Page 1

1

MULTI OUTDOOR UNITS

SERVICE MANUAL

Multi zone

CONDENSING UNITS

Revision C: ODMI-E-1606

Model Numbers:

MCH2U-18PHH2 MCH3U-27PHH2 MCH4U-36PHH2

MCH5U-48PHH2

WARNING

Installation MUST conform with local building codes or, in the absence of local

codes, with the National Electrical Code NFPA70/ANSI C1-1993 or current edition

and Canadian Electrical Code Part1 CSA C.22.1.

The information contained in the manual is intended for use by a qualified service

technician familiar with safety procedures and equipped with the proper tools and

test instruments

Installation or repairs made by unqualified persons can result in hazards to you

and others.

Failure to carefully read and follow all instructions in this manual can result in

equipment malfunction, property damage, personal injury and/or death.

Table of Contents

1. Indoor Unit Combination

2. Suggested Indoor Unit Model Numbers

3. Dimension Of Outdoor Unit

4. Refrigerant Cycle Diagram

5. Installation Details

6. Electronic Function

7. Wiring Diagrams

8. Trouble Shooting

9. Disassembly Instructions

Page 2

2

CONTENTS

1. Indoor Unit Combination .................................................................................................................................... 4

2. Dimension Of Outdoor Unit ................................................................................................................................ 6

3. Refrigerant Cycle Diagram .................................................................................................................................. 7

4. Installation Details ............................................................................................................................................ 10

4.1 Wrench torque sheet for installation .......................................................................................................... 10

4.2 Connecting the cables ................................................................................................................................. 10

4.3 Pipe length and the elevation ..................................................................................................................... 10

4.4 First-Time Installation ................................................................................................................................. 11

4.5 Adding Refrigerant after Long-Term System Operation ............................................................................... 12

4.6 Procedure when servicing the indoor unit refrigeration circuit. ................................................................... 12

4.7 Evacuation after servicing the outdoor unit refrigeration circuit ................................................................. 14

6. Electronic Function ........................................................................................................................................... 15

6.1 Abbreviation ............................................................................................................................................... 15

6.2 Electric Control Working Environment. ....................................................................................................... 15

6.3 Main Protection .......................................................................................................................................... 15

6.4 Control and Functions ................................................................................................................................. 17

7. Wiring Diagrams ............................................................................................................................................... 23

8. Troubleshooting ............................................................................................................................................... 33

8.1Safety .......................................................................................................................................................... 33

8.2 Indoor Unit Error Display ............................................................................................................................. 34

8.3 Outdoor Unit Display .................................................................................................................................. 37

8.4 Diagnosis and Solution ................................................................................................................................ 42

8.5 Trouble Criterion Of Main Parts. ................................................................................................................. 91

9. Disassembly Instructions ................................................................................................................................ 103

MCH2U-18PHH2 (WCA30 metal plate) .............................................................................................. 103

MCH3U-27PHH2 (WD30 metal plate) ................................................................................................. 110

Page 3

3

MCH4U-36PHH2 (WD30 metal plate) ................................................................................................. 118

MCH5U-48PHH2 (WE30 metal plate) ................................................................................................. 125

Page 4

4

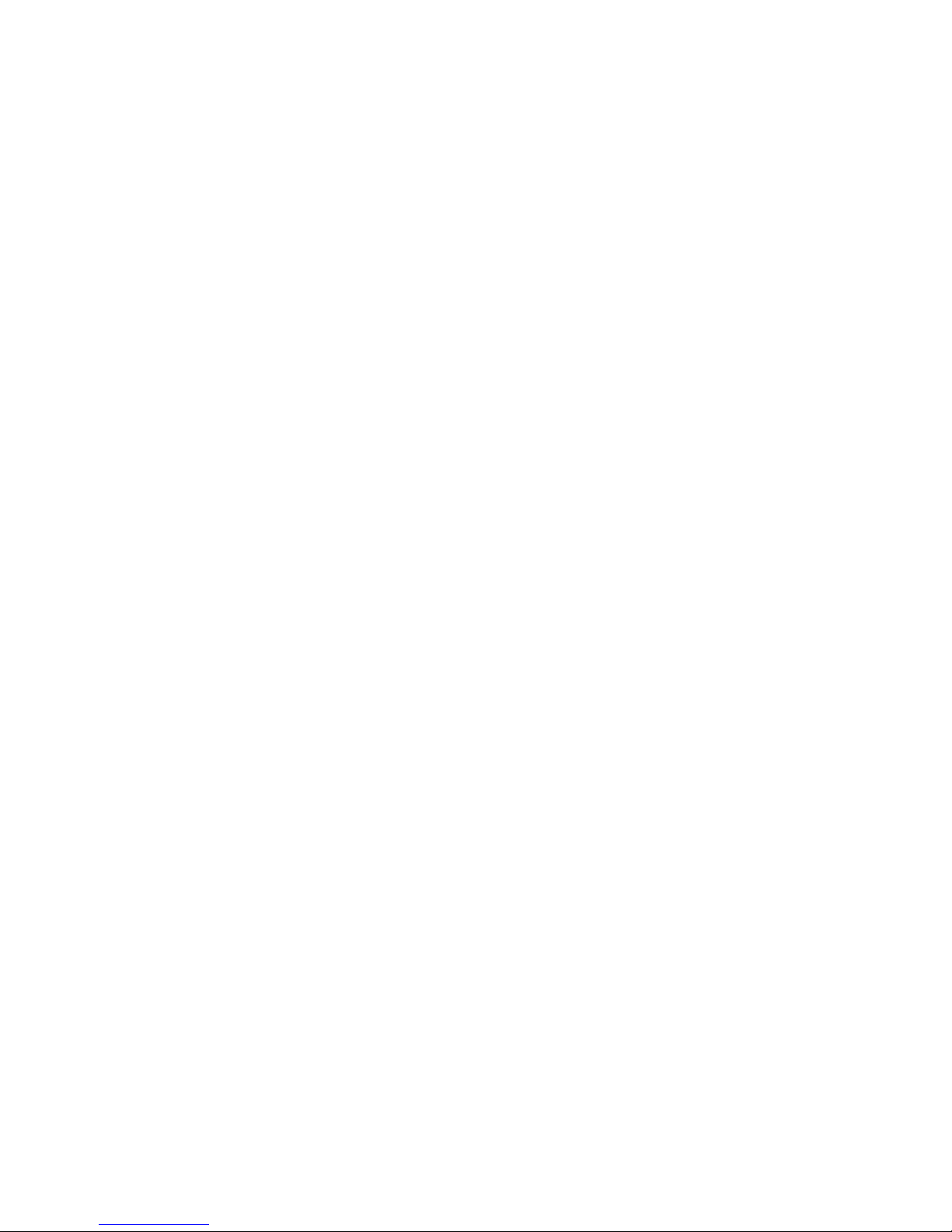

1. Indoor Unit Combination

Multi DC

Outdoor

Unit

Nominal

capacity

Suggested

Combination

Limit

1drive 2 5.2kW

12

None

9+9

9+12

12+12

Multi DC

Outdoor

Unit

Nominal

capacity

Suggested

Combination

Limit

1 drive 5 14kW

18+18

None

18+24

24+24

9+9+18

9+9+24

9+12+12

9+12+18

9+12+24

9+18+18

9+18+24

9+24+24

12+12+12

12+12+18

12+12+24

12+18+18

12+18+24

12+24+24

18+18+18

18+18+24

9+9+9+9

9+9+9+12

9+9+9+18

9+9+9+24

9+9+12+12

Multi DC

Outdoor

Unit

Nominal

capacity

Suggested

Combination

Limit

1drive 3 7.8kW

9+9

None

9+12

9+18

12+12

12+18

18+18

9+9+9

9+9+12

9+9+18

9+12+12

9+12+18

12+12+12

Multi DC

Outdoor

Unit

Nominal

capacity

Suggested

Combination

Limit

1 drive 4 10.5kW

9+18

None

12+12

12+18

18+18

9+9+9

9+9+12

9+9+18

9+12+12

9+12+18

9+18+18

12+12+12

12+12+18

12+18+18

9+9+9+9

9+9+9+12

9+9+9+18

9+9+12+12

9+9+12+18

9+12+12+12

12+12+12+12

Page 5

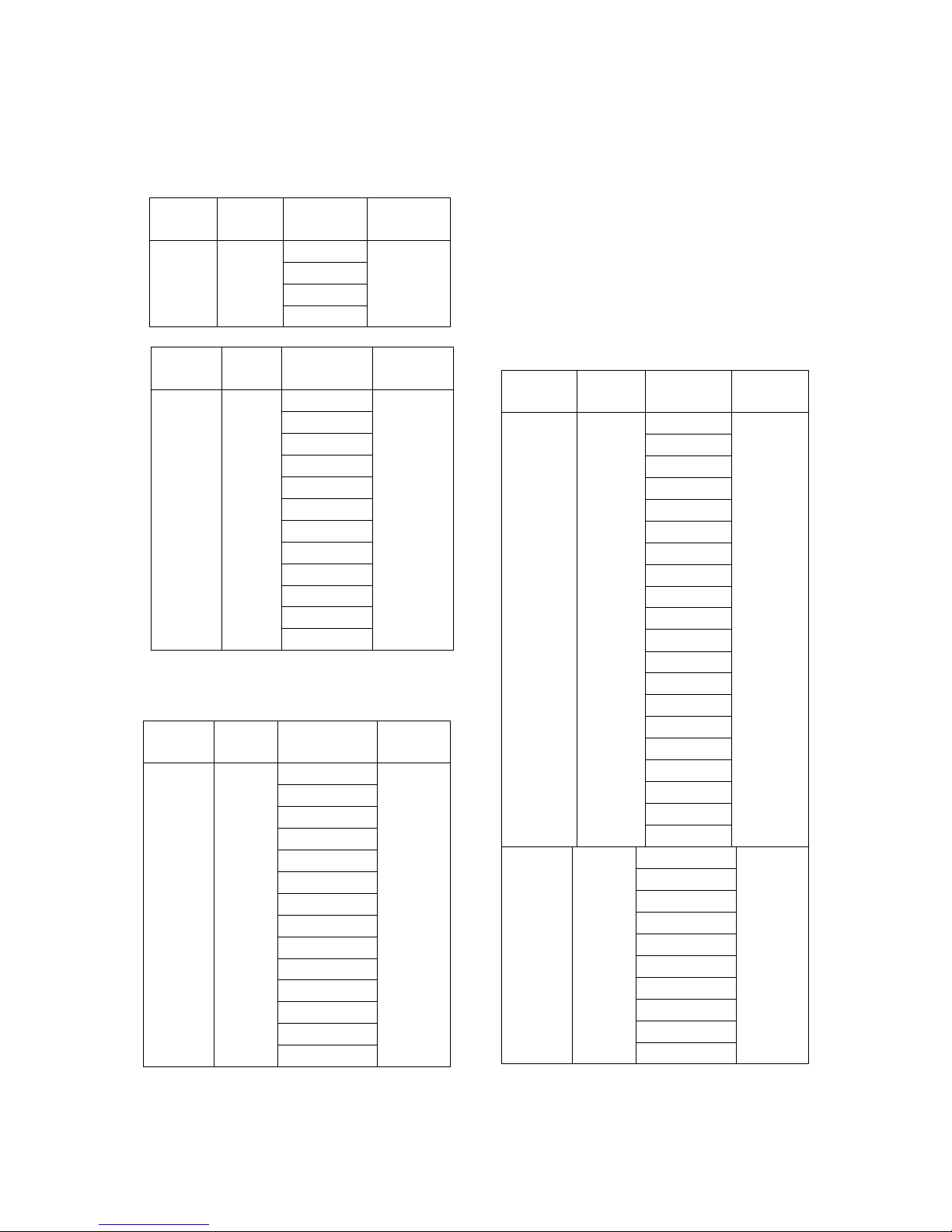

5

9+9+12+18

9+9+12+24

9+9+18+18

9+9+18+24

9+12+12+12

9+12+12+18

9+12+12+24

9+12+18+18

9+18+18+18

12+12+12+12

12+12+12+18

12+12+12+24

12+12+18+18

9+9+9+9+9

9+9+9+9+12

9+9+9+9+18

9+9+9+9+24

9+9+9+12+12

9+9+9+12+18

9+9+9+18+18

9+9+12+12+12

9+9+12+12+18

9+12+12+12+12

9+12+12+12+18

12+12+12+12+12

Page 6

6

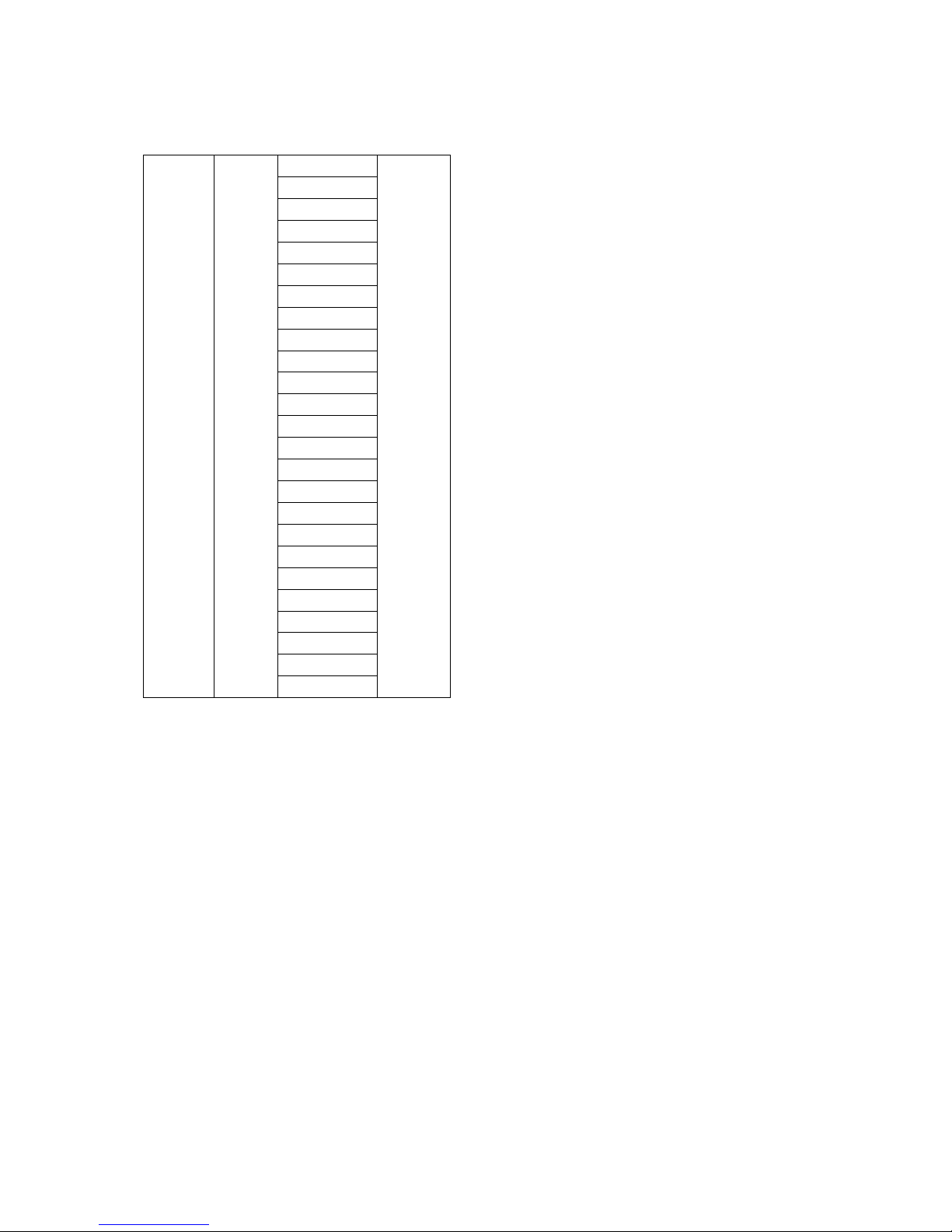

2. Dimension Of Outdoor Unit

Model

Unit:

W D H W1 A B

MCH2U-18PHH2

mm

845 363 702 923 540 350

inch

33.3

14.3

27.6

36.0

21.3

13.8

MCH3U-27PHH2

mm

946 410 810 1034 673 403

inch

37.2

16.5

31.9

40.6

26.5

15.9

MCH4U-36PHH2

mm

946 410 810 1034 673 403

inch

37.2

16.5

31.9

40.6

26.5

15.9

MCH5U-48PHH2

mm

952 415 1333 1060 634 404

inch

37.5

16.3

52.5

41.7

25.0

15.9

A

B

D

Page 7

7

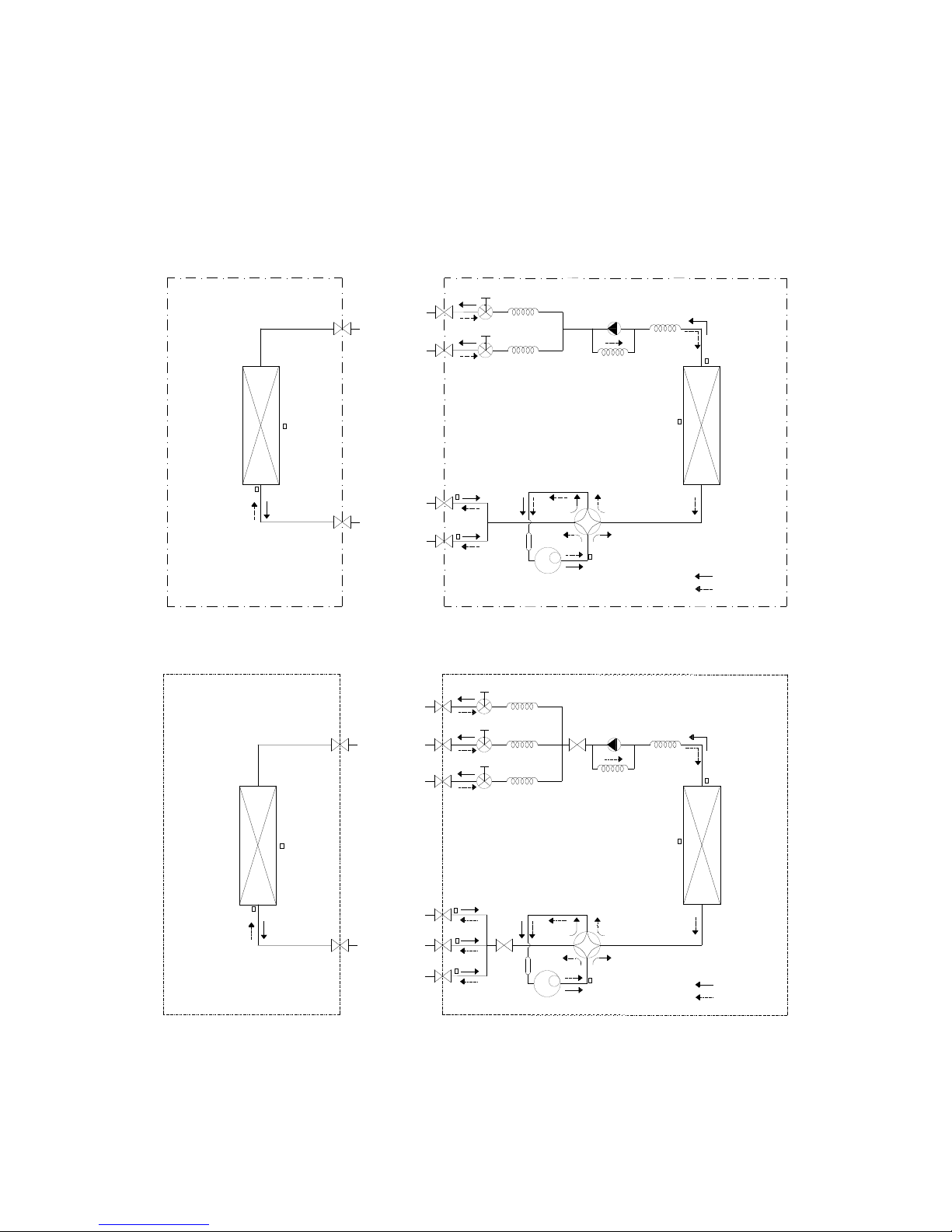

3. Refrigerant Cycle Diagram

3.1 Refrigeration circuit drawing of inverter 1 drive 2 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

middle

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A

CAPILIARY A

CHECK VALVE

CAPILIARY TUBE

EXV B CAPILIARY B

LIQUID VALVE B

GAS VALVE B

Accumulator

T2B-A

Evaporator

temp. sensor outlet

T2B-B

3.2 Refrigeration circuit drawing of inverter 1 drive 3 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

middle

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A CAPILIARY A

CHECK VALVE

CAPILIARY TUBE

EXV B

CAPILIARY B

LIQUID VALVE B

GAS VALVE B

EXV C

CAPILIARY C

LIQUID VALVE C

GAS VALVE C

Accumulator

T2B-A

Evaporator

temp. sensor outlet

T2B-B

T2B-C

Page 8

8

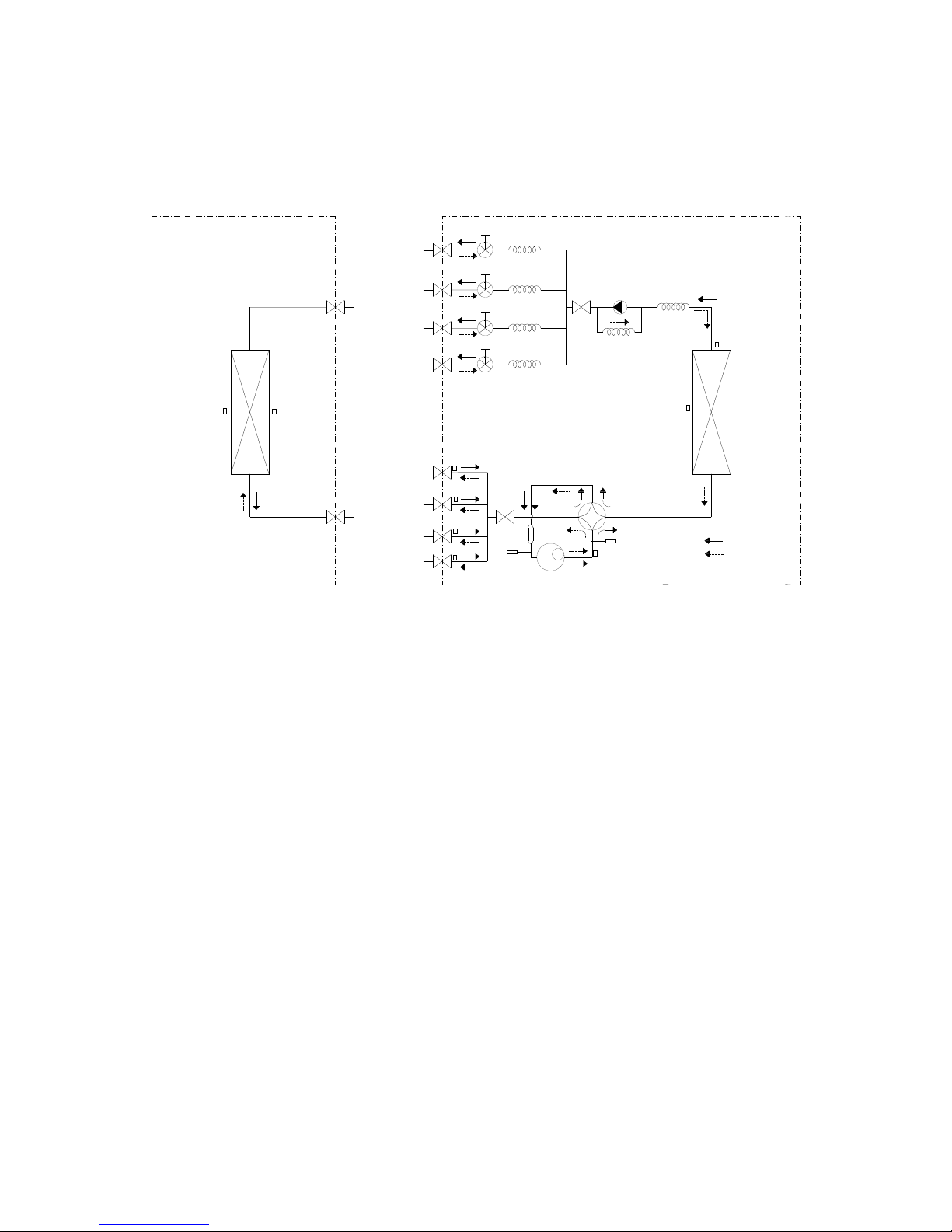

3.3 Refrigeration circuit drawing of inverter 1 drive 4 type

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

Compressor

4-WAY VALVE

COOLING

HEATING

T2 Evaporator

temp. sensor

middle

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T5 Discharge

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A

CAPILIARY A

CHECK VALVE

CAPILIARY TUBE

EXV B CAPILIARY B

LIQUID VALVE B

GAS VALVE B

EXV C

CAPILIARY C

LIQUID VALVE C

GAS VALVE C

EXV D CAPILIARY D

LIQUID VALVE D

GAS VALVE D

Accumulator

High pressure

switch

Low pressure

switch

T2B-A

Evaporator

temp. sensor outlet

T2B-B

T2B-C

T2B-D

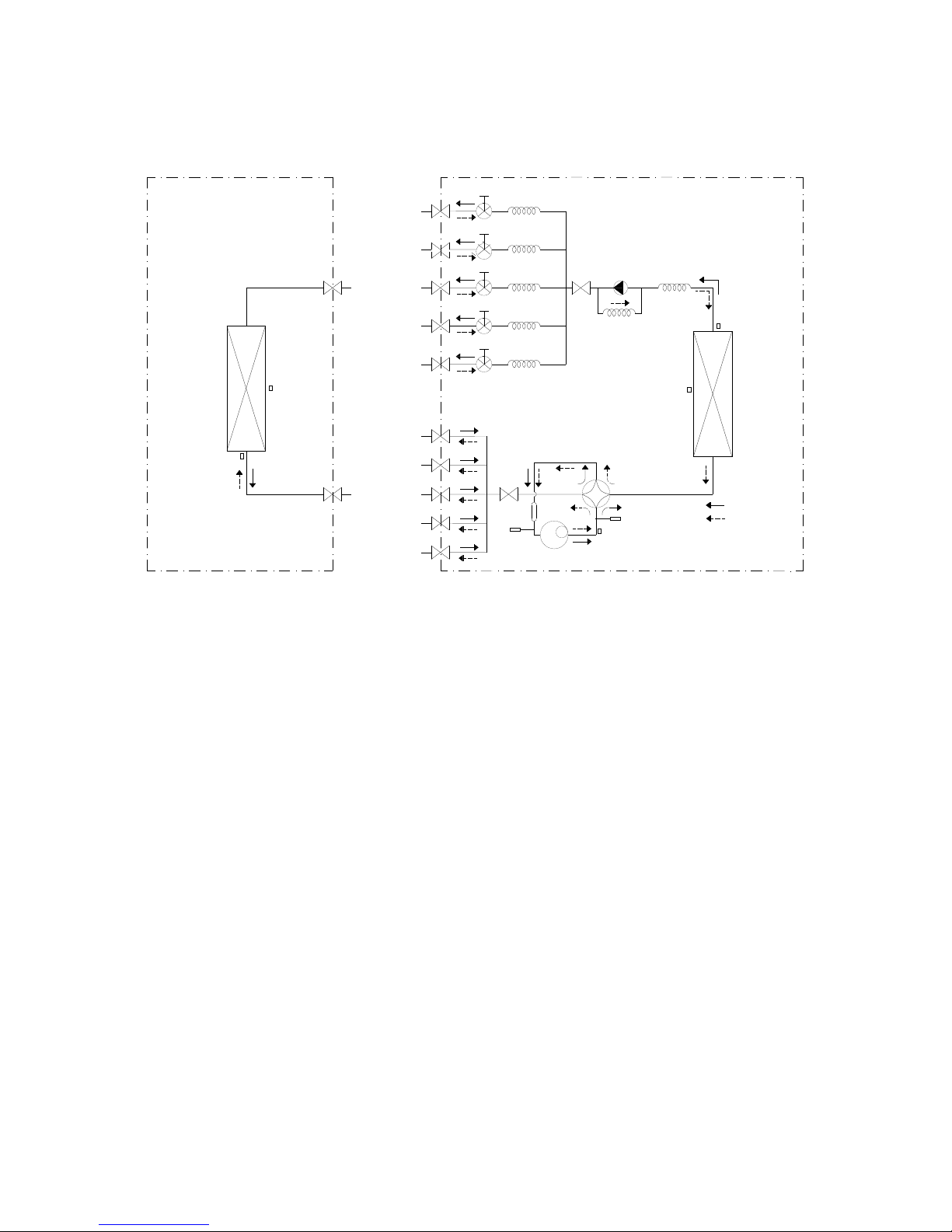

3.4 Refrigeration circuit drawing of inverter 1 drive 5 type

Page 9

9

LIQUID VALVE A

GAS VALVE A

HEAT

EXCHANGE

(EVAPORATOR)

HEAT

EXCHANGE

(CONDENSER)

COOLING

HEATING

T2 Evaporator

temp. sensor

T1 Room

temp. sensor

T3

Condenser

temp. sensor

T4 Ambient

temp. sensor

INDOOR OUTDOOR

EXV A CAPILIARY A

CHECK VALVE

CAPILIARY TUBE

EXV B CAPILIARY B

LIQUID VALVE B

GAS VALVE B

EXV C

CAPILIARY C

LIQUID VALVE C

GAS VALVE C

EXV D

CAPILIARY D

LIQUID VALVE D

GAS VALVE D

EXV E

CAPILIARY E

LIQUID VALVE E

GAS VALVE E

Compressor

4-WAY VALVE

T5 Discharge

temp. sensor

Accumulator

High pressure

switch

Low pressure

switch

T2B-A

Evaporator

temp. sensor outlet

T2B-B

T2B-C

T2B-D

T2B-E

Page 10

10

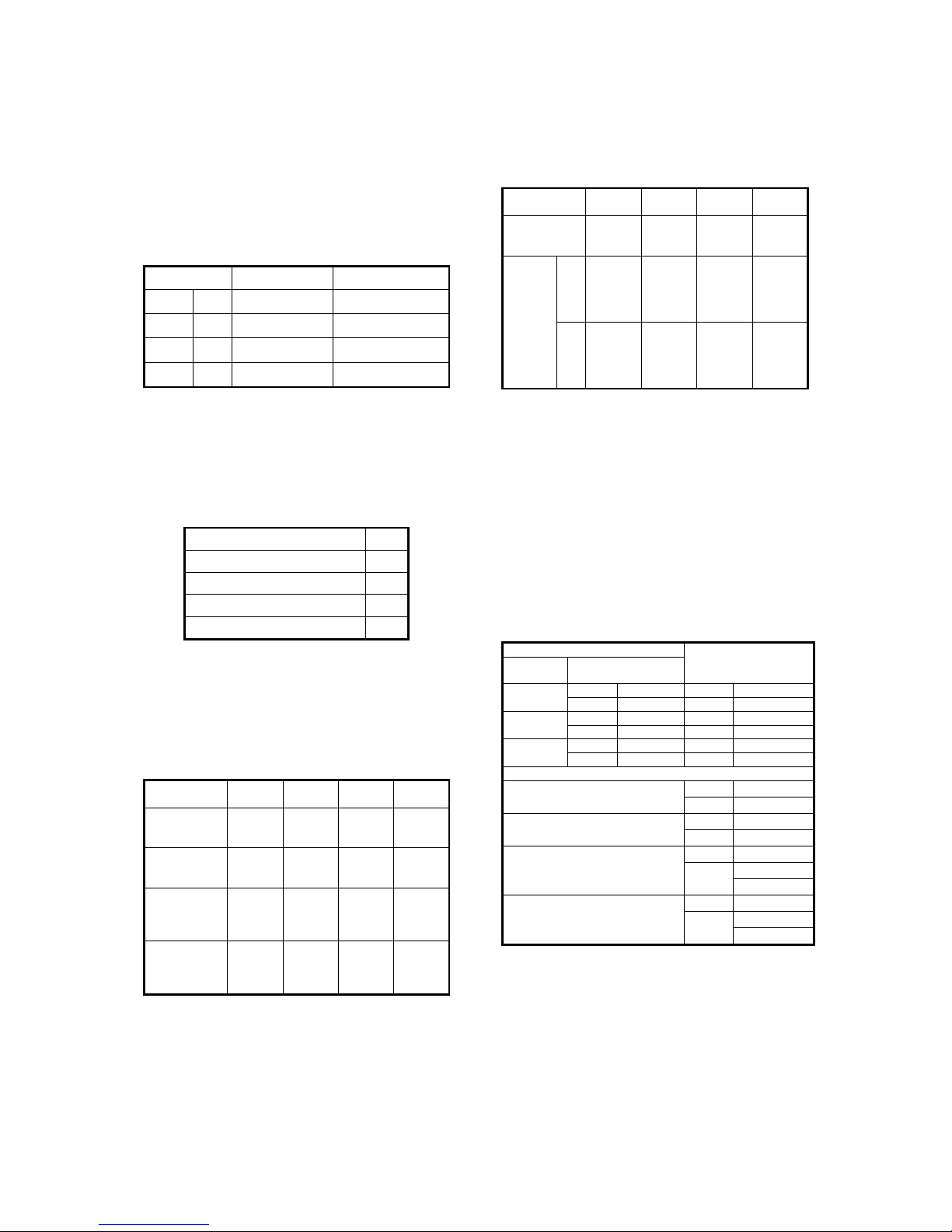

4. Installation Details

4.1 Wrench torque sheet for

installation

Outside

Torque

Additional

mm inch

N.cm N.cm

Ф6.35 1/4 1500(153kgf.cm) 1600(163kgf.cm)

Ф9.52 3/8 2500(255kgf.cm) 2600(265kgf.cm)

Ф12.7 1/2 3500(357kgf.cm) 3600(367kgf.cm)

4.2 Connecting the cables

The power cord connection should be

selected according to the following

specifications sheet.

Unit

AWG

1 drive 2 type (18K outdoor unit) 14

1 drive 3 type (27K outdoor unit). 14

1 drive 4 type (36K outdoor unit) 12

1 drive 5 type (48K outdoor unit) 10

For indoor unit and outdoor unit

connection line, 16AWG is ok for all.

4.3 Pipe length and the elevation

Maximum piping length and height

difference

1 drive 2 1 drive 3 1 drive 4 1 drive

5

Max. length

for all rooms

(m)

40

(131ft)

60

(197ft)

80

(262ft)

80

(262ft)

Max. length

for one IU

(m)

25

(82ft)

30

(98ft)

35

(115ft)

35

(115ft)

Max. height

difference

between IU

and OU (m)

15

(49.2ft)

15

(49.2ft)

15

(49.2ft)

15

(49.2ft)

Max. height

difference

between IUs

(m)

10

(33ft)

10

(33ft)

10

(33ft)

10

(33ft)

Additional refrigerant charge

1 drive 2 1 drive 3 1 drive 4 1 drive

5

Pre-charge

pipe length

(m)

15

(49.2ft)

22.5

(73.8ft)

30

(98.4ft)

37.5

(123ft)

Additio

nal

refriger

ant

charge

g 15 x

(length

for all

rooms -

15)

15 x

(length

for all

rooms

– 22.5)

15 x

(length

for all

rooms -

30)

15 x

(length

for all

rooms

– 37.5)

oz 0.161

x(lengt

h for all

rooms

– 49.2)

(0.161

x(lengt

h for all

rooms

– 73.8)

0.161x(

length

for all

rooms

– 98.4)

.0.161x

(length

for all

rooms

–123)

Caution:

● Refrigerant pipe diameter is different

according to indoor unit to be connected.

When using the extension pipe, refer to

the tables below.

● When refrigerant pipe diameter is

different from that of the outdoor unit

connector (18K indoor unit) an additional

adapter is required.

Indoor unit

Extension pipe

diameter (mm/inch)

Model

Pipe diameter

(mm/inch)

9K

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 9.52(3/8) Gas 9.52(3/8)

12K 18K

Liquid 6.35(1/4) Liquid 6.35(1/4)

Gas 12.7(1/2) Gas 12.7(1/2)

24K

Liquid 9.52 (3/8) Liquid 9.52 (3/8)

Gas 15.9(5/8) Gas 15.9(5/8)

Outdoor unit union diameter (mm/inch)

1 drive 2

Liquid

6.35(1/4)

*2

Gas

9.52(3/8)

*2

1 drive 3

Liquid

6.35(1/4)

*3

Gas

9.52(3/8)

*3

1 drive 4

Liquid

6.35(1/4)

*4

Gas

9.52(3/8)

*3

12.7(1/2) *1

1 drive 5

Liquid

6.35(1/4)

*5

Gas

9.52(3/8)

*3

12.7(1/2) *2

Page 11

11

4.4 First-Time Installation

Air and moisture in the refrigerant system

cause the following problems:

● Increases in system pressure

● Increases in operating current

● Decreases in cooling and heating

efficiency

● Blocks in capillary tubing caused by

moisture in the refrigerant circuit freezing

● Corrosion of parts in the refrigerant

system caused by water

The indoor units and the pipes between

indoor and outdoor units must be tested for

leakages and evacuated to remove gas and

moisture from the system.

Gas leak check with soap water:

Apply soap water or a liquid neutral

detergent on the connections with a soft

brush to check for leakage in the pipe

connecting points. If bubbles emerge, the

pipes are leaking.

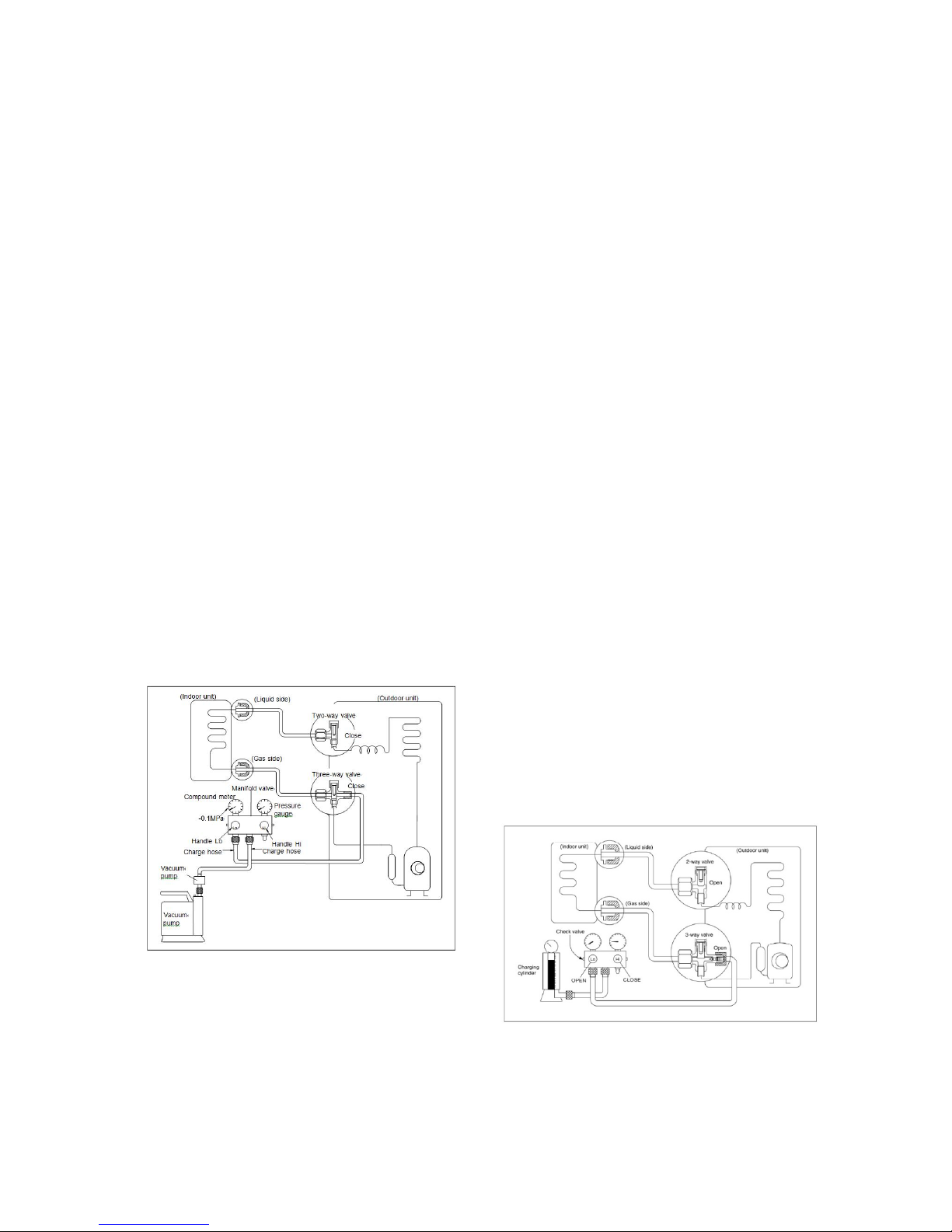

1. Air Purging Using the Vacuum Pump

1. Completely tighten the flare nuts on the

indoor and outdoor units. Confirm that

both the2-way and 3-way valves are set

to the closed position.

2. Connect the charge hose with the push

pin of the Handle Lo to the 3-way valve

gas service port.

3. Connect the charge hose of the Handle

Hi to the vacuum pump.

4. Fully open the Handle Lo of the manifold

valve.

5. Turn on the vacuum pump to begin

evacuation.

6. Conduct a 30-minute evacuation. Check

whether the compound meter indicates -

0.1Mpa(14.5Psi). If the meter does not

indicate -0.1Mpa(14.5Psi) after 30

minutes has elapsed, continue

evacuation for 20 more minutes. If the

pressure does not reach -

0.1Mpa(14.5Psi) after 50 minutes has

elapsed, check if there are any leaks.

Fully close the Handle Lo valve of the

manifold valve and turn off the vacuum

pump. After 5 minutes, confirm that the

gauge needle is not moving.

7. Turn the flare nut on the 3-way valve45°

counterclockwise for 6-7 seconds. Once

gas begins to come out, tighten the flare

nut. Make sure the pressure display on

the pressure indicator is higher than

atmospheric pressure. Then remove the

charge hose from the 3-way valve.

8. Fully open the 2-wayand 3-way valves

and securely tighten the cap on the 3way valve.

2. Adding refrigerant if the pipe length

exceeds chargeless pipe length

Procedure:

Page 12

12

1)

Connect the charge hose to the charging

cylinder and open the 2-way and 3-way

valves.

With the charge hose you disconnected

from the vacuum pump, connect it to the

valve at the bottom of the cylinder.

If the refrigerant is R410A, place the

cylinder bottom-up to ensure liquid charging

is possible.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder

and press the check valve on the charge set

(be careful of the liquid refrigerant).

3) Place the charging cylinder onto the

electronic scale and record the weight.

4) Turn on the air conditioner in cooling

mode.

5) Open the valves (Low side) on the charge

set. Charge the system with liquid refrigerant.

6).When the electronic scale displays the

proper weight (refer to the table), disconnect

the charge hose from the 3-way valve’s

service port immediately and turn off the air

conditioner before disconnecting the hose.

7). Mount the valve stem caps and the service

port

Use a torque wrench to tighten the service

port cap to a torque of 18N.m(13.27 ft·lbs).

Be sure to check for gas leaks.

4.5 Adding Refrigerant after Long-

Term System Operation

Procedure

1)

Connect the charge hose to the 3-way

service port and open the 2-way and 3-way

valve.

Connect the charge hose to the valve at the

bottom of the cylinder. If the refrigerant is

R410A, place the cylinder bottom-up to

ensure liquid charge.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder

and press the check valve on the charge set

to purge the air (be careful of the liquid

refrigerant).

3) Place the charging cylinder onto the

electronic scale and record the weight.

4) Turn on the air conditioner in cooling

mode.

5) Open the valves (Low side)on the charge

set and charge the system with liquid

refrigerant.

6).When the electronic scale displays the

proper weight (refer to the gauge and the

pressure of the low side), disconnect the

charge hose from the 3-way valve’s service

port immediately and turn off the air

conditioner before disconnecting the hose.

7). Mount the valve stem caps and the service

port.

Use torque wrench to tighten the service

port cap to a torque of 18N.m(13.27 ft·lbs).

Be sure to check for gas leaks.

4.6 Procedure when servicing the

indoor unit refrigeration circuit.

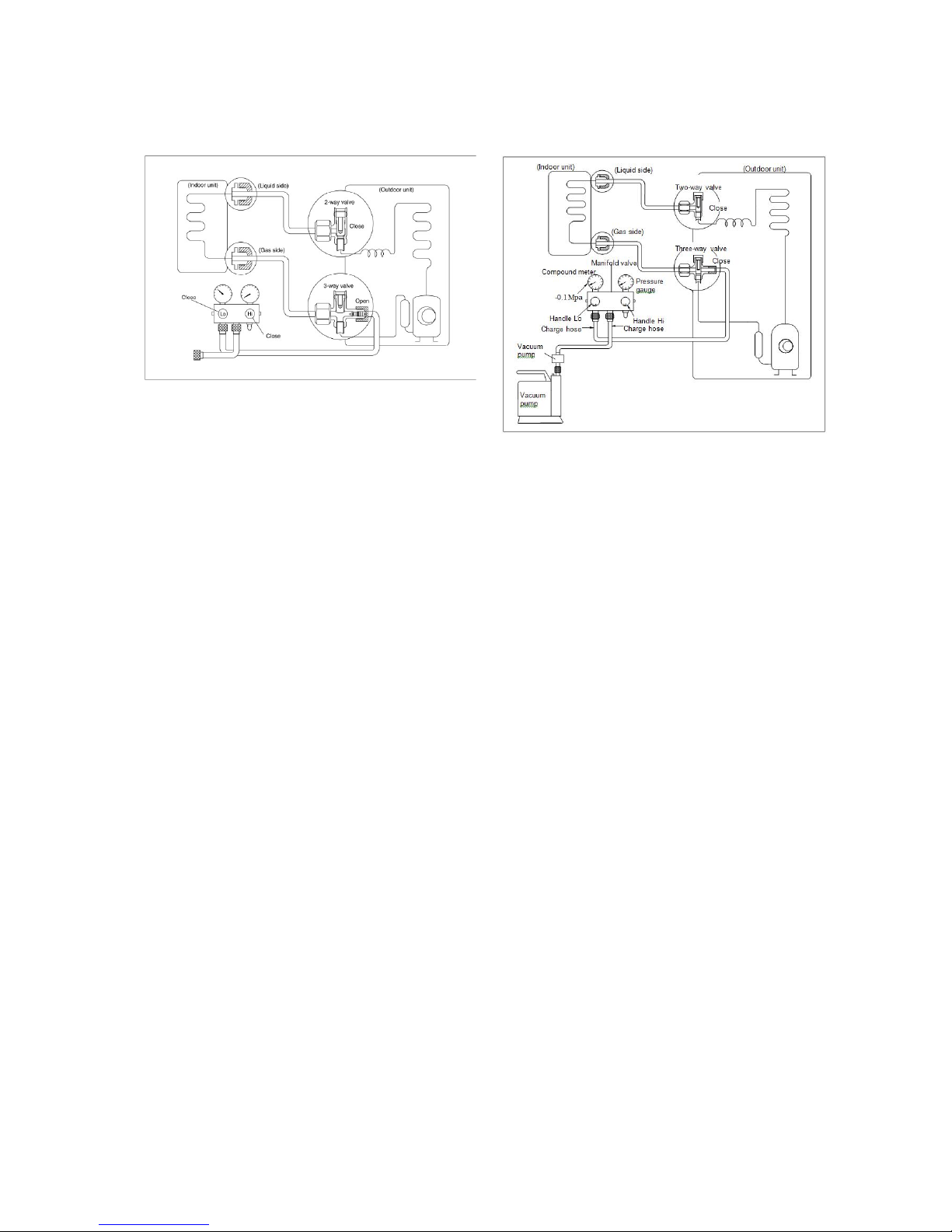

1. Collecting the refrigerant into the

outdoor unit

Page 13

13

Procedure

1). Confirm that both the 2-way and 3-way

valves are set to the opened position

Remove the valve stem caps and confirm that

the valve stems are in the opened position.

Be sure to use a hexagonal wrench to operate

the valve stems.

2). Connect the charge hose with the push pin

of handle lo to the 3-way valves gas service

port.

3). Air purging of the charge hose.

Open the handle Lo valve of the manifold

valve slightly to purge air from the charge

hose for 5 seconds and then close it quickly.

4). Set the 2-way valve to the close position.

5). Operate the air conditioner at the cooling

cycle and stop it when the gauge indicates

0.1MPa.

6). Set the 3-way valve to the closed position

immediately

Do this quickly so that the gauge ends up

indicating 0.3 to 0.5Mpa.

Disconnect the charge set, and tighten the 2way and 3-way valve’s stem nuts.

Use a torque wrench to tighten the 3-way

valves service port cap to a torque of 18N.m.

Be sure to check for gas leakage.

2. Air purging with vacuum pump

1) Completely tighten the flare nuts of the

indoor and outdoor units, confirm that

both the 2-way and 3-way valves are set

to the closed position.

2) Connect the charge hose with the push

pin of handle lo to the 3-way valves gas

service port.

3) Connect the charge hose of handle hi

connection to the vacuum pump.

4) Fully open the handle Lo of the manifold

valve.

5) Operate the vacuum pump to evacuate.

6) Make evacuation for 30 minutes and

check whether the compound meter

indicates -0.1Mpa. If the meter does not

indicate -0.1Mpa after pumping 30

minutes, it should be pumped 20 minutes

more. If the pressure can’t achieve -

0.1Mpa after pumping 50 minutes,

please check if there are some leakage

points.

Fully close the handle Lo valve of the

manifold valve and stop the operation of the

vacuum pump. Confirm that the gauge

needle does not move (approximately 5

minutes after turning off the vacuum pump).

7) Turn the flare nut of the 3-way valves

about 45° counterclockwise for 6 or

7seconds after the gas

coming out, then tighten the flare nut again.

Make sure the pressure display in the

Page 14

14

pressure indicator is a little higher than the

atmosphere pressure. Then remove the

charge hose from the 3 way valve.

8) Fully open the 2 way valve and 3 way

valve and securely tighten the cap of the

3 way valve.

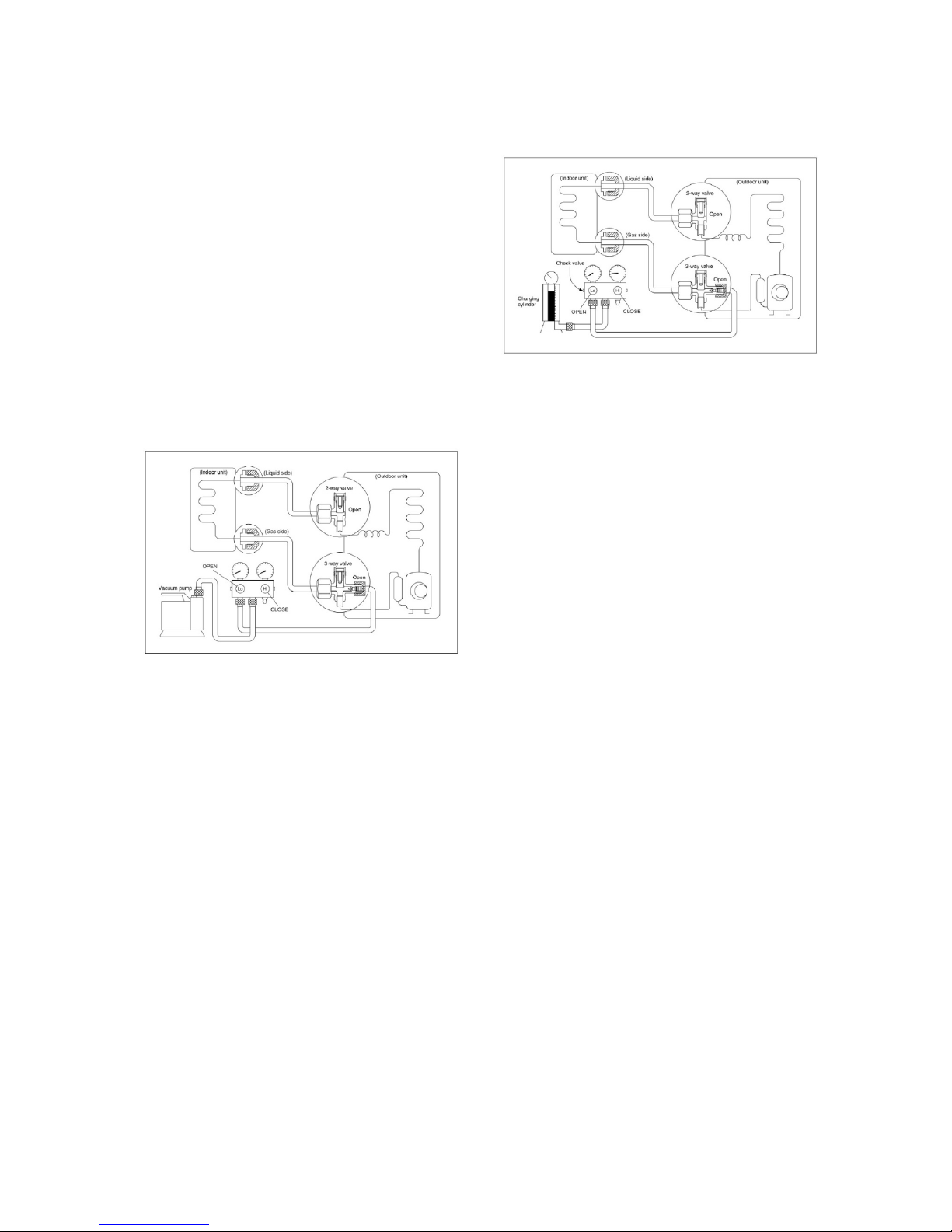

4.7 Evacuation after servicing the

outdoor unit refrigeration circuit

1. Evacuation of the complete

refrigeration circuit, Indoor and outdoor

unit.

Procedure:

1). Confirm that both the 2-way and 3-way

valves are set to the opened position.

2). Connect the vacuum pump to 3-way

valve’s service port.

3). Evacuation for approximately one hour.

Confirm that the compound meter indicates -

0.1Mpa (500 Microns / 29.9 in,hg).

4). Close the valve (Low side) on the charge

set, turn off the vacuum pump, and confirm

that the gauge needle does not move

(approximately 5 minutes after turning off the

vacuum pump).

5). Disconnect the charge hose from the

vacuum pump.

2. Refrigerant charging

Procedure:

1). Connect the charge hose to the charging

cylinder, open the 2-way valve and the 3-way

valve.

Connect the charge hose which you

disconnected from the vacuum pump to the

valve at the bottom of the cylinder. If the

refrigerant is R410A, make the cylinder

bottom up to ensure liquid charge.

2). Purge the air from the charge hose

Open the valve at the bottom of the cylinder

and press the check valve on the charge set

to purge the air (be careful of the liquid

refrigerant).

3) Put the charging cylinder onto the

electronic scale and record the weight.

4). Open the valves (Low side) on the charge

set and charge the system with liquid

refrigerant

If the system cannot be charge with the

specified amount of refrigerant, or can be

charged with a little at a time (approximately

150g each time) , operating the air conditioner

in the cooling cycle; however, one time is not

sufficient, wait approximately 1 minute and

then repeat the procedure.

5).When the electronic scale displays the

proper weight, disconnect the charge hose

from the 3-way valve’s service port

immediately

If the system has been charged with liquid

refrigerant while operating the air conditioner,

turn off the air conditioner before

disconnecting the hose.

6). Mounted the valve stem caps and the

service port. Use torque wrench to tighten the

service port cap to a torque of 18N·m (13.27

ft·lbs).

Always leak check after servicing the

Page 15

15

refrigerant system.

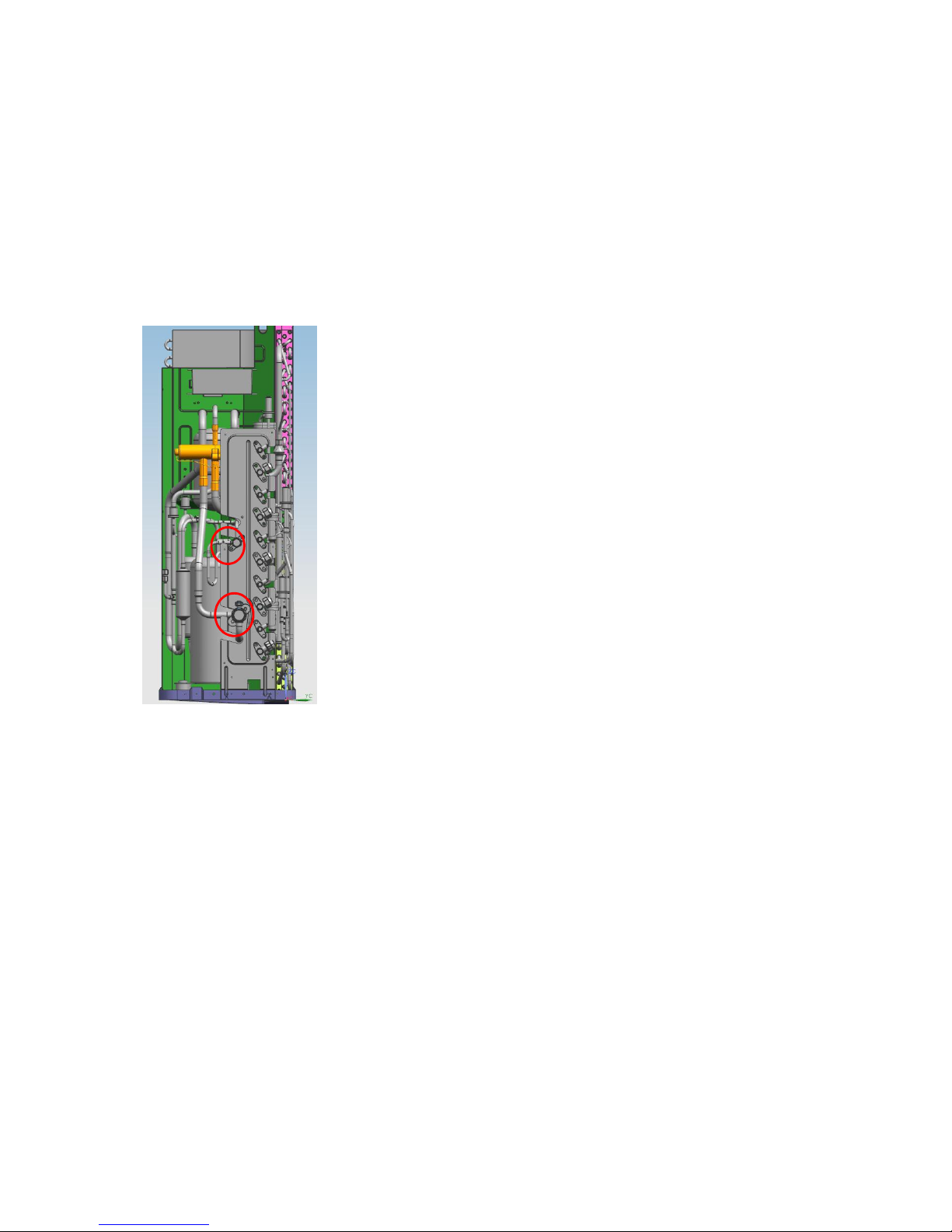

For MCH3U-27PHH2/MCH4U36PHH2/MCH5U-48PHH2

There are one low-pressure centralized valve

and one high-pressure centralized valve, it will

be more time saving when vacuum and

recycle refrigerant. But refer to the previous

instruction when vacuum and recycle

refrigerant.

6. Electronic Function

6.1 Abbreviation

T1: Indoor ambient temperature

T2: Middle indoor heat exchanger coil

temperature

T2B: Indoor heat exchanger exhaust coil

temperature (located on the outdoor unit)

T3: Outdoor heat exchanger pipe

temperature

T4: Outdoor ambient temperature

T5: Compressor discharge temperature

6.2 Electric Control Working

Environment.

6.2.1 Input voltage: 230V.

6.2.2 Input power frequency: 60Hz.

6.2.3 Indoor fan standard working amp.: <1A

6.2.4 Outdoor fan standard working amp.:

<1.5A.

6.2.5 Four-way valve standard amp.: <1A.

6.3 Main Protection

6.3.1 Compressor Restart Delay

---- The compressor takes 1 minute to start

up the first time. Further restarts take 3

minutes.

6.3.2 Temperature Protection of

Compressor Discharge.

When the discharge temperature of the

compressor rises, the running frequency is

limited according to the following rules:

----If 105℃ (221 ℉)≦T5<110℃ (230 ℉),

maintain the current frequency.

Page 16

16

----If the temperature increase and T5≧110℃

(230 ℉), decrease the frequency to a lower

level every 2 minutes till to F1.

---If T5≧115℃ (239 ℉) for 10 seconds, the

compressor stops and then restart untill

T5<90℃ (194 ℉).

6.3.3 Fan Speed Malfunction

---- If outdoor fan speed is lower than

100RPM or higher than 2400RPM for 60

seconds or more, the unit stops and LED

displays E8 failure code.

6.3.4 Inverter Module Protection.

---- The inverter protection module ensures

that faults related to current, voltage, or

temperature does not damage the inverter.

If these protections are triggered, the A/C

unit stops and the LED displays the failure

code.

The unit restarts 3 minutes after the

protection mechanism has turned off.

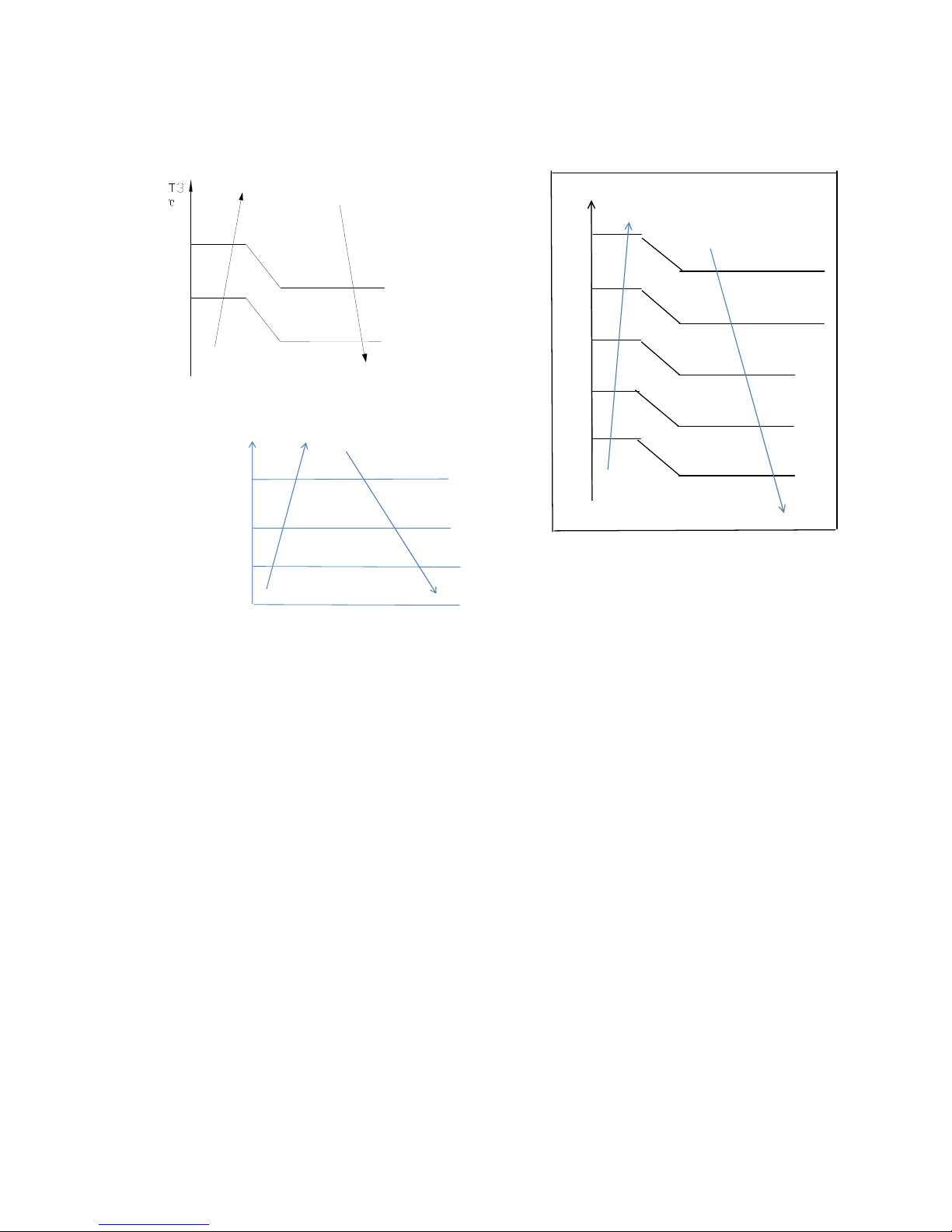

6.3.5 Low Voltage Protection

V O LT A G E

N o l im it

V O L T _ LT M _F R EQ 1_ A D D

V O L T _L T M _F R EQ 2_ A D D

Note: If low voltage protection triggers and

voltage is not restored to normal within 3

minutes, the protection remains active

even after a machine restart.

6.3.6 Compressor Current Limit

Protection

The temperature interval for the current limit

is the same as the range of the T4

frequency limit.

Cooling mode:

CoolReturnI The difference between

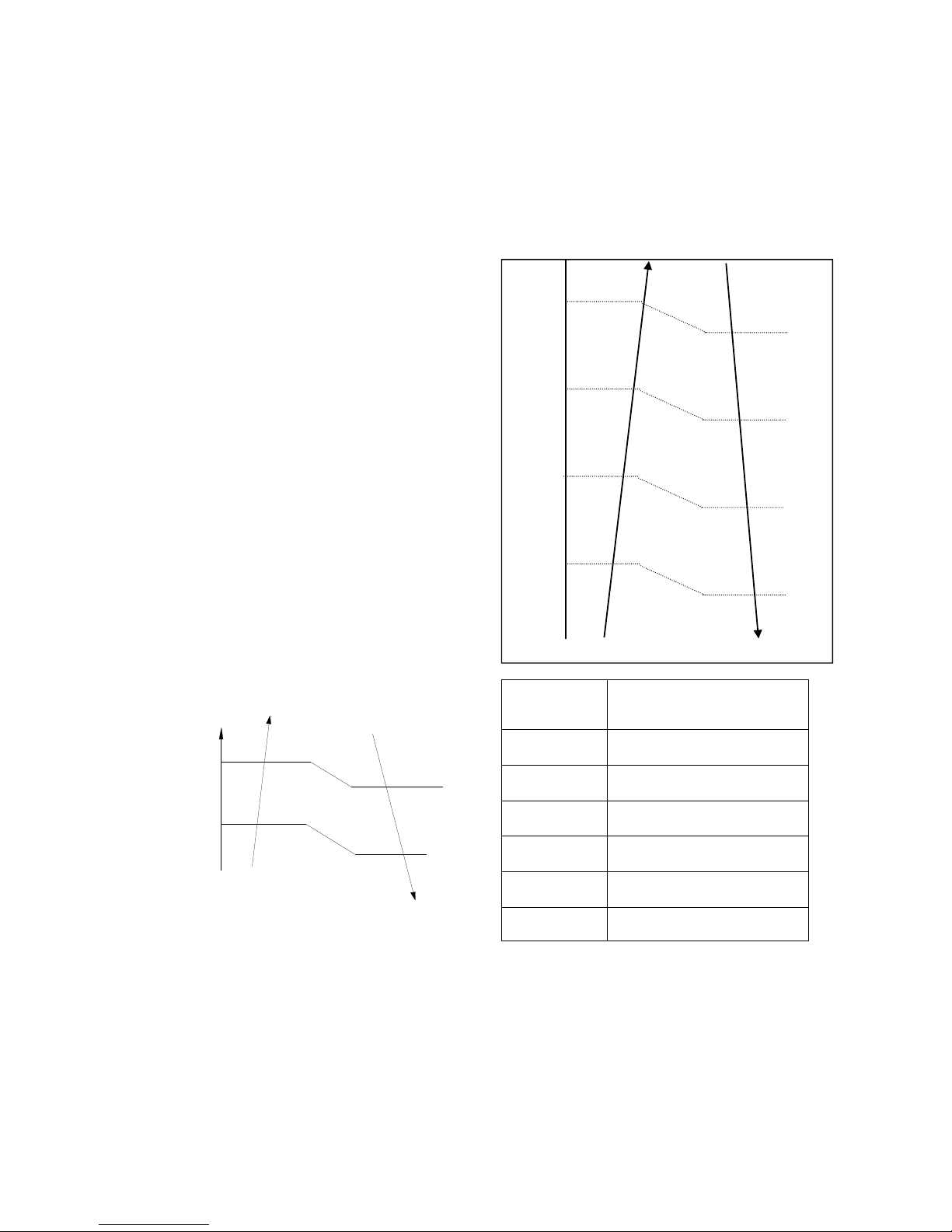

current limit

and shutdown current

CoolT4Zone5I

Cooling T4≥50℃ current

limit value

CoolT4Zone4I

Cooling 49>T4≥45℃

current limit value

CoolT4Zone3I

Cooling 44>T4≥41℃

current limit value

CoolT4Zone2I

Cooling 40﹥T4≥33℃

current limit value

CoolT4Zone1I

Cooling 32>T4℃current

limit value

CoolStopI Cooling stop protection

current value

Heating mode:

℃

CoolT4Zone5I

50

49

45

CoolT4Zone4I

44

41

40

CoolT4Zone3I

33

32

CoolT4Zone2I

Page 17

17

℃

15

14 HeatT4Zone4I

10

9 HeatT4Zone3I

6

5 HeatT4Zone2I

HeatT4Zone1I

HeatReturnI The difference between

current limit

and shutdown current

HeatT4Zone4I

Heating

T4≥15℃

current

limit value

HeatT4Zone3I

Heating

14>T4≥10℃

current limit value

HeatT4Zone2I

Heating

9>T4≥6℃

current limit value

HeatT4Zone1I

Heating

5>T4

current limit

value

HeatStopI Heating stop protection

current value

6.3.7 Indoor / Outdoor Units

Communication Protection

If the indoor units do not receive the

feedback signal from the outdoor units for 2

consecutive minutes, the unit stops. The

unit displays the failure code.

6.3.8 High Condenser Coil Temp.

Protection

6.3.9 Outdoor Unit Anti-Freezing

Protection

When T2<4℃ for 250seconds or T2<0℃,

the indoor unit capacity demand is zero and

resumes normal operation when T2>8℃

and the protection time is no less than 3

minutes.

6.3.10 Oil Return

Rules for Operation

1. If the compressor frequency continues to

be lower than the frequency set for setting

time, the unit raises the frequency to the

frequency set for setting time and then

resumes with the former frequency.

2. The EXV continues at 300p while indoor

units maintain their operation.

If the outdoor ambient temperature is higher

than the set frequency during oil return, the

unit stops the oil return process.

6.3.11 Low Outdoor Ambient

Temperature Protection

When the compressor is off and T4 is lower

than -35℃ for 10 seconds, the unit stops

and displays “LP.”

When the compressor is on and T4 remains

lower than -40℃ for 10 seconds, the unit

stops and displays “LP.”

When T4 is no lower than -32℃ for 10

seconds, the unit exits protection.

6.4 Control and Functions

6.4.1 Capacity Request Calculation

Cooling Mode:

T3

Resume

Off

Decrease

Hold

Page 18

18

T1 Ts

3

1

1

e

c

a

4

2

0

2

3

0

1

f

d

b

Capacity area a b c d e f

Norm code

(N)

3 2 1.5 1 0.5 0

Model 9K 12K 18K 24K

HP 1.0 1.2 1.5 2.5

Note: The final result is an integer.

Use the following table and final capacity

request to confirm the operating

frequency.

Frequency

(Hz)

0

CO

OL_

F1

CO

OL_

F2

…

…

COO

L_F2

4

CO

OL_

F25

Amendatory

capacity

demand.

0 1 2

…

…

24 25

The maximum running frequency is

adjusted according to the outdoor ambient

temperature

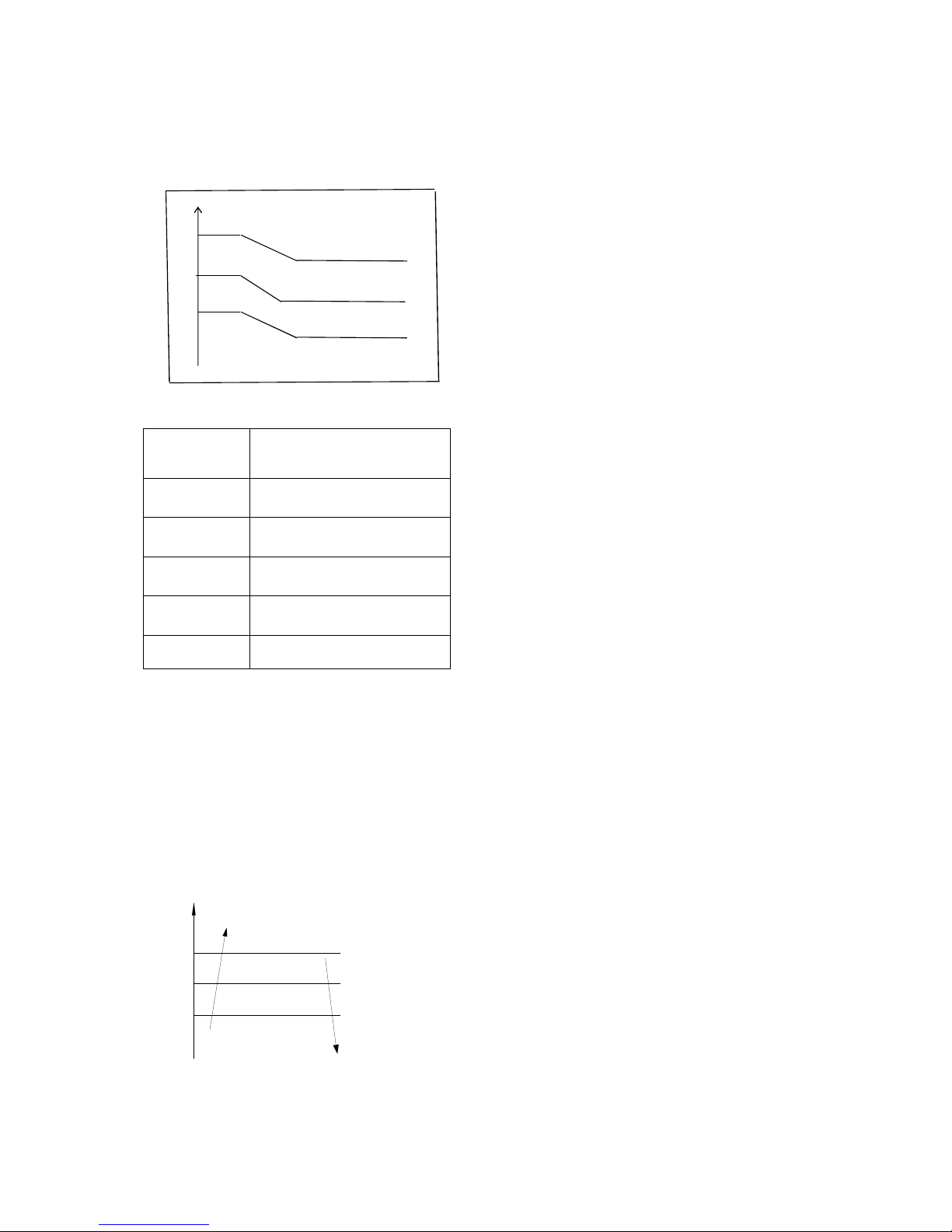

℃

55

54 Fmax=

T4FREMAXC0

51.5

50.5 Fmax= T4FREMAXC1

45.5

44.5 Fmax= T4FREMAXC2

39

38 Fmax= T4FREMAXC3

33

32 Fmax= T4FREMAXC4

30

29 Fmax= T4FREMAXC5

22

20 Fmax= T4FREMAXC6

10

8 Fmax= T4FREMAXC7

0

-2 Fmax= T4FREMAXC8

-10

-12 Fmax= T4FREMAXC9

Fmax= T4FREMAXC10

Heating Mode

T1 Ts

4

0

a

3

1

-1

3

1

2

0

b

c

d

e

f

2

Capacity area a b c d e f

Norm code (N) 3 2 1.5 1 0.5 0

Model 9K 12K 18K 24K

HP 1.0 1.2 1.5 2.5

Note: The final result is an integer.

Page 19

19

Then modify it according to a T2 average

(correction):

Note:Average value of T2:Sum T2 value of

all indoor units)/ (indoor units number

T2 average

Decrease frequency

47

Keep frequency

40 Increase frequency

Use the following table and final capacity

request to confirm the operating

frequency.

Frequency

(Hz) 0

HEA

T_F

1

HEA

T

_F2

…

HEA

T

_F24

HEA

T

_F2

5

Amendatory

capacity

demand.

0 1 2 … 24 25

The maximum running frequency is

adjusted according to the outdoor ambient

temperature

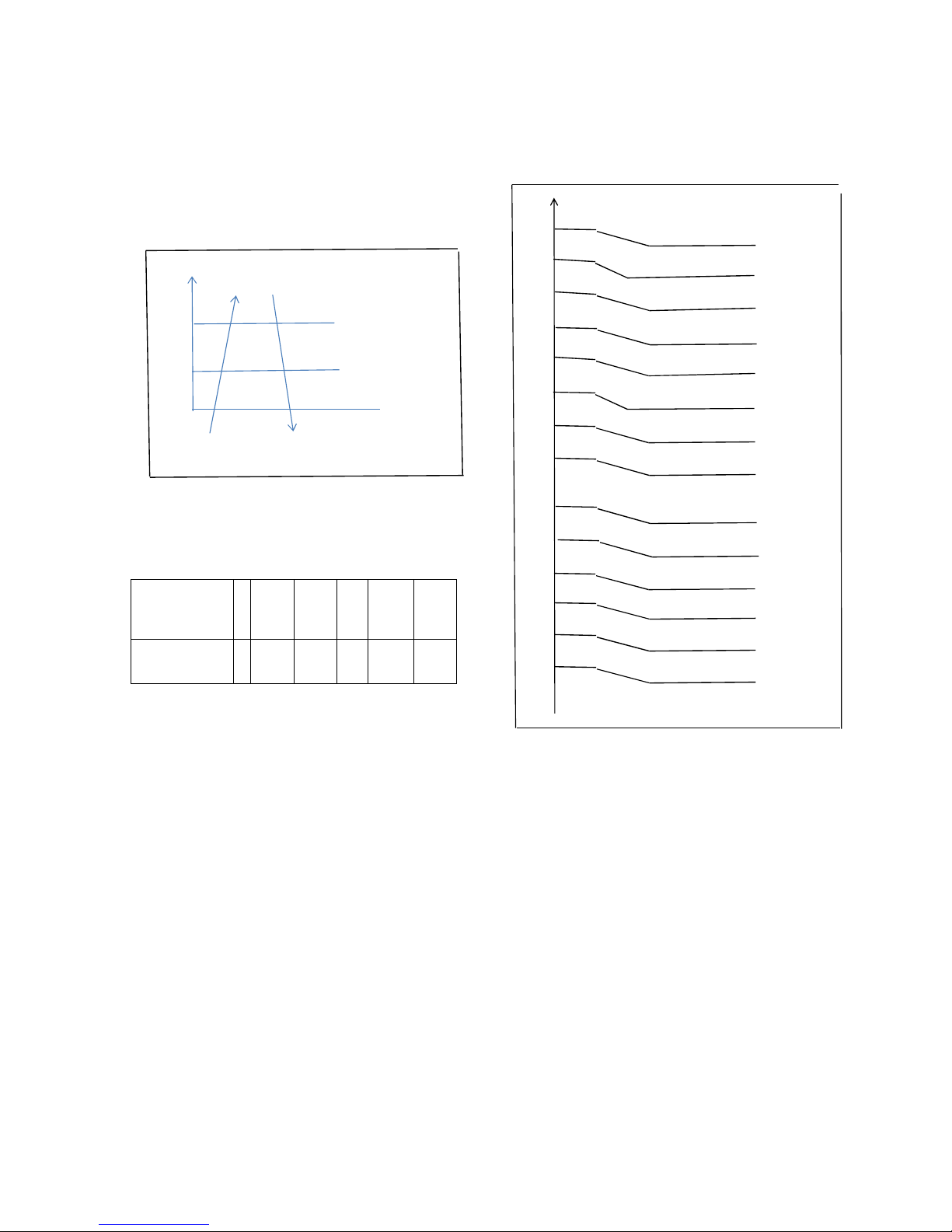

℃

34

33 Standby

28

27 Fmax=T4FREHEATMAX1

25

24 Fmax=T4FREHEATMAX2

22

21 Fmax=T4FREHEATMAX3

19

18 Fmax=T4FREHEATMAX4

17

16 Fmax=T4FREHEATMAX5

15

14 Fmax=T4FREHEATMAX6

12

11 Fmax=T4FREHEATMAX7

6

5 Fmax=T4FREHEATMAX8

1

0 Fmax=T4FREHEATMAX9

-3

-4 Fmax=F21

-7

-8 Fmax=F22

-11

-12 Fmax=F23

-15

-16 Fmax=F24

Fmax=F25

6.4.2 Defrosting Control

Conditions for Defrosting:

After the compressor starts and enters

normal operation, mark the minimum value

of T3 from the 10th to 15th minute as T30.

If any one of the following conditions is

satisfied, the unit enters defrosting mode:

1) If the compressor’s cumulative running

time reaches 29 minutes and T3< TCDI1

and T3+T30SUBT3ONE≦T30.

Page 20

20

2) If the compressor cumulative running

time reaches 35 minutes and T3< TCDI2

and T3+T30SUBT3TWO≦T30.

3) If the compressor cumulative running

time reaches 40 minutes and T3< -24C for 3

minutes.

4) If the compressor cumulative running

time reaches 120 minutes and T3<-15℃.

Defrost Stop Conditions

If any one of the following conditions is

satisfied, defrosting ends and the unit

returns to normal heating mode:

----T3 rises above than TCDE1℃.

----T3 remains at TCDE2℃ or above for 80

seconds.

----The machine runs for 10 consecutive

minutes in defrosting mode.

Defrosting Action:

off on

Cool-F9

10S 30S

TimeA

10S

4-way valve

defrosting Defrosting over

compressor

Indoor fan

Outdoor fan

EXV open

frequency

Max 10 minutes

frequency

Compressor stops

off

Anti-cold control

off

480P 480P for 240s

Condition of ending defrosting:

If any one of following items is satisfied,

defrosting will stop and the machine will turn

to normal heating mode.

① T3 > TempQuitDefrost_ADD ℃;.

② The defrosting time achieves 10min.

③ Turn to other modes or off.

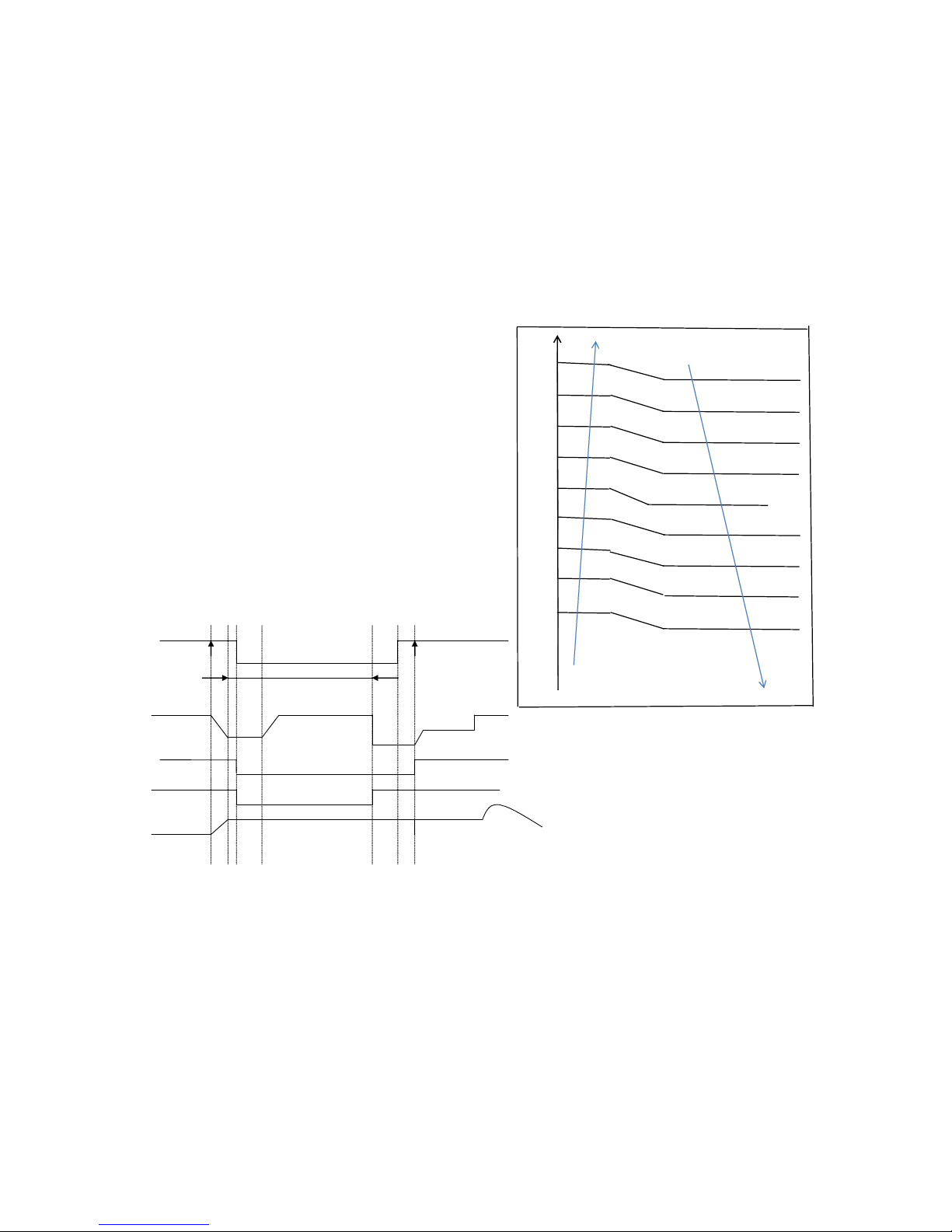

6.4.3 Outdoor Fan Control

6.4.3.1 Cooling Mode

Under normal operating conditions, the

system chooses the running fan speed

according to the ambient temperature:

O

utdoor temperature

℃

45

43 Supper high fan speed

28

26 High fan speed

25

23 Middle fan speed

22

20 Low fan speed

19

17 Supper low fan speed

10

9 Breeze fan speed

0

-1 F fan speed

-5

-6 G fan speed

-10

-11 H fan speed

I fan speed

When low ambient cooling is in effect::

Outdoor fan speed control logic (low

ambient cooling)

When T4 <15 ℃ (59 ℉) and T3 < 30 ℃ (86

℉), the unit enters into low ambient cooling

mode. The outdoor fan chooses a speed

according to T3.

When T3≥38 ℃ (100.4 ℉) or when T4≥20 ℃

(68 ℉), the outdoor fan chooses a speed

according to T4 again.

Page 21

21

38

Exit low ambient cooling

mode, run with high fan

for 1 minute

Low

30

27

23

off

T3

Increase fan spe ed increase

Keep c urrent fan speed

Decrea se fan speed

Fan st op

LowCoolT3_ON

LowCoo lT3_Down

LowCoo lT3_OFF

6.4.3.2 Heating Mode

Under normal operating conditions, the

system chooses a running fan speed

according to ambient temperature:

Outdoor temperature℃

21

Breeze fan speed

19

18

Supper low fan speed

16

15

Low fan speed

13

12

Middle fan speed

10

0

High fan speed

-2

Supper high fan speed

6.4.4 Electronic Expansion Valve (EXV)

Control

1. EXV remains fully closed while the device

is powering up. EXV then remains on

standby with 350P open. It opens to the

target angle after the compressor starts.

2. EXV closes with -160P when the

compressor stops. Then it remains on

standby with 350P open. It opens to the

target angle after the compressor starts.

3. The action priority for the EXVs is A-B-CD-E.

4. The compressor and outdoor fan

commence operation only after EXV

initializes.

6.4.4.1 Cooling Mode

The initial open angle of the EXV depends on

the size of the indoor model. The adjustment

range is 100-400p.

When the unit has been running for 3

minutes, the outdoor receives indoor units'

capacity demand and T2B information and

then calculates their average. After

comparing each indoor’s T2B with the

Page 22

22

average, the outdoor gives the following

modification commands:

---- If the T2B>average, the relevant valve

needs to open 16p more

---- If the T2B= average, the relevant valve’s

open range remains as is

---- If the T2B<average, the relevant valve

needs to close 16p more

This modification is carried out every 2

minutes.

6.4.4.2 Heating Mode

The initial open angle of the EXV depends on

the size of the indoor model. The adjustment

range is 150-350p.

When the unit has been running for 3

minutes, the outdoor unit receives the indoor

units' indoor units' capacity demand and T2

information and then calculates their average.

After comparing each indoor unit’s T2 with

the average, the outdoor gives the following

modification commands:

----If the T2>average+2, the relevant valve

needs to close 16p more

---- If average+2≥the T2≥ average-2, the

relevant valve’s open range remains as is

----If the T2<average-2, the relevant valve

needs to open 16p more

This modification is carried out every 2

minutes.

6.4.5 Four-Way Valve Control

In heating mode, a four-way valve is opened.

In defrosting, a four-way valve operates

according to the current defrosting action.

In other modes, a four-way valve is closed.

When the unit is switched from heating to

other modes, the four-way valve turns off

after the compressor has been off for 2

consecutive minutes.

Failure or protection (excluding discharge

temperature protection and high/low

pressure protection) causes the four-way

valve to immediately shut down.

Page 23

23

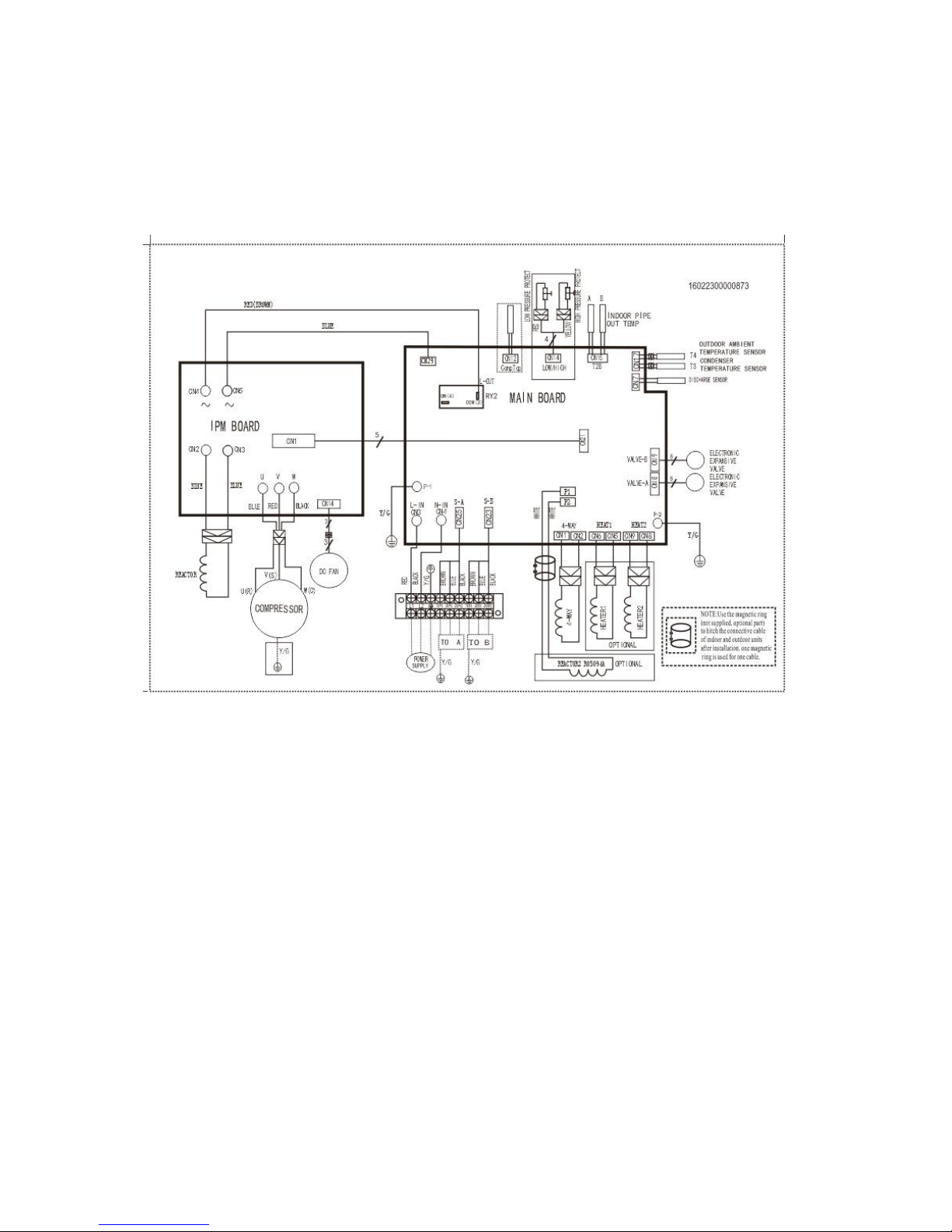

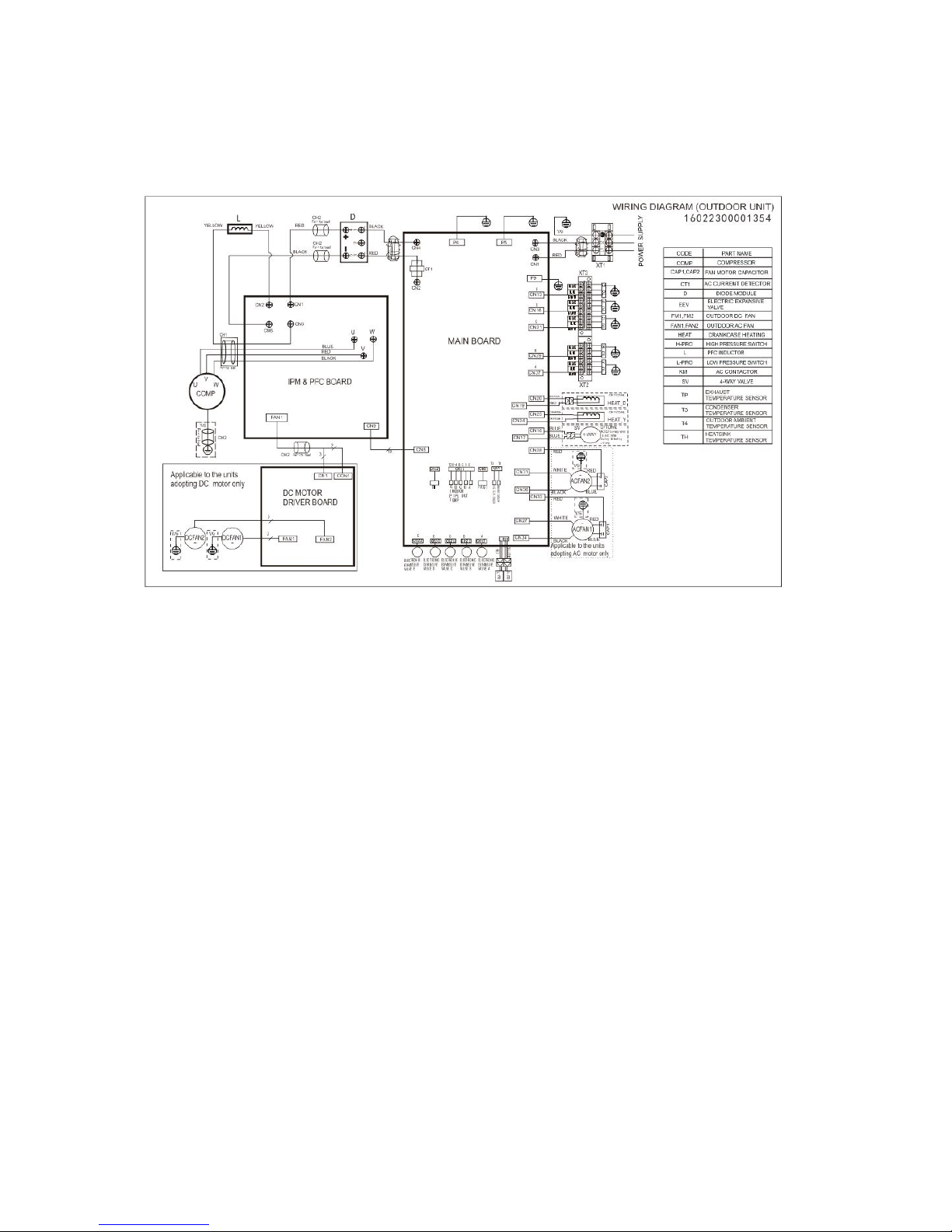

7. Wiring Diagrams

7.1 Wiring diagram of 1 drive 2 outdoor

MCH2U-18PHH2

Page 24

24

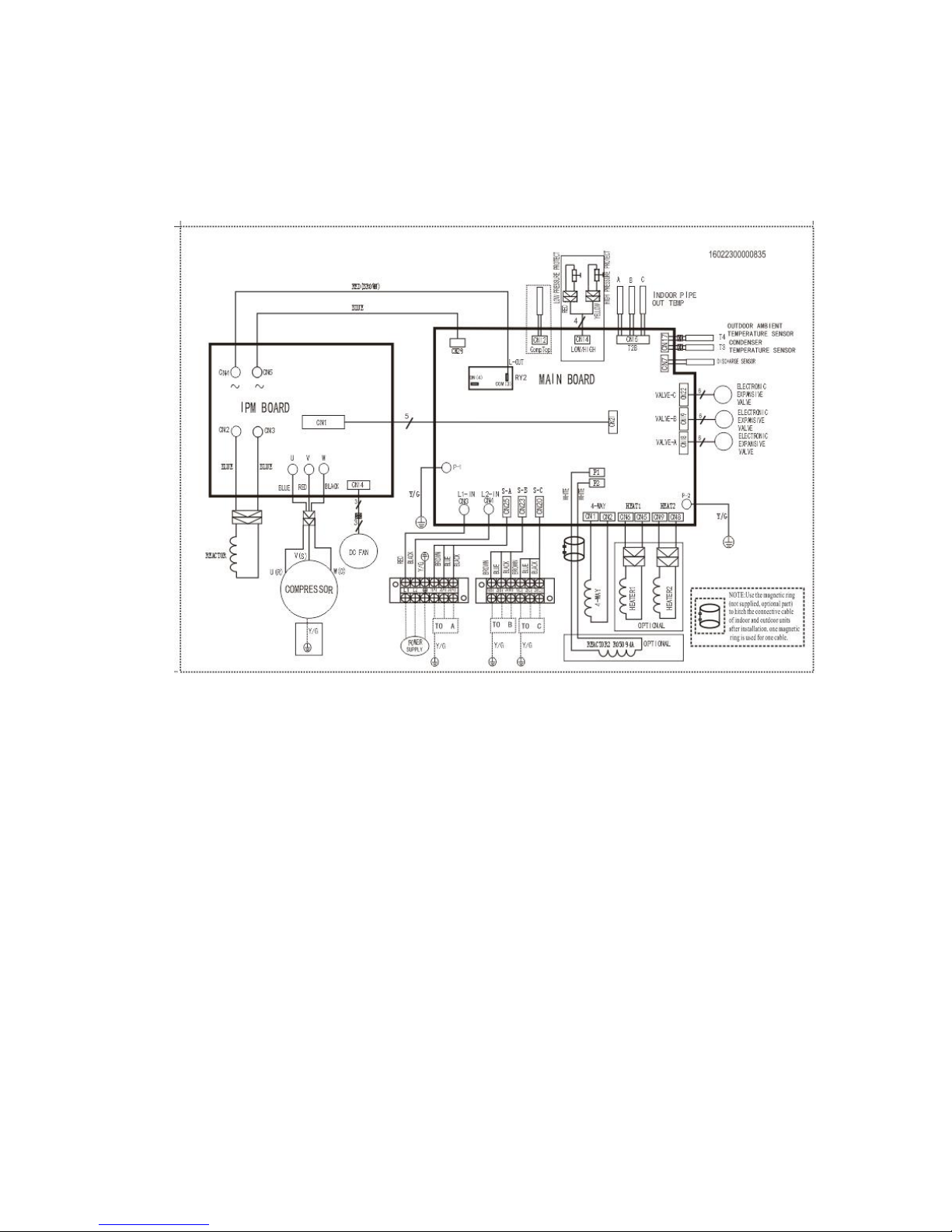

7.2 Wiring diagram of 1 drive 3 outdoor

MCH3U-27PHH2

Page 25

25

7.3 Wiring diagram of 1 drive 4 outdoor

MCH4U-36PHH2

Page 26

26

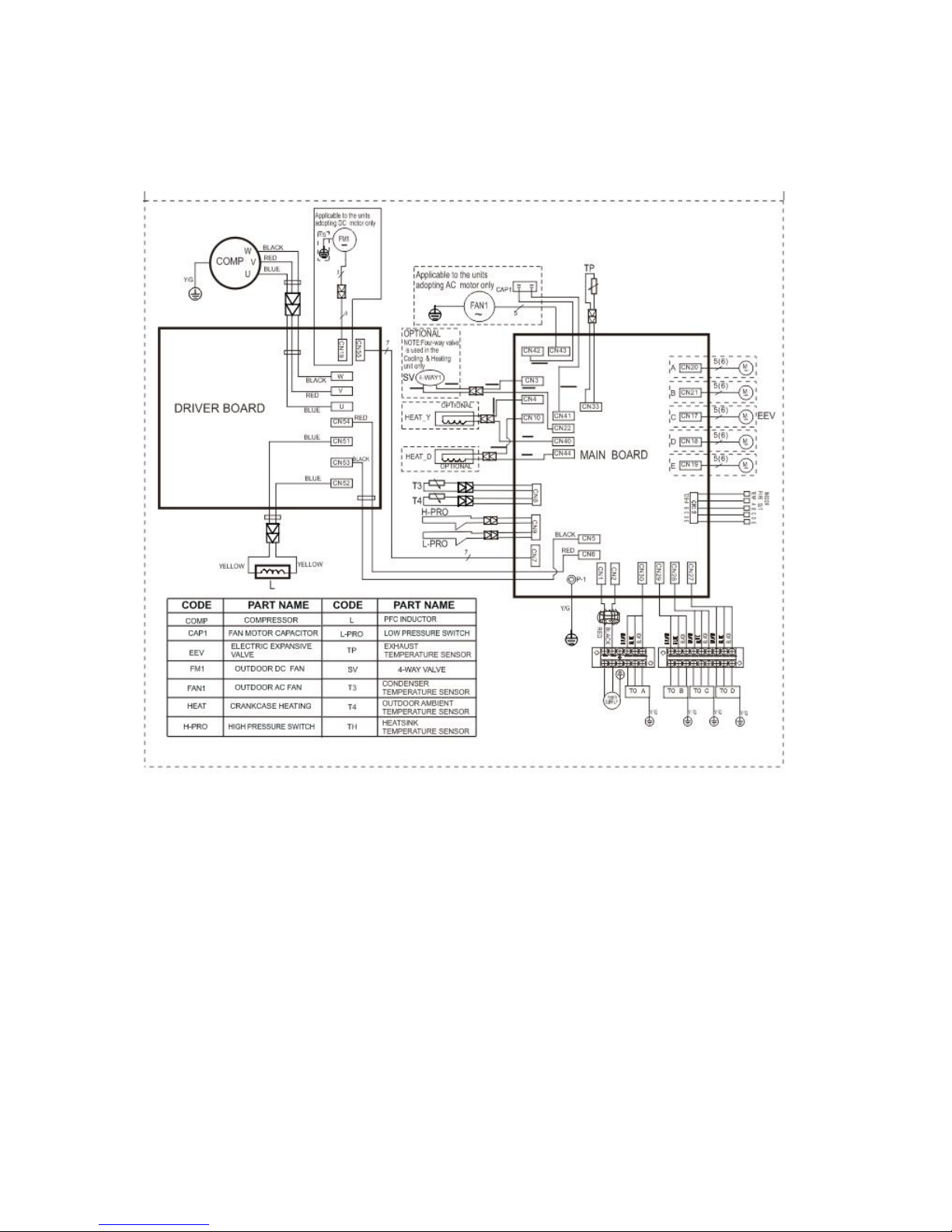

7.4 Wiring diagram of

MCH5U-48PHH2

Page 27

27

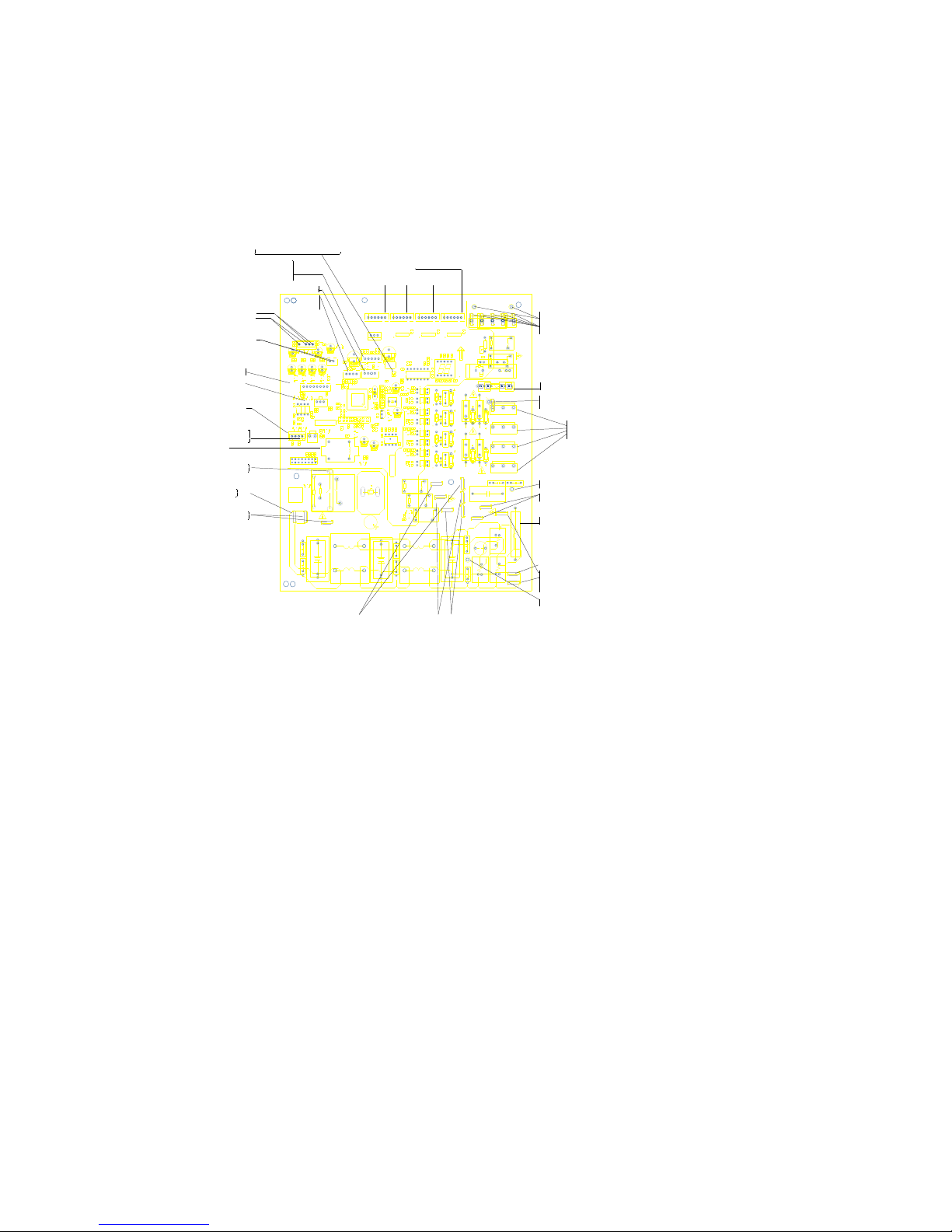

PCB board of MCH2U-18PHH2, MCH3U-27PHH2

S

N L

H

[1.4] 2015.08.27

1

P E Q

L-OUT

S N L

1

1

1

1

1

CE-KFR80W/BP2T4N1(AC MOTOR)-310.JD.FW.WXWKB.WP1-1

1

2

15

16

RUN

1

1

1

17122300001076

R121

CN36 C N35 CN34

CN33

CN32

P2

P1

C81

R119

C80

C50

C2

_1

D18

D16

D10

CN201

AS1

R116

R115

R114

R113

R112

R111

R98

R43

Q8

Q7

Q6

Q5

CN30

CN18

RY2

CN8

N

CN5

N

CN9

HEAT2

CN2

N

CN6

HEAT1

CN1

4-WAY

SW1

CN15

T2B

CN27

PFC-CONTROL

CN26

TestPort

L1

L2

R110

R109

R108

R107

R106

R105

R104

R103

R97

R57

R56

R55

IC9

D28

D27

C79

C78

R77

DSP1

CN11

AC MOTOR

R46

+

E7

+

E8

+

E11

R12

C11

+

-

~

~

RY8

C77

C76

C75

C74

C73

C72

D1

C71

IC1

R87

IC15

D2

ZR3

ZR2

ZR1

RY7

RY6

RY4

RY3

RY1

R102

R101

R100

R99

R96

R95

R94

R93

R92

R91

R90

R89

R88

R86

R85

R84

R83

R82

R81

R80

R79

R78R76

R75

R74

R73

R72

R71

R70

R69

R68

R67

R66

R65

R63

R62

R61

R60

R59

R58

R54

R53

R52

R51

R50

R48

R47

R45

R44

R42

R41

R39

R38

R37

R36

R35

R34

R33

R32

R31

R30

R28

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R11

R10

R9

R8

R7

R6

R5

R4

R3

R2

R1

Q4

Q3

Q2

Q1

PTC1

P-1

GND

IC16

IC14

IC11

IC3

FUSE2

T30A 250VAC

+

E13

+

E12

+

E10

+

E9

+E6+

E4

+

E2

+

E1

D19

D17

D13

D12

D11D9D8

D7

D6

D5

D4

D3

CT1

CONdebug1

CN25

S-A

CN24

D

CN23

S-B

CN22

C

CN21

TO-DRIVE

CN20

S-C

CN19

B

A

CN17

T3/T4

CN16

S-D

CN14

LOW/HIGH

CN13

FAN-C`

CN10

FAN-C

CN7

PAI QI

C59

C58

C57

C56

C55

C54

C53

C51

C49

C47

C46

C44

C43

C41

C40

C39

C38

C37

C35

C33

C32

C31

C30

C28

C26

C25

C24

C23

C22

C21

C20

C17

C16

C15

C14

C13

C12

C10

C9

C5

C4

C3

C1

D20

D15

C60

C61

C62

C63

C64

C65

C66

C67

C68

C69

C70

+

E14

+

E5

IC6

RY5

X1

IC17

C8

C7

C52

C48

C6

CN4

N-IN

CN29

N-OUT

CN28

CN12

CompTop

FUSE1

T5A 250VAC

R120

+

LED1

P-2

GND

CN3

L-IN

R117

R118

D33

D32

D31

R64

R49

R40

R29

IC13

IC12

IC10

IC8

IC7

IC5

IC4

IC2

C45 C36

C34

C29

C27

C19

C18

D34

C42

D14

CN4(N-IN)

power supply

208-230V AC

CN3(L-IN)

connect to the terminal

FUSE2

T30AL/250VAC

T5A 250VAC

FUSE1

CN9-CN8 (controled by RY4 relayer)

connect to the heater

when heater is ON, output 208-230V AC

CN6-CN5 (controled by RY3 relayer)

CN1-CN2 (controled by RY1 relayer)

connect to the 4-WAY

when 4-way is ON, output 208-230VAC

P-1(GND)

connect to the earth

connect to the Earth(Optional)

P-2(GND)

FOR EMC

P1

connect to P2

NO USE

CN20

CN23

CN25

CN16

CN30

connect to the terminal

24VDC Pulse wave betweene (+CN4)-(-CN30)

Signal wire

NO USE

CN36

CN35

CN34

CN10

CN13

FAN-C

FAN-C`

NO USE

CN18

Connect to Electric Expansion Valve

1

2

345

6

+12V DC

+12V DC

+12V DC pulse wave between (+4)-GND

+12V DC pulse wave between (+3)-GND

+12V DC pulse wave between (+2)-GND

+12V DC pulse wave between (+1)-GND

NO USENO USE

CN24 CN22

CN19

status light, by which you can judge the unit Normal or Error

LED1

(standby) Flashing once per second(low speed flashing)

(error) Flashing once p er half second (high speed flashing)

(running) aways on

NO USE

CN21

connect to IPM BOARD CN1

543

2

1

+12V

+5V

Low VOL supply

GND

(+4)-(-3) +5VDC Pulse wave

(+5)-(-3) +5VDC Pulse wave

CN27

room temp sensor RT

pipe temp sensor RT

CN17

Exaust temp sensor RT

CN7

N-OUT

CN15

NO USE

NO USE

CN28

CN14

NO USE

CN12

L-OUT connect to IPM BOARD CN4

connect to IPM BOARD CN5

(L-OUT)-(N-OUT) 208-230V AC

(L-OUT)-(N-OUT) 208-230V AC

connect to the comperssor top temp. sensor

0V DC

NO USE

CN33 connect to DR module RED wire

(L-OUT)-(N-OUT) 208-230V AC

CN32 connect to DR module BLUE wire

NO USE

test port

connect to detector

CN26

connect to DR module

or

Page 28

28

IPM board of MCH2U-18PHH2, MCH3U-27PHH2

BK

RD

BL

1

K

G

S

CTI 600V

17122000018251

W

V

U

17122000018251

250VAC

Time

Constant

IPM OCP

RD

BK

BL

64

16

J2

EU-KFR8 0W/BP 3(IR311+PS21997+

FAN_DC

SIM682 2+LOCK ).D.13.WP2-1

Pin1

CN7

CN9

CN10

5V→3.3V

3.3V→1.8V

U

V

W

3

2

4

CAUTION HI GH VOLTAGE

1

1

2 4

+

+

CN3

NTC1

R3

D2

41

CN8

Program_Debug

6

1

Online writing

R168

+

DZ10

+

DZ9

+

DZ8

R2

PTC2

J7 J6

J9

J8

F_DC Fan

R167

R166

R165

C81

CN1

CN11

ZR3 ZR2

ZR1

C13

R46

+

E15

C85

IC21

7805

C82

R164

C103

R

1

6

3

R162

R

1

6

1

IC2

CN4

L

CN5

N

CN2

R1_1

R1_2

R1_3

R1_4

R17

IC19

7805

CN13

D7

+

DZ6

C99

IC6

7815

R87

D14

R125

IC10 24LC2 5624LC08

C63

C50

C49

CY1

DZ4

R124

C1

+

E6

+

E5

PTC1

FUSE1

T/3.15A

- +

~

BR2

IC3

T1

IPM1

R121

R67

R90

R84

C7 C12

R

1

1

5

R114

R113

R112

R111

R110

R109

R108

R107

R105

R102

R101

R100

R99

R

9

7

R96

R95

R94

R93

R92

R91

R89

R88

R86

R83

R82

R81

R80

R79

R77

R76

R75

R74

R73

R72

R71

R69

R68

R65

R64

R63

R62

R61

R58

R54

R53

R51

R49

R48

R47

R44

R43

R40

R38 R37

R36

R35

R34 R33 R 31

R30

R29

R28

R27

R26

R25

R

2

4

R23

R21

R20

R19

R18 R16

R15

R14

R13

R12

R11

R10

R9

R8R7R6

R4

Q2

OSC1

LED2+LED1

1

17

49

33

IC14

IC13

IC12

IC11

IC9

IC8

IC7

IC4IC1

C100C101

C4

C95

C96

C97

C98

+

E14

+

E13

E12

+

E11

+

+

E9

+

+

E8

C102

+

E4

+

E1

+

DZ5

+ DZ1

D19

D13

D12

+

D11

D6

+

D3

D1

C78

C77

C76

C75

C74

C73

C72

C71

C70

C69

C68

C67

C

6

6

C65

C64

C

6

2

C

6

1

C60

C59

C58

C57

C56

C54

C53

C

5

2

C51

C47

C46

C45

C44

C43

C42

C41

C40

C39

C37

C36

C35

C34

C33

C32

C31

C30

C29

C28

C27

C26

C25

C24

C23

C22

C21

C20

C19

C18

C17

C16

C

1

5

C14

C11

C10

C8

C5

C3

C2

IGBT1

D20

C6

IC15

IPM2

SIM6822M

+

E2

R106

CN16

R118

R85

R119

R120

R57

+

E3

R117

R116

R122

R123

R70

R78

C38

R50

R66

D9

J4

C80

C55

R138

R137

R136

C84

R135

R143

R133

R132

IC17

Q6

IC16

C79

C83

IC5

R145

Q8

Q9

R144

R141

R148

R147

R146

C90

R98

J3

E27

7815

+

DZ7

E26

+

E25

R

1

3

9

R

1

6

0

C91

D21

R158

R157

R156

R159

C

9

2

IC18

R127

C48

R140

R39

R41

D22

R42

D23

R10_1

R10_2

R10_3

R11_1

R11_2

R11_3

J2

R

1

3

4

BR1

C9

C86

L1

R52

CN_COMP

CN_Reactor

R45

R1

J1

J5

R32

R59

R22

Q1

R103

J

1

0

J12

J11

R83_1

J13

R5

power supply

CN4(L)-CN5(N)

connect to the m ain board no use

fuse1 T/3.15A

Compressor drive EEPROM

online writing

Compressor driv e Program

Debug

DC Fan Driver IP M module

10-200VAC (run ning)

0VAC (standby)

connect to the DC FAN motor

TXD

+12V DC

+5V DC

GND For +12V

RXD

5

4

3

2

1

no use

DC Fan fuse for DC FAN

T/3.15A

10-200VAC (run ning)

0VAC (standby)

connect to the c ompressor

no use

connect to the Reactor

Page 29

29

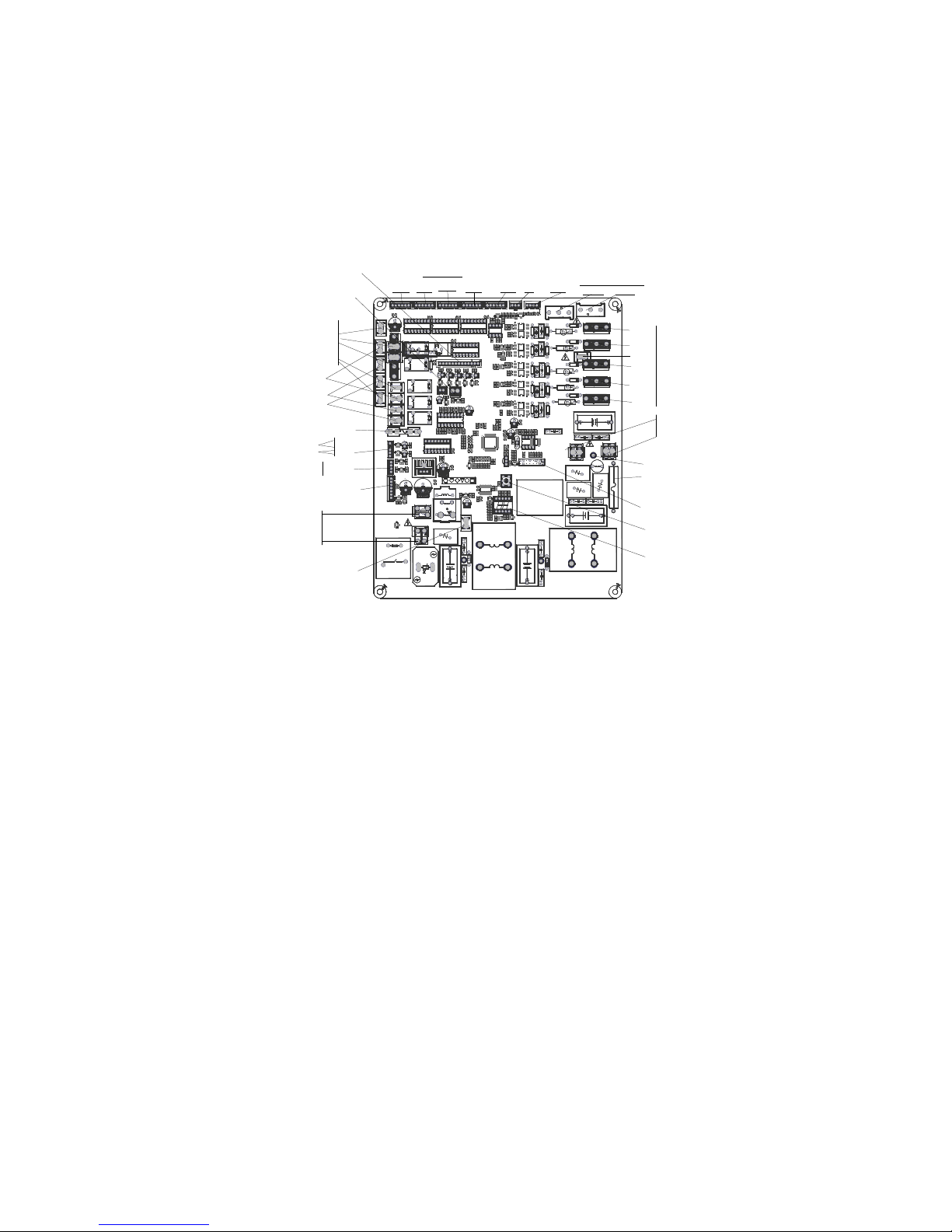

PCB board of MCH4U-36PHH2

N

L

SHOW/SW

EARTH

[1.4]2014.06.26

EU-KFR105W/BP3T5N1-350S.D.13.WP1-1

L-OUT

N-OUT

CONNECT TO INVERTER driver

HIGH

LOW

T2B-E

T2B-D

T2B-C

T2B-BT2B-A

TP

T4 T3

S-E

S-D

S-C

S-B

S-A

FAN_OUT

FAN_IN

Q

E

P

AB

C

D

E

202302141206

CN19

D4

R134

R133

R89

R37

+

E12

+

E15

CN10

N

C18

CN9

ZR3

ZR2

ZR1

X1

S

RY8

RY7

RY6

RY5

RY3

RY2

R213

R212

R211

R210

R180

R170

R140

R131

R130

R129

R128

R127

R126

R125

R124

R123

R121

R120

R118

R117

R116

R115

R114

R113

R112

R111

R110

R109

R108

R107

R106

R105

R104

R103

R102

R101

R100

R99

R98

R96

R95

R94

R93

R92

R91

R90

R88

R81

R80

R79

R78

R77

R76

R75

R74

R73

R72

R71

R70

R69

R68

R67

R66

R65

R64

R63

R62

R61

R60

R59

R58

R57

R56

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39R38

R36

R35

R34

R33

R32

R31

R30

R29

R28

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R16

R15

R14

R13

R12

R11

R10

R9

R8

R7

R6

R5R4R3

R2

R1

Q5

Q2

PTC1

LED1

L3

IC30

IC22

IC21

IC20

IC19

IC18

IC17

IC16

IC15

IC14

IC13

IC12

IC10

IC9

IC8

IC7 IC6

IC5

IC2

IC1

FUSE2

5A/250V

FUSE1

T30A/250V

E21

E20

+

E19

+

E16+E14

E13

E11

E9

E8

E5

E4

E3

E1

DSP1

DSA1

D28

D27

D26

D25

D24

D23

D22

D21

D20

D19

D18

D17

D16

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D3

D2

D1

CONdebug

CN44

HEAT2

CN43

FAN

CN42

C

CN41

C

CN40

HEAT1

CN34

CN33

CN30

CN29

CN28

CN27

CN26

CN22

4-WAY

CN20

CN18

CN17

CN16

CN14

CompTop

CN12

CN11

CN8

CN6

CN5

CN4

N

CN3

N

CN2

N-IN

CN1

L-IN

C103

C98

C97

C96

C95

C94

C93

C92

C91

C90

C72

C70

C69

C68

C67

C66

C65C64

C62

C61

C60

C59

C58

C57

C56

C55

C54

C53

C52

C51

C50

C49

C48

C47

C46

C45

C44

C43

C42

C41

C40

C39

C38

C37

C36

C35

C34

C33 C32

C31

C30

C29

C28

C27

C26

C25

C24

C23

C22

C21

C20

C19

C17

C16

C15

C14

C13

C12

C11

C10

C9C8C7

C6

C5

C4

C3

C2

C1

JP1

JP2

D29

D30

CN23

SSR1

CN7

CN13

P-1

L1

R82

R83

R84

R85

R86

R87

R97

R119

R122

R132

CN35

N

CN37

FAN-L

Q3

Q6

Q7

Q8

Q9

CN36

FAN-H

E2

IC3

Q1

Q4

IC4

ZR4

RY4

CN32

CN38

L2

R135

SW1

CN21

Electric Expansion

Value B

Electric Expansion

Value E

Electric Expansion

Value D

Electric Expansion

Value C

Electric Expansion

Value A

485

communication

testPort

connect to detector

external drive DC fan

motor input terminal

external drive DC fan

motor ouput terminal

current loop

communication A

current loop

communication B

current loop

communication C

current loop

communication D

current loop

communication E

digital display

Fuse

T30A/250V

connect to high and low

pressure sensor

connect to

trmp. sensor

Fuse 5A/250V

connect to earth

CN23 reserve

digital display button

test report

connect to detector

CN43-5,CN43-1/CN41,CN42

AC fan motor capacitor

connector

CN43-4/CN37 CONNECT TO

AC FAN MOTOR(LOW SPEED)

CN43-3/CN36

AC fan motor low speed

connector

CN43-2/CN35

AV fan motor N phase

current loop

communication C

Signal wire

24VDC Pulse wave

connect to the terminal

connect to the terminal

208-230V AC

power supply

room temp sensor

pipe temp sensor

(3.3V)

(3.3V)

high pressure sensor

low pressure sensor

Connect to the Indoor evap.pipe

out temp. sensor

T2B-A、T2B-B、T2B-C、T2B-D、T2B-E

+12V DC pulse wave between (+1)-GND

+12V DC pulse wave between (+2)-GND

+12V DC pulse wave between (+3)-GND

+12V DC pulse wave between (+4)-GND

+12V DC

+12V DC

6 5 4 3 2 1

when 4-way is ON, output 208-230VAC

connect to the 4-WAY

when heater is ON, output 208-230V AC

connect to compressor heater

CN44 L

CN10 N

CN40 L

CN4 N

CN22 L

CN3 N

connect to exhaust

temp. sensor

connect to the terminal

208-230V AC

external drive DC fan

motor connector

T3

T4

electric

heater1

electric

heater 2

Page 30

30

IPM board of MCH4U-36PHH2

202302141237

PFC-L2

[1.6]2014.10.16

EU-KFR105W/BP2T3N1-350(767).D.13.MP2-1

PFC-L1

CN58

EARTH

C57

C56

6

J146J15

R65

C55

C53

E31

C50

D7

C49

+

E30

C47

C9

ZR1

DZ3

R8

E3

E2

CN55

TO-MAIN

E23

C46

R13

IC3

C113

W

V

U

1

6 7

1011

12

1314

15

3

8

T1

R208

R207

R206

R205

R204

R203

R202

R198

R197

R196

R194

R192

R187

R186

R185

R184

R183

R182

R181

R180

R179

R175

R174

R173

R170

R163

R160

R150

R147

R146

R144

R143

R141

R140

R139

R137

R135

R133

R132

R131

R130

R129

R128

R127

R126

R125

R124

R119

R114

R111

R107

R104

R96

R92

R91

R90

R82

R80

R79

R78

R77

R76

R75

R66

R63

R62

R61

R60

R59

R58

R57

R56

R55

R54

R53

R52

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

R41

R40

R39

R38

R37

R36

R35

R33

R32

R31

R30

R29

R27

R26

R25

R24

R23

R22

R21

R20

R19

R18

R17

R15

R14

R12

R11

R10

R9

R7

R5

R2

R1

Q2

OSC1

+

LED4+LED3

JR1

J201

6

J1

IPM2

1

IPM1

1

17

49

33

IC20

IC17

IC16

IC15

24C256

IC1424C08

IC10

IC7

IC4

IC2

E34

E33

E27

E25

+

E24

+

E22

+

E21

+

E20

+

E17

E16

E15

E14

E13

E12

E10

E9

+

E8

+

E7

+

E6

+

E5

E4

E1

+

DZ9

+

DZ8

+

DZ7

+

DZ6

+

DZ1

D26

D14

D13

D12

D11

D10

D9

D8

D6

D5

D4

D3

D2

CN57

1

CN56

CN54

L-IN2

CN53

N-IN2

CN52

CN51

CN19

OUTFAN(DC)

C124

C123

C122

C121

C120

C119

C118

C117

C116

C114

C111

C109

C108

C107

C106

C105

C104

C103

C102

C101

C100

C99

C97

C94

C82

C79

C78

C77

C76

C72

C71

C70

C69

C67

C66

C65

C64

C61

C60

C59

C54

C51

C40

C39

C38

C36

C33

C32

C31

C30

C29

C26

C25

C24

C23

C22

C21

C20

C19

C18

C17

C16

C15

C14

C13

C12

C11

C8

C7

C6

C5

C4

C3

C2

C1

BR1

R3

R4

R6

R16

C27

C28

+

E18

C10

+

E19

C34

+

D1

+

D15

+

D16

22

44

23

IC1

C52

D17

R28

6J36

J4

6

J2

6

J5

6

J6

6

J7

6

J8

6J96

J10

6

J11

6

J12

6

J13

C35

C37

C41

C42

C43

C44

C45

E26

E28

E29

IC11

IC12

R34

R64

C48

E11

CN53

power supply

connect to the terminal

208-230V AC

CN54

CN51

CN52

PFC

inductance

terminal

CN58

EATTH

+

210-300VDC (Running)

CAPACITOR Voltage

290-330VDC (standby)

CN55

TO MAIN

CN19

connect to DC fan motor

U

V

W

10-200VAC (running)

0VAC (standby)

connect to the compressor

U

V

W

10-200VAC (running)

0VAC (standby)

CN57

Debug

Page 31

31

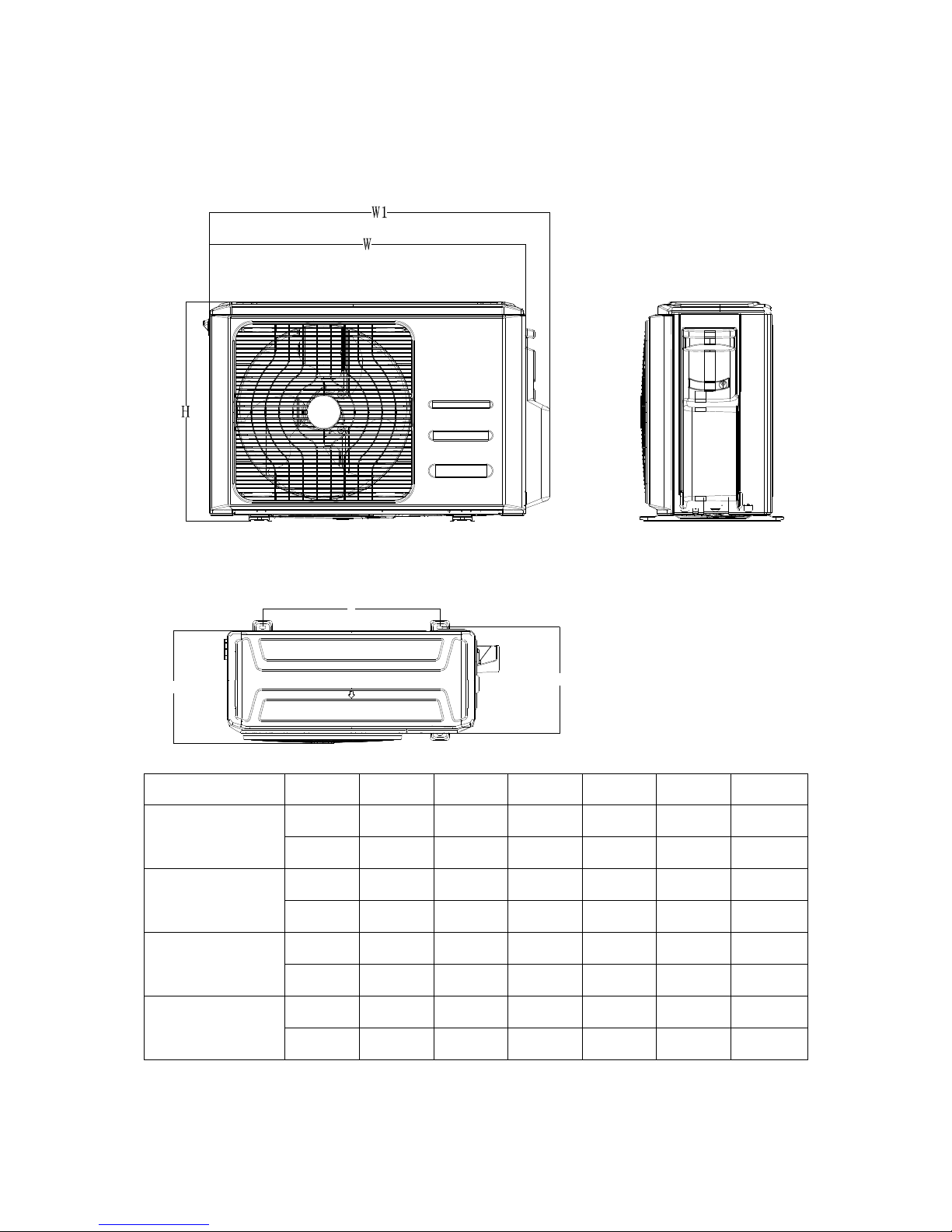

PCB board of MCH5U-48PHH2

Page 32

32

IPM board of MCH5U-48PHH2

Page 33

33

8. Troubleshooting

8.1Safety

Electricity is stored in capacitors, even when the power supply is shut off. Do not forget to

discharge the electricity in the capacitors.

The value of resistance is about 1500 ohm to 2000 ohm

.

Electrolytic Capacitors

(HIGH VOLTAGE! CAUTION!)

Bulb (25-40W)

The voltage in P3 and P4 in outdoor PCB is high voltage about 310V

The voltage in P5 and P6 in outdoor PCB is high voltage about 310V

Page 34

34

8.2 Indoor Unit Error Display

For Old Console series

Operation

Timer

De-

Failure

★

X X Indoor room temperature sensor (T1 ) malfunction

X X

★

Evaporator coil temperature sensor (T2) malfunction

X

★

X Communication malfunction between indoor and outdoor units

★

X Low ambient temperature cut off in heating

★ ★

X Indoor unit EEPROM parameter error

X

★

Outdoor fan speed malfunction

★

X

★

Inverter module (IPM) malfunction

★

★ ★

Outdoor temperature sensor(coil sensor T3 or ambient

temperature sensor T4) malfunction or Outdoor unit EEPROM

★

X Compressor top high temperature protection (OLP)

★ ◎

X Compressor drive protection

★

X

Indoor units mode conflict

★

★

Indoor fan speed malfunction

◎

X X

In standby mode

●

◎ ◎

In force cooling mode

★ flash at 5Hz, light, X extinguished, ◎flash at 0.5Hz

For Old Duct/Cassette/Floor Ceiling

Operation Timer De-

frost

Alar

m

Failure

Display

ODU Error

code

★

X X X

Indoor room temperature sensor

(T1 ) malfunction

E0 ——

X X

★

X

Evaporator coil temperature

sensor (T2) malfunction

E1 ——

X

★

X X

Communication malfunction

between indoor and outdoor units

E2 E2

X X X

★

Water-level alarm malfunction E3 ——

★ ★

X X

Indoor unit EEPROM parameter

E4 ——

★

X X

Inverter module (IPM) malfunction

E5 P6

Page 35

35

★

X X

Outdoor temperature sensor(coil

sensor T3 or ambient temperature

sensor T4) malfunction or

Outdoor unit EEPROM parameter

E6 E0,E4

★

★

X Outdoor fan speed malfunction E7 E8

★

X Indoor fan speed malfunction F5 ——

★

X

Over-voltage or under-voltage

protection

P0 E5

★ ★ ★

X Current overload protection P2 P3

★ ◎

X X Compressor drive malfunction P4 ——

★

X

Indoor units mode conflict P5 ——

★ flash at 2.5Hz, light, X extinguished, , ◎flash at 0.5Hz

For Old Vertu/Luna Series

De-

Timer

Auto

Operatio

Failure

Display

Indoor unit EEPROM parameter error E0

★

★ ★ ★

Communication malfunction between indoor

and outdoor units error

E1

★

★

Zero-crossing signal detection error E2

★

★

Indoor fan speed malfunction E3

X

X

★

Outdoor temperature sensor(coil sensor T3

or ambient temperature sensor T4)

malfunction or Outdoor unit EEPROM

E5

★

Indoor room temperature sensor(room sensor

T1 or coil sensor T2) malfunction

E6

★

★

★

Outdoor fan speed malfunction E7

X

X

★

Inverter module (IPM) malfunction P0

X

★

Over-voltage or under-voltage protection P1

X

X

★

Compressor top high temperature protection

(OLP)

P2

X

★

Low ambient temperature cut off in heating P3

X

★

★

Compressor drive malfunction P4

X

★

★

Indoor units mode conflict P5

For All new models(New Wall mounted(Hi-Wall) series, New Duct/Cassette/Console/Floor

Ceiling):

Operation

lamp

Timer

lamp

Display LED STATUS

ODU

Error

★ 1 time

X E0 Indoor unit EEPROM parameter error

——

Page 36

36

★ 2 times

X E1

Communication malfunction between indoor and

outdoor units

E2

★ 4 times

X E3 Indoor fan speed malfunction

——

★ 5 times

X E4 Indoor room temperature sensor (T1 ) malfunction

——

★ 6 times

X E5

Evaporator coil temperature sensor (T2)

malfunction

——

★ 8 times

X EE Water-level alarm malfunction

★ 1 times

F0 Current overload protection

——

★ 2 times

F1

Outdoor ambient temperature sensor (T4 )

malfunction

E4

★ 3 times

F2

Condenser coil temperature sensor (T3)

malfunction

E4

★ 4 times

F3

Compressor discharge temperature sensor (T5)

malfunction

E4

★ 5 times

F4 Outdoor unit EEPROM parameter error

E0

★ 6 times

F5 Outdoor fan speed malfunction

E8

★ 7 times

F6

Indoor coil outlet pipe sensor(Located on outdoor

unit low pressure valve)

——

★ 8 times

F7

Communication malfunction between Cassette

optional lift panel and the unit.

——

★ 9 times

F8 Cassette optional lift panel malfunction

——

★ 10 times

F9 Cassette optional lift panel not closed

——

★ 1 times ★

P0 Inverter module (IPM) malfunction

P6

★ 2 times ★

P1 Over-voltage or under-voltage protection

E5

★4 times ★

P3 Low ambient temperature cut off in heating

——

★ 5 times ★

P4 Compressor drive malfunction

——

★ 6 times ★

——

Indoor units mode conflict

——

★ flash , light, X extinguished

Outdoor unit error display

MCH2U-18PHH2, MCH3U-27PHH2, MCH4U-36PHH2, MCH5U-48PHH2;

Display

LED STATUS

New indoor

Error

E0 Outdoor unit EEPROM parameter error

F4

E2 Communication malfunction between indoor and outdoor units

E1

E3

Communication malfunction between IPM board and outdoor main

control board

——

E4

Outdoor temperature sensor (coil sensor T3,ambient sensor T4,

Compressor discharge sensor T5、indoor coil outlet pipe sensor T2B)

malfunction

F2/F1/F3/F6

Page 37

37

E5 Over-voltage or under-voltage protection

P1

E6 PFC module protection

——

E8 Outdoor fan speed malfunction

F5

F1 No. A Indoor unit coil outlet temp. sensor malfunction

——

F2 No. B Indoor unit coil outlet temp. sensor malfunction

——

F3 No. C Indoor unit coil outlet temp. sensor malfunction

——

F4 No. D Indoor unit coil outlet temp. sensor malfunction

——

F5 No. E Indoor unit coil outlet temp. sensor malfunction

——

F6 No. F Indoor unit coil outlet temp. sensor malfunction

——

P1 High pressure protection

P2

P2 Low pressure protection

P2

P3 Current overload protection

F0

P4 Temperature protection of compressor discharge

——

P5 Condenser high temperature protection

——

P6 Inverter module (IPM) malfunction P0

8.3 Outdoor Unit Display

8.3.1 Outdoor Unit Point Check Function

A check switch is included on the outdoor PCB.

Push SW1 to check the unit's status while running. The digital display shows the following

codes each time the SW1 is pushed.

Page 38

38

Number

of

Presses

Display Remark

0 Normal display

Displays running frequency, running state, or malfunction

code

1 Quantity of indoor units with working

connection

Actual data

Display Number of indoor unit

1 1

2 2

3 3

4 4

2 Outdoor unit running mode code Off: 0,Fan only: 1, Cooling: 2, Heating: 3, Forced cooling: 4.

Forced defrost:A

3 Indoor unit A capacity

The capacity unit is horse power. If the indoor unit is not

connected, the digital display shows the following: “――”

(9K:1HP,12K:1.2HP,18K:1.5HP)

4 Indoor unit B capacity

5 Indoor unit C capacity

6 Indoor unit D capacity

7 Indoor unit E capacity

8 Indoor unit A capacity demand code

Norm code*HP

(9K: 1HP,12K: 1.2HP,18K: 1.5HP)

9 Indoor unit B capacity demand code

10 Indoor unit C capacity demand code

Page 39

39

11 Indoor unit D capacity demand code

12 Indoor unit E capacity demand code

13 Outdoor unit amendatory capacity demand

code

14 The frequency corresponding to the total

indoor units' amendatory capacity demand

15 The frequency after the frequency limit

16 The frequency sending to compressor

control chip

17 Indoor unit A evaporator outlet temperature

(T2BA)

If the temperature is lower than -9 ℃, the digital display shows “-

9.” If the temperature is higher than 70 ℃, the digital display

shows “70.” If the indoor unit is not connected, the digital display

shows: “――”

18 Indoor unit B evaporator outlet temperature

(T2BB)

19 Indoor unit C evaporator outlet temperature

(T2BC)

20 Indoor unit D evaporator outlet temperature

(T2BD)

21 Indoor unit E evaporator outlet temperature

(T2BE)

22 Indoor unit A room temperature (T1A)

If the temperature is lower than 0 ℃, the digital display shows “0.”

If the temperature is higher than 50 ℃, the digital display shows

“50.” If the indoor unit is not connected, the digital display shows:

“――”

23 Indoor unit B room temperature (T1B)

24 Indoor unit C room temperature (T1C)

25 Indoor unit D room temperature (T1D)

26 Indoor unit E room temperature (T1E)

27 Indoor unit A evaporator temperature (T2A)

If the temperature is lower than -9 ℃, the digital display shows “-

9.” If the temperature is higher than 70 ℃, the digital display

shows “70.” If the indoor unit is not connected, the digital display

shows: “――”

28 Indoor unit B evaporator temperature (T2B)

29 Indoor unit C evaporator temperature (T2C)

30 Indoor unit D evaporator temperature (T2D)

31 Indoor unit E evaporator temperature (T2E)

32 Condenser pipe temperature (T3)

33 Outdoor ambient temperature (T4)

34 Compressor discharge temperature (TP)

The display value is between 30–129 ℃. If the temperature is

lower than 30 ℃, the digital display shows “30.” If the temperature

is higher than 99 ℃, the digital display shows single and double

digits. For example, if the digital display shows “0.5", the

compressor discharge temperature is 105 ℃.

35 AD value of current

The display value is a hex number.

For example, the digital display tube shows “Cd”, it means AD

value is 205.

36 AD value of voltage

37 EXV open angle for A indoor unit

Actual data/4.

If the value is higher than 99, the digital display shows single and

double digits.

For example, if the digital display shows “2.0", the EXV open

angle is 120×4=480p.

38 EXV open angle for B indoor unit

39 EXV open angle for C indoor unit

40 EXV open angle for D indoor unit

41 EXV open angle for E indoor unit

42 Frequency limit symbol

Bit7

Frequency limit caused by IGBT

radiator

The display

value is a

hexidecimal

number. For

example, the

digital display

show 2A, then

Bit6

Frequency limit caused by PFC

Bit5

Frequency limit caused by T4.

Bit4

Frequency limit caused by T2.

Bit3

Frequency limit caused by T3.

Page 40

40

Bit2

Frequency limit caused by T5.

Bit5=1, Bit3=1,

and Bit1=1.

This means

that a

frequency limit

may be caused

by T4, T3, or

the current.

Bit1

Frequency limit caused by current

Bit0

Frequency limit caused by voltage

43 Average value of T2 (Sum T2 value of all indoor units)/(number of indoor units in good

connection)

44 Outdoor unit fan motor state Off: 0, High speed:1, Med speed: 2, Low speed: 3, Breeze:4,

Super breeze: 5

45 The last error or protection code 00 means no malfunction and protection

46 F indoor unit capacity

47 F indoor unit capacity demand code

48 F indoor unit evaporator outlet temperature

(T2BF)

49 F indoor unit room temperature (T1F)

50 F indoor unit evaporator temperature (T2F)

51 EXV open angle for F indoor unit

8.3.2 Outdoor Unit Digital Display

A digital display is featured on the outdoor PCB.

The LED displays different codes in the following situations:

Standby: “- -.”

Compressor operation: the running frequency.

Defrosting mode: “dF” or alternative displays between running frequency and

“dF” (ach appears for 0.5s.)