Page 1

INSTALLATION INSTRUCTIONS

Split System Heat Pump & Air Conditioner

WARNING

These instructions are intended as an aid to qualified

licensed service personnel for proper installation, adjustment and operation of this unit. Read these instructions

thoroughly before attempting installation or operation.

Failure to follow these instructions may result in improper

installation, adjustment, service or maintenance possibly

resulting in fire, electrical shock, property damage,

personal injury or death.

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION

DO NOT DESTROY THIS MANUAL

Please read carefully and keep in a safe place for future reference by a serviceman.

NOTE: Appearance of unit may vary.

16 SEER

Heating & Air Conditioning

Page 2

TABLE OF CONTENTS

1.0 SAFETY..................................................................................................................3

1.1 INSPECTION....................................................................................................4

1.2 LIMITATIONS....................................................................................................4

2.0 GENERAL..............................................................................................................4

3.0 UNIT INSTALLATION............................................................................................6

3.1 LOCATION.......................................................................................................6

3.2 GROUND INSTALLATION...............................................................................6

3.3 ROOF INSTALLATION.....................................................................................6

3.4 UNIT PLACEMENT..........................................................................................6

3.5 PRECAUTIONS DURING LINE INSTALLATION.............................................7

3.6 PRECAUTIONS DURING BRAZING OF LINES..............................................8

3.7 PRECAUTIONS DURING BRAZING SERVICE VALVE..................................9

3.8 UNIT MOUNTING...........................................................................................10

3.9 FACTORY-PREFERRED TIE-DOWN METHOD............................................11

3.10 REMOVING THE TOP PANEL AND MOTOR..............................................12

4.0 ELECTRICAL CONNECTIONS...........................................................................13

4.1 GENERAL INFORMATION & GROUNDING .................................................13

4.2 FIELD CONNECTIONS POWER WIRING ....................................................13

5.0 EVACUATION......................................................................................................14

6.0 INTERCONNECTING TUBING............................................................................14

6.1 VAPOR AND LIQUID LINES .........................................................................14

6.2 MAXIMUM LENGTH OF LINES ....................................................................14

6.3 VERTICAL SEPARATION .............................................................................14

7.0 SYSTEM OPERATION........................................................................................14

7.1 COMPRESSOR CRANKCASE HEATER (CCH)...........................................14

7.2 LINE SIZING..................................................................................................15

7.3 PROTECTION FUNCTION INTRODUCTION...............................................16

7.4 DEFROST MODE..........................................................................................16

7.5 MANUA

DEFROST MODE.............................................................................17

8.0 CHECKING REFRIGERANT CHARGE ..............................................................17

8.1 CHARGING BY LIQUID PRESSURE.............................................................17

8.2 CHARGING BY WEIGHT ..............................................................................18

8.3 FINAL LEAK TESTING ..................................................................................18

9.0 OWNER INSTRUCTIONS .........................……...................................................18

10.0 WIRING DIAGRAM............................................................................................19

2

Page 3

1.0 SAFETY

This is a safety alert symbol. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury.

Understand and pay particular attention to the signal words DANGER, WARNING, or

CAUTION.

DANGER indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not avoided may result

in minor or moderate injury. It is also used to alert against unsafe practices and hazards

involving only property damage.

WARNING

Improper installation may create a condition where the operation of the product

could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Refer to this manual for assistance or for additional

information, consult a qualified contractor, installer or service agency.

This is an attention alert symbol. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury.

CAUTION

This product must be installed in strict compliance with the installation instructions and any applicable local, state, and national codes including, but not

limited to building, electrical, and mechanical codes.

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations of systems nor does

it provide for every possible contingency to be met in connection with installation.

All phases of this installation must comply with NATIONAL STATE AND LOCAL

CODES. If additional information is required please contact your local distributor.

3

WARNING

FIRE OR ELECTRICAL HAZARD

Failure to follow the safety warnings exactly could result in serious injury, death

or property damage.

A fire or electrical hazard may result causing property damage, personal injury

or loss of life.

Page 4

The outdoor units are designed to be connected to a matching indoor coil with sweat

connect lines. Sweat connect units are factory charged with refrigerant for a matching indoor coil plus 25 feet of field supplied lines.

Matching indoor coils are available with a thermostatic expansion valve or an orifice

for the most common usage. The orifice size and/or refrigerant charge may need to

be changed for some indoor-outdoor unit combinations, elevation differences or

total line lengths.

2.0 GENERAL

1.Limitations for the indoor unit, coil and appropriate accessories must also be observed.

2.The outdoor unit must not be installed with any duct work in the air stream. The outdoor fan is

the propeller type and is not designed to operate against any additional external static

pressure.

3.The maximum and minimum conditions for operation must be observed to assure a system

that will give maximum performance with minimum service.

4.This unit is not designed to operate with a low ambient kit. Do not modify the control system

to operate with any kind of Iow ambient kit.

5.The maximum allowable line length for this product is 150 feet Just for Scroll compressor .

1.2 LIMITATIONS

The unit should be installed in accordance with all National, State and Local Safety

Codes and the limitations listed below:

As soon as a unit is received, it should be inspected for possible damage during transit.

If damage is evident, the extent of the damage should be noted on the carrier's delivery

receipt. A separate request for inspection by the carrier's agent should be made in

writing. See Local distributor for more information.

1.1 INSPECTION

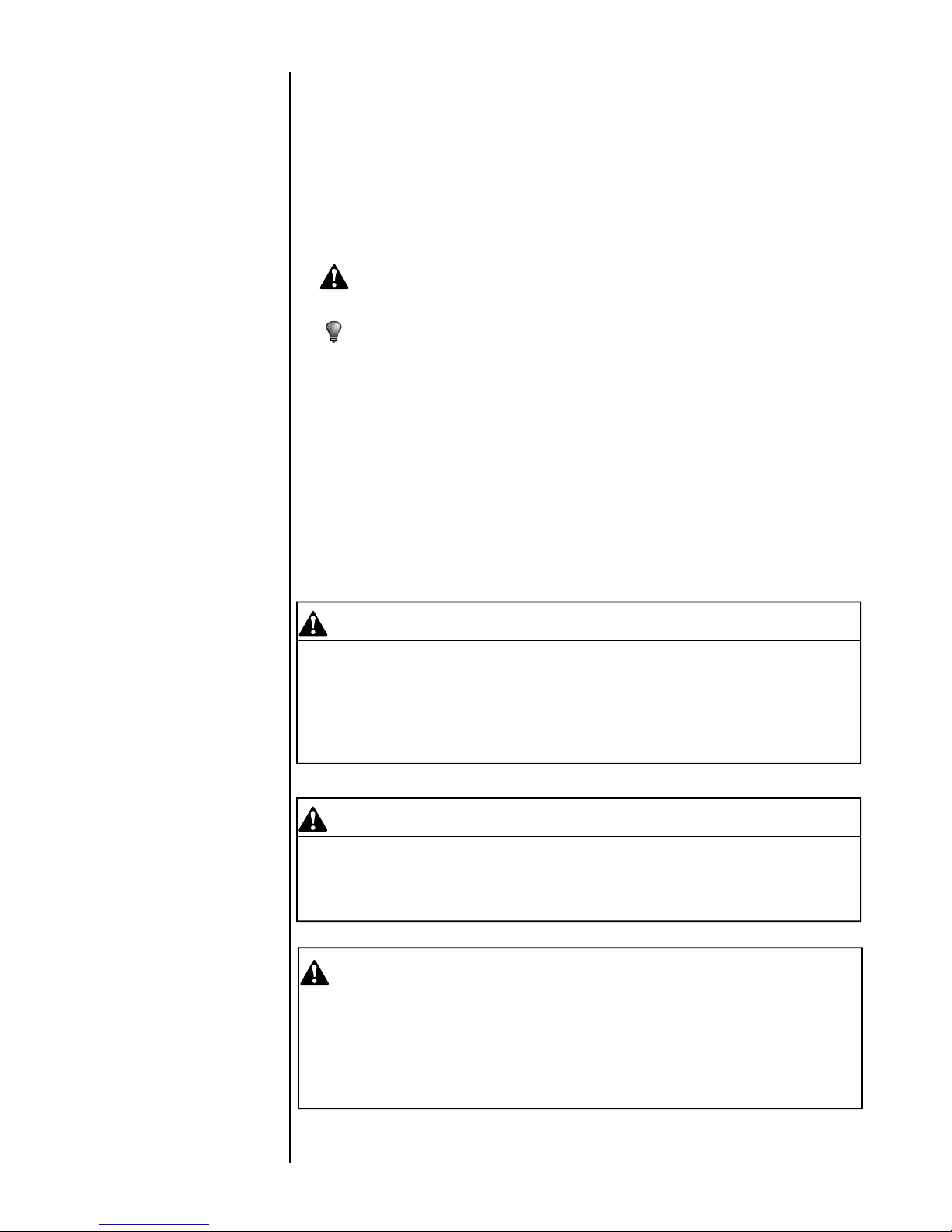

LARGE SERVICE VALVE

Fig.1 Underside Clapboard Location

4

Requirements For Installing/Servicing R410A Equipment

Gauge sets, hoses, refrigerant containers, and recovery system must be designed

to handle the POE or PVE type oils.

Manifold sets should be 800 PSIG high side and 250 PSIG low side with 550 PSIG

Iow side restart.

All hoses must have a 700 PSIG service pressure rating.

Leak detectors should be designed to detect refrigerant.

Recovery equipment (including refrigerant recovery containers) must be specifi cally designed to handle R410A.

Do not use an R-22 TXV.

It will be more convenient to open the Service valve after removing the Underside

Clpboard. see the Fig.1

Underside Clapboard

SMALL SERVICE VALVE

Page 5

5

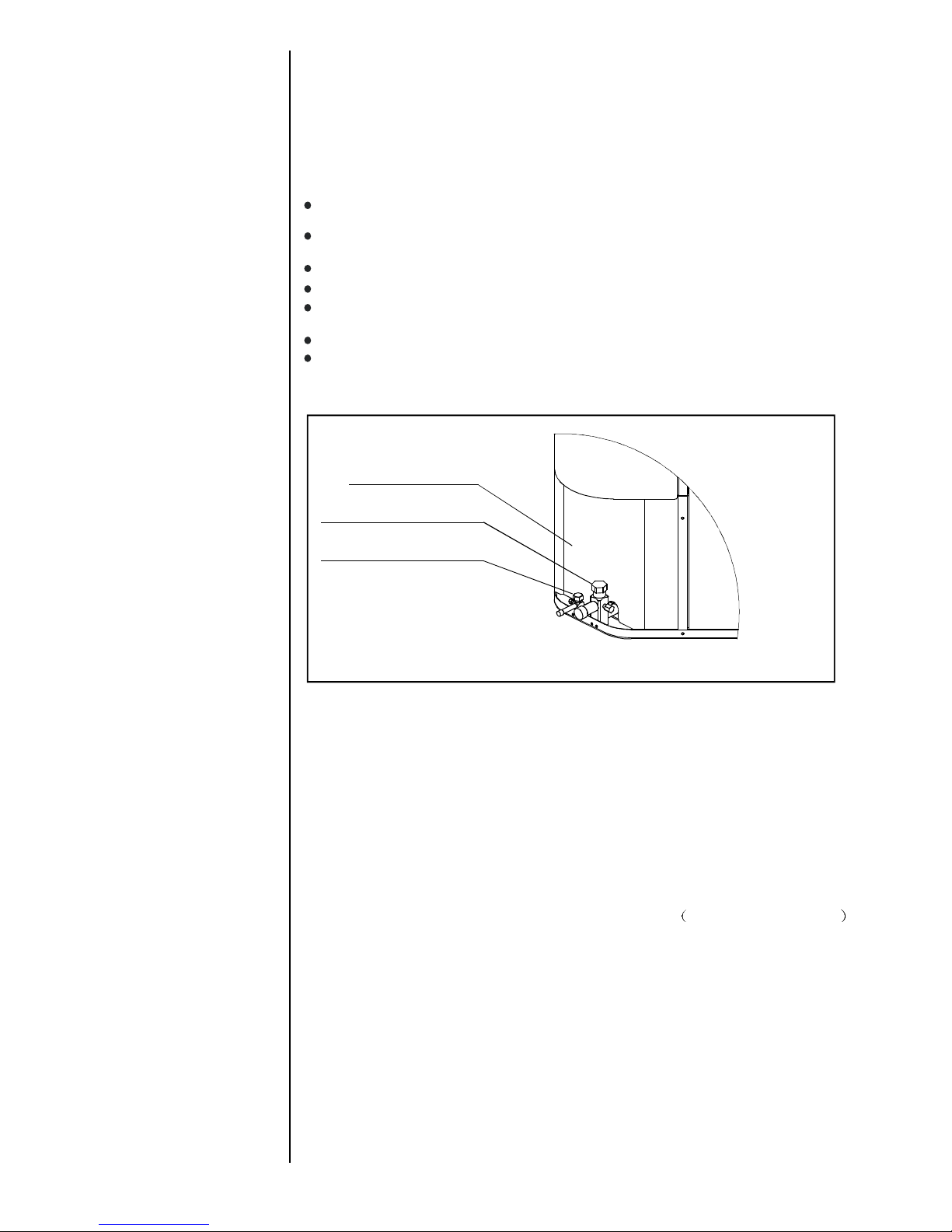

FIG.2 DIMENSIONS

DIMENSIONAL DATA

"H" in. [mm]"W" in. [mm]

"L" in. [mm

]

Liqui

d in.

Vapor in.

18

24-15/16[633]

28[710]

28[710]

3/83/

4

24 29-1/8[740]

29-1/8[740]3/83/4

30 29-1/8[740]

29-1/8[740]3/83/4

36 29-1/8[740]29-1/8[740]

3/87/

8

42 29-1/8[740]

29-1/8[740]3/87/8

Model SIZE(Btu/h)

Dimensions (Inches)

Refrigerant Connection

Service Valve Size

24-15/16[633]

24-15/16[633]

33-3/16[843]

33-3/16[843]

AIR DISCHARGE: ALLOW 60”

MINIMUM CLEARANCE.

VAPOR LINE

CONNECTION

CONTROL WIRING

7/8” (22.2mm)

KNOCKOUT

1-11/32” (34.5mm)

LIQUID LINE

CONNECTION

SERVICE

FITTING

SERVICE

FITTING

POWER WIRING

SEE DETAIL A

DETAIL A

HOLE

1-3/32” (27.8mm)

SERVICE ACCESS

ALLOW 24” CLEARANCE

AIR INLETS

LOUVERED PANELS

ALLOW 18”

MINIMUM

CLEARANCE

NOTE: GRILL APPEARANCE

MAY VARY.

W

Page 6

3.0 UNIT INSTALLATION

3.1 LOCATION

Before starting the installation, select and check the suitability of the location for both

the indoor and outdoor unit. Observe all limitations and clearance requirements. The

outdoor unit must have sufficient clearance for air entrance to the condenser coil, for air

discharge and for service access. See Fig.2

NOTE

For multiple unit installations, units must be spaced a minimum of 18 inches

apart. (Coil face to coil face.)

If the unit is to be installed on a hot sun exposed roof or a black-topped ground area, the

unit should be raised sufficiently above the roof or ground to avoid taking the accumulated layer of hot air into the outdoor unit.

Provide an adequate structural support.

WARNING

The outdoor unit should not be installed in an area where mud or ice could cause

personal injury.

Elevate the unit sufficiently to prevent any blockage of the air entrances by snow in

areas where there will be snow accumulation. Check the local weather bureau for the

expected snow accumulation in your area. Isolate the unit from rain gutters to avoid any

possible wash out of the foundation.

When installing units on a roof, the structure must be capable of supporting the total

weight of the unit, including a padded frame unit, rails, etc., which should be used to

minimize the transmission of sound or vibration into the conditioned space.

3.3 ROOF INSTALLATION

3.4 UNIT PLACEMENT

1. Provide a base in the pre-determined location.

2. Remove the shipping carton and inspect for possible damage.

3. Compressor tie-down bolts should remain tightened.

4. Position the unit on the base provided.

The unit may be installed at ground level on a solid base that will not shift or settle, causing strain on the refrigerant lines and possible leaks. Maintain the clearances shown in

Fig.2 and install the unit in a level position.

3.2 GROUND INSTALLATION

Normal operating sound levels may be objectionable if the unit is placed directly under

windows of certain rooms (bedrooms, study, etc.).

Top of unit discharge area must be unrestricted for at least 60 inches above the unit.

6

Page 7

1. Install the lines with as few bends as possible. Care must be taken not to damage

the couplings or kink the tubing. Use clean hard drawn Copper tubing where no

appreciable amount of bending around obstruction is necessary, if soft copper must

be used, care must be taken to avoid sharp bends which may cause a restriction.

2. The lines should be installed so that they will not obstruct service access to the coil,

air handling system or filter.

3.5 PRECAUTIONS DURING LINE INSTALLATION

CAUTION

This system uses R410A refrigerant which operates at higher pressure than

R-22. No other refrigerant may be used in this system. Gauge sets, hoses,

refrigerant containers, and recovery system must be designed to handle

R410A. If you are unsure, consult the equipment manufacturer.

The outdoor unit must be connected to the indoor coil using field supplied refrigerant

grade copper tubing that is internally clean and dry. Units should be installed only with

the tubing sizes for approved system combinations. The charge given is applicable for

total tubing lengths up to 25 feet.

NOTE

Using a larger than specified line size could result in oil return problems. Using

too small a line will result in loss of capacity and other problems caused by insufficient refrigerant flow. Slope horizontal vapor lines at least 1" every 20 feet

toward the outdoor unit to facilitate proper oil return.

3. Care must also be taken to isolate the refrigerant lines to minimize noise transmis sion from the equipment to the structure.

4. The vapor line and liquid line must be insulated with a minimum of 1/2" foam rubber

insulation (Armafiex or equivalent). Tape and suspend the refrigerant lines as shown.

DO NOT allow tube metal-to-metal contact. See Fig. 3.

5. Use PVC piping as a conduit for all underground installations as shown in Fig. 4.

Buried lines should be kept as short as possible to minimize the build up of liquid

refrigerant in the vapor line during long periods of shutdown.

6. Pack fiberglass insulation and a sealing material such as perma gum around refrig erant lines where they penetrate a wall to reduce vibration and to retain some flexi bility.

7

Page 8

Insulated Liquid Line

Tape

Sheet Metal Hanger

CorrectIncorrect

Fig.5 Typical Installation

Fig.3 Tubing Hanger

Fig.4 Underground Installation

All outdoor unit and evaporator coil connections are copper-to-copper and should be

brazed with a phosphorous-copper alloy material such as Silfos-5 or equivalent. DO

NOT use soft solder. The outdoor units have reusable service valves on both the liquid

and vapor connections. The total system refrigerant charge is retained within the

outdoor unit during shipping and installation. The reusable service valves are provided

to evacuate and charge per this instruction.

Serious service problems can be avoided by taking adequate precautions to assure an

internally clean and dry system.

3.6 PRECAUTIONS DURING BRAZING OF LINES

8

Insulated Vapor Line

TO

INDOOR

BLOWER

TO

POWER

SUPPLY

TO

COIL

WEATHERPROOF

DISCONNECT

SWITCH

Seal opening(s) with

permagumor equivalent

NOTE:All outdoor wiring must be weather proof

Page 9

CAUTION

Dry nitrogen should always be supplied through the tubing while it is being

brazed, because the temperature required is high enough to cause oxidation

of the copper unless an inert atmosphere is provide. The flow of dry nitrogen

should continue until the joint has cooled. Always use a pressure regulator

and safety valve to insure that only low pressure dry nitrogen is introduced into

the tubing.Only a small flow is necessary to displace air and prevent oxidation.

Precautions should be taken to prevent heat damage to service valve by wrapping a wet

rag around it as shown in Fig. 6. Also, protect all painted surfaces, insulation, during

brazing. After brazing cool joint with wet rag.

3.7 PRECAUTIONS DURING BRAZING SERVICE VALVE

Valve can be opened by removing the plunger cap and fully inserting a hex wrench into

the stem and backing out counter-clockwise until valve stem just touches the chamfered retaining wall.

1. Remove the cap and Schrader core from both the liquid and vapor service valve

service ports at the outdoor unit. Connect Iow pressure nitrogen to the liquid line

service port.

Connect the refrigerant lines using the following procedure:

2. Braze the liquid line to the liquid valve at the outdoor unit. Be sure to wrap the valve

body with a wet rag. Allow the nitrogen to continue flowing. Refer to the Tabular Data

Sheet for proper liquid line sizing.

3. Carefully remove the rubber plugs from the evaporator liquid and vapor connections

at the indoor coil.

4. Braze the liquid line to the evaporator liquid connection. Nitrogen should be flowing

through the evaporator coil.

5. Slide the plastic cap away from the vapor connection at the indoor coil. Braze the

vapor line to the evaporator vapor connection. Refer to the Table 1 for proper vapor

line sizing.

6. Protect the vapor valve with a wet rag and braze the vapor line connection to the

outdoor unit. The nitrogen flow should be exiting the system from the vapor service

port connection. After this connection has cooled, remove the nitrogen source from

the liquid fitting service port.

7. Replace the Schrader core in the liquid and vapor valves.

8. Leak test all refrigerant piping connections including the service port flare caps to be

sure they are leak tight. DO NOT OVER TIGHTEN (between 40 and 60 inch -lbs.

maximum).

9. Evacuate the vapor line, evaporator and the liquid line, to 500 microns or less.

9

Fig.6 Heat Protection

service valve

wet rag

Page 10

10. Replace cap on service ports. Do not remove the flare caps from the service ports

except when necessary for servicing the system.

CAUTION

Do not connect manifold gauges unless trouble is suspected. Approximately 3/4

ounce of refrigerant will be lost each time a standard manifold gauge is

connected.

11. Release the refrigerant charge into the system. Open both the liquid and vapor

valves by removing the plunger cap and with an hex wrench back out counter

-clockwise until valve stem just touches the chamfered retaining wall.

12. Replace plunger cap finger tight, then tighten an additional 1/12 turn (1/2 hex flat).

Cap must be replaced to prevent leaks.

Table 1: Refrigerant Connections and Recommended Liquid and Vapor Tube

Diameters (ln.)

WARNING

Never attempt to repair any brazed connections while the system is under pressure. Personal injury could result.

See "System Charge" section for checking and recording system charge.

10

3.8 UNIT MOUNTING

2. If elevating a unit on a flat roof , use 4”× 4”(or equivalent) stringers

positioned to distribute unit weight evenly and prevent noise and vibration

(See fig. 7) .

NOTE:Do not block drain openings shown in fig.7.

3. If unit must be elevated because of anticipated snow fall, secure unit and

elevating stand such that unit and/or stand will not tip over or fall off.

If elevating the heat pump, either on a flat roof or on a slab, observe the following guidelines.

1.The base pan provided elevates the heat pump 2” above the base pad.

NOTE: To tie down unit, see 3.9.

MODEL SIZE

LIQUID

SUCTION

Tube Diameter

Tube Diameter

18

3/8

3/4

24

3/8

3/4

30

3/8

3/4

36

3/8

3/4

42

3/8

48

3/8

60

3/8

7/8

3/4

7/8

Page 11

11

3.9 FACTORY-PREFERRED TIE-DOWN METHOD

Step 3: Using L-shaped bracket to locate holes on concrete and drill pilot holes which is

at least 1/4” deeper than fastener being used.

IMPORTANT

Self drilling screws to base pan should not exceed 3/8” long to avoid damaging

coil.

Step 4: Using conventional practices to install brackets, tighten concrete fasteners and

self-tapping screws (See Fig.8).

NOTE: 1. One bracket for each side. For extra stability, 2 brackets for each side.

2. Do not over-tighten the concrete fastener to avoid weakening the concrete.

Step 1: Prior to installing clear pad of debris.

IMPORTANT

Then cement pad must be made of HVAC-approved materials and must be the

proper thickness to accommodate fasteners.

Step 2: Center and level unit onto pad.

Fig.7 RECOMMENDED ELEVATED INSTALLATION

ELEVATION ABOVE ANTICIPATED

SNOW IS NECESSARY

BASE PAD

(CONCRETE OR

OTHER SUITABLE

MATERIAL)

BASE PAN (BOTTOM VIEW) DO NOT

OBSTRUCT DRAIN HOLES

(SHADED)

IMPORTANT NOTE:

These instructions are intended to provide a method to tie-down system to cement slab

as a securing procedure for high wind areas. It is recommended to check Local Codes

for tie-down methods and protocols.

Page 12

12

1/2” bolt

5/16” bolts

Fig. 9 COVER AND FAN

3.10 REMOVING THE TOP PANEL AND MOTOR

When motor requires changing follow the steps below:

Step 1: Go into electrical panel, disconnect motor power lines.

IMPORTANT NOTE

Disconnect main power to unit. Severe burns and electrical shock will occur if

you do not disconnect main power.

Step 2: Remove cover (be careful of motor wires)

Step 3: Be sure to place fan cover unit on the ground as indicated in Fig. 9

IMPROTANT NOTE

Do not place or lean fan blades on ground or against surface.

Step 4: Remove fan motor by removing 5/16” bolts from cover.

Step 5: Remove fan blade from motor by removing 1/2” bolt and place fan on the ground.

Step 6: Reverse removal process to reinstall the fan and motor.

IMPROTANT NOTE

When connecting motor wires be sure to check motor direction.

Damage will occur to condenser unit

if you remove fan bolts prior to cover removal.

NOTE:

REQUIRED PARTS LIST

SEE DETAIL B

#7 X 3/8” Self Tapping Screws

(Don’t Exceed 3/8” long)

1/4” Χ 1-1/2” Hex Washer Head Concrete Screws

(3/16” Pilot Hole Needed. Pilot Hole Should Be1/4” Deeper

Than The Fastener Embedment)

Fig.8 FACTORY-PREFERRED TIE-DOWN METHOD

DETAIL B

Brackets:

2” width, 1/16” thickness,

height as required.

Available from distributor

or in market place.

The dimension see FIG.2

Page 13

4.1 GENERAL INFORMATION & GROUNDING

Check the electrical supply to be sure that it meets the values specified on the unit

nameplate and wiring label.

Power wiring, control (Iow voltage) wiring, disconnect switches and over current

protection must be supplied by the installer. Wire size should be sized per requirements.

CAUTION

All field wiring must USE COPPER CONDUCTORS ONLY and be in accordance

with Local, National Fire, Safety & Electrical Codes. This unit must be grounded

with a separate ground wire in accordance with the above codes.

The complete connection diagram and schematic wiring label is located on the inside

surface of the unit service access panel and this instruction.

1. Install the proper size weatherproof disconnect switch outdoors and within sight of

the unit.

2. Remove the screws at the side of the corner panel. Slide corner panel down and

remove from unit. See Fig. 10.

3. Run power wiring from the disconnect switch to the unit.

4. Route wires from disconnect through power wiring opening provided and into the

unit control box.

5. Install the proper size time-delay fuses or circuit breaker, and make the power

supply connections.

6. Energize the crankcase heater if equipped to save time by preheating the compres sor oil while the remaining installation is completed.

4.2 FIELD CONNECTIONS POWER WIRING

4.0 ELECTRICAL CONNECTIONS

13

NOTE: When changing the motor, remove top cover first.

Fig.10 Typical Field Wiring

POWER

WIRING

CORNER

PANEL

CONTROL

WIRING

Page 14

It will be necessary to evacuate the system to 500 microns or less. If a leak is

suspected, leak test with dry nitrogen to locate the leak. Repair the leak and test again.

To verify that the system has no leaks, simply close the valve to the vacuum pump

suction to isolate the pump and hold the system under vacuum. Watch the micron

gauge for a few minutes. If the micron gauge indicates a steady and continuous rise,

it's an indication of a leak. If the gauge shows a rise, then levels off after a few minutes

and remains fairly constant, its an indication that the system is leak free but still

contains moisture and may require further evacuation if the reading is above 500

microns.

5.0 EVACUATION

7.0 SYSTEM OPERATION

7.1 COMPRESSOR CRANKCASE HEATER (CCH HEAT BUMP ONLY)

Refrigerant migration during the off cycle can result in a noisy start up. Add a crankcase heater to minimize refrigeration migration, and to help eliminate any start up

noise or bearing “wash out”.

All heaters are located on the lower half of the compressor shell. Its purpose is to drive

refrigerant from the compressor shell during long off cycles, thus preventing damage

to the compressor during start-up.

At initial start-up or after extended shutdown periods, make sure the heater is energized for at least 12 hours before the compressor is started. (Disconnect switch on and

wall thermostat off.)

14

6.0 INTERCONNECTING TUBING

6.1 VAPOR AND LIQUID LINES

Keep all lines sealed until connection is made.

Make connections at the indoor coil first.

Refer to Line Size Information in Tables 2 and 3 for correct size and multipliers to be

used to determine capacity for various vapor line diameters and lengths of run. The

losses due to the lines being exposed to outdoor conditions are not included.

1/4” ± .3 oz. per foot

5/16” ± .4 oz. per foot

3/8” ± .6 oz. per foot

1/2” ± 1.2 oz. per foot

6.2 MAXIMUM LENGTH OF LINES

The maximum length of interconnecting line is 150 feet.

Always use the shortest length possible with a minimum number of bends. Additional

compressor oil is not required for any length up to 150 feet.

NOTE: Excessively long refrigerant lines cause loss of equipment capacity.

6.3 VERTICAL SEPARATION

Keep the vertical separation to a minimum. Use the following g

uidelines when

installing the unit:

1. DO NOT exceed the vertical separations as indicated on Table 3.

2. It is recommended to use the smallest liquid line size permitted to minimize sys tem charge which will maximize compressor reliability.

3. Table 3

may be used for sizing horizontal runs.

The factory refrigerant charge in the outdoor unit is sufficient for the unit and 25 feet

of standard size interconnecting liquid and vapor lines. For different lengths,adjust

the charge as indicated below.

Page 15

15

TABLE 2: SUCTION LINE LENGTH/SIZE VS CAPACITY MULTIPLIER(R410A)

TABLE 3 :LIQUID LINE SIZE (R-410A)

1 1/2 Ton2 Ton2 1/2 Ton3 Ton3 1/2 Ton

3/4" I.D.3/4" I.D.3/4" I.D.7/8" I.D.7/8" I.D.

5/8 Opt.5/8 Opt.5/8 Opt.3/4 Opt.3/4 Opt.

3/4* Std.3/4* Std.3/4* Std.7/8* Std.7/8* Std.

Optional1.001.001.001.001.00

Standard1.001.001.001.001.00

Optional0.970.970.970.980.98

Standard0.980.980.980.990.98

Optional0.940.940.940.960.95

Standard0.950.950.960.970.97

Optional0.900.900.900.940.91

Standard0.920.920.930.950.96

Suction Line Connection Size

System Capacity

Suction Line Run Feet

NOTES:

* Standard size

Using suction line larger than shown in chart will result in poor oil return and is not recommended.

150'

25'

50'

100'

255075100125150

1/42540259N/AN/A

5/16255062585349

3/8*255075727068

1/423N/AN/AN/AN/AN/A

5/1625362923169

3/8*255072706865

1/425N/AN/AN/AN/AN/A

5/1625493827176

3/8*255068656258

5/16255037227N/A

3/8*255068635853

5/1625234N/AN/AN/A

3/8*255043363024

Liquid Line Size

Outdoor unit above or below indoor coil

3 Ton

Total Equivalent Length - Feet

System

Capacity

Line Size

Connection And

Line Size

(Inch I.D.)

Maximum Vertical Separation - Feet

Line Size

Connection Size

(Inch I.D.)

Compress

or

Type

Scroll

Scroll

Scroll

1 1/2 Ton3/8"

2 Ton3/8"

3/8"2 1/2 Ton

NOTES:

* Standard line size

N/A Application not recommended.

Scroll

Scroll3 1/2 Ton

3/8"

3/8"

7.2 LINE SIZING

Page 16

16

7.3 PROTECTION FUNCTION INTRODUCTION (Heat pump only)

Sensor T3 (condenser pipe temperature) and T4 (outdoor ambient temperature)

When open-circuit, compressor, outdoor fan motor and reverse valve will be OFF.

Discharge temperature protection

When discharge temp. is > 275 °F, the compressor will stop.

When discharge temp. is < 194 °F, the compressor will restart.

High perssure protection

When high pressure is > 638 PSIG, the compressor and the outdoor fan motor will stop.

When high pressure is < 464 PSIG, the compressor and the

outdoor fan motor will restart

(3 minutes delay necessary).

Low pressure protection

Low pressure is < 21 PSIG, the compressor and the outdoor fan motor will stop.

Low pressure is > 44 PSIG, the compressor and the outdoor fan motor will restart

(3 minutes delay necessary).

In stand-by status, the compressor will not start in low pressure protection.

Within 30 mins, if 4 protection cycles occurs, system will restore after power cut-down.

When T4 is < 5 °F, the compressor will stop. If the electrical heater kit is installed in

the indoor unit, the outdoor unit would provide a signal to drive up the heater.

When T4 is > 10.4 °F, the compressor will restart.

Error code table for the indicating light:

STEADY ON = NORMAL OPERATIONSTEADY ON = NORMAL OPERATION

OFF = DFC FAILURE OFF = DFC FAILURE

1 FLASH = T3 SENSOR FAILURE1 FLASH = T3 SENSOR FAILURE

2 FLASH = T4 SENSOR FAILURE / HPC OR HGS OPEN2 FLASH = T4 SENSOR FAILURE / HPC OR HGS OPEN

1

2

0

3 FLASH = LPC OPEN3 FLASH = LPC OPEN

3

When JUMP switch is set to “0”:

Compressor keeps running, when T3 is < 32 °F and last for 30 minutes.

7.4 DEFROST MODE* (For HP system only)

Defrosting condition:

When JUMP switch is set to “1”, the defrost mode will start if one of following

conditions is satisfied:

1. Compressor keeps running, when T4 is > 28.4 °F and T3 is < 32 °F and last

for 40 minutes;

2. Compressor keeps running, when T4 is < 28.4 °F and T3 is < 32 °F and last

for 50 minutes.

* When defrosting actions, if the electrical heater kit is installed, the unit would deliver the Aux. heater

operation signal to the electrical heater kit.

Page 17

Charge for all systems should be checked against the Charging Chart inside the

access panel cover.

IMPORTANT:Do not operate the compressor without charge in system. Addition of

R-410A will raise pressures (vapor, liquid and discharge).

If adding R-410A raises both vapor pressure and temperature, the unit is overcharged.

IMPORTANT: Use industry-approved charging methods to ensure proper system

charge.

8.1 CHARGING BY LIQUID PRESSURE

The liquid pressure method is used for charging systems in the cooling and heating

mode. The service port on the liquid (small valve) and suction (large valve) is used

for this purpose.

Verify that the outdoor unit is running and the indoor air mover is delivering the

maximum airflow for this system size. Read and record the outdoor ambient temperature. Read and record the liquid and suction pressures at the ports on the liquid

and suction valves.

8.0 CHECKING REFRIGERANT CHARGE

17

7.5 MANUAL DEFROST MODE (For HP system only)

When MANUAL DEFROST switch in PCB is set to “1”, system will perform as

above 7.4 description.

When the switch is set to “0”, T3 32°F, compressor keeps running and lasting

for 40 seconds, the system turns to the Defrost Mode. By the logic of 7.4 to

exit the Defrost Mode.

Caution: Once finishes the manual defrost, please switch the MANUAL

DEFROST in PCB to “1”.

Fig.11 Switch location in the PCB board

JUMP

MANUAL

DEFROST

Page 18

18

8.2 CHARGING BY WEIGHT

For a new installation, evacuation of interconnecting tubing and indoor coil is

adequate; otherwise, evacuate the entire system. Note that charge value includes

charge required for 25 ft. of standard size interconnecting liquid line. Calculate actual

With an accurate scale (+/-1 oz.) or volumetric charging device, adjust charge

difference between that shown on the unit data plate and that calculated for the new

system Installation. if the entire system has been evacuated, add the total calculated

charge.

8.3 FINAL LEAK TESTING

After the unit has been properly evacuated and charged, a halogen leak detector

should be used to detect leaks in the system. All piping within the condensing unit,

evaporator, and interconnecting tubing should be checked for leaks. If a leak is

detected, the refrigerant should be recovered before repairing the leak. The Clean Air

Act prohibits releasing refrigerant into the atmosphere.

If refrigerant lines are sized using the nameplate charge, the correct liquid pressure is

found at the intersection of the suction pressure and the outdoor ambient.

1. Remove refrigerant charge if the liquid pressure is above the chart value.

2. Add refrigerant charge if the liquid pressure is below the chart value.

9.0 OWNER INSTRUCTIONS

9.1 MAINTENANCE

. Dirt should not be allowed to accumulate on the outdoor coils or other parts in the air

circuit. Clean as often as necessary to keep the unit clean. Use a brush, vacuum

cleaner attachment, or other suitable means.

2.

The outdoor fan motor is permanently lubricated and does not require periodic oiling.

3. If the coil needs to be cleaned, it should be washed with Calgon Coilclean (mix one

part Coilclean to seven parts water). Allow solution to remain on coil for 30 minutes

before rinsing with clean water. Solution should not be permitted to come in contact

with painted surfaces.

4.

Refer to the furnace or air handler instructions for filter and blower motor maintenance.

5. The indoor coil and drain pan should be inspected and cleaned regularly to assure

proper drainage.

CAUTION

It is unlawful to knowingly vent, release or discharge refrigerant into the open air

during repair, service, maintenance or the final disposal of this unit. When the

system is functioning properly and the owner has been fully instructed, secure the

owner’s approval.

Assist owner with processing Warranty cards and/or online registration. Review Owners

Guide and provide a copy to the ower and guidance on proper operation and main-

teance. Instruct the owner or the operator how to start, stop and adjust temperature

setting. The installer should instruct the owner on proper operation and maintenance of

all other system components.

1.

charge required with installed liquid line size and length, please see 6.1 of table of

contents.

Page 19

19

10.0 WIRING DIAGRAM

CAUTION

These units must be wired and installed in accordance with all National and

Local Safety Codes.

Fig.12 Outdoor Unit Wiring Diagram for A/C Systems(208/230V 1P 60Hz).

CCCOMPRESSORCONTACTOR

RC1RUNCAPACITOR1

RC2RUNCAPACITOR2

COMPCOMPRESSOR

LINEVOLTAGE

FACTORYSTANDARD

FIELDINSTALLED

OPTIONAL

LOW

FACTORY

VOLTAGE

FACTORYSTANDARD

FIELDINSTALLED

FACTORYOPTIONAL

USECOPPERCONDUCTORSONLY

WARNING:

CABINETMUSTBEPERMANMENTLY GROUNDED

ANDALLWIRINGTOCONFORMTO I.E.C, N.E.C,

C.E.C, C.L.C, ANDLOCALCODESAS APPLICABLE

REPLACEMENTWIREMUSTBETHESAMEGAUGE

AND INSULATIONTYPEASORIGINALWIRE.

ORANGE

A2

A1

T1

L1

BLACK

YELLOW

C

Y

RC1

L1L2

CC

L1

L2

GND

THERMOSTAT

C

Y

R

G

INDOOR UNIT

OUTDOOR UNIT

G

C

Y

R

C

Fig.13 Control Wiring for A/C Systems.

Suggestion: When choosing a thermostat, choose KJR-25B or a non-programmable

electric thermostat series . Please refer to thermostat electrical manual for wiring

schematic.

Terminal Block

Page 20

20

1

2

0

3

Fig.14 Outdoor Unit Wiring Diagram for H/P Systems(208/230V 1P 60Hz).

THERMOSTAT

C

INDOOR UNITOUTDOOR UNIT

Y

R

G

RY

G

C

C

B

R

B

Fig.15 Control Wiring for H/P Systems.

W2

D

w1

Suggestion: When choosing a thermostat, choose KJR-25B or a non-programmable electric

thermostat. Broken lines means H/P system with electric heating. Please refer to thermostat

electrical manual for wiring schematic.

Terminal Block

Page 21

21

TABLE 4: Electrical Data:

ModelMin. Circuit Ampacity(A)Maximum Circuit Protector(A)

18AC

12.3

20

24AC

17.9

30

30AC

18.7

30

36AC21.935

42AC

23.4

40

18HP

12.3

20

24HP

17.9

30

30HP

18.7

30

36HP

21.9

35

42HP

23.440

NOTES:

AC:Air Conditioner; HP:Heat Pump

Loading...

Loading...