Page 1

INSTALLATION MANUAL

COMPRESSOR CONDENSING UNIT

MCCU-03CN1A

MCCU-05CN1A

MCCU-07CN1A

MCCU-10CN1

MCCU-12CN1

MCCU-16CN1

Thank you very much for purchasing our air conditioner,

Before using your air conditioner, please read this manual carefully and keep it for future reference.

Page 2

Page 3

CONTENTS

CONTENTS

PRECAUTIONS........................................................................................1

PRECAUTIONS........................................................................................1

OUTDOOR UNIT INSTALLATION..............................................................2

OUTDOOR UNIT INSTALLATION..............................................................2

INSTALL THE CONNECTING PIPE............................................................3

INSTALL THE CONNECTING PIPE............................................................3

REFRIGERANT PIPE................................................................................4

REFRIGERANT PIPE................................................................................4

HEAT INSULATION OF THE PIPE .........................................................4

HEAT INSULATION OF THE PIPE .........................................................4

CONNECTIVE DIAGRAM..........................................................................5

CONNECTIVE DIAGRAM..........................................................................5

CONTROL................................................................................................6

CONTROL................................................................................................6

WIRING...................................................................................................6

WIRING...................................................................................................6

ELECTRIC CONNECTION.........................................................................7

ELECTRIC CONNECTION.........................................................................7

ELECTRIC WIRE DIAGRAM .....................................................................7

ELECTRIC WIRE DIAGRAM .....................................................................7

TRIAL RUN .............................................................................................8

TRIAL RUN .............................................................................................8

1. PRECAUTIONS

1. PRECAUTIONS

Precautions before reading the installation manual.

Precautions before reading the installation manual.

Read this user manual carefully before installing the equipment.

Read this user manual carefully before installing the equipment.

The air conditioner must be installed by professional technicians.

The air conditioner must be installed by professional technicians.

Inspect and make sure the piping and cabling are correct before

Inspect and make sure the piping and cabling are correct before

powering on the air conditioner.

powering on the air conditioner.

This information may change with the update of this machine, and

This information may change with the update of this machine, and

no further notice will be given for such change.

no further notice will be given for such change.

The appliance must be positioned so that the plug is

The appliance must be positioned so that the plug is

accessible.

accessible.

The enclosure of the appliance shall be marked by word, or

The enclosure of the appliance shall be marked by word, or

by symbols, with the direction of the fluid flow.

by symbols, with the direction of the fluid flow.

If the supply cord is damaged, it must be replaced by the

If the supply cord is damaged, it must be replaced by the

manufacture or its service agent or a similarly qualified

manufacture or its service agent or a similarly qualified

person in order to avoid a hazard.

person in order to avoid a hazard.

An all-pole disconnection switch having a contact

An all-pole disconnection switch having a contact

separation of at least 3mm in all poles should be

separation of at least 3mm in all poles should be

connected in fixed wiring.

connected in fixed wiring.

CAUTION

CAUTION

Before installing the unit,it is necessary to check whether the

ground wire is charged.

If it is,the unit shall not be installed before correction.

Before installing the unit,be sure to confirm with the user whether

there are wires,water pipes,air pipes and so on in the wall or

ground of the installation site to avoid accidents due to damage.

Install the unit where enough space of installation and

maintenance is available.

Install the unit where the air inlet and outlet are not baffled and

are the least affected by external air.

Install the unit where it is easy to lead out the connective pipe.

Install the unit where no heat is emitted from a heat source

directly.

Installing the equipment in any of the following places may lead

to faults of the equipment (if that is inevitable, consult the

supplier):

The site contains mineral oils such as cutting lubricant.

WARNING

WARNING

Failure to observe a warning may result in death.

Failure to observe a warning may result in death.

CAUTION

CAUTION

Failure to observe a caution may result in injury or damage

Failure to observe a caution may result in injury or damage

to the equipment.

to the equipment.

After completing the installation, make sure that the unit operates

After completing the installation, make sure that the unit operates

properly during the start-up operation. Please instruct the customer

properly during the start-up operation. Please instruct the customer

on how t o operat e t h e unit and keep it maintained.Also, inform

on how t o operat e t h e unit and keep it maintained.Also, inform

customers that they should store this installation manual along with

customers that they should store this installation manual along with

the owner's manual for future reference.

the owner's manual for future reference.

WARNING

WARNING

Decide the correct way of conveying the equipment.

Decide the correct way of conveying the equipment.

Try to transport this equipment with the original package.

Try to transport this equipment with the original package.

If the air conditioner needs to be installed on a metal part of the

If the air conditioner needs to be installed on a metal part of the

building, electric insulation must be performed, and the

building, electric insulation must be performed, and the

installation must meet the relevant technical standards of electric

installation must meet the relevant technical standards of electric

devices.

devices.

The appliance must be installed 2.3m above floor.

The appliance must be installed 2.3m above floor.

The appliance shall not be installed in the laundry.

The appliance shall not be installed in the laundry.

Before obtaining access to terminals, all supply circuits

Before obtaining access to terminals, all supply circuits

must be disconnected.

must be disconnected.

Seaside where the air contains much salt.

Hotpring area where corrosive gases exist, e.g., sulfide gas.

Factories where the supply voltage fluctuates seriously.

Inside a car or cabin.

Place like kitchen where oil permeates.

Place where strong electromagnetic waves exist.

Place where flammable gases or materials exist.

Place where acid or alkali gases evaporate.

Other special environments.

Install the unit where enough space of installation and

maintenance is available.

Install the unit where the air inlet and air outlet are free from

obstacles and strong wind.

Install the unit in a dry and well ventilated place.

Install the unit where the bearing surface is level and can bear

weight of the unit, and is suitable for installing the unit

horizontally without increasing noise or vibration.

Install the unit where the operation noise and the expelling of air

do not affect neighbours.

Install the unit where no flammable gas is leaked.

Install the unit where it is convenient for pipe connection and

electric connection.

installation manual

installation manual

1

1

Page 4

2 OUTDOOR UNIT INSTALLATION

2 OUTDOOR UNIT INSTALLATION

2.1 Installation Place

2.1 Installation Place

The outdoor unit should be installed in the location that

The outdoor unit should be installed in the location that

meets the following requiements:

meets the following requiements:

There is enough room for installation and maintenance.

There is enough room for installation and maintenance.

The air outlet and the air inlet are not impeded, and can

The air outlet and the air inlet are not impeded, and can

not be reached by strong wind.

not be reached by strong wind.

It must be a dry and well ventilating place.

It must be a dry and well ventilating place.

The support is flat and horizontal and can stand the

The support is flat and horizontal and can stand the

weight of the outdoor unit. And will no additional noise or

weight of the outdoor unit. And will no additional noise or

vibration.

vibration.

Your neighborhood will not feel uncomfortable with the

Your neighborhood will not feel uncomfortable with the

noise or expelled air.

noise or expelled air.

It is easy to install the connecting pipes or cables.

It is easy to install the connecting pipes or cables.

Determine the air outlet direction where the discharged air

Determine the air outlet direction where the discharged air

is not blocked.

is not blocked.

There is no danger of fire due to leakage of inflammable

There is no danger of fire due to leakage of inflammable

gas.

gas.

The piping length between the outdoor unit and the indoor

The piping length between the outdoor unit and the indoor

unit may not exceed the allowable piping length.

unit may not exceed the allowable piping length.

In the case that the installation place is exposed to strong

In the case that the installation place is exposed to strong

wind such as a seaside, make sure the fan operating

wind such as a seaside, make sure the fan operating

properly by putting the unit lengthwise along the wall or

properly by putting the unit lengthwise along the wall or

using a dust shield.(Refer to Fig 2.1)

using a dust shield.(Refer to Fig 2.1)

If possible, do not install the unit where it is exposed to

If possible, do not install the unit where it is exposed to

direct sunlight.

direct sunlight.

If necessary, install a blind that does not interfere with the

If necessary, install a blind that does not interfere with the

air flow.

air flow.

During the heating mode, the water drained off the

During the heating mode, the water drained off the

outdoor unit ,The condensate should be well drained away

outdoor unit ,The condensate should be well drained away

by the drain hole to an appropriate place, so as not to

by the drain hole to an appropriate place, so as not to

interfere other people.

interfere other people.

Select the position where it will not be subject to snow

Select the position where it will not be subject to snow

drifts, accumulation of leaves or other seasonal debris. If

drifts, accumulation of leaves or other seasonal debris. If

unavoidable, please cover it with a shelter.

unavoidable, please cover it with a shelter.

as close to the indoor unit as

Locate the outdoor unit

Locate the outdoor unit

possible.

possible.

If possible, please remove the obstacles nearby to prevent

If possible, please remove the obstacles nearby to prevent

the performance from being impeded by too little of air

the performance from being impeded by too little of air

circulation.

circulation.

The minimum distance between the outdoor unit and

The minimum distance between the outdoor unit and

obstacles described in the installation chart does not

obstacles described in the installation chart does not

mean that the same is applicable to the situation of an

mean that the same is applicable to the situation of an

airtight room. Leave open two of the three directions

airtight room. Leave open two of the three directions

(M,N,P) (Refer to Fig.6-5)

(M,N,P) (Refer to Fig.6-5)

as close to the indoor unit as

Strong wind

Strong wind

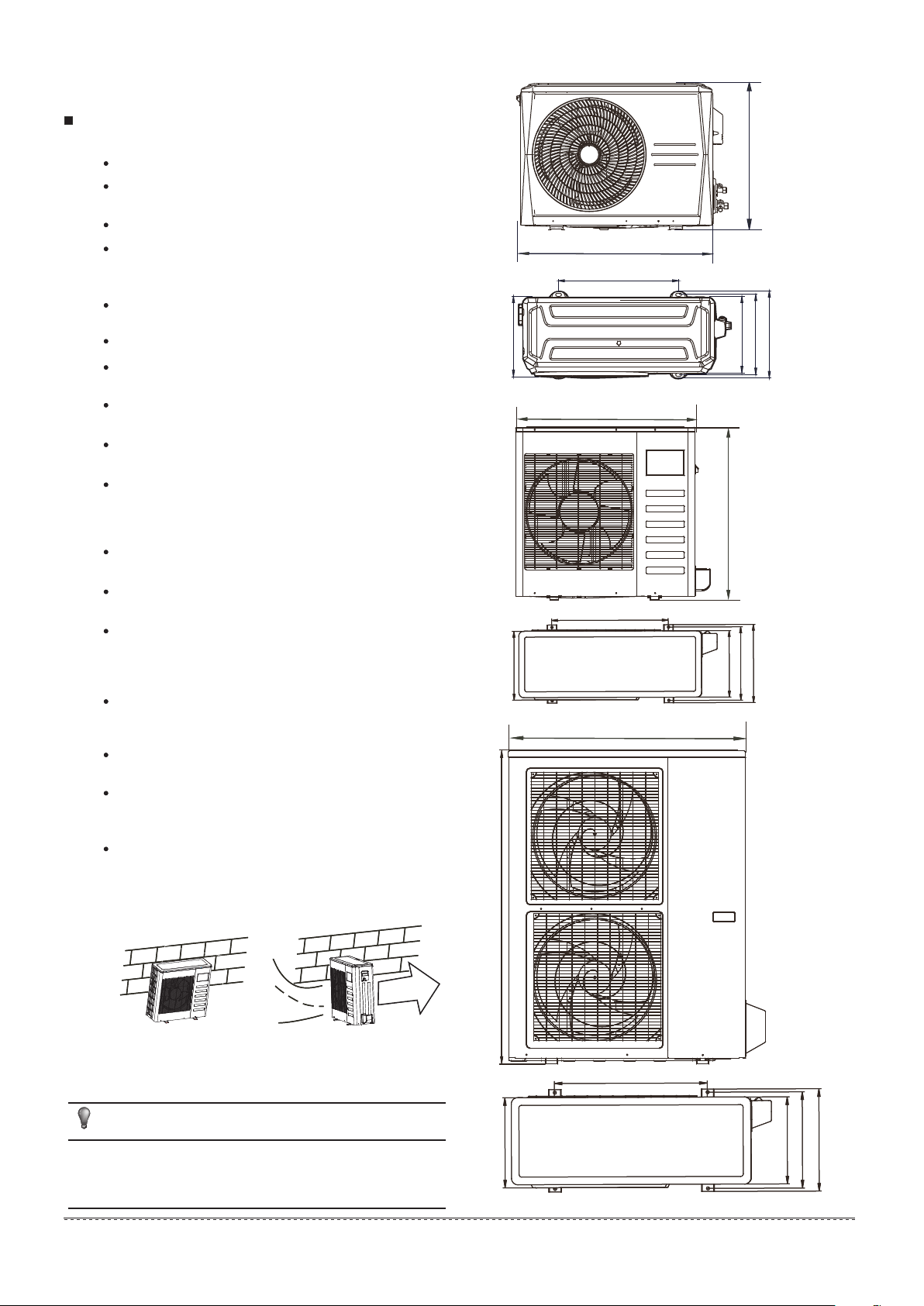

2.2 Figure of body size

A

B

A

B

F

F

A

H

H

H

EFC

D

Fig 2.2

H

D

D

C

C

E

E

Fig 2.3

X

O

O

X

NOTENOTE

All the figures in this manual are for explanation purpose only.

They may be slightly different from the air conditioner you

purchased.The actual uint shall prevail.

installation manual

installation manual

2

2

Fig 2.1

Fig 2.1

mmmm

mmmm

B

F

F

C

C

E

E

Fig 2.4

Fig 2.4

D

D

Page 5

Table 2-1 mm

1170

REMARK

Fig.2-2

Fig.2-2

Fig.2-3

Fig.2-4

MODEL A B C D E H

03

722 453 302 327 260 555300

05~07

14~16

795 514 340 365 287 550330

10

990 624 366 396 340 965345

590 378 400 330 350900

F

(in=mm/25.4)

2.3 Space of installation and maintenance

(Wall or obstacle)

Air inlet

>30cm

/11.81in

N

Air inlet

M

/78.74in

>200cm

Air outlet

>30cm

/11.81in

Maintain channel

>60cm

/23.62in

P

Fig 2.5

3 INSTALL THE CONNECTING PIPE

3.1 Preparation and Caution

Before installation make sure the height difference, the

length of refrigerant pipe, and the number of the bends

between the indoor unit and outdoor unit meet the

following requirements:

Table 3-1

The type of models

R410A Split type air conditioner

Model

03/05/07

10/14/16

The length of

refrigerant pipe

20m/65.8ft

30m/98.7ft

The outdoor unit is charged with rating refrigerant amount in

the factory. Additional charge refers to the table below:

Table 3-2

liquid tube(mm) R410A

Ø6.35

Ø9.53

NOTE:the table above refer to the liquid tube.

NOTE:The number of bends is up to the length of the max

height drop.Usually for each 10m/32.9ft need a bend.

0.022kg/m×(L-5)

0.060kg/m×(L-5)

unit:m

The max

height drop

10m/32.9ft

20m/65.8ft

2.4 Moving and installation

Since the gravity center of the unit is not at its physical

center, so please be careful when lifting it with a sling.

Never hold the inlet of the outdoor unit to prevent it from

deforming.

Do not touch the fan with hands or other objects.

Do not lean it more than 45, and do not lay it sidelong.

Make concrete foundation accoding to the sepecif-ications of

the outdoor units.(Refer to Fig.2-6)

Fasten the feet of this unit with bolts firmly to prevent it from

collapsing in case of earthquake or strong wind.(Refer to

Fig.2-6)

>60cm

/23.62in

Fix with bolt

CAUTION

All field piping must be provided by a licensed

refrigeration technician and must comply with the

relevant local and national codes.

Prevent let air, dust, or other impurities enter in the pipe

system during installation.

Insulation pipe shall be used to the gas piping and the

liquid piping. Otherwise, the condensate may happen.

3.2 The Procedure of Connecting Pipes

1)

Measure the required length of the connecting

pipe, then make it by the following way.

Connect the indoor unit first, then the outdoor unit.

Bend the tubing in proper way. Do not twist the pipe.

Bend the pipe with thumb

min-radius 100mm/3.94in

Fig 3.1

Fig 2.6

Put some refrigerant oil on the surfaces of the flare pipe

and the joint nuts then wrench it for 3~4 rounds with

hands before fasten the flare nuts.

Use frozen oil

Fig 3.2

installation manual

3

Page 6

Be sure to use two wrenches simultaneously when you

connect or disconnect the pipes.

Make the ends straight

Table 4-1

Model

Size of joint pipes for 410A outdoor unit

the size of main pipe(mm)

Gas side Liquid side

Fig 3.3

The service valves of the outdoor unit should be completely

closed(as original status).Every time to connect,first to loosen

nuts, then connect the flare pipes within 5 minutes. If the nuts

have been loosened for a long time, dusts and other impurities

may enter the pipe system and may cause malfunction.So

please expel the air out of the pipe with refrigerant before

connection.

Expel the air after connecting the refrigerant pipe with the

indoor unit and the outdoor unit.

Then fasten the nuts at the service valves.

Bend the connecting pipe of small wall thickness.

Cut out a proper concave at the bending part of the

insulating pipe.

Then expose the pipe(cover it with tapes after bending).

To prevent twist of deforming, please bend the pipe at a

proper radius.

NOTE

The bending angle should not exceed 90 .

Bending position is preferably in the middle of the bendable pipe.

Do not bend the pipe more than three times.

Be sure to use the same insulating materials when you buy the

brass pipe. (More than 9mm/0.35in thick)

03/05

07

10

14/16

Drop height between indoor

unit and outdoor unit

Φ12.7/0.501in

Φ12.7/0.501in

Φ19/0.748in

Φ19/0.748in Φ9.52/0.375in

Outdoor unit

Max.pipe length L≤20m(03/05/07)

Max.pipe length L≤30m(10/14/16)

H≤10m/32.9ft (03/05/07)

H≤20m/65.8ft(10/14/16)

Φ6.35/0.25in

Φ9.52/0.375in

Φ9.52/0.375in

2) Place The Pipe

Drill a hole in the wall (suitable just for the size of the wall

sleeve), then set on the fittings such as the wall sleeve and its

cover.

Bind the connecting pipe and the cables together tightly with

binding tapes.

Pass the bound connecting pipe through the wall sleeve from

outside. Make sure of the pipe allocation not to damage the

copper tubes.

3)

Connect the pipes.

Expel the air with a vacuum pump or refrigerant.

4)

Open the service valves of the outdoor unit .

5)

Check the refrigerant leakage. Check all the joints

6)

with the leak detector or soap water.

Cover the joints of the connecting pipe with the

7)

insulation foam, and bind them well with the tapes to

prevent potential leakage.

4 REFRIGERANT PIPE

Indoor unit

5 REFRIGERANT PIPE CONNECTION

5.1 Expel The Air

Flaring

1)

Cut a pipe with a pipe cutter. (Refer to Fig.5-1)

90

Insert a flare nut into a pipe and flare the pipe.

2)

Fasten the nut

Put the connecting pipes at the proper position,

wrench the nuts with hands then fasten it with

two wrenches simultaneously. (Refer to Fig 5.2)

Lean crude burr

Fig 5.1

Fig 4.1

4.1 Size of joint pipes for outdoor unit

Base on the following tables, select the diameters of

the outdoor unit connective pipes. In case of the

main accessory pipe large than the main pipe, take

the large one for the selection.

installation manual

4

Fig 5.2

Page 7

CAUTION

Too large torque will harm the bellmouthing and too small will

cause leakage. Please determine the torque according to

Table 5-1.

Table 5-1

Pipe gauge

Ø6.35/0.25in 8.3/0.327in 8.7/0.343in

Ø9.52/0.375in 12.0/0.472in 12.4/0.488in

Ø12.7/0.5in 15.4/0.606in 15.8/0.622in

Ø15.9/0.626in

Ø19.1/0.725in

Tightening torque

14.2~17.2 N.m

(144~176 kgf.cm)

32.7~39.9 N.m

(333~407 kgf.cm)

49.5~60.3 N.m

(504~616 kgf.cm)

61.8~75.4 N.m

(630~770 kgf.cm)

97.2~118.6 N.m

(990~1210 kgf.cm)

Flare dimensin A

min max

(mm)

18.6/0.732in 19.0/0.748in

22.9/0.902in 23.3/0.917in

Flare shape

°

4

±

90

45

°

±

2

A

R0.4~0.8

Flare nut

Stopper

Cap

Valve body

Valve stern

Fig 5.4

CAUTION

Both service valves should be open before test operation.

Each air conditioner has two service valves of different

sizes.(Refer to Fig 5.4)

Expel the air with a vacuum pump

3)

(Please refer to its manual for the way of using manifold

valve)

Loosen and remove the nuts of service valves A and B,

and connect the charge hose of the manifold valve with

the maintenance terminator of service valve A. (Be sure

that service valves A and B are both closed)

Connect the joint of the charge hose with the vacuum

pump.

Open the Lo-lever of the manifold valve completely.

Turn on the vacuum pump. At the beginning of pumping,

loosen the nut of service valve B a little to check whether

the air comes in (the sound of the pump changes, and

the indicator of compound meter turns below zero). Then

fasten the nut.

When the pumping has finished, close the Lo-lever of the

manifold valve completely and turn off the vacuum pump.

When you have pumped for over 15 minutes, please

confirm that the indicator of multimeter is on -1.0X10-5Pa

(-76cmHg)

Loosen and remove the nuts of service valves A and B to

open service valve A andB completely, then fasten nuts.

Disassemble the charge hose of service valve A, and

fasten the nut.

Manifold valve

Multi-meter

Pressure meter

5.2 Check the Leakage

Check all the joints with the leak detector or soap water.

(Refer Fig 5.5 as a reference illustration)

in the chart

A......Lo-stop valve

B......Hi-stop valve

C,D..Joints of the connecting pipe to the indoor unit.

D

Check-point of indoor unit

Check-point of outdoor unit

C

B A

Fig 5.5

5.3 Insulation

Be sure to completely insulate all the exposed parts of the flare

pipes.

Incomplete insulation may cause condensate.

6. HEAT INSULATION OF THE PIPE

6.1 Heat Insulation Of The Pipe

In order to prevent faults caused by condensate of the

refrigerant pipe and drain pipe, perform condensate prevention

and heat insulation properly.

-76 cmHg

Lo-lever

Charge hose

Lo-lever

Hi-lever

Charge hose

Vac uum pump

Fig 5.3

CAUTION

If it is forecast that high humidity/temperature environment

(condensate temperature is over 23℃) may exist in the ceiling,

e.g., inside the ceiling with slab, ceiling which is in the same

environment as the outdoor air), it is necessary to apply 10mm

or thicker adiabatic wool (16~20kg/m2 ) to the refrigerant pipe

and the drain pipe in addition to applying the general heat

insulation materials. Enough heat insulation materials should

also be applied to the refrigerant joint and the pipe joint.

installation manual

5

Page 8

6.2 Heat Insulation Of The Refrigerant Pipe

Please use heat-resistant materials as heat insulation materials

of the air-side pipe. (e.g., EPT)

Cover heat insulation materials separately at the liquid side and

the air side. Moreover, perform heat insulation thoroughly for the

air-side pipes of the indoor unit, and prevent water from dripping

outside the unit.

(air-side pipe)

Indoor unit

Fig.6-1

After applying the auxiliary heat insulation materials, use

vinylresin tape to seal it lest water leak.

7 CONNECTIVE DIAGRAM

Gas side

Liquid side

8 WIRING

The appliance shall be installed in accordance with

national wiring regulations.

The air conditioner should use separate power supply

with rated voltage.

The external power supply to the air conditioner should

be grounded, which is linked to the ground wiring of the

indoor and outdoor unit.

The wiring work should be done by qualified persons

according to wiring diagram.

A circuit breaker and a residual current device (RCD) with

above 10mA rating shall be installed in the power circuit

according to the national rule.

Be sure to locate the power wiring and the signal wring

well to avoid cross-disturbance.

Do not turn on the power until you have confirmed

proper wiring.

The power cord type is H07RN-F.

NOTE

Refer to EMC Directive 2004/108/EC

To prevent flicker impressions during the start of the

compressor,following installation conditions do apply.

The power connection for the air conditioner has to be

1

done at the main power distribution. The distribution has

to be of a low impedance, normally the required

impedance reaches at a 32A fusing point.

No other equipment has to be connected with this power

2

line.

For detailed installation acceptance please refer to your

3

power supplier, if restrictions do apply for products like

washing machines, air conditioners or electrical ovens.

4

For power details of the air conditioner refer to the rating

nameplate of the product.

For any question contact your local dealer.

5

Fig 7.1

NOTE

For ensuring throttled efficiency , Please mount the Orifice as

horizontally as possible; and anti-shock rubber should be

wrapped at external of the Orifice for denoise.

8.1

Connect the cable

Disassemble the cover.(If there isn't a cover on the outdoor

unit, disassemble the screw from the maintenance board, and

pull it in the direction of the arrow to remove the protection

board.) (Refer to Fig 8.1)

Connect the cables to the terminals correspondingly.

Re-install the cover or the protection board.

Wiring figure

8.2

Cover

Fig 8.1Protection board

NOTE

All the figures in this manual are for explanation purpose only.

They may be slightly different from the air conditioner you

purchased(depend on model).The actual unit shall prevail.

installation manual

6

Page 9

9 ELECTRIC CONNECTION

Power supply

Power supply

CAUTION

Use special power supply for the air conditioner. Design power

supplies specific to the indoor unit and outdoor unit. The supply

voltage must comply with the nominal voltage.

The external supply circuit of the air conditioner must have a

ground wire, and the power supply ground wire of the indoor unit

must be connected with the external ground wire firmly.

The wiring must be performed by professional technicians

according to the circuit diagram labels.

Distribute the wires according to the relevant electric technical

standards promulgated by the State, and set the Residual

Current-operated Circuit Breaker (RCCB) properly.

The power wire and the signal wire shall be laid out neatly and

properly, without mutual interference or contacting the

connection pipe or valve.

No power cable is attached to this equipment. The user can

select the power cable by reference to the stipulated power

supply specifications. No joint of wires is allowed.

Upon completion of wire connection, double check it and then

connect the power supply.

An all-pole disconnection device which has at least 3mm

separation distance in all pole and a residual current

device(RCD)with the rating of above 10mA shall be incorporated

in the fixed wiring according to the national rule.

The appliance shall be installed in accordance with national

wiring regulations.

Specifications of power supply

Model Power

of the main power

suppliy/fuse(A)

MCCU-03CN1A 20/16

Switch capacity

MCCU-05CN1A 30/20

220-240V~

50Hz

MCCU-07CN1A 40/30

MCCU-10CN1 25/20

MCCU-14CN1 25/20

380-415V

3N~ 50Hz

MCCU-16CN1 45/35

Outdoor unit power

cable includes

grounded wire

RVV-300/500

2X2.5+1X1.5 mm

RVV-300/500

2X4.0+1X2.5 mm

RVV-300/500

2X6.0+1X4.0 mm

RVV-300/500

4X4.0+1X2.5 mm

RVV-300/500

4X4.0+1X2.5 mm

RVV-300/500

4X10.0+1X6.0 mm

Connective

wire of indoor

outside unit

2

2

2

2

RVV-300/500

1X1.0 mm

2

2

Switch/ Fuse

(Available locally)

Power wiring

(indoor)

Power linking wirng(Outdaoor)

Indoor

unit

Outdoor unit

Ground wiring

Ground wiring

Weak elec-signal link wiring

Ground the air conditioner properly in case to affect its

anti-interference function

Fig 9.2

NOTE

Please identify outdoor main unit and auxilary unit. Only main unit

connects with signal wire of indoor unit. Users should adjust the

dial on electric control board of outdoor unit as follows, otherwise

incorrect adjustment may cause malfunction.

10 ELECTRIC WIRE DIAGRAM

Y/G

4

3

(N)

1 2

Y/G

-

SNL

-

2

A B C N 1

Y/G

Power supply:

-2

40V~ 50Hz

220

3-cord cable

RVV-300/500 2X2.5+1x1.5 mm

RVV-300/500 2X4.0+1x2.5 mm

T O INDOOR UNIT

Power supply:

-2

40V~ 50Hz

220

3-cord cable

RVV-300/500 2X6.0+1x4.0 mm

* S: RVV-300/500 1X1.0 mm

T O INDOOR UNIT

Power supply:

-

415V 3N~ 50Hz

380

3-cord cable

RVV-300/500 4X4.0+1x2.5 mm

RVV-300/500 4X4.0+1x2.5 mm

T O INDOOR UNIT

RVV-300/500 4X10.0+1x6.0 mm

* 1: RVV-300/500 1X1.0 mm

2

(MCCU-03CN1A)

2

(MCCU-05CN1A)

2

(MCCU-07CN1A)

2

2

(MCCU-10CN1)

2

(MCCU-14CN1)

2

(MCCU-16CN1)

2

Power wires

The power wires are as follows: (schematic diagram)

RCCB

Outdoor unit

Manual switch

Outdoor unit power supply

Fig 9.1

Fig 10.1

NOTE

Pay attention to the phase sequence of the power supply. If the

phase sequence is reversed, the compressor will not start.

Meanwhile, the fault indicator of the outdoor electric control

board will light up. For details, see Outdoor unit wring diagram

on the cover plate of the electric control box .

After shifting the phase sequence, power on the unit until the

fault indicator goes out and the compressor starts up normally.

installation manual

installation manual

7

Page 10

11 TRIAL RUN

Please conduct in accordance with “Trial Run Tenor Nameplate”

on the electric control box.

CAUTION

Perform the trial run only after the outdoor unit has been

powered on for over 12 hours.

Check that all valves are opened before trial run.

Check the electric safety before trial run.

Do not perform compulsory operation in any way.(It is very

dangerous if the protection device is not active)

Perform trial run only after all installations are finished.

Confirm the following issues before trial operation, and the

box for the confirmed items.

Check whether the indoor unit and the outdoor are

installed properly.

Check whether the piping and wiring are correct.

Check whether the refrigerant pipeline system is

inspected for leakage.

Air flow of the indoor unit

Table 11-2

Model

MCCU-03CN1A

MCCU-05CN1A

MCCU-07CN1A

Air flow of the indoor unit

500~650m3/h

700~900m3/h

1000~1250m

3

/h

Check whether the drain is smooth.

Check whether the heat insulation is perfect.

Check whether the ground cables are connected

correctly.

Check whether the pipe length and the refrigerant

amount are recorded.

Check whether the supply voltage is equal to the rated

voltage of the air conditioner.

Check whether any obstacles exist at the air

inlet/outlet of the indoor or outdoor unit.

Open the gas valve and the liquid valve.

Connect the power supply to preheat the air

conditioner.

Safety precautions

The electric circult must be installed RCCB and manual switch

Table 11-1

Cooling

operation

Dewetting

operation

Outdoor temperature:17~46°C

Intdoor temperature:≥17°C

Outdoor temperature:17~46°C

Intdoor temperature:17~32°C

installation manual

8

Page 11

Page 12

16123000A18669 V1.0

Page 13

本页不打印

规格:A4

材质:100g双胶纸

更改记录

Loading...

Loading...