Page 1

0

Website: www.mideaaircon.com

Service manual

CAUTION

- BEFORE SERVICING THE UNIT, READ THE SAFETY

- PRECAUTIONS IN THIS MANUAL.

- ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODELS:

CE-CF0.3BD/N3-F

CE-CFZ0.3BD/N3-F

Page 2

GD Midea Refrigerant Equipment Co. Ltd Service manual for F Dehumidifier

1

CONTENTS

1. PREFACE

1.1 SAFETY PRECAUTIONS...............................................................................................................1

1.2 INSULATION RESISTANCE TEST................................................................................................1

1.3 FEATURES.....................................................................................................................................2

1.4 CONTROL LOCATIONS................................................................................................................2

1.5 OUTSIDE DIMENSIONS................................................................................................................2

2. ELECTRONIC FUNCTION……………………………………………………………………………………...3

3. TROUBLESHOOTING…………………………………………………………………………………………..4

4. WIRING DIAGRAM.................................................................................................................................8

5. EXPLODED VIEW ..................................................................................................................................8

6. SPARE PARTS LIST…...........................................................................................................................8

1.PREFACE

This SERVICE MANUAL provides various servicing information, including the mechanical and electrical parts,

etc. This dehumidifier was manufactured and assembled under a strict quality control sy stem.

The refrigerant is charged at the factory. Be sure to read the safety precautions prior to servicing the unit.

1.1 SAFETY PRECAUTIONS

1. When servicing the unit, set the POWER SWITCH to OFF and unplug the power cord.

2. Inspect the service cord for damage or wear.

If a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

3. After servicing the unit, make an insulation resistance test to protect the customer from being exposed to

shock hazards.

1.2 INSULATION RESISTANCE TEST

1. Unplug the power cord and connect a jumper lead between the two (2) live pins.

2. The grounding conductor (yellow/green) is to be open.

3. Measure the resistance value with an ohm meter between the jumped lead and each exposed metallic part

on the equipment at all the positions (except OFF) of the ROTARY SWITCH or POWER SWITCH.

4. The value should be over 1MΩ.

Page 3

2

1.3 FEATURES

Auto-defrosting.

Suitable for low-temperature and high-humidity

weather.

water-full alarm and auto shutdown functions.

Powerful dehumidification in wide temperature

range between 5℃~32℃.

LED display.

Humidity display and setting.

Self diagnose and defect display

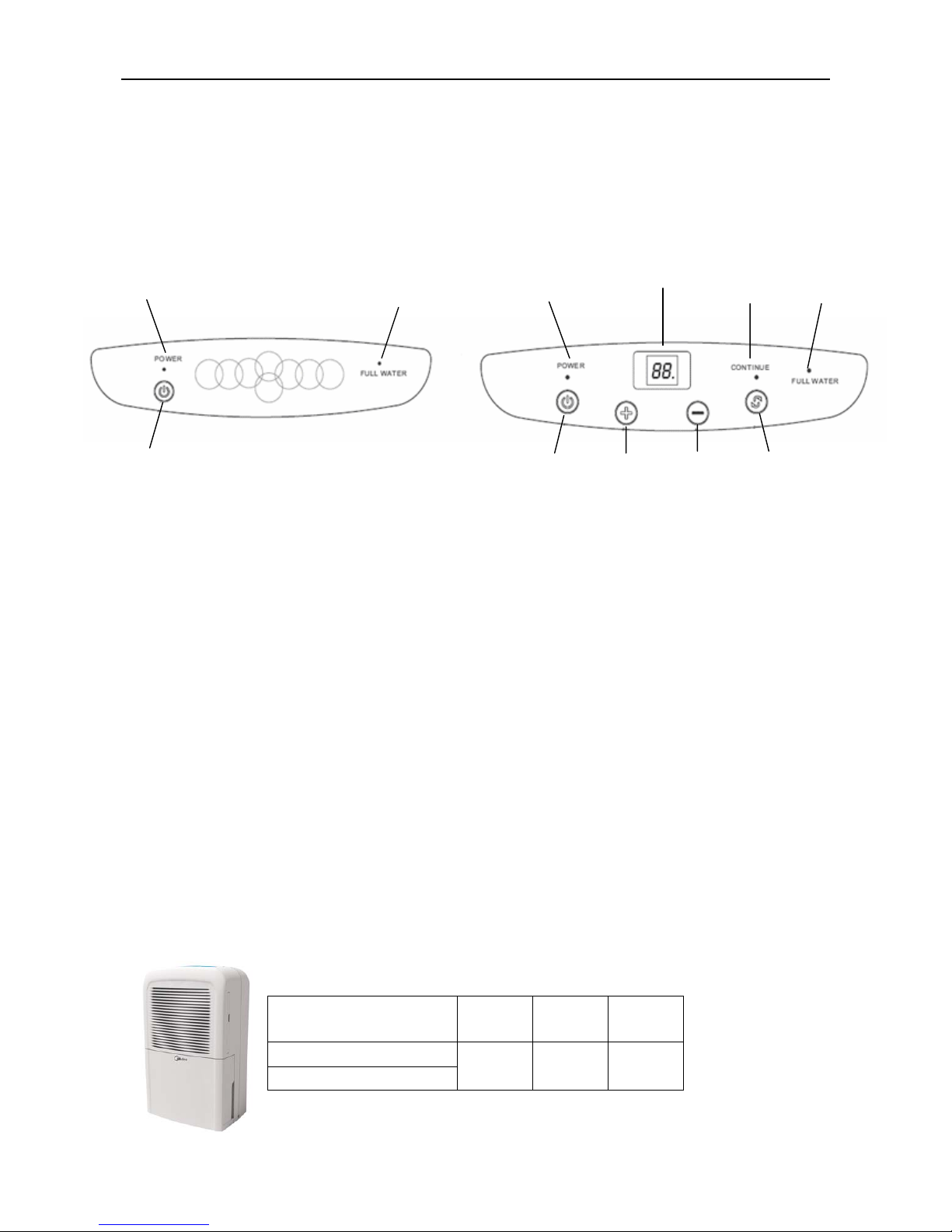

1.4 CONTROL LOCATIONS

2 3 2 8 4 3

1 1 5 6 7

1. ON/OFF Button: Power indicator links

slowly when the power is connected at the

socket (initial power).Press this button at this

time, the unit will directly go into

DEHUMIDIFYING operation with the original

factory humidity setting( 60%RH). Press the

button again, the unit will stop operation.

2 . POWER indicator: At the first time to

connect to the power, it flashes slowly The

POWER indicator lights after the unit is turned

on, and dark after the unit is turned off.

3. FULL WATER indicator: Lights up when the

bucket is full, and the unit stops operating

4.CONTINUE indicator: Lights up when the

unit is on CONTINUOUS DEHUMIDIFYING

mode.

5. HUMIDITY UP Button: When the unit is

operating, the setting humidity will go up by

pressing this button every time, the range of

justment is from 35%RH to 80% RH.

6. HUMIDITY DOWN Button: When the unit is

operating, the setting humidity will come down

by pressing this button every time, the range of

adjustment is from 80%RH to 35%RH.

7. CONTINUE Button: When the unit is

operational, press the Button will go into

CONTINUOUS DEHUMIDIFYING mode.

8. LED Digital display: This area will display the

room relative humidity under normal operation

and display the setting humidity when setting the

desired humidity.

1.5 OUTSIDE DIMENSIONS

Model Width

(mm)

Height

(mm)

Depth

(mm)

CE-CF0.3BD/N3-F

CE-CFZ0.3BD/N3-F

315 505 235

Page 4

GD Midea Refrigerant Equipment Co. Ltd Service manual for F Dehumidifier

3

2 Electronic function

2.1 When the unit is just powered on

When the unit is just powered on or the dropped

power is just restored, the unit will immediately

perform the self-diagnosis. The check items include

the water-full, temperature sensor and humidity

sensor. If there is no defect, the power indicator will

flash at 0.5Hz while all other indicators are off. All

buttons are invalid except the ON/OFF button.

2.2 Operating under setting humidity

When the ON/OFF button is pressed for the first

time after the unit is powered on or the power is just

restored from dropping, the unit will operate with a

original factory humidity 60%RH and the power

indicator will light. Under this condition, the humidity

can be set by pressing the Humidity Up/Down

buttons. When the indoor humidity is 5% higher than

the setting humidity, the compressor will be on.

When the indoor humidity is lower than the setting

humidity, the compressor will be off and the fan will

stop operating 3 minutes after the compressor is

shut down. If the indoor humidity is getting 5%

higher than the setting humidity, the fa n will be on

immediately and the compressor will start too.

2.3 Continuous Dehumidifying mode

The compressor and the fan motor will always

be on and the Continue and power indicator will be

on. The LED will display the indoor humidity. Setting

humidity is not available.

2.4 Stop operation

When the unit is stopped operation by pressing

the ON/OFF button, the compressor and the fan will

shut down and all indicators will be off. The time for

defrost will be cleared. When the unit is restarted by

pressing the ON/OFF button, the unit will start with

previous set mode. Whether the defrost function

starts need to be prejudged. The self-diagnosis

function will just check the water-full defect. The fan

motor will work same as the compressor.

2.5 Compressor delay start

When the mode is changed but the compressor

does not start or the unit restart after stop working, if

the compressor accord with it’s starting condition,

the fan motor will start immediately while the

compressor will delay 3 seconds to re-start.

2.7 Protection and failure mode

2.7.1 Water full protection. When the water tank is

full , the compressor and fan motor will shut down

and the water full indicator will flash with LED

displaying P2. Under this situation, all button is out

of service. After the water is poured, the unit will

restore operating as previous setting.

2.7.2 Anti icing protection.

2.7.2.1 If the time accumulates up to 15 minutes

with compressor operating and the temperature of

evaporator lower than -1

o

C, the Anti-icing protection

function will be activated.

2.7.2.2 When the protection is activated, the

compressor will be off while the fan motor is on with

high speed, and the Turbo indicator will be on with

the LED displaying P1. The time will also be

cleared.

2.7.2.3 If the situation that compressor is off and fan

is on has lasted for 6 minutes or the ON/OFF button

is pressed, the unit will stop anti-icing protection

function.

2.7.2.4 After the Anti-icing function is completed, the

unit will restore operation as previous mode or stop

if the Anti-icing function is completed by pressed the

ON/OFF button.

2.7.3 Sensor failure check. When the output voltage

of sensor is lower than 0.5V or higher than 4.95V,

the unit will alarm and the LED displays E1 for

humidity sensor failure and E2 for temperature

sensor failure. Under this situation, the compressor

and the fan motor will shut down and the Power

indicator will flash at 5Hz. All buttons is out of

service. After the defect is cleared, the unit will not

work until the power to the unit is re-stored.

2.7.4 When the water full and sensor failure occur

together, the water full alarm has the priority on

display.

2.7.5 compressor protection: under all modes, the

compressor will delay 3 minutes to start after it stop.

Page 5

4

3 TROUBLESHOOTING GUIDE

3.1 TROUBLESHOOTING GUIDE

In general, possible trouble is classified in three kinds. One is called S t arting Failure which is cause d from

an electrical defect, another is ineffective Air Conditioning caused by a defect in the refrigeration circuit and

improper application, and the other is called the Structure Damage.

ROOM AIRCONDITIONER VOLT AGE LIMITS:

NAMEPLATE RATING MINIMUM MAXIMUM

220~240V 198V 254V

3.1.1 Water level protection function abnormal

Abnormal water level protection function includes the following: (1) There is an alarm when the water

level is normal and (2) There is no alarm for full water.

3.1.2 Automatic trouble ala rm

When the pipe temperature sensor is defective, the motors of the compressor and the fan will be shut

down, and the power indicator will flash at 5 Hz.

Power indicator flashes at 5 Hz

The connector CN3 in

main PCB is loosed

Place it properly

Pipe temperature sensor trouble

Replace pipe temperature sensor

Trouble in input circuit of water

level switch of drive board

components

Water level

switch broken

Replace

switch

Broken Main

chip of PCB

com

p

onents

Replace PCB

components

Floating ball

of water tank

too heavy

Take out water tank

and remove water

Loosed input plug of

water level switch

Plug it again

prop

erly

Trouble in input circuit of water

level switch of drive board

Water level

switch broken

Replace

switch

Broken main chip of

PCB components

Replace PCB

com

p

onents

No alarm at full water

Water tank not

p

laced properly

Place water

tank carefully

Alarm at normal water

Page 6

GD Midea Refrigerant Equipment Co. Ltd Service manual for F Dehumidifier

5

3.1.3 Humidity sensor check

3.1.4 Fail to start or fail to start motor

3.1.5 Abnormal noise

Humidity display is chaos

Water on the Humidity sensor

board

Dry it over heat

Humidity sensor board trouble

or main PCB defective

Replace humidity sensor

board trouble or main PCB

Page 7

GD Midea Refrigerant Equipment Co. Ltd Service manual for F Dehumidifier

6

3.1.6 Complaint and remedy

Complaint Cause Remedy

Transformer

(Discharge transformer

before testing)

Check resistance between the two input/output lines on

transformer. Replace the transformer if either of the input/output

is open or the transformer is damaged.

No display on

panel or any one of

the button failure.

Display board or main

PCB failure

Replace the display board if it is +5V else replace the main

PCB.

No power Check voltage at electrical outlet. Correct if none.

Power supply cord Check voltage at the power cord terminal on Main PCB.

Replace the power cord if none.

Transformer

(Discharge transformer

before testing)

Check resistance between the two input/output lines on

transformer. Replace the transformer if either of the input/output

is open or the transformer is damaged.

Wire disconnected or

connection loose

Connect w ire. Refer to wiring diagram for terminal

identification. Loose. Repair or replace loss e terminal.

Main PCB failure Select fan speed and Check the voltage of P1, P2 on main

PCB. Replace the main PCB if no voltage.

Capacitor (Discharge

capacitor before testing)

Test capacitor . Replace if not within 10% of manufactur e' s

rating. replace if shorted, open or damaged

Fan motor w ill

not run.

Will not rotate Fan blade hitting shroud or blower hitting scroll. Realign

assembly. Check fan motor bearings. Replace the motor if motor

shaft don't rotate.

Check voltage. Call an electrician if not with in limits.

Test capacitor . Replace if not within 10% of manufactur e' s

rating. Replace if shorted, open or damaged.

Check bearings. Replace the motor if the fan blade can't

rotate freely.

Fan motor runs

intermittently

Revolves on over

load.

Pay attention to any change from high speed to low speed.

Replace the motor if the speed does not change.

Fan Replace the fan if cracked, out of balance, or partially

missing.

Blower Replace the blower if cracked, out of balance, or partially

missing.

Fan motor

noise

Loose screws Tighten them.

Page 8

GD Midea Refrigerant Equipment Co. Ltd Service manual for F Dehumidifier

7

Worn bearings Replace the motor if knocking sounds continue w hen

running or loose, or the motor hums or noise appears to be

internal while running.

Excessive

noise

Copper tubing Remove the cabinet and carefully rearrange tubing not to

contact cabinet, compress or, shroud and barrier.

Voltage Check voltage. Call an electrician if not within limits.

Wiring Check the w ire connections, if loose, repair or replace the

terminal. If wires are of f, refer to wiring diagram for identification,

and replace. Check w ire locations. If not per wiring diagram,

correct.

Main PCB failure Replace the main PCB if open.

Capacitor (Discharge

capacitor before testing)

Check the capacitor. Replace if not within 10% of

manufacturers rating. Replace if shorted, open, or damaged.

Humidity sensor Replace if shorted, open, or damaged.

Compress or

will not run while

fan motor runs

Compressor Check the compressor f or open circuit or ground. If open or

grounded, replace the compressor.

Air filter Clean or replace if restricted.

Condenser and

Evaporator

Clean or replace if restricted.

Fan motor Check the fan capacitor and replace if not within 10% of

manufactures rating.

Room structure Take proper measures to make the door and window s

sealed w ell if gap is found.

Air flow Clean or remove if any barrier is found to block the

inlet/outlet wind flow of the unit.

Less refrigerant Check the tubes for reasons of leakage. Recycle the

refrigerant, correct the leakage points and recharge.

Capillary tube Regulate the flow if capillary tube and make the evaporating

temperature appropriate if the evaporator is frosted.

Insufficient

capacity

Compress The inlet and outlet valve of the compressor is damaged,

making the low pressure connected with the high pressure. The

refrigerating system is difficult to produce high pres sure and low

pressure. Replace the compressor after checking f or the reason.

Refrigerant The amount of the refrigerant is too much, making the

compressor load too big. Recycle and recharge the refrigerant

after checking for the reason.

Stop instantly

after

startup.

Compressor The compressor is heat stuck. Replace after checking for the

reason.

Humidity sensor Check and replace if the Humidity sensor is open or

damaged.

The

compressor not to

stop even the room

humidity has got to

the setting value.

Main PCB Check and replace the main PCB

The unit starts

and s tops

Power supply The input power supply voltage is too low . Call an electrician

if not within limits.

Page 9

GD Midea Refrigerant Equipment Co. Ltd Service manual for F Dehumidifier

8

Humidity sensor Replace it.

frequently.

Main PCB Check and replace the main PCB.

4 WIRING DIAGRAM

4.1 For models:

5 EXPLODED VIEWS

(See attached files)

6 SPECIFICATIONS

(See attached files)

CE-CF0.3BD/N3-F

CE-CFZ0.3BD/N3-F

Loading...

Loading...