Page 1

1

MDV Swimming Pool Type

Heat Pump Water Heater

Technical Manual

Applicable Models:

LRSJ-60/NYN1

LRSJ-80/NYN1

LRSJ-120/NYN1

LRSJ-140/NYN1

Midea reserves the right to discontinue, or change at any time, specifications or designs without notices and

without incurring obligations.

Page 2

2

Contents

Part 1 General Information ........................................................................3

1. Measurements....................................................................................................... 4

2. External Appearance............................................................................................ 4

3. Nomenclature........................................................................................................ 5

4. Features................................................................................................................. 6

Part 2 Outdoor Units...................................................................................7

1. Specifications....................................................................................................... 8

2. Capacity&COP table........................................................................................... 17

3. Dimensions ......................................................................................................... 17

4. Service Space ..................................................................................................... 18

5. Wiring Diagrams................................................................................................. 19

6. System refrigerant Diagrams............................................................................. 17

7. Exploded View .................................................................................................... 22

8. PCB explain......................................................................................................... 22

Part 3 Installation......................................................................................26

1. Precautions......................................................................................................... 27

2. Installation information...................................................................................... 28

3. Unit Appearance and Composition................................................................... 29

4. Accessories......................................................................................................... 30

5. Inspecting and Handling the Unit ...................................................................... 30

6. Electric Wiring..................................................................................................... 31

Part 4 Trial Operation ...............................................................................33

1. Confirmation before the trial operation............................................................ 34

2. OPERATING INSTRUCTION............................................................................... 34

3. PCB explanation.....................................................................

4. Maintenance............................................................................

5. Malfunctions and Resolutions...............................................

Page 3

3

Part 1

General Information

1. Measurements...................................................................4

2. External Appearance........................................................4

3. Nomenclature....................................................................5

4. Features.............................................................................6

Page 4

4

1. Measurements

Model

Dimension

(mm:

W*H*D)

Net weight / Gross weight

(kg)

Power Supply

CE-LRSJ-60/NYN1

1015*705*385 64/73 220~240V-1ph-50Hz

CE-LRSJ-80/NYN1

1015*705*385 66/77

220~240V-1ph-50Hz

CE-LRSJ-120/NYN1

1050*855*315 75/85

220~240V-1ph-50Hz

CE-LRSJ-140/NYN1

1050*855*315 75/85

220~240V-1ph-50Hz

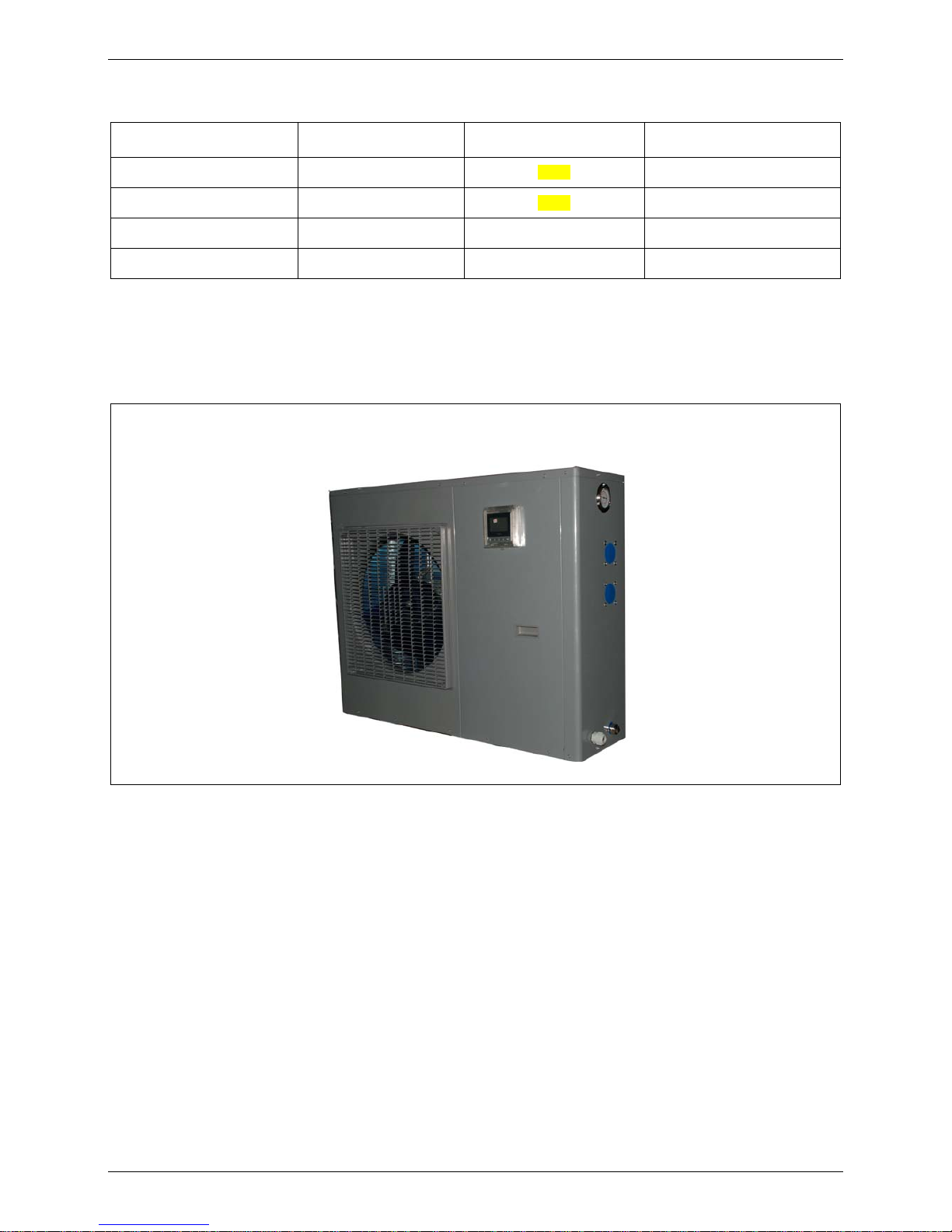

2. External Appearance

LRSJ-60/NYN1 LRSJ-80/NYN1 LRSJ-120/NYN1 LRSJ-140/NYN1

Page 5

5

3. Nomenclature

Household Water Heating Unit

23

45

6

7

8

Power supply specification code

-

Heating mode code

Rated hot water output, unit: 100 W

whether the system with pump

Installation type code

cooling recovery code

Export model code

/

-

9

Other functions code

10 11

12

-

Water supply pump lift code

Refrigerant code

Design code

1

Export model code

For example:

-

/

Water heat ing unit code

Rated hot water output, unit: 100 W

RSJ

L

Wi th cooling function

60

N

Y

N1

No water pump with machine

Heating mode code:swimming pool

Refrigerant type :R410a

Page 6

6

4. Features

4.1 Titanium heat exchanger

a. Excellent prevent eroding material,keep the machine long life.

b. High energy efficiency.

4.2 LCD display and build in high pressure meter in refrigerant side

User can see the machine running parameter and the state quickly.

Engineer can see the machine discharge pressure quickly, get hold of the machine

running reliablity .

4.3 About the 3-minute protection

Restart or open the manual switch after the unit has shut,down. Unit will not start immediately until 3

minutes later,because of the self-protect function of the compressor.

4.4 Dsfrosting function

In case of the unit requiring deicing during heating operation,TO prevent the heating efficiency from decreasing,

defrosting operation will turn on automatically (approx. 2~8 minutes) .

In the process of defrosting operation, the unit air supply motor will stop running.

4.5 Safety

a. Realize isolation between water and electricity. No electric shock problem, more safety.

b. No fuel tubes and storage, no potential danger from oil leakage, fire, explosion etc.

4.6 Autmatic Control:

Automatic start-up and shutdown, automatic defrosting by revising refrigerant cycle. Save you much extra

operation.

4.7 R410a gas, Environmental protection.

a. No discharge of poisonous gas.

b. No pollution to atmosphere and environment

4.8 All-the-weather Running.

Within the temperature range from -7 to 38℃, it will not be affected by night, cloudy sky,

rain even snow whether.

Page 7

7

Part 2

Outdoor Units

1. Specifications....................................................................8

2. Capacity & COP table .....................................................17

3. Dimensions......................................................................17

4. Service Space..................................................................18

5. Wiring Diagrams .............................................................19

6. System refrigerant Diagrams.........................................22

7. Exploded View.................................................................22

8. PCB explain.....................................................................22

Page 8

8

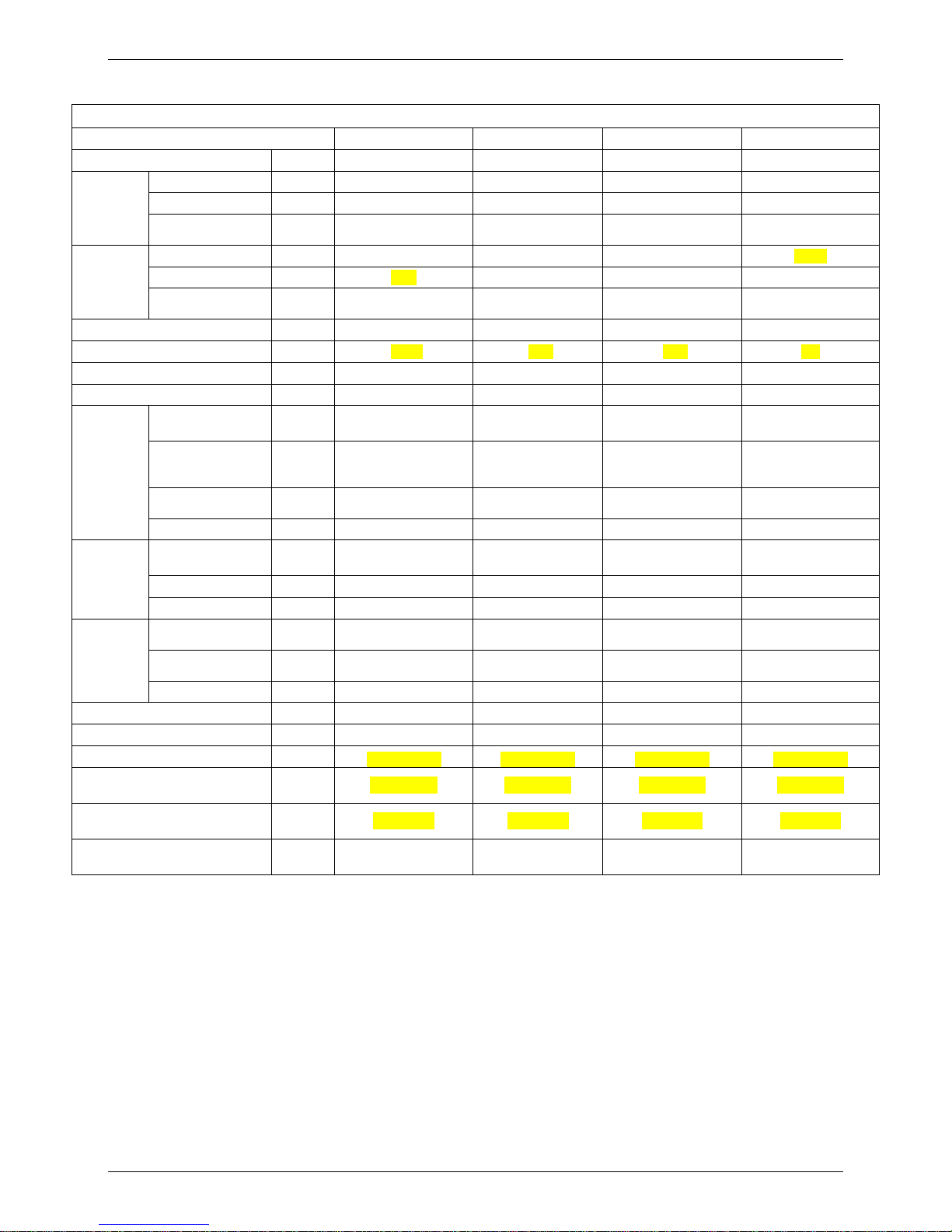

1. Specifications

HPWH SPECIFICATION

Model CE-LRSJ-60/NYN1 CE-LRSJ-80/NYN1 CE-LRSJ-120/NYN1 CE-LRSJ-140/NYN1

Power supply Ph-V-hz 220-240V 50Hz 1Ph 220-240V50Hz1Ph 220-240V 50Hz 1Ph 220-240V 50Hz 1Ph

Capacity

kW 6 8 12 14

Input

kW 1.15 1.52 2.40 2.55

Water

Heating

Outdoor ambient

temperature

(-7℃~38℃) (-7℃~38℃) (-7℃~38℃) (-7℃~38℃)

Capacity kW 4.0 5.8 8.4 10.35

Input kW 1.25 1.5 2.4 2.9

Water

Cooling

Outdoor ambient

temperature

(15℃~43℃) (15℃~43℃) (15℃~43℃) (15℃~43℃)

COP 5.2 5.3 4.9 5.3

Max power kW 1.45 1.9 3.3 3.5

Outdoor noise level

dB(A) 58 58 58 58

Refrigerant type/Quantity

Kg R410A/1.0 R410A/1.25 R410A/1.6 R410A/1.85

Heat exchanger

material

Titanium-tube

thermal exchanger

Titanium-tube

thermal exchanger

Titanium-tube

thermal exchanger

Titanium-tube

thermal exchanger

Water inlet and

outlet pipe

diameter

mm

DN50 DN50 DN50 DN50

Drain pipe

diameter

mm

DN25 DN25 DN25 DN25

Heat

exchanger

Max. pressure

MPa 0.4 0.4 0.4 0.4

Fin type

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Hydrophilic

aluminium

Tube outer type

innergroove tube innergroove tube innergroove tube innergroove tube

Air side

exchanger

Air outflow mode

air flow from rear air flow from rear air flow from rear air flow from rear

Dimension

(W*H*D)

mm

1015*705*385 1015*705*385 1050*855*315 1050*855*315

Packing

(W*H*D) mm 1095*755*455 1095*755*455 1170*905*410 1170*905*410

Outdoor

unit

Net/Gross weight

kg 64/73 66/77 75/85 75/85

Water contented capacity (m3)

40.0 50.0

60~85 75~100

Hot Water Yield

m

3

/h

2.3 2.8 3.8 3.8

Wire controller

KJRH-90B/E KJRH-90B/E KJRH-90B/E KJRH-90B/E

Water Heating Outwater Temp

℃

11℃~35℃ 11℃~35℃ 11℃~35℃ 11℃~35℃

Water Cooling Outwater Temp

℃

6℃~30℃ 6℃~30℃ 6℃~30℃ 6℃~30℃

Compressor current protection

value A

10 12 20 22

Remark:

1. The test conditions: outdoor temp.

Water Heating: outdoor temp. 24/19℃(DB/WB), inlet water temp. 27℃,outlet water temp. 29℃

Water Cooling: outdoor temp. 35/24℃(DB/WB), inlet water temp. 27℃

2. The specification may be changed for product improvement, please refer to the nameplate.

Page 9

9

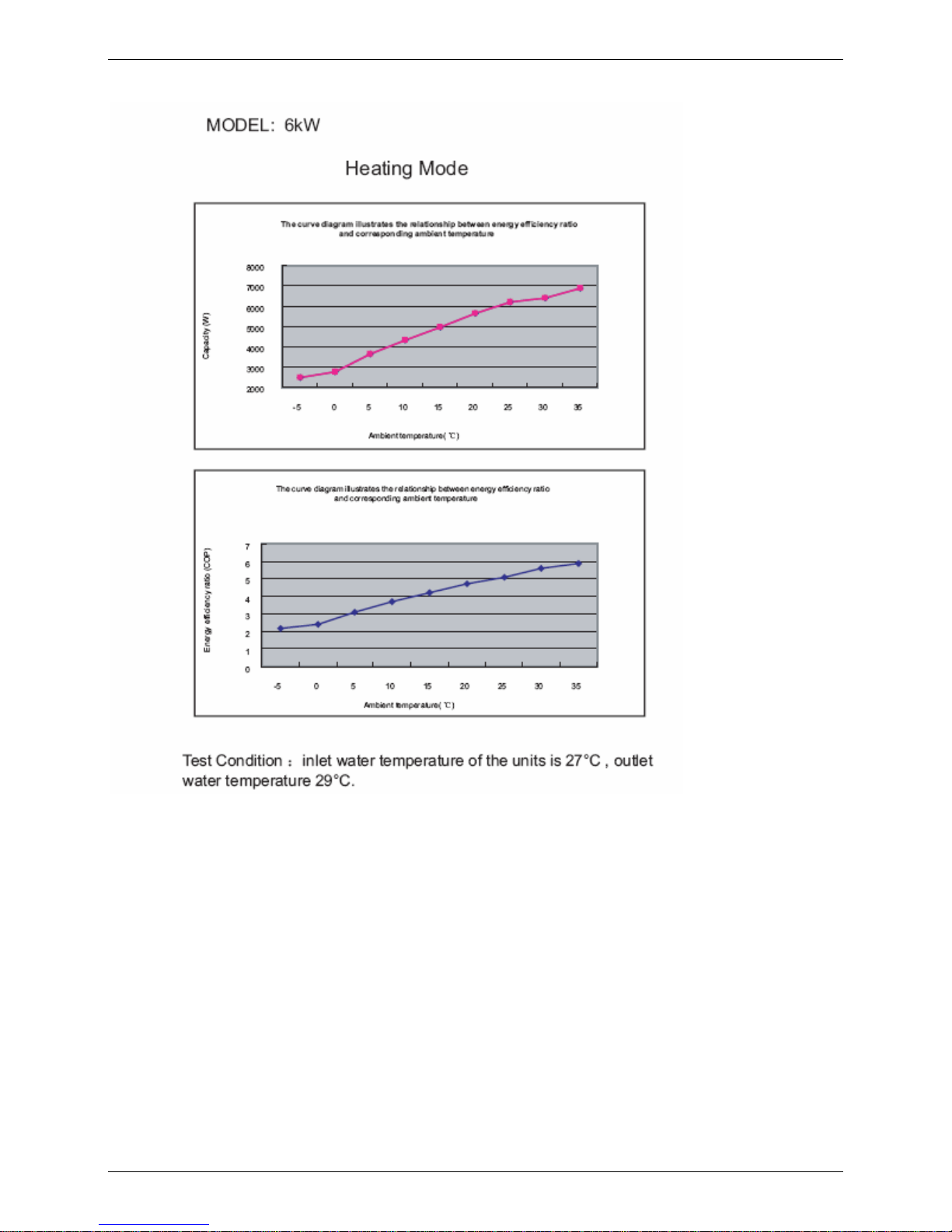

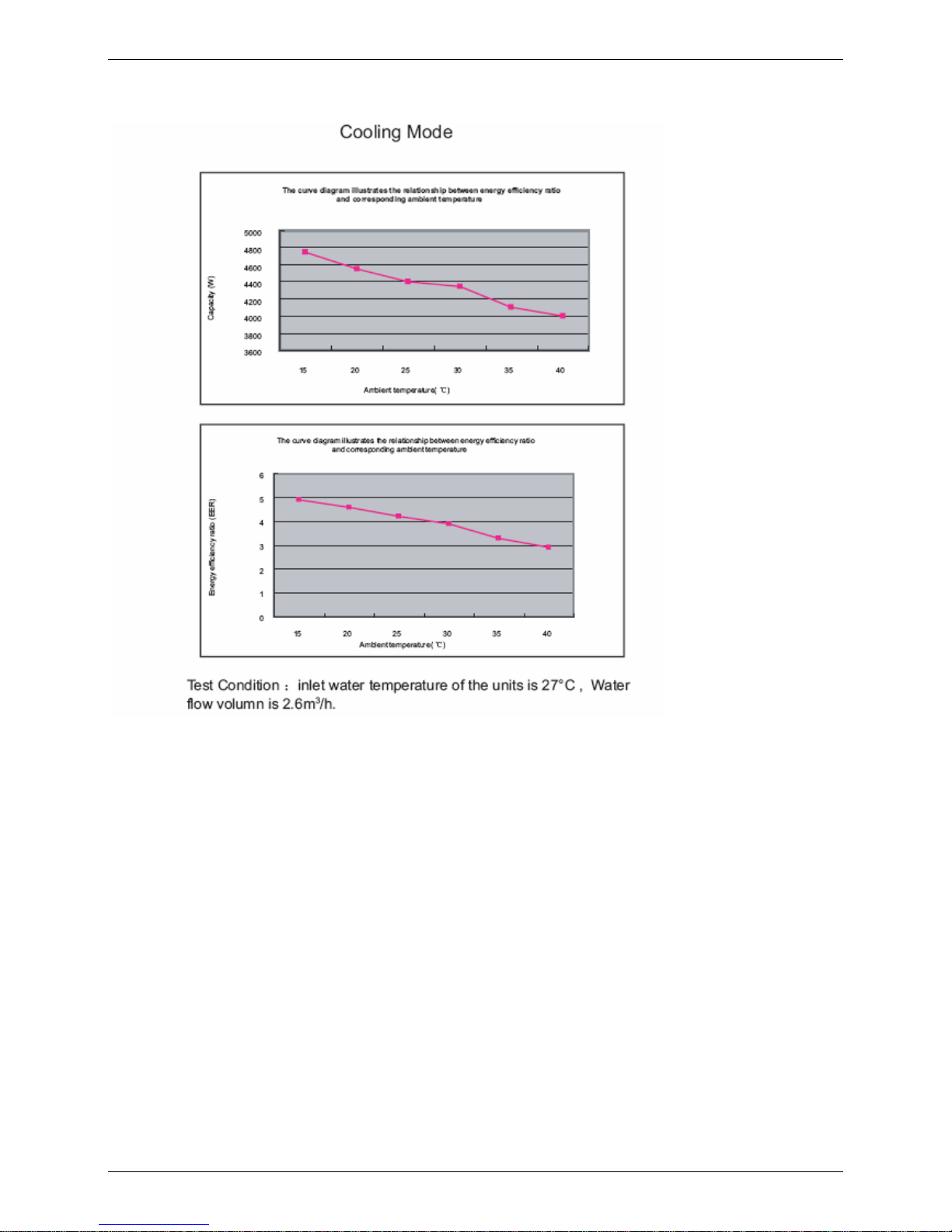

2. Capacity & COP curve

Page 10

10

MODEL : 6 kw

Page 11

11

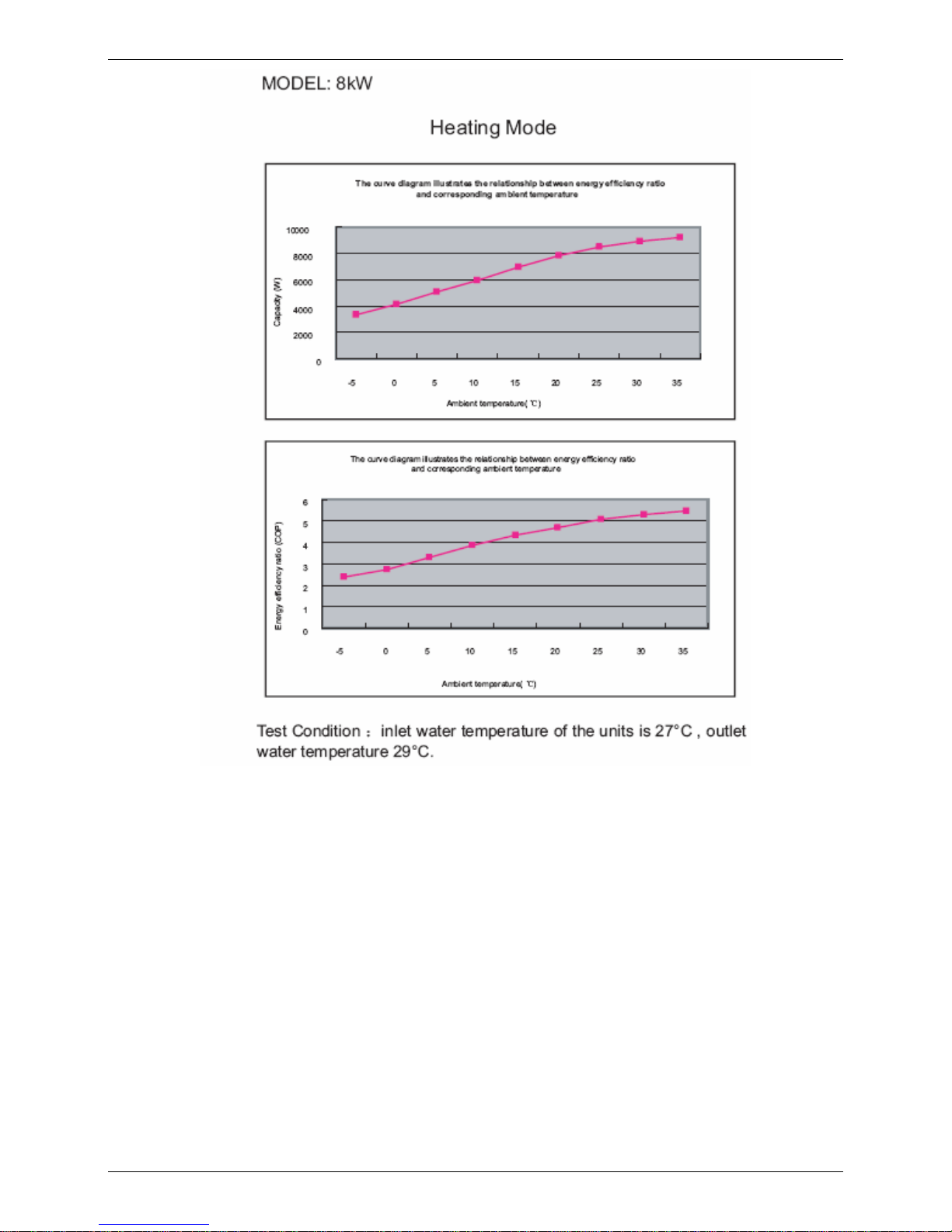

Page 12

12

MODEL :8 kw

Page 13

13

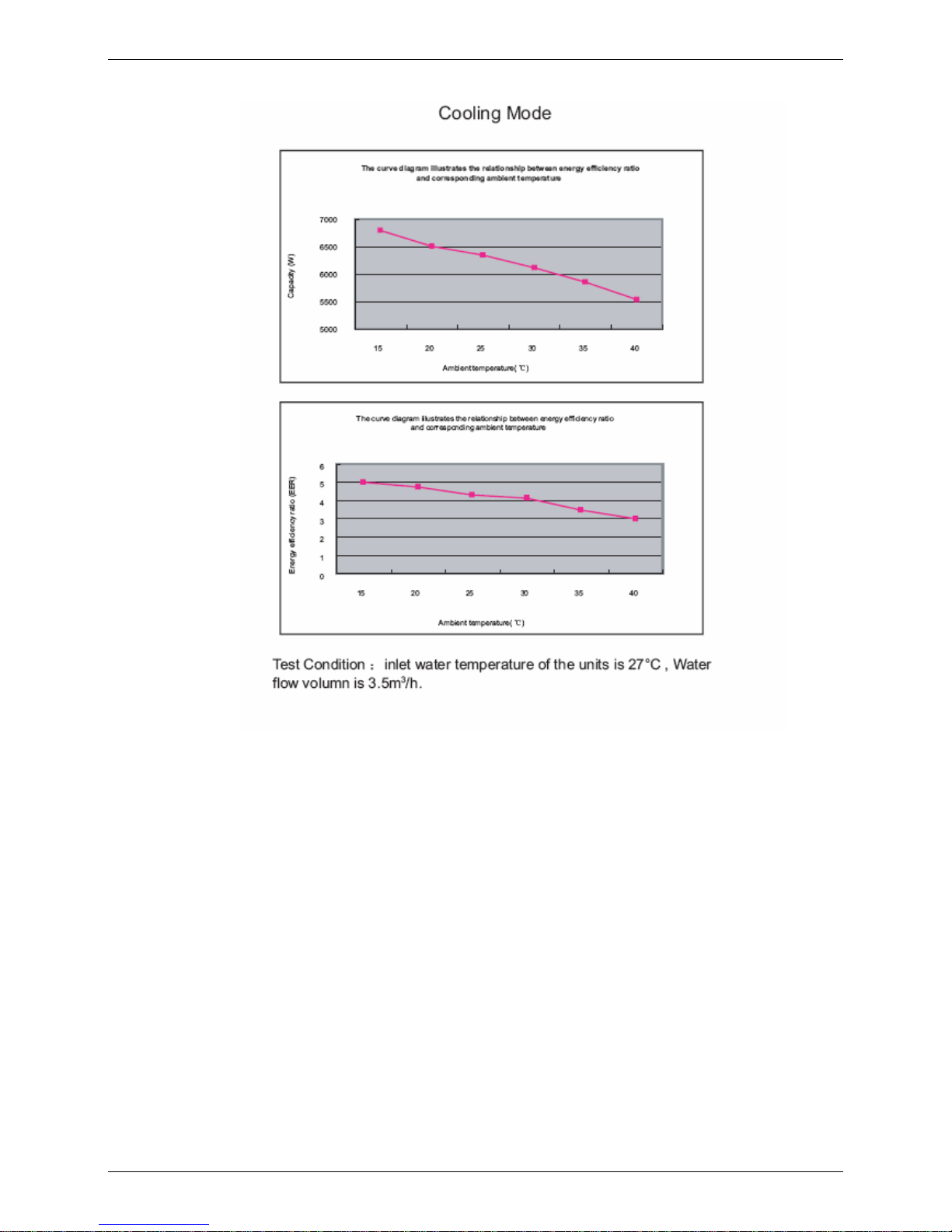

Page 14

MODEL :12 kw

14

Page 15

15

Page 16

16

Page 17

17

3.

Dimensions

855 705 H

315 385 E

1050 1015 D

165 170 C

333 390 B

590 610 A

12KW

14KW

6KW

8KW

MODEL

Page 18

18

4. Service Space

Page 19

19

5. Wiring Diagrams

6Kw and 8Kw wiring diagrams:

Page 20

20

12Kw and 14Kw wiring diagrams:

Page 21

21

6. System Rfrigerant Diagrams

comp.

evaporator

titanium heat

exchanger

four-way

valve

water

pump

T3

T4

T6

Tp

T

out

high pressure

protection valve

Page 22

22

7. Exploded View

MODEL: LRSJ-120/NYN1 & LRSJ-140/NYN1

、

Page 23

23

No. Part Name Quantity No. Part Name Quantity

1

Rear net

1 12.9

Wire joint

1

2

Side board

1 12.10

Wire clamp

2

3

Target switch

1 12.11

Wire joint

2

4

Main capillary ass'y

1 13

Handle

2

5

Titanium heat exchanger

1 14

Wire controller

1

6

Hight pressure meter

1 15

Front side board

1

7

right side board

1 16

Front panel

1

8

Base ass'y

1 17

Grille

1

9

Solenoid

1 18

Axial flow fan

1

10

4-way valve ass'y

1 19

Motor

1

10.1

Pressure controller

1 20

Condenser ass'y

1

10.2

4-way valve

1 20.1

Flute shape pipe ass'y

1

10.3

Accumulator tank

1 21

Left bracket

1

11

Compressor

1 22

Rear supporter

1

12

E-part box ass'y

1 23

Motor bracket ass'y

1

12.1

Main controller board ass'y

1 24

Cover

1

12.2

Middle connection board ass'y

1 25

Partition board ass'y

1

12.3

Relay

1 26

Temperature sensor

2

12.4

Motor capacitor

1 27

Temp.sensor ass'y

1

12.5

Transformer

1 28

Discharge temp sensor ass'y

1

12.6

Compressor capacitor

1 29

room temp sensor ass'y

1

12.7

Contactor

1 30

Compressor electric heater

1

12.8

Wire joint

1

Page 24

24

8. PCB explain

A

Page 25

25

■ A : appliance type dial code

CE-LRSJ-60/NYN1

self-checking

adress :0

CE-LRSJ-80/NYN1

self-checking

adress :1

CE-LRSJ-120/NYN1

self-checking

adress :2

CE-LRSJ-140/NYN1

self-checking

adress :3

Page 26

26

Part 3

Installation

1. Precautions ...................................................................277

2. Installation information................................................288

3. Unit Appearance .............................................................29

4. Accessories.....................................................................30

5. Inspecting and Handling the Unit..................................30

6. Water pipline diagrame ..................................................30

7. Water pump selection.....................................................31

8. Tools required for installation .......................................31

9. Electric connection.........................................................31

Page 27

27

1. Precautions

To prevent injury to the user or other people and property damage, the following instructions must be

followed. Incorrect operation due to ignoring of instructions may cause harm or damage.

The safety precautions listed here are divided into two categories. In either case, important safety

instructions are listed to which close attention must be paid.

WARNING

Failure to observe a warning may result in death.

CAUTION

Failure to observe a caution may result in injury or damage to the equipment.

WARNING

■ The water heating unit must be earthed effectively.

■ A creepage breaker must be installed near the power supply.

■ Ask your supplier for installation of the air source heat pump water heating units. Incomplete installation

performed by yourself may result in water leakage, electric shock, or fire.

■ Ask your supplier for the repair and maintenance. Incomplete repair and maintenance may result in

water leakage, electric shock or fire.

■ In order to avoid electric shock, fire or injury, if any abnormality is detected, such as smell of fire, turn off

the power supply and call your supplier for instructions.

■ Never replace a fuse with that of wrong rated current or other wires when a fuse blows out. Use of

wrong wire or copper wire may cause the unit to break down or a fire.

■ Do not insert fingers, rods or other objects into the air inlet or outlet. When the fan is rotating at high

speed, it will cause injury.

■ Never use a flammable spray such as hair spray, lacquer paint near the unit. It may cause a fire.

■ Never touch the air outlet or the horizontal blades while the swing flap is in operation. Fingers may

become caught or the unit may break down.

■ Never put any objects into the air inlet or outlet. Objects touching the fan of high speed can be

dangerous.

■ Do not dispose this product as unsorted municipal waste. Collection of such waste separately for

special treatment is necessary.

■ The appliance shall be installed in accordance with national wiring regulations.

CAUTION

■ Do not use the air-source water heater for other purposes.

■ Before cleaning, be sure to stop the operation and turn the breaker off or pull out the power cord.

Otherwise, an electric shock and injury may be caused.

■ In order to avoid injury, do not remove the fan guard on the outdoor unit.

■ Do not operate the air-source water heater with a wet hand. An electric shock may be caused.

■ In the place and the wall where water may be spattered, the installation height must be more than 1.8m.

■ At the water inlet, the One Way valve must be installed.

■ It’s normal if some water drips from the hole of PT valve in operation. But, if the water is in a great

amount, call your supplier for instructions.

■ After a long use, check the unit stand and fittings. If damaged, the unit may fall and result in injury.

■ Arrange the drain hose to ensure smooth drainpipe. Incomplete drainpipe may cause wetting of the

building, furniture etc.

■ Never touch the internal parts of the controller.

Page 28

28

■ Do not remove the front panel. Some parts inside are dangerous to touch, and a machine malfunction

may be caused.

■ Never expose babies, plants or animals directly to the air flow. Adverse influence to babies, animals and

plants may be resulted.

2. Installation information

■ Enough space is installation and maintenance shall be preserved.

■ The air inlet and outlet should be free from obstacles and strong wind.

■ The bearing surface should be flat, able to bear weight of the unit and suitable for installing the unit

horizontally without increasing noise or vibration.

■ The operation noise and air flow expelled shall not affect neighbors.

■ No flammable gas is leaked nearby.

■ It is convenient for piping and wiring.

■ The maximum pressure is 0.4 Mpa, when the pressure more than 0.4 Mpa, Please add a pressure relief

valve.

CAUTION

■ Installing the equipment in any of the following places may lead to malfunction of the equipment (if it is

inevitable, consult the supplier):

1) The site contains mineral oils such as cutting lubricant.

2) Seaside where the air contains much salt.

3) Hot spring area where corrosive gases exist, e.g., sulfide gas.

4) Factories where the power voltage fluctuates seriously.

5) Inside a car or cabin.

6) Place like kitchen where oil permeates.

7) Place where strong electromagnetic waves exist.

8) Place where flammable gases or materials exist.

9) Place where acid or alkali gases evaporate.

10) Other special environments.

■ Precautions before installation

1) Decide the correct way of conveying the equipment.

2) Try to transport this equipment with the original package.

3) If the unit has to be installed on a metal part of the building, electric insulation must be installed, and the

installation must meet the relevant technical standards for electric devices.

■ Installation space

Before installing the unit, reserve the space of maintenance .

WARNING

■ Ask your supplier to install the air source heat pump water heating units. Incomplete installation

performed by yourself may result in a water leakage, electric shock, or fire.

■ The place without direct sunlight and other heat supplies. If there’s no way to avoid these, please install

a covering.

■ The unit must be securely fixed, or else, noise and shaking will be resulted.

■ Make sure that there’s no remora around the unit.

■ In the place where there is strong wind like seashore, fix the unit in the location protected from the wind.

Page 29

29

■ Carry the unit onto the site

1) In order to avoid scratch or deformation of the unit surface, apply guard boards to the contacting

surface.

2) No contact of fingers and other things with the vanes.

3) Don’t incline the unit more than 45° in moving, and keep it vertical when installing.

■ Install the unit.

1) The circulating air for every unit should be more than 2400m3/h.

2) Make sure there is enough Installation space.e

3) Outline dimensional drawing

Water treatment

In order to use our appliances under the best conditions, the following parameters must be respected:

free chlorine:max. 2.5mg/l, total bromine: max. 5.5 mg/l, PH between 6.9 and 8.0. If chemical or

electrophysical disinfection systems are used, the installer and user must contact the supplier to ensure they

are compatible with our materials. These systems must be installed after the heating system.

3. Unit Appearance

Page 30

30

4. Accessories

Check whether the following assemblies are complete.

Name Quantity Note Purpose

Installation& Operation Manual 1 —— Installation and Operation instruction

Seal ring 1 —— Discharge condensate water

Water outlet jointing pipe 1 —— Discharge condensate water

5. Inspecting and Handling the Unit

After delivery, the package should be checked and any damage should be reported immediately to the

carrier claims agent.

When handling the unit, take into account the following:

1.

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor damage.

2. Choose before hand the path along which the unit is to be brought in.

3. Move this unit with original package.

4. When lifting the unit , always use protectors to prevent belt damage and pay attention to the balance of

the unit’s gravity.

6. Water pipeline diagram

8.1 Connection is established with a by-pass on the pool filtration circuit after the filter and before the water

treatment device (see diagrams upper). In order to connnect other heat source

8.2 During installation of connective pipe, you must beware not to let any dust or other foreign substance

intrude into pipe system.

8.3 Water inlet and outlet pipes can be installed as long as the water-heating A/C have been fixed.

8.4 Thermal insulation materials should be employed to seal up water outlet and inlet pipes.

8.5 Before operation, please confirm that the specifications of connective pipes are correct, and thermal

nsulation layer have been wrapped on pipes. It requires that all pipes have been sealed up, and no water

leakage has been detected.

Page 31

31

8.6 Hydraulic circuit test pressure: 3 bars - Hydraulic circuit operating pressure: 1.5 bar

pressure drop 2.2 mCE (0.22 bar)

7. Water pump selection

Model Water flow

Recommendatory flow

LRSJ-60/NYN1 0.8~20m3/h

3m3/h

LRSJ-80/NYN1 0.8~20m3/h

4m3/h

LRSJ-120/NYN1 1.5~20m3/h

5m3/h

LRSJ-140/NYN1 1.5~20m3/h

5.8m3/h

8. Tools required for installation

- 1 set of flat head screwdrivers

- 1 set of crosshead screwdrivers

- 1 cutter

- 1 wire stripper

- 1 pipe or round head spanner 13

- 1 ratchet spanner

- 1 pliers

- 2 straps (for handling)

9. Electic connection

9.1 Power specification

Diameter of the thinnest cable (mm2)

(Metal pipe and synthetic resin pipe wiring)

Manual Switch

(A)

Item

Model

Power Supply

Size (continious length

<30 m

Earthling Wire Capacity Fuse

LRSJ-60/NYN1 220~240V-1ph-50Hz 2.5 2.5 ≥30 20

LRSJ-80/NYN1 220~240V-1ph-50Hz 2.5 2.5 ≥30 20

LRSJ-120/NYN1 220~240V-1ph-50Hz 4.0 4.0 ≥30 25

LRSJ-140/NYN1 220~240V-1ph-50Hz 4.0 4.0 ≥30 25

9.2 Power Supply Wiring .

A. Power Supply Schematic Diagram

Earthing

Water Heating Unit

Manual Switch

Power

supply

Creepage Breaker

Warming:

Although there is a leakage protector in the electric control box of the unit, for the security reason, it is

required that a leakage protection equipped cable and Earthing should be applied for the unit according to

the requirement on the above diagram.

B. Cable Diameter Selection

The power supply wiring refers to the wiring to the main line (a) of junction box and the wiring (b) to the

power supply equipment. Please select the cable diameter according to the following methods

Page 32

32

1) Diameter of the main line (a):

Get from the power supply specification table according to the sum of horsepower of the unit.

2) Diameter of the wiring from the junction box to the power supply equipment:

When the water heaters are less than 5 sets, the diameter the wiring from the junction box to the power

supply equipment should be the same as the main line (a); when the water heaters are more than 6 sets, the

power supply equipment should have two sets of electric control box and the diameter should be get from

the power supply specification table according to the sum of horsepower of the units connected by the

electric control box.

9.3 Electric wiring diagram

Electric wiring diagram for Model 6kW 8kW 12kW 14kW

Page 33

33

Part 4

Trial Operation

1. Confirmation Before the Trial Operation......................34

2. Operating Instruction .....................................................34

3. Fault code list.....................................

4. Self-checking......................................

Page 34

34

1. Confirmation Before the Trial Operation

1.1 All the installation is complete.

1.2 Water heater is installed correctly.

1.3 The pipelines and wiring are correct.

1.4 The accessories are installed correctly.

1.5 The drainage is smooth.

1.6 The thermal insulation is sound.

1.7 The earthing wire is connected correctly.

1.8 The power voltage is consistent with the rated voltage of the heater.

1.9 No obstacle at the air inlet and outlet of the unit.

1.10 The leakage protector can work effectively.

2. Operating Instruction

2.1 The appearance of controller

2.2 Name and function description of LCD screen of wire controller

Page 35

35

2.3 Names of keys on the wire controller and the keypad operation description

2.4 Application of wire controller

Preparation before running the unit.

When you run the unit for the first time, all the indicators on the wire controller will light for 3s, and then,

display the fiducial web page. After no operation for 40s, all indicators will go out automatically except POOL

TEMP indicator lighting. When the unit is running, if there is no operation or malfunction for 10s, the

backlight of the display will go out automatically.After 30s ,all indicator will disappear except operation mode

and pool temp.

By default, the unit operates Heat Mode. Change:

Mode Selection

The unit is enhanced with three operation modes, Cool Mode, Heat Mode and Pump Mode.

Cool Mode: The unit cools down swiming pool water by compressor drive according to heat-pump principle.

Used when the swiming temp. is high in summer.

Heat Mode:The unit heats swiming pool water by compressor drive according to heat-pump principle. Used

when the ambient temp. is low.

Pump Mode:The pump run for circling the water. Used when trial run or other necessary situation.

By default, the unit operates Heat Mode. Change:

Page 36

36

Temperature set

Temp. displayed is the setting

water temp. Default is 28℃ and the Cool mode setting range is

10~30℃the heat mode setting range is 20~35℃

Power on/Power off

Press Power On/Power Off button after all the above have finished

and the system will run as the setting. And simply press the same

button to stop it.

Operation status display

Page 37

37

3. Fault code list

4. Self-checking function

1. Nomal display : T6 ;

2. Mode code :(0 6KW; 1 8KW; 2 12KW; 3 14KW);

3. Operate mode:(1 cooling;16 water heating;4 pump );

4. Fan speed(0 stop;1 low ;2 hight);

5. T4;

6. Tp;

7. T3;

8. T6;

9. Tout;

10. Comperssor current ;

11. Ts;

12. The last error code“--”

Loading...

Loading...