Midea CE-SMK-80/CD30GN1, CE-LRSJF-V100/N1-610, CE-SMK-100/CD30GN1, CE-LRSJF-V60/N1-310, CE-SMK-60/CD30GN1 Technical Manual

...Page 1

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

1

Midea M-thermal

Heat Pump Water Heater

Technical Manual

Midea reserves the right to discontinue, or change at any time, specifications or designs without notices and

without incurring obligations.

CE-LRSJF-V120/N1-610

CE-LRSJF-V100/N1-610

CE-LRSJF-V80/N1-310

CE-LRSJF-V60/N1-310

CE-LRSJF-V80/N1-310-B

Outdoor unit

CE-LSX-300XP/D30B11

CE-LSX-200XP/D30B11

CE-LSX-150XP/D30B7

CE-LSX-300XP/SD15B11

Water tank

CE-SMK-120/CD30GN1

CE-SMK-100/CD30GN1

CE-SMK-80/CD30GN1

CE-SMK-60/CD30GN1

CE-SMK-80/CSD80GN1

Indoor unit

CE-TMK-01

Solar kit

Page 2

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

2

Part 1

System Outline

1. Measurements ................................................................................... 3

2. External Appearance ......................................................................... 4

3. Nomenclature .................................................................................... 5

4. Features ............................................................................................. 7

5. Specifications .................................................................................... 8

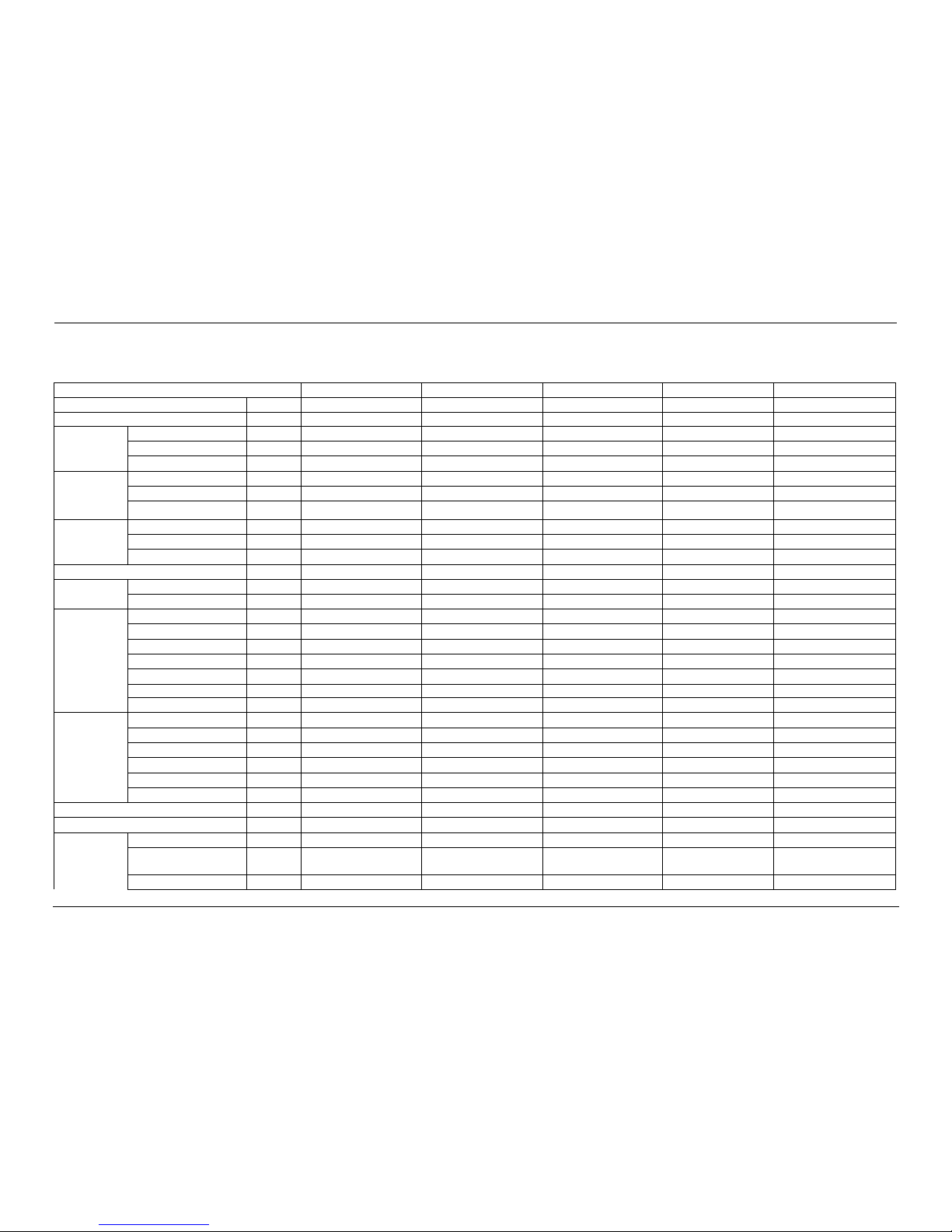

5.1 Specifications of outdoor units ............................................................................... 8

5.2 Specifications of Hydraulic indoor unit .................................................................. 9

5.3 Specifications of water tank and solar kit ............................................................ 10

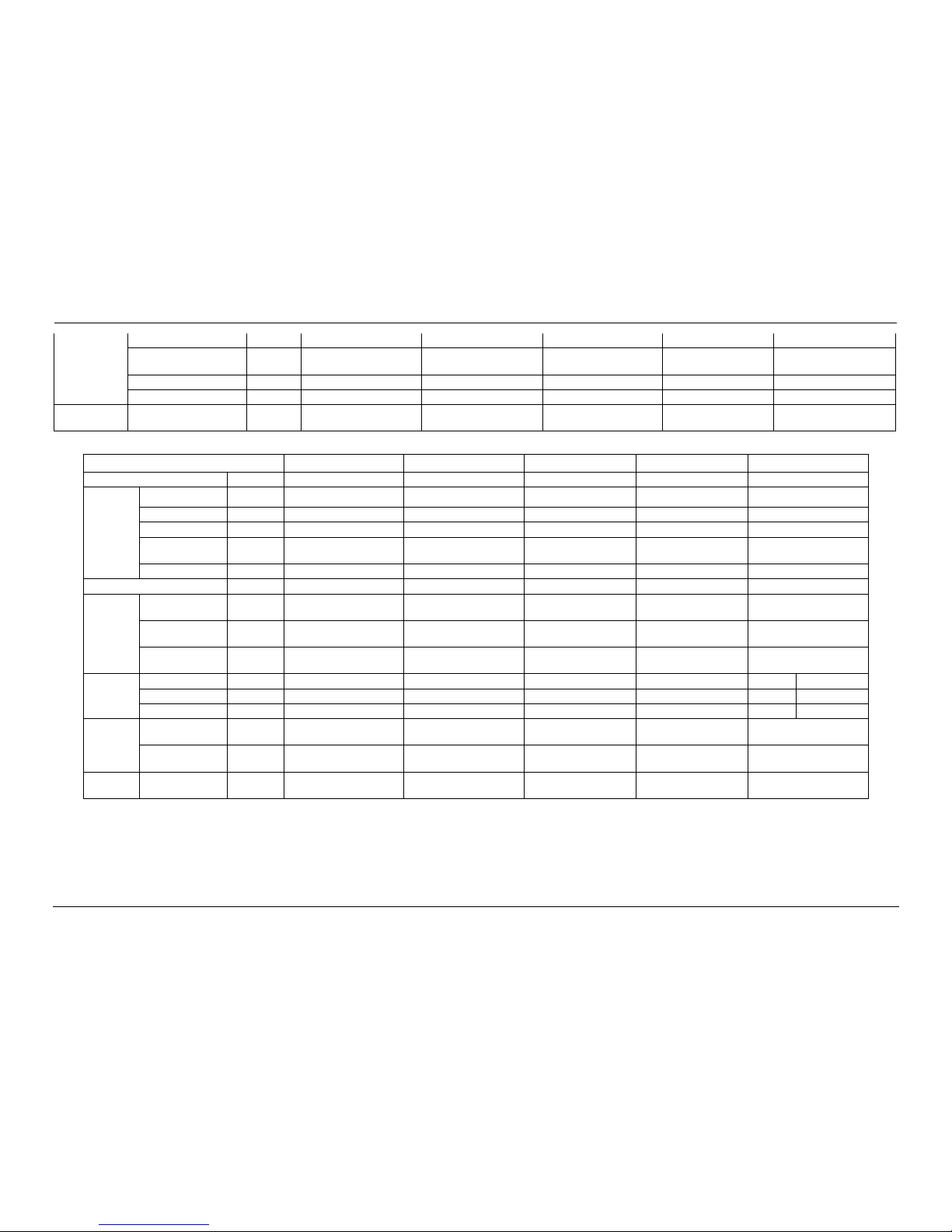

6. Performance data ............................................................................ 11

6.1 Heating performance data of 6/8kw model ........................................................... 11

6.2 Cooling performance data of 6/8kw model .......................................................... 13

6.3 Heating performance data of 10/12kw model ....................................................... 14

6.4 Cooling performance data of 10/12kw model ...................................................... 15

7. Wiring Diagrams .............................................................................. 16

7.1 Outdoor units wiring diagram ............................................................................... 16

7.2 Hydraulic indoor units wiring diagram ................................................................. 18

8. Dimensions ...................................................................................... 20

8.1 Dimensions of outdoor units ................................................................................ 20

8.2 Dimensions of Hydraulic indoor units .................................................................. 21

9. Installation place and service space .............................................. 22

9.1 Outdoor unit service space ................................................................................... 22

9.2 Hydraulic indoor unit installation location and service space ............................ 23

10. Exploded View ........................................................................... 24

10.1 Exploded view of outdoor units ............................................................................ 24

10.2 Exploded view of hydraulic indoor units .............................................................. 28

11. Accessories ............................................................................... 32

12. Functional diagram .................................................................... 33

12.1 Complete system diagram .................................................................................... 33

12.2 Electrical connection diagram and cable specification ...................................... 34

Page 3

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

3

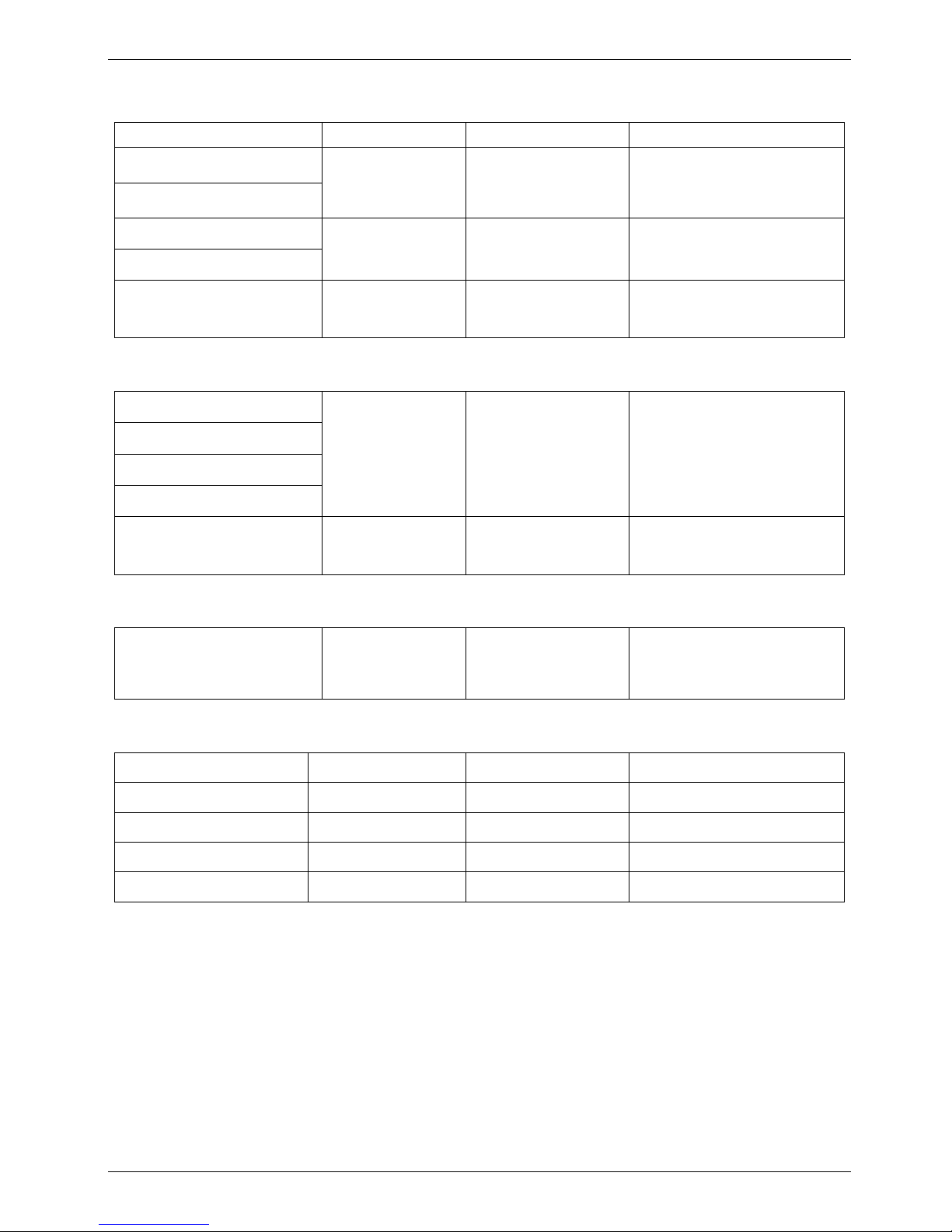

1. Measurements

Outdoor units

Model name

Dimension (mm)

Net/Gross weight (kg)

Power supply

CE-LRSJF-V120/N1-610

Width: 900

Height: 1327

Depth:348

89/101

220~240-50Hz

1 Ph

CE-LRSJF-V100/N1-610

CE-LRSJF-V80/N1-310

Width: 895

Height: 862

Depth:313

66/70

220~240-50Hz

1 Ph

CE-LRSJF-V60/N1-310

CE-LRSJF-V80/N1-310-B

Width: 895

Height: 862

Depth:313

63/67

220~240-50Hz

1 Ph

Hydraulic indoor unit

SMK-120/CD30GN1

Width: 900

Height:500

Depth:375

63/75

220~240-50Hz

1 Ph

SMK-100/CD30GN1

SMK-80/CD30GN1

SMK-60/CD30GN1

SMK-80/CSD80GN1

Width: 900

Height:500

Depth:375

64/77

380V-3Ph-50Hz

Solar kit

CE-TMK-01

Width: 810

Height: 310

Depth:295

8/10

220~240-50Hz

1 ph

Water Tank

Model name

Dimension (mm)

Net/Gross weight (kg)

Packing Dimension W×D×H

CE-LSX-300XP/D30B11

Ф580×1800

75//84

620×1960×635

CE-LSX-200XP/D30B11

Ф580×1320

60/68

670*1400*670

CE-LSX-150XP/D30B7

Ф580×1055

49/55

670*1135*670

CE-LSX-300XP/SD15B11

Ф580×1800

80/91

670×1885×670

Page 4

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

4

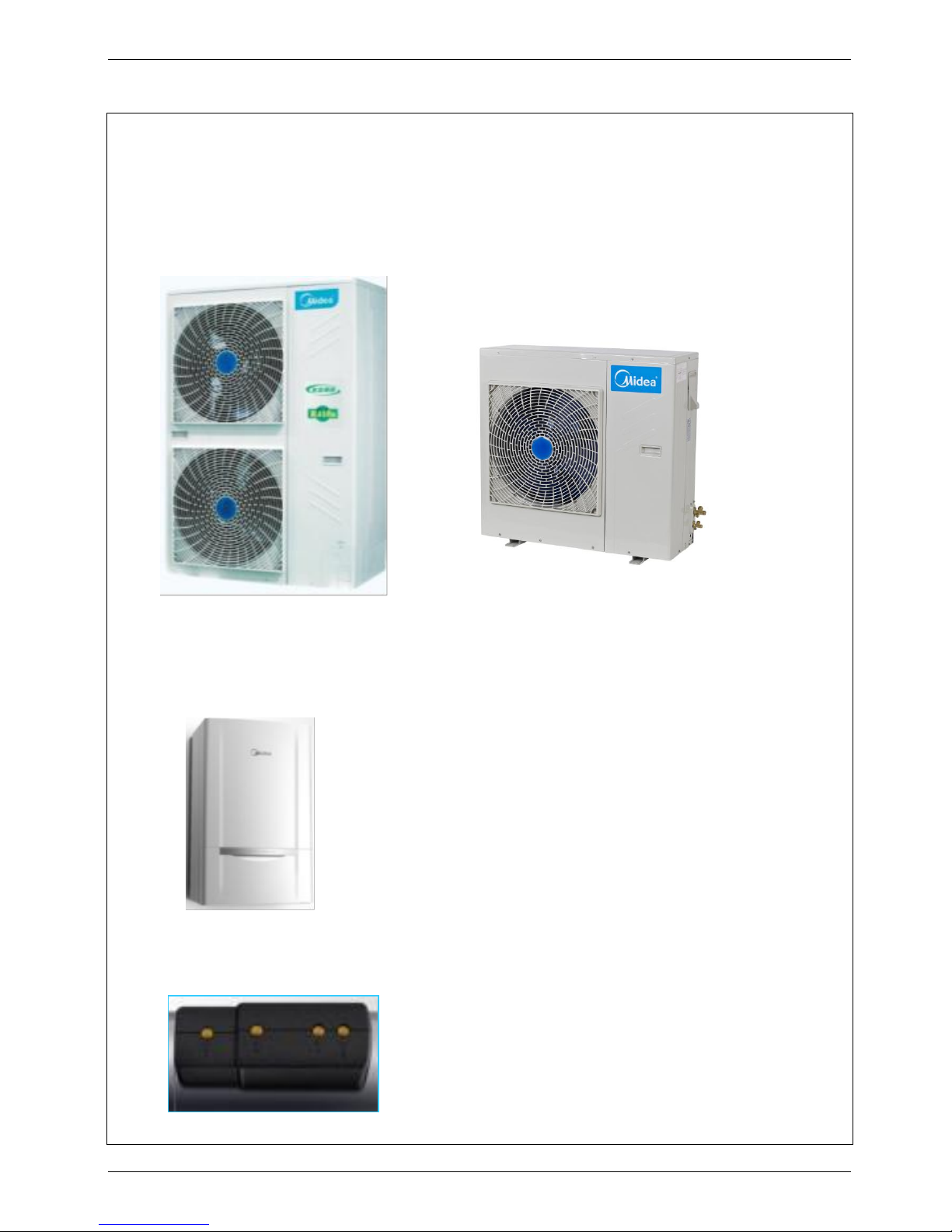

2. External Appearance

CE-LRSJF-V120/N1-610 CE-LRSJF-V80/N1-310

CE-LRSJF-V100/N1-610 CE-LRSJF-V60/N1-310

CE-LRSJF-V80/N1-310-B

CE-SMK-120/CD30GN1 CE-SMK-100/CD30GN1

CE-SMK-80/CD30GN1 CE-SMK-80/CSD80GN1 CE-SMK-60/CD30GN1

CE-TMK-01

Page 5

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

5

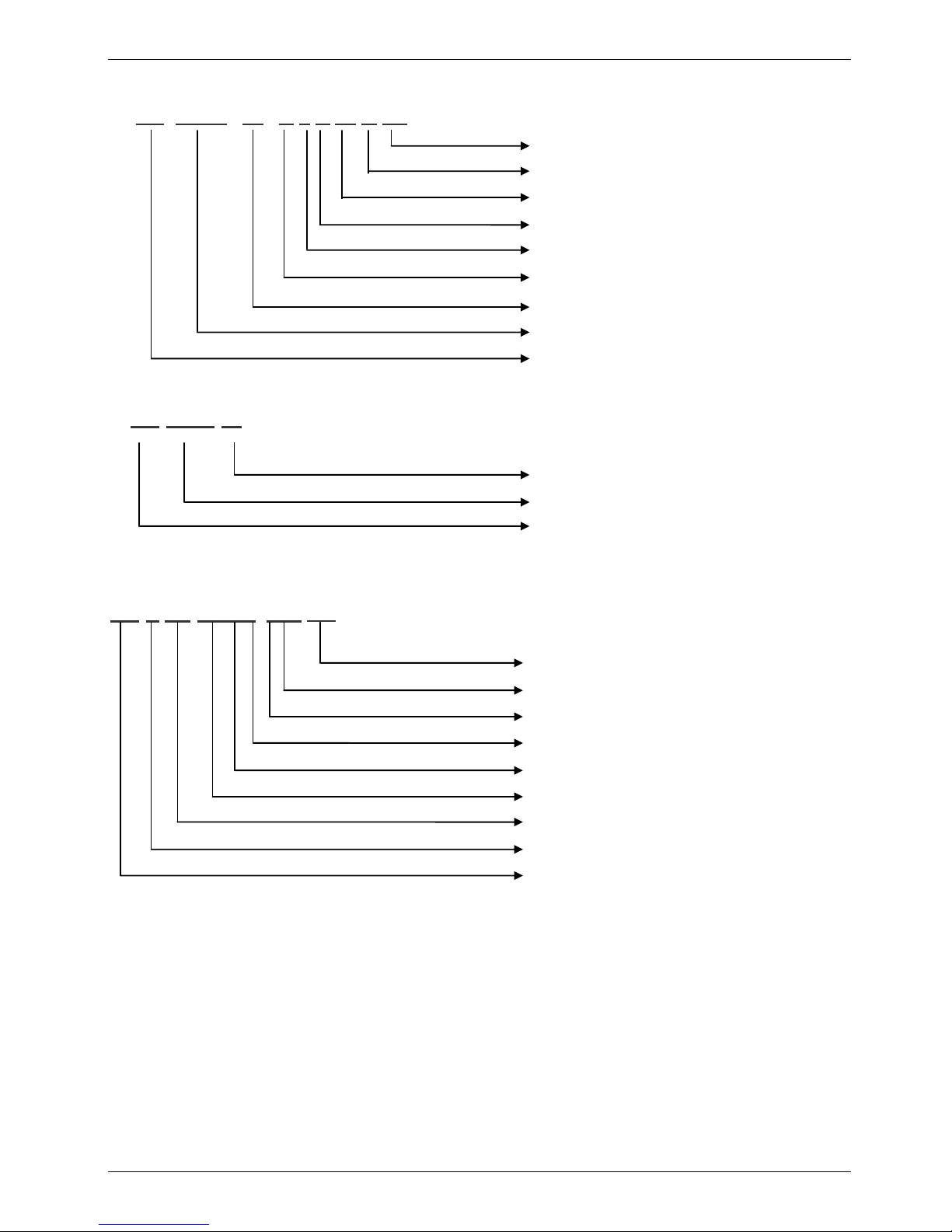

3. Nomenclature

Outdoor unit

CE-L RSJF-V100/N1-610

Design code

Refrigerant type (R410a)

Heating Capacity (8000W)

Compressor type (DC compressor)

Split type

Midea Heat Pump water heater

Heating and cooling mode (Omit for heating)

Export model code

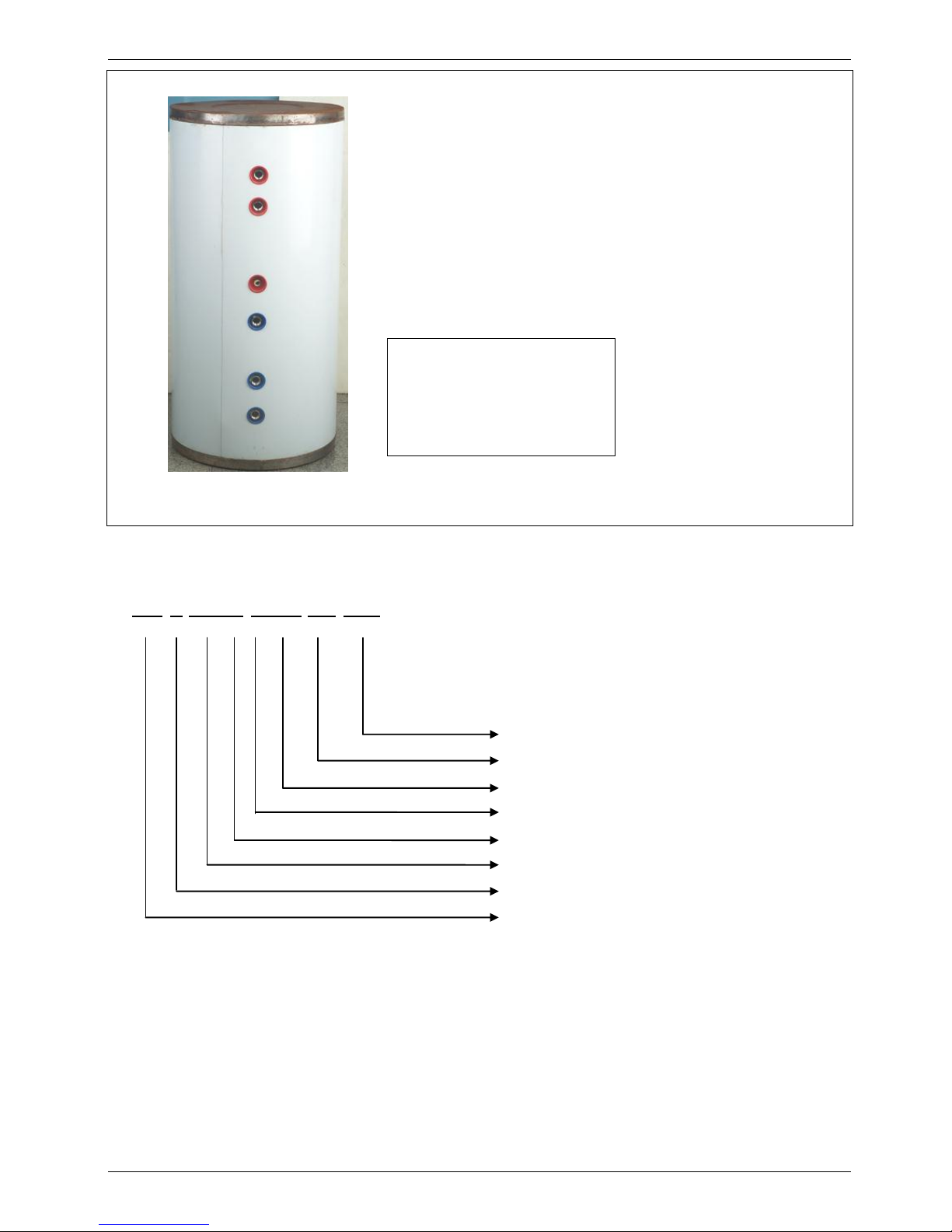

CE-LSX-300XP/D30B11

CE-LSX-200XP/D30B11

CE-LSX-150XP/D30B7

CE-LSX-300XP/SD15B11

Page 6

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

6

Indoor unit

CE- SMK – 80 / C S D 80 G N1

Solar kit

CE-TMK-01

CE-L SX-300XP/ D30 B11

Refrigerant type (R410a)

Installation type (Wall-mounted)

E-heater Capacity (8000W)

Electric heater

Power type (3ph, 380V)

Water cycle type

Heating Capacity (8000w)

Hydraulic modular

Export model code

Design code

Solar heating unit

Export model code

Design code

E-heater power(3000w)

Electric heater

Water tank appearance code (spraying appearance)

Water tank inner tank code (Stainless Steel inner tank )

Water tank volume (300L)

Water tank code

Water tank type code (vertical type)

Export model code

Page 7

MCAC-RTSM-2012-01 M-thermal Technical Manual(part 1)

7

4. Features

4.1 Safety

a. Realize isolation between water and electricity. No electric shock problem, more safety.

b. No fuel tubes and storage, no potential danger from oil leakage, fire, explosion etc.

4.2 Five operating model

a. space cooling

b. space heating

c. water heating

d. space cooling + water heating

E. space heating + water heating

1.3 Environmental friendly.

a. R410a refrigerant;

b. No discharge of poisonous gas;

c. Reduce CO2 emission

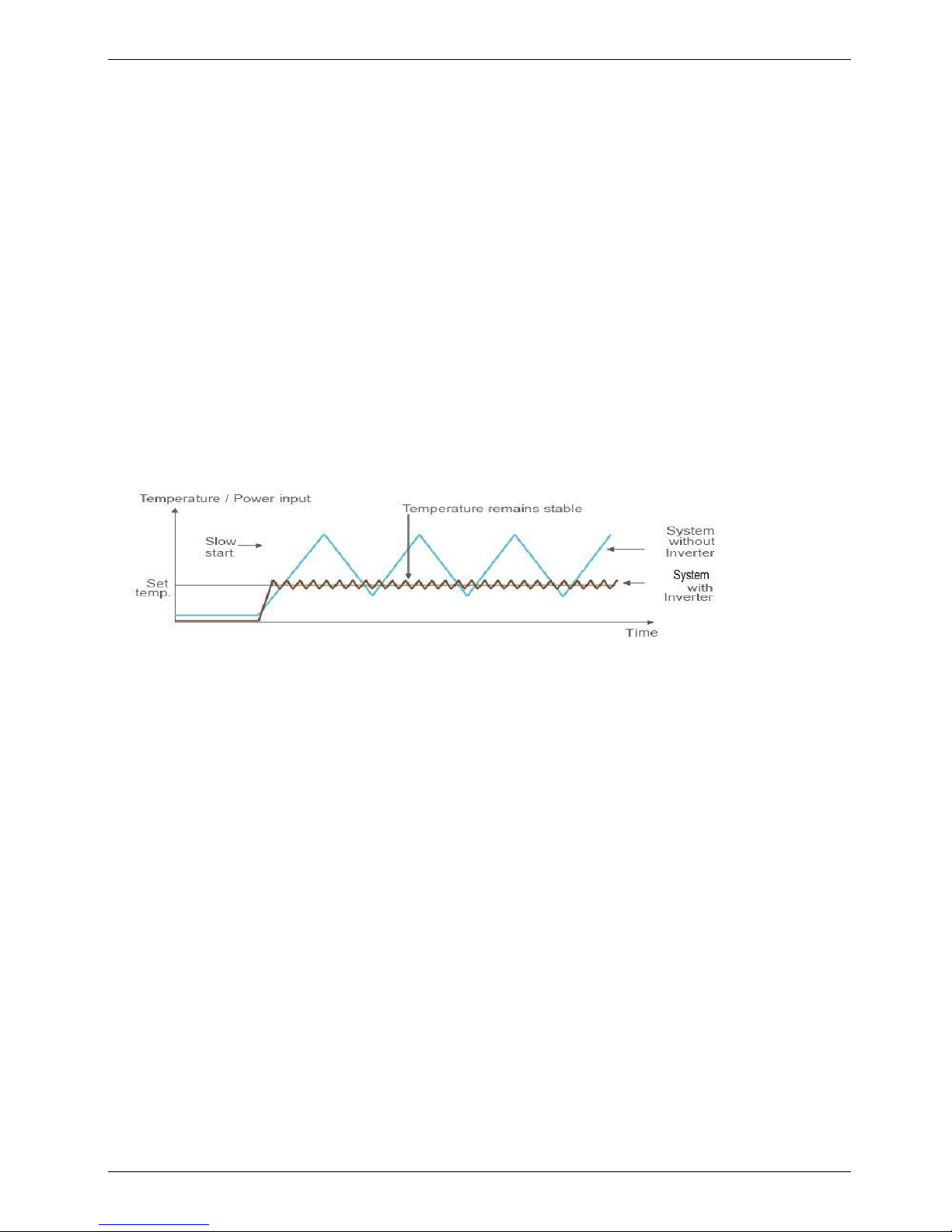

4.4 DC inverter system.

.

4.5 Automatic weekly anti-legionella function

4.6 Easy operation and automatic control.

The system can be controlled simply through the wire controller.

4.7 High efficiency and energy-saving.

The unit adopts heat pump principle, which absorbs heat from outdoor air and produce heat water, thermal

efficiency for water heating be up to 4.3

4.8 All-the-weather running.

Within the temperature range from -20 to 43℃, it will not be affected by night, overcast sky, rain and snow.

4.9 Convenient installation and maintenance

The quadrate type can be easily installed in a corner of the verandah even if it’s very narrow

4.10 Total Heating Solution

When floor heating is conducted in a new house, warm air spreads gently across the house, making it

comfortable and enabling the use of broad space without necessitating radiators or FCU.

4.11 Comfort System

When floor heating is applied, warm air spreads gently across the house, making it comfortable. The system

can help blood circulation and metabolism, further boosting our health.

The installation of M-Thermal will eliminate oil or gas tank, making the household surrounding neat and safe,

enabling the use of more space, and avoiding refueling.

4.11 CE approval

Page 8

MCAC-RTSM-2012-01 M-thermal Technical Manual

8

5. Specifications

5.1 Specifications of outdoor units

DC Inverter outdoor unit

LRSJF-V120/N1-610

LRSJF-V100/N1-610

LRSJF-V80/N1-310

LRSJF-V60/N1-310

LRSJF-V80/N1-310-B

Power supply

Ph-V-Hz

1-220~240-50

1-220~240-50

1-220~240-50

1-220~240-50

1-220~240-50

Max. current

A

23

22

15

14

16

Heating

Capacity

kW

12

10 8 6 8 COP

kW/kW

4.3

4.1

4.08

4.0

4.08

Ambient Temp.

℃

-15~43

-15~43

-15~43

-15~43

-20~43

Cooling

Capacity

kW

9.3

8.5

6.3

6.3

6.3

COP

kW/kW

2.45

2.45

2.23

2.45

2.23

Ambient Temp.

℃

15~43

15~43

15~43

15~43

15~43

Unit

Dimension (W×H×D)

mm

900×1327×348

900×1327×320

895×862×313

895×862×313

895×862×313

Packing (W×H×D)

mm

1016×1456×435

1016×1456×435

1025×910×410

1025×910×410

1025×910×410

Net/gross weight

kg

89/101

89/101

66/70

66/70

63/67

Noise level

dB(A)

58

58

58

58

58

Refrigerant

type/quantity

kg

R410a/2.7kg

R410a/2.7kg

R410a/2.4kg

R410a/2.4kg

R410a/2.4kg

system pressure

MPa

4.4/2.6

4.4/2.6

4.4/2.6

4.4/2.6

4.4/2.6

Compressor

Model

TNB306FPGMC

TNB306FPGMC

TNB220FLHMC

TNB220FLHMC

TNB220FLHMC

Type

Rotary

Rotary

Rotary

Rotary

Rotary

Brand

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Locked rotor current

A

67

67

45

45

45

Rate current

A

13.5

13.5

9.7

9.7

9.7

Crankcase

W

30

30

30

30

30

Capacity

kW

9.8

9.8

7.1

7.1

7.1

Fan motor

Brand

Panasonic

Panasonic

welling

welling

welling

Model

WZDK100-38G(*2)

WZDK100-38G(*2)

YDK75-6H-1

YDK75-6H-1

YDK75-6H-1

Type

DC MOTOR

DC MOTOR

AC MOTOR

AC MOTOR

AC MOTOR

Input w 100*2

100*2

168

168

168

Output

w

110*2

110*2

75

75

75

Speed

r/min

800

800

877/749

877/749

877/749

Max. refrigerant pipe length

m

50

50

25

25

25

Liquid side/ Gas side

mm

Φ9.5/Φ15.9

Φ9.5/Φ15.9

Φ9.5/Φ15.9

Φ9.5/Φ15.9

Φ9.5/Φ15.9

Outdoor coil

Number of rows

2 2 2 2

2

Tube pitch(a)x row

pitch(b)

mm

25.4/22

25.4/22

22*19.05

22*19.05

22*19.05

Tube dia. and type

mm

7.94(female screw)

7.94(female screw)

7.94(female screw)

7.94(female screw)

7.94(female screw)

Page 9

MCAC-RTSM-2012-01 M-thermal Technical Manual

9

Fin space

mm

1.6

1.6

1.7

1.7

1.7

Fin type (code)

Hydrophilic

aluminum

Hydrophilic aluminum

Hydrophilic aluminum

Hydrophilic

aluminum

Hydrophilic aluminum

Coil length x height

1276*870

1276*870

792*38.1

792*38.1

792*38.1

Number of circuits

7 7 8 8

8

Loading

Quantity

20'/40'/40H

Pcs

28/58/58

28/58/58

60/126/126

60/126/126

60/126/126

5.2 Specifications of Hydraulic indoor unit

Hydraulic indoor unit

SMK-120/CD30GN1

SMK-100/CD30GN1

SMK-80/CD30GN1

SMK-60/CD30GN1

SMK-80/CSD80GN1

Power supply

Ph-V-Hz

1-220~240-50

1-220~240-50

1-220~240-50

1-220~240-50

3-380-50

Function

Types

Heating &Cooling

Heating &Cooling

Heating &Cooling

Heating &Cooling

Heating &Cooling

Space Heating

℃

15~55

15~55

15~55

15~55

15~55

Space Cooling

℃

7~22

7~22

7~22

7~22

7~22

Sanitary Hot

Water

℃

35~60

35~60

35~60

35~60

35~60

Max. current

A

27

27

27

27

16

Noise level

dB(A)

32

32

32

32

32

Unit

Dimension

(W×H×D)

mm

900×500×375

900×500×375

900×500×375

900×500×375

900×500×375

Packing

(W×H×D)

mm

1110×610×510

1110×610×510

1110×610×510

1110×610×510

1110×610×510

Net/gross

weight

kg

63/75

63/75

63/75

63/75

64/77

E-heater

Size

kW

1.5

1.5

1.5

1.5

4.5

3.5(spare)

Quantity

2 2 2 2

1

1

Specification

Ph-V

1-220~240

1-220~240

1-220~240

1-220~240

3-380

1-220~240

Water

pipeline

Water inlet

pipe

mm

DN32

DN32

DN32

DN32

DN32

Water outlet

pipe

mm

DN32

DN32

DN32

DN32

DN32

Loading

Quantity

20'/40'/40H

Pcs

66/138/184

66/138/184

66/138/184

66/138/184

66/138/184

The testing Condition:

1. Heating: Outdoor temp. 7/6℃(DB/WB), inlet water temp. 30℃, outlet water temp. 35℃.

2. Cooling: Outdoor temp. 35/24℃(DB/WB), inlet water temp. 12℃, outlet water temp. 7℃.

Page 10

MCAC-RTSM-2012-01 M-thermal Technical Manual

10

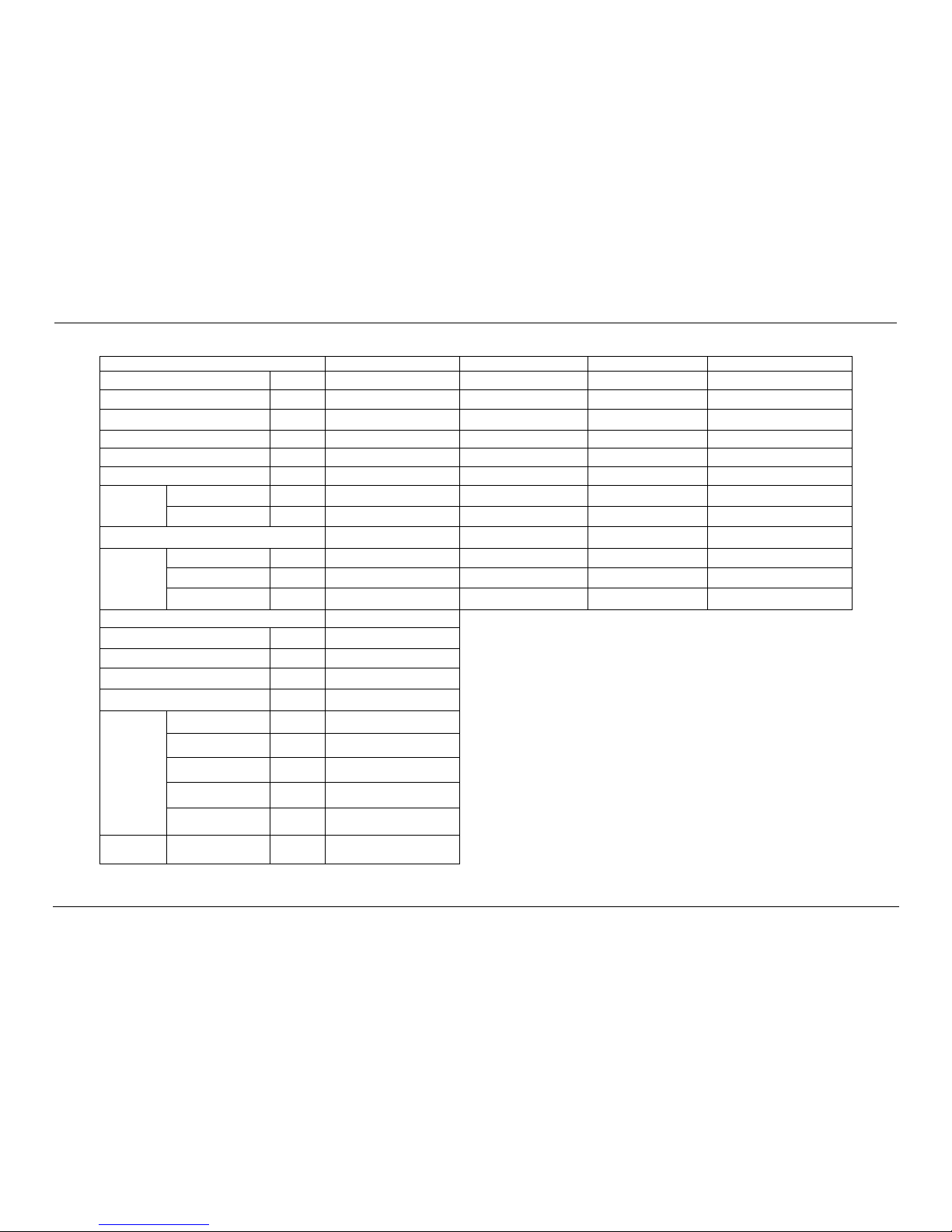

5.3 Specifications of water tank and solar kit

Sanitary hot water tank

LSX-300XP/D30B11

LSX-200XP/D30B11

LSX-150XP/D30B7

LSX-300XP/SD15B11

Power supply

Ph-V-Hz

1-220~240-50

1-220~240-50

1-220~240-50

3-380-50

Storage size

L

300

200

150

300

Max. water output temp.

℃

60

60

60

60

Dimension (D×H)

mm

Ф580×1800

Ф580*1320

Ф580×1050

Ф580×1800

Packing (W×H×D)

mm

670×1885×670

670×1400×670

670×1135×670

670×1885×670

Net//gross weight

kg

75/84

60/68

49/55

80/91

E-heater

specification

kW

3.0

3.0

3.0

1.5

Power supply

Ph-V

1-220~240-50

1-220~240-50

1-220~240-50

3-380-50

Tank material

SUS304

SUS304

SUS304

SUS304

Water

pipeline

Water inlet pipe

mm

DN20

DN20

DN20

DN20

Water outlet pipe

mm

DN20

DN20

DN20

DN20

PT valve joint

MPa

DN20

DN20

DN20

DN20

Solar kit

TMK-01

Power supply

Ph-V-Hz

1-220~240-50

Dimension (W×H×D)

mm

810×310×295

Packing (W×H×D)

mm

830×340×315

Net weight

kg

8/10

solar coils

OD+T

mm*mm

¢22*0.8

length

m

11

material

SUS316L

inlet pipe

mm

DN20

outlet pipe

mm

DN20

Loading

Quantity

20'/40'/40H

Pcs

300/624/728

Page 11

MCAC-RTSM-2012-01 M-thermal Technical Manual

11

6. Performance data

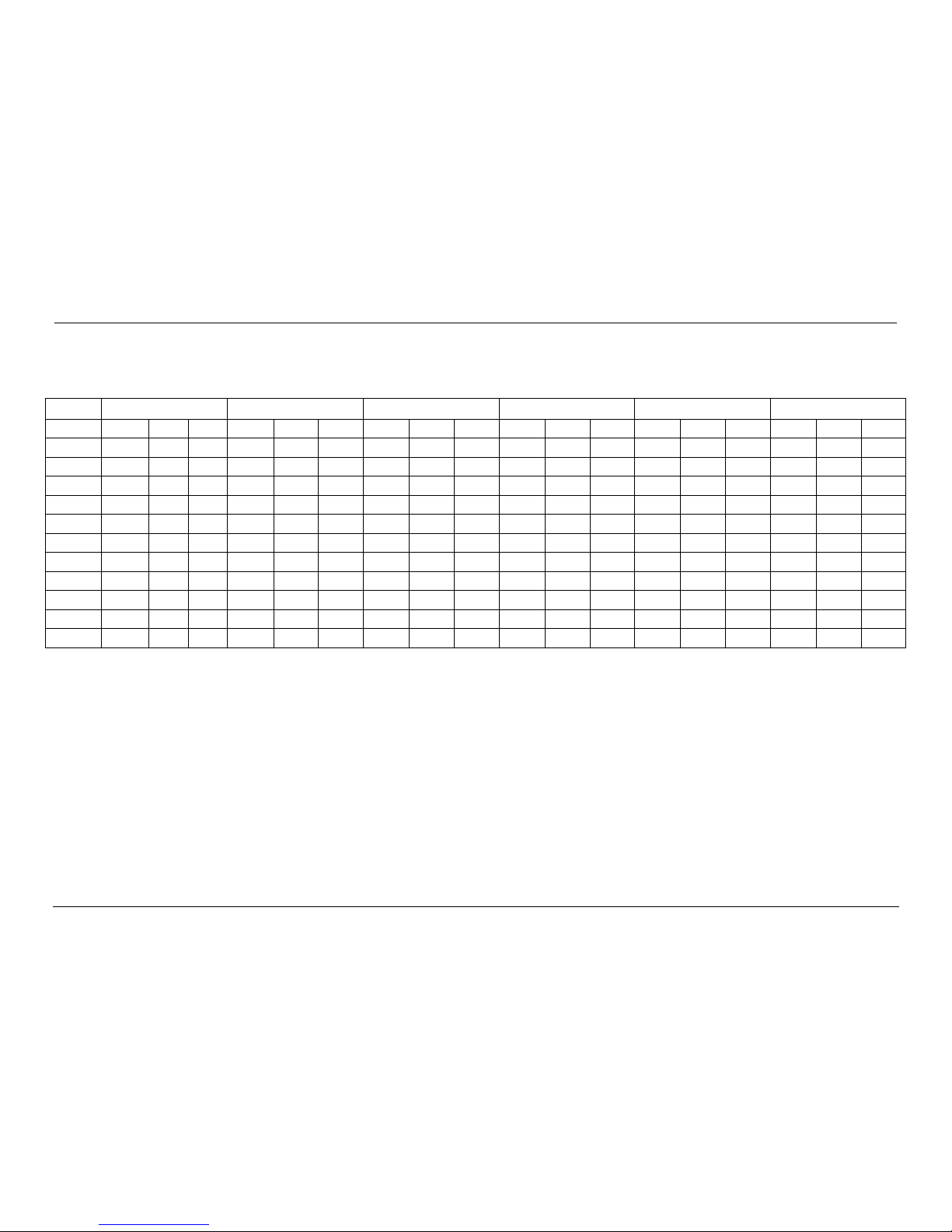

6.1 Heating performance data of 6/8kw model

6kW

LWE[℃]

30

35

40

45

50

55

Tamb [℃]

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

-15

4877

2206

2.21

4870

2377

2.05

4450

2527

1.76

3410

2543

1.34 / / / / / /

-7

6248

2334

2.68

6057

2490

2.43

5889

2650

2.22

4950

2721

1.82 / / / / / /

0

7576

2281

3.32

7322

2447

2.99

6992

2638

2.65

6354

2707

2.35

4962

2522

1.97 / /

/

2/1

6063

2166

2.80

6536

2401

2.72

6143

2574

2.39

5793

2449

2.37

5064

2525

2.01 / / / 7/6

9551

2360

4.05

9000

2518

3.57

8888

2756

3.22

8262

2841

2.91

6380

2623

2.43

1842

1497

1.23

10/8

9858

2400

4.11

10179

2579

3.95

9745

2753

3.54

8686

2826

3.07

7029

2612

2.69

1681

1466

1.15

15/12

9710

2057

4.72

9357

2215

4.22

9445

2409

3.92

9332

2617

3.57

8247

2678

3.08

3215

1493

2.15

20/15

9560

1940

4.93

9797

2105

4.65

9444

2252

4.19

7486

1978

3.79

5593

1718

3.26

3719

1493

2.49

25/17

10220

1913

5.34

10619

2086

5.09

10742

2276

4.72

9888

2288

4.32

7440

1879

3.96

4274

1477

2.96

30/22

11407

1889

6.04

11896

2069

5.75

12026

2267

5.31

11906

2471

4.82

7266

1717

4.23

4013

1409

2.85

35/24 / / / / / /

12652

2184

5.79

12630

2479

5.10

6775

1634

4.15

3820

1433

2.67

Remark:

HC = heating capacity PI = power input

Page 12

MCAC-RTSM-2012-01 M-thermal Technical Manual

12

8kW

LWE[℃]

30

35

40

45

50

55

Tamb [℃]

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

-15

5186

2322

2.23

5178

2502

2.07

4731

2660

1.78

3626

2677

1.35 / / / / / /

-7

6643

2457

2.7

6440

2621

2.46

6262

2789

2.25

5263

2864

1.84 / / / / / / 0 8055

2401

3.35

7785

2576

3.02

7434

2777

2.68

6756

2849

2.37

5276

2655

1.99 / / / 2/1

6512

2280

2.86

7020

2527

2.78

6598

2709

2.44

6222

2578

2.41

5439

2658

2.05 / /

/

7/6

10155

2484

4.09

9569

2650

3.61

9450

2901

3.26

8785

2991

2.94

6784

2761

2.46

1959

1576

1.24

10/8

10482

2526

4.15

10823

2715

3.99

10362

2898

3.58

9236

2975

3.1

7474

2749

2.72

1987

1543

1.29

15/12

10324

2165

4.77

9949

2332

4.27

10042

2536

3.96

9922

2755

3.6

8769

2819

3.11

3418

1572

2.17

20/15

10165

2042

4.98

10417

2216

4.7

10041

2371

4.23

7960

2082

3.82

5947

1808

3.29

3954

1572

2.52

25/17

10867

2014

5.4

11291

2196

5.14

11422

2396

4.77

10514

2408

4.37

7911

1978 4 4651

1555

2.99

30/22

12007

2008

5.98

12522

2200

5.69

12659

2410

5.25

12533

2627

4.77

7648

1826

4.19

4224

1498

2.82

35/24 / / / / / /

13452

2299

5.85

13429

2609

5.15

7204

1720

4.19

4062

1508

2.7

Remark:

HC = heating capacity PI = power input

Page 13

MCAC-RTSM-2012-01 M-thermal Technical Manual

13

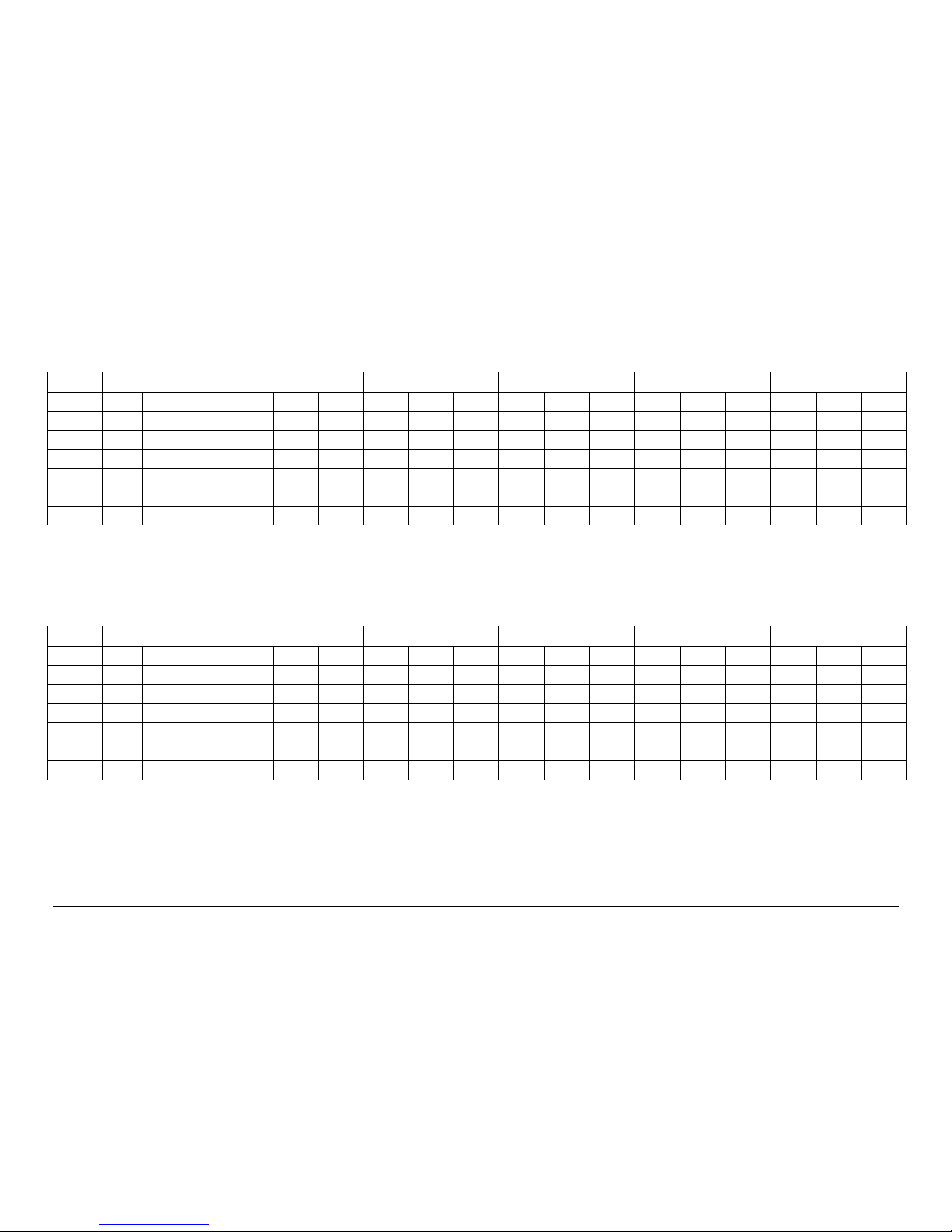

6.2 Cooling performance data of 6/8kw model

6kW

LWE[℃]

7

10

13

15

18

22

Tamb [℃]

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

20

7033

1771

3.97

8800

2066

4.26

8903

2046

4.35

9973

2263

4.41 / / / / / /

25

6917

2060

3.36

6362

1560

4.08

8380

2219

3.78

9896

2398

4.13

11436

2913

3.93

12605

2924

4.31

30

6146

1959

3.14

6367

1980

3.22

8337

2508

3.32

9226

2590

3.56

10853

3084

3.52

11933

3181

3.75

35

3714

1524

2.44

6468

2656

2.43

7122

2718

2.62

8406

3164

2.66

9901

3372

2.94

10615

3432

3.09

40 / / / 4767

2243

2.13

5452

2292

2.38

5955

2327

2.56

6755

2369

2.85

8058

2434

3.31

43 / / / 3858

2072

1.86

4596

2106

2.18

4956

2134

2.32

5724

2173

2.63

6859

2224

3.08

Remark:

CC= cooling capacity PI = power input

8kW

LWE[℃]

7

10

13

15

18

22

Tamb [℃]

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

20

7151

1802

3.97

8838

2106

4.2

8982

2081

4.32

10081

2328

4.33 / / / / / /

25

7205

2147

3.36

6627

1631

4.06

8729

2328

3.75

10308

2502

4.12

11912

3052

3.9

13130

3057

4.30

30

6402

2061

3.11

6632

2083

3.18

8684

2639

3.29

9610

2725

3.53

11305

3245

3.48

12430

3347

3.71

35

3869

1604

2.41

6737

2795

2.41

7419

2860

2.59

8756

3329

2.63

10314

3548

2.91

11057

3611

3.06

40 / / / 4966

2360

2.1

5679

2412

2.35

6203

2448

2.53

7036

2493

2.82

8394

2561

3.28

43 / / / 4019

2180

1.84

4787

2216

2.16

5162

2245

2.3

5963

2286

2.61

7145

2340

3.05

Remark:

CC= cooling capacity PI = power input

Page 14

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

14

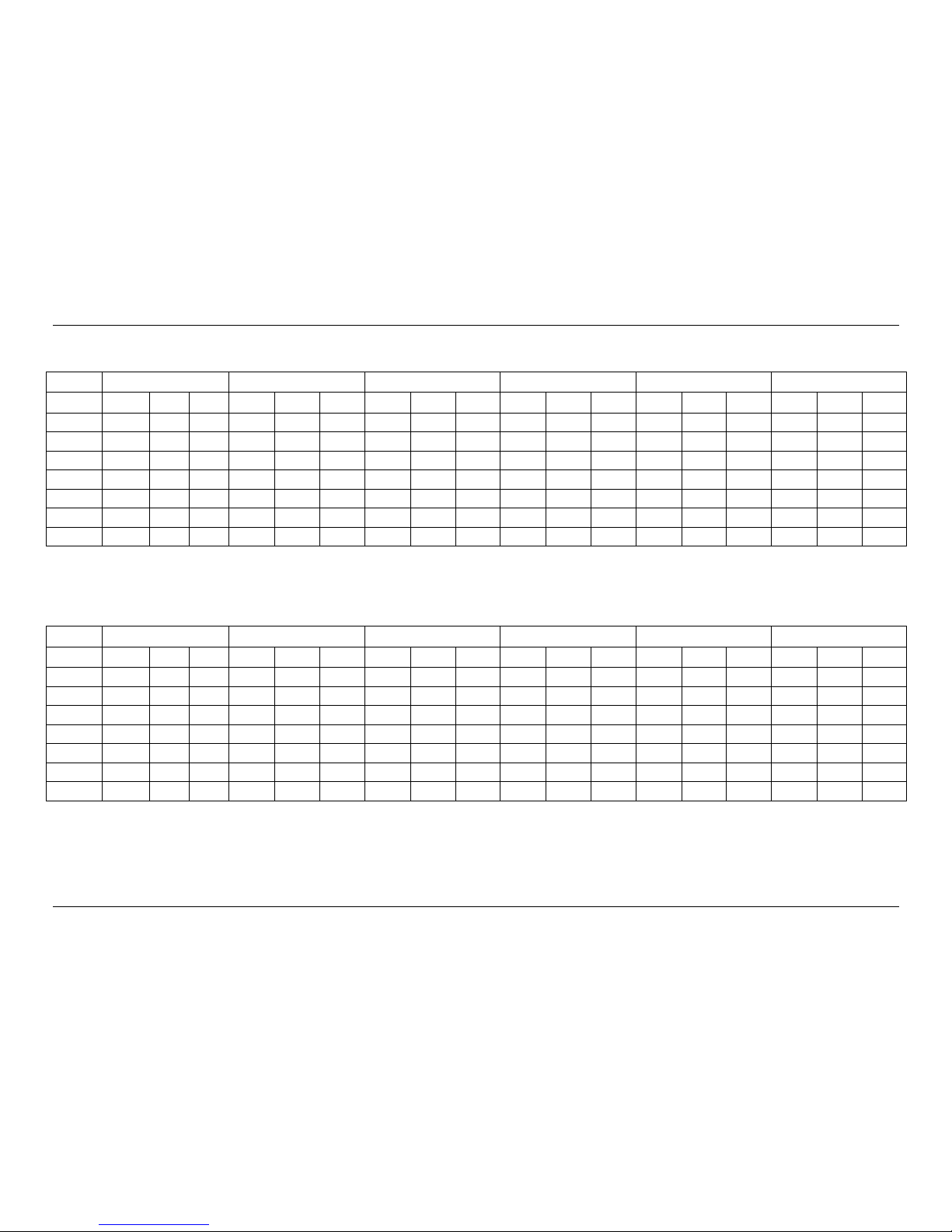

6.3 Heating performance data of 10/12kw model

10kW

LWE[℃]

30

35

40

45

50

55

Tamb [℃]

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

-15

6912

3245

2.13

4619

3009

1.54

5931

3671

1.62

/ / / / / / / / /

-7

8616

3198

2.69

8173

3306

2.47

7551

3598

2.10

5237

3436

1.52

4433

3625

1.22

/ / /

0

10548

3330

3.17

10125

3353

3.02

9355

3574

2.62

10523

4058

2.59

6178

3471

1.78

5245

3606

1.45

2/1

8274

3300

2.51

8855

3185

2.78

9408

3580

2.63

7879

3556

2.22

6622

3530

1.88

5624

3670

1.53

7/6

13655

3366

4.06

11638

2901

4.01

11969

3710

3.23

11097

3966

2.80

8702

3679

2.37

7008

3870

1.81

20/15

13178

2153

6.12

11738

2279

5.15

12980

2591

5.01

10033

2477

4.05

8931

2506

3.56

7399

2682

2.76

35/24

14856

2066

7.19

18012

2594

6.94

14247

2506

5.69

14095

2411

5.85

9143

2471

3.70

9197

2260

4.07

Remark:

HC = heating capacity PI = power input

12kW

LWE[℃]

30

35

40

45

50

55

Tamb [℃]

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

HC[W]

PI[W]

COP

-15

7198

3345

2.15

4810

3102

1.55

6176

3785

1.63 / / / / / / / / / -7

8972

3297

2.72

8511

3408

2.50

7863

3709

2.12

5454

3542

1.54

4616

3737

1.24 / / / 0

10984

3433

3.20

10354

3395

3.05

9742

3685

2.64

10958

4184

2.62

6433

3578

1.80

5462

3718

1.47

2/1

8616

3402

2.53

9221

3283

2.81

9797

3691

2.65

8205

3666

2.24

6896

3639

1.90

5857

3784

1.55

7/6

13932

3400

4.10

11874

2930

4.05

12212

3747

3.26

11322

4006

2.83

8879

3716

2.39

7150

3909

1.83

20/15

13446

2175

6.18

11976

2302

5.20

13244

2617

5.06

10237

2502

4.09

9112

2531

3.60

7549

2709

2.79

35/24

15638

2283

6.85

18325

2756

6.65

14536

2531

5.74

14381

2435

5.91

9329

2496

3.74

9384

2283

4.11

Remark:

HC = heating capacity PI = power input

Page 15

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

15

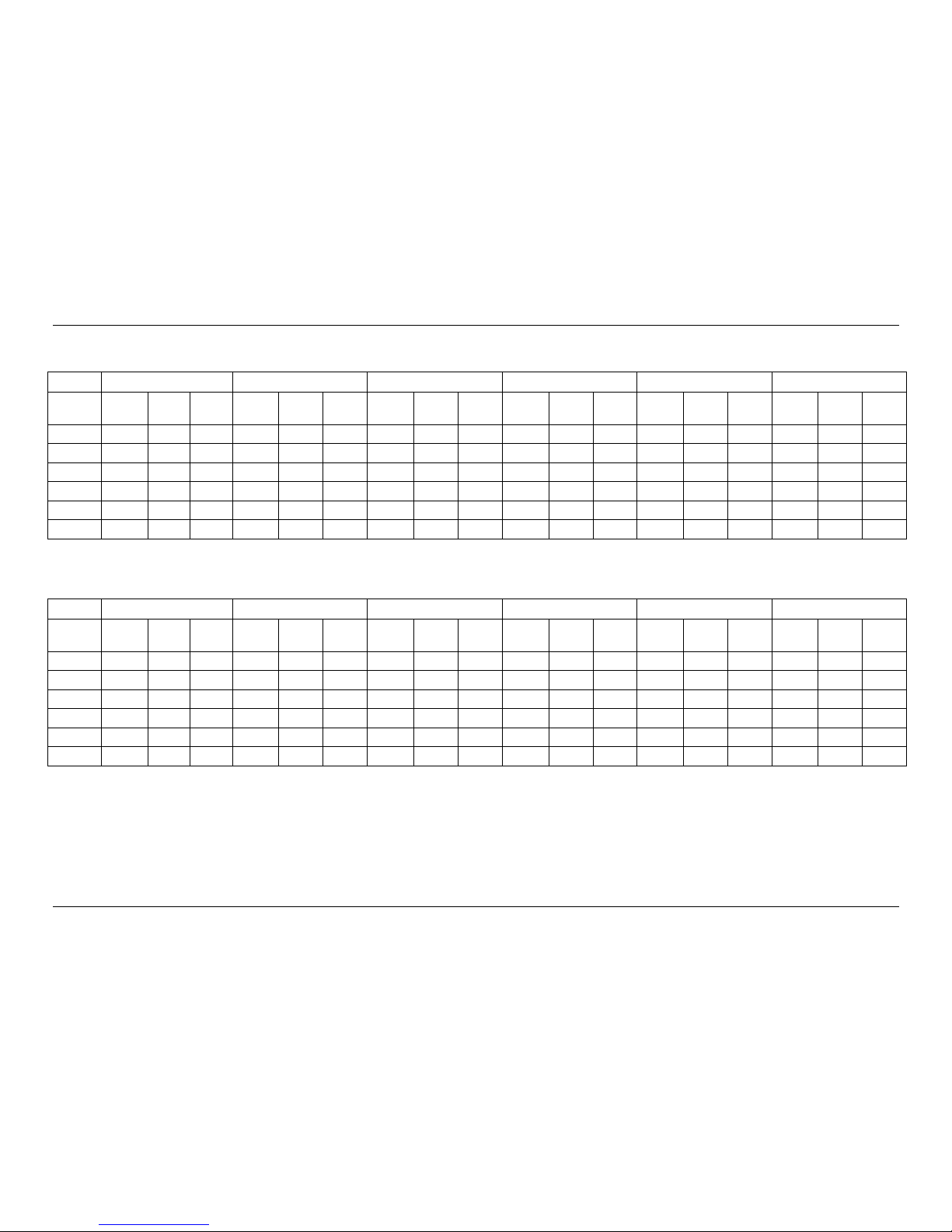

6.4 Cooling performance data of 10/12kw model

10kW

LWE[℃]

7

10

13

15

18

22

Tamb

[℃]

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

20

5498

1250

4.40

9412

2070

4.55

12005

2230

5.38

12906

2539

5.08

14468

2979

4.86

15310

2908

5.26

25

5024

1072

4.69

11458

2742

4.18

11116

3044

3.65

13584

3060

4.44

14486

3295

4.40

17194

3497

4.92

30

7699

2437

3.16

10710

3003

3.57

12601

3319

3.80

13185

3342

3.95

14289

3533

4.04

16444

3772

4.36

35

4020

1372

2.93

10149

3593

2.83

11732

3680

3.19

12369

3715

3.33

13646

3913

3.49

15725

4191

3.75

40

6278

2938

2.14

8345

3468

2.41

9439

3549

2.66

10306

3596

2.87

11478

3662

3.13

13126

3740

3.51

43

5872

3017

1.95

7170

3350

2.14

8334

3419

2.44

9104

3471

2.62

10059

3526

2.85

11683

3603

3.24

Remark:

CC= cooling capacity PI = power input

12kW

LWE[℃] 7 10

13

15

18

22

Tamb

[℃]

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

CC[W]

PI[W]

EER

20

5668

1289

4.40

9703

2134

4.55

12376

2299

5.38

13305

2618

5.08

14915

3071

4.86

15783

2998

5.26

25

5127

1094

4.69

11692

2798

4.18

11343

3106

3.65

13861

3122

4.44

14782

3362

4.40

17545

3568

4.92

30

7856

2487

3.16

10929

3064

3.57

12858

3387

3.80

13454

3410

3.95

14581

3605

4.04

16780

3849

4.36

35

4061

1386

2.93

10252

3629

2.83

11851

3717

3.19

12494

3753

3.33

13784

3953

3.49

15884

4233

3.75

40

6341

2968

2.14

8429

3503

2.41

9534

3585

2.66

10410

3632

2.87

11594

3699

3.13

13259

3778

3.51

43

5931

3047

1.95

7242

3384

2.14

8418

3454

2.44

9196

3506

2.62

10161

3562

2.85

11801

3639

3.24

Remark:

CC= cooling capacity PI = power input

Page 16

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

16

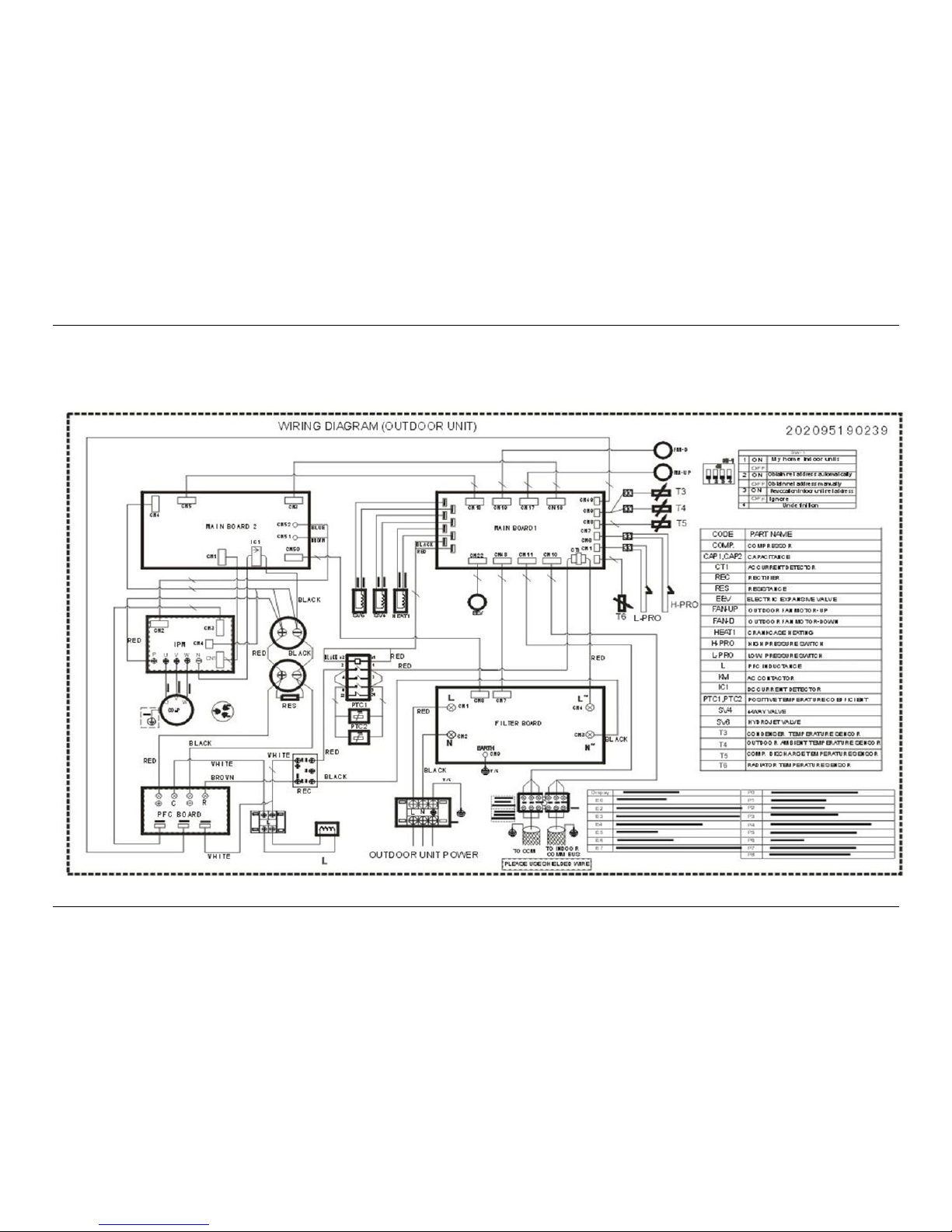

7. Wiring Diagrams

7.1 Outdoor units wiring diagram

Model:CE-LRSJF-V120/N1-610 CE-LRSJF-V100/N1-610

Page 17

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

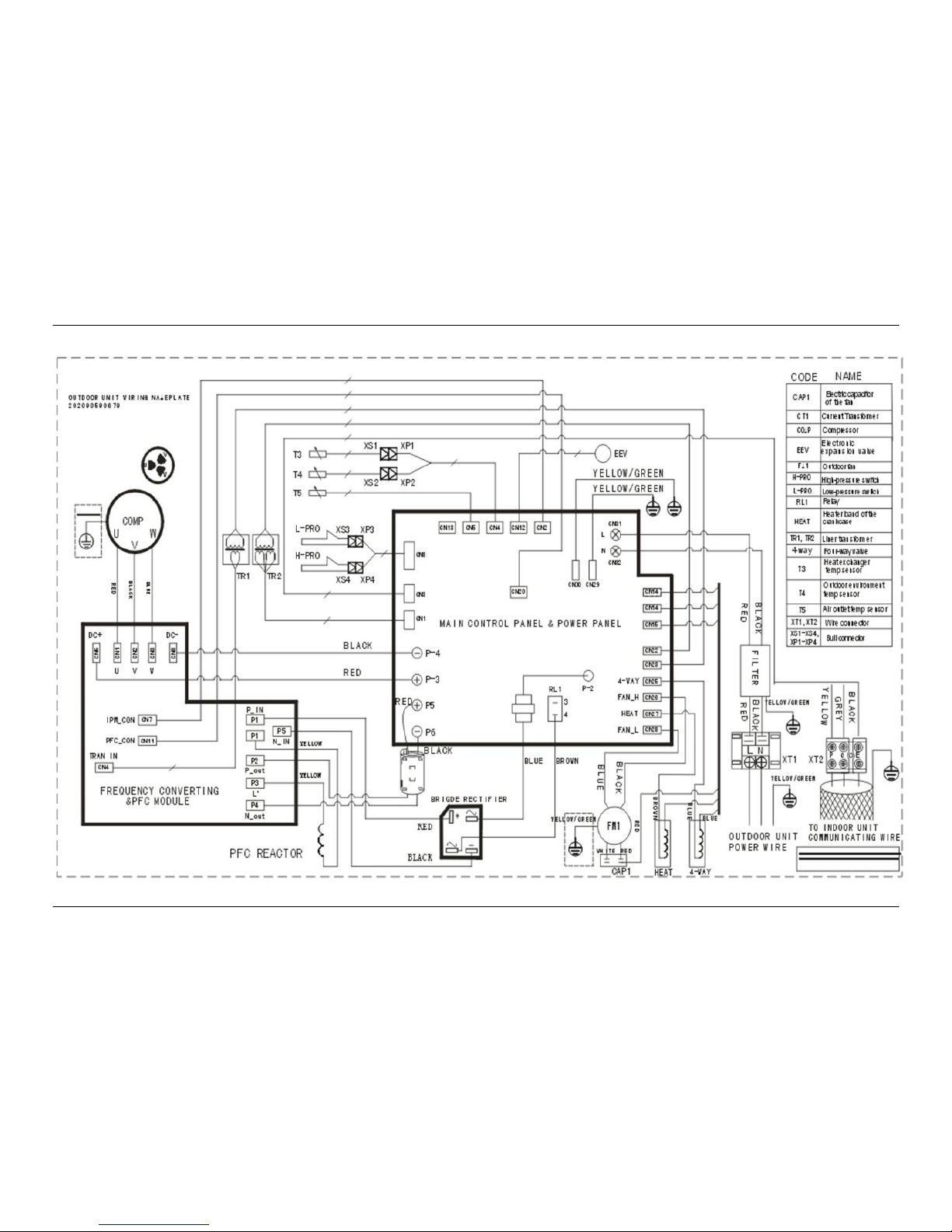

17

Model:CE-LRSJF-V60/N1-310 CE-LRSJF-V80/N1-310 CE-LRSJF-V80/N1-310-B

Page 18

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

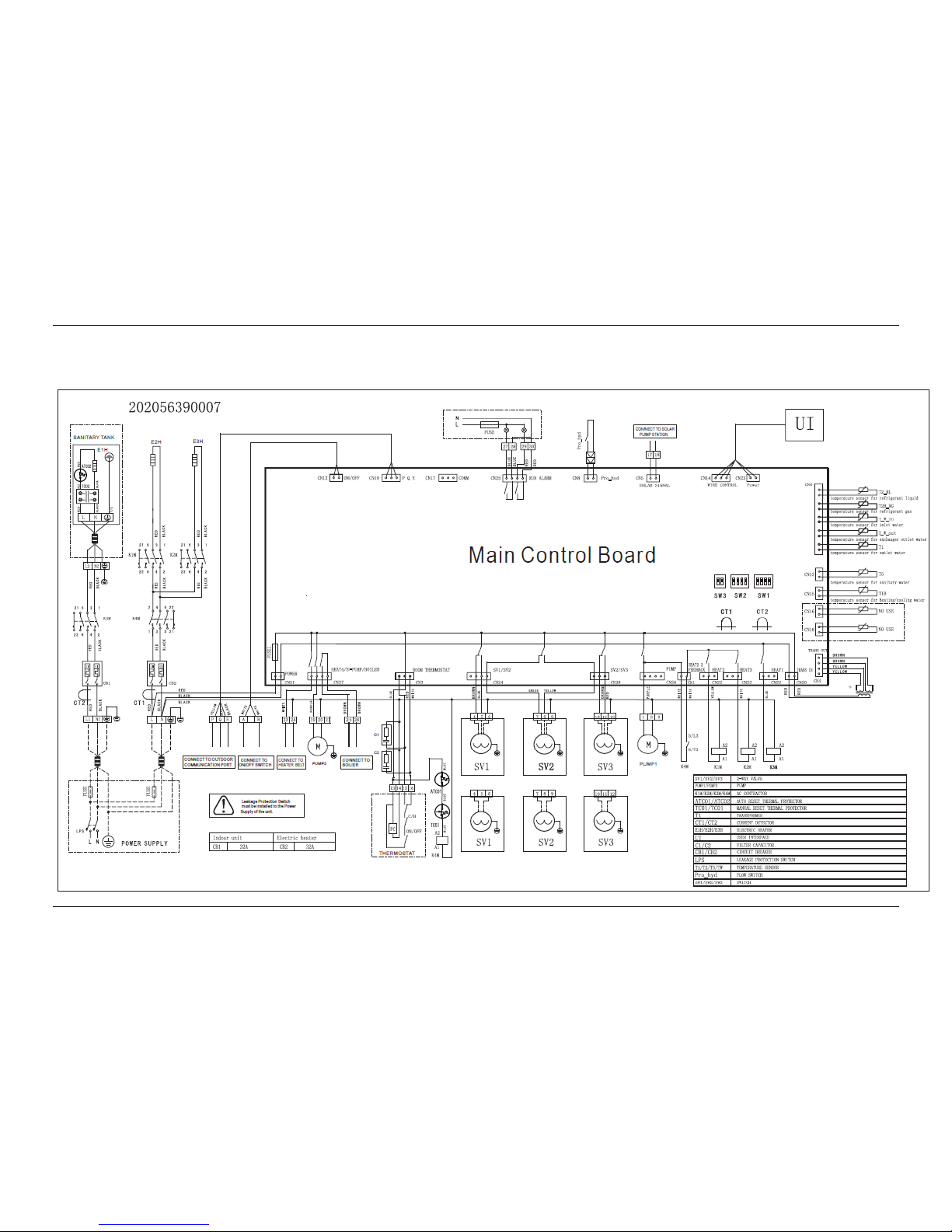

18

7.2 Hydraulic indoor units wiring diagram

Model :SMK-120/CD30GN1 SMK-100/CD30GN1 SMK-80/CD30GN1 SMK-60/CD30GN1

Page 19

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

19

Model :SMK-80/CSD80GN1

Page 20

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

20

8. Dimensions

8.1 Dimensions of outdoor units

Model: CE-LRSJF-V120/N1-610 CE-LRSJF-V100/N1-610

Model: CE-LRSJF-V80/N1-310 CE-LRSJF-V60/N1-310 CE-LRSJF-V80/N1-310-B

Page 21

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

21

8.2 Dimensions of Hydraulic indoor units

Model :SMK-120/CD30GN1 SMK-100/CD30GN1 SMK-80/CD30GN1 SMK-60/CD30GN1

SMK-80/CSD80GN1

Page 22

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

22

9. Installation place and service space

9.1 Outdoor unit service space

a) Selecting an installation location

A place which provides a specified space around the outdoor unit.

A place were the operation noise and discharged air are not given(affected) to your neighbors.

A place that is not exposed to a strong wind.

A place that does not block a passage.

When the outdoor unit is installed in an elevated position, be sure to secure its feet.

There must be sufficient space for carrying in the unit.

A place where the drain water does not make any problem

b) Single unit service place

c) Parallel connect the two units or above

d) Parallel connect the front with rear sides

Page 23

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

23

9.2 Hydraulic indoor unit installation location and service space

a) Selecting an installation location

The indoor unit should be installed in a water proof place, or the safety of the unit and the operator cannot

be ensured.

The indoor unit is to be wall mounted in an indoor location that meets the following requirements:

The installation location is frost-free.

The space around the unit is adequate for service.

The space around the unit allows for sufficient air circulation.

There is a provision for condensate drain and pressure relief valve blow off.

All piping lengths and distance have been taken into consideration.

Requirement

SMK-120/CD30GN1

SMK-100/CD30GN1

SMK-80/CD30GN1

SMK-60/CD30GN1

Maximum allowable refrigerant piping length between outdoor unit

and indoor unit.

50m

25m

Maximum allowable height distance between outdoor

unit and indoor unit when outdoor unit is top.

15m

10m

Maximum allowable height distance between outdoor

unit and indoor unit when outdoor unit is bottom

10m

5m

Maximum allowable distance between the 2-way valve SV1 and

the indoor unit (only for installations with sanitary hot water tank).

3m

3m

Maximum allowable distance between the sanitary hot water tank

and the indoor unit (only for installations with sanitary hot water

tank). The thermistor cable supplied with the indoor unit is 15 min

length.

10m

10m

Maximum allowable be distance between the T1B and the indoor

unit .The temperature sensor cable of T1B supplied with the indoor

unit is 10m in length.

8m

8m

The equipment is not intended for use in a potentially explosive atmosphere.

b) Service space

Page 24

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

24

10. Exploded View

10.1 Exploded view of outdoor units

Model: CE-LRSJF-V120/N1-610 CE-LRSJF-V100/N1-610

Page 25

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

25

No.

Part Name

No.

Part Name

1

E-part box ass'y

7

room temp sensor ass'y

1.1

Outdoor control board assembly

8

Condenser components

1.2

Capacitor card

9

Handle

1.3

Wire joint

10

Cover before the tube

1.4

Outdoor power board assembly

11

After the tube cover

1.5

Resistance

13

Four-way valve parts

1.6

wire clamp

14

Suction pipe ass'y

1.7

Contactor

14.1

Pressure controller

1.8

Inverter module

14.2

Capillary ass'y

1.9

Three phase bridge

15

Compressor discharge tube assembly

1.10

Six Terminal Block

15.1

Oil separator

1.11

Electrical mounting plate Ⅱ

15.2

Strainer

1.12

Discharge temp sensor ass'y

16

Discharge temp sensor ass'y

1.13

Welding pieces of electrical box

17

Expansion valve ass'y

1.14

Rubber ring

17.1

Electronic expansion valve

1.15

Radiator

17.2

EEV solenoid

1.16

Aluminum electro analysis capacitor

17.3

Low pressure valve

1.17

Active PFC module components

18

Gas-liquid separator

1.18

Main control board ass'y

19

Valve mounting plate

1.19

Electrical mounting plate Ⅰ

20

gas-liquid separator plate

1.20

pieces of electrical box

21

Front Panel

2

Inductance box components

22

Grille ass'y

2.1

Inductor lid welding parts

23

Left rear support

2.2

Plate welding pieces of the wind

24

Layering fence

2.3

PFC Inductor

25

Compressor electric heater

2.4

Inductor mounting plate

26

Partition components

3

Compressor

27

Axial fan

4

Temp sensor ass'y

28

DC Motor

5

Right front side components

29

Cover parts

6

Right rear side

30

Motor bracket assembly

7

Room temp sensor ass'y

31

Chassis welding parts

Page 26

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

26

Model: CE-LRSJF-V60/N1-310 CE-LRSJF-V80/N1-310 CE-LRSJF-V80/N1-310-B

Page 27

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

27

No.

Part Name

No.

Part Name

1

Top cover ass'y

9

4-way valve ass'y

2

E-part box ass'y

9.1

Pressure controller

2.1

Main control board ass'y

9.2

Low pressure valve

2.2

Inverter module

9.3

Oil separator

2.3

EMC filter

9.4

Solenoid

2.4

Rectifier

9.5

4-way valve

2.5

PFC inductance

10

Suction pipe ass'y

2.6

Wire joint

10.1

Pressure controller

2.7

Wire joint

11

Accumulator cylinder

2.8

Motor capacitor

12

Compressor

3

Rear right clapboard ass'y

13

Base ass'y

4

Handle

14

Partition board ass'y

5

Big handle ass'y

15

Axial flow fan

6

High pressure valve ass'y

16

Motor

6.1

Strainer

17

Grille ass'y

6.2

High pressure valve

18

Motor bracket ass'y

6.3

EEV solenoid

19

Front panel

6.4

Electronic expansion valve body

20

Condenser ass'y

7

Valve plate

21

Left holder

8

Front clapboard ass'y

22

plate frame

Page 28

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

28

10.2 Exploded view of hydraulic indoor units

Model :SMK-120/CD30GN1 SMK-100/CD30GN1 SMK-80/CD30GN1 SMK-60/CD30GN1

Page 29

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

29

No.

Part Name

No.

Part Name

1

Bottom

18

Outlet pipe fixed plate

2

Flip

19

Right foam refrigerant pipe

3

Decorative ring

20

Target flow switch

4

Decorative plates

21

Left foam refrigerant pipe

5

Magnet sets

22

Right out of the bubble pipe

6

Roof

23

Left out of the bubble pipe

7

Front Panel

24

Electronic box mounting plate

8

E-part box ass'y

25

Electronic box mounting plate

8.1

Main control board ass'y

26

Water tray components

8.2

Wire joint, 6p

27

Connect hose

8.3

AC contactor

28

Safety valve

8.4

Transformer

29

Electric heating pipe water

8.5

Wire joint, 6p

30

Exhaust valve

8.6

Wire joint

31

Small water tank

8.7

32A MCB

32

Outlet pipe components

8.8

Thirty Terminal Block

33

Expansion Tank

9

Electronic control box cover

34

Electric valve

10

Rear

35

Wired remote support

11

Casing components

36

Electric heating cover

11.1

Liquid tube assemblies

37

Pump Bracket 2

11.2

Tracheal components

38

Pump bracket

11.3

Inlet components

39

Hydraulic module wired remote

11.4

Pipe heat exchanger

40

Expansion Tank

12

Pump mounting plate

41

Pipe temperature sensor ass'y

13

Handle

42

Small water tank fixed plate

14

Refrigerant pipe fixed plate

43

Temp sensor

15

Mounting Bracket

44

Thermostat components

16

Fixed plate inlet

45

Drain Pump

17

Expansion tank clamp

46

Hydraulic meter

Page 30

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

30

Model : SMK-80/CSD80GN1

Page 31

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

31

No.

Part Name

No.

Part Name

1

Bottom

18

Outlet pipe fixed plate

2

Flip

19

Right foam refrigerant pipe

3

Decorative ring

20

Target flow switch

4

Decorative plates

21

Left foam refrigerant pipe

5

Magnet sets

22

Right out of the bubble pipe

6

Roof

23

Left out of the bubble pipe

7

Front Panel

24

Electronic control box mounting plate

8

E-part box ass'y

25

Electronic control box mounting plate

8.1

Main control board ass'y

26

Water tray components

8.2

Wire joint, 6p

27

Connect hose

8.3

32A MCB

28

Safety valve

8.4

AC contactor

29

Electric water heating tube

8.5

Transformer

30

Exhaust valve

8.6

Wire joint, 5p

31

Small water tank

8.8

E-part box ass'y

32

Outlet pipe components

8.9

Thirty Terminal Block

33

Expansion Tank

8.10

Contactor

34

Electric valve

8.11

Wire joint

35

Wired remote support

9

Electronic control box cover

36

Electric heating cover

10

Rear

37

Pump Bracket 2

11

Casing components

38

Pump bracket

11.1

Inlet components

39

Hydraulic module wired remote

11.2

Tracheal components

40

Expansion Tank take over the components

11.3

Tube heat exchanger

41

Pipe temperature sensor assemblies

11.4

Liquid tube assemblies

42

Small water tank fixed plate

12

Pump mounting plate

43

Temp sensor

13

Handle

44

Thermostat components

14

Refrigerant pipe fixed plate

45

Drain Pump

15

Mounting Bracket

46

Hydraulic meter

16

Fixed plate inlet

47

Manual ball valve

17

Expansion tank clamp

Page 32

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

32

11. Accessories

Unit

Name

Sharp

Quantity

Outdoor

Unit

Accessories

Outdoor unit

installation manual

1

Outdoor unit

Owner’s manual

1

Outflow

connecting tube

1

Waterproof rubber cap

1

Hydraulic

Indoor

Unit

Accessories

Owner's & Installation

Manual

1

Mounting bracket

1

Two-way valve

3

M4 screws

2

Water tank temperature sensor

1

Y-sharp filter

1

Floor heating inlet

temperature sensor, T1B

1

Drain pan kit

1

M8 expansion screws

5

Solar

Kit

Accessories

Installation & Owner’s

Manual

1

adapter

2

Sealing

6

Screws

2

Washer

2

Water

Tank

Accessories

Owner’s & Installation

Manual

1

Y-shaped Filter

1

One Way Valve

1

Page 33

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

33

12. Functional diagram

12.1 Complete system diagram

NO

Name

NO

Name

NO

Name

1

Outdoor unit

13

By-pass valve (field supply)

25

Solar kit (optional)

2

Indoor unit (Hydro kit)

14

By-pass valve (field supply)

26

Pump for solar kit, Pump 3

3

Refrigerant to water heat

exchanger

15

Collector (field supply)

27

Non-return valve

4

Auxiliary heater vessel

16

Motorized 2-way valve SV3

28

Pump for solar pump station

5

Pump 1

17

Motorized 2-way valve SV1

29

Solar pump station (field supply)

6

Shut-off valve (field supply)

18

Water to water heat exchanger

30

Solar panels (field supply)

7

Auxiliary pump(optional, field

supply)

19

Shut-off valve (field supply)

31

Temperature sensor for

heating/cooling water

8

Water to water heat exchanger

kit

20

Sanitary hot water tank

32

Temperature sensor for sanitary

water T5

9

Boiler (optional, field supply)

21

Electric heater

33

Non-return valve (field supply)

10

Pump 4 (optional, field supply)

22

Non-return valve

34

Non-return valve (field supply)

11

Motorized 2-way valve SV2

23

Non-return valve

35

Y-sharp filter

12

Collector (field supply)

24

Water to water heat exchanger

Page 34

MCAC-RTSM-2009-09 Midea Heat Pump Water Heater Technical Manual

34

12.2 Electrical connection diagram and cable specification

cable specification

NO

Description

Require number of

core

Section of the conductor

1

Power supply cable for indoor unit

2 or 3+GND

2.5 mm2

2

Power supply cable for electric heater

2 or 3+GND

2.5 mm2

3

Temperature sensor cable

2

—

4

Power supply cable from indoor unit to Sanitary

hot water tank

2 or 3+GND

2.5 mm2

5

Power supply cable for Pump of solar kit (Pump

3)

2+GND

1.0 mm2

6

Power supply cable for motorized 2-way valve,

SV3

3

1.0 mm2

7

Power supply cable for motorized 2-way -valve,

SV2

3

1.0 mm2

8

Power supply cable for motorized 2-way valve,

SV1

3

1.0 mm2

9

Power supply cable for auxiliary pump (Pump2)

2+GND

1.0 mm2

10

Communication cable between indoor unit and

boiler

2

1.0 mm2

11

Room thermostat cable

4(L, N, C, H)

1.0 mm2

12

Communication cable between indoor unit and

outdoor unit

3 (P, Q, E)

3×0.5 mm2

(3 -Shield wire)

13

Power supply cable for outdoor unit

2+GND

4.0 mm2

14

Power supply cable for solar pump station

2+GND

1.0 mm2

15

Power supply cable for the pump of solar kit

2+GND

1.0 mm2

16

Signal input from solar pump station to indoor

unit

2

1.0 mm2

17

Power supply cable for the pump of solar kit

2+GND

1.0 mm2

18

Sanitary hot water tank temperature sensor

cable

2

—

19

Sanitary hot water tank temperature sensor

cable

2

—

20

Water circuit temperature senor T1B cable

2

—

Page 35

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

Part 2 trouble shooting

1. Normal Phenomenon ................................................................................................................................................ 2

2. M-thermal system protection in Common ........................................................................................................... 3

3. Trouble and causes of heat pump ......................................................................................................................... 3

4. Malfunction Code and Troubleshooting ............................................................................................................... 4

4.1 Outdoor unit malfunction Code and troubleshooting .......................................................................... 4

A. "E0": Outdoor unit EEPROM malfunction ...................................................................................... 5

B. "E2": Communication error of the outdoor chip and the indoor chip ............................................. 6

C. "E3": Communication error of outdoor chip and DSP ................................................................... 7

D. "E4": Outdoor temperature sensor error ............................................................................................... 8

E. "E5": Voltage protection error ................................................................................................................. 9

F. "E6": Direct-current fan error ................................................................................................................ 10

G. "P1": High pressure protection .................................................................................................... 11

H. "P2": Low pressure protection ..................................................................................................... 12

4.2 Hydraulic indoor unit malfunction Code and trouble shooting ....................................................... 13

A. "E0" "E8": Flow switch error ........................................................................................................ 14

B. “E1 E3 E4 E5 E6 E7 E8 E9 EA Eb”: Temperature sensor error .................................................. 15

C. "E2": UI communication error ...................................................................................................... 16

Page 36

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

1. Normal Phenomenon

1.1 The heat pump does not start immediately after the ON/OFF button on the

remote controller is pressed.

If the operation lamp lights, the system is in normal condition. To prevent overloading of the compressor

motor, the heat pump starts 3 minutes after it is turned ON.

If the operation lamp and the "PRE-DEF indicator (cooling and heating type) or fan only indicator (cooling

only type)" light, it means you choose the heating model.

1.2 Change into the Pump mode during heating mode

When the outlet water temperature drops to the setting temperature, the compressor goes off and the indoor

unit changes to pump mode; when the temperature rises up, the compressor starts again. It is the same with

heating mode.

1.3 White mist comes out of outdoor unit

When the system is changed over to heating operation after defrost operation Moisture generated by defrost

becomes steam and is exhausted.

1.4 Noise of heat pump’s cooling

A continuous low hissing sound is heard when the system is in operation.

This is the sound of refrigerant gas flowing through both indoor and outdoor units.

A hissing sound will be heard at the start or immediately after stopping operation or defrost operation.

This is the noise of refrigerant caused by flow stop or flow change.

If the tone of operating noise changes, this noise is caused by the change of compressor’s frequency.

1.5 Dust comes out of the unit

If the unit is not run for a long time, the dust has gotten into the unit.

1.6 The units can give off odors

The unit can absorb the smell of rooms, furniture, cigarettes etc., and then emit it again.

1.7 The outdoor unit fan does not spin

The speed of the fan is controlled in order to optimize product operation.

In heating mode, when the system defrosting, the fan of outdoor unit will stop

Page 37

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

2. M-thermal system protection in Common

2.1 Compressor protection.

When the power is on, or the machine stops then restarts right away, outdoor unit will run in 3 minutes to protect

the compressor from too frequent starts and stops.

2.2 When the protection device functions, running stops. Refer to the following:

① Forced to start but not possess the start article, and display light lights.

② When cooling running (the operation is cooling), inlet and outlet of outdoor unit are blocked, outside

strong air blows into outdoor unit’s outlet.

③ When heating running, dust adheres to air filter to block inlet or outlet of outdoor unit.

Note: when protecting, please cut the manual power switch. After checking the reason and solving it, restart.

2.3 Power fails.

① If the power supply fails while machine is running normally, system will record this.

② When the machine is powered on(power-on) again, the running light of wire controller would flash to inform

user about this.

③ Press the on/off key of wire controller to confirm this before restart the system.

Note: When running, if system takes place mistaken operation or lighter, please pull down the power supply

switch to cut it off. Before restarting machines, please press the on/off key again as above.

3. Trouble and causes of heat pump

If one of the following malfunctions occur, stop operation, shut off the power, and contact with your dealer.

The lamp is flashing rapidly after turn off the power and turn on again.

Remote controller receives malfunction or the button does not work well.

A safety device such as a fuse, a breaker frequently actuates.

Obstacles and water enter the unit.

Water leaks from indoor unit.

Other malfunctions.

If the system does not properly operate except the cases above mentioned or the malfunction above mentioned

is evident, investigate the system according to the following procedures.

Symptom

Causes

Solution

Unit does not start

Power failure.

Power switch is off.

Fuse of power switch may have burned.

Batteries of remote controller exhausted

or other problem of controller.

Wait for the comeback of power.

Switch on the power.

Replace Location:

Replace the batteries or check the

controller.

Water flowing normally but

completely can't cooling

Temperature is not set correctly.

Be in 3 minutes protection of

compressor.

Set the temperature properly.

Wait.

Units start or stop

frequently

Refrigerant is too little or too much.

Air or no concreting gas in the system

Compressor is malfunction.

Voltage is too high or too low.

System circuit is blocked.

Check leakage, recharge refrigerant.

Vacuum and recharge refrigerant.

Maintenance or change compressor.

Install manostat.

Find reasons and solution.

Low cooling effect

Outdoor unit and indoor unit heat

Clean the heat exchanger.

Page 38

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

exchanger is dirty.

The water filter is dirty.

Inlet/outlet of indoor/outdoor units is

blocked.

Sunlight shines directly.

Too much heat resource.

Outdoor temp. is too high.

Leakage of refrigerant or lack of

refrigerant.

Clean the water filter.

Eliminate all dirties and make air

smooth.

Make curtains in order to shelter from

sunshine.

Reduce heat source.

AC cooling capacity reduces

(normal).

Check leakage and rightly recharge

refrigerant.

Low heating effect

Outdoor temperature is lower than 7℃

Leakage of refrigerant or lack of refrigerant.

Use heating device.

Check leakage and rightly recharge

refrigerant.

4. Malfunction Code and Troubleshooting

If there is phenomenon as follows, please stop running and cut power supply and refer to the following.

If the problem still appears, please contact with your dealer and offer machine’s model and detailed malfunction.

4.1 Outdoor unit malfunction Code and troubleshooting

Display

Malfunction or Protection

Model

10kw and 12kw

6kw and 8kw

E0

EEPROM error

E2

Communication error of the outdoor chip and the indoor chip

E3

Communication error

E4

T3, T4 sensor error

E5

Voltage protection error

E6

Direct-current fan error

——

E7

Heating fan error in the area A lasts for 5 minutes

——

E8

There are two times E6 error in 10 minutes

(recovery will be after power off)

——

P0

The cooling fin high temperature protection

——

P1

High pressure protection

P2

Low pressure protection

P3

Compressor current protection

P4

Discharge temperature protection

P5

Outdoor condenser T3 high temperature protection

P6

Modules protection

P7

Evaporator T2 high temperature protection

P8

Typhoon protection

——

H0

——

Do not match with the indoor and outdoor units

Display Function Instruction:

1. When stand by, LED displaying the amount of indoor units online which communicate with outdoor units.

2. When operation, LED displaying frequency value of compressor. 3. When defrost, LED displaying “dF”.

Page 39

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

A. "E0": Outdoor unit EEPROM malfunction

Outdoor Unit

Display

E0

Method of

malfunction

detection

Check whether EEPROM is normal

Supposed

Causes

1. Something wrong with the outdoor unit PCB.

2. Something wrong with the EEPROM.

3. External factor other than malfunction.

Troubleshooting

E0

Turn the power supply off

once and then back on

Is normal reset

possible?

Turn the power supply off

and replace the EEPROM,

turn the power on again,

is”E0”displayed?

Problem could be cause by External

factor (noise, etc.) other than

malfunction

Replace the main control board.

Replace the EEPROM

YES

NO

YES

NO

Page 40

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

B. "E2": Communication error of the outdoor chip and the indoor chip

Outdoor Unit

Display

E2

Method of

malfunction

detection

Check whether communication cable is normal

Supposed

Causes

1. Communication cable doesn’t connect well.

2. External factor other than malfunction.

Troubleshooting

E2

Turn the power supply off

once and then back on

Is normal reset

possible?

Turn the power supply off and

make sure the communication

cable is in well connection,

turn the power on again,

is”E2”displayed?

Problem could be cause by External

factor (noise, etc.) other than

malfunction

Replace the main control board.

Continue operation

YES

NO

YES

NO

Page 41

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

C. "E3": Communication error of outdoor chip and DSP

Outdoor Unit

Display

E3

Method of

malfunction

detection

Check whether communication cable between chip and DSP is not connected

well.

Supposed

Causes

1. Communication cable between chip and DSP is not connected well..

2. External factor other than malfunction.

Troubleshooting

E3

Turn the power supply off

once and then back on

Is normal reset

possible?

Turn the power supply off and

connect the communication

cable correctly, turn the power

on again, is”E3”displayed?

Problem could be cause by External

factor (noise, etc.) other than

malfunction

Replace the main control board.

Continue operation

YES

NO

YES

NO

Page 42

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

D. "E4": Outdoor temperature sensor error

Outdoor Unit

Display

E4

Method of

malfunction

detection

Check whether T3 and T4 temperature sensor cable are connected correctly.

Supposed

Causes

1. Temperature sensor cables don’t connect correctly.

2. The sensor terminal is loose.

3. The sensor circuit is short or open

4. The main control board's clamp diodes are short or open.

Troubleshooting

E4

Is T3 or T4 port on PCB

loose?

Temperature sensor

is short or defective.

The chip's pins do not match

correctly or the chip is defective.

, turn the power on again,

is”E4”displayed?

Insert the chip correctly or replace it with a

fine one

Replace the temperature sensor

Replace the main control

board.

YES

NO

YES

NO

Fasten the port.

YES

NO

Page 43

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

E. "E5": Voltage protection error

Outdoor Unit

Display

E5

Method of

malfunction

detection

Check whether the power supply voltage is at normal range.

Supposed

Causes

1. The power supply voltage is too high or too low

2. Something wrong with the detecting element on the main board

Troubleshooting

E5

Measure the voltage, is at

the normal range?

Use a voltage regulator, adjust to

normal voltage,

turn the power on

again, is”E5”displayed?

Continue operation

YES

NO

Replace the main board

ON

YES

Replace the main board

Page 44

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

F. "E6": Direct-current fan error

Outdoor Unit

Display

E6

Method of

malfunction

detection

Check whether the wire connection is correct.

Supposed

Causes

1. Fan wire is not connected well or correctly

2. Fan dose not run due to some matter tangled

3. Malfunction of the outdoor unit main board

4. Blowout of fuse

Troubleshooting

E5

Measure the voltage, is at

the normal range?

Check the fan motor connector

correctly connected to the

outdoor main board

Is there any matter around the

fan?

NO

YES

Properly connect the connector

YES

NO

Wait or use a voltage regulator

Remove the motor

connector

NO

Remove the matter

NO

Check the resistance value of the

motor

YES

Replace the motor

Is the fan ratable easily by hand?

Page 45

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

G. "P1": High pressure protection

Outdoor Unit

Display

P1

Error

Explanation

The protection device circuit checks continuity in high pressure switch

Supposed

Causes

1. Refrigerant is excess.

2. Refrigerant does not loop smoothly.

3. The refrigerant loop contains air.

4. Control board is defective.

Troubleshooting

P1: High pressure protection (R22 refrigerant system protects

at 3.3Mpa, recovers at 2.4MPa; R410 refrigerant system

protects at 4.4MPa, recovers at 3.2MPa).

Heat exchanging of ODU is not efficient. This may be

caused by dirty heat exchanger, abnormal ODU fan

running, air flow keeping off to the heat exchanger,

ODU are too near to each other.

System's liquid refrigerant loop is blocked.

This may be caused by blocked valve, pressed

tube, closed blocked valve.

Refrigerant is excess. In this circumstance, the

refrigerant's low pressure is high, so is the

high pressure side, while the discharge

temperature is low.

System contains air or nitrogen. In this

circumstance, the high pressure is high, the

current is large, the discharge temperature is

high, compressor makes noise

Chip is defective or incorrectly installed. Or

the high pressure sensor is disconnected.

Control board is defective.

Check the system and fixed up

the error.

Check the system and get rid of the

block, and make the loop smooth.

Discharge part of the refrigerant.

Add some oil to the system if it

leaks during the discharge.

Discharge the refrigerant. Then vacuumize the

system and refill the refrigerant. Add oil to the

system if it leaks.

Reinstall the chip or replace it

with a fine one.

Replace the main control board.

Page 46

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

H. "P2": Low pressure protection

Outdoor Unit

Display

P2

Error

Explanation

The protection device circuit checks continuity in low pressure switch

Supposed

Causes

1. Faulty low pressure switch

2. Refrigerant is not enough.

3. Refrigerant does not loop smoothly.

4. Efficiency of indoor heat exchange is low.

5. Control board is not defective.

Troubleshooting

P2: Low pressure protection (R22 refrigerant system protects

at 0.03Mpa, recovers at 0.1MPa; R410 refrigerant system

protects at 0.05MPa, recovers at 0.15MPa, or protects at

0.14MPa, recovers at 0.3MPa).

Refrigerant is not enough or the

system leaks refrigerant.

System's gas side is blocked. Phenomenon

may be discharge temperature is high, low

pressure is low, current is small. These are

caused by closed EXV valve, closed stop valve

or blocked filter.

Heat exchanger of IDU is inefficient, which

may be caused by the dirty exchanger or

filter, block of air flow, the fan not running

or running too slowly.

Chip is defective or incorrectly installed. Or

the low pressure sensor is disconnected.

Main control board is defective.

Reinstall the chip or replace it

with a fine one.

Replace the main

control board.

Check the system

over and eliminate

the obstacles.

Clear away the

block.

Add refrigerant or

fix up the system.

Clean the filter. If the

system is block by ice, the

system should also be clean.

Page 47

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

4.2 Hydraulic indoor unit malfunction Code and troubleshooting

Display

Malfunction or Protection

E0

Flow switch error( continuous for 3 times, and should be reset by switch off the power supply )

E1

T2 error

E2

UI communication error

E3

Outdoor unit communication error

E4

T2B error

E5

T5 error

E6

T1 error

E7

T1B error

E8

Flow switch( one time)

E9

TW_in error

EA

TW_out error

Eb

T4 error

Ed

Phase protection

EE

EEPROM error

P0

T2 high temperature protection

P1

T2B low temperature protection

P2

TW_out high temperature protection

P3

TW_out low temperature protection

P4

TW_in high temperature protection

P5

T1 high temperature protection

P6

T1B high temperature protection

P7

Outdoor unit protection

P8

Sanitary hot water tank electric heater protection

P9

Auxiliary heater protection

Pb

Anti -freezing protection

Pc

Temperature controller error(result from the conflict between cool mode and heat mode)

t0~t7

Run test

dF

Defrost

d0

Oil return function

Page 48

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

A. "E0" "E8": Flow switch error

Wire controller

Display

E0 E8

Error

Explanation

E0:Flow switch error( continuous for 3 times, and should be reset by switch off

the power supply )

E8:Flow switch error( one times)

Supposed

Causes

1. The wire terminal is loose or connected incorrectly.

2. The wire circuit is short or open.

3. The pump is not running

4. The main control board's clamp diodes are short or open.

Troubleshooting

E0

Check whether the wire

connected correctly or loose.

Is the wire circuit short or

open?

Turn on the power supply. Is the

water pump running?

Main control board is

defective.

Properly connect the wire.

Replace the flow switch

Check the wire connection or

replace the pump

Replace the main control

board.

NO

YES

NO

NO

YES

YES

Page 49

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

B. “E1 E3 E4 E5 E6 E7 E8 E9 EA Eb”: Temperature sensor error

Wire

controller

Display

E1"E3 E4 E5 E6 E7 E8 E9 EA Eb

Method of

malfunction

detection

Malfunction is detected according to the temperature detected by each

temperature sensor.

Supposed

Causes

1. Temperature sensor cables don’t connect correctly.

2. The sensor terminal is loose.

3. The sensor circuit is short or open

4. The main control board's clamp diodes are short or open.

Troubleshooting

Error code

Is temperature port on PCB

loose?

Temperature sensor is

short or defective.

The chip's pins do not match

correctly or the chip is defective.

, turn the power on again, is the

code displayed?

Insert the chip correctly or replace it with a

fine one

Replace the temperature sensor

Replace the main control

board.

YES

NO

YES

NO

Fasten the port.

YES

NO

Page 50

MCAC-RTSM-2012-01 M-thermal Technical Manual (part 2)

C. "E2": UI communication error

Wire

controller

Display

E2

Method of

malfunction

detection

Check whether communication cable is normal

Supposed

Causes

1. Communication cable doesn’t connect correctly.

2. External factor other than malfunction.

Troubleshooting

E2

Turn the power supply off

once and then back on

Is normal reset

possible?

Turn the power supply off and

make sure the communication

cable is in well connection,

turn the power on again,

is”E2”displayed?

Problem could be cause by External

factor (EMI, etc.) other than malfunction

Replace the main control board.

Continue operation

YES

NO

YES

NO

Page 51

M-thermal technical manual – part 3

Part 3

Test running and maintenance

1 Pre-test and test running ................................................................................. 2

1.1 Checks before initial start-up ..................................................................................................... 2

1.2 Powering up the indoor unit ....................................................................................................... 3

2 Setting the pump speed .................................................................................. 3

3 Field Settings ..................................................................................................................................................... 3

3.1 Setting Procedure ........................................................................................................... 4

3.2 Detailed description ........................................................................................................ 4

3.3 Field setting table ........................................................................................................... 7

4 Maintenance ..................................................................................................... 8

Page 52

M-thermal technical manual – part 3

1 Pre-test and test running

1.1 Checks before initial start-up

Warning: Switch off the power supply before making any connections.

After the installation of the unit, check the following before switching on the circuit

breaker:

A. Field wiring

Make sure that the field wiring between local supply panel and indoor unit, outdoor unit and

indoor unit, indoor unit and valves (when applicable), indoor unit and room thermostat (when

applicable), and indoor unit and sanitary hot water tank has been connected correctly. The wiring

diagrams should be according to European and national regulations.

B. Fuses or protection devices

Check that the fuses or the locally installed protection devices are of the right size and type.

Make sure that neither a fuse nor a protection device has been bypassed.

C. Electric heater circuit breaker

Do not forget to turn on the electric heater circuit breaker in the control box (applies only to units

with optional sanitary hot water tank installed).

D. Earth wiring

Make sure that the earth wires have been connected properly and that the earth terminals are

tightened.

E. Internal wiring

Visually check the control box on loose connections or damaged electrical components.

F. Fixation

Check that the unit is properly fixed, to avoid abnormal noises and vibrations when starting up the

unit.

G. Damaged equipment

Check the inside of the unit on damaged components or squeezed pipes.

H. Refrigerant leak

Check the inside of the unit on refrigerant leakage. If there is a refrigerant leak, call your local

dealer.

I. Power supply voltage

Check the power supply voltage on the local supply panel. The voltage must correspond to the

voltage on the identification label of the unit.

J. Air purge valve

Make sure the air purge valve is open (at least 2 turns).

K. Pressure relief valve

Check if the auxiliary heater vessel is completely filled with water by operating the pressure relief

valves. It should purge water instead of air.