Page 1

1

Technical Service

Manual

French Door Refrigerator

HC-702WE

Page 2

2

Content

Chapter 1: Functions and Characteristics

Chapter 2: Technical Parameters

Chapter 3: Cycle Diagram of the System

Chapter 4: Electric Schematic Diagram and Circuit

Wiring Diagram

Chapter 5: Guide for Maintenance of R134a Refrigerator

Chapter 6: Failure Predication Flow Chart

Chapter 7: Exploded View of the Product and Parts List

Page 3

3

Chapter 1: Functions and Characteristics

Midea Brand

● DC frequency conversion technology;

● Double evaporator system, chill and refrigerate food separately, so as to

prevent from tainting by odor;

● High moisture system, with moisture rate up to 80%, so as to increase the

freshness retaining of fruits and vegetables;

● Mute design; noise level≤45dB;

● According to the actual frequency of usage, intelligent defrosting is adopted

for the frosting speed, which is better for energy saving;

● Thermostatic preservation technology, with independent air circulation

system designed in the chilling chamber, so that the temperature can be

independently controlled, the storage temperature is stable, and the freshness

of food can be retained longer.

Page 4

4

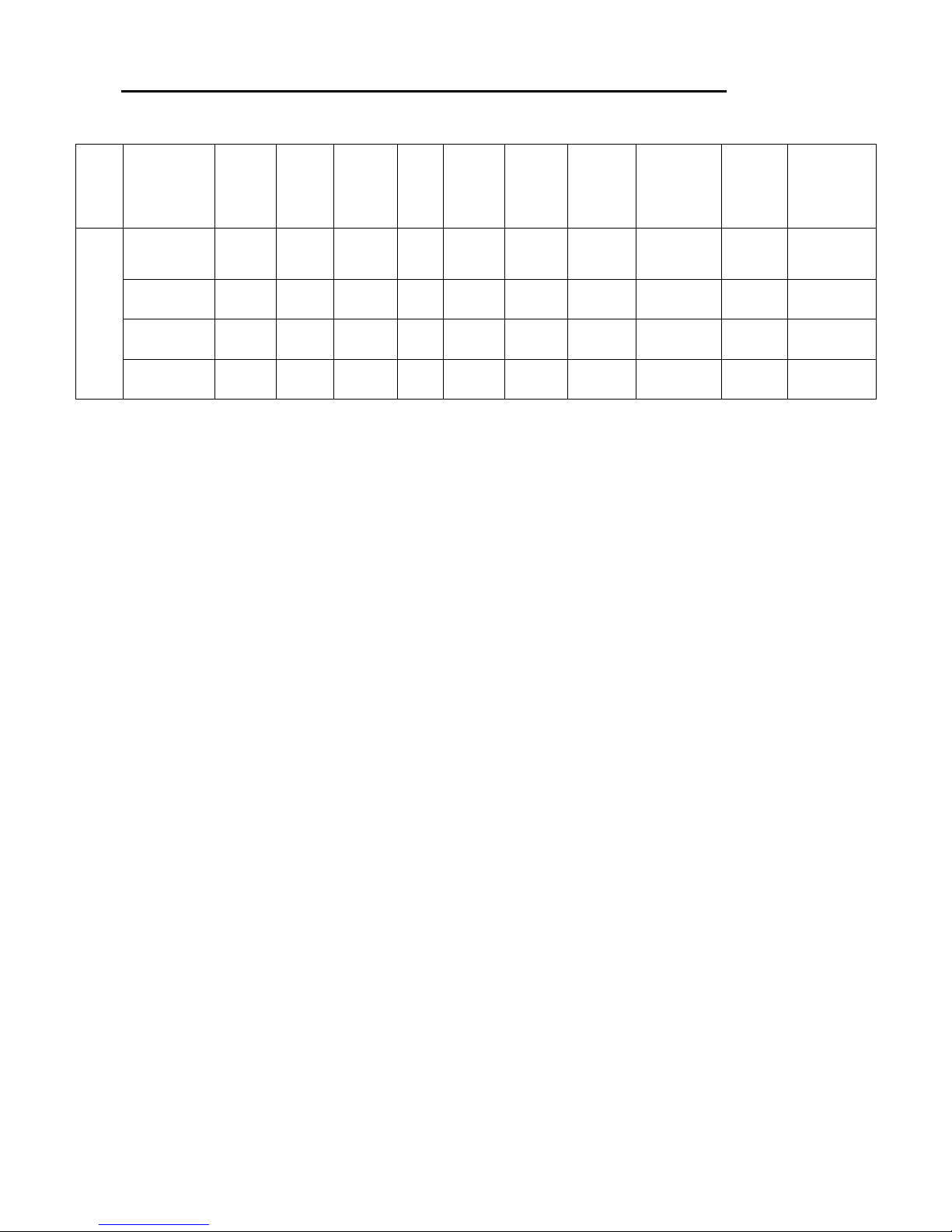

Chapter 2: Technical Parameters

1.

Specifications and main parameters of Midea Brand

Series

Model

Effective

/refrigera

tion

(L)

Climate

type

Refrigerat

ing

capacity

(kg/24h)

Net

weight

(kg)

Product

size

(mm)

Power

consump

tion

(kW·h/24h

)

Energy

consum

ption

grading

Compressor

Temp.

control

Refrigerant/in

jection rate

(g)

HC-702WE

540/420

T 10 137

911×728.

5×1775(

without

handles)

1.18 A+

Embraco

VEGZ7H

Computer R134a/180

Dual system

refrigerator

Page 5

5

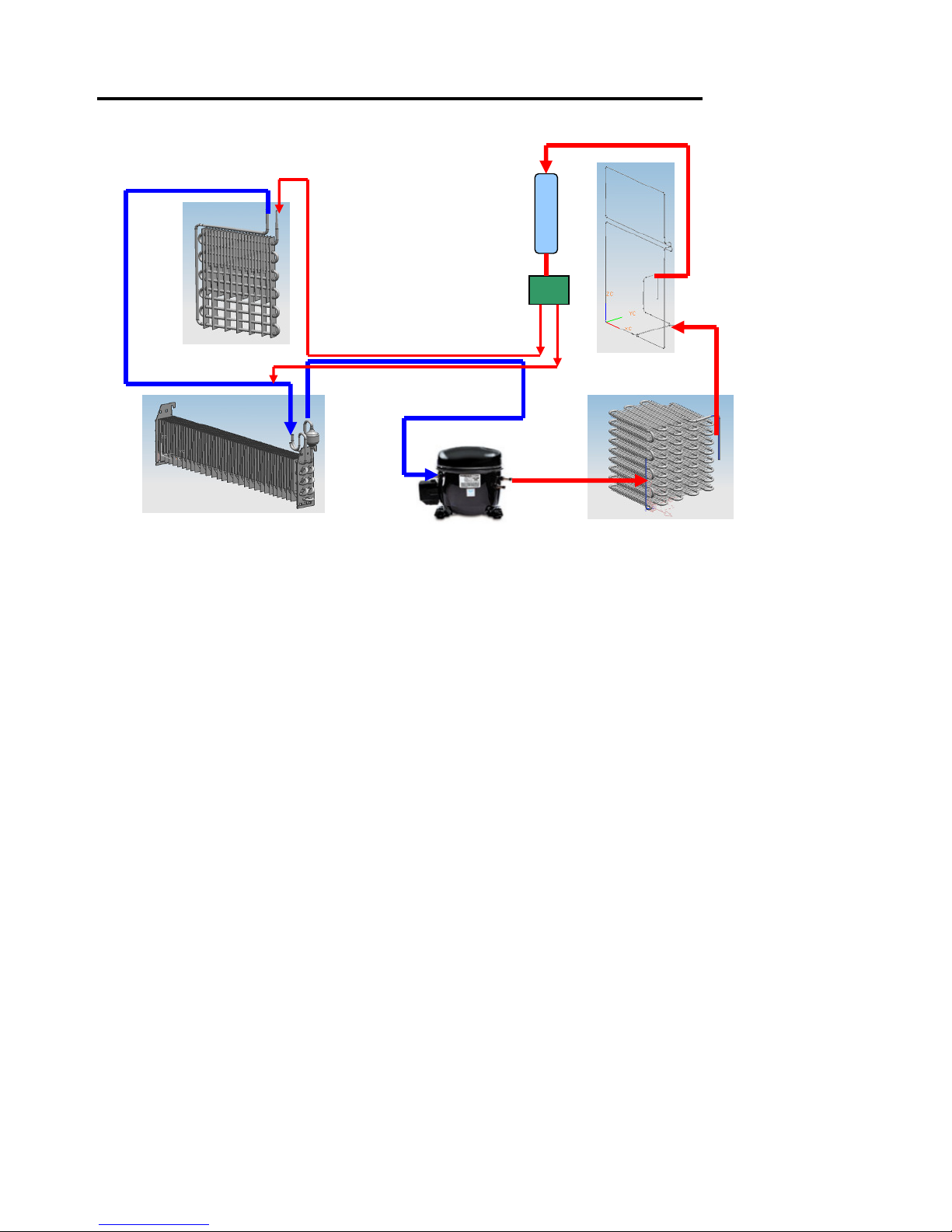

Chapter 3: Cycle Diagram of the System

Applicable for: HC-702WE (economic development zone)

The size on the drawing is a theoretical size, and it is different from full size.

Compresso

Condenser

Dew eliminating tube

Chilling capillary

Freezing capillary

Freez

ing evaporator

Chilling evaporator

Dry Filter

Solenoid valve

Page 6

6

Chapter 4: Electric Schematic Diagram

and Circuit Wiring Diagram

Electric schematic diagram:

Circuit wiring diagram:

11

1287

CN

2

3

4

CN14

CN13

5

7

8

JM

32

4

1 3

5

CN

1

CN15

8

1

2

CN 16

541

1 2

3

6

3

7

6

1

32

5 4

10

9

2

1

3

21

6

CN

11

1 3 5

7 9

3

42

1

3

4

2

1

2

1

1 2

3

4

2

4

67

1

234

123

4 5

1

2 3

3

2 1

1 2 3

1 3

CN

6

5

6

2

4

3131

CN3CN

4

12 43 65 87 12 43 651

CN

5

22

4 6

8 10

CN12

541 32 67

1

2

3

CN10

9 8 7

6 5

4 3 2

1

GM

CN9

5

4

1 32 6

10

11

9

CN7

变温室控制板

5

6

2

blackblack

red

yellow

white

blue

cyan

purpleorange red whiteblack

blue

yellowbrown

greenpink

blue/white

gray

control circuit board

red

white

white

white

white

white

white

white

red

red

red red

red

red red

blue

blue

blue

blue

blue

blue

blue

blue

blue

black

black

black

black

black

black

black

black

yellow

yellow

yellow

yellow

yellow

yellow

gray

gray

gray

purple

purple

purple

purple

purple

pink

pink

orange

orange orange

brown

brown

white cyan

cyan

cyan

tawny

tawny

tawny

red

white

pink

blue

purple

door display panel

black

white

ambient

temperature sensor

inlet pipe heater strip

compressor frequency

conversion board

brown blue

black

brown

blue

fan electromotor

black

black

red red

purple

purple

defrost sensor

chilling chamber

sensor

chilling chamber ceiling lamp

chilling chamber side lamp

chilling chamber side lamp

chilling chamber

temperature-variable

chamber

temperature-variable

chamber sensor

UV-LIGHT WAVE PRESERVING LAMP

temperature-variable

chamber motorized

operated damper

fuse

chilling chamber defrosting heater

door turnover beam heater

door turnover beam component

defrost sensor

red

red

purple

purple

black

black

black

black

purple

purple

purple

purple

red

red

red

red

fan electromotor

chilling chamber sensor

fuse

refrigerating defrost heater

white

white

yellow

yellow

blue

blue

blue blue

blue

blue

ice maker electric machine

switch

ice maker water

pump

refrigerating

ceiling lamp

yellow-green

yellow-green

yellow-green

yellow-green

electric

changeover

valve

compressor

brownblueblack

yellow-green

filter

brown/

white

blue

/white

yellow

/green

brown

blue

cool chamber

tawny

tawny

yellow-green

yellow-green

This wiring diagram is applicable for: the Midea Brand refrigerator produced in the economic

development zone

Page 7

7

Chapter 5: Guide for Maintenance of

R134a Refrigerator

I. Property of the R134a refrigerant

R134a, also named as tetrafluoroethane, is one of the hydrofluorocarbon (HFC for short), The

molecular weight of it is 102, and its structural formula is CH2FCF3. It is colorless transparent liquid,

without turbidity and foreign odor. Its ozone depleting potential (ODP: ozone depletion potential) = 0. and

its greenhouse effect potential (GWP: global warming potential) = 1300. ASHRAE safety class: A1. I is

non-toxic and non-flammable.

II. Maintenance technology of R134a refrigerator

1. General requirement: no matter whether there is leakage of the system, reliable earthing for all the

equipment is necessary when filling the refrigerant, so as to avoid sparks resulting from possible static

electricity. Besides, all the wiring must be firm, and wrong wiring is not permitted.

2. Firstly, check whether there is fire source around, and keep favorable ventilation;

3. Get the equipment and fittings ready which are specially used for maintenance;

4. Check the safety of maintenance equipment and main supply;

5. Check whether there is leakage, loose for the emptying clamp, and adjust it to the proper position;

6. Lead the exhaust pipe to the outdoor, get the emptying clamp stuck at the dry filter, start the

compressor, and stop after 5-minute operation. Vibrate the compressor, so as to discharge the

isobutane dissolved with lubricating oil. After 3-minute suspension, re-plug to operate for 5 minutes, so

as to minimize the isobutane content in the pipe system;

7. Cut off the power supply, seal the air vent of dry filter, get the special emptying clamp stuck at the low

voltage tube of the compressor, use the R134a vacuum pump to evacuate, and operate for 10 minutes;

8. Remove the compressor, dry filter using pipe cutter, and adopt nitrogen to blow the pipe for more than

5 seconds;

9. Change the R134a compressor, dry filter, and weld each interface by gas welding;

10. Blow the nitrogen to check the leakage, with nitrogen pressure no larger than 0.8Mpa, and use soap

water to check the leakage;

11. Discharge the nitrogen, and evacuate for more than 20 minutes, so that the vacuum degree will

reach up to specified value;

12. In order to ensure the accuracy of recharge, electronic scale shall be adopted for the weighting

during the filling. Plug the refrigerator to operate;

13. There is no abnormal seal;

14. Use suds to check leakage of the seal;

15. Plug the refrigerator to operate, and test its performance.

III. Precautions

1. If it is required to change the compressor during repair, the recharged amount shall be specified value;

no need to change the compressor, the recharged amount shall be 90% of the specified value.

2. It is not advisable to open the refrigerating system to operate at home by the users in principle,

because it is dangerous.

IV. Servicing installation and tools

1) R134a evacuating placer

2) Electronic scale

3) Emptying clamp

4) Sealing clamp

Page 8

8

Chapter 6: Flow Chart of Refrigerator

Failure Predication

● For different products, there is some difference for the predication of failure, thus, it is un-necessary to

explain each point clearly.

● For products with inleakage and in need of repair, excavate the foaming material according to the

pipeline location drawing in Chapter 3. Carry out repair welding for the inleakage point, and conduct

pressure maintaining and leakage detecting. No leakage found, fill it with foaming material.

Figure -1

Use oscilloscope to

check whether

signal is output here

abnormal operation

of refrigerator

check the power

supply and voltage

electroless

too low voltage

check the

plug and

socket fuse

check indoor

power circuit

normal

The compressor

can be started and

Whether the display

displays normally,

whether there is

trouble code

yes

yes yes

yes yes

yes

yes

yes

yes

yes

no

no

no

no

no

no

no

no

no

Firstly, eliminate the

trouble according to

the trouble code

and instruction.

no

See Figure-4

See Figure-5

See Figure-1

See Figure-2

See Figure-3

The

compressor

fails to start

display and light

off

display and light on

check the

power line

Use the oscilloscope to

check whether there is

signal sent out from the

main control panel

poor refrigeration of

chilling chamber

poor refrigeration

of refrigerating

chamber

Whether the chilling

chamber blower fan

works normally

Whether the

refrigerating chamber

blower fan works

normally

Whether the chilling

chamber defrosting

heater is normal

Check the chilling

blower fan circuit

or change the

chilling blower fan

Whether the

refrigerating

defrost heater is

normal

Check the refrigerating

blower fan circuit or

change the chilling

blower fan

Check the heater

circuit or change the

chilling chamber

Check whether the

electric changeover

valve works normally

Check the heater

circuit or change the

refrigerating defrost

heater

Check which one is

larger, the compressor

power or the rated

power

smaller

smaller

larger

larger

Check the electric

valve circuit or

change the electric

changeover valve

Check which one is

larger, the compressor

power or the rated

power

There is insufficient

coolant in the

system, and refilling

is required

There is insufficient

coolant in the

system, and refilling

is required

The system pipeline is

blocked up. Find out

the blocking point,

weld and refill again

The system pipeline is

blocked up. Find out

the blocking point,

weld and refill again

abnormal operation

of the

temperature-variabl

e chamber

whether the

temperature of

temperature-variable

chamber is normal

on the high side on the low side

the temperature-variable air

duct is blocked up or the

temperature-variable

damper is not open

temperature-varia

ble damper opens

all the time and

cannot be closed

clear out the foaming material in

the temperature-variable air

duct, or check the damper

circuit and change the

temperature-variable damper

change the

temperature-vari

able damper

poor refrigeration

of the chilling and

refrigerating

chamber

whether the chilling

chamber blower

fan works

there is no sound of

flowing coolant at

the inlet of

evaporator

check the

condensate fan or

change the blower

fan

very low power

dissect the process

tube after closing

down

master control

board trouble

change the

master control

board

check whether there

is voltage output from

the frequency

conversion board

check whether the

frequency

conversion board

and compressor

connector are

correctly erected

frequency

conversion board

trouble

change the

frequency

conversion board

wrong terminal

linear ordering may

cause compressor

trouble easily

compress

or trouble

change the

compressor

change the

compressor

change the

compressor

there is

no

liquid ejected

there is liquid

ejected

all the coolant

is leaked

find out the

leakage point,

pump out and

refill the coolant

restarted, there

is no suction at

the cutting

restarted, there

is suction at the

incision

compressor is

out of work

there is blockage on

the high voltage side

clear the blockage,

evacuate and refill

the coolant.

Page 9

9

Figure -2

Figure -3

Figure -4

Sensor failure Failure code Remarks

Chilling chamber E1

Refrigerating chamber E2

Incasement sensor failure

Temperature-variable

chamber

E3

Chilling defrost sensor E4 Defrost sensor failure

Refrigerating defrost sensor E5

Ambient temperature sensor

failure

Ambient temperature

sensor

E7

Communication failure - E9

High temp. alarm of

refrigerating chamber

- EA

Figure -5

Rated power table of refrigerator in different ambient temperature

Scope of ambient temperature

Below 22℃℃℃℃ 22~28℃℃℃℃ 28~35℃℃℃℃ Over 35℃℃℃℃

Variation range of rated power 80~105W 95~130W 125~160W 140~190W

Note: If the difference between actual power and the above rated power is within 10W, it can be

considered to be normal.

Check that whether

voltage is output here

Page 10

10

Chapter 7: Exploded View of the Product

and Parts List

Exploded view of product:

Parts list:

S/N Name Material /specification Qty.

1 Display panel decorative part

IMD technology /ABS 1

2 Rubber keying of display panel

Silicon rubber 2

3

PCB dead plate of display panel

ABS 1

4 Display panel

Component 1

5 Cross recessed pan head tapping screw

Q215 4

6 Magnet-fixed box

POM 2

7 Magnet

High magnetic 8

8 Cold storage door handle component Stainless steel304

2

9 Preassemble of the left cold storage door

Component

1

10 Handle set bolt

45#+heat treatment 8

11 Cold storage door seal component

Component

2

12 Rollover beam cover plate

Cold-rolled plate Q235 (t0.8)

1

13 Rollover beam heater

Component

1

14 Torsional spring sleeve

Copper pipe

1

15 Rollover beam down-pivot housing

ABS

1

16 Rollover beam down-pivot

POM

1

Page 11

11

17 Torsional spring

1Cr9Ni18Ti

1

18 Rollover beam upper-pivot

POM

1

19 Rollover beam pivot upper housing

ABS

1

20 Rollover beam foam

EPS

1

21 Rollover beam slide reinforcement

POM

1

22 Cross recessed pan head tapping screw

Q235A

1

23 Rollover beam body

ABS

1

24 Cross recessed pan head tapping screw

Q215

4

25 Foldaway of grease box

Transparent PS

2

26 Left grease box body

HIPS

1

27 Left gallon bottle pedestal

Transparent PS

2

28 Left special-shaped bottle pedestal

Transparent PS

1

29 Right door preassembly of cold storage

Component

1

30 Door-closing arresting device - right

POM

1

31 Door-open arresting device - right

Hot rolling pickled plate

Q235/t2.5

1

32 Right grease box body

HIPS

1

33 Right special-shaped bottle pedestal

Transparent PS

1

34 Right gallon bottle pedestal

Transparent PS

2

35 Allotype egg stand

Transparent PS

2

36 Big sealed case

Transparent GPPS

1

37 Small sealed case

Transparent GPPS

2

38 Small sealed case cover

HIPS

2

39 Big sealed case cover

Transparent GPPS

1

40 Splitter plate of temperature-variable drawer

HIPS

1

41 Full width temperature-variable drawer component

Component

1

42 Left fruit vegetable box component

Component

1

43 Sliding cantilever rack component

Component

1

44 Left cantilever rack component

Component

1

45 Conditioning plate of fruit vegetable box

ABS

2

46 Card of conditioning plate

PS

2

47 Strengthened iron of fruit vegetable box cover plate

Q215A

2

48 Water tank component

Component

1

49 Cover plate of fruit vegetable box

HIPS

1

50 Right cantilever rack component

Component

1

51 Folded cantilever rack component

Component

1

Page 12

12

52 Rack glass of fruit vegetable box

Glass

1

53 Cover plate decorative part of cold storage air duct

PS, spraying with dull silver

1

54 Screw cap of cold storage

PS

1

55 Cross recessed pan head tapping screw

Q235A

2

56 Middle support iron of cantilever rack

t2/Cold-rolled plate

1

57 Chilling chamber temperature sensor

Component

1

58 Cover plate of cold storage air duct

PS

1

59 Flotation sponge of cold storage air duct

LC

1

60 Main foam of cold storage air duct

EPS

1

61 Left cover of cold storage air duct foam

EPS

1

62 UV preserving lamp shade

Translucent PS

2

63 Right cover of cold storage air duct foam

EPS

1

64 Cross recessed pan head tapping screw

Q215

10

65 Cold storage blower fan support

Modified pp

1

66 Main cover of cold storage air duct foam

EPS

1

67 Front cover of evaporator

t0.4/ aluminizing zinc plate

1

68 UV preserving LED lamp

Component

1

69 Chilling chamber fin evaporator component

Component

1

70 Water collector of cold storage

t0.4/ aluminizing zinc plate

1

71 Left support of fruit vegetable box cover plate

ABS

1

72 Fruit vegetable box cushion

Silicon rubber

4

73 Right support of fruit vegetable box cover plate

ABS

1

74 Fruit vegetable box roller

POM

4

75 Rollover beam guide holder

ABS

1

76 Cold storage ceiling lamp shade

GPPS

1

77 Cold storage upper LED lamp

Component

1

78 Cold storage ceiling lamp base

PS

1

79 Cold storage side lamp base

Translucent GPPS

2

80 Cold storage side LED lamp

Component

2

81 Left top hinged cover

ABS

1

82 Left top hinge

Hot rolling pickled plate

Q235

1

83 cantilever rack side support iron

t2/Cold-rolled plate

2

84 Left middle hinge

Hot rolling pickled plate

Q235

1

85 Cold storage door switch

Component

2

86 Right top hinged cover

ABS

1

Page 13

13

87 Cross recessed pan head tapping screw

Q215

21

88 Cross recessed hexagon bordered screw

1022, galvanization

6

89 Right top hinge

Hot rolling pickled plate Q235

1

90 Box assembly

Component

1

91 Frequency conversion plate

Component

1

92 Mains filter

Component

1

93 Main control panel

Component

1

94 Main control panel cover

t0.4/ aluminizing zinc plate

1

95 Foam seal

PE foam

1

96 Compensator component

Component

1

97 Back cover of compressor

t0.35/ aluminizing zinc plate

1

98

Y-shape pan head tapping screw

15# carburized surface

galvanizing passivation

4

99 Drain connection

Blow molding PP

2

100 Drain blind joint

Rubber

2

101 Evaporating pan

PP

1

102 Compressor component

Component

1

103 Back cushion blocking of blower fan

NR

3

104 Chilling fan electromotor

Component

1

105 Front cushion blocking of blower fan

NR

3

106 Blower fan box

Antiflaming PP

3

107 Side cushion blocking of blower fan

NR

3

108 Chilling electromotor support

PP

1

109 Chilling fan blade

ABS

1

110 Dry filter

Copper pipe

1

111 Cushion cover of compressor

Rubber

4

112 Back roller

POM

2

113 Caster axle

Cold-rolled plate

2

114 Floor plate of compressor

t1.5 hot zinc plate

1

115 Power line

Component

1

116

Cross recessed countersunk head stainless steel

tapping screw /

4

117

Right middle hinge component

Hot rolling pickled plate

Q235, chrome-plating

1

118 Middle sleeve

POM

2

119

Cross recessed pan head shoulder locking screw

20#, white galvanized

4

120 Leveling adjuster

POM

2

121 Right support of refrigeration slide

ABS

2

Page 14

14

122 Refrigeration lamp base

PS

1

123 Refrigeration LED lamp

Component

1

124 Refrigeration lamp shade

Transparent GPPS

1

125 Cross recessed pan head tapping screw

Q215

14

126 Left support of refrigeration slide

ABS

2

127 Right support of temperature-variable drawer

HIPS

1

128 Left support of temperature-variable drawer

HIPS

1

129 Cross recessed pan head tapping screw

Q235A

2

130 Temperature-variable chamber control panel

Component

1

131 Temperature-variable chamber control face mask

PC

1

132 Right slide of temperature-variable drawer

Component

1

133 Refrigerating chamber fin evaporator component

Component

1

134 Refrigeration water collector

Aluminizing zinc plate

1

135

Refrigeration air duct thermal insulation small

sponge aluminum foil

XPE+aluminum-plated

membrane

1

136 Left slide of temperature-variable drawer

Component

1

137 Refrigerating chamber fan electromotor

Component

1

138

Refrigeration air duct thermal insulation large

sponge aluminum foil

XPE+aluminum-plated

membrane

1

139 Cross recessed pan head tapping screw

Q215

10

140 Refrigeration motor bracket

PP

1

141 Cold storage fan blade

ABS

2

142 Refrigeration air duct separator

Aluminizing zinc plate

1

143 Mud sill dog

PS

1

144 Damper water-proof sponge

EPDM

1

145 Temperature-variable chamber damper foam

EPS

1

146 Motorized operated damper

Component

1

147

Temperature sensor of the temperature-variable

chamber Component

1

148 Refrigeration air duct foam

EPS

1

149 Damper casing of temperature-variable chamber

PP

1

150 Cross recessed pan head tapping screw

Q215A

4

151 Front shroud of the special-shaped water pipe

PS

1

152 Water-pipe insulation casing

PE foaming

1

153 Special-shaped water-pipe

blow molding PP

1

154 Rubber coating of refill tube

Silicon rubber

1

155 Refrigeration air duct cover plate

PP

1

156 Cross recessed pan head tapping screw

Q215A

3

Page 15

15

157 Feed water pump box

PS

1

158 Outlet pipe of water pump

Silicon rubber

1

159 Built-in water pump for ice maker

Component

1

160 Feed water pump box cover

PS

1

161 Inlet of water pump

Silicon rubber

1

162 Water tank limit buckle

POM

1

163 Ice exploration rod of ice maker

PP

1

164 Ice maker spacing

PS

1

165 Ice maker hanger

PS

1

166 Ice maker hanging button

PS

1

167 Cross recessed pan head tapping screw

Q215

4

168 Right fruit vegetable box component

Component

1

169 Frame of ice maker & ice cube tray

PS

1

170 Twisting ice cube tray

PP

1

171 Frame cover of ice maker & ice cube tray

PS

1

172 Lower refrigeration drawer dog

Modified PP

1

173 Lower refrigeration drawer

Modified PP

1

174 Strengthened iron of lower drawer

Q235

1

175 Separator of lower refrigeration drawer

Modified PP

1

176 Refrigeration drawer synchronous gear

POM

4

177 Refrigeration synchronous gear connecting rod

Q235

2

178 Right refrigeration slide component

Component

2

179 Quick freezing pan

AL

1

180 Separator of upper refrigeration drawer

Modified PP

1

181 Upper refrigeration drawer

Modified PP

1

182 Left refrigeration slide component

Component

1

183 Ice storage box

Transparent PS

1

184 Refrigeration door switch dog

PP

2

185 Left strut member of refrigeration drawer

Q215+anti-corrosion

2

186 Refrigeration lower door seal component

Component

1

187

Preassembly of refrigeration lower door Component 1

188

Ice scoop PP 1

189

Right strut member of refrigeration drawer Q215+anti-corrosion 2

190

Hexagon flange tapping screw \ 12

191

Cross recessed pan head tapping screw Q215 8

Page 16

16

192 Refrigeration upper door seal component

Component

1

193 Preassembly of refrigeration upper door

Component

1

194 Refrigeration handle component

Stainless steel304

2

195 Hexagon flange tapping screw

20#

2

196 Right door-closing arresting device

POM

1

197 Cross recessed screw

10#

4

198 Right door-open arresting device

Q215A

1

199

200

201

This detail is compiled referring to the Midea Brand HC-702WE product, and there is some difference

with other products. For the electric parts, please refer to the Electric Schematic Diagram and Circuit

Wiring Diagram in Chapter 4.

Loading...

Loading...