Page 1

Midea R410A 50Hz

Compressor Condensing Unit

Technical Manual

DM15-01.01.17en

Applicable Model:

MCCU-03CN1 MCCU-05CN1

MCCU-07CN1 MCCU-10CN1

MCCU-12CN1 MCCU-16CN1

MCCU-22CN1 MCCU-28CN1

MCCU-35CN1 MCCU-45CN1

MCCU-53CN1 MCCU-61CN1

MCCU-70CN1 MCCU-105CN1

Midea reserves the right to discontinue, or change specification or designs at any time without notices and

without incurring obligations.

1

Page 2

Midea R410A 50Hz T1 Compressor Condensing Unit

Content

Part. 1 Performance ............................. 3

Part. 2 Installation .............................. 38

Appendix: VRF Solution .................... 67

2

Page 3

Midea R410A 50Hz T1 Compressor Condensing Unit

Part. 1 Performance

1. Product lineup ................................................................ 4

2. External Appearance ..................................................... 4

3. Nomenclature ................................................................. 6

4. Specifications ................................................................ 7

5. Dimensions (Unit: mm) ............................................... 18

6. Refrigerant circuits ...................................................... 24

7. Wiring Diagrams .......................................................... 28

8. Electrical datas ............................................................ 34

9. Sound Levels ............................................................... 34

10. Connection accessory list (Optional) ...................... 35

3

Page 4

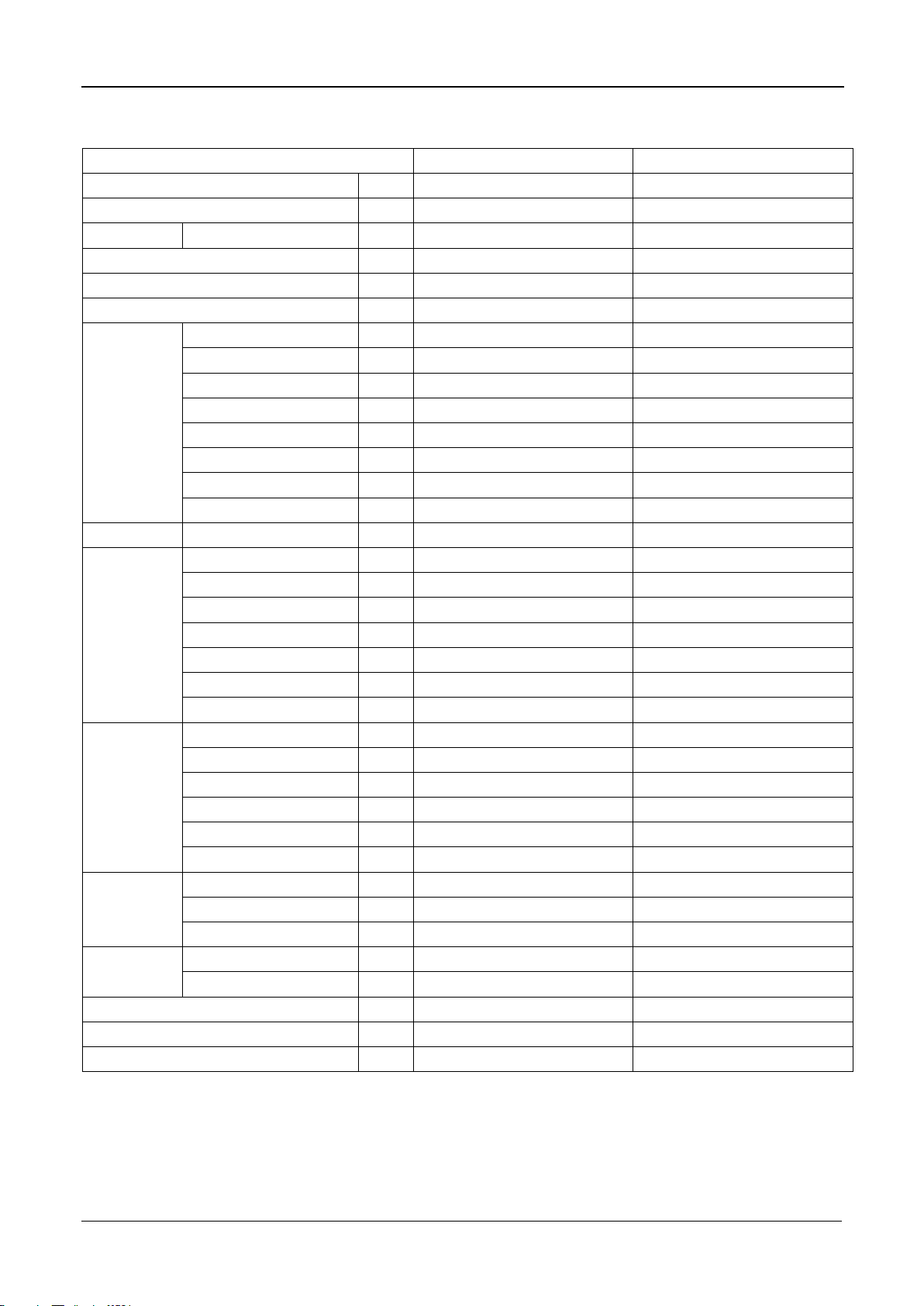

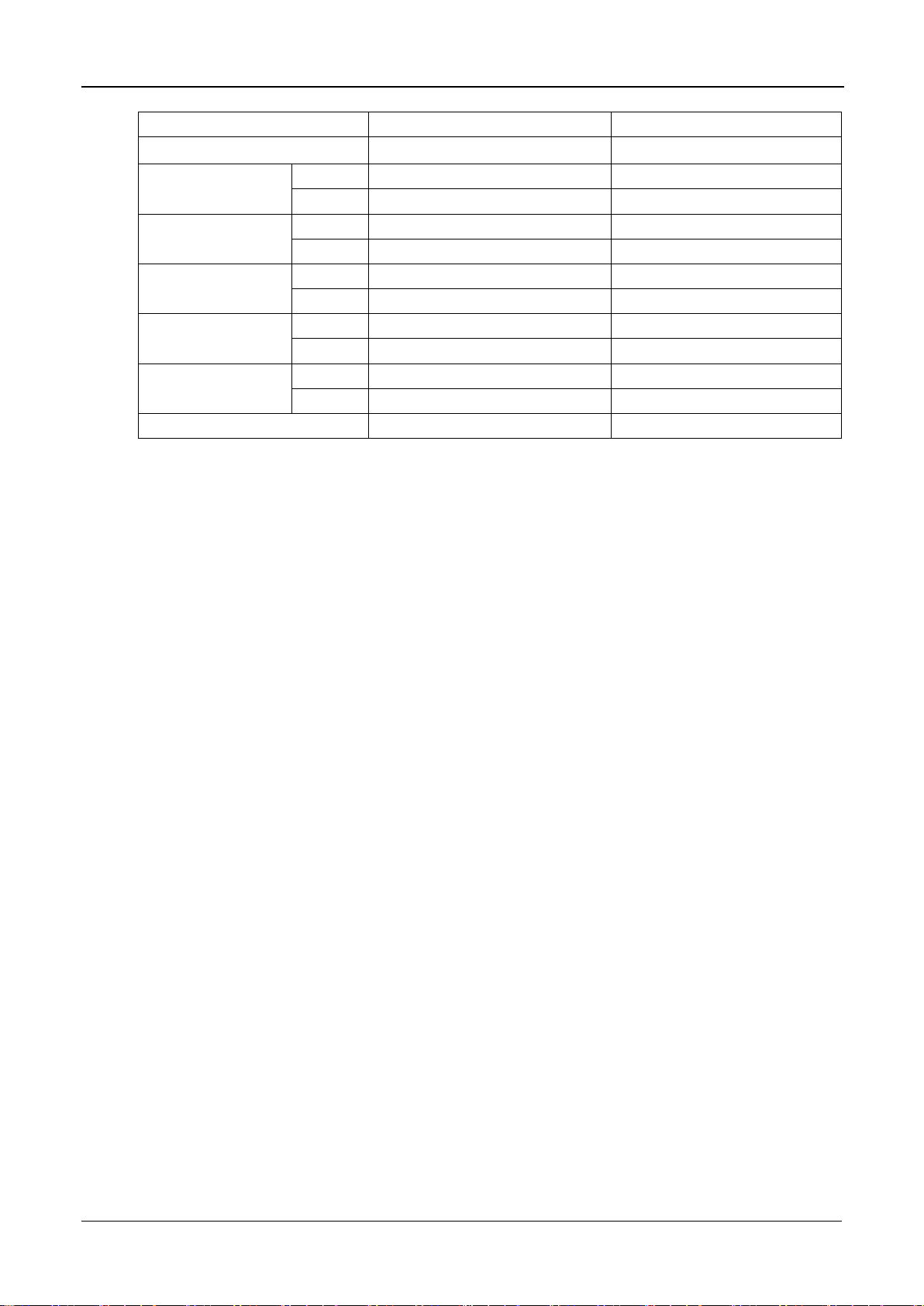

1. Product lineup

Outdoor unit

Cooling capacity

Model

Power supply

W

Btu/h

MCCU-03CN1

220-240V~, 1Ph, 50Hz

3,200

10,920

MCCU-05CN1

5,300

18,080

MCCU-07CN1

7,100

24,230

MCCU-10CN1

380-415V~, 3Ph, 50Hz

10,500

35,830

14,000

47,770

MCCU-16CN1

16,000

54,590

MCCU-22CN1

22,000

75,060

MCCU-28CN1

28,000

95,540

MCCU-35CN1

380-400V~,3Ph, 50Hz

35,000

119,420

MCCU-45CN1

380-415V~, 3Ph, 50Hz

45,000

153,540

MCCU-53CN1

380-400V~,3Ph, 50Hz

53,000

180,840

MCCU-61CN1

61,000

208,130

MCCU-70CN1

70,000

238,840

MCCU-105CN1

105,000

358,260

MCCU-03CN1

MCCU-05CN1

MCCU-07CN1

MCCU-10CN1

Model names of units with cooling only:

MCCU-12CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

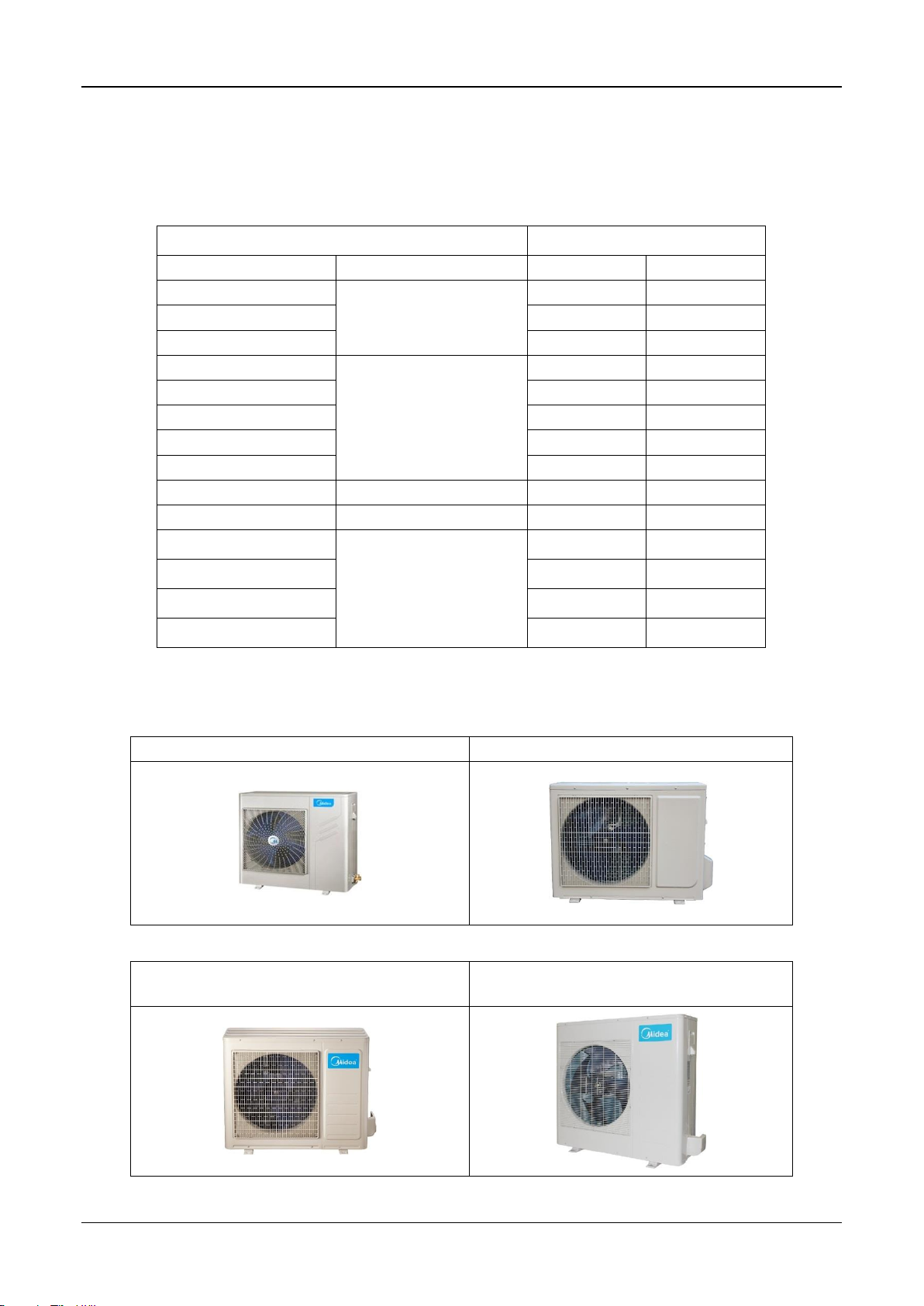

2. External Appearance

4

Page 5

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-22CN1

MCCU-28CN1

MCCU-35CN1

MCCU-45CN1

MCCU-53CN1, MCCU-61CN1

MCCU-70CN1, MCCU-105CN1

MCCU-12CN1

MCCU-16CN1

5

Page 6

3. Nomenclature

M CCU – 53 C N1

Midea R410A 50Hz T1 Compressor Condensing Unit

Refrigerant type: R410A

Function code

C: Cooling only

H: Heat pump

Nominal cooling capacity (53×1,000W)

Compressor Condensing Unit

Midea

6

Page 7

Midea R410A 50Hz T1 Compressor Condensing Unit

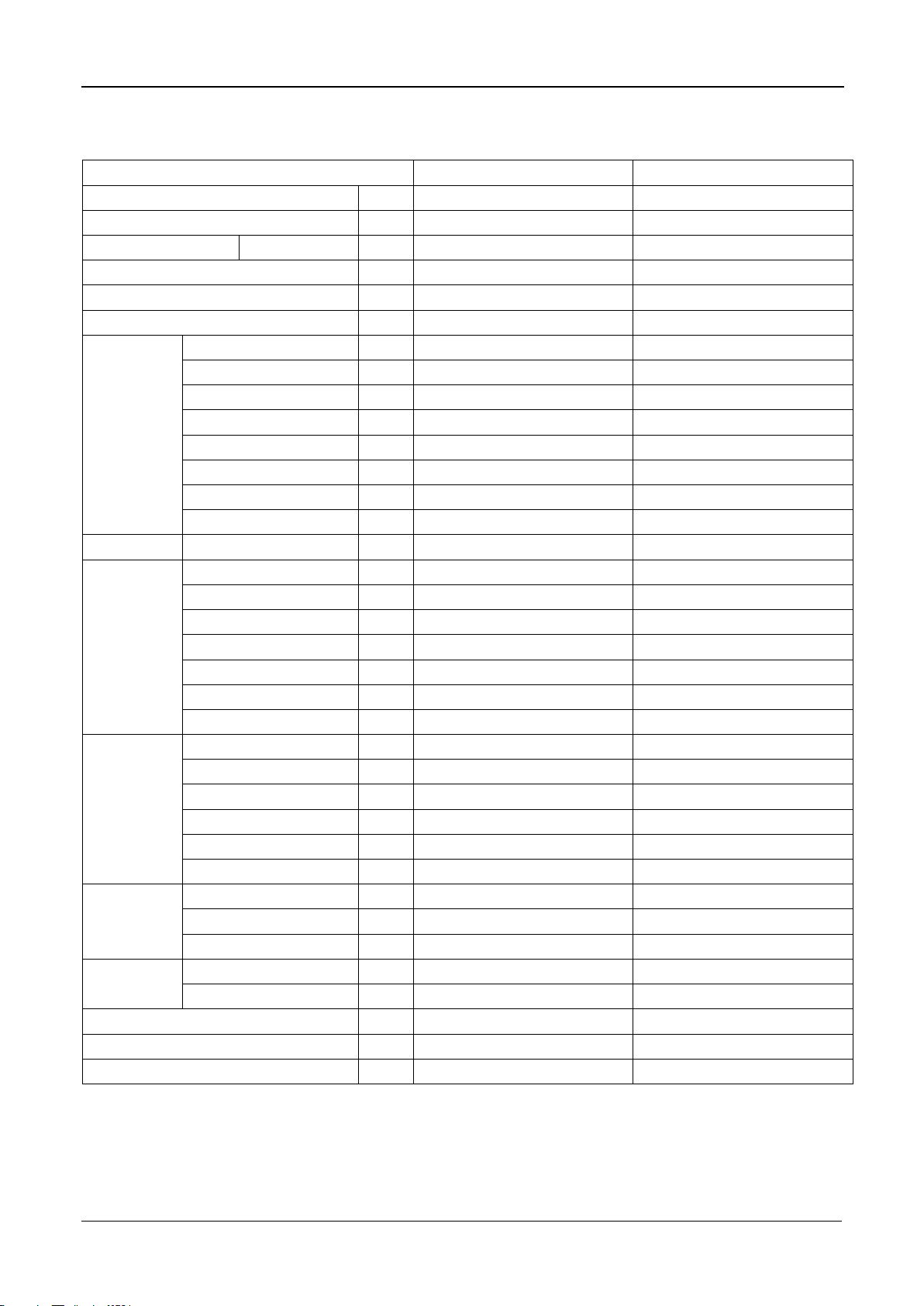

Model

MCCU-03CN1

MCCU-05CN1

Power supply

\

220-240V~, 1Ph, 50Hz

220-240V~, 1Ph, 50Hz

Ambient temperature range

°C

17~46

17~46

Cooling

Capacity

kW

3.2

5.3

Max. input

kW

1.60

2.85

Max. current A 7.5

15.0

Noise level

dB(A)

29.4

44.0

Compressor

Type / Quantity \ Rotary / 1

Rotary / 1

Model \ PA150X2C-4FT

PA225M2CS-4KU2

Brand

\

GMCC

GMCC

Capacity W 3,660

5,500

Input

W

1,260

1,835

Capacitor \ 35µF/450V

50µF/450V

Rated current (RLA)

A

5.8

8.5

Oil charge \ 480 (Ester oil VG74)

750 (Ester oil VG74)

Refrigerant

Type / Charged

\

R410A / 800g

R410A / 860g

Fan

Type / Quantity

\

Axial fan / 1

Axial fan / 1

Motor model \ YDK24-6F(B)

YDK48-6H(A)

Fan dimension

mm

Φ401

Φ424

Drive type \ Direct

Direct

Capacitor \ 2.5µF/450V

3µF/450V

Motor input W 63

111

Motor speed

rpm

800

890

Coil

Type \ Copper tube and aluminum fin

Copper tube and aluminum fin

Tube size

mm

Φ7.94

Φ7

No. of rows \ 1

2

Fin space

mm

1.6

1.4

Length × Height

mm

762×484

658×546

Number of circuits \ 2

8

Refrigerant

pipe

Liquid side / Gas side

mm

Φ6.35/Φ12.7

Φ6.35/Φ12.7

Max. pipe length m 20

20

Max. difference in level

m

10

10

Connection

wire

Power wire

\

2×2.5mm2+1×1.5mm2 (Ground)

2×4.0mm2+1×2.5mm2 (Ground)

Signal wire \ 1×1.0mm

2

1×1.0mm

2

Dimension (W×H×D)

mm

848×549×300

825×597×315

Packing (W×H×D)

mm

910×575×335

890×650×360

Net / Gross weight

kg

30.5/33

36.5/39.5

4. Specifications

Notes:

Nominal cooling capacities are based on the following conditions: Indoor temperature: 27°CDB/19°CWB; outdoor

temperature: 35°CDB/24°C WB. Equivalent refrigerant pipe: 7.5m.

7

Page 8

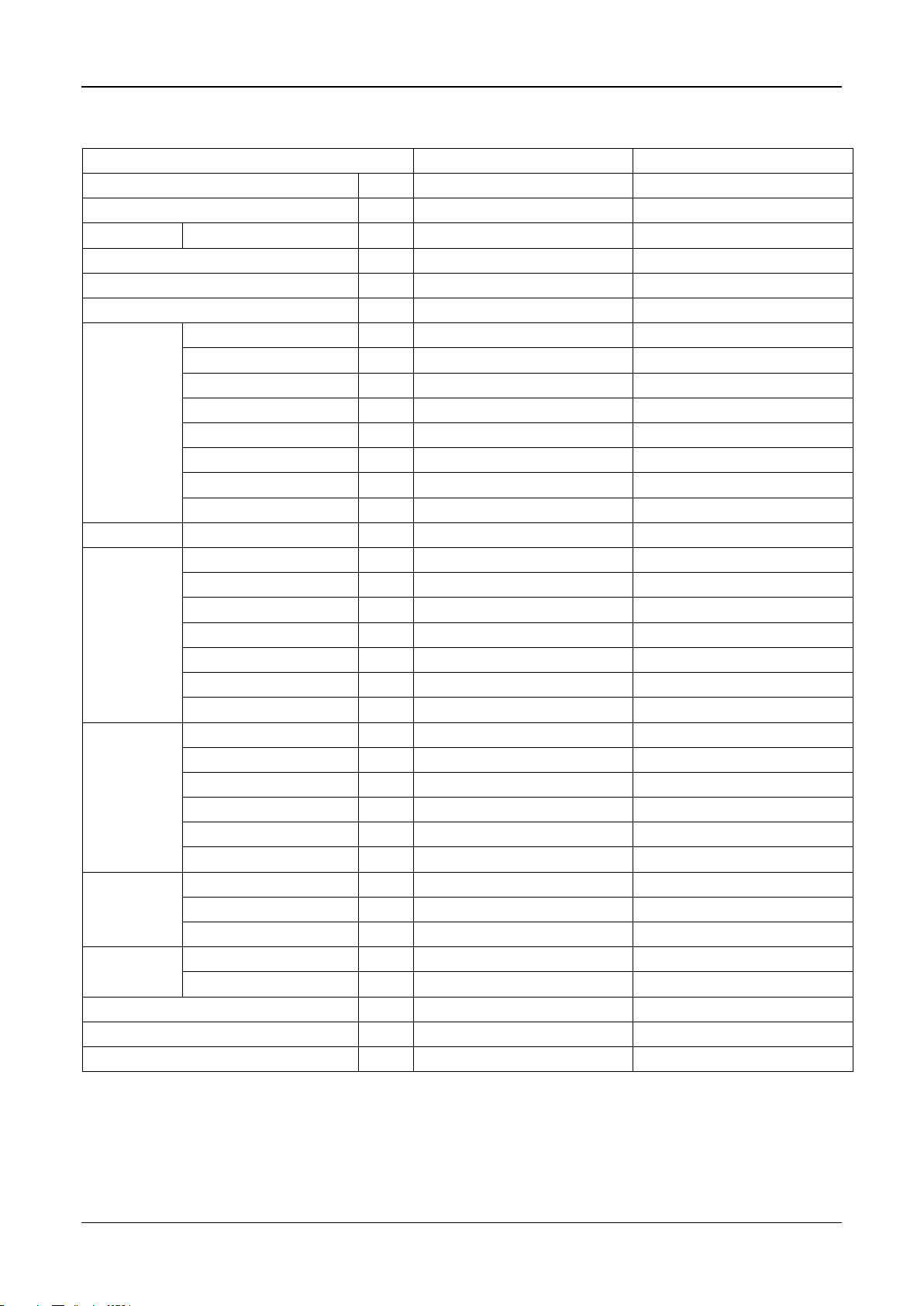

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-07CN1

MCCU-10CN1

Power supply

\

220-240V~, 1Ph, 50Hz

380-415V~, 3Ph, 50Hz

Ambient temperature range

°C

17~46

17~46

Cooling

Capacity

kW

7.1

10.5

Max. input

kW

3.50

5.30

Max. current A 18.0

10

Noise level

dB(A)

72.6

58

Compressor

Type / Quantity \ Rotary / 1

Scroll / 1

Model \ PA290G2CS-4MU1

C-SBN303H8D

Brand

\

GMCC

Sanyo

Capacity W 7,260

9,800

Input

W

2,430

3,650

Capacitor \ 50µF/450V

/

Rated current (RLA)

A

11.65

6.58

Oil charge \ 850 (Ester oil VG74)

1,700 (FV68S)

Refrigerant

Type / Charged

\

R410A / 1,350g

R410A / 2,500g

Fan

Type / Quantity

\

Axial fan / 1

Axial fan / 1

Motor model \ YDK53-6C

YDK190-6D(B)

Fan dimension

mm

Φ460

Φ560

Drive type \ Direct

Direct

Capacitor \ 3µF/450V

10µF/450V

Motor input W 136

290

Motor speed

rpm

800

830

Coil

Type \ Copper tube and aluminum fin

Copper tube and aluminum fin

Tube size

mm

Φ7

Φ7

No. of rows \ 2

1.6

Fin space

mm

1.5

1.5

Length × Height

mm

766×630

898×882

Number of circuits \ 4

7

Refrigerant

pipe

Liquid side / Gas side

mm

Φ9.52/Φ12.7

Φ9.52/Φ19

Max. pipe length m 20

30

Max. difference in level

m

10

20

Connection

wire

Power wire

\

2×6.0mm2+1×4.0mm2 (Ground)

4×4.0mm2+1×2.5mm2 (Ground)

Signal wire \ 1×1.0mm

2

1×1.0mm

2

Dimension (W×H×D)

mm

916×702×360

1,077×967×396

Packing (W×H×D)

mm

965×755×420

1,120×1,100×435

Net / Gross weight

kg

48.5/52

85.8/95.6

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

8

Page 9

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-16CN1

Power supply

\

380-415V~, 3Ph, 50Hz

380-415V~, 3Ph, 50Hz

Ambient temperature range

°C

17~46

17~46

Cooling

Capacity

kW

14.0

16.0

Max. input

kW

6.10

8.50

Max. current A 12

13

Noise level

dB(A)

58

59

Compressor

Type / Quantity \ Scroll / 1

Scroll / 1

Model \ C-SBN373H8D

C-SBN453H8D

Brand

\

Sanyo

Sanyo

Capacity W 14,100

16,400

Input

W

4,750

5,750

Capacitor

\

/

/

Rated current (RLA)

A

8.22

9.77

Oil charge \ 1,700 (FV68S)

1,700 (FV68S)

Refrigerant

Type / Charged

\

R410A / 3,000g

R410A / 3,050g

Fan

Type / Quantity

\

Axial fan / 2

Axial fan / 2

Motor model \ YDK65-6F(B)

YDK65-6F(B)

Fan dimension

mm

Φ455

Φ455

Drive type \ Direct

Direct

Capacitor \ 4µF/450V

4µF/450V

Motor input W 174

174

Motor speed

rpm

825

825

Coil

Type \ Copper tube and aluminum fin

Copper tube and aluminum fin

Tube size

mm

Φ7

Φ7.94

No. of rows \ 2

2

Fin space

mm

1.5

1.6

Length × Height

mm

845×1,092

837×1,100

Number of circuits \ 8

8

Refrigerant

pipe

Liquid side / Gas side

mm

Φ9.52/Φ19

Φ9.52/Φ19

Max. pipe length m 30

30

Max. difference in level

m

20

20

Connection

wire

Power wire

\

4×4.0mm2+1×2.5mm2 (Ground)

4×10.0mm2+1×6.0mm2 (Ground)

Signal wire \ 1×1.0mm

2

1×1.0mm

2

Dimension (W×H×D)

mm

987×1,167×400

987×1,167×400

Packing (W×H×D)

mm

1,032×1,307×443

1,032×1,307×443

Net / Gross weight

kg

91.6/102

96.6/107

MCCU-12CN1

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

9

Page 10

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-22CN1

Power supply

\

380-415V~, 3Ph, 50Hz

Ambient temperature range

°C

17~52

Cooling

Capacity

kW

22.0

Max. input

kW

11.70

Max. current

A

19.3

Noise level

dB(A)

65

Compressor

Type / Quantity

\

Scroll / 1

Model

\

ZP90KCE-TFD-522

Brand

\

Copeland

Capacity

W

21,900

Input

W

6,950

Capacitor

\ / Rated current (RLA)

A

16.5

Oil charge

\

2,513 (POE)

Refrigerant

Type / Charged

\

R410A / 5,400g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YDK210-6A

Fan dimension

mm

Φ530

Drive type

\

Direct

Capacitor

\

10μF/450V

Motor input

W

Hi: 284; Lo: 202

Motor speed

rpm

Hi: 920/930; Lo: 650/710 (4 blades/3 blades)

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Ф7.94

No. of rows

\ 2 Fin space

mm

1.4

Length × Height

mm

2,177×880

Number of circuits

\

9

Refrigerant

pipe

Liquid side / Gas side

mm

Ф9.52/Ф22

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

5×6.0mm

2

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

1,260×908×700

Packing (W×H×D)

mm

1,320×1,060×730

Net / Gross weight

kg

171/190

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

10

Page 11

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-28CN1

Power supply

\

380-415V~, 3Ph, 50Hz

Ambient temperature range

°C

17~52

Cooling

Capacity

kW

28.0

Max. input

kW

14.40

Max. current

A

23.7

Noise level

dB(A)

67

Compressor

Type / Quantity

\

Scroll / 1

Model

\

ZP120KCE-TFD-522

Brand

\

Copeland

Capacity

W

29,200

Input

W

9,200

Capacitor

\ / Rated current (RLA)

A

20

Oil charge

\

3,253 (POE)

Refrigerant

Type / Charged

\

R410A / 6,000g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YDK400-4C

Fan dimension

mm

Φ530

Drive type

\

Direct

Capacitor

\

25μF/450V

Motor input W Hi: 621/587; Lo: 388/388 (4 blades/3 blades)

Motor speed

rpm

Hi: 1,180/1,230; Lo: 790/870 (4 blades/3 blades)

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Ф7

No. of rows

\ 3 Fin space

mm

1.3

Length × Height

mm

2,179×882

Number of circuits

\

20

Refrigerant

pipe

Liquid side / Gas side

mm

Ф9.52/Ф25

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

5×6.0mm

2

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

1,260×908×700

Packing (W×H×D)

mm

1,320×1,060×730

Net / Gross weight

kg

185/202

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

11

Page 12

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-35CN1

Power supply

\

380-400V~, 3Ph, 50Hz

Ambient temperature range

°C

17~52

Cooling

Capacity

kW

35.0

Max. input

kW

17.30

Max. current

A

28.5

Noise level

dB(A)

69

Compressor

Type / Quantity

\

Scroll / 1

Model

\

SH140A4ALC

Brand

\

Danfoss

Capacity

W

34,700

Input

W

10,862

Capacitor

\ / Rated current (RLA)

A

21.4

Oil charge

\

3,300 (POE-160SZ)

Refrigerant

Type / Charged

\

R410A / 7,200g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YDK400-4C

Fan dimension

mm

Φ530

Drive type

\

Direct

Capacitor

\

25μF/450V

Motor input W Hi: 621/587; Lo: 388/388 (4 blades/3 blades)

Motor speed

rpm

Hi: 1,180/1,230; Lo: 790/870 (4 blades/3 blades)

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Ф7

No. of rows

\ 3 Fin space

mm

1.3

Length × Height

mm

(1,380×882)+(1,380×882)

Number of circuits

\

20+20

Refrigerant

pipe

Liquid side / Gas side

mm

Ф12.7/Ф28.6

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

5×6.0mm

2

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

1,260×908×700

Packing (W×H×D)

mm

1,320×1,060×730

Net / Gross weight

kg

199/215

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

12

Page 13

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-45CN1

Power supply

\

380-415V~, 3Ph, 50Hz

Ambient temperature range

°C

17~46

Cooling

Capacity

kW

45.0

Max. input

kW

26.90

Max. current

A

47.9

Noise level

dB(A)

70

Compressor

Type / Quantity

\

Scroll / 3

Model

\

E605DH-59D2YG

Brand

\

Hitachi

Capacity

W

15,390

Input

W

5,130

Capacitor

\ / Rated current (RLA)

A

8.8

Oil charge

\

500 (FVC68D)

Refrigerant

Type / Charged

\

R410A / 10,000g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YDK380-4D

Fan dimension

mm

Φ560/Φ562

Drive type

\

Direct

Capacitor

\

20μF/450V

Motor input W Hi: 615/580; Lo: 425/420 (4 blades/3 blades)

Motor speed

rpm

Hi: 1,000/1,090; Lo: 780/870 (4 blades/3 blades)

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Ф7.94

No. of rows

\ 2 Fin space

mm

1.6

Length × Height

mm

2,286×1,232

Number of circuits

\

28

Refrigerant

pipe

Liquid side / Gas side

mm

Ф16/Ф32

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

5×15.0mm

2

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

1,250×1,615×765

Packing (W×H×D)

mm

1,305×1,790×820

Net / Gross weight

kg

288/308

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

13

Page 14

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-53CN1

Power supply

\

380-400V~, 3Ph, 50Hz

Ambient temperature range

°C

18~46

Cooling

Capacity

kW

53.0

Max. input

kW

23.70

Max. current

A

45.2

Noise level

dB(A)

73

Compressor

Type / Quantity

\

Scroll / 2

Model

\

SH105A4ALC

Brand

\

Danfoss

Capacity

W

26,816

Input

W

8,472

Capacitor

\ / Rated current (RLA)

A

16.4

Oil charge

\

3,300ml (POE-160SZ)

Refrigerant

Type / Charged

\

R410A / 11,000g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YS600-6P

Fan dimension

mm

Φ650

Drive type

\

Direct

Capacitor

\ \ Motor input

W

750

Motor speed

rpm

930

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Φ7.94

No. of rows

\ 3 Fin space

mm

1.6

Length × Height

mm

2,209×1,100

Number of circuits

\

12+12

Refrigerant

pipe

Liquid side / Gas side

mm

(Ф12.7/Ф25)×2

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire \ 4×16.0mm2+1×10.0mm2 (Ground)

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

1,825×1,245×899

Packing (W×H×D)

mm

1,844×1,272×924

Net / Gross weight

kg

395/405

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

14

Page 15

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-61CN1

Power supply

\

380-400V~, 3Ph, 50Hz

Ambient temp range

°C

17~46

Cooling

Capacity

kW

61.0

Max. input

kW

28.20

Max. current

A

51.0

Noise level

dB(A)

76

Compressor

Type / Quantity

\

Scroll / 2

Model

\

SH120A4ALC

Brand

\

Danfoss

Capacity

W

29,950

Input

W

9,462

Capacitor

\ / Rated current (RLA)

A

20.7

Oil charge

\

3,300ml (POE-160SZ)

Refrigerant

Type / Charged

\

R410A / 12,400g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YS1100-6

Fan dimension

mm

Φ700

Drive type

\

Direct

Capacitor

\ \ Motor input

W

1,300

Motor speed

rpm

940

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Φ7.94

No. of rows

\ 3 Fin space

mm

1.6

Length × Height

mm

2,209×1,100

Number of circuits

\

12+12

Refrigerant

pipe

Liquid side / Gas side

mm

(Ф12.7/Ф25)×2

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

4×25.0mm2+1×16.0mm2 (Ground)

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

1,825×1,245×899

Packing (W×H×D)

mm

1,844×1,272×924

Net / Gross weight

kg

395/405

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

15

Page 16

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-70CN1

Power supply

\

380-400V~, 3Ph, 50Hz

Ambient temperature range

°C

17~46

Cooling

Capacity

kW

70.0

Max. input

kW

31.80

Max. current

A

56.5

Noise level

dB(A)

76

Compressor

Type / Quantity

\

Scroll / 2

Model

\

SH140A4ALC

Brand

\

Danfoss

Capacity

W

34,700

Input

W

10,862

Capacitor

\ / Rated current (RLA)

A

21.4

Oil charge

\

3,300ml (POE-160SZ)

Refrigerant

Type / Charged

\

R410A / 17,000

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YS1100-6

Fan dimension

mm

Φ750

Drive type

\

Direct

Capacitor

\ \ Motor input

W

1,300

Motor speed

rpm

940

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Φ7.94

No. of rows

\

3.6

Fin space

mm

1.6

Length × Height

mm

(1,355×1,100)+(1,325×1,100)

Number of circuits

\

25+25

Refrigerant

pipe

Liquid side / Gas side

mm

(Ф12.7/Ф25)×2

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

4×25.0mm2+1×16.0mm2 (Ground)

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

2,158×1,258×1,082

Packing (W×H×D)

mm

2,168×1,275×1,105

Net / Gross weight

kg

508/523

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

16

Page 17

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-105CN1

Power supply

\

380-400V~, 3Ph, 50Hz

Ambient temp range

°C

17~46

Cooling

Capacity

kW

105.0

Max. input

kW

40.70

Max. current

A

71.8

Noise level

dB(A)

78

Compressor

Type / Quantity

\

Scroll / 2

Model

\

SH184A4ALC

Brand

\

Danfoss

Capacity

W

44,661

Input

W

13,732

Capacitor

\ / Rated current (RLA)

A

27.6

Oil charge

\

3,600ml (POE-160SZ)

Refrigerant

Type / Charged

\

R410A / 18,000g

Fan

Type / Quantity

\

Axial fan / 2

Motor model

\

YS1500-6

Fan dimension

mm

Φ802

Drive type

\

Direct

Capacitor

\ \ Motor input

W

1,690

Motor speed

rpm

910

Coil

Type

\

Copper tube and aluminum fin

Tube size

mm

Φ7

No. of rows

\

3.6

Fin space

mm

1.5

Length × Height

mm

(1,325×756)×2+(1367×756)×2

Number of circuits

\

24+24

Refrigerant

pipe

Liquid side / Gas side

mm

(Ф12.7/Ф25)×2

Max. pipe length

m

50

Max. difference in level

m

30

Connection

wire

Power wire

\

4×35.0mm2+1×16.0mm2 (Ground)

Signal wire

\

2×1.0mm

2

Dimension (W×H×D)

mm

2,158×1,669×1,082

Packing (W×H×D)

mm

2,168×1,686×1,105

Net/ Gross weight

kg

570/582

Notes:

Nominal cooling capacities are based on the following conditions:

Indoor temperature: 27°CDB, 19°CWB; Outdoor temperature: 35°CDB, 24°C WB; Equivalent refrigerant pipe: 7.5m.

17

Page 18

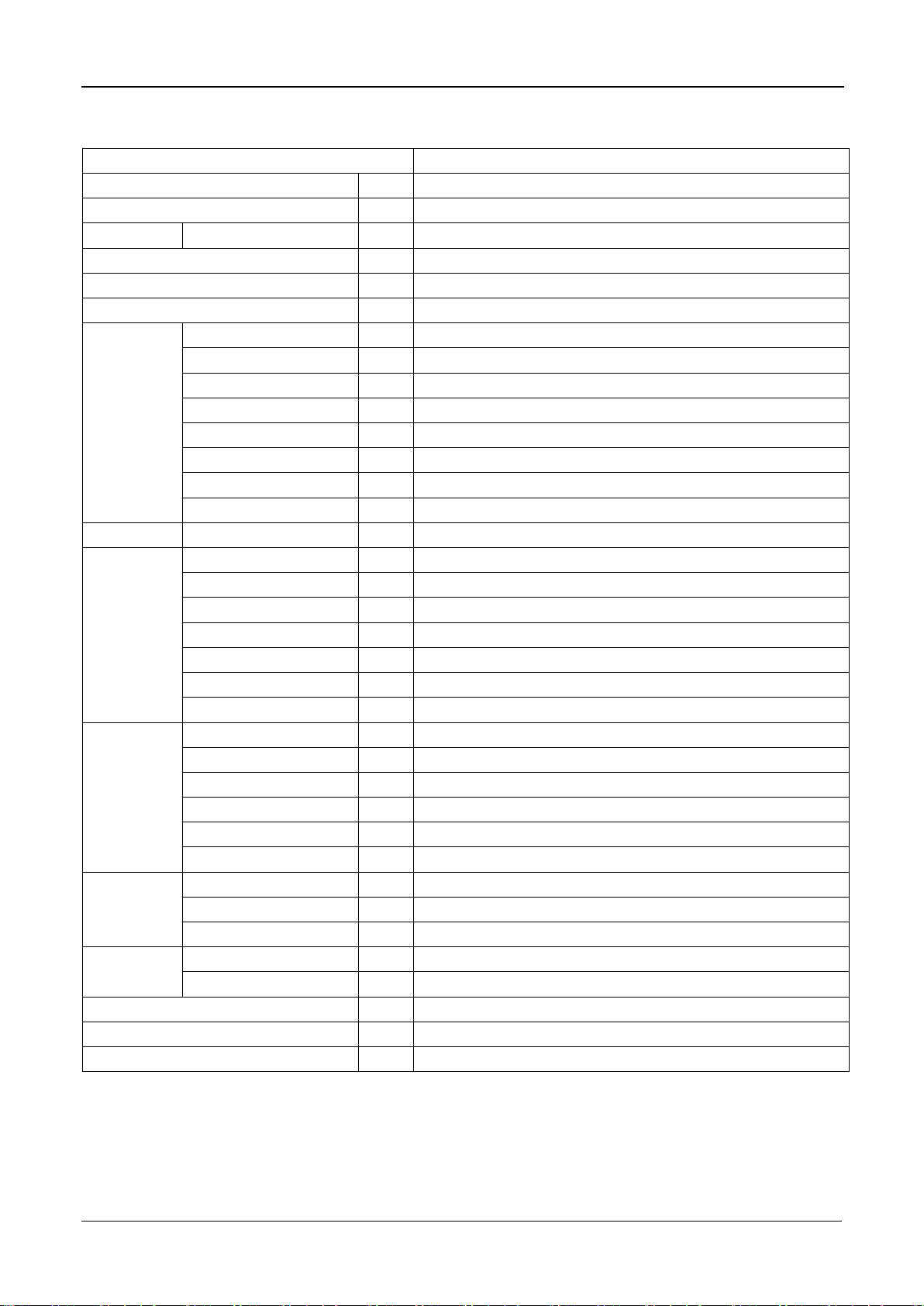

5. Dimensions (Unit: mm)

MCCU-03CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-05CN1

18

Page 19

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-07CN1

MCCU-10CN1

19

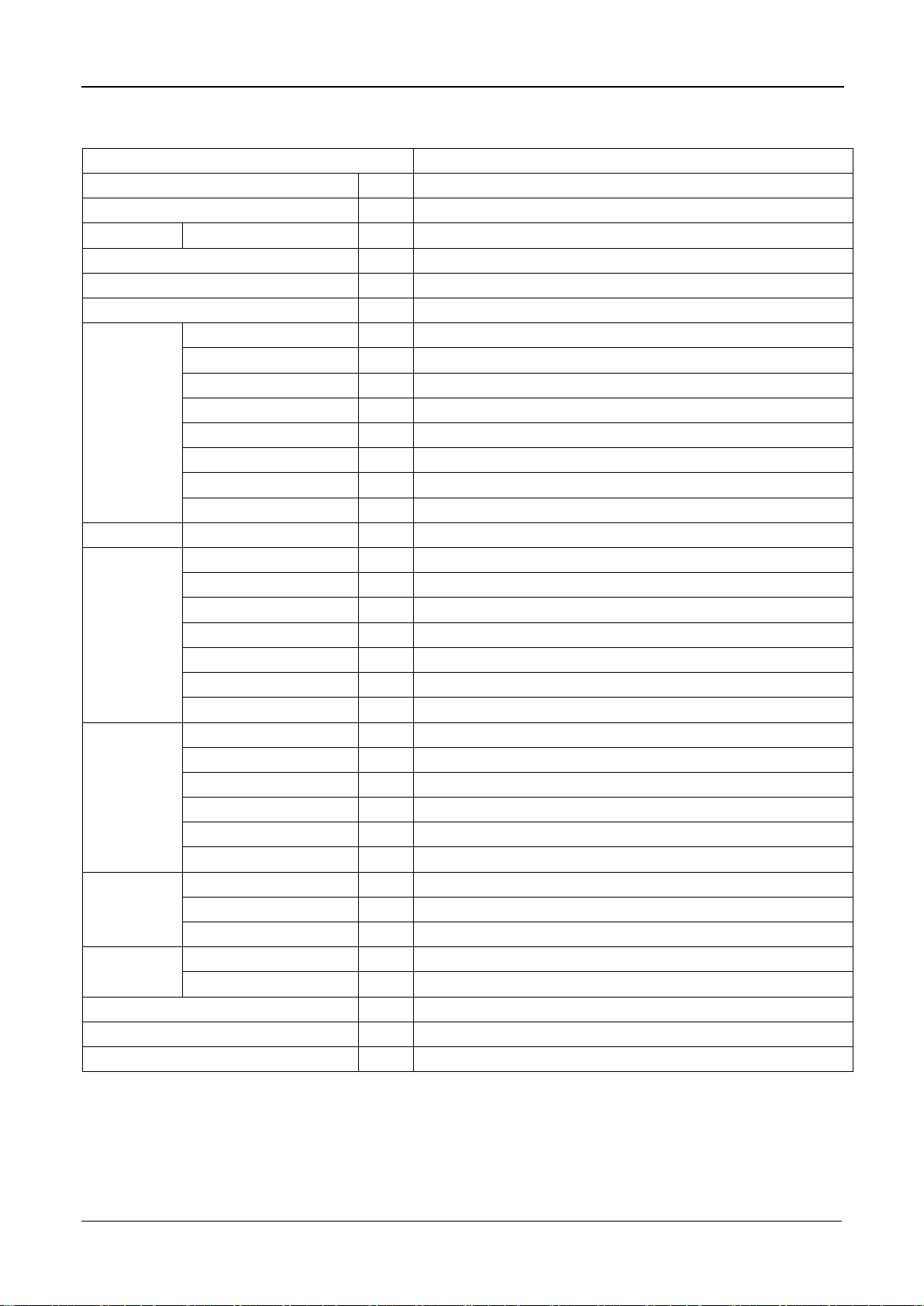

Page 20

MCCU-12CN1, MCCU-16CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

20

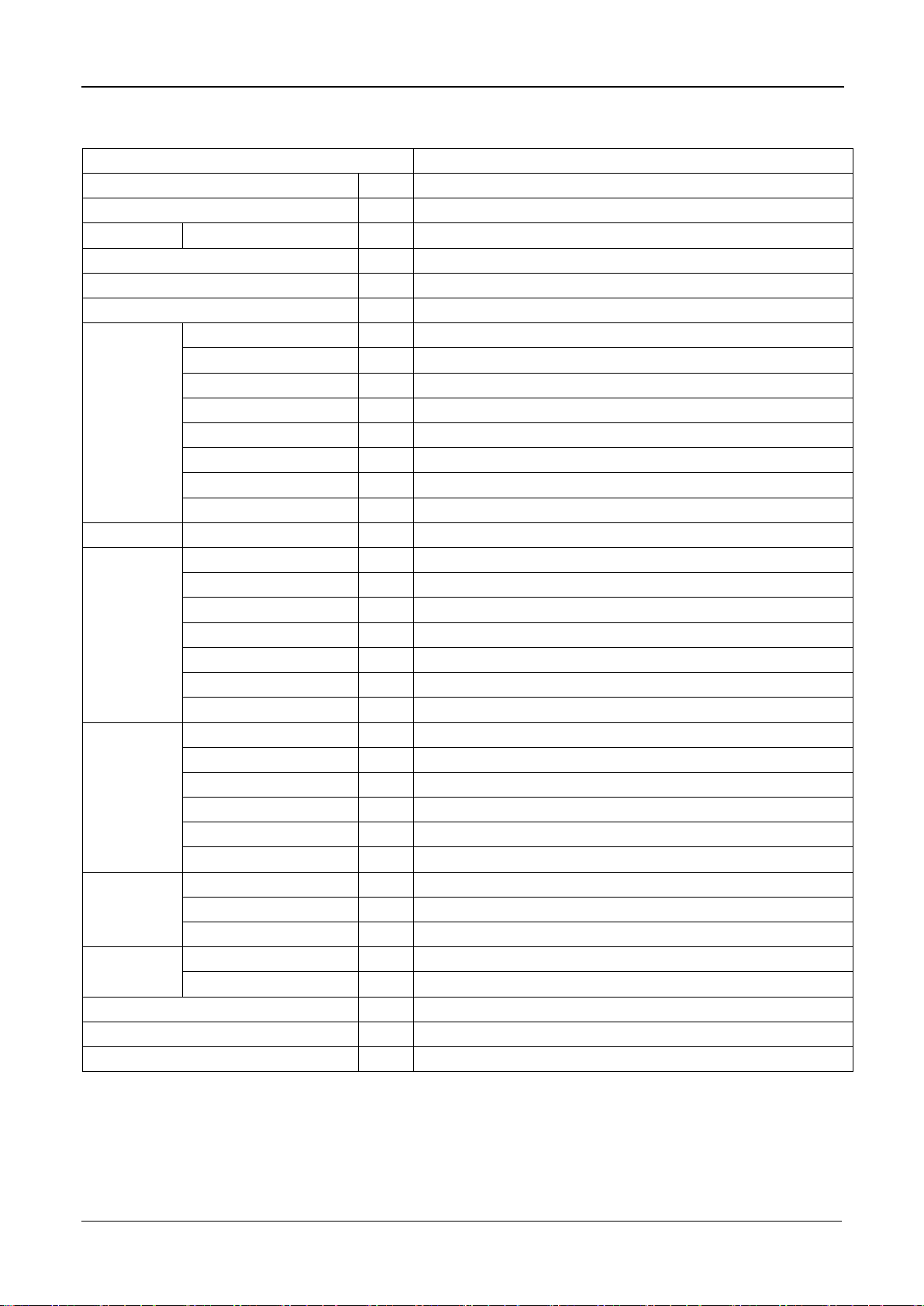

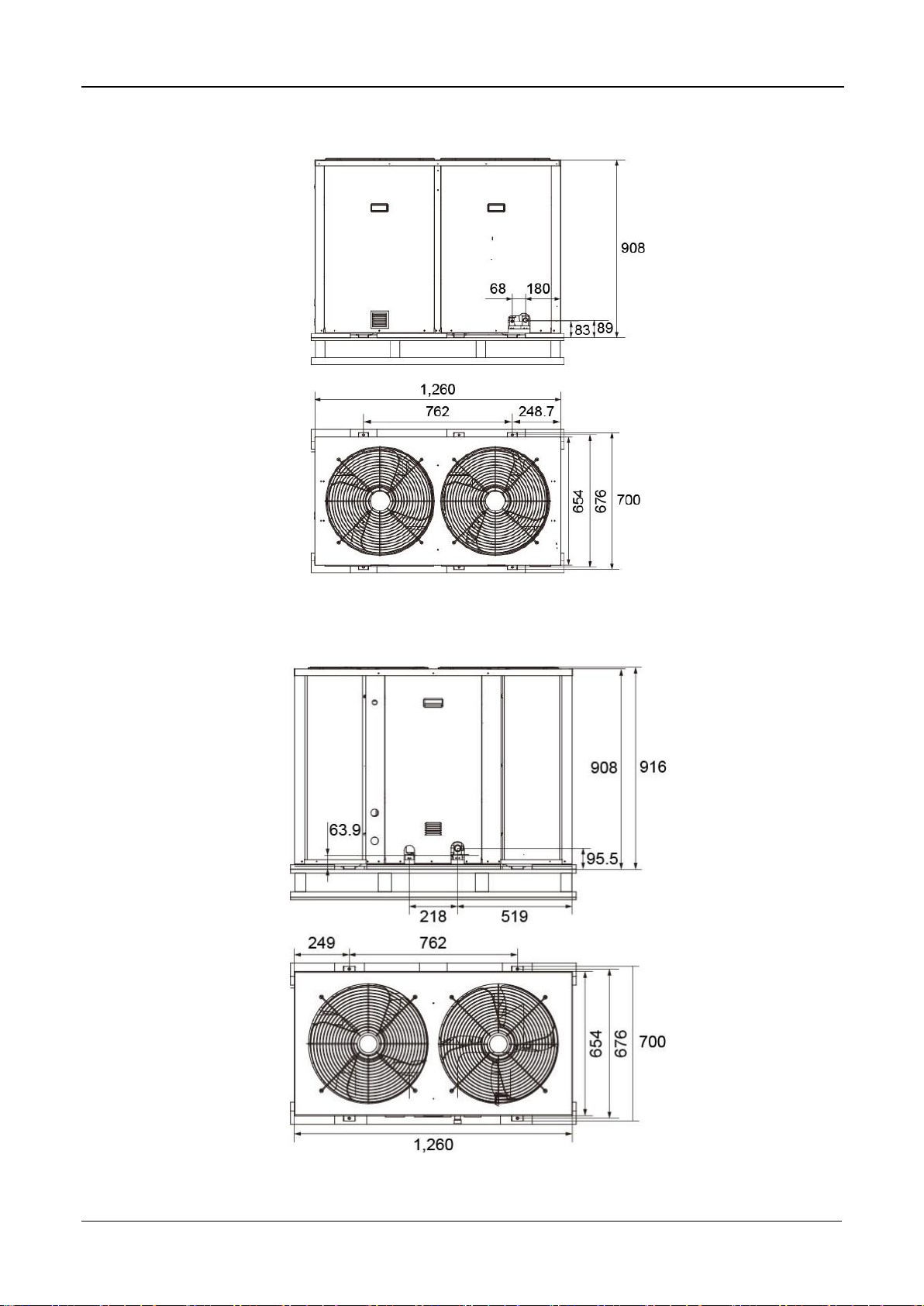

Page 21

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-22CN1, MCCU-28CN1

MCCU-35CN1

21

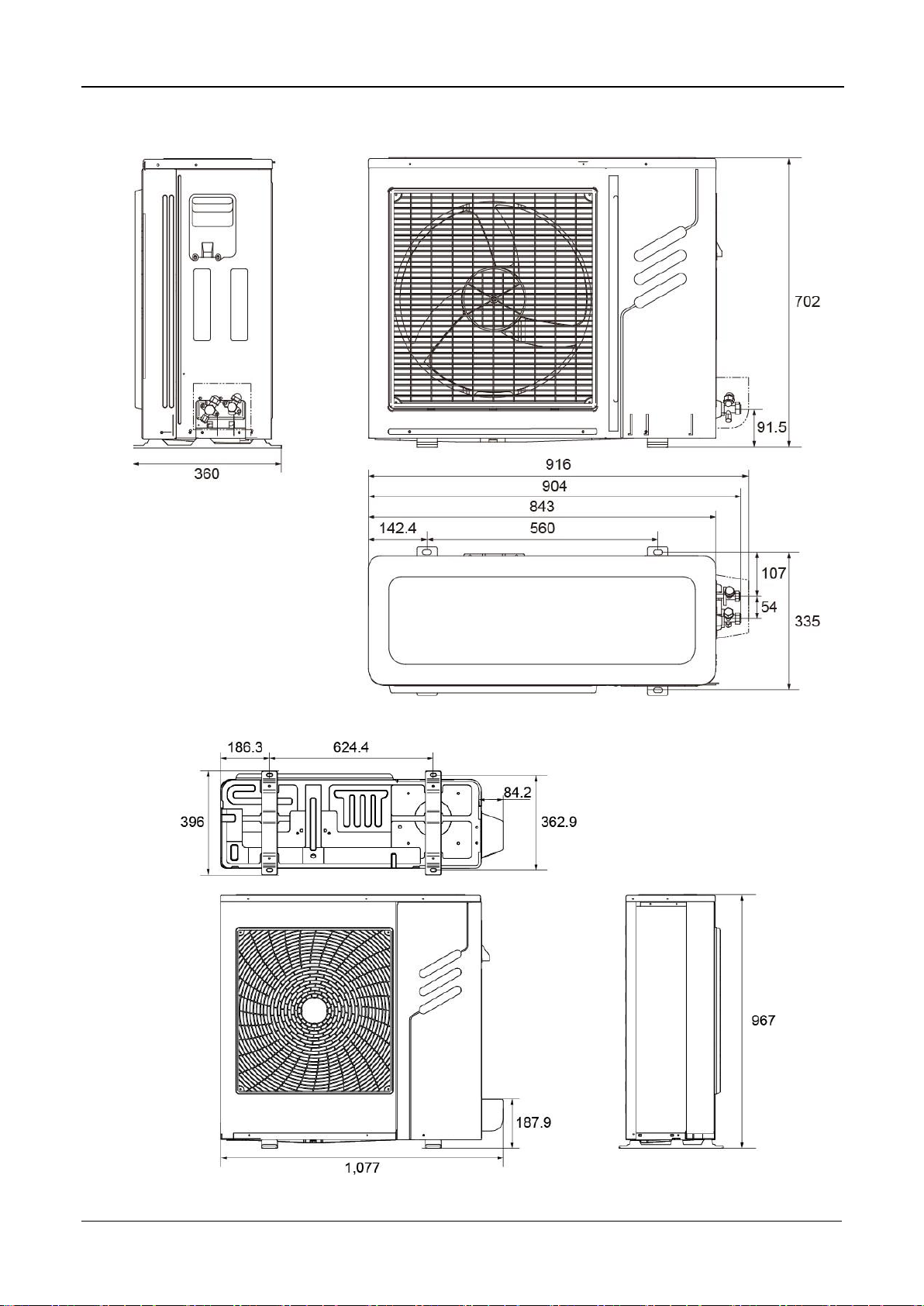

Page 22

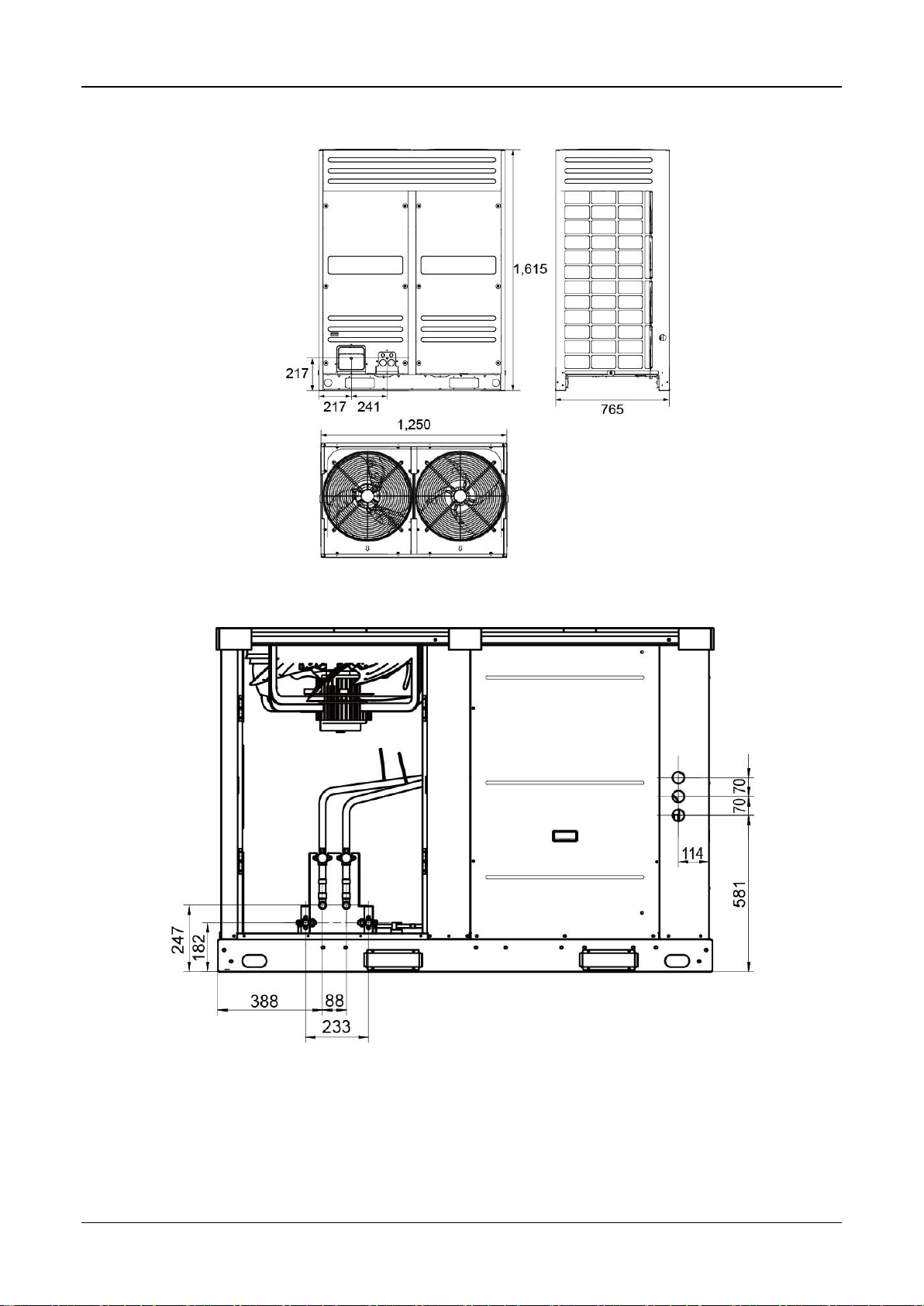

MCCU-45CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-53CN1, MCCU-61CN1

22

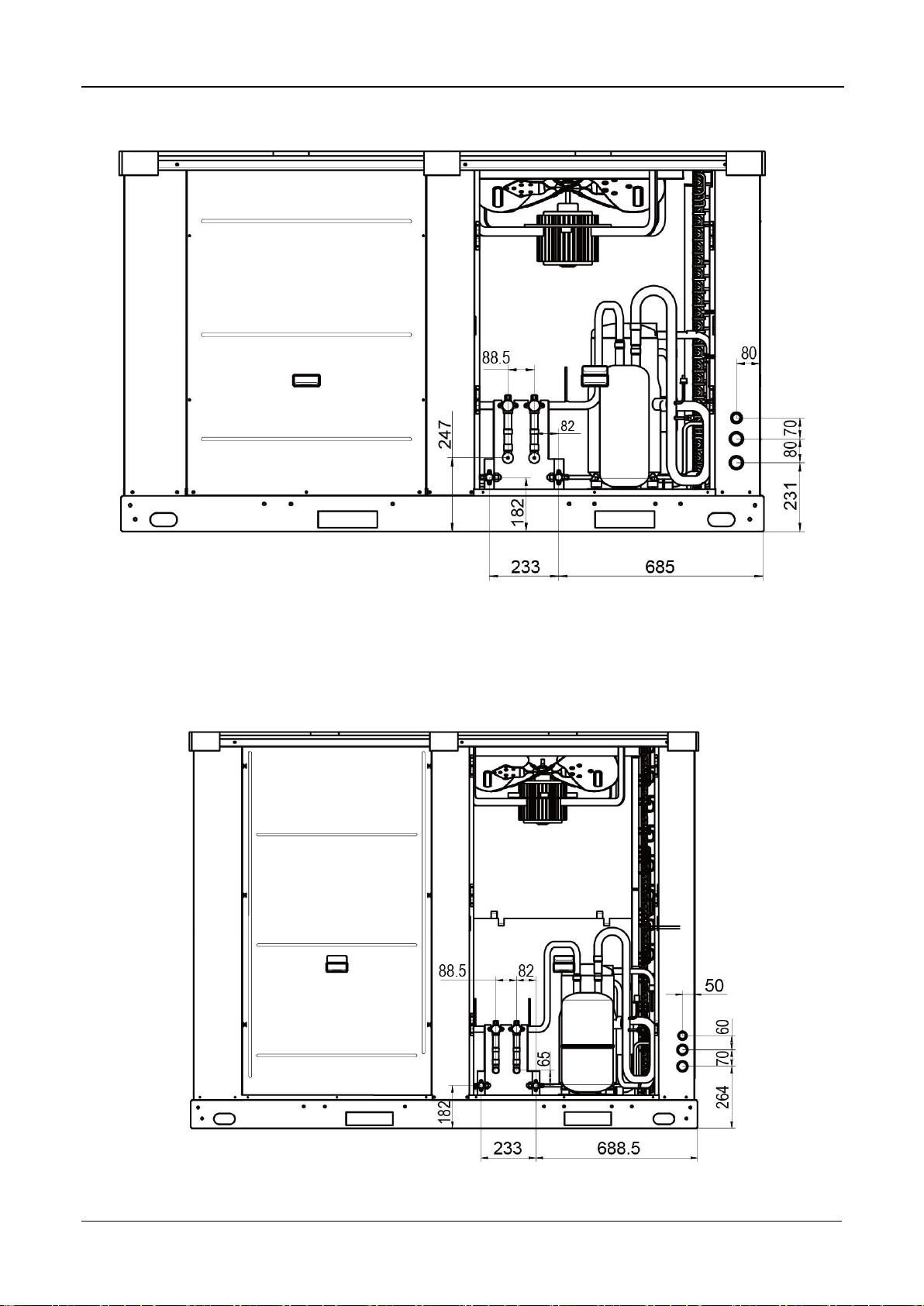

Page 23

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-70CN1

MCCU-105CN1

23

Page 24

6. Refrigerant circuits

MCCU-03CN1, MCCU-05CN1, MCCU-07CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

24

Page 25

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-10CN1, MCCU-12CN1, MCCU-16CN1, MCCU-22CN1, MCCU-28CN1, MCCU-35CN1

25

Page 26

MCCU-45CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

26

Page 27

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-53CN1, MCCU-61CN1, MCCU-70CN1, MCCU-105CN1

Notes: Two 4-way valves connected in refrigerant pipe systems are invalid.

27

Page 28

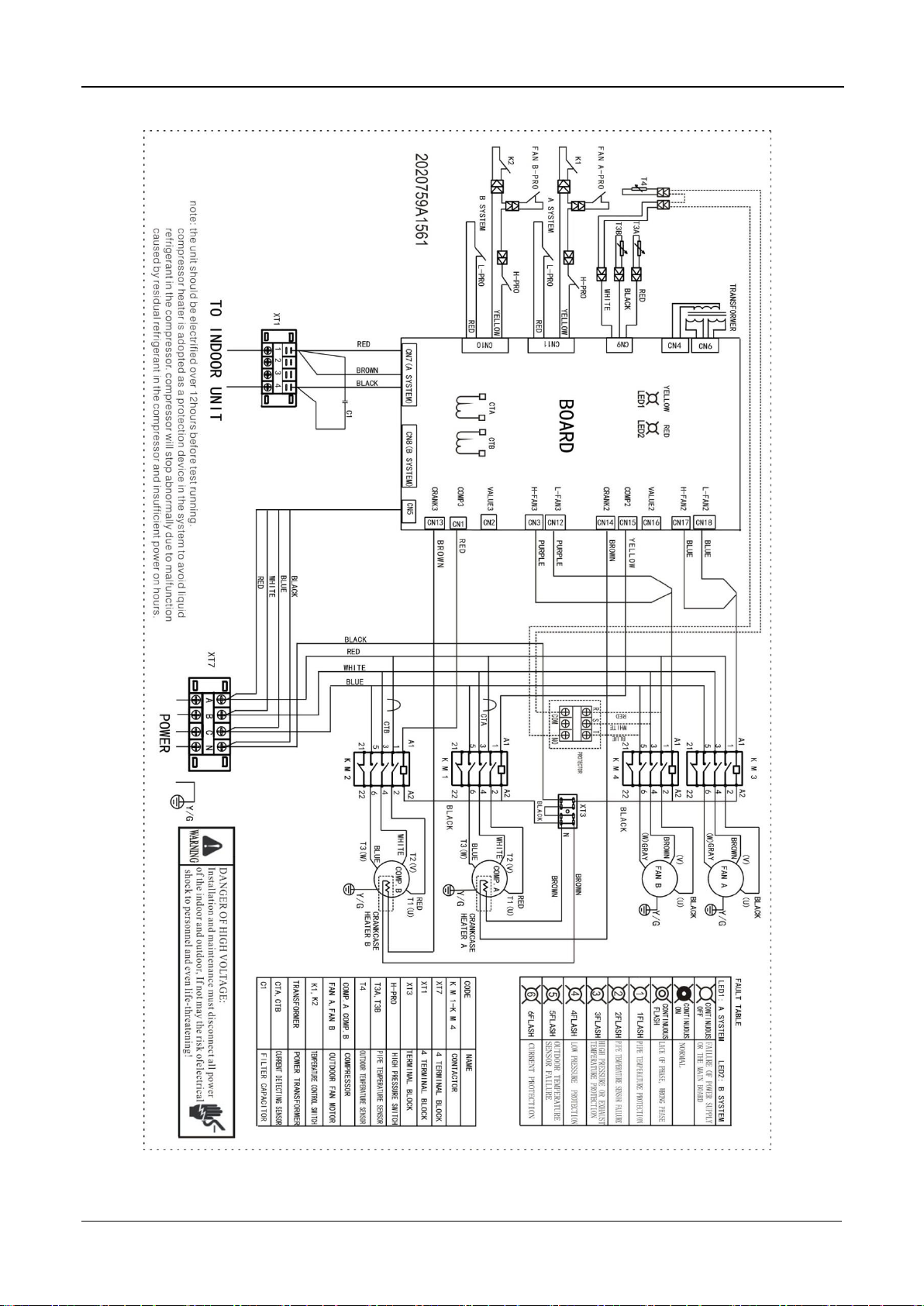

7. Wiring Diagrams

MCCU-03CN1, MCCU-05CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-07CN1

28

Page 29

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-10CN1

MCCU-12CN1

29

Page 30

MCCU-22CN1, MCCU-28CN1, MCCU-35CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

30

Page 31

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-45CN1

31

Page 32

MCCU-53CN1, MCCU-61CN1, MCCU-70CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

32

Page 33

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-105CN1

33

Page 34

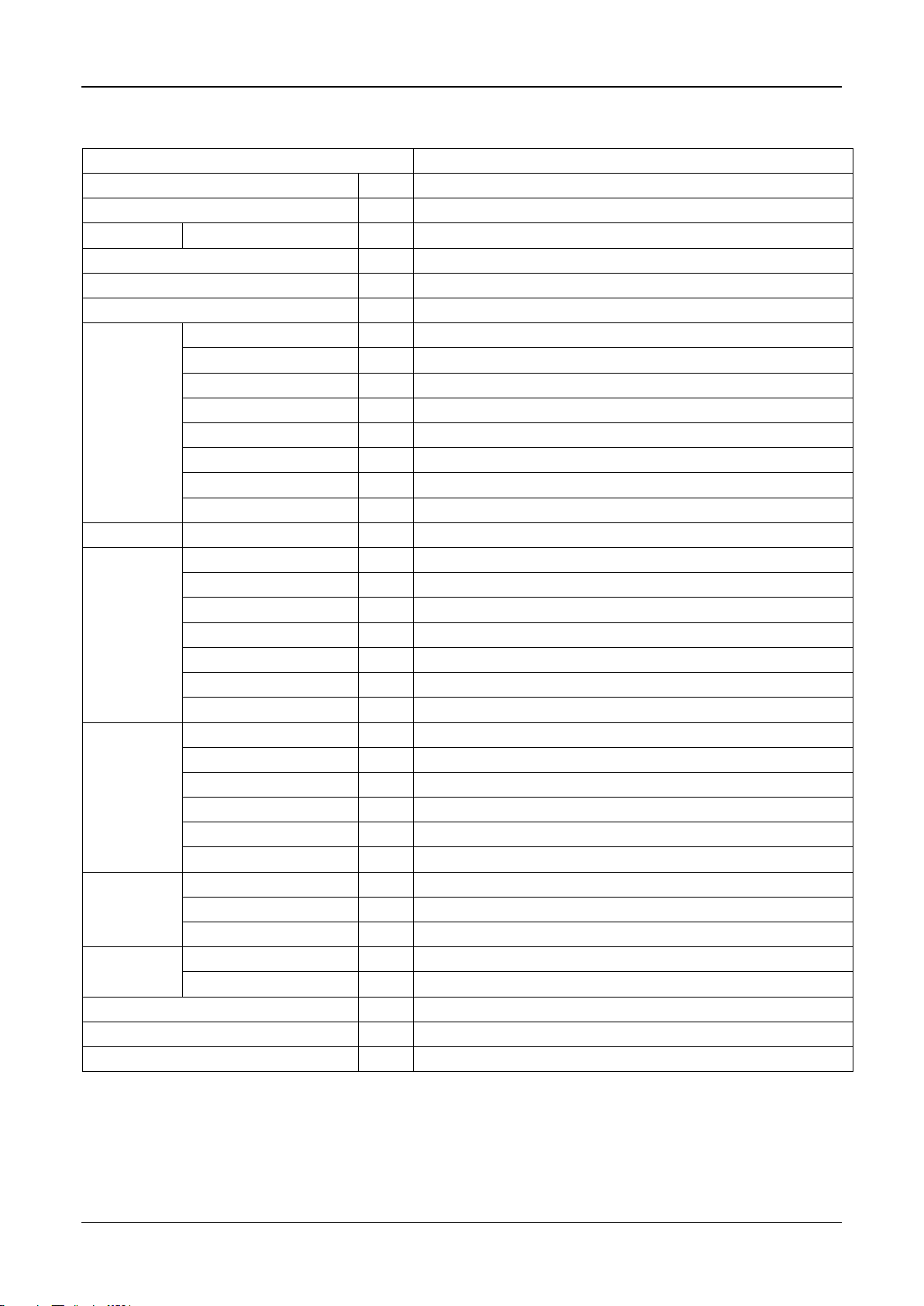

8. Electrical datas

Model

Whole units

Power Supply

Compressor

OFM

Hz

Voltage

Min.

Max.

MCA

TOCA

MFA

MSC

RLA

kW

FLA

MCCU-03CN1

50

220~240V

198V

254V

7.8

8.6

20.0

29.9

5.8

0.024

0.28

MCCU-05CN1

50

220~240V

198V

254V

11.5

15.2

40.0

40.0

8.5

0.048

0.49

MCCU-07CN1

50

220~240V

198V

254V

17.0

18.7

60.0

66.0

12.6

0.053

0.61

MCCU-10CN1

50

380~415V

342V

440V

9.2

9.4

20

52

6.58

0.19

1.31

50

380~415V

342V

440V

10.8

10.9

25

66

8.2

0.13

1.6

MCCU-16CN1

50

380~415V

342V

440V

12.6

15.2

35

67

9.7

0.13

1.6

MCCU-22CN1

50

380~415V

342V

440V

17.5

18

20.5

86

16.5

0.573

2.613

MCCU-28CN1

50

380~415V

342V

440V

20

21

23.8

110

20

1.373

6.26

MCCU-35CN1

50

380~400V

342V

440V

25

28.6

30

147

21.4

0.604

2.93

MCCU-45CN1

50

380~415V

342V

440V

37.1

47.9

52.7

62

8.8

0.76

5.48

MCCU-53CN1

50

380~400V

342V

440V

49.6

54.8

60.3

142

16.4

1.2 4 MCCU-61CN1

50

380~400V

342V

440V

67.5

66.8

73.5

142

20.7

2.2

5.4

MCCU-70CN1

50

380~400V

342V

440V

69.2

70.8

77.9

147

21.4

2.2

5.2

MCCU-105CN1

50

380~400V

342V

440V

90.5

87.2

95.9

197

27.6 3 6.6

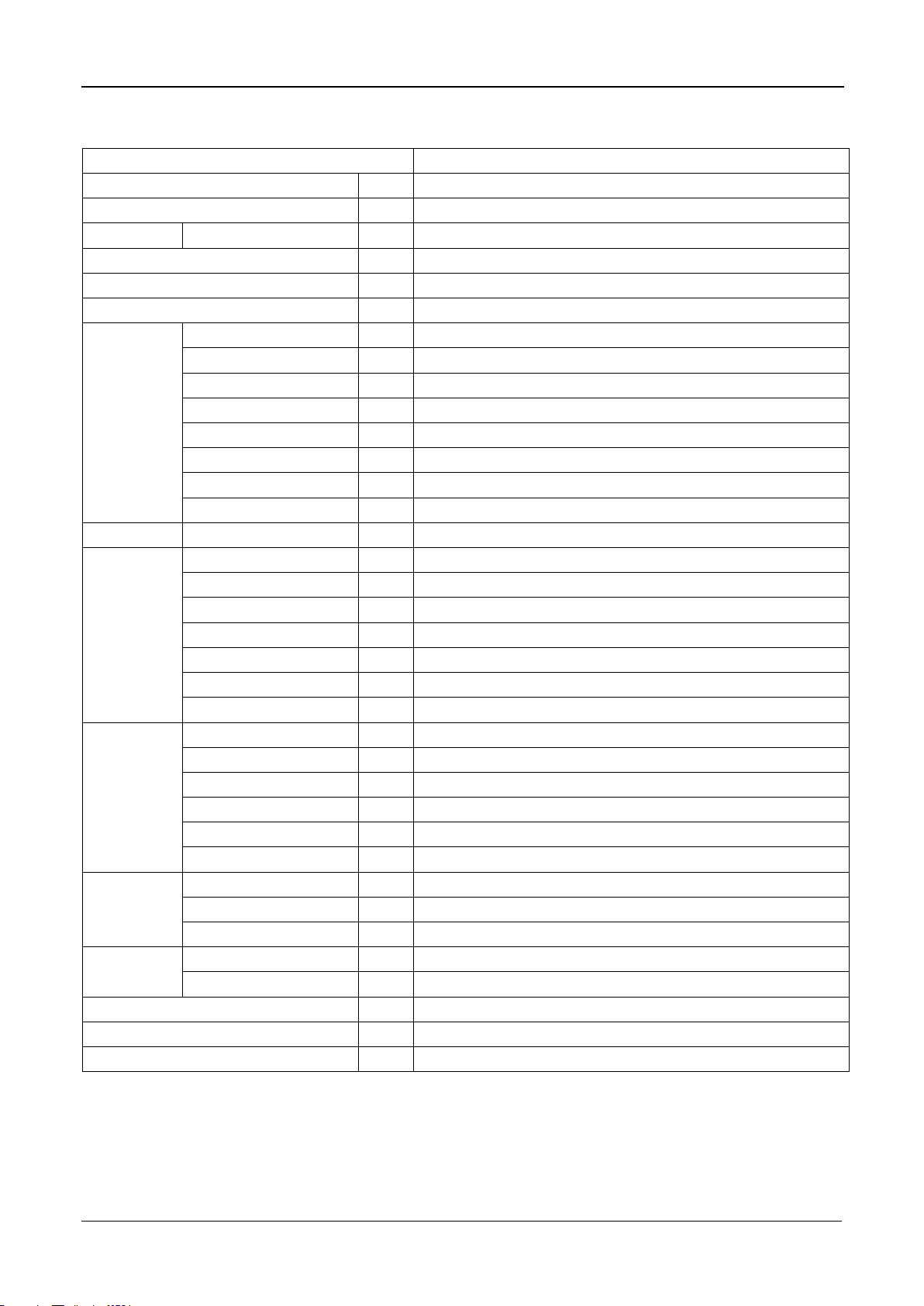

Model

Noise level

MCCU-03CN1

65 dB(A)

MCCU-05CN1

67 dB(A)

MCCU-07CN1

69 dB(A)

MCCU-10CN1

70 dB(A)

73 dB(A)

MCCU-16CN1

76 dB(A)

MCCU-12CN1

Midea R410A 50Hz T1 Compressor Condensing Unit

Notes:

MCA: Min. Current Amps. (A) TOCA : Total Over-current Amps. (A)

MFA: Max. Fuse Amps. (A) MSC: Max. Starting Amps. (A)

RLA: Rated Locked Amps. (A) OFM: Outdoor Fan Motor

kW: Fan Motor Rated Output (kW) FLA: Full Load Amps. (A)

9. Sound Levels

MCCU-12CN1

34

Page 35

Midea R410A 50Hz T1 Compressor Condensing Unit

Front

h

H

1 m

Model

Noise level

MCCU-22CN1

65 dB(A)

MCCU-28CN1

67 dB(A)

MCCU-35CN1

69 dB(A)

MCCU-45CN1

70 dB(A)

MCCU-53CN1

73 dB(A)

MCCU-61CN1

76 dB(A)

MCCU-70CN1

76 dB(A)

MCCU-105CN1

78 dB(A)

CCU-10N1(C)

CCU-11N1(C)

CCU-01N1(C)

Available CCU model

MCCU-03CN1

MCCU-05CN1

MCCU-07CN1

Thermal expansion

valve

Model

BAE 1 ZW195

BAE 1-1/2 ZW195

BAE 2 ZW195

Quantity 1 1

1

Filter drier

Model

DML032S 023Z5048

DML032S 023Z5048

DML033S 023Z5050

Quantity 1 1

1

Sight glasses

Model

SGP 6sN(014L0181)

SGP 6sN(014L0181)

SGP 10sN(014L0182)

Quantity 1 1

1

Electromagnetic valve

Model

EVR3-1/4-032F1206

EVR3-1/4-032F1206

EVR3 (032F1204)

Quantity 1 1

1

Electromagnetic valve

solenoid

Model

DCFXQ-018F6905

DCFXQ-018F6905

DCFXQ-018F6905

Quantity 1 1

1

Package size (mm)

400×215×290

400×215×290

400×215×290

Notes:

1. H=(h+1)/2m.

2. The sound pressure value is the weighted average of four sides which include front, rear, left and right

side of the unit.

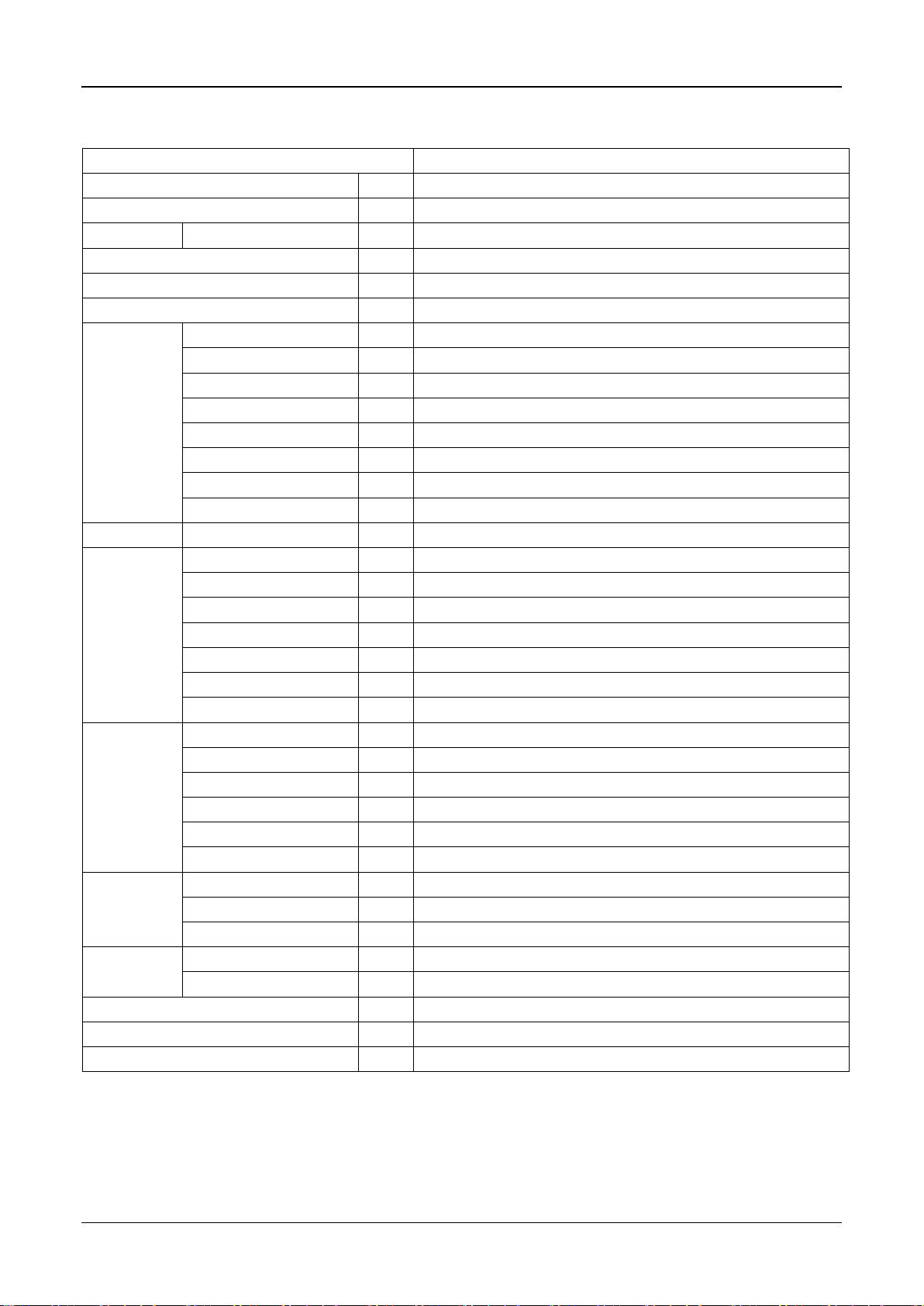

10. Connection accessory list (Optional)

35

Page 36

Midea R410A 50Hz T1 Compressor Condensing Unit

CCU-02N1(C)

CCU-03N1(C)

CCU-04N1(C)

Available CCU model

MCCU-10CN1

MCCU-16CN1

Thermal expansion

valve

Model

BAE 3 ZW195

TGEL4.5 067N3172

TGEL4.5 067N3172

Quantity 1 1

1

Filter drier

Model

DML033S 023Z5050

DML053S 023Z5054

DML053S 023Z5054

Quantity 1 1

1

Sight glasses

Model

SGP 10sN(014L0182)

SGP 10sN(014L0182)

SGP 10sN(014L0182)

Quantity 1 1

1

Electromagnetic valve

Model

EVR6 (032F1212)

EVR6 (032F1212)

EVR6 (032F1212)

Quantity 1 1

1

Electromagnetic valve

solenoid

Model

DCFXQ-018F6905

DCFXQ-018F6905

DCFXQ-018F6905

Quantity 1 1

1

Package size (mm)

400×215×290

400×215×290

400×215×290

CCU-05N1(C)

CCU-06N1(C)

CCU-07N1(C)

Available CCU model

MCCU-22CN1

MCCU-28CN1

MCCU-35CN1

Thermal expansion

valve

Model

TGEL6.5 067N3174

TGEL9 067N3176

TGEL13 067N3177

Quantity 1 1

1

Filter drier

Model

DML083S 023Z5058

GZGLQ-DML164S

GZGLQ-DML164S

Quantity 1 1

1

Sight glasses

Model

SGP 10sN(014L0182)

SGP 12sN(014L0183)

SGP 12sN(014L0183)

Quantity 1 1

1

Electromagnetic valve

Model

EVR6 (032F1212)

EVRH10 (032G1054)

EVRH10 (032G1054 )

Quantity 1 1

1

Electromagnetic valve

solenoid

Model

DCFXQ-018F6905

DCFXQ-018F6905

DCFXQ-018F6905

Quantity 1 1

1

Package size (mm)

400×215×290

400×215×290

400×215×290

CCU-08N1(C)

Available CCU model

MCCU-45CN1

MCCU-53CN1

MCCU-61CN1

Thermal expansion

valve

Model

TGEL13 067N3177

TGEL9 067N3176

TGEL9 067N3176

Quantity 1 2

2

Filter drier

Model

GZGLQ-DML165S

DML 305 FS

DML 305 FS

Quantity 1 2

2

Sight glasses

Model

SGP 16sI(014L0044)

SGP 12sN(014L0183)

SGP 12sN(014L0183)

Quantity 1 2

2

Electromagnetic valve

Model

EVRH15(032G1056)

EVR10(032F1217)

EVR10(032F1217)

Quantity 1 2

2

Electromagnetic valve

solenoid

Model

DCFXQ-018F6905

018F6251

018F6251

Quantity 1 2

2

Package size (mm)

400×215×290

290×265×226

290×265×226

MCCU-12CN1

T-KF530W/RN1.7

36

Page 37

Midea R410A 50Hz T1 Compressor Condensing Unit

Available CCU model

MCCU-70CN1

MCCU-105CN1

Thermal expansion

valve

Model

TGEL13 067N3177

TGEL15 067N3159

Quantity

2

2

Filter drier

Model

DML 305 FS

DML 305 FS

Quantity

2

2

Sight glasses

Model

SGP 12sN(014L0183)

SGP 16sN(014L0184)

Quantity

2

2

Electromagnetic valve

Model

EVR10(032F1217)

EVR10(032F1217)

Quantity

2

2

Electromagnetic valve

solenoid

Model

018F6251

018F6251

Quantity

2

2

Package size (mm)

290×265×226

290×265×226

T-KF700W/RN1.11 T-KF1050W/RN1.8

37

Page 38

Midea R410A 50Hz T1 Compressor Condensing Unit

Part. 2 Installation

1. Notes ............................................................................ 39

2. Transport and Fixed units ......................................... 40

3. Connection of Refrigerant Pipe ................................ 43

4. Heat Insulation of Refrigerant Pipe .......................... 54

5. Electric Connection .................................................... 54

6. Trial Run ...................................................................... 56

7. Trouble shooting ........................................................ 57

8. Maintenance ................................................................ 65

38

Page 39

Midea R410A 50Hz T1 Compressor Condensing Unit

1. Notes

CAUTION:

Install the unit where enough space of installation and maintenance is available.

Install the unit where the air inlet and outlet are not baffled and the least affected by external air.

Install the unit where it is easy to lead out the connective pipe and the drain pipe.

Install the unit where no heat is emitted from a heat source directly.

Installing the equipment in any of the following places may lead to faults of the equipment (if that

is inevitable, consult the supplier):

The site contains mineral oils such as cutting lubricant.

Seaside where the air contains much salt.

Hot ring area where corrosive gases exist, e.g., sulfide gas.

Factories where the supply voltage fluctuates seriously.

Inside a car or cabin.

Place like kitchen where oil permeates.

Place where strong electromagnetic waves exist.

Place where flammable gases or materials exist.

Place where acid or alkali gases evaporate, or other special environments.

Install the unit where enough space of installation and maintenance is available.

Install the unit where the air inlet and air outlet are free from obstacles and strong wind.

Install the unit in a dry and well ventilated place.

For side-discharge outdoor unit, the air outlet and inlet are not impeded, and cannot be reached

by strong wind.

Install the unit where the bearing surface is level and can bear weight of the unit, and is suitable

39

Page 40

Midea R410A 50Hz T1 Compressor Condensing Unit

for installing the unit horizontally without increasing noise or vibration.

Install the unit where the operation noise and the expelling of air do not affect neighbors.

Install the unit where no flammable gas is leaked.

Install the unit where it is convenient for pipe connection and electric connection.

2. Transport and Fixed units

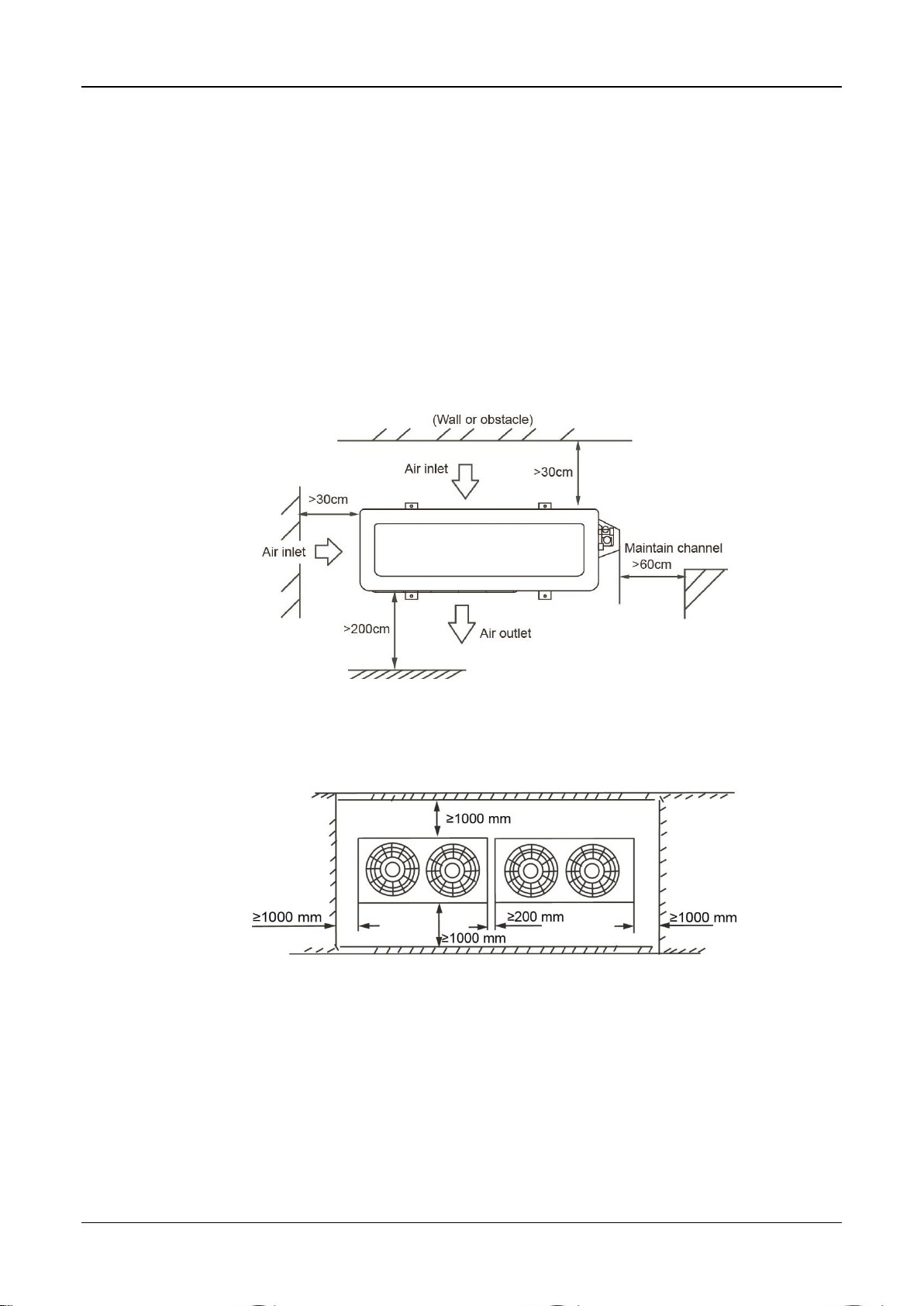

When installing the unit, leave a space for maintenance shown in the following figure. Install the

power supply at the side of the outdoor unit.

MCCU-03CN1, MCCU-05CN1, MCCU-07CN1, MCCU-10CN1, MCCU-12CN1, MCCU-16CN1:

In case any obstacles exist above the outdoor unit, such obstacles must be 600mm above the

outdoor unit.

MCCU-22CN1, MCCU-28CN1, MCCU-35CN1:

Top view of the outdoor unit (Multiple units installed)

In case any obstacles exist above the outdoor unit, such obstacles must be 2000mm above the

outdoor unit.

40

Page 41

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-45CN1, MCCU-53CN1, MCCU-61CN1, MCCU-70CN1, MCCU-105CN1:

In case any obstacles exist above the outdoor unit, such obstacles must be 2000mm above the

outdoor unit.

Use 4 steel ropes of a diameter 6mm or bigger size to hoist the outdoor unit and move it into the

site.

In order to prevent scratch and deformity the unit, apply a guard board to the surface between

the steel wire and the air conditioner.

Remove the cushion for use in the transport after finishing the transport.

The distance of the foundation bolt is shown in following picture.

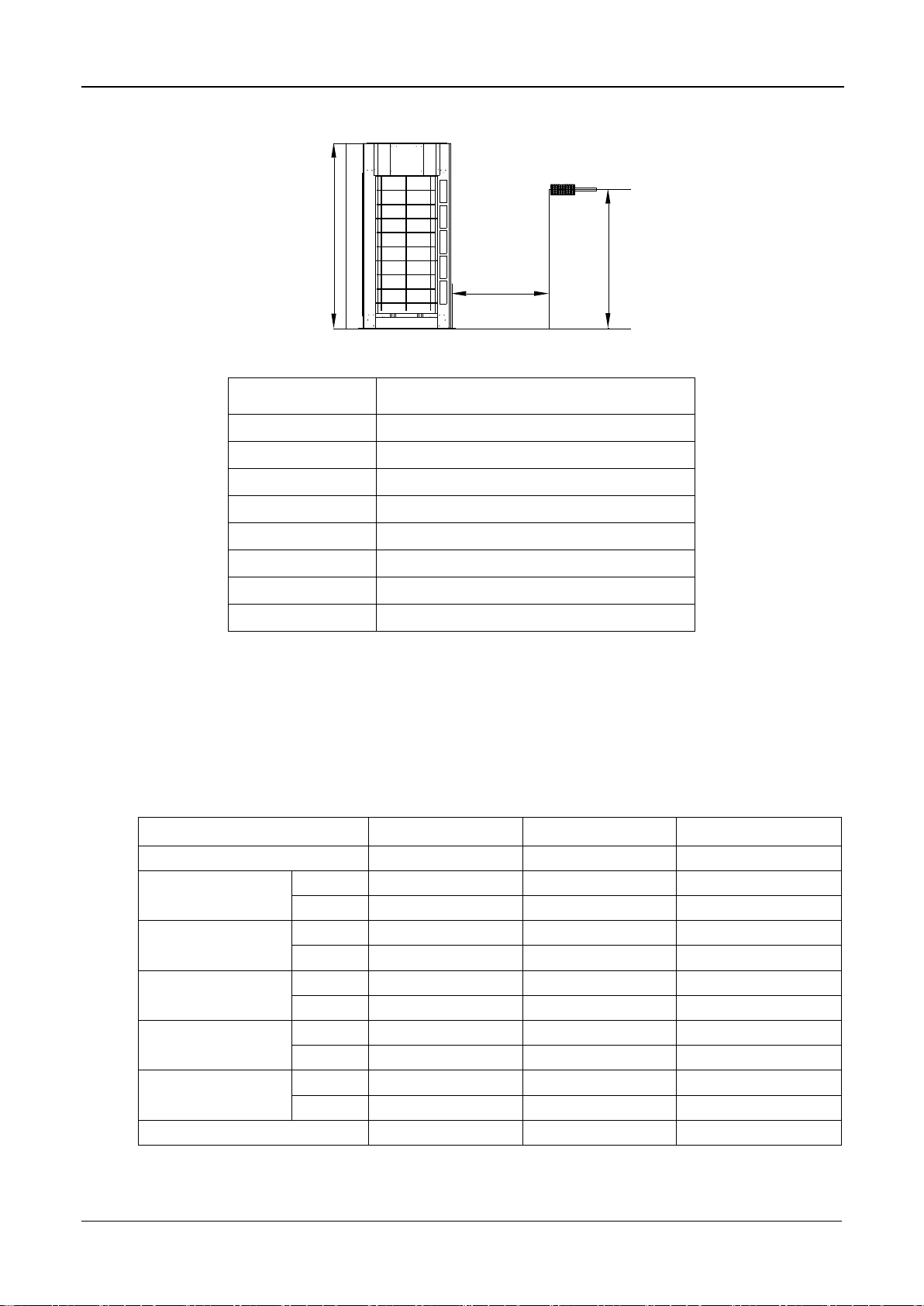

MCCU-03CN1, MCCU-05CN1, MCCU-07CN1, MCCU-10CN1, MCCU-12CN1, MCCU-16CN1:

41

Page 42

Midea R410A 50Hz T1 Compressor Condensing Unit

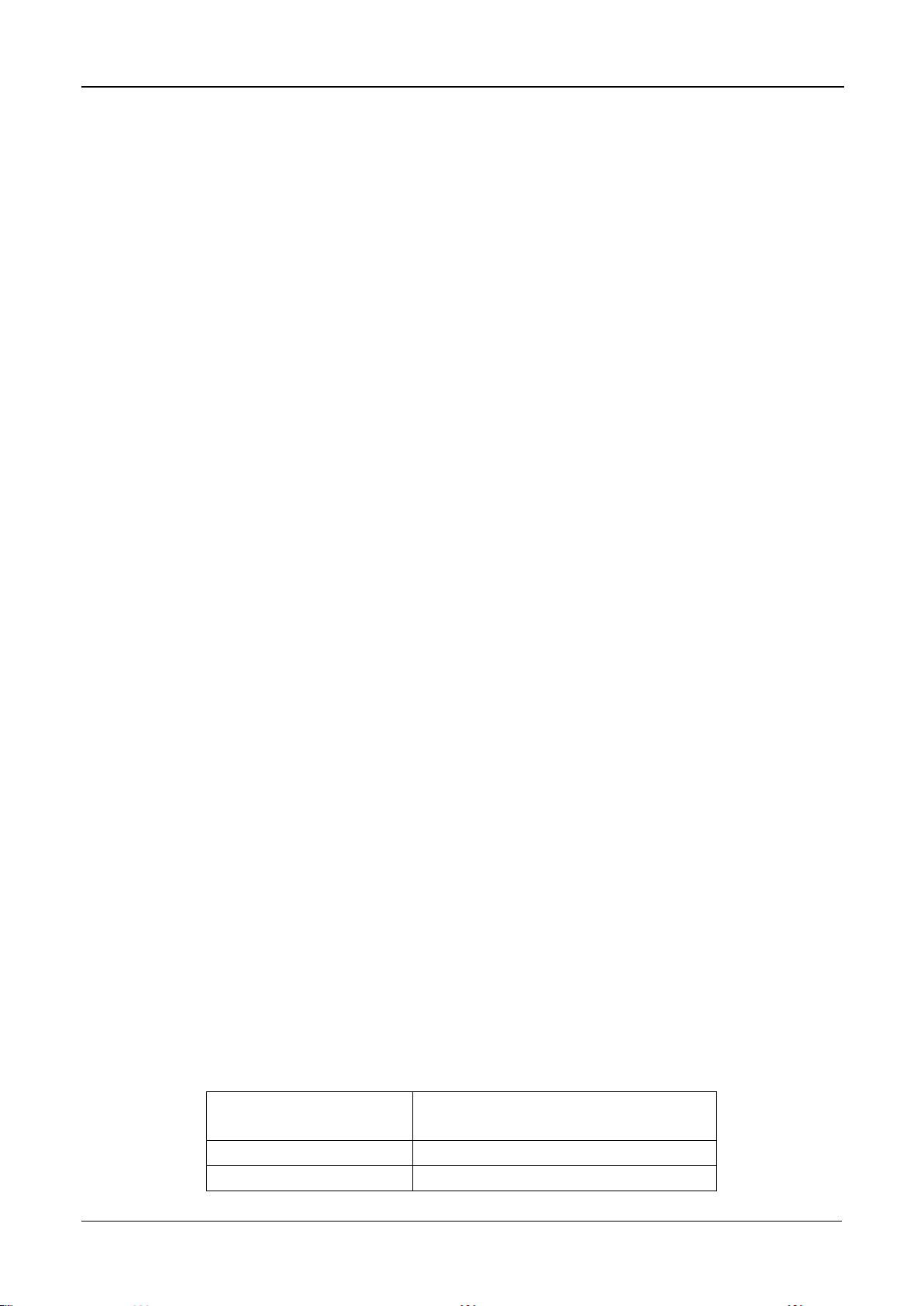

Model

W

W1

W2 D D1

MCCU-03CN1

780

845

123

300

276

MCCU-05CN1

760

530

117

315

290

MCCU-07CN1

843

560

142.4

360

335

MCCU-10CN1

990

624.4

186.3

396

362.9

900

590

129

400

378

MCCU-16CN1

900

590

129

400

378

MCCU-22CN1

1,260

762

249.3

700

676

MCCU-28CN1

1,260

762

249.3

700

676

MCCU-35CN1

1,260

762

249

700

676

MCCU-45CN1

1,250

1,120

64

765

736

MCCU-53CN1

1,825

1,568

129.5

899

635

MCCU-61CN1

1,825

1,568

129.5

899

635

MCCU-70CN1

2,158

1,872

143

1,082

774

MCCU-105CN1

2,158

1,872

143

1,082

774

MCCU-22CN1, MCCU-28CN1, MCCU-35CN1:

MCCU-45CN1, MCCU-53CN1, MCCU-61CN1, MCCU-70CN1, MCCU-105CN1:

MCCU-12CN1

(Unit: mm)

42

Page 43

Midea R410A 50Hz T1 Compressor Condensing Unit

Snow protection facilities must be installed in the snowfall areas. In order to prevent influence

caused by snow, set up raised pavilion, and install snow protection sheds at the air inlet and air

outlet. The snow protection facilities are provided in the site.

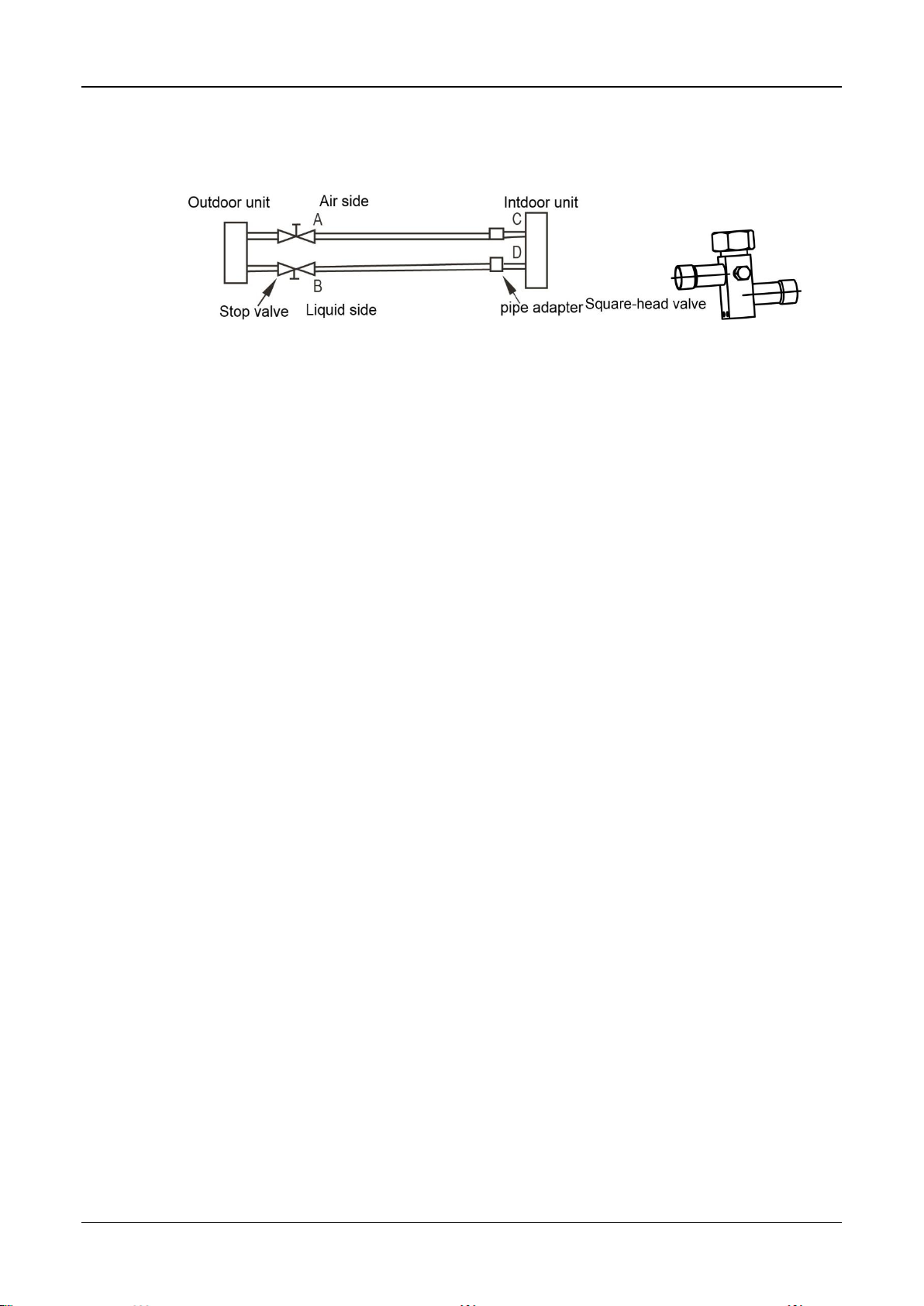

3. Connection of Refrigerant Pipe

Schematic diagram of connection between indoor unit and outdoor unit:

MCCU-03CN1, MCCU-05CN1, MCCU-07CN1, MCCU-10CN1:

MCCU-12CN1, MCCU-16CN1:

43

Page 44

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-22CN1, MCCU-28CN1, MCCU-35CN1, MCCU-45CN1:

MCCU-53CN1, MCCU-61CN1, MCCU-70CN1, MCCU-105CN1:

The refrigerant pipe adapter is located inside the outdoor unit. So remove the right front board

first.

When the pipe is connected from the front side, the pipe can be led out through the right front

board.

The units which capacities are 53kW, 61kW, 70kW and 105kw have two separate systems, so

please mark the system codes, and correctly connect the pipes of each system.

When welding the refrigerant pipe, in order to prevent internal oxidation of the pipe, nitrogen

44

Page 45

Midea R410A 50Hz T1 Compressor Condensing Unit

Liquid pipe

Gas pipe

MCCU-03CN1

Φ6.35mm

Φ12.7mm

Single pipe

MCCU-05CN1

Φ6.35mm

Φ12.7mm

Single pipe

MCCU-07CN1

Φ9.52mm

Φ12.7mm

Single pipe

MCCU-10CN1

Φ19mm

Φ9.52mm

Single pipe

Φ19mm

Φ9.52mm

Single pipe

MCCU-16CN1

Φ19mm

Φ9.52mm

Single pipe

MCCU-22CN1

Φ9.52mm

Φ22mm

Single pipe

MCCU-28CN1

Φ9.52mm

Φ25mm

Single pipe

MCCU-35CN1

Φ12.7mm

Φ28.6mm

Single pipe

MCCU-45CN1

Φ16mm

Φ32mm

Single pipe

MCCU-53CN1

Φ12.7mm

Φ25mm

Double pipes

MCCU-61CN1

Φ12.7mm

Φ25mm

Double pipes

MCCU-70CN1

Φ12.7mm

Φ25mm

Double pipes

MCCU-105CN1

Φ12.7mm

Φ25mm

Double pipes

must be filled in. Otherwise, the oxidized chips may block refrigerating circulatory system.

Trash and foreign matters may come into the pipe in the process of installing the refrigerant pipe.

Be sure to blow them off with nitrogen before connecting the pipe to the outdoor units.

Use high-pressure nitrogen to clean the pipelines. Do not use the refrigerant of the outdoor unit

for cleaning.

Pipes size of the units.

MCCU-12CN1

All connections between indoor unit and outdoor unit are copper-to copper and should be brazed

with a phosphorous-copper alloy material such as Silfos-5 or equivalent. Do not use soft solder.

The outdoor units have reusable valves on both the liquid and vapor connections. The total

system refrigerant charge is retained within the outdoor unit during shipping and installation. The

reusable valves are provided to evacuate and charge per the instruction.

Dry nitrogen should always be supplied through the tubing while it is being brazed, because the

temperature required is high enough to cause oxidation of the copper unless an inert

atmosphere is provided. The flow of dry nitrogen should continue until the joint has cooled.

Always use a pressure regulator and safety valve to insure that only low pressure dry nitrogen is

introduced into the tubing. Only a small flow is necessary to displace air and prevent oxidation.

Install the connective pipe only after fixing the indoor unit and outdoor unit. Keep dry when

installing the connective pipe. Do not let moist intrude into the pipeline system.

The bending angle of refrigerant should not exceed 90°. Bending position is preferably in the

45

Page 46

Midea R410A 50Hz T1 Compressor Condensing Unit

MCCU-03CN1, MCCU-05CN1, MCCU-07CN1:

Allowed value

Max. actual length of pipe (L)

20m

Max. height difference between

indoor and outdoor unit

Outdoor unit (upper)

10m

Outdoor unit lower (lower)

10m

middle of the bendable pipe. Do not bend the pipe more than three times.

Be sure to use the same insulation materials when you buy the brass pipe.

Bend the tubing in proper way. Do not twist the pipe.

Put some refrigerant oil on the surfaces of the flare pipe and the joint nuts when wrench it for 3~4

rounds with hands before fasten the flare nuts.

Drill a hole in the wall (suitable just for the size of the wall sleeve), then set on the fittings such as

the wall sleeve and its cover.

Bind the connecting pipe and cables together tightly with binding tapes. Pass the bound

connecting pipe through the wall sleeve from outside. Make sure of the pipe allocation not to

damage the copper tubes.

Allowed length of refrigerant pipe and height difference.

MCCU-03CN1, MCCU-05CN1, MCCU-07CN1,

MCCU-10CN1, MCCU-12CN1, MCCU-16CN1:

46

Page 47

Midea R410A 50Hz T1 Compressor Condensing Unit

Allowed value

Max. actual length of pipe (L)

30m

Max. height difference between

indoor and outdoor unit

Outdoor unit (upper)

20m

Outdoor unit lower (lower)

20m

Allowed value

Max. actual length of pipe (L)

50m

Max. height difference between

indoor and outdoor unit

Outdoor unit (upper)

30m

Outdoor unit lower (lower)

25m

Max. number of bends

15

MCCU-10CN1, MCCU-12CN1, MCCU-16CN1:

Notes: The number of bends is up to the length of the Max. height drop. Usually for each 10m need a

bend. (It is only available for the units below 16kW.)

MCCU-22CN1, MCCU-28CN1, MCCU-35CN1, MCCU-45CN1,

MCCU-53CN1, MCCU-61CN1, MCCU-70CN1, MCCU-105CN1:

Do not increase or decrease piping sizes.

As shown in following picture, when brazing the indoor and outdoor connective lines, pad a

sheet metal under the valve avoids the flame burning the chassis.

Precaution should be taken to prevent heat damage to the valve by wrapping a wet rag around it.

Remove the cap and Schrader core from both the liquid and vapor service valve service ports at

47

Page 48

Midea R410A 50Hz T1 Compressor Condensing Unit

Pipe gauge

Tightening torque

Flare dimension A

Flare shape

N.m

Kgf.cm

Min.

Max.

Φ6.35mm

14.2~17.2

144~176

8.3mm

8.7mm

Φ9.52mm

32.7~39.9

333~407

12.0mm

12.4mm

Φ12.7mm

49.5~60.3

504~616

15.4mm

15.8mm

Φ16mm

61.8~75.4

630~770

18.6mm

19.0mm

Φ19mm

97.2~118.6

990~1,210

22.9mm

23.3mm

the outdoor unit. Connect low pressure nitrogen to the liquid line service port.

Braze the liquid line to the high pressure valve (liquid valve) at the outdoor unit. Be sure to wrap

the valve body with a wet rag. Allow the nitrogen to continue flowing.

Carefully remove the rubber plugs from the evaporator liquid and vapor connections at the

indoor unit.

Braze the liquid line to the indoor liquid connection. Nitrogen should be flowing through the

evaporator coil.

Slide the plastic cap away from the vapor connection at the indoor coil. Braze the vapor line to

the evaporator vapor connection.

Too large torque will harm the bell mouthing and too small will cause leakage. Please determine

the torque according to the following table:

Protect the vapor valve with a wet rag and braze the vapor line connection to the outdoor unit.

Replace the Schrader core in the liquid and vapor valves.

Leak test all refrigerant piping connections including the service port flare caps to be sure they

The nitrogen flow should be exiting the system from the vapor service port connection. After this

connection has cooled, remove the nitrogen source from the liquid fitting service port.

are leak tight.

48

Page 49

Midea R410A 50Hz T1 Compressor Condensing Unit

Length of connective pipe

(Single pass)

Procedure of expelling air

Less than 5m

Use refrigerant in the outdoor unit.

5~15m

Use vacuum pump or refrigerant tank.

Do not over tighten. (between 40 and 60 inch-lbs. maximum)

Evacuate the vapor line, evaporator and the liquid line, to 500 microns or less.

Replace cap on service ports. Do not remove the flare caps from the service ports except when

necessary for servicing the system.

Do not connect manifold gauges unless trouble is suspected. Approximately 3/4 ounce of

refrigerant will be lost each time a standard manifold gauge is connected.

Release the refrigerant charge into the system. Open both the liquid and vapor valves by

removing the plunger cap and with a hex wrench back out counter-clockwise until valve stem

just touches the chamfered retaining wall.

Replace plunger cap finger tight, then tighten an additional 1/12 turn (1/ hex flat). Cap must be

replaced to prevent leaks.

Never attempt to repair any brazed connections while the system is under pressure. Personal

injury could result.

After the pipes between the indoor unit and the outdoor unit are connected, replenish

compressed nitrogen to perform airtight test.

The airtight test is performed by using the compressed nitrogen, 2.94MPa (30kg/cm2G).

Leak test with a bubble type leak detector. Do not use the system refrigerant in the outdoor

unit to purge or leak test.

Tighten the spool of the low pressure valve and high pressure valve before compressing the

nitrogen.

Compress the nitrogen at the air vent of the gas valve.

The low pressure valve and high pressure valve are closed in the process of compressing

the nitrogen.

Do not use oxygen, flammable gas or toxic gas in the airtight test.

Vacuum

49

Page 50

Midea R410A 50Hz T1 Compressor Condensing Unit

Note: If the air conditioner is relocated, be sure to use a vacuum pump or refrigerant tank to expel air.

Use the refrigerant in the outdoor unit to expel air.

Screw up the pipe nuts at A, B, C and D completely.

Loosen and remove the square-head cover of valves A and B, rotate the square-head

spool of valve B counter-clockwise for 45 degrees and stay for about 10 seconds, and

then close the spool of valve B tightly.

Detect leak for all adapters at A, B, C and D. After making sure that no leak exists, open

the maintenance orifice nut of valve A. After all air is expelled, tighten the maintenance

orifice nut of valve A.

Open the spools of valves A and B completely.

Tighten the square-head cover of valves A and B completely.

Use refrigerant tank to expel air.

Screw up the pipe nuts at A, B, C and D completely.

Loosen and remove the square-head cover and maintenance orifice nut of valves A

and B.

Connect the filler hose of refrigerant tank with the maintenance orifice of valve A.

Loosen the valve of the refrigerant tank, continue filling refrigerant for 6 seconds to

expel the air, and tighten the nut of valve B quickly.

Loosen the valve of the refrigerant tank again, and fill the refrigerant for 6 seconds.

Detect leak for all adapters at A, B, C and D. After making sure that no leak exists,

screw off the filler hose. After all the filled refrigerant is expelled, screw up the

maintenance orifice nut of valve A quickly.

Open the square-head pools of valves A and B completely.

Tighten the square-head cover of valves A and B.

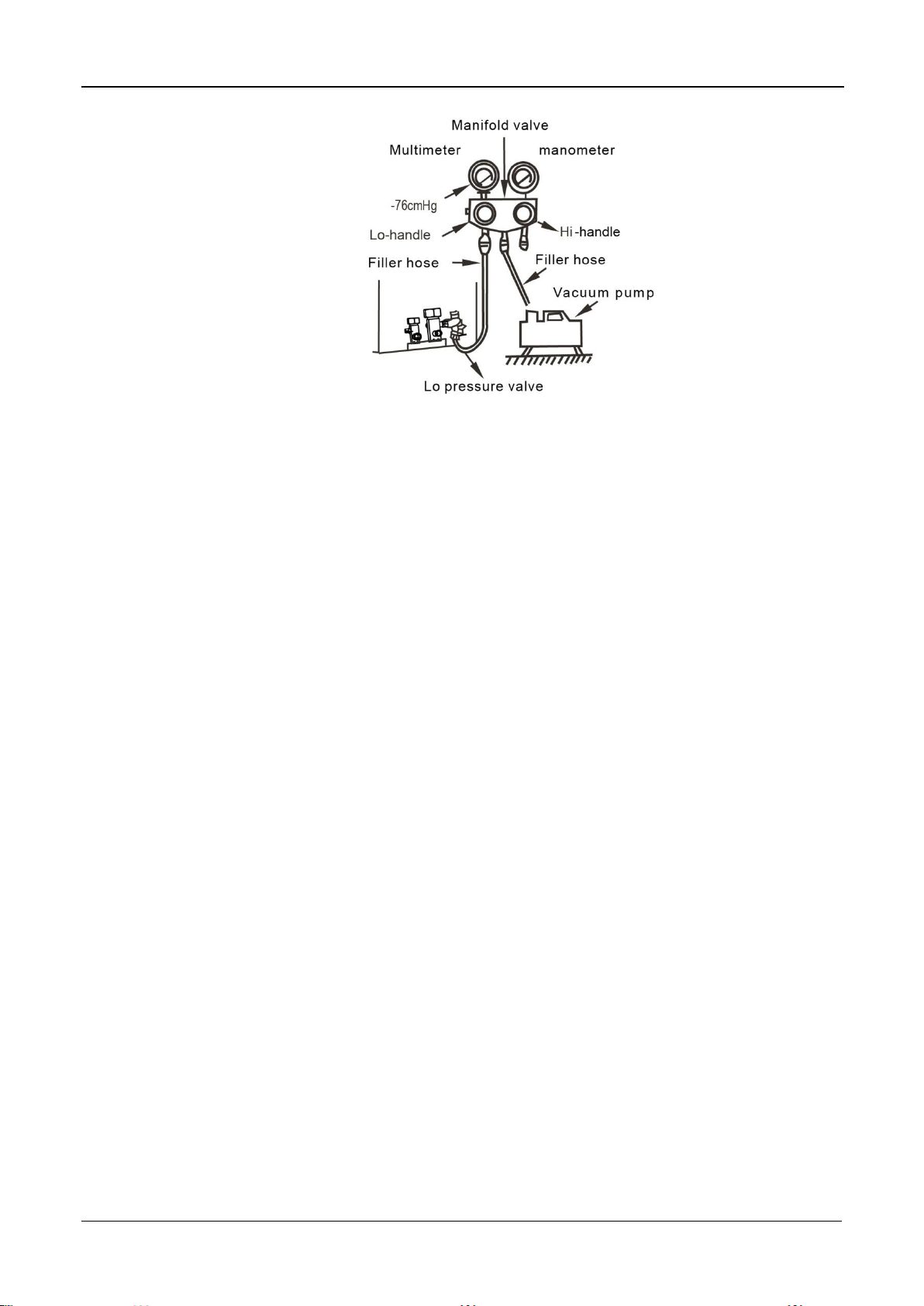

Use a vacuum pump

50

Page 51

Midea R410A 50Hz T1 Compressor Condensing Unit

Loosen and remove the maintenance orifice nut of valve A, and connect the filler hose

of the manifold valve to the maintenance orifice of valve A (Tighten both valve A and

valve B).

Connect the filler hose adapter to the vacuum pump.

Open the low (Lo) pressure handle of the manifold valve completely.

Start the vacuum pump to extract air. At the beginning of extracting air, slightly loosen

the maintenance orifice nut of valve B, check whether any air enters it (The vacuum

pump noise changes, and the multi-meter indicates from negative to 0.). Then tighten

this maintenance orifice nut.

Upon completion of vacuuming, tighten the low pressure handle of the manifold valve

completely and stop the vacuum pump. Keep extracting air for over 15 minutes. Check

whether the multi-meter points at -1.0×10Pa (-76cmHg).

Loosen the remove the square-head cover of valves A and B. After opening valves A

and B completely, tighten the square-head cover of valves A and B.

Remove the filler hose of the maintenance orifice of valve A, and then tighten the nut.

Procedure of using stop valve

51

Open the spool until it touches the stop block. Do not attempt to open further.

Use a spanner or a similar tool to tighten the bonnet.

Upon completion of installation, open all valves before trial run. Each unit has two valves of

different sizes located at the outdoor unit side. Of the two valves, one is gas valve and the

other is liquid valve. The procedure of opening / closing the valve is shown in following

picture.

Page 52

Midea R410A 50Hz T1 Compressor Condensing Unit

Diameter of liquid-side pipe

Quantity of refrigerant replenished

for 1m pipe length

Φ6.35mm

0.022kg

Φ9.52mm

0.06kg

Φ12.7mm

0.12kg

Φ16mm

0.18kg

Procedure of opening the valve: Open the square-head cover, use a spanner to capture the

square head and open it thoroughly. Then tighten the square-head cover.

Procedure of closing the valve: Same as the procedure of opening the valve, but rotate the

spanner clockwise thoroughly.

After vacuum, according to the diameter and length of the connective pipe of liquid side between

the indoor unit and outdoor unit, calculate the refrigerant replenishment quantity. The refrigerant

for replenishment is R410A.

Notes:

Please check and record the replenished quantity of the air conditioner.

Refrigerant leak precautions. This air conditioner uses refrigerant R410A. R410A is safe

refrigerant which is harmless and non-flammable. The room for placing the air conditioner should

have a proper space. Even if refrigerant leakage occurs, the density threshold will not be

crossed. Additional measures may also be taken.

Density threshold: Density of the Freon gas that does not harm the human body. Density

threshold of R410A: 0.3kg/m3.

Calculate the total quantity of refrigerant to be replenished [A (kg)].

Total refrigerant quantity = refrigerant replenishment quantity upon shipment + additional

refrigerant replenishment corresponding to the pipe length.

52

Page 53

Midea R410A 50Hz T1 Compressor Condensing Unit

Calculate out the indoor volume [B (m3)] (according to the minimum volume)

Calculate out the refrigerant density:

[A (kg)] / [B (m3)] ≤ Density threshold: 0.3kg/m

3

Measures against crossing of the refrigerant density threshold.

In order to keep the refrigerant density below the threshold value, please install a mechanic

ventilation device. (Perform ventilation often.)

In case frequent ventilation is impossible, please install the leakage detection alarm device

linked with the mechanical ventilation device.

53

Page 54

Midea R410A 50Hz T1 Compressor Condensing Unit

4. Heat Insulation of Refrigerant Pipe

In order to prevent faults caused by condensate of the refrigerant pipe and drain pipe, perform

condensate prevention and heat insulation properly. If it is forecast that high humidity and

temperature environment (Condensate temperature is over 23°C ) may exist in the ceiling, e.g., inside

the ceiling with slab, ceiling which is in the same environment as the outdoor air. It is necessary to

apply 10mm or thicker adiabatic wool (16~20kg/m2) to the refrigerant pipe and the drain pipe in

addition to applying the general heat insulation materials. Enough heat insulation materials should

also be applied to the refrigerant joint and the pipe joint.

Note: the heat insulation of drain pipe refer to the installation of indoor unit.

Please use heat-resistant materials as heat insulation material of the air-side pipe. (e.g., EPT)

Cover heat insulation materials separately at the liquid side and the air side. Moreover, perform

heat insulation thoroughly for the air-side pipes of the indoor unit, and prevent water from

dripping outside the unit.

After applying the auxiliary heat insulation materials, use vinyl resin tape to seal refrigerant pipe

and drainage pipe to prevent water leak.

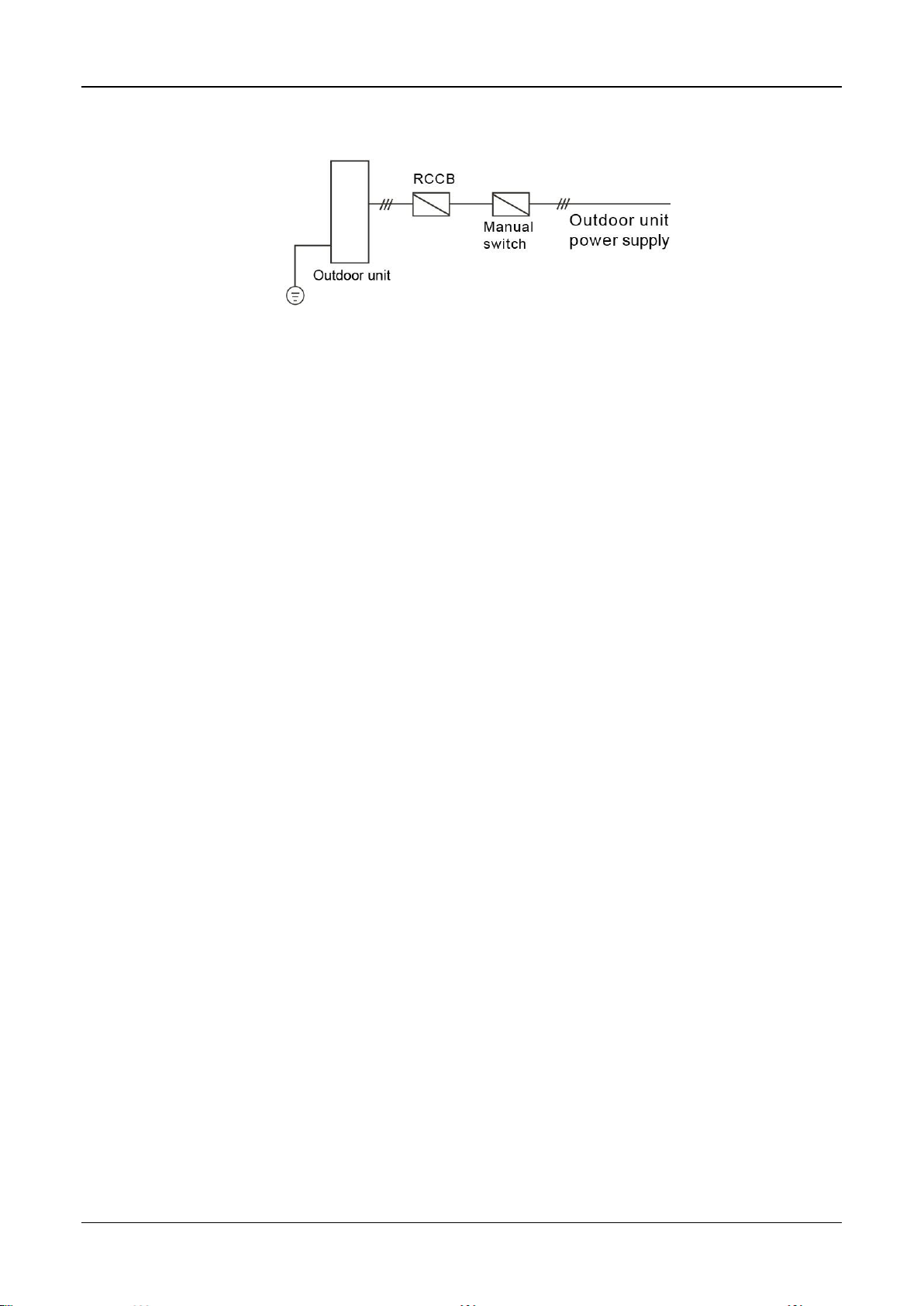

5. Electric Connection

5.1 Caution

Use special power supply for the air conditioner. Design power supplies specific to the indoor

unit and outdoor unit. The supply voltage must comply with the nominal voltage.

The external supply circuit of the air conditioner must have a ground wire, and the power supply

ground wire of the indoor unit must be connected with the external ground wire firmly.

The wiring must be performed by professional technicians according to the circuit diagram

labels.

Distribute the wires according to the relevant electric technical standards promulgated by the

State, and set the Residual Current-operated Circuit Breaker (RCCB) properly.

54

Page 55

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

Power

Switch capacity of

the main power

supply / Fuse

Power cable

Connective wire

of indoor

&outdoor unit

MCCU-03CN1

220-240V~,

1Ph, 50Hz

20A/16A

2×2.5mm2+1×1.5mm2

\

MCCU-05CN1

30A/20A

2×4.0mm2+1×2.5mm2

MCCU-07CN1

40A/30A

2×6.0mm2+1×4.0mm2

1×1.0mm2

MCCU-10CN1

380-415V~,

3Ph, 50Hz

25A/20A

4×4.0mm2+1×2.5mm

2

25A/20A

4×4.0mm2+1×2.5mm

2

MCCU-16CN1

45A/35A

4×10.0mm2+1×6.0mm

2

MCCU-22CN1

380-415V~,

3Ph, 50Hz

60A/40A

5×6.0mm

2

2×1.0mm

2

MCCU-28CN1

60A/40A

5×6.0mm

2

MCCU-35CN1

380-400V~,

3Ph, 50Hz

60A/40A

5×6.0mm

2

MCCU-45CN1

380-415V~,

3Ph, 50Hz

70A/50A

5×15.0mm

2

MCCU-53CN1

380-400V~,

3Ph, 50Hz

80A/60A

4×16mm2+1×10mm2

2×1.0mm2

MCCU-61CN1

90A/70A

4×25mm2+1×16mm2

MCCU-70CN1

100A/80A

4×25mm2+1×16mm2

MCCU-105CN1

120A/100A

4×35mm2+1×16mm2

The power wire and the signal wire shall be laid out neatly and properly, without mutual

interference or contacting the connection pipe or valve.

No power cable is attached to this equipment. The user can select the power cable by reference

to the stipulated power supply specifications. No joint of wires is allowed.

Upon completion of wire connection, double check it and then connect the power supply.

An all-pole disconnection device which has at least 3mm separation distance in all pole and a

residual current device (RCD) with the rating of above 10mA shall be incorporated in the fixed

wiring according to the national rule.

The appliance shall be installed in accordance with national wiring regulations.

In order to prevent disoperation of the air conditioner, do not interleave or entwine the power

cable with the connection wires (Low-voltage wires) of the indoor and outdoor unit.

5.2 Specifications of power supply

MCCU-12CN1

55

Page 56

Midea R410A 50Hz T1 Compressor Condensing Unit

5.3 Schematic diagram

5.4 Electric wire diagram

When connect the wire, pay attention to the phase sequence of the power supply. If the phase

sequence is reversed, the compressor will not start. Meanwhile, the fault indicator of the outdoor

electric control board will light up. After shifting the phase sequence, power on the unit until the

fault indicator goes out and the compressor starts up normally.

6. Trial Run

Please conduct in accordance with the nameplate of Trial Run Tenor on the electric control box.

Perform the trial run only after the outdoor unit has been powered on for over 12 hours.

Check whether all valves are opened before trial run.

Check the electric safety before trial run.

Do not perform compulsory operation in any way, because it is very dangerous if the protection

device is not active.

Perform trial run only after all installations are finished.

Confirm the following issues before trial operation:

Whether the indoor and outdoor units are installed properly.

Whether the refrigerant pipeline system is inspected for leakage.

Whether the drain is smooth of CCU.

Whether the heat insulation of pipeline system is perfect.

Whether the ground cable is connected correctly.

Whether the pipe length and the refrigerant amount are recorded.

Whether the supply voltage is equal to the voltage of unit.

Whether the liquid and gas valves are opened.

56

Page 57

Midea R410A 50Hz T1 Compressor Condensing Unit

Symptom

Possible causes

Way of handing

The cooling effect is

poor.

The condenser or evaporator is

too dirty, or block.

Clean the heat-exchanger. Remove

foreign matters to keep well ventilated.

The door or window is opened.

Close all the windows and doors.

Directly exposed to sunlight.

Obstruct sunlight by curtains or

jalousie.

Too many heat sources.

Reduce heat sources.

Too high outdoor environment

temperature.

It is normal, and the cooling effect of the

air conditioner is deteriorated.

The refrigerant is leaked or the

replenishment is deficient.

Detect leak, and fill the refrigerant of a

correct quantity.

Symptom

Possible causes

Way of handing

The system does

not run.

Power supply fails.

Operate it after power supply resumes

and connect the power supply properly.

Power switch is disconnected.

The fuse blows out or the circuit

breaker acts.

Replace the fuse or check whether

electric leakage occurs.

The Indoor unit

sends air out without

cool air.

3-minutes protection of the

compressor.

Waiting for 3 minutes.

7. Trouble shooting

7.1 Phenomena not attributable to faults of air conditioner

The system does not run.

It does not run immediately because the safety device in the system is active to prevent

overload.

Three minutes later, the air conditioner compressor will run automatically.

7.2 Faults of air conditioner and cause

If any of the following exceptions occur, operation of the air conditioner will be immediately

stopped. Turn off the power switch, and check it.

The fuse blows out frequently, or the circuit breaker protection occurs frequently.

Foreign substance or moist enters the air conditioner or other exceptions occur.

If the air conditioner fails but does not meet the foregoing phenomena obviously, check the

system in the following procedure:

57

Page 58

Midea R410A 50Hz T1 Compressor Condensing Unit

Type

LED1

LED2

LED3

Phase sequence protection

★

◇

◇

Lack of phase (Phase A or B)

★

◇

◇

Lack of phase (Phase C)

◇

◇

◇

Protection of low pressure

★

★

◇

Protection of over-current

◇

◇

★

Communication failure

★ ◇ ★

Outdoor condenser Temp. sensor error

◇

★

★

Outdoor ambient Temp. sensor error

◇

★

◇

Protection of condenser hi-temp.

★ ★ ★

Type

LED1

LED2

Phase sequence protection

◆

●★

Communication failure

◆

●●★

Outdoor condenser Temp. sensor error

◆

●●●★

Outdoor ambient Temp. sensor error

◆

●●●●★

Protection of low pressure

◇

●★

Protection of high pressure

◇

●●★

Protection of over-current

◇

●●●★

Protection of condenser hi-temp.

◇

●●●●★

7.3 Outdoor unit malfunction and protection codes

MCCU-10CN1, MCCU-12CN1, MCCU-16CN1:

Notes:

★: Flash

◇: Extinguish;

MCCU-22CN1, MCCU-28CN1, MCCU-35CN1:

Notes:

☆: Light for 1 second, extinguish for 1 second;

◆: Light;

◇: Extinguish;

●: Light for 0.4 second, extinguish for 0.4 second;

★: Light for 2 second, extinguish for 2 second.

58

Page 59

Midea R410A 50Hz T1 Compressor Condensing Unit

Type

LED1

LED2

Phase sequence or lack of phase.

●

☆★

Communication error.

●

☆☆★

Condenser temperature sensor error.

●

☆☆☆★

Ambient temperature sensor error

●

☆☆☆☆★

System low pressure protection.

O

☆★

Three times low pressure protections within 1 hour.

☆

☆★

System hi-pressure protection, hi-temperature protection

of compressor discharger.

O

☆☆★

Current overload protection.

O

☆☆☆★

High temperature protection of condenser.

O

☆☆☆☆★

Type

LED1

LED2

Phase sequence or lack of phase.

☆

☆

Condenser temperature sensor error.

☆5/3S

Low temperature protection of suction, system A.

☆1/3S

O

Fault of suction temperature sensor, system A.

☆2/3S

O

Discharge temperature or hi-pressure protection, system A.

☆3/3S

O

Low pressure protection, system A.

☆4/3S

O

Current over-load protection, system A.

☆6/3S

O

Low temperature protection of suction, system B.

O

☆1/3S

Fault of suction temperature sensor, system B.

O

☆2/3S

Discharge temperature or hi-pressure protection, system B.

O

☆3/3S

Low pressure protection, system B.

O

☆4/3S

Current over-load protection, system B.

O

☆6/3S

MCCU-45CN1:

Notes:

●: Light ○: Extinguishing ☆: Rapidly flash ★:Slowly flash

When the outdoor unit protections of temperature or system pressure are triggered three times within 1

hour, the unit will resume after power on again.

MCCU-53CN1, MCCU-61CN1, MCCU-70CN1, MCCU-105CN1:

Notes:

○: Extinguishing ☆: Rapidly flash

☆1/3S: Rapidly flash1 times, and then stop for 3 seconds.

☆2/3S: Rapidly flash2 times, and then stop for 3 seconds.

59

Page 60

Midea R410A 50Hz T1 Compressor Condensing Unit

☆3/3S: Rapidly flash3 times, and then stop for 3 seconds.

☆4/3S: Rapidly flash4 times, and then stop for 3 seconds.

☆5/3S: Rapidly flash5 times, and then stop for 3 seconds.

☆6/3S: Rapidly flash 6 times, and then stop for 3 seconds.

If a system has error or protection, another one will be stopped operation after 1 hour. If two systems

have error or protection at the same time, then only system A will be display the codes.

Phase sequence or lack of phase

Condenser temperature sensor error

60

Page 61

Midea R410A 50Hz T1 Compressor Condensing Unit

Low temperature protection of suction

Fault of suction temperature sensor

61

Page 62

Discharge temperature protection

Midea R410A 50Hz T1 Compressor Condensing Unit

62

Page 63

Midea R410A 50Hz T1 Compressor Condensing Unit

Hi-pressure protection

63

Page 64

Low pressure protection

Midea R410A 50Hz T1 Compressor Condensing Unit

64

Page 65

Midea R410A 50Hz T1 Compressor Condensing Unit

Model

MCCU-10CN1

MCCU-16CN1

Ir

8.7A×2

8.7A×2

10A×2

Model

MCCU-22CN1

MCCU-28CN1

MCCU-35CN1

MCCU-45CN1

Ir

26A

28A

30A

26A

Model

MCCU-53CN1

MCCU-61CN1

MCCU-70CN1

MCCU-105CN1

Ir

23A

28A

30A

37A

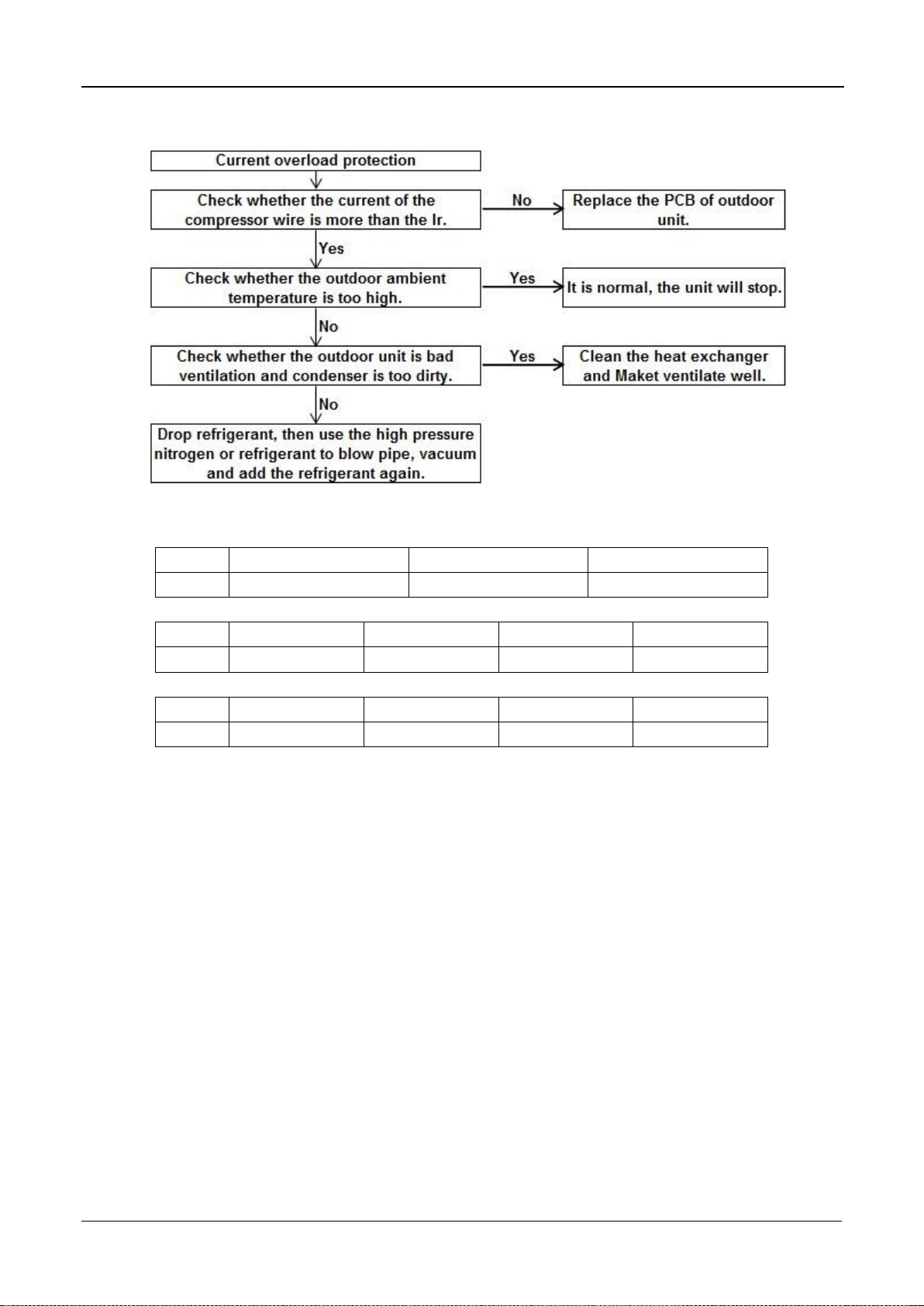

Current overload protection

Notes:

8. Maintenance

Operation required before leaving the unit idle for a long period.

When the main power switch is turned on, a certain extent of electric power is

consumed even if the air conditioner does not run. Turning off the main power switch

can save energy.

MCCU-12CN1

65

After the air conditioner has been in service for several seasons, foreign substance

accumulates inside the unit to an extent dependent on the working conditions.

Therefore, shut down the air conditioner and cut off the power supply.

Startup after a long period out of service.

Check the following issues:

Check whether the air inlet or outlet of the unit is blocked. Remove foreign substance if

Page 66

Midea R410A 50Hz T1 Compressor Condensing Unit

any.

Check whether the ground wire is connected properly.

Check whether the insulation work of refrigerant circuit and ventilating duct is on sound

status.

Check whether the installing seat is corroded or rusted.

Startup

Connect the indoor unit 12 hours after connect the outdoor unit to power supply.

Maintenance and upkeep of outdoor unit

The edge of some sheet metal assemblies and the fin of the condenser are very sharp.

Incorrect operation may cause harm. Be cautious when cleaning them up.

Check the air inlet and outlet of the outdoor unit periodically to see whether they are

blocked by stain or lampblack.

66

Page 67

Midea R410A 50Hz T1 Compressor Condensing Unit

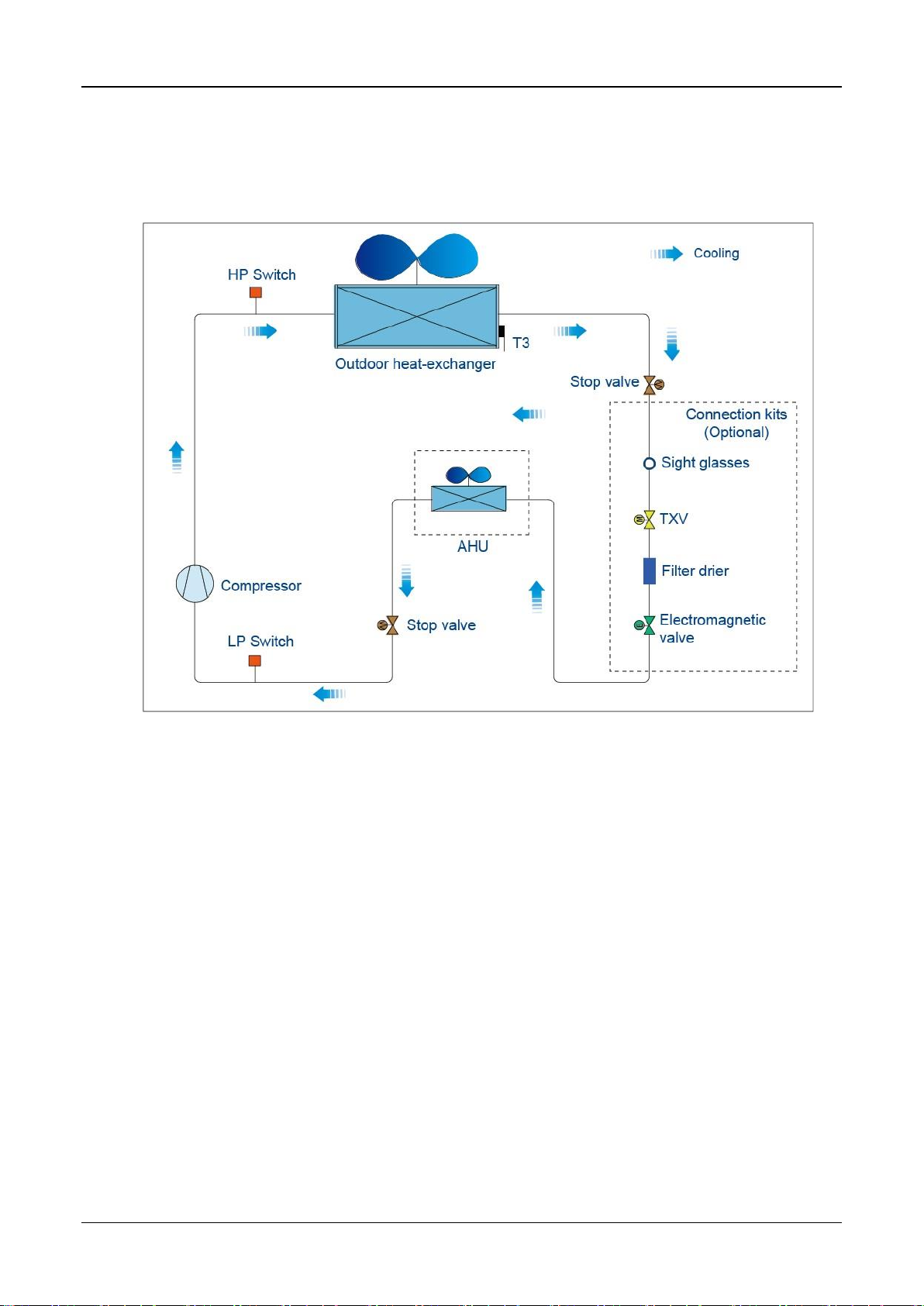

Appendix: VRF Solution

Midea VRF units also have another solution of DX AHU applications, through the AHU connection kit.

The AHU connection kit is consisted of controller, EXV (electronic expansion valve), distributor and

sensor, the external appearance as the following picture:

Midea VRF units totally have6 standard models: 25.2kW, 28kW, 33.5kW, 40kW, 45kW and 50kW.

They can be freely combined to achieve larger capacities, and the largest capacity could reach

180kW. VRF units adopt DC inverter compressor or digital scroll compressor, adjustable output to fit

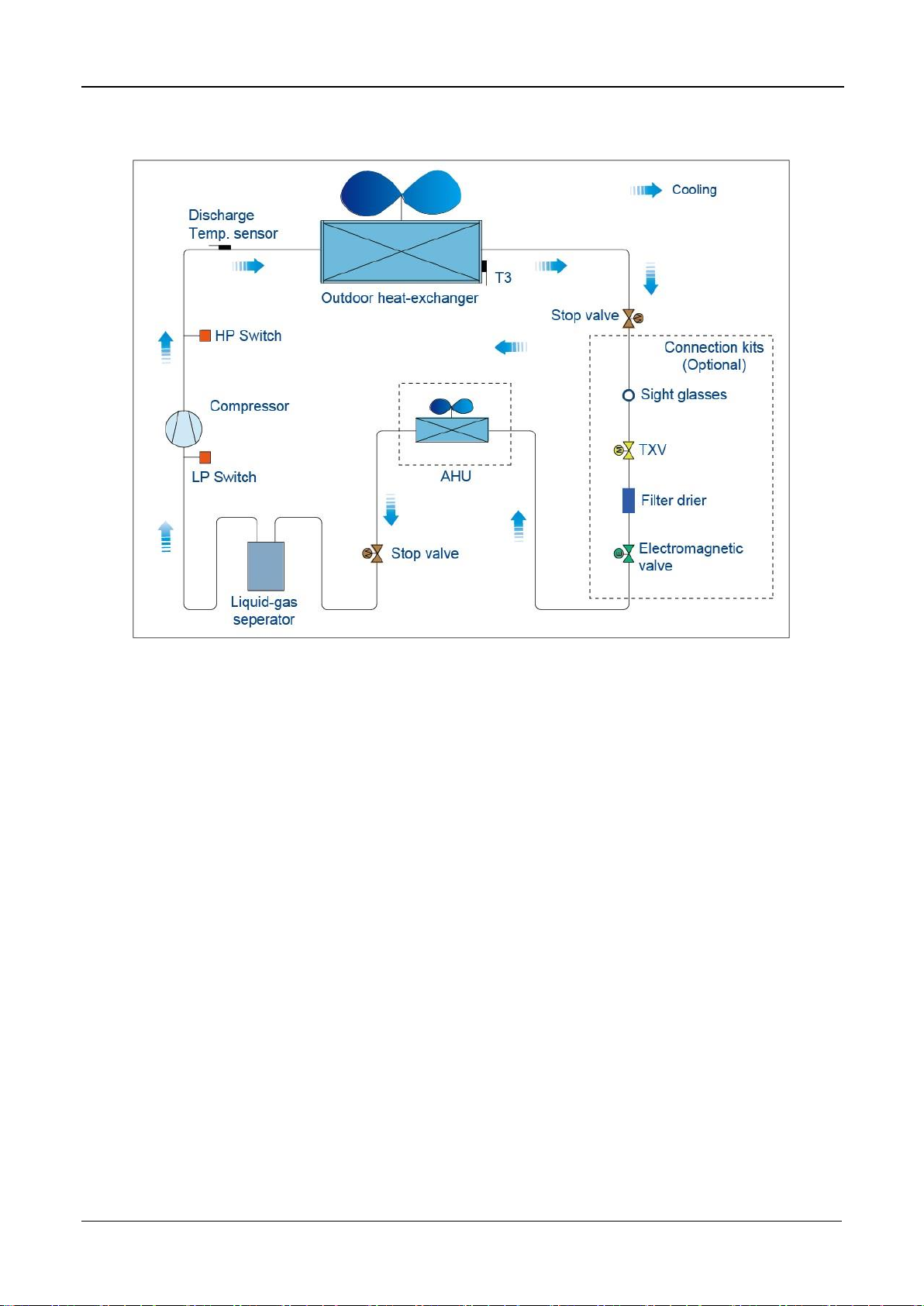

the change of cooling and heating load. The VRF solution is shown as following picture:

67

Loading...

Loading...