Page 1

f

9.5

f

12.7

f

15.9

0.065kg

0.115kg

0.190kg

H 8m

L

1

L

2

L

3

L

4

L

5

L

6

F

G

H

I

J

Outdoor Unit (one or more outdoor units)

The first Line Branch Pipe

Indoor Unit

Indoor Unit

Indoor Unit to Indoor Unit

Drop Height

Maximum Piping Equivalent Length L

(From the first Line branch pipe) Maximum piping

Equivalent Length L 20m

Drop Height between Indoor

unit and outdoor Unit H 50m

Digital Scroll Central Air Conditioner (Family used)

(Outdoor Unit)

Installation Manual

PRECAUTION

Precautions before reading the installation

manual.

1. This installation manual is for the outdoor

unit.

2. Refer to the indoor unit installation manual

for indoor parts installation.

3.Please read the power source unit installation

manual to install the power source unit .

4. Please refer to the refrigerant distributor

installation manual to install the refrigerant

distributor.

IMPORTANT CHECKING POINTS DURING INSTALLATION

INSTALLATION

Confirm the model and name of your air

conditioner to avoid installation mistakes.

REFRIGERANT PIPING

Separately purchased refrigerant distributor (branch connection, header branch

pipe) should be used in the process or

refrigerant piping.

Refrigerant piping should meet the specified diameters.

Charge nitrogen under certain pressure in

the refrigerant piping before welding.

Refrigerant piping should undergo the heat

insulation process.

After the installing refrigerant piping, do not

electrify the indoor unit before the airtight

test and vacuum.

AIRTIGHT TEST

Refrigerant piping must be tested for gas

2

proof [2.94Mpa(30kg/cm ) nitrogen]

VACUUM

Vacuum pump must be used, and vacuuming should be done from the gas side and

liquid side simultaneously.

ADD REFRIGERANT

When the actual pipe length is longer than

the base length,the every outdoor unit added

refrigerant volume is decided on the

calculating according to the actual length

of pipes.

Fill the form on the outdoor unit electric

control box with the added volume, length

of pipes (actual length) and the relative

height drop between outdoor unit and indoor

unit.

WIRING

Choose power capacity and wire diameter

according to the design manual. The power

cord of the air conditioner should be wider

than the power cord of ordinary motor.

Never unwind or cross the power cord

(380V~) with signal wire (low voltage)

between indoor and outdoor unit, or malfunction

is unavoidable.

Connect the indoor unit to the power after

airtight test and vacuuming.

INSTALLATION LOCATION

CAUTION:CAUTION:

There is combustible gas leakage existing.

There is much oil (including engine oil)

ingredient.

1. Please keep away from the following

place, or malfunction of the machine

may be caused:

There is salty air surrounding(near the

coast)

There is caustic gas (the sulfide, for example) existing in the air (near a hotspring).

A place the heat air expelled out from the

outdoor unit can reach your neighbor's

window.

A place that the noise interferes your

neighbors every day life.

A place that is too weak to bear the

weight of the unit.

Uneven place.

Insufficient ventilation place.

Near a private power station or high

frequency equipment.

2. The insulation of the metal parts of the

building and the air conditioner should

comply with the regulation of National

Electric Standard.

INSTALLATION SPACE

CARRY IN THE OUTDOOR UNIT

Give owner

Give owner

For maintenance

For the toggle switch

1

1

1

1

1

ACCESSORIES(outdoor unit)

Model

Name

Outline

Usage

Outdoor unit installation manual

Indoor unit owner s manual

Screws bag

Screw driver

This manual

Size and Connecting Method

Outdoor Unit

The first line branch pipe

1

1

2

2

2

2

2

3

3

3

3

3

3 3

3

3

3

f19

(Flaring nut )

f9.53

(Flaring nut)

1. Table 1

Piping sizes and connecting method of the

outdoor unit.

Models

Gas Side

Liquid Side

3. Table 3

Piping sizes and connecting method of the

Indoor Unit.

4. Table 4

Select branch pipe

2. Table 2

Piping sizes at the branch pipe

f19(Welding)

f9.53(Welding)

Gas Side

Liquid Side

f19.0(Flaring nut)

f9.53(Flaring nut)

Gas Side

Liquid Side

Header branch pipe

FQG-01

Length and Drop Height Permitted of the Refrigerant piping

20m

20m

20m

8m

100m

L1+L2+L3+L4+L5+L6

L1+L3+L4+L5+L6+e

L3+L4+L5+L6+e

+A+b+c+d+e

Permitted value

Total Pipe Length (Actual)

Maximum Piping (L)

Indoor Unit to Indoor Unit Drop Height

Indoor Unit-Outdoor

Unit Drop Height

Piping (farthest from the first line

pipe branch) Equivalent Length

Actual Length

Equivalent Length

Outdoor Unit Up

Outdoor Unit Down

Pipe Length

Drop

Height

Piping

Make sure there is no any dirt or water

before connecting the piping to the outdoor

Units.

Wash the piping with high pressure nitrogen,

never use refrigerant of the outdoor unit.

Remove Dirt or Water in the Piping

Airtight Test

Charge pressured nitrogen after connecting

indoor unit/outdoor unit piping to do airtight

test.

CAUTION

2

1. Pressured nitrogen [2.94MPa (30kg/cm )]

should be used in the airtight test.

2. Tighten high pressure/low pressure

valves before applying pressured nitrogen.

3. Apply pressure from air vent mouth on the

high pressure/low pressure valves.

4. The high pressure/low pressure valves

are closed when applying pressured nitrogen.

5. The airtight test should never use any

oxygen, flammable gas or poisonous gas.

Air Purge with Vacuum Pump

Open All Valves

Refrigerant Amount to be Added

Using vacuum pump to do the vacuum,never

using refrigerant to expel the air .

Vacuuming should be done from both liquid

side and gas side simultaneously.

Calculate the added refrigerant according to the

diameter and the length of the liquid side

pipe of the outdoor unit/indoor unit connection.

OUTDOOR UNIT INSTALLATION

TEST RUNNING

The test running can not begin until the outdoor

unit has been connected to the power for 12hr.

e c

Outdoor unit owner s manual

1

1.25

1.7

2

2.5

Outdoor Unit

Capacity Rating

28 type

45type

36 type

56 type

Capacity Rating

Capacity

(horsepower)

Capacity

(horsepower)

Capacity of outdoor

unit(horsepower)

Sum Capacity of indoor

unit(horsepower)

Maximum Quantity

of Indoor unit

71 type

22 type

0.8

Model: MDV-D100W/S MDV-D140W/S

MDV-D100W/SN2 MDV-D140W/SN2

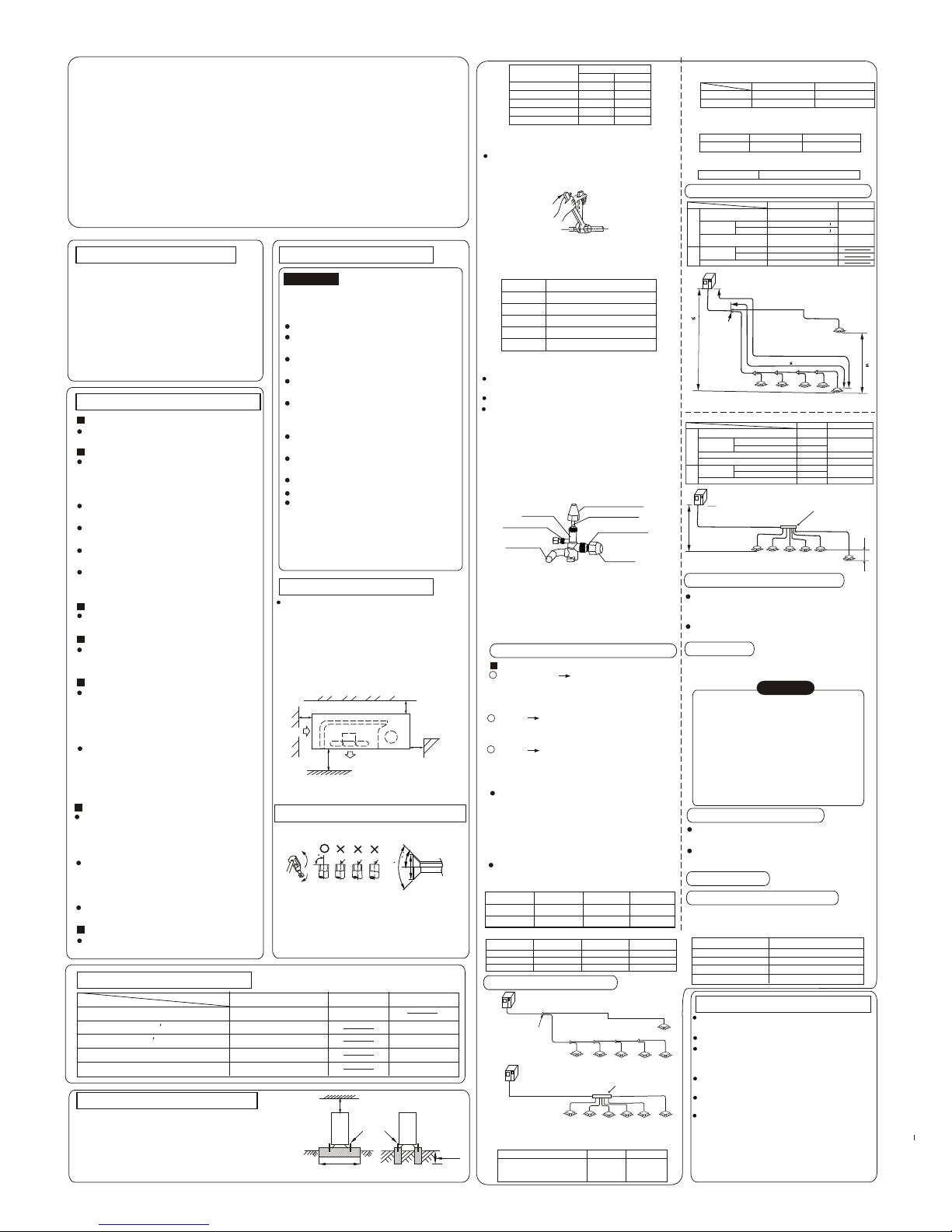

If possible, please remove the obstacles nearby

to prevent the performance from being impeded

by too little of air circulation.

The minimum distance between the outdoor unit

and obstacles described in the installation chart

does not mean that the same is applicable to the

situation of an airtight room. Leave open two of

the three directions (A,B,C)

>30cm

>60cm

>30cm

>2

0

0

cm

(Wall or obstacle)

Maintain channel

Air outlet

Air inlet

Air inlet

A

C

B

REFRIGERANT PIPE CONNECTING

FLARING

>6

0

cm

Fix with bolt

Necessary width

Deep foundation

Since the gravity center of this unit is not at its physical center,

so please be careful when lifting it with a sling.

Never hold the air-in of the outdoor unit to prevent it from deforming.

Do not touch the fan with hands or other objects.

0

Do not lean it more than 45 , and do not lay it sidelong.

Please fasten the feet of this unit with bolts firmly to prevent it from

collapsing in case of earthquake or strong wind.

90

Lean crude burr

Chart

22

A

90+4

_

45+2

_

Chart 23

1. Cut a pipe with a pipe cutter.

2. Insert a flare nut into a pipe and flare

the pipe.(Table 1)

A(mm)

Max

Min

6.35

8.3

9.53

12.4

12.7

15.8

16

19.0

19

23.3

Outside-diameter

(mm)

8.3

12.0

15.4

18.6

22.9

Table 1

FASTEN THE NUT

Put the connecting tubing at the proper position,

wrench the nuts with hands, then fasten it with a

wrench.( Refer to Chart24)

Chart 24

Too large torque will harm the bellmouthing and

too small will cause leakage. Please determine

the torque according to Table 2.

f6.35

.

1000~1200 N cm

f9.53

.

1500~1800Ncm

f12.7

.

2000~2300Ncm

f166

.

2800~3200Ncm

f199

.

3500~4000Ncm

Tubing Size

Torque

Table 2

CAUTION

Operate the stop values

Open the value stem until it reaches the limitator.

Do not open it any further.

Fasten the stop values with a wrench or such tools.

The wrench torque is listed in the Table 2

mentioned above.

CAUTIONS

All the stop values should be opened before test

operation. Each air conditioner has two stop values

of different sizes on the side of the outdoor unit

which operate as Lo-stop value and Hi-stop value,

respectively. The ON/OFF operation is described

in the left chart. (Refer to Chart 28)

Chart 28

Trap body

Repair mouth

System joint

Quadrangle-cover

Quadrangle-lever

Linking pipe joint

Joint nut

1) ON operation: Take off quadrangle cover, clip

the quadrangle head with a wrench and turn

it anticlockwise to the end. Then fasten the

quadrangle cover.

2) OFF operation: The operation is the same as

the ON operation, but you should turn it

clockwise this time.

Branch Piping between indoor units

(Indoor piping)

Refer to table 3 for indoor unit connection

pipes.

Branch Connection Selection

Select according to the indoor units general

design capacity which it connects to.But if

the indoor units design capacity is more than

the outdoor unit design capacity, then select

branch connection according to the outdoor

unit.

Header Branch Selection.

The selection should according to the

number of branches it connects to.

3

Branch Piping between branches

Select pipe diameters according to the

table 2.

2

Select Sizes of Refrigerant Pipes and Materials

Select Sizes of Refrigerant Pipes

Outdoor Unit the Piping at the first

branch (Main piping)

Refer to table 1 for outdoor unit pipe

sizes.

1

4

5

5

6

2~5

2~7

3

3

Method 1: Weld the branches

Method 2:Screw the branches

Outdoor Unit

f19(Flaring nut)

f9.53(Flaring nut)

Method 1

Method 2

TYPE

22~36

60m(140W)or 45m (120W,100W )

70m(140W)or 45m (120W,100W )

Liquid Side Piping

Diameter

Refrigerant to be Added

per meter piping

L

1

A

B

C

D

Outdoor Unit (one or more outdoor units)

Indoor Unit

50m

55m

10m

20m

20m

8m

100m

L1+A+B+C+D+E+F

L1+ F

Permitted value

Total Pipe Length (Actual)

Maximum Piping (L)

Indoor Unit to Indoor Unit Drop Height

Indoor Unit-Outdoor

Unit Drop Height

Piping (farthest from the BS Equipment) Equivalent Length

Actual Length

Equivalent Length

Outdoor Unit Up

Outdoor Unit Down

Pipe Length

Drop

Height

Piping

E

F

Piping (farthest from the BS Equipment) Equivalent Length

40m

A or B,C,D,E,F

L1

L2

L3

Method 1

Method 2

L2

L3

2

Refrigerant Divider

(BS Equipment)

Refrigerant Divider

(BS Equipment)

Keep this unit away from direct radiation of the

sun or other heaters.

If unavoidable, please cover it with a shelter.

In places near coast or with a high attitude where

the wind is violent, please install the outdoor unit

against the wall to ensure normal performance.

Use a baffle when necessary.

In the case of extremely strong wind, please

prevent the air from flowing backwards into the

outdoor unit. ( Refer to chart 16)

Locate the outdoor unit as close to the indoor

unit as possible.

The minimum distance between the outdoor unit

and obstacles described in the installation chart

does not mean that the same is applicable to the

situation of an airtight. Leave open two of three

directions A,B,C..

MDV-03I-010aW

MDV-D100W/S MDV-D140W/S

MDV-D100W/SN2 MDV-D140W/SN2

MDV-D100W/S

MDV-D100W/SN2

MDV-D140W/S

MDV-D140W/SN2

MDV-D100W/S

MDV-D140W/S

MDV-D100W/SN2

MDV-D140W/SN2

f 19

0.280kg

Page 2

Non Electric

Heating

ELECTRICAL WIRING

CAUTION:

Please select power source for indoor unit and outdoor unit

respectively.

The power supply has specified branch circuit with leakage

protector and manual switch.

The power supply leakage protector and manual switch

on all the indoor unit connecting to the same outdoor unit

should be universal.(Please set all the indoor unit power

of one system into the same branch circuit.)

Please put the connective piping system between indoor

unit and outdoor unit with the refrigerant system together.

Use 2-core screened wire as indoor and outdoor control

wire.

Please design a separate circuit for compressor heater

inside the unit for it is frequently heated in using season.

The installation should comply with relevant national electric

standard.

Power wiring should be engaged by specialized electrician.

< Outdoor Unit Wiring>

Separate Power Supply (without power facility)(Table 1)

ITEM

MODEL

Power

source

25

16

380V

3N~

50Hz

Leakage

protector

Capacity

Fuse

Manual switch(A)

100mA

0.1sec or

less

POWER WIRING

NOTE: The wire diameter and continuous length is under the

condition that the voltage vibration is within 2%. If the

continuous length is exceed the above value, choose

the wire diameter according to relevant regulation.

Model of indoor unit

Room Name

For example: Indoor unit (A)

of the first system on second

floor is record as: 2F 1A.

£¬

TEST RUNNING

Operate according to "gist for test running" on the electric control

box cover

CAUTION:

Test running can not start until the outdoor unit has been

connected to the power for 12hr.

Test running can not start until all the valves are affirmed open.

Never make the forced running .(Or the protector sits back ,

danger will occur.)

FILL THE NAME OF CONNECTION SYSTEM

To clearly identify the connection systems between two or

more indoor unit and outdoor unit, selects names for every

system and records them on the nameplate on the outdoor

electric control box cover.

PRECAUTION ON REFRIGERANT LEAK

A[kg]

3

B[m ]

This air conditioner (A/C) adopts R407C or R22 as refrigerant,

which is innocuous and nonflammable. The locating room of

the A/C should big enough that any refrigerant leakage is unable

to reach critical thickness. So certain essential action can be

taken on time.

Critical thickness------the Max. thickness of Freon without

any harm to person.

3

Refrigerant critical thickness: 0.3[kg/m ]

Confirm the critical thickness through follow steps, and take

necessary actions.

1. Calculate the sum of the charge volume (A[kg]) Total

Refrigerant volume of 10HP= factory refrigerant volume +

superaddition

3

2. Calculate the indoor cubage (B[m ]) (as the minimum

cubage)

3. Calculate the refrigerant thickness

Countermeasure against over high thickness

1. Install mechanical ventilator to reduce the refrigerant thic kness under critical level. (ventilate regularly)

2. Install leak alarm facility related to mechanical ventilator if

you can not regularly ventilate.)

3

critical thickness: 0.3[kg/m ]

b. Leak alarm related to mechanical ventilator

A. Ventilation

peristome

(Leak hunting siren should be installed

in places easily keep refrigerant)

Indoor unit

Outdoor unit

Indoor

unit

Room full of leak refrigerant

(All refrigerant has run up)

The owner's manual of indoor unit and owner's manual of

outdoor unit must be turned over to the customer.

Explain the contents in the owner's manual to the customers

in details.

TURN OVER TO CUSTOMER

X

O

Chart 16

Strong wind

Selection of the Power Cable

(mm ) (Please use wire tube

to wrap the cables)

2

MDV-D100W/S

MDV-D140W/S

MDV-D100W/SN2

MDV-D140W/SN2

RVV-450/750

5*2.5mm

2

< Indoor Unit Wiring>

Separate Power Supply (without power facility)(Table 2)

ITEM

MODEL

Power

source

10 5

Leakage

protector

Capacity

Fuse

Manual switch(A)

Selection of the Power Cable

(mm ) (Please use wire tube

to wrap the cables)

2

RVV-300/500

3*1.5mm

2

220V~

50HZ

220V~

50HZ

RVV-300/500

3*2.5mm

2

25

16

20A 30mA

0.1sec or

less

With Electric

Heating

Indoor Unit

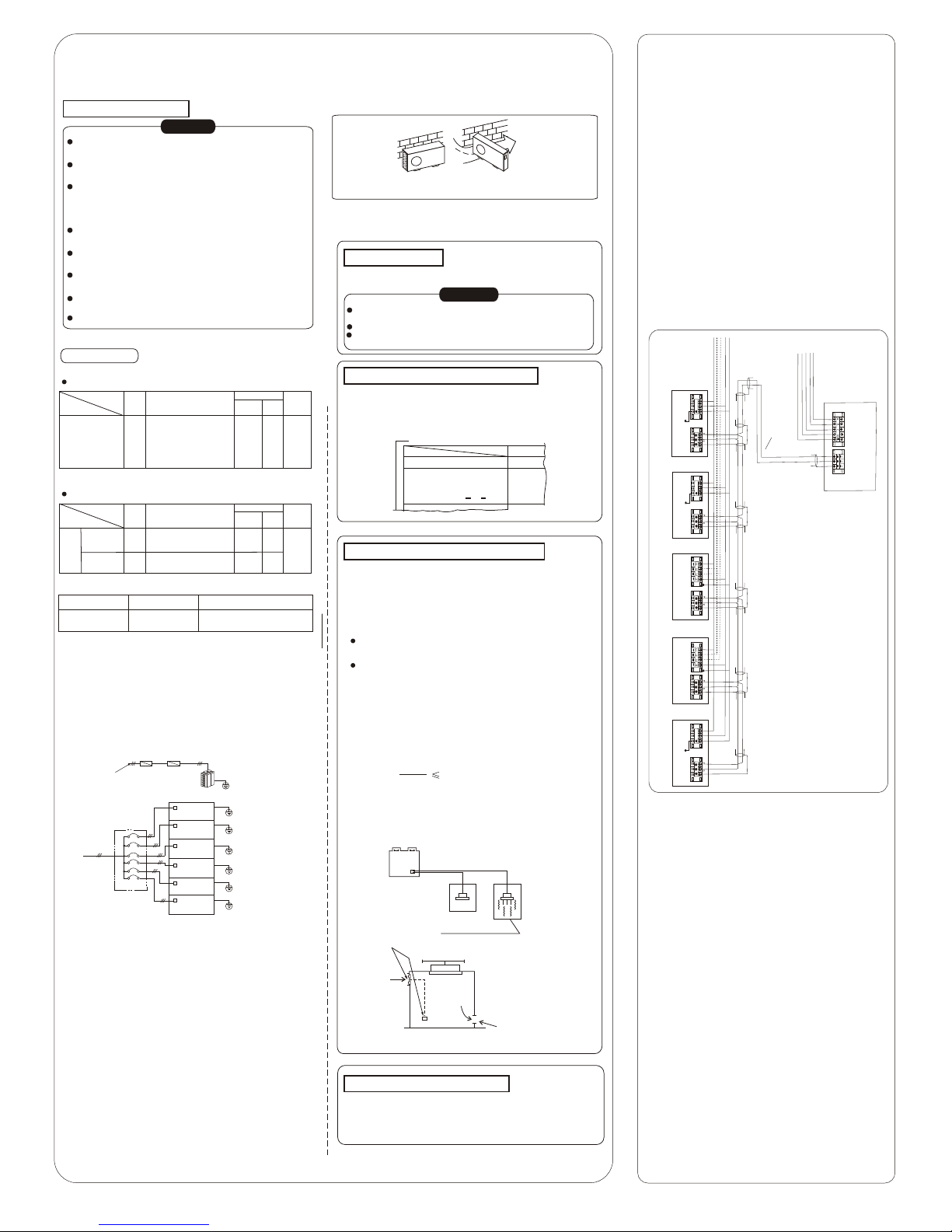

<Signal Wiring for the Controller> (Table 1)

NAME

Insulation Shield Cable

TYPE

RVVP-300/500

2*0.5mm

NOTE

The shied surface of the cable must be

connected to the signal endding(E) of

the outdoor and indoor unit

Outdoor power

supply

380V 3N~

50Hz

Leakage protector

Leakage protector

Manual switch

Junction part

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Outdoor

unit

Manual

switch

Grounding

Grounding

Grounding

Grounding

Grounding

Grounding

End of Grounding

FOR Model:

MDV-D100W/S MDV-D100W/SN2

MDV-D140W/S MDV-D140W/SN2

NOTE:

1. Please connect the signal wire correctly, for they have

difference of anode and cathode.

2. Please do not put the signal wire and the power wire

in the same wire tube; the distance between the two

wire tube must be in the range of 300~500mm.

3. Refrigerant piping system, indoor unit -indoor unit signal

wires and indoor unit-outdoor unit signal wire are in the

same system.

4. After finishing connection, do not use Megger to have

insulation check to the signal wire.

L N

£¨E£©

£¨E£©

£¨E £©

L N

£¨E£©

L N

£¨E£©

POWER:

380V 3N~ 50Hz

(E)

MDV-D100W/S MDV-D140W/S

MDV-D100W/SN2 MDV-D100W/SN2

NOTE:

1.When the indoor unit s power source is 1 phase, it has no

links listed by broken line.

2. The quantity of the indoor unit can be chosen by actual needing.

MEANING OF LETTERS:

A: Indoor Unit Power B: Connecting with Outdoor Unit

C: Indoor Electric Controller

Outdoor Unit Controller

Outdoor

Unit Power

Connecting With

Indoor Unit

Xt1

Xt2

Q

P

A

B

A

B

C

A

B

C

A

B

C

A

B

C

C

Indoor-Outdoor Unit

Connecting Signal Wire

(2-core shield wire)

Power:

380V 3N~ 50HZ

220V~ 50HZ

Air Conditioner Link Circuit

XT2

XT2

XT2

XT2

XT2

XT1

XT1

XT1

XT1

XT1

,

Loading...

Loading...