Midea MEHSU-18CHC2, MEHSU-09CHC2, MEHSU-18CHD2, MEHSU-18CHF2, MEHSU-24CHC2 Service Manual

...Page 1

CONTENTS

1. Precaution ..................................................................................................................................................... 1

1.1 Safety Precaution .......................................................................................................................... 1

1.2 Warning .......................................................................................................................................... 1

2. Part Names and Features ............................................................................................................................ 4

2.1 Model Names of Indoor/Outdoor units .......................................................................................... 4

2.2 Part names of Indoor/Outdoor units .............................................................................................. 5

2.3 Features ......................................................................................................................................... 9

3. Dimension ................................................................................................................................................... 18

3.1 Indoor Unit ................................................................................................................................... 18

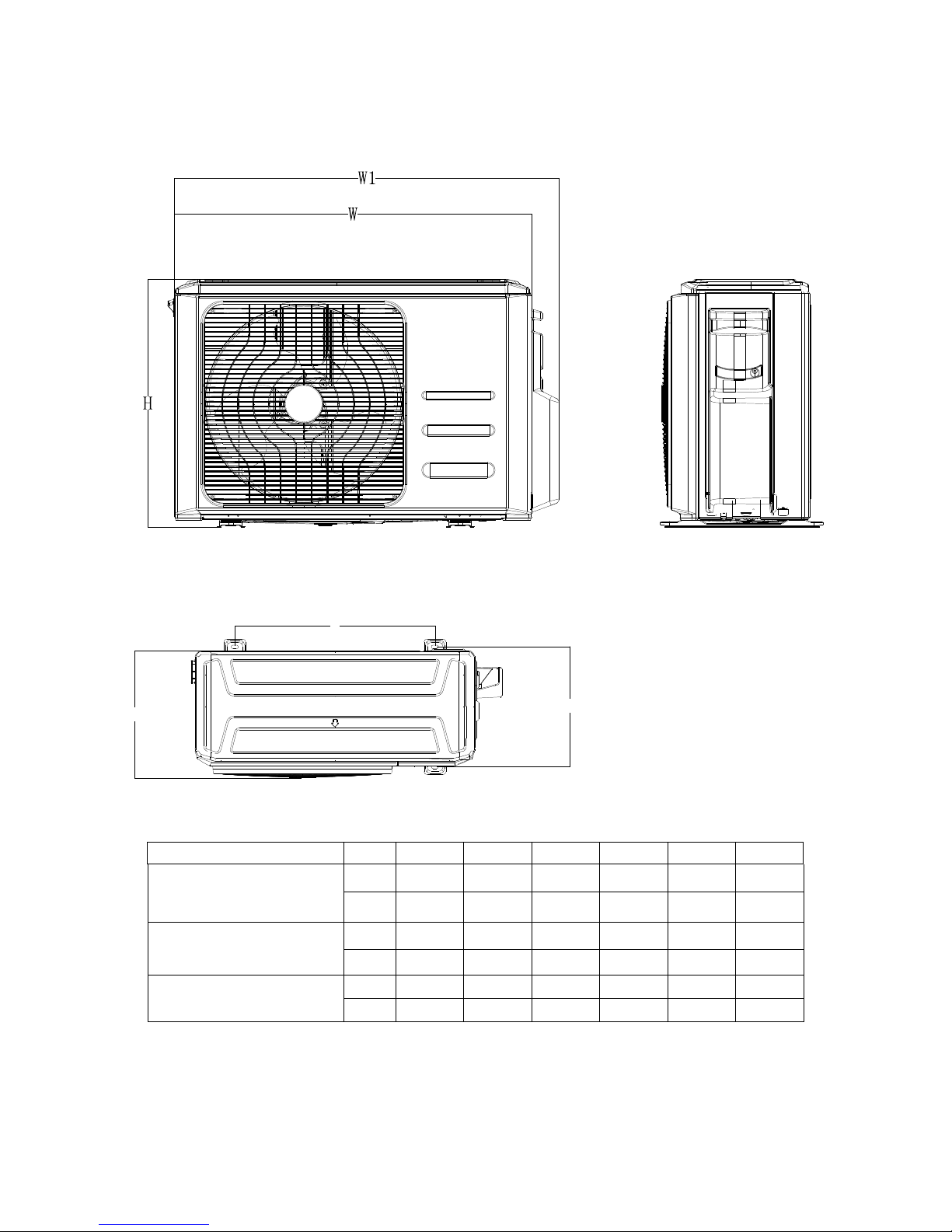

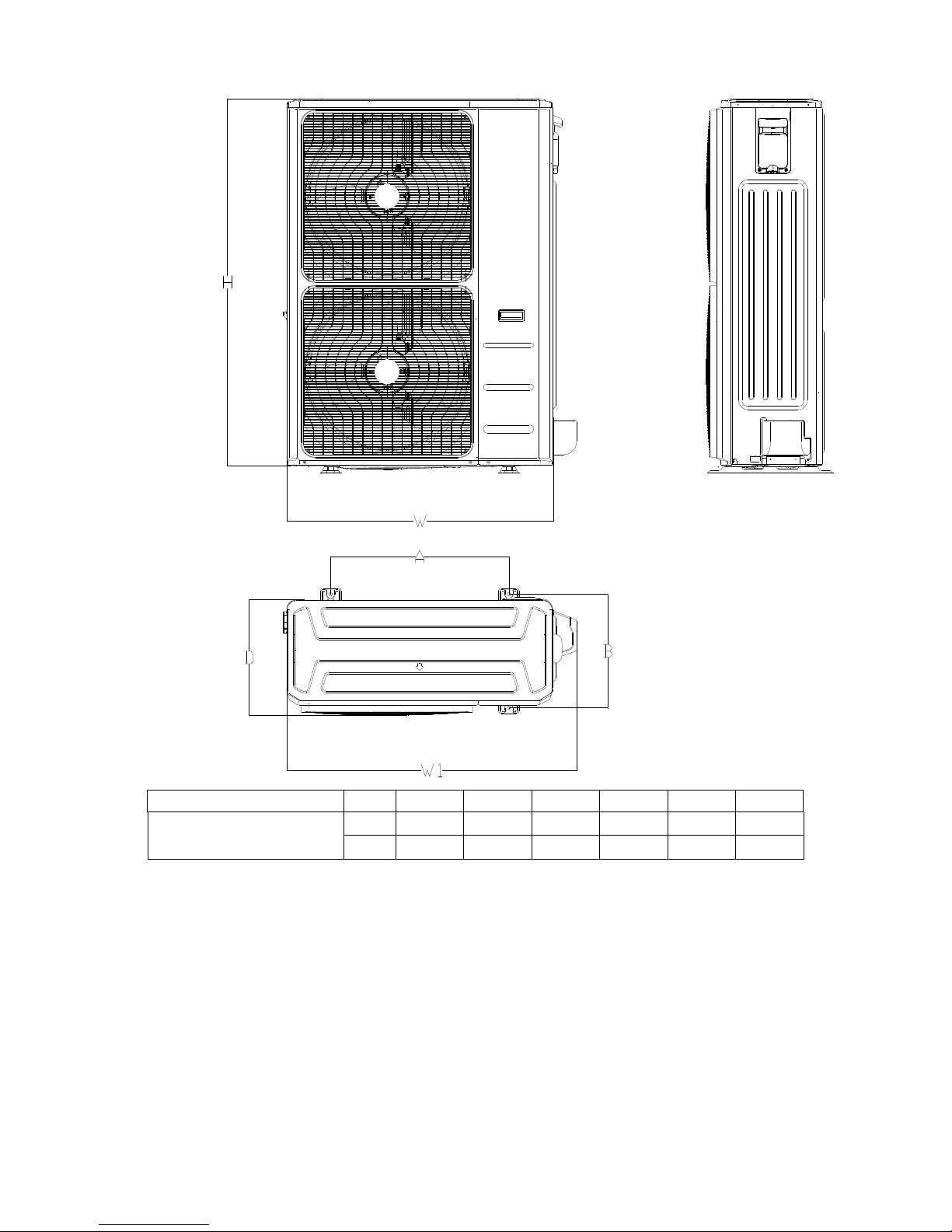

3.2 Outdoor Unit ................................................................................................................................ 23

4. Service Space ............................................................................................................................................. 25

4.1 Indoor Unit ................................................................................................................................... 25

4.2 Outdoor Unit ................................................................................................................................ 27

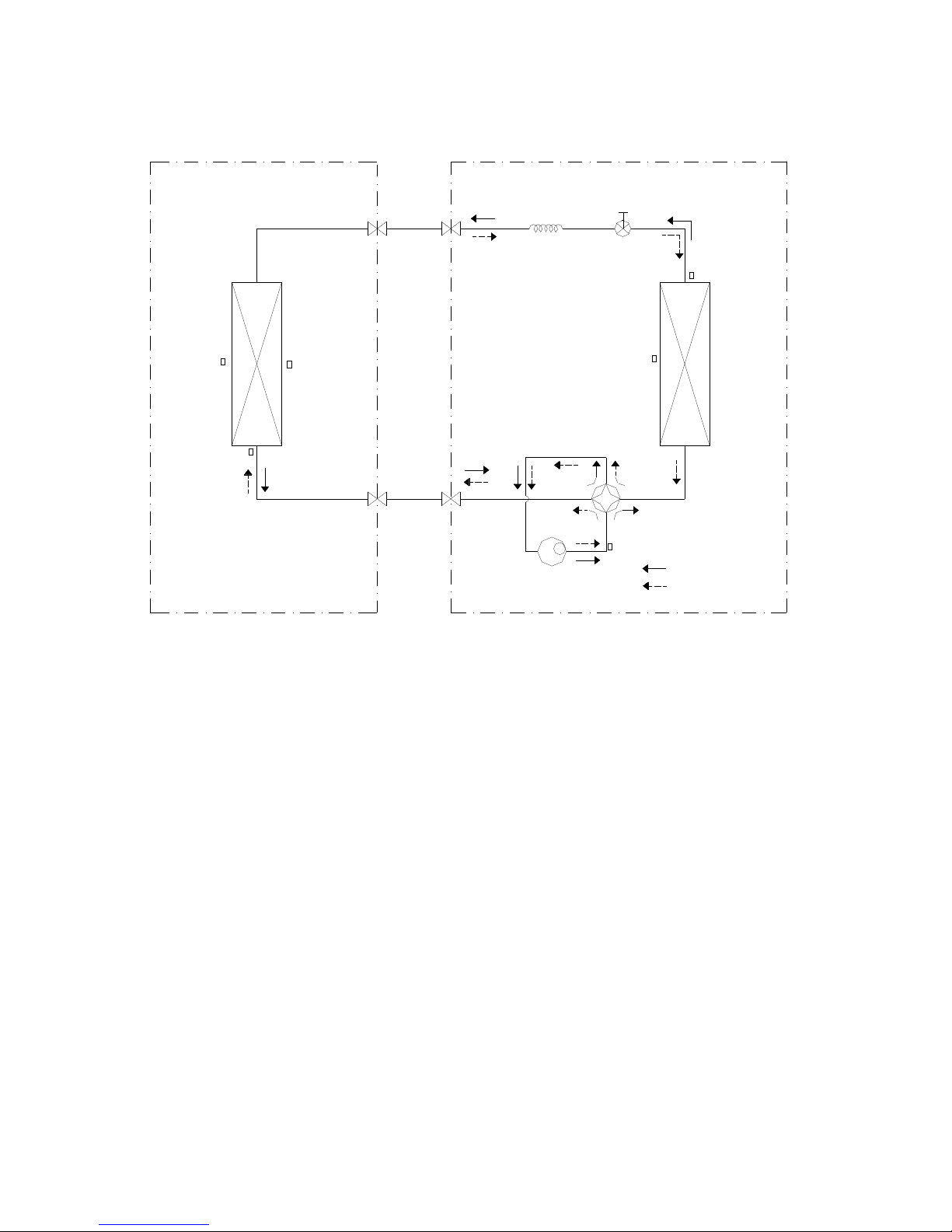

5. Refrigerant Cycle Diagram ........................................................................................................................ 28

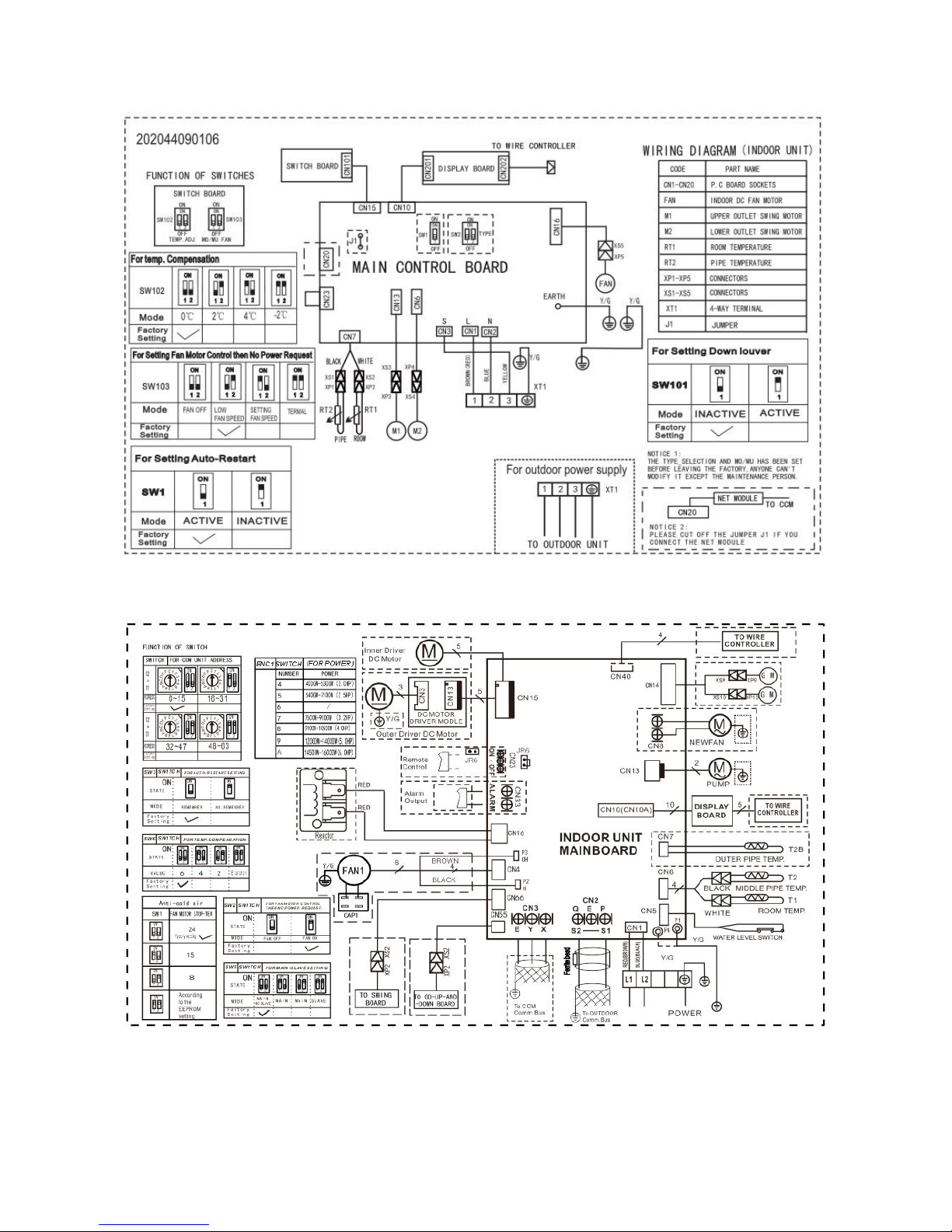

6. Wiring Diagram ........................................................................................................................................... 29

6.1 Indoor Unit ................................................................................................................................... 29

6.2 Outdoor Unit ................................................................................................................................ 34

7. Fan Curves .................................................................................................................................................. 41

8 Electric Characteristics .............................................................................................................................. 48

9 Sound Level ................................................................................................................................................. 49

9.1 Indoor unit .................................................................................................................................... 49

9.2 Outdoor unit ................................................................................................................................. 52

10 Accessories ............................................................................................................................................... 53

11 The Specification of Power ...................................................................................................................... 55

12 Installation Details .................................................................................................................................... 57

12.1 Location selection ................................................................................................................... 57

12.2 Indoor unit installation ............................................................................................................. 57

12.3 Outdoor unit installation .......................................................................................................... 64

12.4 Refrigerant pipe installation .................................................................................................... 65

12.5 Drainage pipe installation ....................................................................................................... 69

12.6 Vacuum Drying and Leakage Checking ................................................................................. 72

12.7 Additional refrigerant charge .................................................................................................. 73

12.8 Engineering of insulation ........................................................................................................ 74

12.9 Engineering of electrical wiring ............................................................................................... 75

12.10 Test operation ...................................................................................................................... 75

13. Operation Characteristics ....................................................................................................................... 77

14. Electronic Function .................................................................................................................................. 78

14.1 Abbreviation ............................................................................................................................... 78

Page 2

14.2 Display function ......................................................................................................................... 78

14.3 Main Protection .......................................................................................................................... 78

14.4 Operation Modes and Functions ............................................................................................... 79

16. Troubleshooting ....................................................................................................................................... 85

16.1 Indoor Unit Error Display ........................................................................................................... 86

16.2 Outdoor unit error display .......................................................................................................... 87

For 9K-24K outdoor unit: ................................................................................................................... 87

For 36K-48K Outdoor Unit ................................................................................................................. 88

Outdoor check function ...................................................................................................................... 88

16.3 Diagnosis and Solution .............................................................................................................. 91

16.4 Main parts check ...................................................................................................................... 107

17. Disassembly Instructions ..................................................................................................................... 114

17.1 Indoor unit ................................................................................................................................ 114

17.2 Outdoor unit ............................................................................................................................. 131

Page 3

1

1. Precaution

1.1 Safety Precaution

To prevent injury to the user or other

people and property damage, the following

instructions must be followed.

Incorrect operation due to ignoring

instruction will cause harm or damage.

Before service the unit, be sure to

read this service manual at first.

1.2 Warning

Installation

Do not use a defective or underrated

circuit breaker. Use this appliance on a

dedicated circuit.

There is risk of fire or electric shock.

For electrical work, contact the dealer,

seller, a qualified electrician, or an

authorized service center.

Do not disassemble or repair the product,

there is risk of fire or electric shock.

Always ground the product.

There is risk of fire or electric shock.

Install the panel and the cover of

control box securely.

There is risk of fire of electric shock.

Always install a dedicated circuit and

breaker.

Improper wiring or installation may cause

electric shock.

Use the correctly rated breaker of

fuse.

There is risk of fire or electric shock.

Do not modify or extend the power

cable.

There is risk of fire or electric shock.

Do not install, remove, or reinstall the

unit by yourself (customer).

There is risk of fire, electric shock, explosion,

or injury.

Be caution when unpacking and

installing the product.

Sharp edges could cause injury, be especially

careful of the case edges and the fins on the

condenser and evaporator.

For installation, always contact the

dealer or an authorized service center.

Do not install the product on a

defective installation stand.

Be sure the installation area does not

deteriorate with age.

If the base collapses, the air conditioner could

fall with it, causing property damage, product

failure, and personal injury.

Do not let the air conditioner run for a

long time when the humidity is very high

and a door or a window is left open.

Take care to ensure that power cable

could not be pulled out or damaged during

operation.

There is risk of fire or electric shock.

Do not place anything on the power

cable.

There is risk of fire or electric shock.

Do not plug or unplug the power

supply plug during operation.

There is risk of fire or electric shock.

Do not touch (operation) the product

with wet hands.

Do not place a heater or other

appliance near the power cable.

There is risk of fire and electric shock.

Do not allow water to run into

electrical parts.

It may cause fire, failure of the product, or

electric shock.

Do not store or use flammable gas or

combustible near the product.

There is risk of fire or failure of product.

Do not use the product in a tightly

closed space for a long time.

Oxygen deficiency could occur.

When flammable gas leaks, turn off

the gas and open a window for ventilation

before turn the product on.

Page 4

2

If strange sounds or smoke comes

from product, turn the breaker off or

disconnect the power supply cable.

There is risk of electric shock or fire.

Stop operation and close the window

in storm or hurricane. If possible, remove

the product from the window before the

hurricane arrives.

There is risk of property damage, failure of

product, or electric shock.

Do not open the inlet grill of the

product during operation. (Do not touch the

electrostatic filter, if the unit is so equipped.)

There is risk of physical injury, electric shock,

or product failure.

When the product is soaked, contact

an authorized service center.

There is risk of fire or electric shock.

Be caution that water could not enter

the product.

There is risk of fire, electric shock, or product

damage.

Ventilate the product from time to

time when operating it together with a stove

etc.

There is risk of fire or electric shock.

Turn the main power off when

cleaning or maintaining the product.

There is risk of electric shock.

When the product is not be used for a

long time, disconnect the power supply plug

or turn off the breaker.

There is risk of product damage or failure, or

unintended operation.

Take care to ensure that nobody

could step on or fall onto the outdoor unit.

This could result in personal injury and

product damage.

CAUTION

Always check for gas (refrigerant)

leakage after installation or repair of

product.

Low refrigerant levels may cause failure of

product.

Install the drain hose to ensure that

water is drained away properly.

A bad connection may cause water leakage.

Keep level even when installing the

product.

It can avoid vibration of water leakage.

Do not install the product where the

noise or hot air from the outdoor unit could

damage the neighborhoods.

It may cause a problem for your neighbors.

Use two or more people to lift and

transport the product.

Do not install the product where it will

be exposed to sea wind (salt spray) directly.

It may cause corrosion on the product.

Corrosion, particularly on the condenser and

evaporator fins, could cause product

malfunction or inefficient operation.

Operational

Do not expose the skin directly to

cool air for long time. (Do not sit in the

draft).

Do not use the product for special

purposes, such as preserving foods, works

of art etc. It is a consumer air conditioner,

not a precision refrigerant system.

There is risk of damage or loss of property.

Do not block the inlet or outlet of air

flow.

Use a soft cloth to clean. Do not use

harsh detergents, solvents, etc.

There is risk of fire, electric shock, or damage

to the plastic parts of the product.

Do not touch the metal parts of the

product when removing the air filter. They

are very sharp.

Do not step on or put anything on the

product. (outdoor units)

Always insert the filter securely.

Clean the filter every two weeks or more

often if necessary.

A dirty filter reduces the efficiency of the air

conditioner and could cause product

malfunction or damage.

Page 5

3

Do not insert hands or other objects

through air inlet or outlet while the product

is operated.

Do not drink the water drained from

the product.

Use a firm stool or ladder when

cleaning or maintaining the product.

Be careful and avoid personal injury.

Replace the all batteries in the remote

control with new ones of the same type. Do

not mix old and new batteries or different

types of batteries.

There is risk of fire or explosion.

Do not recharge or disassemble the

batteries. Do not dispose of batteries in a

fire.

They may burn of explode.

If the liquid from the batteries gets

onto your skin or clothes, wash it well with

clean water. Do not use the remote of the

batteries have leaked.

Page 6

4

2. Part Names and Features

2.1 Model Names of Indoor/Outdoor units

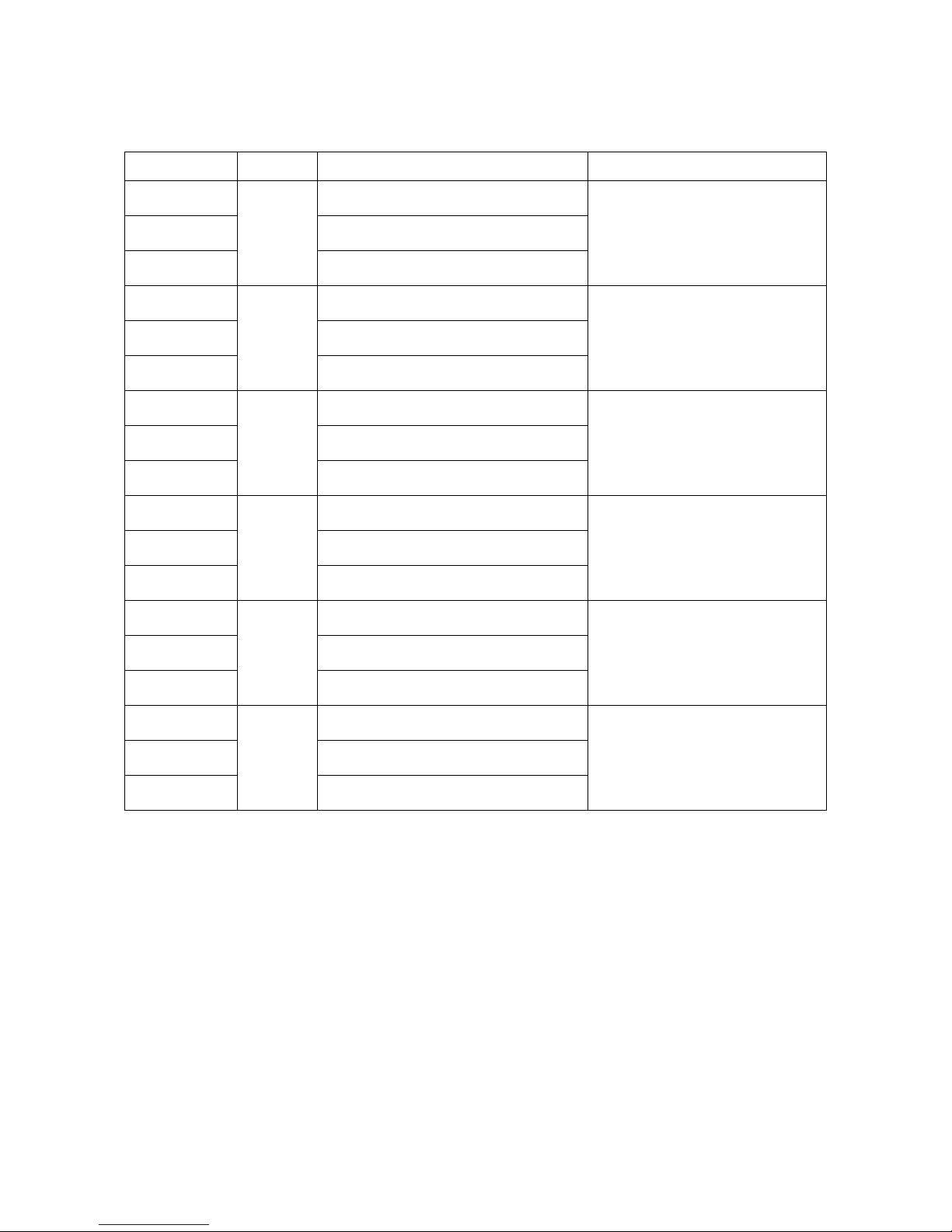

Series Capacity

Indoor units

Outdoor units

Cassette

9K

MEHSU-09CHC2

MCHSU-09PHH2

Duct

MEHSU-09CHD2

Console

MEHSU-09CHN2

Cassette

12K

MEHSU-12CHC2

MCHSU-12PHH2

Duct

MEHSU-12CHD2

Console

MEHSU-12CHN2

Cassette

18K

MEHSU-18CHC2

MCHSU-18PHH2

Duct

MEHSU-18CHD2

Floor Ceiling

MEHSU-18CHF2

Cassette

24K

MEHSU-24CHC2

MCHSU-24PHH2

Duct

MEHSU-24CHD2

Floor Ceiling

MEHSU-24CHF2

Cassette

36K

MEHSU-36CSC2

MCHSU-36CSH2

Duct

MEHSU-36CSD2

Floor Ceiling

MEHSU-36CSF2

Cassette

48K

MEHSU-48CSC2

MCHSU-48CSH2;

Duct

MEHSU-48CSD2

Floor Ceiling

MEHSU-48CSF2

Page 7

5

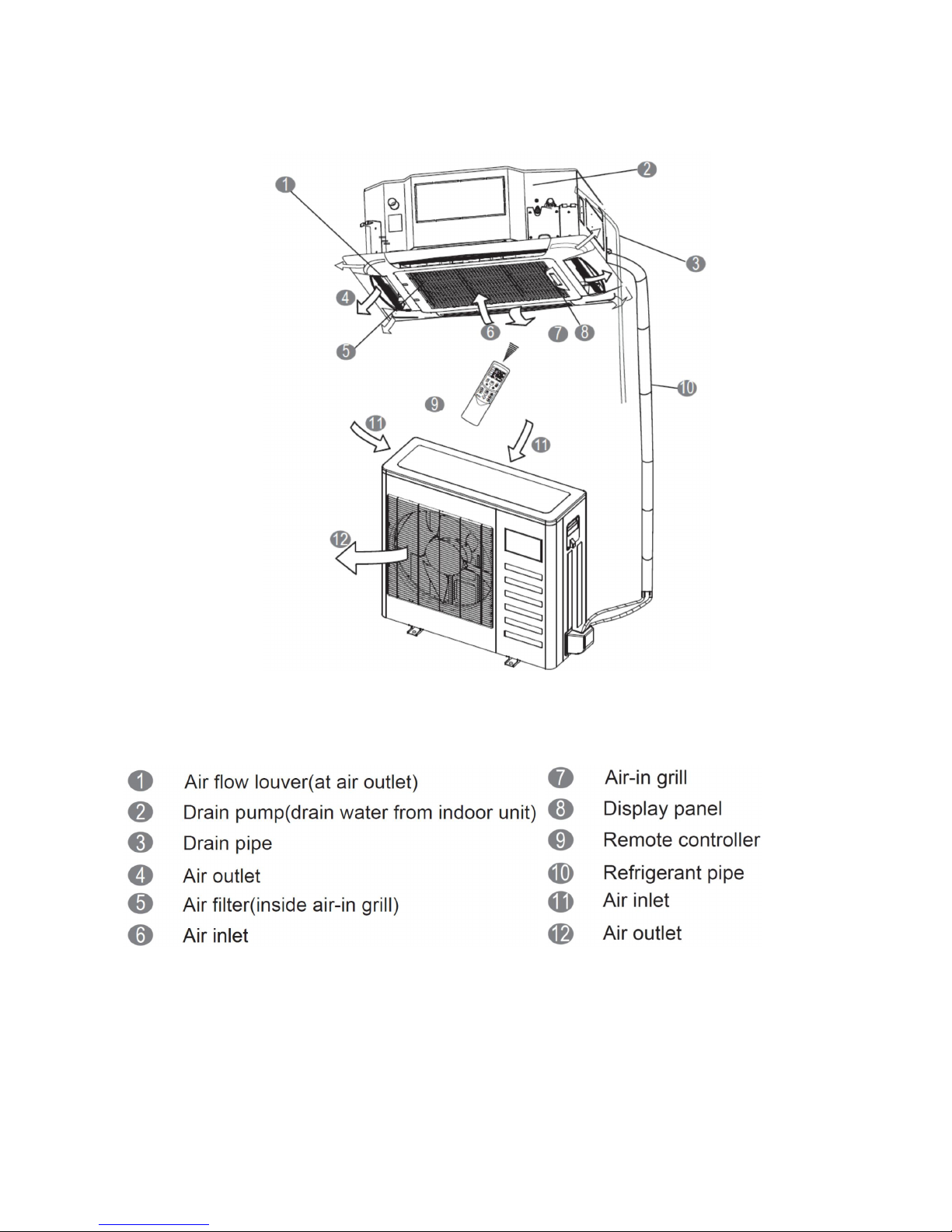

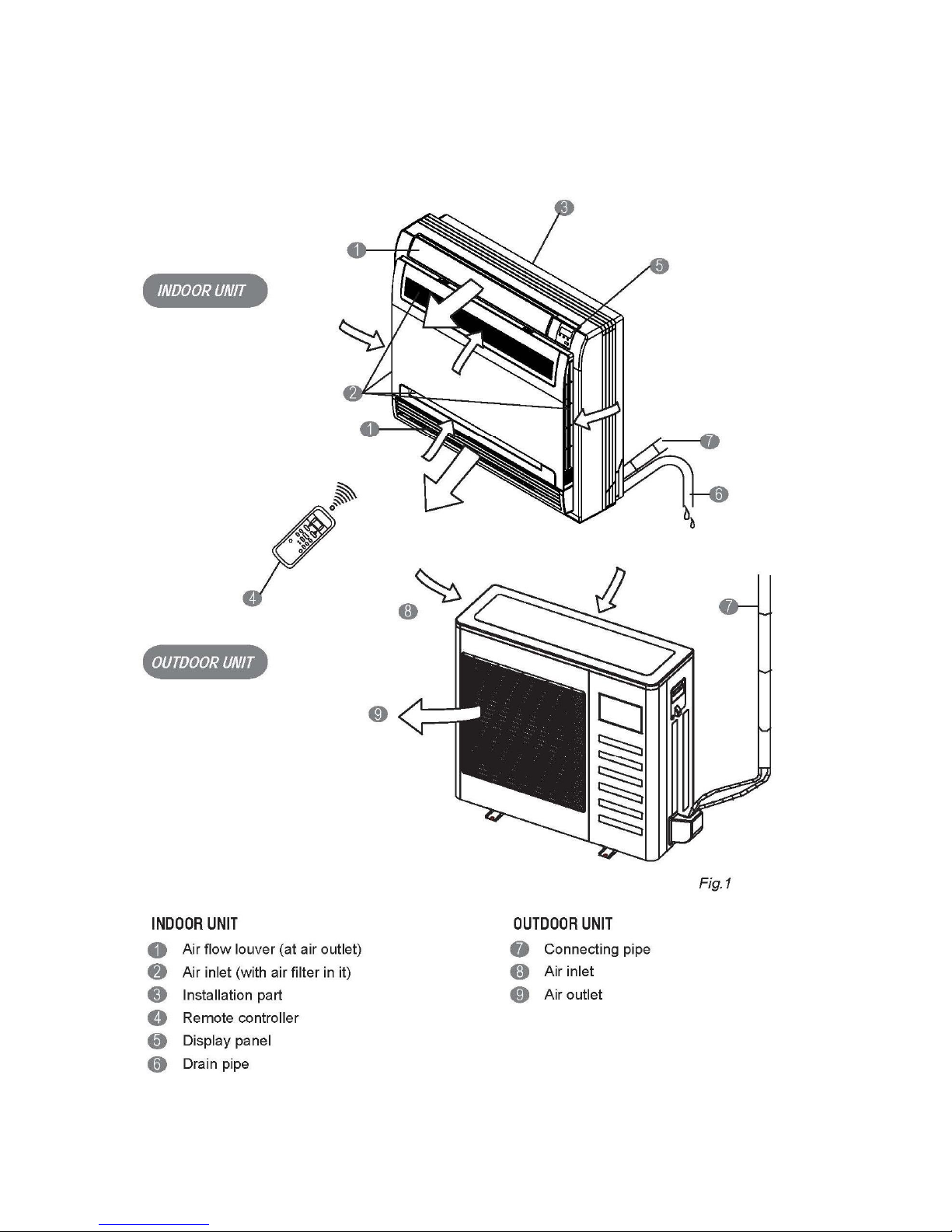

2.2 Part names of Indoor/Outdoor units

Cassette Unit

Page 8

6

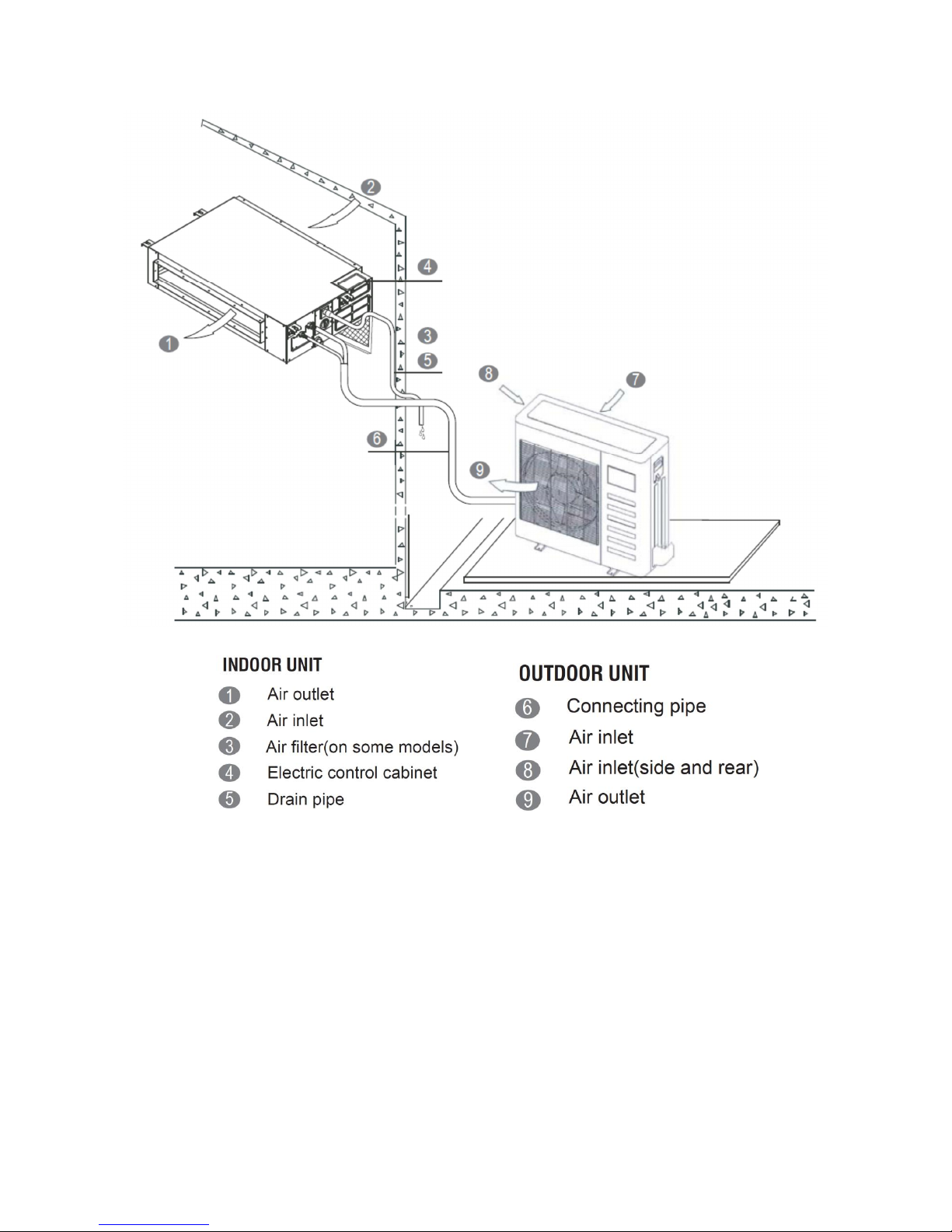

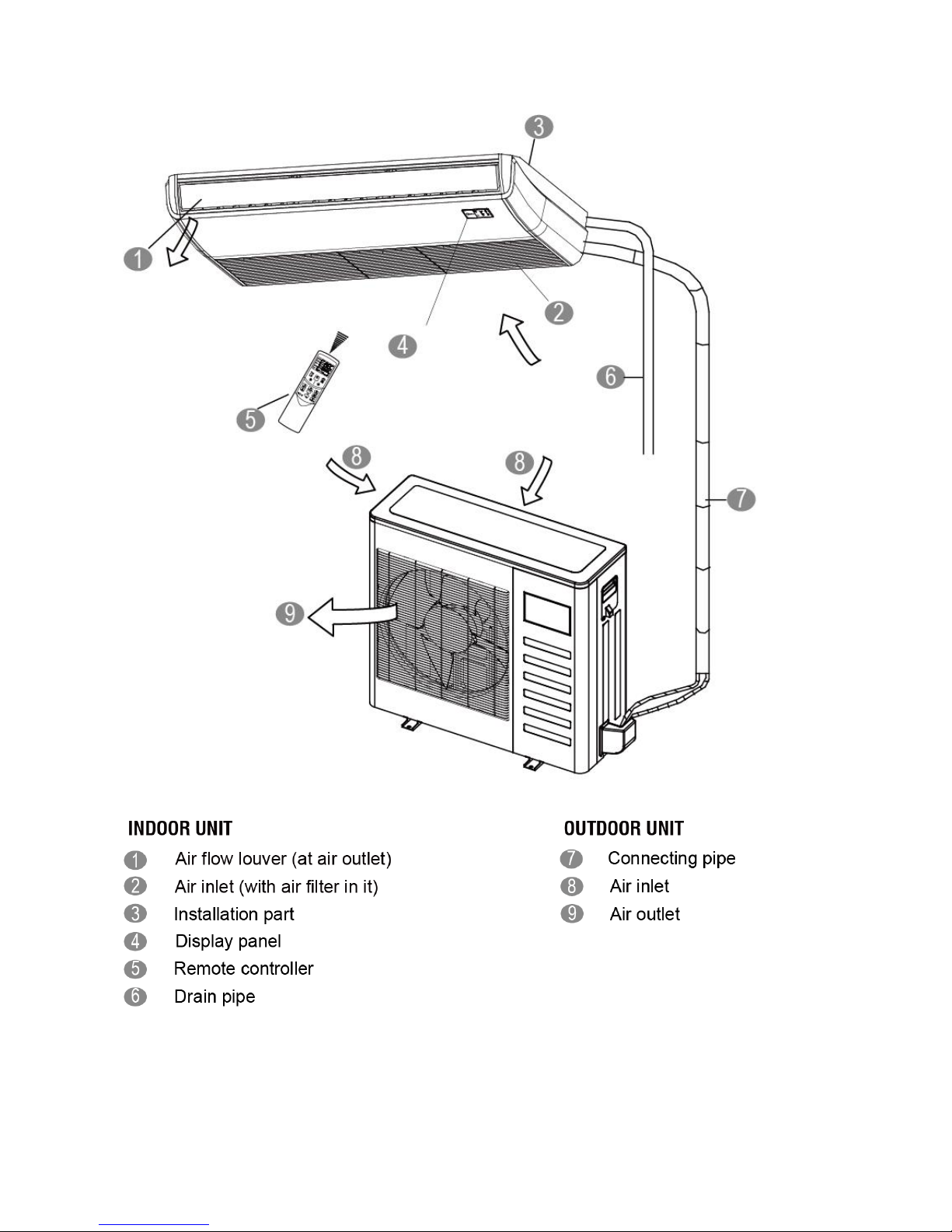

Duct Units

Page 9

7

Console

Page 10

8

Ceiling-floor Units

Page 11

9

2.3 Features

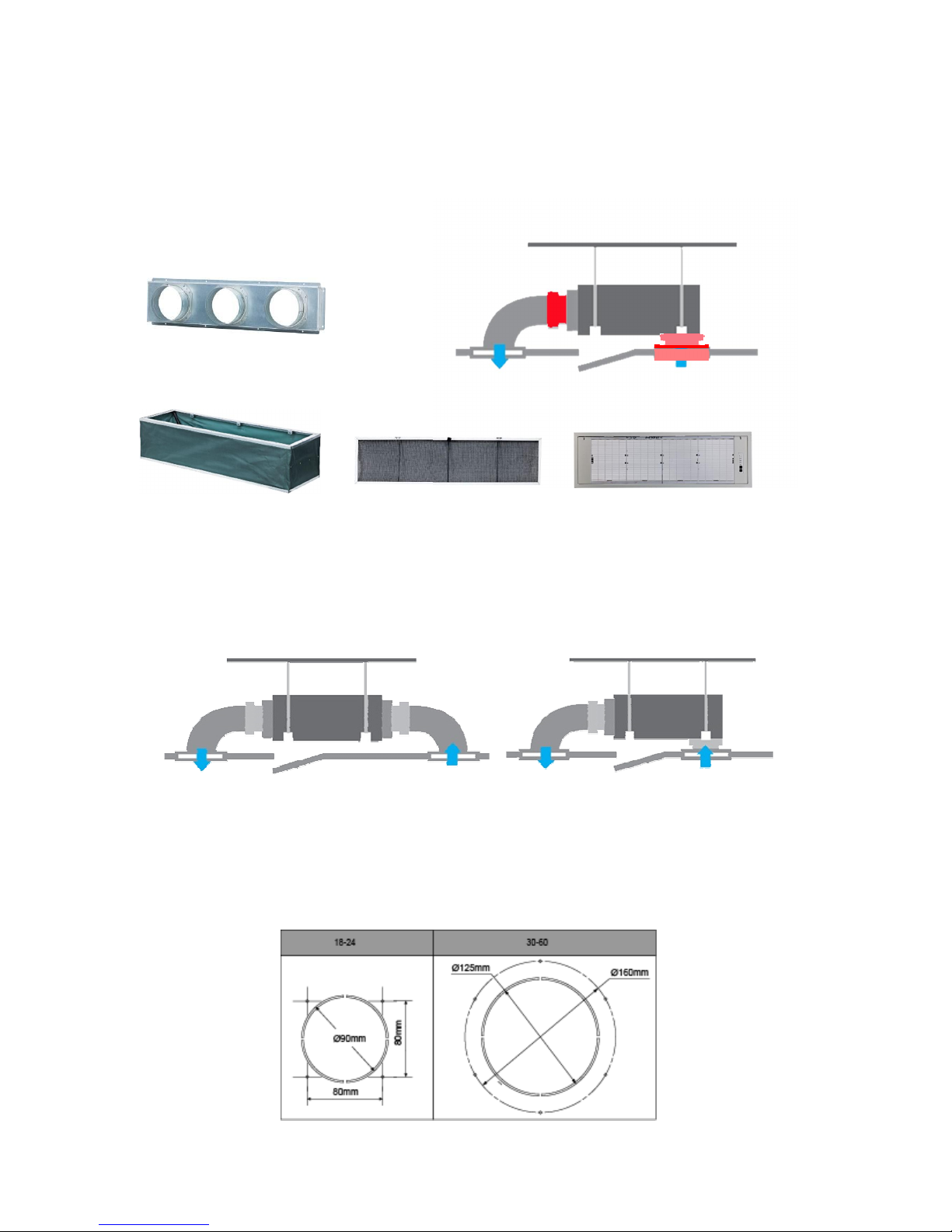

2.3.1 Duct Units

2.3.1.1 Installation Accessories: (Optional)

Front Board, Canvas Air Passage, Filter, Panel, for easy installation

2.3.1.2 Easy Installation: Two air Inlet Styles (Bottom side or Rear side)

Air inlet from rear is standard for all capacity; air inlet from bottom is optional.

The size of air inlet frame from rear and bottom is same, it’s very easy to move the cover from

bottom to rear side, or from rear to the bottom, in order to matching the installation condition.

2.3.1.3 Fresh Air Intake Function

Install one duct from the reserved fresh-air intake to outdoor.

Continually inhale the fresh air to improve the quality of the indoor air, fulfills air quality more

healthy and comfortable.

Panel

Air intake from rear (Standard)

Air intake from bottom (Optional)

6.30in

4.92in

3.15in

3.54in

Page 12

10

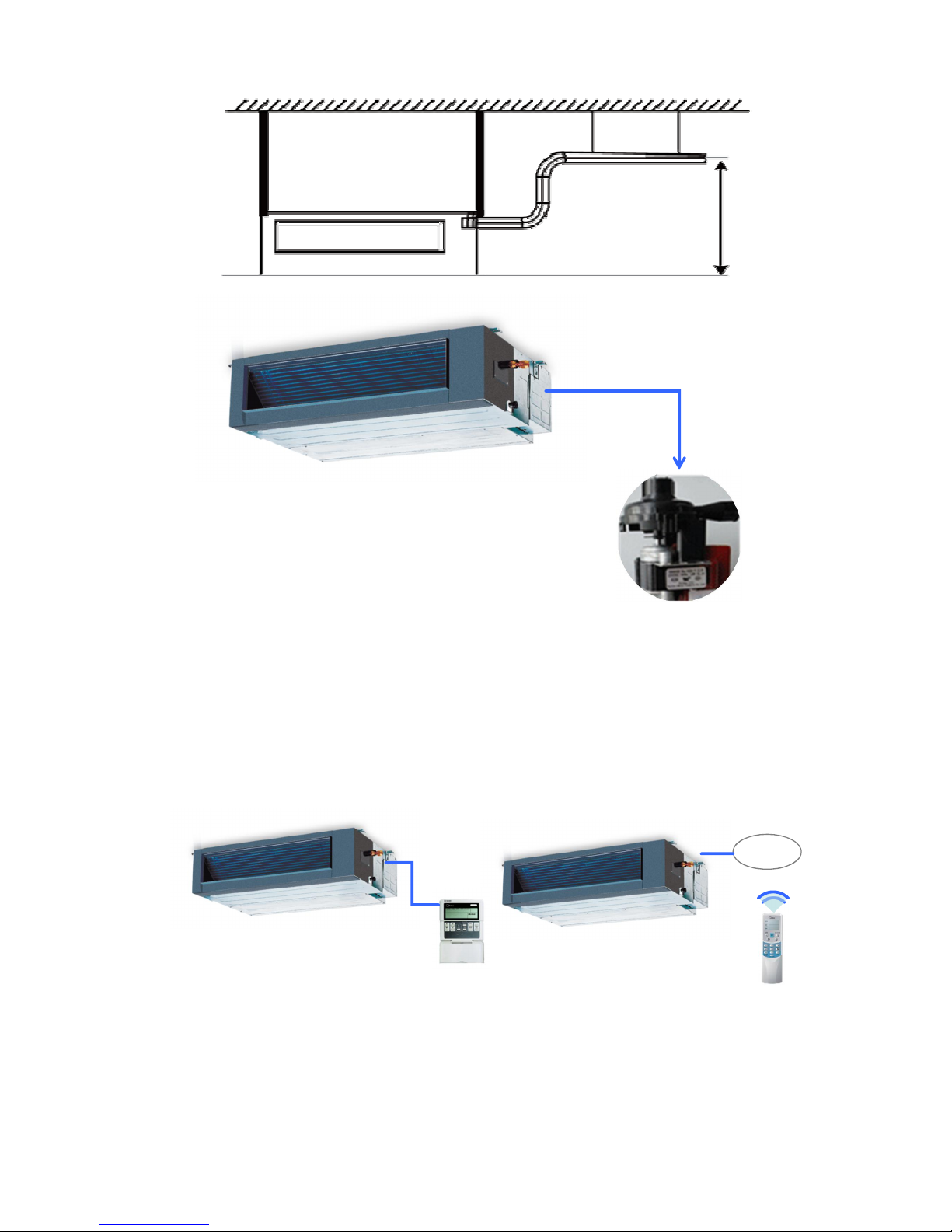

2.3.1.4 Easy Maintenance

Clean the filter (Optional, standard product without filter)

It is easy to draw out the filter from the indoor unit for cleaning, even the filter is installed in rear

side or bottom side.

Replace the motor or centrifugal fan

Remove the ventilated panel firstly. Remove a half of blower housing and take out the motor with

centrifugal fan. Directly remove two bolts, and then replace the motor or centrifugal fan easily.

2.3.1.5 Reserved Remote On-off and Central Control Ports

Reserved remote on-off ports and central control ports, can connect the cable of an on-off

controller or a central controller to realize remote on-off control function or group control function.

2.3.1.6 Built-in Drain Pump (Optional):

Built-in drain pump can lift the water to 750mm(29.53in) upmost. It’s convenient to install drainage

piping under most space condition.

Motor

Blower Housing

Ventilated Panel

Remote on-off ports Central control ports

Page 13

11

2.3.1.7 Built-in Display Board

The standard indoor unit can be controlled by wired controller.

There is a display board with a receiver in the E-box. Move out the display, and fix it in other place,

even in the distance of 2m(6.56ft). The unit will realized remoter control.

The wired controller and the display board can display the error code or production code when the

chips detect some failure.

Display

750mm(29.53in) upmost

Wired Controller (Standard)

Remote Controller (Optional)

Page 14

12

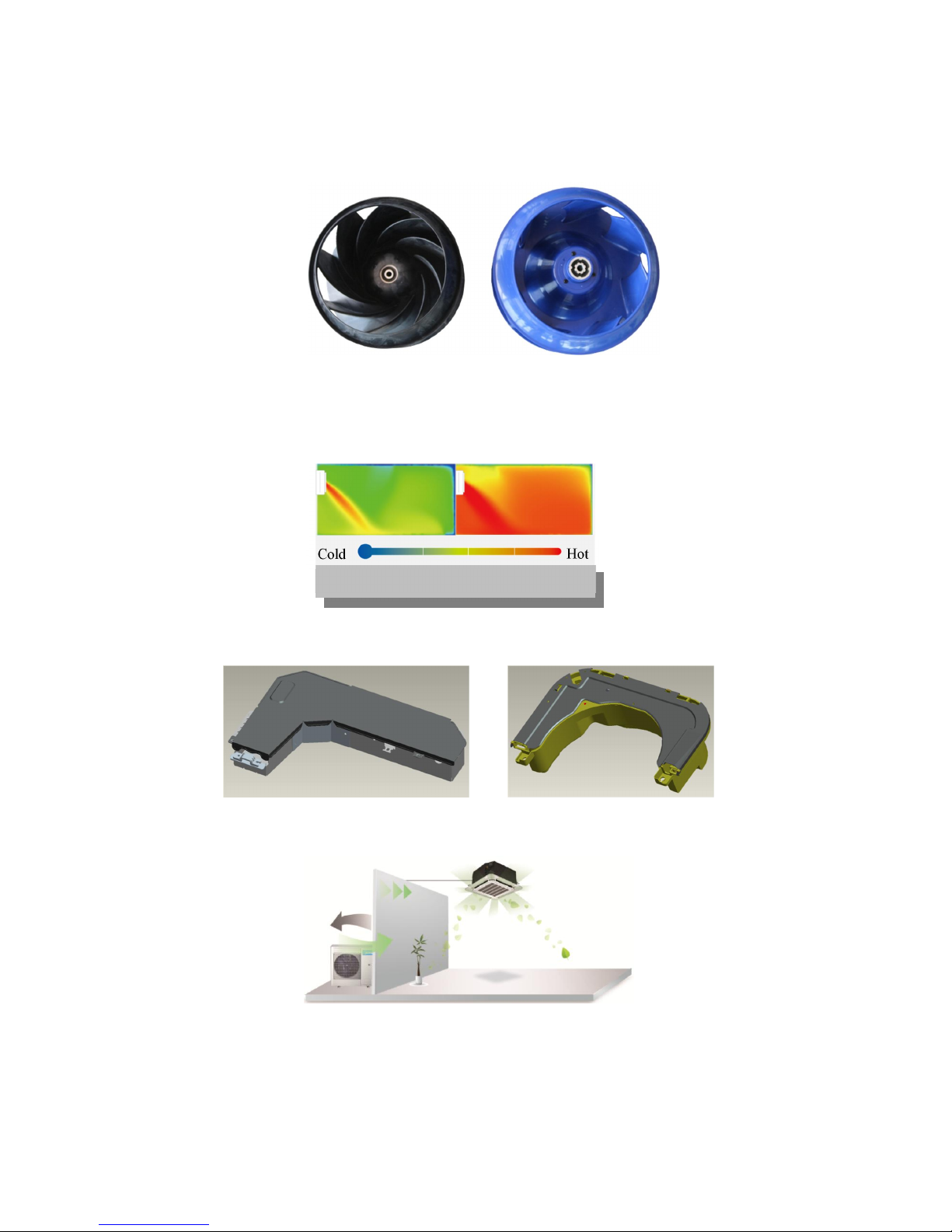

2.3.2 Cassette Unit

2.3.2.1 Lower Noise

Optimize air channel system design to ensure the maximum quietness and comfort.

Noise max down 6dB.

2.3.2.2 Turbo Mode (Optional)

Turbo function can boost cooling or heating speed in a short period, and makes the room cool

down or heat up rapidly.

2.3.2.3 Fire-proof Controller Box

Electrical control box adopts new design, which can meet higher fire safety requirements.

2.3.2.4 Fresh Air

Fresh air intake function bring you fresh and comfortable air feeling.

2.3.2.5 Wired Controller (Optional)

Compared with infrared remote controller, wired controller can be fixed on the wall and avoid

mislaying. It's mainly used for commercial zone and makes air conditioner control more

convenient.

Old

New

Turbo Mode (After 30 min)

Cold

Hot

Common vs. Turbo

Old

New

Page 15

13

2.3.2.6 Build-in Drain Pump

The drain pump can lift the condensing water up to 750mm(29.53in) upmost.

It’s convenient to install drainage piping under most space condition.

2.3.2.7Terminals For Alarm Lamp and Long-distance On-off Controller Connection Are

Standard

Reserve terminals for the connection of alarm lamp and long-distance on-off controller, more

human control.

Page 16

14

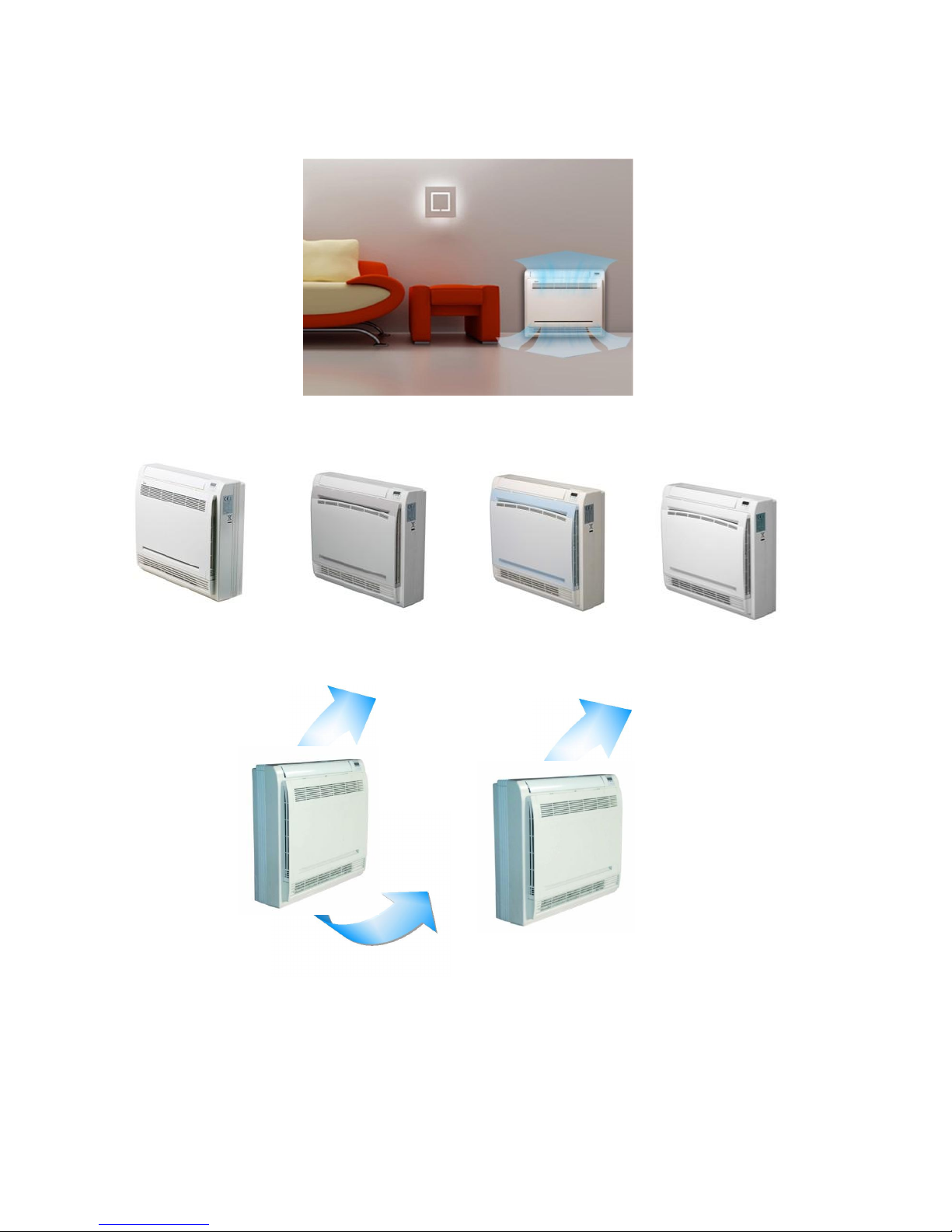

2.3.3 Console

2.3.3.1. Modern and Elegant Appearance

The simple and stylish designs can nicely harmonies with your living space.

3.2.3.2. Four Panels optional

2.3.3.3. Two Air-outlet Ways

Cooling mode

Quick Cooling To maintain room temp

Air outlet from top and bottom to make quick cooling ------When the A/C is just switched on, or

room temp. is still high, cold air will be blown out from top and bottom air outlet to cool down the

room quickly

Air outlet from top to maintain room temp. ----When the room has been cooled down, or the A/C

has been opened over 1 hour, cold air only from the top outlet to keep constant room temp

Page 17

15

Heating mode

Anti-cold air ------When the AC is just turn on, temperature of evaporator is very low, in this case,

in order to prevent cold air direct blowing, only the upper louver is opened in a high position, the

lower louver closed.

2.3.3.4. Four Air Inlets

2.3.3.5. Low Noise

DC indoor fan motor, which has five speeds.

Low noise and energy saving.

Advanced centrifugal fan technology makes a fast airflow and reduces the indoor noise.

2.3.3.6. Golden fin is optional.

2.3.3.7. Active carbon filter is standard

Page 18

16

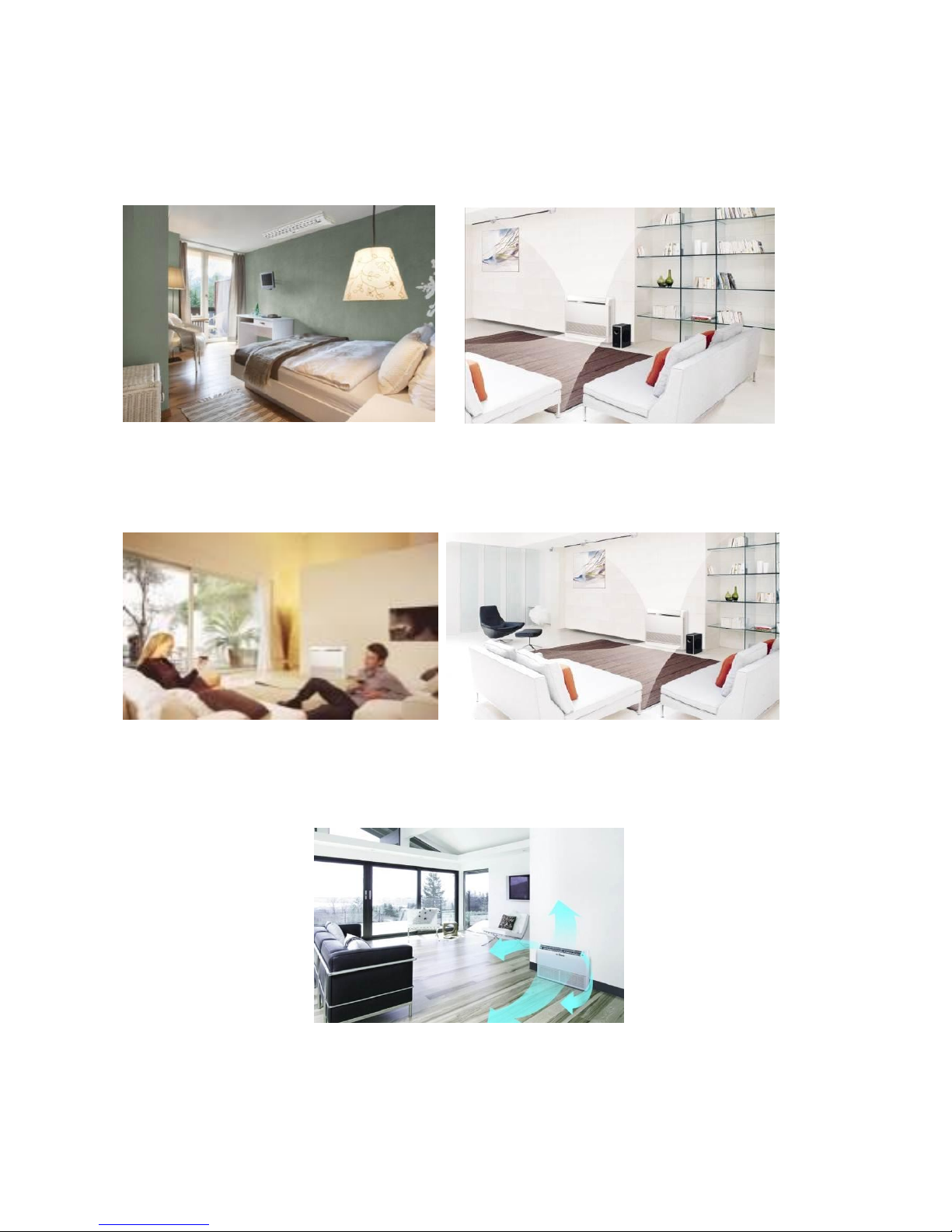

2.3.1 Ceiling-floor Units

2.3.1.1 Two-way Installation

The rounded design of the ceiling and floor type air conditioner allows either ceiling or floor-level

installation. Ceiling installation saves room space, while floor installation helps prevent the loss of

warm air.

2.3.1.2 Brief Design

Brief design that is suitable for any interior will not only give you cooling and heating performance

but also upgrade your lifestyle.

2.3.1.3 3D Airflow

Vertical air flow and horizontal airflow can be adjusted by remote controller, the cooperation of the two

airflow ways help to spread air comfortably throughout even a large room. With these functions, the

whole room can be evenly air-conditioned for both floor-level and ceiling installation.

Page 19

17

2.3.1.4 Optional Drainage Pipe Connection

Both right side and left side drainage holes are available to avoid the space limitation for drainage

pipe installation. Make you more convenient during installation.

C Panel (LED display) D Panel

2.3.1.5 Convenience Operating and Easy Maintenance

Remote controller as standard, wired controller for optional.

The filter without screw fixed, can be took out easily.

2.3.1.6 Easy Installation, Save Working Time

The pipes can be connected from bottom, back and right side, makes the installation more easily.

The wiring works can be finished before installation.

2.3.1.7 Outside Water Pump for Ceiling Installation Only. Floor Mount will require an

External Pump or Gravity Drain

Page 20

18

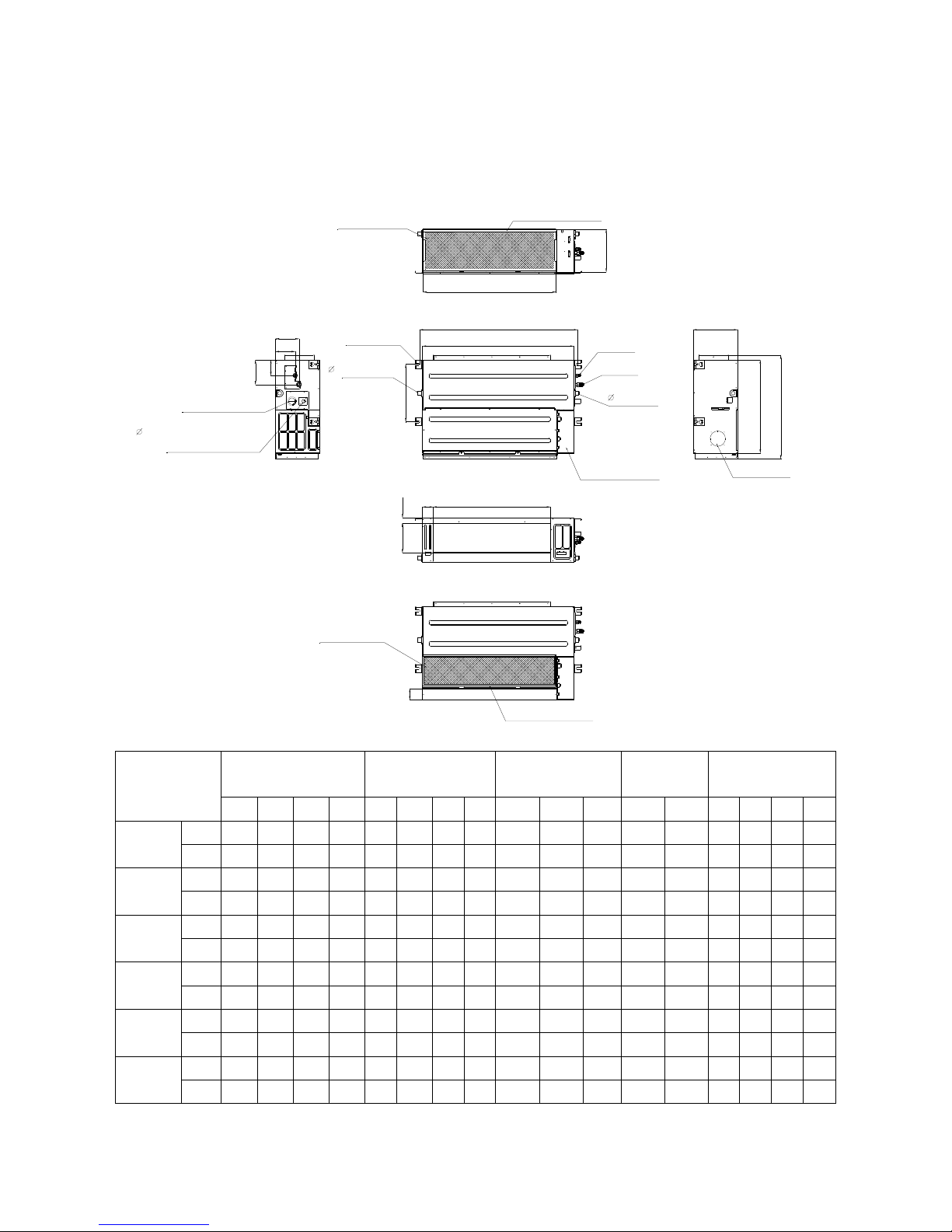

3. Dimension

3.1 Indoor Unit

Duct Units

A

C

B

D

J

I

K

Air filter ( optional )

air inlet from rear side

air inlet from bottom side

FE

GH

Electric control box

Air filter ( optional )

L

4-install hanger

Gas side

Liquid side

M

W1

W2

H1

H2

25 Drain connecting pipe

( for pump )

Test mouth & Test cover

Fresh air intake

25 Drain pipe

25 Drain pipe

Capacity (KBtu)

Outline dimension(mm) Air outlet opening size Air return opening size

Size of install

hanger

Size of refrigerant pipe

A B C D E F G H

I J K L M H1 H2 W1 W2

9

mm

700 210 635 570 65 493 35 119 595 200 80 740 350 120 143 95 150

in

27.56 8.27 25 22.44 2.56 19.41 1.38 4.69 23.43 7.87 3.15 29.13 13.78 4.72 5.63 3.74 5.91

12

mm

700 210 635 570 65 493 35 119 595 200 80 740 350 120 143 95 150

in

27.56 8.27 25 22.44 2.56 19.41 1.38 4.69 23.43 7.87 3.15 29.13 13.78 4.72 5.63 3.74 5.91

18

mm

920 210 635 570 65 713 35 119 815 200 80 960 350 120 143 95 150

in

36.22 8.27 25.00 22.44 2.56 28.07 1.38 4.69 32.09 7.87 3.15 37.80 13.78 4.72 5.63 3.74 5.91

24

mm

920 270 635 570 65 713 35 179 815 260 20 960 350 120 143 95 150

in

36.22 10.63 25.00 22.44 2.56 28.07 1.38 7.05 32.09 10.24 0.78 37.80 13 .78 4.72 5.63 3.74 5.91

36

mm

1140 270 775 710 65 933 35 179 1035 260 20 1180 490 120 143 95 150

in

44.88 10.63 30.51 27.95 2.56 36.73 1.38 7.05 40.75 10.24 0.78 46.46 19 .29 4.72 5.63 3.74 5.91

48

mm

1200 300 865 800 80 968 40 204 1094 288 45 1240 500 175 198 155 210

in

47.24 11.81 34.06 31.50 3.15 38.11 1.57 8.03 43.07 11.34 1.77 48.82 19 .69 6.89 7.80 6.10 8.27

1 in

Page 21

19

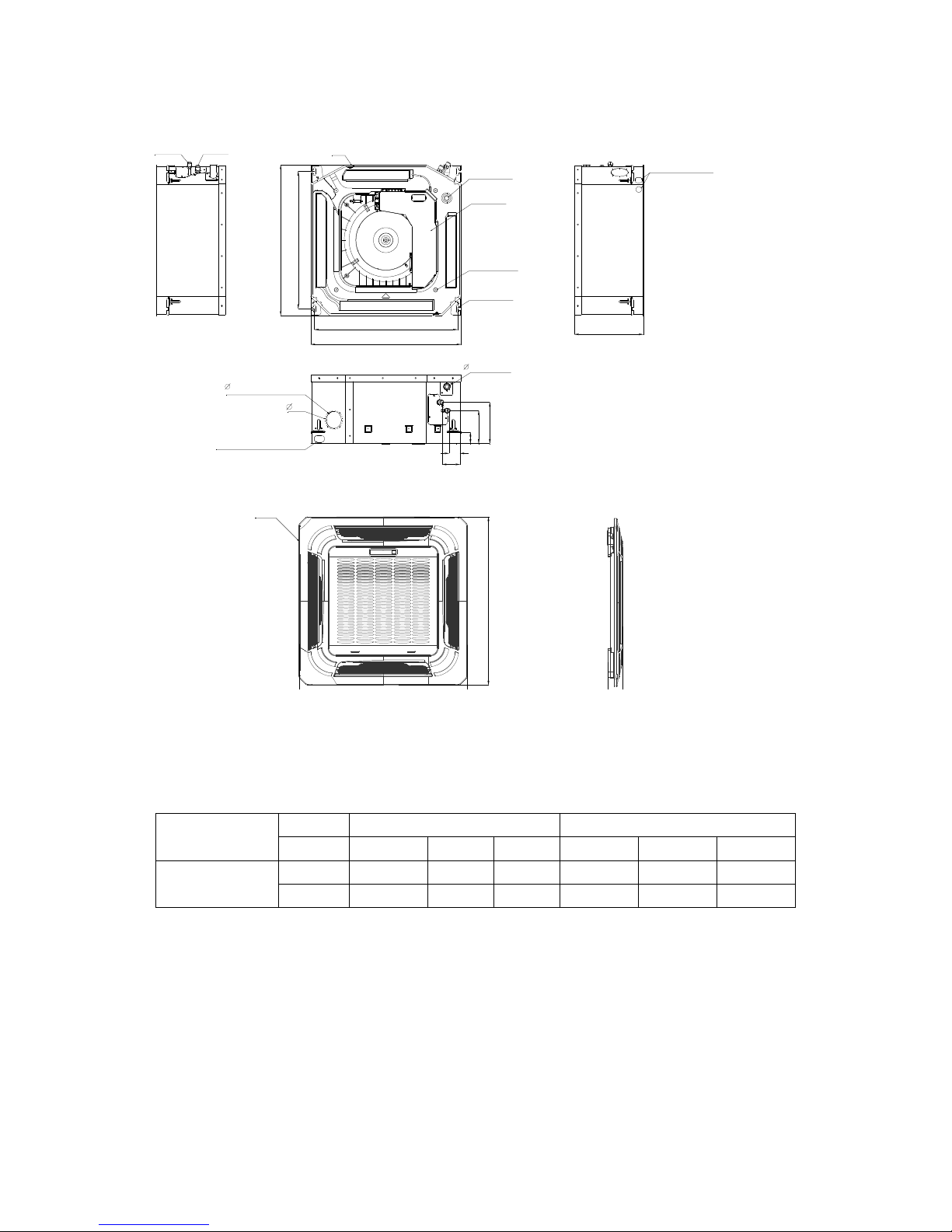

Cassette Units(9K, 12K, 18K)

Panel

Gas side

Liquid side

4-install hanger

Body

Drain pipe32

Fresh air intake

65

647

Drain hole

( for Service )

545

570

260

68

42

157

126

44

Wiring connection port

75

E-parts box

4-Screw hole

(for install panel)

523

570

Wiring connection port

Capacity (Btu/h)

Body Panel

W D H W1 D1 H1

9K/12K/18K

mm 570 260 570 647 50 647

inch 22.44 10.24 22.44 25.47 1.97 25.47

22.44in

(21.46in)

10.24in

25.47in

(20.59in)

1-1/4in

2.95in

2.56in

Page 22

20

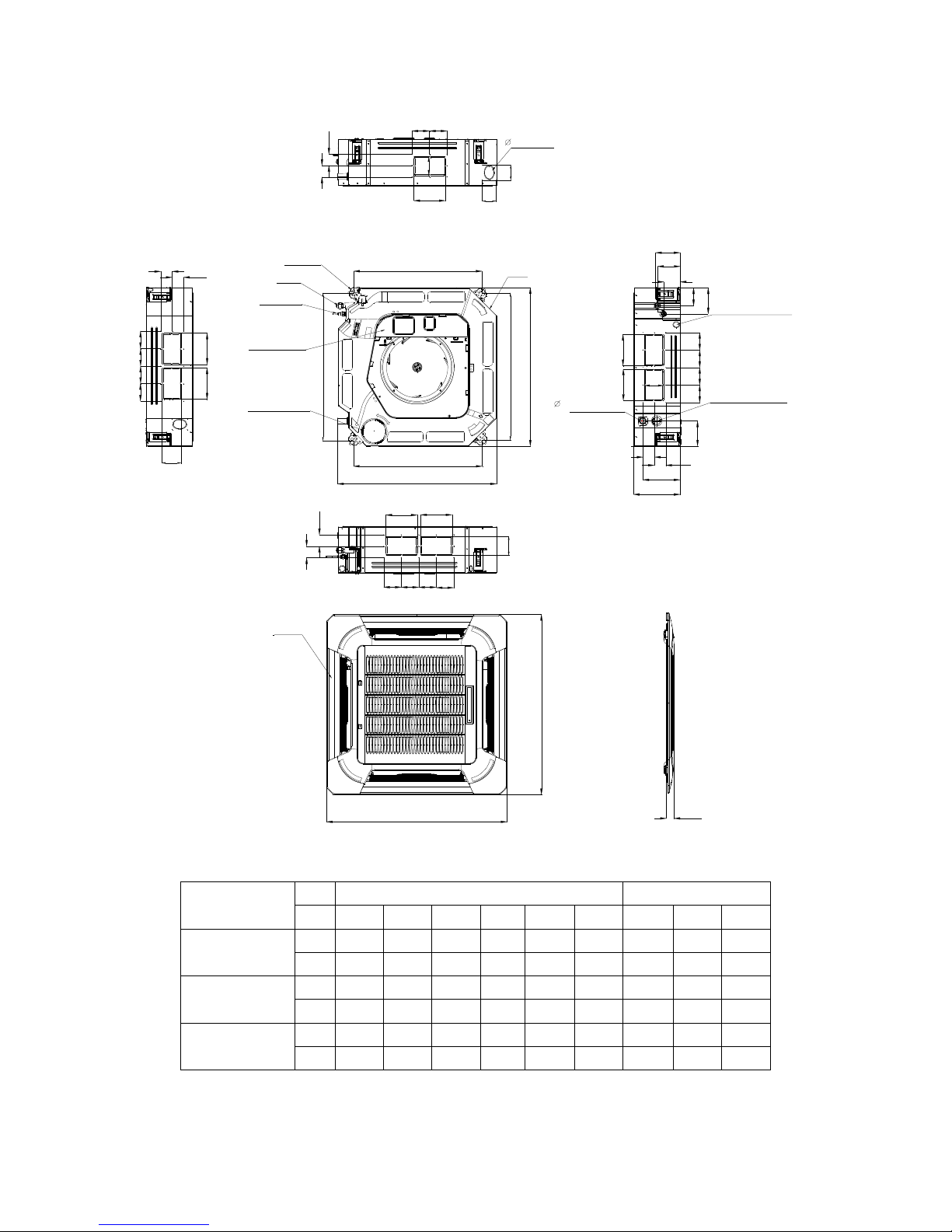

Cassette Units (24K, 36K, 48K)

840

840

950

950

C

Test mouth &

Test cover

Drain hole

32

Wiring connection port

680

780

780

680

136

126

91

196

132

A

A

B

A

A

B

AA

B

A

B

Service hole for

draining pump

Fresh air intake

75

55

80

80

4-install hanger

Gas side

Liquid side

E-parts box

135

90

Panel

Body

92929292

D

D

92 92

D

D

D

D

92

9292

92

92 92 92

92

D

D

Capacity

(Btu/h)

Body Panel

W C H A B D W1 D1 H1

24K

mm 840 205 840 160 75 50 950 55 950

inch 33.07 8.07 33.07 6.30 2.95 1.97 37.40 2.17 37.40

36K

mm 840 245 840 160 95 60 950 55 950

inch 33.07 9.65 33.07 6.30 3.74 2.36 37.40 2.17 37.40

48K

mm 840 287 840 160 95 60 950 55 950

inch 33.07 11.30 33.07 6.30 3.74 2.36 37.40 2.17 37.40

2.95in

3.62in

1-1/4in

3.15in

26.77in

(5.35in)

(4.96in)

(37.40in)

(2.17in)

(3.58in)

(33.07in)

(30.70in)

(7.72in)

(5.20in)

(5.31in)

Page 23

21

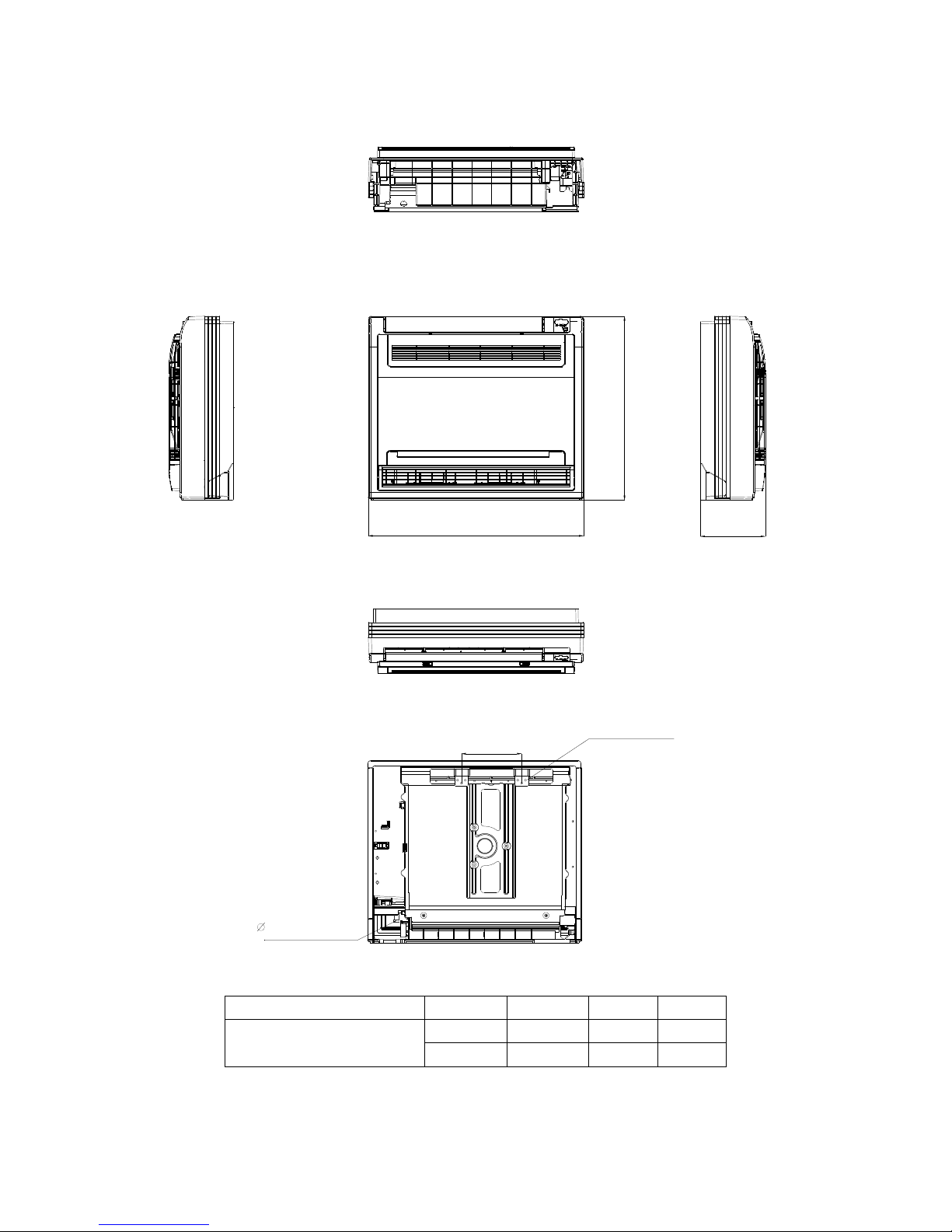

Console Units

16 Drain pipe

195

Hanging arm

Unit: mm

700

600

210

Capacity (Btu/h)

W D H

9K / 12K

mm 700 210 600

inch 27.56 8.27 23.62

(27.56in)

(23.62in)

(8.27in)

(7.68in)

(5/8in)

Page 24

22

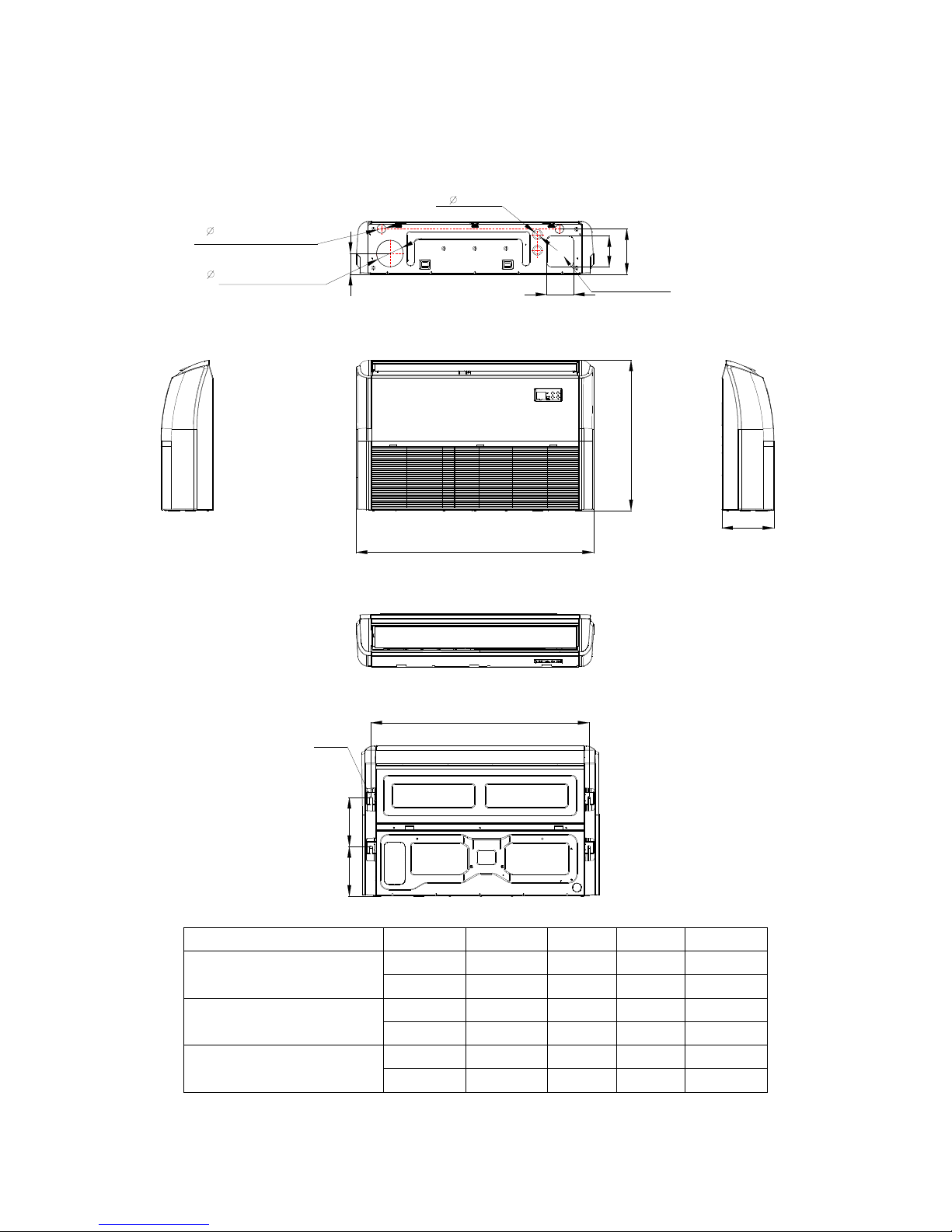

Ceiling-floor Units (18K-48K)

A

B

220

222

C

120

2

-

4

0

120

140

2

-

3

3

Wiring connection port

204

94

Fresh air intake

Drain discharge port

Refrigerant pipe hole

Hanging arm

D

Capacity (Btu/h)

A B C D

18K / 24K

mm 1068 675 235 983

inch 42.05 26.57 9.25 38.70

36K

mm 1285 675 235 1200

inch 50.59 26.57 9.25 47.24

48K

mm 1650 675 235 1565

inch 64.96 26.57 9.25 61.61

(1.30in)

(1.57in)

(4.72in)

(4.72in)

(8.03in)

(5.51in)

(8.66in)

(8.74in)

Page 25

23

3.2 Outdoor Unit

Note: The above drawing is only for reference. The appearance of your units may be different.

Model W D H W1 A B

MCHSU-09PHH2

MCHSU-12PHH2

mm

800 333 554 870 514 340

inch

31.5 13.1 21.8 34.3 20.2 13.4

MCHSU-18PHH2

mm

845 363 702 914 540 350

inch

33.3 14.3 27.6 36.0 21.3 13.8

MCHSU-24PHH2

MCHS-30PSH2

mm

946 420 810 1030 673 403

inch

37.2 16.5 31.9 40.6 26.5 15.9

A

B

D

Page 26

24

Model W D H W1 A B

MCHSU-48CSH2

mm

952 415 1333 1045 634 404

inch

37.5 16.3 52.5 41.1 25.0 15.9

Page 27

25

4. Service Space

4.1 Indoor Unit

Duct Units

Ensure enough space required for installation and maintenance.

200mm(7.87in) or more

300mm(11.81in) or more

600mmx600mm/23.62inx23.62in

Check orifice

All the indoor units reserve the hole to connect the fresh air pipe. The hole size as following

Cassette Units

Unit: mm/inch

39.3

98.43

11.42

39.3

10.24

6.30in

4.92in

3.15mm

3.54mm

Page 28

26

Console Unit

Ceiling-floor Units

39.37

39.37in

3.94in

39.37in

1.38in

Page 29

27

4.2 Outdoor Unit

More than 30cm

(11.81in)

More than 60cm

(23.62in)

More than 200cm(78.74in)

Air inlet

Air inlet

More than 30cm(11.81in)

Air outlet

(Wall or obstacle)

Maintain channel

More than 60cm

(23.62in)

Page 30

28

5. Refrigerant Cycle Diagram

LIQUID SIDE

GAS SIDE

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

2-WAY VALVE

3-WAY VALVE

4-WAY VALVE

COOLING

HEATING

T2B Evaporator

temp. sensor

outlet

T1 Room temp.

sensor

T3 Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

T2 Evaporator

temp. sensor

middle

Electronic

expansion valve

CAPILIARY TUBE

Page 31

29

6. Wiring Diagram

6.1 Indoor Unit

MEHSU-09CHC2, MEHSU-12CHC2, MEHSU-18CHC2,

MEHSU-24CHC2

MEHSU-09CHD2, MEHSU-12CHD2, MEHSU-18CHD2,MEHSU-24CHD2

Page 32

30

MEHSU-09CHN2, MEHSU-12CHN2

MEHSU-36CSC2, MEHSU-48CSC2

Page 33

31

MEHSU-36CSD2, MEHSU-48CSD2

Page 34

32

MEHSU-18CHF2, MEHSU-24CHF2

MEHSU-36CSF2

Page 35

33

MEHSU-48CSF2

MEHSU-36CSF2,MEHSU-48CSF2

Page 36

34

6.2 Outdoor Unit

MCHSU-09PHH2 ,MCHSU-12PHH2 , MCHSU-18PHH2

Page 37

35

MCHSU-24PHH2

Page 38

36

MCHSU-36CSH2

Page 39

37

MCHSU-48CSH2

PCB board of

MCHSU-09PHH2, MCHSU-12PHH2, MCHSU-18PHH2

Suction

Exhaust

+

17122200000309

HuiQi

TestPort

1

1

HEAT

4-WAY

W

BLUE

BLACK

RED

V

U

TPT3T4

No

NO

NO

YES

Low-Fre

No

Have

YES

Have

Temp-Pro

Rdi

Ripm

11

PMV

44

15V17V

[V1.8] 2015-01-16

7815

22

1

34

REACTOR

311 TEST

7805

N-IN

DC-FAN

AC-FAN

L-IN

S

KFR-72W/BP2-(311+0515+6061HD+PSS30S92F6-AG+6822+HEAT).D.13.WP2.1

12V 5V

CN3

DSA1

K

A

K

D5

R18

R46

R

1

0

7

A

R515A

R316A

R18A

IC403

D4

C21

R54

R55

R68

R69

R56

R90

C14

J4

R16

R52

J5

+

LED1

R78

R142

R141

R155

R154

R153

R152

R151

R150

C3

R108

R107

RC2

RC4

RC1

RC3

C1

FUSE1

65T 250V30A

ZR1

ZR2

CN30

R109

R58

R61

R60

R59

C301

C76

C312

R315

C83

C85

C86

C91

R156R158

R169

R170

R171

R172

IC34

D11

R157

R159

C310

C306

C308

C311

C307

C309

R110

E305

C302

+

DZ301

Q3

R75

R84

C103

CN28

CN29

CN6-1

CN6

CN13

CN12

CN2

CN8

CN7

CN22

DR

CN21

DR

R102

J6

PTC1

CN414

R127

C105

+

E5

IPM2

C501

C503

C507

C508

C509

C510

C511

C512

C517

+

DZ501

R501

R502

R503

R504

R505

R506

R509

R510

R511

R512

R513

R514

R523

C502

C505

+

DZ502

R515

R522

+

DZ504

C504

R316

~ ~

IN

AC

-

+

R101

R100

R71

C42

CN20

RY5

CN16

CN18

NTC4

C8

C513

C514

C515

C516

R516

R517

R518

R519

R520

R521

C27

IC7

24LC512

33

49

17

1

IC9

R53

IC101

R160

+

E4

+

E3

R83

R82R81

R80

R79

R50

C47

C20

R322

R321

R320

Q2

IC405

+

E10

R120

R167

R166

R32

+

E1

R12

+

LED3

R412

R413

R414

R415

Rdi

Ripm

R13

CN24

R72

R8

R87

R74

J3

IC17

+

E24

D2

R124

C2

J2

J1

C77

AC AC

+

-

BR1

C13

D3

R7

RY3

RY4

RY2

CN5

R23

R24

R25

R26

R27

C74

C75

RY1

+

E14

C9

C17

C18

C19

C23

C24

C26

C32

C33

C35

C36

C37

C39

C43

C48

C49

C52

C65C67

C78

C87

C89

C90

C92

C147

C153

C25

CN9

CN23

CN39

+

E17

+

E23

+

E28

IC8

24LC08

IC12

24LC08

IC14

+

LED2

OSC1

R5

R30

R31

R40

R41

R42

R48

R49

R62

R64

R65 R66

R70

R73

R76

R77

R86

R92

R97

R161

R162

R163

R164

R165

R176

R177

R419

X1

C58

+

+

E405

IC404

R45

Q1

C15

C22

R21

R22

R28

R29

R33

+

E22

R3

R4

R121

C5

+

E6

R10

C28

C4

CN38

IC10

C79

C80

D7

C6

R148

R63

C506

R507

R508

+

E11

R106

C73

IC21

PC817

IC31

PC817

R175

R178

C409

IC402

C403

IC11

+

E402

D401

C401

R403

C411

C40

C50

D403

R401

R405

R406

R404

+

E404

D402

D404

C408

C402

+

E403

R407

R408

C404

C110

+

E409

+

E401

R402

C405

10

9

7

6

5

4

3

1

T401

C406

C407

D13

D14

+

E406

+

E407

+

E408

+

E502

+

E503

+

E504

+

DZ503

CN25

R6

R9

CN60

IC406

IC407

C7

D1

R1

R137

IC2

PC851

IC1

PC817

R2

R126

R125

R123

R122

R119

R118

R117

R15

R14

C99

C98

C97

C96

C95

C94

C93

C66

D20

R17

CN17

CN10

CN1

C41

R38

C45

C44

R136

R135

R134

R104

D12

D10

C54

+

D8

D9

R57

R20

C242

C243C244

R89

E2

R67

C84

C10

C11

IC4

C12

C38

R34

R47

R88

IC32

R39

R35

R36

R19

+

DZ6

R37

C46

C51

C53

CN19

+

DZ2

+

E27

IC3

PC817

IC5

PC817

Q8

R43

R44

R85

R91

R93

R95

R96

R99

D15

R51

+

E410

+

E8

C60

C61

E302

E303

E304

C62

VN1

VP1

U

P

VUB

U+

W

V+

V

W+

U-

VVB

VWB

FO

WV-

NV

NW

NU

VNC

CIN

IPM1

+

DZ304

+

DZ303

+

DZ302

C314

C316

C318

C30

C34

C31

ZR3

ZR4

C82

L1

R11

R140

CN27

E301

R168

IGBT1

connect to the DR module

connect to earth

fuse 250V 30A

connect to reactance

290-330VDC standby

210-300VDC running

power supply 208-230V AC connect to the terminal

connect to 4-way valve

when 4-way is on, output 208-230V AC

AC FAN mototr

connect to compressor heater

when heater is on, output 208-230V AC

1 low speed

2 hign speed

3 ground

external drive motor

connect to DC motor

0V AC standby

10~200V AC’ running

U

V

W

connect to electric expansion valve

6 5 4 3 2 1

+12VDC

+12VDC

+12V DC pulse wave between( +4)-GND

+12V DC pulse wave between( +3)-GND

+12V DC pulse wave between( +2)-GND

+12V DC pulse wave between( +1)-GND

EEPROM Programmer Port

reserve

test port

Connect to PC

communication

V

U

W

connect to PC communication

test port

LED2 (red)&LED3(green): status light

combination LED2 and LED3 show errors

(

refer to the attechment Word

)

LED: status light(yellow

)

slow flicker:standby(0.5Hz

)

quick flicker:error (2Hz

)

continuous light: running

internal drive motor

6 5 4 3 1

rotate speed feedback signal

0-15V square signal

drive power voltage: +15VDC

DC negative pole: GND

DC positive pole P: 315VDC

exhaust temp. sensor

pipe temp.sensor& room temp. sensor

TP T4 T3

7 6 5 4 3 2 1

RT

+5V DC

RT

RT

+5V DC

+5V DC

CN5/CN4 connect to chassis heater

when heater is on, output 208-230V AC

connect to DC motor

0V AC standby

10~200V AC’ running

bridge

IGBT

fast recovery diode

(FRD)

IPM for compressor

IPM for DC FAN

reserve

P

N

Page 40

38

For MCHSU-24PHH2, MCHSU-36CSH2,

N

L

SHOW/SW

EARTH

[1.4]2014.06.26

EU-KFR105W/BP3T5N1-350S.D.13.WP1-1

L-OUT

N-OUT

CONNECT TO INVERTER driver

HIGH

LOW

T2B-E T2B-DT2B-C

T2B-B

T2B-A

TP

T4

T3

S-E

S-D

S-C

S-B

S-A

FAN_OUT

FAN_IN

Q

E

P

AB

C

D

E

202302141206

CN19

D4

R134

R133

R89

R37

+

E12

+

E15

CN10

N

C18

CN9

ZR3

ZR2

ZR1

X1

S

RY8

RY7

RY6

RY5

RY3

RY2

R213

R212

R211

R210

R180

R170

R140

R131

R130

R129

R128

R127

R126

R125

R124

R123

R121

R120

R118

R117

R116

R115

R114

R113

R112

R111

R110

R109

R108

R107

R106

R105

R104

R103

R102

R101

R100

R99

R98

R96

R95

R94

R93

R92

R91

R90

R88

R81

R80

R79

R78

R77

R76

R75

R74

R73

R72

R71

R70

R69

R68

R67

R66

R65

R64

R63

R62

R61

R60

R59

R58

R57

R56

R55

R54 R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R36

R35

R34

R33

R32

R31

R30

R29

R28

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

Q5

Q2

PTC1

LED1

L3

IC30

IC22

IC21

IC20

IC19

IC18

IC17

IC16

IC15

IC14

IC13

IC12

IC10

IC9

IC8

IC7

IC6

IC5

IC2

IC1

FUSE2

5A/250V

FUSE1

T30A/250V

E21

E20

+

E19

+

E16+E14

E13

E11

E9

E8

E5

E4

E3

E1

DSP1

DSA1

D28

D27

D26

D25

D24

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D3

D2

D1

CONdebug

CN44

HEAT2

CN43

FAN

CN42

C

CN41

C

CN40

HEAT1

CN34

CN33

CN30

CN29

CN28

CN27

CN26

CN22

4-WAY

CN20

CN18

CN17

CN16

CN14

CompTop

CN12

CN11

CN8

CN6

CN5

CN4

N

CN3

N

CN2

N-IN

CN1

L-IN

C103

C98

C97

C96

C95

C94

C93

C92

C91

C90

C72

C70

C69

C68

C67

C66

C65

C64

C62

C61

C60

C59

C58

C57

C56

C55

C54

C53

C52

C51

C50

C49

C48

C47

C46

C45

C44

C43

C42

C41

C40

C39

C38

C37

C36

C35

C34

C33

C32

C31

C30

C29

C28

C27

C26

C25

C24

C23

C22

C21

C20

C19

C17

C16

C15

C14

C13

C12

C11

C10

C9

C8

C7

C6

C5

C4

C3

C2

C1

JP1

JP2

D29

D30

CN23

~ ~

-++-

SSR1

CN7

CN13

P-1

L1

R82

R83

R84

R85

R86

R87

R97

R119

R122

R132

CN35

N

CN37

FAN-L

Q3

Q6

Q7

Q8

Q9

CN36

FAN-H

E2

IC3

Q1

Q4

IC4

ZR4

RY4

CN32

CN38

L2

R135

SW1

CN21

Electric Expansion

Value B

Electric Expansion

Value E

Electric Expansion

Value D

Electric Expansion

Value C

Electric Expansion

Value A

485

communication

testPort

connect to detector

external drive DC fan

motor input terminal

external drive DC fan

motor ouput terminal

current loop

communication A

current loop

communication B

current loop

communication C

current loop

communication D

current loop

communication E

digital display

Fuse

T30A/250V

connect to high and low

pressure sensor

connect to

trmp. sensor

Fuse 5A/250V

connect to earth

CN23 reserve

digital display button

test report

connect to detector

CN43-5,CN43-1/CN41,CN42

AC fan motor capacitor

connector

CN43-4/CN37 CONNECT TO

AC FAN MOTOR(LOW SPEED)

CN43-3/CN36

AC fan motor low speed

connector

CN43-2/CN35

AV fan motor N phase

current loop

communication C

Signal wire

24VDC Pulse wave

connect to the terminal

connect to the terminal

208-230V AC

power supply

room temp sensor

pipe temp sensor

(3.3V)

(3.3V)

high pressure sensor

low pressure sensor

Connect to the Indoor evap.pipe

out temp. sensor

T2B-A、T2B-B、T2B-C、T2B-D、T2B-E

+12V DC pulse wave between (+1)-GND

+12V DC pulse wave between (+2)-GND

+12V DC pulse wave between (+3)-GND

+12V DC pulse wave between (+4)-GND

+12V DC

+12V DC

6 5 4 3 2 1

when 4-way is ON, output 208-230VAC

connect to the 4-WAY

when heater is ON, output 208-230V AC

connect to compressor heater

CN44 L

CN10 N

CN40 L

CN4 N

CN22 L

CN3 N

connect to exhaust

temp. sensor

connect to the terminal

208-230V AC

external drive DC fan

motor connector

T3

T4

electric

heater1

electric

heater 2

Page 41

39

For MCHSU-48CSH2

Page 42

40

IPM board of MCHSU-24PHH2,

MCHSU-36CSH2,

202302141237

PFC-L2

[1.6]2014.10.16

EU-KFR105W/BP2T3N1-350(767).D.13.MP2-1

PFC-L1

CN58

EARTH

C57

C56

6

J146J15

R65

C55

C53

E31

C50

D7

C49

+

E30

C47

C9

ZR1

DZ3

R8

E3

E2

CN55

TO-MAIN

E23

C46

R13

IC3

C113

W

V

U

1

6

7

10

11

12

1314

15

3 8

T1

R208

R207

R206

R205

R204

R203

R202

R198

R197

R196

R194

R192

R187

R186

R185

R184

R183

R182

R181

R180

R179

R175

R174

R173

R170

R163

R160

R150

R147

R146

R144

R143

R141

R140

R139

R137

R135

R133

R132

R131

R130

R129

R128

R127

R126

R125

R124

R119

R114

R111

R107

R104

R96

R92

R91

R90

R82

R80

R79

R78

R77

R76

R75

R66

R63

R62

R61

R60

R59

R58

R57

R56

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R33

R32

R31

R30

R29

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R15

R14

R12

R11

R10

R9

R7

R5

R2

R1

Q2

OSC1

+

LED4+LED3

JR1

J201

6

J1

IPM2

1

IPM1

1

17

49

33

IC20

IC17

IC16

IC15

24C256

IC14

24C08

IC10

IC7

IC4

IC2

E34

E33

E27

E25

+

E24

+

E22

+

E21

+

E20

+

E17

E16

E15

E14

E13

E12

E10

E9

+

E8

+

E7

+

E6

+

E5

E4

E1

+

DZ9

+

DZ8

+

DZ7

+

DZ6

+

DZ1

D26

D14

D13

D12

D11

D10

D9

D8

D6

D5

D4

D3

D2

CN57

1

CN56

CN54

L-IN2

CN53

N-IN2

CN52

CN51

CN19

OUTFAN(DC)

C124

C123

C122

C121

C120

C119

C118

C117

C116

C114

C111

C109

C108

C107

C106

C105

C104

C103

C102

C101

C100

C99

C97

C94

C82

C79

C78

C77

C76

C72

C71

C70

C69

C67

C66

C65

C64

C61

C60

C59

C54

C51

C40

C39

C38

C36

C33

C32

C31

C30

C29

C26

C25

C24

C23

C22

C21

C20

C19

C18

C17

C16

C15

C14

C13

C12

C11

C8

C7

C6

C5

C4

C3

C2

C1

BR1

R3

R4

R6

R16

C27

C28

+

E18

C10

+

E19

C34

+

D1

+

D15

+

D16

22

44

23

IC1

C52

D17

R28

6J36

J4

6

J2

6

J5

6

J6

6

J7

6

J8

6J96

J10

6

J11

6

J12

6

J13

C35

C37

C41

C42

C43

C44

C45

E26

E28

E29

IC11

IC12

R34

R64

C48

E11

CN53

power supply

connect to the terminal

208-230V AC

CN54

CN51

CN52

PFC

inductance

terminal

CN58

EATTH

+

210-300VDC (Running)

CAPACITOR Voltage

290-330VDC (standby)

CN55

TO MAIN

CN19

connect to DC fan motor

U

V

W

10-200VAC (running)

0VAC (standby)

connect to the compressor

U

V

W

10-200VAC (running)

0VAC (standby)

CN57

Debug

For MCHSU-48CSH2

Page 43

41

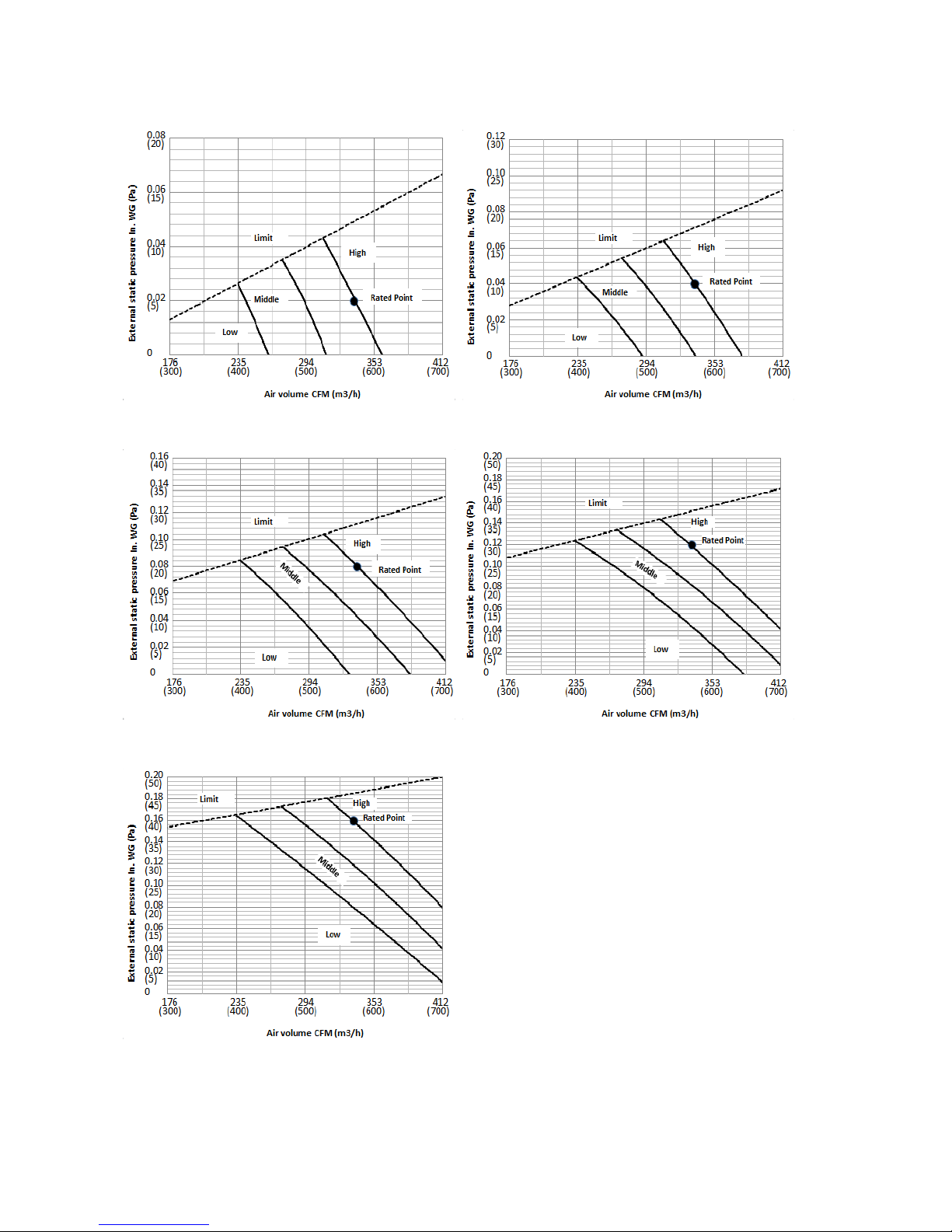

7. Fan Curves

ENC2

Static Pressure

Range In. WG (Pa)

Model

(K Btu/h)

Model 0 1 2 3 4

Model≤12

0.02

(5)

0.04

(10)

0.08

(20)

0.12

(30)

0.16

(40)

0-0.18

(0-45)

Model=18

0.04

(10)

0.10

(25)

0.14

(35)

0.18

(45)

0.22

(55)

0-0.28

(0-70)

18<Model≤24

0.04

(10)

0.10

(25)

0.16

(40)

0.22

(55)

0.28

(70)

0-0.40

(0-100)

24<Model≤60

0.08

(20)

0.14

(35)

0.20

(50)

0.26

(65)

0.32

(80)

0-0.40

(0-100)

Factory Setting √

Page 44

42

MEHSU-09CHD2,

Code 0 Code 1

Code 2 Code 3

Code 4

Page 45

43

MEHSU-12CHD2

Code 0 Code 1

Code 2 Code 3

Code 4

Page 46

44

MEHSU-18CHD2

Code 0 Code 1

Code 2 Code 3

Code 4

Page 47

45

MEHSU-24CHD2

Code 0 Code 1

Code 2 Code 3

Code 4

Page 48

46

MEHSU-36CSD2

Code 0 Code 1

Code 2 Code 3

Code 4

Page 49

47

MEHSU-48CSD2

Code 0 Code 1

Code 2 Code 3

Code 4

Page 50

48

8 Electric Characteristics

Model

Indoor Unit

Hz Voltage Min. Max.

MEHSU-09CHC2 60 208-230V 187V

253V

MEHSU-09CHD2 60 208-230V 187V

253V

MEHSU-09CHN2 60 208-230V 187V

253V

MEHSU-12CHC2 60 208-230V 187V

253V

MEHSU-12CHD2 60 208-230V 187V

253V

MEHSU-12CHN2 60 208-230V 187V

253V

MEHSU-18CHC2 60 208-230V 187V

253V

MEHSU-18CHD2 60 208-230V 187V

253V

MEHSU-18CHF2 60 208-230V 187V

253V

MCHSU-36CSH2 60 208-230V 187V

253V

MEHSU-24CHD2 60 208-230V 187V

253V

MEHSU-24CHF2 60 208-230V 187V

253V

MEHSU-36CSC2 60 208-230V 187V

253V

MEHSU-36CSD2 60 208-230V 187V

253V

MEHSU-36CSF2 60 208-230V 187V

253V

MEHSU-48CSC2 60 208-230V 187V

253V

MEHSU-48CSD2 60 208-230V 187V

253V

MEHSU-48CSF2 60 208-230V 187V

253V

Page 51

49

9 Sound Level

9.1 Indoor unit

Suction

Discharge

Microphone

1.4m

Concealed Duct Type

DuctDuct

Model

Noise level dB(A)

H M L

MEHSU-09CHD2

37 34 31

MEHSU-12CHD2

39 36 32

MEHSU-18CHD2

35 33 31

MEHSU-24CHD2

50 47 45

MEHSU-36CSD2

53 49 45

MEHSU-48CSD2

44 47 41

(4.59ft)

Page 52

50

1.4m

Micro phone

Model

Noise level dB(A)

H M L

MEHSU-09CHC2

41 39 37

MEHSU-12CHC2

41 38 35

MEHSU-18CHC2

46 43 41

MEHSU-24CHC2

51 47 43

MEHSU-36CSC2

52 47 44

MEHSU-48CSC2

53 49 45

(4.59ft)

Page 53

51

1.5m

1m

Microphone

Model

Noise level dB(A)

H M L

MEHSU-09CHN2 45 41 35

MEHSU-12CHN2 44 42 38

Microphone

1m

1m

Air outlet side

1.5m

1m

Microphone

Model

Noise level dB(A)

H M L

MEHSU-18CHF2

47 44 38

MEHSU-24CHF2

53 49 45

MEHSU-36CSF2

55 48 41

MEHSU-48CSF2

57 54 52

(4.92ft)

(3.28ft)

(3.28ft)

(3.28ft)

(4.92ft)

(3.28ft)

Page 54

52

9.2 Outdoor unit

Note: H= 0.5 × height of outdoor unit

Model Noise Level dB(A)

MCHSU-09PHH2 59

MCHSU-12PHH2 56

MCHSU-18PHH2 59

MCHSU-24PHH2 61

MCHSU-36CSH2

65

MCHSU-48CSH2 63

H

1.0m

Outdoor Unit

Microphone

(3.28ft)

Page 55

53

10 Accessories

Duct Units

Name Shape Quantity

Tubing & Fittings

Soundproof / insulation sheath

2

Binding tape

1

Seal sponge

1

Drainpipe Fittings

(for cooling & heating)

Drain joint

1

Seal ring

1

Wired controller & Its Frame

Wired controller

1

Others

Owner,s manual

1

Installation manual

1

EMS & It’s fitting

Magnetic ring (twist the electric wires L

and N around it to five circles)

1

Cassette Units

Name Shape Quantity

Installation Fittings

Installation paper board

1

Tubing & Fittings

Soundproof / insulation sheath

1

Drainpipe Fittings

Out-let pipe sheath

1

Out-let pipe clasp

1

Drain joint

1

Seal ring

1

Remote controller & Its

Frame(The product you

have might not be

Remote controller & Its Frame

1

Page 56

54

provided the following

accessories)

Remote controller holder

1

Mounting screw(ST2.9×10-C-H)

2

Remote controller manual

1

Alkaline dry batteries (AM4)

2

Others

Owner's manual

1

Installation manual

1

Installation accessory

(The product you have

might not be provided the

following accessories

Expansible hook

4

Installation hook

4

Orifice

1

Console Units

Name Shape Quantity

Installation fittings

Hook

2

Remote controller & Its Frame

Remote controller

1

Frame

1

Mounting screw(ST2.9×10-C-H)

2

Alkaline dry batteries (AM4)

2

Others

Installation manual / 1

Owner's manual / 1

Ceiling-floor Units

Remote controller & Its

holder

1. Remote controller

1

2. Remote controller holder

1

3. Mounting screw (ST2.9×10-C-H)

2

4. Alkaline dry batteries (AM4)

2

Others

5. Owner's manual

1

6. Installation manual

1

7. Remote controller manual

1

Page 57

55

11 The Specification of Power

Type

9K-18K

24K

Power

Phase 1-phase 1-phase

Frequency and Voltage 208-230V, 60Hz 208-230V, 60Hz

Circuit Breaker/ Fuse (A) 25/20 40/30

Indoor Unit Power Wiring (mm2)

Indoor/Outdoor

Connecting

Wiring

Ground Wiring 2.5 2.0

Outdoor Unit Power Wiring

3×2.5 3×2.0

Strong Electric Signal 4×1.0 4×1.5

Weak Electric Signal

Model 36K 48K

Power

Phase 1-phase 1-phase

Frequency and Voltage 208-230V, 60Hz 208-230V, 60Hz

Circuit Breaker/ Fuse (A) 60/40 70/55

Indoor Unit Power Wiring (mm2)

Indoor/Outdoor

Connecting

Wiring

Ground Wiring 4.0 4.0

Outdoor Unit Power Wiring

3×4.0 3×4.0

Strong Electric Signal 3×1.5 3×1.5

Weak Electric Signal 3×0.5 3×0.5

Page 58

56

12 Field Wiring

36K, 48K

Page 59

57

12 Installation Details

12.1 Location selection

12.1.1

Indoor unit location selection

The place shall easily support the indoor

unit’s weight.

The place can ensure the indoor unit

installation and inspection.

The place can ensure the indoor unit

horizontally installed.

The place shall allow easy water drainage.

The place shall easily connect with the

outdoor unit.

The place where air circulation in the room

should be good.

There should not be any heat source or

steam near the unit.

There should not be any oil gas near the unit

There should not be any corrosive gas near

the unit

There should not be any salty air neat the

unit

There should not be strong electromagnetic

wave near the unit

There should not be inflammable materials

or gas near the unit

There should not be strong voltage vibration.

12.1.2

Outdoor unit location selection

The place shall easily support the outdoor

unit’s weight.

Locate the outdoor unit as close to indoor

unit as possible

The piping length and height drop cannot

exceed the allowable value.

The place where the noise, vibration and

outlet air do not disturb the neighbors.

There is enough room for installation and

maintenance.

The air outlet and the air inlet are not

impeded, and not face the strong wind.

It is easy to install the connecting pipes and

cables.

There is no danger of fire due to leakage of

inflammable gas.

It should be a dry and well ventilation place

The support should be flat and horizontal

Do not install the outdoor unit in a dirty or

severely polluted place, so as to avoid

blockage of the heat exchanger in the

outdoor unit.

If is built over the unit to prevent direct

sunlight, rain exposure, direct strong wend,

snow and other scraps accumulation, make

sure that heat radiation from the condenser

is not restricted.

More than 30cm/11.81in

More than 60cm/23.62in

More than 200cm/78.74in

More than 30cm/11.81in

More than

60cm/23.62in

(Service space)

F

e

n

c

e

o

r

o

b

s

t

a

c

l

e

s

12.2 Indoor unit installation

12.2.1

A5 duct indoor unit installation

12.2.1.1 Service space for indoor unit

12.2.1.2 Bolt pitch

7.87in

11.81in

23.62inx23.62in

Page 60

58

12.2.1.3 Install the pendant bolt

Select the position of installation hooks

according to the hook holes positions showed

in upper picture.

Drill four holes of Ø12mm(0.47in),

45~50mm(1.57~1.97in) deep at the selected

positions on the ceiling. Then embed the

expansible hooks (fittings).

12.2.1.4 Install the main body

Make the 4 suspender through the 4 hanger of

the main body to suspend it. Adjust the

hexangular nuts on the four installation hooks

evenly, to ensure the balance of the body. Use

a leveling instrument to make sure the

levelness of the main body is within ±1°.

12.2.1.5 Install the air filter

Insert the air filter through the filter slot and fix it

with 2 screws.

12.2.1.6 Install the air duct

Please design the air duct as below

recommended picture

12.2.1.7 Change the air inlet direction

① Take off ventilation panel and flange, cut off

the staples at side rail.

② Stick the attached seal sponge as per the

indicating place in the following fig, and then

change the mounting positions of air return

panel and air return flange .

Capacity(KBtu)

Size of outline dimension mounted

plug

L M

9

mm

740 350

in

29.13 13.78

12

mm

740 350

in

29.13 13.78

18

mm

960 350

in

37.80 13.78

24

mm

960 350

in

37.80 13.78

36

mm

1180 490

in

46.46 19.29

48

mm

1240 500

in

48.82 19.69

Page 61

59

③ When install the filter mesh, please plug it

into flange inclined from air return opening, and

then push up.

④ The installation has finish, upon filter mesh

which fixing blocks have been insert to the

flange positional holes.

12.2.2 Compact cassette indoor unit

installation

12.2.2.1 Service space for indoor unit

12.2.2.2 Bolt pitch

12.2.2.3 Install the pendant bolt

Select the position of installation hooks

according to the hook holes positions showed

in upper picture.

Drill four holes of Ø12mm(0.47in), 45~50mm

(1.57in~1.97in) deep at the selected positions

on the ceiling. Then embed the expansible

hooks (fittings).

Face the concave side of the installation hooks

toward the expansible hooks. Determine the

length of the installation hooks from the height

of ceiling, then cut off the unnecessary part.

39.37in

25.47in

22.44in

21.46in

20.59in

Page 62

60

If the ceiling is extremely high, please

determine the length of the installation hook

depending on the real situation.

12.2.2.4 Install the main body

Make the 4 suspender through the 4 hanger of

the main body to suspend it. Adjust the

hexangular nuts on the four installation hooks

evenly, to ensure the balance of the body. Use

a leveling instrument to make sure the

levelness of the main body is within ±1°.

Adjust the position to ensure the gaps between

the body and the four sides of ceiling are even.

The body's lower part should sink into the

ceiling for 10~12 mm (0.39-0.47in). In general,

L is half of the screw length of the installation

hook.

Locate the air conditioner firmly by wrenching

the nuts after having adjusted the body's

position well.

12.2.2.5 Install the panel

Remove the grille

Hang the panel to the hooks on the mainbody.

Tighten the screws under the panel hooks till

the panel closely stick on the ceiling to avoid

condensate water.

6.93in

(0.39-0.47in)

Page 63

61

Hang the air-in grill to the panel, then connect

the lead terminator of the swing motor and that

of the control box with corresponding

terminators on the body respectively.

Note: The panel shall be installed after the

wiring connected.

12.2.3 Console indoor unit installation

12.2.3.1 Service space for indoor unit

12.2.3.2 Install the main body

Fix the hook with tapping screw onto the

wall

Hang the indoor unit on the hook.

(The bottom of body can touch with floor or

suspended, but the body must install vertically.)

14.2.4 Ceiling-floor unit installation

12.2.4.1 Service space for indoor unit

12.2.4.2 Bolt pitch

① Ceiling installation

Capacity (Btu/h)

D E

18K / 24K

mm 983 220

inch 38.70 8.66

36K

mm 1200 220

inch 47.24 8.66

48K

mm 1565 220

inch 61.61 8.66

1.38in

39.37in

Page 64

62

② Wall-mounted installation

12.2.4.3 Install the pendant bolt

① Ceiling installation

Select the position of installation hooks

according to the hook holes positions showed

in upper picture.

Drill four holes of Ø12mm(0.47in),

45~50mm(1.77~1.97in) deep at the selected

positions on the ceiling. Then embed the

expansible hooks (fittings).

② Wall-mounted installation

Install the tapping screws onto the wall.(Refer

to picture below)

12.2.4.4 Install the main body

① Ceiling installation (The only installation

method for the unit with drain pump)

Remove the side board and the grille.

Locate the hanging arm on the hanging screw

bolt. Prepare the mounting bolts on the unit.

Put the side panels and grilles back.

② Wall-mounted installation

Hang the indoor unit by insert the tapping

screws into the hanging arms on the main unit.

(The bottom of body can touch with floor or

suspended, but the body must install vertically.)

0.79in

Page 65

63

12.2.5 Slim cassette indoor unit

installation

12.2.5.1 Service space for indoor unit

Capacity (Btu/h) A H

24K

mm 205 >235

inch 8.07 >9.25

36K

mm 245 >275

inch 9.65 >10.83

48K

mm 287 >317

inch 11.30 >12.48

12.2.5.2 Bolt pitch

12.2.5.3 Install the pendant bolt

Select the position of installation hooks

according to the hook holes positions showed

in upper picture.

Drill four holes of Ø12mm(0.47in),

45~50mm(1.77~1.97in) deep at the selected

positions on the ceiling. Then embed the

expansible hooks (fittings).

12.2.5.4 Install the main body

Make the 4 suspender through the 4 hanger of

the main body to suspend it. Adjust the

hexangular nuts on the four installation hooks

evenly, to ensure the balance of the body. Use

a leveling instrument to make sure the

levelness of the main body is within ±1°.

Adjust the position to ensure the gaps between

the body and the four sides of ceiling are even.

The body's lower part should sink into the

ceiling for 10~12 mm(0.39~0.47in). In general,

L is half of the screw length of the installation

hook.

Locate the air conditioner firmly by wrenching

the nuts after having adjusted the body's

position well.

39.37in

34.65in

98.43in

5.35in

(0.39~0.47in)

Page 66

64

12.2.5.5 Install the panel

Remove the grille

Remove the 4 corner covers.

Hang the panel to the hooks on the mainbody. If

the panel is with auto-lift grille, please watch the

ropes lifing the grille, DO NOT make the ropes

enwinded or blocked.

Tighten the screws under the panel hooks till

the panel closely stick on the ceiling to avoid

condensate water.

Hang the air-in grill to the panel, then connect

the lead terminator of the swing motor and that

of the control box with corresponding

terminators on the body respectively.

Install the 4 corner covers back.

Note: The panel shall be installed after the

wiring connected.

12.3 Outdoor unit installation

12.3.1 Service space for outdoor unit

More than 30cm

(11.81in)

More than 60cm

(23.62in)

More than 200cm(78.74in)

Air inlet

Air inlet

More than 30cm(11.81in)

Air outlet

(Wall or obstacle)

Maintain channel

Page 67

65

More than 60cm

(23.62in)

12.3.2 Bolt pitch

For the value of A,B and D, please refer to

the dimension part.

14.3.3 Install the Unit

Since the gravity center of the unit is not at its

physical center, so please be careful when

lifting it with a sling.

Never hold the inlet of the outdoor unit to

prevent it from deforming.

Do not touch the fan with hands or other

objects.

Do not lean it more than 45, and do not lay it

sidelong.

Make concrete foundation according to the

specifications of the outdoor units.

Fasten the feet of this unit with bolts firmly to

prevent it from collapsing in case of earthquake

or strong wind.

12.4 Refrigerant pipe installation

12.4.1 Maximum pipe length and height

drop

Considering the allowable pipe length and

height drop to decide the installation position.

Make sure the distance and height drop

between indoor and outdoor unit not exceeded

the date in the following table.

Model

Max. Length Max. Elevation

m Ft. m Ft.

9,000Btu/h 25 82.2 10 32.9

12,000Btu/h 25 82.2 10 32.9

18,000Btu/h 30 98.7 20 65.8

24,000Btu/h 50 164.5 25 82.2

36,000Btu/h 65 213.8 30 98.7

48,000Btu/h 65 213.8 30 98.7

12.4.2 The procedure of connecting pipes

1. Choose the pipe size according to the

specification table.

2. Confirm the cross way of the pipes.

3. Measure the necessary pipe length.

4. Cut the selected pipe with pipe cutter

Make the section flat and smooth.

90

Lean

Crude

Burr

o

5. Insulate the copper pipe

Before test operation, the joint parts should

not be heat insulated.

6. Flare the pipe

Insert a flare nut into the pipe before flaring

the pipe

According to the following table to flare the

pipe

A

B

D

Page 68

66

Pipe

diamete

r

Flare dimension A

(mm/in)

Flare shape

Min Max

1/4"

(6.35)

8.3/0.33 8.7/0.34

R0.4~0.8

A

4

5

°

90

°

4

-

+

3/8"

(9.52)

12.0/0.4

7

12.4/0.49

1/2"

(12.7)

15.4/0.6

1

15.8/0.62

5/8"

(15.9)

18.6/0.7

3

19.1/0.75

3/4"

(19)

22.9/0.9

0

23.3/0.92

After flared the pipe, the opening part must

be seal by end cover or adhesive tape to

avoid duct or exogenous impurity come into

the pipe.

7. Drill holes if the pipes need to pass the

wall.

8. According to the field condition to bend the

pipes so that it can pass the wall smoothly.

9. Bind and wrap the wire together with the

insulated pipe if necessary.

10. Set the wall conduit

11. Set the supporter for the pipe.

12. Locate the pipe and fix it by supporter

For horizontal refrigerant pipe, the distance

between supporters should not be exceed

1m.

For vertical refrigerant pipe, the distance

between supporters should not be exceed

1.5m.

13. Connect the pipe to indoor unit and outdoor

unit by using two spanners.

Be sure to use two spanners and proper

torque to fasten the nut, too large torque

will damage the flare, and too small torque

may cause leakage. Refer the following

table for different pipe connection.

Pipe

Diameter

Torque Sketch map

(kgf.cm) (N.cm)

1/4" (6.35) 144~176

1420~1720

3/8" (9.52) 333~407

3270~3990

1/2" (12.7) 504~616

4950~6030

5/8" (15.9) 630~770

6180~7540

3/4" (19) 990~1210

9270~11860

12.4.3 First-Time Installation

Air and moisture in the refrigerant system

cause the following problems:

● Increases in system pressure

● Increases in operating current

● Decreases in cooling and heating efficiency

● Blocks in capillary tubing caused by

moisture in the refrigerant circuit freezing

● Corrosion of parts in the refrigerant system

caused by water

The indoor units and the pipes between

indoor and outdoor units must be tested for

leakages and evacuated to remove gas and

moisture from the system.

Gas leak check with soap water:

Apply soap water or a liquid neutral

detergent on the connections with a soft brush

to check for leakage in the pipe connecting

points. If bubbles emerge, the pipes are

leaking.

1. Air Purging Using the Vacuum Pump

1) Completely tighten the flare nuts on the

indoor and outdoor units. Confirm that both

the2-way and 3-way valves are set to the

closed position.

2) Connect the charge hose with the push pin

of the Handle Lo to the 3-way valve gas

service port.

3) Connect the charge hose of the Handle Hi

to the vacuum pump.

4) Fully open the Handle Lo of the manifold

valve.

Page 69

67

5) Turn on the vacuum pump to begin

evacuation.

6) Conduct a 30-minute evacuation. Check

whether the compound meter indicates

-0.1Mpa(14.5Psi). If the meter does not

indicate -0.1Mpa(14.5Psi) after 30 minutes

has elapsed, continue evacuation for 20

more minutes. If the pressure does not

reach -0.1Mpa(14.5Psi) after 50 minutes

has elapsed, check if there are any leaks.

Fully close the Handle Lo valve of the manifold

valve and turn off the vacuum pump. After 5

minutes, confirm that the gauge needle is not

moving.

7) Turn the flare nut on the 3-way valve45°

counterclockwise for 6-7 seconds. Once

gas begins to come out, tighten the flare nut.

Make sure the pressure display on the

pressure indicator is higher than

atmospheric pressure. Then remove the

charge hose from the 3-way valve.

8) Fully open the 2-wayand 3-way valves and

securely tighten the cap on the 3-way valve.

2. Air Purging Using Refrigerant

Procedure:

1). Confirm that both the 2-way and 3-way

valves are set to the closed position.

2). Connect the charge set and a charging

cylinder to the service port on the 3-way valve.

3). Air purging:

Open the valves on the charging cylinder and

the charge set. Loosen the flare nut on the

2-way valve approximately 45° for 3 seconds

then closing it for 1 minute. Repeat 3 times.

After purging the air, use a torque wrench to

tighten the flare nut on the 2-way valve.

4). Check for gas leaks.

Check the flare connections for gas leaks.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and

discharge the refrigerant by loosening the flare

nut on the 2-way valve approximately 45° until

the gauge displays a value between 0.3 to 0.5

Mpa(43.5 to 72.5Psi)

6). Disconnect the charge set and the charging

cylinder. Set the 2-way and 3-way valves to the

open position.

Be sure to use a hexagonal wrench to open and

close the valve stems.

7). Mount the valve stems nuts and the service

port cap.

Be sure to use a torque wrench to tighten the

service port cap to a torque of 18N·m.