Midea JZ*-Q40 SERIES, 75G50*****-G SERIES, JZ*-Q501G SERIES, JZ*-Q44 SERIES, JZ*-Q41 SERIES Service Manual

...Page 1

1

Service Manual

For Built-in gas hob

Model list:

JZx-Q40xxxx, JZx-Q41xxxx,

JZx-Q44xxxx, JZx-Q45xxxx

JZx-Q501Gxx JZx-Q502Gxx

JZx-Q502Sxx 60Qxxxxxxx

60Gxxxxxxx- xxx 70Gxxxxxxx- xxx

75G50xxxxx- Gxx 75G50xxxxx- Sxx

90Gxxxxxxx- Gxx 90Gxxxxxxx- Sxx

Warnings:

This service manual is not available to the general users, but only applies to

professional technicians with relevant qualifications. Any incorrect maintenance

may result in other dangers!

The power and gas supply must be cut off before maintenance!

A new power cord which meets the relevant technical requirements must be used

once possible hidden malfunctions are found with the current power cord (refer to

this Manual)!

Please read carefully all safety warnings in this Manual before maintenance!

The product is prohibited from using until test is conducted as per relevant

regulations after maintenance!

This service manual applies to many models, so the specific operations please prevail in

kind!

V3.0

May, 2015

Page 2

2

Catalogue

1. Precaution ........................................................................................................................ 4

1.1. Safety Precaution ............................................................................................................................................ 4

1.2. Warning ........................................................................................................................................................... 4

2. Description of the appliance ............................................................................................ 5

2.1. Features ........................................................................................................................................................... 5

2.2. Components and parts .................................................................................................................................... 6

3. Installation ....................................................................................................................... 7

3.1. Dimension ........................................................................................................................................................ 7

3.2. Installation Dimension ..................................................................................................................................... 8

4. Electric Diagram ....................................................................................................................................... 9

5. Reassembly and Disassembly ........................................................................................ 10

5.1. Safety precautions ......................................................................................................................................... 11

5.2. Tools .............................................................................................................................................................. 11

5.3 Disassembly .................................................................................................................................................... 12

5.3.1. Disassemble the Top Plate ..................................................................................................................... 12

5.3.2. Disassemble the Thermocouple ............................................................................................................. 13

5.3.3. Disassemble of the Ignition Pin .............................................................................................................. 13

5.3.4. Disassemble of the Microswitch Harness .............................................................................................. 13

5.3.5. Disassemble of the Gas Pipe .................................................................................................................. 14

5.3.6. Disassemble of the Bottom Cup ............................................................................................................. 14

5.3.7. Disassemble of the Power Cord Assembly ............................................................................................. 14

5.3.8. Disassemble of the igniter ...................................................................................................................... 15

5.3.9. Disassemble of the Valve & Manifold Pipe Assembly ............................................................................ 15

5.310. Disasmble of the Gas Connection ......................................................................................................... 16

5.3.11. Disassemble of thebottom plate .......................................................................................................... 16

5.4. Reassembly .................................................................................................................................................... 17

5.4.1. Reassemble of the Ignition Pin ............................................................................................................... 17

5.4.2. Reassemble of the Thermocouple.......................................................................................................... 17

5.4.3. Reassemble of the Gas Pipe……………………………………………………………………………………………………………..17

5.4.4. Check Point after assemble .................................................................................................................... 17

6. Troubleshooting ............................................................................................................. 17

6.1. Troubleshooting ............................................................................................................................................ 18

6.2. Problems and Corrective Measures .............................................................................................................. 19

6.3. Maintenance and test ................................................................................................................................... 21

7. Gas Conversion .............................................................................................................. 22

7.1. Replacement of gas-type fitting .................................................................................................................... 22

Page 3

3

7.2. Replacement of the injector of the burners .................................................................................................. 22

8. Appendix ........................................................................................................................ 24

Technical & quality requirements for Built-in gas hob......................................................................................... 24

Page 4

4

1. Precaution

1.1. Safety Precaution

1. Do not modify this appliance. This appliance should be serviced by an authorized person.

2. All repairs should be done in accordance with the procedures described in this manual.

3. Before you begin, turn off the gas and electricity supply to the appliance. Remove

remaining gas in product completely by igniting burner.

4. Be sure that all of built-in protective devices are replaced. Restore any missing protective

shields.

5. Do not connect the gas and electricity supply before replacement complete.

6. Use replacement components that have the same ratings. A replacement part that does not

have the same safety characteristics as the original might create shock, fire or other

hazards

7. You must conduct a gas leakage test after receiving after-sales service in gas pipe and gas

connector. Never touch any circuit wiring with your hand nor with uninsulated tool during

operation.

1.2. Warning

1. The power cord shall be replaced with the original power cord, specifications for an

insulation power line which is no less than AWG8*2 +AWG10*1 and resists

temperature of greater than 60℃.

2. All apparatus within a radius of 50mm from this product must resist temperature of

greater than 75°C, otherwise, deformations are easily to be caused during the

application process of this product.

3. When the wrapping materials are removed, keep such materials like metal sheet,

packing bag, foam and screws out of reach of children’s reach to avoid potential

dangers. For example, the children may suffocate as a result of swallowing tiny

components or playing with packing bag.

Page 5

5

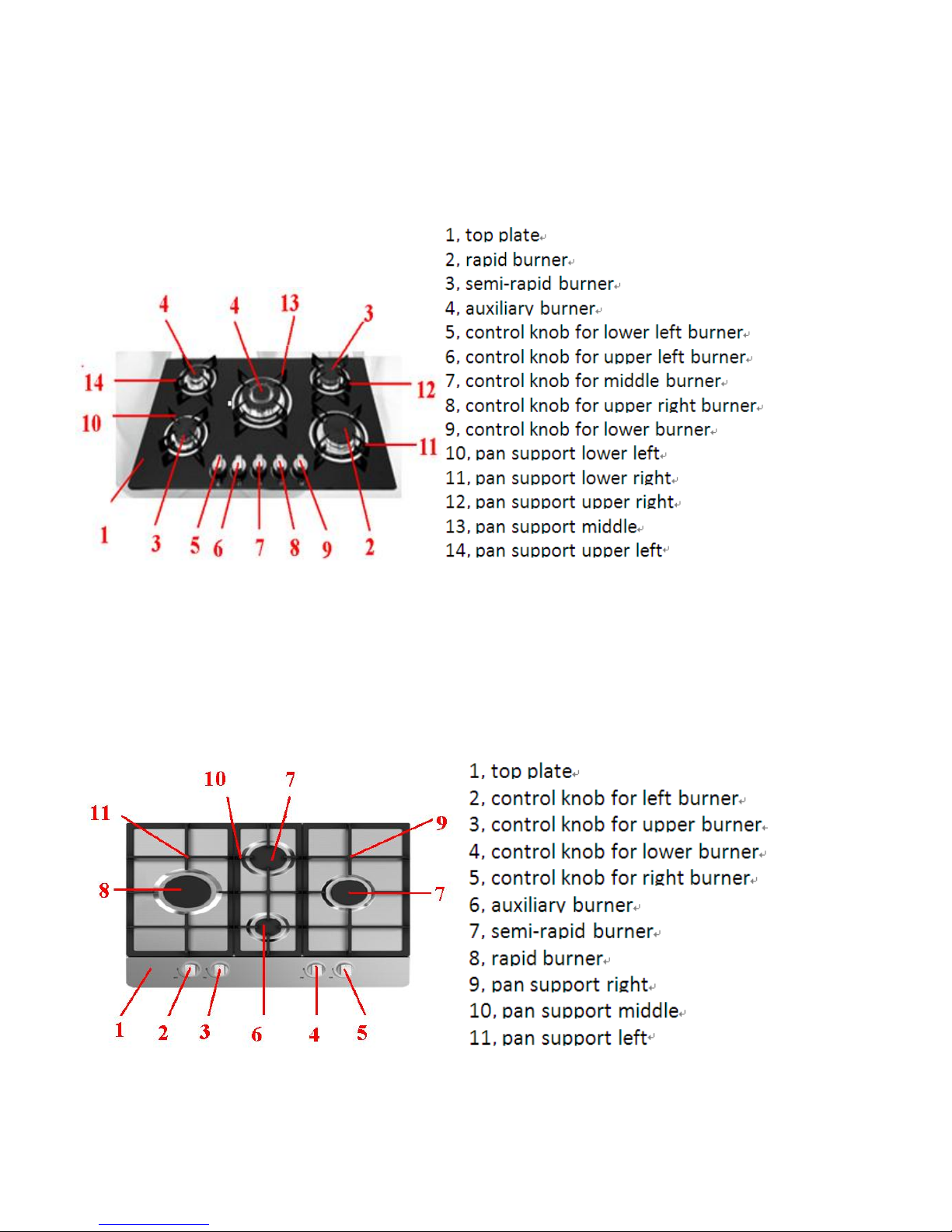

2. Description of the appliance

2.1. Features

Glass: Q502 GXX

Stainless:Q411 SXX

Page 6

6

2.2. Components and parts

(1). Burner

(2) .Pan support

(3). Knob

(4) .Drip tray

Page 7

7

3. Installation

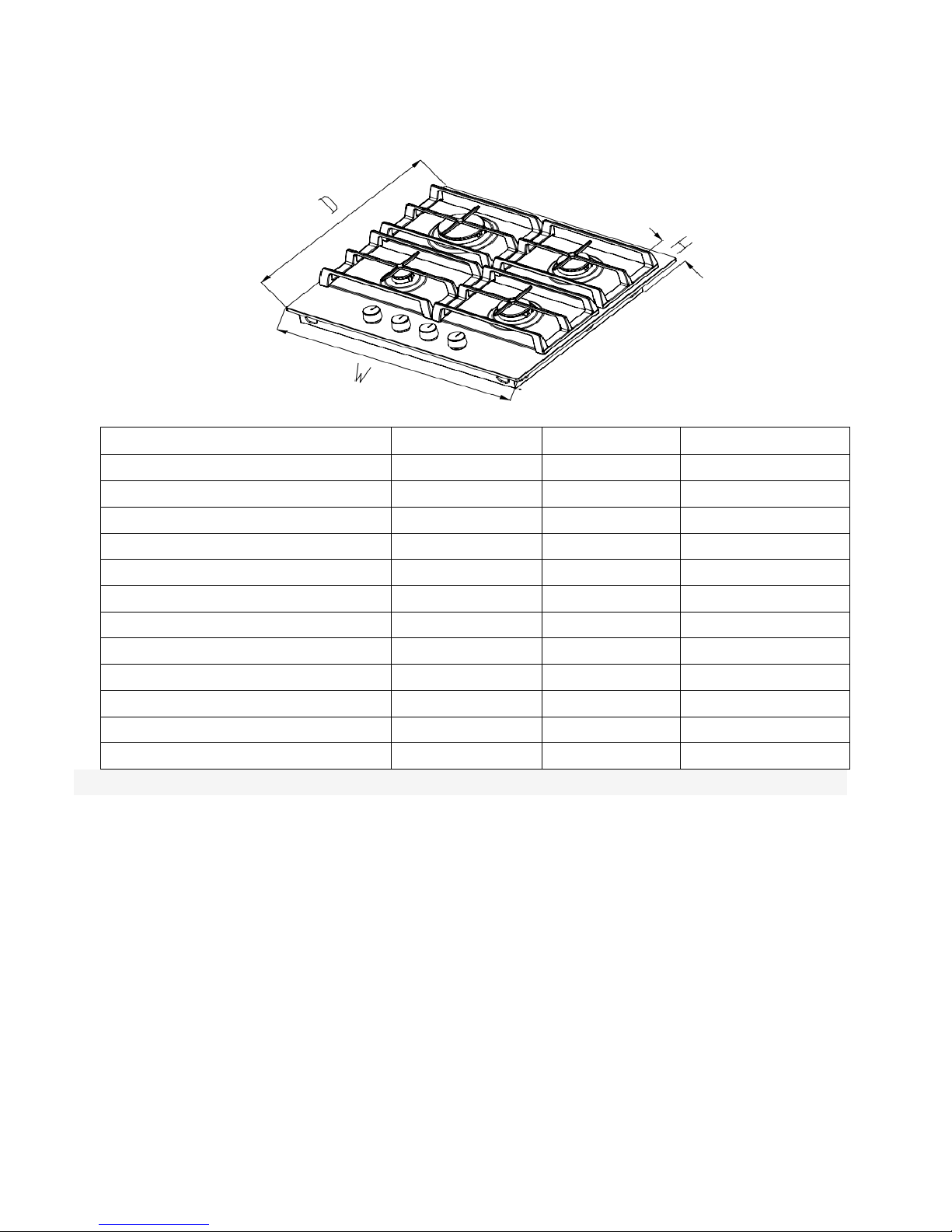

3.1. Dimension

Model

W (mm)

H (mm)

D (mm)

Q40xxxx

590

95

500

Q41xxxx

590

95

500

Q44xxxx

580

95

510

Q45xxxx

600

95

510

Q501Gxx

705

110

460

Q502Gxx

770

110

510

Q502Sxx

760

110

500

60Qxxxxxx

580

86

500

60Gxxxxxxx- xxx

600

110

510

70Gxxxxxxx- xxx

705

110

510

75G50xxxxx- xxx

750

90

510

90Gxxxxxxx- xxx

860

100

520

Note: Dimensions for reference only

Page 8

8

3.2. Installation Dimension

Cut out size:

Model

W(mm)

D (mm)

T(mm)

Q40xxxx

553

473

30(min)

Q41xxxx

553

473

30(min)

Q44xxxx

560

490

30(min)

Q45xxxx

580

490

30(min)

Q501Gxx

667

470

30(min)

Q502Gxx

730

470

30(min)

Q502Sxx

730

470

30(min)

60Qxxxxxxx

560

480

30(min)

60Gxxxx08x- xxx

553

473

30(min)

60Gxxxx4xx- xxx

553

473

30(min)

60Gxxxx006- xxx

580

490

30(min)

60Gxxxxxxx- xxx

560

490

30(min)

70Gxxxxxxx- xxx

560

490

30(min)

75G50xxxxx- xxx

730

490

30(min)

90Gxxxxxxx- xxx

850

490

30(min)

Note: Dimensions for reference only

Page 9

9

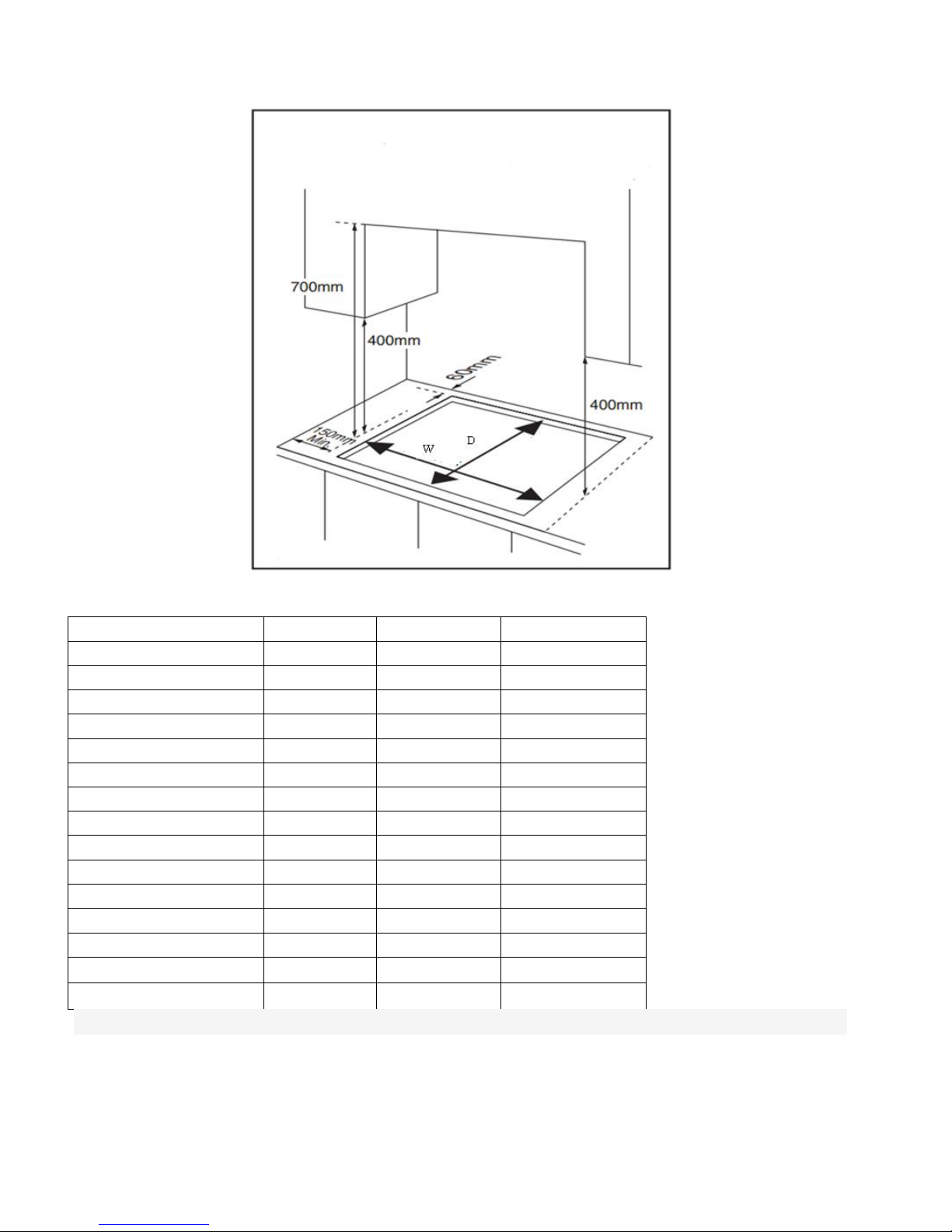

This appliance is to be built into a kitchen unit or worktop of right size, providing the following minimum

distances are allowed;

– The edge of the appliance must be a minimum distance of 55mm from a rear wall.

– A minimum distance of 150mm must be left between the side edges of the appliance and any adjacent

cabinets or walls.

– The minimum distance combustible material can be fitted above the appliance in line with the ed ges

of the appliance is 400mm.

– The minimum distance combustible material can be fitted directly above the appliance is 700mm.

–This panel (a) must be positioned at a maximum distance of 150mm below the worktop.

Gas pipe or connector shouldn't be bent or blocked by any other appliances

– You must conduct a gas leakage test after installation over gas connection and gas pipe.

– An oven must have forced ventilation to install a hob above it.

– Check the dimensions of the oven in the installation manual.

– The cut out size must obey the indication.

Page 10

10

4. Electric Diagram

a. Four burners model

b. Five burners model

Page 11

11

5. Reassembly and Disassembly

5.1. Safety precautions

5.2. Tools

Most of the tools that you might need are shown below. Some are optional.

WARNING

Turn off power for safety and appliance protection.

Close middle valve to prevent gas leakage

Keep away from inflammable materials around appliance.

Before work, put on gloves.

CAUTION

Cool off the appliance for a while right after using appliance for your safety because you can get

burners by high temperature from the appliances.

Page 12

12

5.3 Disassembly

5.3.1. Disassemble the Top Plate

Step 1: Remove parts on the Top Plate

a. Remove parts on the top plate: Burner lids, Flame spreaders, Control handles

b. When disassembling, keep parts safe, do not drop them to the appliance.

Step 2: Disassemble of Screws on the Top Plate

a. Remove the screws of the burner

b. In some versions, remove screws on the side of bottom plate.

c. Be careful in order not to damage screw heads when disassembling.

d. Be careful not to damage the top plate.

Step 3:Detachment of the Top Plate

a. Separate the top plate.(In case of stainless steel model, take off the sponge.)

b. During assembly, be careful in order not to give physical impact on parts such as ignition devices,

flame supervision devises..

Page 13

13

5.3.2. Disassemble the Thermocouple

Step 1: Unscrew the nut out.

Step 2: Pull the silver terminal of Thermocouple

Step 3: When reassembling, replace parts correctly

5.3.3. Disassemble of the Ignition Pin

Step 1: Pull the washer and take off ignition pin

Step 2: Pull the housing of Ignition pin out of the igniter.

Step 3: When reassembling, replace parts correctly.

5.3.4. Disassemble of the Microswitch Harness

Step 1: Before you disassemble the harness, take off the plastic e – ring.

Step 2: When you take off the micro switch harness , please be careful not to break the hook.

Step 3: When you reassemble the harness, replace it correctly.

Step 4: Detach the wire from the power cord assembly harness.

Step 5: Hold housing of the wire by hand and pull it out of the igniter

.

Page 14

14

5.3.5. Disassemble of the Gas Pipe

Step 1: Unscrew the nuts out. at both ends of the pipes

Step 2: Pull the pipes

5.3.6. Disassemble of the Bottom Cup

Step 1: Remove all screws on the bottom cup

Step 2: Detach the bottom cup from the base box burner

5.3.7. Disassemble of the Power Cord Assembly

Step 1 . Detach the wire from the Microswitch Harness.

Step 2 . Hold housing of the wire by hand and pull it out of the igniter.

Step 3. For power cord grounding, you must use grounding screw attached with washer.

Step 4 . Remove 2 screws and detach the power cord ass’y set

Page 15

15

5.3.8. Disassemble of the igniter

Step1. Remove 2 screws

Step2. Detach the igniter from the base box burner.

5.3.9. Disassemble of the Valve & Manifold Pipe Assembly

Step 1. Remove 5 screws

Step 2. Remove the screw to take off pipe assy.

Step 3. Remove 2 screws and detach the valve from the manifold pipe assembly

Step 4. You must check the gasket when you disassemble or assemble.

Step 5. If you have faulty one, replace it with new one.

Step 6. Conduct a leakage test after reassembling.

screws

Page 16

16

5.3.10. Disasmble of the Gas Connection

Step 1. When you disassemble/assemble gas connection, use 2 spanners. One for fixing gas connection

elbow, the other for tightening gas hose.

Step 2. Tighten enough to prevent gas leakage.

Step 3. Once you’re done, conduct leakage test

5.3.11. Disassemble of the bottom plate

Step 1. Separate casing on sink.

Step 2. Detach the appliance as checking the status of the gas connection and the power cord assembly set.

Page 17

17

5.4. Reassembly

5.4.1. Reassemble of the Ignition Pin

Step 1. Pull the line of the ignition pin in to the hole on bottom cup along the gap on bottom cup

Step 2. Push ignition pin to adjust the position

Step 3. Klemm ignition pin with snap spring to fox the ignition pin.

5.4.2. Reassemble of the Thermocouple

Step 1. Insert thermocouple into the the relevant hole of the bottom cup from bottom to top.

Step 2. Adjust position of the thermocouple in the hole of the bottom cup.

Step 3. screw up the nut to fix the thermocouple.

5.4.3. Reassemble of the Gas Pipe

Step 1.Insert the head of the gas pipe into installation parts of the bottom cup or the valve

Step 2.Screw up the nut of the joint with spanner

5.4.4. Check Point after assembly

a. At completion of the appliance repair, assemble after removing tools inside of the appliance.

b. You must conduct a leakage test after repairing.(refer to the leakage test on 5.3)

c. If ignition does not work, repeat ignition several times so that you

can remove remaining air in the gas connection

d. Check combustion status by conducting aging

Page 18

18

6. Troubleshooting

6.1. Troubleshooting

Page 19

19

6.2. Problems and Corrective Measures

Page 20

20

Note!

1 Check the ground wire before the fault is detected;

2 Enough attention must be given to high voltage circuit.

Page 21

21

6.3. Maintenance and test

Air leakage test

Tool: Air leakage device, soapy water

1. Professional repair procedures

a) Connect product to the air leakage device and set the test pressure at 15kPa;

b) The plug valve shall be kept closed and the gas pipelines may be tested its leakage through air leakage

device;

c) All plug valves shall be kept open, block the injectors at the burner, the flame-out protection valve shall

be kept open and the gas pipelines may be tested their leakage through air leakage device.

The maximum leakage must be controlled below 0.5mL/min as required in the test.

2. Simple procedures:

a) Connect the product to the gas source being used;

b) Smear soapy water at each joint of the product gas pipelines, the plug valve is kept closed, check

visually each joint for air bubbles;

c) Smear soapy water at each joint of product gas pipelines, all plug valves shall be kept open, block the

injectors at the burner, the flame-out protection device valve shall be kept open and check visually for any air

bubbles.

No air bubbles shall be detected at each joint as required in the test.

Note: Any component of the product gas pipelines shall not be disassembled or replaced only if the air

leakage is proved in conformity with relevant requirements.

Page 22

22

7. Gas Conversion

All work must be carried out by a qualified technician,

Before you begin, turn off the gas and electricity supply to the appliance.

7.1. Replacement of gas-type fitting

Tool: Open-end wrench

Steps for operation:

a) Disassemble with a wrench the gas-type fittings from main gas tube.

b) Lock tightly a replaceable gas-type fitting onto the main gas tube.

7.2. Replacement of the injector of the burners

Tool: 7mm box spanner

Steps for operation:

Step 1: Remove the pan support,,burner lid and flame spreader.

Step 2: Unscrew the injector with a 7 mm box spanner and replace it with the stipulated injector for new

gas supply.(see the following table)

Step 3: Carefully reassemble all the components.

After injectors are replaced ,it is advisable to tighten the injector in place. strongly.

injector

Joint

Seal washer

Gas tube

Page 23

23

注:

Comparison list for injector replacement

Nominal heat input and rates see below at 15℃ at 1013mbar

Page 24

24

8. Appendix

Technical & quality requirements for Built-in gas hob

a) Use of natural gas burner when the burner works 10 minutes in rated power,turn it to little fire

and keep 60 seconds,reduce the gas pressure to 1400pa,the fire shouldn’t extinct.

b) Neither flame off nor back burning should appear when the flame is in the fire hole of burner.

c) There should be no cracks and graze in the glass components and china components, besides the

fringe of them.

d) In Rated gas\rated gas pressure,ignite the burner,test the time from ignition to burner working

stably,it should not be more than 5 seconds.

e) In Rated gas\rated gas pressure,after the burner working for 15 minutes,turn off the plug valve,

then test the time during turning off plug valve and flame-out protection device shutting down,it

should be less than 90 seconds.

f) Every burner should be test ignition ,fuse transferring time\ flame stabilization,ignition\ fuse

transferring time should be less than 5 seconds. Flame-out will be allowed in 5 seconds after

ignition,but flame should be stable in 1 minute.

g) If it may cause security problems after corrosion, electric current and other mental parts should be

corrosion resistance under the normal conditions of use. Live parts and heat insulator should be

prevented to contact with each other unless the heat insulator is corrosion resistance ,

non-hygroscopic and flame-retardant.

h) The shaft of Knob, handle ,control stick and other similar parts should be electrically neutral unless

the shaft is out of the reach when the other parts are taken down.

i) The clamp device of ground terminal should be tight enough to avoid accidental loosening. The wire

length from power cord block terminal or cord fixing device to block terminal should be

appropriate .If the flexible cord slips off from the cord block terminal, current carrying conductor

should tighten firstly compared with earth conductor.

j) Phenomenon that may reflect cooking appliance performance should not appear of the pan support

in normal use.

k) Gas tightness should be accord with standard request after the gas connection was disassembled five

times.

Loading...

Loading...