reduce the affection by

collective snow, please lift the bracket high, and install shelf

at the air inlet and air outlet.

ELECTRICAL WIRING

CAUTION:

Please select power source for indoor unit and outdoor unit

respectively.

The power supply has specified branch circuit with leakage

protector and manual switch.

The power supply leakage protector and manual switch

on all the indoor unit connecting to the same outdoor unit

should be universal.(Please set all the indoor unit power

of one system into the same branch circuit.)

Please put the connective piping system between indoor

unit and outdoor unit with the refrigerant system together.

Use 2-core screened wire as indoor and outdoor control

wire.

Please design a separate circuit for compressor heater

inside the unit for it is frequently heated in using season.

The installation should comply with relevant national electric

standard.

Power wiring should be engaged by specialized electrician.

< Outdoor Unit Wiring>

Separate Power Supply (without power facility)(Table 1)

ITEM

MODEL

Power

source

2

Minimum wire diameter(mm )

Dimension(m)

(continuous length)

MDV-D280W/SN2

MDV-D280W/S

25(46)

16(29)

35(78)

16

60 50

380~415V

3N~

50Hz

Leakage

protector

Grounding Capacity

Fuse

Manual switch(A)

100mA

0.1sec or

less

POWER WIRING

NOTE: The wire diameter and continuous length is under the

condition that the voltage vibration is within 2%. If the

continuous length is exceed the above value, choose

the wire diameter according to relevant regulation.

With Power Facility

Outdoor power

supply

380~415V 3N~

50Hz

Leakage protector

Leakage protector

Manual switch

Junction part

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Manual

switch

Grounding

Grounding

Grounding

Grounding

Grounding

Grounding

( a )

(b)

(b)

Junction part

Power facility

(with leakage protector)

Outdoor

unit

Outdoor

unit

Manual switch( A )

Grounding

Grounding

Grounding

Grounding

Grounding

Grounding

The power wiring is the mainline (a) to the junction box and

the wiring (b) from the junction box to power facility. Please

choose as following:

(1) Diameter of the mainline (a)

Index Table 2: the sum of the outdoor unit horsepower.

For example: (5 horsepower X 1 unit + 8 horsepower X1

unit + 10 horsepower X 1 unit) = 23 horsepower (The total horsepower)

2

(table.2) wire diameter=60mm (50m below)

(2) Wire diameter(b) between junction box and power

Facility

When the assembled outdoor units is 5 or less, the same

with the mainline. When the group is up to 6 or more, the

control box of the power facility will be divided

into two, and index Table 2 with the sum of the outdoor unit

horsepower.

Choose the wire diameter

2

Choose wire diameter (not less than)(Unit: mm )

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

9

9

13

13

13

13

23

23

23

23

23

23

36

36

36

36

36

36

36

60

60

60

60

60

60

60

60

60

60

60

90

90

90

90

90

90

90

90

90

90

90

60

60

60

60

60

60

90

90

90

90

90

90

90

90

90

90

90

90

90

90

23

23

23

23

36

36

36

36

36

36

36

36

60

60

60

60

60

60

60

60

60

Sum of

Horsepower

Sum of

Horsepower

20m or less 20m or less

Wire length is Wire length isWire length is Wire length is

50m or less 50m or less

Choose the manual switch and fuse capacity for junction box.

(1) Decided by the connected outdoor unit (See Table 1),

when power facility is not concerned.

(2) As concerning to the power facility, according to the outdoor

unit horsepower sum to choose .(See Table 3)

Sum of Horsepower, Manual Switch and Fuse capacity List

(Table 3)

10~14

100 75

15~18

100 100

19~28

150 150

Sum of Horsepower

Manual Switch (A) Fuse (A)

29~36

200 200

37~47

300 250

48~50

300 300

Sum of Horsepower

Manual Switch (A) Fuse (A)

POWER WIRING

< Indoor Unit Wiring>

Power Supply (Table 1)

NOTE: The wire diameter and continuous length is under the

condition that the voltage vibration is within 2%. If the

continuous length is exceed the showing value, choose

the wire diameter follow relevant regulation.

Single Phase 220-240V~ 50Hz

Current leakage Protector

Manual Switch

Wire Distribution Box

Indoor Unit

Indoor Power Supply

1

9

2103

11

4

12

5

13

6

14

7

1515

8

1616

CAUTION

1. Refrigerant piping system indoor unit-indoor unit connection

signal wires and indoor unit-outdoor unit connection signal wire

are in the same system.

2. When power cord is parallel with signal wire, please put

them into separate wire distribution pipes, and leave a proper

distance.

(Reference distance: It is 300mm when current capacity of

power cord is less than 10A, or 500mm when 50A).

Please use shield wire as indoor unit/outdoor unit signal

wire.

Indoor/Outdoor unit signal wire wiring

TEST RUNNING

Operate according to "gist for test running" on the electric control

box cover

CAUTION:

Test running can not start until the outdoor unit has been

connected to the power for 12hr.

Test running can not start until all the valves are affirmed open.

Never make the forced running .(Or the protector sits back ,

danger will occur.)

FILL THE NAME OF CONNECTION SYSTEM

To clearly identify the connection systems between two or

more indoor unit and outdoor unit, selects names for every

system and records them on the nameplate on the outdoor

electric control box cover.

PRECAUTION ON REFRIGERANT LEAK

A[kg]

3

B[m ]

This air conditioner (A/C) adopts R407C or R22 as refrigerant,

which is innocuous and nonflammable. The locating room of

the A/C should big enough that any refrigerant leakage is unable

to reach critical thickness. So certain essential action can be

taken on time.

Critical thickness------the Max. thickness of Freon without

any harm to person.

3

Refrigerant critical thickness: 0.3[kg/m ]

Confirm the critical thickness through follow steps, and take

necessary actions.

1. Calculate the sum of the charge volume (A[kg]) Total

Refrigerant volume of 10HP= factory refrigerant volume +

superaddition

3

2. Calculate the indoor cubage (B[m ]) (as the minimum

cubage)

3. Calculate the refrigerant thickness

Countermeasure against over high thickness

1. Install mechanical ventilator to reduce the refrigerant thic kness under critical level. (ventilate regularly)

2. Install leak alarm facility related to mechanical ventilator if

you can not regularly ventilate.)

3

critical thickness: 0.3[kg/m ]

b. Leak alarm related to mechanical ventilator

A. Ventilation

peristome

(Leak hunting siren should be installed

in places easily keep refrigerant)

Indoor unit

Outdoor unit

Indoor

unit

Room full of leak refrigerant

(All refrigerant has run up)

The owner's manual of indoor unit and owner's manual of

outdoor unit must be turned over to the customer.

Explain the contents in the owner's manual to the customers

in details.

TURN OVER TO CUSTOMER

Indoor/Outdoor unit signal wire is low voltage circuit.

Do not let it touch the high voltage power wire and put

it to gather with power cord in the same wire distribution pipe.

CAUTION

Wire Size and Quantity

1. Signal wire is 2-core, polarized wire. Use 2-core shield wire

to prevent interference from outdoor. The grounding method

now is grounding the closed end of the shield wire and

opening (insulating) at the end. One point on outdoor side

is to be grounded.

2. The control between outdoor unit and indoor unit is

BUS type. Addresses is set on field during the installation.

Leakage protector

Table 2

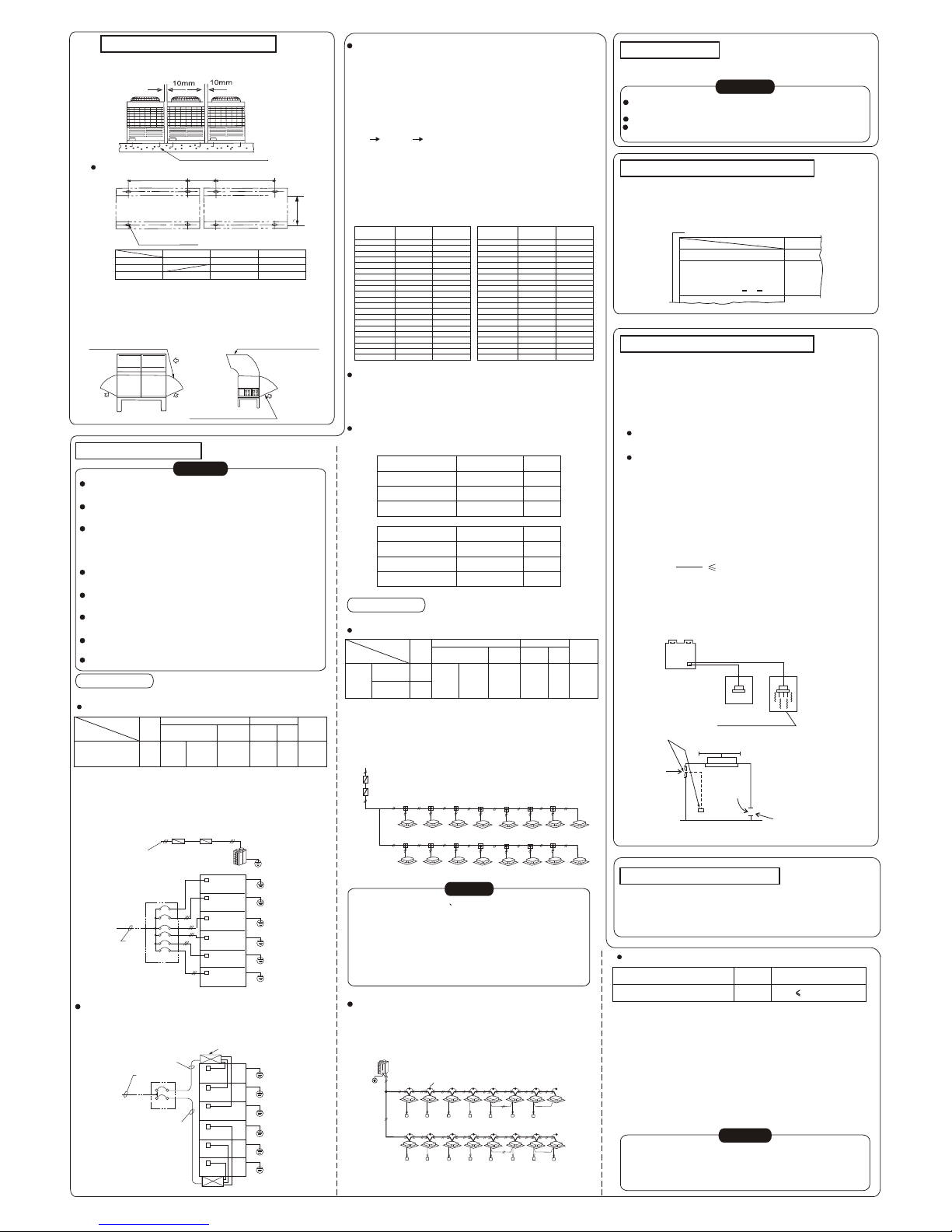

OUTDOOR UNIT INSTALLATION

1. A 10mm distance should be left

between outdoor units.

M12 Foot screw 4Pieces per unit

<650mm

Type

Size

A

B

C

10HP 20HP

30HP

1030

1030

2025

55

2025

3020

55

3020

The power supply of 20HP or 30HP is separated. Each item supply please refer to above MDV-D280W/SN2 .

Loading...

Loading...