Page 1

Service Manual

Washing Machine

Model:C01

Note:

Before service the unit, please read this manual first.

Contact with your service center if meet problem

Page 2

1 PRECAUTION………………….………………..…………………………………………………. 3

1.1 Safety Precautions

1.2 Servicing Precaution

1.3 Cautions For Safety

2 FACTORY PATTEN DETECTION …………….………………………………………………. 7

3 UNPACKING WAYS OF MAIN PARTS……………………………………………………… 10

4 MALFUNCTIONS CODES AND EXPLANATIONS ……………………………………… 18

5 TROUBLESHOOTING …………………………………………………………………………… 20

5.1 Maintenance non-heating malfunction

5.2 Door non-locked & its maintenance

5.3 Door non-locked & its maintenance

5.4 Heating beyond the setting temperature its maintenance

5.5 Maintenance of non-drain or drain exceed the setting time

5.6 Water inlet overflow malfunction maintenance

5.7 Drum non-rotating malfunction maintenance

5.8 Maintenance water inlet and water outlet at the same time

6 CHECK POINT OF CIRCUIT …………………………………………………………………… 30

7 SERVICE TOOLS……..………………............................................................................... 31

8 APPENDIX………………………………………………………………………………………….. 32

Contents

2

Page 3

1 Precaution

3

When performing troubleshooting and part replacement during servicing, note the

following safety

precautions:

1.1 Safety Precautions

1.1.1 Use Genuine Parts

The components of the washing machine have safety features such as non-combustibility

and voltage with standing. Therefore, always use the same part as suggested by the maker.

In particular be sure to use only designated parts in case of major safety parts identified

by the marker.

1.1.2 Grounding

Connect the grounding wire to the shell plate ,and bury it under at least 25cm of earth:

alternatively, connect the ground wire to the appropriate pin on a properly grounded

power receptacle. Never connect the wire to a telephone line, lightning rod, or gas pipe.

1.2 Servicing Precautions

1.2.1 Observe Warnings

Be sure to follow special warning and precautions that are described on part labels and in

the owner manual.

1.2.2 Parts Assembly and Wiring

Be sure to use insulation material(such as tube and tape).And be sure to restore all parts

and wires to their original position. Take special care to avoid contact with sharp edges.

1.2.3 Perform Safety Checks after Servicing

After servicing, check to see that the screws, parts, and wiring are restored to their

original positions, and check the insulation between the external metals and the socket

plug. In addition, place the washing machine in a level position (less than 1 degree)to

prevent vibration and noise during operations.

1.2.4 Insulation Checks

Pull out the plug from the power receptacle, pour water into the spin tub, and then set

the timer.

Check to see that the resistance insulation between the terminals of the plug and the

externally

exposed metal is greater than 1M .

Note :When it is impossible to insulation check with a 500V insulation resistance

tester, use other testers for inspection.

Page 4

1.3 CAUTIONS FOR SAFETY

• Please observe the following notes for safety.

• The symbols indicate as follows.

4

Symbol Meaning

WARNING

Indicates possibility of death or serious injury of a repair

technician and a person nearby through the misconducted

work , or of a user by a defect of the product after the work

performed by the technician.

CAUTION

Indicates possibility of injury or physical damages* of a

repair technician and a person nearby through the

misconducted work , or of a user by a defect of the product

after the work performed by the technician.

Symbol Meaning

ELECTRIC SHOCK

Indicates a caution (including a warning).

Specific instruction is followed by a graphic or characters in

or near.

Symbol left warns an electric shock.

DO NOT DISASSEMBLE

Indicates prohibition (act must not be conducted).

Specific instruction is followed by a graphic or characters in

or near.

DO NOT Symbol left warns not to disassemble.

UNPLUG

Indicates forcing (act must be conducted).

Specific instruction is followed by a graphic or characters in

or near .

Symbol left warns to unplug the power cord.

* Means secondary damages of property, furniture , domestic animal and pet.

Symbol Meaning

OUT OF CHILD

Advise the customer to keep children out of the work place.

Children may be injured with a tool or a disassembled part.

UNPLUG POWER

Unplug power cord for the work such as disassembling

which is not

unnecessary to power on . Do not hold the plug by a wet hand.

Failing to unplug may cause an electric shock.

USE REPAIR PARTS

Use the specified repair parts when repairing the product.

Otherwise , amalfunction or a defect may occur.

Also , a short circuit , ignition or other danger to the

customer may occur.

1 Precaution

Page 5

5

WARNING

CHECK INSULATION

RESISTANCE

After repair, measure insulation resistance between the

charging part(power cord plug) and the non-charging

metallic part (ground) with an insulation resistance meter

(500V).The resistance shall be 10M or more.

Failing to check the insulation resistance may cause a short

circuit, electric shock or other diseases to the customer.

DO NOT MODIF

Do not modify the product.

An electric shock or ignition may occur.

DO NOT MODIFY

Only a repair technician can disassemble and repair.

An electric shock, ignition or malfunction may cause injury.

USE EXCLUSIVE

SOCKET

Use an exclusive 110 VAC/15 A socket for the washing

machine.

Use an exclusive 220VAC/17A socket for the washing

machine.

Otherwise , an electric shock or ignition may cause. Sharing

the same socket with other instrument causes heating of a

branch socket and result in a fire.

CONNECT

GROUNDING WIRE

Connect the grounding wire.

Failing to do so may cause an electric shock when a short

circuit occurs.

Consult an electric work shop or a sales shop.

DO NOT USE WET

PLACE

Do not install in a bath room or a place exposed to wind or

rain.

An electric shock or a short circuit may cause a fire.

DO NOT SPLASH

WATER

Do not pour or immerse electrical parts into water or liquid

solution.

An electric shock or ignition may occur.

REMOVE DUST

Wipe off dust adhered to the plug of power cord.

Dust may cause a fire.

AVOID

INFLAMMABLE

Do not put inflammable into the washing tub.

Do not put cloths stained with kerosene, gasoline, benzene,

thinner, alcohol, etc. It may cause a fire or explosion.

1 Precaution

Page 6

6

WARNING

DO NOT TOUCH

Do not touch the laundry before the spin basket stops

completely.

The laundry entangles your hand causing an injury even if

the basket rotates slowly. Pay special attention to children.

INSTALL

CAREFULLY

Ask an electric work shop to install the product.

Install the product securely and safely according to the

electrical equipment technical standard and the wiring

standard.

Incorrect work causes an electric shock and a fire.

DO NOT PULL

Do not pull the power cord when unplugging.

Hold the power plug to unplug.

An electric shock or short circuit may cause a fire.

DANGER HAND

Do not insert your hand under the washing machine during

operation.

There is a rotary part under the machine which may cause

an injury.

WATER LEAKAGE

Before starting washing, open the faucet and check water

supply hose joint which shall not be loosened for no water

leaks.

The loose screw or hose joint may cause water leakage

resulting in an unexpected damage.

1 Precaution

Page 7

2 FACTORY PATTEN DETECTION

7

2.1 Service mode

Before entering into service mode, make sure no water remains in the inner drum, if

not, select drain only program to drain them out.

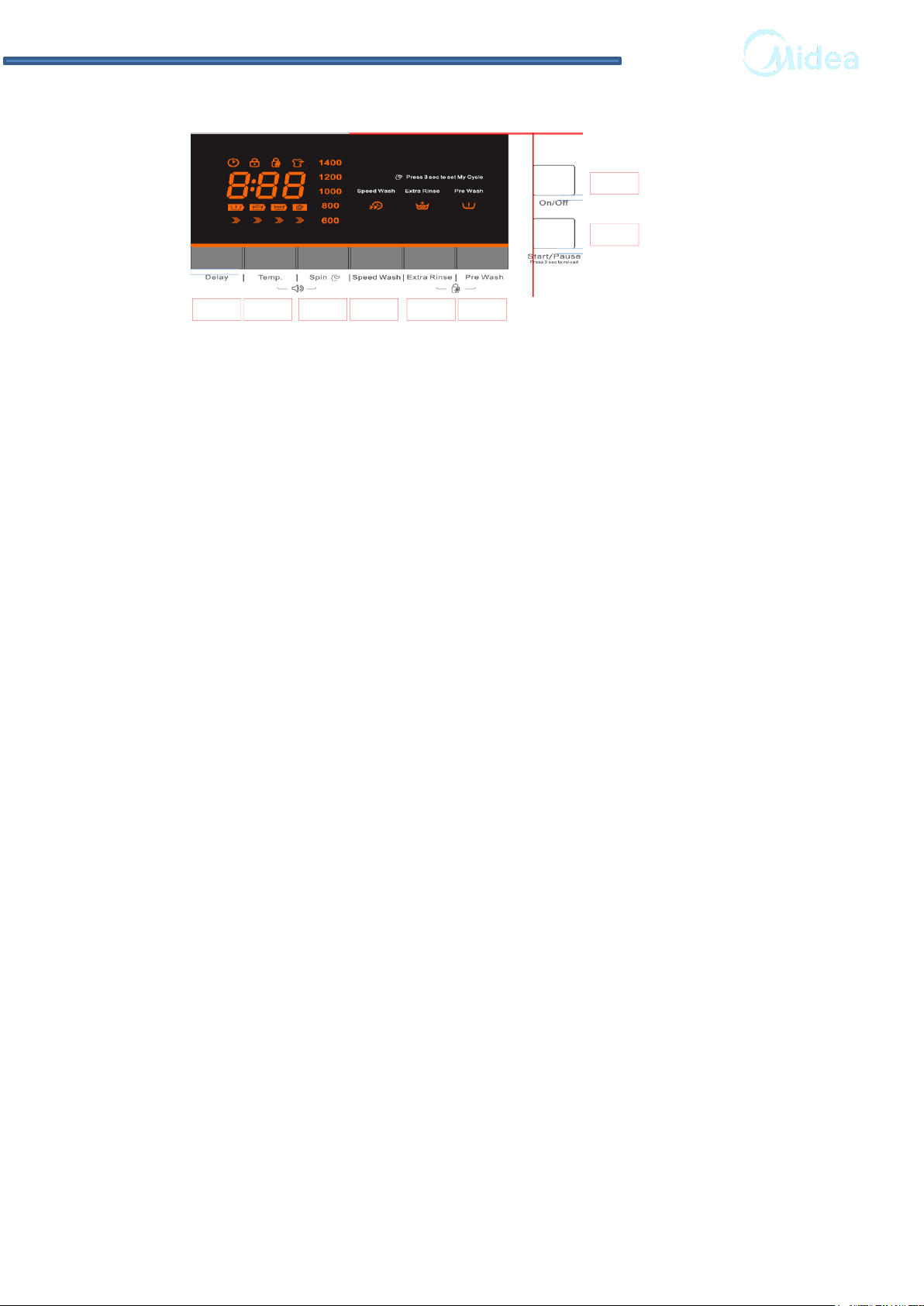

Turn on the machine and take turns [K3] [K5] [K3] [K5] buttons in 30s.

Press [K1] or [K2] to select test program. Press [K8] button to confirm your selection

and start the selected test. If you want to go back to test selection interface, press the

[K8] button to cancel previous selection.

2.1.1 Version switchover (t01)

1) Enter into service mode, LED displays “t01”

2) Press [K8] button, LED displays “0xx”.x means current version.

3) Press [K2] to confirm switchover.

4) Press [K3] to change version.

5) Press [K2] button continuously for 3s to confirm your change.

6) Press [K8] button to close all output and exit this program. LED displays “t01”.

2.1.2 Error code checking (t02)

1) Enter into error code mode, LED displays “Err”. Press [K8] button and LED displays

EXX(x=1,2,3….)

2) Press [K1] to show the last code and press [K2] to show the next code. The latest 10

error codes

can be found in system, and same error code is recorded one time even if it occurs

more than one time

3) If no error information found, LED shows E00.

4) Press [K2] and [K3] button at the same time continuously for 3s, after hearing the

beep, all the error codes records deleted, LED displays E00.

5) Press [K8] button to exit, LED display t02.

2.1.3 Version information checking (t03)

Version information checking is used to show the current version information stored in

nonvolatile memory applications.

1) Enter into service mode, LED displays “cod”.

2) Press [K8], LED displays project number.

3) Press [K1] button, LED displays version number.

4) Press [K8] to go back to version information checking status, LED display “t03”.

K1 K2 K3 K4 K5 K6

K7

K8

Page 8

8

2.1.4 UI Checking (t04)

1) Press [K8] button to illuminate the whole LED display.

2) Press [K1] button, the whole LED display flashes.

3) Press [K8] to stop flash, LED display “t04”

2.1.5 Drain pump checking (t05)

1) Enter into service mode, LED displays “pup”.

2) Press [K8] button to drain out all the remaining water. If all water drained out, LED

displays “god”,and 6 minutes later ,if there is still water remains in it, LED displays

“FP”.

3) Press [K8] button to exit, LED displays “t05”

2.1.6 Pressure switch checking (t06)

1) Enter into service mode, drain out the water, LED displays LL.

2) Press [K8] button to activate inlet valve. LED displays level frequency once water

lever get the main wash level,after the water level reaching the overflow line, drain out

all the water.

2.1.7 Water temperature sensor and heater checking (t07)

1) Press [K8] button to activate the main inlet valve and get the water lever to heating

level then turn on the heater and 5 min later turned off automatically.

2) After heater turned on, LED displays the current temperature. Detect the real

temperature of inner drum and check with the numbers on the display.

3) Press [K8] button to exit, LED displays “t07”

2.1.8 Inlet valve checking (t08)

1) Enter into service mode, drain out the water, LED displays “UU”. Press [K8] button,

LED displays “out”.

2) Press [K1] button, LED displays “u2” and switch on prewash valve for 5s.

3) Press [K1] button, LED displays “u1” and switch on the main wash inlet valve for5s.

4) Press [K1] button to switch on main wash and prewash valve and get the water lever

to setting level, then drain out the water.

2.1.9 Rotating checking (t09)

1) Enter into service mode, LED displays “tUB”

2) Press [K8] button, inner drum rotates in 45r/m clockwise for 10s and stop for 10s,

over and over again.

3) Press [K8] button to turn off the motor and exit, LED displays “t09”.

2.1.10 Spin speed checking (t10)

1) Press [K8] to enter into service mode, LED displays “spn”.

2) Press [K8] button again, the number on the display goes up in the same pace with

the real speed and when it reach 400rpm, you need to press [K1] button to get the

machine to reach its target speed.

( If declared speed ≥1000rpm, target speed is 1000rpm and if declared speed <

1000rpm,target speed is its declared speed)

3) Press [K8] button to exit and LED displays “t10”.

2 FACTORY PATTEN DETECTION

Page 9

9

2.2 Self-check

- Turn on the machine , to take turns 【K3】【K5】【K3】【K5】,the door locked,

enter the test mode, display the T01, press the 【K1】or 【K2】 to show “T15”.

- Press [K8] button, put into the function test mode, display TST, then press again,

display version number and project number;

- Press 【K1】or 3 seconds later again, display the temperature of NTC;

- Press 【K1】or 3 seconds later again, display water level frequency;

- Press 【K1】or 3 seconds later again, display “U2”,main wash valve is open;

- Press 【K1】or 3 seconds later again, display “U1”,main wash valve is close ,pre-

wash valve is open;

- Press 【K1】or 3 seconds later again, display “PuP”, pre-wash valve is close, drain

pump is open;

- Press 【K1】or 3 seconds later again, display “HEA”, drain pump is close , HTC is

open;

- Press 【K1】or 3 seconds later again, the heater is close ,the motor rotates forward 3

seconds, stop 2 seconds, display the motor speed, accelerate to 1000 rpm;

- Press [K8], display the “T15”, back to the function test mode.

- Exit need to close the power.

2.3 Marketing-show (no-water testing)

The sales display mode can not be used in this PCB.

2 FACTORY PATTEN DETECTION

Page 10

3. UNPACKING WAYS OF MAIN PARTS

1. Undo the back cover

2. Undo top cover

3. Undo the control panel

4. Undo the lower panel

5. Undo the door lock

6. Undo the front plate

7. Undo the facade counterweight

8. Undo the gasket

9. Undo the PCB panel

10. Undo the detergent box

11. Undo the inlet valve

12. Undo the pressure

13. Undo the pulley

14. Undo the absorber pin

15. Undo the filter

16. Undo the drain pump

17. Undo the heater

18. Undo the NTC

19. Undo the door glass

20. Undo the panel support

21. Undo the drum tub assembly

22. Undo the absorber

23. Undo the motor

3 UNPACKING WAYS OF MAIN PARTS

10

Page 11

111111

Operation Picture

1

. Undo the back cover

Undo four screws fit

between back plate and

cabinet, and then pull out.

2

. Undo the top cover

I.Undo 2 screws fit back

Cabinet.

II.Push back the top cover

15mm until it leaves away

from the control

panel,

and then take it down.

3

. Undo the control panel

I.Departing the top cover

II.Draw out the detergent

drawer.

III.Loosen two screws fit

on the control panel .

IV.Loosen two screws fit

on the control panel.

V.Take out the control

Panel inclined from the

panel .

3 UNPACKING WAYS OF MAIN PARTS

Page 12

1212

4

. Undo the service plate

box

I.Open the filter

cover,

release the screw on

the

lower panel.

II.Turn the washing

machine back at an angle,

pinch the clasp ,and push

it out.

5

. Undo the door lock

I.Open the door of

washing machine.

II.Take the outer gasket

Take the outer gasket

III.Remove two screws on

the door lock, and take

down the door lock.

IV.Take out the door lock

and draw out the plug.

6

. Undo the front plate

I.Remove the service

plate

box

.

II.Undo five screws in

front plate

III.Put the front plate up to

the clasp of the front plate

away from the loading

holder, and then take off

the front plate.

7.

Undo the lower

counterweight

I.Undo the front plate

II.Remove

four screws pull

out the lower

counterweight.

3 UNPACKING WAYS OF MAIN PARTS

Page 13

13

3 UNPACKING WAYS OF MAIN PARTS

1313

8. Undo the gasket

I.Undo

the top cover,

control panel, service

plate box, machine door

and the front plate.

II.Remove

the outer gasket

clamp between the door

seal and the front plate.

III.Loosen

the inner gasket

clamp between the door

seal and the front of the

outer tub.

9. Undo the PCB panel

I.Undo the control panel

II.remove 5 screws

between the control panel

and PCB panel

10

. Undo the detergent box

I.Undo

the top cover and

the control pane

II.Release the hose clamp

and pull out the inlet hose.

III.Release

the hose clamp

and pull out the detergent

box hose, and then take

out the detergent box.

11

. Undo the inlet valve

I.Remove the top cover

II.Undo 2 screws between

cabinet and inlet valve.

III.Release the clamp

fixing

the inlet valve and the

inlet hose, and then pull

out the inlet hose.

IV.Take out the inlet

valve

Page 14

141414

12

. Undo the pressure switch

I.Undo the top cover

II.Pull out the plugs on the

pressure switch.

II.Loosen the pressure

switch hose clamp, and

pull out the hose from the

pressure switch interface.

III.Rotate the pressure

switch anticlockwise by

90º, and then pull out the

pressure switch.

13

.Undo the pulley

I.Undo the back cover

II.Rotate the pulley and at

the same time pull out the

belt.

II.Remove the screw on

the

pulley and then take

down

the pulley.

14

.Undo the upper

counterweight

I. Undo the top cover

II. Remove four screws fit

on the upper

counterweight and then

pull out the upper

counterweight.

15

. Undo the absorber pin

I.Undo the front plate

II.Use pliers to pinch the

absorber pin’s

protuberance, and knock

the absorber pin out from

back lightly; in the same

way, remove the other

two.

3 UNPACKING WAYS OF MAIN PARTS

Page 15

151515

16

.Undo the filter

Open the filter cover.

Rotate the filter knob

anticlockwise, and then

pull out the filter.

17. Undo the drain pump

I.Undo the top cover,

control panel, service

plate box

and front plate.

II. Remove four screws

and

plug and nip out clamp

between drain hose and

the drain pump, and then

pullout the drain hose.

18

.Undo the heater

I.Undo the top cover

II.Undo control panel,

service plate box, motor

and front plate

III.Remove the bolt and

pull out the heater plug.

3 UNPACKING WAYS OF MAIN PARTS

Page 16

161616

19

. Undo the NTC

I.Undo the top cover,

control panel, service

plate box and front plate.

II.Undo the NTC with

special tools.

20

.Undo the door glass

I. Open the door, remove

two screws fixing the

hinge and front plate,

and

then remove the door.

II. Remove eleven

screws

on the inner door.

III. Remove the outer

door

and the inner door

with

special tool.

21

.Undo the panel support

I. Undo the top cover

II.Undo the control panel.

III.Remove two screws

fixing the panel support,

and then remove it.

22.Undo

the drum tub

assembly

I.Remove the motor

II.Pull out the heater.

III.Remove the belt.

VI.Remove the screws

fixing the pulley, and then

take out the pulley.

V.Remove the screws

fixing

the front and rear tub,

and

then remove the tub.

VI.Remove the inner drum

kit.

3 UNPACKING WAYS OF MAIN PARTS

Page 17

171717

23

.Undo the absorbers

I.Lift out the outer tub kit.

II.Undo the absorbers pin

between absorber and

rear tub, remove the

absorbers.

24

.Undo the motor

I.First let the machine lie

down on the back and

then pullout the motor

wire and grounding wire.

II.Use spanner to remove

the motor screws, and lift

up the motor with the

other hand in case of

falling to the drain pump

3 UNPACKING WAYS OF MAIN PARTS

Page 18

18

Malfunction

code

Reason Description Solution

E10

Inlet water

overtime

The water level

doesn’t changed in 3

minutes during filling

the water.

Open the water tap, to check if the

inlet hose is squashed or kinked,

check the filter in the inlet valve is

blocked or not; check if the water

pressure is too low.

E12

Overflow

The water level is

higher than the

overflow water level.

Check the water inlet valve, Valve fail

E20

Fault connection

of the drain pump

The

water level

doesn’t changed in 3

minutes during drain

the water.

Check the drain pump.

Check the filter of the drain pump

to prevent jam.

Check the drain hose to prevent

jam.

E21

Overtime 3min

of the drainage

The

water level.

Overtime draining

E30

The door has not

been closed over

3 times

Fail to lock the door

lock for 6 times when

the PCB ties to lock the

door lock after you

press the Start keys.

Check the door hook and the door

lock to get correct location.

E31

Don’t unlock the

door lock

Fail to unlock the door

lock 6 times

Check the door Lock

E33

Water level

sensor fail

The frequency of the

water level sensor is

out of the spec.

Check the water level sensor

E34

Temperature

sensor fail

The temperature

sensor(NET) get broken

Check the PCB and the motor

E60

The motor don’t

drive

The motor don’t drive

for

5 times

Water temperature sensor

cutting

out

Check the PCB and the motor

Check the motor communicate

wire

E61

The speed don’t

transmit signal

The PCB can’t get

speed transmit signal

when the motor drive

Check the speed transmit line of

the motor to prevent fall

of

Check the PCB and the motor

Check the motor communicate

wire

4 MALFUNCTION CODES AND EXPLANATIONS

Schedule of failure alarm

Page 19

19

Malfunction

code

Reason Description Solution

E62

The speed

don’t transmit

signal

abnormality

Triac

get broken

Check the speed transmit line

of the motor to prevent fall of

Check the PCB and the motor

Check the motor communicate

wire

E70

The button get

stuck when

press it over 10

second

The Power

button

lodge in the panel

Check the button install

and

control

4 MALFUNCTION CODES AND EXPLANATIONS

Page 20

5 TROUBLESHOOTING

20

Fault tree

1. Maintenance non-heating malfunction

Whether the pressure

switch is well or not

Change the control

panel

Whether the

connect is well

heating

Reliable connection

Whether NTC is

short or open

circuit

Change NTC

Whether to set up

non-heating

Choosing new heating

temperature

Non-heating

Change the heater

Whether the heater

is well

Y

Y

Y

Y

Y

N

N

Y

N

N

Page 21

21

2. Door non-locked & its maintenance

Whether push the

start /pause

button

Whether the harness

connection between the

door lock and the main

board is well

Whether the voltage open

between harness 1 harness 3

is about 220vand circuit

The door lock is

invalid and should be

replaced

Whether the door

is closed correctly

Close the door

correctly

Door non-locked

Change the heater

Change the

control panel

Push the start button

to start the program

N

N

N

N

Y

Y

Y

Y

Y

5 TROUBLESHOOTING

Page 22

3. No water inlet or water inlet overtime

Connect

connections

Whether press

start/pause button

after choosing the

program

Change main

board

No water inlet or

water inlet

overtime

Change the

pressure switch

Push start/pause

button

Change the inlet valve

Whether the door

is closed correctly

Whether door lock 3

and 2 is connected

correctly

Whether the

electromagnetic valve

buzz

Whether the connections

of inlet valve is well

Whether the inlet

valve coil is well

Whether the connection

of pressure switch is well

Door lock is invalid

and should be

replaced

Whether the voltage

between door lock 1

and is 220V

Whether the tap is

opened

Whether the inlet

pipe is fold or the

water is cut off

Whether the inlet filter

net is blocked

Whether the

pressure switch is

well

Change the control

panel

Whether the

connection is well

Cleaning with

brush

Y

Y

Y

Y

Y

Y

Y

N

Y

Y

N

N

N

N

N

N

N

5 TROUBLESHOOTING

22

Page 23

23

4. Cleaning with brush

Whether the

connection is well

circuit open

circuit

Change NTC

Over heating

N

N

Y

Y

Whether NTC is

short circuit or open

circuit

Whether the

connection is well

or not

5 TROUBLESHOOTING

Page 24

24

5. Maintenance of non-drain or drain exceed the setting time

Change the drain

pump

Whether the filter

is blocked

Reliable

connection

Whether the door

lock is well

Whether it is in

the state of pause

Push start/pause

button

Non-drain or

overtime drain

Whether the drain

pipe is too high

The means of detecting

door switch refers to the

paragraph of "no water

inlet".

Whether the

connection

between the

pump and the

board is

loosened

Change the

control panel

Close

the

door

Cleaning

the filter

button

N

Whether the

pump is blocked

or burned out

between the

door lock and

the main board

is well

Whether the

door is closed

Whether the

pump is

vibrating

Return to the normal

station

N

N

N

N

Y

Y

Y

Y

Y

Y

N

N

Y

Y

5 TROUBLESHOOTING

Page 25

25

6. Water inlet overflow malfunction maintenance

Whether the

water is in

without power

Change the control

panel

Whether the

electric

connection of

pressure switch is

normal

Reliable connection

Whether the gas

pipe or the

connection is

leaking or dead

lock

Change or revive the

gas pipe

Whether the drain

hose is hung up

Hang the hose well

Water inlet overflow

Change the inlet valve

Whether the

pressure switch is

well

N

N

N

N

Y

Y

Y

Y

Y

Y

5 TROUBLESHOOTING

Page 26

26

Whether the door

lock is well

Change the control panel

Whether the door is

closed correctly

Drum non-rotating

Whether the motor

is well

Close the door

Waiting inlet or inspect

overtime water inlet

malfunction

Replace it

Reliable connection

Detach strap,

whether the drum is

rotating flexibly

Change the door lock

Replace it

The drum is blocked

N

Whether the inlet is

correct

Replace it

N

N

N

N

N

N

N

Y

Y

Y

Y

Y

Y

Y

Y

5 TROUBLESHOOTING

7. Drum non-rotating malfunction maintenance

Whether the inner

wire connection is

correct

Shut down the power,

open the door and

Rotate the drum .

check the drum rotate

flexibly or not.

Page 27

27

8. Maintenance water inflow and drain off water at the same time

Whether the

washer is

disposing the

foam in the drum

Change the control

panel

Normal phenomenon

Hang the hose well

Water inflow and drain

off water at the same

time

Whether the drain

hose is hung up

too low

N

N

Y

Y

Y

5 TROUBLESHOOTING

Page 28

28

Description Solution

The washing machine

does not work

Close the washing machine's door.

Water leakage

Correctly connect the inlet water pipe.

The speed of the clothes is

abnormal

Reload and distribute the laundry evenly in the drum.

There is the peculiar smell

in the washing machine

Run a Self clean(Drum clean) cycle without any clothes.

No water is visible in the

drum

No fault

-water is under the visible area.

There is the remaining

water in the softener's box

No fault

- the effect of the softener will not be affected.

The remaining detergent

is left on the clothes

The water

-fast component of the non-phosphorus.

detergent will be left on the clothes to form the line scale.

Please select

【rinse】 or【 spin 】programme or brush

away the fleck with the brush when the clothes is dried.

The washing machine

does not fill

Open the water tap.

Check the selection of the procedure.

Check the water.

Pressure to see if the water pressure is insufficient.

Put through the

feed-water.

Close the washing machine's door.

To check it the inlet water pipe is bent or blocked.

The washing machine fills

and empties at the same

time.

Make sure the end of the drainage pipe to be higher.

Check if the drainage pipe and sewage have been sealed,

if they have been, there will be the poor ventilation to

cause the sip

hon age effect.

No drainage of the

washing machine

Check if the drainage pump is blocked.

Check if the drainage pipe is bent or blocked.

Check the height of the drainage nozzle, make sure it

is0.6

-1 meter from the bottom of the washing machine.

Malfunction and solution

5 TROUBLESHOOTING

Page 29

29

Vibration of the washing

machine

Level the washing machine.

Level the washing machine.

Fasten the footing.

To check if the internal packing for the transportation

have all been removed.

The bubble spills from

the detergent

Check if the detergent is excessive, if it is the specialized

detergent for the cylinder washing machine.

Dip one scoop of the softener mixed with 1/2 liter of

water to the detergent box II.

Reduce the usage amount of the detergent in the next

time's wash.

The machine stops when

the procedure has not

been finished

Power failure or water cut.

The drainage pump has

noise during the

operation when the water

has just been drained

The inner barrel water of the washing machine has been

drained but there is still a small amount of water in the

drainage pump and pipe. The drainage pump

continuously operates and takes in the air, and at this time

there is the noise, which is normal situation.

To stop for some time

during the wash

procedure

The washing machine adds water automatically.

Because there is too much bubble in the tube, the

washing machine is cleaning the bubble.

If

you cannot solve the above abnormal situations, would you please:

1. To turn the procedure knob to

【OFF】, pull out the attachment plug;

2. To close the water tap, and contact the nearest service

center.

5 TROUBLESHOOTING

Page 30

Before repairing, use multimeter to judge circuit stand of fail

.

6 CHECK POINT OF CIRCUIT

30

No

Parts Picture Test Description Parameter remarks

1

NTC

Check the resistance

Resistance

value range

4

-6KΩ–PASS

2

Water

Level

Sensor

Check the resistance

between 1 and 3

Resistance value range

about 10

-50 Ω -PASS

3

Door

lock

Check the resistance

2 seconds after the

power supply can

automatically locked

Resistance

value range

30

-300Ω-PASS

4

Water

valve

Check the resistance

Resistance value range 3-

6KΩ

-PASS

5

Drain

pump

Check the resistance

Resistance

value range

15

0-250Ω-PASS

6

Heater

Check the resistance

Resistance

value range

20

-35Ω-PASS

Page 31

31

7 SERVICE TOOLS

Page 32

32

8 APPENDIX

Page 33

The end!

Loading...

Loading...