Page 1

Shunde Midea Dishwasher Manufacturing Co., Ltd.

Dishwasher Service Manual

Midea

Life can be lovelier.

Fully Automatic Double Pump

Page 2

For the sake of safe and efficient manipulation, you should prepare and learn to

use the following tools prior to servicing the dishwater: plus screwdriver, minus

screwdriver, H screwdriver, torque spanner, OTK caliper and universal meter.

Attention: never measure the resistance of live cord. Otherwise, you measuring

device may be damaged.

1. Dishwater does not work when

turned ON (No power indication).

Phenomena

Power socket defect.

Power cord defect.

Broken timer cord.

Lock malfunction.

Power switch failure.

Check socket.

See power cord.

See timer.

See door lock assembly.

See option switch and power switch.

Possible Causes

Service Instructions

Inlet valve core will not close.

Timer failure.

3. Overflowing incoming water.

Commonly Used Tools

Trouble Shooting

1

See protection and working

pressure switches.

See inner connecting wires.

Twisted inlet hose.

Excessive lower water pressure or

blocked water tap.

Inlet valve malfunction or blocked valve

filter.

Working pressure switch failure.

2. Small or no incoming

water.

4. Drainage activates again and

again without washing.

Working and protection

pressure switches failure.

See protection and working

pressure switches.

See inlet valve.

See timer.

Straighten up the inlet hose.

Check the water tap.

Check the inlet valve.

See protection and working

pressure switches and check

appropriate connecting wires.

5. Timer does not work.

6. Incomplete drainage.

7. Leakage.

Timer cord failure.

Timer failure.

Heating element failure (for heated

washing).

Thermostat failure.

Insufficient water.

See connecting wires.

See timer.

See heating element.

See thermostat.

See 2.

Twisted or blocked drain hose.

Pump motor failure.

Check drain hose.

See water pump motor assembly.

Tilted dishwater.

Unlocked door.

Broken connecting hose in

dishwasher.

Aged gasket.

Loose or defect inlet valve

connector.

Damaged pump.

Pump gasket failure.

Adjust the machine foot.

Lock the door.

Replace connecting hose.

Replace gasket.

Tighten the inlet valve. See inlet valve.

Reconnect the pump and the sump,

add gasket at the connector and

tighten the wedge.

See water pump motor assembly.

8. Dishwater powder retained in

the powder trough.

9. No brightness liquid from

dispenser.

10. Bad dispenser sealing

Caked dishwater powder.

Dishes block the water flow to the

dishwasher powder.

No brightness liquid in dispenser.

Electromagnetic valve does not

work.

See dishwater powder and

brightness liquid.

See loading of dishes.

See dispenser and inner

connecting wires.

Sealing cap failure.

Broken dispenser case.

Replace dispenser.

Protection or working pressure

switch failure.

Incorrect cord connection.

Page 3

Many of the performance failures of the dishwasher are not the result of mechanical troubles. And the

unsatisfactory washing result can usually be corrected without any service.

This manual deals first with the problems in performance. To have satisfactory washing result, you have to use the

machine correctly. First thing first, the dishes shall be placed in a correct manner. If the machine works well and

the washing result is unsatisfactory, you should check the layout of the dishes as follows:

Load the dishes as instructed in the user's manual.

Preparation of the dishes such as dumping the remaining food, and removing from the dishes food lumps,

starches in particular, shall be done prior to loading.

The dishes shall face the water flow from the spray arm for free washing. Do not place the dishes in an

overlapped way.

Load heavy pans and large soup bowls downwards. If the upper racks are barred from water flows, do not

place articles on them any more.

Leave some space in the front of the wire basket so that the water flow may wash out the dishwater powder

from the powder trough in the inner door.

On the fork/knife rack, the tableware shall be placed with handle down evenly. Do not load there the

articles that may fall out from the bottom.

2

11. Unsatisfactory washing

result.

13. Water drops at the door.

12. Unsatisfactory drying.

14. Difficult opening/shutting

of the door.

15. Excessive working noise.

16. Water accumulated in

bottom pan.

Bad sealing of hose connectors.

Salt spoon, colophony spoon or

water tank leakage.

Incomplete sealing of inner

container from sump.

Incomplete sealing of thermostat.

Collision of dishes.

Vibrating pump motor assembly.

Foreign articles in the pump.

Loose screws.

Improper loading of dishes.

Aged, incorrect or insufficient dishwater

powder.

Improper procedure selection.

Twisted or blocked drain hose.

Foreign articles in the main washing

system.

Blocked spray arm.

Brightness liquid leaks into the inner

container during washing.

Filter screen not clipped to the right

position.

Improper loading of dishes.

Brightness liquid not used.

Heating element problem.

Heated wash mode not selected.

Condensed vapor from air

vent.

Dislocated door gasket.

Bent lock linkage.

Disalignment of lock hook.

See loading of dishes.

Add brightness liquid.

See heating element.

Reselect procedure.

Normal phenomena.

Press gasket back to position.

See door lock assembly.

See door lock assembly.

See loading of dishes.

See motor and pump assembly.

Check screws.

Check water hoses.

Check water softener (WP5F).

Check the contact.

Check the contact.

See loading of dishes.

See dishwasher powder and brightness

liquid.

Reselect procedure.

Check drain hose.

Clean spray arm.

Replace dispenser.

Clip filter screen to the right position.

Note: in the narration of this manual, the number in brackets behind the part stands for the serial

number of the part in the explosion diagram. The double pump model in the explosion

diagram is equipped with a WP5E. The actual configuration may be different.

III. Check of Performance: Loading of Dishes

IV. Check of Performance: Dishwasher Powder and Brightness Liquid

The water (pressure, hardness and temperature) and the dishwasher powder are the major elements that affect the

washing effect of the machine. Choose the right dishwasher powder and dosage according to the local water

condition, you will have satisfactory washing result.

Use only the fresh and dry dishwasher powder of the designated brand. Outdated powder will reduce the

washing effect.

Contact the local water supply company for the water condition, if applicable. The higher the water hardness is,

the more powder shall be used.

Check the brightness liquid in the dispenser and add without delay if it is insufficient. The brightness liquid

helps the water to drip, making the dishes easy to dry and curbing the formation of water specks on the surface

of the dishes.

Page 4

¡¾Í¼1¡¿

A

B

¡¾Í¼2¡¿ ¡¾Í¼3¡¿

C

C

D

3

V. Power cord

The power cord of the dishwasher usually has a three-pin plug. Connect

the power supply as instructed in the user's manual.

If the dishwasher does not work, the power cord might be in the fault.

Most of the power cord troubles arise from damaged cord or loose

connection, and are visible.

Attention: to avoid electric shock, the power socket and power cord shall

be well grounded. Never use two-hole conversion connector that has no

ground terminals.

Steps for the check:

A. Disconnect the power prior to check.

b. Check the power plug. Improper connection may lead to bad contact.

c. Pull out the power plug in one stroke. Never pull at the power cord or use

a knife or other sharp tools that may cut the cord.

d. Check the power plug for overheat caused damage, corrosion or

looseness. In case of troubles, remove the outer casing (1) first, then the

rear panel (97) and replace the power cord (see Process 6).

e. Open the power cord clamp (96), remove the old power cord and replace

a new one with terminals. Secure the power terminals to the connection

terminals, and replace the power cord clamp.

f. Replace the rear panel and the outer casing.

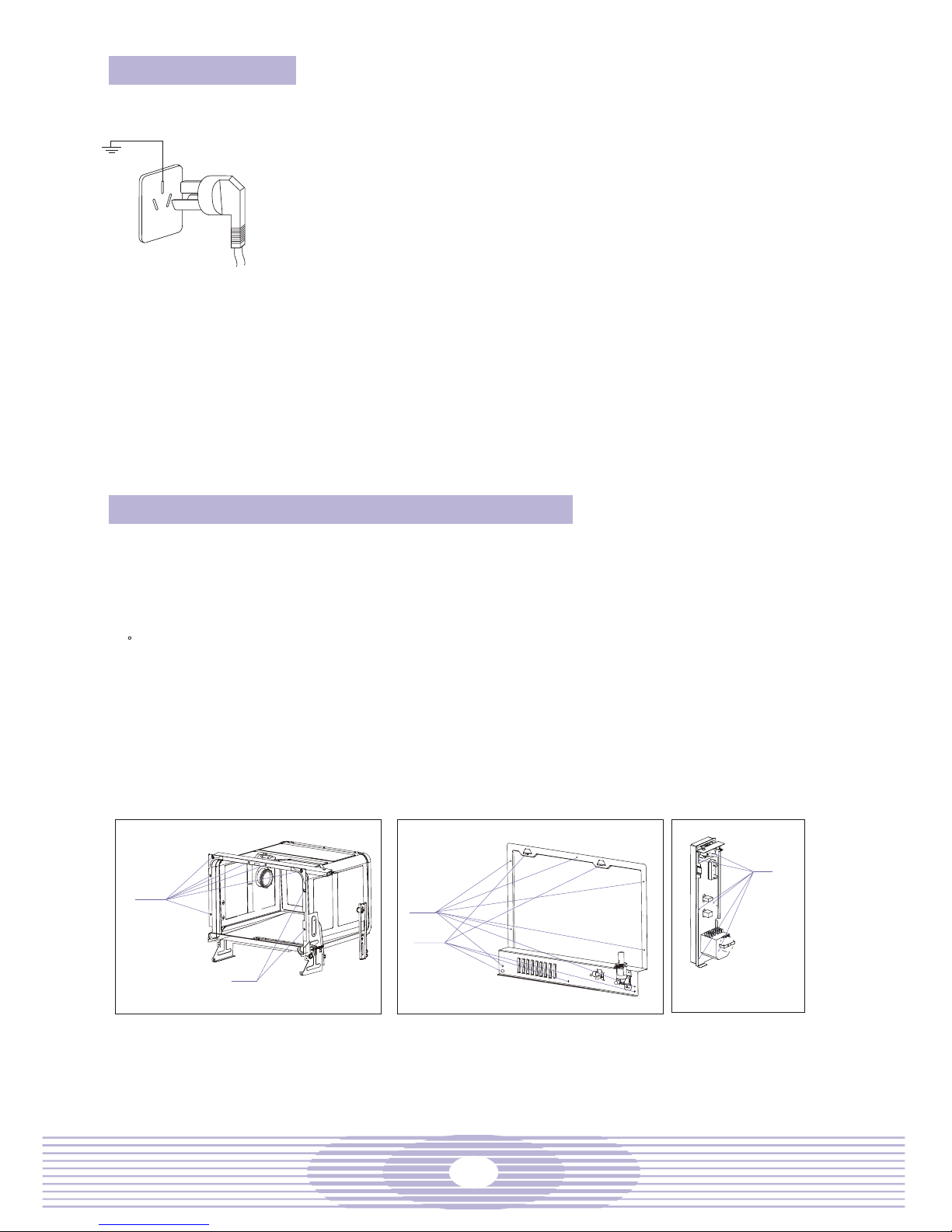

VI. Removal of Outer Casing, Control Panel, Rear

This dishwasher is completely sealed. In order to repair internal parts, you have to remove the

outer casing before you can check and repair the parts.

Steps for the check:

a. Remove the three screws on the sides of the outer casing.

b. Open the door, and remove the six screws in the front of the inner container (see fig. 1 below). Note: do

not mix these stainless steel screws with the other ordinary ones.

c. Remove the seven screws in the back of the outer casing (see fig. 2 below).

d. Remove the screws in position D in fig. 2 below and take away the rear panel.

e. Lift up and away the outer casing from the dishwasher, and check and repair the internal parts.

f. Remove the six screws from the control panel bracing bar (58) (see fig. 3 below) and the two stainless

steel screws in position C of the inner container (see fig. 1 below), and pull out the control panel.

g. Remove the timer knob (see 1 in the appending diagram).

h. Turn the dishwasher upside down, remove all the screws in the bottom pan, open the cord clamp and

remove the bottom pan.

Page 5

Turn all the switches to OFF and pull out the power cord plug.

An ohmmeter and the ability to read circuit diagrams are needed in this step.

Remove the outer casing.

Pull out the two input terminals of the timer motor and measure them with an ohmmeter (use the

range of R 100). If the pointer does not sweep partly across the line, replace the timer.

Refer to the circuit diagram to check the connection of the timer terminal to the elements.

4

VII. Check Internal Connecting Wire

The internal connecting wire connects the timer (60), the power switch (61), the inlet valve (95), the heating

elements (45) and other electric elements together. The wires shall be kept intact. Any damage to the wire

may cause overheat and result in broken wire. Common troubles to the internal connecting wire are broken

wire, bad connection terminal contact, and connection terminal insulation layer damages.

To repair the dishwasher, the ground shall be connected. When an electric component is replaced, check

whether the ground is connected again. This is a crucial step to avoid electric shock and short circuit.

Attention: to replace electric cord, use the cord of the same temperature resistance and specifications. The

specifications and temperature rise are marked on the cord.

Turn all the control knobs to OFF and pull out the power cord plug.

Open the outer casing, and, if necessary, remove the bottom pan.

Check the wires and connectors and replace the damaged ones.

Steps for the check:

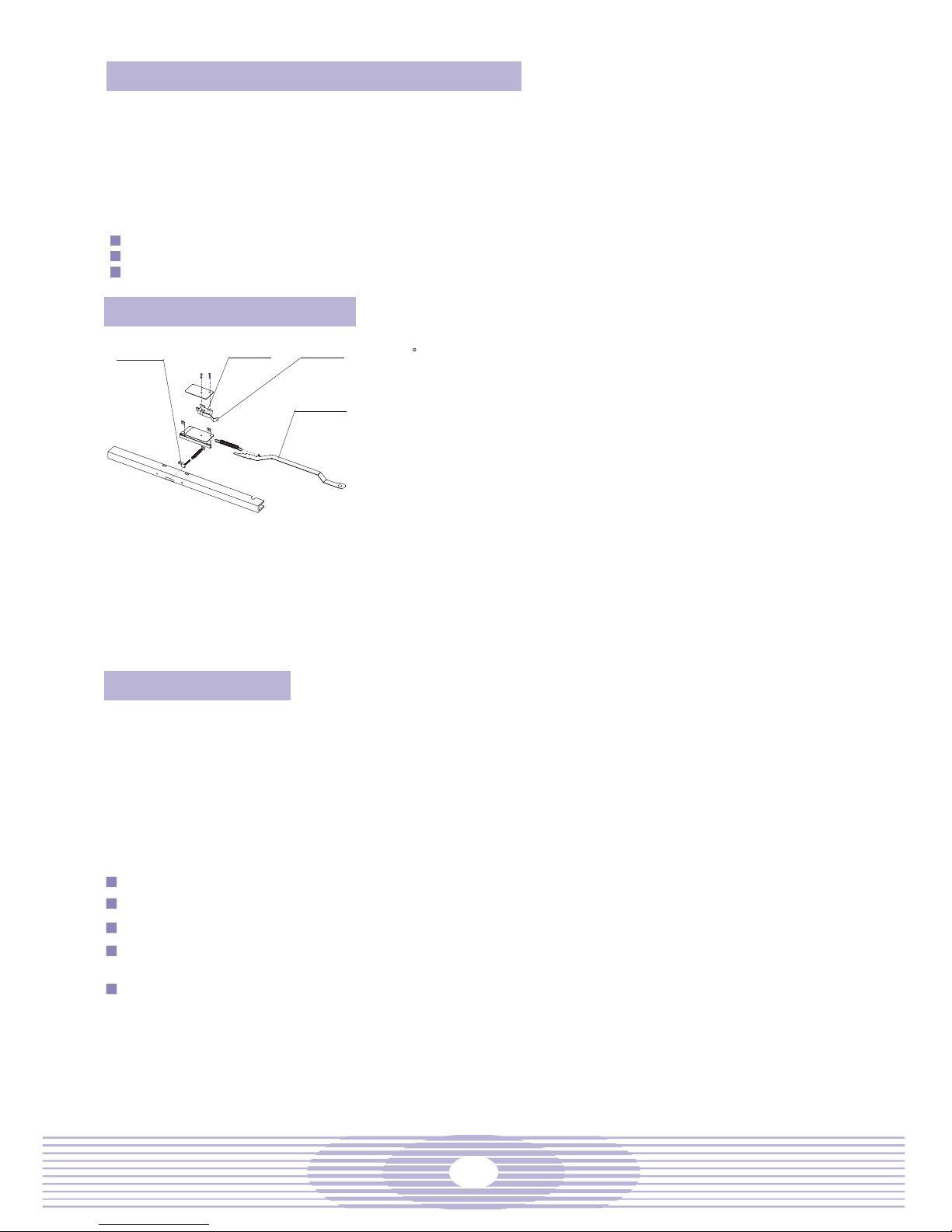

VIII. Door Lock Assembly

Slider

micro switch

Micro switch spring

Linkage

The working mechanism of the door lock is that the linkage (8)

bolts up the door hook, which, in its turn, presses the micro switch

spring in the lock assembly to form a closed circuit. The lock

mechanism consists of the door lock holder (11), the slider (10)

and the micro switch (3). When the door is opened, the door hook

is withdrawn to release the micro switch, cutting the power supply

for open door protection.

In case of worn out slider, micro switch failure or deformed micro

switch spring, troubles may occur and the dishwasher will stop to

work as usual.

Steps for the check:

a. Pull out the power cord plug prior to servicing the door lock

mechanism.

b. Remove the outer casing.

c. If micro switch failure is the case, disconnect the micro switch,

remove the two screws and replace a new micro switch.

d. In case of deformed micro switch spring, adjust the spring

with nipper pliers so that the micro switch returns to its

original position when the slider is released and the micro

switch closes when the slider is pressed tight.

IX. Timer

The timer of the dishwasher consists of a synchronous motor and various switches, and controls the

various operations of the dishwasher automatically. The step motor, like a clock, runs at constant speed.

When it passes through the selected procedure, the internal switches will open or close at a precise

sequence, realizing the control of the circuit over the internal components.

The output cords of the timer are in different colors. With a copy of the circuit diagram in hand, you can

track the circuit from the timer to any element.

The timer is a very reliable unit. In case of dishwasher troubles, check other causes first before focusing

on and replacing the timer.

Steps for the check:

Page 6

The option switch and power switch are push-button switches. Abrasion and use after an extensive period

may cause switch failure. When the switch is pressed, the power or high temperature pilot will not light up.

Check the power switch or the option switch.

Steps for the check:

Turn all the switches to OFF and pull out the power cord plug.

Remove the outer casing.

Press the power or option switch and check with an ohmmeter whether the normally open terminal

is closed. If it is not closed, replace the switch.

Remove the control panel, unscrew the screws to remove the defect switch, and replace with a new

one.

Connect the wires behind the switch and check if they are connected fast.

Replace the control panel and the outer casing.

The pressurecontrol of the dishwasher is realized through a float pressure switch composed of two micro

switches. The larger contact current (10A) controls the working level and the smaller current (3A) controls

the protection level. The working level is set at 78 85mm above the sump bottom, and the protection level

is 3mm or more below the brink of the inner container.

The check and adjustment of the pressure switch:

If pressure switch trouble is suspected, check whether the dishwasher is set level. If it is in level

position, remove the outer casing.

Add water to the inner container, and check whether the float and lever is choked. In case of

choking, correct it.

If the working pressure switch remains placid when the pressurein the water tank rises over 94mm,

the switch might be obstructed by the lever or damaged. In case of damaged switch, replace it.

X. Option Switch and Power Switch

5

XI. Inlet Valve

The inlet valve controls the water volume into the dishwasher. The electromagnetic valve is fixed on the

valve base. When it is powered, a magnetic field will come and pull the valve core to let in the water.

The feeding of the water depends on the timer, which controls the opening of the electromagnetic valve.

In normal circumstance, the pressurein the inner container of the dishwasher shall be 78 85mm above the

sump bottom. Open the door to check the pressurewhen water is filled.

During the washing operation, the inlet valve may open to add some water.

Steps for the check:

Check and replace the inlet valve.

a. Turn the power of the dishwasher to OFF, and pull out the power cord plug (guard against sharp edge

from hurting the power cord).

b. Check with an ohmmeter as instructed.

c. Remove the outer casing and the rear panel.

d. Check the connecting wire of the inlet valve for looseness and the valve for crevice.

e. Check the connection of the inlet hose.

f. If the incoming pressurein the water tank is lower than the normal level, remove the inlet hose, clean,

or, if necessary, replace the filter screen, and reconnect the inlet hose.

g. Check the inlet valve terminals with an ohmmeter. The probes should touch the terminals of the inlet

valve. If the pointer does not move, replace the inlet valve with a new one.

h. When replacing the inlet valve, turn down the water tap and remove the wedge and the connecting

tube.

j. Unscrew the screws in the inlet valve support (96), replace the inlet valve with a new one, and

reconnect the tube and wire. Connect the inlet hose when the dishwasher is ready.

XII. Protection Pressure Switch and Working Pressure Switch

Page 7

Ø

6

If the protection pressure switch remain placid when the

pressurein the water tank approaches 2mm below the brink of

the inner container, the protection pressure switch might be

broken or dislocated due to loose mounting screws.

Tighten the mounting screws and adjust the protection pressure

switch as follows: (1)Short circuit the normally open terminal

and the common terminal of the working pressure switch;

(2)Unscrew the fastening screws in the adjusting plate of water

level; (3)Turn counterclockwise the adjusting screw in the

adjusting plate of pressuretill the required water level;

(4)Remove the short circuit cord on the working pressure switch,

and wrench tight the fastening screws in the adjusting plate of

water level.

Try the pressureagain. If the pressureis higher than expected,

go over again the adjustment above till the requirement is met.

After adjustment, seal the screws with thread gum. Otherwise,

the screws may get loose, causing the pressureto change.

XIII. Water Pump Motor Assembly

XIV. Heating Element and Protective Thermostat

The heating element is located in the sump. When it is powered in the heated washing cycle, it warms up

the water, which will clean the dishes more effectively, and generates heat after washing to dry the

dishes.

The heating element has a nichrome filament inside. You can measure the resistance with a universal

meter to check its condition.

The protective thermostat is a temperature limitation switch and a safety device. In case the dishwasher

fails and the temperature inside the inner container rises above a specific limitation, the thermostat will

cut the heating element circuit to avoid any damage to the machine.

Steps for the check:

Remove the outer casing.

From the left side, you can see the heating element assembly installed to the end of the sump. Pull out

the connecting terminal of the heating element.

Check the heating element with an ohmmeter for damage and replace the damaged one.

Remove the connecting nut and the thermostat.

Remove the end cap of the heating element and take the heating element out of the sump.

Replace a new heating element and install the assembly as usual. Note: install the thermostat end with

heat conducting silicone grease, tighten the heating element nut, and secure the gasket and end cap.

The screws shall be wrenched tight. No leakage is allowed. The connecting terminal shall be upright, and

the heating element terminal shall be securely connected.

Connect the power cord and reinstall the machine.

adjusting screw

common terminal

Lever

Float

normally open terminal

working pressure switch

protection pressure switch

Mounting screw

fastening screw

Water Pump Motor Assembly

The dish washing is a joint accomplishment of the circulation pump (77) and the drain pump (82). The

possible troubles of the water pump motor assembly include burnt motor coils, starting capacitor (74)

damage, damaged pump sealing spring, broken sealing, broken connecting tube, etc.

Steps for the check:

a. Remove the outer casing, and turn the dishwasher upside down.

b. Remove the connecting screws around the bottom pan and the screws to the circulation motor

support, the drain motor and the pressure switch bracing bar.

c. Check the capacitor and, if necessary, replace a new one.

d. Check the circulation pump for defects. In case of defective pump, replace it in the following manner:

(1) Remove the inlet hose wedge and the circulation pump; (2) Replace a new circulation pump; (3)

Put on a new inlet hose wedge and connect the tubes and wires; (4) Tighten the wedge.

e. Check the drain pump for defects. In case of defective pump, replace it in the following manner: (1)

Remove the inlet hose wedge and the drain pump; (2) Replace a new drain pump; (3) Put on a new

inlet hose wedge and connect the tubes and wires; (4) Tighten the wedge.

f. Check the connecting tubes and replaced the damaged ones.

Removal of Drainage Troubles

a. Check the drain hose for twist, air bubble or blockage and make necessary correction.

b. Check whether the motor is burnt. If so, replace the drain pump as specified above.

Page 8

7

XV. Overheat Thermostat

This thermostat is designed to prevent overheating of the heating element. The temperature limitation is

set at 115 . Below this limitation, the circuit is closed. Once the temperature rises above this limitation,

the circuit is cut, protecting the heating element from being burnt.

Steps for the check:

Remove the outer casing.

Remove the thermostat connecting wire and check with an ohmmeter whether the thermostat circuit is

closed in normal temperature and opened when temperature rises above 120 . If the result if positive,

the thermostat is normal. Otherwise, it fails and shall be replaced.

From the lower left side, you can see the thermostat at the end of the sump. Remove the nuts on the

thermostat mounting plate.

Remove the mounting plate and the thermostat.

Replace a new thermostat and add some heat conducting silicone grease to its end.

Wrench tight the nuts on the thermostat mounting plate and connect the thermostat connecting wires.

Replace the outer casing.

XVI. Water Temperature Thermostat

This thermostat (47) is designed to inspect the water temperature and control the heating element. The

temperature control point is set at 62 (different temperatures are available and can be observed from the

thermostat). The circuit is opened below this temperature and closed above it.

Steps for the check:

Remove the outer casing and bottom pan.

Remove the connecting wires behind the sump and check with an ohmmeter whether the thermostat

circuit is opened in normal temperature and closed when temperature rises above 67 . If the result if

positive, the thermostat is normal. Otherwise, it fails and shall be replaced.

Remove the screws and the mounting plate.

Replace a new thermostat and the mounting plate. The mounting plate shall press tight to prevent

water leakage at the thermostat end.

Replace the connecting wires, bottom pan and outer casing.

The dispenser (32) releases automatically the brightness liquid into the machine at the final rinsing stage.

The brightness liquid reduces the surface tension of the water and eliminates dirty spots from the dish

surface.

The dispenser can hold brightness liquid for one month use. At the final rinsing stage, the timer activates

the electromagnetic valve of the dispenser and pulls the rubber gasket of the valve core to release a

suitable amount of brightness liquid, which is carried away in the flowing water.

Steps for the check:

Check and replace the dispenser.

a. Turn the power switch to OFF, and pull out the power cord. Guard against sharp edge from cutting the

power cord.

b. Open the door, remove the four screws in the sides of the inner door, unscrew the knob cap of the

dispenser and the two locknuts, and remove the inner door.

c. Check the dispenser for any leakage or release of brightness liquid. If no brightness liquid is released,

check if there is brightness liquid in the dispenser. If there is brightness liquid in the dispenser, check

the terminals connected to the dispenser for looseness and fallout.

d. Pull out the two terminals of the connecting wire connected to the dispenser and remove the dispenser.

e. Check the electromagnetic valve of the dispenser with an ohmmeter. If the dispenser is broken,

replace it.

f. Connect the terminals of the connecting wire of the dispenser and replace the inner door.

g. Wrench tight the two locknuts and knob cap of the dispenser and check the dispenser for tightness.

XVII. Dispenser

Page 9

8

XVIIII. Spray Arm Assembly

If the spray arm assembly is blocked, unscrew the nut beneath the spray arm and remove

the spray arm to wash out the obstacles. Note: the spray arm nut is turned to the left. When

removing the obstacles, do not dig or pry the spray arm and nozzle. Otherwise, the washing

effect and the service life of the spray arm may be compromised.

XX. Explosion Diagram and Schedule

XXI. Circuit Diagram

XXII. Consumables List

container of the dishwasher. It slows the growth of sediment in the inner container and

improves the efficiency of the dishwasher powder.

The water softener may have such troubles as

a. After five rounds of salted washing, the out-of-salt pilot remains on.

Possible causes and solutions:

(1) Incorrect float position in the salt spoon. Replace the salt spoon.

(2) Switch subassembly failure. Replace the switch subassembly.

(3) Twisted hose. Straighten up the hose.

(4) Incorrect wire connection. Check the wires.

b. After 50 rounds of salted washing, the out-of-salt pilot remains off.

Possible causes and solutions:

(1)Electromagnetic valve failure in the salt spoon. Replace the electromagnetic valve.

(2) One-way valve failure in the salt spoon. Replace the one-way valve.

(3) Incorrect float position in the salt spoon. Replace the salt spoon.

(4) Pilot failure. Replace pilot.

(5) Switch subassembly failure. Replace the switch subassembly.

(6) Incorrect wire connection. Check the wires.

(7) Twisted hose. Straighten up the hose.

c. During the feeding of the water, large amount of water directly flows from the water tank

to the inner container.

(1) Incorrect water distribution in the water tank. Replace the water tank.

(2) Twisted inlet hose. Straighten up the hose.

XIX. Water Softener

Page 10

No. Parts Specifications Materials Qty.

1 Outer casing ä=0.6mm A3

2 Insulation piece PVC1000

3

Micro switch X3M302K2KA

4 Door lock screw A3

5 Door lock bas e POM M90-04

6 Door lock sp ring #2 1Cr18Ni9

7 Spring washer A3

8 Linkage SECC

9 Door lock spring #1 1Cr18Ni9

10 Slider POM M90-04

11 Door lock holder SECC

12 Top rubber plate Asphalt Plate

13 Inner container assem bly AISI304

14 Rear left bracing bar SECC

15 Condenser PP T30S

16 Condenser gasket EPDM

17 Condenser nut PP T30S

18 Door gasket 2 EPDM

19 Front left bracing bar SECC

20 Spray arm assembly

21 Spray arm nut PC L-1250Y

22 Spray arm support loc knut ROM TF20

23 Spray arm b ase nut PP+30% fiberglass

24 Spray arm b ase gasket EPDM

25 Filter assem bly

26 Front cover bracing b ar SECC

27 Door spring 1Cr18Ni9

28 Inner door cover PC L-1250Y

29 Inner door cover gasket EPDM

30 Door hook 1Cr18Ni9

31 Inner door Stainless Steel

32 Dispenser as sembly

33 Door seal Formed Rubber

34 Door left hi nge 1Cr18Ni9

35 Pulley POM M90-04

36 Outer door ABS LG HI-121H

37 Outer door cover Clear AS 117L200

38 Door gasket EPDM

39 Pulley axial A3

40 Door right hinge 1Cr18Ni9

41 Thermostat #1 clamp SECC

42 Thermostat #1

43 Heating elem ent mounting p late SECC

44 Heating elem ent gasket Silicone Rubber

45 Heating elem ent

9

WP5E Parts List

Page 11

Heating element mounting p late SECC

Heating element gasket Silicone Rubber

Heating element

Sump gasket EPDM

Thermostat

Thermostat gasket EPDM

Sump PP+30% Talc Powder

Front cover ABS LG HI-121H

Foot Chemigum

Bottom pan SECC

Turn knob ABS LG HI-121H

Switch button ABS LG HI-121H

Door button ABS LG HI-121H

Control panel ABS LG HI-121H

Pilot cover Clear AS 117L200

Control panel br acing bar SECC

Power switch braci ng bar SECC

Tim er

Power switch

Option switch

Tumbling rod hinge SECC

Tumbling rod POM M90-04

Pilot holder ABS LG HI-121H

Pilot

Float bracing bar SECC

Float body PP T30S

Micro switch (prot ection)

Float cover POM M90-04

Micro switch (working)

Float PP+30% Fiberglass

Lever POM M90-04

Capacitor

Pressure switch connecting tube EPDM

Motor base rubber pad Chemigum

Circulation pump assembly

Circulation pump inlet hose Silicone Rub ber

Spray arm base connecting tub e Silicone Rubber

Drain pump drain hose PP+PE

Drain pump inlet hose Silicone Rubber

Drain pump

Front right bracing b ar SECC

Forel ring Chemigum

Wobbler POM M90-04

Rear right bracing b ar SECC

Inlet gasket EPDM

10

Page 12

11

Rear right bracing b ar SECC

Inlet gasket EPDM

Inlet connector #1 PP T30S

Lug Copper

Power cord clamp PA66

Insulation porcelain Porcelain

Inlet tube EPDM

Absorption proofed connecting hose PVC

Inlet valve

Inlet valve mounting p late A3

Rear panel A3

Drain hose connector PP T30S

Power cord pad PP T30S

Power cord

Name plate Polyester Film

Drain hose assem bly PVC 540IT

Inlet hose assembly EP35

Wire basket assem bly

Salt spoon tube A

Wedge (Ö 16.6)

Inlet tube B

Inlet tube C

Cross recessed pan head tapping screw

Colophony spoon subassembl y

Salt spoon tube B

Switch subassembly

Airproof

Electromagnetic valv e subassem bly

Salt spoon

Water tank subassembly

Screw

Screw

Airproof A

Screw

Airproof

Note: This list is for reference only. The parts specifications listed above may vary with

the model of the machine and the region of sale and use. The service shall be

done according to the actual situation of the model.

Page 13

12

No. Parts Specifications (Ref. O nly)

Capacitor

Heating element

Thermostat #1

Thermostat

Thermostat gas ket

Spray arm base tube

Micro switch (working)

Micro switch (protec tion)

Micro switch

Circulation pump

Circulation pump inlet hos e

Drain pump

Drain pump inlet hose

Outer door

Outer door cover

Inner door

Inner door cover

Inner door cover gasket

Power c ord

Pilot

Power s witc h

Option switc h

Timer

Spray arm ass embly

Spray arm nut

Spray arm locknut 165 (163, 096)

Outer c asing nut

Dispenser as sembly

Dispenser elec tromagnetic valve

Water softener

XXII. Consumables List

Consumables for WP5 Series Double Pump Models

Note: The parts specifications listed above may vary with the model of the

machine and the region of sale and use.

The service shall be done according to the actual

situation of the model.

Page 14

13

µç·ͼ

R

C

C

C

C

b

CP

DP

T>

C

C

T>

E

L

N

͹ÂÖ

΢¶¯

¿ª¹Ø

5

a

b

4

b

a

T

p

>

TM

F

b

a

3

b

6

a

T

a

2

p

>

Note:

1. This circuit diagram applies to WP5 series double pump

dishwashers (220V-240V, 50Hz) embedded with electric filter

and water softener and equipped with timer 165.

2. The working thermostat may choose among 55 , 58 and 62

in accordance with the user preference and the region.

Power switch

door switch

Electric Filter

dry reed relay

salt spoon electromagnetic valve

out-of-salt pilot

power pilot

dispenser

option switch

Heating element

Thermofuse

thermostat

timer motor

thermostat (working)

float switch (working)

circulation pump

135 fuse

drain pump

capacitor

inlet valve

float switch (protection)

R

C

C

C

C

b

CP

DP

T>

T>

E

L

N

5

a

b

4

b

a

T

p>

T

M

F

b

a

3

b

6

a

T

a

2

p

>

Power switch

door switch

Electric Filter

dry reed relay

out-of-salt pilot

power pilot

dispenser

option switch

Heating element

Thermofuse

thermostat

timer motor

thermostat (working)

float switch (working)

circulation pump

135 fuse

drain pump

capacitor

inlet valve

float switch (protection)

Note:

1. This circuit diagram applies to WP5 series double pump

dishwashers (120V, 60Hz) embedded with electric filter and

without water softener and equipped with timer 165 .

2. The working thermostat may choose among 55 , 58 and 62

in accordance with the user preference and the region.

Page 15

14

E

L

N

5

a

b

11

5°

C

T>

TM

3

4

a

b

C

62°

T>

b

a

F

a

2

b

p>

p>

b

a

6

C

P

µçÈÝ

T

C

D

P

F

E

L

N

5

a

b

115°

C

T>

T

M

3

4

a

b

C

62°

T>

b

a

F

a

2

b

p>

p>

b

a

6

CP

T

C

D

P

¹¹¡¢¹¹¡¢

±¸ ×¢:

¹¹¡¢¹¹¡¢¹¹¡¢¹¹¡¢

Note:

1. This circuit diagram applies to WP5 series double

pump dishwashers (120V, 60Hz) embedded without

water softener and equipped with timer 163.

2. The working thermostat may choose among 55 , 58

and 62 in accordance with the user preference and

the region.

power switch

door switch

Power switch

power pilot

out-of-salt pilo

dry reed relay

dispenser

option switch

Thermostat (working)

heating element

115 thermostat

timer motor

float switch (working)

circulation pump

150 fuse

drain pump

capacitor

inlet valve

float switch (protection)

power switch

door switch

power switch

power pilot

Out-of-salt pilot

dry reed relay

cam wheel

softening valve

dispenser

option switch

thermostat (working)

float switch (working)

Circulation pump

heating element

115 thermosta

timer motor

inlet valve

float switch (protection)

drain pump

150 fuse

Note:

1. This circuit diagram applies to WP5 series double

pump dishwashers (120V, 60Hz) embedded with

water softener and equipped with timer 163.

2. The working thermostat may choose among 55 ,

58 and 62 in accordance with the user preference

and the region.

Loading...

Loading...