Page 1

MODEL:HS-338FWEN-W

Instruction Manual

Upright Freezer

Page 2

Page 3

Important Safety Notice

The Maintenance Manual is only for the use of maintenance personnel with certain experience and

background in electrical, electronic and mechanical field.

Any attempt to repair main devices may lead to personal injury and property loss.

Manufacturers or distributors are not responsible for the content of the Manual and interpretation

thereof.

Midea Refrigerators

Technical Maintenance Manual

Copyright @2016

All rights reserved. Replication of all or part of the Manual in any forms shall not be allowed without

written approval by the Overseas Sales Corporation of Midea Refrigerators.

Page 4

Contents

1.SAFETY WARNING CODE ......................................................................................................... 1

1.1WARNING FOR OPERATION SAFETY ................................................................................................... 1

1.2SAFETY INSTRUCTION FOR REFRIGERANT ......................................................................................... 4

2.DESCRIPTION FOR PRODUCT FEATURES ............................................................................ 5

3.INSTALLATION AND COMMISSIONING ................................................................................ 6

3.1HANDLING ....................................................................................................................................... 6

3.2DISASSEMBLY (NONE) ...................................................................................................................... 6

3.3 INSTALLATION LOCATION ................................................................................................................ 6

3.4 LEVELING OF THE REFRIGERATOR .................................................................................................... 6

3.5CHANGE THE DOOR OPENING DIRECTION .......................................................................................... 7

3.6 INSTALLATION OF HANDLE .............................................................................................................. 9

3.7 INSTALLATION OF DOOR LOCK(NONE) ...................................................................................... 10

3.8 ADJUSTMENT TO LEVEL THE DOOR(NONE) ............................................................................... 10

3.9 ADJUSTMENT TO SHELVES(NONE) ............................................................................................ 10

4.TERMS ........................................................................................................................................ 10

4.1 DEFINITION OF MODEL(NONE) ...................................................................................................... 10

4.2LOCATION OF NAMEPLATE .............................................................................................................. 10

5.PRODUCT SPECIFICATION .................................................................................................... 11

5.1 TYPESPECIFICATION(NONE) ........................................................................................................... 11

5.2 ELECTRICAL PARAMETERS ............................................................................................................. 11

5.3REFRIGERATING TEMPERATURE ...................................................................................................... 11

5.4DEFROSTING PARTS ........................................................................................................................ 12

5.5CIRCUIT DIAGRAM.......................................................................................................................... 12

6.INTERNAL VIEW AND DIMENSION ...................................................................................... 13

6.1MAIN PARTS AND THEIR NAMES ...................................................................................................... 13

6.2EXTERNAL DIMENSION ................................................................................................................... 13

7.REFRIGERATING PIPING SYSTEM AND CIRCULATING ROUTE OF COOLING AIR7.1 REFRIGERATING

PIPING SYSTEM .................................................................................................................................... 15

7.2CIRCULATING ROUTE OF COOLING AIR ............................................................................................ 16

8. DISMANTLING OF PARTS ...................................................................................................... 17

8.1 PARTS ON THE DOOR ...................................................................................................................... 17

8.2PARTS INSIDE THE REFRIGERATOR .................................................................................................. 17

8.3 LIGHT SYSTEM ............................................................................................................................... 18

8.4AIR DUCT AND FAN MOTOR ............................................................................................................. 18

8.5EVAPORATOR AND TEMPERATURE SENSING SYSTEM ....................................................................... 19

8.6COMPRESSOR CASE ........................................................................................................................ 20

Page 5

8.7DISPLAY AND MAIN CONTROL PANEL .............................................................................................. 21

8.8 BAR COUNTER(NONE) ................................................................................................................... 22

8.9 WATER DISPENSER(NONE) ............................................................................................................. 22

8.10 ICE MAKER(NONE) ...................................................................................................................... 22

9. FUNCTION AND OPERATION9.1 OPERATION PANEL ........................................................................... 23

9.2 BUTTON......................................................................................................................................... 23

9.3 DISPLAY SCREEN ........................................................................................................................... 24

9.4 DISPLAY ........................................................................................................................................ 24

IF NO FAILURE OCCURS, THE CURRENT OPERATION GEAR WILL BE DISPLAYED.9.5 SETTING OF THE GEAR

............................................................................................................................................................ 24

9.6 SUPER FREEZE ............................................................................................................................... 24

9.7 FAULT CODE AND SOLUTIONS ........................................................................................................ 24

9.8DEFROSTING FUNCTION ................................................................................................................. 25

9.9TEST MODE..................................................................................................................................... 25

9.10SELF-DIAGNOSIS .......................................................................................................................... 26

10.CIRCUIT DESCRIPTION10.1 POWER SUPPLY .................................................................................... 27

10.2DOOR TRIP TEST CIRCUIT .............................................................................................................. 27

10.3TEMPERATURE TEST CIRCUIT ........................................................................................................ 27

10.4FAN MOTOR CIRCUIT OF THE FREEZING CHAMBER ........................................................................ 28

10.5REFRIGERATOR FAN MOTOR CIRCUIT (NONE) ............................................................................... 29

10.6CONDENSING FAN MOTOR CIRCUIT (NONE) .................................................................................. 29

10.7DAMPER MOTOR CIRCUIT (NONE) ................................................................................................ 29

10.8RESISTANCE VALUE OF THE SENSOR (R/T) .................................................................................... 29

11.TROUBLESHOOTING METHOD........................................................................................... 30

11.1 NO REFRIGERATION ..................................................................................................................... 30

11.2 COMPRESSOR FAILURE................................................................................................................. 31

11.3 DEFROSTING IS NOT WORKING ..................................................................................................... 31

11.4 FAN IN THE FREEZING CHAMBER IS ABNORMAL ........................................................................... 32

11.5 DAMPER IS ABNORMAL(NONE) .................................................................................................... 32

11.6 LIGHTS INSIDE THE REFRIGERATOR DON’T LIGHT UP .................................................................... 32

12. FIGURES AND DETAILS OF REPAIR PARTS(DOCUMENTS ARE PROVIDED

SEPARATELY) ............................................................................................................................... 33

12.1 FIGURE ........................................................................................................................................ 33

12.2 LIST OF PARTS AND COMPONENTS ................................................................................................ 33

13APPENDIX: ...................................................................................................................................... 33

13.1ELECTRICAL SCHEMATIC DIAGRAM ............................................................................................. 33

13.2REFRIGERATOR MAINTENANCE TOOLING AND EQUIPMENT AND MATERIAL .................................. 33

Page 6

1

1.Safety Warning Code

1.1Warning for operation safety

Page 7

2

Page 8

3

Page 9

4

1.2Safety instruction for refrigerant

Page 10

5

2.Description for product features

This product is provided with following features:

(The picture is only for reference, and specific appearance and configuration are subject to the real

product)

1) Full air-cooling and frost-free design

2) Display control board is located on the door

3) Magnetically control switch

4) Electronic temperature control system with more accurate temperature control.

Page 11

6

3.Installation and commissioning

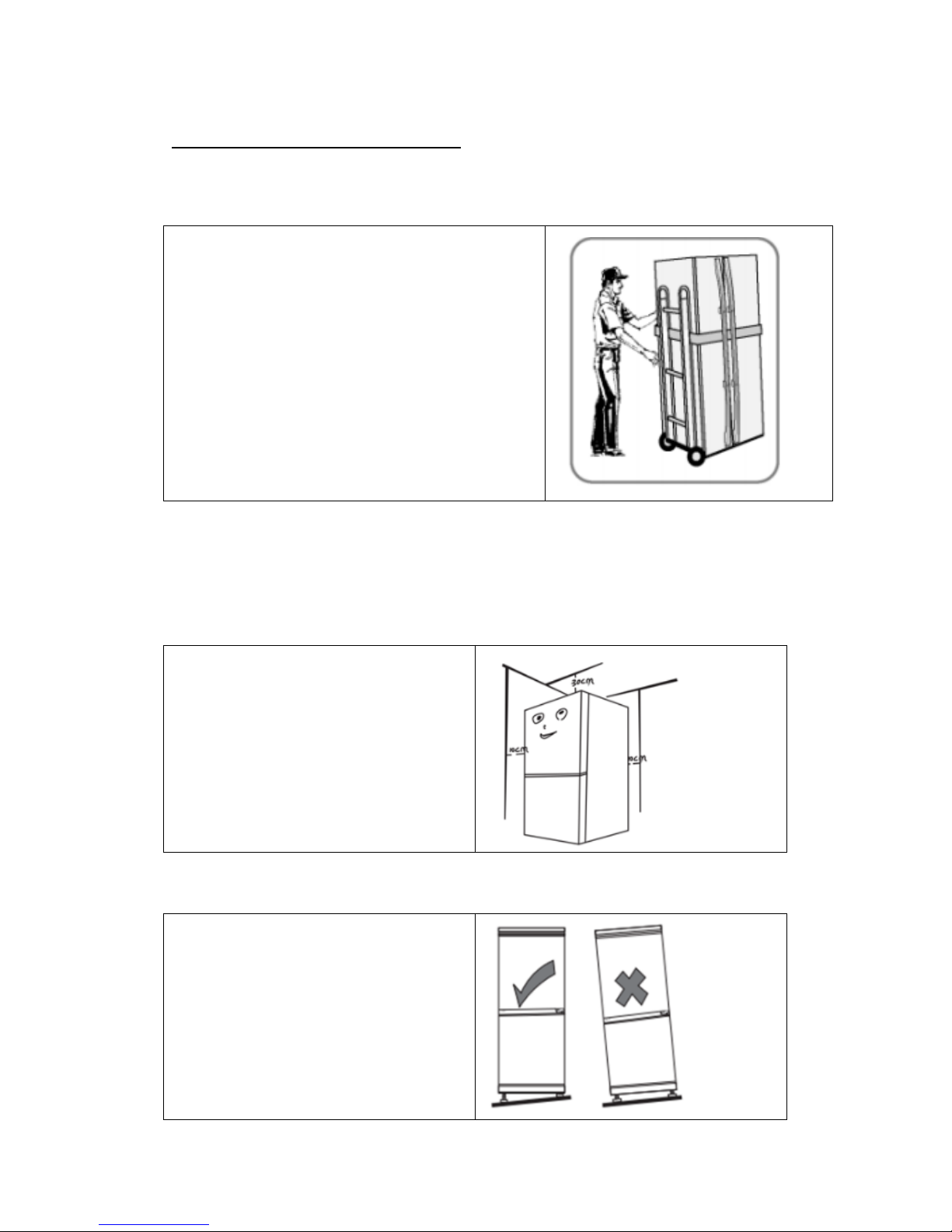

3.1Handling

1) Protecttherefrigeratorinmovingit

Sameasshownasleftphoto,pleasemoveitbyhandcartwi

thcushion

2) Removeallpackingmaterialsandbottomcushion,then

moveintohouseforplacement

3) Aftermovingittoappropriatelocation,waitfor2hoursbe

forepoweron.

3.2Disassembly (None)

The refrigerator door needs to be dismantled if it cannot enter the room in the whole.

3.3 Installation location

Location that is easy for ventilation shall be

chosen to facilitate heat dissipation, enhance

its performance and reduce the energy

consumption.

3.4 Leveling of the refrigerator

If the refrigerator cannot be placed steadily,

adjust the footing to level it.

Page 12

7

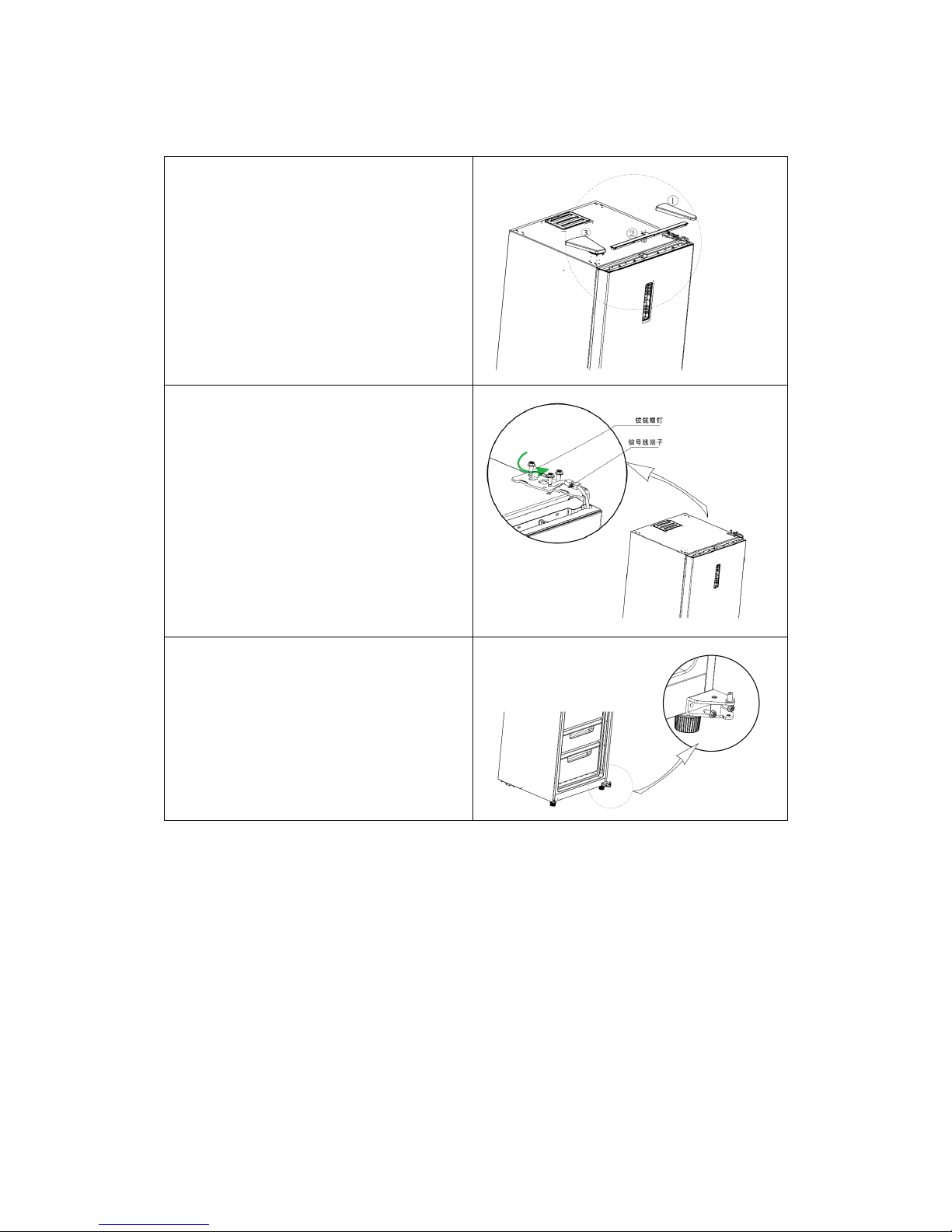

3.5Change the door opening direction

1、Remove the hinge cover and plates from the

top of refrigerator

2、Pull out the fast connector of door signal

wire, remove the upper hinge screw, then

remove the upper hinge

3、Pull out the door ,remove the bottom hinge

Page 13

8

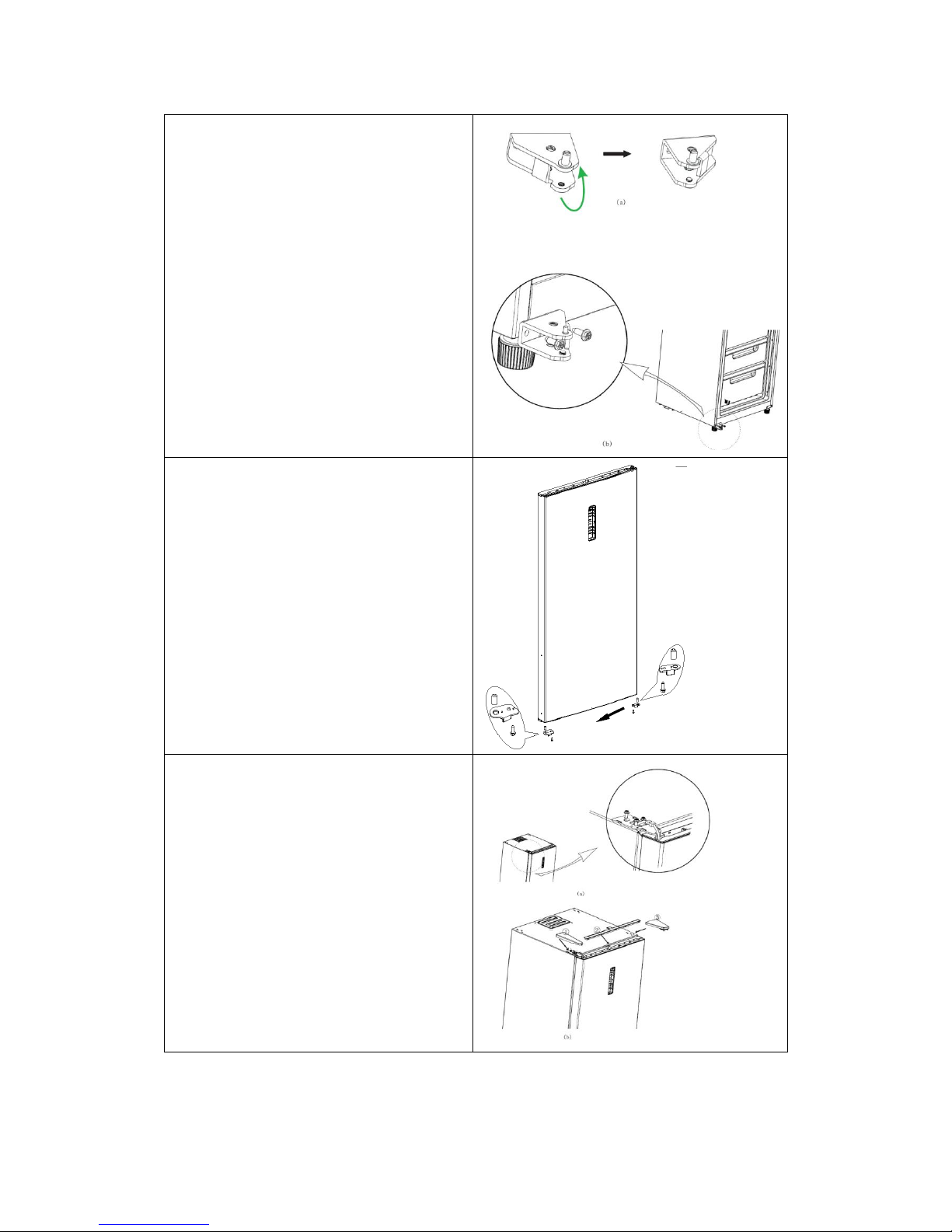

4、

Reversal the bottom hinge, Unscrew the hinge

pin from the bottom hinge and move it to the

other side(a), then secure the bottom hinge to the

bottom left side of the refrigerator

5、Remove the door block from the bottom, right

side of the door and attach it to the other side.

6、

Install the door and the signal to other side,

connect the terminal and install upper hinge(a),

lid the upper hinge cover and the door end cap

Page 14

9

3.6 Installation of handle

Note: Figures in the user manual are only for reference. The actual product may differ slightly.

The refrigerator must be disconnected from the source of electrical supply before attempting the

installation of accessory.

Schematic diagram of handle installation

Design sketch of installed handle

①

1) Remove the insert pin ①

①

2)Adjust the handle ③ to the installing hole

and tighten screw ②.

②

③

3Cover the nut cap ④ of handle hole

④

(Pictures and objects are not consistent, in order to prevail in kind)

Page 15

10

3.7 Installation of door lock(None)

3.8 Adjustment to level the door(None)

3.9 Adjustment to shelves(None)

4.Terms

4.1 Definition of model(None)

4.2Location of nameplate

(The picture is only for reference, and specific appearance and configuration are subject to the real

product)

Label

Page 16

11

5.Product specification

5.1 typespecification(None)

5.2 Electrical parameters

Product Name

CE-BD260WE-ST

Product Code

22031010001022

Name

Item

Type

Specification

Compressor

Compressor

/

PZ80E1A

Starter

PTC

8EA19C3/QP2-15

Overload protector

OLP

4TM117NFBYY/DRB12N61A1

Winding resistance of

compressor wiring terminal

Rmc:10~20Ω

Rsc:30~50Ω

Rms=Rmc+Rsc

Motor

Fan motor of the freezing

chamber

DC12V/≤3W

Ventilation door of the

refrigerating chamber

/

/

Condensation fan

/

/

Lights inside the

refrigerator

Lights inside the freezing

chamber

/

/

Lights inside the refrigerating

chamber

/

/

Switch of the refrigerator door

DC12V

5.3Refrigerating temperature

Temperature tolerance ≤ 2°C

Compartment

The highest (°C)

Lowest (°C)

Freezing

-14

-24

Page 17

12

Refrigerating

/

/

Variable temperature

/

/

5.4Defrosting parts

Defrosting period

Initial defrosting period

Normal defrosting period

Temperature is lower than 0°C

6~24 hours

Defrosting sensor

NTC

B3839

Thermal fuse

73/77℃

Defrosting heater in freezing chamber

230V/245W

5.5Circuit diagram

Page 18

13

6.Internal view and dimension

6.1Main parts and their names

1 top beam

2.Air duct components in freezing chamber

3. Flipping cover

4.Glass shelve

5. F upper drawer assembly

6. F middle drawer assembly

7. F bottom drawer assembly

8.Bottle frame in freezing chamber

9. Door handle of fridge compartment

6.2External dimension

Front view

Side view

Page 19

14

Down view

Open Door

Maximum open angle of door(135°)

(The picture is only for reference, and specific appearance and configuration are subject to the real

product)

Page 20

15

7.Refrigerating piping system and circulating route of cooling air7.1

Refrigerating piping system

Compressor →Condenser →Anti-condensation tube →Dry filter → Capillary tube

→ Evaporator → Regenerator → Suction tube → Compressor

(The picture is only for reference, and specific appearance and configuration are subject to the real

product)

Page 21

16

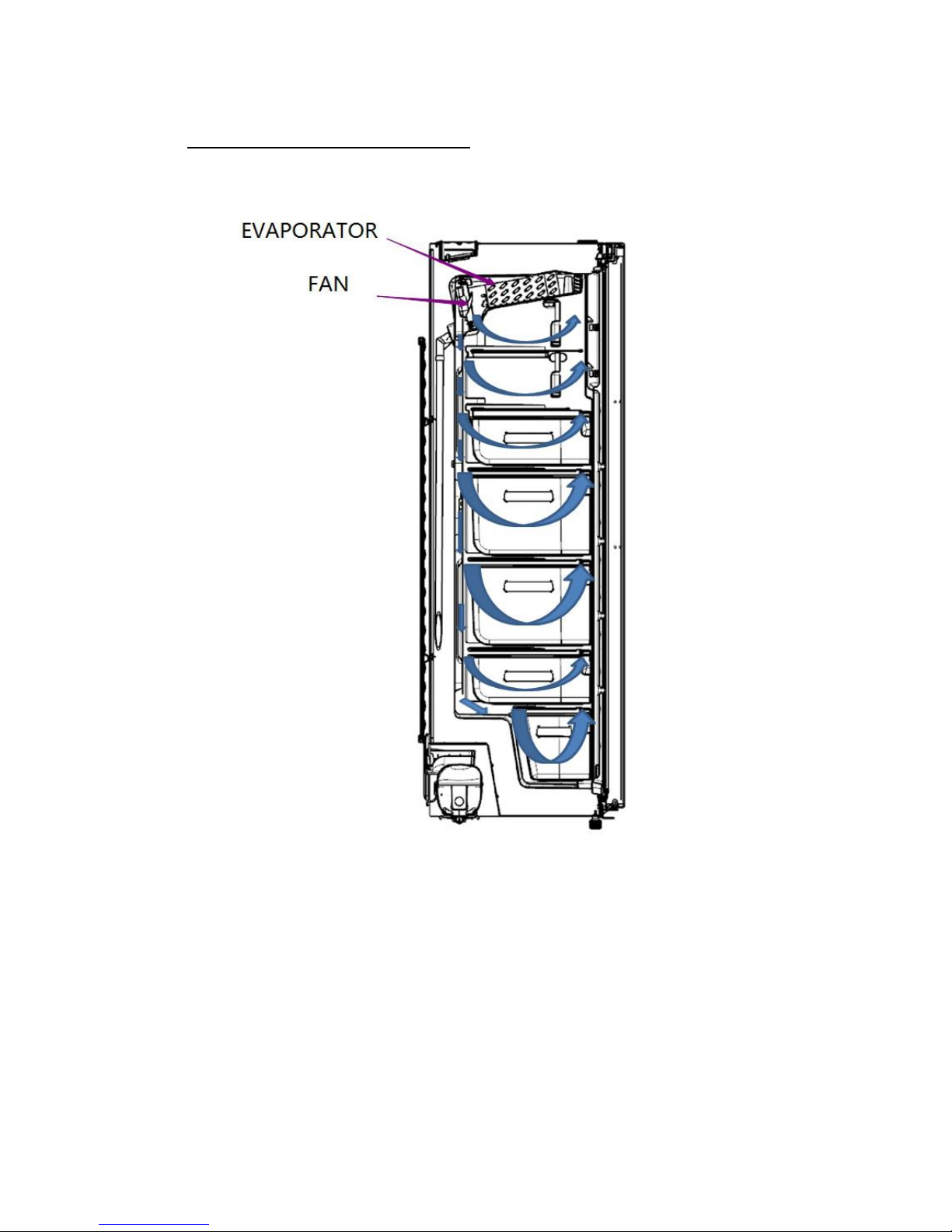

7.2Circulating route of cooling air

(The picture is only for reference, and specific appearance and configuration are subject to the real

product)

Page 22

17

8. Dismantling of parts

8.1 Parts on the door

Door seal

Door seal is installed into door liner groove.

1) Open the refrigerator door.

2) Take the door seal out of door liner.

Door tray

Lift up the bottle frame and take it out from the door

liner of the refrigerator.

8.2Parts inside the refrigerator

Refrigerator Fruit box cover

None

Shelves

None

Ice tray

None

Refrigerator tray

None

Drawer

The bottom of the drawer is located in the freezer

1)take it out from the refrigerator.

Reversal cap panel

Page 23

18

1.Reversal the cap to up

2.Remove the reversal cap panel

8.3 Light system

Light

None

Light switch

None

8.4Air duct and fan motor

Air duct components in freezing chamber

All accessories in the freezing chamber should be

dismantled before removing the air duct components.

1) use cross screwdriver to remove the 2 pcs screws of

air duct cover

2) Pull out the FRZ. chamber air duct components

3) Remove the evaporator from the air duct

components

4) Pull out the connector terminal of the fan motor;

Fan motor

Page 24

19

1) Loosen the plastic clips

2) Replace the fan motor, the inverse operation to

complete installation

Damper assembly

None

8.5Evaporator and temperature sensing system

Evaporator in freezing chamber

1) Remove the air duct components in freezing

chamber.

2) Disconnect all connectors.

3) Remove the welding on inlet and outlet tubes.

4) Remove two screws which are used to fix the

evaporator and remove the evaporator.

Components on the evaporator

❶Fuse

The fuse is located on top of the evaporator

1) connect the fuse connector.

2) Cut off the band which fixes the fuse.

3) Separate the fuse and the evaporator.

*Don’t break the welding of the evaporator in case that

only the fuse needs to be replaced.

❷Defrost sensor

The defrost sensor is located on top of the evaporator.

1) Disconnect the connector of defrost sensor

2) Cut off the band which fixes the sensor.

3) Separate the sensor and the evaporator.

*Don’t break the welding of the evaporator in case that

only the sensor needs to be replaced.

❸Defrost heater

The defrost heater is located at bottom of the evaporator.

1) Disconnect the connector of defrost heater.

2) Cut off the band which fixes the defrost heater.

3) Take off the defrost heater from the evaporator.

*Don’t break the welding of the evaporator in case that

only the defrost heater needs to be replaced.

❷

❶

❸

Page 25

20

Ambient temperature sensor

None

Ambient temperature sensor

Ambient temperature sensor is located in main control

board box and sends temperature signal to

microprocessor.

/

Freezer sensor

1) The sensor is located at the freezer chamberBefore

pull out the sensors,must be removed the air duct

cover of freezer chamber

2) Remove the sensors

8.6Compressor case

Rear cover and compressor case

None

Condenser fan moto

None

Terminal box of the compressor

None

Standby condenser

None

Piping system in the compressor case

1.Compressor

2.Exhaust transition pipe

5.Dry filter

6.Capillary

Page 26

21

3.Condenser

4.Anti-condensationg tube

7.Suction pipe

8.Return transition pipe

Starter and protector of the compressor

1. Remove the screws

1) Two screws outside

2) One screw inside

2. Remove the clipping strip

Slowly pull it out

3. Remove the protective cover

1)Pry the protective cover slowly from the upper part,

2)Pull it out and remove it.

4. Remove the starter and protector

Unplug the starter and protector (you can use a screwdriver

to pry it slowly)

5. The reverse process can complete installation.

/

8.7Display and main control panel

Display control board

Page 27

22

1) Use vacuum cap to pull the control panel outwards

2) Disconnect the connector of display control board,

remove it

Main control board

Main control board is located in the top of the

refrigerator

1) Remove the main control board screw with a Phillips

screwdriver

2) Disconnect the connector of main control board,

remove it

8.8 Bar counter(None)

Disassembly and installation of bar counter

None

Disassembly and installation bar doorseal

None

8.9 Water dispenser(None)

Disassembly and installation of water valve

None

Disassembly and installation of water tank

None

8.10 Ice maker(None)

Disassembly and installation of ice maker

None

Disassembly and installation of water system

None

Disassembly and installation ice machine sensor

None

Page 28

23

9. Function and operation9.1 Operation panel

See figure below for buttons and display arrangement of human-machine interface:

Gear 5

Gear 4

Gear 3

Gear 2

Gear 1

Super Freeze

9.2 Button

SET:Gear set button

Page 29

24

9.3 Display screen

1 Super Freeze

2 Gear 1—— -24℃

3 Gear 2—— -22℃

4 Gear 3—— -20℃

5 Gear 4—— -18℃

6 Gear 5—— -16℃

9.4 Display

At the first time of power-on, the display screen (including button light) will be bright for 3

seconds and then press the middle gear to show operation

Normal operation display

When failure occurs, the corresponding LED light group will display fault code (circular

display);

If no failure occurs, the current operation gear will be displayed.9.5

Setting of the gear

9.6 Super Freeze

Enter: Cyclic Modulation Quick freezer mode

Operation: The “super” indicator light is on and the refrigerator is running at super freezer

mode

Exit:

1.Ssuper freezer mode running 24hour

2.Super freezer mode, the temperature can be cooled out of the cold

9.7 Fault code and solutions

Fault

code

Fault

content

Code

visible

Display Steps for maintenance methods

E1

Temperatur

e sensor

fault in

refrigerating

chamber

Yes

“On”

of

Super and -24

simultaneousl

y

Step 1: Check whether the terminal CN4 is well stuck,

pull out the terminal and re-stick it in place

Step 2: Check to see if there’re foreign matters

on the

terminal.

Step 3: inspect the refrigerating sensor whether contact

is bad, and resend contact the fast connector

Step 4: Replace main control board

Page 30

25

E5

Fault of F

frost sensor

Yes

“On” of

Super and -22

simultaneousl

y

Step 1: Check whether the terminal CN4 is well stuck,

pull out the terminal and re-stick it in place

Step 2: Check to see if there’re foreign matters on the

terminal.

Step 3: inspect the defrost sensor whether contact is

bad, and resend contact the fast connector

Step 4: Replace main control board

E6

Communica

tion failure

Yes

“On” of -22

and -24

simultaneousl

y

Step 1: Check whether the terminal CN6 and CN7 is

well stuck, pull out the terminal and re-stick it in place

Step 2: Check to see if there’re foreign matters on the

terminal.

Step 3: inspect the display control board terminal

whether contact is bad, and resend contact the fast

connector

Step 4: Replace main control board

Step 5: Replace display control boardStep 6: Replace

main wire

E7

Ambient

temperature

sensor fault

Yes

“On” of

Super and

-20simultane

ously

Step 1: Check whether the terminal CN4 is well stuck,

pull out the terminal and re-stick it in place

Step 2: Replace ambient temperature sensor

9.8Defrosting function

1.Defrost the freezing chamber as per the accumulative operation time of the Compressor

2.If power failure occurs abruptly to the Compressor and the defrosting sensor in freezing chamber

is less than 0 oC after powering on, then first conduct defrosting once. If more than 0 oC, then

defrosting is not needed.

After that, conduct defrosting according to using condition and ambient temperature in a period

between 6 and 24 hours as per the accumulative operation time of the Compressor.

9.9Test mode

Test

module

Test

items

Testing Method

Expected result

Test

Mode

Enter Test

Mode

Keep pressing the SET button

for 5 seconds and release

LED indicators on quick freezer and Gear 1, 2,

3, 4 light up and flicker in the frequency of 0.5s,

then the refrigerator enters into test mode

After entering into test mode,

if no button is pressed within

15 seconds

then the refrigerator will exit the test mode and

return to normal operation mode

Select to

enter into

forced

cooling

mode

Enter into test mode and press

button for the first time

LED indicators on Gear 1, 2 and quick freezer

light up and other LED indicators light off, then

the compressor and the fan will start working

In forced cooling mode, if no

button is pressed within 36

hours,

then the refrigerator will exit the test mode and

return to normal operation mode

Page 31

26

Select to

enter into

forced

defrosting

mode

Enter into test mode and press

button for the second time

LED indicators on Gear 2, 3 and 4 light up and

other LED indicators light on, then the

compressor and the fan will stop working, The

heater open, refrigerator into forced frost

In forced defrosting mode,

when the defrosting sensor

reach a temperature of 12°C

and the defrosting heater has

been working for 3 minutes,

then the refrigerator will exit the test mode and

return to normal operation mode

In forced defrosting mode, if

the temperature of defrosting

sensor is always lower than

12°C and the defrosting heater

has been working for 1 hour,

then the refrigerator will exit the test mode and

return to normal operation mode

Select to

exit the

test mode

Enter into test mode and press

button for the third time

then the refrigerator will exit the test mode and

return to normal operation mode

9.10Self-diagnosis

Conditions for entering into this mode

When the power is on for the first time, here is no sensor failure and the defrost sensor

temperature is equal to or more than 0°C.

Self-diagnosis process

1. Defrost heater is on for 2 seconds and off for 2 seconds;

2.The fan is on for 10 seconds and off for 2 seconds;

3.The refrigerator is refrigerating for 20 minutes. (The compressor fans are all on)

Exit out of self-diagnosis

1.Stop self-diagnosing and turn into normal mode;

2.Failure occurs to the sensor during self-diagnosis and exit out of self-diagnosis mode;

3.Set forced defrosting function during self-diagnosis.

Page 32

27

10.Circuit description10.1 Power Supply

The AC input power is reduced in voltage by SMPS control chip and filtered off wave by the

inductance-capacitance filter, then output the DC 12V power which will mainly power the relay

that controls strong current. Relay is used to control the strong current loaded switches of

compressor, ice maker and defrost heater. The DC 12V power will output stable 5V electricity

after passing through the adjustor 7805, to power for the main control chip and thus monitor the

temperature changes in refrigerator.

10.2Door trip test circuit

The door switch input circuit is used to detect the refrigerator door open or not the circuit module.

Chip I/O PORT port. by testing the continuous high level + 5V to determine whether the door is

open. And then drive the relevant load

10.3Temperature test circuit

It’s conducted by the sensor, making use of the characteristics that resistance value reduces as the

temperature increases, and the thermistor that has temperature coefficient of resistance in medium

temperature.

Page 33

28

The characteristic that resistance value reduces as the temperature increases is deemed to have

negative slope or negative temperature coefficient (NTC), and such thermistor is called as NTC

thermistor. The resistance value changes sensitively with temperature and typically changes 7% ~

3% per degree centigrade. Sensor used in the refrigerator is NTC thermistor.

There is following computing formula for the sensor:

Sampling voltage / reference voltage = R1 / (RNTC + R1)

AD value / reference AD value = R1 / (RNTC + R1)

The reference voltage is 5V, RNTC is the resistance value of the sensor, R1 is R31\R32\R33 in

schematic diagram that is 5.1K

10.4Fan motor circuit of the freezing chamber

The fan in the freezing chamber is running when the compressor is operating. Check 12V and

Page 34

29

FAN to see if there is a voltage of 12V. When in normal operation, the fan is in low level and the

voltage between 12V and FAN is more than 11V. If there’s no voltage when the compressor is in

operation, fan motor or electric control panel can be replaced.

10.5Refrigerator fan motor circuit (None)

10.6Condensing fan motor circuit (None)

10.7Damper motor circuit (None)

10.8Resistance value of the sensor (R/T)

Tx(℃)

R(KΩ)

Tx(℃)

R(KΩ)

Tx(℃)

R(KΩ)

Tx(℃)

R(KΩ)

Tx(℃)

R(KΩ)

-30

33.81

-15

14.31 0 6.495

15

3.141

30

1.617

-29

31.85

-14

13.55 1 6.175

16

2.999

31

1.55

-28

30.01

-13

12.83 2 5.873

17

2.865

32

1.486

-27

28.29

-12

12.16 3 5.587

18

2.737

33

1.426

-26

26.68

-11

11.52 4 5.315

19

2.616

34

1.368

-25

25.17

-10

10.92 5 5.06

20

2.501

35

1.312

-24

23.76

-9

10.35 6 4.818

21

2.391

36

1.259

-23

22.43

-8

9.82 7 4.589

22

2.287

37

1.209

-22

21.18

-7

9.316 8 4.372

23

2.188

38

1.161

-21

20.01

-6

8.841 9 4.167

24

2.094

39

1.115

-20

18.9

-5

8.392

10

3.972

25

2.005

40

1.071

-19

17.87

-4

7.968

11

3.788

26

1.919

41

1.029

-18

16.9

-3

7.568

12

3.613

27

1.838

42

0.9885

-17

15.98

-2

7.19

13

3.447

28

1.761

43

0.9506

-16

15.12

-1

6.833

14

3.29

29

1.687

44

0.914

Page 35

30

11.Troubleshooting Method

11.1 No refrigeration

Page 36

31

11.2 Compressor failure

11.3 Defrosting is not working

Page 37

32

11.4 Fan in the freezing chamber is abnormal

Refer to this method for other fans.

11.5 Damper is abnormal(None)

11.6 Lights inside the refrigerator don’t light up

Page 38

33

12. Figures and details of repair parts(Documents are provided

separately)

12.1 Figure

12.2 List of parts and components

13Appendix:

13.1Electrical Schematic Diagram

(Model: ***)

13.2refrigerator maintenance tooling and equipment and material

Tooling

No.

Name

Photo

Main Usage

1

Phillips screwdriver

screw assemble and disassemble

Page 39

34

2

slotted screwdriver/scraper

screw and rivet assemble and

disassemble

3

Socket spanner 5/16″

hinge and compressor screw

assemble and disassemble

4

Sucker

display panel and air duct

cover disassemble

5

Allen wrench(2.8~4mm)

handle assemble and

disassemble

6

Vise grip pliers

sealing process tube

7

Pipe cutter

pipe cutting

8

Knife

assistive tool

Page 40

35

9

Nipper pliers

assistive tool

10

Capillary tube scissors

Shear capillary

Equipment

No.

Name

Photo

Main Usage

1

Vacuum pump

vacuum pumping

2

Electronic scale

weighing refrigerant/gas

3

High pressure nitrogen with

piezometer

pipe and cooling

system(condenser, evaporator,

etc) impurities clean

4

Soldering gun

heating and welding

Page 41

36

5

Quick coupling

connection process

pipeline,vacuumorchargerefriger

antwillbeused.

6

hand leak detector

welding point leakage detect, if

no, use soap-suds

material

No.

Name

Photo

Main Usage

1

Process pipeline

Chargetherefrigerant

2

Dry filter

Involving a system failure to be

replaced

3

Copper welding rod

tube welding

4

Refrigerant/gas

Add refrigerant to the system

5

Sealing tape

door fixing for reversible door

option

Loading...

Loading...