Page 1

PS670 Series

Gas

Domestic & Std. Export

ENGLISH

P/N 58814

January 18, 2006

PS670 Series Gas Ovens

Model:

• PS670G Gas

Combinations:

• Single Oven

• Double Oven (Two-Stack)

• Triple Oven (Three-Stack)

OWNER'S OPERATING AND

INST ALLATION MANUAL

for domestic and standard export ovens

©2006 Middleby Marshall Inc.

is a registered trademark of Middleby Marshall, Inc. All rights reserved.

Middleby Cooking Systems Group • 1400 Toastmaster Drive • Elgin, IL 60120 • (847)741-3300 • FAX (847)741-4406

Page 2

2

Page 3

Table of Contents

Page

SECTION 1

DESCRIPTION .................................................................... 4

I. OVEN USES .................................................................... 4

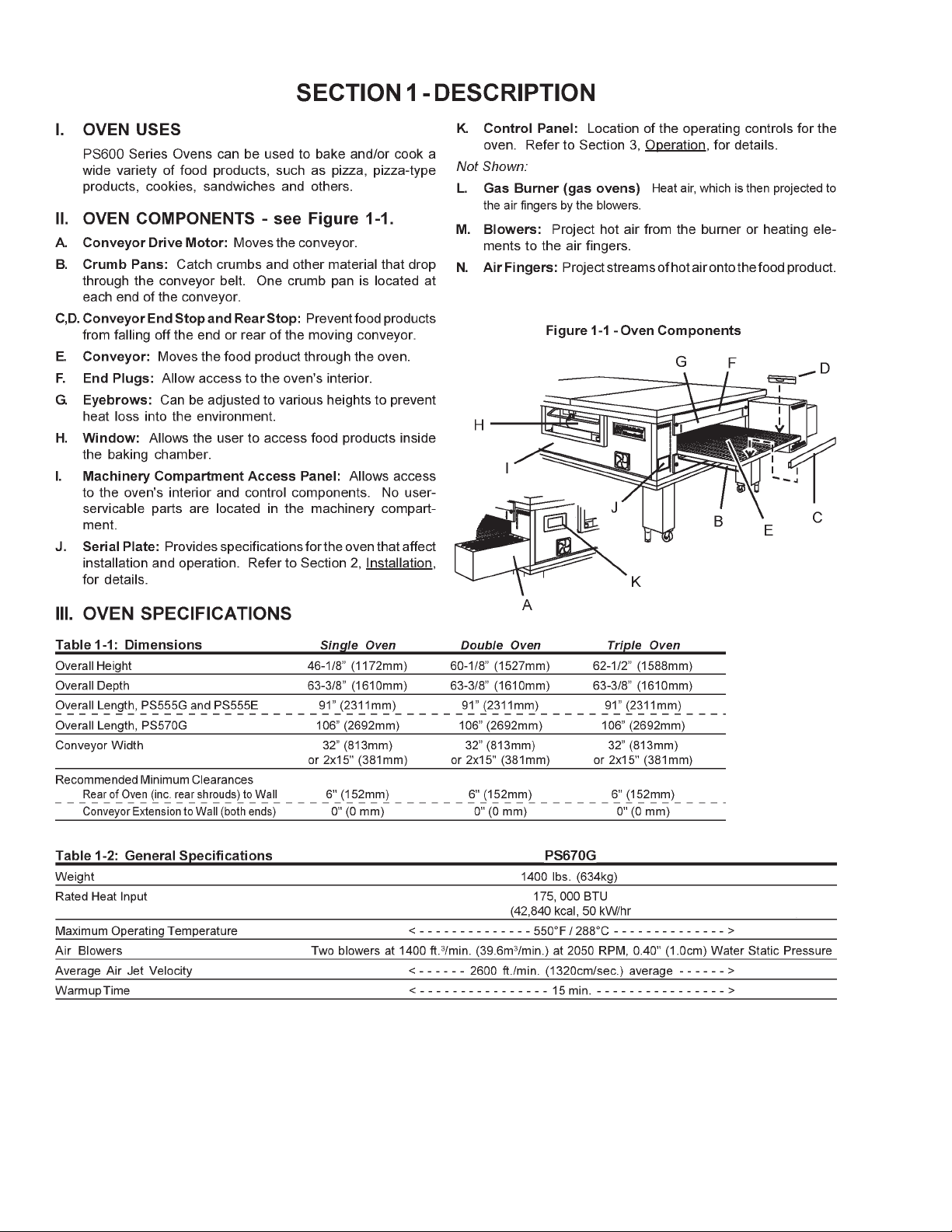

II. OVEN COMPONENTS .................................................... 4

A. Conveyor Motor Drive .............................................. 4

B. Crumb Pans ............................................................... 4

C. Conveyor End Stop ................................................... 4

D. Conveyor Rear Stop ................................................. 4

E. Conveyor .................................................................... 4

F. End Plugs .................................................................... 4

G. yebrows ...................................................................... 4

H. Window ....................................................................... 4

I. Machinery Compartment Access Panel ................... 4

J. Serial Plate ................................................................. 4

K. Control Panel ............................................................. 4

L. Gas Burner ................................................................. 4

M. Blowers ...................................................................... 4

N. Air Fingers ................................................................. 4

III. OVEN SPECIFICATIONS ................................................. 4

A. Dimensions ................................................................ 4

B. General Specifications ............................................. 4

C. Electrical Specifications for PS670G Gas Ovens ... 5

D. Gas Orifice and Pressure Specifications

for PS670G Gas Ovens ........................................... 5

SECTION 2

INSTALLATION .................................................................. 5

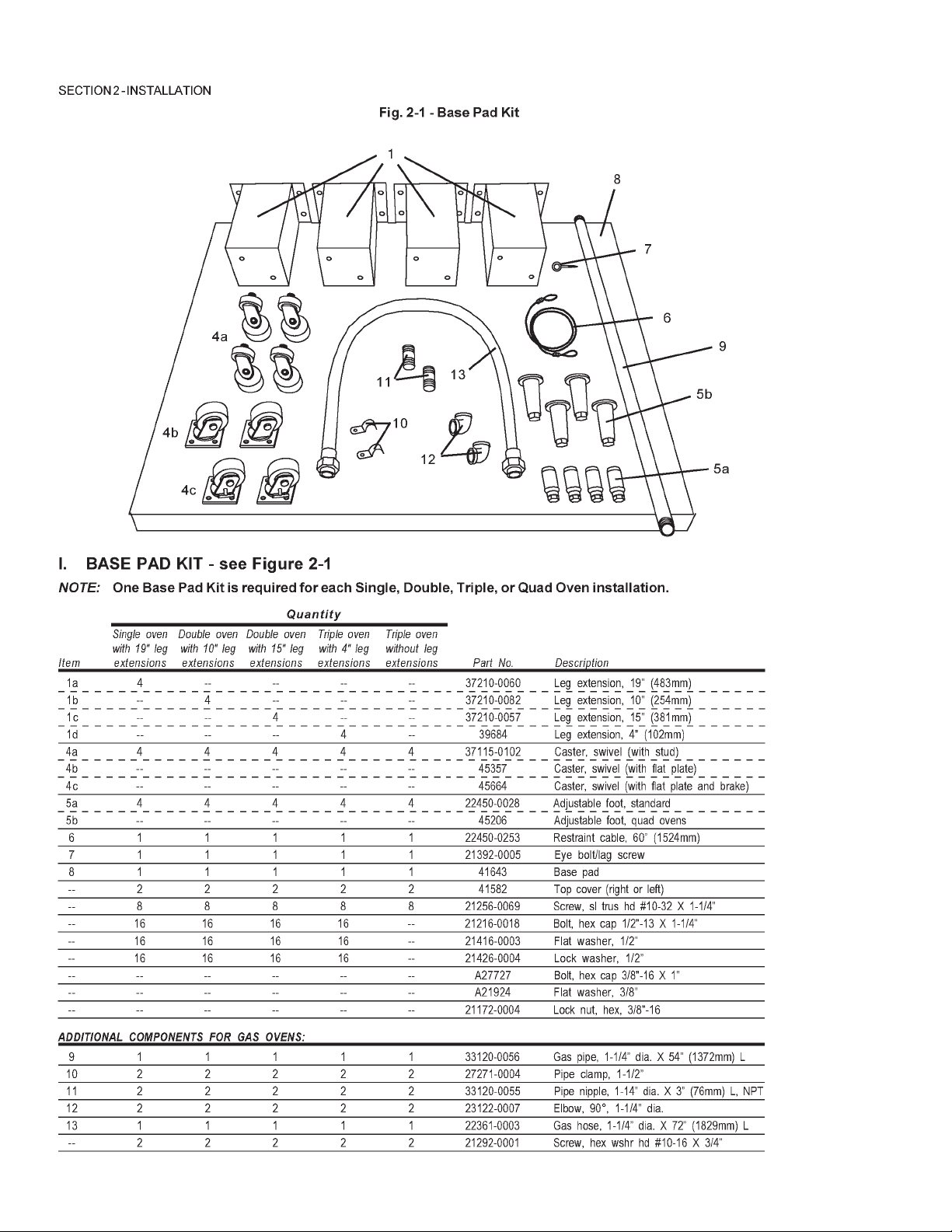

I. BASE PAD KIT ............................................................... 6

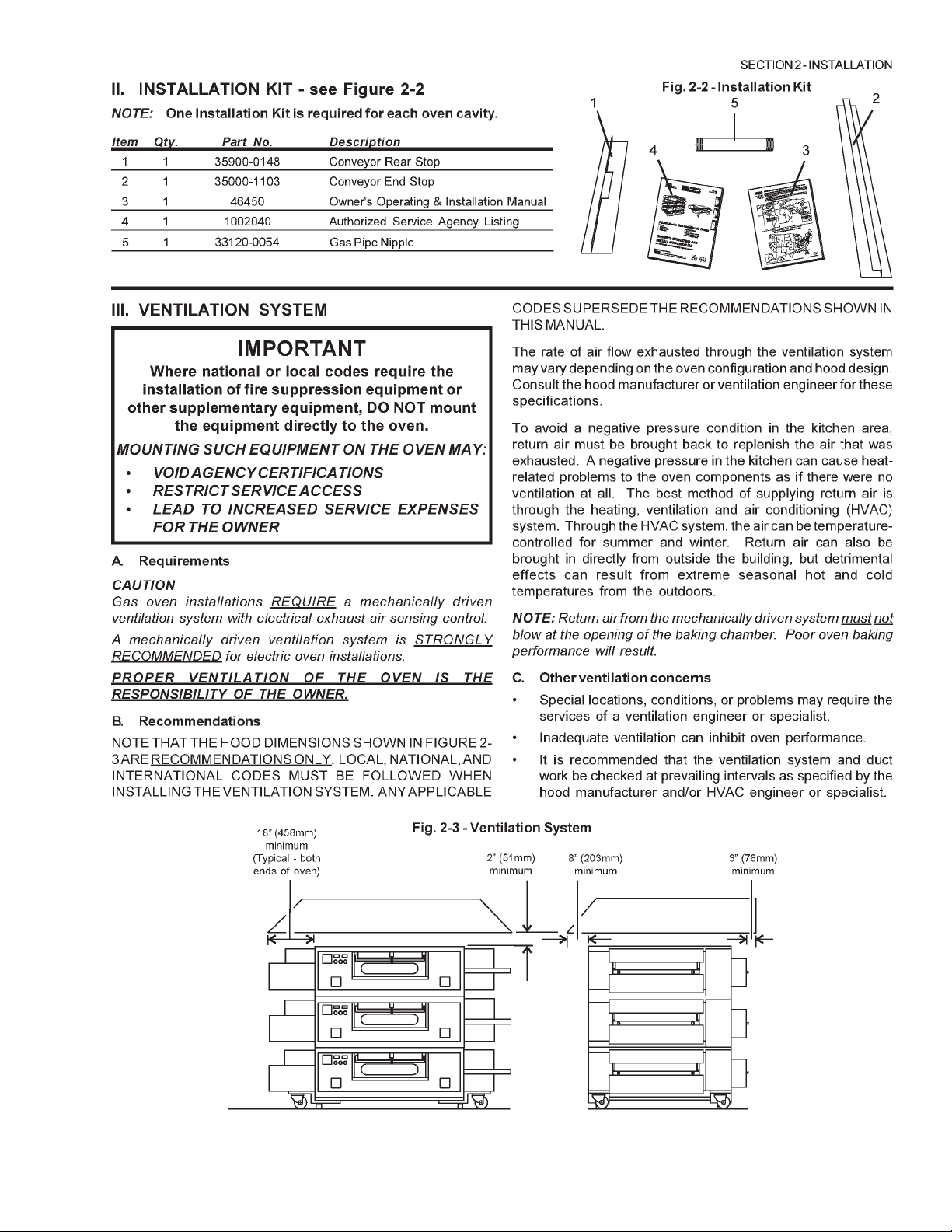

II. INSTALLATION KIT ........................................................ 7

III.VENTILATION SYSTEM ................................................. 7

A. Requirements ............................................................ 7

B. Recommendations .................................................... 7

C. Other Ventilation Concerns ...................................... 7

Page

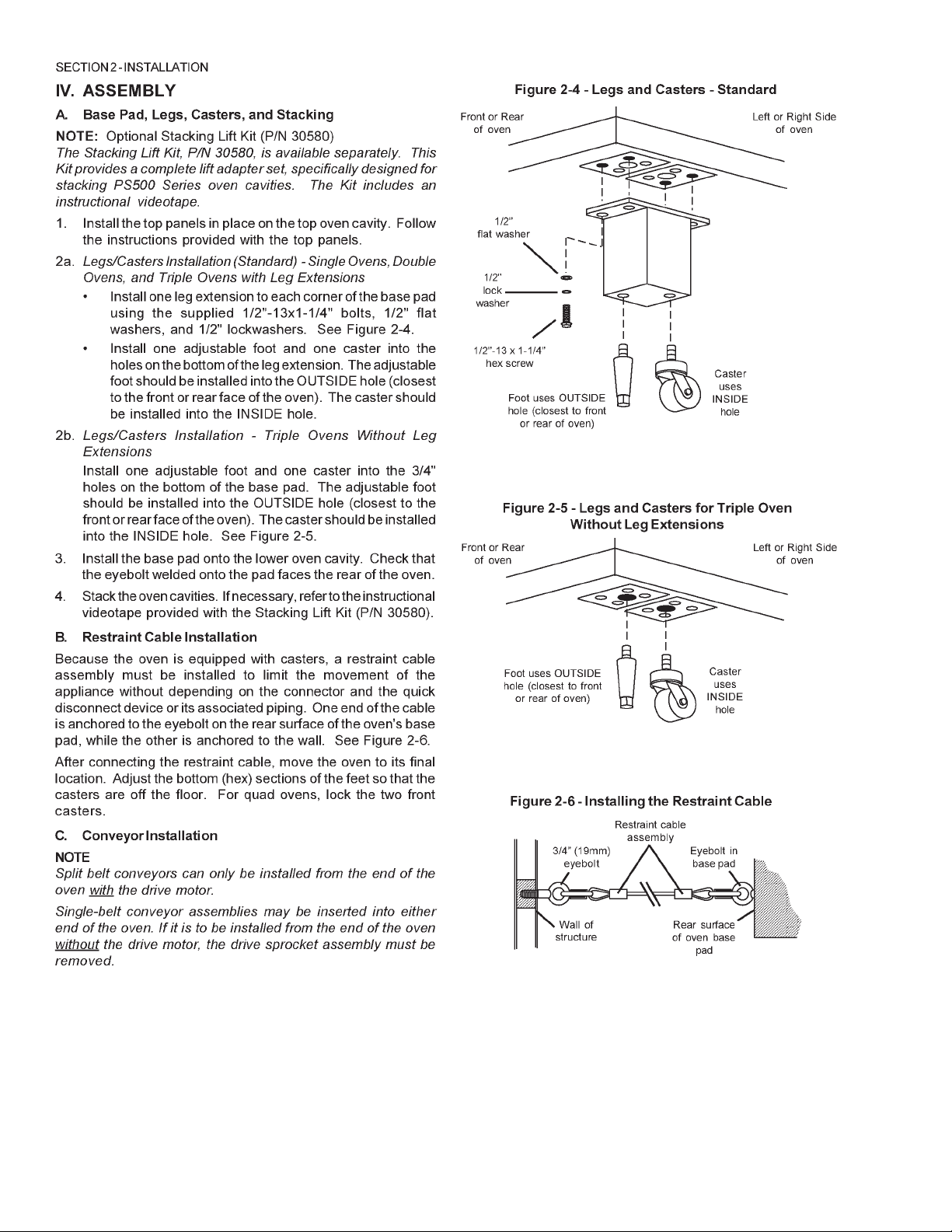

IV. ASSEMBLY ...................................................................... 8

A. Base Pad, Legs, Casters, and Stacking .................. 8

B. Restraint Cable Installation ...................................... 8

C. Conveyor Installation ................................................ 8

D. Conveyor Installation ................................................ 8

V. FINAL ASSEMBLY ....................................................... 10

VI. ELECTRICAL SUPPLY ............................................... 10

A. Additional Information - Gas Ovens ....................... 10

B. Connection ............................................................... 1 0

VII. GAS SUPPLY ............................................................. 11

A. Gas Utility Rough-In Recommendations ............... 11

B. Connection ............................................................... 1 2

C. Gas Conversion ....................................................... 12

SECTION 3

OPERATION ........................................................................ 13

I. LOCATION AND DESCRIPTION OF CONTROLS ....... 13

II. NORMAL OPERATION, STEP-BY-STEP ..................... 14

A. Daily Startup Procedure ......................................... 14

B. Daily Shutdown Procedure ..................................... 14

III. QUICK REFERENCE: DIGITAL TEMPERATURE

CONTROLLER ........................................................... 14

IV. QUICK REFERENCE: TROUBLESHOOTING ............ 1 5

SECTION 4

MAINTENANCE .................................................................. 16

I. MAINTENANCE - DAILY .............................................. 16

II. MAINTENANCE - MONTHLY ....................................... 17

III. MAINTENANCE - EVERY 3 MONTHS ........................ 18

IV. MAINTENANCE - EVERY 6 MONTHS ....................... 1 9

V. KEY SPARE PARTS KIT ............................................. 20

SECTION 5

ELECTRICAL WIRING DIAGRAMS ................................... 2 1

I. WIRING DIAGRAM, 670 GAS OVEN, 208/240V,

50/60 Hz, 1 Ph ............................................................... 39

3

Page 4

456789101112

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Increase Decrease

A. Main On/Off Button

SECTION 3 - OPERATION

C. Temperature Control Display

E. Message Bar

D. TEMP Set

Left

LOCATION AND DESCRIPTION OF CONTROLS

A. Main On/Off Button

Turns all oven functions on or off. If the oven is below the set

point, it will rise to the set point and turn the conveyor on.

If it is turned off and the oven is above 200° F, the blowers

will remain on until the oven drops below 200° F.

B. Conveyor Time Setting

Adjusts and displays the conveyor bake time. Dual belt

ovens have two displays, single units have one.

B. Conveyor Time Setting

Right

C. Temperature Control/Display

Displays the set point of both right and left sides of the

oven.

D. TEMP Set

Pressing on the “TEMP” button shows individual displays

and combined adjustments.

E. Message Bar

Indicates various messages pertaining to current oven

conditions.

13

Page 14

NORMAL OPERATION - STEP-BY-STEP-

A. Main Screen

1. When the unit has been “OFF” for more than 1 minute

the controller will display the screen saver, as shown

in Figure 3-1. To start operation, push the “Enter/

Reset” button. The controller will display the “OFF”

screen, as shown in Figure 3-2.

Figure 3-1 Screen Saver

2. Push the “ON/OFF” button to start the oven. The

controller will display the screen, as shown in

Figure 3-3.

ON/OFF button

Figure 3-3 Main Screen ON

3. To change the temperature, push the “TEMP” button.

The controller will display the screen, shown in

Figure 3-4. To change the left temperature, push the

←←

“

←” arrow button. Then push either the “↑” arrow or “↓”

←←

arrow buttons to increase or decrease temperatures

respectively. To change the right temperature, push

the “→” arrow button. Then push either the “↑” arrow or

“↓” arrow buttons to increase or decrease temperatures accordingly. When the proper temperatures are

entered, push the “Enter/Reset” button. The controller

will now show the display shown in Figure 3-3.

Figure 3-2 Main Screen OFF

TEMP Set button

Figure 3-4 Temperature Screen

14

Page 15

4. To change the conveyor belt speed, push the “TIME”

button. The controller will display the screen, shown in

Figure 3-5. To change the minute setting, push the “

←←

←”

←←

arrow button. Then push either the “↑” arrow or “↓” arrow

buttons to increase or decrease the time accordingly.

To change the second setting, push the “→” arrow

button. Then push either the “↑” arrow or “↓” arrow

buttons to increase or decrease the time accordingly.

When the proper times are entered, push the “ENTER/

RESET” button. The controller will now show the

display shown in Figure 3-3.

Message Bar

ON/OFF button

Energy Level Indicators

TEMP button

TIME button

Figure 3-5 Belt Speed Screen

B. Daily Startup Procedure

1. Check that the circuit breaker/fused disconnect is in

the On position. Check that the window is closed. The

touch panel display should be lit.

2. Adjust the conveyor to the desired bake time.

3. Press the temperature button to display right and left

hand oven settings. Set temperatures as desired.

4. Press the “ON” button to activate the oven. The

conveyor will not run, until the oven temperature has

reached the set points.

C. Daily Shutdown Procedure

1. Make certain there are no products left on the conveyor

in the oven.

2. Press the “ON/OFF” button to turn the oven off.

3. Open the window to allow the oven to cool faster.

4. After the oven has cooled and the blowers have turned off,

the circuit breaker/fused disconnect may be turned off.

Quick Reference – Touch Screen Controller

A. Main Screen

1. ON/OFF button - Used to turn oven On and Off.

2. TIME - See Separate Instructions.

3. TEMP - See Separate Instructions.

4. Energy level indicators - Indicators to either side of the

screen indicate the energy input to that side of the

oven.

5. Message bar - Indicates various messages pertaining

to current oven conditions.

B. Oven Temperature/Set Point/Indicator Screen

1. Right actual temperature - Indicates current average

temperature of the right side of the oven.

2. Left actual temperature - Indicates current average

temperature of the left side of the oven.

3. Set point temperature - Pressing on this value allows

the user to adjust the set point of the oven.

4. Exit - Returns to the main screen.

C. Energy Modes

Energy Mode One - This mode is automatic, and starts

(bake time +1 minute) after the last product has entered

the oven. In this mode, the main oven blowers will lower to

1500 RPM, while the oven maintains temperature and belt

speed.

15

Page 16

III. QUICK REFERENCE: TROUBLESHOOTING

SYMPTOM PROBLEM SOLUTION

Oven will not

turn On.

Oven will not

heat.

Oven is operating, but

little or no air is coming

from the fingers.

Conveyor will not move.

No electrical power • Check that the circuit breaker/fused disconnect is on. Make

sure the emergenct stop button is on.

No gas pressure

Burner did not light

Air fingers may be assembled incorrectly after

cleaning.

Oven is not up to operating

temperature.

Conveyor may be jammed.

• Make sure main gas is on.

• Turn oven off, and restart. If it still does not light, call for

service.

• Turn oven off, and allow to cool. Reassemble fingers

correctly.

• Allow oven to preheat.

• Turn oven off, and allow to cool. Check conveyor for blockage.

IV. SCREEN ALERTS

SYMPTOM PROBLEM SOLUTION

lower right hand corner

The internal battery needs

to be replaced to retain

energy mode timings.

• A qualified service technician should accomplish this.Battery Symbol in the

High Control Compart-

ment Temperature

Combustion Blower

problem.

Control Over Temp Front filters are clogged • Clean or replace filters.

Front belt jammed Front belt has stopped • Remove obstruction, and restart oven.

Rear Belt jammed Rear belt has stopped • Remove obstruction, and restart oven.

High Temp Error Thermocouple or • Call service

Belt off-Oven not Normal operation until

in temperature Oven reaches operating

Energy Saving Mode 1 Normal operation

Energy saving mode 2 Normal Operation

Clean and replace the

front fan filters.

The computer has

detected a problem with

either the main, or burner

blowers.

PLC malfunction

temperature

• Failure to do this will eventually shut down the oven due to

excessive temperature.

• This should be corrected by a qualified service technician.Main Blower problem or

• If no obstruction, call service.

• If no obstruction, call service.

Energy saving Mode 3 Normal operation

16

Page 17

1718192021

Page 18

Page 19

Page 20

Page 21

ITEM QTY. P/N DESCRIPTION

1 1 59083 DIGITAL DISPLAY

2 1 58678 MOTOR, CONVEYOR DRIVE

3 2 58679 CONVEYOR CONTROL BOARD

4 1 58276 INVERTER

5 1 M9608 POWER SUPPLY

6 1 33984 KIT, THERMOCOUPLE

7 1 M9616 FAN, COOLING

8 1 57288 MOTOR, BLOWER

9 1 57141 AIR SWITCH

10 1 54727 KIT, IGNITION MODULE

11 1 M9887 ASSEMBLY, BURNER BLOWER/MOTOR

12 1 41647 VALVE, MODULATING GAS, 1/2"

13 1 31651 AMPLIFIER, MODULATING VALVE

14 1 33983 HIGH LIMIT CONTROL MODULE, 240V

15 1 32108 TRANSFORMER, 240Vp:24Vs

16 1 60088 PLC MODULE

17 1 58668 THERMOCOUPLE MODULE

18 1 58669 CURRENT MODULE

19 1 58363 PHOTOCELL

12 345

10

15

16, 17, 18

19

Page 22

Wiring Diagrams (electrical schematics)

54745B

22

G208-240 volt 50/60 Hz, 1 Phase

Page 23

NOTES

23

Page 24

Loading...

Loading...