Page 1

Installation and Maintenance Manual

CSU-05HCAA CSU-07HCAA

CSU-09HCAA CSU-12HCAA

CSU-18HCAA CSU-21HCAA

CSU-24HCAA

CSU-09HHAA CSU-12HHAA

CSU-18HHAA CSU-21HHAA

CSU-24HHAA

Page 2

Content

I.Designations and Functions of parts

II

. Dimensions

III.Specification............................

IV.Wiring diagram...............

V. Refrigeration circuit

VI.Installation Instruction........................................13

VII. Troubleshooting.

VIII.Parts list

Page 3

Installation & Maintenance Manual

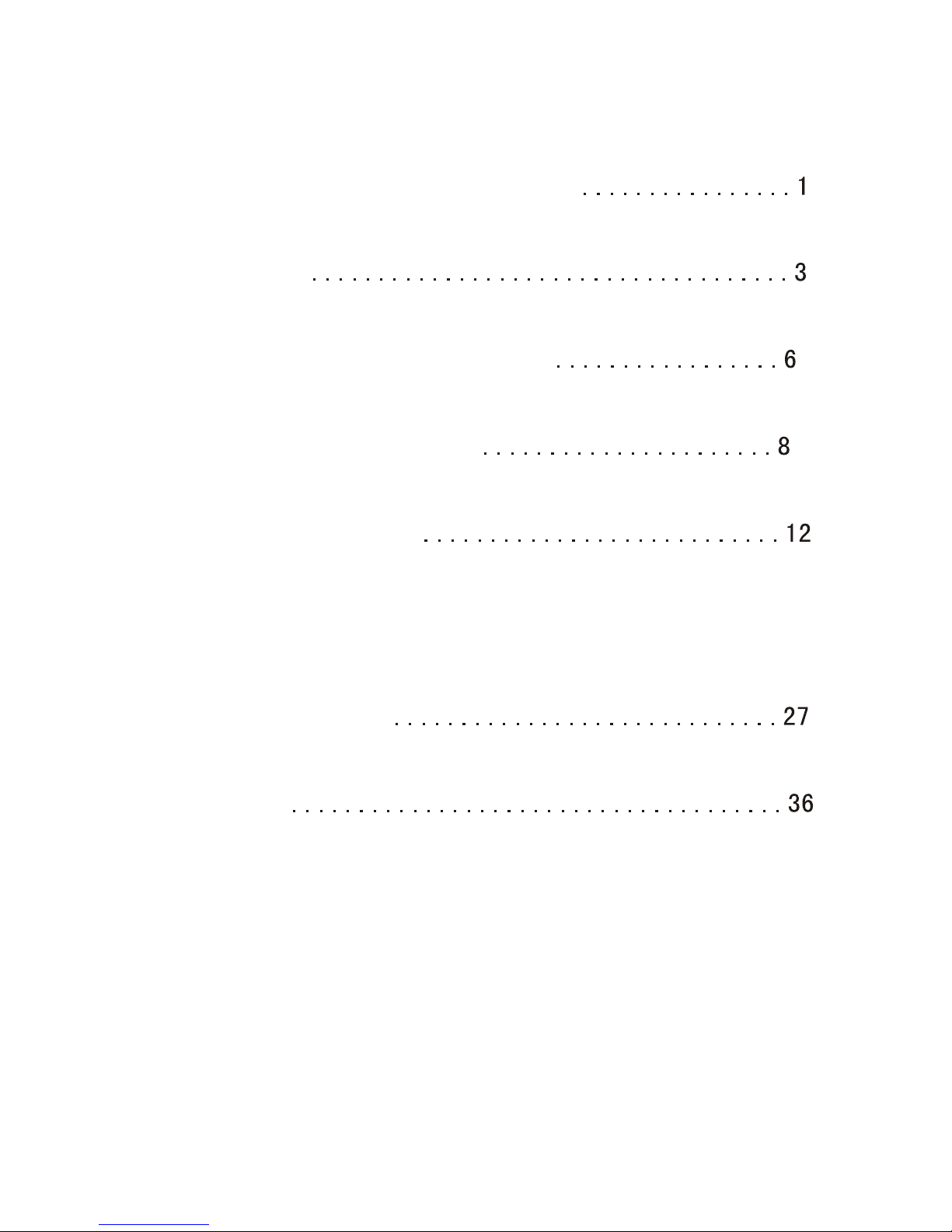

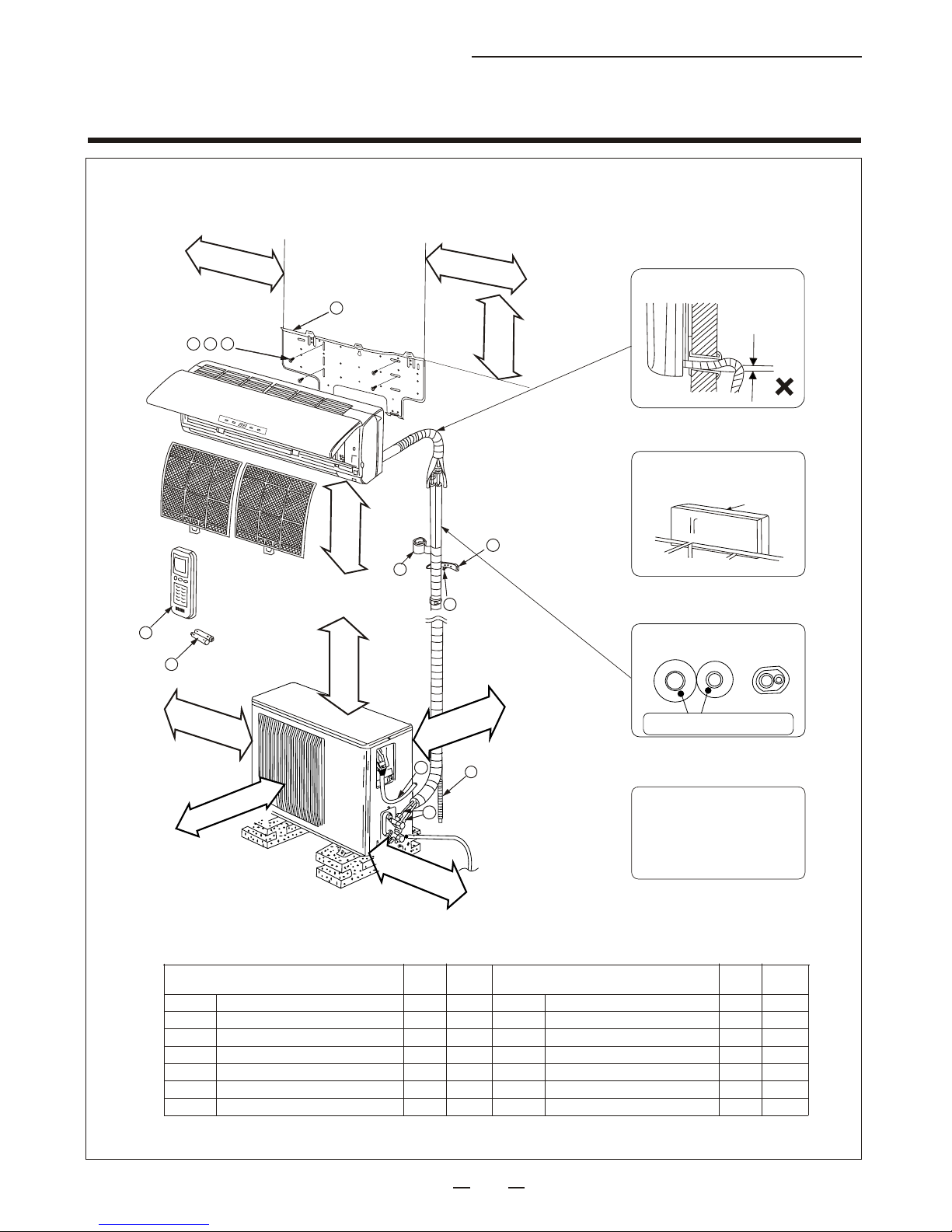

I. Designations and functions of parts

5K/7K/9K/12K/18K/21K/24K Series Indoor Unit

panel

air inlet

HUALING

operating section

(with the front panel opened)

power connection

display part

filter net

Run indication

Sleep indication

Remote control signal receiving window(only 9k)

horizontal vane

Double ,8, display

Timer indication

HUALING

Operation section of

9K series units

(standby configuration)

5K/7K/9K Series Outdoor unit

Power indication

vertical vane

Power indication

Remote controller

Remote control signal

Operation section of

12K series units

Temperature

indication

Run indication

Emergency

switch

receiving window

Operation section of

18K/21K/24K series units

Air inlet

Piping

Drainage hose

Air outlet

1

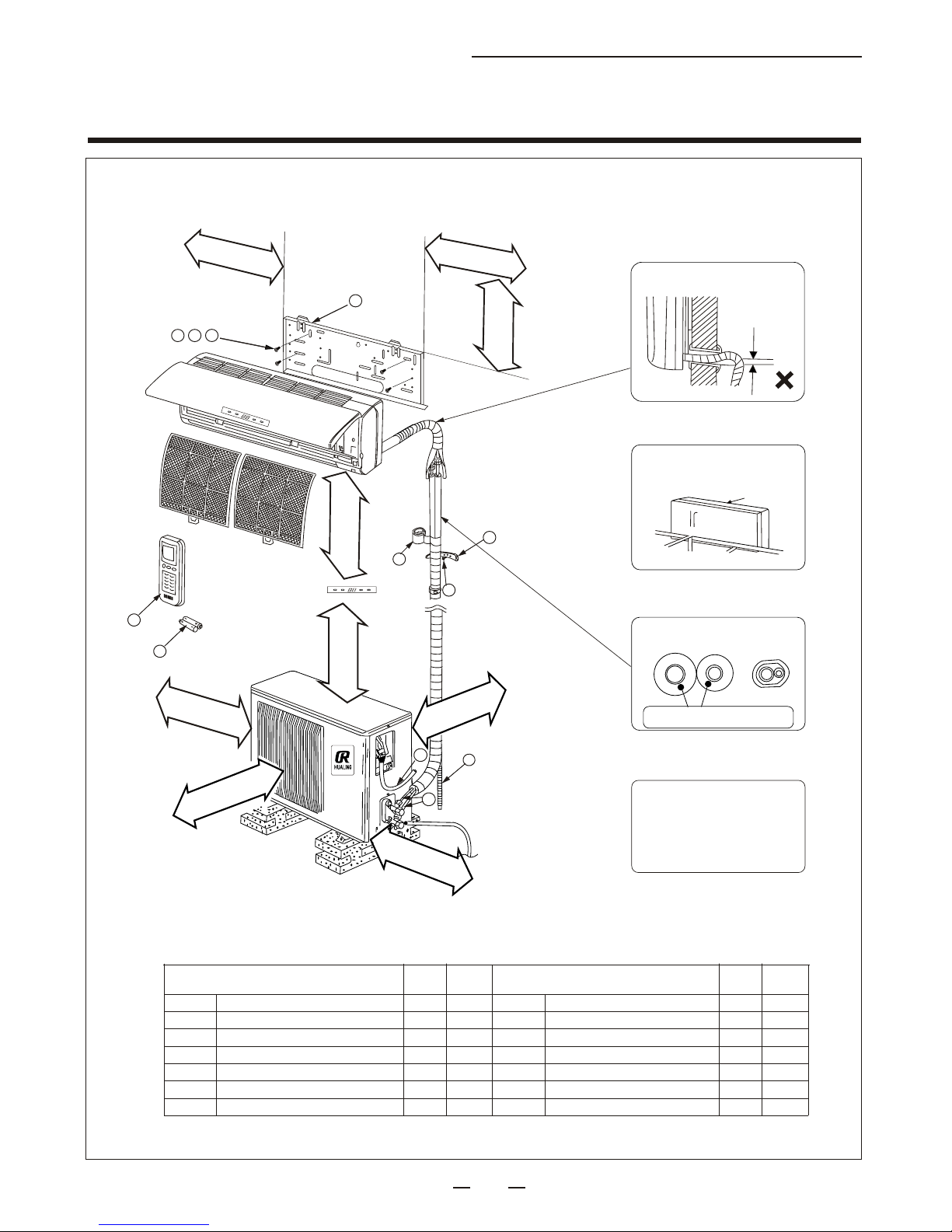

Page 4

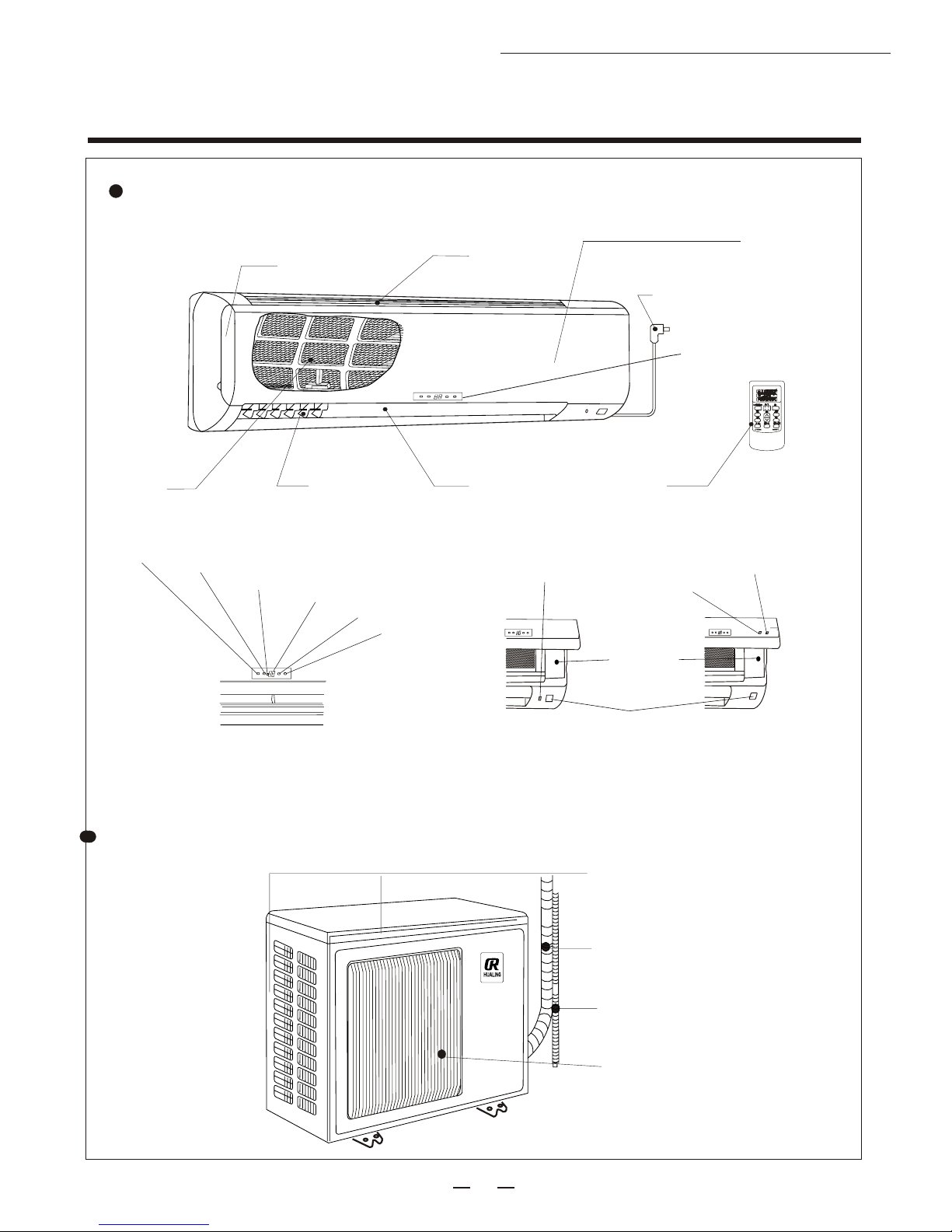

Installation & Maintenance Manual

I. Designations and functions of parts

12K/18K Series Outdoor unit

Air inlet

Piping

Drainage hose

21K/24K Series Outdoor unit

Air outlet

Air inlet

Piping

Drain hose

Air outlet

2

Page 5

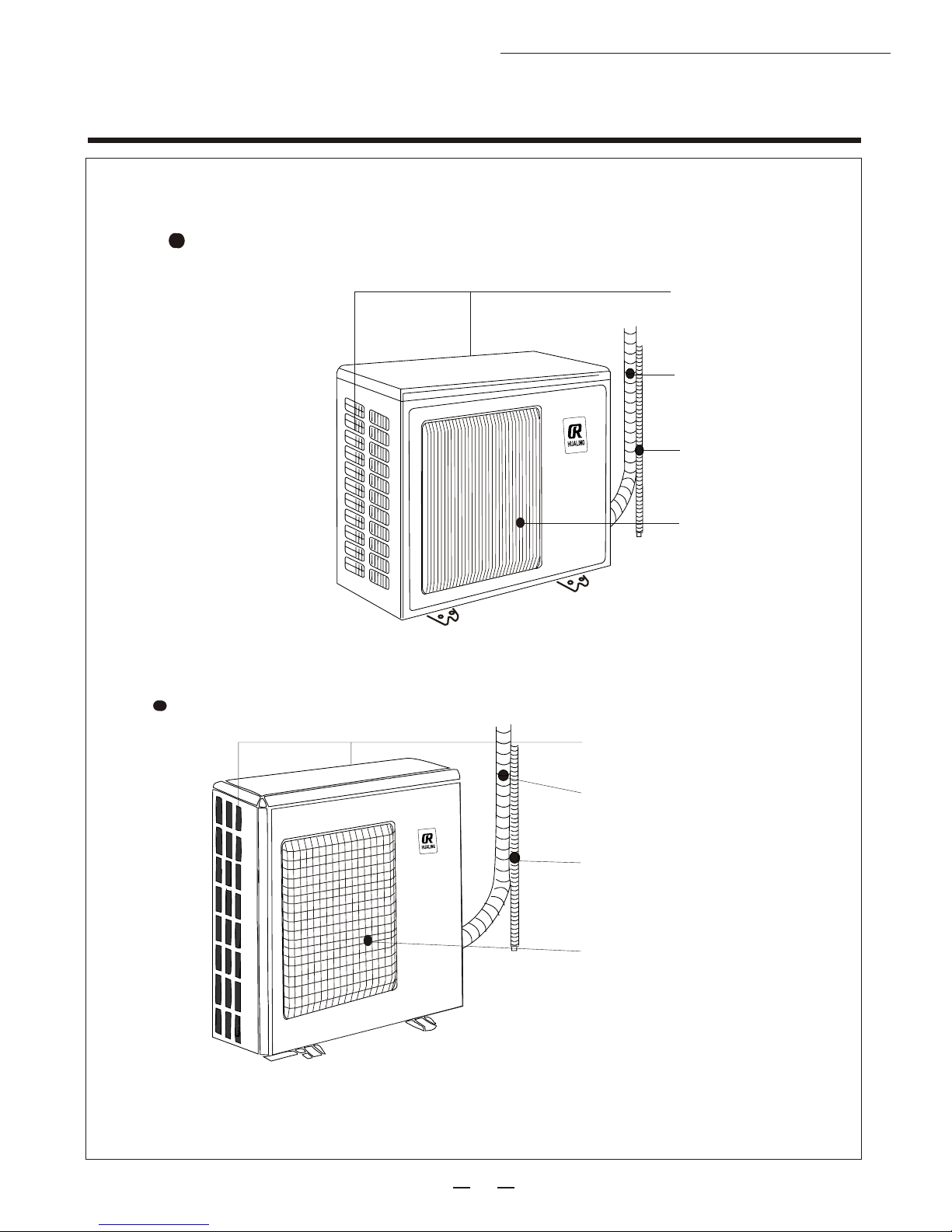

•••

Installation & Maintenance Manual

II .Dimensions

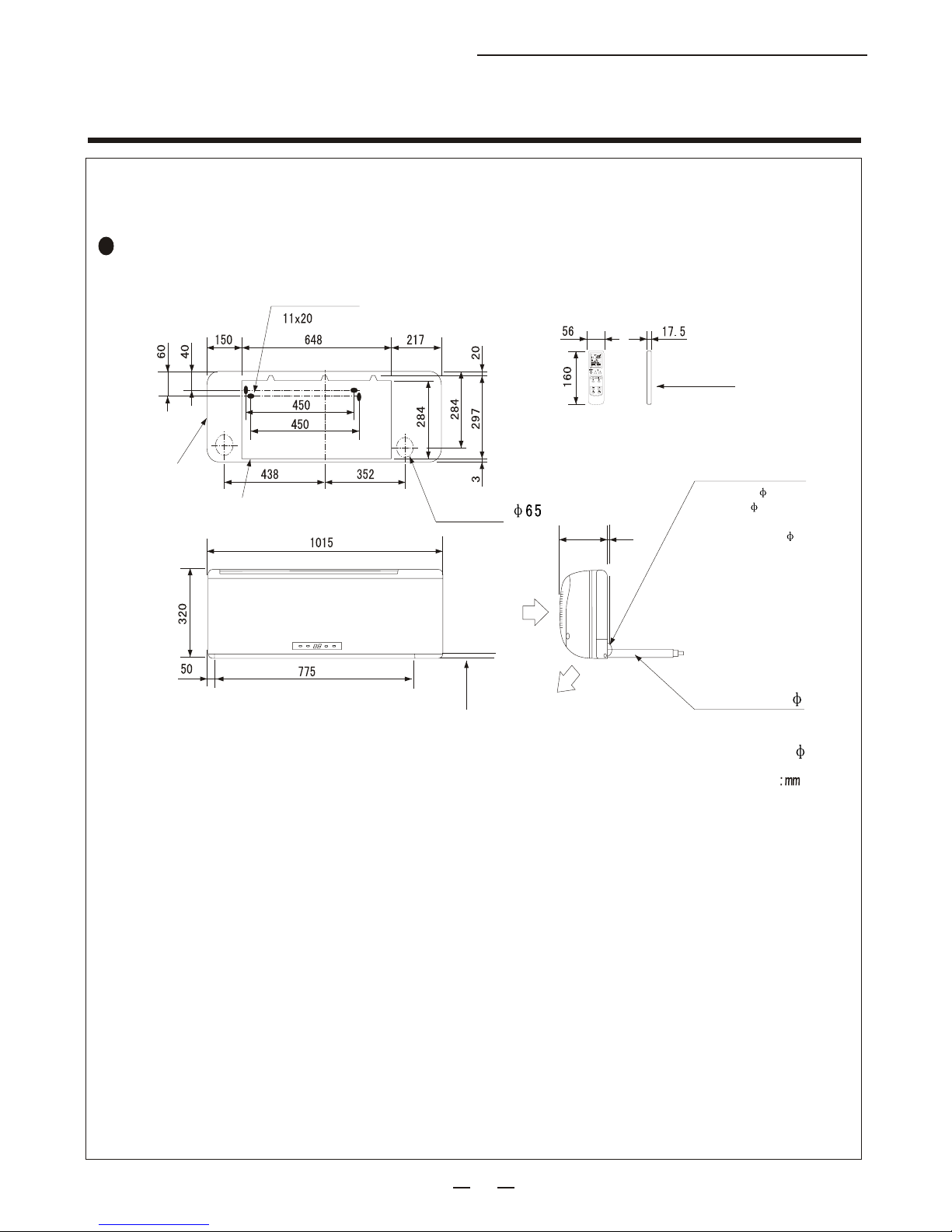

CSU-05HCAA CSU-07HCAA CSU-09HCAA

CSU-09HHAA indoor unit

mounting unit

•••

••

Body Center

•••

HUALING

•••

indoor unit

porthole

air inlet

Power Cable

air outlet

CSU-12HCAA CSU-12HHAA indoor unit

Wireless Remote controller

mounting unit

liquid pipe 6.35 1/4F

gas pipe 9.52 3/8F

external diameter after

heat insulation

drain hose

external diameter after

heat insulation

28

Unit:mm

mounting unit

HUALING

indoor unit

porthole

3

air inlet

air outlet

wireless remote controller

Mounting board

liquid pipe 6.35 1/4F

gas pipe 12.7 1/2F

external diameter after

heat insulation 35

drain hose

external diameter after

heat insulation

Unit

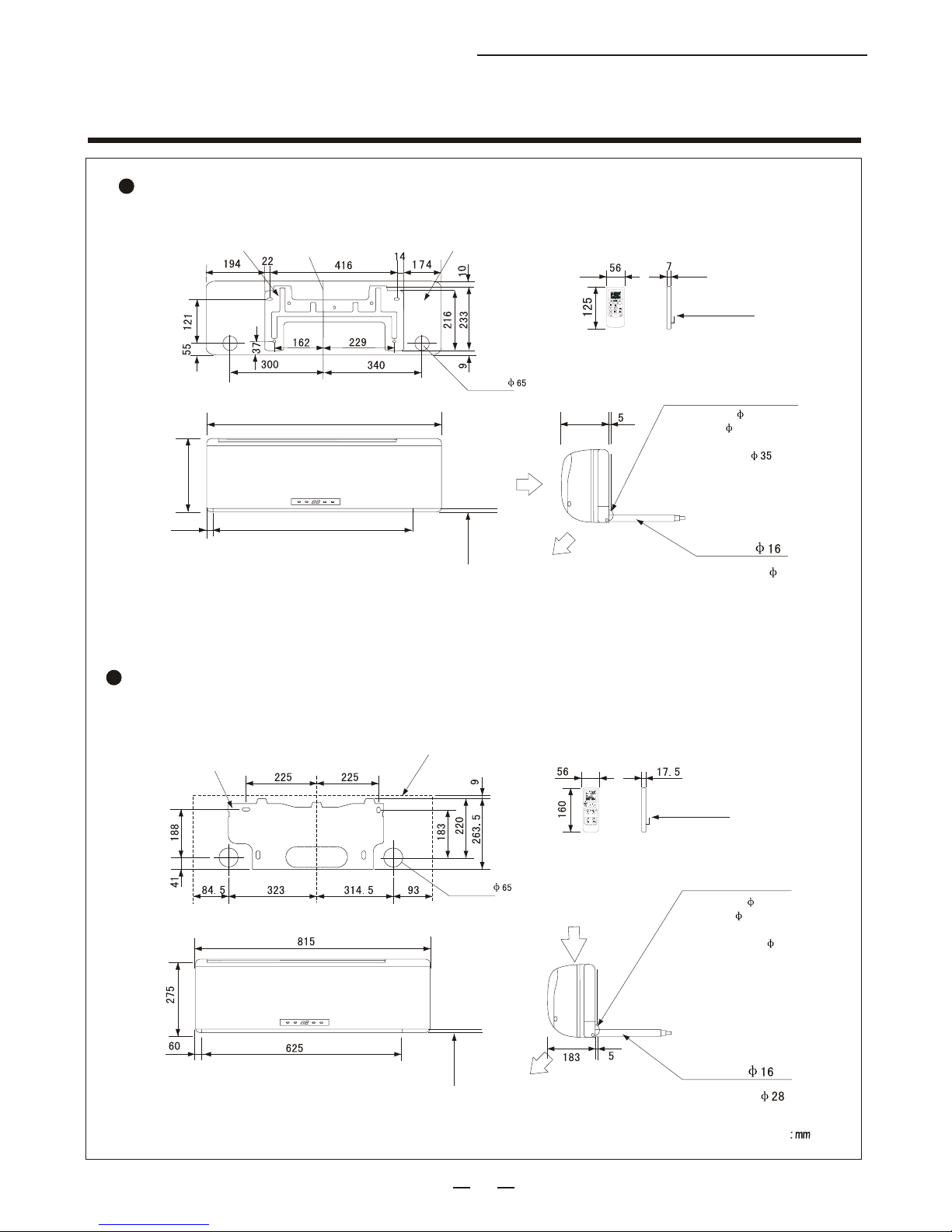

Page 6

Installation & Maintenance Manual

II.Dimensions

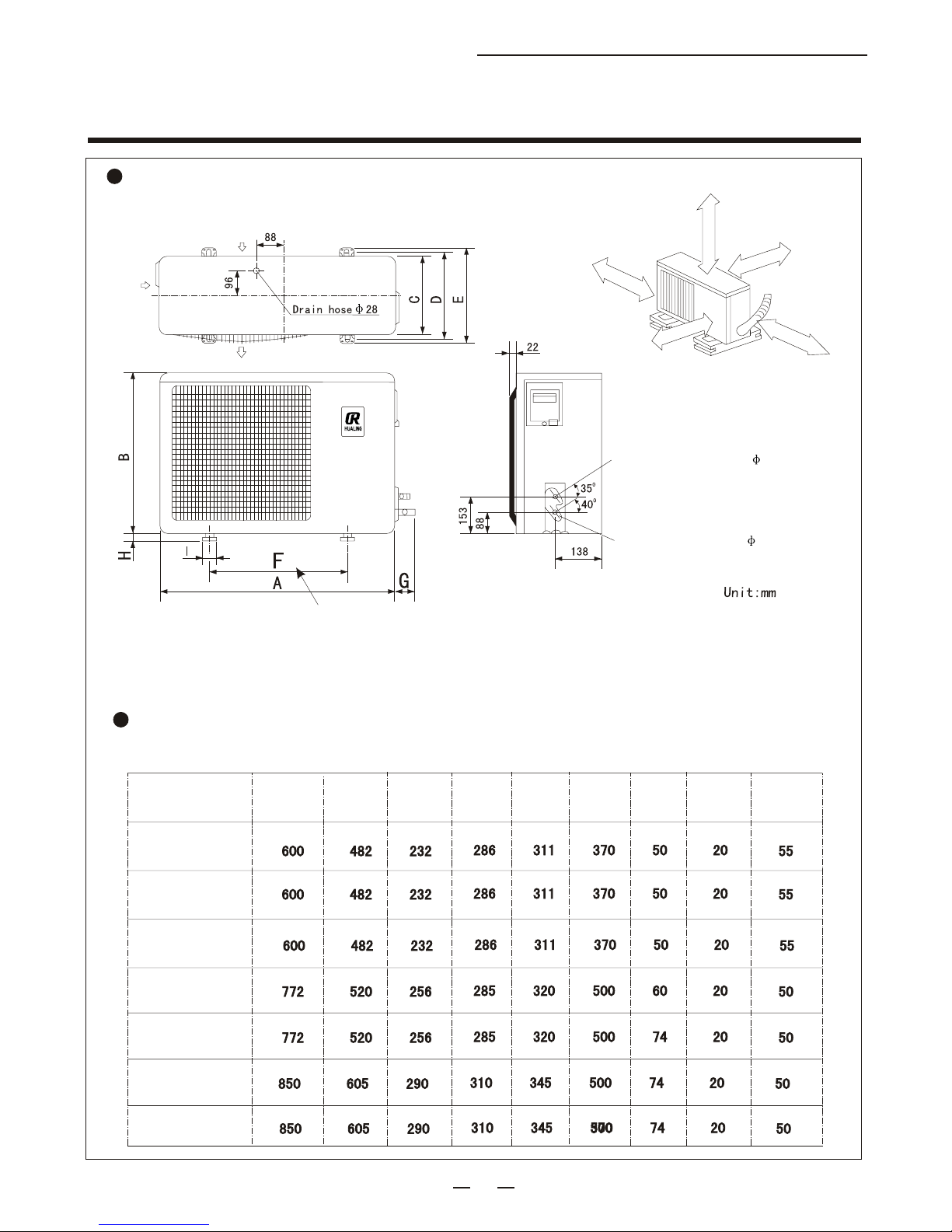

CSU-18HCAA CSU-18HHAA CSU-21HCAA CSU-21HHAA

CSU-24HCAA CSU-24HHAA indoor unit

Four holes

Wireless remote controller

Indoor unit

Mounting board

HUALING

Porthhole

Air inlet

Power cable

2m to the right side

1m to the left side

Air outlet

190

Mounting board

liquid pipe 6.35 1/4F

gas pipe 12.7 1/2F

5

external diameter after

heat insulation 35

Drainage pipe

16

external diameter after

heat insulation

28

unit

4

Page 7

II.Dimensions

Outdoor unit

air inlet

air inlet

air outlet

Installation & Maintenance Manual

Above

100mm Above

100mm Above

350mm Above

If there exists only

50-60 cm clearance

from the back to the wall,

the left side of the outdoor

unit must be entirely open.

100mm Above

500mm

piping for liquid pipe joint 6.35

mounting hole distance

OUTDOOR UNITS DIMENSION

Model

CU-05CA

CU-07CA

CU-09C(H)A

A

B

C

D

E

piping for gas pipe joint 12.7

F

G

H

I

CU-12C(H)A

CU-18C(H)A

CU-21C(H)A

CU-24C(H)A

5

Page 8

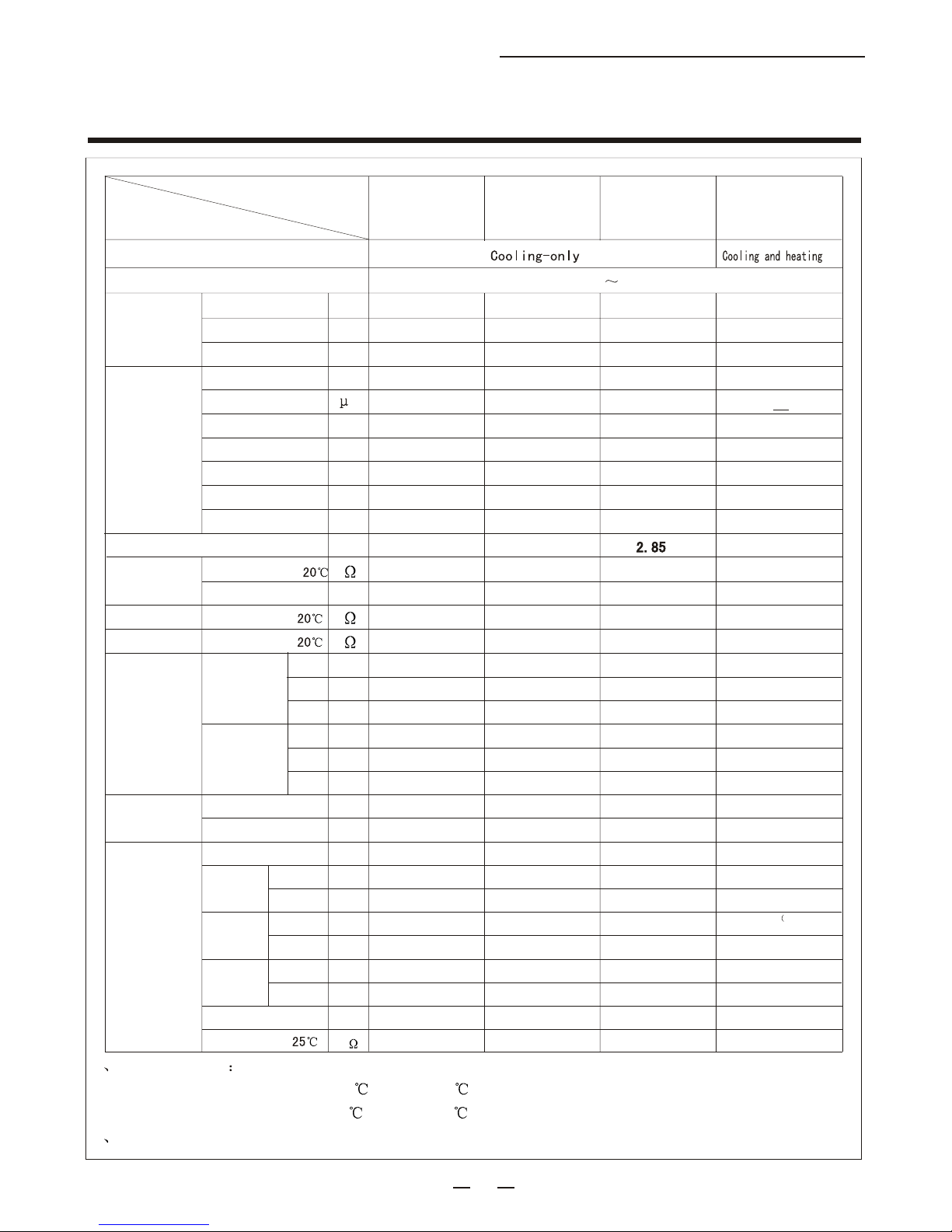

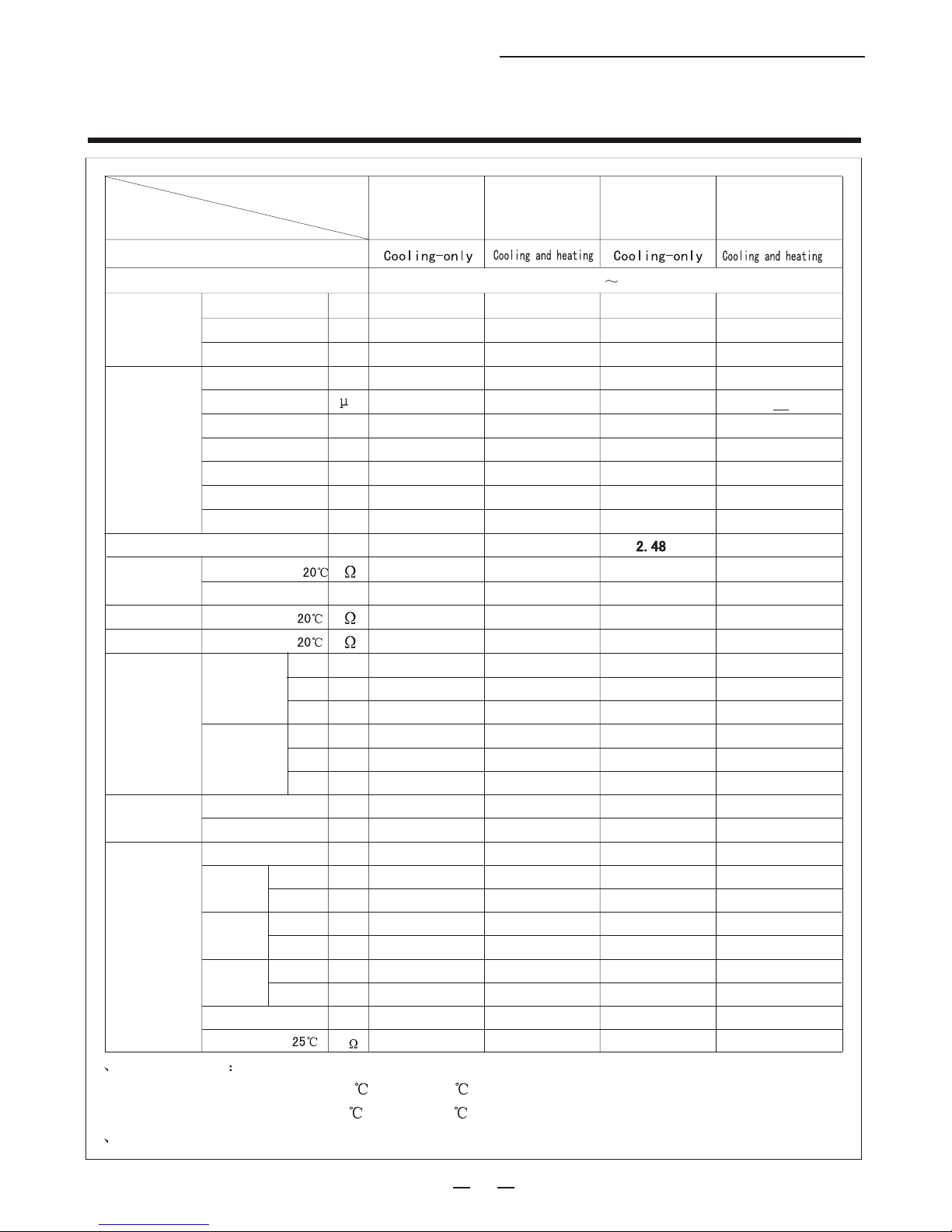

III. Specification

Installation & Maintenance Manual

Model

CSU-05HCAA

CSU-07HCAA

CSU-09HCAA

CSU-09HHAA

Performance data

Functions

Power supply

kW

l/h

3

m/h

A

F

kW

%

A

A

A

Capacities

Other

electrical

data

Capacity

Dehumidifying capacity

Air supply capacity

Power supply capacity

Running capacitor

Input power

Power factor

Stockstill current

Compressor motor current

Fan motor current

EER

Winding resistance(at )

Compressor

Indoor fan motor

Outdoor fan motor

Dimensions

Weight

Other data

Model

Winding resistance(at )

Winding resistance(at )

Length

Indoor unit

Width

Heigth

Length

Outdoor unit

Width

Height

Indoor unit

Outdoor unit

Noise

Fan speed

Fan speed

stage

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Refrigerant R22

Thermister(at )

mm

mm

mm

mm

mm

mm

kg

kg

( )

dB A

( )

dB A

r/min

r/min

g

k

1 Test conditions

cooling indoor unit dry bulb 27 wet bulb19

outddor unit dry bulb 35 wet bulb 24

2 The data should subject to the nameplate they are different from those on the nameplate.

1.42

0.6

410

10

20

0.5

97

12

2.4

In0.22/out0.25

3.1

SD091CV-H3BU

740

243

200

600

600

232

232

502

502

7

23

5 and swing

26-39

54

1100/980/900

870

3

1

400

10 10

In0.23/out0.48

PH108X1C

220 VAC 50Hz

1.932

0.65

430

10

25

0.62

97

15

2.8

3.12

740

243

200

600

232

502

7

23

5 and swing

26-39

54

1100/980/900

870

3

1

470

10

2.2

0.91

430

15

25

0.775

97

19.8

3.4

in0.23/out0.48

PH135X1C-8DZD2

740

243

200

600

232

502

7

23

5 and swing

29-39

54

1100/980/900

870

3

1

645

10

0.82/0.72

in0.35/out0.86

KH145VHEA

5 and swing

1100/980/900 cooling)

950/870/800(heating)

2.2/2.4

0.91

430

15

20

97

18

3.9

2.7

740

243

200

600

232

502

7

23

29-39

54

870

3

1

680

6

Page 9

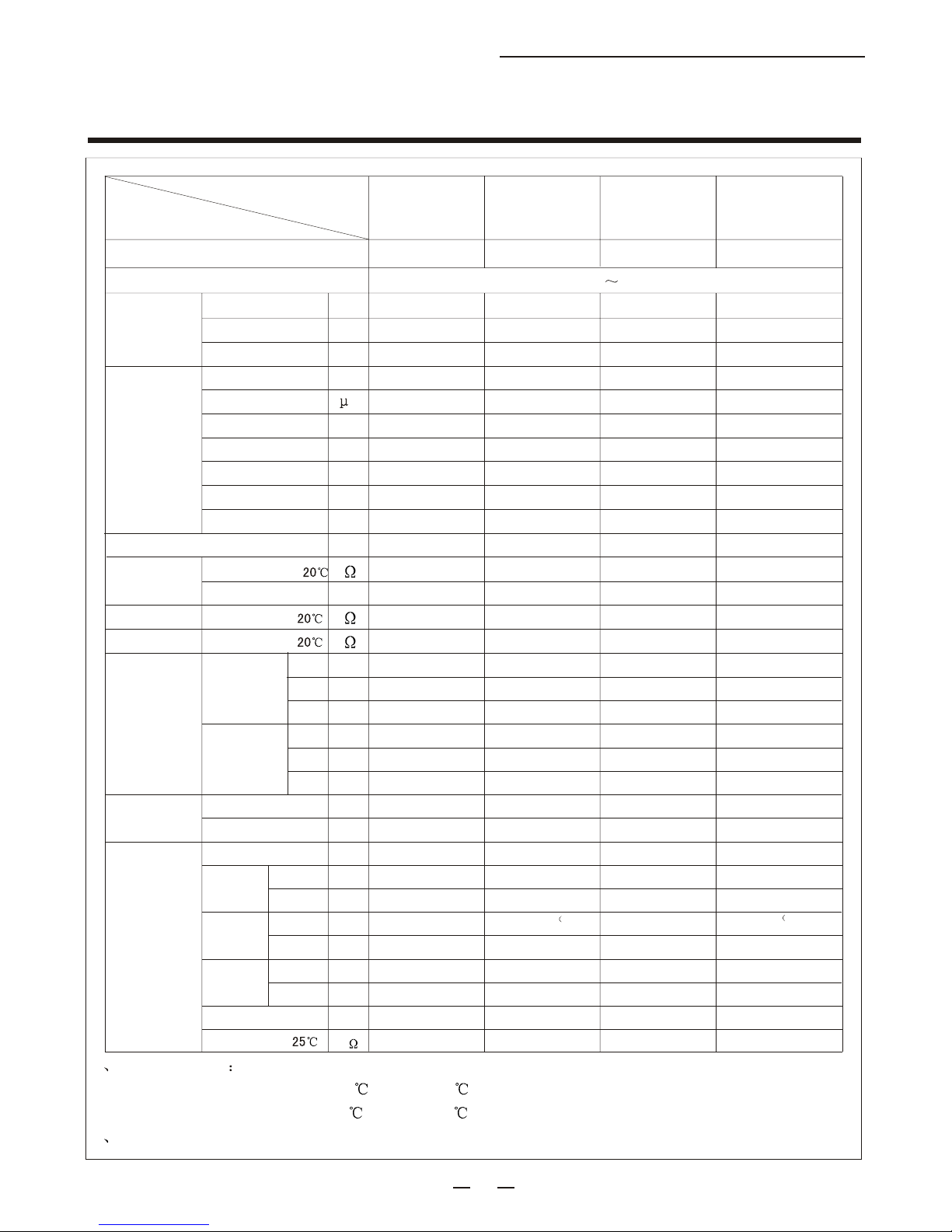

III. Specification

Installation & Maintenance Manual

Model

CSU-12HCAA

CSU-12HHAA

CSU-18HCAA

CSU-18HHAA

Performance data

Cooling-only

4.5

1.9

680

8.35

50

1.8

97

39

8.1

in0.28/out0.56

2.5

Capacities

Other

electrical

data

Functions

Power supply

Cooling capacity

Dehumidifying capacity

Air supply capacity

Power supply capacity

Running capacitor

Input power

Power factor

Stockstill current

Compressor motor current

Fan motor current

EER

m/h

kW

l/h

3

A

F

kW

%

A

A

A

Cooling-only

3.1

1.27

490

5.4

35

1.15

97

29.9

5.55

in0.28/out0.56

2.68

Cooling AND HEATING

220 VAC 50Hz

3.2/3.42

1.31

490

5.4/5.2

35

1.16/1.13

97

29.9

5.55

in0.23/out0.48

2.75/3.0

Winding resistance(at )

Compressor

Indoor fan motor

Outdoor fan motor

Dimensions

Weight

Other data

Model

Winding resistance(at )

Winding resistance(at )

Length

Indoor unit

Width

Heigth

Length

Outdoor unit

Width

Height

Indoor unit

Outdoor unit

Noise

Fan speed

Fan speed

stage

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Refrigerant R22

Thermister(at )

PH215X2C-8FTC

mm

mm

mm

mm

mm

mm

kg

kg

( )

dB A

( )

dB A

r/min

r/min

g

k

740

200

243

772

254

540

8

35

5 and swing

35-41

54

1100/980/900

780

3

1

780

10

PH215X2C-8FTC

740

200

243

772

254

540

8

35

5 and swing

35-41

54

1200/1120/1050 cooling)

1260/1160/1100(heating)

780

3

1

115 0

10

TH310VEEC

1015

320

200

772

254

540

14

35

5 and swing

35-46

55

1050/980/900

780

3

1

1020

10

1 Test conditions

cooling indoor unit dry bulb 27 wet bulb19

outddor unit dry bulb 35 wet bulb 24

2 The data should subject to the nameplate they are different from those on the nameplate.

Cooling AND HEATING

8.35/7.6

1.8/1.65

8.1

in0.23/out0.48

TH310VEEC

5 and swing

1050/980/900 cooling)

1050/1000/960(heating)

4.48/4.98

2.3

680

50

97

39

2.5/3.0

1015

320

200

772

254

540

14

35

35-46

55

780

3

1

1130

10

7

Page 10

III. Specification

Installation & Maintenance Manual

Model

CSU-21HCAA

CSU-21HHAA

CSU-24HCAA

CSU-24HHAA

Performance data

Functions

Power supply

kW

l/h

3

m/h

A

F

kW

%

A

A

A

Capacities

Other

electrical

data

Capacity

Dehumidifying capacity

Air supply capacity

Power supply capacity

Running capacitor

Input power

Power factor

Stockstill current

Compressor motor current

Fan motor current

EER

Winding resistance(at )

Compressor

Indoor fan motor

Outdoor fan motor

Dimensions

Weight

Other data

Model

Winding resistance(at )

Winding resistance(at )

Length

Indoor unit

Width

Heigth

Length

Outdoor unit

Width

Height

Indoor unit

Outdoor unit

Noise

Fan speed

Fan speed

stage

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Indoor unit

Outdoor unit

Refrigerant R22

Thermister(at )

mm

mm

mm

mm

mm

mm

kg

kg

( )

dB A

( )

dB A

r/min

r/min

g

k

1 Test conditions

cooling indoor unit dry bulb 27 wet bulb19

outddor unit dry bulb 35 wet bulb 24

2 The data should subject to the nameplate they are different from those on the nameplate.

5.1

2.0

680

8.9

50

1.92

97

42

9.3

in0.22/out0.25

2.65

SHW33TC4-U

1015

320

200

850

290

610

14

47

5 and swing

46

59

1200/1120/1000

820

3

1

1300

10 10

In0.23/out0.48

TH310VEEC

1260/1160/1100(heating)

220 VAC 50Hz

5.08/5.8

2.1

680

8.7/8.5

50

1.96/1.85

97

38/42

8.1

2.58/3.1

1015

320

200

850

290

610

14

47

5 and swing

46

59

1200/1120/1050

820

3

1

1300

10

5.98

2.45

730

11.5

35

2.4

97

52

11.5

In0.23/out0.48

SHV33YC6-G

1015

320

200

850

290

610

14

53

5 and swing

46

59

1280/1150/1050(cool)

910

3

1

1600

10

11.4/11.4

2.38/2.38

in0.35/out0.86

SHV33YC6-G

5 and swing

1280/1150/1050

5.94/6.63

2.43

730

50

97

52

11.5

2.48/2.8

1015

320

200

850

290

610

14

53

46

59

910

3

1

1600

8

Page 11

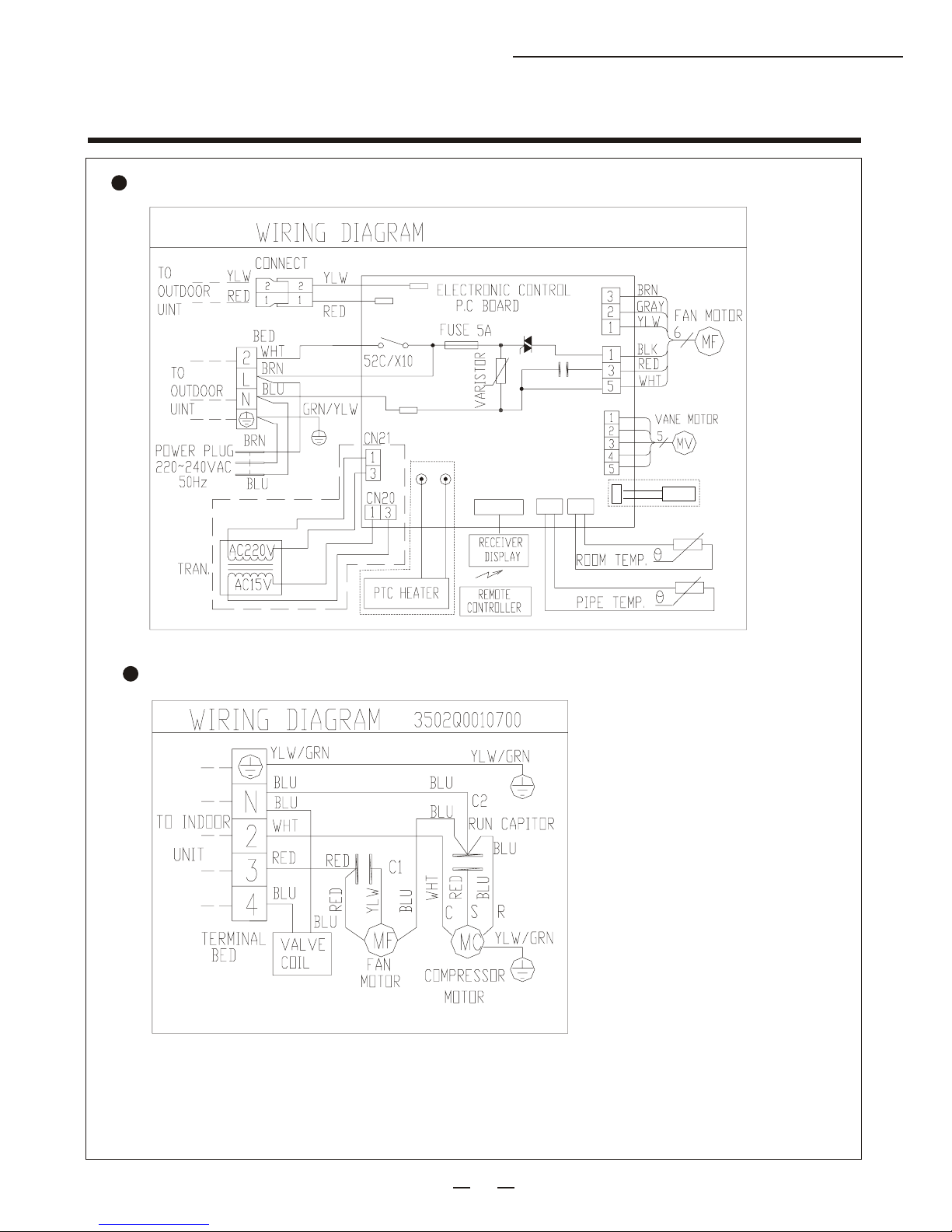

Installation & Maintenance Manual

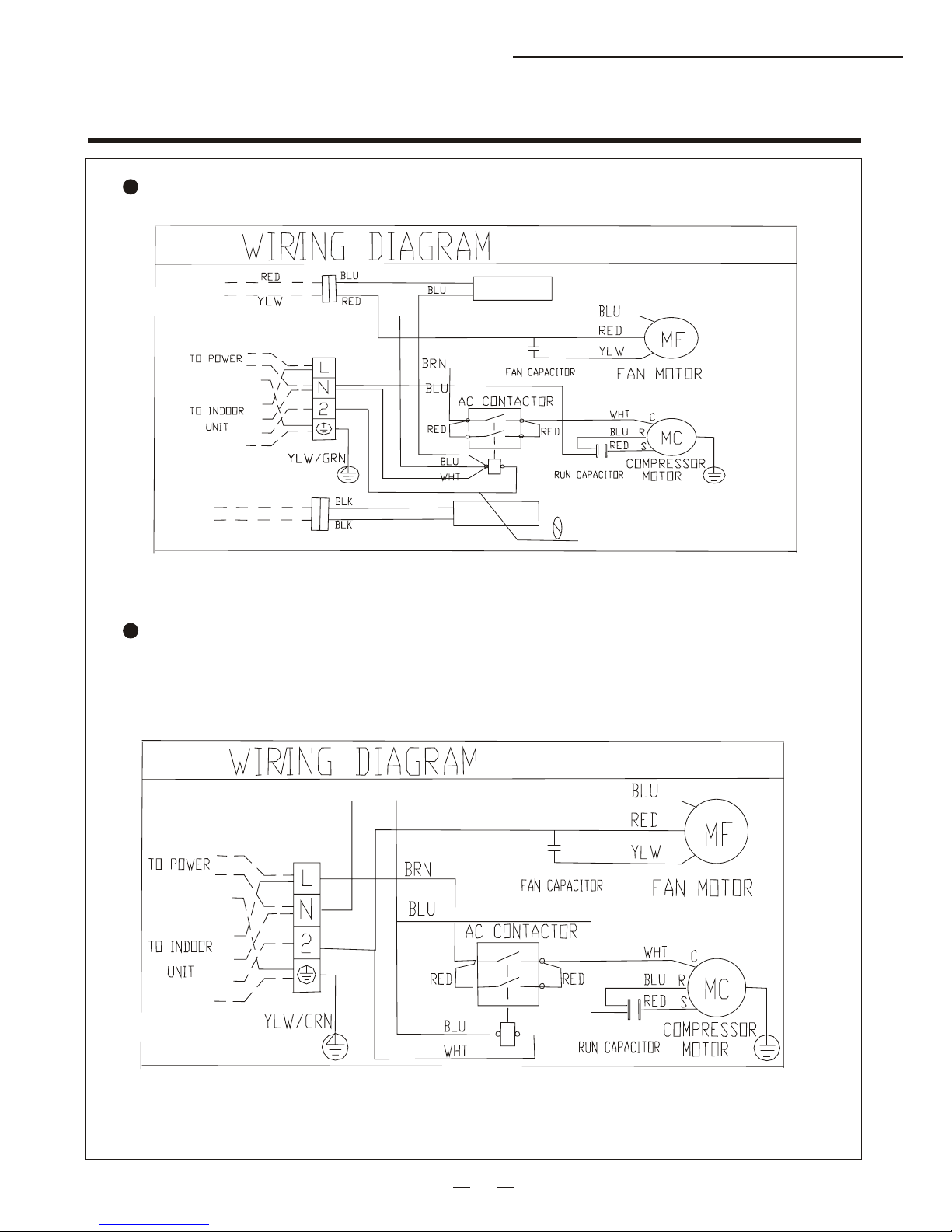

IV. Wiring diagram

Wiring diagram for heat pump indoor unit 5K/7K/9K/12K

3502Q0027230

AC-L44

TERMINAL

AC-L33

3/ON

4/COM

CNO7

Cn22

AC-N

AC-L55

AC-N1

HEAT

CNO8/CNO9

PT

CNO2

RT

CNO1

CNO4

CLEAR

CNI2

Optional

Wiring diagram for heat pump outdoor unit 5K/7K/9K/12K

9

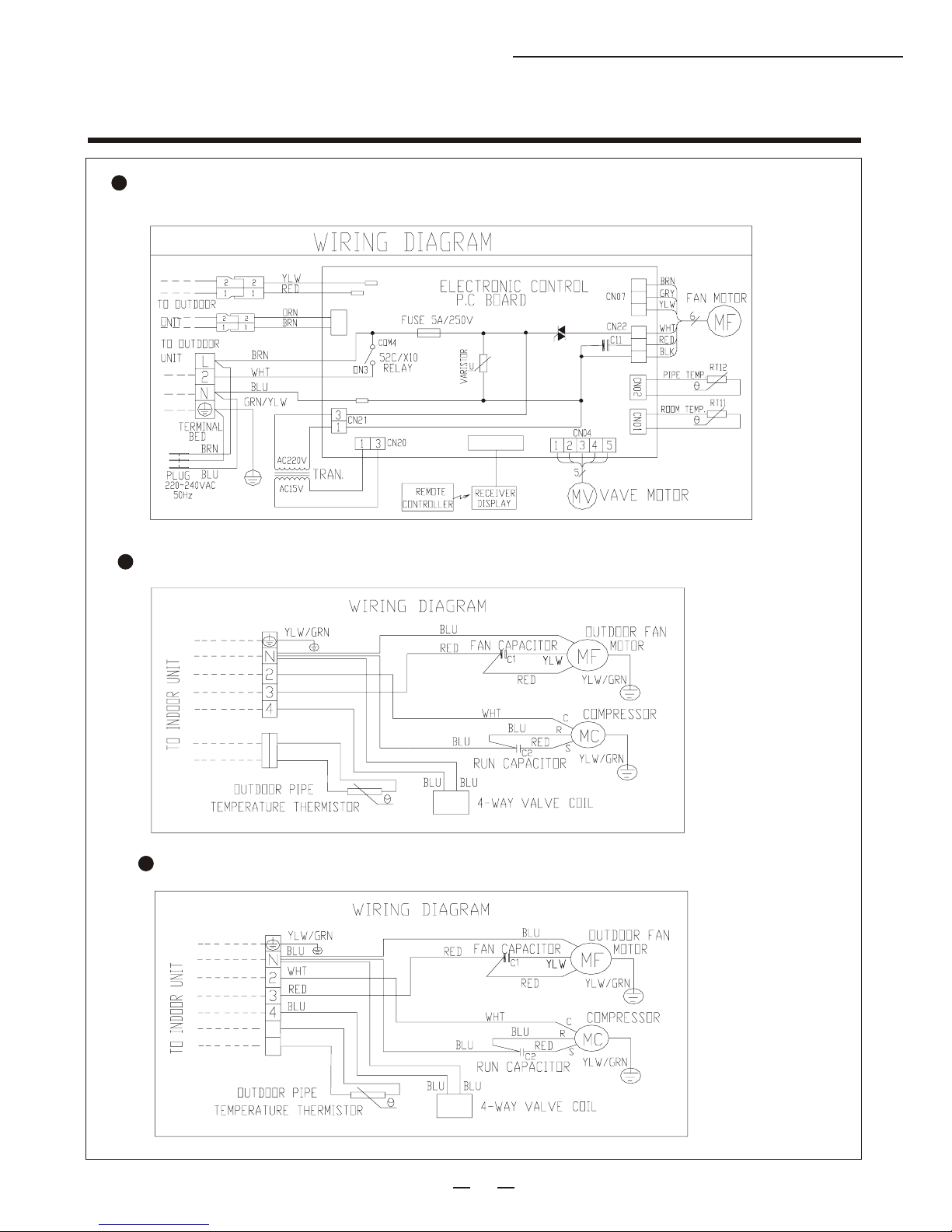

Page 12

Installation & Maintenance Manual

IV. Wiring diagram

Wiring diagram for heat pump indoor unit 18K/21K

VALVE

AC-L44

AC-L33

OUTFAN

CN-03

AC-N

CN08/CN09

3502Q0028679

Circuit principle diagram for outdoor unit 18K

3502Q0010653

Circuit principle diagram for outdoor unit 21K

3502Q0011916

BLK

S1

BLK

S2

10

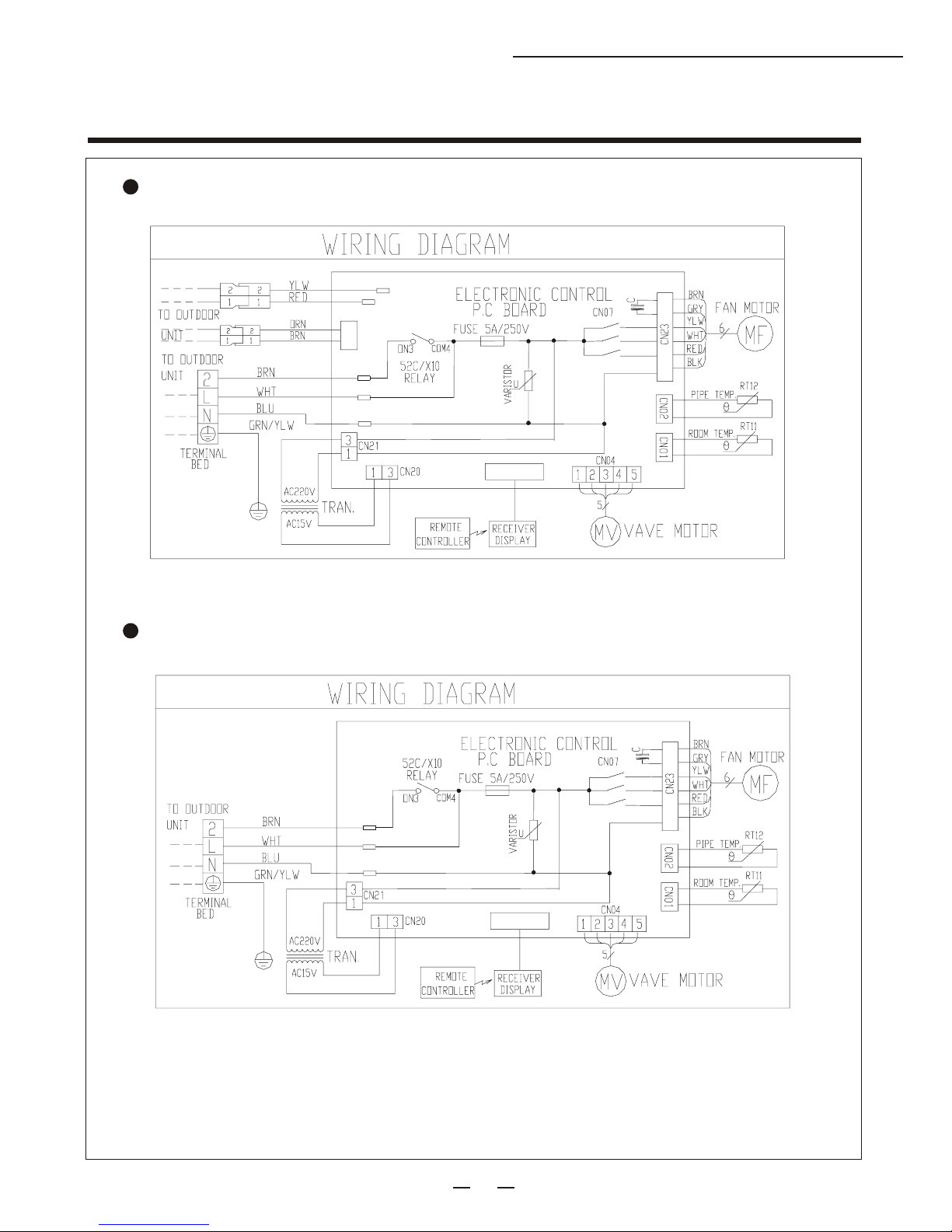

Page 13

Installation & Maintenance Manual

IV. Wiring diagram

Wiring diagram for heat pump indoor unit 24K

VALVE

AC-L44

AC-L33

OUTFAN

CN-03

AC-L22

AC-L

AC-N

CN08/CN09

3502Q0028680

X1

X2

X3

RELAY

Wiring diagram for only cooling indoor unit 24K

AC-L22

AC-L

AC-N

CN08/CN09

RELAY

3502Q0028680

X1

X2

X3

11

Page 14

Installation & Maintenance Manual

IV. Wiring diagram

Wiring diagram for heat pump outdoor unit 24K

TO INDOOR UNIT

3502Q0027178

4-WAY VAVLE COIL

TO INDOOR UNIT

TEMP. THERMISTOR

Wiring diagram for only cooling outdoor unit 24K

3502Q0017666

12

Page 15

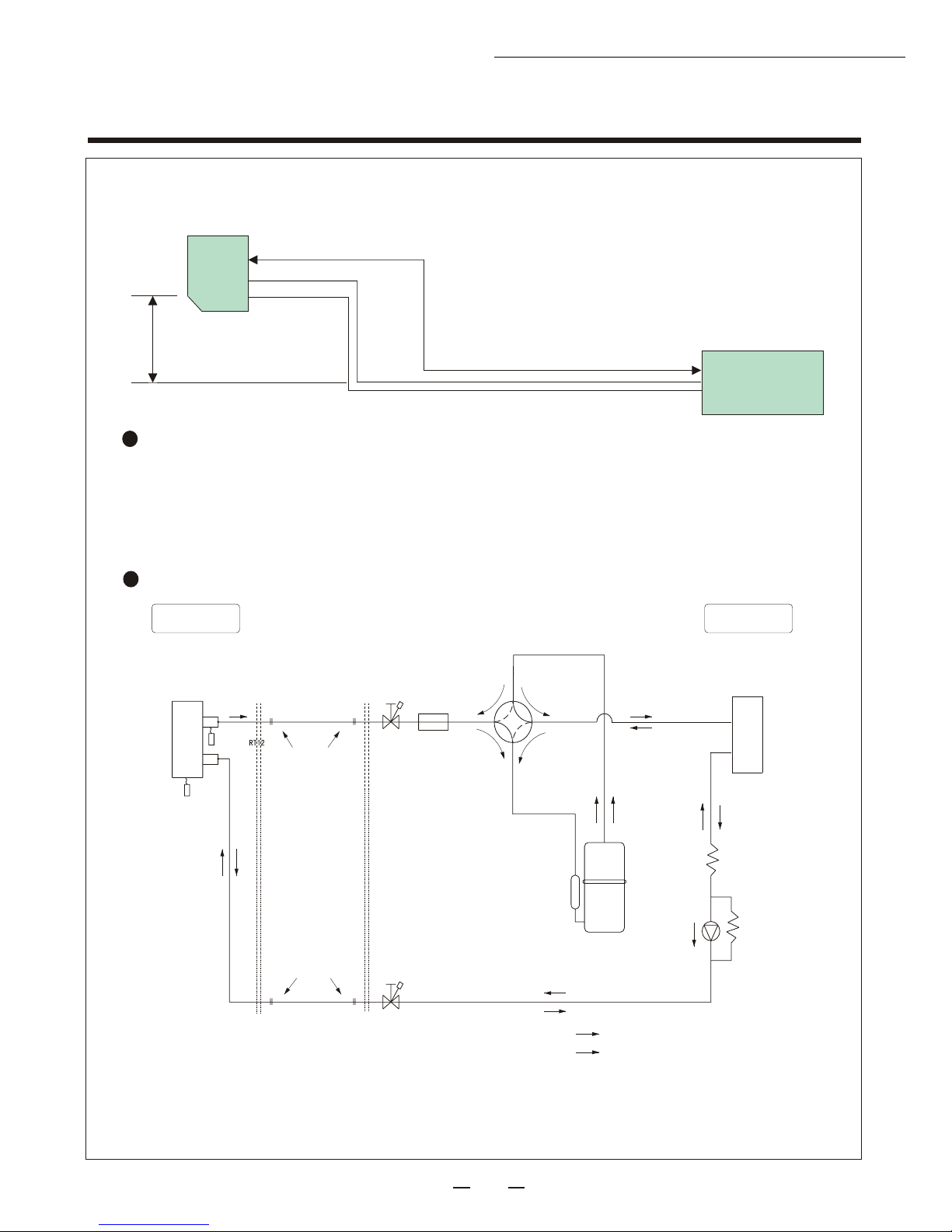

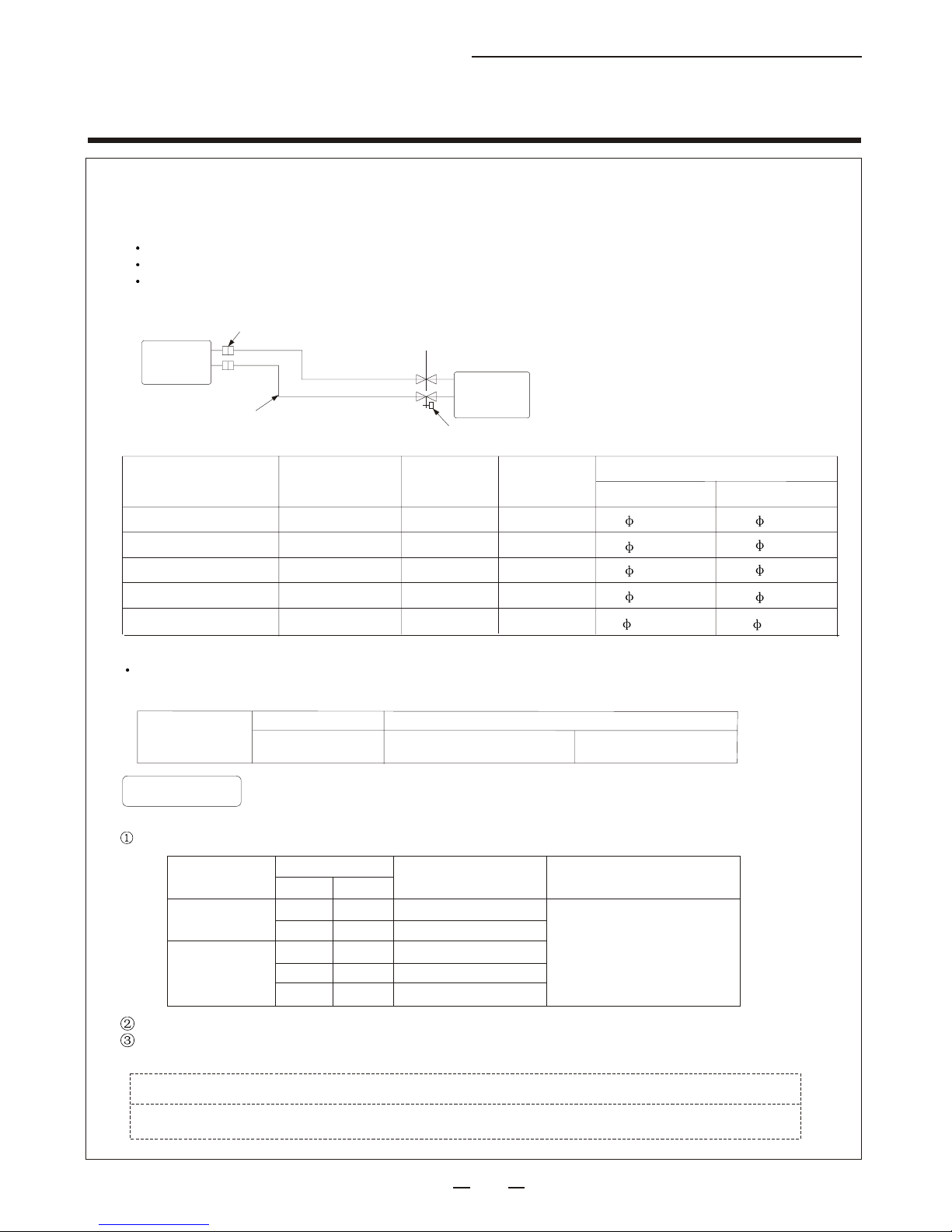

V. Refrigerating circuit

Indoor

unit

Installation & Maintenacne Manual

Maximum height difference 5m

(regardless either unit is higher)

Max. Lenth of extended fitting pipe

Outdoor unit

Refrigerant replenishment (R22:g):

No refrigerant replenishment is required if extended length of fitting pipe is less than 7m.

If extended length of fitting pipe is over 7m, replenishing volume of refrigerant should be

calculated as per the following formula: replenishing volume Xg=15g/mX(A-7)m

Refrigerating circuit for heat pump type

Indoor unit Outdoor unit

4-way valve

Indoor heat

exchanger

Room-temperature

thermistor RT11

Pipe-temperature

thermisto

Connecting pipe

(with heat-insulating

pipe casing)

Joint of flared pipe

Shutoff valve

(with access door)

exchanger

Outdoor heat

Joint of flared pipe

Connecting pipe

(with heat-insulating

pipe casing)

Shutoff valve

13

Check valve

Compressor

Flow direction of refrigerant

Flow direction of refrigerant

Capillary(cooling)

Capillary(heating)

for cooling

for heating

Page 16

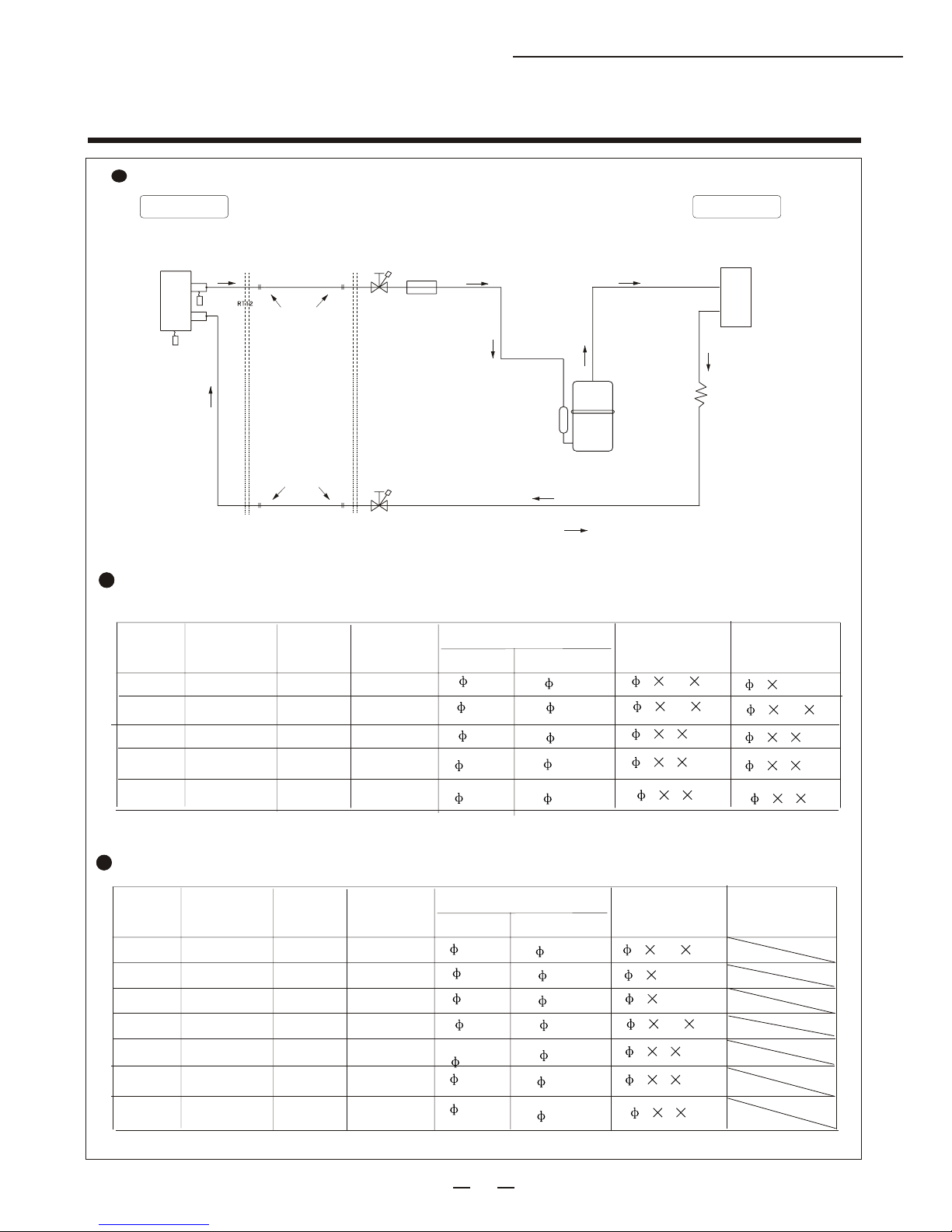

V. Refrigerating circuit

Refrigerating circuit for only cooling type

Indoor unit Outdoor unit

Installation & Maintenance Manual

4-way valve

exchanger

Room-temperature

thermistor RT11

Indoor heat

Pipe-temperature

thermisto

Connecting pipe

(with heat-insulating

pipe casing)

Joint of flared pipe

Joint of flared pipe

Connecting pipe

(with heat-insulating

pipe casing)

Shutoff valve

(with access door)

Shutoff valve

Compressor

Flow direction of refrigerant

exchanger

Outdoor heat

Capillary (cooling)

Maxinmum length of fitting capillary pipe for heat pump unit

Outer diameter of fitting pipe:(mm)

Gas pipe

9.52

12.7

12.7

15.8

15.8

Liquid pipe

6.35

6.35

6.35

9.52

9.52

Capillary

(cooling)

3 1.4 850

3 1.6 650

4 2 900

4 2 800

42550

Model

9K

12K

18K

21K

24K

Max length

of extended

fitting pipe (m)

10

15

15

15

15

Max Height

difference

(m)

5

5

5

7

7

Max number

of bent pipes

10 spots

10 spots

10 spots

10 spots

10 spots

for cooling

Capillary

(heating)

3 1.6X450

3 1.6 350

4 2 650

4 2 600

4 2 250

Maxinmum length of fitting capillary pipe for only cooling unit

Max length

Model

5K

7K

9K

12K

18K

21K

24K

of extended

fitting pipe (m)

10

10

10

15

15

15

15

Max Height

difference

(m)

5

5

5

5

5

7

7

Max number

of bent pipes

10 spots

10 spots

10 spots

10 spots

10 spots

10 spots

10 spots

Outer diameter of fitting pipe:(mm)

Gas pipe

9.52

9.52

9.52

12.7

12.7

15.8

15.8

Liquid pipe

6.35

6.35

6.35

6.35

6.35

9.52

9.52

14

Capillary

(cooling)

3 1.4 1000

3 1.4X1000

3 1.4X1000

3 1.6 600

4 2 1000

42700

42500

Capillary

(heating)

Page 17

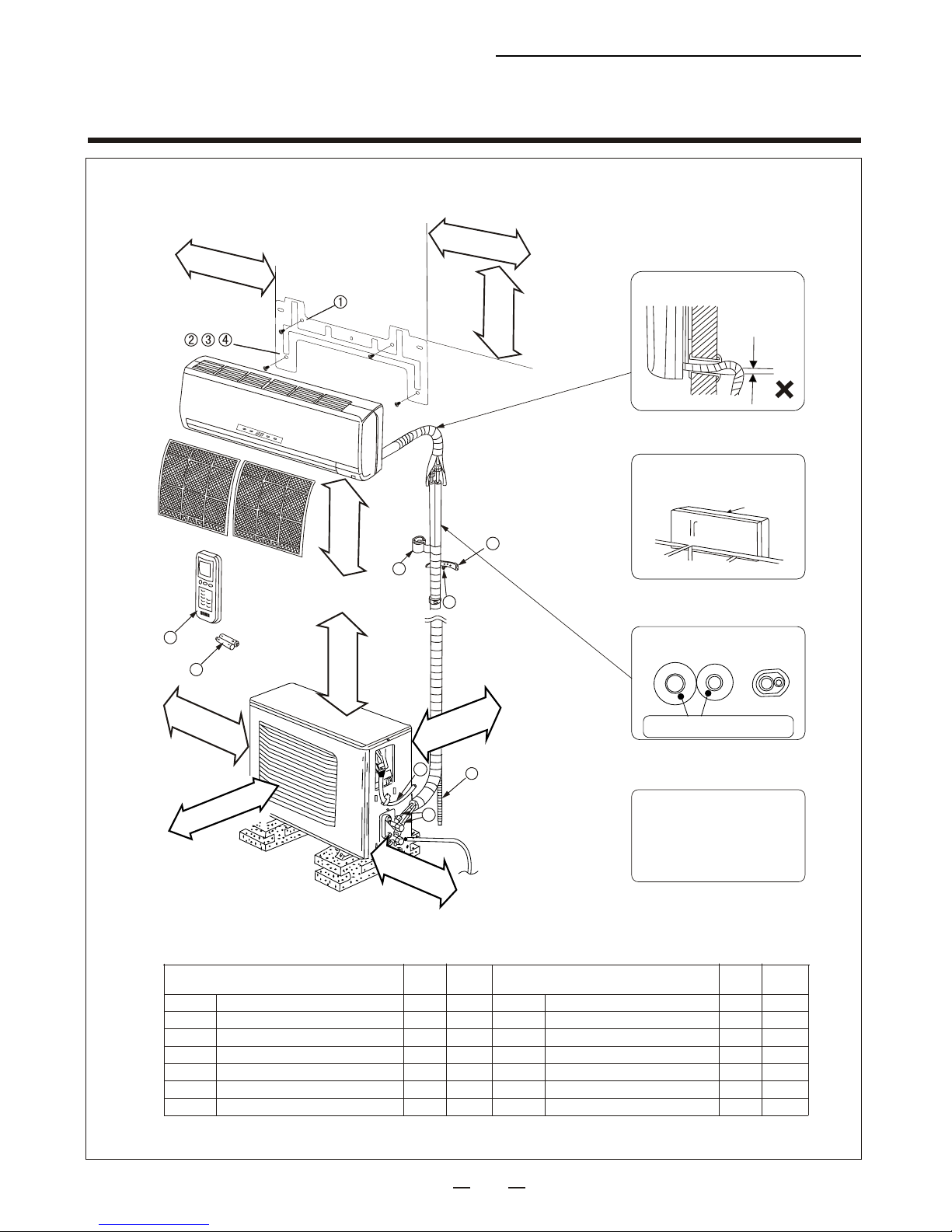

VI. Installation instructions

1. Installation diagram

1-1.5K/7K/9K/12K

Above 120mm

H

UA

LING

Above 70mm

B

Installation & Maintenance Manual

Above 195mm

Above 30mm

C

Be careful!

Do not let drain hose run up.

Fitting pipe of pipeline may be led out

from back side, right side, lower side,

left side or left rear side.

Back side

Right

Rear

Downwards

Left rear

Front side

Left

6

5

Above 100mm

Above 500mm

Enclosed attachments

1

Mounting plate

2

Tapping screw ST4*25

3

Expansion plug

4

Expansion bolt

5

Battery for remote controller

6

Remote controller

Connecting cable

7

Above 100mm

Above 350mm

D

Above 100mm

7

E

A

Qty

Unit

Piece

1

Pcs

5

Pieces

5

Pieces

2

Pcs

2

Piece

1

Piece

1

Connect the pipeline at two sides, and

insulation should be carried out respectively.

Aerated plastics with a thickness of

8mm for heat insulation

If the pipeline is to be installed upon a

wall equipped with steel sheet

(galvanized sheet) or metal net, plank

with a thickness of 20mm should be

positioned between the wall and the

pipeline, or the pipeline should be

wrapped with 7~8 layers of insulating

plastic tape.

Installation attachments

A

Connecting pipe

Bandage

B

C

Tensioning rope

D

Masonry nail

Drain hose

E

Putty

F

G

Sealing oil

Qty

2

1

3

5

1

1

1

Unit

Pieces

Piece

Pcs

Pcs

Piece

Box

Bottle

15

Page 18

VI. Installation instructions

1. Installation diagram

1-2.18K

Installation & Maintenance Manual

Above 105mm

1

234

Above 155mm

Be careful!

Do not let drain hose run up.

Above 24mm

HUALING

Fitting pipe of pipeline may be led out

from back side, right side, lower side,

left side or left rear side.

Back side

Right

C

Above 70mm

B

D

6

5

Rear

Downwards

Connect the pipeline at two sides, and

insulation should be carried out respectively.

Left rear

Front side

Left

Above 100mm

Above 500mm

Enclosed attachments

1

Mounting plate

2

Tapping screw ST4*25

3

Expansion plug

4

Expansion bolt

5

Battery for remote controller

6

Remote controller

Connecting cable

7

Above 100mm

Above

ove 100mm

Ab

7

A

350mm

Qty

1

5

5

2

2

1

1

E

Unit

Piece

Pcs

Pieces

Pieces

Pcs

Piece

Piece

Aerated plastics with a thickness of

8mm for heat insulation

If the pipeline is to be installed upon a

wall equipped with steel sheet

(galvanized sheet) or metal net, plank

with a thickness of 20mm should be

positioned between the wall and the

pipeline, or the pipeline should be

wrapped with 7~8 layers of insulating

plastic tape.

Installation attachments

A

Connecting pipe

Bandage

B

C

Tensioning rope

D

Masonry nail

Drain hose

E

Putty

F

G

Sealing oil

Qty

2

1

3

5

1

1

1

Unit

Pieces

Piece

Pcs

Pcs

Piece

Box

Bottle

16

Page 19

VI. Installation instructions

1. Installation diagram

1-3.21K/24K

Installation & Maintenance Manual

Above

234

175mm

1

Above

242mm

Be careful!

Do not let drain hose run up.

Above 60mm

HUA

LING

Fitting pipe of pipeline may be led out

from back side, right side, lower side,

left side or left rear side.

Back side

70mm

C

Above

HUALING

6

5

Above

100mm

Above

100mm

B

D

100mm

Above

Right

Rear

Downwards

Connect the pipeline at two sides, and

insulation should be carried out respectively.

Aerated plastics with a thickness of

8mm for heat insulation

Left rear

Front side

Left

500mm

Above

Enclosed attachments

1

Mounting plate

2

Tapping screw ST4*25

3

Expansion plug

4

Expansion bolt

5

Battery for remote controller

6

Remote controller

Connecting cable

7

Above

7

A

350mm

Qty

1

5

5

2

2

1

1

E

Unit

Piece

Pcs

Pieces

Pieces

Pcs

Piece

Piece

Installation attachments

A

Connecting pipe

Bandage

B

C

Tensioning rope

D

Masonry nail

Drain hose

E

Putty

F

G

Sealing oil

17

If the pipeline is to be installed upon a

wall equipped with steel sheet

(galvanized sheet) or metal net, plank

with a thickness of 20mm should be

positioned between the wall and the

pipeline, or the pipeline should be

wrapped with 7~8 layers of insulating

plastic tape.

Unit

Qty

Pieces

2

Piece

1

Pcs

3

Pcs

5

1

Piece

Box

1

Bottle

1

Page 20

Installation & Maintenance Manual

VI. Installation instructions

2.Safety Regulations

Please read safety instructions carefully before installation

All items listed here are extremely important safety instructions, which must be followed.

Legends and their meanings are listed as follows:

Warning

Users don't try to install by themselves

Improper installation may cause fire,

electric shock, loose of parts or water

leakage. Please contact a Hualing agent

for installation and maintenance.

Cover of electrical components on

indoor unit and maintenance board on

outdoor unit must be installed properly.

Improper installation of cover or panel

may cause fire or electric shock due to

dust or water.

Cables between indoor and outdoor

units must be properly connected by

specified cables and make sure that

joints properly fixed

If installed at a place without enough

strength, the unit may fall and hurt people

Installation must be made according

to installation instructions, the special

cables should be used

Inefficient capacity of the cable or

Improper installation may cause fire,

electric shock, loose of parts fall and

hurt people or water leakage.

The grounding is necessary

in construction

The ground wire must not be connected to

gas pipe, water pipe, lightning rod, telephone

ground wire. Improper connection of ground

wire may cause electric shock

Must not be installed at a place where

inflammable gas is leaking

If inflammable gas accumulated around

the unit, explosion may happen

Electrical components must be installed

according to instructions, and must use

specific electrical power supply

Insufficient electrical power capacity

or improper installation may cause fire

or electric shock.

The units must be installed at a place

where it can hold certain weight

If installed at a place without enough

strength, the unit may fall and hurt people

The attached or specified installation

accessories should be used in

installation

Improper accessory may cause fire, electric shock

or Fall unit and hurt people as well as water leakage

Don't crass to power cables in the

installation of electrical components,

don't use extension wire or octopuses

like wiring

Improper grounding or insulation may

cause fire or electric shock

After installation, make sure there is

no leakage of refrigerant

If the until is installed in a humid

environment, a switch for prevention

of electricity leakage must be installed

Without leakage prevention switch,

electric shock may happen

Drain hose and pipe must be installed

according to installation instructions

Improper installation of drain hose or pipe

may damage the unit or home furniture

18

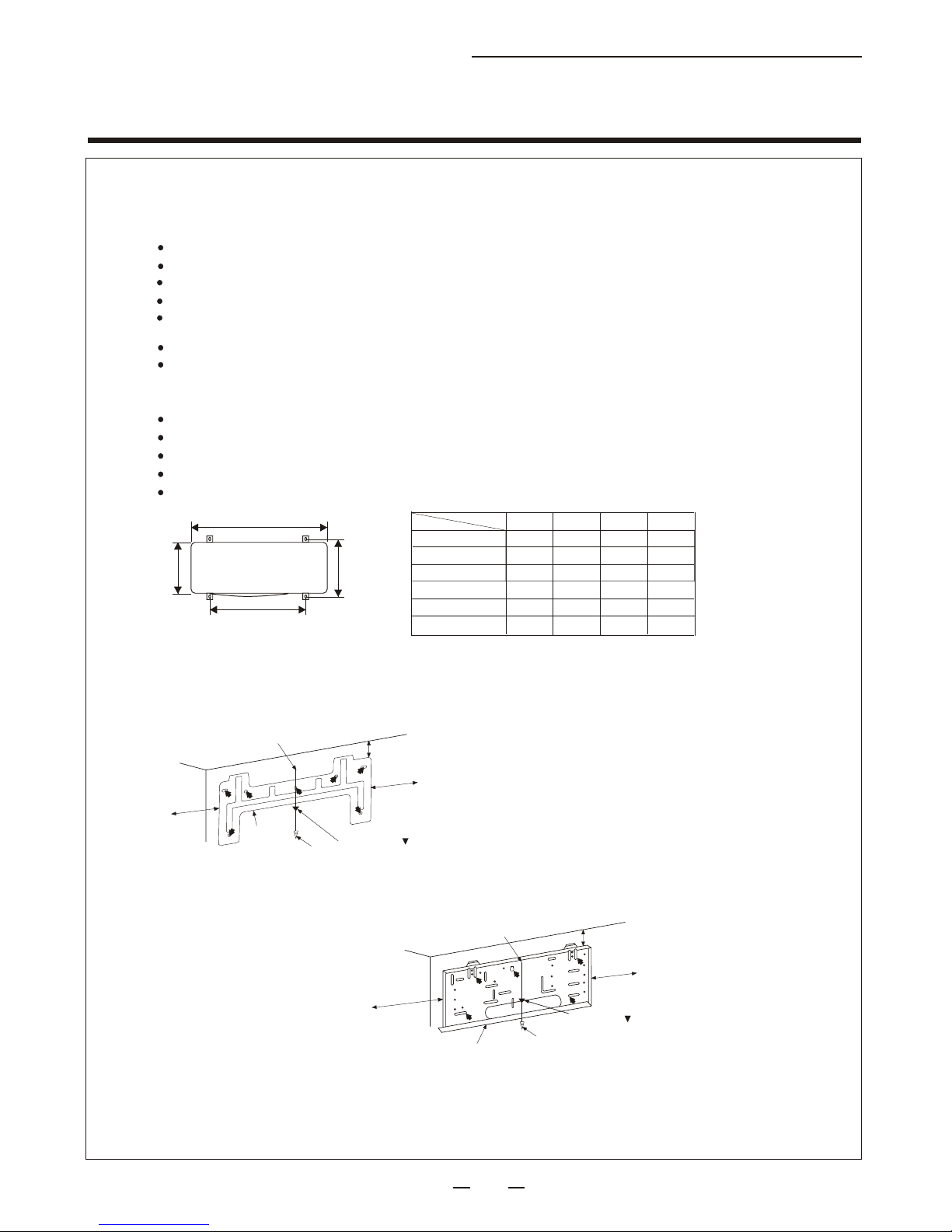

Page 21

VI. Installation instructions

3.Installation of Unit:

3-1.How to select installing location:

3-1-1. How to select installing location for indoor unit

Air inlet/ air outlet should be far away from obstacles, ensuring that air flow must not be kept back;

Do not install the unit at a spot with direct sunshine;

Select a spot convenient for removal of condensed water and easy connection to outdoor unit;

The distance between the spot and TV set or acoustic equipment should be 1m at least;

Keep away from fluorescent lamps or incandescent lamps; (otherwise, it is possible that the wireless remote

controller cannot not be normally utilized to controlled)

Select a solid wall which can bear weight of machine body, free of increase of operating noises or vibration;

Maximum height difference between indoor unit and outdoor unit should be 5m.

3-1-2. How to select installing location for outdoor unit

The installing location can bear weight of machine body, free of strong vibration.

Select a spot with good ventilation, less dust, free of rainwater and direct sunshine

Select a spot from which the operating noise and exhausted hot air can not affect the neighbors;

There should be no obstacles around the outdoor unit, which keep back inlet air/outlet air for the unit;

Select a spot free of leakage of inflammable gases or erosive gases;

L1

L4

L2

L3

Model

5K/7K

09K

12K

18K

21K

24K

Dimension

Installation & Maintenance Manual

Unit: mm

L1

L2

368

600

600 368 278 235

780 500 280 250

780 500 280 250

850 500

850 500 310 290

278

310

L4

L3

235

290

3-2.How to fix the mounting plate

Find a structural member of a wall (e.g. column etc.), and fix the mounting plate onto it horizontally.

5K/7K/9K/12K series

bove 120mm

A

(Away from

the wall)

Note:

Tie the rope at central hole

Mounting plate

Plumb bob

1. To avoid microshock of mounting plate, the hole pointed at by solid arrow must be secured.

2. If expansion bolt is adopted, it is required to adopt slotted holes 11*20or 11*26 with interval of over 450mm

to fix the mounting plate

Above 30mm

Above 195

(Away from

the wall)

Align the rope to the symbol

Tie the rope at central hole

175mm

Above

(Away from

the wall)

18K ,21K ,24K series

Mounting plate

Plumb bob

Above 60mm

242mm

Above

(Away from

the wall)

Align the rope to the symbol

19

Page 22

VI. Installation instructions

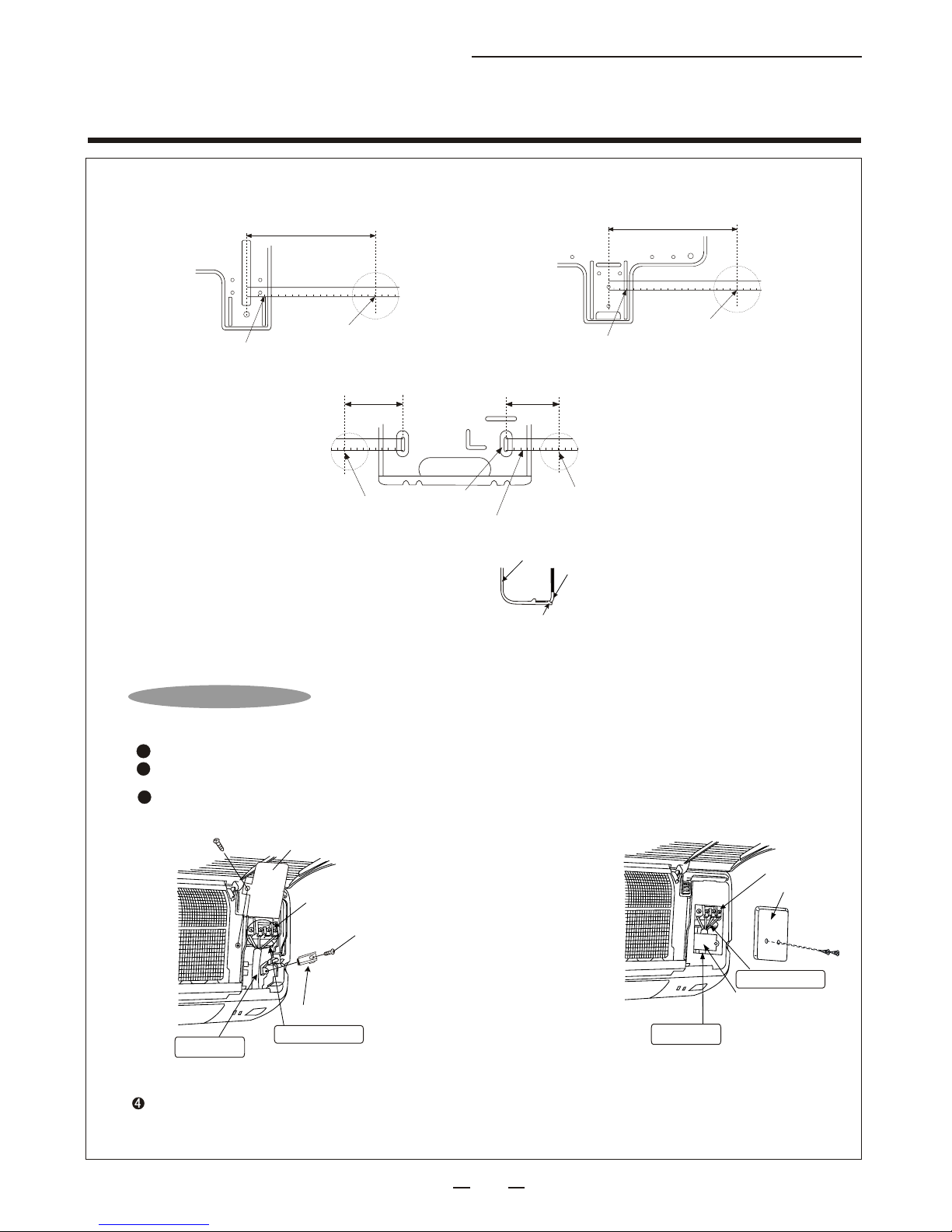

3-3.Drill holes on the wall

9K series 12K series

180mm

Installation & Maintenance Manual

180mm

Mounting plate

10

Align the measuring rule to str aight line

18

Center of a hole with

diameter of 65mm

Align the measuring rule to str aight line

18K,21K,24K series

82mm99mm

10

Center of a hole with

diameter of 65mm

Insert the measuring

Align the measuring rule to str aight line

Indoor unit

3-4.How to install indoor unit

Outlet the pipeline through the wall hole,

and hoist the unit onto the mounting plate.

Bottom surface of indoor unit

Hang the rib into the hole in mounting plate.

3-5.How to connect wires for indoor/ outdoor units

Indoor unit Section:

8

Center of a hole with

diameter of 65mm

Mounting plate

Mounting plate

10

Center of a hole with

diameter of 65mm

18

Wire connection

Open the return air grille;

1

Remove screw for fixing electrical box cover, open (or remove) the electrical box cover;

2

remove fixing screws of clamping plate, and remove the clamping plate;

3

Properly connect the connecting cables, and tightly clamp the connecting cable by the removed clamping plate.

See the Figure as below:

Fixing screw

Connecting cable

(three core)

5K/7K/9K/12K series

Reassemble the electrical box cover, and close the return air grille.

Electrical box cover

Connecting terminal board

Fixing screw

Clamping plate

Ensure to insert the core

wire completely.

Clamping plate

Connecting cable

(four core)

18K,21K,24K series

Connecting terminal board

Electrical cover

Ensure to insert the core

wire completely.

20

Page 23

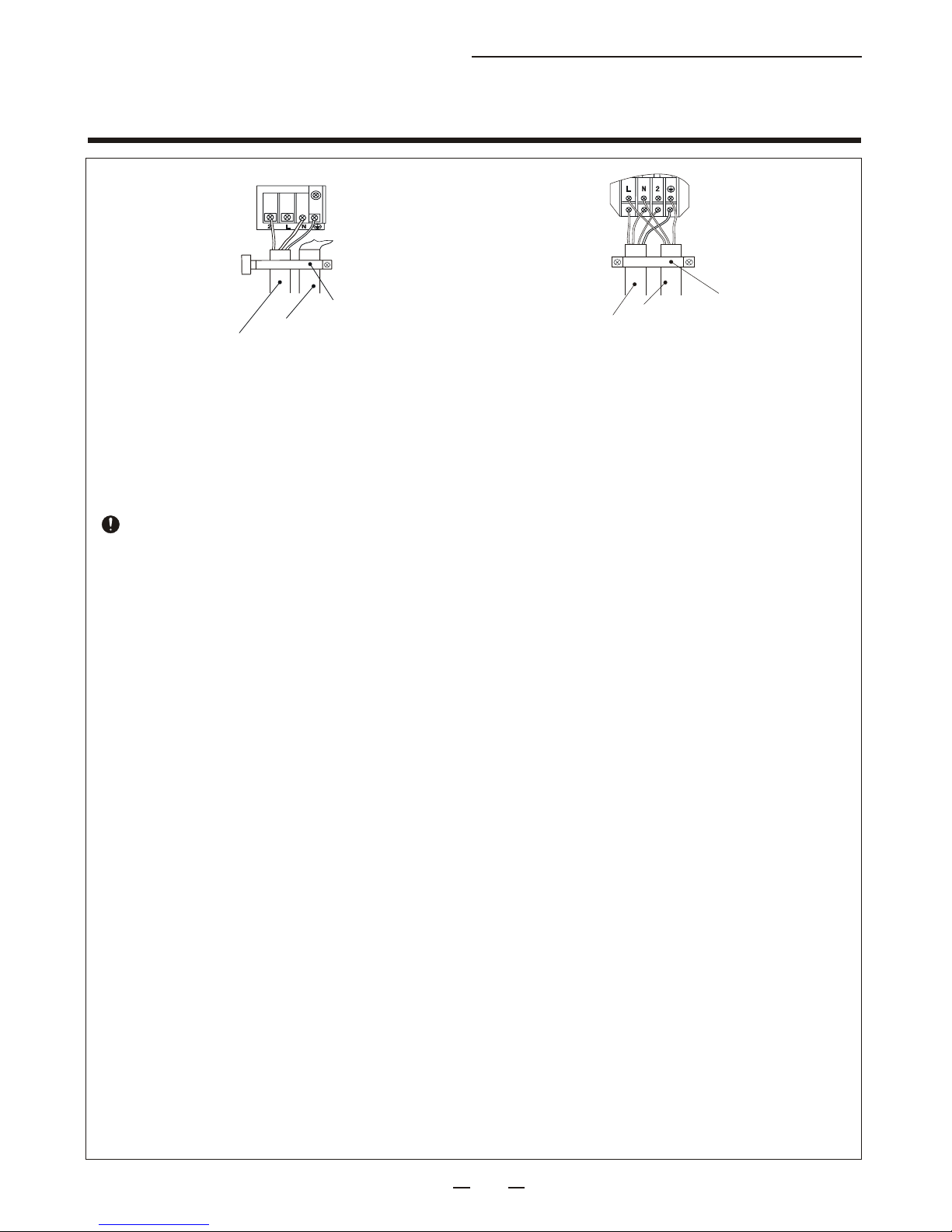

VI. Installation instructions

Installation & Maintenance Manual

Press plate

Power cord

Connecting cable

5K/7K/9K/12K BTU

Warning

1. It is required to adopt specified cable for wiring between indoor/outdoor units, ensuring that the connecting

terminals must be securely fixed, free of the direct influence of external forces. if it is improperly connected or

fixed, it is possible to cause a fire.

2. Indoor unit's cover of electrical box must be properly fixed. Otherwise, dust or water might cause a fire or

electrical shock.

3. The power cable for indoor unit of the air conditioner should be PVC-cased cord (cord 53# in IEC227) at least.

4. The power cable for outdoor unit of the air conditioner should be butadiene rubber cased cord

(cord 57# in IEC245) at least.

Power cord

Connecting cable

18K/21K/24K BTU

Press plate

21

Page 24

VI. Installation instructions

outdoor unit:

Installation & Maintenance Manual

outdoor connection

terminal board

cable connecting

indoor and outdoor units

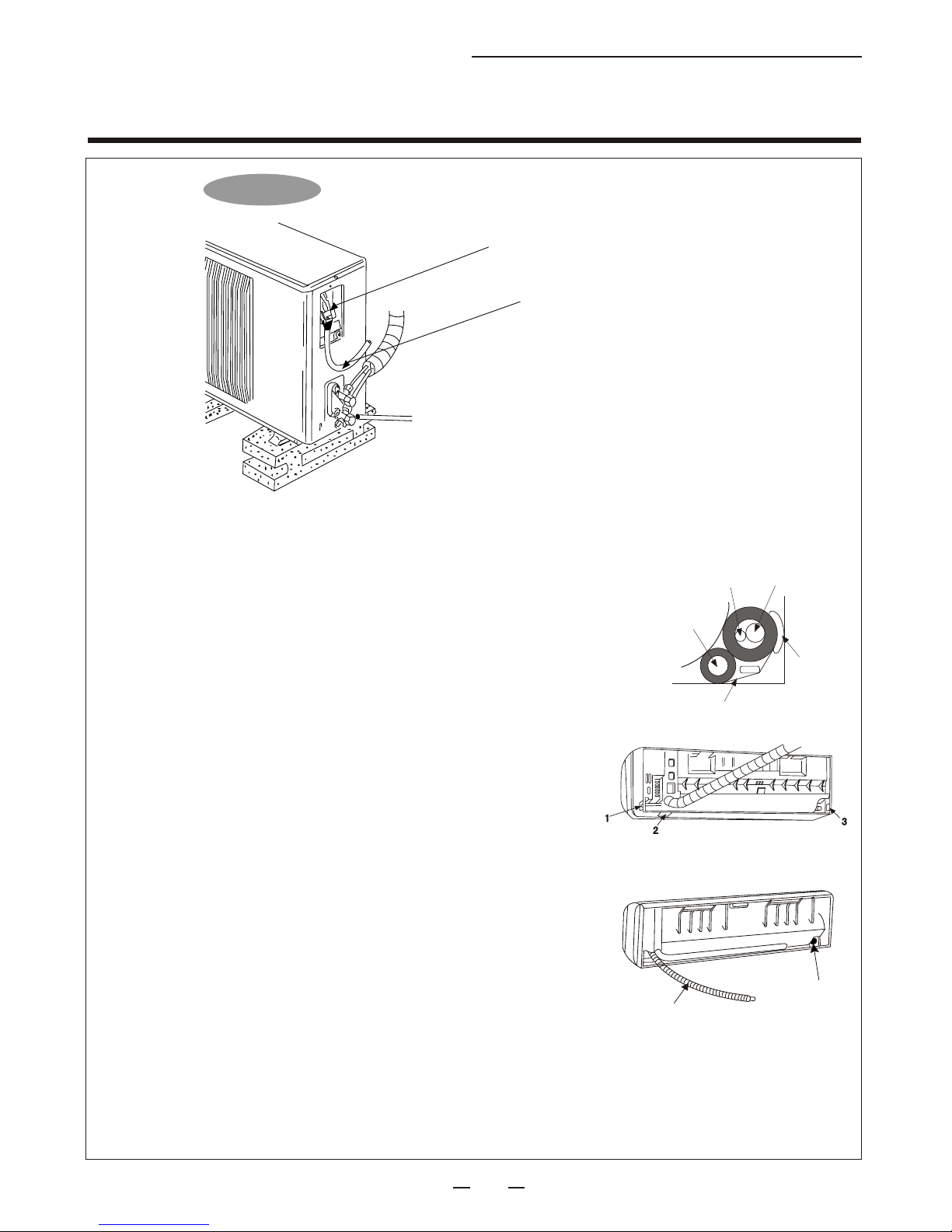

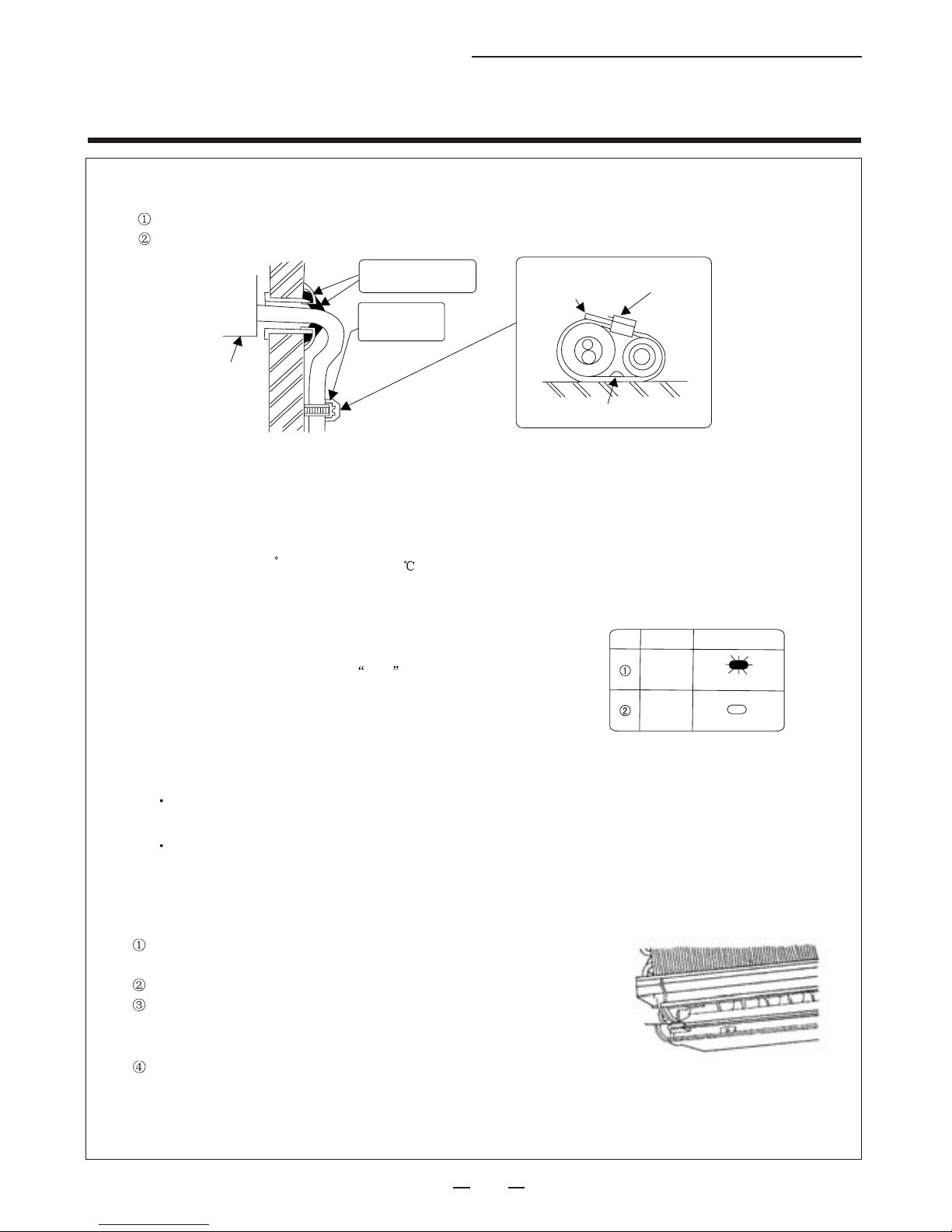

3-6. Arrangement of refrigerant pipe and drain hose of indoor unit

3-6-1. Precautions:

Drain hose must be located below the coolant pipeline;

Do not hunch up or bend the drain hoses;

Do not pull at the drain hose to carry out wrapping operation;

If drain hose must pass through indoors, it must be wrapped

with heat-insulating material available in the market;

Use felt tape to wrap up fitting pipe and drain hose, and place

heat-insulation cushion upon the wall that contacts the aforesaid

two.

3-6-2. Direction of fitting pipe :

As shown in the Figure, part 1 of the case should be cut off if

fitting pipe is led out from right side; part 2 of the case should be

cut off if fitting pipe is led out from right lower side, part 3 of the

case should be cut off if fitting pipe is led out from left side.

3-6-3. Recondition of drain hose:

Drain hose

Liquid pipe

Felt tape

Gas pipe

Heat-insulation

cushion

If fitting pipe is led out from right or right lower side, it is

required to condition the drain hose, for fear of water leakage.

Drain plug

Drain hose

22

Page 25

Installation & Maintenance Manual

VI. Installation instructions

4. Completed connection of indoor and outdoor units and test run

4-1 flared joint

The flared joint is located on the indoor and outdoor sides.

Remove the valve cap of outdoor unit, and then connect the pipelines.

As shown in Figure below, coolant pipeline is used to connect indoor unit and

outdoor unit.

Connector

Indoor unit

Refrigerant pipeline

Model

5K/7K/9k

12k

18k

21k

24k

Liquid pipe

Gas pipe

Max length

of extended

fitting pipe (m)

10

15

15

15

15

Outdoor unit

Access door

Max Height

difference (m)

5

5

5

5

5

Max number

of bent pipes

10 spots

10 spots

10 spots

10 spots

10 spots

Outer diameter of fitting pipe:(mm)

Gas pipe

9.52

12.7

12.7

15.8

15.8

Refrigerant adjustment... If pipeline length is over 7m, auxiliary refrigerant (R22) is required.

(7m pipeline for outdoor unit is filled with refrigerant)

Pipeline length

Pipeline preparation

Maximum length 7m

Longer than 7m

Requiring no refrigerant replenishment

Requiring refrigerant

replenishment

50g/m

Liquid pipe

6.35

6.35

6.35

9.52

9.52

Fitting pipes of 3m or 4m are available.

Pipeline specifications listed in table below:

Pipeline

For liquid

Outer diameter

Mm

6.35 1/4

9.52 3/8

9.52 3/8

For gas

12.7 1/2

15.88 5/8

It is required to properly insulate the 2 pcs of refrigerant pipeline so as to avoid condensation.

Bending radius of refrigerant pipeline must be greater than 100mm.

Cautiously select the specified insulation thickness. Excessive thickness may disturb the cumulation

at back side of indoor unit while insufficient thickness may lead to condensed water dripping.

Inch

Insulation thickness

6mm

6mm

6mm

6mm

6mm

Precautions:

23

Insulating material

Specific gravity of insulating

plastic foam is 0.045

Page 26

Installation & Maintenance Manual

VI. Installation instructions

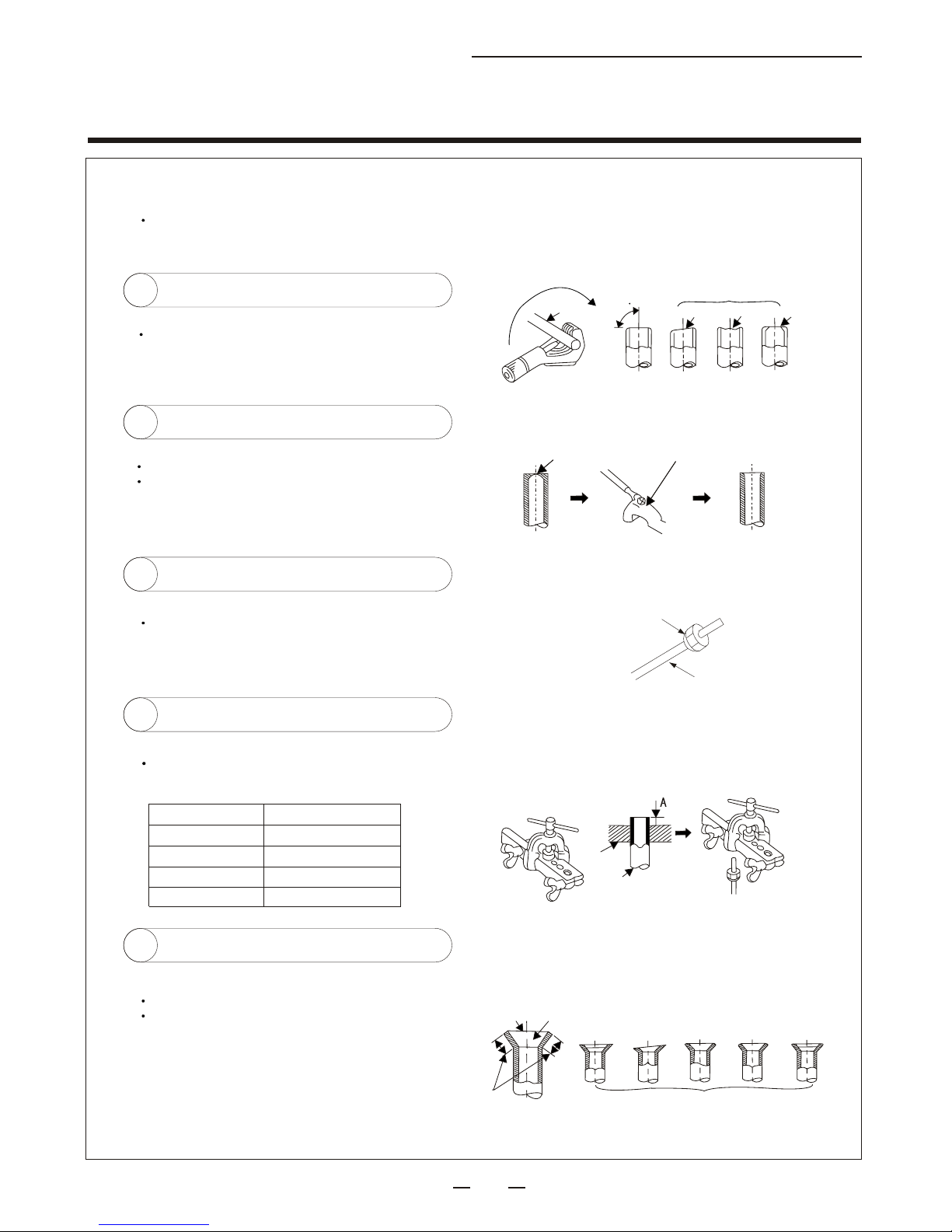

4-2 Flared pipe processing

Defect in flared pipe processing will be a major cause of gas leak. Please

carry out flared pipe processing properly according to the following method:

1

Cut off tube

Use pipe cutting machine to cut off copper tubes correctly.

2

Deburring

Completely remove the burr on cut-off section of the pipe.

To prevent burr from dropping into the pipe, the cut off

opening of pipe line should be positioned downwards

during deburring operation

3

Assemble the nut

Remove the conical nut attached to indoor and outdoor unit, and

then fix them inside the pipes free of burr.

(After flared processing of pipe, it is impossible to fix them inside it.)

4

Flared pipe processing

Copper pipe

Burr

Good

90

Declined cutoff opening

Reamer-type pipe cutter

Conical nut

Poor

Burr

Copper pipe

Carry flaring process by the tools listed below.

Outer diameter

6.35mm

9.52mm

12.7mm

15.88mm

5

Check

Compare the flared shape to the right Figure.

If visible defect exists in flaring process, just

cut off the processed section, and flare it

again.

A( )mm

2.0--2.5

3.0--3.5

3.5--4.0

4.0--4.5

Tools for flaring process

Smooth periphery

Uniform peripheral length

24

Tongs

Smooth inner side free of scratch

Too much

Inclined

Conical nut

Flared surface

with scratch

Poor sample

Copper pipe

With cracks

York tongs

Uneven

Page 27

Installation & Maintenance Manual

VI. Installation instructions

4-3 Pipeline connection

Pipeline connection for indoor unit

Connect liquid/gas fitting pipes to indoor unit.

Apply a layer of sealing oil on surface of pipe saddle (put it inside

installation attachments) .

Firstly align it to the center and connect it, and then manually screw down

the conical nut for 3-4 turns.

Refer to the following moment table; use 2 pcs of spanners to fasten the

pipe joints at side of indoor unit.

Pipeline diameter

6.35mm(1/4")

9.52mm(3/8")

12.7mm(1/2")

15.88mm(5/8")

To rq u e (N M)

13.7--17.6

34.3--41.2

49.0--56.4

73.0--78.0

Pipe connection of outdoor unit

As per the same method for indoor unit, connect the fitting pipe to pipe joint.

of shutoff valve (2-way and 3-way valves) on outdoor unit.

Use torque -adjustable spanner or wrench to fasten it at same moment as that for indoor unit.

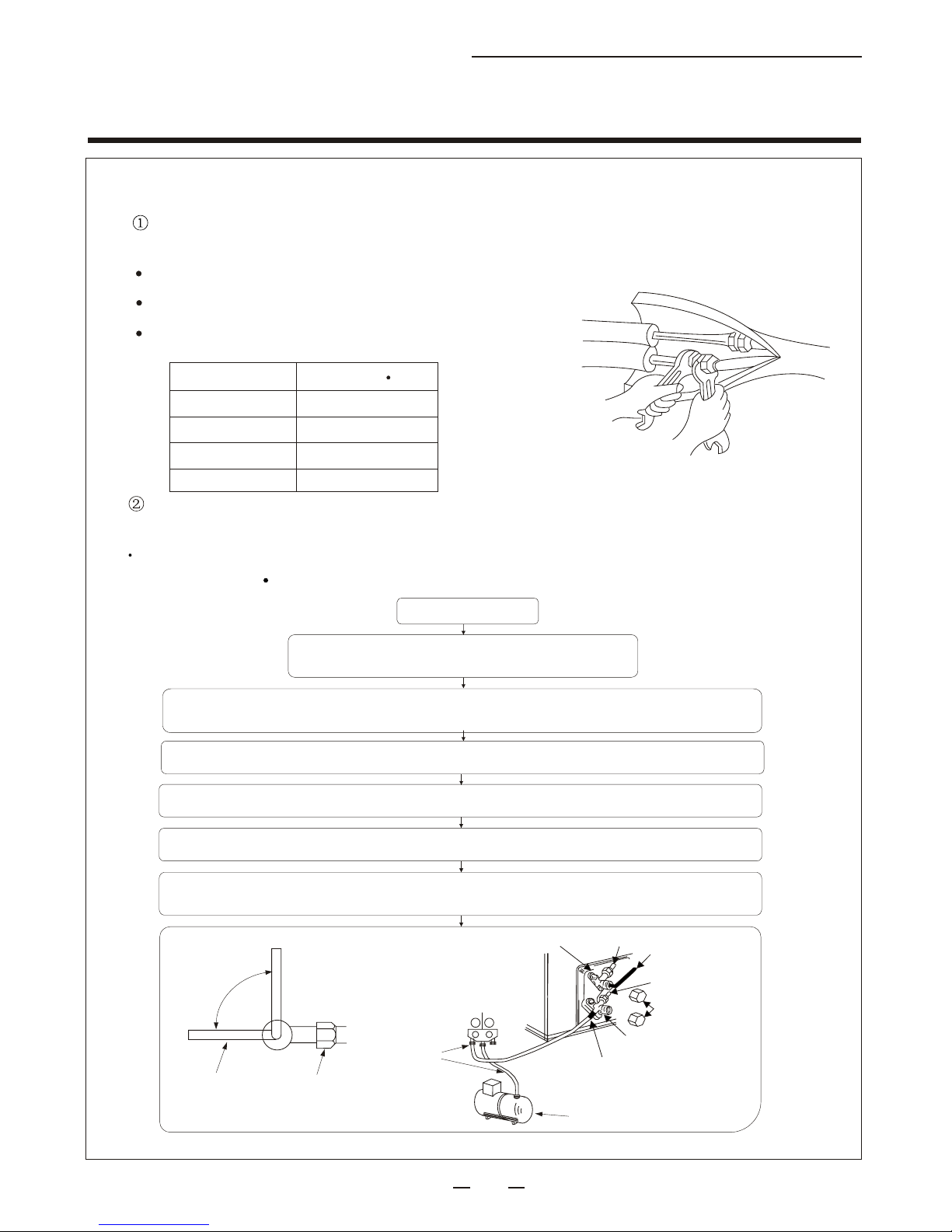

4-4 air purge Leak test

Air purge procedures

Connect the coolant pipeline (liquid and gas pipelines)

between indoor unit and outdoor unit.

Remove the access door cover of shutoff valve aside the gas pipeline of outdoor unit. (The shutoff valve

reserved in factory-leaving state cannot function, because it is still completely sealed by a cap).

Connect the gauge manifold valve and vacuum pump to the access

door of shutoff valve aside the gas pipeline of outdoor unit.

Rotate the vacuum pump (vacuumize it for 15 minutes at least).

Use gauge manifold valve to check the vacuum degree,

and close the gauge manifold valve, stop the vacuum pump.

Lay it aside for one two minutes, and then check if the pointer of gauge manifold valve still points

to the original position. Check if the pressure is -0.1mega pascal (-76cm mercury column).

Close

Open

Allen wrench Shutoff valve

Gauge manifold valve

Connecting pipeline

25

Shutoff valve

Liquid pipeline

Allen wrench

Gas pipeline

Cap

Shutoff valve

Access door

Vacuum pump

Page 28

VI. Installation instructions

Quickly remove gauge manifold valve from access door for shutoff valve.

Properly connect and evacuate the refrigerant pipeline, and fully open all shutoff

valves aside the gas and liquid pipeline. If it is not operated with fully opened shutoff

valves, performance of the unit may be degraded, resulting in troubles.

Installation & Maintenance Manual

Maximum pipeline

length of 7m,

requiring no aeration.

If pipeline length is

longer than 7m,

aerate it with amount of gas.

Screw down the access door cover to get the initial state.

And then screw down the cap.

Screwing-down torque

(N m) (Kgf cm)

Leak test

Access door cover

Valve rod cap of

shutoff valve

13.7 17.7

19.6 29.4

140 180

200 300

4-5 Insulation and bandage wrapping

Cover the fitting pipe sleeve by pipe cap;

All fitting pipes and valves of outdoor unit should be heat-insulated;

All fitting pipes from the fitting pipe entry of outdoor unit must be wrapped with pipeline bandage;

Fix the ends of pipeline bandage by tapes applied with adhesive;

if fitting pipe passes ceiling board, lavatory or other place with high temperature and humidity,

the thickness of heat-insulating material should be increased for fear of condensation.

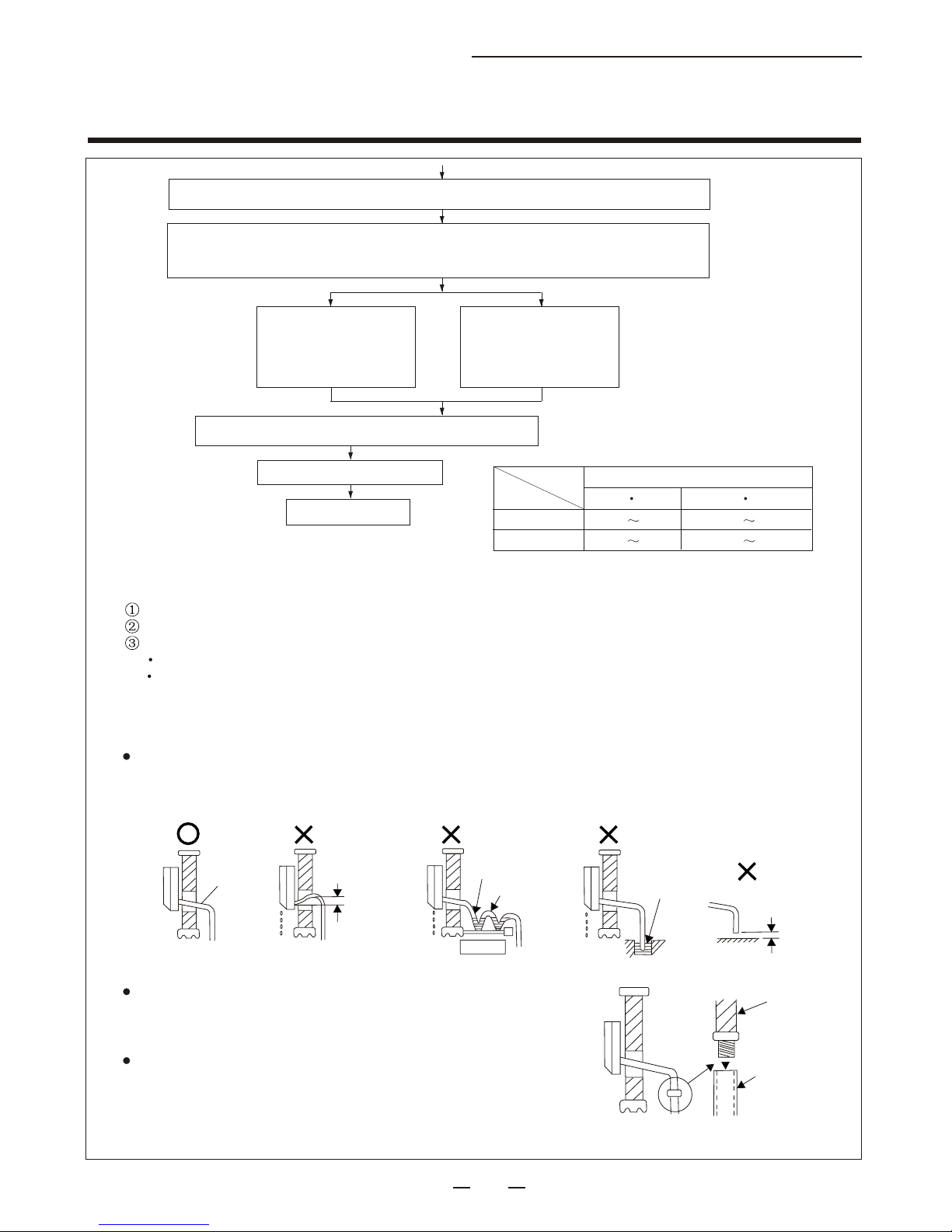

4-6 Arrangement of drain pipeline

For easier drainage through drain pipeline, ensure that the drain pipeline should be

positioned in a declined mode (as shown in Figure 1).

Do not connect the drain pipeline in the same way as shown in Figure 2 - Figure 5.

Declined

(Figure 1)

Water leak

(Figure 2)

If the length of drain hose assembled on the indoor unit is too short for

operation, just connect the drain hose in the attachment box to it for

operation.

If the drain hose has to pass the indoor spaces, it must be wrapped with

heat-insulating material available in the market.

Upwards

Water leak

Drain retention

Air retention

inside pipeline

(Figure 3)

26

(Figure 4)

End of drain hose

dipping into water

Less than 50mm

above the floor

(Figure 5)

Drain hose

Hose (inner diameter

of 15cm) or hard PVC pipe

Air

Water leak

Page 29

Seal it with putty

VI. Installation instructions

4-7 Wall hole sealing and pipeline fixing

.Seal the wall hole with putty;

.Use straining rope to fix the pipeline at appointed position.

Installation & Maintenance Manual

Cut off the surplus section

Fix it by

straining rope

Indoor unit

Masonry nail

Straining rope

4-8 Test run

Note:

1. Before test run, it is required to check once again if there is any incorrect wire connection, and check if any leak

occurs in the pipe joint (by soap water).

2. It is possible to start up the unit by pressing emergency operation switch. Once the emergency operation switch

is pressed, the unit will begin continuous test run in cooling mode for 30 minutes. Within the 30 minutes, the

preset temperature does not work; after the 30 minutes, the unit will begin emergency operation in cooling

mode at a certain preset temperature (24 ).

Test run procedures:

1. Press the emergency operation switch for the first time, the air

conditioner begins emergency cooling operation; press the switch for

the second time, the air conditioner stops all operations.

2. Press the ON/OFF button on the remote controller, and check if the

indoor unit gives out a sound toot ; if yes, it indicates that the

remote controller can function, and the emergency operation is

released. After that, press every button on the remote controller, and

check if operation modes of the unit vary respectively.

(Emergency operating mode of air conditioner can be displayed in the

operation indicator.)

Cooling

Shutdown

Mode

Power indicator

(On)

4-9 Explanations to the customers

In accordance with the operation instructions, show the customers relevant methods for temperature

adjustment, disassembling method for air filter, cleaning methods, installating and disassembling method

for remote controller, and precautions during operation.

Urge and demand the customers to read the operation instructions.

5. Displacing installation and maintenance after initial installation

5-1 How to fix the face plate

Before installation of front panel, please set vertical

vane at the position as shown on Figure 1.

Close the front panel and match the panel with the unit.

Gently press emergency switch on the front

panel and see if the emergency button is

properly matched with inside emergency switch

Fix screw and fix the front panel on the air-conditioner and

replace the screw cover.

Air guide

downward

slightly

Figure 1

27

Page 30

Installation & Maintenance Manual

VI. Installation instructions

5-2 Disassembly of indoor unit

Release the bottom edge of indoor unit from the mounting plate.

Use Allen wrench

As shown in Figure below, use Allen wrench to pull

downward the bottom edge of indoor unit, and then pull

out the unit slight so as to release the bottom buckles;.

Insert the Allen

wrench, and hook the end.

Allen wrench (4cm)

In case the method in left column cannot be taken

If the method cannot be taken, just remove the face plate.

As shown in Figure below, insert the allen wrench into

the left and right square openings; and then push the

allen wrench upward so as to descend the indoor unit,

Square opening

Push

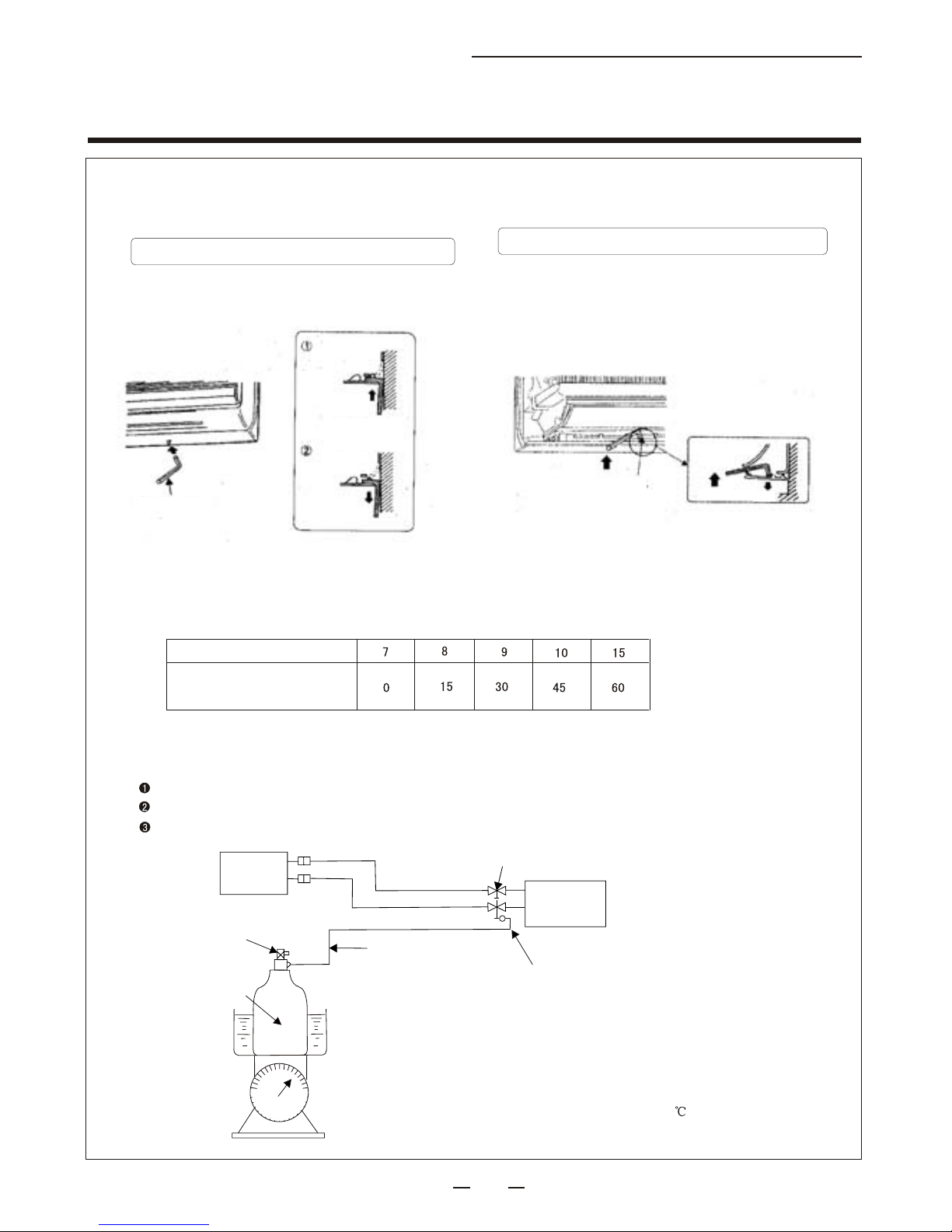

5-3 Refrigerant replenishment

If connecting pipe length is over 7m, refrigerant replenishment is required.

Refrigerant replenishing volume for cooling/heating unit are listed as follow: A = 15g/m * (L-7) .

(A in the formula indicates the refrigerant replenishing volume in g; L indicates connecting pipe length in m)

Pipe length (m)

Refrigerant replenishing

volume for unit(g)

Downward

Note: maximum length of connecting pipe for models 25 Series must not be longer than 10m, and the maximum

length of connecting pipe for models 35/50/70 Series must not be longer than 15m.

Detailed operation steps are listed as follow:

Align and connect the gas bomb onto access door of gas valve;

Carry out the air purge for pipeline (or hose) from gas bomb of refrigerant;

Replenish refrigerant of specified volume for normal operation of the air conditioner.

Indoor unit

Operation valve of

gas bomb for coolant

Charging bottle

of coolant

Connecting pipe

Liquid pipe

Gas pipe

Charging hose

Shutoff valve

Outdoor unit

Access door

Note:

1. During charing operation, do not turn over the gas

bomb for refrigerant replenishing for fear of any

Spring balance

(R-22 liquid ) charging

problem;

2. To keep the high pressure in the gas bomb, please

heat it by warm water (40 ) in cold seasons. Do not

put it on fire, or heat it by hot steam.

28

Page 31

installation & Maintenance Manual

VII. Troubleshooting

1. Precautions for malfunction repair:

(1) Before repairing, check the power supply to see if it is normal, also check the

connection of indoor and outdoor units to see if there is any error in connection.

(2) Play attention to the following items during repair:

Before disassembling the front panel, unit box, top plate and control panel,

disconnect the power supply.

When moving the control panel, please hold its edges, don't press any components.

When disassembling and installing connecting cable, please hold the plug instead

of pulling the cable.

cable

Pay attention to the following items during fault handling

Check the operation pilot lamp on the indoor unit to see if it's flashing, and

confirm the fault indication by 2 or 3 times.

If the fault is in the control panel, check its components to see if components

burnout or turned colors, and check the connection terminal to see if the

connection is correct.

When a fault occurs, make check and repair according to "Troubleshooting

Flow Chart" and "Table for Fault Handling and Repairing".

Replace batteries for remote controller

Old batteries will affect normal operation, old batteries must be replaced.

After replacing, press the "reset" button on the back of the remote controller.

cable plug

reset button

Special attention:

Indoor unit may not receive signals from remote controller in room with

florescent light because periodically-connected high-voltage manostat

or blocking oscillator (electric rectifier) are used.

29

Page 32

VII. Troubleshooting

2.Troubleshooting Flow Chart

installation & Maintenance Manual

start

indoor unit operates

but outdoor unit

doesn`t operates

outdoor unit

is in test

running mode.

check room

temperature

thermistor

Outdoor unit

is not in test

running mode

see page 34 for

"inspection on

outdoor unit"

indoor unit cannot

receive signal from

remote control

see page 33 for

" inspection on

receiver circuit board"

Reasons: indoor unit

flash twice- faults of room temperature

thermistor and pipe temperature

thermistor Flash thrice- faults of

indoor fan motor

check room temperature

thermistor, see page

32 for "check point

and its voltage"

indoor unit operation

pilot lamp flashes

(see the fault problem

self-check table)

see page 32 for

"inspection of

indoor fan motor"

indoor unit cannot receive

signal from remote controller,

operation pilot lamp doesn`t

flash when pressing

emergency switch

See page 34 for "inspection

on electric control board

check pipe temperature

thermistor, see page 32

for "check point and its voltage"

30

Page 33

Installation & Maintenacne Manual

Maintenance

Check if thermistor is

out of work

--

the plug

Reconnect the plug

Check the indoor

circuit board

unplug the plug CN211,

verify if signal is over 1.5V

measure the section

between Cn121 , and

Check the indoor fan mot or

Check the indoor electrical

control board

Replug

ork

Check if the thermistor is

out of w

Reconnect the plug

Check the indoor circuit

board

Check to see whether

thermistor is ineffective.

Reconnect socket.

Check indoor circuit

board.

Verifying method

Symptom

Double 8 of LED display

Trouble display

During operation,

shortcircuit and open

circuit the indoor room

temperature thermistor

Outdoor unit

fails to run

E2

or 5

During operation,

for 2 seconds respectively.

When the indoor fan motor

runs for the 12 seconds, it is

impossible to emit feedback

signal of rotation speed.

Indoor fan motor

runs for 12

seconds and

stops for 3

minutes. Motor

is damaged,and

fan fails to run.

E6

thermistor for 2 seconds

the indoor pipe-temperature

shortcircuit and open circuit

Outdoor unitfails

to run

E1

After compressor is

started, defrost

Outdoor unit

doesn't

thermistor is connected

E5

or disconnected.

operate

Trouble source

9K/12K/18K

Before troubleshooting, ensure that the symptom reoccurs for precise judgement.

VII.Troubleshooting

3. Trouble selfchecking table

NO,

Flickers twice and ON f

seconds repeatedly

Room

temperature

thermistor

1

Flickers thrice and ON for

5 seconds repeatedly.

Indoor fan

motor

2

Flickers for four times and ON

for 5 seconds repeatedly.

Pipe-

temperature

thermistor

3

sting

Outdoor

defro

thermistor

4

Page 34

installation & Maintenance Manual

VII.Troubleshooting

4. Fault standards of main components

Name of

component

Room

temperature

thermistor

and pipe

temperature

thermistor

commpressor

indoor fan

motor

Test methods and standards

use instruments to measure the resistor (at 10-30 )

Normal

8K ~20K

short circuit or open circuit

Abnormal

use instruments to measure the resistor (winding temperature at 20

Normal

CSU-09HHAA CSU-12HHAA CSU-21HHAA CSU-24HHAB

3.528

2.510

use instruments to measure the resistor between connecting terminals (winding

temperature at 10-30 )

2.0

4.61

1.04

2.860

0.885

1.773

Normal

12K 18K-21K

267 ~

295 ~

218 ~

~

24K

~138

87 ~107

whiteblack

black-

Power cable

red

5K-9K

267 ~

295 ~

Connect power, test voltage of cable

brown-yellow

yellow-gray

signal cable

Normal

~

fan turns once 0V 5V 0V

Abnormal

keep 0V

or 5V

Abnormal

short

circuit

or open

circuit

Abnormal

short

circuit

or open

circuit

Schematic

diagram

WHI

compressor

5K-21K:

WHI

RED

BLU

fan

motor

YLW

GRAY

BRN

24K:

WHT

BLK

BLU

F

a

n

m

o

YLW

t

r

o

RED

ORG

BLURED

Use instruments to measure the resistor between connecting terminals

(winding resistance at 10-40 )

outdoor

fan motor

5K-9K

315 ~385

(red-blue)

~308

(yellow- )blue

use instruments to measure the resistor (when at 10-30

stepper

motor

Normal

~

short circuit or open circuit

Normal

12K

~

18K-21K

76 ~93

24K

33 ~40

(red-blue) (red-blue) (red-blue)

~

81 ~

58 ~70

(yellow- )blue (yellow- )blue (yellow- )blue

Abnormal

Normal

350 ~400

Abnormal

short circuit or open circuit

32

Abnormal

short

circuit

or open

circuit

red

yellow

fan

motor

blue

Page 35

installation & Maintenance Manual

VII.Troubleshooting

A.Inspection of indoor fan motor (apply only to 9K/12K)

Trun off power, check socket CN211

no

connect wire

is the wire connected well

yes

Are the weld point all reght

yes

Re-weld

Pull out the wire from socket CN211 of indoor

circuit board, measure DCresistor value

between wire - and -

Resistance is 0V (short circuit)

or (open circuit)

yes 0 or

no

Replace indoor

electric board

Replace indoor fan motor

B. Inspection on the receiver circuit board

Indoor unit is able to operate when the emergency switch is pressed, but unable

to operate with remote controller.

check the model of

remote controller

is the LCD clear

yes

Take batteries out

and re-insert,

does the remote

controller work?

yes

no

no

Is there any counter-phase fast

-start fluorescent lamp within 1 meter ?

Replace batteries

Turn on a radio and switch to AM,

press remote controller button

Is there any noise in the radio

yes

no

no

Replace remote controller

yes

Keep indoor unit far away from

fluorescent lamp

Apply a filter on its receiving section

switch on the power, press on/off button on remote controller,

measure the voltage between NO.1 and NO.2 of the connector CN100(9K/12K) : on the control board;

(18K) : measure the voltage between NO.1 and NO.2 of the connector LD101T on the control board;

(24K): measure the voltage between NO.3 and NO.5 of the connector CN70 on the control board;

is the voltage close to 4V DC

no 5V or 0V

Replace receiver

33

yes

Replace indoor electric control board

Page 36

installation & Maintenance Manual

VII.Troubleshooting

C.inspection on indoor electric control board

indoor remoter controller doesn`t work, at the same time, the operation pilot lamp

is not lit when the emergency switch is pressed button

Replace fuse

Fault of electric

control board

Is the voltage

close to 220V

Carefully check the

components side

and the circuit of

electric control board

on indoor unit

YES

Is fuse F11 Fuse melt down

Is varistor NR11 burn out

NO

NO

1.switch on the power

2.measure voltage between

TAB2 and optional pole of

protector tube for 9K/12K

/ LN of the terminal board

for 18K/24K)

YES

NO

YES

Replace varistor

D. Inspection of outdoor unit

Compressor and outdoor fan don't operate (only indoor fan operates)

start

press emergency switch: (at

this moment,3 minute delay

mode starts, test running

time is 30 minutes)

measure voltage between 2

and N of outdoor unit

terminals bed to see if it is

220V

NO

measure voltage between 2

and N of indoor terminals to

see if it is 220V

YES

YES

check outdoor fan motor and compressor

check indoor and outdoor connection

wires to see if they are normal

Power fault

NO

replace indoor electric

control board

34

Page 37

installation & Maintenance Manual

HL25GVX002A

BUZ

R21

RT1

RT2

R20

CN112(PT)

R47

SW1

C33

C26

C27

J18

CN111(RT)

R31

R48

CN121

1

3

R23

IEC127fuseT5AL250V

UL-fuse 5A 250V

CN151

5 1

D6

C32A

J1

D7

D8

RB3

RA3

TR16

JPH

J17

RU3

RU4

JPM

1

R32

7

CN100

R14

R12

R44

R11

IC6

J16

R53

TR13

RU2

R54

R55

RU1

R52

JF1

JF2

C25

C24

J2

CST

IC2

C14

R49

D9

RB1

CLK

C31

J14

J15

A/B

J13

R13

RB2

RB4

R22

IC1

24

IC1

R51

R50

J10

8

TR10

DATE:2003-10-16

9012

TR15

TR14

+5V

J12

TR17

RA2

RA4

RA1

IC3

IEC127fuseT5AL250V

CAUTION: HIGH VOLTAGE !

X64

LD62(YLW)

X63

LD63(RED)

X62

UL-fuse 5A 250V

R62

C5

R63

C6

TAB2(BLU)

FUSE

NR11

CN211

LD65(BLU)

C7

R61

+

R40

52C/X10

TR11

J4

J3

R25

J6

J5

LD64(BRN)

TR12

R46

C32

R24

J8

C13

C28

D1

C30

R43

D4

D3

D2

R30

J7

R45

J9

C1

L102

C4

J19

IC8

TRAN

D10

C22

J11

R42

C23

R41

GND

D5

C12

+

C21

IC5

C11

+

C10

C20

IC4

R60

IC7

C3

R145

VII.Troubleshooting

E. Location of detecting points and their voltage

1.5K/7K/9K/12K series

DATE:2003-10-16

CN100

C27

C26

Pipe-temperature

thermistor

TR17

RA3

JPM

JPH

RU4

JF2

RU2

BUZ

RT2

RT1

J17

Emergency switch

HL25GVX002A

TR14

RU1

RB2

CST

IEC127fuseT5AL250V

C32A

Room temperature

thermistor

Indoor electrical control board

J7

LD64(BRN)

LD62(YLW)

LD63(RED)

52C/X10

CAUTION: HIGH VOLTAGE !

NR11

LD65(BLU)

FUSE

IEC127fuseT5AL250V

UL-fuse 5A 250V

C1

TAB2(BLU)

Characteristics of resistors RT11 and RT12

CN211

R60

Resistance value

K

Temperature

35

Page 38

installation & Maintenance Manual

-

+

DC12V

DC5V

+

-

VII.Troubleshooting

E. Location of detecting points and their voltage

3.18K/21K/24K series

DC12V

Stepping motor

Emergency switch

Indoor electrical control board

Room temperature thermistor

Pipe-temperature

thermistor

Remove frost

thermistor

36

Fuse AC250V/5A

Resistance value

Input power supply

AC220V/240V

Characteristics of resistors RT11 and RT12

Temperature

Page 39

VIII.Parts list

indoor unit

Installation & Maintenance Manual

13

12

11

10

9

8

3

No.

7

14

6

15

5

4

19

20

17

18

16

22

21

24

23

25

27

28

2

indoor unit

Name Quantity Code Remark

Display board

Box for display board

Front panel

Air filter

Air filtert

Panel frame

Optional

1

37

Page 40

VIII.Parts list

Installation & Maintenance Manual

Number

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Designation

Evaporator

Bearing holderl

Cross flow fan ,assy

Air out frame

Drain hose

Chassis

Installation plate

Louver motor

Horizontal louverr

Fan motor

Fixing part for motor

Indoor temp. Sensor

Evaporator temp. Sensor

Wired controller

E- part box cover

Main control board

Tranformer

E-parts box

Qty Code

1

Remark

26

27

Wire clamp for power cord

Wire joint

38

Page 41

VIII.Parts list

18K/21K/24K indoor unit

Installation & Maintenance Manual

No.

7

8

9

10

11

12

13

14

15

Name Quantity Code Remark

Display board

Box for display board

Front panel

Air filter

Air filtert

Panel frame

Evaporator

Bearing holderl

Cross flow fan ,assy

Air out frame

Drain hose

Chassis

Installation plate

Louver motor

Horizontal louverr

Optional

1

1

16

17

18

19

20

21

22

23

24

25

26

27

Fan motor

Fixing part for motor

Indoor temp. Sensor

Evaporator temp. Sensor

Wired controller

E- part box cover

Main control board

Tranformer

E-parts box

Wire clamp for power cord

Wire joint

39

Page 42

VIII.Parts list

5K,7K,9K, series outdoor unit

19

Installation & Maintenance Manual

3

4

5

6

7

8

9

2

40

Page 43

VIII.Parts list

5K/7K/9K series outdoor unit

Installation & Maintenance Manual

Number

1

2

3

4

5

6

7

8

9

10

11

12

Designation

Top plate

Right side plate

Heat exchanger

Motor mounting

Fan motor

Capacity of fan

Capacity of compressor

Terminal block

Return air pipe

Shutoff valve (liquid)

Shutoff valve (gas)

Rubber shock absorber

of compressor

Qty

Code Note

MF

C1

TB

YDK-20AF-6

1.5 F/450V

30 F/450V

3

1/4F

3/8F

13

14

15

16

17

18

19

Compressor

Base

Maintenance panel

Foreplate

Outdoor grille

Axial flow fan

Capillary

MC

1

44R212AE-FJS

41

Page 44

VIII.Parts list

12K,18K series outdoor unit

20

Installation & Maintenance Manual

15

16

14

13

11

3

4

5

6

7

8

9

10

19

17

18

42

Page 45

VIII.Parts list

12K;18K series outdoor unit

Installation & Maintenance Manual

No.

Name Quantity Code Remark

Toppanel

Roar plate

Fan capacitor

Compressor capacitor

Terminal board

Process pipe

Stop valve (liquid)

Stop valve (gas)

Upper cover of sound-proof pad

Compressor anti-vibration pad

Compressor

Base support

TB

1/2F

44R332AK-5ES

Heat exchanger

Motor support

Fan motor

Axial flow fan

Front panel

Outdoor grid

Handle

Capillary

YDK-45M-6

See (page 9) cooling loop

for detailed specification

43

Page 46

VIII.Parts list

21K,24K series outdoor unit

Installation & Maintenance Manual

No.

Name Quantity Code Remark

Front panel

Outdoor grid

Maintenance board

Outdoor heat exchanger

Motor support

Compressor

Base support

Outdoor fan motor

Axial flow fan

Compressor capacitor

Outdoor fan capacitor

Terminal board

Capillary

Compressor rubber pad

Stop valve (liquid)

Stop valve (gas)

Rear plate

MC

MF

C1

TB

48R502AQ+51S

YDK-50AB-6

40 F

4.0 F

4

1/4F

1/2F

44

Page 47

VIII.Parts list

Remote control and others

Installation & Maintenance Manual

No.

5K/7K/9K/12K/18K/21K/24K Series

Name Quantity Code Remark

Remote controller

Battery cover

Wrapping tape

Screws

45

Page 48

2005.12.20

Page 49

Page 50

第 2 页 共 59 页

Contents

1、Summary…………………………………………………………………………………………………………3

2、Model explaining…………………………………………………………………………………………….4

3、Installation…………………………………………………………………………………………………………5

4、Exploded view and part list……………………………………………………………………… 20

5、Operation principle……………………………………………………………………………………… 22

6、Parameter…………………………………………………………………………………………………………42

7、PCB function…………………………………………………………………………......47

8、Troubleshooting……………………………………………………………………………58

Page 51

第 3 页 共 59 页

1. Summary

1.1 indoor unit

Model 77

1.2 outdoor unit

CS-23H3-V77AY1A CS-25H3-V**AY1A CS-32H3-V**AH4

KFR-51GW/Bc

CS-66H3-N**AS

CS-88H3-Q**AT

Page 52

第 4 页 共 59 页

model

CS-23H3-V77AY1A CS-25H3-V**AY1A CS-32H3-V**AH4 KFR-51GW/Bc

indoor unit 746*245*196 746*245*196 746*245*196 940*270*180

Net

Dimension

outdoor

unit

700*225*500 700*225*500 795*255*540 795*255*540

model

CS-66H3-N**AS CS-88H3-Q**AT

indoor unit 1000*320*200 1225*330*245

Net

Dimension

outdoor

unit

870*310*700 900*330*835

2、Model explaining

c

Improve an ordinal number

Divide the body outdoors box a body code

External appearance characteristic code

Separately the body indoor machine(or whole type) style code

Code of refrigerant type:no code - R22;C-R407c、A-R410a

Power type:1:115v/60Hz 2:220V/60Hz;3:220-240V/

50Hz;4:240V/50Hz;

Main function code: c-Cold breeze type;H-Hot pump type;A-Hot

pump the type take assistance electricity to heat;E-The electricity

heat

Capacity code: x1000W

Separately the body pit code inside the indoor machine(or whole

type)

Structure form code

Special craft code:Q-Deal with contact quickly;S-Soft start;dOutside tube in addition to frost

The weather type code(T1 type code abridge)

"C" CHIGO brand

Model :CS-25C3A-V85AY1

T1 climate type,wall split type air conditioner, cooling capacity is 2500W,power is 220V~

/50Hz/1PH,refrigeration is R410A,the kernel of indoor unit is fresh 98,the pattern no . is 85,first

time design, outdoor unit is 1HP of 2003 year。

Indoor unit modle is:

CS-25C3A-V85A,outdoor unit model is:CS-25C3A-Y1。

Page 53

第 5 页 共 59 页

3. Attention of installation

3.1 Safety Precaution

■To prevent injury to the user or other people and property damage, the following instructions must be followed.

■

Incorrect operation due to ignoring instruction will cause harm or damage.

■Before service unit, be sure to read this service manual at first.

3.2 Warning

﹥Installation<

■Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

There is risk of fire or electric shock.

■For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized service center.

Do not disassemble or repair the product, there is risk of fire or electric shock.

■Always ground the product.

There is risk of fire or electric shock.

■Install the panel and the cover of control box securely.

There is risk of fire of electric shock.

■Always install a dedicated circuit and breaker.

Improper wiring or installation may cause fore or electric shock.

■ Use the correctly rated breaker of fuse.

There is risk of fire or electric shock.

■Do not modify or extend the power cable.

There is risk of fire or electric shock.

■Do not install, remove, or reinstall the unit by yourself (customer).

There is risk of fire, electric shock, explosion, or injury.

■ Be caution when unpacking and installing the product.

Sharp edges could cause injury, be especially careful of the case edges and the fins on the condenser and

evaporator.

■ For installation, always contact the dealer or an Authorized service center.

There is risk of fire, electric shock, explosion, or injury.

■Do not install the product on a defective installation stand.

It may cause injury, accident, or damage to the product.

■Be sure the installation area does not deteriorate with age.

If the base collapses, the air conditioner could fall with it, causing property damage, product failure, and personal

injury.

■Do not let the air cond itioner run for a long time when th e humidit y is very h igh and a door or a windows is

left open.

Moisture may condense and wet or damage furniture.

■Take care to ensure that power cable could not be pulled out or damaged during operation.

There is risk of fire or electric shock.

■ Do not place anything on the power cable.

There is risk of fire or electric shock.

■Do not plug or unplug the power supply plug during operation.

There is risk of fire or electric shock.

■Do not touch (operation) the product with wet hands.

There is risk of fire or electric shock.

■Do not place a heater or other appliance near the power cable.

Page 54

第 6 页 共 59 页

There is risk of fire and electric shock.

■Do not allow water to run into electric parts.

It may cause fire, failure of the product, or electric shock.

■Do not store or use flammable gas or combustible near the product.

There is risk of fire or failure of product.

■ Do not use the product in a tightly closed space for a long time.

Oxygen deficiency could occur.

■When flammable gas leaks, turn off the gas and open a window for ventilation before turn the product on.

Do not use the telephone or turn switches on or off. There is risk of explosion or fire.

■If strange sounds, or small or smoke comes from product. Turn the breaker off or disconnect the power

supply cable.

There is risk of electric shock or fire.

■Stop operation and close the window in storm or hurricane. If possible, remove the product from the window

before the hurricane arrives.

There is risk of property damage, failure of product, or electric shock.

■Do not open the inlet grill of the product during operation. (Do not touch the electrostatic filter, if the unit is so

equipped.)

There is risk of physical injury, electric shock, or product failure.

■When the product is soaked (flooded or submerged), contact an Authorized service center.

There is risk of fire or electric shock.

■Be caution that water could not enter the product.

There is risk of fire, electric shock, or product damage.

■ Ventilate the product from time to time when operating it together with a stove, etc.

There is risk of fire or electric shock.

■Turn the main power off when cleaning or maintaining the product.

There is risk of electric shock.

■When the product is not be used for a long time, disconnect the power supply plug or turn off the breaker.

There is risk of product damage or failure, or unintended operation.

■Take care to ensure that nobody could step on or fall onto the outdoor unit.

This could result in personal injury and product damage.

﹥CAUTION<

■Always check for gas (refrigerant) leakage after installation or repair of

product.

Low refrigerant levels may cause failure of product.

■Install the drain hose to ensure that water is drained away properly.

A bad connection may cause water leakage.

■ Keep level even when installing the product.

To avoid water leakage from vibration。

■Do not install the product where the noise or hot air from the outdoor unit could damage the neighborhoods.

It may cause a problem for your neighbors.

■ Use two or more people to lift and transport the product.

Avoid personal injury.

■Do not install the product where it will be exposed to sea wind (salt spray) directly.

It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator fins, could cause

product malfunction or inefficient operation.

Page 55

第 7 页 共 59 页

>

Operation <

■Do not expose the skin directly to cool air for long periods of time. (Do not sit in

the draft).

This could harm to your health.

■ Do not use the product for special purposes, such as preserving foods, works of art, etc. It is a consumer air

conditioner, not a precision refrigerant system.

There is risk of damage or loss of property.

■ Do not block the inlet or outlet of air flow.

It may cause product failure.

■ Use a soft cloth to clean. Do not use harsh detergents, solvents, etc.

There is risk of fire, electric shock, or damage to the plastic parts of the product.

■ Do not touch the metal parts of the product when removing the air filter. They are very sharp.

There is risk of personal injury.

■ Do not step on pr put anything on the product. (outdoor units)

There is risk of personal injury and failure of product.

■Always insert the filter securely. Clean the filter every two weeks or more often if necessary.

A dirty filter reduces the efficiency of the air conditioner and could cause product malfunction or damage.