Midea MDV-D252W/CS, MDV-D, MDV-D280W/CS, MDV-D335W/CS, MDV-D450W/CS Installation Manual

...Page 1

MDV[D] Series

Digital Scroll Central Air Conditioner Outdoor Unit

INSTALLATION MANUAL

Model:

MDV-D252W/CS

MDV-D280W/CS

MDV-D335W/CS

MDV-D400W/CS

MDV-D450W/CS

Page 2

PRECAUTIONS

1. This installation manual is for the outdoor unit.

2. Refer to the indoor unit installation manual for indoor parts

installation.

3. Please read the power source unit installation manual to

install the power source unit .

4. Please refer to the refrigerant distributor installation

manual to install the refrigerant distributor.

KEY POINTS IN INSTALLATION

INSTALLATION

Confirm the model and name of your air conditioner

to avoid installation mistakes.

REFRIGERANT PIPING

Separately purchased refrigerant distributor (branch

joint, branch header pipe) should be used in the process

of refrigerant piping.

Refrigerant piping should accord with specified

diameter.

Charge nitrogen under certain pressure in the refrigerant

piping before welding.

Heat insulation should be done to refrigerant piping.

After the installing refrigerant piping, do not electrify the

indoor unit before the airtight test and vacuum.

AIRTIGHT TEST

Refrigerant piping must be tested for gas proof

[2.94MPa(30kg/cm ) nitrogen.]

VACUUM

Vacuum pump must be used, and vacuuming should

be done from the gas side and liquid side

simultaneously.

ADD REFRIGERANT

When the actual pipe is longer than the fiducial length,

the added refrigerant volume of every outdoor unit

depends on the calculating according to the actual length.

Fill the form on the outdoor unit electric control box with

the added volume, length of pipes (actual length) and the

relative height drop between outdoor unit and indoor unit.

WIRING

Choose power capacity and wire diameter according to

the design manual. The power cord of the air conditioner

should be wider than the power cord of ordinary motor.

Do not twist or cross the power cord with wiring (low

voltage) between indoor and outdoor unit, or mishandling

may occur.

Connect the indoor unit to the power after airtight test

and vacuuming.

Set the address of outdoor unit, see Address dial

of outdoor unit

TEST RUNNING

Remove six sponges at the back of unit. Please handle

with care to avoid damage to fin, which will decrease

heat exchanging efficiency.

The test running can not begin until the outdoor unit has

been connected to the power for 12hr.

2

INSTALLATION LOCATION

CAUTION

1. Please keep away from the following place, or

malfunction of the machine may be caused:

There is combustible gas leakage.

There is much oil (including engine oil) ingredient.

There is salty air surrounding(near the coast)

There is caustic gas (the sulfide) existing in the air (near

a hotspring).

A place the heat air expelled out from the outdoor unit

can reach your neighbor's window.

A place that the noise interferes your neighbors every

day life.

A place that is too weak to bear the weight of the unit.

Uneven place.

Insufficient ventilation place.

Near a private power station or high frequency equipment.

A place with strong electromagnetic interference.

2. The insulation of the metal parts of the building and the

air conditioner should comply with the regulation of

National Electric Standard.

ACCESSORIES

Name

Outdoor unit installation manual

Outdoor unit owner s manual

Indoor unit owner s manual

Service manual(guarantee

and bar code inside)

Screw bag

Straight screwdriver

Gauge joint

90 elbow

(Outdoor unit)

Qty.

Outline

This manual

1

1

2

1

1

1

1

2

Function

(Given to users)

(Given to users)

(Given to users)

Spare

Dialling

For airtight test

Pipe connecting

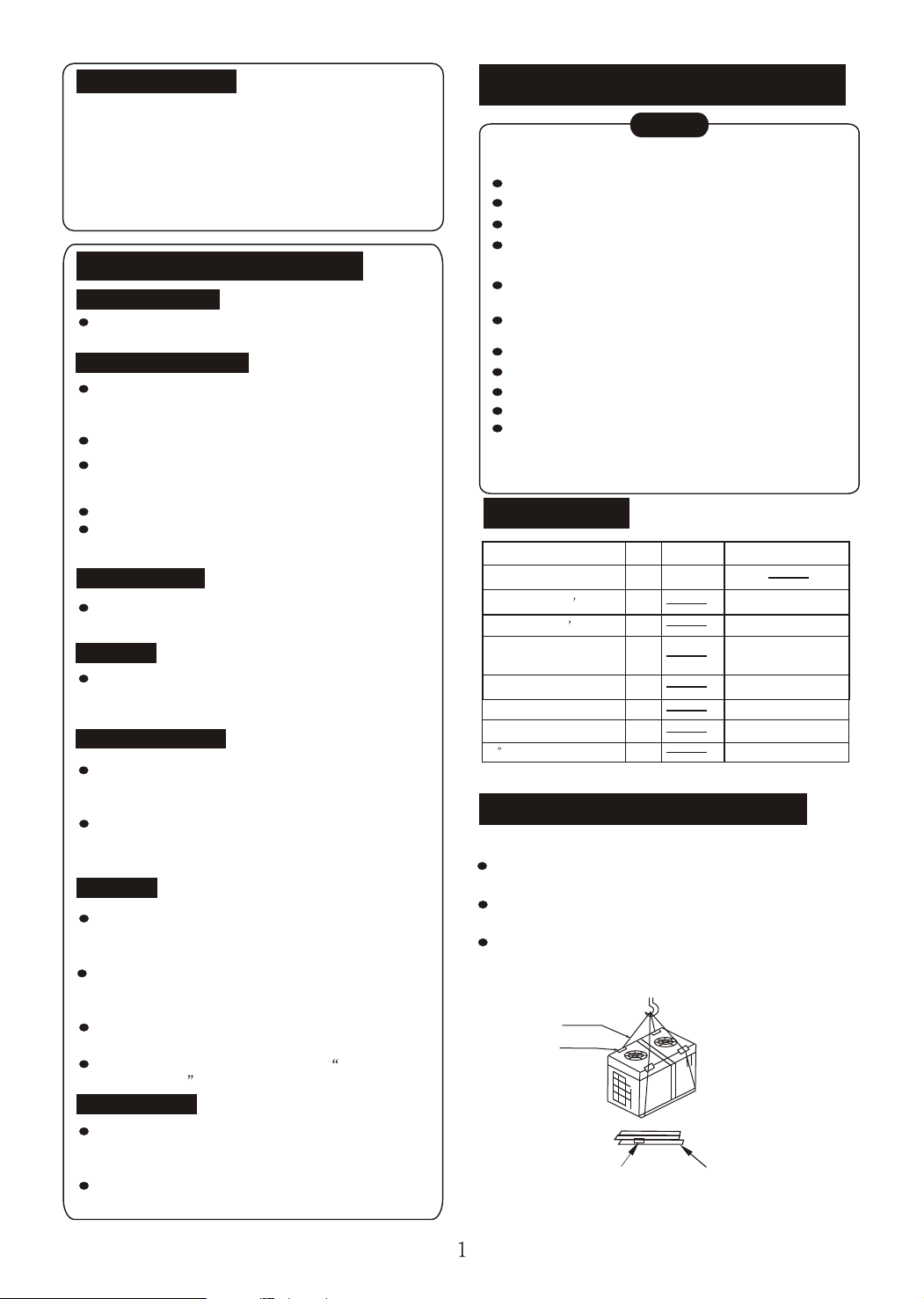

CARRY IN THE OUTDOOR UNIT

1. Carry in with steel wire:

Sling the outdoor unit and carry it in with 4 steel wire

(f6mm or more)

Use soft board to protect the unit surface from scratch

and distortion where contact the steel wire.

Remove the transportation board after carrying in the

outdoor unit.

2. Carry in with a fork lift

Steel wire

Protection board

Hole site for fork lift

Chassis

Page 3

INSTALLATION SPACE

1. Leave enough space for maintenance (see following

picture) and install power unit on the side of outdoor

unit. Refer to power unit installation manual.

2. Keep the modules in one system at the same level.

(Air-out )

(Air-in )

(Air-in )

5. If through the front, please remove the clapboard

at corresponding place first.

CAUTION

To prevent the inside of piping from oxidizing

when welding, it is necessary to charge nitrogen,

or oxide may block the circulation.

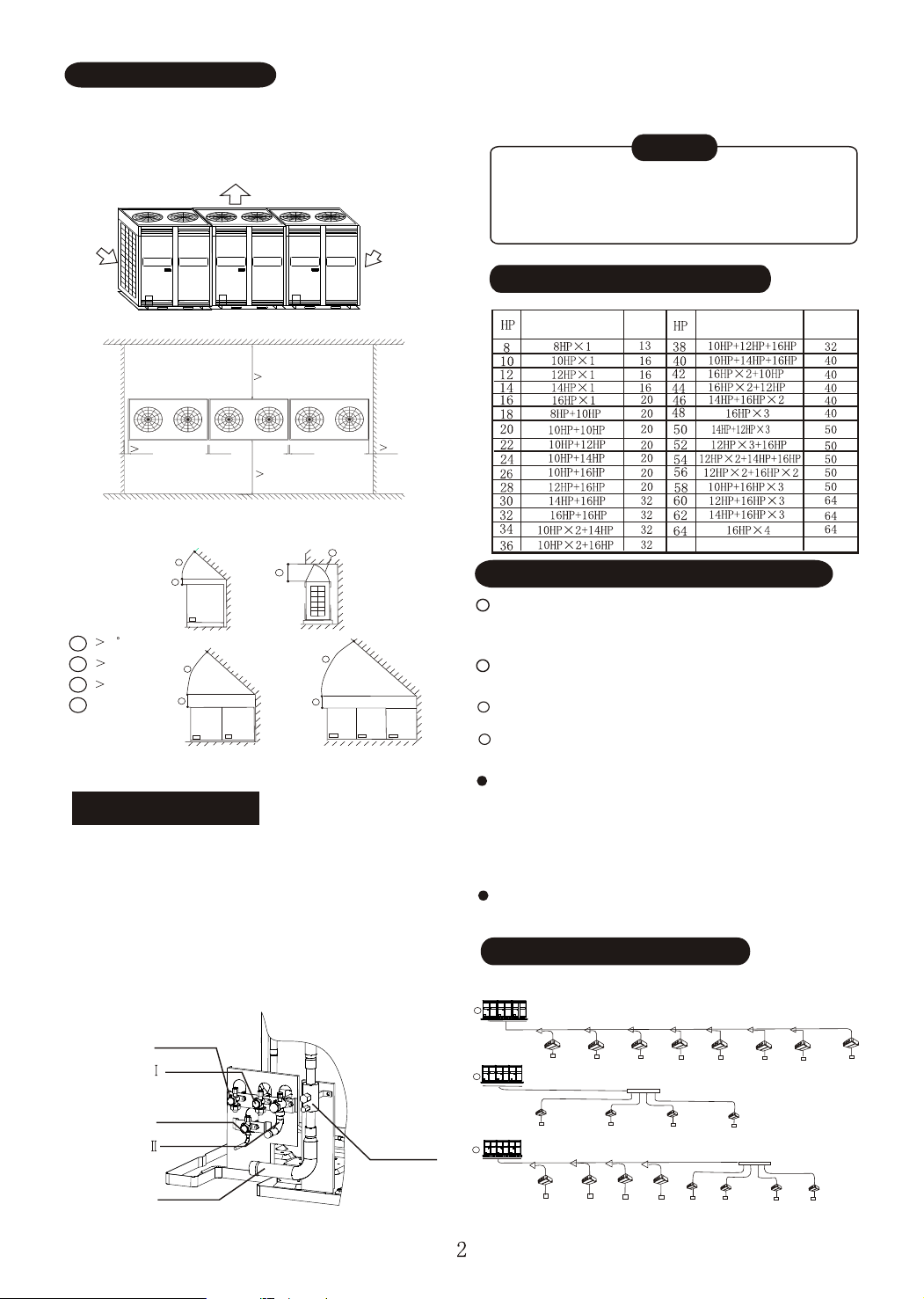

OUTDOOR UNIT COMBINATION

Installation and maintenance surface

1000mm

1000mm

20mm~ 500mm

20mm~ 500mm

1000mm

1000mm

Outdoor unit planform

2. When there is obstacle above the outdoor unit:

A

B

Front view

45

A

300mm

B

1000mm

C

D

Airflow deflector

Front view

NOTE: The top of any pile around the outdoor unit should at least 800mm

below the top of unit. If not, please install mechanical air discharge equipment.

A

B

C

Side view

Front view

D

A

B

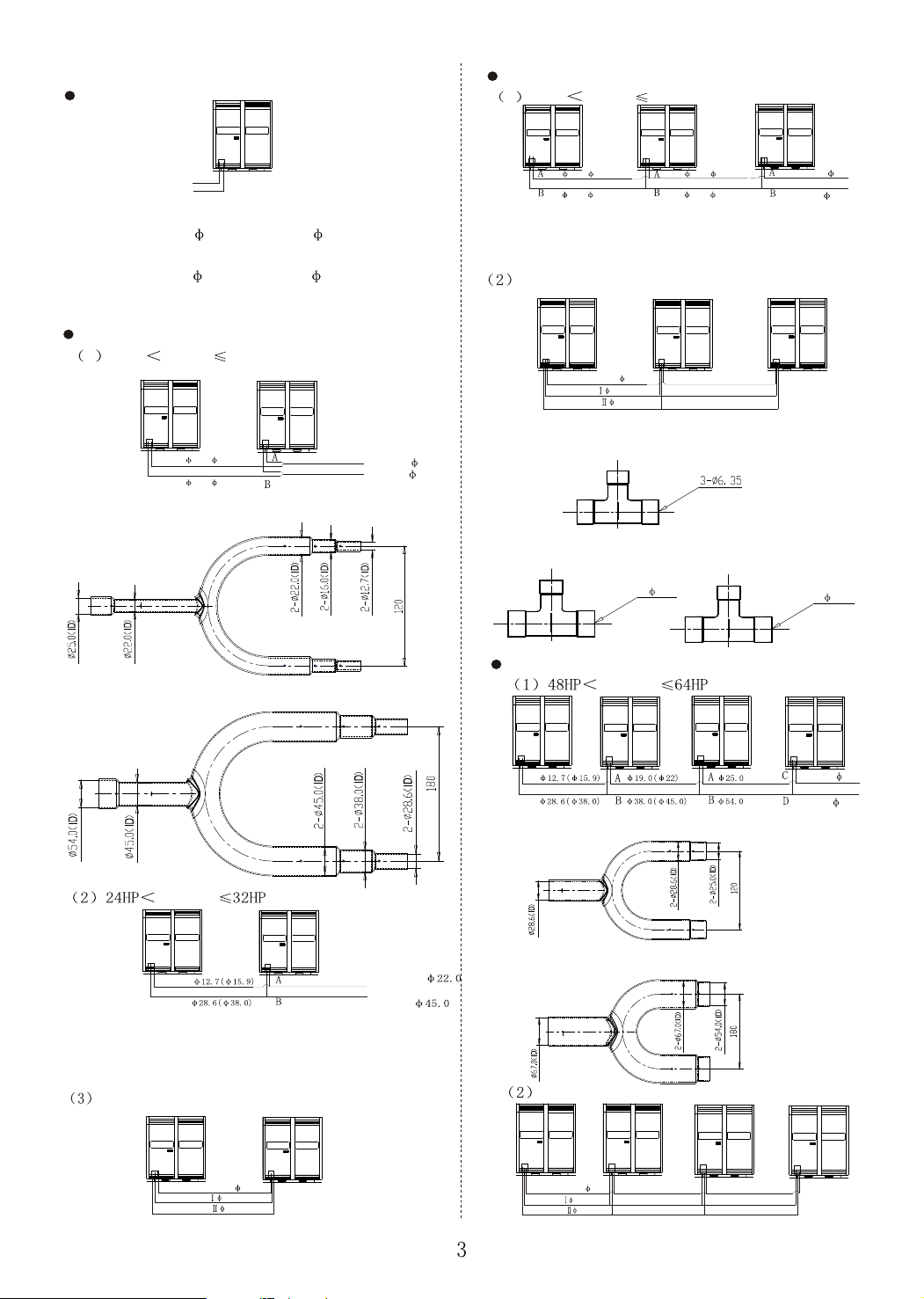

REFRIGERANT PIPE

1. Refrigerant piping connection is inside the outdoor

unit, please remove the front clapboard.

2. The piping can be led through the down-left of the

outdoor unit or the soleplate gap.

3. When through the front, piping is led by wiring from

the panel, then connect branch pipes towards left

or right.

4. When through the soleplate gap, install the branch

pipe towards left, right or back.

To liquid side pipe

To gas balance pipe

(flaring nut)

To oil balance pipe

To gas balance pipe

(welding)

To gas side pipe

NOTE: No connection

with gas and oil balance

pipes for single module.

Low-pressure

ball valve

Mode

Qty. of

indoor unit

Mode

SELECT SIZES OF REFRIGERANT PIPES

1

Pipe between outdoor unit and the first

branch (Main pipe)

Refer to table 1 for outdoor unit pipe sizes.

Size of main pipe connecting multi-modules

2

See table 2

3

Pipe between branches

See table 3

4

Pipe between branch and indoor unit

See table 4

Select branch joint

Select the joint according to the total designed

capacity of indoor units which it connects to. If this

capacity is more than that of the outdoor unit, then

select the connection according to the outdoor unit.

The selection of branch header depends on

the quantity of branches it connects to.

22

33

33

(See table 3)

22

33

33

33

PIPE SIZE AND CONNECTION

Outdoor unit

11

11

Outdoor unit

22

Outdoor unit

33

11

22

33

33

22

33 33

33

11

22 22

22

33

33 33 33

22 22 22

33 33

33

33

Qty. of

indoor unit

33

33

Page 4

<Module installation chart>

Single module

Three modules

1 32HP capacity 48HP

Liquid pipe

Gas pipe

NOTE: Pipe size of model 8HP, 10HP and 12HP:

liquid side 12.7, gas side 28.6.

Pipe size of model 14HP and 16HP:

liquid side 15.9, gas side 38.0.

Gas and oil balance pipes should be sealed by welding

for single module.

Two modules

1 16HP capacity 24HP

12.7( 15.9)

28.6( 38.0)

Liquid pipe 19.0

Gas pipe 38.0

NOTE: See following chart for size of Y-shaped

pipe A on liquid side:

See following chart for size of Y-shaped

pipe B on gas side:

12.7( 15.9)

28.6( 38.0)

19.0( 22)

38.0( 45.0)

Liquid pipe 25.0

Gas pipe 54.0

NOTE: The size of Y-shaped pipes A and B on liquid

side and gas side respectively are the same

with that specified in item(1) of two modules.

Connection of oil and gas balance pipes

Oil balance pipe 6.35

Gas balance pipe 15.9(flaring nut)

Gas balance pipe 19.0(welding)

X

Y

Z

NOTE: See following chart for size T-shaped pipe X

connecting with oil pipe.

See following chart for size T-shaped pipes Y and Z

connecting with gas pipe.

Y

Four modules

3- 15.9

Z

3- 19.0

capacity

capacity

Liquid pipe

Gas pipe

NOTE: The size of Y-shaped pipes A and B on liquid

side and gas side respectively are the same

with that specified in item(1).

Connection of oil and gas balance pipes

NOTE: Wrap the valves

with wet cloth when welding,

or the valves may be

Oil balance pipe 6.35

Gas balance pipe 15.9(flaring nut)

Gas balance pipe 19.0(welding)

damaged to cause leakage.

NOTE: See following chart for size of Y-shaped

pipe C on liquid side:

See following chart for size of Y-shaped

pipe D on gas side:

Connection of oil and gas balance pipes

Oil balance pipe 6.35

Gas balance pipe 15.9(flaring nut)

Gas balance pipe 19.0(welding)

X

Y

Z

X

Y

Z

Liquid pipe 28.6

Gas pipe 67.0

Page 5

NOTE: The size of T-shaped pipe X connecting with

oil pipe is the same with that specified in three modules.

The sizes of T-shaped pipes Y and Z connecting with

gas pipe are the same with that specified in three modules.

1 Table 1

Pipe size and connection of outdoor unit

Model

MDV-D252W/CS

MDV-D280W/CS

MDV-D335W/CS

MDV-D400W/CS

MDV-D450W/CS

Gas side

28.6(welding)

28.6(welding)

28.6(welding)

38.0(welding)

38.0(welding)

Liquid side

12.7(flaring nut)

12.7(flaring nut)

12.7(flaring nut)

15.9(flaring nut)

15.9(flaring nut)

2 Table 2

Size of main pipe connecting multi-modules (unit: mm)

Capacity of parallel unit A (HP) Pipe size (gas/liquid)

3 Table 3

Type of pipe

Name

Branch pipe

Main pipe

4 Table 4

Size of main pipe

A: Capacity of all the indoor units.

A(horsepower)

A12

12A16

16A24

24A32

32A48

48A64

Main pipe(gas side/liquid side) Branch joint

Pipe location

Directly connect to indoor unit

Not directly connect to indoor unit

F28.6/ F12.7

F38.0/ F15.9

F38.0/ F19.0

F45.0/ F22.0

F54.0/ F25.0

F67.0/ F28.6

MDV-BY101

MDV-BY102(A) (refit)

MDV-BY102(A)

MDV-BY103(A)

MDV-BY104

MDV-BY105

Number in chart

3

12

Note: Select the first branch joint based on the capacity of outdoor

unit, which should be larger than other branch joints.

4.Take 30HP outdoor unit for example:

1 a 2 b 3 c 4 d 5 e 6 f 13

7 8 9 10 11 12

#

#2#3#4#

1

(5P) (5P) (5P) (5P) (3P) (2P)

5

Determine pipe size

1. Branch pipes: No.7, 8, 9, 10,11, 12 and 13 the size is F19.0/F9.53

2. 6# and 7# indoor units connect with pipe 6, total HP is 2+5=7P 10P pipe size is

F28.6/F12.7, model of branch join: MDV-BY101

3. Subordinate indoor units of pipe 5 are :5#, 6# and 7#, total HP is 3+2+5=10P 10P,

pipe size is F28.6/ F12.7, model of branch joint: MDV-BY101

4. Subordinate indoor unis of pipe 4 are 4#, 5#, 6# and 7#, total HP is 5+3+2 +5=15P

16P, pipe size is F38.0/F15.9, model of branch joint:MDV-BY102(A)

5. Subordinate indoor units of pipe 3 are 3#, 4#, 5#, 6# and 7#, total HP is 5+5+3+2+5=

20P 24P, pipe size is F38.0/F19.0, model of branch joint:MDV-BY102(A)

6. Subordinate indoor units of pipe 2 are 2# 7#, totel HP is 5+5+5+3+2+5=25P 32P,

pipe size is F45.0/F22.0, model of branch joint:MDV-BY103(A)

7. Pipe 1 is main pipe, the size is F45.0/F22.0, model of branch joint: MDV-BY103(A)

4. Table 5

Pipe size and connection of indoor unit

Gas side

F19.0 flaring nut 9.53 flaring nut

Length and Drop Height Permitted of the Refrigerant piping

Permitted value

20HP

Total Pipe Length (Actual)

Max Piping (L)

Pipe Length

Piping (farthest from the first line

pipe branch) Equivalent Length (l)

Indoor-Outdoor Unit

Drop Height(H)

Drop

Height

Indoor Unit to Indoor Unit Drop Height(h)

Actual Length

Equivalent Length

Outdoor Unit Up

Outdoor Unit Down

20HP

130m

150m

40m

50m

30m

15m

250m

300m

7#

5P

#

6

Liquid side

Piping

L1+L2+L3+L4+L5+L6

+a+b+c+d+e+f+g+h+i

L1+L3+L4+L5+L6+i

L3+L4+L5+L6+i

Outdoor Unit (one or more outdoor units)

L

Branch header

2

b

Indoor Unit

L

5

f

c

L

6

g

h

a

Max Piping Equivalent Length L 125m

L

4

Indoor Unit

d

h 15m

Indoor Unit to Indoor Unit

Drop Height

i

Drop Height between Indoor

unit and outdoor Unit H 50m

L

1

First branch

L

3

(From the first branch) Max piping Equivalent Length l 40m

e

Remove Dirt or Water in the Piping

Make sure there is no any dirt or water before

connecting the piping to the outdoor units.

Wash the piping with high pressure nitrogen, never

use refrigerant of the outdoor unit.

Airtight Test

1. Connect piping on hi-pressure side with hi-pressure

valve. (For multi-modules parallel connection, please

connect gas and oil balance valves.)

2. Weld the piping on low-pressure side with gauge joint.

3. Charge nitrogen from hi-pressure valve core and gauge

joint.

4. After airtight test, weld low-pressure ball valve and

piping on low--pressure side.

CAUTION

1. Pressured nitrogen [2.94MPa (30kg/cm ) should be used in the

airtight test.

2. Do not connect piping on low-pressure side and low-pressure ball

valve before charging nitrogen.

3. The airtight test should never use any oxygen, flammable gas

or poisonous gas.

4. Wrap low-pressure valve and balance valves with wet cloth while welding.

Gas balance valve

Gas balance valve

Oil balance valve

Hi-pressure valve

Gauge joint

Indoor unit and branch joint

2

Low-pressure ball valve

Vacuum with vacuum pump

Do vacuum with vacuum pump instead of refrigerant.

Vacuuming should be done from liquid and gas side

simultaneously. The pressure should be lower than

30Pa.

Open all valves

Refrigerant Amount to be Added

Calculate the added refrigerant according to the diameter

and the length of the liquid side pipe of the ou tdoor/indoor

unit connection. The refrigerant is R22.

Pipe size on liquid side

f

9.53

f

12.7

f

15.9

f

19.0

f

22.0

f

25.0

f

28.6

Refrigerant to be Added per meter

0.065kg

0.115kg

0.190kg

0.290kg

0.380kg

0.580kg

0.760kg

Page 6

Outdoor unit address

setting switch

Outdoor unit capacity

setting switch

Mode setting

switch

Constraint

cool button

Query button

(Chart 2)

Page 7

(Chart 2) Function description

Discharge temp detecting point, No.2 fixed compressor

Discharge temp detecting point, No.1 fixed compressor

Discharge temp detecting point, digital compressor

Phase detecting point

C-phase power supply

Power input of transformer

Load output

Load output

Load output

Load output

Power output of transformer

Load output

Electronic expansion valve driving port

Electronic expansion valve driving port

Indoor to outdoor unit communication port

Current detecting inductor, No.2 fixed compressor

Current detecting inductor, No.1 fixed compressor

Current detecting inductor, digital compressor

Outdoor temp detecting point

Outdoor condenser temp detecting point

Signal input port, low-pressure detecting switch

Signal input port, hi-pressure detecting switch

Outdoor to outdoor unit communication port

Reserved

Reserved

Reserved

Reserved

Reserved

Please complete address setting of indoor and outdoor

units before debugging.

HV inside electric control box, do not touch!

Address dial of outdoor unit

The quantity of outdoor unit is searched.

The address dial is shown below:

Address 0: outdoor main unit;

Address 1: outdoor auxiliary unit;

Address 2: outdoor auxiliary unit;

Address 3: outdoor auxiliary unit;

Address higher than 3: ineffective address, error occurs.

QUERY DESCRIPTION

SW4 query instructions:

Normal display

Display content

Normal display

ADDR of outdoor unit

Cap. of outdoor unit

Qty. of outdoor unit

Effective to main unit

Total cap. of outdoor units

Cap. REQT. of indoor units

Cap. REQT. of main unit (after correction)

Effective to main unit

Effective to main unit

Running mode

Actual running cap. of outdoor unit

Fan speed

T2 average

T3 pipe temp

T4 ambient temp

Discharge temp, digital compressor

Discharge temp, No.1 fixed compressor

Discharge temp, No.2 fixed compressor

Current, digital compressor

Current, No.1 fixed compressor

Current, No.2 fixed compressor

Opening degree, electronic expansion valve A

Opening degree, electronic expansion valve B

Qty. of indoor unit

The last error or protection code

Actual value

Actual value

Actual value

Actual value

Actual value

Actual value

Actual value

Actual value

Actual value

Actual value 8

Actual value 8

Actual value

No protection or error, display 00

End of query

Normal display:

Display qty. of indoor units which communicate with outdoor unit on

standby mode. In case of cap. requirement, display opening degree

of unloading valve PWM of digital compressor.

Running mode:

OFF: 0--OFF, 1-- FAN, 2-- COOL, 3-- HEAT, 4-- Constraint cool

Fan speed: 0--OFF, 1-- LOW, 2--HIGH

PWV opening: pulse count=displayed value 8

SW1: outdoor unit cap. setting switch

SW3: constraint cool button

SW5: mode locking switch

The outdoor unit of 8Hp, 10Hp and 12Hp exclude the part in broken

line circle and relevant wiring (including the wiring with CT2 current

inductor and HEAT2) on nameplate.

SW2: outdoor unit ADDR setting switch

SW4: query button

Mode setting switch

See following chart:

Mode setting

COOL HEAT

Note

or

AUTO (Default)

Distance between ground bolt is shown below: (Note: Outdoor units in

the same system should be located in the same level.

Through hole(15X20 long hole)

Outdoor unit

Page 8

NAME

Digital compressor

Auxil. 4-way valve

Fixed compressor

Capacitor, fan

Main 4-way valve

Relay

Contactor

Terminal

Low-pressure switch

Hi-pressue switch

Electronic expansion valve

Middle terminal

Middle terminal

Pipe temp sensor

Outdoor temp sensor

Current inductor

Fan

Discharge temp sensor, digital compressor

Solenoid valve

Discharge temp sensor, fixed compressor

Power transformer

Crankcase heating

PWM unloading valve

DSP1

Outdoor unit COMM error

Phase protection

COMM error with indoor unit

T3 pipe temp sensor errror

Mode conflict

T4 outdoor temp sensor error

Discharge temp sensor error, digital compressor

Outdoor unit address error

Chip COMM error

Qty of outdoor unit decreases

Qty of outdoor unit increases

Hi-pressure protection

Low-pressure protection

Over-current protection, digital compressor

Compressor overhigh discharge temp protection

Outdoor condenser hi temp protection

Current protection, No.1 fixed compressor

Current protection, No.2 fixed compressor

CODE

Blue

White

White

Black

Blue

Red

Red

Yellow

Yellow

Blue

Brown

White

Black

White

Red

Red

Main control board

Red

Red

Red

Red

Red

Red

Red

Blue

Black

White

Yellow

Green

Brown

Yellow

Green

Red

Red

Blue

Blue

White

Red

Red

Red

Blue

Blue

Blue

Blue

Blue

Black

Black

Black

Blue

Green

Yellow

Blue

Green

Yellow

Red

Brown

White

Black

Blue

Blue

Blue

Blue

Blue

(Reserved)

Blue

Blue

(Load patch board)

Blue

Blue

Black

Black

Black

Black

Black

Black

Blue

Blue

Blue

Blue

Blue

Black

Orange

Green

Black

Grey

Yellow

To indoor COMM.

To outdoor COMM.

Black

Blue

White

Red

3-phase power supply

Brown

Red

White

Blue

Red

Blue

Black

Black

Blue

Black

Red

White

Outdoor unit

wiring nameplate

Black

Yellow/green

Yellow/green

Red

White

Capacity setting

SW1 capacity setting (unchangeable)

or

Auxiliary unit2 Auxiliary unit3

AUTO (Default)

Black

Auxiliary unit1

Main unit

Address setting

Red

COOL HEAT

Mode setting

White

Blue

Yellow/green

Red

Red

Blue

White

Red

Red

Red

Blue

White

Red

Red

Blue

White

Red

Black

Blue

White

Red

Black

Yellow/green

Yellow/green

Page 9

OUTDOOR UNIT INSTALLATION

In snowy areas, facilities should be installed to

prevent snow. (See the chart below)(defective

facilities may cause malfunction.) Please lift the

bracket higher and install snow shed at the air

inlet and air outlet.

Snow shed for air inlet

Snow shed for air outlet

Note: Select power cord these five models separately

according to relevant standard.

MDV-D252( 8)W/S-830,MDV-D280(10)W/S-830,

MDV-D335(12)W/S-830, MDV-D400(14)W/S-830,

MDV-D450(16)W/S-830

Note: The wiring diameter and the length in the table indicate

the condition that the voltage dropping range is within

2%. If the length exceeds the above figure, please select

the wire diameter according to relevant standard.

Snow shed for air inlet

ELECTRIC WIRING

CAUTION

Please select power supply for indoor unit and

outdoor unit separately.

The power supply should have specified branch

circuit with leakage protector and manual switch.

The power supply, leakage protector and manual of all

the indoor units connecting to the same outdoor unit

should be universal. (Please set all the indoor unit power

supply of one system into the same circuit.)

Please put the connective wiring system between

indoor unit and outdoor unit with refrigerant piping

system together.

It is suggested to use 2-core shielded wire as signal

wire between indoor and outdoor units, multi-core wire

is unavailable.

Please comply with relevant National Electric Standard.

Power wiring should be done by professional electrician.

POWER WIRING

<Outdoor unit>

Separate Power Supply (without power facility)

(See table below)

Item

Model

MDV-D252W/CS

MDV-D280W/CS

MDV-D335W/CS

MDV-D400W/CS

MDV-D450W/CS

Min. Power wire diameter

Wiring of mental and synthetic resin

Power

supply

Size Size

380V 3N~

16(29)

50Hz

380V 3N~

16(29)

50Hz

mm

25 (46)

35 (78)

25 (46)

35 (78)

(A)

Grounding

wire

16

16

2

Manual switch

Fuse

Capacity

60

80

50

70

Leakage

protector

100mA

0.1sec or

less

Outdoor unit

power supply

380V 3N~

50Hz

Leakage

protector

Manual

switch

a

Branch box

Leakage

protector

With power facilities

Leakage

protector

Manual

switch

a

Branch box

Manual

switch

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Power facilities

(with leakage protector)

b

Outdoor unit

b

Outdoor unit

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

Select the wire diameter

Power wiring refer to the main wire (a) connecting to

branch box and the wiring (b) between branch box and

power facilities. Please select the wire diameter according

to the following requirement.

(1) Diameter of main wire (a)

Depends on the total horsepower of outdoor unit and

following table.

E.g In system:(5Hp 1unit+8Hp 1unit+10Hp 1unit)

Total Hp=23Hp (Table ) size of wire=70mm (within

50m)

(2) Wiring(b) between branch box and power equipment

Depends on the number of combined outdoor unit. If fewer

than 5, the diameter is the same as that of main wire (a);

if more than6, there will be 2 electric control boxes, and the

diameter of wiring depends on the total horsepower of

outdoor connecting to and

units each electric control box

following table.

Select wire diameter ( ) (table) (unit :mm)

2

2

Page 10

Total Hp

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

<20m

10

10

16

25

25

25

25

35

35

35

35

50

50

50

50

25

25

25

35

35

35

35

70

70

70

70

70

70

70

70

Total Hp

38

40

42

44

46

48

50

52

54

56

58

60

62

64

<20m<50m <50m

70

70

70

70

70

70

95

95

95

95

95

95

95

95

95

95

95

95

95

95

120

120

120

120

120

120

120

120

Select the capacity of manual switch and fuse of the branch box.

(1) See following table when without power facilities,

depends on the outdoor unit it connecting to.

(2) See table below when there is power facility,

depends on the total horsepower.

Total horsepower, capacity of manual switch and fuse

29~36

37~47

48~50

Manual

switch (A)

200

300

300

Fuse(A)

200

250

300

Total Hp

10~14

15~18

19~28

Manual

switch (A)

100

100

150

Fuse(A)

75

100

150

Total Hp

Indoor power supply

Single-phase 220V~ 50Hz

Leakage protector

Manual switch

1

9

2

10311

Branch box

4

Indoor unit

12

13

7

6

5

14

8

CAUTION

1. Set refrigerant piping system, signal wires between

indoor-indoor unit, and that between outdoor-outdoor unit

into one system.

2. Please do not put the signal wire and power wire in the

same wire tube; keep distance between the two tubes.

(Current capacity of power supply: less than 10A--300mm,

less than 50A--500mm.)

3. Make sure to set address of outdoor unit in case of parallel

multi-outdoor units.

Signal wire of indoor/outdoor unit adopts 2-core

shielded wire ( 0.75mm )which has polarity, please

2

connect it correctly.

Signal wire of indoor/outdoor units

Outdoor unit

Outdoor unit

Outdoor unit

(main unit)

(auxil unit)

Signal wire between outdoor units

To closed end of shield wire

(auxil unit)

Outdoor unit

(auxil unit)

(All shield terminals of shield wires

connect to COMM terminal E)

<Indoor unit>

Power cord

Item

Model

Non auxil

All

heater

models

Auxil

heater

Power

supply

Single-phase

220V~ 50Hz

380V 3N~

50Hz

Min. Power wire diameter

mm

Size Size

2.5

3.5

30m

50m

2

(A)

Grounding

wire

f1.6mm

Manual switch

Capacity

Fuse

30 15

Signal wire of

indoor/outdoor

units

Leakage

protector

20A 30mA

0.1sec or

less

Note: The length in the table equals the value of power cord

connecting parallel indoor units, indicating the condition

that the voltage dropping range is within 2%. If the length

exceeds the above figure, please select the wire diameter

according to relevant standard.

Group control

(Open)

Test running

Please follow the gist for test running on electric

control box cover.

CAUTION

1. Do not start test running until the outdoor

unit has been connected to the power for 12hr.

2. Make sure to open all valves before test running.

3. Do not make forced running .(Or the protection

device will not work, which is very dangerous.)

Page 11

FILL THE NAME OF CONNECTED SYSTEM

To clearly identify the connected systems between

two or more indoor units and outdoor unit, select

names for every system and record them on the

nameplate on the outdoor electric control box cover.

Model (indoor unit)

Room Name

E.g.: Indoor unit (A) of the

first system on second floor

is recorded as: 2F 1A.

b. Leakage detector alarming device

related to mechanical ventilator

Indoor unit

OA

a. Ventilation

peristome

(Leakage detector alarming device should

be installed in places easily keeping refrigerant)

CAUTION ON REFRIGERANT LEAKAGE

This air conditioner adopts R22 as refrigerant, which is

safe and noncombustible. The room for air conditioner

should be big enough that refrigerant leakage can not

reach the critical thickness. Besides this, you can take

some action on time.

Critical thickness the max thickness of Freon

without any harm to person. R22 critical

thickness:

0.3 [ kg/m ]

Outdoor unit

Calculate the critical thickness through following

steps, and take necessary actions.

1. Calculate the sum of the charge volume (A[kg])

Total refrigerant volume= refrigerant volume when

delivered(13[kg])+superaddition

2. Calculate the indoor cubage (B[m ]) (as the

minimum cubage)

3. Calculate the refrigerant thickness

A [ kg]

3

B [ m ]

Countermeasure against overhigh thickness

1. Install mechanical ventilator to reduce the refrigerant

thickness under critical level. (ventilate regularly)

2. Install leakage detector alarming device related to

mechanical ventilator if you can not regularly

ventilate.

3

Indoor unit

Room full of leaking refrigerant

(All the refrigerant has leaked)

3

Critical thickness 0.3 [ kg/m ]

3

TURN OVER TO CUSTOMER

The owner's manuals of indoor unit and outdoor

unit and Service manual must be turned over to

the customer.

Particularize the contents in the owner's manual

to the customers.

Dimension and the quantity of electric wire

Name

Signal wire

of indoor/

outdoor unit

1. Signal wire of indoor/outdoor unit adopts 2-core shielded

wire which has polarity. For least interference, the closed

ends of shield wire should be connected continuously and

the shielding layer should be connected to the end E on

outdoor terminal block.

2. 5-core shield wire is used for wire controller (terminals

A, B, C, D and E)

3. The controlling between indoor and outdoor units is

realized by RS485 communication, and the address is

set while installation.

Signal wire of indoor/outdoor unit and wiring

of wire controller belong to low voltage circuit,

which should not contact power cord with high

voltage.

Type

2-core

Size

22

0.75mm 500m RVVP-0.75mmx 2

CAUTION

Page 12

Loading...

Loading...