Page 1

Midea Precision AC Technical Manual-Down Delivery Series MCAC-RTSM-2013-04

0

Midea Precision Air Conditioner

Technical Manual

(Down delivery series)

Midea reserves the right to discontinue, or change specification or designs at any time without

notices and without incurring obligations.

Page 2

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

1

Content

1. GENERAL INFORMATION ................................................................... 3

1.1 MEASUREMENTS ............................................................................................................ 3

1.2 EXTERNAL APPEARANCE ................................................................................................. 4

1.3 NOMENCLATURE ............................................................................................................. 5

2. SPECIFICATION & PERFORMANCE .................................................. 6

2.1FEATURES ...................................................................................................................... 6

2.2

REFRIGERANT CIRCUIT .................................................................................................... 8

2.3 SPECIFICATIONS ........................................................................................................... 10

2.4 DIMENSION (UNIT: MM) .................................................................................................. 32

2.5 SERVICE SPACE ............................................................................................................ 36

2.6 WIRING DIAGRAM ......................................................................................................... 37

3. INSTALLATION .................................................................................. 40

3.1 STORAGE ENVIRONMENT ............................................................................................... 42

3.2 INDOOR INSTALLATION ................................................................................................... 42

3.3 INSTALLING OUTDOOR UNITS .......................................................................................... 45

3.4 CONNECTING REFRIGERANT PIPE ................................................................................... 46

3.5 VACUUM AND ADD REFRIGERANT .................................................................................... 49

3.6

WATER PIPE INSTALLATION ............................................................................................ 50

3.7

ELECTRIC CONNECTION ................................................................................................ 52

3.8 TRIAL RUN ................................................................................................................... 55

4. CONTROL SYSTEM ........................................................................... 61

4.1 TABLE OF MAIN CONTROL COMPONENTS AND CONTROL LOAD ............................................ 61

4.2 MAIN CONTROL FUNCTION ............................................................................................. 64

5. OPERATION ....................................................................................... 65

Page 3

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

2

5.1 TEMPERATURE/HUMIDITY SET POINT SETTING FUNCTION .................................................. 65

5.2 QUERY FUNCTION FOR KEY COMPONENTS OPERATING STATUS .......................................... 65

5.3 SETTING FUNCTION OF USING PARAMETERS .................................................................... 67

5.4 MAINTENANCE MANAGEMENT ........................................................................................ 68

5.5 CLOCK MANAGEMENT ................................................................................................... 69

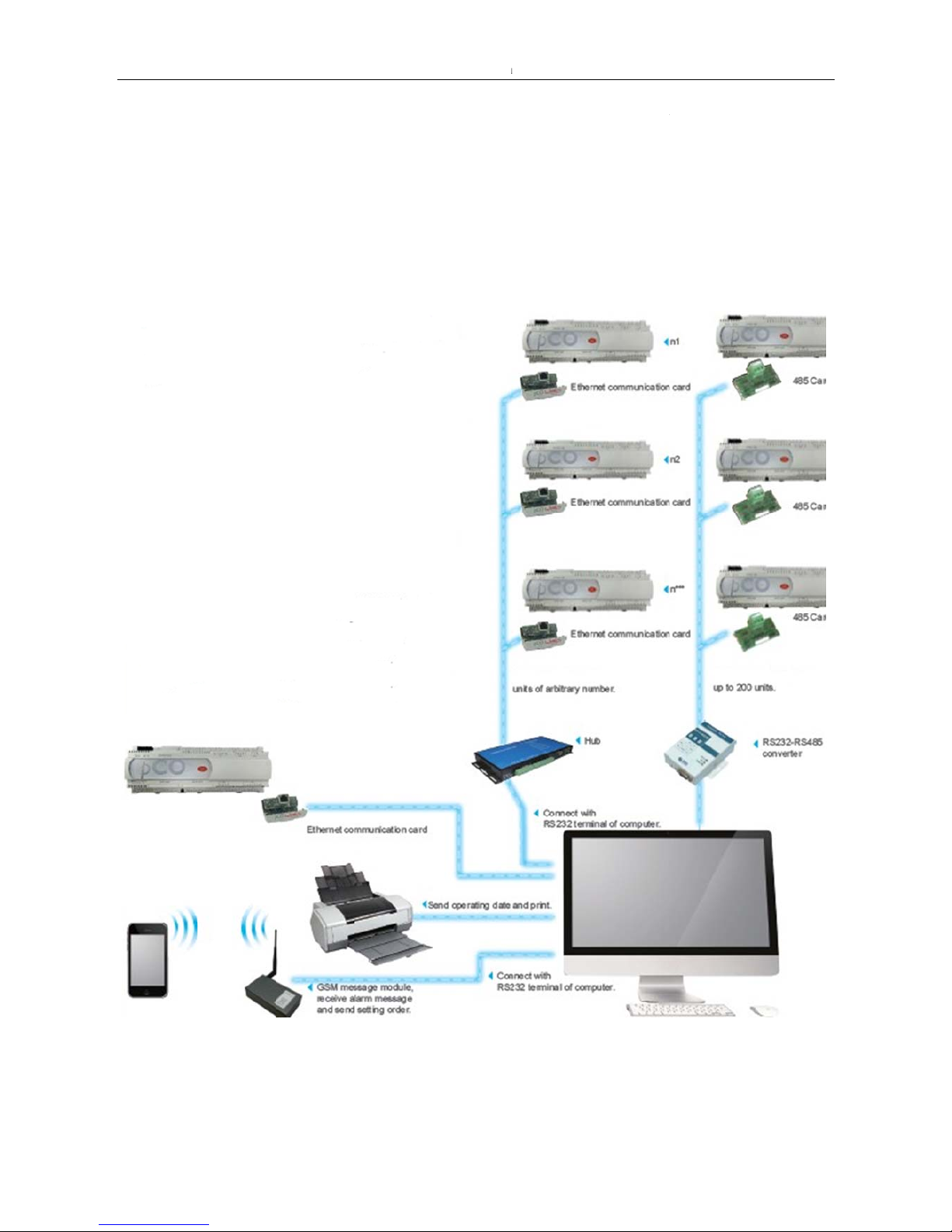

6. NETWORK FUNCTION INTRODUCTION ......................................... 71

6.1 GROUP CONTROL NETWORK SETTING ............................................................................. 72

6.2 THE ETHERNET COMMUNICATION CARD INTRODUCTION .................................................... 78

7. MAINTENANCE .................................................................................. 81

7.1 ELECTRICAL MAINTENANCE ........................................................................................... 81

7.2 CONTROL MAINTENANCE ............................................................................................... 81

7.3 FILTER SCREEN MAINTENANCE ....................................................................................... 82

7.4 INDOOR FAN COMPONENTS MAINTENANCE ...................................................................... 83

7.5 HUMIDIFIER MAINTENANCE ............................................................................................ 83

7.6 ELECTRICAL HEATING COMPONENTS ............................................................................... 85

7.7 REFRIGERATION SYSTEM ............................................................................................... 85

7.8 COMPRESSOR MONITORING AND REPLACEMENT .............................................................. 86

7.9

OUTDOOR FAN MAINTENANCE ........................................................................................ 87

8. TROUBLE SHOOTING ....................................................................... 88

9. ACCESSORIES .................................................................................. 93

ANNEX I: ALARM TABLE ...................................................................... 94

Page 4

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

3

1. General information

1.1 Measurements

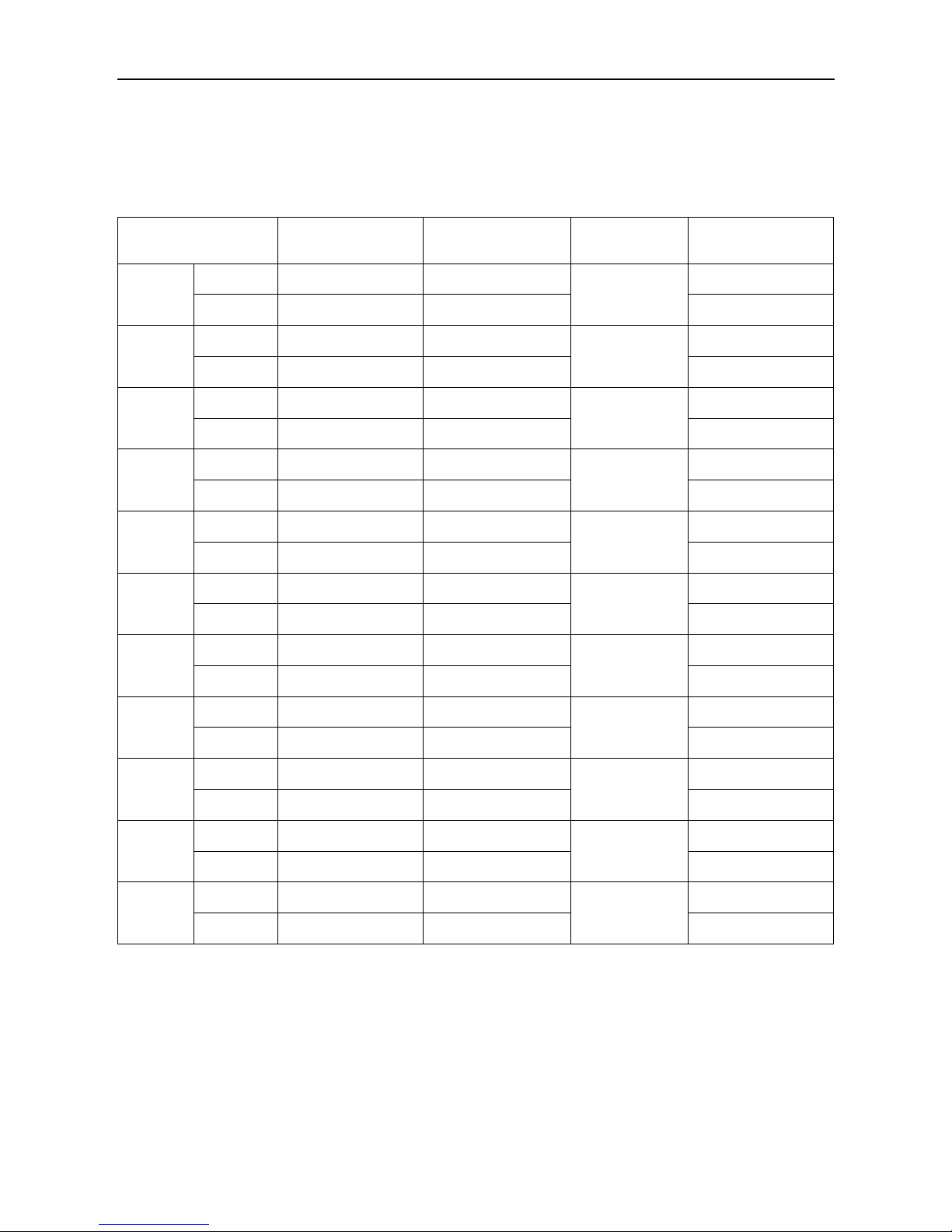

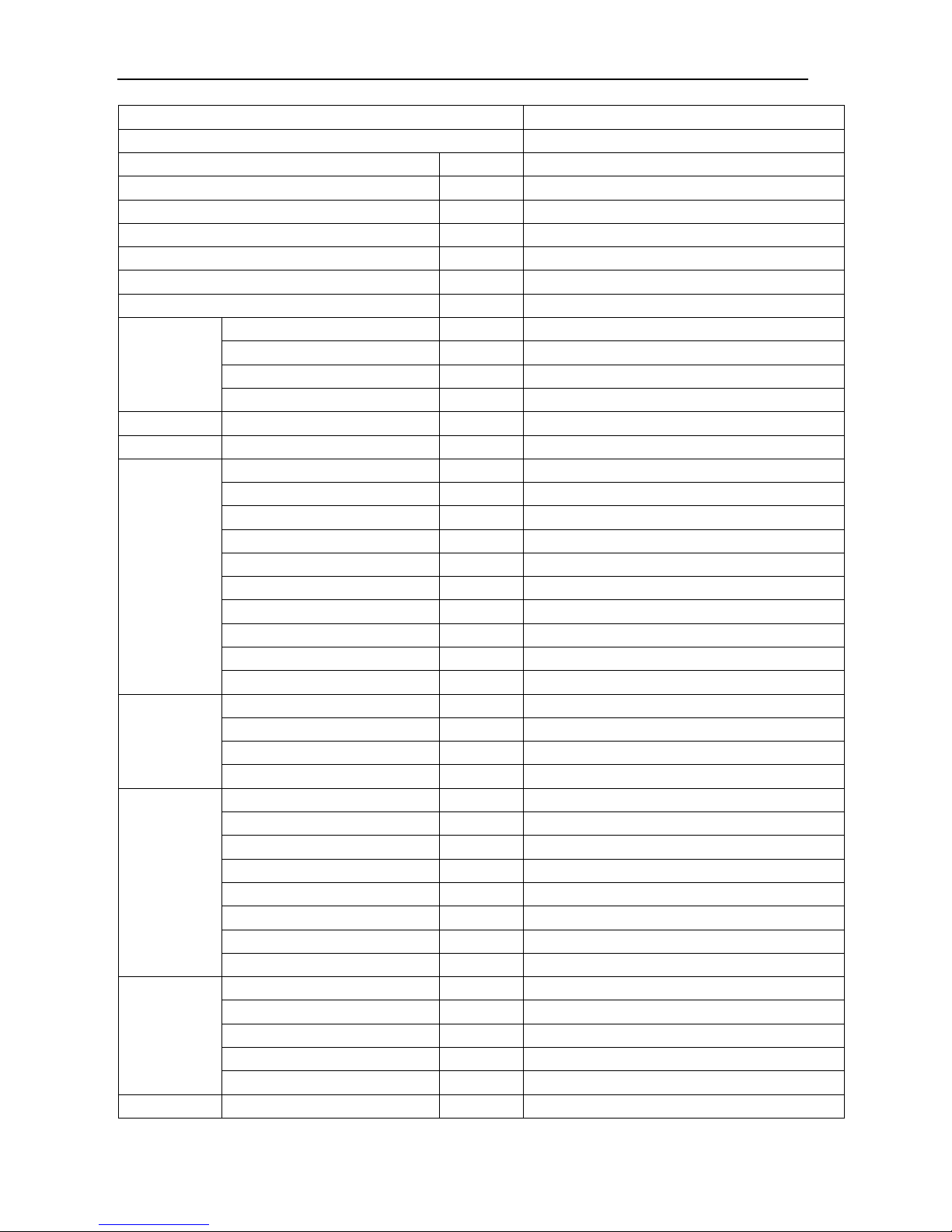

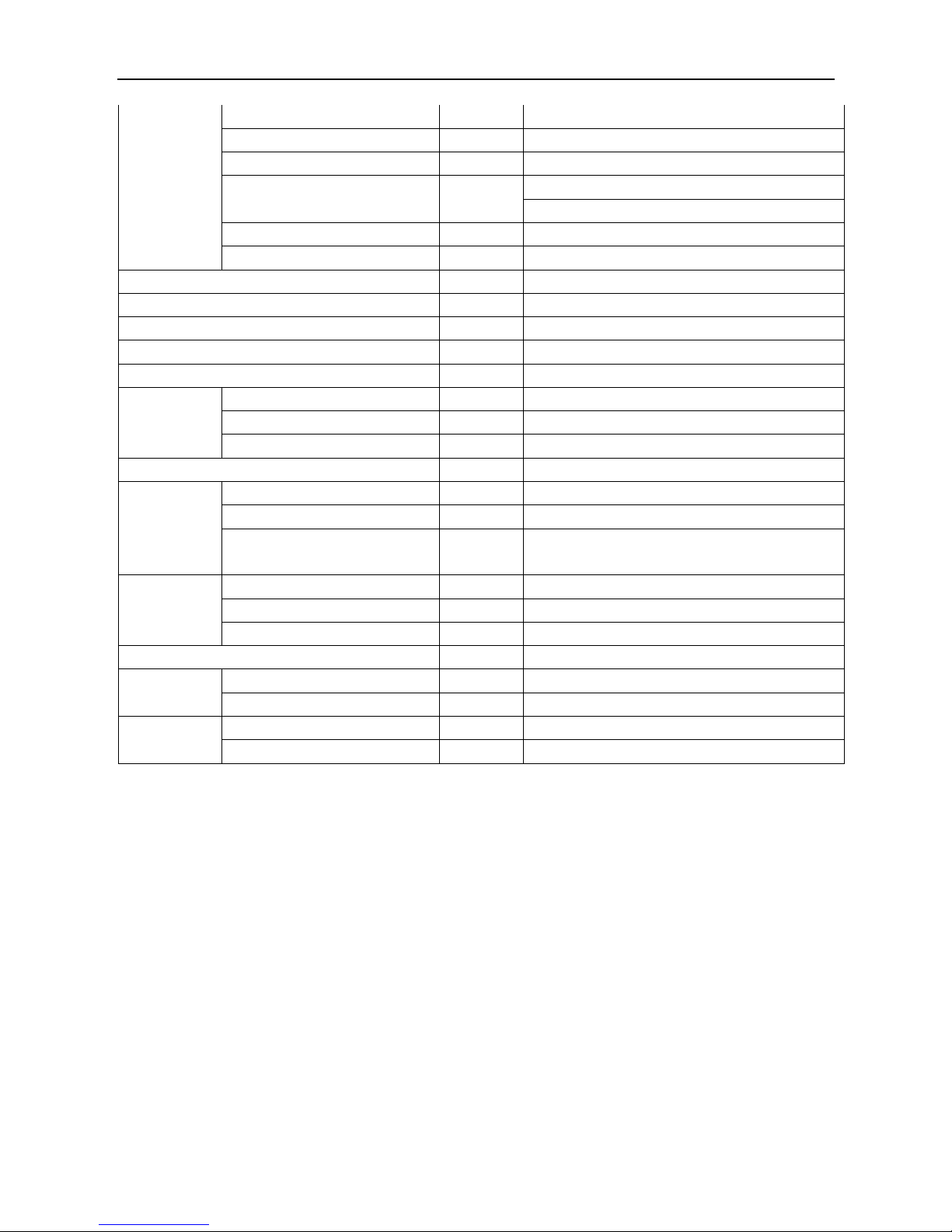

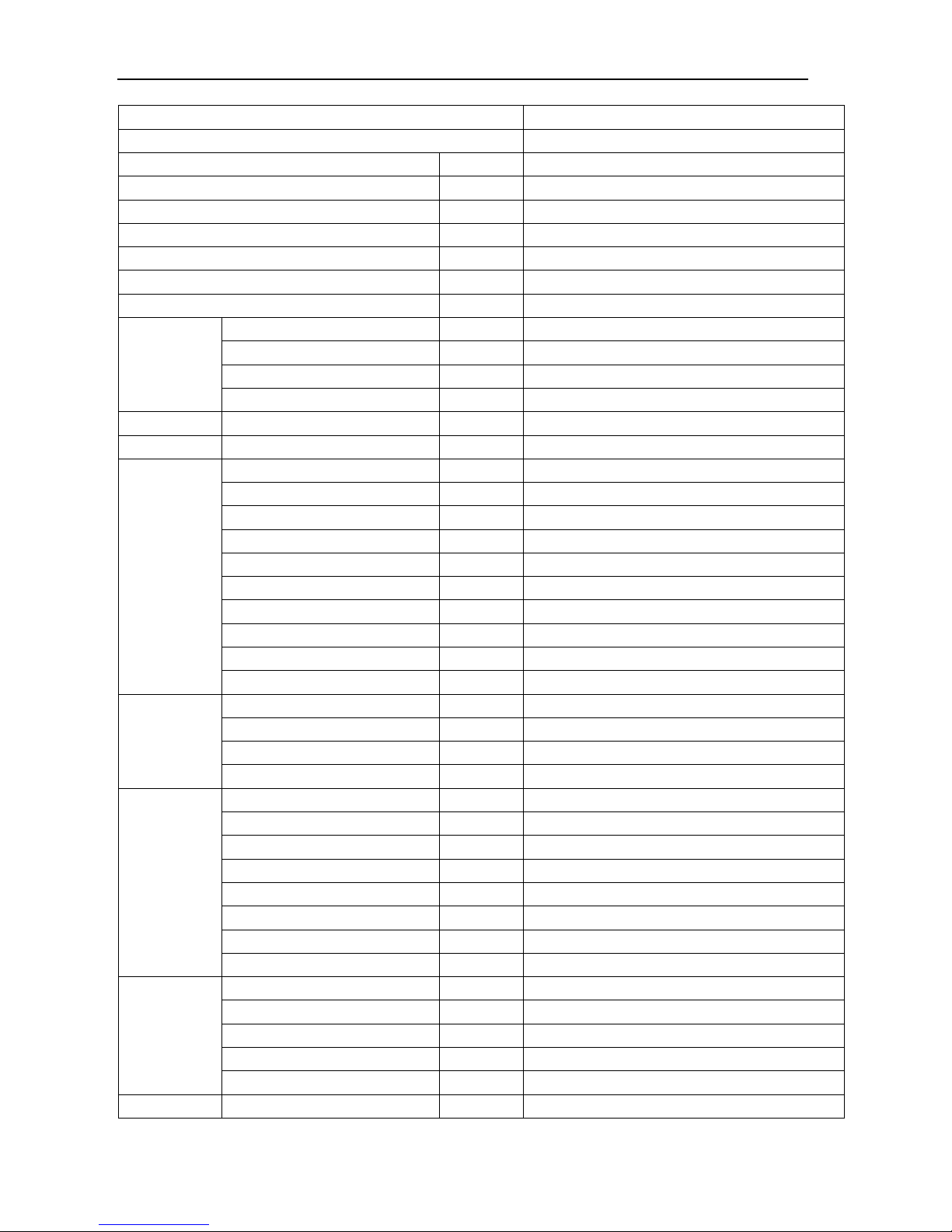

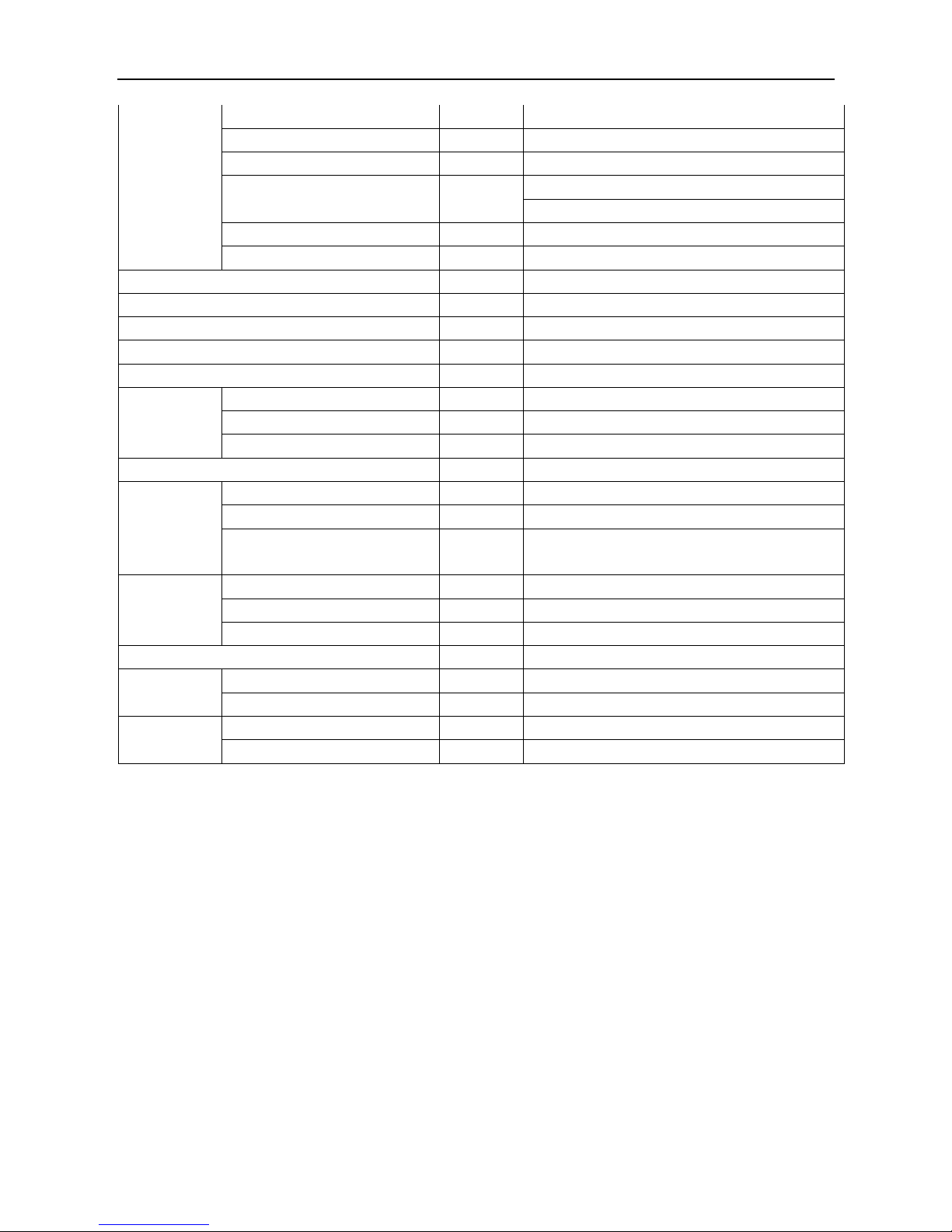

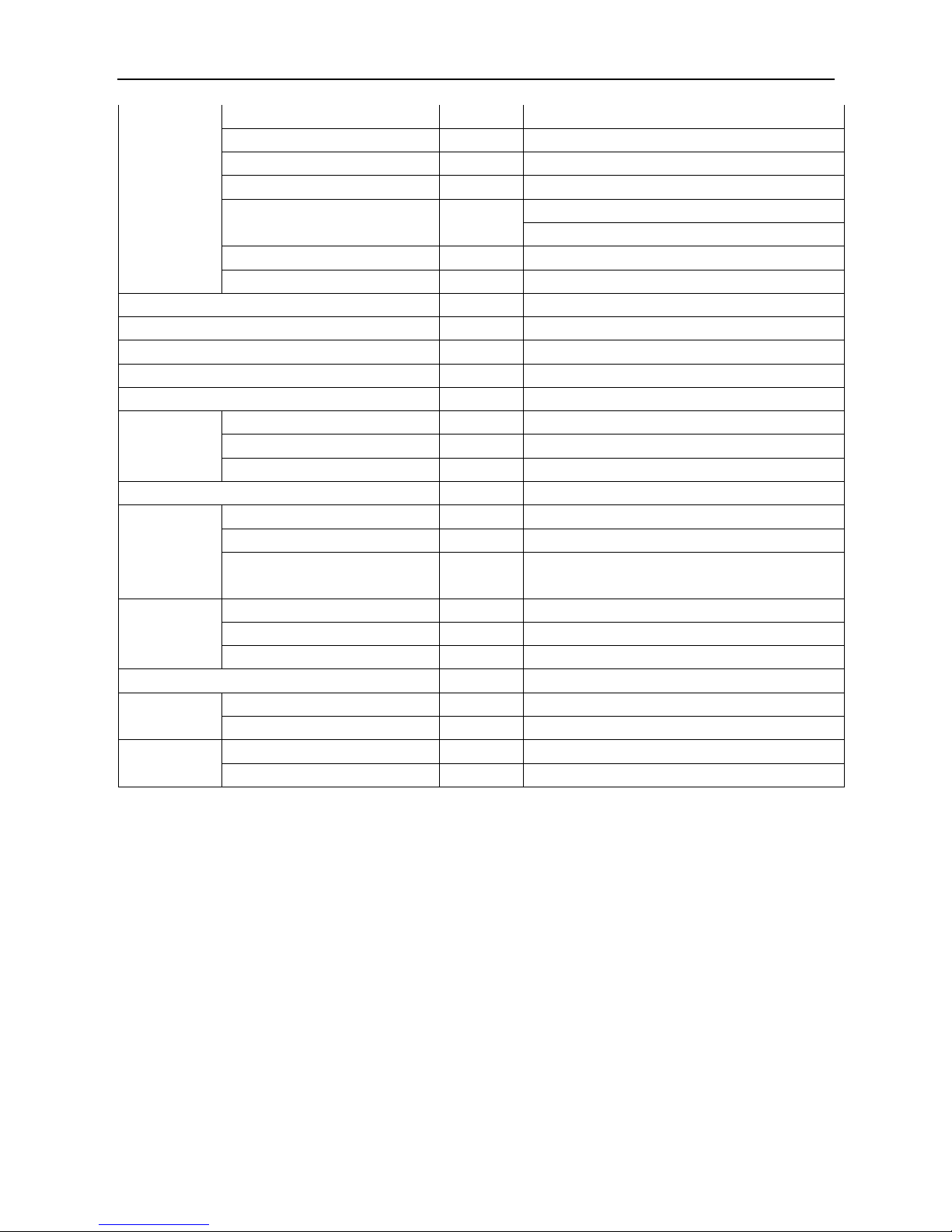

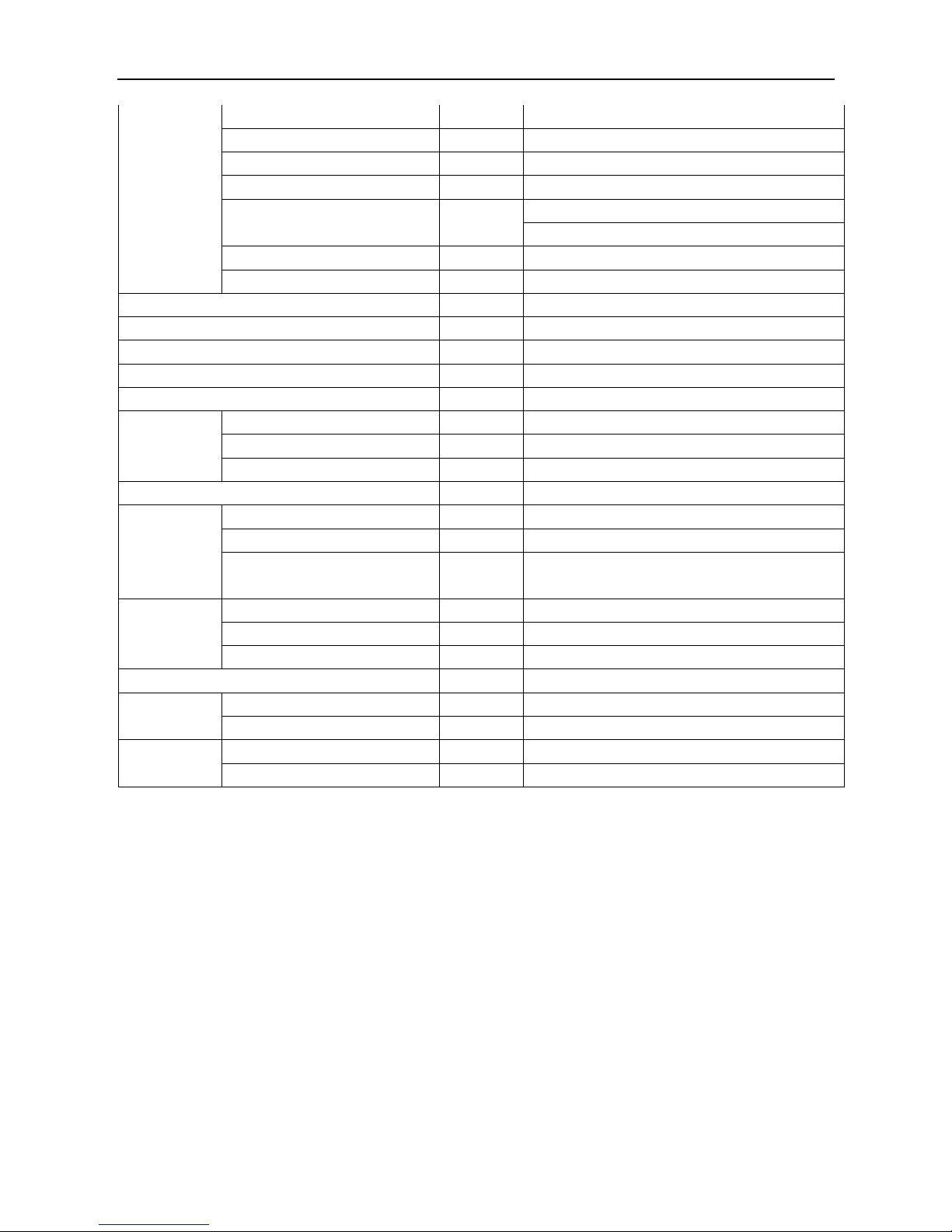

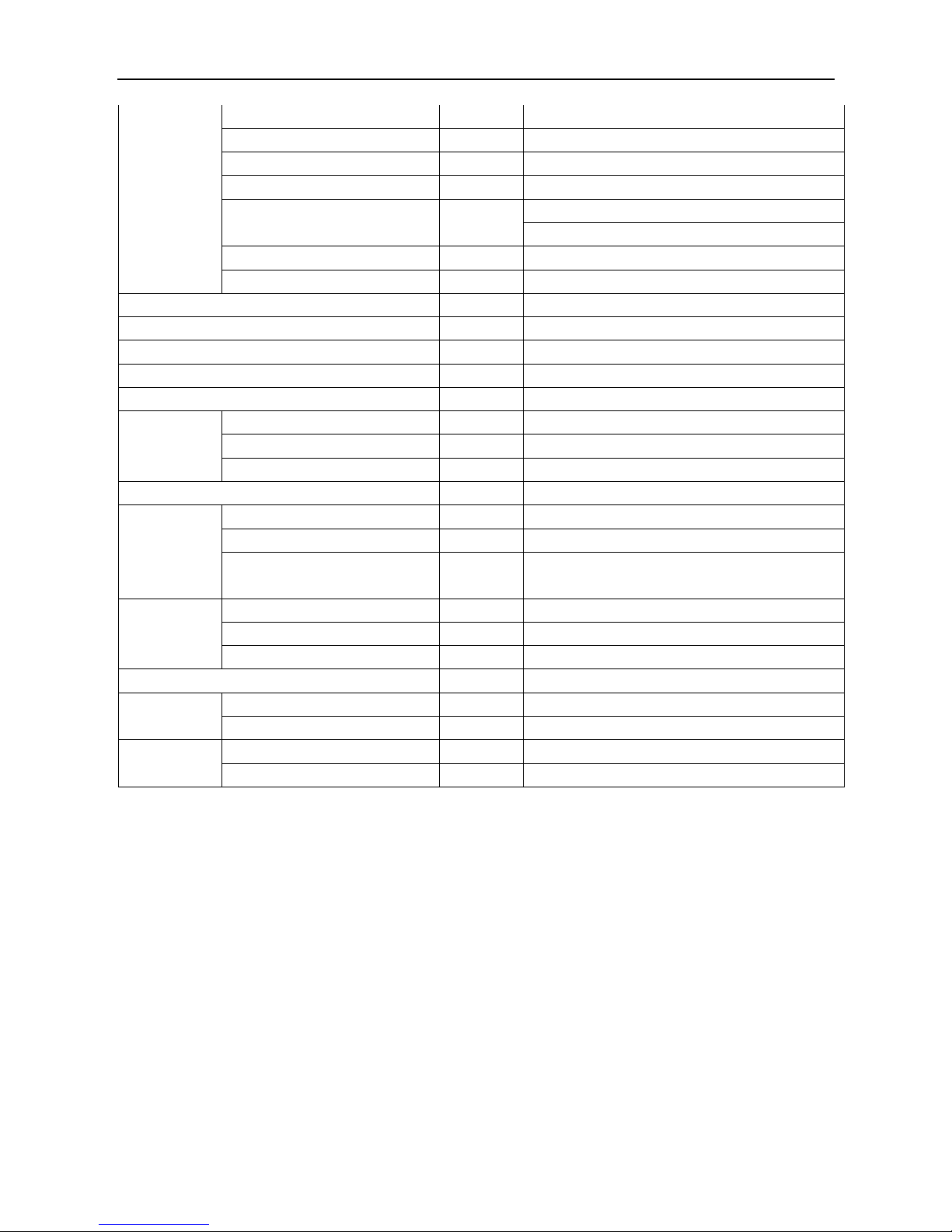

Type Model

Dimension

(mm, W×H×D)

Outdoor unit

(Quantity)

Power Supply

20kW

Indoor MAD020T1N1S1 895×1,971×870

1

380V~,3Ph,50Hz

Outdoor MA0331 1,470×988×870 380V~,3Ph,50Hz

25kW

Indoor MAD025T1N1S1 895×1,971×870

1

380V~,3Ph,50Hz

Outdoor MA0431 1,470×988×870 380V~,3Ph,50Hz

30kW

Indoor MAD030T1N1S1 895×1,971×870

1

380V~,3Ph,50Hz

Outdoor MA0541 1,660×1,290×870 380V~,3Ph,50Hz

35kW

Indoor MAD035T1N1S1 1,400×1,971×870

1

380V~,3Ph,50Hz

Outdoor MA0601 1,660×1,290×870 380V~,3Ph,50Hz

40kW

Indoor MAD040T2N1S1 1,790×1,971×870

2

380V~,3Ph,50Hz

Outdoor MA0331 1,470×988×870 380V~,3Ph,50Hz

45kW

Indoor MAD045T1N1S1 1,790×1,971×870

1

380V~,3Ph,50Hz

Outdoor MA0752 1,980×1,290×870 380V~,3Ph,50Hz

50kW

Indoor MAD050T2N1S1 1,790×1,971×870

2

380V~,3Ph,50Hz

Outdoor MA0431 1,470×988×870 380V~,3Ph,50Hz

60kW

Indoor MAD060T2N1S1 1,790×1,971×870

2

380V~,3Ph,50Hz

Outdoor MA0541 1,660×1,290×870 380V~,3Ph,50Hz

70kW

Indoor MAD070T2N1S1 2,685×1,971×870

2

380V~,3Ph,50Hz

Outdoor MA0601 1,660×1,290×870 380V~,3Ph,50Hz

80kW

Indoor MAD080T2N1S1 2,685×1,971×870

2

380V~,3Ph,50Hz

Outdoor MA0752 1,980×1,290×870 380V~,3Ph,50Hz

90kW

Indoor MAD090T2N1S1 2,685×1,971×870

2

380V~,3Ph,50Hz

Outdoor MA0982 2,480×1,290×870 380V~,3Ph,50Hz

Page 5

Midea Precisi

4

1.2 Exter

n

Indoo

r

Indoo

r

Indoo

r

on AC Techni

c

al appea

r

unit-20kW

,

unit-35kW

,

unit-70kW

,

c

al Manual

ance

25kW, 30

k

40kW, 45

k

80kW, 90

k

W:

W, 50kW,

6

W:

0kW:

M

MCAC-PDS

M

-2013-01

Page 6

MCAC-PDS

M

Outdo

o

Outdo

o

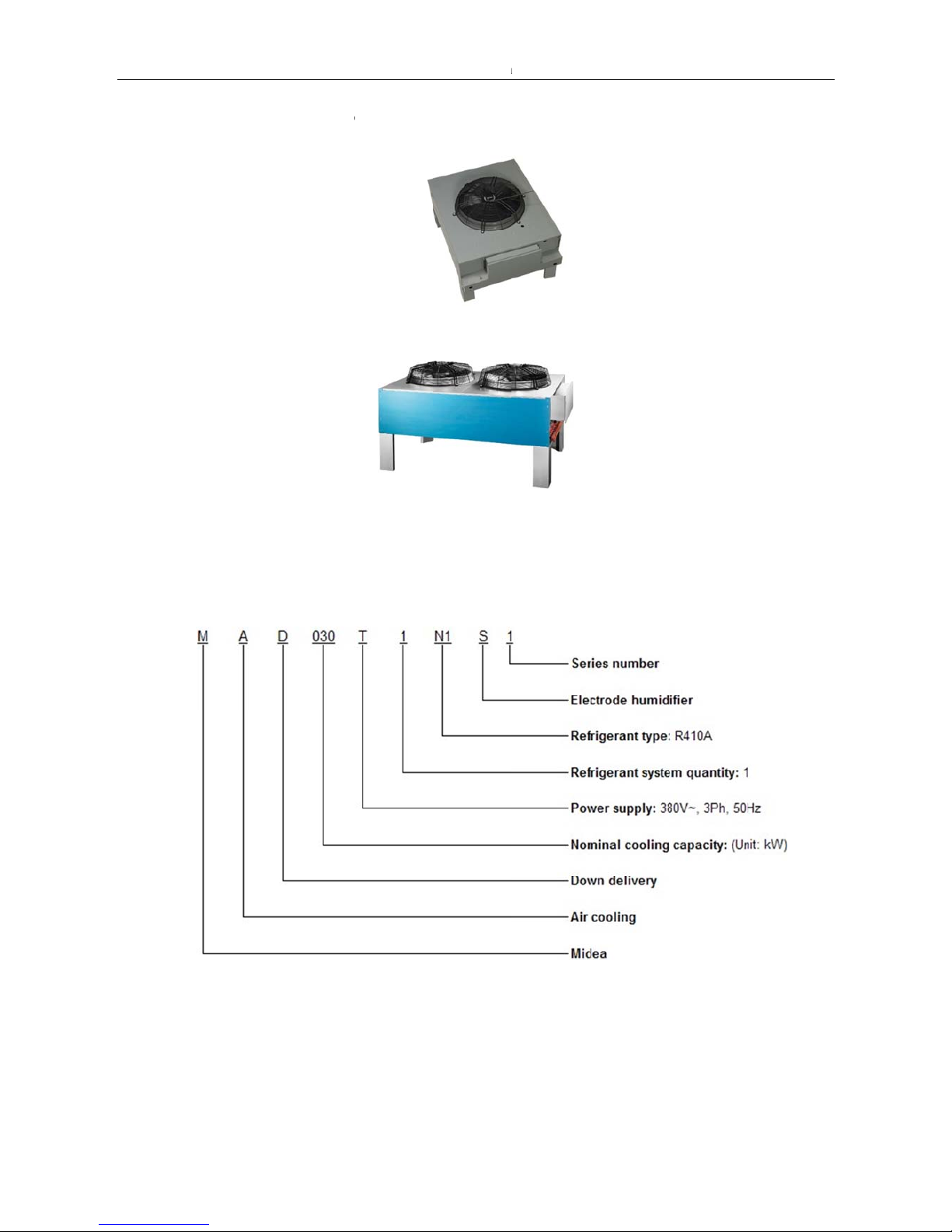

1.3 Nome

Indoor u

n

-2013-04

r unit-Sin

g

r unit-Do

u

nclature

it

le fan mot

o

ble fan mo

r:

tors:

Mide

a

Precision A

C

Technical Manual-Down Delivery Series

5

Page 7

Midea Precisi

6

Outdo

o

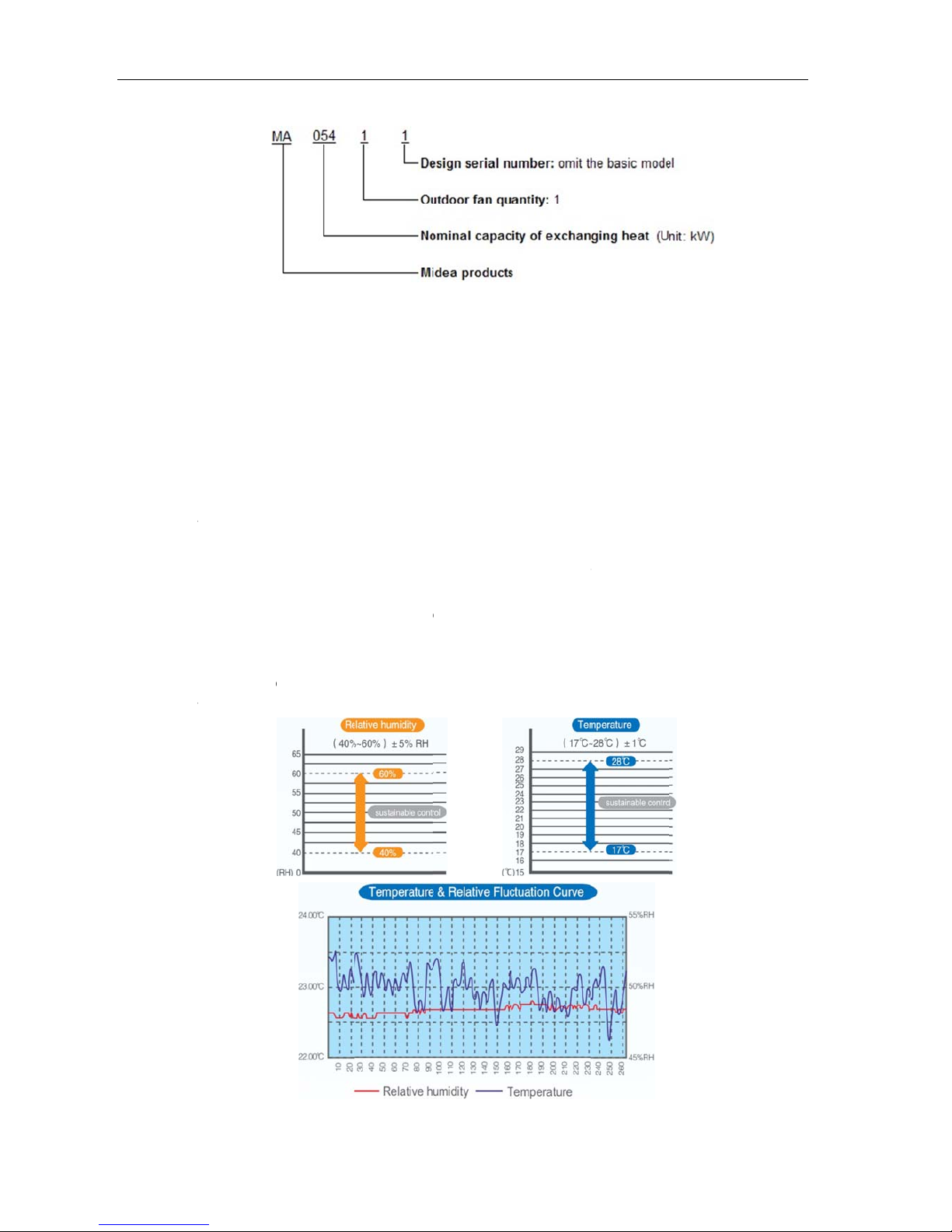

2. Spec

i

2.1Feature

s

V sha

p

pipe.

Chang

e

tempe

r

Reliabl

e

Doubl

e

from th

Copel

a

Adopt

a

integra

t

Accura

tempe

r

on AC Techni

c

r unit

ficatio

n

e design h

i

the valid

e

ature fluctu

a

electric h

e

wall desig

n

e unit body.

nd, special

dvantage

t

ed control

s

te micropr

o

ature & hu

m

al Manual

& perf

o

gh efficient

vaporator

a

tion.

ater.

, heat-insul

high efficie

n

echnology

o

olution of h

cessor con

t

idity senso

rmanc

e

evaporato

r

rea by ele

c

ated casin

g

t compress

o

f immerse

d

umidity.

rol technol

o

, frequenc

y

with hydr

o

tric valve t

o

reduces th

or.

electrode

gy and ke

converter,

p

philic alumi

reduce th

e

e exchang

e

humidifier,

c

y

parts: Hi

g

ressure se

M

num fin an

d

relative h

u

d heat and

arel clean

a

h quality h

nsor.

MCAC-PDS

M

inner gro

o

midity with

o

prevent th

e

ble steam

c

umidity co

n

-2013-01

ved coppe

ut appare

n

condensat

e

ylinder, an

d

trol modul

e

r

t

,

Page 8

MCAC-PDS

M

Multipl

e

The ru

n

100 pi

e

Three

t

Rotary

whole

y

To en

h

comm

u

capabil

-2013-04

protection

s

ning para

m

ces of erro

r

ypes of pa

s

function, s

t

ear.

ance rem

o

nication ca

r

ities as the

: High and

eter can b

e

records ca

sword: use

r

andby fun

c

te commu

n

d (optional

requiremen

t

low pressu

r

displayed i

be stored.

password,

tion and jo

i

ications a

n

part) and

R

s.

Mide

a

e protectio

n

n the scree

n

maintenan

c

in-in functi

o

nd control

S485 card

Precision A

C

, discharge

of the con

t

e passwor

d

n can ens

u

the precisi

(optional p

a

Technical M

a

temperatur

e

rol panel.

, factory pa

s

re the unit

s

on air con

rt) can sup

nual-Down D

e protectio

n

ssword.

keep ope

ditioners, t

port the co

m

elivery Series

7

, etc.

rating in th

e

he Ethern

e

municatio

n

t

Page 9

Midea Precisi

8

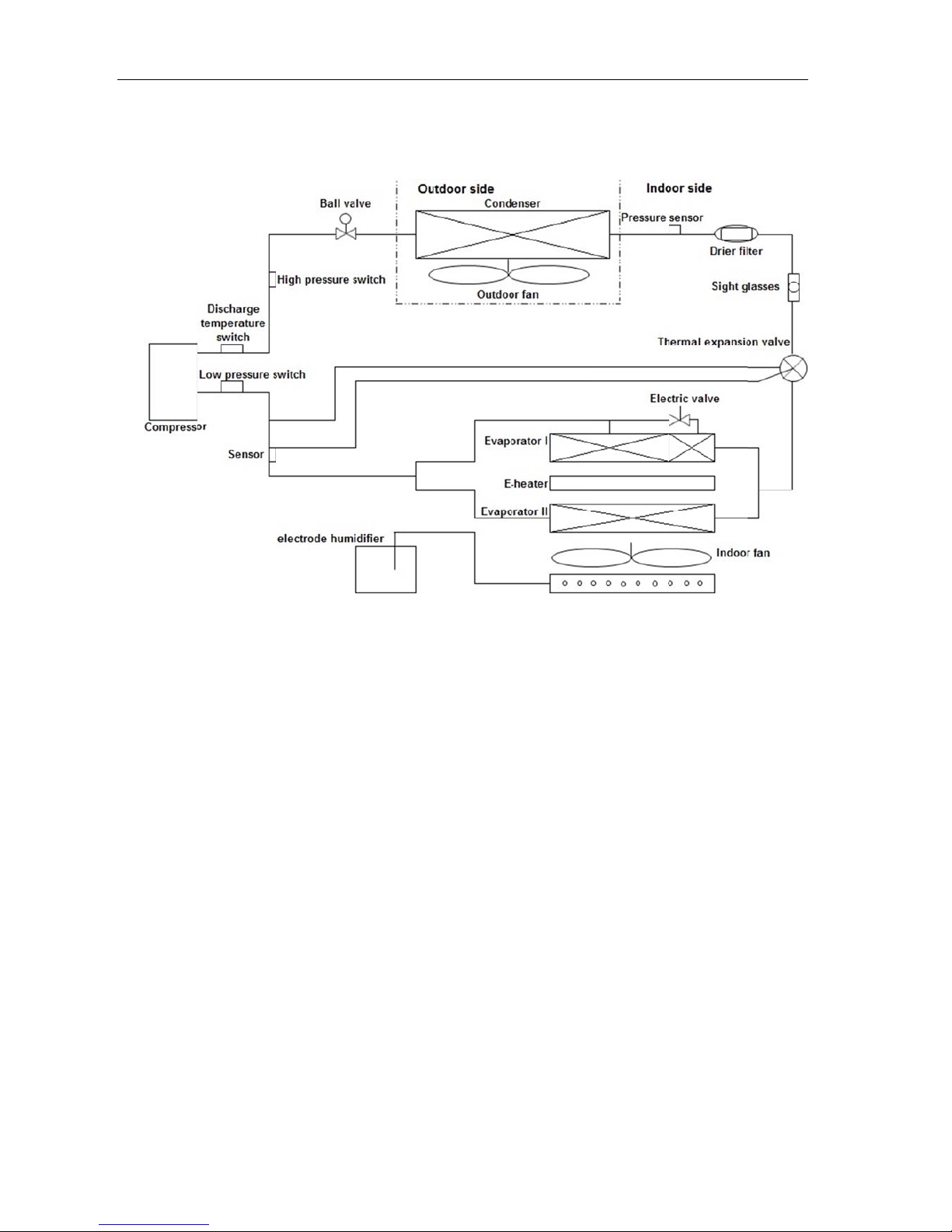

2.2 Refri

g

Single

on AC Techni

c

erant cir

c

refrigeran

t

al Manual

uit

circuit typ

e:

MMCAC-PDSM-2013-01

Page 10

MCAC-PDS

M

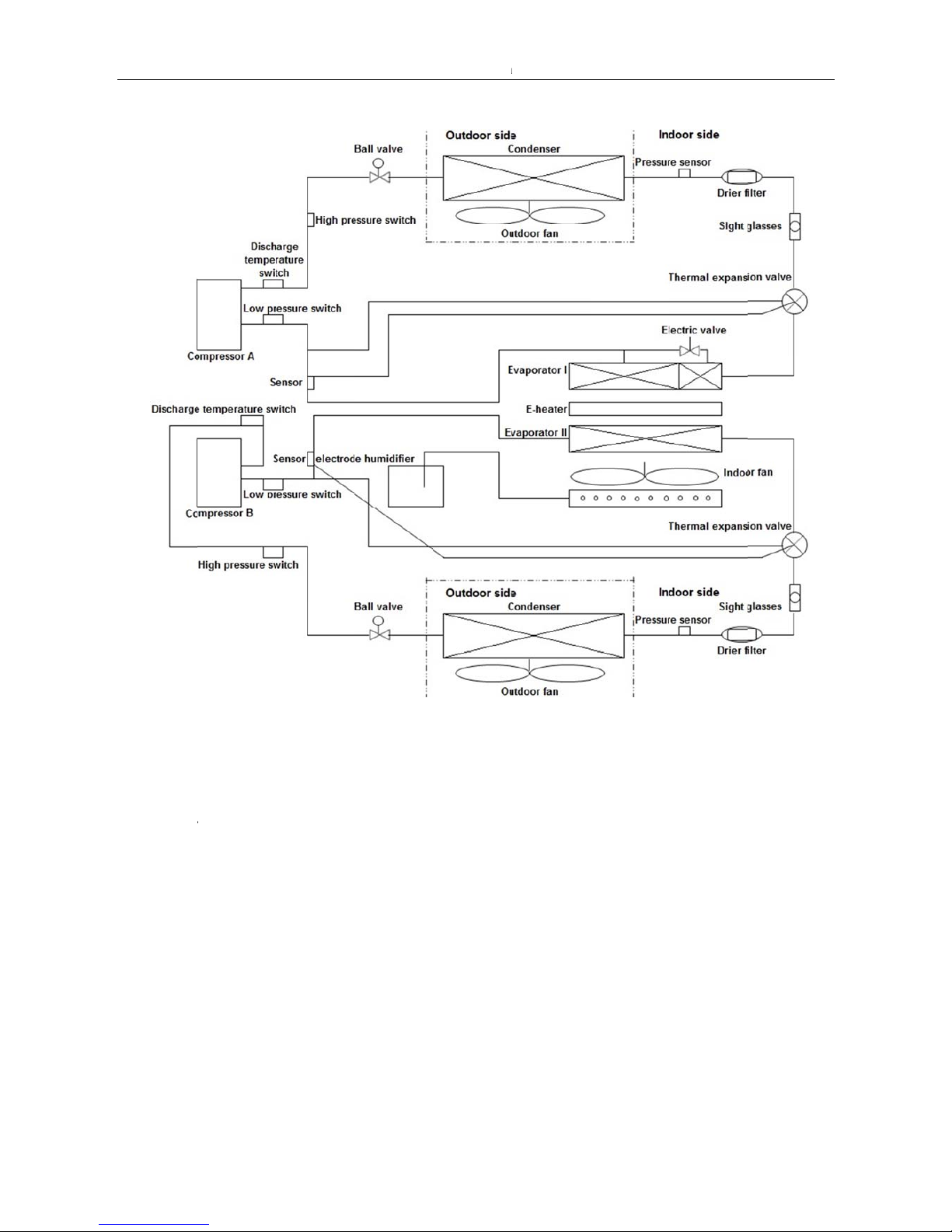

Dual-r

e

Comp

r

Evapo

r

Indoo

r

Outdo

o

-2013-04

frigerant

c

essor: R41

ator (Heat

Fan: Centr

i

r Fan: Axi

a

ircuits typ

e

0A, scroll c

o

exchange

r

fugal fan

l fan

:

mpressor.

): Copper t

u

Mide

a

be and alu

m

Precision A

C

inum fin t

y

Technical M

a

pe heat ex

c

nual-Down D

hanger.

elivery Series

9

Page 11

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

10

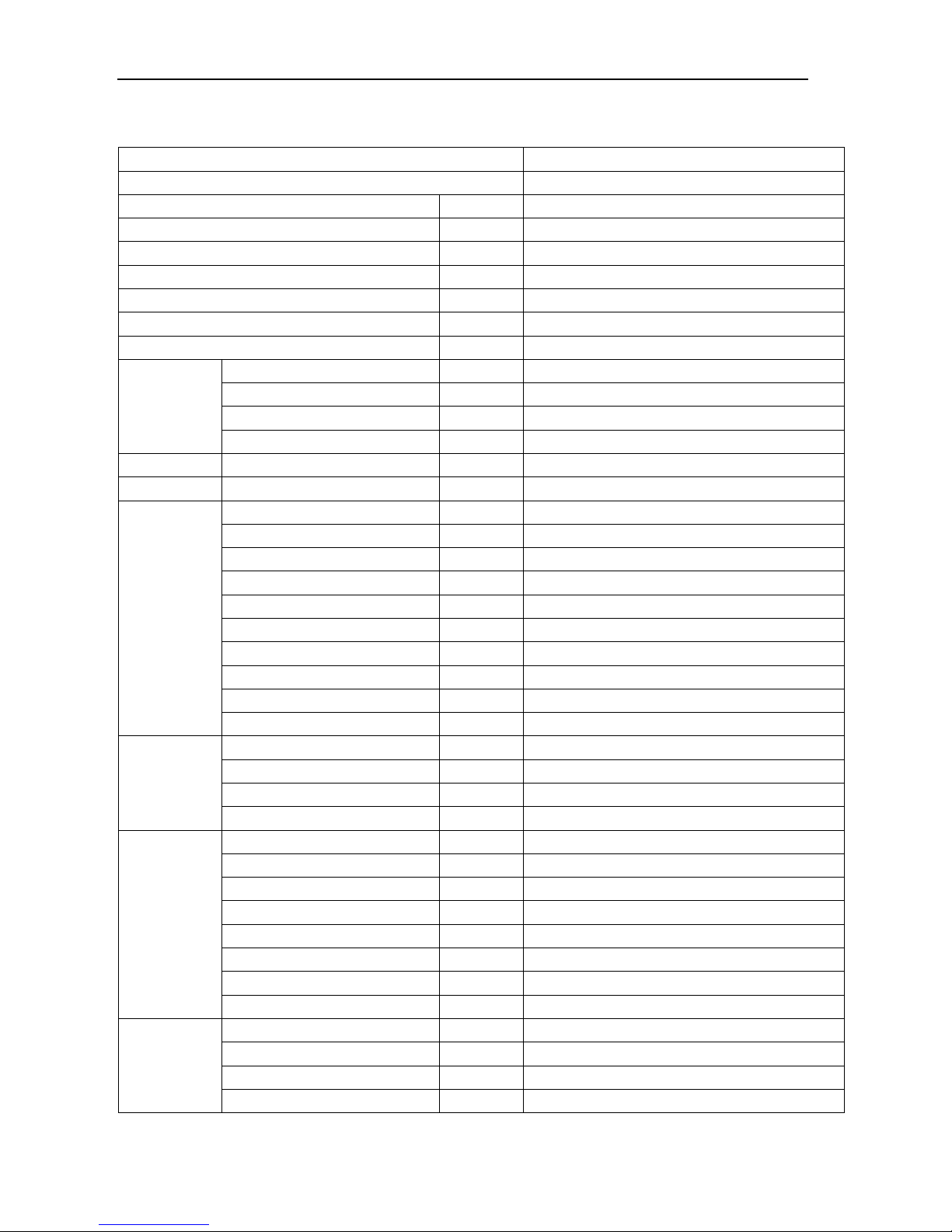

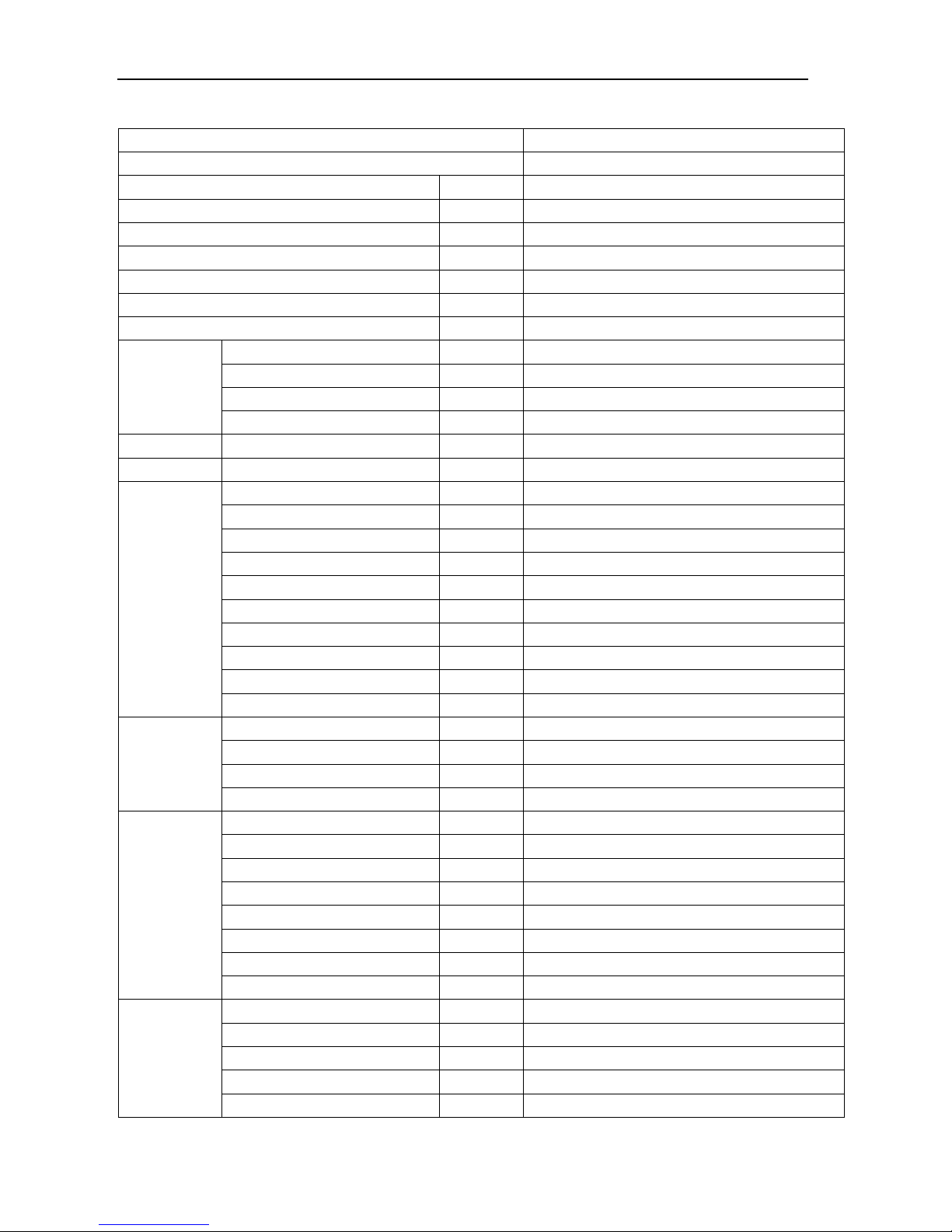

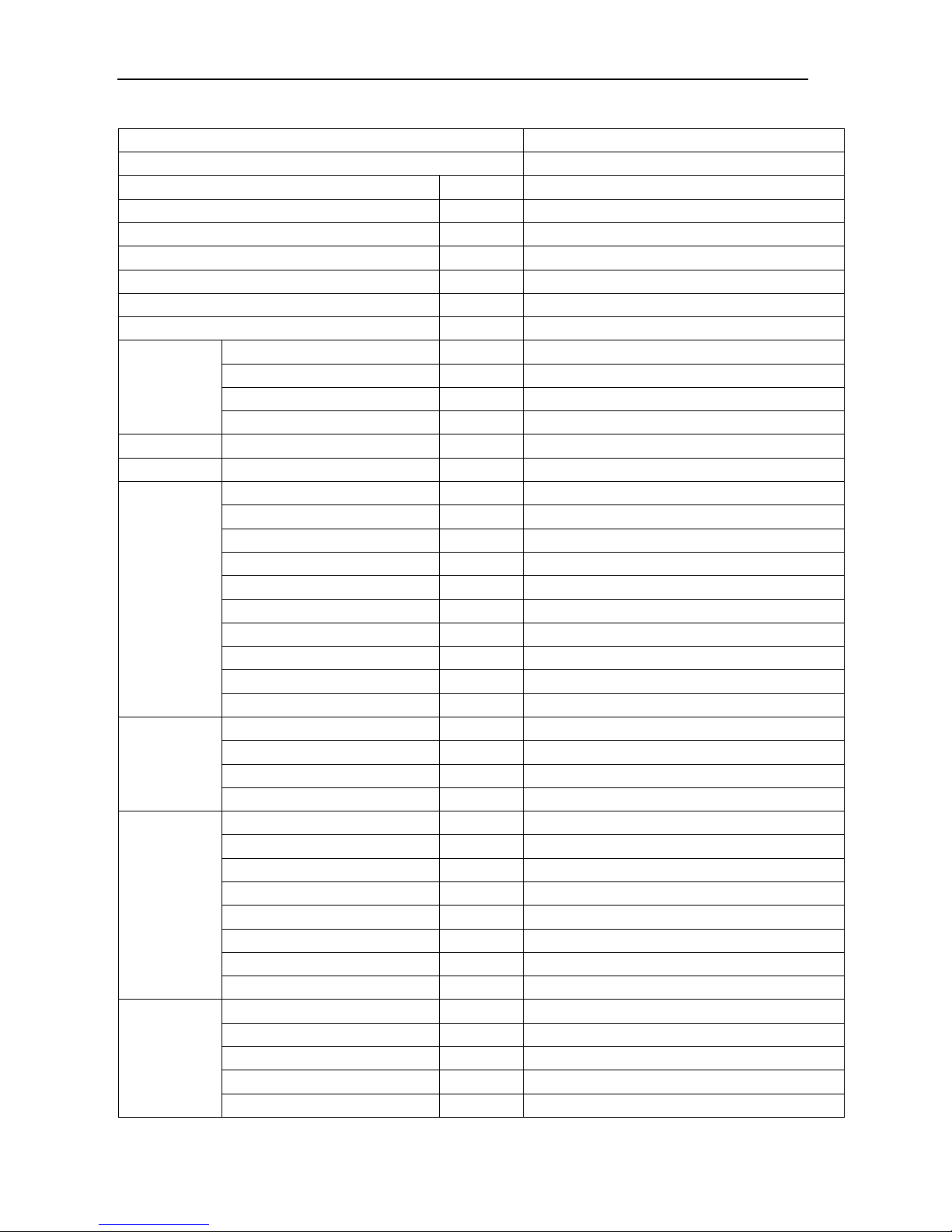

2.3 Specifications

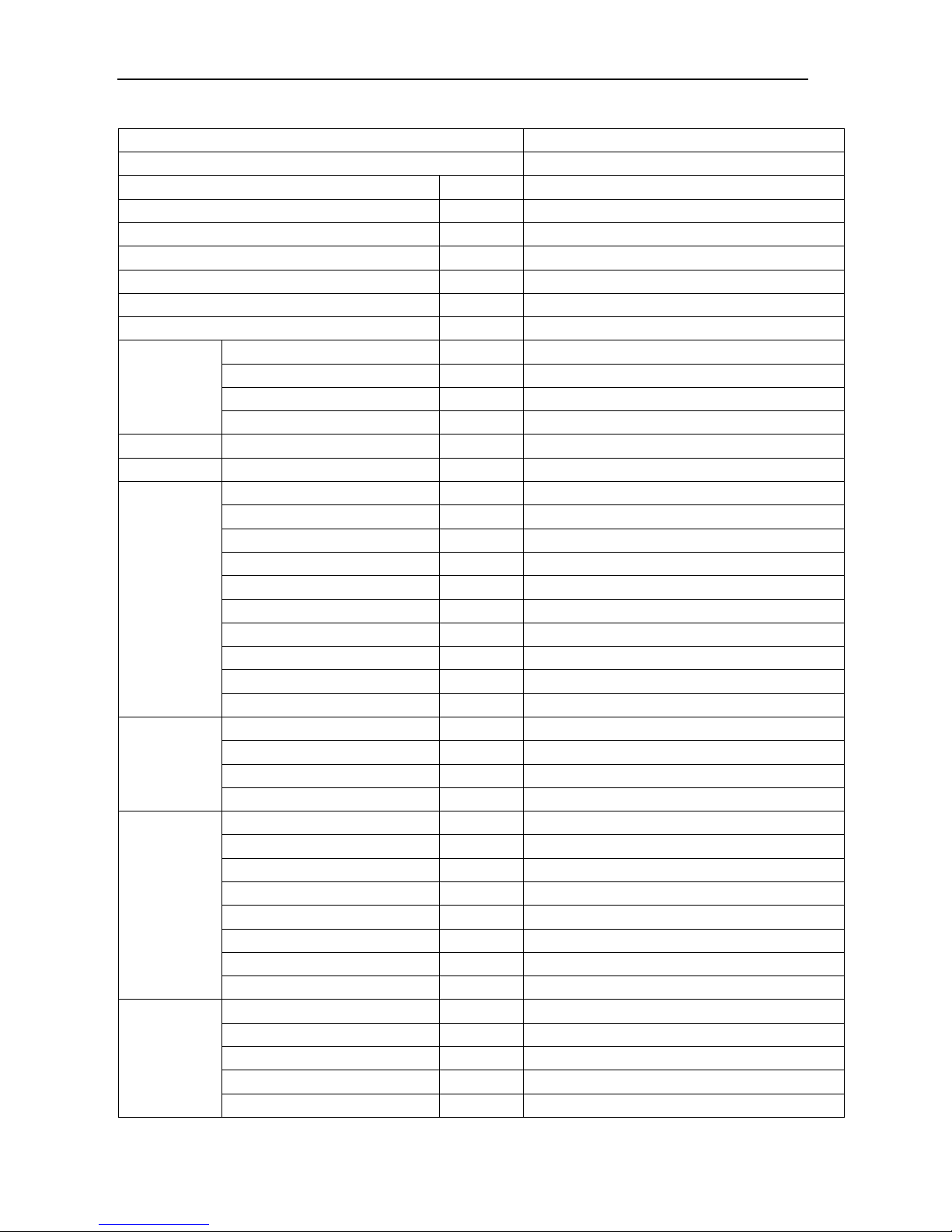

Indoor model

MAD020T1N1S1

Outdoor model (×Quantity)

MA0331 (×1)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 15,000

Whole unit Rated current A 26.8

Cooling

Total capacity W 20,200

Sensible capacity W 18,580

Input W 7,800

EER W/W 2.59

E-heater Capacity W 6,000

Humidification Capacity kg/h 5

Compressor

Model \ ZP83KCE-TFD-522

Type \ Scroll

Qty. \ 1

Brand \ Copeland

Capacity W 20,000

Input W 6,400

Rated current (RLA) A 13.6

Locked rotor Amp (LRA) A 101

Thermal protector \ Internal

Refrigerant oil ml 1,774 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L1-4-2.2KW(YRZ) (×1)

Brand \ Huanqiu/Wolong

Input W 2,200

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (726×686)+(726×686)

Number of circuits \ 9+9

Outdoor fan

Type \ Axial fan

Motor Model (× Quantity) \ FN071-SDK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 940

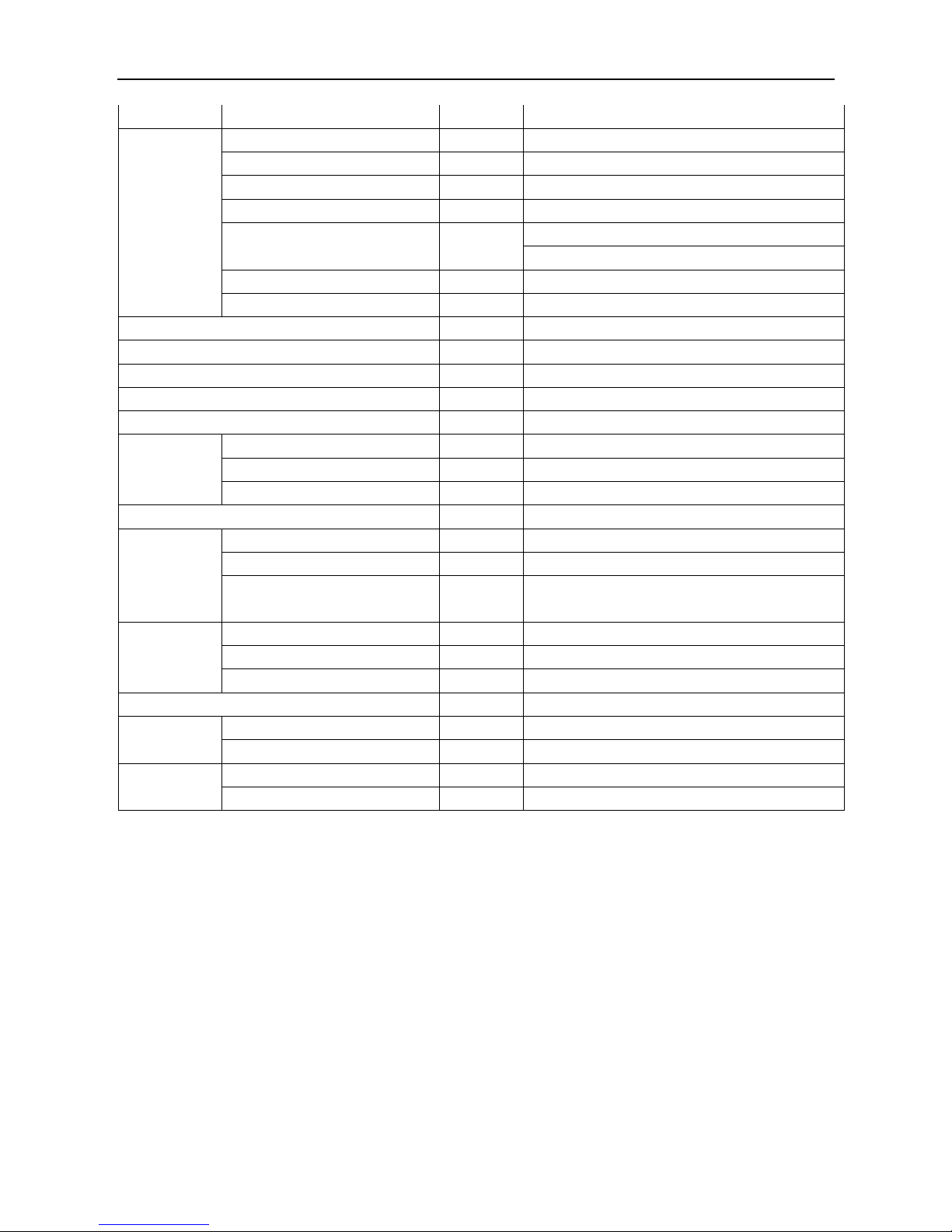

Page 12

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

11

Speed r/min 900

Outdoor coil

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,250×914.4

Number of circuits \ 6

Indoor air flow m3/h 6,225

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤66

Outdoor noise level dB(A)

≤64

Refrigerant

Type \ R410A

Recharged (After installation) g 7,500

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 4×1.0mm2

Signal wire mm2 4×1.0mm2

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 895×1,971×870

Net weight kg 340

Outdoor unit

Net dimension (W×H×D) mm 1,470×988×690(No include supporting bar)

Net weight kg 105

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 13

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

12

Indoor model

MAD025T1N1S1

Outdoor model (×Quantity)

MA0431 (×1)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 16,500

Whole unit Rated current A 30

Cooling

Total capacity W 26,000

Sensible capacity W 23,920

Input W 9,400

EER W/W 2.77

E-heater Capacity W 6,000

Humidification Capacity kg/h 5

Compressor

Model \ ZP103KCE-TFD-522

Type \ Scroll

Qty. \ 1

Brand \ Copeland

Capacity W 25,200

Input W 7,800

Rated current (RLA) A 18.6

Locked rotor Amp (LRA) A 111

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L2-4-3KW(YRZ) (×1)

Brand \ Huanqiu/Wolong

Input W 3,000

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (726×686)+(726×686)

Number of circuits \ 9+9

Outdoor fan

Type \ Axial fan

Motor Model (× Quantity) \ FN080-ADK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100

Speed r/min 680

Outdoor coil No. of rows \ 3

Page 14

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

13

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,250×914.4

Number of circuits \ 6

Indoor air flow m3/h 7,010

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤66

Outdoor noise level dB(A)

≤64

Refrigerant

Type \ R410A

Recharged (After installation) g 9,500

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm

2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 4×1.0mm2

Signal wire mm2 4×1.0mm2

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 895×1,971×870

Net weight kg 360

Outdoor unit

Net dimension (W×H×D) mm 1,470×988×690(No include supporting bar)

Net weight kg 105

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 15

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

14

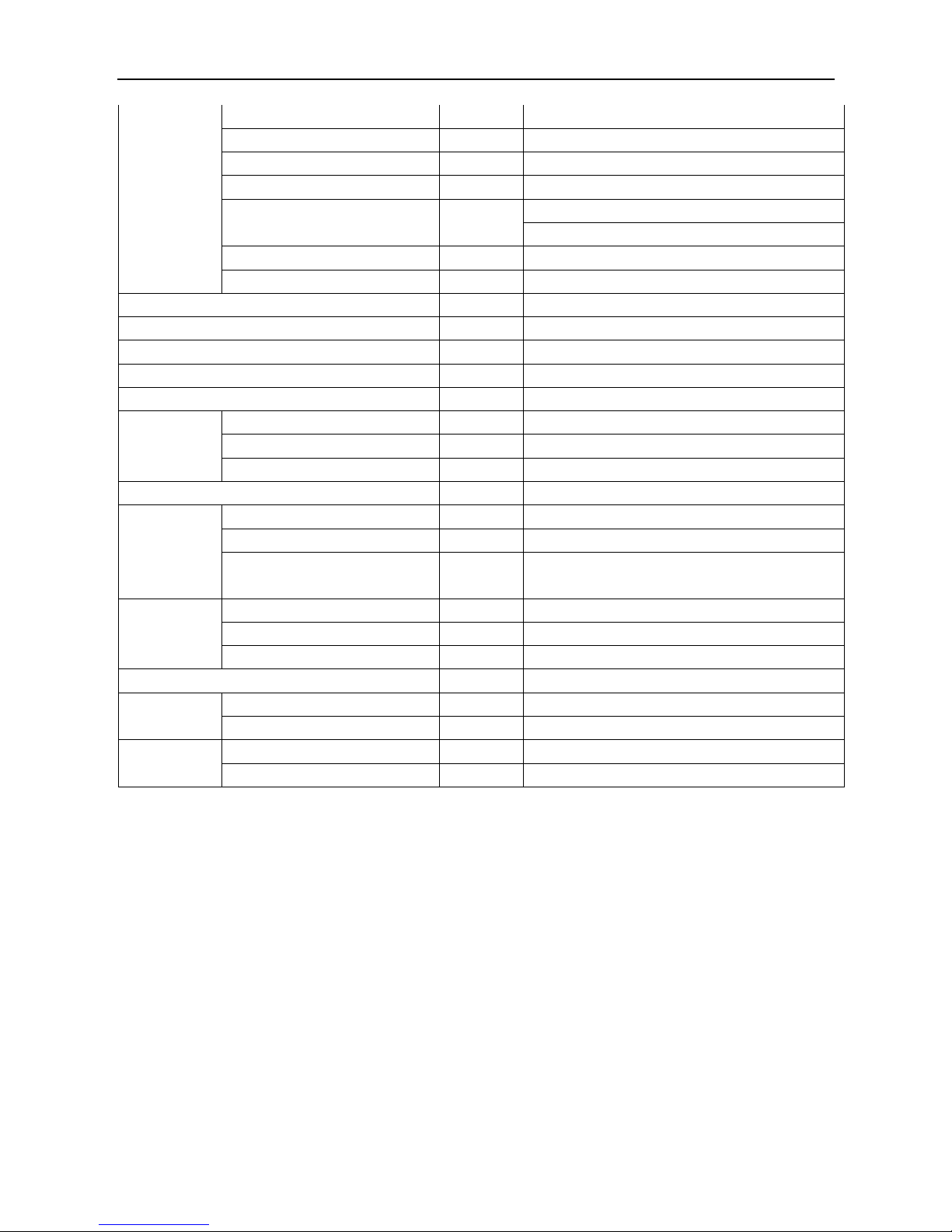

Indoor model

MAD030T1N1S1

Outdoor model (×Quantity)

MA0541 (×1)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 18,500

Whole unit Rated current A 33

Cooling

Total capacity W 30,900

Sensible capacity W 27,810

Input W 11,300

EER W/W 2.73

E-heater Capacity W 6,000

Humidification Capacity kg/h 5

Compressor

Model \ ZP120KCE-TFD-522

Type \ Scroll

Qty. \ 1

Brand \ Copeland

Capacity W 29,200

Input W 9,200

Rated current (RLA) A 20

Locked rotor Amp (LRA) A 118

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y2FD100L2-4 (×1)

Brand \ Huanqiu/Wolong

Input W 3,000

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (726×686)+(726×686)

Number of circuits \ 9+9

Outdoor fan

Type \ FN type, AC axial fan

Motor Model (× Quantity) \ WZZ800-8 (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100/760

Speed r/min 680/530

Outdoor coil No. of rows \ 3

Page 16

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

15

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1447×1219

Number of circuits \ 12

Indoor air flow m3/h 8,825

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A) 67

Outdoor noise level dB(A) 65

Refrigerant

Type \ R410A

Recharged (After installation) g 12,000

Control \ Thermal expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm

2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 4×1.0mm2

Signal wire mm2 4×1.0mm2

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 895×1,971×870

Net weight kg 365/432

Outdoor unit

Net dimension (W×H×D) mm 1,660×1,290×690 (Without supporting bar)

Net weight kg 140/250

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 17

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

16

Indoor model

MAD035T1N1S1

Outdoor model(×Quantity)

MA0601 (×1)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 25,000

Whole unit Rated current A 46

Cooling

Total capacity W 34,000

Sensible capacity W 31,280

Input W 12,500

EER W/W 2.72

E-heater Capacity W 6,000

Humidification Capacity kg/h 5

Compressor

Model \ ZP137KCE-TFD-522

Type \ Scroll

Qty. \ 1

Brand \ Copeland

Capacity W 32,600

Input W 10,200

Rated current (RLA) A 20.7

Locked rotor Amp (LRA) A 118

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L2-4-3KW(YRZ) (×1)

Brand \ Huanqiu/Wolong

Input W 3,000

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (1,210×660.4)+(1,210×660.4)

Number of circuits \ 13+13

Outdoor fan

Type \ Axial fan

Motor Model (× Quantity) \ FN080-ADK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100

Speed r/min 680

Page 18

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

17

Outdoor coil

No. of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,448×1,219.2

Number of circuits \ 12

Indoor air flow m3/h 10,400

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤69

Outdoor noise level dB(A)

≤64

Refrigerant

Type \ R410A

Recharged (After installation) g 13,500

Control \ Thermal expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 4×1.0mm2

Signal wire mm2 4×1.0mm2

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 1,400×1,971×870

Net weight kg 460

Outdoor unit

Net dimension (W×H×D) mm 1,660×1,290×690(No include supporting bar)

Net weight kg 150

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 19

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

18

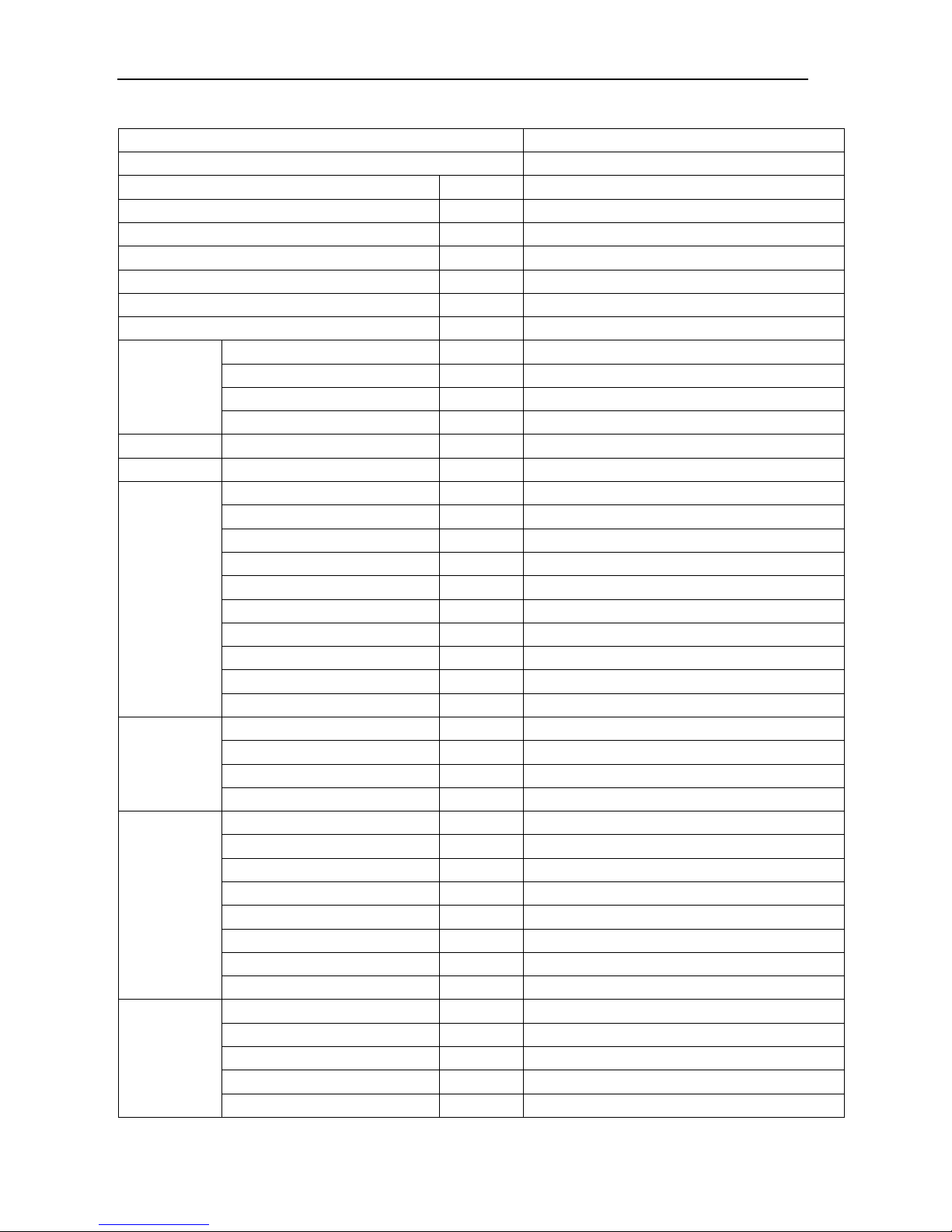

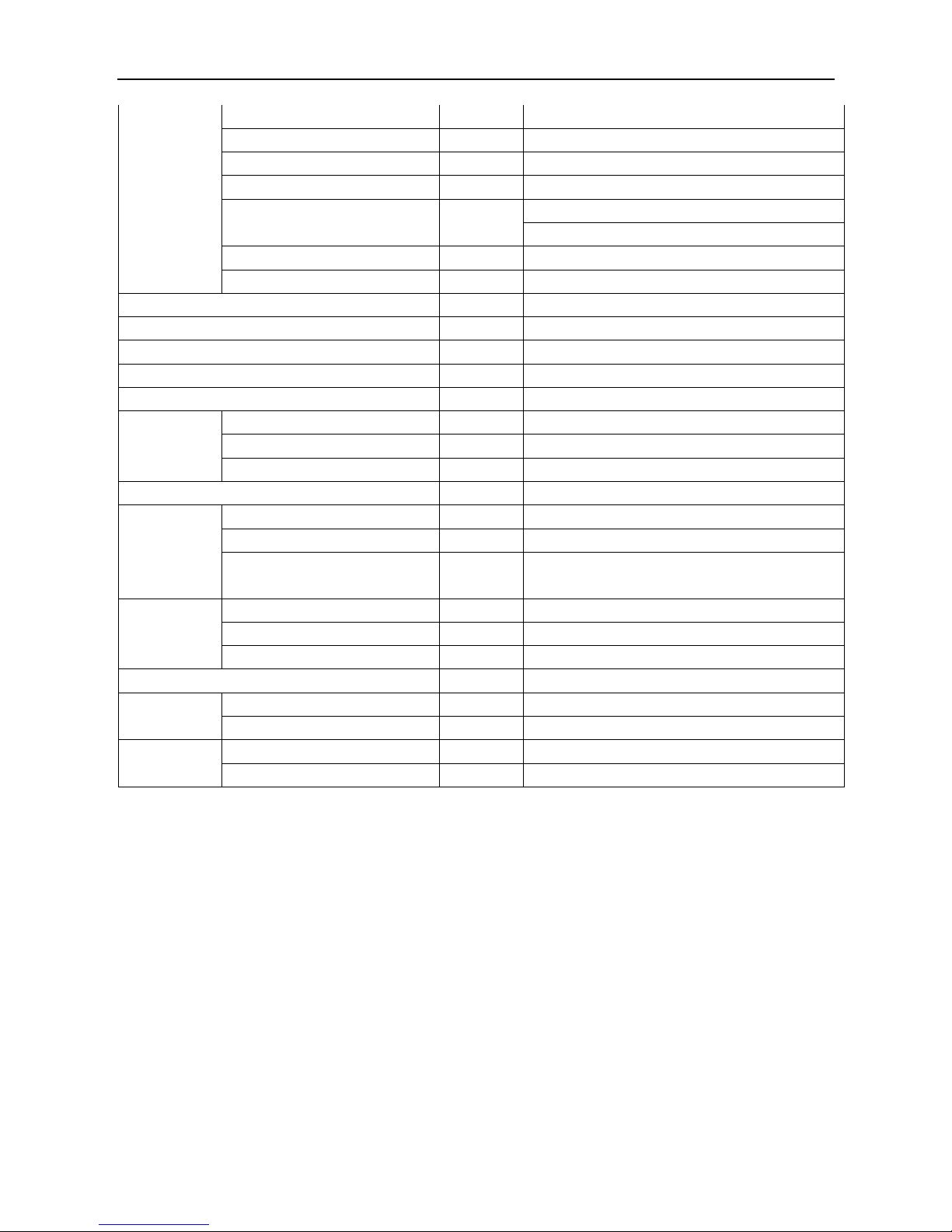

Indoor model

MAD040T2N1S1

Outdoor model(×Quantity)

MA0331 (×2)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 32,000

Whole unit Rated current A 60

Cooling

Total capacity W 40,300

Sensible capacity W 38,290

Input W 15,400

EER W/W 2.62

E-heater Capacity W 9,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP83KCE-TFD-522

Type \ Scroll

Qty. \ 2

Brand \ Copeland

Capacity W 20,000

Input W 6,400

Rated current (RLA) A 13.6

Locked rotor Amp (LRA) A 101

Thermal protector \ Internal

Refrigerant oil ml 1,774 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L1-4-2.2KW(YRZ) (×2)

Brand \ Huanqiu/Wolong

Input W 2,200

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (1,590×685.8)+(1,590×685.8)

Number of circuits \ 18+18

Outdoor fan

(Single

outdoor unit)

Type \ Axial fan

Motor Model (× Quantity) \ FN071-SDK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 940

Speed r/min 900

Page 20

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

19

Outdoor coil

(Single

outdoor unit)

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,250×914.4

Number of circuits \ 6

Indoor air flow m3/h 11,980

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤69

Outdoor noise level dB(A)

≤64

Refrigerant

Type \ R410A

Recharged (After installation) g 8,500×2

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 (4×1.0mm2)+(4×1.0mm2)

Signal wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 1,790×1,971×870

Net weight kg 563

Outdoor unit

(Single)

Net dimension (W×H×D) mm 1,470×988×690(No include supporting bar)

Net weight kg 105

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 21

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

20

Indoor model

MAD045T1N1S1

Outdoor model(×Quantity)

MA0752 (×1)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 33,000

Whole unit Rated current A 62

Cooling

Total capacity W 44,900

Sensible capacity W 41,310

Input W 16,900

EER W/W 2.66

E-heater Capacity W 9,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP182KCE-TFD-522

Type \ Scroll

Qty. \ 1

Brand \ Copeland

Capacity W 44,000

Input W 13,500

Rated current (RLA) A 29.3

Locked rotor Amp (LRA) A 174

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L1-4-2.2KW(YRZ) (×2)

Brand \ Huanqiu/Wolong

Input W 2,200

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (1,590×685.8)+(1,590×685.8)

Number of circuits \ 18+18

Outdoor fan

Type \ Axial fan

Motor Model (× Quantity) \ FN071-SDK (×2)

Motor Brand \ Ziehl-Abegg

Motor Input W 940

Speed r/min 900

Page 22

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

21

Outdoor coil

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,750×1,219.2

Number of circuits \ 18

Indoor air flow m3/h 13,030

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤69

Outdoor noise level dB(A)

≤64

Refrigerant

Type \ R410A

Recharged (After installation) g 17,000

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 4×1.0mm2

Signal wire mm2 4×1.0mm2

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 1,790×1,971×870

Net weight kg 560

Outdoor unit

Net dimension (W×H×D) mm 1,980×1,290×690(No include supporting bar)

Net weight kg 170

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 23

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

22

Indoor model

MAD050T2N1S1

Outdoor model(×Quantity)

MA0431 (×2)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 36,000

Whole unit Rated current A 65

Cooling

Total capacity W 49,700

Sensible capacity W 45,230

Input W 19,100

EER W/W 2.6

E-heater Capacity W 9,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP103KCE-TFD-522

Type \ Scroll

Qty. \ 2

Brand \ Copeland

Capacity W 25,200

Input W 7,800

Rated current (RLA) A 18.6

Locked rotor Amp (LRA) A 111

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L2-4-3KW(YRZ) (×2)

Brand \ Huanqiu/Wolong

Input W 3,000

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (1,590×685.8)+(1,590×685.8)

Number of circuits \ 18+18

Outdoor fan

(Single

outdoor unit)

Type \ Axial fan

Motor Model (× Quantity) \ FN080-ADK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100

Speed r/min 680

Page 24

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

23

Outdoor coil

(Single

outdoor unit)

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,250×914.4

Number of circuits \ 6

Indoor air flow m3/h 14,500

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤69

Outdoor noise level dB(A)

≤64

Refrigerant

Type \ R410A

Recharged (After installation) g 9,500×2

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Signal wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 1,790×1,971×870

Net weight kg 665

Outdoor unit

(Single)

Net dimension (W×H×D) mm 1,470×988×690(No include supporting bar)

Net weight kg 105

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 25

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

24

Indoor model

MAD060T2N1S1

Outdoor model(×Quantity)

MA0541 (×2)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 39,000

Whole unit Rated current A 70

Cooling

Total capacity W 59,100

Sensible capacity W 53,190

Input W 22,600

EER W/W 2.62

E-heater Capacity W 9,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP120KCE-TFD-522

Type \ Scroll

Qty. \ 2

Brand \ Copeland

Capacity W 29,200

Input W 9,200

Rated current (RLA) A 20

Locked rotor Amp (LRA) A 118

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L2-4-3KW(YRZ) (×2)

Brand \ Huanqiu/Wolong

Input W 3,000

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (1,590×685.8)+(1,590×685.8)

Number of circuits \ 18+18

Outdoor fan

(Single

outdoor unit)

Type \ Axial fan

Motor Model (× Quantity) \ FN080-ADK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100

Speed r/min 680

Page 26

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

25

Outdoor coil

(Single

outdoor unit)

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1447×1219

Number of circuits \ 12

Indoor air flow m3/h 17,000

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤72

Outdoor noise level dB(A)

≤66

Refrigerant

Type \ R410A

Recharged (After installation) g 11,500×2

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Signal wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 1,790×1,971×870

Net weight kg 680

Outdoor unit

(Single)

Net dimension (W×H×D) mm 1,660×1,290×690(No include supporting bar)

Net weight kg 140

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 27

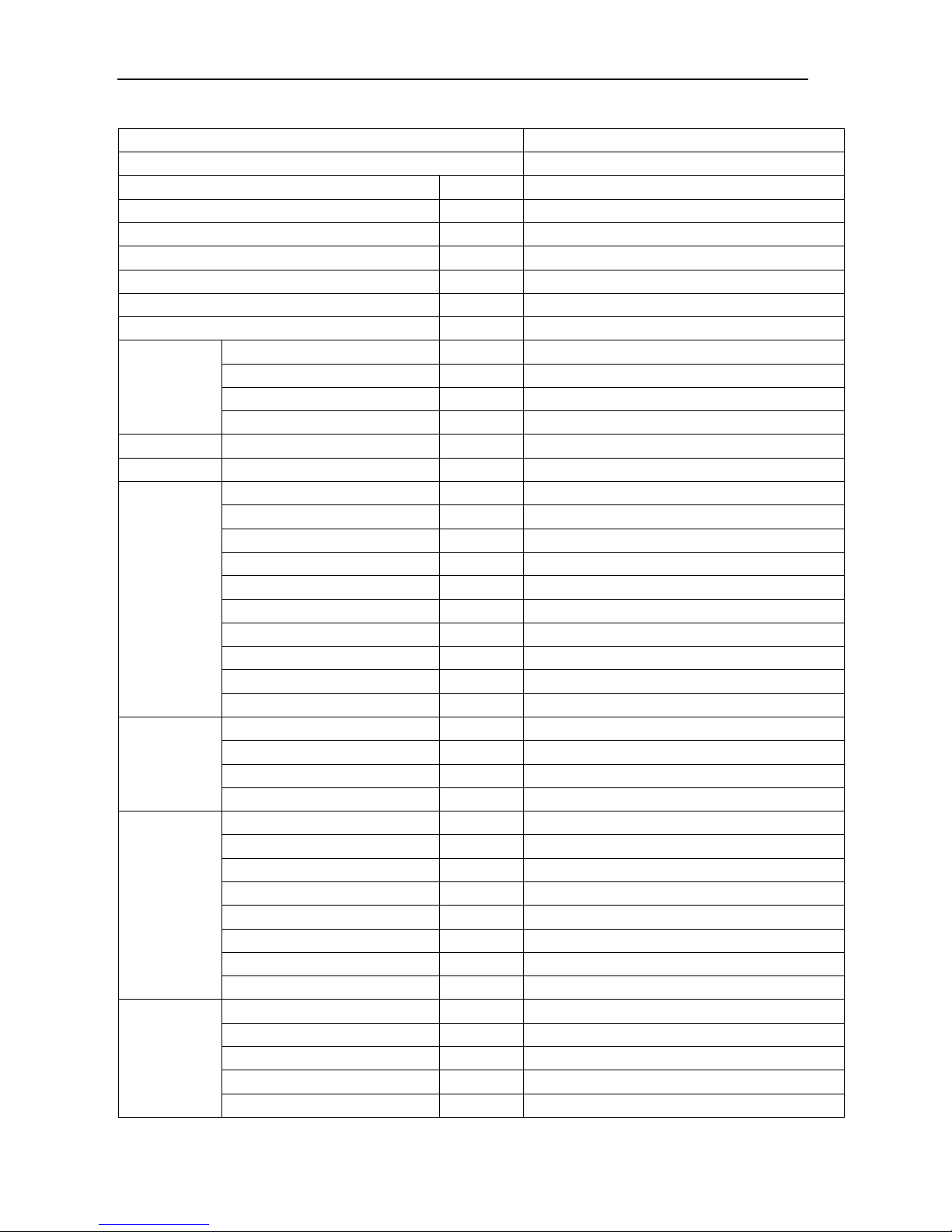

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

26

Indoor model MAD070T2N1S1

Outdoor model(×Quantity) MA0601 (×2)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 42,000

Whole unit Rated current A 74

Cooling

Total capacity W 71,100

Sensible capacity W 67,550

Input W 26,800

EER W/W 2.65

E-heater Capacity W 12,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP137KCE-TFD-522

Type \ Scroll

Qty. \ 2

Brand \ Copeland

Capacity W 32,600

Input W 10,200

Rated current (RLA) A 20.7

Locked rotor Amp (LRA) A 118

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L1-4-2.2KW(YRZ) (×3)

Brand \ Huanqiu/Wolong

Input W 2,200

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (2,453×660.4)+(2,453×660.4)

Number of circuits \ 26+26

Outdoor fan

(Single

outdoor unit)

Type \ Axial fan

Motor Model (× Quantity) \ FN080-ADK (×1)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100

Speed r/min 680

Page 28

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

27

Outdoor coil

(Single

outdoor unit)

No. of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,448×1,219.2

Number of circuits \ 12

Indoor air flow m3/h 20,800

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤72

Outdoor noise level dB(A)

≤66

Refrigerant

Type \ R410A

Recharged (After installation) g 13,000×2

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Signal wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 2,685×1,971×870

Net weight kg 910

Outdoor unit

(Single)

Net dimension (W×H×D) mm 1,660×1,290×690(No include supporting bar)

Net weight kg 150

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 29

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

28

Indoor model

MAD080T2N1S1

Outdoor model(×Quantity)

MA0752 (×2)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 48,000

Whole unit Rated current A 91

Cooling

Total capacity W 81,100

Sensible capacity W 73,800

Input W 30,700

EER W/W 2.64

E-heater Capacity W 12,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP154KCE-TFD-522

Type \ Scroll

Qty. \ 2

Brand \ Copeland

Capacity W 37,300

Input W 11,600

Rated current (RLA) A 25

Locked rotor Amp (LRA) A 140

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L1-4-2.2KW(YRZ) (×3)

Brand \ Huanqiu/Wolong

Input W 2,200

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (2,453×660.4)+(2,453×660.4)

Number of circuits \ 26+26

Outdoor fan

(Single

outdoor unit)

Type \ Axial fan

Motor Model (× Quantity) \ FN071-SDK (×2)

Motor Brand \ Ziehl-Abegg

Motor Input W 940

Speed r/min 900

Page 30

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

29

Outdoor coil

(Single

outdoor unit)

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 1,750×1,219.2

Number of circuits \ 18

Indoor air flow m3/h 23,300

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤72

Outdoor noise level dB(A)

≤66

Refrigerant

Type \ R410A

Recharged (After installation) g 17,000×2

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Signal wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 2,685×1,971×870

Net weight kg 920

Outdoor unit

(Single)

Net dimension (W×H×D) mm 1,980×1,290×690(No include supporting bar)

Net weight kg 170

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 31

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

30

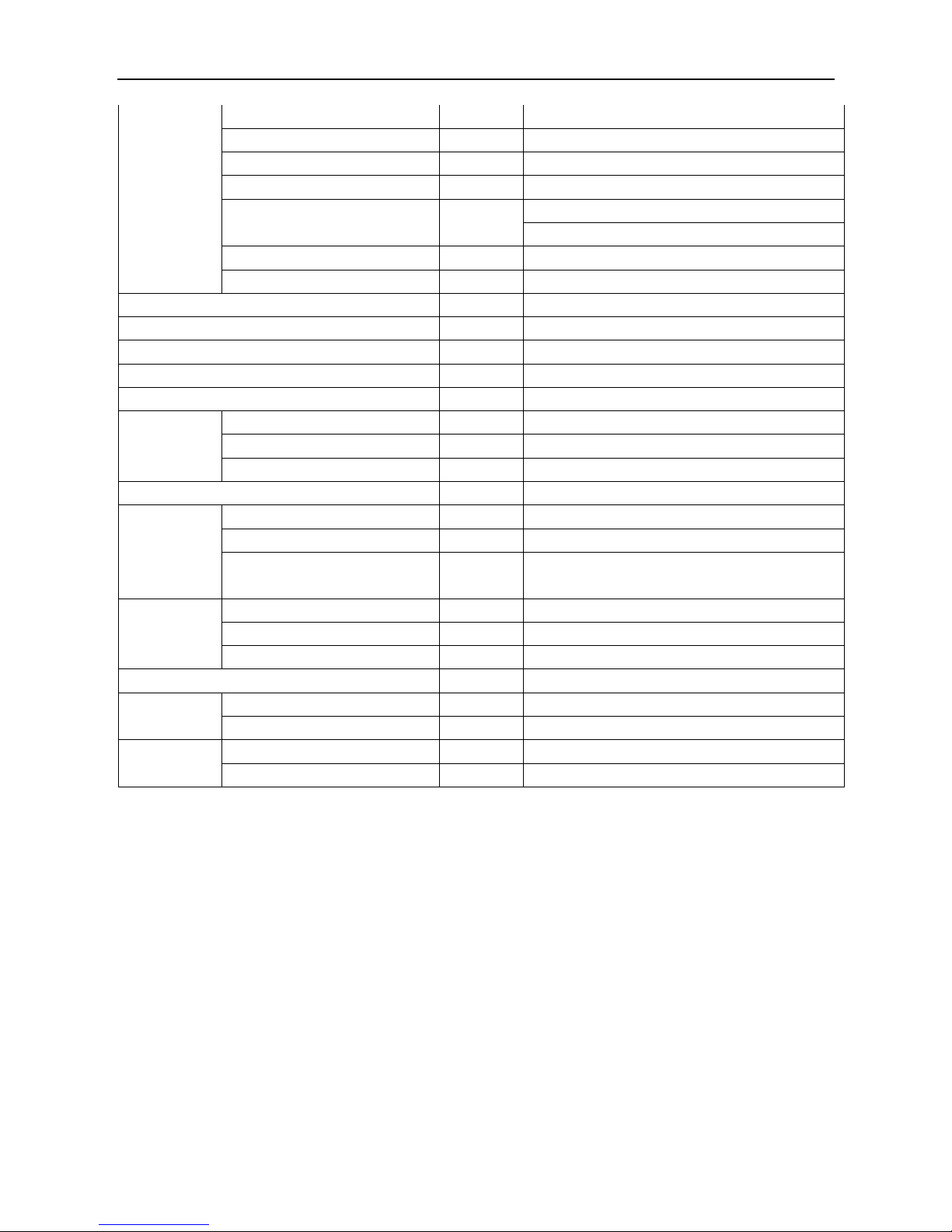

Indoor model

MAD090T2N1S1

Outdoor model(×Quantity)

MA0982 (×2)

Indoor operating ambient temperature range °C 0~40

Outdoor operating ambient temperature range °C -20~45, (-40~45, with low ambient temperature kit)

Altitude \

≤1000m (higher than 1000m, derating use)

Indoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Outdoor Power supply V, Ph, Hz 380V~,3Ph,50Hz

Whole unit Rated input W 55,000

Whole unit Rated current A 98

Cooling

Total capacity W 90,100

Sensible capacity W 81,090

Input W 34,300

EER W/W 2.63

E-heater Capacity W 12,000

Humidification Capacity kg/h 10

Compressor

Model \ ZP182KCE-TFD-522

Type \ Scroll

Qty. \ 2

Brand \ Copeland

Capacity W 44,000

Input W 13,500

Rated current (RLA) A 29.3

Locked rotor Amp (LRA) A 174

Thermal protector \ Internal

Refrigerant oil ml 3,253 (POE)

Indoor fan

Model (× quantity) \ Y(2)100L2-4-3KW(YRZ) (×3)

Brand \ Huanqiu/Wolong

Input W 3,000

Speed r/min 1,420

Indoor coil

Number of rows \ 4

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 1.8

Fin type \ Hydrophilic aluminum fin

Pipe size mm Ф9.52

Pipe type \ Inner grooved copper pipe

Coil(W×H) mm (2,453×660.4)+(2,453×660.4)

Number of circuits \ 26+26

Outdoor fan

(Single

outdoor unit)

Type \ Axial fan

Motor Model (× Quantity) \ FN080-ADK (×2)

Motor Brand \ Ziehl-Abegg

Motor Input W 1,100

Speed r/min 680

Page 32

MCAC-PDSM-2013-04 Midea Precision AC Technical Manual-Down Delivery Series

31

Outdoor coil

(Single

outdoor unit)

No. of rows \ 3

Tube pitch(a)×row pitch(b) mm 25.4×22

Fin spacing mm 2.2

Fin type \ Hydrophilic aluminum fin

Pipe outside dia. and type mm

Ф9.52

Inner grooved copper pipe

Coil (W×D) mm 2,250×1,219.2

Number of circuits \ 18

Indoor air flow m3/h 24,800

Indoor external static pressure Pa 20

Indoor drain pipe I.D. mm Ф30

Indoor noise level dB(A)

≤72

Outdoor noise level dB(A)

≤66

Refrigerant

Type \ R410A

Recharged (After installation) g 17,000×2

Control \ Thermostatic expansion valve

Maximum refrigeration pipe pressure MPa 4.4

Refrigerant

pipe

Max. pipe length m 60

Max. difference in level (O.U. up) m 20

Max. difference in level (O.U.

down)

m 5

Connection

wire

Indoor power wire mm2

3×10.0mm

2

(A,B,C)+2×6.0mm2(N,GND)

Outdoor power wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Signal wire mm2 (4×1.0mm2)+ (4×1.0mm2)

Filter \ G4

Indoor unit

Net dimension (W×H×D) mm 2,685×1,971×870

Net weight kg 920

Outdoor unit

(Single)

Net dimension (W×H×D) mm 2,480×1,290×690(No include supporting bar)

Net weight kg 220

Notes:

1. The nominal cooling capacity is based on the following conditions. Indoor temperature: 24°CDB, 17°CWB;

Outdoor temperature: 35°CDB, pipe length is 10 meters.

2. The noise is measured in the semi suppression lab.

3. Specifications are subject to change without prior notice for product improvement.

Page 33

Midea Precisi

32

2.4 Dime

n

Indoo

r

on AC Techni

c

sion (Uni

unit: MAD

0

al Manual

t: mm)

20T1N1S1

, MAD025

T

1N1S1, M

A

D030T1N1

S

M

1

MCAC-PDSM-2013-01

Page 34

MCAC-PDS

M

Indoo

r

-2013-04

unit: MAD

0

35T1N1S1

Mide

a

View of o

p

Precision A

C

ened doo

r

Technical M

a

nual-Down Delivery Series

3

3

Page 35

Midea Precisi

34

Indoo

r

Indoo

r

on AC Techni

c

unit: MAD

0

unit: MAD

0

al Manual

40T2N1S1

70T2N1S1

, MAD045

T

, MAD080

T

1N1S1, M

A

2N1S1, M

A

D050T2N1

S

D090T2N1

S

M

1, MAD06

0

1

MCAC-PDS

M

T2N1S1

-2013-01

Page 36

MCAC-PDS

M

Outdo

o

Outdo

o

-2013-04

r unit: M

A

r unit: M

A

0331, MA0

4

0752, MA0

9

Mod

e

MA03

3

MA04

3

MA05

4

MA06

0

MA07

5

MA09

8

31, MA05

4

82

l

L

1

14

7

1

1

16

6

1

2 19

8

2 24

8

Mide

a

1, MA0601

0

9

0

1

0

0

Precision A

C

H

88

290

Technical M

a

W

690

nual-Down Delivery Series

3

5

Page 37

Midea Precisi

36

2.5 Servi

c

Indoo

r

Outdo

o

Outdo

o

on AC Techni

c

e space

unit (Unit:

r unit wit

h

r unit wit

h

al Manual

mm)

horizontal

vertical in

s

installatio

n

tallation (

U

(Unit: mm

nit: mm)

) MMCAC-PDS

M

-2013-01

Page 38

M

3

2

idea Precision AC

7

.6 Wiring dia

g

E-box view

o

Technical Manual-

D

ram

f indoor unit

own Delivery Series MCAC-RTSM-2013-04

Page 39

M

3

idea Precision AC

8

Indoor unit

w

Available for

M

Indoor unit

w

Available for

M

Technical Manual

ith single sys

t

AD020T1N1S1,

M

ith dual-syste

m

AD040T2N1S1,

M

em- Controllin

g

AD025T1N1S1, M

A

- Controlling

c

AD050T2N1S1, M

A

connection a

m

A

D030T1N1S1, an

onnection am

p

A

D060T2N1S1, M

A

plification figu

r

d MAD035T1N1S,

lification figur

e

D070T2N1S1, M

A

e:

MAD045T1N1S1

:

D080T2N1S1, and

MAD090T2N1S1

MCAC-PDSM-2013-01

Page 40

Midea Precisi

39

Outdo

o

Outdo

o

on AC Techni

c

r unit- M

A

r unit- M

A

al Manual-D

o

0331, MA0

4

0752, MA0

9

wn Delivery

S

31, MA05

4

82

eries

1, MA0601

MCAC-R

T

SM-2013-04

Page 41

Midea Precisi

40

3. Insta

l

Th

eout

Be

f

se

r

pip

Ins

Th

e

Notes:

——: Pi

------: T

h

※ : Fo

r

(D

o

+ : W

co

on AC Techni

c

lation

indoor uni

t

door unit is

ore the ins

t

vice, and c

o

eline laying

,

tallation wo

r

whole sys

t

pelines prov

i

e site-laying

system nor

m

ne by sit)

hen the equi

v

mponents. (

T

al Manual

must be in

installed on

allation, co

n

nfirm whet

h

wiring and

k must stri

c

em layout

d

ded by man

u

pipeline (D

o

al operatio

n

altent lengt

h

hese option

a

stalled on t

h

the ground

firm wheth

e

er the buil

d

ventilation

p

tly follow th

iagram:

facturer

ne by techni

c

and mainte

n

of the pipe

l compone

n

e ground o

f

of the outd

o

r the install

ings need t

o

ipe.

e design dr

a

ians)

nance conve

exceeds 30

m

ts need to b

e

the device

ors or oth

e

ation envir

o

be config

u

wing.

nience, the

c

eters, then

purchased

M

room or co

m

r rooms.

ment meet

t

red with th

e

omponents

a

t should be

e

y another o

MCAC-PDS

M

puter roo

m

he require

m

constructi

o

re suppose

d

qquipped

w

rder).

-2013-01

. And the

ents of

n work of

to be used.

ith these

Page 42

MCAC-PDS

M

W

h

of

re

v

co

T

h

-2013-04

en the con

d

the conden

erse bend,

pper pipe o

f

e installatio

enser is hi

g

ser, to avoi

d

it must ens

u

condenser

n diagram,

w

her than c

o

liquid refri

re that the

hen the in

d

Mide

a

mpressor, i

gerant bac

k

top elbow

p

oor unit is

h

Precision A

C

nstall rever

s

flow when

t

ipe of the r

e

igher than

Technical M

a

e bend on

t

he units st

o

verse bend

outdoor uni

t

nual-Down D

he inlet an

d

ps. When

i

higher tha

n

t

.

elivery Series

4

1

outlet pipe

s

nstalling th

e

the top ro

w

Page 43

Midea Precisi

42

3.1 Stora

g

St

oAmAmSto

3.2 Indoo

r

Ta

w

o

M

othe

In

onor

Co

m

o

co

n

Ou

de

h

inh

wi

n

Be

cdam

ind

To

uni

Do

ref

r

on AC Techni

c

e enviro

n

Items

rage enviro

n

bient humid

i

bient tempe

r

rage time

installat

i

ke down th

e

oden case.

ve the bac

k

bolts with

w

rder to ens

mally, it sh

o

mputer roo

m

isture-proo

f

crete wall

a

tdoor air en

t

umidifyting

aled quanti

t

dows shoul

ause the a

age of oth

e

oor unit, an

d

ensure the

n

t installatio

n

not install t

h

igeration c

y

al Manual

ment

ment Ind

ty 5%

ature Ind

To

t

mo

on

packaging

plate, and

rench.

ure that the

uld do the

m

should ha

layer of cei

nd ground

m

er into the

r

load, so it i

s

y should re

m

d be fully e

n

ir condition

e

r precision

the install

a

ormal ope

r

site.

e indoor u

n

cle, and th

e

oor, clean.

~85% RH (

N

oor unit: -20

°

al time of tr

nths. If exce

case, acco

r

the unit ba

s

environme

n

oisture-pr

o

v

e good th

e

ling and wa

l

ust be mo

oom may i

n

necessar

y

ain below

closed typ

e

r will produ

c

equipment

s

tion scene

ation of ind

o

it in the na

r

n leads to

a

R

o condens

a

°C~54°C; Ou

t

ansportatio

n

ed 6 month

s

rding to the

e was fixe

d

t control s

y

of and hea

t

rmal insula

t

ll must use

p

isture-proof

crease the

to minimiz

e

5%of whol

e

, and apert

ce the cond

nearby, th

e

of air condi

t

or unit, it s

row space,

short circu

equiremen

t

tion)

door unit:

-4

0

and storag

, it need to

r

package di

a

in the bott

o

stem in the

preservati

o

ion and se

a

olyethylen

e

.

system coo

outdoor ai

indoor air

c

ure are as

s

ensate and

re is not th

ioner must

hould choo

s

or it would

b

it of returni

n

M

s

°C~70°C.

time shou

e-calibrate t

h

gram to re

m

m wood tra

y

air conditio

n

n work.

led moistur

e

film mater

i

ling, heatin

g

r enter into

t

irculation a

m

mall as pos

water leak

a

precision

e

be provided

e capaciou

s

lock the ai

r

g air and ai

MCAC-PDS

M

ld not exce

e

e capacity.

ove the p

a

y with M8 b

ing room

w

-proof lay

e

ials. The pa

, humidifyi

n

he room.

O

ount, all t

h

sible.

ge may ca

u

equipment

s

the draina

g

space as

t

flow, and

s

r noise.

-2013-01

d 6

ckaging

lts, remov

e

orks

r, the

inting of

g and

utdoor air

e doors an

d

se the

near the

e pipelines

he indoor

horten the

.

Page 44

MCAC-PDS

M

Do

Do

th

e

Do

Ac

c

ins

t

Pl

a

De

t

ins

t

Us

e

All

ch

o

Si

n

Du

a

-2013-04

not fix the i

not make s

unbalance

d

not install

o

ording to t

h

t

alled.

ce rubber d

ermine the

t

all the inst

a

bolts, cus

h

outside pla

t

osing insta

gle-door u

n

l-door unit

ndoor unit i

n

everal indo

o

competiti

o

ther equip

m

e bottom in

amping ma

t

installation

llation bas

e

ion, flat m

a

es of the u

n

llation angl

e

it installatio

n

installation

the sunke

n

r units to b

e

n operation

ents on its

stallation si

z

s on the to

p

osition, an

d

at the sele

c

t and nuts t

it should n

o

s and fixed

basing si

z

basing size

:

Mide

a

place or a

t

huddled t

o

.

upper part,

e of the in

d

of the inst

a

according

ted positio

n

o fix the air

t allow bea

r

holes.

e: (Unit: m

m

: (Unit: mm)

Precision A

C

the end of

gether, to

a

convenient

oor unit, th

e

llation bas

e

to the site

c

.

conditioner

ing weight,

)

Technical M

a

the long an

d

void crossi

n

for its norm

a

installatio

n

and steel

p

ondition an

d

on the bas

e

it must be

c

nual-Down D

narrow ro

o

g the air a

n

l maintena

base shou

late botto

m

user’s req

.

onsidered

w

elivery Series

4

3

m.

d producin

g

nce.

ld be

.

uierments t

o

hen

Page 45

Midea Precisi

44

Th

r

I

Steel plate

Angle iron (S

t

Anti-shock

rubber pa

d

Fixing hole fo

H

Notes:

The in

To

re

d

fa

s

Fi

r

fa

s

on AC Techni

c

ee-door un

i

tem

eel channel)

Top

Botto

m

r expansion b

stallation ba

s

prevent de

f

uction mat

e

teners and

st dismantl

e

tening torq

u

al Manual

t installatio

n

Spec

100

40×4

0

Th

Thi

c

olt

e should be

ormation a

n

rials on th

e

vibration re

d three L s

h

e: 12±1N.

m

basing siz

e

ification (m

m

×100×(5~6.5)

×3 (50×37×4

.

ickness: 3~5

kness: 10~1

2

300

strong to su

d damage

d

key place

s

duction ma

t

ape fixed

m

.

: (Unit: m

m

)

5)

Rubbe

r

rubber

o

Install

a

This is

o

needs

o

pport the in

d

uring tran

s

when the

u

erials befor

e

etal plates

)

materical ca

n

r rubber gas

k

s user requir

e

nly for refer

e

f users.

oor unit.

portation, it

nit left fact

o

installing

a

, and install

M

Rema

r

choose isop

r

et with the s

a

ments.

nce, it should

was added

ry. Remove

nd debugg

i

the bolts a

n

MCAC-PDS

M

k

rene rubber,

d

me similar p

r

according to

fasteners

o

the transp

o

ing the unit.

d gaskets

w

-2013-01

ifferent bulyl

operties.

the actual

r vibration

rtation

ith the bolt

s

Page 46

MCAC-PDS

M

3.3 Instal

l

Af

t

To

av

It i

h

e

In

s

W

h

rel

T

h

O

u

H

In

sins

For ho

In

s

(

M

-2013-04

ing outd

o

er the unit

a

ensure the

oid places

w

s suggeste

d

lp to low do

tall the unit

en it is ins

t

ated local r

u

e installatio

tdoor unit

h

orizontal:

ide the pa

c

allation.

rizontal in

s

tall the out

d

6×23 Scre

w

or units

rrives, che

c

heat dispe

r

ith dust, s

n

that user

s

wn the nois

e

far away fr

o

alled at the

les.

n direction

p

as two met

h

kage of out

d

tallation:

oor unit su

p

s in acces

s

k whether i

sion o

f

the

u

ow, etc. It

w

hould horiz

o

.

m the resi

d

top of the b

lease refer

s

ods of inst

a

oor unit, th

porting ba

r

ories pack

a

Mide

a

t is damag

e

nit, intall th

ill block th

e

ntal intall t

h

ential area.

uilding, pay

to the inst

a

llation: hor

V

erti

ere are fou

r

to ghe unit

ge), totally

4

Precision A

C

d during th

e

e outdoor u

n

condense

d

e unit if th

e

attention t

o

llation arro

zontal inst

a

cal (Top vie

supporting

first, use 6

bars.

Technical M

a

shipment.

it at the wil

coils.

installation

the water

p

w

label on t

h

llation and

v

w

):

bars which

crews to fi

x

nual-Down D

l-ventilatde

conditions

roof layer

a

he outdoor

u

ertical inst

a

are fixed in

the suppo

r

elivery Series

4

5

outdoor,

allow, whic

h

nd obey th

e

nit.

llation.

horizontal

ting bar

Page 47

Midea Precisi

46

It i

For ve

r

It i

s

3.4 Conn

e

F

othe

D

oob

co

p

a

It

n

on AC Techni

c

Mod

e

MA03

3

MA04

3

MA05

4

MA06

0

MA07

5

MA09

8

s suggeste

d

tical insta

l

s suggeste

d

cting ref

r

r ensure sa

nitrogen i

n

the heat in

stacles, vib

r

pper pipes

d

rticles and

s

eeds to ap

p

al Manual

l

1

1

1

1

1

1

2

12 2

that use

M

lation

that use

M

igerant p

i

fety, before

the air con

sulation for

ation isolat

i

irect conta

c

o on away

f

ly high qu

a

L1

112

310

604

105

6×20 expa

n

6×20 expa

n

pe

welding the

ditioner sys

t

the copper

p

ng measur

e

t with the

w

f

rom the co

p

lity silver fi

b

H1

764

1066

sion bolt fo

sion bolt fo

pipelines a

em, which

c

ipes. Whe

n

ments as s

all, meanw

per pipes.

er for weldi

D1

49

r fixing the

m

r fixing the

m

nd welding

s

an release

the coppe

r

hock pad s

h

ile pay att

e

ng the pipel

M

(U

n

ounting b

a

ounting ba

pots, must

the system

pipes go t

h

ould be do

n

ntion to ke

e

ine connect

MCAC-PDS

M

nit: mm)

D2

63

se.

se.

completely

pressure.

rough the

w

e for avoid

i

p dust, aq

u

ors. During

-2013-01

discharge

alls or oth

e

ng the

eous vapor

,

the welding

r

Page 48

MCAC-PDS

M

pr

o

M

a

M

a

Fil

T

h

sh

If

o

ou

w

h

In

s

T

helb

to

W

h

ou

m

a

W

h

va

an

-2013-04

cess, it ne

e

ke sure th

e

ke sure th

e

l refrigerant

e pipeline

p

ould be con

ne way eq

u

tdoor units

i

ether need

Outdo

o

Outdo

o

tall grease

e suggeste

d

ow and th

e

the site con

Out

d

liqui

d

en the unit

tdoor unit i

s

terials bef

o

en weldin

g

lve before

w

d side pan

e

ds to char

g

right conn

e

outdoor u

n

and add re

f

ressure dr

o

sidered dur

i

ivalent len

g

s higher th

a

to add the

e

R

r unit install

e

r unit install

e

traps (oil lo

o

pipeline si

valve have

ditions.

oor diamet

e

pipe (Inch

3/8

1/2

5/8

3/4

7/8

1-1/8

leave the f

a

filled with

n

re connect

t

the copper

elding. Dur

i

l of unit.

e nitrogen i

cting pipe

s

it installatio

n

rigerant an

d

ps, compre

s

ng the desi

g

th is longe

r

n the num

b

xtended c

o

elative pos

i

d level is hi

d level is lo

w

p) every 7.

5

zes in the f

o

counted. T

h

r of

90°

B0.20.20.2

0.

0.

40.5

ctory, it will

itrogen gas

he indoor u

pipe with t

h

ng welding,

Mide

a

nto the pip

e

ize.

n height of

u

add refrig

e

sor oil retu

n and con

s

than 30m,

o

erical show

mponents

b

tion

gher than in

d

wer than in

d

5 meters of

llowing tab

e installer

w

Equiv

a

end 45°

B1 0

4 0

.

7 0

.

3 0

.

4 0

.6 0

has a smal

to stay the

nit and out

d

e indoor a

n

pay attenti

o

Precision A

C

line for prot

nit pipeline

rant oil of

u

n, noise re

d

truction pr

o

r the verti

c

ed in follow

i

efore instal

oor unit

oor unit

the all verti

c

e are equiv

ill confirm

w

lent length

(

end T-s

h

.1

12

15

18

24

.3

l amount of

pressure, a

oor unit at

s

d outdoor u

n to do not

Technical M

a

ction.

installation

.

nit pipeline

uction and

cesses.

al height de

ng table, th

e

lation.

Valu

e

Max. 2

Max. -

5

al height t

u

lent length

hether it i

s

Meter)

ape three-

w

0.76

0.76

0.76

0.76

1.1

1.4

refrigerant i

d must be

ite.

nit, pack th

e

burn the la

b

nual-Down D

installation.

vibration re

fference of

n it needs

e

0m

m

bes.

, the frictio

n

appropriat

e

ay

n the indoo

r

put off all t

h

wet cloth

o

els near th

e

elivery Series

4

7

uction

indoor and

t

o confirm

losses of

according

unit, the

ese

n the ball

base pan

e

l

Page 49

Midea Precision AC Technical Manual MCAC-PDSM-2013-01

48

Do not open the system pipeline more than 15 minutes, or it will lead to freeze the cooling oil and

influence the usage lifespan of the key parts in the system and the system operation stability.

The horizontal part of the gas pipe should be sloped down part after led out from the compressor,

its gradient at least should be 1:200 (every 1m should drop 5mm). But if the air exhaust pipe is

located at the place of cooling equipments (including under the block up floor) then it should be

insulated.

Considering the diameter will cause the system pressure drop loss, the copper pipes diameters

connecting between indoor and oudoor units.

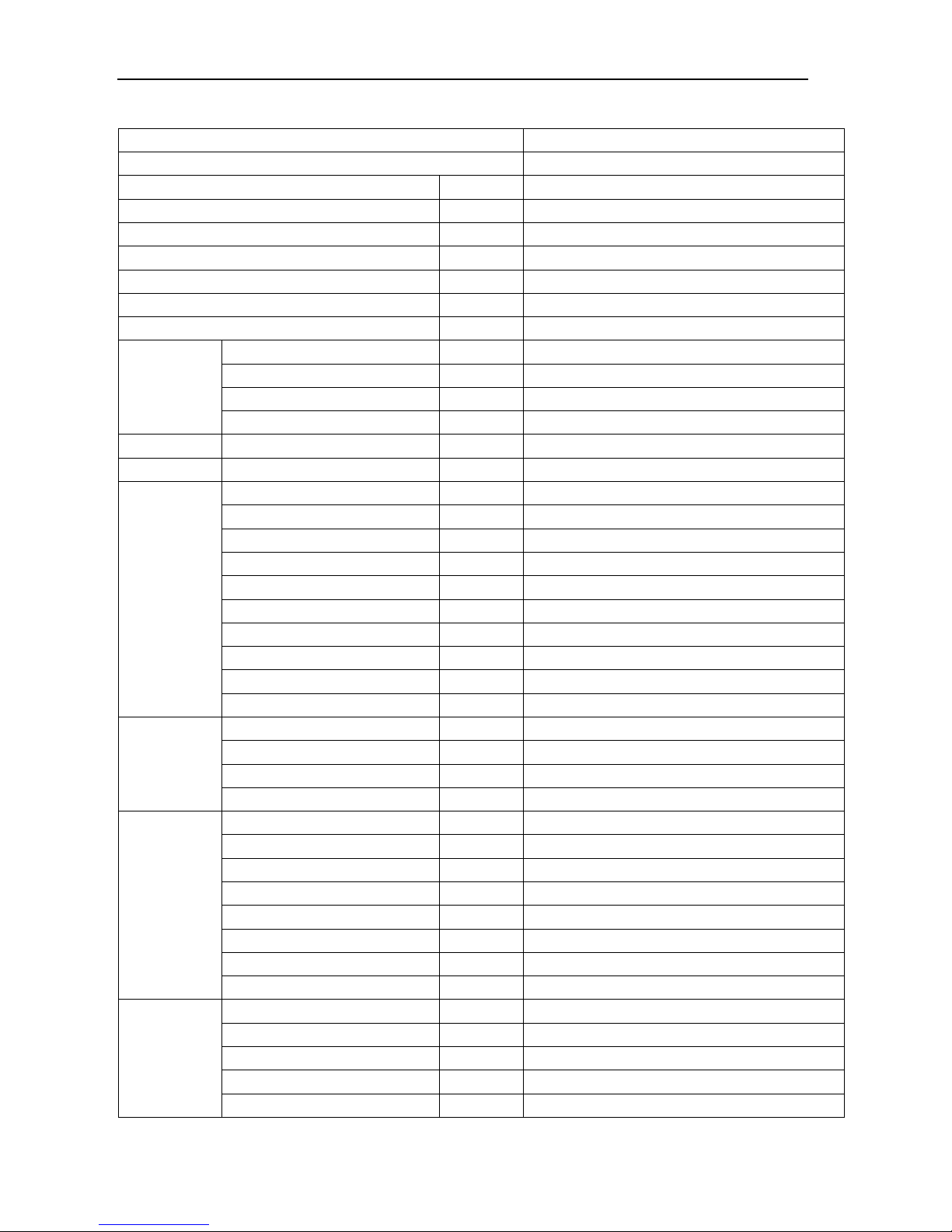

Indoor unit model Length 10m 20m 30m 40m 50m 60m

MAD020T1N1S1

Gas pipe 22mm 22mm 22mm 22mm 22mm 22mm

Liquid pipe 13mm 13mm 13mm 13mm 16mm 16mm

MAD025T1N1S1

Gas pipe 22mm 22mm 22mm 22mm 25mm 25mm

Liquid pipe 13mm 13mm 16mm 16mm 16mm 16mm

MAD030T1N1S1

Gas pipe 22mm 22mm 22mm 22mm 25mm 25mm

Liquid pipe 13mm 16mm 16mm 16mm 16mm 16mm

MAD035T1N1S1

Gas pipe 22mm 22mm 22mm 22mm 25mm 25mm

Liquid pipe 13mm 16mm 16mm 16mm 16mm 16mm

MAD040T2N1S1

Gas pipe 22mm 22mm 22mm 22mm 22mm 22mm

Liquid pipe 13mm 13mm 13mm 13mm 13mm 16mm

MAD045T1N1S1

Gas pipe 22mm 22mm 25mm 25mm 28mm 28mm

Liquid pipe 16mm 16mm 16mm 16mm 19mm 19mm

MAD050T2N1S1

Gas pipe 22mm 22mm 22mm 22mm 25mm 25mm

Liquid pipe 13mm 13mm 16mm 16mm 16mm 16mm

MAD060T2N1S1

Gas pipe 22mm 22mm 22mm 22mm 25mm 25mm

Liquid pipe 13mm 16mm 16mm 16mm 16mm 16mm

MAD070T2N1S1

Gas pipe 22mm 22mm 22mm 22mm 25mm 25mm

Liquid pipe 13mm 16mm 16mm 16mm 16mm 16mm

MAD080T2N1S1

Gas pipe 22mm 22mm 25mm 25mm 28mm 28mm

Liquid pipe 16mm 16mm 16mm 16mm 19mm 19mm

MAD090T2N1S1

Gas pipe 22mm 22mm 25mm 25mm 28mm 28mm

Liquid pipe 16mm 16mm 16mm 16mm 19mm 19mm

Notes:

If the pipe length is more than 60m, please consult the manufacturer.

When the pipe equivalent length is more than 30m, then it needs to install the extended

components. During the extended components installation, to prevent pipelines open, it

suggested that install the extended the electromagnetic valve body components on the outside

of the liquid pipe ball valve, or int the outside or the bottom of the equiment.

So in the electromagnetic valve installation operation process, it do not need to cut the indoor

pipeline, and after the whole system installation, then open the ball valve for pressurizing and

vacuum operation, to avoid moisture absorption of the compressor frozen oil, and ensure that

Page 50

MCAC-PDS

M

th

e

pi

pthe

T

h

3.5 Vacu

u

Af

tthefor

U

nsysgla

Af

tam

If

t

12

W

hsys

as

-2013-04

operation

o

e in the pr

o

pipe to th

e

e electrom

a

m and ad

er finished

n filled wit

h

24 hours.

der the pip

e

tem loop t

o

sses in ind

o

er the vacu

ount liquid

he connecti

kg.

en the con

tem for th

e

the folling

f

f the com

p

cess of pip

e

outdoor u

n

gnetic valv

e

d refriger

piping conn

e

30kgf/cm2

line press

u

below 20

P

or unit will

um inspecti

o

refrigerant

a

ng pipe len

g