Page 1

Service Manual

Drum Washing Machine

Http://global.midea.com.cn

Note:

Before serving the unit,please read this at first,

Always contact wih your service center if meet problem.

A1/D1(4.5/5.0/6.0/7.0kg)

Page 2

1.

…...................................................................................................................

2. INTRODUCTION

....................…...........…............................................

2.1 Characteristics of product

..................................................................................................................

2.2

.............................................................................................................................

SAFETY PRECAUTION

OF WASHING MACHINE

Working principle

3

4

5

5

P.02

TABLE OF CONTENTS

3.TROUBLESHOOTING

.3 3 Fault tree

3.3.1 non-heating malfunctionMaintenance

...........................................................................................

10

3.3.2 Door non-locked & its maintenance

..............................................................................................

11

3.3.3 No water inlet or water inlet overtime

............................................................................................

12

3.3.4. Heating beyond the setting temperature its maintenance

.......................................…....................

13

3.3.5. of non-drain or drain exceed the setting timeMaintenance

............................................................

14

3.3.6. Water inlet overflow malfunction maintenance

............................................................................

15

3.3.7. Drum non-rotating malfunction maintenance

................................................................................

16

3.3.8. water inlet and water outlet at the same time Maintenance

............................................................

17

..........................................................................................................

4.1.1Undo the back cover

.........................................................................................................................

4.1.2 Undo the top cover

.........................................................................................................................

4.1.3 Undo the control panel

.....................................................................................................................

4.1.4 Undo the lower panel

...................................................................................................................

4.1.5 Undo the door lock

...........................................................................................................…..........

4.1.6 Undo the front panel

.......................................................................................................................

4. UNPACKING WAYS OF MAIN PARTS

4.1 Overeview the unpacking step

........................…........................................................................................

6

3.1 Malfuction and solution

4.1.11 Undo the pressure switch

.............................................................................................................

4.1.12 Undo the pulley

............................................................................................................................

4.1.13 Undo the upper counterweight

......................................................................................................

4.1.14 Undo the absorber pin

..................................................................................................................

4.1.15 Undo the filter

..............................................................................................................................

4.1.16 Undo the drain pump

...................................................................................................................

4.1.7 Undo the gasket

..............................................................................................................…..........

4.1.8 Undo the PCB panel

...................................................................................................................

4.1.9 Undo the detergent box

....................................................................................................................

4.1.10 Undo the inlet valve

.....................................................................................................................

4.1.18 Undo the NTC temperature sensor

.............................................................................................

4.1.19 Undo the door glass

.....................................................................................................................

4.1.20 Undo the panel support

................................................................................................................

4.1.21 Undo the drum tub assembly

........................................................................................................

4.1.22 Undo the absorber

......................................................................................................................

4.1.24 Undo the motor

19

19

19

19

20

20

18

22

23

23

24

23

23

21

21

22

24

24

25

25

26

...........................................................................................................................

26

24

4.1.17 Undo the heater

...........................................................................................................................

3.2 Schedule of failure alarm

.......................…....…...............................................................................

8

23

4.1.23 Undo the conterweight

................................................................................................................

26

Page 3

P.03

TABLE OF CONTENTS

5. CIRCUIT DIAGRAM

6. EXPLORED VIEW & LIST OF PARTS

5.1 The failure diagnosing and changing components

6.1.5 Door_assembly

6.1.4 Dispenser_assembly

6.1.3 Top cover_sub

6.1.1 Cabinet_sub

6.1.2 Tub_sub

28

30

31

32

33

33

..........................................................................

...............................................................................................................................

..............................................................................................................................

.................................................................................................…......................

...............................................................................................................

...........................................................................................................................

6.1 Explored view & of PartsList

29

...................................................................................................

Page 4

1.SAFETY PRECAUTION

P.04

1.Do not try to repair the machine by yourself. The machine may be damaged and its life be shortened.

What is worse, it will injure yourself.

2.Pull out its plug from the power socket before maintenance. Electricity!

3.Do not use several power plug with one socket.

To avoid fire, don’t use any socket with its actual current more than rated current.

4.Please check the power plug and socket whether damaged or not.

To avoid an electrical shock and fire, the power plug and socket should be replaced if they are damaged.

.Don’t try to clean up the washing machine with water, or else, it’s possible to cause an electrical shock or

and shorten its life. fire

6.Forbid the harness contact with water for avoiding wet and don’t extend it during maintenance. Don’t twist

the harness to avoid it distorted.

7.Please clean up the dirt and dust on the surface of the cabinet, harness and connection parts during

Please avoid fire because of the electric leakage of harness.

8.Check electrical parts, harness whether they have become moist and replace them if they are wet.

9.Check all parts of the machine and make sure to keep them in good condition after maintenance.

10.Fasten upon the power plug and pullit out .

Be careful of a fire and electric shock when power cord is damaged.

11.Pull out its power plug when this machine doesn’t work.

Be careful of an electric shock and fire because of levin.

12.Don’t put tinder or sprayer beside the washing machine.

Be careful of a fire and explosion because of electric spark.

13.Don’t put a basin of water or wet clothes on the washing machine.

It is possible to cause an electric shock or fire if water from wet clothes leaks in to the washing machine.

14.Do not place the washing machine in the place where it can be exposed to rain and snow. Or else, it may

cause an electric shock or fire, and therefore shorten its life.

15.Don’t press the button with sharp items such as nail, screw etc. Or else, it may cause an electric shock or

other damages.

16.This machine should be placed on the horizontal ground and installed correctly. The machine is liable to

shift on the gradient ground.

17.If the harness is damaged, it should be replaced completely.

18.It is necessary to put a mat on the floor and recline down the washing machine along its side when repair it.

It is possible to damage the electrical components if the front of the washing machine is placed at the ground.

19.During changing the heater of this machine, please check whether it is fixed on the blanket correctly and

whether the screw is fastened tight or not.

5

maintenance.

Page 5

2.INTRODUCTION OF PRODUCTS

P.05

It is the latest designed machine, which have many advantages such as fashion, large rated washing

and large washing range. Specifically, its feature is as following:capacity

1.Large washing range from cotton to wool and silk.

2.Gentle washing: no twist and little abrasion.

3.Electron auto-balance system, that is, the PCB panel controls the speed of spin and ensures uniform

distribution of clothes to reduce the wear of textile caused by its vibration.

4.The drum of this machine is made of stainless steel of high quality and the cabinet is durable.

5.The maximum temperature of washing water could be controlled independently and it is up to 90℃.

6.Unique washing methods: rain, soak, throwing-knocking knead and so on, which can wash clothes

uniformly and improve washing performance.

7.Safety guard: water level control, door lock etc.

8.Anti-crease function: there is an automatic anti-crease and soak function in the synthetic program,

that’s, it doesn't drain at the end of washing and leave the clean extile in the water of the drum

to achieve the function of less crease, especially silk.

9.Function of adjusting speed : select different spin speed according to textile.

10.Electronic water distribution system: The machine uses PCB to control the inlet valve and

water properly at the different stages and dissolve detergent and softener distribute absolutely

to improve washing performance.

2.2.Working principle

Drum washing machine wash clothes mainly in virtue of mechanical friction, chemical force and

temperature force. When the machine works, the motor runs clockwise several seconds and runs

anti-clockwise several seconds to drive the drum whose three lifters hold up the clothes pressing

the inside of the drum. When clothes rise close to the against top, because the speed of motor is

low and the centrifugal force is not enough to overcome the gravity, clothes fall and impinge with

washing liquid (like manual throwing-knocking washing). The second force is the extrusion force

of clothes (like manual extrusion). The last force is the friction between clothes,clothes and

lifters(like manual knead). To improve washing performance, automatic drum washing machine

could automatically heat the washing liquid, whose temperature can be adjusted from 30℃ to 90℃.

The high temperature quickens the movement of the numerator of the washing liquid and speedups

2.1 haracteristics of product

C

the Chemical reaction. In a word, drum washing machine destroys bonding force between dirt and

clothes in virtue of intergraded force of water, detergent and mechanical force, to clean away the dust.

Page 6

3.TROUBLESHOOTING

SolutionDescription

The washing machine does not work

Close the washing machine's door.

Confirm and press the start key.

Water leakage Correctly connect the inlet water pipe.

The spin of the clothes is abnormal

Reload and distribute the laundry evenly in the drum.

Thereis the peculiar smell in the

washing machine

Run a Self-clean cycle without any clothes.

No water is visib le in the drum No fault-water is under the visible area.

There is the remaining water in the

softener's box

No fault- the effect of the softener will not be affected.

The remaining detergent is left on

the clothes

The water-fast component of the non-phosphorus

detergent will be left on the clothes to form the line

scale. Plesae select 【rinse】 or【 spin 】programme

or brush away the fleck with the brush when the

clothes is dried.

The washing machine does not fill

The washing machine fills and

empties at the same time.

Make sure the end of the drainage pipe to be higher

than the water level of the inside the machine .

Check if the drainage pipe and sewage have been

sealed, if they have been, there will be the poor

ventilation to cause the siphonage effect.

No drainage of the washing machine

Check if the drainage pumps is blocked.

Check if the drainage pipe is bent or blocked.

Check the height of the drainage nozzle, make sure it is

0.6-1 meter from the bottom of the washing machine.

Vibration of the washing machine

Level the washing machine.

Fasten the footing.

To check if the internal packing for the transportation

have all been removed.

Check the selection of .the procedure

Check the water

Put through the feed-water.

To check it the inlet water pipe is bent or blocked.

Close the washing machine's door.

Pressure to seeif the water pressure is insufficient.

Open the water tap.

The bubble spills from the detergent

box

Check if the detergent is excessive, if it is the

specialized detergent for the cylinder washing machine.

Reduce the usage amount of the detergent in the next

time's wash.

Dip one scoop of the softener mixed with 1/2 liter of

water to the detergent box II.

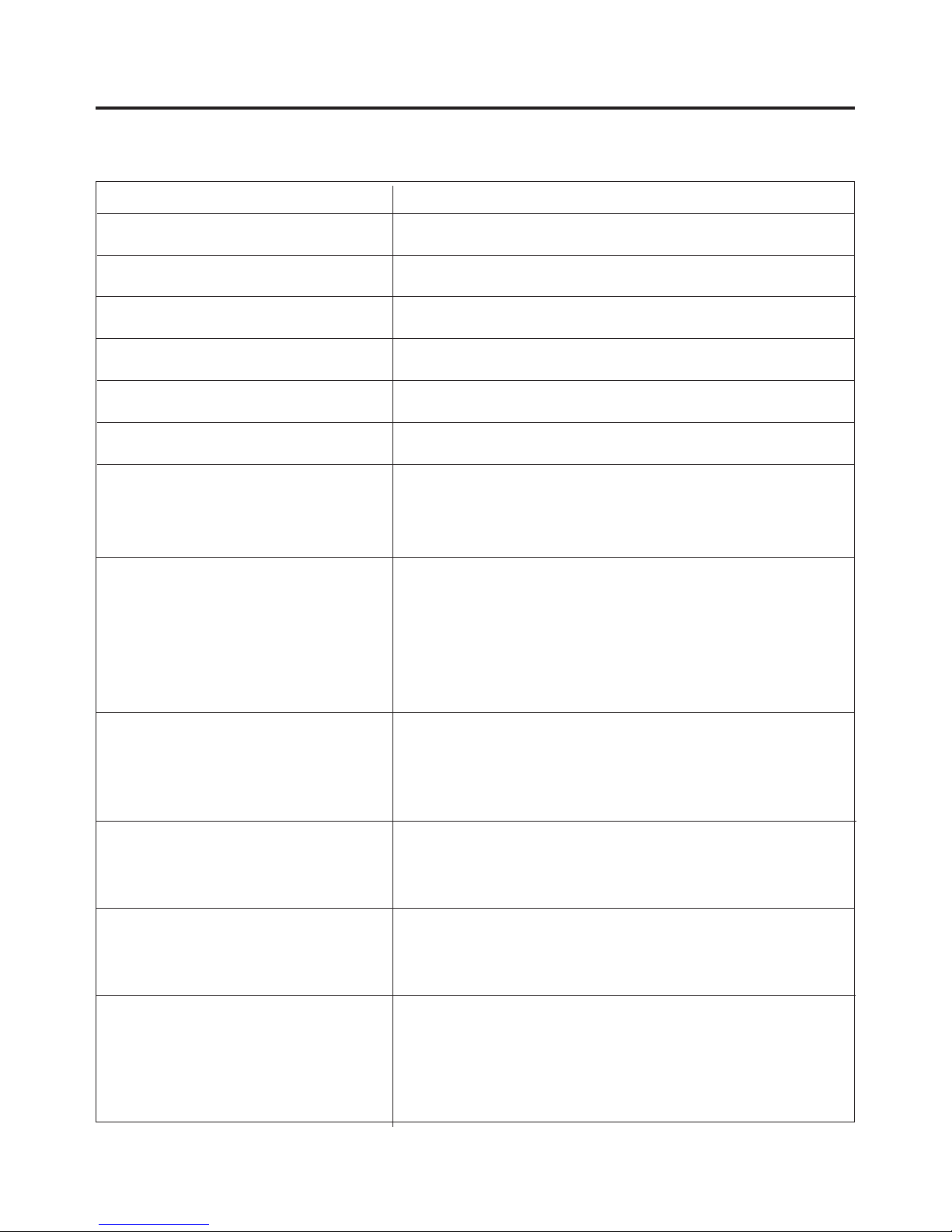

3.1 Malfuction and solution

P.06

Page 7

3.TROUBLESHOOTING

The machine stops when the

procedure has not been finished

Power failure or water cut.

The drainage pump has noise during

the operation when the water has

just been drained

To stop for some time during the

wash procedure

contact the nearest service centre.

If you cannot solve the above abnormal situations, would you please, 1. To turn

the procedure knob to 【OFF】, pull out the attachment plug; 2. to close the water tap,

and

The washing machine adds water automatically.

Because there is too much bubble in the tube, the

washing machine is cleaning the bubble.

SolutionDescription

The inner barrel water of the washing machine has

been drained but there is still a small amount of

water in the drainage pump and pipe. The drainage

pump continuously operates and takes in the air, and

at this time there is the noise, which is normal

situation.

P.07

Page 8

P.08

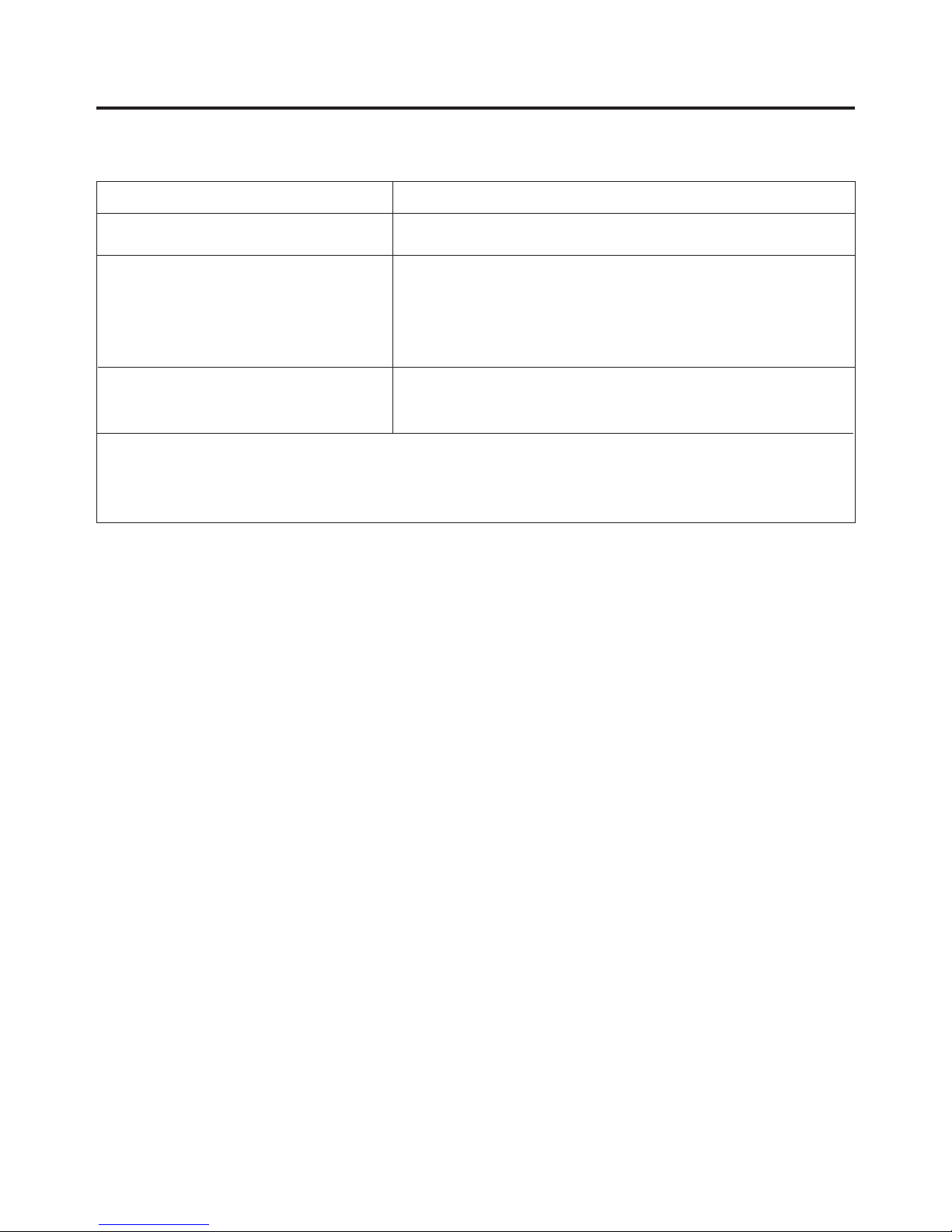

3.2 Schedule of failure alarm

3.TROUBLESHOOTING

A1-D1 has no display screen; the alarm display is as below :

Status of Corresponding

Indicators

Off

Off

Flash

Door lock

problem

Door is not closed properly.

Restart after the door is closed

Reason

Solution

Description

Please call up service line if there are still troubles.

OffFlash

Off

Flash

Flash

Drain problem

while washing

(drain time

exceeds 9 minutes)

Water injecting

problem when

washing (water

injecting time

exceeds 5

minutes)

Tap is not opened or water

flows too slowly.

Inlet valve filter is blocked.

Inlet pipe is twisted.

If water is not supplied

Open the tap or wait till

the water supply

becomes normal.

Check inlet valve filter.

Straighten the water pipe

Check the other taps in

the room.

Please call up service line if there are still troubles.

Please call up service line if there are still troubles.

Outlet hose is blocked or

twisted

Drain pump is blocked

Wash and straighten outlet

hose.

Wash drain pump filter

Please call up the service line if there is any other problem.

Tem p. 90

Temp.60

Tem p. 40

Temp.cold

Off

Off

Off

Off

It suitable for use these model :A1/D1

Page 9

P.09

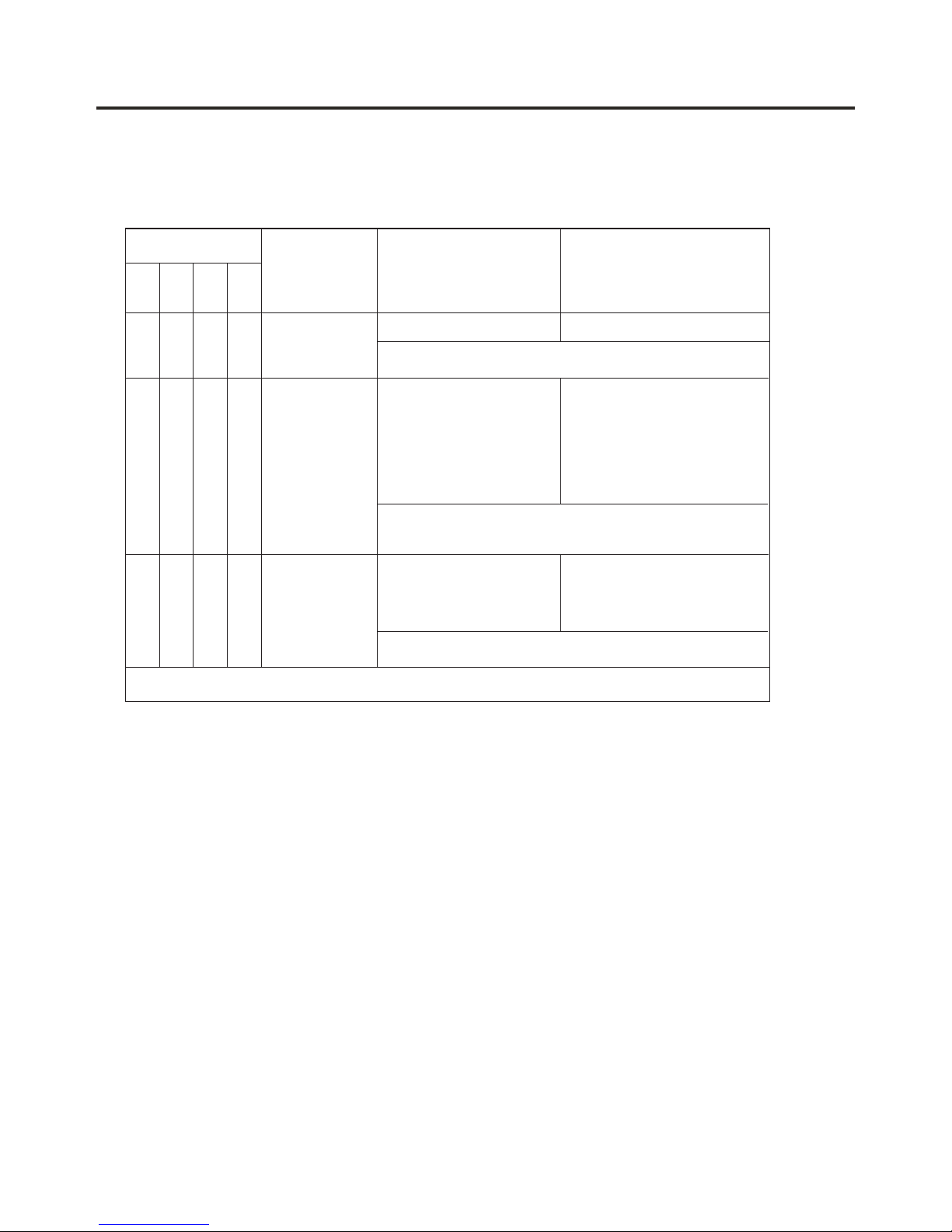

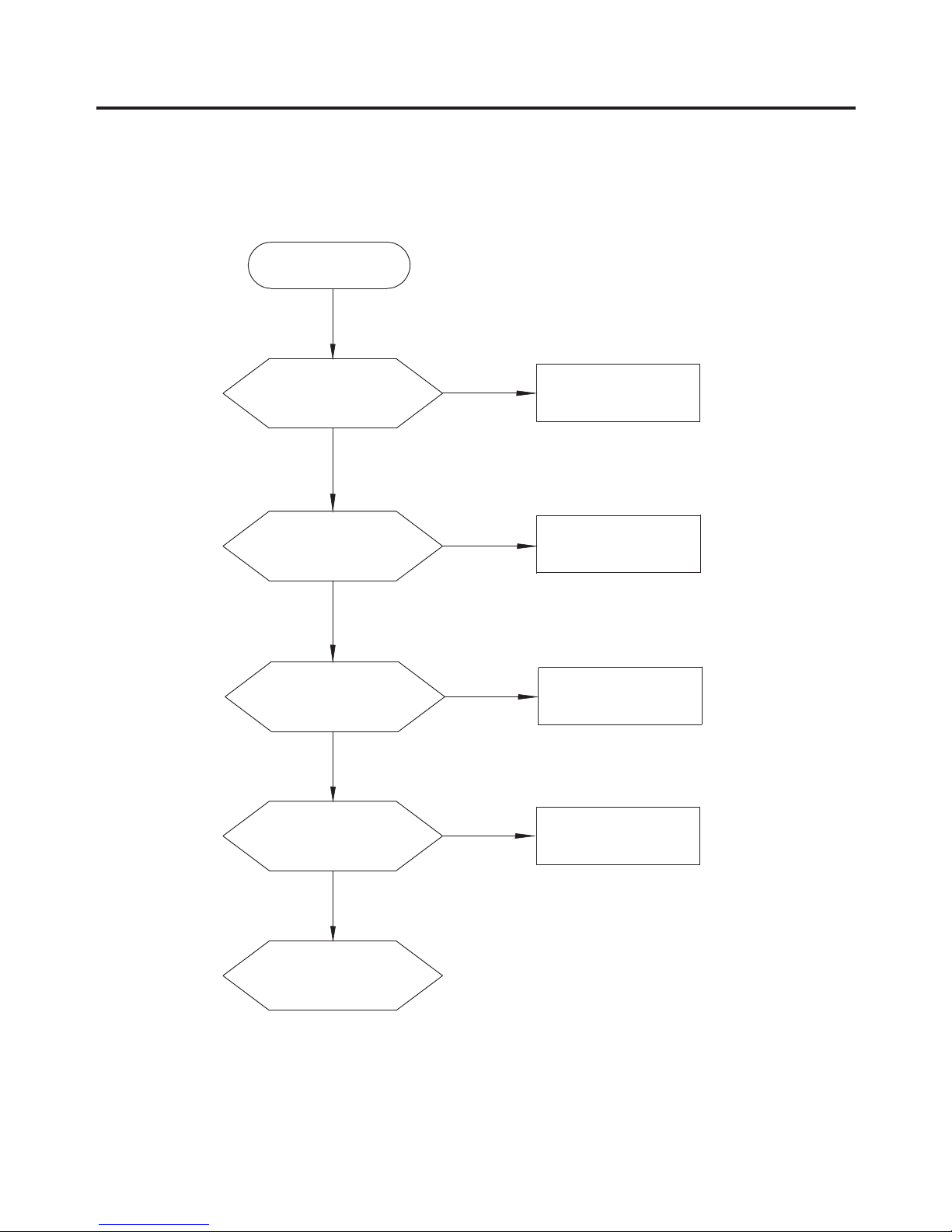

3.3Fault tree

Reliable connection

Y

N

Whether the connect

is well

Change NTC

Y

N

Whether NTC is short

or open circuit

Y

Whether the pressure

switch is well or not

N

Y

Choosing new heating

temperature

Y

Whether to set up

non-heating

Non-heating

Whether the heater

is well

N

Change the heater

Y

Change the control panel

Maintenance non-heating malfunction1.

3.TROUBLESHOOTING

Page 10

P.10

2. Door non-locked & its maintenance

Close the door correctly

Whether the door is

closed correctly

Y

N

N

Push the start button

to start the program

N

Reliable connection

The door is

invalid and should

be replaced

lock

Y

Y

Y

Y

N

Door non-locked

Whether push the

start /pause button to

start theprogram

Change

the control panel

Whether the voltage

between harness 1 and

harness 3 is about 220v

Whether the harness

connection between the

door lock and the main

board is well

3.TROUBLESHOOTING

Page 11

P. 11

Change main board

Y

Whether the

connection is well

N

Door is invalid and

should be replaced

lock

Y

N

Y

Whether the door

is closed correctly

N

Y

Y

Whether the tap is opend

Y

No water inlet or

water inlet overtime

N

Y

N

Y

Y

N

N

N

Change the inlet valve

N

N

Change the control panel

Whether the

switch is well

pressure

Y

N

Y

Push start/pause button

Cleaning with brush

Change the

switch

pressure

3. No water inlet or water inlet overtime

Whether press

start/pause button

after choosing the

program

Whether door

lock 3 and 2 is

connected correctly

Whether the voltage

between door lock 1

and 3 is 220V

Whether the

electromagnetic

valve buzz

Whether the

connections of inlet

valve is well

Whether the inlet pipe

is fold or the water is

cut off

Whether the

inlet valve coil is

well

Whether the inlet filter

net is blocked

Whether the

connection of

pressure switch is

well

Connect

connections

3.TROUBLESHOOTING

Y

Page 12

P.12

4. Heating beyond the setting temperature its maintenance

Change NTC

Y

Whether the

connection is well

N

Whether NTC is

short circuit or

open circuit

Y

加热过度

Y

Change the control panel

Over heating

3.TROUBLESHOOTING

Page 13

P.13

N

Y

N

Whether the

door lock is

well

Close the door

Whether the

door is closed

Y

Y

Non-drain or

overtime drain

Change

panel

the control

N

Reliable connection

N

N

Y

Return to the normal station

Change the

drain pump

Y

Cleaning the

filter

N

Y

N

Y

Y

5. of non-drain or drain exceed the setting time Maintenance

Whether it is in

the state of pause

Push start/pause button

Whether the

pump is vibrating

Whether the

connection between

the pump and the main

board is loosened

Whether the

pump is blocked

or burned out

Whether the filter

is blocked

Whether the drain

pipe is fold or hung

too high

3.TROUBLESHOOTING

The means of detecting door

switch refers to the paragraph

of "no water inlet".

Page 14

P.14

6. Water inlet overflow malfunction maintenance

Hang the hose well

Whether the drain

hose is hung up

Y

N

Y

C

inlet valve

hange the inlet

Y

N

Reliable connection

Y

Y

N

Y

N

Water inlet overflow

Whether the electric

connection of pressure

switch is normal

Change the control panel

Whether the water

is in without power

Whether the gas pipe

or the connection is

leaking or deadlock

Change or revive

the gas pipe

Whether the

switch is well

pressure

3.TROUBLESHOOTING

Page 15

P.15

7. Drum non-rotating malfunction maintenance

Change the control panel

N

The drum is blocked

Drum non-rotating

Y

Whether the door

is closed correctly

Close the door

Whether the door

lock is well

Y

N

Change the door lock

N

Y

Y

Y

Whether the motor

is well

Whether the

connection of main

and auxiliary wiring

harness is well

N

Reliable connection

Y

Whether the inlet

is correct

N

Waiting inlet or inspect

overtime water inlet

malfunction

Whether the

switch is well

pressure

Y

Y

N

Replace it

N

Replace it

Detach strap,

whether the drum

is rotating flexibly

3.TROUBLESHOOTING

Page 16

P.16

8. water inlet and water outlet at the same time Maintenance

Whether the washer is

disposing the foam in

the drum

Change the control panel

N

Y

Normal phenomenon

Y

Water inlet and water outlet

at the same time

Whether the drain hose

is hung too low

N

Y

Hang the hose well

3.TROUBLESHOOTING

Page 17

P.17

4.UNPACKING WAYS OF MAIN PARTS

4.1 Overeview the unpacking step

1.

2. Undo top cover

3. Undo the control panel

4. Undo the lower panel

5. Undo the door lock

6. Undo the front plate

7.

8. Undo the gasket

9. Undo the PCB panel

10.Undo the detergent box

11.Undo the inlet valve

12.Undo the pressure

13.Undo the pulley

14.Undo the upper counterweight

15.Undo the absorber pin

16. Undo the filter

17.Undo the drain pump

18.Undo the heater

19.Undo the NTC

20.Undo the door glass

21.Undo the panel support

22.Undo the drum tub assembly

24.Undo the motor

Undo the back cover

Undo the facade counterweight

23.Undo the absorber

Page 18

P.18

4.UNPACKING WAYS OF MAIN PARTS

Operation step Picture

1 Undo the back cover

Undo two screws fit

between back plate and

cabinet, and then pull out

the back plate

.

2 Undo top cover

Undo 2 screws fit

between the top cover and

back cabinet

Push back the top cover

15mm until it leaves away

from, the control panel,

and then take it down.

①

.

②

3 Undo the control panel

Departing the top cover

(means as above)

Draw out the detergent

drawer

Loosen two screws fit

on the control panel

(facial).

Loosen two screws fit

on the control panel(top)

①

.

②

.

③

④

.

Press three clasps

between top control panel

and panel support.

Take out the control

panel inclined from the

cabinet

⑤

⑥

.

(5.0/6.0/7.0 counterweight)

(4.5kg counterweight)

Page 19

P.19

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

4 the lower panel

Open the filter cover,

release the screw on the

lower panel.

Turn the washing machine

back at an angle, pinch the

clasp ,and push it out.

Undo

①

②

5 Undo the door lock

Open the door of

washing machine.

Take the outer gasket

clamp to the drum.

①

②

Remove two screws on

the door lock, and take

down the door lock.

Take out the door lock

and draw out the plug; pay

attention to the position

of the plug so as not to

connect a wrong circuit

next time.

③

④

6 Undo the front plate

Undo the door lock

(methods as followed).

Remove the lower

cover(methods as

followed).

①

②

Page 20

P.20

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

Picture

③

④

Undo five screws in

the front plate.

Put the front plate up

to the clasp of the front

plate away from the

loading holder, and then

take off the front plate.

①

②

.

③ Loosen

8 Undo the gasket

Undo the top cover,

control panel, lower cover,

machine door and the front

plate(methods as

followed).

Remove the outer

gasket clamp between the

door seal and the front

plate

the inner gasket

clamp between the door

seal and the front of the

outer tub, and take out the

gasket.

9 Undo the PCB panel

Undo the top cover

and control panel(methods

as followed).

7Undo the facade counterweight

Undo the front plate

(methods as followed).

Remove six screws pull out

①

②

the facade counterweight.

Page 21

P.21

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

10 the detergent Undo box

Undo the top cover

and the control panel

(methods as followed).

①

Release the hose clamp

and pull out the inlet hose.

Release the hose clamp

and pull out the detergent

box hose, and then take

out the detergent box.

②

③

11 Undo the inlet valve

Remove the top cover

(methods as followed).

Undo 2 screws between

cabinet and inlet valve.

①

②

Undo the PCB from the

E-housing

PCB panel: draw out the

plug after remove the

screws and then undo the

PCB panel.

Page 22

P.22

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

12 Undo the pressure switch

Undo the top cover

(methods as followed).

Pull out the plugs on the

pressure switch. Mind the

position of the plug to avoid

error during the following

assembly.

Loosen the pressure switch

hose clamp, and pull out the

hose from the pressure switch

interface.

Rotate the pressure switch

anticlockwise by 90º, and then

pull out the pressure switch.

①

②

③

④

13 Undo the pulley

Undo the back cover

(methods as followed).

Rotate the pulley and at

the same time pull out the belt,

and then remove the belt

Remove the screw on the

pulley and then take down the

pulley.

①

②

.

③

Release the clamp

fixing the inlet valve and

the inlet hose, and then

pull out the inlet hose.

Take out the inlet valve

and plug. Pay attention to

the position of the plug so

asnot to connect a wrong

circuit next time

③

Page 23

P.23

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

15 Undo the absorber pin

Undo the front plate

(methods as followed).

Use pliers to pinch the

absorber pin’s

protuberance, and knock

the absorber pin out from

back lightly; in the same

way, remove the other one.

①

②

16 Undo the filter

Open the filter cover.

Rotate the filter knob

anticlockwise, and then

pull out the filter.

①

②

17 Undo the drain pump

Undo the top cover,

control panel, lower cover

and front plate(methods as

followed).

Nip out clamp between

the drain hose and the

drain pump, and then pull

out the drain hose.

①

②

14 Undo the upper

counterweight

Undo the top cover

(methods as followed).

Remove three screws

fit on the upper counterweight

and then pull out the upper

counterweight

①

②

.

(4.5kg counterweight)

(5.0/6.0/7.0kg counterweight)

(4.5kg counterweight)

(5.0/6.0/7.0kg counterweight)

Page 24

P.24

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

18 Undo the heater

Undo the top cover,

control panel, lower cover

and front plate(methods

as followed).

Pull out the heater

plug. Pay attention to the

position of the plug so as

to not connect a wrong

circuit next time

①

②

.

Release the screw

fixing the heater.

Take out the heater.

③

④

19 Undo the NTC

temperature sensor

Undo the top cover,

control panel, lower cover

and front plate(methods as

followed).

Undo the NTC with

special tools.

①

②

Heater

NTC

In the red circle it is the

heater support, clamping

the heater.

Nip out the clamp

between the outlet hose

and the drain pump, pull

out the outlet hose.

Loosen the screws

fitted on the drain pump,

and then pull out the drain

pump

③

④

.

Page 25

P.25

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

21 Undo the panel support

Undo the top cover

(methods as followed).

Undo the control panel.

Remove two screws

fixing the panel support,

and then remove it.

①

②

③

22 Undo the drum tub assembly

Remove the motor in

24(methods as followed).

Pull out the heater.

Remove the belt.

①

②

③

Remove the screws

fixing the pulley, and then

take out the pulley.

④

20 Undo the door glass

Open the door, remove

two screws fixing the

hinge and front plate, and

then remove the door.

Remove six screws on

the inner door.

Remove the outer door

and the inner door with

special tool.

Take out the door glass.

①

②

③

④

Page 26

P.26

Operation step Picture

4.UNPACKING WAYS OF MAIN PARTS

23 Undo the absorber

Lift out the outer tub kit

(means as 21 above).

Undo the absorber pin

between absorber and rear

tub, remove the absorber.

①

②

24 Undo the motor

First let the machine lie

down on the back and then pull

out the motor wire and

grounding wire. Use spanner to

remove the motor screw, and

lift up the motor with the other

hand in case of falling to the

drain pump

①

.

After two screws are

removed, change the motor.

First support it to clasp the

correct position, then install

the screws, and then install the

belt

②

.

减震器销

密封条

Pin

Airproof Ring

Remove the screws

fixing the front and rear

tub, and then remove the

Remove the inner drum kit.

⑤

⑥

tub.

Page 27

P.27

5.CIRCUIT DIAGRAM

5.1 During the failure diagnosing and changing components, please do it as following:

1)There is some static harm to the electrical

parts from colophony in the washing machine

or humans. So it is better to eliminate the

potential static by grounding the humans or

touching the plugs.

2)The rated voltage of the SCR in PCB is

220-240V, so it's possible to be electrical

shock. Please take care while strong and

weak electricity is alternative.

3)The design of PCB is out of failure, so

prohibit to change the PCB panel according

to its alarm. Please do it according to the

failure diagnose program.

POWER SUPPLY PLUG

Page 28

5.2 The circuit program & wiring connection figure

5.TROUBLESHOOTING

P.28

Pressure

switch

P

S10

S9

S8

M1

M5

M8

M9

M

T

M3

M4

M10

S3

S6

S2

Option

Hot valve

Main valve

Pre valve

S7

#3

#1

#2

PTC

S5

S4

H

Heater

EMI filter

AC source

Power switch

Pump

Stator

Rotor

Tacho

Motor

Wash NTC

Door lock

N

N

NLL

PE

PE

L

1

2

3

6

1

2

1

5

S8-1

S8-2

S8-3

S8-4

S8-5

S8-6

S8-7

S8-8

S8-9

S5-1

S5-2

S5-3

S5-4

S2-5

S2-4

S2-3

S2-2

S2-1

S6-10

S6-9

S6-6

S6-4

S6-2

S7-1

S7-2

S6-8

S6-7

S6-5

S6-3

S6-1

Page 29

2.Overview of products

P.29

2.Overview of products

6.EXPLORED VIEW & LIST OF PARTS

1. Cabinet_sub

6.1 Explored view & of PartsList

01 PRESSURE SWITCH

02 PRESSURE CHAMBER

03 Service Panel

04 Leg_Sub

05 Water_ Inlet_Pipe_Kit

06 The Bend Of Drain Hose

07 Transport Bolt Kit

Rear_ Cover

09 Water_ Inlet_ Valve

FILTER

Suspension Spring

Spring Hanger

Top_ Bracket

08

10

11

12

13

Page 30

2.Overview of products

P.30

2.Overview of products

6.EXPLORED VIEW & LIST OF PARTS

2. Tub_sub

14 Belt

15 Driving_Pulley

16 SCREW

17 UPPER COUNTERWEIGHT

18 REAR TUB

Tub_Seal

Drum Kit

Front_Tub

INNER GASKET CLAMP

GASKET

OUTER GASKET CLAMP

19

20

21

22

23

24

Front_Right_Counterweight

Front_Left_Counterweight

NTC

HEATER

HEATING BRACKET

HOSE CLAMP

Pump

Tub_Drain_Hose Kit

Damper_Pin

Damper

Motor

25

26

27

28

29

30

31

32

33

34

35

Page 31

2.Overview of products2.INTRODUCTION OF PRODUCTS

P.31

2.Overview of products

6.EXPLORED VIEW & LIST OF PARTS

3. Top cover_sub

36 Control Panel Sub

Selec_Light_Transferrer

Control_Panel

PCB

36.4 Power Switch

36.5 Power Button

36.6 Light_Transferrer

36.7 Start_Pause_Button

37 Top_Cover_Board

38 Cycle_Select_Knob

36.1

36.2

36.3

Page 32

2.Overview of products

P.32

2.Overview of products

6.EXPLORED VIEW & LIST OF PARTS

4. Dispenser_assembly

39 HOSE CLAMP

40 INLET HOSE

41 SOFTENER CAP

42 DETERGENT BOX

43 DRAWER PANEL

44 Tub Water Inlet Hose

Page 33

2.Overview of products

6.EXPLORED VIEW & LIST OF PARTS

P.33

5. Door_assembly

Model MG52-6001/MG52-8002

45 DOOR SUPPORT PLATE

46 Front Panel

47 Door Sub

47.1 Door Glass

47.2 Door_Plunger_Spring

47.3 HOOK PIN

47.4 Door Plunger

47.5 Inner Ring

47.6 Door Handle

47.7 Outer_Frame

47.8 Door_Hinge_Pin_Cover

47.9

Door Hinge

48

Door Lock

Loading...

Loading...