Midea MCA-24HRN2,MCA-24CRN2, MCA-24HRN2, MCA-24CRN2, MCA-36HRN2, MCA-36CRN2 Installation Manual

...Page 1

CASSETTE TYPE

Thank you very much for purchasing our air conditioner, please read this owner's

manual carefully before using your air conditioner.

INSTALLATION MANUAL

AIR CONDITIONER

MODEL:

MCA-24HRN2

MCA-24CRN2

MCA-36HRN2

MCA-36CRN2

MCA-42HRN2

MCA-42CRN2

MCA-48HRN2

MCA-48CRN2

Page 2

CONTENTS PAGE

1. PRECAUTIONS................................................................................................1

2. INSTALLATION INFORMATION.. ...2

3. ATTACHED FITTINGS.... ....3

4. INSTALLATION PLACE.. ...4

5. INDOOR UNIT INSTALLATION.. ....5

6. OUTDOOR UNIT INSTALLATION.. .9

7. INSTALL THE CONNECTING PIPE.. .10

8. CONNECT THE DRAIN PIPE. .....14

9. WIRING.... .16

10. TEST OPERATION..... ....20

.................................................................

.............................................................................

..............................................................................

.................................................................

................................................................

............................................................

..................................................................

.....................................................................................................

.............................................................................

Page 3

PRECAUTIONS

SAFETY CONSIDERATIONS

Installation and servicing of air conditioning equipment can be hazardous due to system pressure and

electric components. Only trained and qualified service personnel should install, repair or service air

conditioning equipment.

All other operations should be performed by trained service personnel. When working on air conditioning equipment, observe precautions in the literature, tags and labels attached to the unit and other

safety precautions that may apply. Follow all safety codes. Wear glasses and work gloves. Use quenching cloth for brazing and unbrazing operations. There are fire extinguishers available for all brazing

operations.

WARNING

WARNING

WARNING

This manual describes the installation of specified indoor and outdoor units. Do not install them connected with any other indoor or outdoor unit .Mismatching of units and incompatibility between control

devices in the two units could lead to damage of both units .

Before performing service or maintenance operations on system, turn off main power switch of the unit.

Electrical shock could cause personal injury.

This unit shall be installed in accordance with national wiring regulations.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or similarly

qualified person in order to avoid a hazard.

The means for disconnection from the supply having a contact separation of at least 3 mm in all poles.

CAUTION

1. Wire the outdoor unit, then wire the indoor unit. You are not allow to connect the air conditioner with

the power source until wiring and piping the air conditioner is done.

2. For installation of the indoor unit, outdoor unit, and connection piping in between, follow the instru ctions given in this manual as strictly as possible.

3. Installation in the following places may cause trouble. If it is unavoidable using in such places,

please consult with the dealer.

(1) A place full of machine oil.

(2) A saline place such as coast.

(3) Hot-spring resort.

(4) A place full of sulfide gas.

(5) A place where there are high frequency machines such as wireless installation, welding machine,

medical facilities.

(6) A place of special environmental conditions.

4. Don't install this unit in the laundry.

1

Page 4

Remark per EMC Directive 89/336/EEC

For to prevent flicker impressions during the start of the compressor (technical process) ,following

installation conditions do apply.

1. The power connection for the air conditioner has to be done at the main power distribution. The

distribution has to be of a low impedance, normally the required impedance reaches at a 32 A

fusing point.

2. No other equipment has to be connected with this power line.

3. For detailed installation acceptance please refer to your contract with the power supplier, if restric tions do apply for products like washing machines, air conditioners or electrical ovens.

4. For power details of the air conditioner refer to the rating plate of the product.

5. For any question contact your local dealer.

NOTE

INSTALLATION INFORMATION

2

1. Select the location;

2. Install the indoor unit;

3. Install the outdoor unit;

4. Install the connecting pipe ;

5. Connect the drain pipe;

6. Wiring;

7. Test operation.

To install properly, please read this "installation manual" at first.

The air conditioner must be installed by qualified persons.

When installing the indoor unit or its tubing, please follow this manual as strictly as possible.

When all the installation work is finished, please turn on the power only after a thorough check.

Regret for no further announcement if there is any change of this manual caused by product

improvement.

CAUTIONS FOR THE REMOTE CONTROLLER OPERATION

Please do not throw the remote controller or beat it.

Please use the remote controller within the allowed distance, and keep the transmitter toward the

receiver of the indoor unit.

Please keep the remote controller more than 1m away from TV or stereo set.

Never put the remote controller at the place with humid or direct sunlight, or near heaters.

Please insert the batteries properly.

INSTALLATION ORDER

Page 5

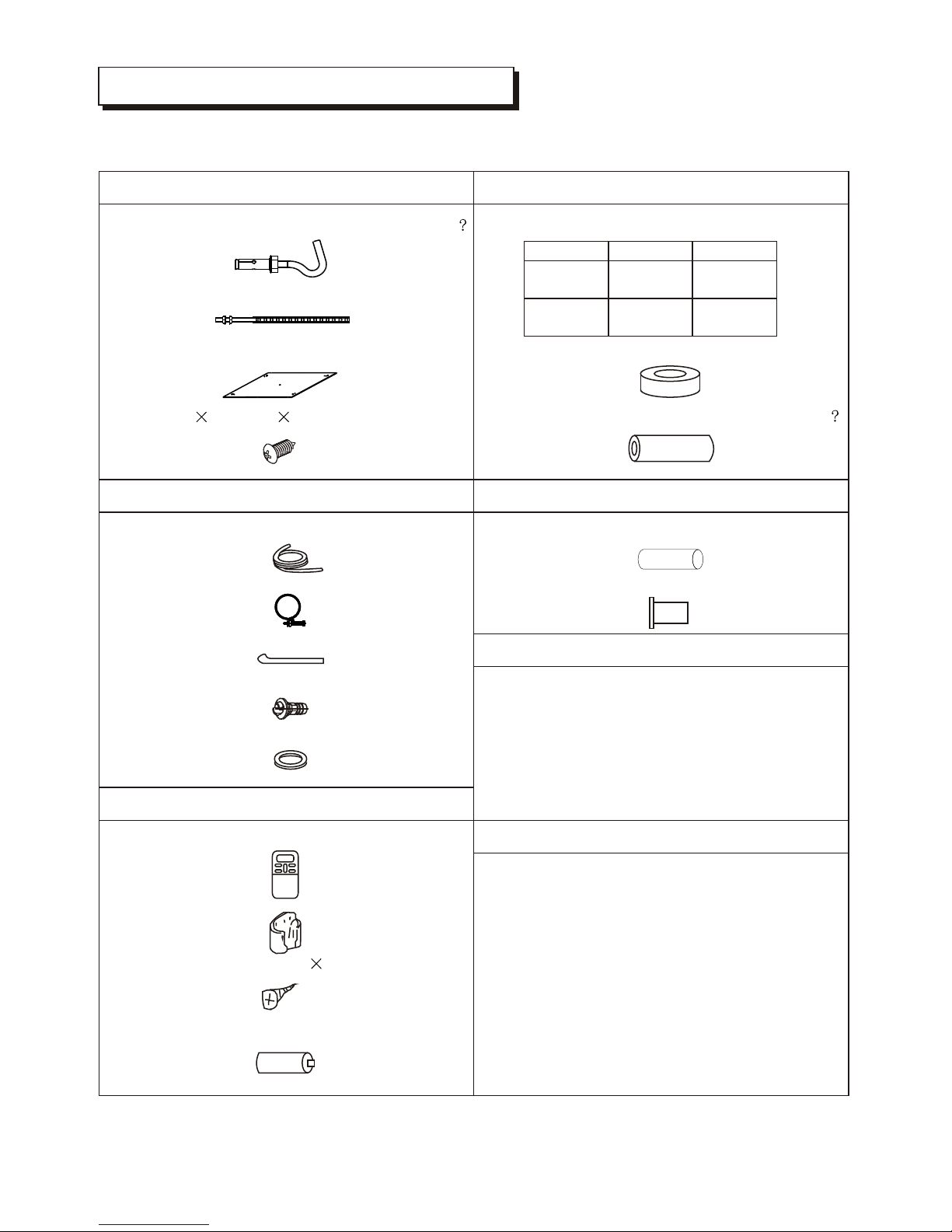

Please check whether the following fittings are of full scope. If there are some attached fittings free

from use, please restore them carefully.

Installation Fittings

Tubing & Fittings

1. Expansible hook..........................................4

2. Installation hook..........................................4

3. Installation paper board...............................1

4. Bolt M5 16 or M6 12.............................4

ATTACHED FITTINGS

5. Connecting pipe group...............................1

7. Soundproof / insulation sheath...................2

6. Binding tape................................................6

8. Out-let pipe sheath.......................................1

9. Out-let pipe clasp.........................................1

10. Tightening band.......................................20

11. Drain elbow.................................................1

12. Seal ring.....................................................1

13. Wall conduit..............................................1

14. Wall conduit cover....................................1

Power/Signal Wiring Group

15. Power wiring of the indoor unit.................1

16. Weak electrical wiring between

the indoor and outdoor units....................1

Drainpipe Fittings Protect Pipe Fittings

Remote controller & Its Frame

Others

21. Owner's manual.......................................1

22. Installation manual...................................1

17. Remote controller......................................1

18. Frame........................................................1

19. Mounting screw(ST2.9 10-C-H) .............2

20. Alkaline dry batteries (AM4)......................2

3

Liquid-side

tubing

MCA-42(36,48)CRN2

MCA-42(36,48)HRN2

gas-side

tubing

f9.53mm f12.7mm

f16mm f19mm

MCA-24CRN2

MCA-24HRN2

Page 6

INSTALLATION PLACE

4

There is enough room for installation and maintenance.

The air outlet and the air inlet are not impeded, and can not be reached by strong wind.

It must be a dry and well ventilating place.

The support is flat and horizontal and can stand the weight of the outdoor unit. And will no additional

noise or vibration.

Your neighborhood will not feel uncomfortable with the noise or expelled air.

There is no leakage of combustible air.

It is easy to install the connecting pipe or cables.

Determine the air outlet direction where the discharged air is not blocked.

A place free of a leakage of combustible gases.

In the case that the installation place is exposed to a strong wind such as a seaside or high position,

secure the normal fan operation by putting the unit lengthwise along the wall or using a duct or shield

plates.

If possible, do not install the unit where it is exposed to direct sunlight.

If necessary, install a blind that does not interfere with the air flow.

During the heating mode, the water drained off the outdoor unit ,The condensate should be well drained away by the drain hole to an appropriate place, so as not to interfere other people or public.

Select the position where it will not be subject to snow drifts, accumulation of leaves or other seasonal

debris. It is important that the air flow for the outdoor unit is not impeded as this will result in reduction

in heating or cooling performance.

CAUTIONS

Location in the following places may cause malfunction of the machine.(If unavoidable, please consult

your local dealer)

a. There is petrolatum existing.

b. There is salty air surrounding (near the coast).

c. There is caustic gas (the sulfide, for example) existing in the air (near a hot spring).

d. The Volt vibrates violently (in the factories).

e. In buses or cabinets.

f. In kitchen where it is full of oil gas.

g. There is strong electromagnetic wave existing.

h. There are inflammable materials or gas.

i. There is acid or alkaline liquid evaporating.

j. Other special conditions.

NOTICES BEFORE INSTALLATION

1. Select the correct carry-in path.

2. Move this unit as originally packaged as possible.

3. If the air conditioner is installed on a metal part of the building, it must be electrically insulated acc ording to the relevant standards to electrical appliances.

1. The indoor unit

There is enough room for installation and maintenance.

The ceiling is horizontal, and its structure can endure the weight of the indoor unit.

The air outlet and the air inlet are not impeded, and the influence of external air is the least.

The air flow can reach throughout the room.

The connecting pipe and drainpipe could be extracted out easily.

There is no direct radiation from heaters.

2. The outdoor unit

Page 7

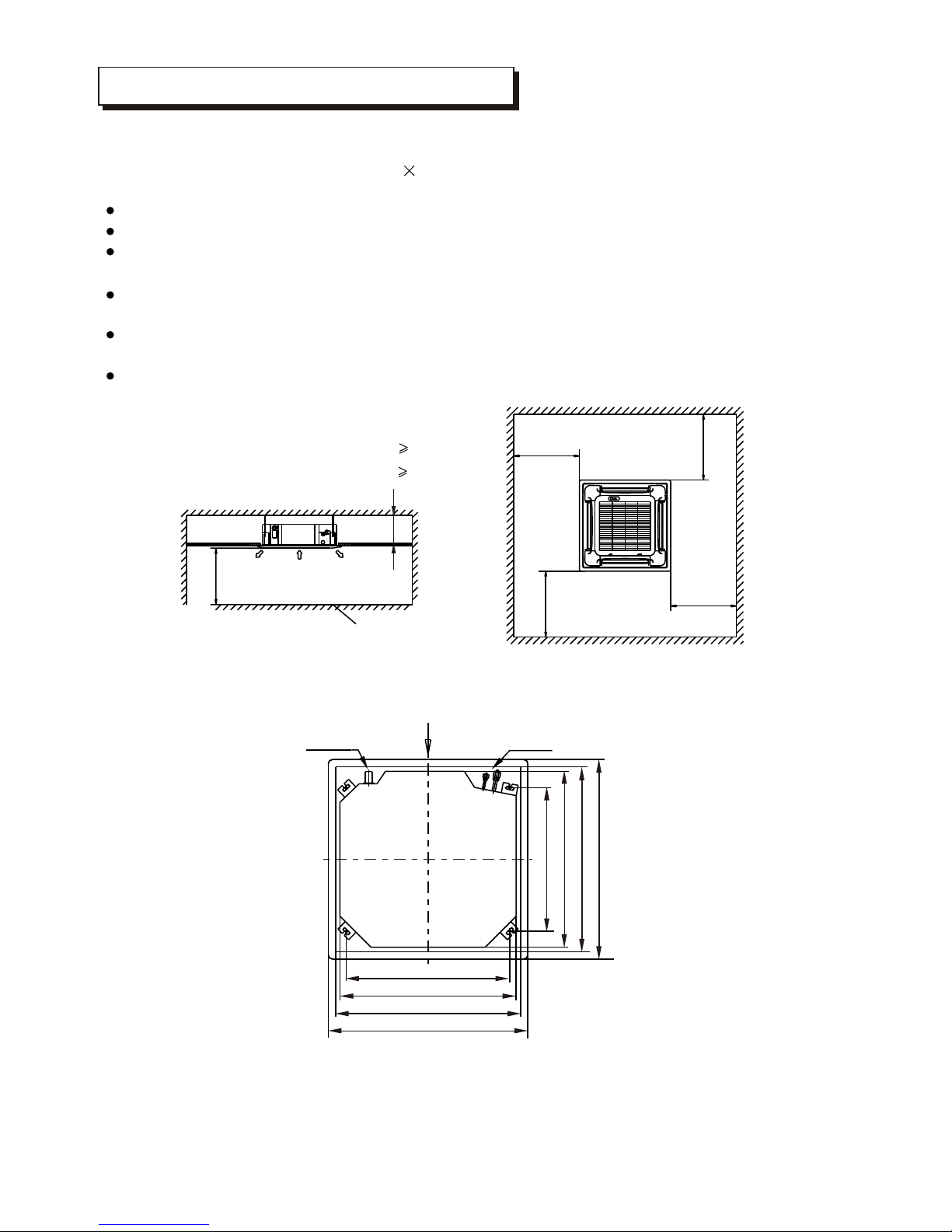

INDOOR UNIT INSTALLATION

5

>1000mm

>1000mm

>1000mm

>1000mm

Chart 2

A

Drain side

Tubing side

(Unit: mm)

680(Hook-location)

780(Hook-location)

840(Body)

840(Body)

880(Ceiling hole)

880(Ceiling hole)

950(Panel)

950(Panel)

1. Install the main body

A. The existing ceiling (to be horizontal)

a. Please cut a quadrangular hole of 880 880mm in the ceiling according to the shape of the installation

paper board. (Refer to Chart3, 4)

The center of the hole should be at the same position of that of the air conditioner body.

Determine the lengths and outlets of the connecting pipe, drainpipe and cables.

To balance the ceiling and to avoid vibration, please enforce the ceiling when necessary.

b. Please select the position of installation hooks according to the hook holes on the installation board.

Drill four holes of f12mm, 45~50mm deep at the selected positions on the ceiling. Then embed the

expansible hooks (fittings).

Face the concave side of the installation hooks toward the expansible hooks. Determine the length

of the installation hooks from the height of ceiling, then cut off the unnecessary part.

If the ceiling is extremely high, please determine the length of the installation hook according to facts.

Necessary room

>2500mm

outlet intlet outlet

ground

A

Chart 1

Note:

MCA-24CRN2 MCA-24HRN2

MCA-42(36,48)CRN2

MCA-42(36,48)HRN2

Chart 3

A 330mm

Series A 260mm

Series

Page 8

The length could be calculated from Chart5

Chart5: Length=H-181+L (in general, L=100mm and is half of the whole length of the installation hook)

c. Please adjust the hexangular nuts on the four installation hooks evenly, to ensure the balance of the

body.

If the drainpipe is awry, leakage will be caused by the malfunction of the water-level switch.

Adjust the position to ensure the gaps between the body and the four sides of ceiling are even. The

body's lower part should sink into the ceiling for 10~12 mm (Refer to chart 5).

Locate the air conditioner firmly by wrenching the nuts after having adjusted the body's position well.

A

Nut

Body

Ceiling

880mm

Hook

B

Panel

Chart 4

Note: Series B=240mm

Series B=310mm

MCA-24CRN2, MCA-24HRN2

MCA-42(36,48)CRN2, MCA-42(36,48)HRN2

Body

L

Chart 5

H (Ceiling height)

Ceiling

10-12mm

136mm

34mm

Chart 6

Bolt

Chart 7

Central hole

Bolt M6X12

Installation paper board

6

Page 9

B. New built houses and ceilings

a. In the case of new built house, the hook can be embedded in advance (refer to the A.B mentioned

above). But it should be strong enough to bear the indoor unit and will not become loose because

of concrete shrinking.

b. After installing the body, please fasten the installation paper board onto the air conditioner with

bolts(M6 12) to determine in advance the sizes and positions of the hole opening on ceiling.

Please first guarantee the flatness and horizontal of ceiling when installing it.

Refer to the A.a mentioned above for others.

c. Refer to the A.c mentioned above for installation.

d. Remove the installation paper board.

2. Install The Panel

CAUTIONS

CAUTIONS

After completion of installing the body, the four bolts(M6 12)must be fastened to the air

conditioner to ensure the body is grounded well.

Never put the panel face down on floor or against the wall, or on bulgy objects.

Never crash or strike it.

(1) Remove the inlet grid.

a. Slide two grid switches toward the middle at the same time, and then pull them up. (Refer to chart 8)

0

b. Draw the grid up to an angle of about 45 , and remove it. (Refer to chart 9)

Grid switch

Chart 8

45

Chart 9 Chart 10

(2) Remove the installation covers at the four corners.

Wrench off the bolts, loose the rope of the installation covers, and remove them. (Refer to chart 10)

(3) Install the panel

a. Align the swing motor on the panel to the tubing joints of the body properly. ( Refer to chart 11)

b. Fix hooks of the panel at swing motor and its opposite sides to the hooks of corresponding water

receiver. ( Refer to chart 11 ) Then hang the other two panel hooks onto corresponding hangers of

the body. ( Refer to chart 11 )

CAUTIONS

Do not coil the wiring of the swing motor into the seal sponge.

7

Page 10

Chart 14

Loosen upper nut

Adjust lower nut

Gap not allowed

Chart 13

Leakage

Ceiling

Pollution

Water condensation

8

Cross-screwdriver

Outlet joint

Tubing joint

Hook panel

Swing Motor

Hook-boit

Water- receiver

Chart 11

panel sponge

Chart 12

body

Ceiling

panel

panel foam1

air out

tan

panel foam 2

4-6mm

outlet foam

c. Adjust the four panel hook screws to keep the panel horizontal, and screw them up to the ceiling

evenly. ( Refer to chart 11 )

d. Regulate the panel in the direction of the arrow in Chart11 slightly to fit the panel's center to the

center of the ceiling's opening. Guarantee that hooks of four corners are fixed well.

e. Keep fastening the screws under the panel hooks, until the thickness of the sponge between the

body and the panel's outlet has been reduced to about 4~6mm. The edge of the panel should

contact with the ceiling well. (Refer to chart 12)

Malfunction described in Chart13 can be caused by inappropriate tightness the screw.

If the gap between the panel and ceiling still exists after fastening the screws, the height of the

indoor unit should be modified again. ( Refer to chart 14-left)

You can modify the height of the indoor unit through the openings on the panel's four corners, if the

lift of the indoor unit and the drainpipe is not influenced (refer to chart 14-right).

(4) Hang the air-in grid to the panel, then connect the lead terminator of the swing motor and that of

the control box with corresponding terminators on the body respectively.

(5) Relocate the air-in grid in the procedure of reversed order.

(6) Relocate the installation cover.

a. Fasten the rope of installation cover on the bolt of the installation cover. (Refer to chart 15-left)

b. Press the installation cover into the panel slightly. (Refer to chart 15-right)

Chart 15

,

Installation cover s rope

Tap Screw

Slide the four sliders

in the corresponding

channel when installing

the cover

Page 11

OUTDOOR UNIT INSTALLATION

9

(Refer to chart 17,chart 18)

If possible, please remove the obstacles nearby to prevent the performance from being impeded by too

little of air circulation.

The minimum distance between the outdoor unit and obstacles described in the installation chart does

not mean that the same is applicable to the situation of an airtight room. Leave open two of the three

directions (A,B,C)

CAUTIONS

Keep this unit away from direct radiation of the sun or other heaters.

If unavoidable, please cover it with a shelter.

In places near coast or with a high attitude where the wind is violent, please install the outdoor unit

against the wall to ensure normal performance.

Use a baffle when necessary.

In the case of extremely strong wind, please prevent the air from flowing backwards into the outdoor

unit. ( Refer to chart 16)

Locate the outdoor unit as close to the indoor unit as possible.

The minimum distance between the outdoor unit and obstacles described in the installation chart

does not mean that the same is applicable to the situation of an airtight. Leave open two of three

directions A,B,C..

X

O

Chart 16

Strong wind

NECESSARY ROOM FOR INSTALLATION AND MAINTENANCE

>30cm

>60cm

>30cm

>2

0

0c

m

Chart 17

(Wall or obstacle)

Maintain channel

Air outlet

Air inlet

Air inlet

A

C

B

Chart 18

>6

0

c

m

Fix with bolt

Necessary width

Deep foundation

Since the gravity center of this unit is not at its physical center, so please be careful when lifting it

with a sling.

Never hold the air-in of the outdoor unit to prevent it from deforming.

Do not touch the fan with hands or other objects.

0

Do not lean it more than 45 , and do not lay it sidelong.

Please fasten the feet of this unit with bolts firmly to prevent it from collapsing in case of earthquake

or strong wind.

MOVING AND INSTALLING

Page 12

INSTALL THE CONNECTING PIPE

10

Daub the surfaces of the flare pipe and the joint nuts with frozen oil, and wrench it for 3~4 rounds

with hands before fasten the flare nuts.(Refer to chart 19)

Be sure to use two wrenches simultaneously when you connect or disconnect the pipes.

CAUTIONS

CAUTIONS

CAUTION

Check whether the height drop between the indoor unit and outdoor unit, the length of refrigerant pipe, and the number of the bends meet the following requirements:

The max height drop......................................................................................................................20m

(If the height drop is more than 10m, you had better put the outdoor unit over above the indoor unit.)

The length of refrigerant pipe..........................................................................................less than 30m

The number of bends.........................................................................................................less than 15

Do not let air, dust, or other impurities fall in the pipe system during the time of installation.

The connecting pipe should not be installed until the indoor and outdoor units have been fixed already.

Keep the connecting pipe dry, and do not let moisture in during installation.

The Procedure of Connecting Pipes

1. Measure the necessary length of the connecting pipe, and make it by the following way.

(Refer to "Connect The Pipes" for details)

1) Connect the indoor unit at first, then the outdoor unit.

Bend the tubing in proper way. Do not harm to them.

Chart 19 Chart 20 Chart 21

Use frozen oil

Bend the pipe with thumb

min-radius 100mm

Make the end straight

Cut out a desired concave at the bending part of the insulating pipe.

Then expose the pipe (cover it with tapes after bending).

To prevent collapsing or deforming, please bend the pipe at its biggest radius.

Use bender to get a small radius pipes.

2) The stop value of the outdoor unit should be closed absolutely (as original state). Every time you

connect it, first loosen the nuts at the part of stop value , then connect the flare pipe immediately (in

5 minutes). If the nuts have been loosened for a long time, dusts and other impurities may enter the

pipe system and may cause malfunction later. So please expel the air out of the pipe with refrigerant

(R407C) before connection.

3) Expel the air (refer to the "Expel The Air") after connecting the refrigerant pipe with the indoor unit.

Then fasten the nuts at the repair-points.

Notices For Bendable Pipe

0

The bending angle should not exceed 90 .

Bending position is preferably in the middle of the bendable pipe. The larger the bending radius the

better it is.

Do not bend the pipe more than three times.

Bend the connecting pipe of small wall thickness ( 9.53mm)

Page 13

(kg)

2. Locate The Pipes

Drill a hole in the wall (suitable just for the size of the wall conduit, 53, 71 series diameter is 90mm,

and 120,105,140 series diameter is 105 in general), then set on the fittings such as the wall

conduit and its cover.

Bind the connecting pipe and the cables together tightly with binding tapes. Do not let air in, which

will cause water leakage by condensation.

Pass the bound connecting pipe through the wall conduit from outside. Be careful of the pipe alloc ation to do no damage to the tubing.

3. Connect the pipes.

4. Then, open the stem of stop values of the outdoor unit to make the refrigerant pipe connec ting the indoor unit with the outdoor unit in fluent flow.

5. Be sure of no leakage by checking it with leak detector or soap water.

6. Cover the joint of the connecting pipe to the indoor unit with the soundproof / insulating

sheath (fittings), and bind it well with the tapes to prevent leakage.

Use the market brass pipe

Be sure to use the same insulating materials when you buy the brass pipe (more than 9mm thick).

Flaring

90

Lean crude burr

Chart

22

A

90+4

_

45+2

_

Chart 23

1. Cut a pipe with a pipe cutter.

2. Insert a flare nut into a pipe and flare

the pipe.

A(mm)

Max

Min

6.35

8.3

9.53

12.4

12.7

15.8

16

19.0

19

23.3

Outside-diameter

(mm)

8.3

12.0

15.4

18.6

22.9

Fasten the nuts

Put the connecting tubing at the proper position,

wrench the nuts with hands, then fasten it with a

wrench.( Refer to Chart24)

CAUTIONS

Too large torque will harm the bellmouthing

and too small will cause leakage. Please

determine the torque according to Table 2.

f6.35

1420~1720

.

N cm .(144~176kgf cm)

f9.53

3270~3990 .N cm .(333~407kgf cm)

f12.7

4950~6030

.

N cm .(504~616kgf cm)

f166

6180~7540 .N cm .(630~770kgf cm)

f199

9720~11860

.

N cm .(990~1210kgfcm )

Tubing Size

Torque

Table 2

11

Chart 24

Page 14

( Refer to Chart 25)

(please refer to its manual for the way of using manifold value)

1. Loosen and remove the maintenance nuts of stop values A and B, and connect the charge hose of

the manifold value with the maintenance terminator of stop value A. (Be sure that stop values A and

B are both closed)

2. Connect the joint of the charge hose with the vacuum pump.

3. Open the Lo-lever of the manifold value completely.

4. Turn on the vacuum pump. At the beginning of pumping, loosen the maintenance terminator nut of

stop value B a little to check whether the air comes in (the sound of the pump changes, and the

indicator of compound meter turns below zero). Then fasten the nut.

5. When the pumping has finished, close the Lo-lever of the manifold value completely and turn off the

vacuum pump.

When you have pumped for over 15 minutes, please confirm that the indicator of multi-meter is on

-5

1.0 10 Pa(-76cmHg).

6. Loosen and remove the quadrangle cover of stop values A and B to open stop value A and B com-

pletely, then fasten them.

12

Capacity

LENGTH(L)

Less than 8m (one-way)

Added Refrigerant When Over 8m(one-way)

Table 3

Please record and reserve well the refrigerant stow capacity of your air conditioner for later maintenance.

MCA-24CRN2

MCA-24HRN2

MCA-42(36,48)CRN2

MCA-42(36,48)HRN2

0.065 (L-8)

Necessary Refrigerant Stow Capacity

Expel the air with a vacuum pump

Page 15

7. Disassemble the charge hose from the repair-mouth of stop value A, and fasten the nut.

-76 cmHg

Lo-lever

Hi-lever

Charge hose

Charge hose

Vacuum pump

Lo-lever

Manifold valve

Multi-meter

Pressure meter

NOTE: in the chart

A...........Lo-stop value

B...........Hi-stop value

C,D.......Joints of the connecting pipe

to the indoor unit.

CAUTIONS

All the stop values should be opened before test operation. Each air conditioner has two stop values

of different sizes on the side of the outdoor unit which operate as Lo-stop value and Hi-stop value,

respectively. (Refer to Chart 26)

Chart 27

CHECK THE LEAKAGE

INSULATION

Check all the joints with the leak detector or soap water. (refer to Chart 29)

13

Be sure to with insulating materials cover all the exposed parts of the flare pipe joints and refrigerant pipe on the liquid-side and the gas-side. Ensure that there is no gap between them.

Incomplete insulation may cause water condensation.

Check-point of indoor unit

Check-point of outdoor unit

D

B

C

A

Flare nut

Stopper

Cap

Valve body

Valve stern

Chart 26

Page 16

CONNECT THE DRAIN PIPE

14

1-1.5 m

a

b

>1.5m

c

Lean over 1/50

Constrict here

Drainpipe

Linking pipe

Chart 28

>200mm

>1-1.5 m

>200mm

Lean over 1/50

Chart 29

Note:

MCA-24CRN2, MCA-24HRN2 Serie C=200mm

Series C=212mmMCA-42(36,48)CRN2, MCA-42(36,48)HRN2

Pump-pipe clasp

(the fittings)

1. Install the drainpipe of the indoor unit

You can use a polyethylene tube as the drainpipe (out-dia.37-39mm, in-dia.32mm). It could be

bought at local market or from your dealer.

Set the mouth of the drainpipe onto the root of the body's pump-pipe, and clip the drainpipe and the

out-let pipe sheath (fittings) together firmly with the out-let pipe clasp (fitting).

CAUTIONS: Use your strength carefully to prevent the pump-pipe from breaking.

The body's pump pipe and the drainpipe (especially the indoor part) should be covered evenly with

the out-let pipe sheath (fittings) and be bound tightly with the constrictor to prevent condensation

caused by entered air.

To prevent water from flowing backwards into the air conditioner while the air conditioner stops,

please lean the drainpipe down toward outdoor (outlet-side) at a degree of over 1/ 50. And please

avoid any bulge or water deposit.( Refer to Chart 28.a)

Do not drag the drainpipe violently when connecting to prevent the body from being pulled. Meanwhile, one support-point should be set every 1~1.5m to prevent the drainpipe from yielding (Refer

to Chart 28.b). Or you can tie the drainpipe with the connecting pipe to fix it.(Refer to Chart 28.c)

In the case of prolonged drainpipe, you had better tighten its indoor part with a protection tube to

prevent it from loosing.

If the outlet of the drainpipe is higher than the body's pump joint, the pipe should be arranged as

vertically as possible. And the lift distance must be less than 200mm, otherwise the water will

overflow when the air conditioner stops.( Refer to Chart 29)

The end of the drainpipe should be over 50mm higher than the ground or the bottom of the drainage

chute, and do not immerse it in water. If you discharge the water directly into sewage, be sure to

make a U-form aquaseal by bending the pipe up to prevent the smelly gas entering the house

through the drain pipe.

C

Page 17

15

2. Drainage test

Check whether the drainpipe is unhindered

New built house should have this test done before paving the ceiling.

1) Remove the test cover, and stow water of about 2000ml to the water receiver through the stow

tube. ( Refer to Chart 30)

Pump joint

Test mouth

Body

Water-receiver

Test cover

Stow tube

Drain plug

Chart 30

3. Drain Elbow Installation (Cooling Only Type Without)

Fit the seal into the drain elbow, then insert the drain elbow into the base pan hole of outdoor, rotate

0

90 to securely assemble them. Connect the drain elbow with an extension drain hose (Locally

purchased), in case of the condensate draining off the outdoor unit during the heating mode.

2) Turn on the power, and operate the air conditioner under the "COOLING" mode. Listen to the

sound of the drain pump. Check whether the water is discharger well (a lag of 1min is allowed

before discharging, according to the length of the drain pipe), and check whether water leaks

from the joints.

CAUTIONS: If there is any malfunction, please resolve it immediately.

3) Stop the air conditioner, turn off the power, and reset the test cover to its original position.

The drain plug is used to empty the water-receiver for maintenance of the air conditioner. Please

stuff it imposition at all times during operation to avoid leakage.

Chart 31

Seal

The base pan hole

of outdoor unit

Drain elbow

Seal

The base pan

of outdoor unit

Drain

elbow

Page 18

WIRING

CAUTION

1. The Specification of Power

TYPE

POWER

PHASE 1-PHASE

3-PHASE

CIRCUIT BREAKER/FUSE (A)

1. The air conditioner should use separate power supply with rated voltage.

2. The external power supply to the air conditioner should have ground wiring, which is linked to the

ground wiring of the indoor and outdoor unit.

3. The wiring work should be done by qualified persons according to circuit drawing.

4. A disconnection device having an air gap contact separation in all active conductors should

incorporated in the fixed wiring according to the National wiring regulation.

5. Be sure to locate the power wiring and the signal wring well to avoid cross-disturbance and their

contact with connecting pipe or stop value body.

6. The wiring attached to this air conditioner is 6m long. Be sure to prolong it with wiring of the same

type and proper length if necessary. Generally, do not twist two wiring together unless the joint is

soldered well and covered with insulator tape.

7. Do not turn on the power until you have checked carefully after wiring.

40/25

1.0

2.5

2.5

2.5

20/13

1.0

2.5

2.5

2.5

2. Remove the protection board.

Disassemble the bolts from the maintenance board, and pull it in the direction of the arrow to remove

the protection board.

Notice: Do not scratch the surface during operation.

Chart 32

Protection board

Terminator

ATTENTION: Chart 32 is based on the standard model, which may look a little different from your

own outdoor unit.

16

VOLT (V)

GROUND WIRING

POWER (INDOOR/OUTDOOR

CONNECTING WIRING)

STRONG ELEC-TRIC SIGNAL

(INDOOR/OUTDOOR

CONNECTING WIRING)

50Hz 50Hz

FREQUENCY (Hz)

220-240V~ 380V 3N~

WIRING

SIZE

2

(mm )

POWER WRING (INDOOR UNIT)

MCA-24CRN2

MCA-24HRN2

MCA-42(36,48)CRN2

MCA-42(36,48)HRN2

Page 19

2. Wiring chart

Power

Switch/Fuse

Power linking wiring (indoor)

Strong elec-signal link wiring

Weak elec-signal link wiring

Indoor

Unit

Outdoor

Unit

Chart 33

17

Chart 34

Note: The cooling only type without the link listed by broken line.

MCA-24CRN2, MCA-24HRN2

air conditioner link-circuit

1

OUTDOOR UNIT

INDOOR UNIT

N

L1 L

1 N 3 4 5

N

3-core cable

3-core cable

220~240VAC 50Hz

(3-core cable

2

3x2.5mm)

2

3x1mm

2

3x2.5mm

N1

3 4 5

3-core AWG24

Please ground air conditioner well. Otherwise, an important grounding may affect anti-jamming

performance of whole unit

Page 20

18

Chart 35

Power

380V~

50Hz

5-core Cable

2

H07RN 5x2.5mm

5-core Cable

2

H07RN 5x2.5mm

2

1. H07RN 4X1.0mm

1. Cooling/Heating type

2

2. H07RN 3X1.0mm

2. Cooling only type

INDOOR UNIT

123456

1234

ABCN

C1 C B A N

Outdoor unit

NOTE: The cooling only type without the links listed by broken line.

MCA-42(36,48)CRN2

MCA-42(36,48)HRN2

3-core AWG24

air conditioner link-circuit

Page 21

TEST OPERATION

A protection feature prevents the air conditioner from being activated for approximately 3 minutes when

it is restarted immediately after shut off.

1. The test operation must be carried out after the entire installation has been completed.

2. Please confirm the following points before the test operation:

The indoor unit and outdoor unit are installed properly.

Tubing and wiring are correctly completed.

The refrigerant pipe system is leakage-checked.

The drainage is unimpeded.

The heating insulation works well.

The ground wiring is connected correctly.

The length of the tubing and the added stow capacity of the refrigerant have been recorded.

The power voltage fits the rated voltage of the air conditioner.

There is no obstacle at the outlet and inlet of the outdoor and indoor units.

The gas-side and liquid-side stop values are both opened.

The air conditioner is pre-heated by turning on the power.

3. According to the user's requirement, install the remote controller frame where the remote controller's

signal can reach the indoor unit smoothly.

4. Test operation

Set the air conditioner under the mode of "COOLING" with the remote controller, and check the

following points per the "Owner's Manual". If there is any malfunction, please resolve it as per

chapter "Troubles And Cause" in the "Owner's Manual".

1) The indoor unit

a. Whether the switch on the remote controller works well.

b. Whether the buttons on the remote controller works well.

c. Whether the air flow louver moves normally.

d. Whether the room temperature is adjusted well.

e. Whether the indicator lights normally.

f. Whether the temporary buttons works well.

g. Whether the drainage is normal.

h. Whether there is vibration or abnormal noise during operation.

I. Whether the air conditioner heats well in the case of the HEATING/COOLING type.

2) The outdoor unit

a. Whether there is vibration or abnormal noise during operation.

b. Whether the generated wind, noise, or condensed of by the air conditioner have influenced your

neighborhood.

c. Whether any of the refrigerant is leaked.

CAUTION

19

Page 22

A

CS0174N

Loading...

Loading...